A kind of production technology of gypsum self-leveling material

A production process and self-leveling technology, which is applied in the direction of sales of raw material supply devices, liquid ingredient supply devices, grain processing, etc., can solve the problems of poor timing, poor control of weight, and inability to balance efficiency, so as to achieve difficult cleaning, Excellent mixing effect, avoiding the effect of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

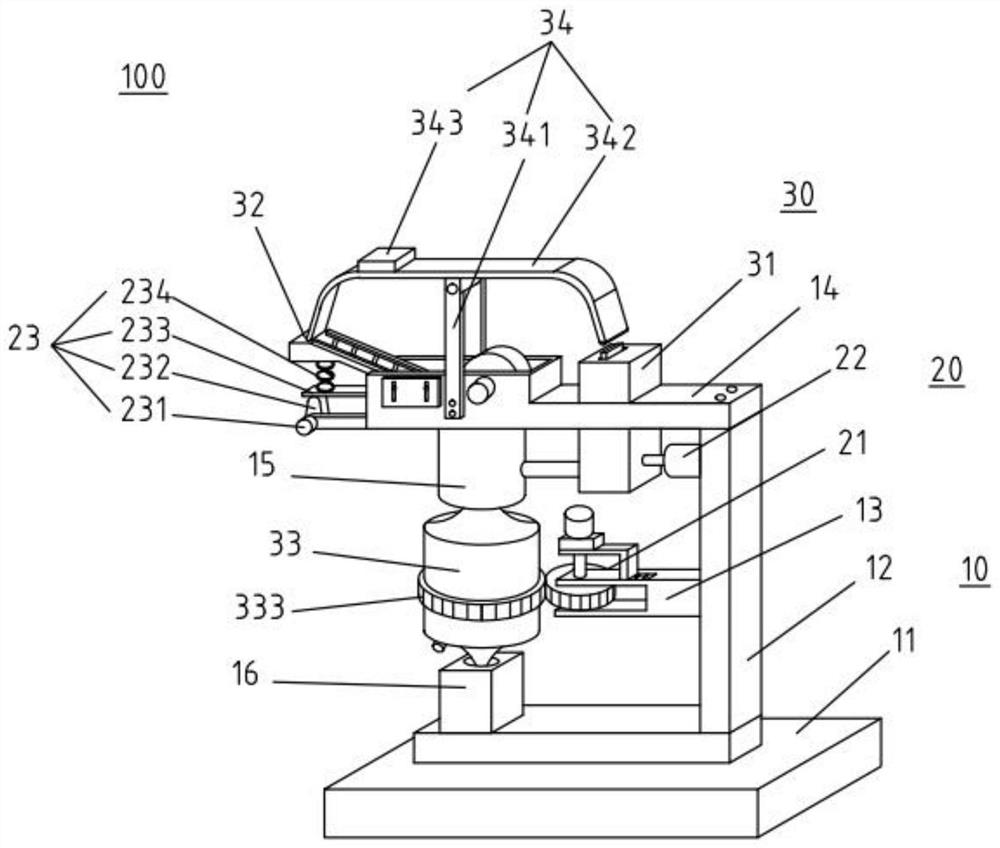

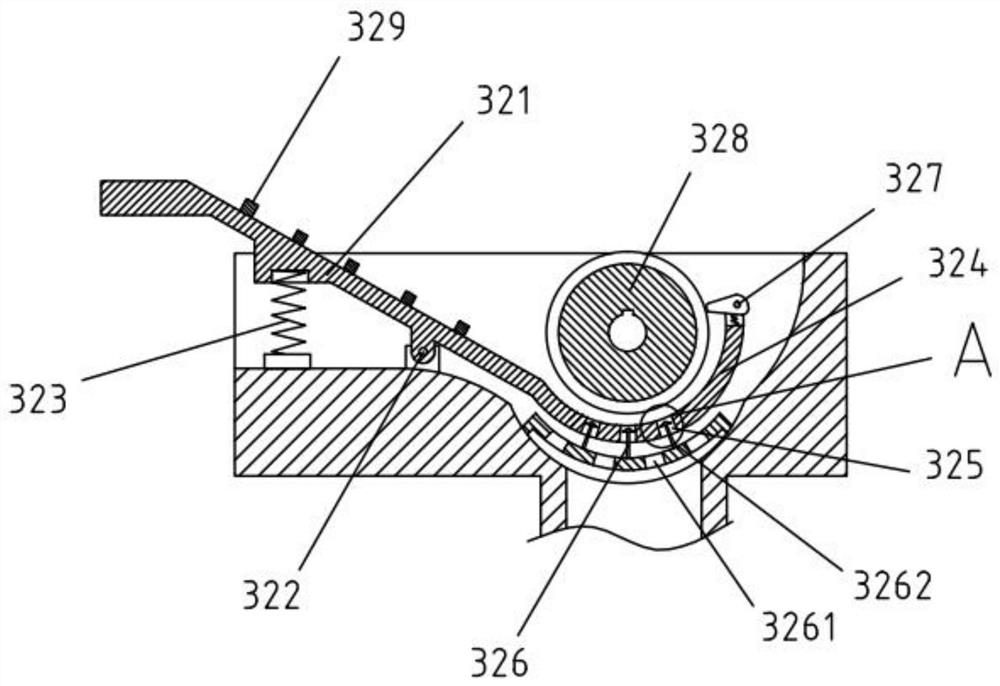

[0039]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

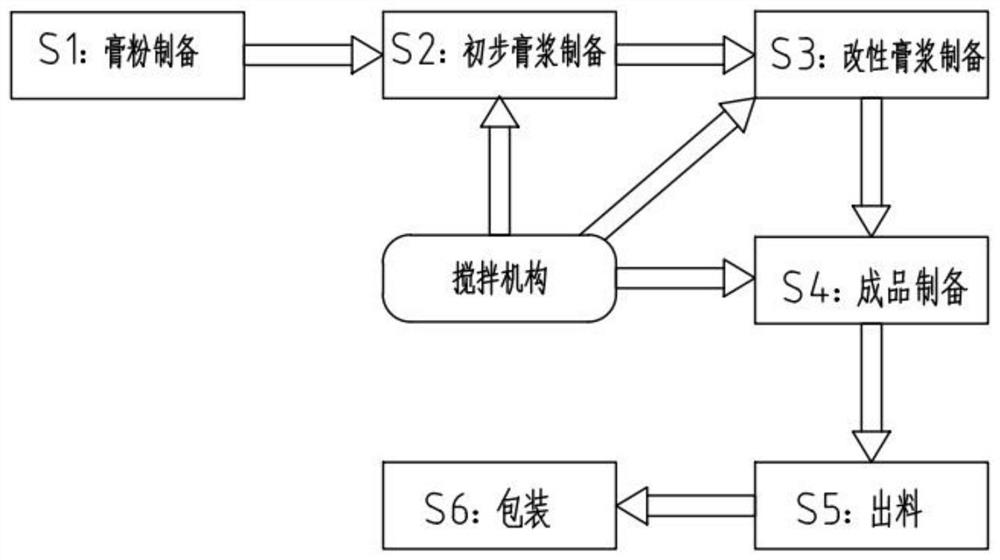

[0040] Such as Figure 1 to Figure 12 As shown, a production process of gypsum self-leveling material, the specific production process steps are as follows:

[0041] S1. Preparation of paste powder: first, phosphogypsum is pulverized by gypsum grinding equipment, and then sieved by sieving equipment. During this process, attention is paid to dust removal by dust removal equipment, and refined phosphogypsum is initially obtained;

[0042] S2. Preliminary slurry preparation: dilute the gypsum slurry, inject pure water into the gypsum powder obtained in step S1, and stir evenly with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com