Control device for a compressed air preparation device of a vehicle, compressed air preparation device, vehicle system, vehicle, and method for controlling the same

A technology for compressed air and control devices, which is used in air handling devices, brake safety systems, vehicle components, etc. to achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

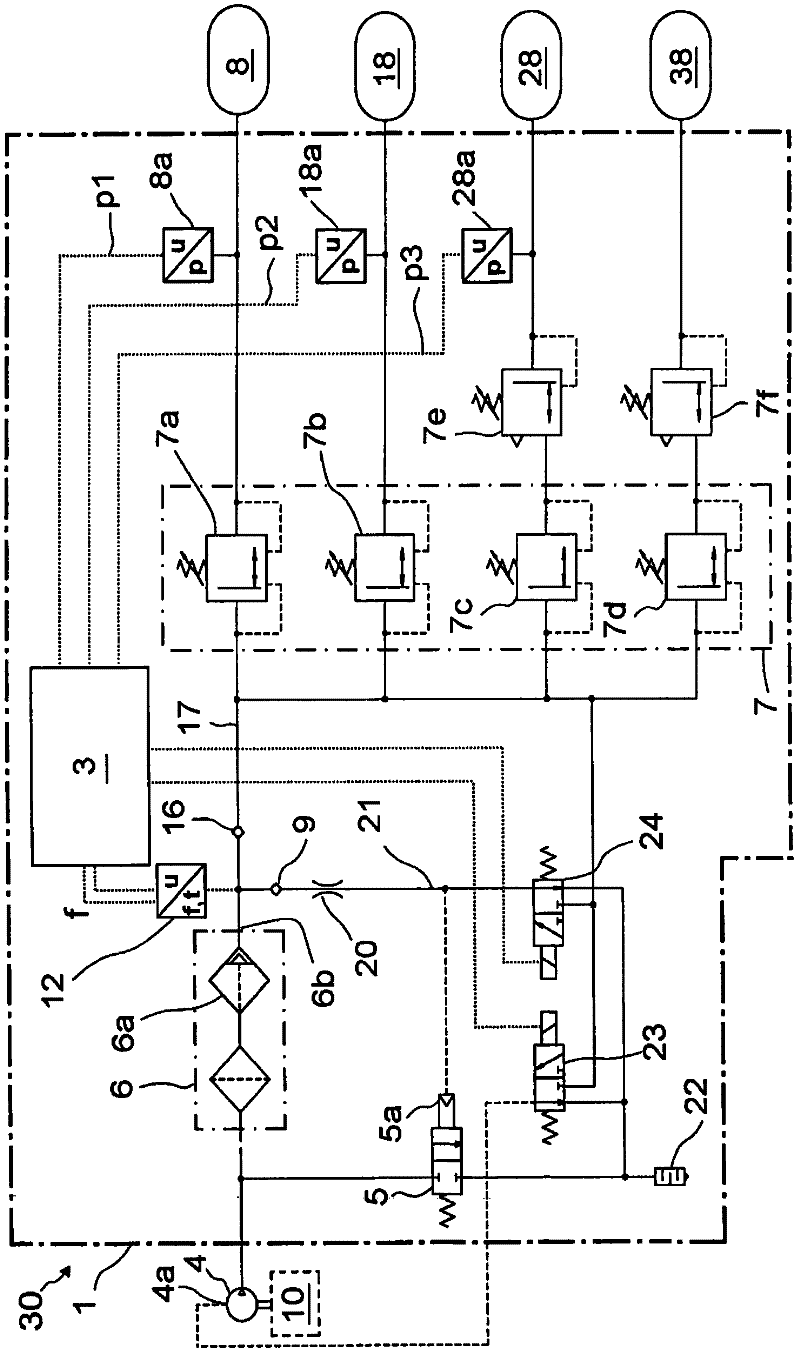

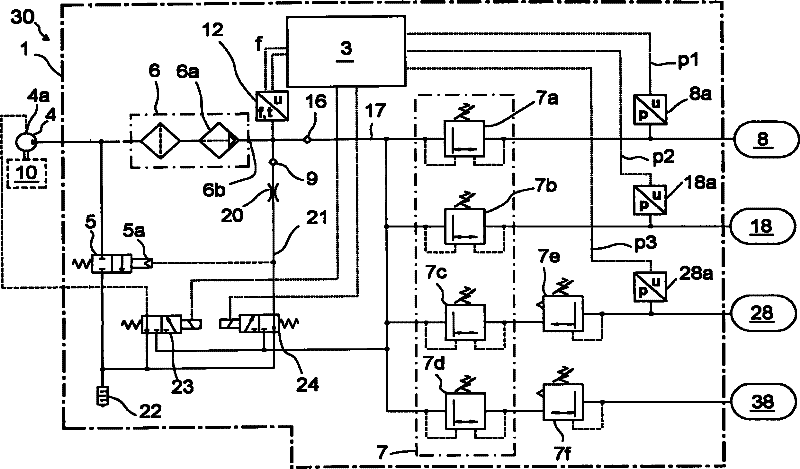

[0025] according to figure 1 The compressed air preparation device 1 of a commercial vehicle 2 with a vehicle engine 10 and pneumatic brakes and air springs has an electronic control unit 3 which directly or indirectly controls the operating state of a compressor 4 driven by the engine 10 . The compressor 4 may for example be arranged directly on the engine shaft and be driven directly by the vehicle engine 10 or driven by the vehicle engine 10 via a coupling. As a result, for example coupling and disengagement of the compressor 4 from the engine 10 or, in the case of a rigid coupling of the compressor 4 at the engine 10 , idling without compressed air delivery can be adjusted.

[0026] Connected to the output of the compressor 4 is an air dryer 6 in which a desiccant 6a, for example dry granules, is accommodated. Connected to the outlet 6b of the air dryer 6 via a non-return valve 16 is a compressed air supply line 17 with a four-circuit protective valve 7 having, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com