Large-tonnage narrow-gauge tunnel project heavy-haul train bogie frame

A technology for tunnel engineering and heavy-duty trains, which is applied to bogies, railway car body parts, transportation and packaging, etc. It can solve the problem that the narrow-gauge bogies have small space and compact layout, and the box-type beam structure is difficult to meet the viscosity-weight matching. , process difficulty and high cost, to achieve the effect of saving installation space, simple structure and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

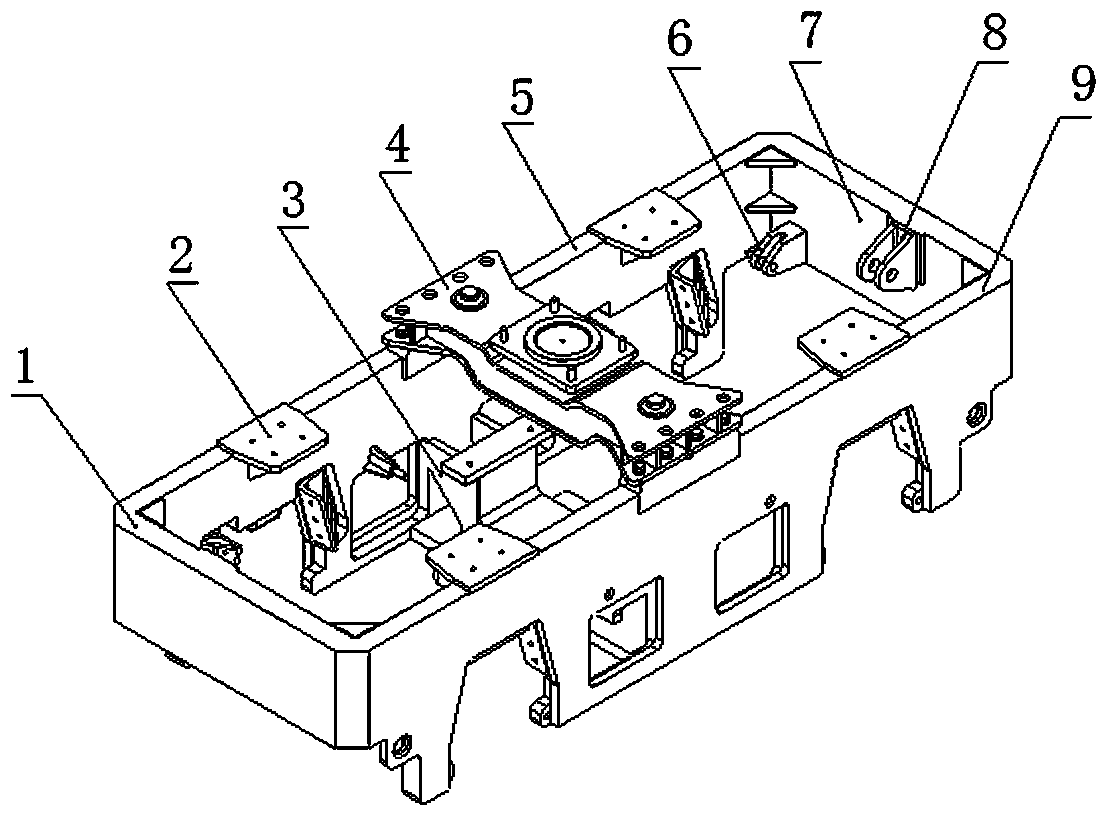

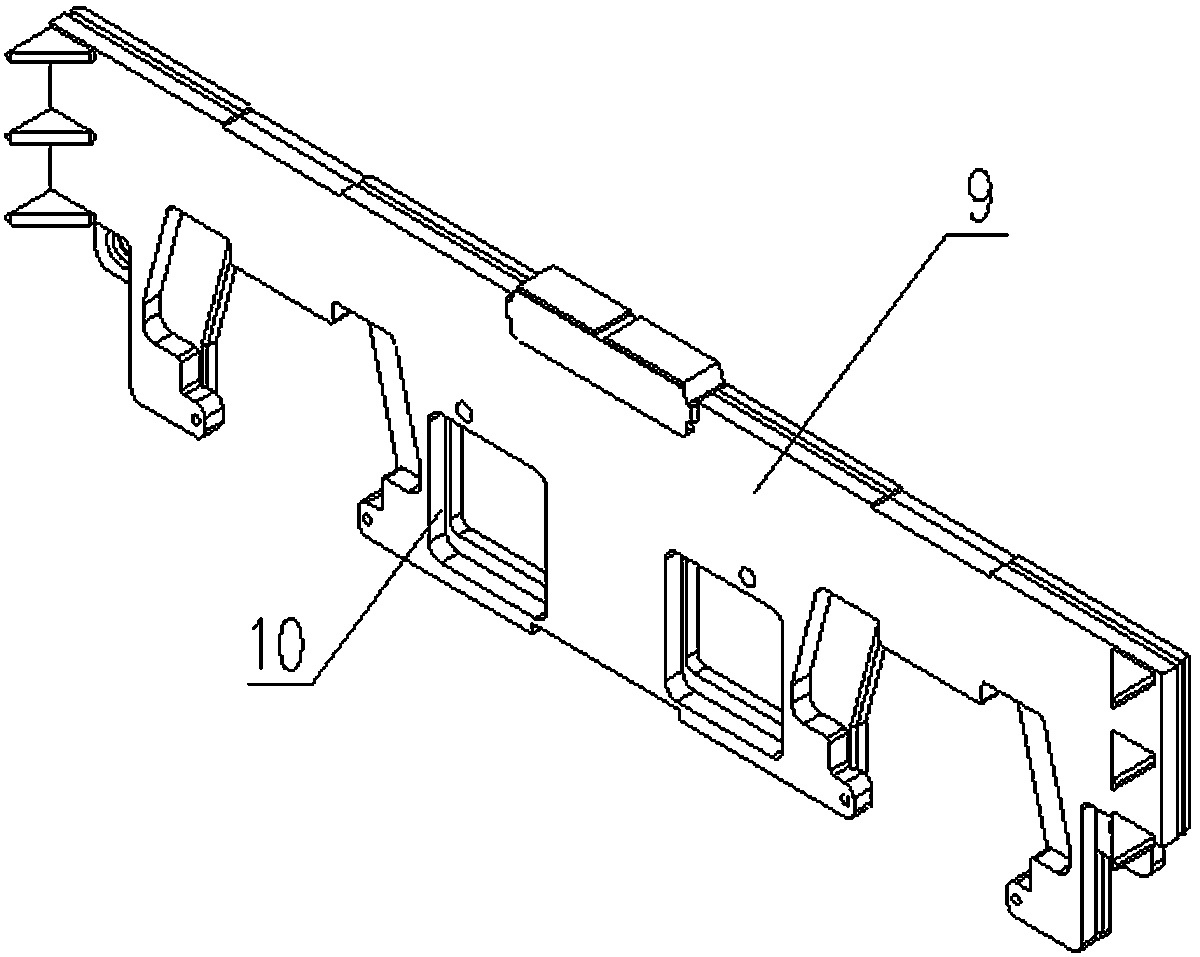

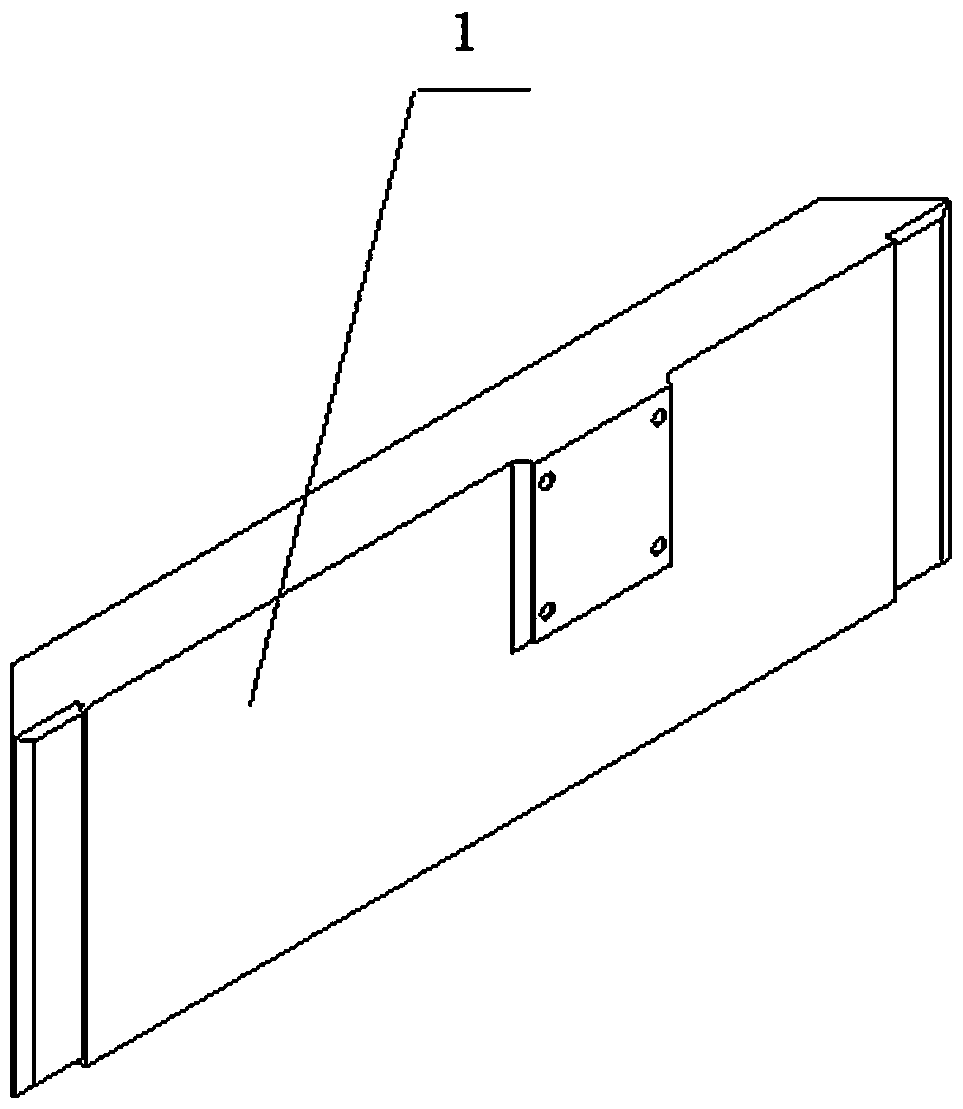

[0028] refer to figure 1 , the heavy-duty train bogie frame of the large-tonnage narrow-gauge tunnel project in this embodiment includes a front end beam 1, a bottom beam 3, an upper traction beam 4, a right side beam 5, a brake support 6, a rear end beam 7, and a torsion arm Seat 8, left side beam 9, front end beam 1, right side beam 5, rear end beam 7 and left side beam 9 are sequentially welded end to end to form a hollow frame with upper and lower openings, bottom beam 3 is arranged at the bottom of the frame, and bottom beam The two ends of 3 are respectively welded to the right side beam 5 and the left side beam 9, the upper drawing beam 4 is arranged on the top of the frame body and directly above the bottom beam 3, and the two ends of the upper drawing beam 4 are connected to the right side beam 5 and the left side beam respectively. The beam 9 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com