Patents

Literature

50results about How to "Large assembly space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

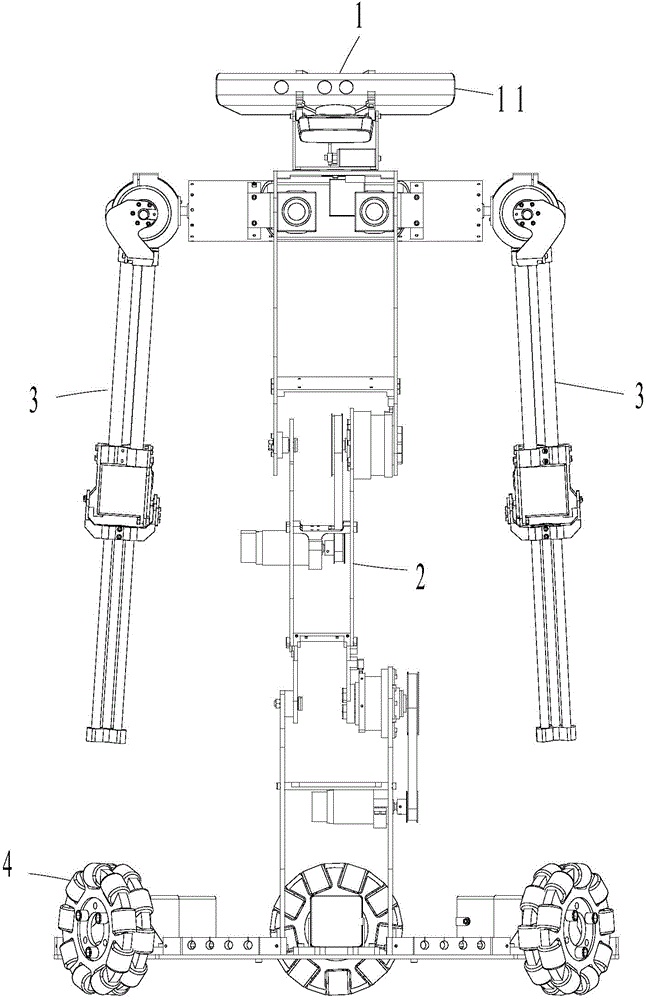

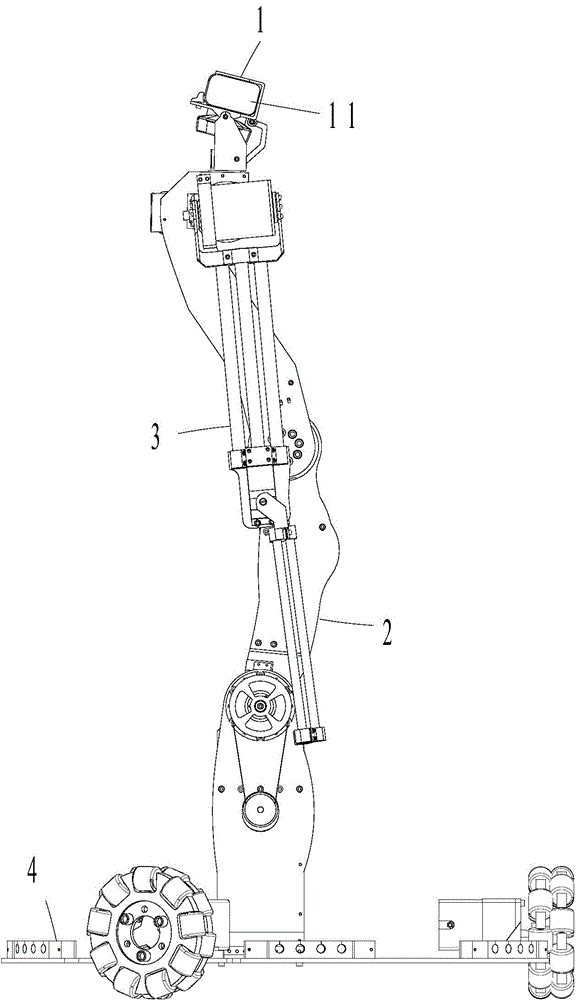

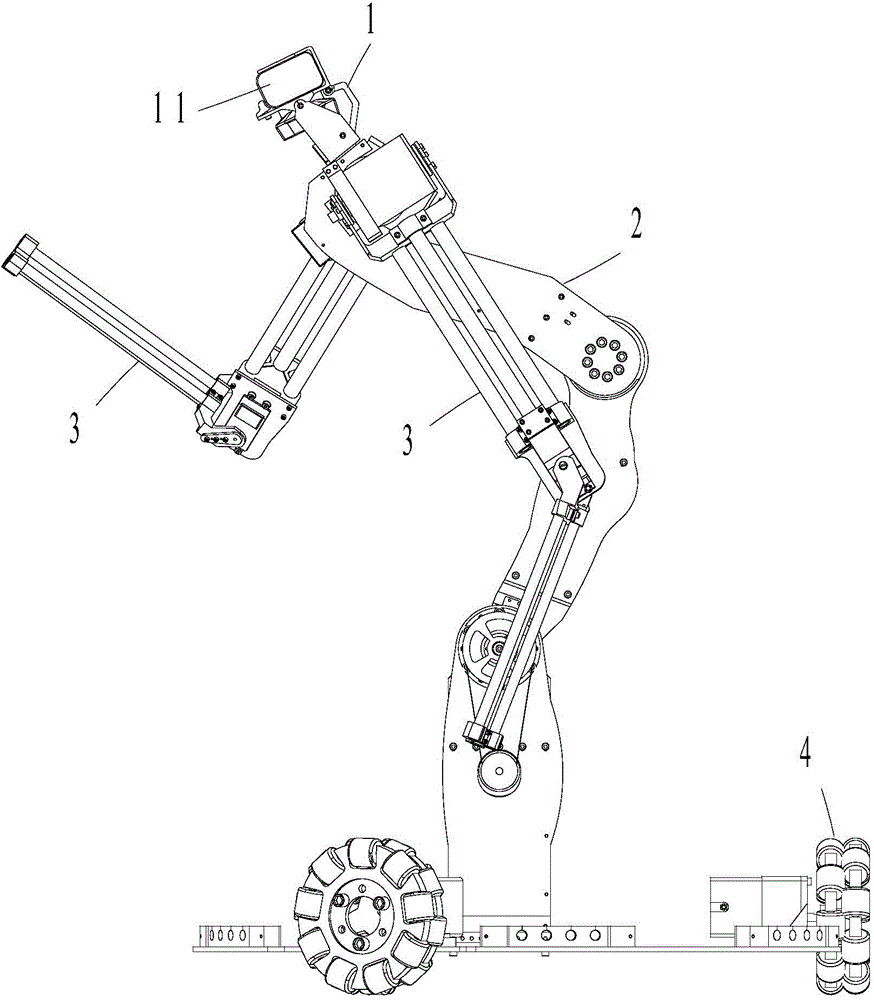

Home service robot

The invention discloses a home service robot which comprises a body, a head, upper limbs and a bottom disc. The head is rotationally arranged on the body and comprises a visual sensor used for acquiring external environment information. The upper limbs comprise two upper limb frameworks which are located on the two sides of the body and can be bent. The bottom disc can move horizontally and rotate. The body can be bent. The visual sensor transmits the information to a control system. The control system controls the body, the head, the upper limbs and the bottom disc to move. The home service robot acquires the external environment information through the visual sensor, through processing of the control system, the bottom disc is driven to move forwards, backwards, leftwards and rightwards and rotate, the body can be driven to be bent, the upper limbs can be driven to move, and various human-imitating actions of the robot can be achieved; and in the target tracking processing process, the robot can track a target, the robot is suitable for home services and other service occasions, and the robot can particularly conduct human-imitating accompanying and care work for an old person living alone or a patient.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

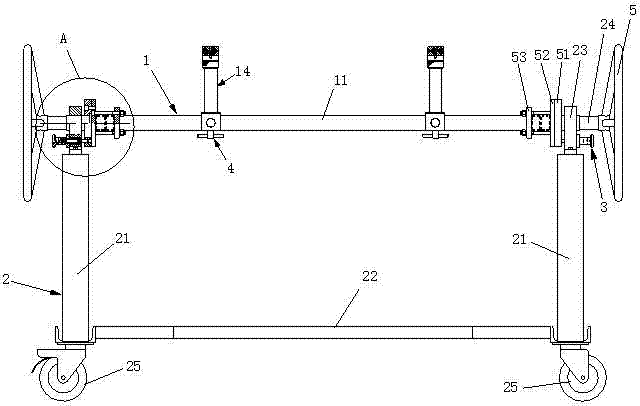

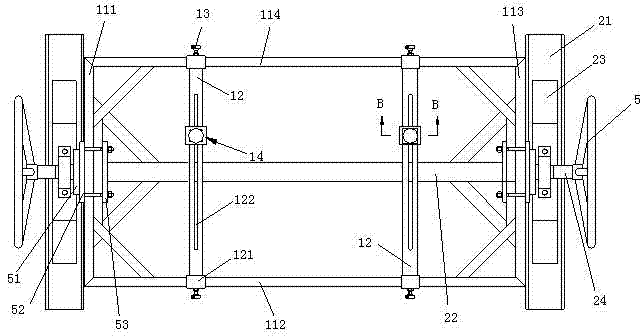

Overturning tool for mounting instrument desk electric appliance

The invention relates to an overturning tool for mounting instrument desk electric appliance. The overturning tool comprises a supporting device used for fixedly supporting an instrument desk, wherein the supporting device is fixedly arranged on an underframe; rotational cooperation is formed between the supporting device and the underframe; and a positioning device used for fixing the rotating position of the supporting device is also arranged on the underframe. According to the technical scheme, the instrument desk is fixedly arranged on the supporting device and is at the proper position where the electric appliance is convenient to mount through the rotation of the supporting device, the supporting device is positioned through a positioning device, the electric appliance is conveniently assembled by an assembling worker, the whole assembling process is operated offline, the assembling space is large, the operation is simple and convenient to perform, the online time is not taken, and the assembling efficiency and the assembling quality are improved.

Owner:ANHUI ANKAI AUTOMOBILE

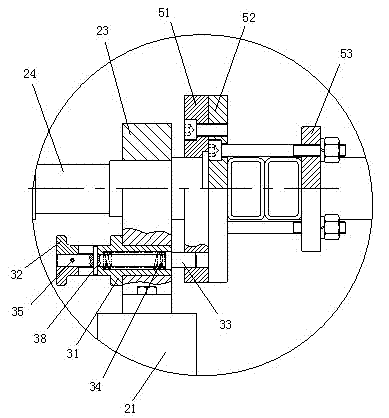

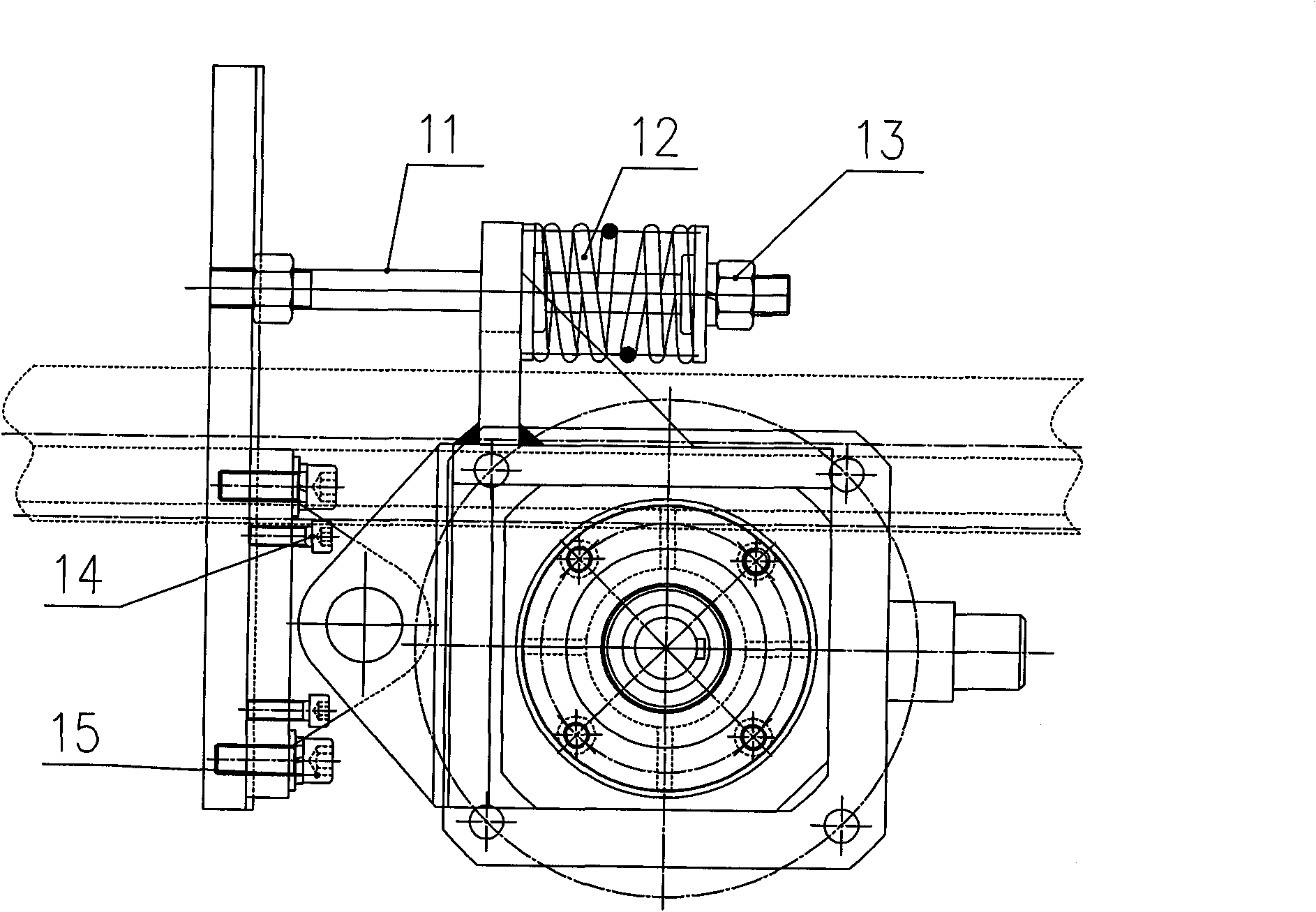

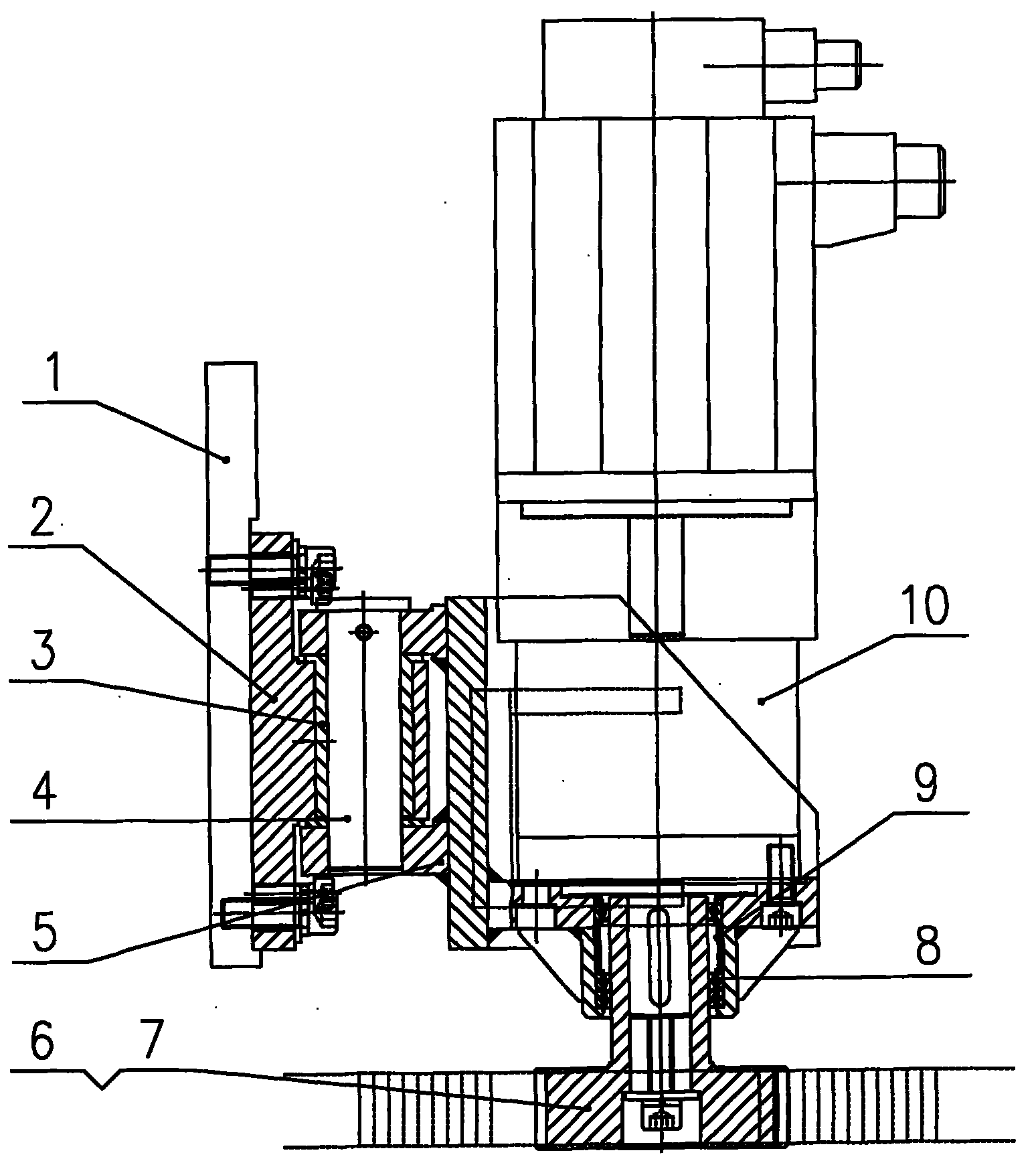

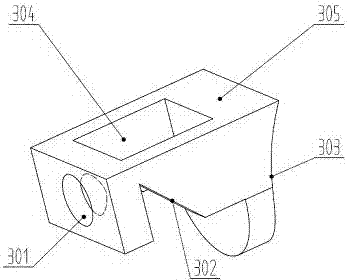

Transmission gap adjusting mechanism of gantry numerical control cutting machine

ActiveCN101920417ASimple structureEasy to adjustWelding/cutting auxillary devicesPortable liftingNumerical controlReduction drive

The invention relates to a transmission gap adjusting mechanism of a gantry numerical control cutting machine, which is mainly as follows: bearings are mounted in a mounting seat, a spacing sleeve is used for positioning between the bearings, the spacing sleeve compresses outer rings of the bearings, a speed reducer is fixed on the mounting seat, a gear is connected with an output shaft of the speed reducer, a fixed seat is arranged in a copper sleeve, the mounting seat is connected with the fixed seat by a rotating shaft, the fixed seat is mounted on a frame by a first bolt and a second bolt, a screw rod is screwed in the frame, a spring is arranged in the screw rod, a nut is screwed in and compresses the gear, and the gear is meshed with a rack. The first bolt is used for regulating the verticality between the gear and the rack. The transmission gap adjusting mechanism of the numerical control cutting machine has simple structure, convenient regulation and large assembly space, and can facilitate the processing of the frame, improve the rigidity of the frame, reduce the phenomenon of fracture of the expensive output shaft of a reduction gearbox, reduce the maintenance ratio of replacing the reduction gearbox, further reduce the manufacturing cost and improve the product quality.

Owner:WUXI HUALIAN SCI & TECH GROUP

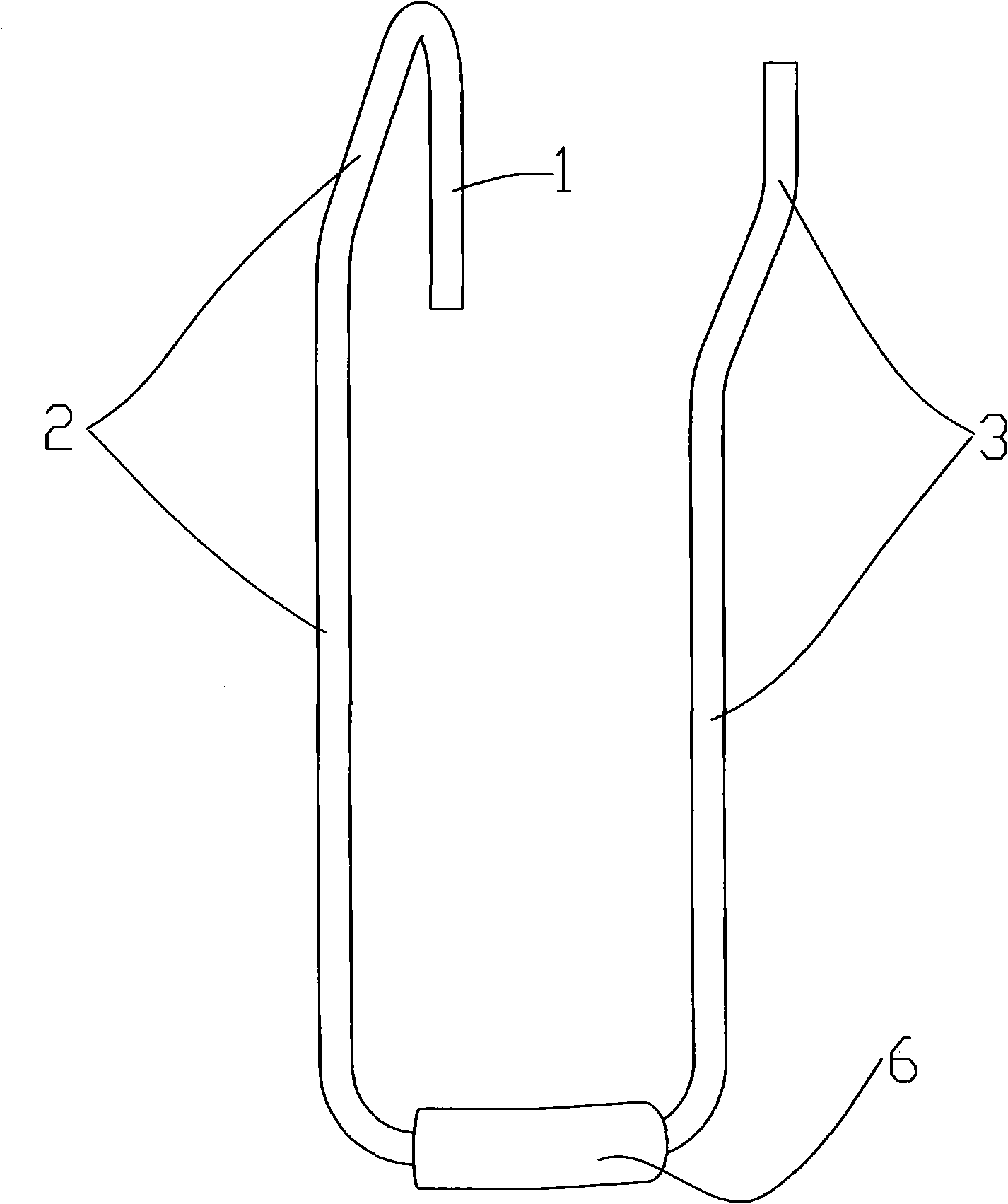

Exhausting pipe of air conditioner compressor

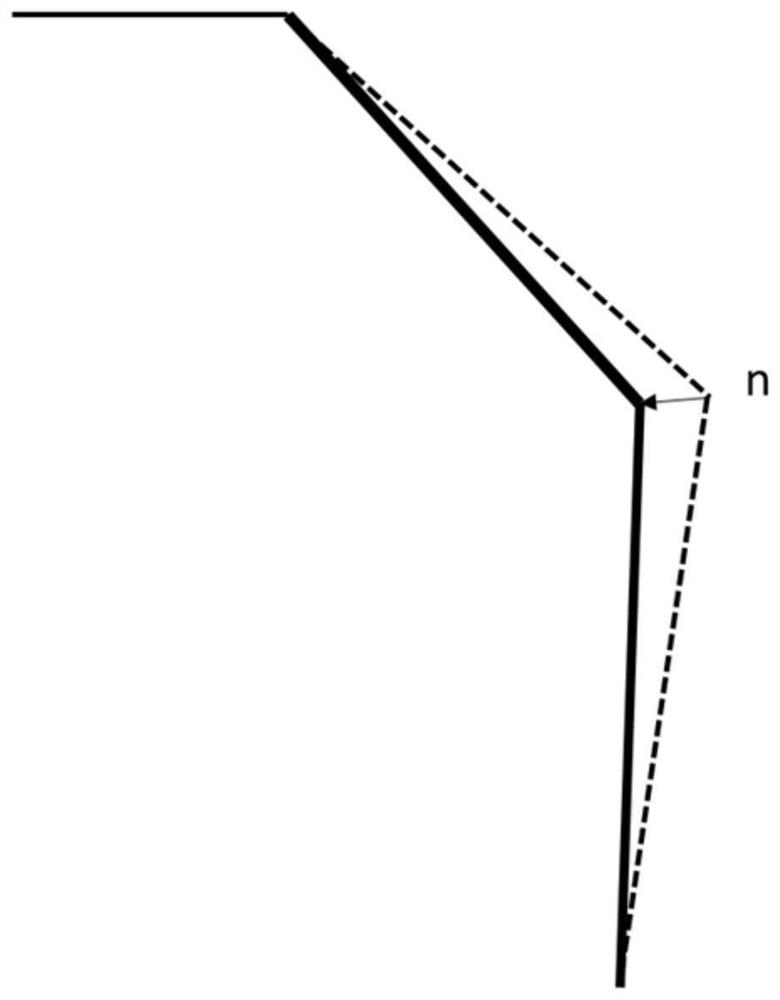

InactiveCN101303008AAvoid fatigue fractureReduce shockPositive displacement pump componentsPositive-displacement liquid enginesStress distributionBusiness efficiency

The invention discloses an exhaust pipe used for an air-conditioner compressor, which is connected between the compressor and a valve. The exhaust pipe comprises a front section vertical to an exhaust port of the compressor and a rear section connected to the valve, wherein, the front section and the rear section are connected through a connecting section which at least comprises an arc section. The improved exhaust pipe can not only effectively reduce the impact of coolant in the pipe on the pipeline as well as the vibration and noise of the pipeline, but also can reduce the stress value of the pipeline, improve the stress distribution and avoid the break of the exhaust pipe due to fatigue. Meanwhile, the exhaust pipe has good comprehensive performance in the aspects of improving the energy-efficiency ratio of the air-conditioner and the reliability of dropping transport, etc.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

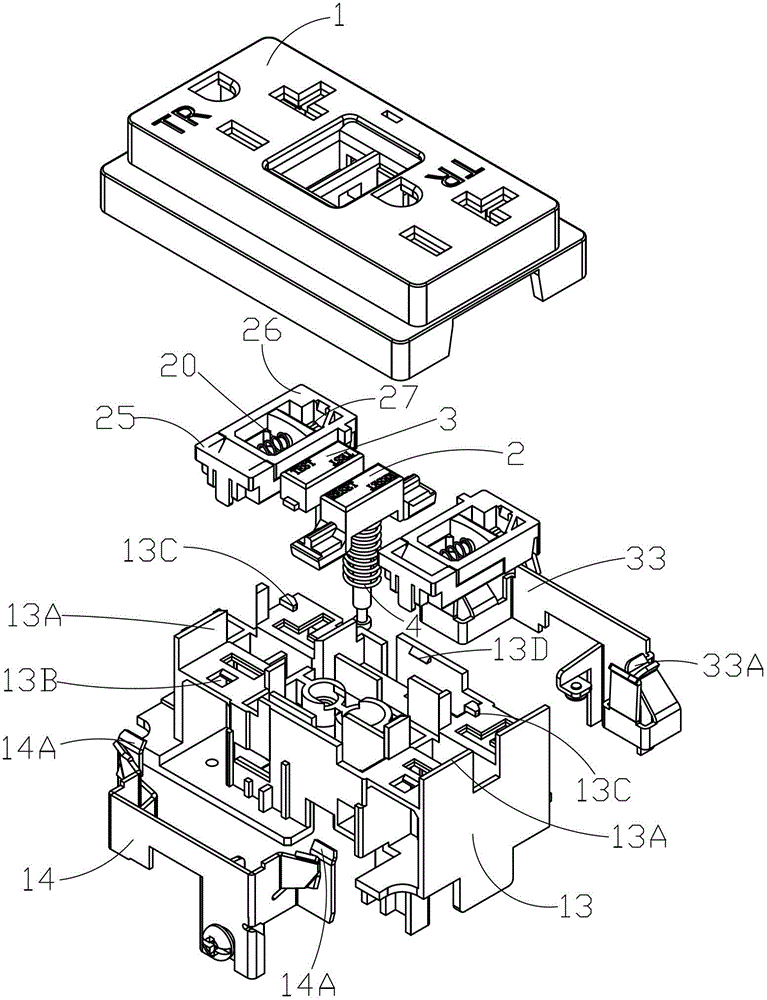

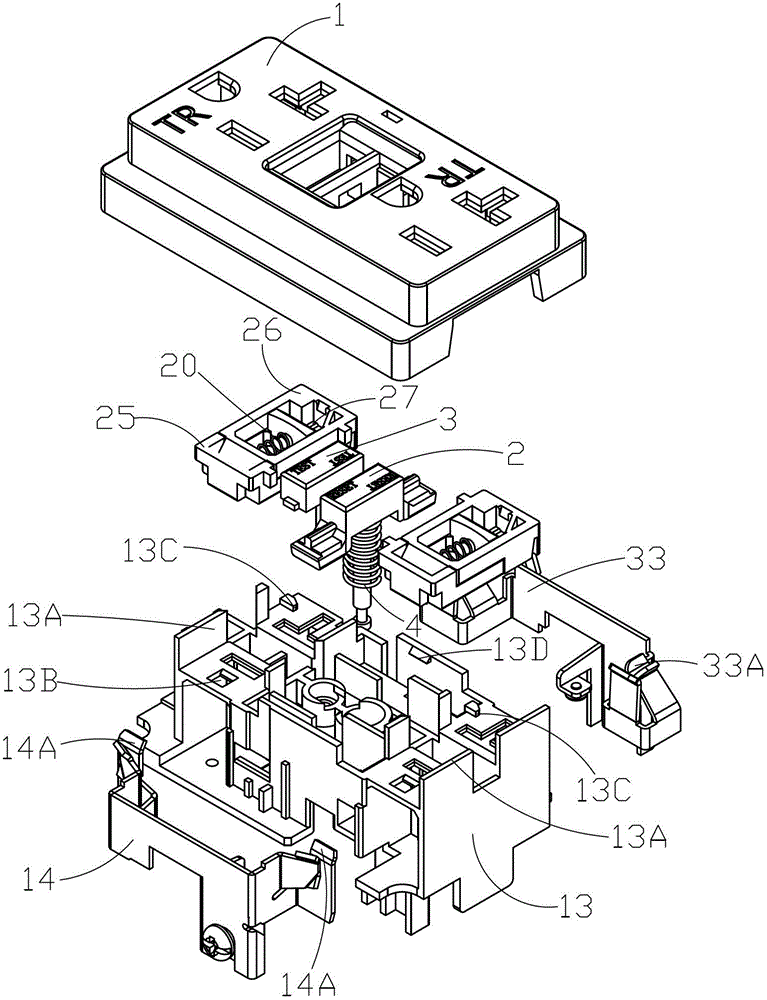

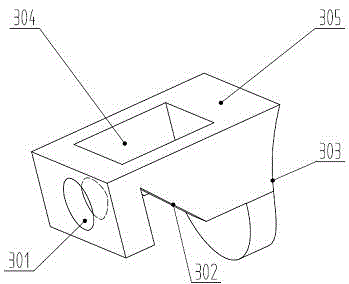

Earth leakage protection socket with jack baffle device

InactiveCN102916278AGuaranteed uptimeReasonable structureCoupling device detailsStructural engineeringMechanical engineering

The invention provides an earth leakage protection socket with a jack baffle device. The earth leakage protection socket comprises a housing, conductive plug bushes mounted on a middle-layer support and the jack baffle device, wherein a guide jack is formed on the middle-layer support; the jack baffle device comprises a left baffle, a right baffle and a small baffle; a guide rail allowing the small baffle to slide and translate therein is formed at one end of the lower part of the right baffle through stripping, and a first guide groove matched with the guide rail of the right baffle is formed at the upper part of the small baffle; and an elastic support leg extends from the other end of the lower part of the right baffle, opposite to the guide rail, and a positioning hole corresponding to the elastic support leg of the right baffle is formed in the housing. The earth leakage protection socket has the benefits that the left baffle, the right baffle and the small baffle adopt reasonable structures and matched with one another reasonably, the action is smooth and steady; the guide rail matched with the guide groove of the small baffle is formed on the right baffle through stripping, the assembly space of the small baffle is increased, and the small baffle can run more steadily and reliably; and during plugging-out of a plug, the elastic support leg pushes the left and the right baffles to be in place, so that transplacement between the baffles and the conductive plug bushes is effectively avoided.

Owner:黄德富

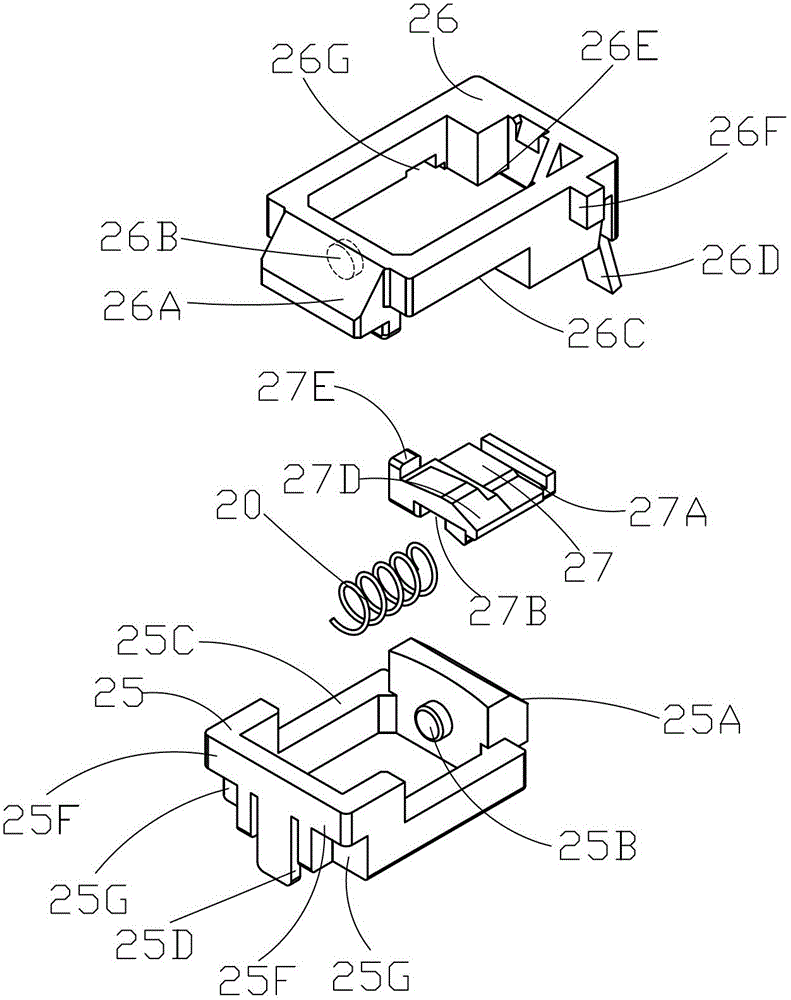

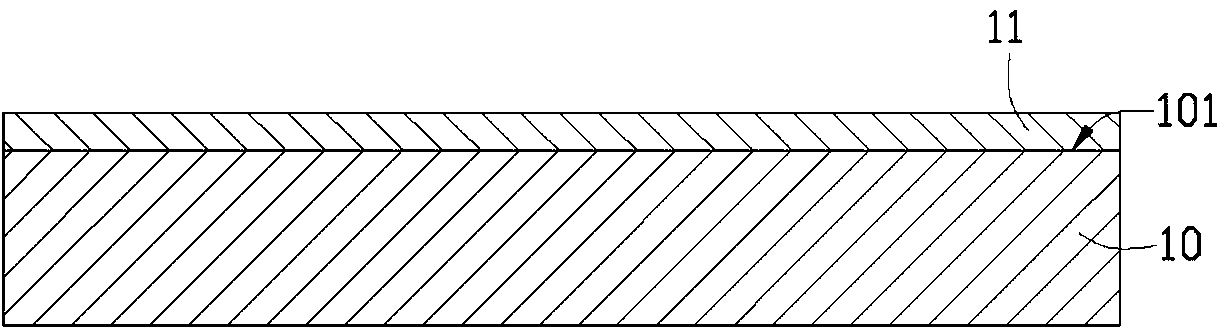

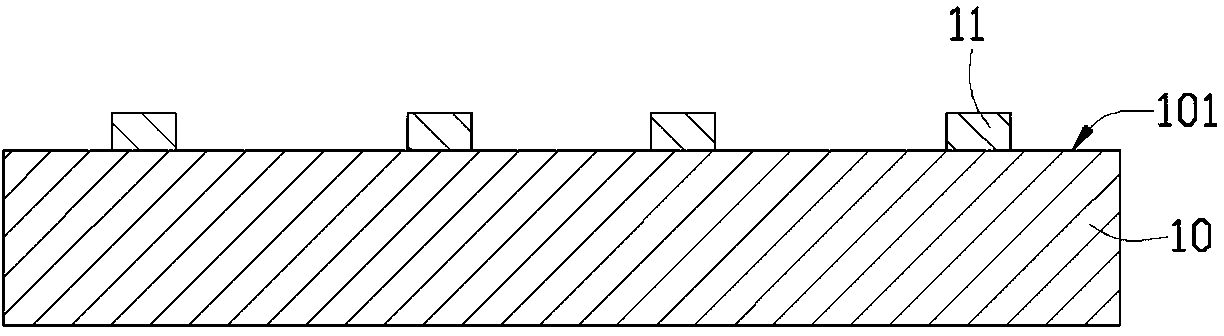

Circuit board and manufacture method thereof

InactiveCN103108491ALow costLarge assembly spaceConductive material chemical/electrolytical removalPrinted element electric connection formationCopper foilEngineering

The invention provides a manufacture method of a double-faced circuit board. The manufacture method of the double-faced circuit board comprises the following steps: providing first copper foil which is provided with a first surface and a second surface, wherein the first surface and the second surface are opposite to each other; etching the first copper foil from the first surface to form a middle structure, wherein the middle structure comprises a base and a plurality of first protrusions, and each protrusion is exposed on the first surface; filling insulating materials among the plurality of first protrusions; pressing fit second copper foil on the first surface; etching the middle structure from the second surface to form a plurality of second protrusions which are exposed on the second surface, wherein the plurality of second protrusions are respectively connected with the plurality of first protrusions in a corresponding mode so as to form a plurality of copper cylinders; filling the insulating materials among the plurality of second protrusions; pressing fit third copper foil on the second surface; using the second copper foil to form a second line pattern, and using the third copper foil to form a third line pattern, wherein the second line pattern and the third line pattern are electrically connected through the plurality of copper cylinders. According to the technical scheme, the manufacture method of the double-faced circuit board is in no need of manufacturing through holes.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

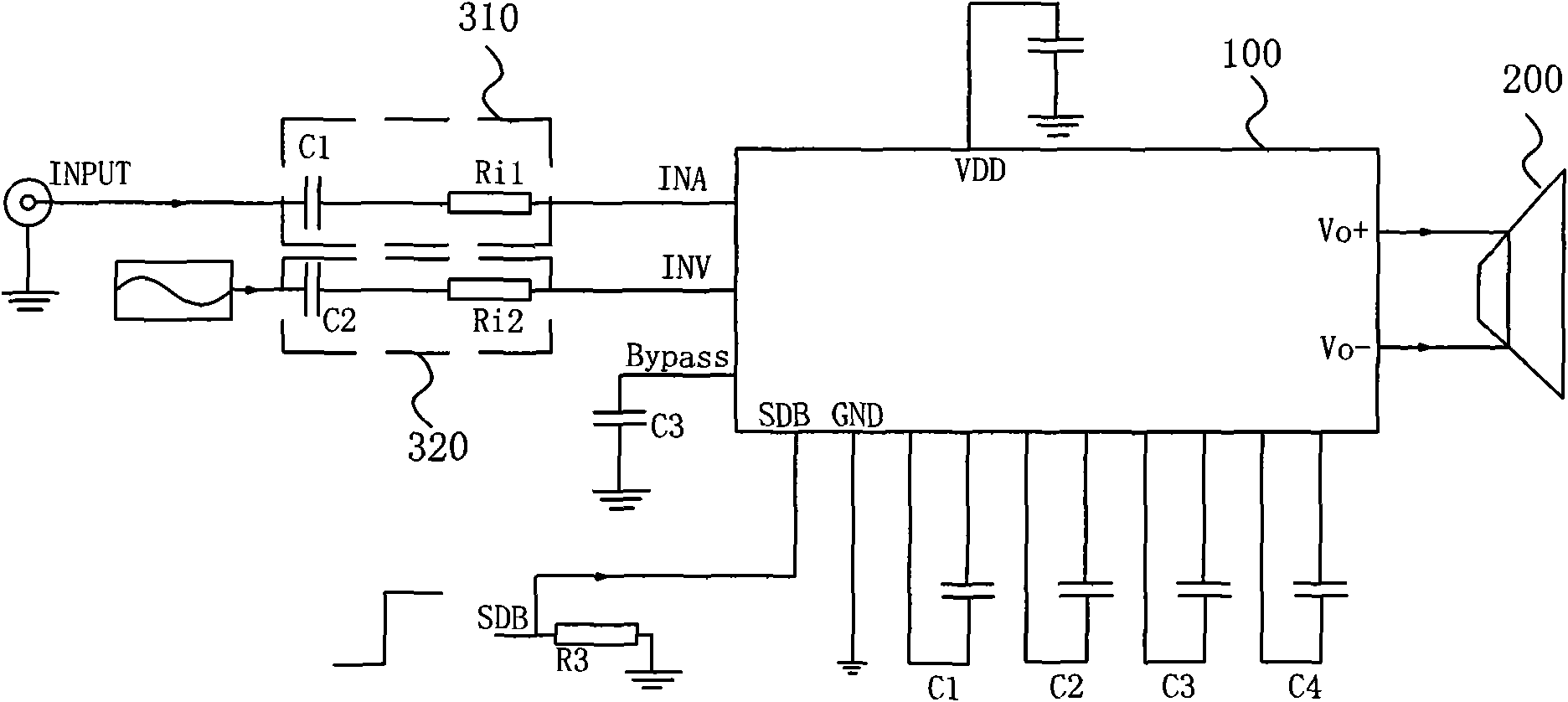

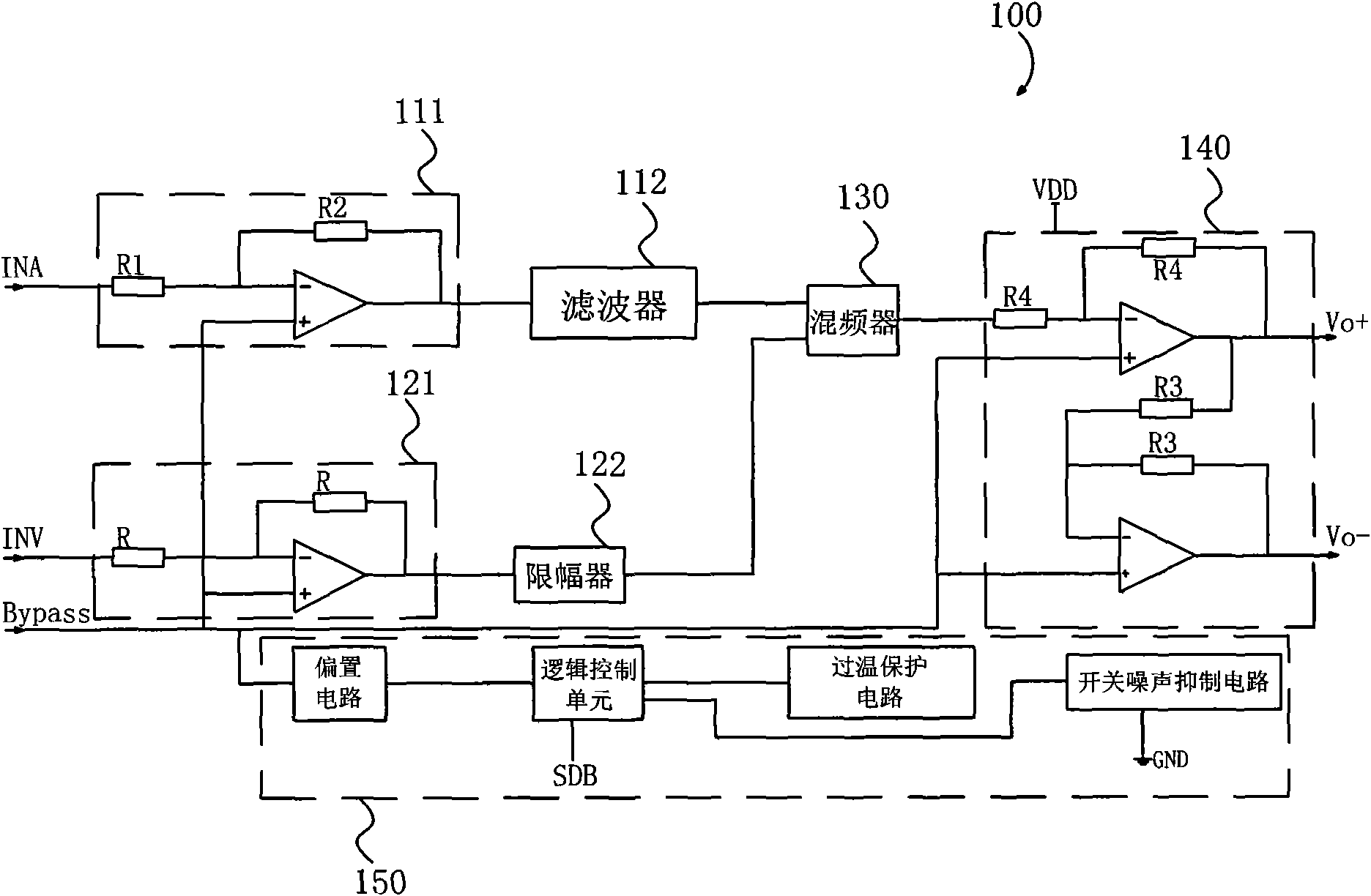

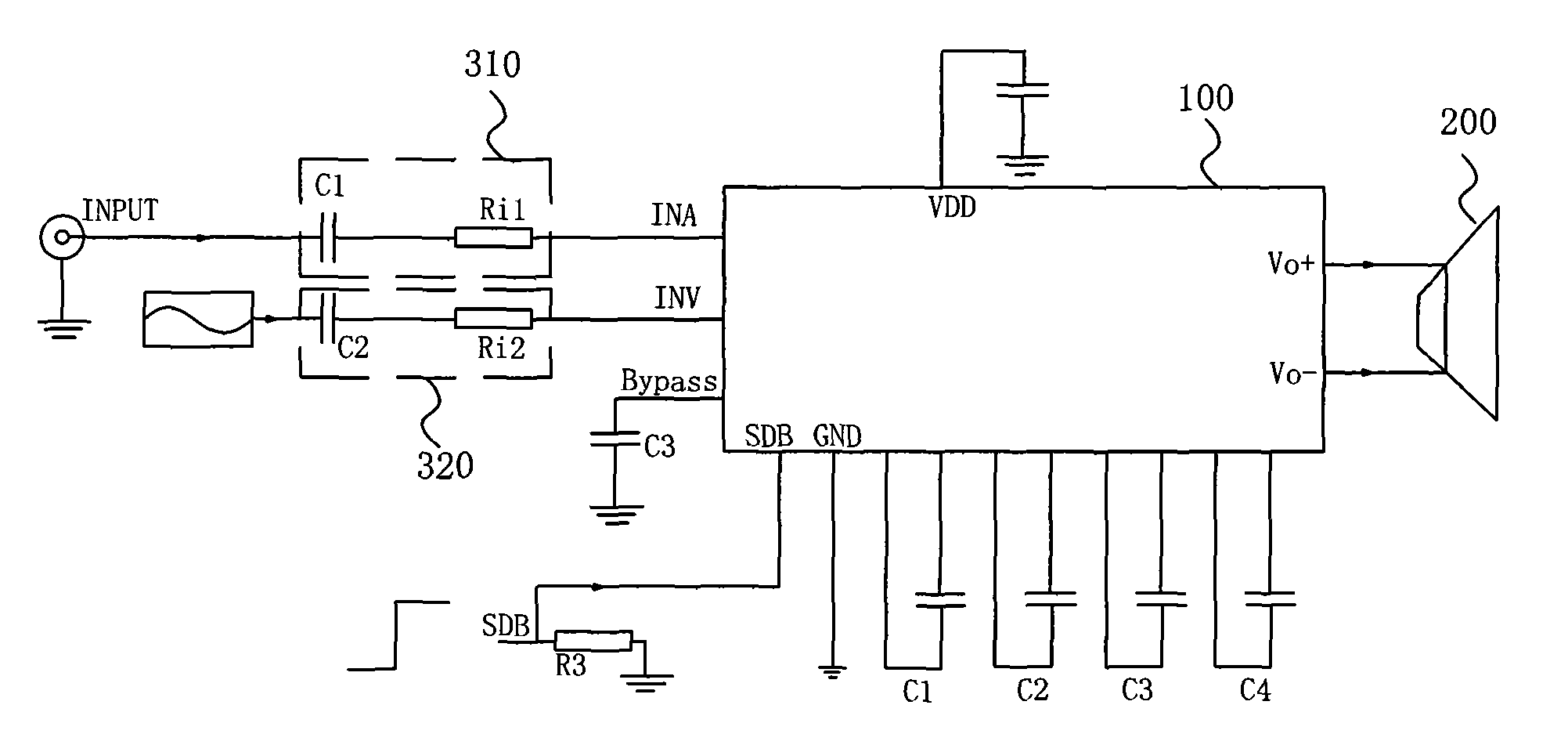

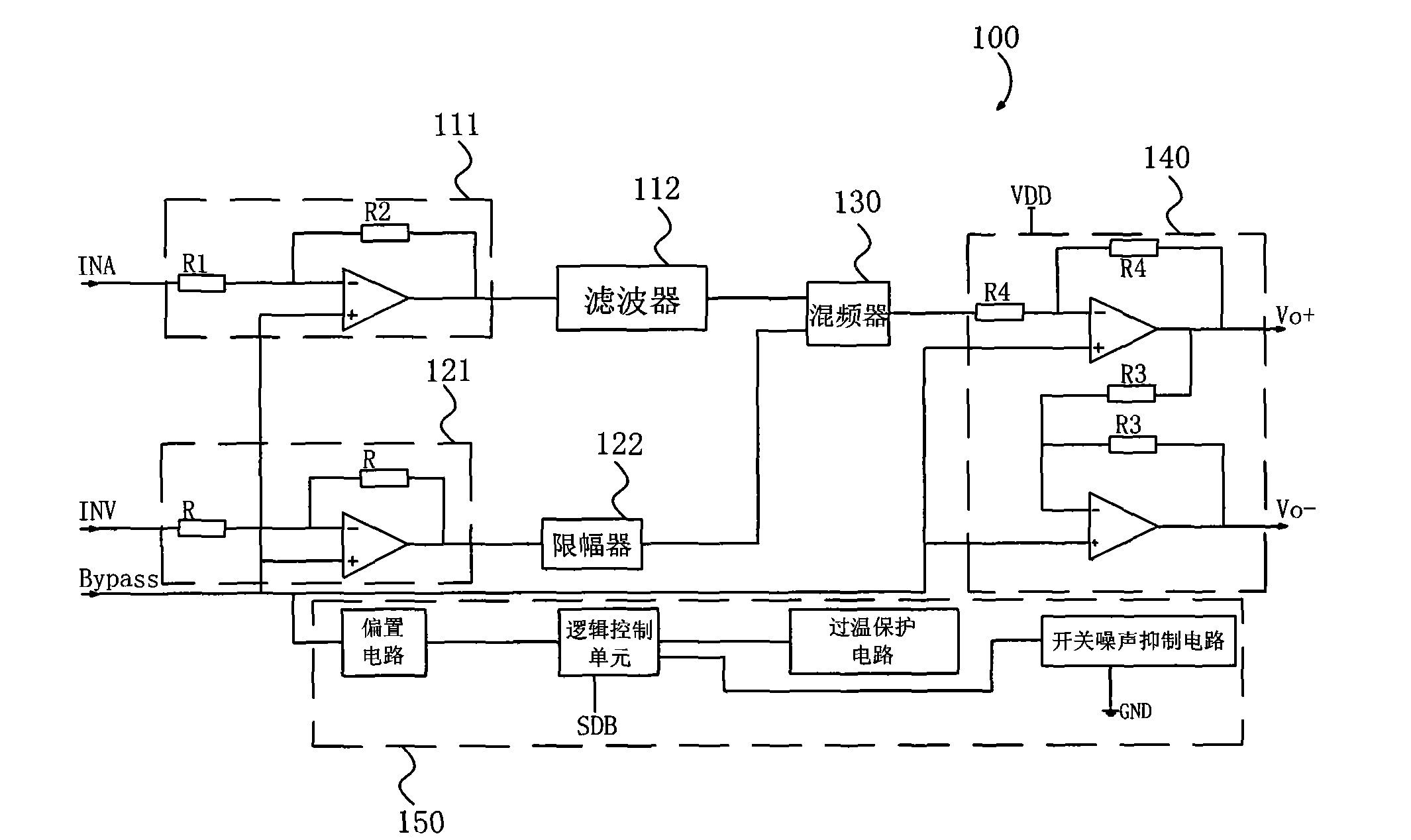

Integrated drive circuit for multifunctional electrical sound generation device

InactiveCN101594565AAvoid damageAvoid complexityStereophonic circuit arrangementsSpeech analysisSound energyLoudspeaker

The invention relates to the field of electric and sound energy conversion devices, in particular to an integrated drive circuit for a multifunctional electrical sound generation device. A drive circuit is integrated in a micro chip, so large assembly space is saved, the complexity of the assembly of electric elements is avoided and product reliability is increased. In the circuit, a four-stage active high-pass filter and a front amplifier are integrated on the same chip, so the low frequency components, which can possibly bring vibration to loudspeakers, of an audio signal are effectively filtered out and the damages to the sound generation device are avoided. The drive circuit independently inputs and controls the audio signal and a vibration signal, thereby realizing the drive of the vibrating loudspeakers. Based on stable and mature standard CMOS process design, the drive circuit can be widely used on mobile phones, PDAs or various potable electronic devices.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

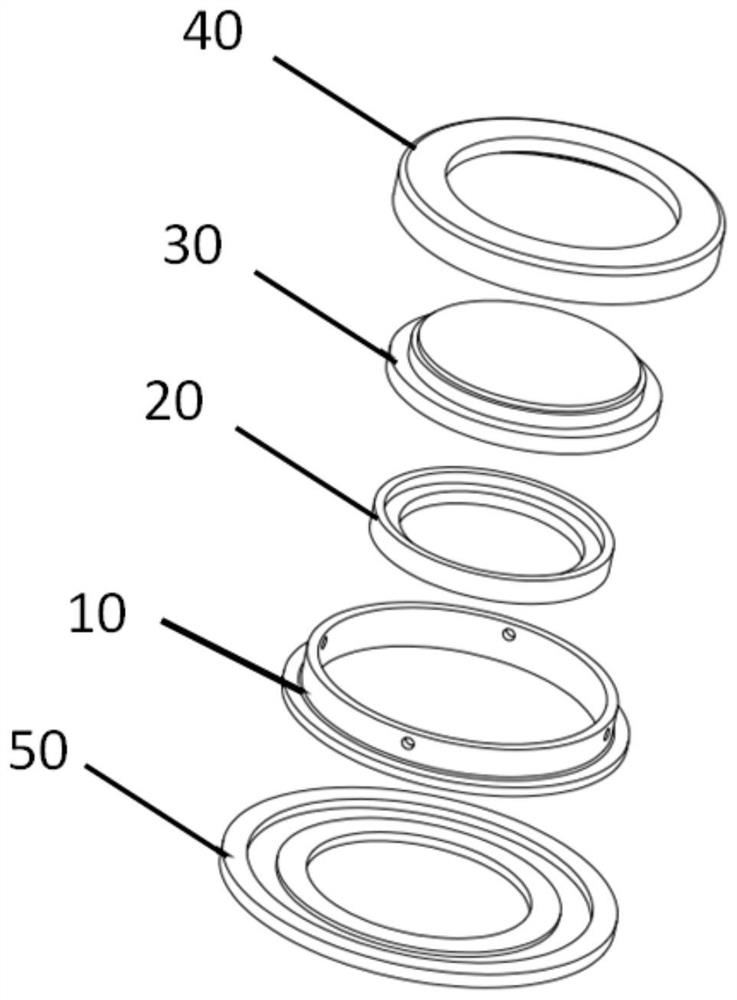

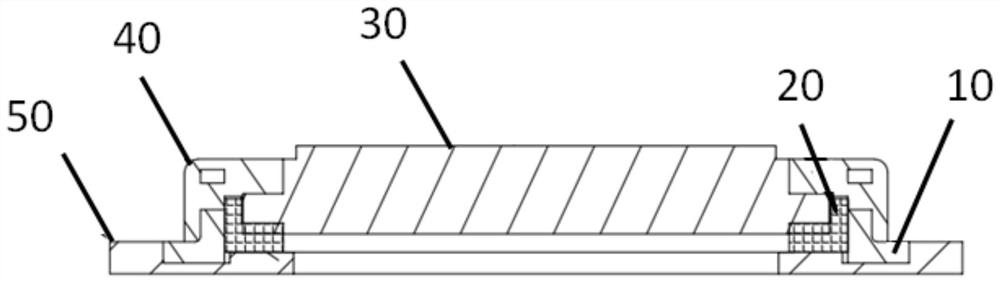

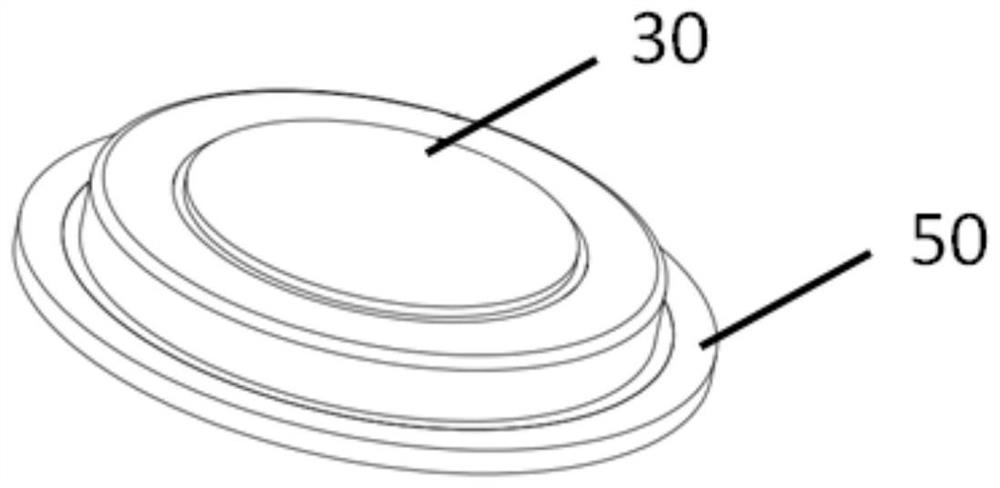

Integrated pole, top cover assembly, battery and battery module

PendingCN114865179ASimple structureIncrease energy densityFinal product manufactureCell component detailsEngineeringBattery cell

The invention provides an integrated pole, a top cover assembly, a battery and a battery module, the integrated pole comprises a first welding ring, the inner side of the first welding ring is provided with a sealing ring, the sealing ring sleeves the periphery of the pole, the periphery of the first welding ring, the periphery of the sealing ring and the periphery of the pole are sleeved with injection molding parts, and the injection molding parts are connected with the top cover assembly. The first welding ring, the sealing ring and the pole are fixed into a whole by the injection molding part, and the first welding ring is welded on the second welding ring to form an integrated structure. According to the integrated pole provided by the invention, the structure of the pole and the assembly of the top cover assembly are simplified at the same time, the assembly efficiency is improved, and the manufacturing cost is reduced; and the integrated pole is integrally assembled outside the top cover plate, so that the space utilization rate in the shell is higher, and the energy density of the battery is effectively improved. In addition, the integrated pole provided by the invention is thinner, the weight of a battery cover plate is reduced, and the energy density of the battery is further improved.

Owner:TIANJIN ENERGIES

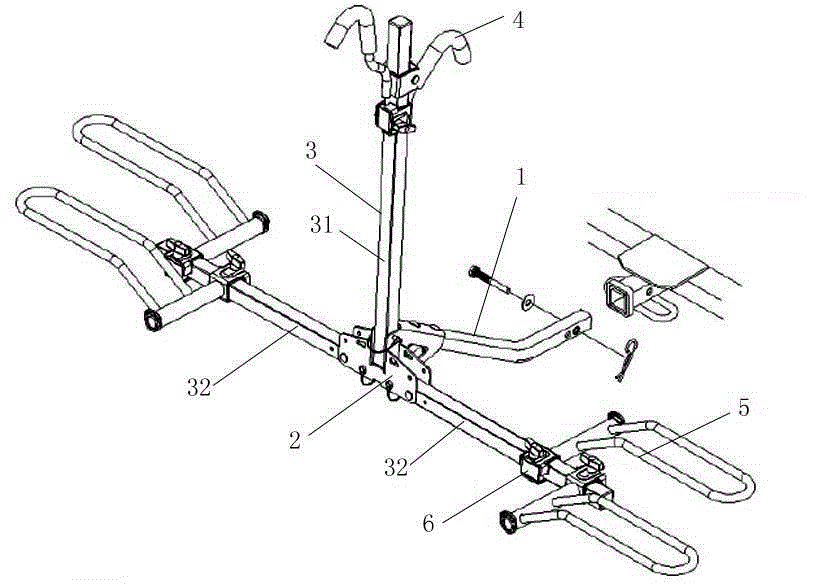

Vehicle-mounted bicycle all-around fixing bracket

InactiveCN104691431ALarge assembly spaceSave storage spaceSupplementary fittingsVehicle frameIn vehicle

The invention discloses a vehicle-mounted bicycle all-around fixing bracket which comprises main support rod, a T-shaped fixed seat and an extension rod, wherein the extension rod is hinged in the fixed seat; the extension rod comprises a vertical rod in the vertical direction and two horizontal rods in the horizontal direction; the fixed seat comprises a vertical cup joint part and horizontal cup joint parts; one end of the vertical cup joint part is connected with the main support rod; a vertical notch which is used for connecting the vertical rod is formed in the other end of the vertical cup joint part; the horizontal cup joint parts are fixedly connected to the two sides of the vertical cup joint part and respectively connected with horizontal rods; wheel fixing components which are used for fixing the bicycle wheel positions are arranged on the horizontal rods; and a longitudinal fixing component which is used for fixing the bicycle frame position is arranged on the vertical rod. The bracket is simple in structure, convenient to mount, low in cost, good in fixing effect, effective to decrease the storage space and convenient to convey.

Owner:HANQIAO HUZHOU HARDWARE PROD

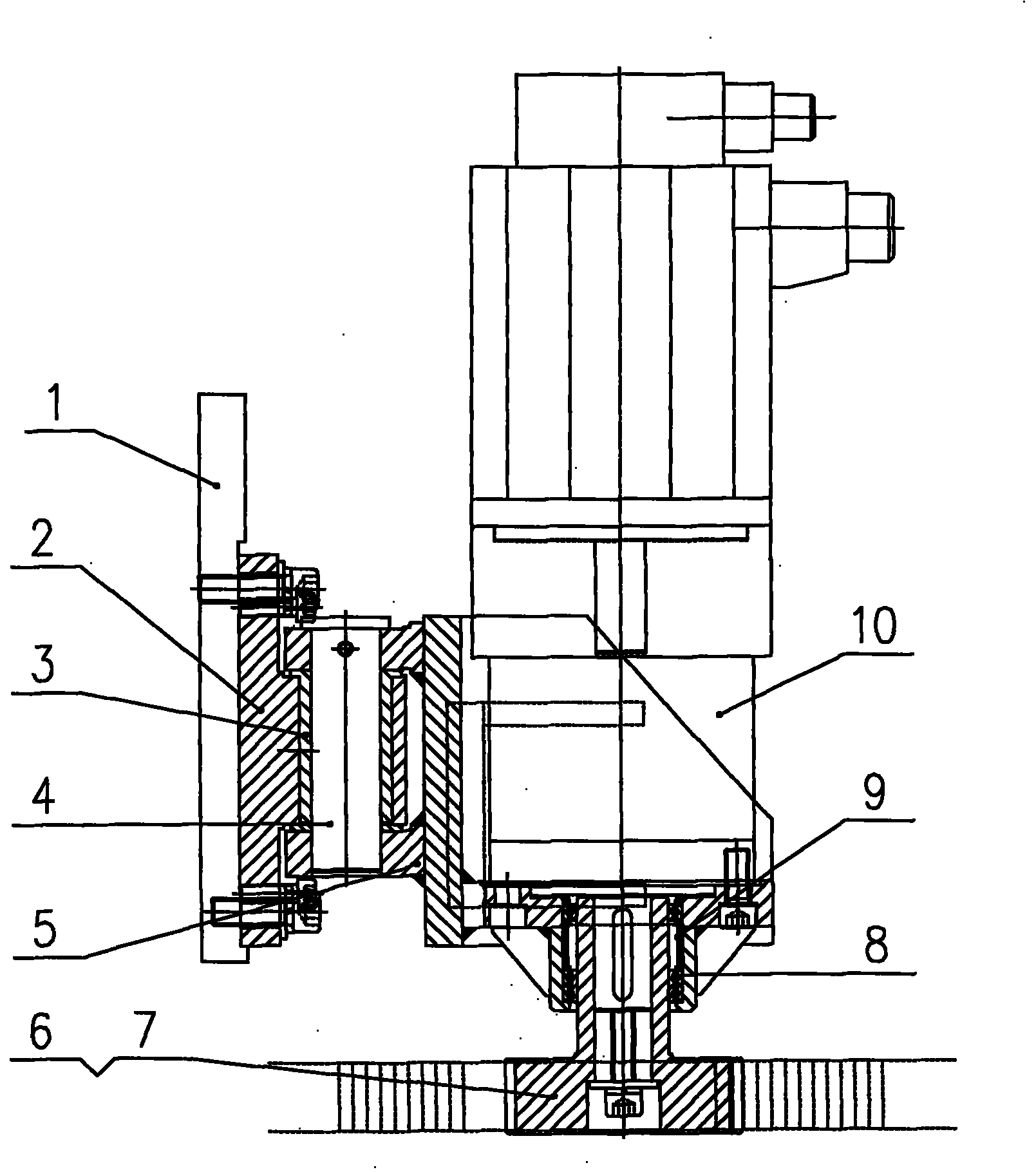

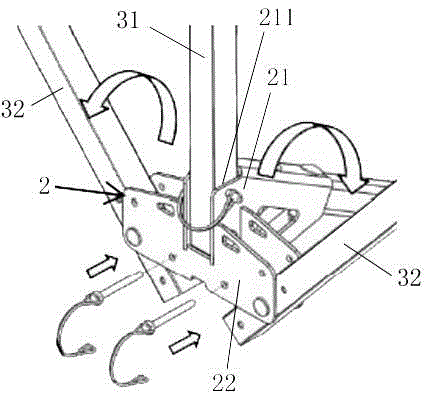

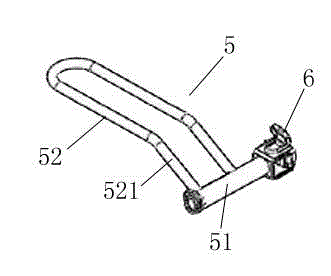

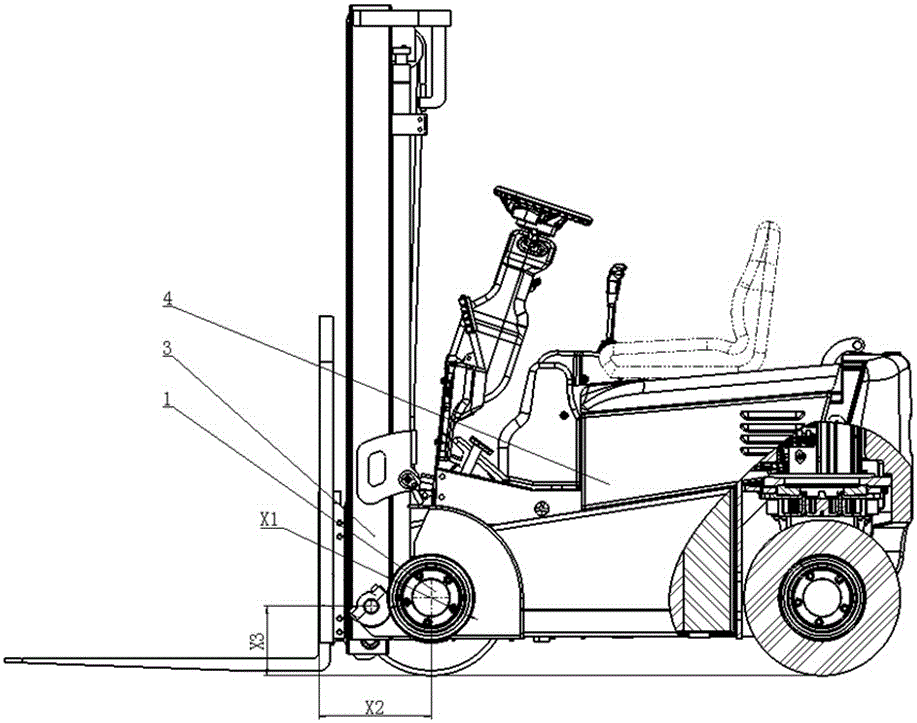

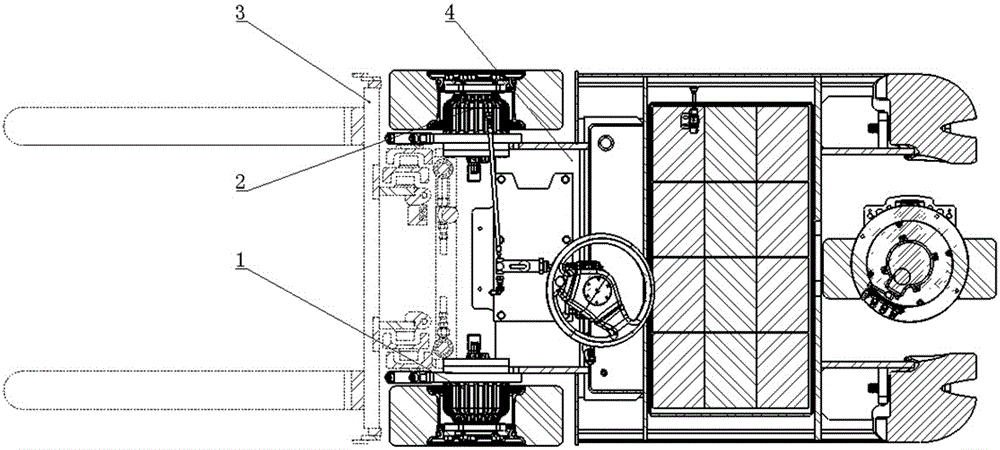

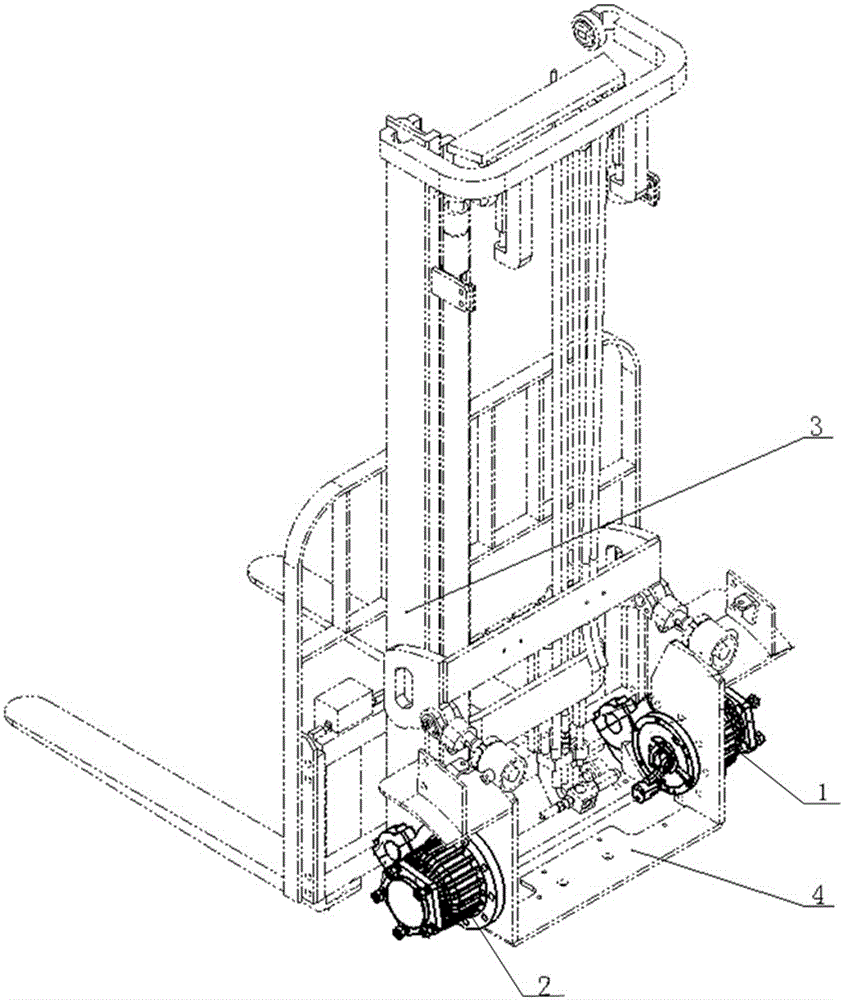

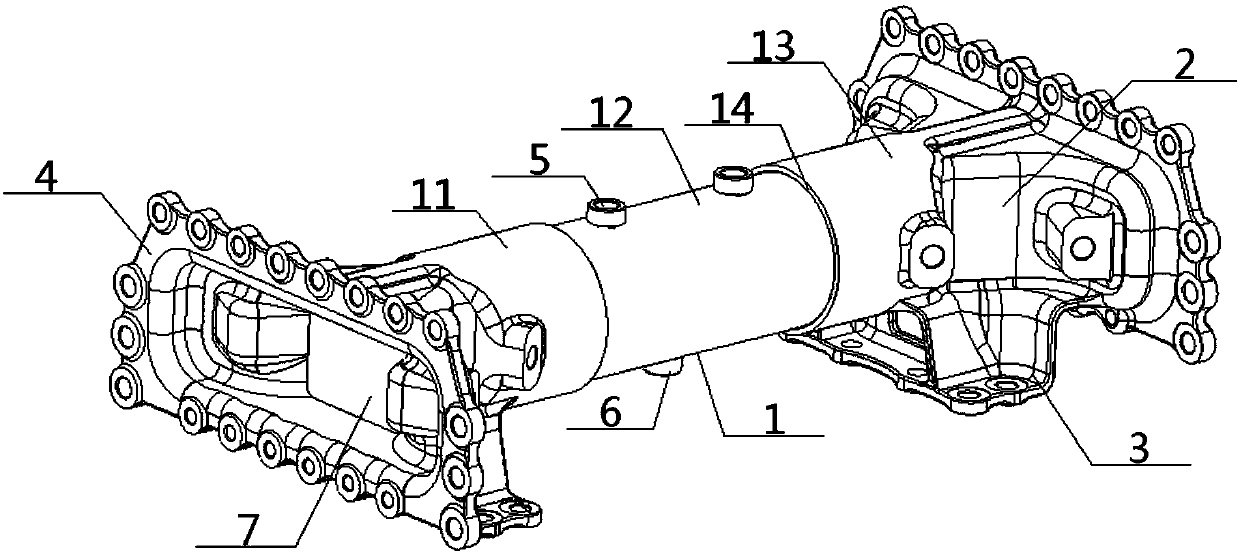

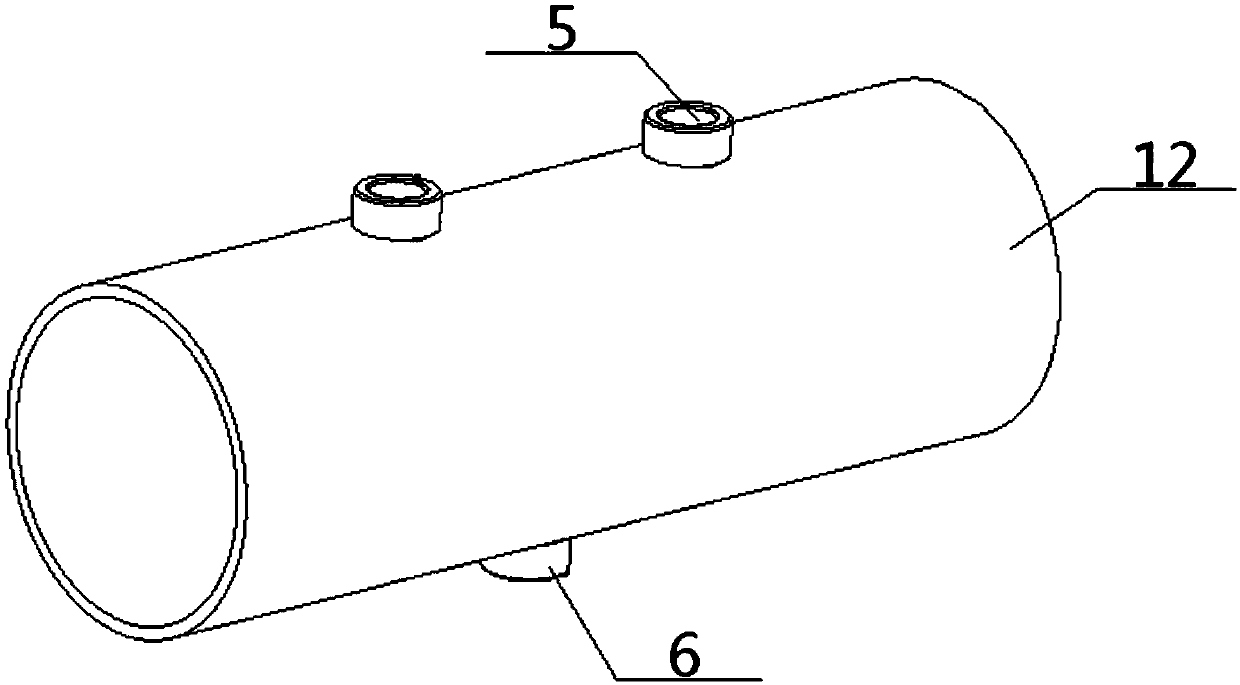

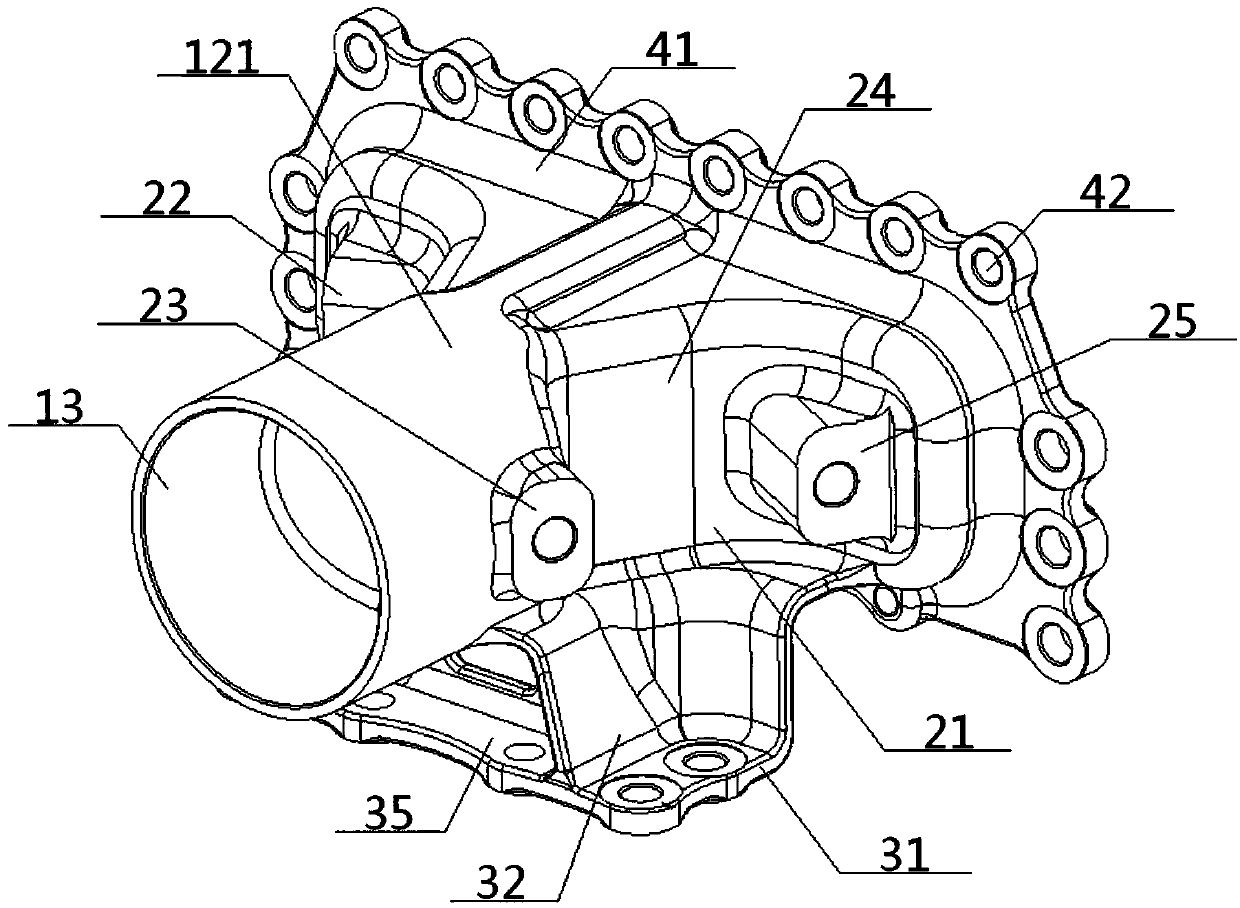

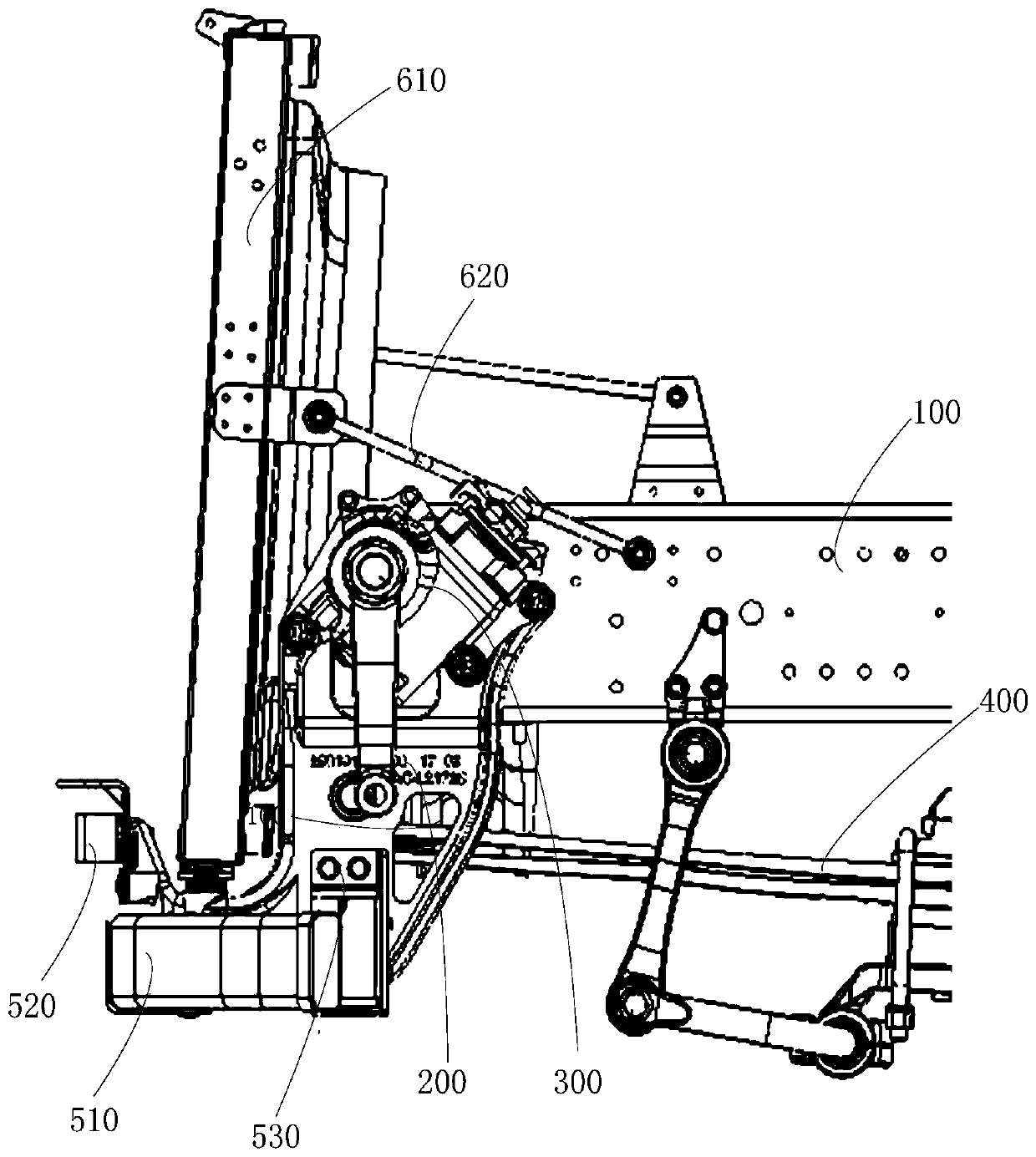

Rear wheel drive electric forklift provided with wet-type braking front axles

InactiveCN105034797AIncrease armReduce tensionFluid actuated brakesLifting devicesVehicle frameControl theory

The invention relates to a rear wheel drive electric forklift provided with wet-type braking front axles. The electric forklift comprises a front axle mechanism, a hoisting system and a forklift body system. The forklift body system comprises a frame, a driving rear axle and a driving steering mechanism. The front axle mechanism has a split type structure, and is composed of a left front axle and a right front axle. The left front axle and the right front axle are the same in structure but opposite in direction, and are respectively arranged on the left side and right side of the front part of the frame. The left front bridge or the right front bridge comprises a tubular axle housing, a planetary gear output mechanism, a wet-type braking mechanism, and a left front wheel or a right front wheel; the planetary gear output mechanism and the wet-type braking mechanism are disposed inside the axle housing; a housing cover is arranged at the axial end of the axle housing; the planetary gear output mechanism comprises an output shaft and a planetary gear mechanism; one end of the output shaft extends to the exterior of the axle housing; and the left front wheel or the right front wheel is arranged at the outward extending end of the output shaft. According to the invention, the load supporting point of a gantry of the hoisting system is lowered, the size of a front overhang is reduced by 19%, the turning radius of the electric forklift is reduced to 1445mm from 1600mm, and the ergonomic design of the electric forklift is optimized.

Owner:ANHUI HELI CO LTD

Integrated balance suspension cross beam assembly

ActiveCN107839426AImprove torsion resistanceIncrease profitInterconnection systemsPivoted suspension armsPhysicsRolling chassis

Provided is an integrated balance suspension cross beam assembly. A cross beam body in the integrated balance suspension cross beam assembly has a hollow sealed cylindrical structure. An air inlet andoutlet, and a water drain valve are arranged at the top and bottom of the middle section of the cross beam body respectively. Both ends of the cross beam body are connected with thrust rod connectingportions, large bracket connecting portions and longitudinal beam connecting portions. The cross beam body may be left, middle and right cylindrical portions which are sequentially connected. The longitudinal beam connecting portions include connecting bottom plates, and longitudinal beam connecting holes and bottom plate inner chambers arranged above the connecting bottom plates. The thrust rodconnecting portions comprise front and rear thrust rod connecting branch portions which are symmetrically arranged front and back with a center axis of the cross beam body as a symmetry line. The large bracket connecting portions comprise bracket bottom plates, bracket bottom holes, and front and rear support plates. This design has uniform stress distribution under torsional conditions and can increase the torsional performance of the cross beam. The integrated balance suspension cross beam assembly has the function of acting as an air reservoir, the manufacturing and assembly efficiency canbe improved, and the overall weight is reduced so as to be conducive to the modular layout of chassis.

Owner:DONGFENG COMML VEHICLE CO LTD

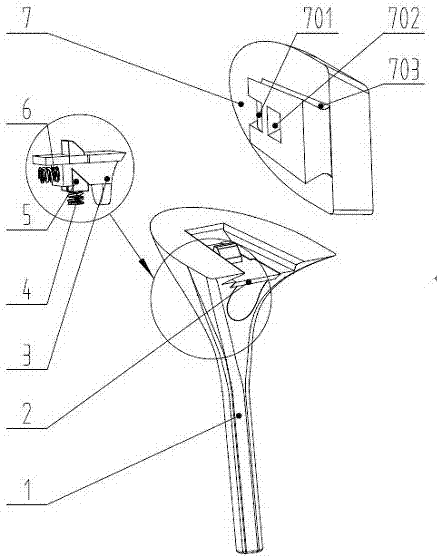

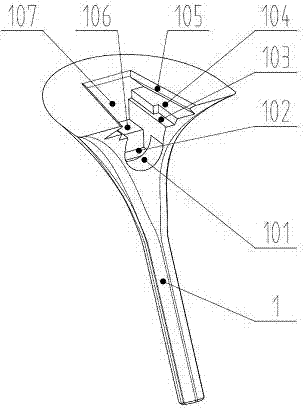

Hidden button type heel-replaceable high-heeled shoes

InactiveCN105639849AEasy to remove and replaceImprove the firmness of useHeelsTop-piecesEngineeringPush-button

The invention discloses hidden button type heel-replaceable high-heeled shoes, wherein each of the high-heeled shoes comprises a heel, a pressing plate, a button, a first compression spring, a jacking rod, a second compression spring and a sole, wherein a first groove, a second groove and a third groove are formed in the middle of the heel; the button and the jacking rod are arranged inside the first groove; the pressing plate is arranged inside the second groove; the button can move forwards and backwards along the first groove; the jacking rod can move upwards and downwards along the first groove; the pressing plate is fixedly connected with the bottom surface of the second groove. According to the hidden button type heel-replaceable high-heeled shoes, the heel is connected with the molded surface of the sole in a matched manner, through the interaction among the button, the jacking rod and the spring, the bulge of the jacking rod can ascend or descend, so that the heel can be connected with or separated from the sole, the button can move inwards along the bottom surface of the pressing plate by only slightly pressing the button inwards, then the jacking rod can be driven to move downwards, the bulge of the jacking rod can be separated from a fifth groove in the sole, and the heel can be separated from the sole by pulling down the heel with a slight force at the moment, so that the heel can be conveniently and rapidly disassembled and replaced.

Owner:HANGZHOU JIUBA HONGTU TECH CO LTD

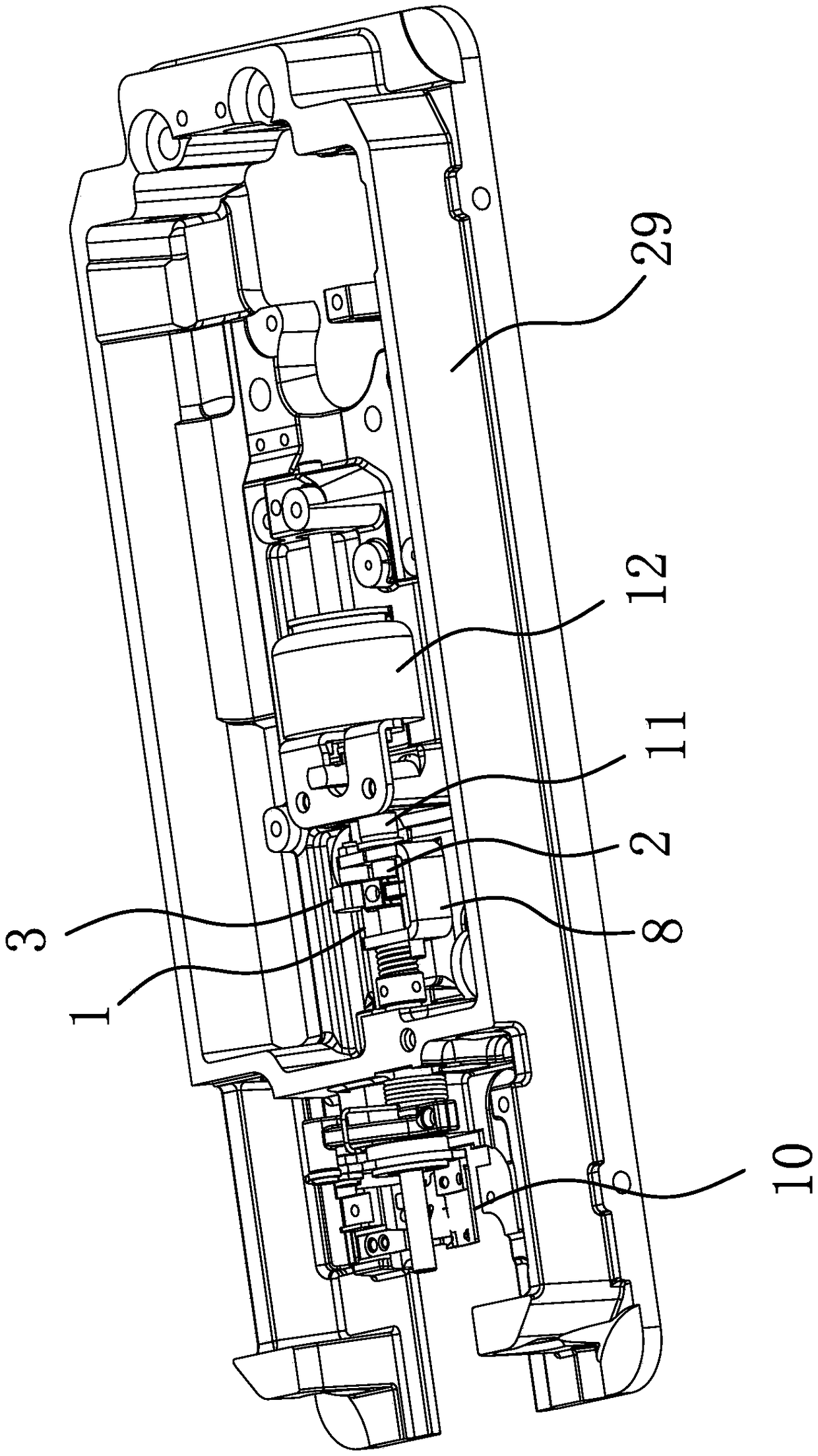

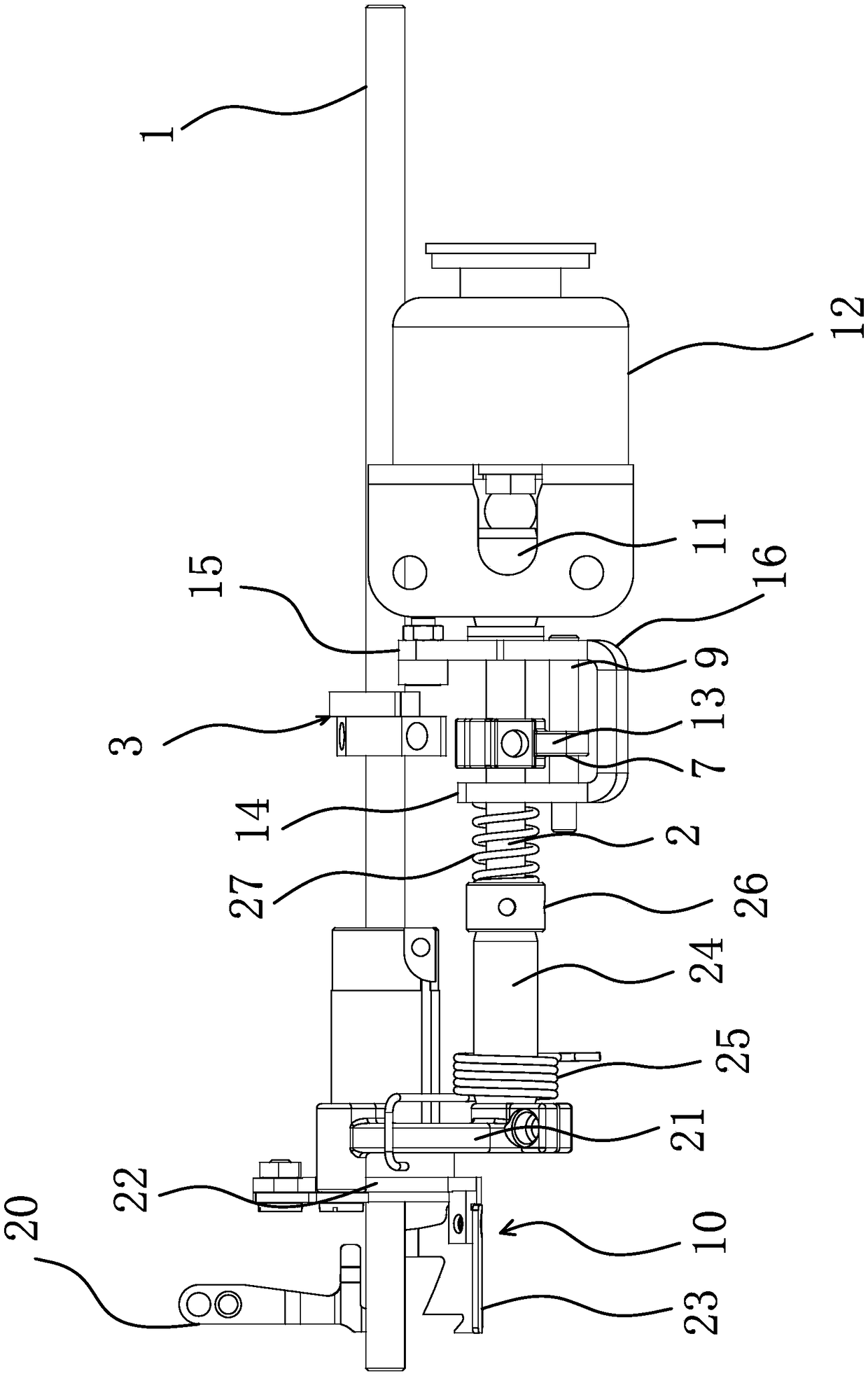

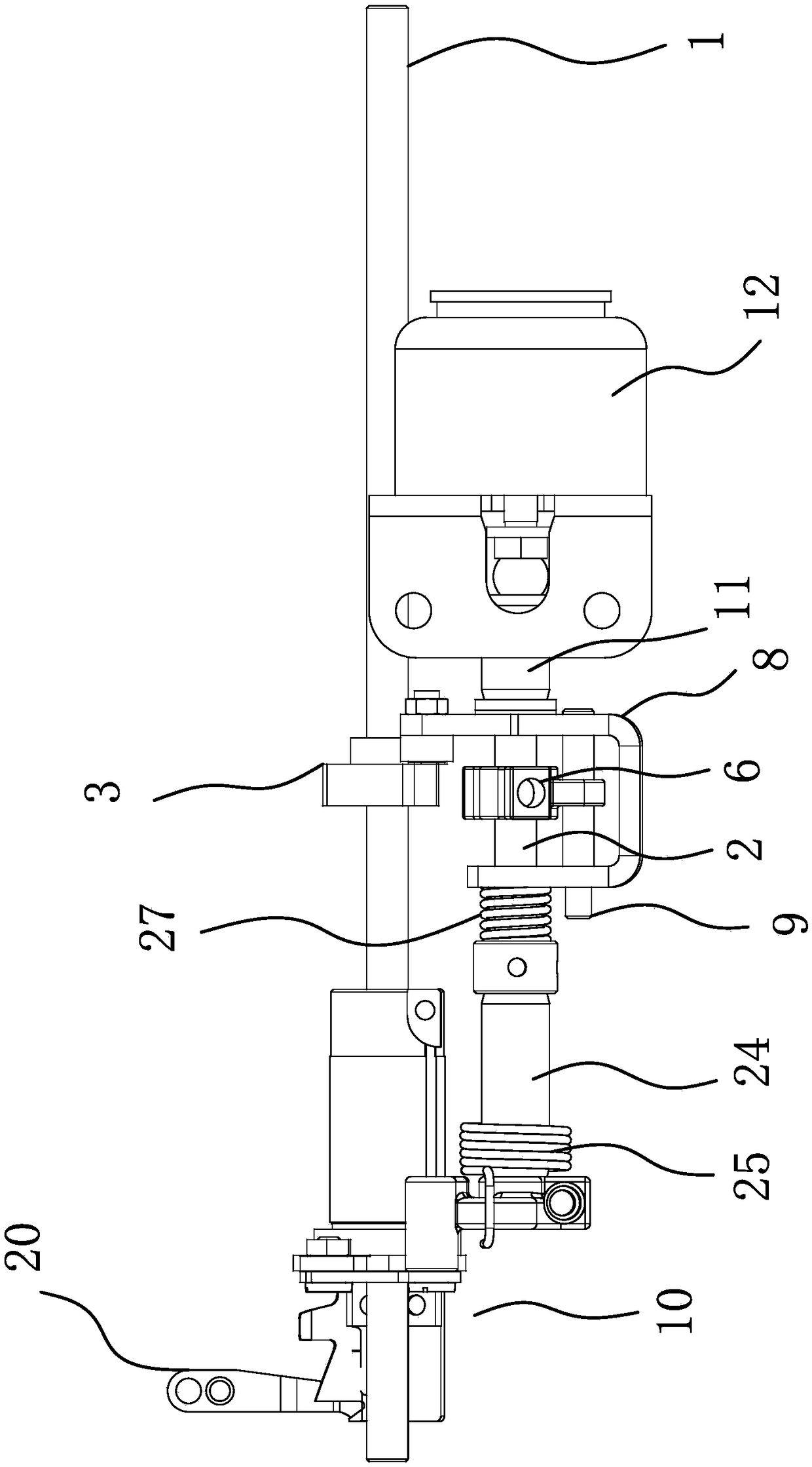

Automatic thread shearing mechanism of sewing machine and sewing machine

The invention belongs to the technical field of sewing equipment, and relates to an automatic thread shearing mechanism of a sewing machine and the sewing machine. The technical problems that an existing automatic thread shearing mechanism is likely to be stuck and the like are solved. The automatic thread shearing mechanism comprises a lower shaft and a thread shearing shaft, the lower shaft is rotationally arranged on a bottom plate of the sewing machine, and a thread shearing cam is fixed to the lower shaft; the thread shearing cam is provided with a thread cutting section and a forced cutter returning section; the thread shearing shaft is rotationally arranged on the bottom plate of the sewing machine, and a forced cutter returning crank is fixed to the thread shearing shaft; a connecting hole which is parallel to the thread shearing shaft is formed in the forced cutter returning crank; a thread shearing driving crank is further slidably arranged on the thread shearing shaft, and aconnecting pin which is in sliding fit with the connecting hole is arranged on the thread shearing driving crank; the thread shearing shaft is connected with a thread shearing movable cutter assemblyand is provided with a sliding sleeve, and the bottom plate of the sewing machine is fixedly provided with a driving source capable of driving the sliding sleeve to slide in the direction of the thread shearing driving crank. According to the mechanism, the phenomena of blocking and the like can be effectively avoided.

Owner:ZHEJIANG MAQI SEWING MACHINE

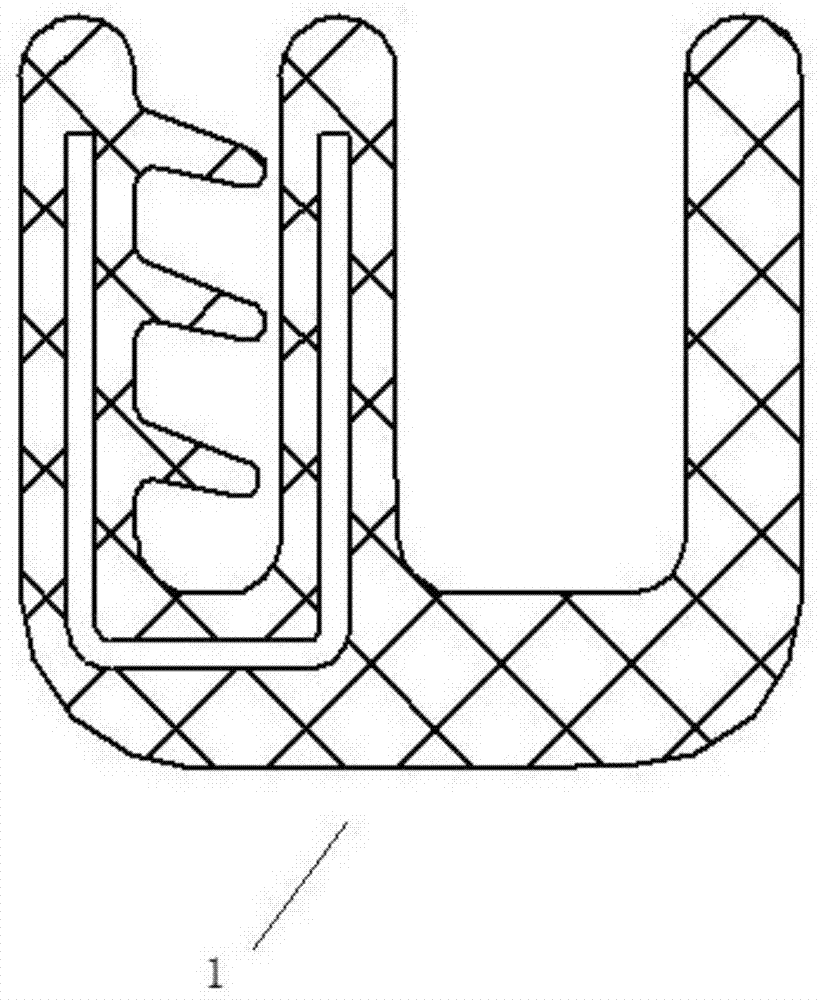

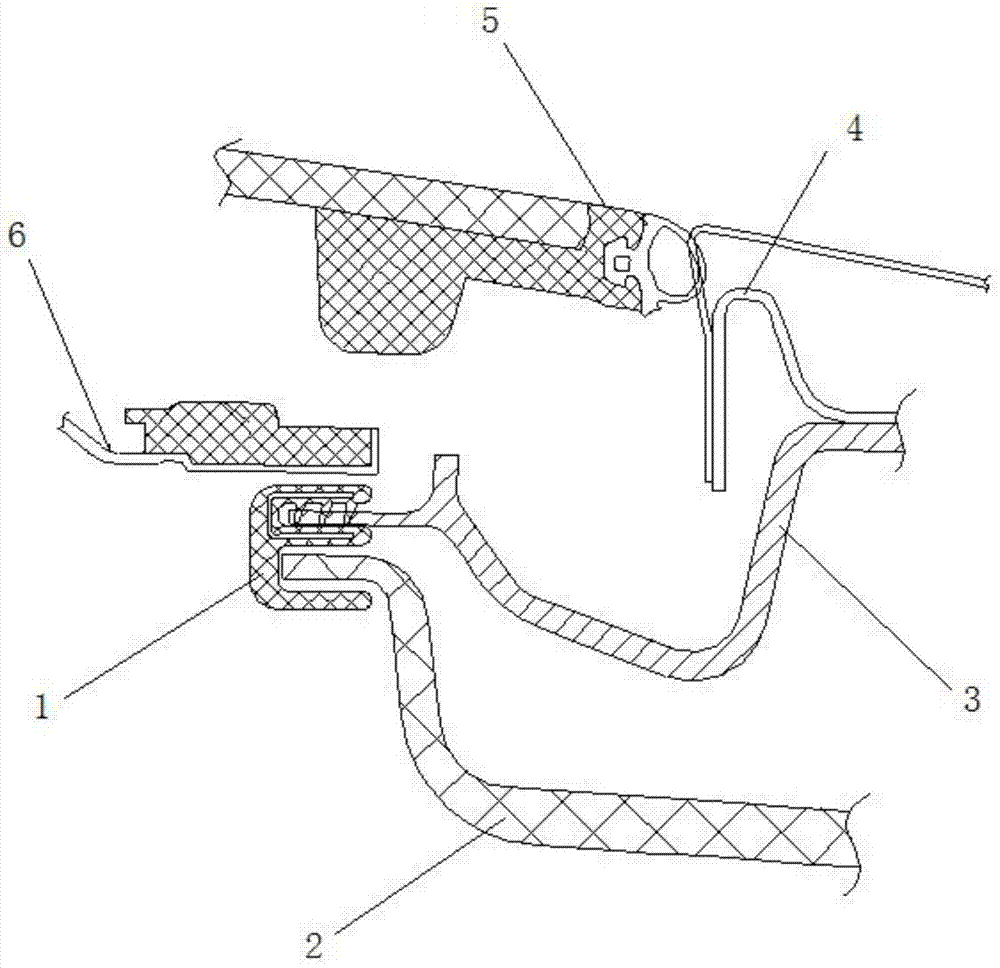

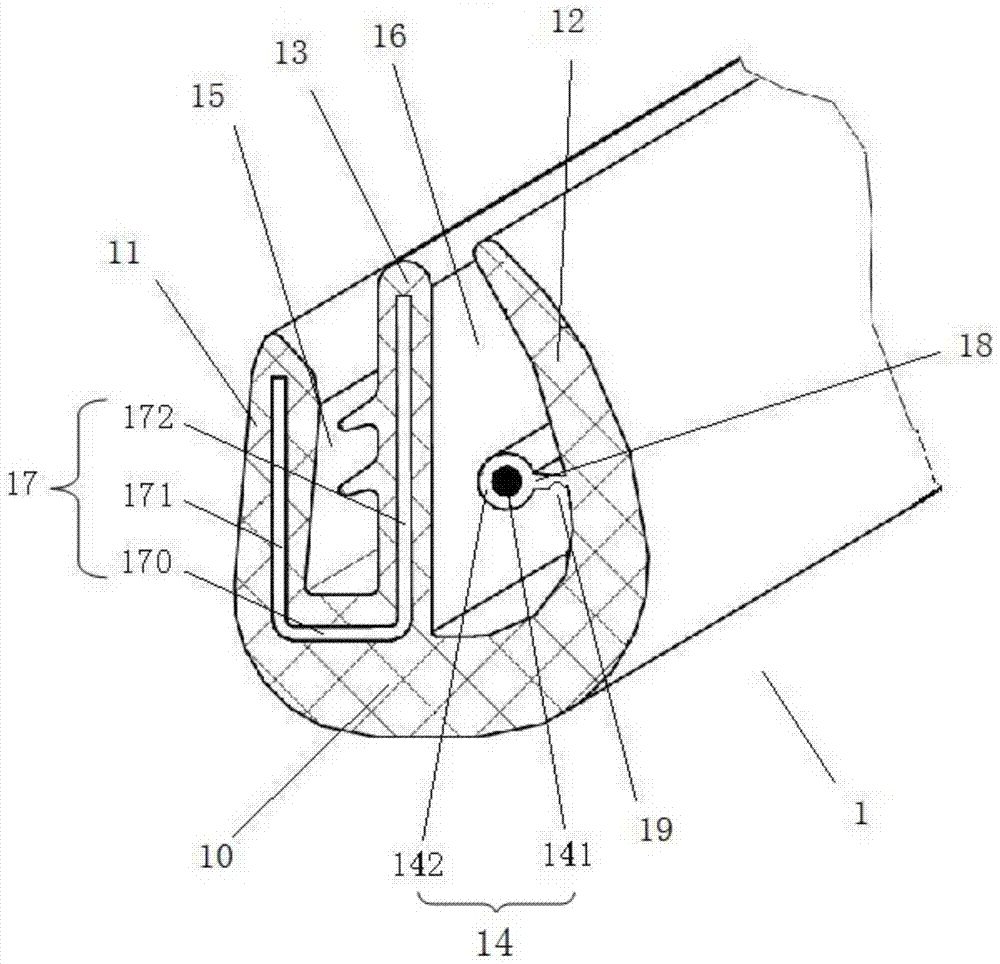

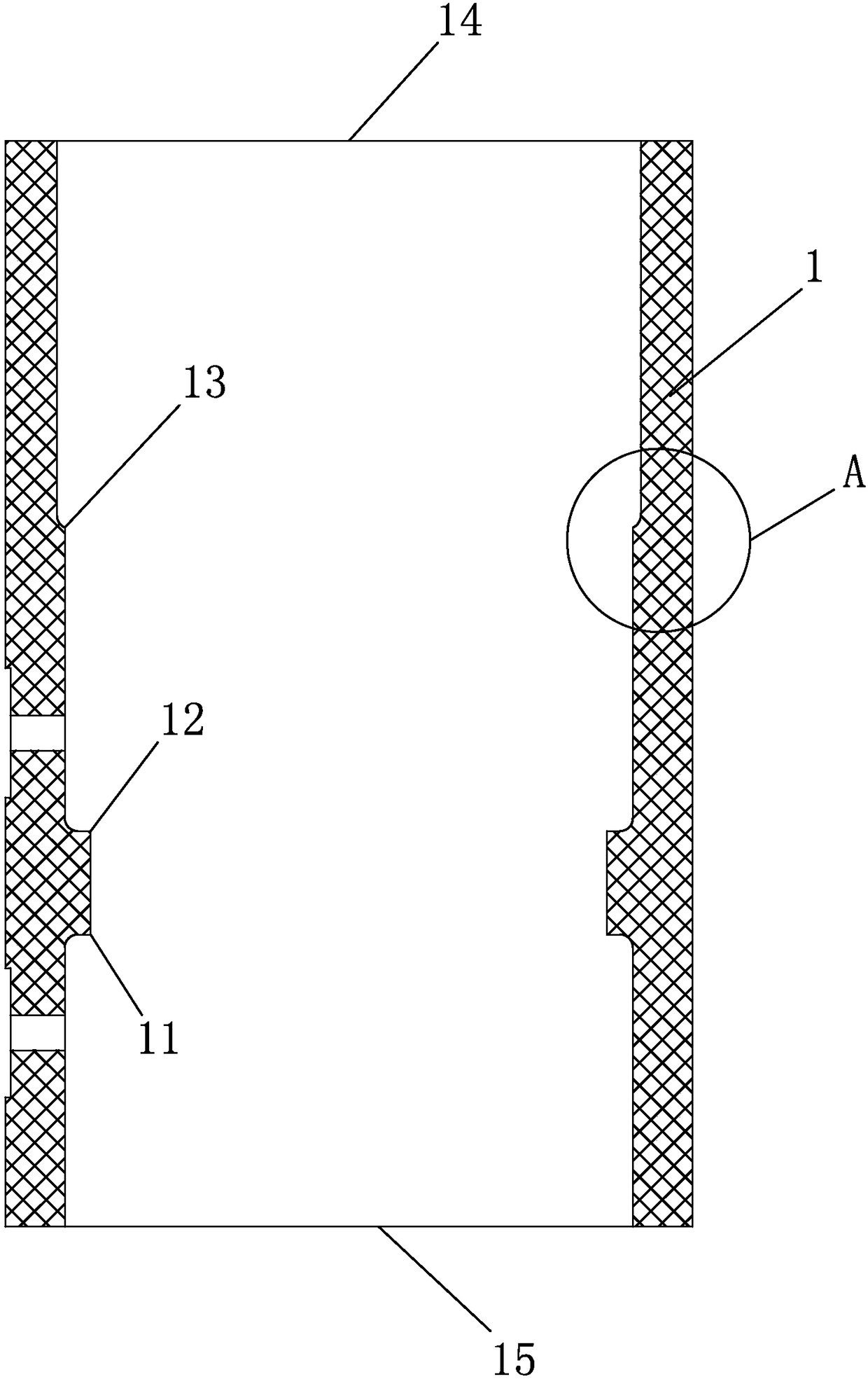

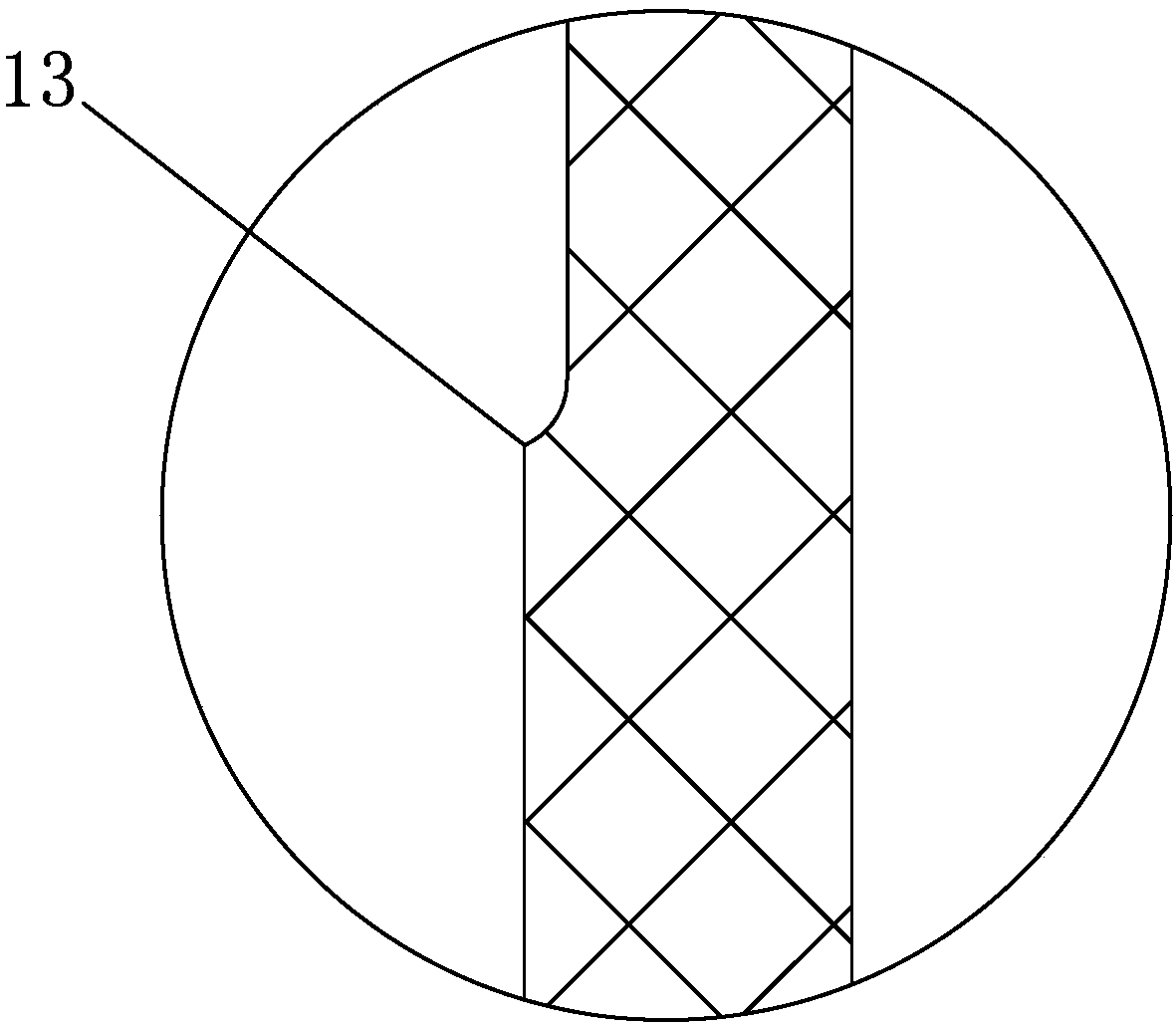

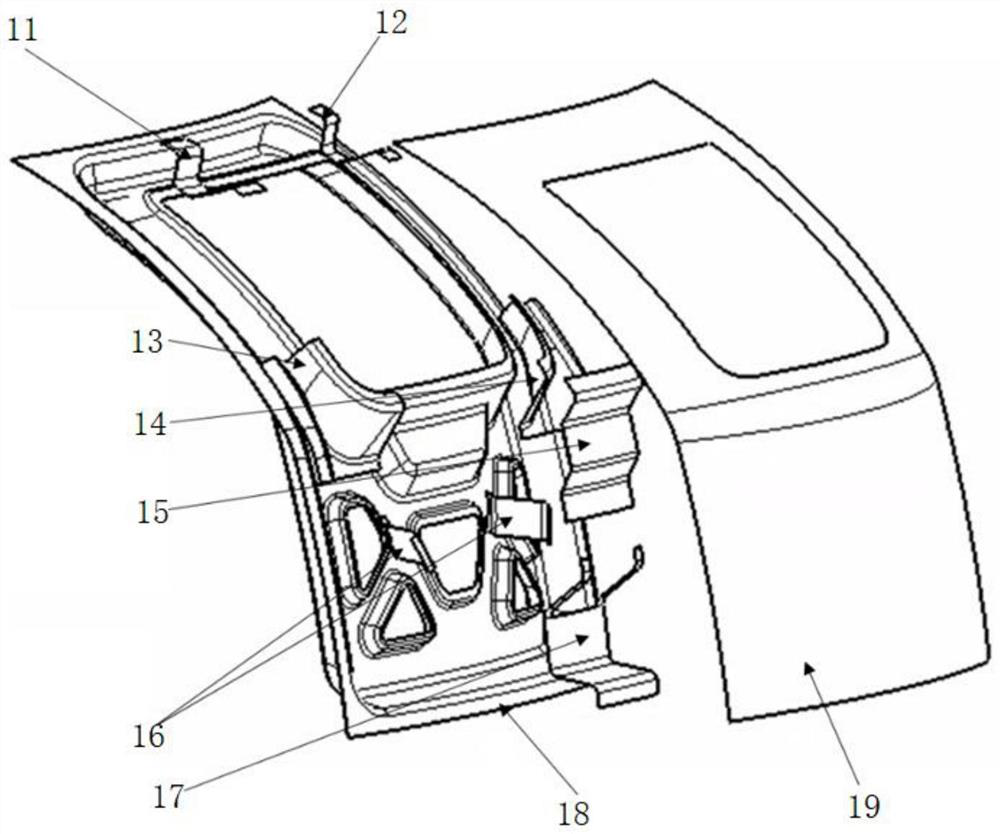

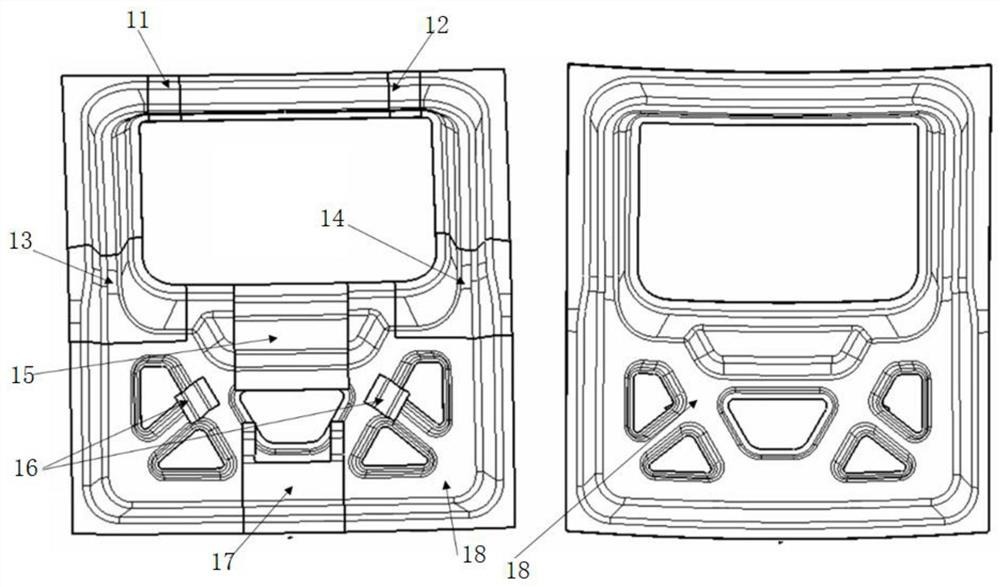

Skylight trim strip, skylight trim strip component and assembly method of skylight trim strip

InactiveCN104842891ALarge assembly spaceEasy to operateSuperstructure subunitsMechanical engineeringSunroof

The invention discloses a skylight trim strip, a skylight trim strip component and an assembly method of the skylight trim strip. The skylight trim strip comprises a base (10), and a first lip edge (11) and a second lip edge (12) extending from the same side of the base (10), wherein the second lip edge (12) is a flexible lip edge; and a pull belt (14) is arranged at the inner side of the second lip edge (12) in an extension direction of the skylight trim strip. The skylight trim strip component comprises a skylight body (3) and the skylight trim strip. The assembly method of the skylight trim strip comprises the steps of: preparing the skylight trim strip component (100) according to the claim 13; mounting the skylight body (3) of the skylight trim strip component on a vehicle body top cover (4); mounting a ceiling (2) on the vehicle body; and pulling out the pull belt (14) of the skylight trim strip (1), guiding and fastening the second lip edge (12) onto a stop port (21) of the ceiling (2), and taking out the pull belt (14).

Owner:BEIQI FOTON MOTOR CO LTD

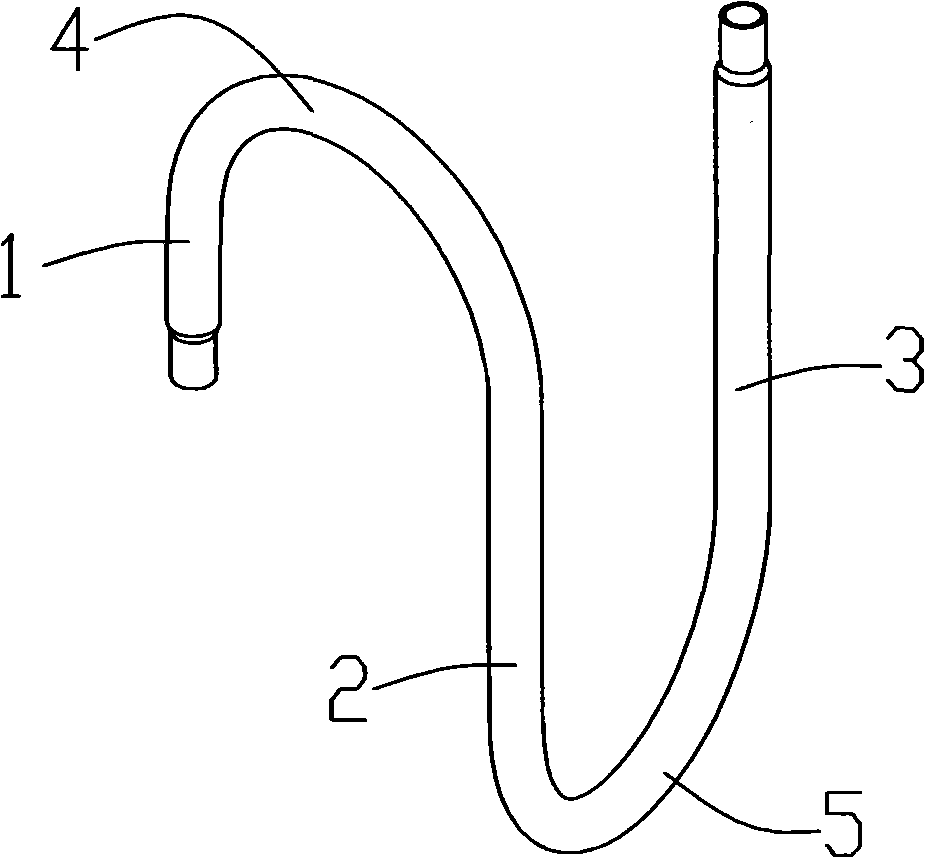

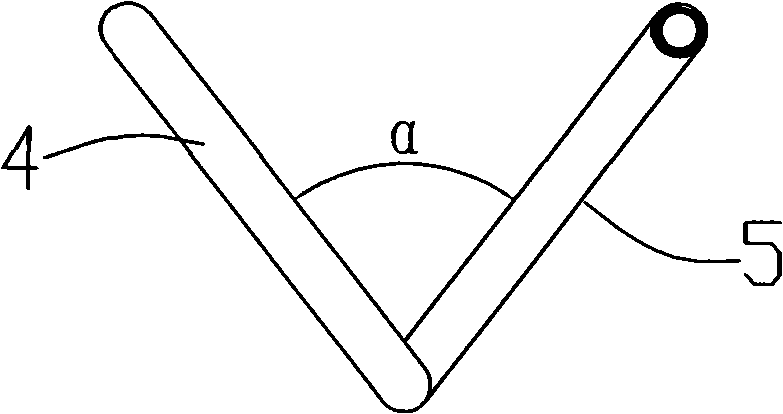

Automobile exhaust treatment ammonification system

PendingCN109488423ALow costLarge assembly spaceInternal combustion piston enginesExhaust apparatusUreaDiesel particulate filter

The invention relates to an automobile exhaust treatment ammonification system. A transition part between a diesel particulate filter (DPF) input end and an SCR output end comprises a transition partshell and a transition cavity arranged in the transition shell; the transition shell comprises a transition front plate, a transition rear plate and an annular transition side body clamped between thetransition front plate and the transition rear plate; a front plate inlet and a front plate outlet are formed in the top part and the bottom part of the transition front plate; a flow-guiding panel is clamped into the front plate inlet; an arc-shaped crusher and a flow-guiding bend pipe are arranged at the position, close to the front plate inlet, in the transition cavity; the flow-guiding panel,the arc-shaped crusher, the flow-guiding bend pipe, the transition rear plate and the transition side body enclose to form a No.1 cavity communicating with the transition cavity; and a urea sprayinghole communicating with the No.1 cavity is formed in the top part of the transition side body. According to the design, no mixer needs to be extraly arranged, so that the cost and the assembling spaceare saved, the risk of urea crystallization can be reduced, and an ammonia gas generation effect is good.

Owner:DONGFENG COMML VEHICLE CO LTD

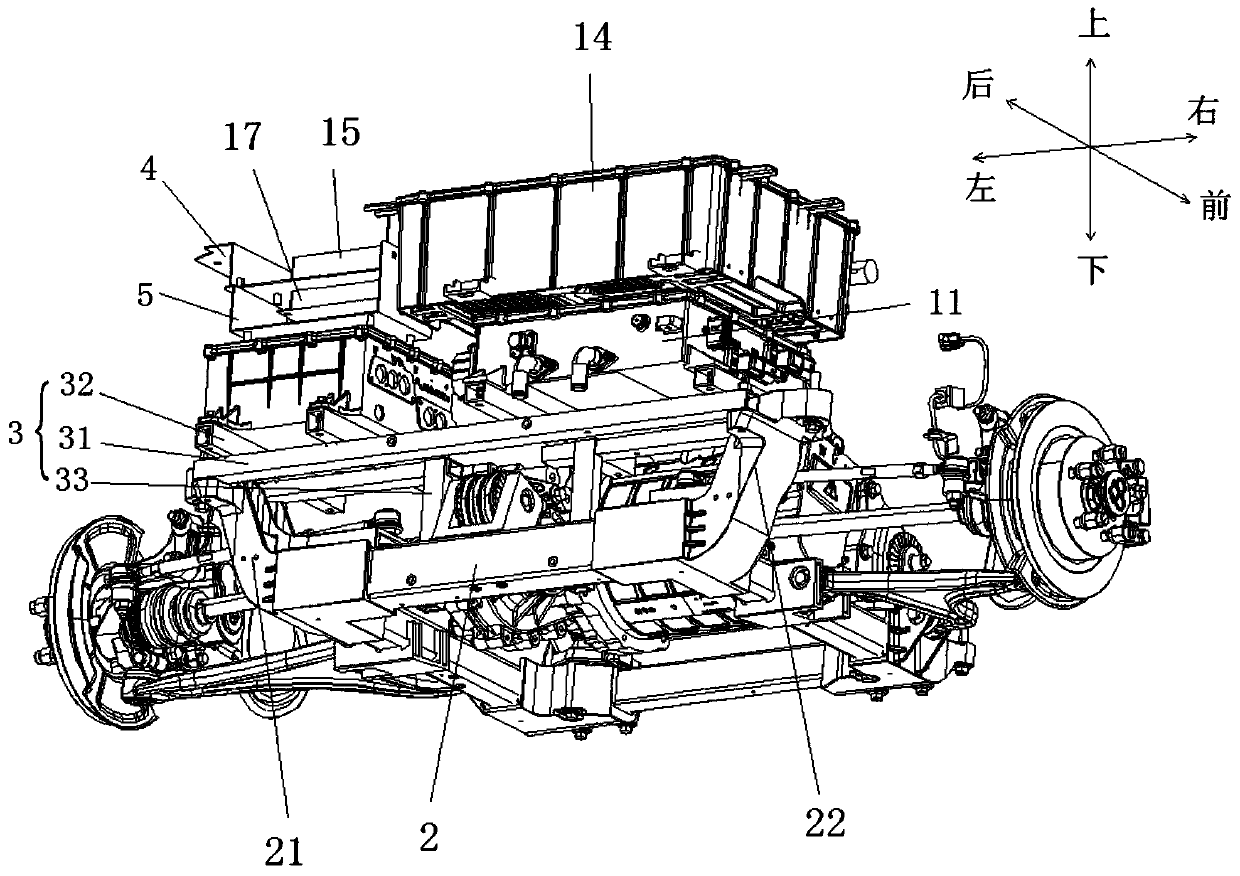

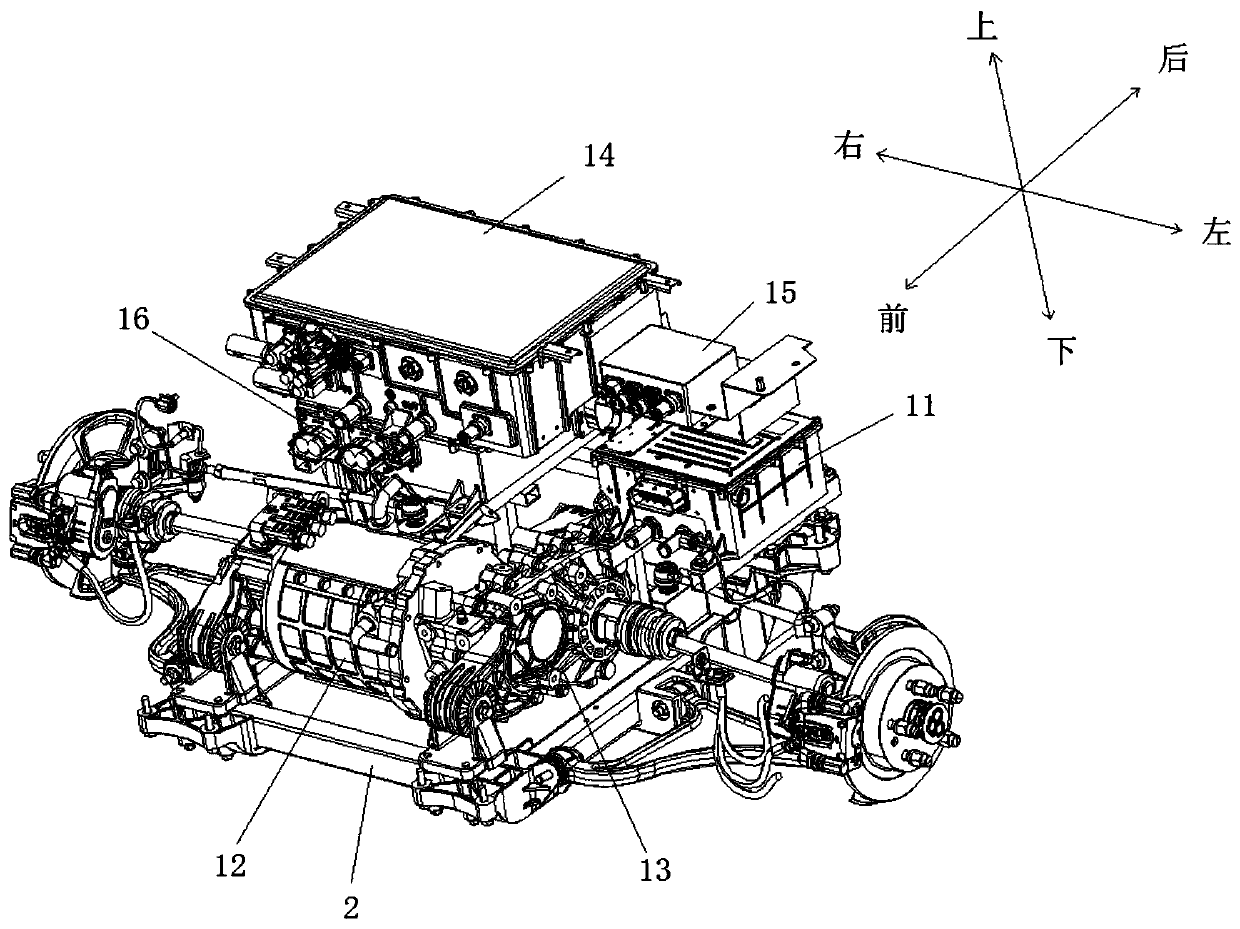

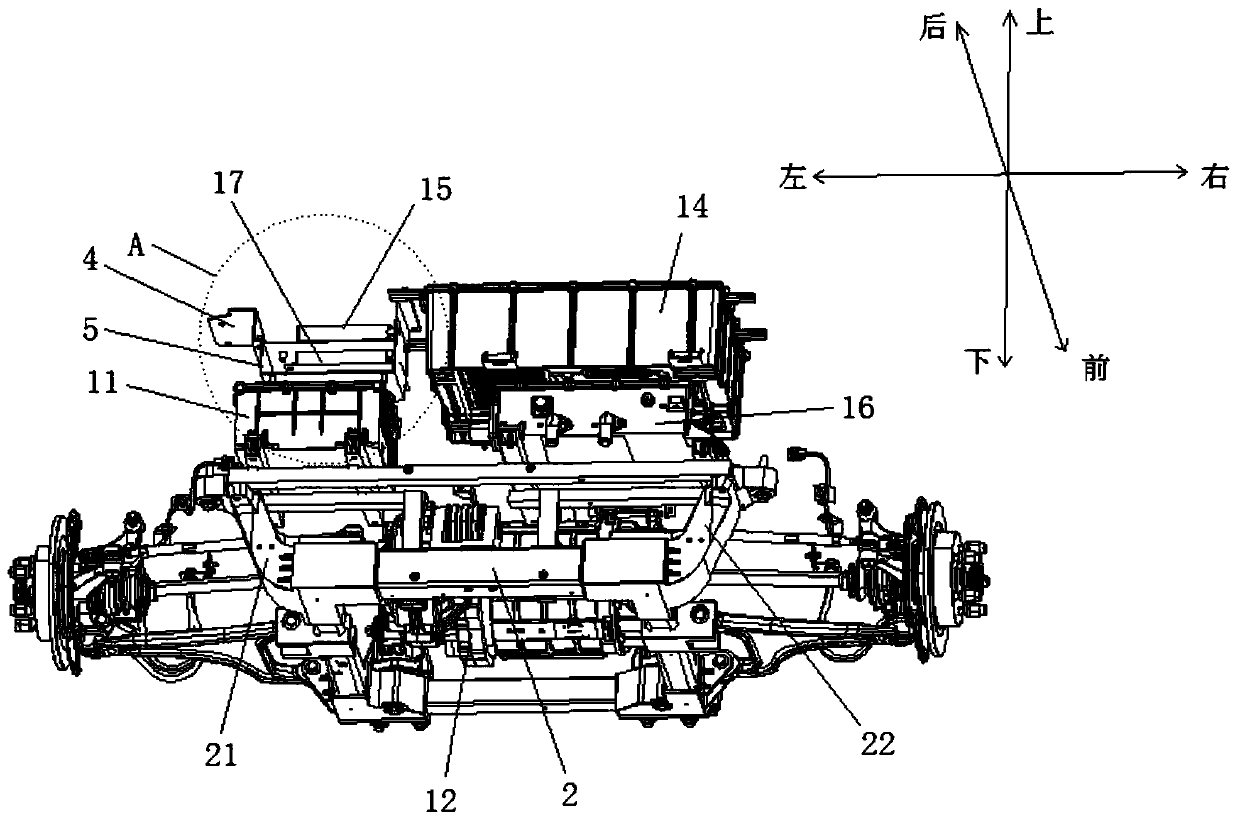

Hydrogen energy automobile power system arrangement structure and hydrogen energy automobile

PendingCN110576906AReduce distanceReduce complexityElectric devicesElectric propulsion mountingHydrogenVehicle frame

The invention provides a hydrogen energy automobile power system arrangement structure and a hydrogen energy automobile. The hydrogen energy automobile power system arrangement structure comprises a motor controller, a drive motor, a speed reducer, a fuel battery DC / DC converter, an energy manager, a whole automobile controller and a rear cabin, wherein the speed reducer, the fuel battery DC / DC converter, the energy manager, the whole automobile controller and the rear cabin are connected with the drive motor. All the parts are arranged in the rear cabin in multiple layers, a horizontal support is arranged in the rear cabin, an auxiliary frame extends in the left-right direction, a left supporting base and a right supporting base are formed at the left end and the right end of the auxiliary frame in an upward extending mode, and the horizontal support is fixed to the left supporting base and the right supporting base. The drive motor and the speed reducer are located on the lowermost layer and fixed to the frame type auxiliary frame, the motor controller and the energy manager are located on a middle layer and fixed to the horizontal support, and the fuel battery DC / DC converter, the whole automobile controller and a DC / DC terminal box are located on the uppermost layer and fixed to the bottom of a trunk floor. According to the technical scheme, the hydrogen energy automobile power system arrangement structure and the hydrogen energy automobile have the advantages that the parts of the power system of the hydrogen energy automobile are reasonably arranged, and vehicle allocation integration is improved.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

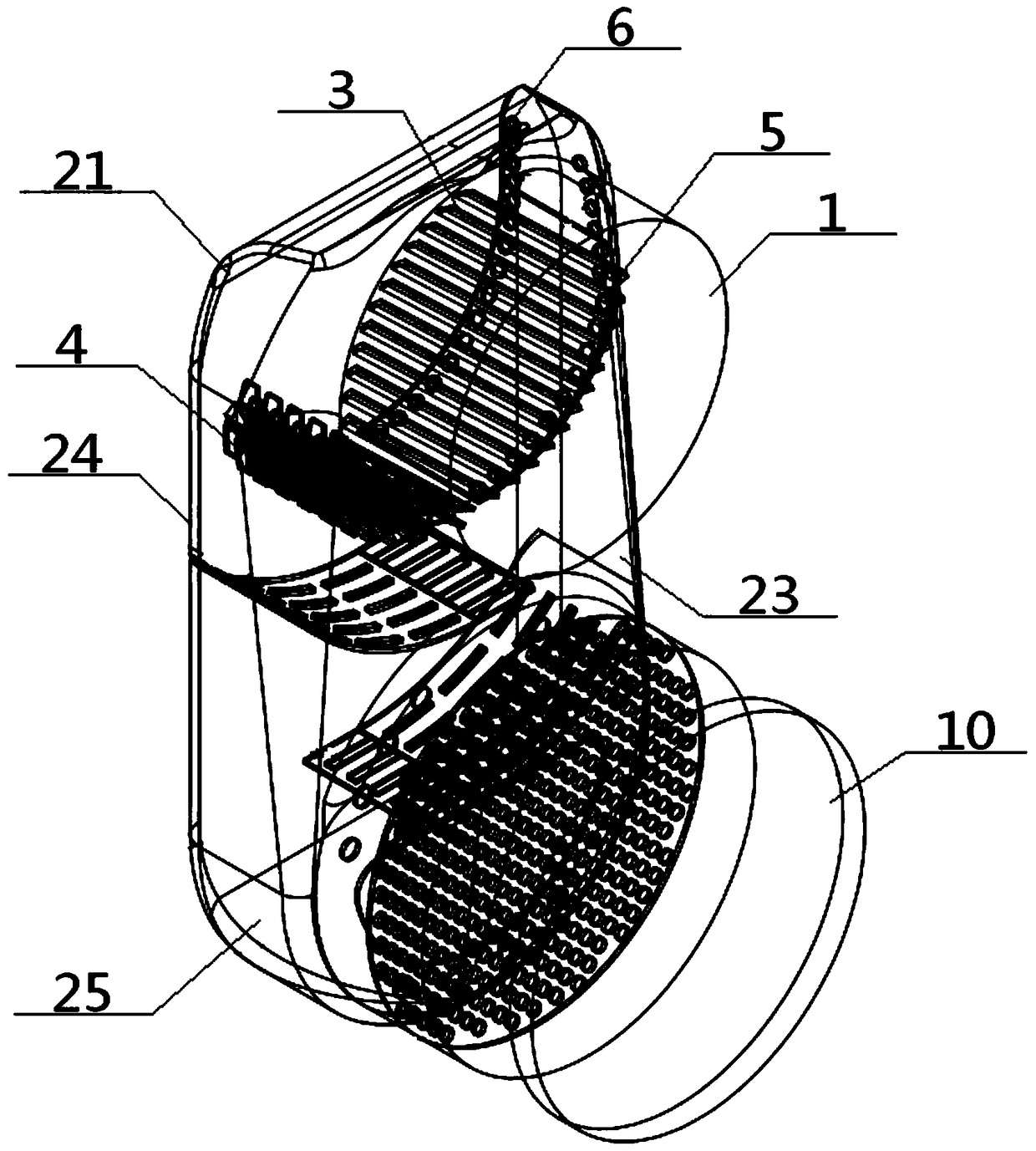

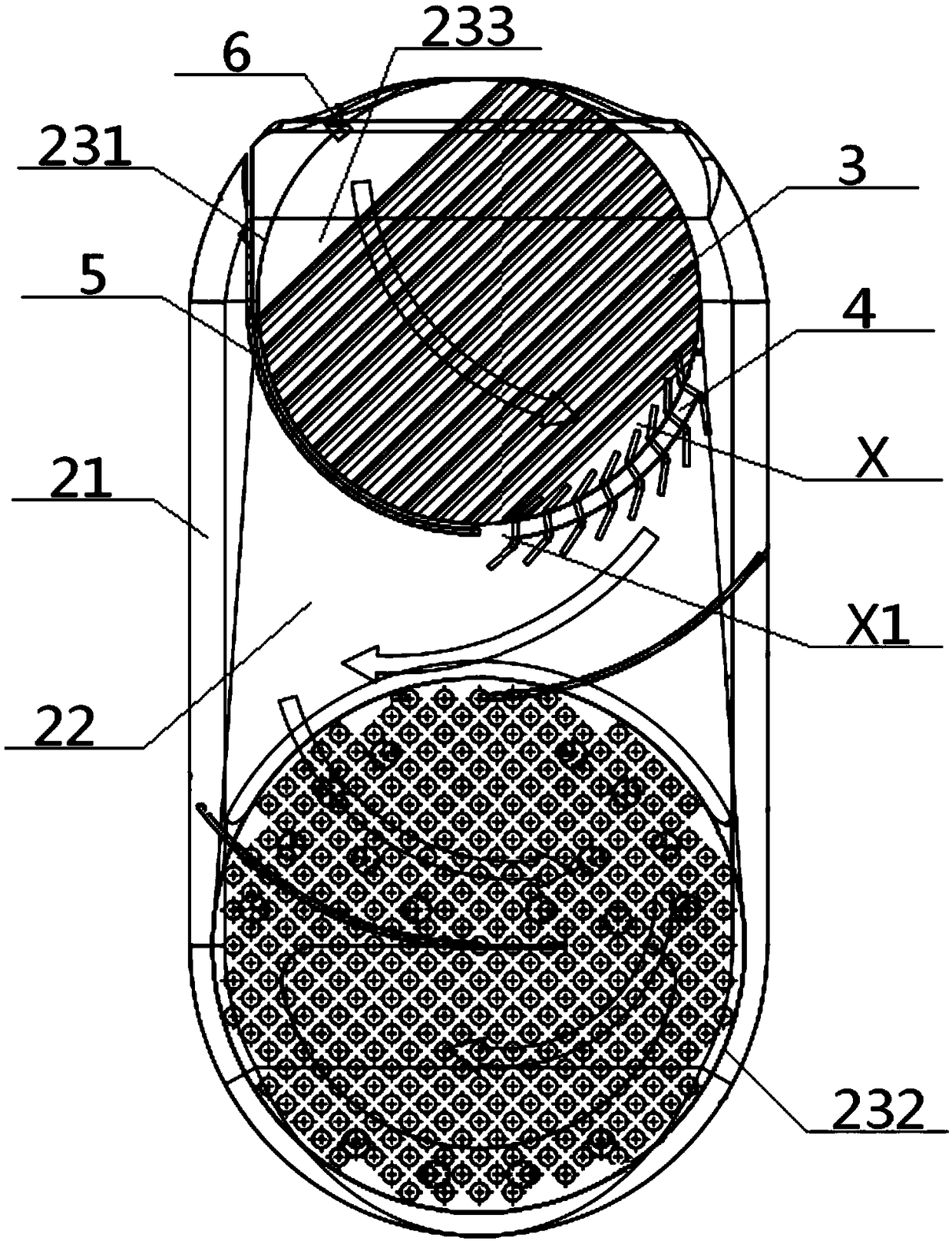

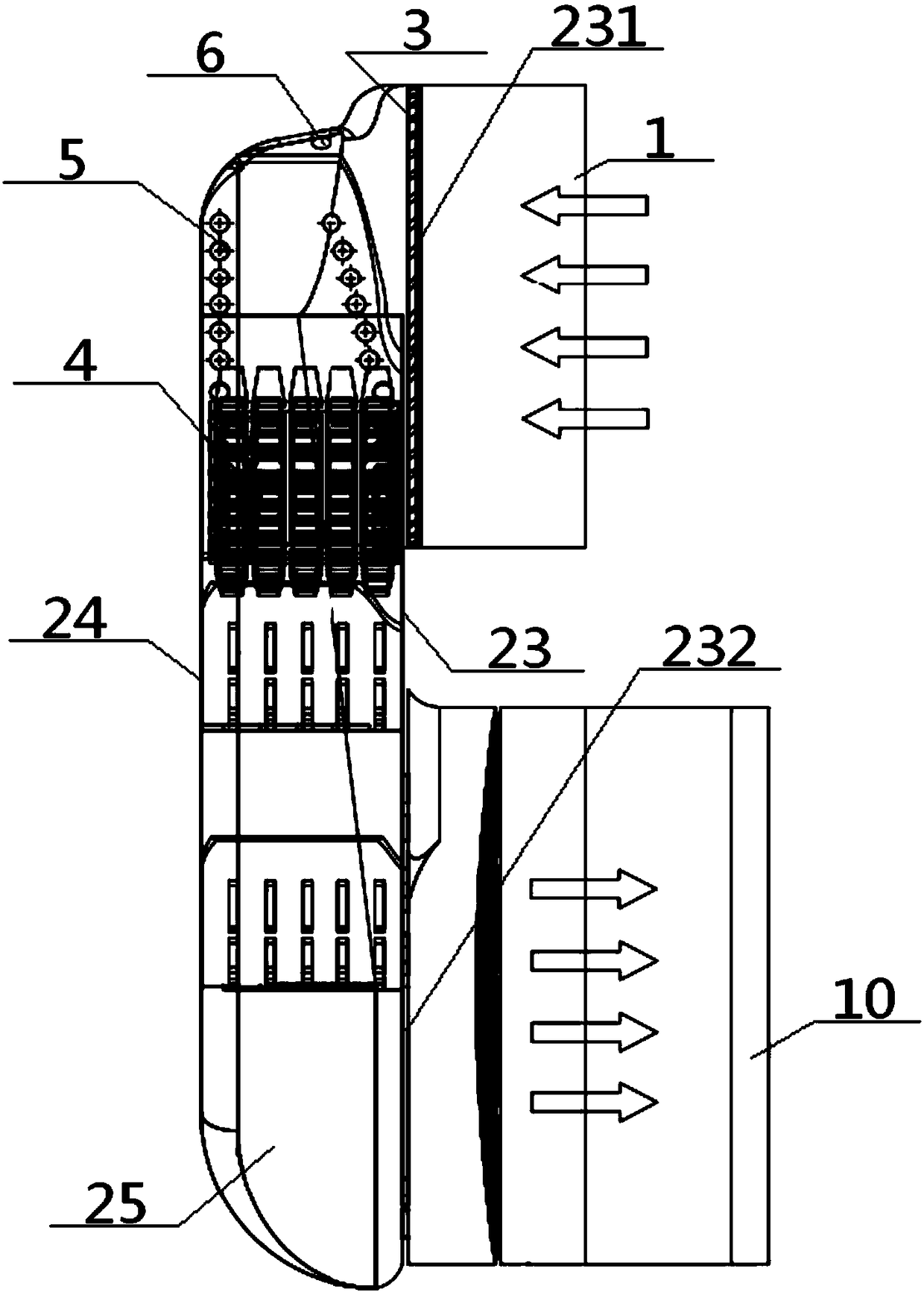

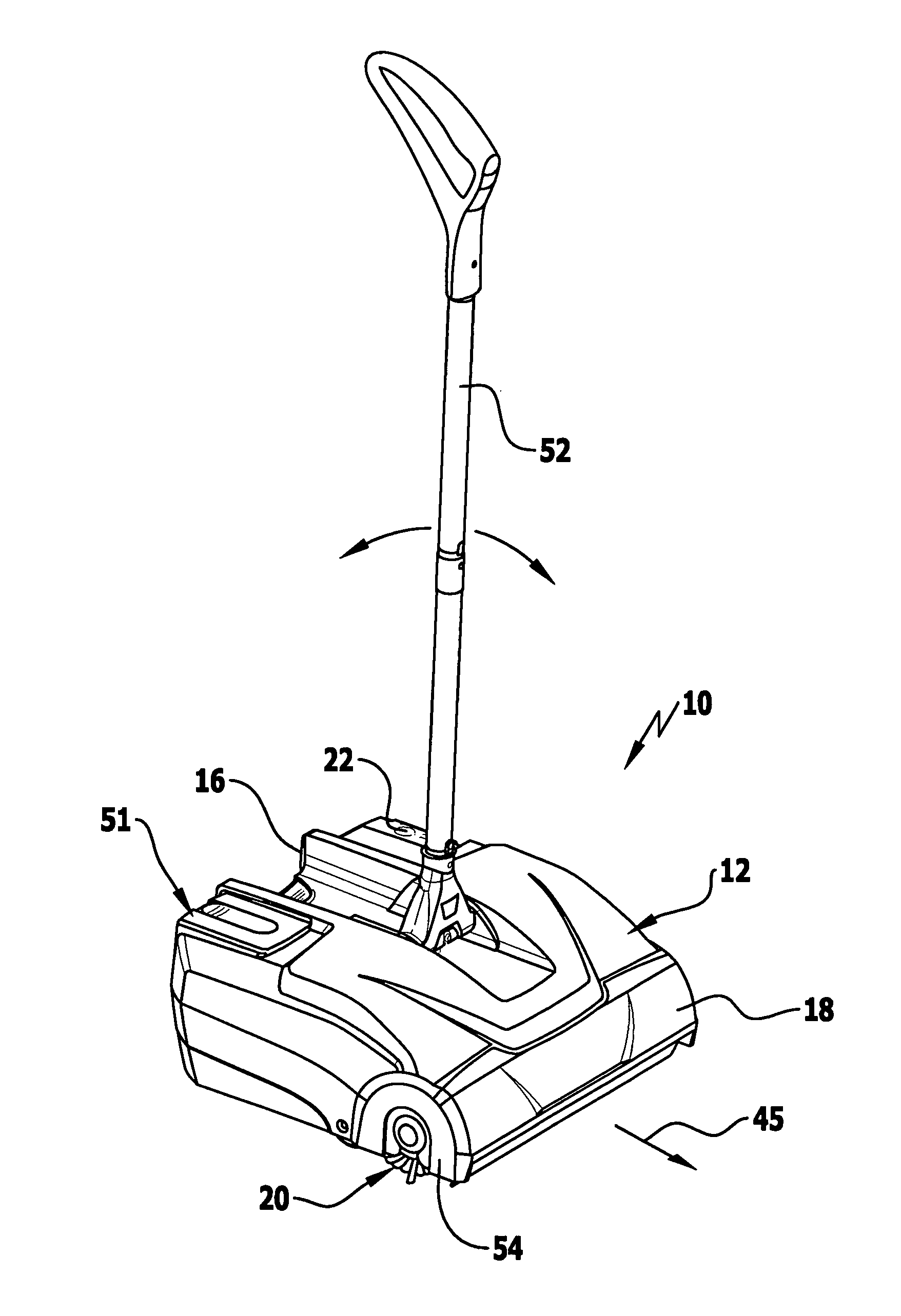

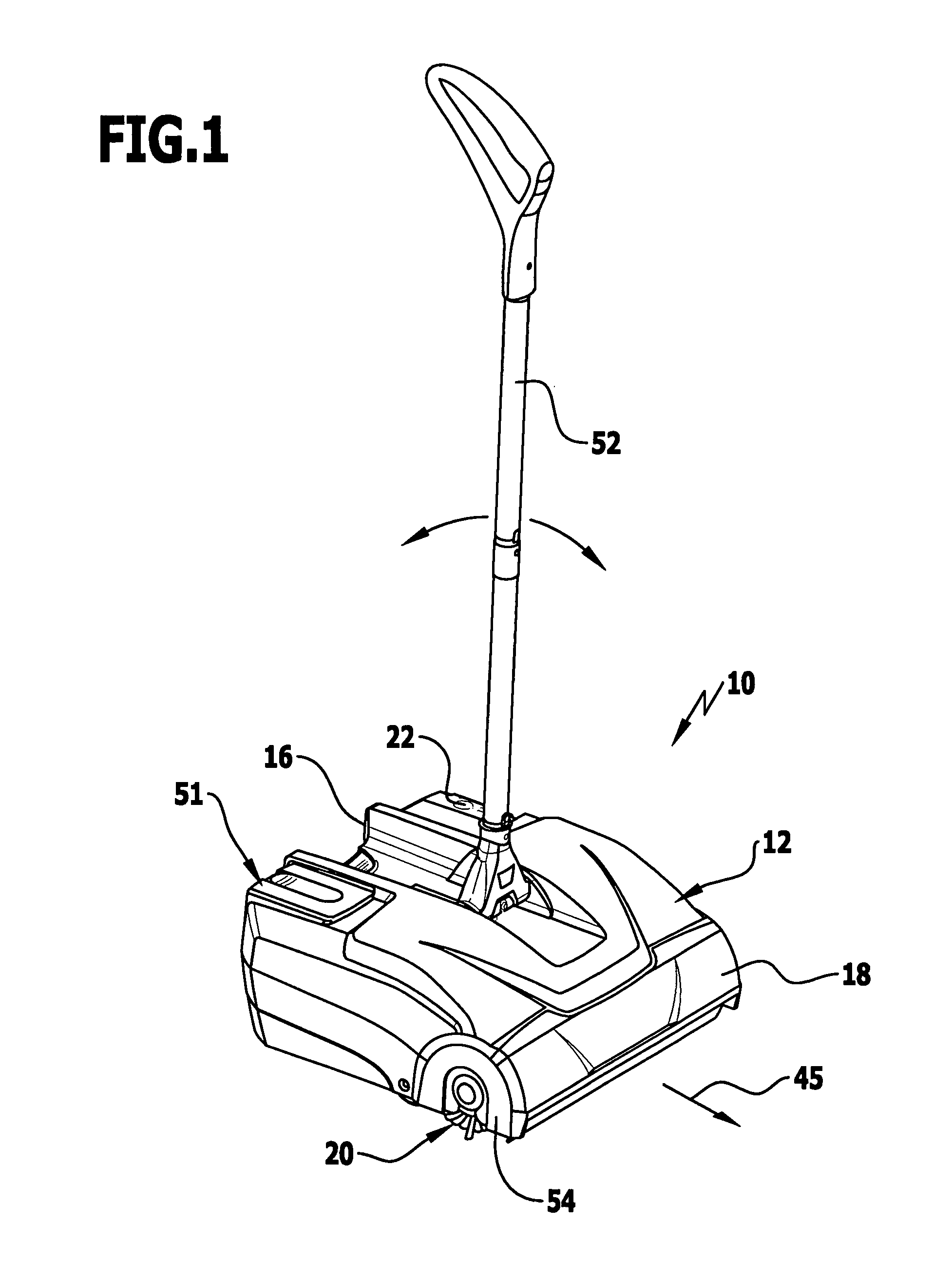

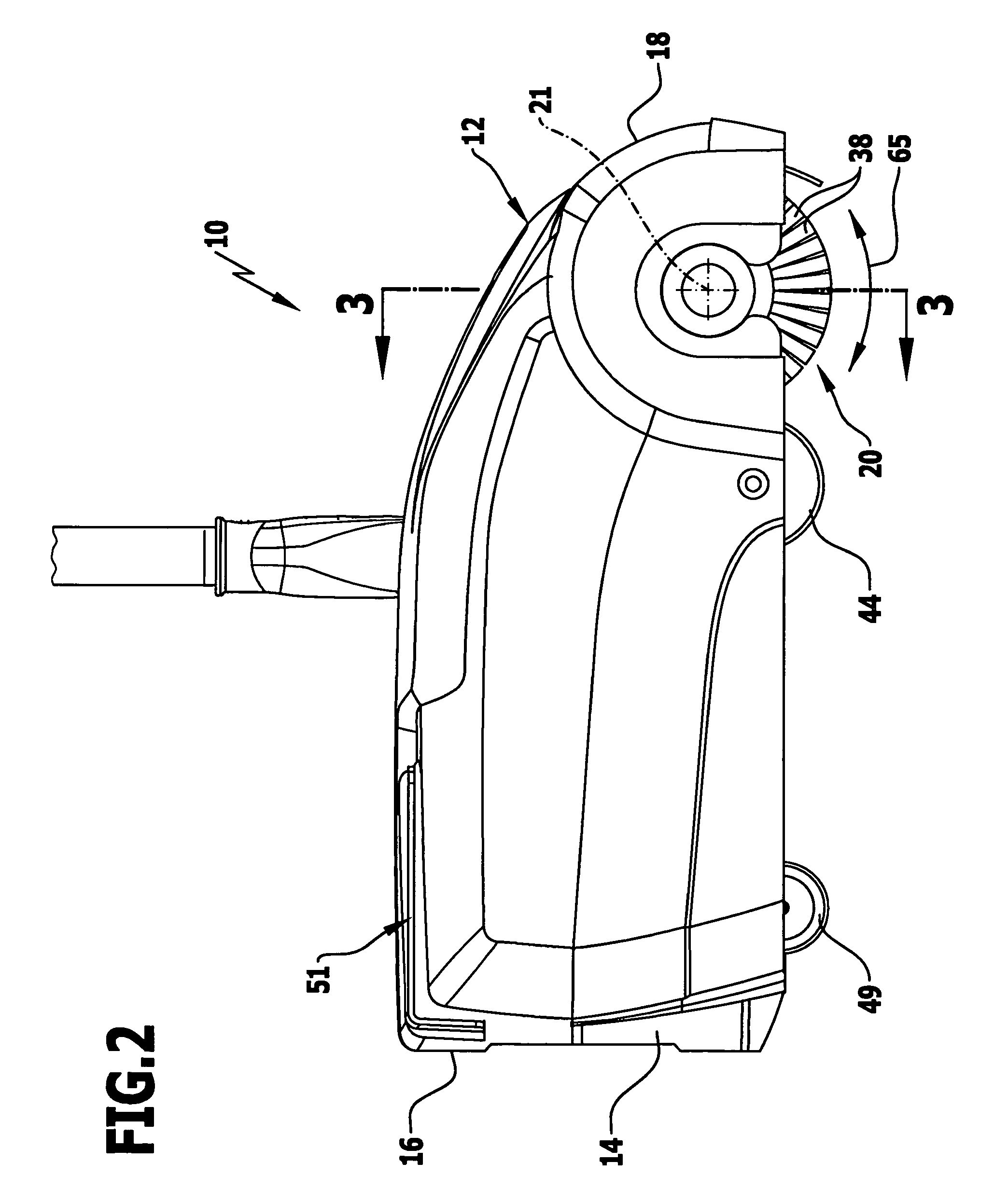

Mobile sweeper

InactiveUS8621700B2Promote sportsIncrease resistanceBowling gamesMechanical cleaningEngineeringElectric motor

The invention relates to a mobile sweeper comprising a housing, in which a sweeping roller driven by an electric motor is mounted for rotation, and a sweepings container for receiving sweepings, wherein there are mounted on the housing adjacent to the sweeping roller two front supporting wheels and at a distance from these at least one rear supporting wheel, each for rotation about an axis of rotation. In order to further develop the sweeper such that with the occurrence of surface unevennesses, there is no risk of the sweeping roller becoming blocked or of the sweeper tilting, it is proposed in accordance with the invention that the axis of rotation of a first front supporting wheel be arranged coaxially with the axis of rotation of the sweeping roller and, in relation to the main direction of movement of the sweeper, offset from the axis of rotation of the second front supporting wheel.

Owner:ALFRED KARCHER GMBH & CO KG

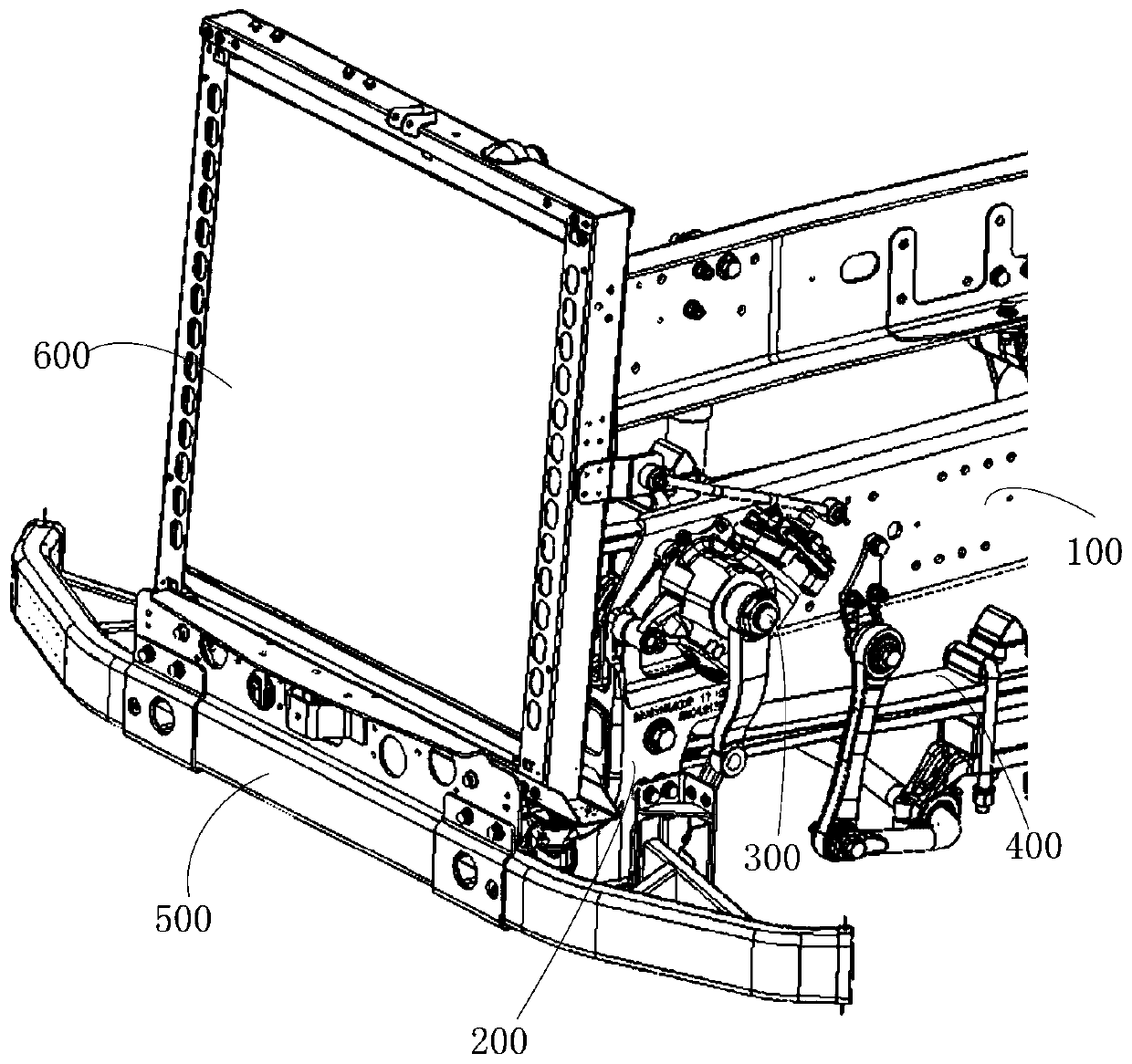

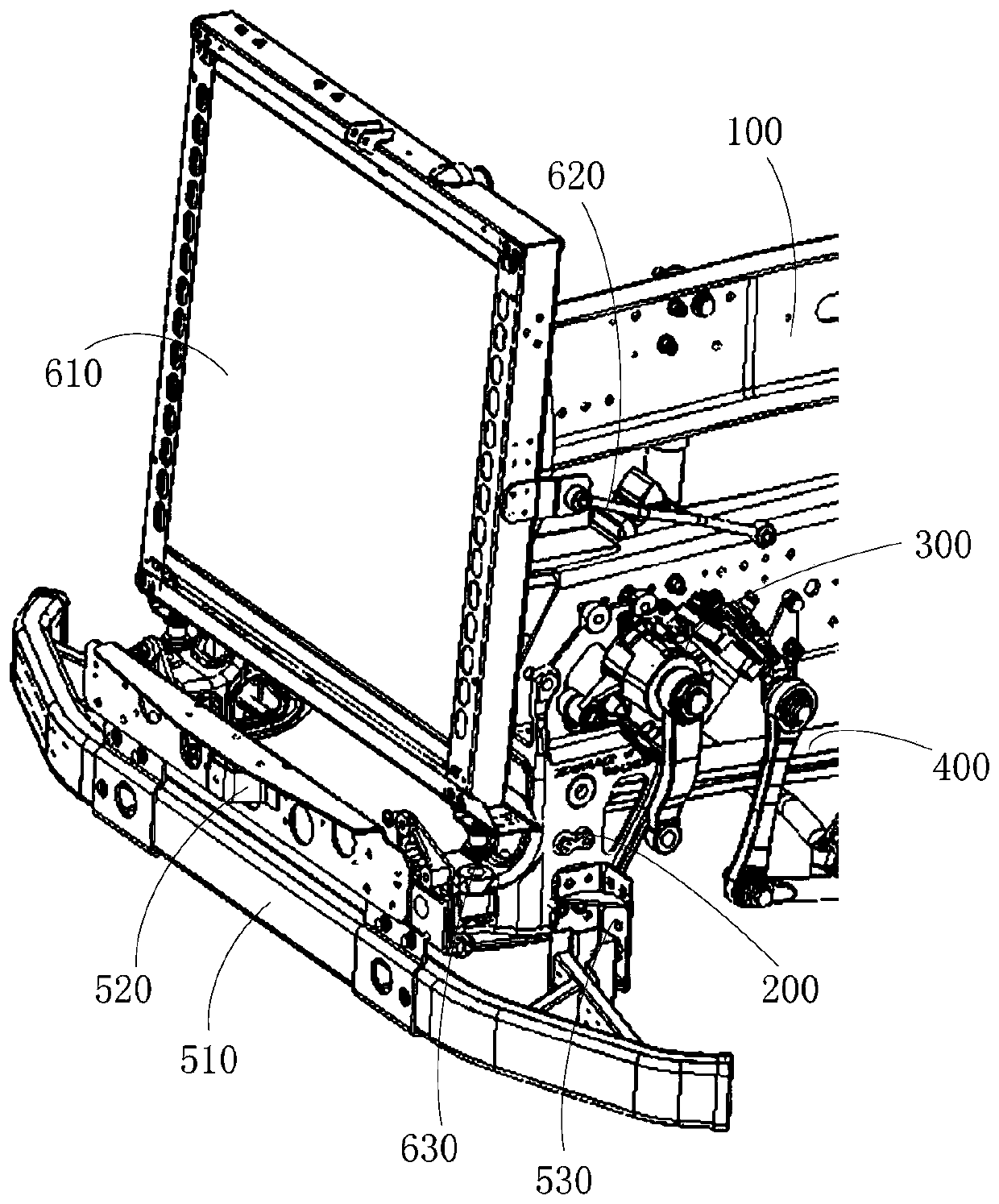

Heavy truck chassis front end module structure and chassis frame structure

ActiveCN110861712ALarge assembly spaceImprove assembly efficiencyUnderstructuresVehicle frameControl theory

The invention relates to a heavy truck chassis front end module structure and a chassis frame structure. The heavy truck chassis front end module structure comprises a chassis front end bracket, two front combined bracket structures arranged on the two sides of the chassis front end bracket respectively, a steering engine assembly arranged on the outer side of the front combined bracket structures, a front steel plate spring assembly arranged between the inner sides of the two front combined bracket structures, a radiator assembly and a front protection assembly. The bottom of the radiator assembly is arranged at the front ends of the two front combined support structures, the upper part of the radiator assembly is connected to the chassis front end bracket, the middle part of the front protection assembly is installed at the front ends of the two front combined bracket structures, and the two sides of the front protection assembly are correspondingly connected to the outer sides of the two front combined bracket structures respectively. The heavy truck chassis front end module structure aims to solve the problem that in a traditional technology, the front end structure of a chassis cannot meet the assembly performance and manufacturability requirements of a whole vehicle.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

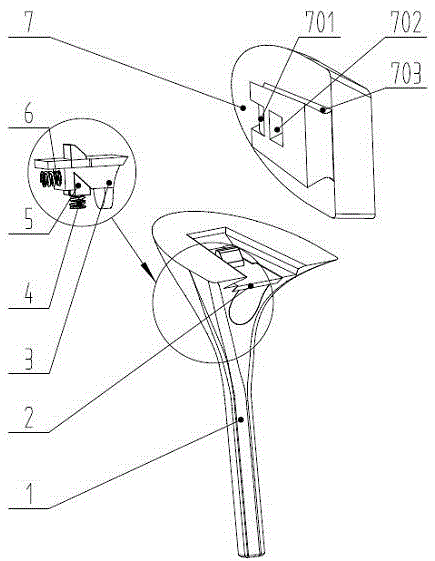

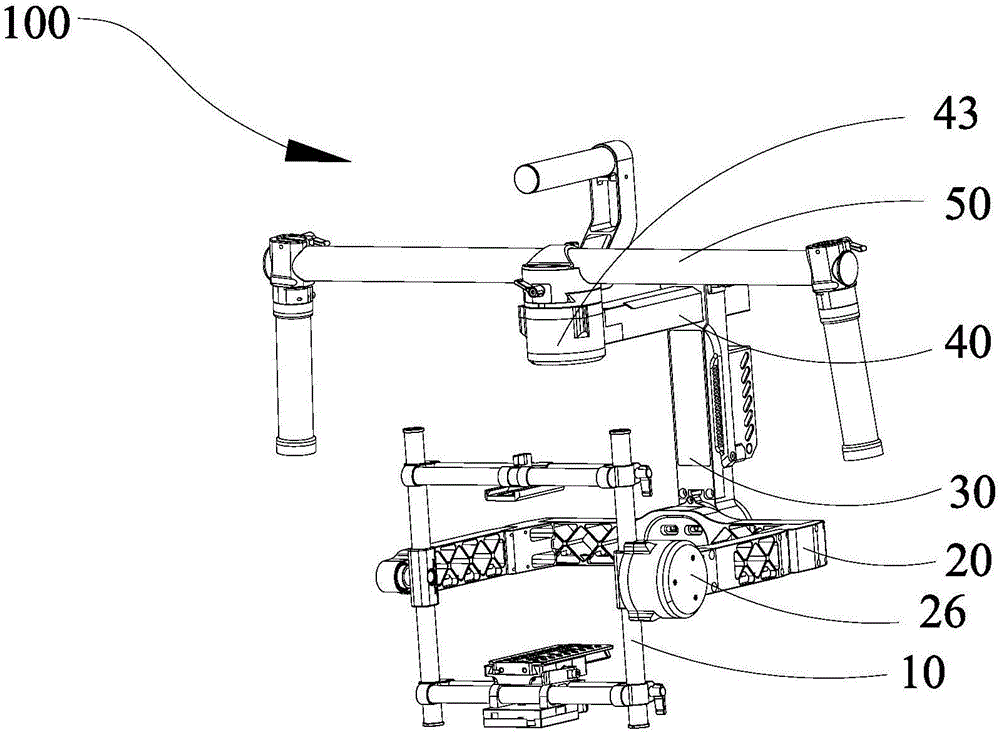

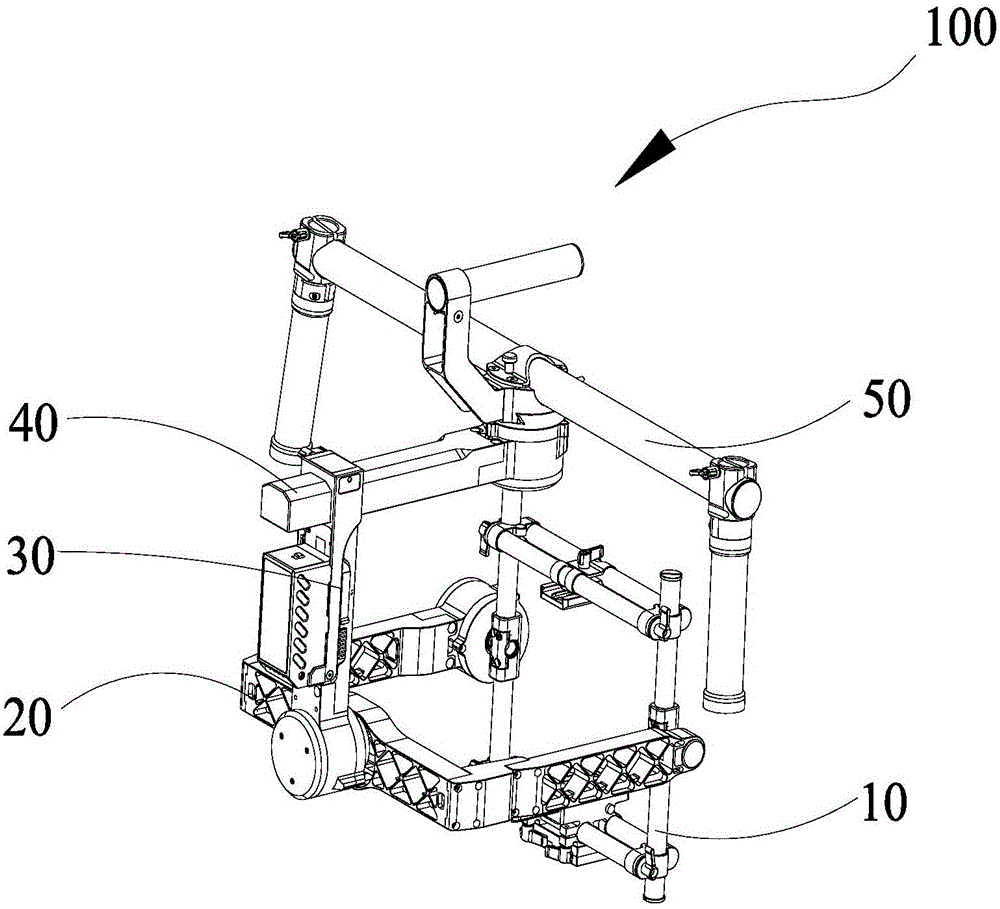

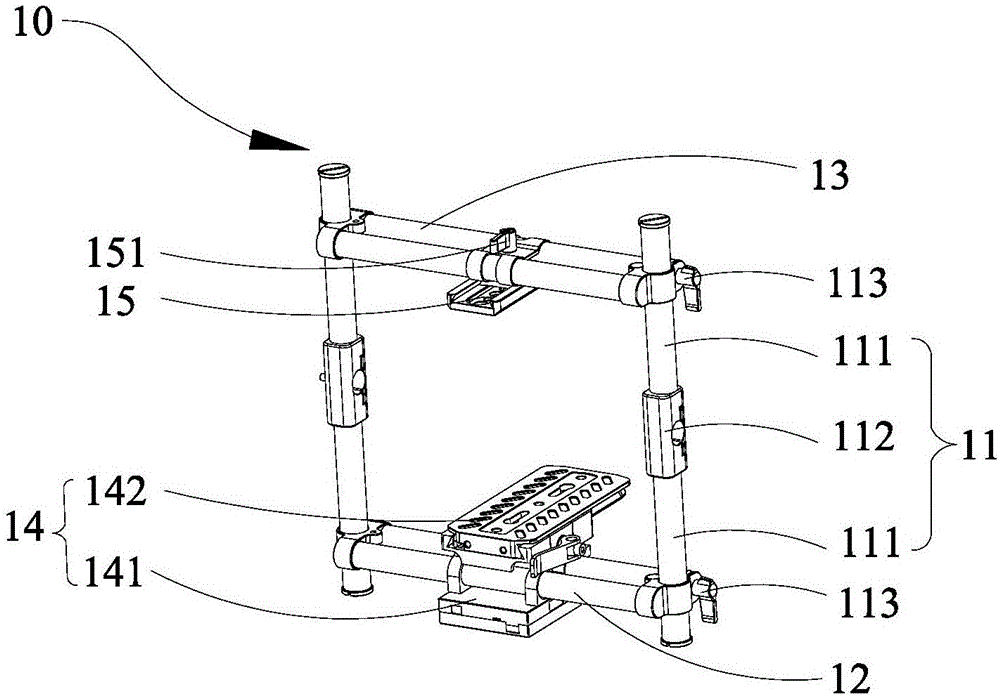

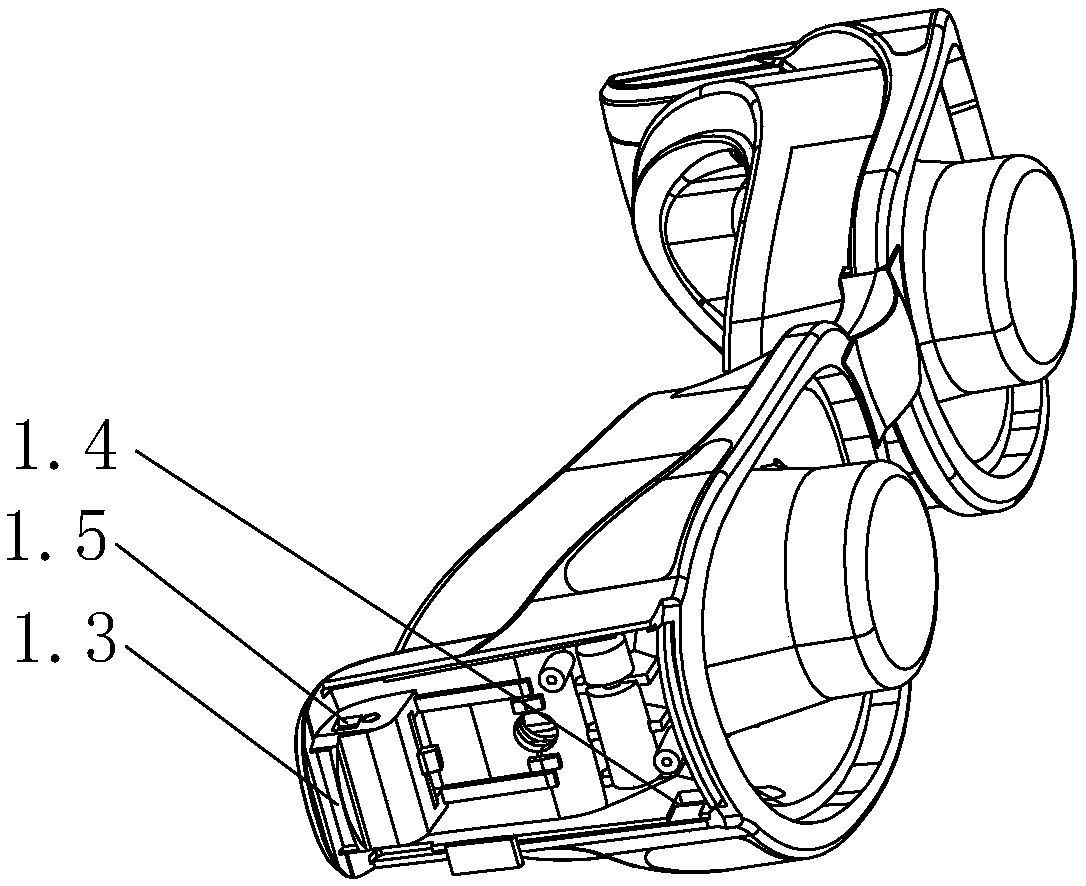

Stable balancing device for camera

ActiveCN106545735ALarge assembly spaceAdapt to assembly needsMachine supportsCamera body detailsEngineering

The invention discloses a stable balancing device for a camera. The stable balancing device for the camera comprises a camera mounting frame, a transverse rolling arm assembly connected to the camera mounting frame, a mainboard cabin connected to the transverse rolling arm assembly, a Z-axis arm assembly connected to the mainboard cabin and a handle portion connected to the Z-axis arm assembly. The transverse rolling arm assembly comprises a first straight arm, a first straight arm lengthened block, a transverse rolling arm, a second straight arm lengthened block and a second straight arm. The Z-axis arm assembly comprises a Z-axis arm and a Z-axis arm lengthened piece. The first straight arm lengthened block and the second straight arm lengthened block are detachably connected to the first straight arm and the second straight arm separately, and the Z-axis arm lengthened piece is detachably connected to the Z-axis arm, so that the operating requirements on cameras in different dimensions can be adapted. Moreover, weight-reducing structures are arranged for the transverse rolling arm assembly, the mainboard cabin and the Z-axis arm assembly, so that the weight of the stable balancing device for the camera can be alleviated, and the stable balancing device for the camera is convenient to use.

Owner:SHENZHEN GUDSEN TECH CO LTD

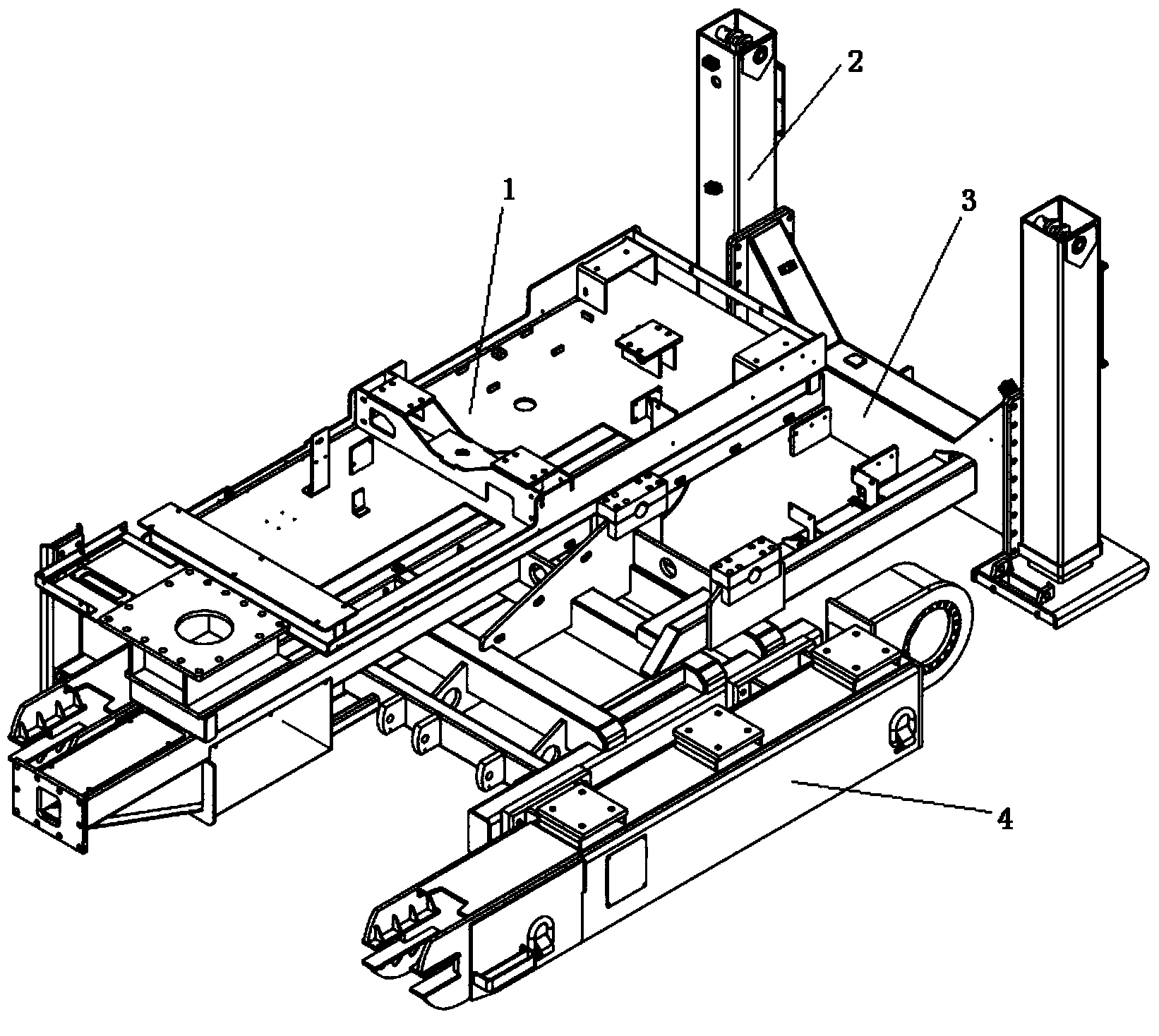

Horizontal guiding drilling machine chassis

InactiveCN103661600ALoad largeHigh strengthVehicle fittings for liftingUnderstructuresVehicle frameLoad capacity

Owner:TIANJIN BAO HONGYUAN MACHINERY MFG

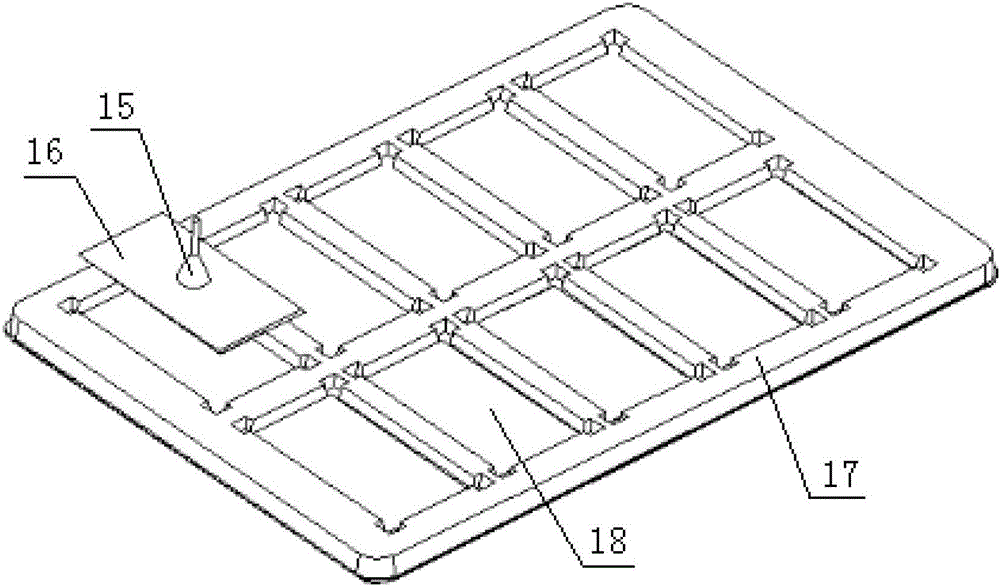

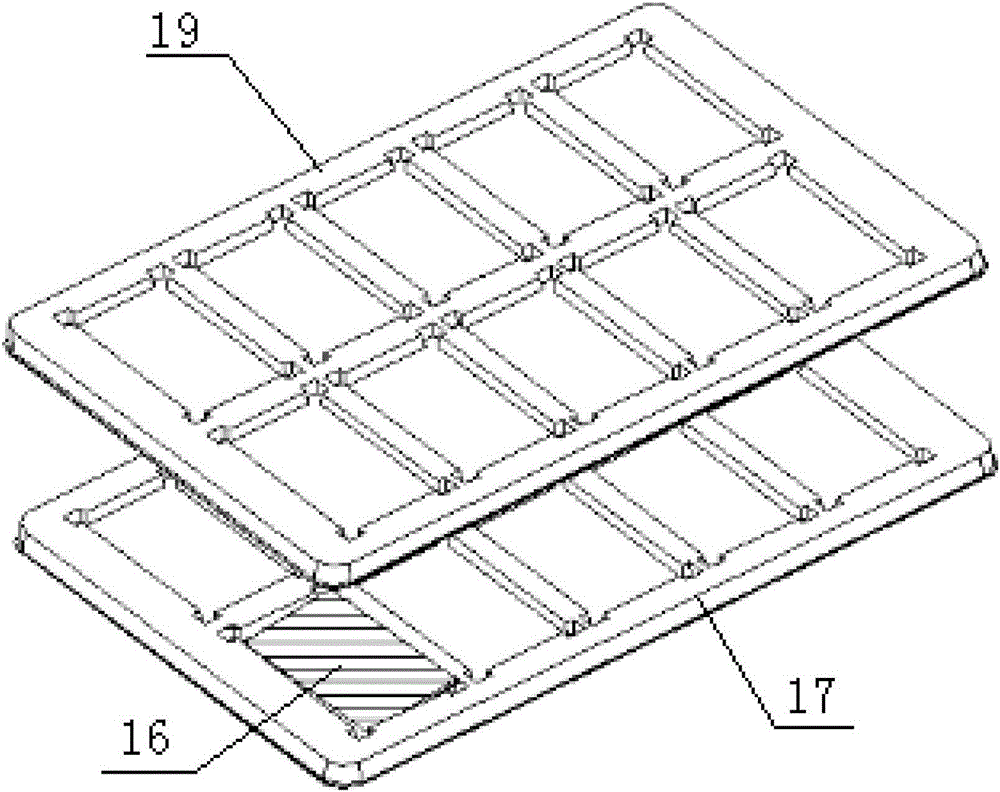

Packaging tray for liquid crystal display panel and extensible and retractable unit pieces constituting packaging tray

ActiveCN106219019AImprove packaging qualityAvoid damageRigid containersLiquid-crystal displayEngineering

The invention provides a packaging tray for a liquid crystal display panel and extensible and retractable unit pieces constituting the packaging tray. The packaging tray for the liquid crystal display panel and the extensible and retractable unit pieces constituting the packaging tray solve the problems that because the assembly gap between a tray and the panel is narrow, the difficulty degree for automatic packaging equipment to place the panel is increased, the placed panel is aligned inaccurately, and the panel is damaged on the next procedure, and the packaging quality is influenced seriously. The packaging tray for the liquid crystal display panel comprises the extensible and retractable unit pieces. The extensible and retractable unit pieces are arranged in a rectangular array and are sequentially and fixedly connected to be integrated and form a tray body. Each extensible and retractable unit piece comprises a four base plate and four edges. Each base plate is horizontally arranged, and the shape of the base plate is a quadrangle when people look down the base plate. The four edges of each extensible and retractable unit piece are sequentially arranged around the periphery of the corresponding base plate and protrude outwards in the direction perpendicular to the corresponding base plate. Each edge is fixedly connected to one brim of the corresponding base plate and is an extensible and retractable edge. The adjacent extensible and retractable unit pieces are spaced through the edges. The inner portion of each extensible and retractable unit piece can contain a glass substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

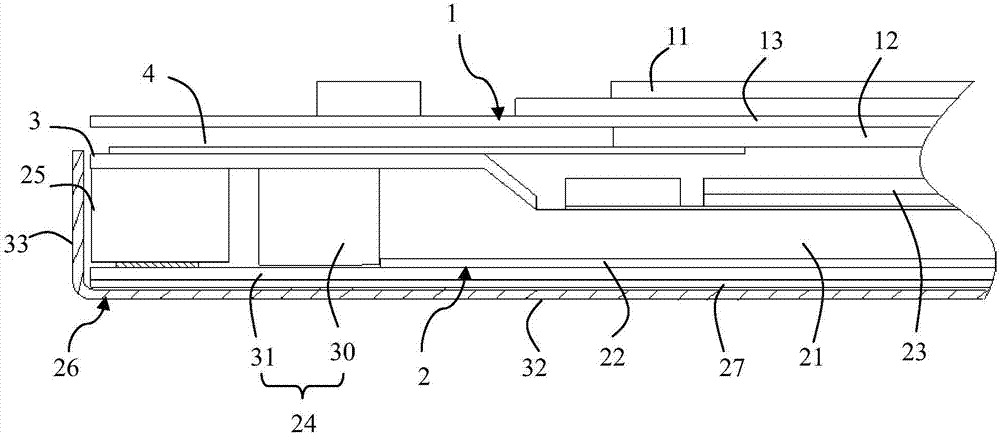

Liquid crystal display device and backlight module thereof

InactiveCN107121724ASmall sizeImprove cooling effectOptical light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention provides a liquid crystal display device and a backlight module thereof. The backlight module comprises a light guide plate, a reflecting layer, an optical diaphragm assembly and a light emitting assembly, wherein the optical diaphragm assembly is arranged at the top of the light guide plate, the reflecting layer is arranged at the bottom of the light guide plate, the light emitting assembly comprises an LED strip corresponding to a light incoming surface of the light guide plate and a substrate arranged at the bottom of the LED strip, and the substrate extends to the bottom of the reflecting layer. The substrate is arranged at the bottom of the reflecting layer, and the substrate extends to the bottom of the reflecting layer, so that an assembling space of the substrate is increased, the size of the substrate can be larger, the heat radiation of the LED strip can be facilitated, the service life of the LED strip and the liquid crystal display device can be prolonged, and the performance of the liquid crystal display device can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

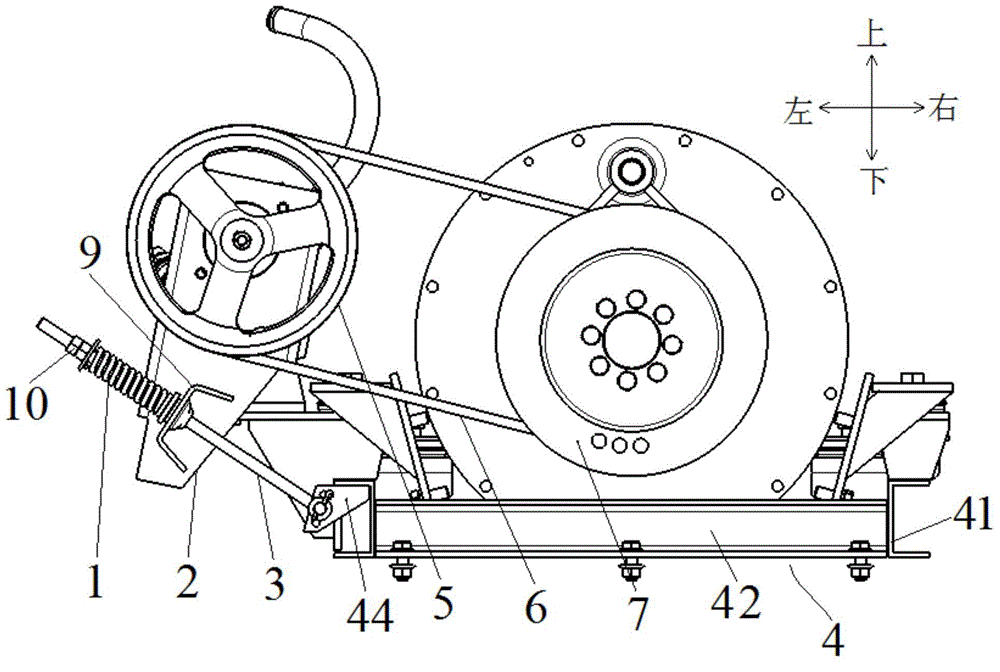

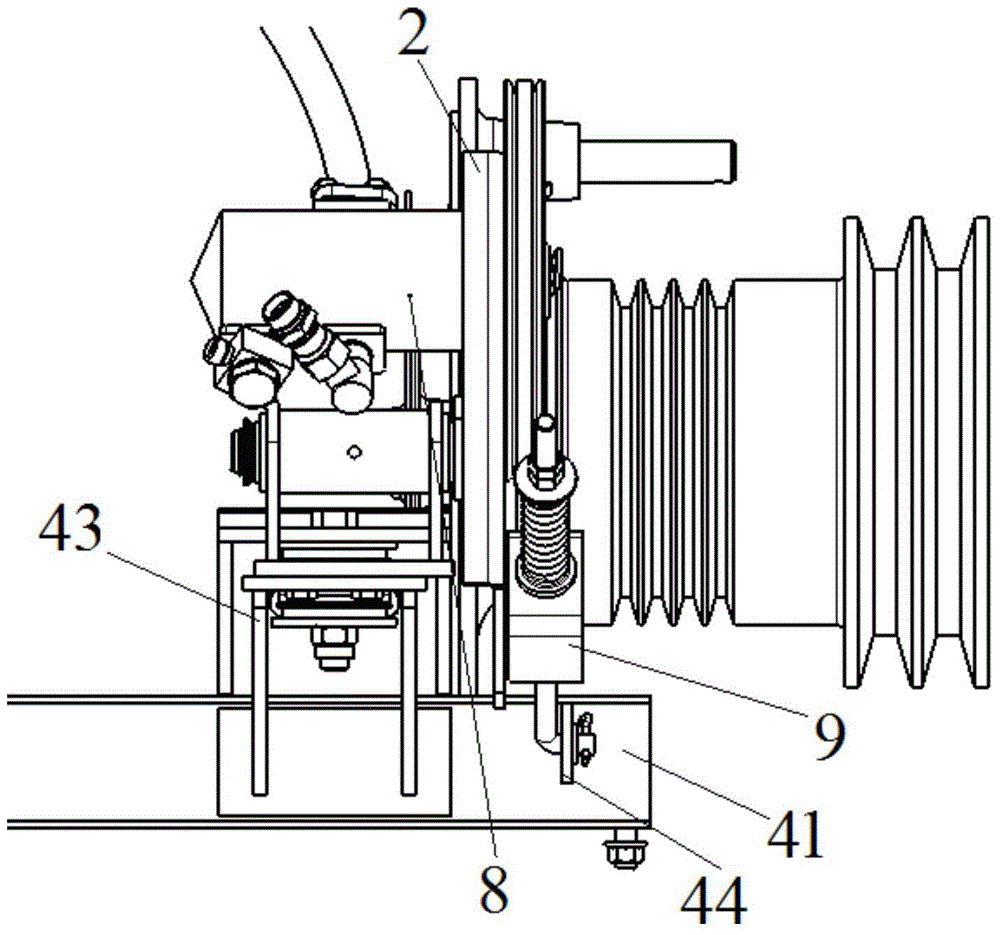

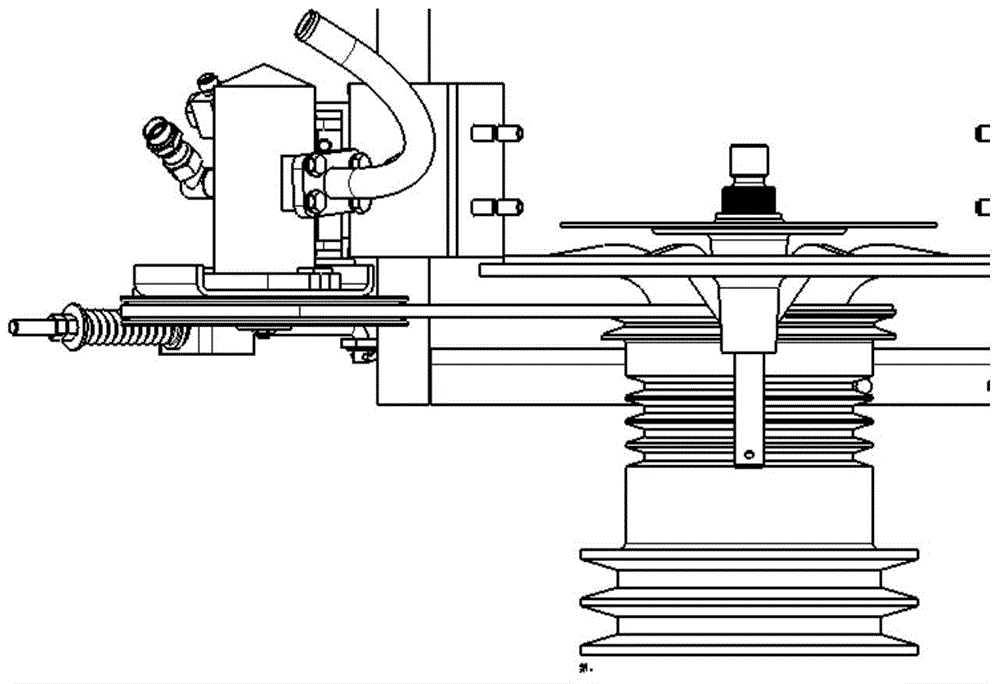

Hydraulic generating device and agricultural machine with same

InactiveCN104405636ALarge assembly spaceAssembly saves labor and timeGearingRotary/oscillating piston combinationsFailure rateGear pump

The invention discloses a hydraulic generating device and an agricultural machine with the same. The hydraulic generating device comprises a gear pump which is positioned outside an engine of the agricultural machine, and a main shaft of the gear pump is connected with a power output end of the engine through a transmission mechanism. The hydraulic generating device disclosed the invention is applied on the agricultural machine, the gear pump is arranged outside the engine, and the engine is used for supplying driving force to the gear pump, so that the assemble space of the gear pump is enlarged, and the failure rate of the gear pump is reduced; the assembling labor and the assembling time for a workshop are reduced, and the maintenance is convenient and fast; besides, a pressure spring sleeves a connecting rod to form a tension mechanism, so that the pressure spring on the connecting rod is not easy to fall down, and reliable adjustment of the tension is ensured.

Owner:ZOOMLION HEAVY MASCH CO LTD

Integrated drive circuit for multifunctional electrical sound generation device

InactiveCN101594565BAvoid damageAvoid complexityStereophonic circuit arrangementsSound producing devicesSound energyLoudspeaker

The invention relates to the field of electric and sound energy conversion devices, in particular to an integrated drive circuit for a multifunctional electrical sound generation device. A drive circuit is integrated in a micro chip, so large assembly space is saved, the complexity of the assembly of electric elements is avoided and product reliability is increased. In the circuit, a four-stage active high-pass filter and a front amplifier are integrated on the same chip, so the low frequency components, which can possibly bring vibration to loudspeakers, of an audio signal are effectively filtered out and the damages to the sound generation device are avoided. The drive circuit independently inputs and controls the audio signal and a vibration signal, thereby realizing the drive of the vibrating loudspeakers. Based on stable and mature standard CMOS process design, the drive circuit can be widely used on mobile phones, PDAs or various potable electronic devices.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

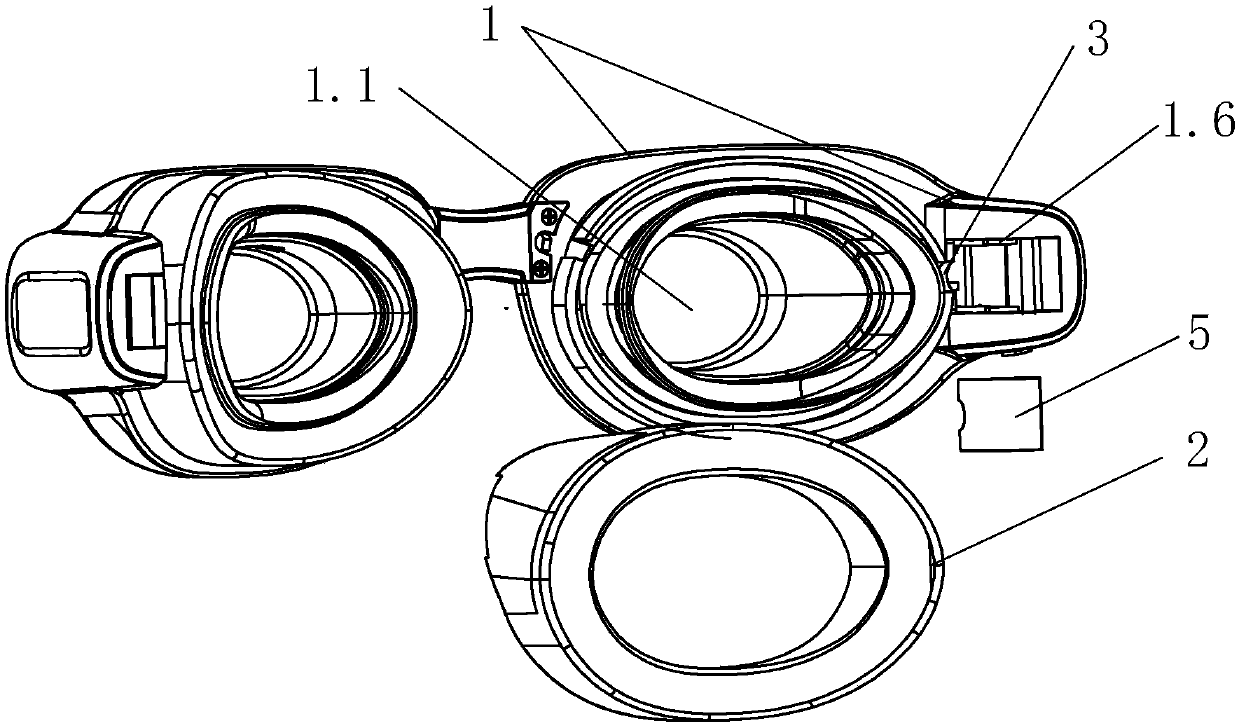

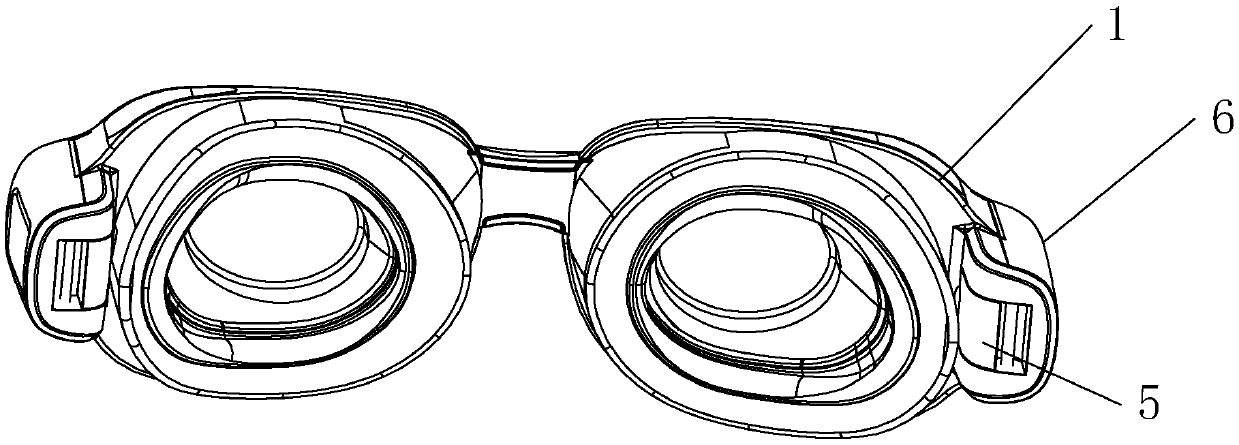

Detachable electric eyewash

ActiveCN106265041BLarge assembly spaceEasy to installVibration massageBathing devicesEngineeringEyes sockets

Owner:NINGBO YOUSHIJIA VISION CARE

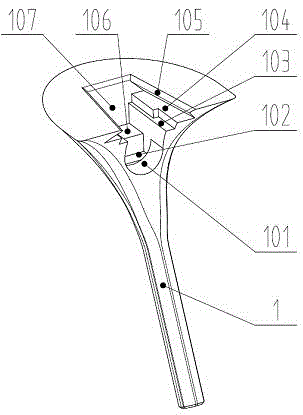

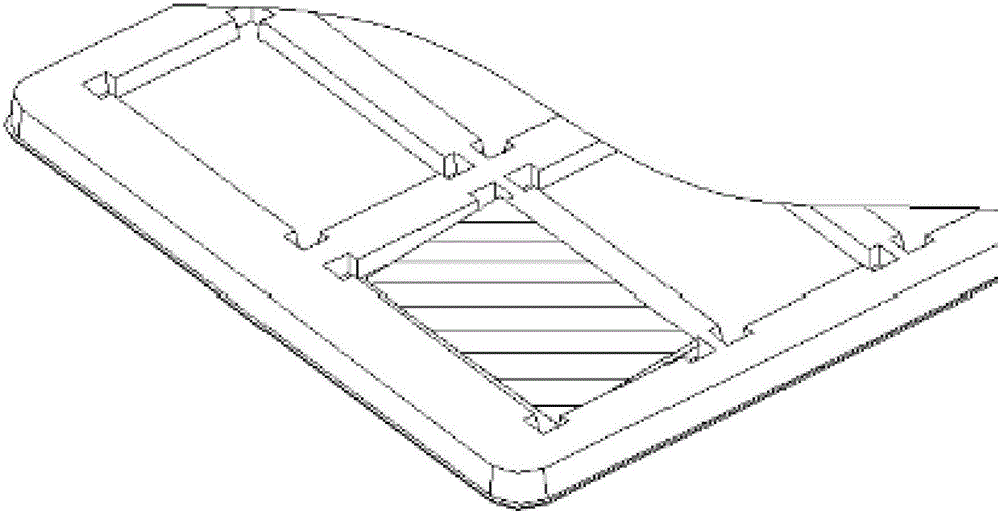

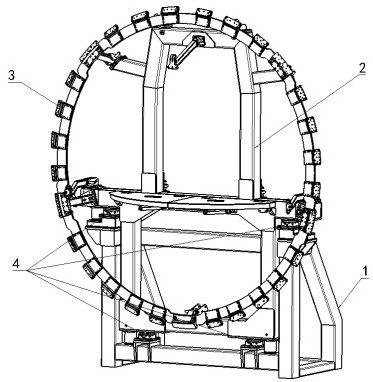

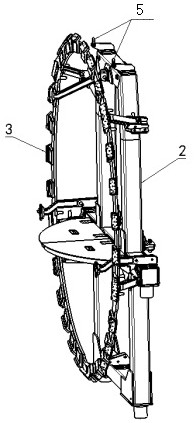

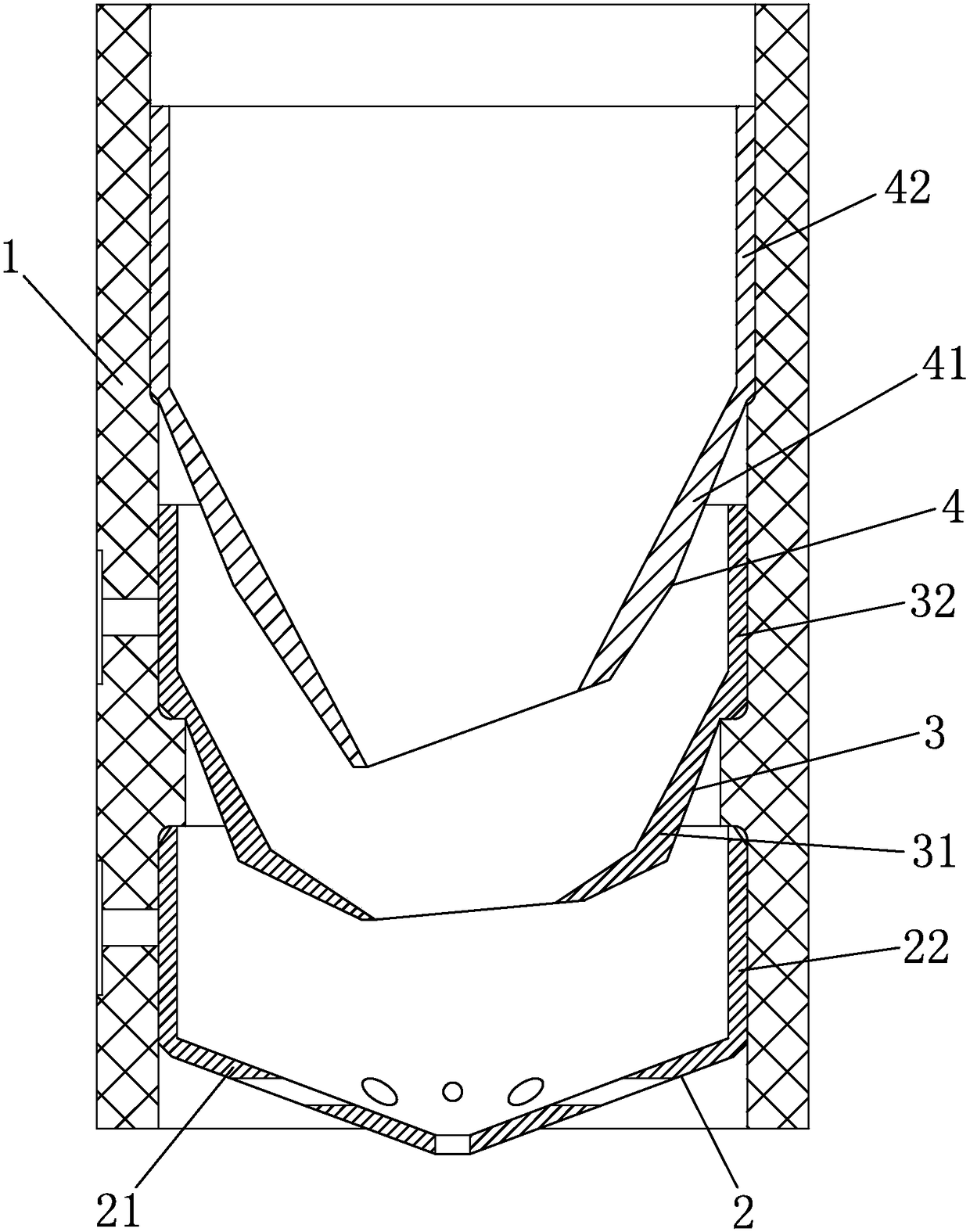

Aircraft spherical frame conformal positioning tooling

ActiveCN109227448BLarge assembly spaceFast positioningWork holdersStructural engineeringSkin protection

The invention discloses a shape-preserving positioning tool for an aircraft spherical frame, which is characterized in that it includes a fixed frame (1), a movable frame (2), a skin shape-preserving component (3) and a rapid positioning system (4). The leather protection component (3) is set on the movable frame (2), and the quick positioning system (4) is set on the fixed frame (1), and the fixed frame (1) and the movable frame (2) pass through the fast Zero point locator connection in positioning system (4). Compared with the prior art, the beneficial effect of the present invention is that the aircraft spherical frame shape-preserving positioning tooling of the present invention, compared with domestic traditional tooling, can realize that the spherical frame is detached from the aircraft main body tooling, and the spherical frame shape-keeping can be carried out independently on the outside After the operation, the hoisting movable part and the spherical frame are placed on the main body tooling of the aircraft, and the zero point locator in the rapid positioning system is quickly combined with the main body tooling of the aircraft. .

Owner:大连四达高技术发展有限公司

Collector porcelain cylinder on multi-stage depressurization collector and collector including the same

ActiveCN106373844BSmall toleranceAvoid stacking effectsTravelling-wave tubesTransit-tube collectorsThree stageEngineering

Owner:北京真空电子技术研究所

Automotive back door panel structure

Owner:DONGFENG MOTOR CORP HUBEI

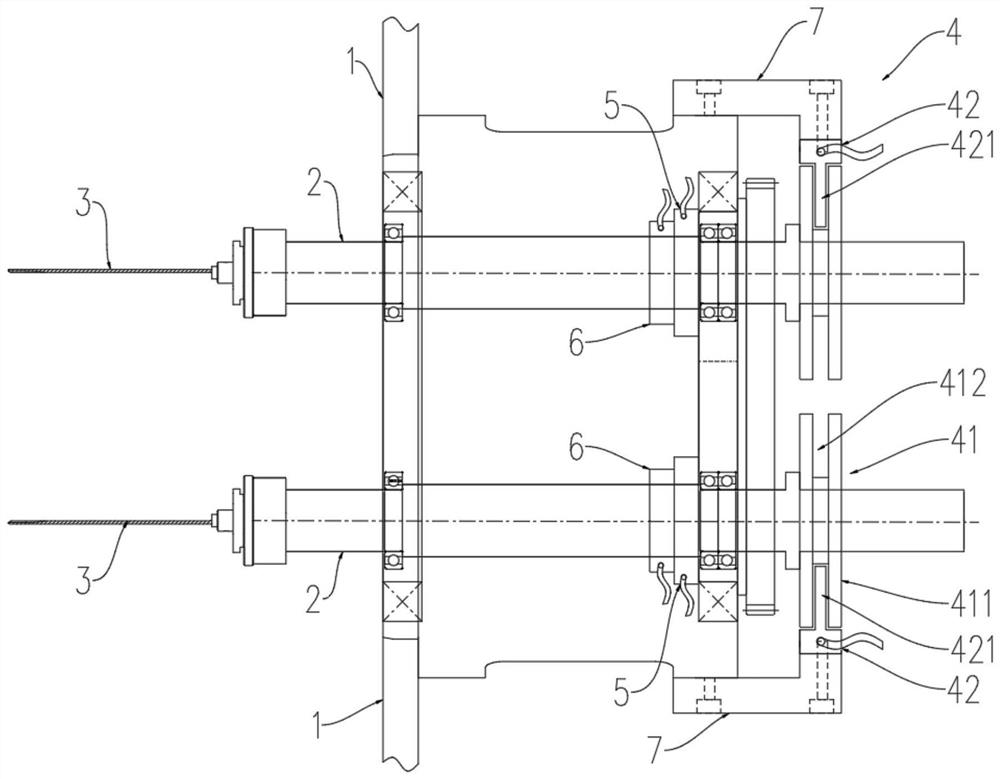

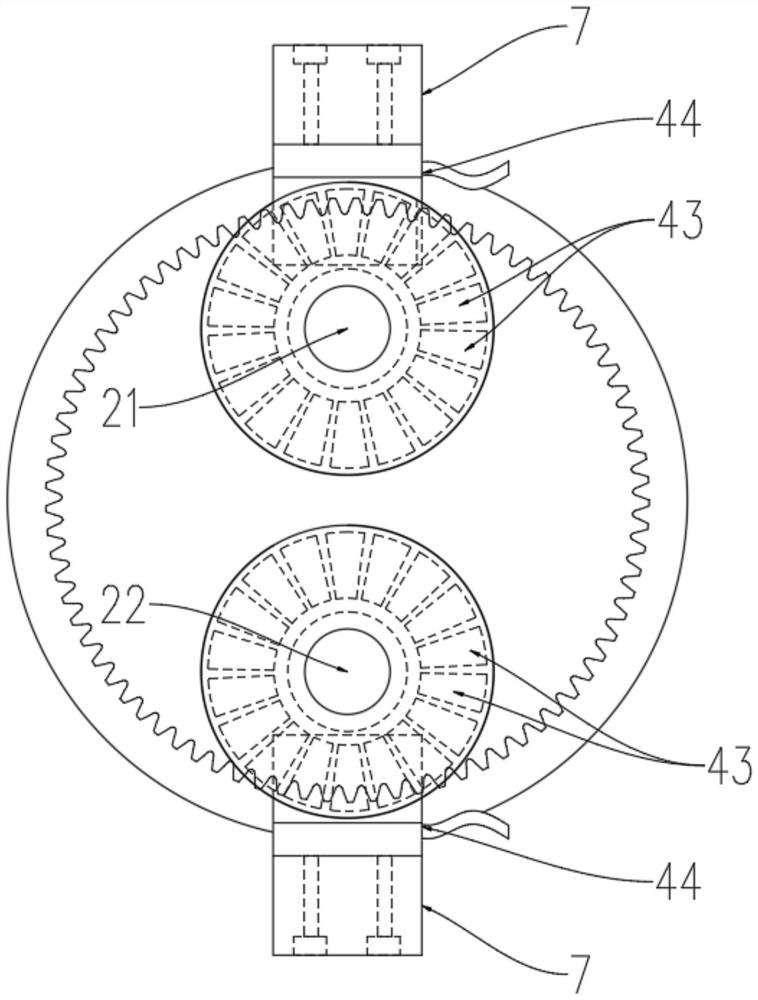

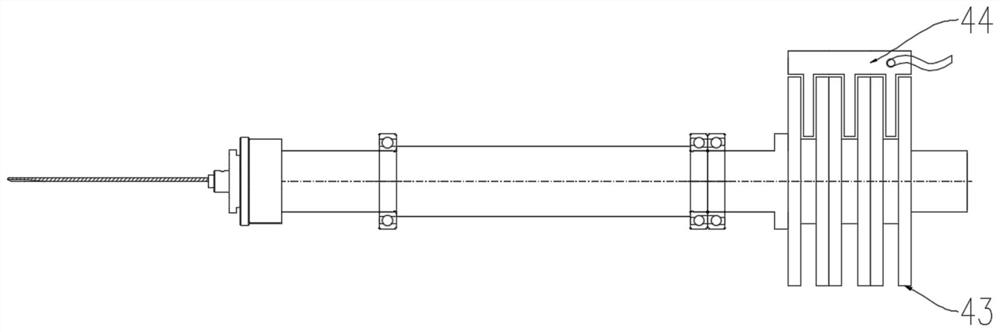

Winding needle driving device, winding head and winding machine

PendingCN114497756ALight in massIncrease speedFinal product manufactureLi-accumulatorsWinding machineEngineering

The invention provides a winding needle driving device, a winding head and a winding machine, and relates to the technical field of lithium battery equipment. The winding needle driving device comprises a winding needle shaft and a magnetic driving mechanism. Wherein the winding needle shaft can be sequentially switched among a plurality of stations; the magnetic driving mechanism is arranged at one end of the winding needle shaft and comprises a rotor and a plurality of stators, the rotor is fixedly connected with the winding needle shaft, the stators and the stations are fixed on a rack of the winding needle driving device in a one-to-one correspondence manner, and the stator on any station is suitable for being in driving connection with the rotor and is used for driving the winding needle shaft to rotate. The rotary inertia of the reel can be reduced, the energy consumption of the winding machine is reduced, a high-power and large-specification magnetic driving mechanism can be selected, and the production efficiency of the winding machine is improved; the magnetic driving mechanism is of a non-contact type, fixed-point driving is achieved, one magnetic driving mechanism can drive the winding needle shafts to rotate, the number of driving devices is reduced, and cost is saved.

Owner:三一技术装备有限公司

Hidden button type replaceable high-heeled shoes

The invention discloses hidden button type heel-replaceable high-heeled shoes, wherein each of the high-heeled shoes comprises a heel, a pressing plate, a button, a first compression spring, a jacking rod, a second compression spring and a sole, wherein a first groove, a second groove and a third groove are formed in the middle of the heel; the button and the jacking rod are arranged inside the first groove; the pressing plate is arranged inside the second groove; the button can move forwards and backwards along the first groove; the jacking rod can move upwards and downwards along the first groove; the pressing plate is fixedly connected with the bottom surface of the second groove. According to the hidden button type heel-replaceable high-heeled shoes, the heel is connected with the molded surface of the sole in a matched manner, through the interaction among the button, the jacking rod and the spring, the bulge of the jacking rod can ascend or descend, so that the heel can be connected with or separated from the sole, the button can move inwards along the bottom surface of the pressing plate by only slightly pressing the button inwards, then the jacking rod can be driven to move downwards, the bulge of the jacking rod can be separated from a fifth groove in the sole, and the heel can be separated from the sole by pulling down the heel with a slight force at the moment, so that the heel can be conveniently and rapidly disassembled and replaced.

Owner:HANGZHOU JIUBA HONGTU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com