Collector porcelain cylinder on multi-stage depressurization collector and collector including the same

A collector and cylinder technology, applied in the field of collectors, can solve the problems of increasing the assembly space of the inner collector, limiting the miniaturization of the collector, and cumbersome assembling process of the ceramic cylinder, so as to avoid the superposition effect, improve the efficiency, and be easy to locate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

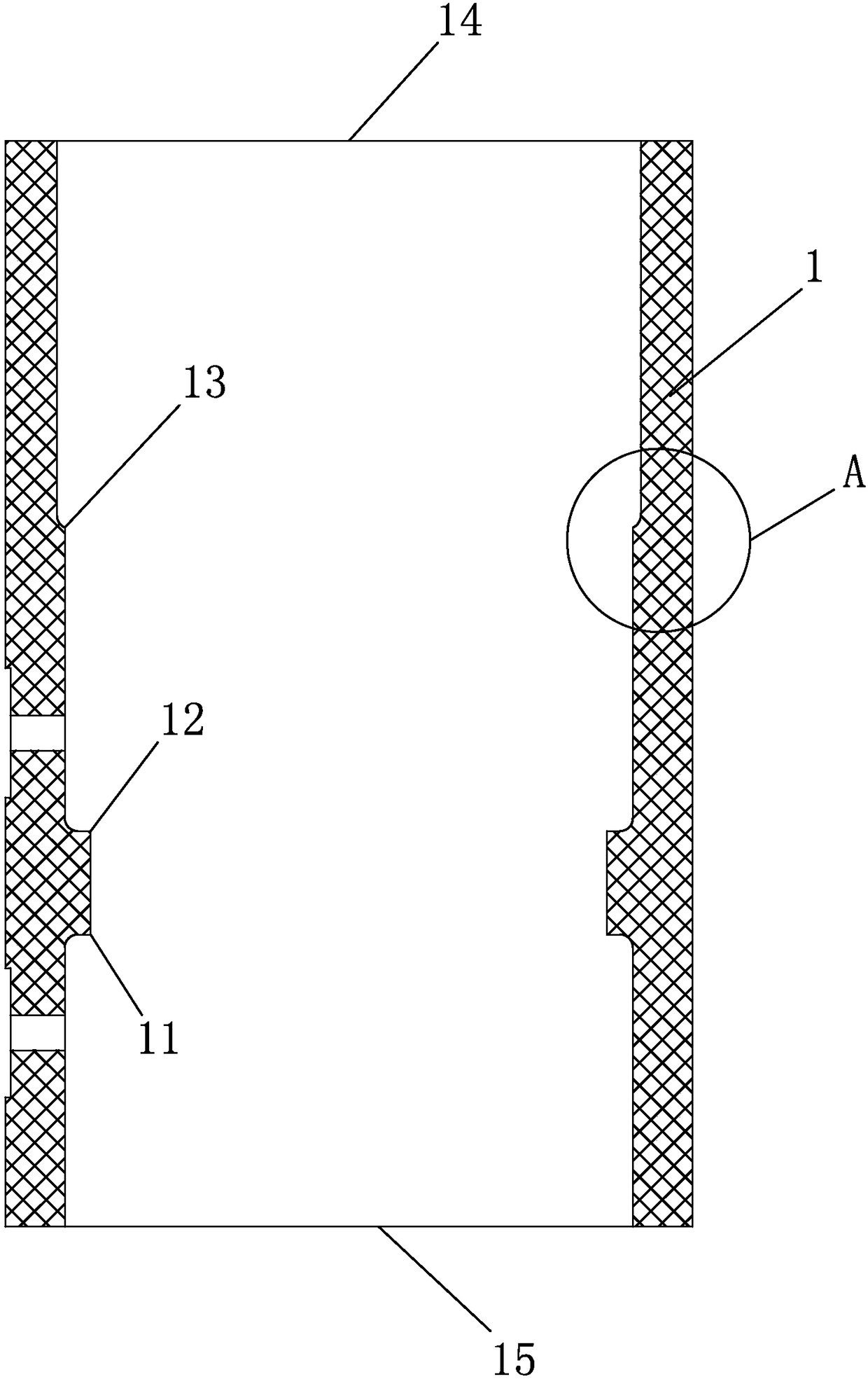

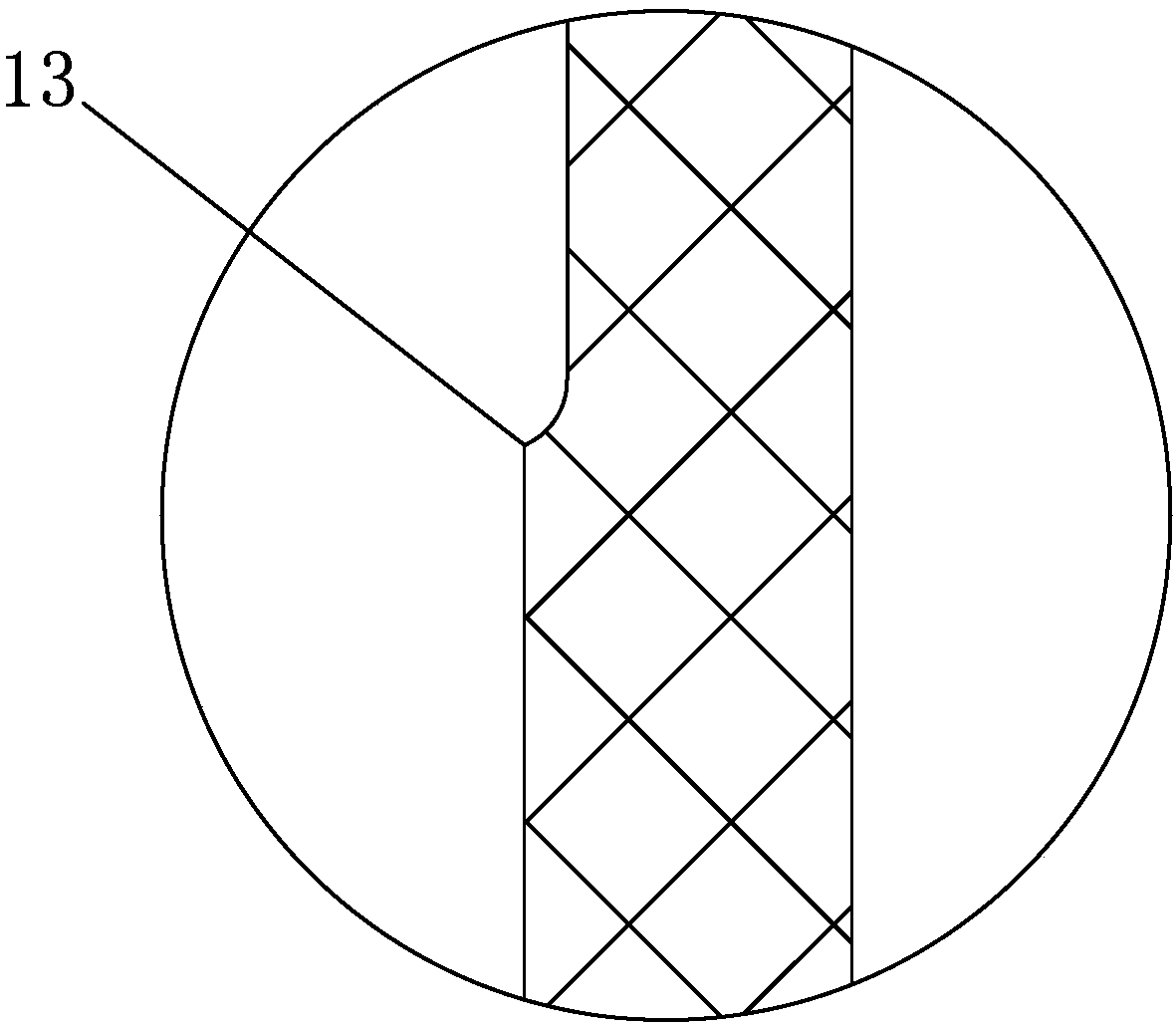

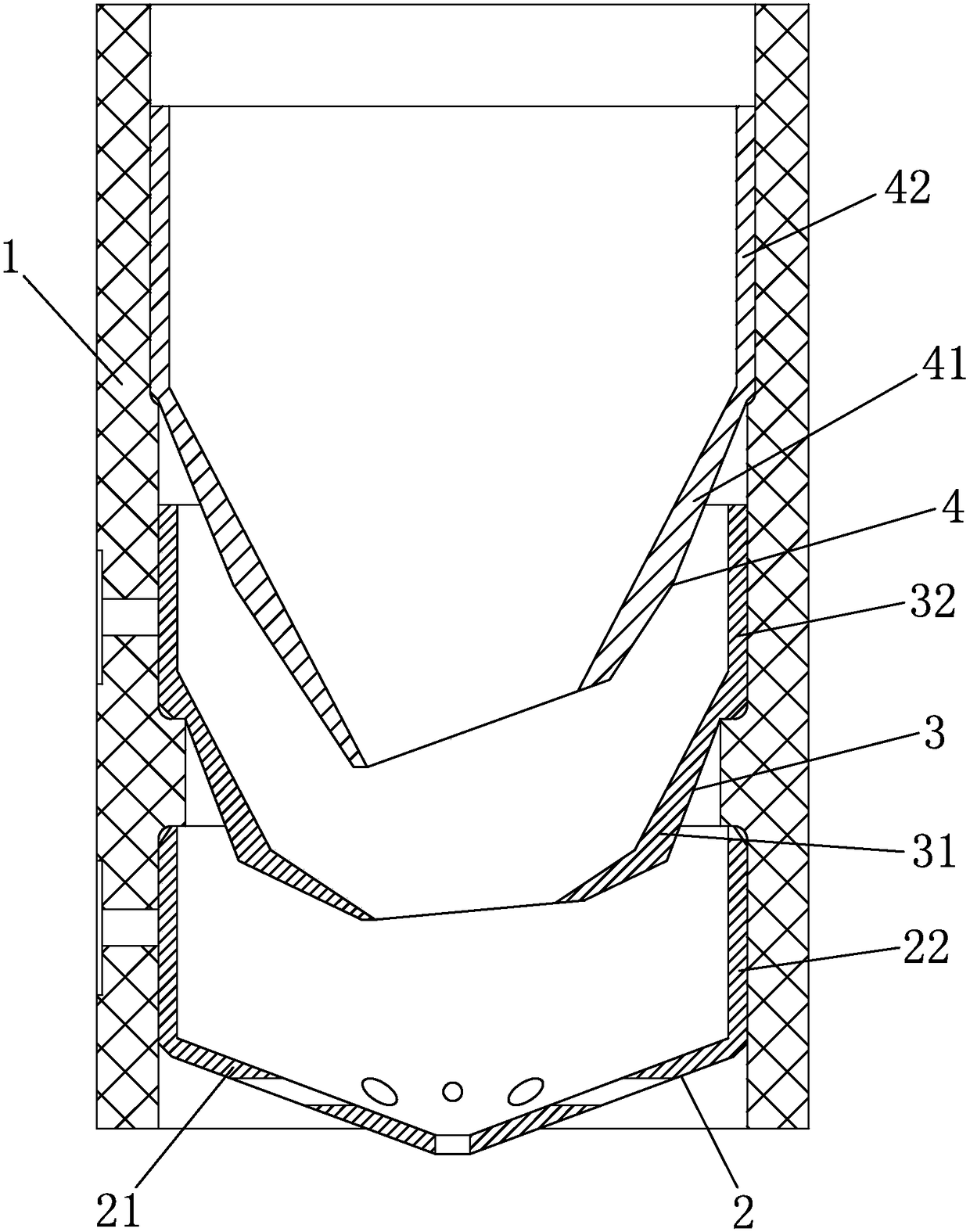

[0053] Such as figure 1 , 2 As shown in , 3, a collector porcelain cylinder on a multi-stage decompression collector, in this embodiment, the collector porcelain cylinder 1 is a cylinder body with a three-stage depressurization function, and the collector pole porcelain cylinder 1 The cylinder body is a cylindrical integrated structure; the cylinder inner wall of the collector porcelain cylinder 1 is provided with a limit boss for positioning and installing the inner collector set in the collector porcelain cylinder;

[0054] The limiting boss includes a first limiting platform 11 for positioning and installing the first inner collector 2, a second limiting platform 12 for positioning and installing the second inner collector 3, and a second limiting platform for positioning and installing. The third limiting platform 13 of the third inner collector 4 .

[0055] The setting direction of the second limiting platform 12 is the same as that of the third limiting platform 13, bo...

Embodiment 2

[0061] Such as Figure 4 , 5 As shown, a collector porcelain cylinder on a multi-stage decompression collector. In this embodiment, the collector porcelain cylinder 1 is a cylinder body with a three-stage depressurization function, and the cylinder of the collector pole ceramic cylinder 1 The body is a cylindrical integrated structure; the inner wall of the collector porcelain cylinder 1 is provided with a limit boss for positioning and installing the inner collector set in the collector porcelain cylinder;

[0062] The limiting boss includes a first limiting platform 11 for positioning and installing the first inner collector 2, a second limiting platform 12 for positioning and installing the second inner collector 3, and a second limiting platform for positioning and installing. The third limiting platform 13 of the third inner collector 4 .

[0063] The setting direction of the first limiting platform 11, the setting direction of the second limiting platform 12 and the se...

Embodiment 3

[0070] Such as Image 6 , 7 As shown, a collector porcelain cylinder on a multi-stage decompression collector. In this embodiment, the collector porcelain cylinder 1 is a cylinder body with a three-stage depressurization function, and the cylinder of the collector pole ceramic cylinder 1 The body is a cylindrical integrated structure; the inner wall of the collector porcelain cylinder 1 is provided with a limit boss for positioning and installing the inner collector set in the collector porcelain cylinder;

[0071] The limiting boss includes a first limiting platform 11 for positioning and installing the first inner collector 2, a second limiting platform 12 for positioning and installing the second inner collector 3, and a second limiting platform for positioning and installing. The third limiting platform 13 of the third inner collector 4 .

[0072]The setting direction of the first limiting platform 11, the setting direction of the second limiting platform 12 and the sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com