Patents

Literature

480results about "Reservoir arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

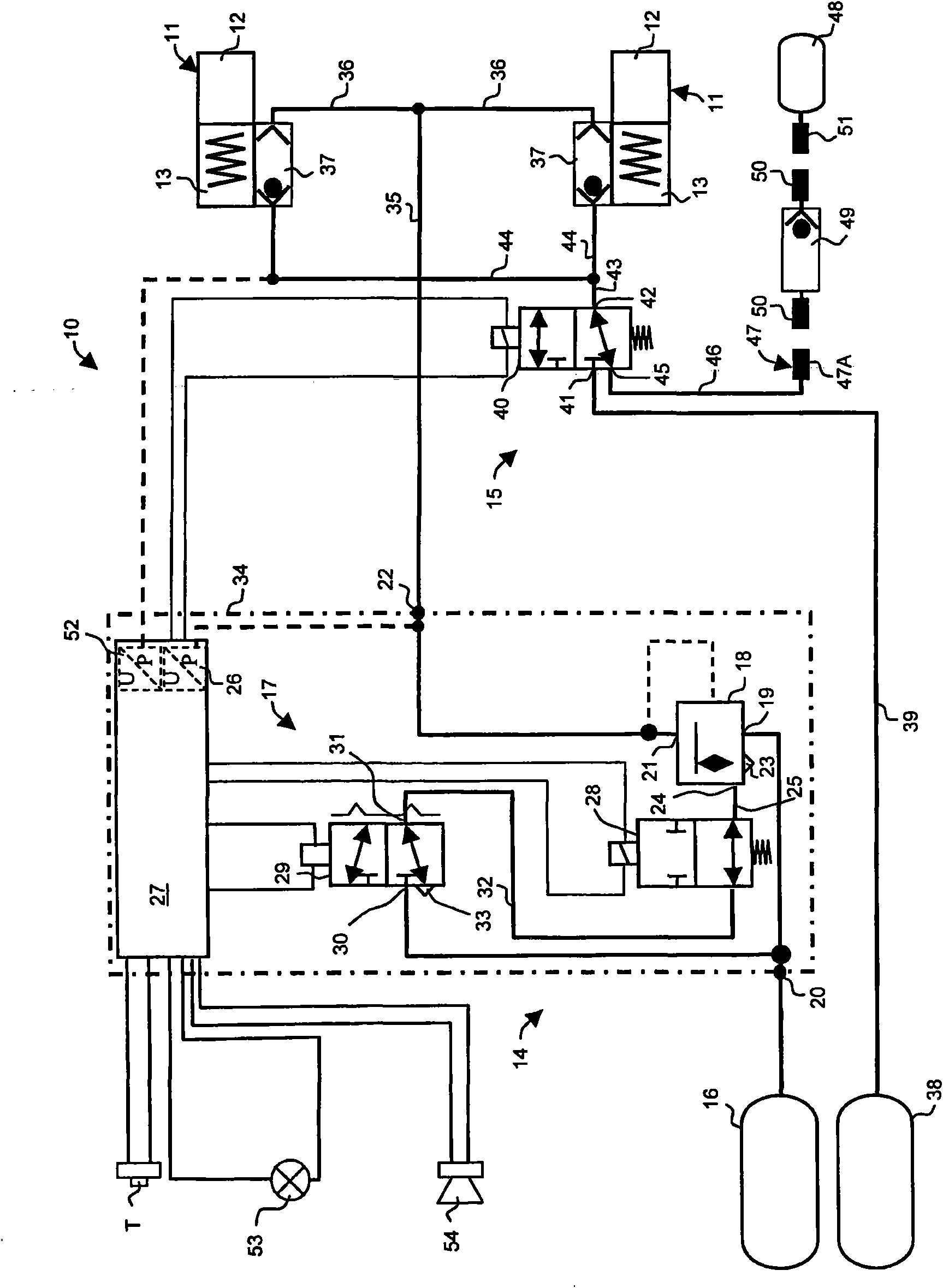

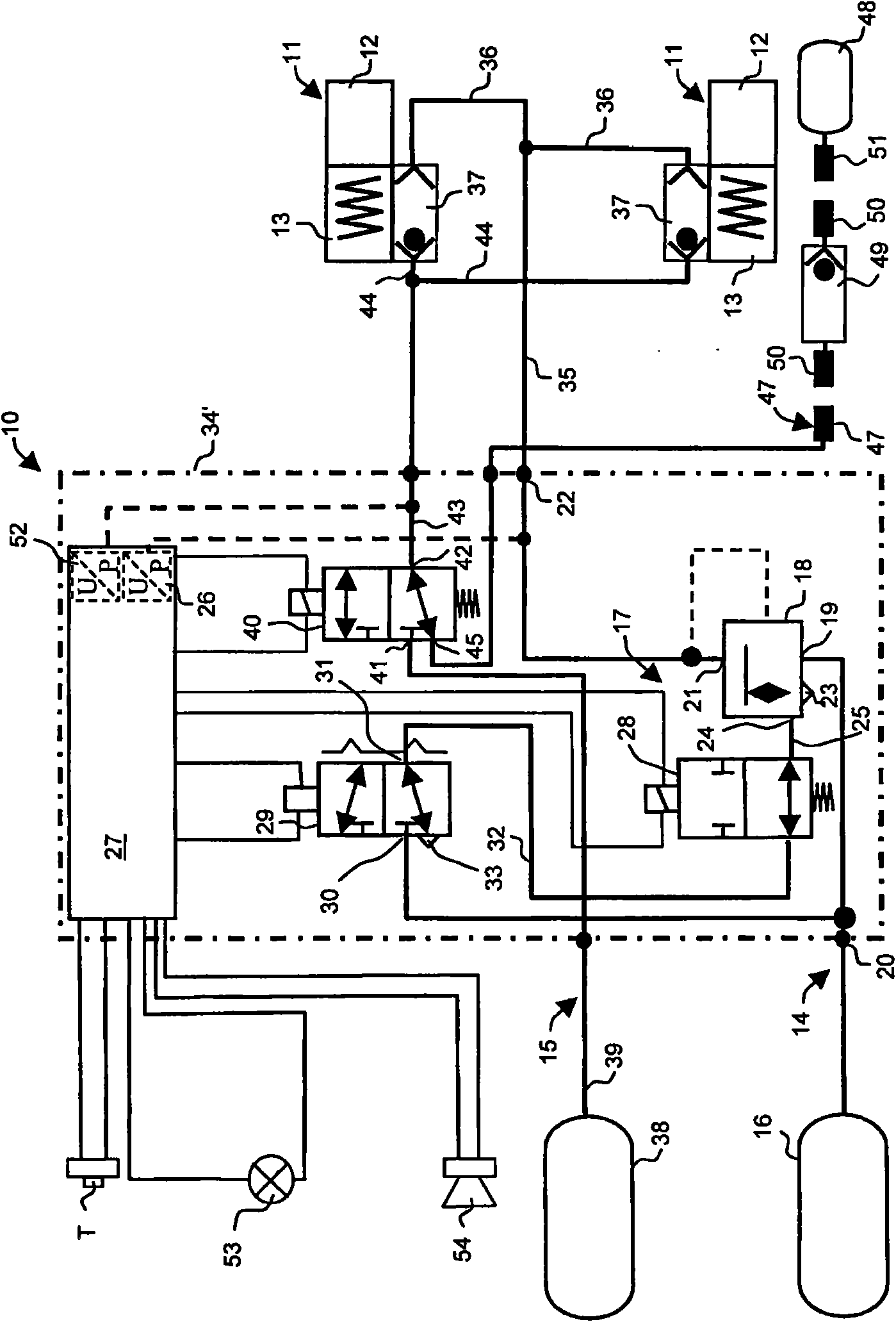

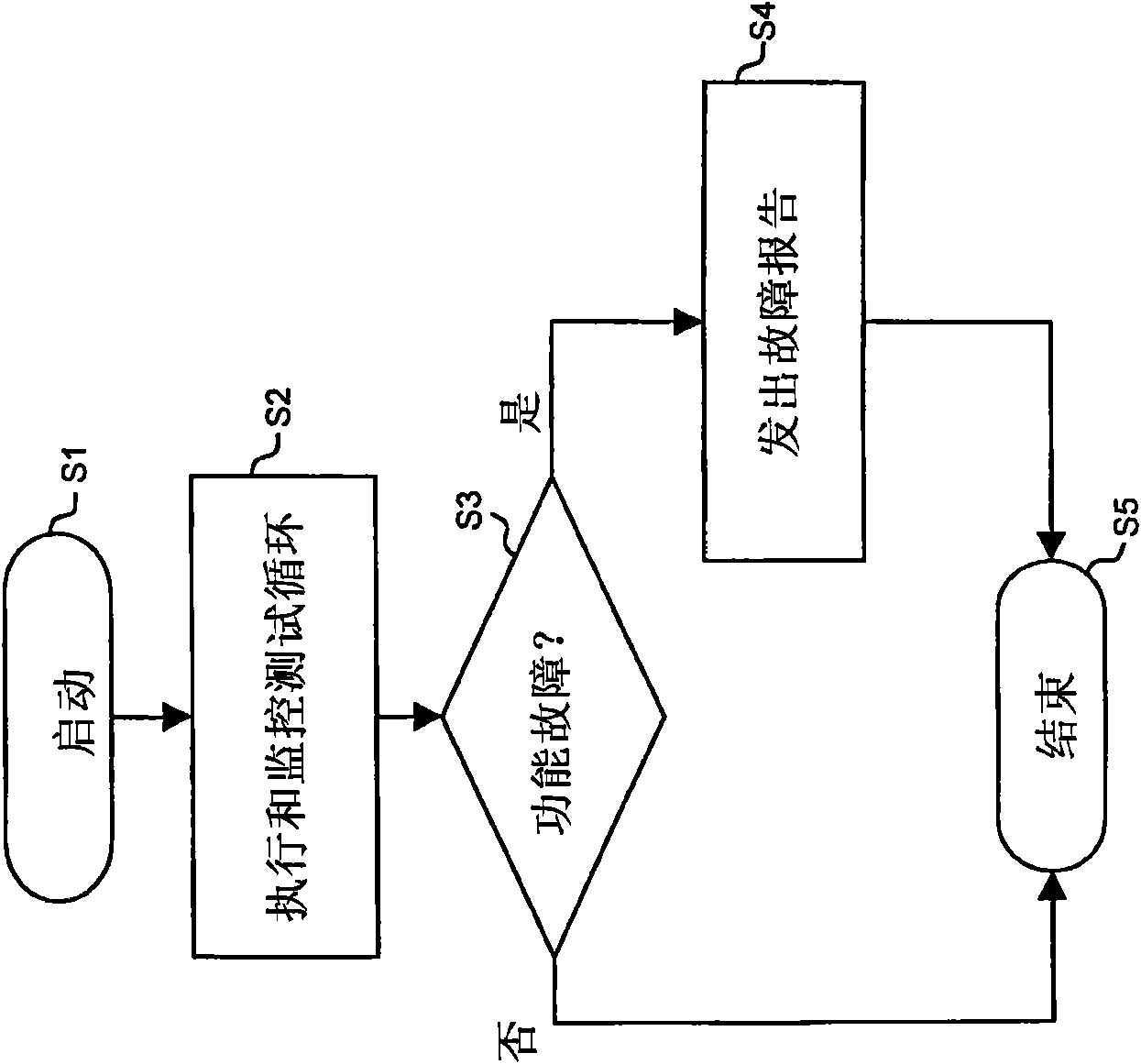

Parking brake device of a vehicle with emergency release function and method for operating such a parking brake device

ActiveCN101622164AStop stickingStopper rustsReservoir arrangementsBrake safety systemsParking brakeStorage tank

The invention relates to a parking brake device (10) of a vehicle, especially a utility vehicle, with an emergency release function, comprising at least one spring brake cylinder (11) for releasing or engaging a parking brake and a first electro-pneumatic parking brake circuit (14) with a first compressed air storage tank (16) and a first valve control device (17) for aerating or deaerating the spring brake cylinder (11). A second electro-pneumatic parking brake circuit (15) for emergency release of the parking brake in the event of failure of the first parking brake circuit (14) is further provided, which comprises a second compressed air storage tank (38) and a second valve control device (40) for aerating the spring brake cylinder (11) in the event of an emergency release. The second valve control device (40) comprises an aeration connection (41) connected to the second compressed air storage tank (38), a deaeration connection (45) that can be connected to the atmosphere and a third connection (42) that can be connected to the spring brake cylinder (11). According to a first aspect of the invention and in order to improve the releasability of the parking brake device in the event of an emergency release, the deaeration connection (45) of the second valve control device (40) is connected to a compressed air line (46) which terminates at an outer region of the vehicle, wherein compressed air can be fed in this compressed air line (46) from an external compressed air source (48) to the spring brake cylinder (11) via the deaeration connection (45) and the third connection (42) of the second valve control device (40).

Owner:WABCO EURO BVBA SPRL

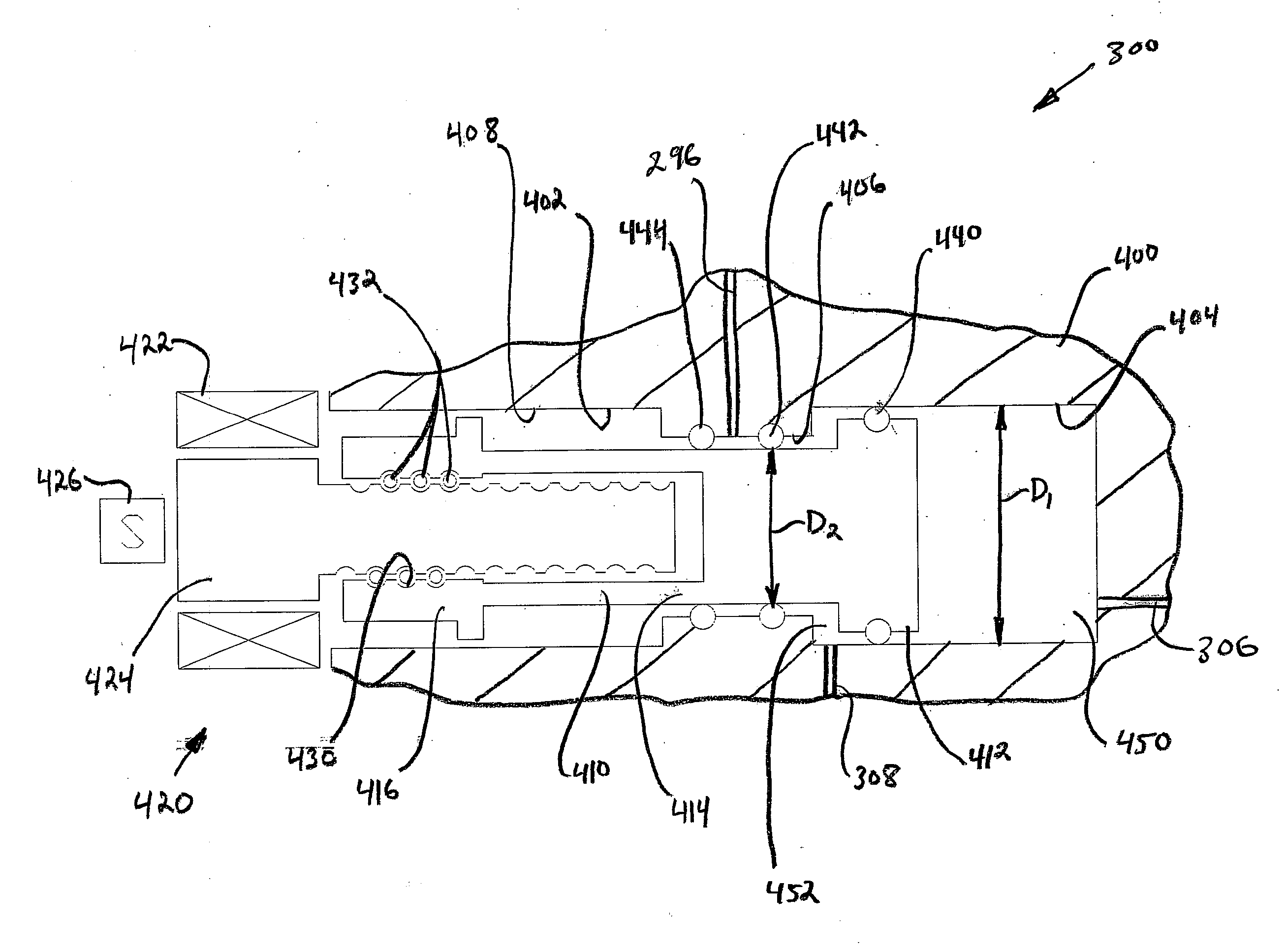

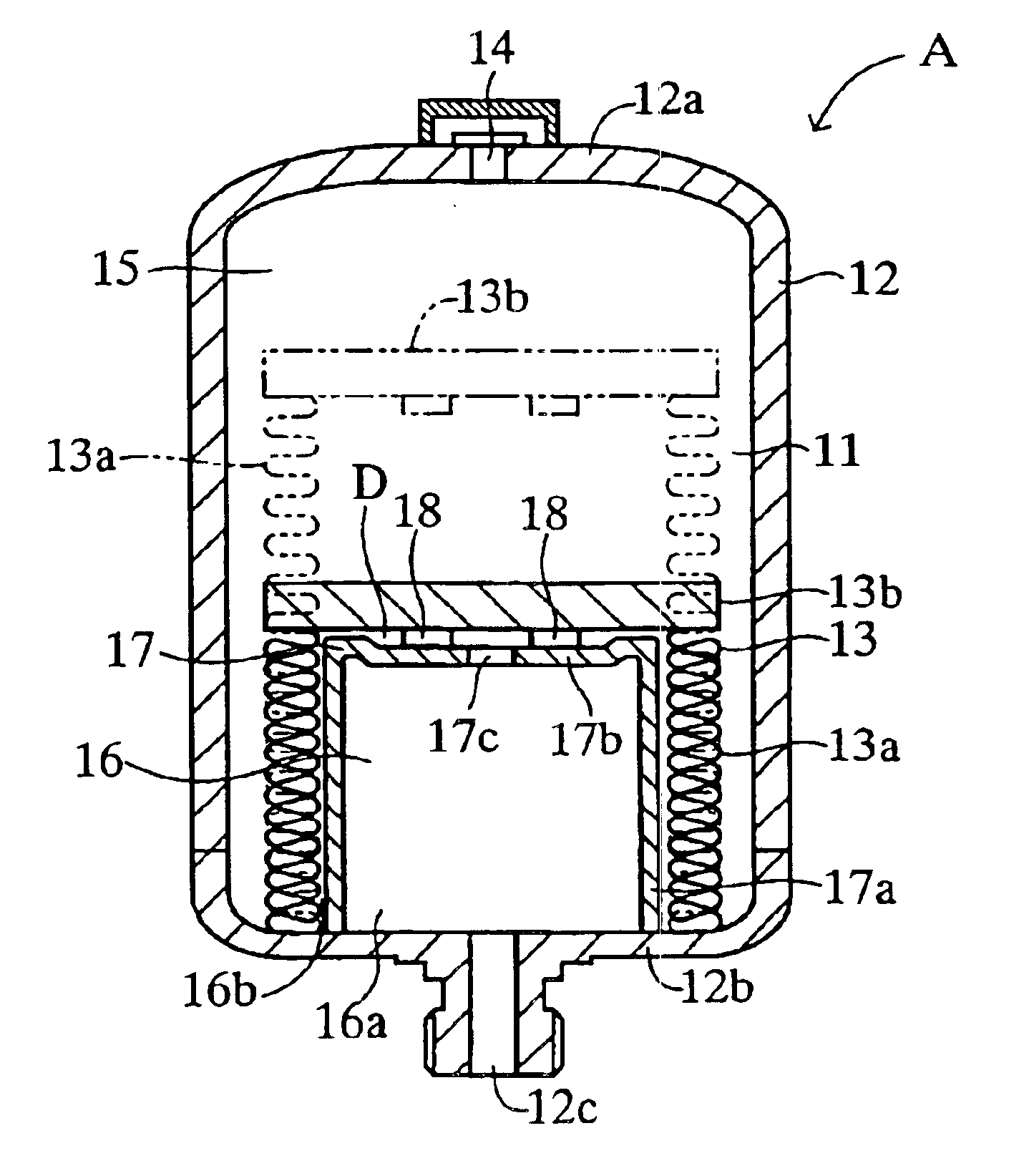

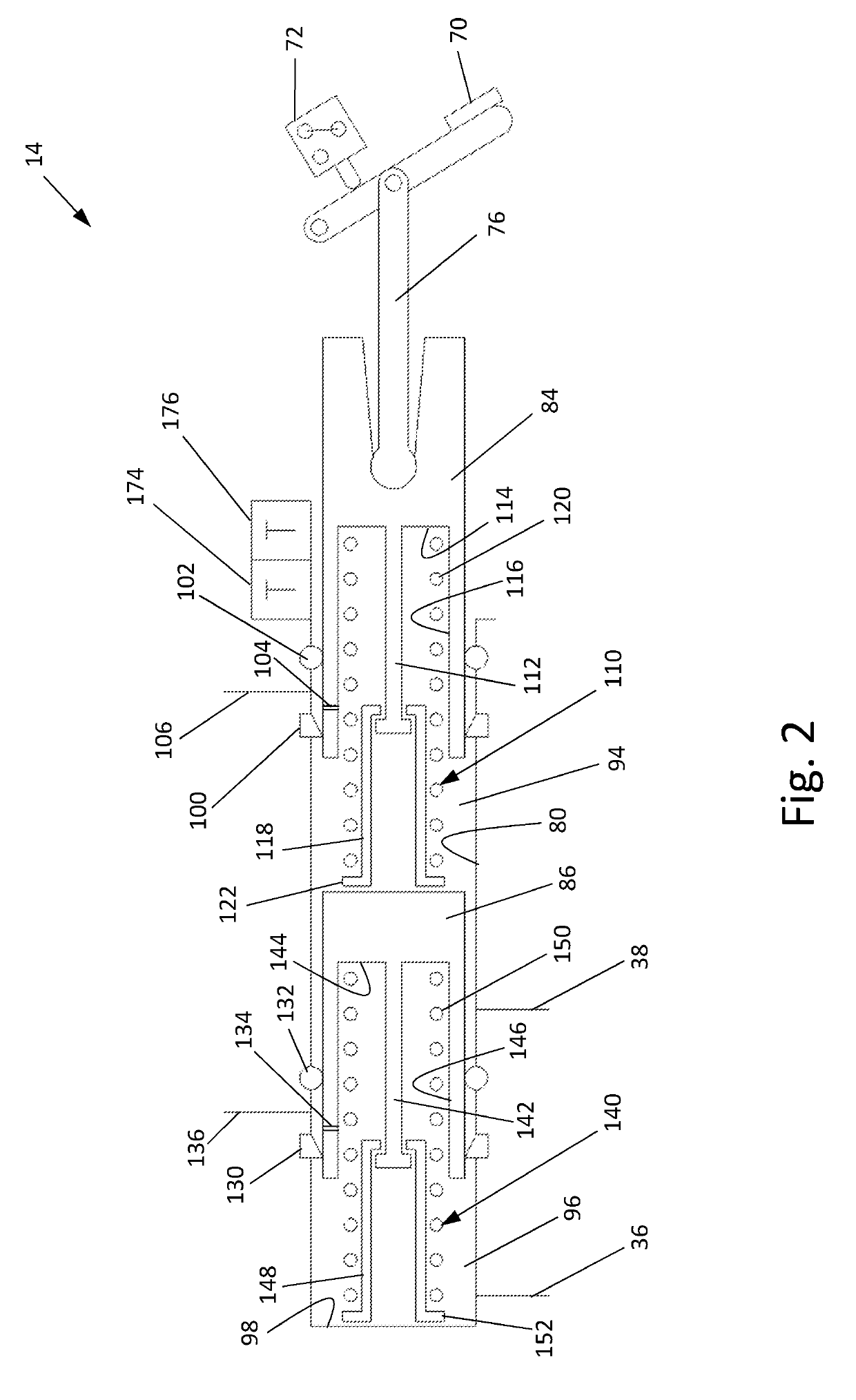

Vehicle Brake System With Dual Acting Plunger Assembly

A plunger assembly for use as a pressure source for a brake system includes a housing having first and second ports. A motor is mounted on the housing for driving an actuator. A piston is connected to the actuator. The piston is slidably mounted within the housing. The piston pressurizes a first chamber when the piston is moving in a first direction to provide fluid out of the first port. The piston pressurizes a second chamber when the piston is moving in a second direction to provide fluid out of the second port.

Owner:KELSEY HAYES CO

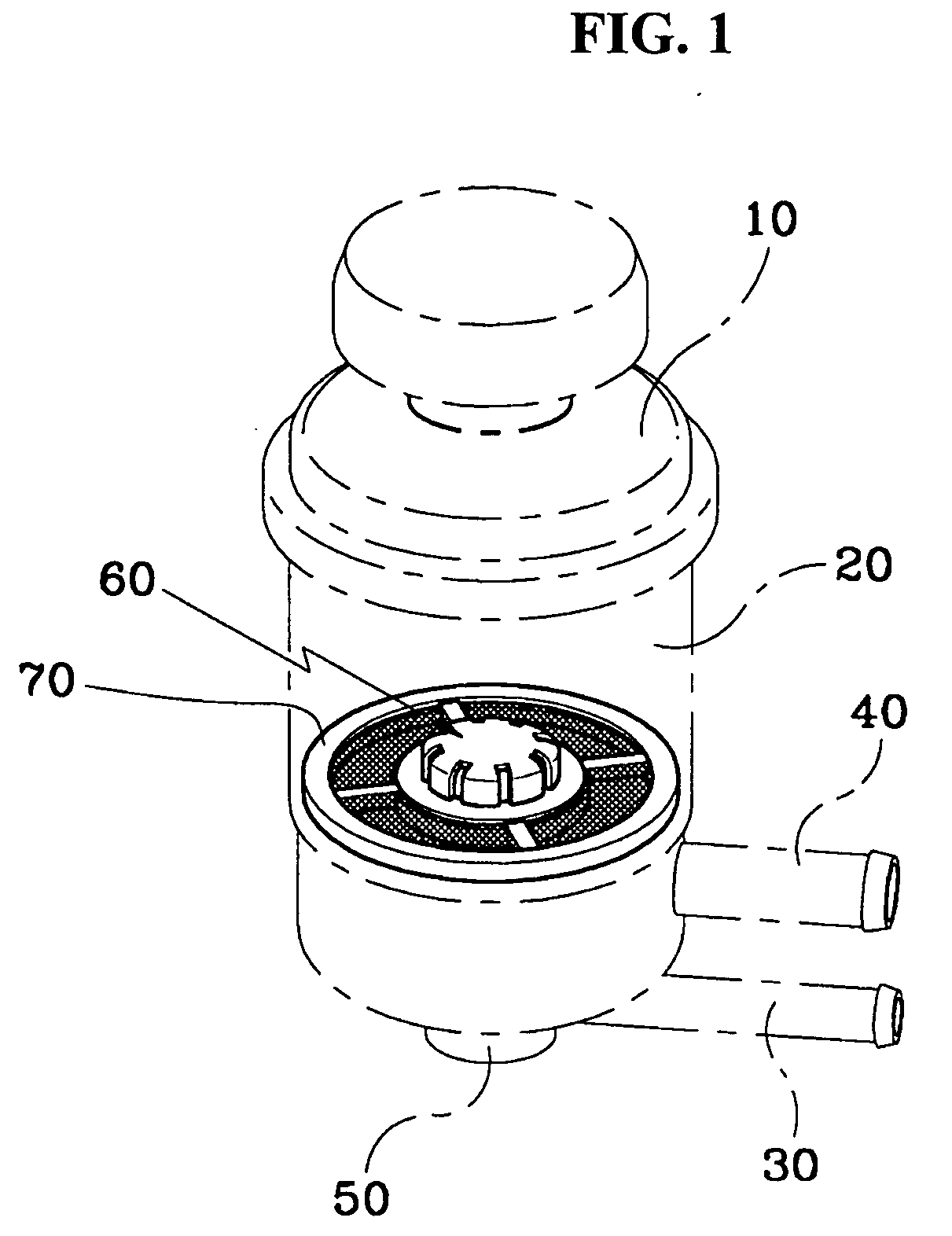

Power steering fluid reservoir cap with a mist condensing filter

A cap assembly is provided for a container that defines a reservoir for power steering fluid. The cap assembly has an outer cap adapted to be secured to an open mouth of the container and an inner cap secured to the outer cap and adapted to extend through the open mouth into a neck of the container. The inner cap has an O-ring adapted to seal against a neck of the container. A build-up of air in the reservoir is vented to the outside atmosphere through a passageway in the cap assembly. A filter in the passageway is adapted to pass the air but not to pass a mist emanating from the power steering fluid. The filter condenses the mist for return to the reservoir

Owner:DAIMLER CHRYSLER CORP +2

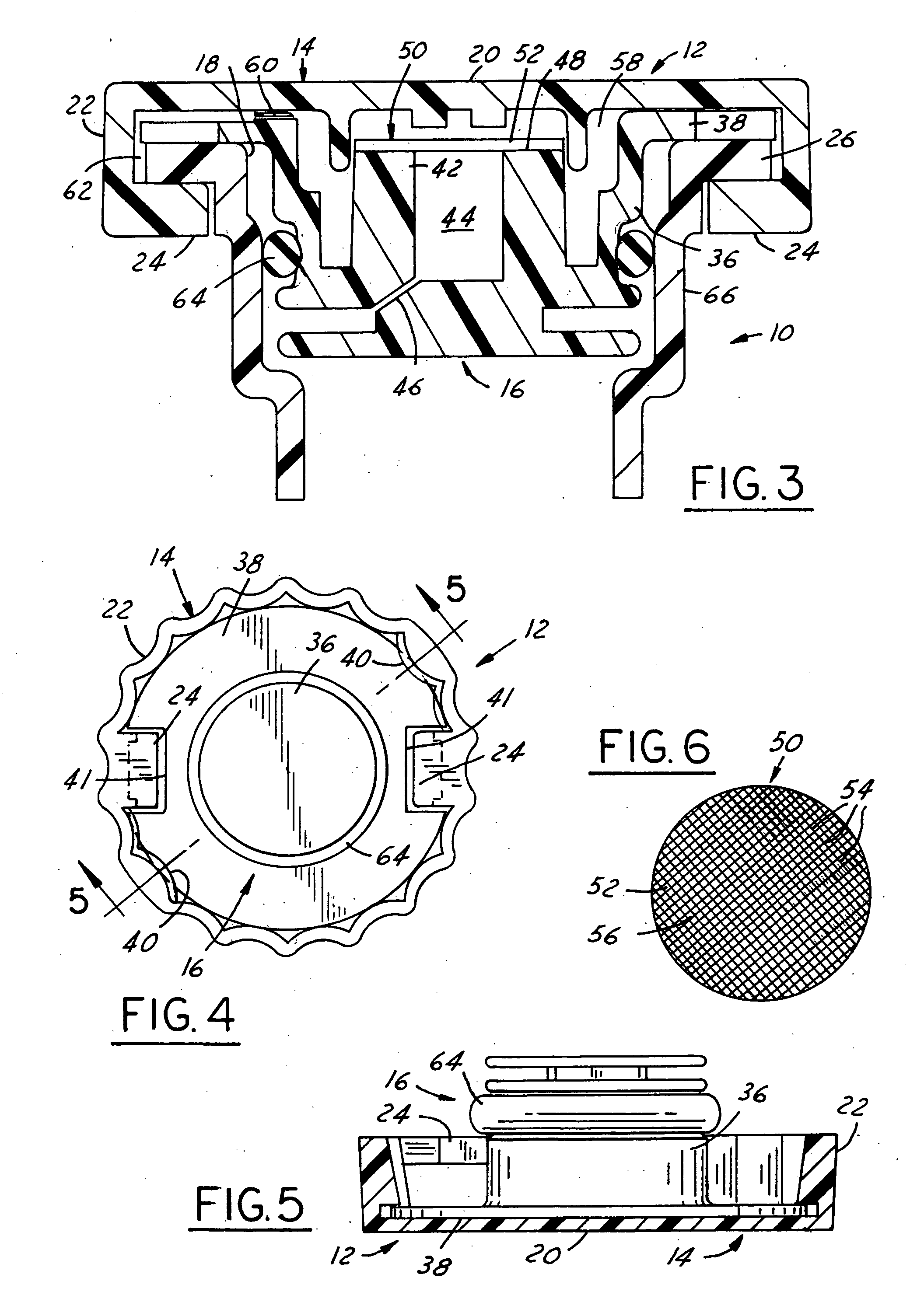

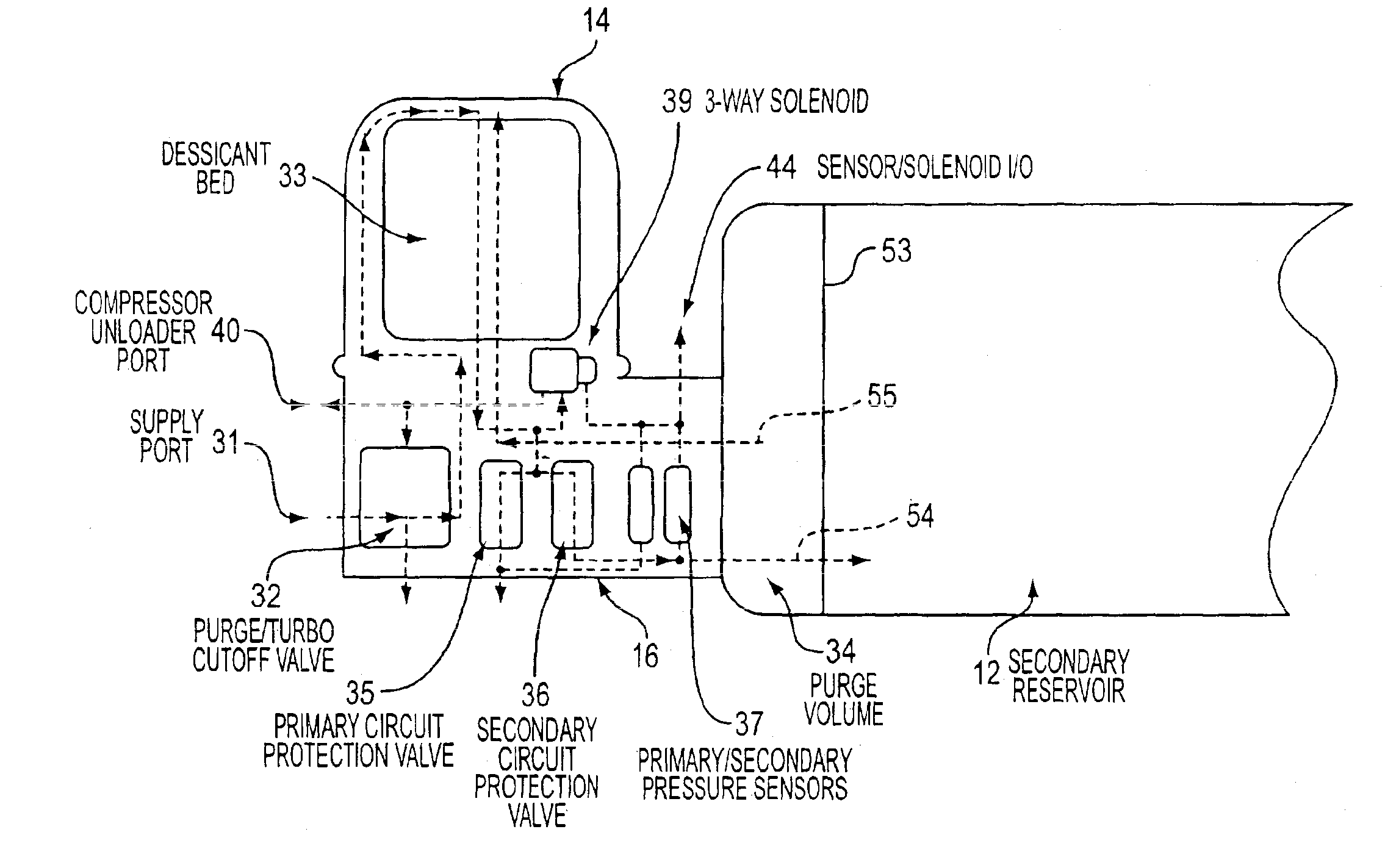

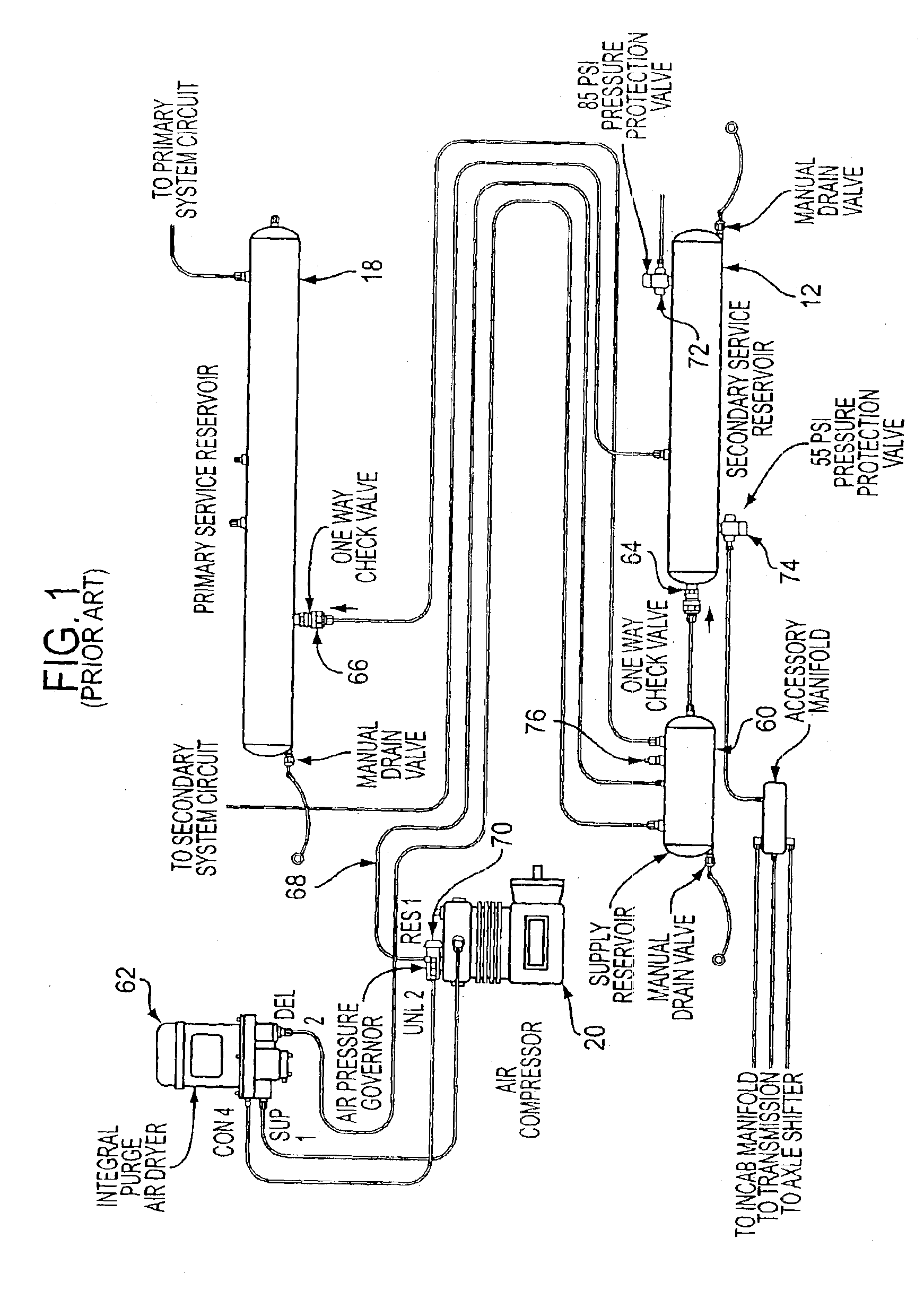

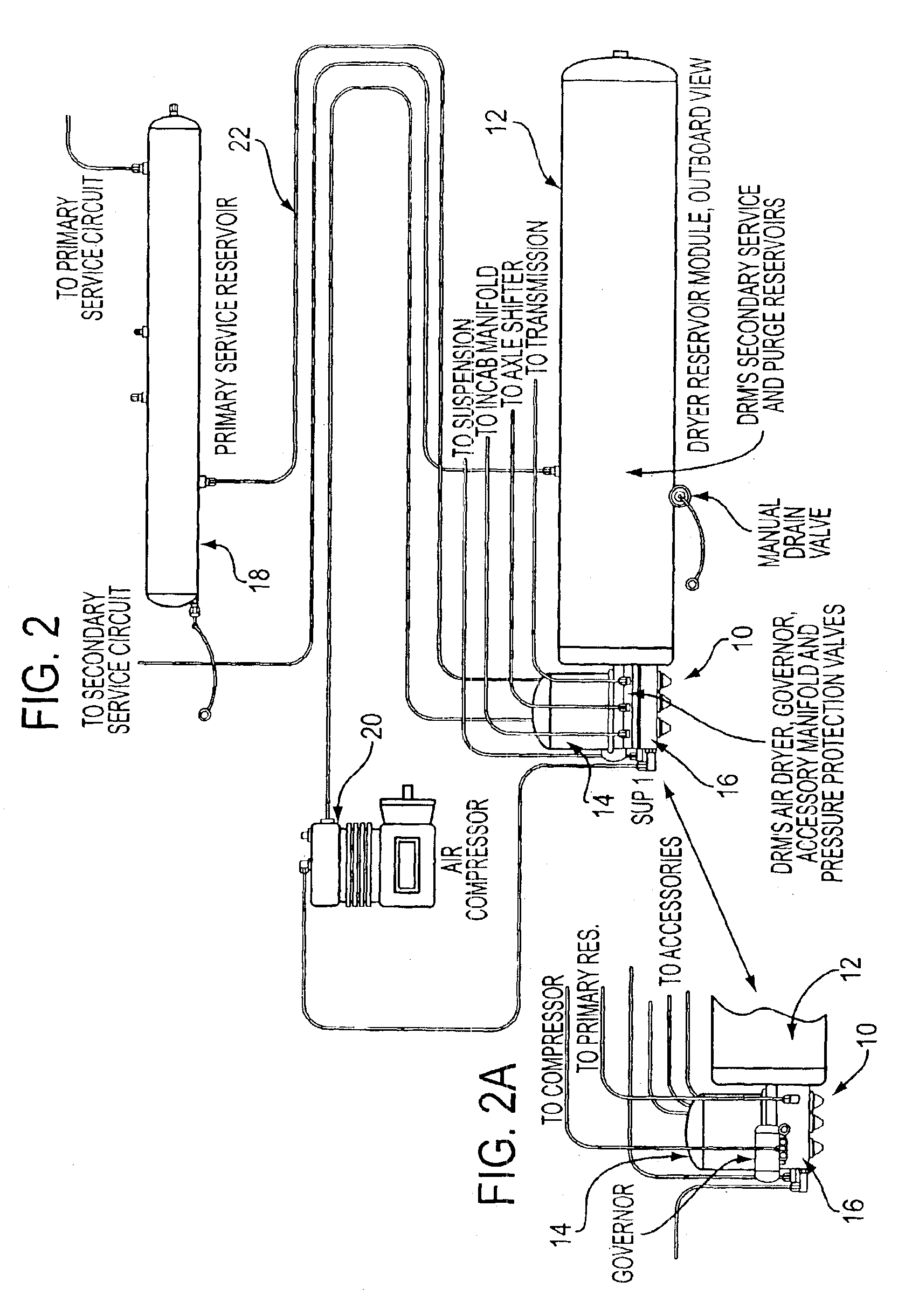

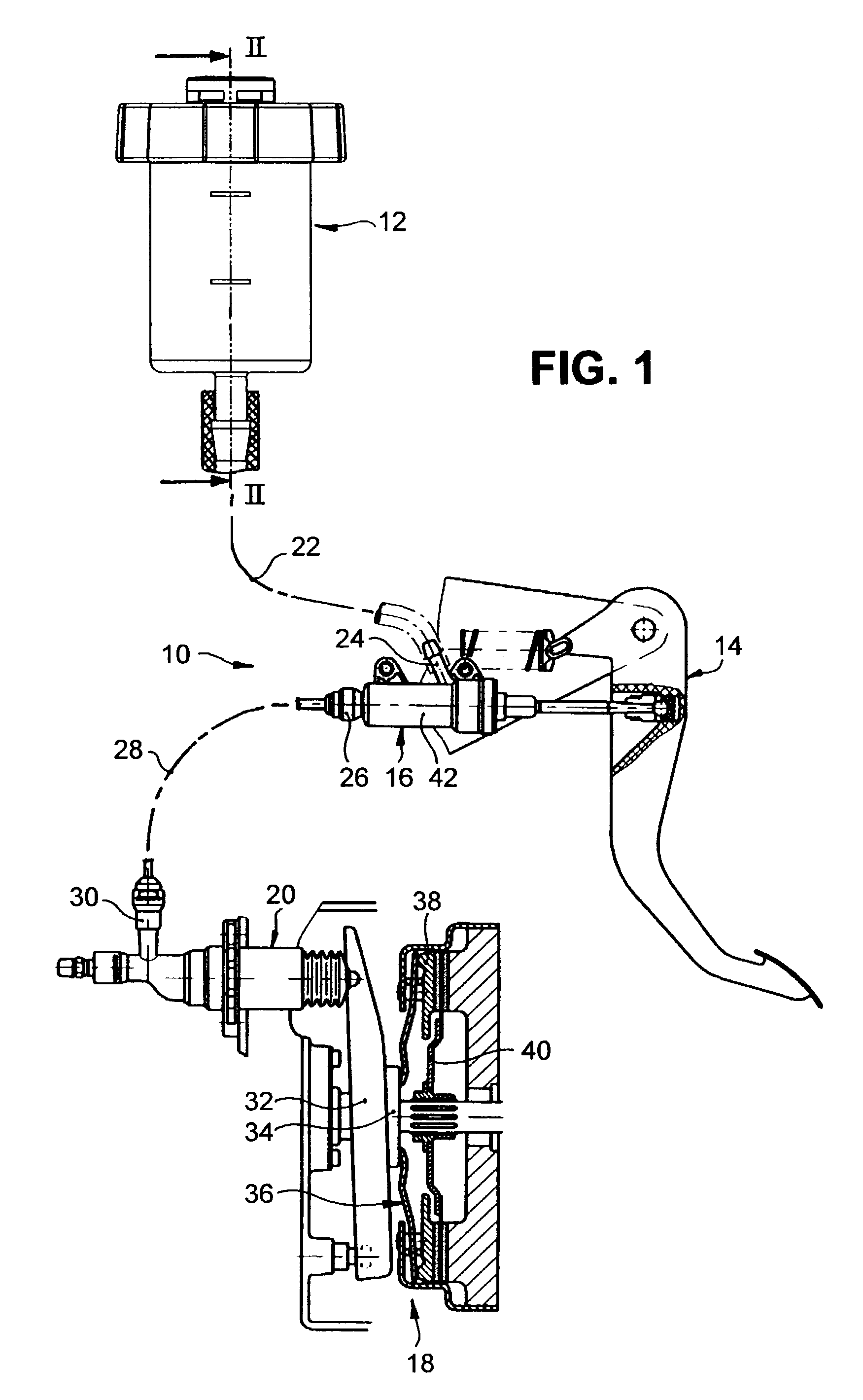

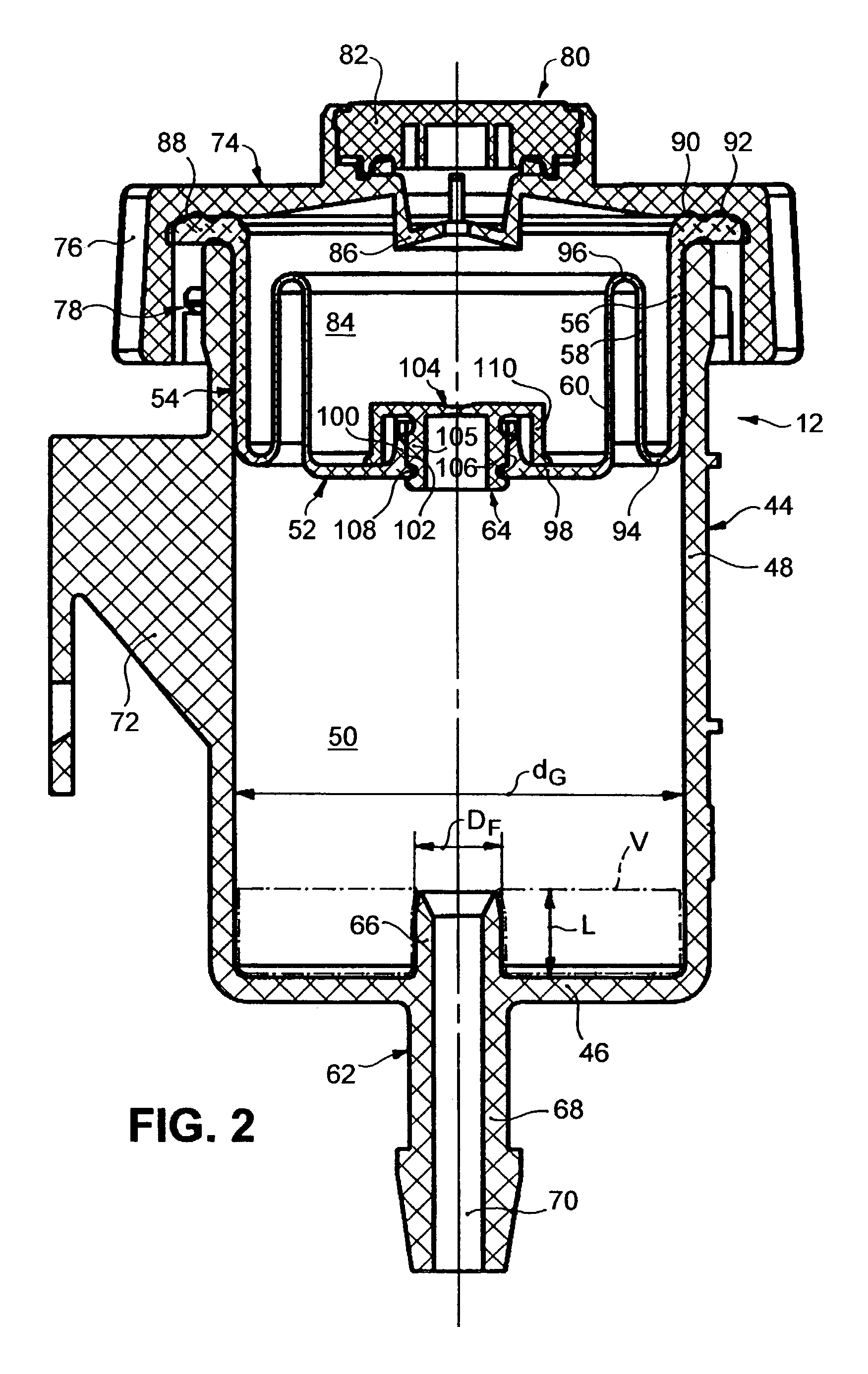

Air dryer module

InactiveUS6858066B2Cost effectiveReduced failure modesGas treatmentAccumulator installationsGas compressorAir compressor

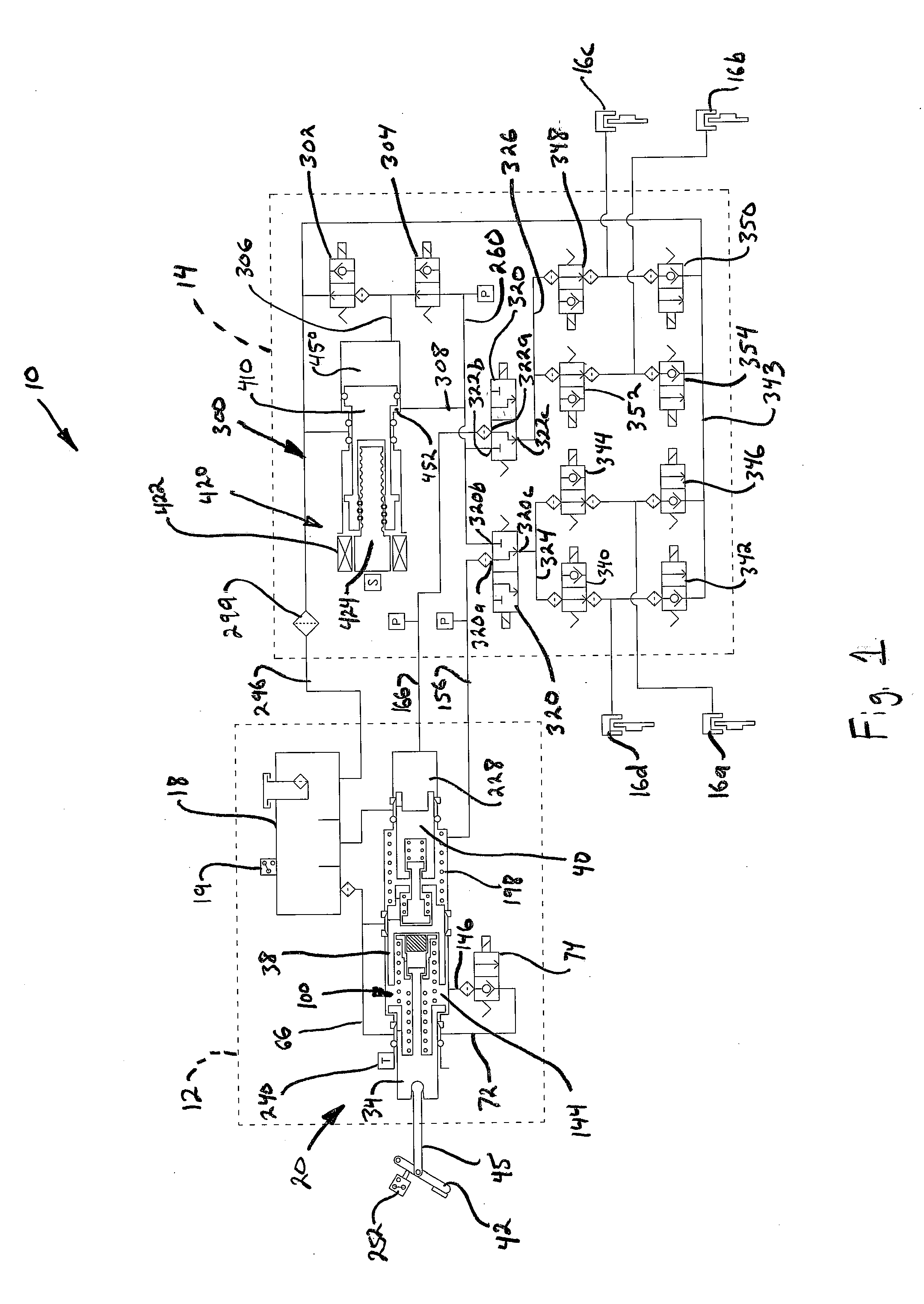

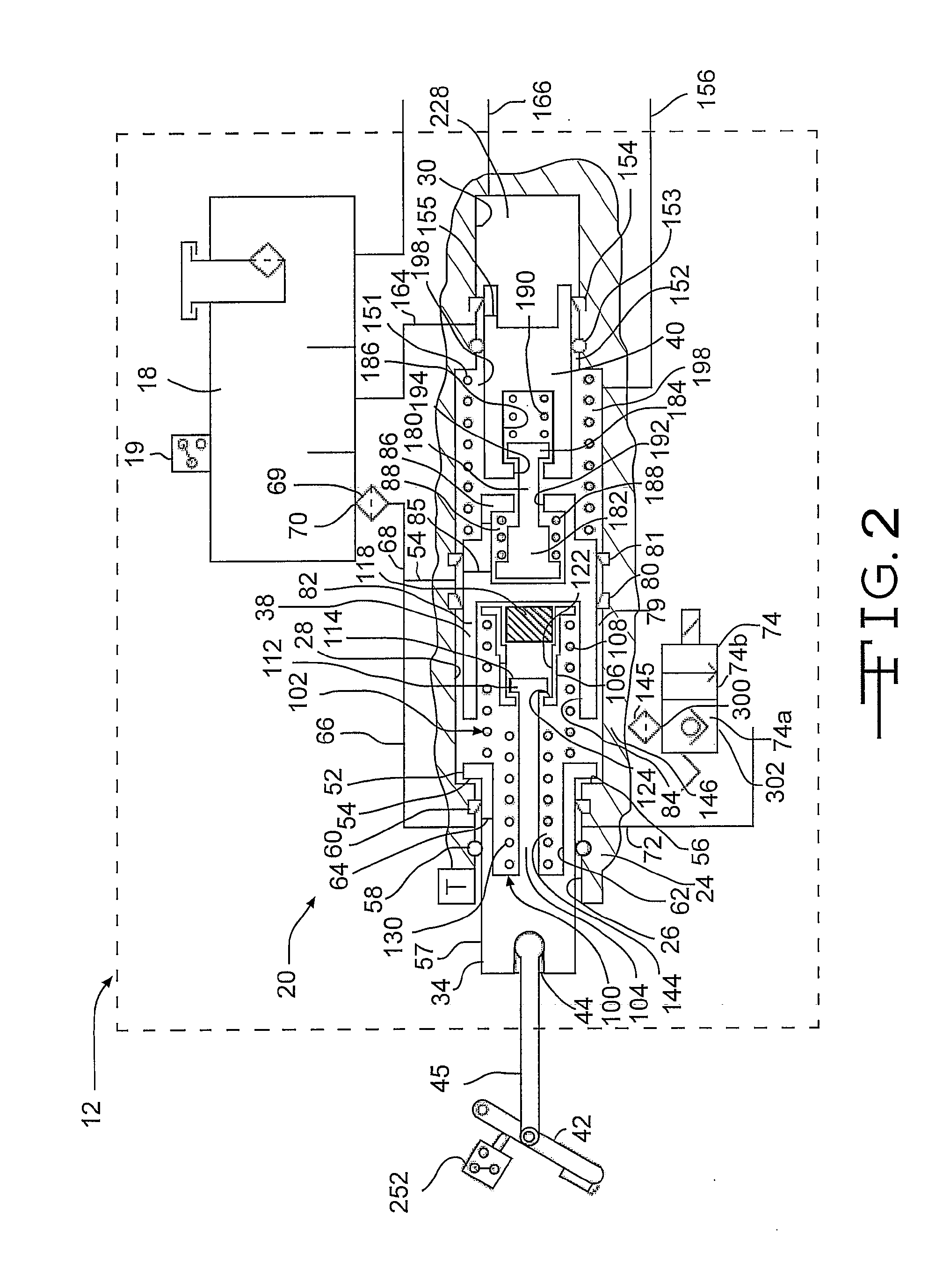

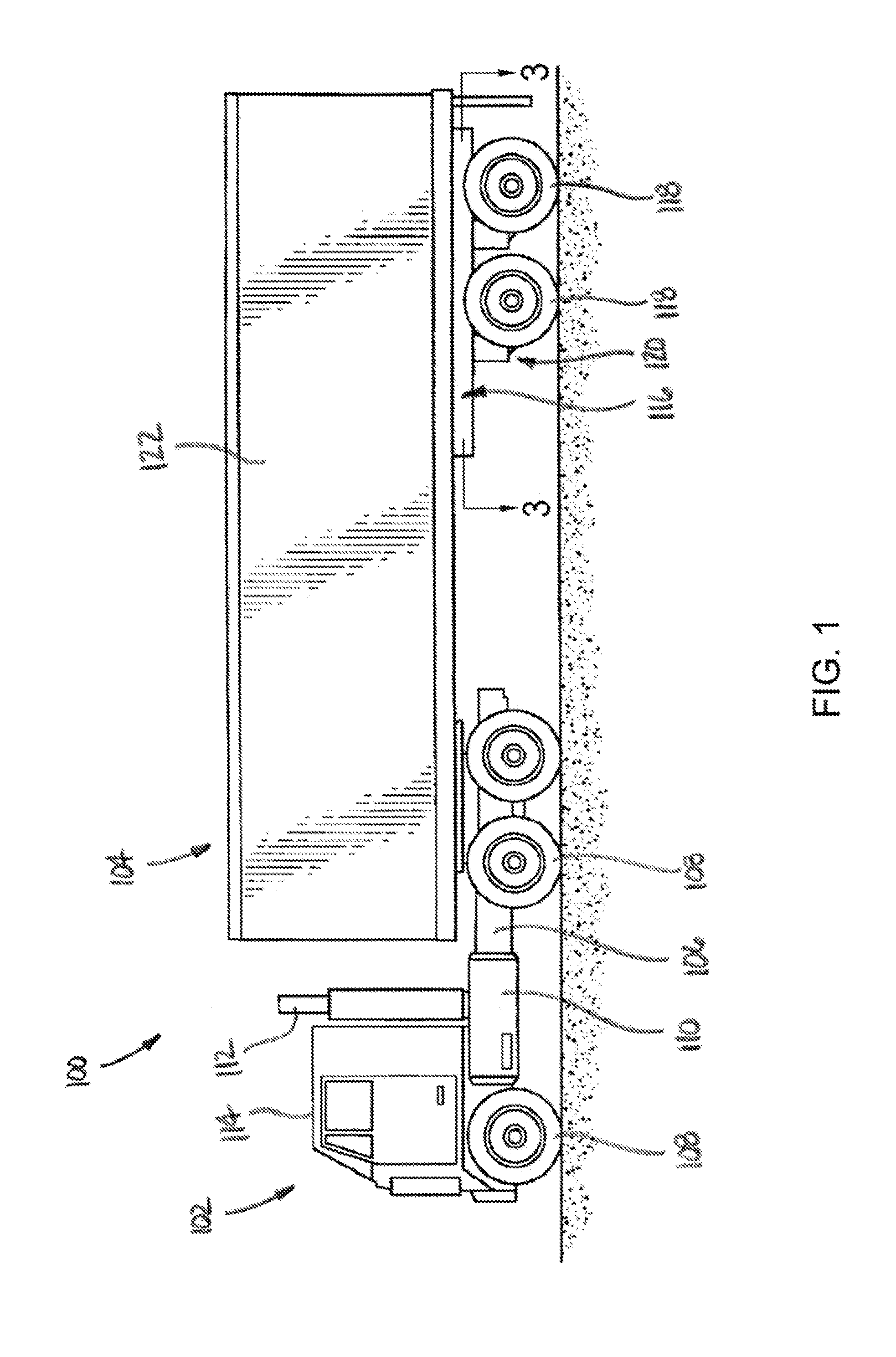

An air dryer and reservoir assembly for providing compressed air from an air compressor (20) on a heavy motor vehicle which includes an air dryer (14) connected to receive compressed air from the air compressor (20) and a secondary reservoir (12), including an integral purge volume (34), for storing compressed air which passes through the air dryer (14), with the air dryer (14) and the secondary reservoir (12) being securely attached to a housing (16) to form an air dryer reservoir module (10). A primary, reservoir (18) for storing compressed air from the air dryer (14) is located remote from the air dryer reservoir module (10). A pressure equalizing mechanism (57) is disposed between the primary reservoir (18) and the secondary reservoir (12) for keeping pressure in the two reservoirs (12,18) equal. Components located within the housing (16) control air flow between the air dryer (14) and the primary and secondary reservoirs (18,12) and also monitor the pneumatic brake system circuits fed by the primary and secondary reservoirs (18,12).

Owner:BENDIX COMML VEHICLE SYST LLC

Reservoir tank of a power steering system for a car

A reservoir tank of power steering system for a car includes an inlet port delivering oil through a swirl prevention member. The oil is then allowed to flow so swirl does not form in the oil flow of a reservoir tank. Furthermore, bubble formation in the oil is minimized.

Owner:HYUNDAI MOTOR CO LTD

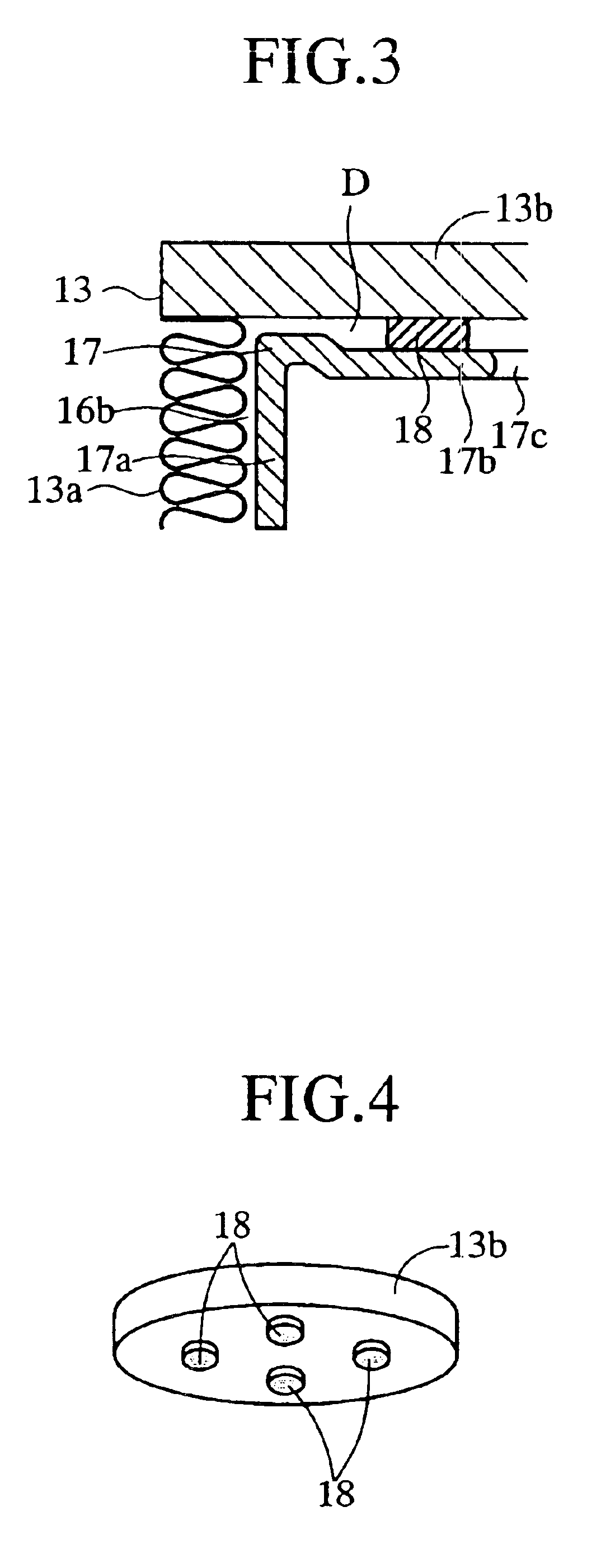

Metal bellows accumulator

InactiveUS6871670B2Compact manufacturingReliably accumulatingAccumulator installationsPipe elementsProduct gasGas chamber

In a metal bellows accumulator, a metallic bellows unit is disposed within a pressure space defined in a main shell, and one end of the metallic bellows unit is fixedly secured to one end wall of the main shell. The metallic bellows unit sections the pressure space into an outer chamber serving as a gas chamber in which a pressurized gas is enclosed, and an inner chamber serving as a liquid chamber communicating with a liquid port formed in the end wall of the main shell. A stopper (auxiliary shell) for limiting collapsing movement of the metallic bellows unit is disposed within the liquid chamber and has a communication passage hole. The liquid port always communicates with a liquid chamber to which an inner circumferential surface of a bellows portion of the metallic bellows unit is exposed via the communication passage hole.

Owner:ADVICS CO LTD

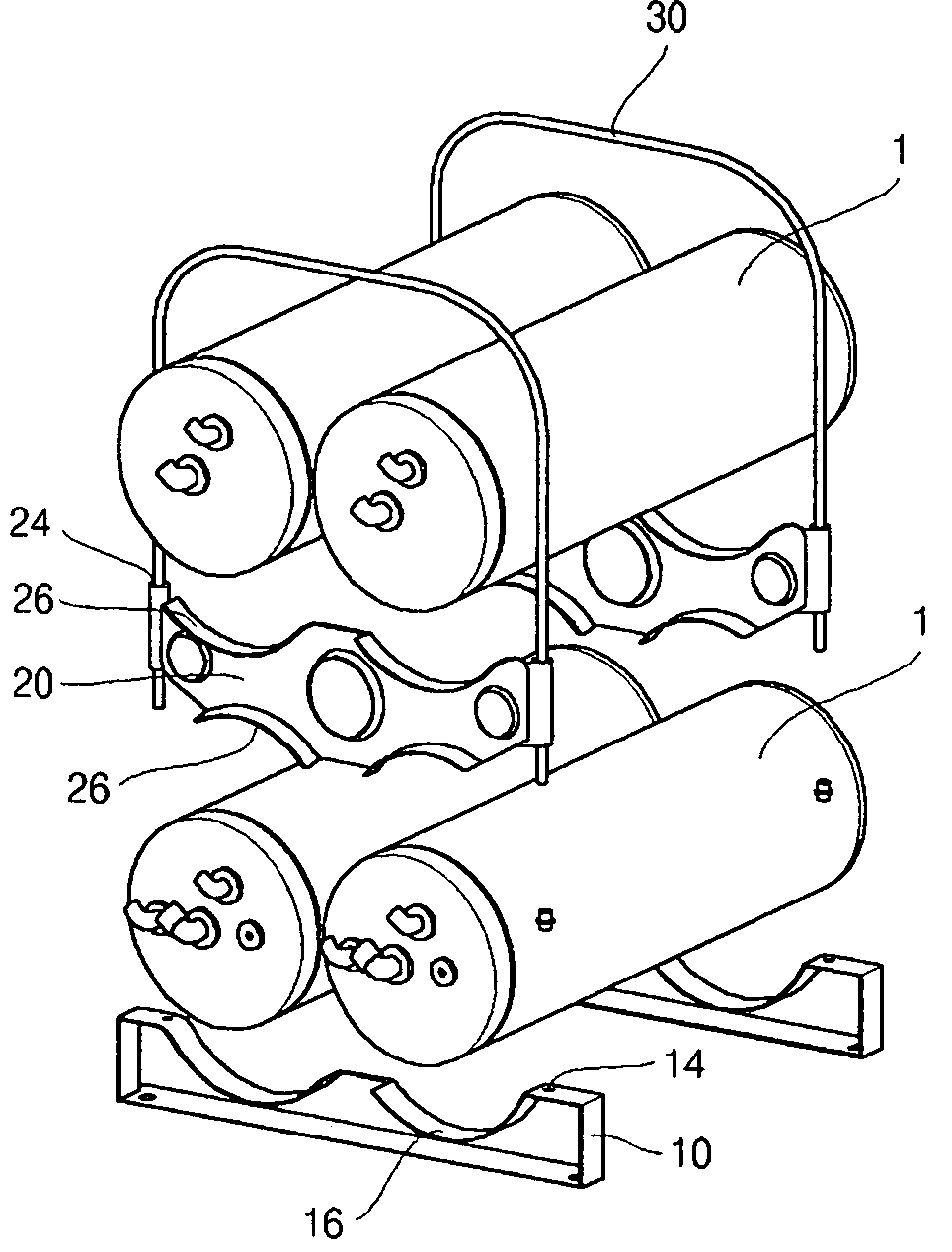

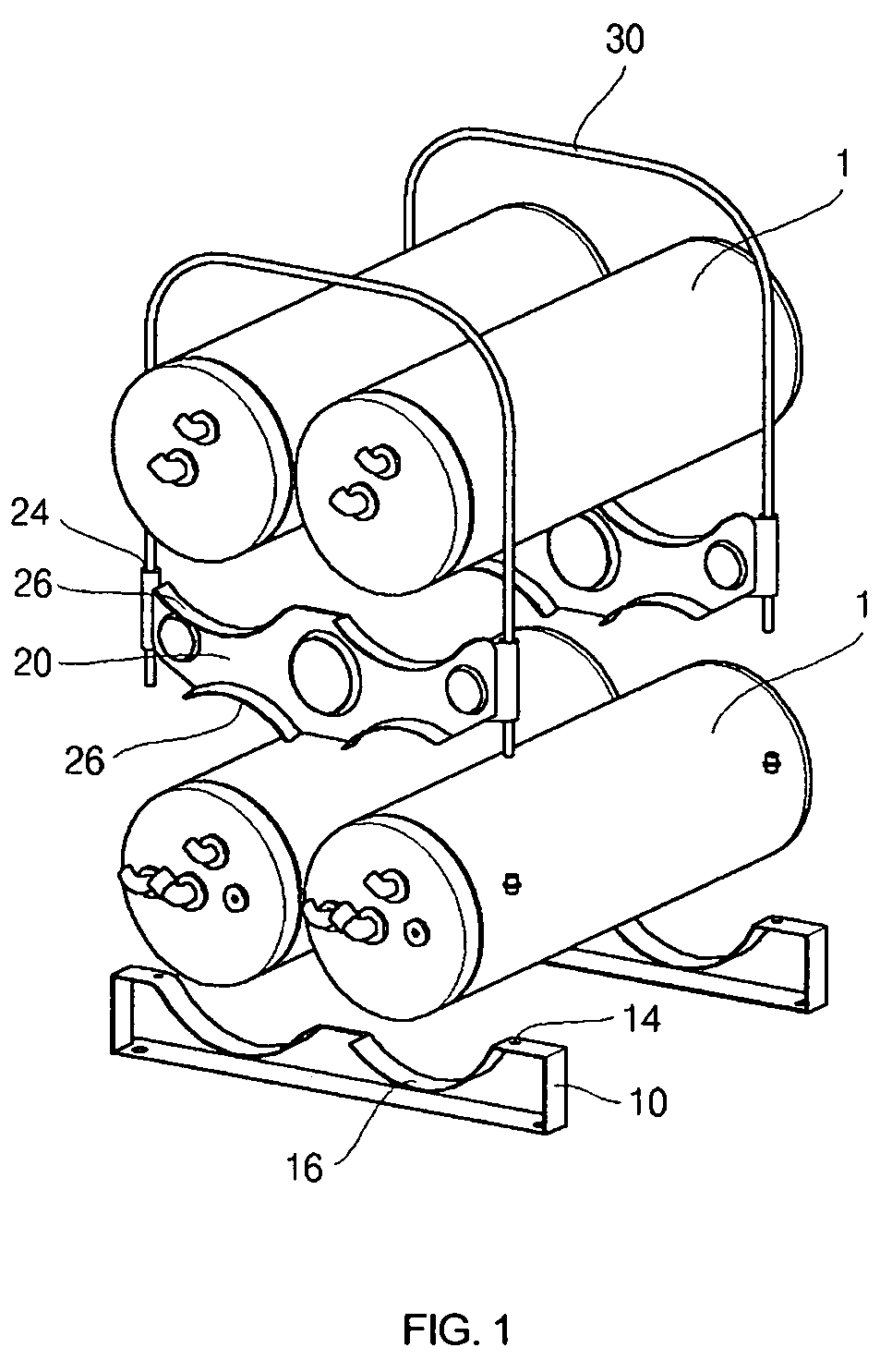

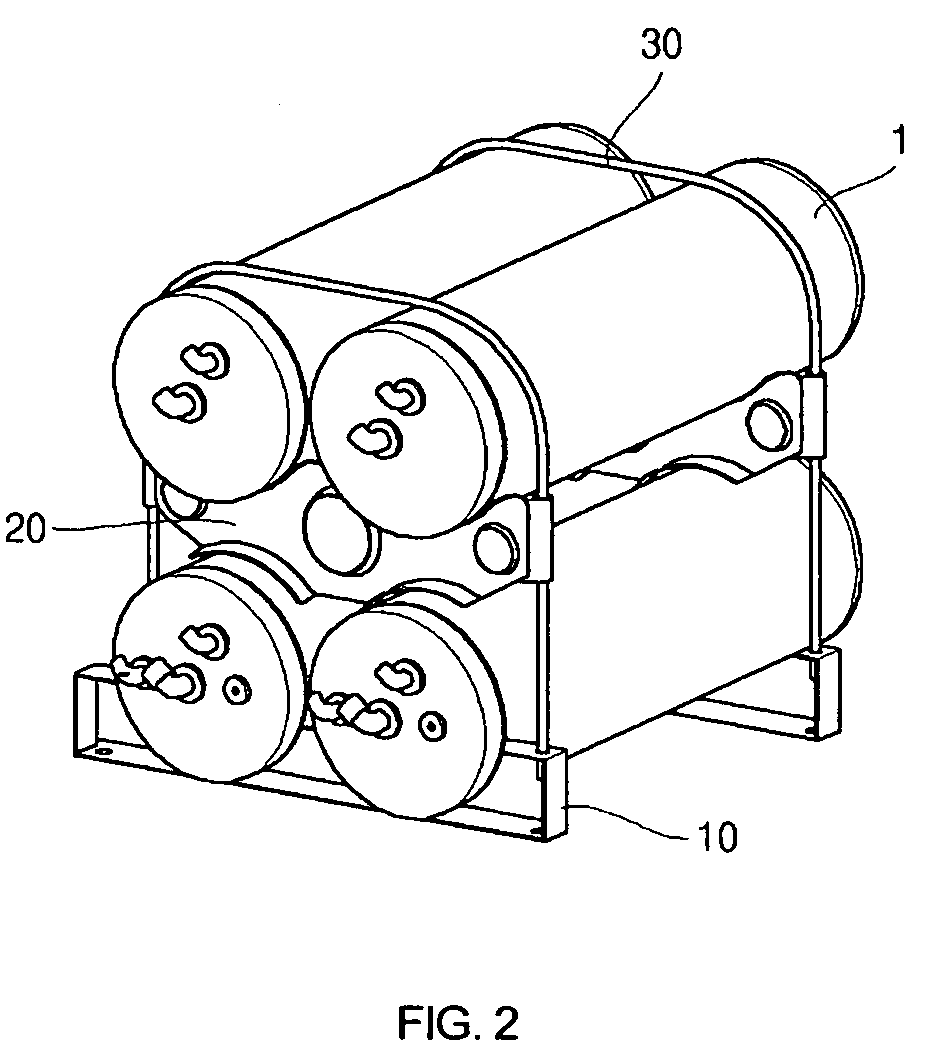

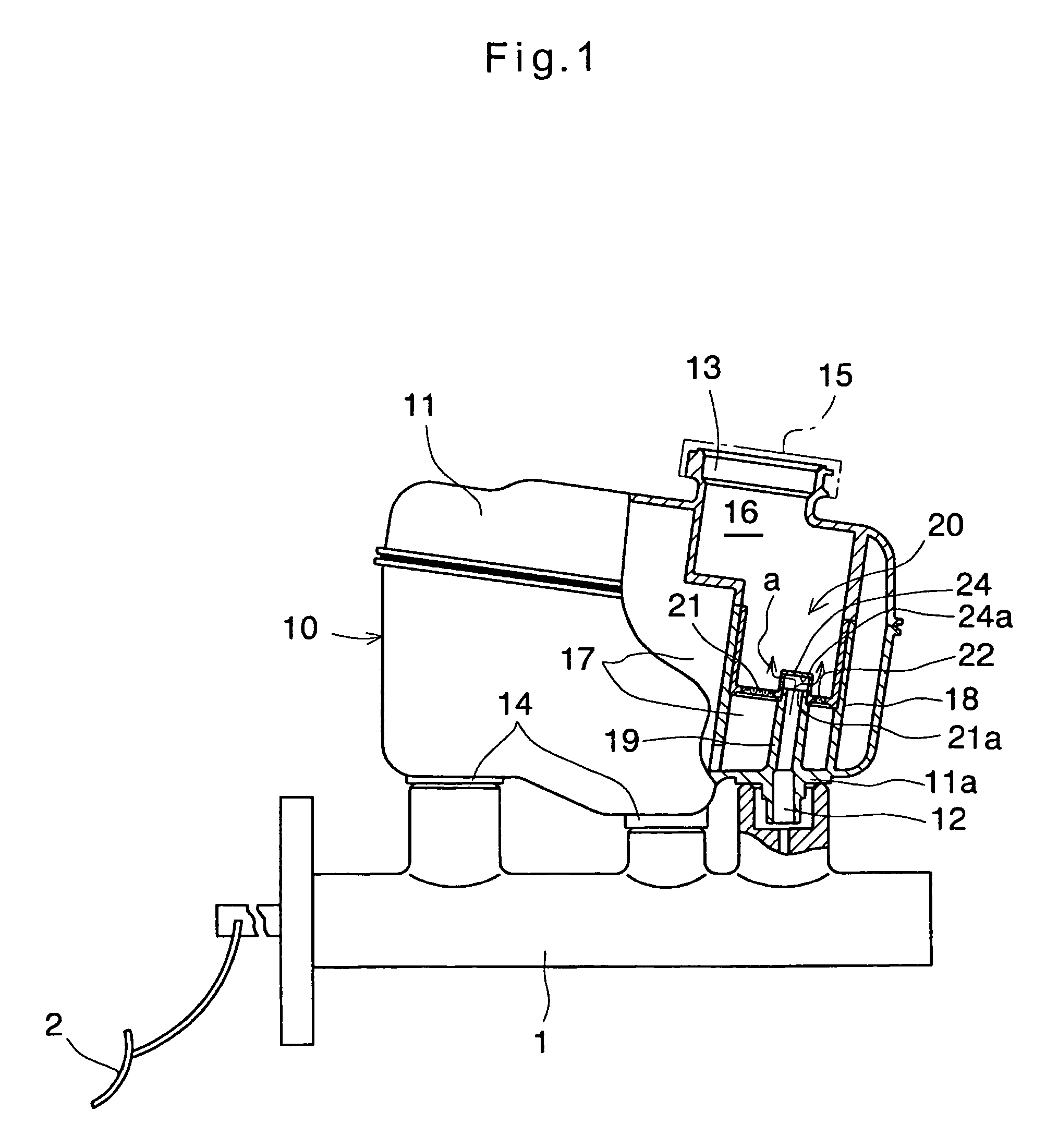

Air tank fixing structure for commercial vehicles

An air tank fixing structure is disclosed for vehicles capable of integrally fixing air tanks which are used for supplying air upon activation of a brake system or air suspension of the vehicle. In a specifically preferred system, the air tank fixing structure includes a first air tank fixing member fixed onto a body frame at one side thereof, and formed with at least one first fixing element in which at least one air tank for the vehicle is fixed at the other side; a second air tank fixing member formed with at least one second fixing element and placed on the air tank.

Owner:HYUNDAI MOTOR CO LTD

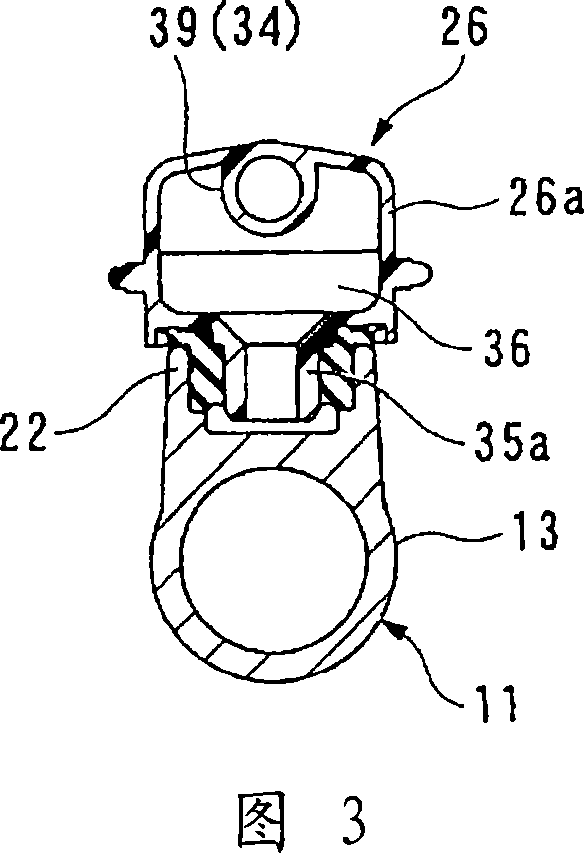

Reservoir apparatus for a bicycle brake lever device

A reservoir apparatus for a bicycle brake lever device comprises a master cylinder and a fluid reservoir including first and second reservoirs. The master cylinder has a master cylinder chamber dimensioned for receiving a master cylinder piston therein. The first reservoir has a first reservoir chamber in fluid communication with the master cylinder chamber for supplying a hydraulic fluid to the master cylinder chamber. At least a portion of the first reservoir chamber is disposed below a portion of the master cylinder chamber. The second reservoir has a second reservoir chamber in fluid communication with the first reservoir chamber, wherein the second reservoir chamber includes an air entrainment surface. The air entrainment surface is positioned higher than an upper surface of the first reservoir chamber.

Owner:SHIMANO INC

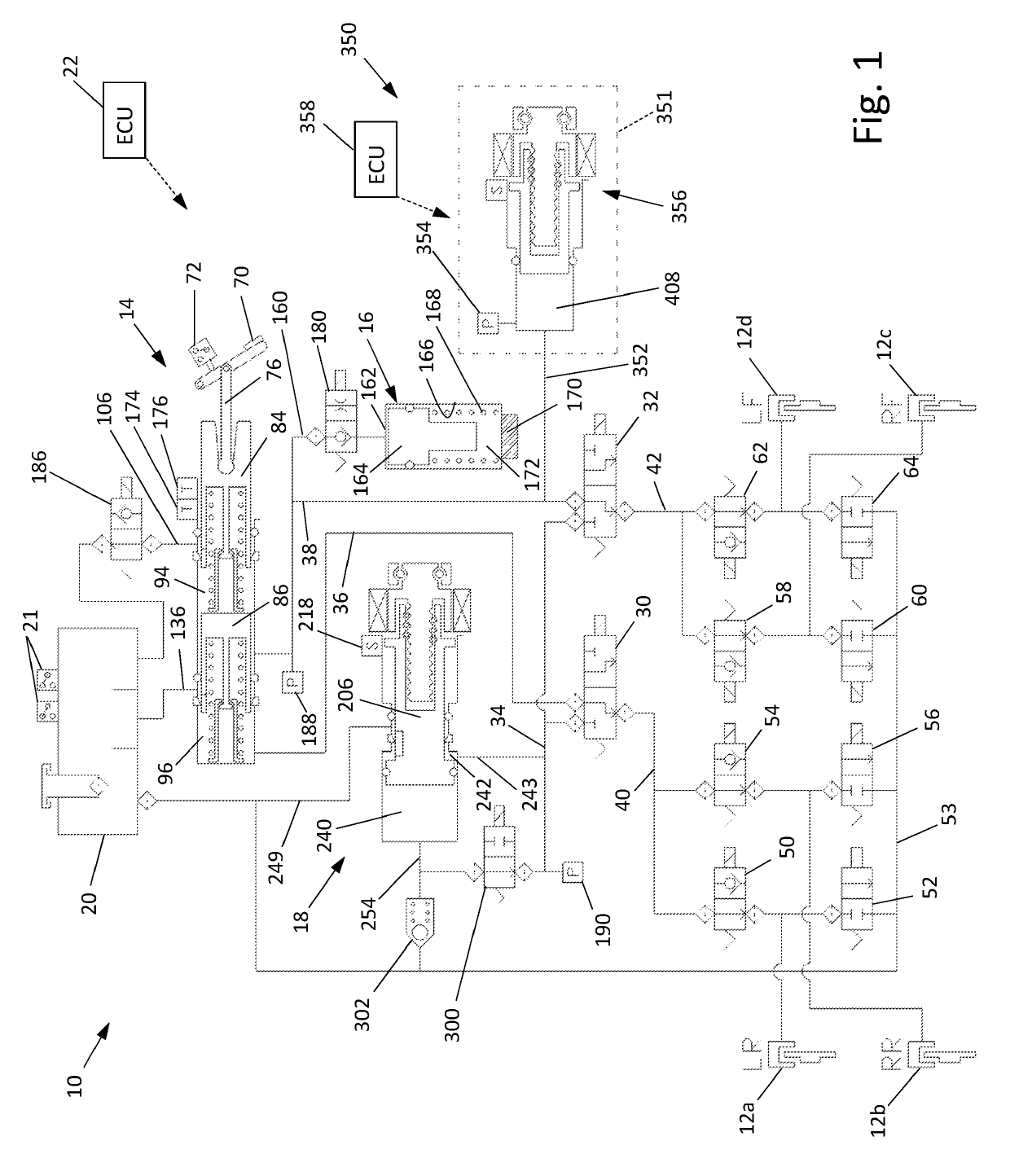

Vehicle Brake System With Secondary Brake Module

A brake system has a wheel brake and is operable under a non-failure normal braking mode and a manual push-through mode. The system includes a master cylinder operable by a brake pedal during a manual push-through mode to provide fluid flow at an output for actuating the wheel brake. A first source of pressurized fluid provides fluid pressure for actuating the wheel brake under a normal braking mode. A secondary brake module includes a plunger assembly for generating brake actuating pressure for actuating the wheel brake under the manual push-through mode.

Owner:KELSEY HAYES CO

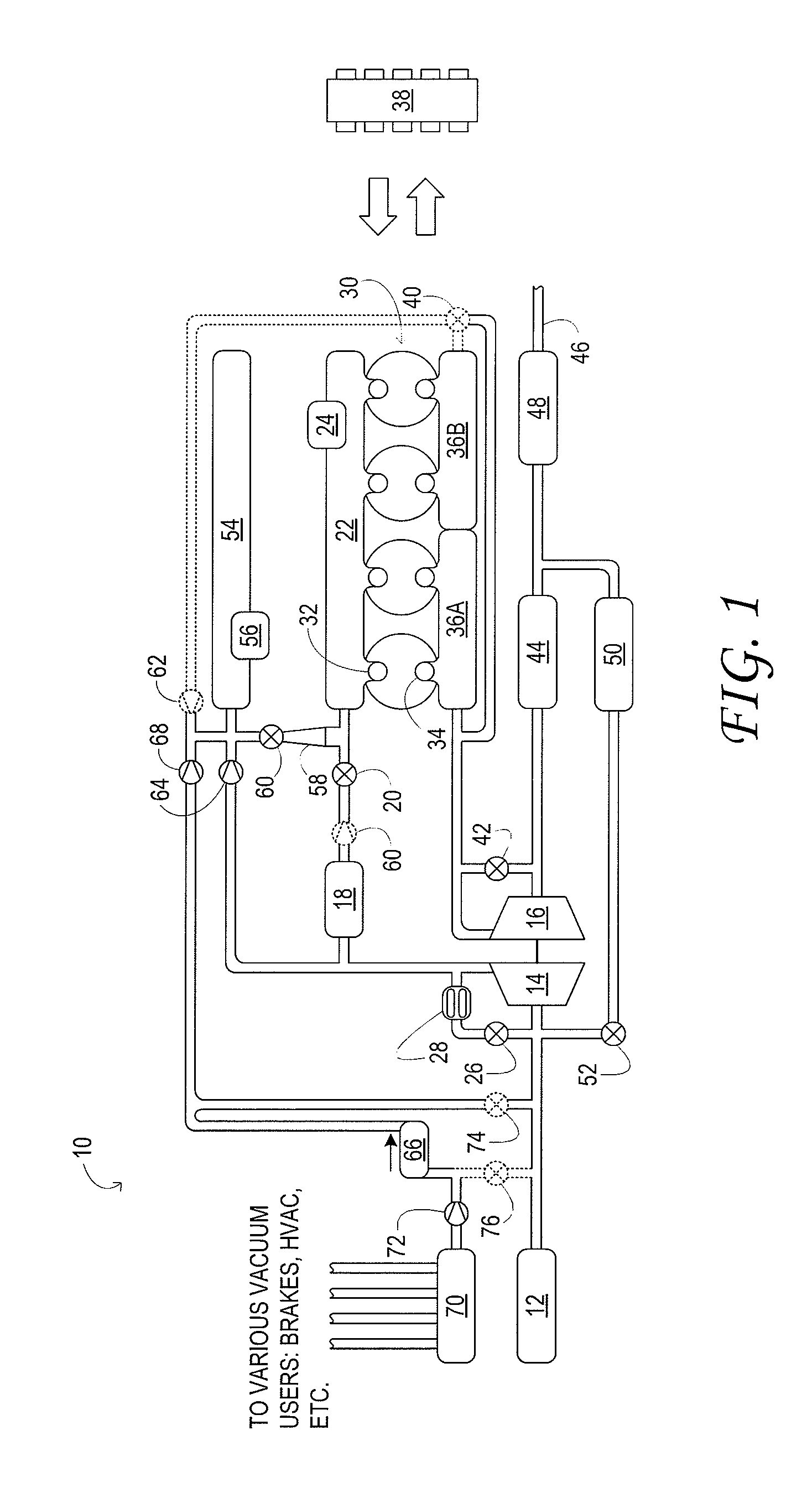

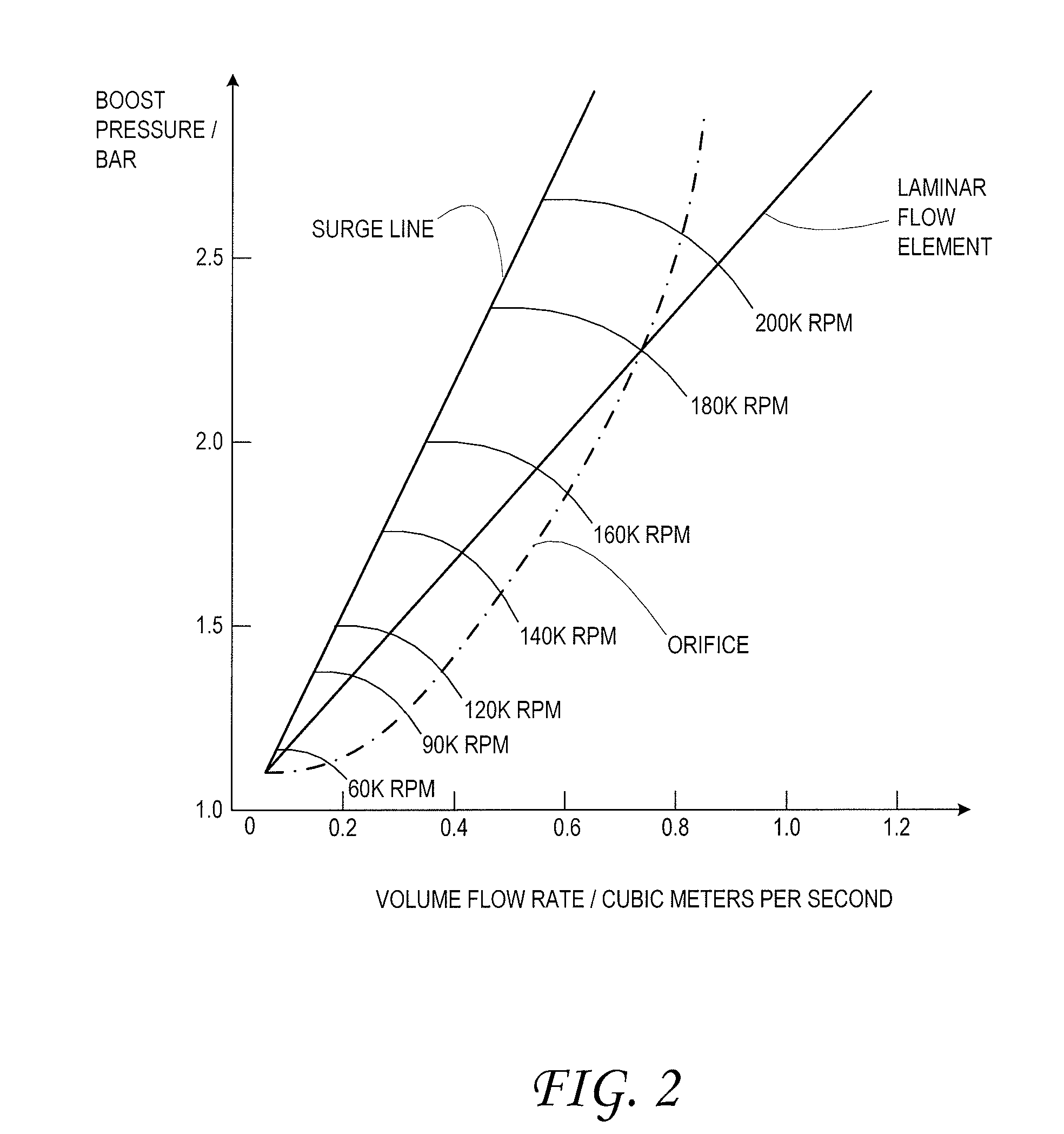

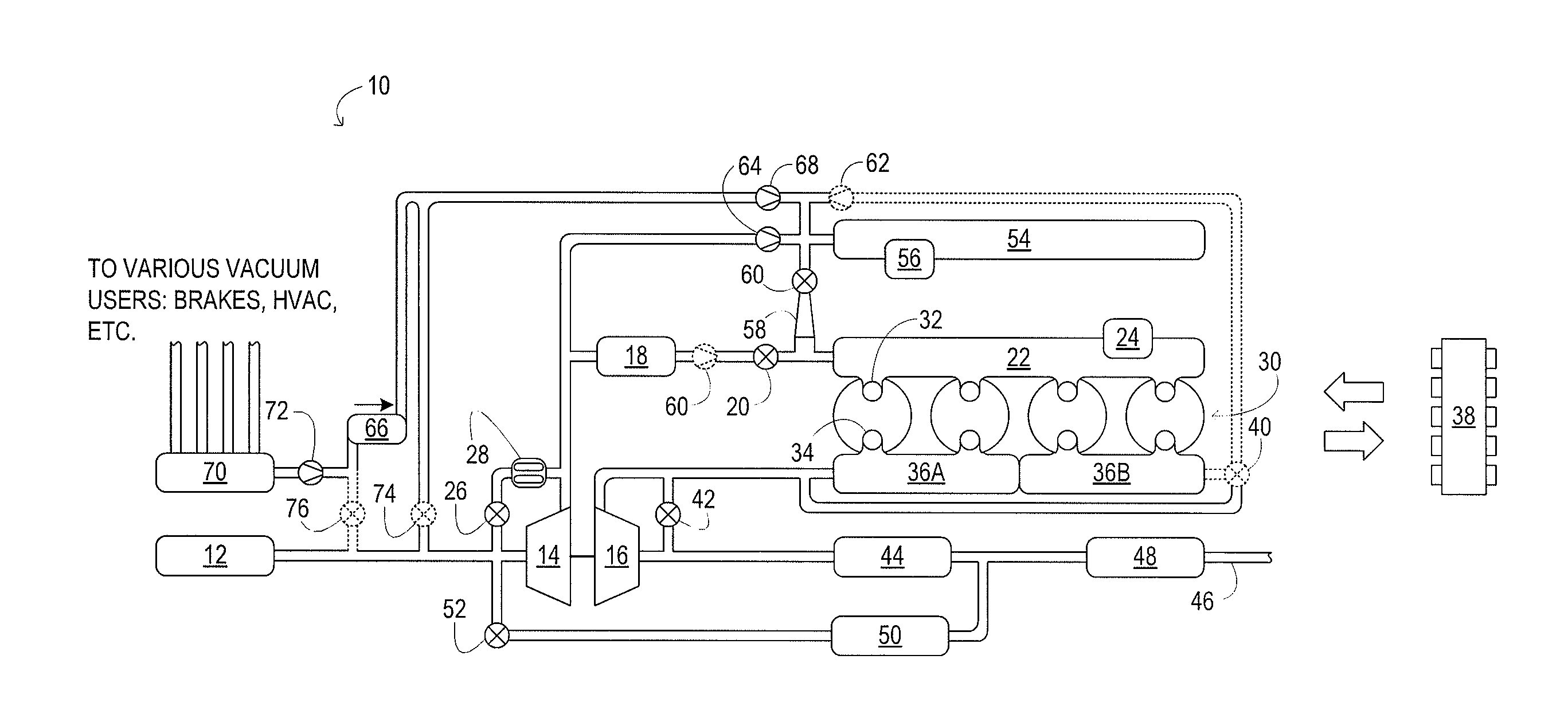

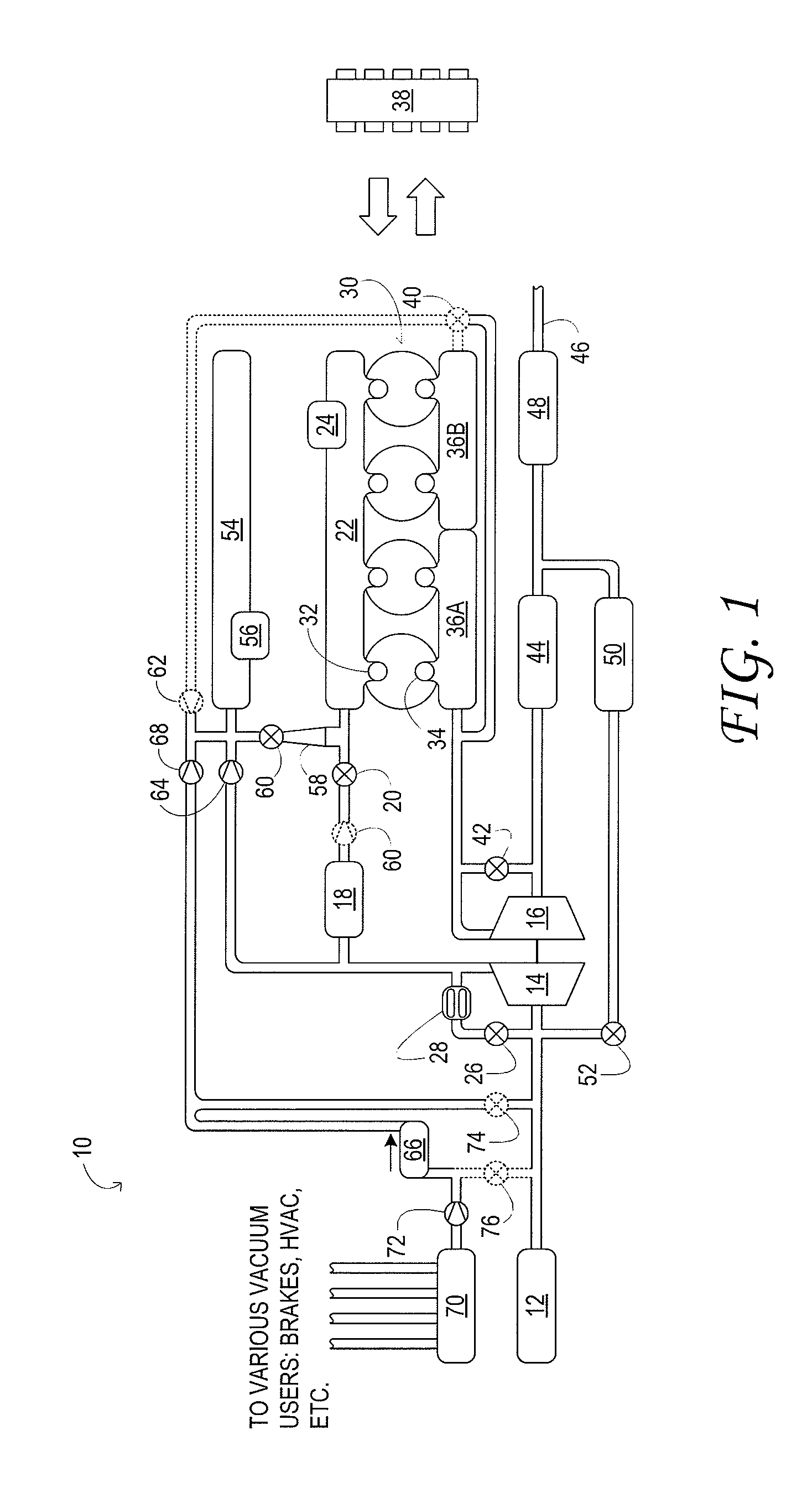

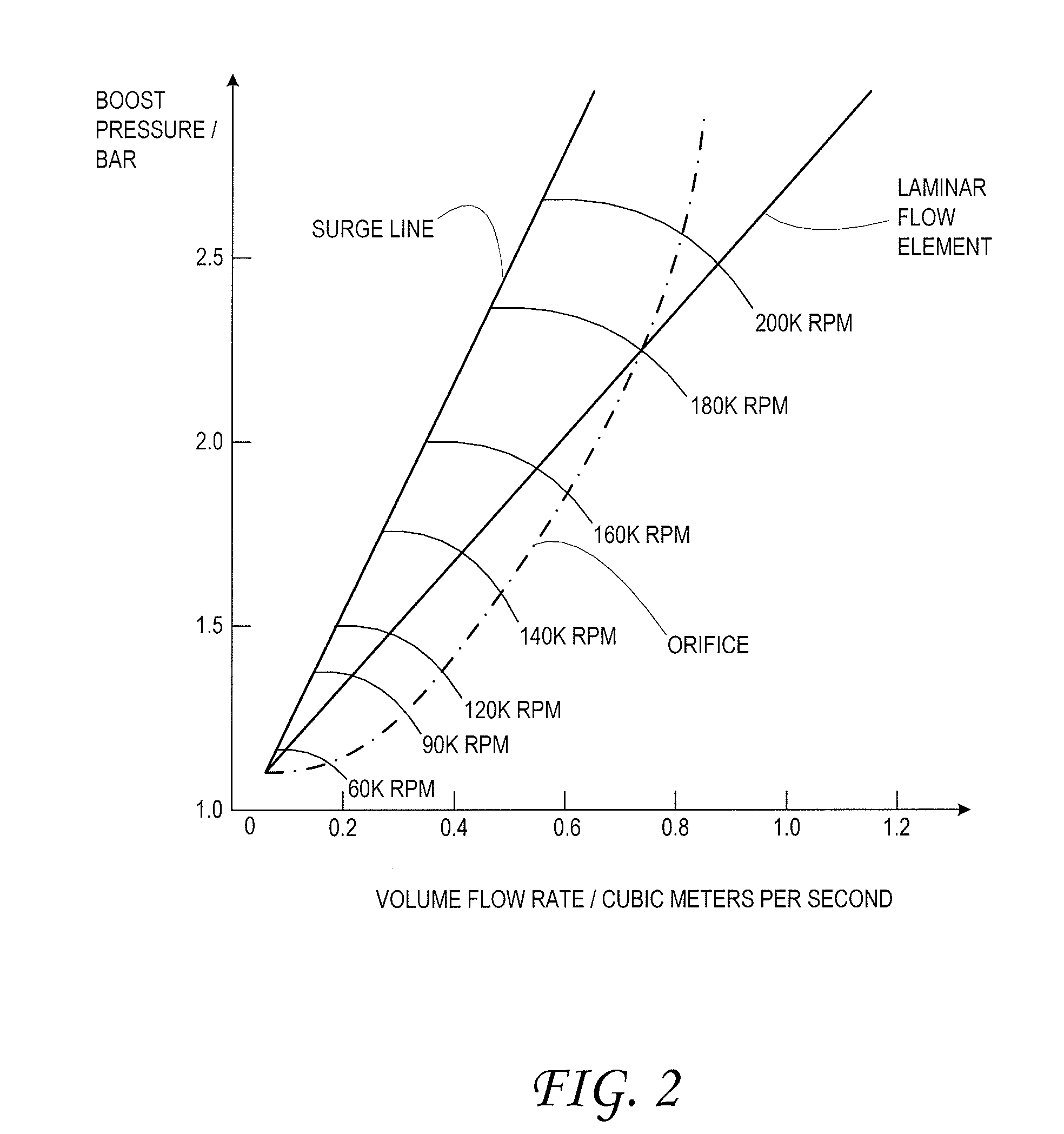

Stored compressed air management and flow control for improved engine performance

InactiveUS8371276B2Increase the effective amountIncrease flexibilityElectrical controlNon-fuel substance addition to fuelCombustion chamberEngineering

A method for providing air to a combustion chamber of an engine, the engine including a compressor and a boost tank selectably coupled to an intake manifold. The method comprises admitting air from the compressor to the intake manifold via a main throttle valve, storing some air from the compressor in a boost tank, and discharging some of the air stored in the boost tank to the intake manifold via an auxiliary throttle valve distinct from the main throttle valve.

Owner:FORD GLOBAL TECH LLC

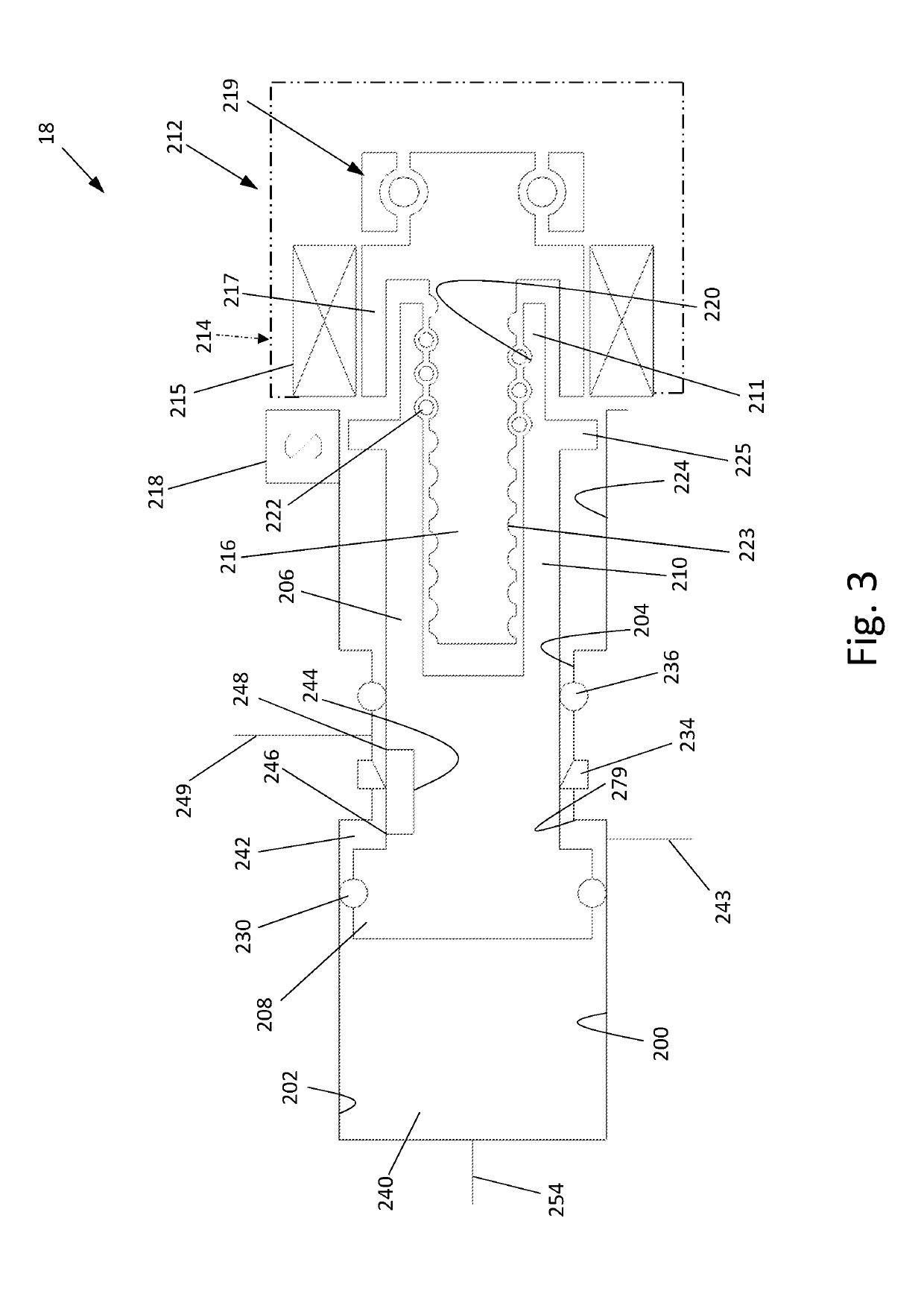

Vehicle brake system having plunger power source

A brake system includes first and second wheel brakes, a reservoir, and a brake pedal unit having a housing and a pair of output pistons slidably disposed in the housing. The output pistons generate brake actuating pressure during a manual push-through mode for actuating the first and second wheel brakes. The system further includes a plunger assembly having a housing having first and second ports, a motor driving an actuator, and a piston connected to the actuator. The piston pressurizes a first chamber when the piston is moving in a first direction to provide fluid flow out of the first port. The piston pressurizes a second chamber when the piston is moving in a second direction opposite the first direction to provide fluid flow out of the second port. The first and second ports are selectively in fluid communication with the wheel brakes.

Owner:KELSEY HAYES CO

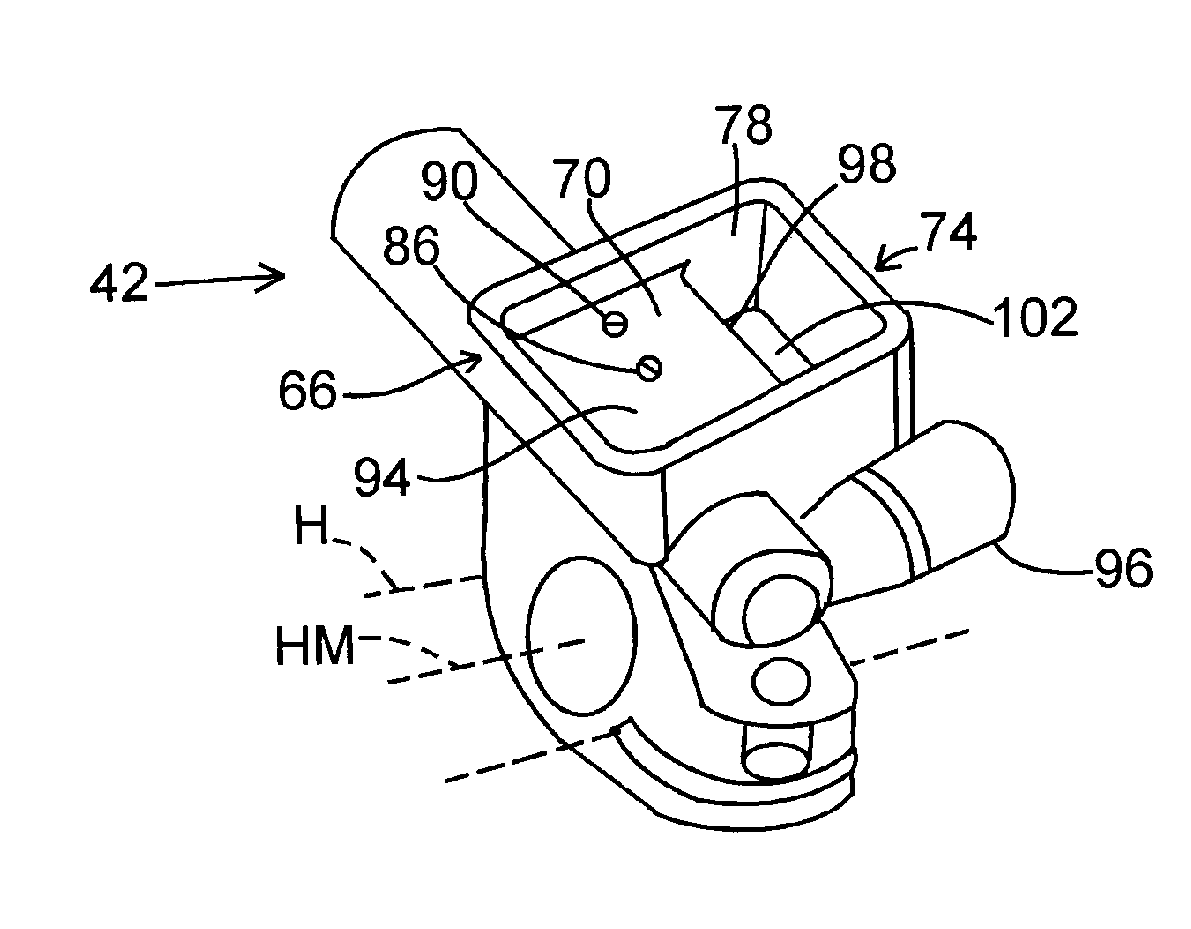

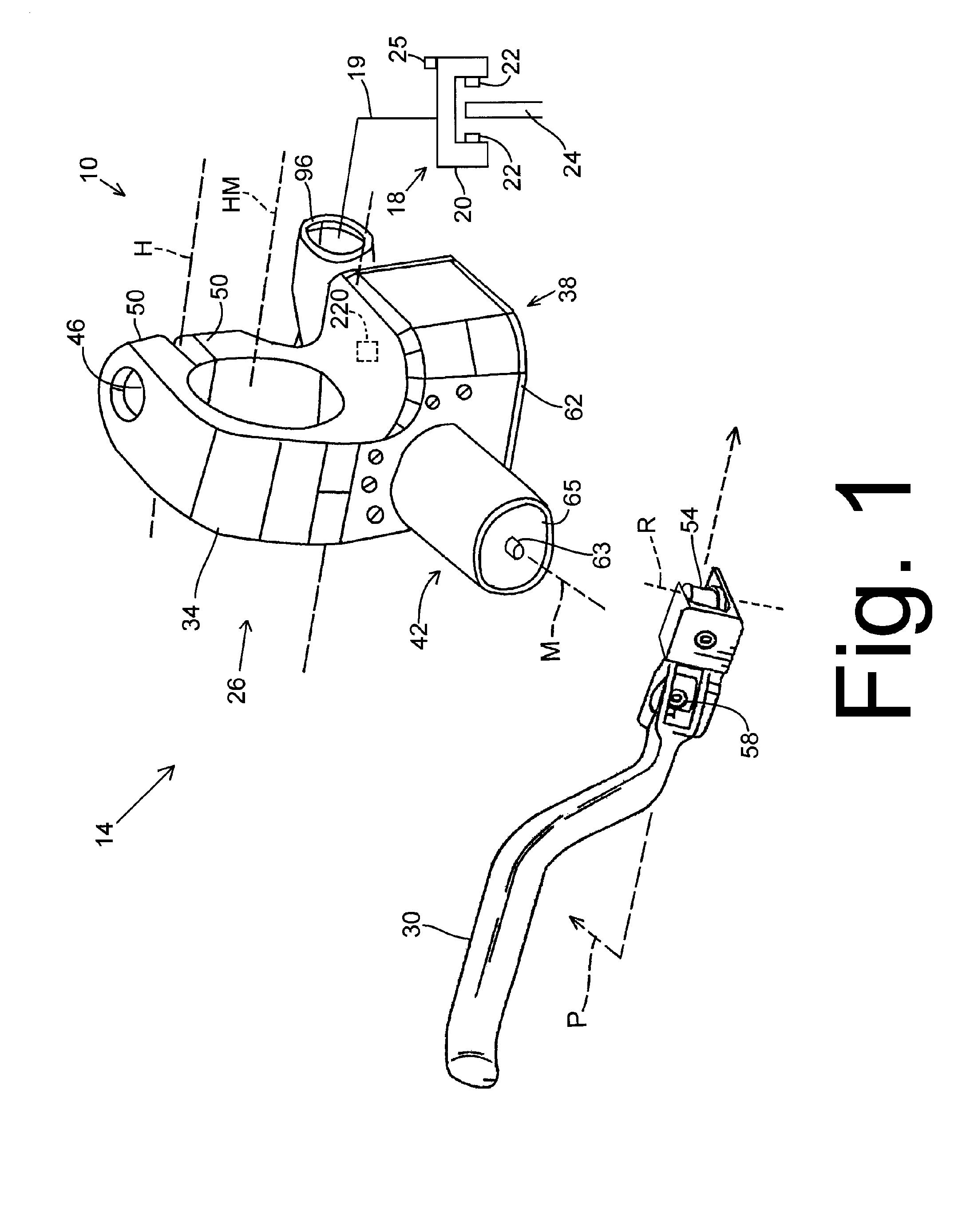

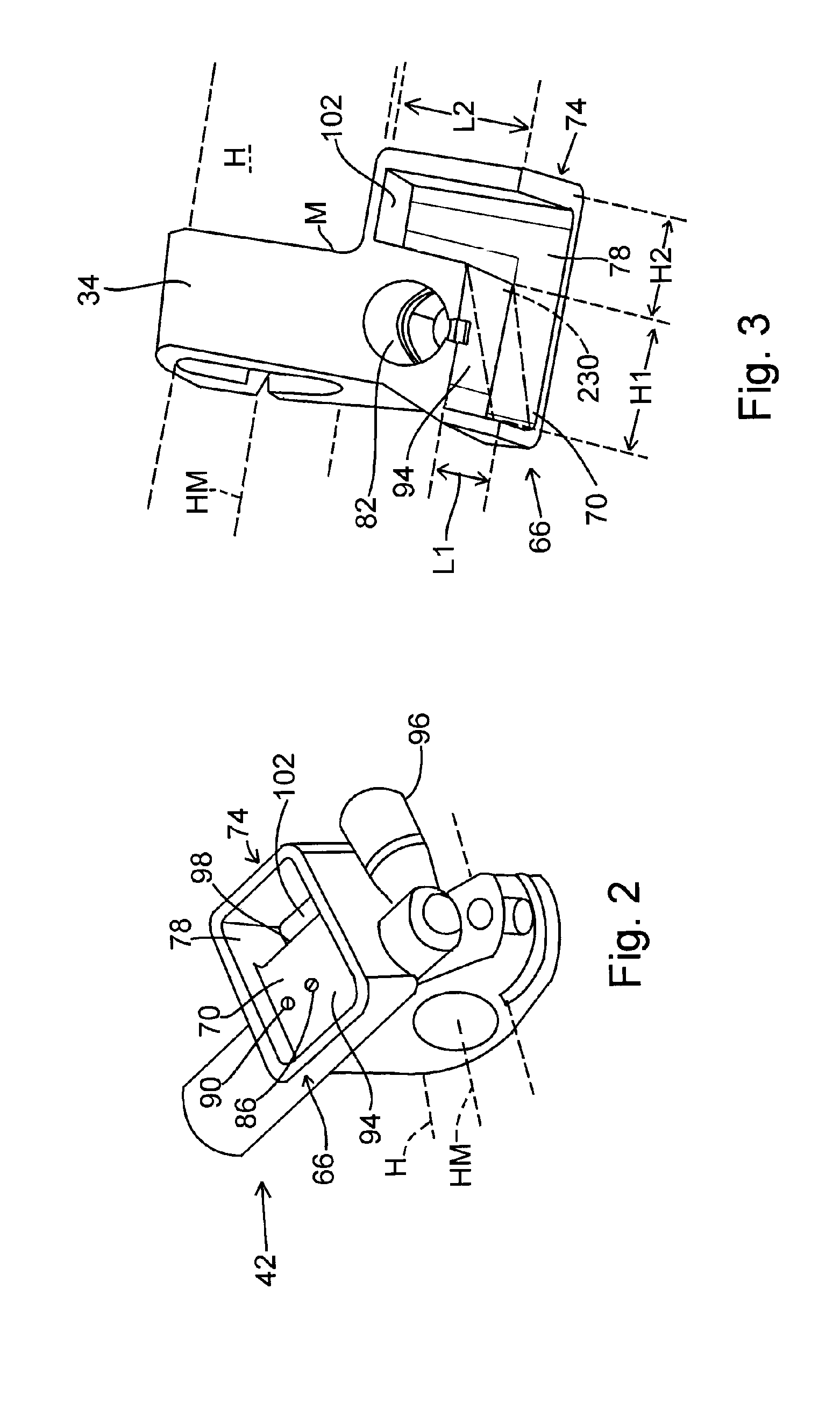

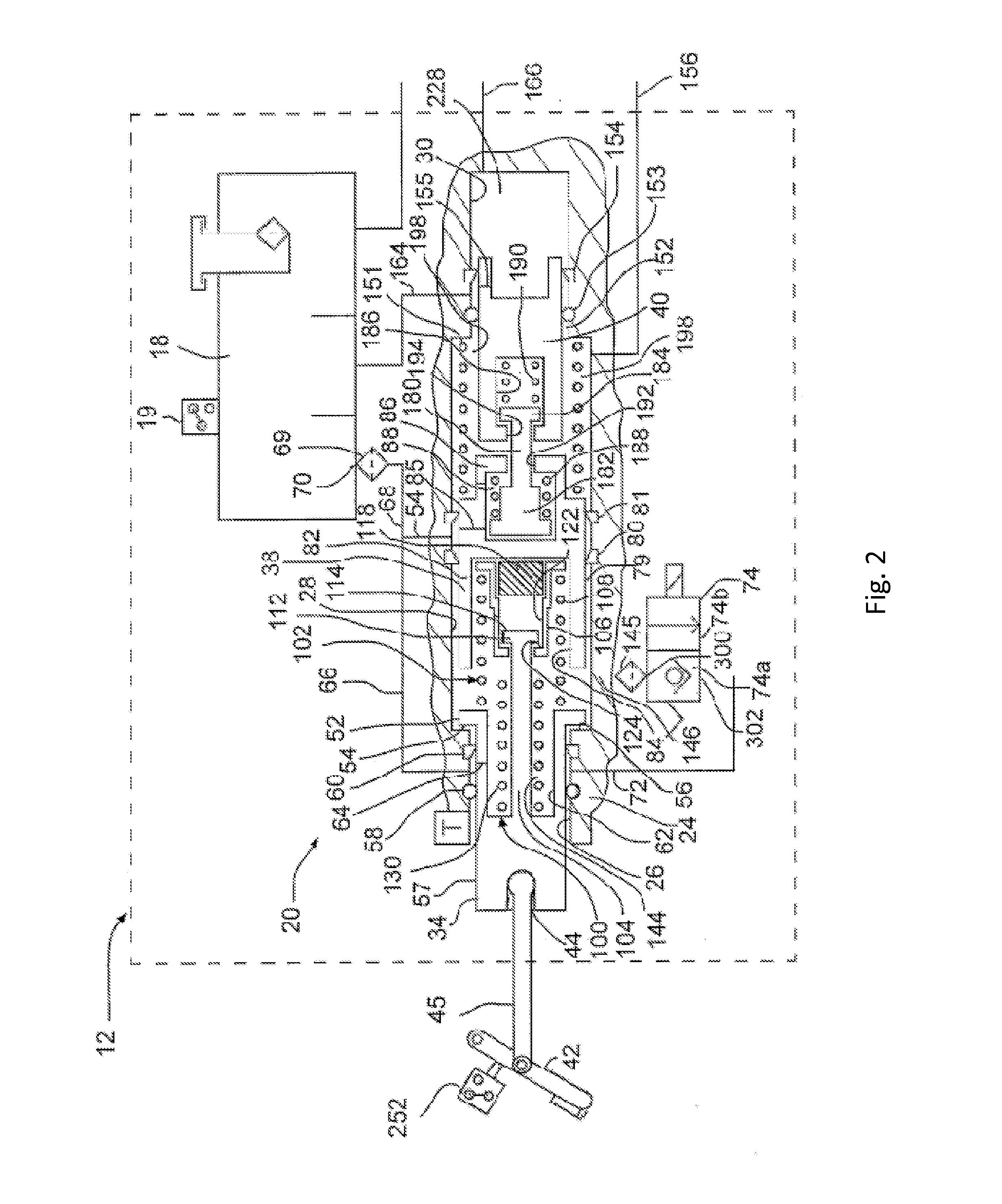

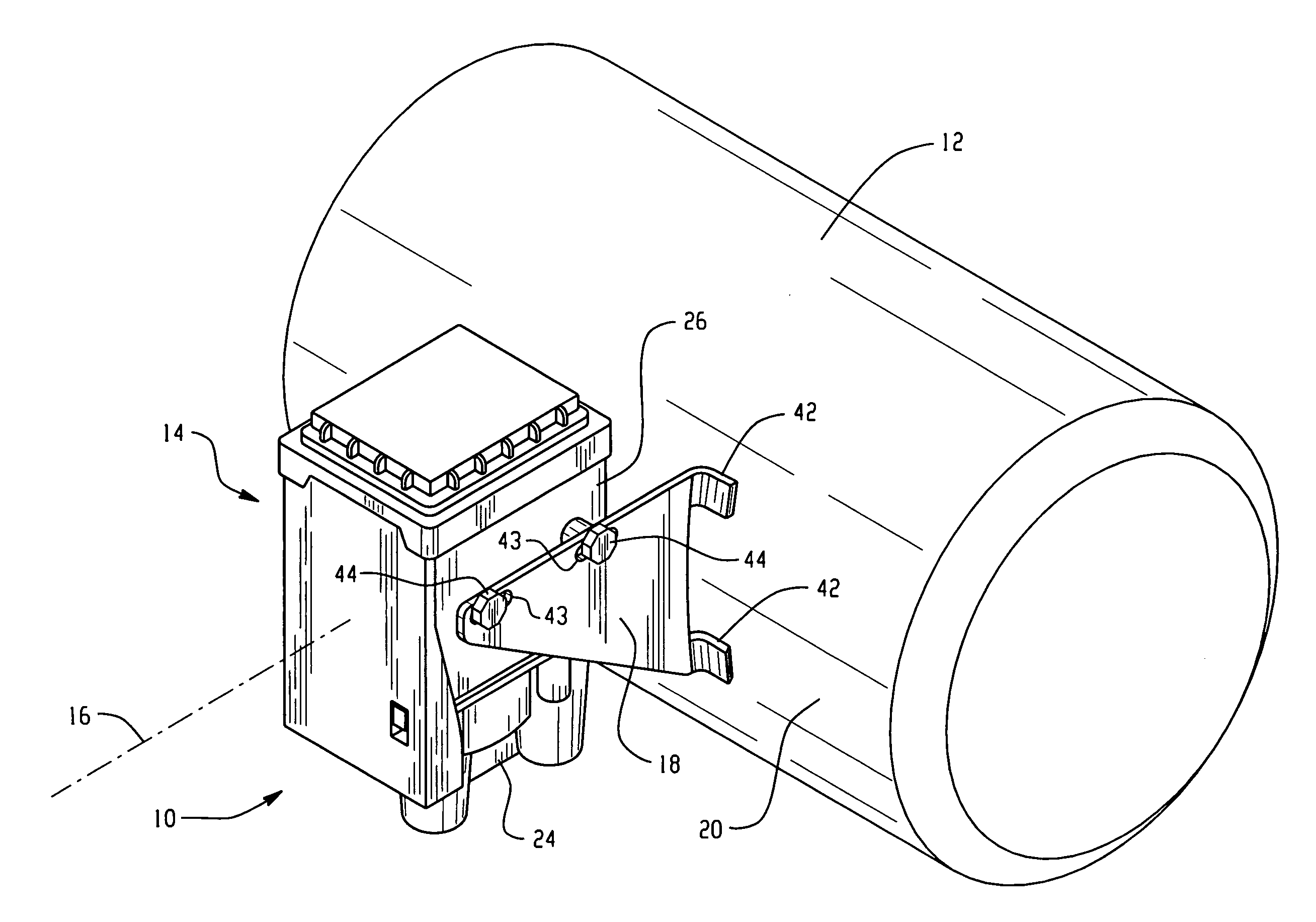

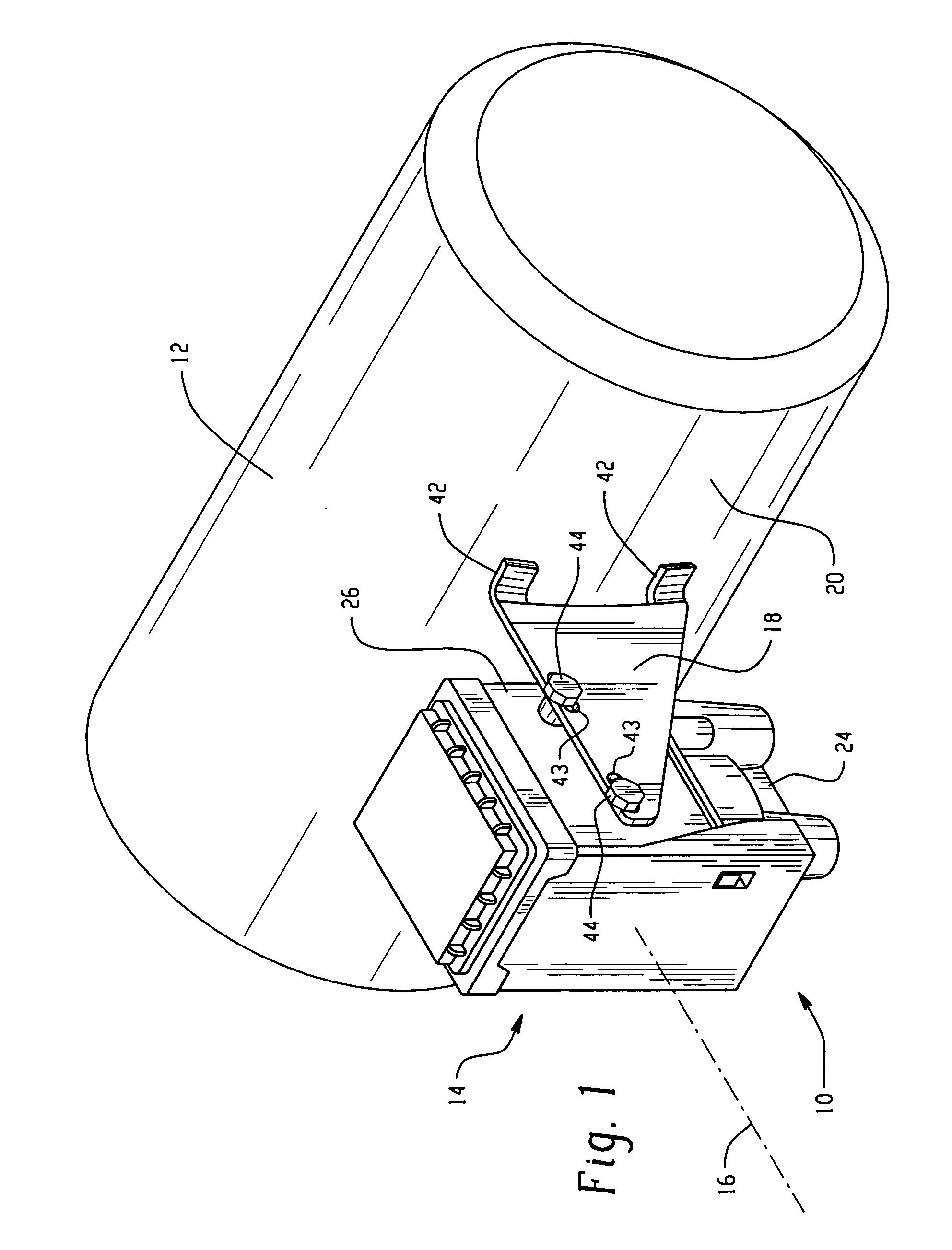

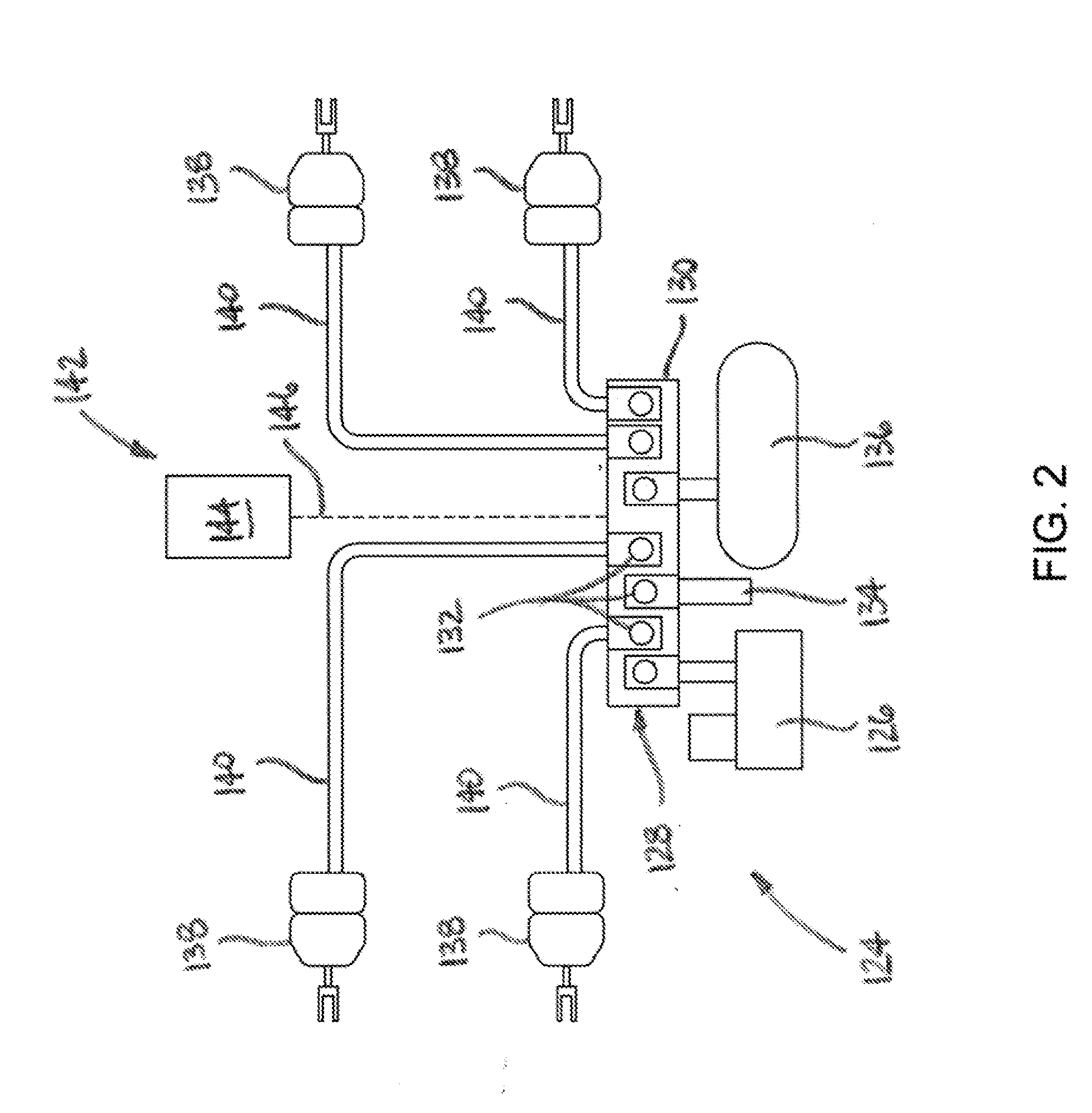

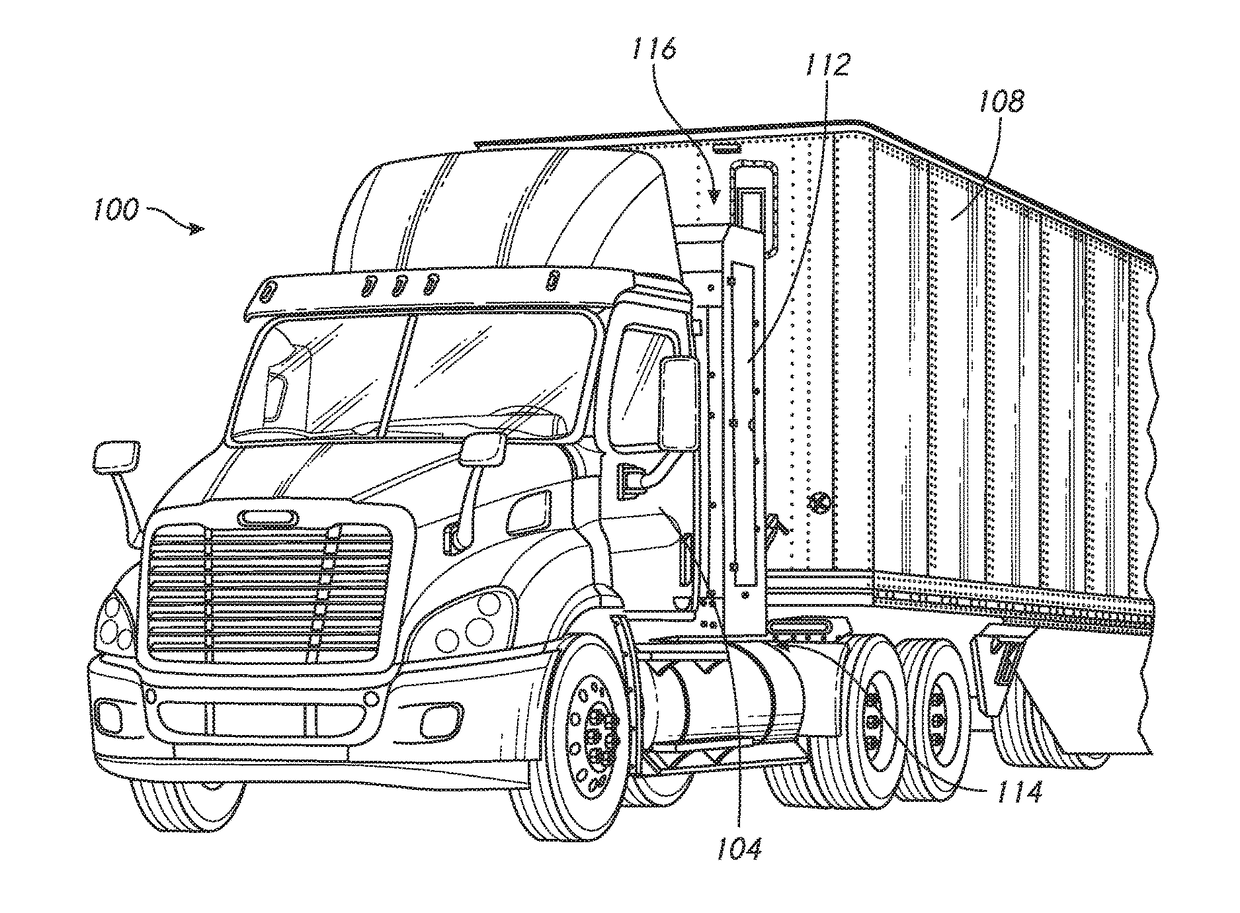

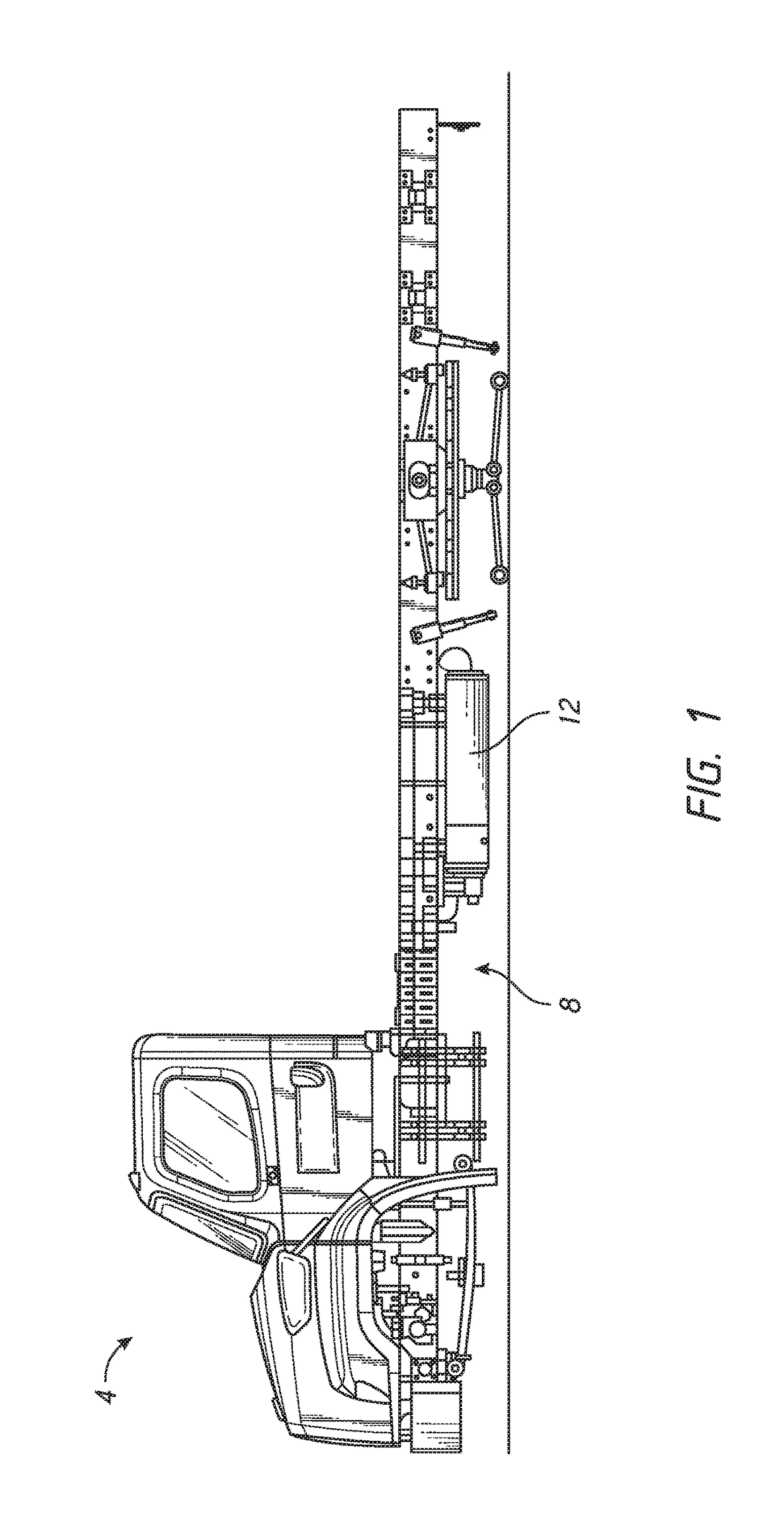

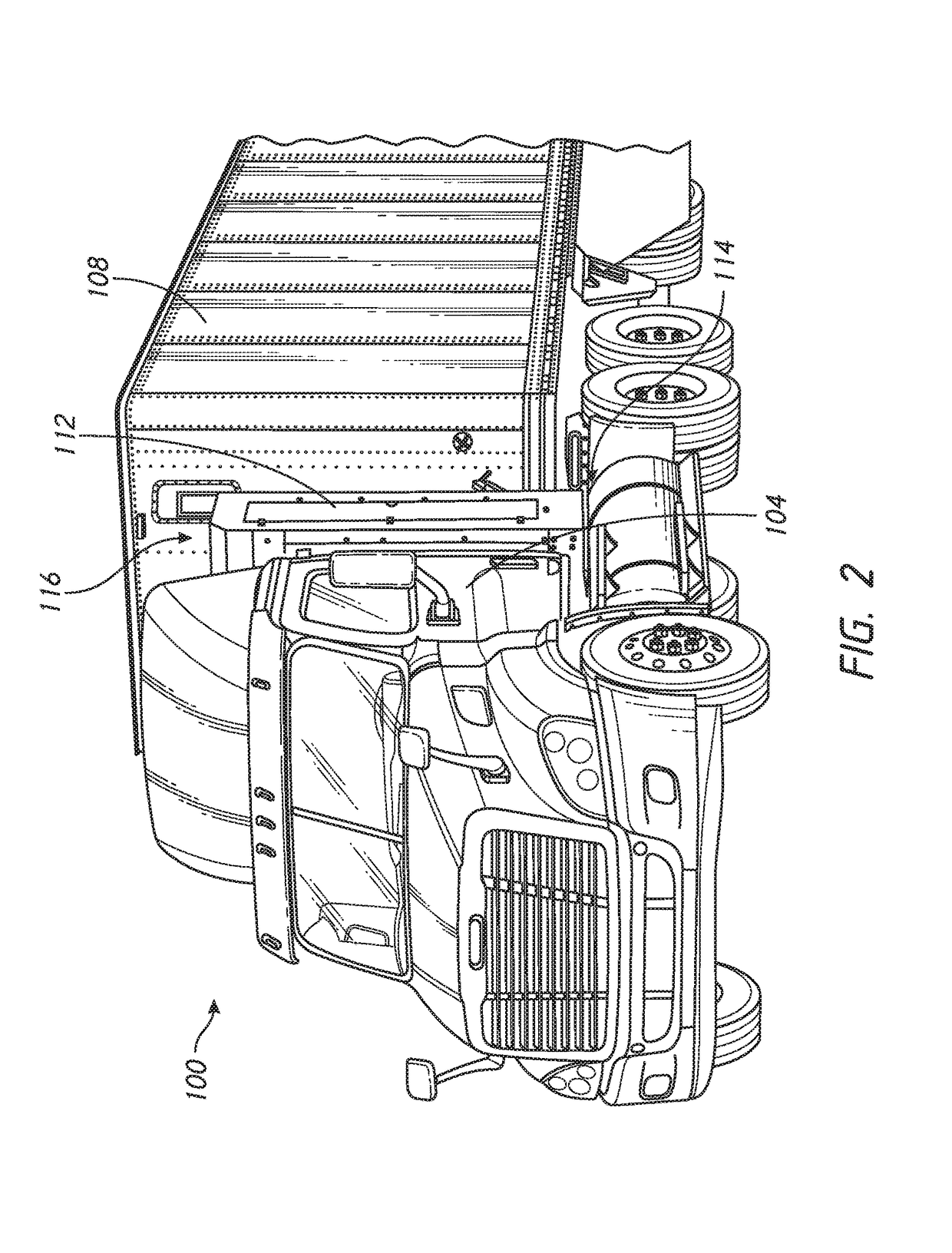

Method and apparatus for positioning a reservoir-mounted component

InactiveUS20080030072A1Precise positioningBraking action transmissionReservoir arrangementsRelative motionEngineering

An improved configuration for a vehicle system having a brake system component mounted to an air reservoir and an apparatus for positioning or leveling the brake system component relative to a reference point. The apparatus may include a first end portion having one or more contact points for engaging the reservoir along a curved surface and a second end portion positioned proximate to the component. The apparatus being adapted resist relative movement between the component and the reservoir.

Owner:BENDIX COMML VEHICLE SYST LLC

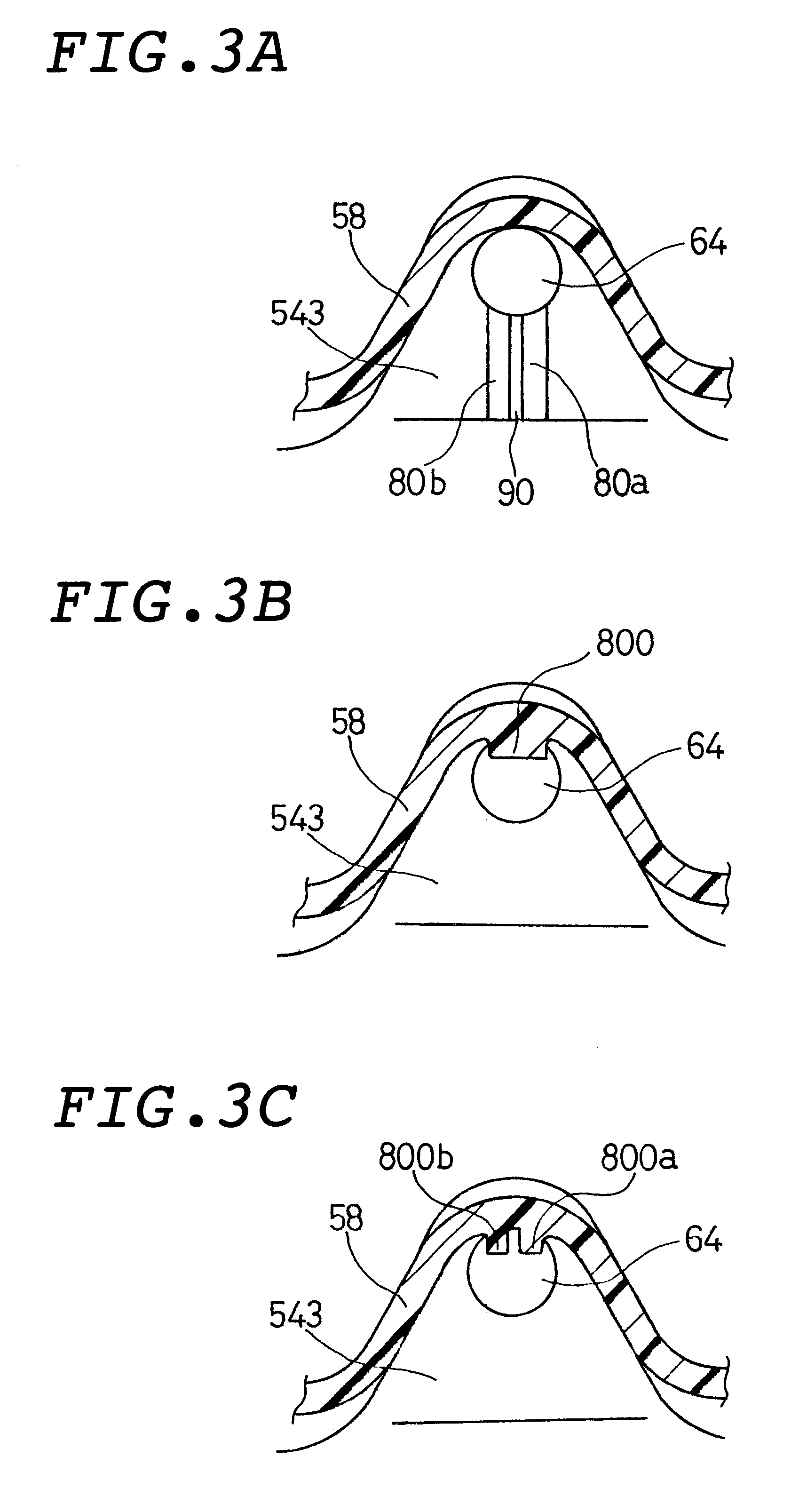

Breather with independent inlet/outlet flow paths

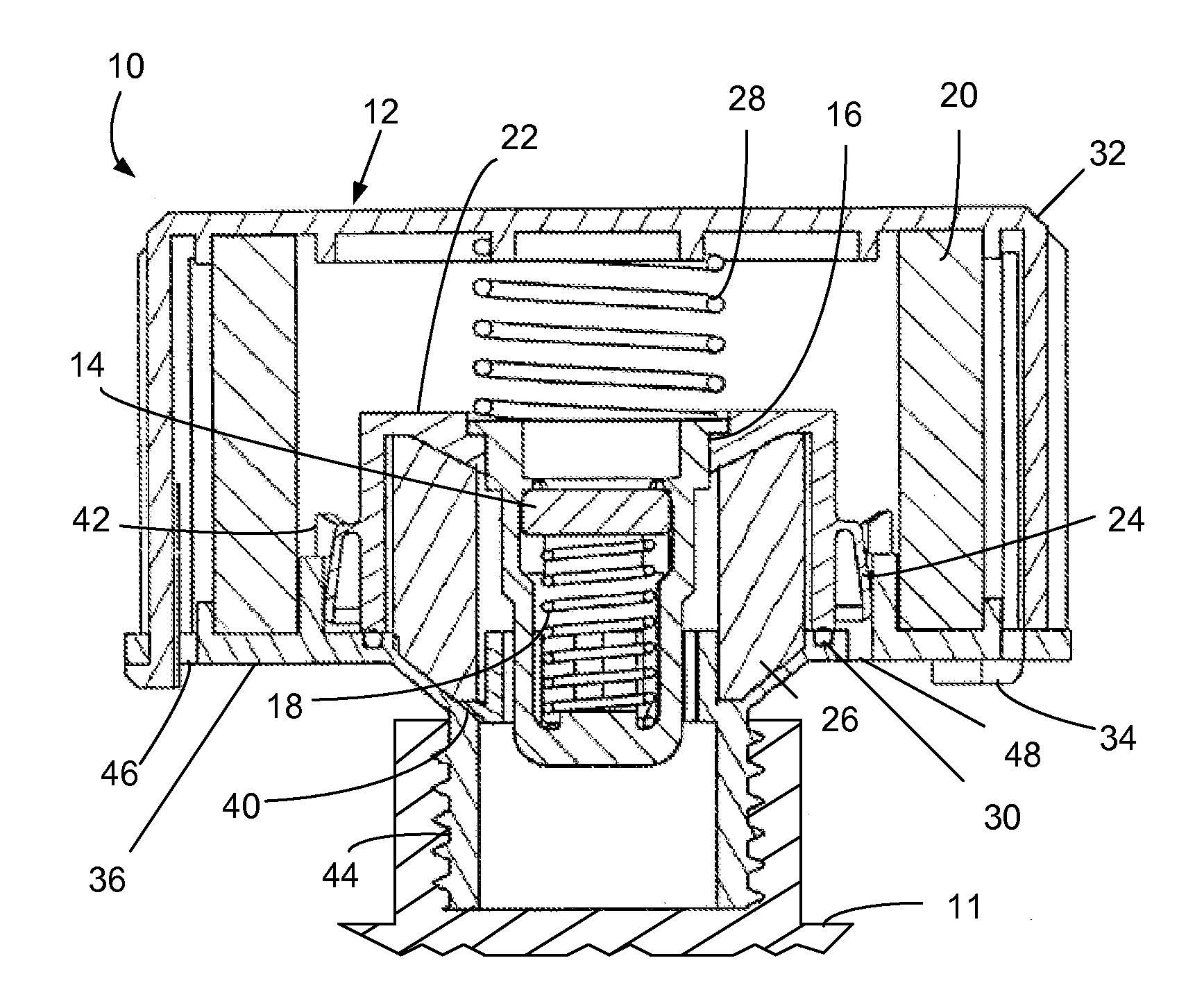

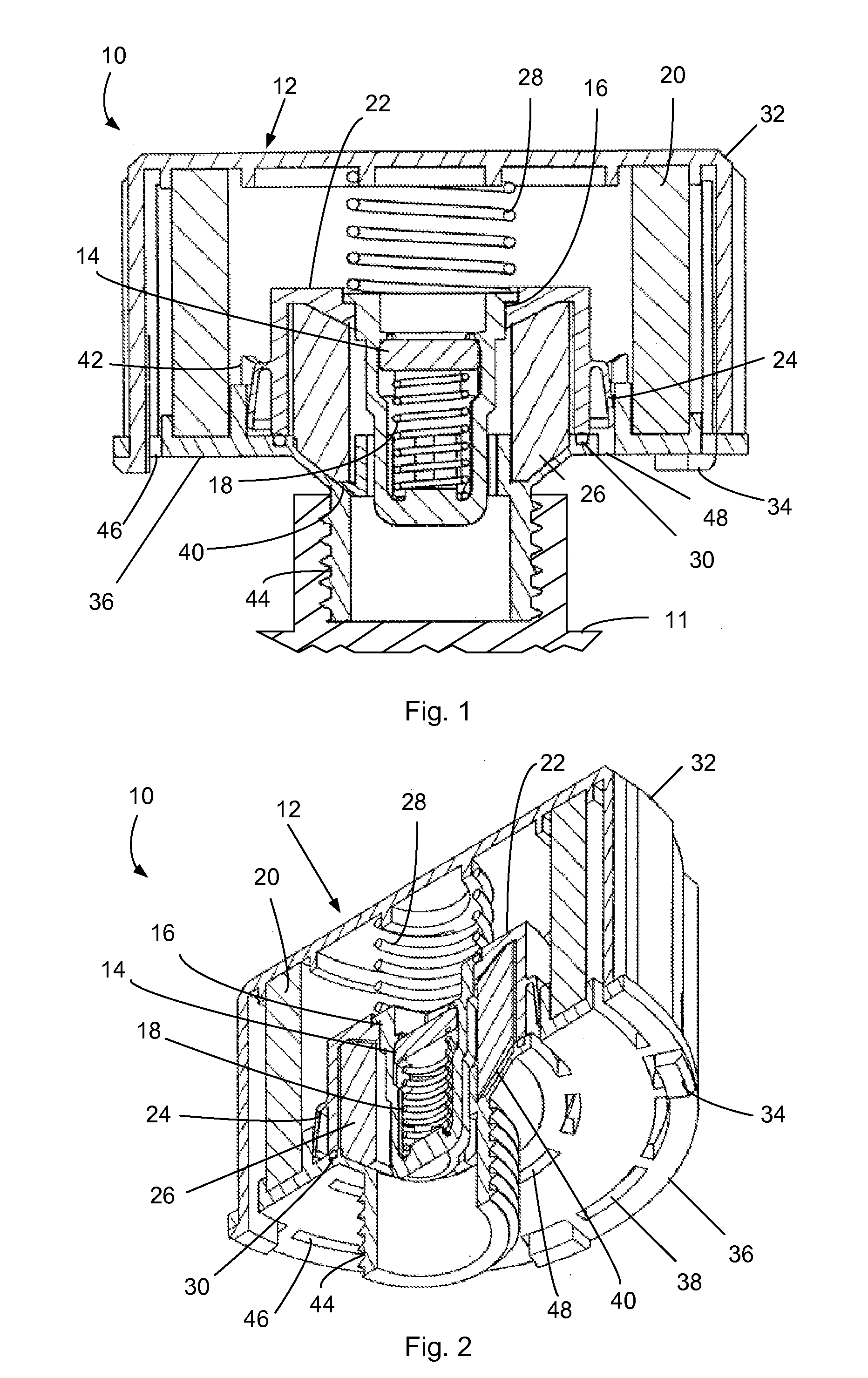

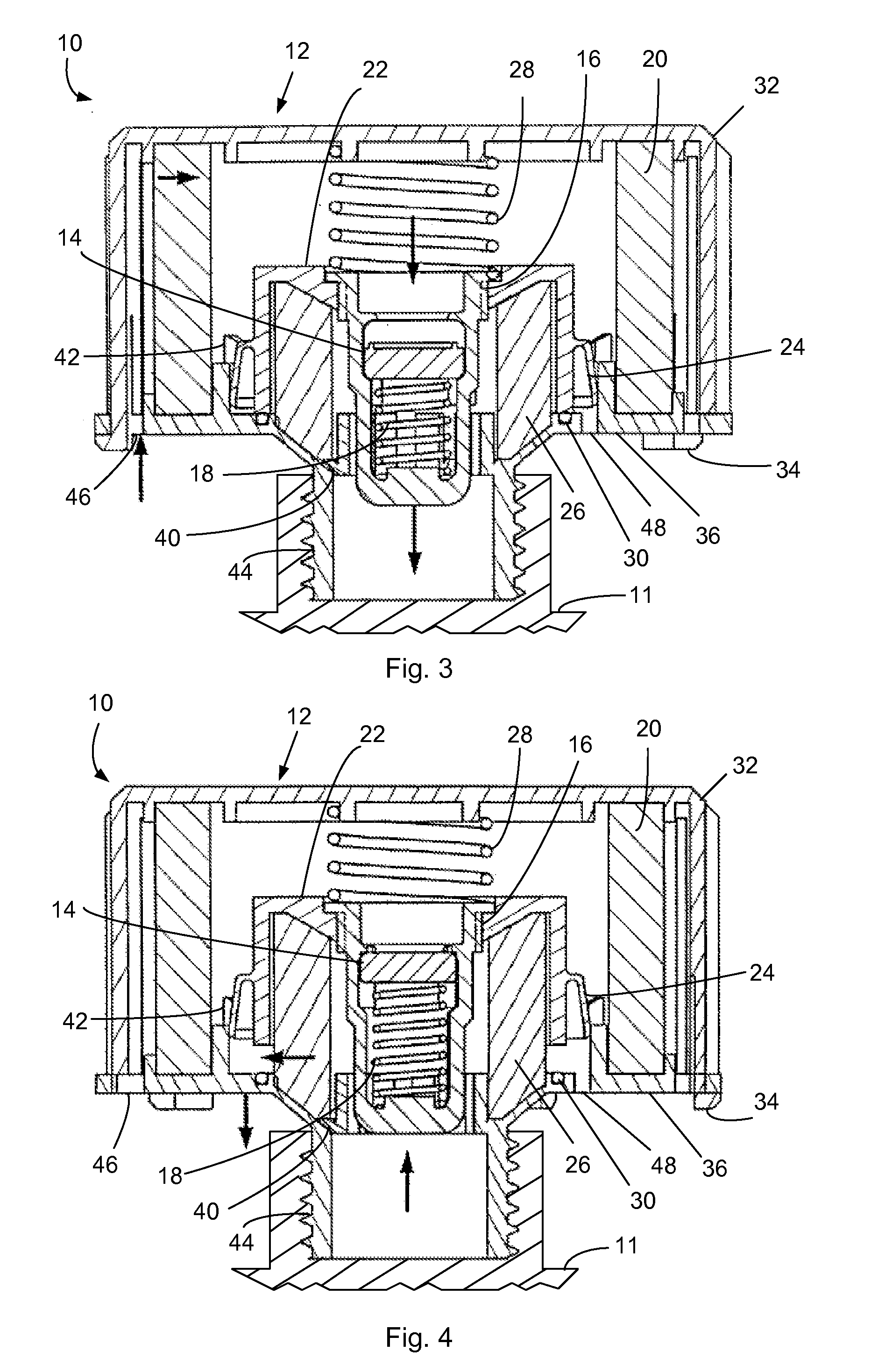

ActiveUS20110067392A1Improve protectionImprove filtering effectRotary clutchesTelemotorsBreatherEngineering

The present invention provides an apparatus and method for filtering fluid in a breather assembly and providing uncontaminated fluid to a reservoir. The breather allows in-take fluid traveling through a first flow path to be filtered before entering the reservoir through a first directional valve. The breather also allows exhaust fluid traveling through a second flow path, separate from the first flow path, to exit through a second directional valve.

Owner:PARKER INTANGIBLES LLC

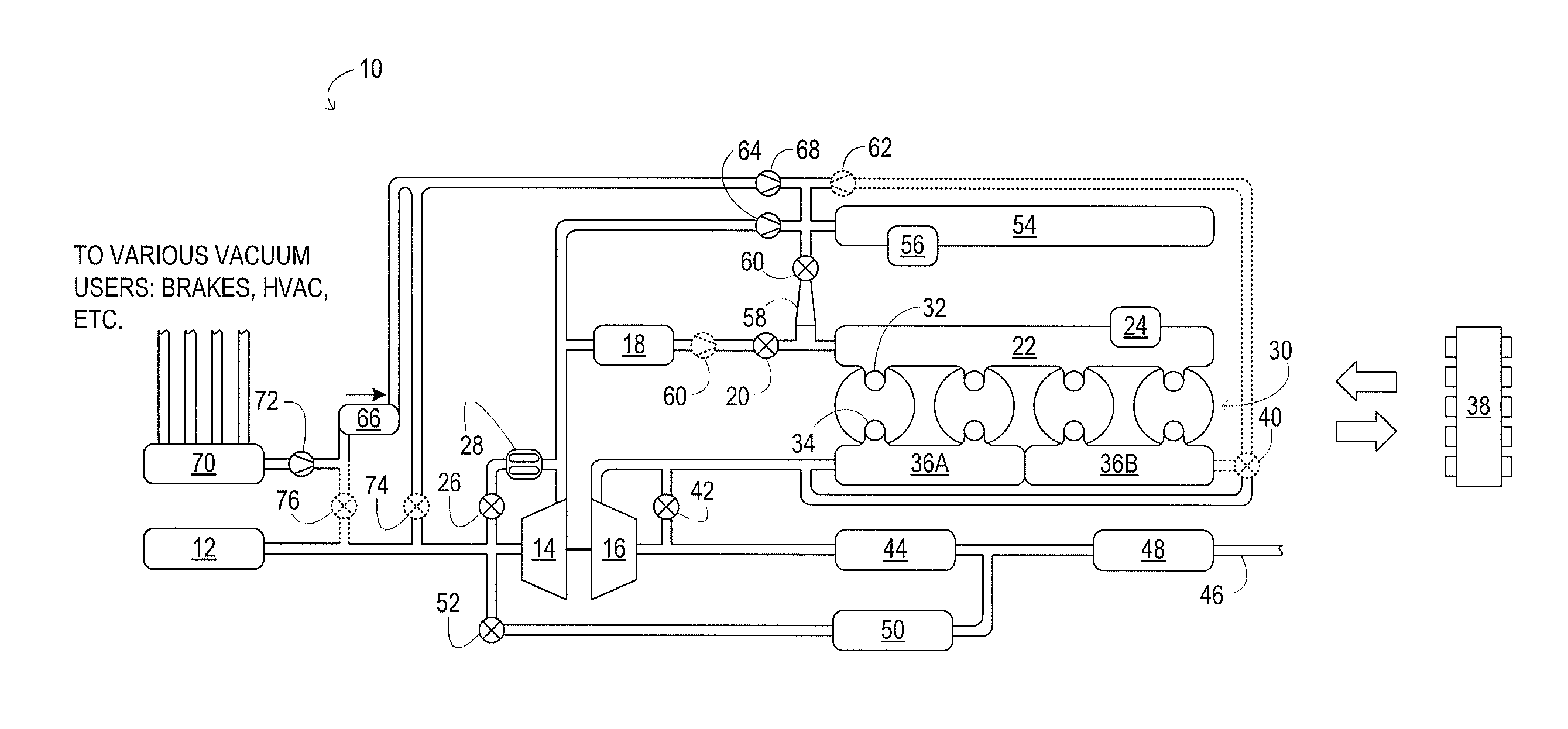

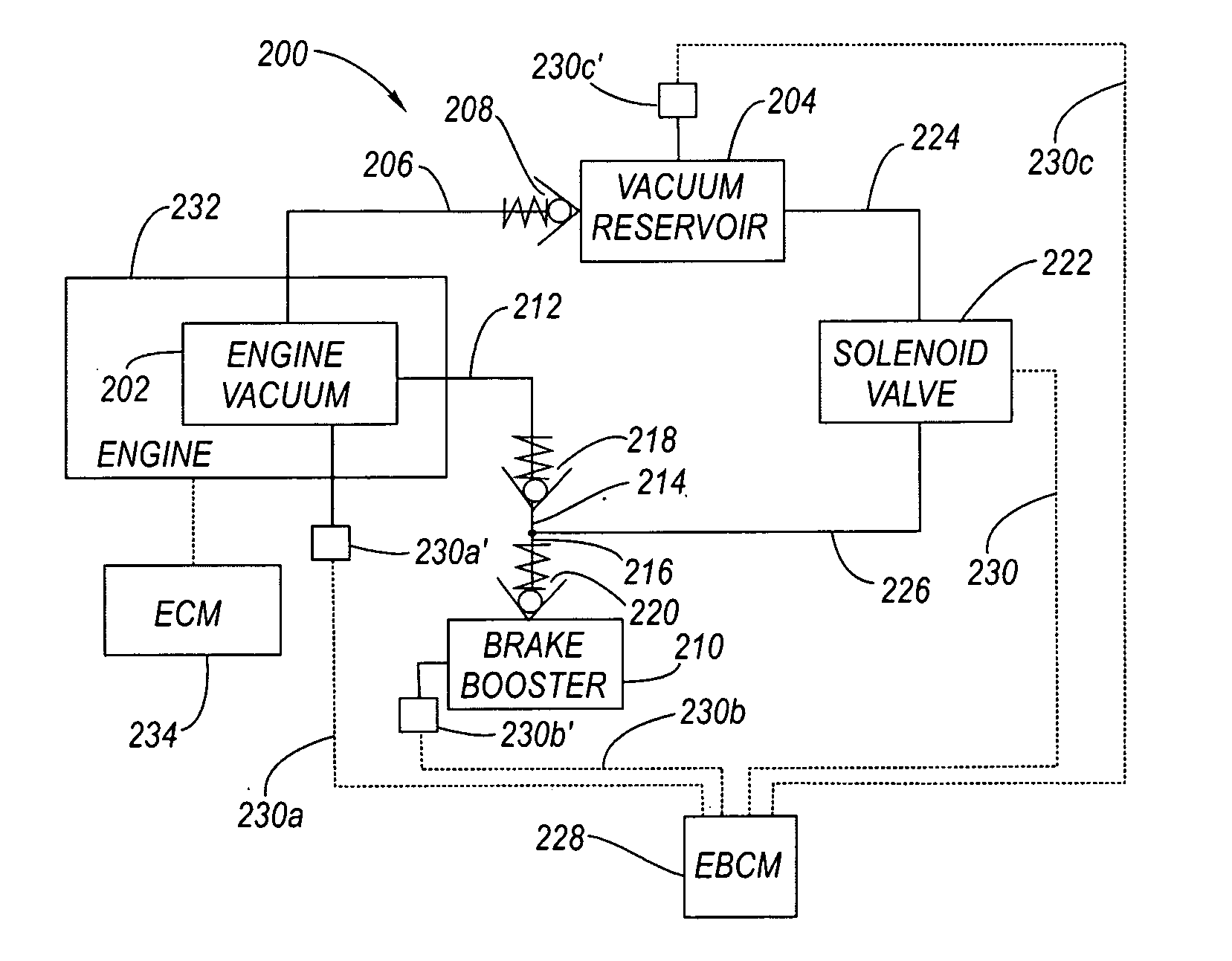

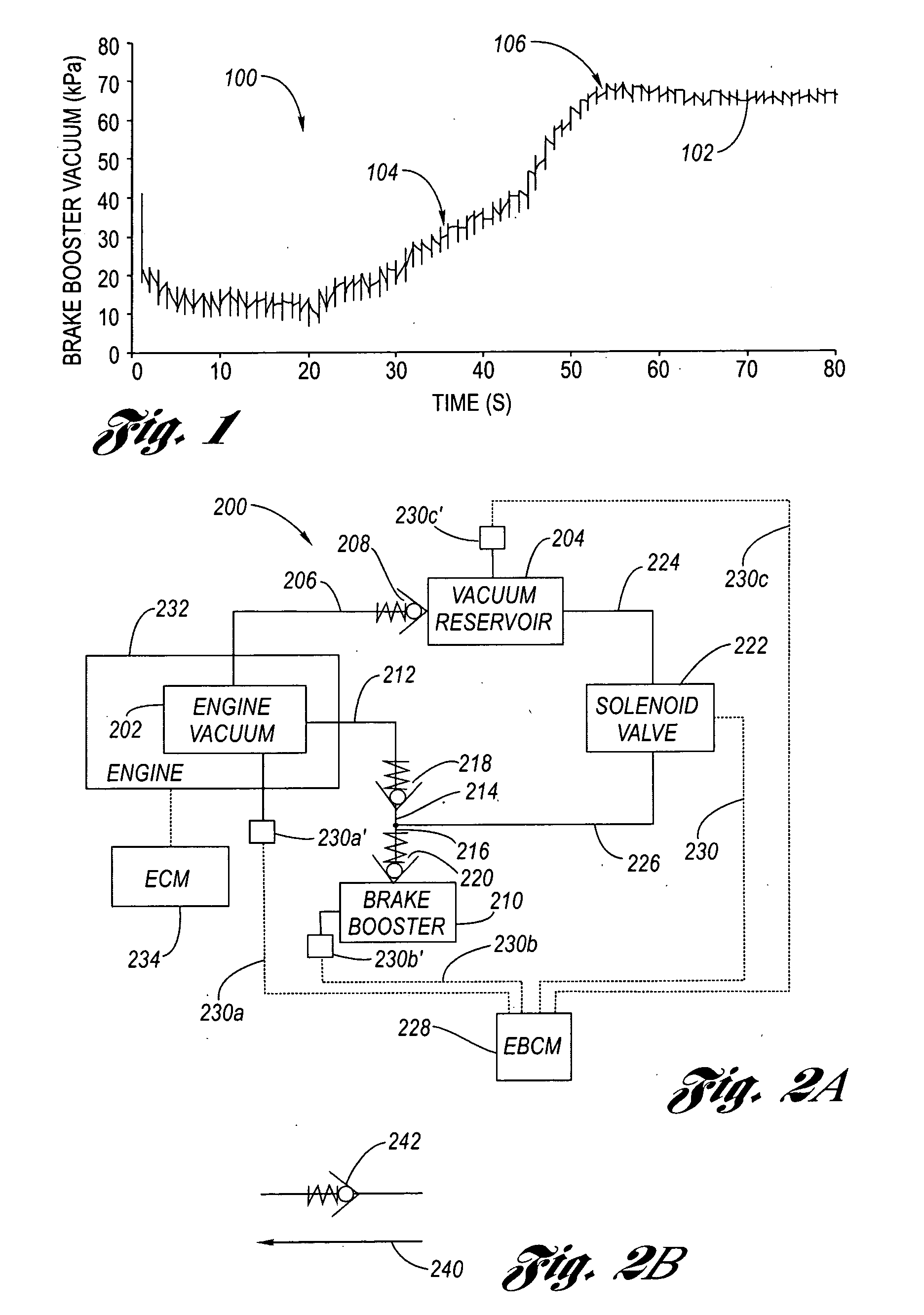

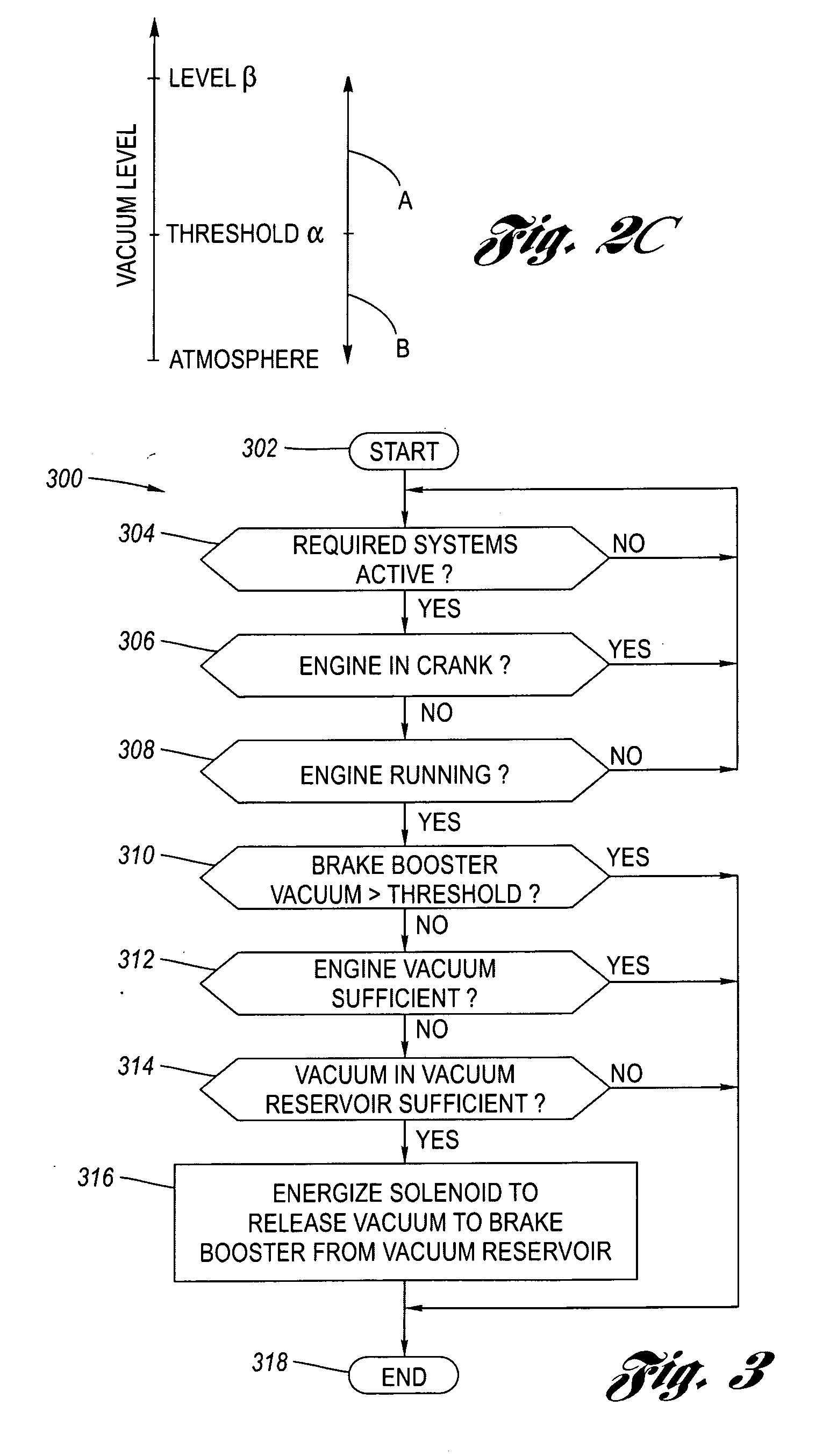

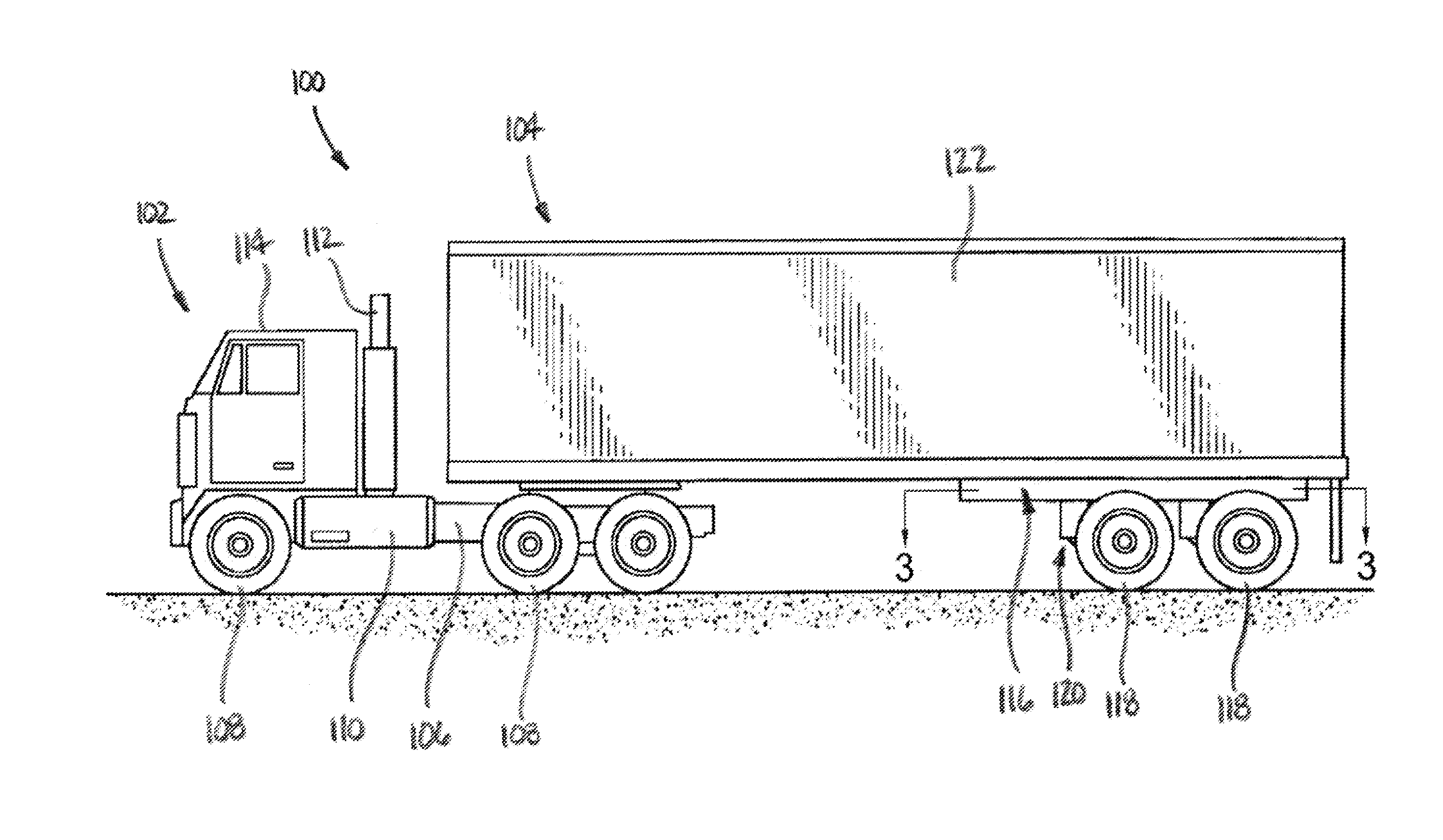

Enhanced Brake Booster Vacuum Support

InactiveUS20100193311A1Mitigate less than optimal brake pedal performanceEnhance brake booster vacuumBraking action transmissionServomotor componentsMobile vehicleDriver/operator

An apparatus and method for providing enhanced vacuum to a brake booster of a braking system under certain operational conditions. Vacuum is stored in a reservoir and is controllably released to the brake booster to provide a brake booster vacuum level of at least a predetermined vacuum level threshold in order to avoid brake pedal performance issues being perceived by the driver of motor vehicles utilizing engines utilizing a supplemental brake assist system under conditions where the brake booster vacuum level is less than the predetermined vacuum level threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pressurized gas reservoirs including an elastomeric wall

A pressurizable gas reservoir can include a first end member and a second end member that is disposed in longitudinally-spaced relation to the first end member. A flexible reservoir member can extend between opposing first and second ends. The first end secured to the first end member and the second end secured to the second end member. The flexible reservoir member at least partially defines a reservoir chamber between the first and second end members that is capable of storing a quantity of pressurized gas for an extended duration of time. The first and second end members can be maintained in substantially-fixed axial position relative to one another. A suspension system including such a pressurized gas reservoir and a method of assembly are also included.

Owner:FIRESTONE IND PROD COMPANY

Stored Compressed Air Management and Flow Control for Improved Engine Performance

InactiveUS20110253098A1Increase the effective amountIncrease flexibilityElectrical controlNon-fuel substance addition to fuelCombustion chamberInlet manifold

A method for providing air to a combustion chamber of an engine, the engine including a compressor and a boost tank selectably coupled to an intake manifold. The method comprises admitting air from the compressor to the intake manifold via a main throttle valve, storing some air from the compressor in a boost tank, and discharging some of the air stored in the boost tank to the intake manifold via an auxiliary throttle valve distinct from the main throttle valve.

Owner:FORD GLOBAL TECH LLC

Vehicle fluid handling systems

ActiveUS20170282710A1Easy to integrateContainer filling methodsGas handling applicationsEngineeringFluid system

A fluid system for a vehicle is provided. The fluid system is configured to couple to a chassis of the vehicle. A frame assembly of the fluid system is configured to couple with the chassis directly or with another component that is coupled, directly or indirectly, with the chassis. A cowling of the fluid system can enclose a fuel pressure vessel and an auxiliary fluid vessel. The auxiliary fluid vessel is configured to be placed in fluid communication with the component powered or operated by the fluid therein.

Owner:AGILITY FUEL SYST LLC

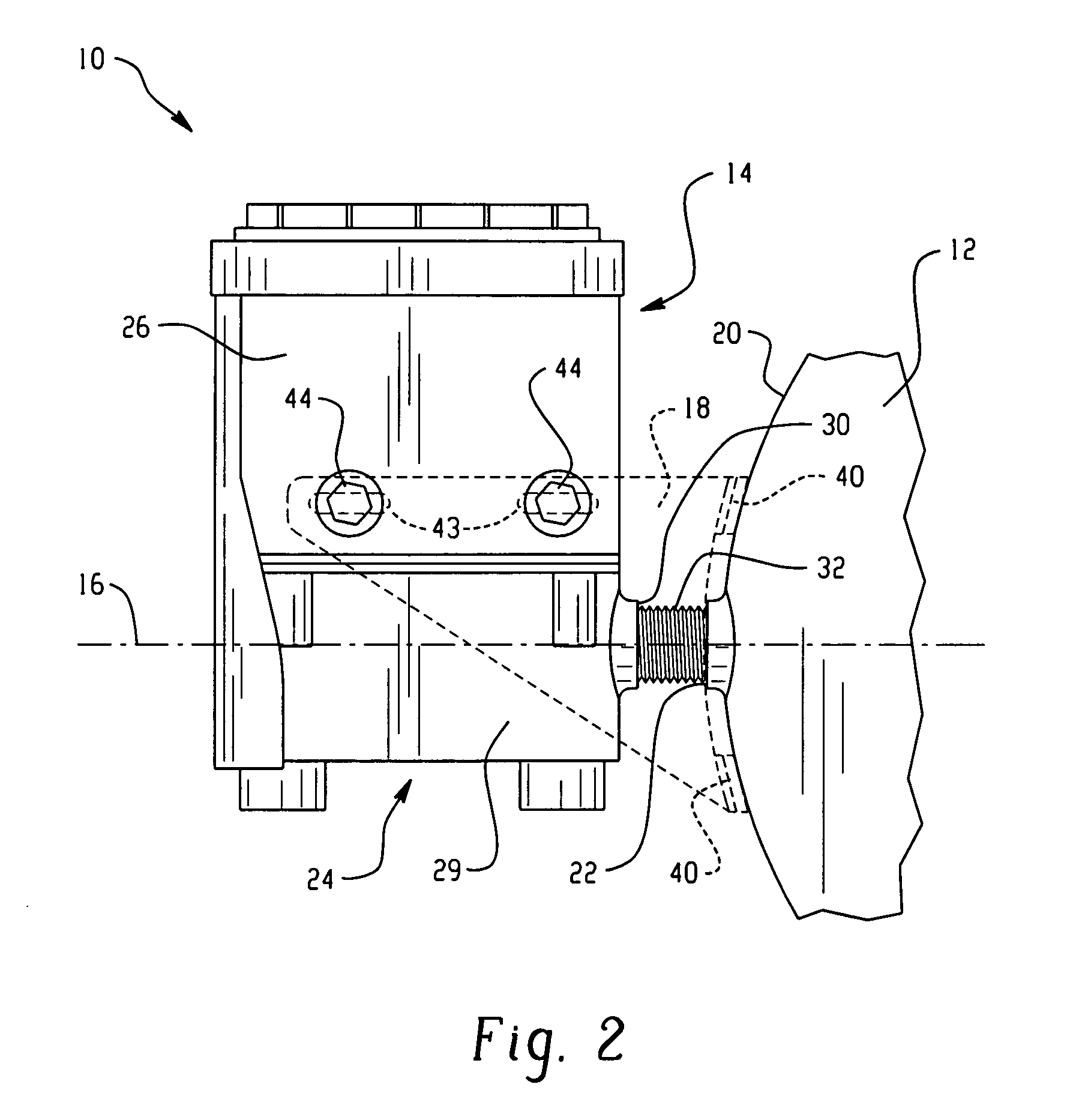

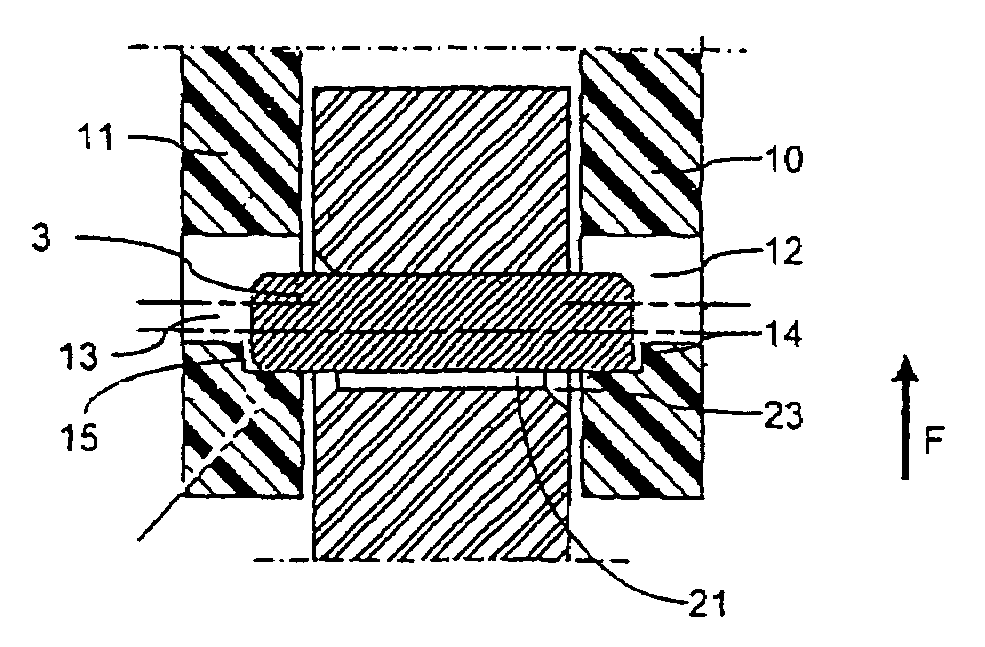

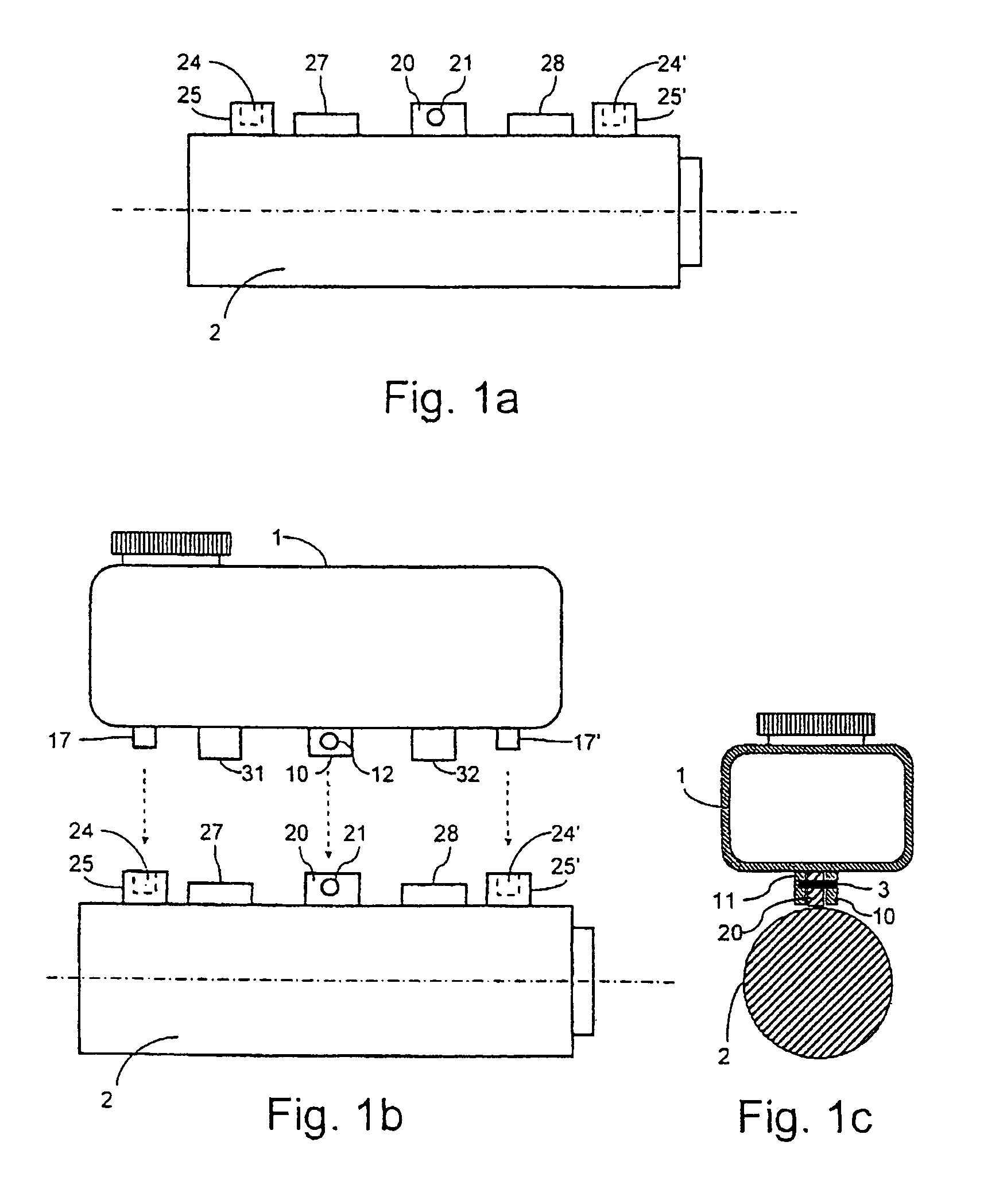

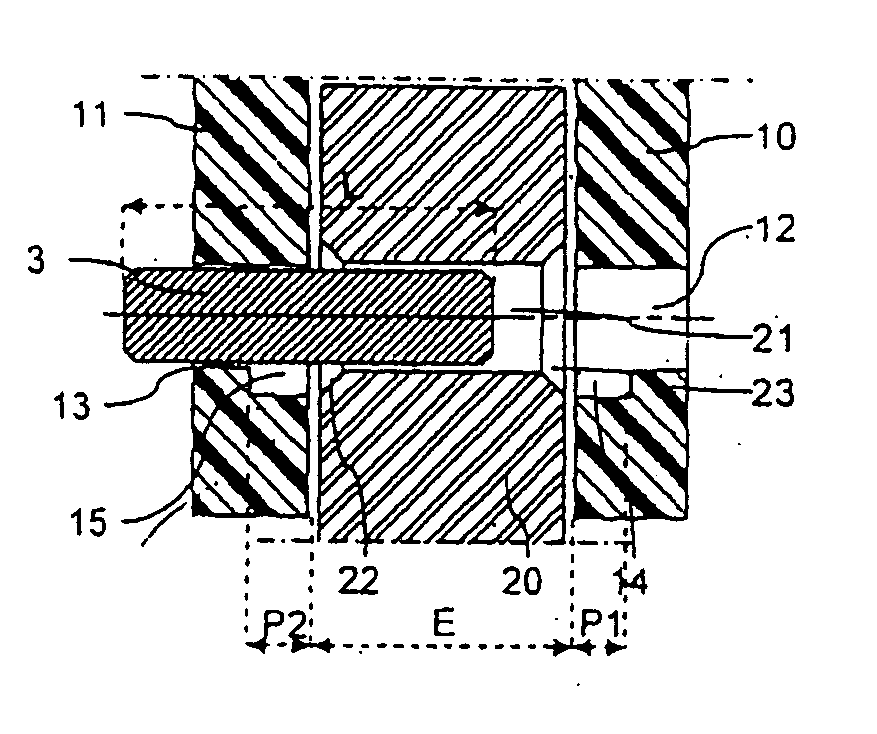

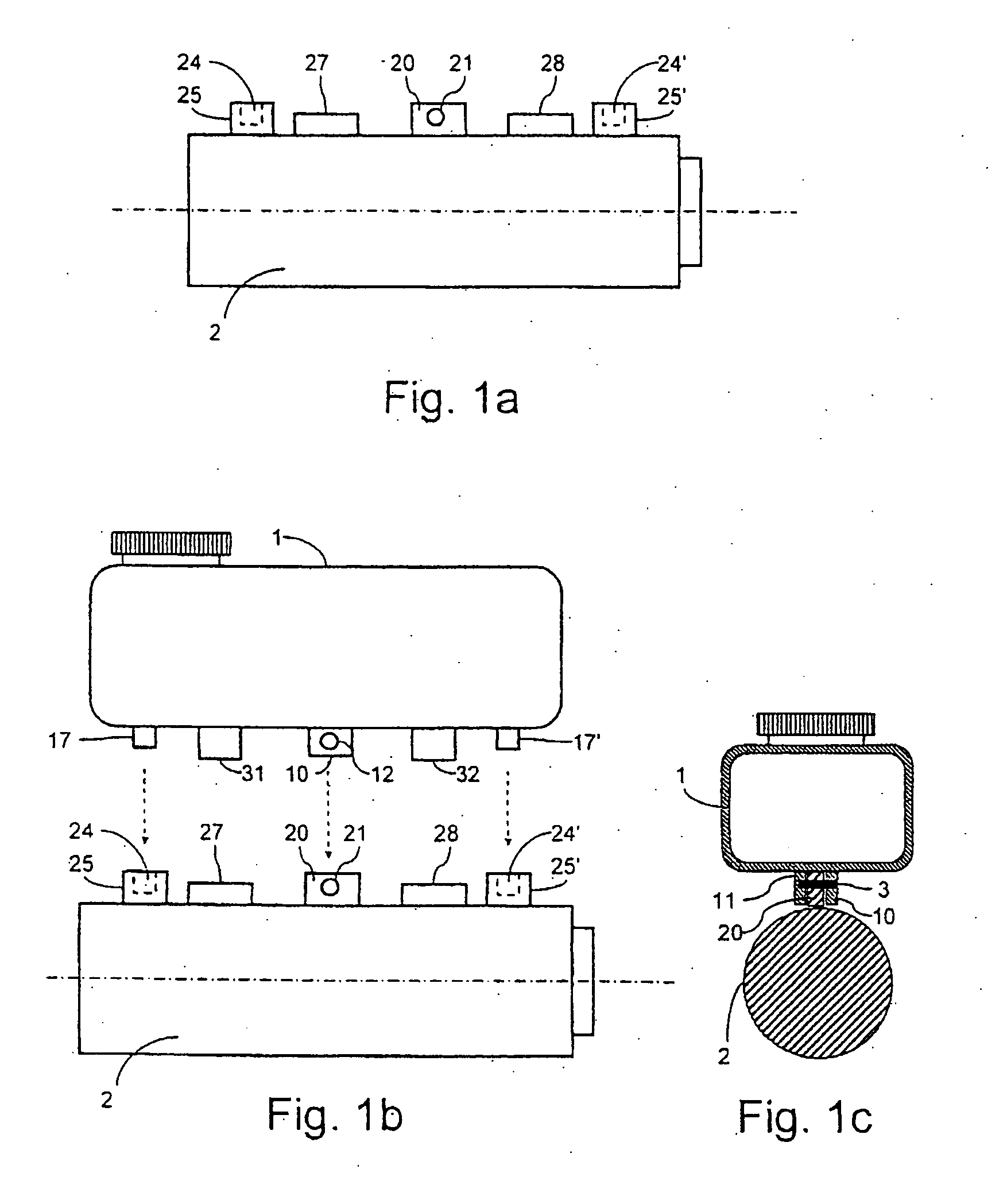

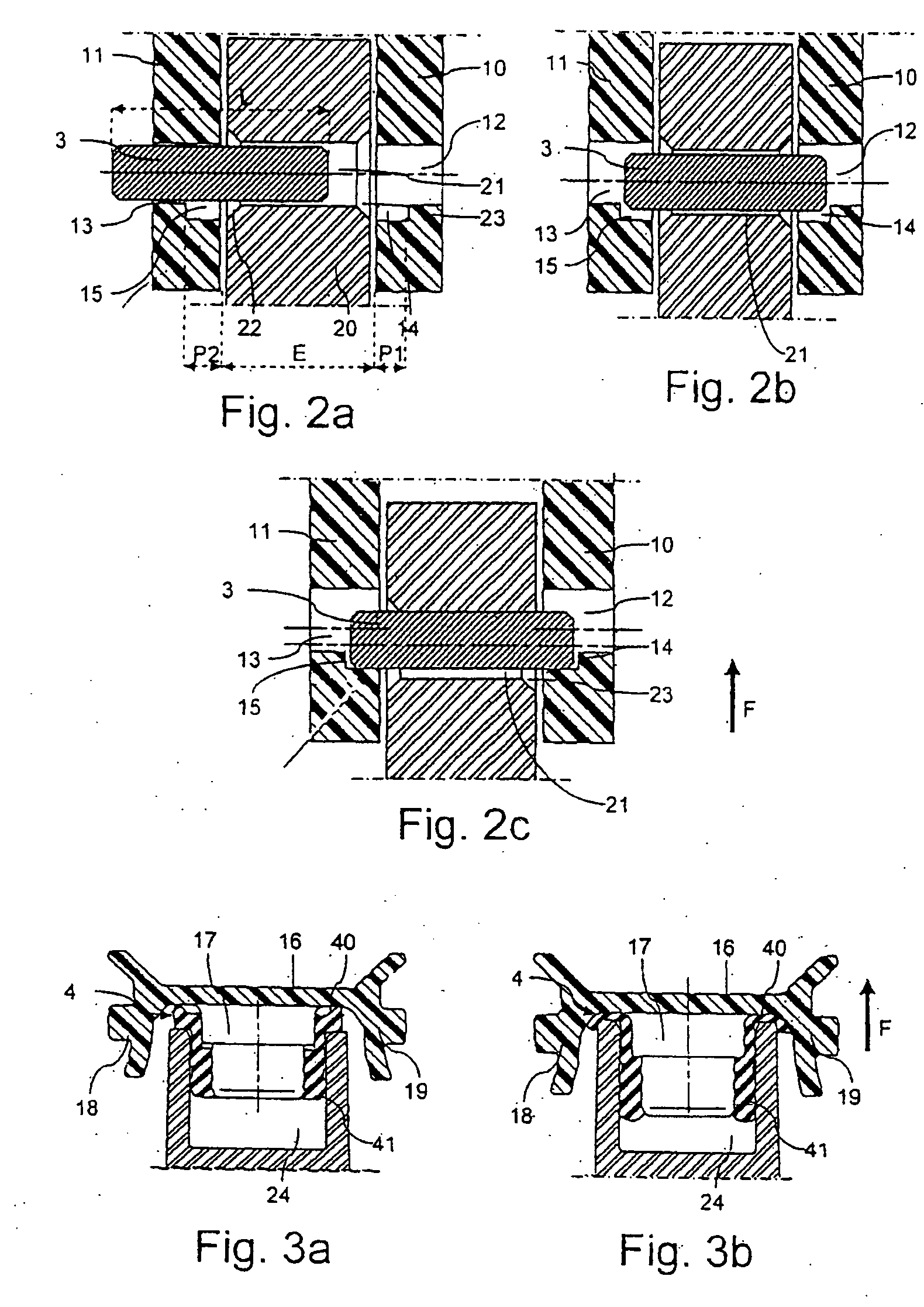

Fixing of a brake-fluid reservoir

ActiveUS7441408B2Facilitates fitting and removingRotary clutchesTelemotorsMaster cylinderEngineering

The invention relates to a brake fluid reservoir comprising at least two lateral mounting lugs (10, 11) designed to be placed either side of a central mounting lug (20) of a brake master cylinder. Collinear holes (12, 13, 21) traverse these lugs and are designed to receive a mounting pin (3). The said lugs include at least one device for the axial immobilization of the mounting pin (3).

Owner:ROBERT BOSCH GMBH

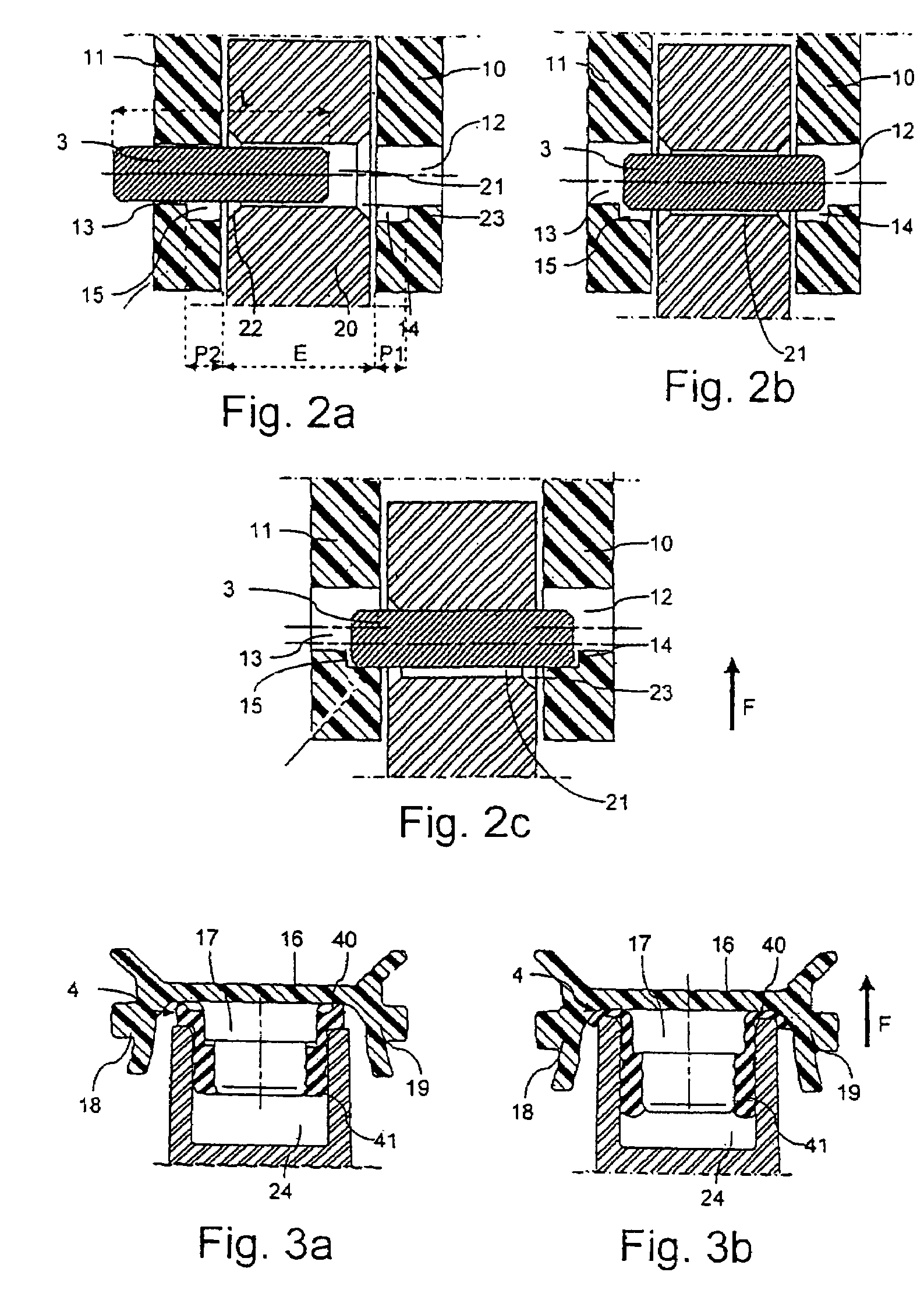

Brake system of empty container forklift

The invention relates to a brake system of an empty container forklift. The brake system of the empty container forklift comprises a braking oil tank, a gear pump, a prefill valve, a reducing valve, a two-position three-way electromagnetic valve, a gearbox clutch, a first bag type accumulator, a right-foot brake valve, a left-foot brake valve, a shuttle valve, and a stopping brake valve block. A brake oil radiator, the brake oil tank, an overflow valve, a second bag type accumulator and a backpressure valve are additionally arranged in the system. Through adding of the brake oil radiator, the temperature of the whole brake system is effective controlled to be around 60 DEG C, and therefore a sealing part of the whole brake system is well protected. Through adding of the brake oil tank, hydraulic oil which is not suitable for brake friction is not applied to the brake system, and heavy-load wet-type axle brake liquid which is specially prepared is used, so that howling generated by a friction piece and a partition piece in a drive axle is reduced in the process of brake, the whole vehicle brake distance is shortened, and reliability of the whole brake system is improved.

Owner:ANHUI HELI CO LTD

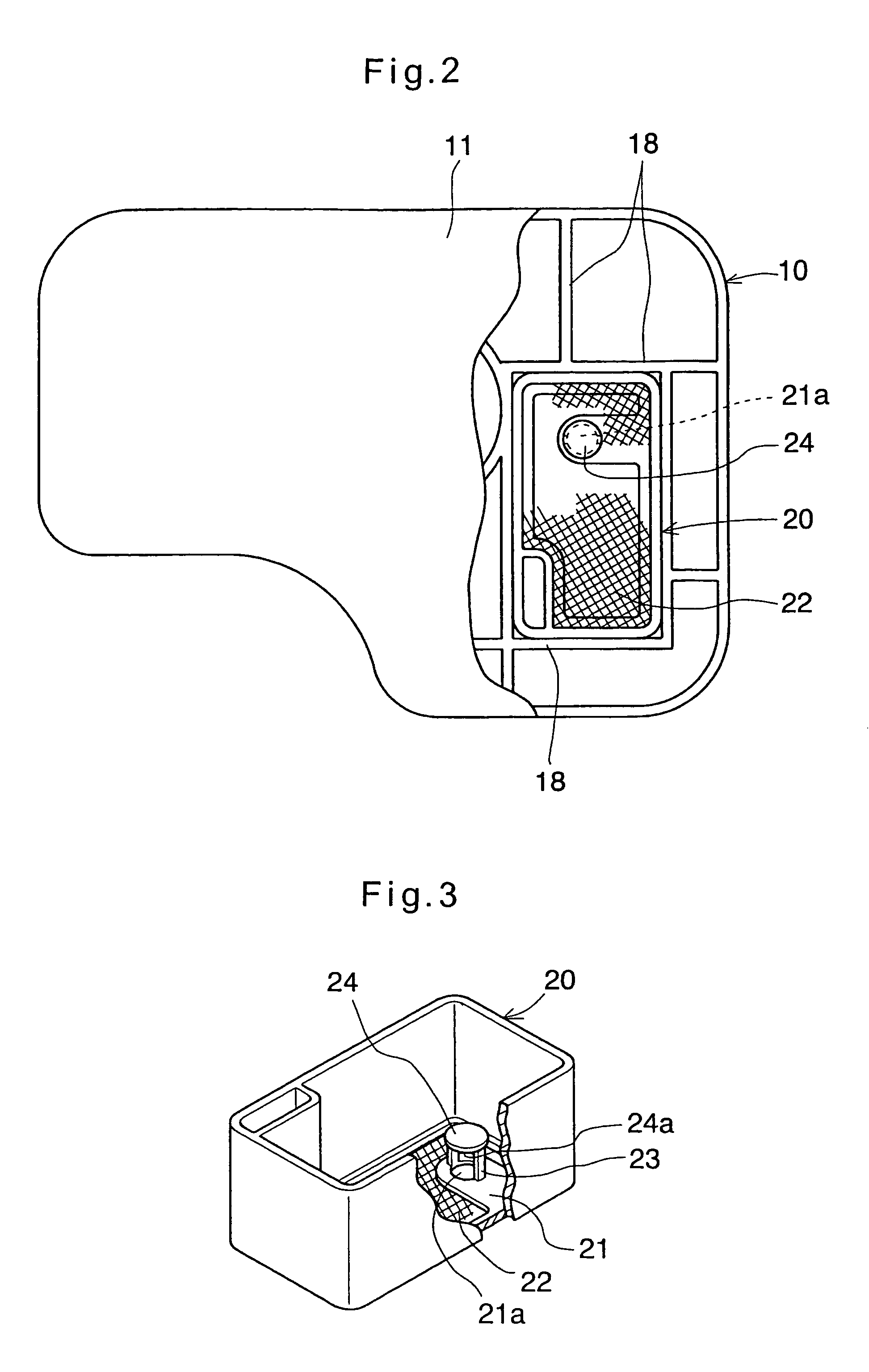

Reservoir tank for vehicle brake system

A reservoir tank has an inlet / outlet port communicating with a master cylinder, and a hydraulic fluid supply port provided directly opposite the inlet / outlet port. A tubular portion is provided on the inner surface of the tank. The tubular portion has an internal passage communicating with the inlet / outlet port and having a top opening. A box-shaped member has its bottom plate fitted on the tubular member. The bottom plate is formed of a filter material. A deflector plate is supported on legs extending upwardly form the bottom plate of the box member so as to be disposed right over the top opening of the tubular portion. The deflector plate deflects the flow of hydraulic fluid such that it will not be directed toward the hydraulic fluid supply port, thereby preventing hydraulic fluid from being blown out through the hydraulic fluid supply port even if this port is open.

Owner:ADVICS CO LTD

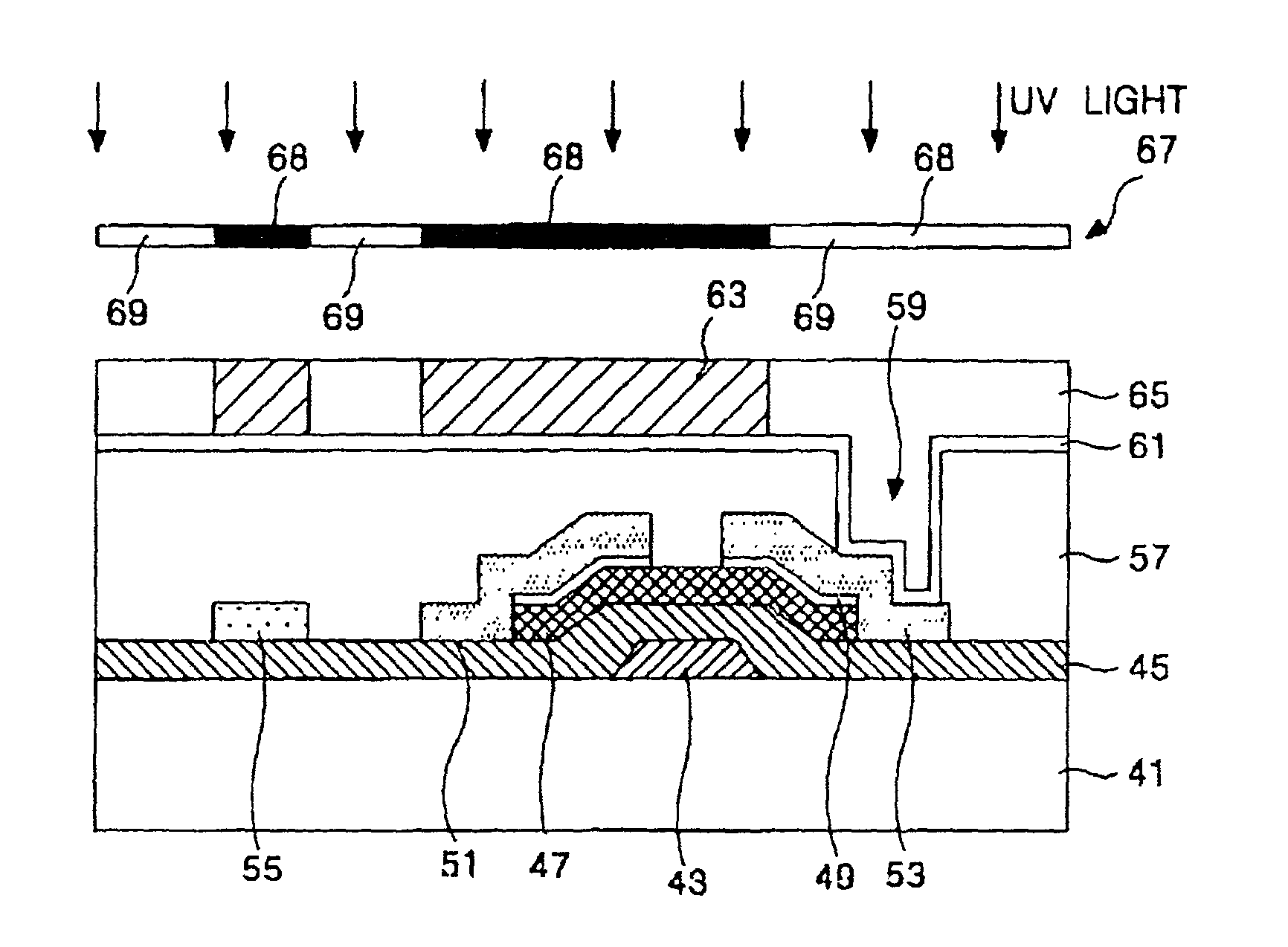

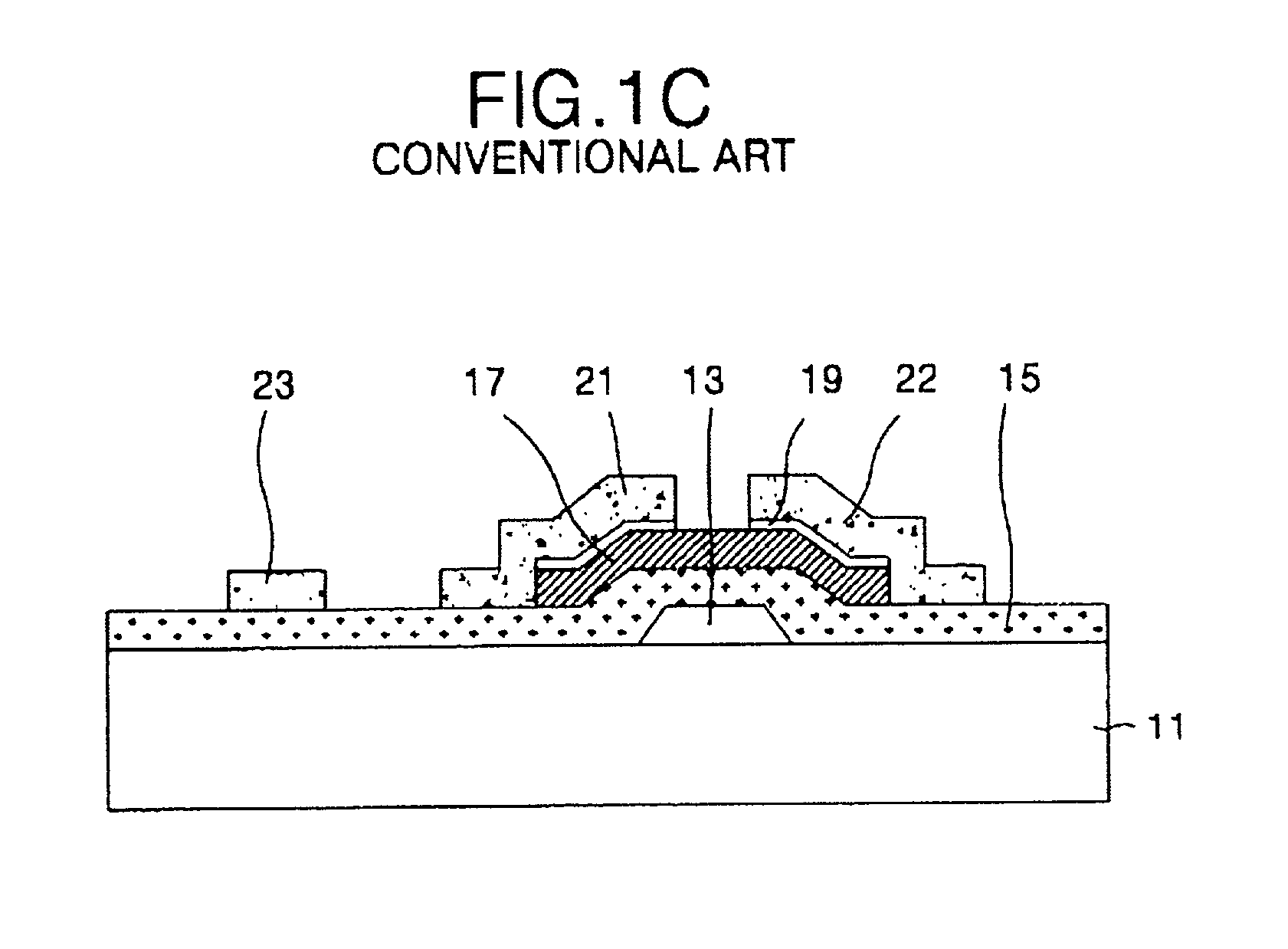

Method of fabricating liquid crystal display

InactiveUS6999152B2Preventing electrical shortVehicle sub-unit featuresReservoir arrangementsNegative typeLiquid-crystal display

A method of fabricating a liquid crystal display using a negative photo-resist. A passivation layer covering a thin film transistor, a data line, and a gate line is formed on a transparent substrate. The passivation layer is patterned to define a contact hole that exposes a drain electrode. A transparent conductive film in electrical contact with the drain electrode via the contact hole is then formed on the passivation layer. A negative-type photoresist is coated on the transparent conductive film. The transparent conductive film is then exposed with an image of the desired pixel electrode. The negative-type photoresist is then developed to expose portions of the transparent conductive film over a data line, a gate line, and the area of the thin film transistor area. The exposed transparent conductive film is then etched.

Owner:LG DISPLAY CO LTD

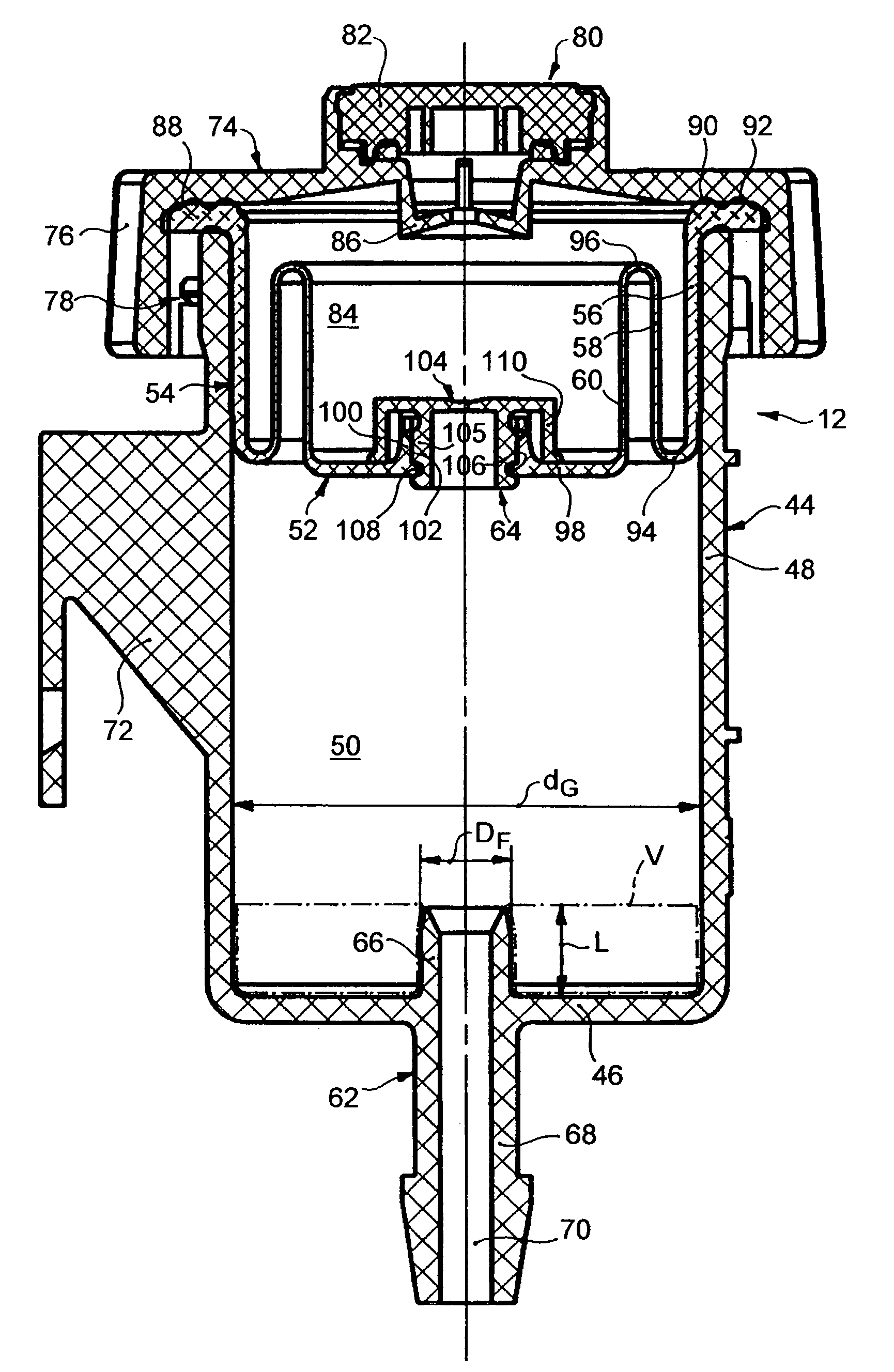

Expansion reservoir for a master cylinder of a hydraulic force transmission system

InactiveUS6996985B2Simple and low-costGood flexibilityRotary clutchesTelemotorsAir volumeMaster cylinder

An expansion reservoir is disclosed, which has a fluid chamber defined by a reservoir bottom and a flexible reservoir top movable relative to the reservoir bottom as a function of the reservoir filling level, wherein a hydraulic connection to a master cylinder is provided at the reservoir bottom while the reservoir top comprises a substantially liquid-tight but air-permeable connection to the atmosphere, in order to allow pressure compensation between an air volume left in the filled fluid chamber and the atmosphere. The hydraulic connection to the master cylinder comprises an extension protruding into the fluid chamber, which extension defines a predetermined volume V in the fluid chamber which is larger than the air volume left in the filled fluid chamber. In addition thereto, the reservoir top may take the form of a rolling lobe bellows, which comprises a plurality of wall portions substantially concentric at least in the undeformed state.

Owner:FTE AUTOMOTIVE GMBH & CO KG

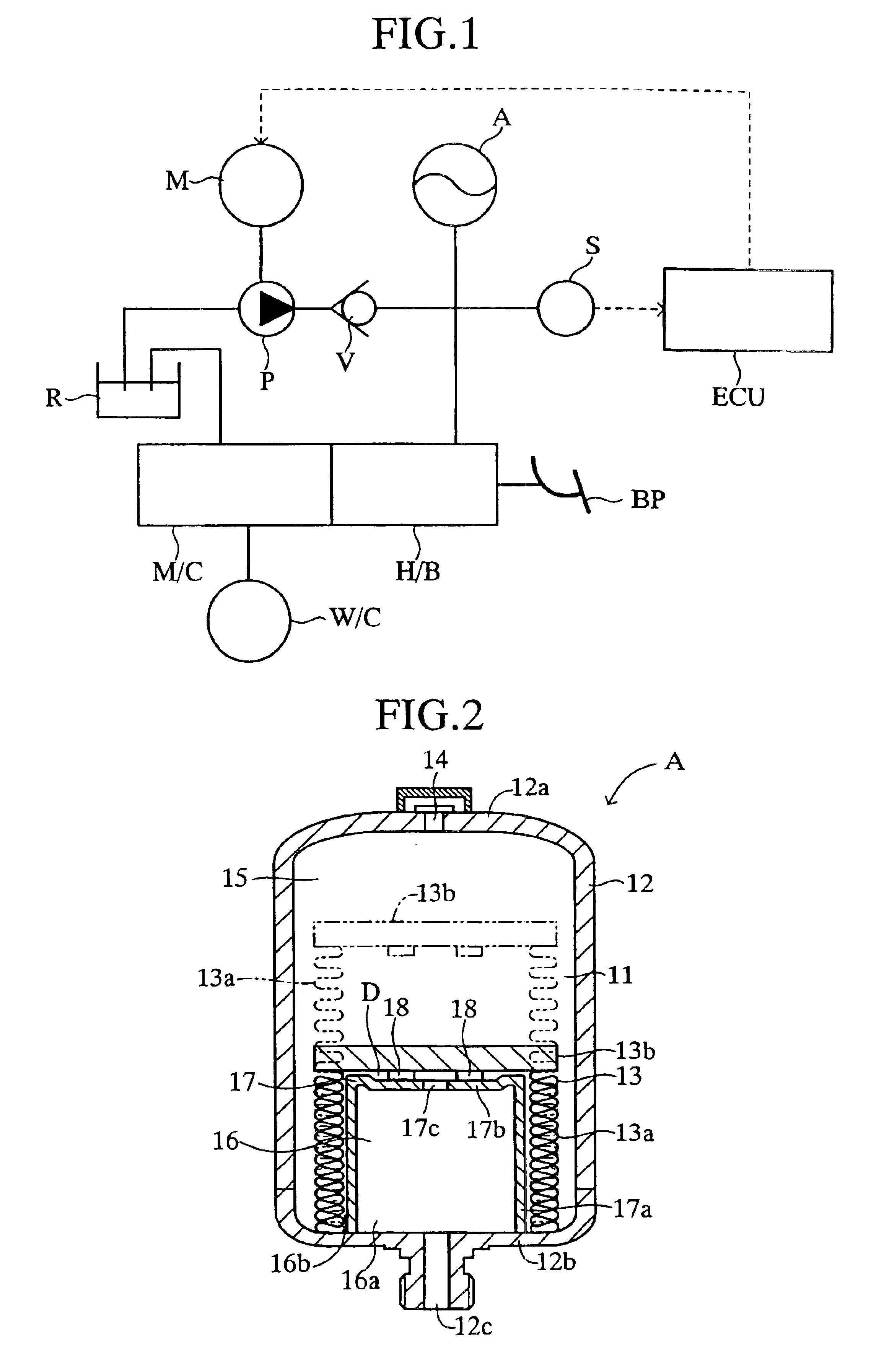

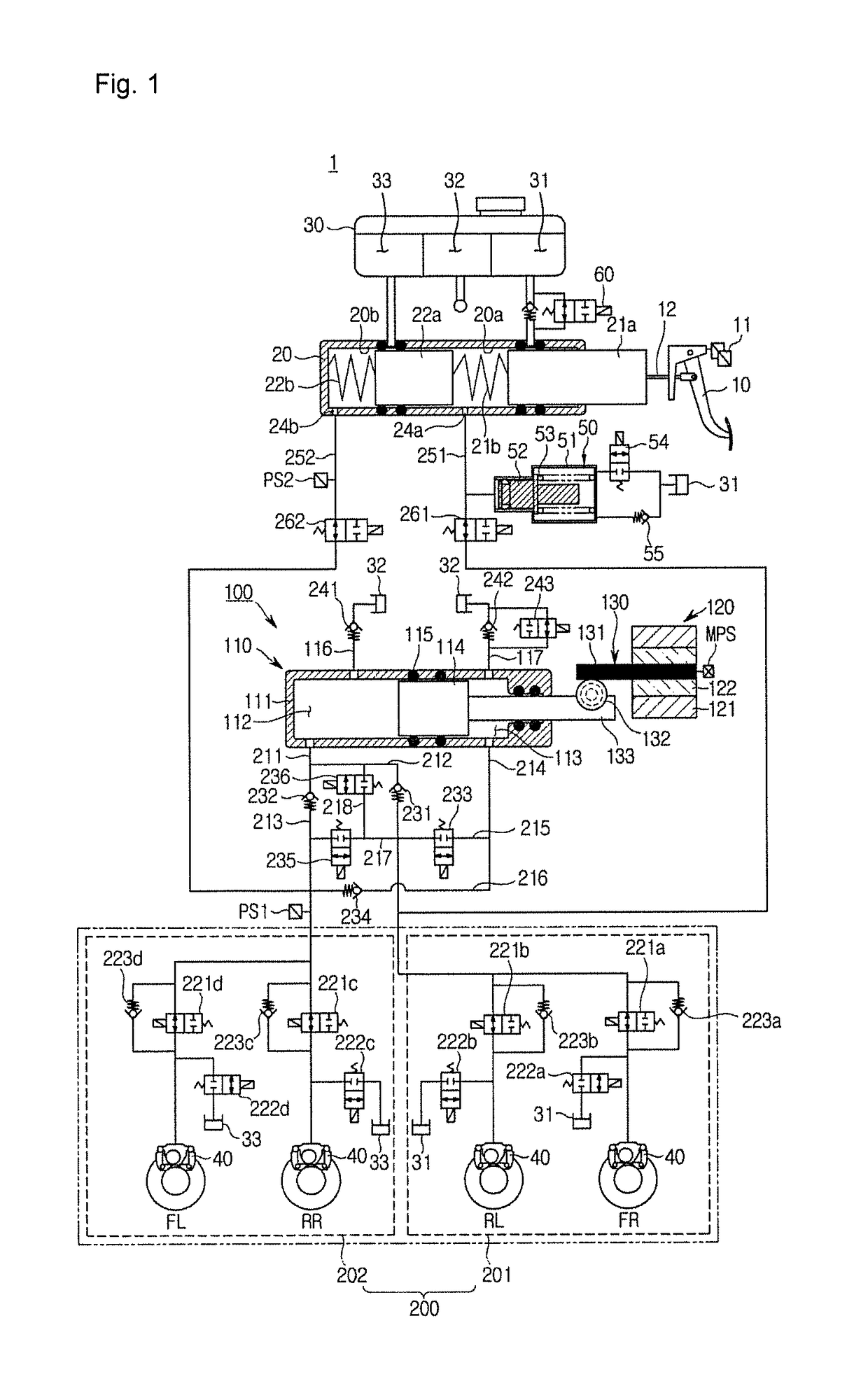

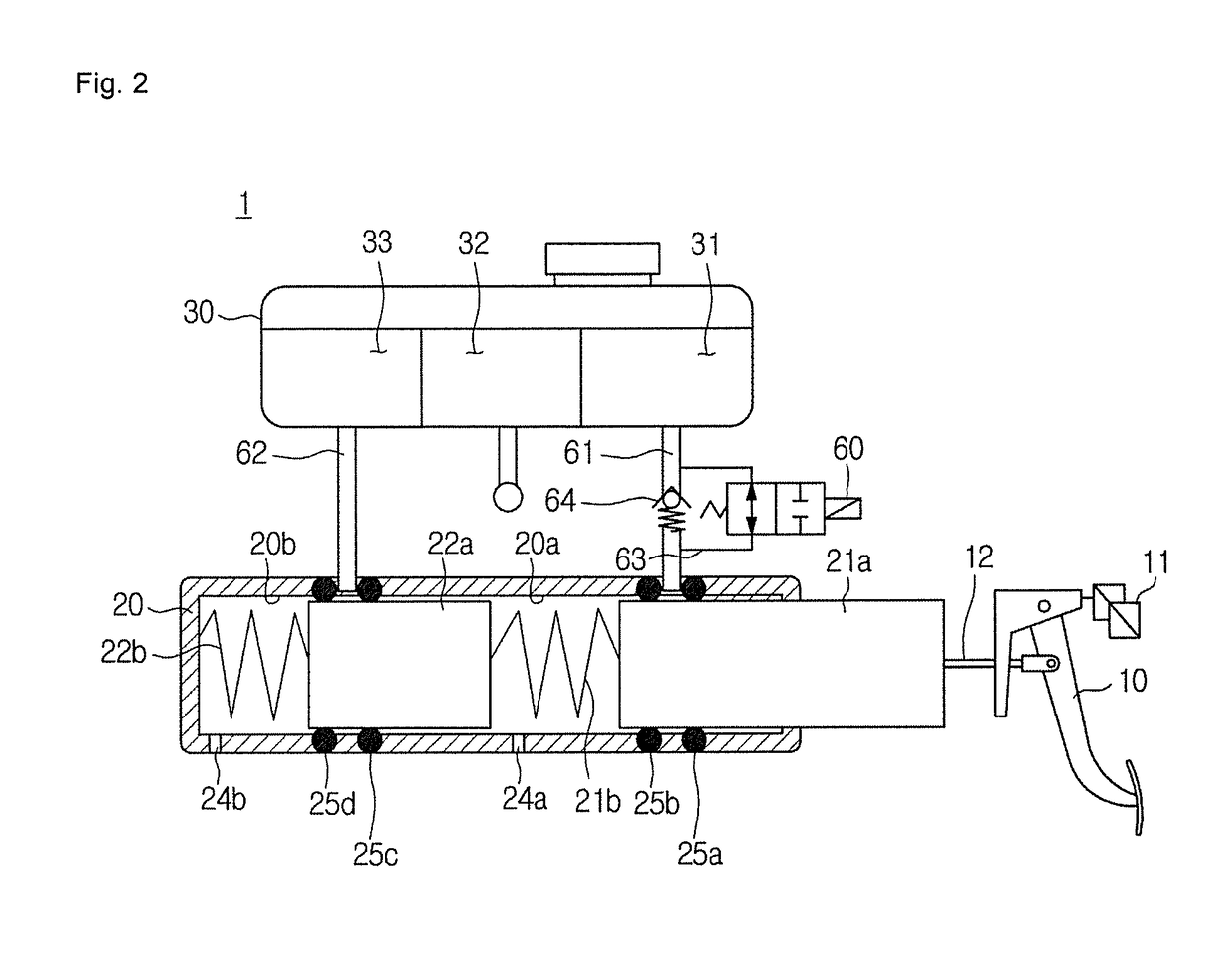

Electric brake system

ActiveUS20180111594A1Control flowMaintain efficiencyBrake control systemsFluid braking transmissionHydraulic control unitWheel cylinder

Disclosed is an electric brake system. The electric brake system includes a reservoir configured to store oil, a master cylinder connected to the reservoir, provided with first and second master chambers and first and second pistons respectively provided at the first and second master chambers, and configured to discharge oil according to pedal effort of a brake pedal; a hydraulic pressure supply device operated to generate a hydraulic pressure by an electrical signal output in response to displacement of the brake pedal; and a hydraulic pressure control unit configured to deliver the hydraulic pressure discharged from the hydraulic pressure supply device to a wheel cylinder provided at each of wheels, wherein the reservoir includes a first reservoir chamber connected to the master cylinder and configured to supply the oil thereto, and a second reservoir chamber connected to the hydraulic pressure supply device, configured to supply the oil thereto and provided to be separated from the first reservoir chamber.

Owner:HL MANDO CORP

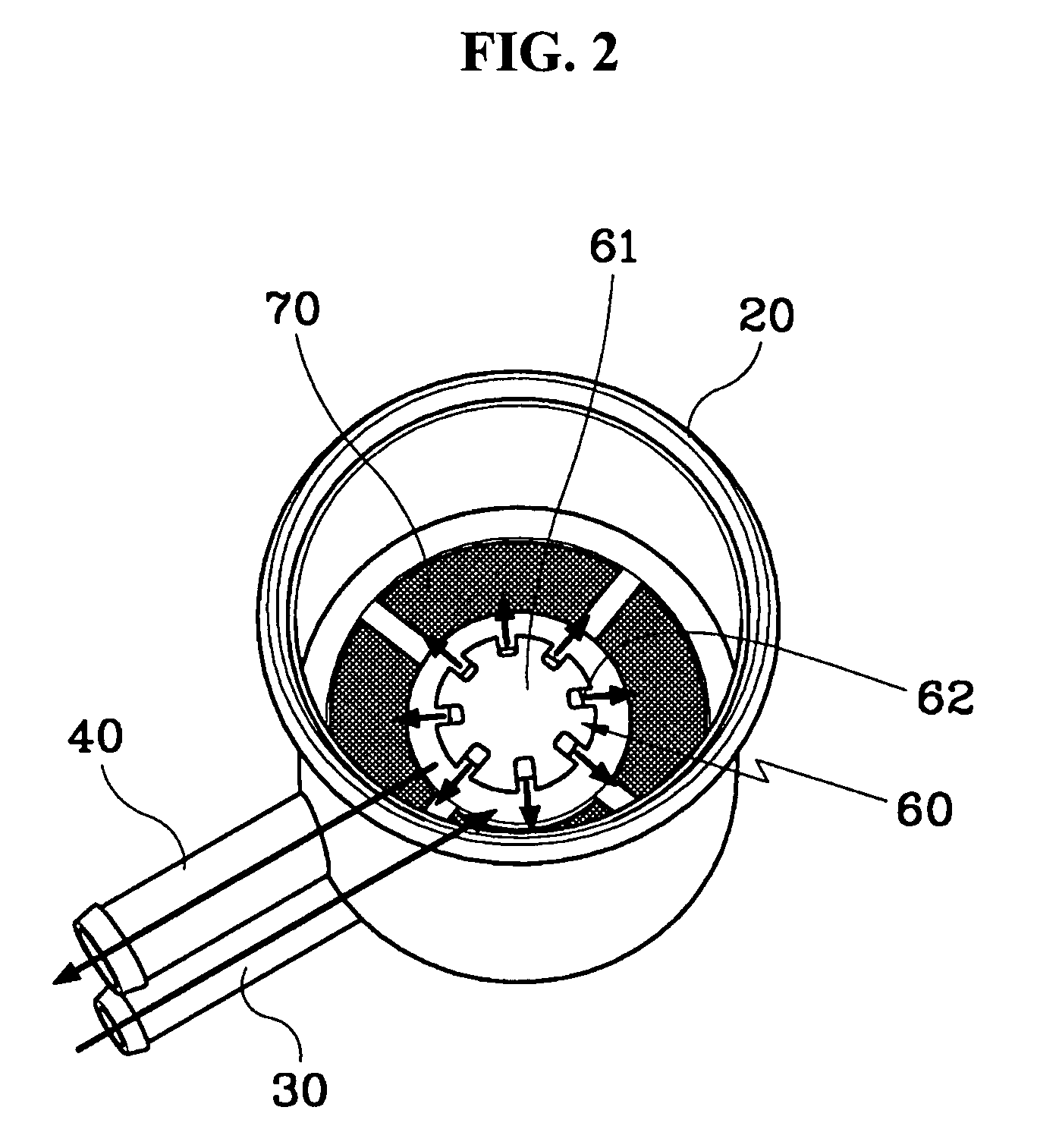

Reservoir tank of a power steering system for a car

A reservoir tank of power steering system for a car includes an inlet port delivering oil through a swirl prevention member. The oil is then allowed to flow so swirl does not form in the oil flow of a reservoir tank. Furthermore, bubble formation in the oil is minimized.

Owner:HYUNDAI MOTOR CO LTD

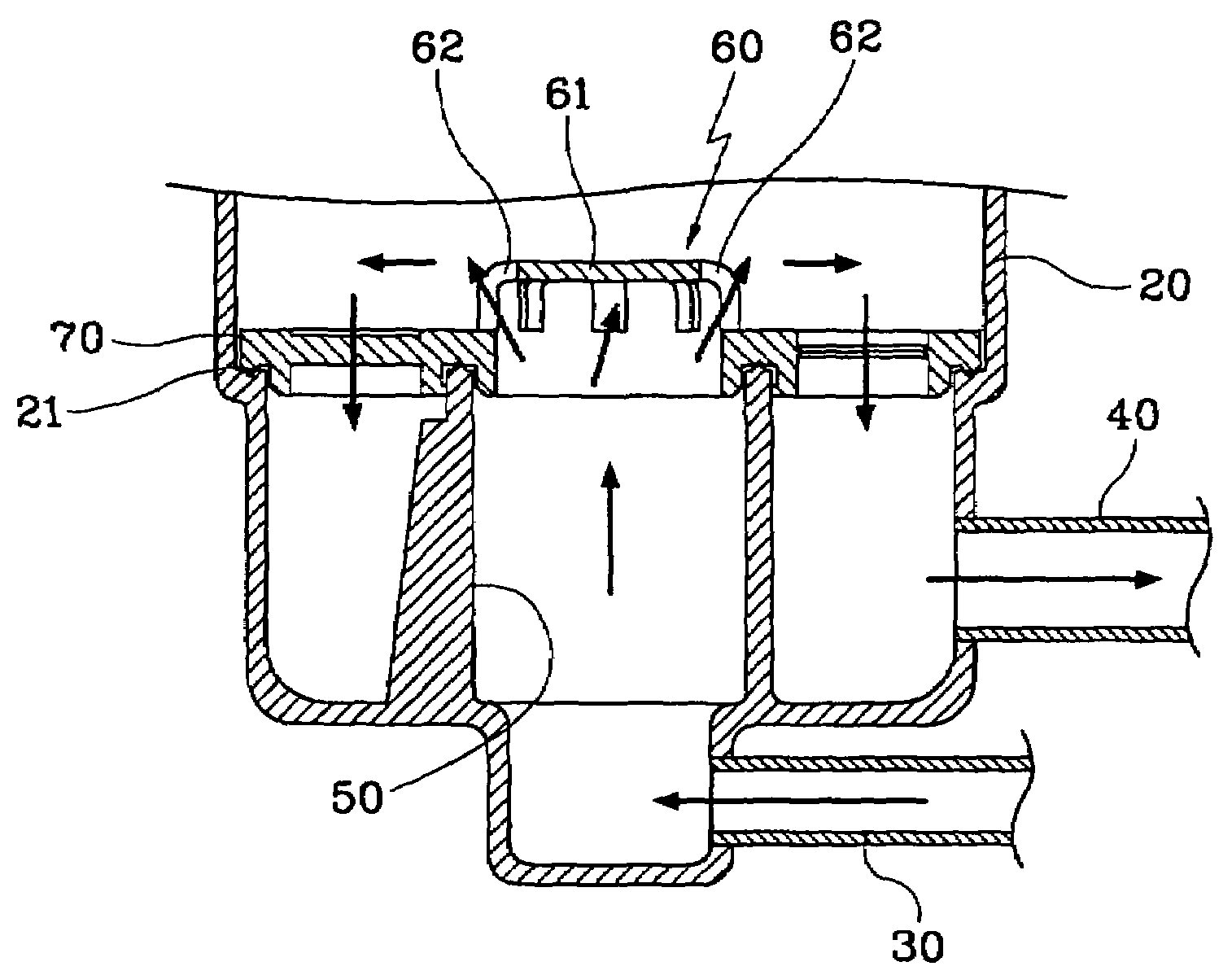

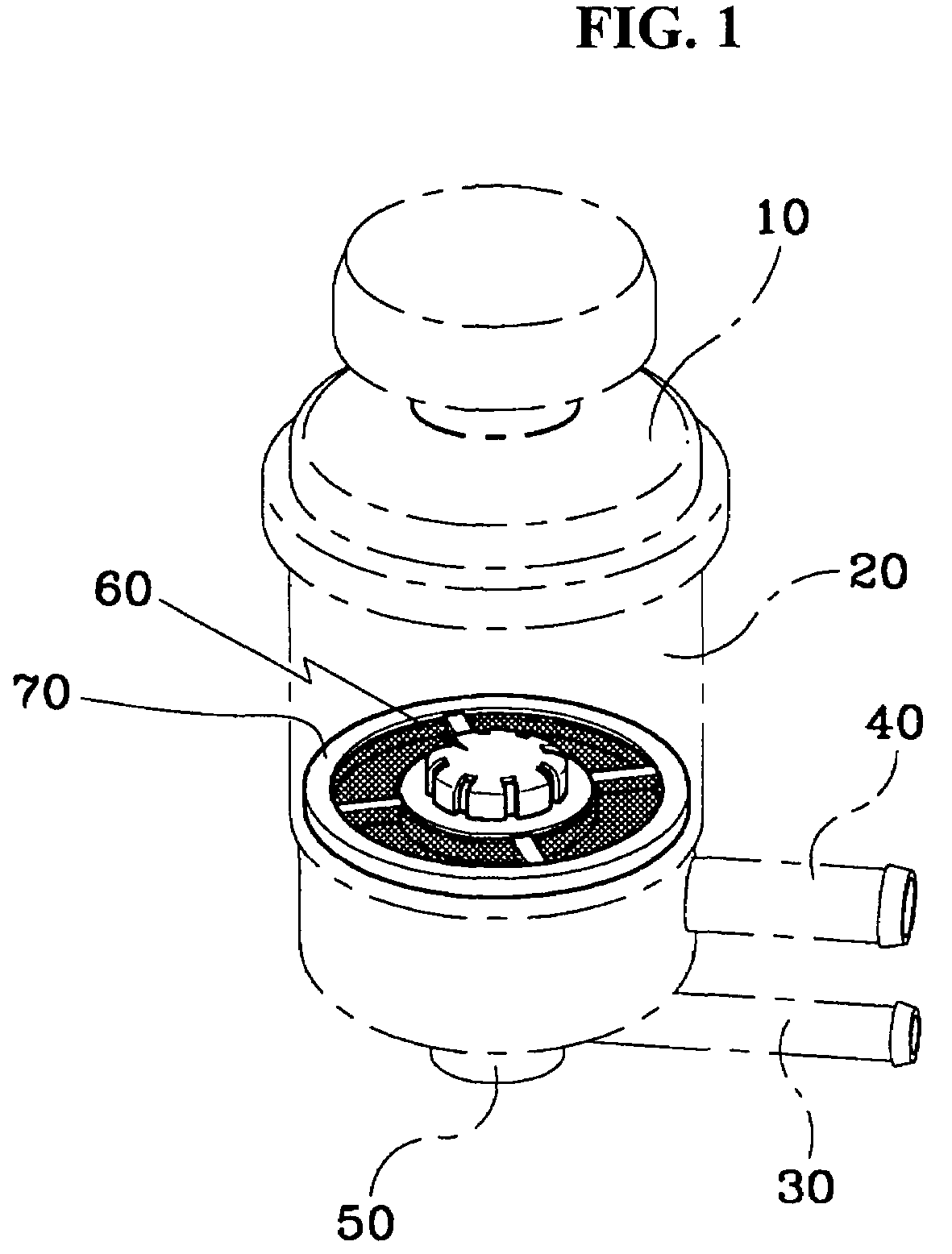

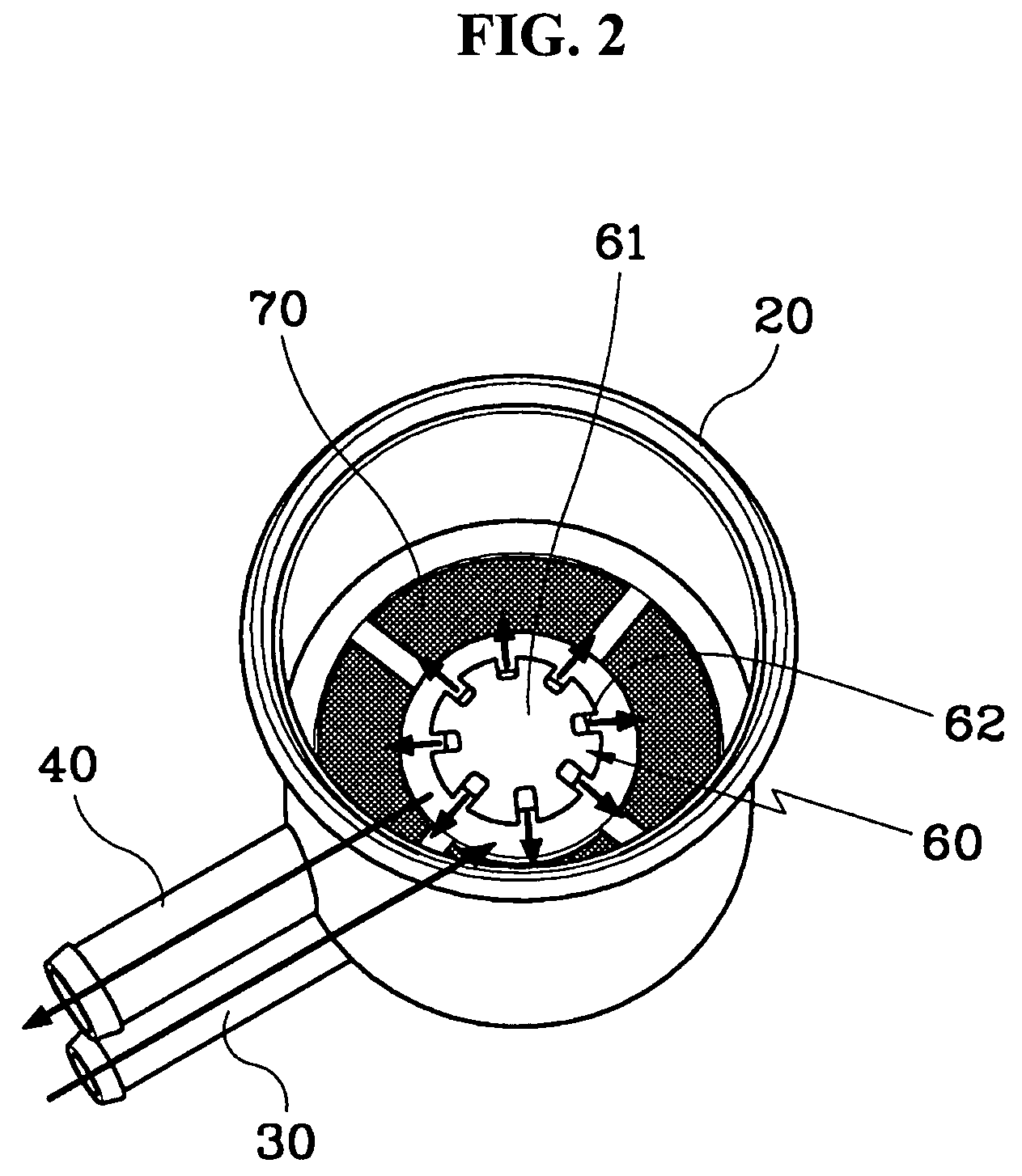

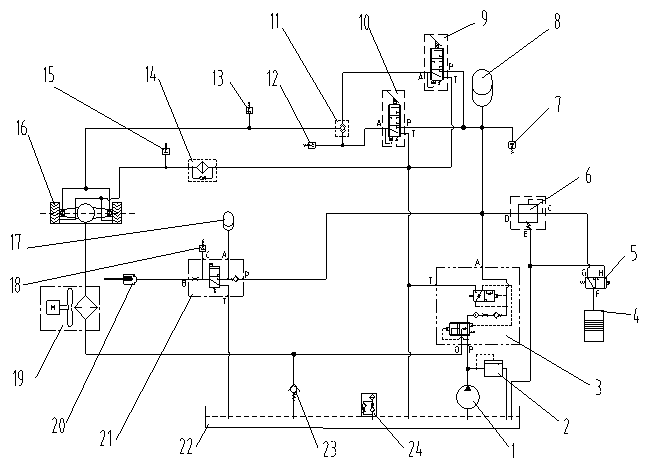

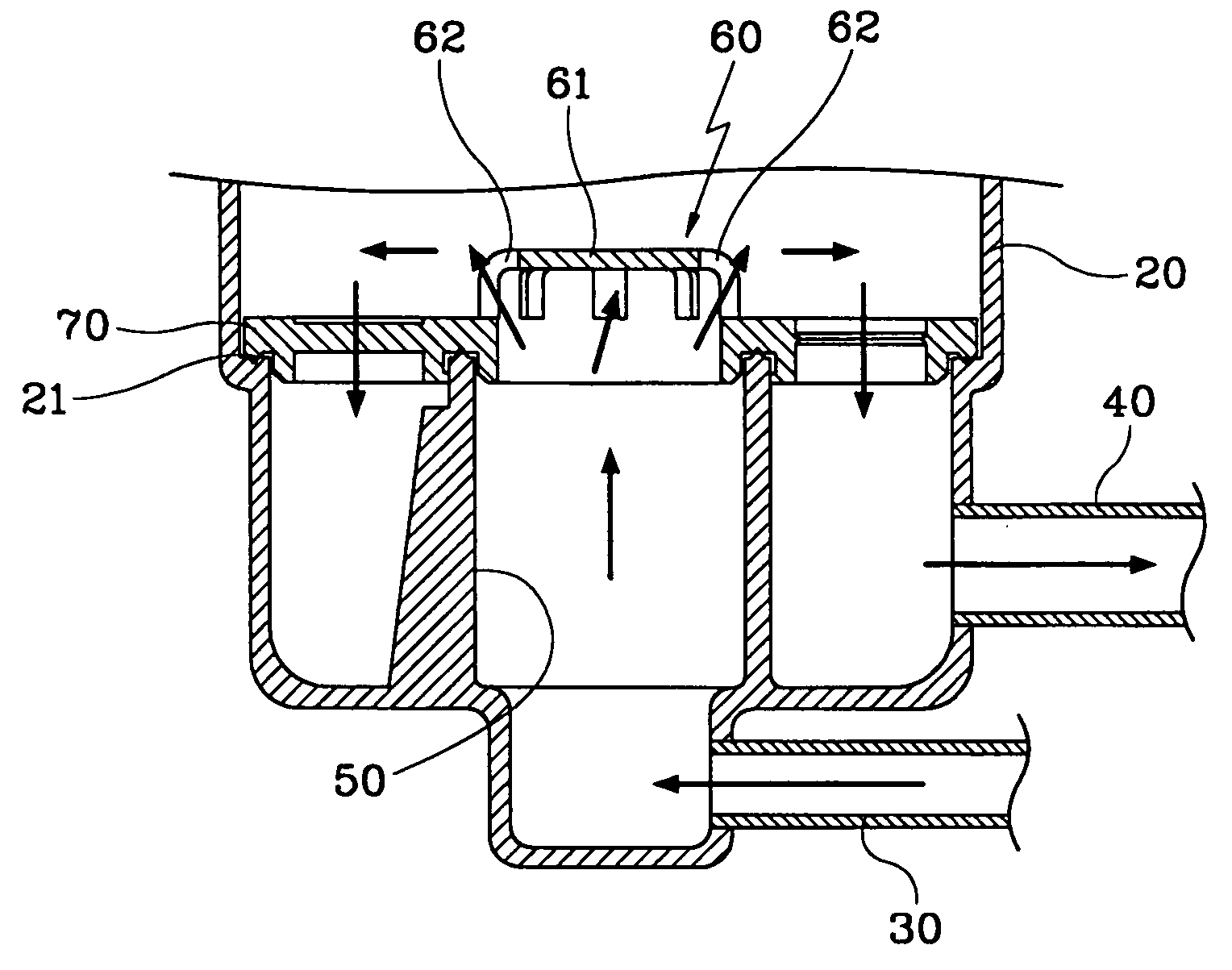

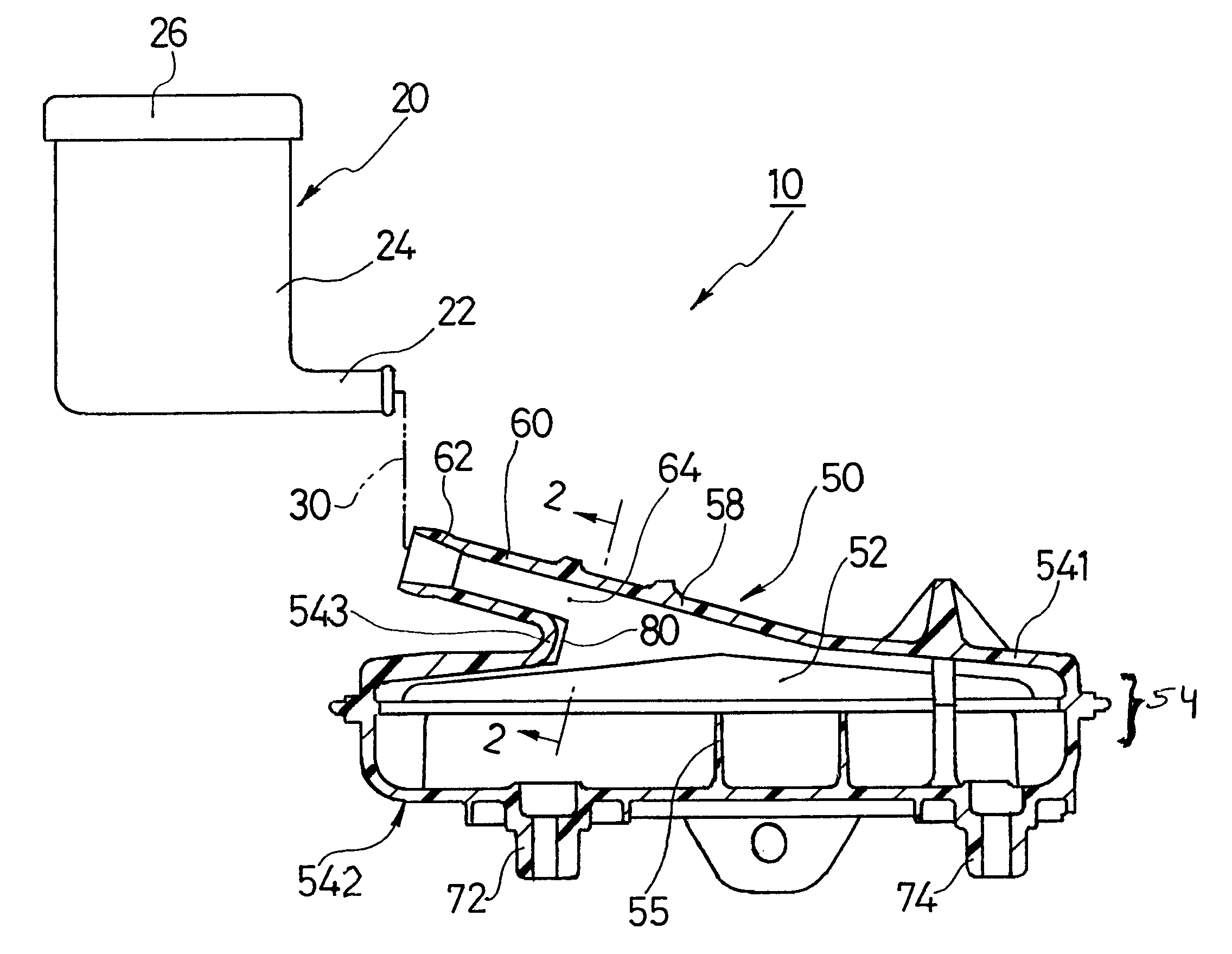

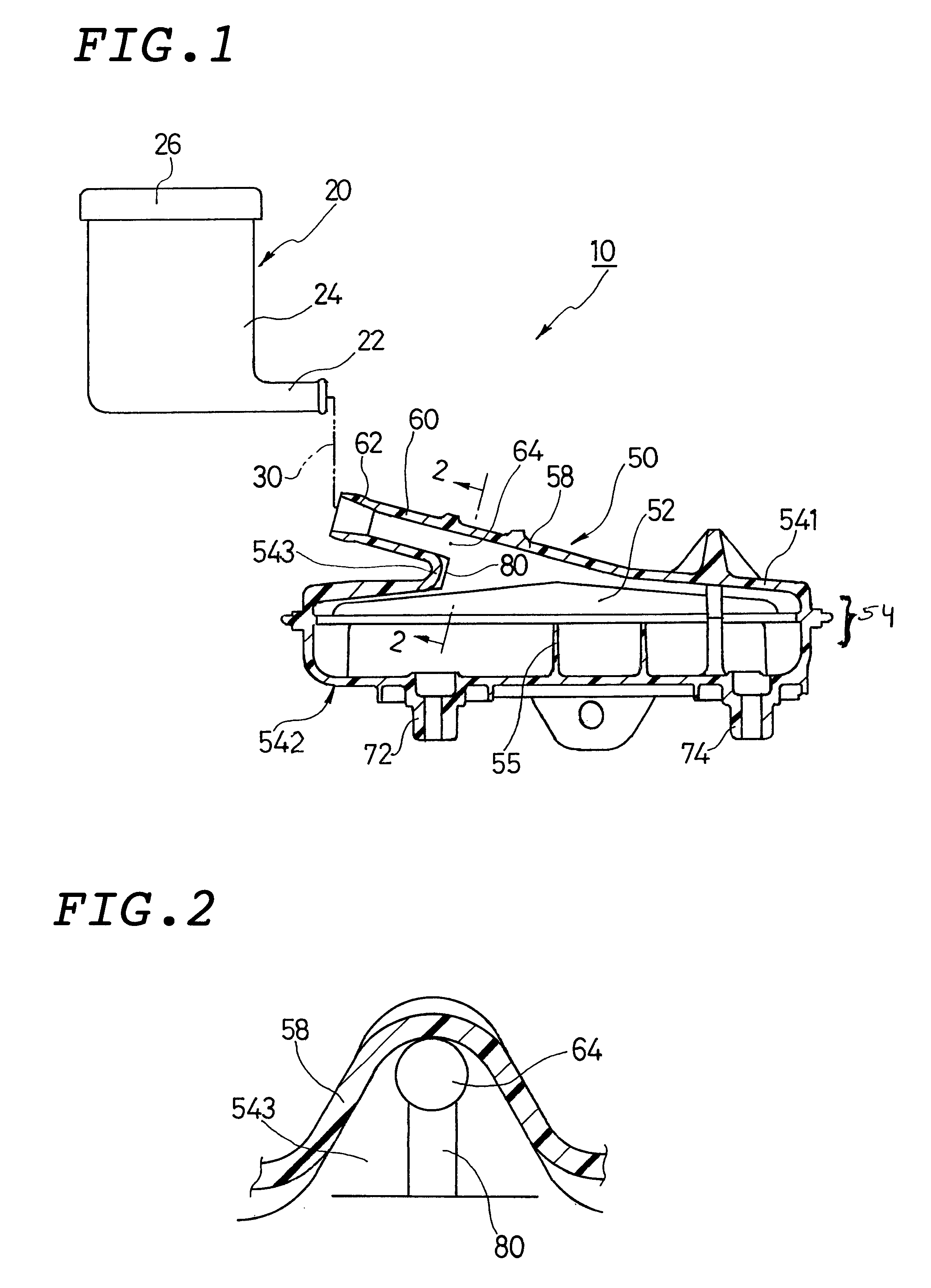

Reservoir apparatus and auxiliary reservoir

InactiveUS6550591B2Reduced opening sizeSmall sizeRotary clutchesTelemotorsWorking fluidAtmospheric air

To provides a technique capable of replenishing a working fluid smoothly while employing a method for replacing an atmospheric air with the working fluid. The reservoir apparatus (10) includes a main reservoir (20) having an inlet opening for feeding a hydraulic fluid, and an auxiliary reservoir (50) connecting thereto through a piping (30). There is a diagonally extending connecting pipe (60) at the auxiliary reservoir (50). There is a recessed portion (80) at an opening portion (64) of an inner periphery of the connecting pipe (60). This recessed portion (80), when compared with the case where there is no such a recessed portion, serves to enlarge the opening portion (64) of the connecting pipe (60) and more smoothly flow the replenishment working fluid at a nearby area of the opening portion (64). By doing so, the opening portion (64) of the connecting pipe (60) can be more enlarged at the time of replenishment of the working fluid and formation of a film of the working fluid can be prevented at the opening portion (64).

Owner:DIESEL KIKI CO LTD

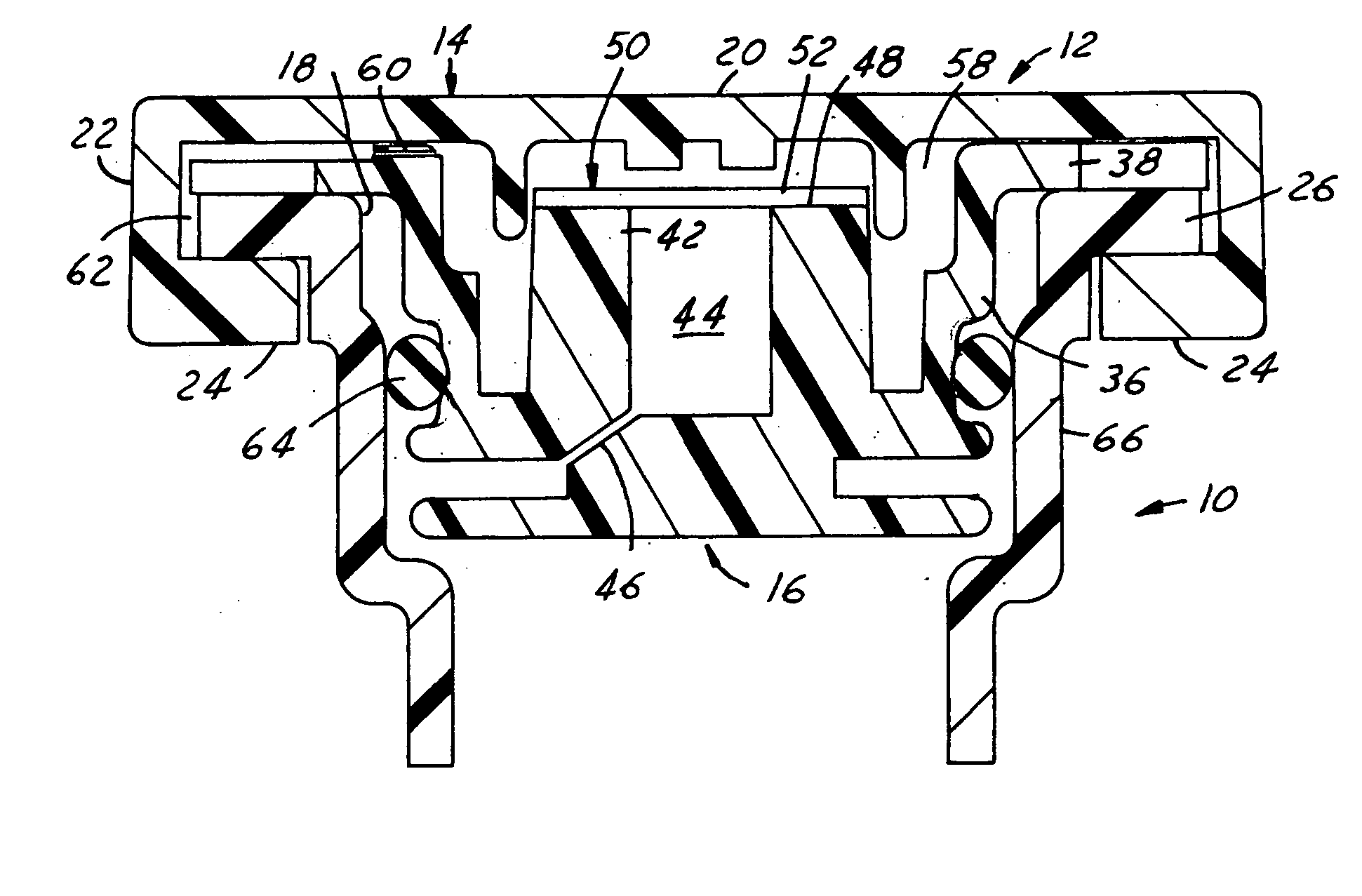

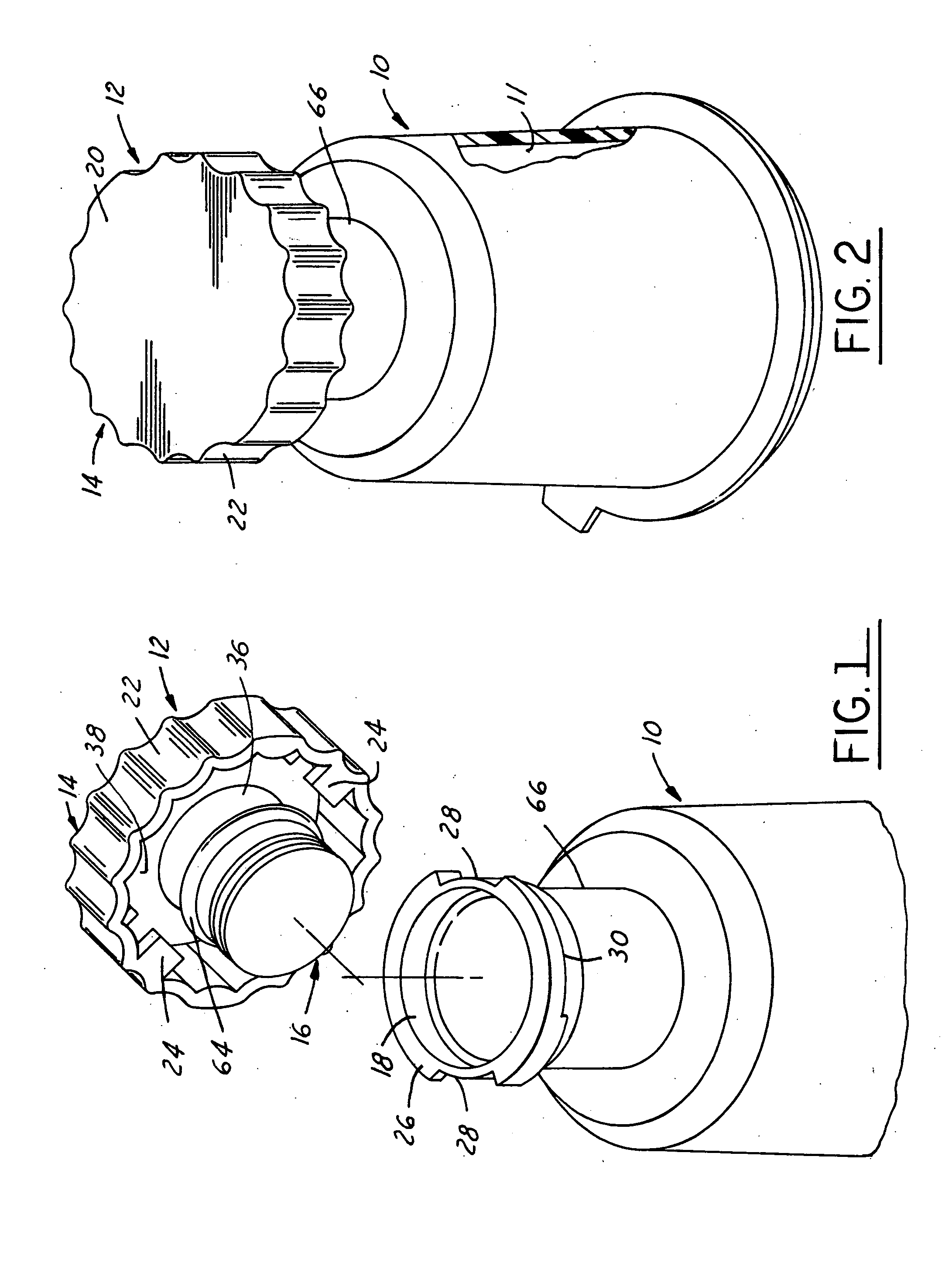

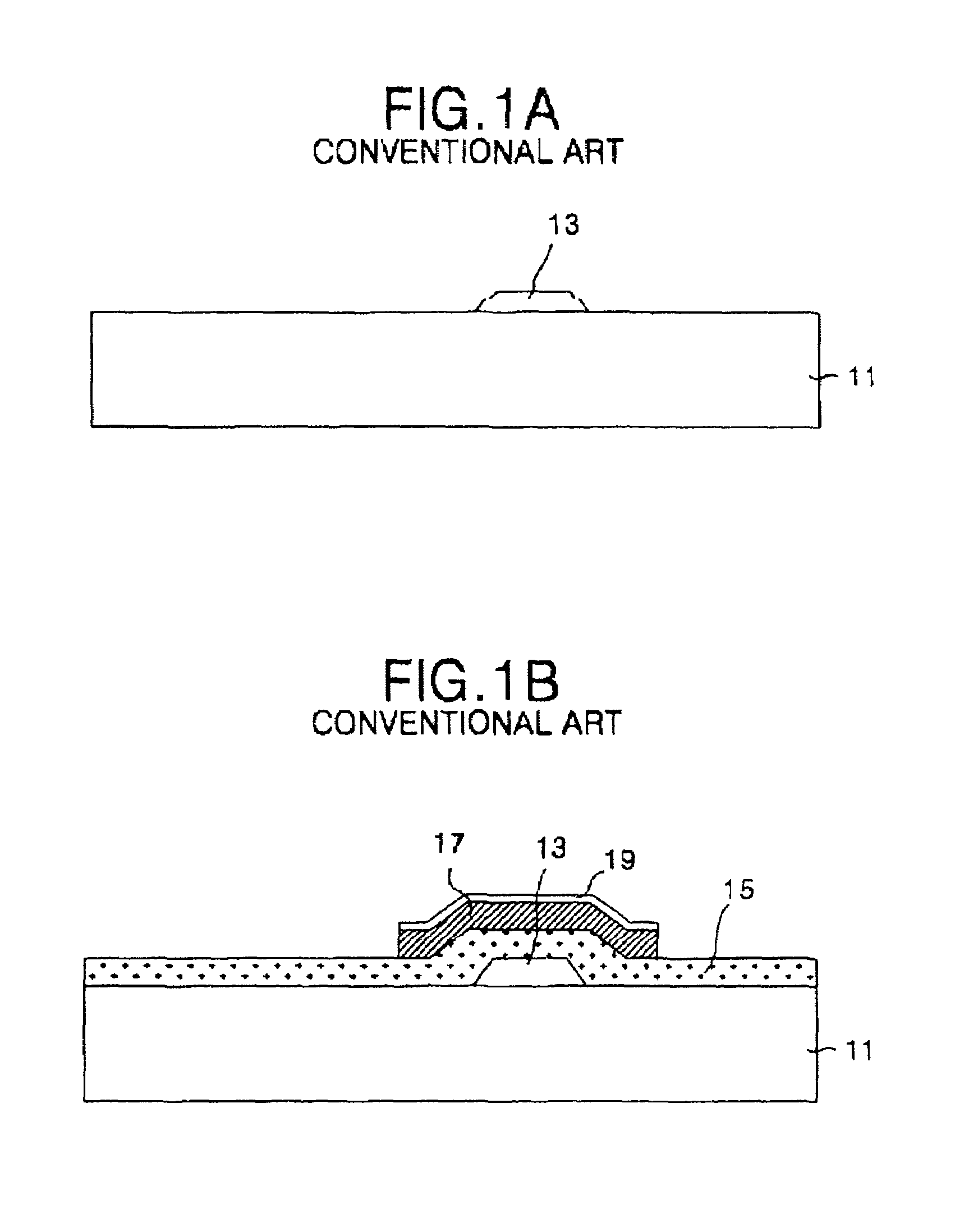

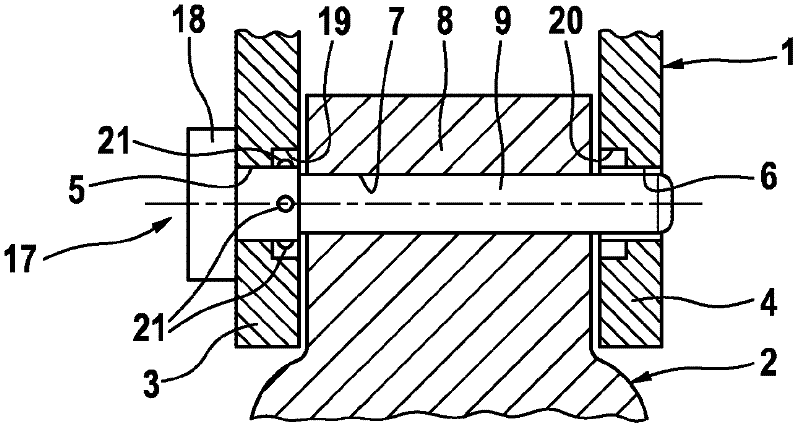

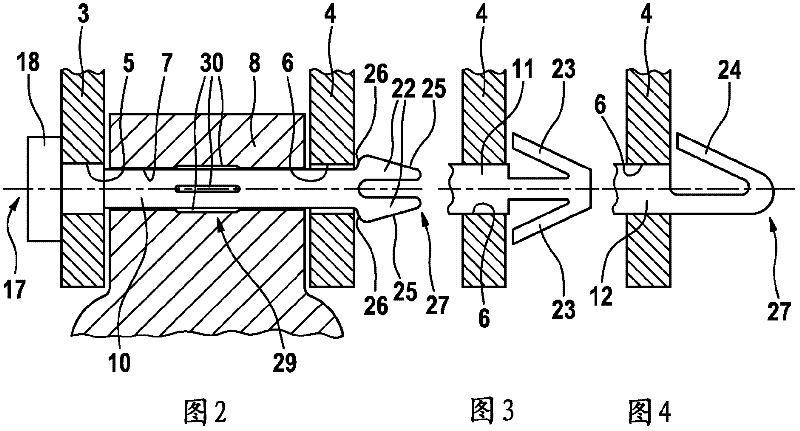

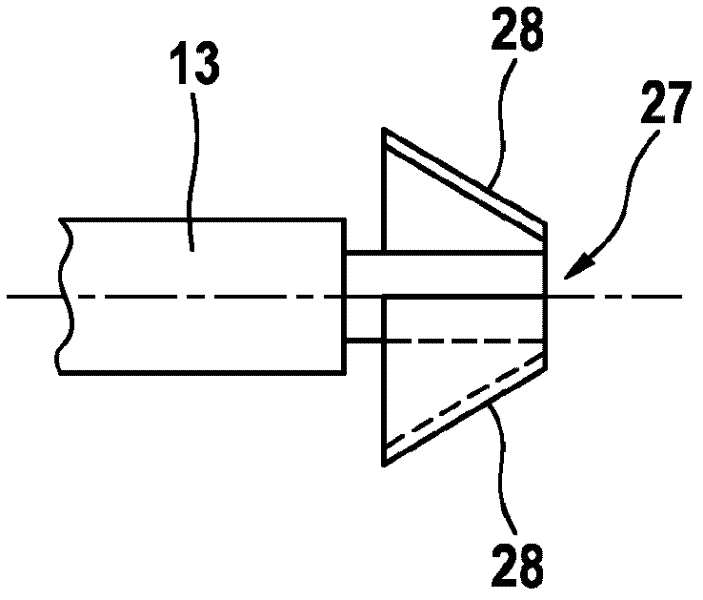

Assembly made of a compensating tank and a master cylinder for a hydraulic motor vehicle brake system

The invention relates to an assembly made of a compensating tank 1 and a master cylinder 2 for a hydraulic motor vehicle brake system, wherein the compensating tank 1 has two fastening attachments 3, 4, each with an opening 5, 6, wherein openings 5, 6 align with an opening 7 in master cylinder 2, and compensating tank 1 is fastened by a detachable connection by means of a fastening pin 9; 10; 11; 12; 13; 14; 15; 16 that extends through the aligned openings 5, 6, 7. In order to improve the installation and possible dismantling of the fastening pin, and at the same time to maintain an optimized assembly weight, the invention proposes that fastening pin 9; 10; 11; 12; 13; 14; 15; 16 be made of plastic and interact in a positive- or force-locking manner with at least one of the openings 5, 6 of fastening attachments 3, 4.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

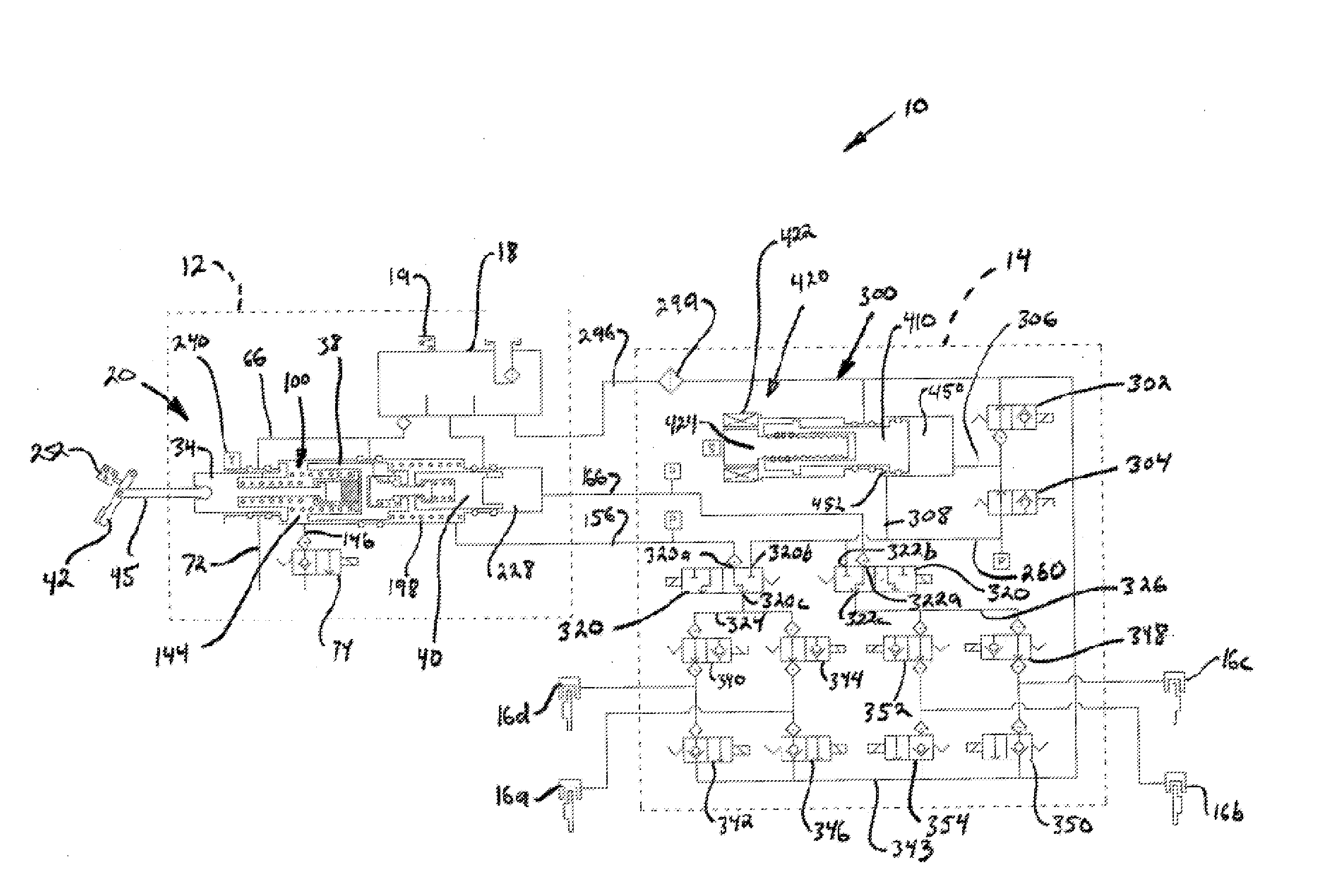

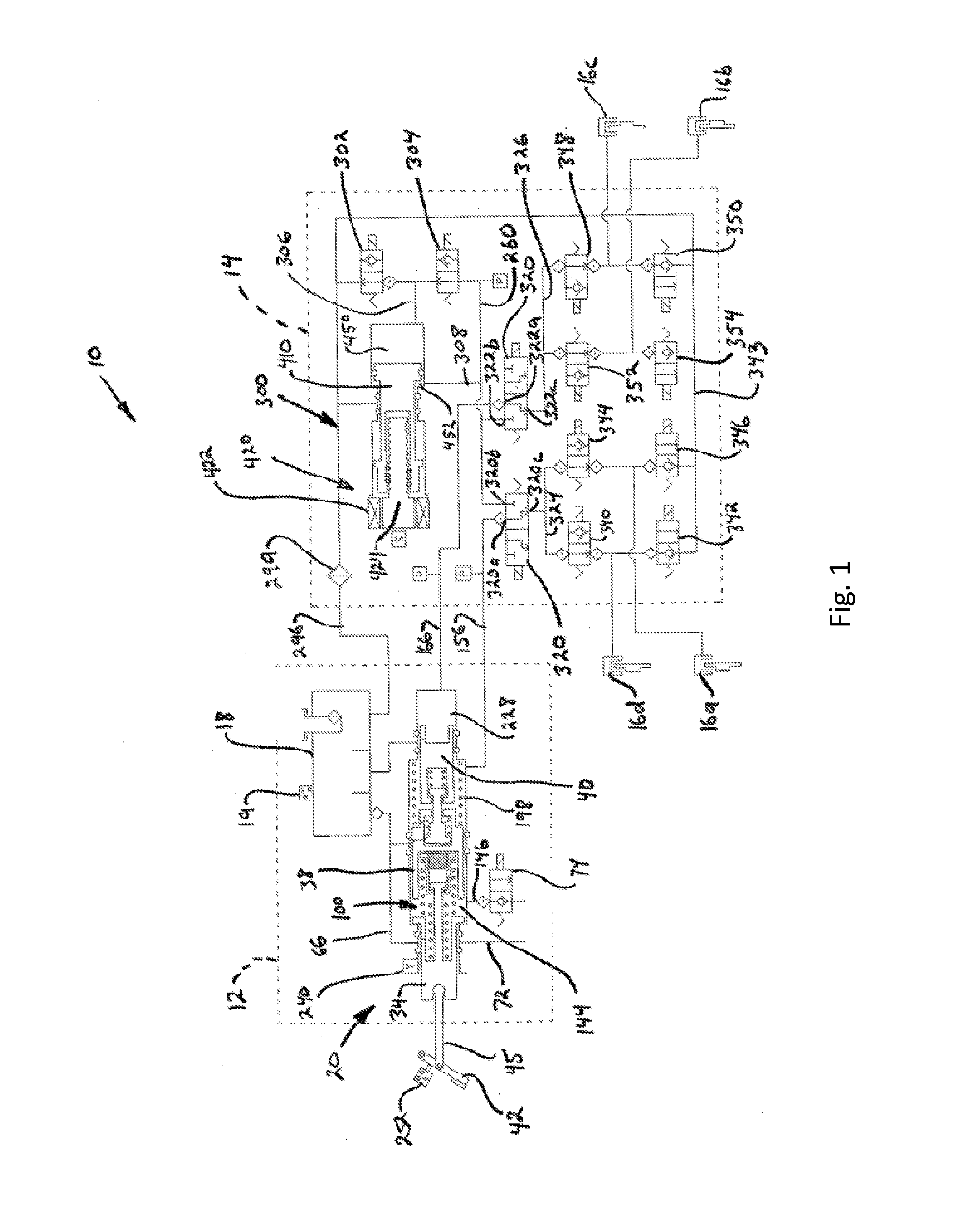

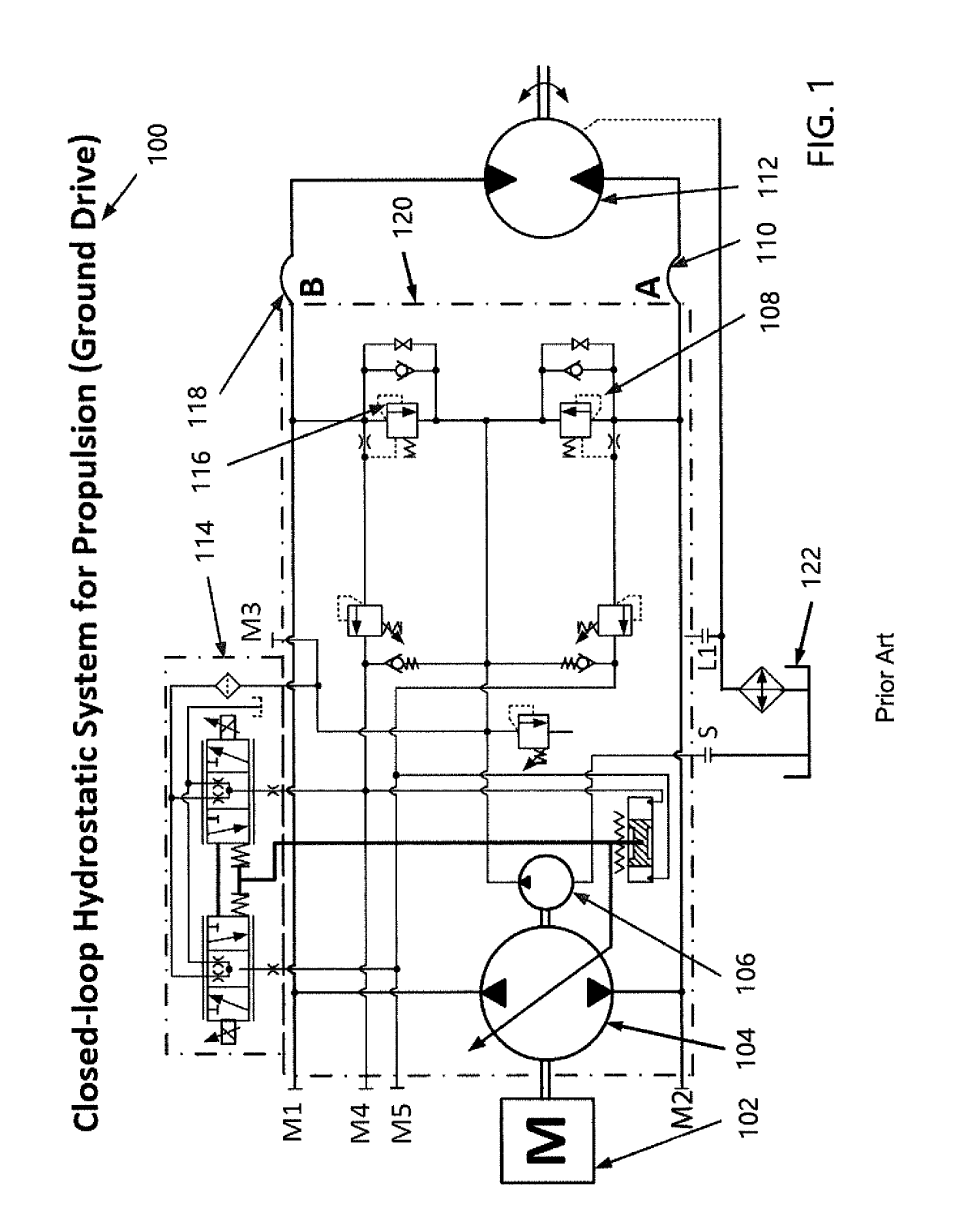

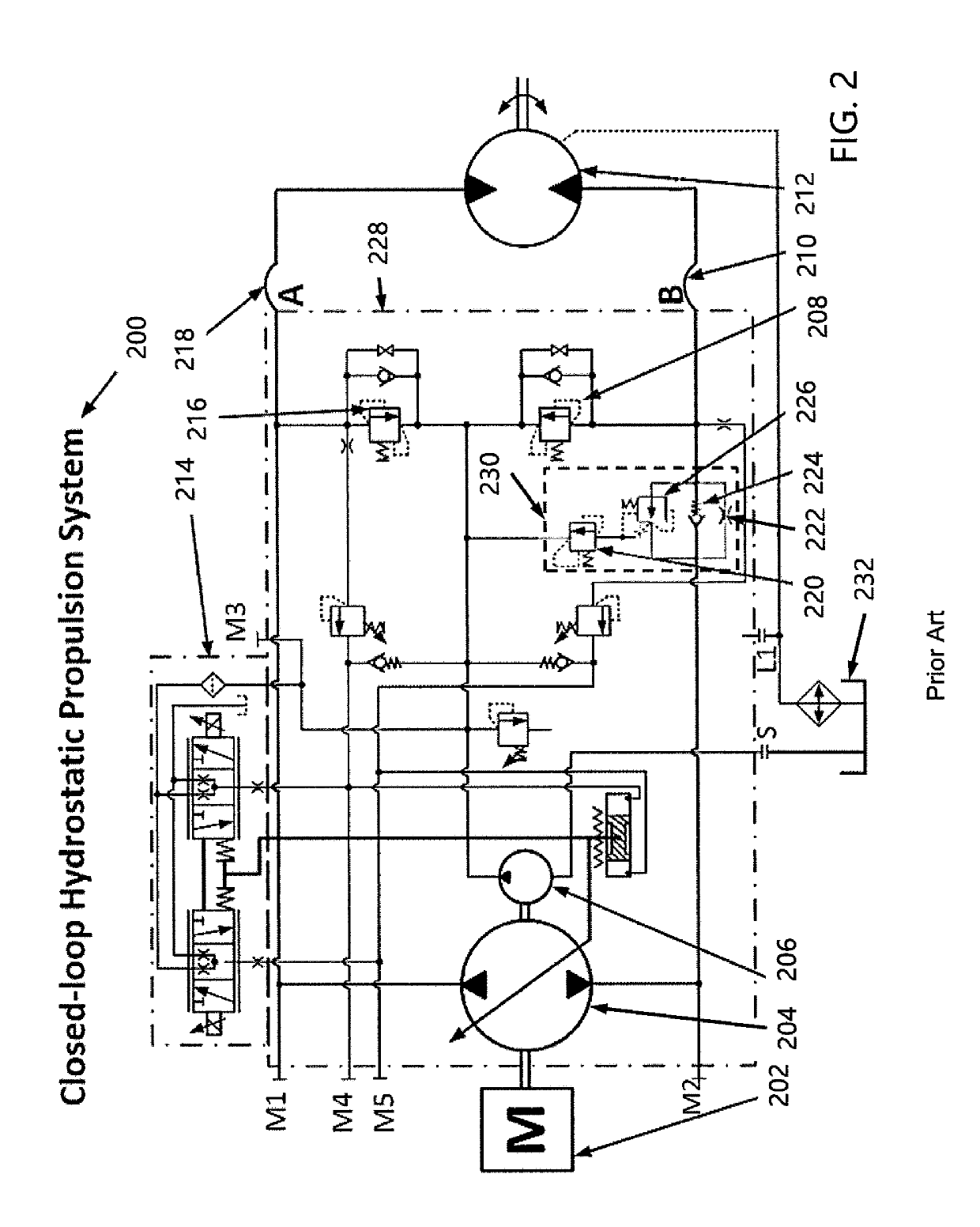

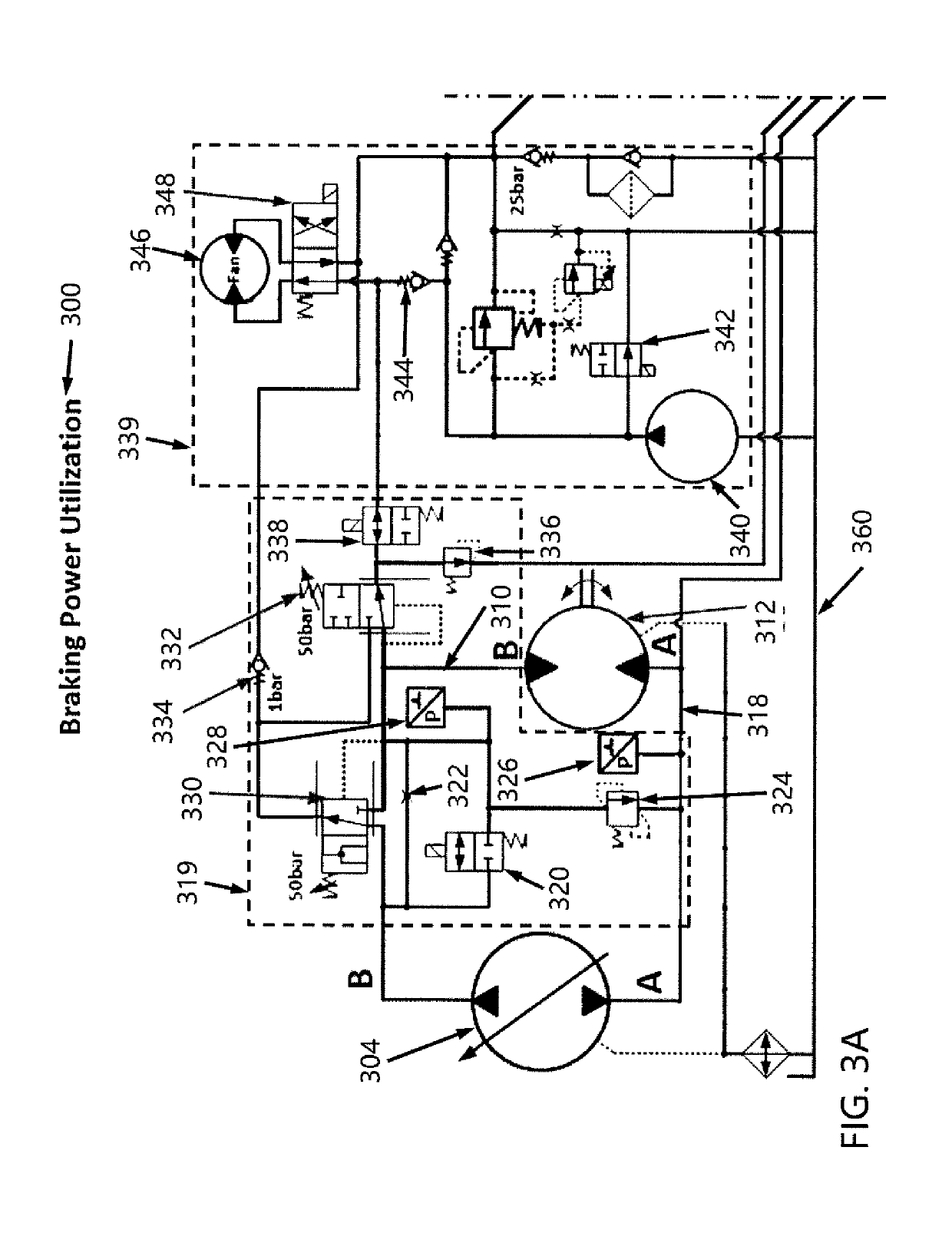

Hydraulic Braking Emergency Utilization for Steering, Braking, Charging Accumulators(s), and/or Work Functions to Reduce or Prevent Engine from Overspeed, Assist Acceleration and/or Unlimited Towing

ActiveUS20190136877A1Minimizing heat generationPrevent speedingBraking action transmissionBrake control systemsHydraulic circuitWork function

A system and method configured to direct the braking energy from a high-pressure port at the motor side of a hydraulic circuit to emergency steering, braking, accumulator(s) charging, and / or various work functions. The system and method are also configured to return hydraulic fluid back to the same high-pressure port when the motor is running as a pump.

Owner:APPLIED IND TECH

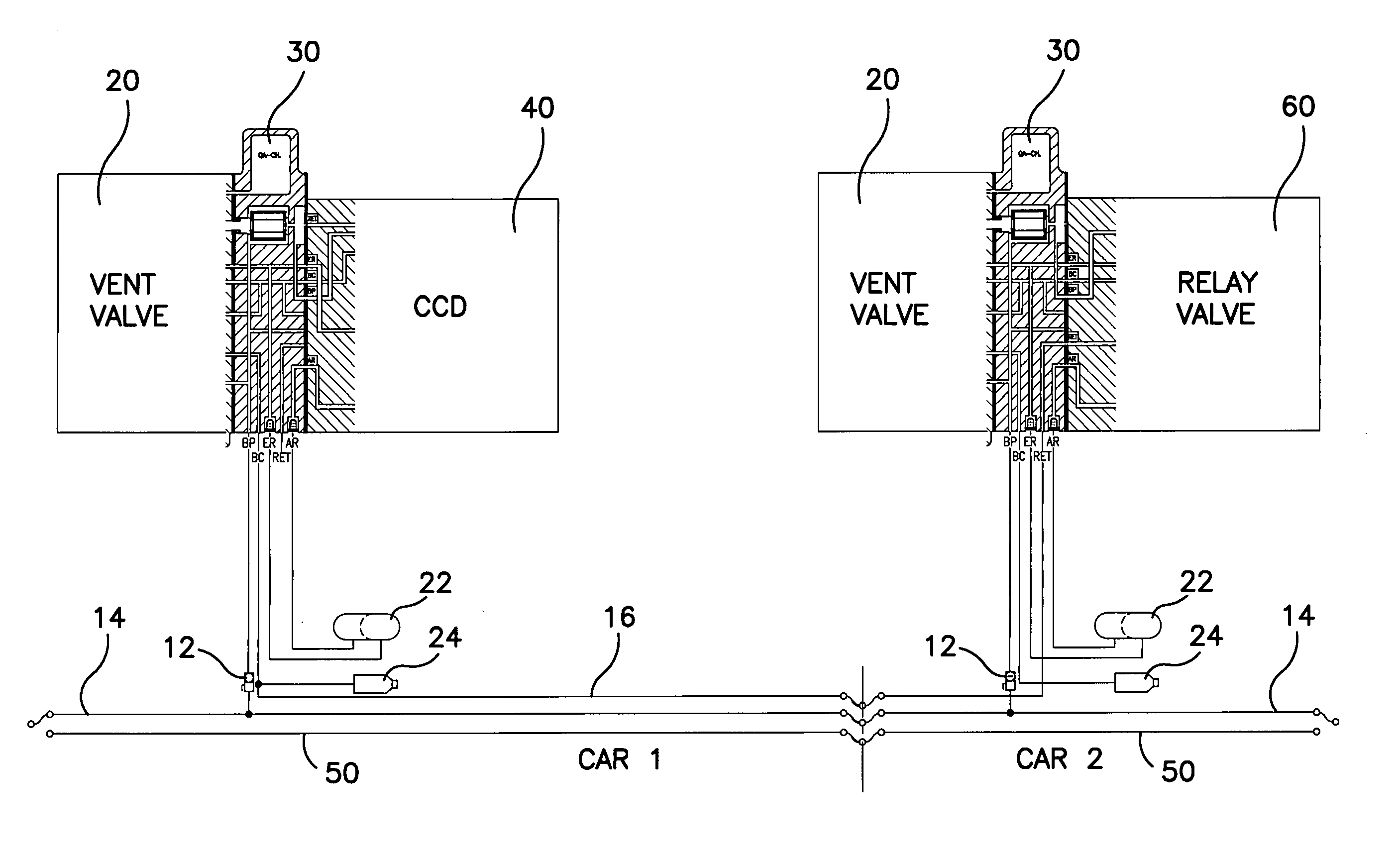

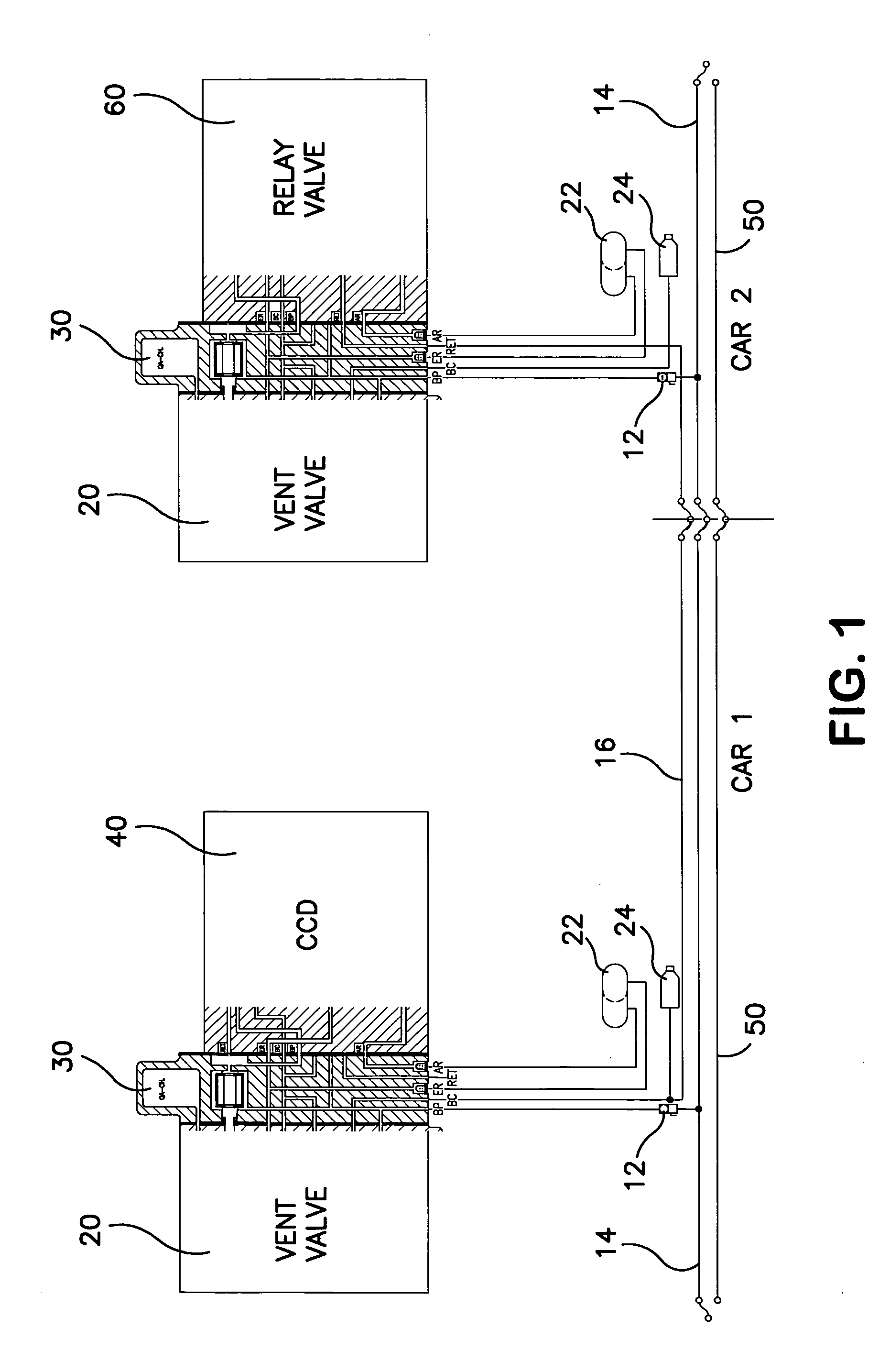

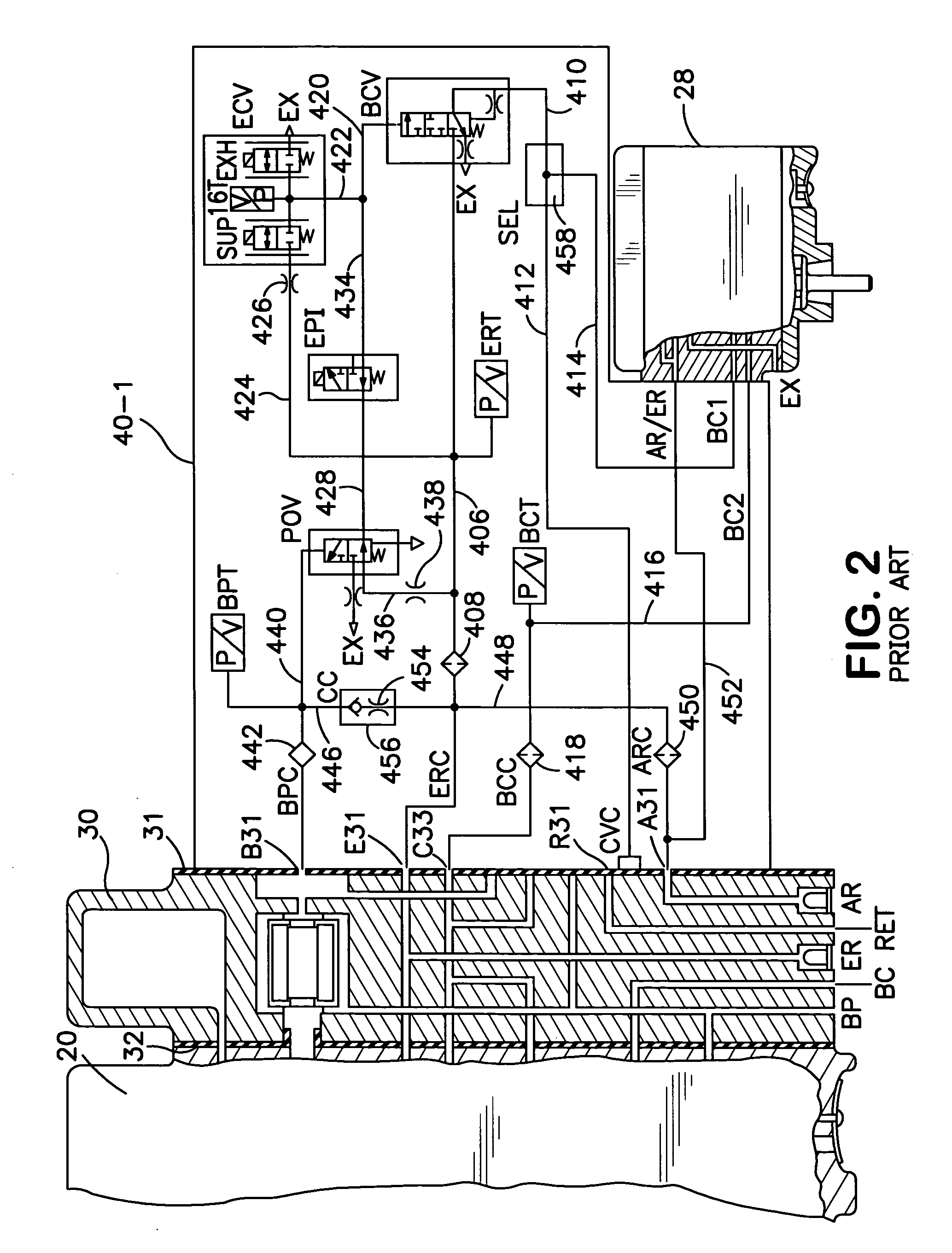

Relay configuration for an electro-pneumatic train

ActiveUS20060138856A1Reduce in quantityFluid braking transmissionApplication and release valvesRelay valveCheck valve

A relay valve configuration which can be used with various cars in an electropneumatic train and under the control of one of the electropneumatic brake control valves. The improved brake control valve includes a relay valve mounted at an interface of the manifold. The valve has a source inlet connected to the reservoir interface port, an inlet connected to atmosphere, an outlet connected to the brake cylinder interface port and a control inlet connected to the exhaust interface port. The valve is responsive to the control inlet connected to the exhaust interface port to selectively connect the brake cylinder interface port either to the reservoir interface port or atmosphere. The exhaust interface port in AAR is known as the retainer port. A check valve / choke is also mounted on the manifold of the interface and is in the same housing as the relay valve.

Owner:NEW YORK AIR BRAKE CORP

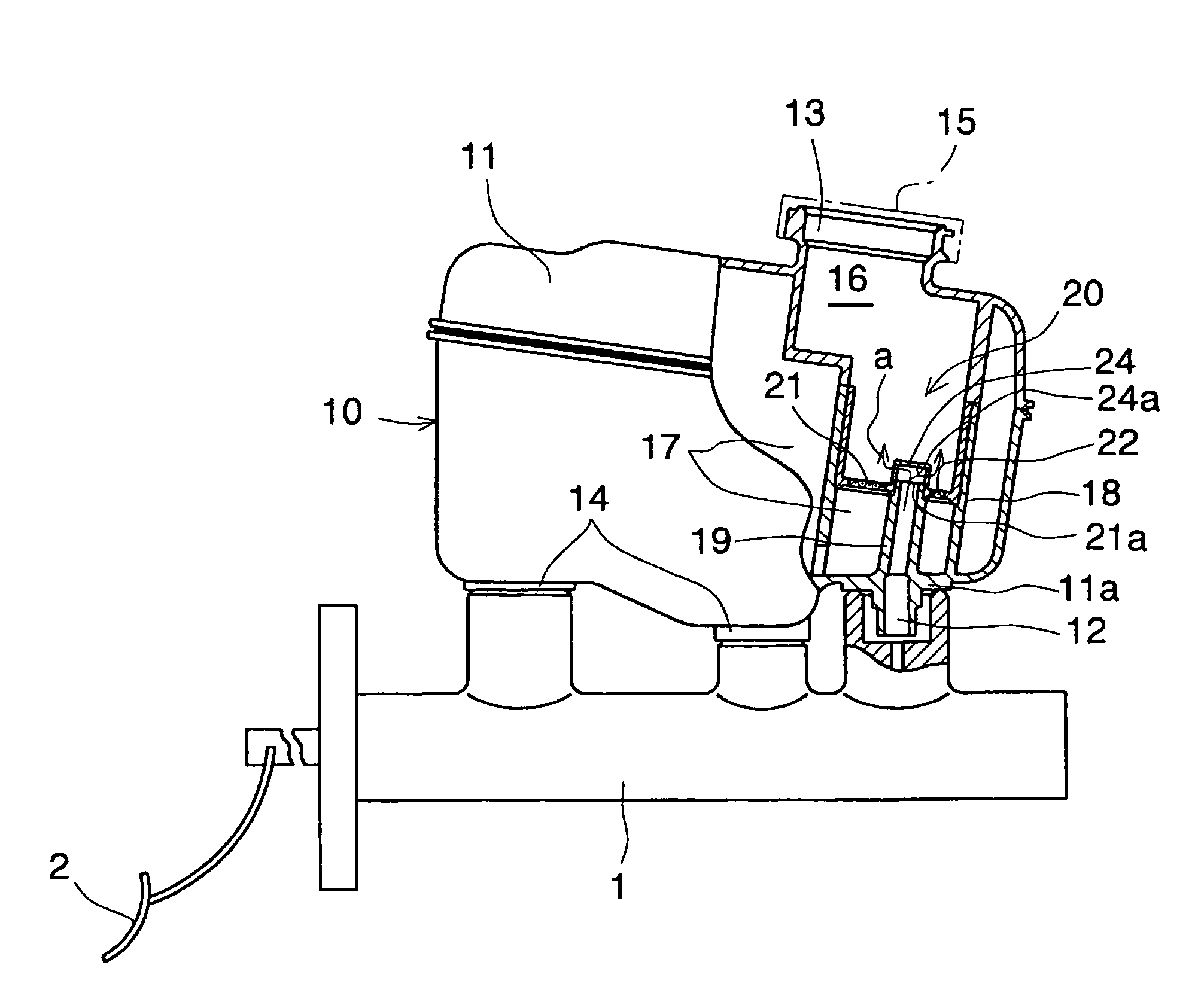

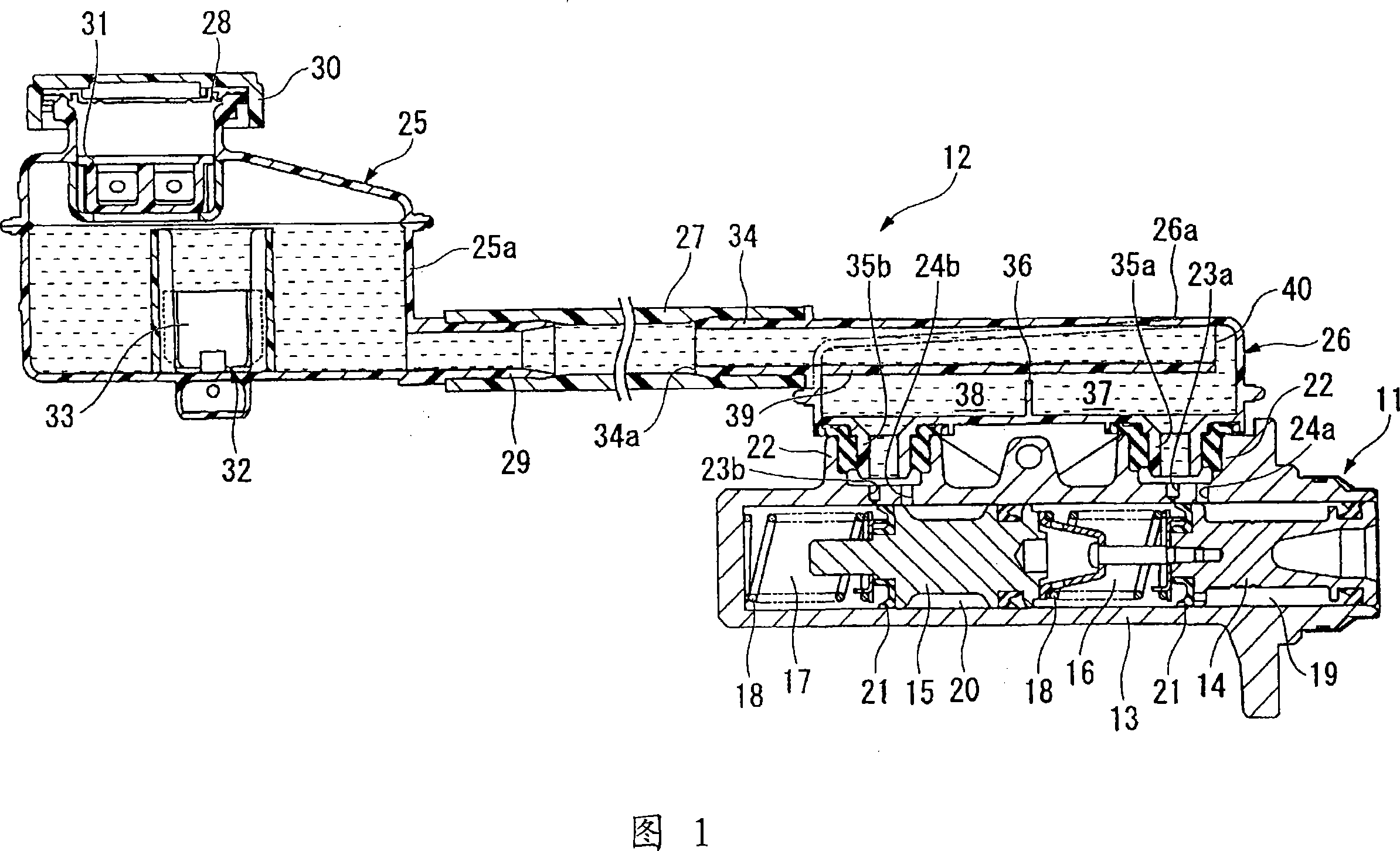

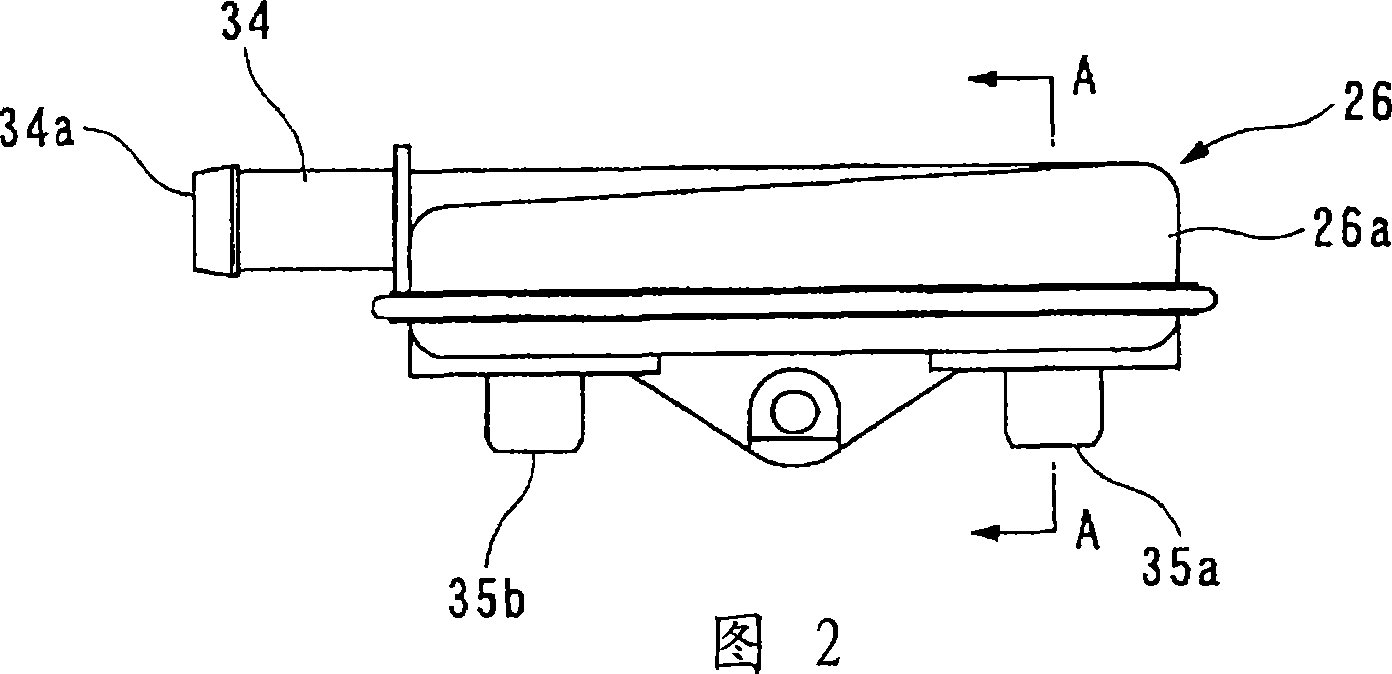

Storage device for vehicle brake and auxiliary tank

InactiveCN101062681ALower the liquid levelImprove maintainabilityFluid braking transmissionReservoir arrangementsMaster cylinderBrake fluid

The present invention provides a brake fluid storage device for a vehicle and an auxiliary tank used in the storage device. The storage device can improve maintainability when the brake fluid is replenished, etc., and can also be reliably used when the vehicle is tilted. The brake fluid level in the auxiliary tank is suppressed from falling. A main tank (25) having a brake fluid injection port (28) at the top and an auxiliary tank (26) having communication ports (35a, 35b) with the master cylinder (11) are connected by pipes (27). Make the connection port (34) of the main tank (25) side of the auxiliary tank (26) extend into the tank body (26a), and arrange the opening end (40) of the connection port (34) on the pipe (27) from The auxiliary tank (26) is positioned farther from the main tank (25) than the conduction port (35a) toward the main extension direction of the main tank (25).

Owner:HITACHI LTD

Fixing of a brake-fluid reservoir

The invention relates to a brake fluid reservoir comprising at least two lateral mounting lugs (10, 11) designed to be placed either side of a central mounting lug (20) of a brake master cylinder. Collinear holes (12, 13, 21) traverse these lugs and are designed to receive a mounting pin (3). The said lugs include at least one device for the axial immobilization of the mounting pin (3). Applications: brake fluid reservoir mounting.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com