Patents

Literature

44results about How to "Avoid pressure rises" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal combustion engine with auto ignition

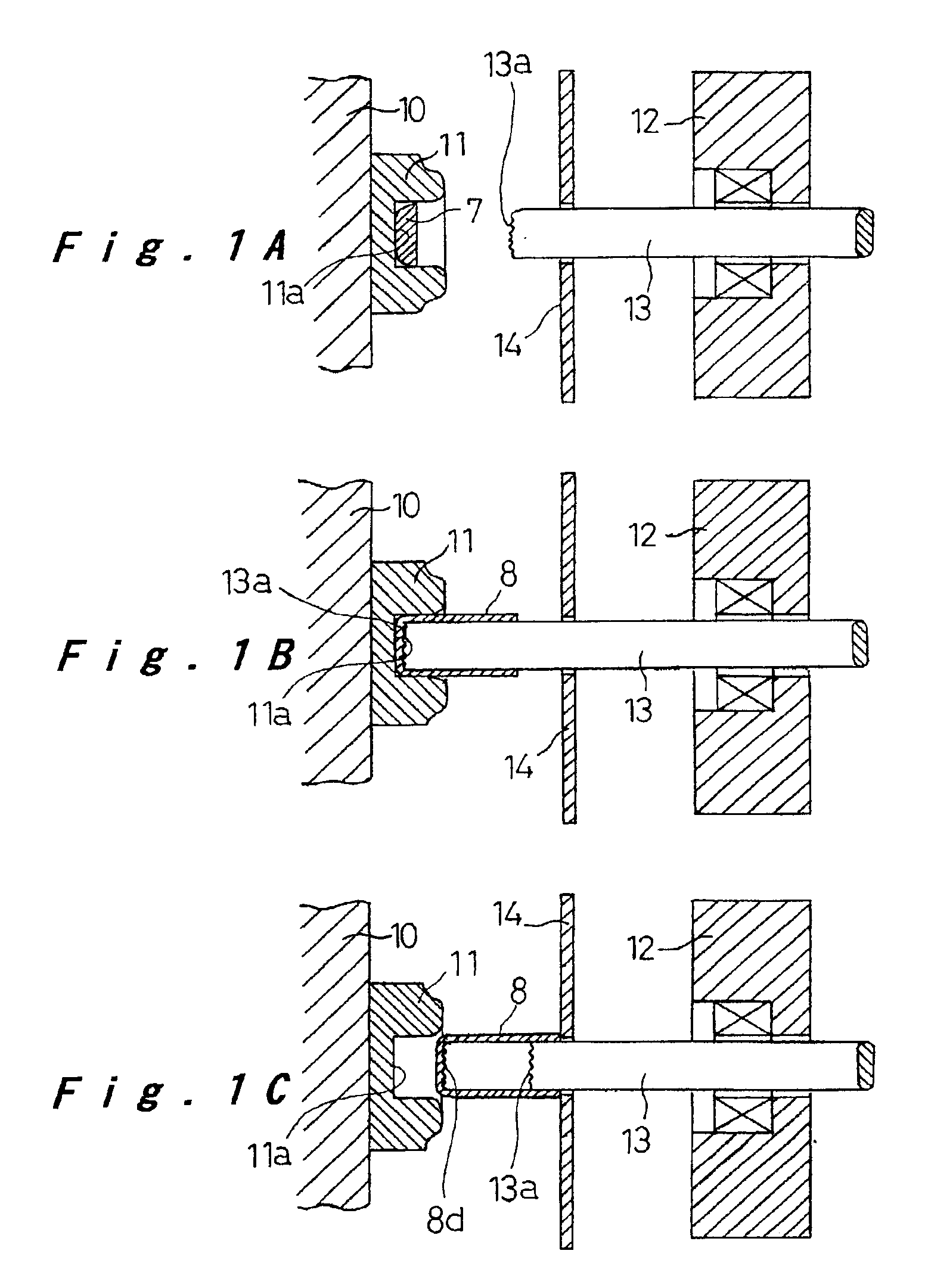

InactiveUS20060037563A1Prevent wettingMinimize wettingElectrical controlNon-fuel substance addition to fuelCombustion chamberInternal combustion engine

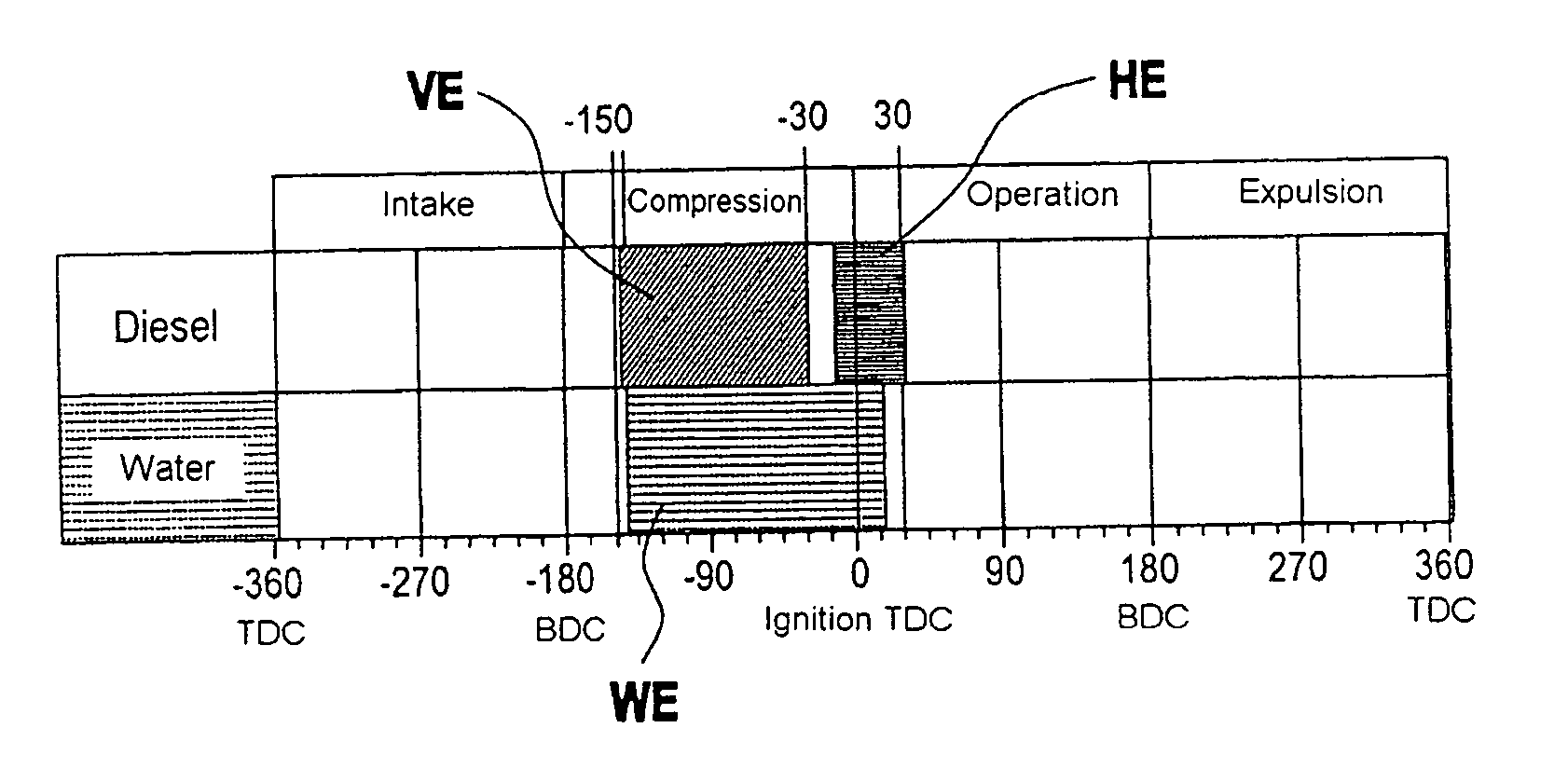

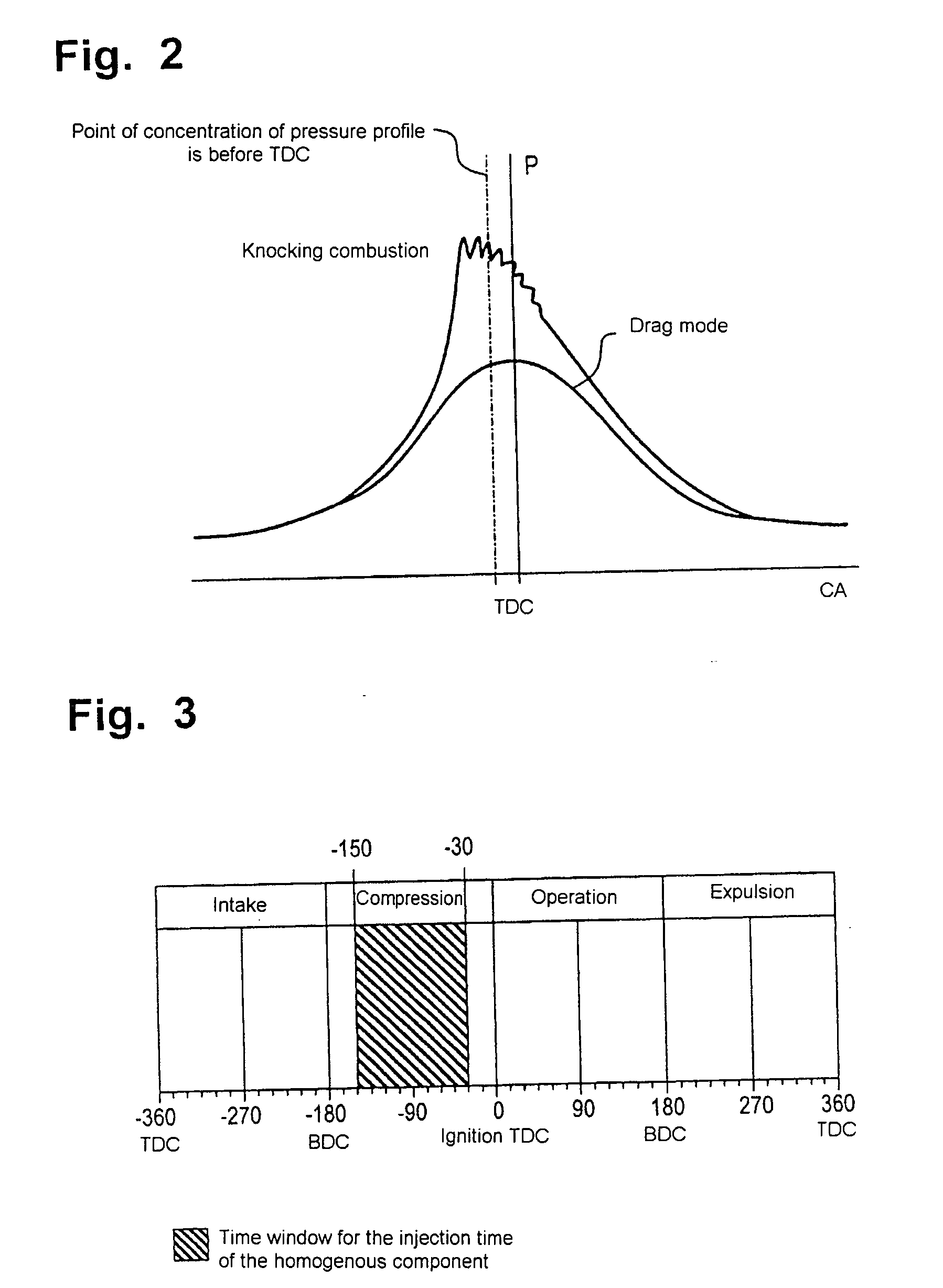

In a method for operating an internal combustion engine in which fuel is injected directly into a combustion chamber in a pre-injection and a main fuel injection step, and, if appropriate, also in a post-injection step by means of an injection nozzle with a plurality of injection bores, the injection of fuel takes place in a timed fashion and, to limit pressure and temperature during combustion of the fuel in the combustion chamber, a quantity of water is introduced into the combustion chamber during or after the pre-injection step.

Owner:DAIMLER AG

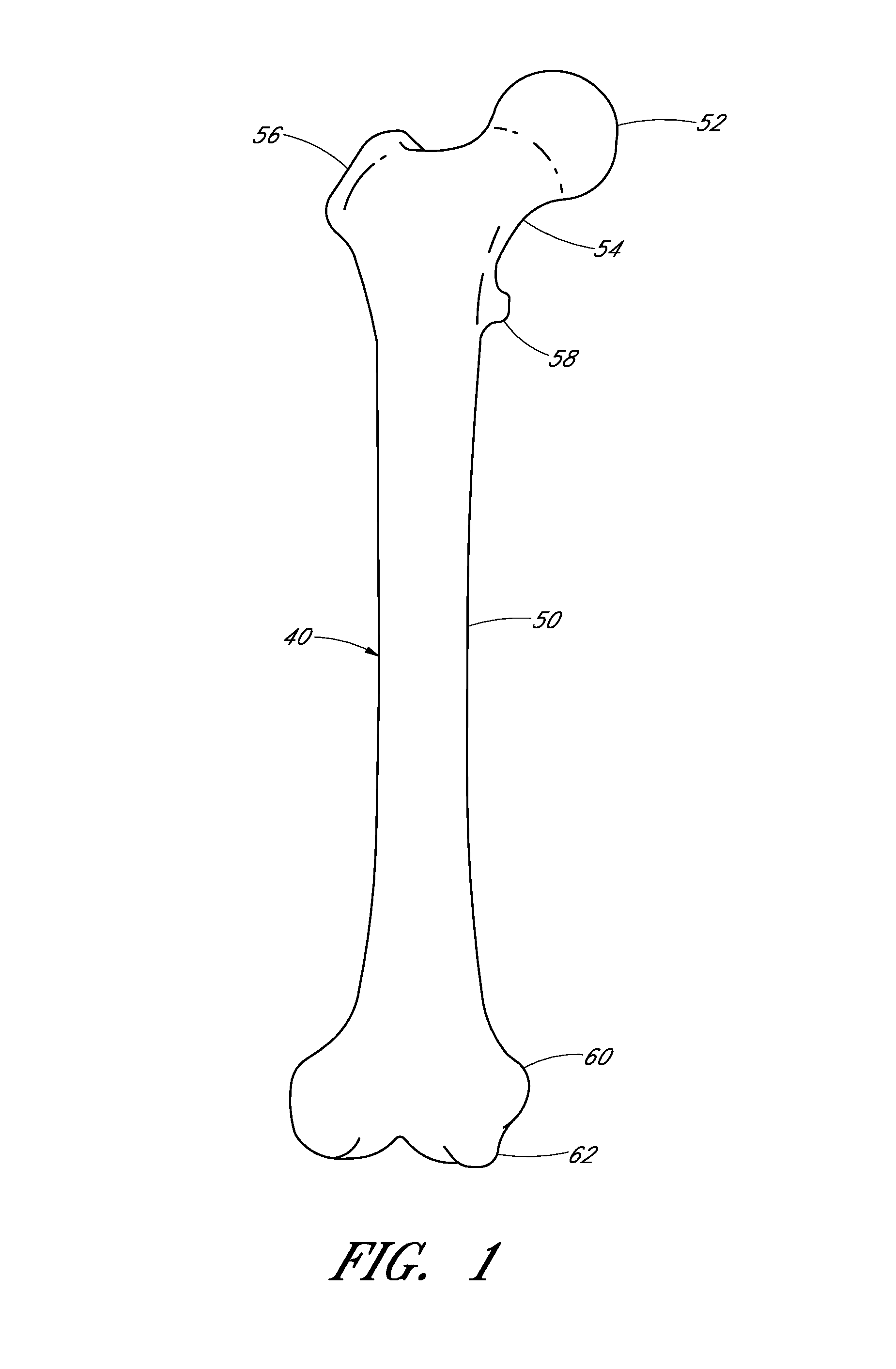

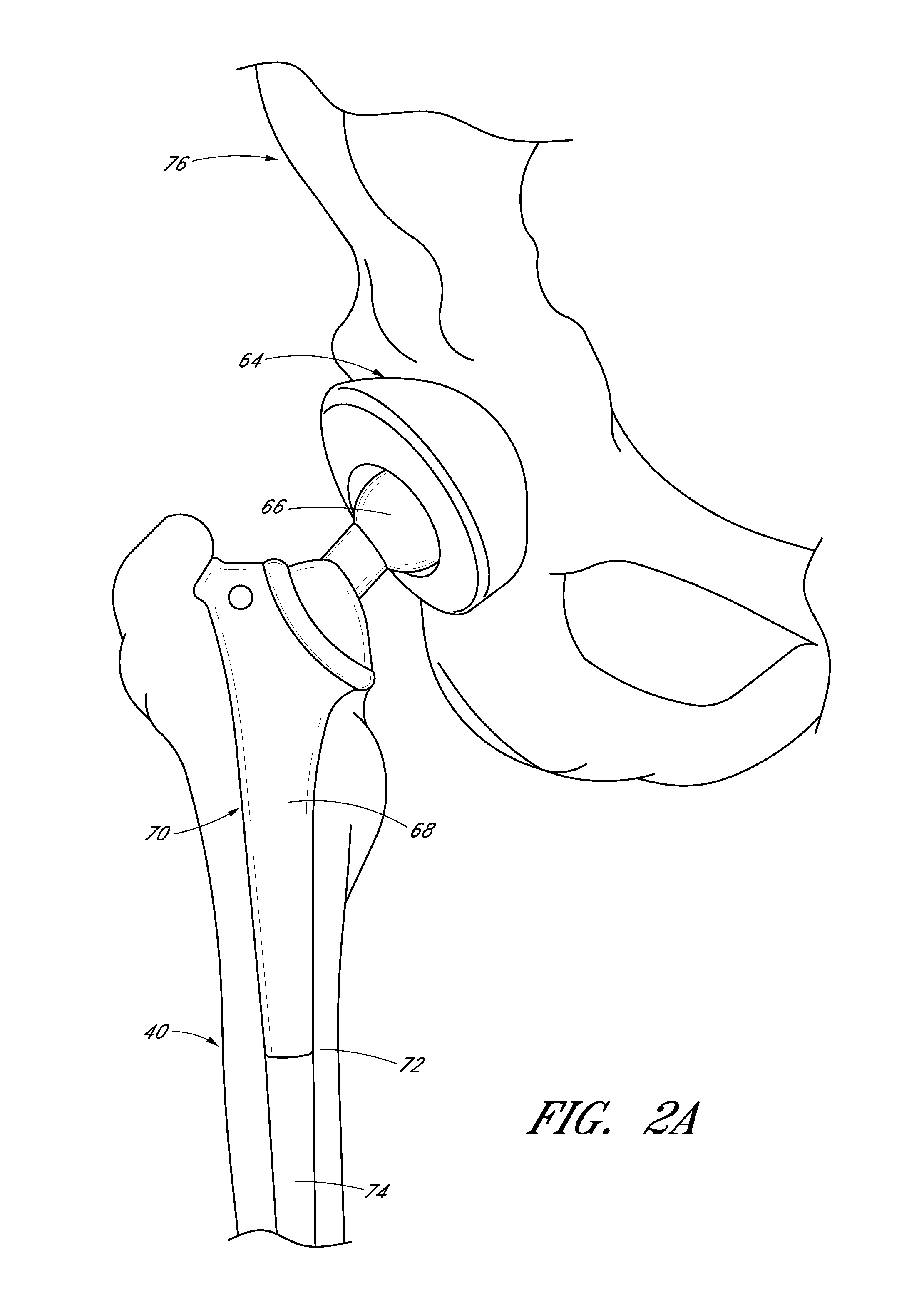

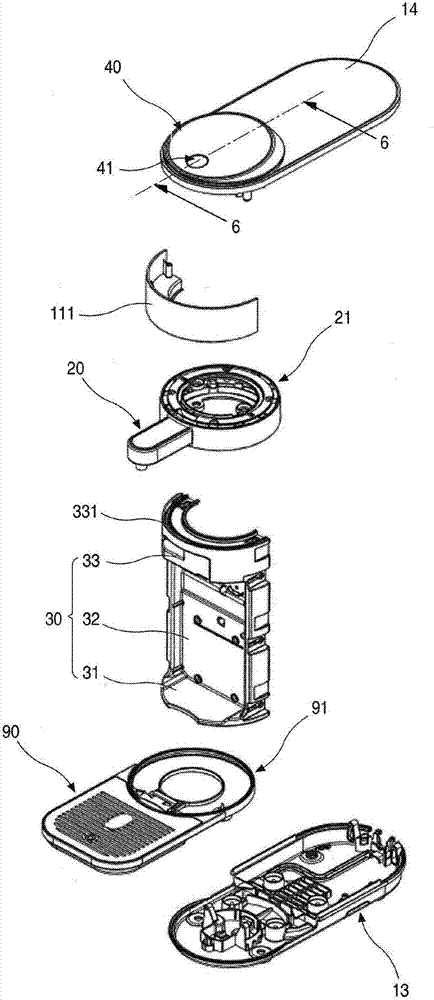

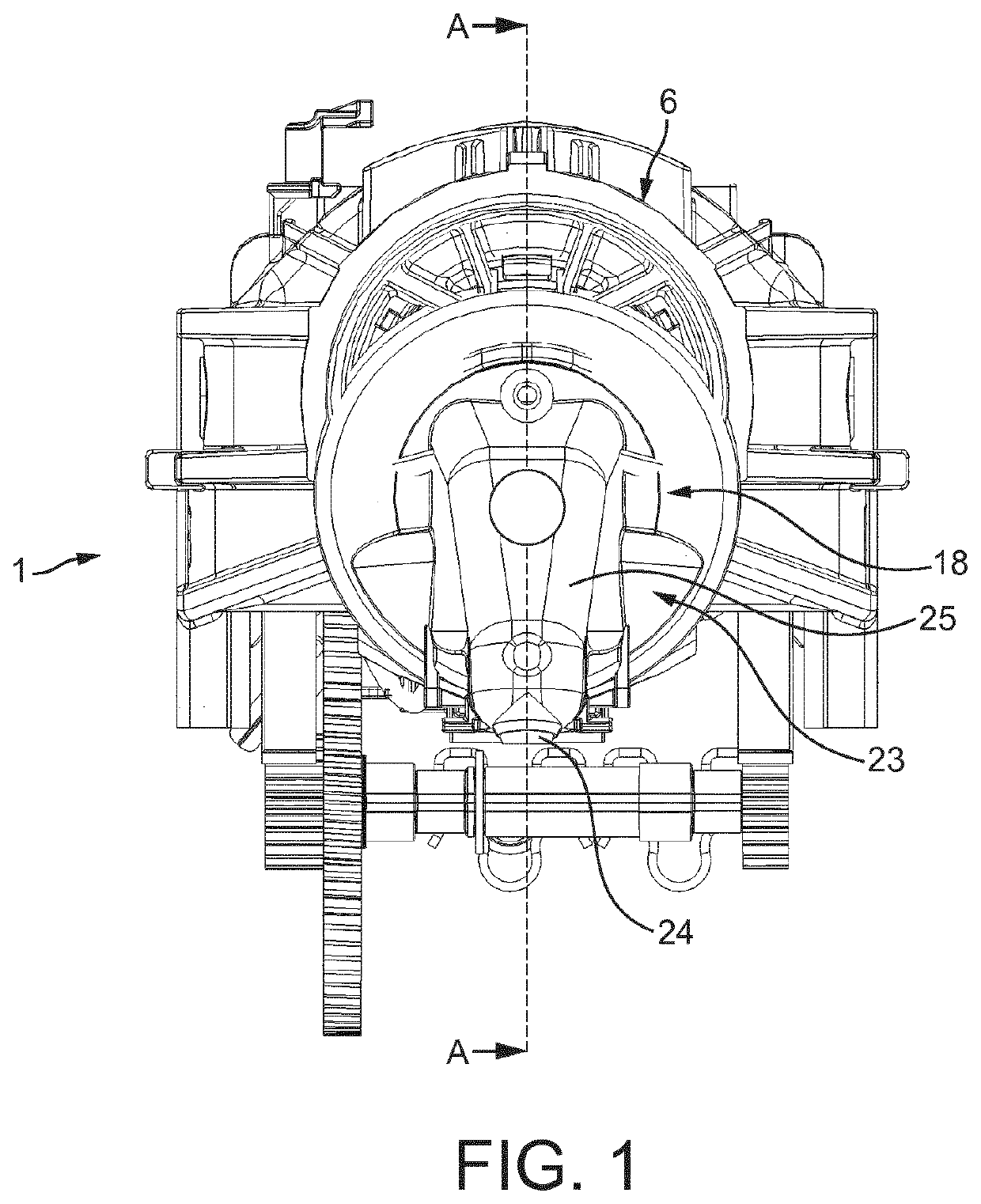

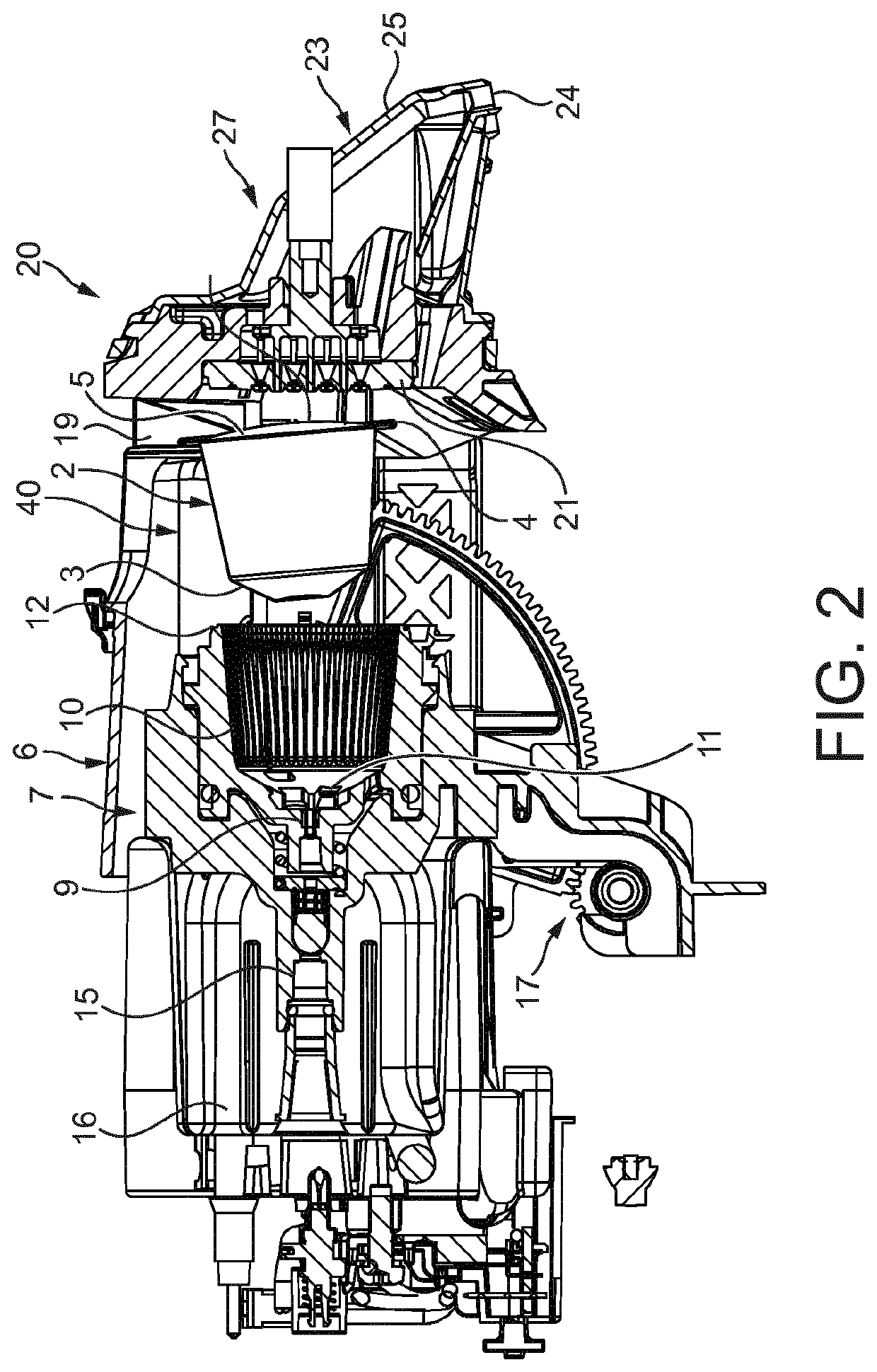

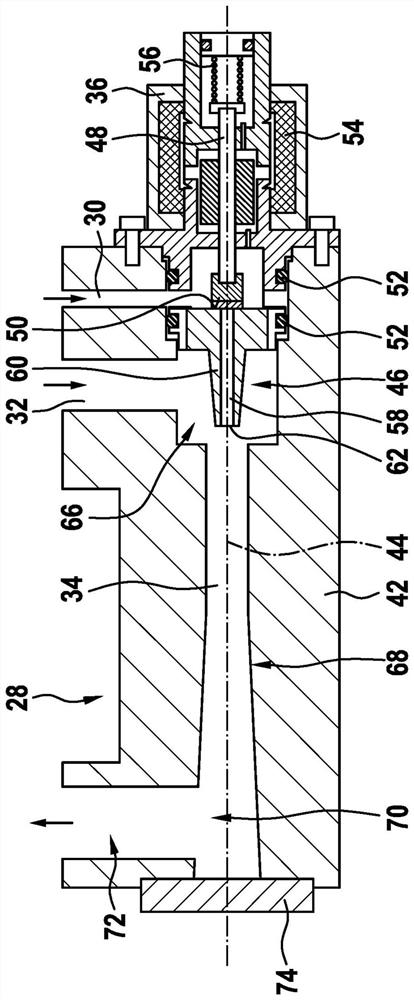

Intramedullary linkage device, system, and method for implantation

ActiveUS8668692B1Easy to fixAvoid pressure risesInternal osteosythesisJoint implantsLONG BONE FRACTUREProsthesis

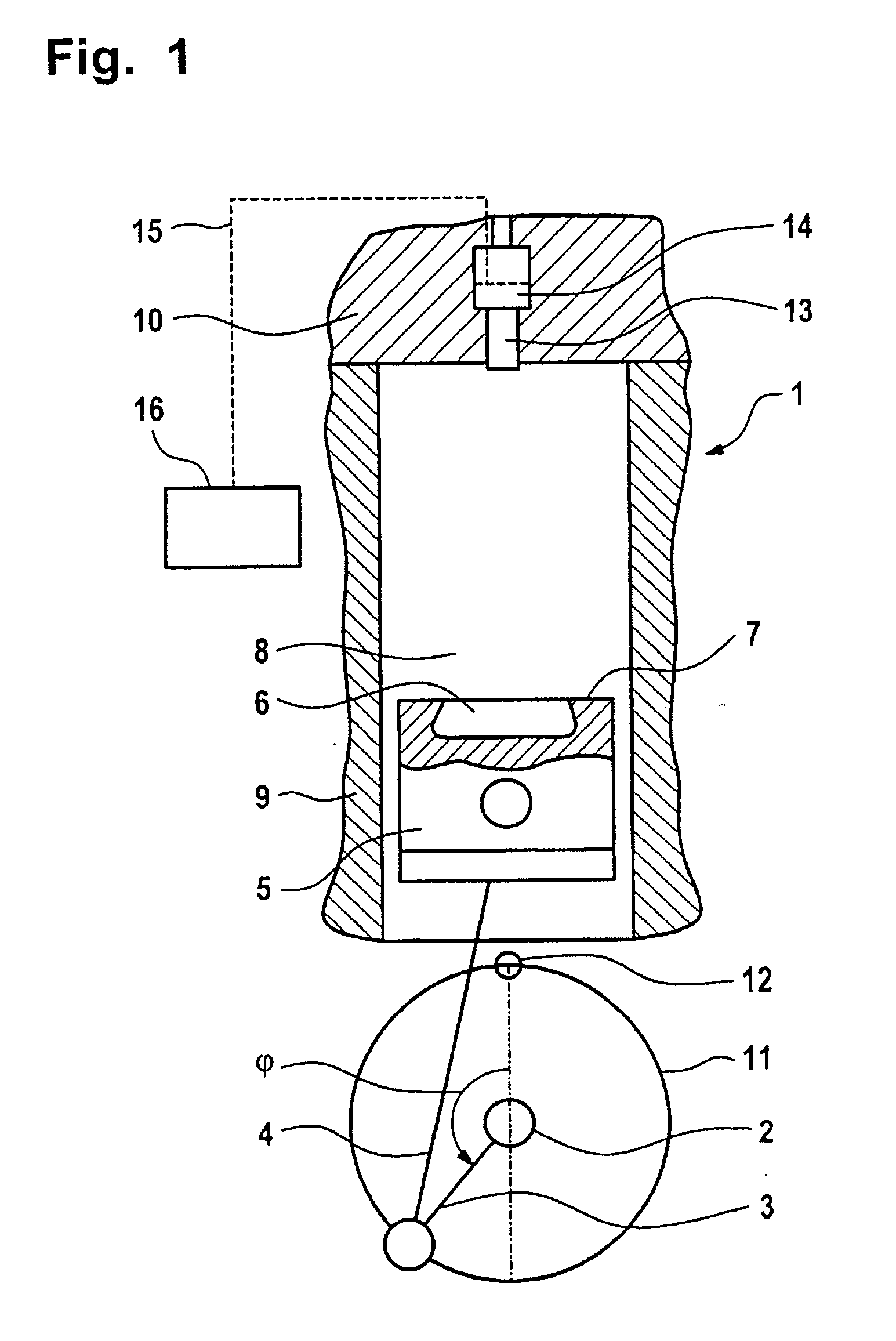

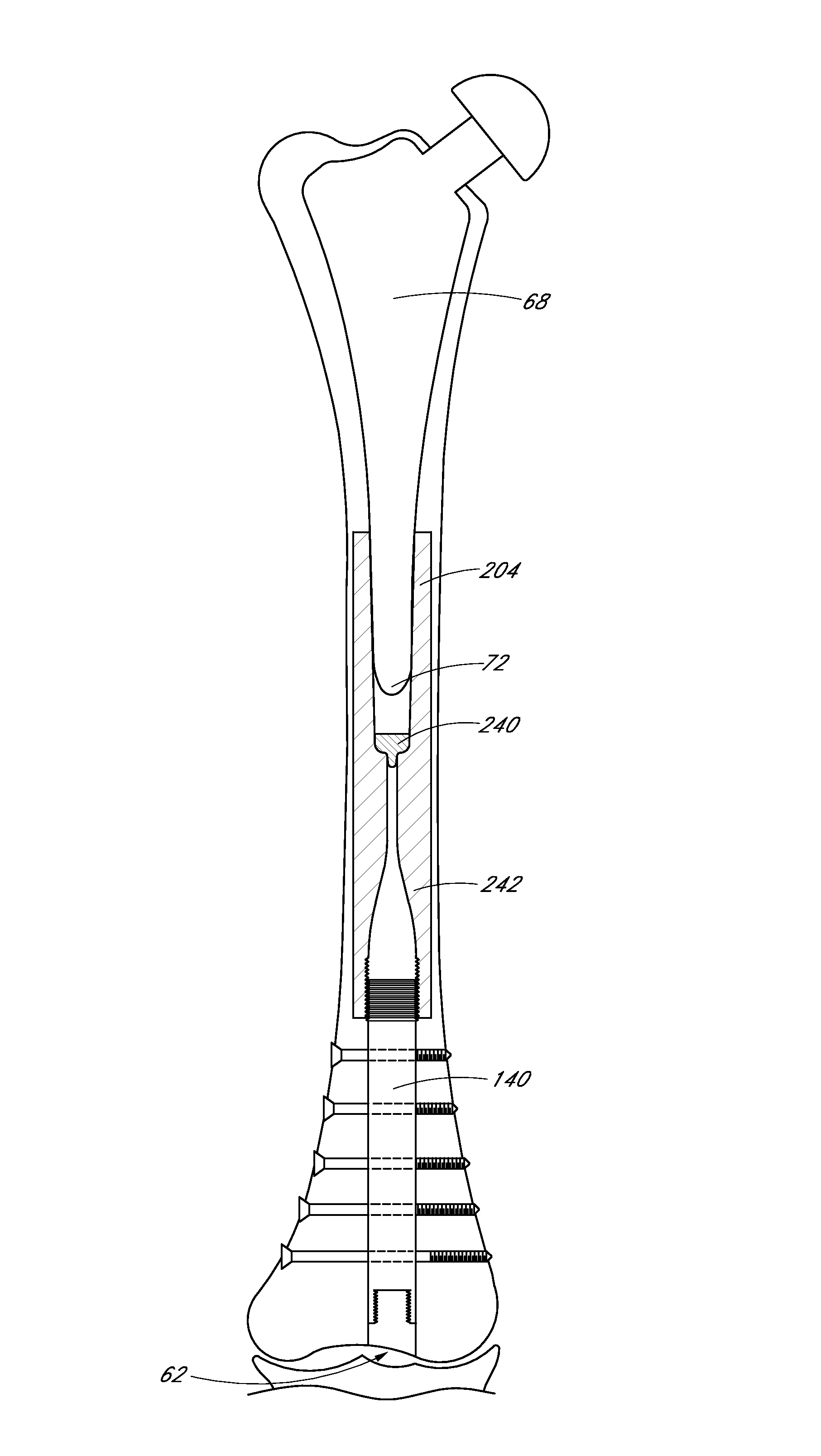

The invention relates to an intramedullary linkage device for treatment of peri-prosthetic long bone fractures, system for long bone fracture treatment in the setting of pre-existing intramedullary implant using an intramedullary linkage device and intramedullary fracture fixation device, and methods of treating peri-prosthetic long bone fracture in the setting of pre-existing intramedullary implant using an intramedullary linkage device and intramedullary fracture fixation device.

Owner:LINDVALL ERIC M

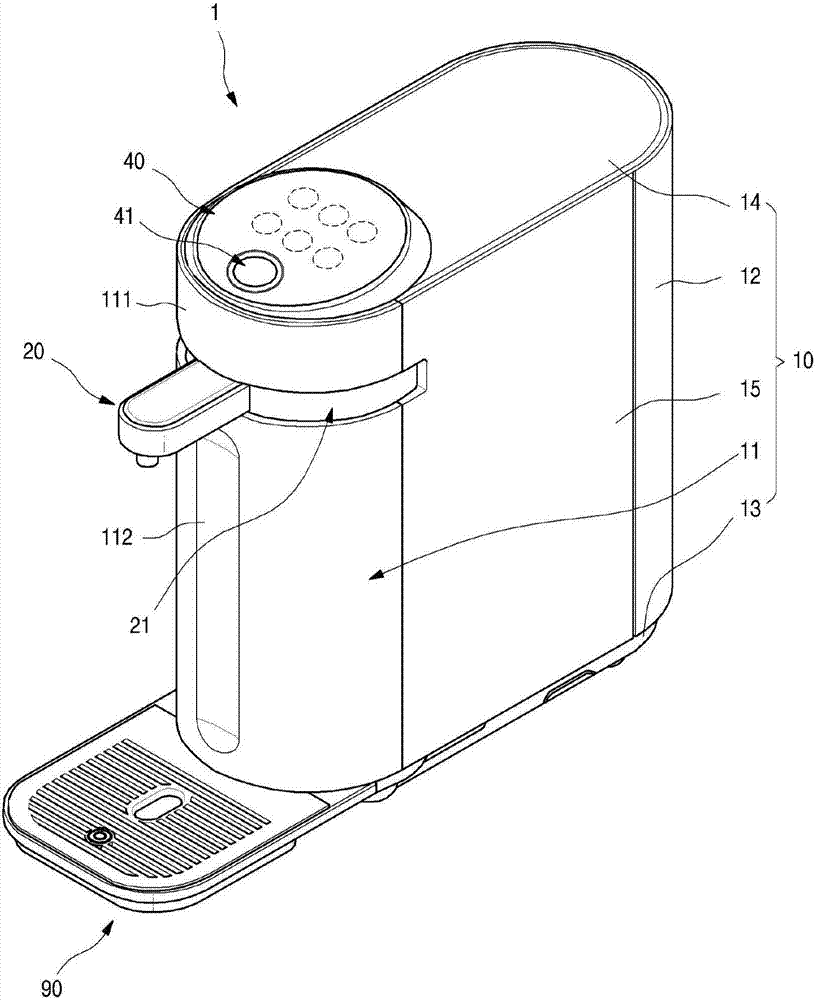

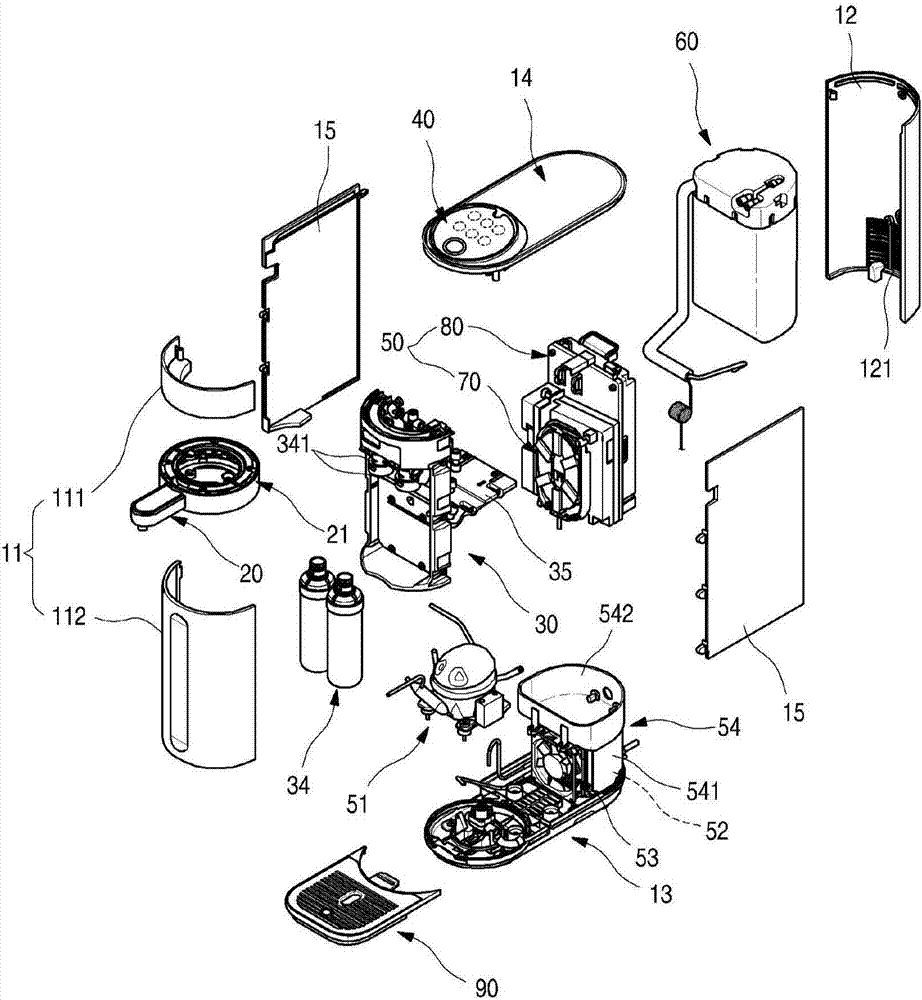

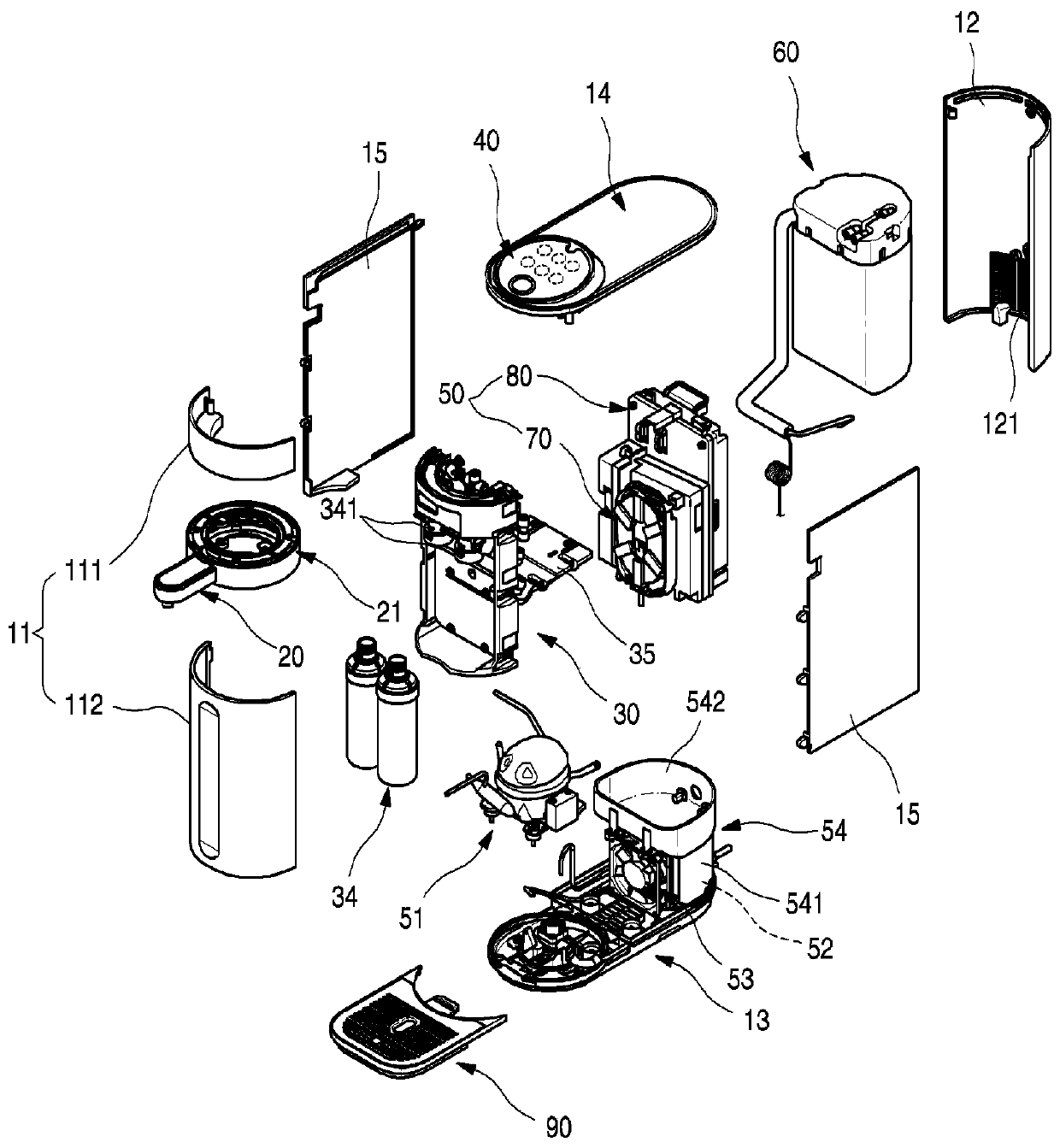

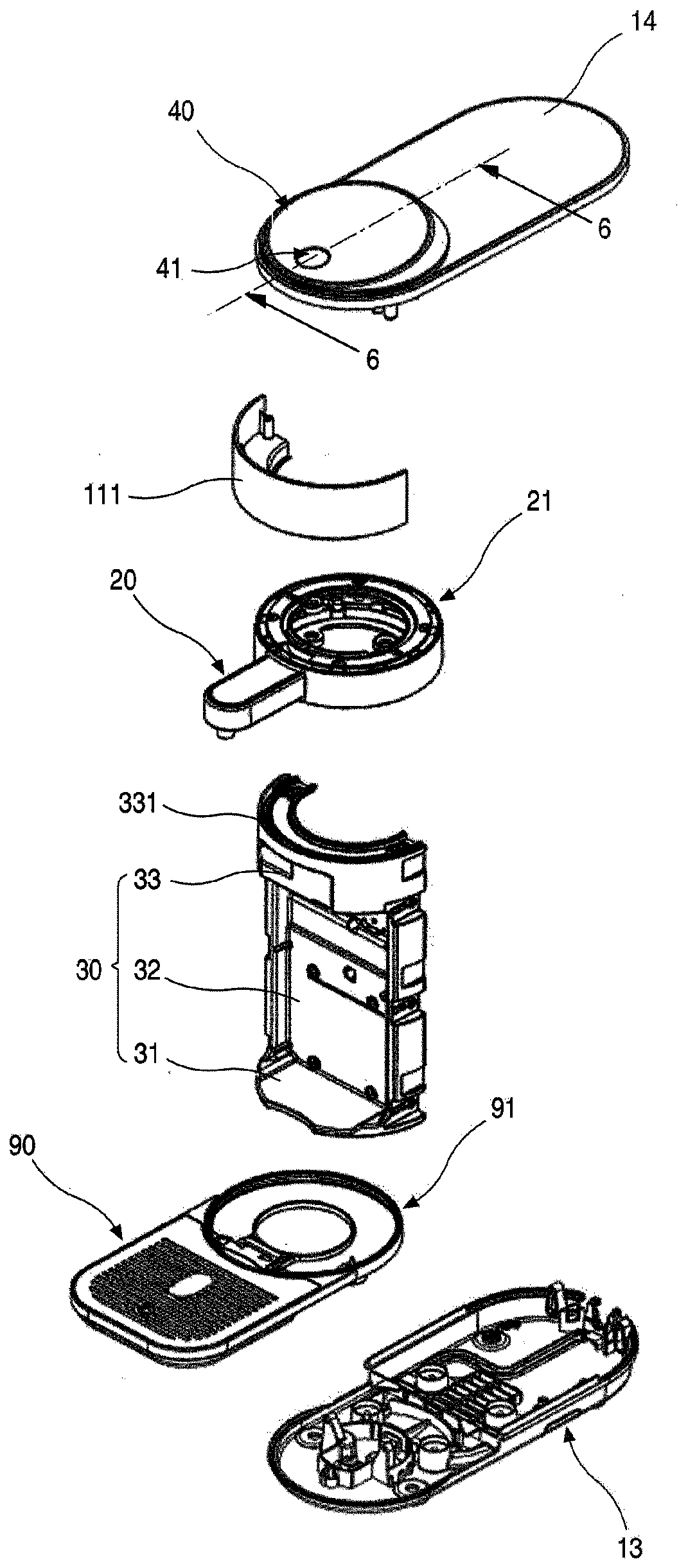

Water purifier

ActiveCN106963241AImprove efficiencyIncrease productivityWater treatment parameter controlLighting and heating apparatusWater filterFilter holder

The invention provides a water purifier. The water purifier according to the embodiment of the invention includes a shell used for forming a shape; a filter support arranged inside the shell and equipped with a filter and a valve; a condenser support arranged inside the shell and separated from the filter support, a condenser being accommodated on the condenser support; a cooling box placed at the upper end of the condenser support and used for cooling water purified by the filter; a support plate connecting the filter support and the cooling box and dividing space between the filter support and the cooling box vertically; a compressor arranged under the support plate; and a control assembly mounted on the support plate.

Owner:LG ELECTRONICS INC

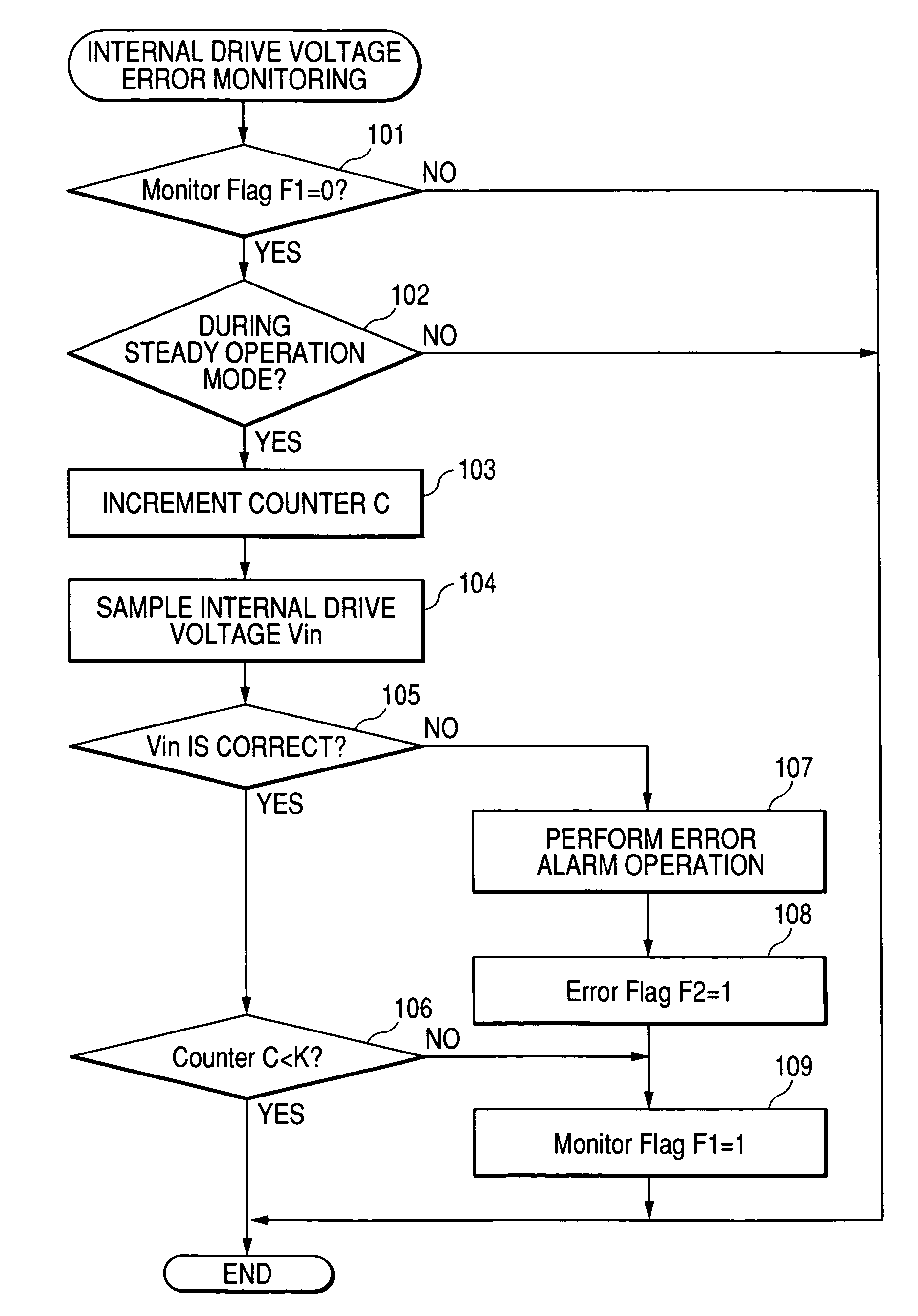

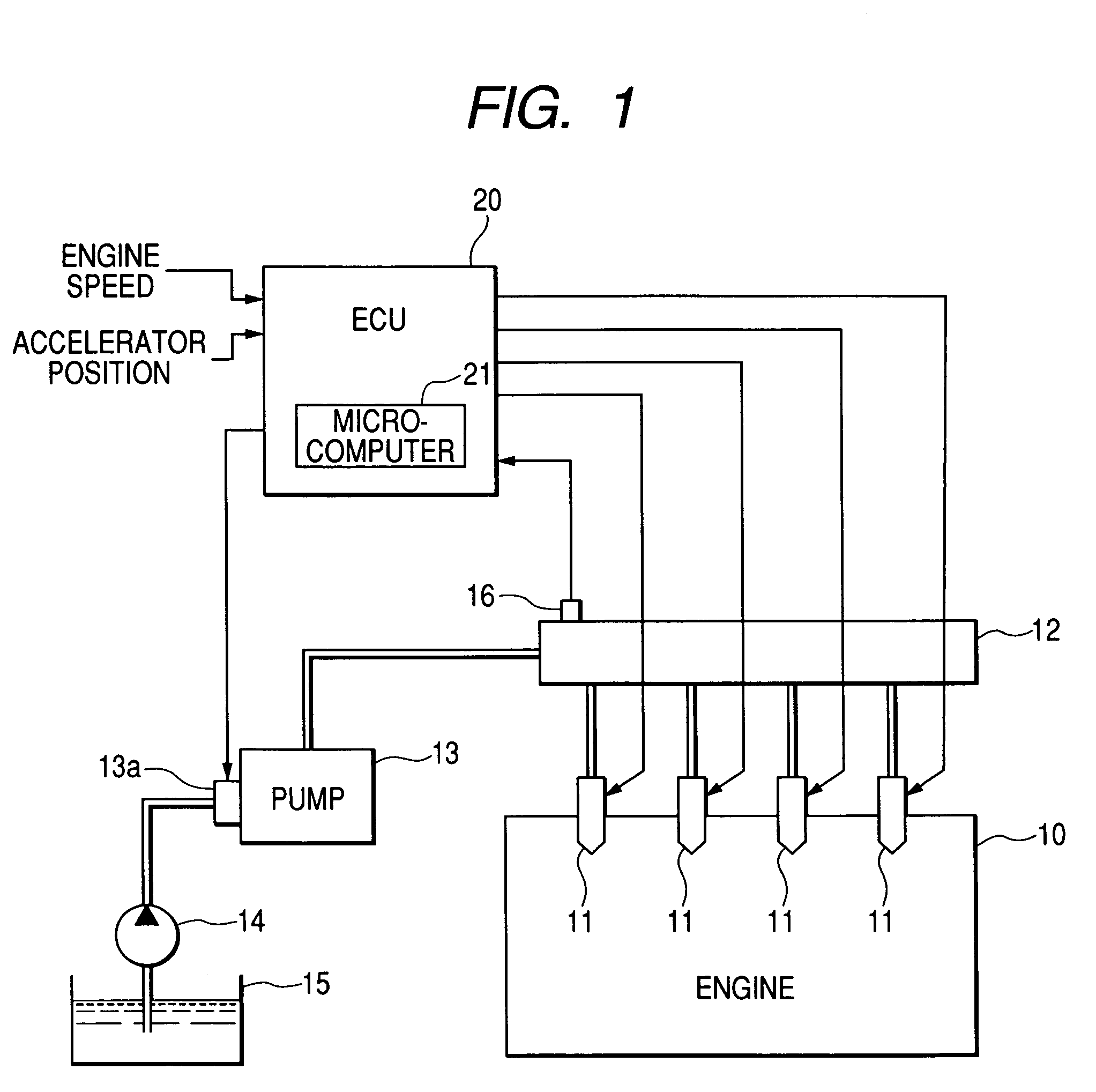

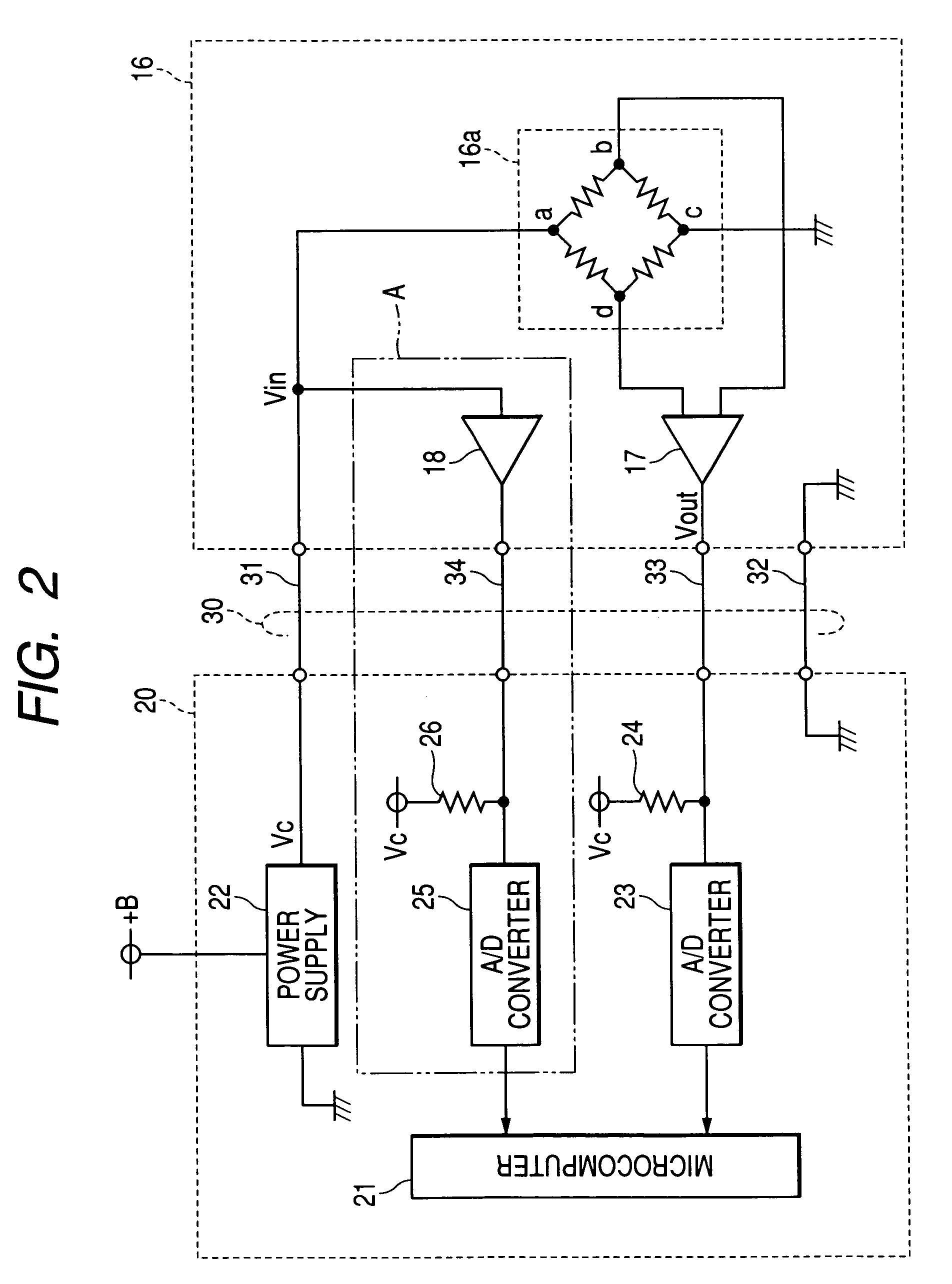

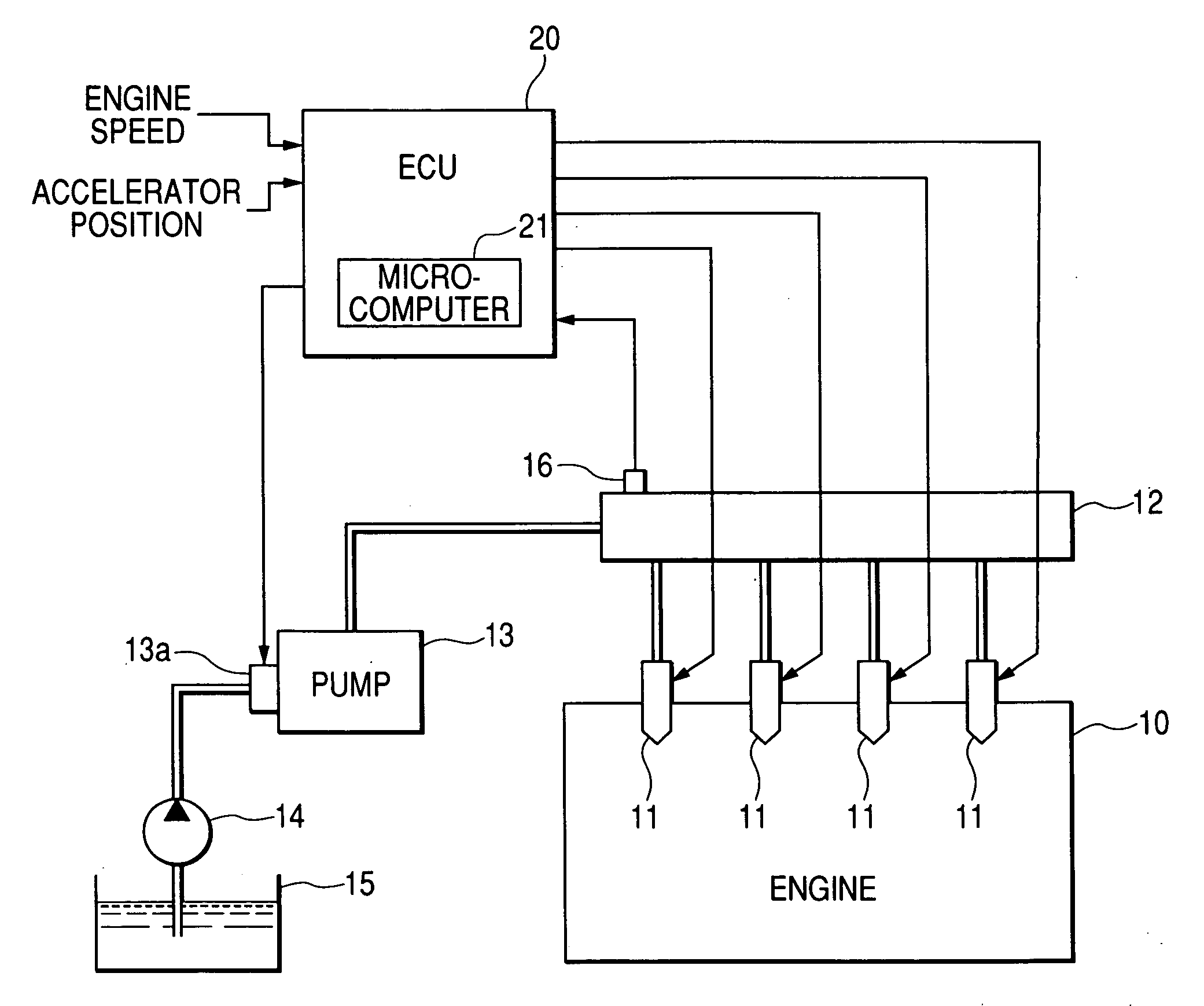

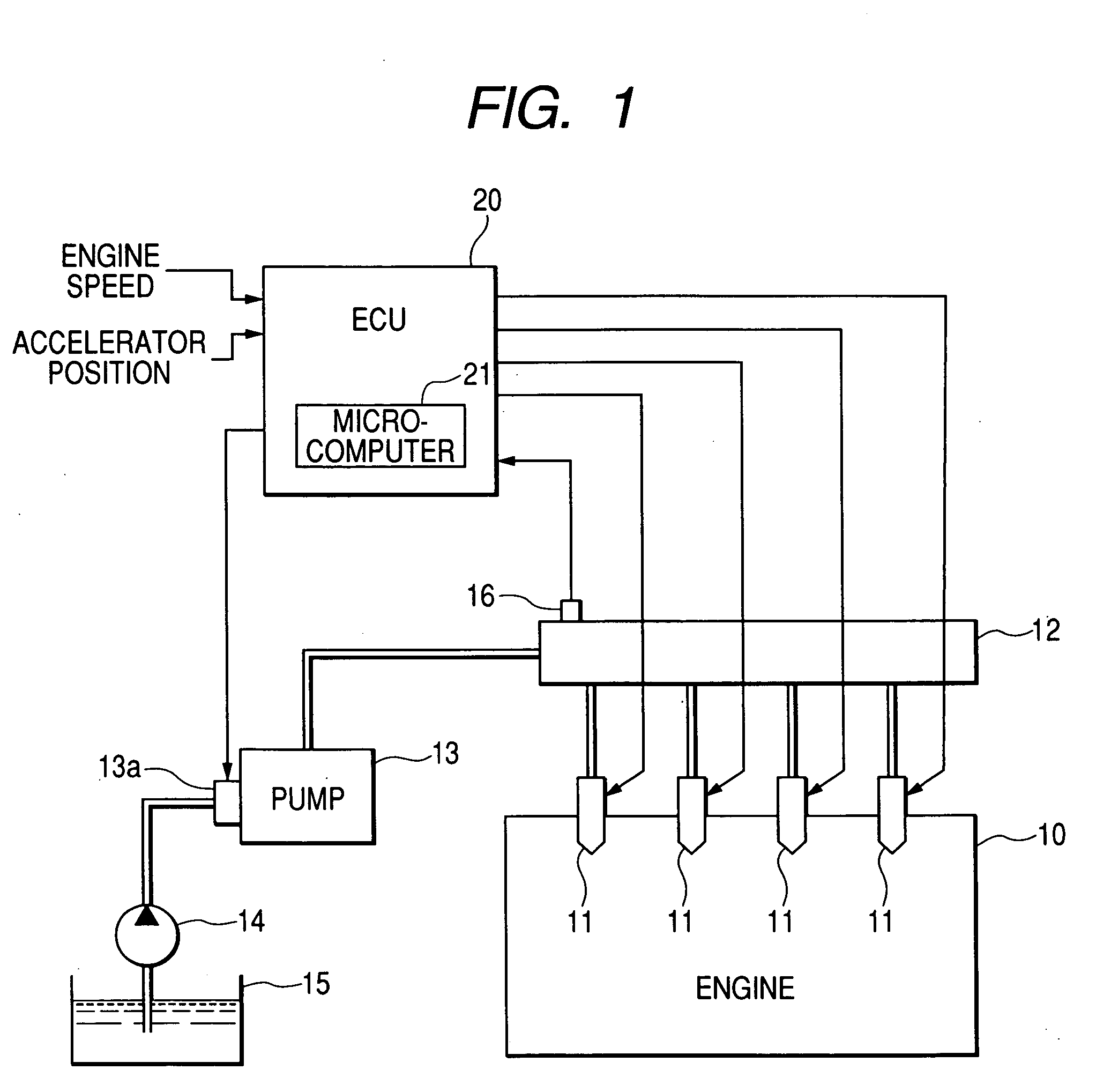

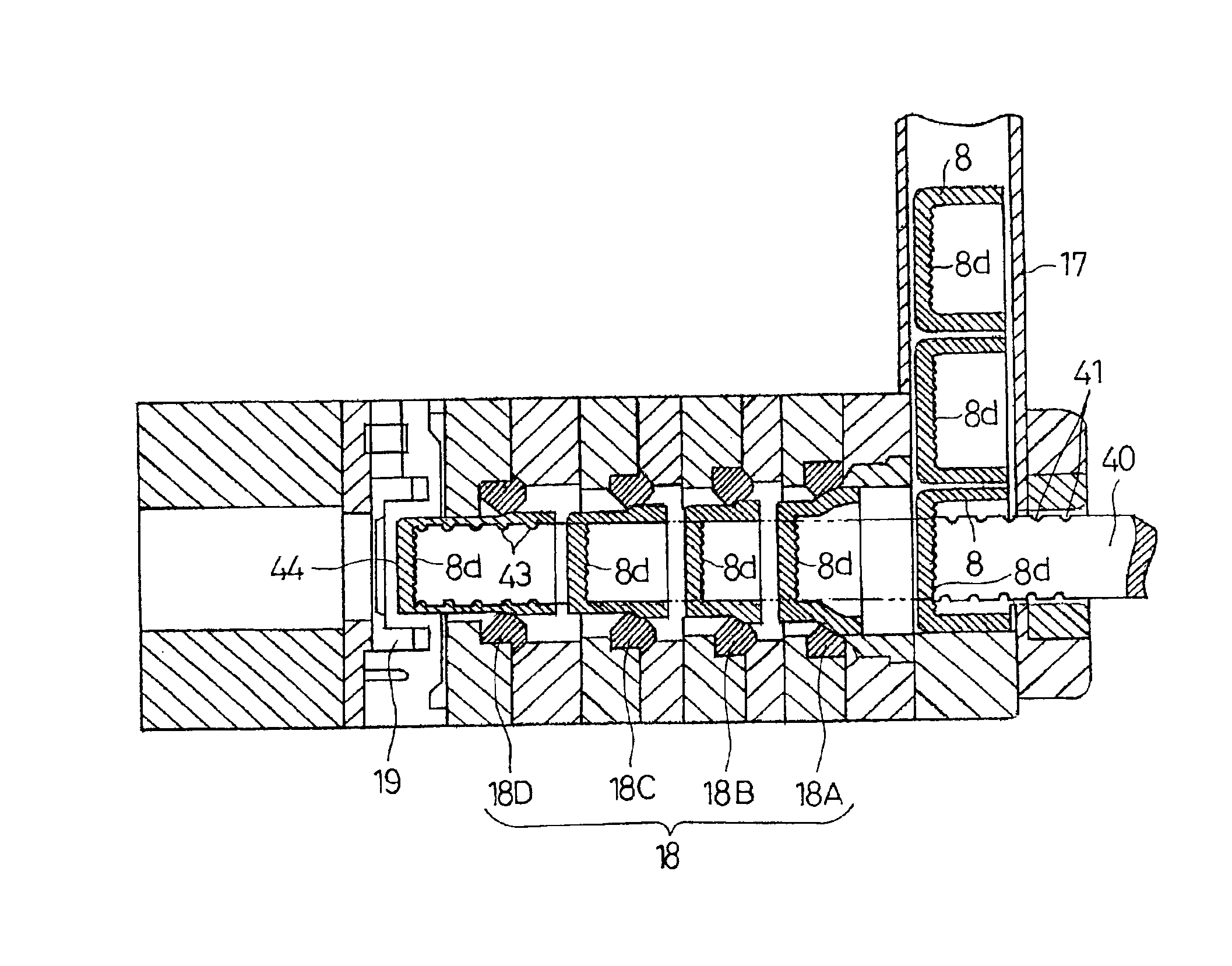

Common rail fuel injection system designed to avoid error in determining common rail fuel pressure

InactiveUS7552716B2Increase productionMinimize damageElectrical controlAnti-theft devicesSystems designCommon rail

A common rail fuel injection system includes an electronic control unit and a fuel pressure sensor. The electronic control unit is equipped with a power supply circuit which supplies a power supply voltage to the fuel pressure sensor through a harness. The power supply voltage is used in the pressure fuel sensor as a drive voltage to drive a sensor element of the fuel pressure sensor. The electronic control unit monitors an output voltage of the fuel pressure sensor to determine the pressure of fuel in a common rail and also monitors the drive voltage applied to the fuel pressure sensor to determine whether the drive voltage is undesirably lower than the power supply voltage or not. If such a condition is encountered, the electronic control unit takes measures to avoid an excessive rise in pressure in the common rail to protect the common rail physically.

Owner:DENSO CORP

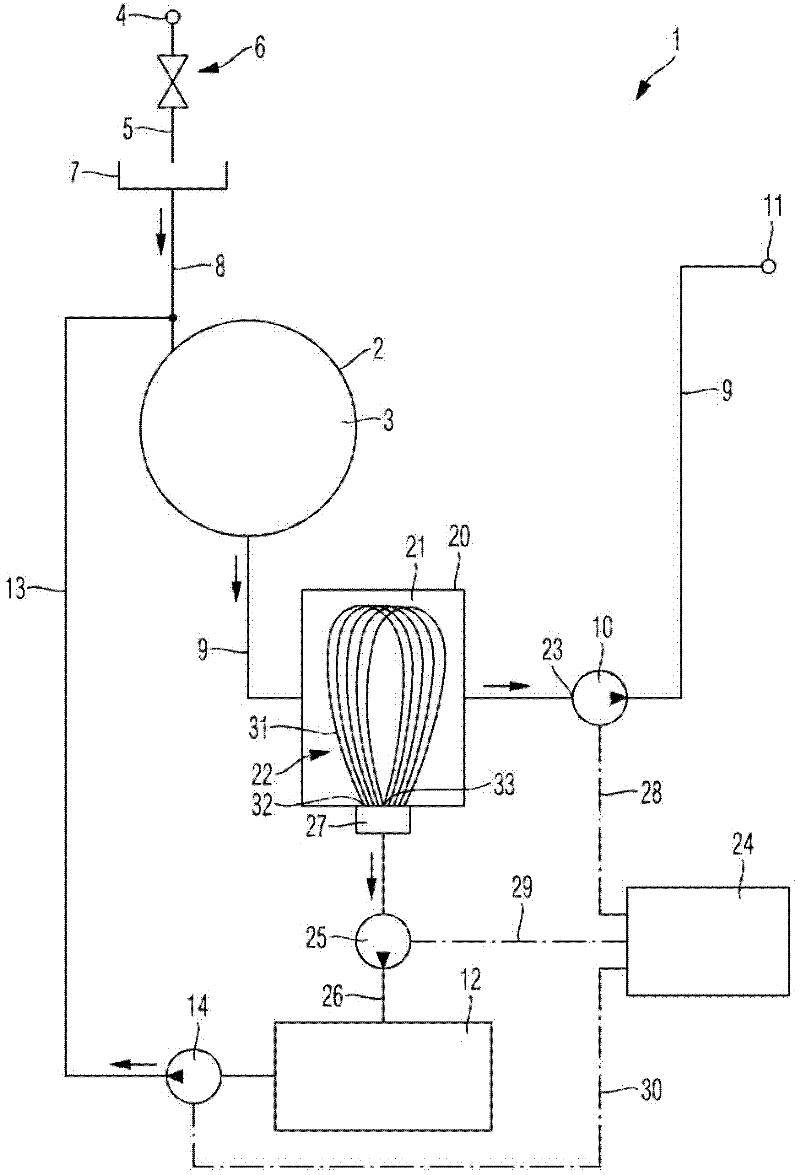

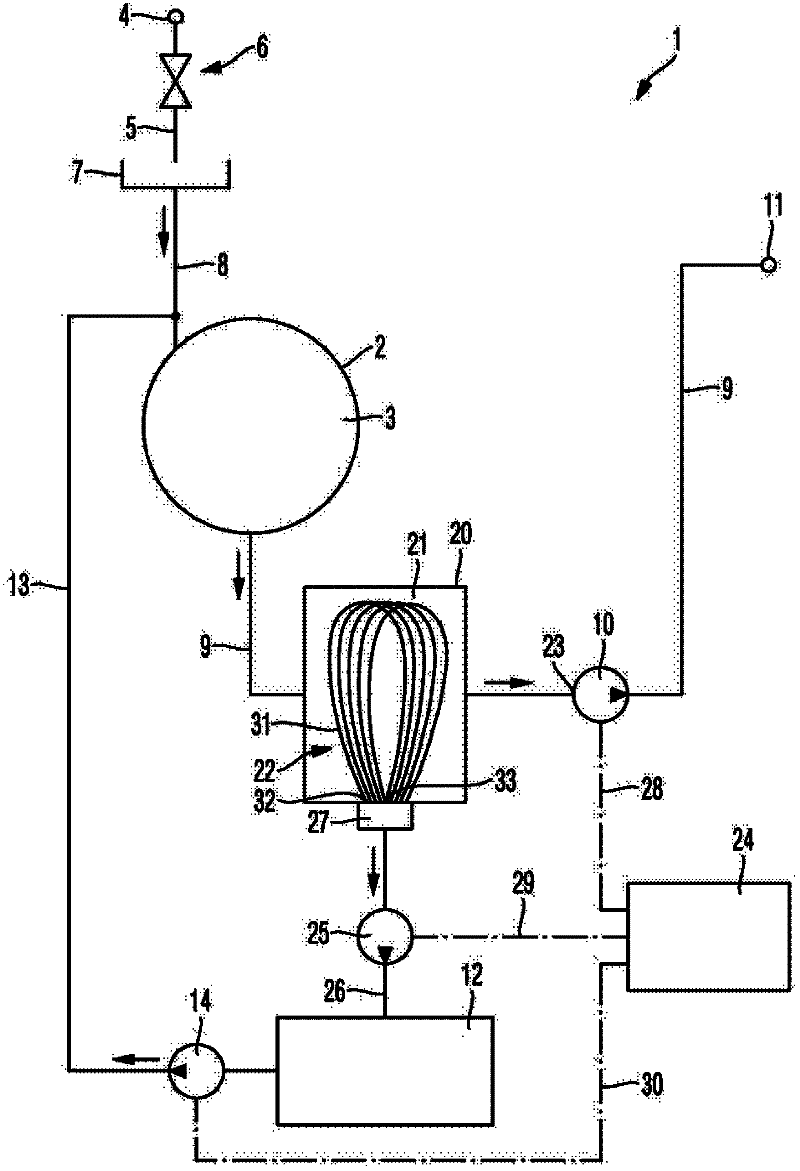

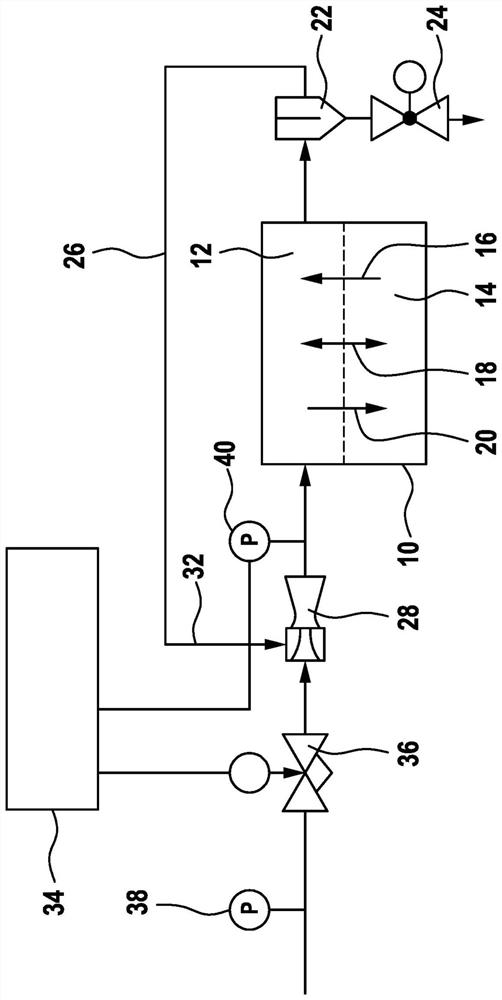

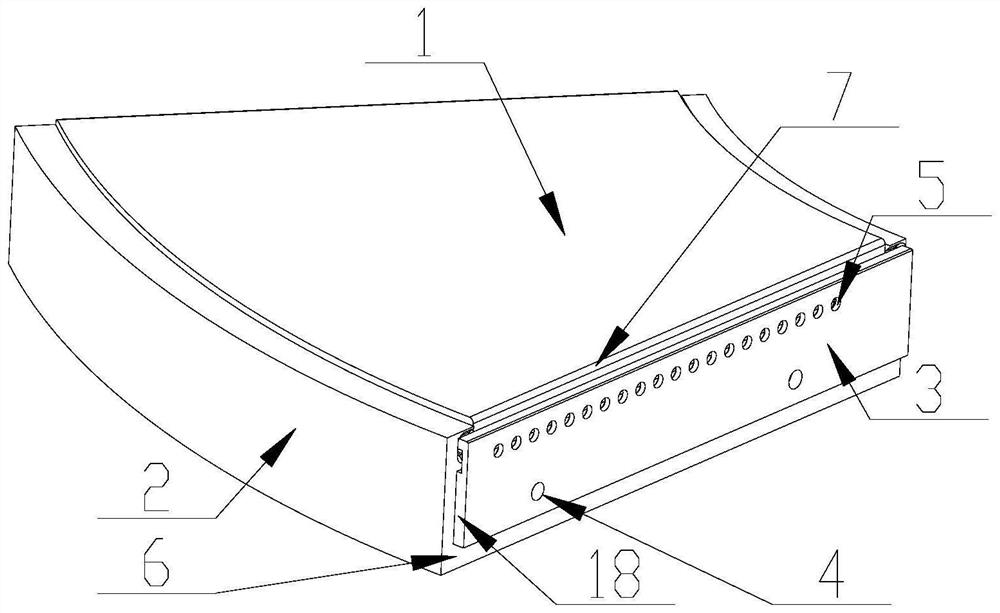

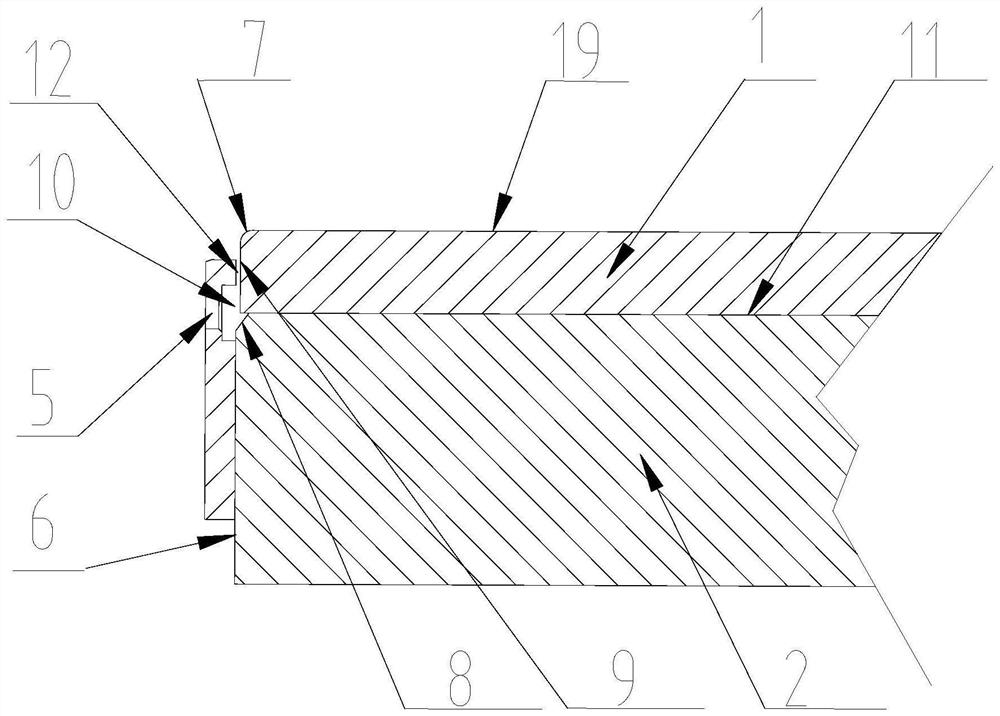

Water-bearing household appliance having a filter device in the pumping-away section and storage tank

ActiveCN102471981AFavorable mode of operationAvoid pressure risesOther washing machinesTableware washing/rinsing machinesWater storage tankProcess region

A water-bearing household appliance (1) which serves, in particular, as a laundry treatment unit for washing and / or drying laundry comprises a treatment region (3) which is surrounded by a container (2), a pumping-away section (9) which is connected to the treatment region (3), a discharge pump (10) which is arranged in the pumping-away section (9), a filter device (20) which is arranged in the pumping-away section (9), and a water storage tank (12) which is connected to the filter device (20) via a pump (25). By actuation of the pump (25), water can be branched off into the water storage tank (12) from the pumping-away section (9) via a filter (22) of the filter device (20). The water which is stored in the water storage tank (12) can replace part of the supplied fresh water in the case of a further programme run. The embodiment of the filter device (20) makes self-cleaning of the filter (22) possible.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

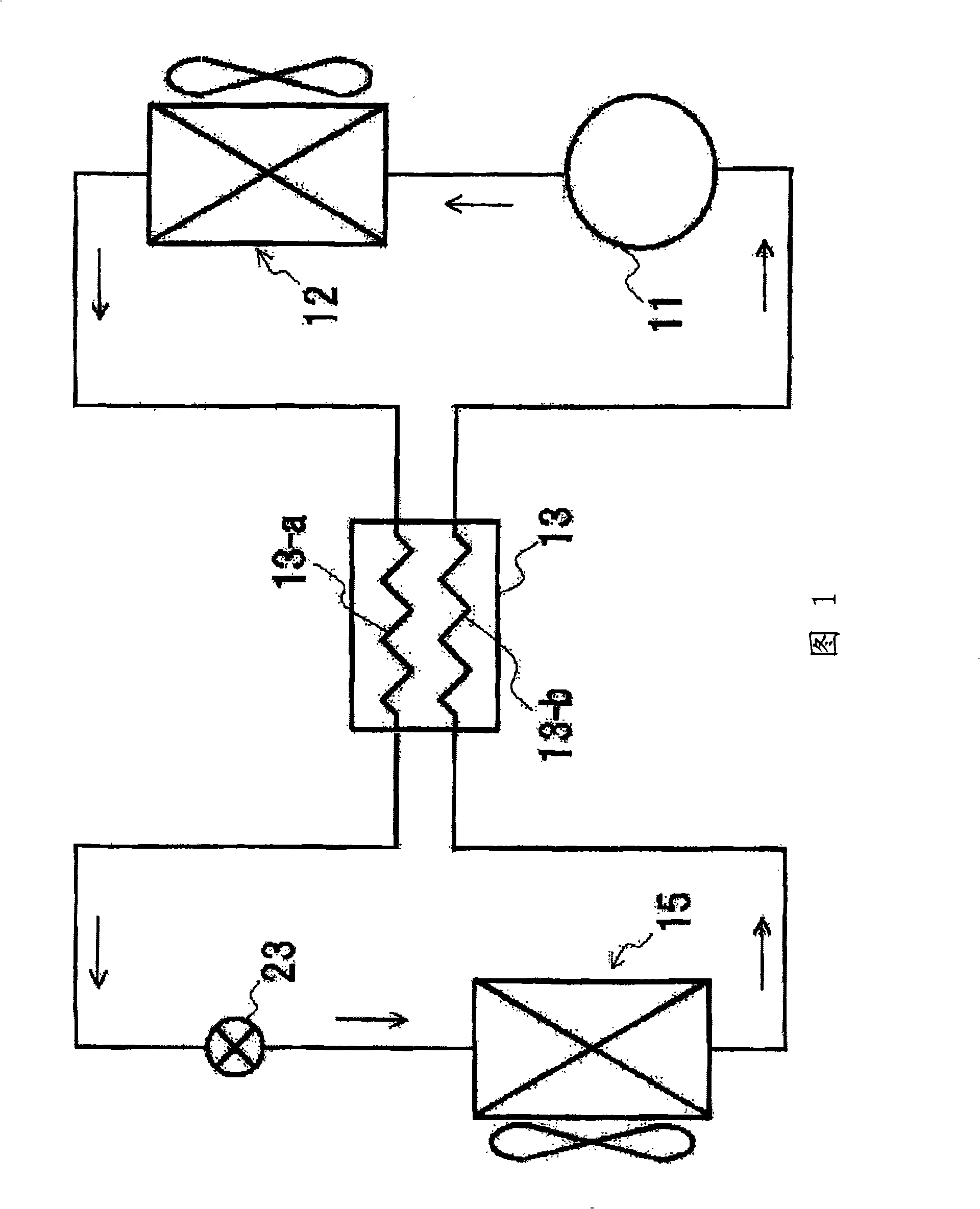

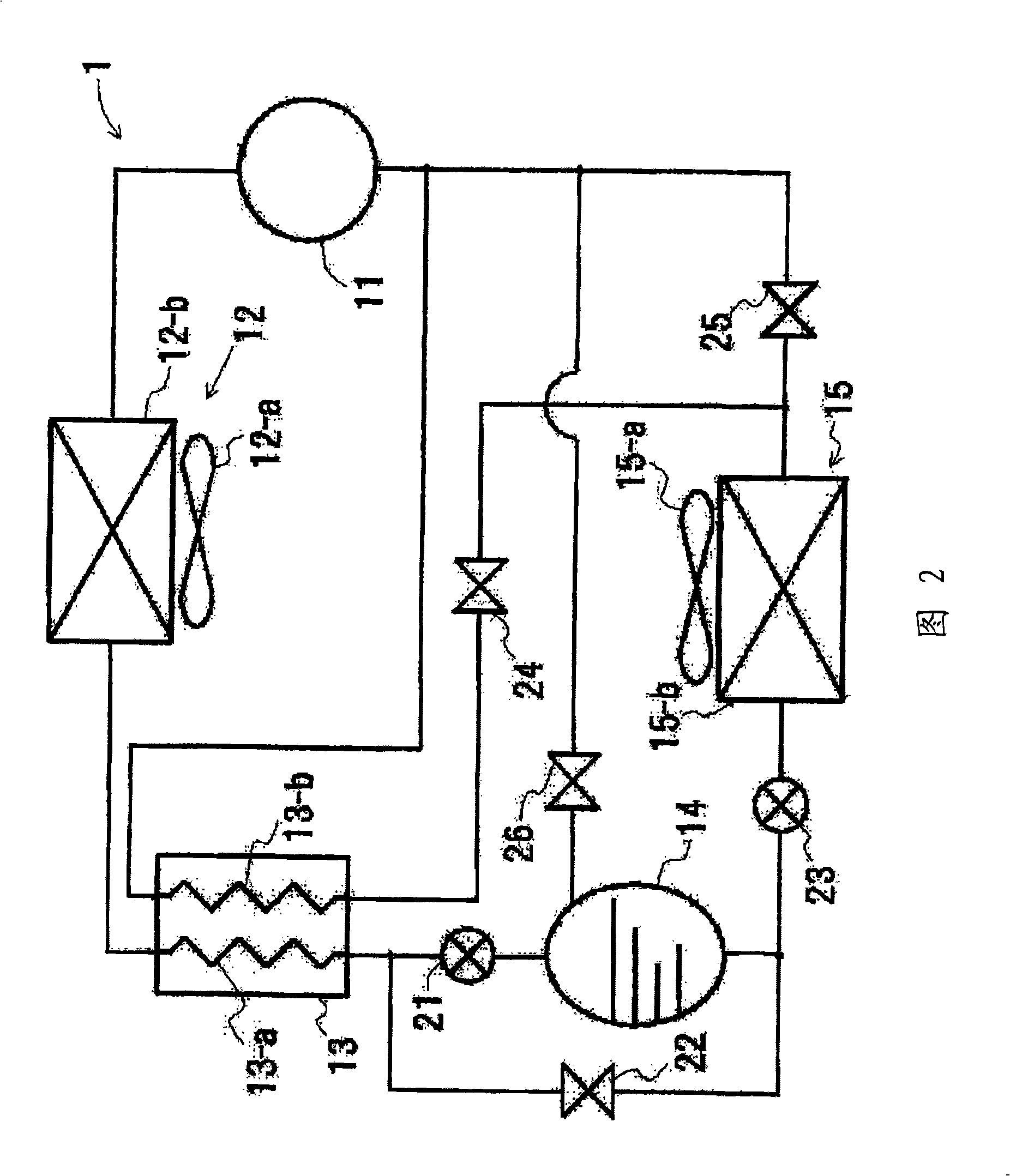

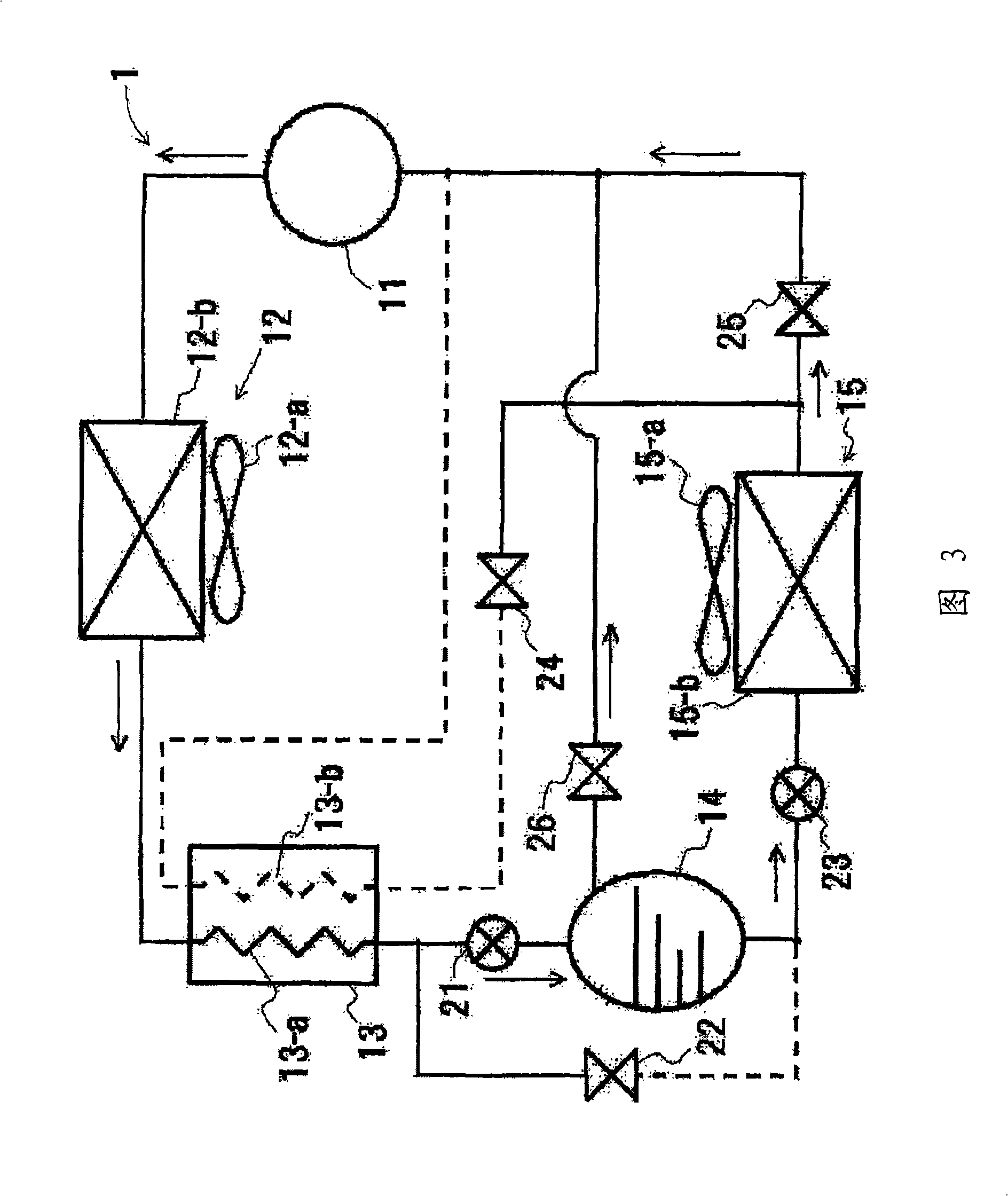

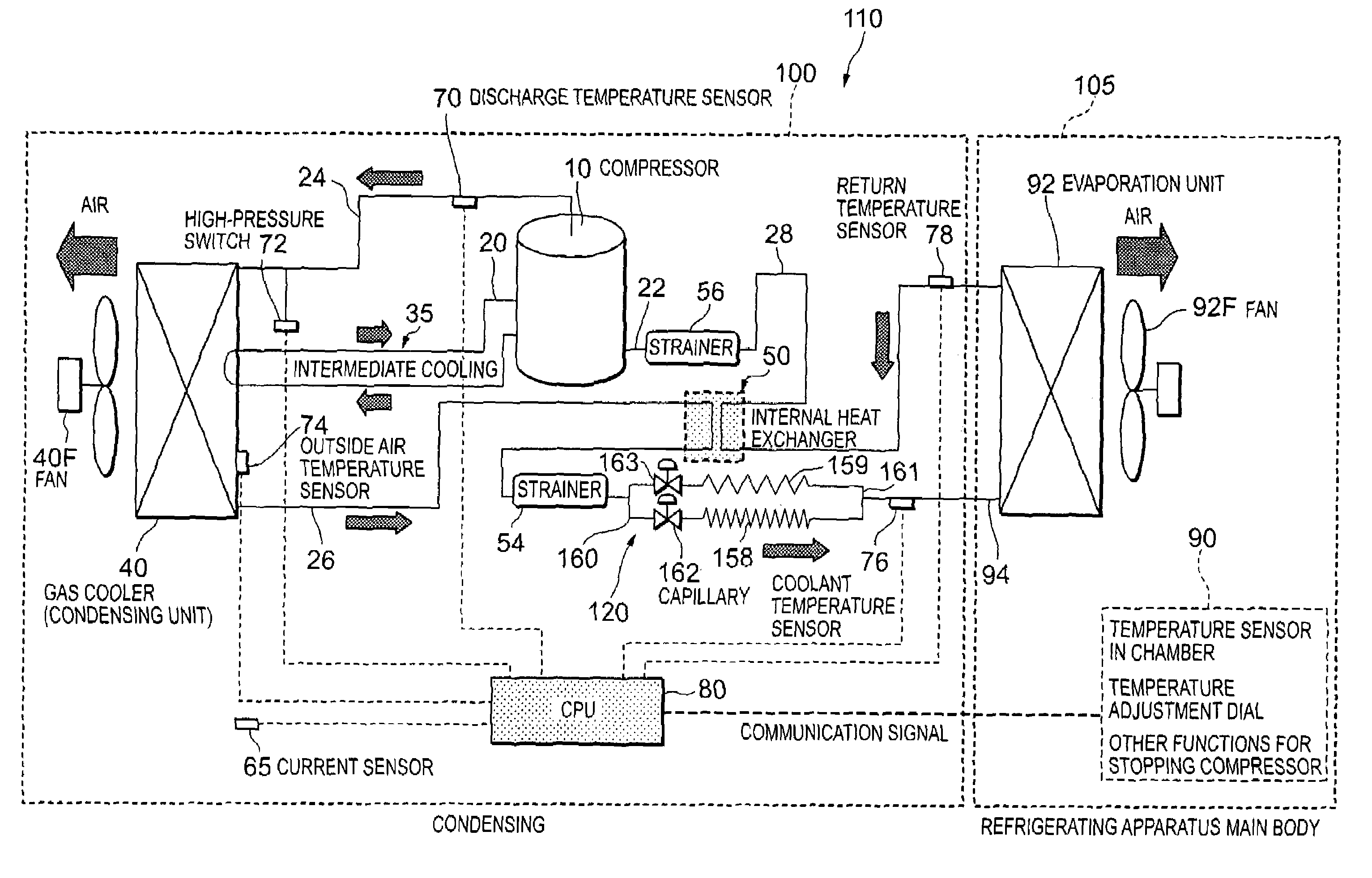

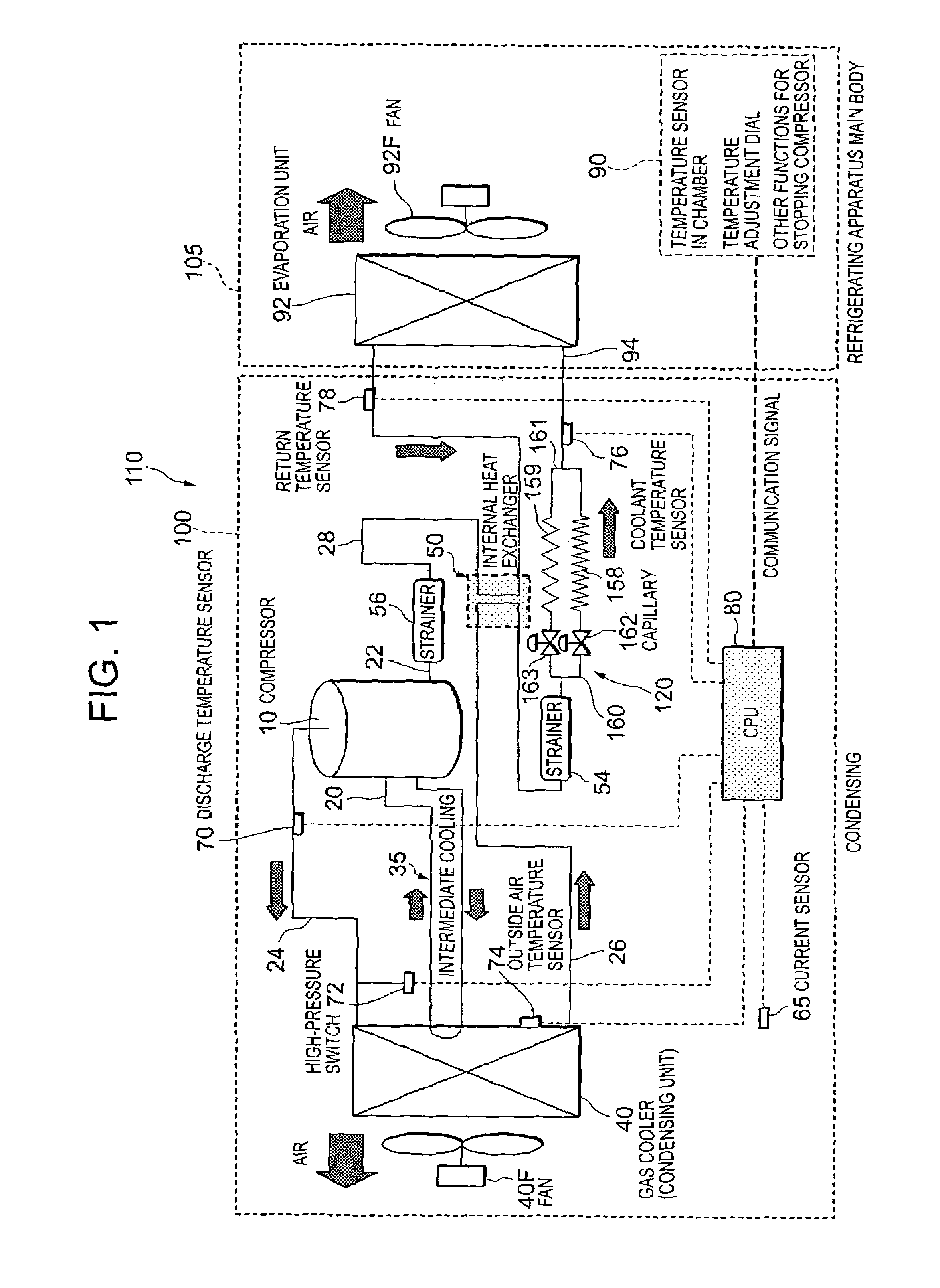

Refrigerating device

ActiveCN101410678AImprove stress reliefImprove freezing effectCompression machines with non-reversible cycleRefrigeration componentsGas coolerEngineering

A freezing apparatus using such a coolant as will take a supercritical state when discharged from a compressor is troubled by a problem that the charge of the coolant has to be increased to quicken the cooling operation, because of shortage of the freezing power. Another problem is that an excess coolant is much produced in a coolant circuit when the freezing apparatus is sufficiently cooled. Provided is a coolant circuit, in which a compressor, a gas cooler, a first pressure reducing device and an evaporator are sequentially piped and connected in an annular shape. The coolant circuit comprises a second pressure reducing device and a liquid receiver between the gas cooler and the first pressure reducing device, and the liquid receiver and the suction port of the compressor are piped and connected. The opening degree of the second pressure reducing device is controlled according to the pressure difference between the discharge side pressure and the suction side pressure of the compressor, so that the circulation rate of the coolant can be adjusted by increasing the coolant circulation rate in case the freezing ability is short and by reserving the excess coolant in the liquid receiver in case the freezing ability is excessive.

Owner:SANYO ELECTRIC CO LTD

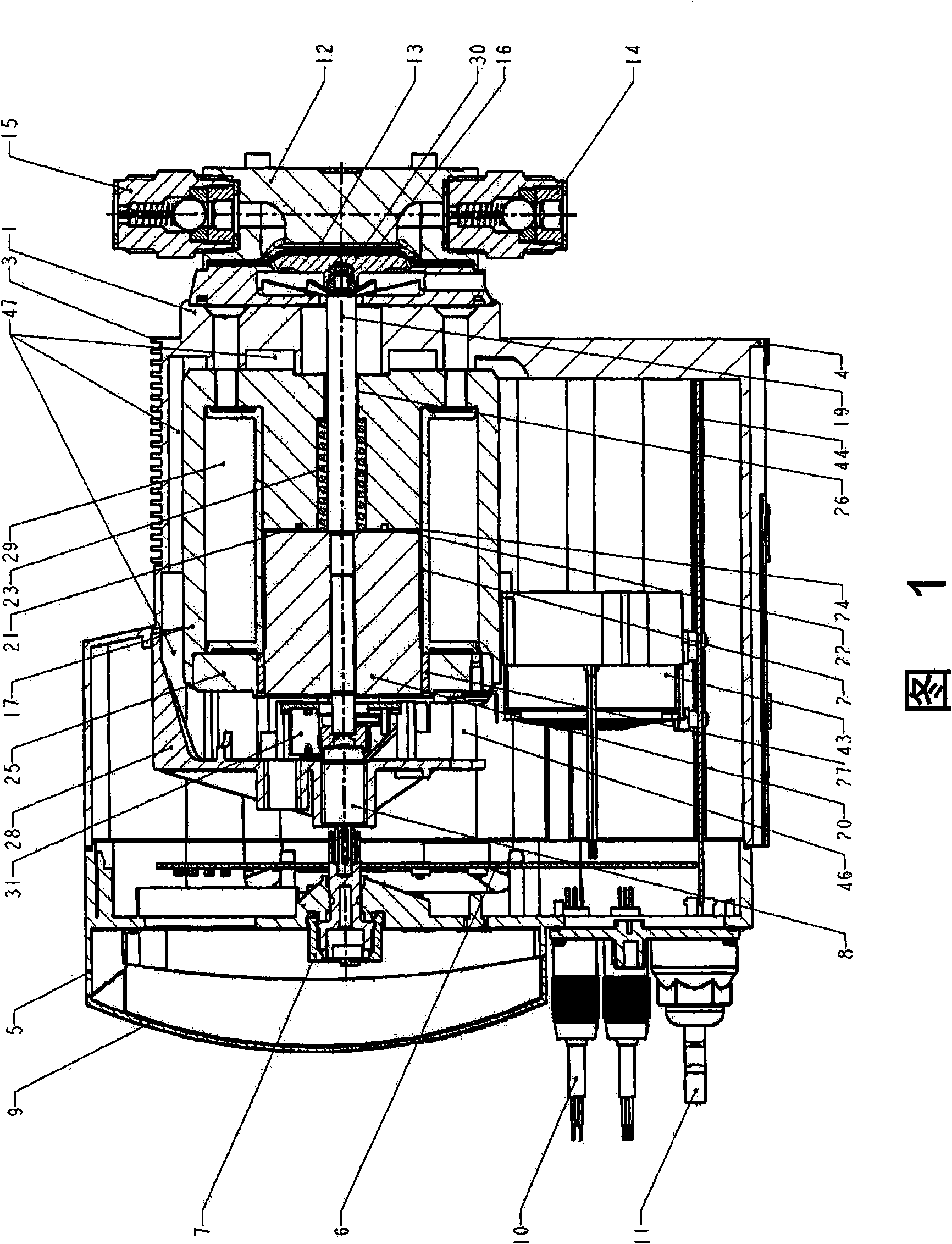

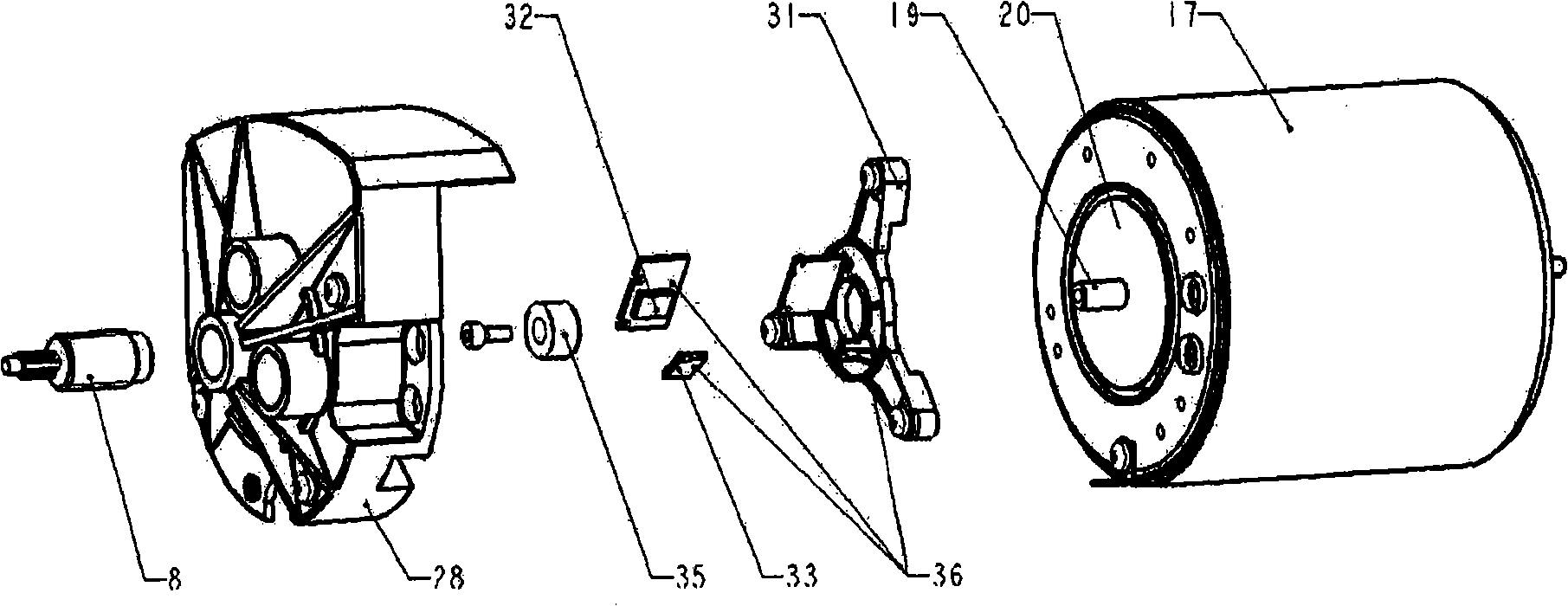

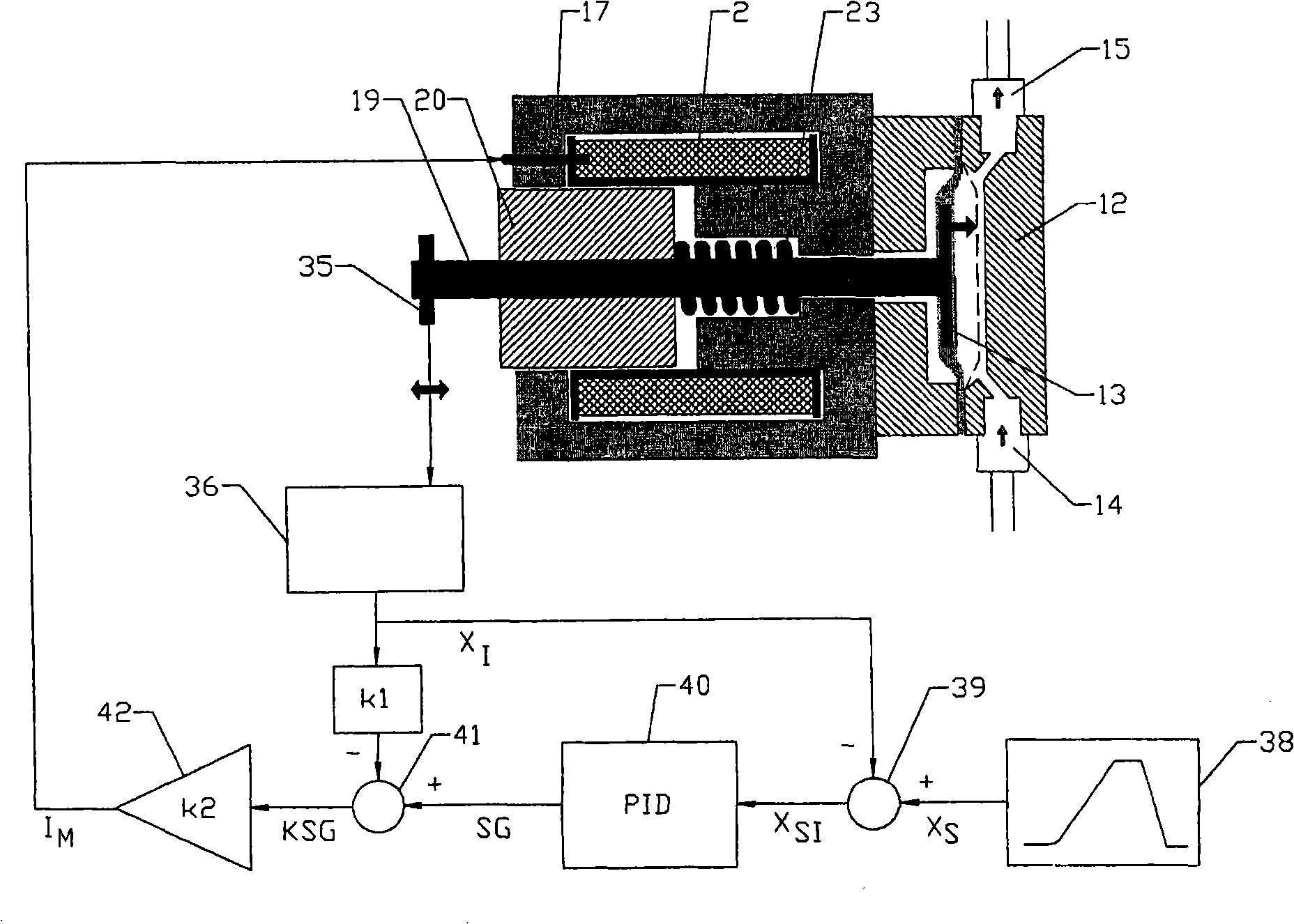

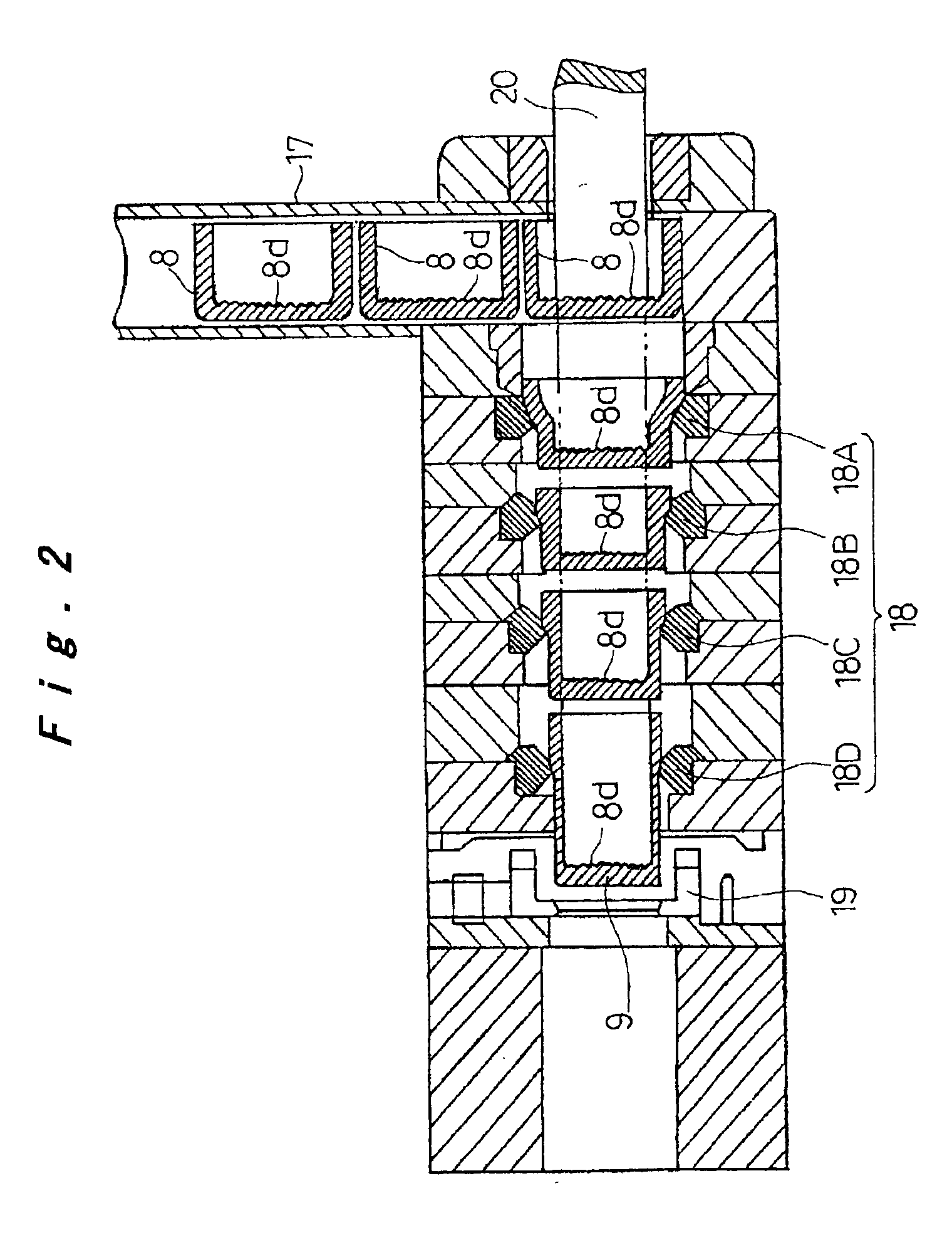

Magnetic driven metering pump

ActiveCN101245776AReduce stroke lengthReduce heat lossPositive displacement pump componentsFlexible member pumpsElectricityInlet valve

The invention provides a magnetic driving metering pump. A movable pushing part which is fixed on a connecting rod can axially move on a longitudinal shaft in a magnetic cover plate which is fixedly anchored in a pump shell; therefore, after a magnetized coil is driven (started) by getting electricity, the pushing part and the connecting rod overcome the force of a recovery spring and are then pulled into the magnetic cover plate and enter one hole in the magnetic cover plate by reducing the clearance; the pushing part returns to an original position by the recovery spring after the magnet is stopped; therefore, under the continuous starting and stopping of the magnetized coil, the pushing part and an elastic displacement part are driven to carry out vibration; wherein, a diaphragm is alternatively matched with an outlet valve and an inlet valve; a pumping stroke (pressure stroke) and an injection stroke are generated in a metering head which is arranged along the direction of the longitudinal axis. In the magnetic driving metering pump, a benchmark part is connected with a module which consists of the pushing part and the connecting rod; the position of the benchmark part is detected by a position sensor; wherein, the position sensor provides a practical signal which has a fixed relation with the position of the benchmark part; furthermore, the motion precision of the unit which consists of the pushing part and the connecting rod is controlled by a control circuit so as to meet a prearranged nominal drawing.

Owner:PROMINENT

Common rail fuel injection system designed to avoid error in determining common rail fuel pressure

InactiveUS20070044764A1Increase productionMinimize damageElectrical controlAnti-theft devicesSystems designCommon rail

A common rail fuel injection system includes an electronic control unit and a fuel pressure sensor. The electronic control unit is equipped with a power supply circuit which supplies a power supply voltage to the fuel pressure sensor through a harness. The power supply voltage is used in the pressure fuel sensor as a drive voltage to drive a sensor element of the fuel pressure sensor. The electronic control unit monitors an output voltage of the fuel pressure sensor to determine the pressure of fuel in a common rail and also monitors the drive voltage applied to the fuel pressure sensor to determine whether the drive voltage is undesirably lower than the power supply voltage or not. If such a condition is encountered, the electronic control unit takes measures to avoid an excessive rise in pressure in the common rail to protect the common rail physically.

Owner:DENSO CORP

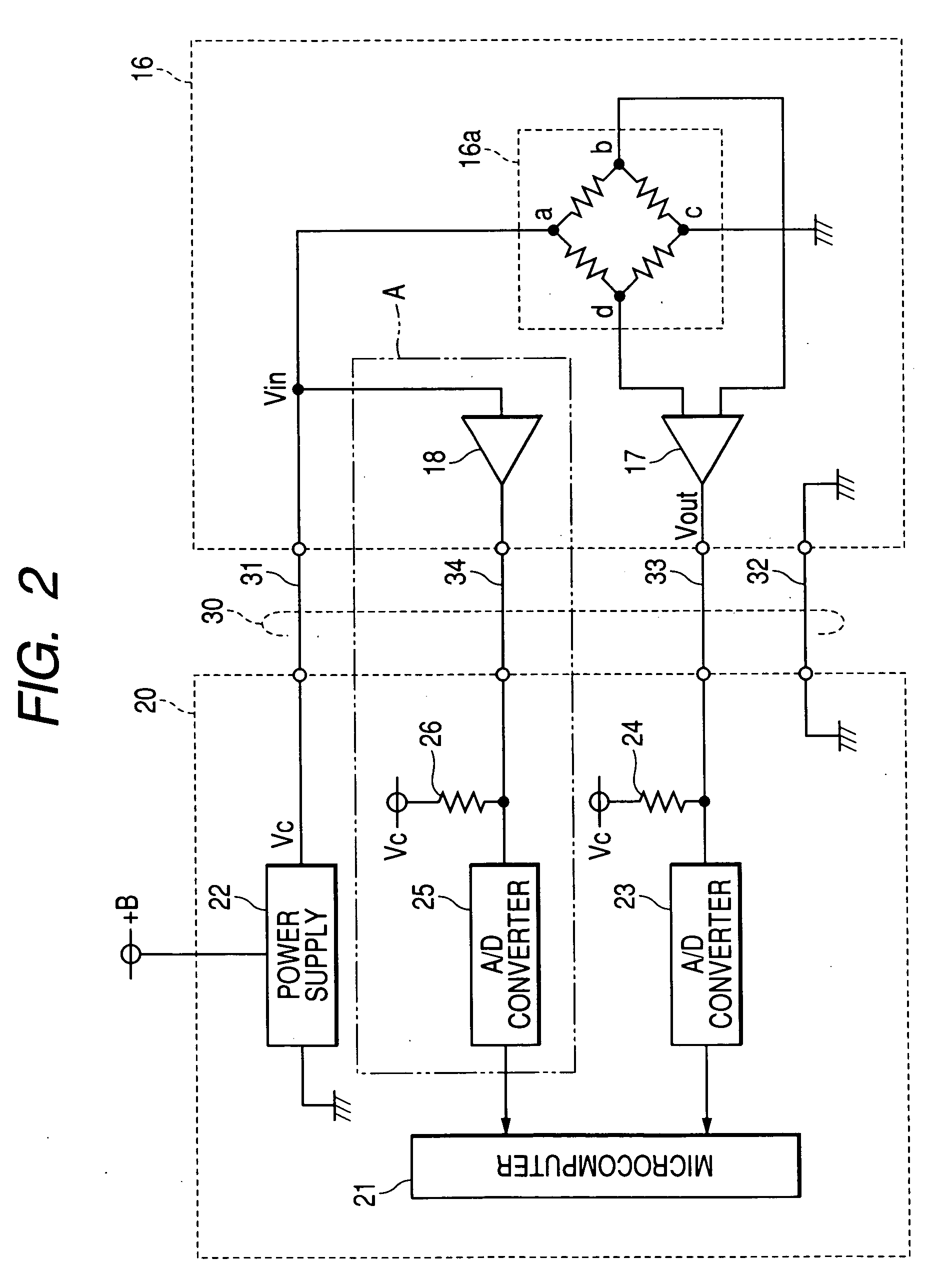

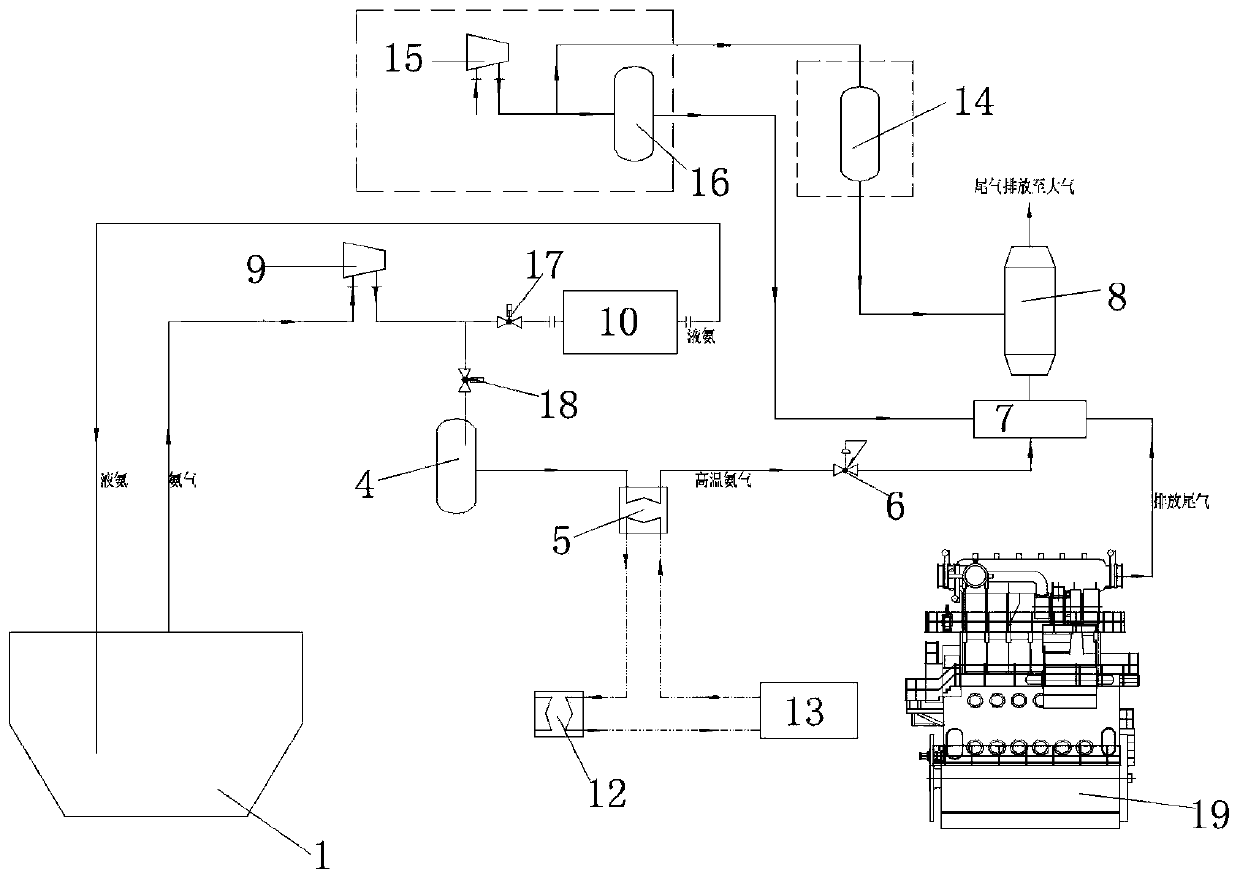

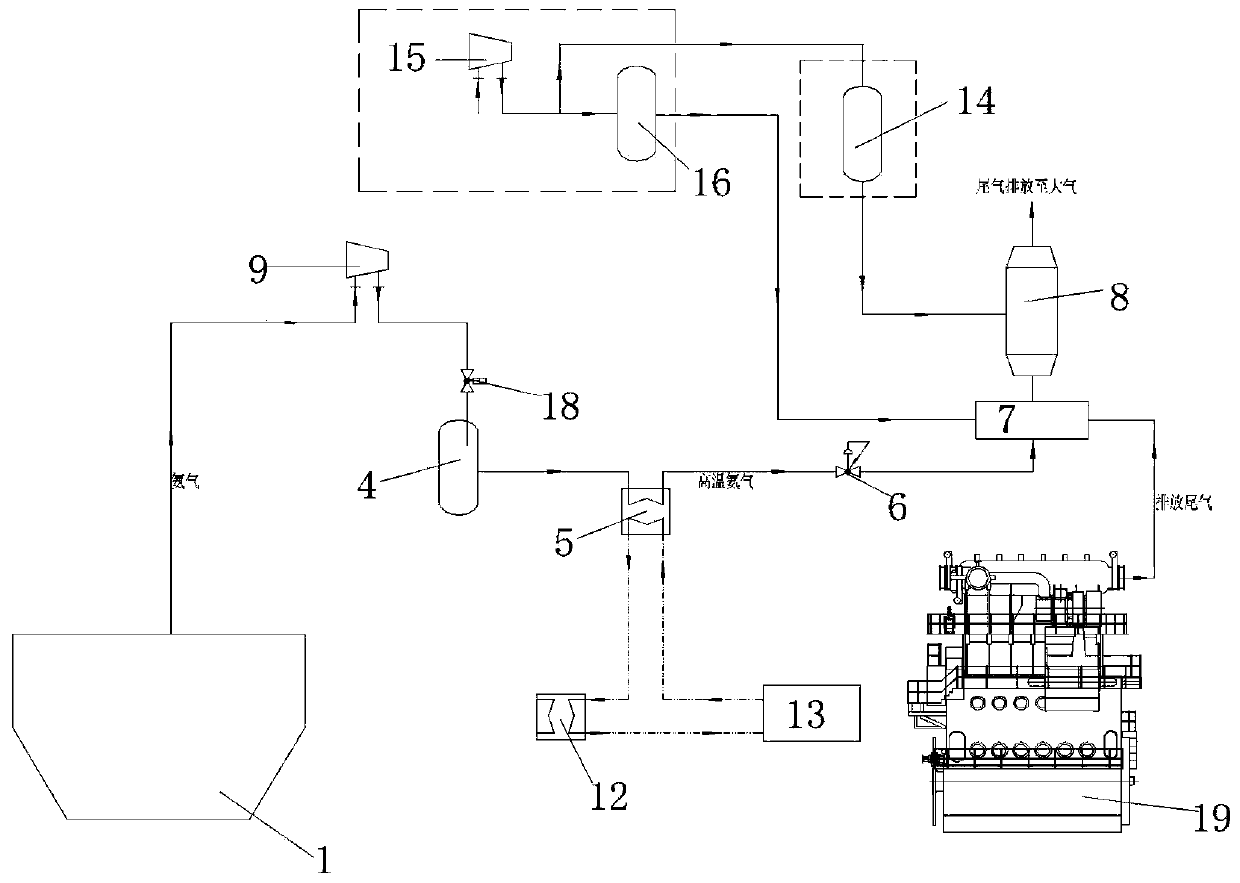

Novel ship tail gas treatment system

A novel ship tail gas treatment system is provided with an air compression system and a soot blower, the air compression system is connected with a flue gas mixer, the flue gas mixer is connected withan SCR reactor, the soot blower is connected with the SCR reactor, tail gas exhausted by a fuel main engine enters the flue gas mixer, and the flue gas mixer is connected with an ammonia gas conveying system. The ammonia gas conveying system is provided with a liquid ammonia fuel storage tank and an ammonia gas liquefaction device, a liquid ammonia low-pressure pump is arranged in the liquid ammonia fuel storage tank, and liquid ammonia is pumped out through the liquid ammonia low-pressure pump and finally enters the flue gas mixer. Volatile gas in the liquid ammonia fuel storage tank is fully utilized, the method is preferentially applied to ammonia fuel main engine tail gas denitrification treatment, and the ammonia gas liquefaction device is arranged as a supplement means for ammonia volatile gas treatment, so that the volatile gas in the liquid ammonia storage tank can be completely treated, the pressure rise and structural damage of the liquid ammonia storage tank caused by continuous accumulation of the ammonia volatile gas are avoided, a large amount of the ammonia volatile gas is prevented from being discharged to the atmosphere, and the safety of the liquid ammonia storage tank and a ship is guaranteed.

Owner:DALIAN SHIPBUILDING IND

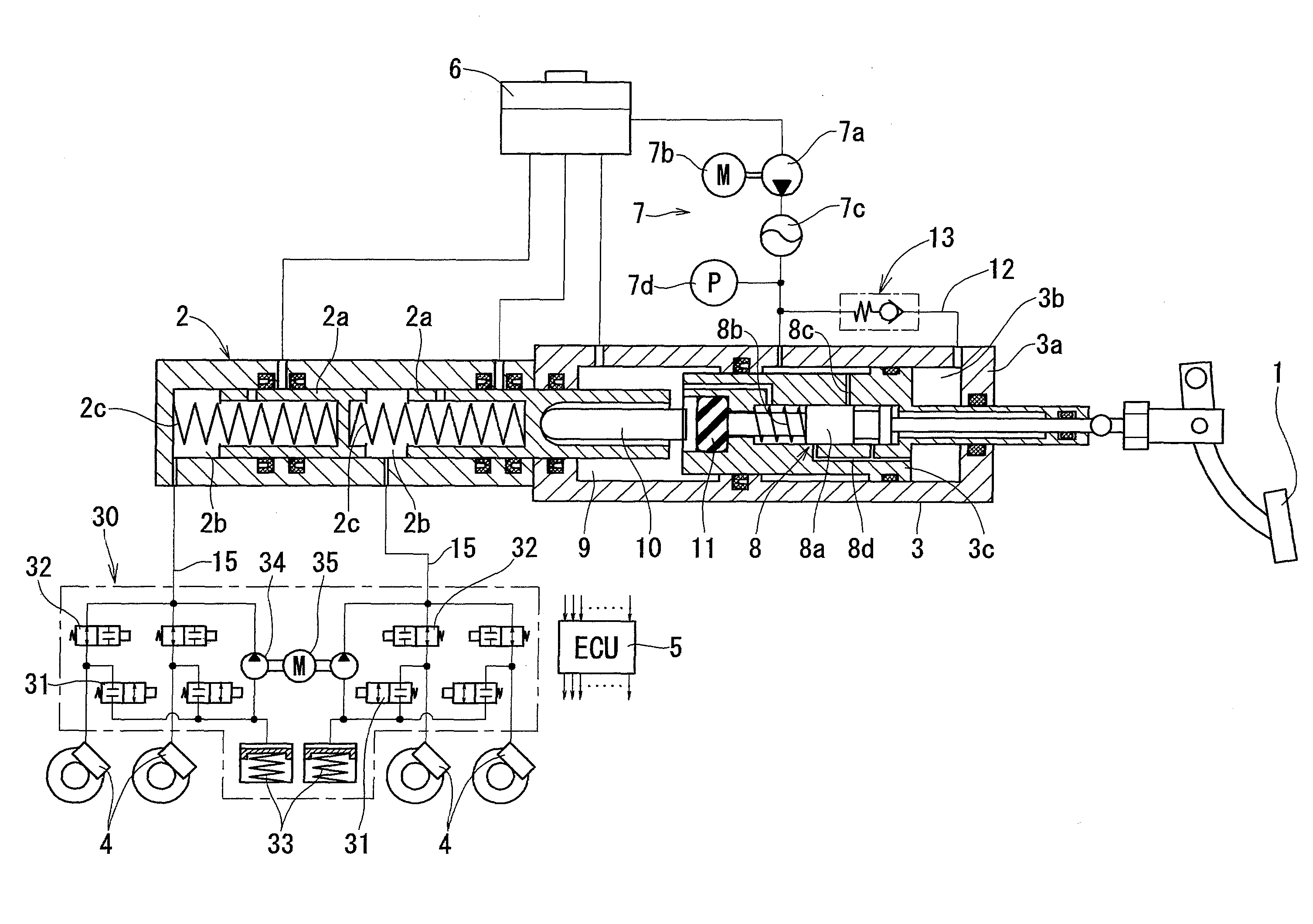

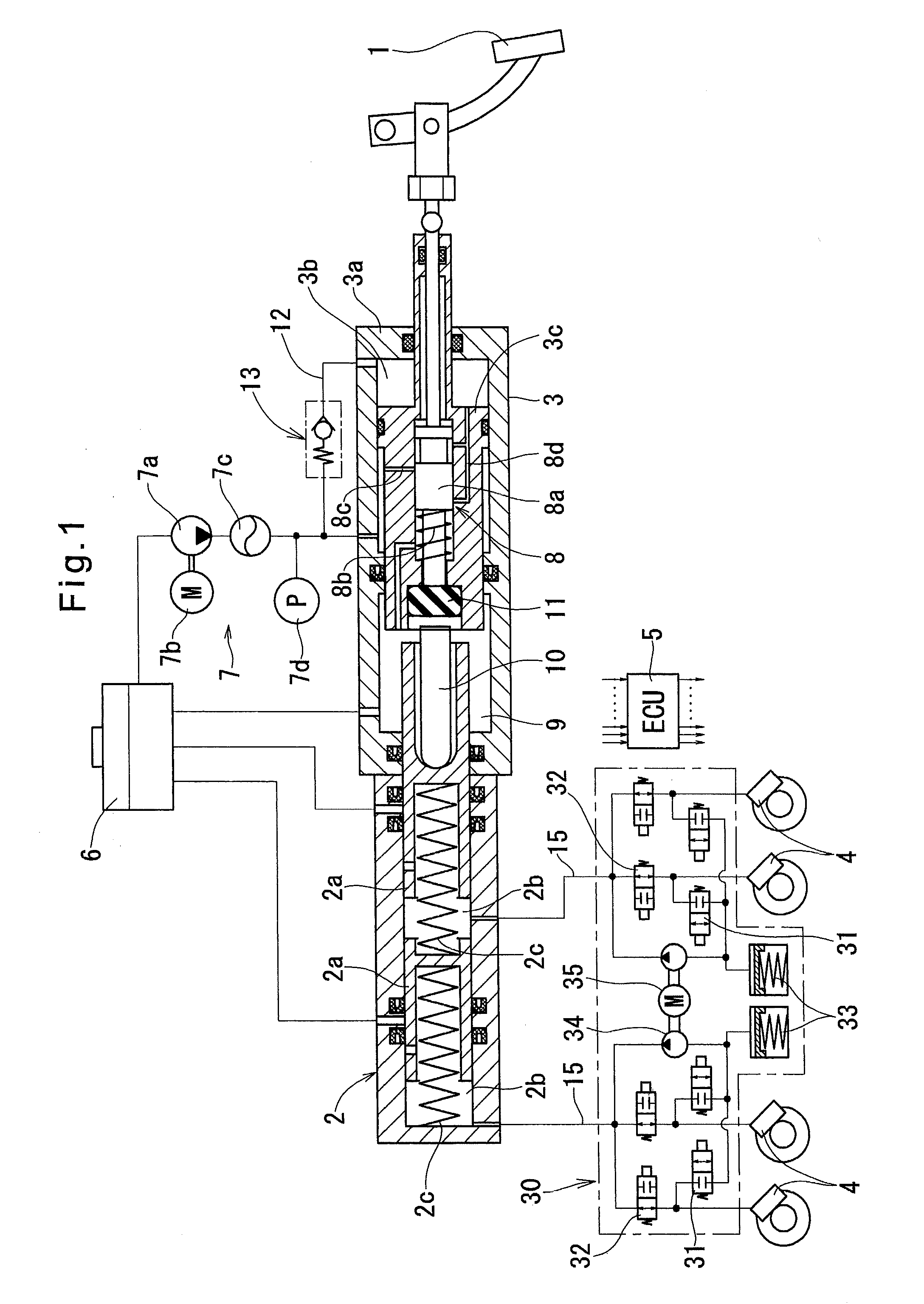

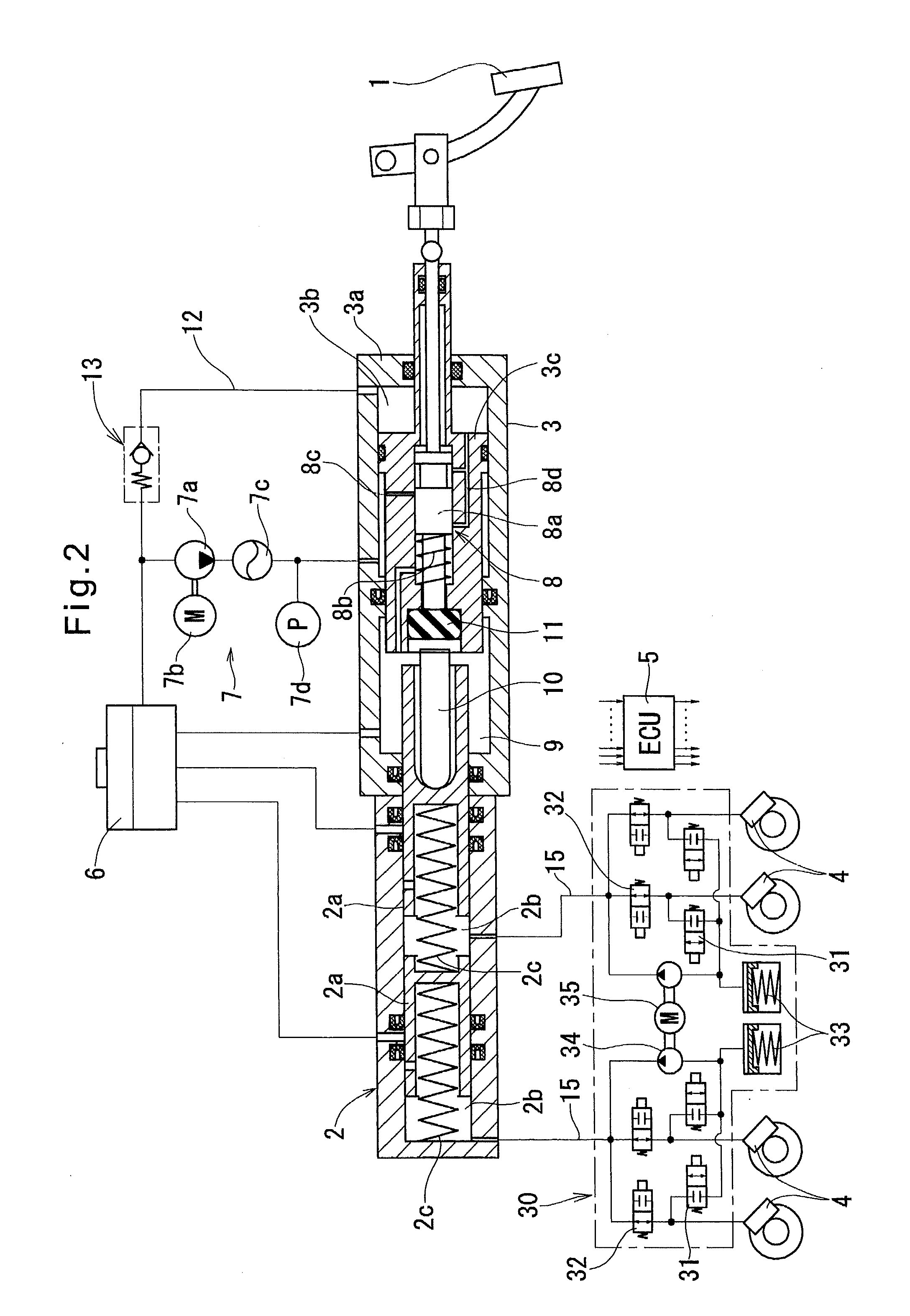

Hydraulic booster and hydraulic brake system using the same

ActiveUS8534773B2Avoid pressure risesReduced durabilityBraking action transmissionBrake action initiationsCheck valvePressure controlled ventilation

A hydraulic brake system is proposed which includes a hydraulic booster for boosting brake operation, and a circulation type pressure control unit. The hydraulic brake system further includes a hydraulic booster including an auxiliary hydraulic pressure source, a pressure regulator for adjusting the hydraulic pressure supplied therefrom to a value corresponding to an operating amount of a brake operating member and introducing the thus adjusted hydraulic pressure into a boost chamber, and a boost piston for actuating a master piston with a force boosted by an assisting force generated by the hydraulic pressure introduced into the boost chamber. The hydraulic booster further includes a hydraulic line bypassing the pressure regulator and extending from the boost chamber to the auxiliary hydraulic pressure, and a check valve provided in the hydraulic line and configured to allow only a discharge of hydraulic pressure from the boost chamber into the auxiliary hydraulic pressure source.

Owner:ADVICS CO LTD

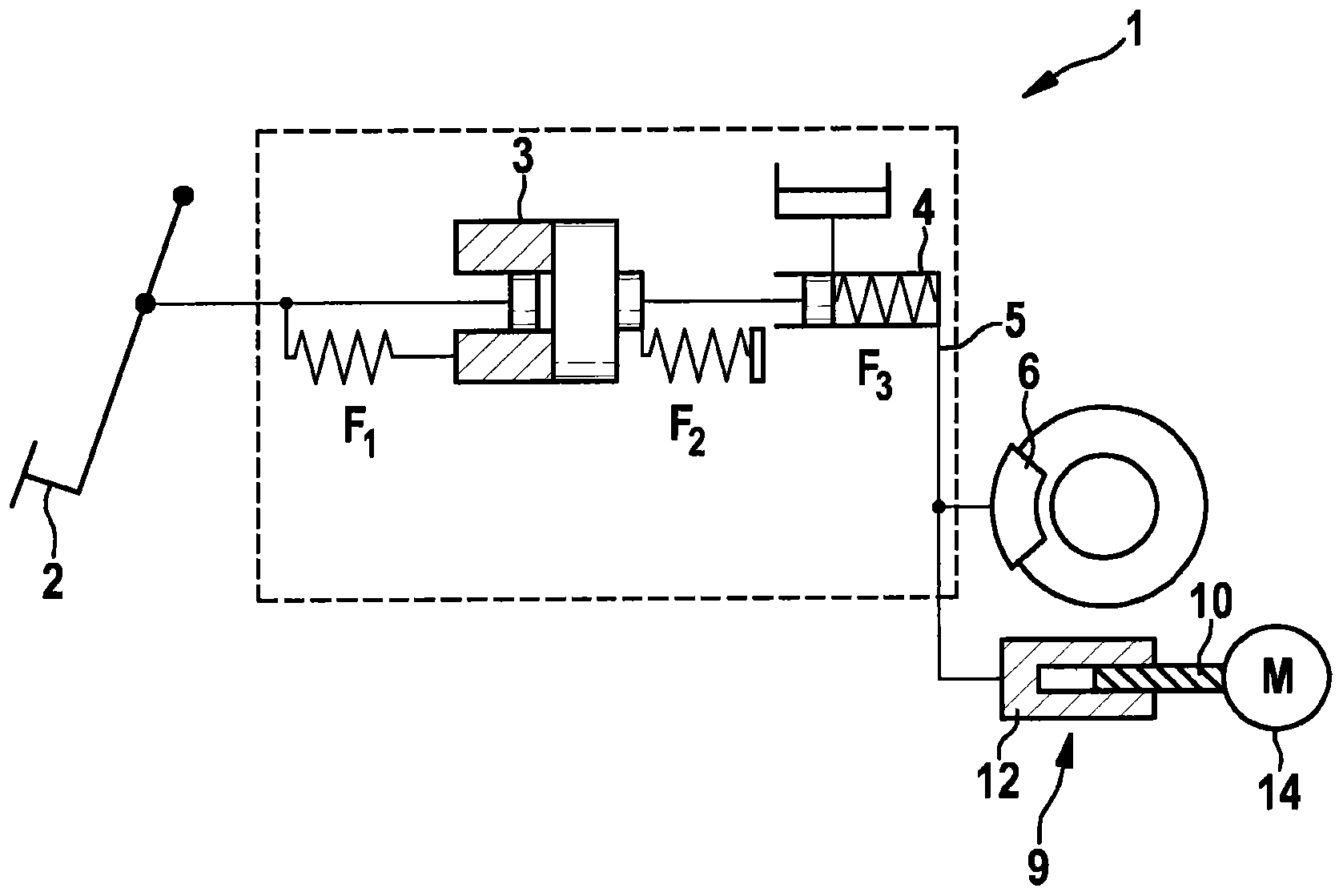

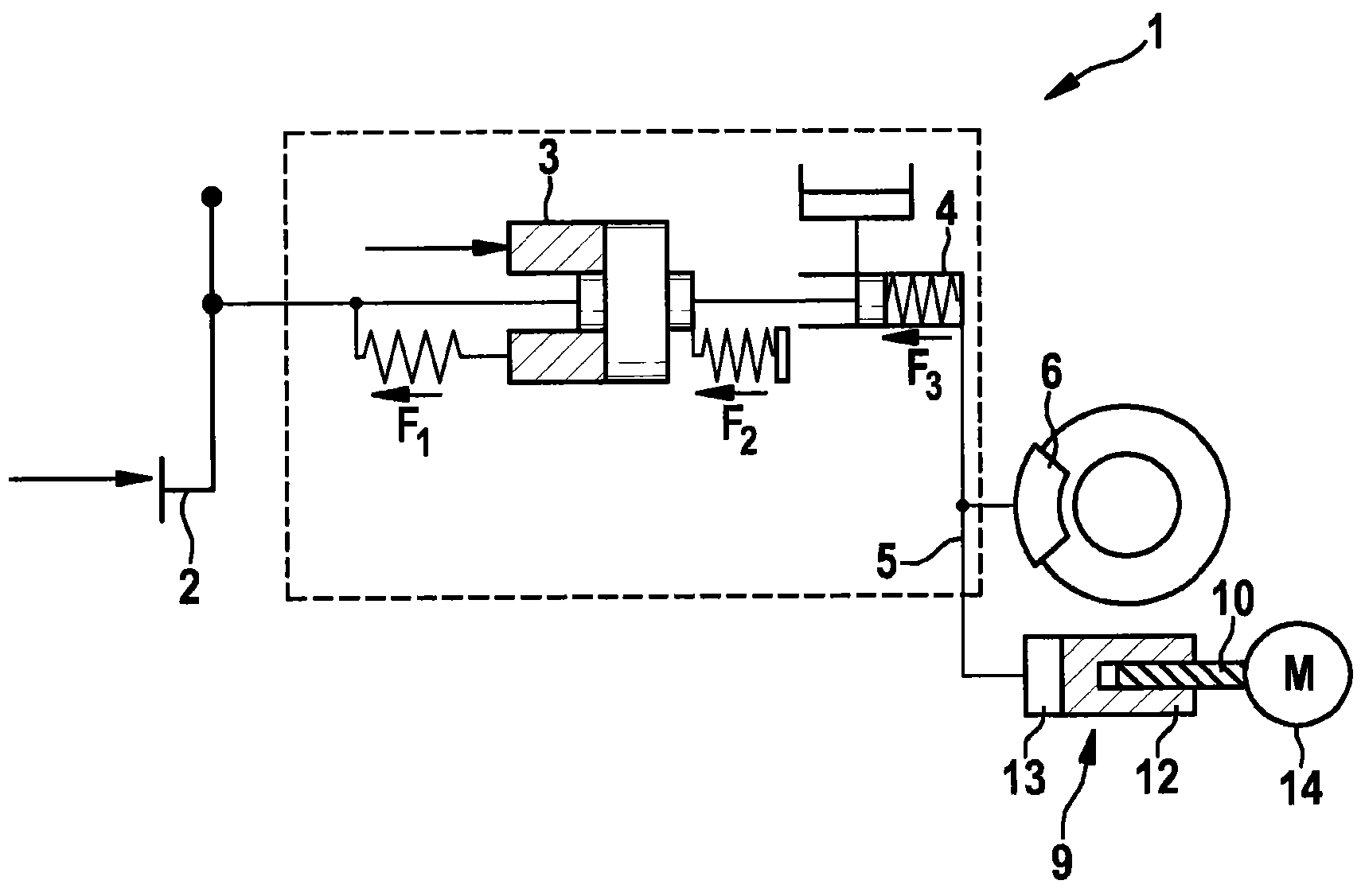

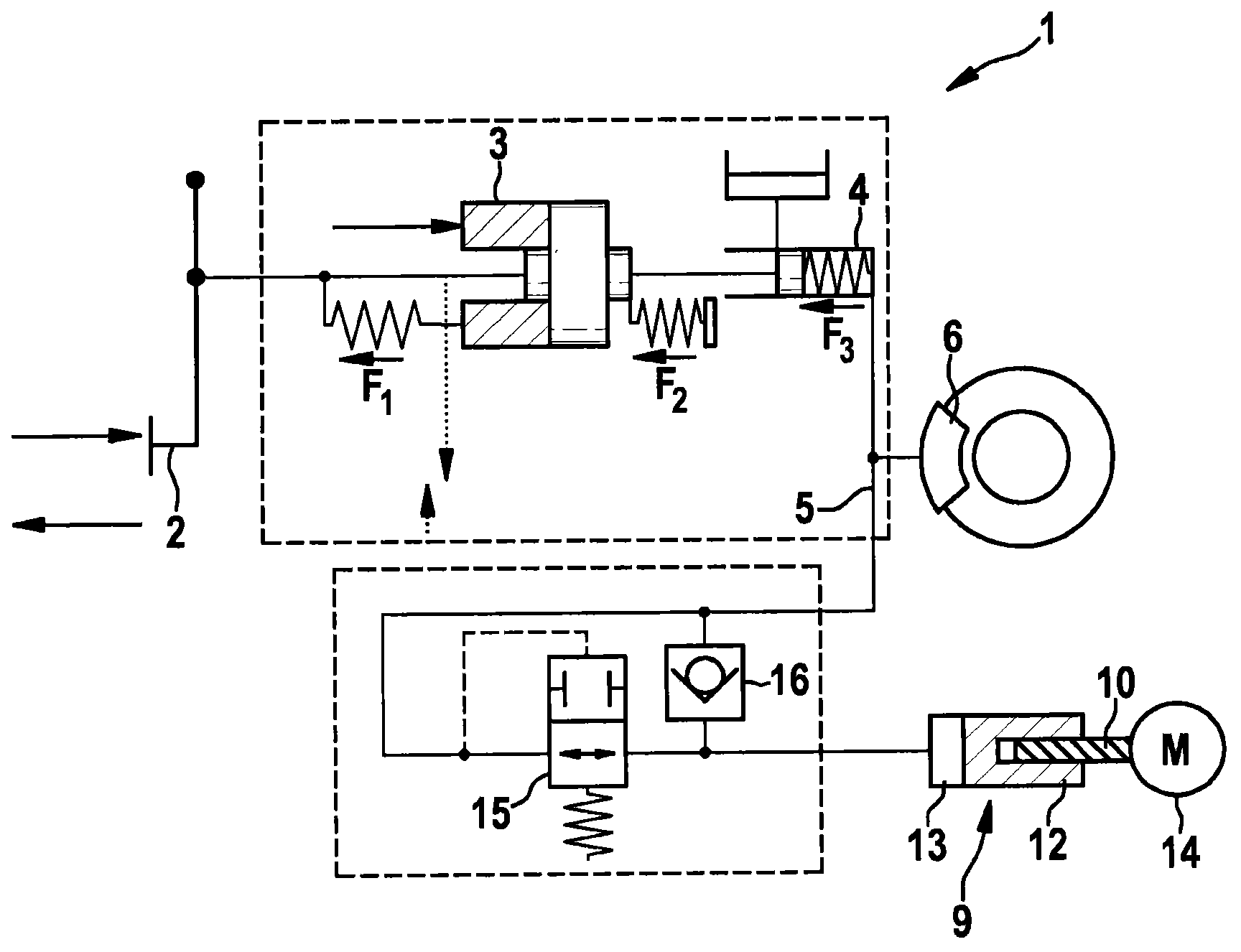

Compensation device for a brake system, and brake system having a compensation device of this type

InactiveCN103906661AProtection of large opening cross-sectionsDoes not impede flowBraking action transmissionBrake control systemsActuatorPressure threshold

The invention relates to a compensation device (9) having a variable compensation volume (13, 22) for use in a brake system (1) in order to carry out a recuperation operation, comprising: an electrohydraulic actuator (10) for providing a variable compensation volume (13, 22); and a guard valve (15) which is configured to separate the compensation volume (13, 22) from an inlet-side inlet volume (31) with respect to an external pressure change if an absolute pressure in the inlet volume (31) exceeds a predefined pressure threshold value. Furthermore, the invention relates to a motor-vehicle brake system having a compensation device of this type.

Owner:ROBERT BOSCH GMBH

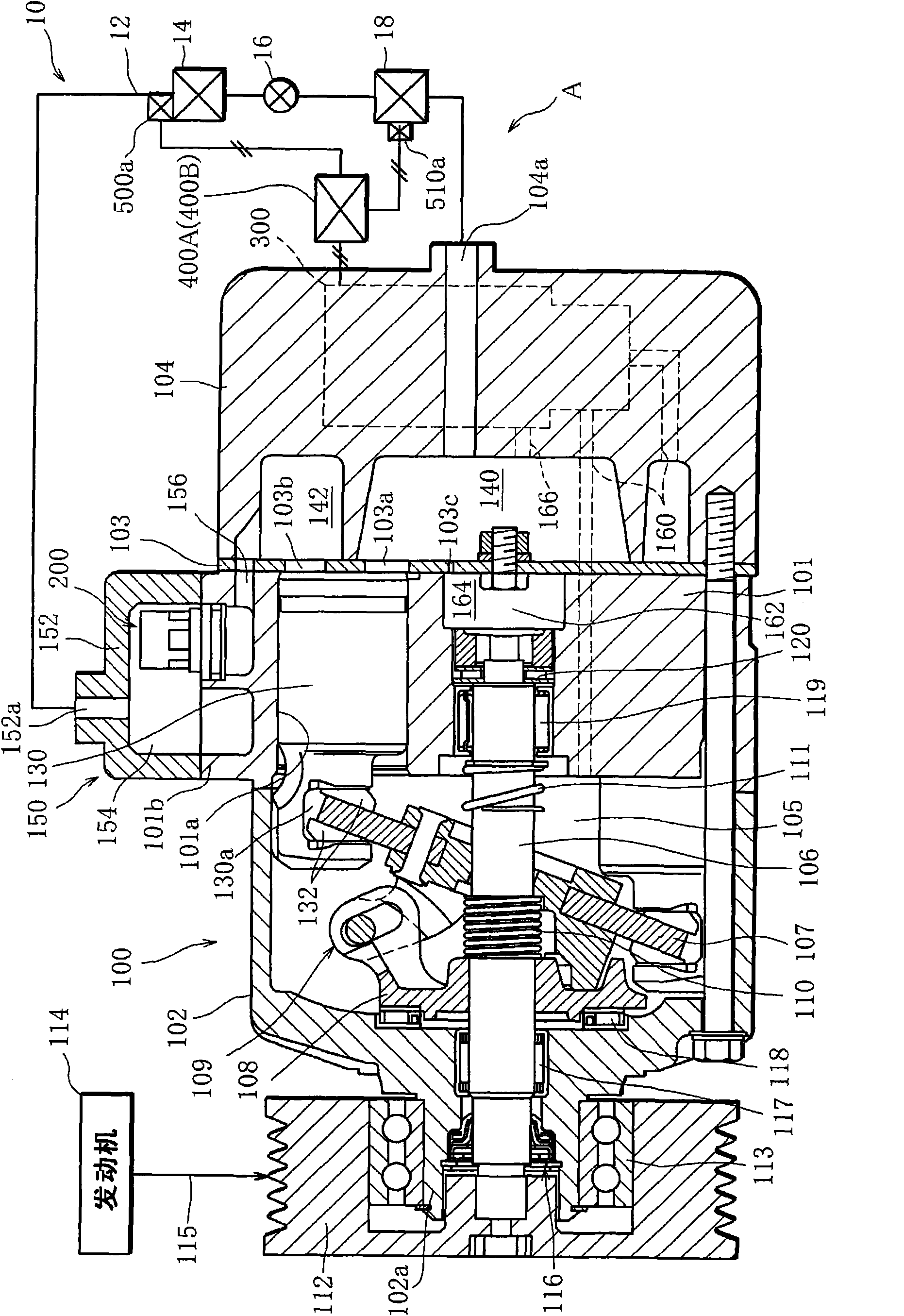

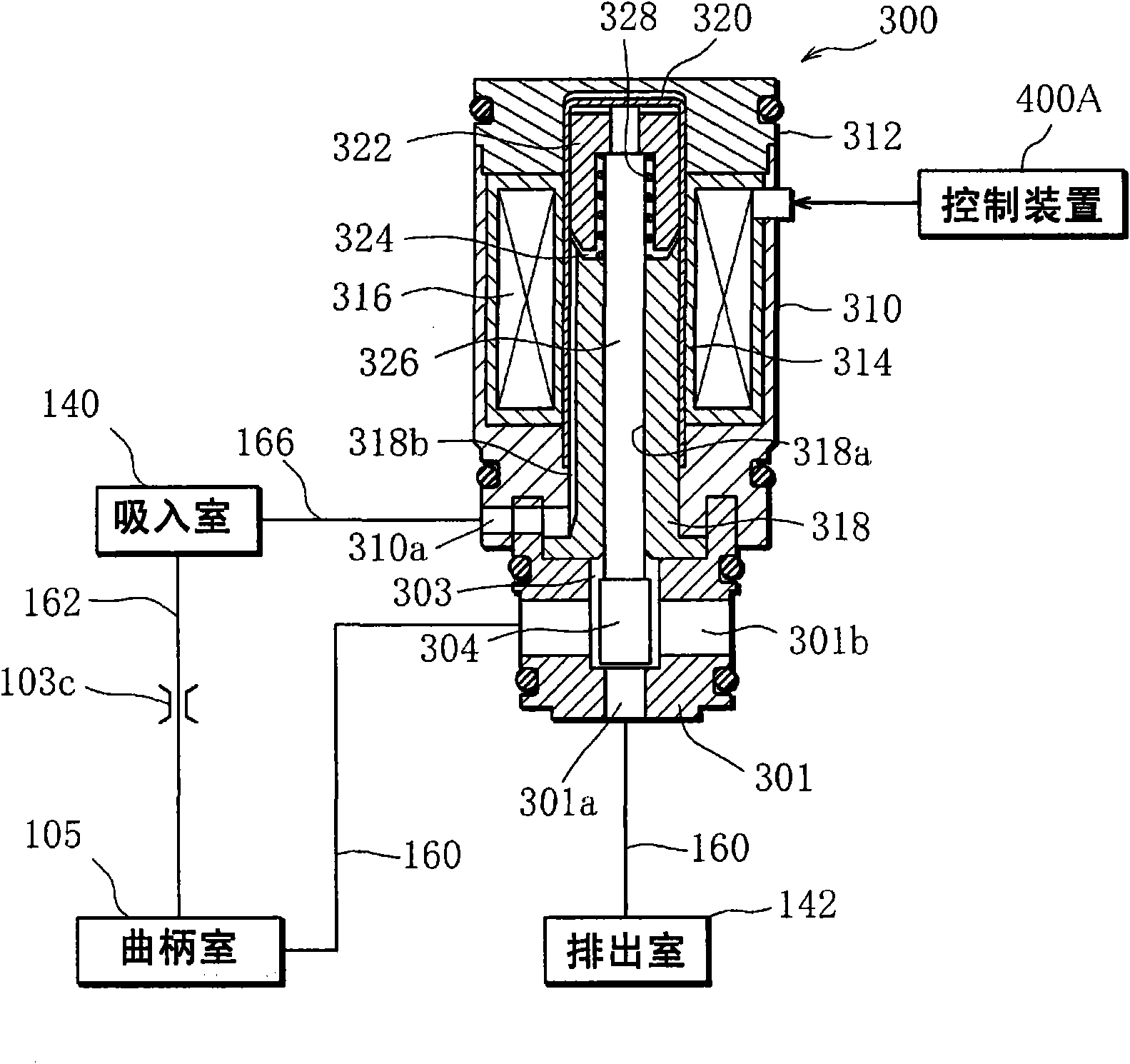

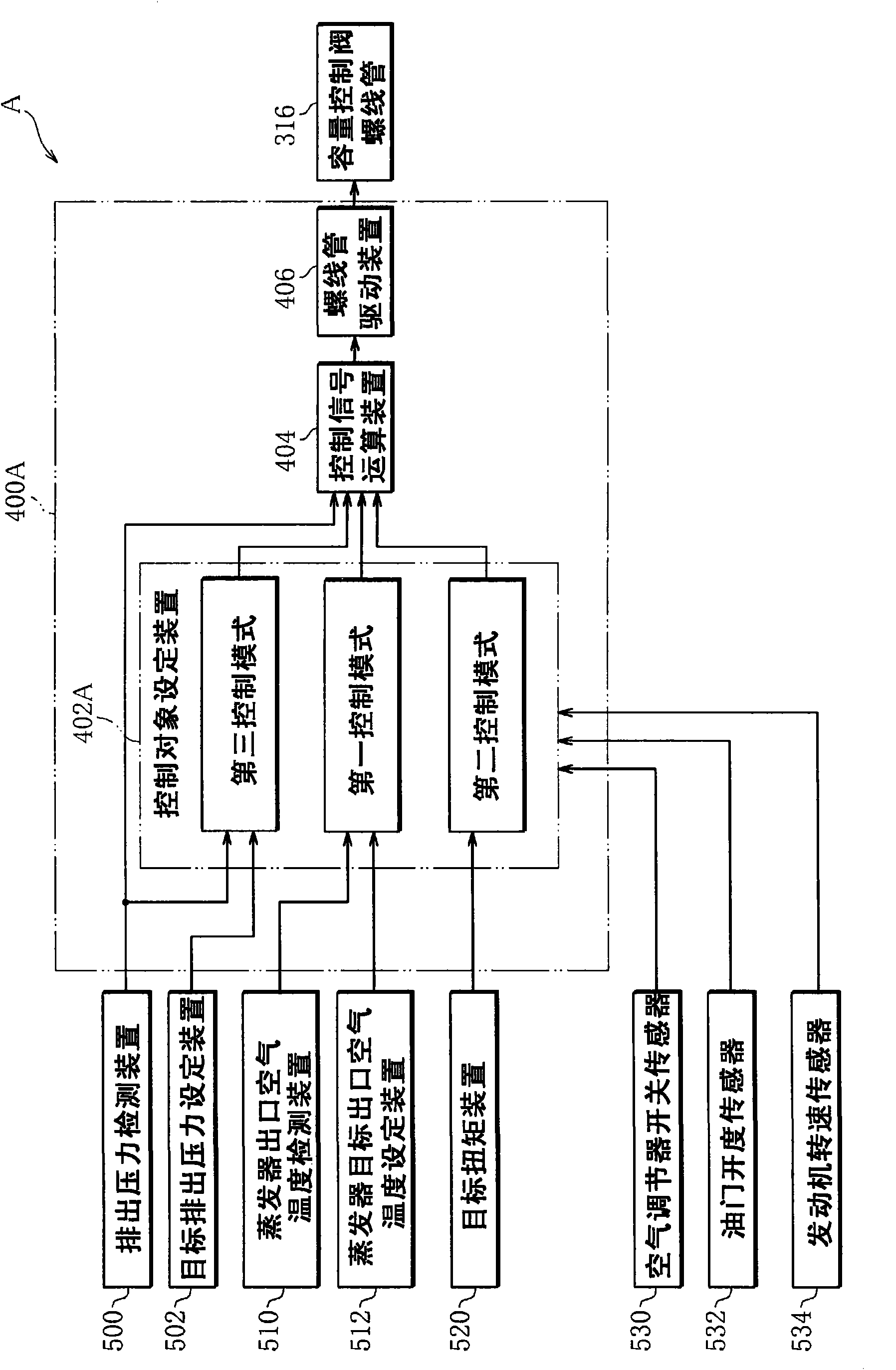

Variable displacement compressor and displacement control system

InactiveCN101688529AGuaranteed reliabilityAvoid pressure risesFluid parameterPump controlControl systemEngineering

A discharge displacement control system for a variable displacement compressor has control target setting means. The control target setting means selects one control mode from among two or more control modes based on external information detected by external-information detection means and sets a target of control according to the selected control mode. In a first control mode which is one of thecontrol modes, the control target setting means sets as the target of control a target level of either the pressure in a suction pressure region or the pressure in a crank chamber based on the external information detected by the external-information detection means. In a second control mode which is one of the control modes, the control target setting means sets as the target of control a targetoperation pressure difference that is a target difference between the pressure in a discharge pressure region and either the pressure in the suction pressure region or the pressure in the crank chamber.

Owner:SANDEN CORP

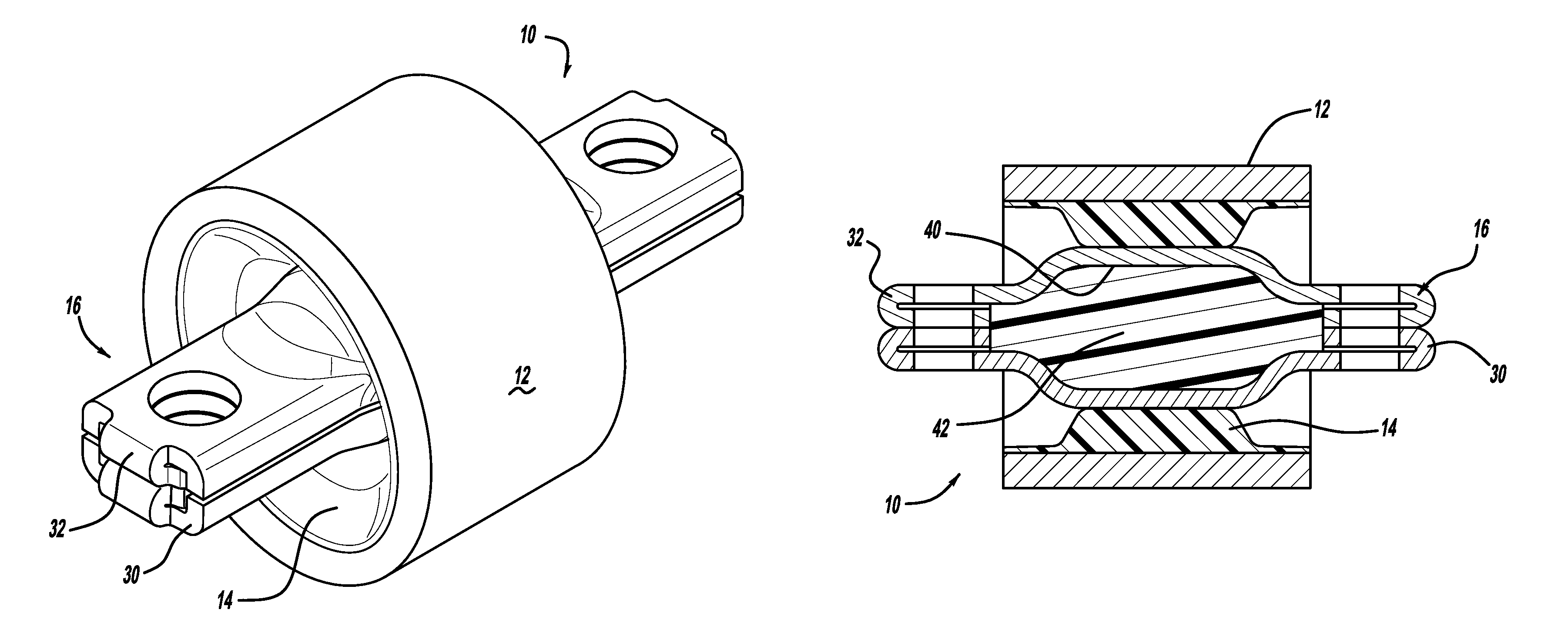

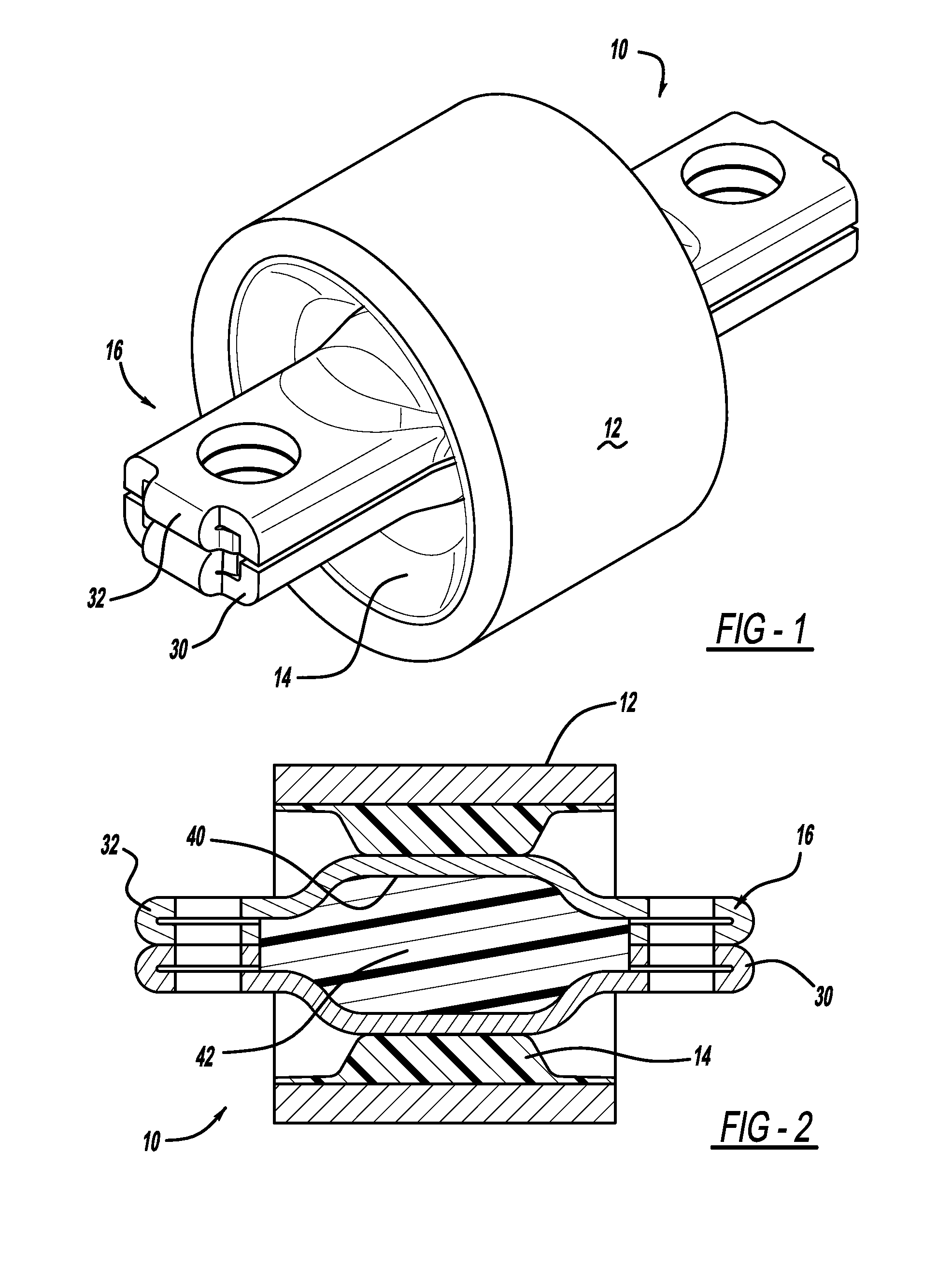

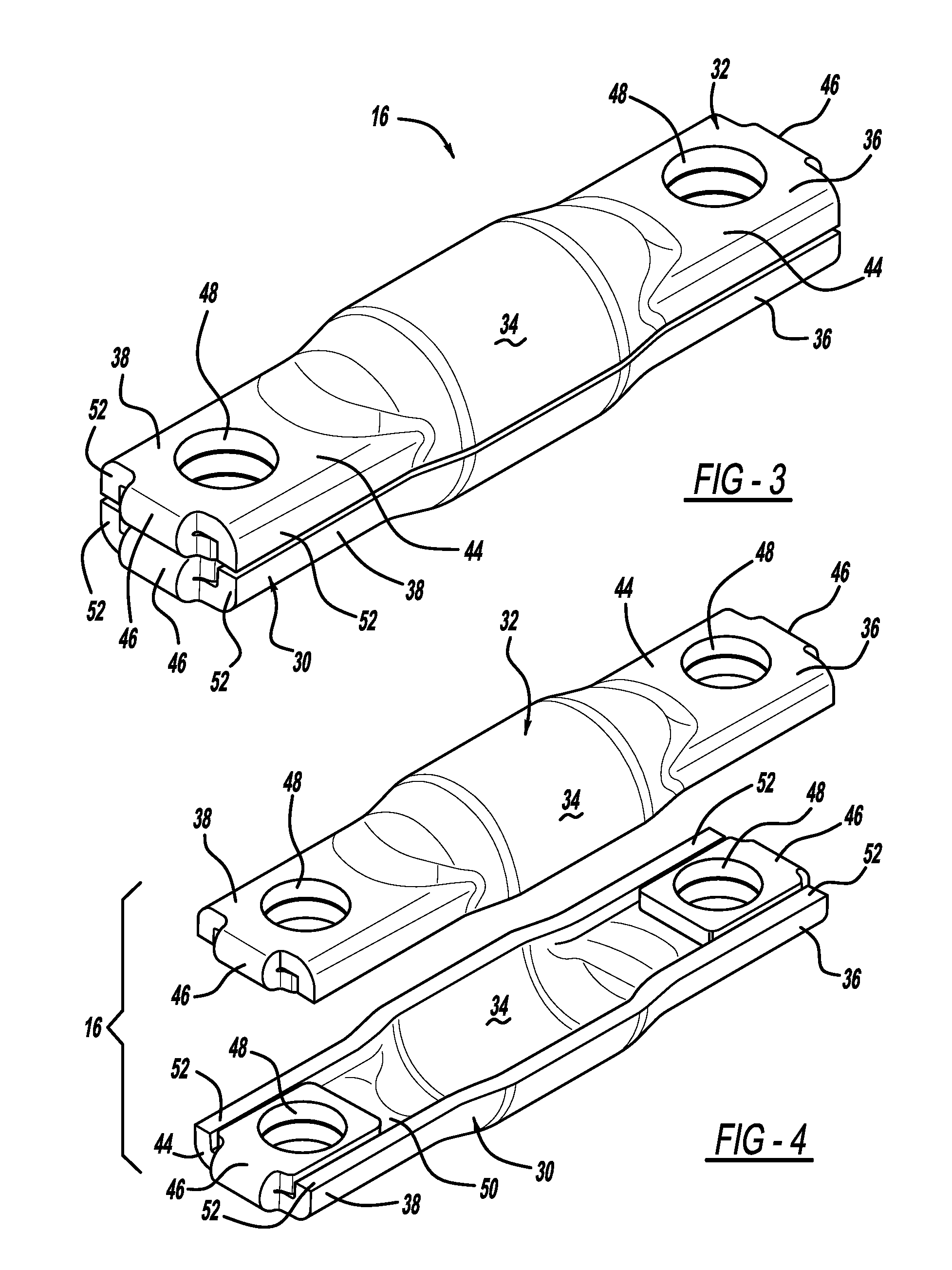

Elastomeric bushing assembly with multi-piece bar pin

InactiveUS8226100B2Increasing the thicknessAvoid pressure risesTorsion springsInterconnection systemsElastomerEngineering

The present disclosure provides an elastomeric bushing assembly that includes a multi-piece inner metal component. The inner metal component is formed from a plurality of stamped components that when assembled form a hollow chamber in the center section of the inner metal component. Flat sections at opposite ends of the center section include folded over tabs which increase the strength of the flat sections.

Owner:THE PULLMAN CO

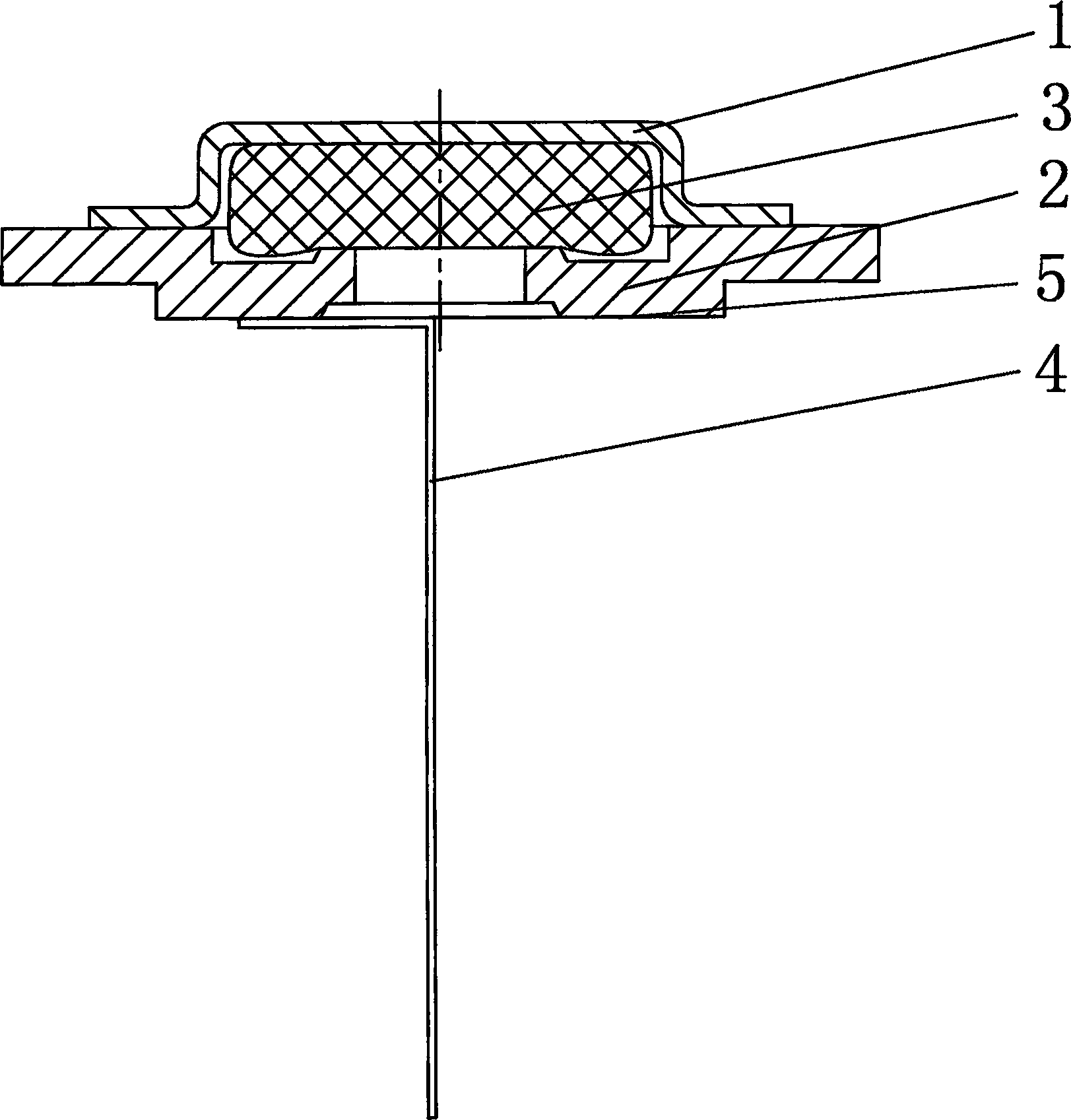

Combined covering cap in use for columniform secondary battery of zinc-nickel

The disclosed composite covering cap is composed of end cap, bottom cover, and explosion prevention piece. Being connected to afflux body of zinc negative pole, the bottom cover is made from metal or alloy, or which is setup on surface of the bottom cover, with high over potential for separating out hydrogen. Corrosion preventive paint coat is coated on surface of the bottom cover, and surface of the connected afflux body. Being selected from metlbond-acetal type polymer, epoxy-butyronitrile type polymer, or epoxy-nylon polymer etc, the corrosion preventive paint coat possesses characteristics: good affinity, cohesiveness to surface of metal so as to contact surface of metal fully; not checking property of resisting dipping in alkali for long time. Thus, the bottom cover can prevent corrosion from appearing on surfaces of bottom cover or afflux body. The invention possesses marked effect on accumulation of hydrogen, and against step up internal pressure.

Owner:山东国金汽车工程技术有限公司

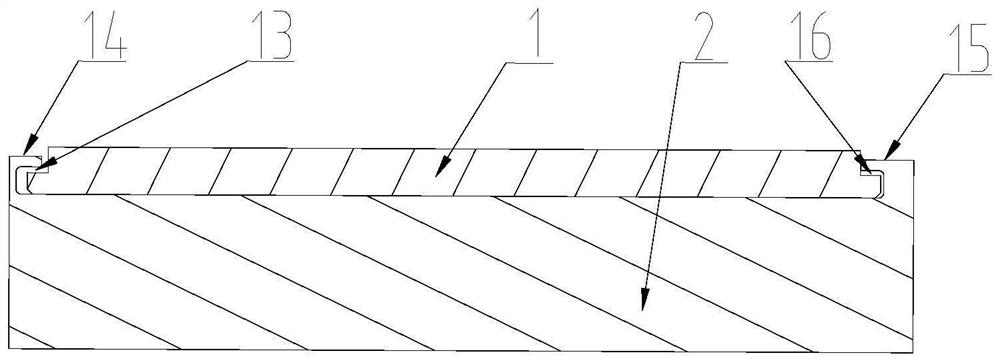

Square battery container, method of manufacturing the container, and square battery using the container

InactiveUS6946221B2Sufficient pressure resisting strengthImprovement in energy density per volumeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsProduction rateHigh dimensional

A prismatic battery case with high dimensional precision is manufactured, while pursuing an improvement in productivity, with a manufacturing method of a prismatic battery case that includes a first step for molding an intermediate cup body (8) by impact molding a pellet (7) of prescribed shape, and a second step for molding a prismatic battery case (9) with a cross section of substantially rectangular shape by DI processing the intermediate cup body (8). The DI processing conducts drawing and ironing continuously, in one action.

Owner:PANASONIC CORP

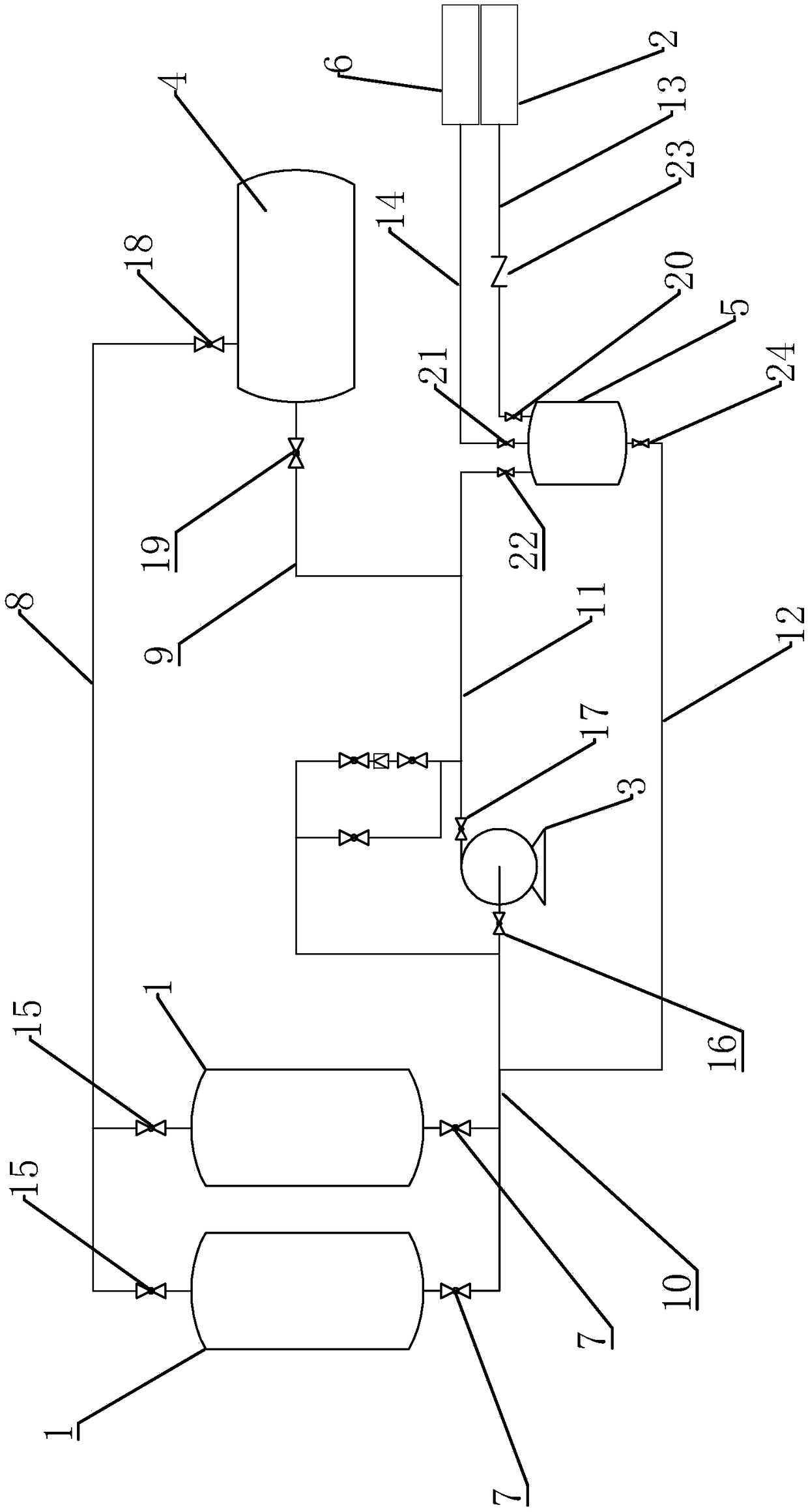

Ammonia water recovery system and ammonia water recovery method

PendingCN109399540AAvoid pressure risesAvoid harmLiquid transferring devicesRecovery methodAmmonia storage

The invention provides an ammonia water recovery system and an ammonia water recovery method. The ammonia water recovery system comprises an ammonia water storage tank, an air compressor, a charging pump, a loading and unloading arm, an ammonia water tank car, a recovery tank and a fan. The loading and unloading arm comprises a gas phase pipeline of the loading and unloading arm and a liquid phasepipeline of the loading and unloading arm, a liquid inlet connecting end, an air inlet connecting end and an air outlet connecting end are arranged on the top of the recovery tank, the ammonia waterstorage tank is connected to the inlet of the charging pump through a first liquid phase pipeline of ammonia water, the outlet of the charging pump is connected to the liquid inlet connecting end of the recovery tank through a second liquid phase pipeline of ammonia water, the second liquid phase pipeline of ammonia water is connected to the liquid phase port of the ammonia water tank car, the gasphase port of the ammonia water tank car is connected to the gas phase port of the ammonia storage tank through the gas phase pipeline of the loading and unloading arm, the air inlet connecting end at the top of the recovery tank is connected to the air compressor through a compressed air pipeline, and the air outlet connecting end of the recovery tank is connected to the fan through an exhaust pipeline. The recovery tank is used for recovering residual ammonia water in the pipeline, so that no ammonia is leaked in the process of removing the tank car and the pipelines.

Owner:浙江英德赛半导体材料股份有限公司

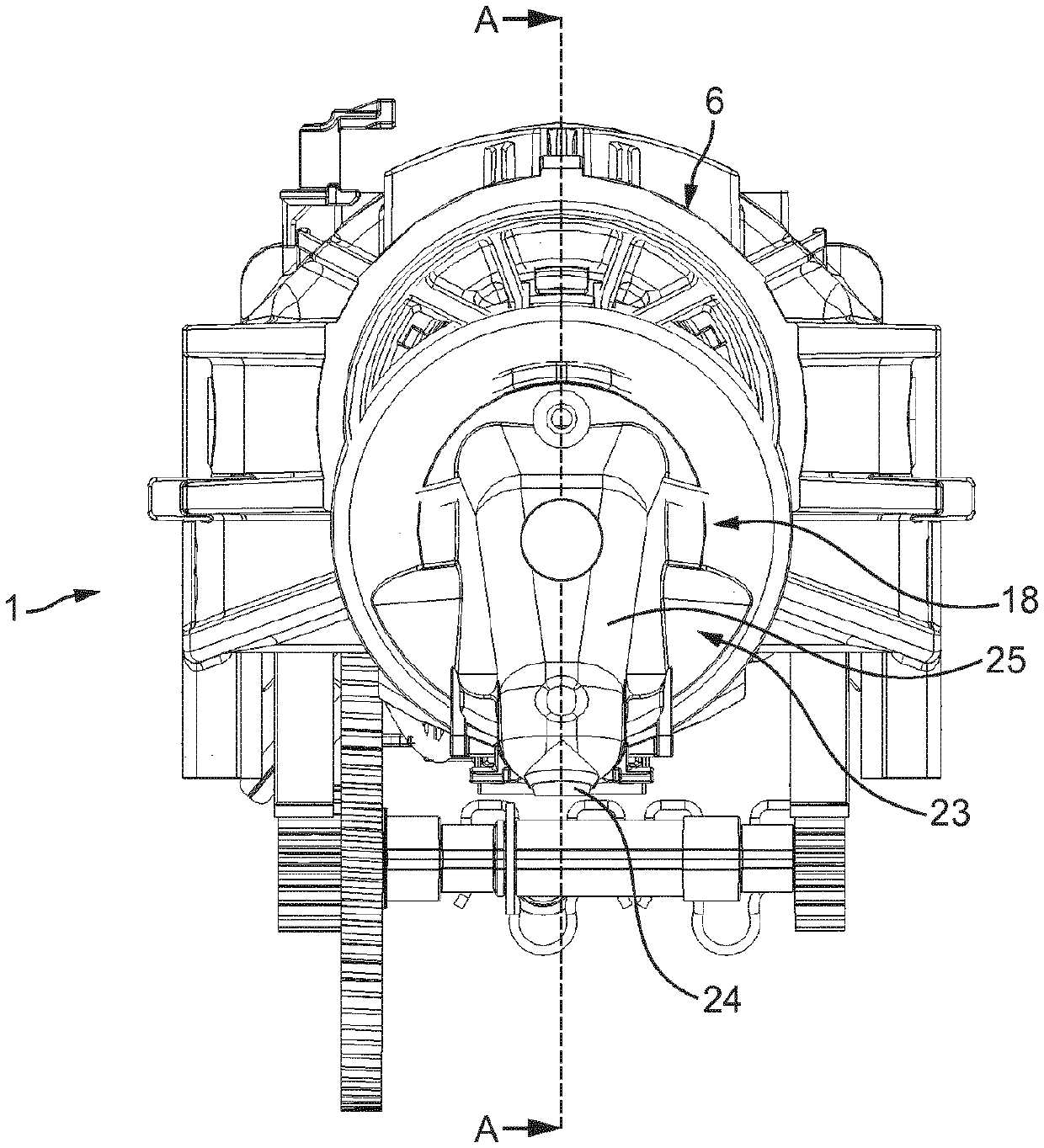

Beverage extraction unit for selectively providing orifices of different types in a capsule for extraction of the beverage

PendingUS20210007538A1Avoid pressure risesReduce stressTransportation and packagingBeverage vesselsProcess engineeringBiology

The invention relates to beverage extraction unit (1) for extracting a beverage from an exchangeable capsule (2) containing beverage ingredients and being configured for operating according to two beverage extraction modes, e.g. at respectively high pressure or low pressure. The invention also relates to the beverage machine comprising the extraction unit.

Owner:NESTEC SA +1

Refrigerant cycle apparatus

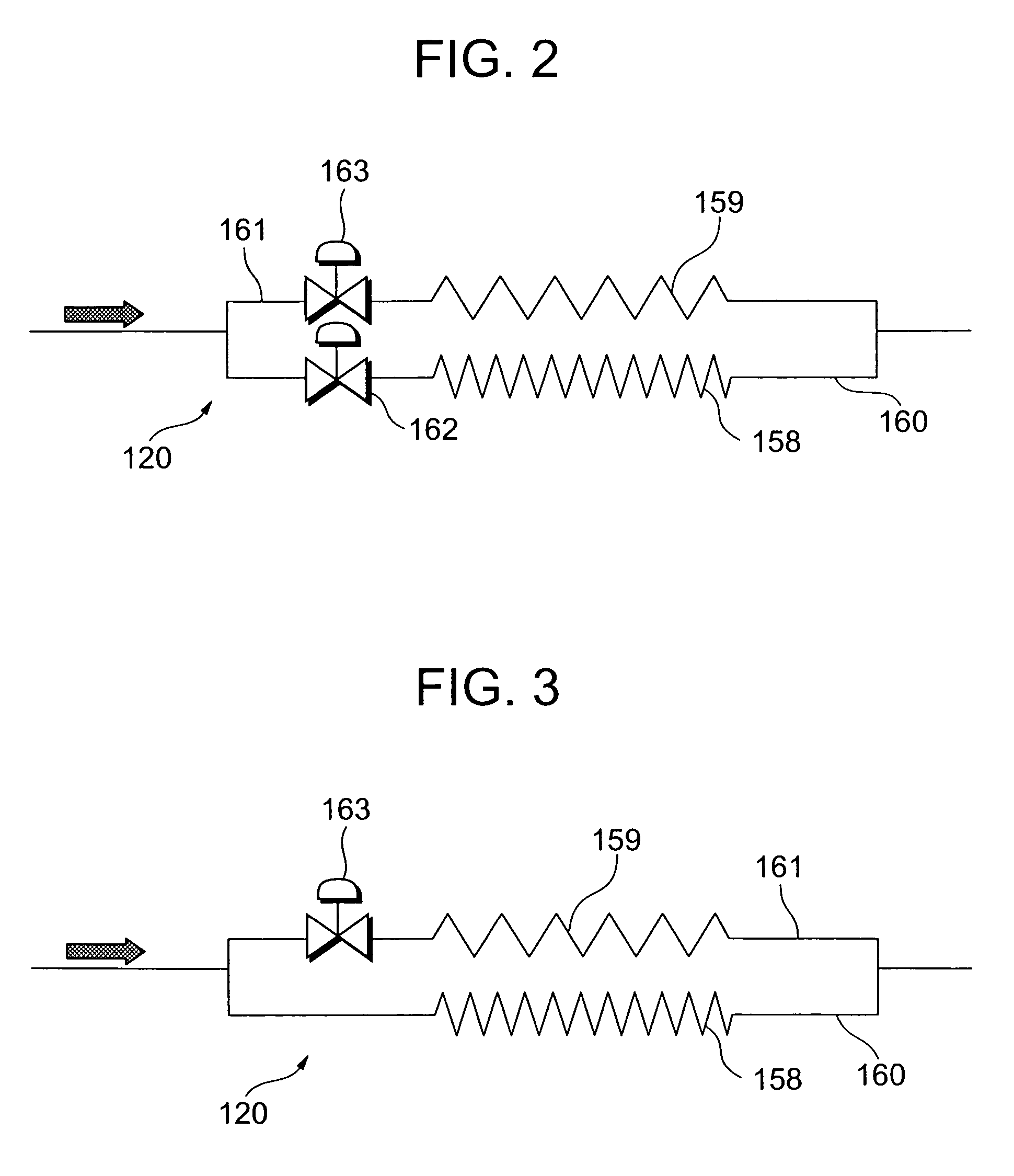

ActiveUS7143593B2Avoid pressure risesAvoiding abnormal riseMechanical apparatusCompression machines with non-reversible cycleEngineeringHigh pressure

There is disclosed a refrigerant cycle apparatus capable of avoiding occurrence of an abnormal rise in a pressure on a high-pressure side in advance, comprising: a throttling mechanism including a first capillary tube, and a second capillary tube which is connected in parallel to the first capillary tube and whose flow path resistance is smaller than that of the first capillary tube; and a valve device for controlling refrigerant circulation into the first and second capillary tubes, so that a refrigerant is passed into the second capillary tube at the time of starting of a compressor.

Owner:SANYO ELECTRIC CO LTD

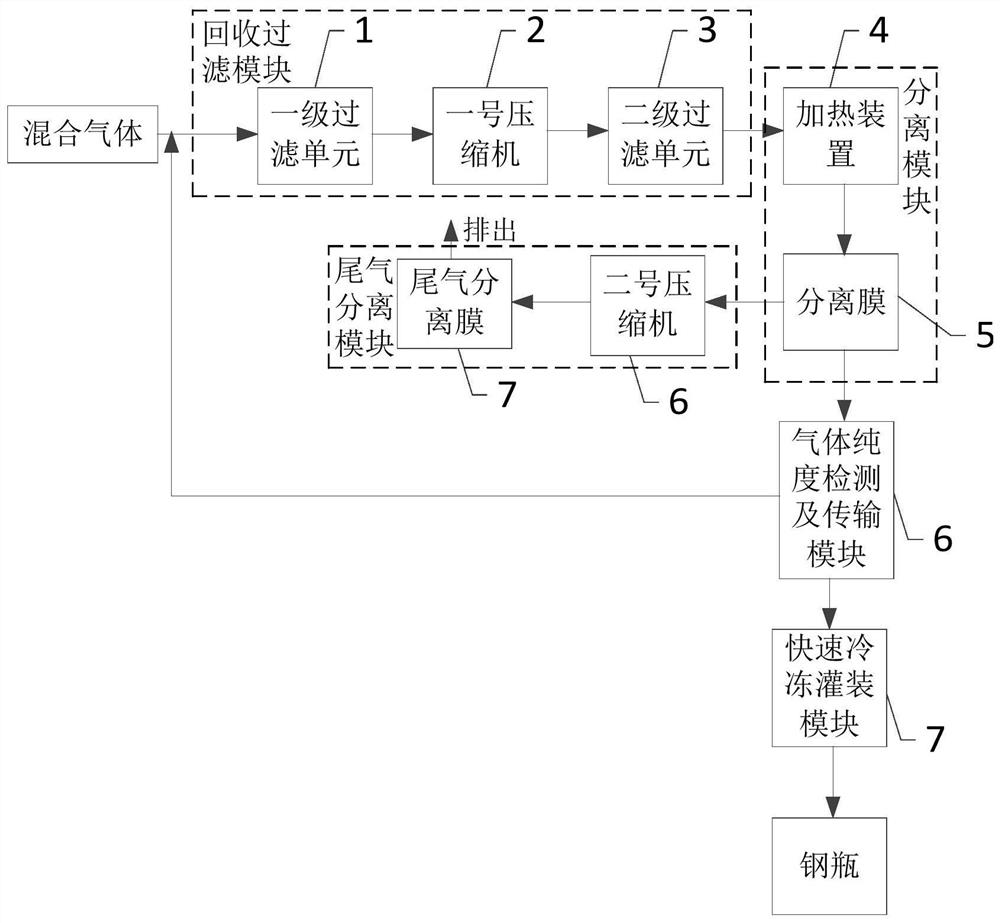

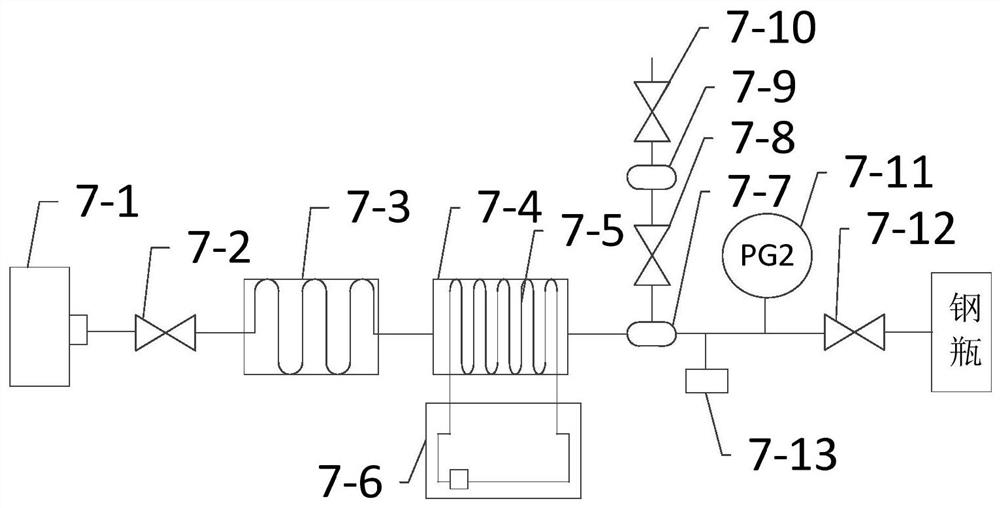

Sulfur hexafluoride gas separation and recovery device

InactiveCN113701047AMeet the liquefaction speed requirementsImprove heat transfer efficiencyChemical industryGas handling/storage effectsSulfur hexafluoridePhysical chemistry

The invention discloses a sulfur hexafluoride gas separation and recovery device and belongs to the field of gas recovery. The sulfur hexafluoride gas separation and recovery device aims to solve the problems of low SF6 gas recovery efficiency and poor purification precision in the prior art. Mixed gas is pumped out by a recovery and filtering module to be filtered, and the filtered gas is pressurized and transferred to a separation module; the separation module is used for separating the filtered gas into sulfur hexafluoride gas and gas except the sulfur hexafluoride gas; a tail gas separation module is used for separating the gas except the sulfur hexafluoride gas, and the separated gas is respectively discharged; a gas purity detection and transmission module detects the purity of the sulfur hexafluoride gas, if the purity of the sulfur hexafluoride gas is larger than or equal to the set purity, the sulfur hexafluoride gas is transmitted to a rapid freezing and filling device, and if the purity of the sulfur hexafluoride gas is smaller than the set purity, the sulfur hexafluoride gas serves as mixed gas and is transmitted to the recovery and filtering module; and the sulfur hexafluoride gas is recovered into a steel cylinder by the rapid freezing and filling device. The device is used for recovering and purifying SF6 gas.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER CO LTD ELECTRIC POWER RES INST +1

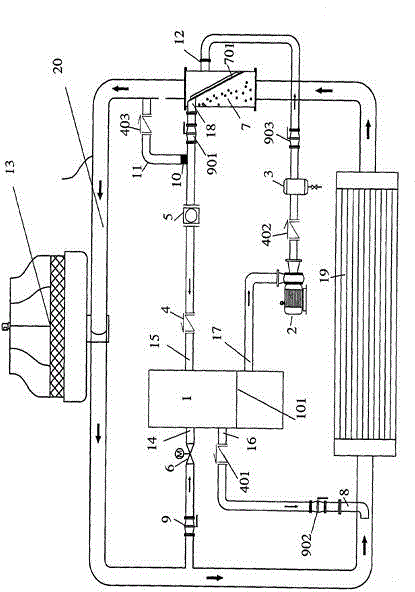

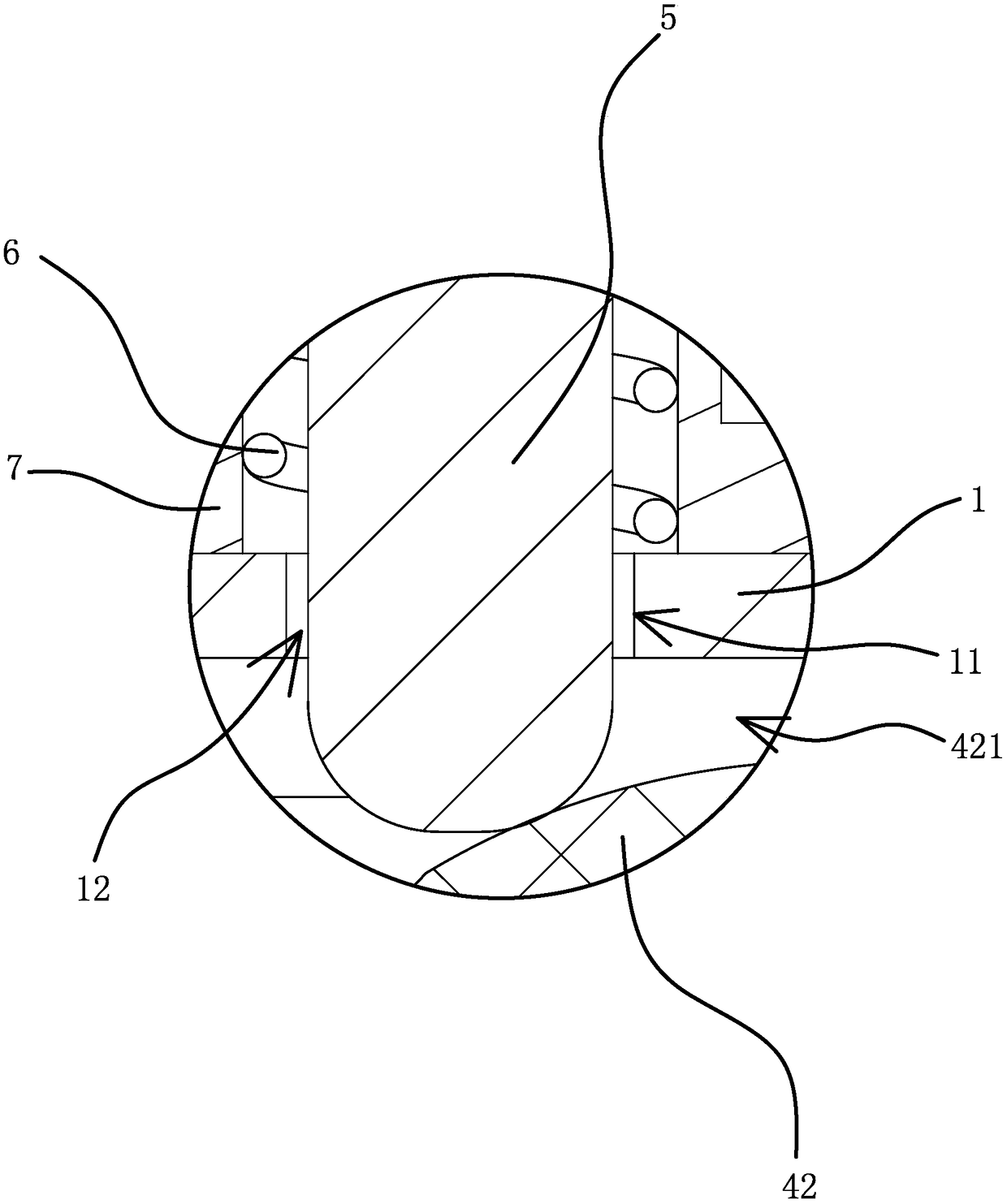

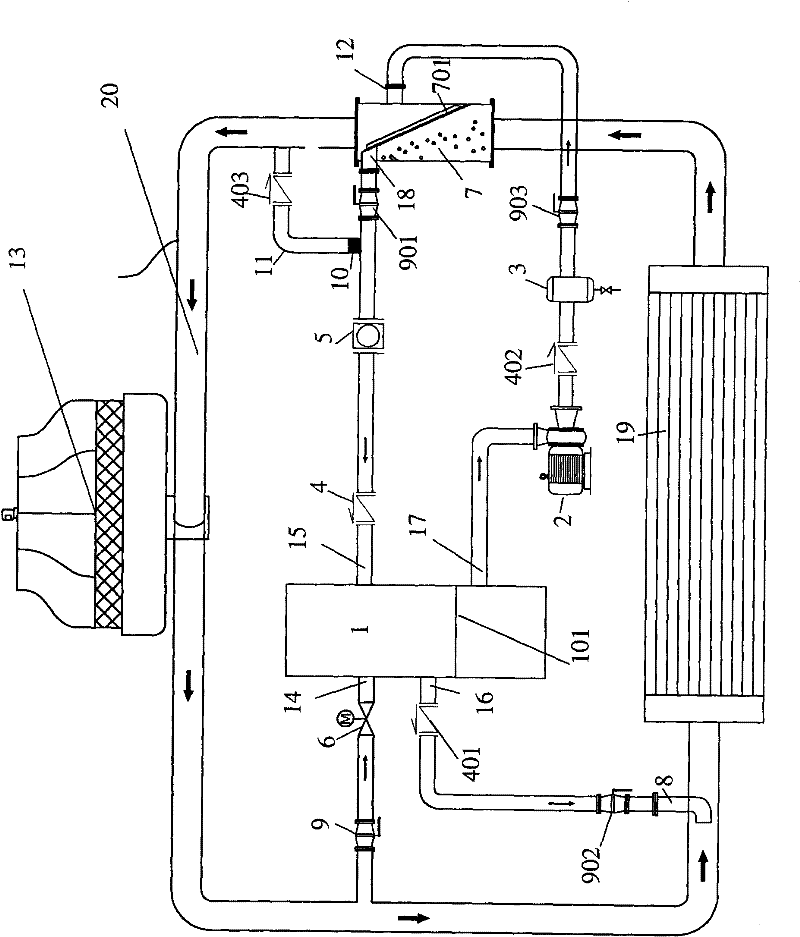

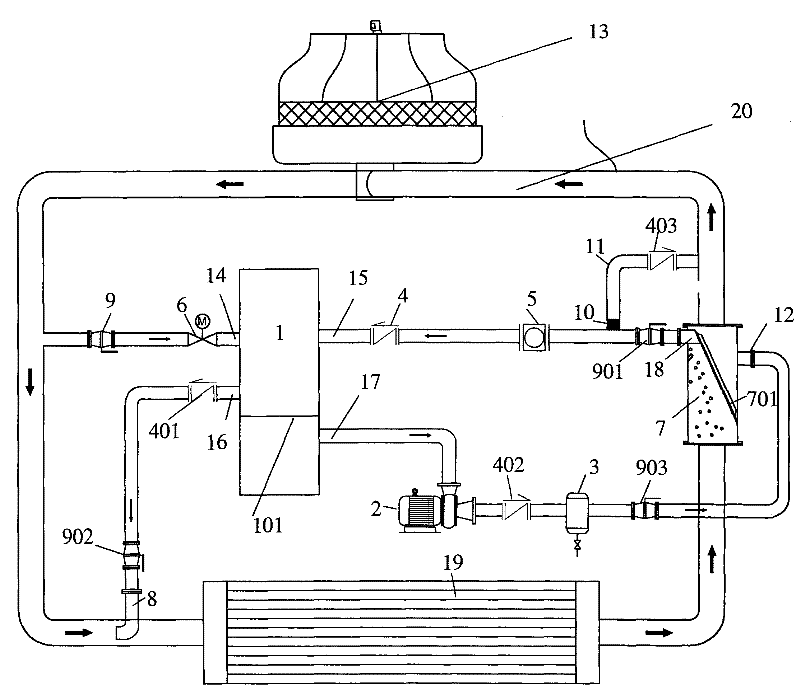

Online cleaning system for central air conditioner condenser

The invention discloses an online cleaning system for a central air conditioner condenser. The online cleaning system comprises a ball loading device 1, the condenser 19 and a ball receiver 7, the two ends of the condenser 19 communicate with a cooling pipeline 20, rubber balls are arranged in an upper container of the ball loading device 1, and a water inlet 14, a ball return opening 15 and a ball outlet 16 are arranged. A pipeline, communicating with the cooling water pipeline 20, of the water inlet 14 is a water inlet pipeline. A spraying opening of a ball spryer 8 is inserted into the cooling water pipeline 20 at an inlet of the condenser 19. The online cleaning system is characterized in that a branch 11 is arranged on a ball return pipeline and a cooling water return pipeline, a check valve 403 is arranged in the branch 11, and a screen mesh 10 is arranged between the branch 11 and a ball recycling pipeline. The online cleaning system has the following beneficial effect that the rubber balls are not likely to block a ball recycling outlet. The rubber balls and garbage are not extruded on a ball recycling screen mesh, the rubber ball recycling rate reaches 100%, it is ensured that each pipeline of the condenser is cleaned in place, and it is guaranteed that the inner pipe wall of the condenser is clean all the time.

Owner:ZHONGHUI ELECTROMECHANICAL TECH

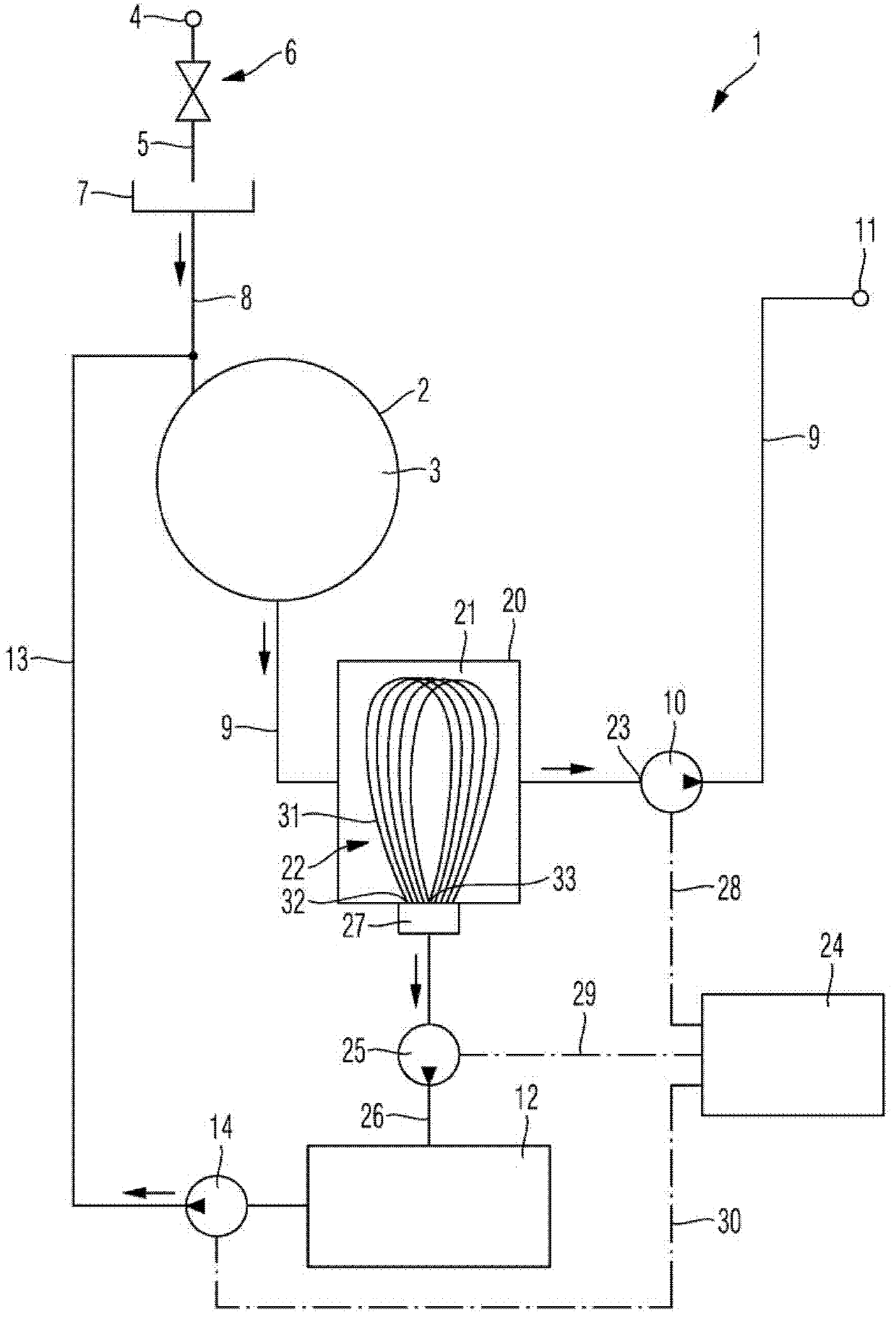

Water-bearing household appliance having a filter device in the pumping-away section and storage tank

ActiveCN102471981BAvoid pressure risesReduce maintenanceOther washing machinesTextiles and paperWater storage tankProcess region

A water-bearing household appliance 1 which serves, in particular, as a laundry treatment unit for washing and / or drying laundry comprises a treatment region 3 which is surrounded by a container 2, a pumping-away section 9 which is connected to the treatment region 3, a discharge pump 10 which is arranged in the pumping-away section 9, a filter device 20 which is arranged in the pumping-away section 9, and a water storage tank 12 which is connected to the filter device 20 via a pump 25. By actuation of the pump 25, water can be branched off into the water storage tank 12 from the pumping-away section 9 via a filter 22 of the filter device 20. The water which is stored in the water storage tank 12 can replace part of the supplied fresh water in the case of a further programme run. The embodiment of the filter device 20 makes self-cleaning of the filter 22 possible.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

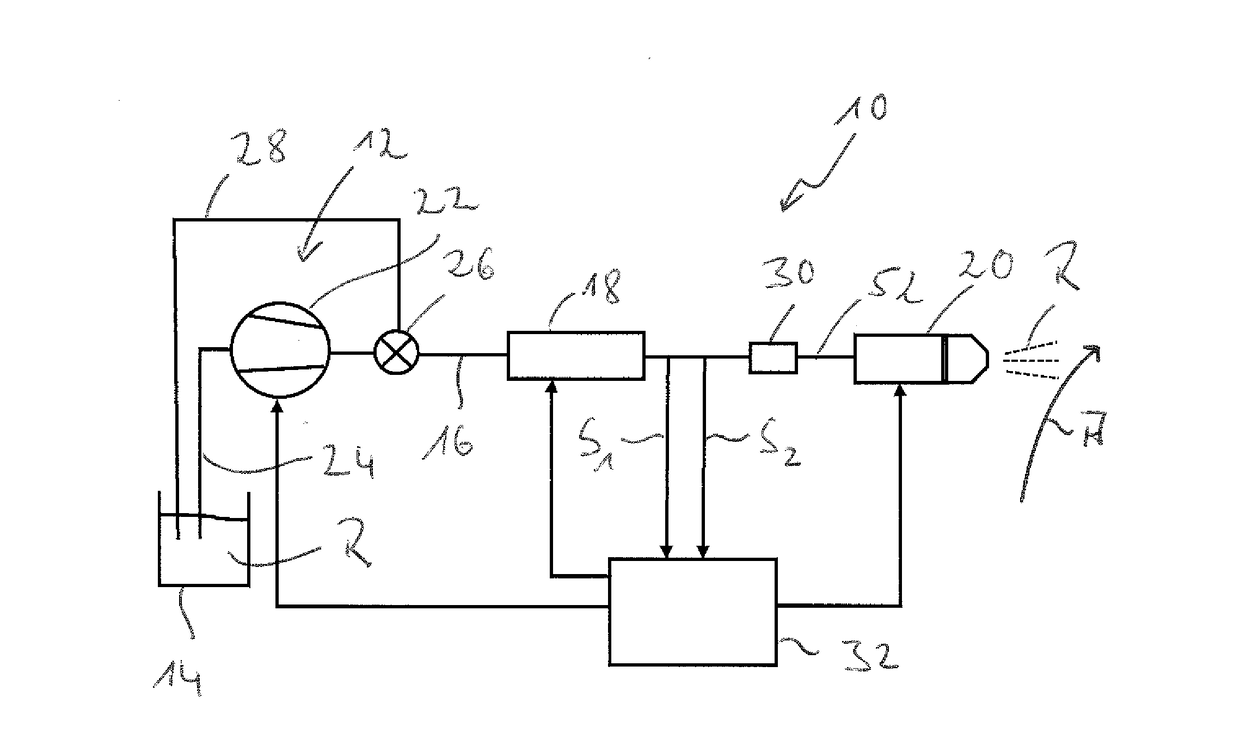

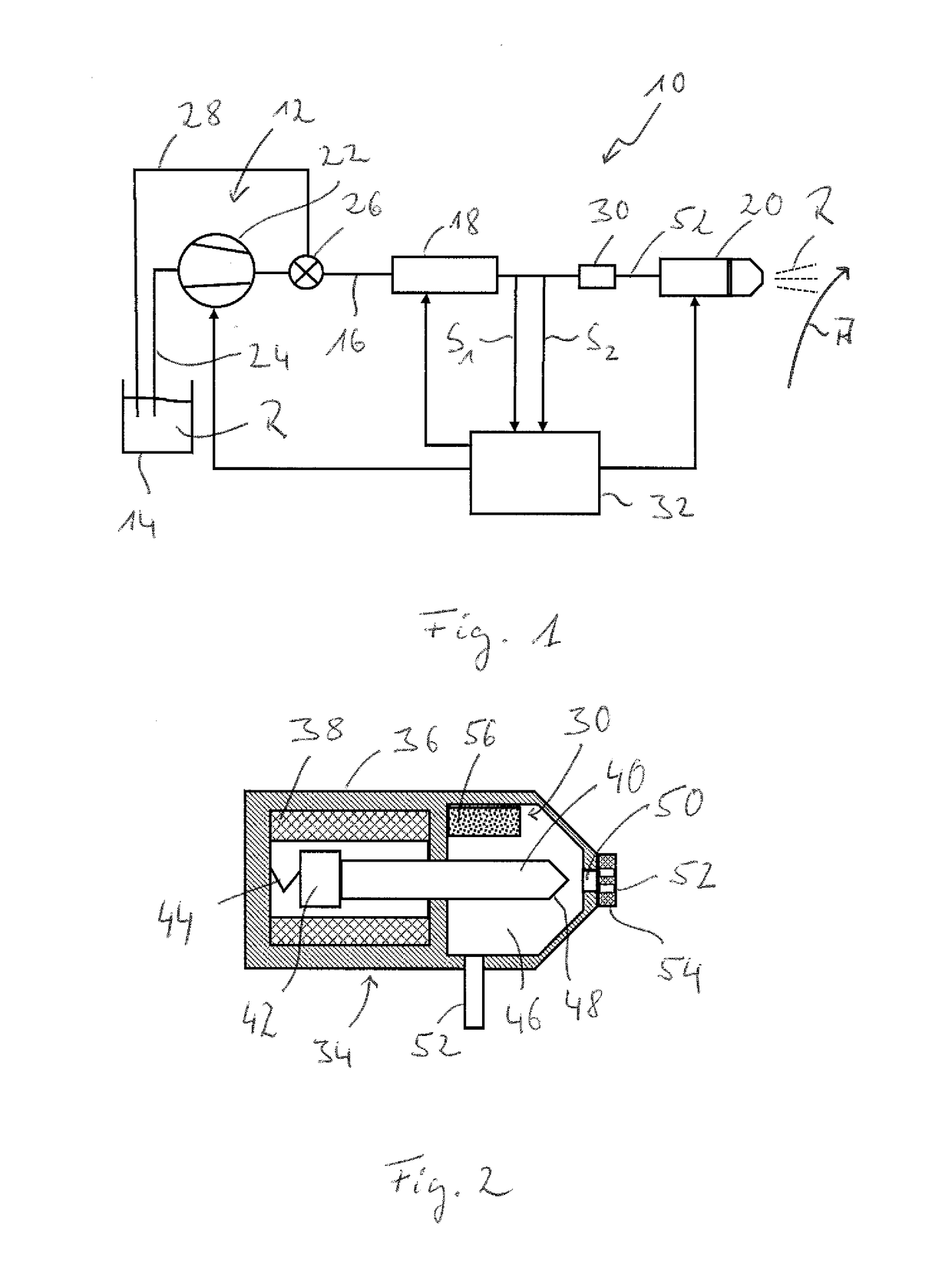

Device for release of reactant into the exhaust gas stream of an internal combustion engine

ActiveUS20170122167A1Efficient mixingQuality improvementGas treatmentExhaust apparatusInternal combustion engineBiomedical engineering

A device for releasing reactant (R) into the exhaust gas stream (A) of an internal combustion engine includes a reactant injection unit (20), a reactant delivery unit (12) for delivering reactant (R) from a reactant reservoir (14) to the reactant injection unit (20), a heating unit (18) for heating reactant (R) delivered by the reactant delivery unit (12) to the reactant injection unit (20). An actuating unit (32) actuates the reactant delivery unit (12), the heating unit (18) and the reactant injection unit (20). An overpressure valve (26) or / and a pressure storage unit (30) is provided downstream of the reactant delivery unit (12).

Owner:PUREM GMBH

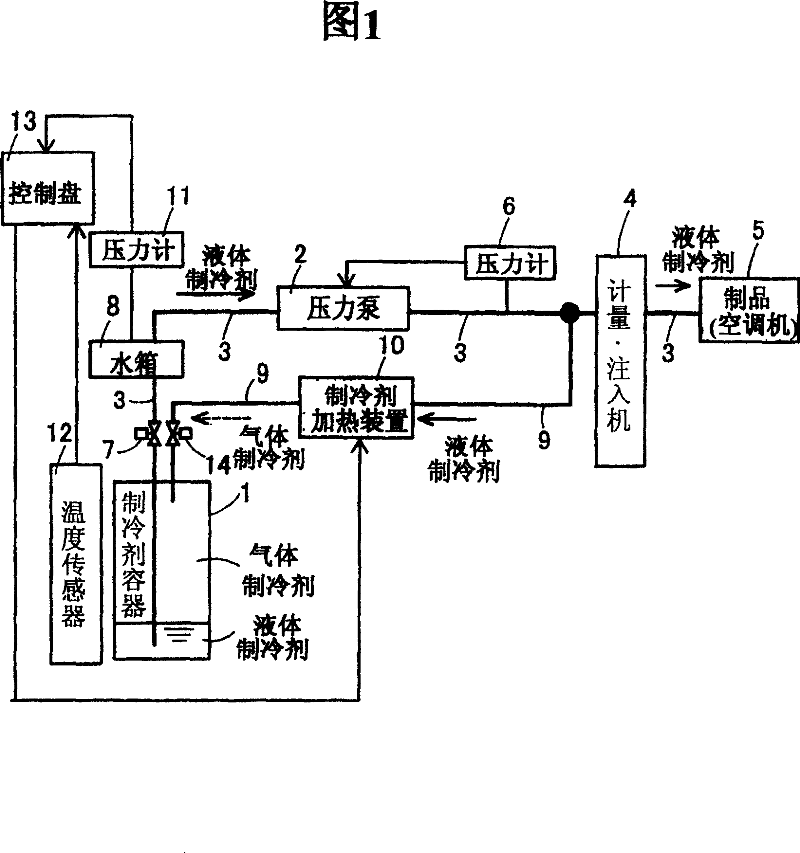

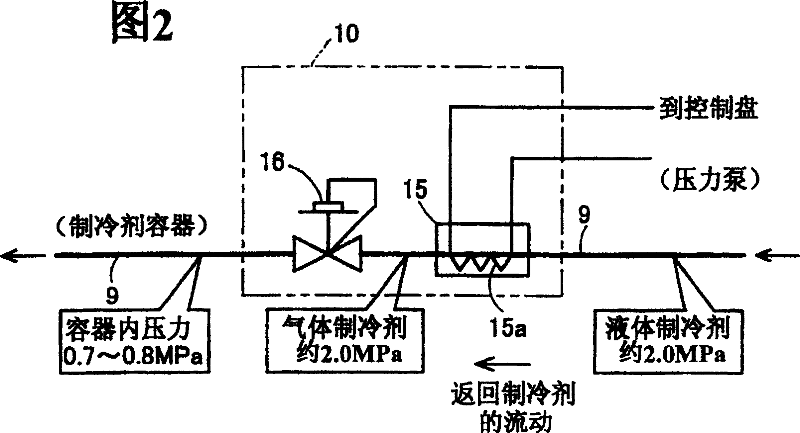

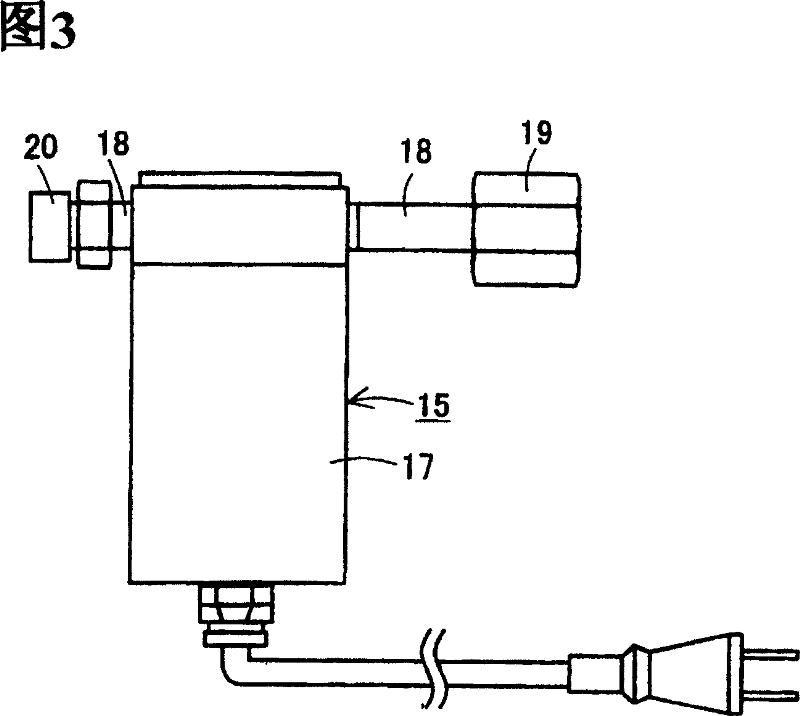

Refrigerant supplying device

InactiveCN100338418CQuickly pick upImprove heating efficiencyMechanical apparatusCompression machinesProduct gasRefrigerant

The purpose of this invention is to increase the heating efficiency of a liquid refrigerant by relatively reducing the size of a structure for filling a refrigerant container with a gas refrigerant. This refrigerant feeder force-feeds the liquid refrigerant in the refrigerant container 1 by a force-feed pump 2 to supply the liquid refrigerant to a product 5 through a supply pipe 3. A return pipe 9 leading to the refrigerant container 1 after branching from the supply pipe 3 is installed on the downstream side of the force-feed pump 2. The liquid refrigerant flowing in the return pipe 9 is heated and evaporated by a heater contained in a refrigerant heating device 10, and the evaporated gas refrigerant is depressed by a pressure reducing valve contained in the device 10. A pressure gauge 11 measuring a refrigerant pressure in a header is installed in the header 8 installed in the supply pipe 3. A temperature sensor 12 detecting the temperature of the refrigerant container 1 is installed in the refrigerant container. A control panel 13 controls the heater 15 based on the detected refrigerant pressure and the temperature of the container.

Owner:AISIN SEIKI KK +2

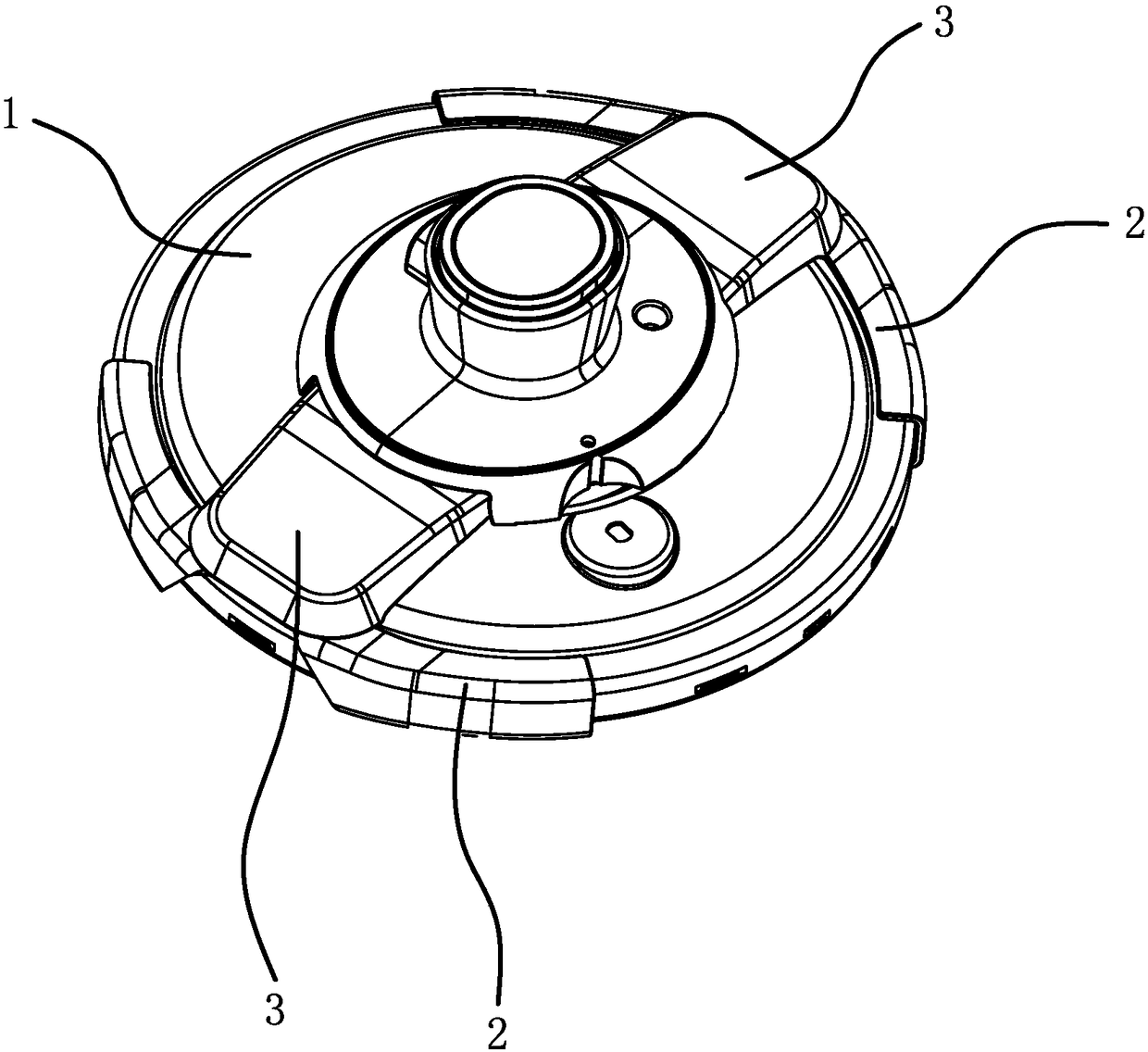

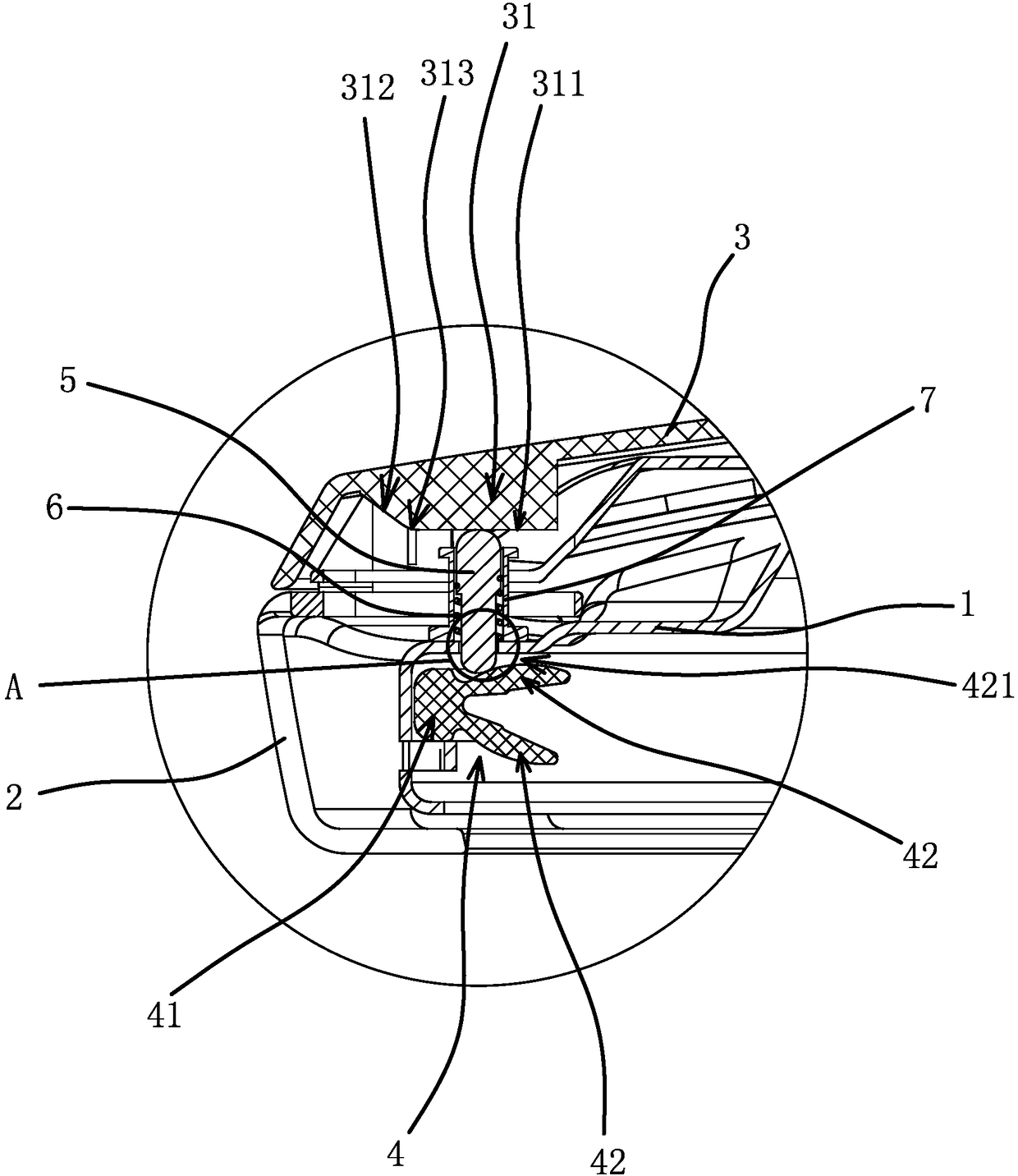

Cover safety structure of a pressure cooker lid

The invention provides a pressure cooker cover closing safety structure and belongs to the technical field of cookers. The technical problem that an existing pressure cooker cover has the safety risk and the like is solved. A pressure cooker cover comprises a cover body, a clamp and a cover piece, wherein a sealing rubber ring is arranged on the inner side edge of the cover body. The cover closing safety structure comprises an ejection rod and an elastic part, a through hole is formed in the cover body, the ejection rod penetrates into the through hole, an air passing gap is reserved between the inner walls of the ejection rod and the through hole, the ejection rod is located between the sealing rubber ring and the cover piece, the elastic part makes the outer end of the ejection rod always abut against the cover piece, the inner side face of the cover piece is provided with an abutting plane and an oblique yield plane, the inner end of the ejection rod abuts against h the sealing rubber ring and a ventilation gap is formed between the sealing rubber ring and the inner side face of the cover body when the outer end of the ejection rod abuts against the abutting plane. The inner end of the ejection rod is separated from the sealing rubber ring when the outer end of the ejection rod abuts against the oblique yield plane. The pressure cooker cover closing safety structure has the advantages that the pressure in the pressure cooker can be prevented from rising when the pressure cooker cover is not completely closed on a cooker body.

Owner:浙江福腾宝家居用品有限公司

Central air-conditioning condenser online cleaning system

An online cleaning system for central air-conditioning condensers, including: a ball loader, a ball collector, and cooling pipes connected at both ends of the condenser. The ball loader divides it into upper and lower containers through a grille. The ball is provided with a water inlet, a ball return port, and a ball outlet; the pipe connecting the water inlet to the cooling water pipe is the water inlet pipe; the pipe connecting the ball outlet to the ball sprayer is the ball delivery pipe, and the nozzle of the ball sprayer is inserted into the condenser inlet The cooling water pipeline at the place; the ball return port is connected with the ball collector to form the ball return pipeline, which is characterized in that: a branch is set on the ball return pipeline and the cooling water return pipeline, and a check valve is set in the branch, and A screen is set between the branch and the recovery ball pipeline. It avoids the clogging of the rubber balls at the outlet of the ball return device and the extrusion of the rubber balls and garbage on the surface of the ball collection net, causing the water flow to be blocked and the pressure of the system water to rise. It saves energy and ensures the stability of the system. The ball rate reaches 100%, and the condenser pipes are cleaned in place.

Owner:北京北交富沃机电工程科技有限公司

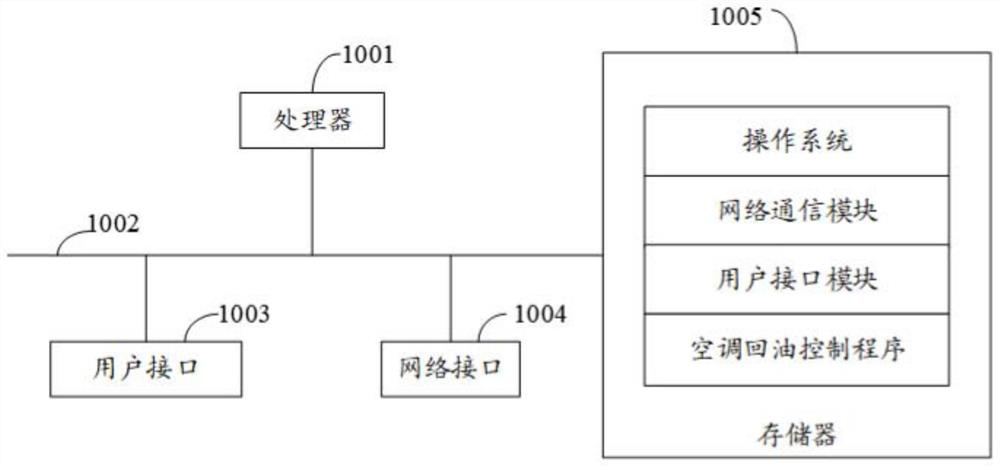

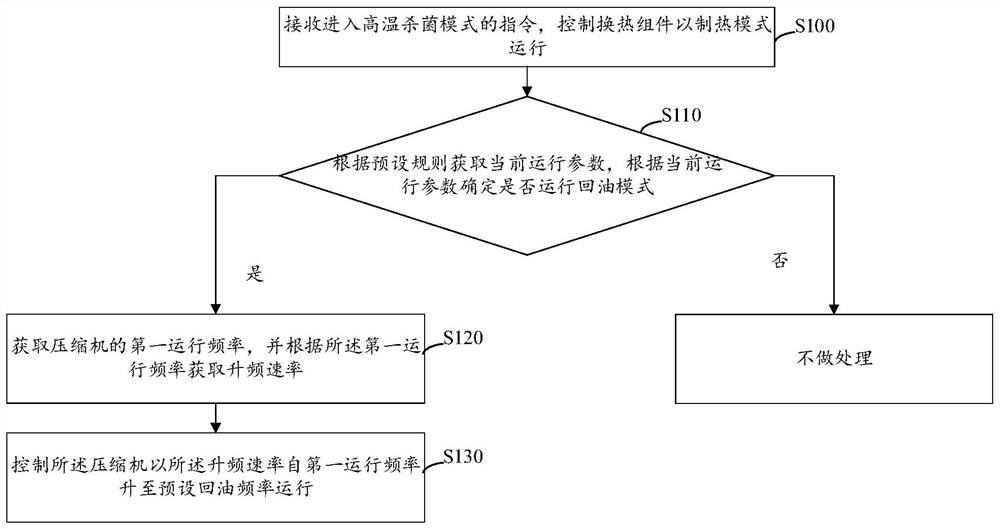

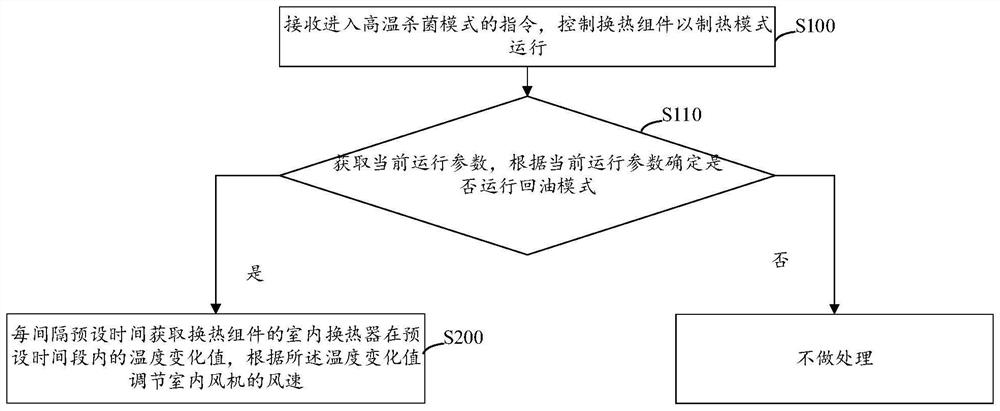

Air conditioner oil return control method, air conditioner and readable storage medium

ActiveCN111536677BAvoid pressure risesGuaranteed reliabilityCompressorMechanical apparatusThermodynamicsEngineering

The invention discloses an air conditioner oil return control method, an air conditioner and a readable storage medium. The air conditioner oil return control method includes: receiving an instruction to enter a high-temperature sterilization mode, controlling a heat exchange component to operate in a heating mode; obtaining the current Operating parameters, determine whether to operate the oil return mode according to the current operating parameters; if it is determined to operate the oil return mode, then obtain the first operating frequency of the compressor, and obtain the frequency increase rate according to the first operating frequency; control the compressor to The frequency increase rate increases from the first operating frequency to the preset oil return frequency. When the air conditioner enters the high-temperature sterilization mode and operates in the oil return mode, the present invention can prevent the pressure of the air conditioner from increasing due to the excessively fast frequency increase of the compressor, thereby ensuring the reliability of the air conditioner.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Method for actuating a dosing valve

PendingCN114467206AReliable removalStart blockingReactant parameters controlJet pumpsFuel cellsEngineering

The invention relates to a method for switching off a fuel cell system (10), comprising a jet pump (28) for feeding a gas flow on the anode side into a recirculation path (26), the jet pump (28) comprising a metering valve (36) for metering H2. During cooling of the fuel cell system (10), the nozzle (46) is driven in a pulsating through-flow manner at least once in order to discharge condensed water. The invention further relates to a jet pump (28) having a metering valve (36) and to the use of a method for switching off a fuel cell system (10).

Owner:ROBERT BOSCH GMBH

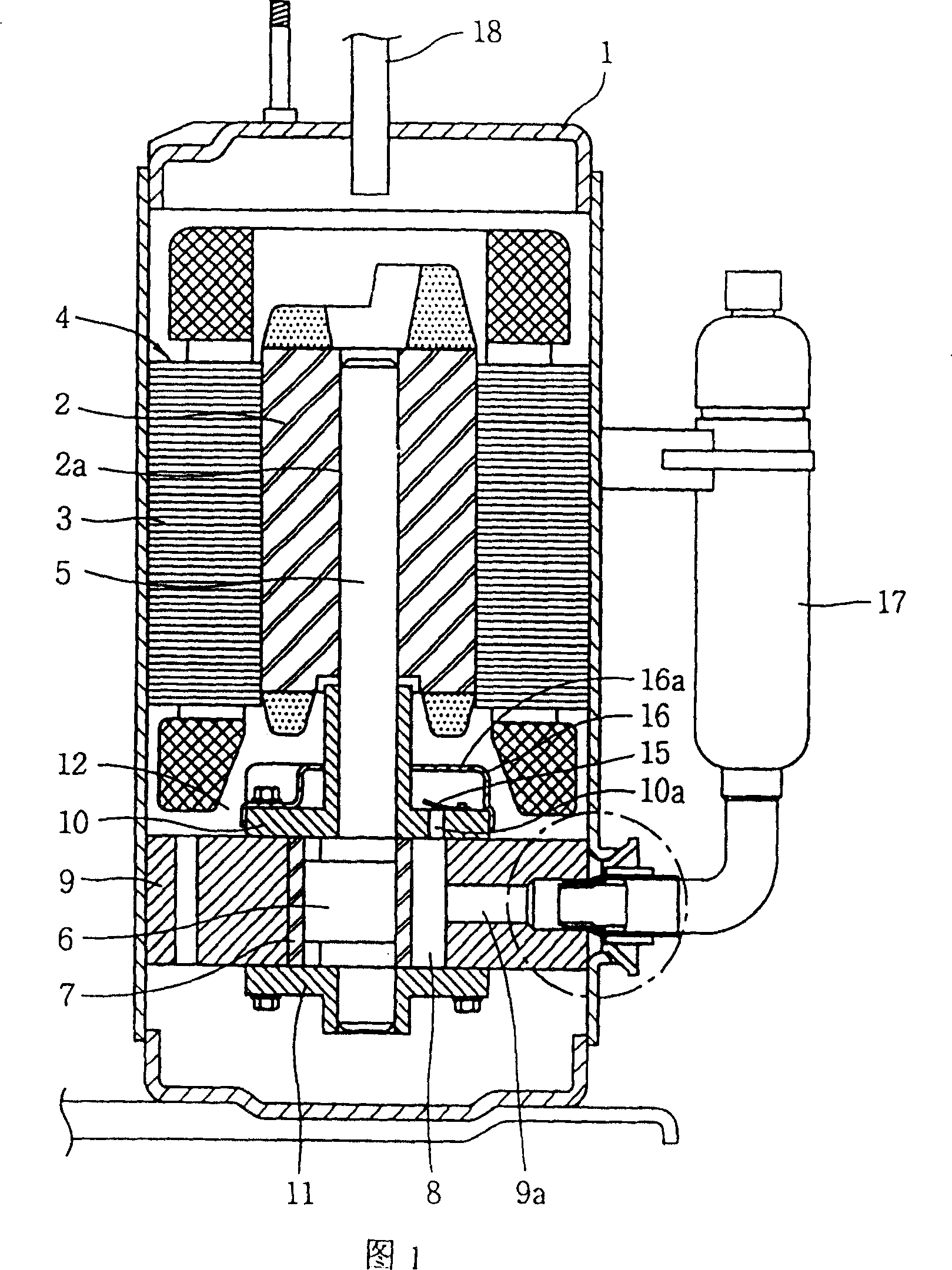

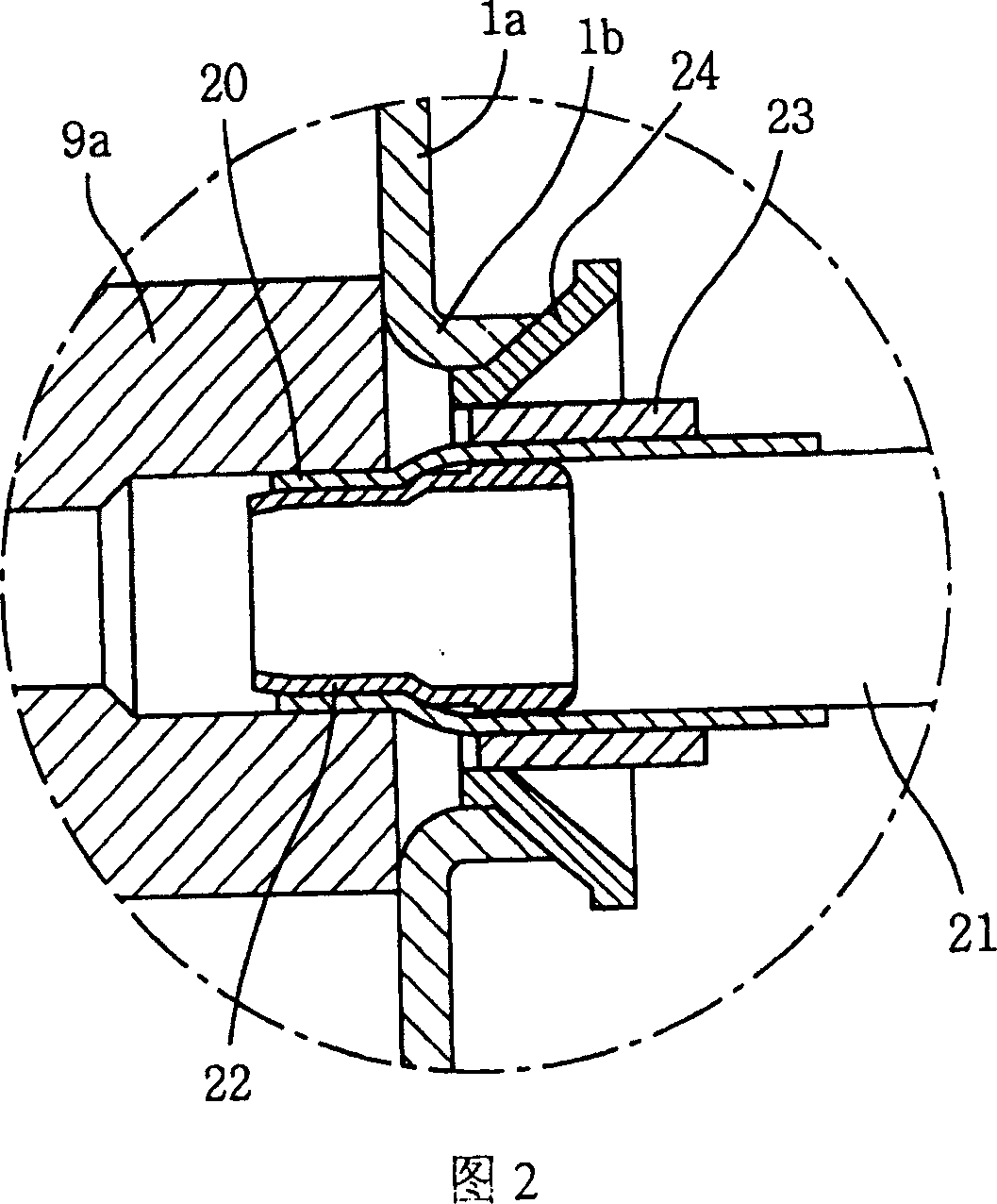

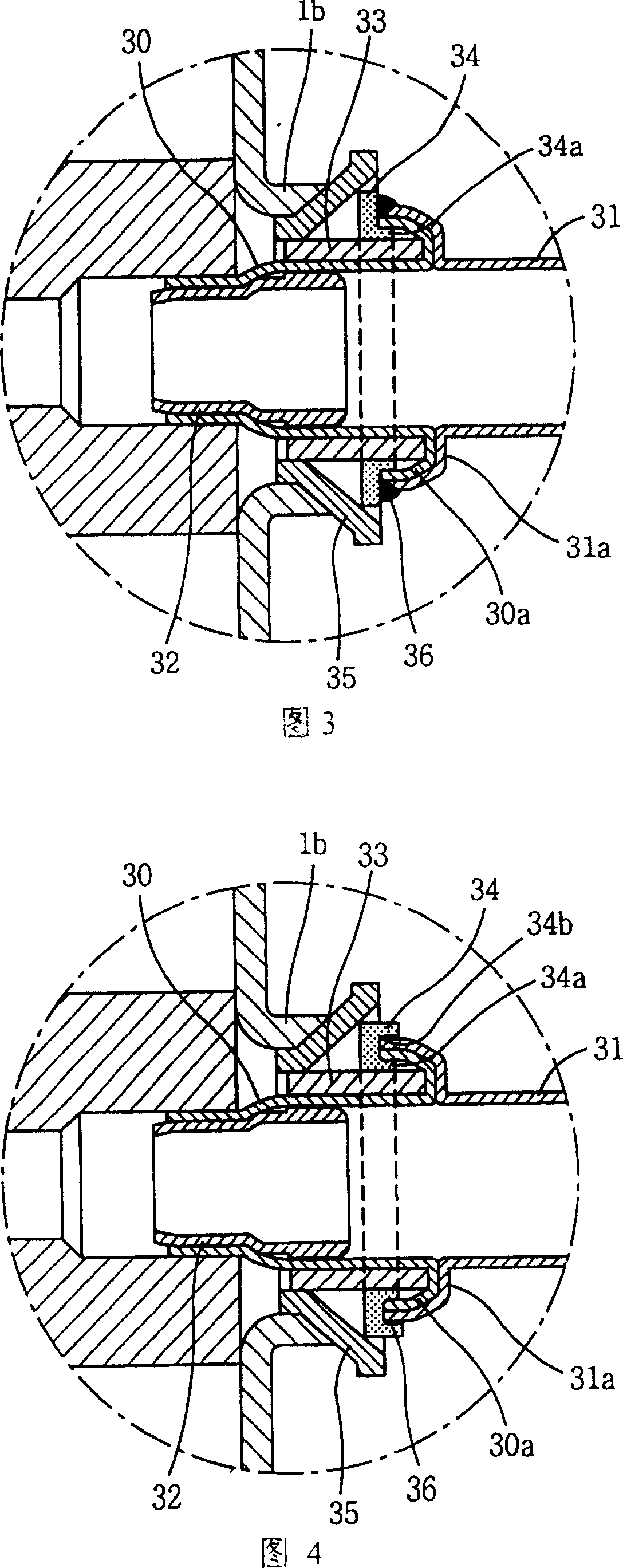

Air suction connecting apparatus for closed rotary compressor

InactiveCN100371602CEasy to operateImprove performanceRotary/oscillating piston pump componentsLiquid fuel engine componentsVapor–liquid separatorThermal deformation

The present invention discloses gas sucking pipe connecting unit of sealed rotary compressor, and belongs to the field of compressor structure. The present invention includes pressing annular inlet pipe into the inlet of the cylinder, pressing the outside of the inlet pipe into outside of the sucking pipe and welding the inside of the canal of liquid storage to the outside of the inlet pipe. The present invention can prevent the surface of the cylinder and the rotor inside the compressor from becoming uneven during the welding and ensure the smooth running of the compressor. Said method can minimize the thermal deformation during welding. Therefore, the present invention can raise the performance and quality of sealed rotary compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

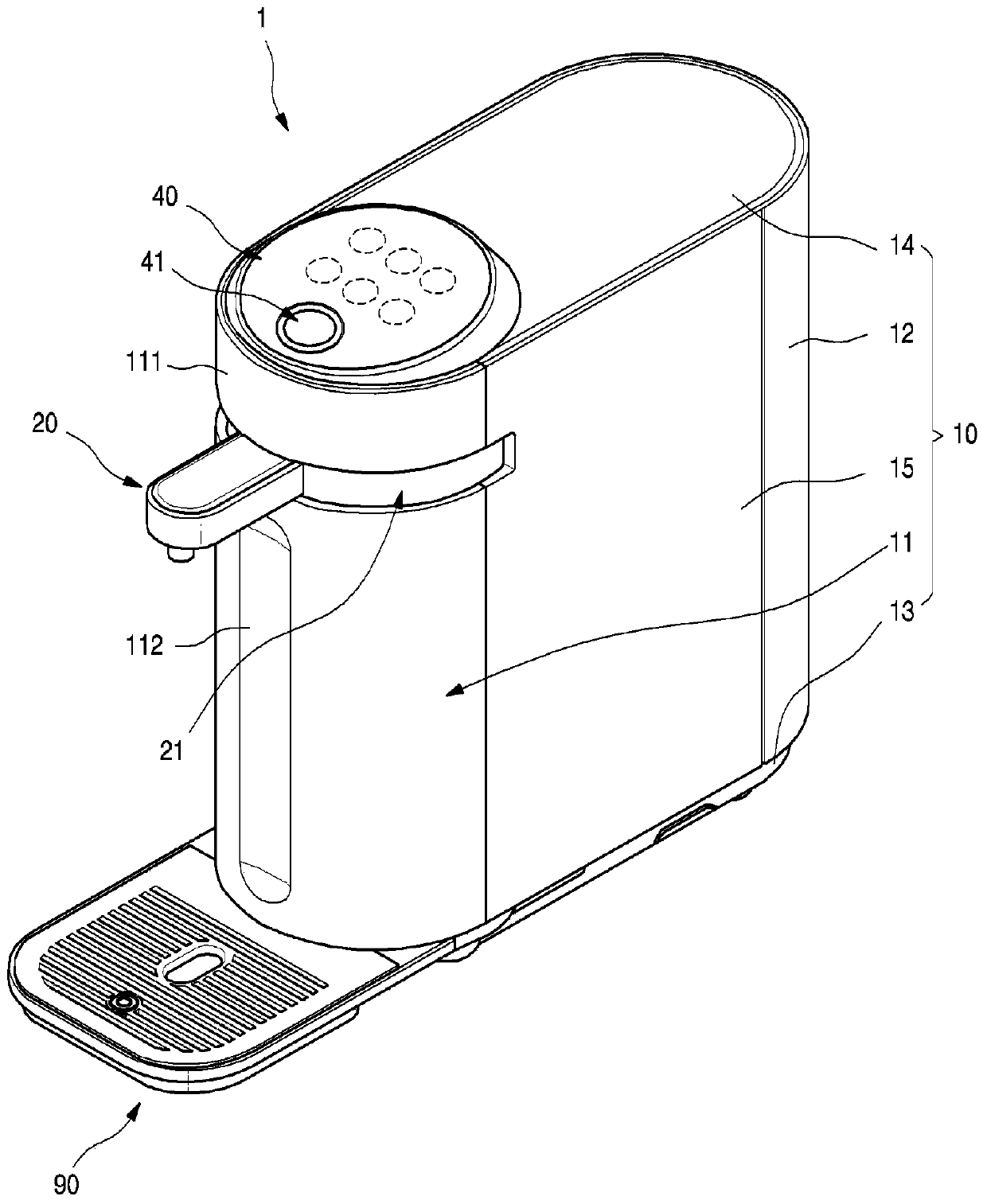

Water Purifier

ActiveCN106963241BImprove efficiencyIncrease productivityWater treatment parameter controlEvaporation with vapour compressionEngineeringFilter holder

The present invention provides a water purifier, the water purifier according to the embodiment of the present invention, which includes: a shell, used to form a shape; a filter bracket, arranged inside the shell, and equipped with a filter and a valve; a condenser The bracket is arranged inside the casing spaced from the filter bracket, and the condenser is accommodated in the condenser bracket; the cooling box is arranged at the upper end of the condenser bracket for cooling the water purified by the filter The support plate is connected between the filter bracket and the cooling box, and the space between the filter bracket and the cooling box is divided up and down; the compressor is arranged on the support plate below; and a control assembly mounted on the support plate.

Owner:LG ELECTRONICS INC

Structure for preventing tile from being separated from tile base

PendingCN114412916AAvoid pressure risesReduce direct impactShaftsSliding contact bearingsEngineeringStructural engineering

The invention relates to a structure for preventing a tile from being separated from a tile base, a first limiting step (14) and a second limiting step (15) are arranged on two sides of the tile base (2), the tile (1) is positioned on the bottom surface of the tile base (2) and in a space formed by the first limiting step (14) and the second limiting step (15), and an axial mounting gap (13) exists between the tile (1) and the first limiting step (14) of the tile base (2). An axial mounting gap (16) is formed between the tile block (1) and the first limiting step (15) of the tile base (2); the baffle (3) is fixed on the side surface (6) of the tile base (2) through the mounting hole (4), and a radial gap (12) is formed between the baffle (3) and the tile base (2); the baffle (3) is provided with a cooling water collecting groove (10), and the collecting groove (10) is provided with a plurality of through-flow pressure relief holes (5). By applying the fluid dynamics principle, the tile blocks can be effectively prevented from being separated from the tile bases under fluid impact, upwarp of the incident flow sides of the tile blocks is prevented, impact with a rotating thrust disc is avoided, and safe operation of a nuclear main pump is ensured.

Owner:HARBIN ELECTRIC POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com