Integrated balance suspension cross beam assembly

A technology for balancing suspension and beam assembly, applied in the direction of suspension, cantilever mounted on the pivot, interconnection system, etc., can solve the problems of inability to have both the function of the air tank and uneven stress distribution, and achieve improved assembly. The effect of manufacturability, improving utilization, and improving torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

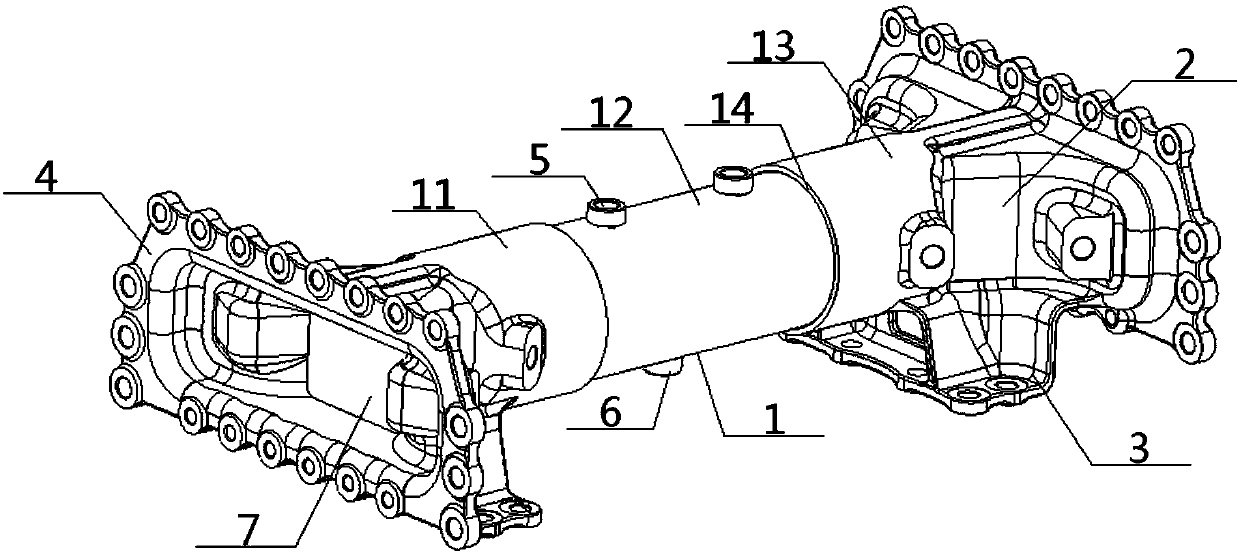

[0046] see Figure 1 to Figure 7 , an integrated balanced suspension crossbeam assembly, including a crossbeam body 1, a thrust rod connecting part 2, a large bracket connecting part 3 and a longitudinal beam connecting part 4, and the crossbeam body 1 is connected through the thrust rod connecting part 2 and the large bracket The part 3 and the longitudinal beam connecting part 4 are respectively connected with the thrust rod, the large bracket of the balance suspension and the longitudinal beam of the vehicle frame in one-to-one correspondence;

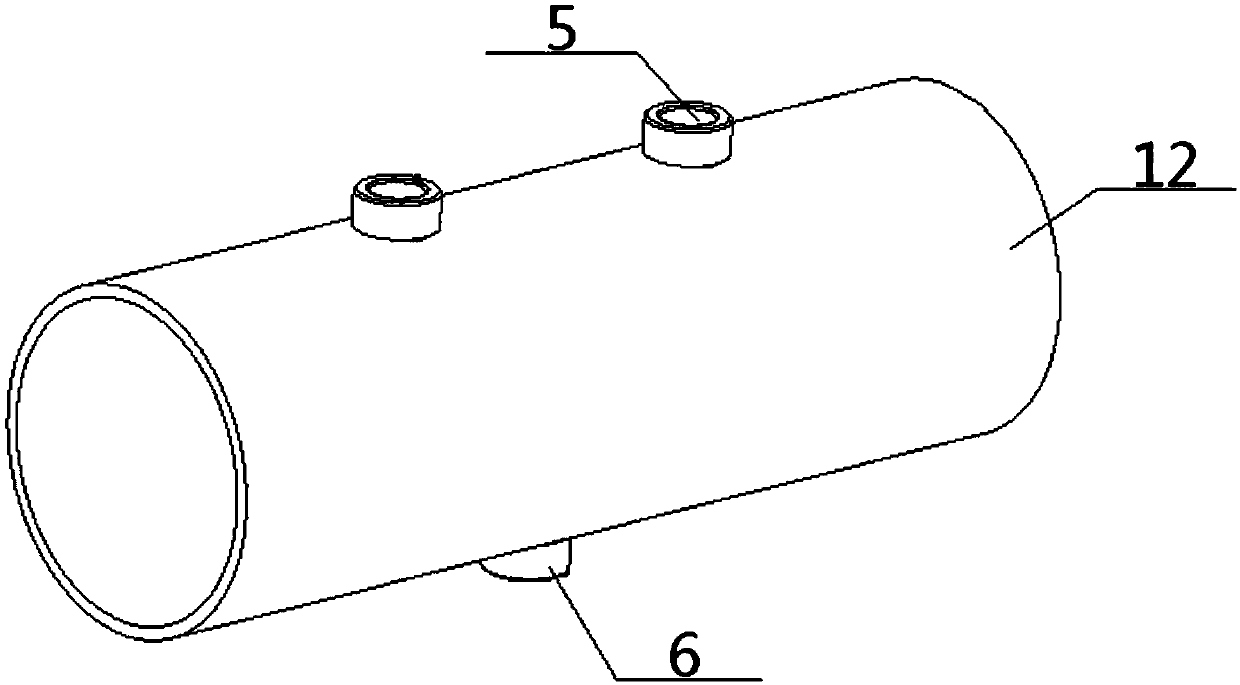

[0047] The beam body 1 is a hollow sealed cylindrical structure, and the top and bottom of the middle section of the beam body 1 are respectively provided with an inlet and outlet port 5 and a drain valve 6, and the inlet and outlet ports 5 are arranged higher than the drain valve 6, and Both ends of the beam body 1 are respectively connected with a thrust rod connecting portion 2 , a large bracket connecting portion 3 and a longitu...

Embodiment 2

[0049] Basic content is the same as embodiment 1, the difference is:

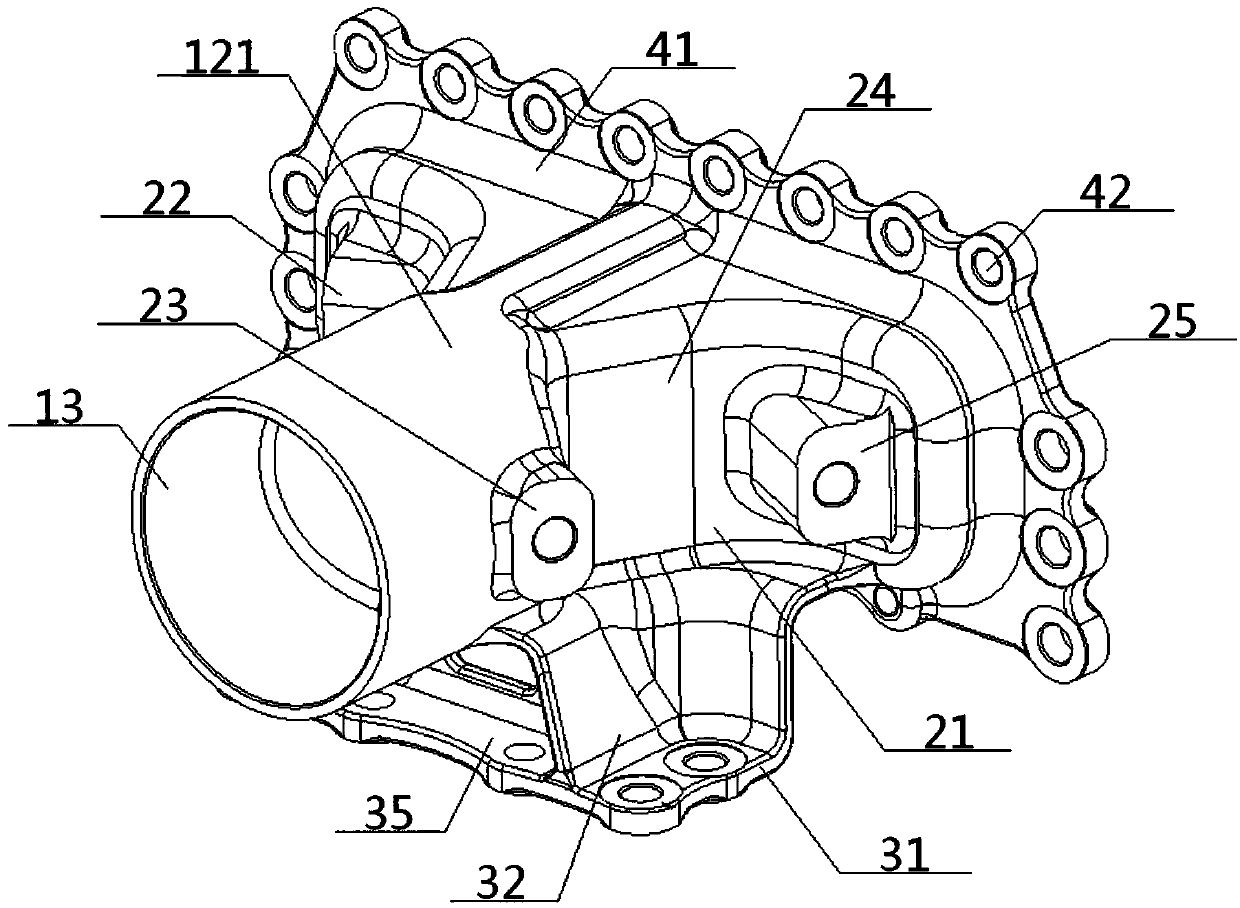

[0050] The beam body 1 includes a left cylindrical part 11, a middle cylindrical part 12 and a right cylindrical part 13 which are connected in sequence, and the diameters of the left cylindrical part 11 and the right cylindrical part 13 are larger than the diameter of the middle cylindrical part 12. , the two ends of the middle cylindrical part 12 are respectively located inside the inner end of the left cylindrical part 11 and the inner end of the right cylindrical part 13, and the outer walls of the two ends of the middle cylindrical part 12 are connected with the inner end of the left cylindrical part 11 and the right cylindrical part respectively. The inner walls of the inner ends of 13 are in contact, and the outer ends of the left cylindrical part 11 and the outer ends of the right cylindrical part 13 are respectively connected with a thrust rod connecting part 2, a large bracket connecting part 3 and...

Embodiment 3

[0053] Basic content is the same as embodiment 2, the difference is:

[0054] The longitudinal beam connection part 4 includes a connection base plate 41, a longitudinal beam connection hole 42 and a base plate inner cavity 43, the inner end of the connection base plate 41 is vertically connected with the two ends of the beam body 1, and the periphery of the connection base plate 41 is provided with a plurality of The longitudinal beam connection hole 42 connected with the frame longitudinal beam, the middle part of the outer end connecting the bottom plate 41 is provided with a bottom plate inner cavity 43, and the bottom plate inner cavity 43 is provided with a partition plate 7 for sealing and matching with the two ends of the cross beam body 1 . A pair of inwardly extending bosses 44 are arranged in the inner cavity 43 of the bottom plate, and a partition 7 is arranged between adjacent bosses 44 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com