Motor-pump aggregate

一种电机泵、泵壳的技术,应用在泵、泵元件、机械设备等方向,能够解决高成本等问题,达到简化装配、平顺运转、简单制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

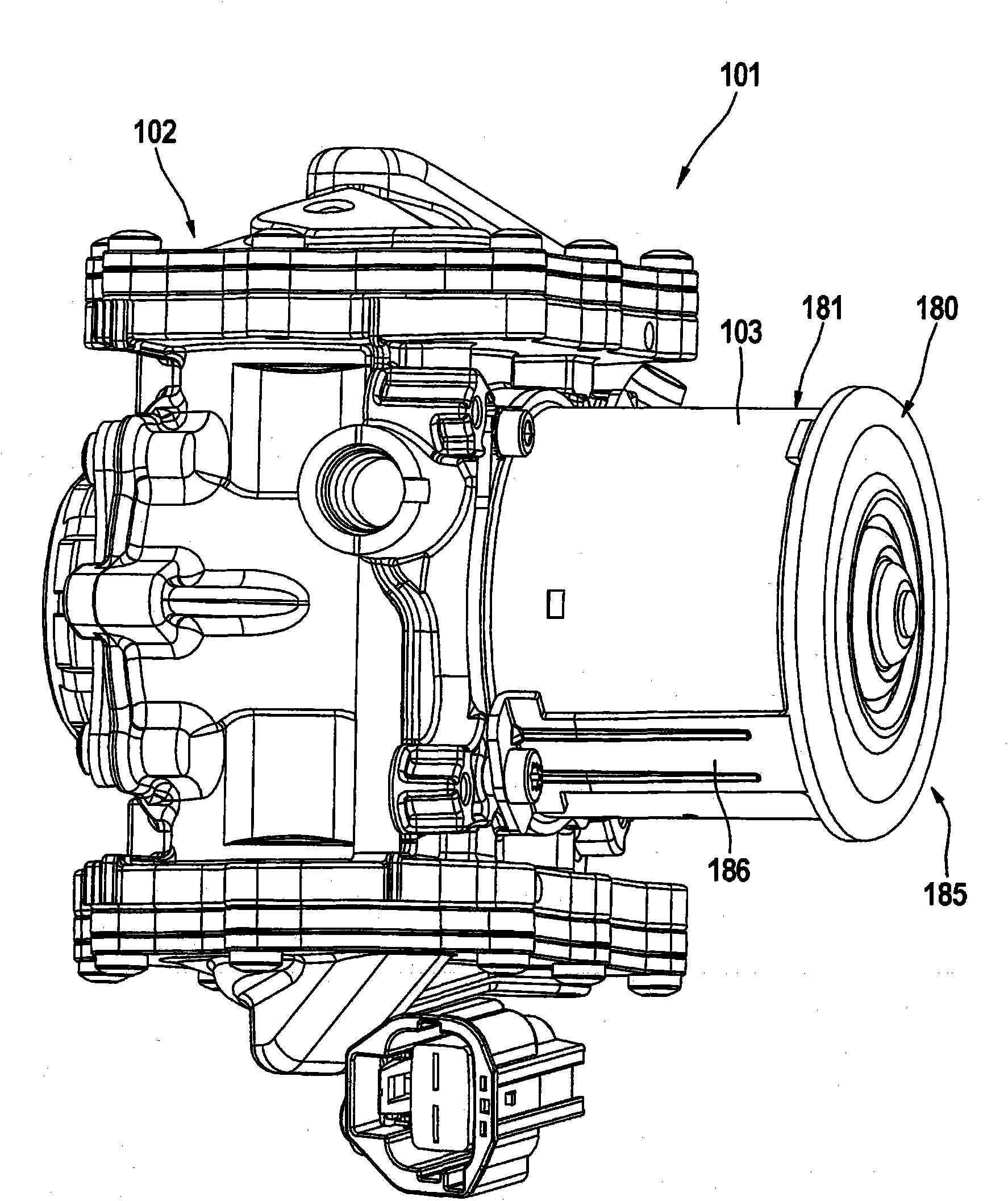

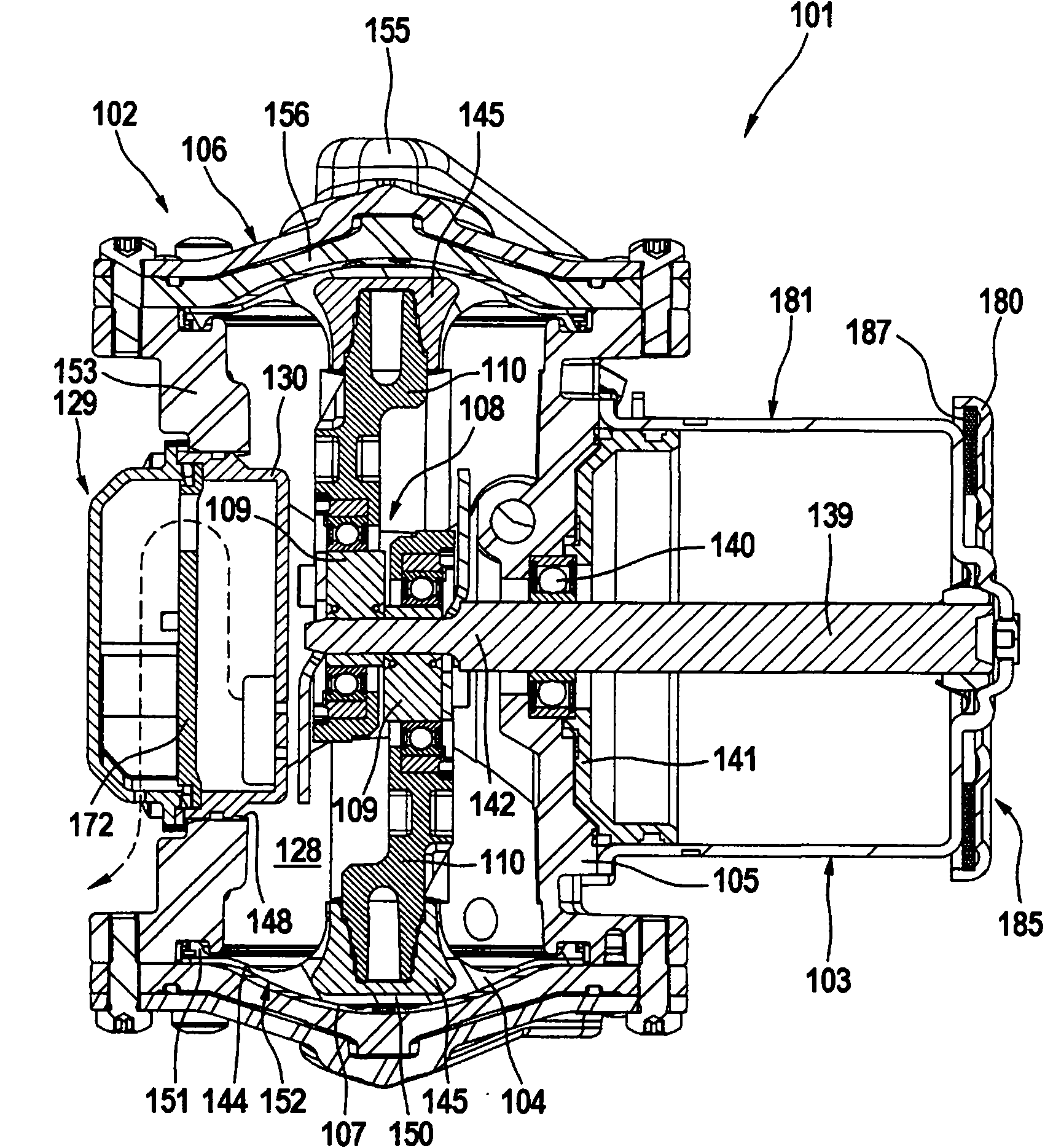

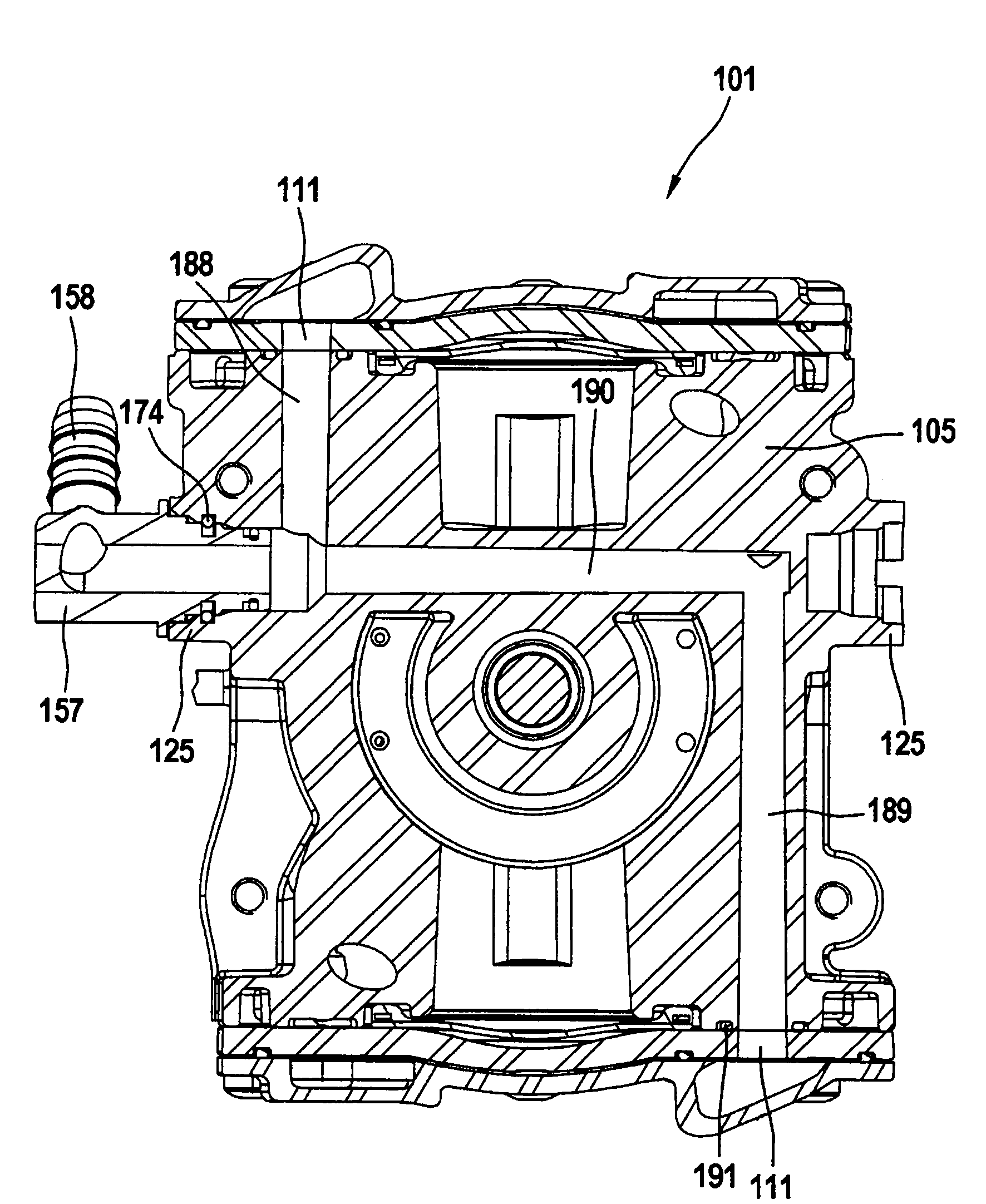

[0053] Figure 1 to Figure 7 One embodiment of a motor-pump unit 101 is shown.

[0054] figure 1 A motor-pump assembly 101 is shown in perspective, comprising a pump 102 with a pump housing 105 and an electric motor 103 driving the pump 102 , wherein the electric motor 103 can be designed as a DC motor, for example.

[0055] figure 2 The motor-pump unit 101 is shown in longitudinal section along a first plane, as figure 2 In particular, the pump 102 is shown as a double-diaphragm pump with two opposing working diaphragms 104 which are each tensioned between a pump housing 105 and a working chamber cover 106 and thus delimit a working chamber 107 . The working diaphragms 104 can be moved in the opposite direction by means of a crank drive 108 which includes an eccentric body 109 and a connecting rod 110 for each working diaphragm 104 .

[0056] exist Figure 7 The working chamber cover 106 of the motor-pump unit 101 is shown in a sectional view. As can be seen from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com