Linear filling plug-hanging and cover-hanging cover pressing machine

A straight-line, capping machine technology, applied in the field of oral liquid packaging, can solve problems such as affecting the operation of the machine, incapable of capping, and contamination of bottle contents, and achieves safe and reliable work, easy to organize production, and a high degree of generalization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

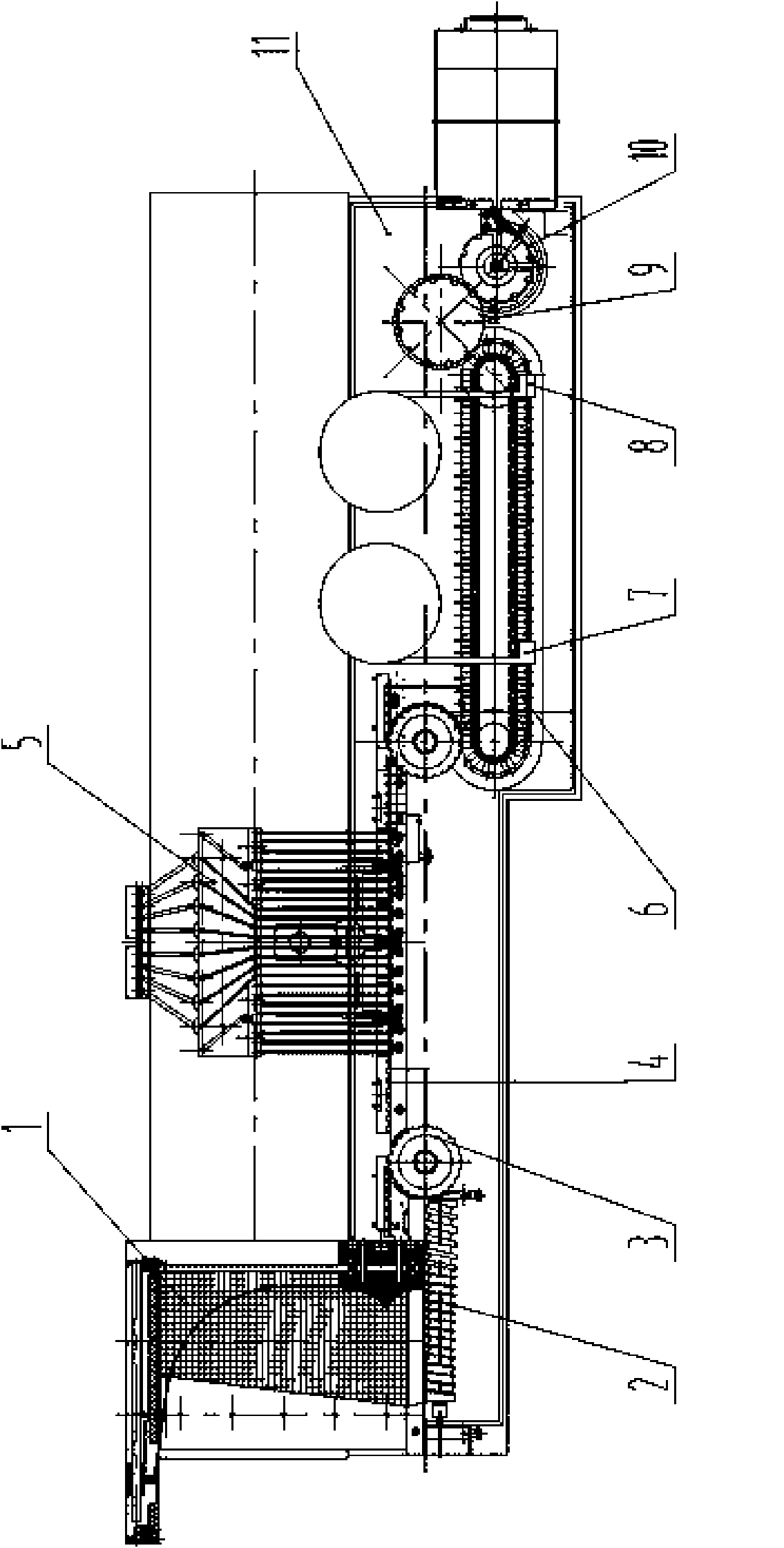

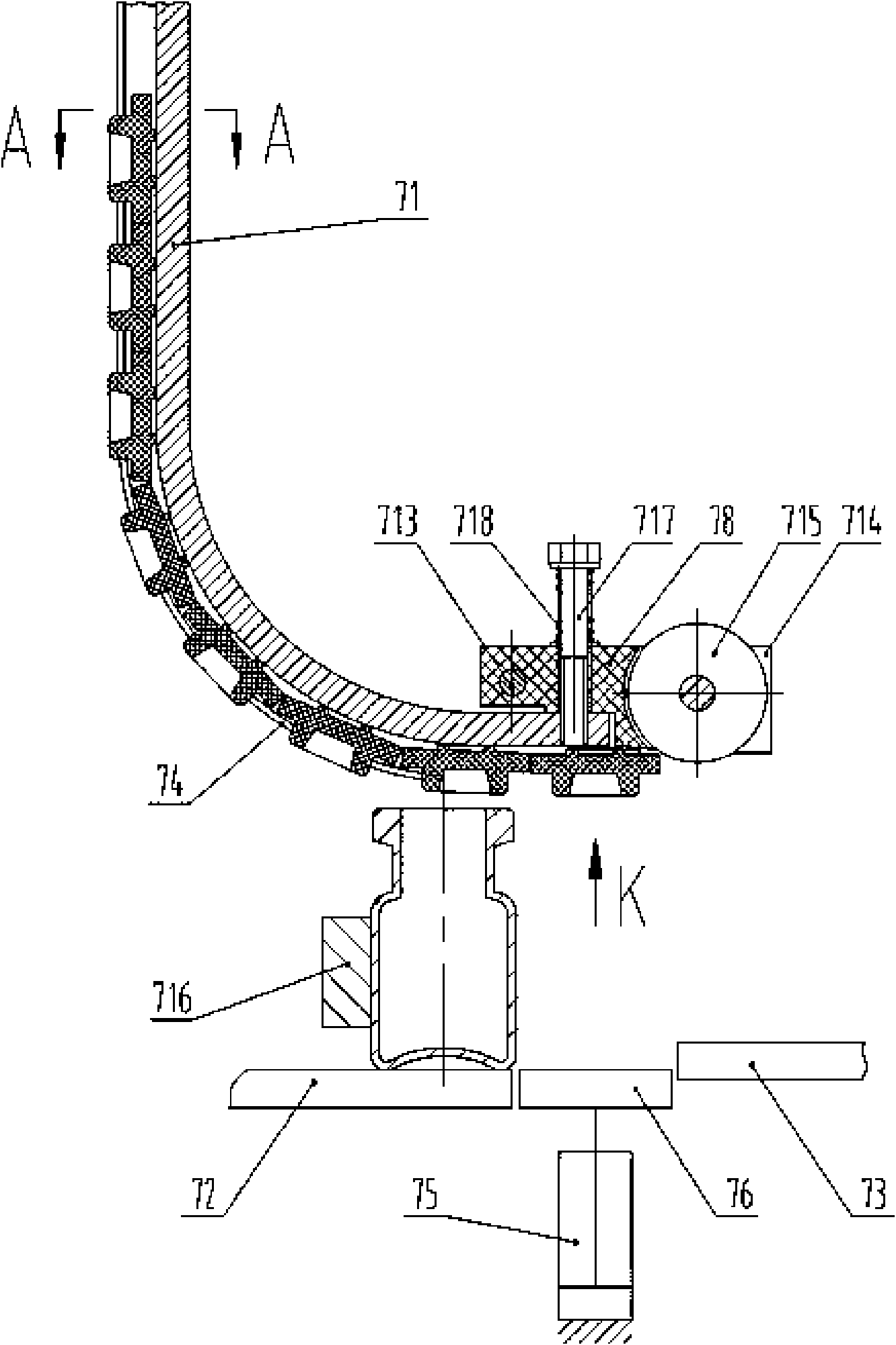

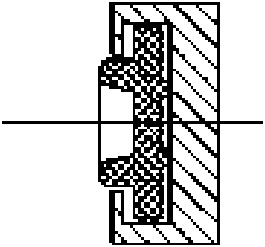

[0021] Such as Figure 1 to Figure 4 As shown, the linear filling, plugging, capping and capping machine of the present invention includes a frame 11 and a bottle-infeeding and unscrambling part, a filling part 5, a capping part 9 and a bottle-out dial mounted on the frame 11. Part 10. The bottle-feeding and unscrambling part is composed of a bottle-feeding mesh belt 1, a bottle-feeding auger 2 and a bottle-feeding dial wheel 3; the filling part 5 includes a walking beam bottle conveying mechanism 4, and in this embodiment, the filling part 5 adopts the same ampoule The structure of the packing and sealing machine is similar, and its filling principle is the same; the capping part 9 and the bottle-discharging dial part 10 are also common to the prior art, so the present invention is generalized and standardized, with simple production organization and low production cost . The bottle feeding mesh belt 1 is connected with the input end of the bottle feeding auger 2, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com