Patents

Literature

94results about How to "Lower temperature level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal combustion engine with auto ignition

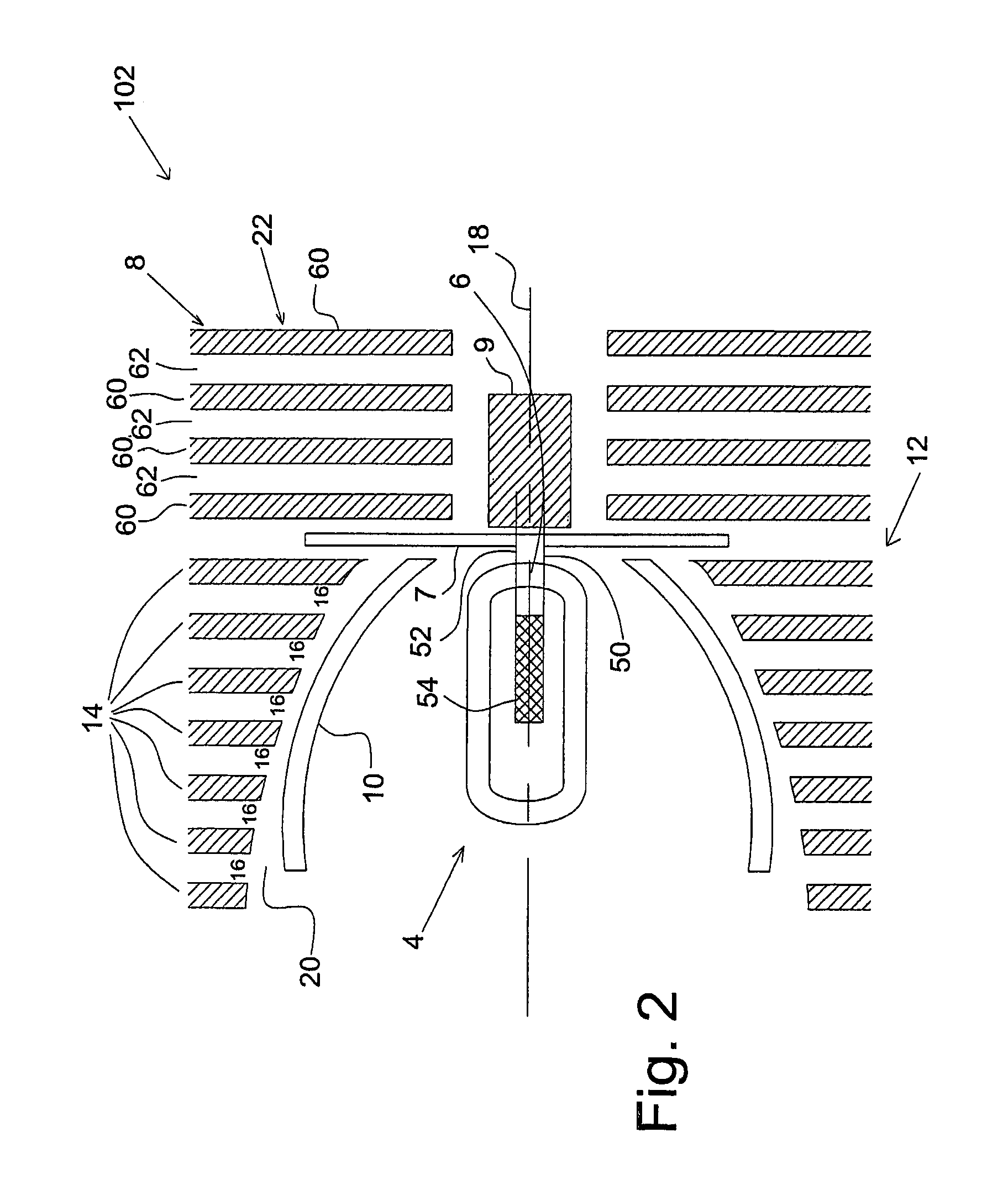

InactiveUS20060037563A1Prevent wettingMinimize wettingElectrical controlNon-fuel substance addition to fuelCombustion chamberInternal combustion engine

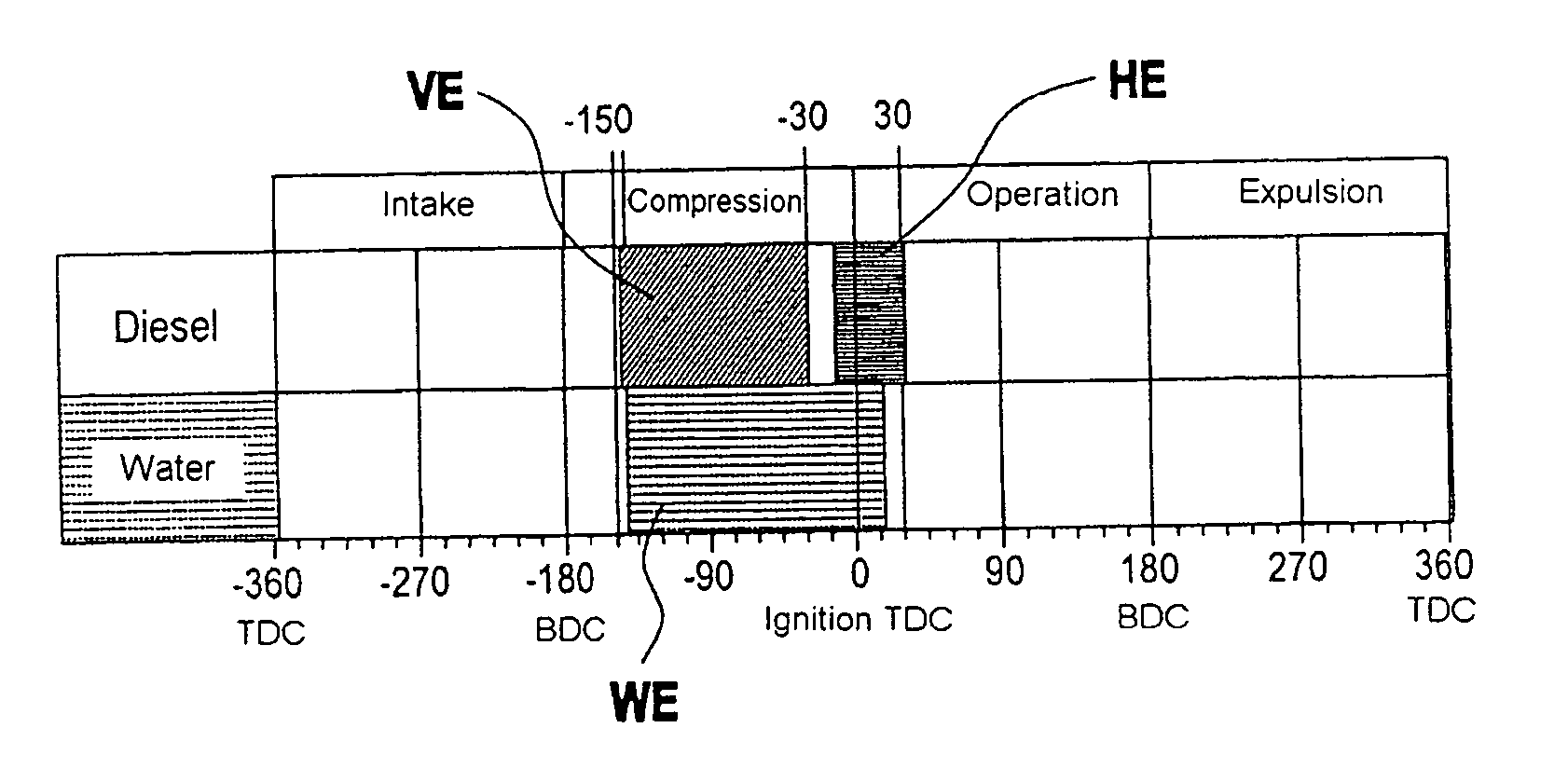

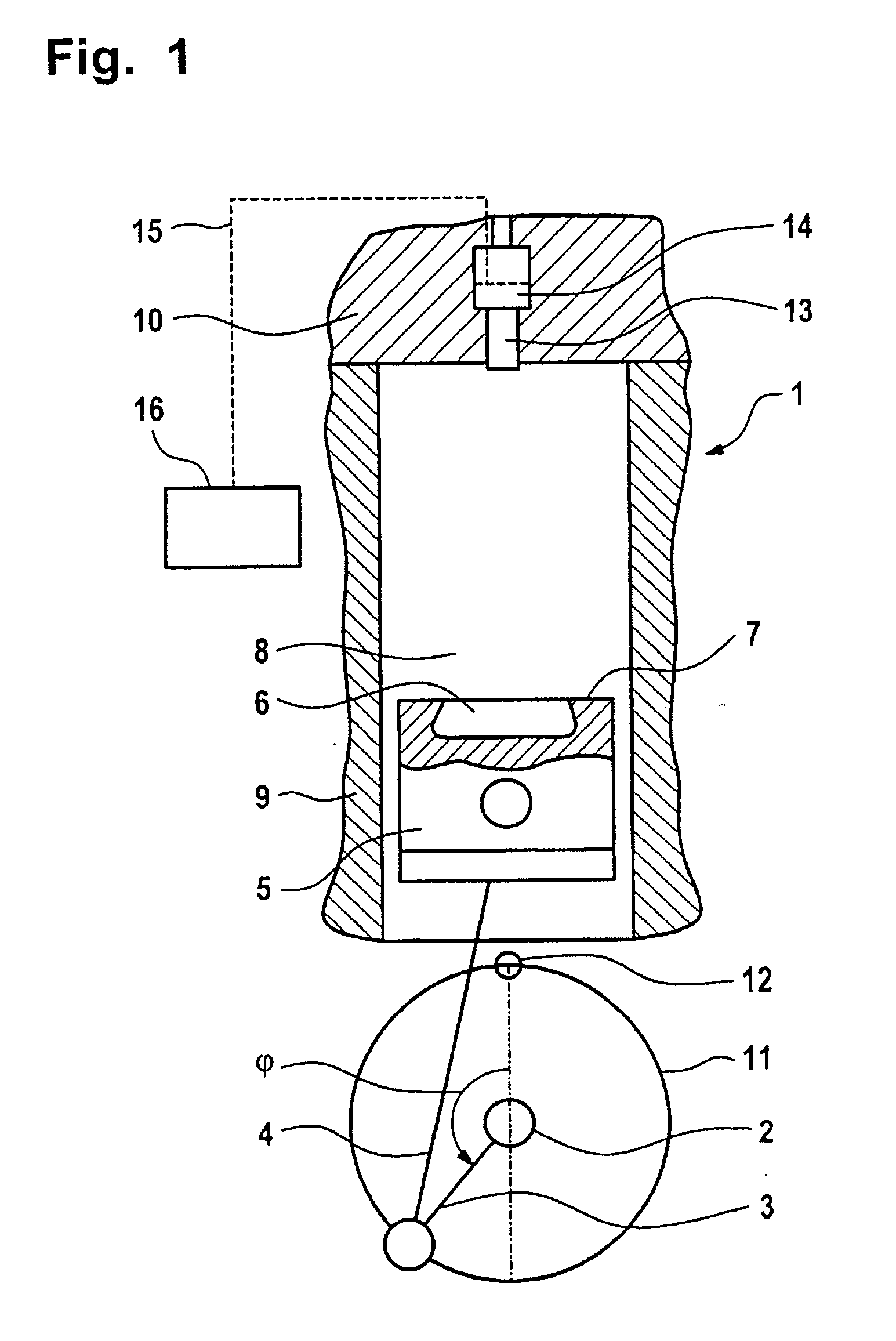

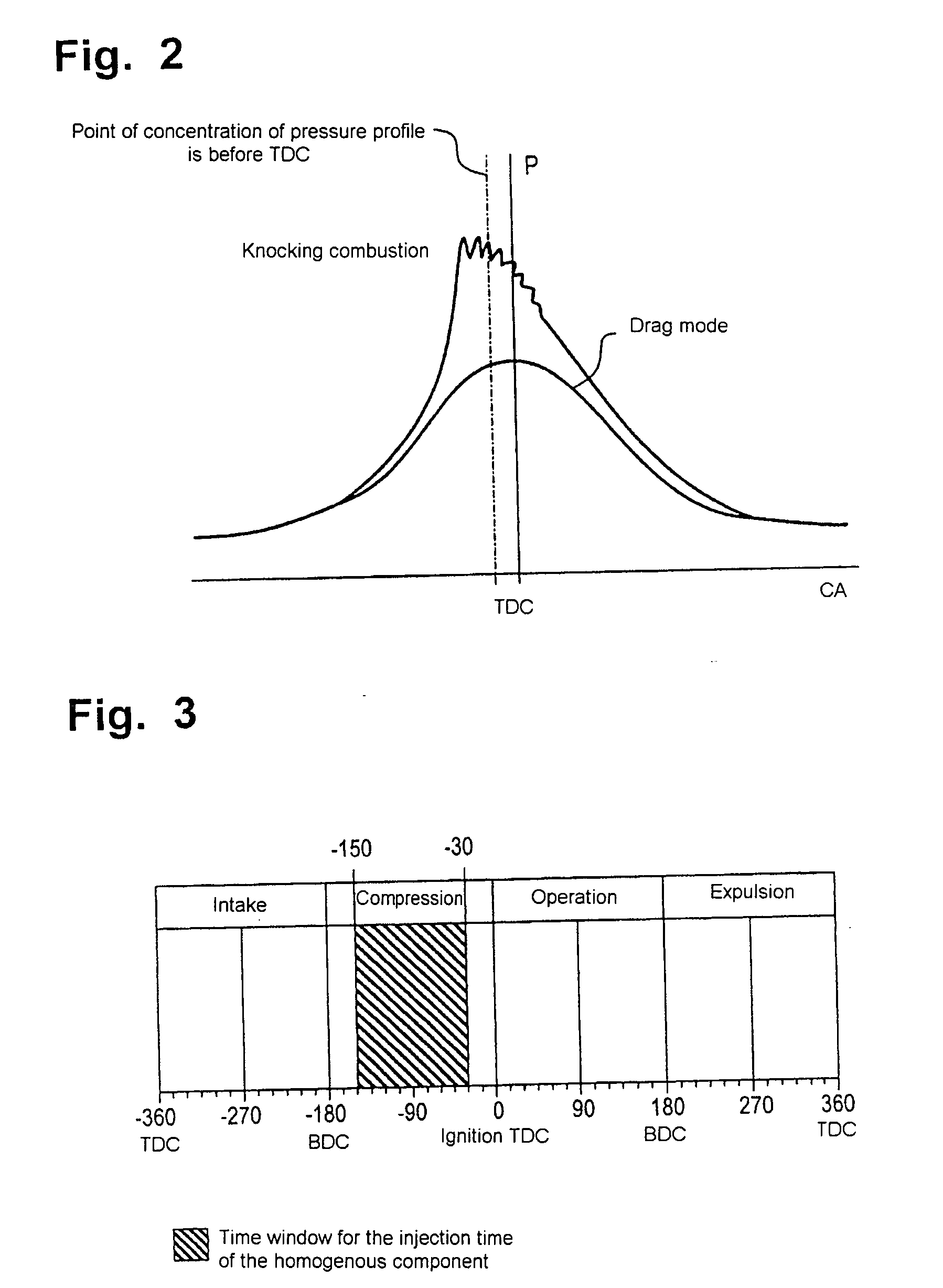

In a method for operating an internal combustion engine in which fuel is injected directly into a combustion chamber in a pre-injection and a main fuel injection step, and, if appropriate, also in a post-injection step by means of an injection nozzle with a plurality of injection bores, the injection of fuel takes place in a timed fashion and, to limit pressure and temperature during combustion of the fuel in the combustion chamber, a quantity of water is introduced into the combustion chamber during or after the pre-injection step.

Owner:DAIMLER AG

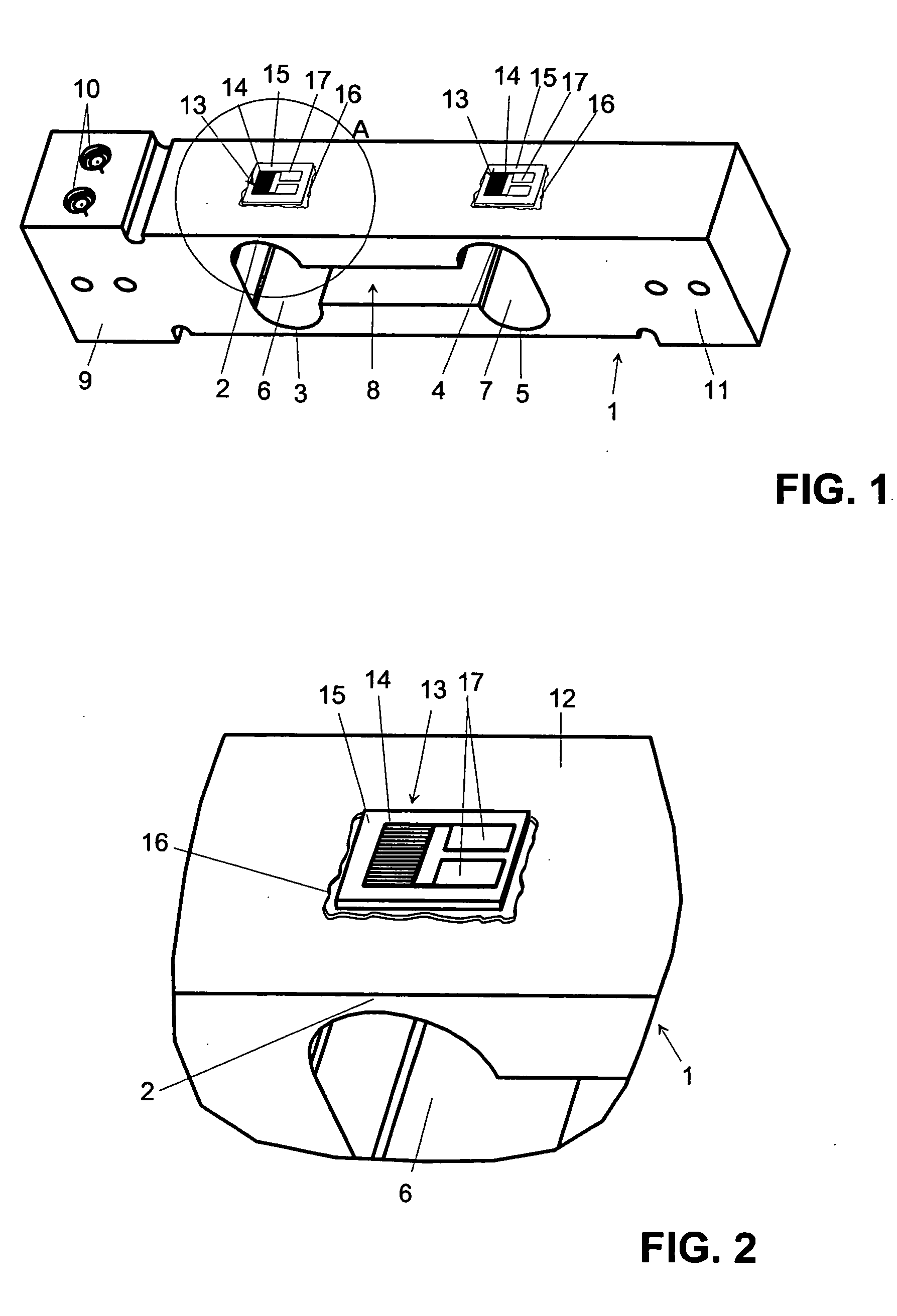

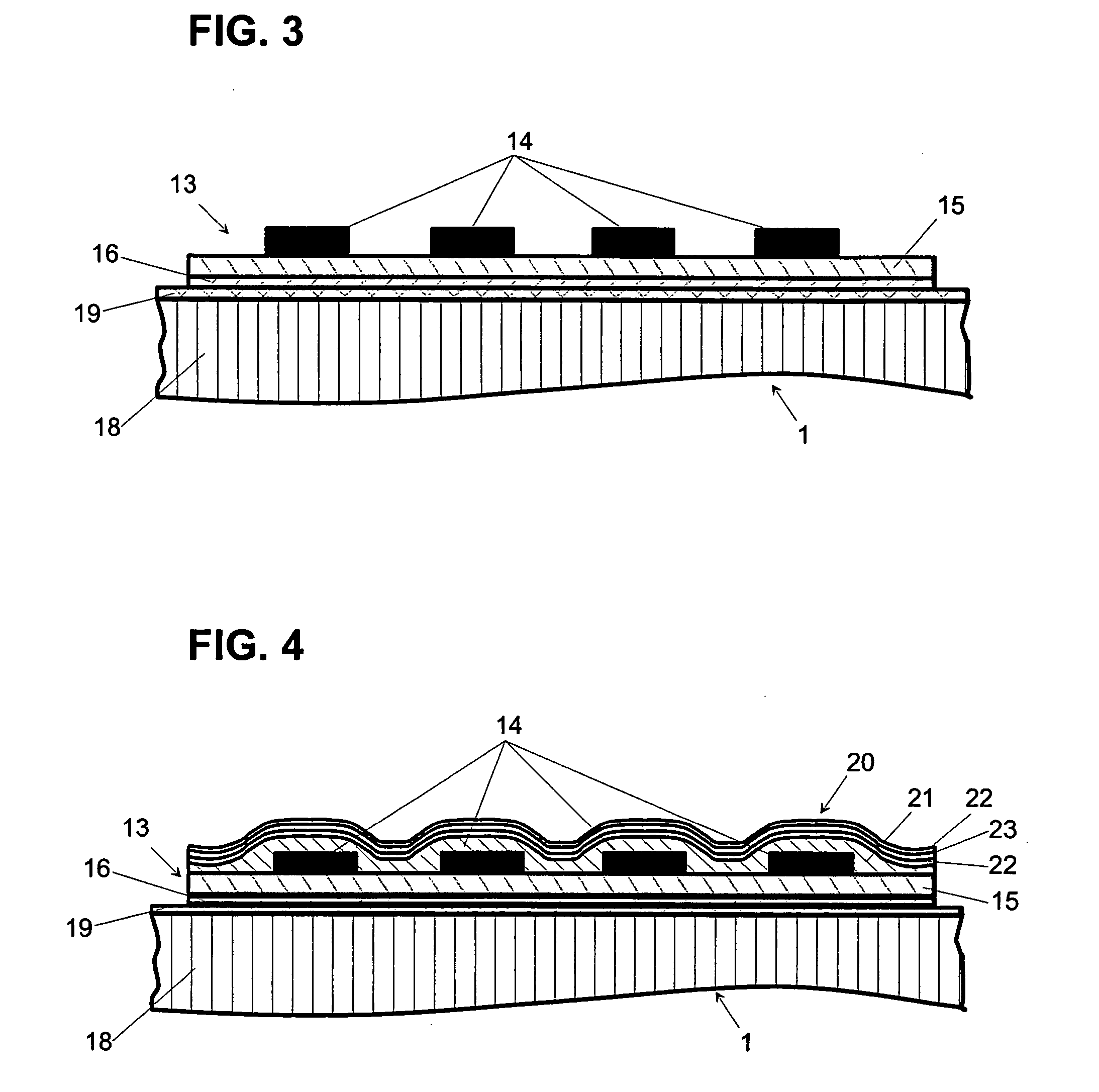

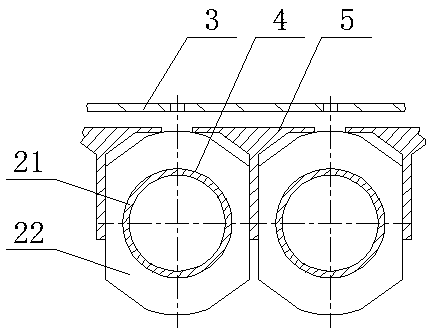

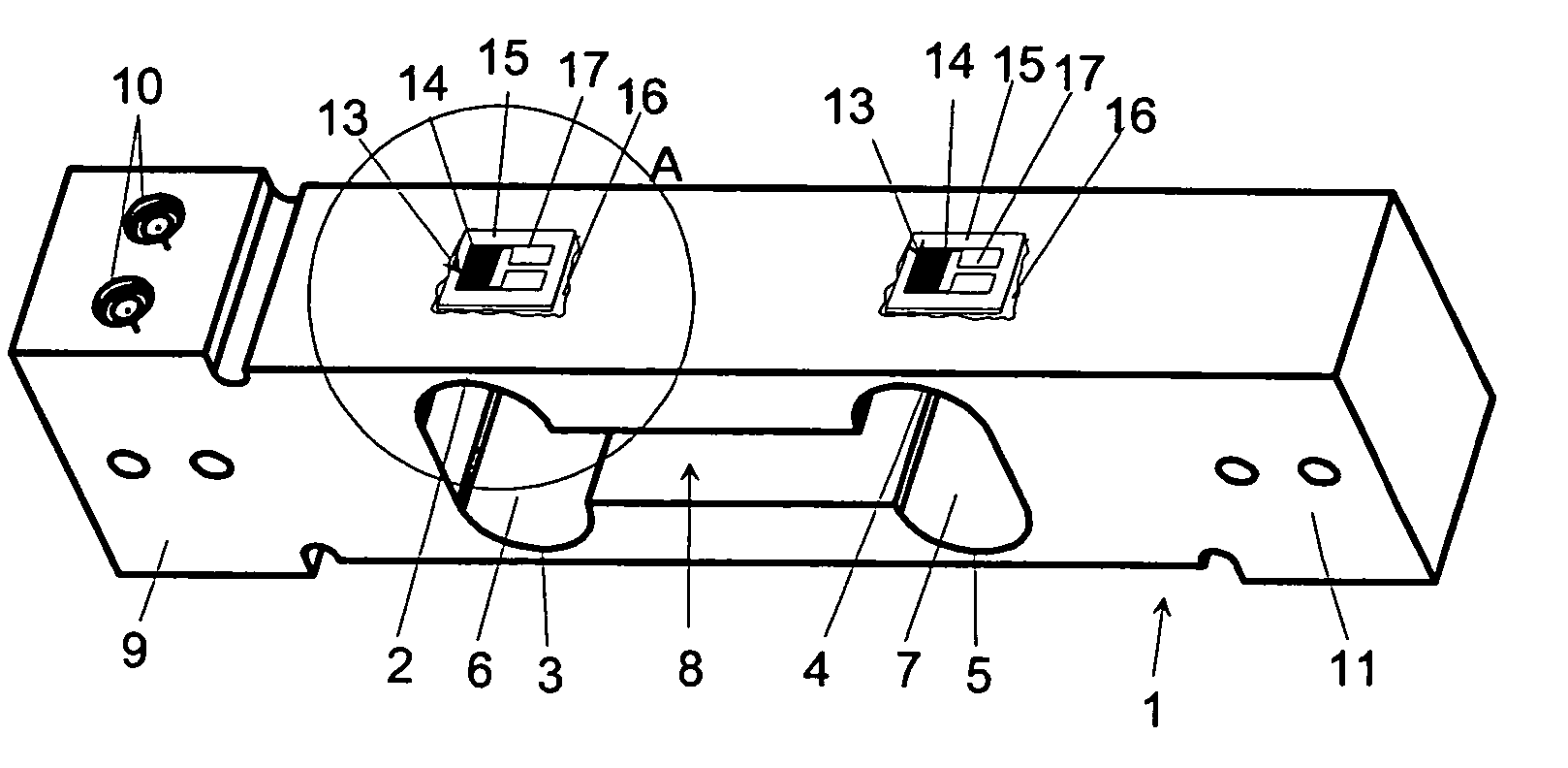

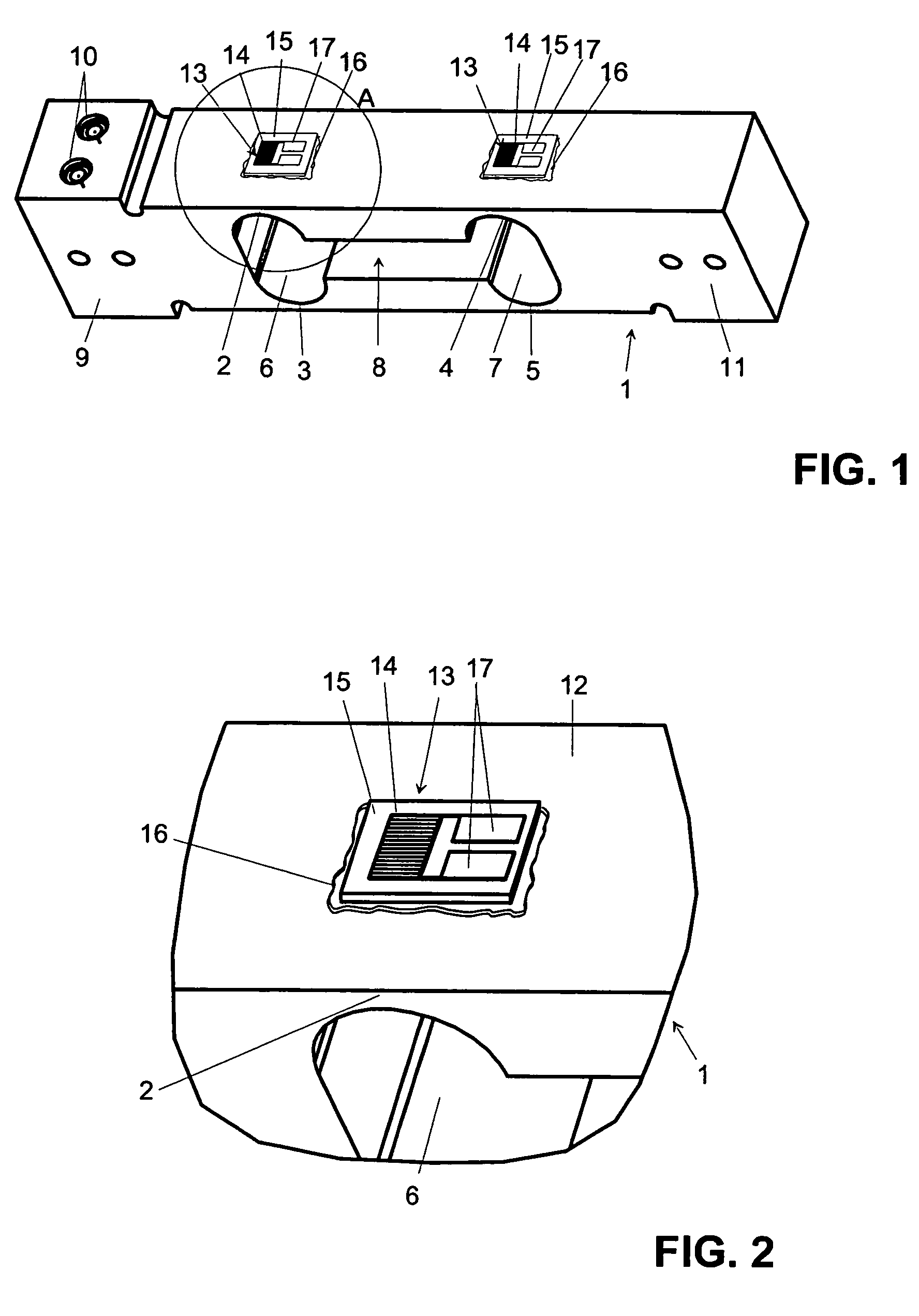

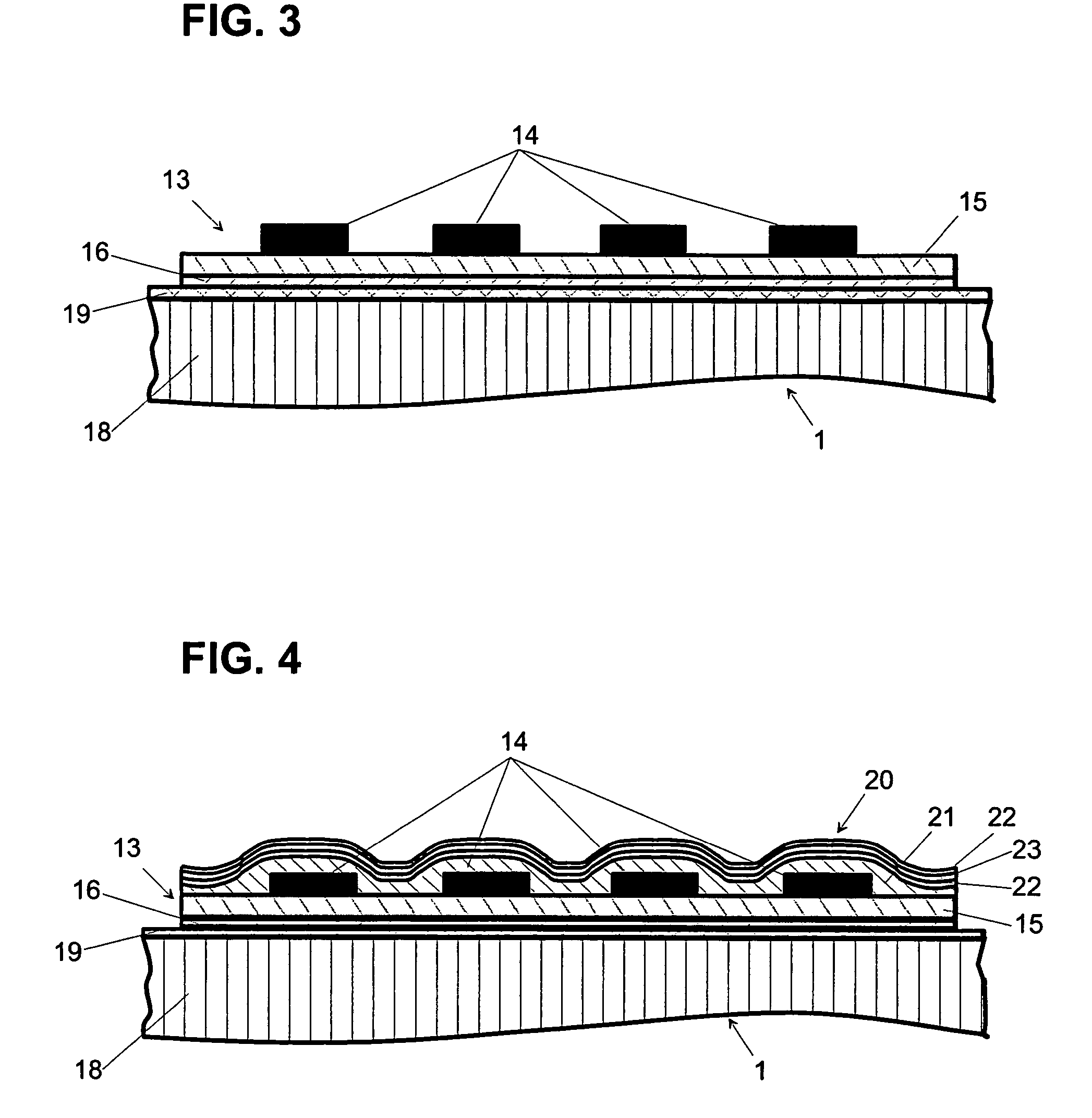

Bonding of strain gauges to the deformable body of a force-measuring cell

ActiveUS20050160837A1Favorable hysteresis behaviorReduce driftForce measurement by measuring frquency variationsWeighing apparatus using elastically-deformable membersEngineeringStrain gauge

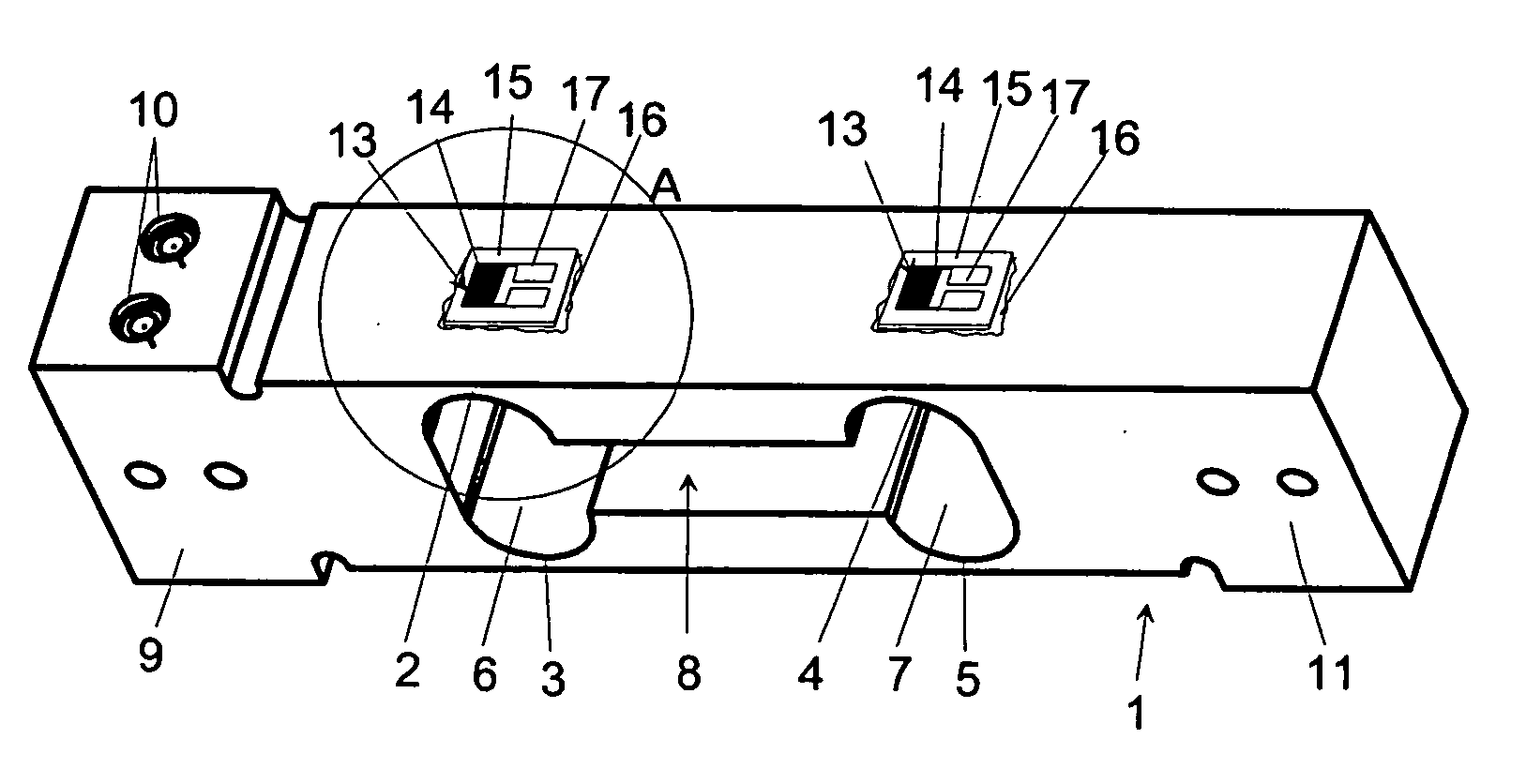

In a force-measuring cell with a deformable body and with at least one strain gauge which has a strain-sensitive electrical resistor track arranged on a polymer carrier substrate, the strain gauge is bonded to the deformable body by an adhesive layer of an inorganic-organic hybrid polymer. For the bonding of the strain gauge to the deformable body, an adhesive compound having an inorganic-organic hybrid polymer in solution is applied to the deformable body, whereupon the strain gauge is placed on the hybrid polymer layer, and the adhesive layer is subsequently hardened at a temperature between 80° C. and 130° C. For the hardening of the adhesive layer, the deformable body with the strain gauge is exposed to the increased temperature for a time period between a half hour and three hours.

Owner:METTLER TOLEDO GMBH

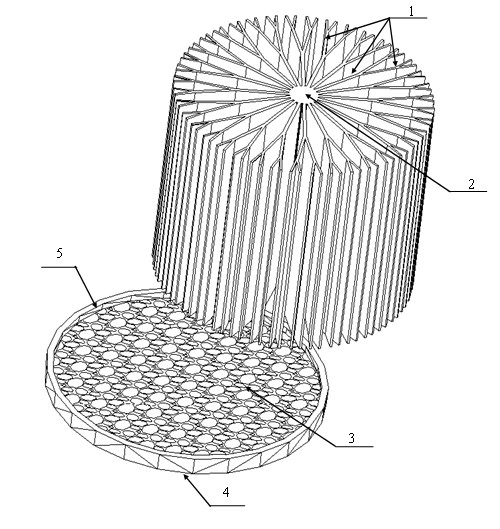

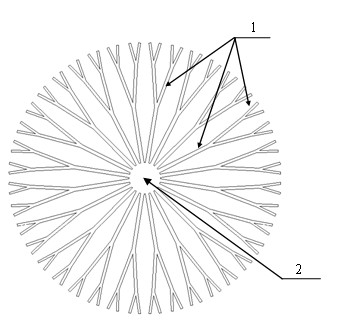

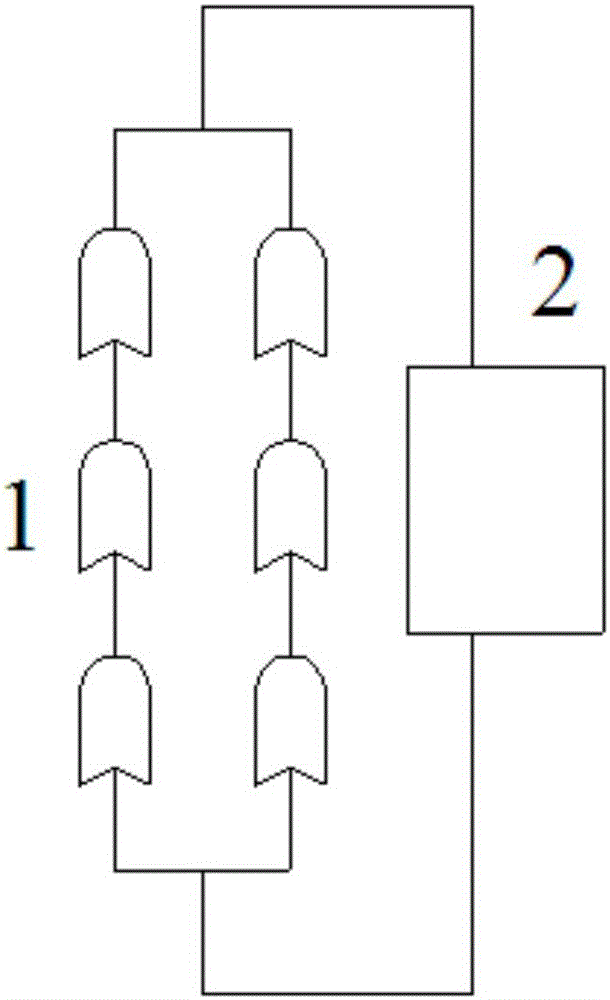

Configurational tree-shaped heat pipe radiator

ActiveCN102034773AImprove cooling effectReduce the temperature level of the heating surfaceSemiconductor/solid-state device detailsSolid-state devicesHeat flowEngineering

The invention discloses a configurational tree-shaped heat pipe radiator. The radiator consists of a high-thermal conductivity base plate, liquid-absorption cores, a radiating fin and working media, wherein narrow cavities are formed inside the base plate; the radiating fin is connected with the narrow cavities; communicated cavities are formed inside the radiating fin; the liquid-absorption cores are filled in the narrow cavities; the working media are filled in the narrow cavities and the communicated cavities; the radiating fin has a configurational tree-shaped structure and consists of a main communicated channel and at least two forked connection fins; the forked connection fins are arranged at the periphery of the main communicated channel circularly; and the communicated cavities inside the forked connection fins are communicated with the main communicated channel. The heat pipe radiator can quickly remove the heat which is generated by a plurality of (a single) local high-temperature heat flow heat source points (point) through phase change of the working media, so that local hot points are effectively eliminated, temperature of a heating surface of the heat pipe radiator is reduced, and safe, stable and efficient operation of electronic equipment is further guaranteed.

Owner:SOUTHEAST UNIV

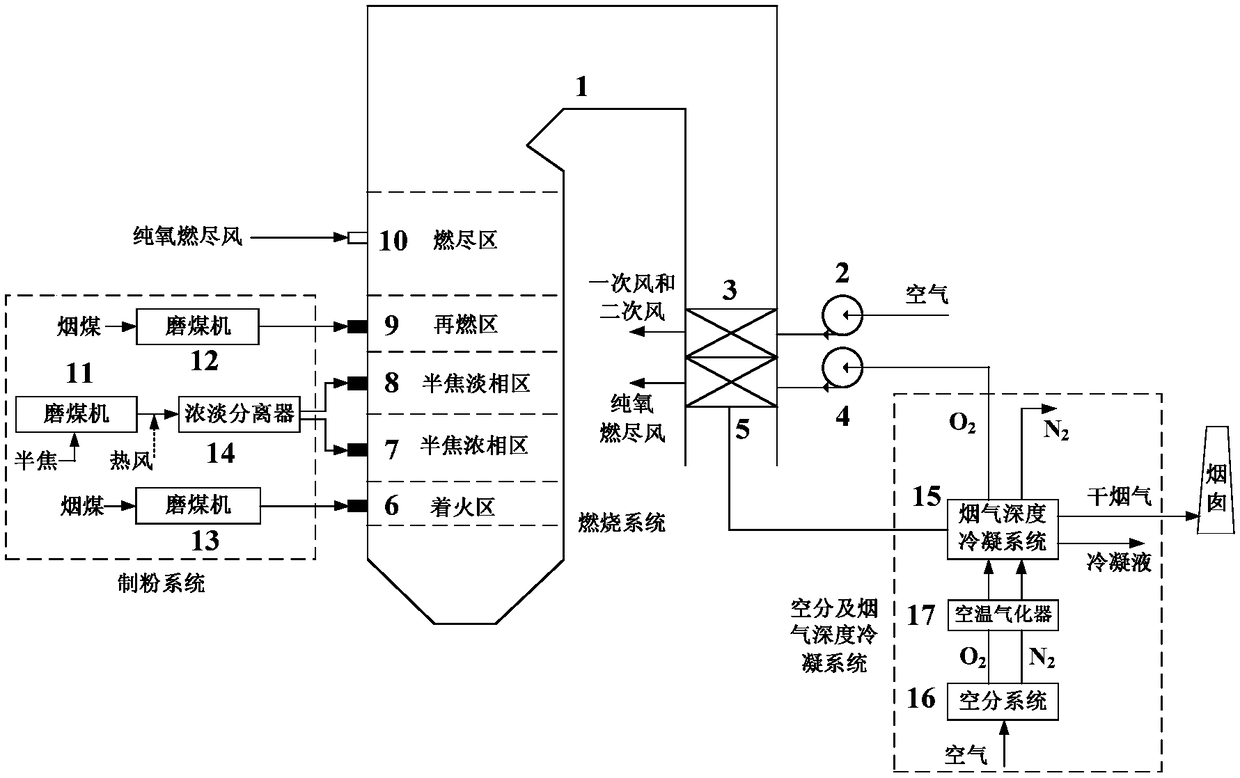

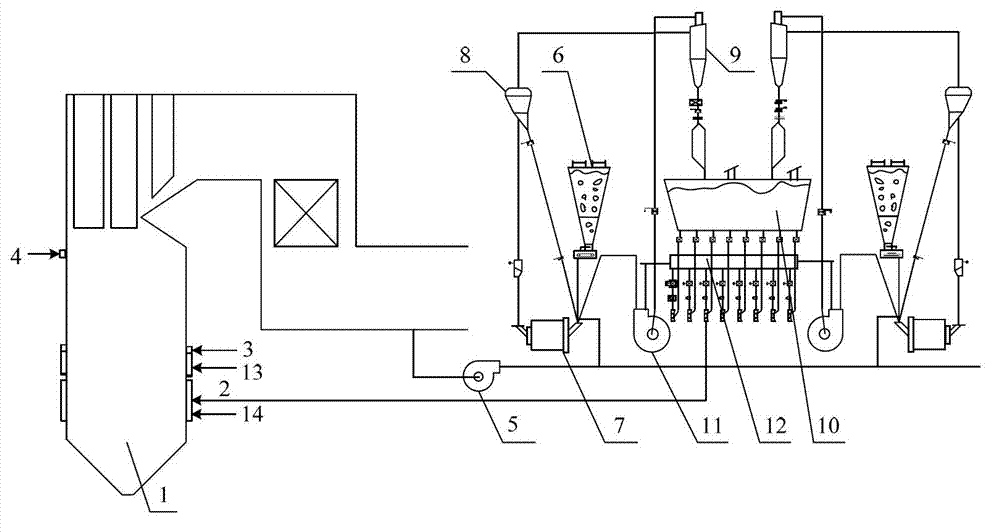

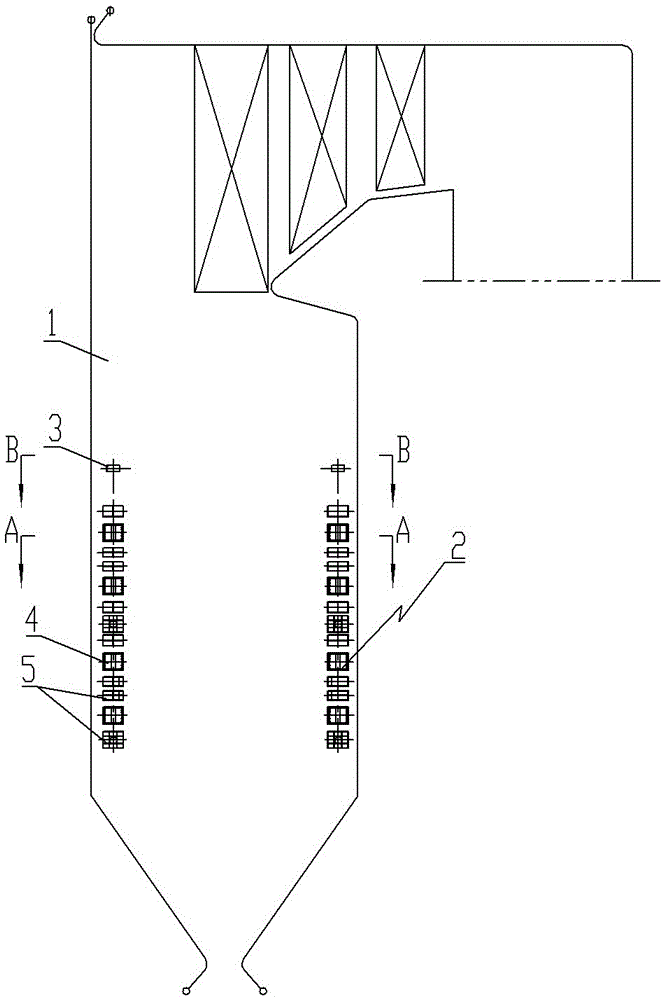

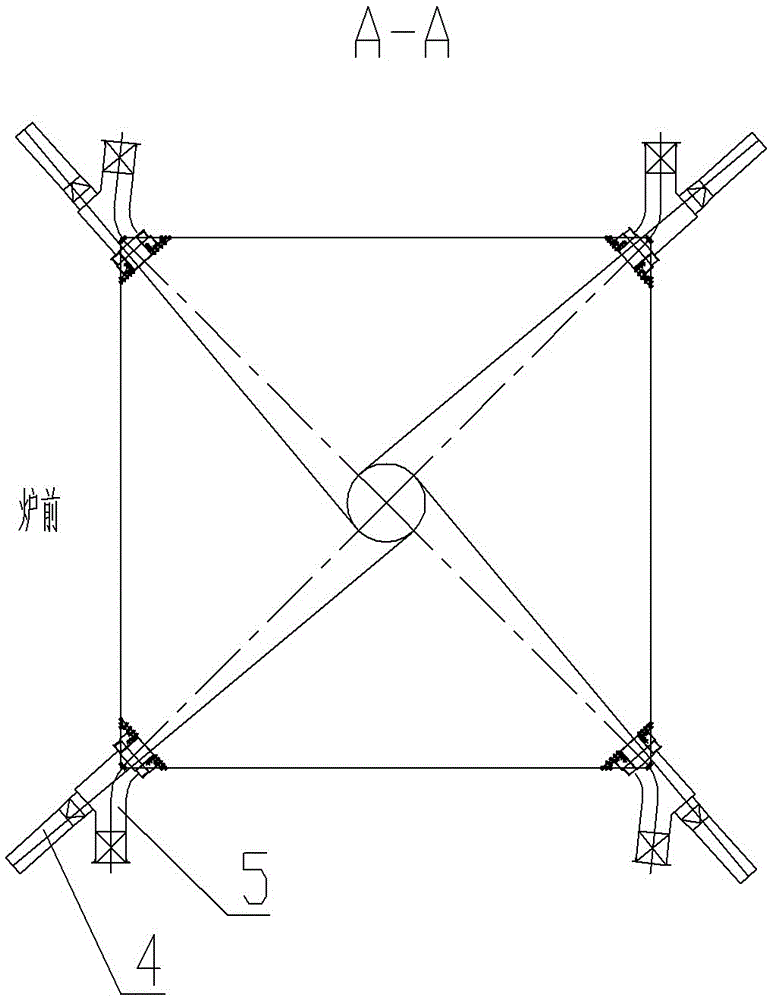

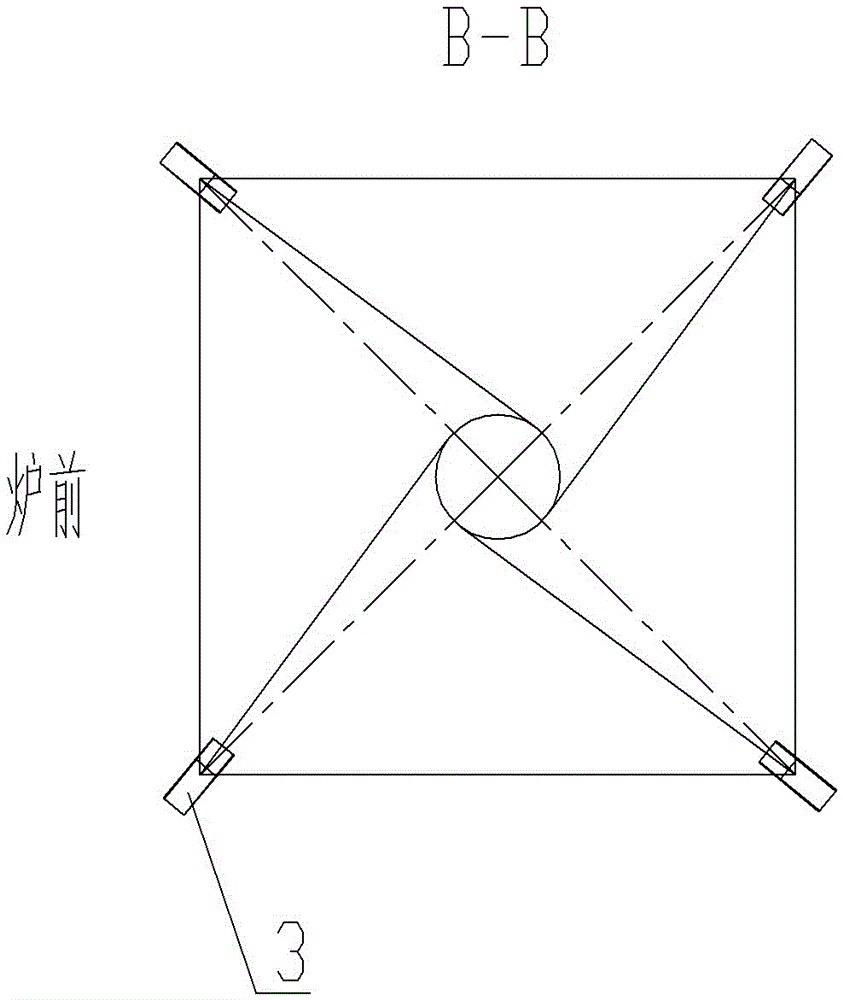

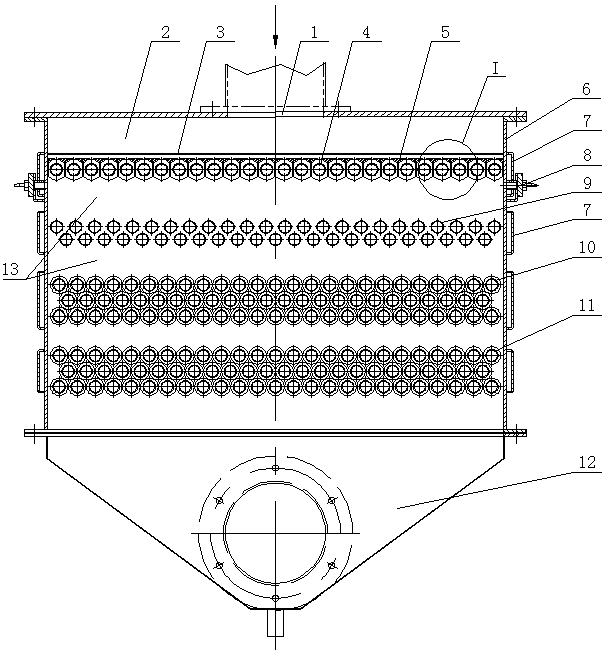

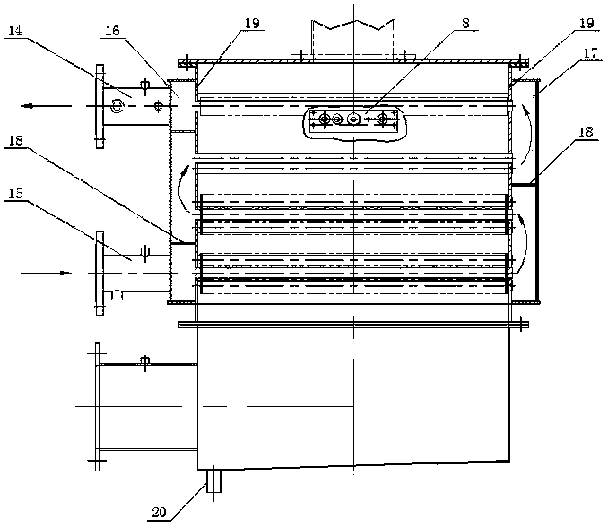

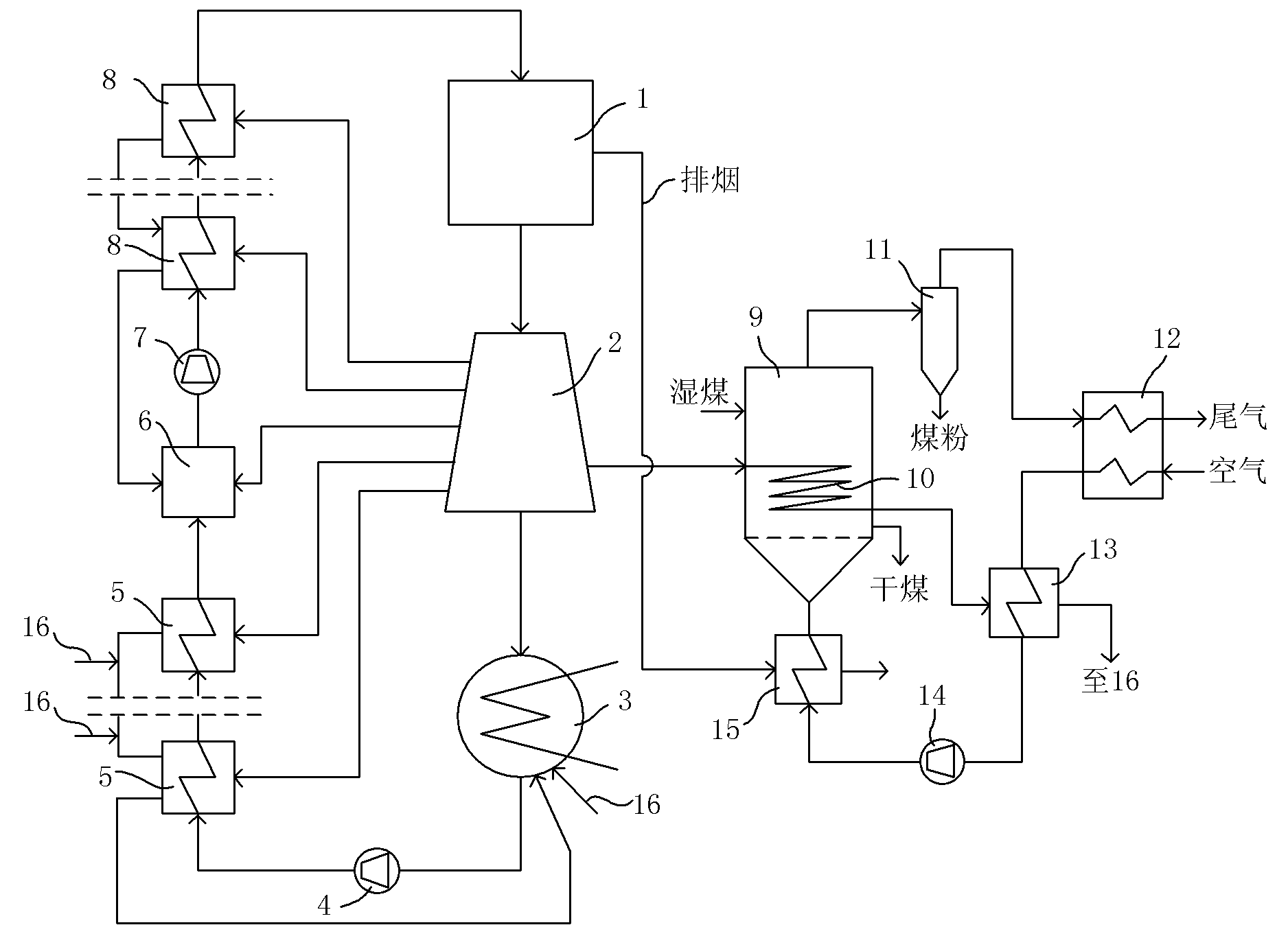

System and blending combustion method for coal-fired power station boiler for large-proportion blending combustion of semi-coke

ActiveCN108151051APromote fireImprove combustion characteristicsLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationFlue gasEngineering

The invention relates to a system and a blending combustion method for a coal-fired power station boiler for large-proportion blending combustion of semi-coke. According to the system and the blendingcombustion method, the problems that the low-volatile semi-coke fuel is difficult to fire, poor in burnout performance and high in NOx emission during combustion are solved; optimization of a pulverizing system, dense-dilute regional combustion of semi-coke fuel, in-furnace layered blending combustion of the semi-coke and bituminous coal, pure oxygen over fire air arrangement and cold energy comprehensive utilization are comprehensively considered; a four-corner tangential combustion mode is adopted, a boiler hearth five-zone combustion environment is built, and a power station boiler systemfor large-proportion blending combustion of the semi-coke is developed, so that the proportion of blending combustion of the semi-coke is larger than or equal to 45%; low NOx emission of an outlet ofa hearth is realized while high-efficiency combustion of the semi-coke is realized; and low-temperature O2 and low-temperature N2 which are close to 0 DEG C and are obtained by air separation and obtained through an air-temperature type gasifier are used for realizing deep condensation of desulfurized clean flue gas, so that water in the clean flue gas is reduced to the maximum degree, corrosion of a chimney is reduced, white smoke is also eliminated, and visual pollution around a power station is reduced.

Owner:XI AN JIAOTONG UNIV

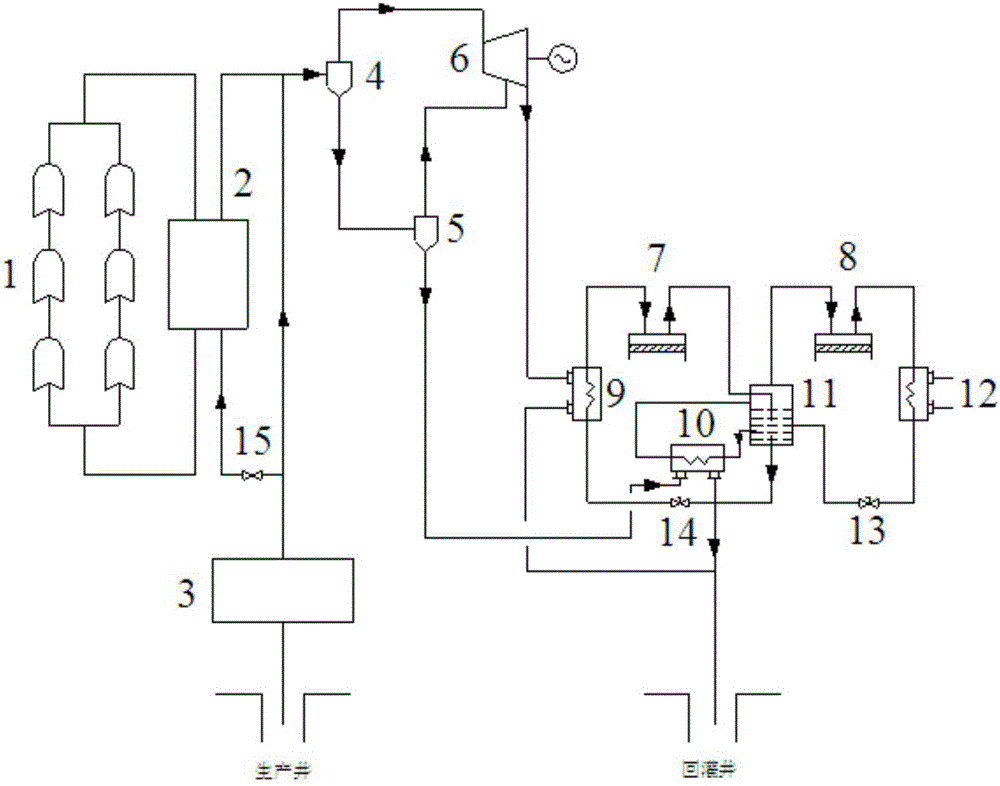

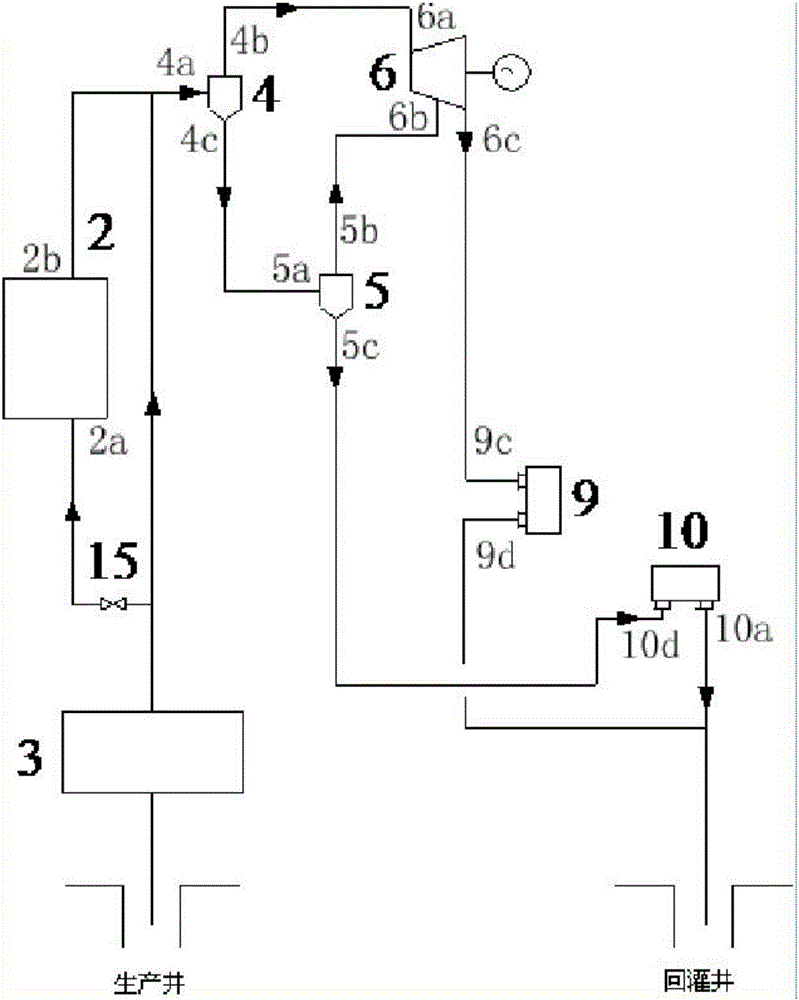

Solar energy and terrestrial heat combination two-level flash double-working-medium cycle power generation hot water system

ActiveCN105888992AImprove working abilityImprove system efficiency and power generationSolar heating energyFrom solar energyChillerEvaporator

The invention provides a solar energy and terrestrial heat combination two-level flash double-working-medium cycle power generation hot water system. The solar energy and terrestrial heat combination two-level flash double-working-medium cycle power generation hot water system comprises a groove type solar energy heat collector, a heat storage device, a terrestrial heat processing device, a first-level flash vessel, a second-level flash vessel, a steam turbine, a low-pressure compressor, a high-pressure compressor, an evaporator, a middle evaporator, a middle cooler and a condenser, wherein the terrestrial heat processing device, the first-level flash vessel, the second-level flash vessel, the steam turbine, the low-pressure compressor, the high-pressure compressor, the evaporator communicate to a production well, the middle evaporator, the middle cooler and the condenser communicate to a recharge well, and the heat storage device and the groove type solar energy heat collector communicate with each other and form a closed cycle.

Owner:SOUTHEAST UNIV

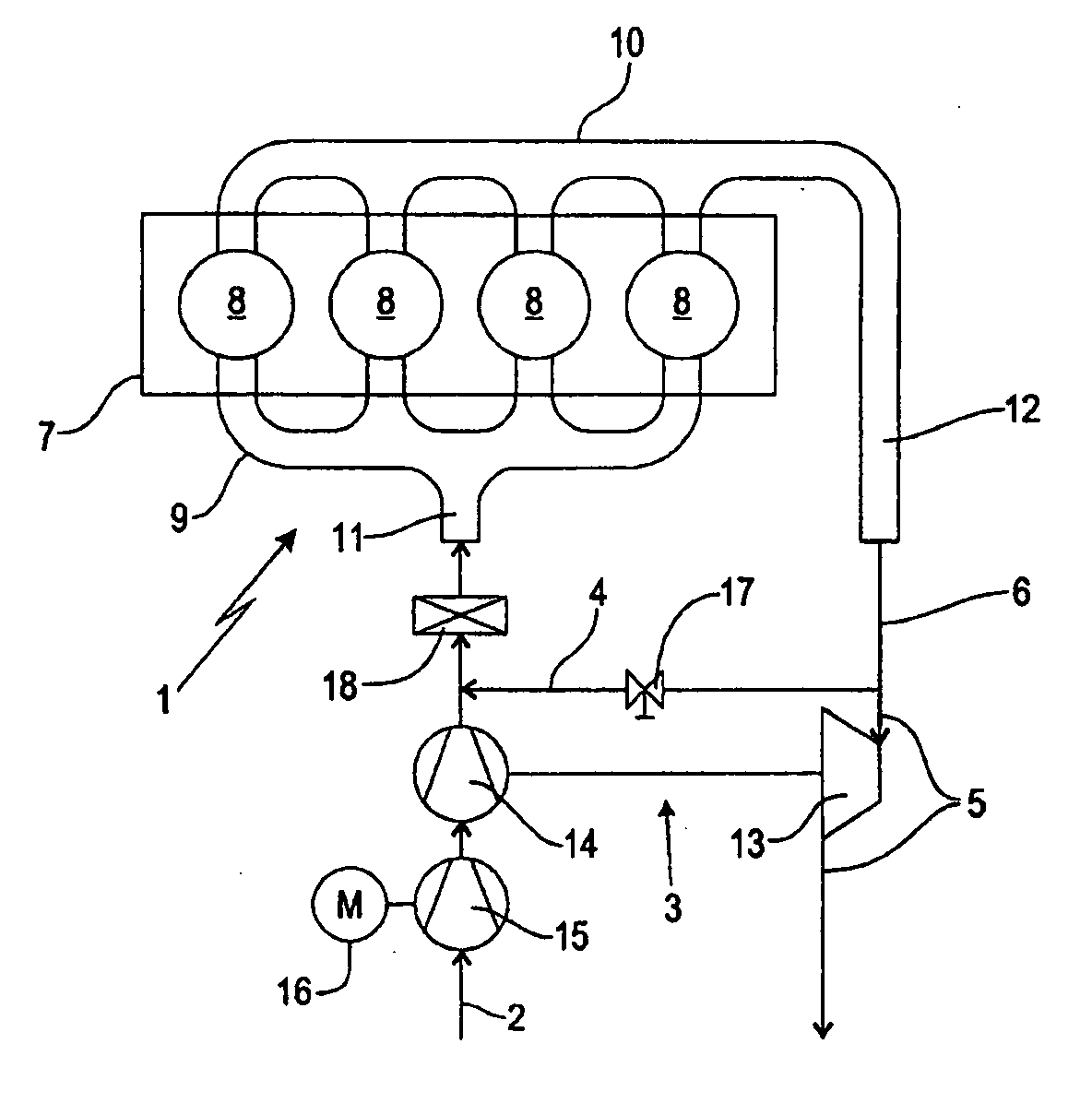

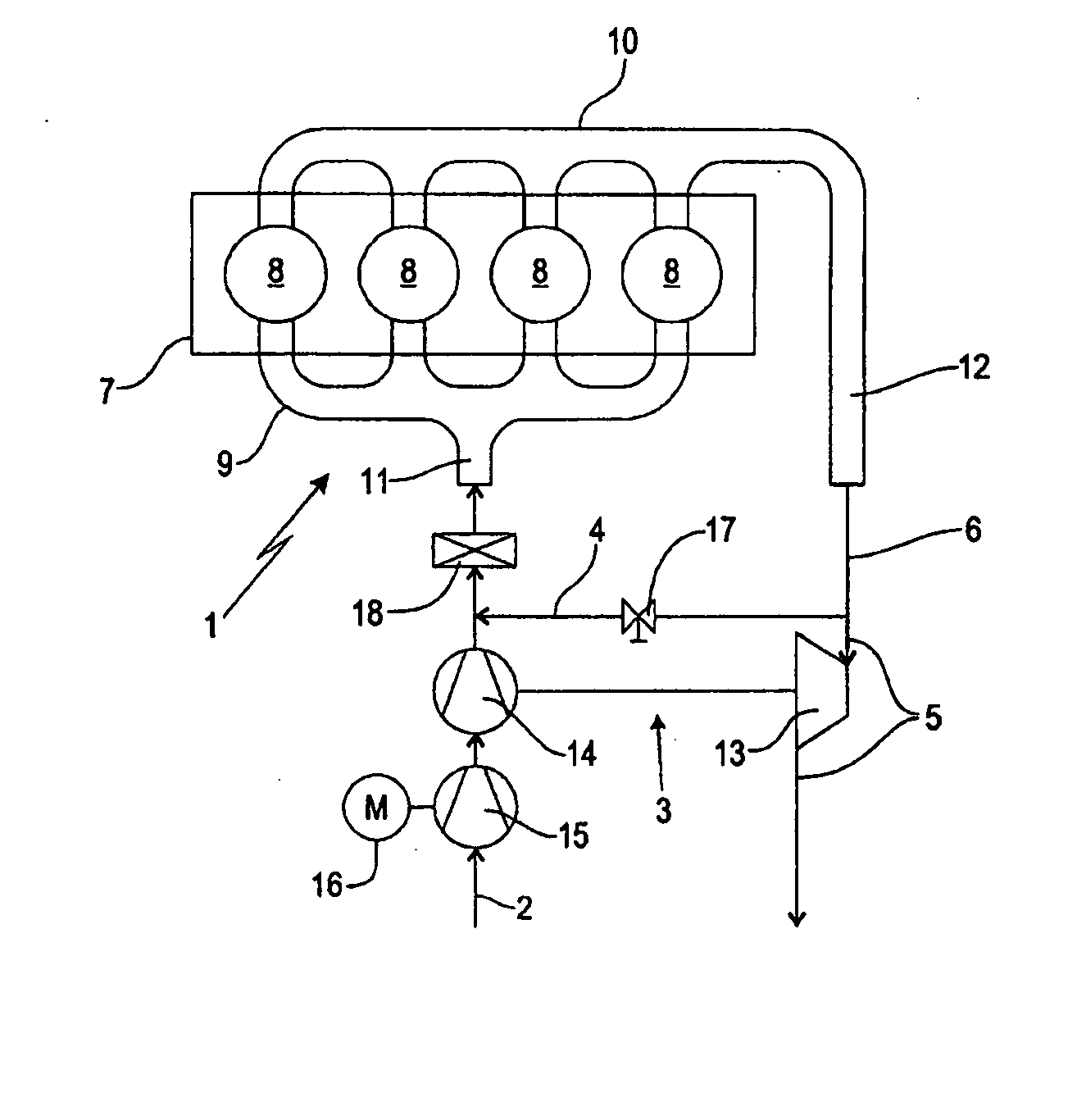

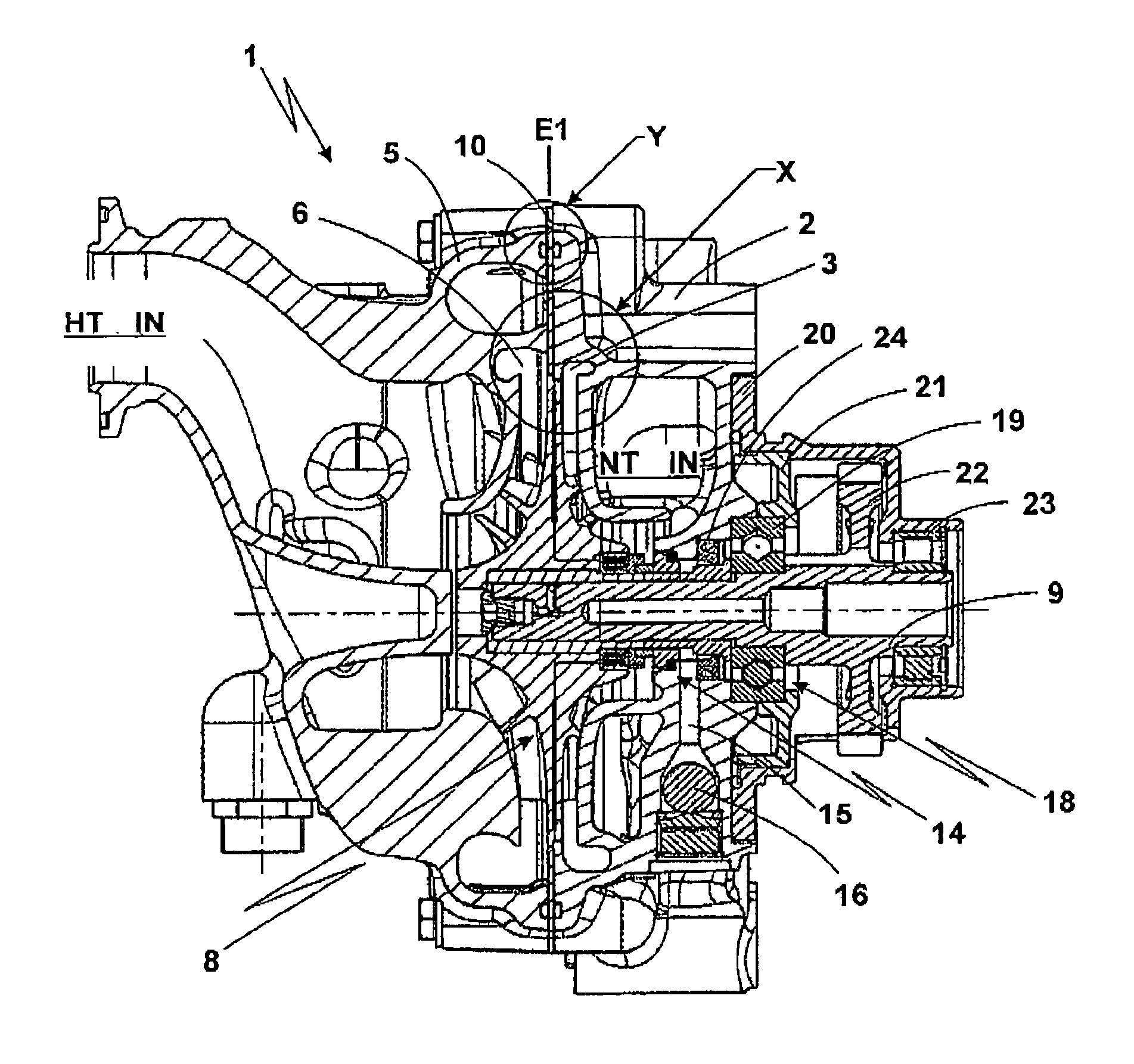

Method for operating a spark ignition engine

ActiveUS20090173319A1Lower temperature levelAdequate power levelValve arrangementsElectrical controlBattery chargerExhaust gas

In a method for operating a spark ignition engine, wherein the inlet valves of the spark ignition engine are closed very early or very late, and a combustion air flow which is supplied to the spark ignition engine is compressed by means of a charger, and, under full load operation, the inlet valves are closed either early or late to avoid knocking of the engine, a partial flow of re-circulated exhaust gas is supplied to the combustion air flow supplied to the engine also during full load engine operation.

Owner:DAIMLER AG

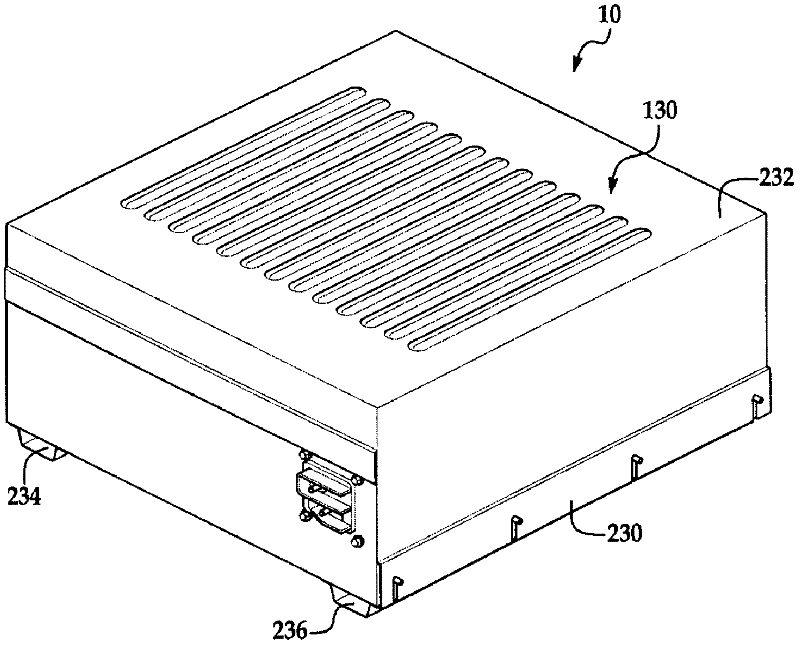

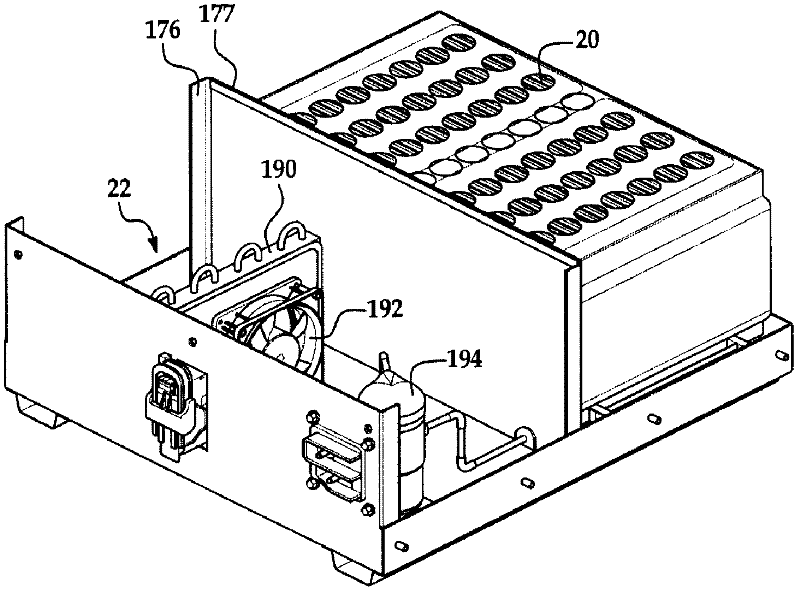

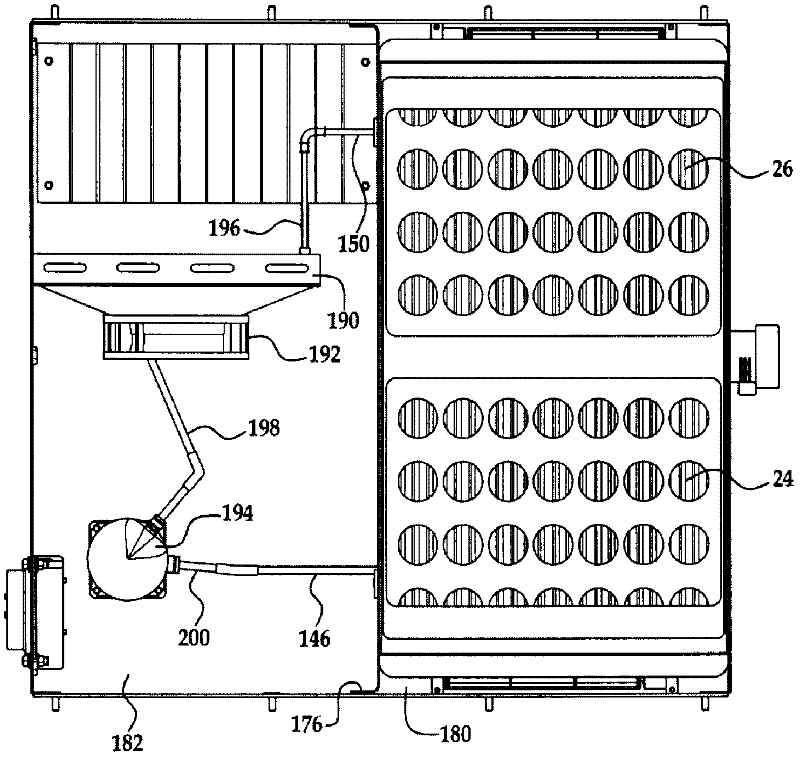

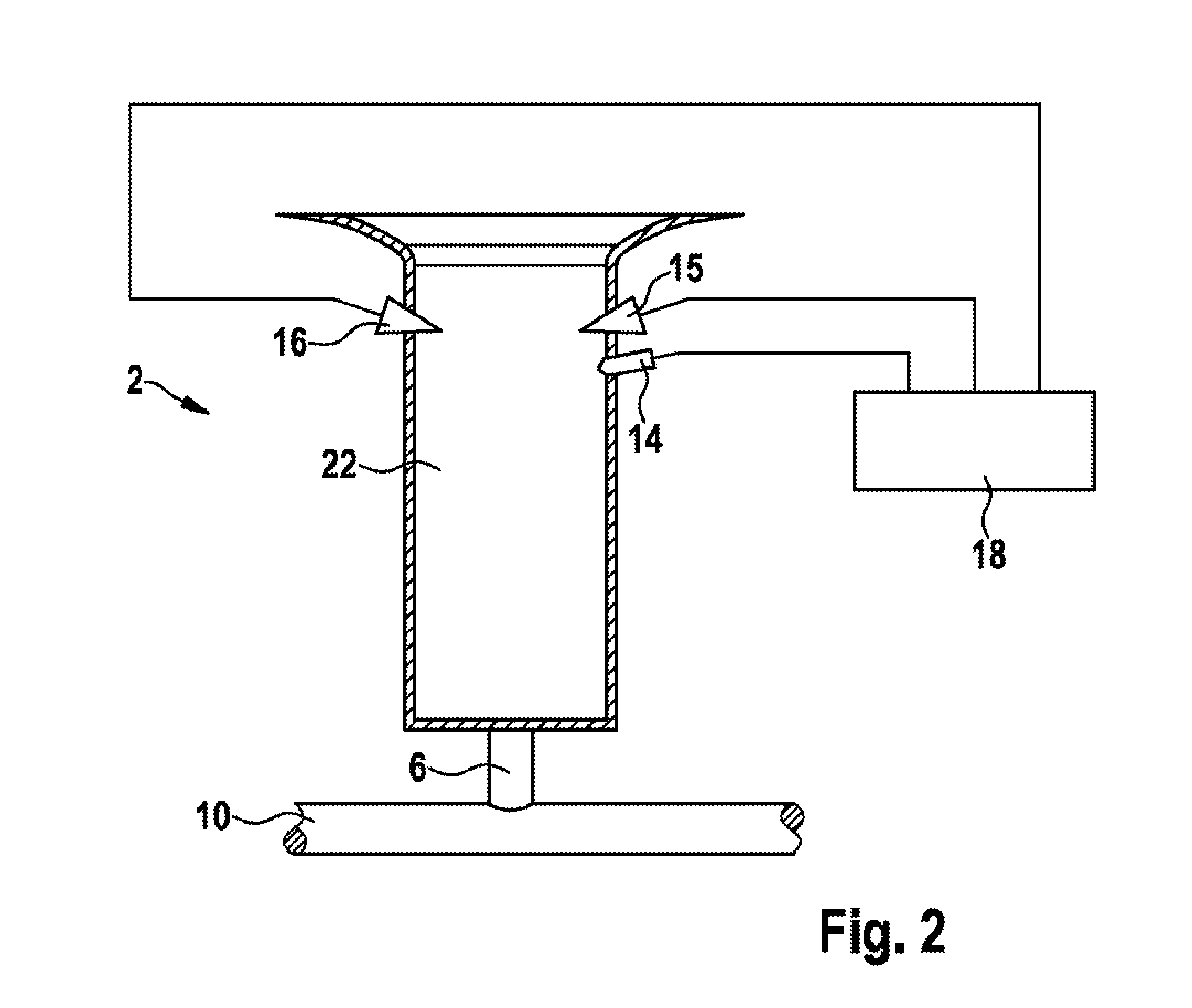

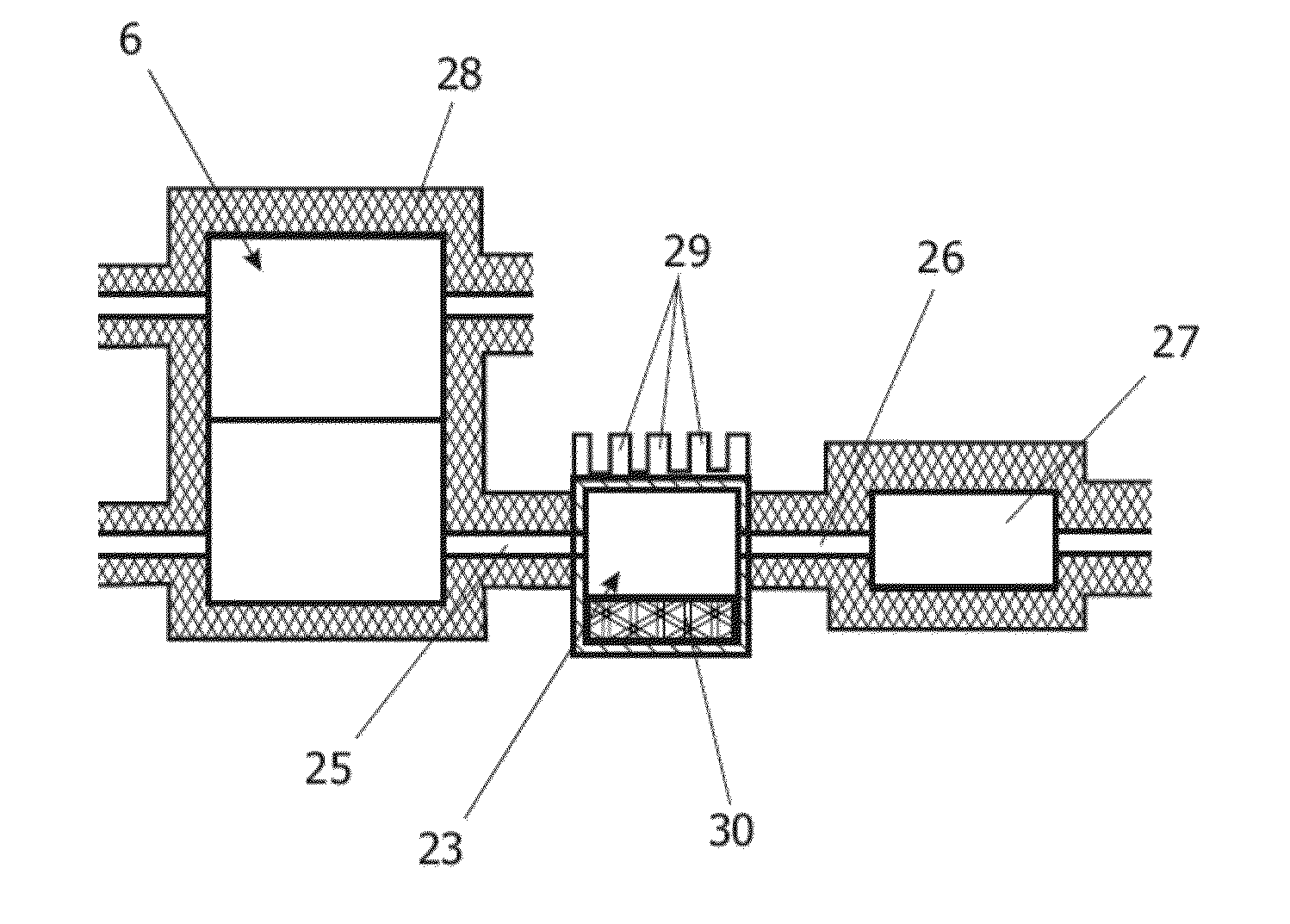

Cooling system for battery systems and a method for cooling battery systems

ActiveCN102396098ALower temperature levelLighting and heating apparatusCurrent conducting connectionsBattery systemHeating energy

Owner:LG ENERGY SOLUTION LTD

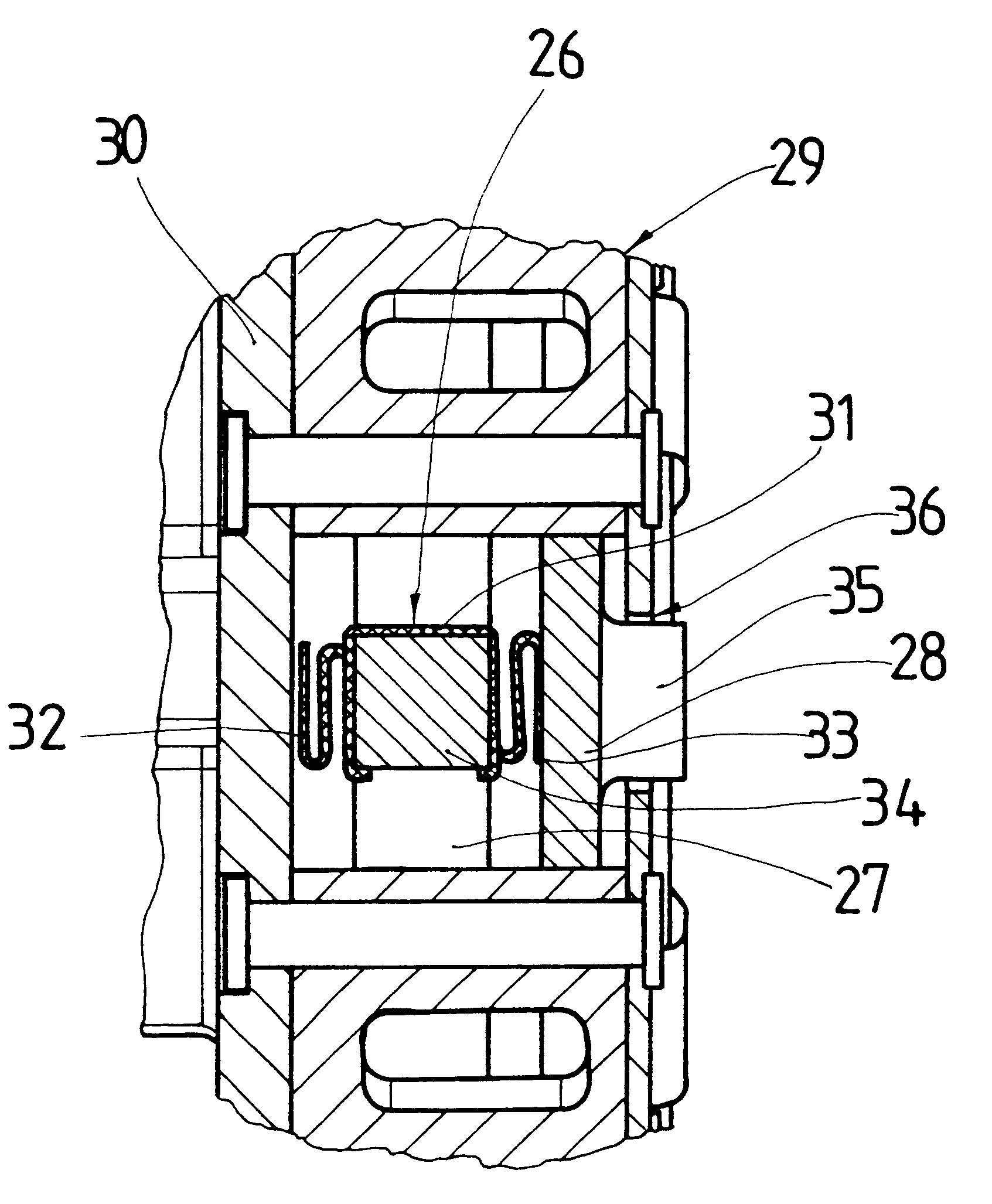

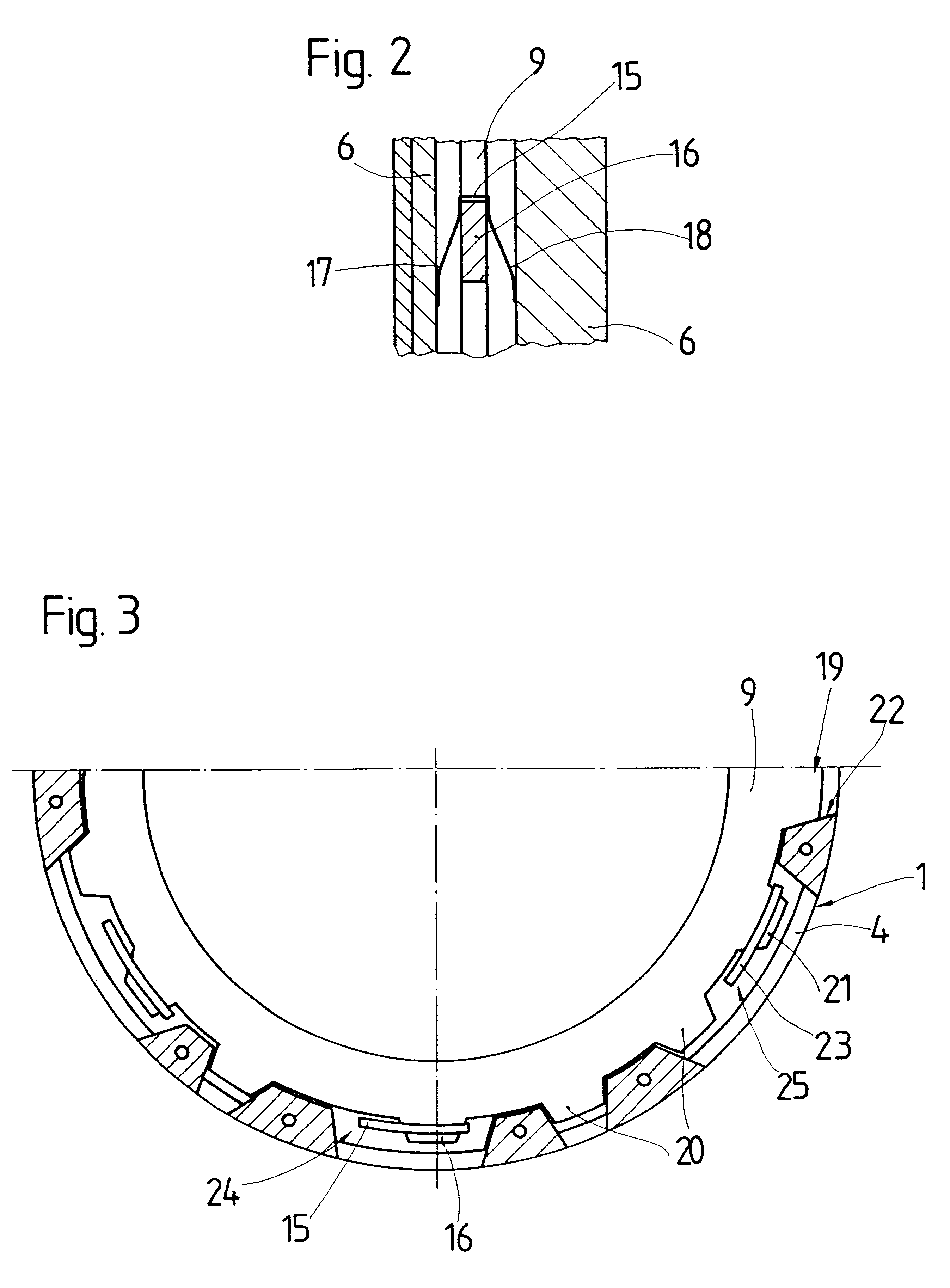

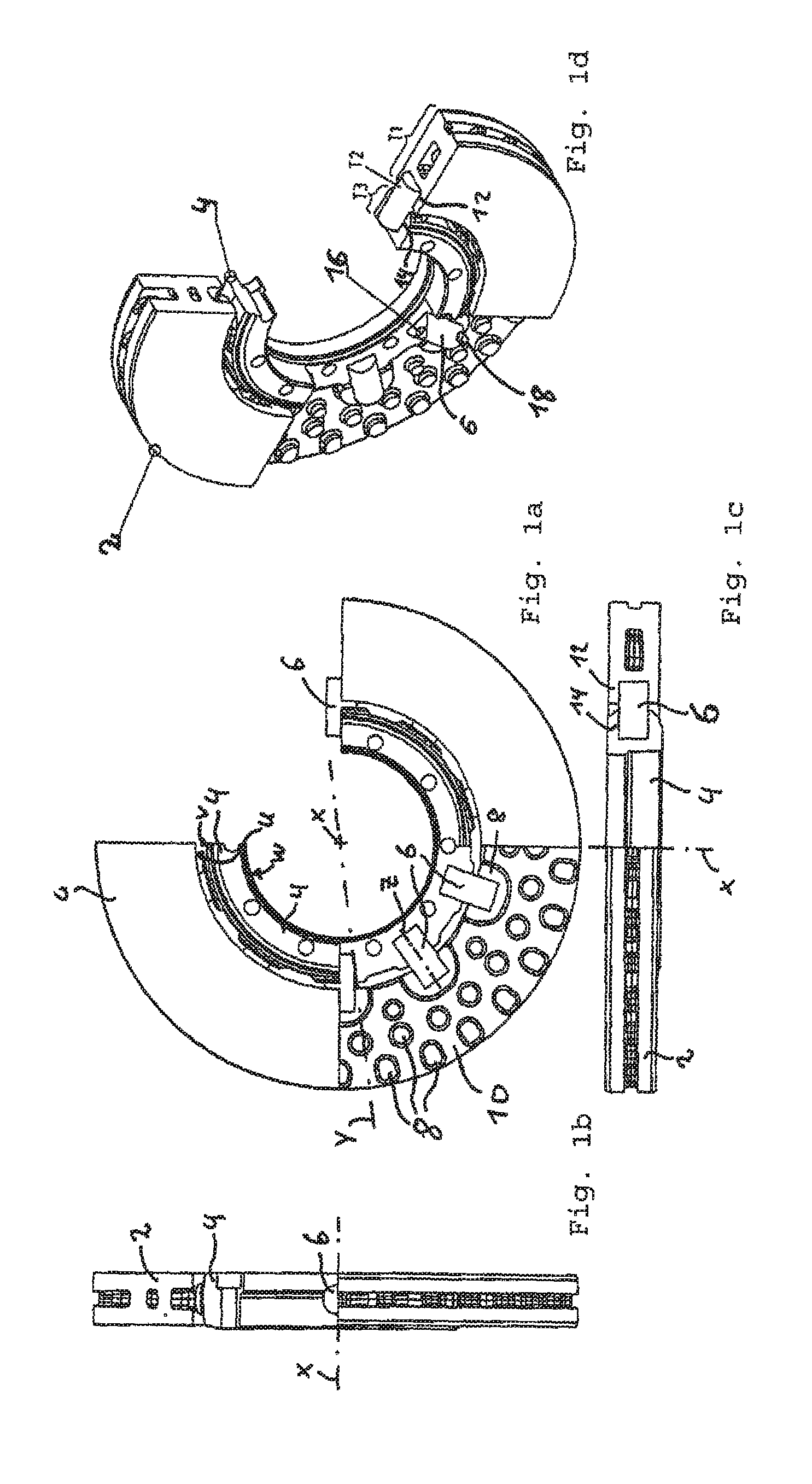

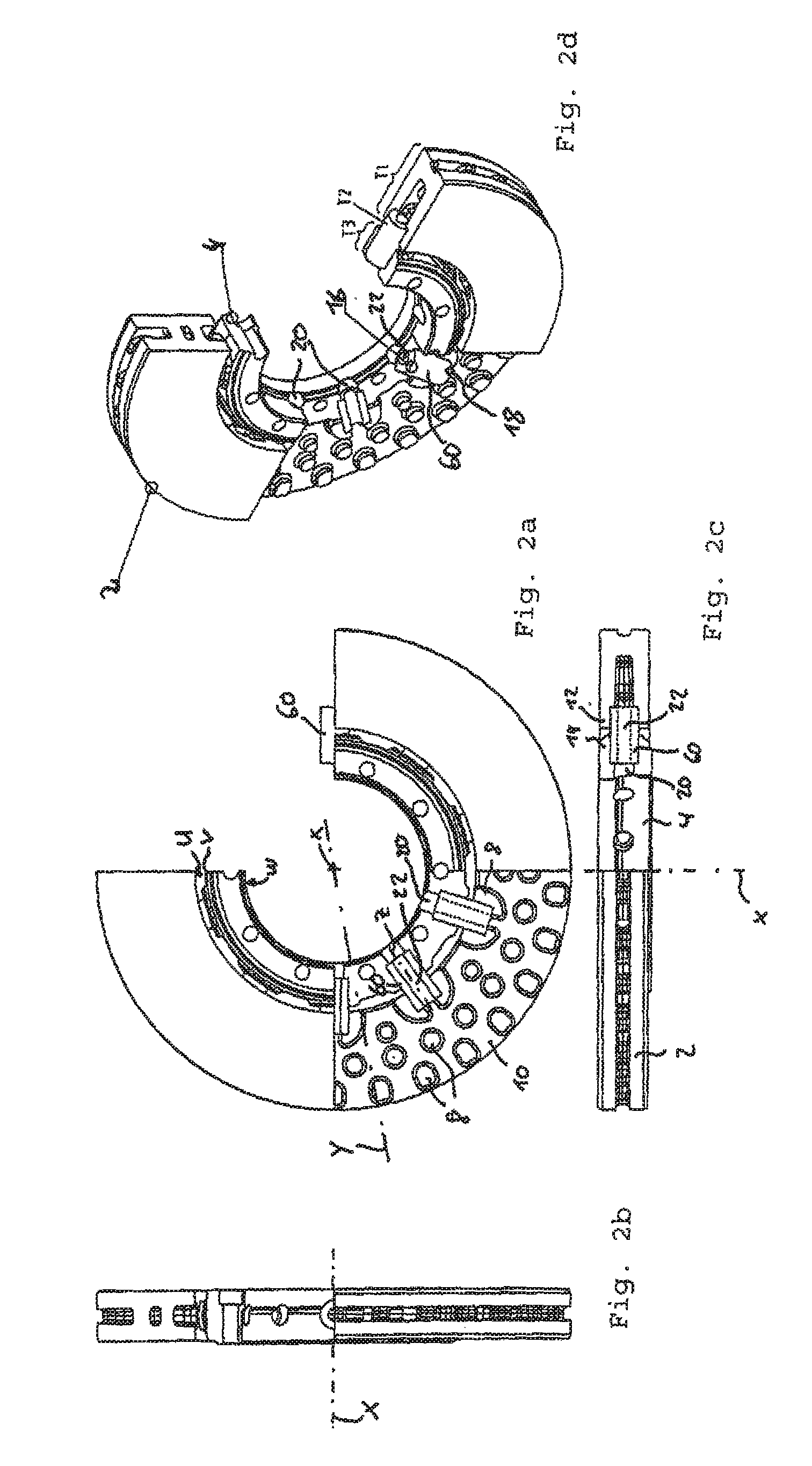

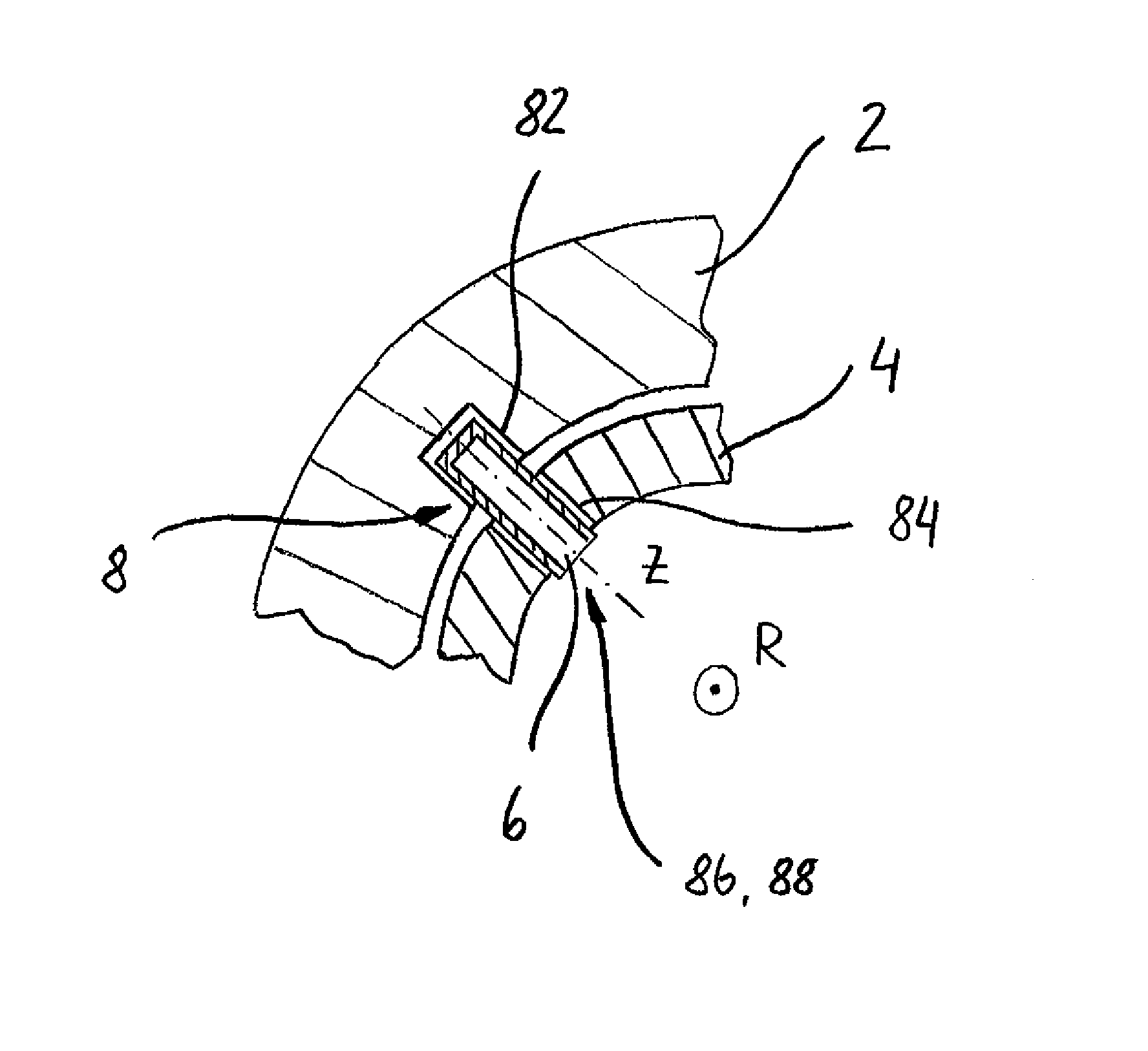

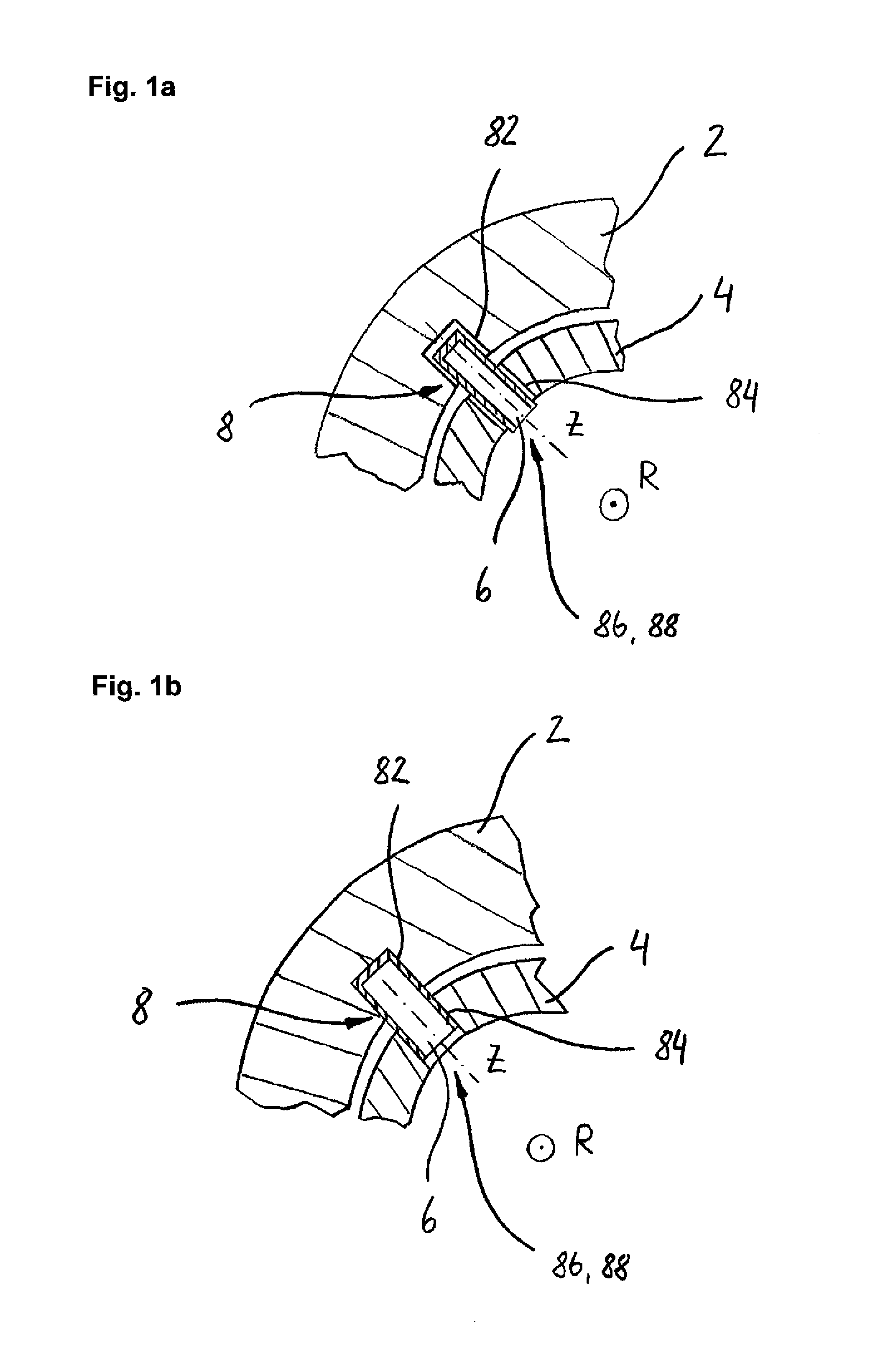

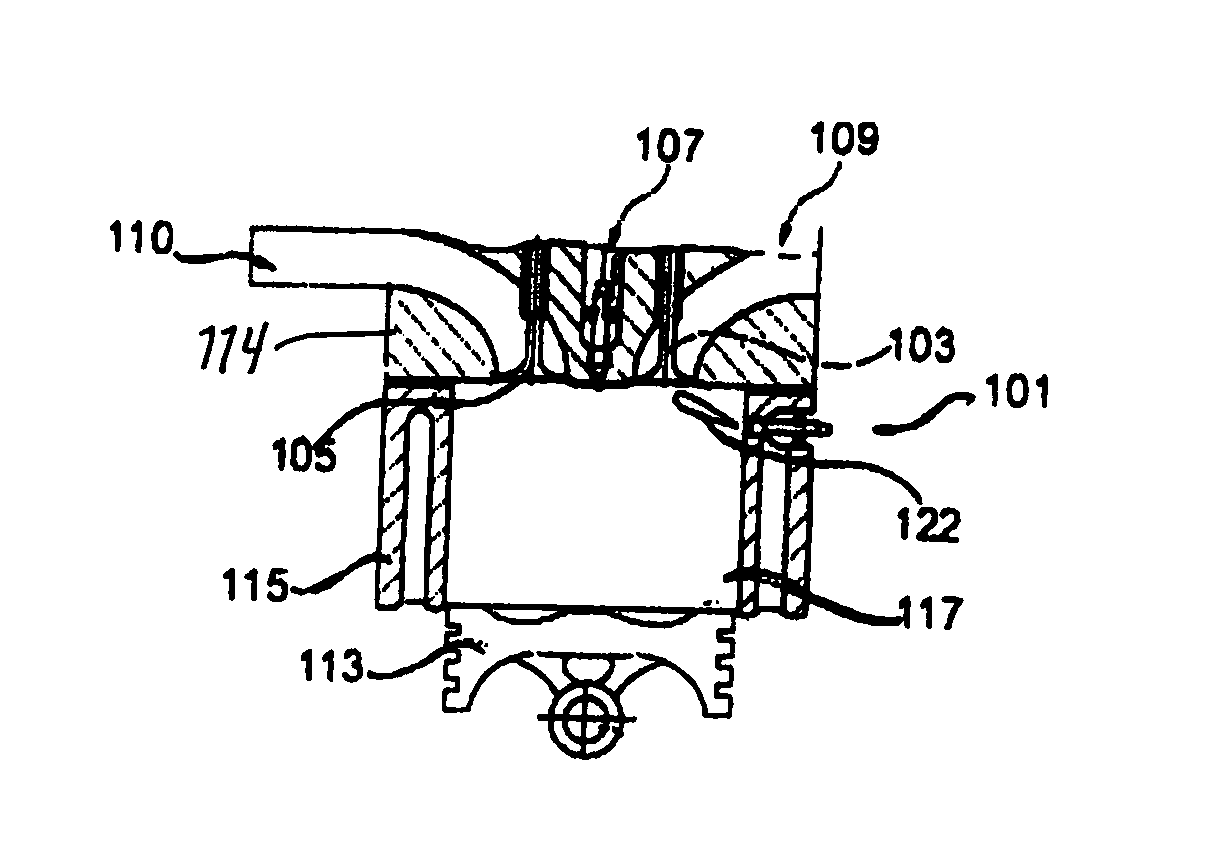

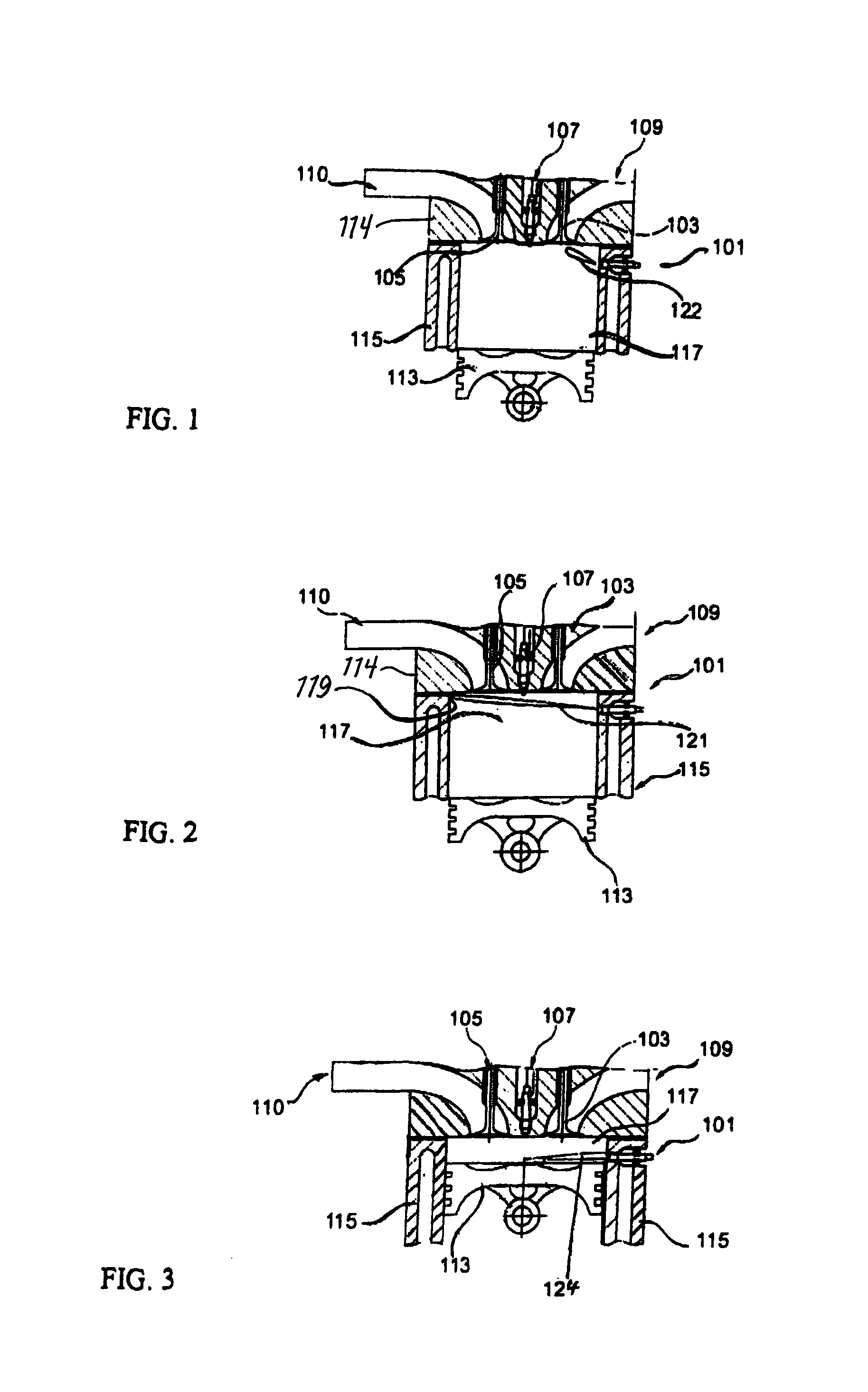

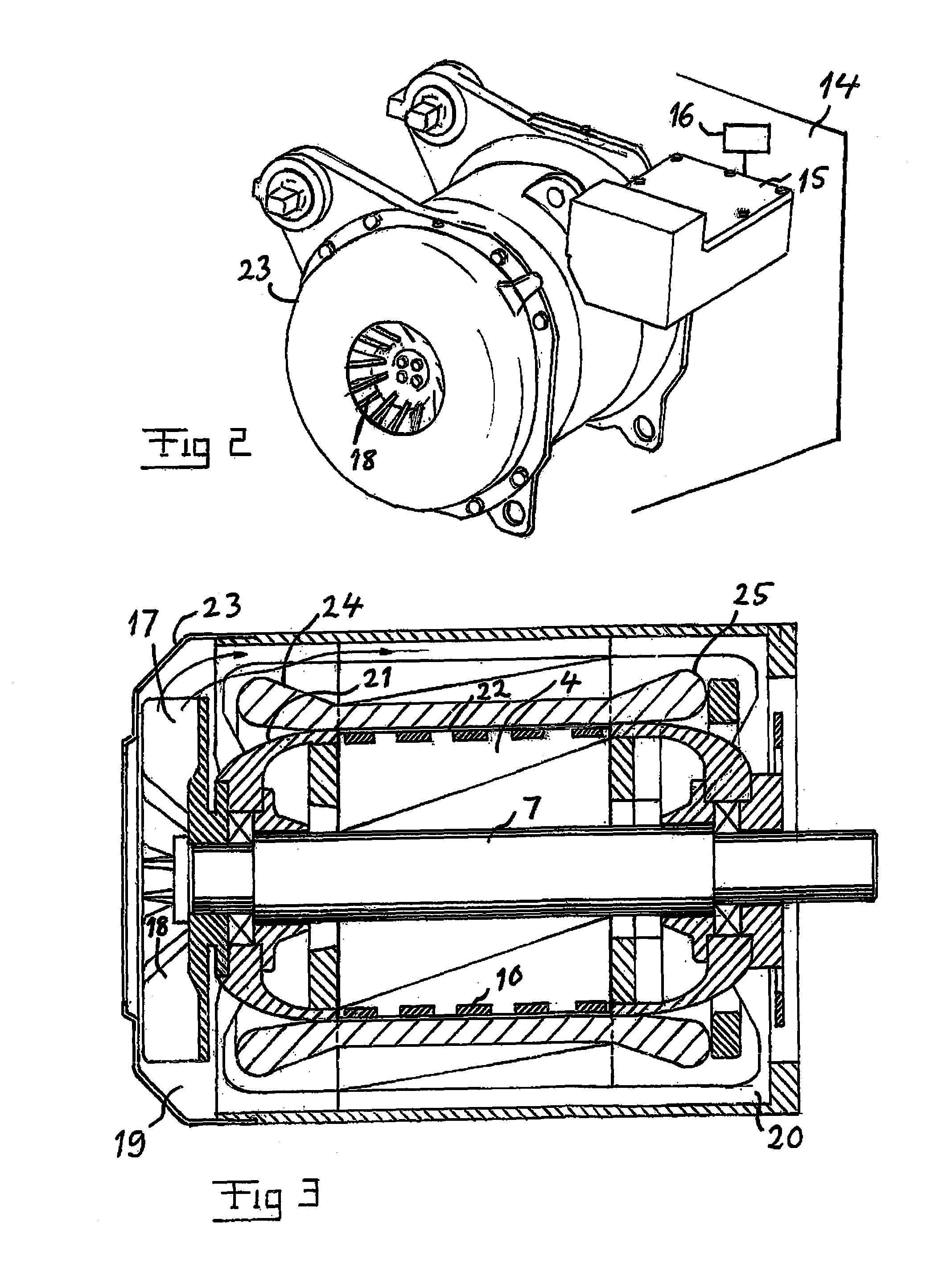

Multi-plate clutch for a motor vehicle

A multi-plate clutch for a motor vehicle has a U-shaped spring element fastened to an intermediate plate for holding adjacent pressure plates at a distance from one another. The intermediate plate is reliably held between the pressure plates. Grinding of friction facings arranged between the intermediate plate and the pressure plates is accordingly minimized. The spring element is arranged in an area of an external toothing of the intermediate plate and therefore does not contribute to an increase in the radial dimensions of the multi-plate clutch.

Owner:ZF FRIEDRICHSHAFEN AG

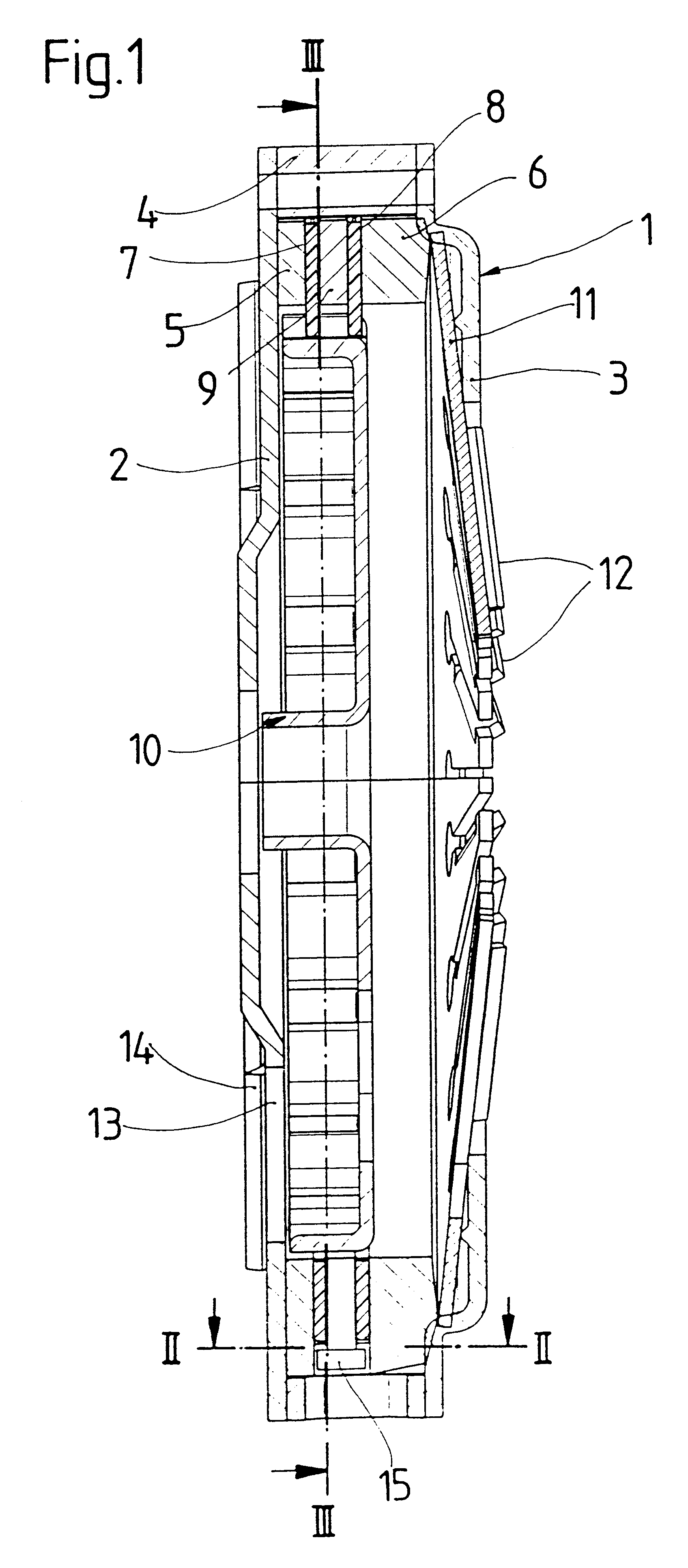

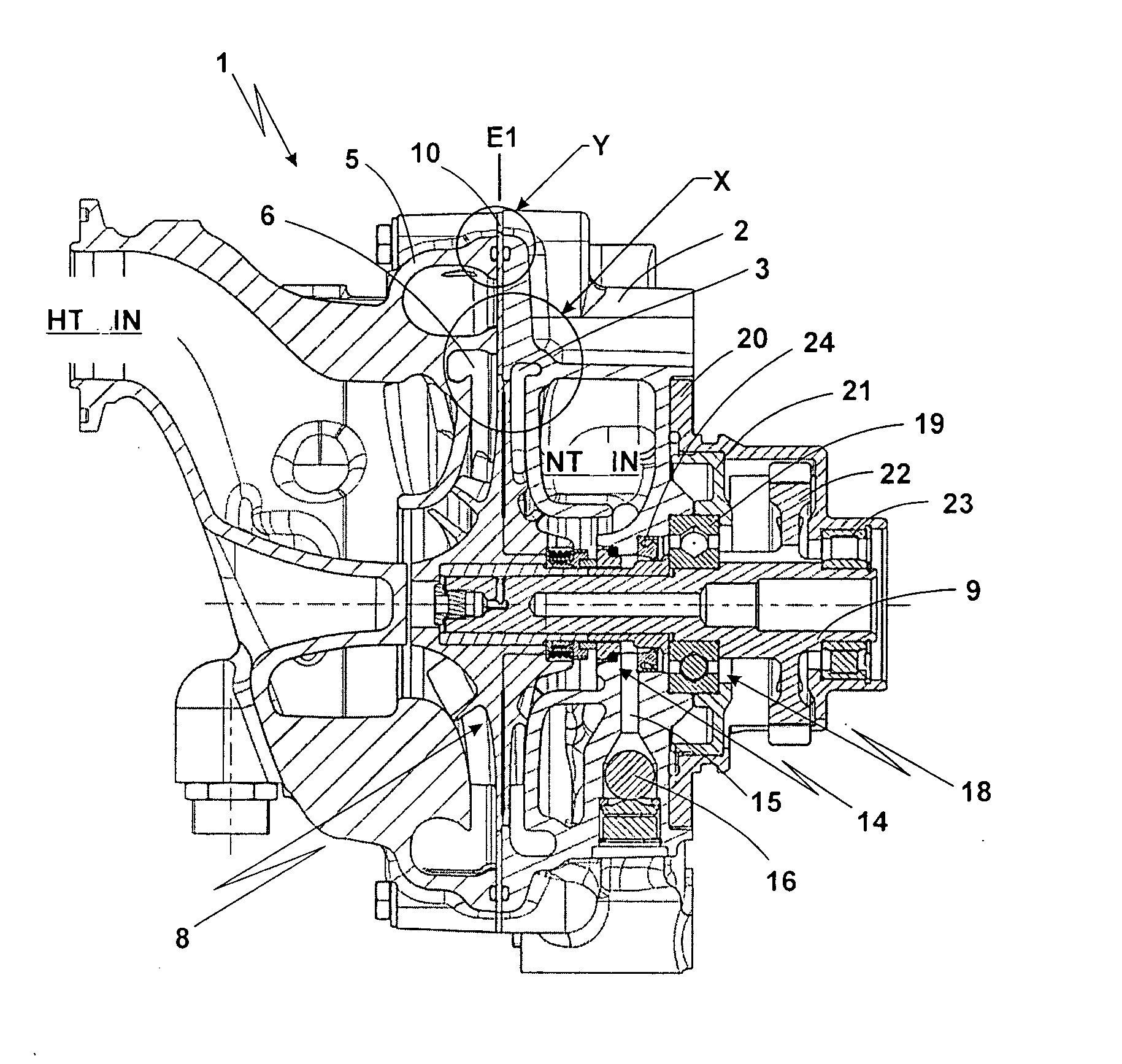

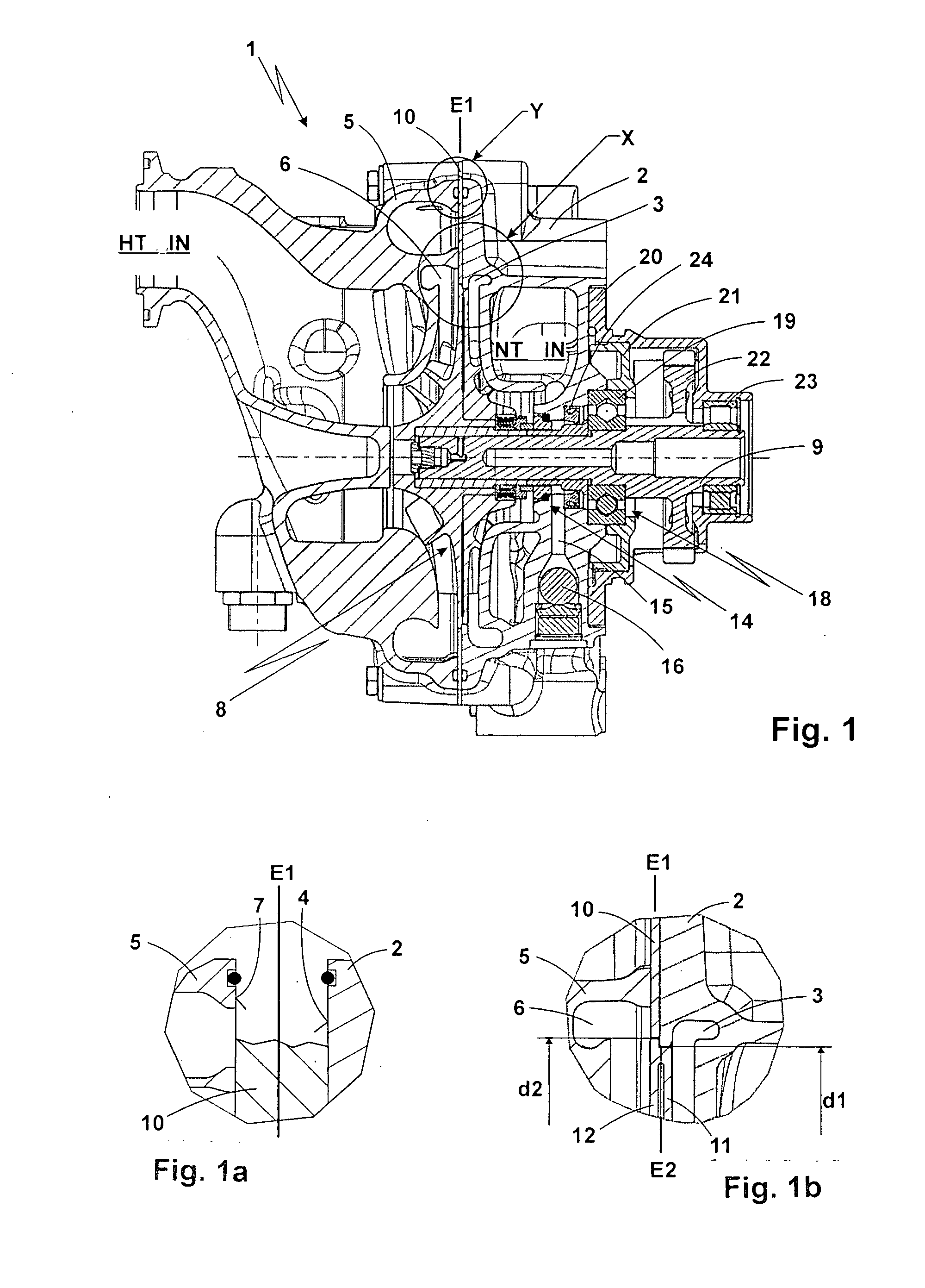

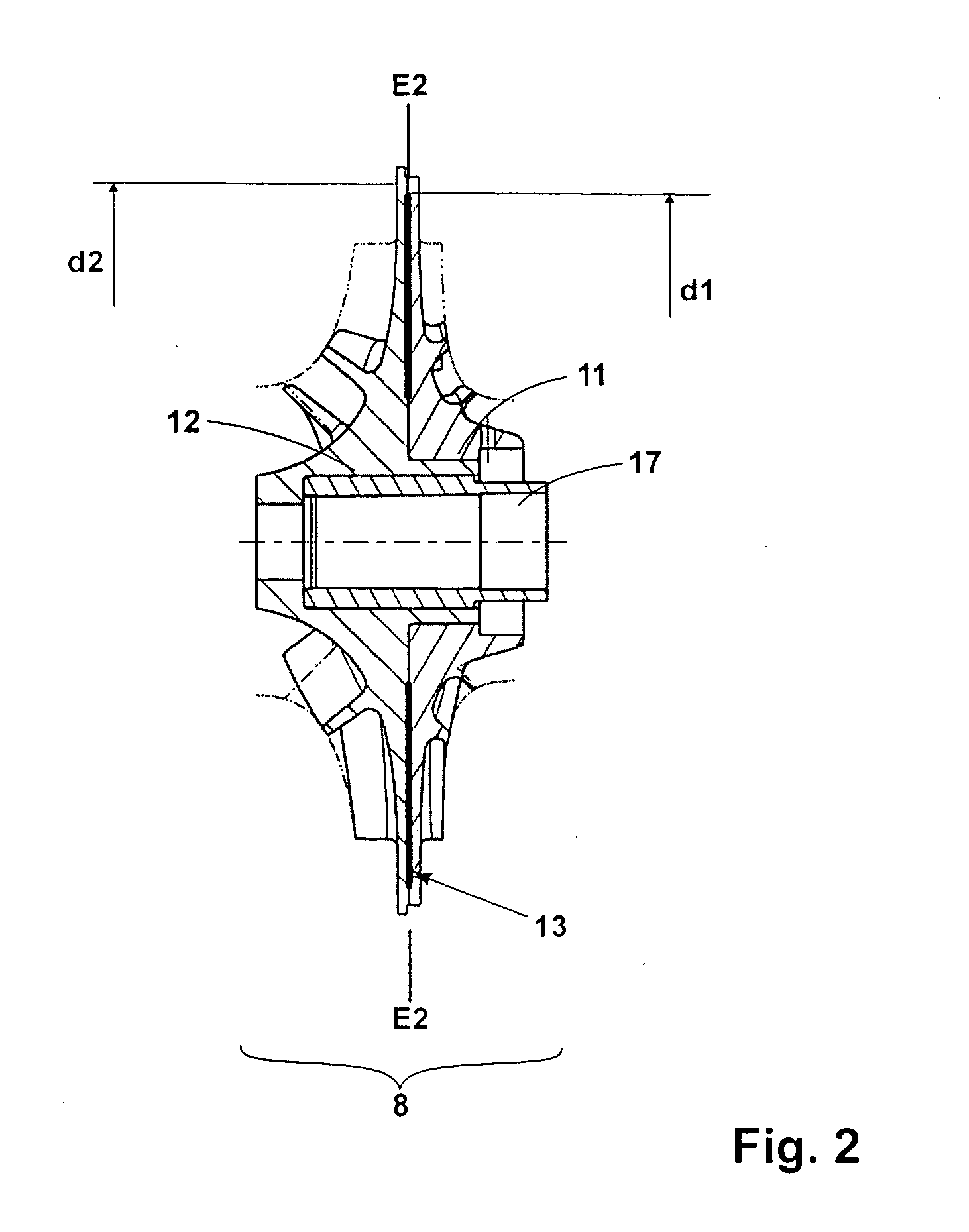

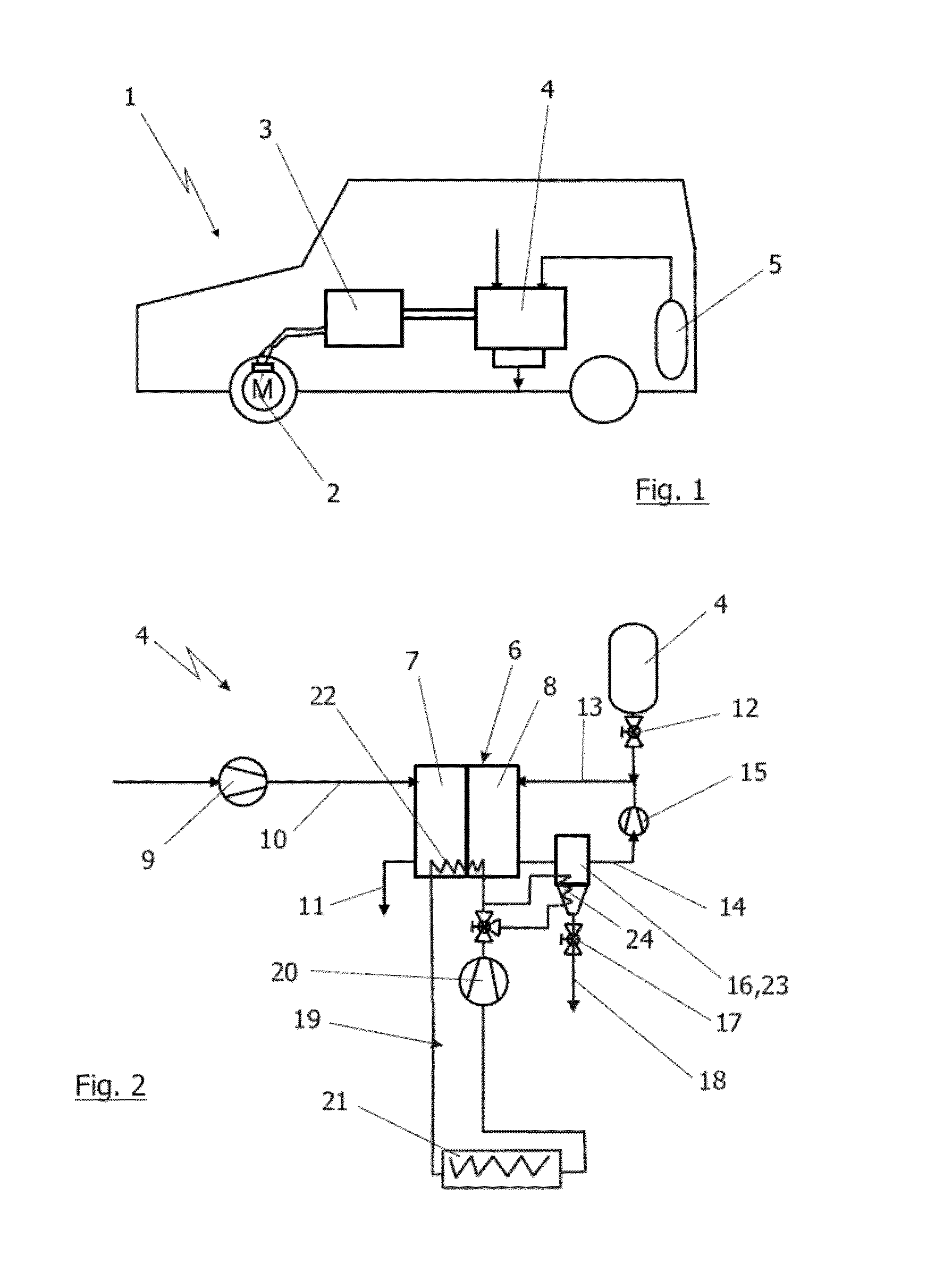

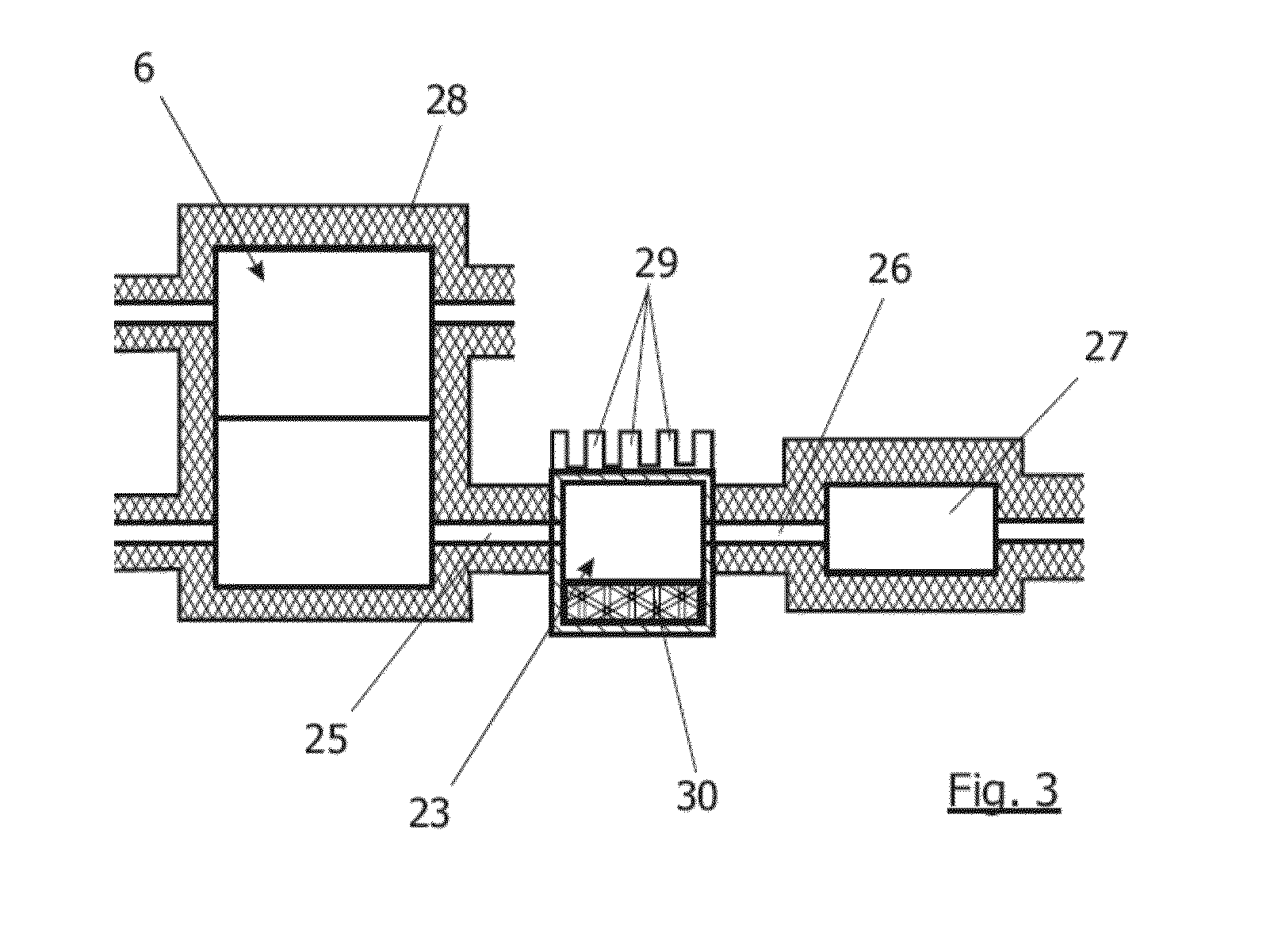

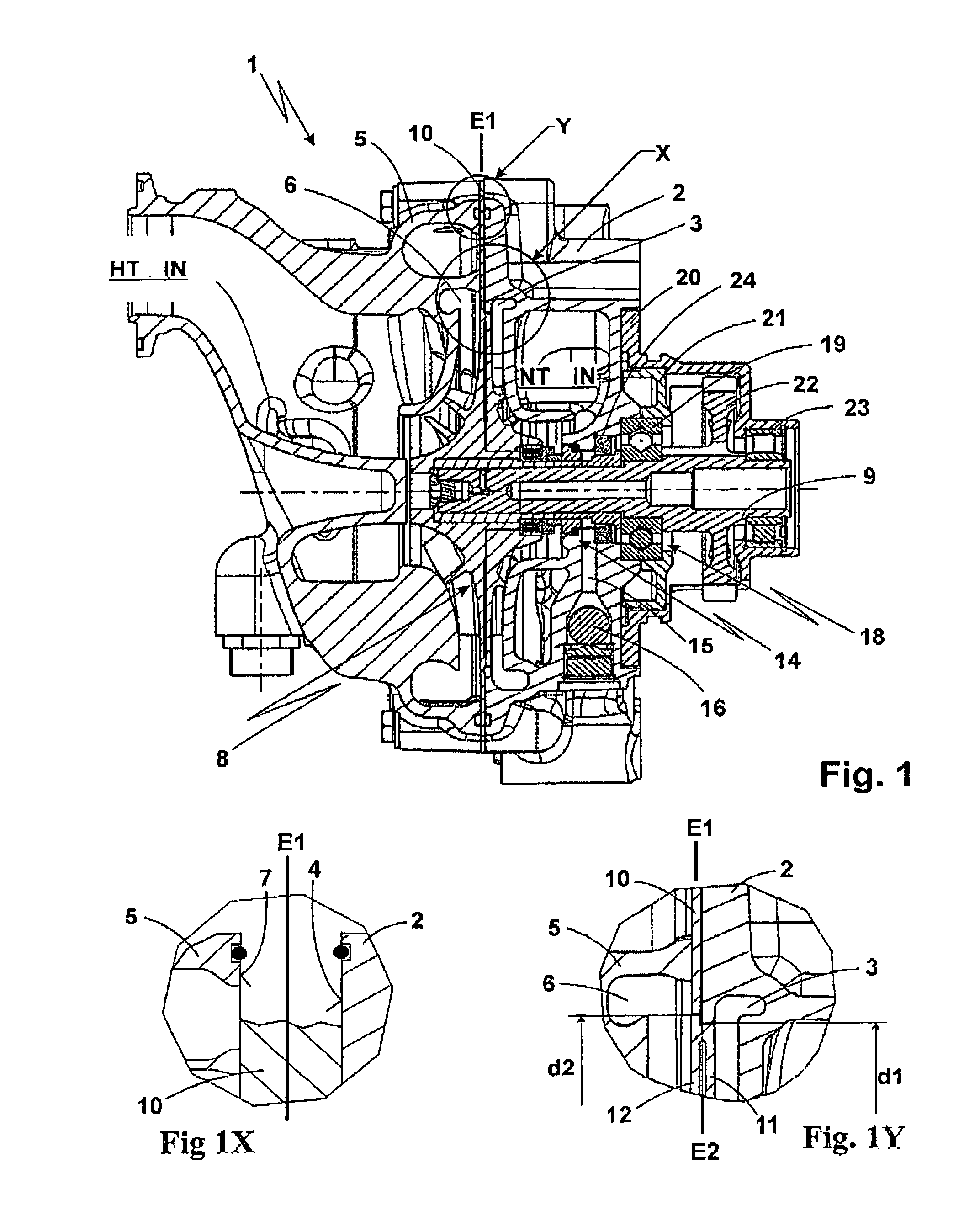

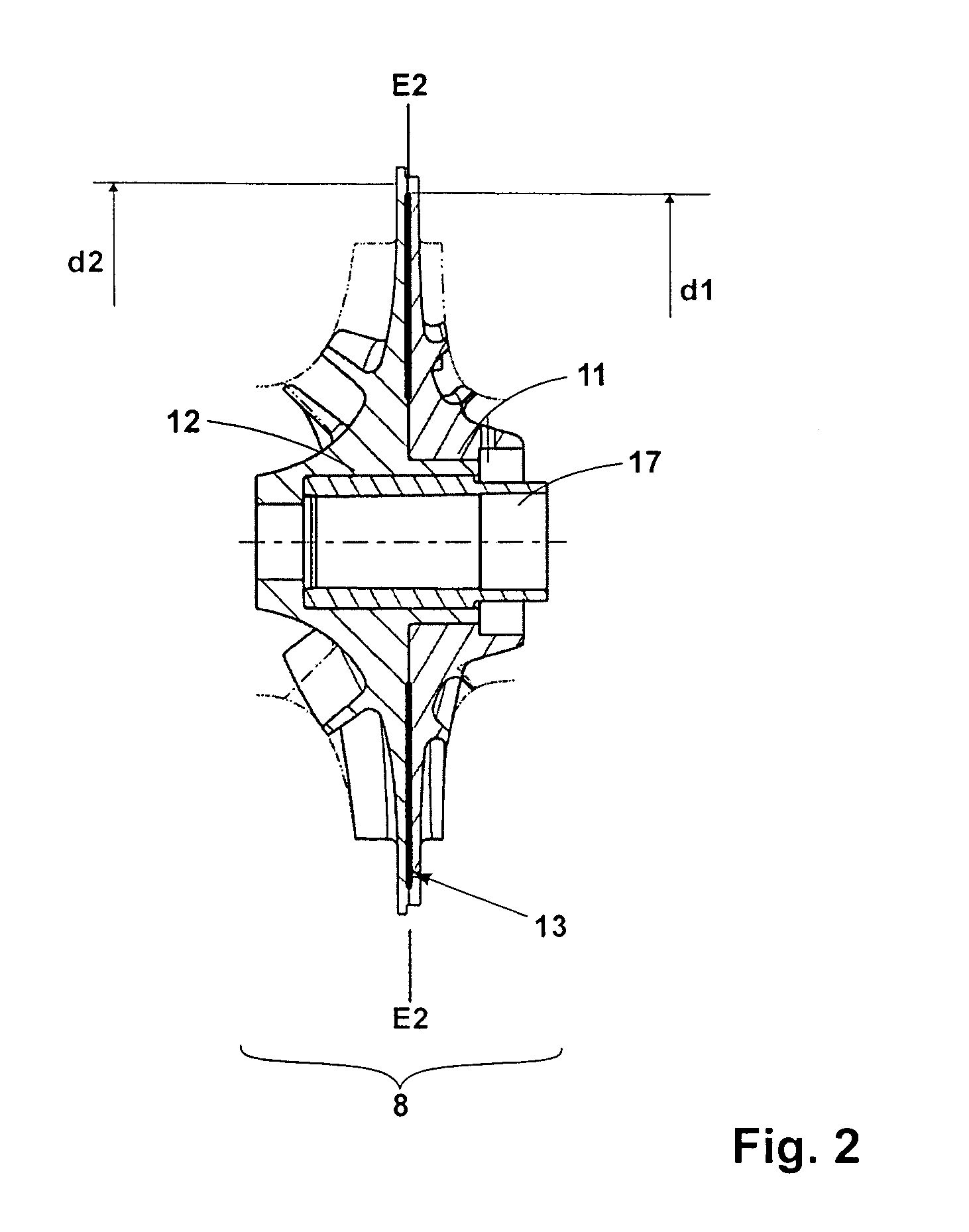

Water pump for pumping coolant in a low temperature and in a high temperature circuit

InactiveUS20100143109A1Prevent heat transferLess heat energyPump componentsReaction enginesHeat transmissionProcess engineering

In a water pump for pumping coolant in a low temperature and a high temperature circuit with low temperature and high temperature housings each including a spiral flow guide structure, and a single rotor disposed in the joined housings and having a low temperature rotor part for pumping coolant through the low temperature circuit and a high temperature rotor part for pumping coolant through the high temperature circuit, the housings are joined with a heat isolating structure disposed between the flow guide structures of the high temperature and the low temperature housings to limit heat transfer from the high temperature coolant pumped through the high temperature housing to the low temperature coolant pumped through the low temperature housing.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

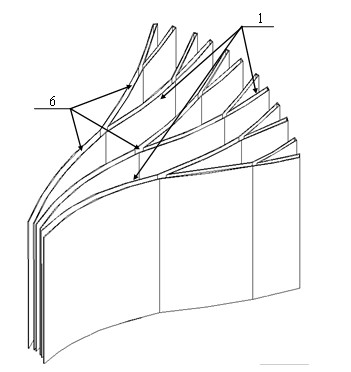

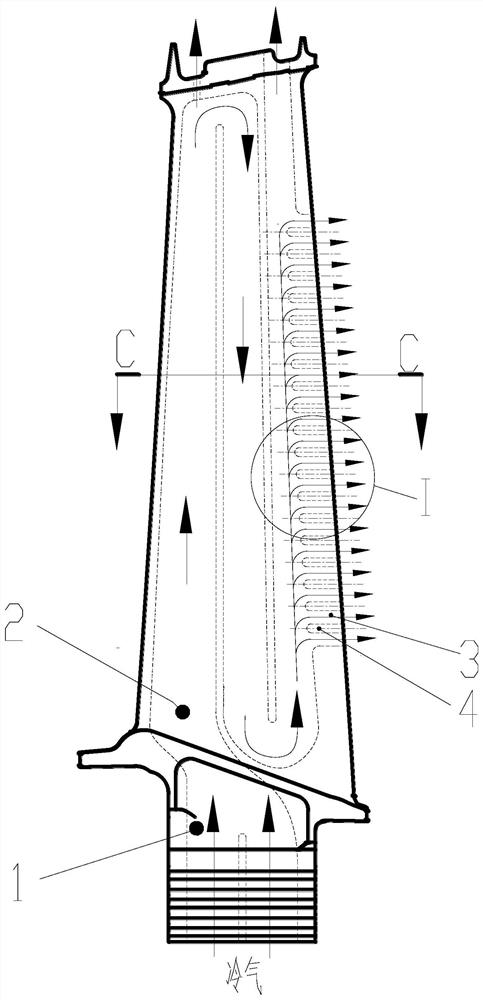

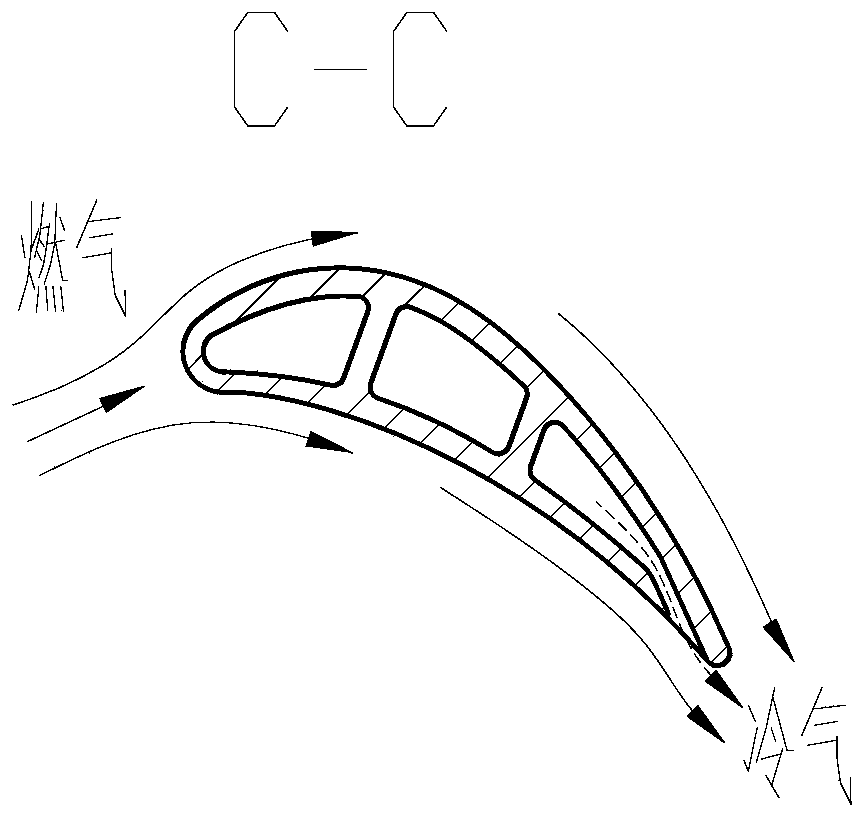

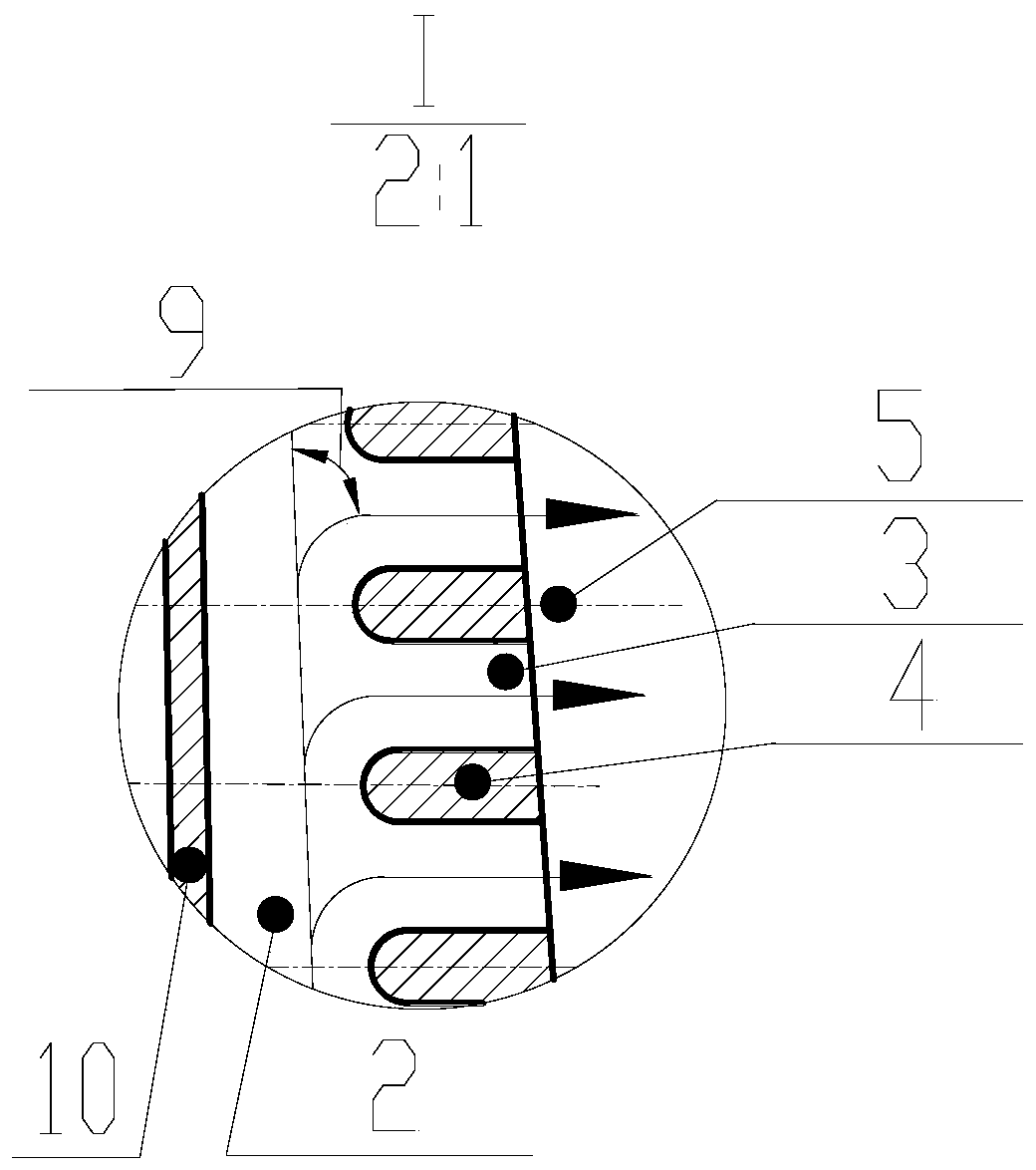

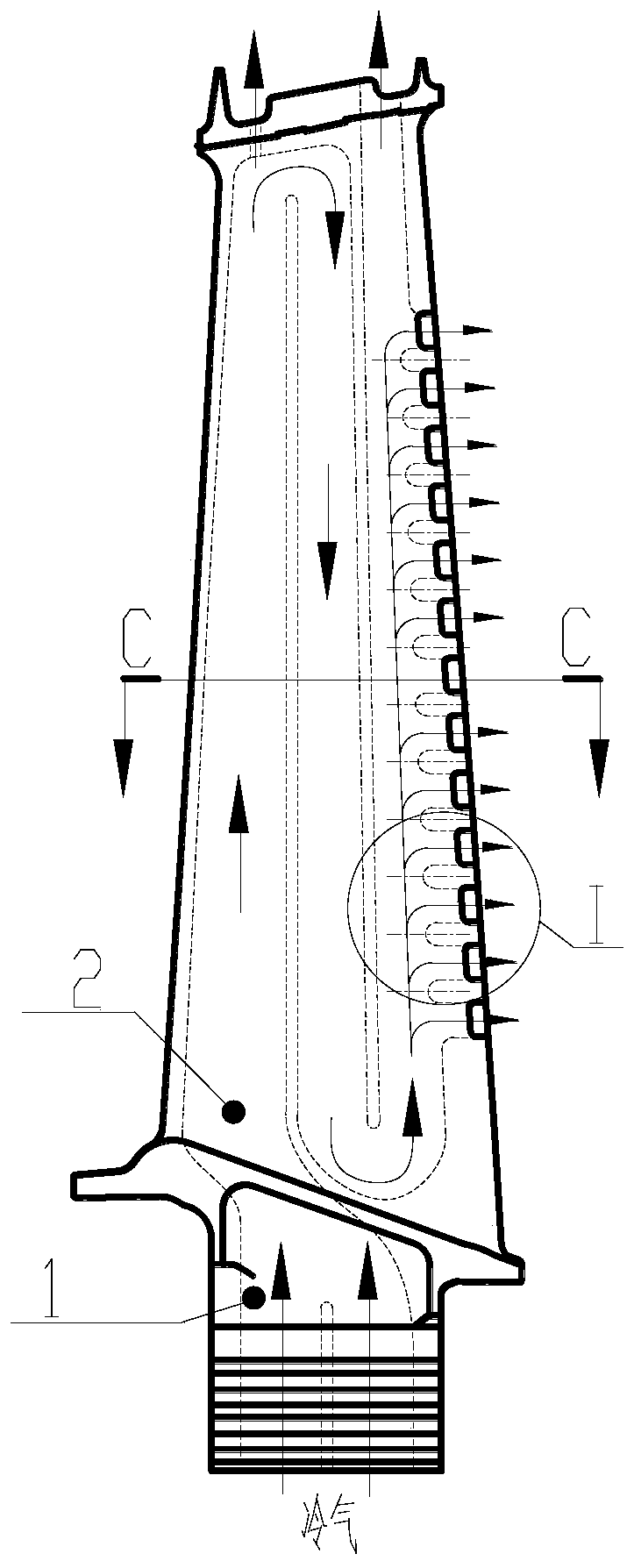

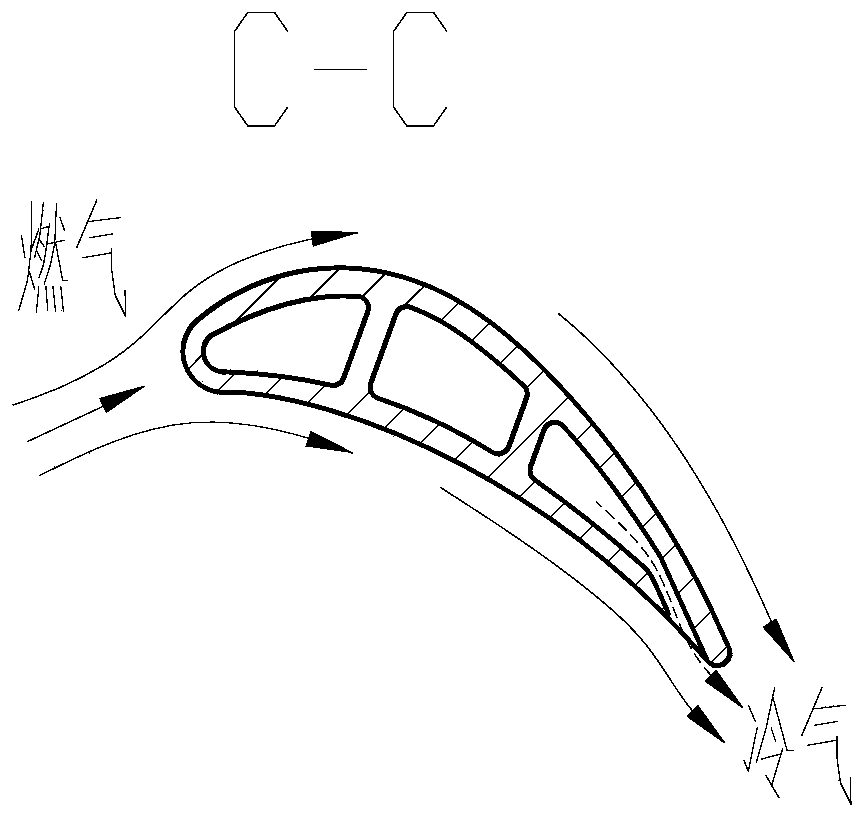

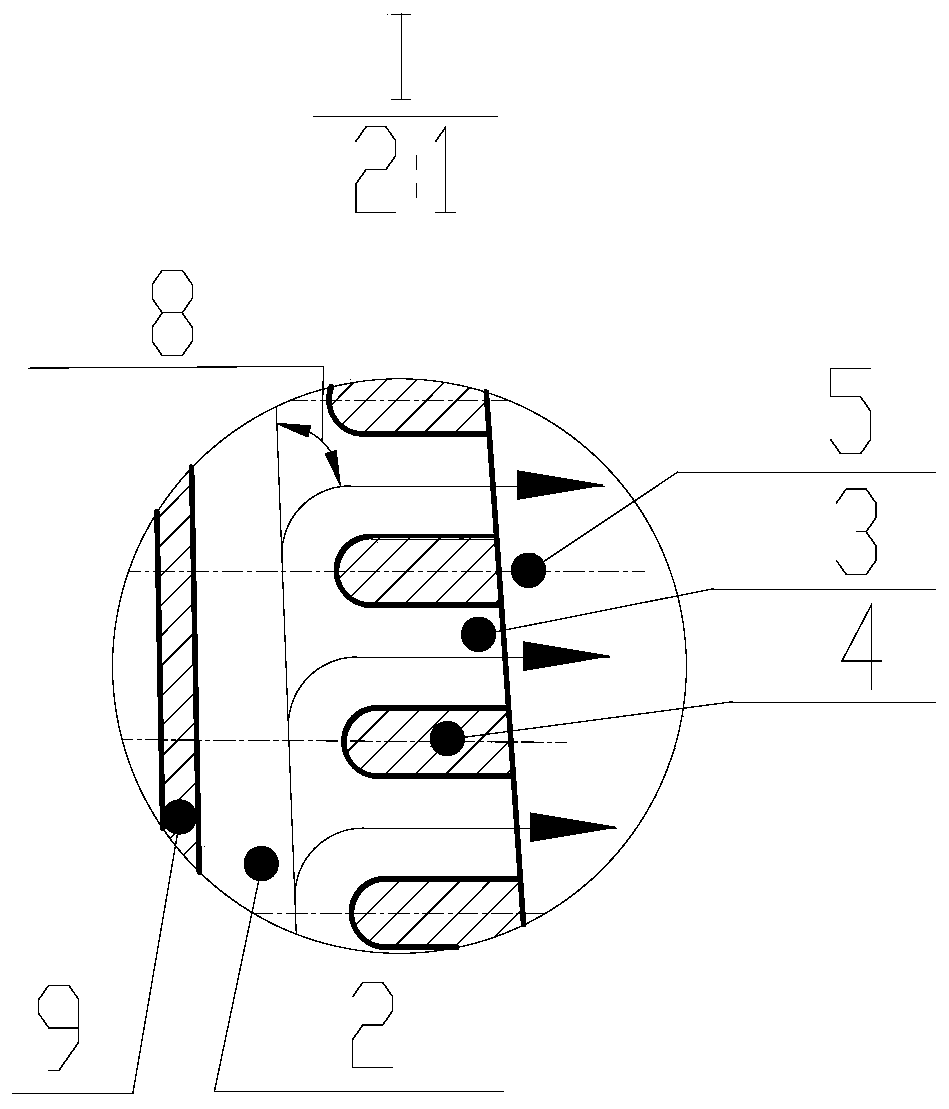

Turbine blade trailing edge slit cooling structure adopting wavy partition ribs

ActiveCN112177682AImprove heat transfer capacityGood cooling effectBlade accessoriesMachines/enginesPhysicsTrailing edge

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade trailing edge slit cooling structure adopting wavy partition ribs. The trailing edge slit cooling structure comprises a hollow turbine blade, an inner cavity cool gas channel, trailing edge exhaust slit channels and the trailing edge slit partition ribs, wherein an inner cavity cool gas channel is formed inside the hollow turbine blade, a wavy trailing edge exhaust slit is formed in the trailing edge of the hollow turbine blade in the chordwise direction, the plurality of wavy trailing edge slit partition ribs are evenly arranged inside the wavy trailing edge exhaust slit, and are arranged side by side to form the discrete trailing edge exhaust slit channels so as to allow cool gas to be exhausted out of the blade. Through the structure of the trailing edge slit partition ribs, the structural strength of the trailing edge of the blade can be improved, the internal heat exchange area of the blade can be increased, and meanwhile, the cool gas in an inner cavity of the blade is guided, and the flowing direction of the cool gas is turned; and according to the trailing edge slit cooling structure, a cool gas flowing path is lengthened favorably, so that the cool gas is utilized more fully, the convective heat exchange area is increased, boundary layers are restrained, and theheat exchange effect is enhanced.

Owner:DALIAN UNIV OF TECH

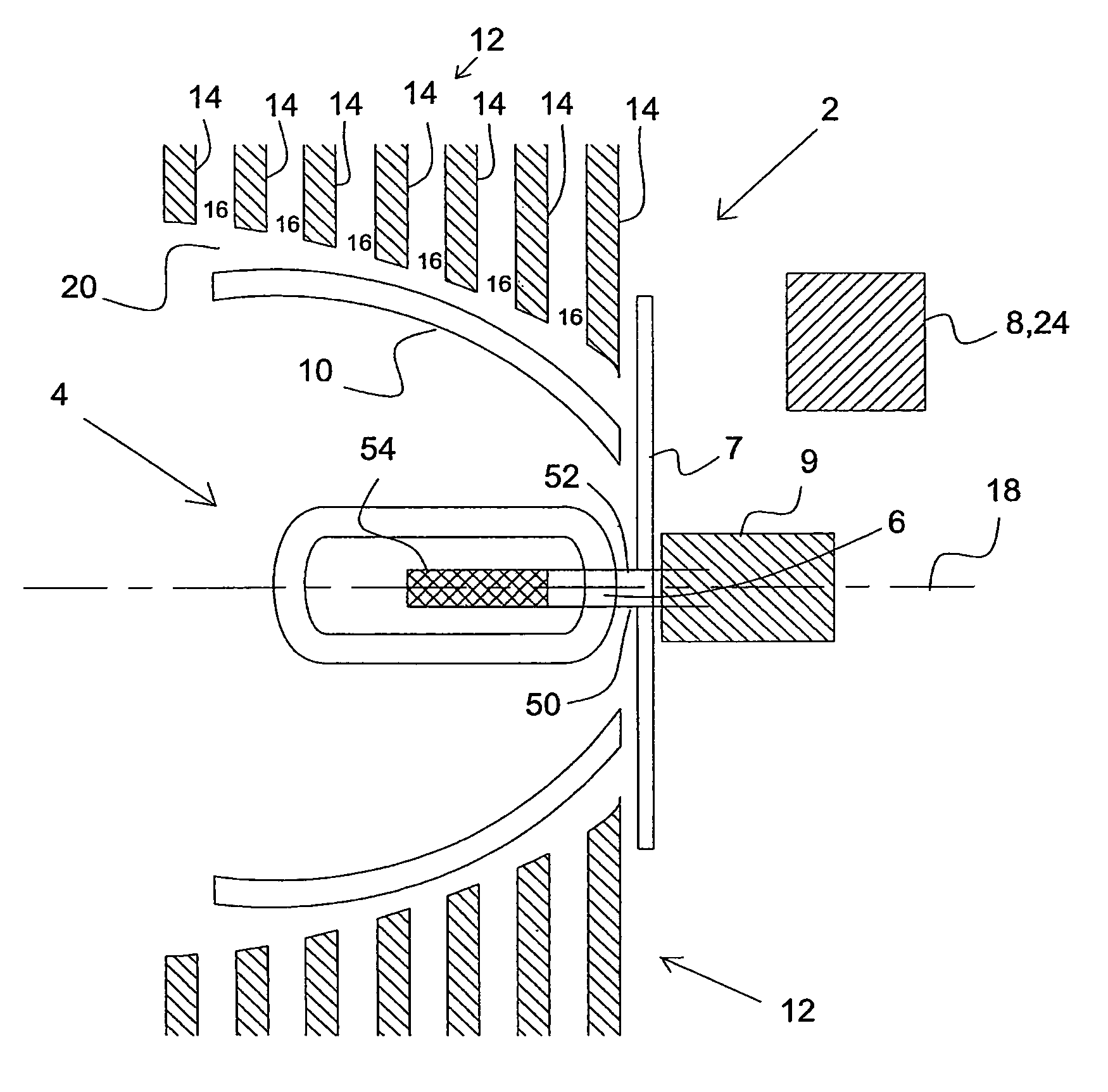

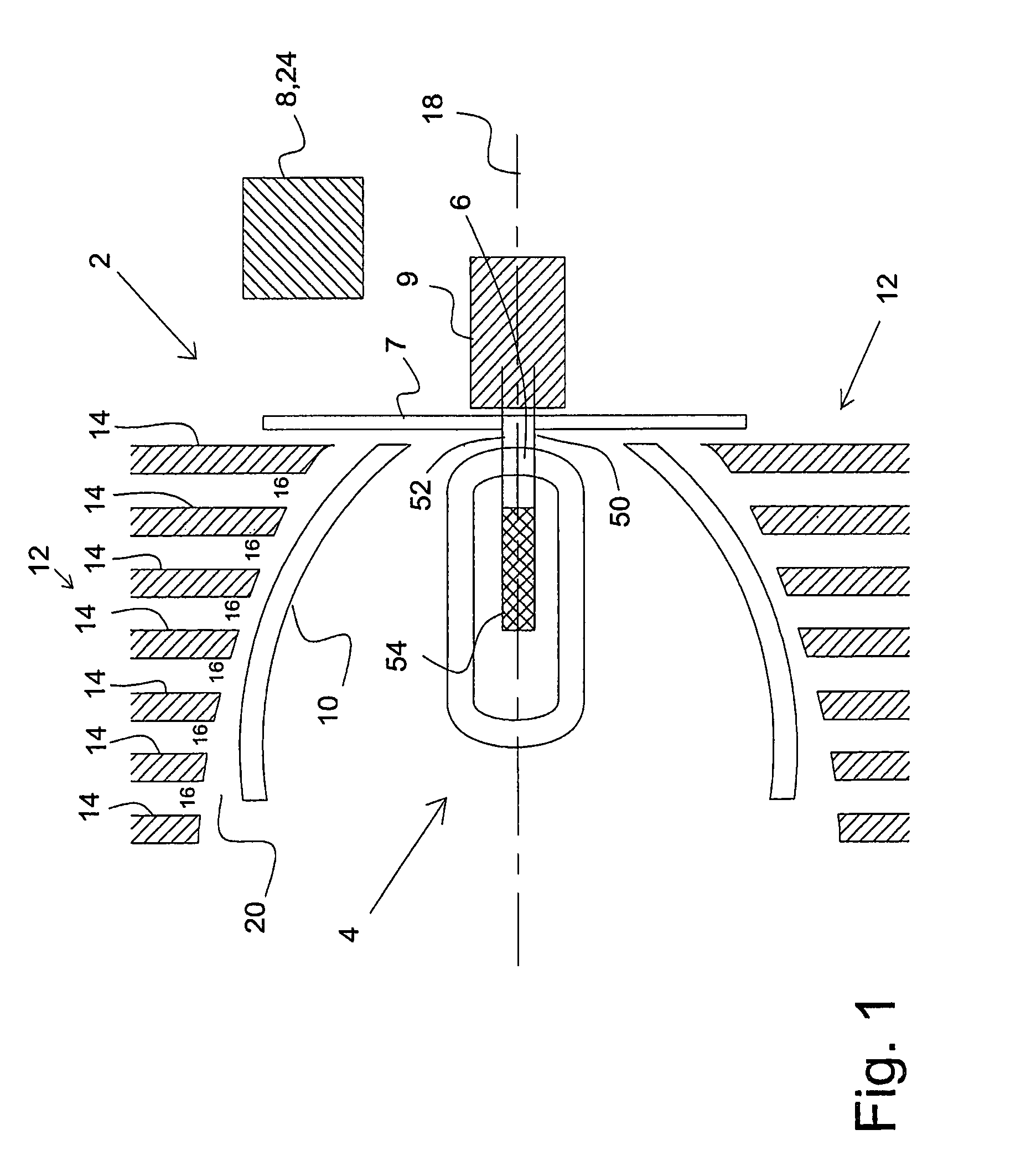

Brake disc arrangement for disc brakes

InactiveUS8967339B2Improve heat balanceLower temperature levelBraking element arrangementsBraking discsEngineeringMechanical engineering

A brake disc arrangement for disc brakes, in particular for land vehicles, including a friction ring, an attachment adapter for attaching the brake disc arrangement to a wheel hub, and at least one connection element for connecting the friction ring and the attachment adapter, wherein the attachment adapter comprises a fastening area in which the connection element is stationarily fixed, and wherein the friction ring comprises a receptacle area in which the connection element is accommodated such that the friction ring can move radially relative to the connection element.

Owner:SAF HOLLAND GMBH

Light source module

ActiveUS7559676B2Increase lifetime of lampReduce the temperatureLighting heating/cooling arrangementsOptical signallingOptoelectronicsHeat spreader

Owner:MARTIN PROFESSIONAL

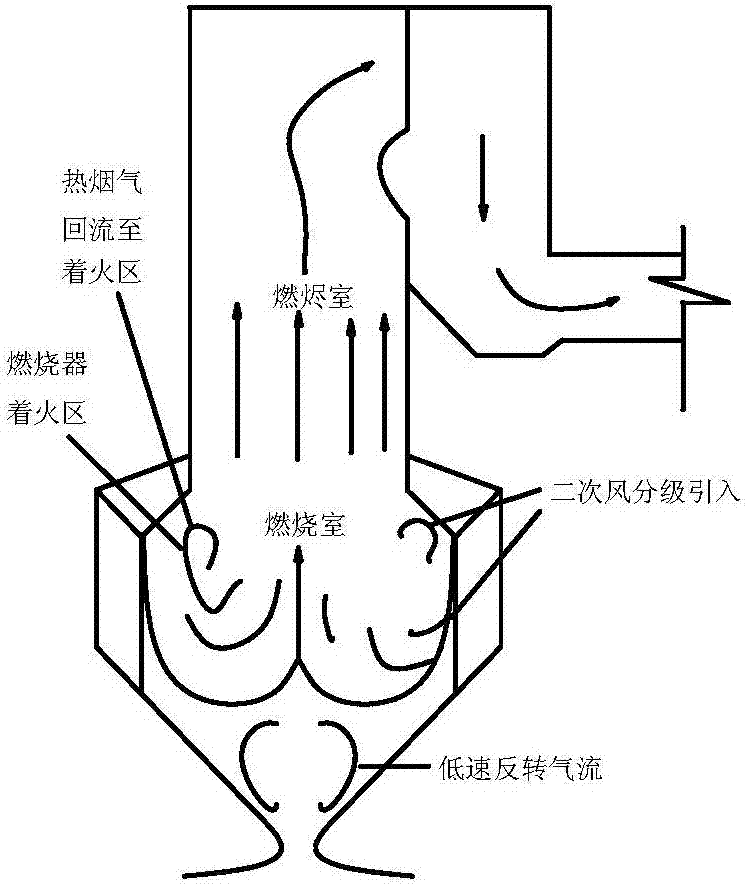

Method for reducing W-type flame boiler NOx emission

ActiveCN107355809AReduce generationIncrease contentCombustion using gaseous and pulverulent fuelAir supply regulationFlue gasProcess engineering

The invention relates to a method for reducing W-type flame boiler NOx emission. Fuel burns in a staged combustion manner, the method for reducing W-type flame boiler NOx emission specially comprises that free-burning coal and anthracite in a predetermined proportion are selected, the free-burning coal is employed to react with oxygen to form first stage combustion, wherein the free-burning coal is bituminous coal or a mixture of bituminous coal and meager coal; a high temperature flue gas atmosphere is formed in the first stage, being coerced by high temperature flue gas, the anthracite is ignited to form second stage combustion, the volatile component content of the free-burning coal is higher than of the anthracite, the volatile component content is larger than 25%, and the ratio of the bituminous coal to the anthracite is larger than 1:1; the dry ash-free basis volatile component content of as-fired coal keeps satisfying the formula: 15% < Vdaf < 20 %, the lower heating value of the as-fired coal keeps satisfying the formula: 20 MJ / kg < Qnet, ar < 22.5 MJ / kg, when the bituminous coal, the meager coal and the anthracite burn in a staged manner, Vdaf > 10 %. According to the invention, by employing a staged combustion control strategy, NOx generated by boiler combustion is reduced.

Owner:中国大唐集团科学技术研究总院有限公司

Brake Disc Arrangement for Disc Brakes

InactiveUS20150053515A1Improve corrosion resistanceHigh degree of deformationBraking discsMetal working apparatusRotational axisEngineering

A brake disc arrangement for disc brakes comprising a friction ring, a mounting adapter for mounting the brake disc arrangement on a wheel hub, at least one connecting element for connecting the friction ring and the mounting adapter, and at least one contour having a friction ring-side and an adapter-side contour region, wherein the contour is shaped along a longitudinal axis by recesses in the friction ring and the mounting adapter running perpendicular to a rotational axis of the brake disc arrangement, wherein the connecting element may be brought from a first state where the connecting element is arranged inside the contour and a second state where the outer diameter of the connecting element is enlarged, such that the connecting element is connected to the friction ring-side and / or the adapter-side contour region by form fit and / or friction fit.

Owner:SAF HOLLAND GMBH

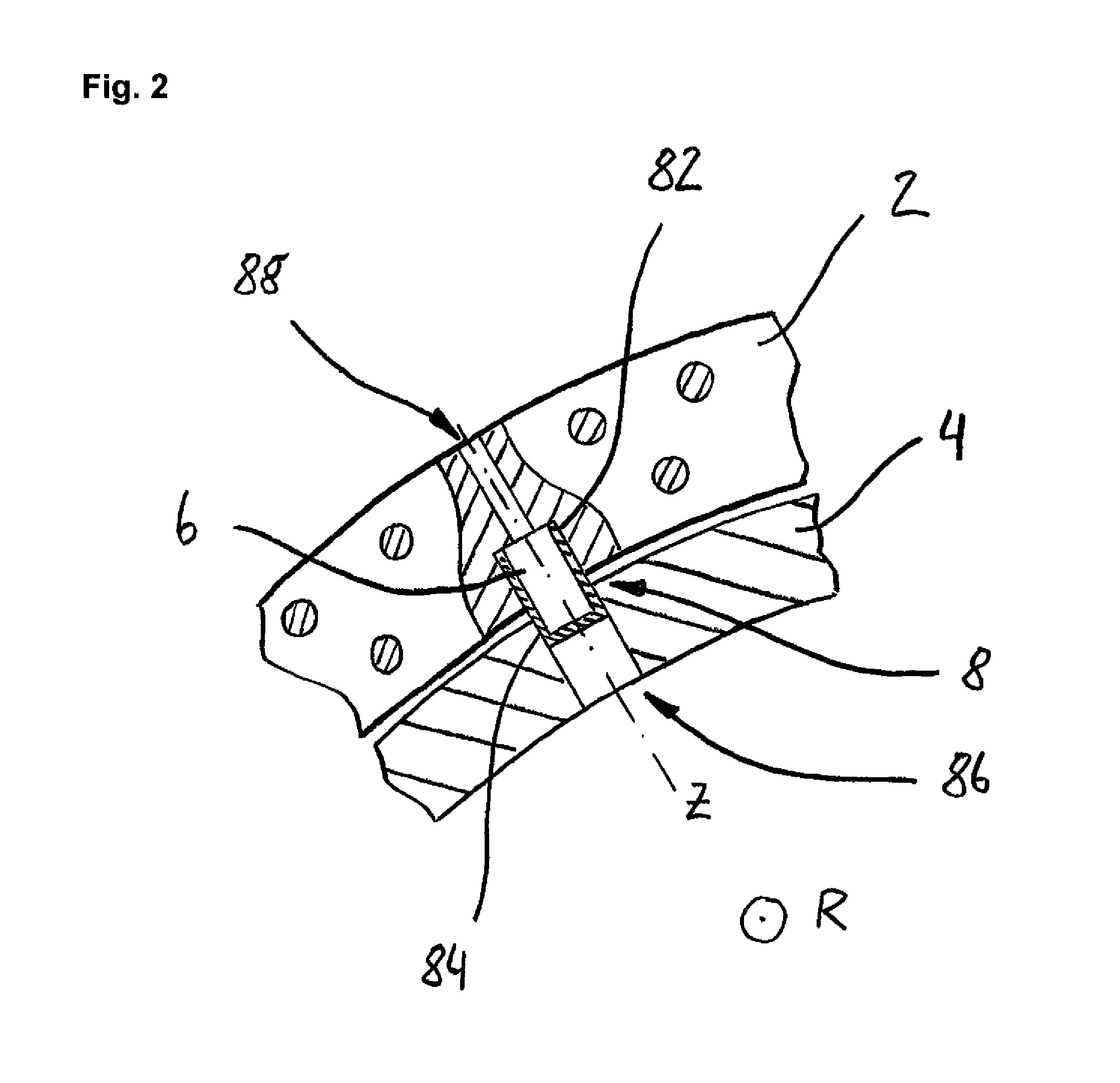

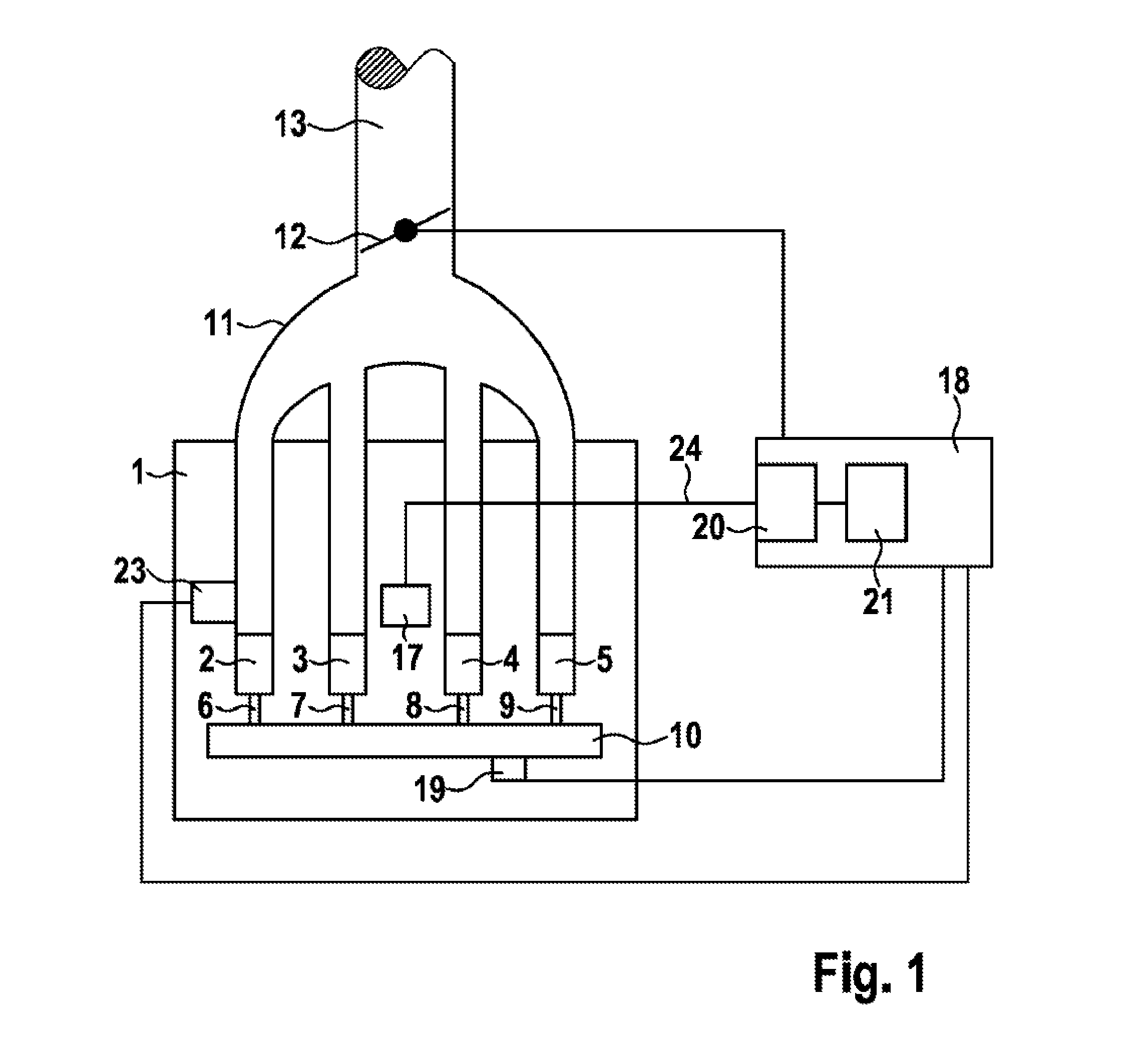

Method and device for setting an emergency operational mode in a system which detects pre-ignitions in a combustion engine, and which contains errors

InactiveUS20130166184A1Lower temperature levelReliable preventionAnalogue computers for vehiclesElectrical controlCombustionOperation mode

The invention relates to a method for setting an emergency operational mode in a system which detects pre-ignitions in a combustion engine and which contains errors. The system consists of at least one sensor (17) and / or at least one sensor cable (24) and / or a sensor signal evaluation device (20), and is subject to a diagnosis to detect an error. In order to prevent damage to the combustion engine if the system for detecting pre-ignitions does contain an error, a standard path (26), which comprises sensor signal capturing, sensor signal evaluation, detection of pre-ignitions and initiation of measures to counter the pre-ignitions, is interrupted when the diagnosis detects an error in the system (17, 24, 29), and a safety path (27) is activated as an emergency operational mode.

Owner:ROBERT BOSCH GMBH

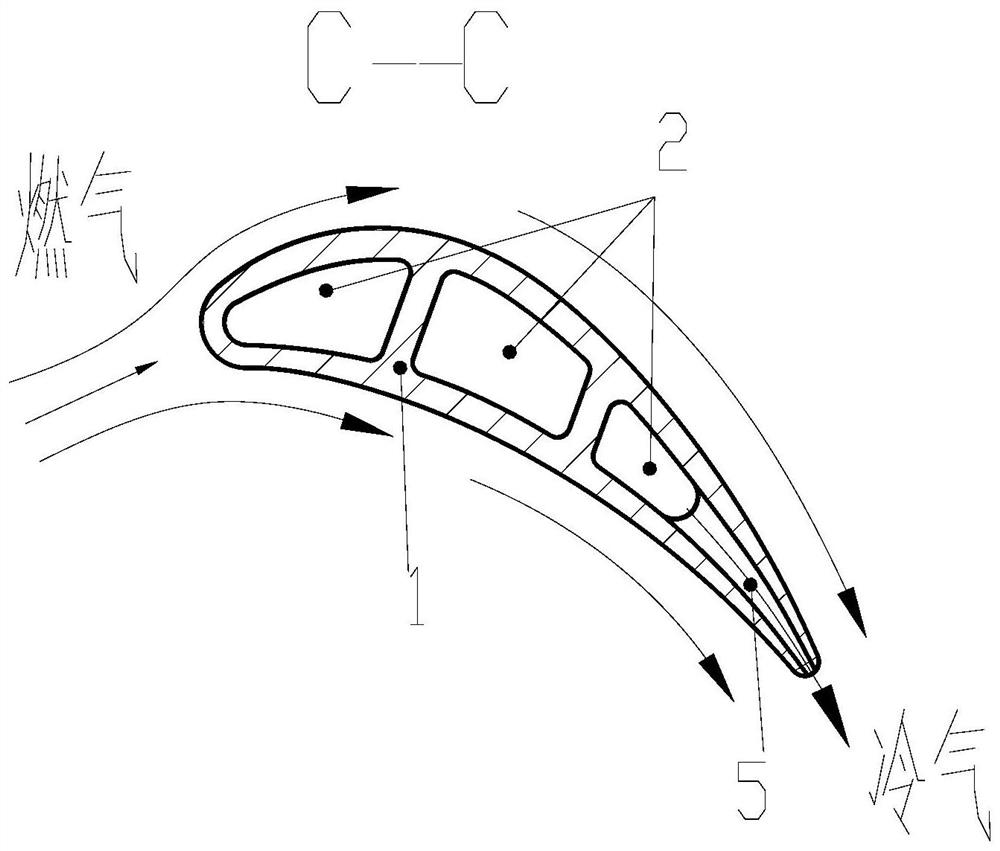

Turbine blade tailing edge curved type exhaust crack structure

ActiveCN111022127ALow flow resistanceReduce flow lossBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of cooling of aero-engine turbines, and relates to a turbine blade tailing edge curved type exhaust crack structure. The curved type exhaust crack structure comprises hollow turbine blades, inner cavity cold air channels, tailing edge exhaust crack channels and tailing edge crack partition ribs. The inner cavity cold air channels are formed in the hollow turbine blades so that low-temperature cooling air can flow in the blades and cool the blades. The tailing edge crack partition ribs arrayed side by side are arranged on the tailing edges of the hollow turbine blades. The tailing edge exhaust crack channels are formed between the tailing edge crack partition ribs arrayed side by side so that cooling air can be discharged out of the blades. Bladetailing edge cracks are designed to have an inclined curved type exhausting function, the turning angle of the cooling air in the cracks is reduced, the turning process is continuous and gentle, andtherefore the flowing resistance and loss of the cooling air in inner cavities of the blades are reduced, and the flowing resistance can be reduced by about 20%.

Owner:DALIAN UNIV OF TECH

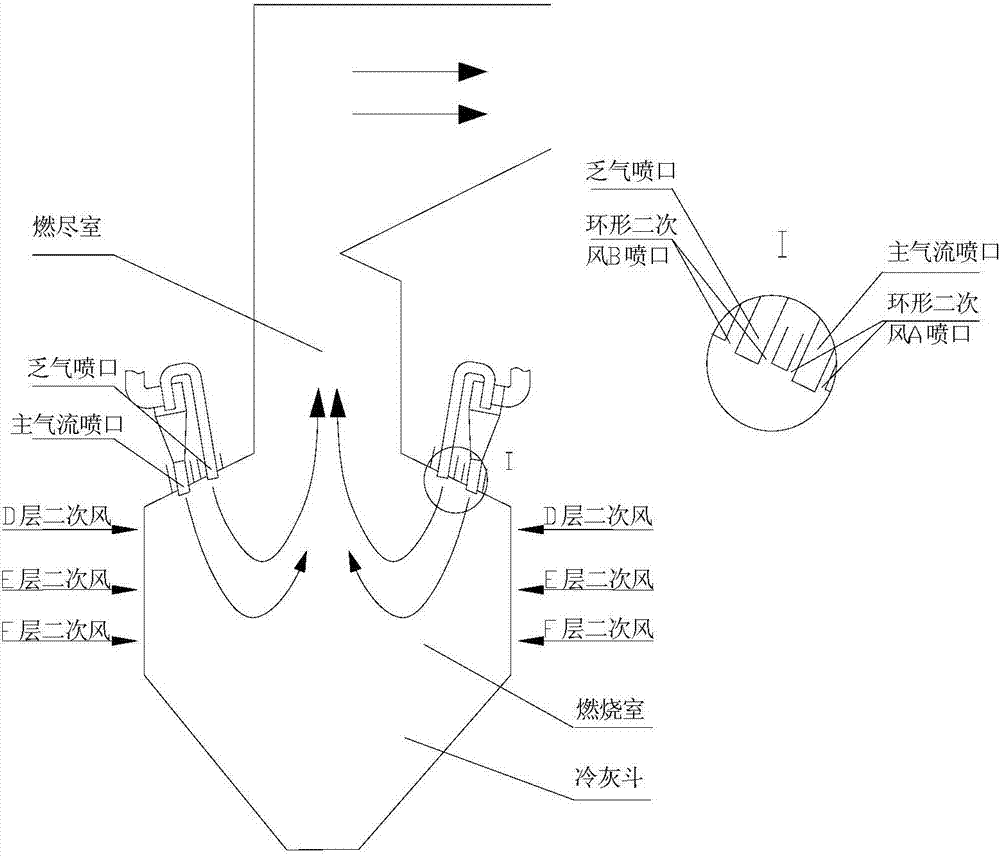

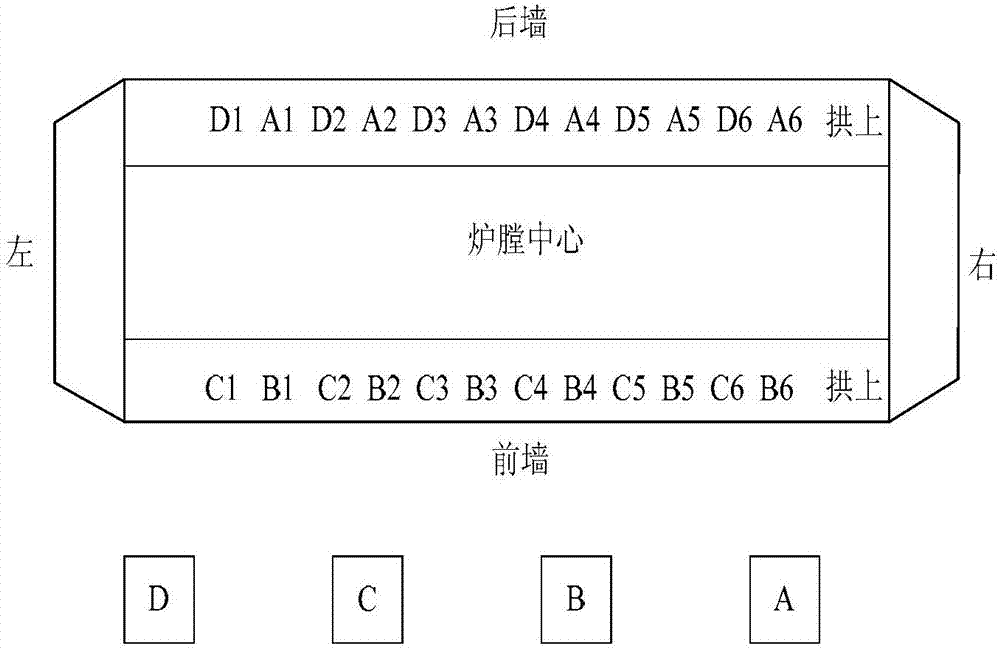

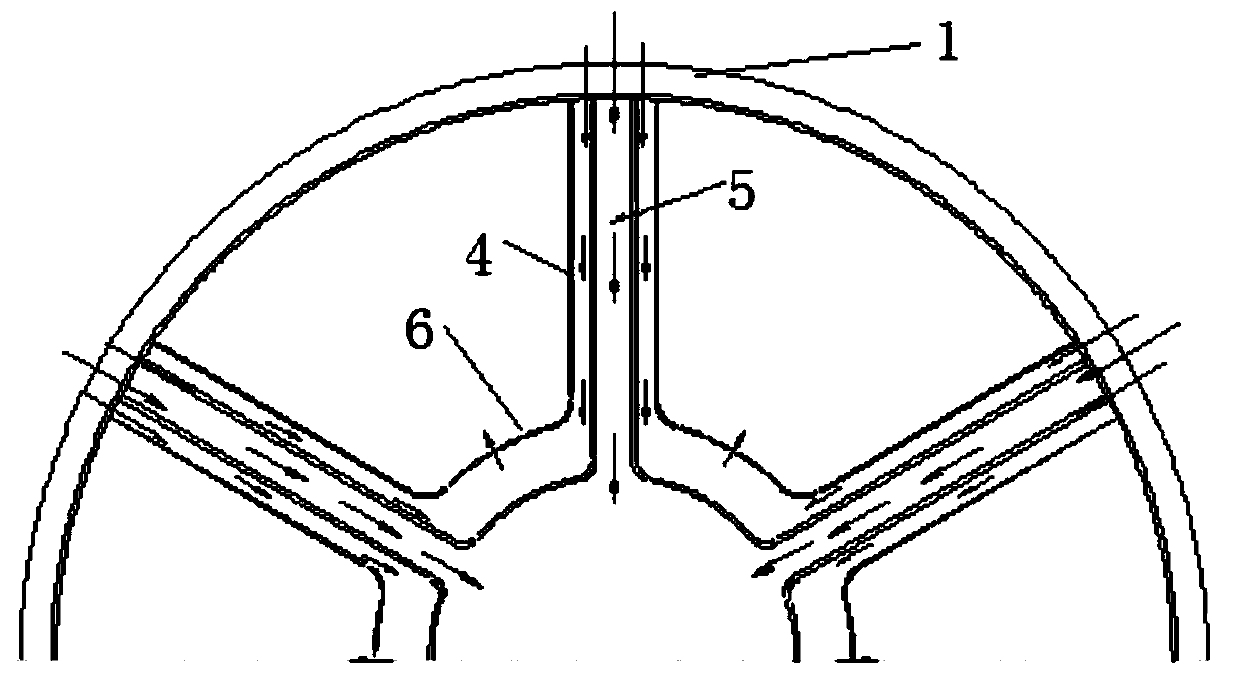

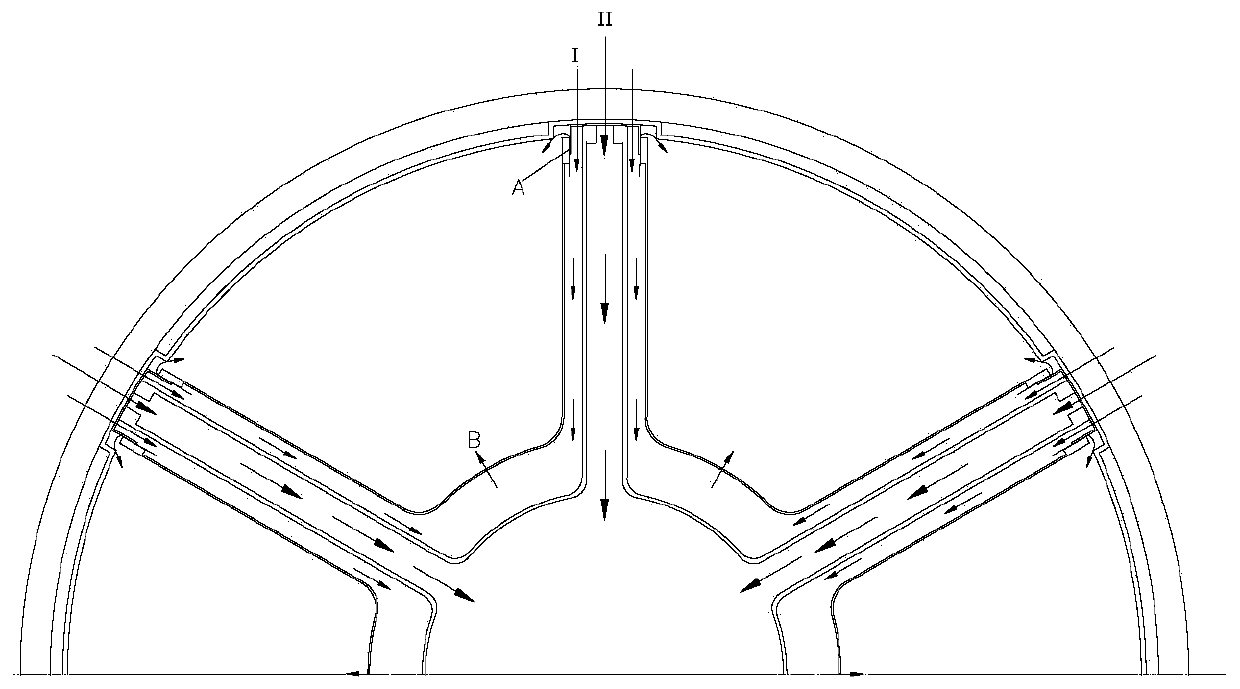

Multi-coal-type adaptive type low-NOx burning system

ActiveCN103206716AEmission reductionSuppress generationLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationCombustion systemBoiler slag

Provided is a multi-coal-type adaptive type low-NOx burning system. Boiler smoke in a boiler tail smoke channel is delivered into an inlet of a coal pulverizing system through a boiler smoke fan and a corresponding pipe, exhaust gas in the coal pulverizing system can enter a primary-air bellows through a corresponding pipe system to participate in pulverized coal delivery, simultaneously the primary-air bellows can be connected with an angle adjustable type high-speed over fire air (OFA) nozzle on the upper portion of a boiler, and a part of hot primary air of a high pressure head is utilized as high speed OFA to be delivered into a boiler cavity. The system can reduce burning strength of the pulverized coal in the boiler and the temperature level of a main burning area by means of the smoke recirculation burning, can achieve the effect that the pulverized coal is burned in grading mode along the air depth in the height direction of the boiler by means of the angle adjustable type high speed OFA, screen bottom air and the like, improves adapting capability to the pulverized coal, restrains generation of NOx, prevents boiler slag bonding, and ensures operation safety and economy of the boiler.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

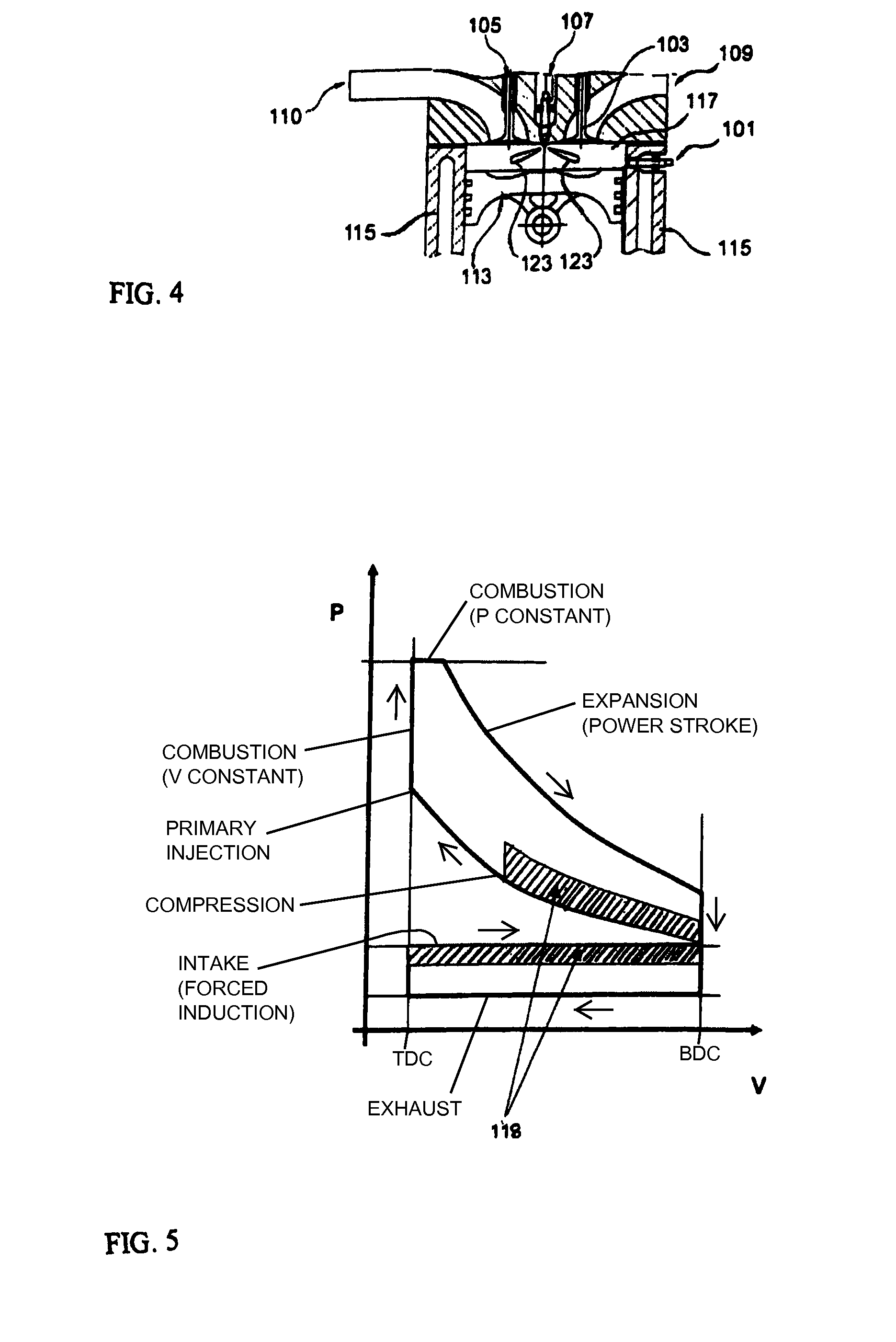

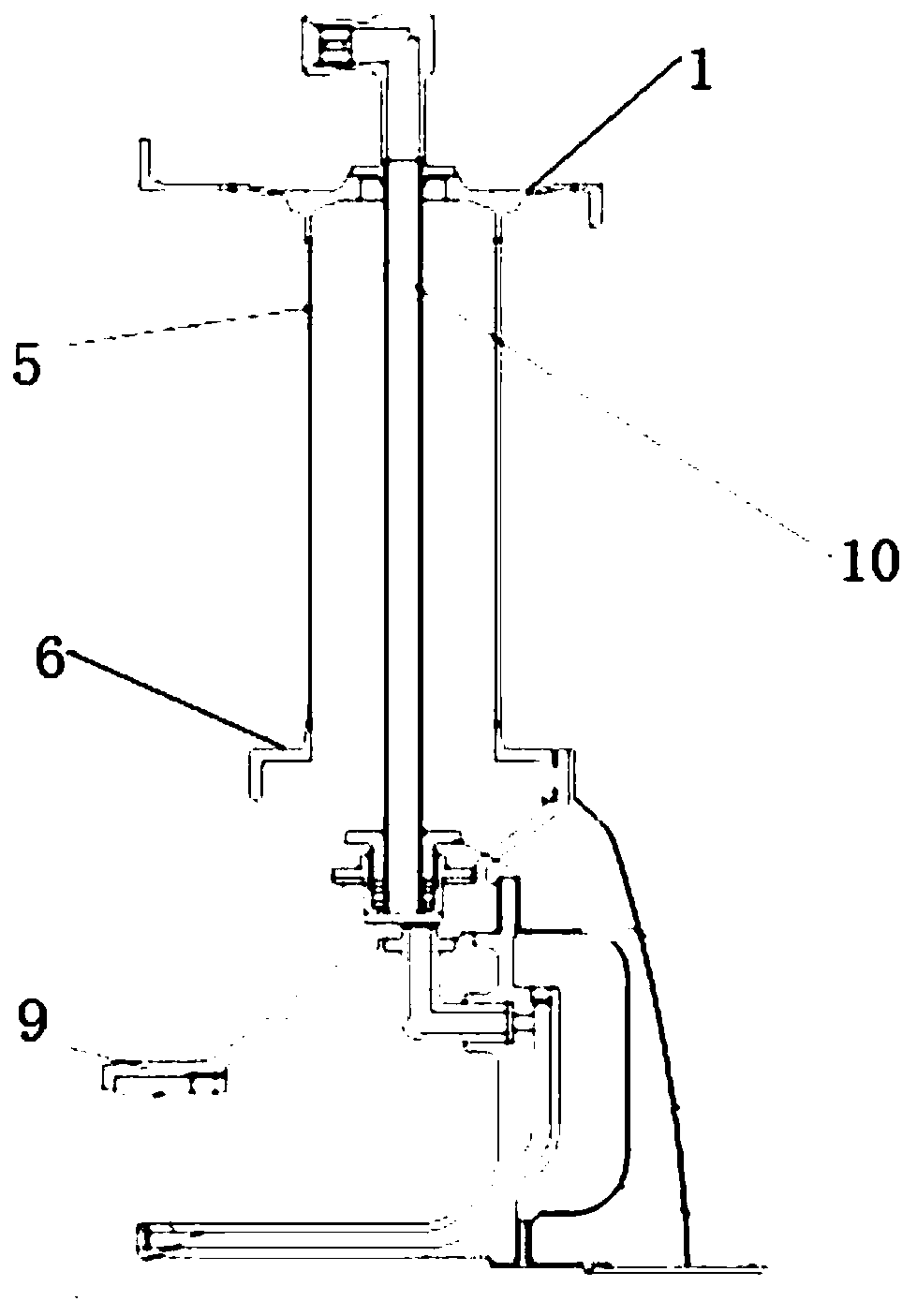

Fuel Injection System for Diesel Engines with Compression Ignition

InactiveUS20130319376A1Control quantityQuantity of air becomes excessiveElectrical controlInternal combustion piston enginesCombustion chamberExhaust valve

In a fuel injection system and method for a diesel engine with compression induced ignition, NOx emissions are reduced by providing a supplemental fuel injection from a supplemental injection nozzle, in addition to the primary fuel injection through a primary injection nozzle. The supplemental injection nozzle injects a supplemental quantity of fuel onto a vaporization surface such as an exhaust valve, a flame ring area, or a top surface of the piston, in the combustion chamber, whereupon the supplemental fuel vaporizes and forms a lean air / fuel mixture. Thereafter, the primary injection nozzle injects the main fuel charge into the combustion chamber, to produce a rich air / fuel combustion mixture, which is then ignited and combusts.

Owner:ABB TURBO SYST

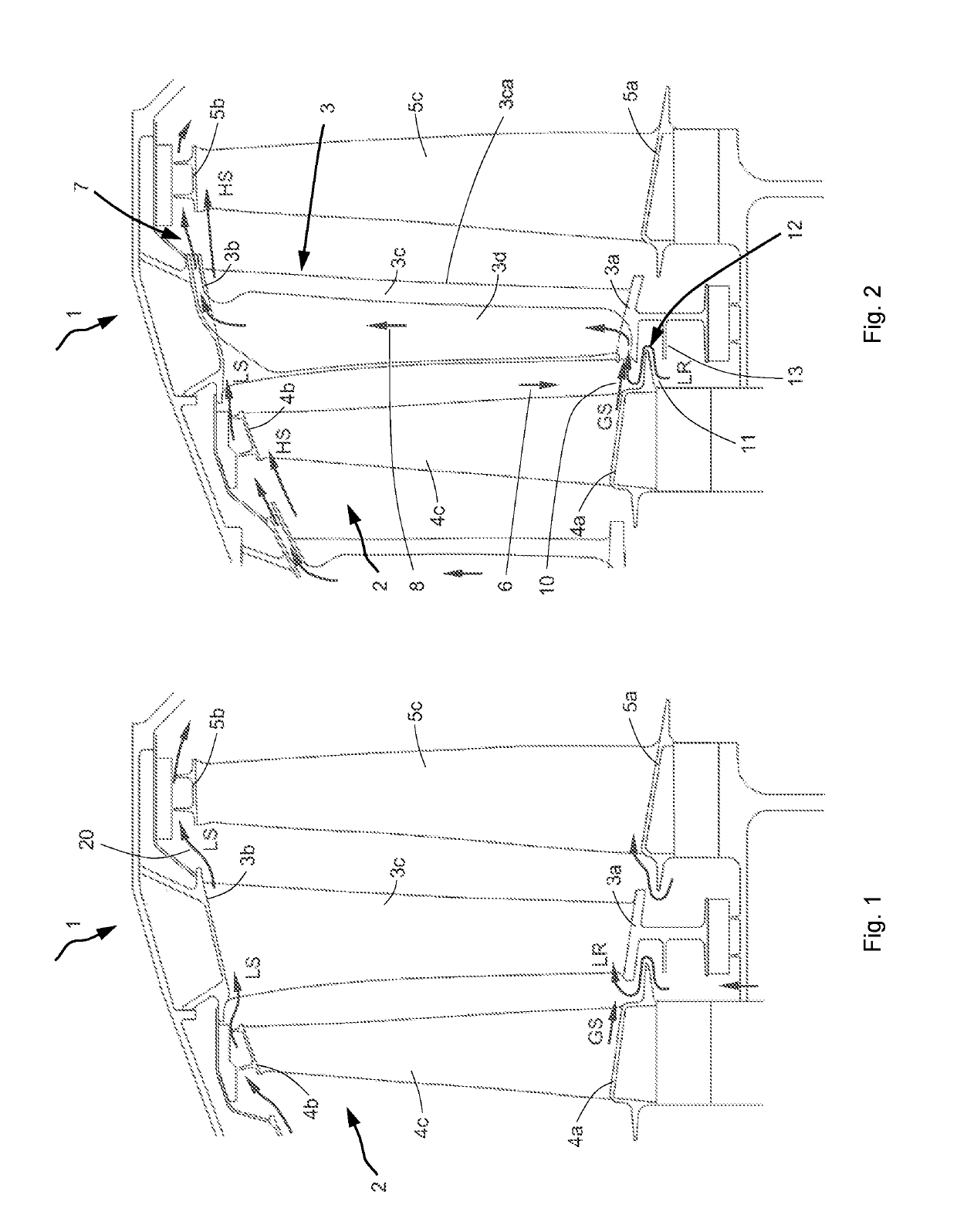

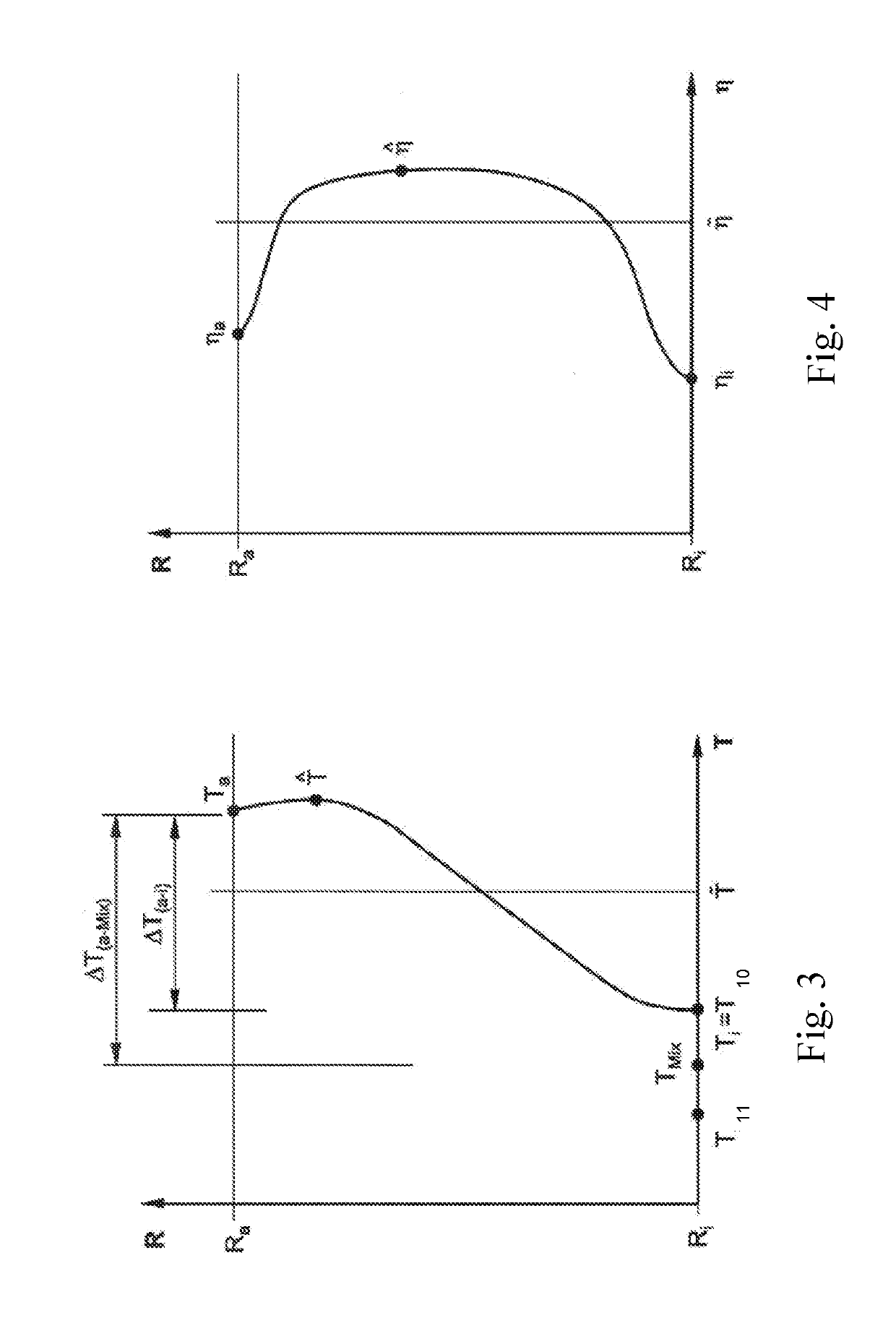

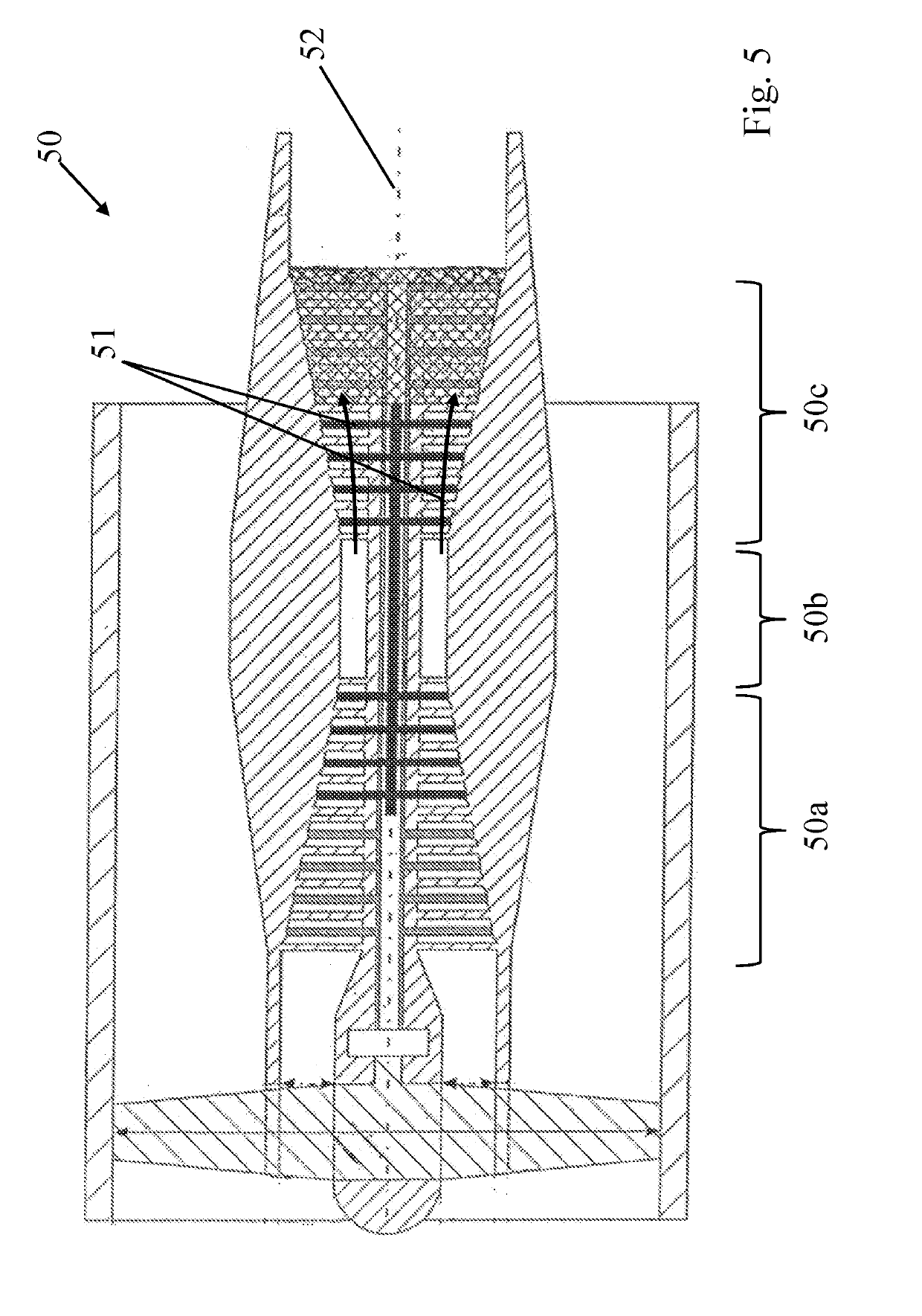

Stator vane for a turbine of a turbomachine

ActiveUS20190331000A1Reduce efficiency lossMinimize frictional lossEngine fuctionsLeakage preventionEngineeringTurbine

A stator vane (3) for a turbine (50c) of a turbomachine (50), the stator vane having a stator vane airfoil (3c), an inner shroud (3a) and an outer shroud (3b), the inner shroud (3a) and the outer shroud (3b) bounding an annular space (2), in which working gas (51) is conveyed during operation, radially with respect to a longitudinal axis (52) of the turbomachine (50), and the stator vane airfoil (3c) having a stator vane airfoil channel (3d) extending through its interior between a radially inner inlet (6) and a radially outer outlet (7). A characteristic features is that the inlet (6) is disposed in such a manner that a gas (8) flowing through the stator vane airfoil channel (3d) during operation is at least partially formed of the working gas (51) conveyed in the annular space (2), and thus the working gas is redistributed from radially inward to radially outward.

Owner:MTU AERO ENGINES GMBH

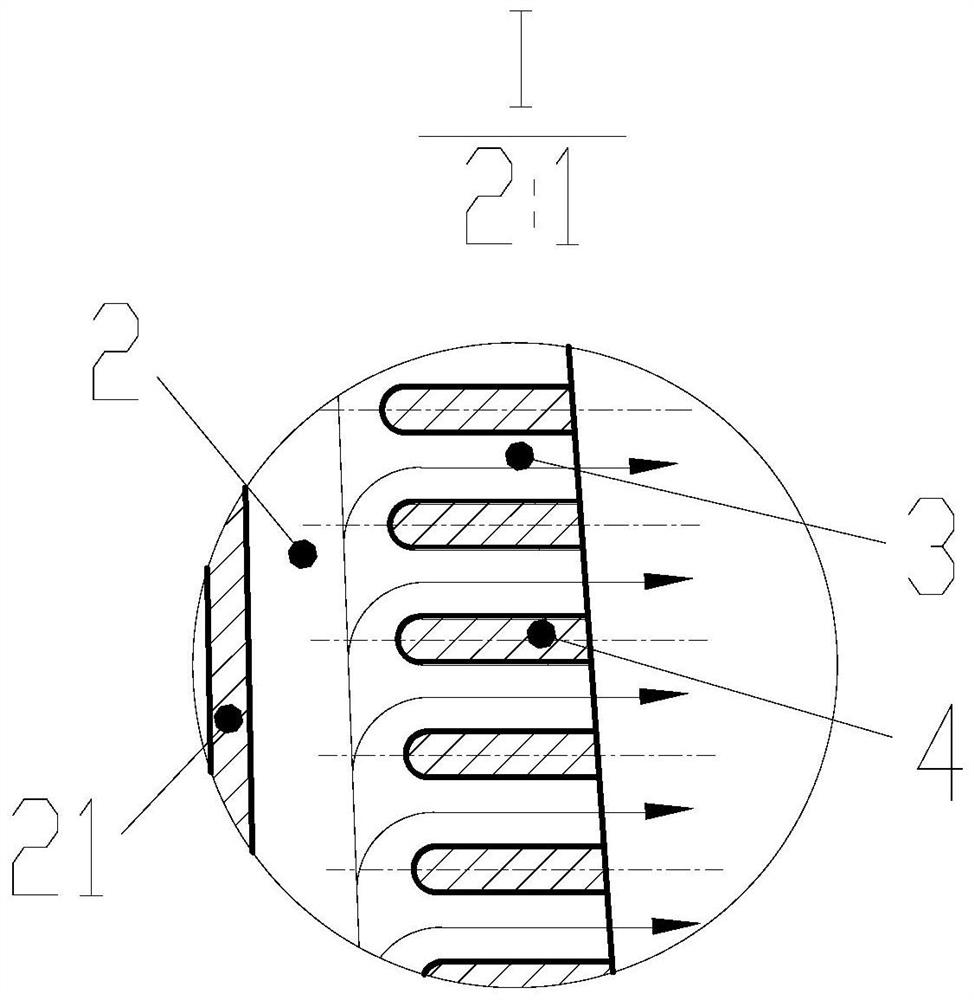

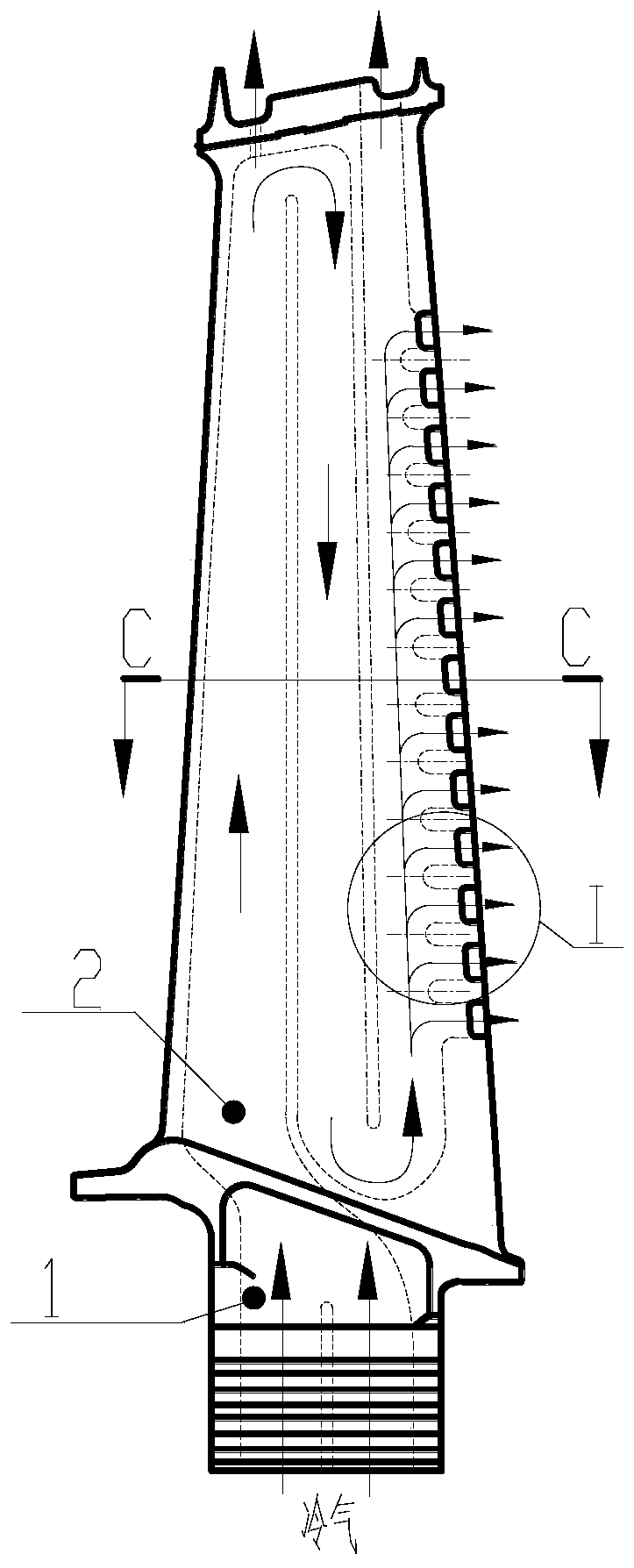

Turbine blade trailing edge fold line type exhaust split seam structure

ActiveCN110748384AIncrease widthLower temperature levelBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade trailing edge fold line type exhaust split seam structure. The turbine blade trailing edge fold line type exhaust split seam structure comprises a hollow turbine blade, an inner cavity cold air channel, a trailing edge exhaust split seam channel and trailing edge split seam partition ribs, wherein the inner cavity cold air channel is formed in the hollow turbine blade, and low-temperature cooling gas flows in the blade to cool the blade; the trailing edge split seam partition ribs arranged side by side are arranged on the trailing edge of the hollow turbine blade; and the trailing edge exhaust split seam channel is formed between the trailing edge split seam partition ribs arranged side by side. According to the turbine blade trailing edge fold line type exhaust split seam structure, a trailing edge exhaust split seam is designed into an inclined fold line type exhaust mode, theturning angle of the cooling gas in the split seam is reduced, and cold air is turned twice or multiple times instead of being turned once, so that the flow resistance and loss of the cold air in an inner cavity of the blade are reduced, and the flow resistance can be reduced by about 19%.

Owner:DALIAN UNIV OF TECH

Flue gas recirculation boiler structure of combustor

InactiveCN106287687ALower temperature levelLow costFluidized bed combustionApparatus for fluidised bed combustionCombustorAir interface

The invention relates to the technical field of flue gas recirculation in a boiler, in particular to a flue gas recirculation boiler structure of a combustor, and the flue gas recirculation boiler structure can reduce a hearth temperature without increasing a hearth temperature so as to control slagging generation and reduce cost. The flue gas recirculation boiler structure comprises the hearth; a main combustor is mounted on the hearth; the main combustor comprises a primary air interface and a secondary air interface; an air outlet direction of the primary air interface and an air outlet direction of the secondary air interface are positively tangential to a tangent circle of the main combustor; four flue gas recirculation spray holes which are uniformly distributed are formed above the main combustor; and the air outlet directions of the flue gas recirculation spray holes are reversely tangential to the tangent circle of the main combustor separately.

Owner:WUXI HUAGUANG BOILER

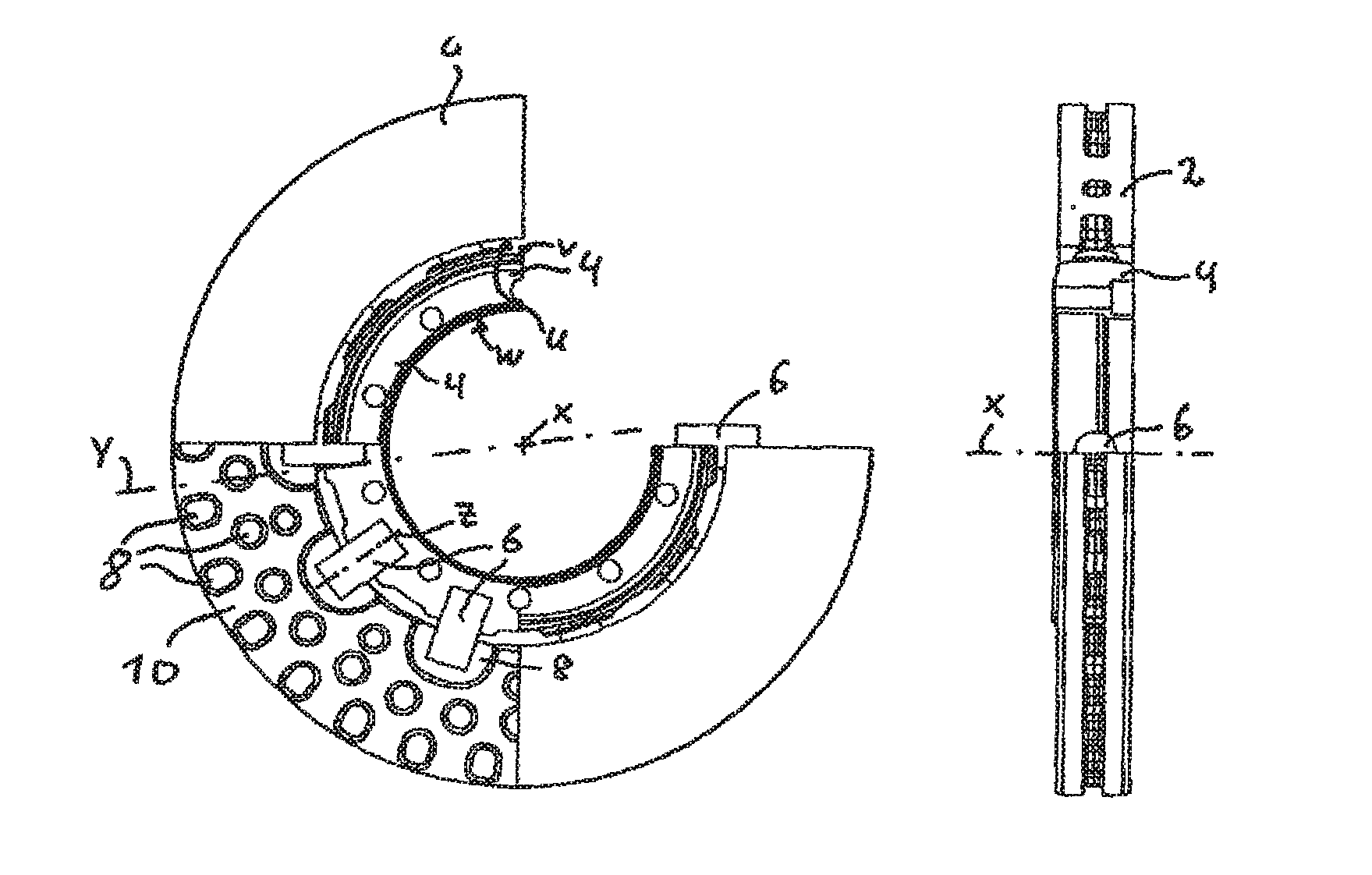

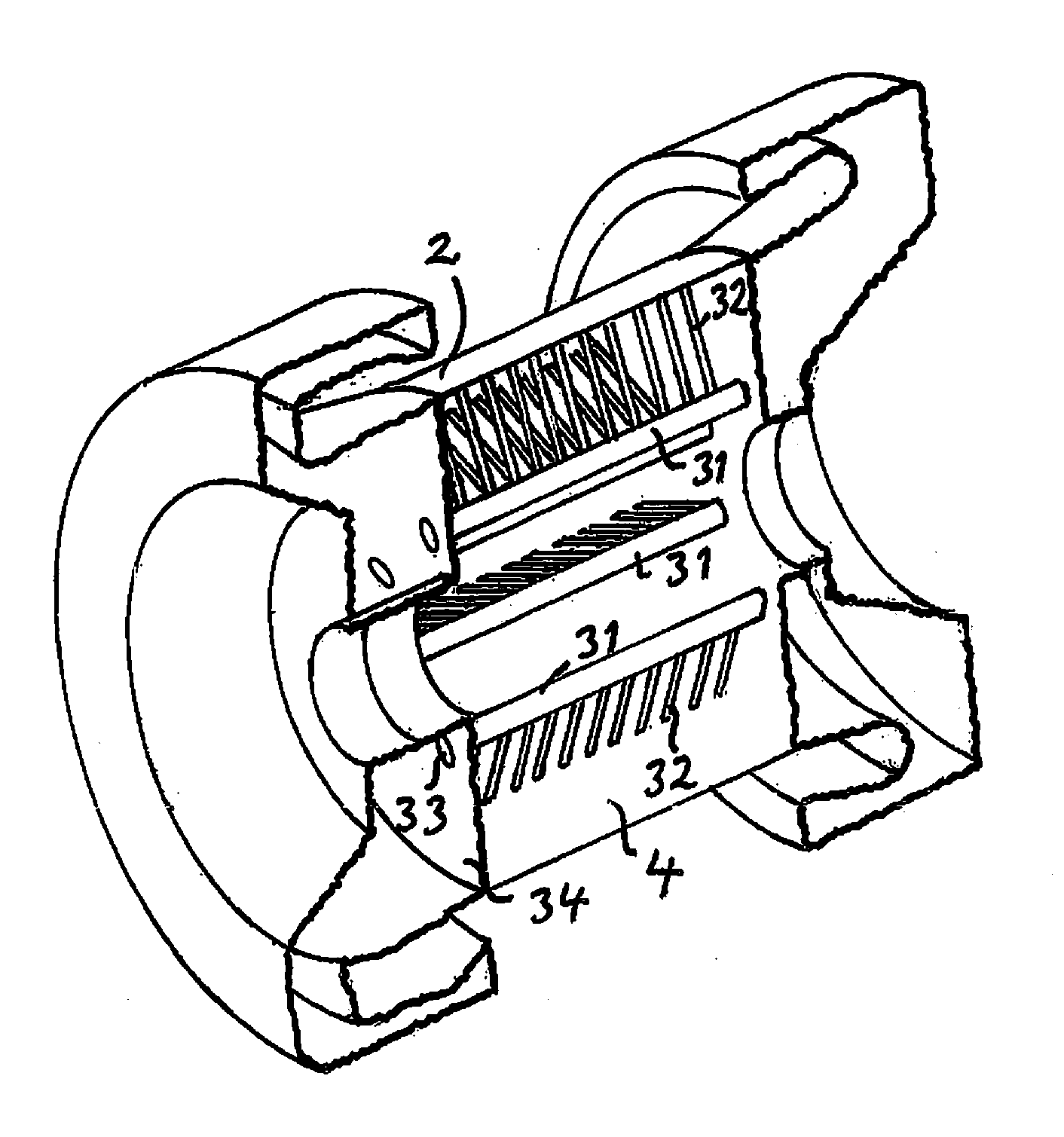

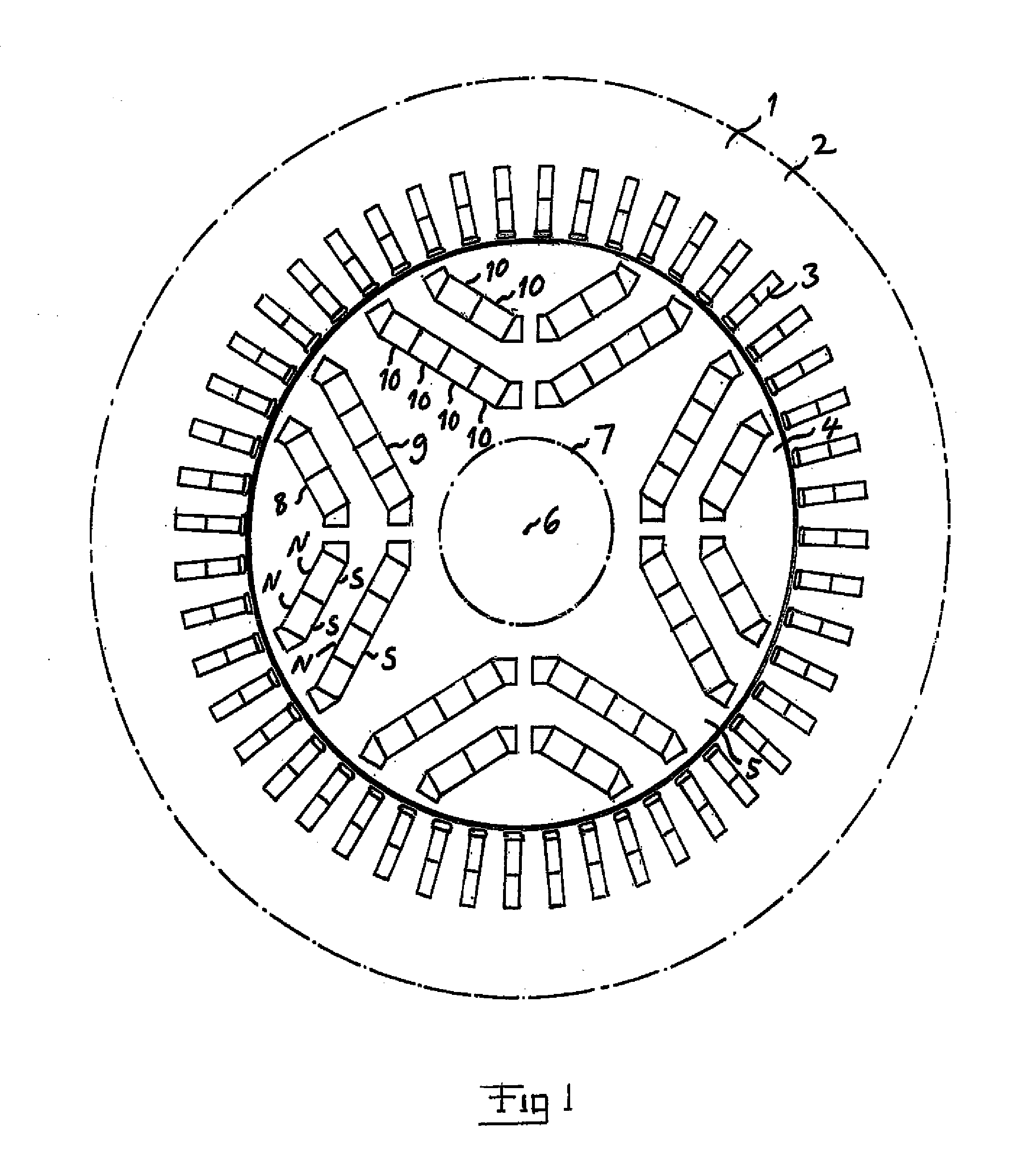

Electric machine

InactiveUS20140054990A1Promote coolingEfficiently coolMagnetic circuit rotating partsCooling/ventillation arrangementMagnetEngineering

An electric machine with a rotor (4) rotatably disposed within a stator (2) has a plurality of permanent magnets received in the rotor body of the rotor. Rotor body plates are stacked so as to form at least two first channels (31) extending inside the rotor body from one axial end of the rotor to an opposite axial end thereof and having an opening (33) to the exterior of the rotor body in an end surface of the latter at at least one of these axial ends, and at least one separate second channel (32) associated with each first channel and connecting the respective first channel to a space circumferentially surrounding the rotor and separating the rotor and the stator by opening at the periphery of the rotor body so as to upon rotation of the rotor throw air out from said second channel to said space for cooling the rotor body.

Owner:BOMBARDIER TRANSPORTATION GMBH

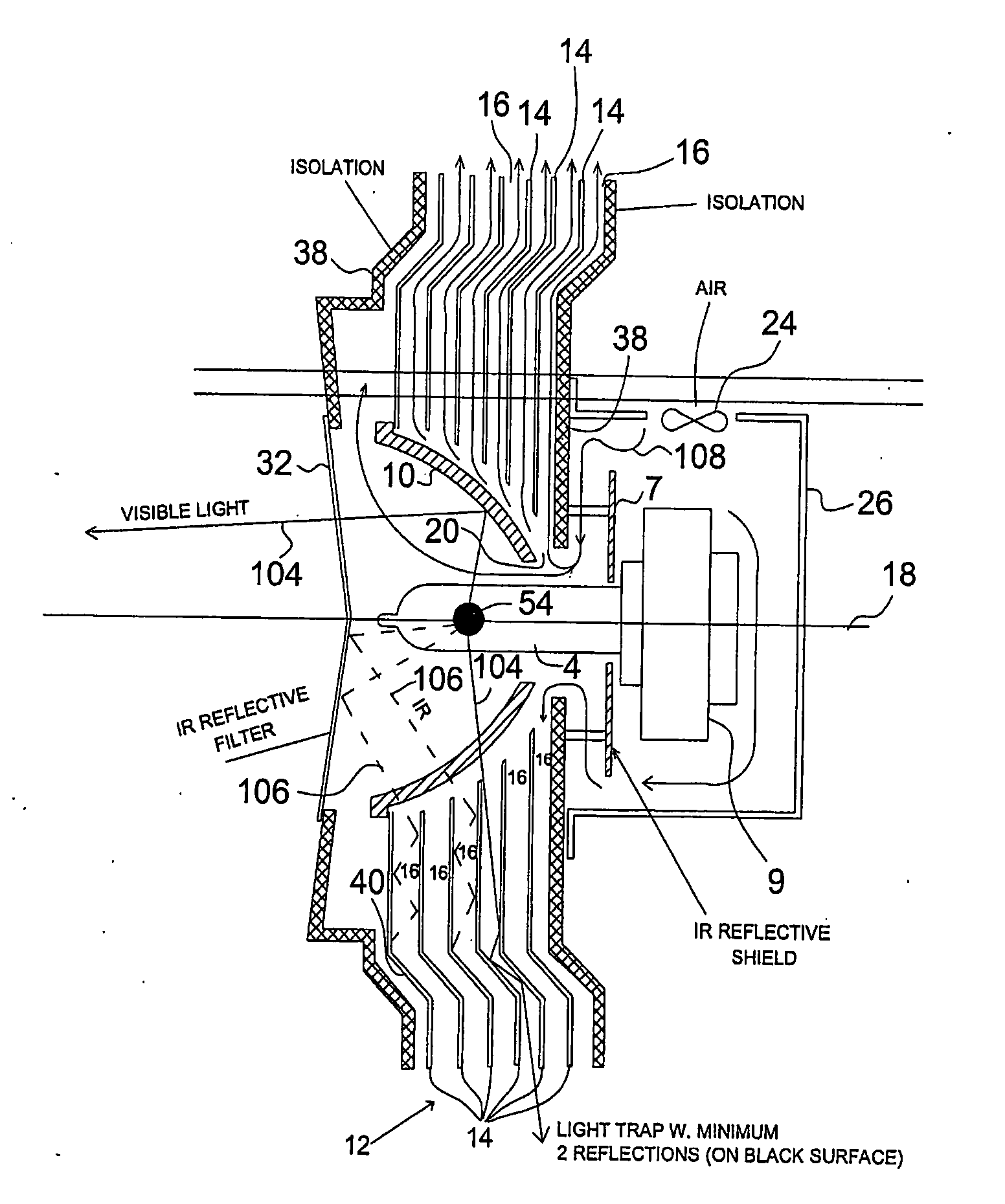

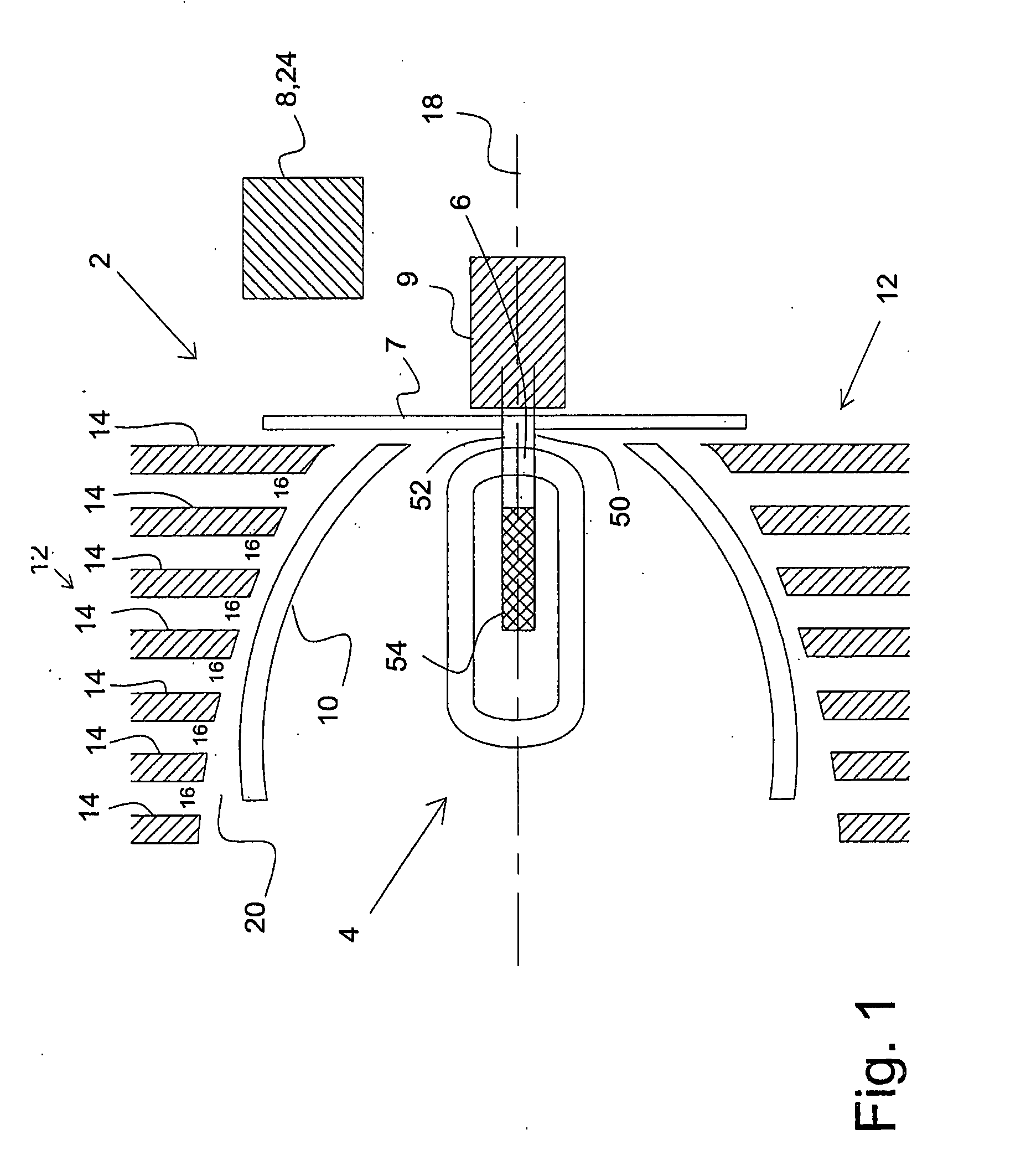

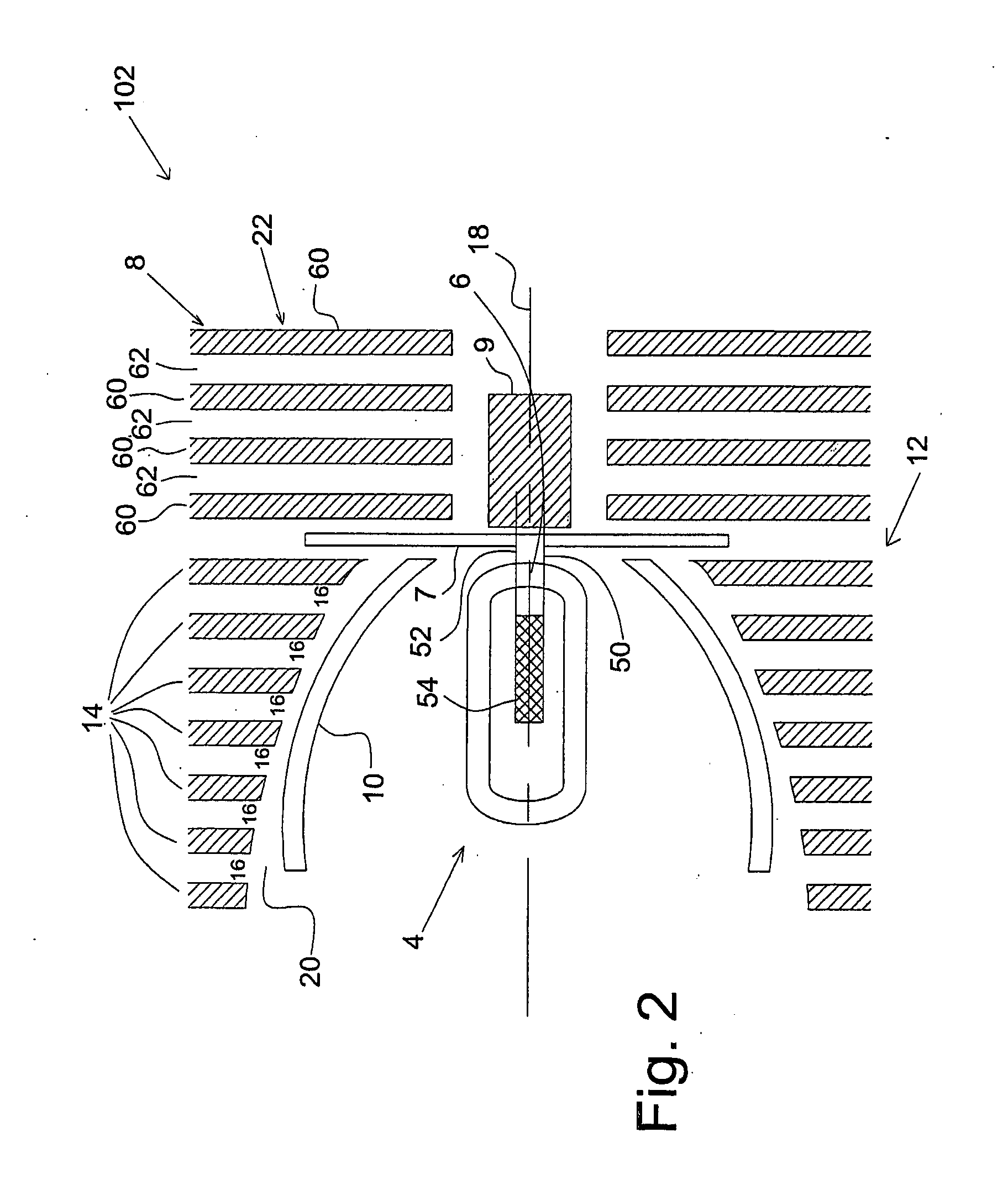

Light Source Module

ActiveUS20080089066A1Reduce the temperatureIncrease lifetime of lampLighting heating/cooling arrangementsOptical signallingOptoelectronicsHeat spreader

The present invention relates to a light source module comprising a light source, which light source module comprises cooling means for cooling the light source base, which light source module further comprises a dechroic reflector, where at least one heat sink surrounds the dechroic reflector. The object of the present invention is to reduce the temperature at the lamp base to increase the lifetime of a lamp. This can be achieved by a light source module that comprises at least a first heat sink, which first heat sink comprises a number of dishes, which dishes are formed to achieve air gabs there between, which dishes comprises at least one opening for the dechroic reflector, which dishes are placed radially around the dechroic reflector, which air gabs between the dishes are directed mostly perpendicularly to a centre axis of the light source module. Hereby, it is achieved that most of the infrared light, which is radiated in the direction of the dechroic reflector is absorbed in the dishes of the heat sink, and because the direction of the dishes is perpendicular to the main axis of the lamp module, the dishes conduct the heat radially towards the outer surface of the dishes.

Owner:MARTIN PROFESSIONAL

Rear casing of gas turbine engine

ActiveCN110761855AReduce heat loadImprove reliabilityMachines/enginesEngine componentsLap jointTurbine

The application belongs to the technical field of gas turbine design, and relates to a rear casing of a gas turbine engine. The rear casing comprises an outer casing, an inner casing and a plurality of force bearing frames arranged between the outer casing and the inner casing, wherein the inner wall of the outer casing is circumferentially provided with a heat shield, a notch which is concave tothe outer casing is arranged at the joint of the heat shield and the force bearing frames, a support plate limiting sleeve fixedly connected with the heat shield is arranged in the notch, and the support plate limiting sleeve comprises side plates extending to two sides of the force bearing frames; the outer side of each force bearing frame is wrapped with a rectification support plate, one end ofthe rectification support plate is connected with each force bearing frame, the other end of the rectification support plate is in lap joint with the outer side of each side plate of the support plate limiting sleeve, a first air cooling channel is formed between each force bearing frame and the rectification support plate, a second air cooling channel is formed in each force bearing frame, and the rectification support plate extends under the action of thermal stress, extends outwards under the guiding action of the support plate limiting sleeve, and releases the thermal stress, so that therear casing keeps good rigidity, reliability and durability.

Owner:AECC SHENYANG ENGINE RES INST

Full premixed water-cooled low nitrogen condensing stainless steel hot water boiler

PendingCN110553260AReduce volumeReduce heat transfer areaWater heatersGaseous fuel burnerCombustorLow nitrogen

The invention relates to a full premixed water-cooled low nitrogen condensing stainless steel hot water boiler, which comprises a water-cooled burner, an optical tube, a primary heat exchanger, a secondary condensation heat exchanger, a water chamber, a body frame, and a flue gas collector. The water-cooled burner, the optical tube, the primary heat exchanger, the secondary condensation heat exchanger, the water chamber, and the flue gas collector are all installed on the body frame, the optical tube, the water-cooled burner and heat exchange elements in the primary heat exchanger and the secondary condensation heat exchanger are all made of stainless steel, the space between the water-cooled burner and the primary heat exchanger forms a low-temperature furnace, the water-cooled burner, the optical tube, the primary heat exchanger and the secondary condensation heat exchanger successively communicate through the water chamber, the water-cooled burner, the low-temperature furnace, the primary heat exchanger, the secondary condensation heat exchanger and the flue gas collector are arranged from top to bottom, and cold water successively flows through the two-stage condensation heat exchanger, the primary heat exchanger, the low-temperature furnace and the water-cooled burner. According to the full premixed water-cooled low nitrogen condensing stainless steel hot water boiler, energy conservation and environment protection are achieved, NOx emission is less than 30 mg / m<3>, the floor space is small, safety and stability are high, and environmental adaptability strong.

Owner:杭州卡瓦顿热能科技有限公司

Bonding of strain gauges to the deformable body of a force-measuring cell

ActiveUS7243558B2Less timeLower temperature levelForce measurement by measuring frquency variationsWeighing apparatus using elastically-deformable membersEngineeringStrain gauge

In a force-measuring cell with a deformable body and with at least one strain gauge which has a strain-sensitive electrical resistor track arranged on a polymer carrier substrate, the strain gauge is bonded to the deformable body by an adhesive layer of an inorganic-organic hybrid polymer. For the bonding of the strain gauge to the deformable body, an adhesive compound having an inorganic-organic hybrid polymer in solution is applied to the deformable body, whereupon the strain gauge is placed on the hybrid polymer layer, and the adhesive layer is subsequently hardened at a temperature between 80° C. and 130° C. For the hardening of the adhesive layer, the deformable body with the strain gauge is exposed to the increased temperature for a time period between a half hour and three hours.

Owner:METTLER TOLEDO GMBH

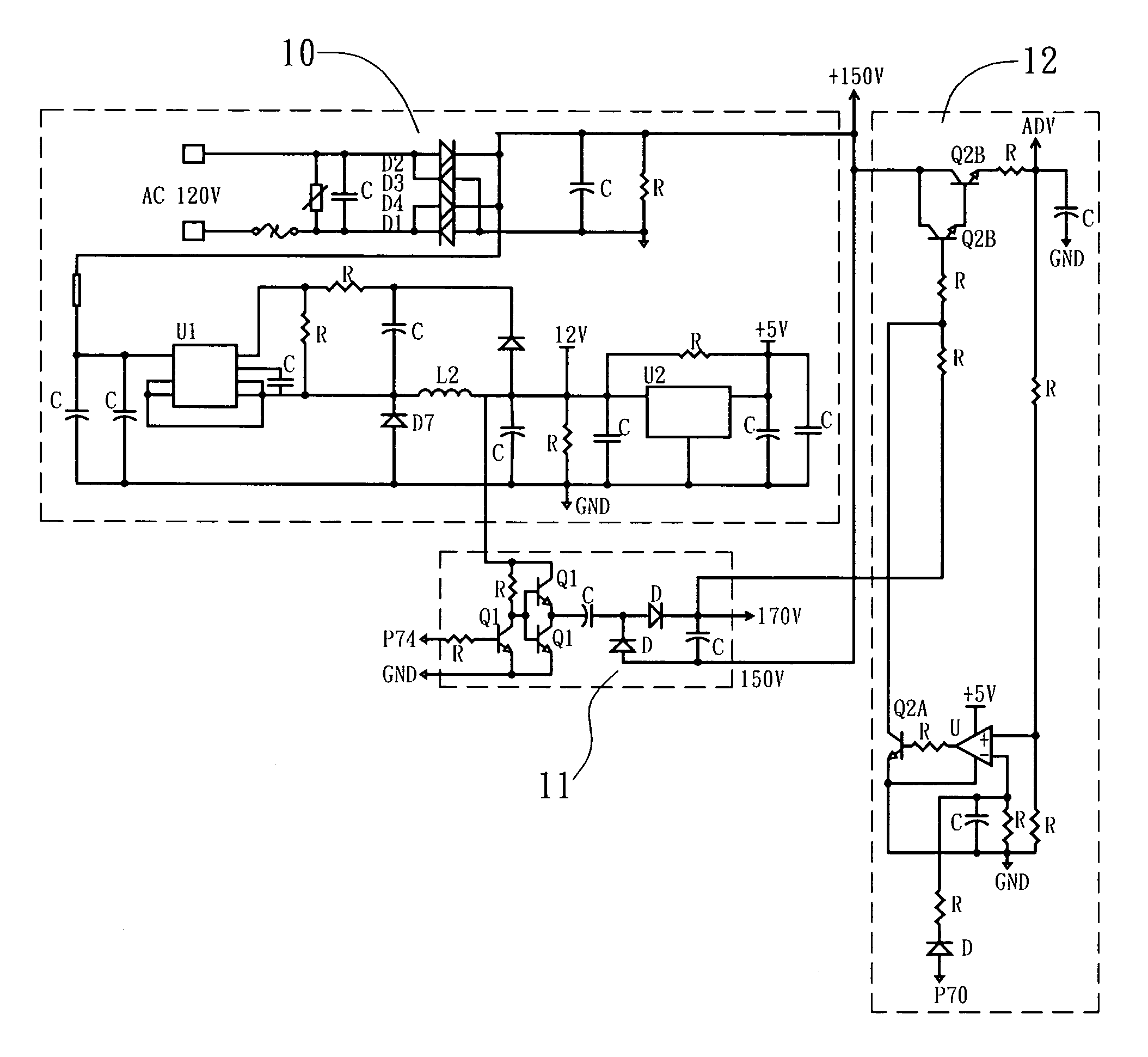

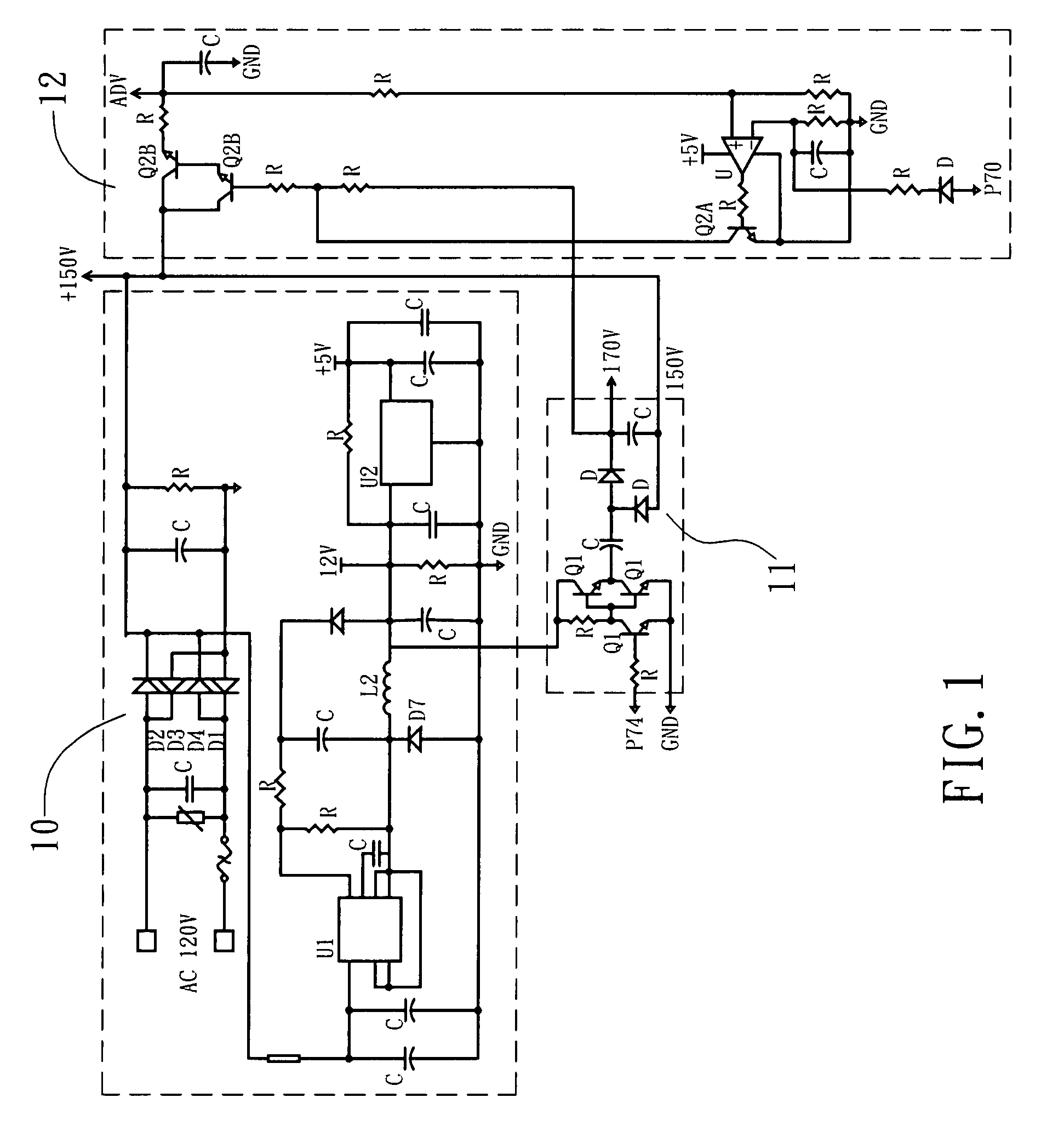

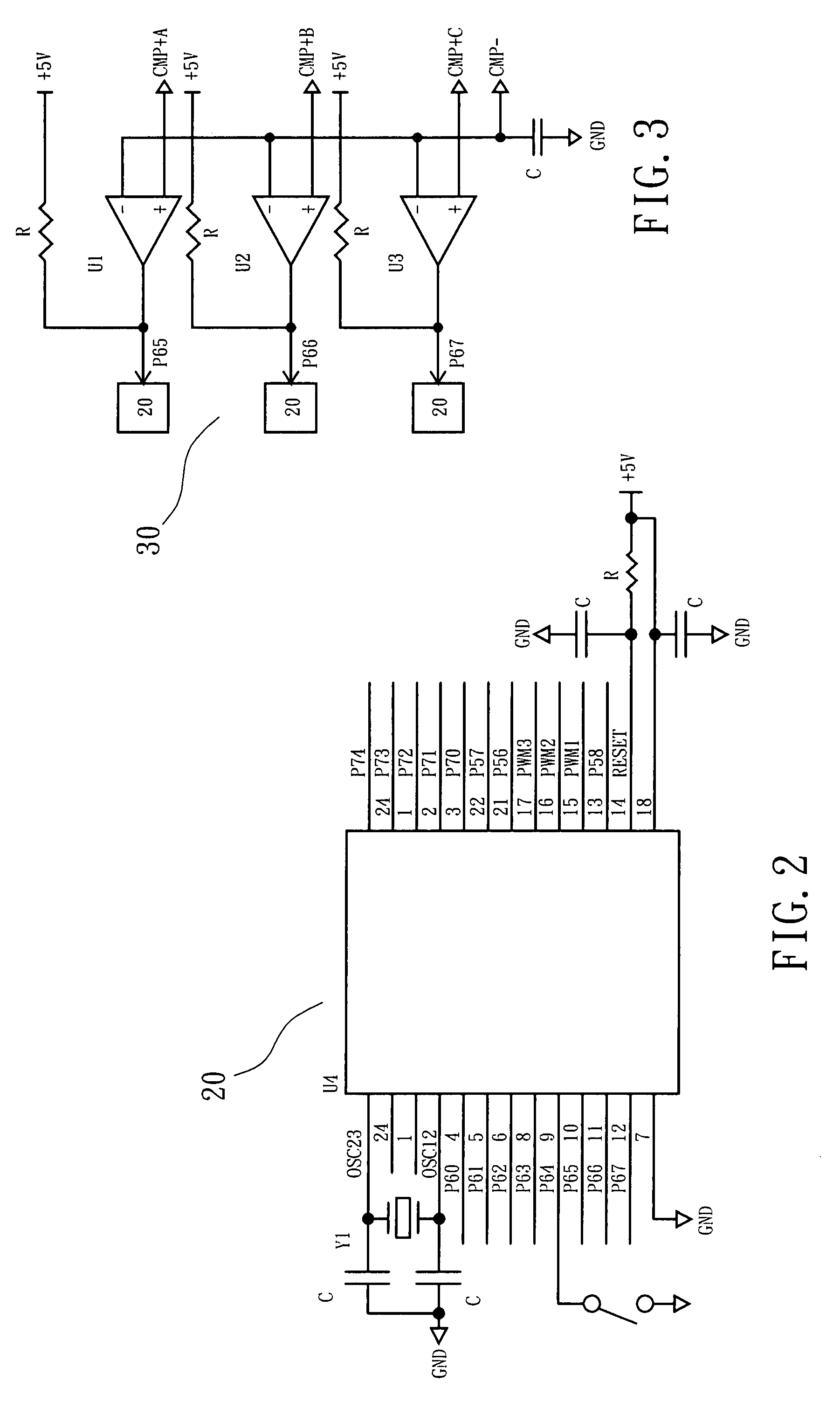

Brushless motor control circuit assembly for ceiling fan

InactiveUS7557526B2Lower temperature levelMore power consumptionSynchronous motors startersDC motor speed/torque controlCeiling fanBrushless motors

A power-saving, high-performance, low-noise brushless motor control circuit assembly is disclosed formed of a power supply circuit, a booster and compensation circuit, a voltage regulator circuit, a microprocessor, a back electromagnetic force sensor, three driver circuits, and three output circuits. By means of detecting back electromagnetic force, the magnetic pole position of the brushless motor is known accurately, ensuring accurate operation control. By means of providing a high voltage to drive the drive circuits, the field effect transistors of the output circuits are operated under full conduction, saving much power consumption and lowering the working temperature of the brushless motor.

Owner:LEE HSIEN MENG +1

Fuel Cell System

InactiveUS20140308595A1Reduce service lifeEasily resultFuel cell auxillariesAutomotive engineeringLine element

A fuel cell system includes at least one fuel cell, line elements for supplying and discharging starting materials and / or products to / from the fuel cell, and at least one condensation unit. The condensation unit is situated in at least one of the line elements and, at least in individual operating phases of the fuel cell, the condensation unit is at a lower temperature level than the areas surrounding it and the fuel cell.

Owner:DAIMLER AG

Water pump for pumping coolant in a low temperature and in a high temperature circuit

InactiveUS8403627B2Prevent heat transferLess heat energyPump componentsReaction enginesEngineeringSpiral flow

In a water pump for pumping coolant in a low temperature and a high temperature circuit with low temperature and high temperature housings each including a spiral flow guide structure, and a single rotor disposed in the joined housings and having a low temperature rotor part for pumping coolant through the low temperature circuit and a high temperature rotor part for pumping coolant through the high temperature circuit, the housings are joined with a heat isolating structure disposed between the flow guide structures of the high temperature and the low temperature housings to limit heat transfer from the high temperature coolant pumped through the high temperature housing to the low temperature coolant pumped through the low temperature housing.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

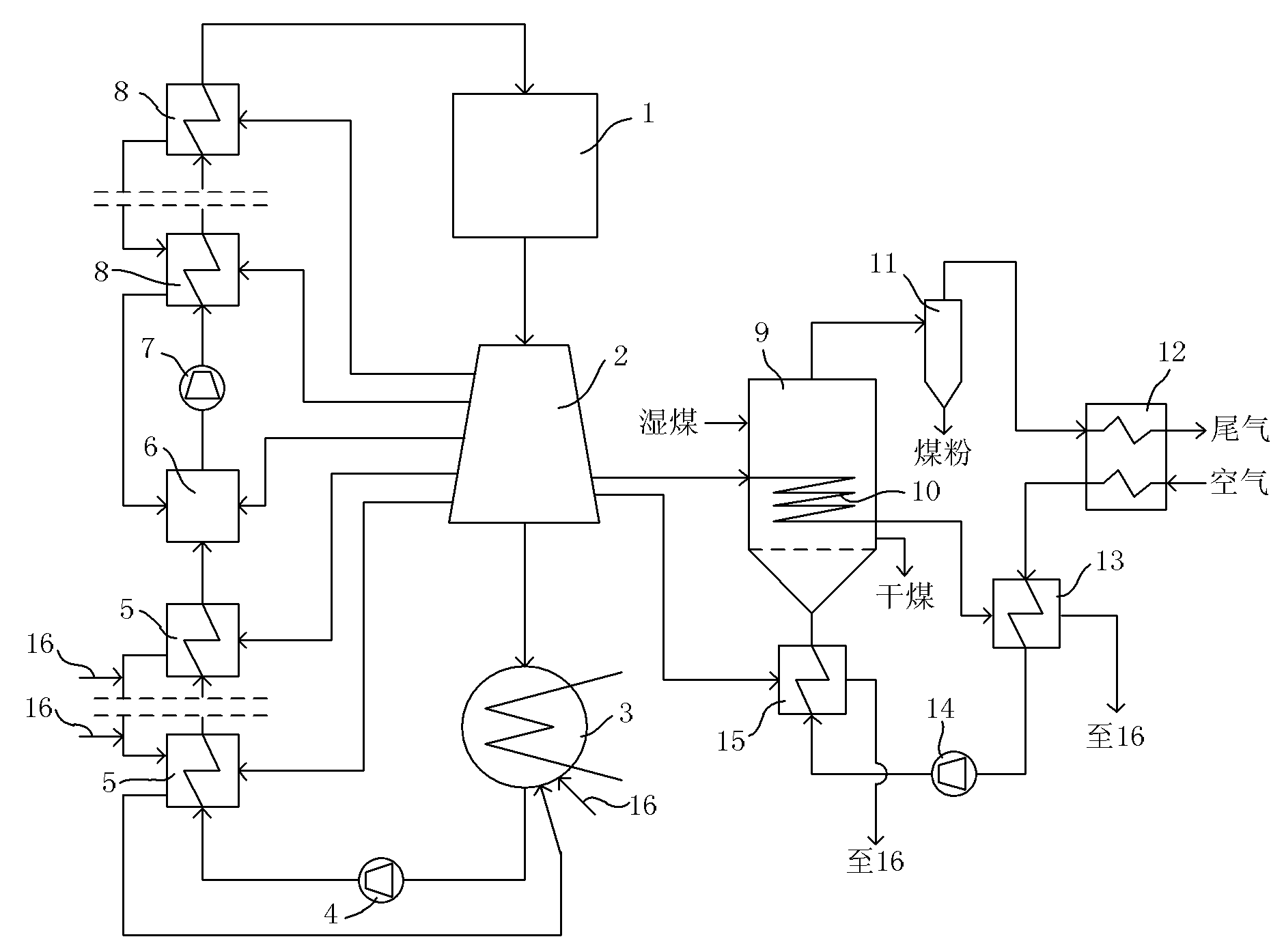

High-moisture-content lignite predrying method and system integrated with thermal power plant

InactiveCN102353237BWith drying capacityKeep dryDrying solid materials with heatFeed water supplyThermal energyFluidized bed drying

The invention discloses a high-moisture-content lignite predrying method and system integrated with a thermal power plant. In the method, lignite is dried by using hot air as a fluidizing agent and a drying medium in a fluidized bed dryer; and a heater is built in the fluidized bed dryer to supply partial heat for drying. The lignite predrying system integrated with the thermal power plant comprises the fluidized bed dryer, the heater built in the dryer, a deduster, a gas-gas heat exchanger, a gas-water heat exchanger, an air heater and a fan. According to the system, waste heat in the system and low-grade heat energy in the power plant are fully utilized to dry the lignite. By applying the method and the system disclosed by the invention, the moisture content of the lignite fed into a furnace can be reduced, the heat loss of a boiler due to exhaust gas can be reduced, and the efficiency of the lignite boiler is increased; the low-grade heat energy and waste heat resources in the thermal power plant are fully utilized, so that the consumption of high-grade energy sources in a drying process is reduced, and the power generation efficiency of a lignite power plant is increased.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com