Winding needle driving device, winding head and winding machine

A driving device and winding head technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of large moment of inertia of the reel, low production efficiency, low motor power, etc., and achieve responsive The effect of fast speed, lower quality and higher speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

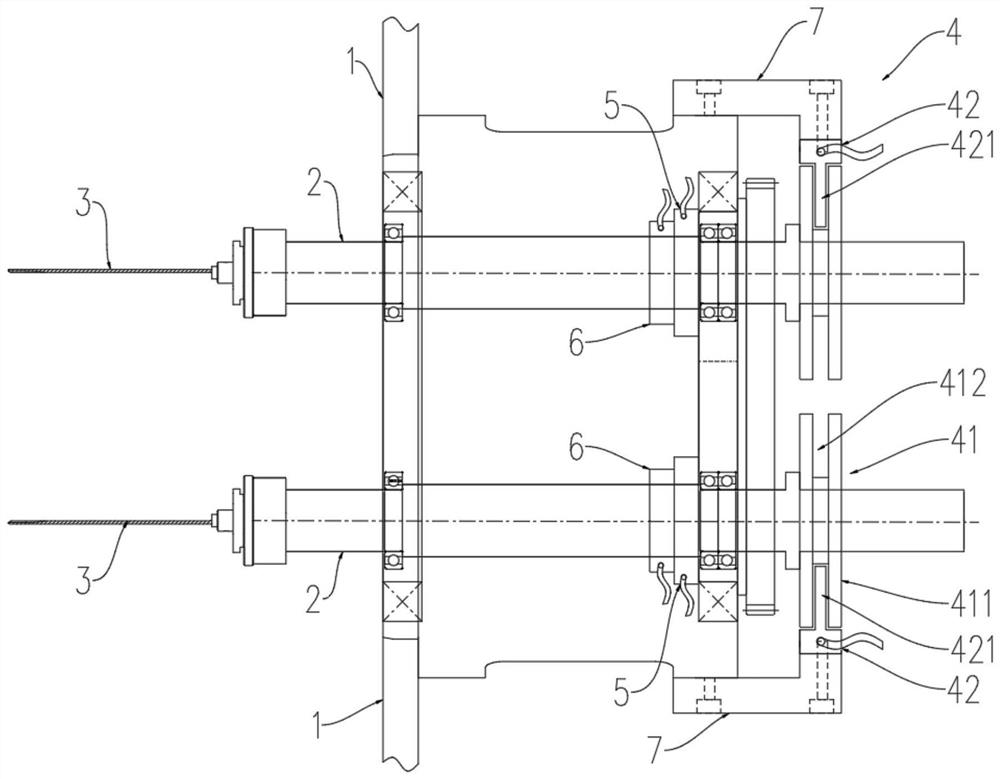

[0049] Reference Figure 1 and Figure 2 , a needle reel drive device, including needle reel shaft 2 and magnetic drive mechanism 4. Wherein, the needle reel 2 can be switched sequentially between multiple stations; the magnetic drive mechanism 4 is located at one end of the needle reel 2, the magnetic drive mechanism 4 includes rotor 41 and a plurality of stators 42, the rotor 41 is fixed with the needle reel 2 fixed, the stator 42 and the station one-to-one corresponding to the frame of the needle reel drive device, the stator on either station is suitable for connection with the rotor drive, for driving the needle reel 2 rotation.

[0050] Using the technical scheme of the present invention, the needle reel 2 is provided on the rotor 41 and stator 42, by the magnetic drive mechanism 4 to drive the rotation of the needle reel 2, the magnetic drive mechanism 4 in the stator 42 fixed on the frame of the reel drive device, to achieve the needle reel 2 drive device from the reel 1 de...

Embodiment 2

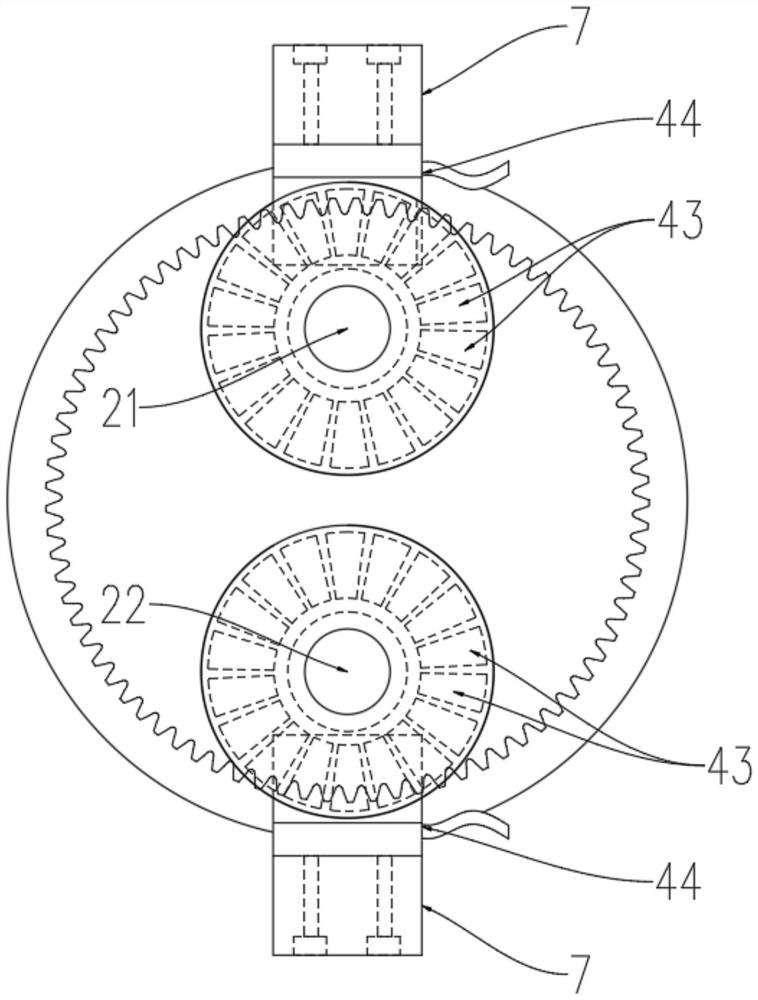

[0063] The present embodiment provides a second embodiment of the magnetic drive mechanism 4. Reference Figure 3 , the difference with Example 1 is that one end of the needle reel 2 is provided side by side with three turntable bodies 411, each turntable body 411 is opened with a ring groove to form a docking gap 412. Three side-by-side turntable bodies 411 constitute three docking clearances 412. Correspondingly, the stator 42 and three insertion gaps 412 one-to-one corresponding to the setting of three inserts 421, the shape of the insert 421 is not limited, in the present embodiment, the insert 421 is a rectangular block, with reference Figure 2 。 That is, the stator 42 is disposed on one side of the turntable body 411, which corresponds only to the local permanent magnet 43 on the turntable body 411. Of course, as a deformed embodiment of the present embodiment, three parallel turntable bodies 411 may be provided in one piece, that is, a turntable body 411, along the axial jux...

Embodiment 3

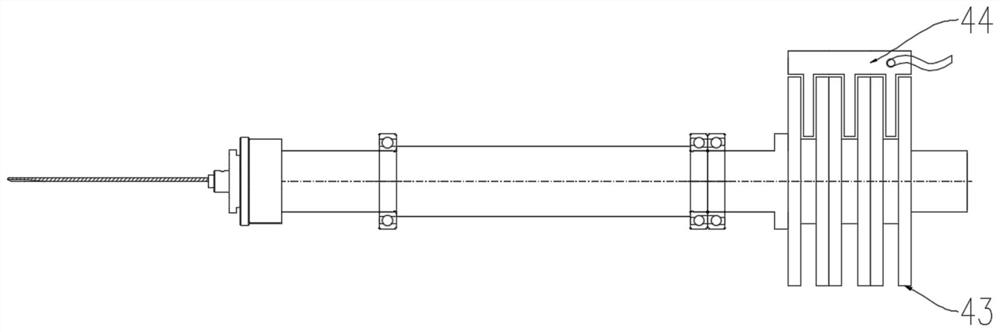

[0065] The present embodiment provides a third embodiment of the magnetic drive mechanism 4. Reference Figure 4 , the difference from Example 1 is that the rotor 41 comprises an excitation winding 44, the stator 42 includes a permanent magnet 43. Specifically, the turntable body 411 includes an iron core, the core is wound with excitation windings 44, the excitation windings 44 are connected to the control power supply; stator 42 includes a permanent magnet 43 in conjunction with the excitation windings 44. Permanent magnet 43 is disposed on the stator insert 421. Specifically, each insert 421 either faces the side wall of the turntable body 411 is spaced on a plurality of permanent magnets 43, likewise, the adjacent two permanent magnets 43 are located at the opposite end of the polarity of the magnetic pole.

[0066] The turntable body 411 is provided with a ring groove to form a docking gap 412. Stator 42 is provided with a plug 421 mating with the docking gap 412 mating. Stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com