Configurational tree-shaped heat pipe radiator

A heat pipe radiator and configuration technology, applied in the field of heat dissipation devices, can solve the problems of heat dissipation performance of heat dissipation fins affected by heat source distance, poor temperature uniformity, limited heat dissipation efficiency, etc., so as to improve heat dissipation performance, efficient operation, and increase heat dissipation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Carry out further detailed description below in conjunction with accompanying drawing:

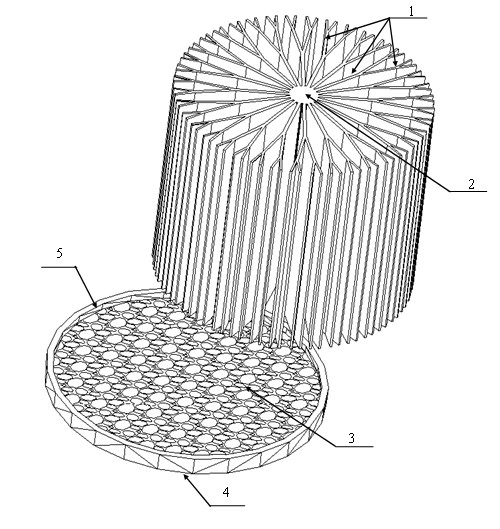

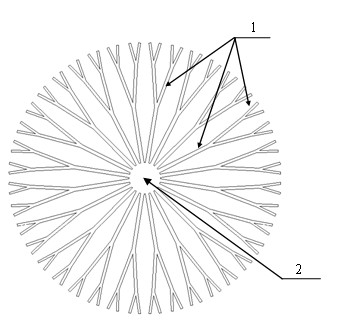

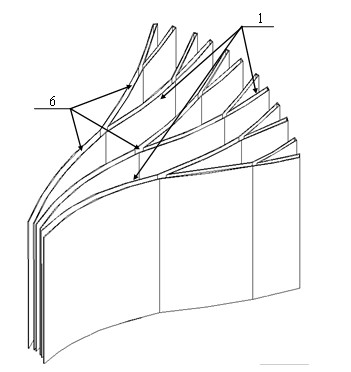

[0029] figure 1 A schematic diagram of the three-dimensional structure of the heat pipe radiator is given. The invention relates to a heat pipe radiator combined with characteristic fins of a tree-like structure, which is composed of a high heat-conducting substrate 4, a liquid-absorbing core 3, a heat-dissipating fin 1 and a working medium. The bifurcated connecting ribs 1 are arranged in a ring shape around the main through passage 2 . The bifurcated connecting fins 1 arranged in a ring shape form the cooling fins. A narrow cavity 5 is set in the high thermal conductivity substrate 4, and the liquid-absorbing core 4 is filled in the narrow cavity 5, and the bifurcated connection fin 1 is connected to the narrow cavity, and the through cavity 6 of the narrow cavity 5 and the heat dissipation fin is filled. with working medium. The high thermal conductivity substrate 4 is in clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com