Assembly made of a compensating tank and a master cylinder for a hydraulic motor vehicle brake system

A technology for hydraulic braking and motor vehicles, which can be applied to hydraulic braking transmissions, connecting components, mechanical equipment, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

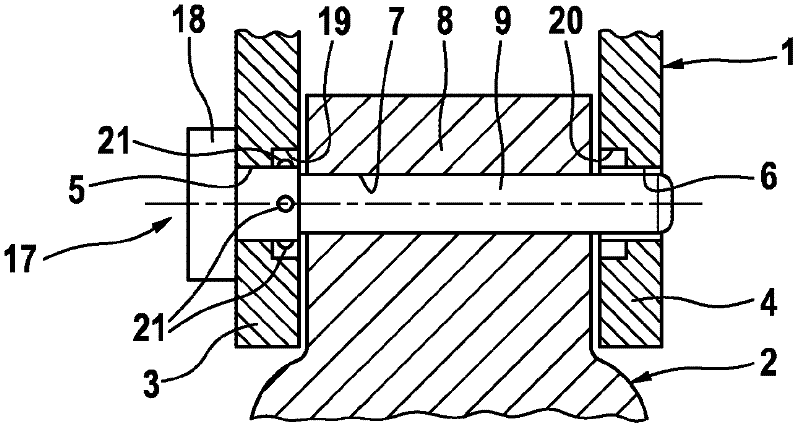

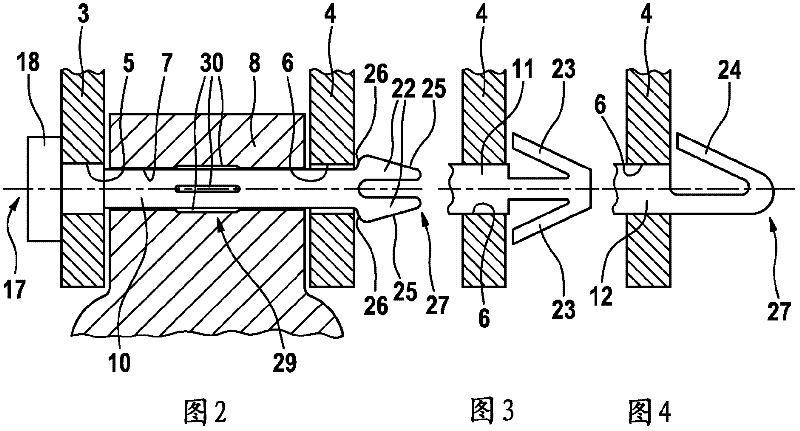

[0030] Figure 1 to Figure 10 An embodiment of an assembly comprising a compensating container 1 and a master cylinder 2 according to the invention is shown schematically for a hydraulic brake system of a motor vehicle, the structure and function of which are basically known. After the compensation container 1 has been mounted on the master cylinder 2, its non-illustrated connection piece is accommodated in a corresponding port of the master cylinder 2, and the pressure medium chamber of the compensation container 1 is connected to the main cylinder in a known manner. The pressure spaces (pressure zones) of cylinders 2 are connected.

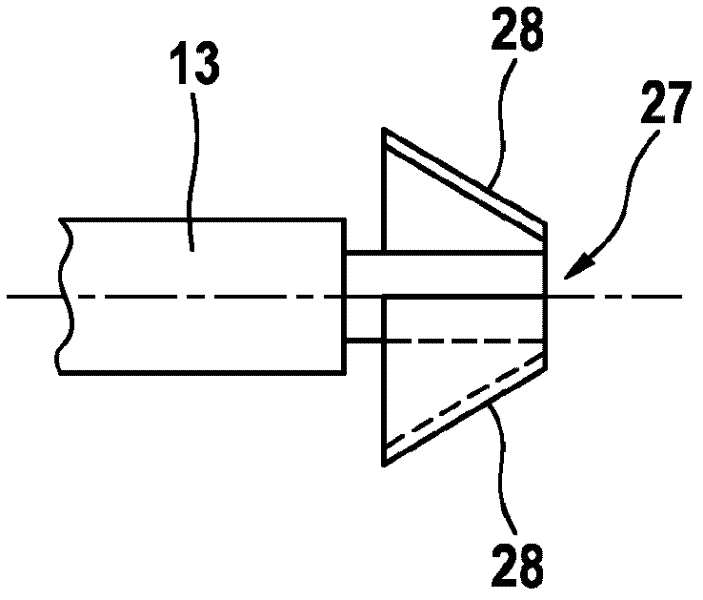

[0031] For a releasable connection to the master cylinder 2 , the compensation container 1 has two fastening fittings 3 , 4 which each have an opening 5 , 6 . These openings 5 , 6 are aligned with the opening 7 of the master cylinder 2 after the compensation container 1 has been mounted on the master cylinder 2 . For fastening, fastening pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com