Patents

Literature

589results about "Air treatment devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

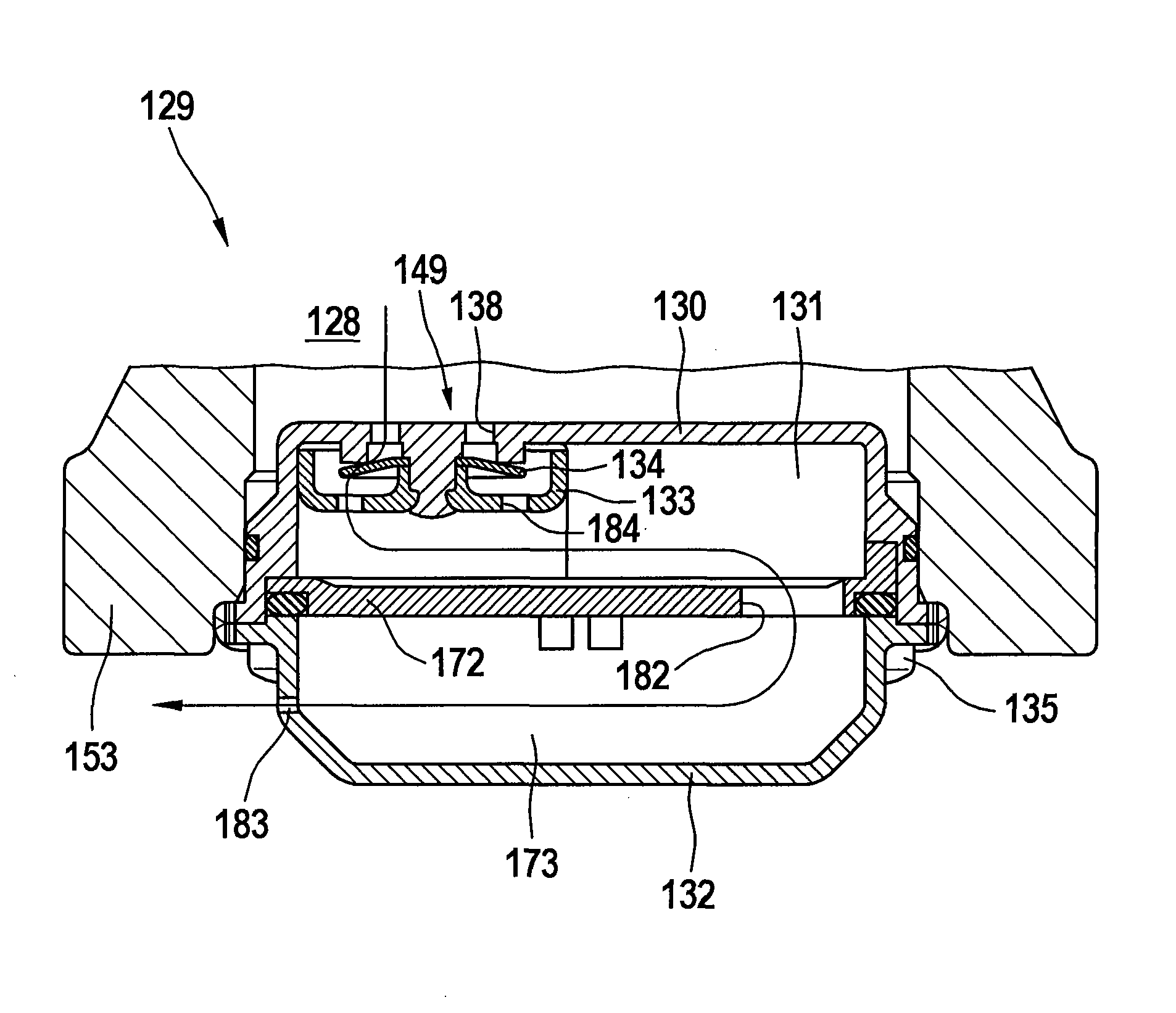

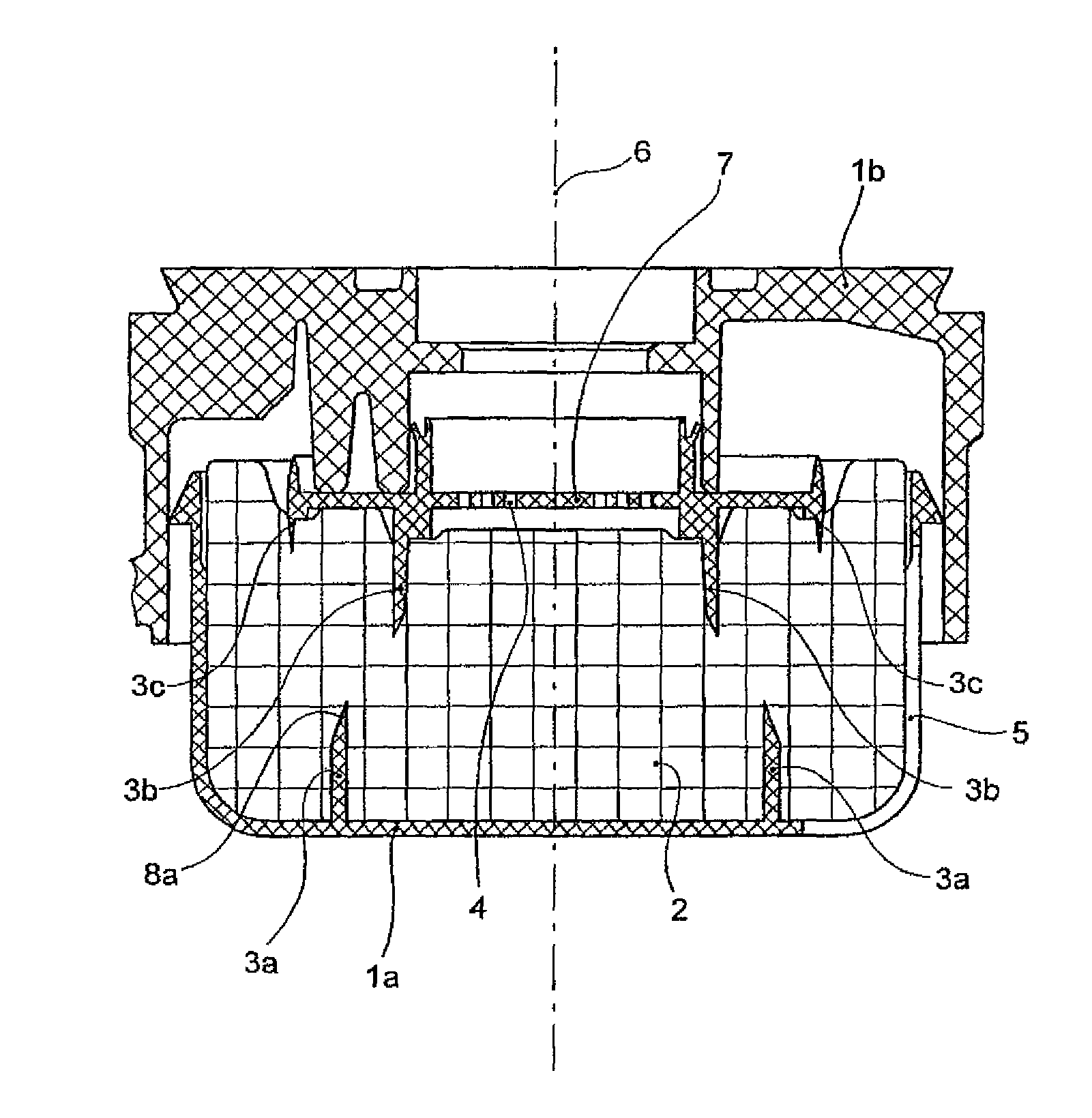

Cartridge for cleaning compressed air in compressed air supply systems of motor vehicles

ActiveUS20060123743A1Reduce continued transferExtended service lifeDispersed particle filtrationAir treatment devicesCheck valveTruck

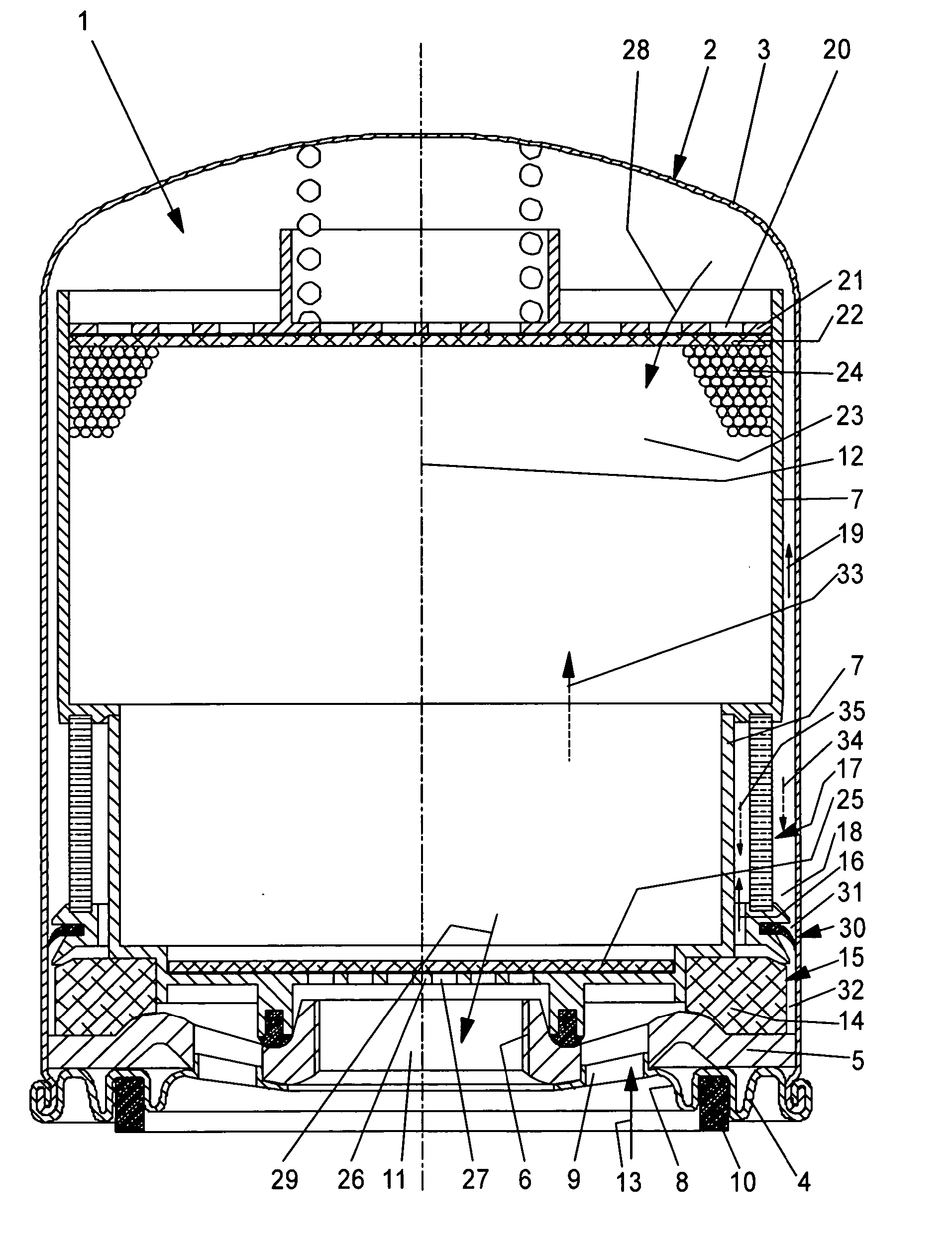

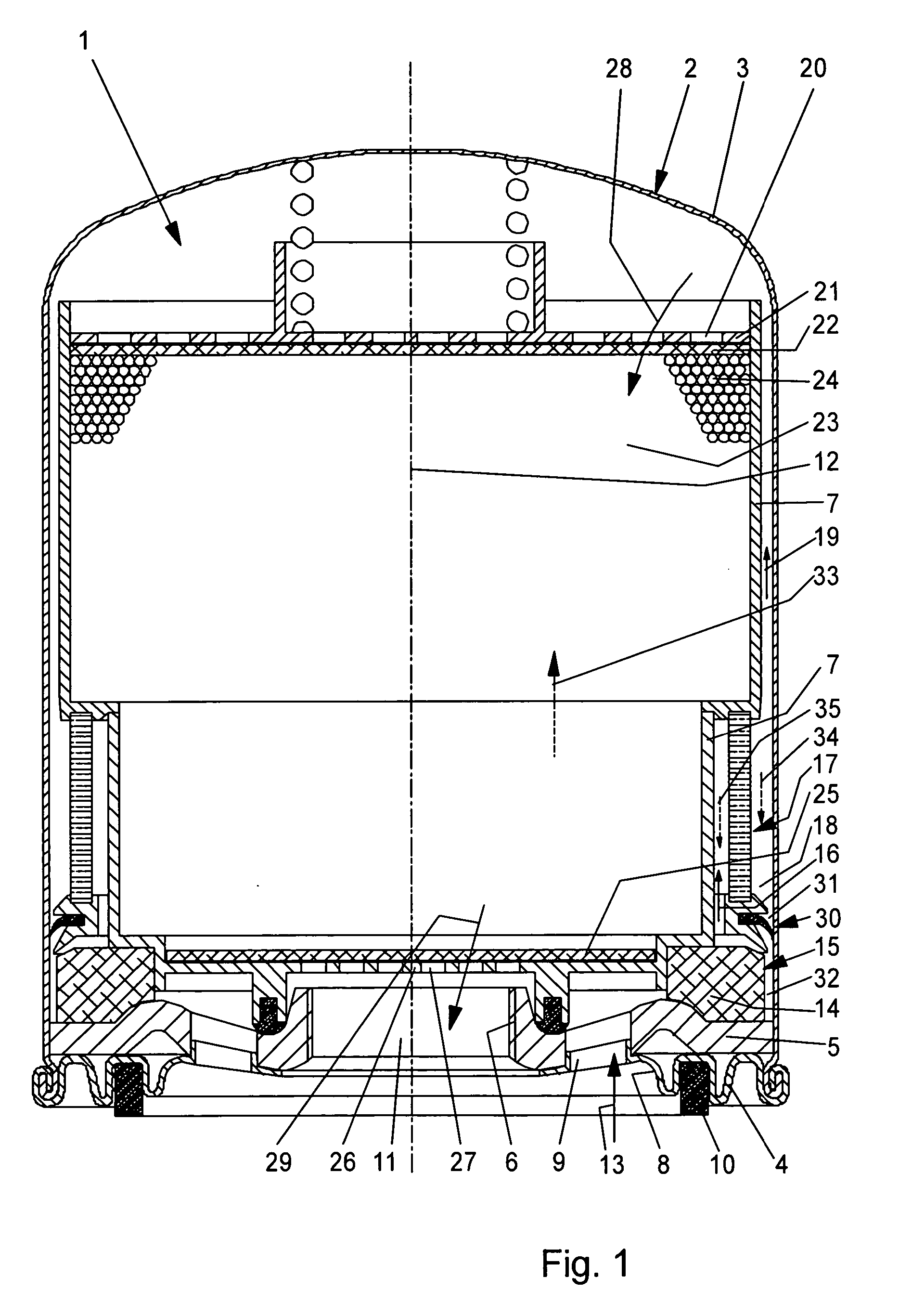

A cartridge of an air dryer serves for cleaning compressed air to be used in compressed air supply systems of motor vehicles, especially trucks. The cartridge includes a housing, a pre-filter, a deposit chamber, a coalescing filter, a bypass conduit and a check valve. The deposit chamber is located downstream of the pre-filter. The deposit chamber is filled with a treating substance. The coalescing filter is arranged between the pre-filter and the deposit chamber. The bypass conduit is designed and arranged to bypass the coalescing filter and not to bypass the pre-filter. The check valve is arranged in the bypass conduit in a way that it opens during regeneration of the cartridge.

Owner:HALDEX BRAKE PROD AB

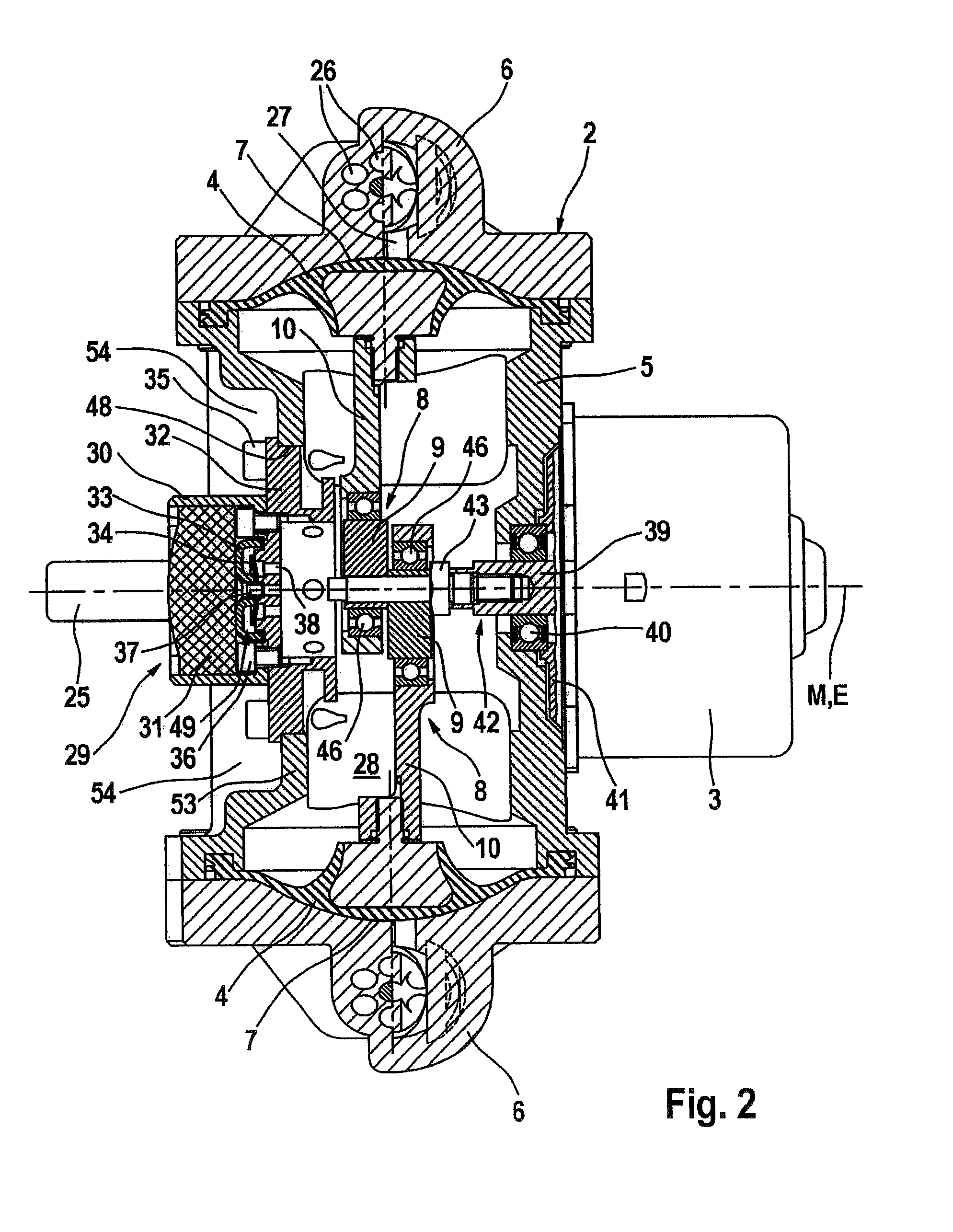

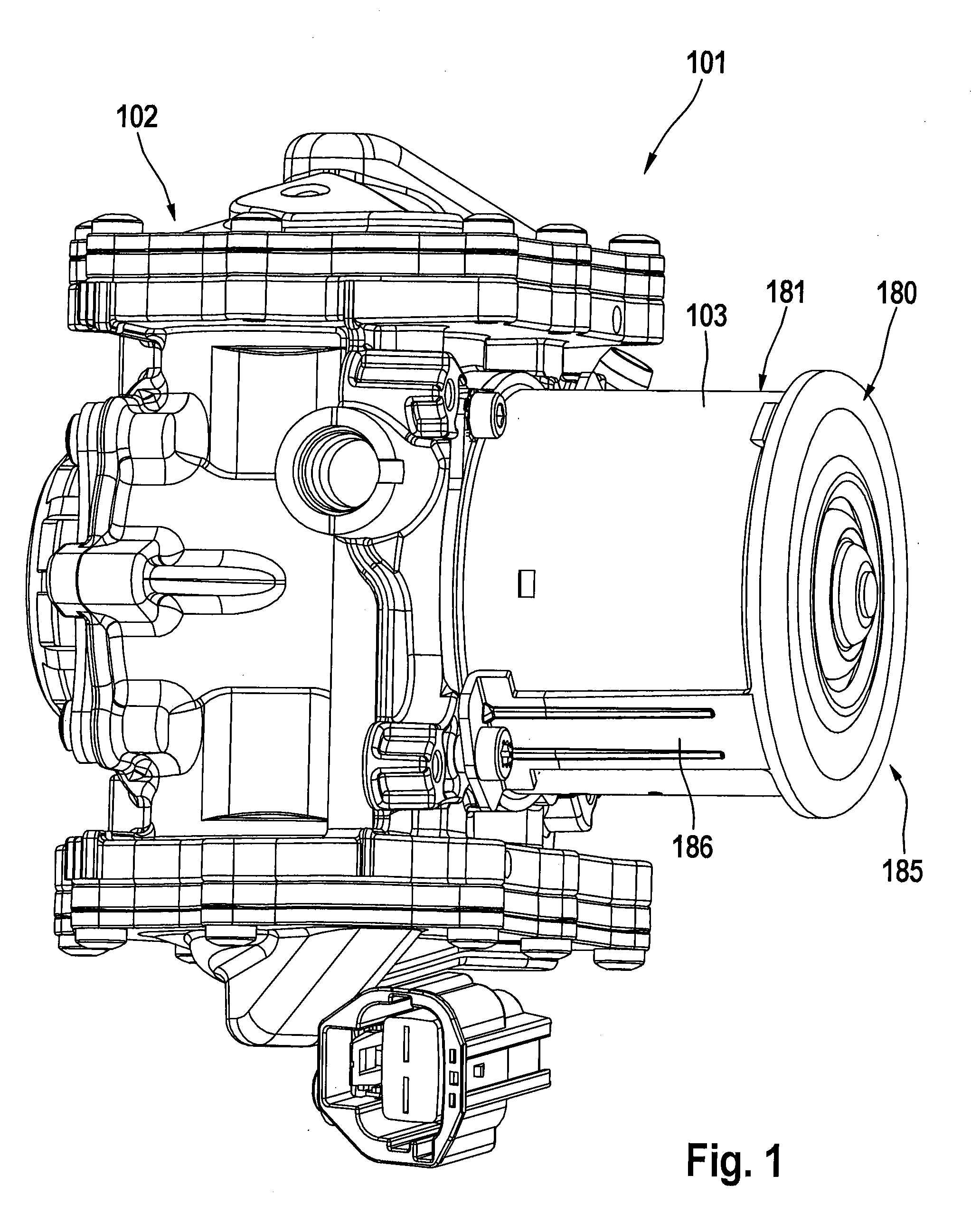

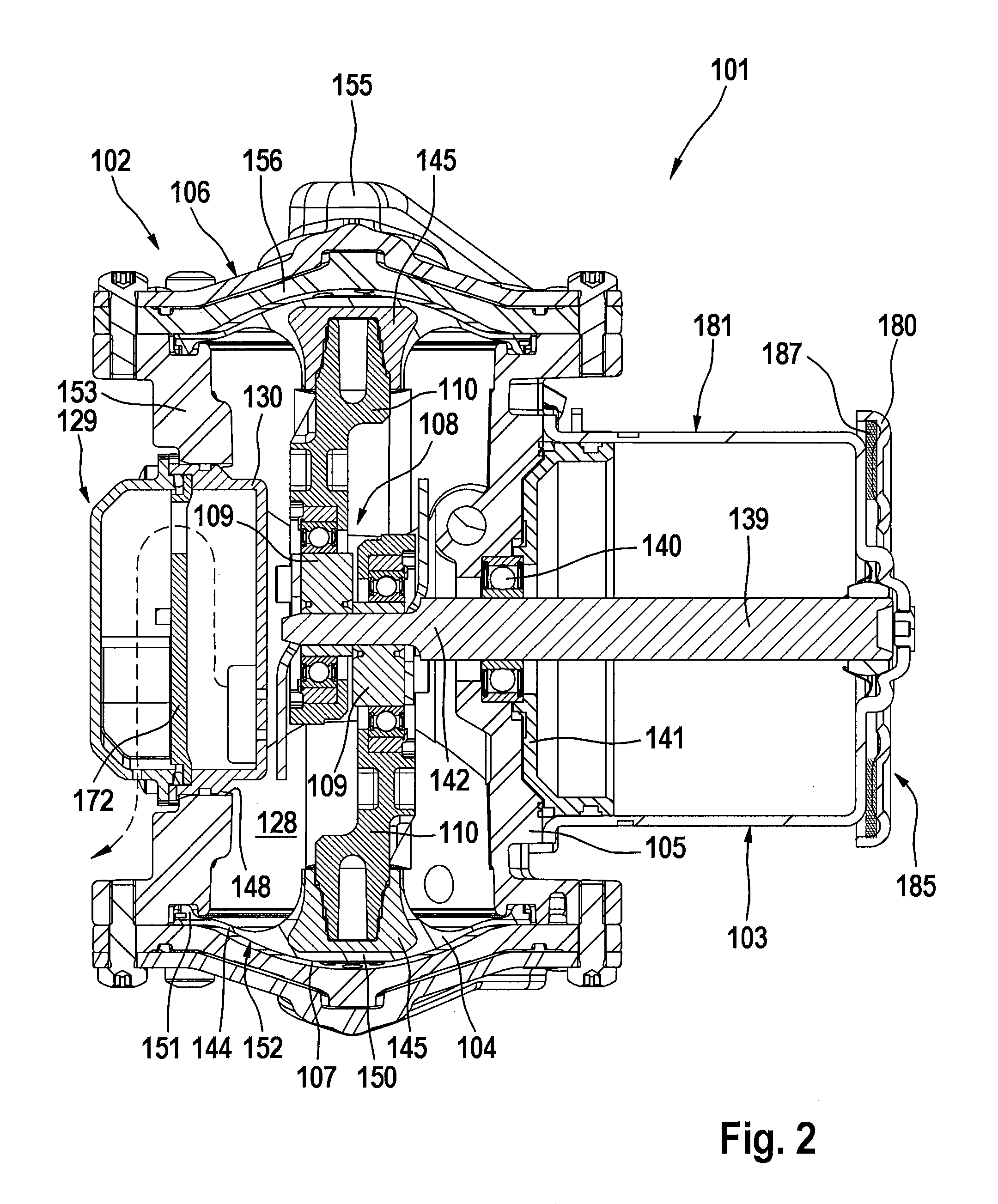

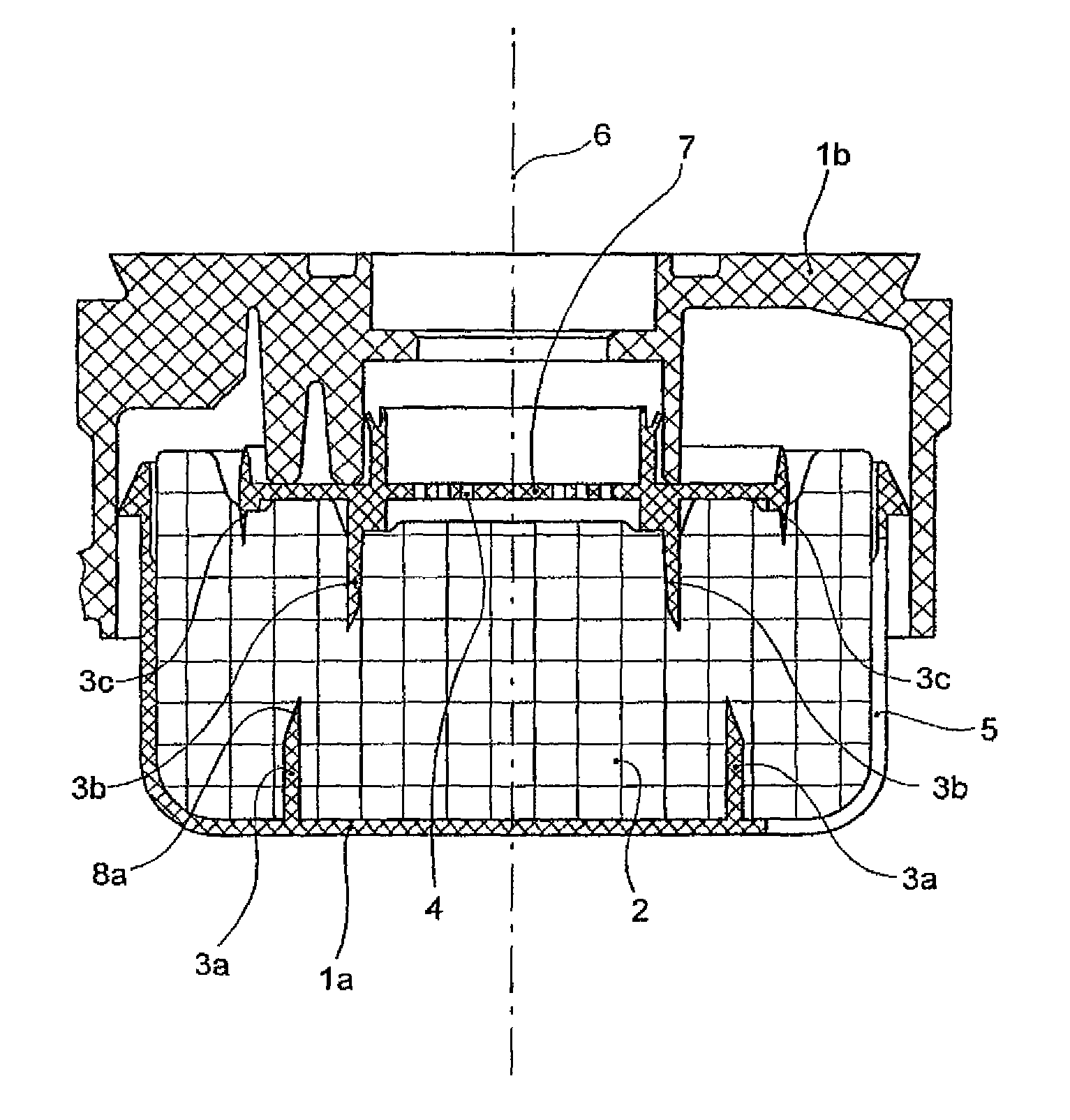

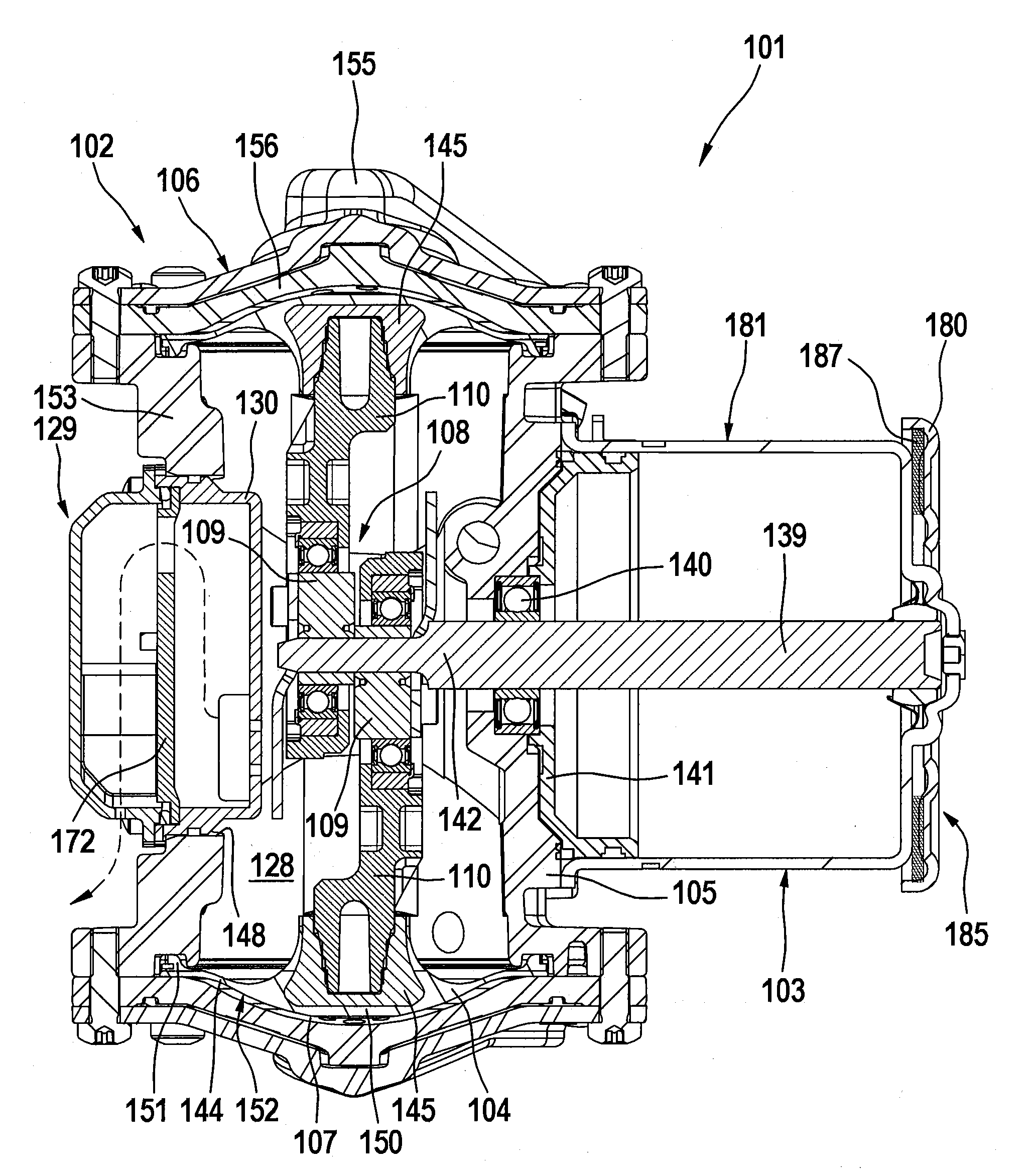

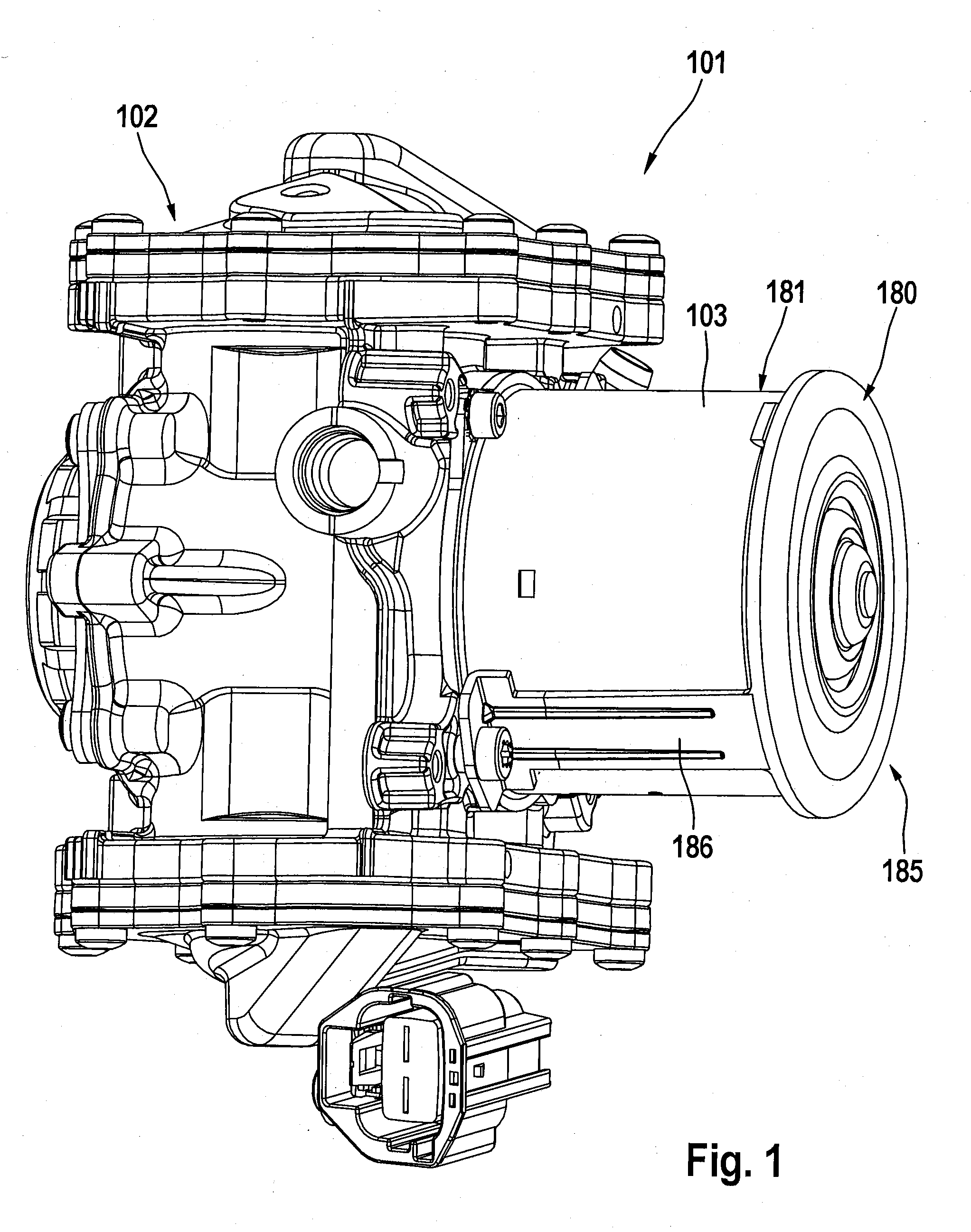

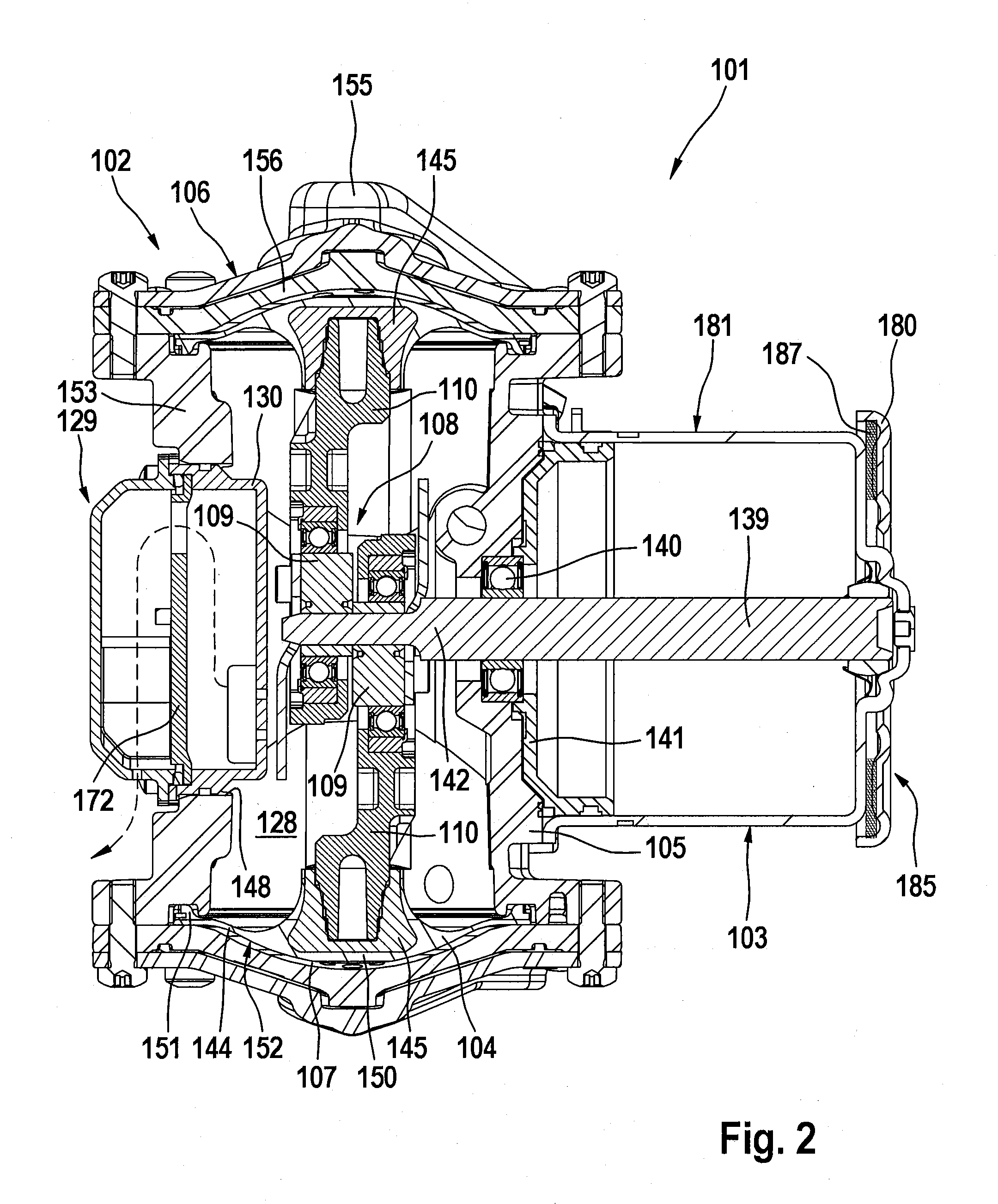

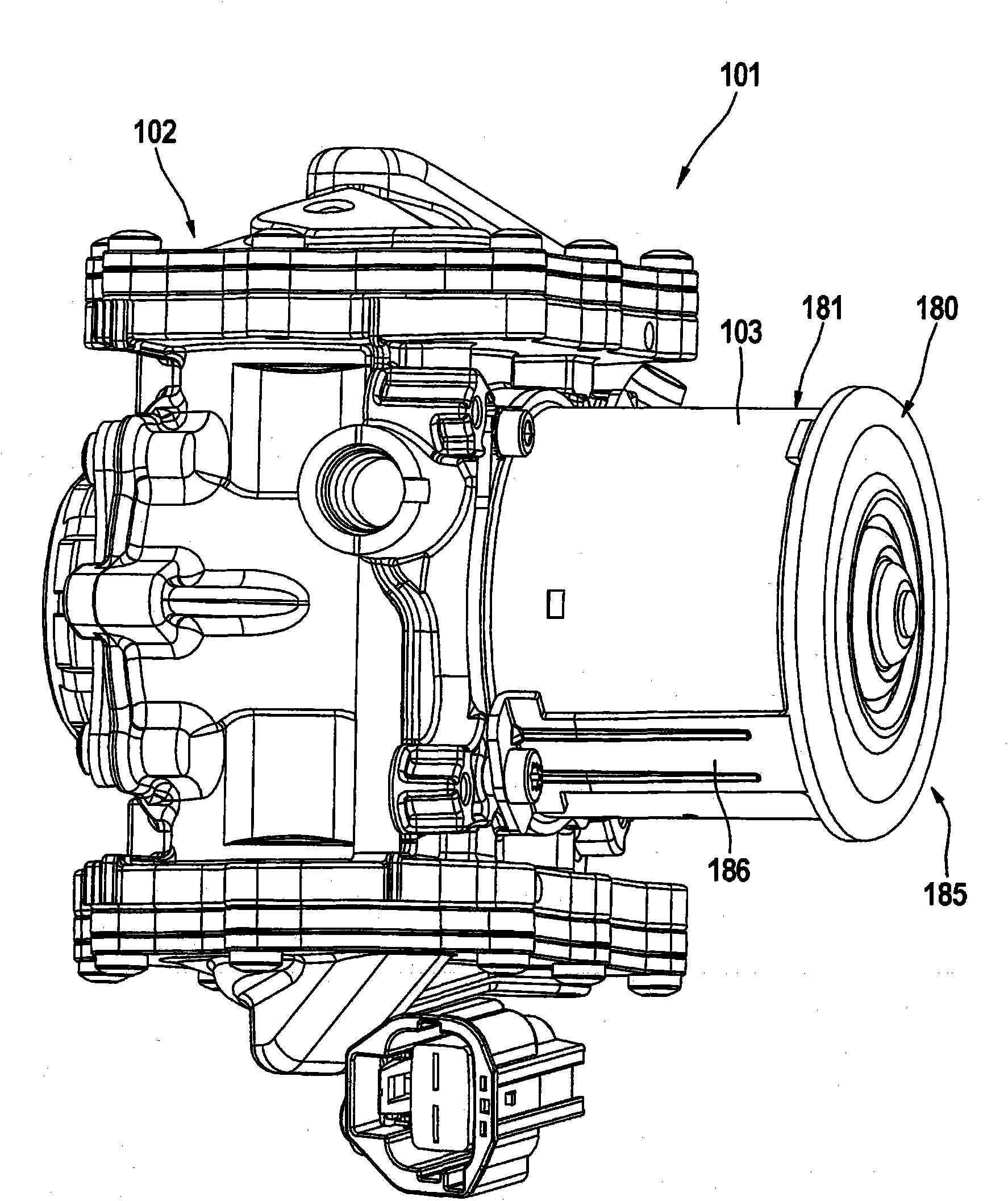

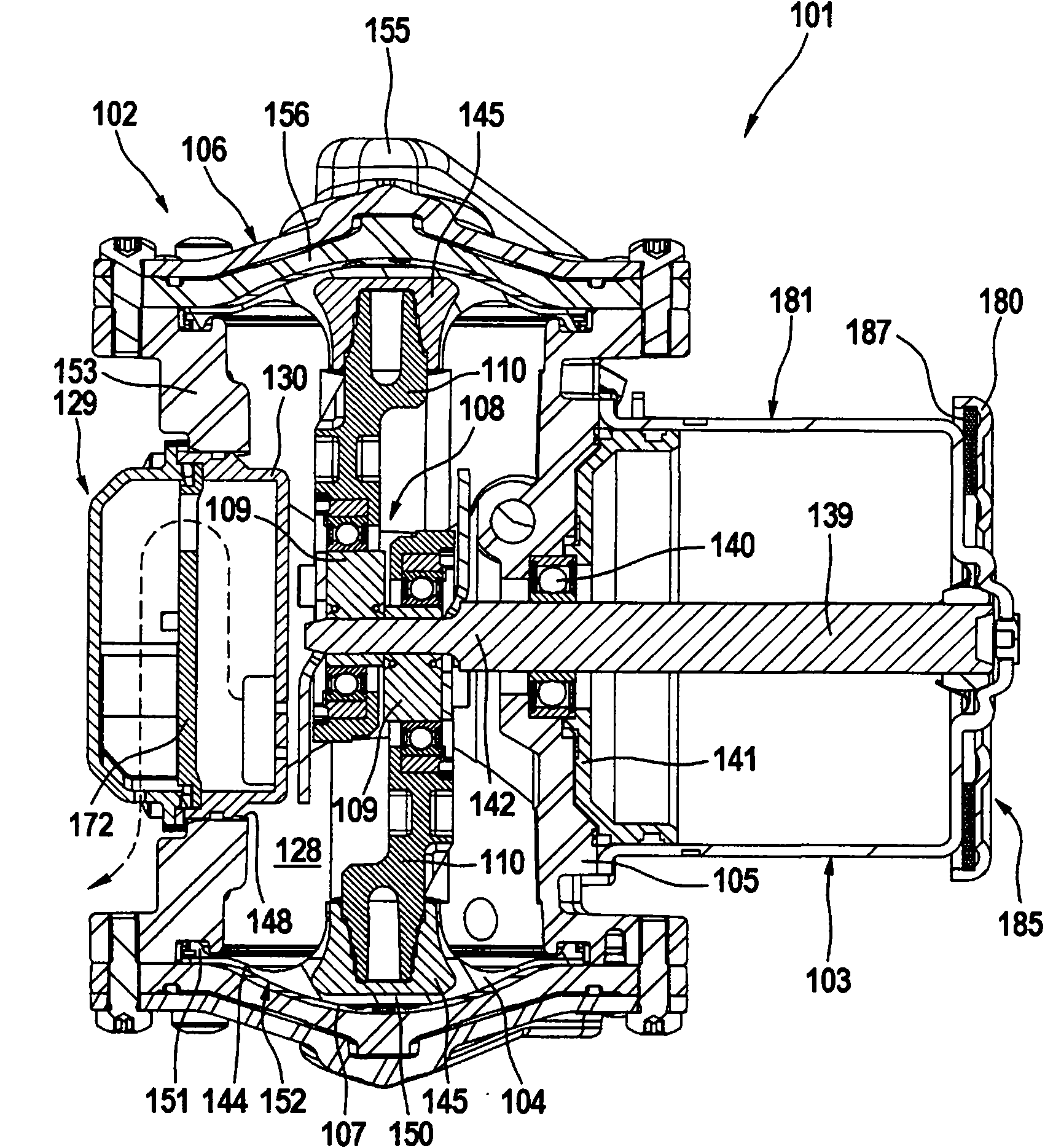

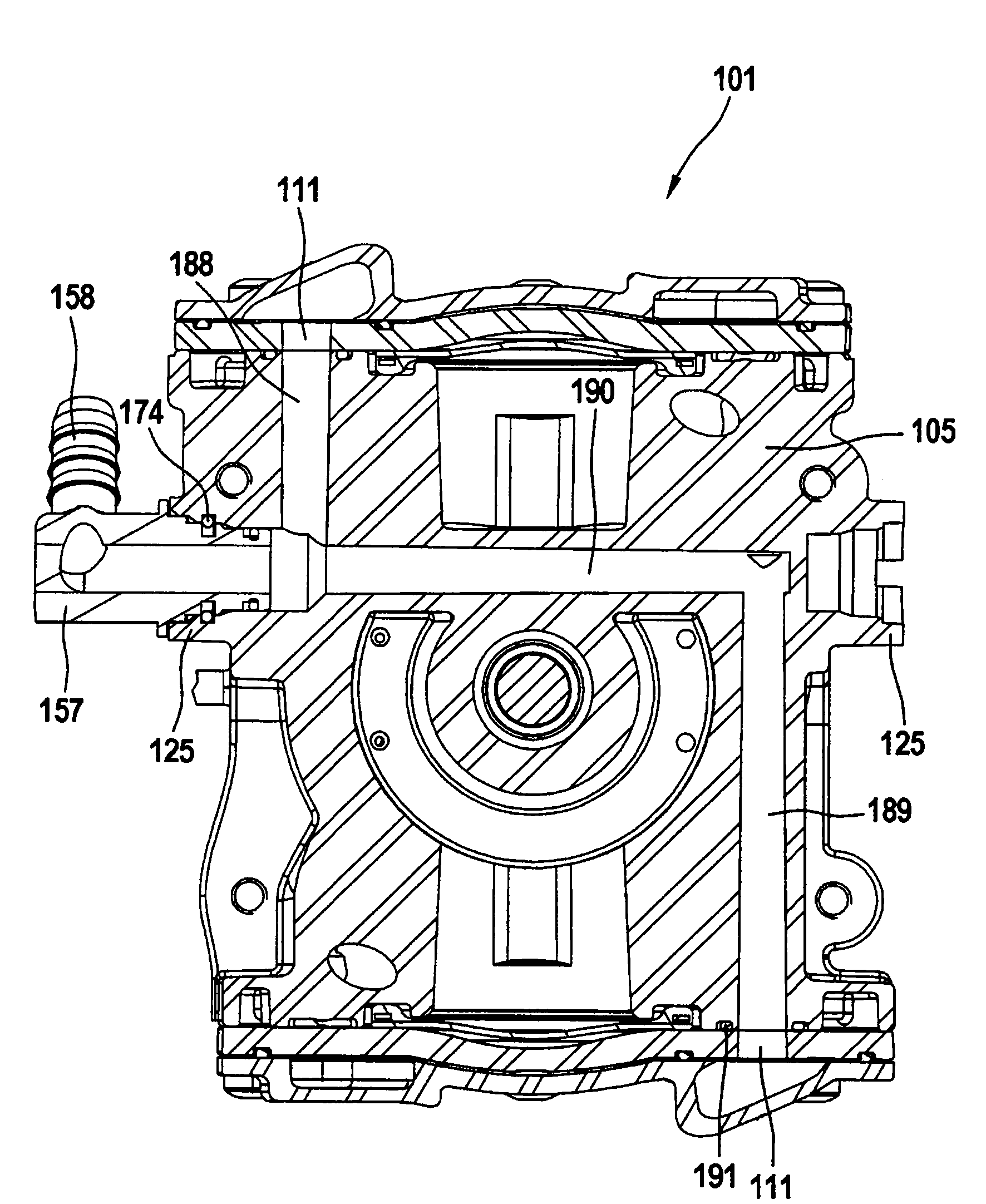

Motor/Pump Assembly

InactiveUS20100045096A1Avoid developmentReduce noisePositive displacement pump componentsBraking action transmissionInterior spaceDiaphragm pump

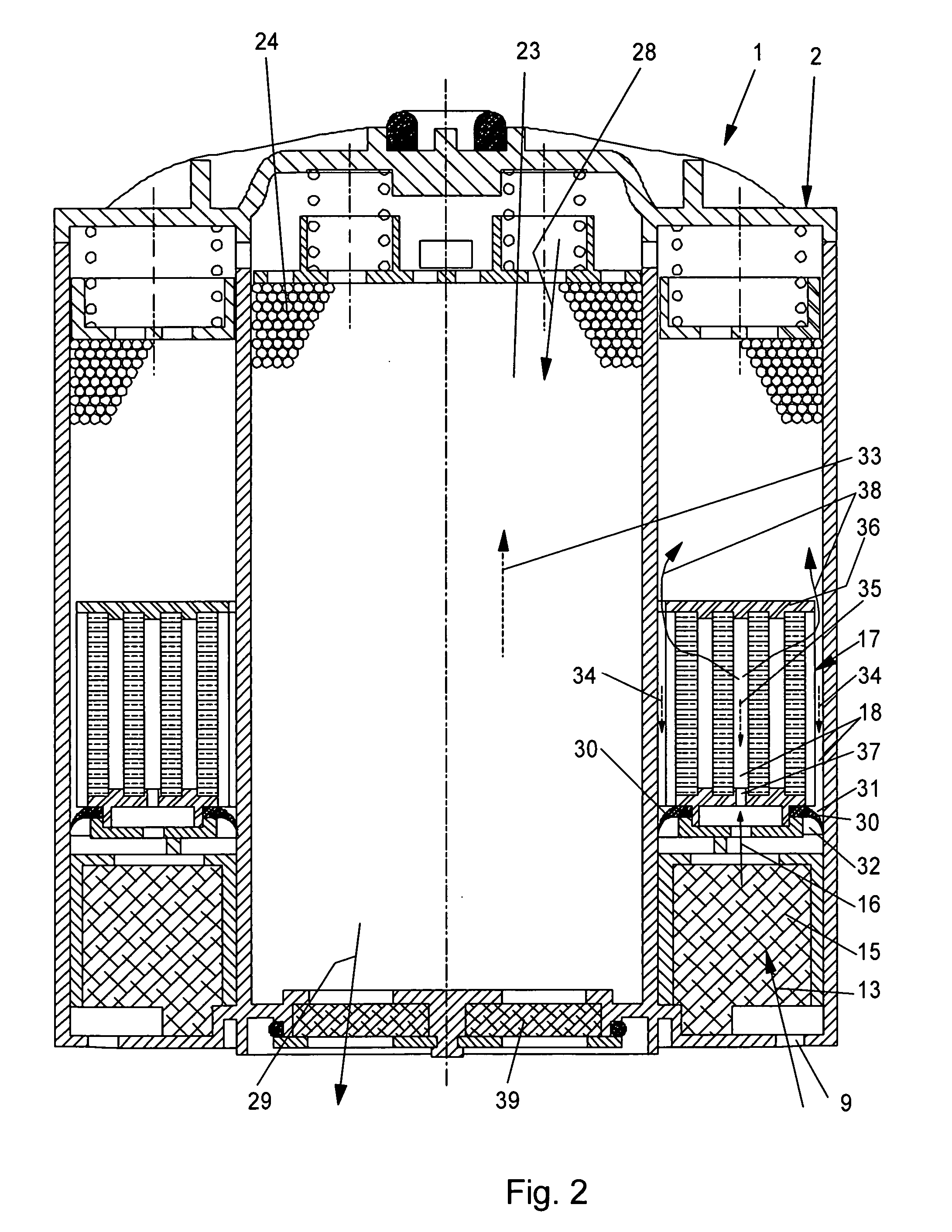

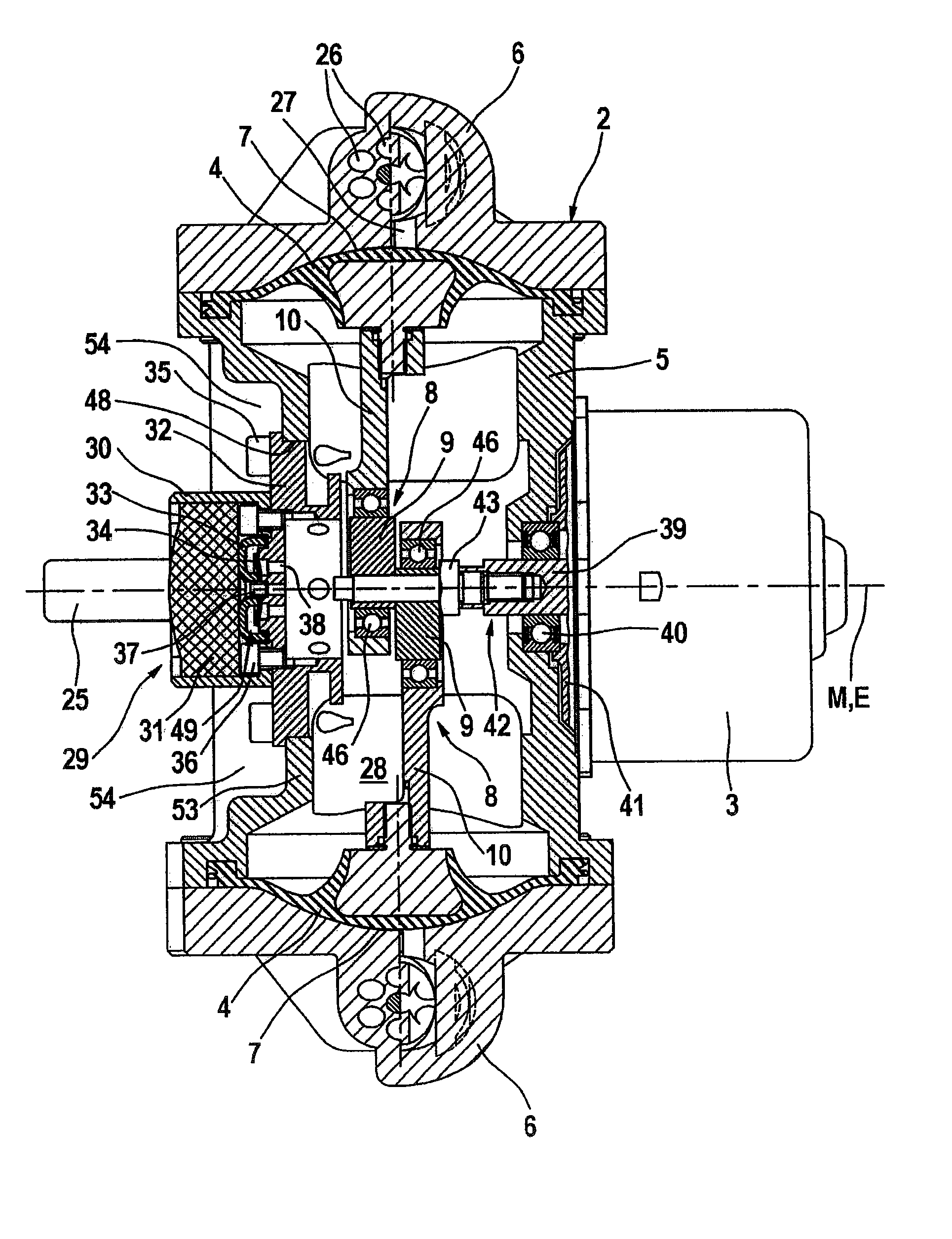

A motor and pump assembly for providing pressure to a brake actuating device of a motor vehicle brake system is described herein. The assembly comprises an electric motor and a double diaphragm pump. The pump includes a pump housing, two opposed working diaphragms, and crank drives each being coupled between the electric motor and a respective diaphragm for moving the diaphragm. A working chamber is defined between the pump housing and a working chamber cover. Each working chamber including an inlet channel, an inlet valve associated with the inlet channel, an outlet channel, and an outlet valve associated with the outlet channel, wherein the outlet channels are defined in the covers of the working chamber and in the pump housing to direct air displaced from the working chambers into an inside space of the pump housing. An air outlet unit is provided for exhausting the air from the inside space.

Owner:CONTINENTAL TEVES AG & CO OHG

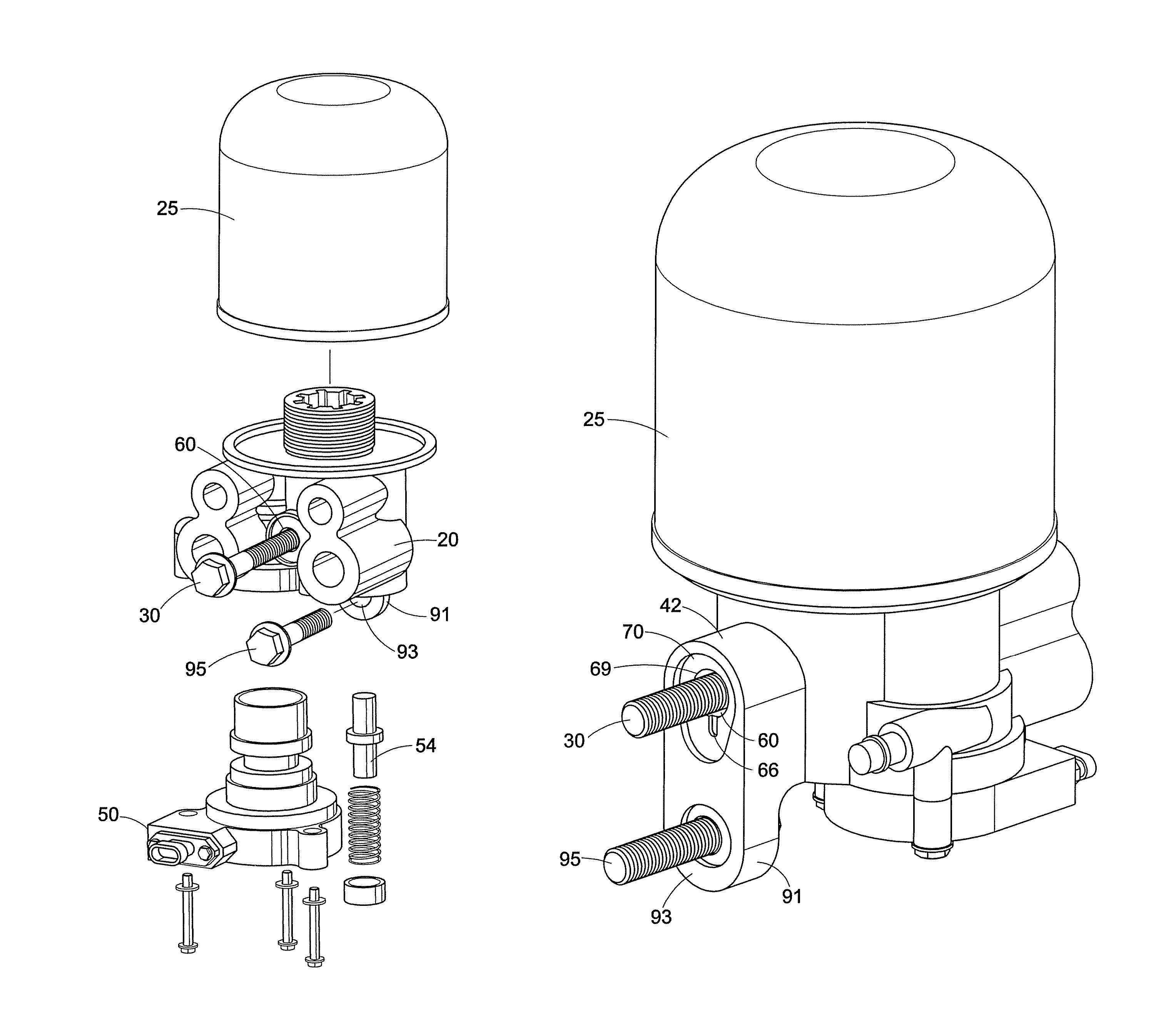

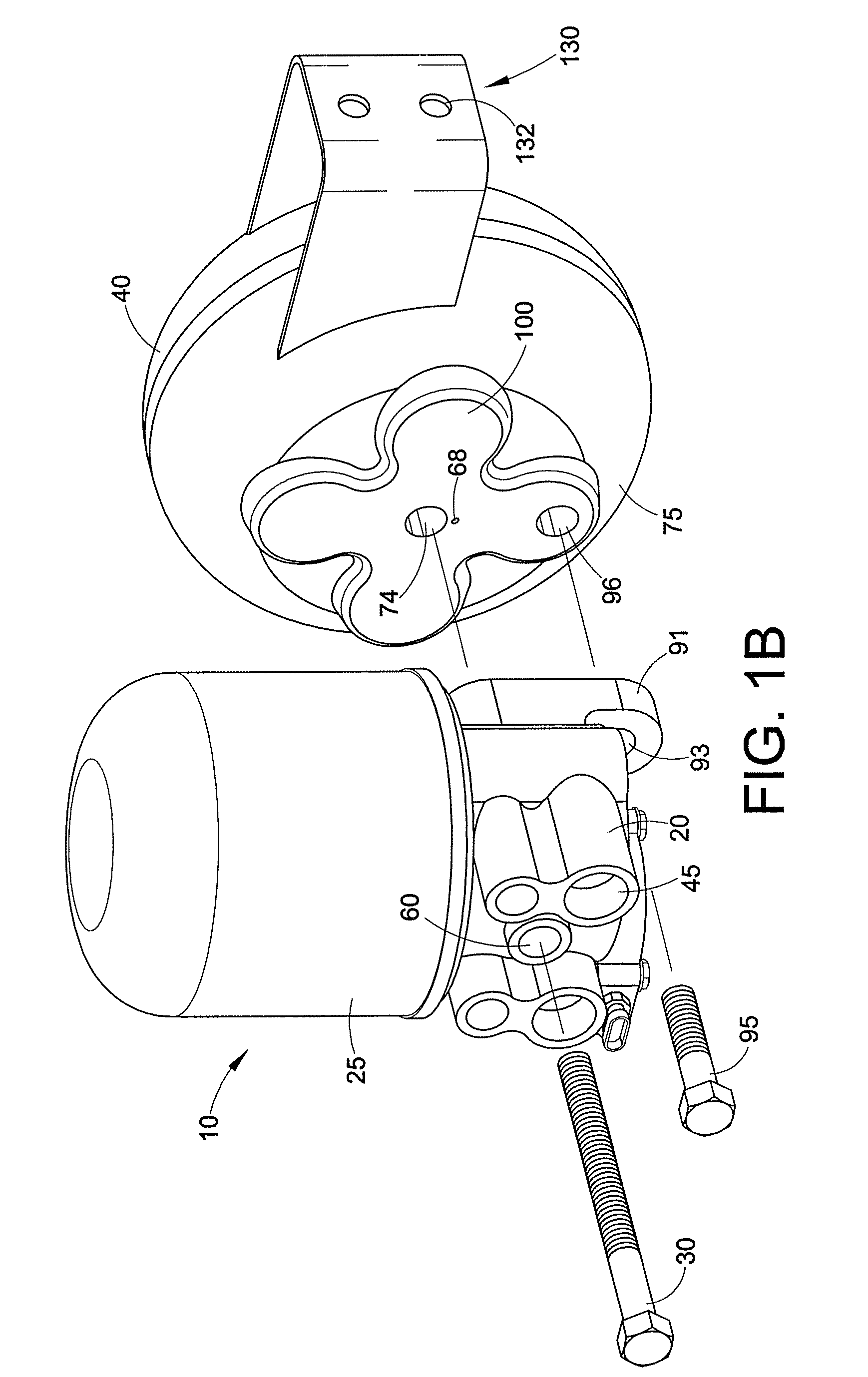

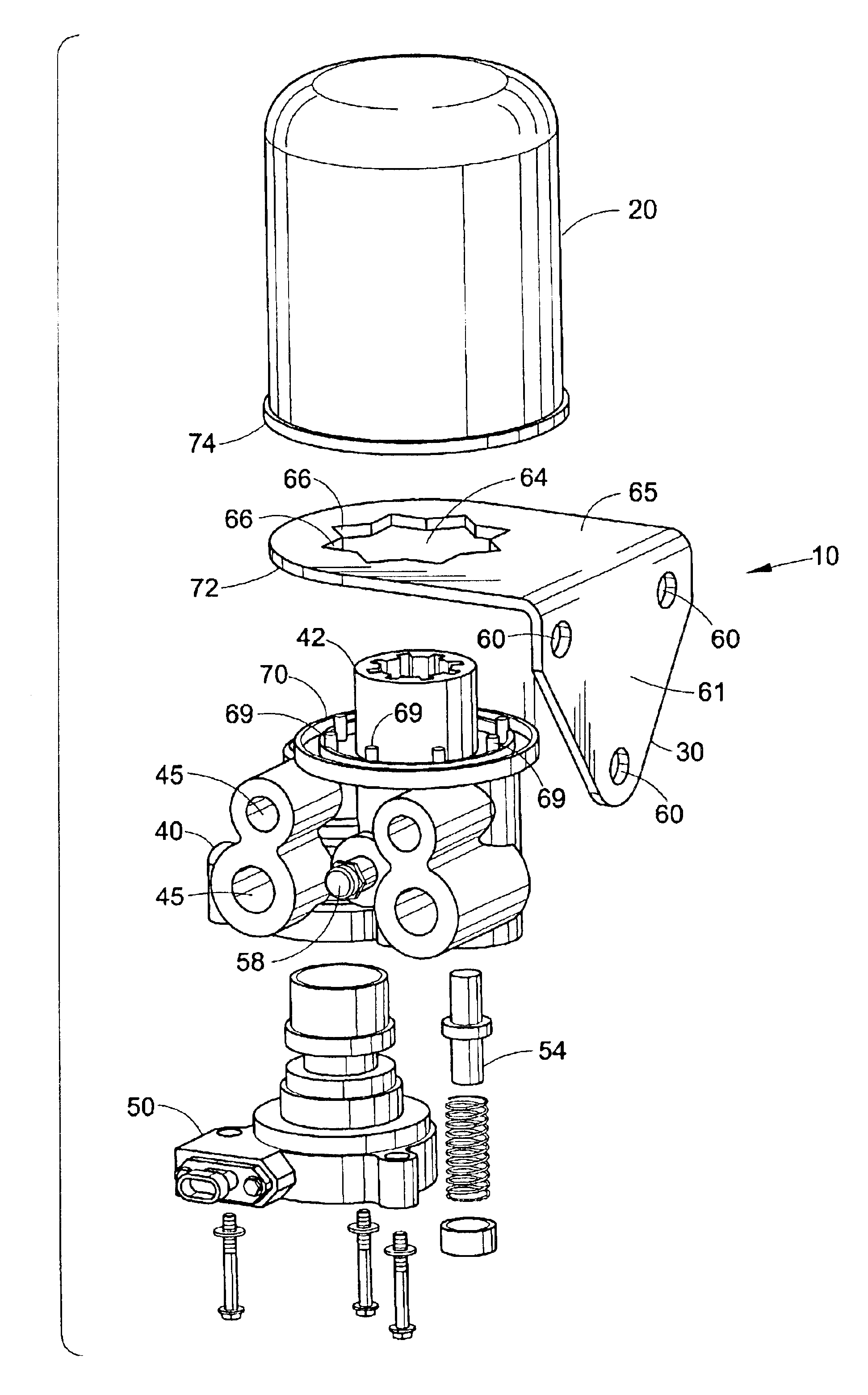

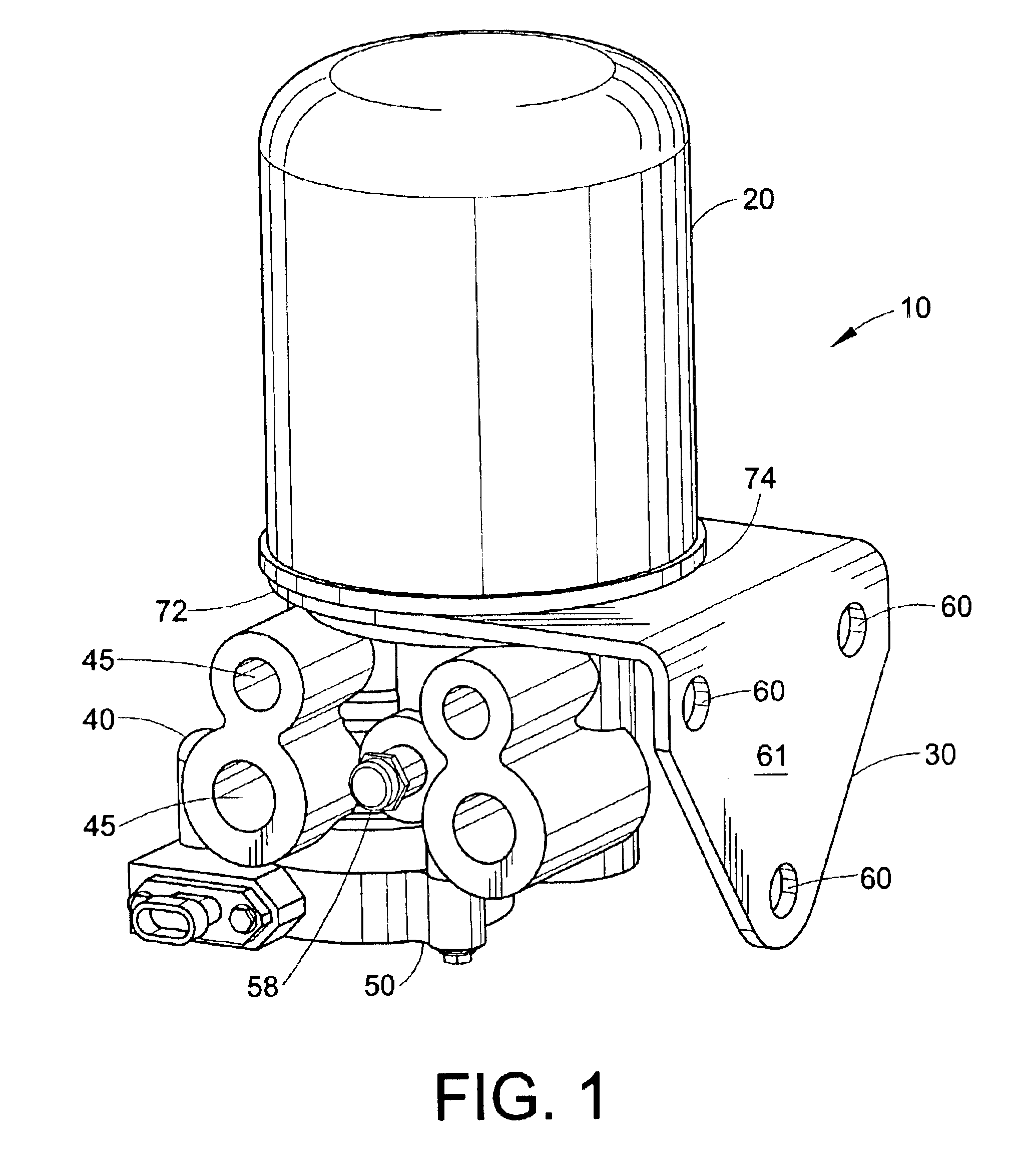

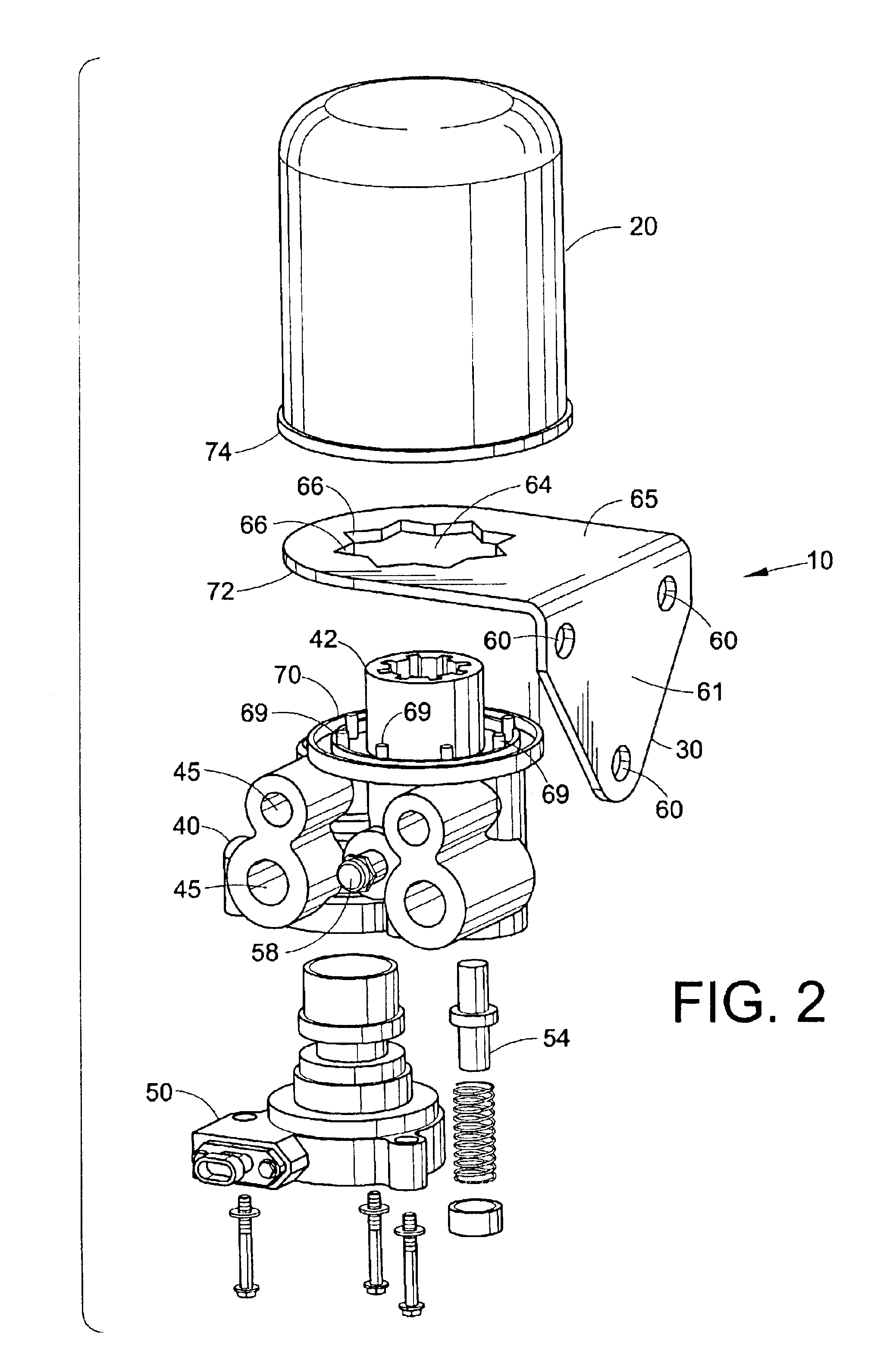

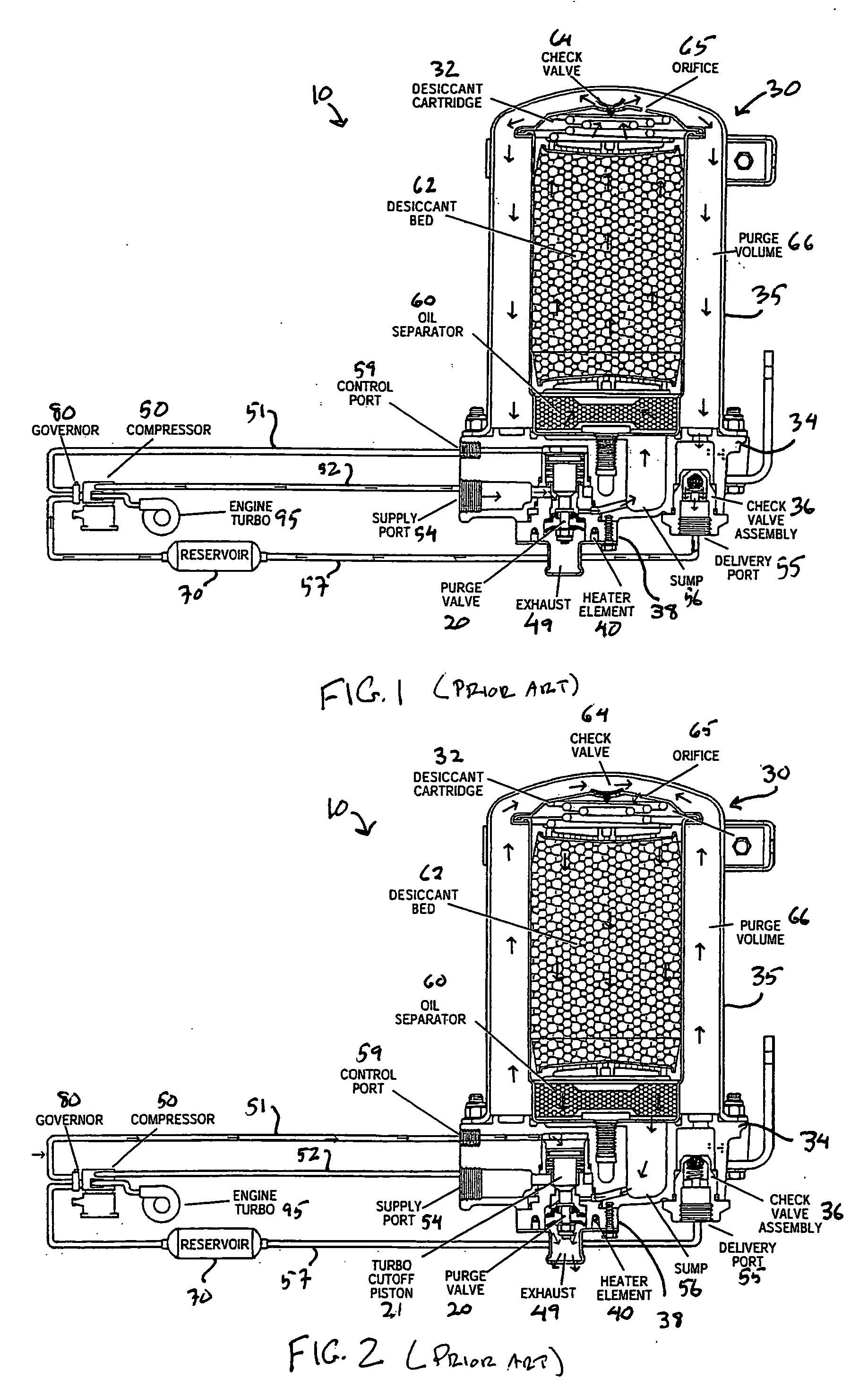

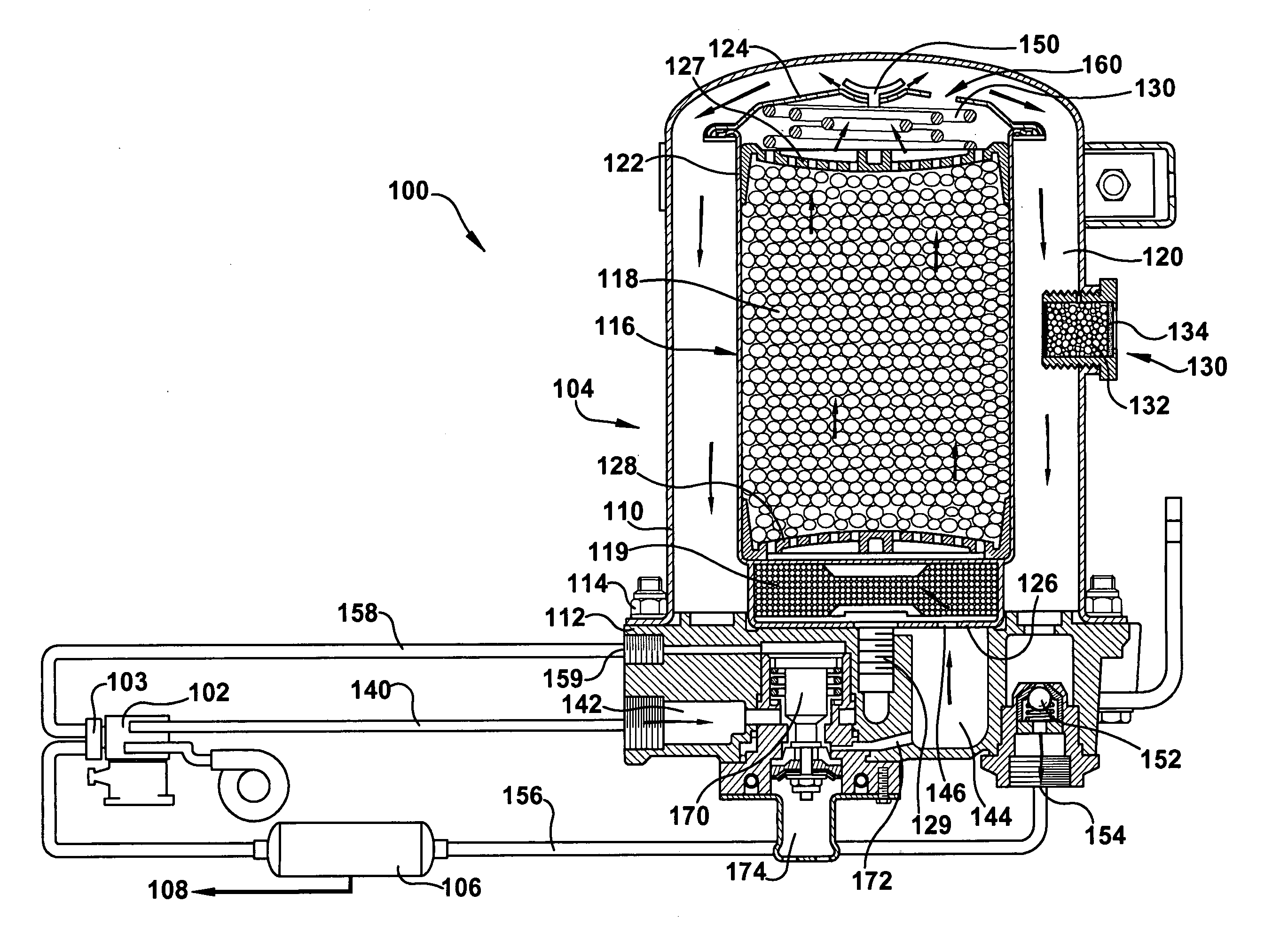

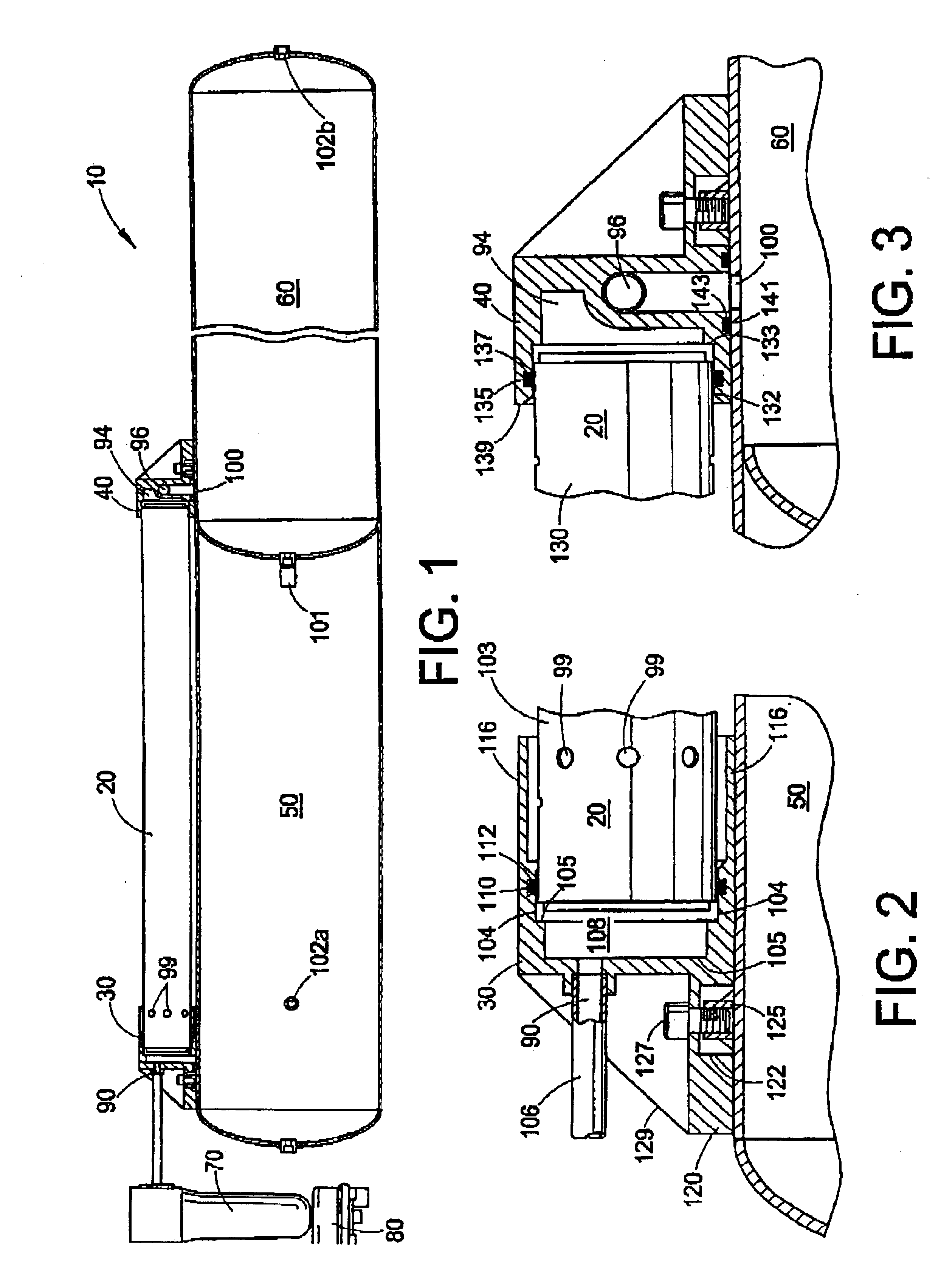

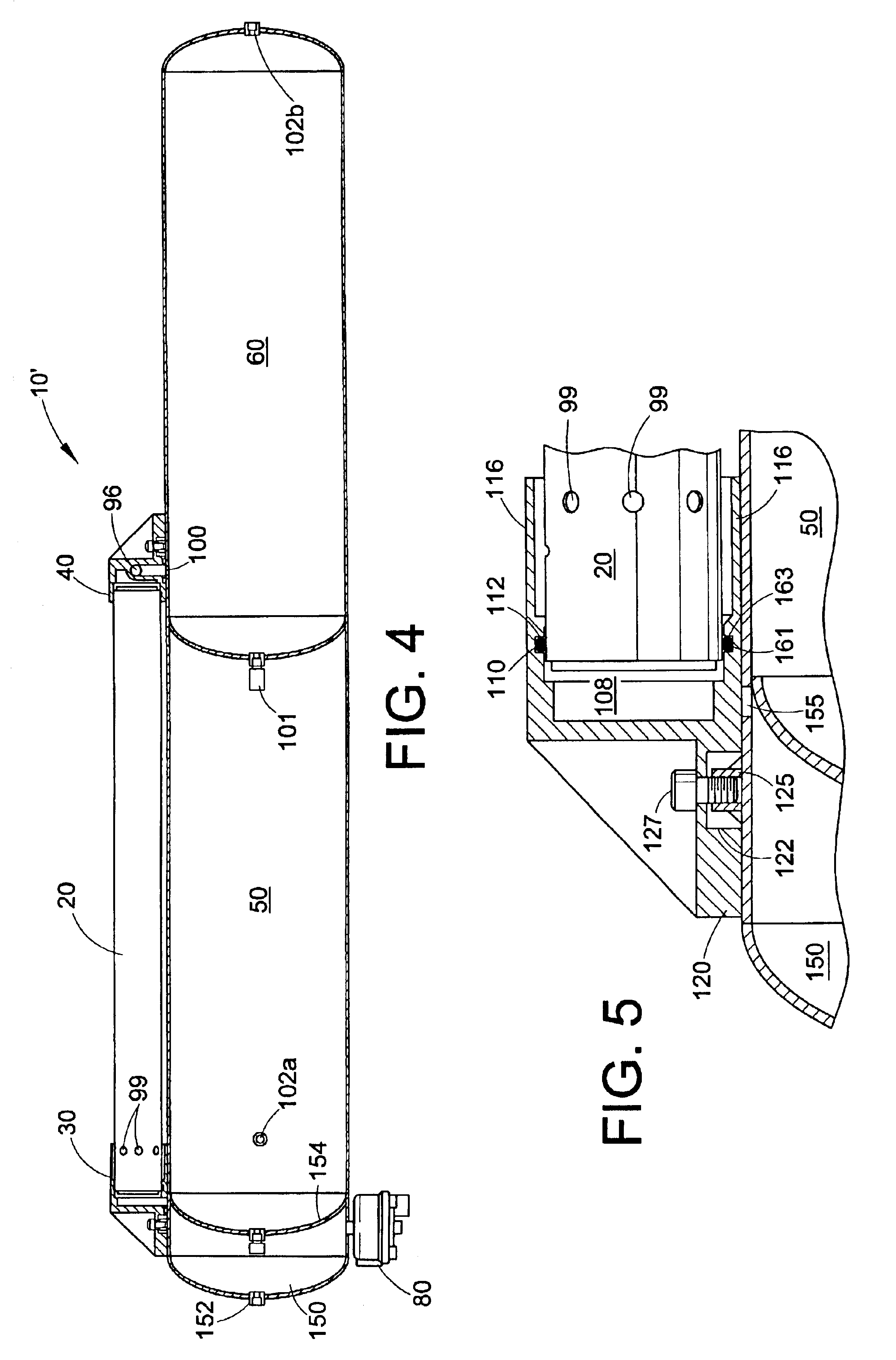

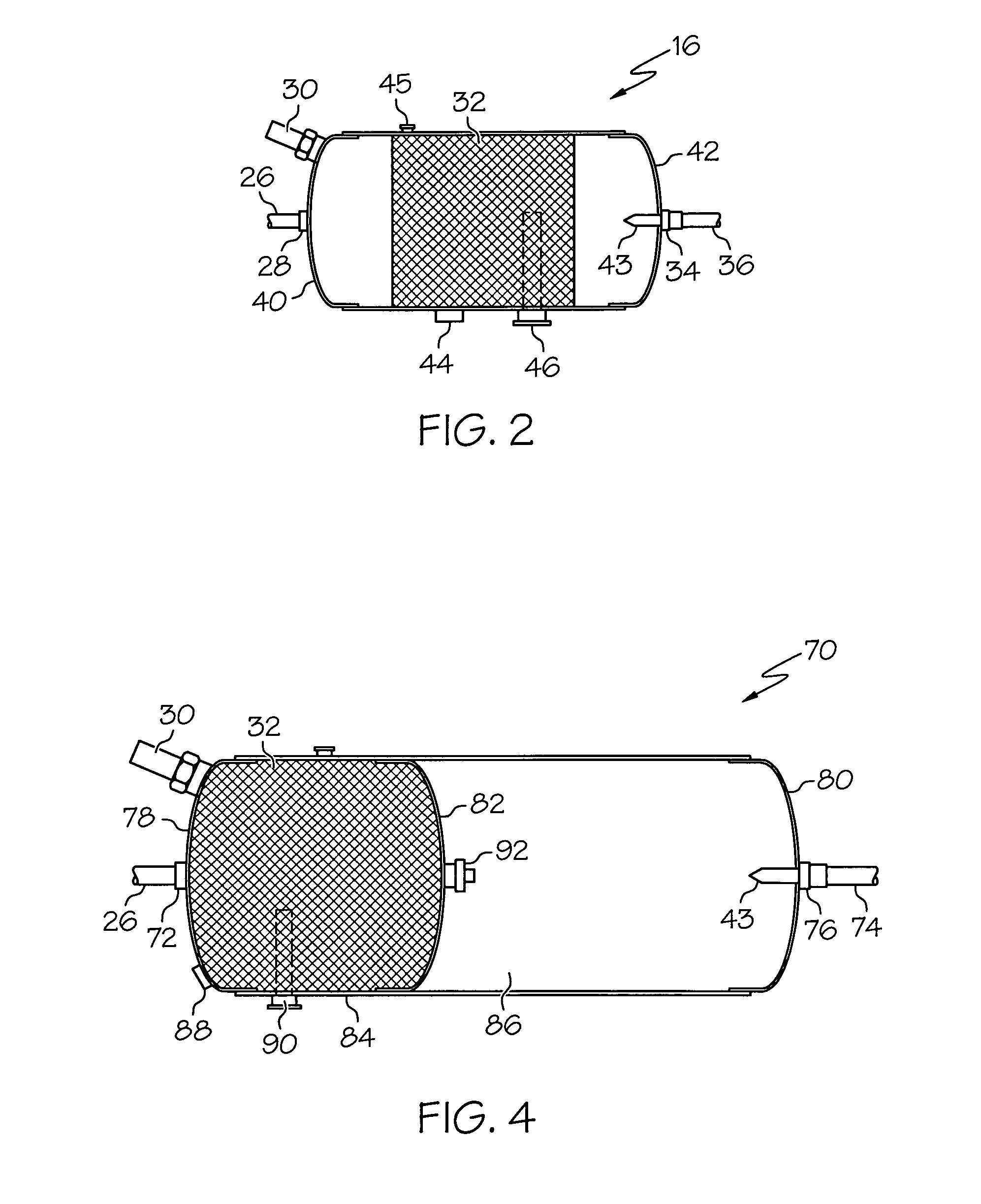

Air dryer mounting assembly

InactiveUS7100305B2Easy to assembleThe process is compact and efficientCombination devicesPipe supportsDesiccantEngineering

An improved system and method for mounting an air dryer is provided. The improved system and method employs a single centralized special fitting that secures the air dryer manifold to a reservoir. The bore in which the fitting is disposed is used to communicate air from the reservoir to the air dryer in order to purge the desiccant in the air dryer. The mounting assembly includes anti-rotational mechanisms which prevent the air dryer from rotating about its axis. The mounting assembly may also include a reservoir and a mounting bracket for the reservoir which uses less than 75 percent of a truck mounting rail height.

Owner:BENDIX COMML VEHICLE SYST LLC

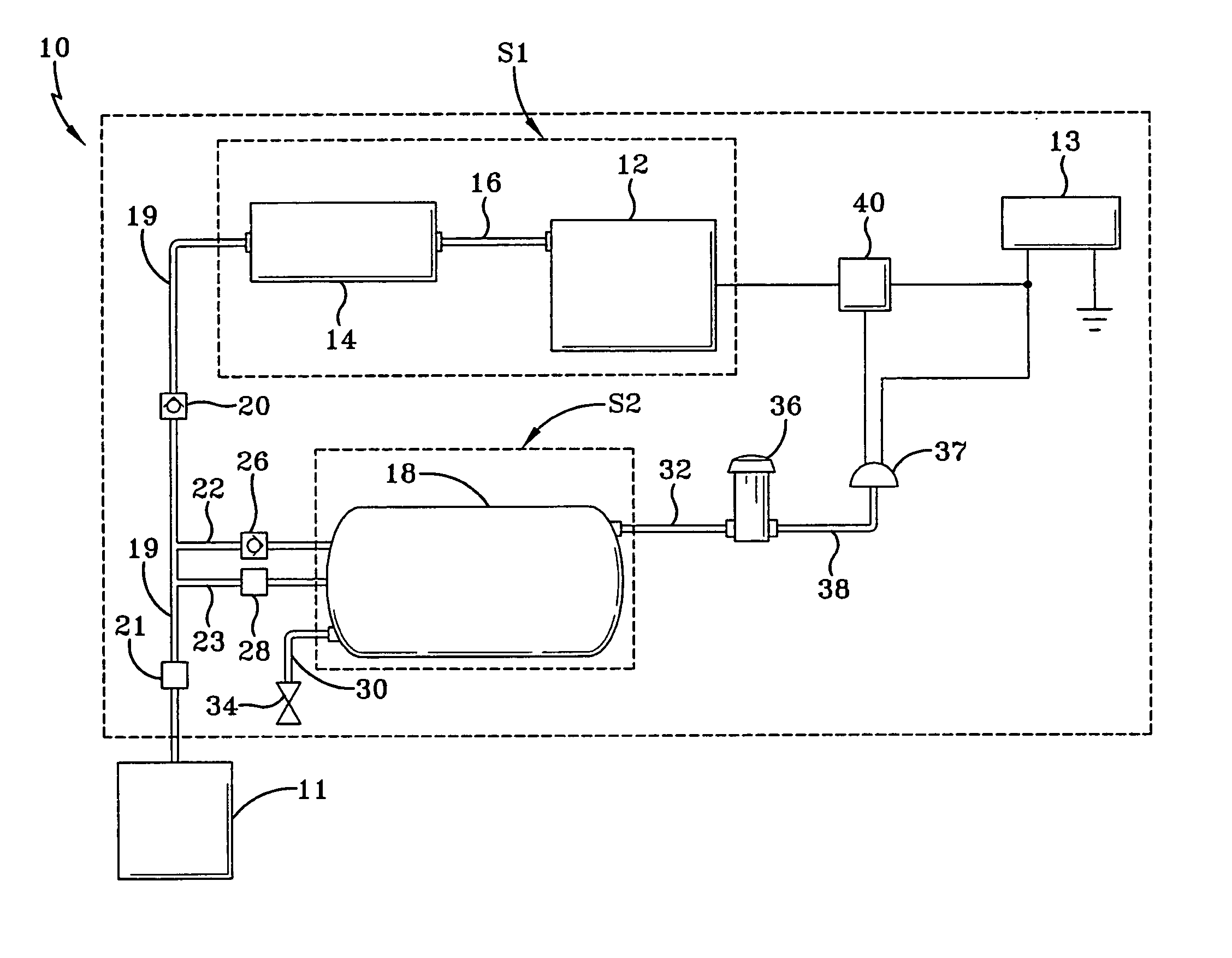

Vehicle air system having an indicator device and method

Various compressed air systems for commercial vehicles are disclosed. In one embodiment, a compressed air system is provided that includes a compressor, an air dryer apparatus, a purge reservoir, and an indicator device. The indicator device comprises a moisture-indicating material that is in contact with the purge air within the purge reservoir.

Owner:BENDIX COMML VEHICLE SYST LLC

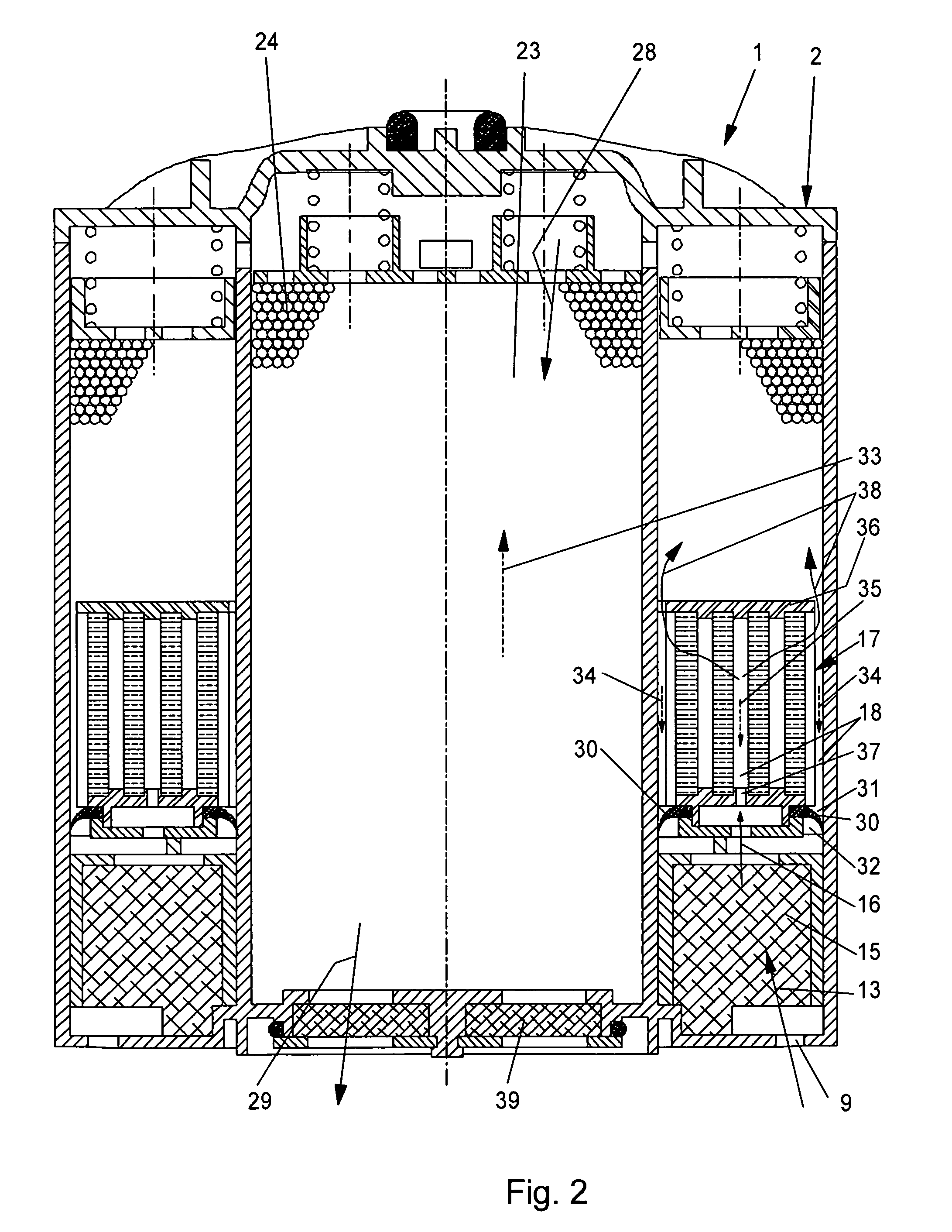

Motor/pump assembly

ActiveUS8585372B2Reduce noise levelAvoid noisePositive displacement pump componentsBraking action transmissionLow noiseInterior space

A motor / pump assembly for a motor vehicle brake system including a pump and a motor driving the pump, the pump having opposite working diaphragms which are, in each case, mounted between a pump casing and a cover and thereby delimit a space and which can be moved by a crank drive, the space being assigned, in each case, an inlet duct with an inlet valve and an outlet duct with an outlet valve. The outlet ducts are arranged in the covers and in the pump casing such that air displaced out of the spaces is conducted into an inner space surrounding the crank drive of the pump casing and that an air outlet unit be provided, which allows a low-noise blow-out of the air from the inner space as a result of the deflection of the air.

Owner:CONTINENTAL TEVES AG & CO OHG

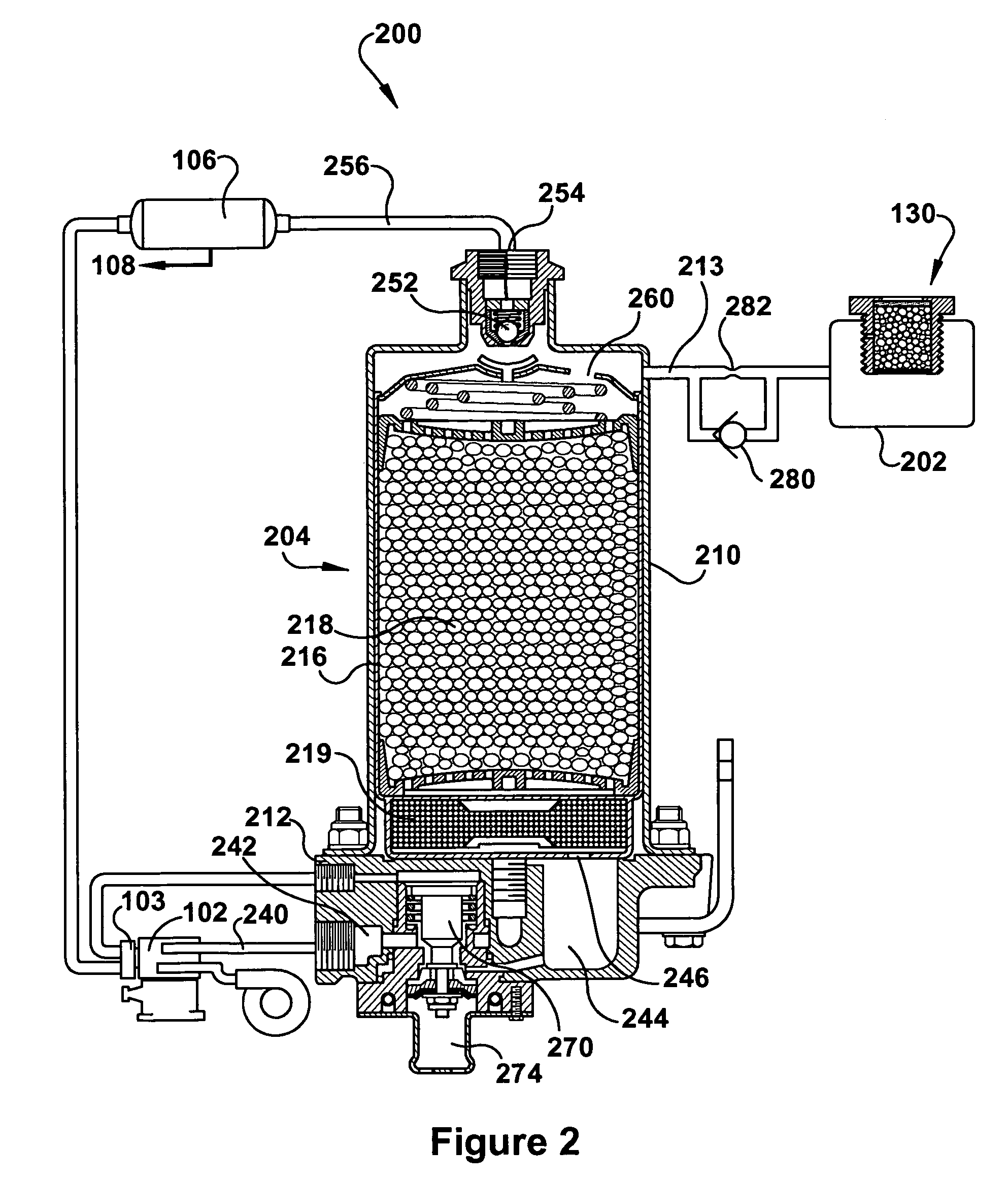

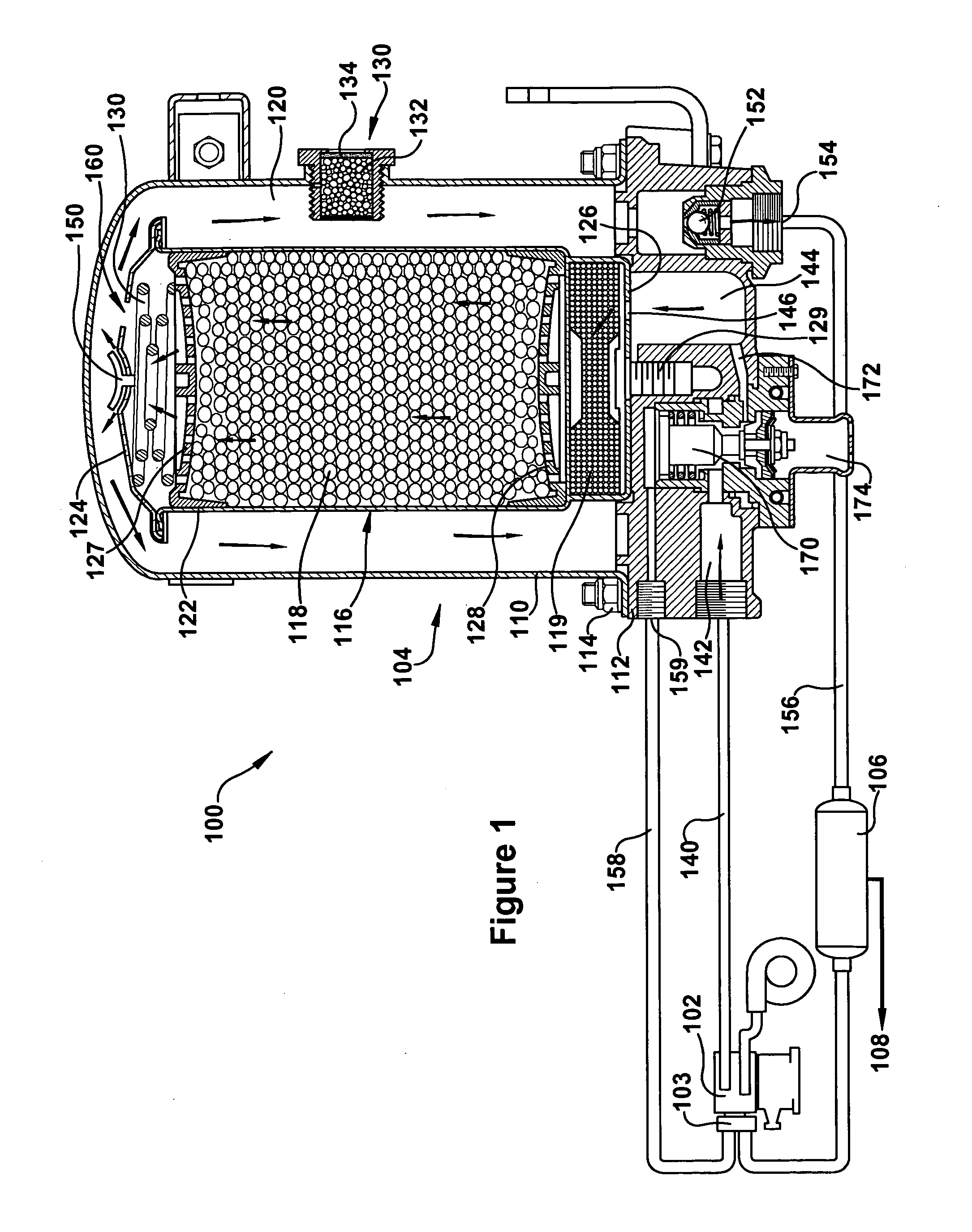

Remote purge drying unit for compressed gas

An air dryer assembly and mounting bracket for mounting an air dryer to a vehicle. The air dryer assembly has a manifold and a canister which seal against the surface of the mounting bracket. Orientation pegs are provided along the sealing surface of the air dryer manifold and receive corresponding indented regions in a cut out region in the mounting bracket. By providing a number of orientation pegs on the surface of the manifold, a number of mounting orientations for the air dryer assembly can be achieved.

Owner:BENDIX COMML VEHICLE SYST LLC

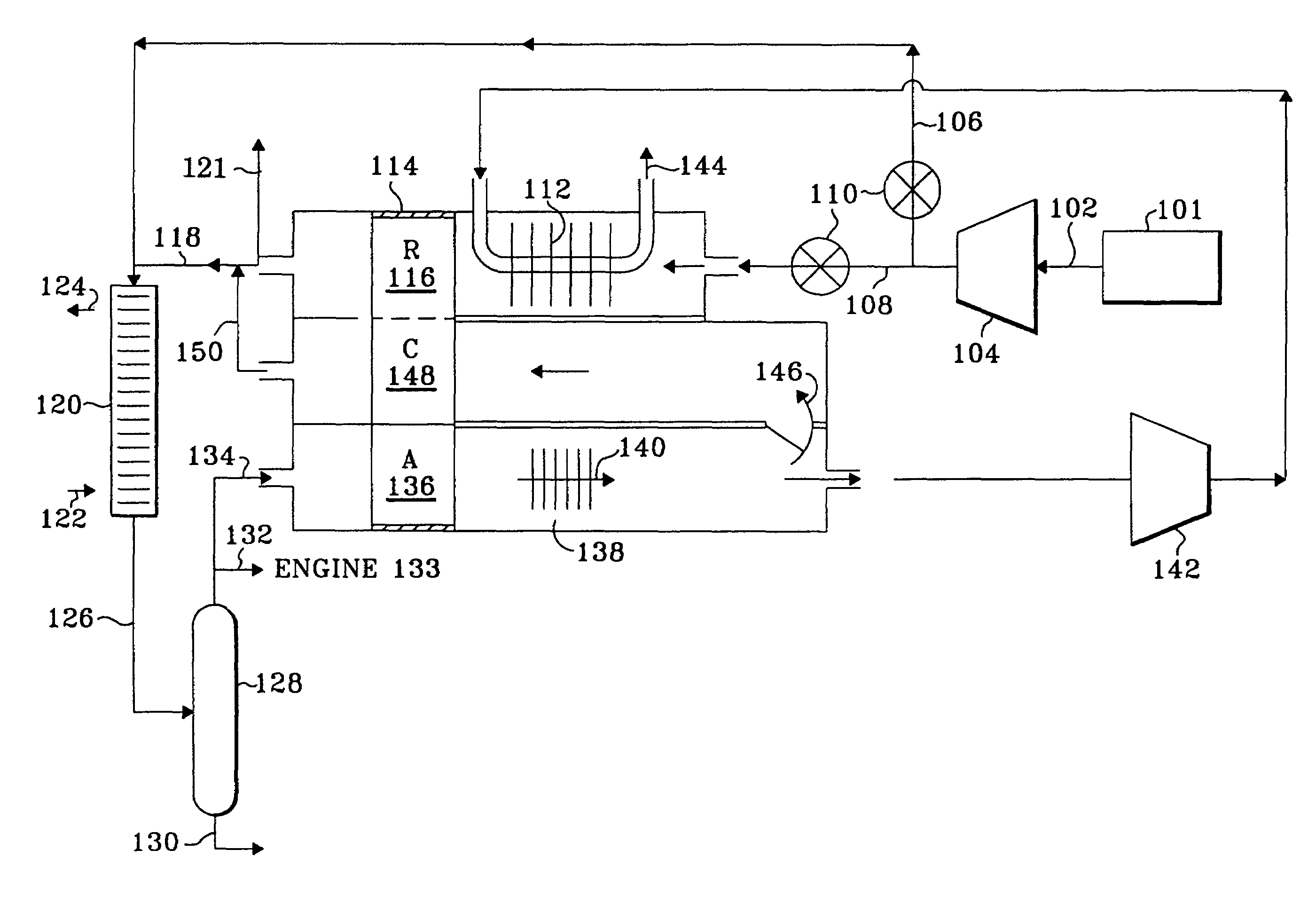

Brake air drying using low pressure desiccant wheel

The invention comprises a temperature swing adsorption system for providing dry air to an air brake system. More particularly, there is provided a desiccant wheel upstream of the air compressor to dry air prior to its compression.

Owner:UOP LLC

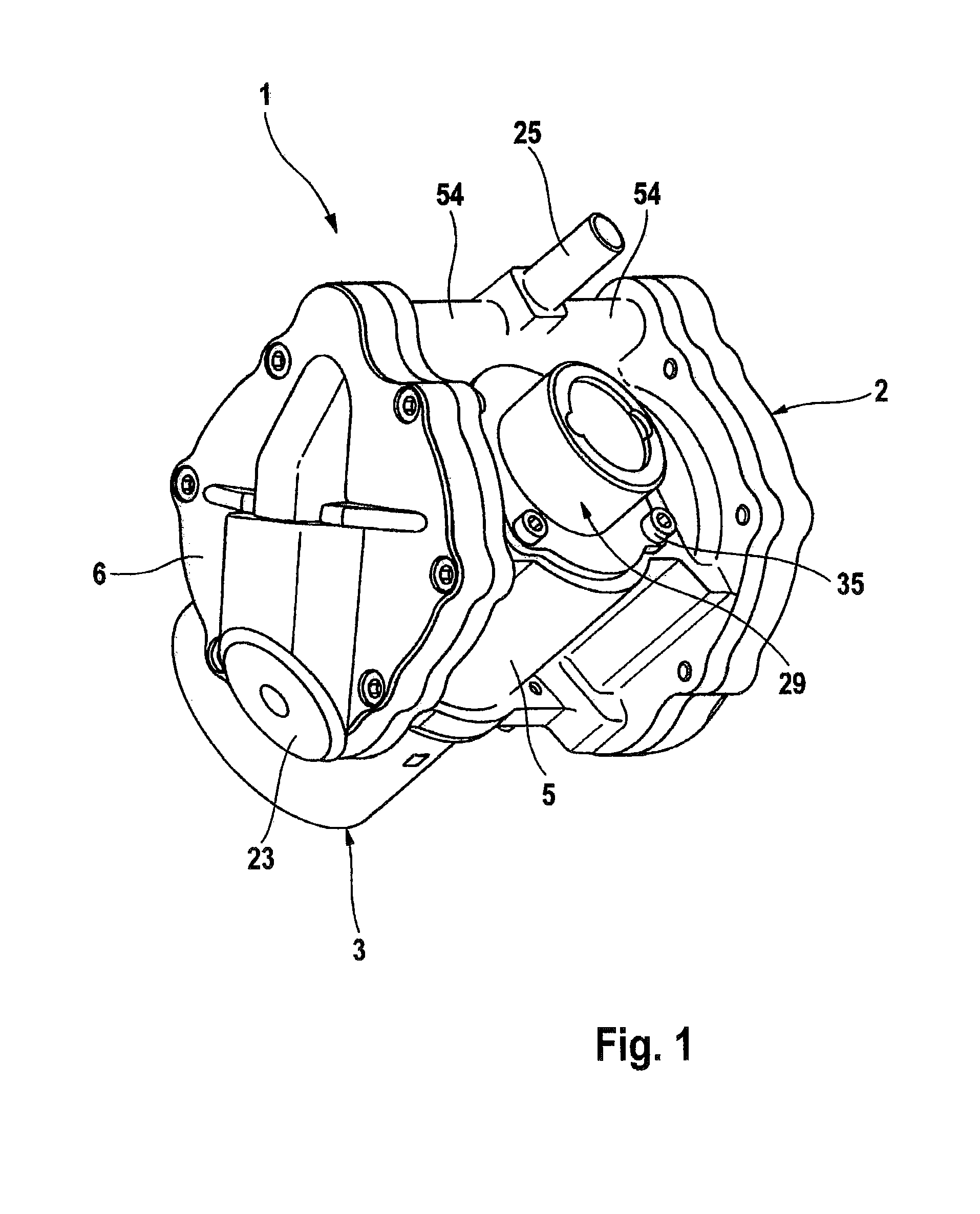

Air Processing Device with Two Air Dryer Cartridges

ActiveUS20120031273A1Widen the optionsAdd optionsGas treatmentIsotope separationAir treatmentAir dryer

An air processing device for a utility vehicle includes a compressor and two air dryer cartridges. The air dryer cartridges are located in two parallel paths. A control unit controls a regeneration of one of said air dryer cartridges independent from a load phase of the other of said air dryer cartridges.

Owner:HALDEX BRAKE PROD AB

Cartridge for cleaning compressed air in compressed air supply systems of motor vehicles

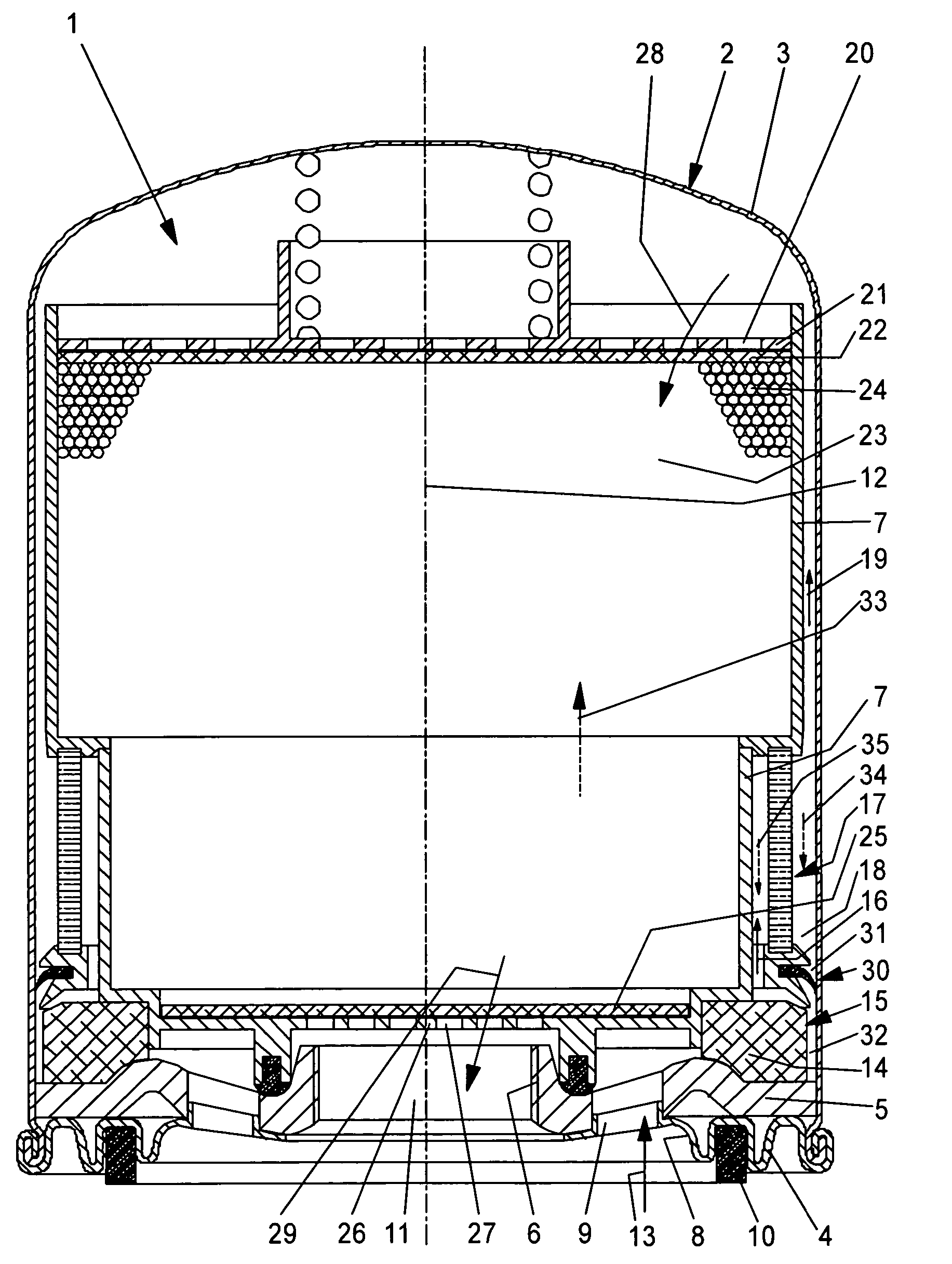

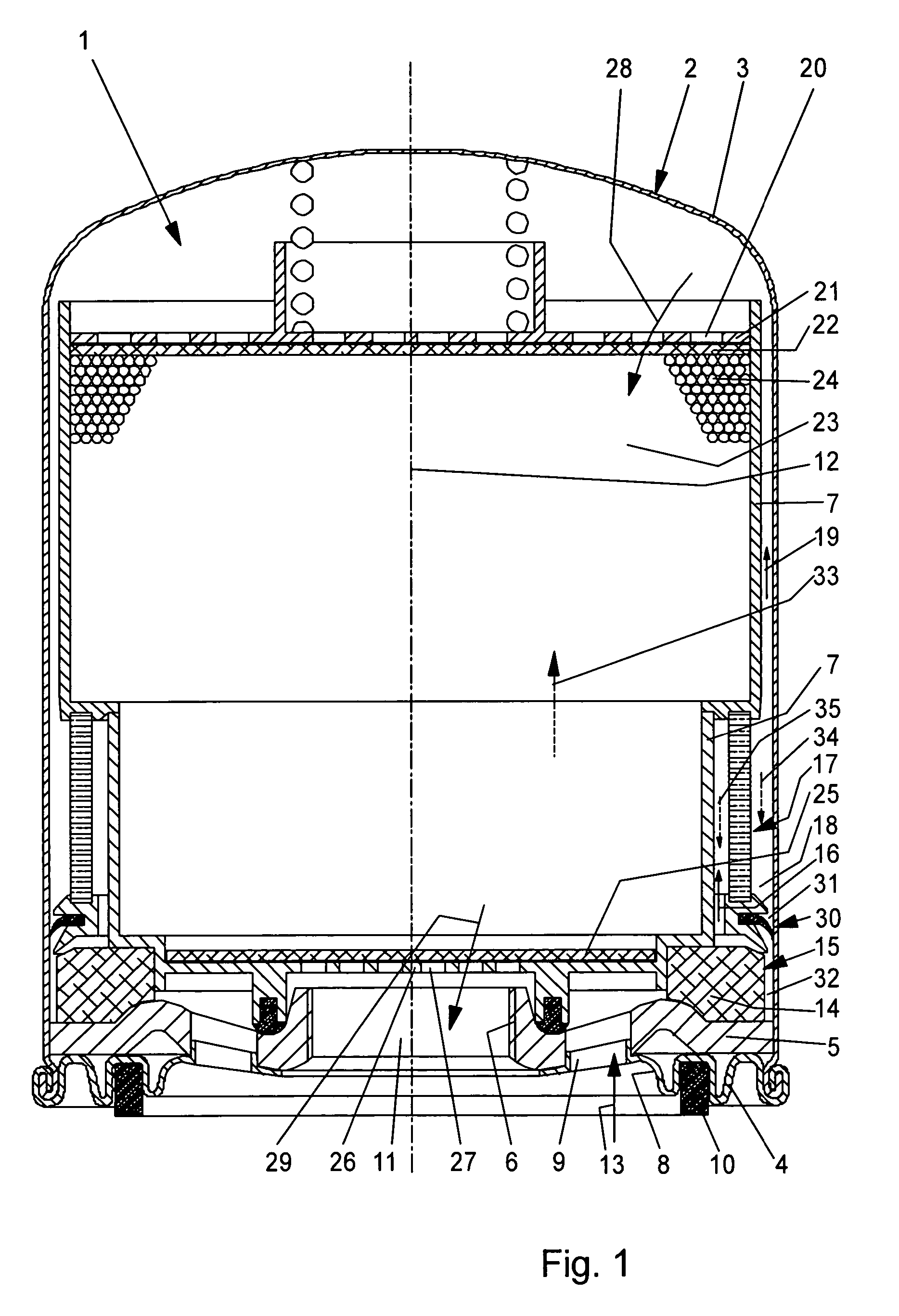

ActiveUS7625437B2Reduce continued transferExtended service lifeDispersed particle filtrationIsotope separationTruckCheck valve

A cartridge of an air dryer serves for cleaning compressed air to be used in compressed air supply systems of motor vehicles, especially trucks. The cartridge includes a housing, a pre-filter, a deposit chamber, a coalescing filter, a bypass conduit and a check valve. The deposit chamber is located downstream of the pre-filter. The deposit chamber is filled with a treating substance. The coalescing filter is arranged between the pre-filter and the deposit chamber. The bypass conduit is designed and arranged to bypass the coalescing filter and not to bypass the pre-filter. The check valve is arranged in the bypass conduit in a way that it opens during regeneration of the cartridge.

Owner:HALDEX BRAKE PROD AB

Charging system

A charging system used for supplying compressed air to a destination includes a compressor for generating the compressed air and a reservoir capable of being alternately discharged and recharged with the compressed air. A supply line fluidly connects the compressor, the reservoir, and the destination. A control valve positioned along the supply line is used in controlling flow of the compressed air from the charging system to the destination. A first branch line and a second branch line are positioned between the reservoir and the supply line. A check valve is positioned along the first branch line that when opened allows the compressed air to flow out of the reservoir into the supply line and when closed prohibits the compressed air from flowing into or out of the reservoir. A pressure protection valve is positioned along the second branch that opens to allow the compressed air to flow into the reservoir when the pressure in the supply line is above a threshold pressure.

Owner:BENDIX COMML VEHICLE SYST LLC

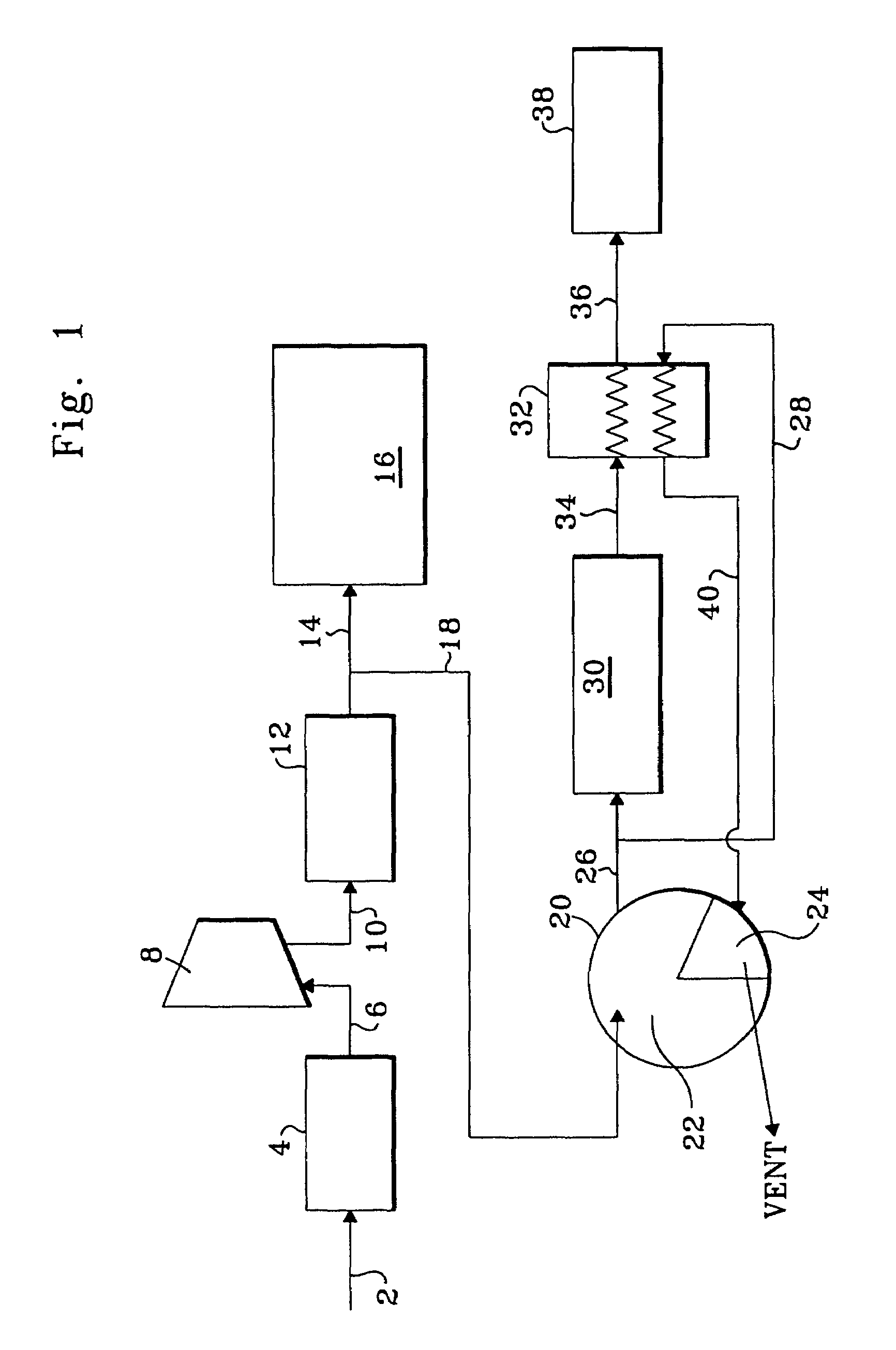

Membrane air dryer for vehicle air brake system

An air drying system for a vehicle including a membrane air dryer is provided. The air dryer is supplied with a stream of compressed air that has a low and constant concentration of oil vapor. A coalescing filter element may be used to maintain the oil vapor concentration. The filtered material may be discharged from the coalescing filter by a pressure swing drain valve, which discharges the filtered material upon unloading of the compressor.

Owner:BENDIX COMML VEHICLE SYST LLC

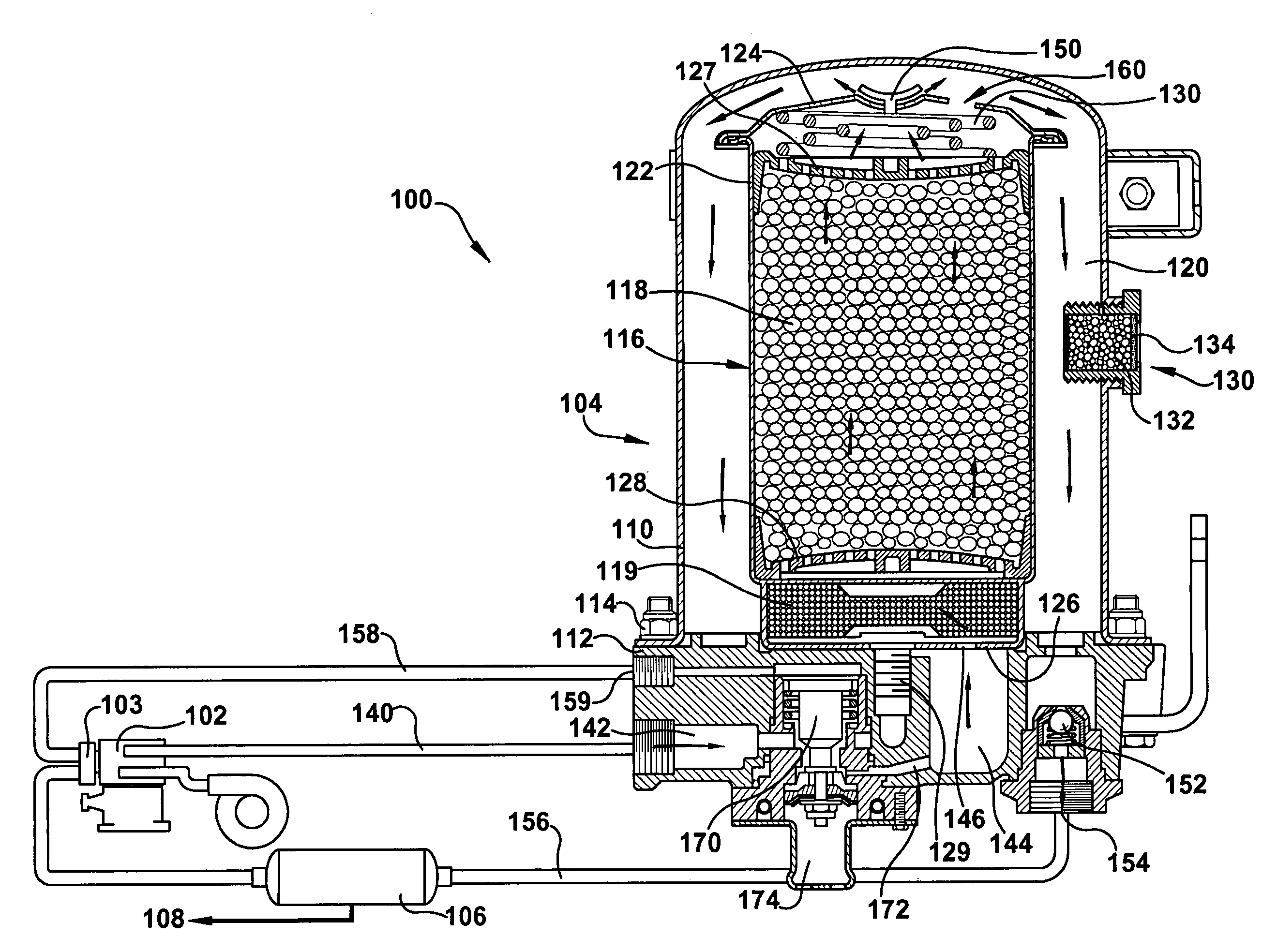

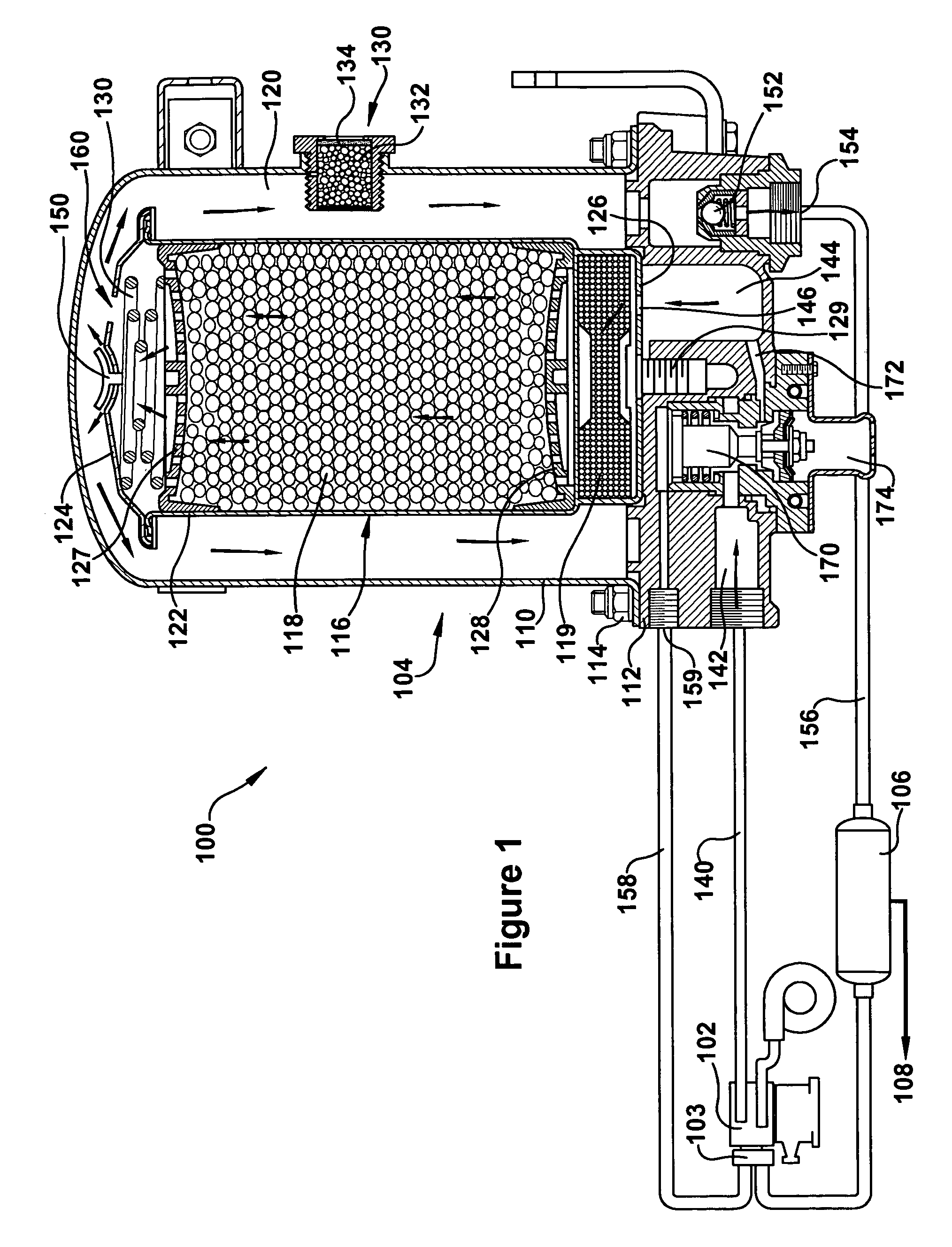

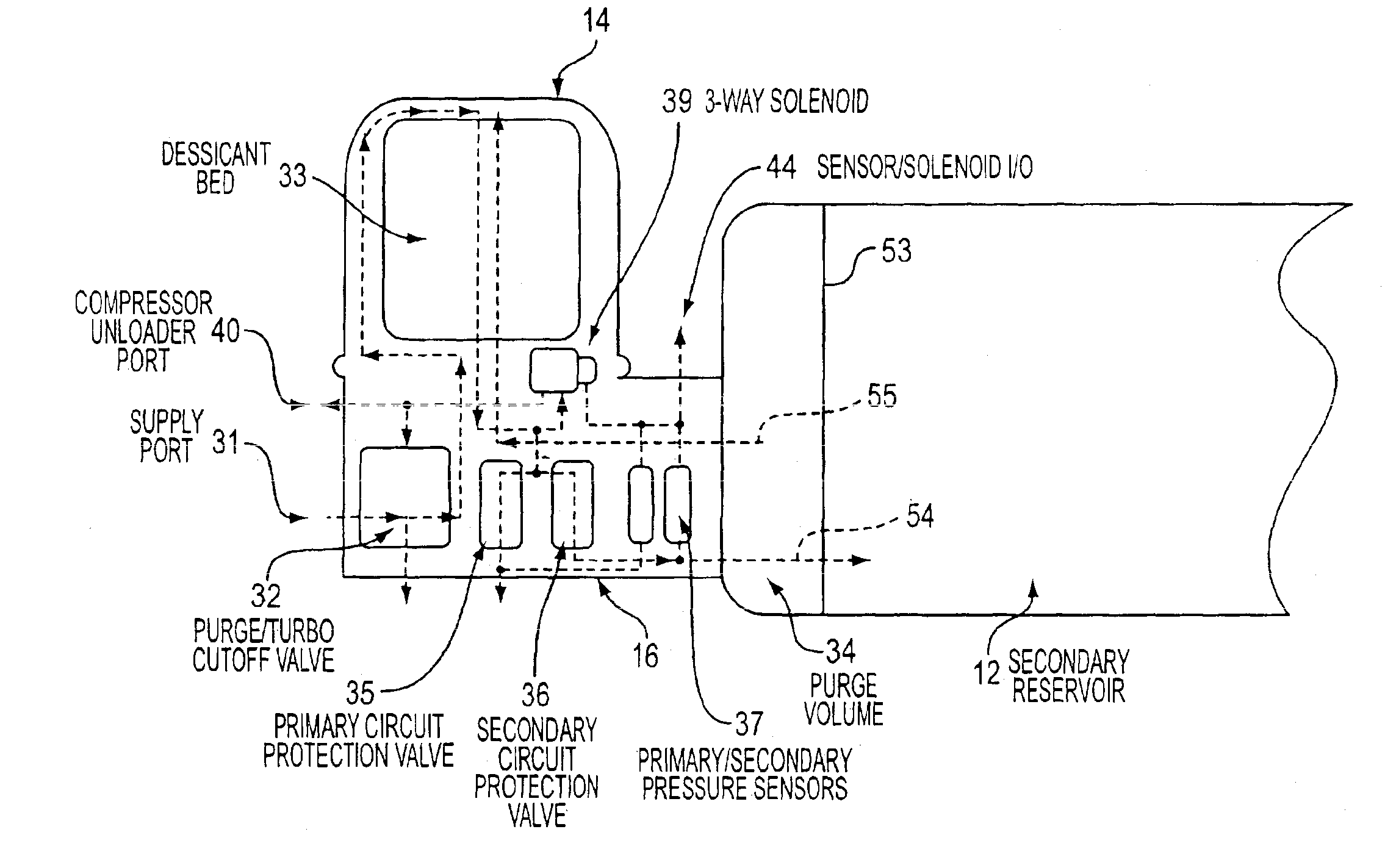

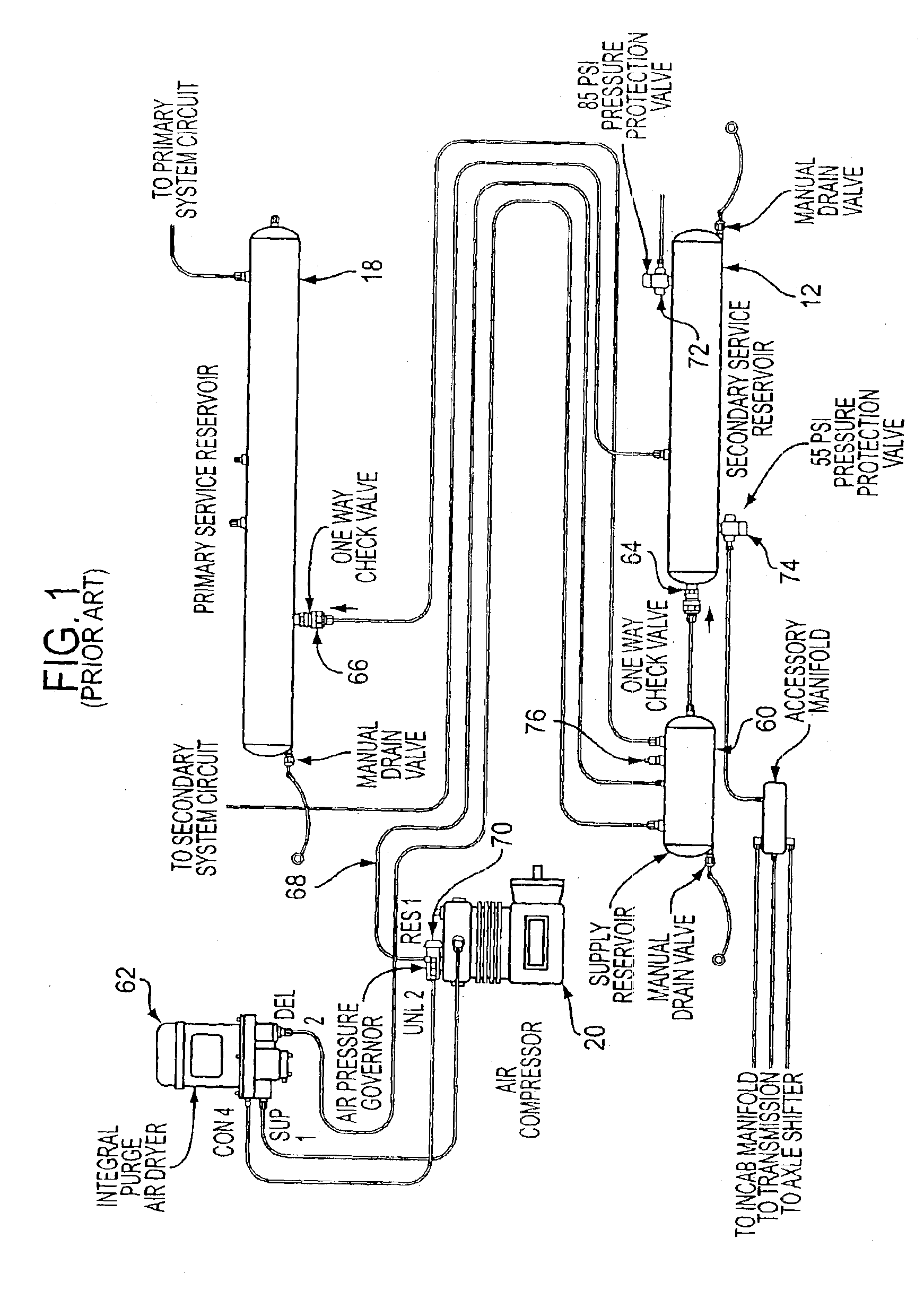

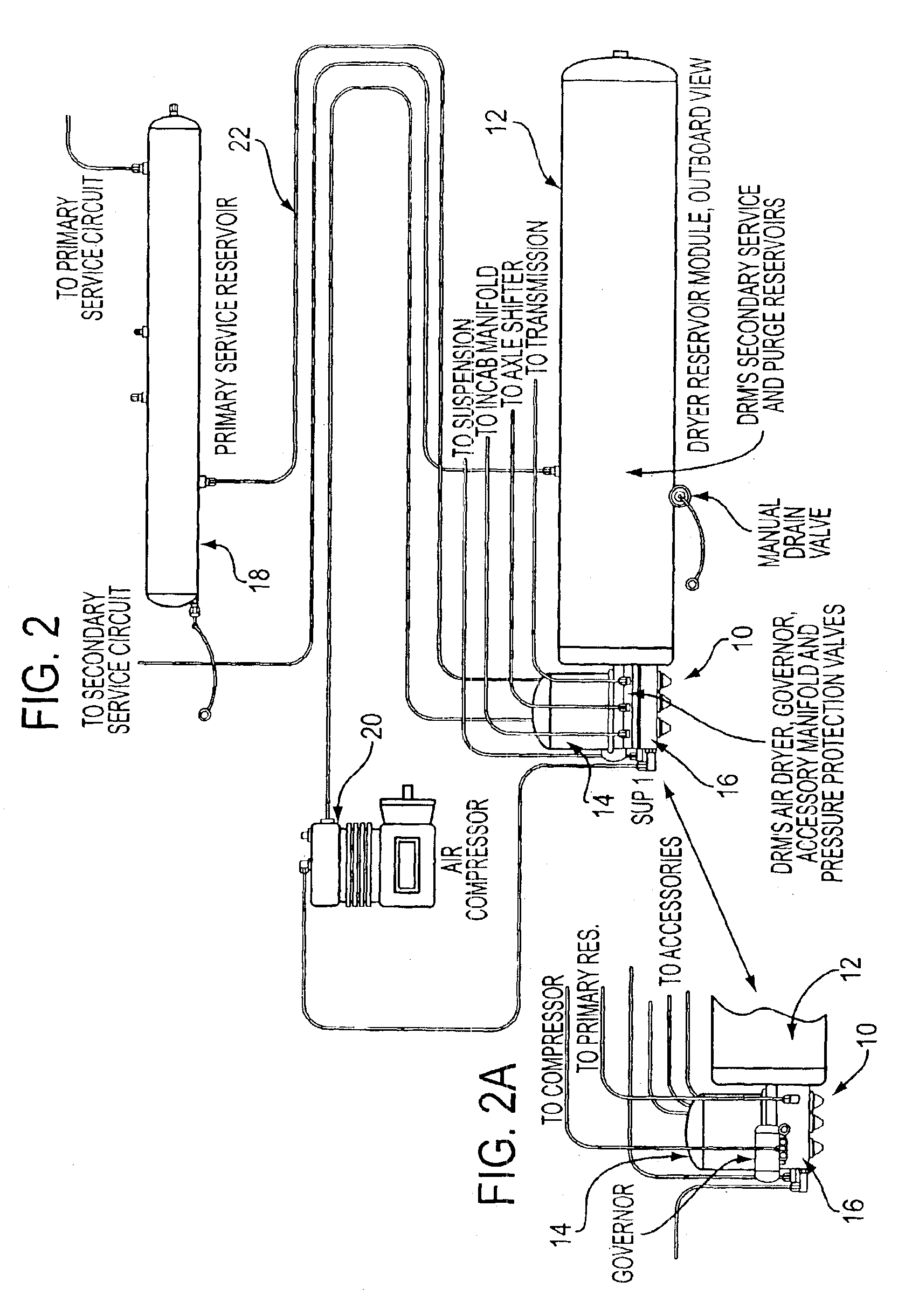

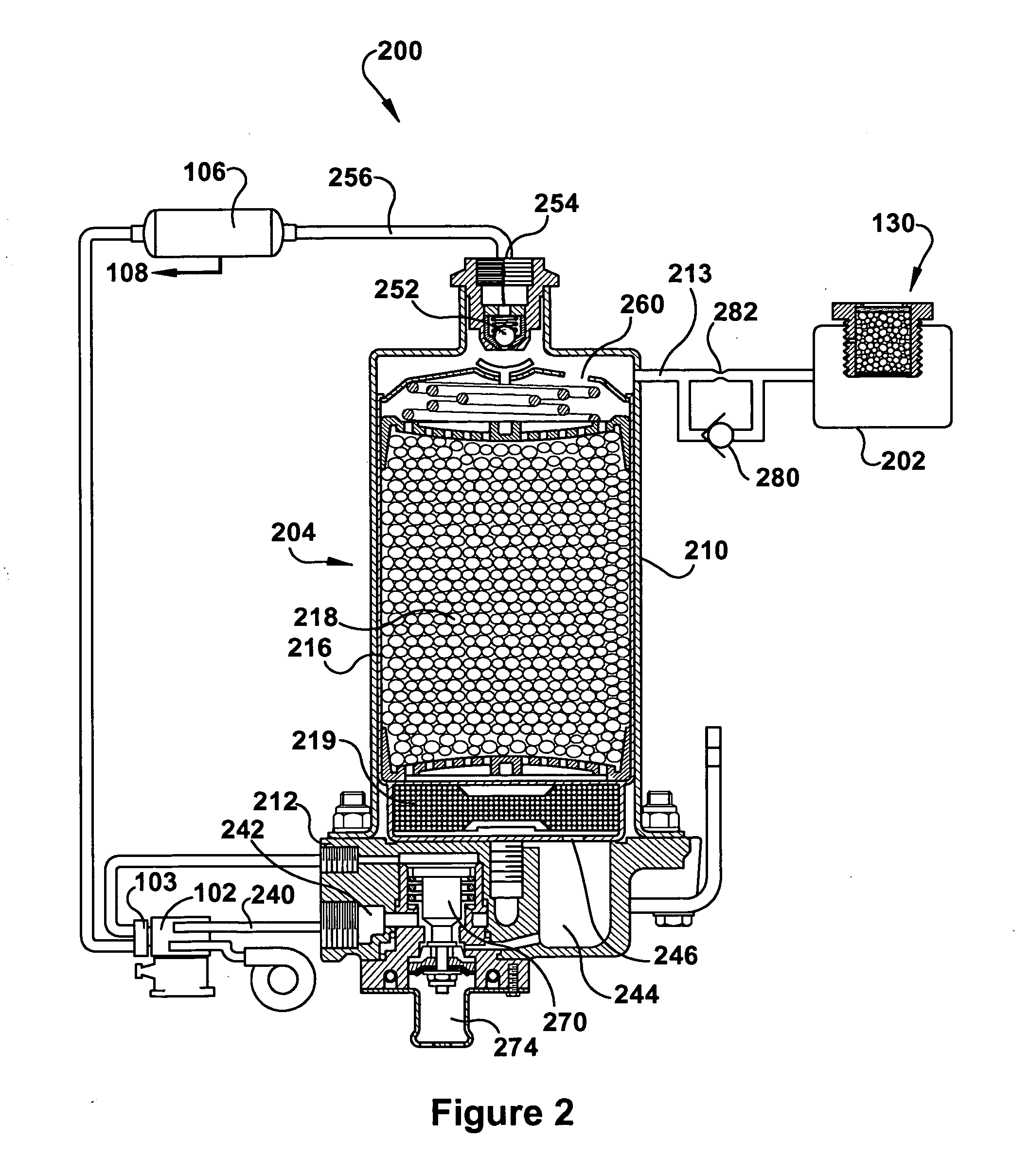

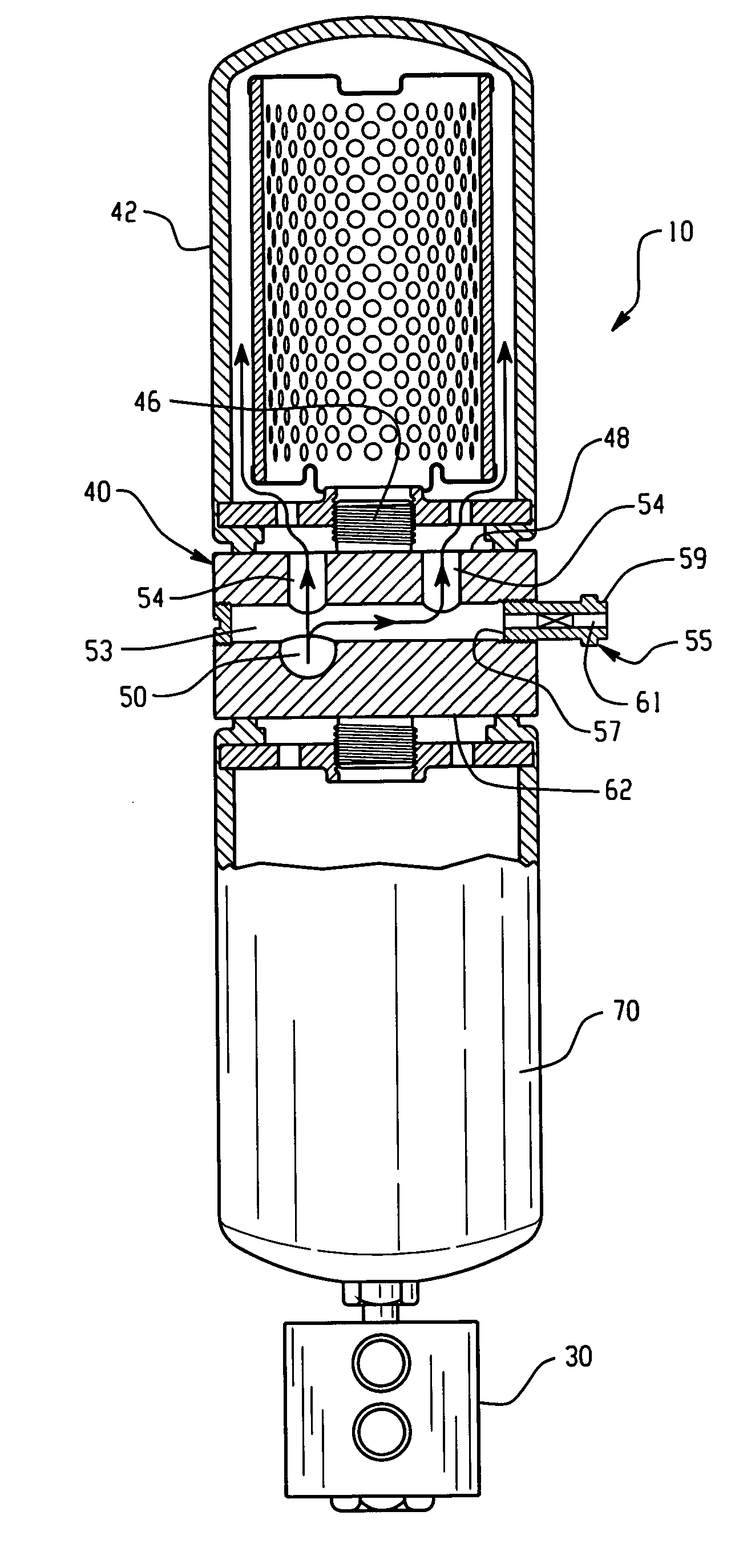

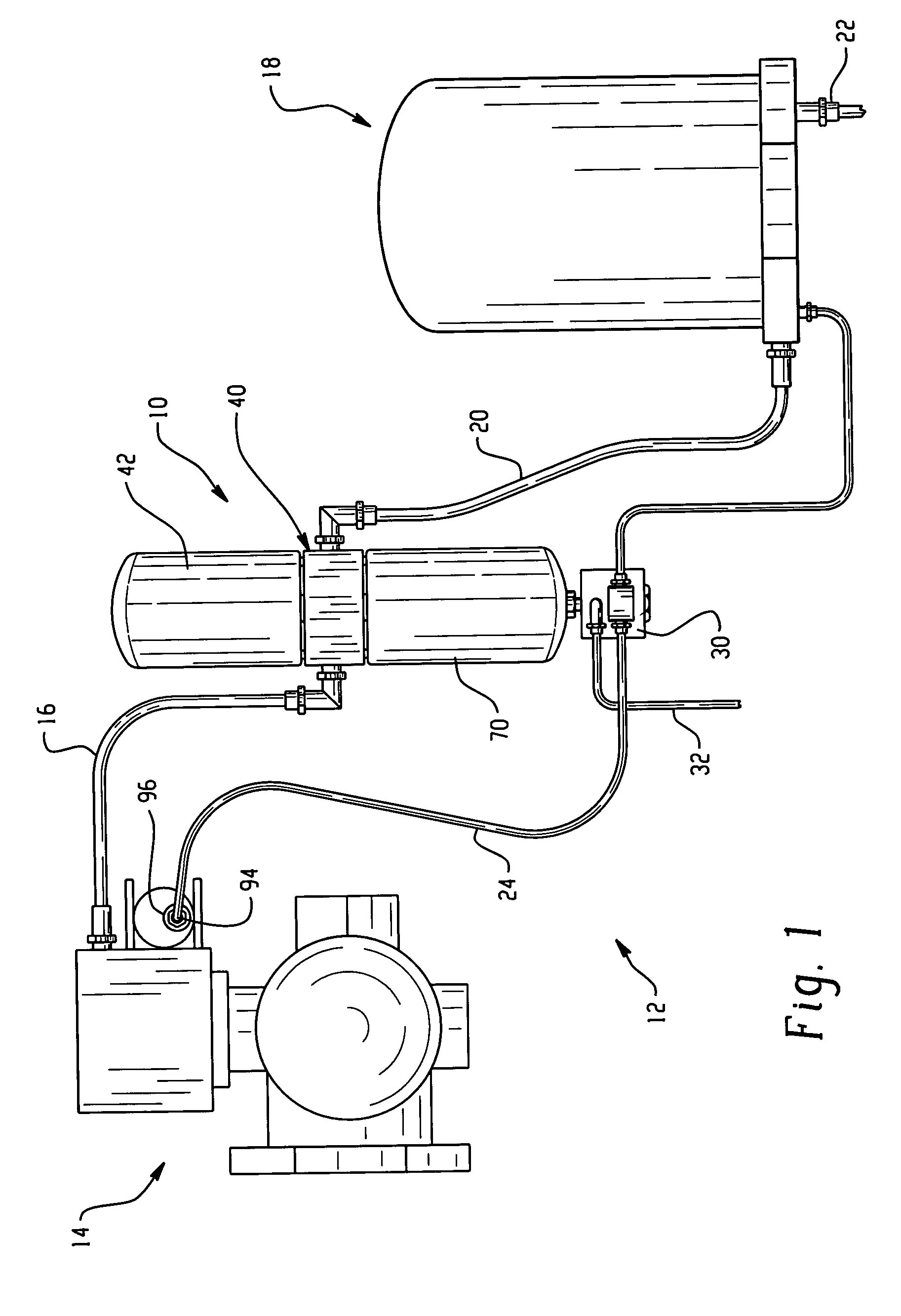

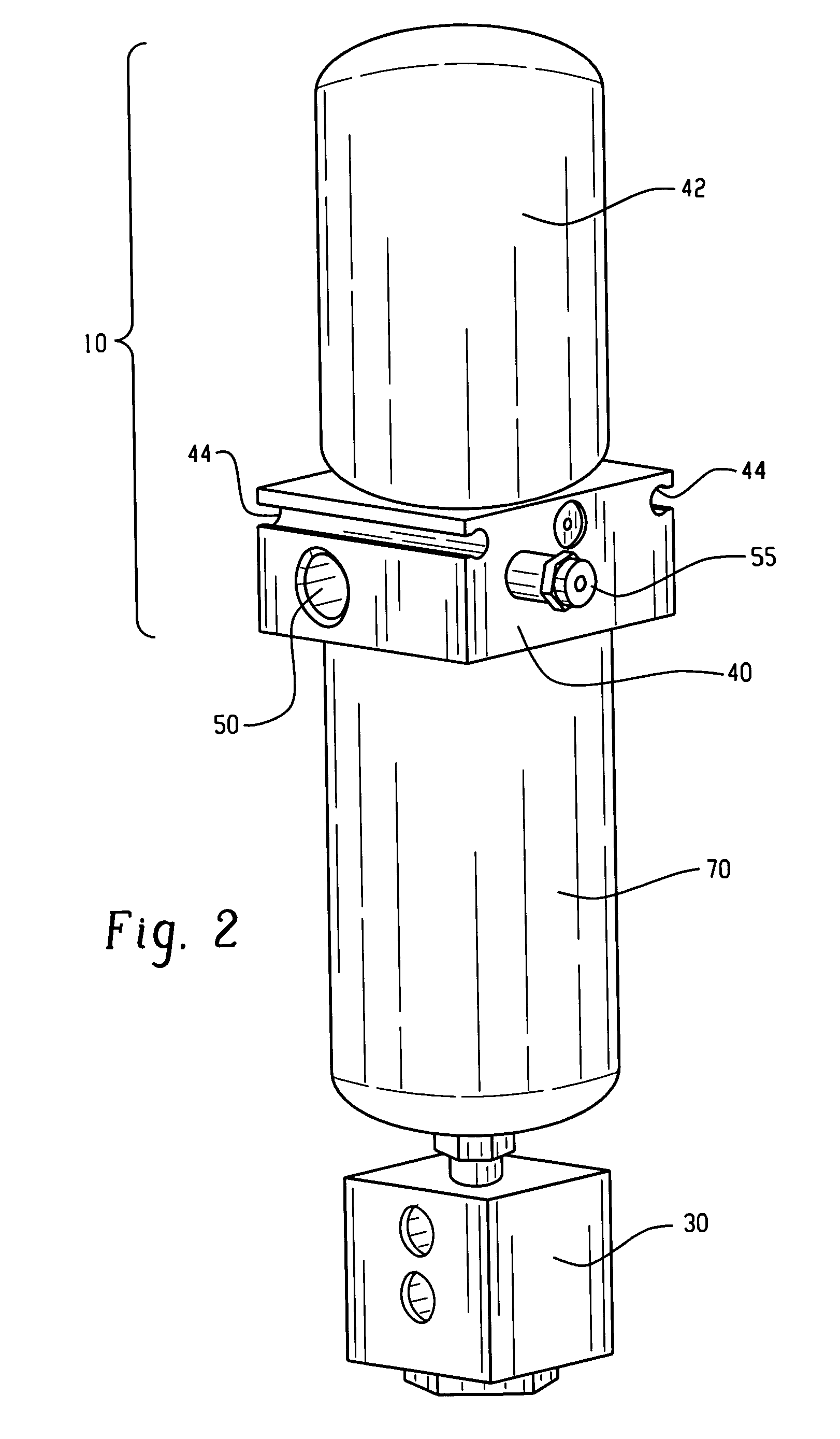

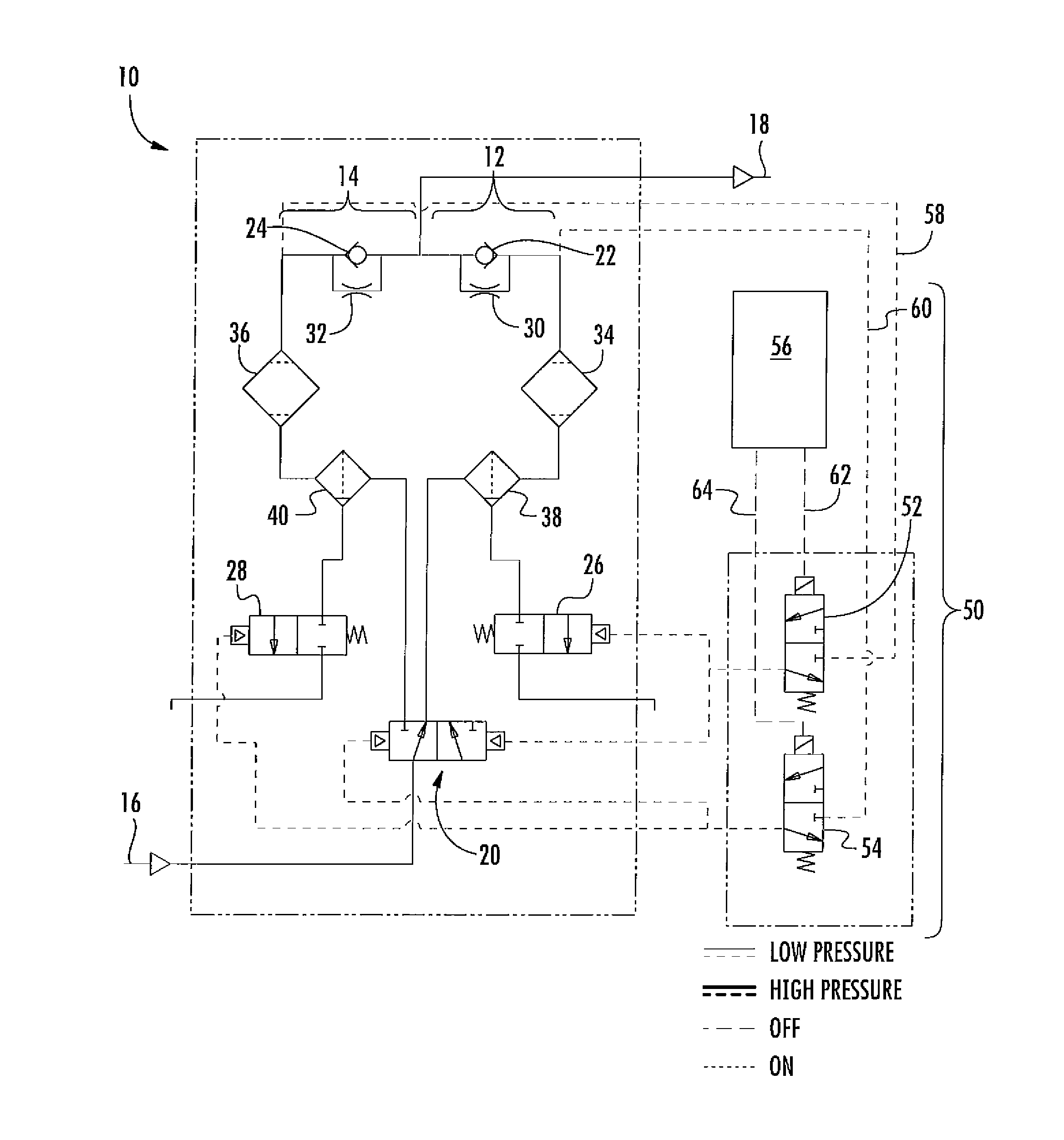

Air dryer module

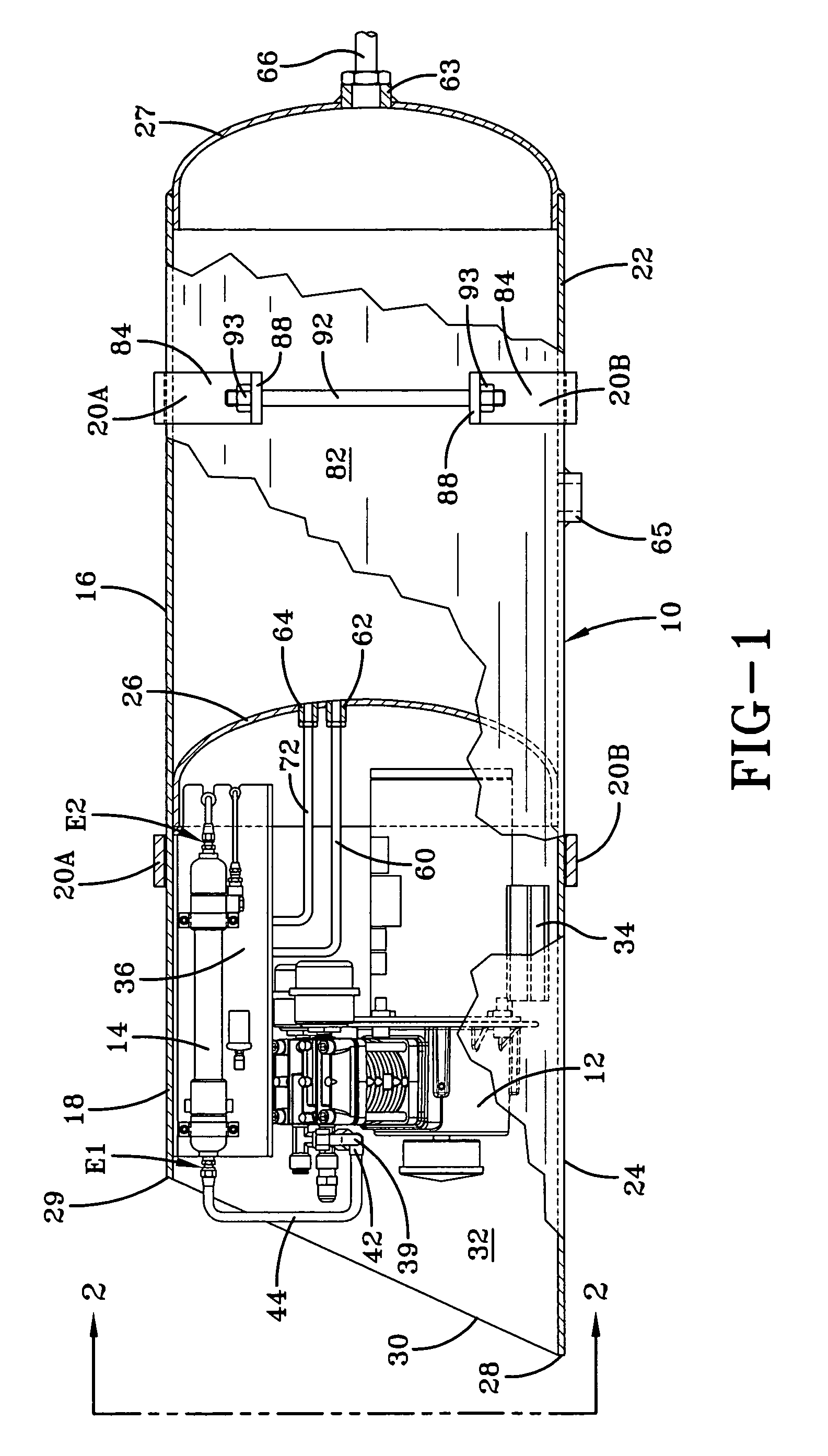

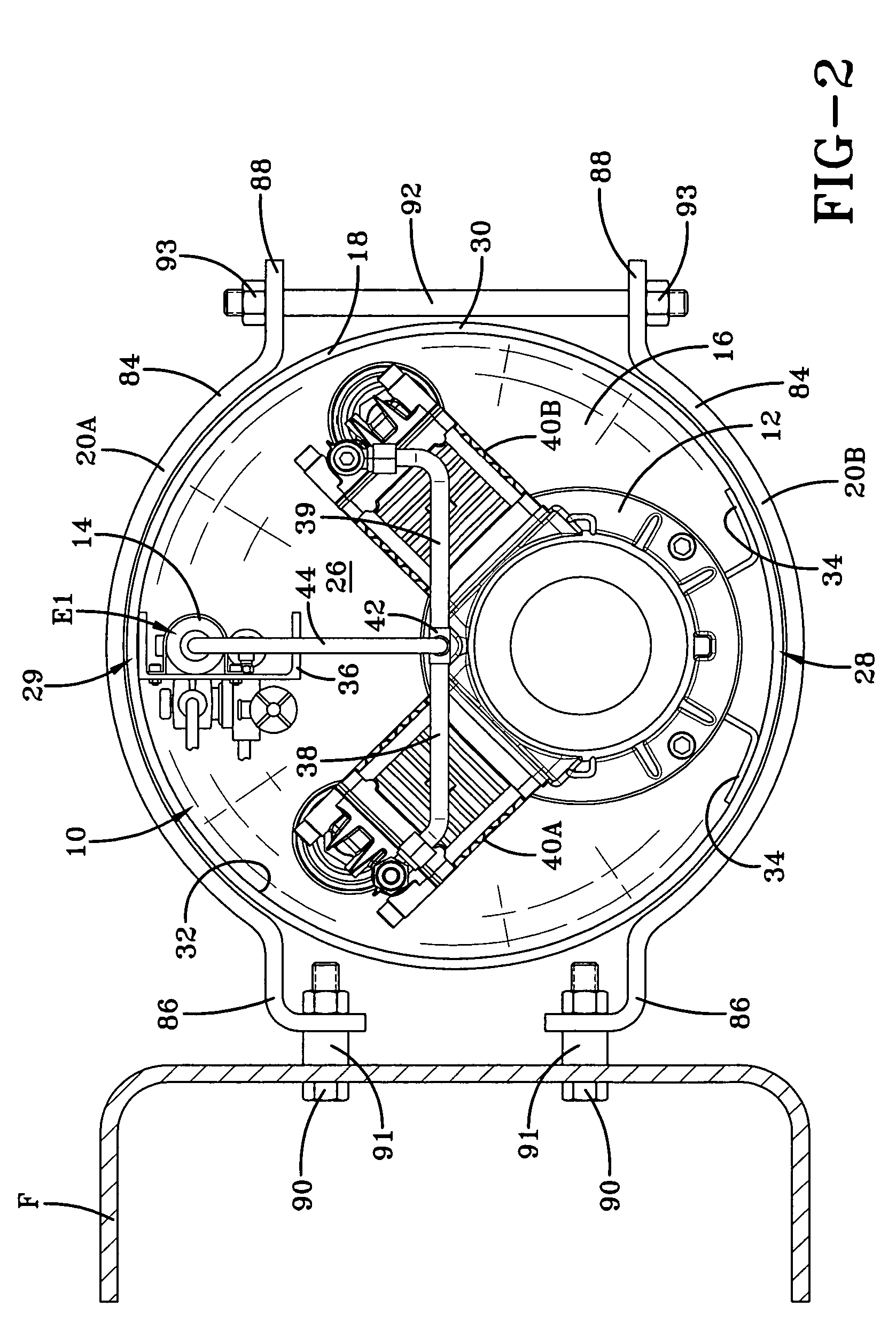

InactiveUS6858066B2Cost effectiveReduced failure modesGas treatmentAccumulator installationsGas compressorAir compressor

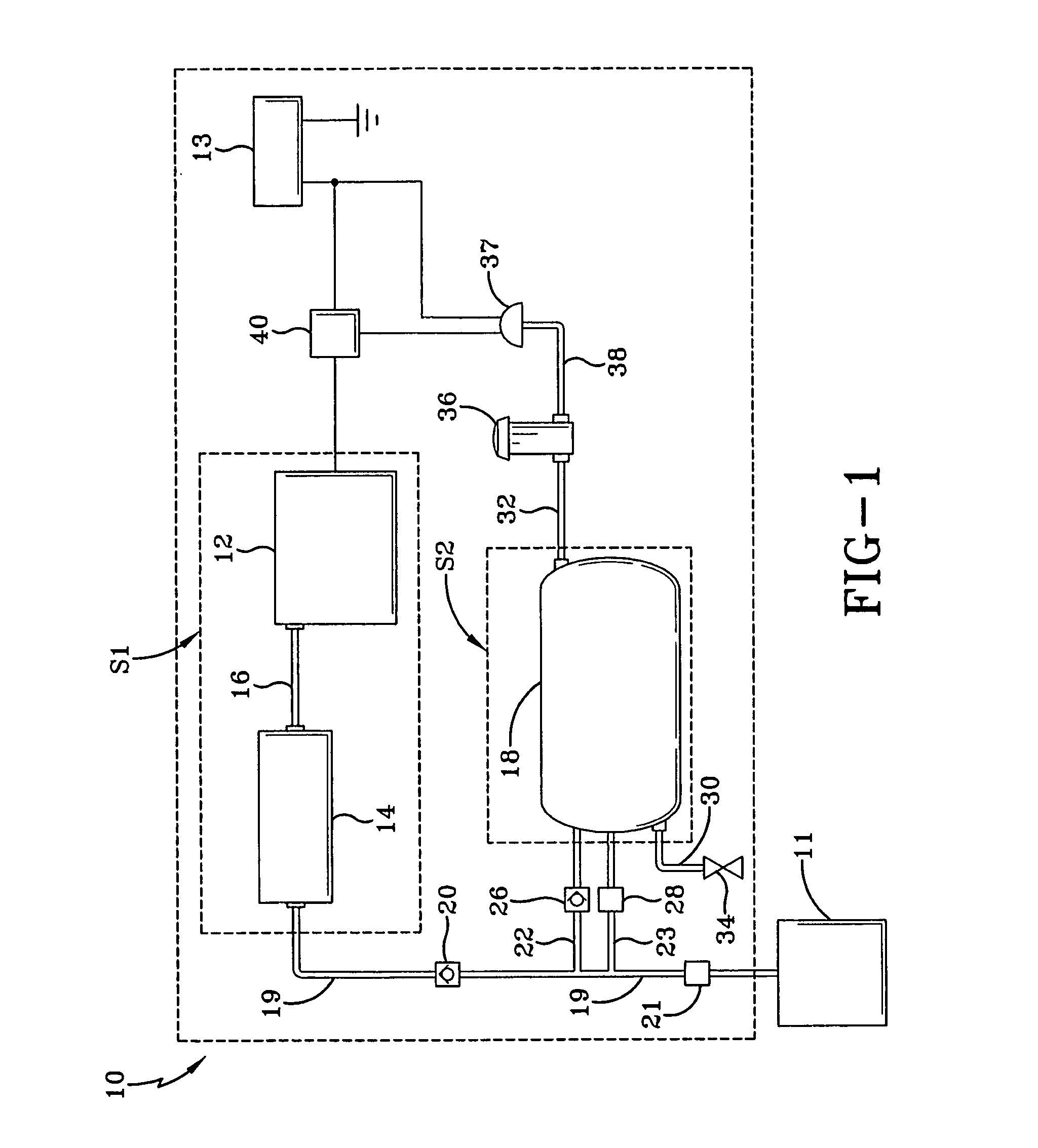

An air dryer and reservoir assembly for providing compressed air from an air compressor (20) on a heavy motor vehicle which includes an air dryer (14) connected to receive compressed air from the air compressor (20) and a secondary reservoir (12), including an integral purge volume (34), for storing compressed air which passes through the air dryer (14), with the air dryer (14) and the secondary reservoir (12) being securely attached to a housing (16) to form an air dryer reservoir module (10). A primary, reservoir (18) for storing compressed air from the air dryer (14) is located remote from the air dryer reservoir module (10). A pressure equalizing mechanism (57) is disposed between the primary reservoir (18) and the secondary reservoir (12) for keeping pressure in the two reservoirs (12,18) equal. Components located within the housing (16) control air flow between the air dryer (14) and the primary and secondary reservoirs (18,12) and also monitor the pneumatic brake system circuits fed by the primary and secondary reservoirs (18,12).

Owner:BENDIX COMML VEHICLE SYST LLC

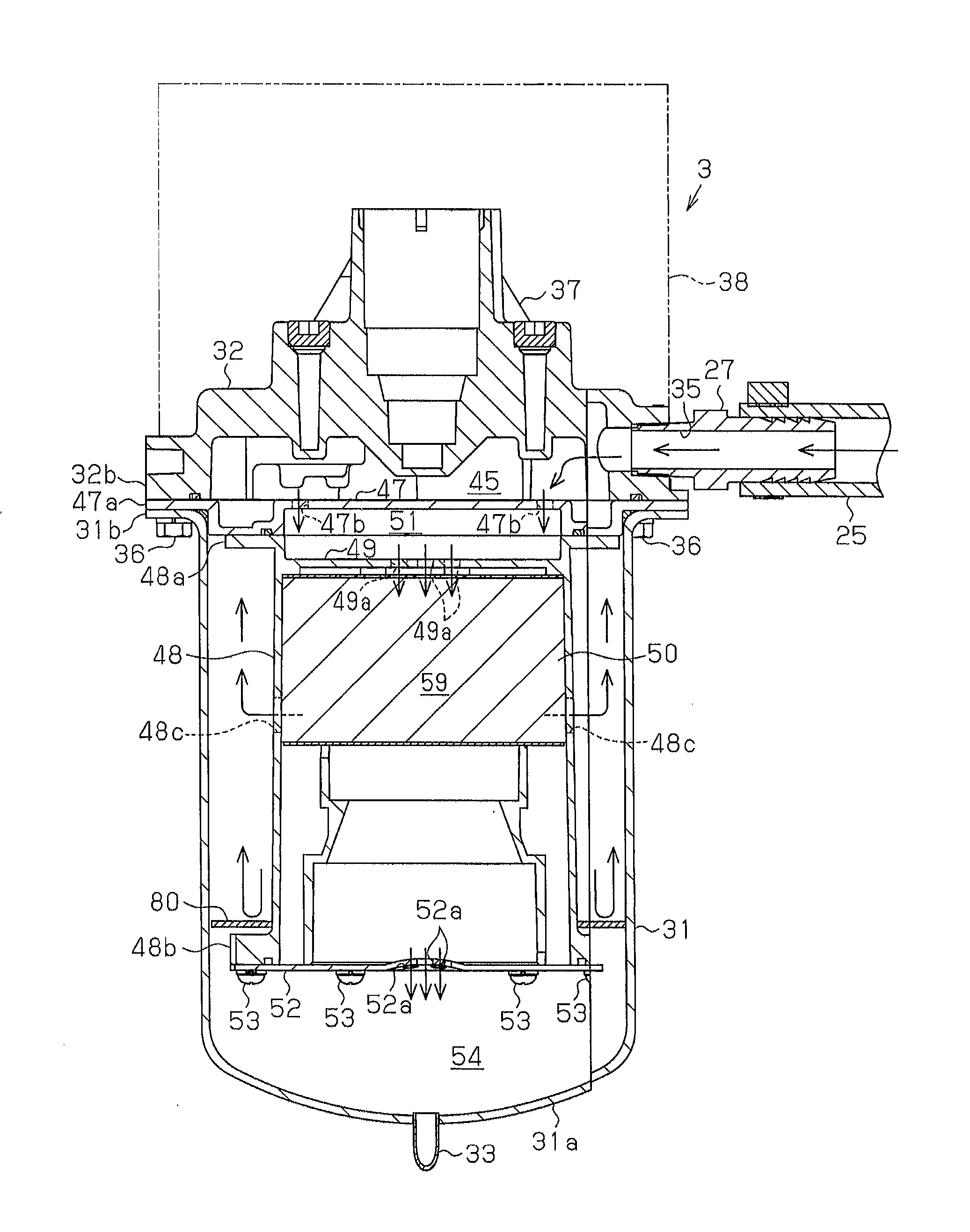

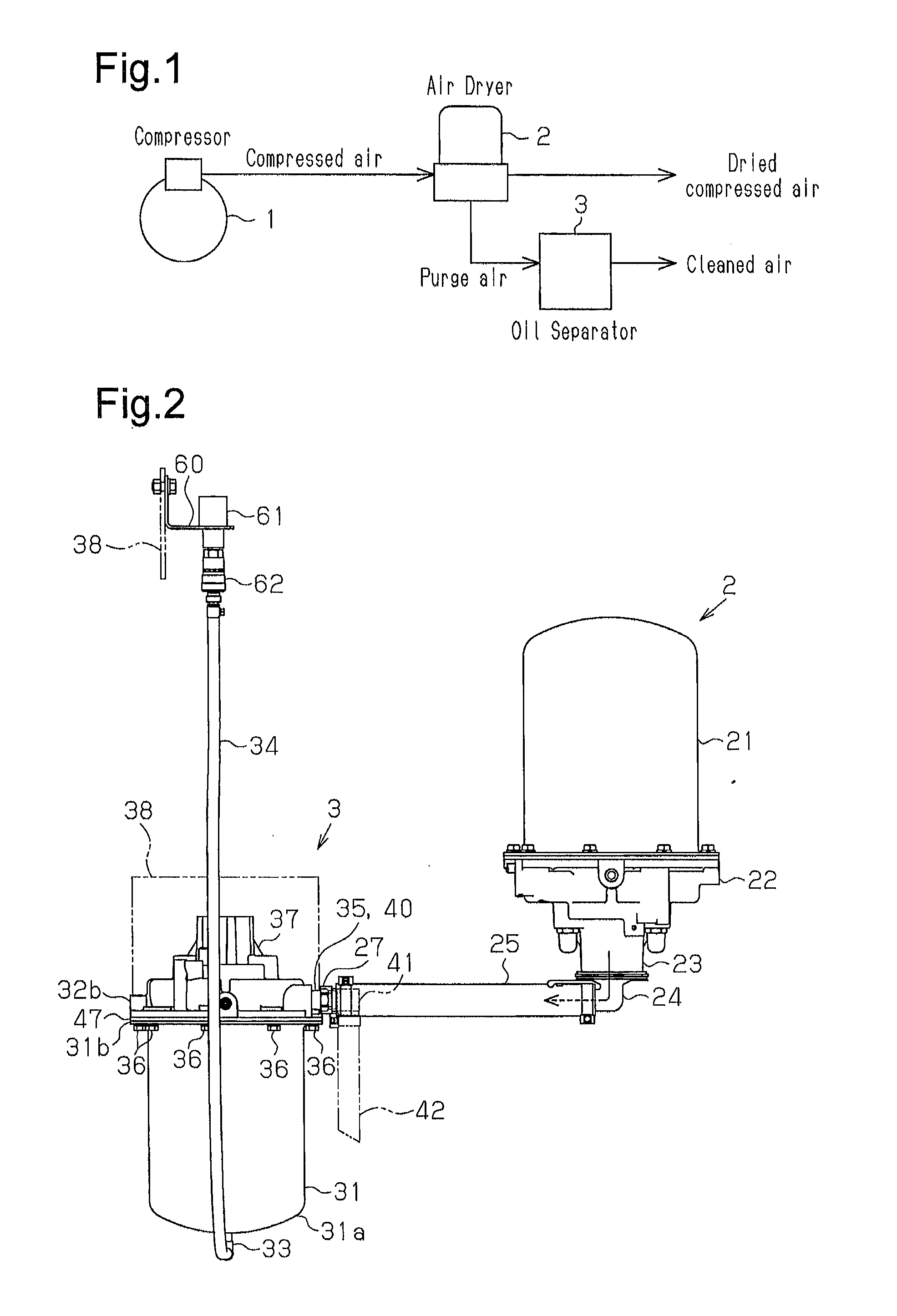

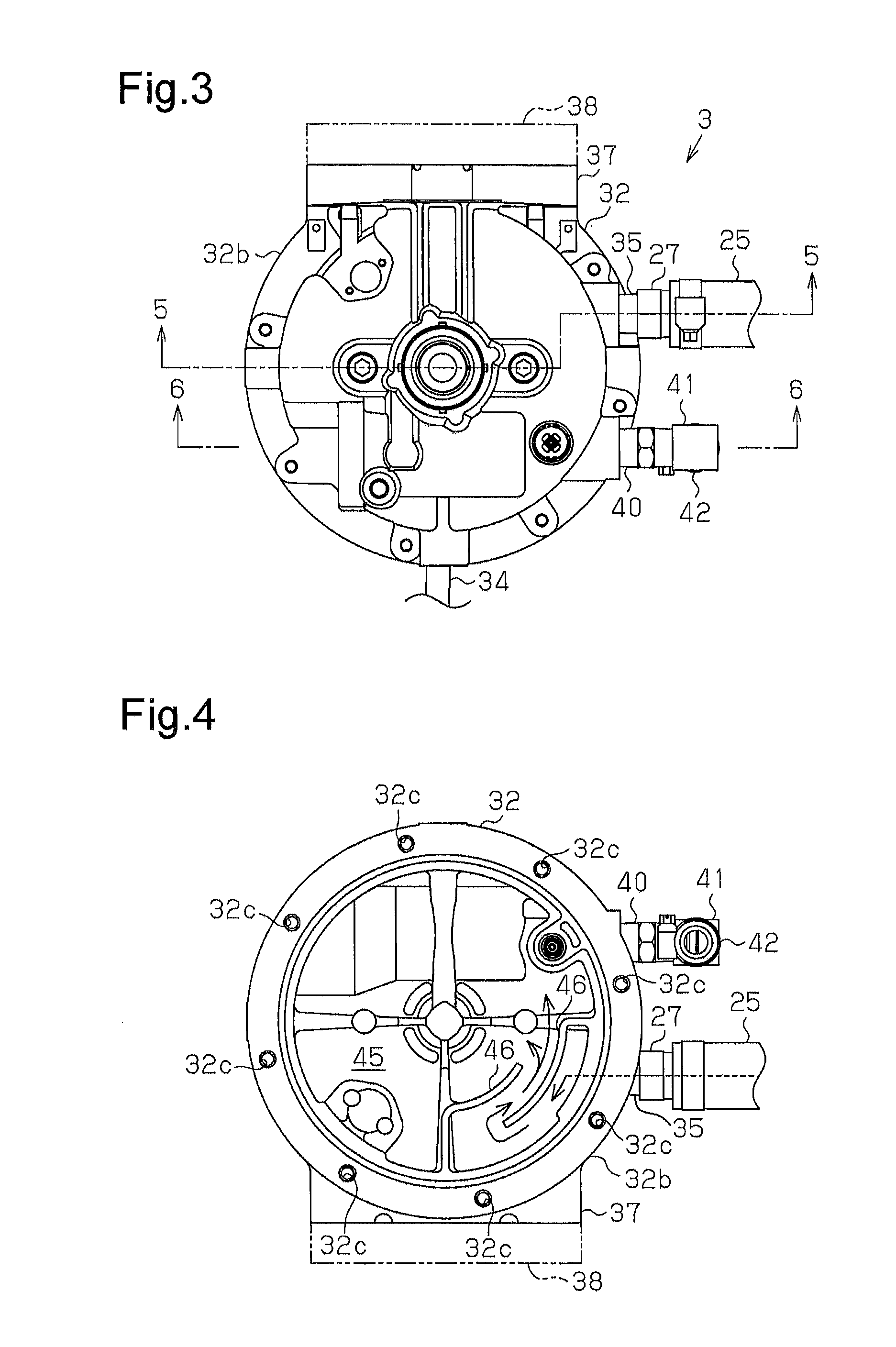

Oil separator

An oil separator is provided that restrains cleaned air from entraining collected liquid. An oil separator causes purge air, which has flowed into a case from an air dryer, to strike an impingement member, to separate oil, thereby recovering liquid containing oil and discharging cleaned air. The oil separator includes, inside the case, a baffle plate, which restrains cleaned air from coming contacting collected liquid.

Owner:NABTESCO AUTOMOTIVE CORP

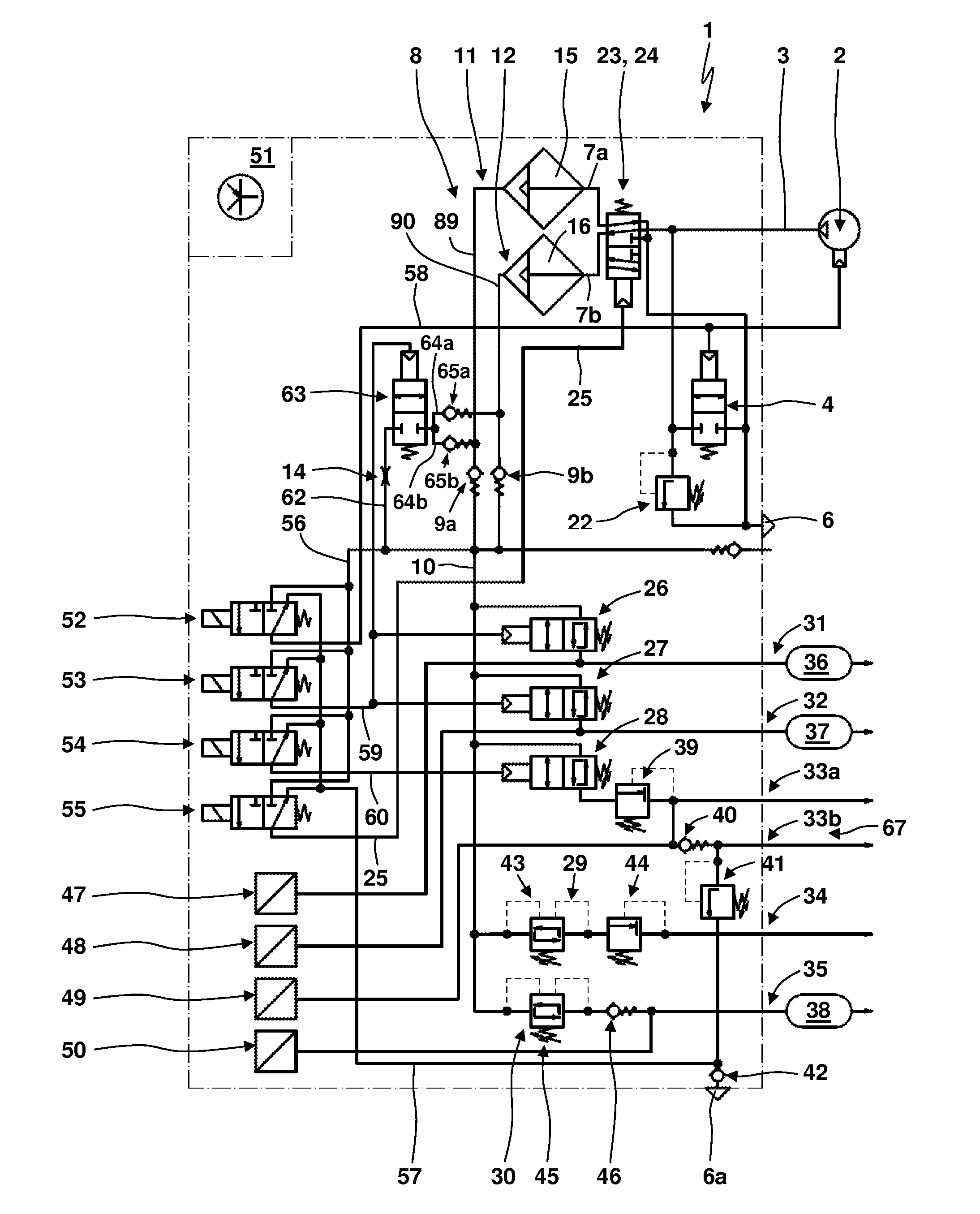

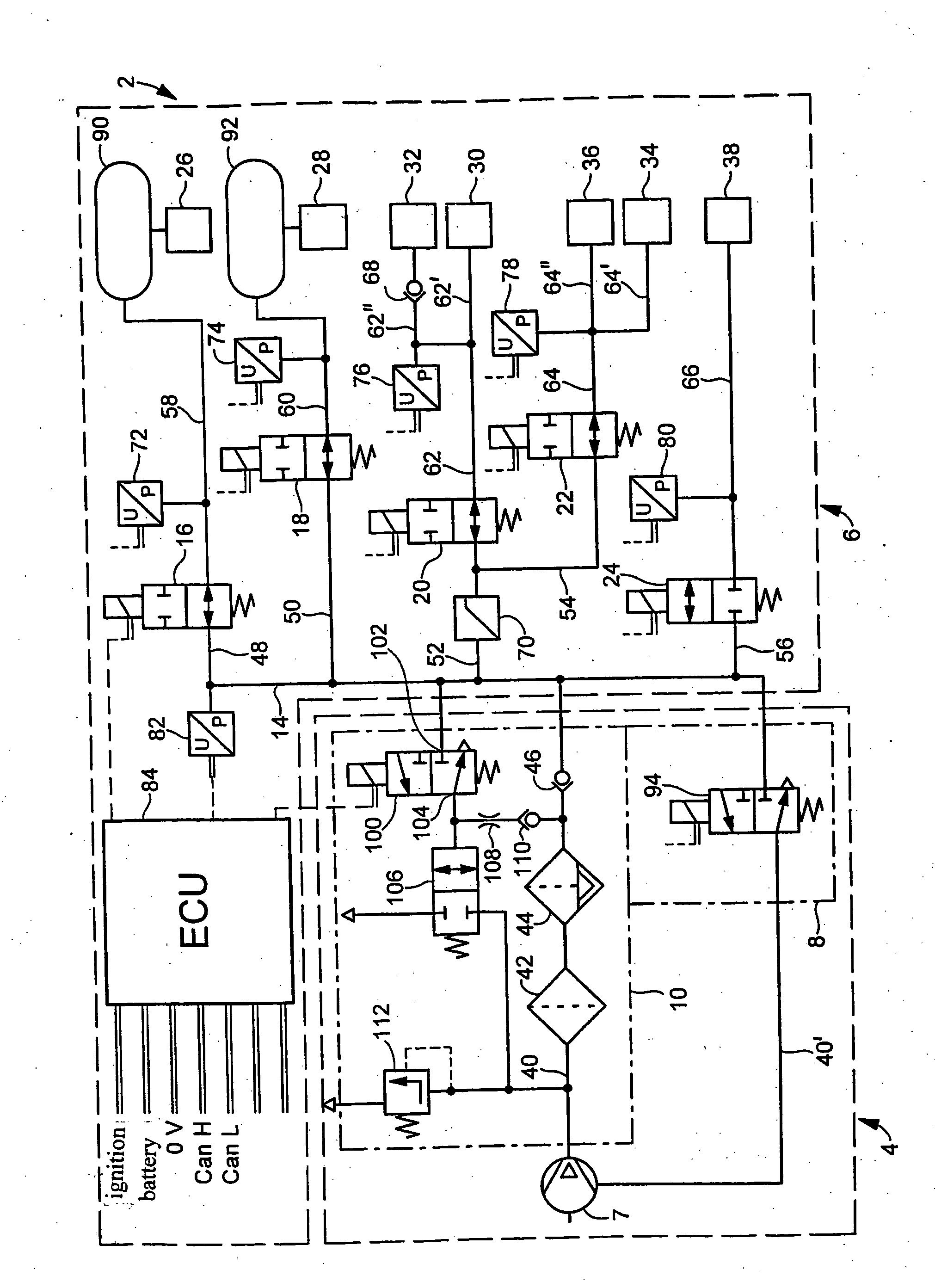

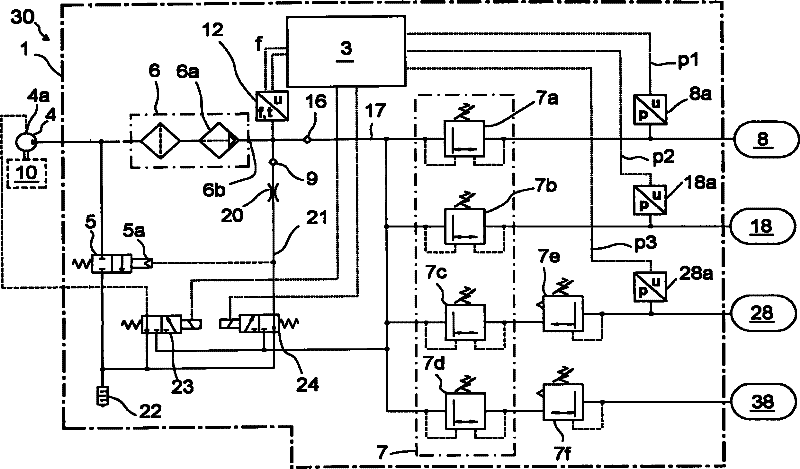

Electronic Compressed-Air System

InactiveUS20070246998A1Eliminate needCompressed-air reservoirs can be very largely eliminatedBraking action transmissionApplication and release valvesLoad circuitSolenoid valve

An electronic compressed-air system includes a compressed-air supply part having a compressor and a consumer part having load circuits. The load circuits are supplied with compressed-air via solenoid valves. At least one load circuit is provided with a pressure reservoir. The pressure in the load circuits is monitored by pressure sensors, whose signals are evaluated by an ECU that controls the solenoid valves. The load circuits include service-brake circuits having a compressed-air reservoir, secondary load circuits and a high-pressure circuit, wherein the solenoid valves of the service-brake circuits and the solenoid valves of the secondary load circuits are open in a de-energized normal state and the solenoid valve of the high-pressure circuit is closed in the de-energized normal state.

Owner:WABCO EURO BVBA SPRL

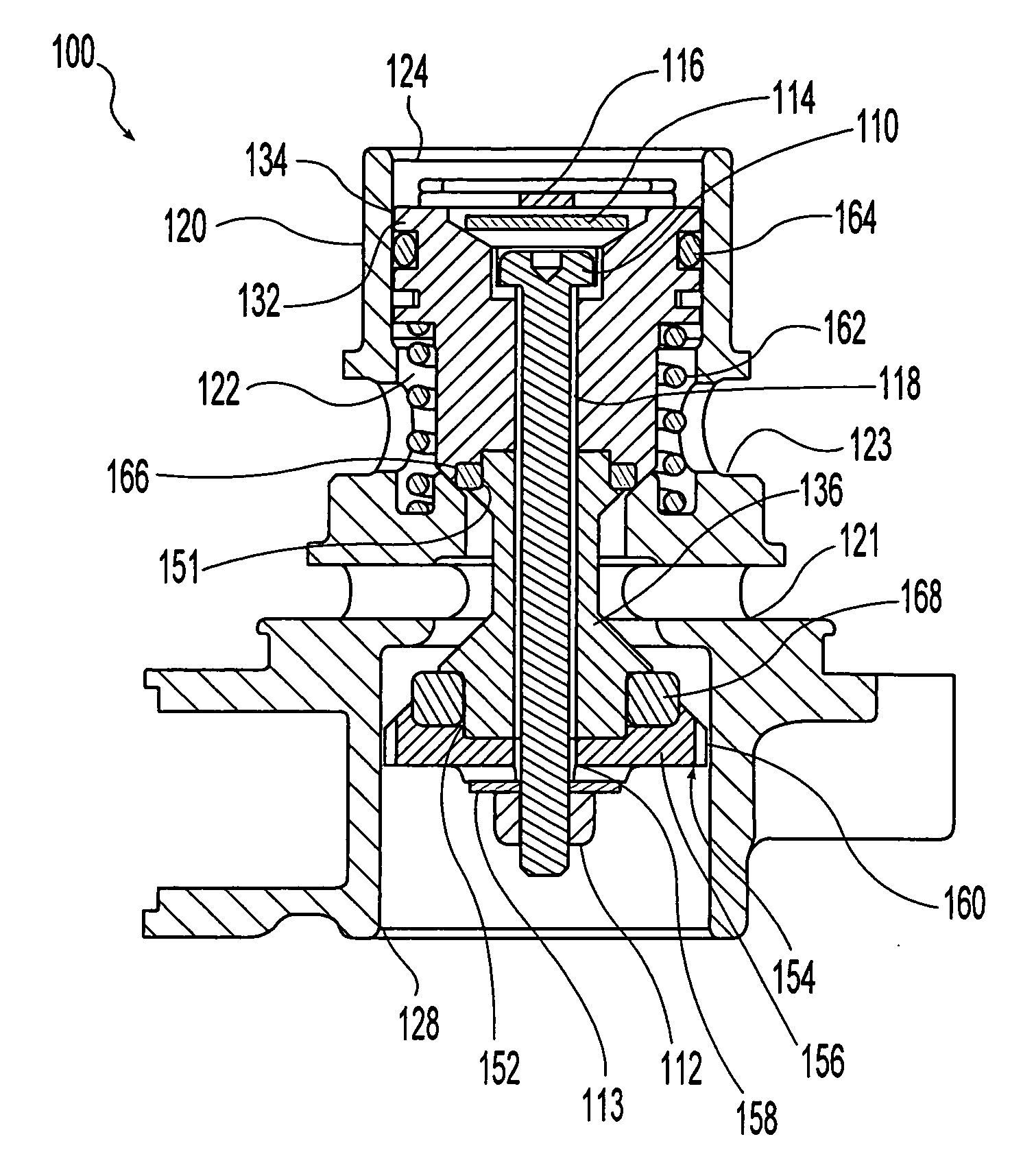

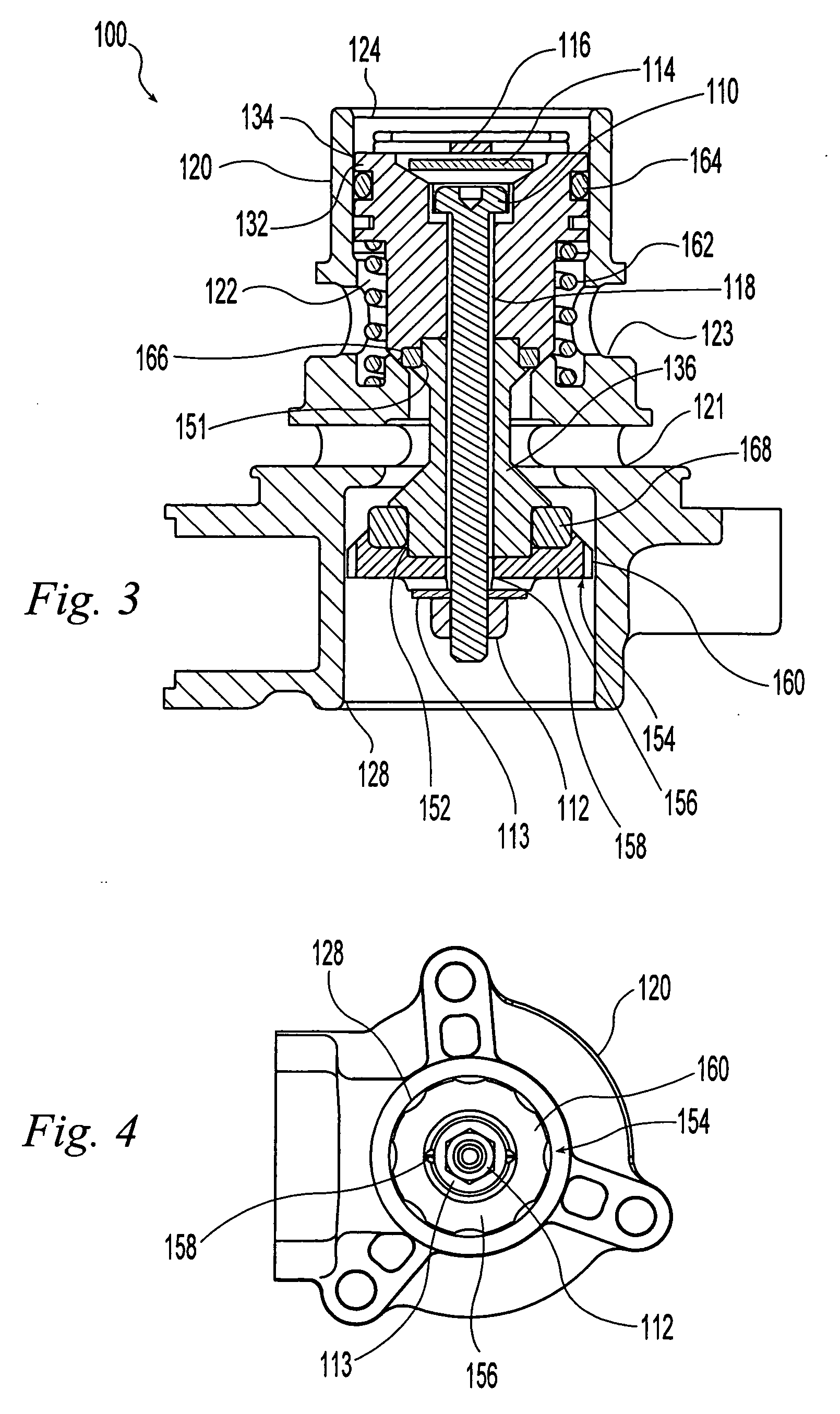

Purge valve

A purge valve for use with an air drying system is provided. The valve includes a housing or body, a piston disposed within the body, and a valve in communication with the piston. The respective geometries of the piston body and the valve define a circumferential cavity between and around the piston body and the valve. A sealing means is disposed within the circumferential cavity for forming a seal between the valve and the body. A plurality of guide members attached to or formed integrally with the valve provide positional stability to the valve within the body and provide enhanced airflow in, through, and around the valve.

Owner:BENDIX COMML VEHICLE SYST LLC

Vehicle air system having an indicator device and method

Various compressed air systems for commercial vehicles are disclosed. In one embodiment, a compressed air system is provided that includes a compressor, an air dryer apparatus, a purge reservoir, and an indicator device. The indicator device comprises a moisture-indicating material that is in contact with the purge air within the purge reservoir.

Owner:BENDIX COMML VEHICLE SYST LLC

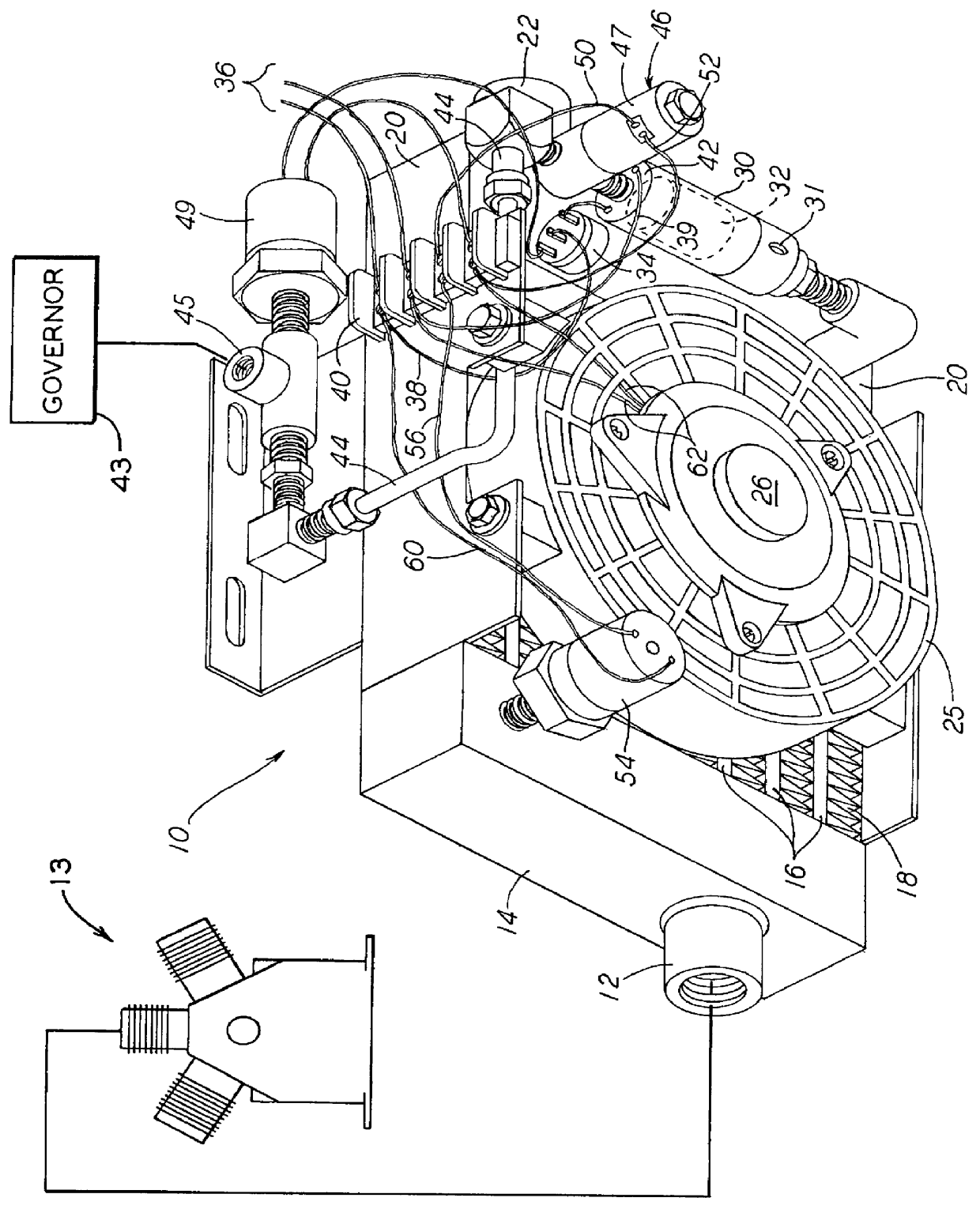

Air compressor aftercooler with automatic heated drain valve and start-up shut-off

A water release system includes a compact aftercooler connected to receive hot, moisture laden compressed air from a compressor having a load cycle under control of a governor. A water release valve is connected between a header of the aftercooler and an unloader pressure line connected to the governor. The valve ordinarily remains open until it receives a certain, pressure value signal from the unloader line which is effective to close the valve. A switch is located in pressure sensing relationship with the aftercooler, and a solenoid valve is electrically connected to the pressure sensitive switch and pneumatically connected between the water release valve and the governor. When the pressure sensed by the switch is somewhat above that at which the water release value ordinarily closes, the pressure sensitive switch closes to energize the solenoid valve and thereby open the same, after which the water release valve operates automatically to open and close in response to pressure and lack thereof in the unloader line.

Owner:CHOVAN DALE A

Sound damper for vehicle compressed air systems

ActiveUS8215448B2Ensures effective conductionEfficient conductionExhaust apparatusCombustion-air/fuel-air treatmentEngineeringCompressed air

A sound damper for compressed air systems of vehicles includes a housing, an insulator and at least one web. The housing has an air inlet and an air outlet. The insulator is located in the housing, and the web is located in the housing such that it protrudes at least partially into the insulator. Air that flows through the housing from the air inlet to the air outlet is conducted by the web into the insulator.

Owner:WABCO EURO BVBA SPRL

Motor/pump assembly

ActiveUS20100202893A1Quiet operationReduce noise levelPositive displacement pump componentsBraking action transmissionLow noiseInterior space

A motor / pump assembly for a motor vehicle brake system including a pump and a motor driving the pump, the pump having opposite working diaphragms which are, in each case, mounted between a pump casing and a cover and thereby delimit a space and which can be moved by a crank drive, the space being assigned, in each case, an inlet duct with an inlet valve and an outlet duct with an outlet valve. The outlet ducts are arranged in the covers and in the pump casing such that air displaced out of the spaces is conducted into an inner space surrounding the crank drive of the pump casing and that an air outlet unit be provided, which allows a low-noise blow-out of the air from the inner space as a result of the deflection of the air.

Owner:CONTINENTAL TEVES AG & CO OHG

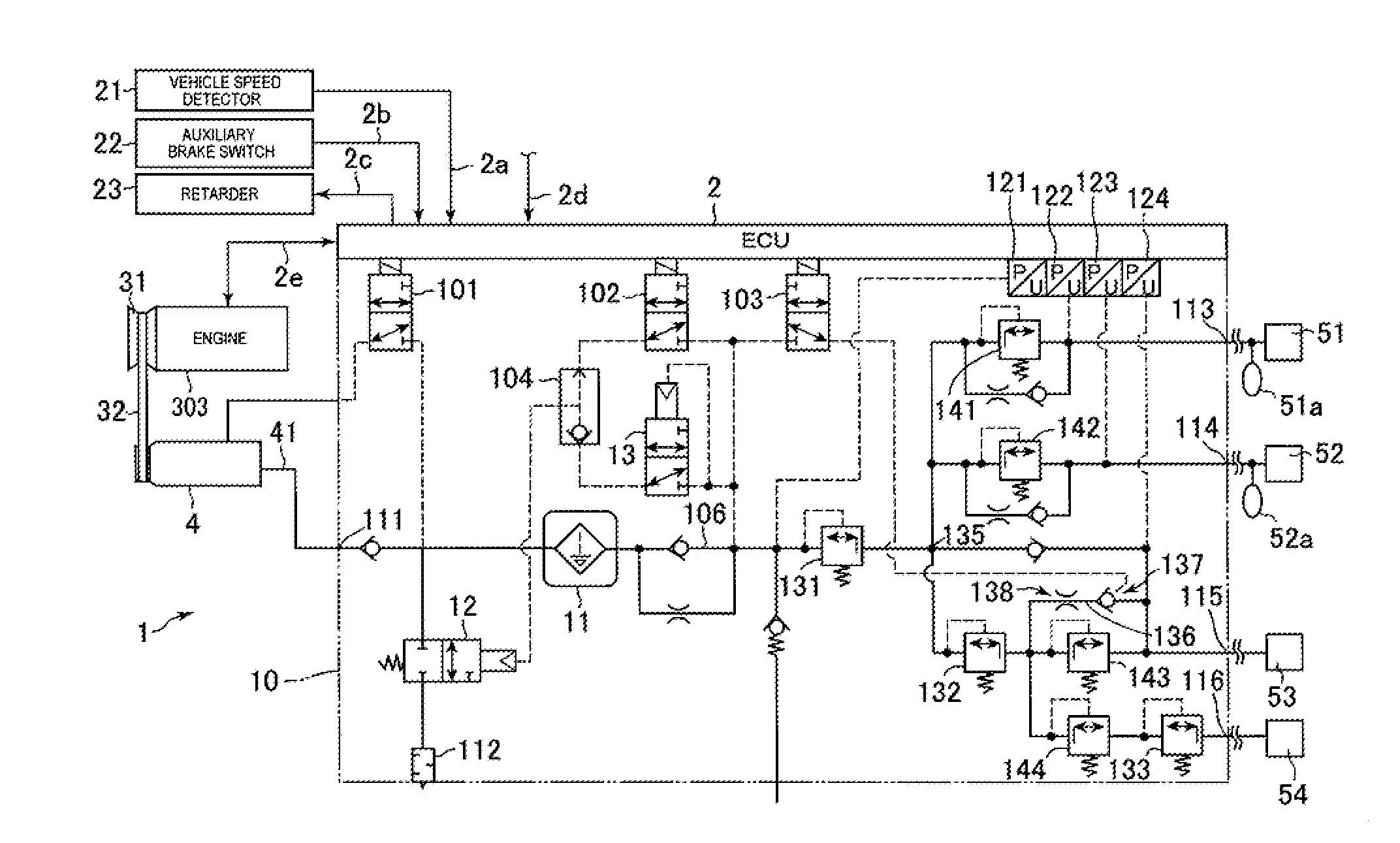

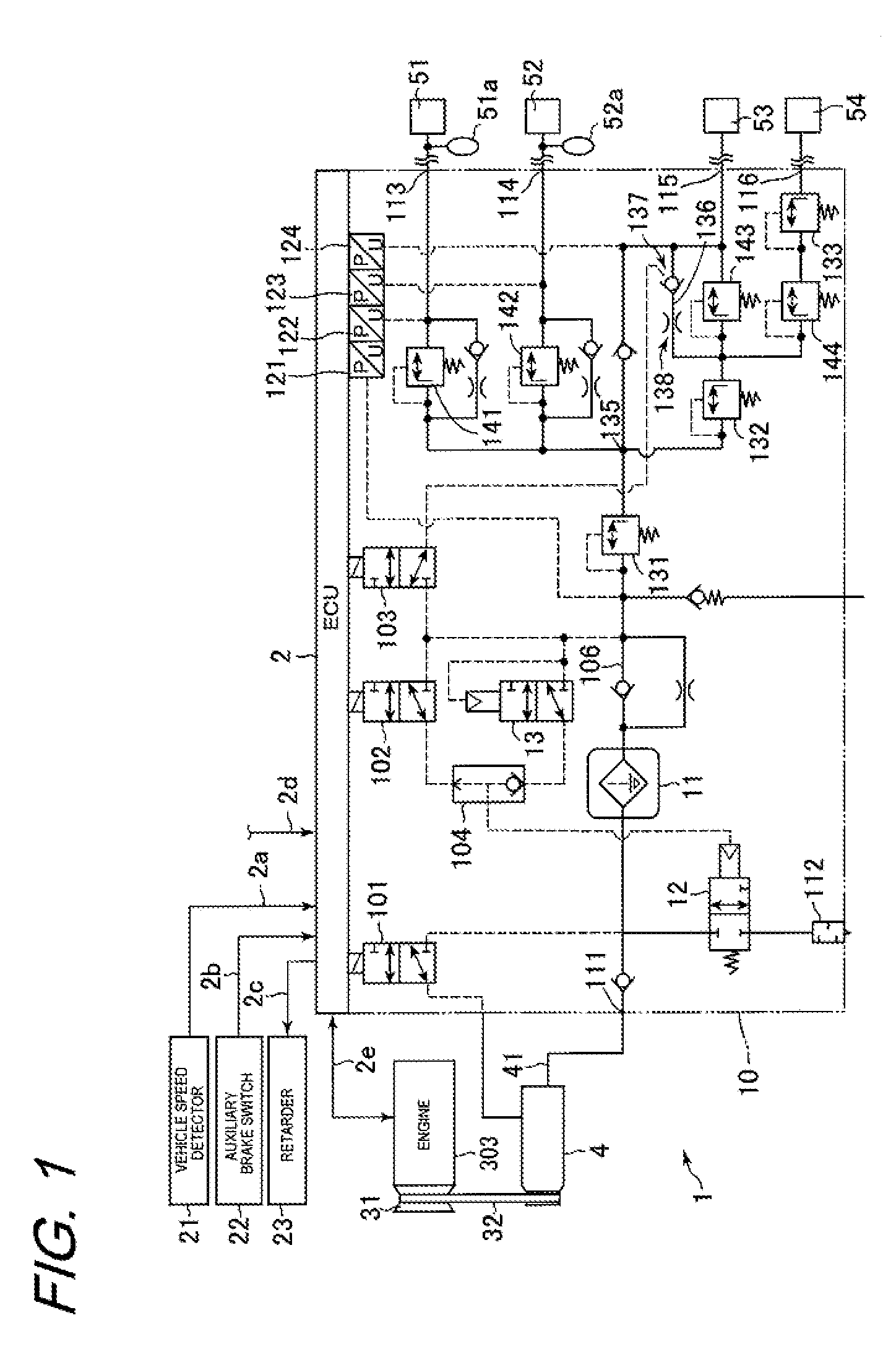

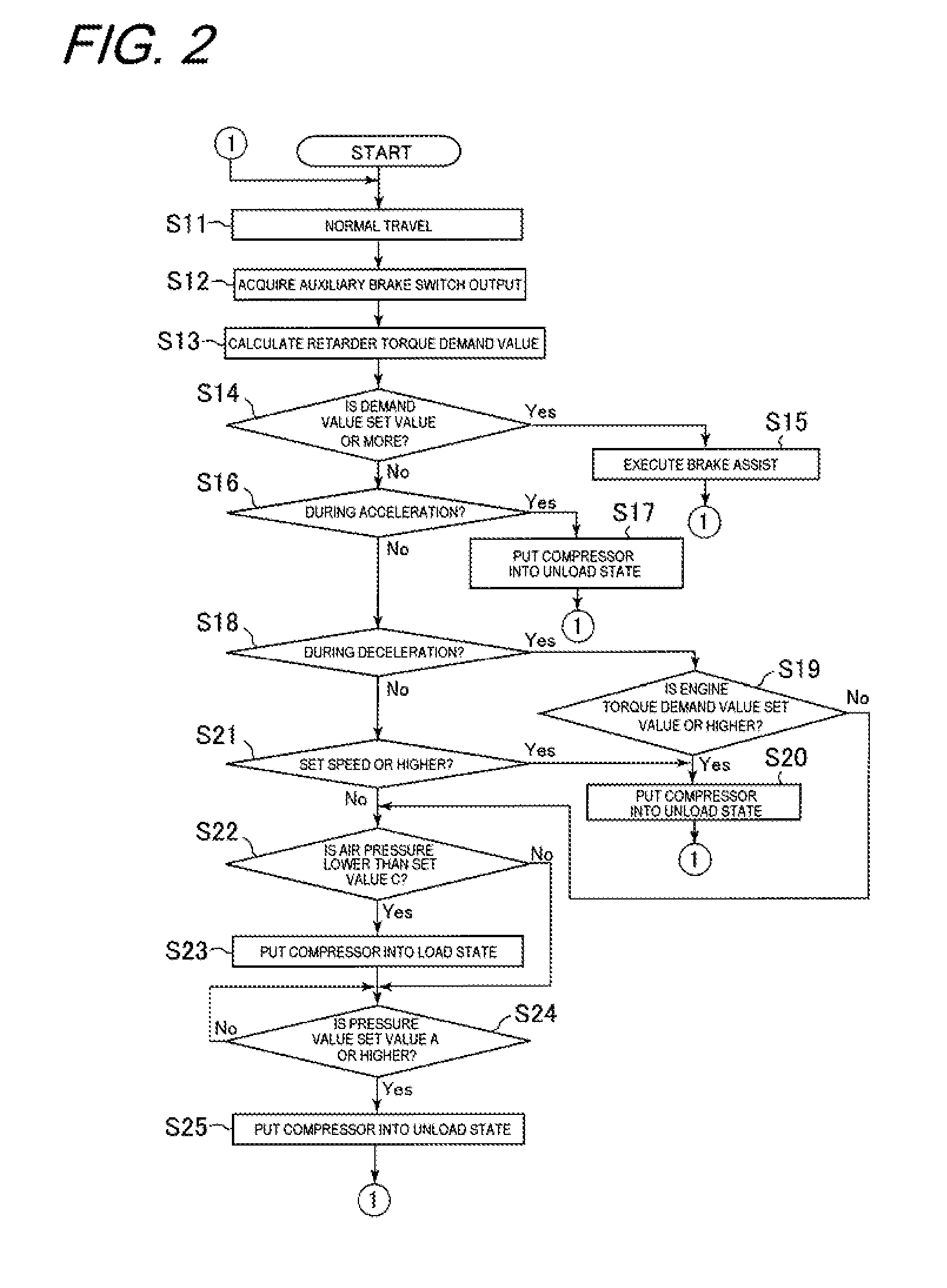

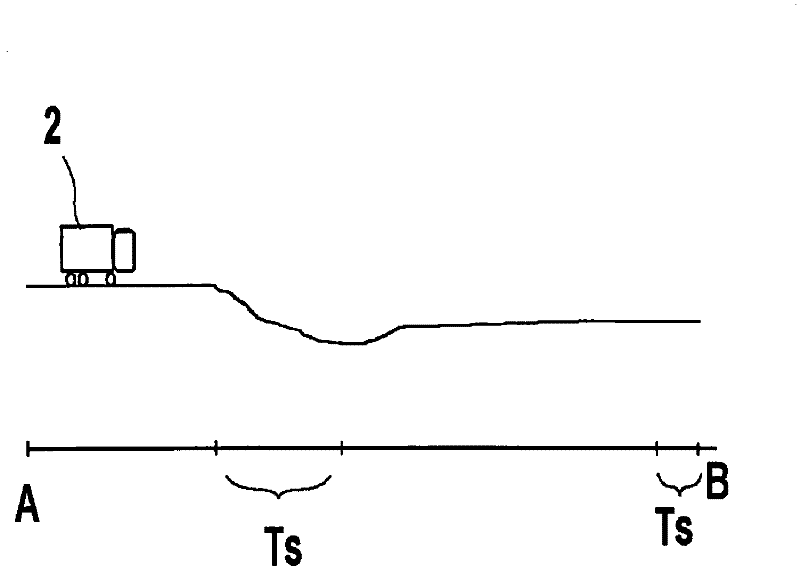

Compressed air supply system, compressed air supply device for vehicle, and method of controlling air compressor

ActiveUS20120153711A1Prevent freezingImprove vehicle performanceGas treatmentBraking action transmissionGas compressorAir compressor

The operation of an air compressor is controlled to control engine performance to thereby improve the performance of the vehicle. A compressor (4) driven by an engine (3) of a vehicle and supplying compressed air to loads (51-54) is controlled by an ECU (2). A loaded state and an unloaded state of the compressor (4) are switched between each other according to the requirements from the loads (51-54). When the vehicle requires braking force, the compressor (4) is set to the loaded state irrespective of the requirements from the loads (51-54).

Owner:NABTESCO AUTOMOTIVE CORP

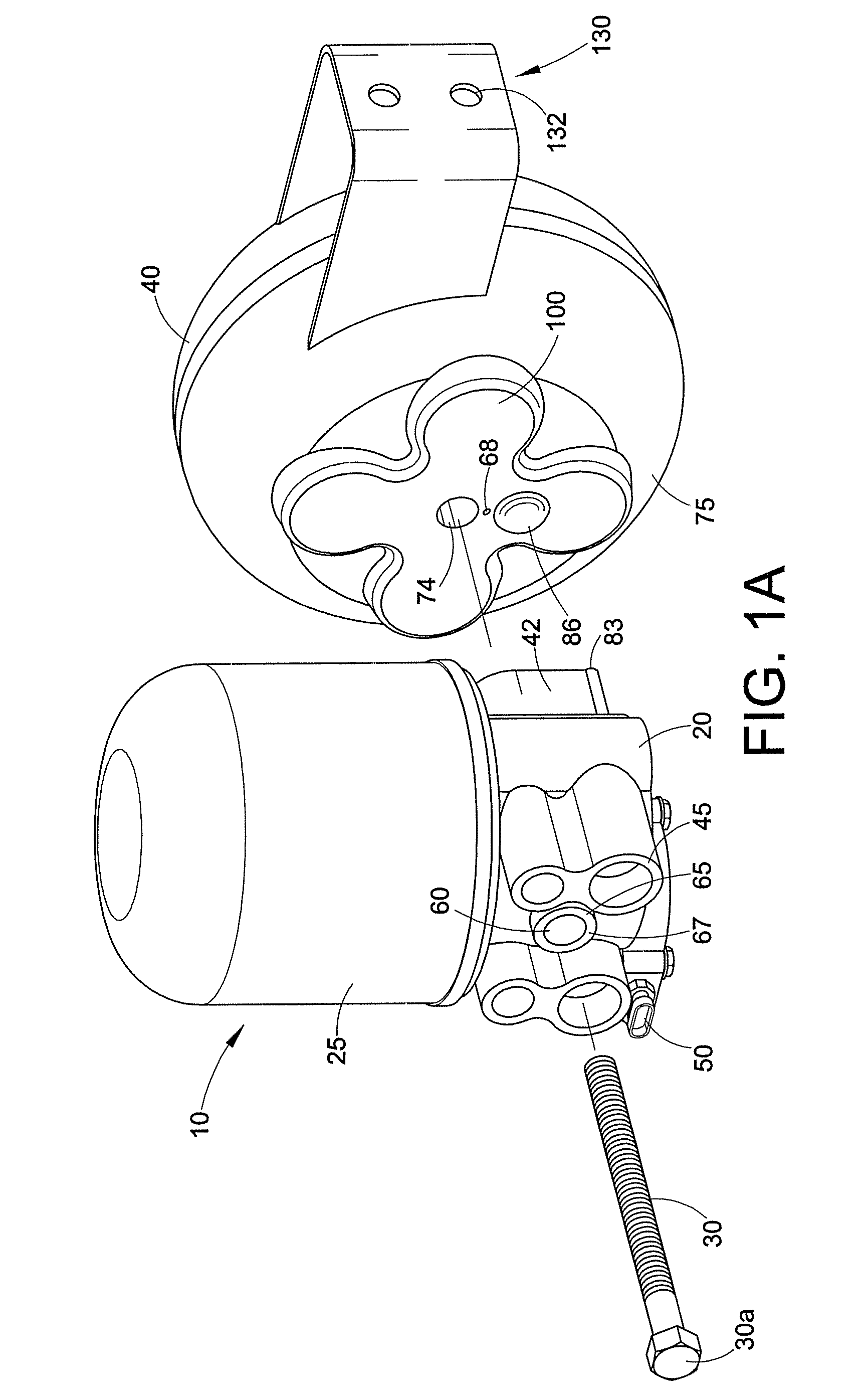

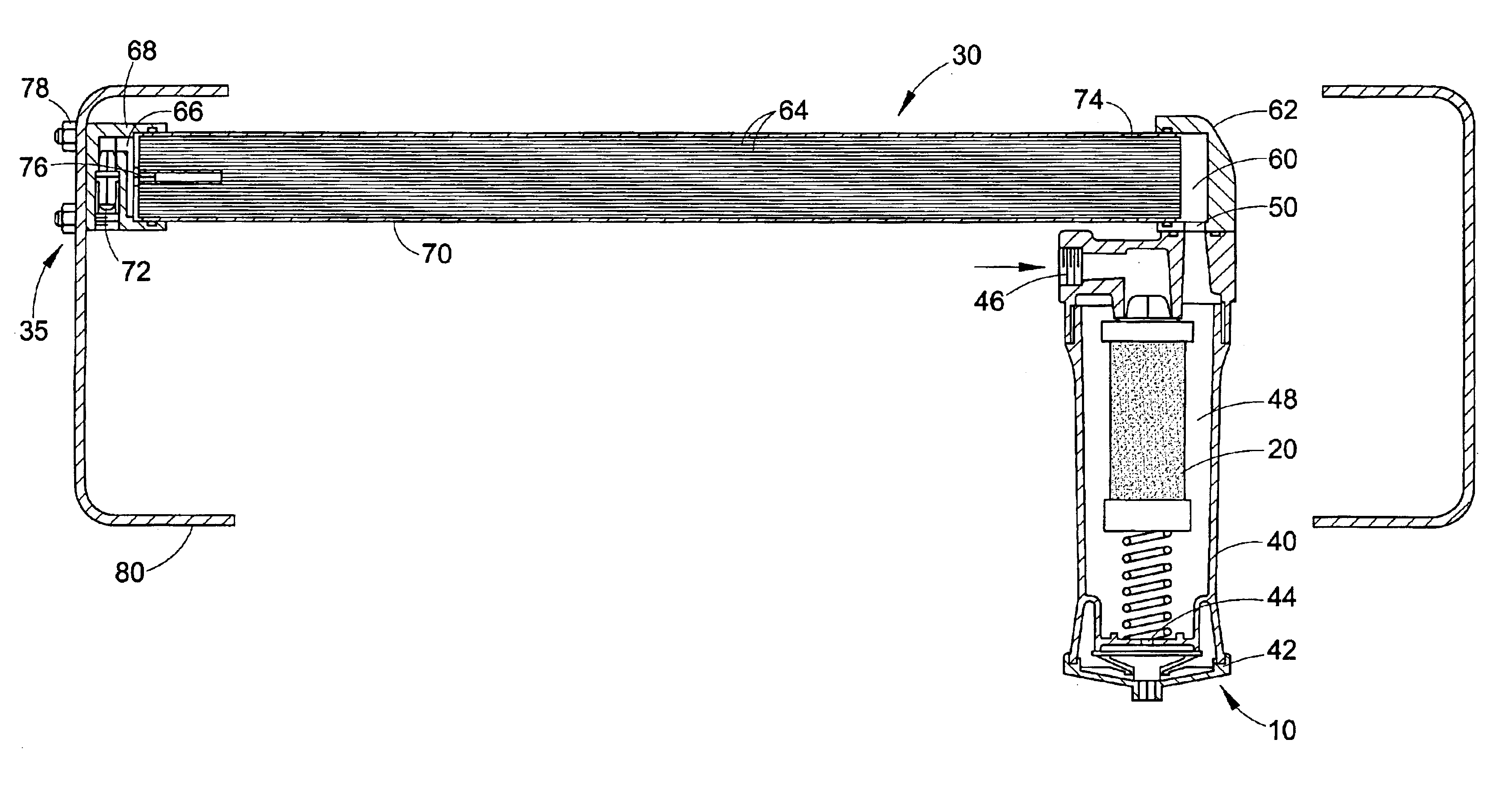

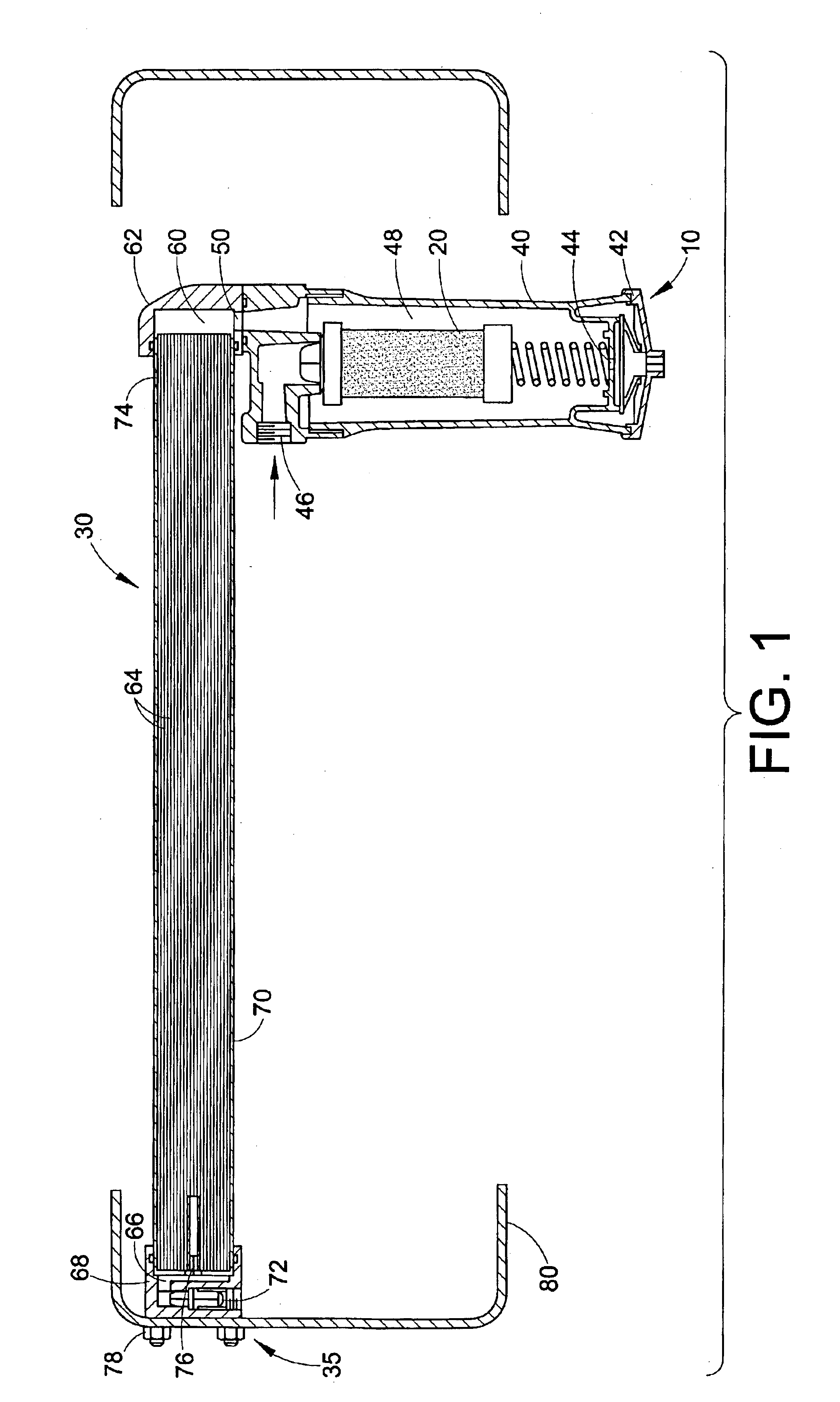

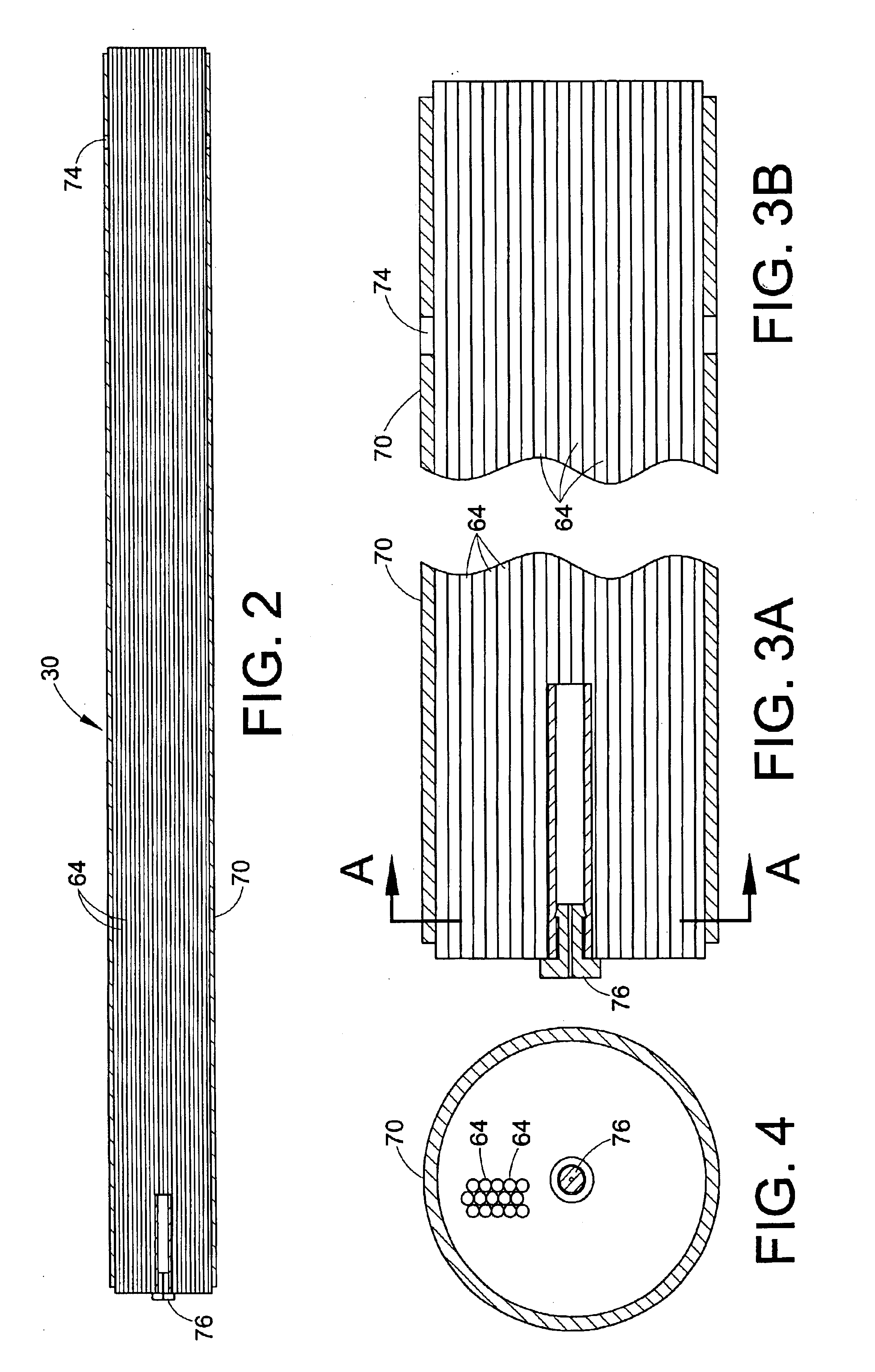

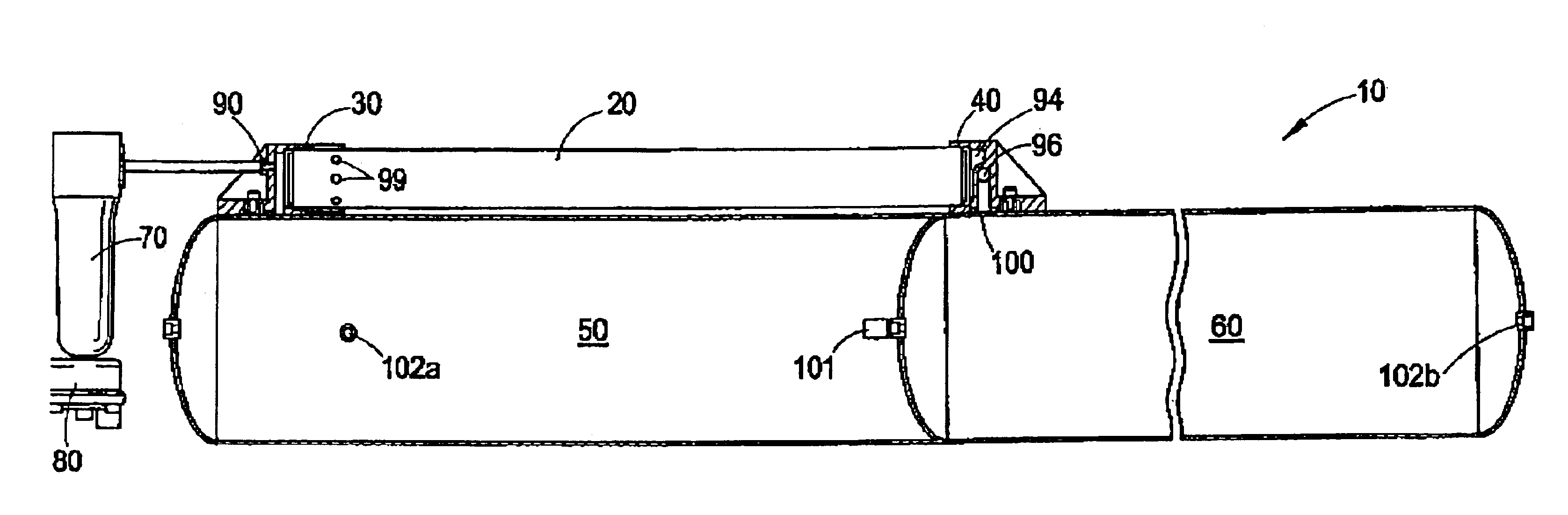

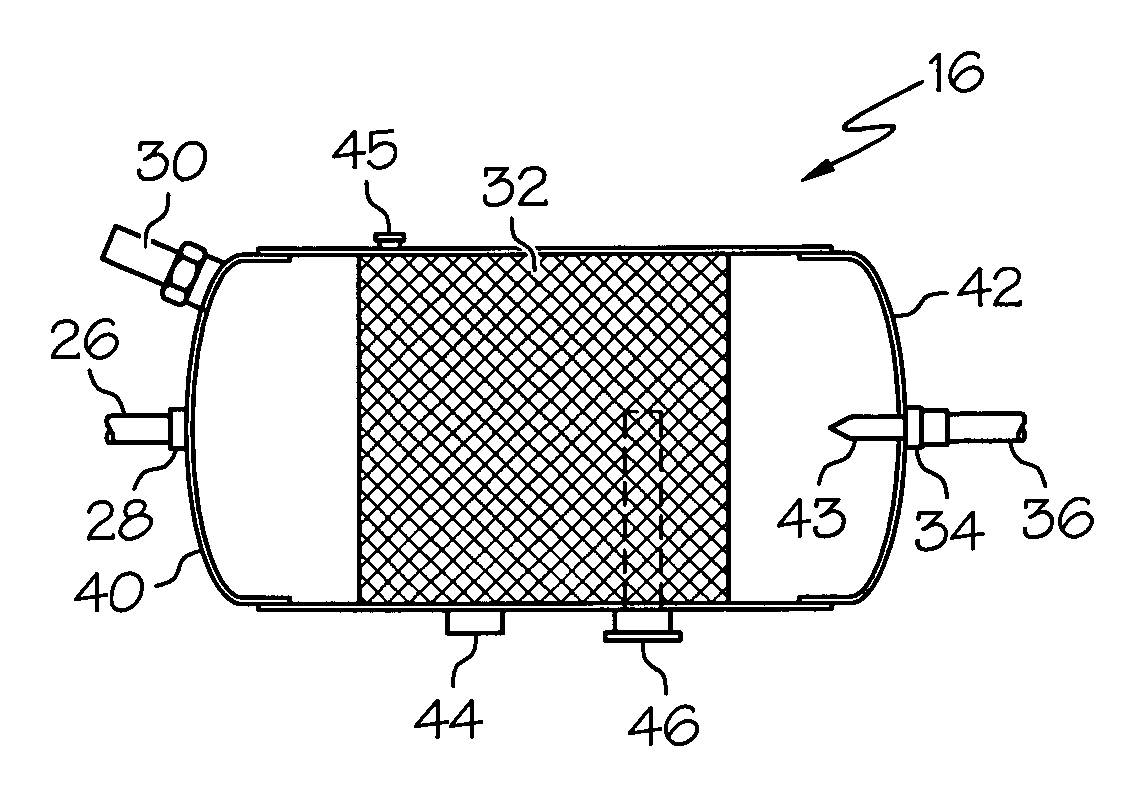

Membrane air dryer and method of mounting a membrane dryer to a vehicle

A method and apparatus for mounting an air dryer to a commercial vehicle is provided. The end caps of the membrane air dryer are used to retain the membrane air dryer core and attach the membrane air dryer to the surface of the air supply reservoir. Bosses can be welded to the external surface of the air supply reservoir, which can then be used to mount the membrane air dryer by bolting the end caps to the bosses. The method and apparatus can be applied to two or three tank air supply reservoir systems. A disengagement tank may be included within the air dryer system, in place of a coalescing filter, to reduce the amount of moisture that reaches the membrane air dryer core.

Owner:NEW YORK AIR BRAKE CORP

Water and oil mist elimination apparatus for a vehicular compressed air storage system

A moisture removal apparatus for a vehicular compressed air storage system includes a canister of mist-eliminating mesh that collects moisture and oil droplets in the air and exhausts them through a gravity drain. The mesh coalesces droplets of both water and oil vapor in the air stream, and is not contaminated by either. The mist eliminating canister can be a stand-alone device through which compressed air is delivered to a pressure tank, or may be integrated into a pressure tank for space efficiency.

Owner:JOHNSON WELDED PRODS

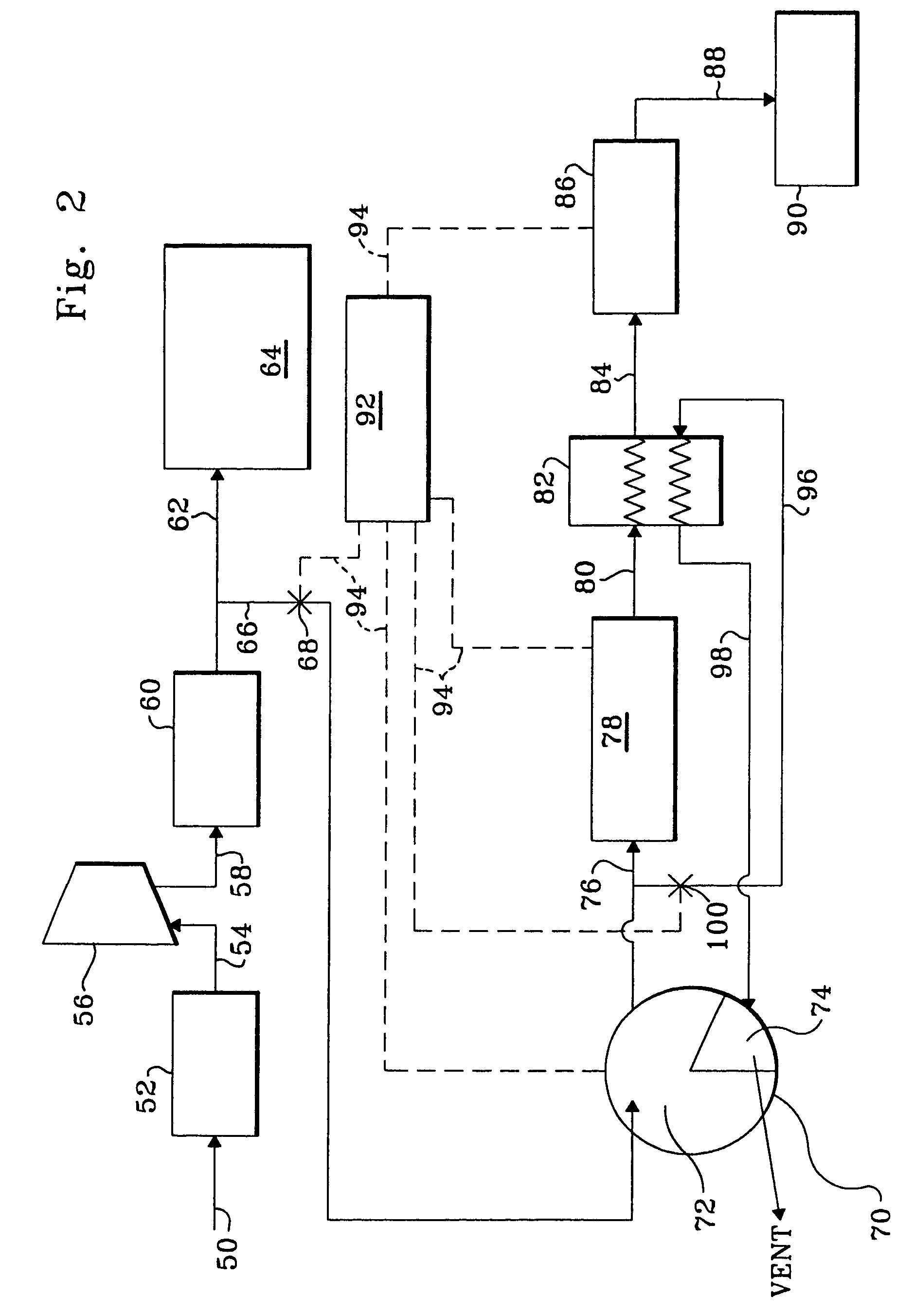

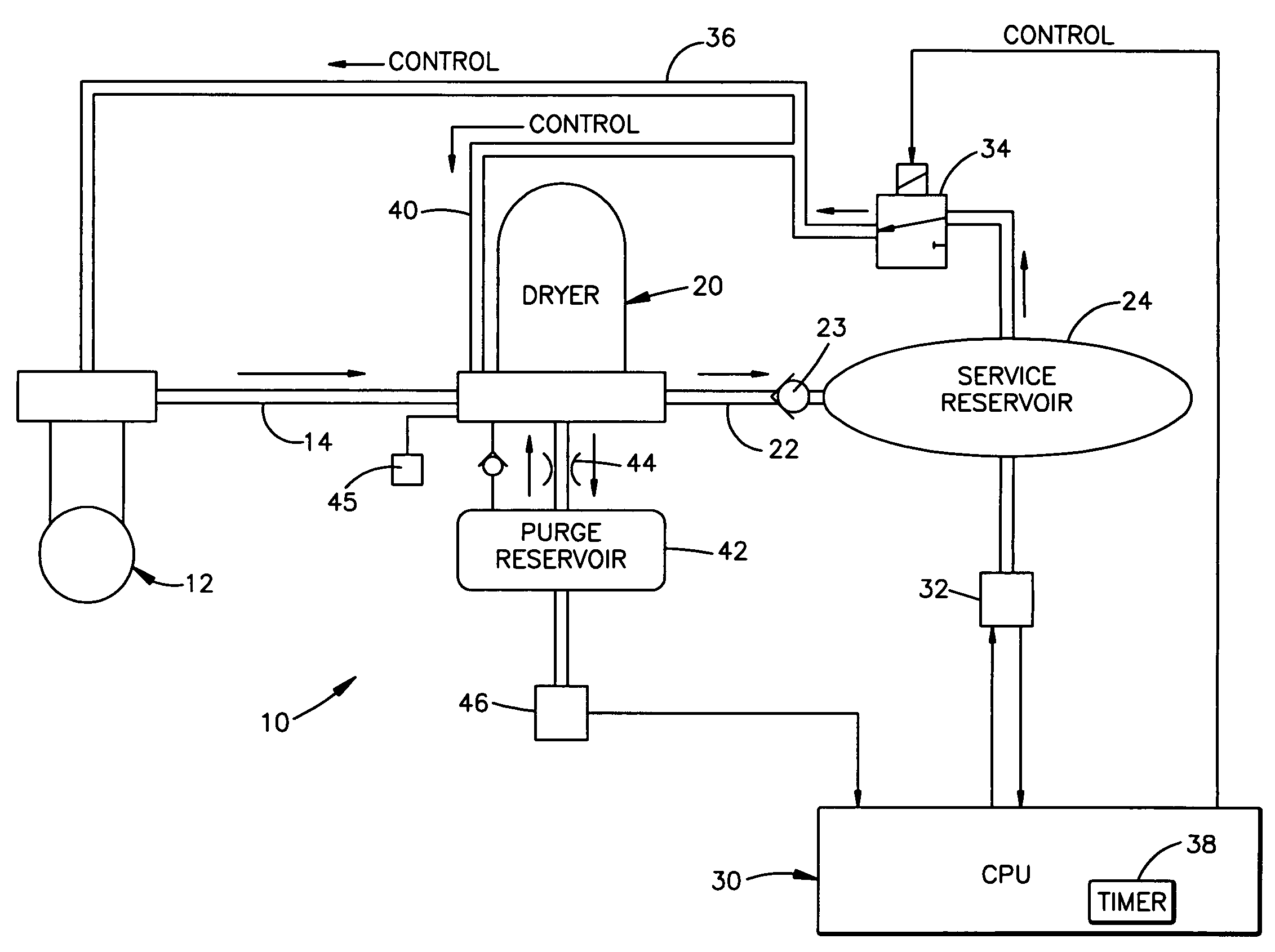

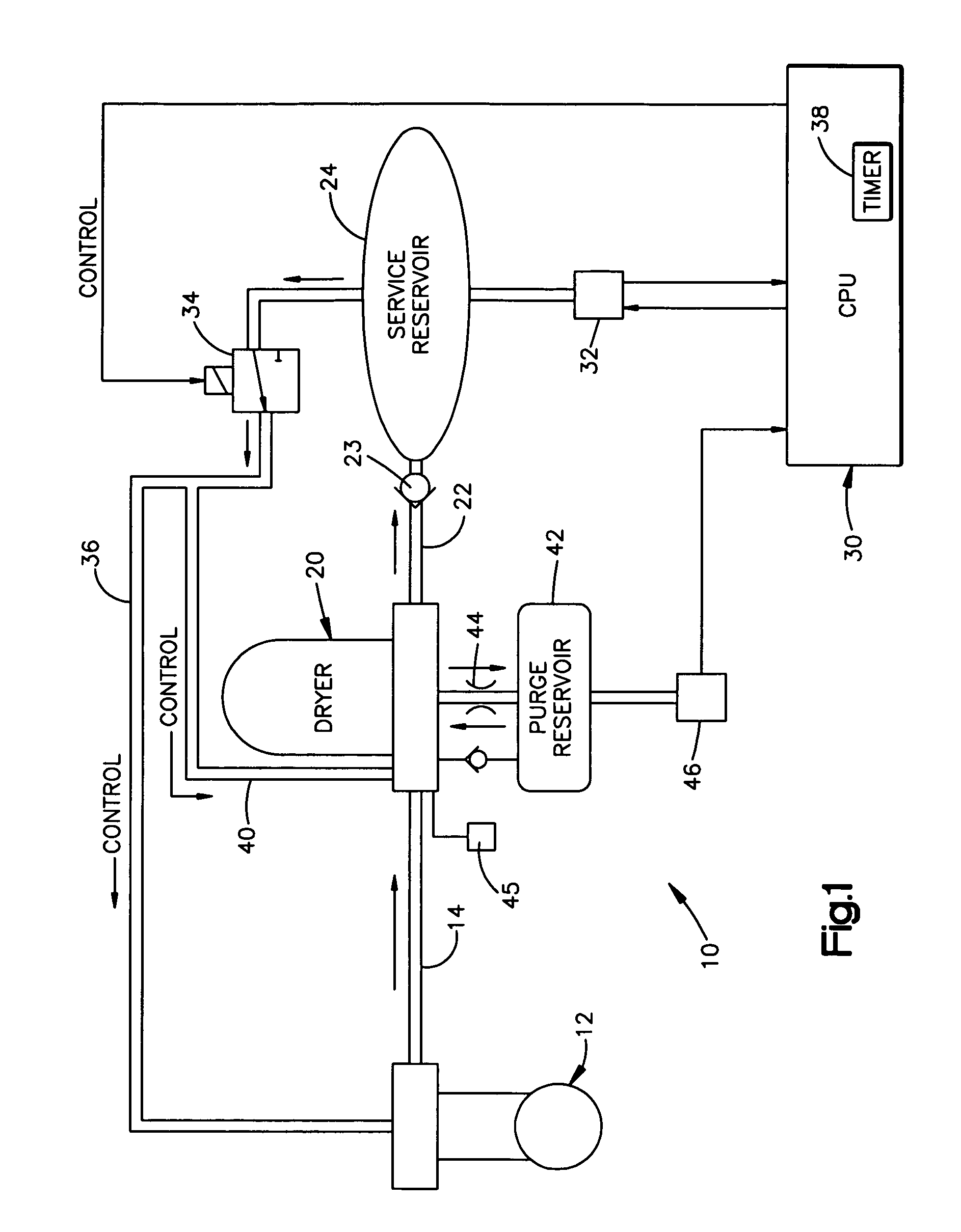

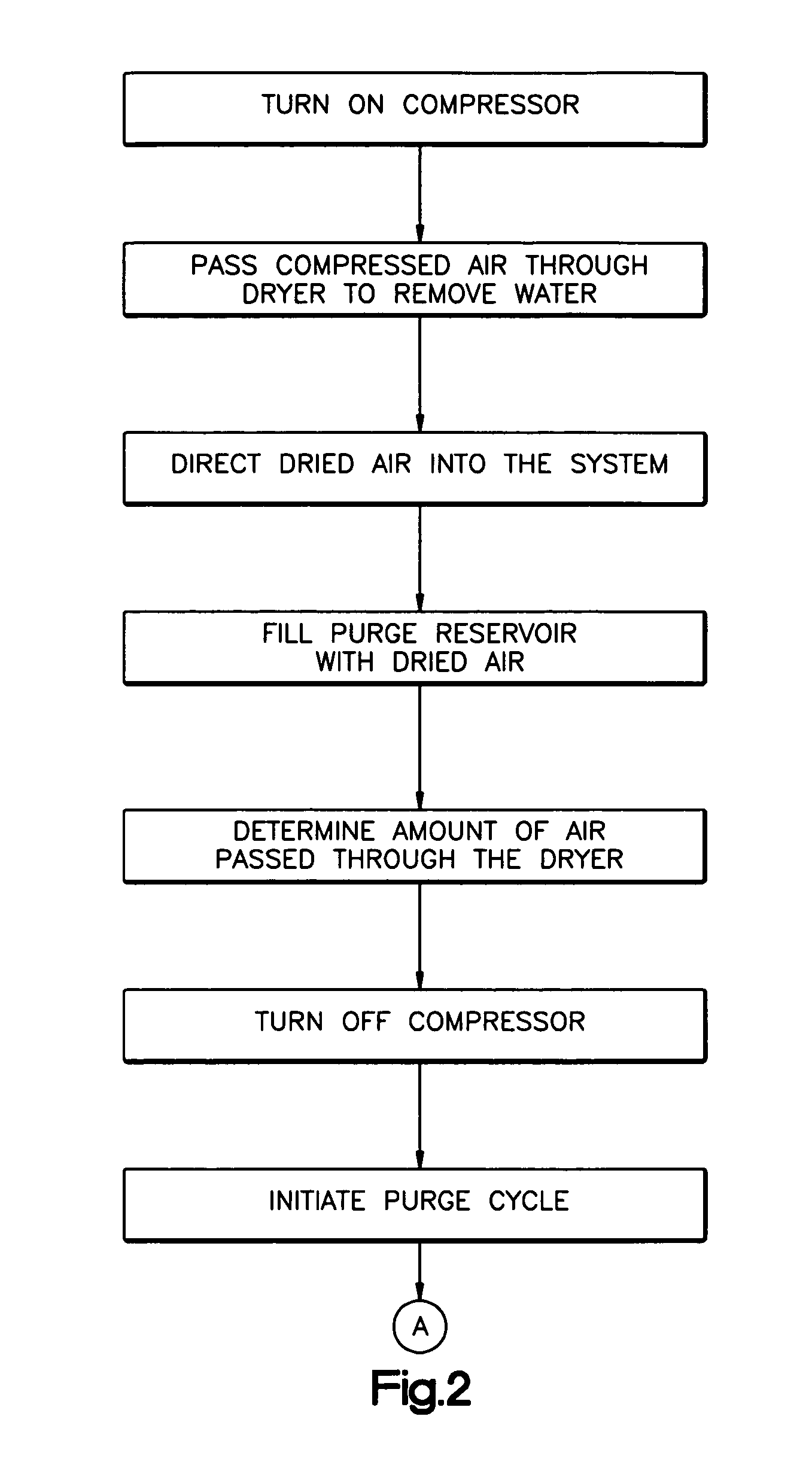

Vehicle air system and method with forced purging

A method and apparatus provide multiple consecutive purges of an air dryer in a vehicle compressed air system. A dryer throughput sensor has an output indicative of the amount of compressed air that is passed through the dryer. In response, a CPU determines the number of purges needed to purge the dryer; and a valve is operated by the CPU to initiate multiple purges of the dryer when the compressor is unloaded.

Owner:BENDIX COMML VEHICLE SYST LLC

Oil separator for vehicle air system

An oil separator for use in a vehicle air system includes a recycling valve for removing coalesced oil. The recycling valve may include a piston movable in a cylinder in response to a control air pressure to open the recycling valve and thus drain coalesced oil from a sump under the influence of residual air pressure in the sump. The separator may include a fixture for mounting the separator to a vehicle, including a plurality of ports extending from an inlet port for directing air into the cartridge with a combined flow area at least equal to the flow area of the inlet port. The plurality of ports preferably extend at a right angle to the direction of flow of air through the inlet port. A safety relief valve on the separator releases air when the pressure exceeds a predetermined pressure.

Owner:BENDIX COMML VEHICLE SYST LLC

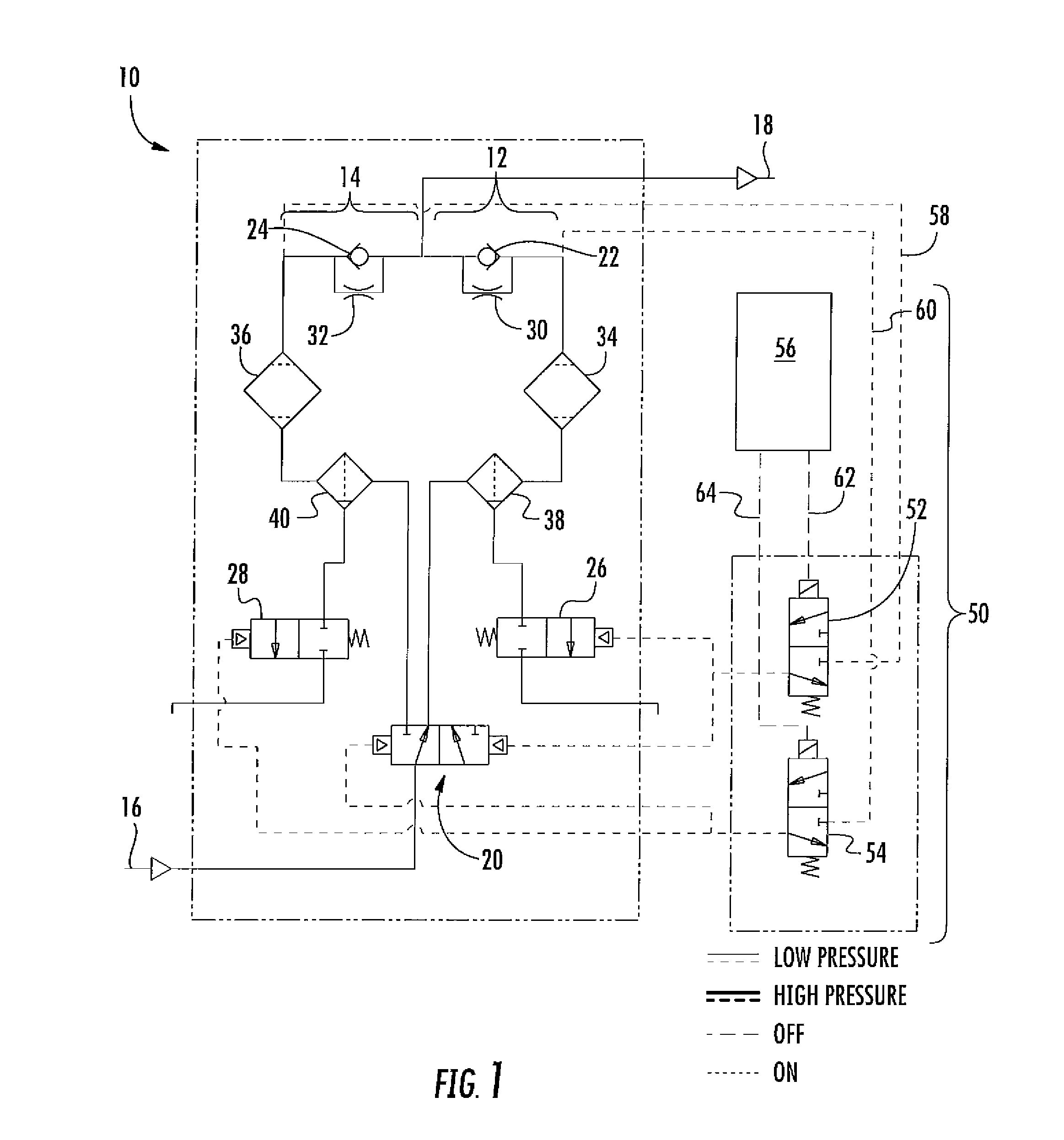

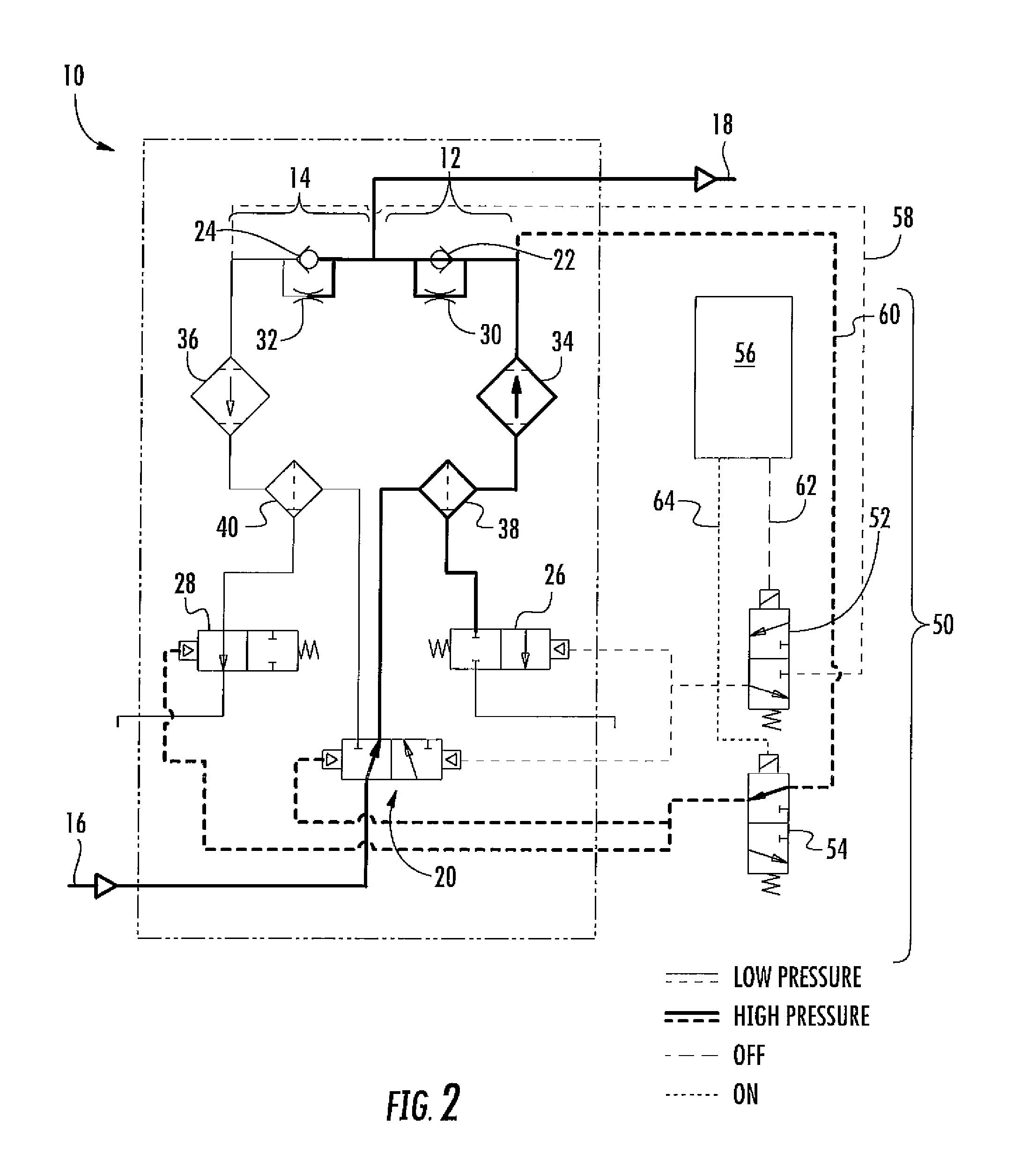

Air dryer

An air dryer includes first and second flow paths. Each flow path includes a check valve that prevents fluid flow into the flow path and an exhaust valve having an open position that permits fluid flow out of the flow path and a shut position that prevents fluid flow out of the flow path. A diverter valve has a first position that provides fluid communication to the first flow path and a second position that provides fluid communication to the second flow path. An interlock operably connected to the diverter valve and the exhaust valves prevents positioning the diverter valve to the first position when the exhaust valve in the first flow path is in the open position and prevents positioning the diverter valve to the second position when the exhaust valve in the second flow path is in the open position.

Owner:GRAHAM WHITE MFG

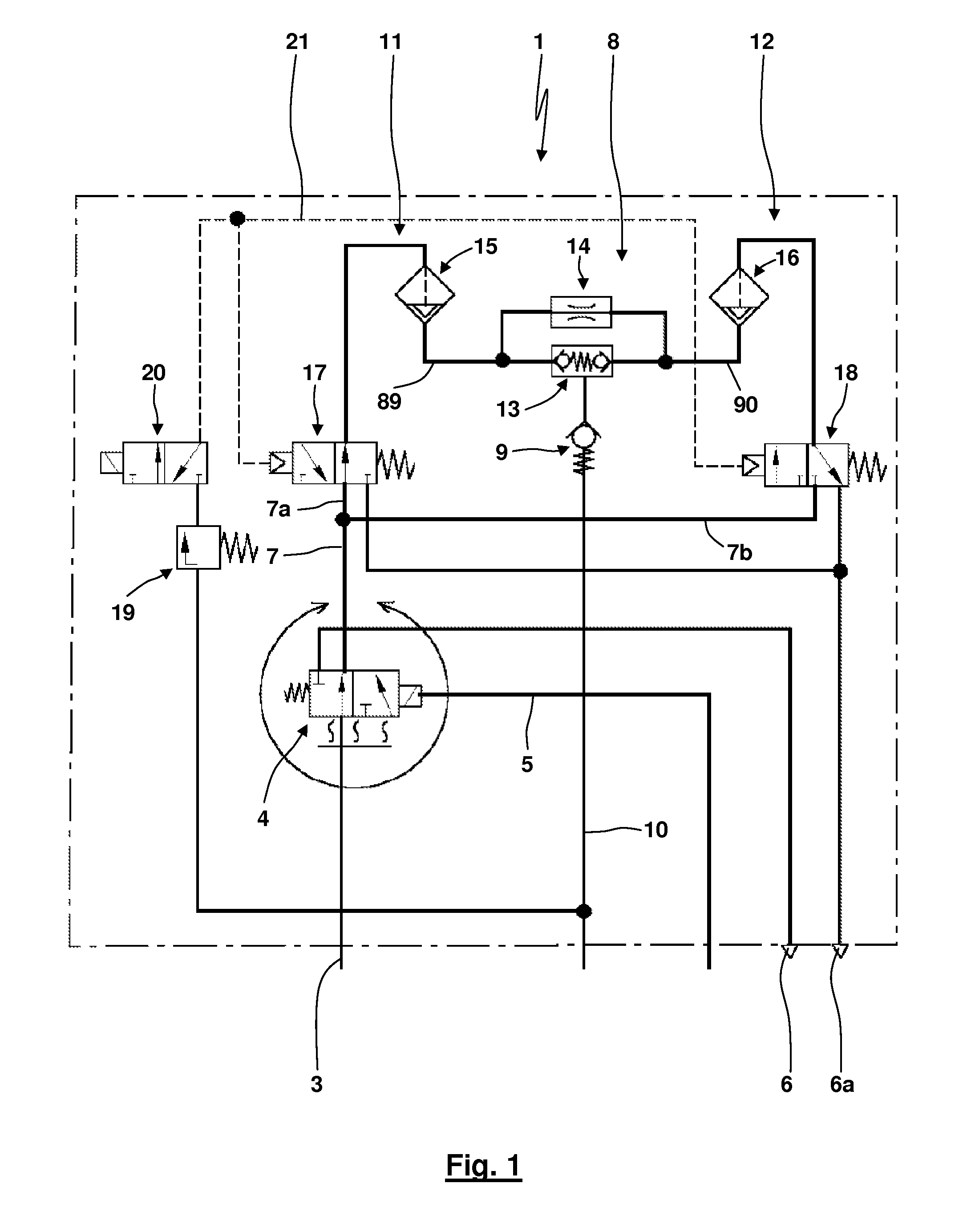

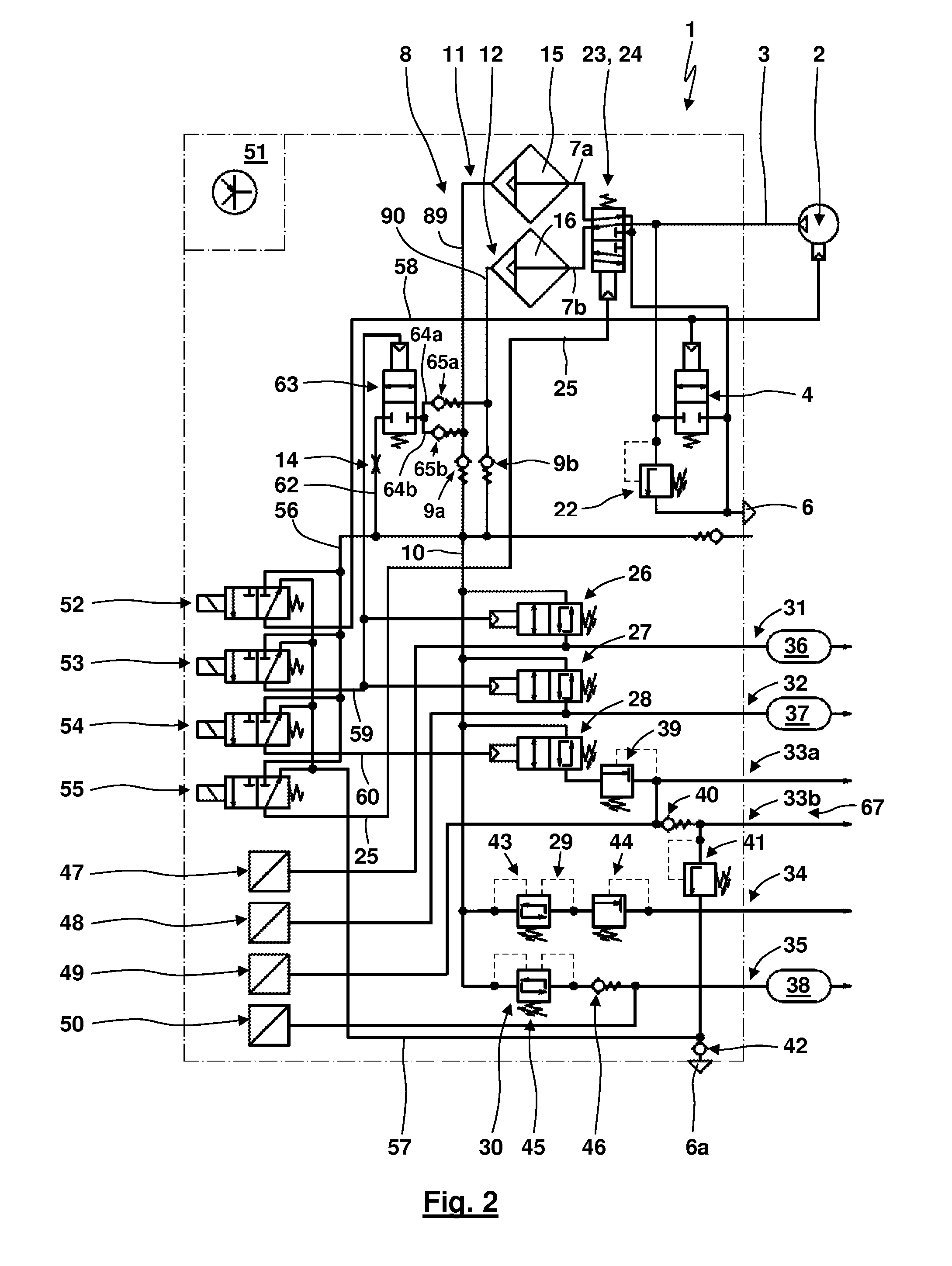

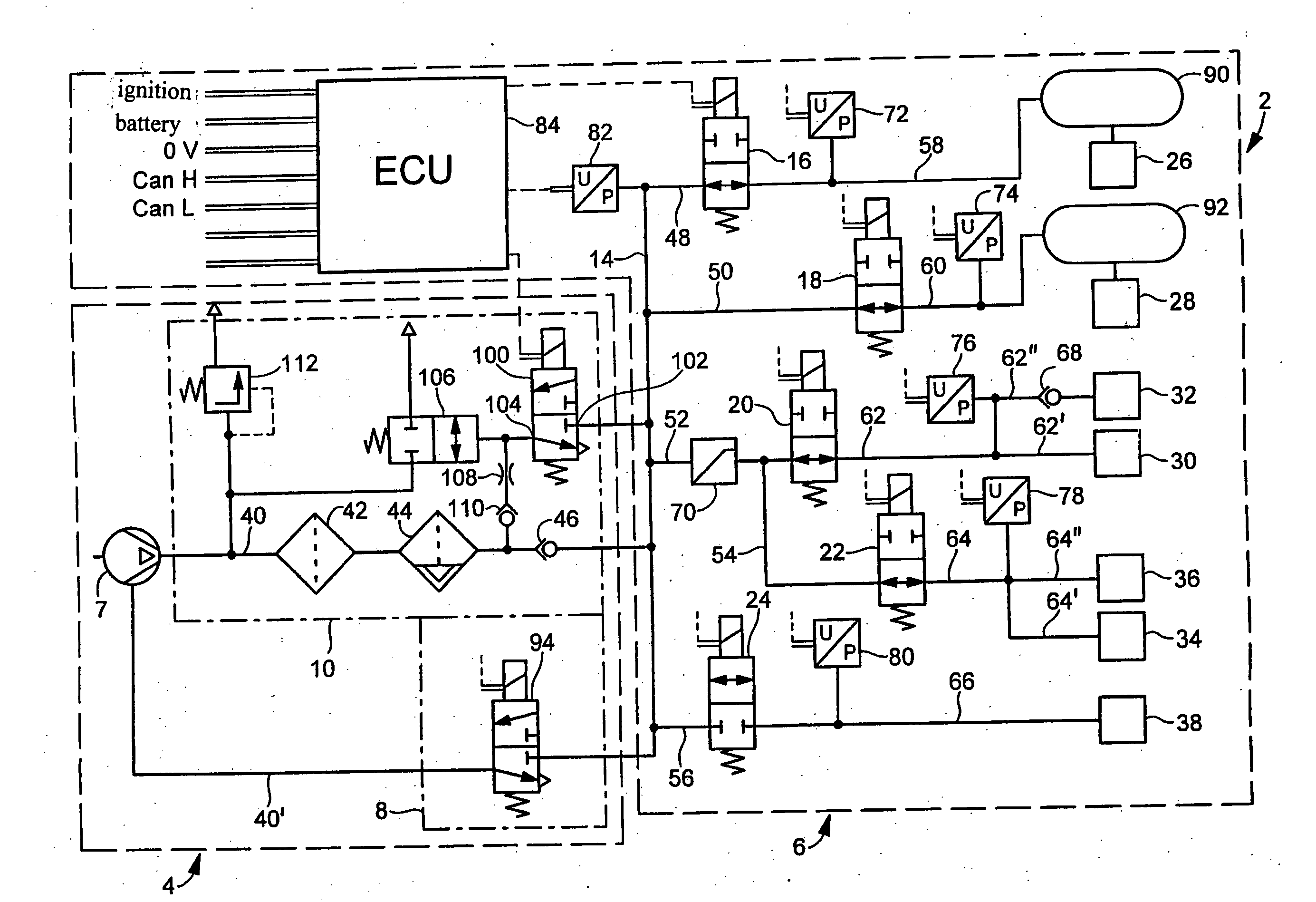

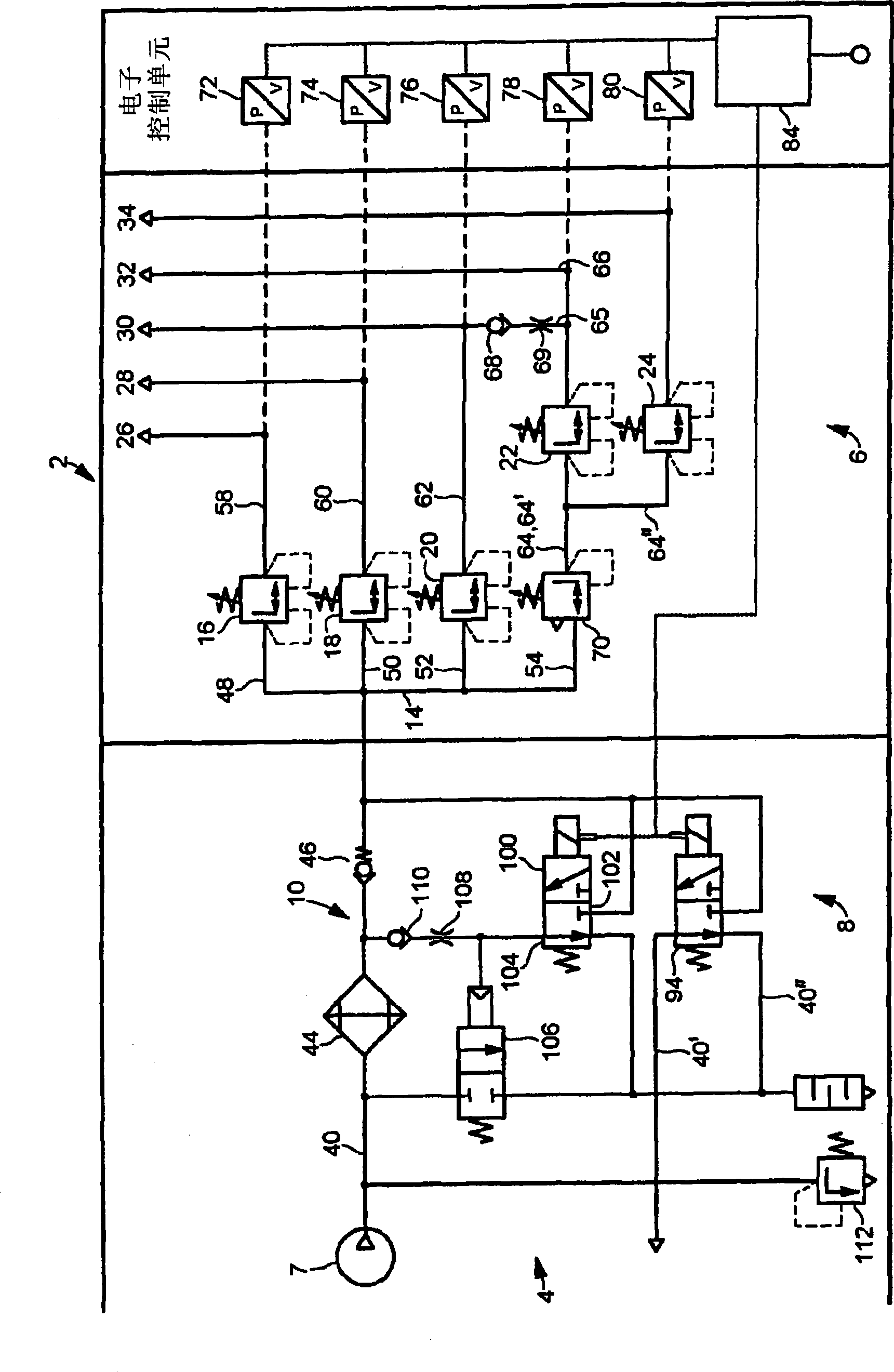

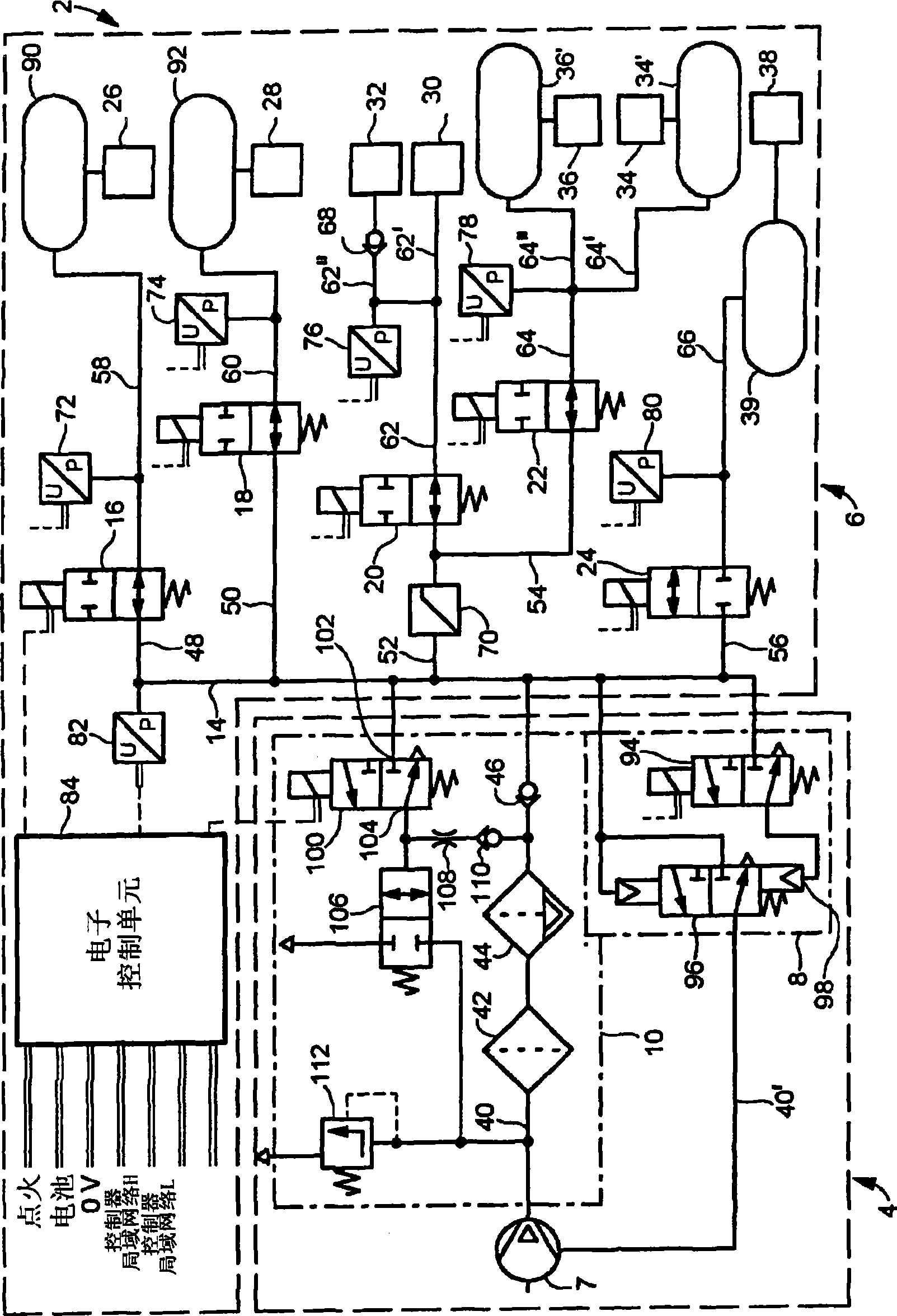

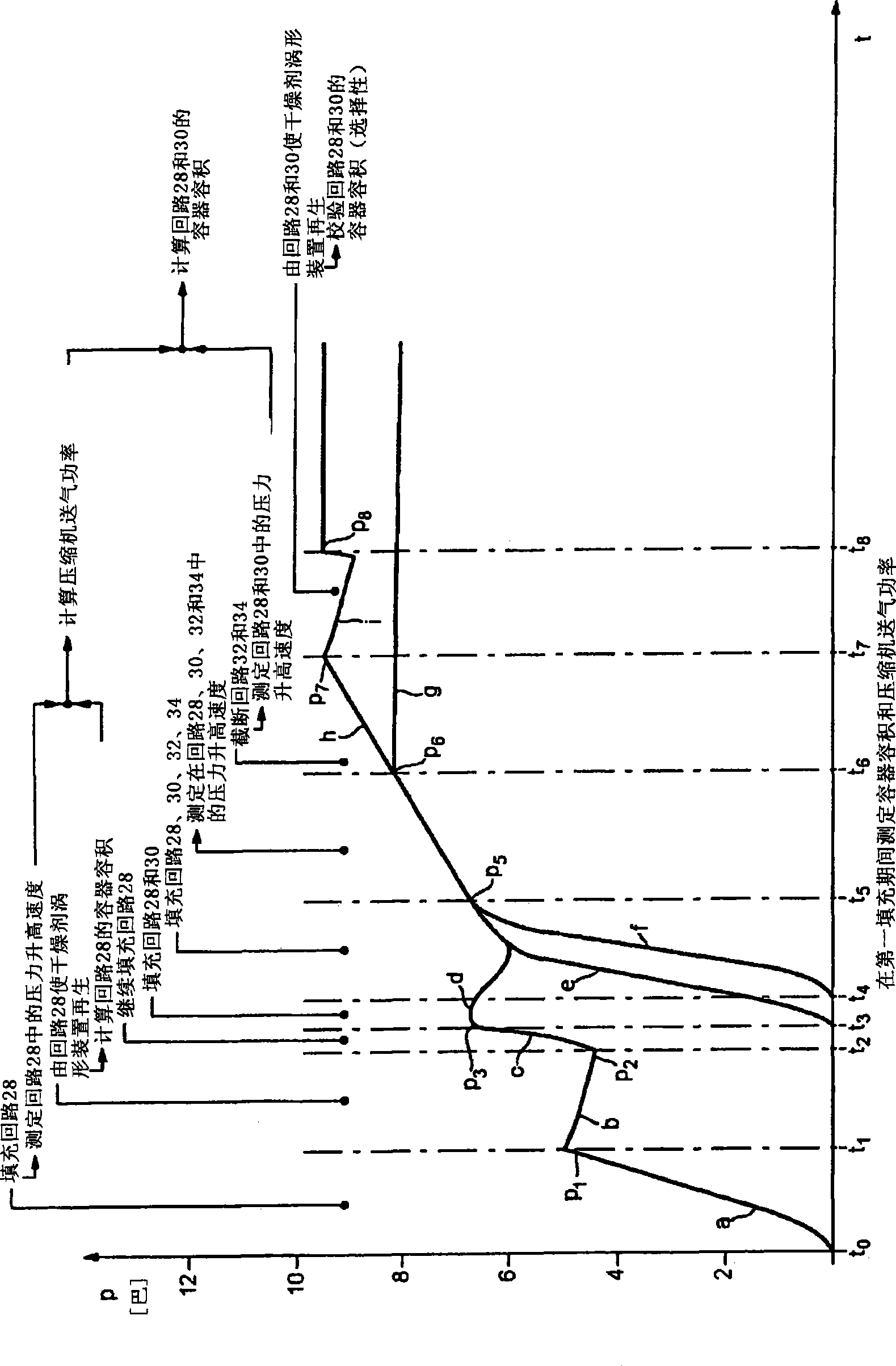

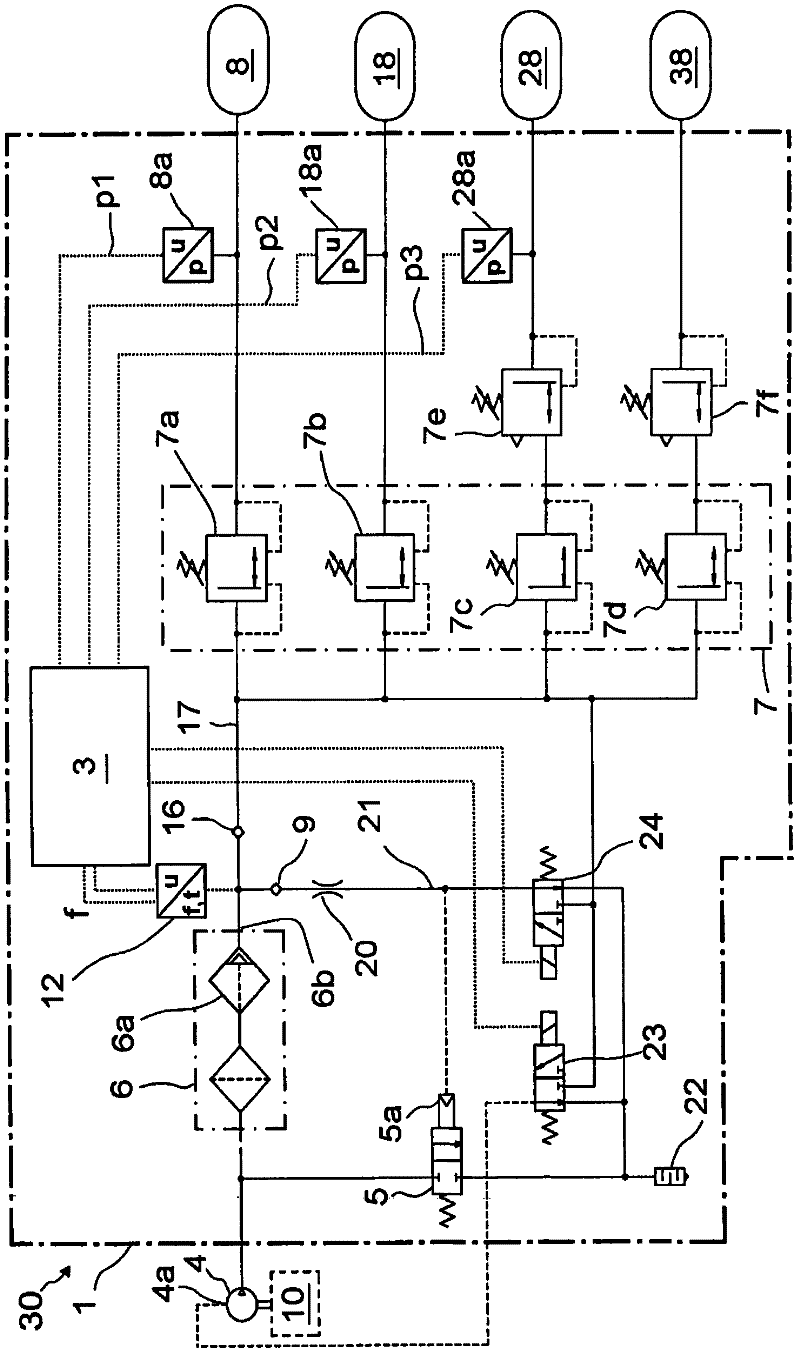

Compressed air supply system and method for determining the parameters of said system

ActiveCN101522491AOptimize drying performanceReduce consumptionPump/compressor arrangementsAir treatment devicesEngineeringAir dryer

The invention relates to a compressed air supply system for motor vehicles comprising a compressed air supply part consisting of a compressor, an air drying part comprising an air dryer, a filter, a valve and a compressed air consumer part consisting of compressed air consumer circuits provided with operational brake circuits, which are supplied with compressed air via a multi-circuit safety valve. The operational brake circuits and optionally, at least one other compressed air consumer circuit comprises compressed air containers and the pressure in said compressed air consumer circuits is monitored by sensors, the electric signals of which are evaluated by an electronic control device. Said electronic control device (84) is configured in such a manner that in order to determine parameters of the compressed air supply system (2) and the size of the compressed air containers and the output of the compressor (7), when filling the compressed air consumer circuits (26, 28, 30, 32, 34, 36, 38), the compressed air increasing speed in a compressed air consumer circuit and the compressor speed and an air drying regeneration process is carried out after the compressed air consumer circuit is filled with compressed air from the container of said circuit. The time period of a predefined fall in pressure or the fall in pressure is determined over a predefined time period and the amount of air necessary for carrying out said regeneration process is deducted from the value of the fall in pressure, the regeneration time and the known diameter of the filter (108) and the volume of the container is determined therefrom. The output of the compressor (7) is determined from the volume of the container, the determined compressed air increasing speed and the compressor speed.

Owner:WABCO EURO BVBA SPRL

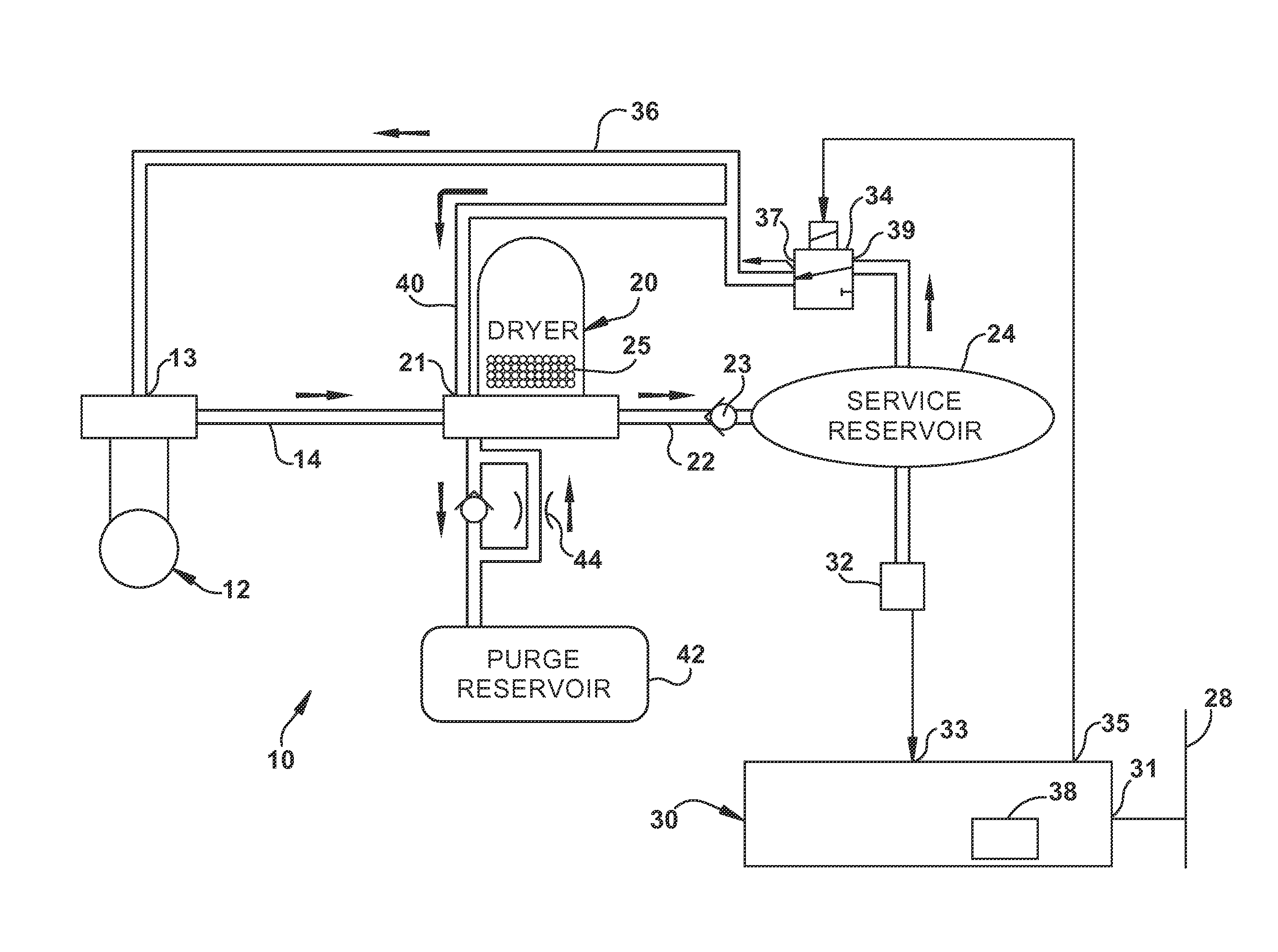

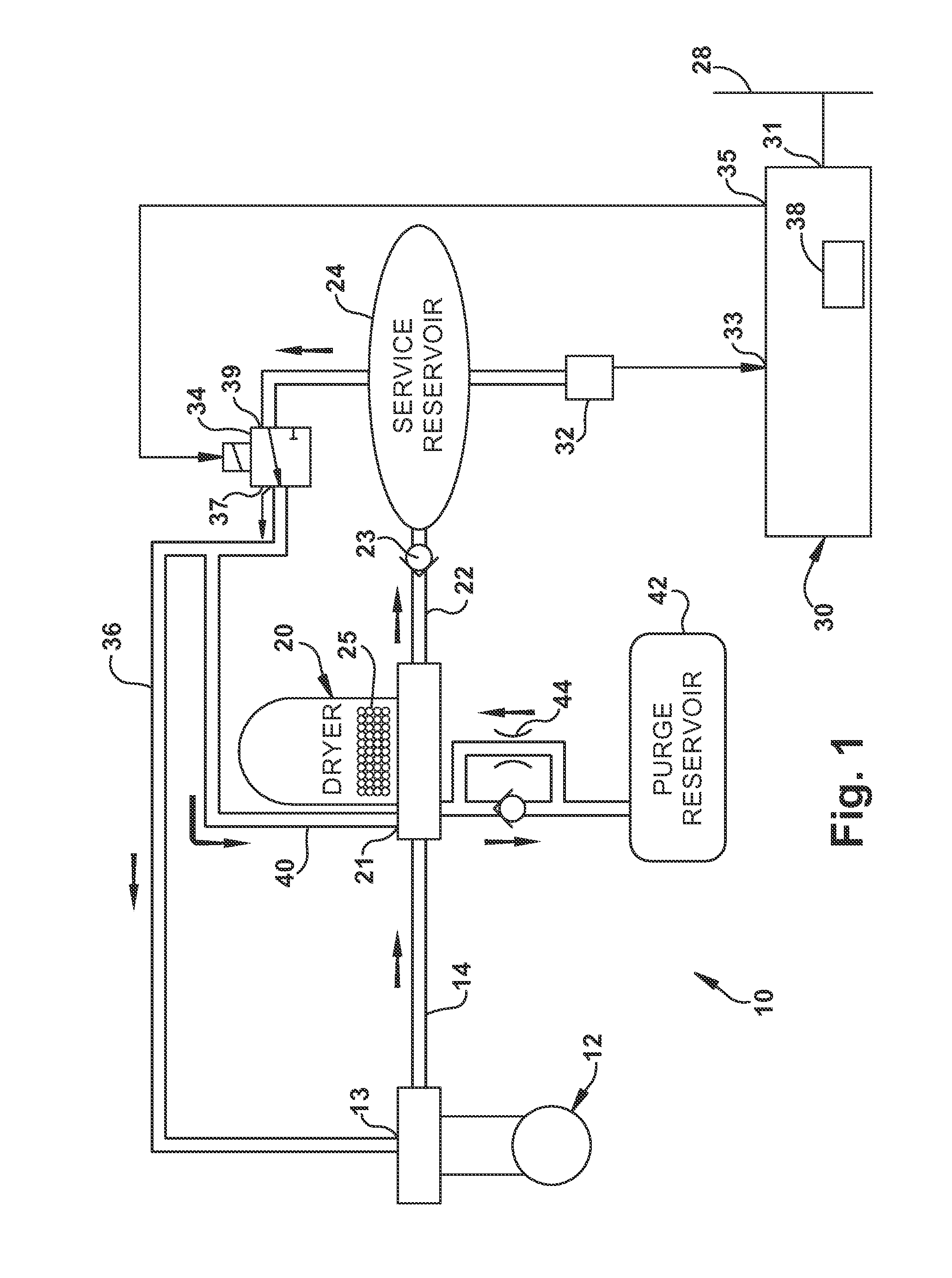

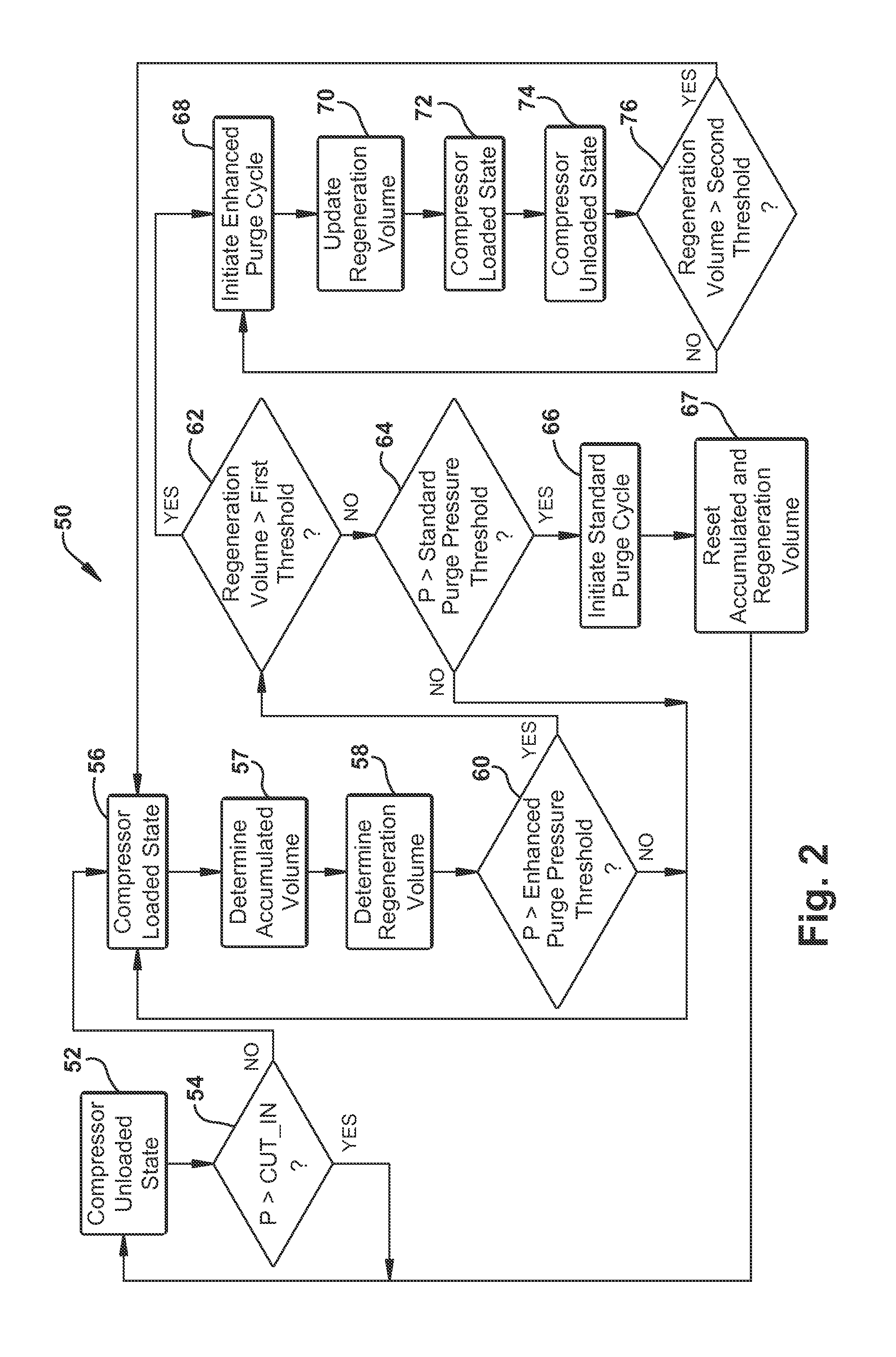

Air Dryer Purge Controller and Method

A method and controller for controlling the purge cycling of an air dryer assembly is disclosed. The controller includes a control output for transmitting a control signal for controlling the air dryer. The controller is capable of initiating an enhanced purge cycle for the air dryer based on a regeneration volume value. The regeneration volume value is based on the accumulated volume of air delivered to the air dryer for a first time or since a prior standard purge cycle.

Owner:BENDIX COMML VEHICLE SYST LLC

Motor-pump aggregate

ActiveCN101801749AOptimized installation spaceEasy to installPositive displacement pump componentsFlexible member pumpsLow noiseExhaust valve

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

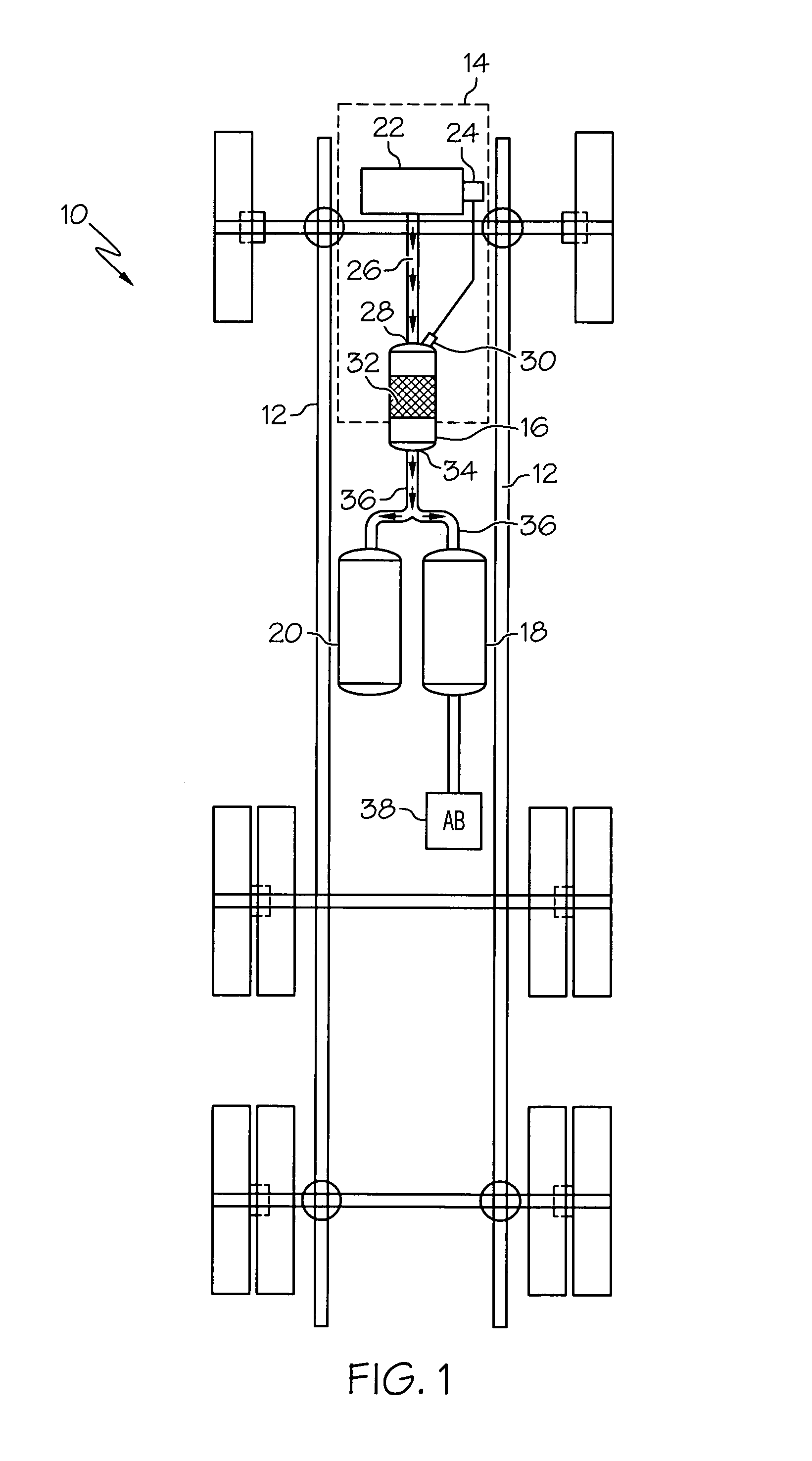

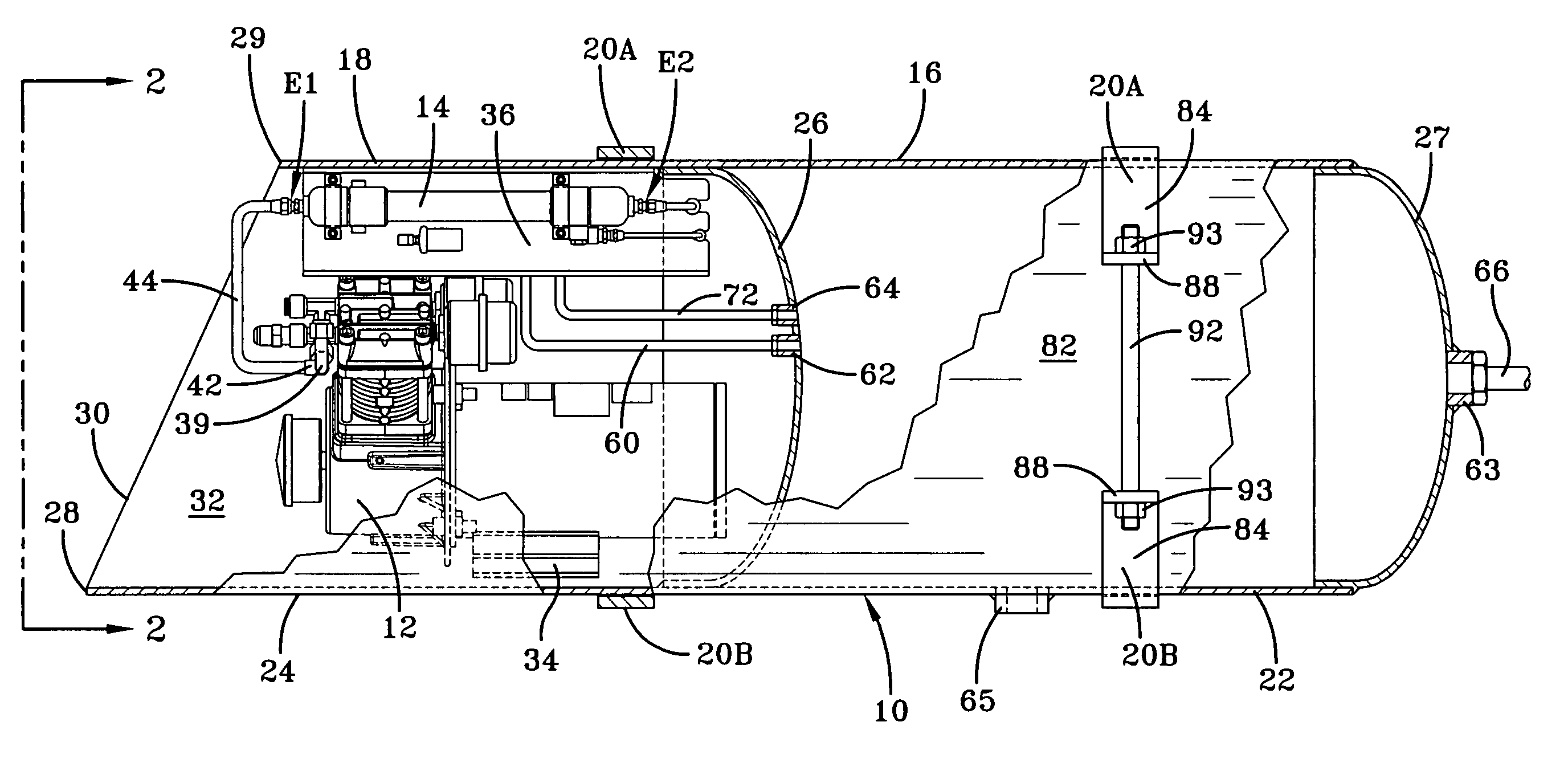

Dry compressed air supply module

InactiveUS20070234904A1Positive displacement pump componentsIsotope separationEngineeringAir compressor

A dry compressed air module is provided for attachment to the frame of commercial vehicle. The dry compressed air module includes a shell, an air compressor, an air dryer, and a reservoir. The air compressor, the air dryer, and the reservoir are disposed on the shell, and can be collectively attached to the frame using the shell. The air dryer is provided with compressed air from the air compressor, and the reservoir is provided with dry compressed air from the air dryer. The reservoir capable of storing and supplying the dry compressed air to the vehicle.

Owner:BENDIX COMML VEHICLE SYST LLC

Control device for a compressed air preparation device of a vehicle, compressed air preparation device, vehicle system, vehicle, and method for controlling the same

ActiveCN102186706ALow costIncrease consumptionAir treatment devicesBrake safety systemsDesiccantAir dryer

The invention relates to a control device (3) for a compressed air preparation device (1) of a vehicle (2), wherein the control device (3) outputs output signals for adjusting feed phases and regeneration phases of the compressed air preparation device (1), wherein a compressor (4) feeds compressed air via an air dryer having a desiccant (6a) into a compressed air reservoir (8) in a feed phase, and compressed air is fed out of the compressed air reservoir (8) through the air dryer (6) for drying the desiccant (6a) in a regeneration phase. According to the invention, the control device (3) adjusts the regeneration phases depending on a current or future engine load and / or a current or future consumption of compressed air by the vehicle (2). Particularly in coasting phases, excessive drying of the desiccant to a low moisture can occur, in order to save fuel in later travel segments. Route-optimized regeneration of the desiccant as a function of engine load and / or utilization phases is also possible.

Owner:ZF CV SYST EURO BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com