Paper heating device used for color printing packaging

A heating device and paper technology, applied in packaging, etc., can solve the problems of reduced running speed, increased steam consumption, unstable product quality, etc., and achieve the goals of improving stability and reliability, improving stability, and improving connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

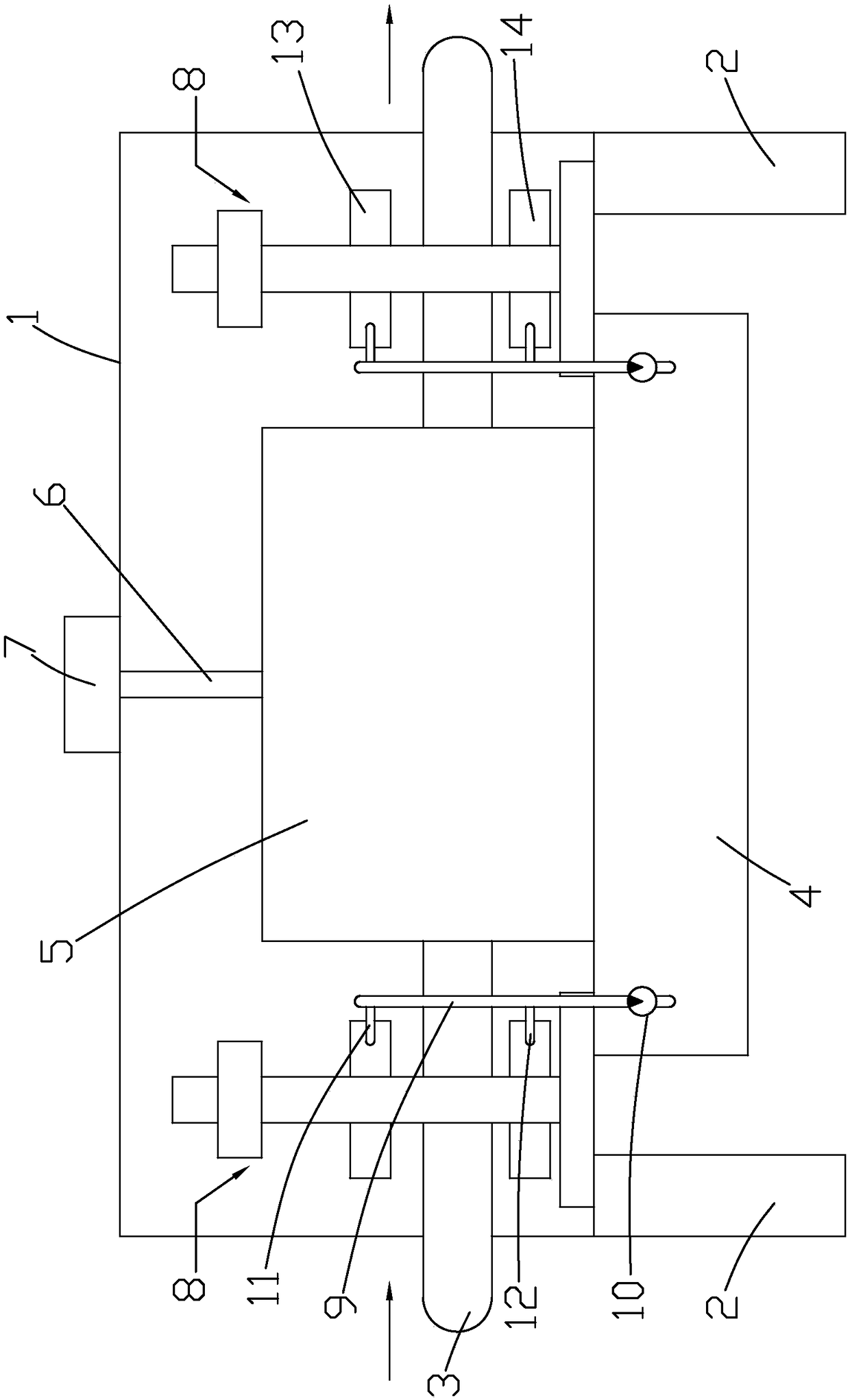

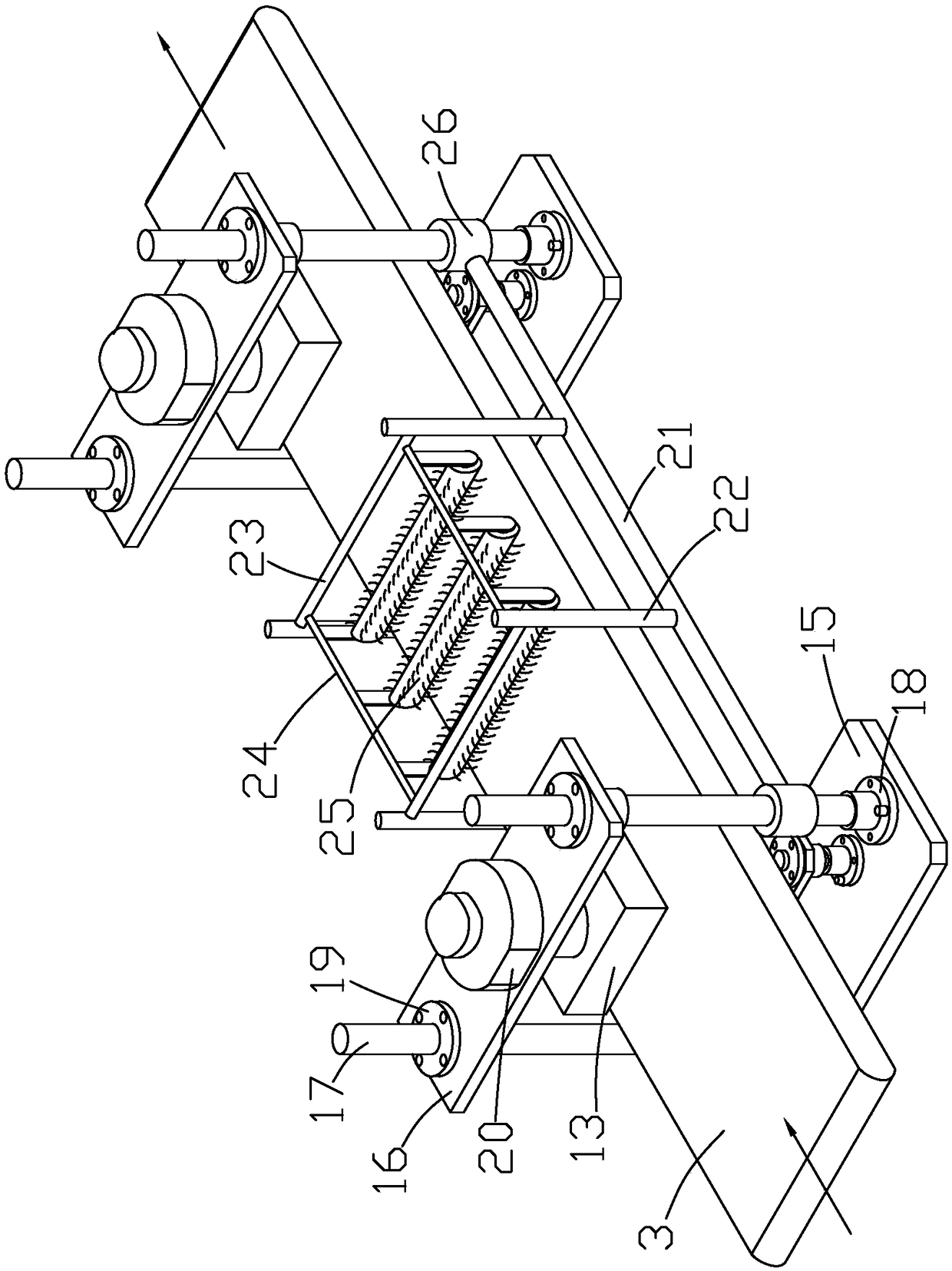

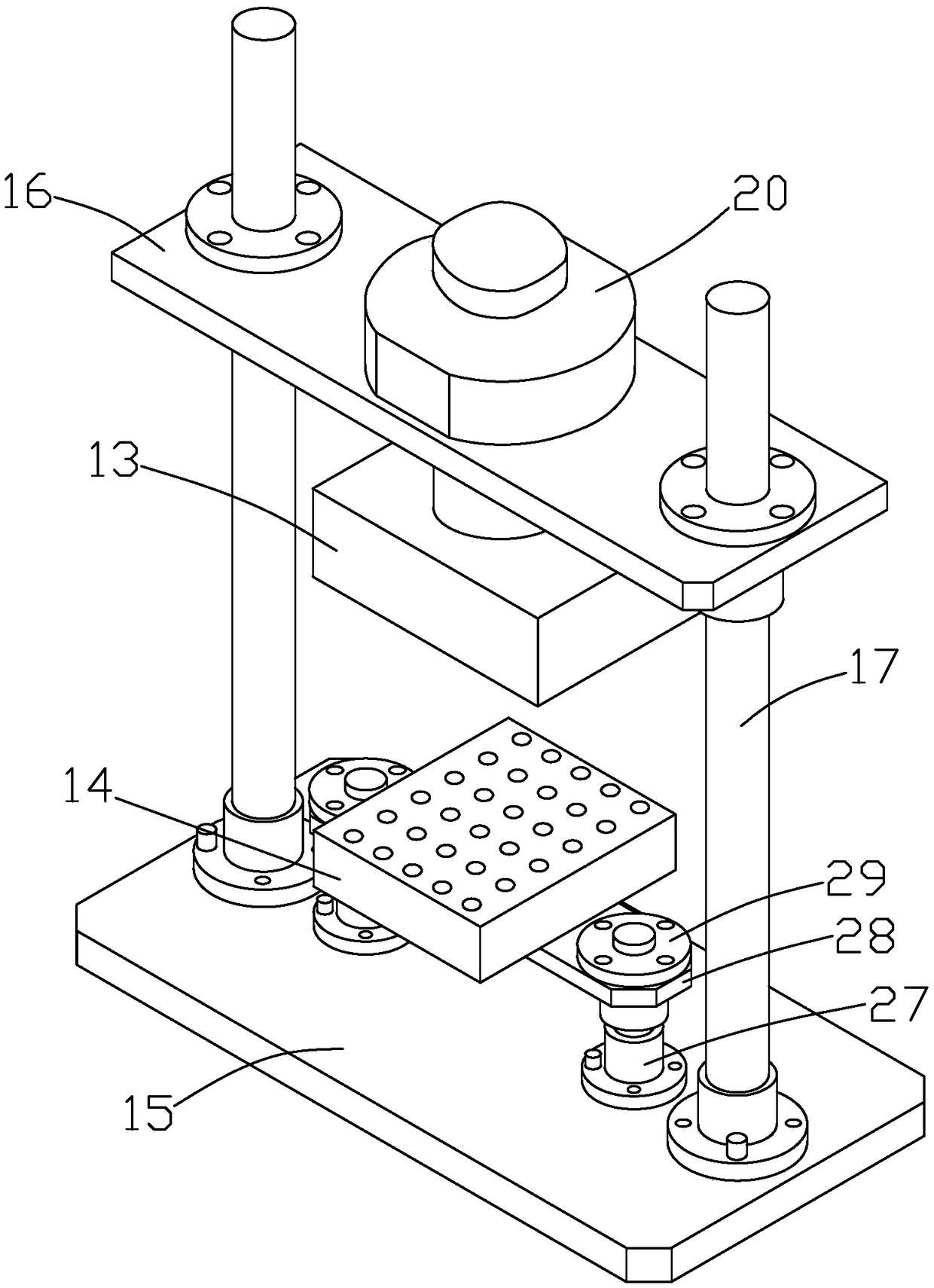

[0027] Such as Figure 1 to Figure 6 As shown, it is a paper heating device for color printing packaging according to the present invention, which includes a box body 1, a support foot 2 and a liquid storage tank 4 are arranged at the bottom of the box body 1, and a paper conveying plate 3, cleaning Box 5, the first steam heating drying plate 13 and the second steam heating drying plate 14, the paper conveying plate 3 runs through the box body 1 horizontally, the cleaning box 5 is located at the center of the box body 1, and a fan is installed on the top surface of the box body 1 7. The fan 7 is connected to the cleaning box 5 through the suction pipe 6, and the fan 7 can suck out the dust and impurities in the cleaning box 5 through the suction pipe 6, so as to prevent the dust swept away in the cleaning box 5 from adhering to the surface of the paper again, forming Secondary pollution.

[0028] A cleaning mechanism is provided in the cleaning box 5, and the cleaning mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com