Patents

Literature

132results about How to "Does not impede flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

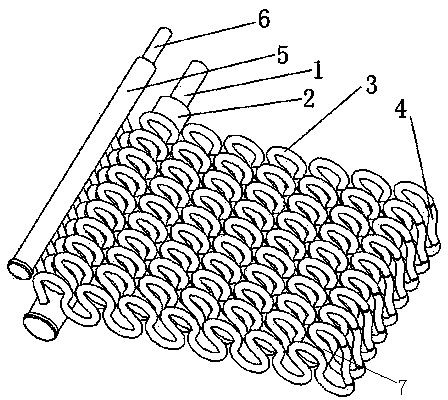

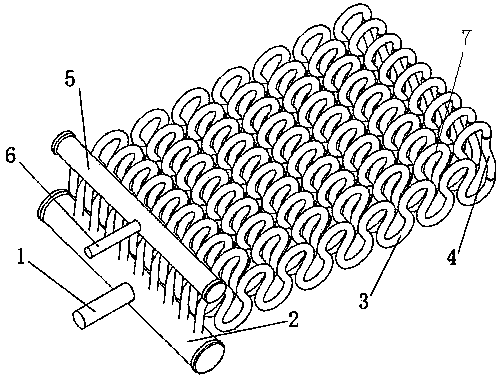

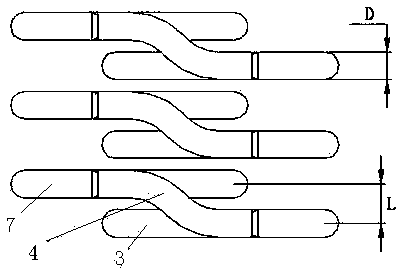

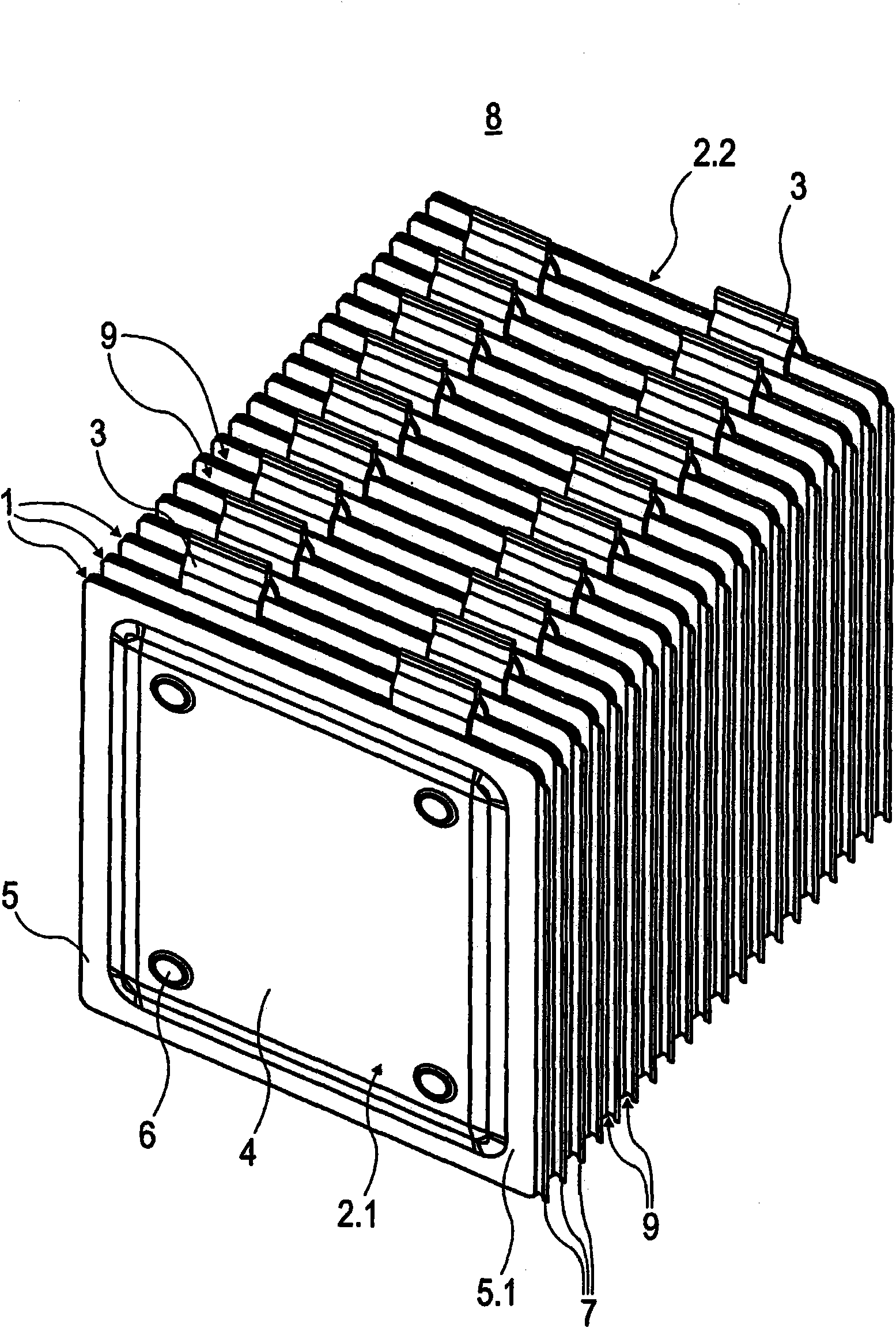

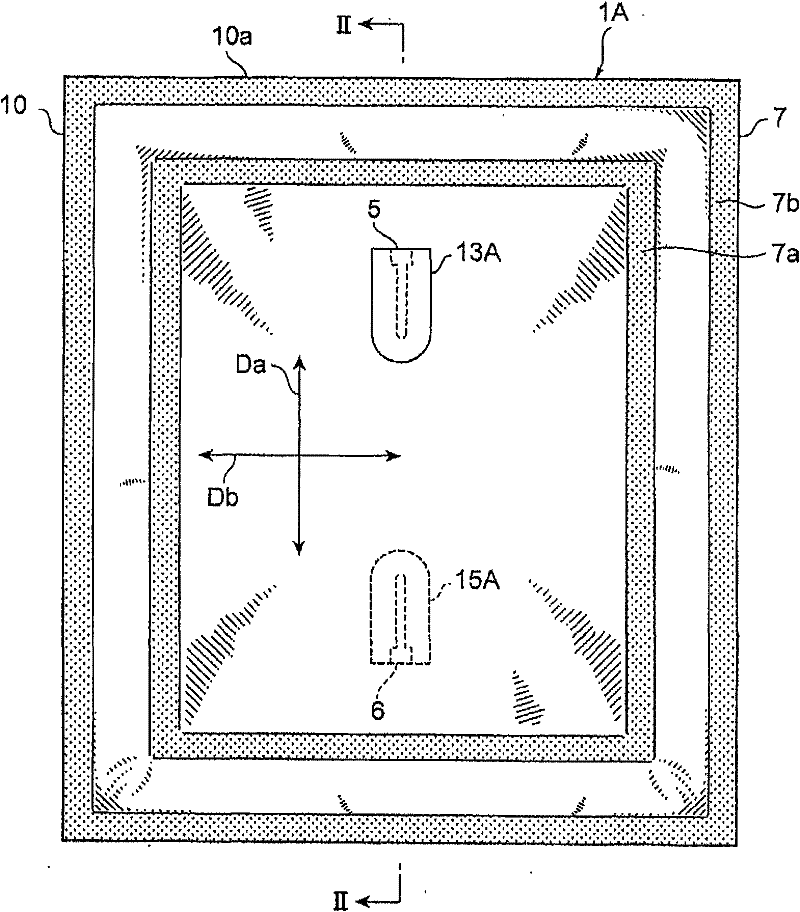

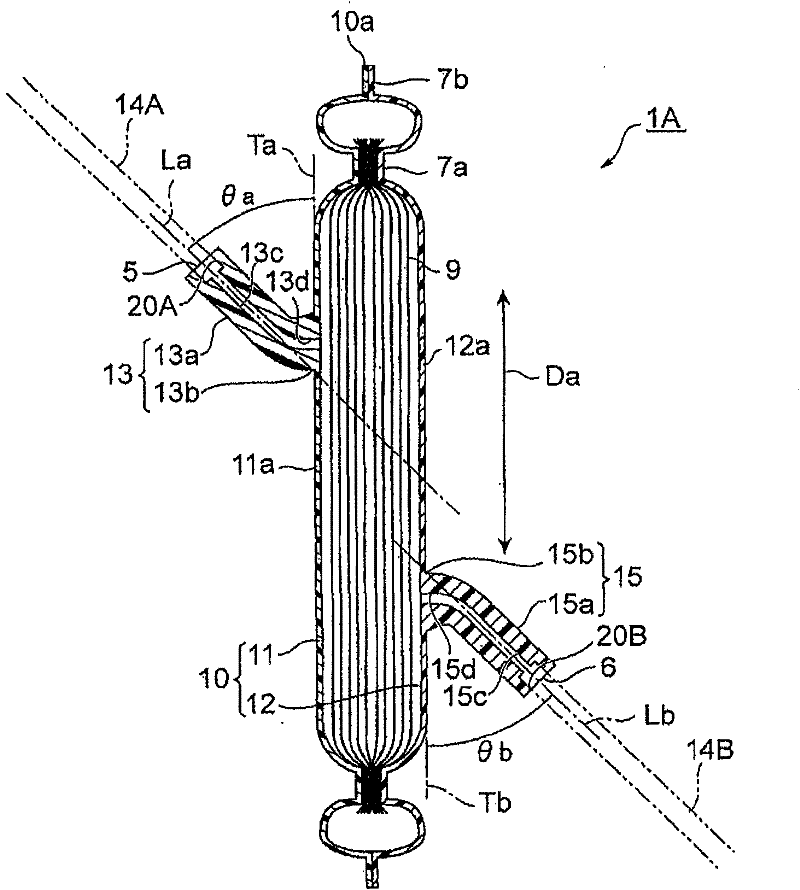

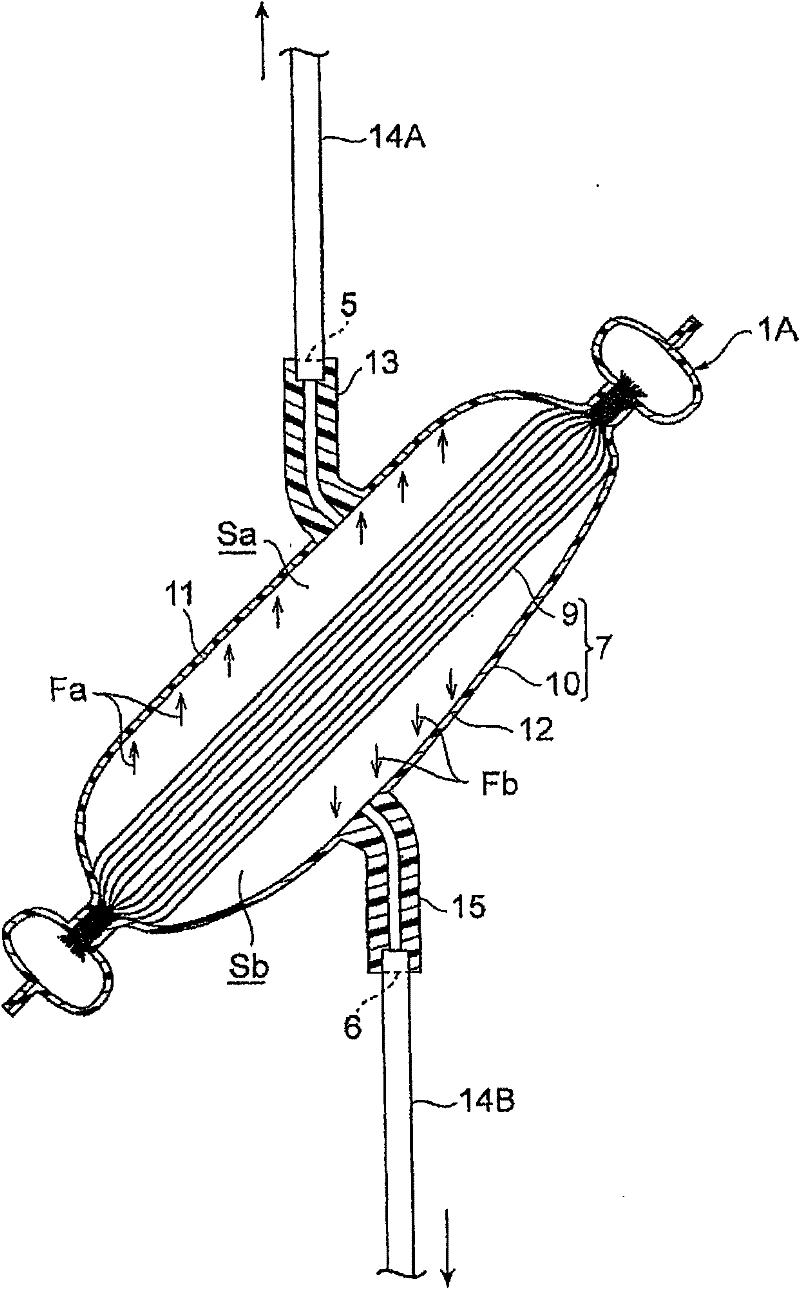

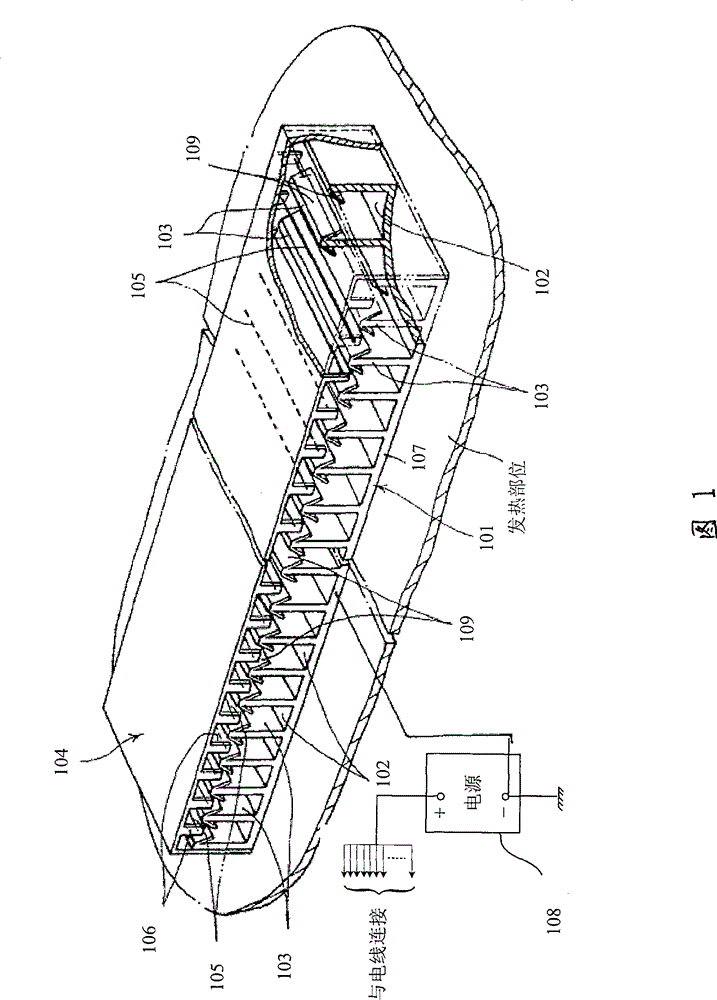

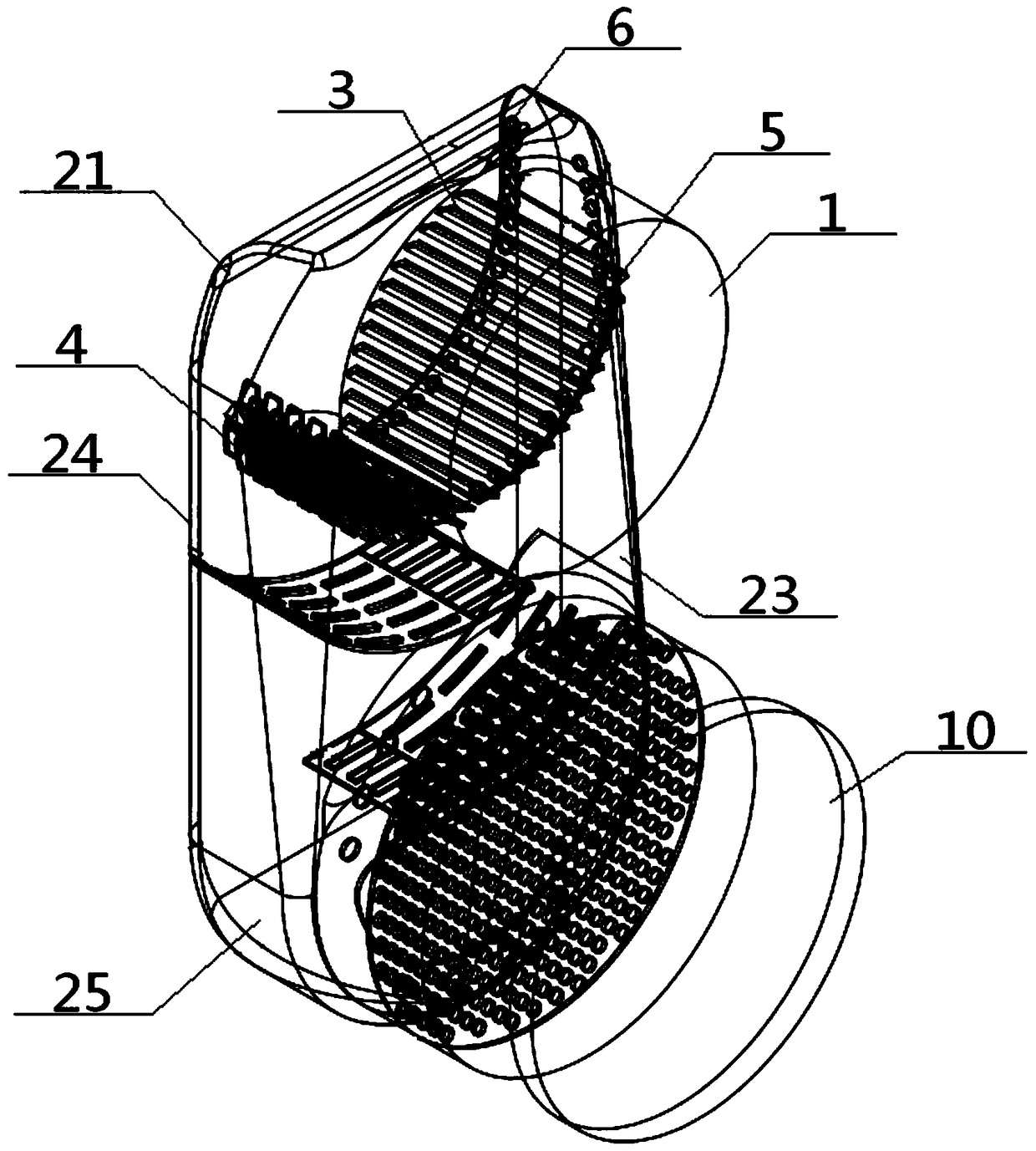

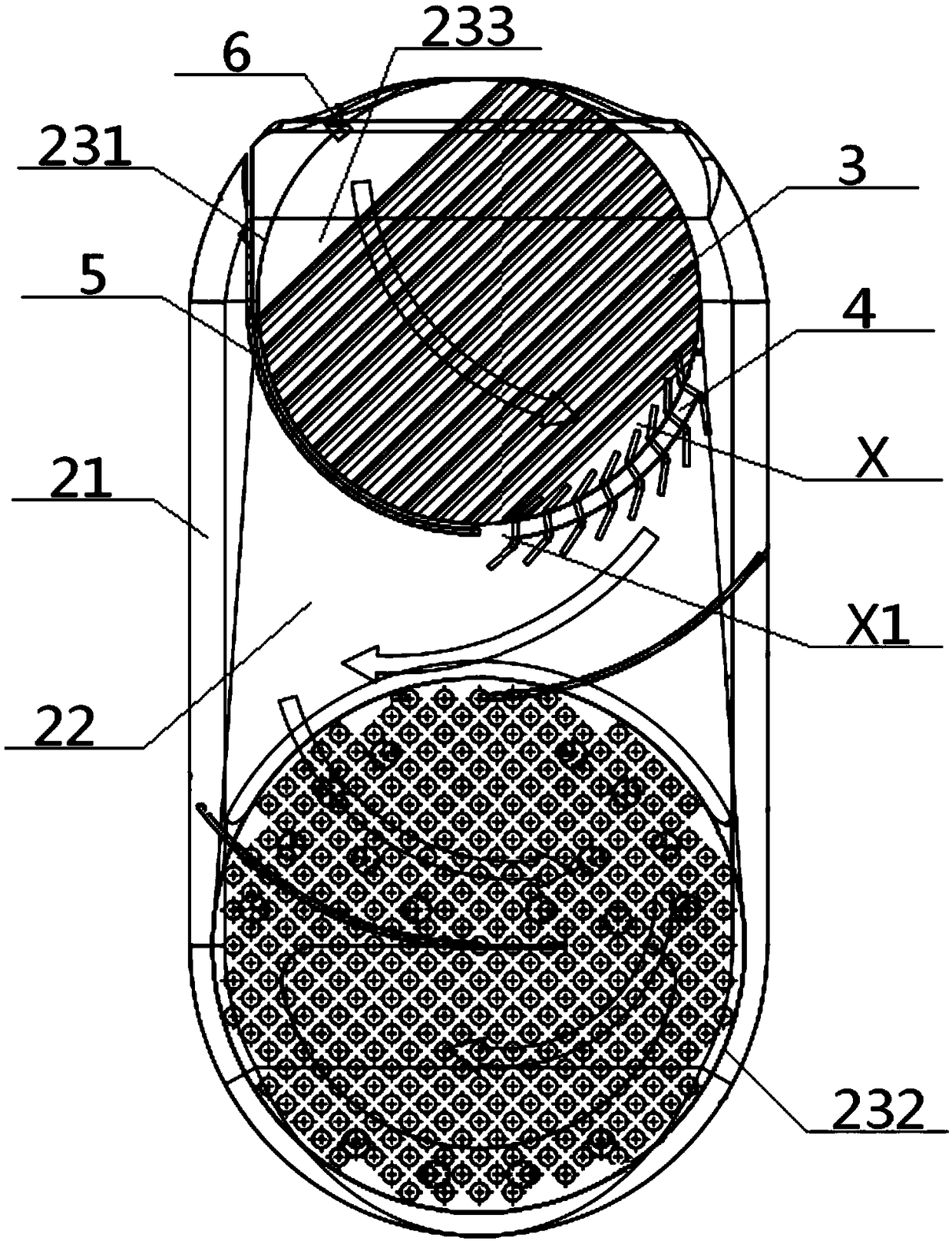

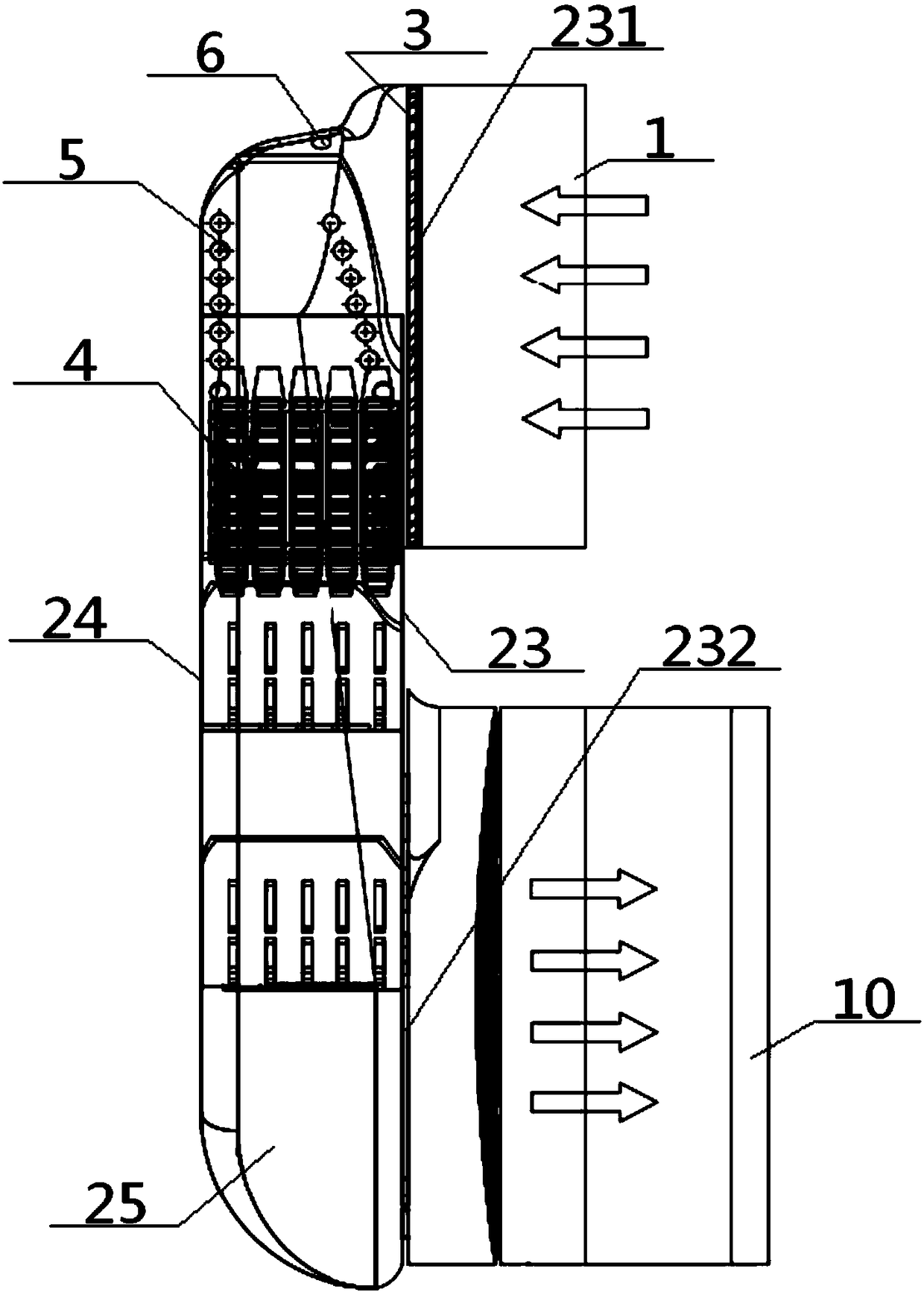

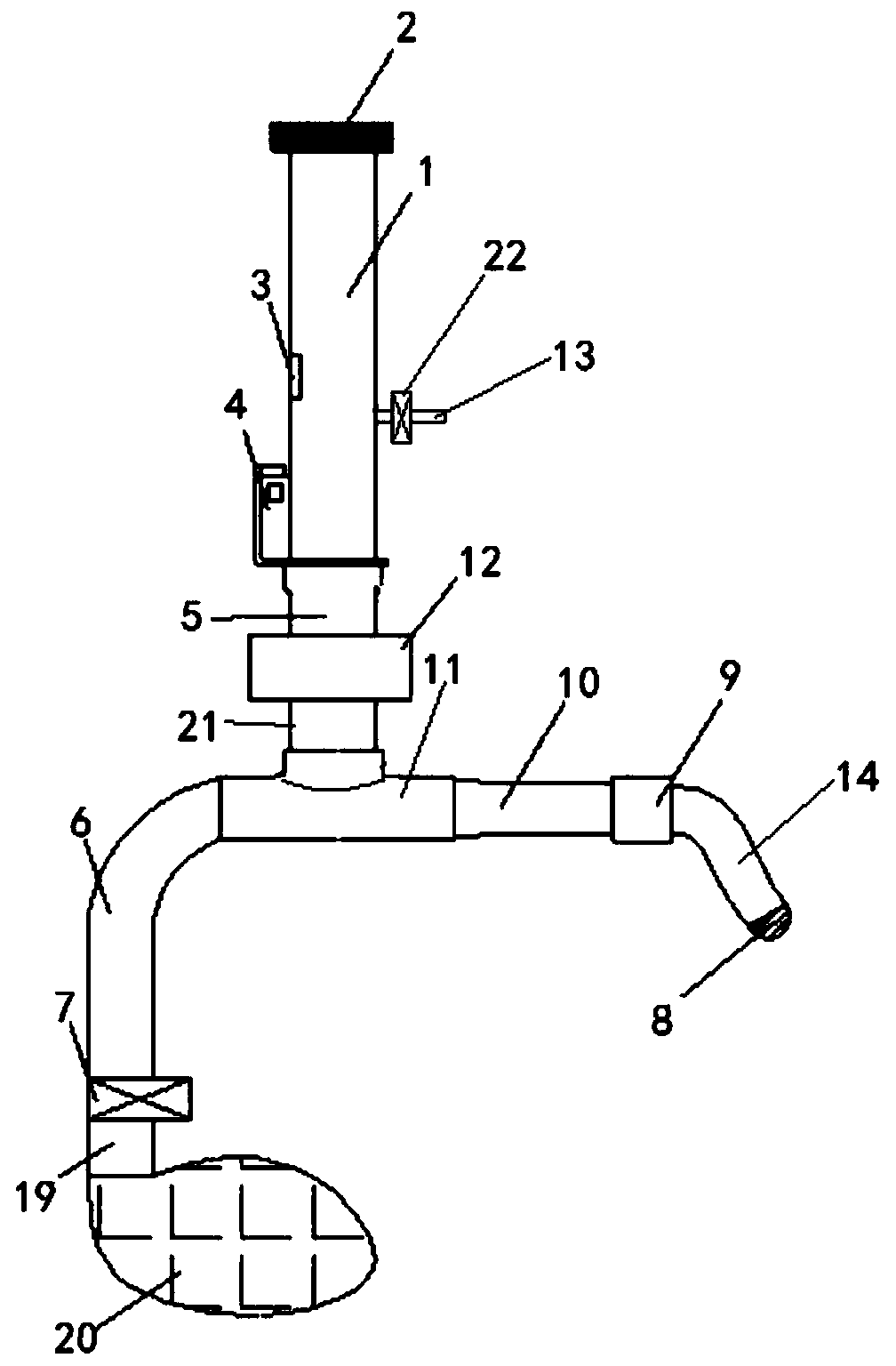

Efficient heat exchange tube and evaporative condenser

ActiveCN103808185AEvenly distributedReduce resistanceEvaporators/condensersTubular elementsGas collecting tubeCondenser (heat transfer)

The invention discloses an efficient heat exchange tube. The efficient heat exchange tube comprises a gas collecting tube and a liquid collecting tube. A plurality of heat exchange tube units are communicated between the gas collecting tube and the liquid collecting tube. Each heat exchange tube unit comprises a first heat exchange tube, a second heat exchange tube and a corner elbow. The inlets of the first heat exchange tubes are communicated with the gas collecting tube. The outlets of the second heat exchange tubes are communicated with the liquid collecting tube. The second heat exchange tubes are vertically layered and arranged in a staggered mode relative to the first heat exchange tubes. The corner elbows are arranged between the first heat exchange tubes and the second heat exchange tubes. The outlets of the first heat exchange tubes are communicated with the inlets of the second heat exchange tubes. The efficient heat exchange tube solves the problems that in the prior art, the heat exchange tubes of an evaporative condenser are low in inner side heat exchange coefficient and large in outer side wind resistance, and is good in heat conduction performance and small in tube diameter; the evaporative condenser is good in heat transfer performance, high in pressure resistance, compact in structure and small in occupied space.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

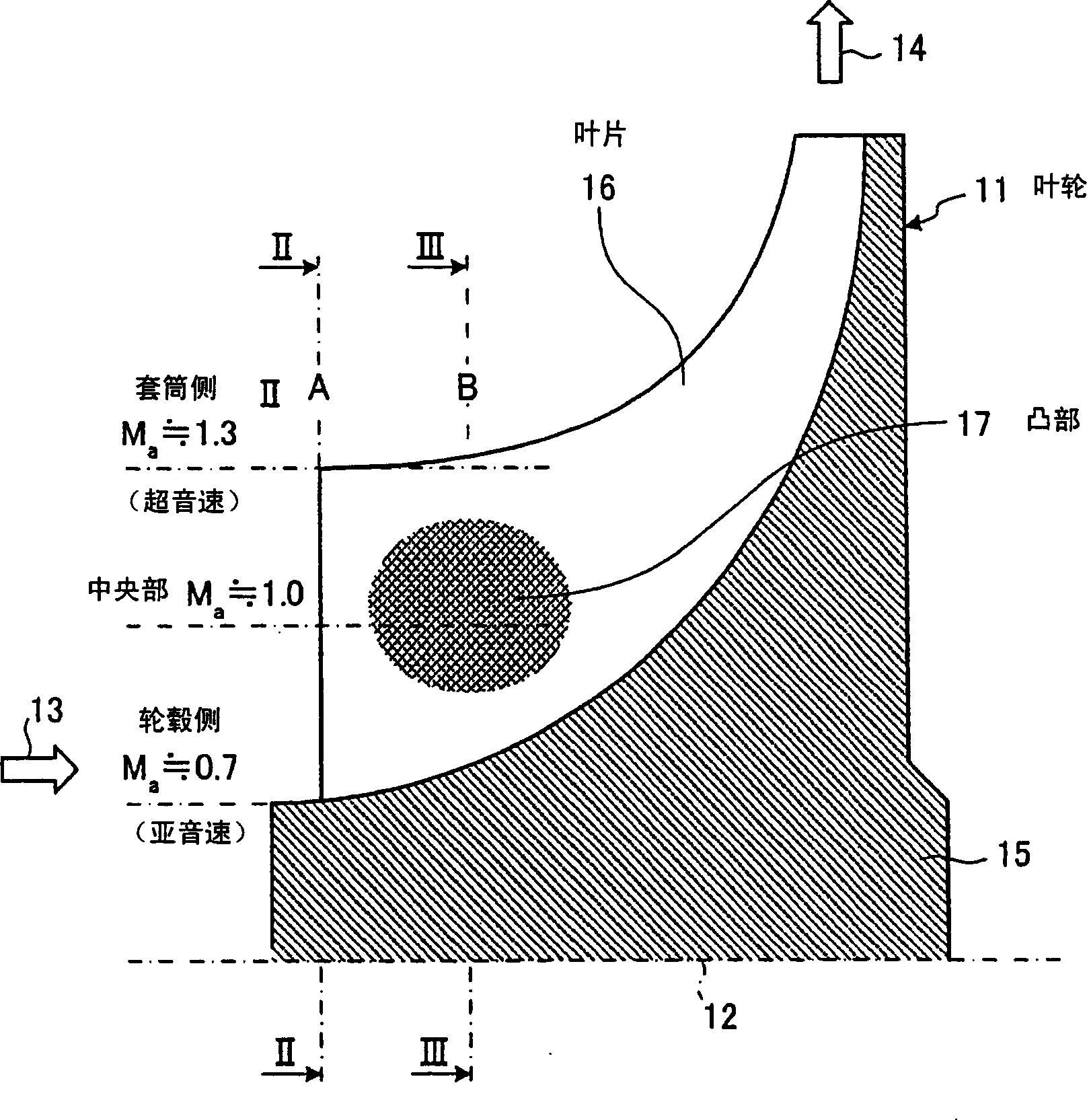

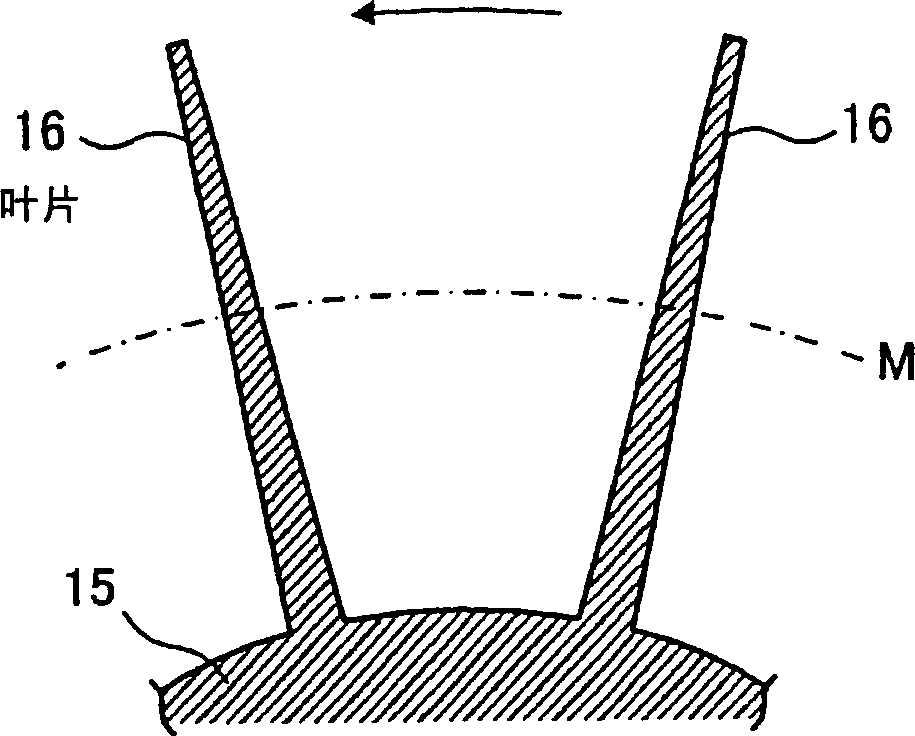

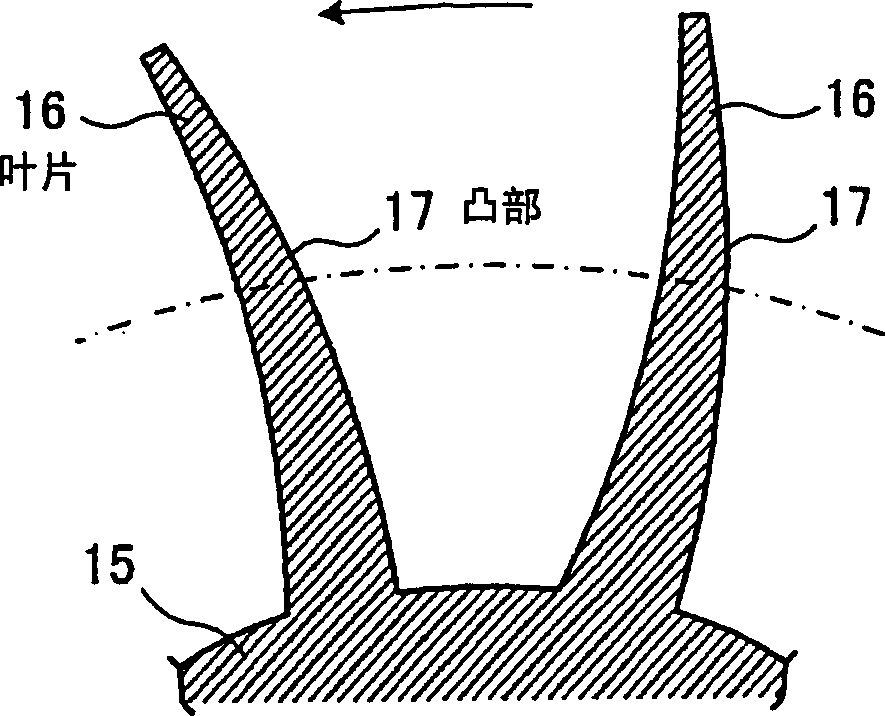

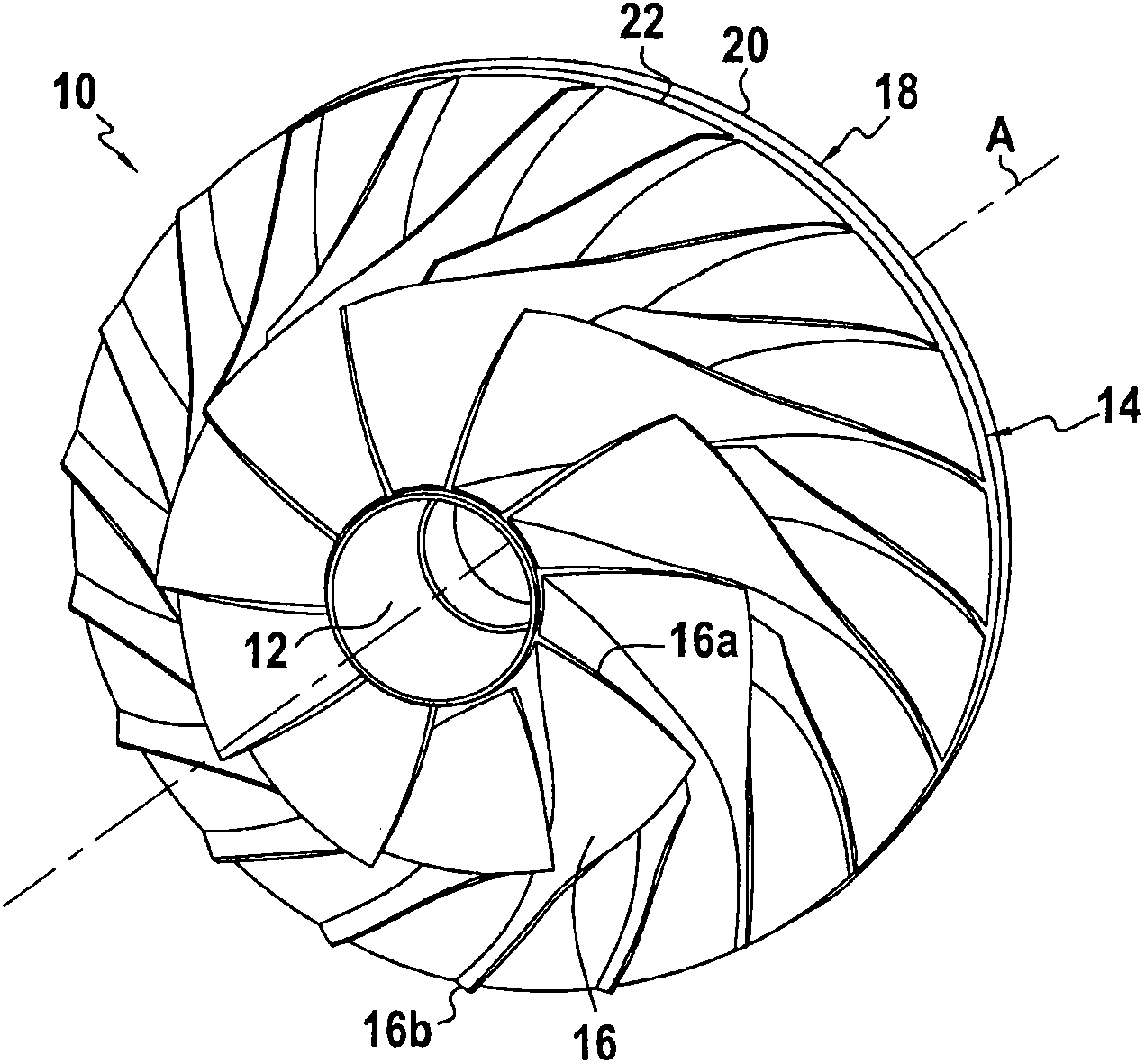

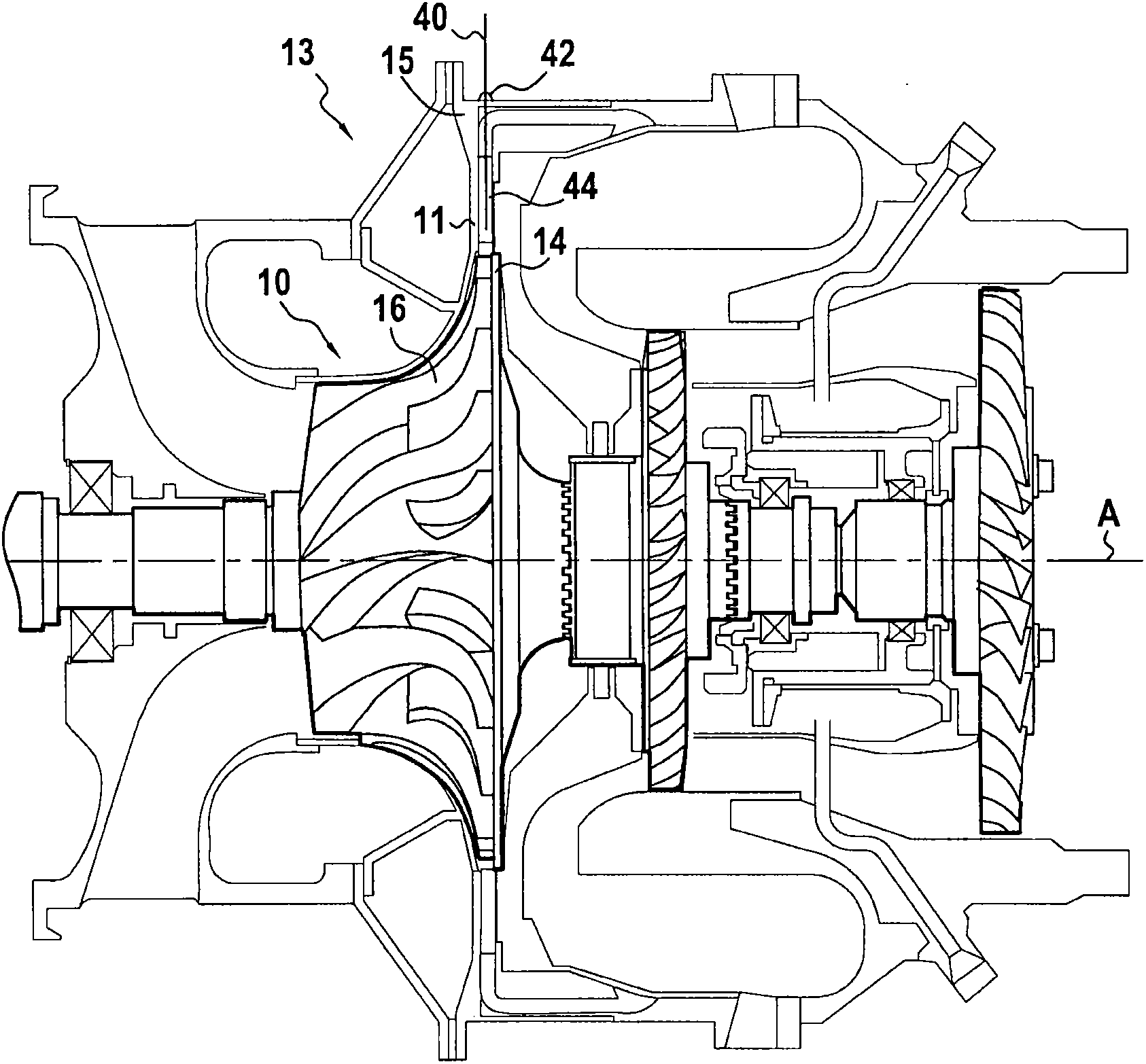

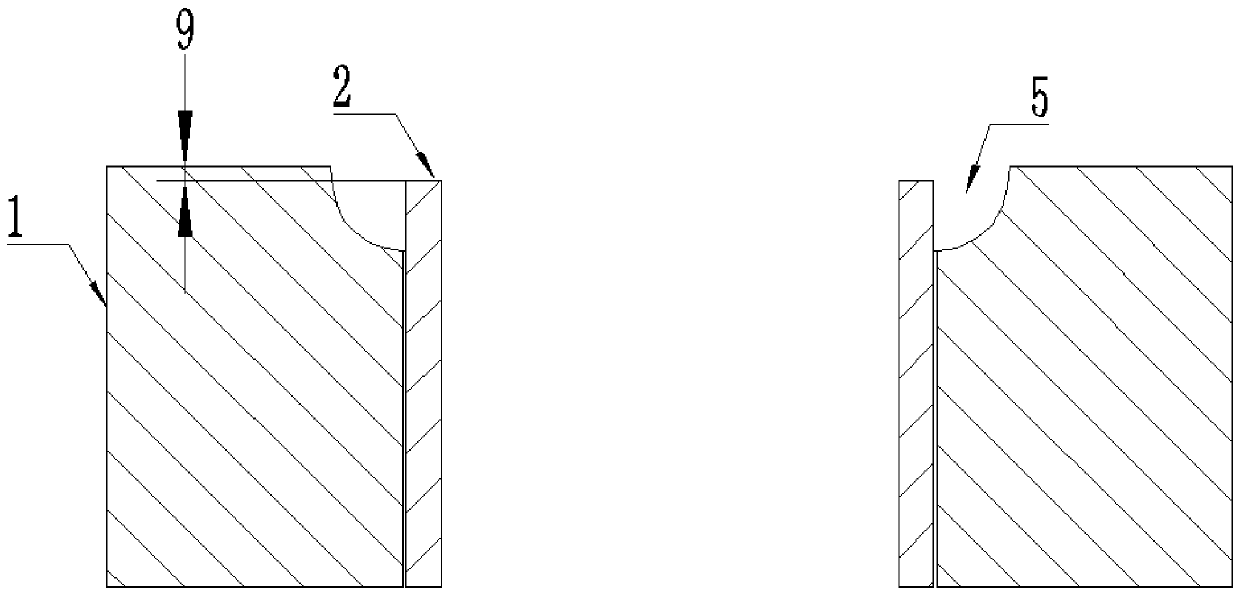

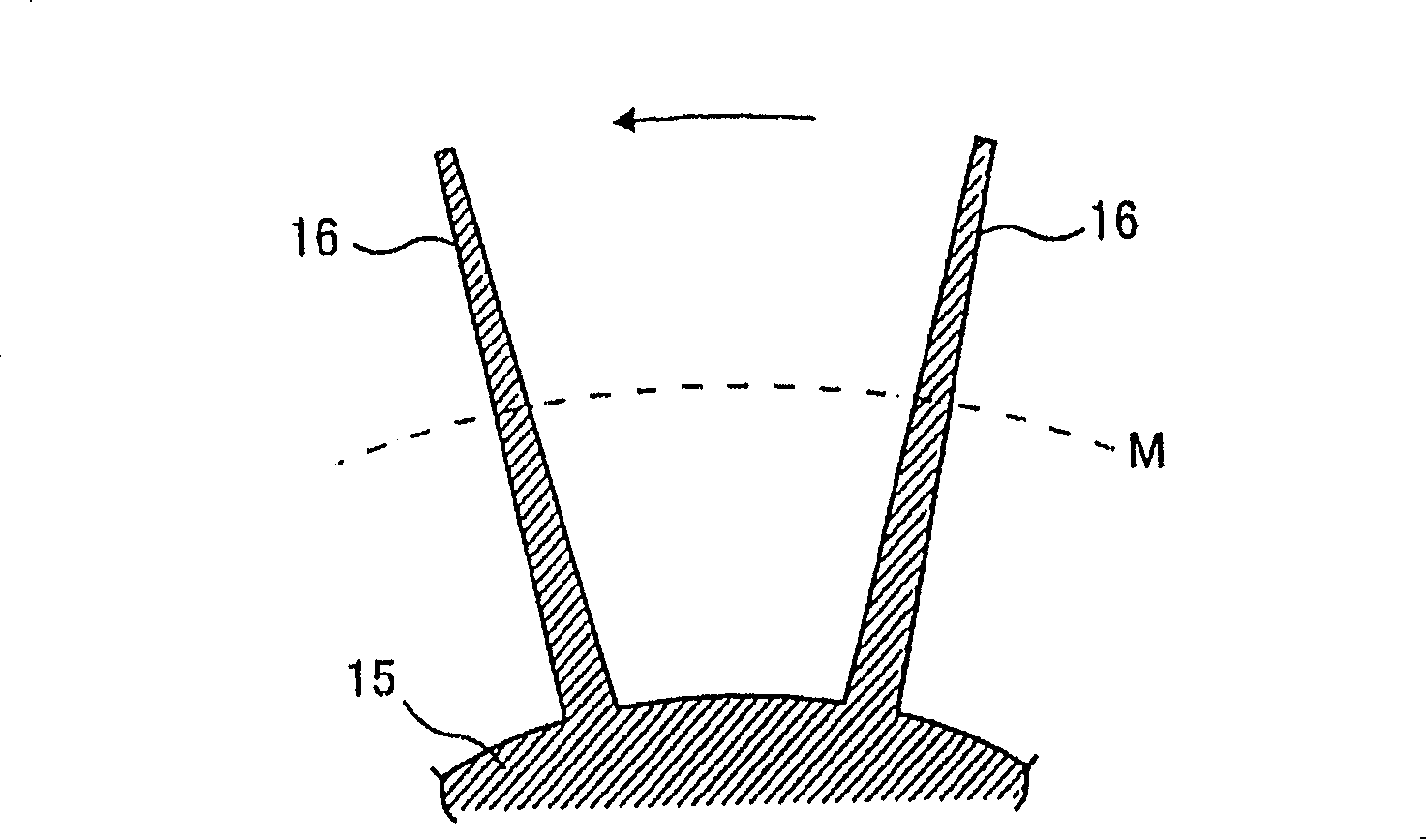

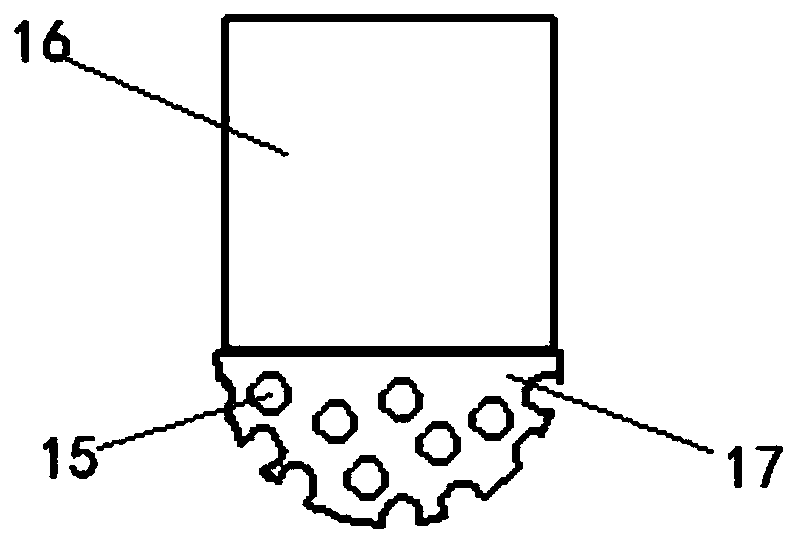

Centrifugal compressor and manufacturing method for impeller

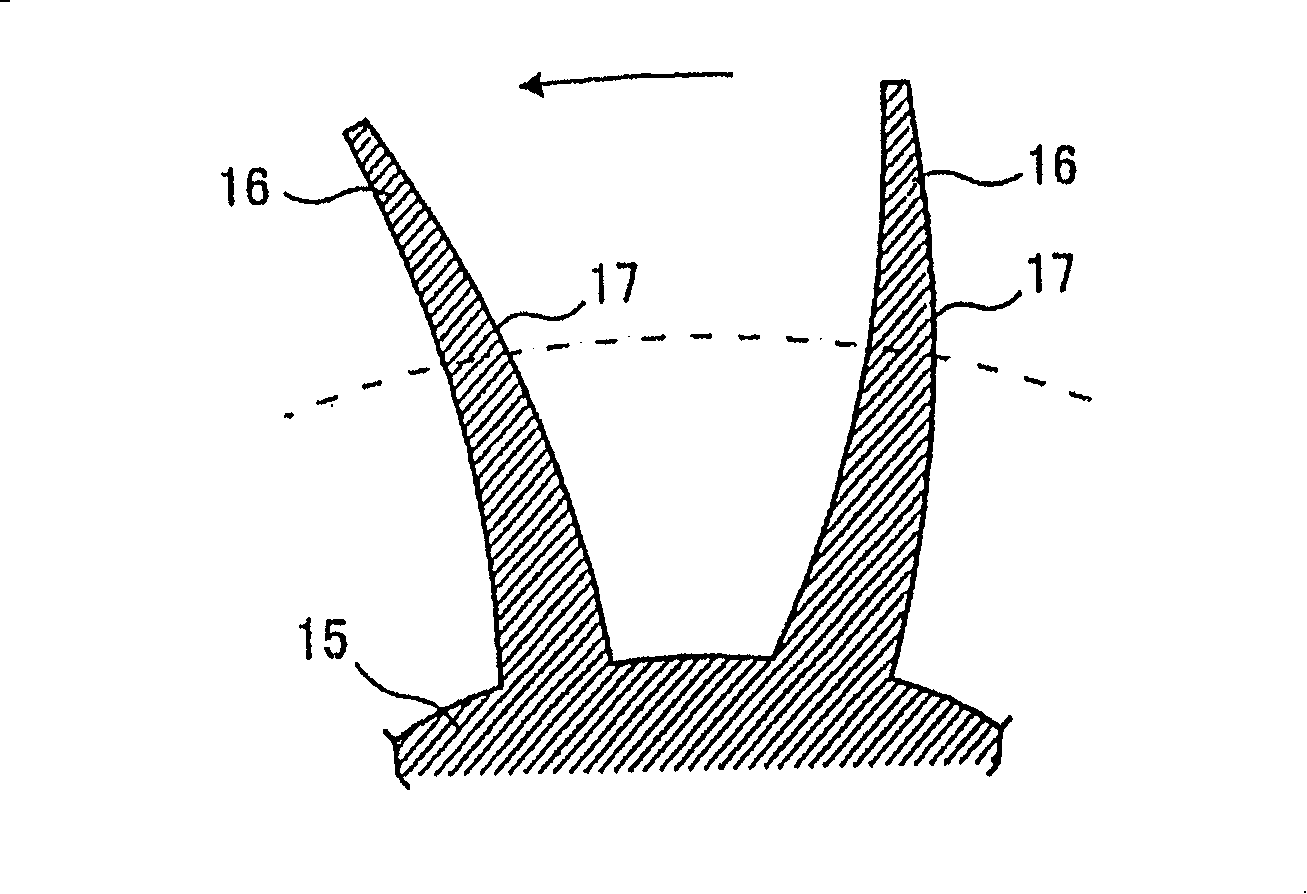

The invention provides a manufacturing method of a centrifugal compressor and an impeller. On the side of the negative pressure surface of the vane (16) of the impeller (11), a convex portion (17) is formed in a curved line from the front edge portion (A) to the slit portion (B) at approximately the central portion in the radial direction, and the convex portion ( 17) By forming it so as to form a curve from the slit portion (B) to the rear edge portion, it will be formed at the position where the relative inflow velocity of the fluid flowing to the impeller (11) reaches the Mach number Ma≒1 The convex part (17) can improve the operation efficiency and expand the adaptable flow range, and further realize the improvement of performance.

Owner:MITSUBISHI HEAVY IND LTD

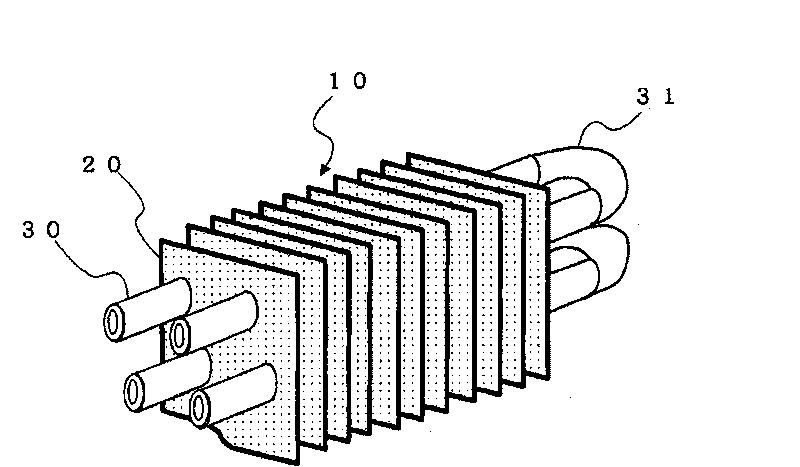

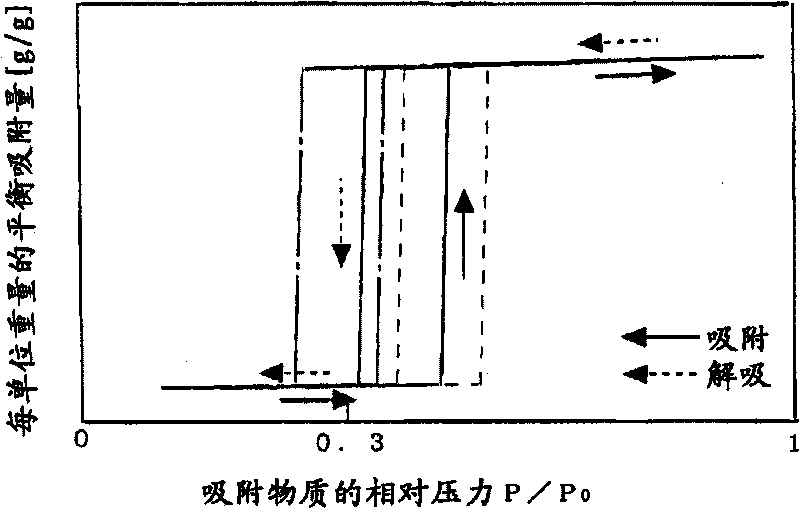

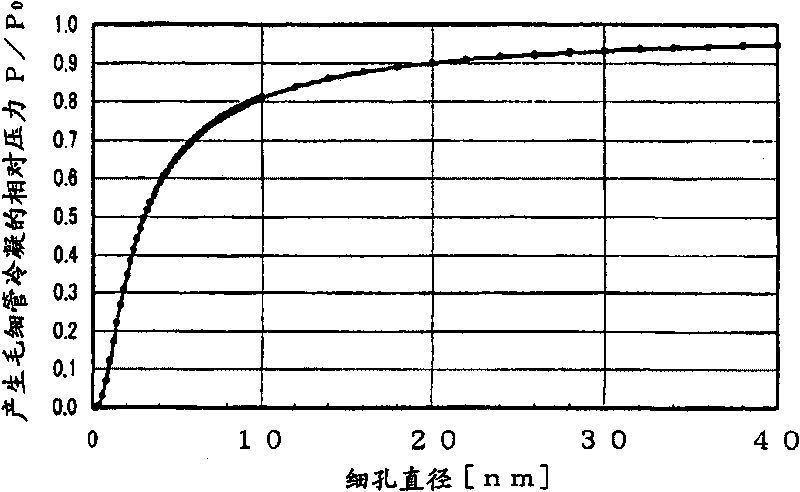

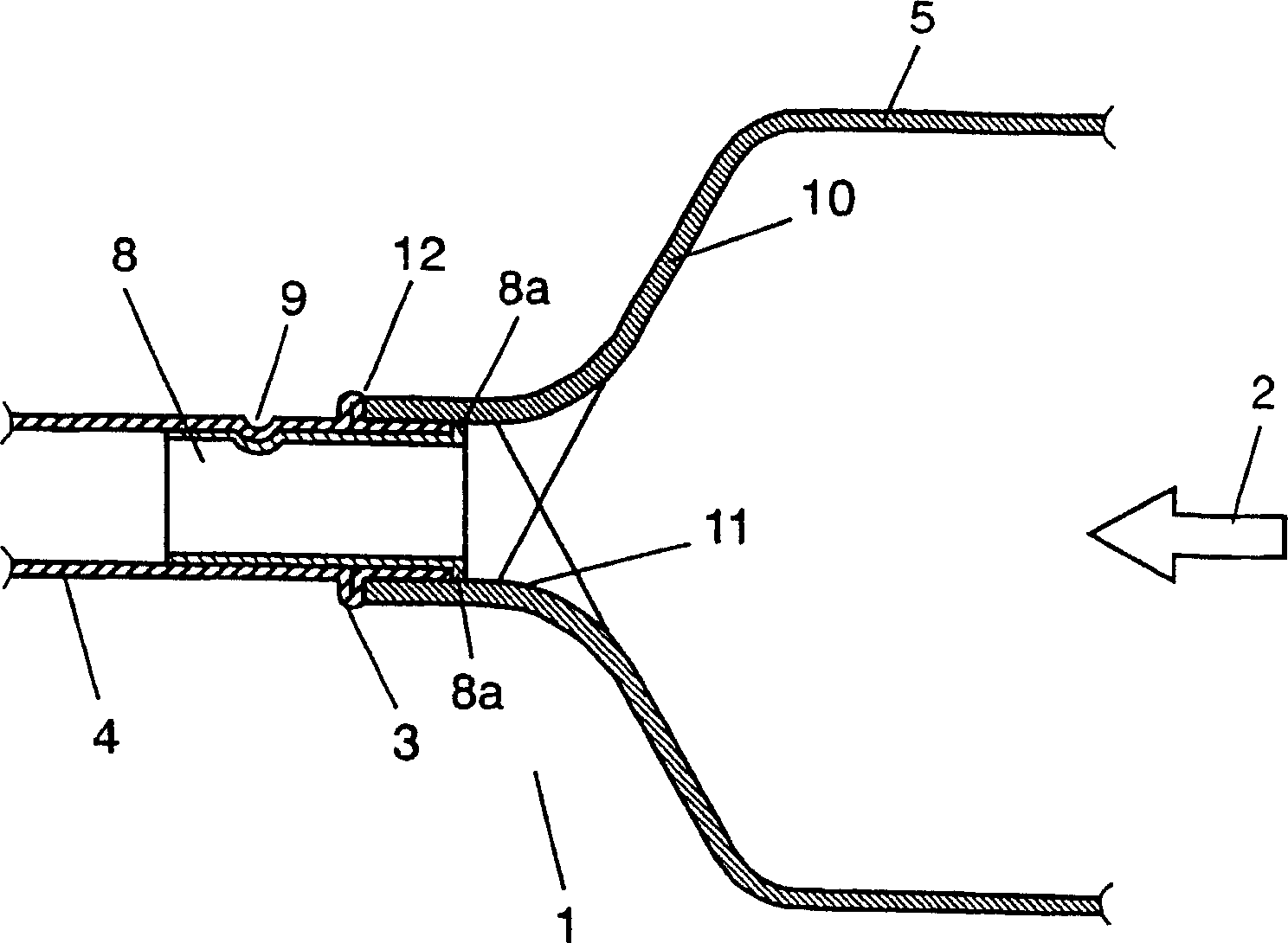

Heat exchanger, method of producing the heat exchanger

InactiveCN101765753AStrengthen security managementImprove adsorption capacityDispersed particle separationStationary conduit assembliesRelative pressureEngineering

Owner:MITSUBISHI ELECTRIC CORP

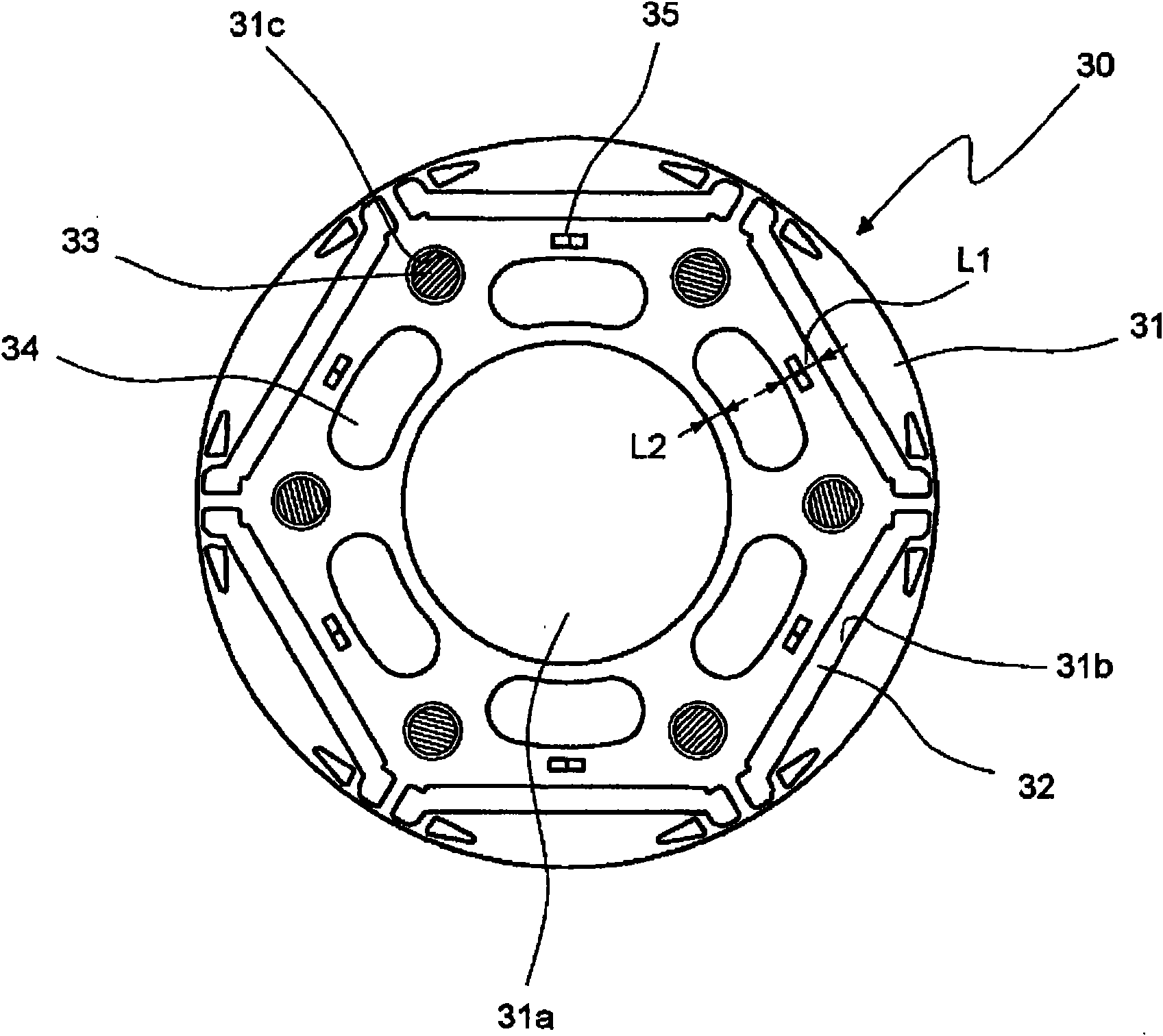

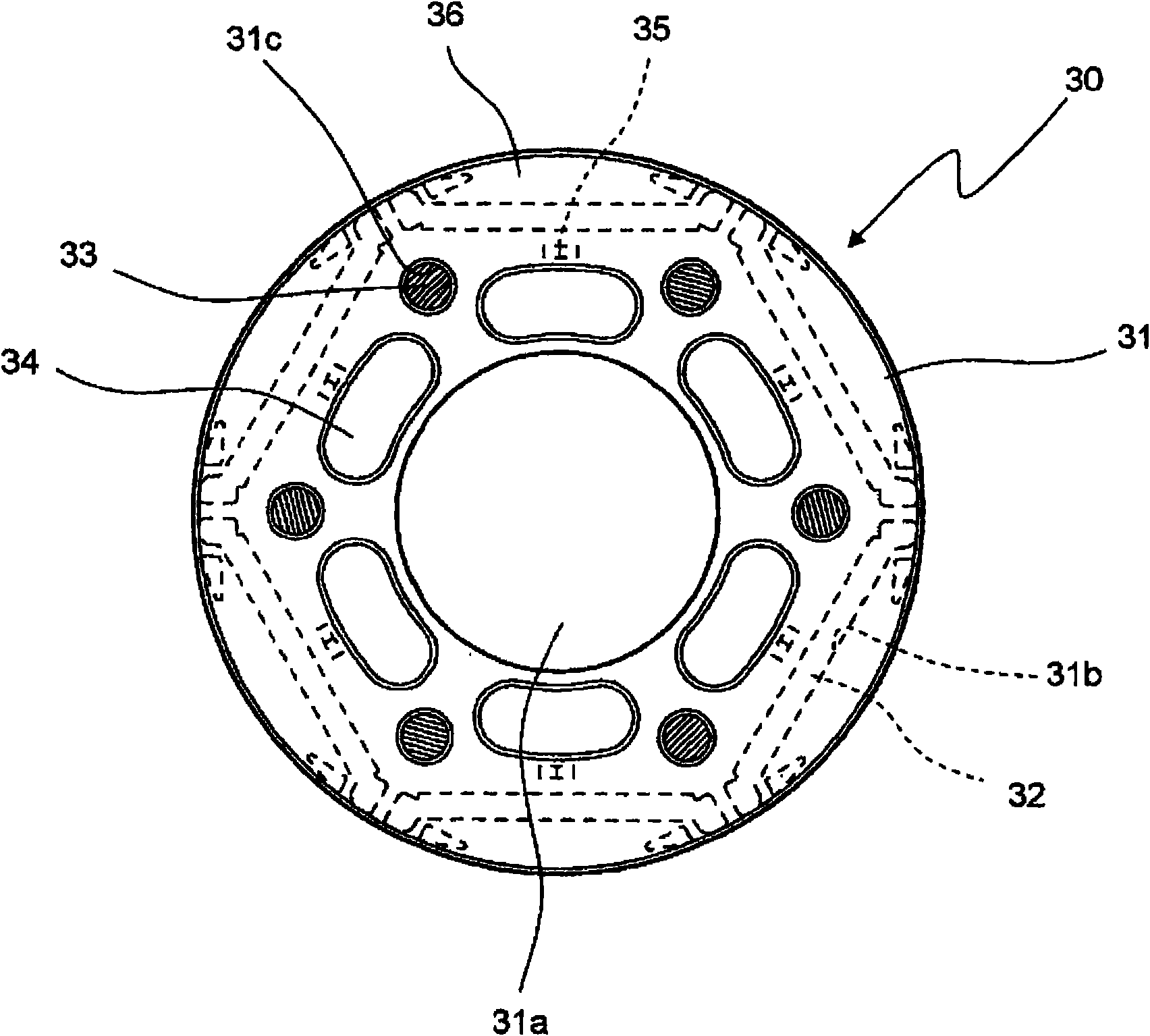

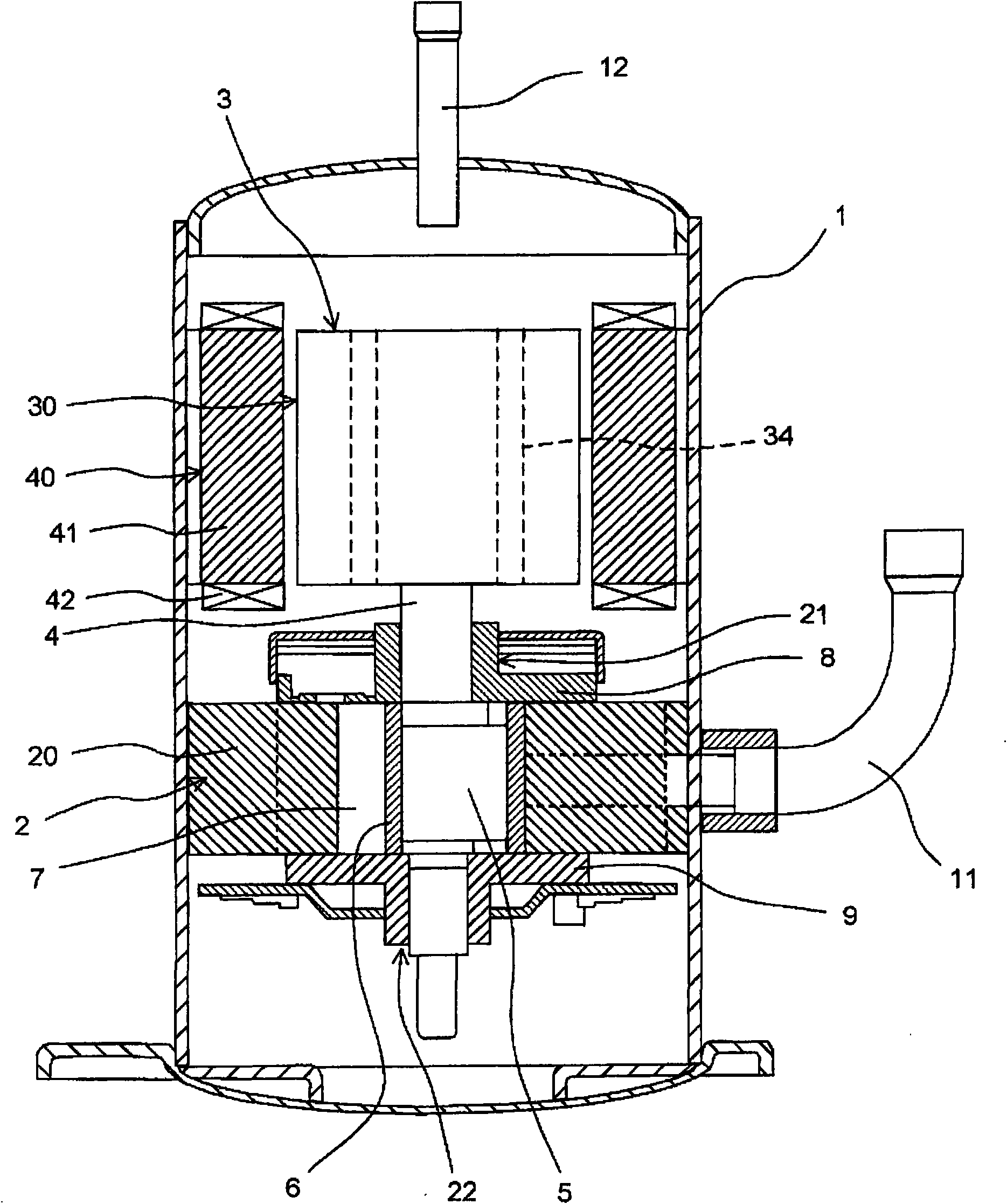

Motor, and compressor

ActiveCN101584099ADoes not impede flowEnsure the cross-sectional area of the flow pathRotary/oscillating piston combinations for elastic fluidsMagnetic circuit rotating partsEngineeringRivet

Owner:DAIKIN IND LTD

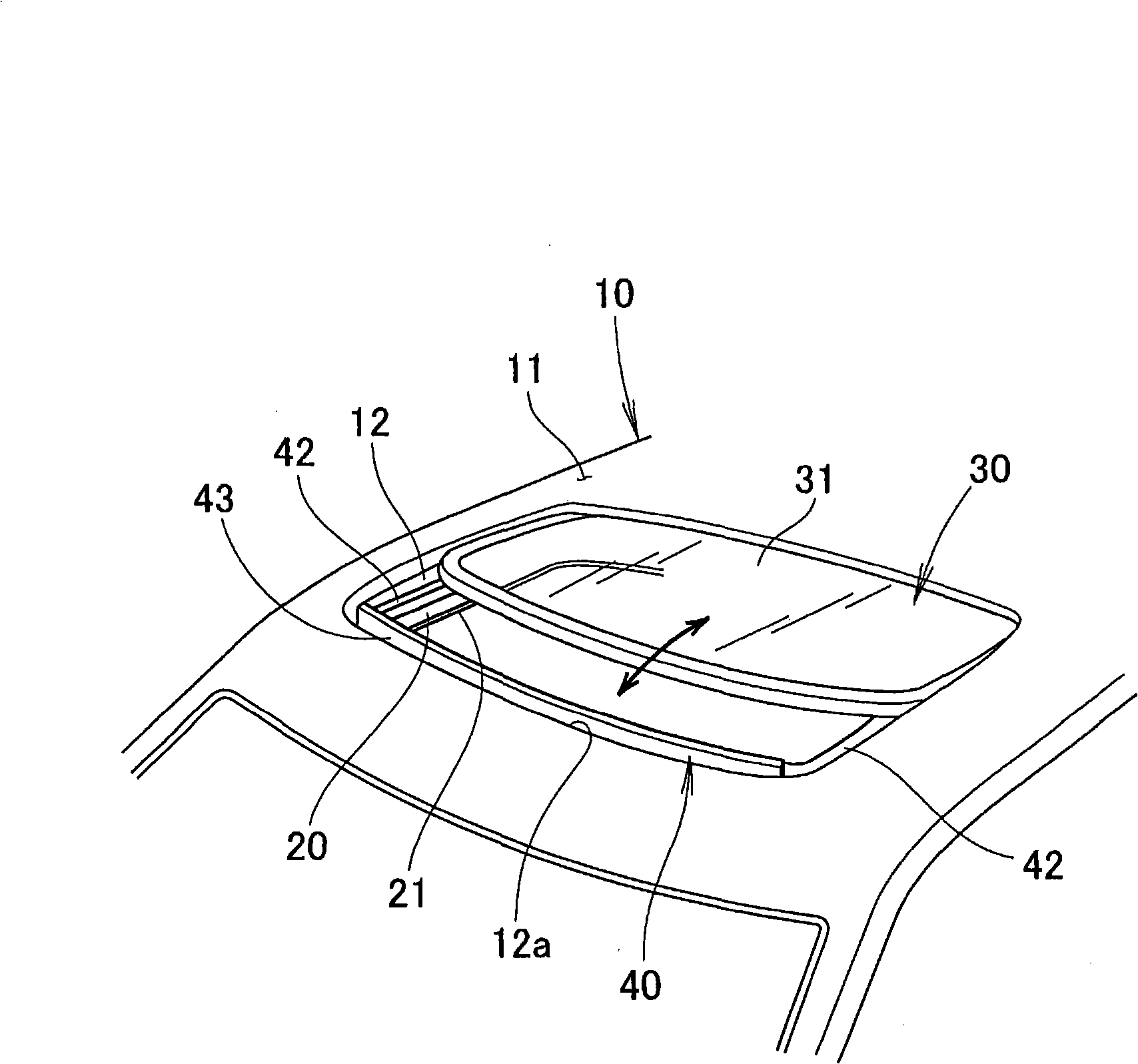

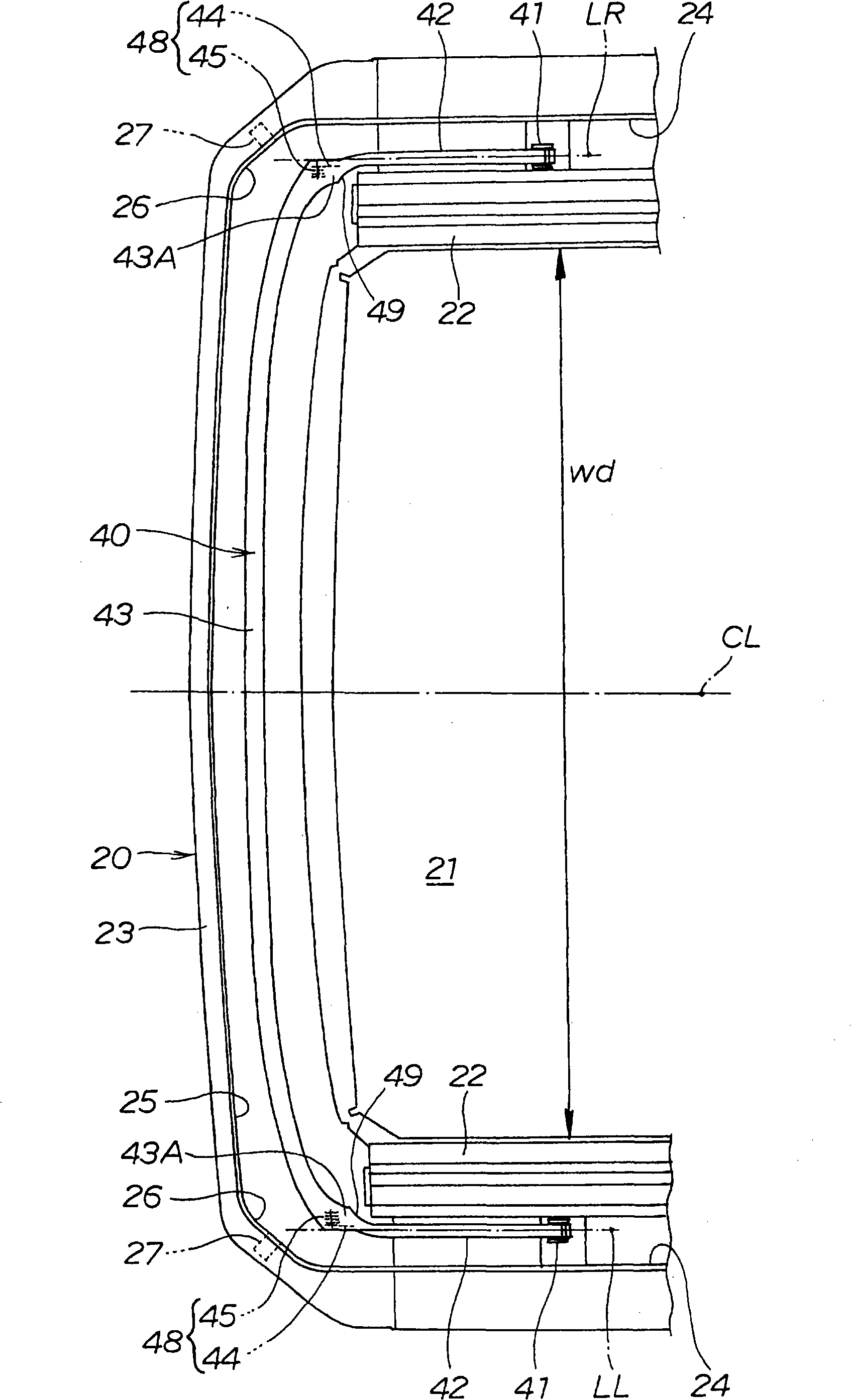

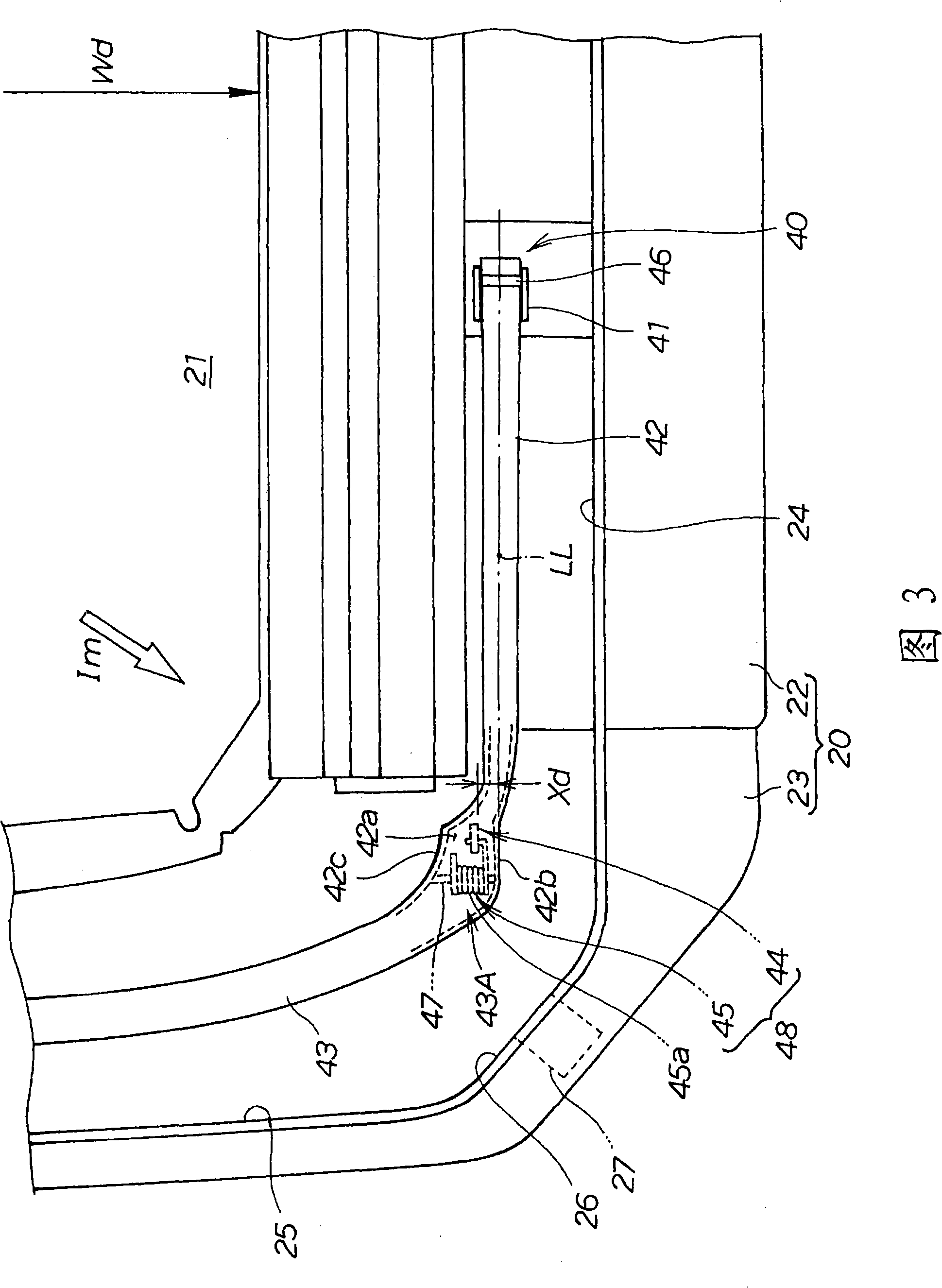

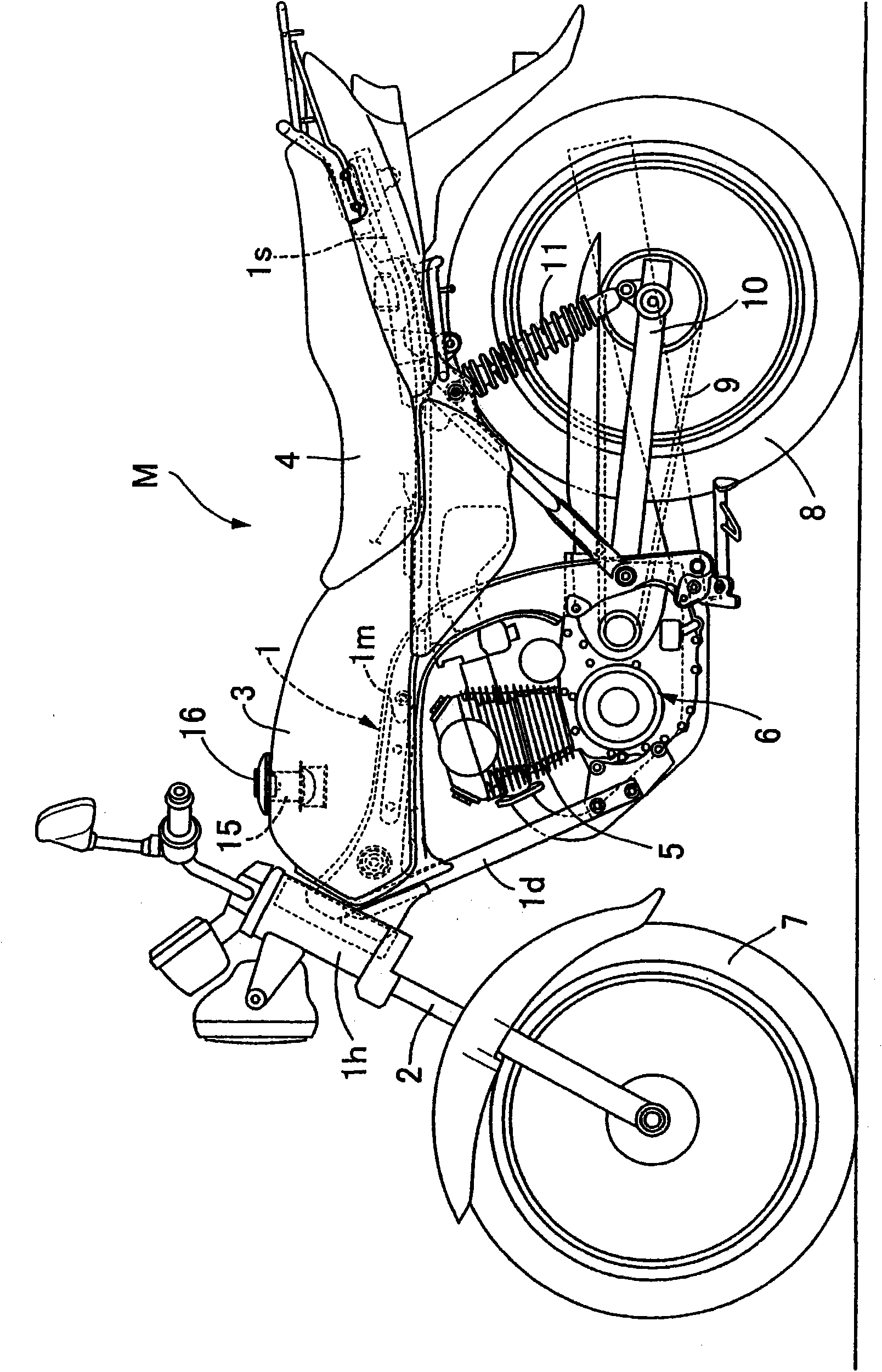

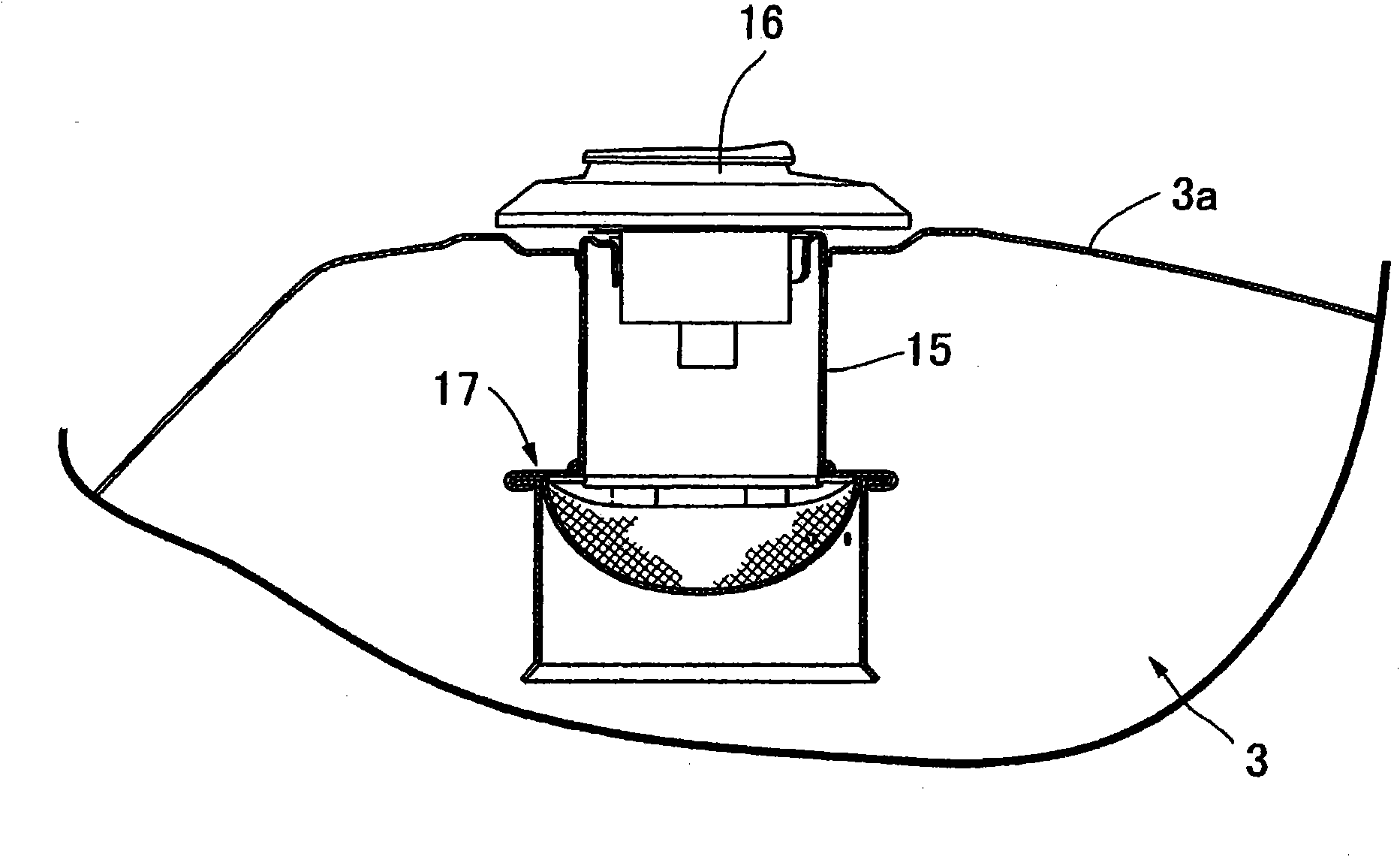

Ventilating device for sun roof device of vehicle

The invention provides an air guider (40) of skylight device (30) for vehicles, composed of an arm support part (41), an arm part (42), an air guide element (43), a suspension part (44) and a twisting coil spring (45). The arm support part and the suspension part are mouthed on a frame (20) for vehicle roof (11). The arm support part is capable of supporting back end of the arm part with a swung mode up and down. The air guide element is mounted on front end of the arm part. The twisting coil spring, of which one end (45b) is hung on the arm part, applies a force upwards to front section of the arm part, and the other end (45c) of the twisting coil spring may be hung on the suspension part with certain distance sliding front and rear.

Owner:YACHIYO IND CO LTD +1

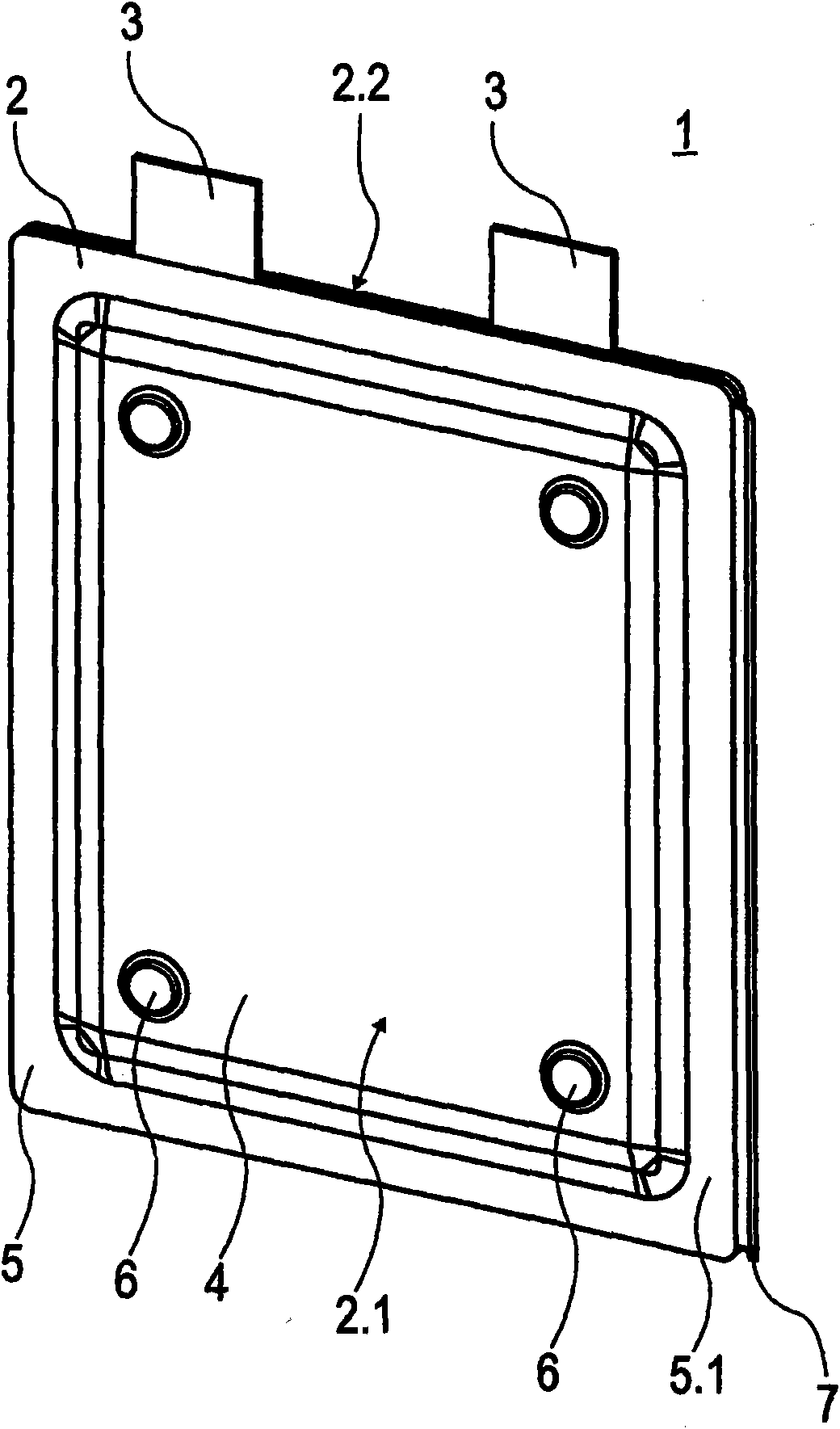

Battery housing having an attached fluid flow guiding unit

InactiveCN101772851ALow costSave installation spacePrimary cell to battery groupingLarge-sized flat cells/batteriesBattery packElectrical and Electronics engineering

Owner:DAIMLER AG

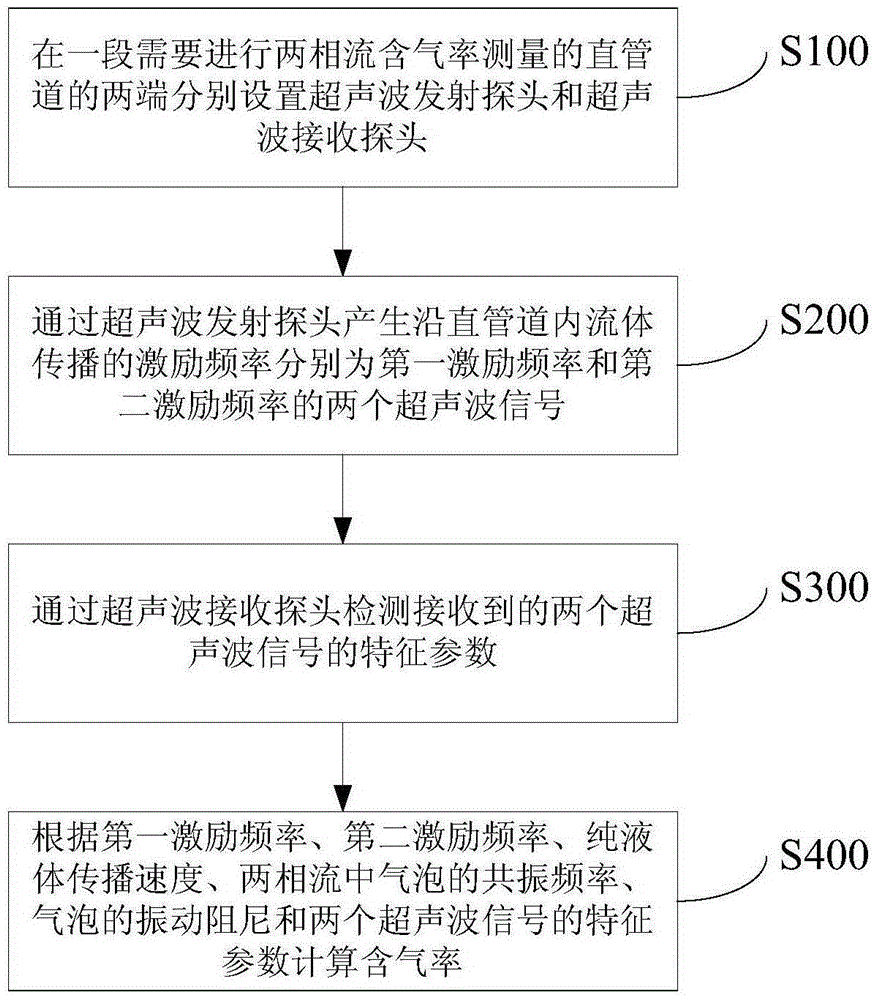

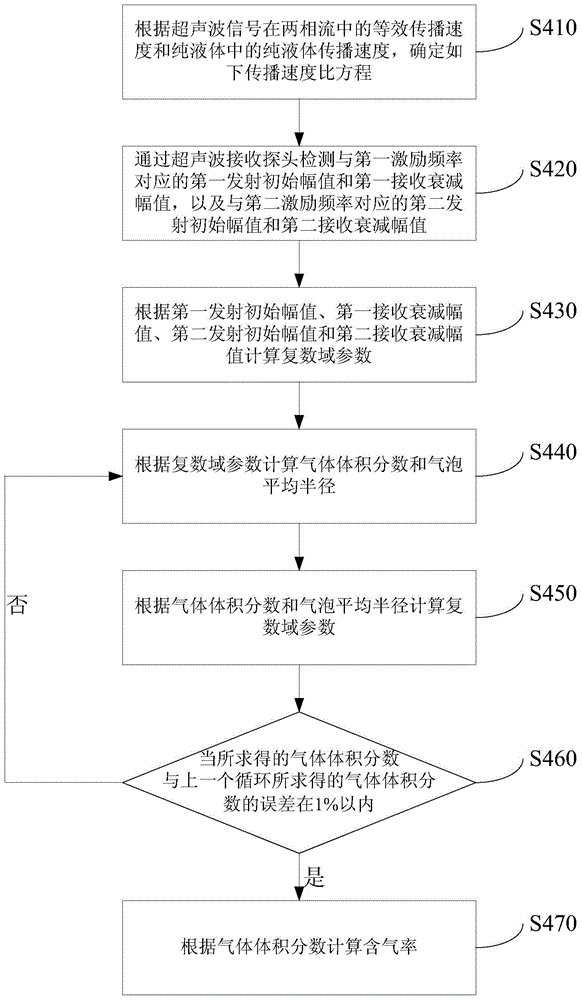

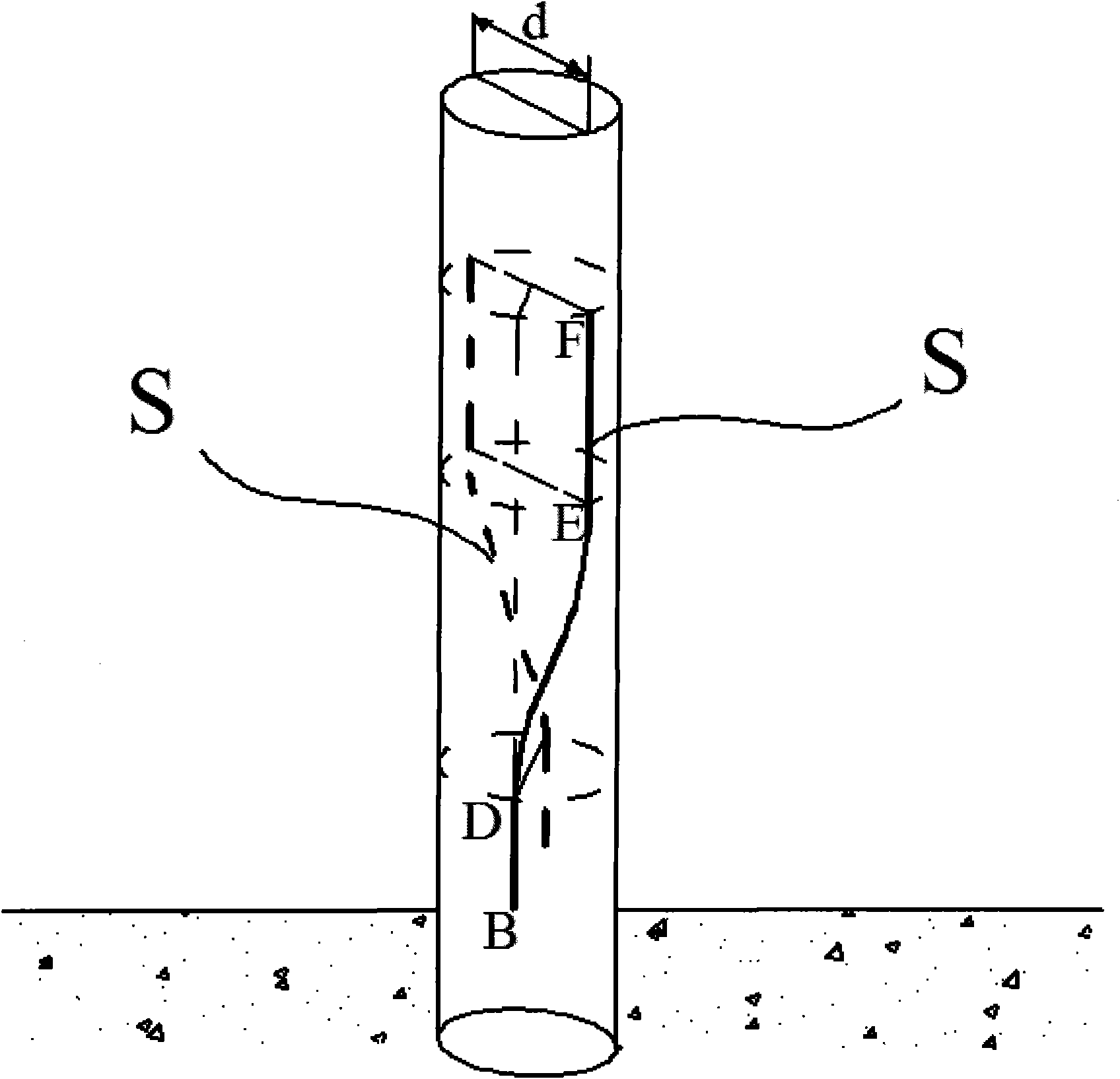

Method for measurement of two-phase flow gas holdup based on ultrasonic two-frequency signal

ActiveCN105181793ARealize non-contact measurementDoes not impede flowAnalysing fluids using sonic/ultrasonic/infrasonic wavesDouble frequencyMechanics

The invention discloses a method for measurement of two-phase flow gas holdup based on an ultrasonic two-frequency signal. The method comprises the steps of: arranging an ultrasonic transmitting probe and an ultrasonic receiving probe respectively at both ends of a section of straight pipeline needing two-phase flow gas holdup measurement; by means of the ultrasonic transmitting probe, generating two ultrasonic signals that are propagated along the fluid in the straight pipeline and have the excitation frequencies of a first excitation frequency and a second excitation frequency respectively; detecting the characteristic parameters of the received two ultrasonic signals by the ultrasonic receiving probe; and calculating the gas holdup according to the first excitation frequency, the second excitation frequency, the pure liquid propagation velocity, the resonant frequency of bubbles in the two-phase flow, the bubble vibration damping and the characteristic parameters of the two ultrasonic signals. The ultrasonic probes are installed on the outer wall of the straight pipeline, and are not needed to be arranged in the two-phase flow in the pipeline, thus realizing non-contact measurement of the two-phase flow gas holdup. The data processing amount is very small, and flow of the two-phase flow in the pipeline is not hindered in the measurement process.

Owner:NAT UNIV OF DEFENSE TECH

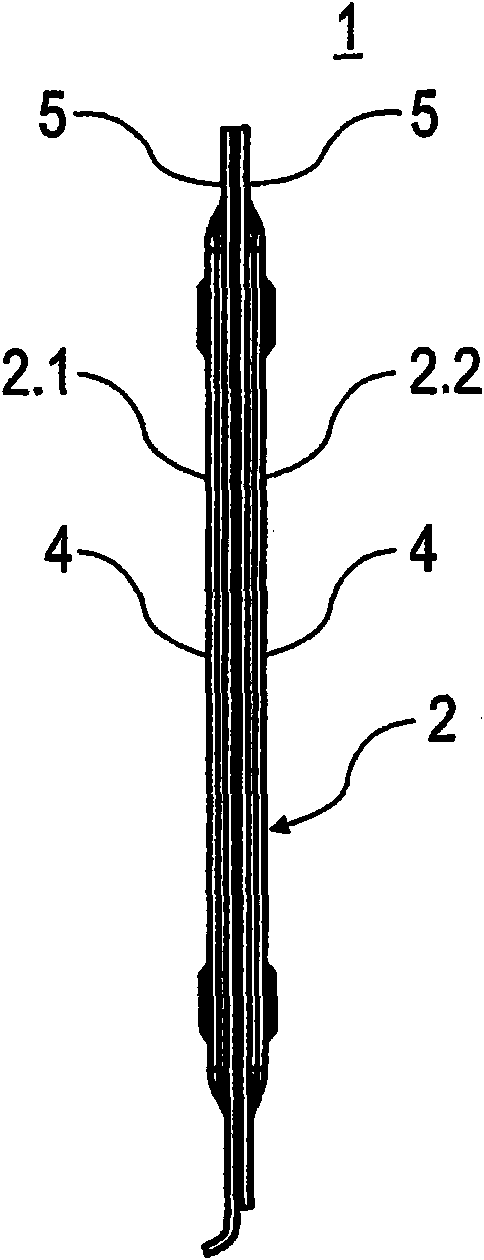

Blood processing filter and blood filtering method adopting same

ActiveCN102205154ANot easy to bendNot easy to occludeOther blood circulation devicesBlood transfusionFilter materialGuide tube

The invention provides a blood processing filter and a blood filtering method adopting the same. The blood processing filter includes the flexible container having an inlet and an outlet for blood and the sheet-like blood processing filter material which is arranged to separate the inside of the container into the inlet side and the outlet side, wherein the flexible container includes a container body for accommodating the blood processing filter material and an inlet side port which is fixed to the container body to form the inlet or outlet, the inlet side port has an inlet side main tube section connected to a conduit that transports the blood and a fixed part which communicates the inlet side main tube section into the container body and fixes the inlet side main tube section to the outer surface of the container body, and the axis of main tube section inclines relative to the tangent of the outer surface of the container body.

Owner:ASAHI KASEI MEDICAL CO LTD

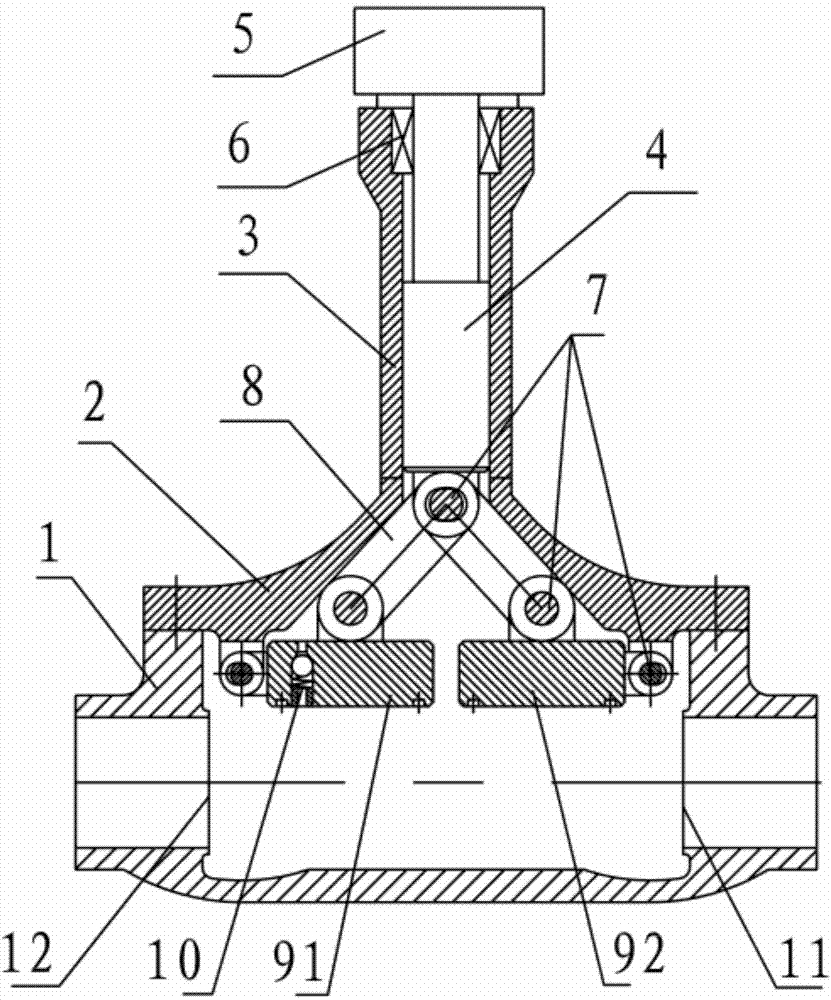

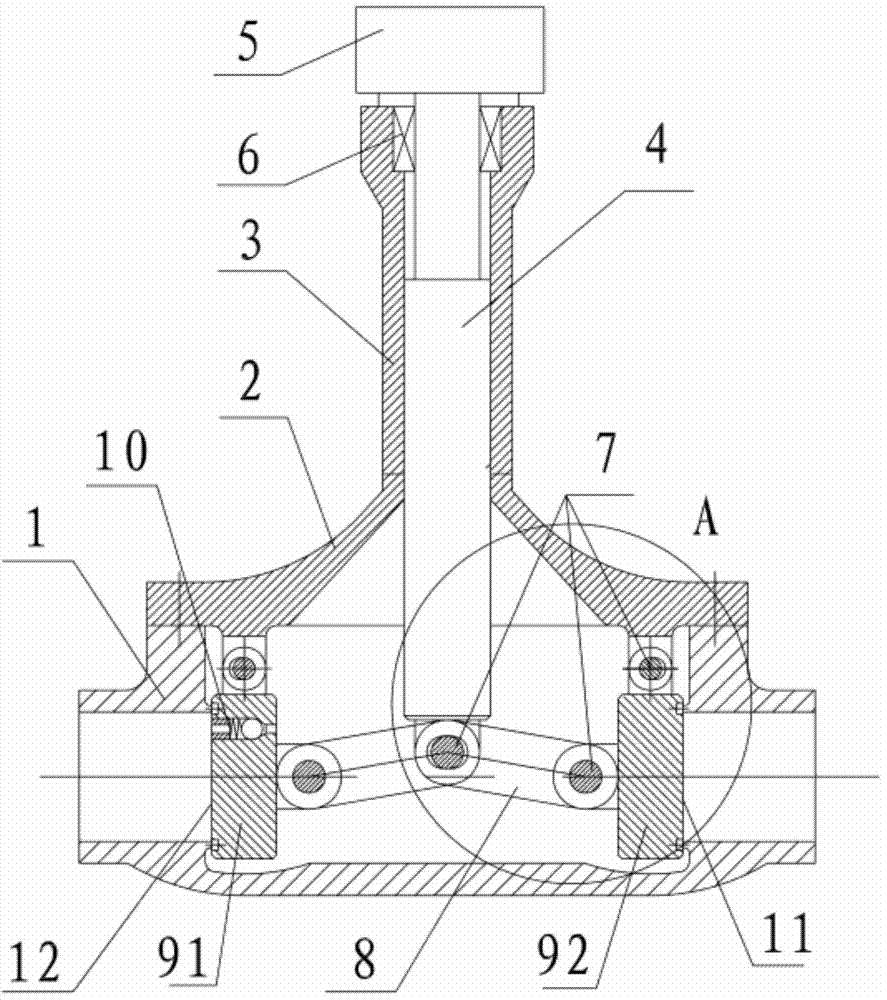

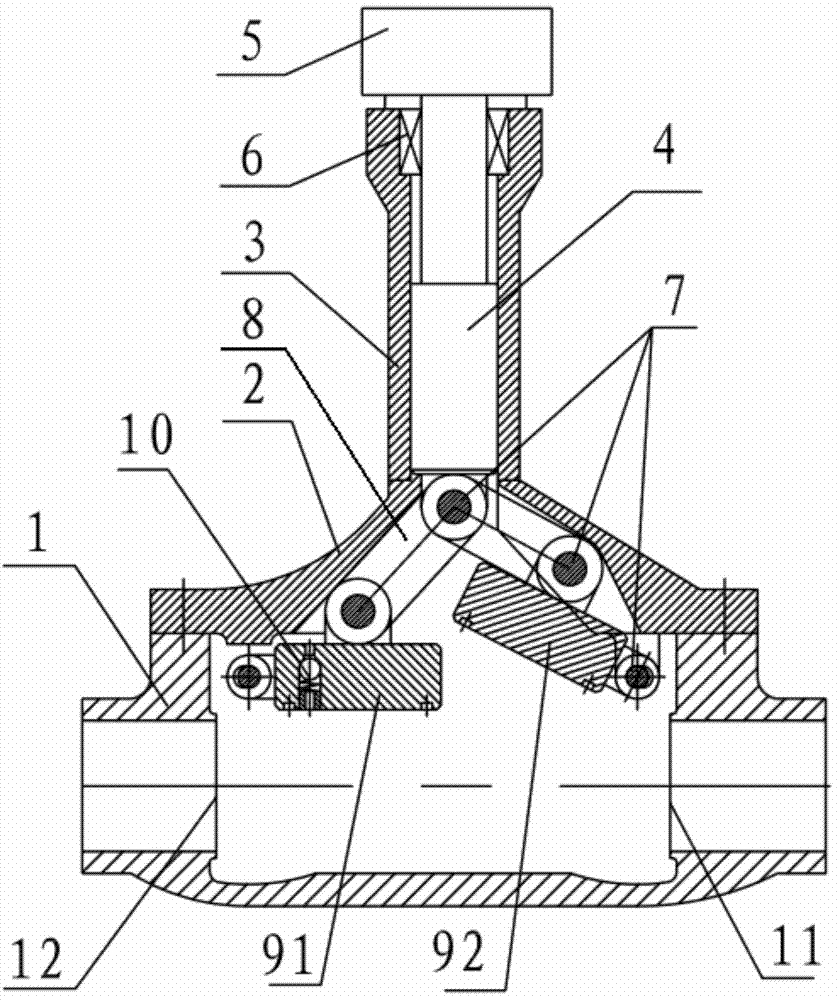

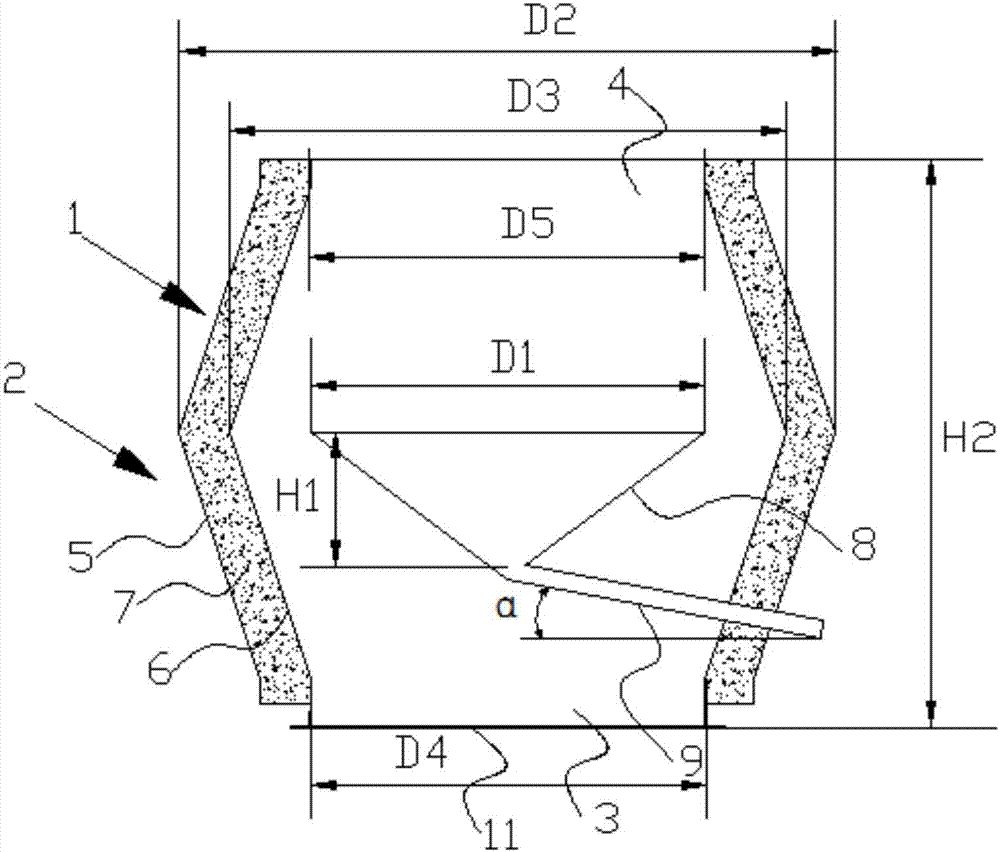

Bi-directional seal low-flow-resistance stop valve

ActiveCN104712772ASmall flow resistanceDoes not impede flowLift valveEngineeringMechanical engineering

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD +1

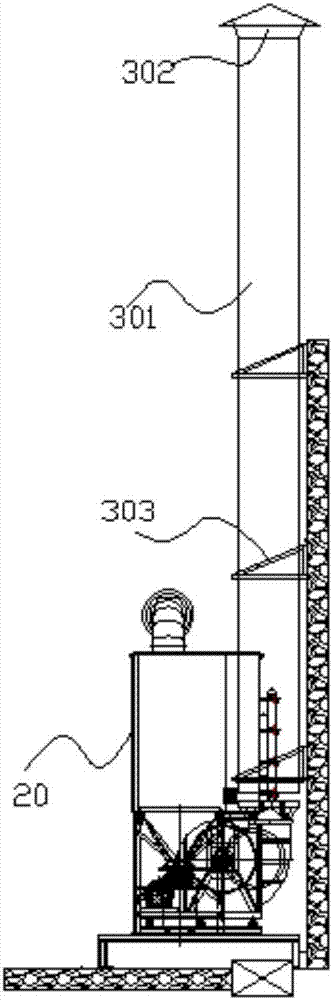

Noise-reducing and rain-proof drainage hood

InactiveCN108006681AEliminate Radiation NoiseImprove the noise reduction effectChimneysPunchingEmission standard

The invention discloses a noise-reducing and rain-proof drainage hood. The noise-reducing and rain-proof drainage hood comprises a cylinder body. The cylinder body comprises an upper cone cylinder anda lower cone cylinder. Each of the cylinder walls of the upper cone cylinder and the lower cone cylinder comprises an inner cylinder wall body, an outer cylinder wall body and a silencing layer. An open lower cone cap is mounted in the cylinder body. A water guide pipe is connected to the lower end of the lower cone cap. The water guide pipe inclines downwardly, penetrates the cylinder wall of the lower cone cylinder and extends out of the cylinder body. According to the noise-reducing and rain-proof drainage hood, noise enters from an air inlet, the noise is absorbed by a punching slicing plate of the lower cone cylinder and the silencing layer, then rebounded to a punching slicing plate of the upper cone cylinder and the silencing layer and then transmitted out through an air outlet; inthe process, the noise is subjected to multiple times of rebounding, slicing and noise reduction, the noise can be lowered to 50-60 dB, the slicing and noise reduction effects are ideal and meet andexceed the national emission standards, and the noise-reducing and rain-proof drainage hood has the function of eliminating the radiated noise of an air outlet of a chimney; and besides, the hood meets the requirements on ventilation and prevention of invasion of sand and dust blown by wind, rainwater and snow water and has the beneficial effects of being small in size, low in weight, easy and convenient to mount, low in cost and the like.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

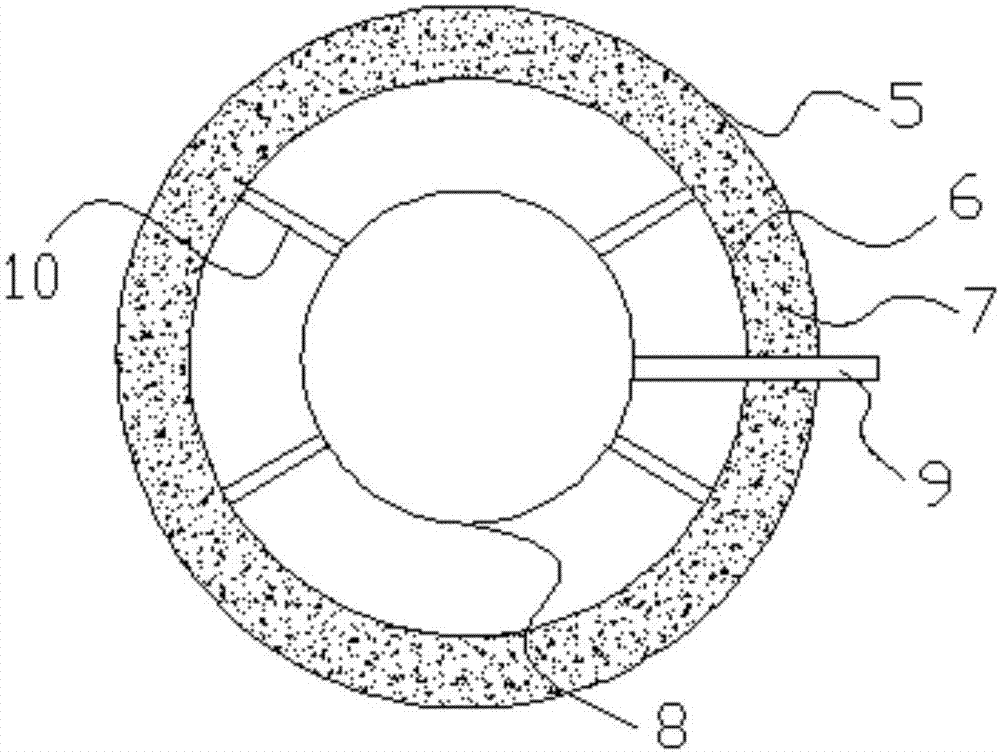

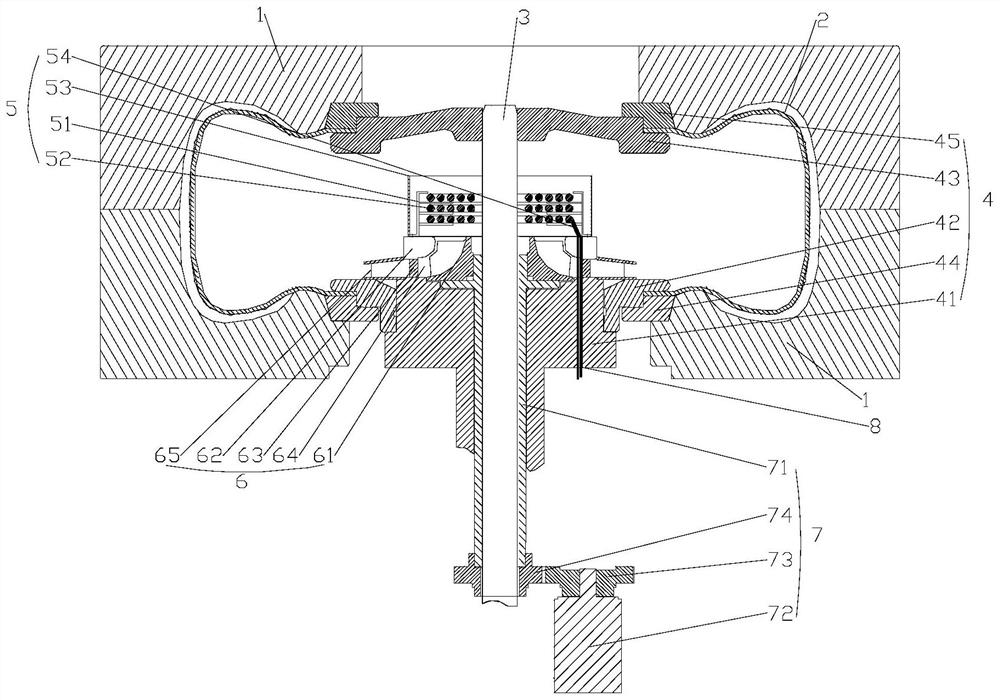

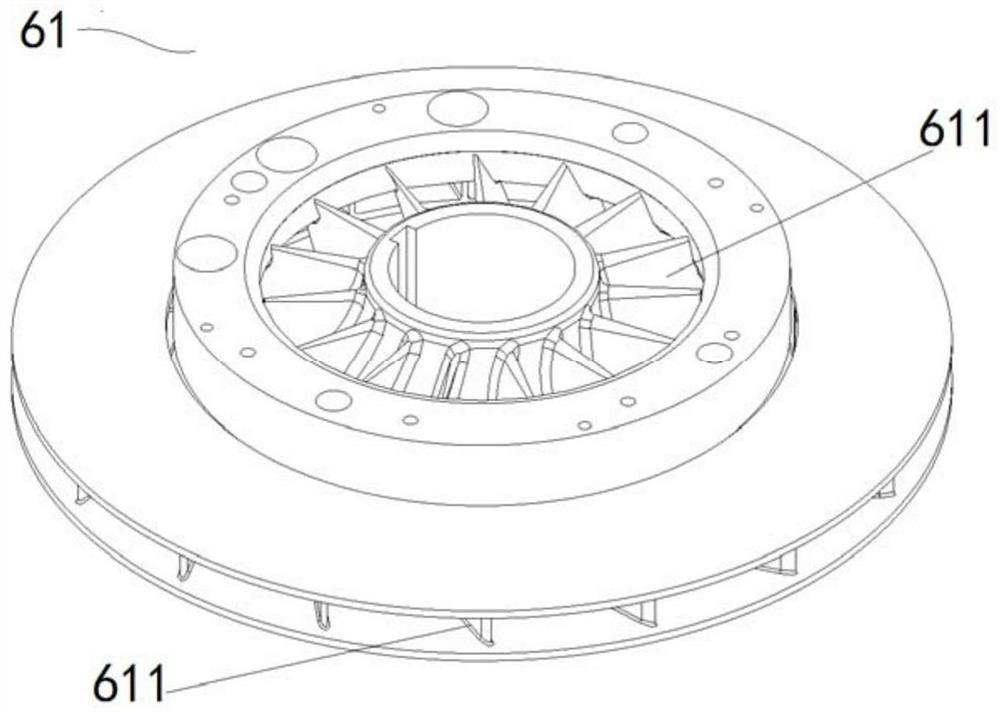

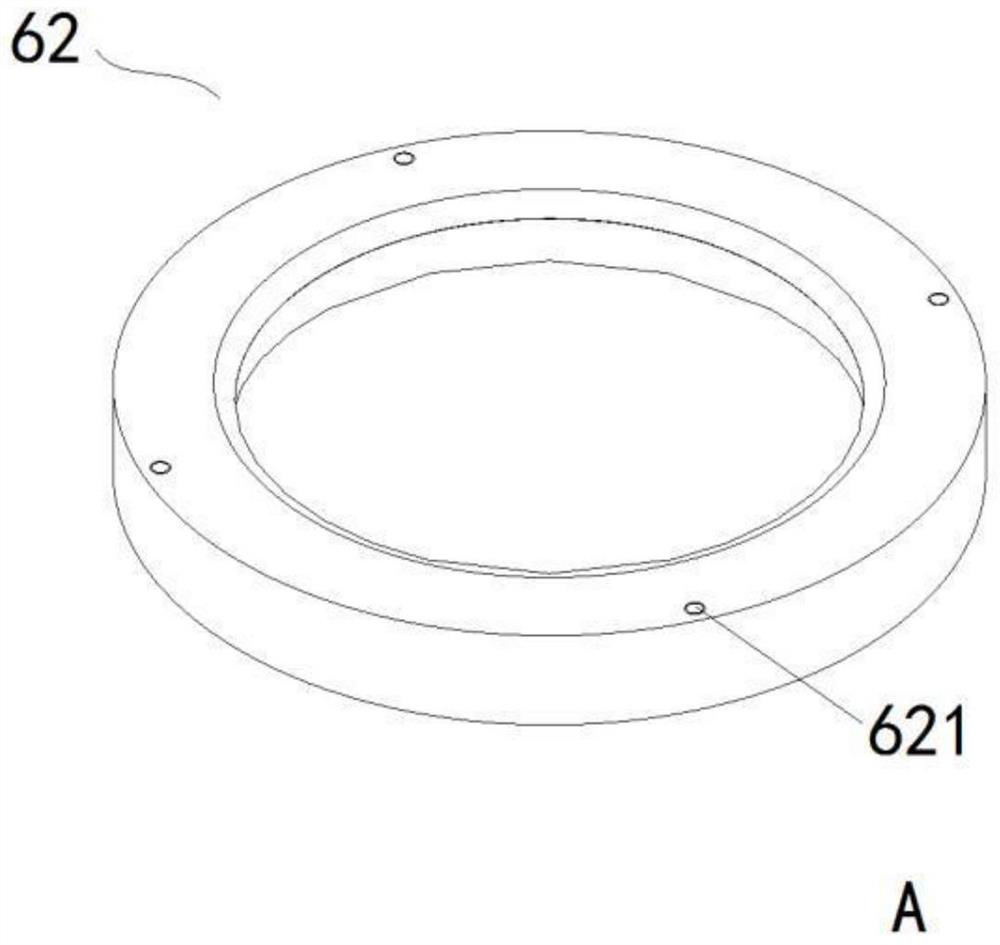

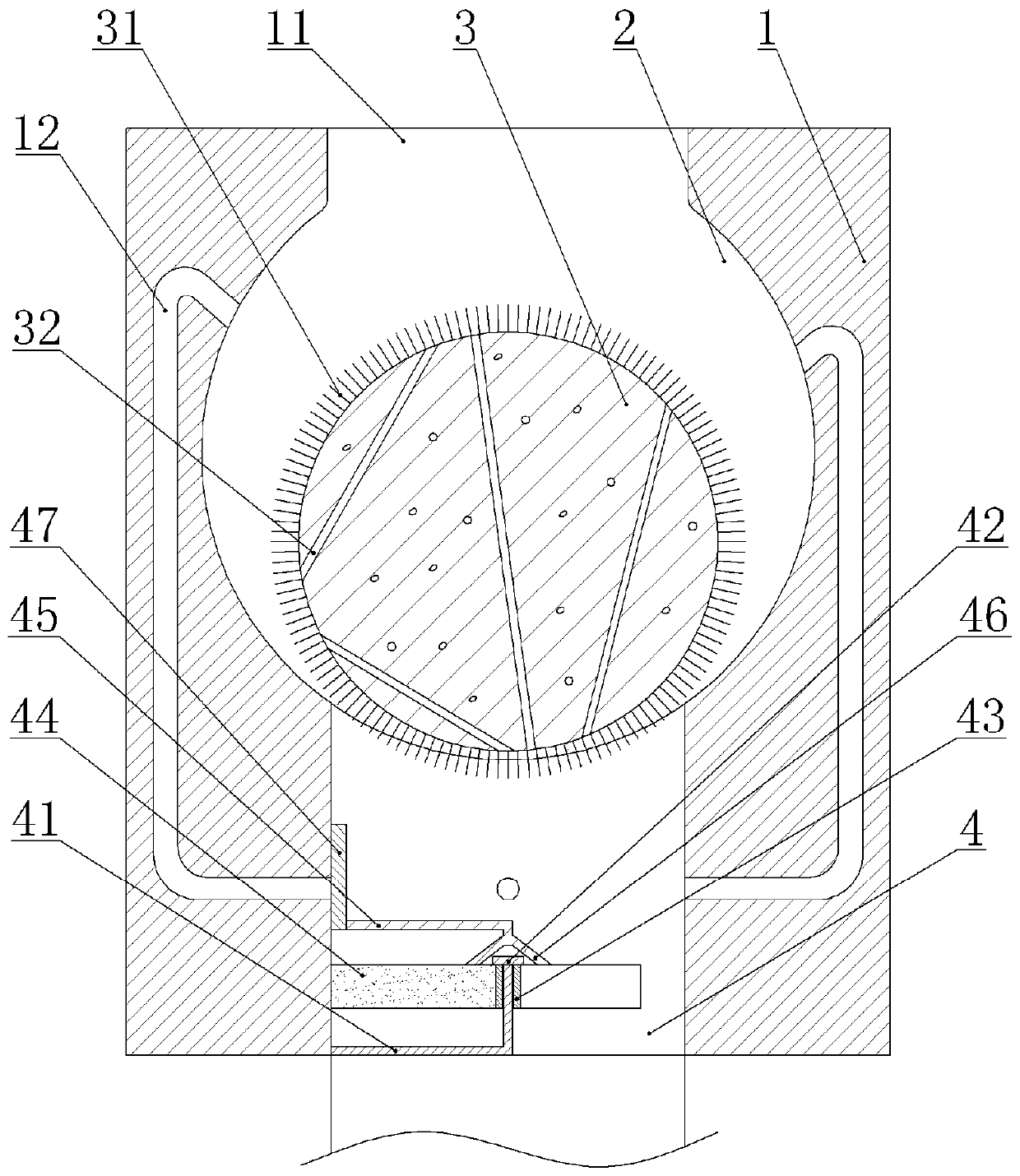

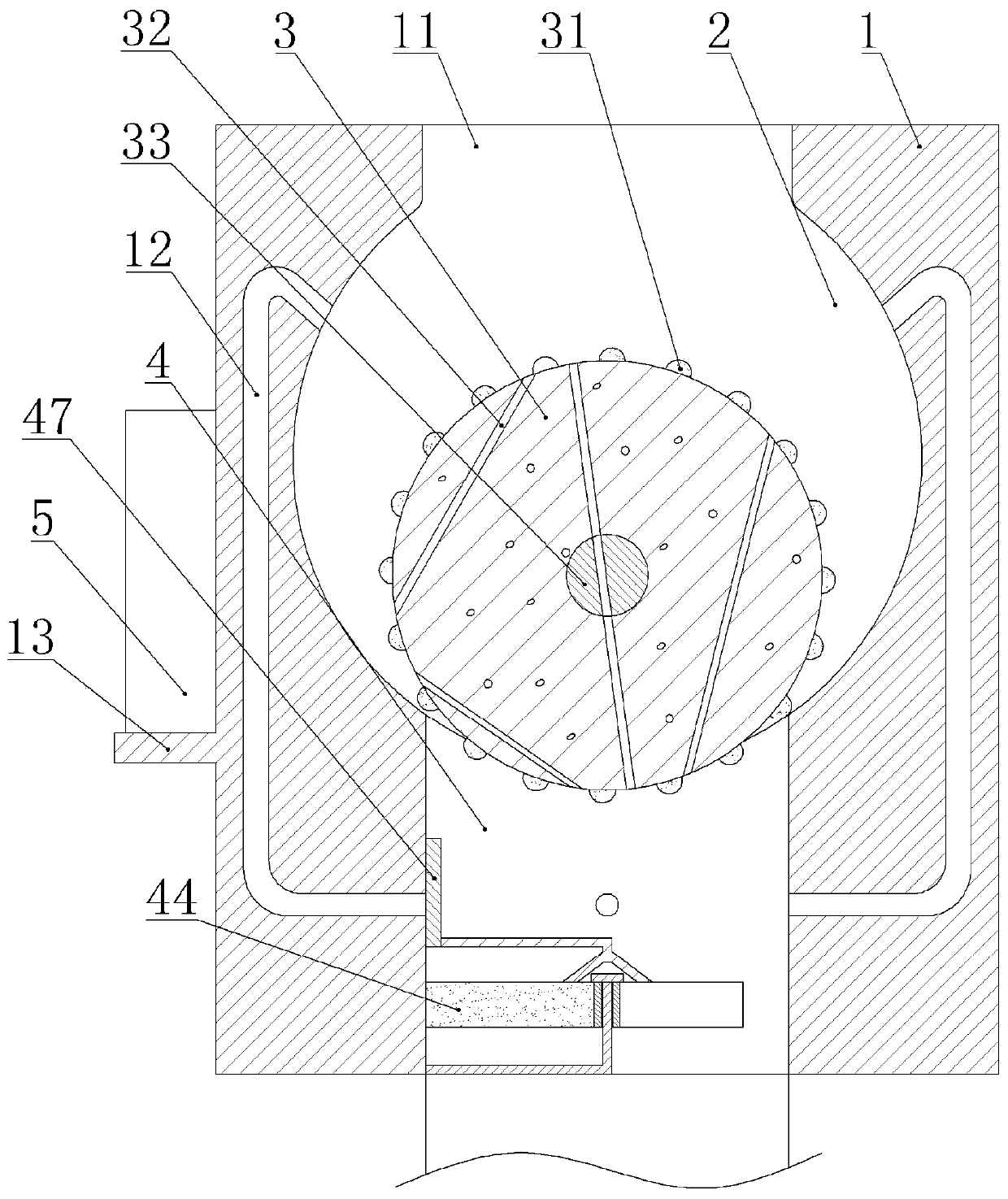

Vulcanizing equipment

The invention relates to the technical field of vulcanizing devices, in particular to vulcanizing equipment which comprises a vulcanizing mold, a vulcanizing device and a vulcanizing device. The vulcanizing capsule is suitable for being placed in the vulcanizing cavity; the supporting assembly comprises a center rod and a clamping device arranged on the center rod, and the clamping device is suitable for installing the curing bladder in the cavity in a sealed mode; the device further comprises a heating assembly and a gas circulation assembly, the heating assembly and the gas circulation assembly are arranged in the curing bladder in a stacked mode in the axial direction of the center rod, and the gas circulation assembly is suitable for enabling a heated heating medium to circulate in the curing bladder in a circulating mode. The driving assembly comprises a rotating shaft sleeve which is arranged on the outer side of the center rod in a clearance fit mode and connected with the gas circulation assembly. The invention provides vulcanizing equipment which overcomes the defects that in the prior art, equipment with horizontally-arranged vulcanizing capsules occupies too large space, the processing specification of vulcanized tires is limited, and gas circulation in the vulcanizing capsules is not facilitated.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

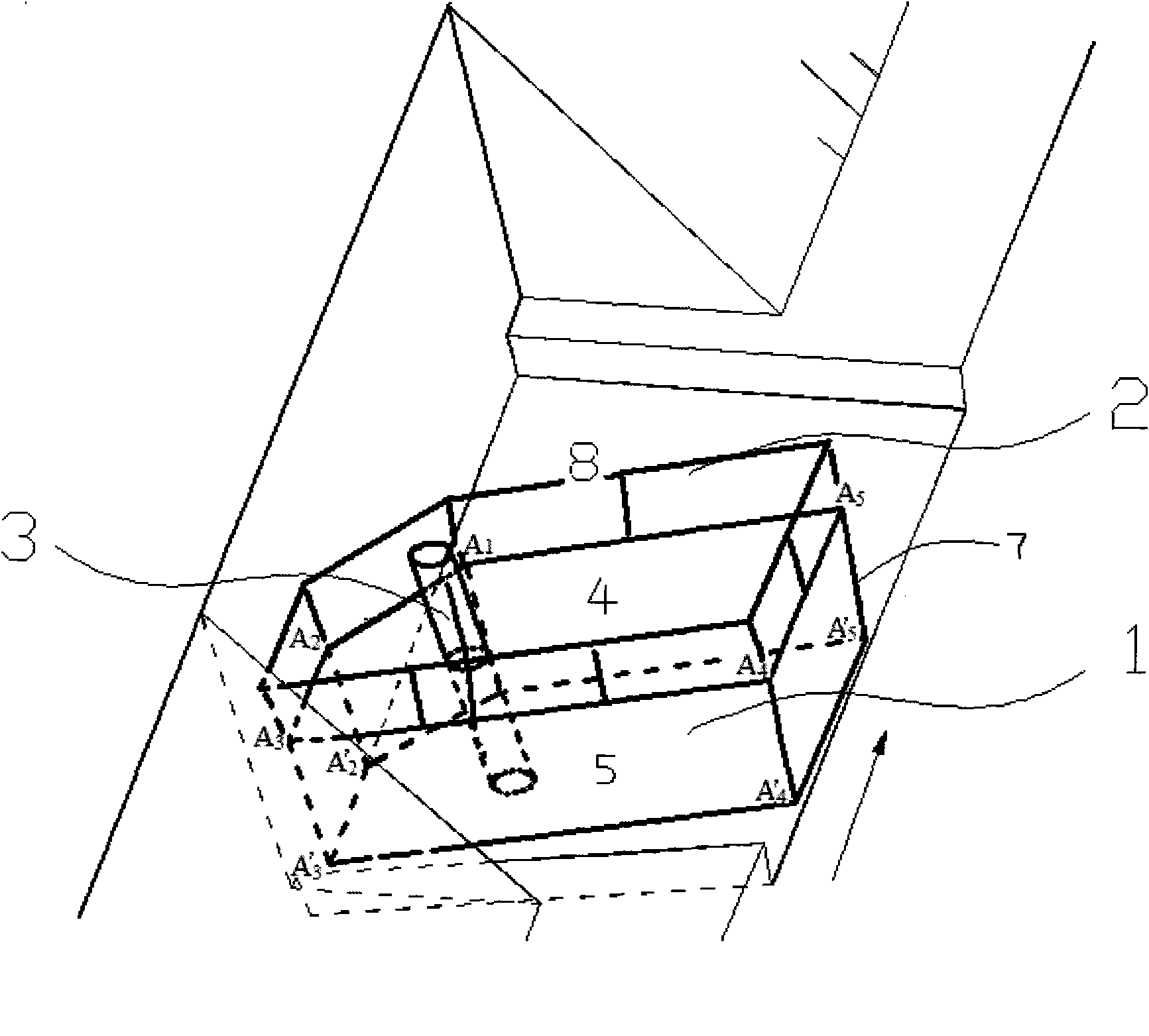

Toughening material of composite material and preparation method toughening material

ActiveCN102505355AThe overall thickness is thinSmall fiber diameterNon-woven fabricsYarnPolymer science

The invention belongs to a composite material high performance technology, relates to toughening material of composite material and a preparation method of the toughening material. The toughening material is made of non-woven cloth comprising thermoplastic polymer fiber, the thickness of the non-woven cloth is 5 to 50 micrometers, and the fiber diameter of the non-woven cloth is about 0.2 to 5 micrometers. The preparation method comprises the steps as follows: yarns are sprayed out through solution; the yarns are deposited to become the non-woven cloth; and then the fiber non-woven cloth toughening material is formed through drying and collection. The method adopting a solution spray process to prepare the non-woven cloth toughening material can effectively improve the preparation efficiency, and realize the mass manufacture of the toughening material. The toughening material prepared by the method can obviously improve the compression performance of impacted resin matrix composites, and compared with the prior art, the method has the advantages that the compression strength of the impacted resin matrix composites is improved by 50 to 150 percent, the heat resisting property and the mechanical property of composite material, as well as the flowing of resin during the forming of the composite material, are not affected, and the yield and the quality stability of the composite material are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

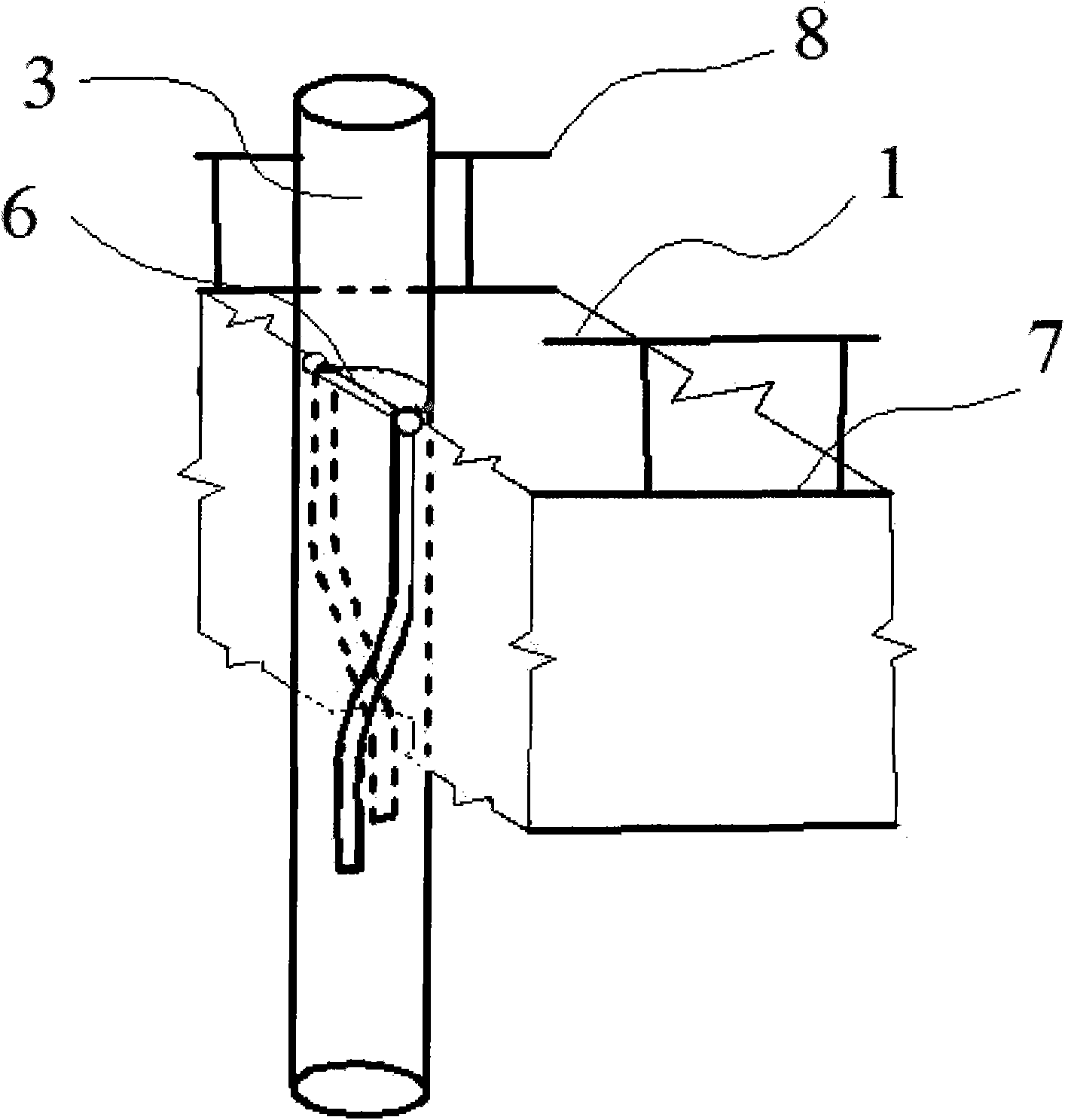

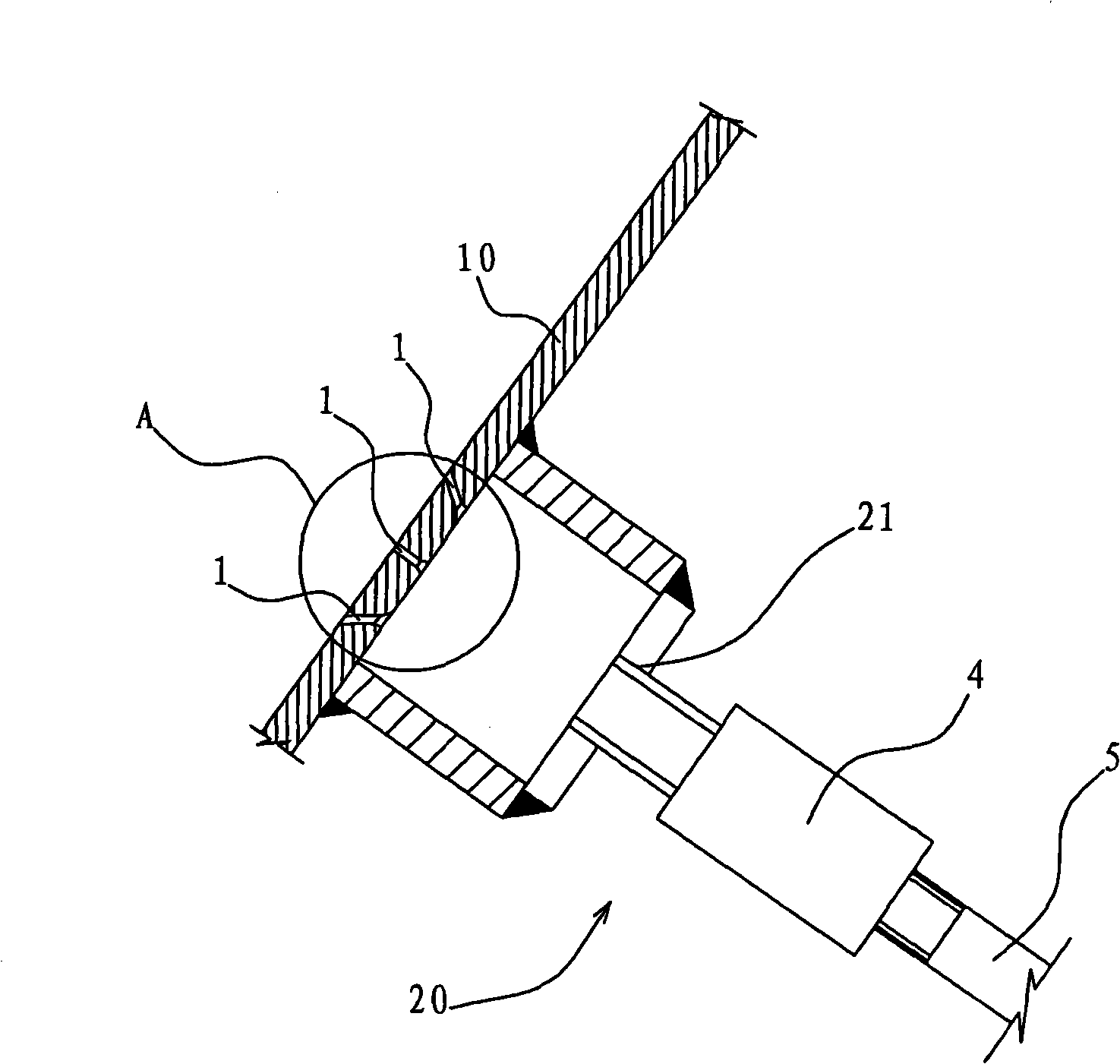

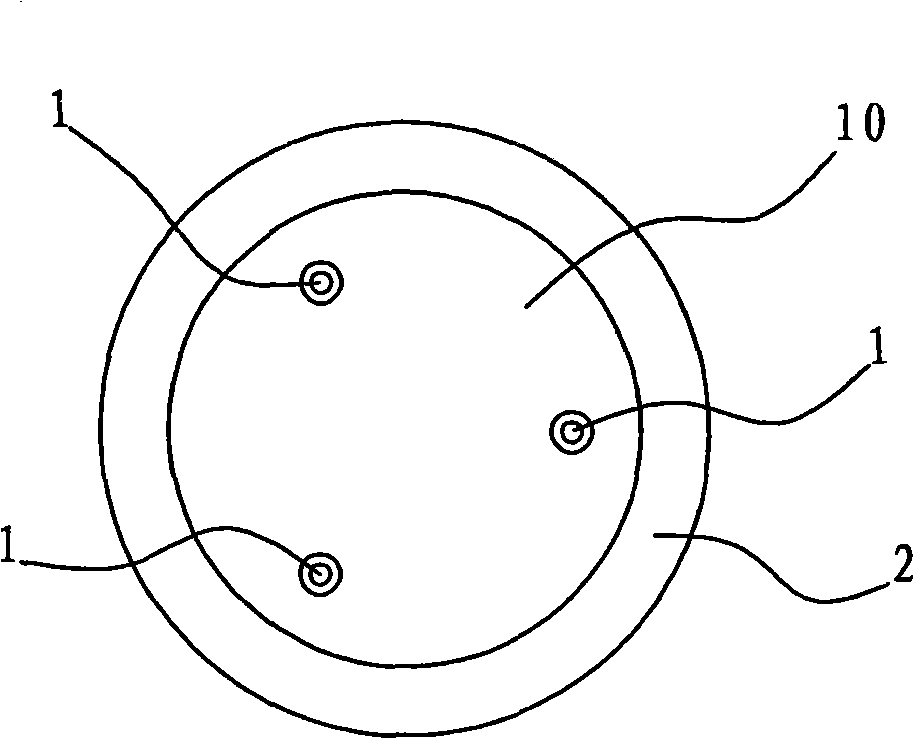

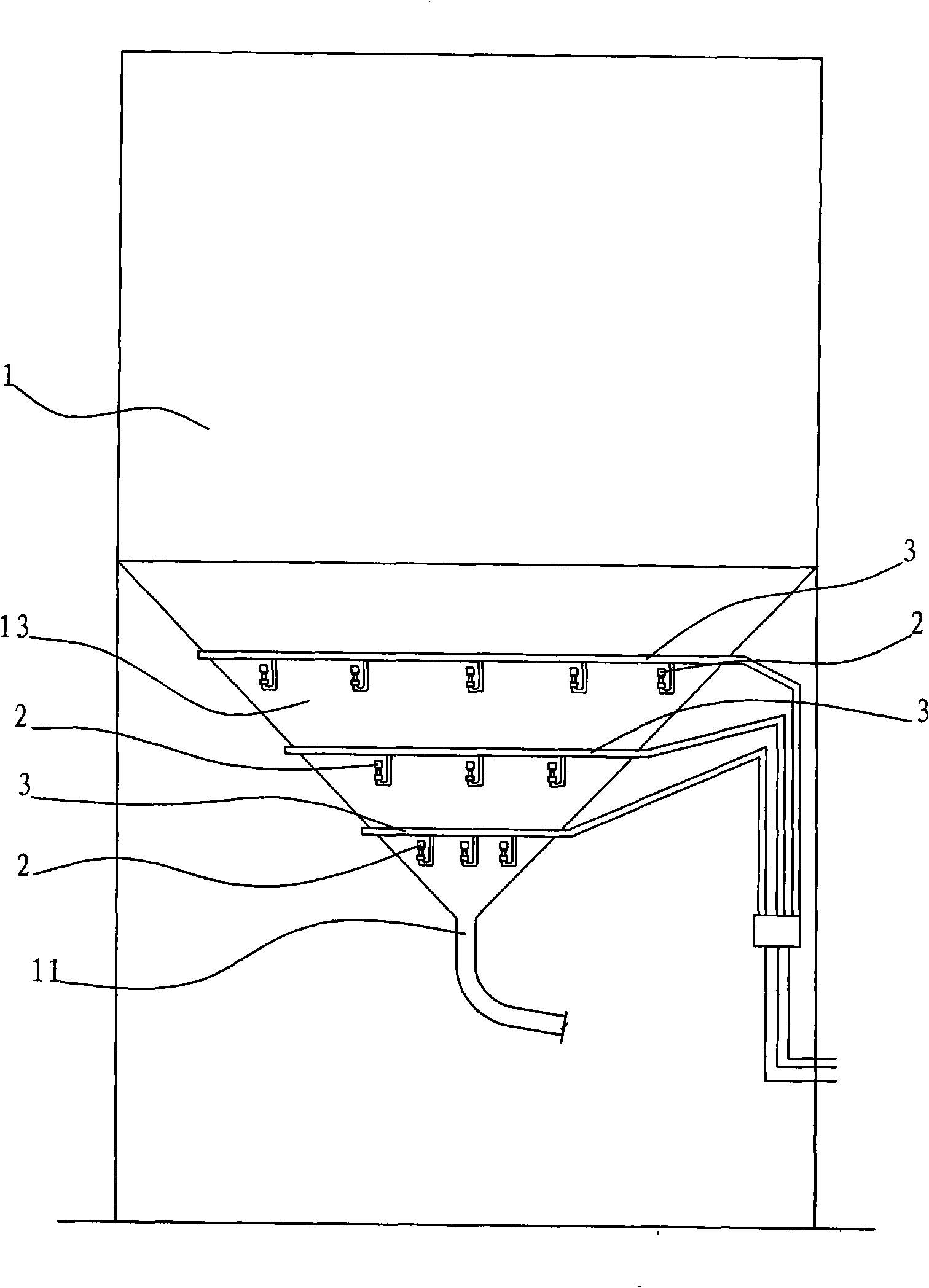

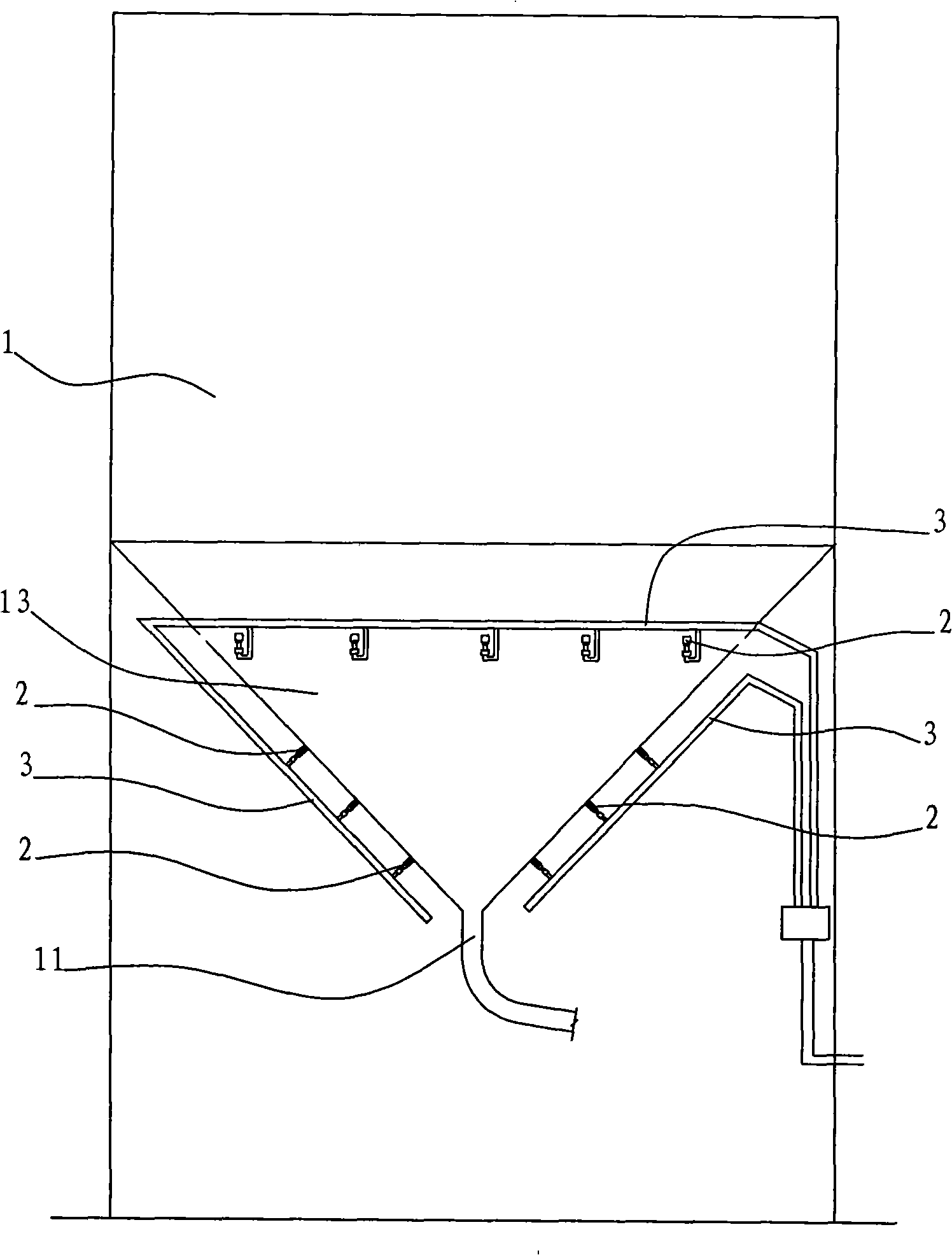

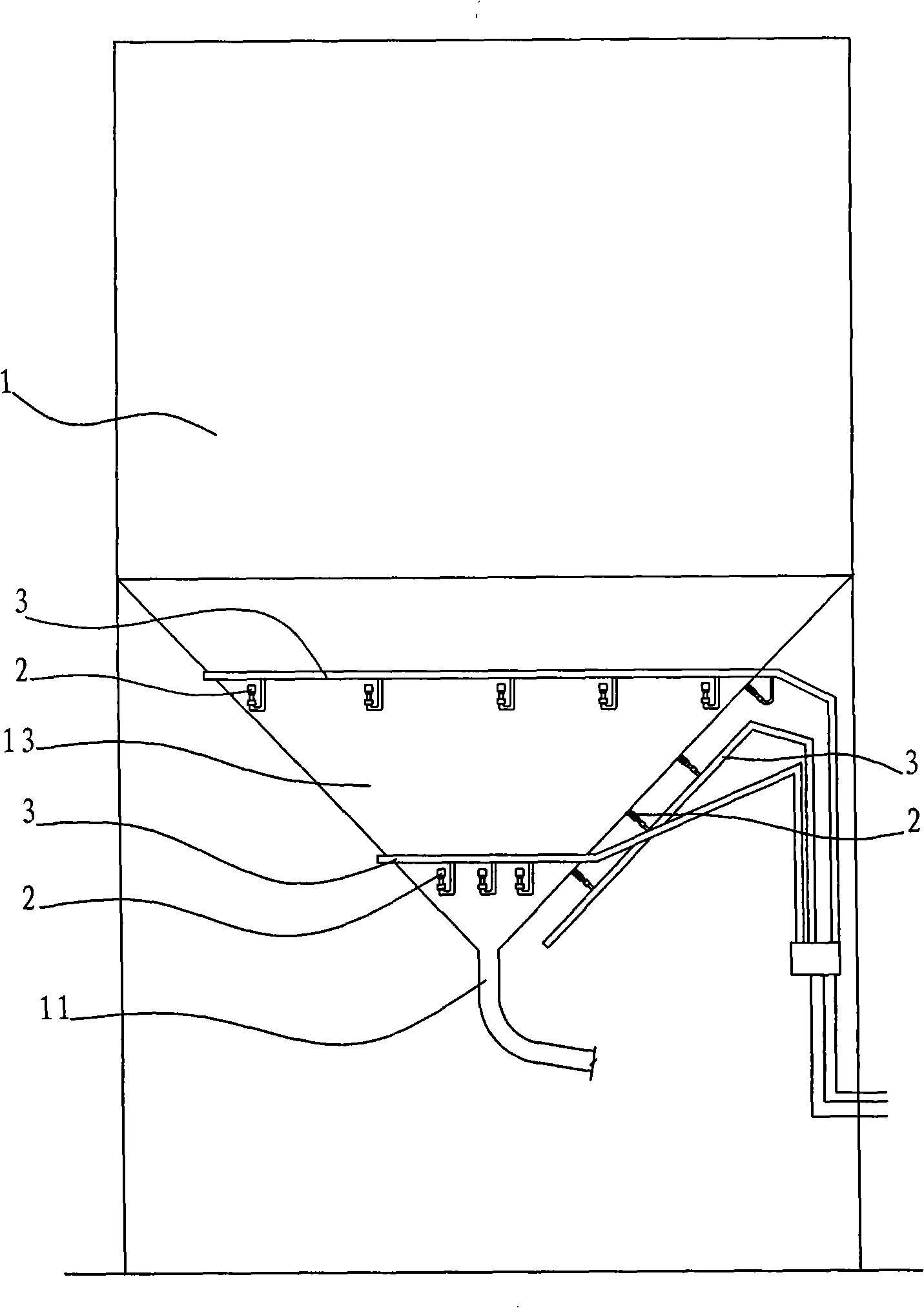

Reciprocating type plant grid system and application thereof

InactiveCN101844832AGood removal effectEffective interceptionBiological water/sewage treatmentReciprocating motionSewage

The invention relates to a reciprocating type plant grid system and an application thereof, belonging to the technical field of a rural non-point pollution treating process. The reciprocating type plant grid system is characterized by comprising a plant grid area (1), a water storage area (2) and a fixed joint shaft (3), wherein the bottom of the fixed joint shaft (3) is fixed in the water storage area (2); the fixed joint shaft (3) is provided with a sheathing part (6) which freely move up and down along the fixed joint shaft (3) and is connected with the plant grid area (1); and the self weight of the plant grid area (1) is more than or equal to the buoyancy force in sewage. The open-close state of the grid gate of the reciprocating type plant grid system automatically conducts the reciprocating motion along with change of the water level in a ditch. The system has the characteristics of simplicity, flexibility, beautiful appearance, small occupied area, convenient replacement and cleaning, good N and P removing effect, low operating cost, easy management and the like.

Owner:HOHAI UNIV

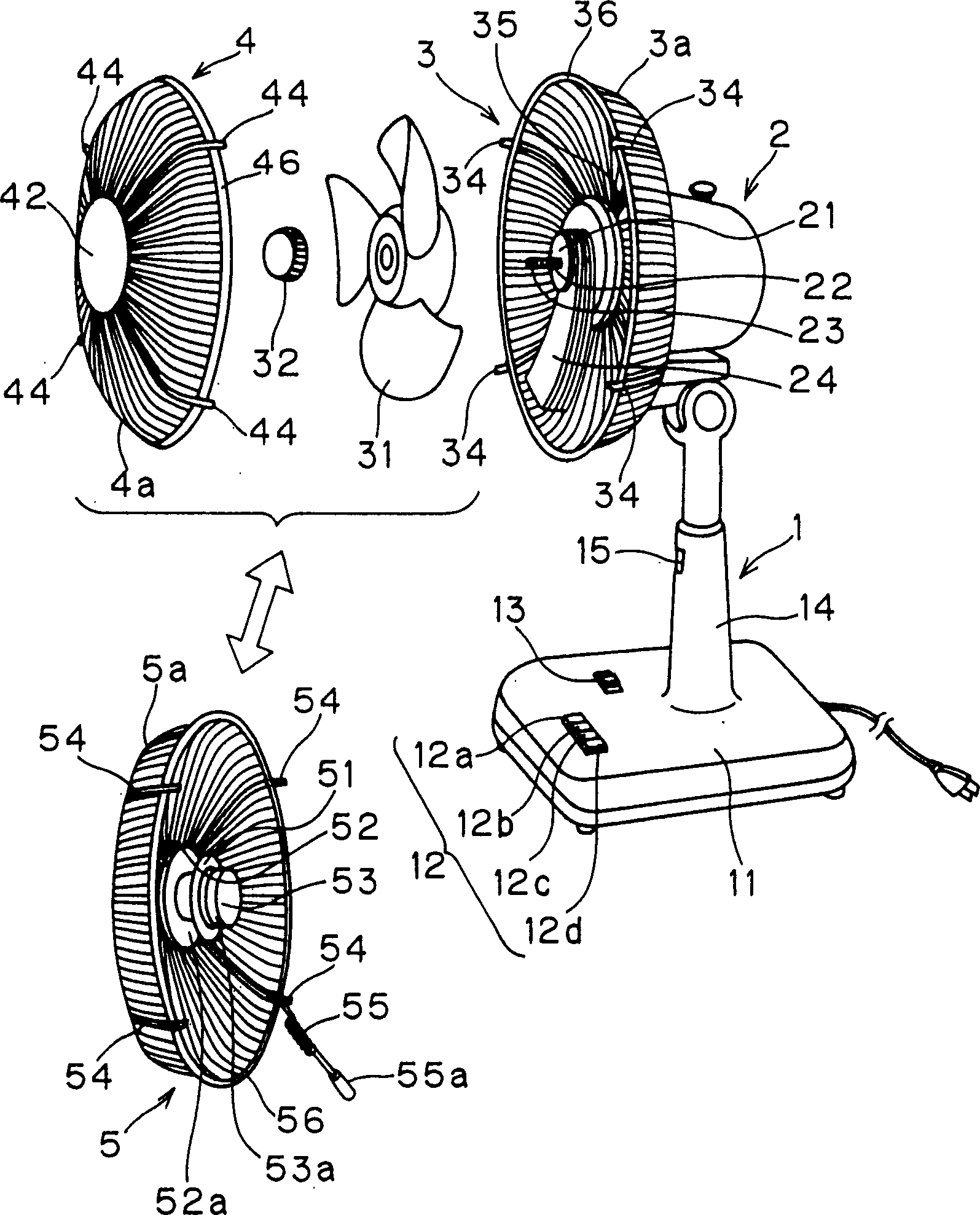

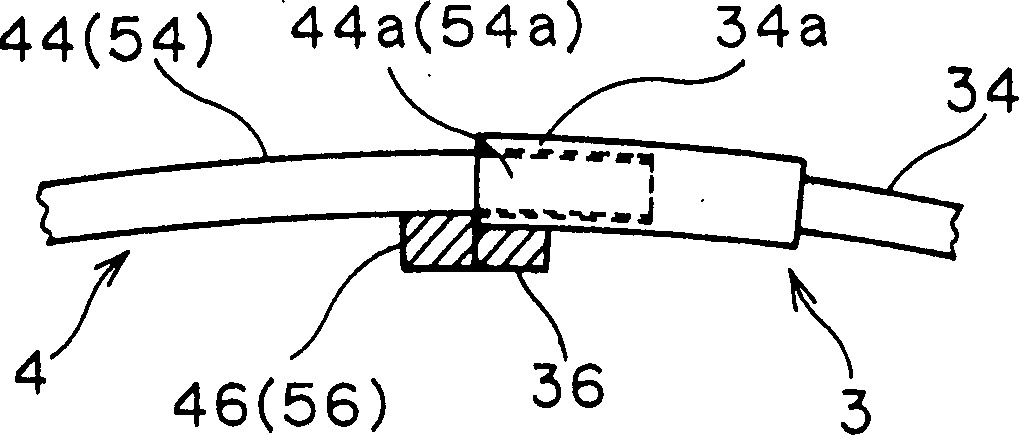

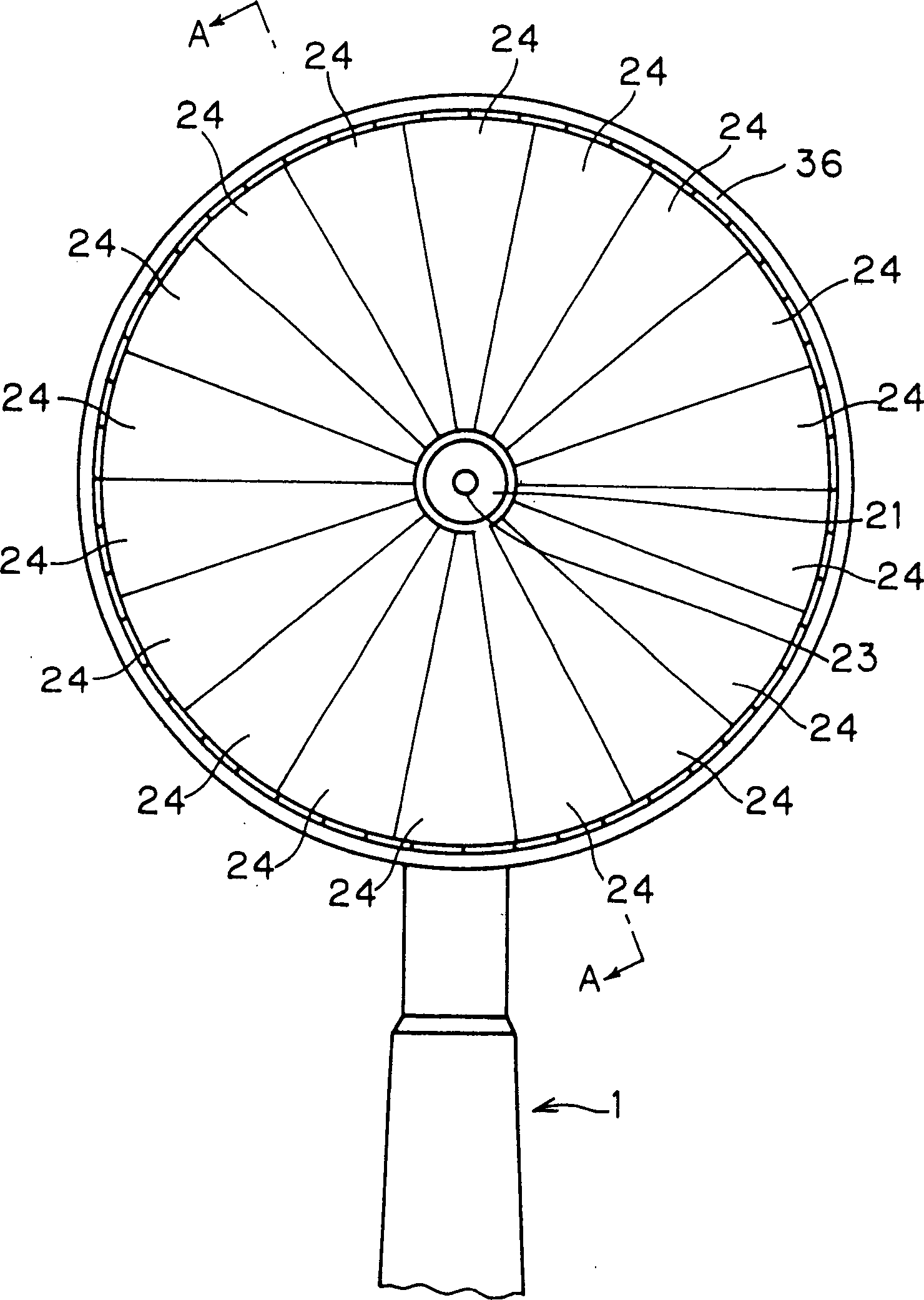

Electric fan which can be used as heater at same time

InactiveCN1455850AEffective reflectionGuaranteed functionPump componentsAir heatersEngineeringFront edge

The electric fan concurrently being used as heater comprises rear protective net fitted on the motor shell and the shaft hub at the front of the motor, motor shaft through the through-hole formed on the shaft hub and projected from the front of the motor, rotary blade detachable fixed on the motor shaft, the front protective net detachable fixed at the front edge of the rear protective net, multiple division reflection boards which is supported ratatablly freely on the periphery direction of the shaft hub, and has a connection heater and power supply socket.

Owner:佐藤忠

Ionic wind radiating device

InactiveCN101662120BSimple structureReduce volumeCasings/cabinets/drawers detailsSemiconductor lasersElectricityEngineering

Owner:PHOEBUS VISION OPTO ELECTRONICS TECH +1

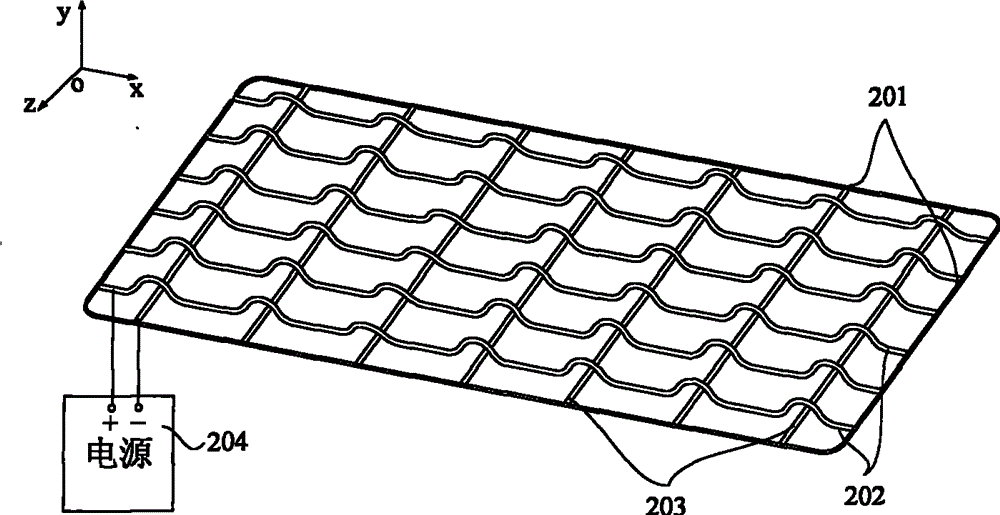

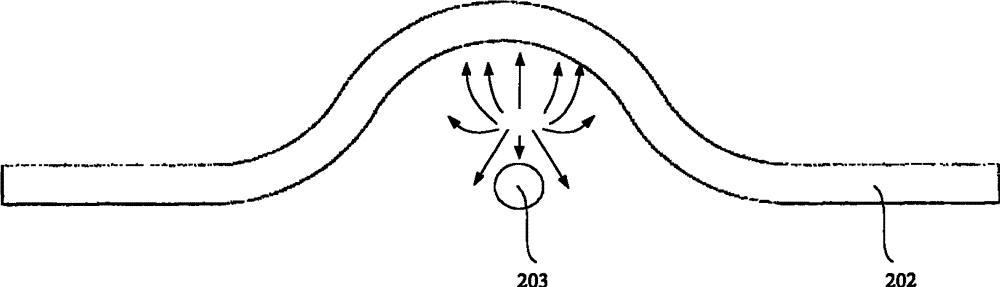

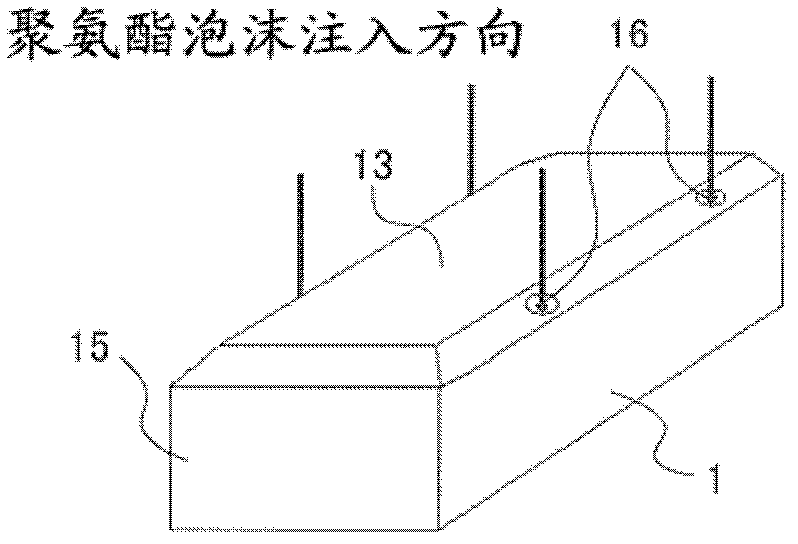

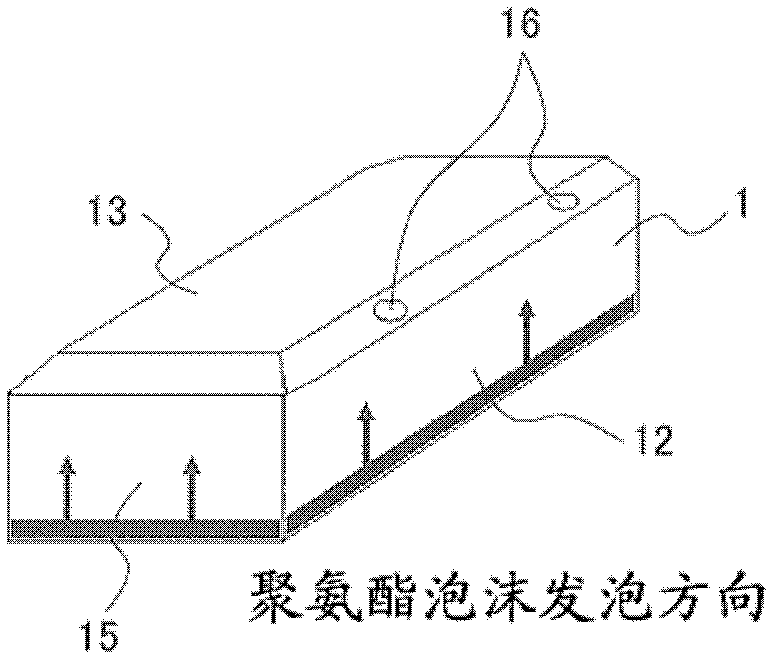

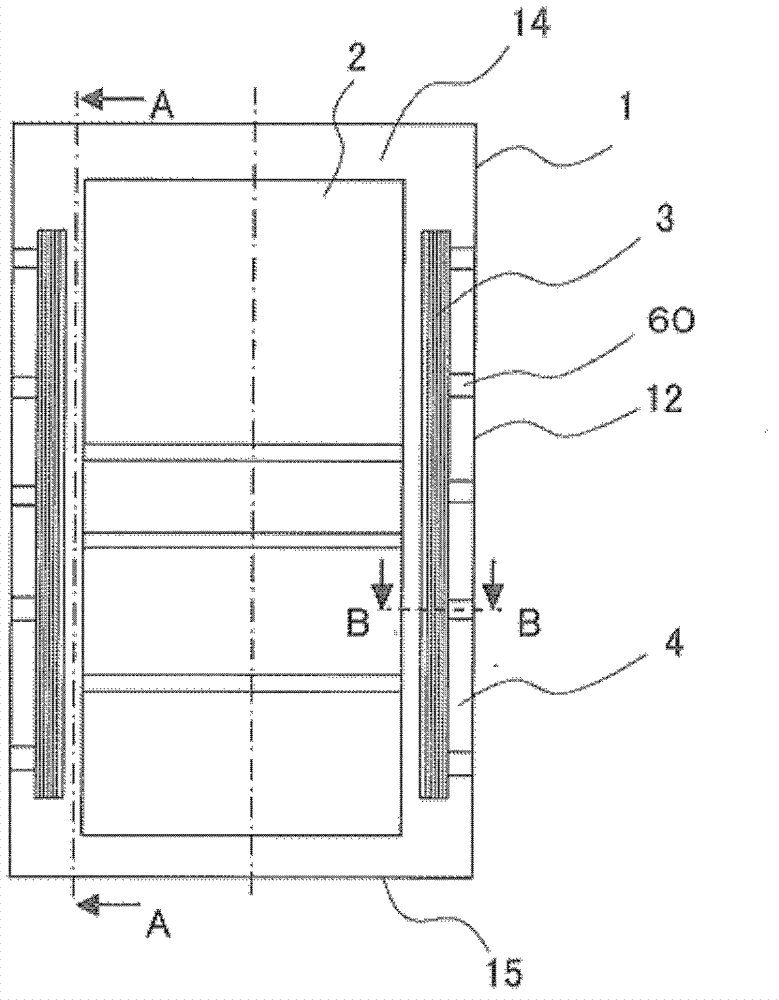

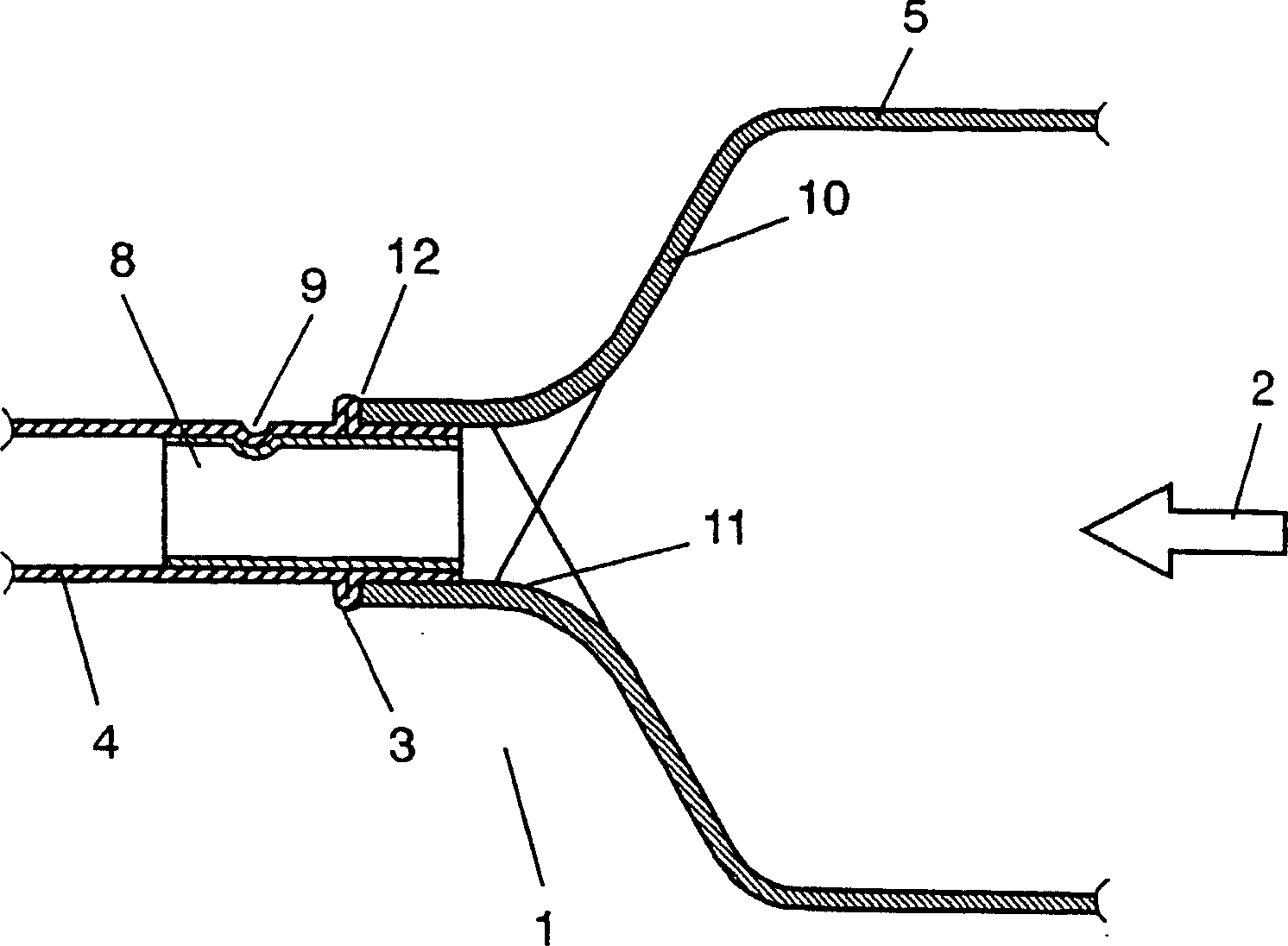

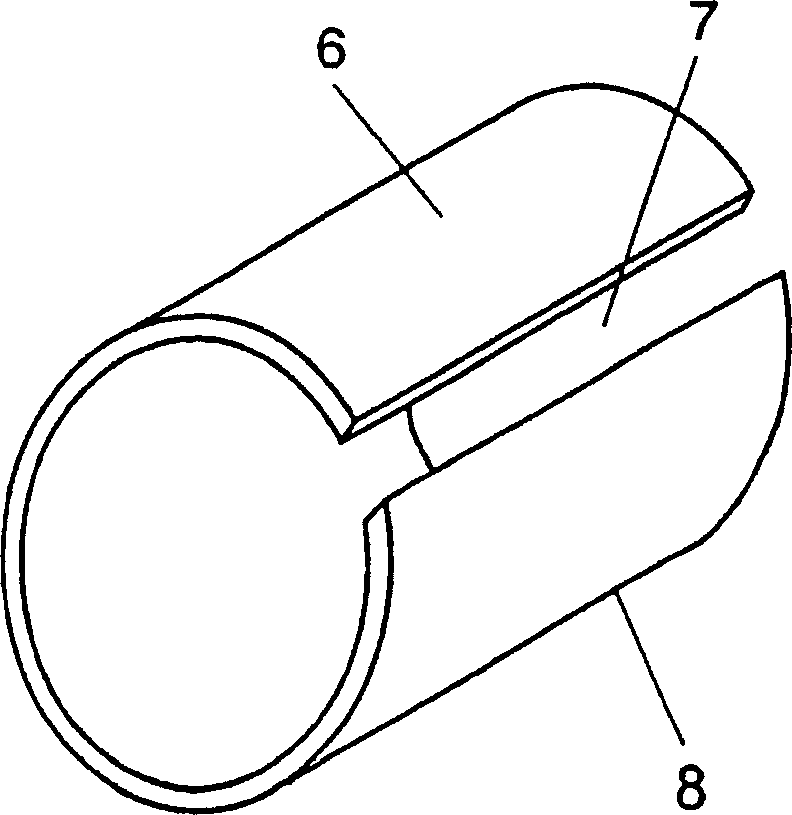

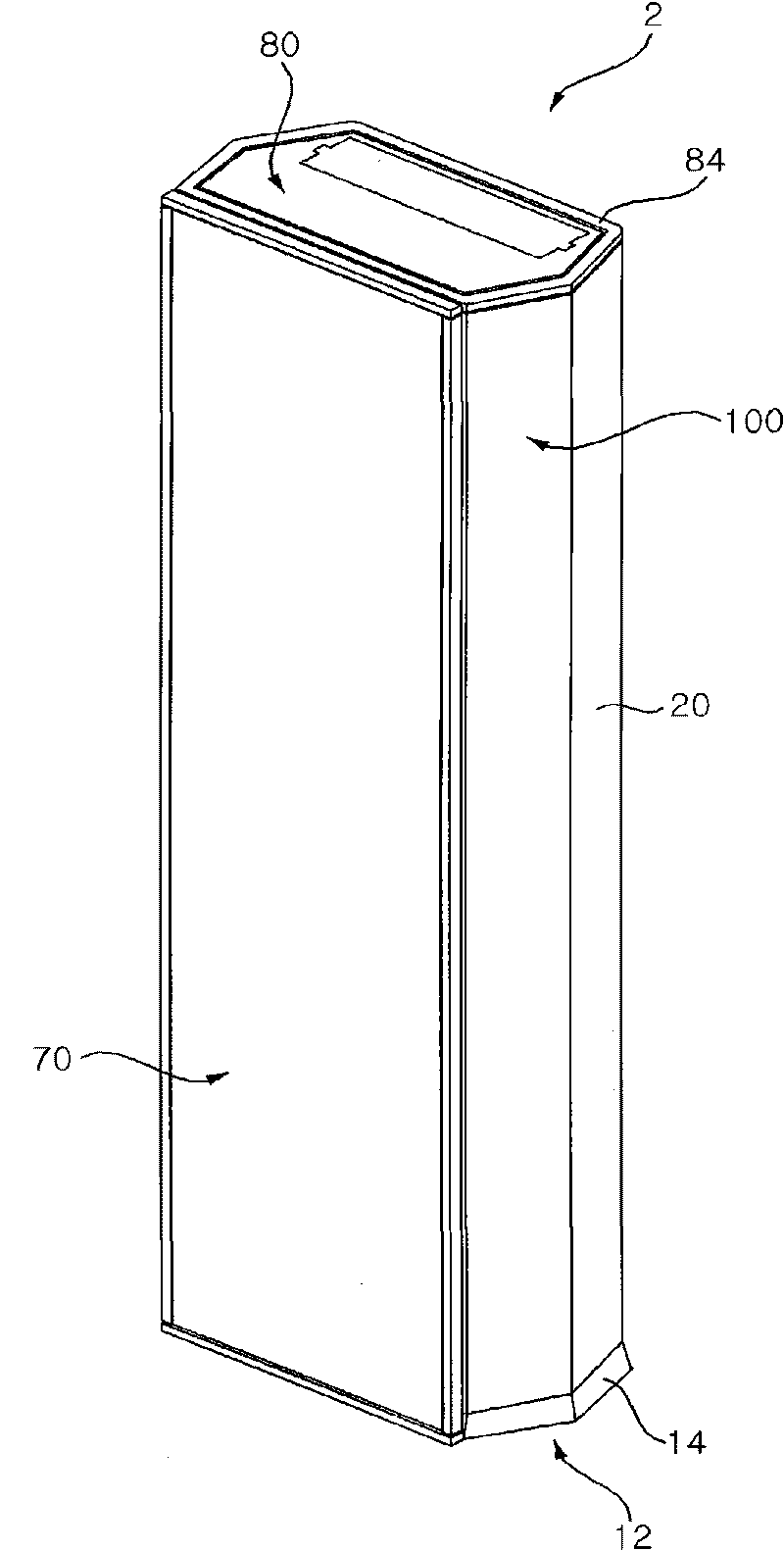

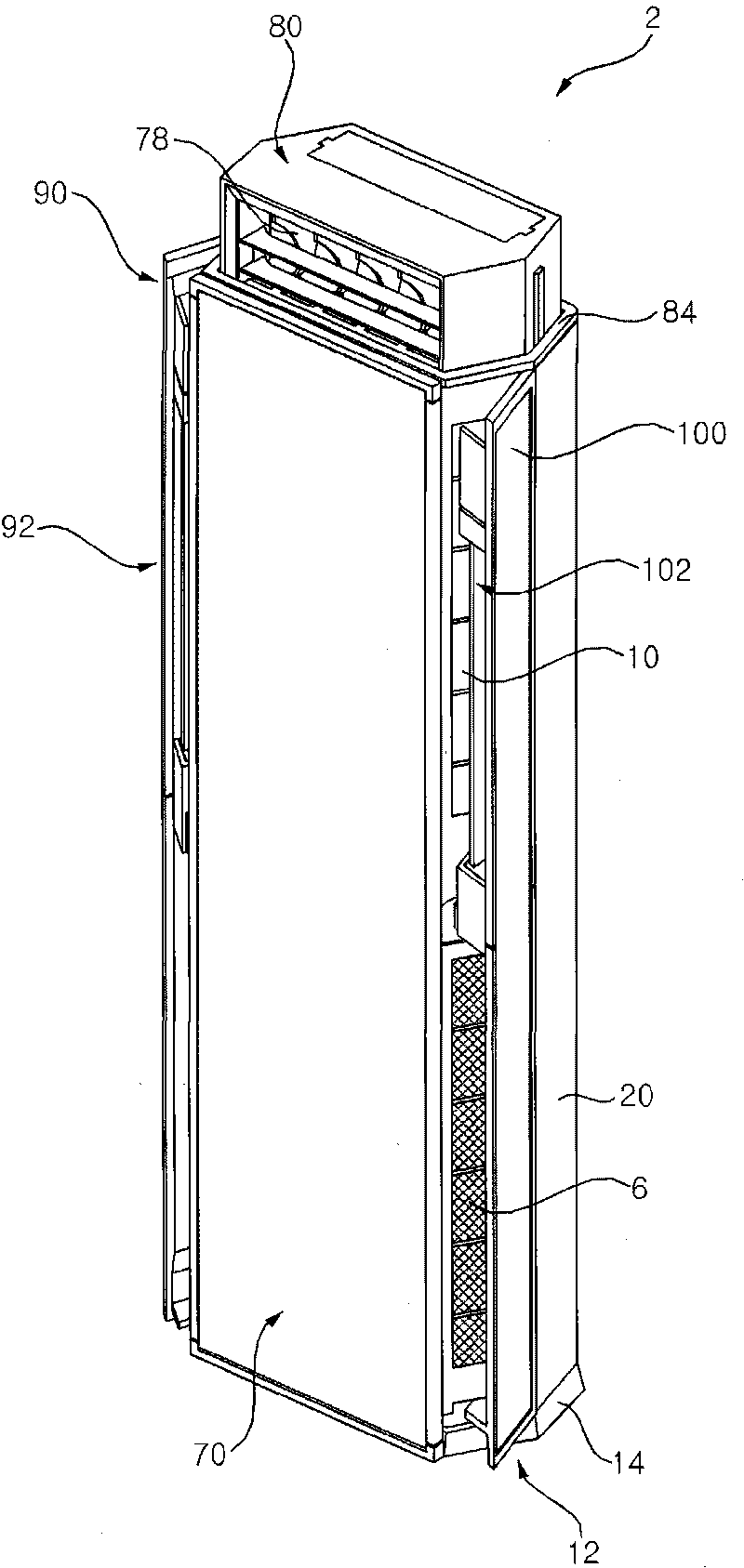

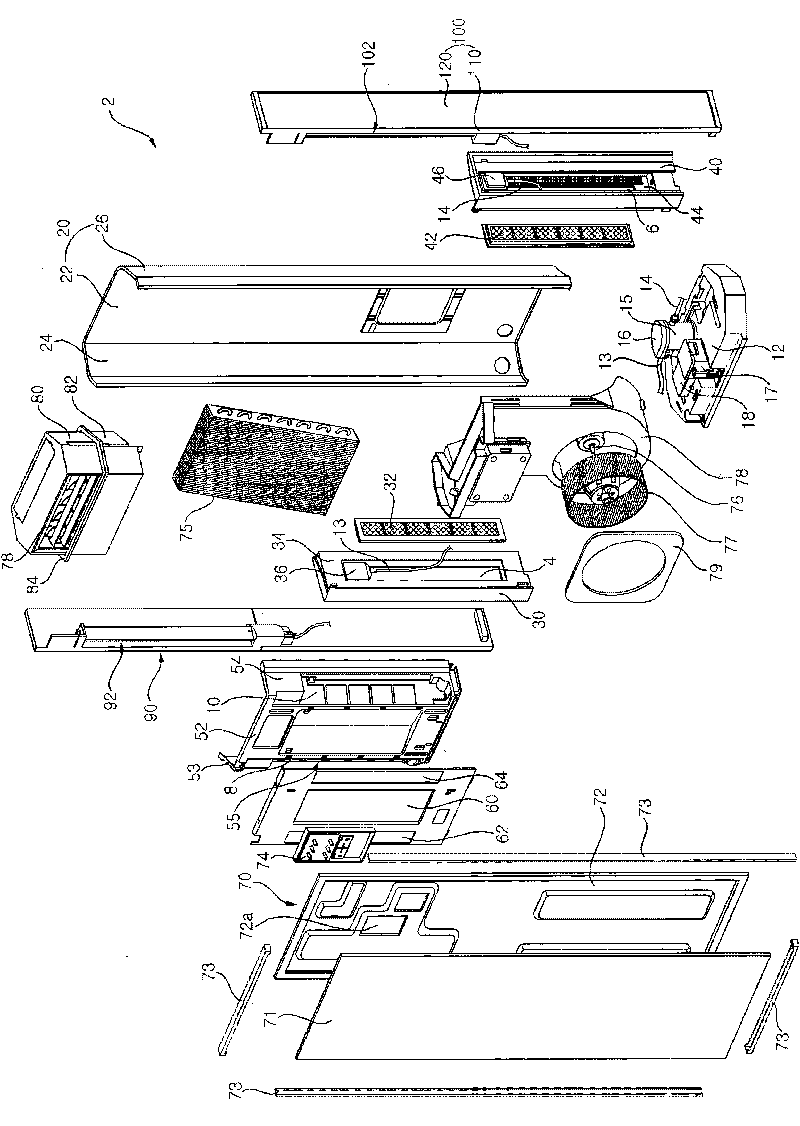

Refrigerator

InactiveCN102735015AReduce in quantityAvoid deflectionDomestic cooling apparatusLighting and heating apparatusWave shapeEngineering

The invention provides a refrigerator which can inhibit vacuum insulation material from bending and reduce the number of distance pieces. A vacuum insulation material (3) supported by a distance piece (60) and polyurethane foam (4) which is injected for foaming and filled in a manner of burying the vacuum insulation material (3) are disposed between an outer casing (1) and an inner casing (2). The distance piece (60) is formed by a rectangular wave-shaped plate (6). Top faces (6a) of protruding parts of the rectangular wave-shaped plate (6) are used as supporting parts of the vacuum insulation material (3), and bottom faces of recessed parts (6b) are used as abutting parts of the outer or inner casing. The top faces (6a) of protruding parts of the rectangular wave-shaped plate (6) are provided with extension parts (6d) extending in a regulated amount along the side direction.

Owner:MITSUBISHI ELECTRIC CORP

Welding structure and welding method for aluminum accumulator and heat exchanger

ActiveCN1910004ADoes not impede flowImprove reliabilityMechanical apparatusEvaporators/condensersAluminiumPlate heat exchanger

A welding structure and a welding method for an aluminum accumulator capable of reducing defective welding and smoothly flowing a refrigerating machine oil and a heat exchanger. The welding structure for the aluminum accumulator comprises an aluminum pipe having a beading processed part, the aluminum accumulator, and a stainless steel sleeve. The stainless steel sleeve is inserted into the end part of the aluminum pipe so that the end face of the stainless steel sleeve matches the end face of the aluminum pipe. The aluminum pipe is inserted into the aluminum accumulator up to the beading processed part, and the aluminum pipe and the aluminumaccumulator are welded to each other at a joint part where the aluminum pipe, the aluminum accumulator, and the stainless steel sleeve are overlapped with each other.

Owner:PANASONIC CORP

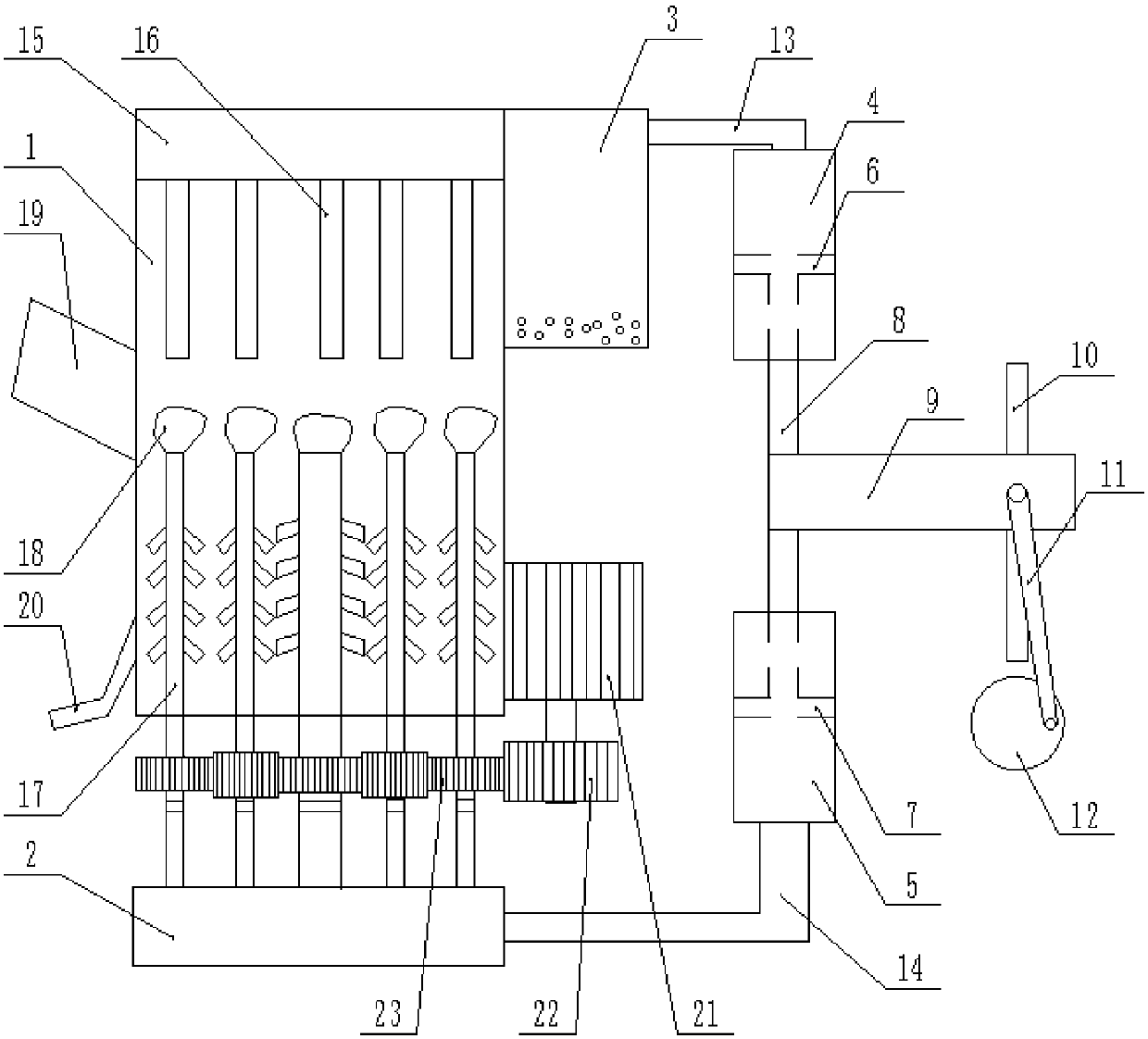

Rice cleaning device

The invention relates to a rice cleaning device. The rice cleaning device comprises a cleaning chamber; a suction cavity is arranged above the cleaning chamber; a gas tank is arranged below the cleaning chamber; one side of the cleaning chamber is provided with an upper piston cavity and a lower piston cavity; a plurality of stirring pipes are rotationally connected in the cleaning chamber; the tops of the stirring pipes are sleeved with balloons; the gas tank is connected with blowing pipes communicating with the bottom ends of the stirring rods; the bottom of the suction cavity communicateswith a plurality of suction pipes, and the bottom ends of the suction pipes extend into the cleaning chamber; the outer side of the cleaning chamber is provided with an impurity storage chamber communicating with the suction cavity; an upper piston is connected in the upper piston cavity in a sliding mode, a lower piston is connected in the lower piston cavity in a sliding mode, and a piston rod is connected between the upper piston and the lower piston; a guide rail, a sliding block and a rotary plate are arranged on one side of the piston rod; the sliding block is connected to the guide railin a sliding mode and connected with the piston rod; a connecting rod is rotationally connected between the sliding block and the rotary plate; the top of the upper piston cavity communicates with the impurity storage chamber; and the bottom of the lower piston cavity communicates with the gas tank. By means of the scheme, impurities floating on the water surface can be removed.

Owner:重庆市合川区云天食品科技有限公司

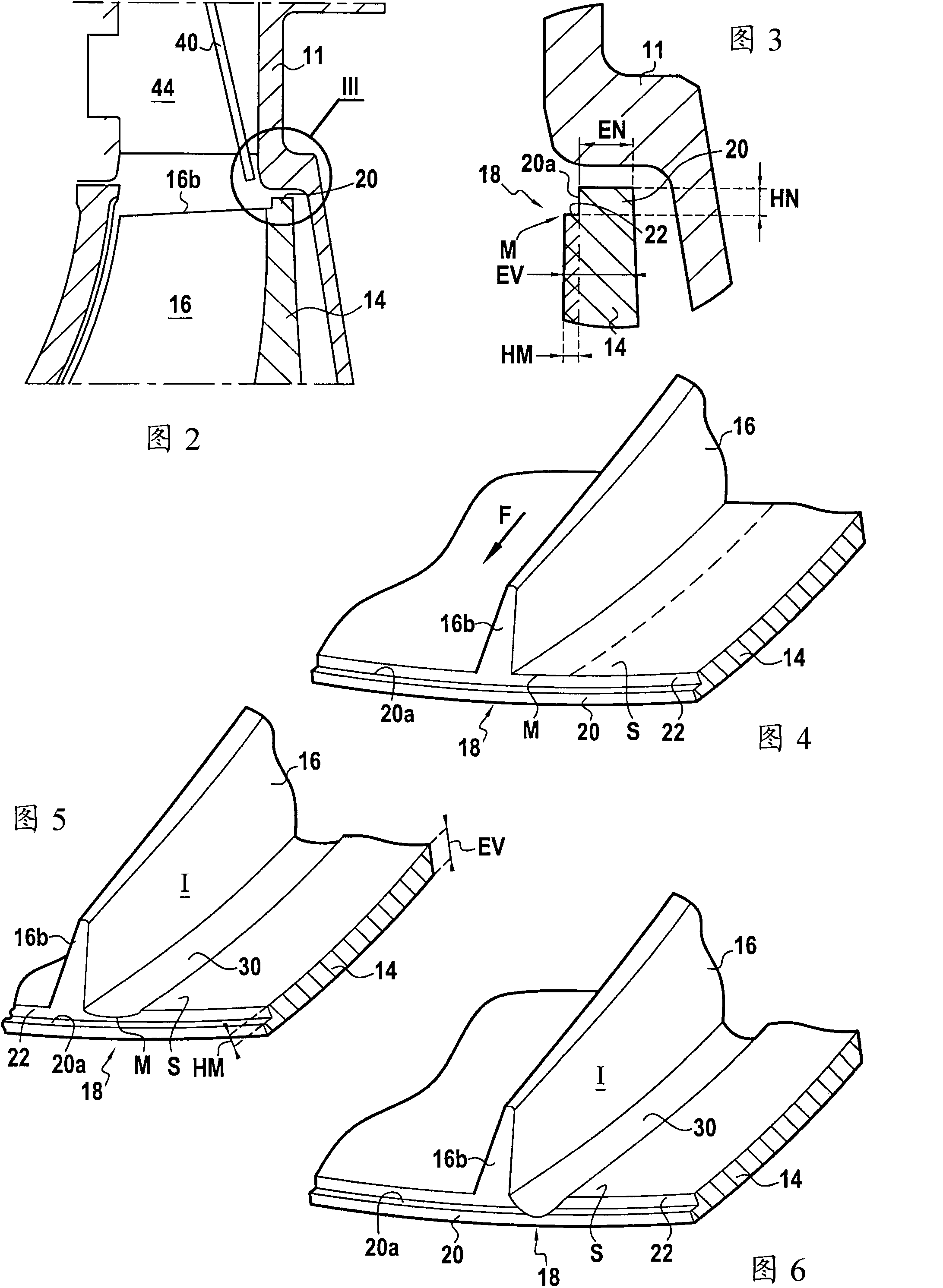

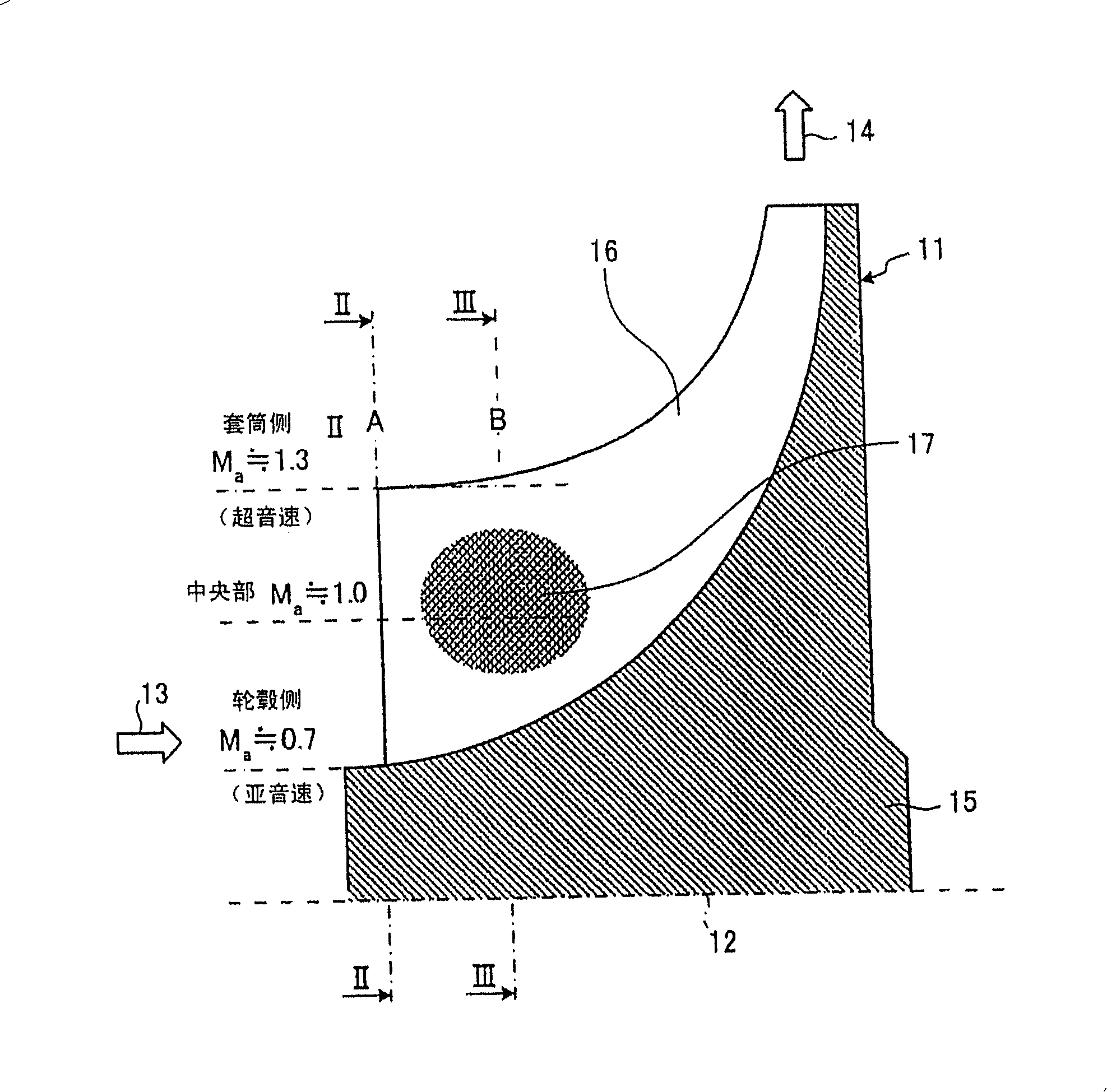

Erosion indicator for compressor wheel

ActiveCN102326003AEasy to checkDoes not impede flowPump componentsEngine fuctionsMechanical engineeringCentrifugal compressor

The invention relates to a centrifugal compressor wheel (10) that comprises a hub (12), a web (14) radially extending from the hub and supporting a plurality of blades (16). The invention is characterized in that the web includes a wheel erosion indicator (18).

Owner:TURBOMECA SA

Spray dust removal device

ActiveCN110237621APlay the role of coveringCan't clean upGas treatmentUsing liquid separation agentMain channelEngineering

The invention relates to the field of dust removal, and particularly discloses a spray dust removal device. The spray dust removal device comprises a water mist generator and a spray head; the spray head is internally provided with an injection channel and an arc-shaped cavity with an arc surface, wherein the spray channel communicates with the arc cavity; a cleaning ball with a diameter smaller than the diameter of the arc cavity is contained in the arc cavity; the cleaning ball comprises a spherical central body and a plurality of flexible parts fixed on the outer wall of the central body; a plurality of ventilating channels are formed in the central body; and the spray head is provided with a main channel for communicating the arc cavity with the water mist generator. When the spray dust removal device is used, dust inside the spray head can be automatically cleaned, so that the dust is prevented from blocking the spray head.

Owner:CHONGQING VOCATIONAL INST OF ENG

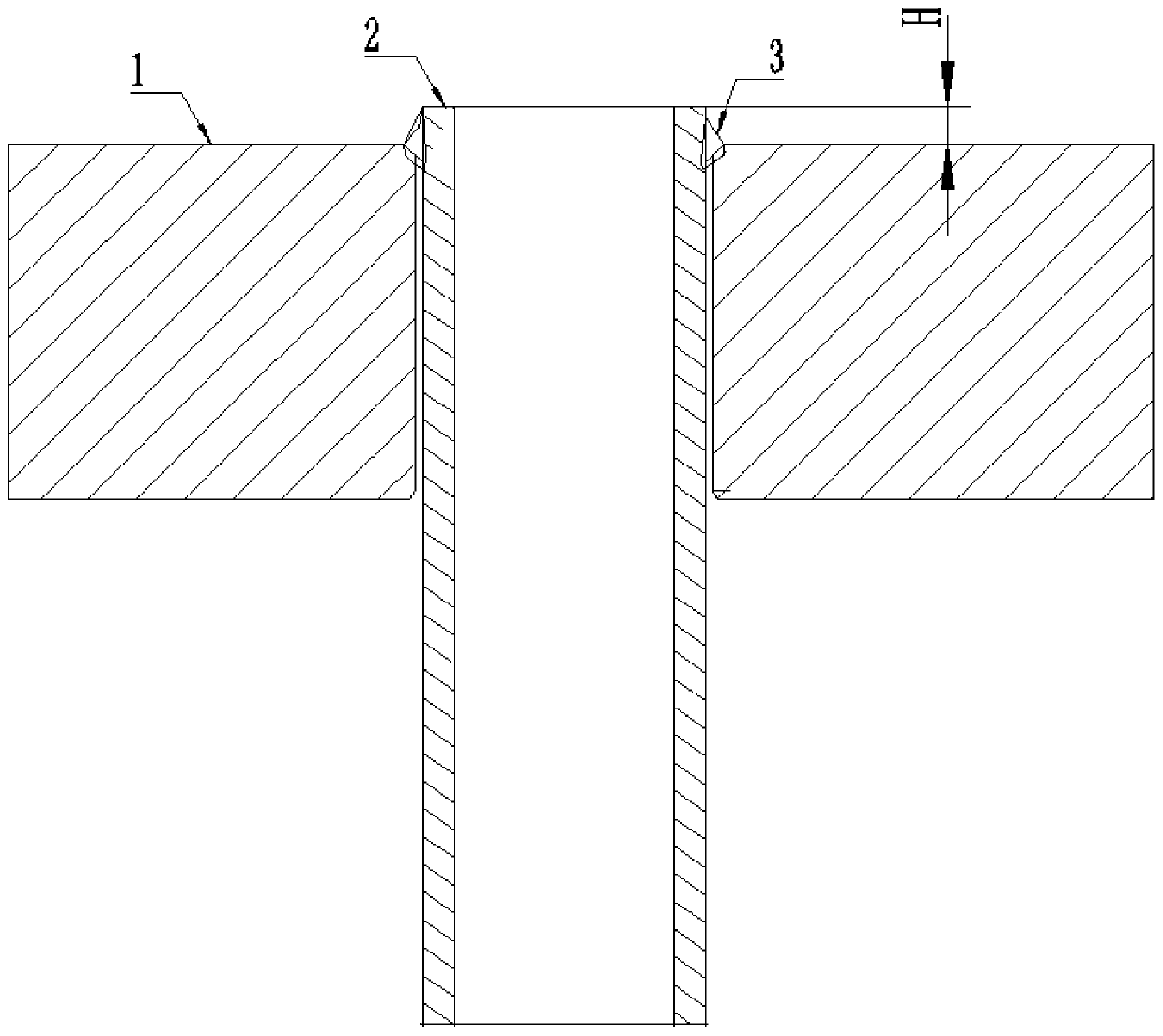

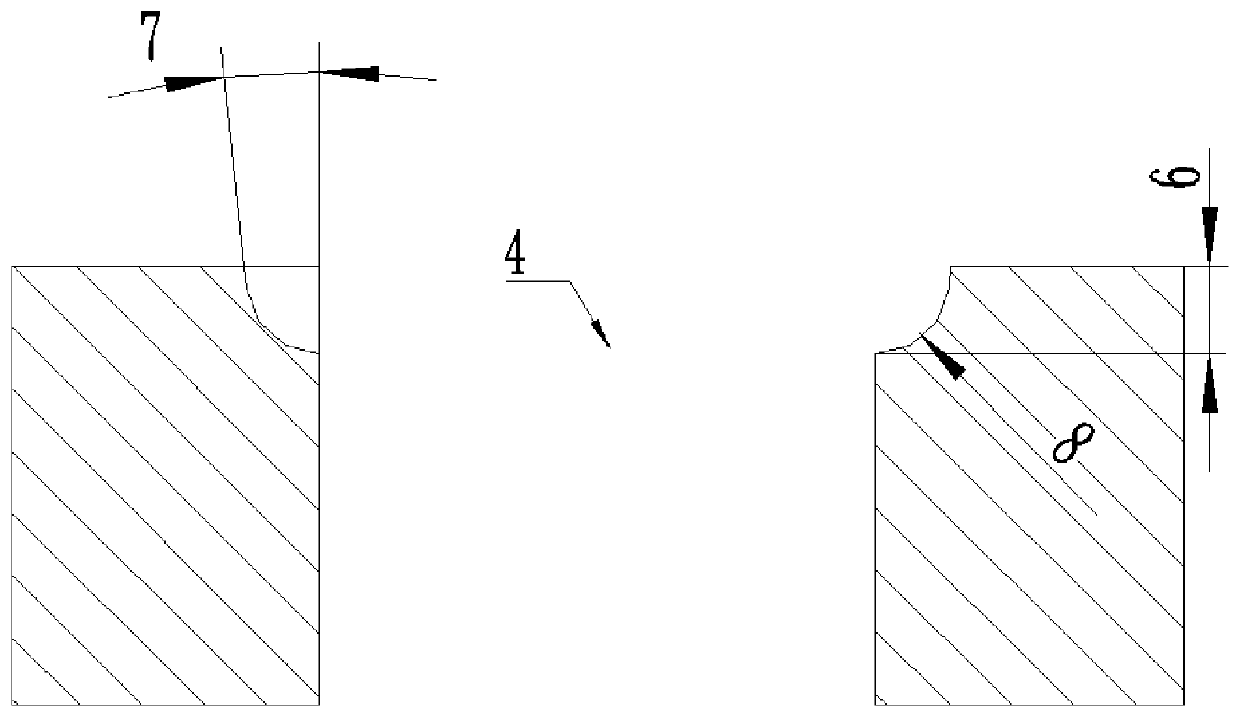

Heat exchange pipe and pipe plate welding method and application thereof

PendingCN110682024AAvoid corrosionEasy to integrateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention relates to the technical field of heat exchanger preparation, in particular to a heat exchange pipe and pipe plate welding method and application thereof. The method comprises the following steps of (1) chamfering at the edge of a pipe hole, and then inserting a heat exchange pipe into the pipe hole so as to be paired with a pipe plate, wherein the end port of the end to be welded ofthe heat exchange pipe is lower than the end surface of the pipe plate, but the pipe wall of the heat exchange pipe can always contact the wall surface of the pipe hole, and a 'U'-shaped groove is formed; and (2) welding the heat exchange pipe and the pipe plate which are assembled in the step (1), connecting the end surface of the pipe plate and the end port of the end to be welded of the heat exchange pipe through a welding seam, then processing the welding seam to form an arc shape, and enabling the form of the welding seam to be in a streamline shape. According to the heat exchange pipe and pipe plate welding method and the application thereof provided by the invention, the end port of the end to be welded of the heat exchange pipe is lower than the end surface of the pipe plate, namely, the heat exchange pipe is retracted for a certain distance relative to the end surface of the pipe plate, so that the form of the welding seam can be in the streamline shape, meanwhile, the thickness of the welding seam is larger than the thickness of a welding seam under a traditional welding manner, and the binding force between the heat exchange pipe and the pipe plate is improved.

Owner:LUXI IND EQUIP

Centrifugal compressor and manufacturing method for impeller

A centrifugal compressor and a method of manufacturing an impeller, the method wherein a projected part (17) is formed at the approximately radial center part of the impeller (11) on the negative pressure surface side of its a blade (16) so as to form a curve from the leading edge part (A) to the throat part (B) thereof. The projected part (17) is formed to be curved and then to be flat from the throat part (B) to the trailing edge part thereof. The projected part (17) is formed at a position where the relative inflow velocity of the fluid into the impeller (11) is nearly 1 in Mach number Ma. Thus, since an operating efficiency can be increased and an applicable flow range can be increased, the performance of the impeller can be increased.

Owner:MITSUBISHI HEAVY IND LTD

Thickening machine

ActiveCN101357271AImprove stabilityDoes not impede flowSedimentation settling tanksEmulsionPower unit

A thickener comprises a tank body with a sand discharge hole at the bottom thereof and a feed inlet at the top thereof, a power unit which is arranged at the top of the tank body, a stirring device which is arranged inside the tank body and is driven by the power unit to rotate, a nozzle which is arranged on the outer wall of the tank body and comprises a spout formed on the tank body, and a cover body which is fastened at the spout and fixed on the outer wall of the tank body. A connection part is arranged on the cover body, and suitable for connecting with a pipeline outside the tank body, the inner cavity of the cover body is communicated with the inner cavity of the tank body by the spout so as to eject fluid to the inner cavity of the tank body. The thickener is additionally provided with a nozzle which can regulate the material thickness inside the tank body and is helpful in discharging the material. Furthermore, the spout inside the nozzle is arranged on the tank body wall, and the cover body is fixed on the outer wall of the thickener, an emulsion tube is not needed to be provided in the cover body, thus the thickener has the advantages of simple structure and long service life.

Owner:CHINA ENFI ENGINEERING CORPORATION

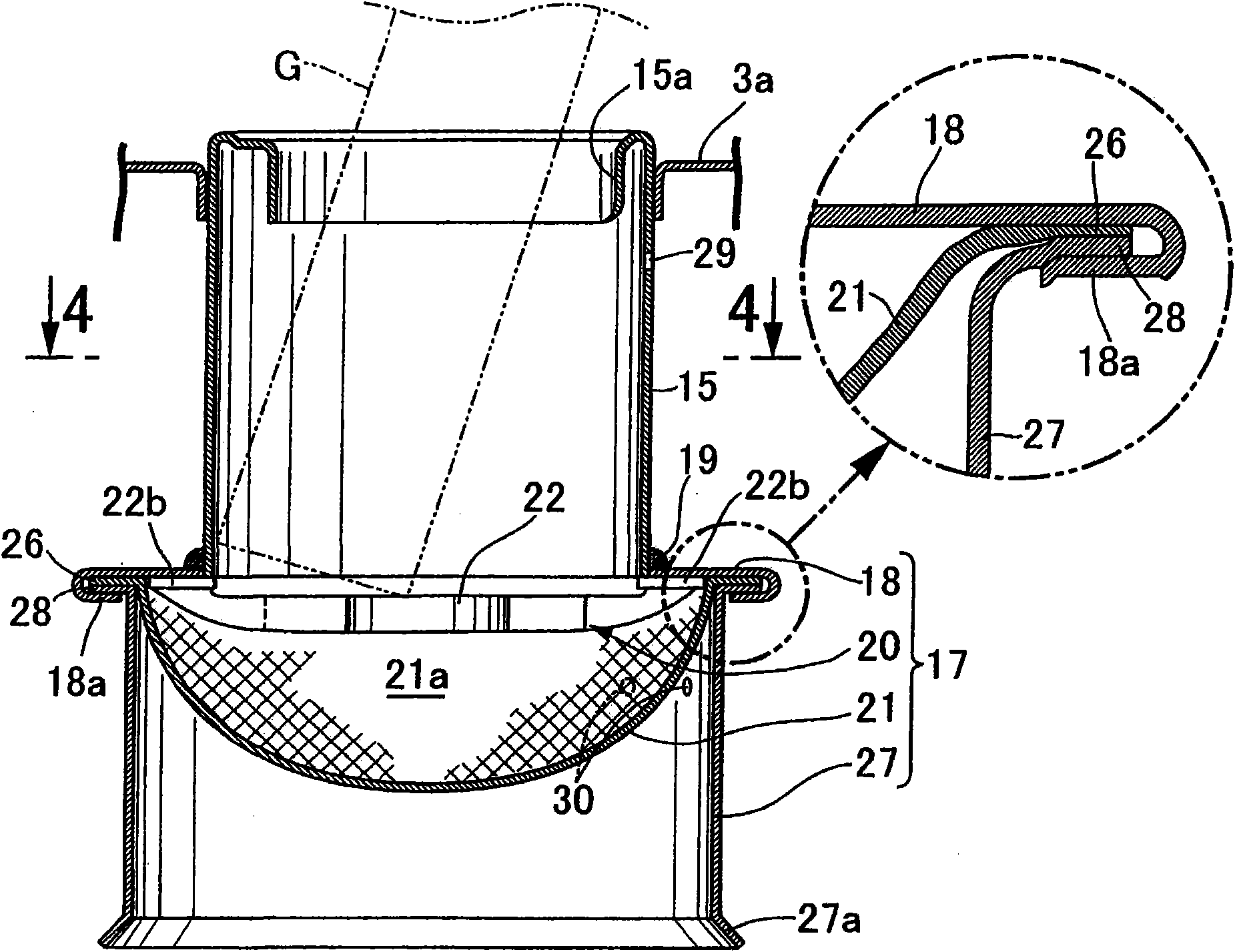

Fuel filling device for vehicle fuel tank

Owner:HONDA MOTOR CO LTD

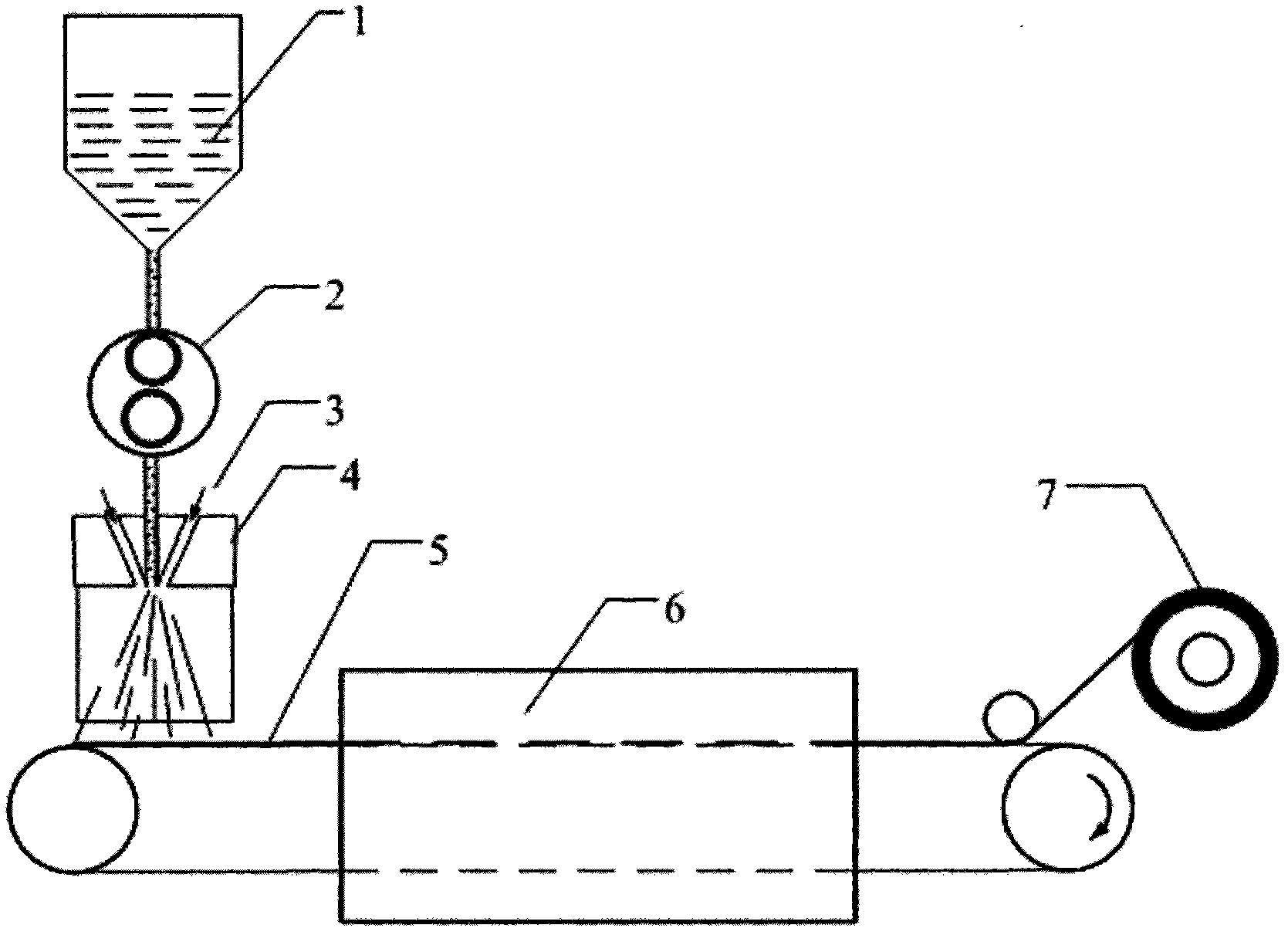

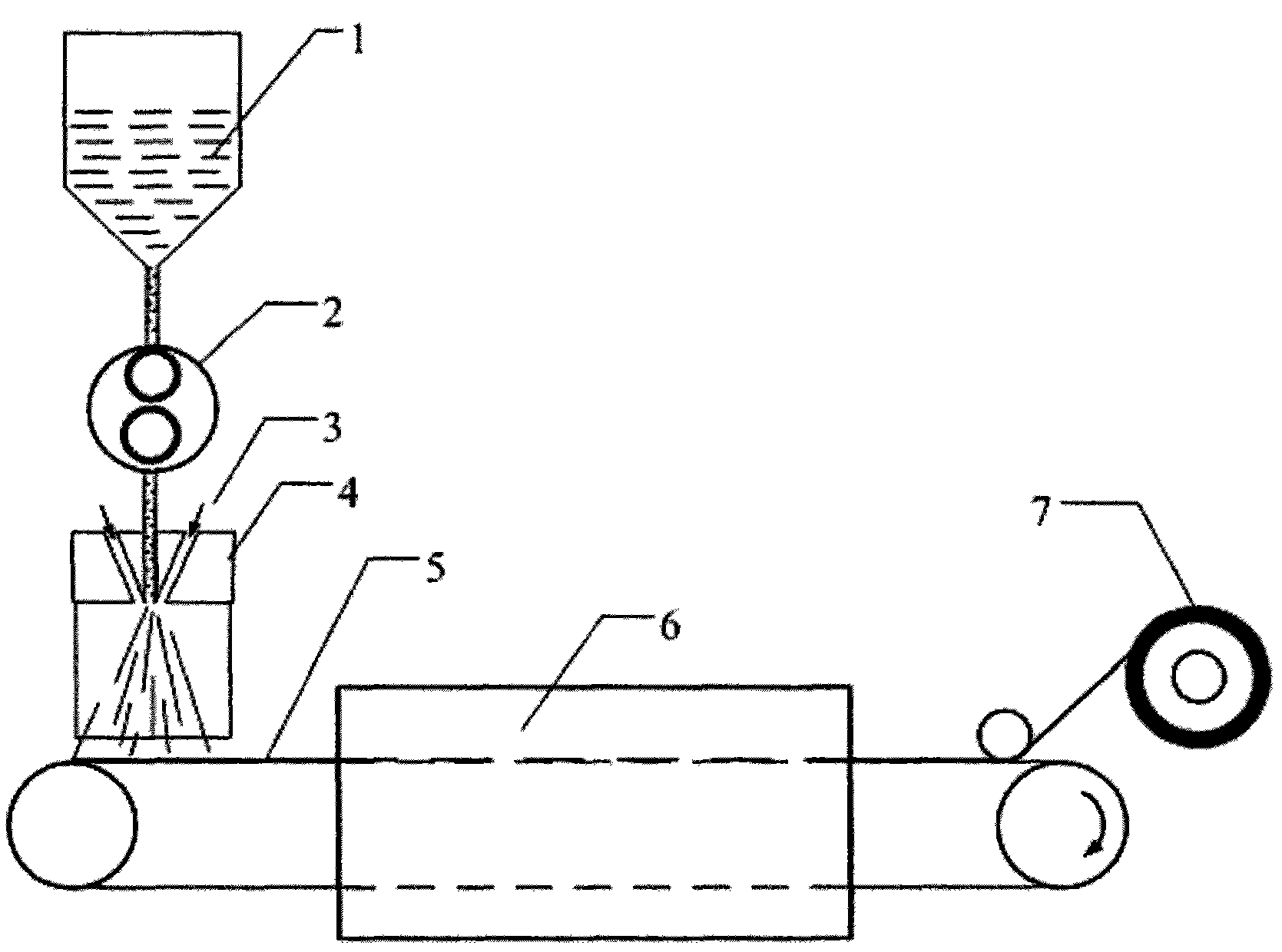

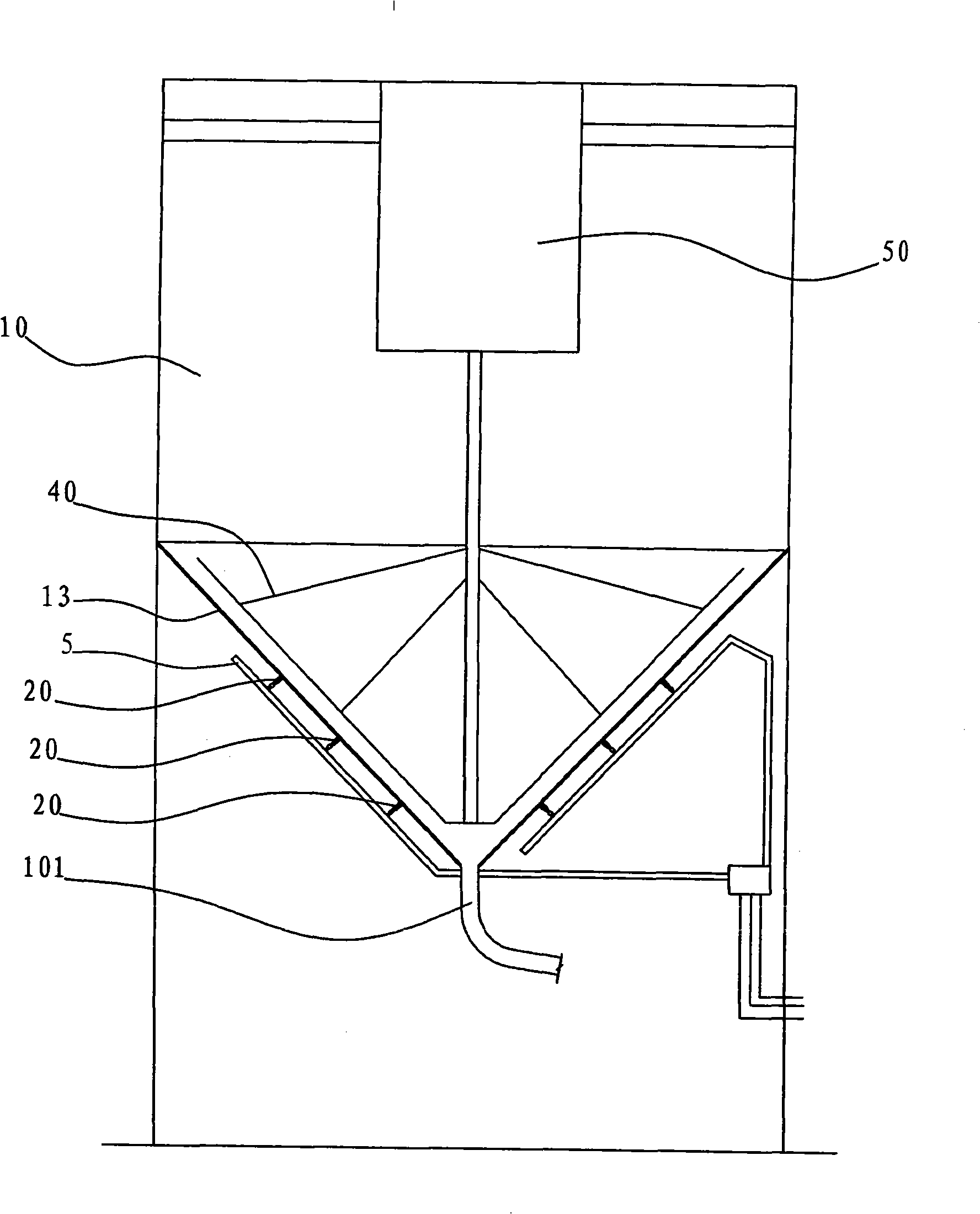

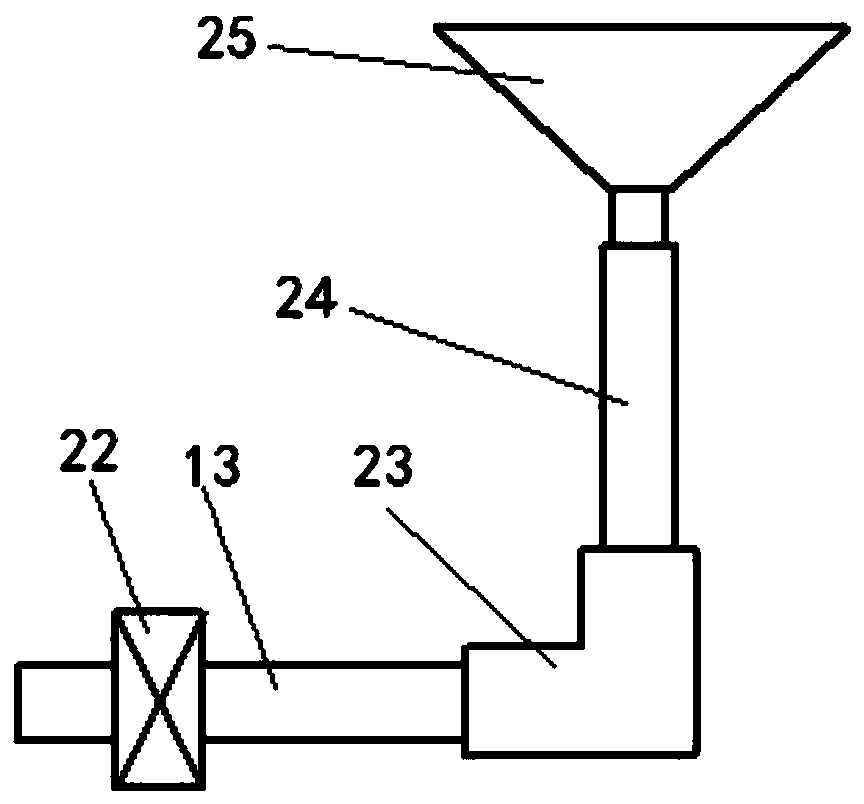

Sand warehouse for filling device

A sand bunaker used in a filling device includes a body, a pipeline and a jet nozzle. The bottom part of the body is provided with a hole for holding sand; besides, a through hole is arranged on the wall of the body; the pipeline is fixed on the outer wall of the body and is suitable for being connected with a fluid source; the jet nozzle is arranged on location of the through hole and is arranged on the outer wall of the body; the jet nozzle is communicated with the pipeline; the inner cavity of the jet nozzle is communicated with the inner cavity of the body by the through hole, thereby jetting the fluid to the inner cavity of the body. The pipeline and the jet nozzle of the invention are arranged outside the body; the pipeline and the jet nozzle are mounted and changed from the outside of the body; thus being more simply arranged and more conveniently maintained; the pipeline and the jet nozzle can not be impacted or eroded by the materials in the body, thus prolonging the service life of the jet nozzle; simultaneously, the floating of the materials in the body can not be baffled, thereby being beneficial to successfully discharging the materials in the body.

Owner:CHINA ENFI ENGINEERING CORPORATION

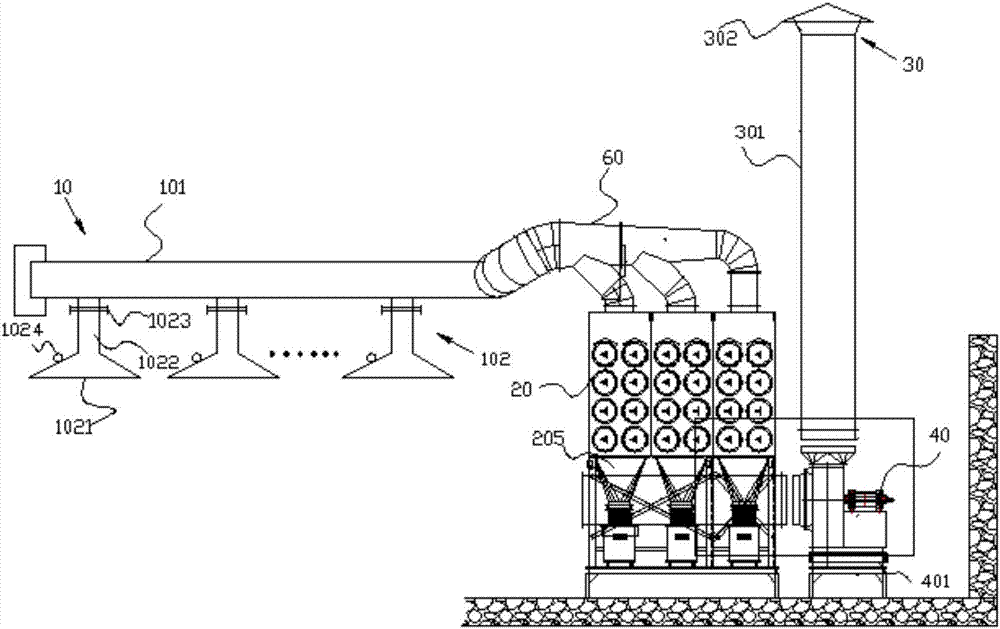

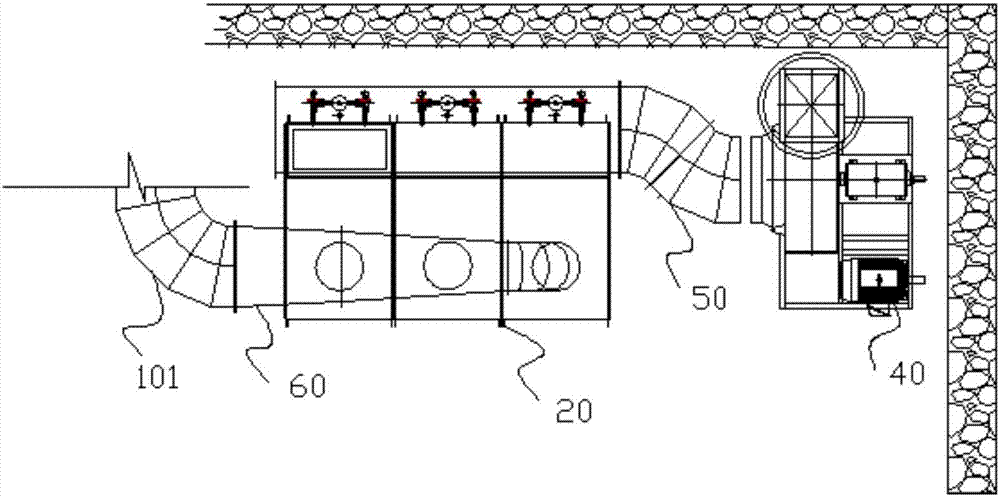

Dust treatment system for dusting workshop

InactiveCN107970705AImprove filtering effectSlow down the flowDispersed particle filtrationTransportation and packagingEmission standardEngineering

The invention discloses a dust treatment system for a dusting workshop. The dust treatment system for the dusting workshop comprises a dust collecting device, a horizontal filter drum type dust collector and a smoke exhausting device which are sequentially arranged in a dust flow direction, and an induced draft fan is further arranged on a dust flow channel; the dust collecting device communicateswith the horizontal filter drum type dust collector, and the horizontal filter drum type dust collector communicates with the smoke exhausting device; the horizontal filter drum type dust collector is provided with at least one dust treatment bin, each dust treatment bin comprises a first support, a bin body, an exhaust gas inlet, a clean air outlet and a dust collecting hopper. The dust treatment system for the dusting workshop, disclosed by the invention, is adopted to perform centralized treatment on dust in the workshop, so that the dust with large particle size is prevented from enteringa filter cylinder, dust airflow flowing into the equipment can be uniform, the flow velocity of the dust airflow on the outer wall of the filter cylinder is decreased, the filter effect of the filtercylinder is improved, the cleanliness of discharged gas is enhanced, the dust concentration in the gas is less than or equal to 30mg / m3, noise can be reduced to 30 to 40dB, the effects of sound elimination and noise reduction are ideal, national emission standards are met, and the standards of the dust treatment system for the dusting workshop are higher than the national emission standards.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

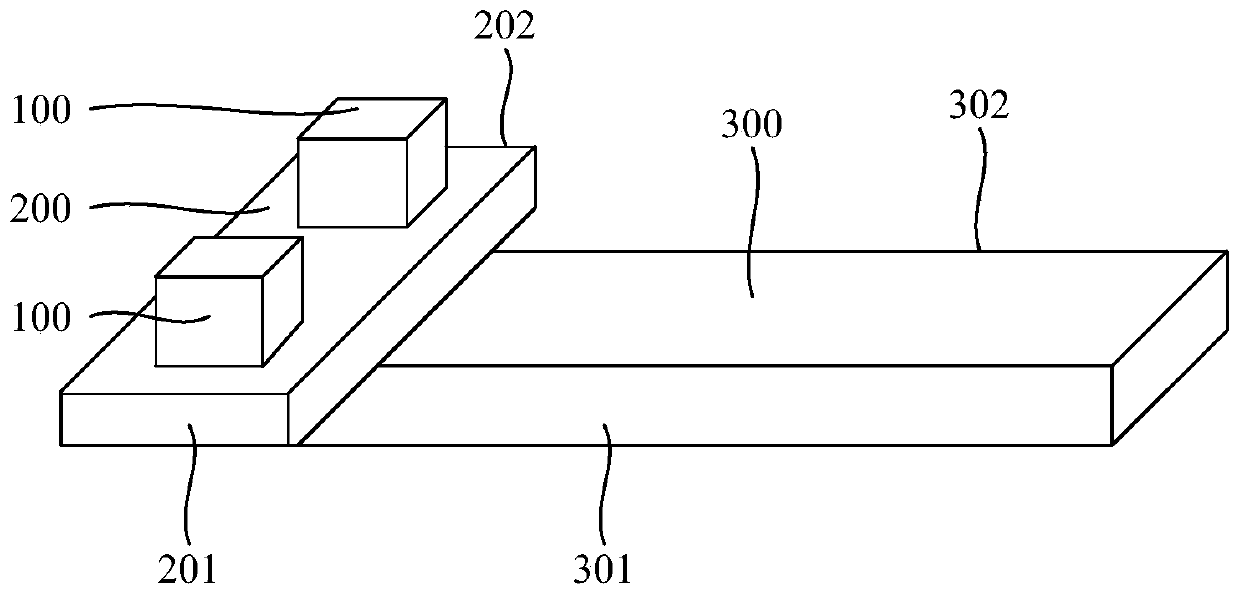

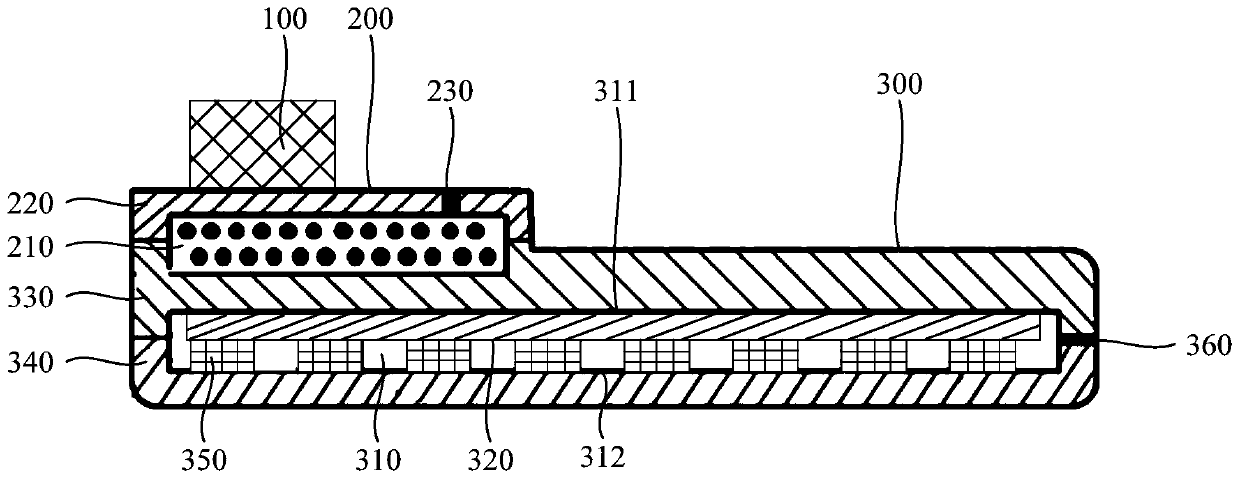

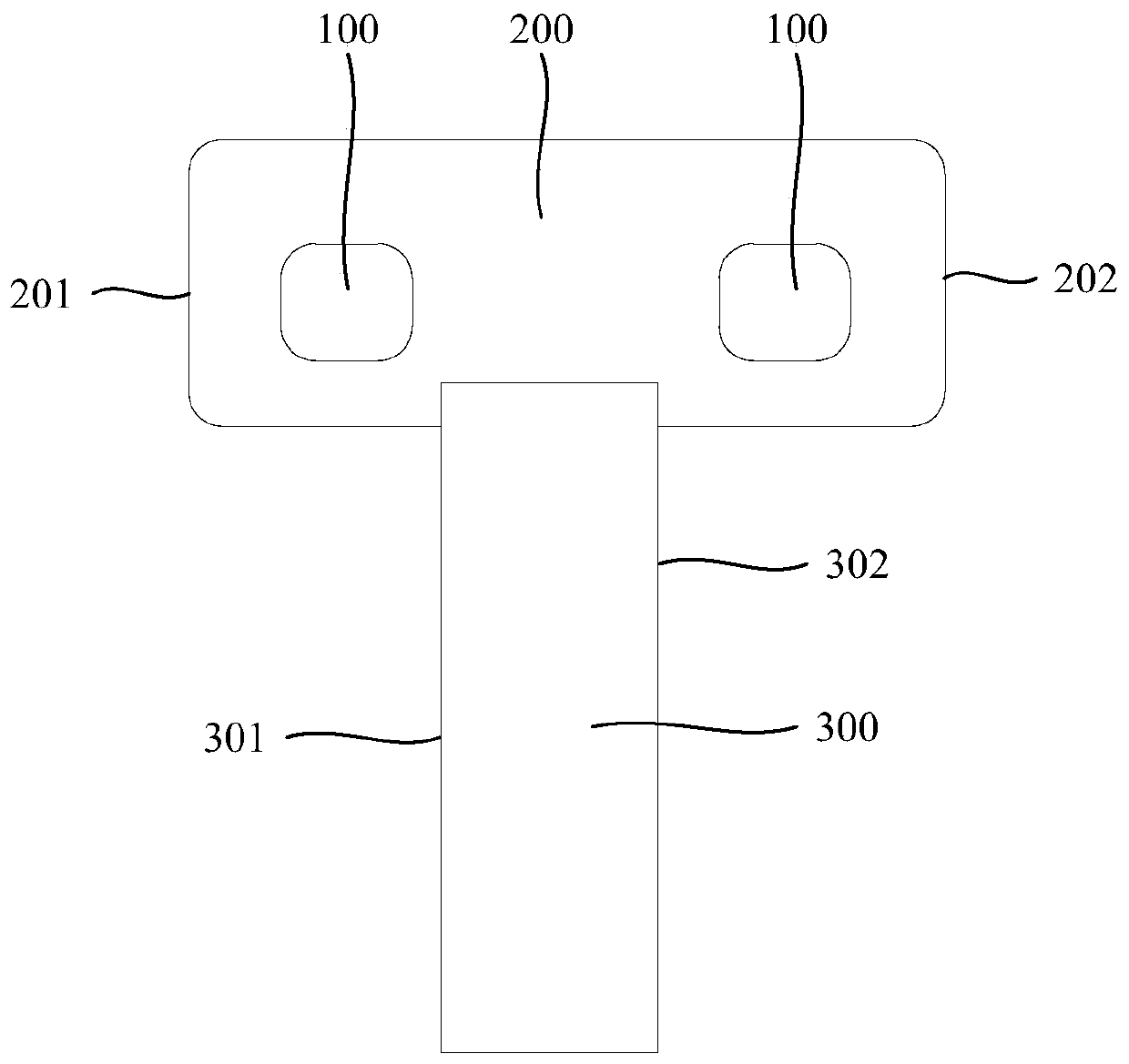

Heat dissipation assembly and electronic equipment

ActiveCN110621144ADoes not impede flowImprove securityModifications using liquid coolingModifications by conduction heat transferHeat conductingSoftware engineering

The invention discloses a heat dissipation assembly and electronic equipment. The heat dissipation assembly comprises at least one component, a heat collection part, and a heat dissipation part, wherein the heat collection part is provided with a first inner cavity, the first inner cavity is filled with a heat conducting medium, the heat collection part is in contact with the component, the heat dissipation part makes contact with the heat collection part, the heat dissipation part is provided with a second inner cavity, the second inner cavity is filled with the heat dissipation medium, the heat dissipation medium is a phase change medium, and a capillary structure is arranged in the second inner cavity. The heat dissipation assembly is advantaged in that the heat of the component is gathered on the heat collection part, the heat gathered on the heat collection part is radiated out through the heat dissipation part, due to the fact that the heat of the components around the heat dissipation part is gathered on the heat collection part, flowing of the phase change medium in the heat dissipation part cannot be hindered, heat transfer circulation in the heat dissipation part is smoothly completed, and safety and reliability of the electronic equipment are improved.

Owner:VIVO MOBILE COMM CO LTD

Automobile exhaust treatment ammonification system

PendingCN109488423ALow costLarge assembly spaceInternal combustion piston enginesExhaust apparatusUreaDiesel particulate filter

The invention relates to an automobile exhaust treatment ammonification system. A transition part between a diesel particulate filter (DPF) input end and an SCR output end comprises a transition partshell and a transition cavity arranged in the transition shell; the transition shell comprises a transition front plate, a transition rear plate and an annular transition side body clamped between thetransition front plate and the transition rear plate; a front plate inlet and a front plate outlet are formed in the top part and the bottom part of the transition front plate; a flow-guiding panel is clamped into the front plate inlet; an arc-shaped crusher and a flow-guiding bend pipe are arranged at the position, close to the front plate inlet, in the transition cavity; the flow-guiding panel,the arc-shaped crusher, the flow-guiding bend pipe, the transition rear plate and the transition side body enclose to form a No.1 cavity communicating with the transition cavity; and a urea sprayinghole communicating with the No.1 cavity is formed in the top part of the transition side body. According to the design, no mixer needs to be extraly arranged, so that the cost and the assembling spaceare saved, the risk of urea crystallization can be reduced, and an ammonia gas generation effect is good.

Owner:DONGFENG COMML VEHICLE CO LTD

Irrigation filtering apparatus

The invention discloses an irrigation filtering apparatus. The apparatus comprises a primary filter, a water inlet pipe, a water return pipe, a water return valve, a connection pipe, a secondary filter, a water pump, a filter installation pipe and a water outlet pipe, wherein two ends in the axial direction of the connection pipe are respectively provided with an inlet and a first outlet, the sidewall of the connection pipe is also provided with a second outlet, the primary filter is connected with one end of the water inlet pipe, the other end of the water inlet pipe is connected with the inlet, two ends of the filter installation pipe are respectively connected with a water inlet of the water pump and the second outlet, the secondary filter is arranged in the filter installation pipe, the water inlet end of the secondary filter extends into the connection pipe and a flow gap exists between the water inlet end of the secondary filter and the inner wall of the connection pipe, one endof the outlet pipe is connected with a water outlet of the water pump, the water return pipe is connected with the first outlet, and the water return valve is arranged on the water return pipe. The two-stage filters filter irrigation water, the blocking or damaging of the water pump by impurities is prevented, the water flow takes away the impurities at the secondary filter by opening the water return valve, the impurities are self-cleaned, and thereby the continuous operation of the irrigation filtering apparatus is ensured.

Owner:AGRI INFORMATION INST OF CAS

Air conditioner

InactiveCN101737871ADoes not impede flowMaximize airflow resistanceSpace heating and ventilation safety systemsLighting and heating apparatusWind directionAerospace engineering

An air conditioner according to the invention comprises the following components: a body which is formed with an air suction inlet; a discharge outlet body which is installed on the body with a liftable mode and is formed with an air discharge outlet; a plurality of left-and-right wind direction adjusting components which are rotatablely installed on the inner side of discharge outlet body; a left-and-right rotation mechanism which rotates the plurality of left-and-right wind direction adjusting components; and a supporting member which is formed with a plurality of supporting feet that support the left-and-right wind direction adjusting components and is formed with a path for the passing of air among the plurality of supporting feet. The left-and-right wind direction adjusting components are positioned at the deep part of inner part of discharge outlet body and can prolong the guiding length. Therefore the air conditioner according to the invention has the advantage that the discharged air can be discharged and diffused to a far position and the air flow is smooth.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com