Patents

Literature

1023results about "Pump/compressor arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

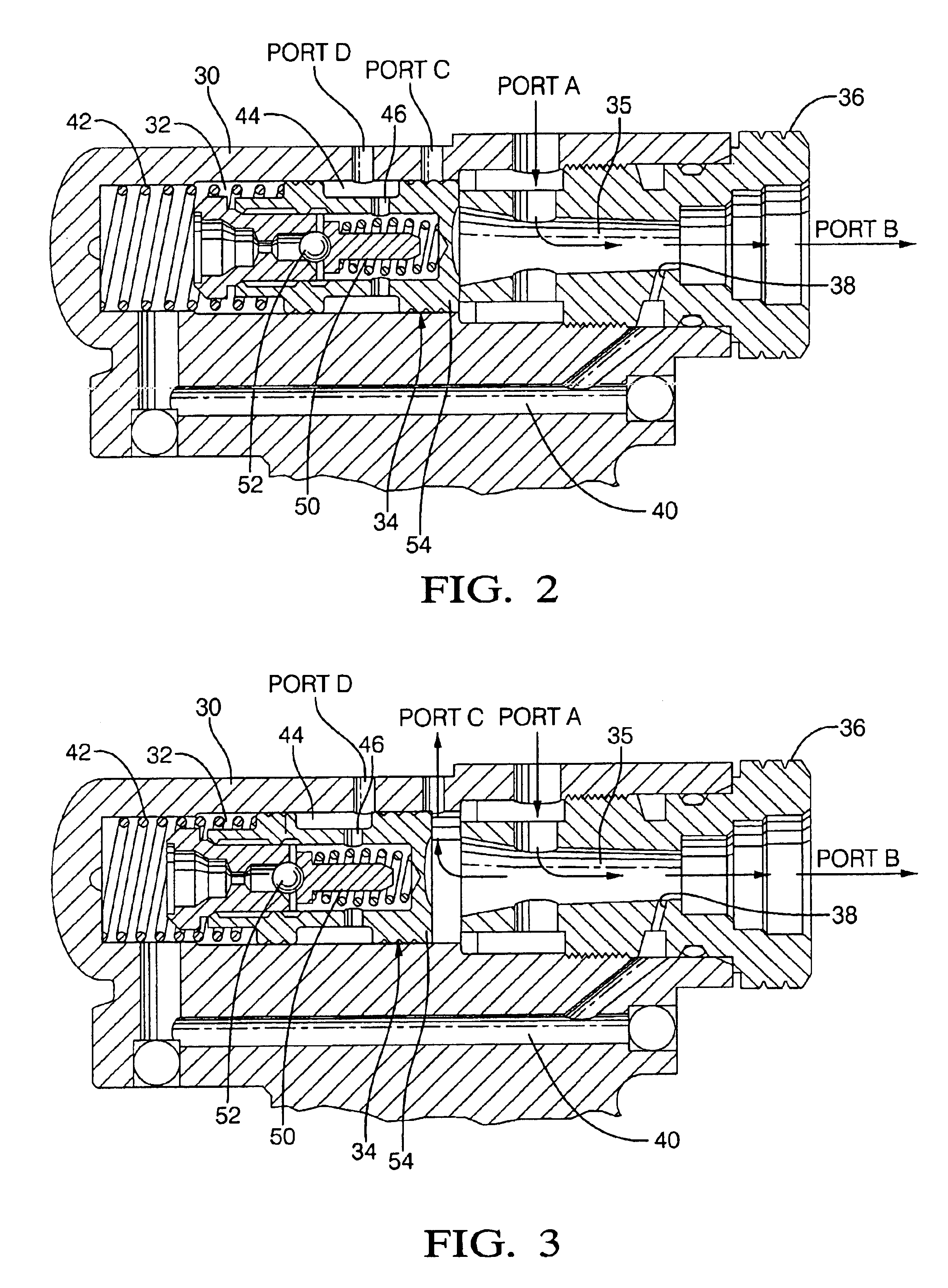

Check valve

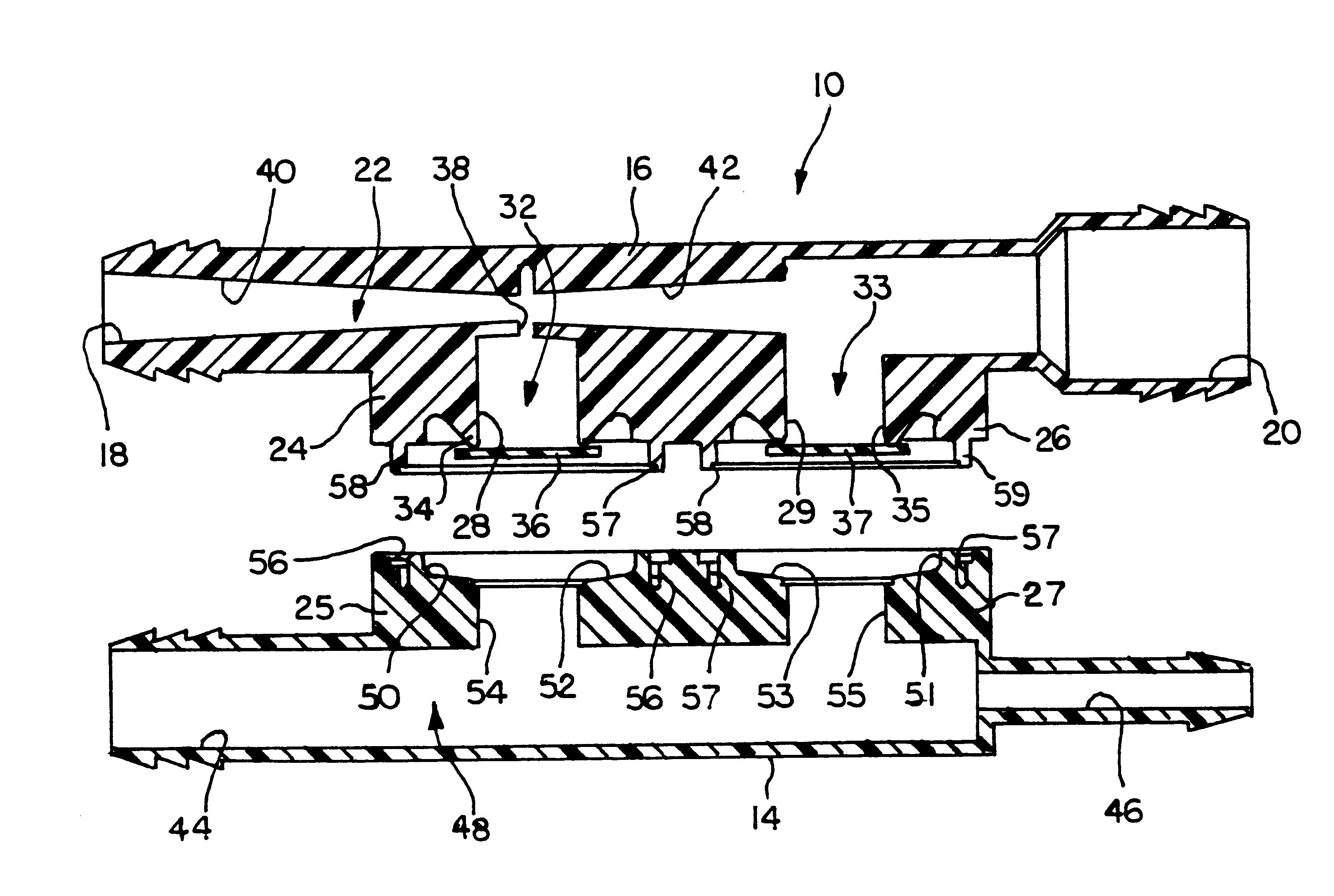

InactiveUS20110186151A1Maximum vacuum boostIncrease airflowCheck valvesEqualizing valvesEngineeringInternal combustion engine

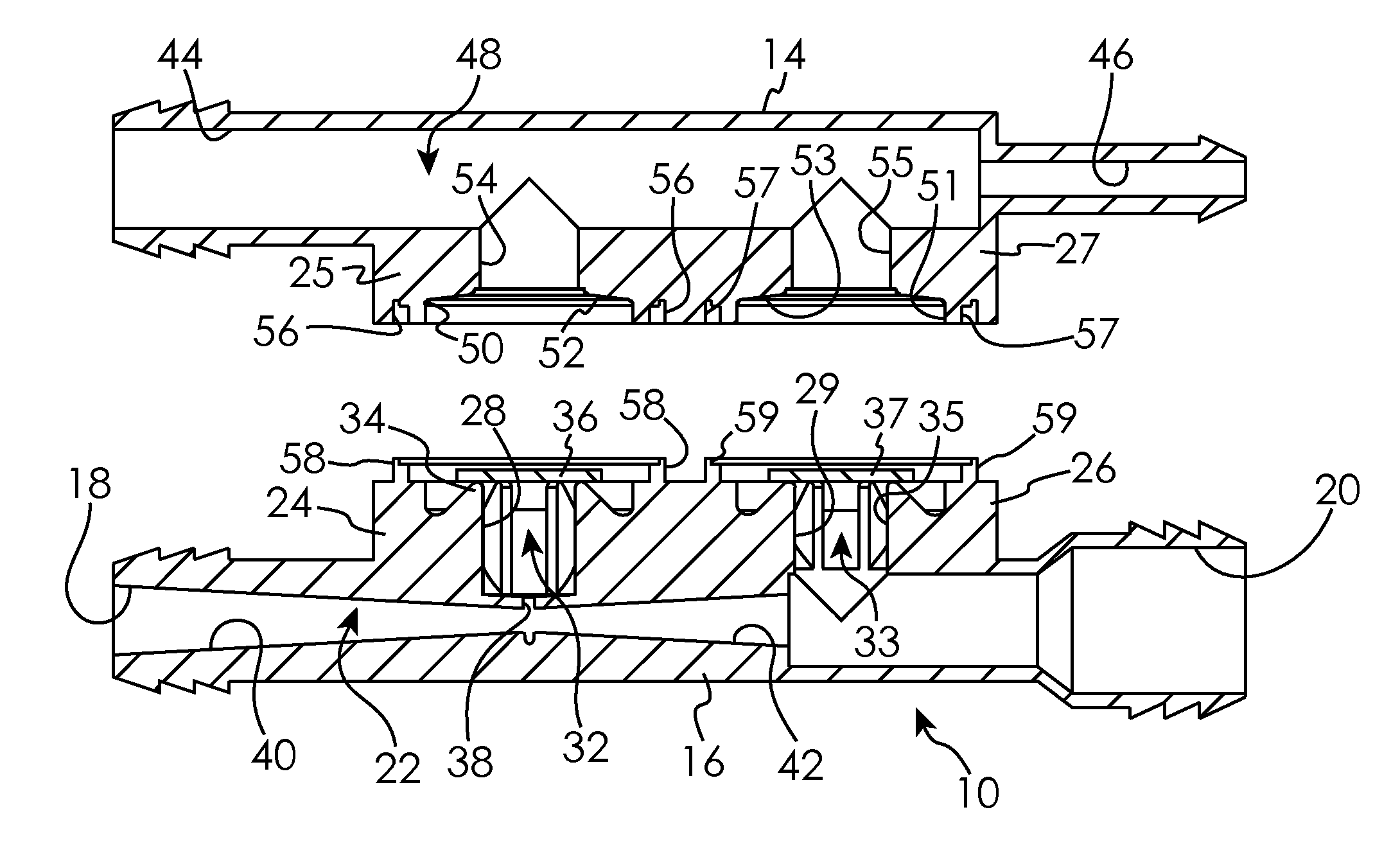

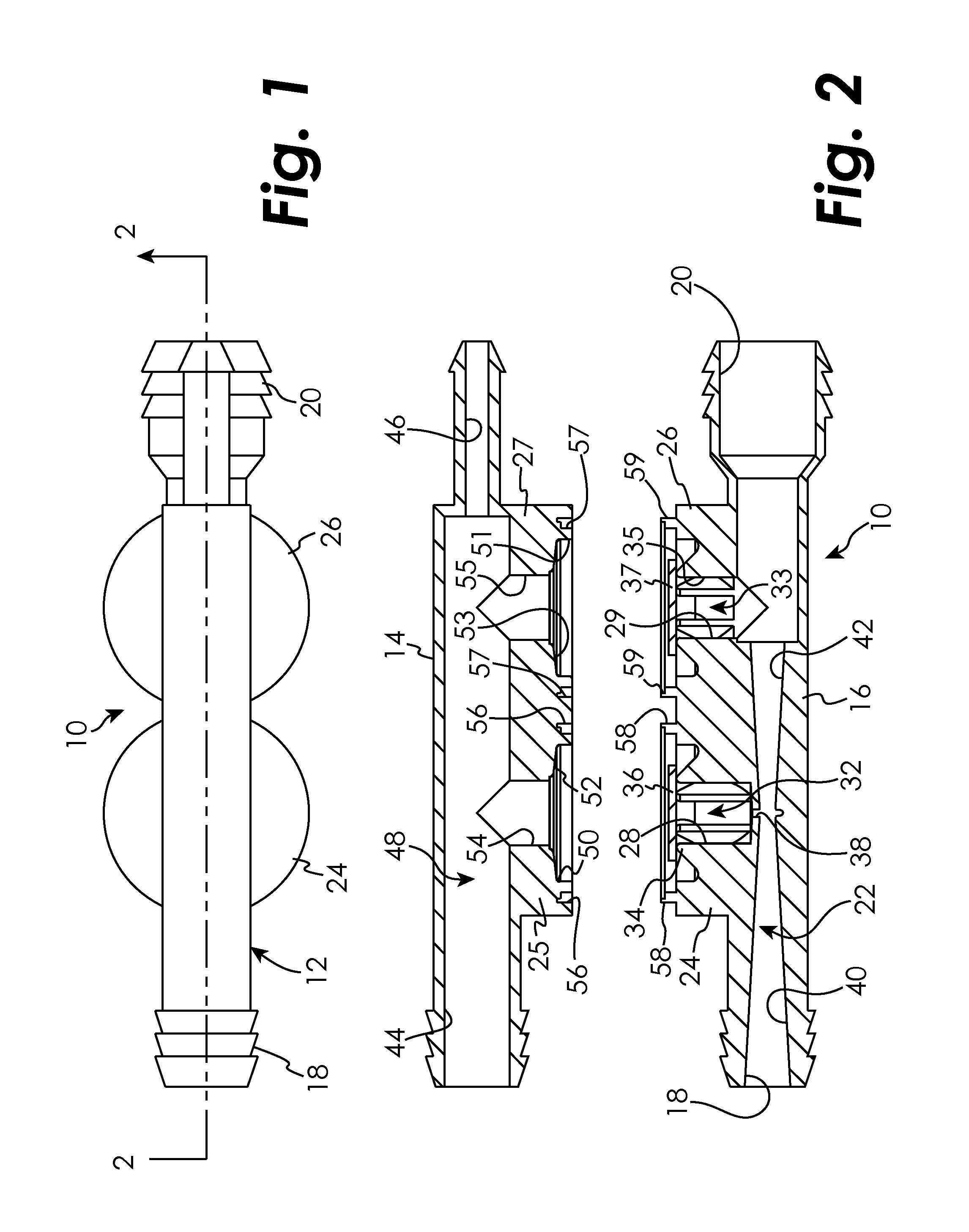

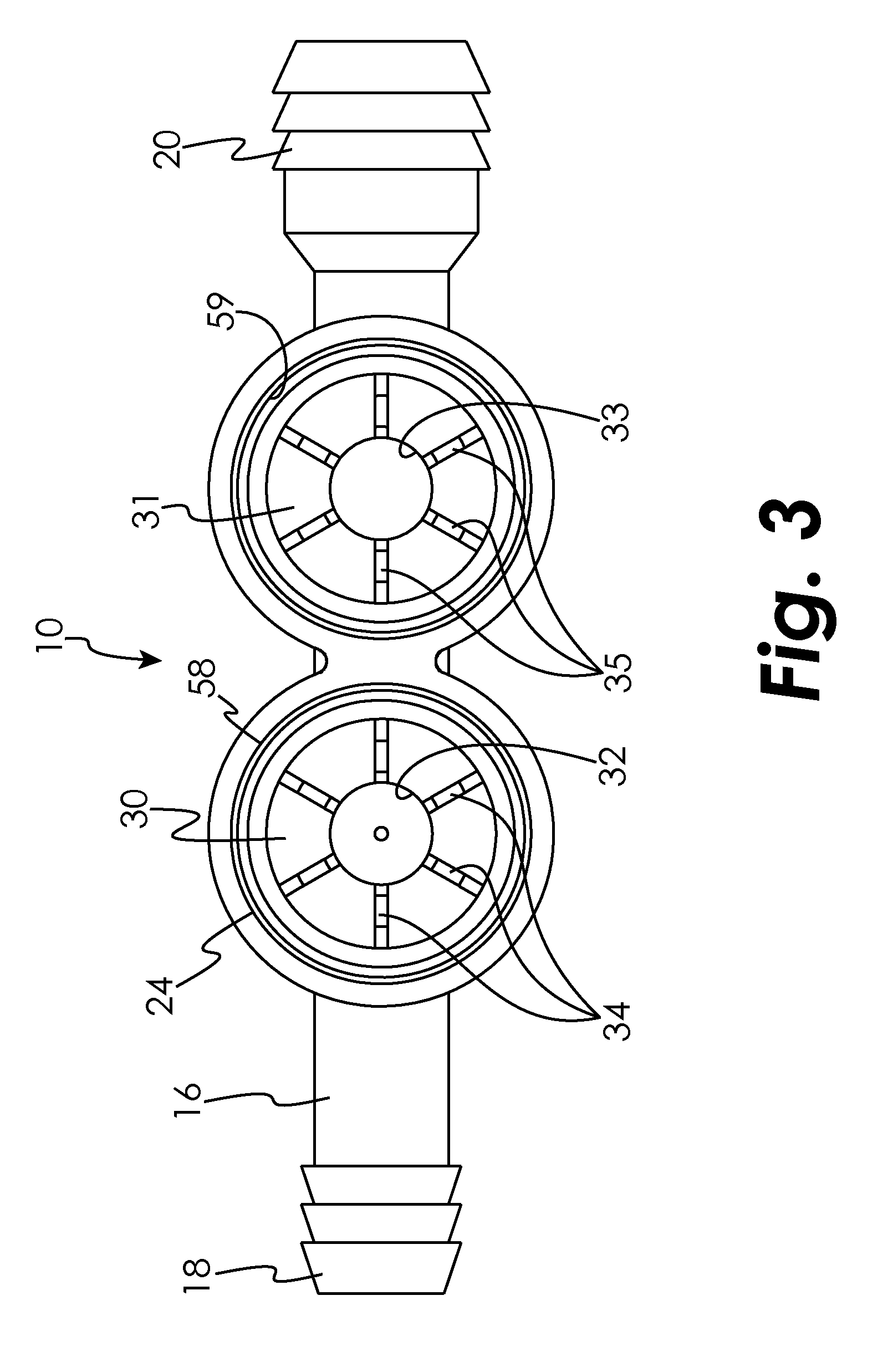

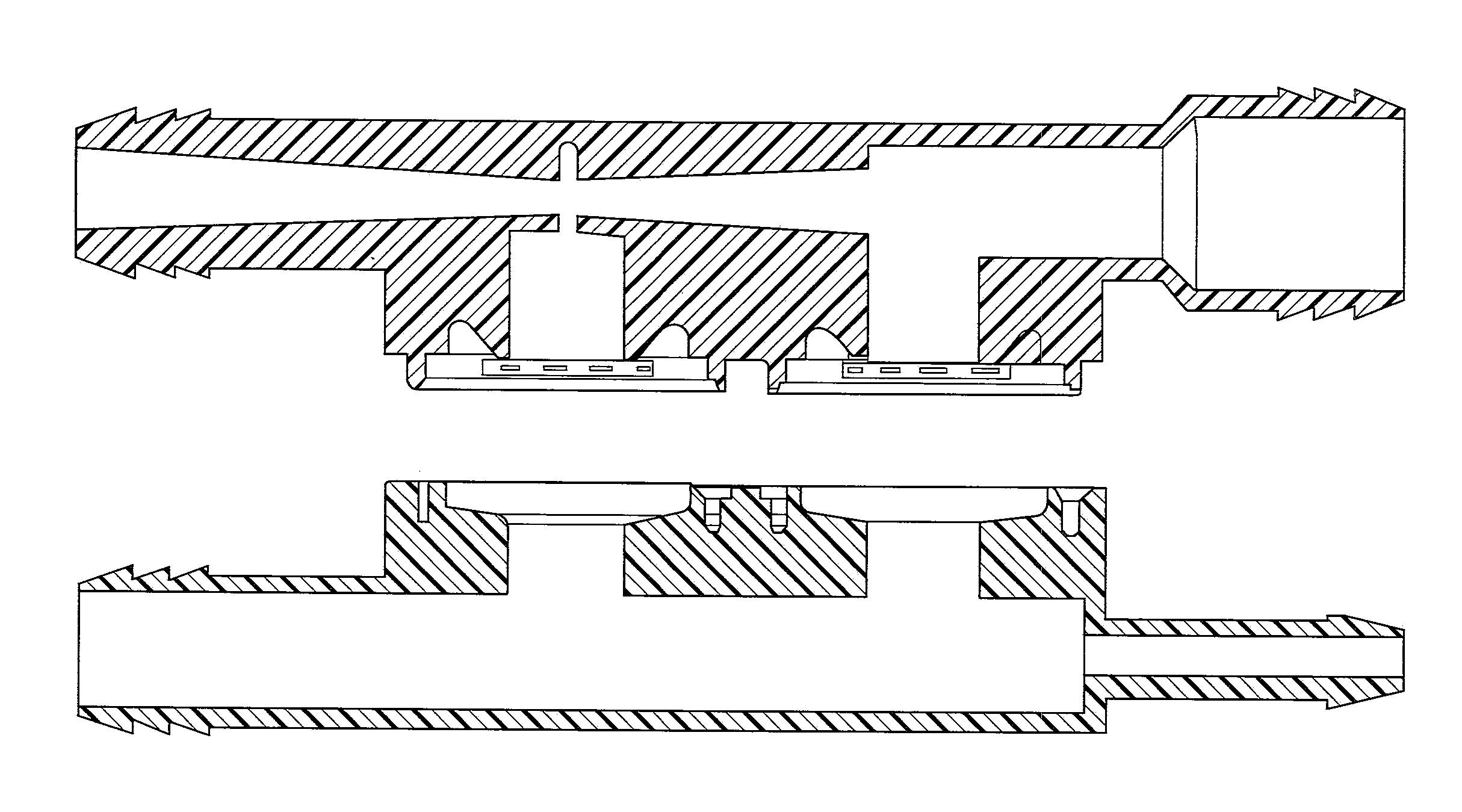

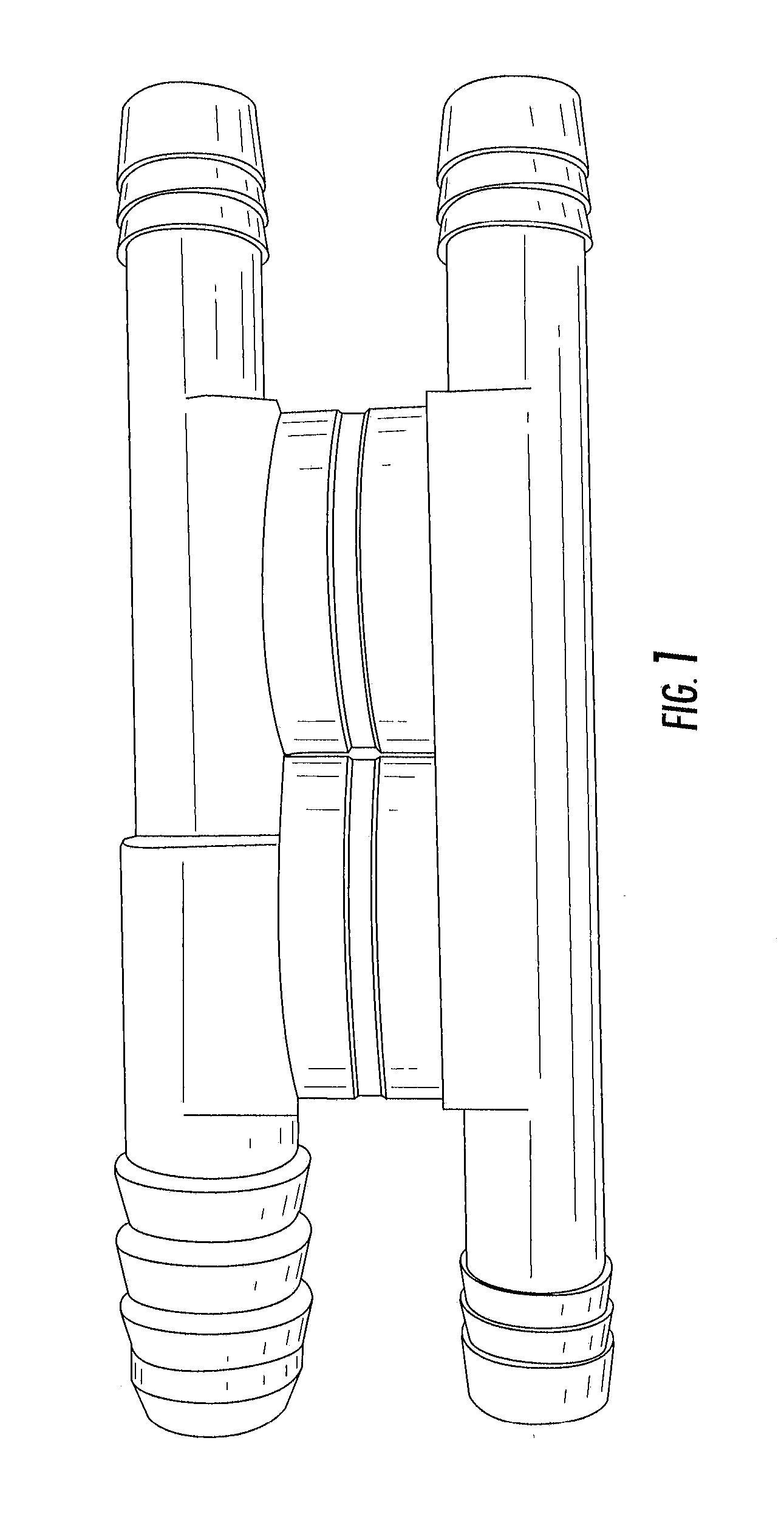

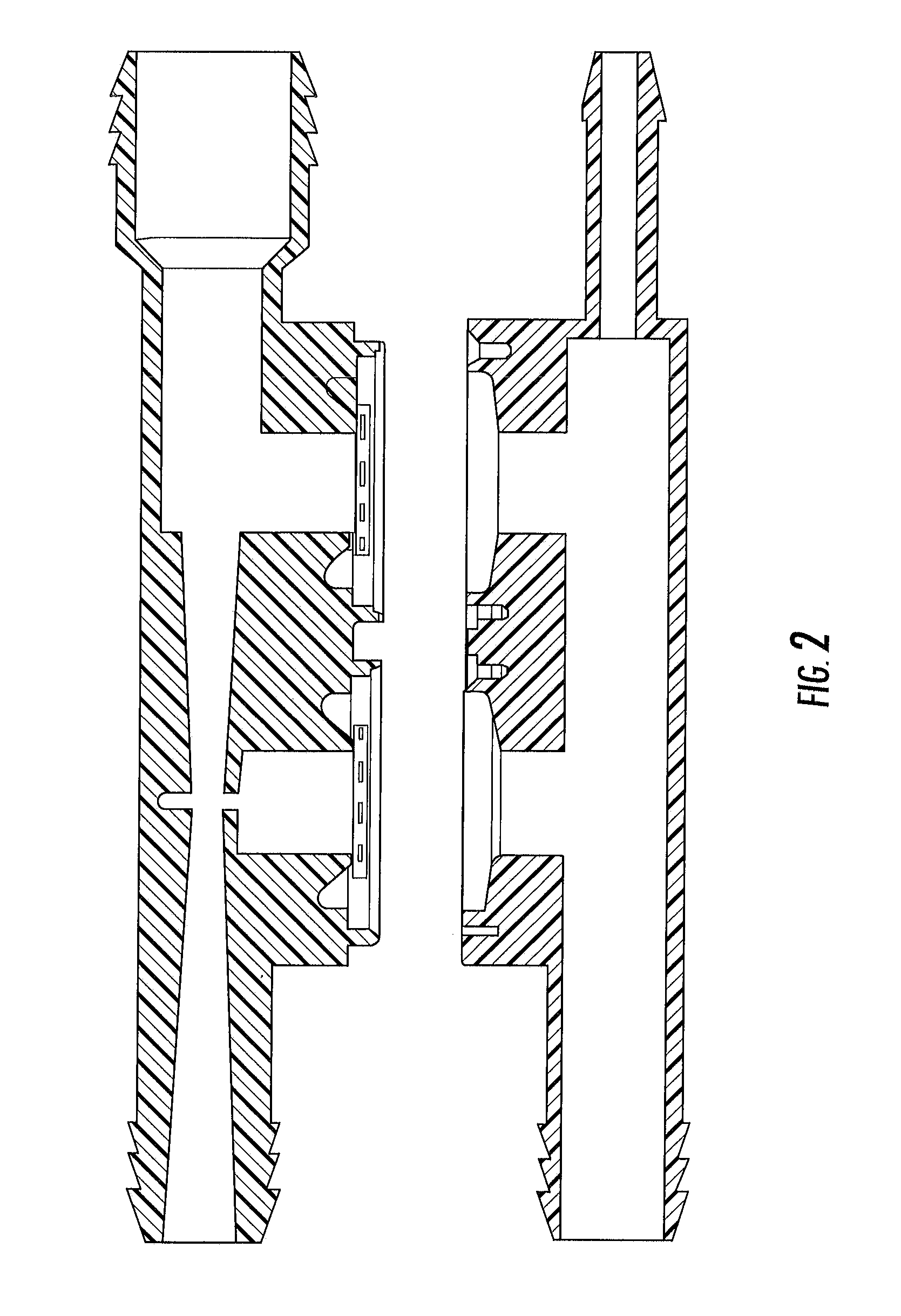

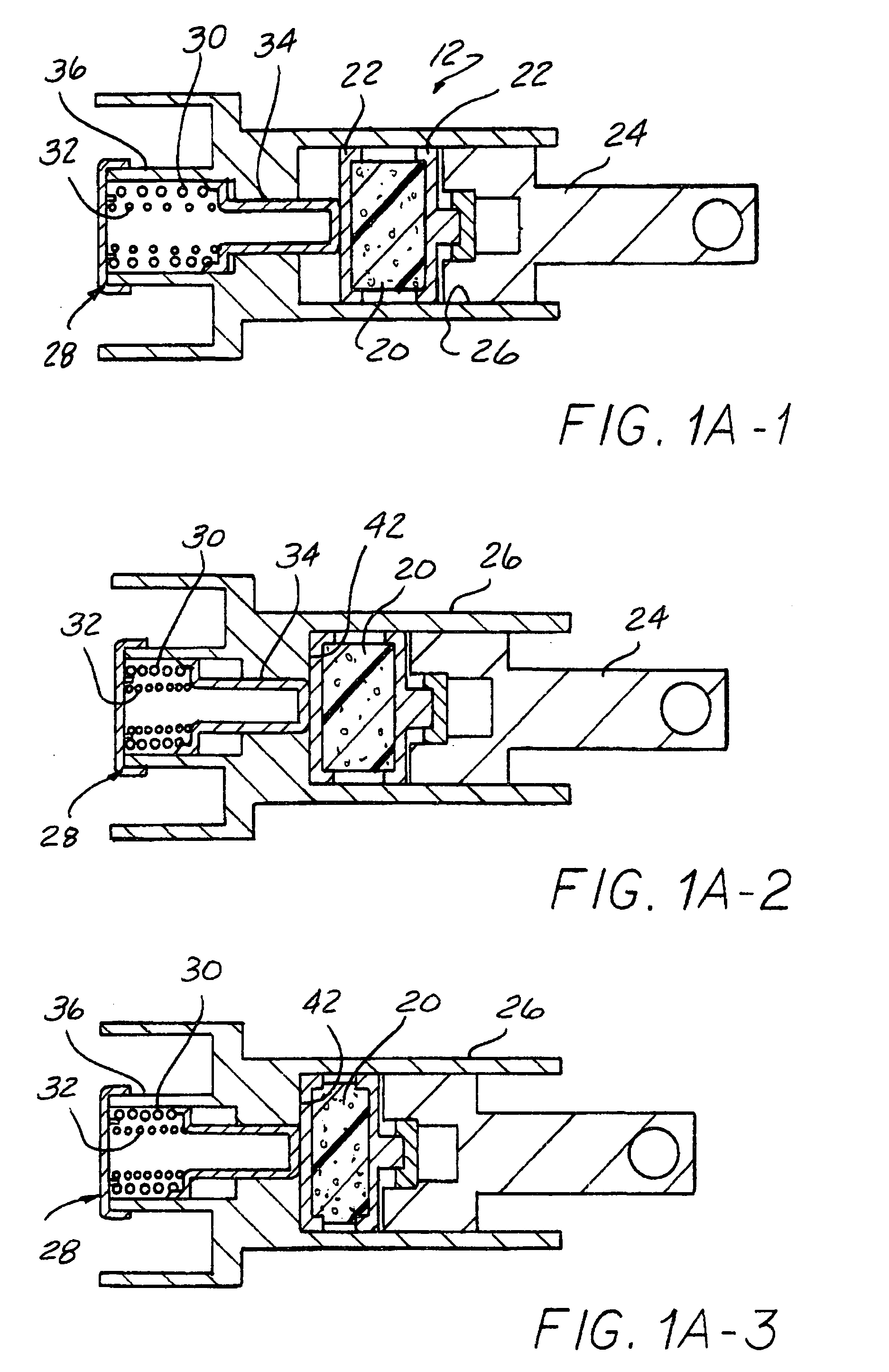

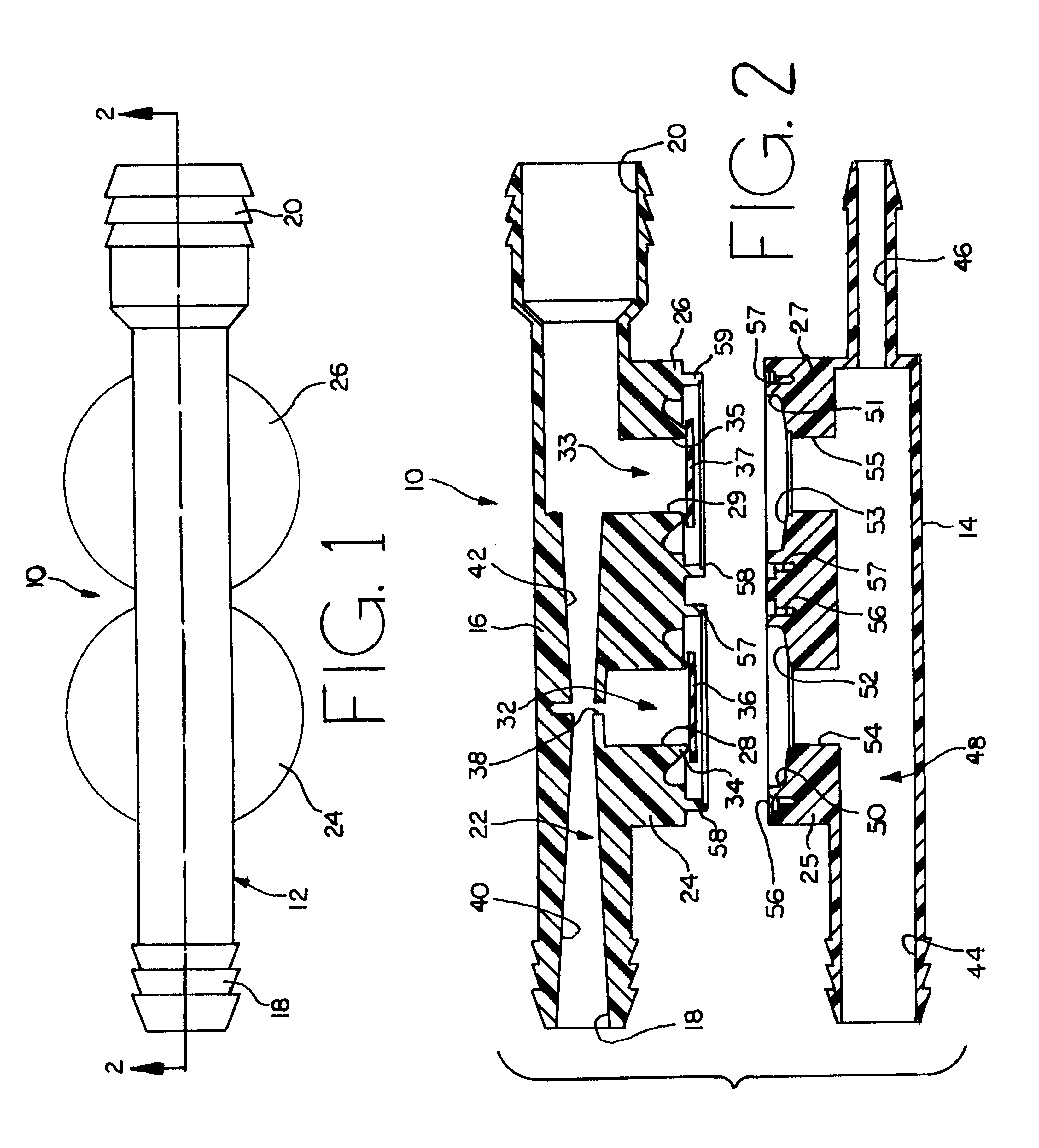

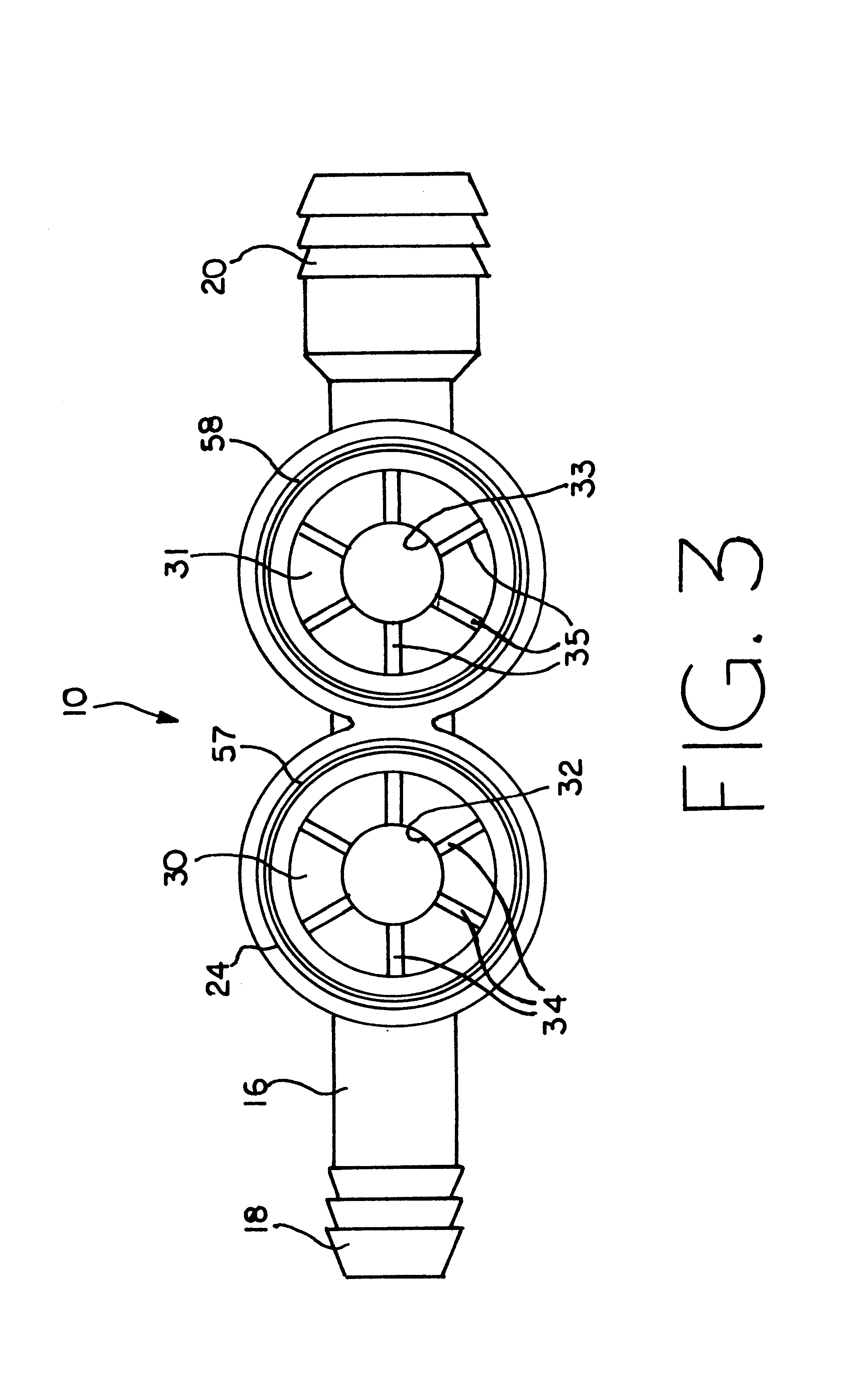

A check valve which is positioned in the vacuum air line of an internal combustion engine. The check valve includes a single-piece valve body having an outlet port and two or more inlet ports, with one outlet port located substantially in line with the inlet port and connected by a venturi tube. The second inlet port is separated from the main air flow line by the valve stem and a diaphragm which allows communication there between and prevents back pressure. The second inlet port communicates with the outlet port through the valve stem and a second venturi tube which provides a vacuum boost to a device, usually vehicle brakes, connected to the inlet. The use of seal diaphragms having a non-constant radius allows for faster recovery time for replenishment than prior art devices.

Owner:TECHNIPLAS US LLC

High mass flow check valve aspirator

The embodiments disclosed herein provide a check valve aspirator including a venturi pipe having a converging section with a converging inlet and a converging outlet, and a diverging section with a diverging inlet and a diverging outlet. The converging outlet is in fluid communication with the diverging inlet. An outlet channel is in fluid communication with the venturi pipe and has an outlet port. A ratio of a diameter of the converging section outlet to a diameter of the outlet port is less than 0.4.

Owner:TECHNIPLAS US LLC

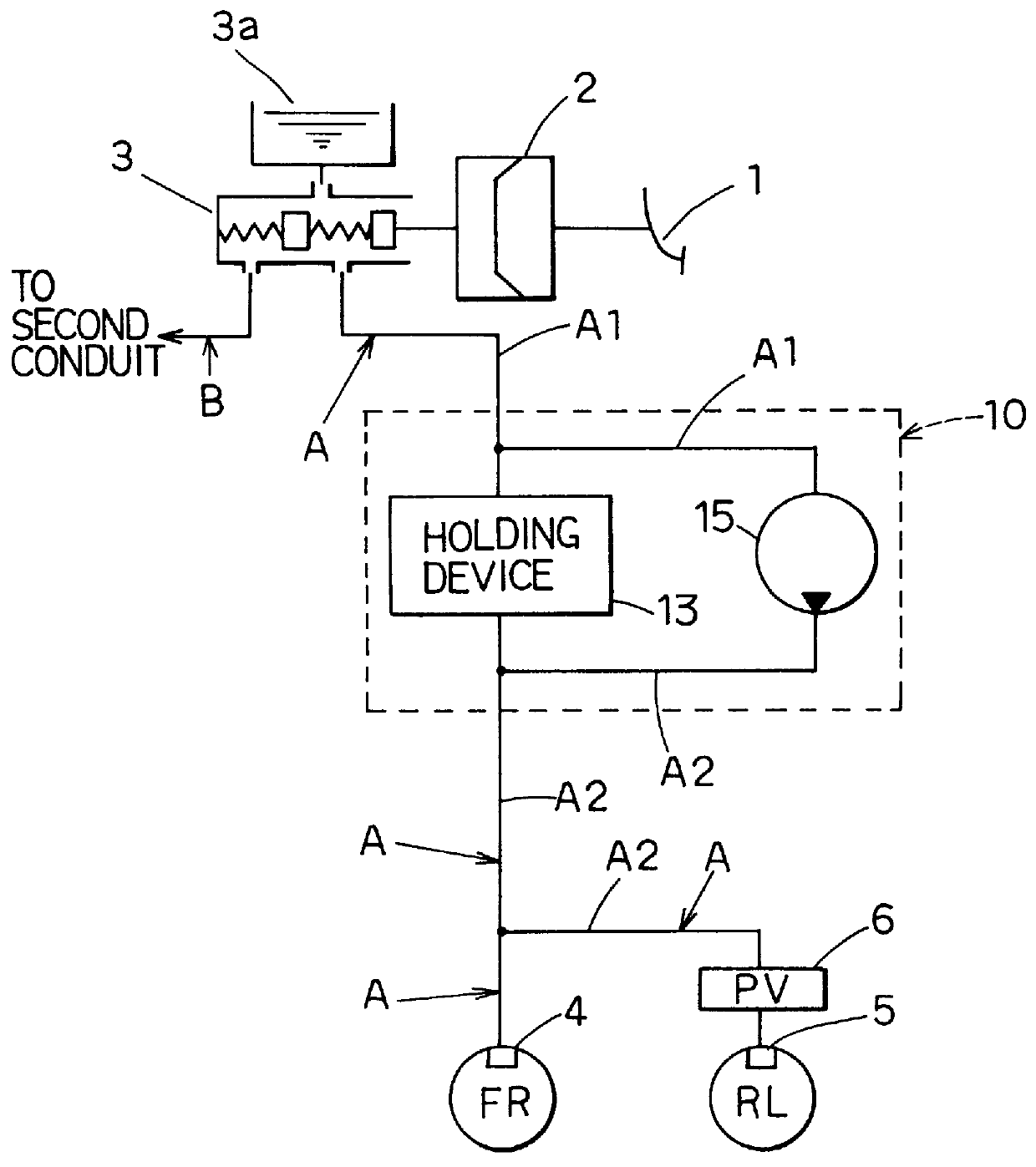

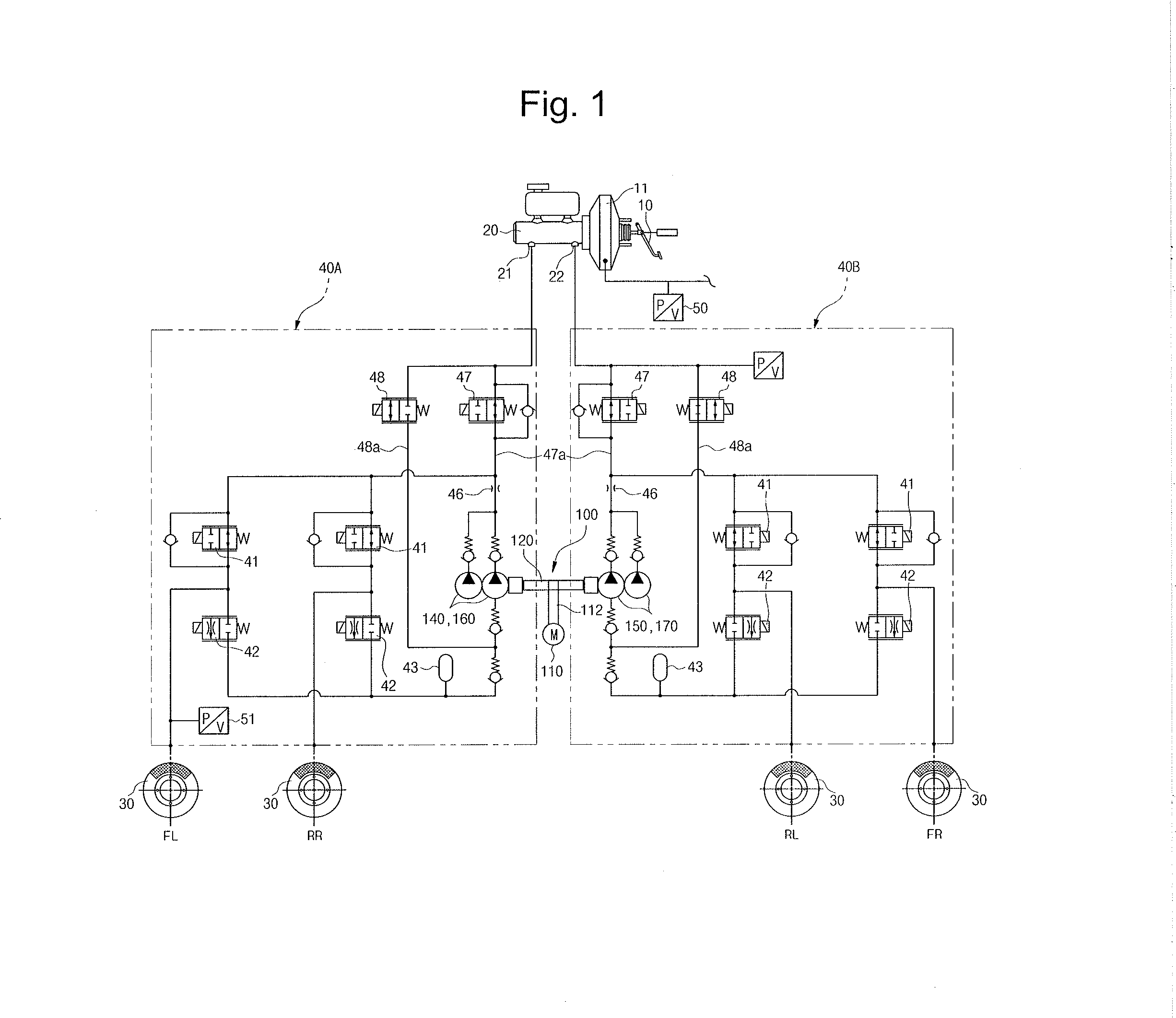

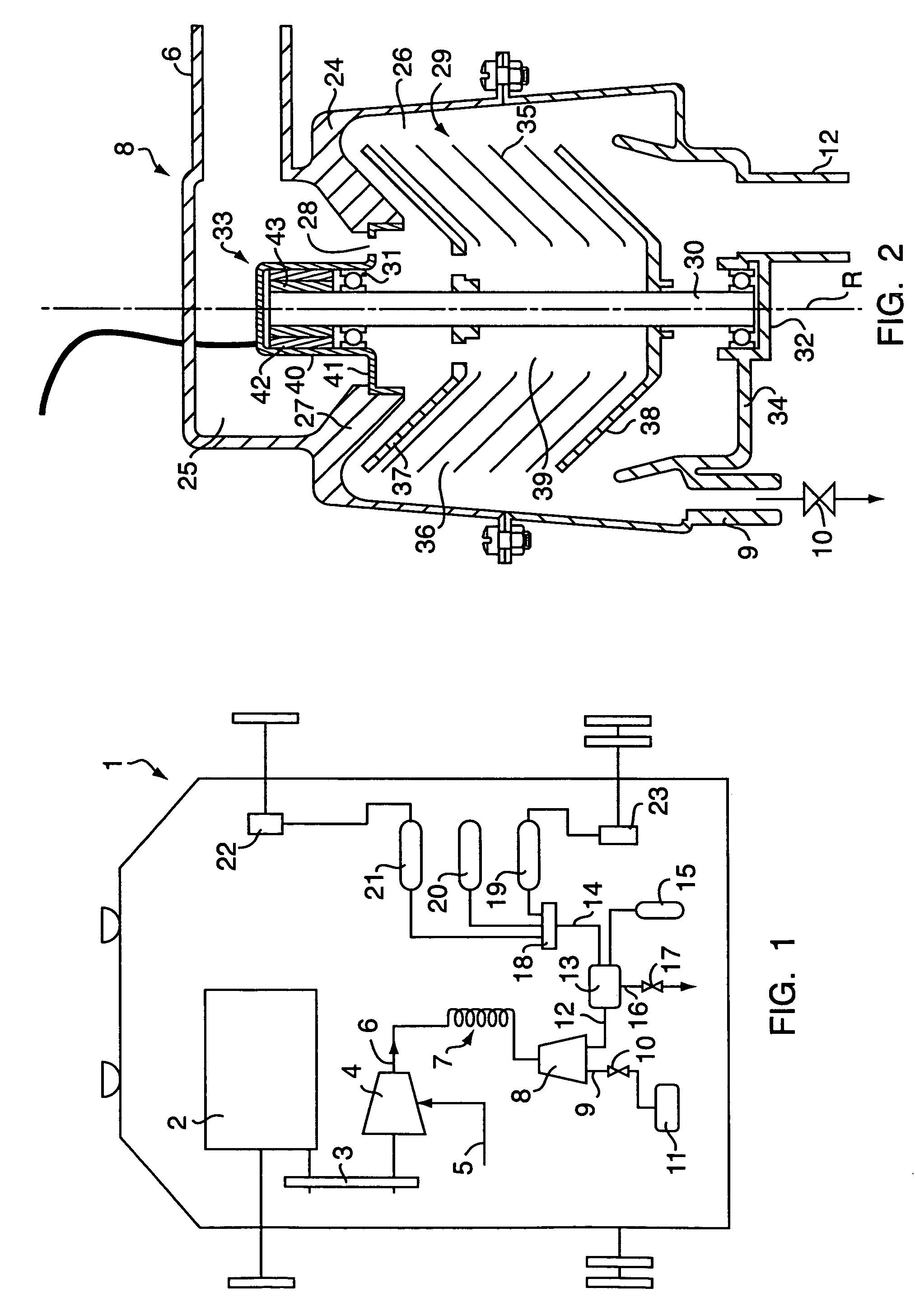

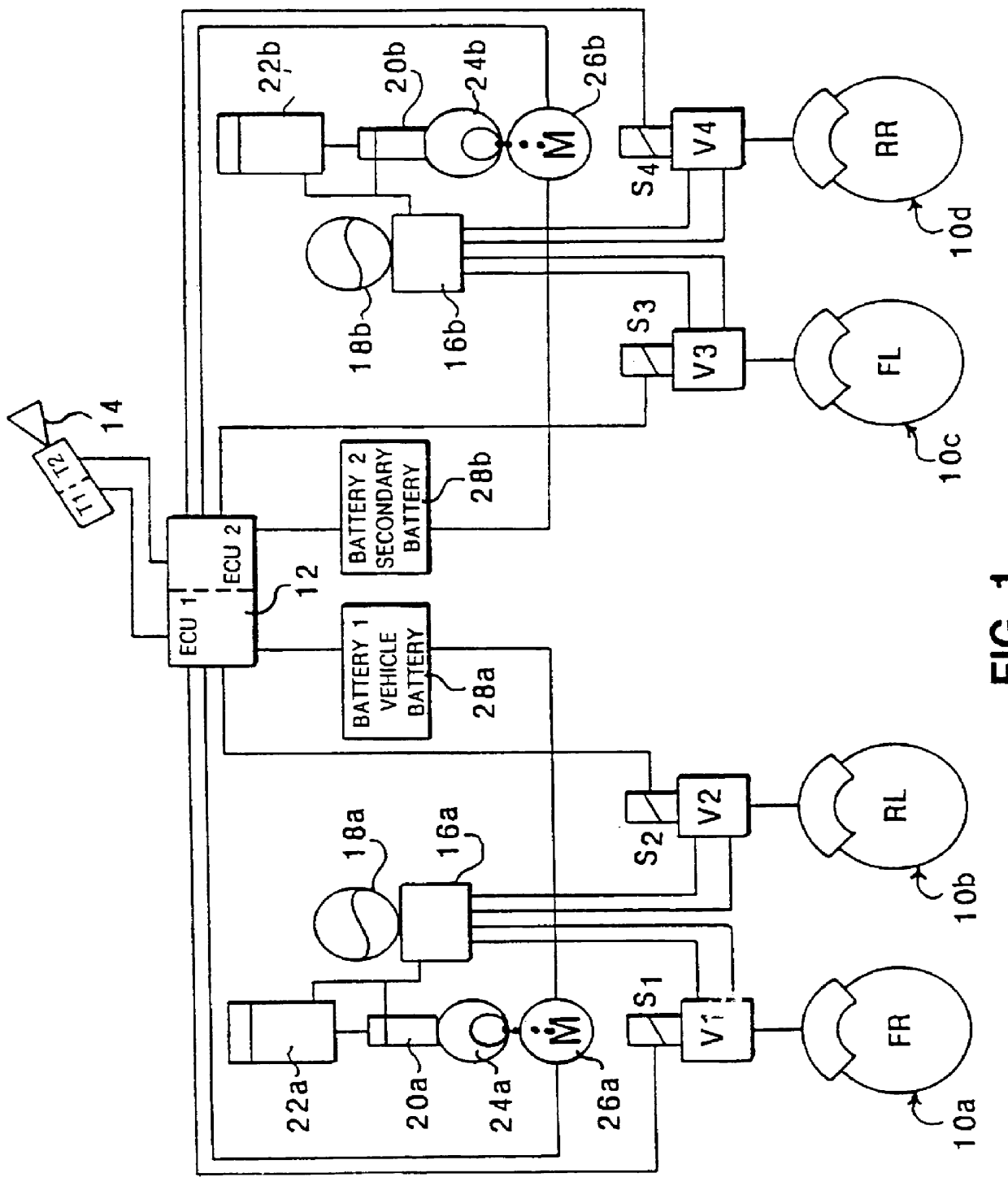

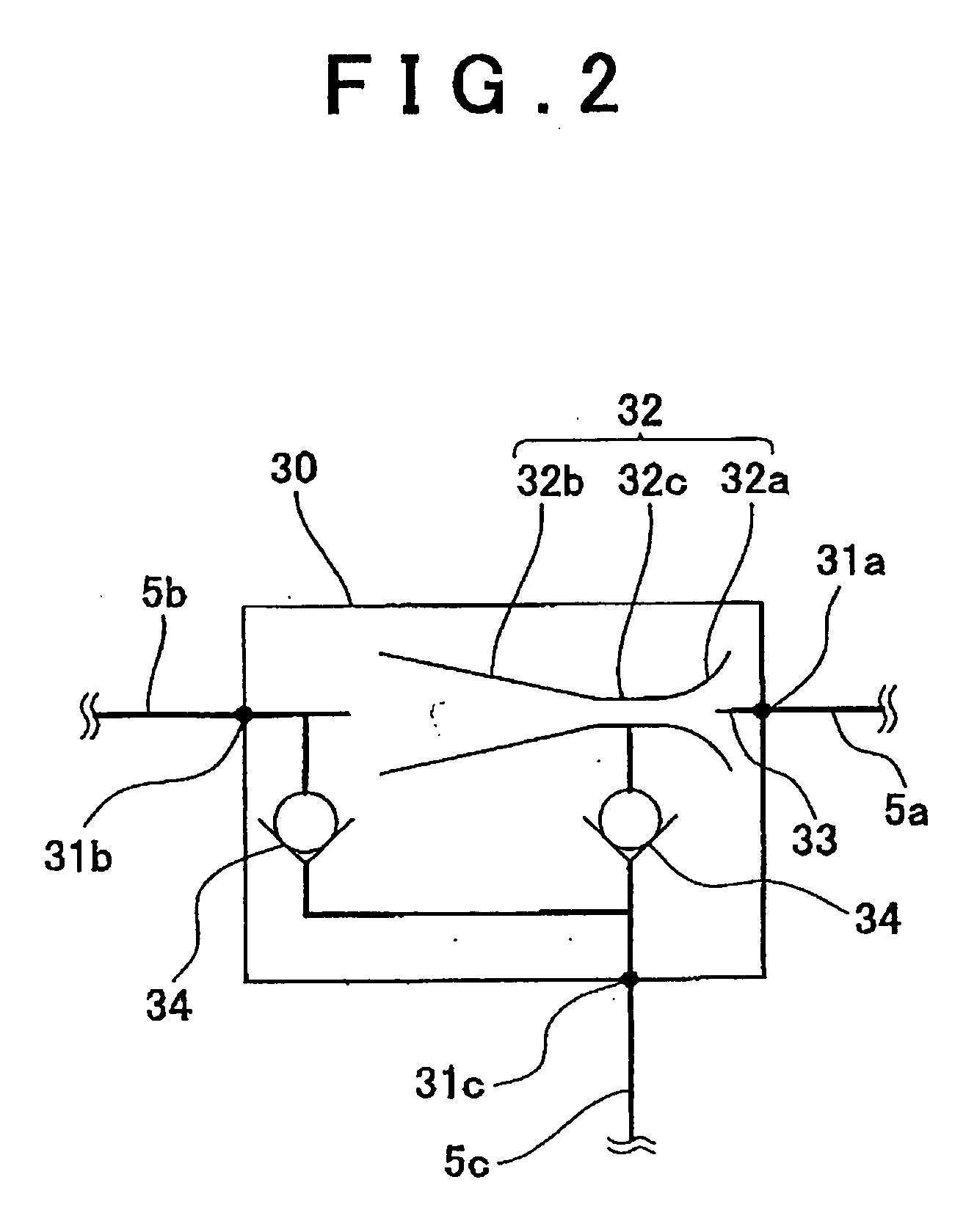

Hydraulic circuit having a rotary type pump and brake apparatus for a vehicle provided with the same

InactiveUS6142581APrevent leakagePrevent liquid leakageBraking action transmissionAutomatic initiationsRotary pumpDrive shaft

A hydraulic circuit has a rotary type pump comprising a rotor rotating with a driving shaft and a casing which holds the rotor and the driving shaft. The casing further comprises an inlet port through which fluid is introduced to spaces formed by the rotor, an outlet port through which fluid is discharged from the spaces, and a hydraulic path for leading fluid from clearance around said driving shaft to the outside of the casing. A reservoir is provided to store fluid coming through the hydraulic path. A return conduit is disposed between the reservoir and an upstream side conduit connected to the inlet port in order that fluid stored in the reservoir is returned to the upstream side conduit. In the return conduit, a check valve is disposed to prevent the reverse flow of fluid from the upstream side conduit to the reservoir.

Owner:DENSO CORP

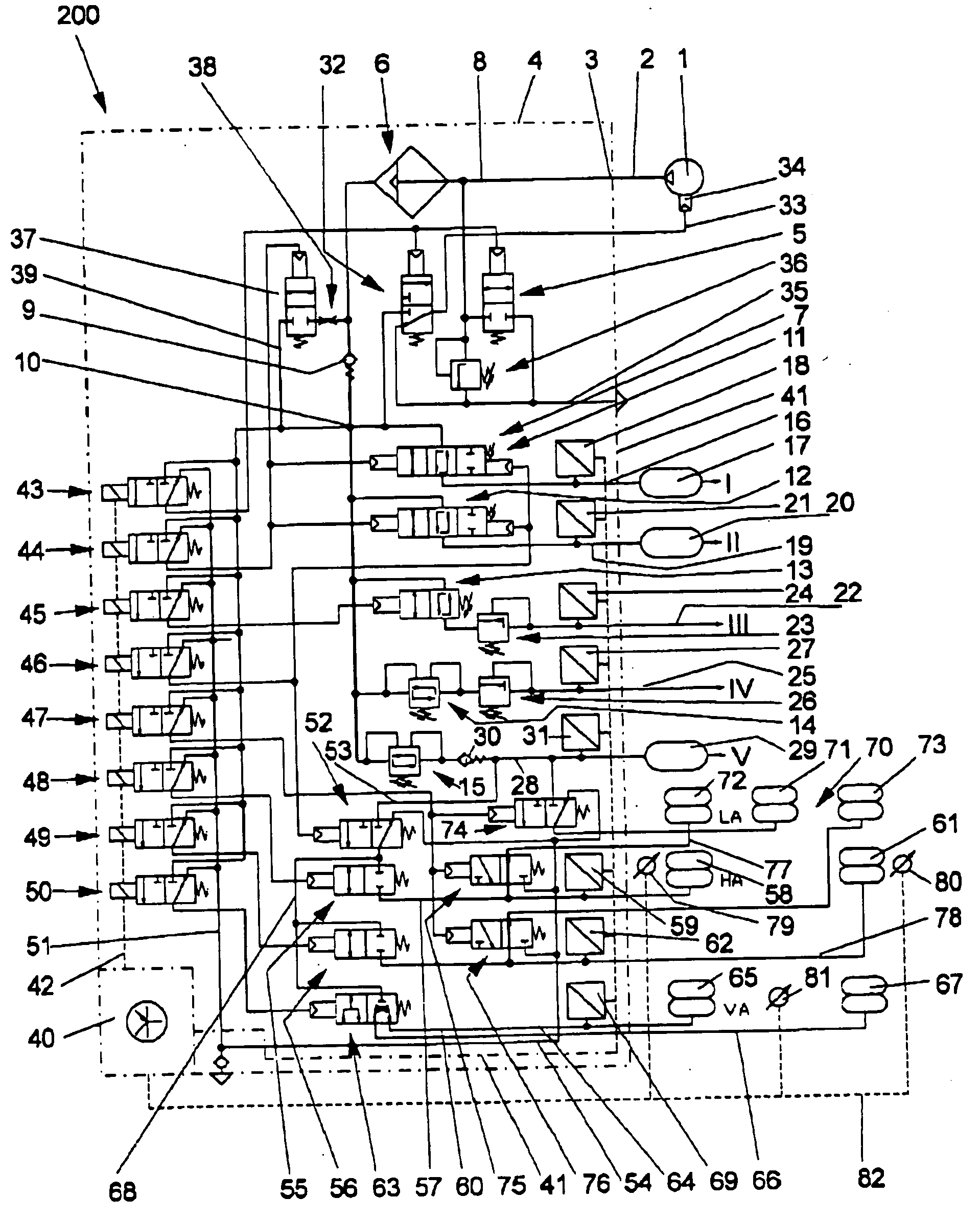

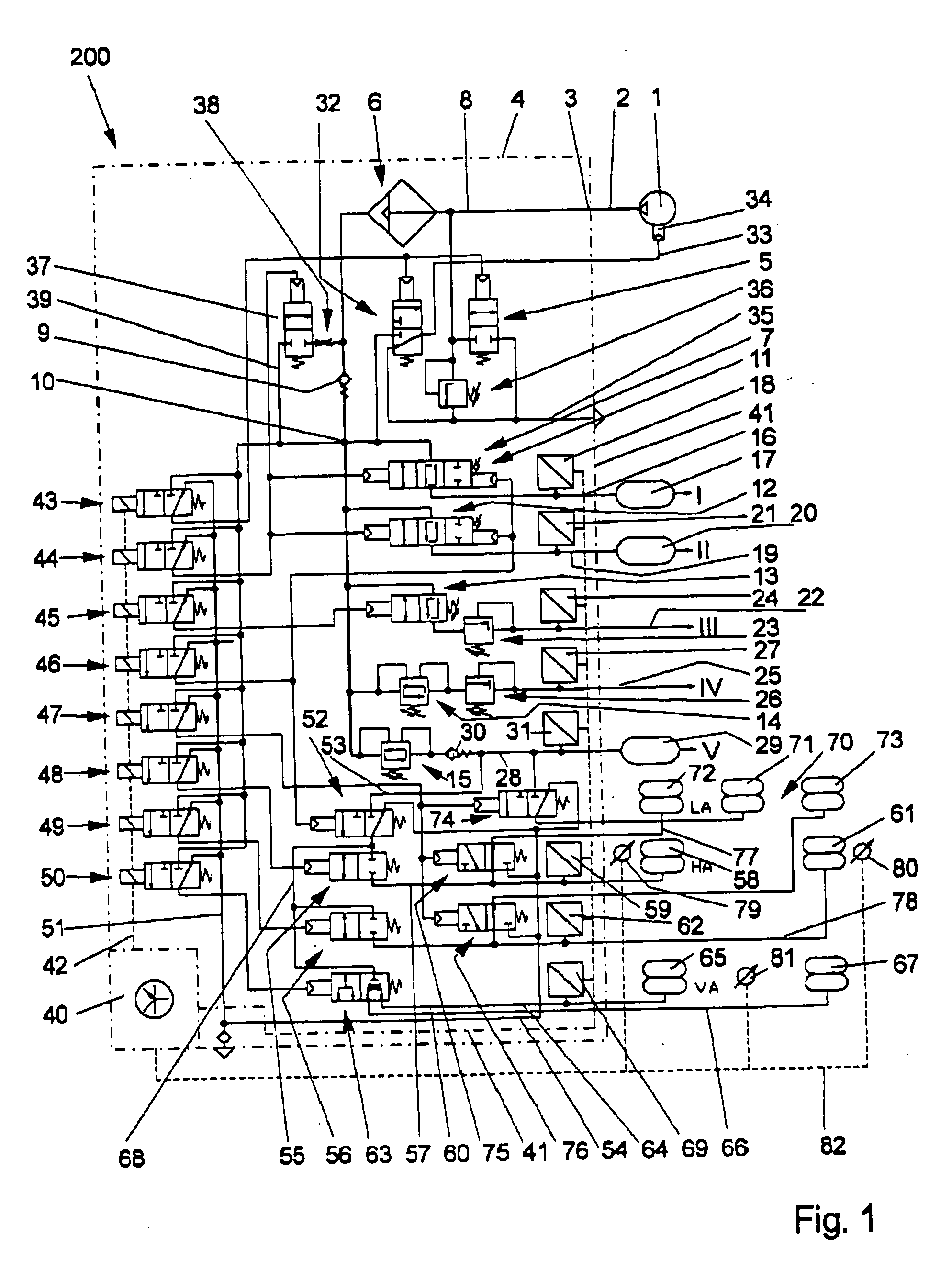

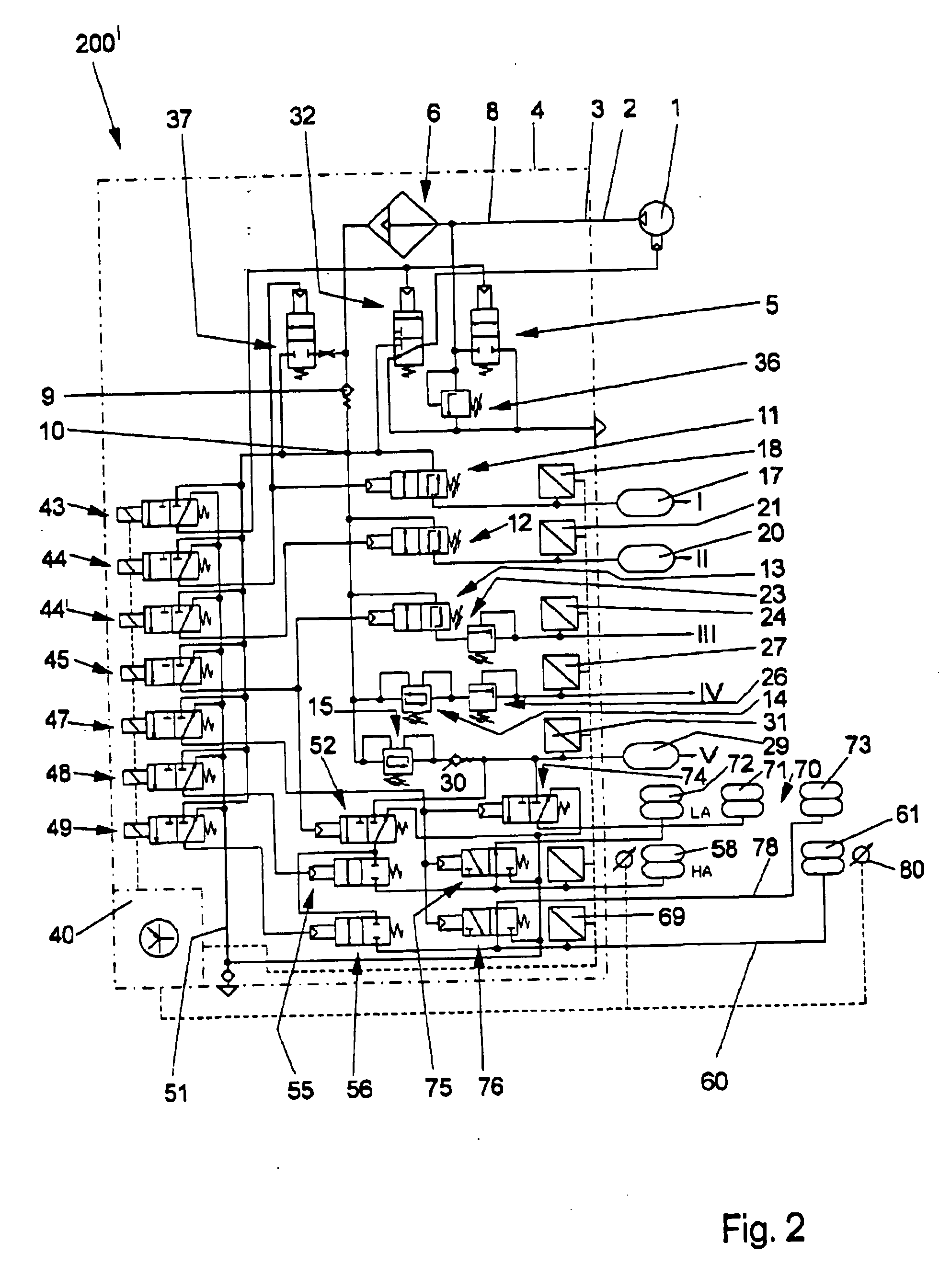

Hydraulic braking system for automobiles

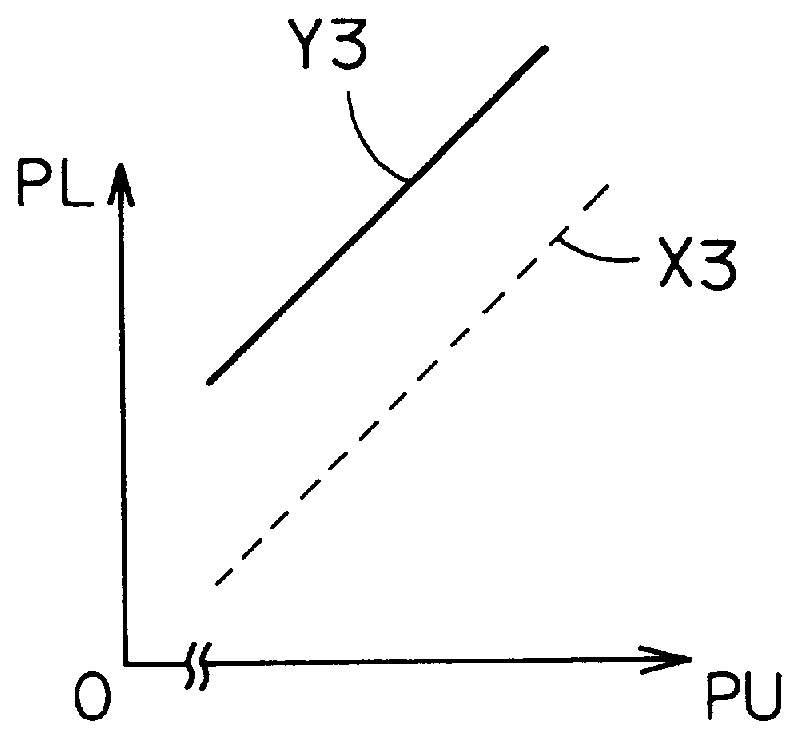

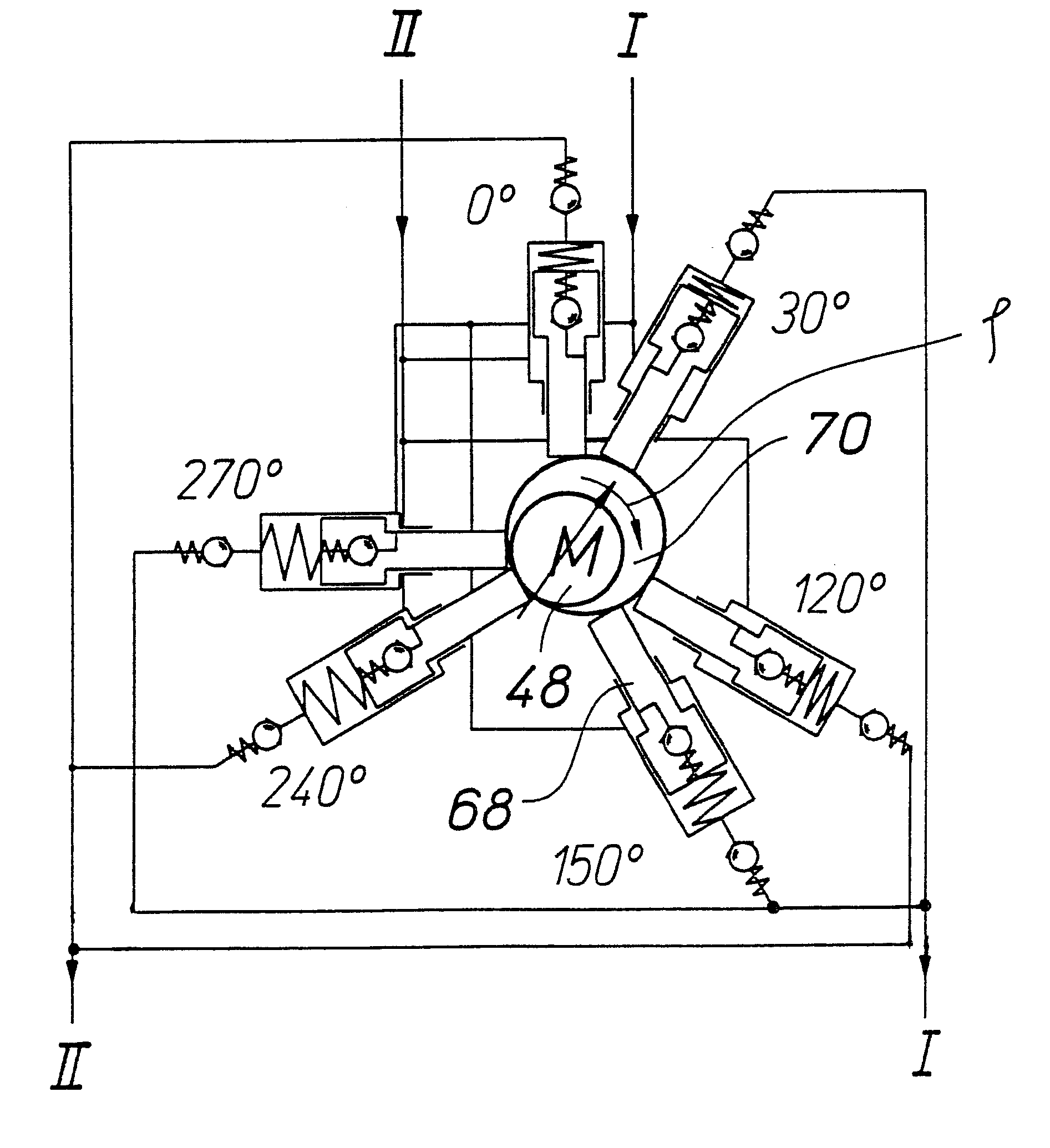

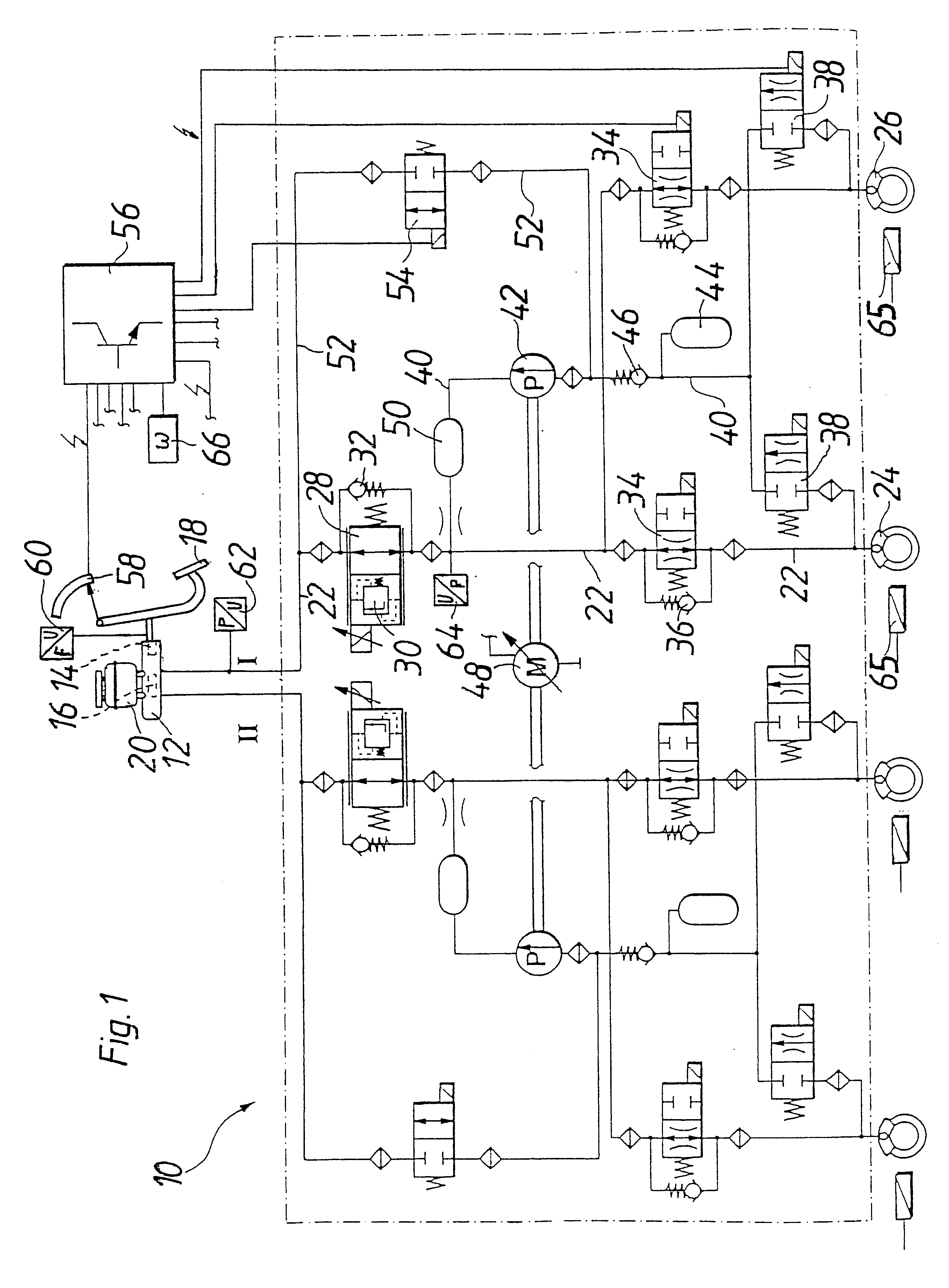

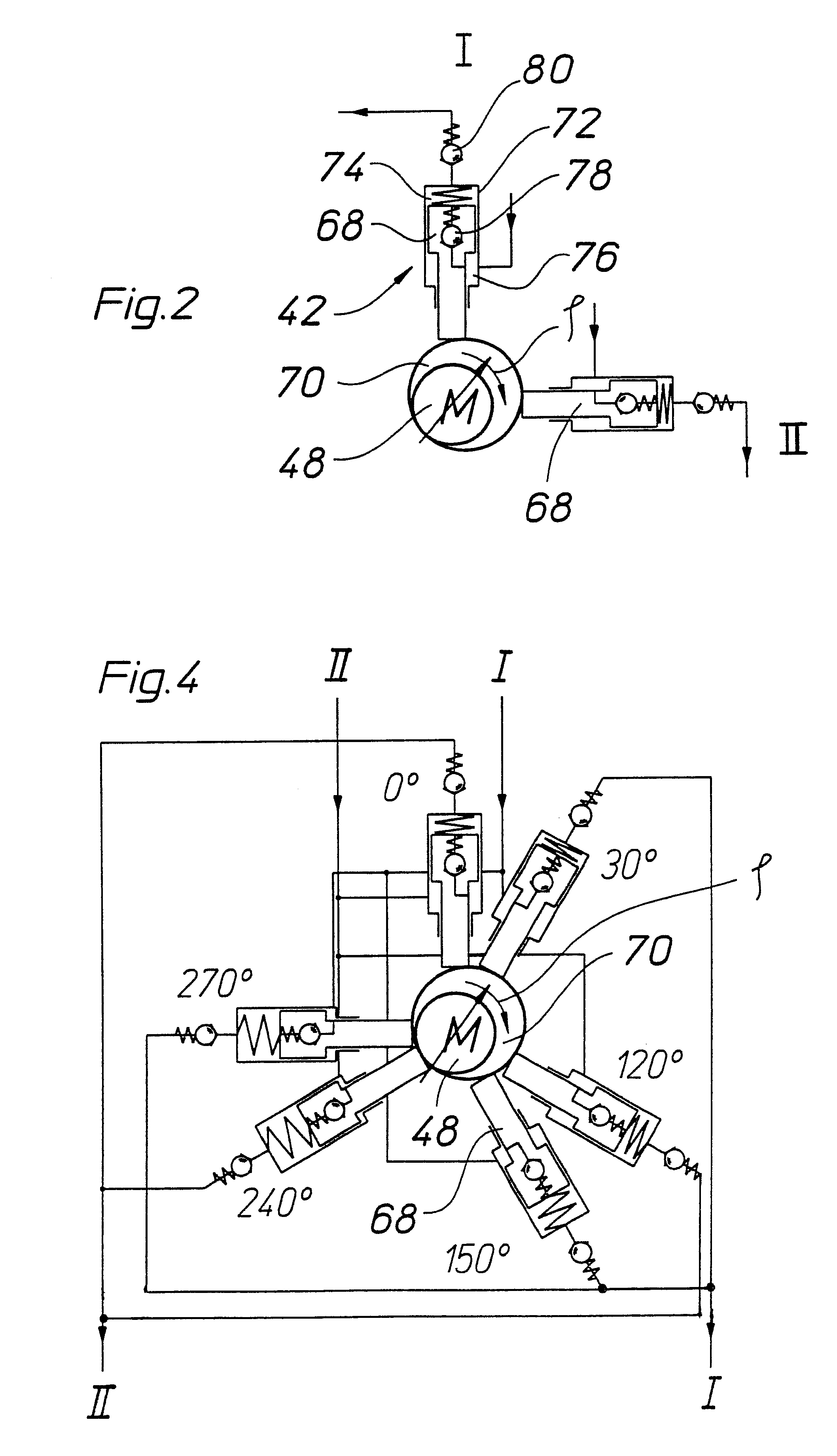

The invention relates to a vehicle hydraulic brake system with electrohydraulic brake boosting by a piston pump. In order to reduce pressure pulsations on an intake side of the multi-piston pump, the brake system embodies a multi-piston pump, for example, as a six-piston pump with stepped pistons that are driven with an alternating phase shift of 30° and 90° in relation to one another. The phase shift of the drive of the stepped pistons is selected so that the intake volume flows have a uniform phase shift, by which the total intake volume flow of the multi-piston pump has a reduced amplitude of the pressure pulsation, which reduces the repercussions on a master cylinder.

Owner:ROBERT BOSCH GMBH

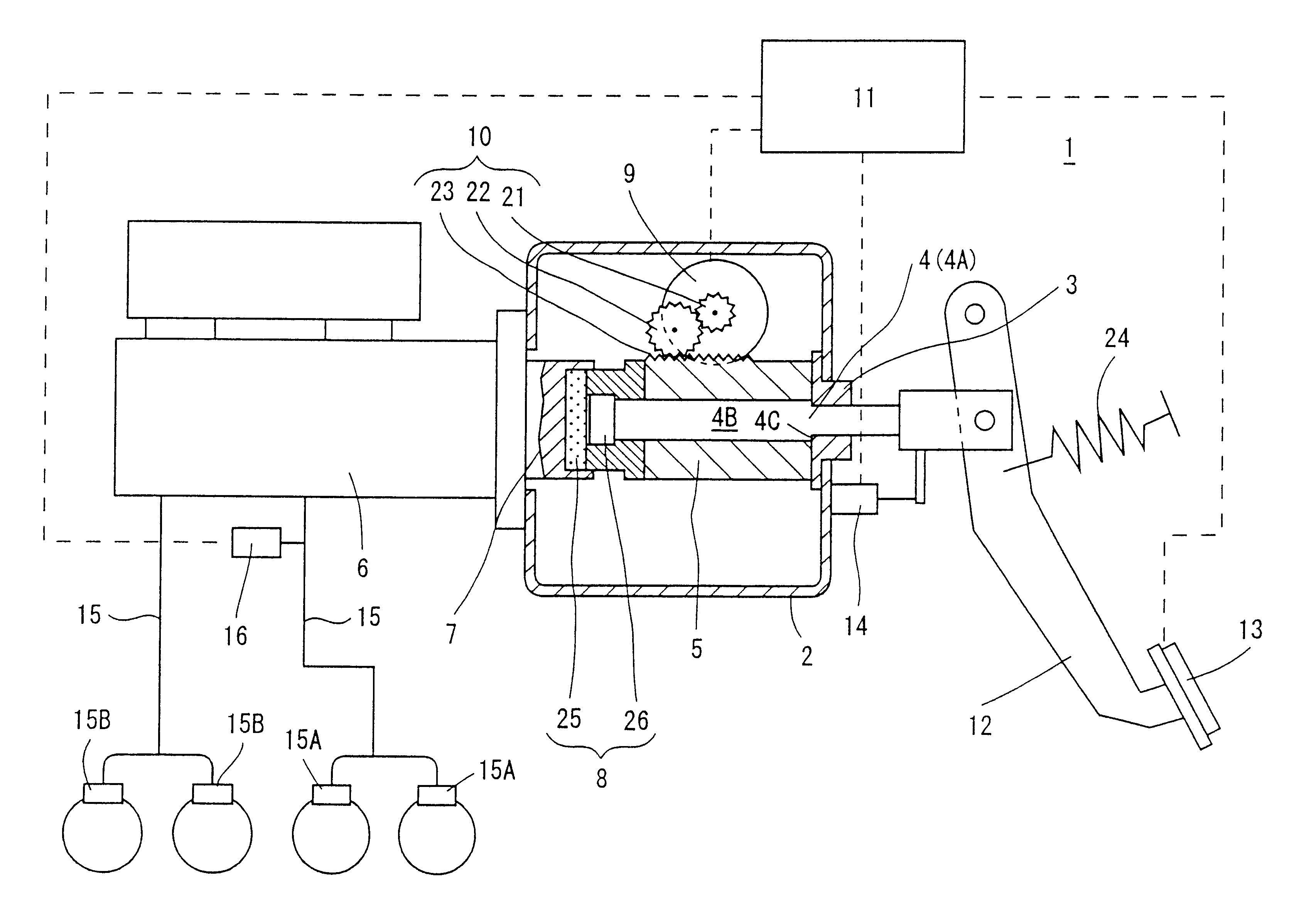

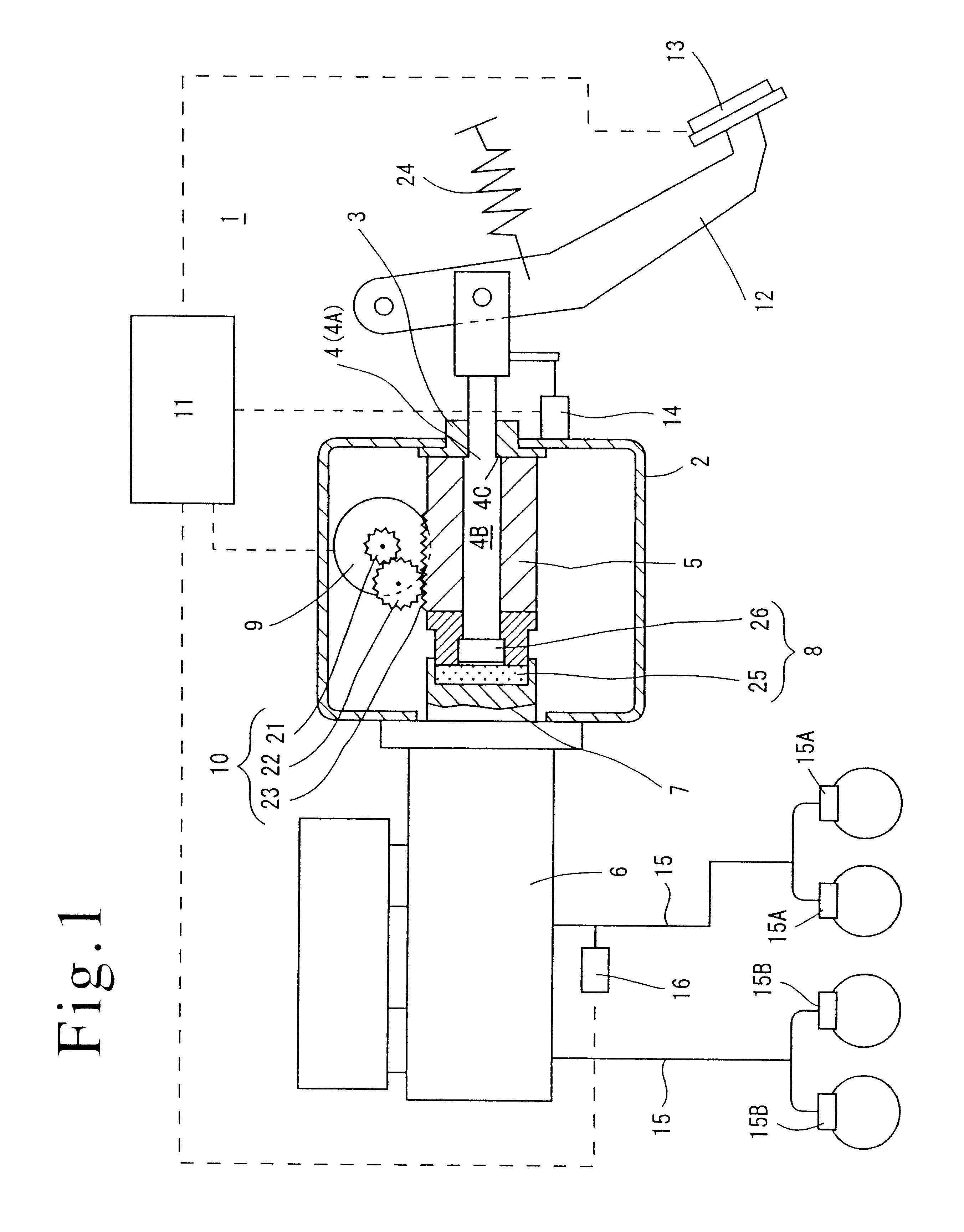

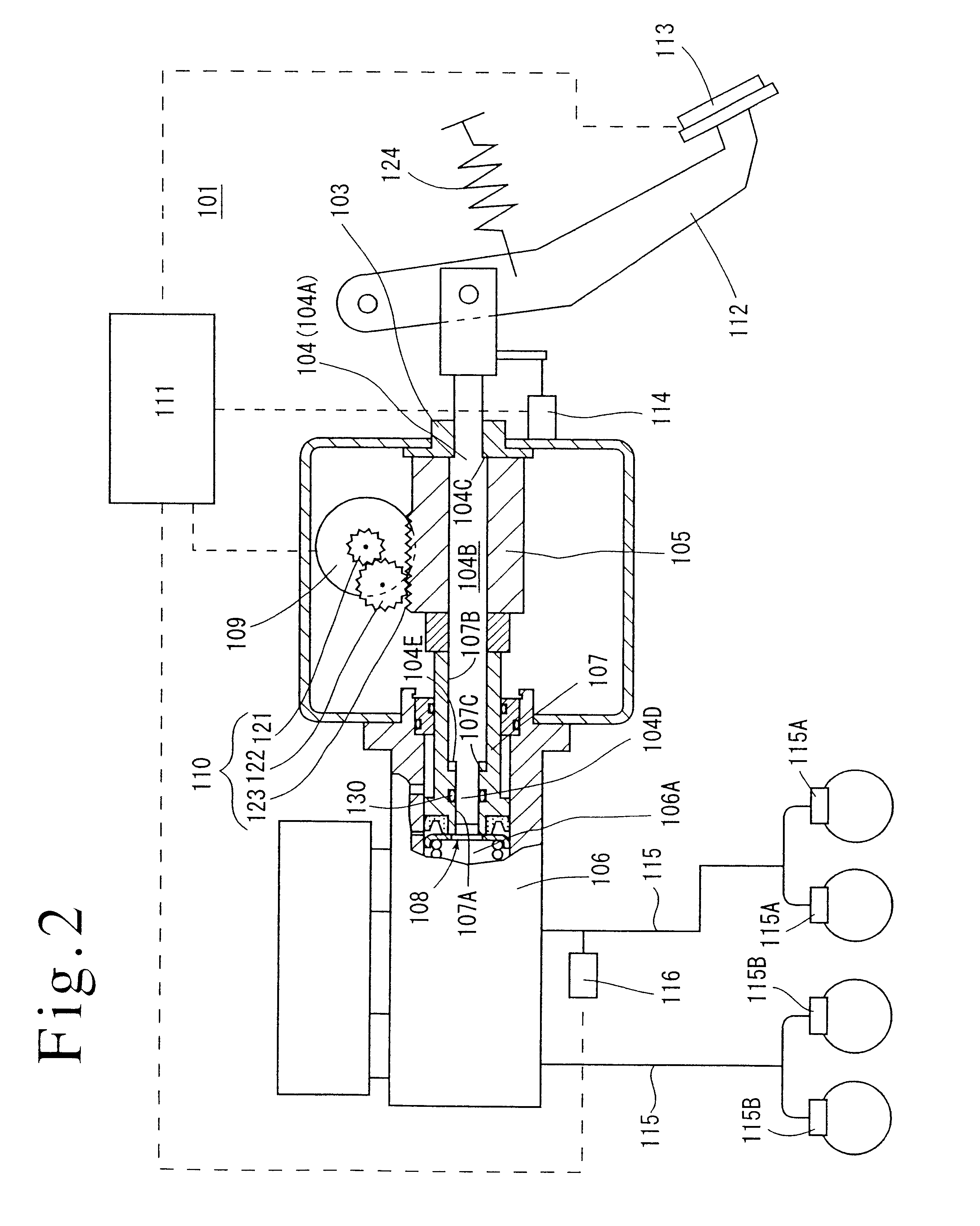

Electrically driven brake booster

InactiveUS6634724B2Reduce weightEasy constructionServomotor componentsRotary clutchesLinear motionMaster cylinder

An electrically driven brake booster (1) includes an input member (4) disposed in operative association with a brake pedal (12), an output member (5) disposed in operative association with the master cylinder (6), and drive transmitting device (10) for translating a rotating motion of a motor (9) into a linear motion to be transmitted to the output member (5). The drive transmitting device (10) comprises a rack (23) formed on the output member (5), and pinions (21, 22) disposed in operative association with the motor (9) and in meshing engagement with the rack (23). Also, reaction transmitting device (8) which transmits a brake reaction to the input member (4) and the output member (5) at a given proportion is provided. In comparison to conventional drive transmitting device, the drive transmitting device (10) of the present invention has a simple construction, a reduced weight and a better transmission efficiency. The provision of reaction transmitting device allows a correct brake control to be achieved on the basis of a brake reaction.

Owner:DIESEL KIKI CO LTD

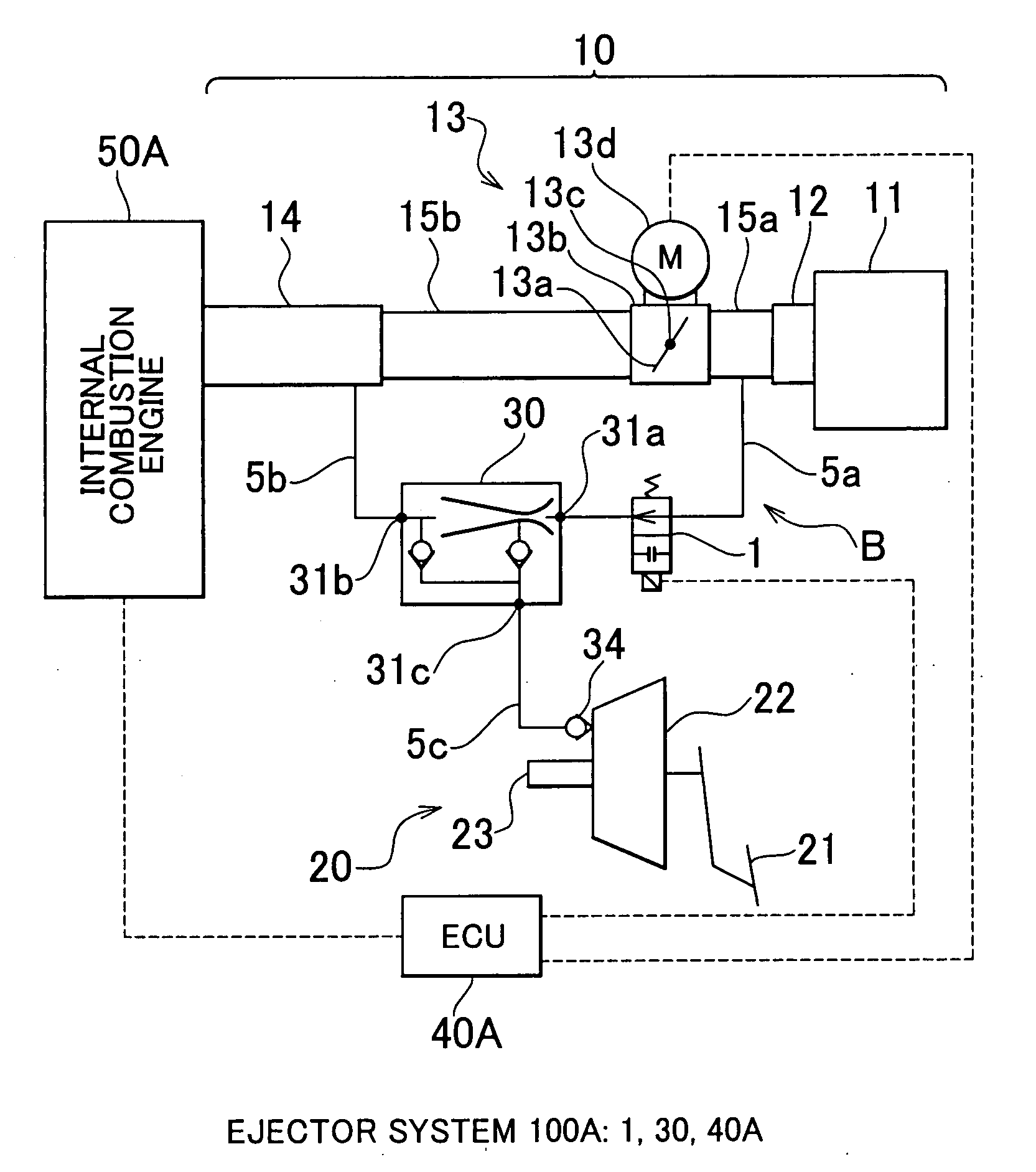

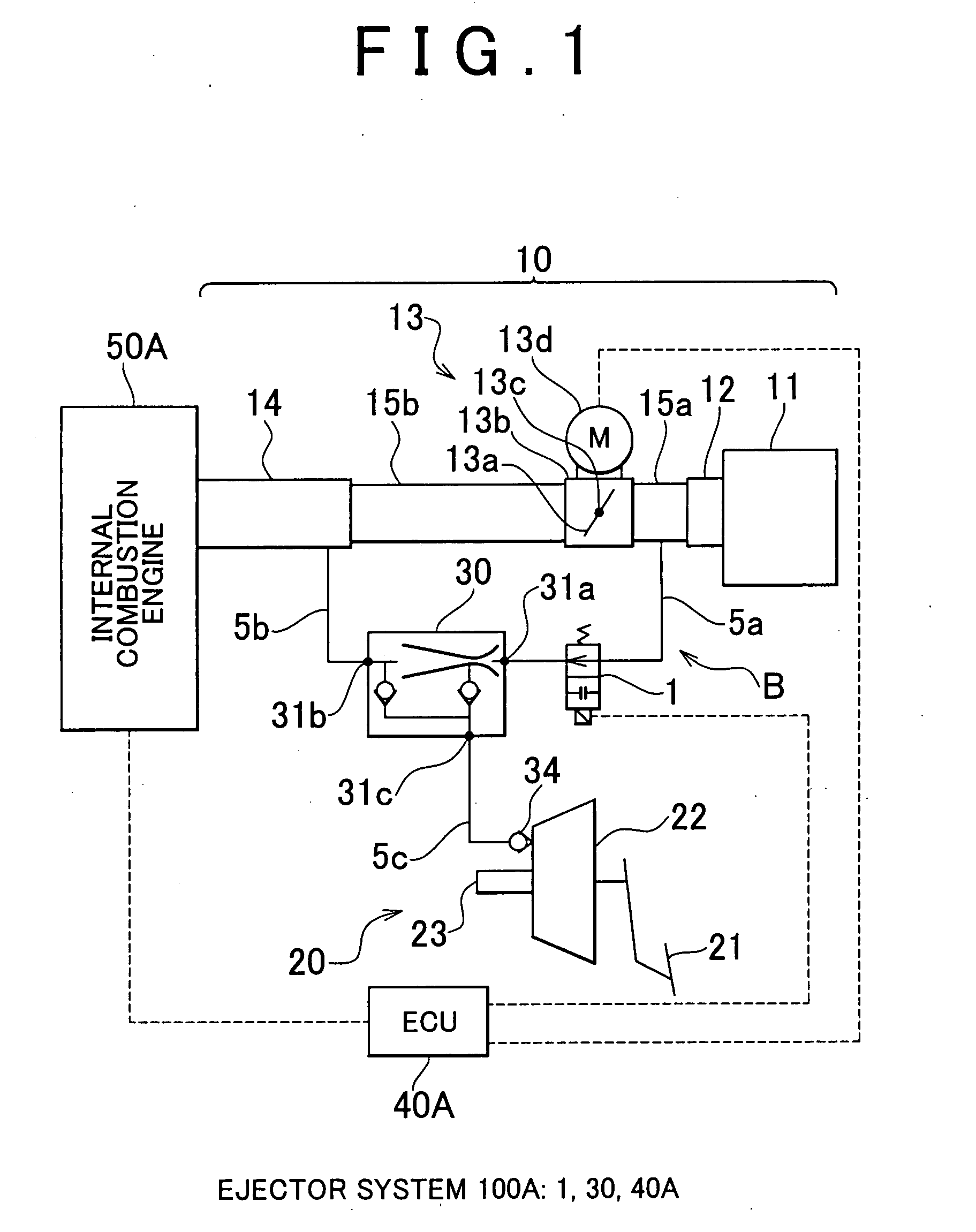

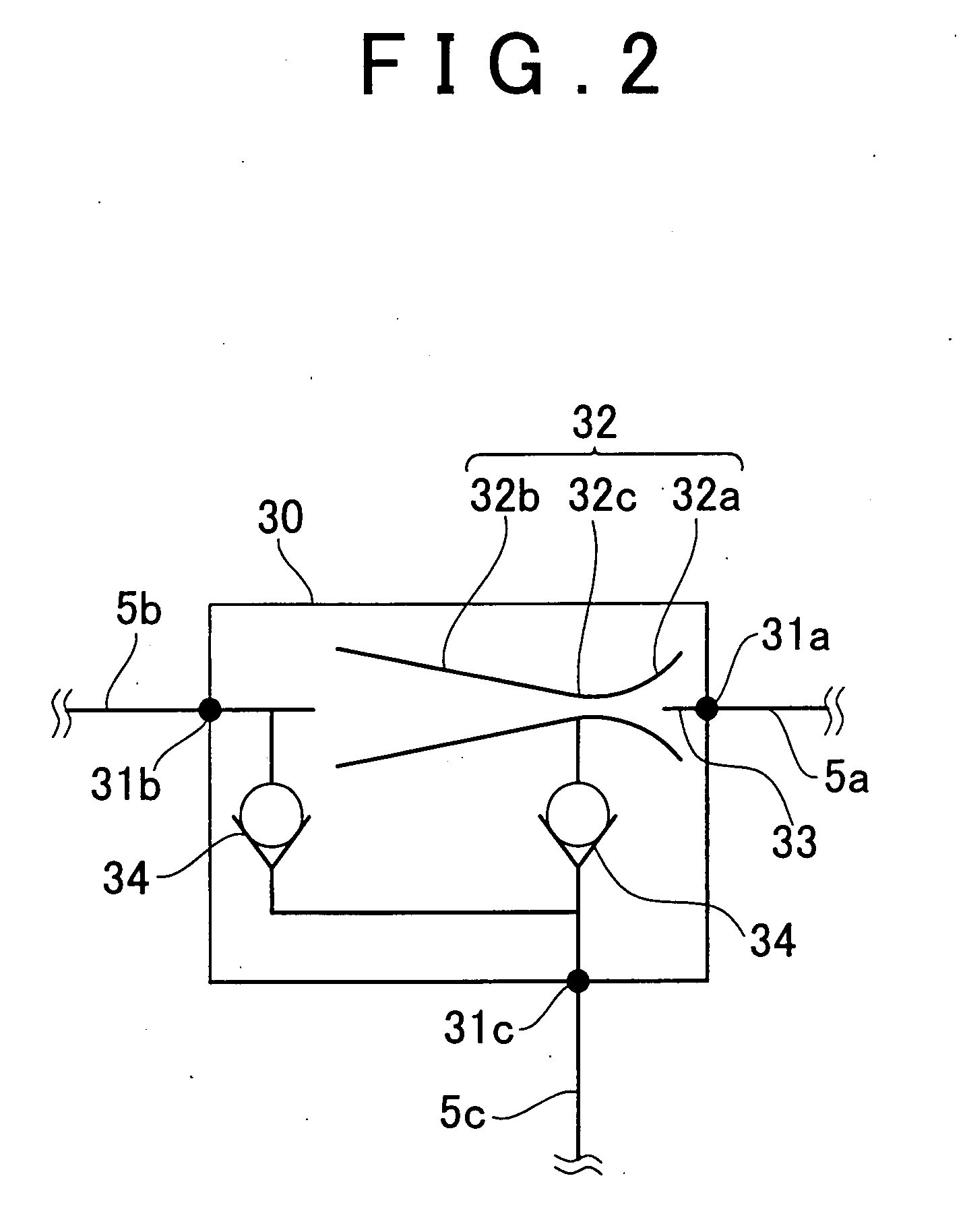

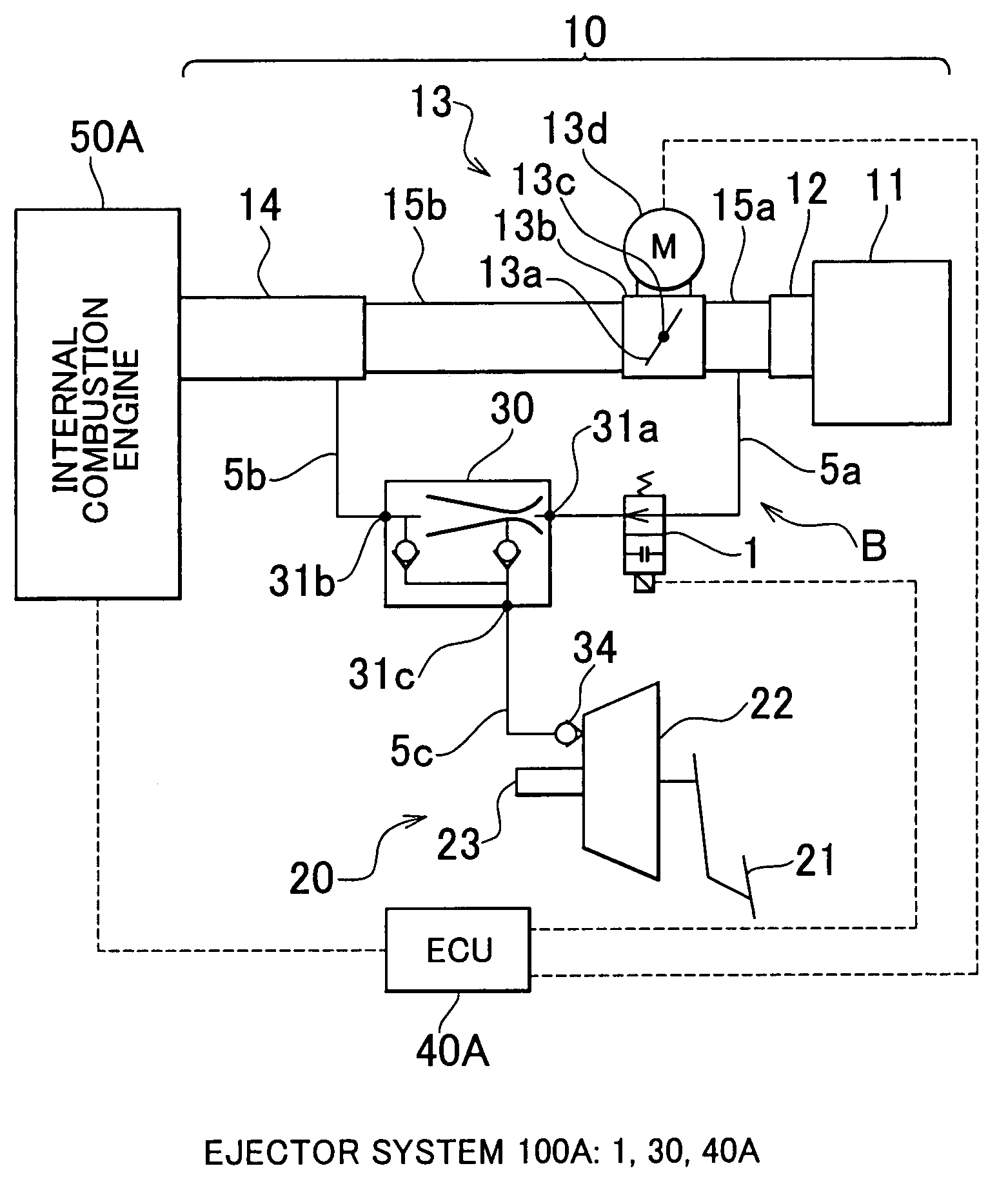

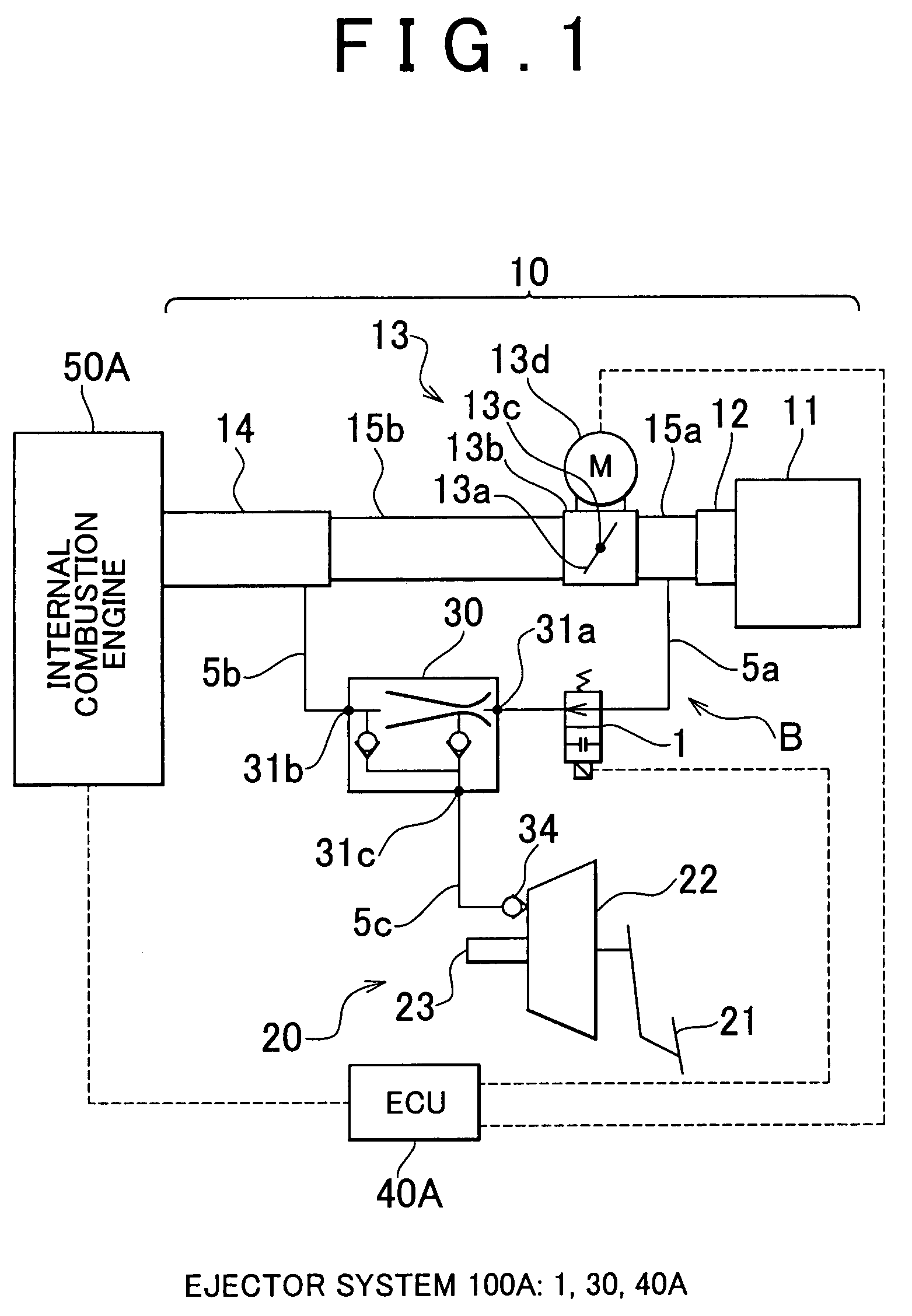

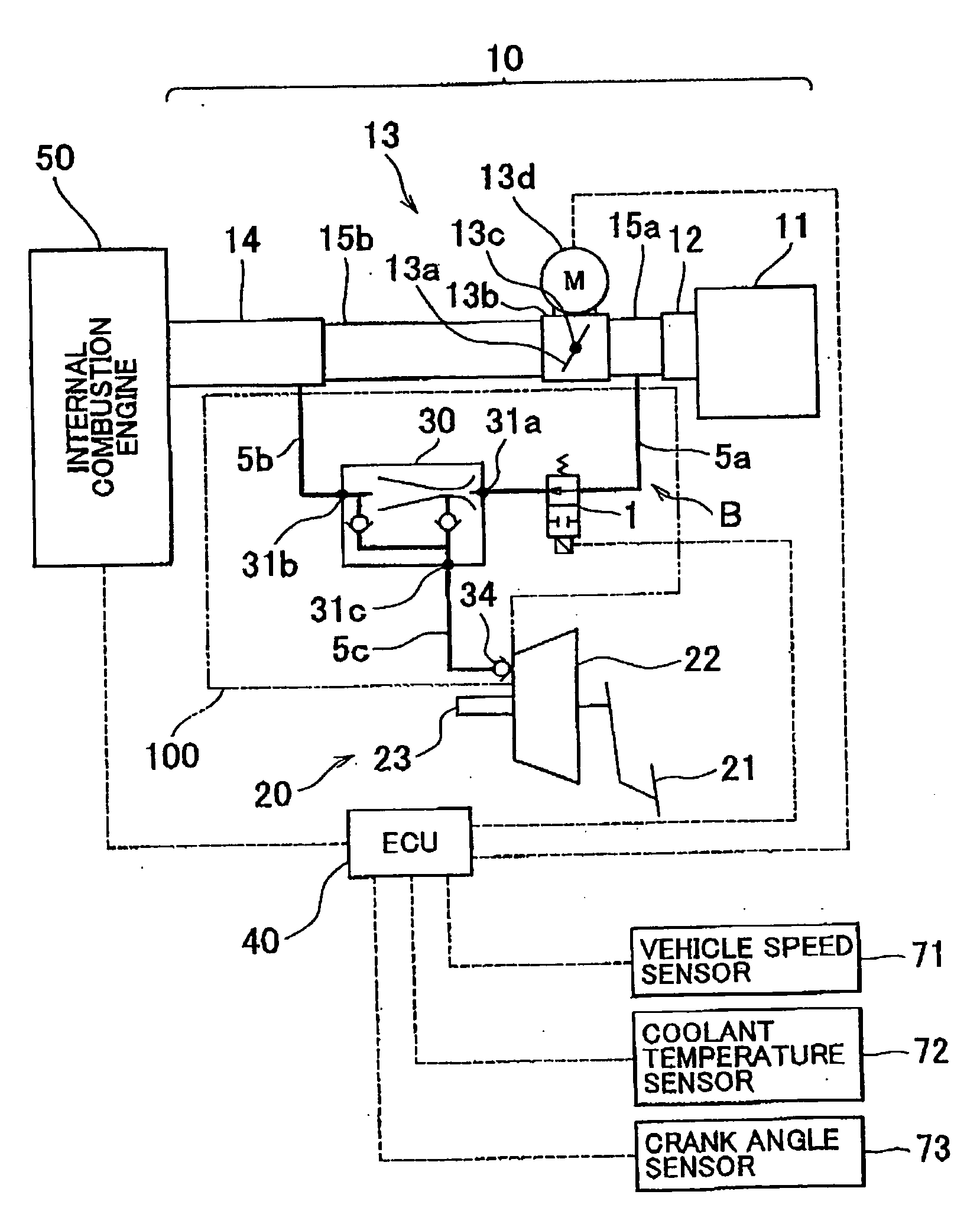

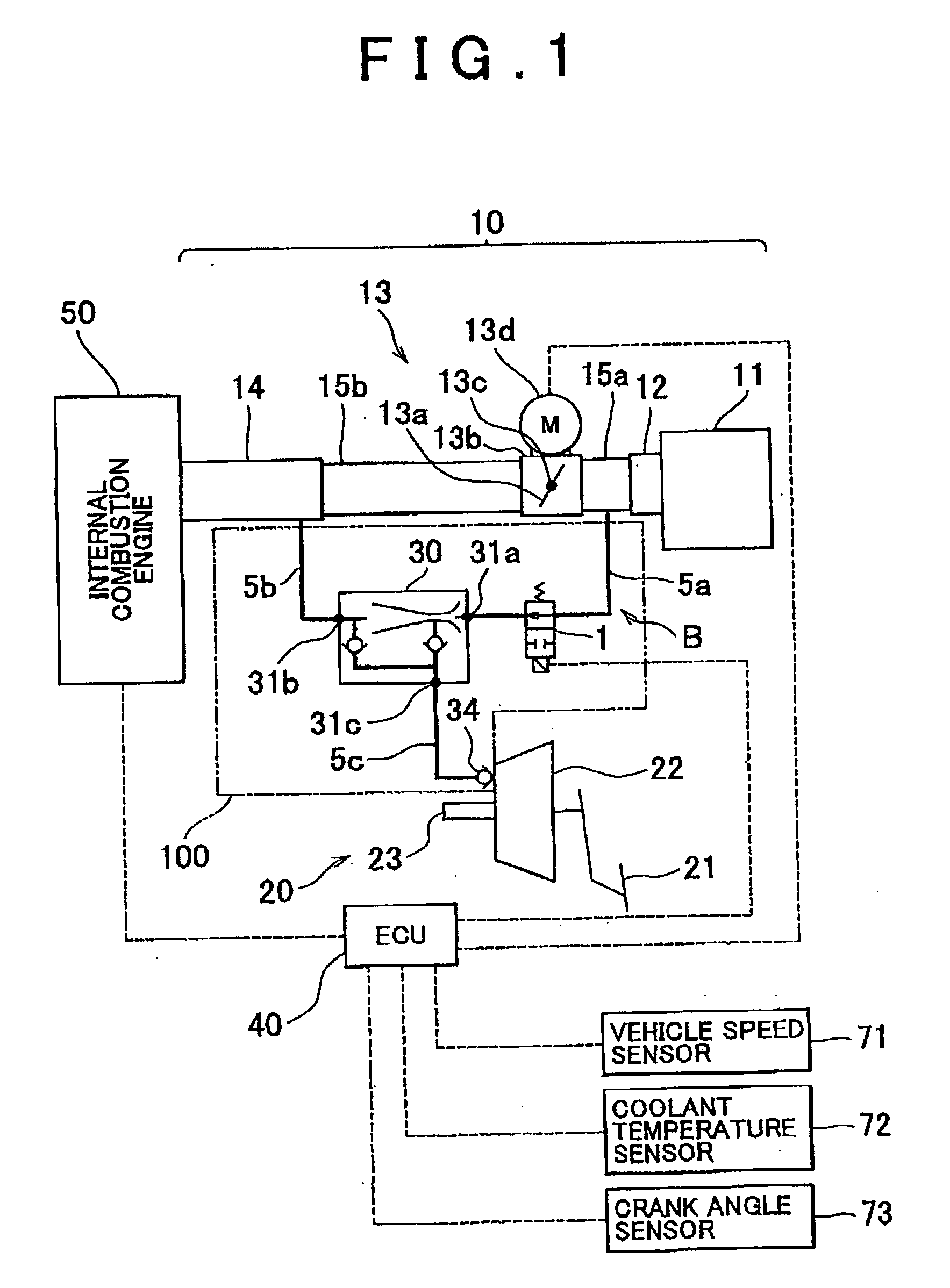

Vehicular ejector system and control method thereof

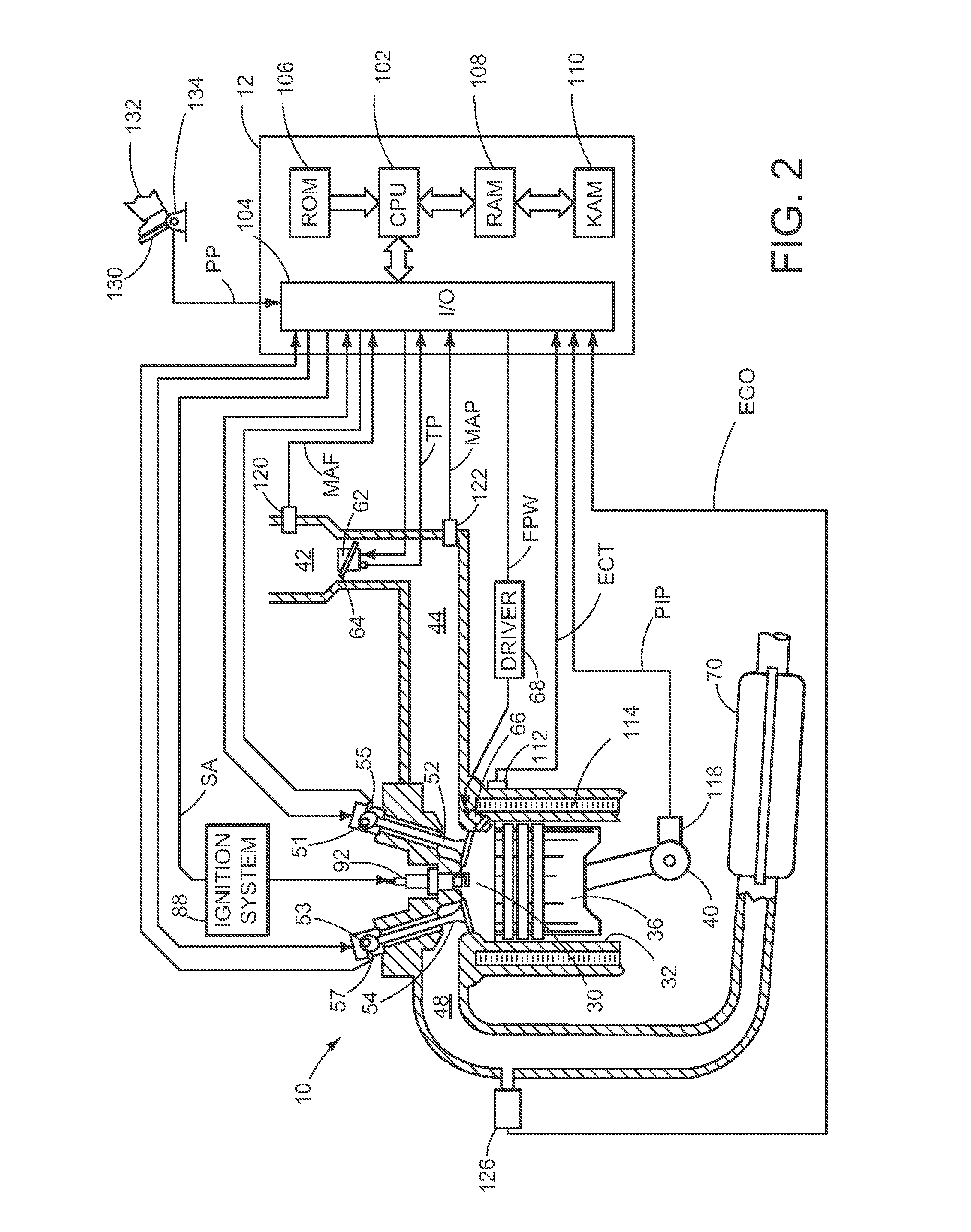

InactiveUS20070295303A1Reduce vehicle costReduce adverse effectsElectrical controlDigital data processing detailsInlet manifoldThrottle

A vehicular ejector system having an ejector that generates a negative pressure that is greater than the intake manifold negative pressure that is to be extracted from an intake manifold, a VSV that causes the ejector to function or stop functioning, and an ECU that controls the VSV. The ECU includes a control device that controls the VSV so as to cause the ejector to function if an ISC request amount for controlling, during idling, a throttle valve that adjusts the intake air flow amount supplied to the internal combustion engine is greater than a predetermined amount.

Owner:TOYOTA JIDOSHA KK

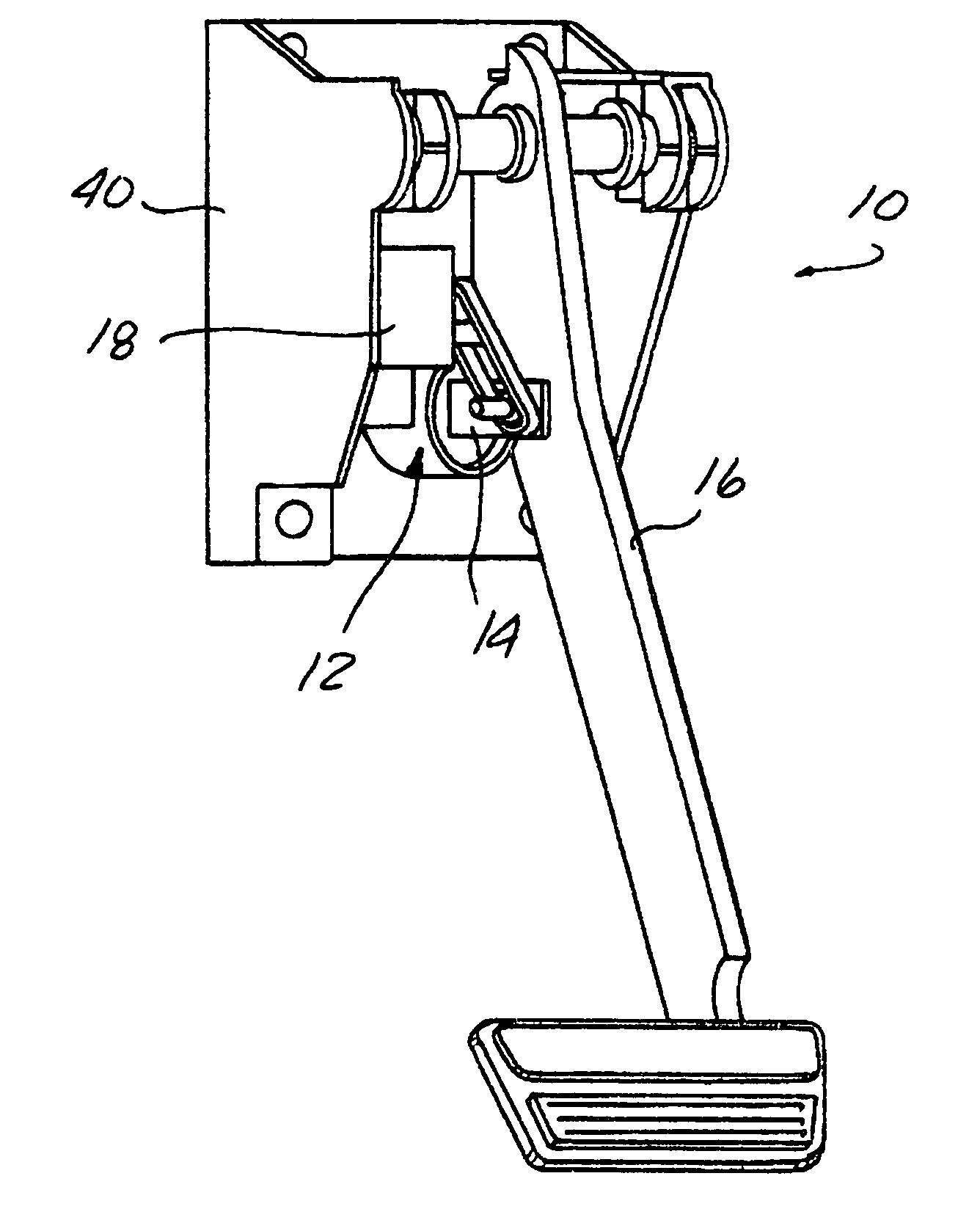

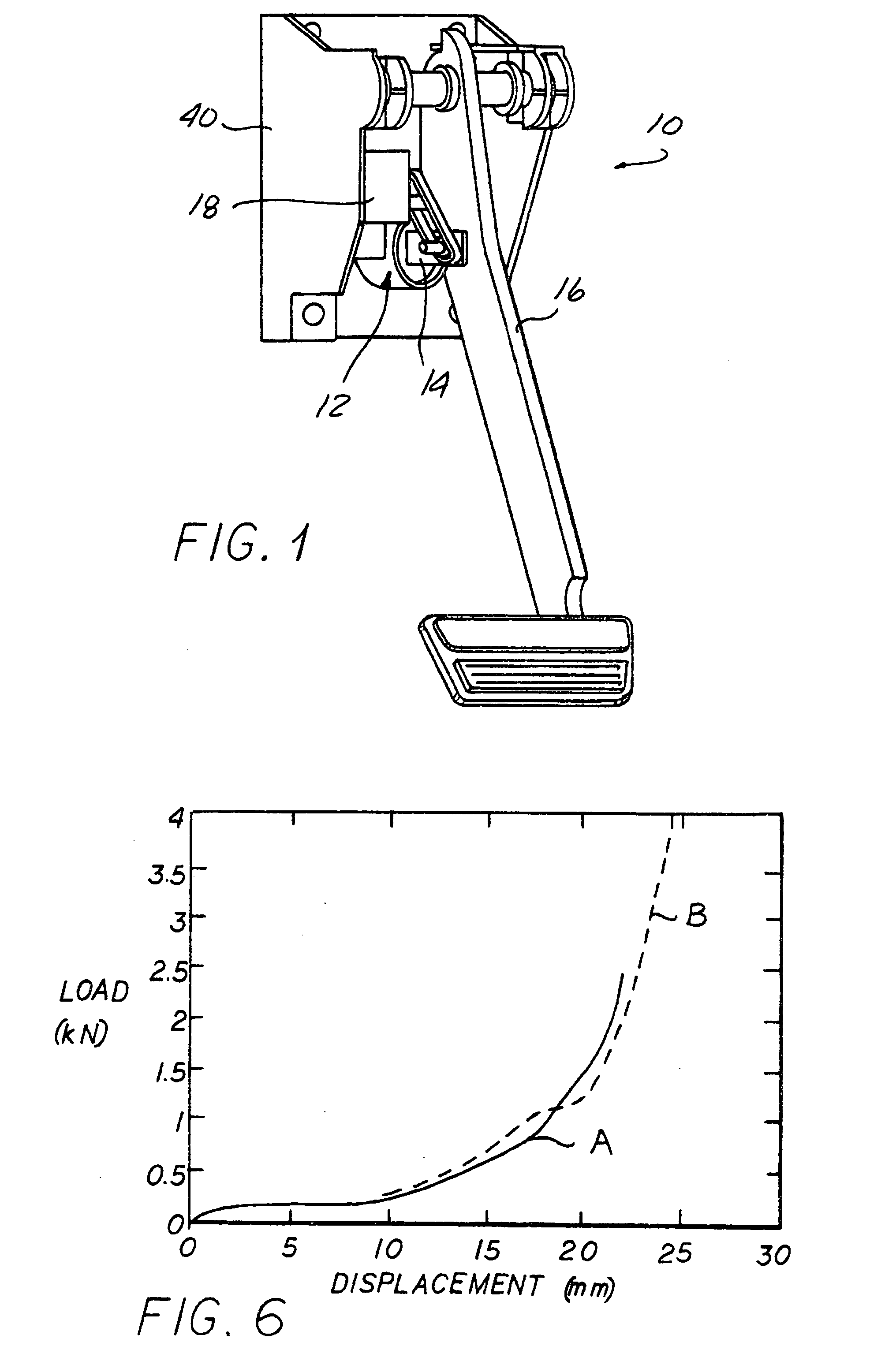

Pedal feel emulator mechanism for brake by wire pedal

InactiveUS20050082909A1Optimization mechanismIncrease rate increaseControlling membersBraking action transmissionHysteresisGas spring

A brake pedal emulator mechanism includes a foamed plastic elastomeric piece compressed by a brake pedal which piece has a variable spring rate and produces hysteresis when compressed to emulate the brake pedal feel of a conventional hydraulic brake system. The foamed plastic may comprise microcellular urethane or a foamed silicone elastomer. Various combinations of the foamed plastic piece with mechanical springs, solid elastomeric pieces, or gas springs can be used to create a particular reaction force characteristic, as well as various shapes of the foamed plastic elastomeric piece itself.

Owner:DURA GLOBAL TECH

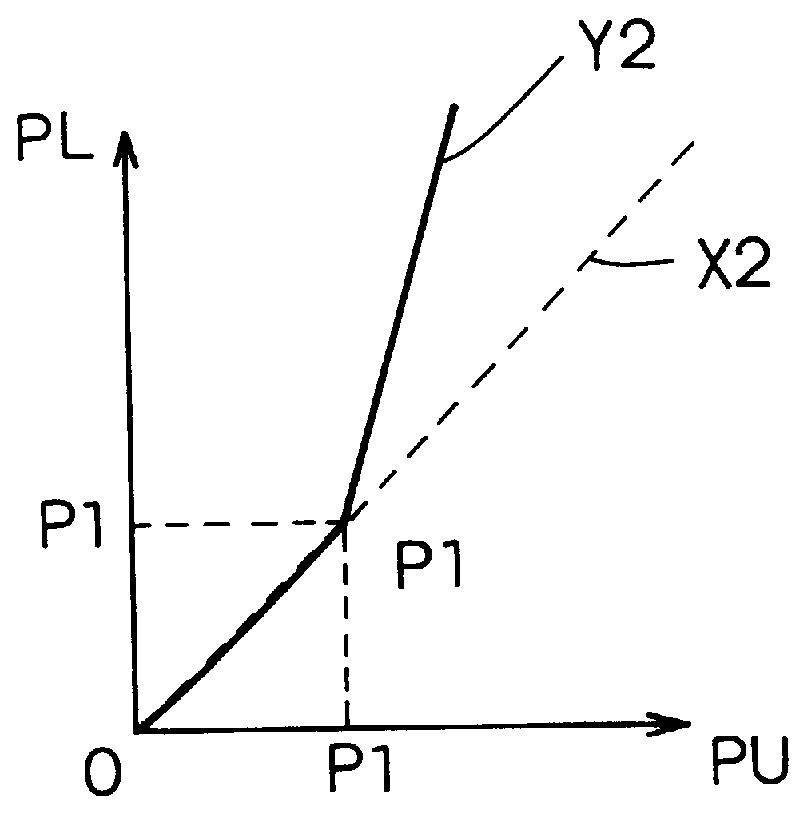

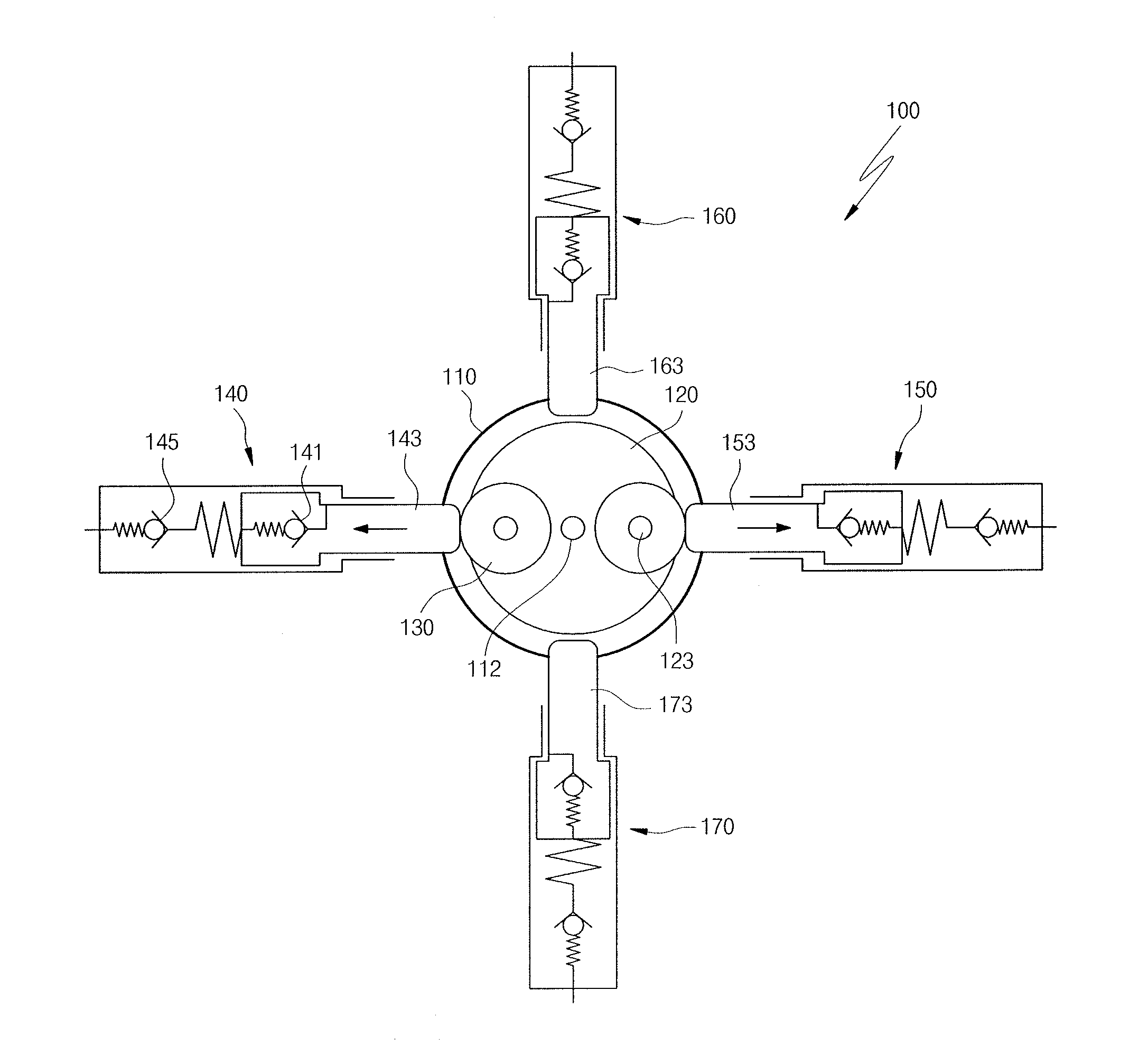

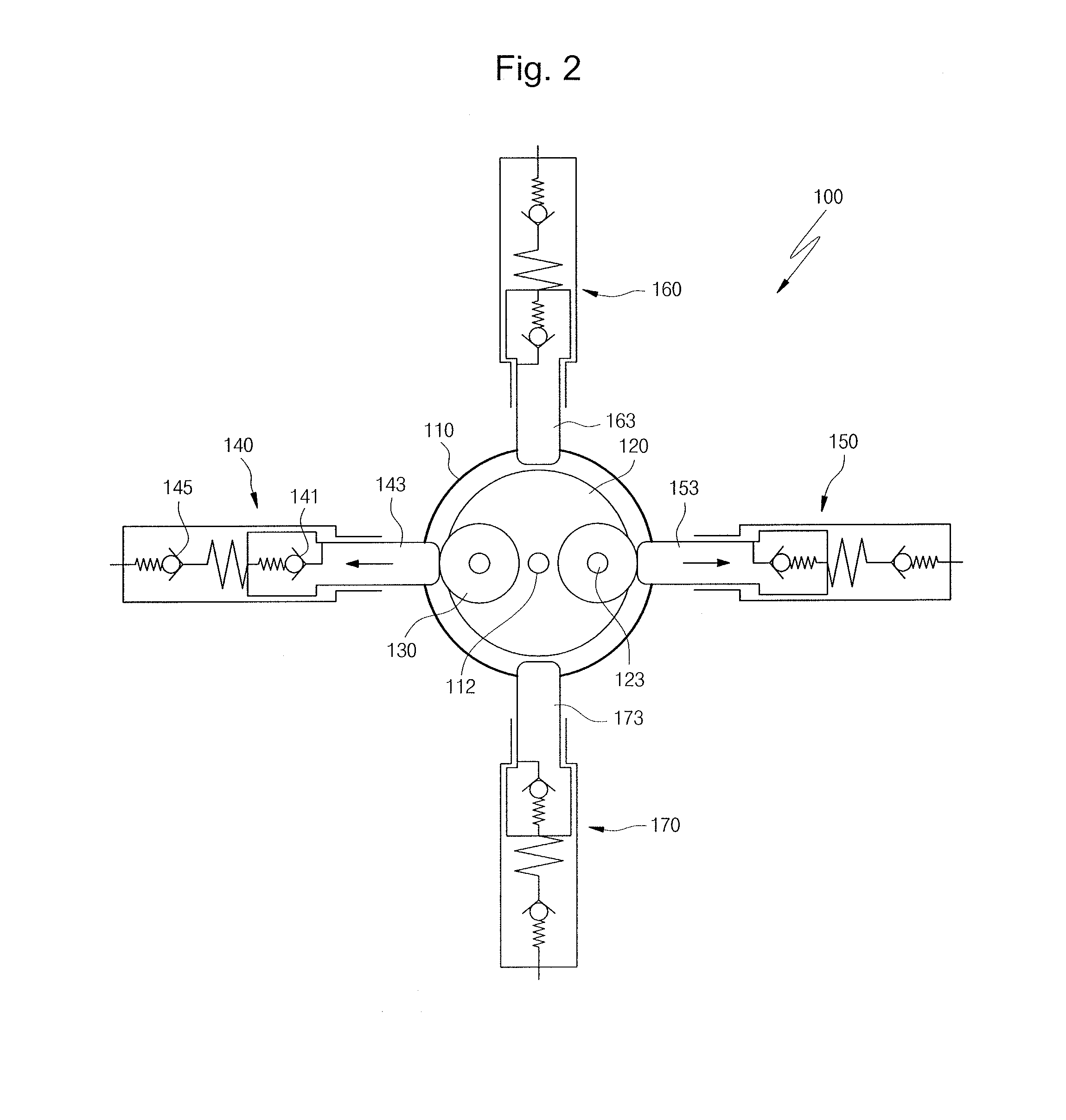

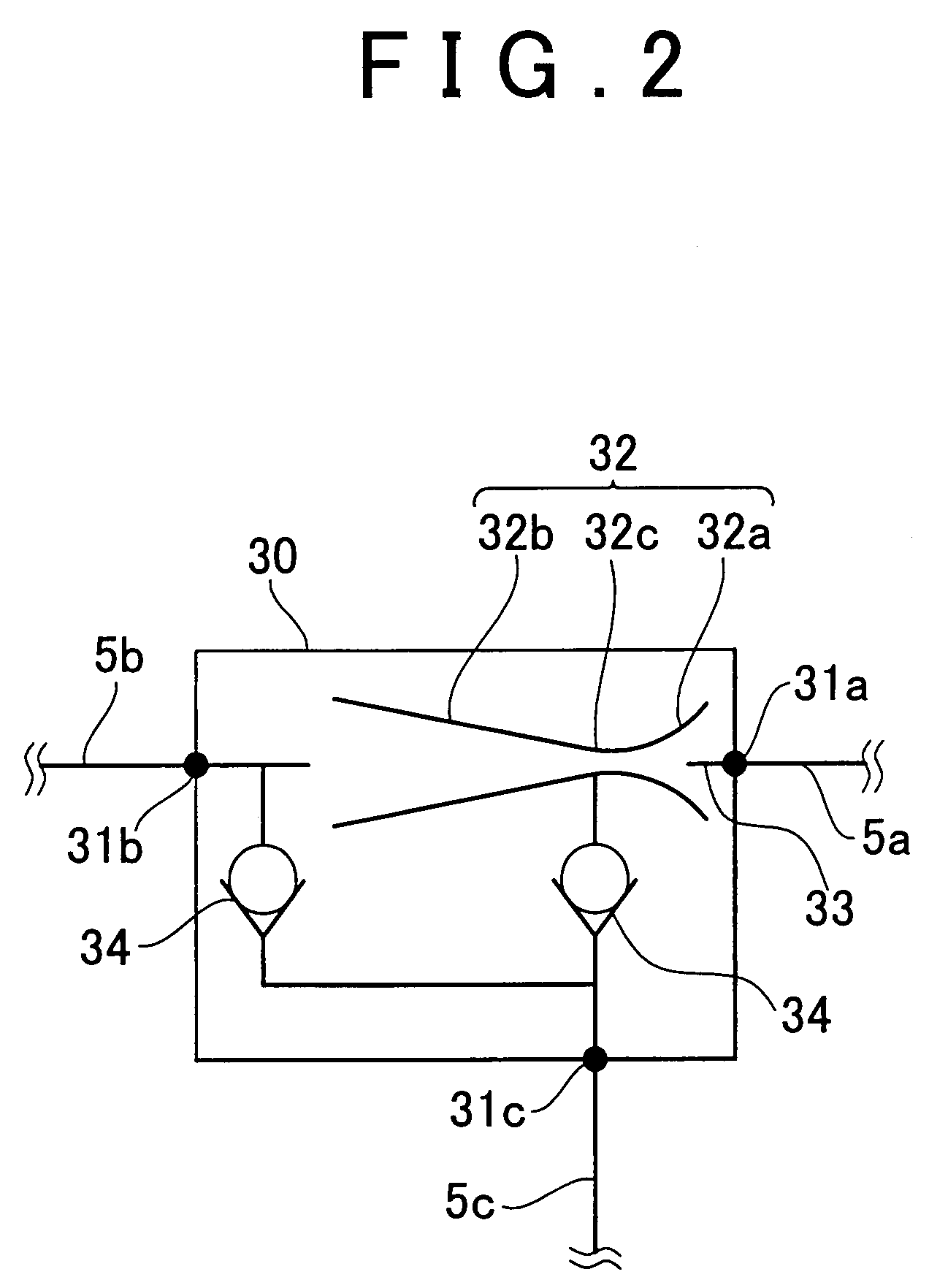

Ejector and negative pressure supply apparatus for brake booster using the ejector

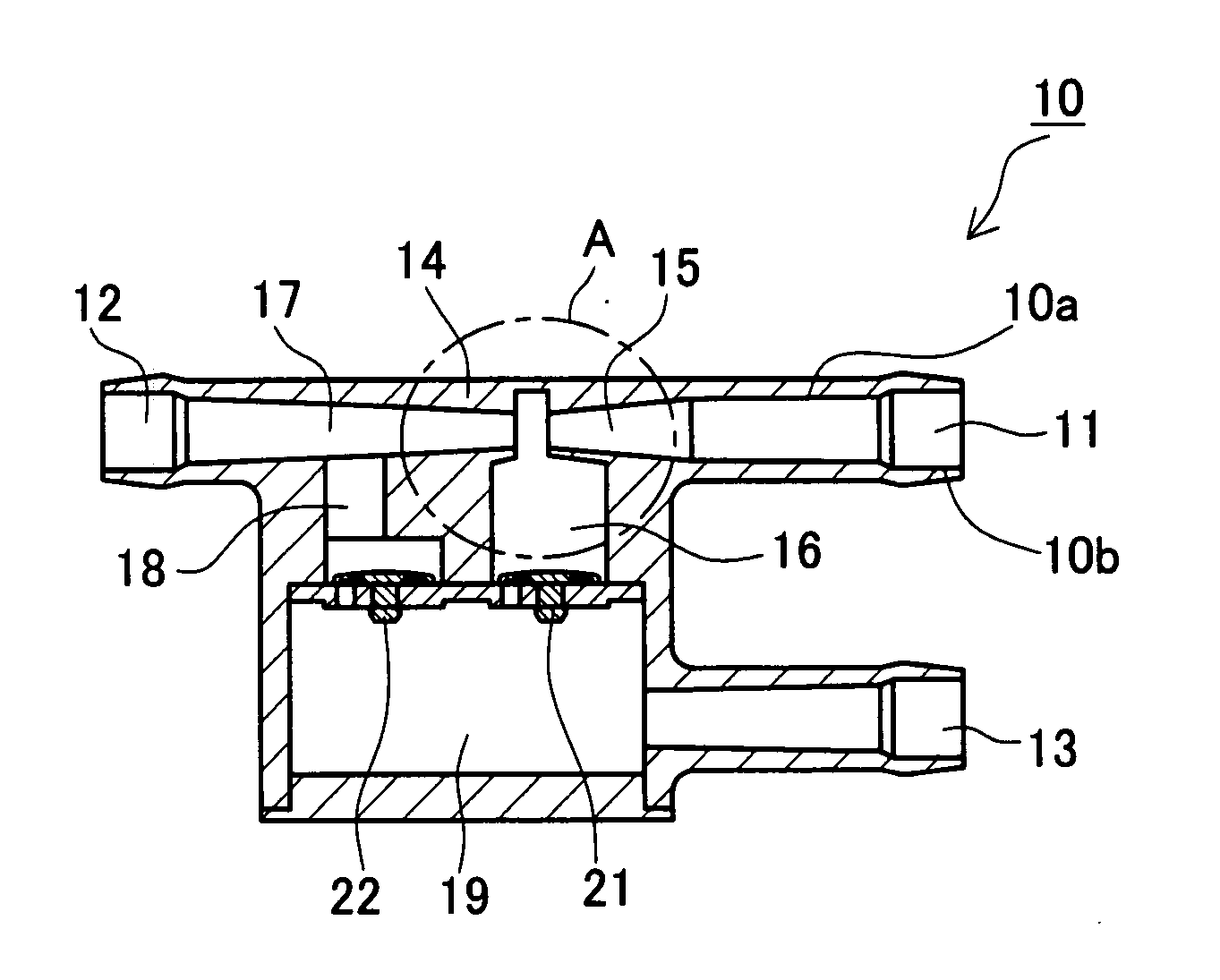

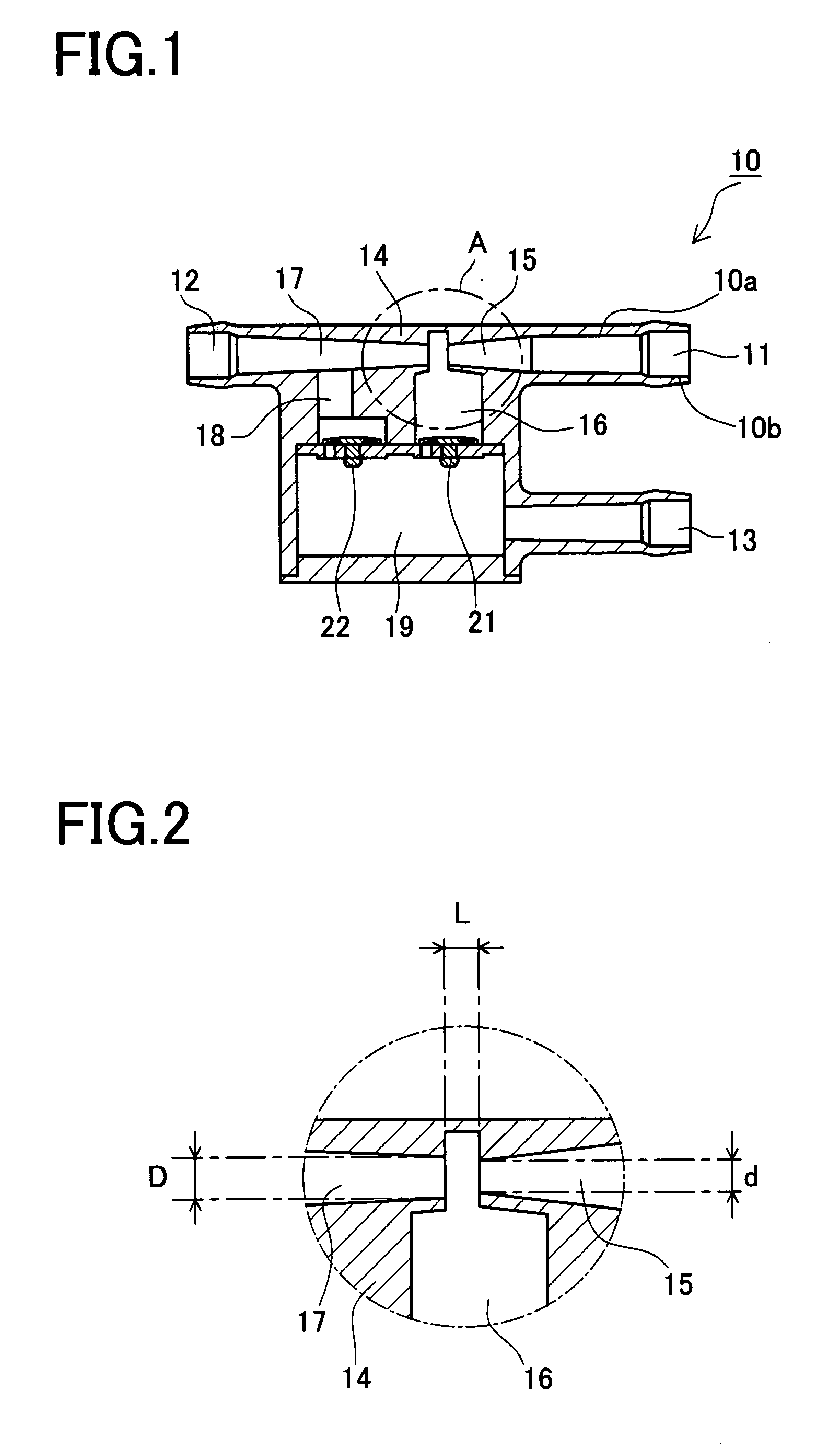

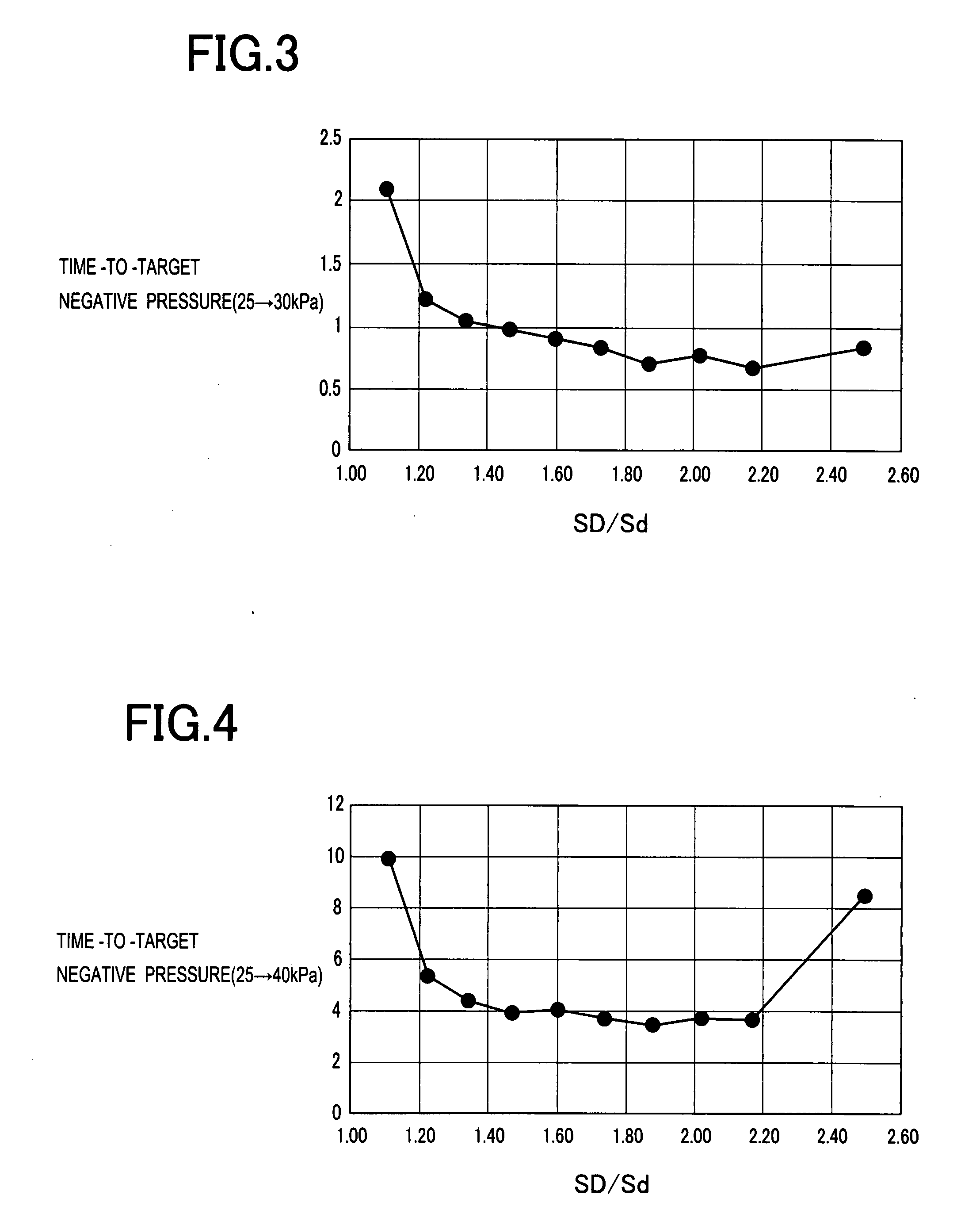

InactiveUS20080121480A1Short operating timeBraking action transmissionPump/compressor arrangementsDecompression chamberEngineering

An ejector including a nozzle communicating with a fluid inlet, a diffuser communicating with a fluid outlet, and a decompression chamber placed between the nozzle and he diffuser. The ejector is arranged to generate a negative pressure in the decompression chamber by a fluid ejected from the nozzle. A target negative pressure P in the decompression chamber is set in a range of “40 kPa<P≦50 kPa”. A SD / Sd ratio between a sectional area SD of an inlet of the diffuser and a sectional area Sd of an outlet of the nozzle is determined to meet a relation:“1.20≦SD / Sd≦4.08−0.047P”.

Owner:AISAN IND CO LTD

Pump unit of electronic control brake system

InactiveUS20150030483A1Reduce vibrationReduce noiseHydrostatic brakesBraking action transmissionRotational axisReciprocating motion

Disclosed is a pump unit of an electronic control brake system installed in a bore formed in a modulator block, the pump unit including a motor having a rotating shaft, a carrier having a center portion thereof installed on the rotating shaft, and provided with connecting shafts that are spaced apart from the center portion to both sides by a predetermined interval to be disposed in line with each other, a pressing member installed on each of the connecting shafts, and a first piston pump and a second piston pump each provided with a piston configured to be reciprocated by making contact with an outer circumferential surface of the pressing member according to rotation of the carrier, the first piston pump and the second piston pump disposed in line with each other.

Owner:HL MANDO CORP

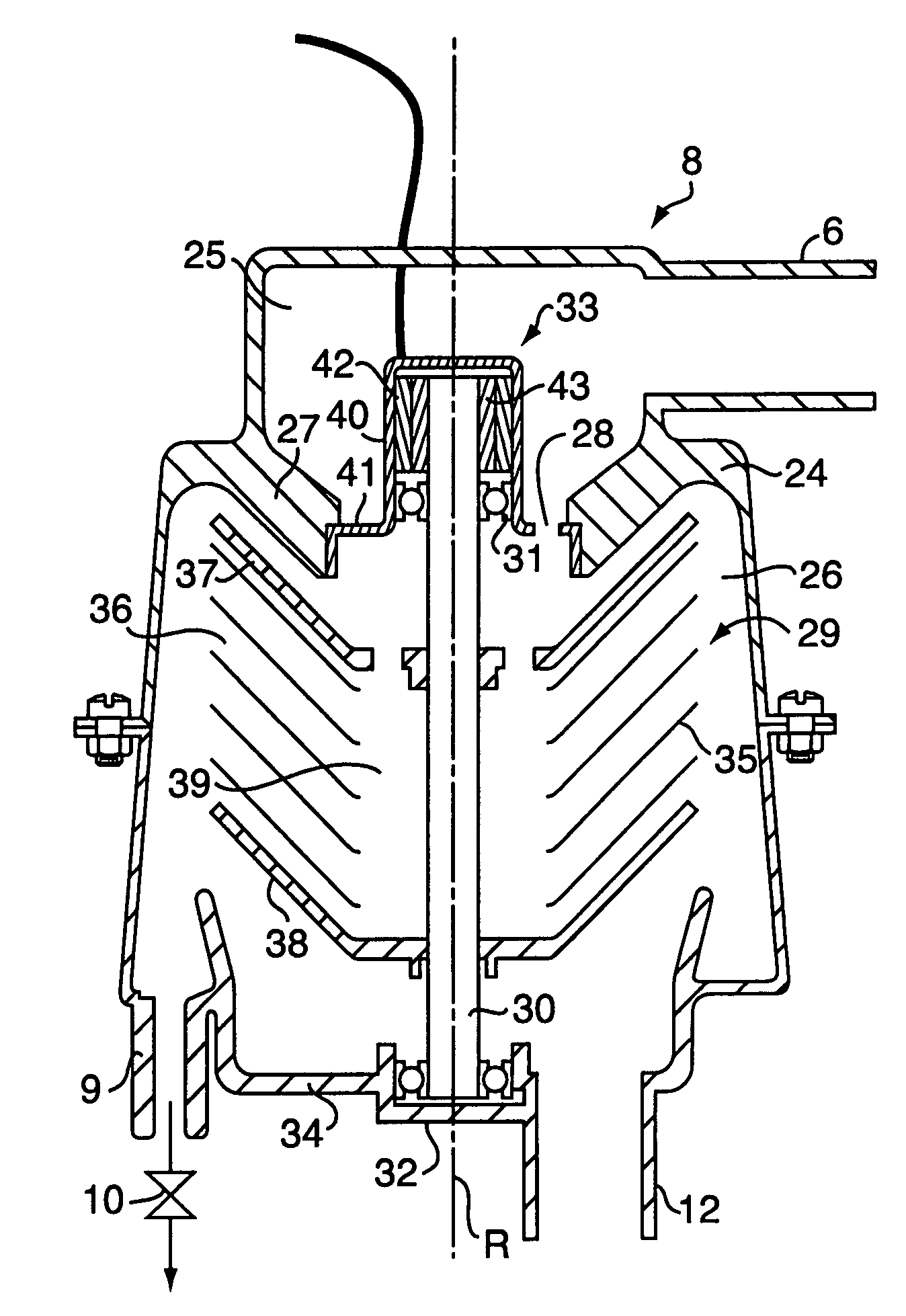

Method of treating air on board on a vehicle, and a device for use when performing the method

InactiveUS7022163B2Compact structureReduce manufacturing costHuman health protectionCombination devicesOn boardSolid particle

In a vehicle air is compressed for being used in the brake system of the vehicle, for instance. In the compressor, used for the compression, the air is contaminated with oil and solid particles. In order to be relieved from these particles, before the air is conveyed through a drying filter, the compressed is brought to rotation by means of a rotating member in a centrifugal separator. The rotating member may advantageously include a pile of conical separation discs forming flow passages between each other for the compressed air to be cleaned. By means of an efficient cleaning of the compressed air from particles the life time of the drying filter may be increased.

Owner:ALFA LAVAL CORP AB +1

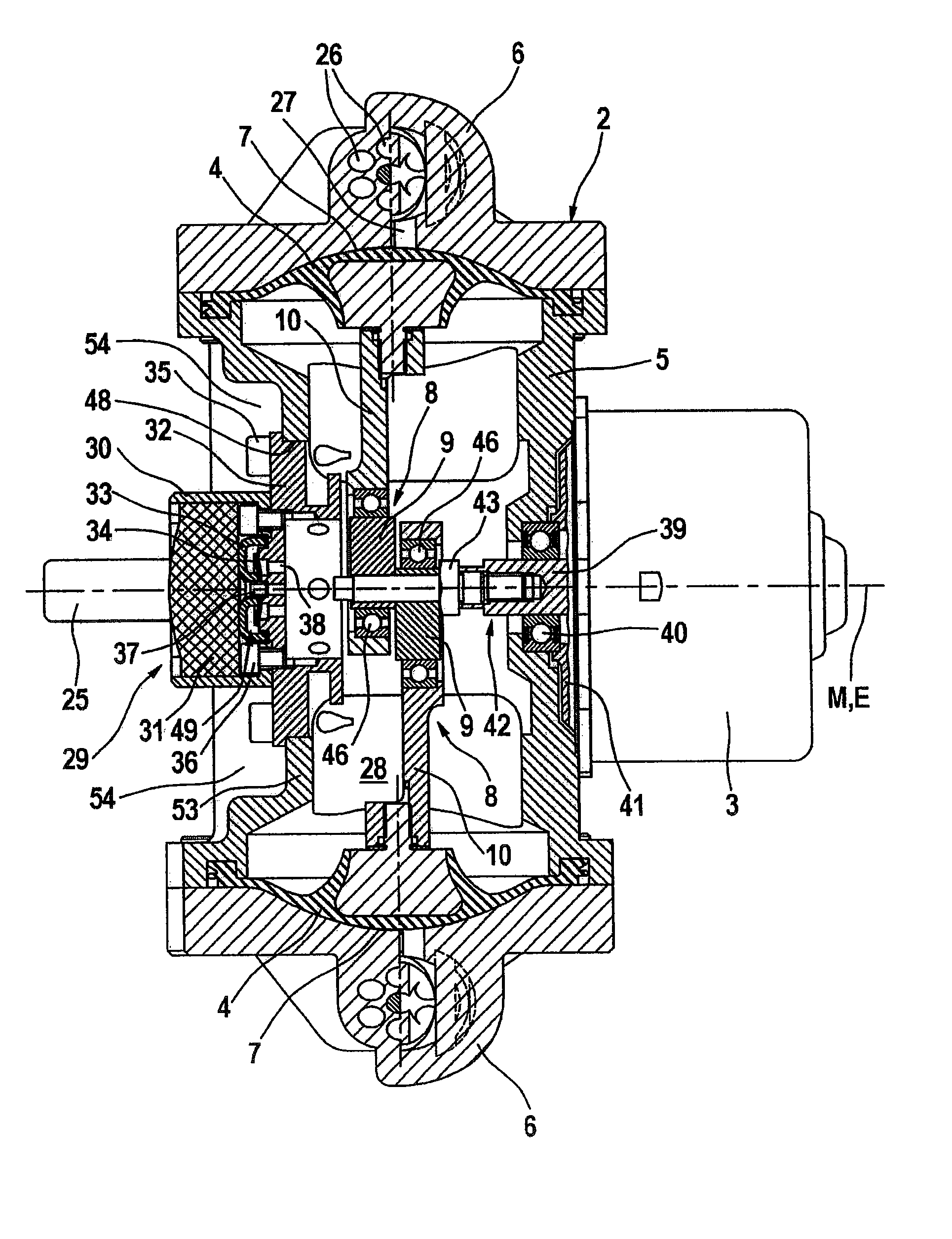

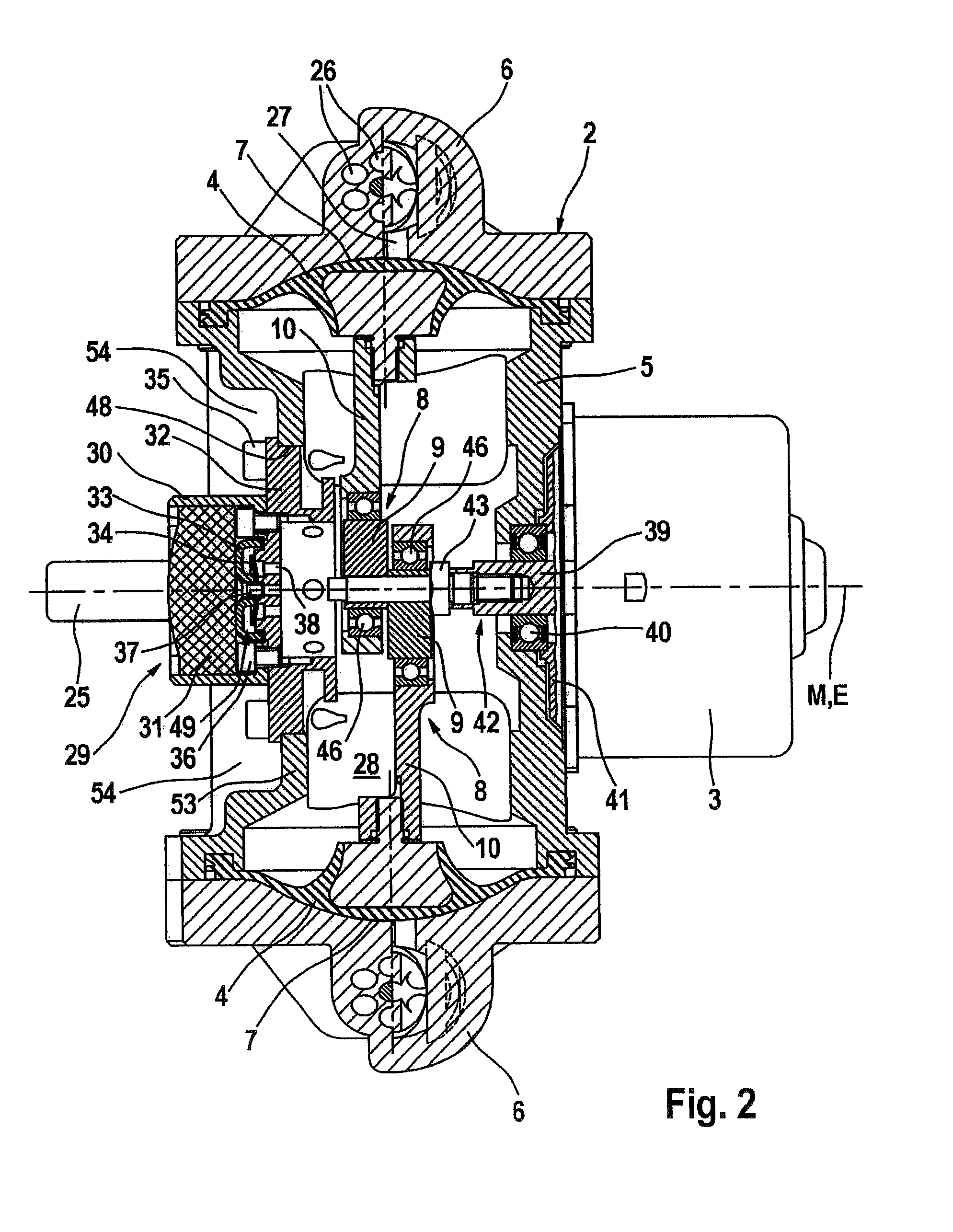

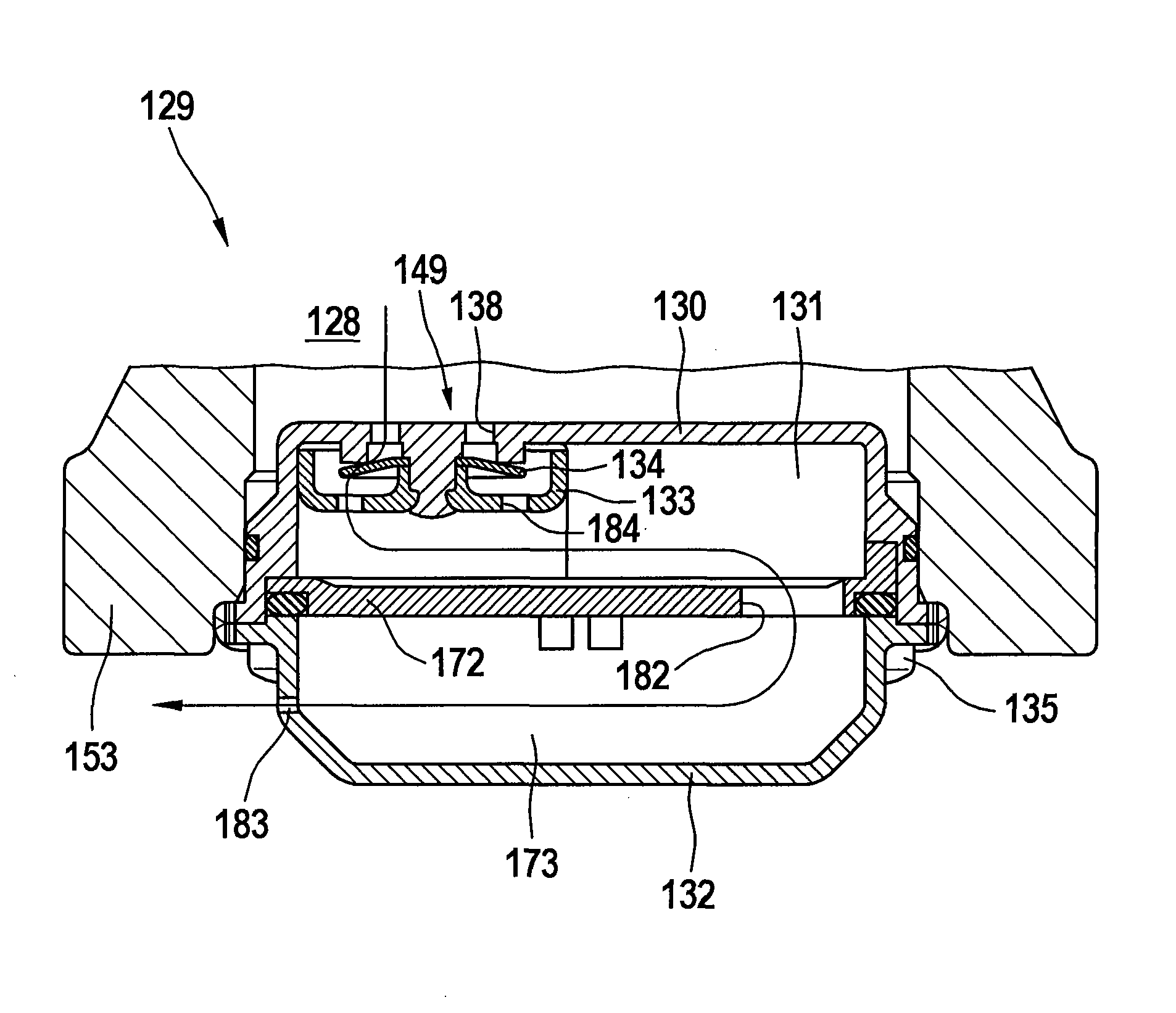

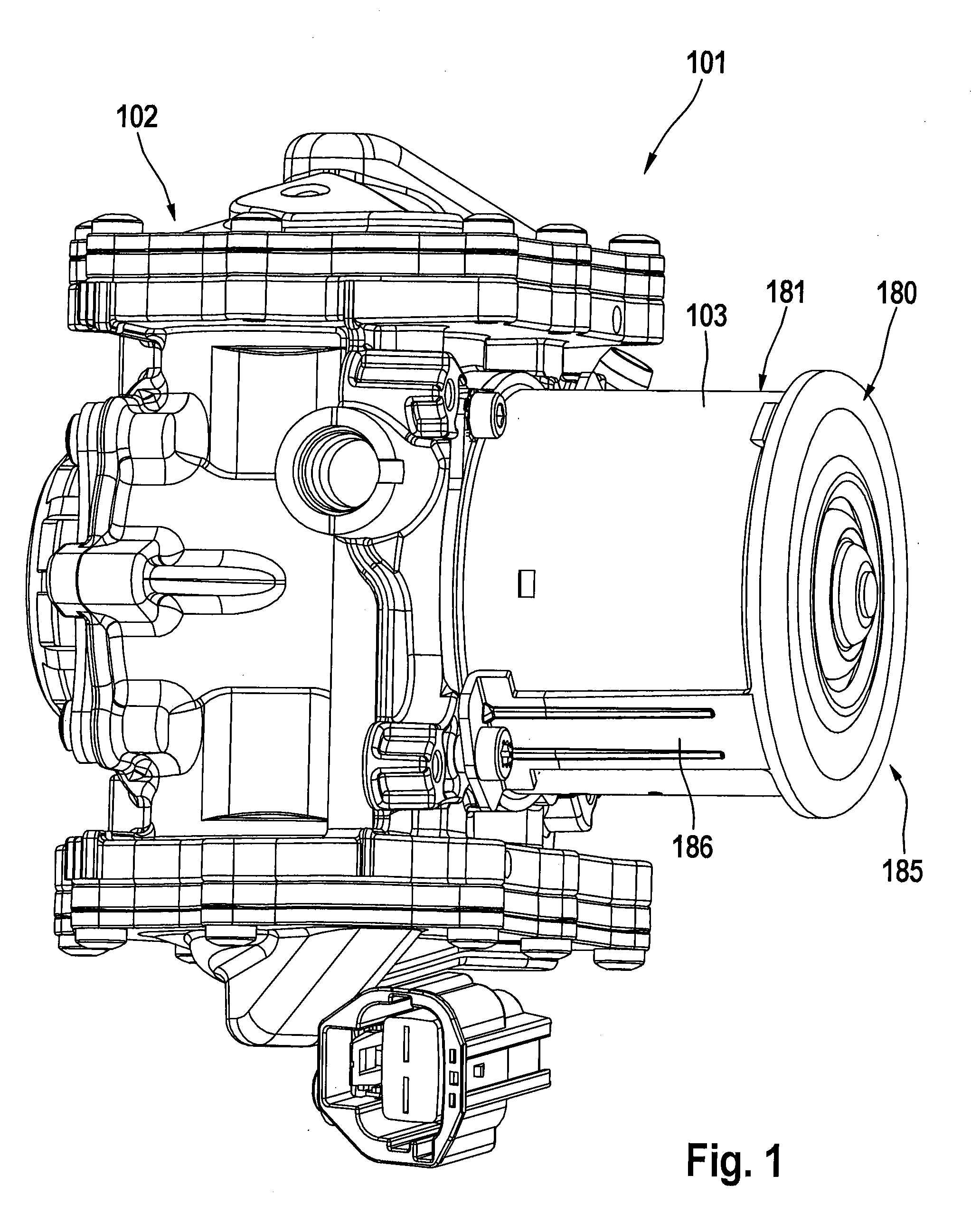

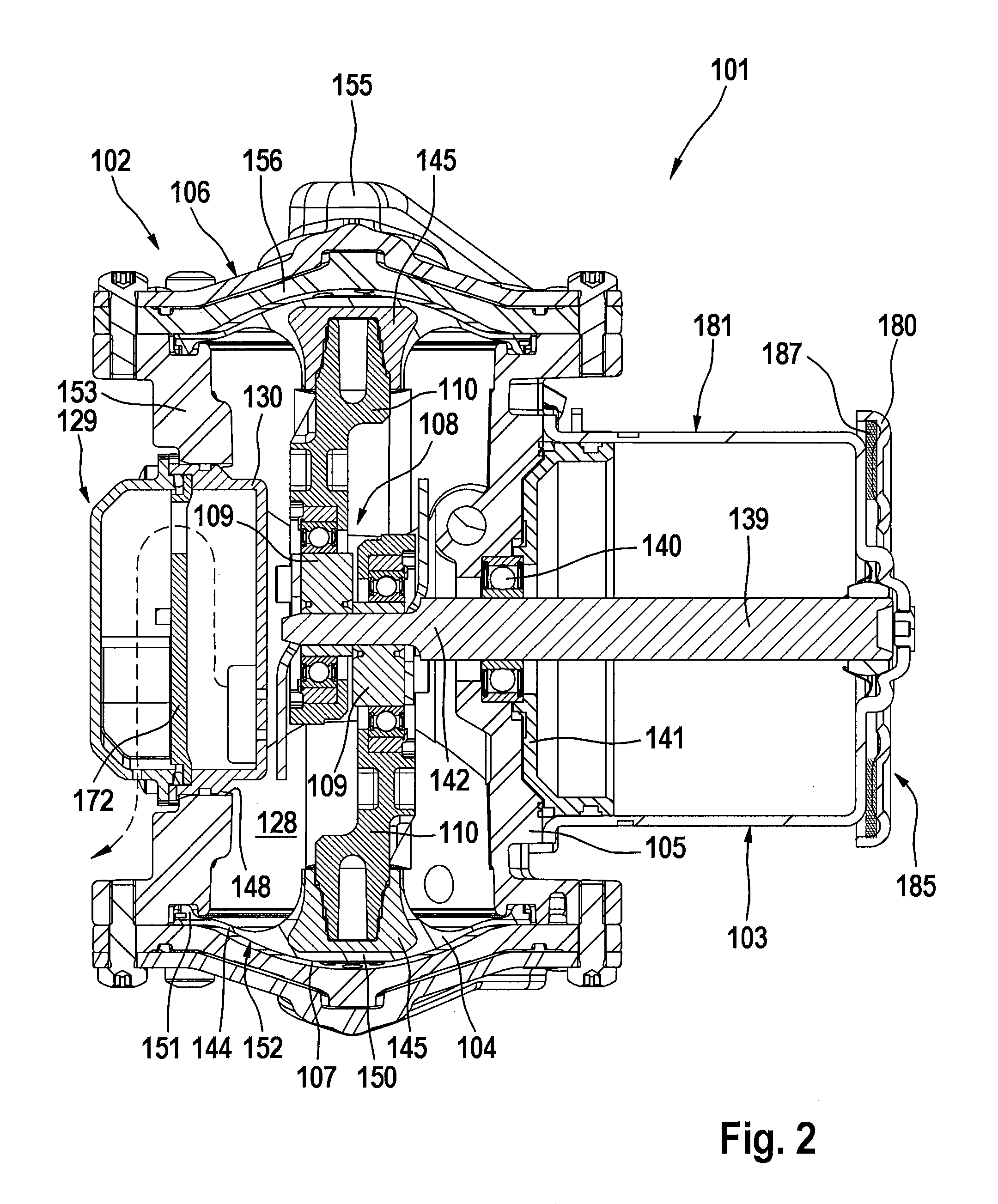

Motor/Pump Assembly

InactiveUS20100045096A1Avoid developmentReduce noisePositive displacement pump componentsBraking action transmissionInterior spaceDiaphragm pump

A motor and pump assembly for providing pressure to a brake actuating device of a motor vehicle brake system is described herein. The assembly comprises an electric motor and a double diaphragm pump. The pump includes a pump housing, two opposed working diaphragms, and crank drives each being coupled between the electric motor and a respective diaphragm for moving the diaphragm. A working chamber is defined between the pump housing and a working chamber cover. Each working chamber including an inlet channel, an inlet valve associated with the inlet channel, an outlet channel, and an outlet valve associated with the outlet channel, wherein the outlet channels are defined in the covers of the working chamber and in the pump housing to direct air displaced from the working chambers into an inside space of the pump housing. An air outlet unit is provided for exhausting the air from the inside space.

Owner:CONTINENTAL TEVES AG & CO OHG

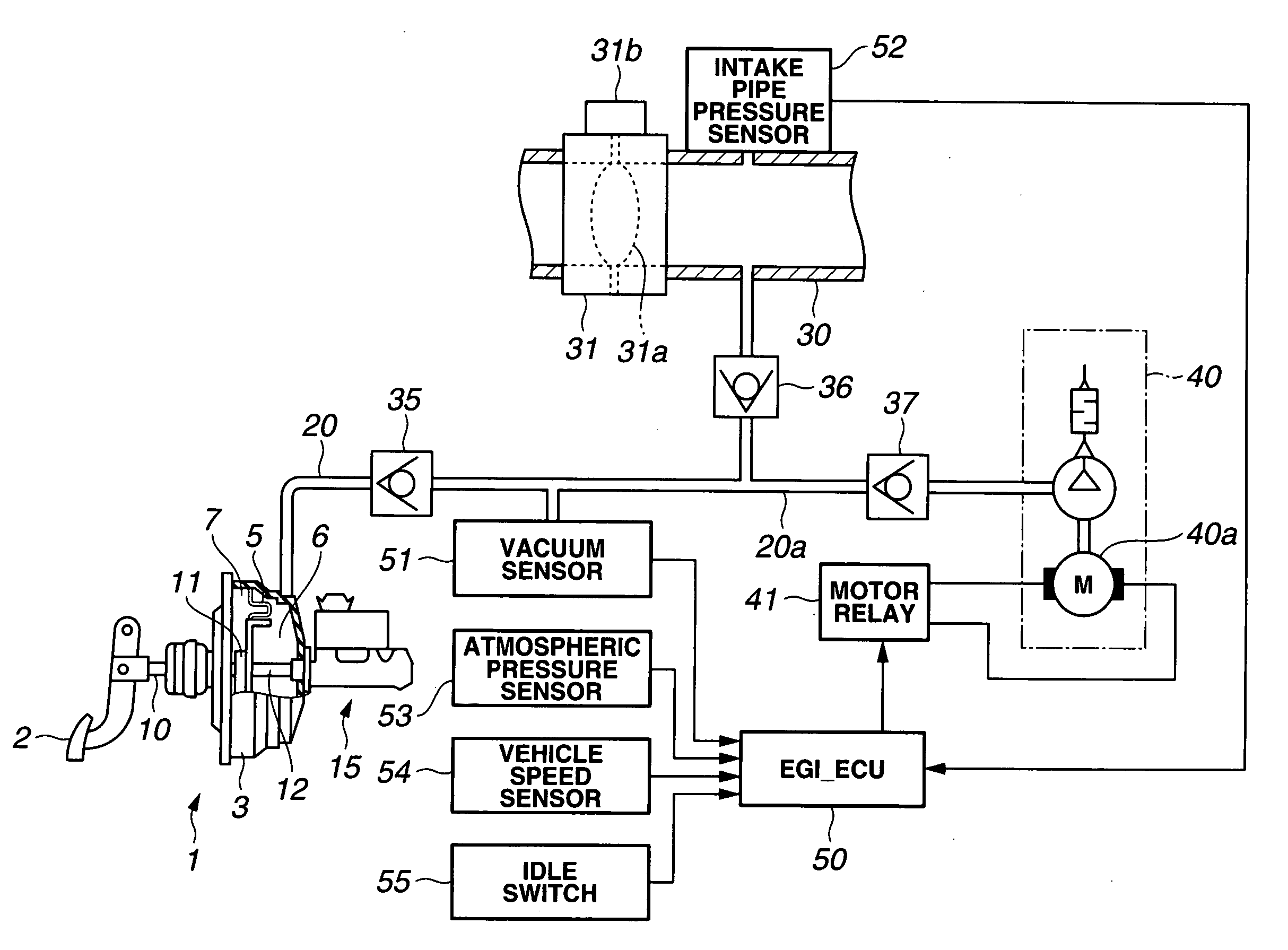

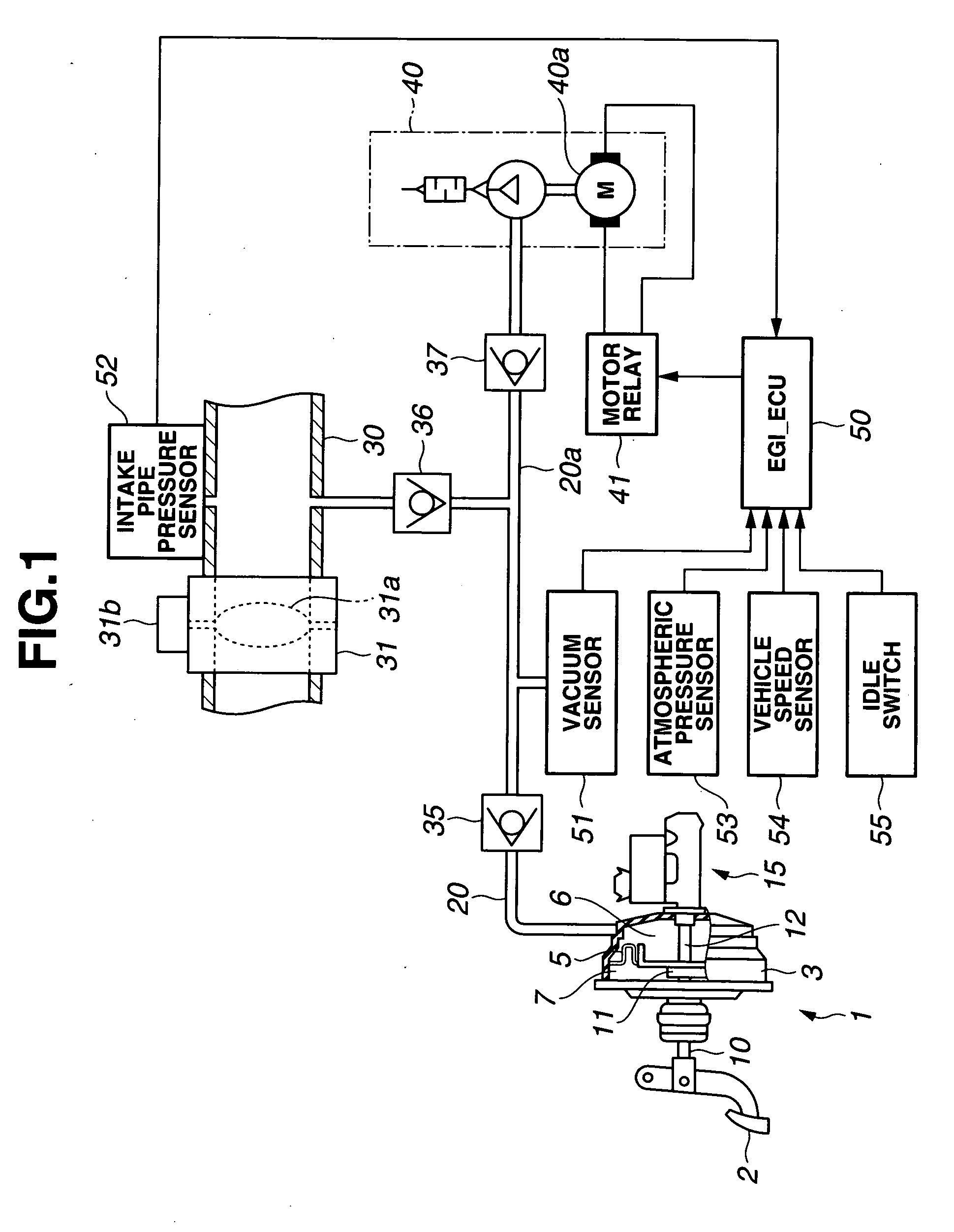

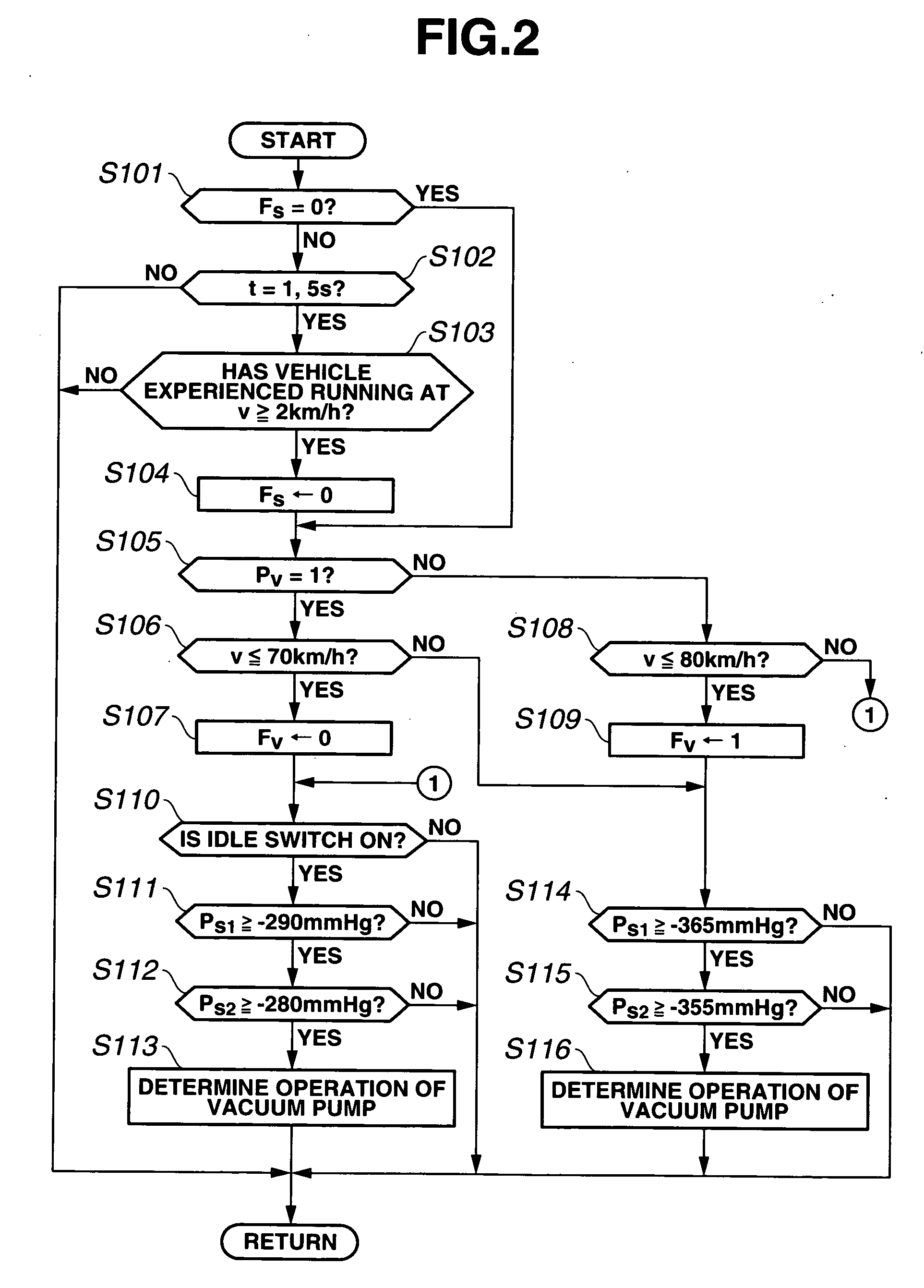

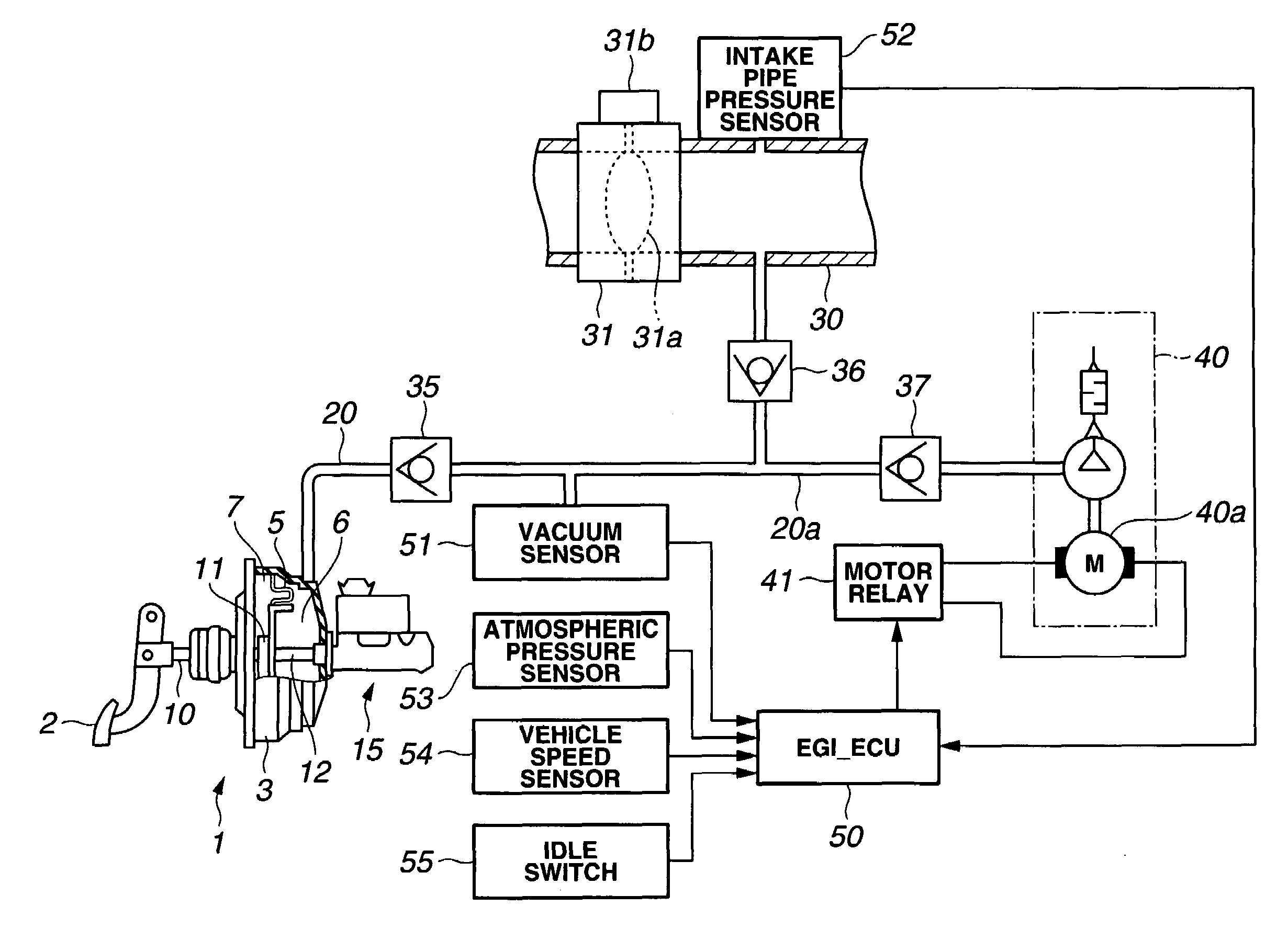

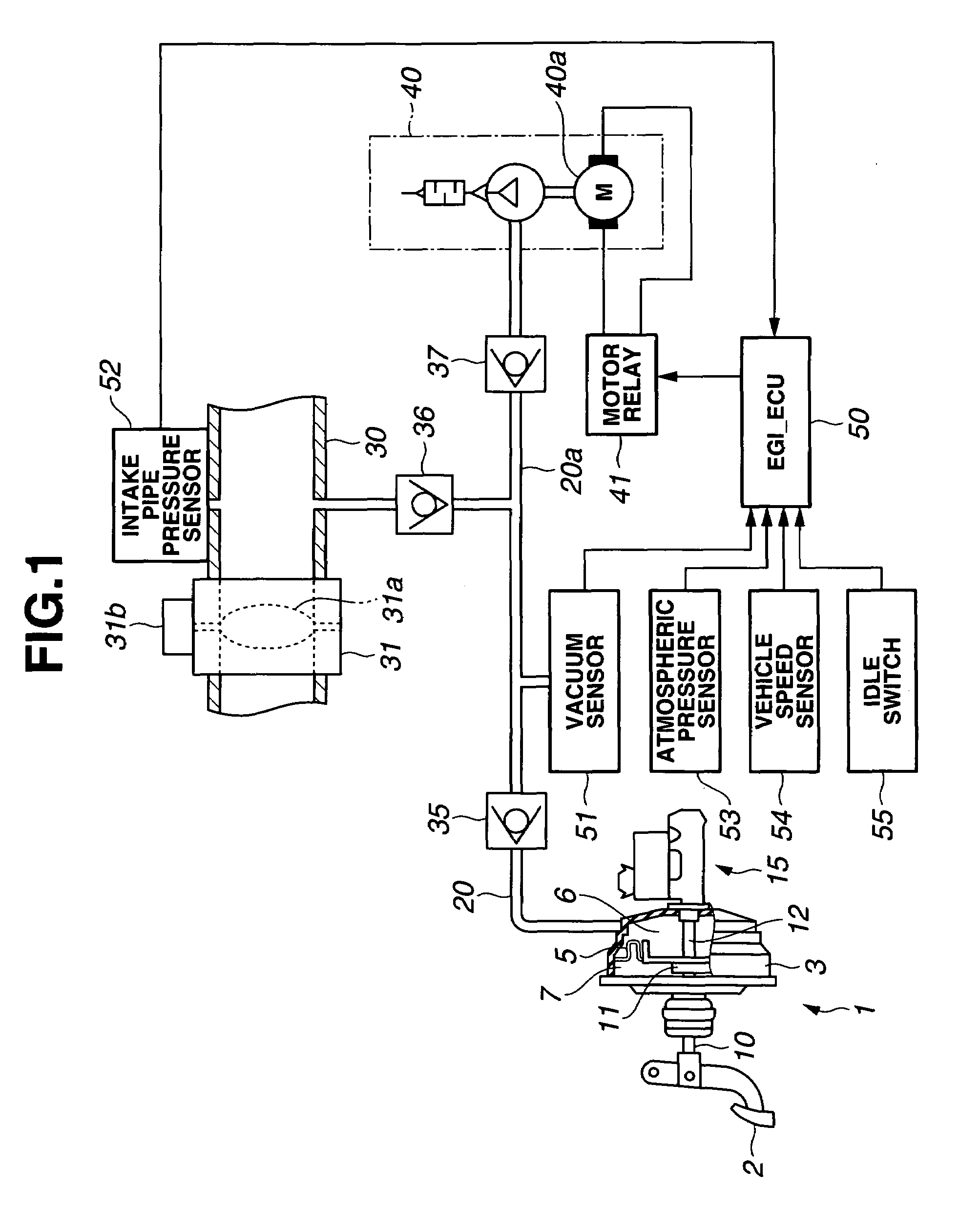

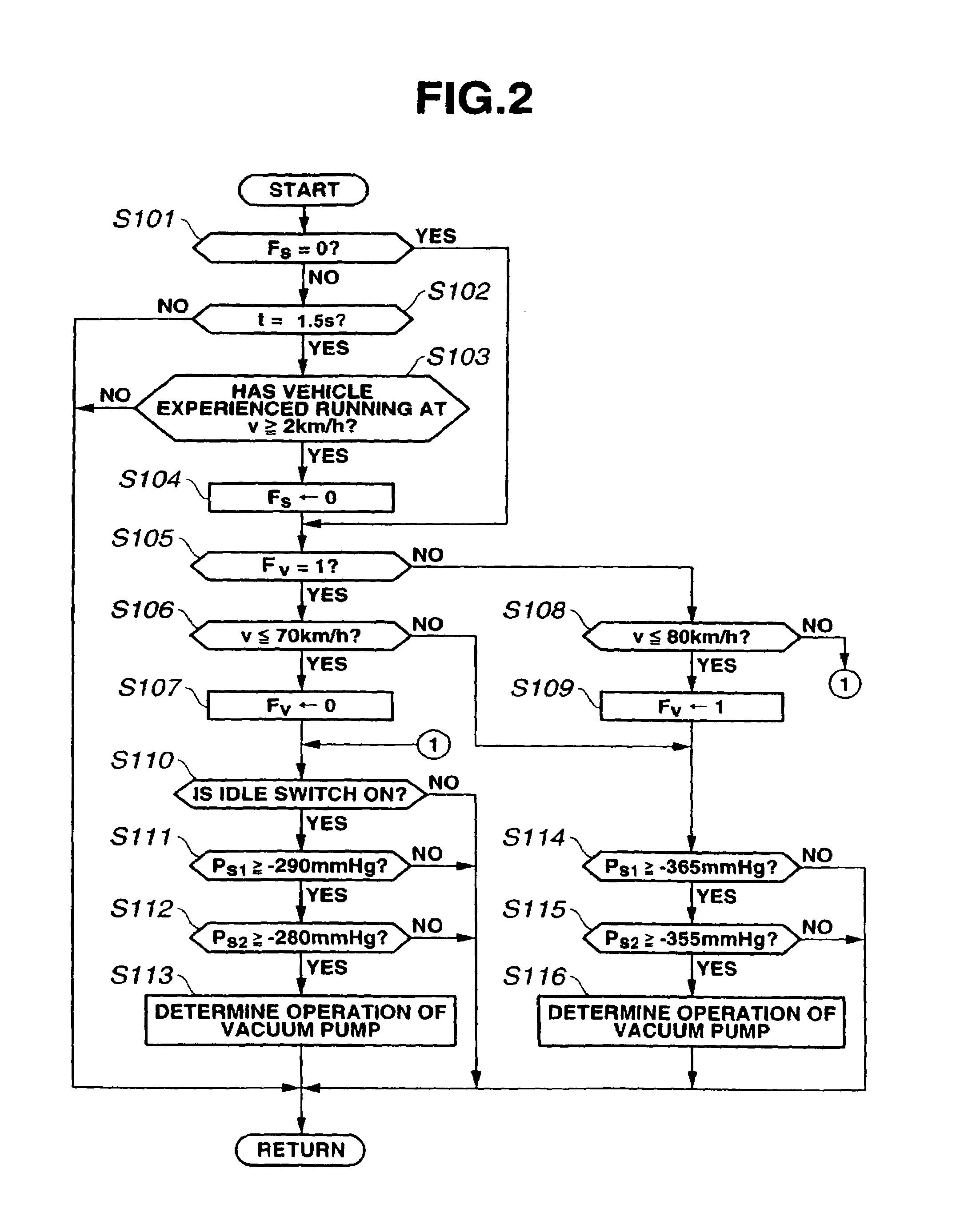

Control system for brake vacuum pump

A control system for a brake vacuum pump, the system being capable of accumulating a negative pressure required for a vacuum chamber, without excessively operating the vacuum pump. In this system, an EGI_ECU determines whether a vehicle has experienced running at a speed equal to or higher than a preset creep vehicle speed after the startup of an engine. The EGI_ECU prohibits the operation of the vacuum pump until the time when the vehicle experiences running at a speed equal to or higher than the creep vehicle speed. Thereby, in a situation obviously not requiring a strong braking force, such as in a stopped state immediately after the startup of the engine, the operation of the vacuum pump can be prohibited, which allows the vacuum pump to be accurately prevented from an unnecessary drive.

Owner:SUBARU CORP

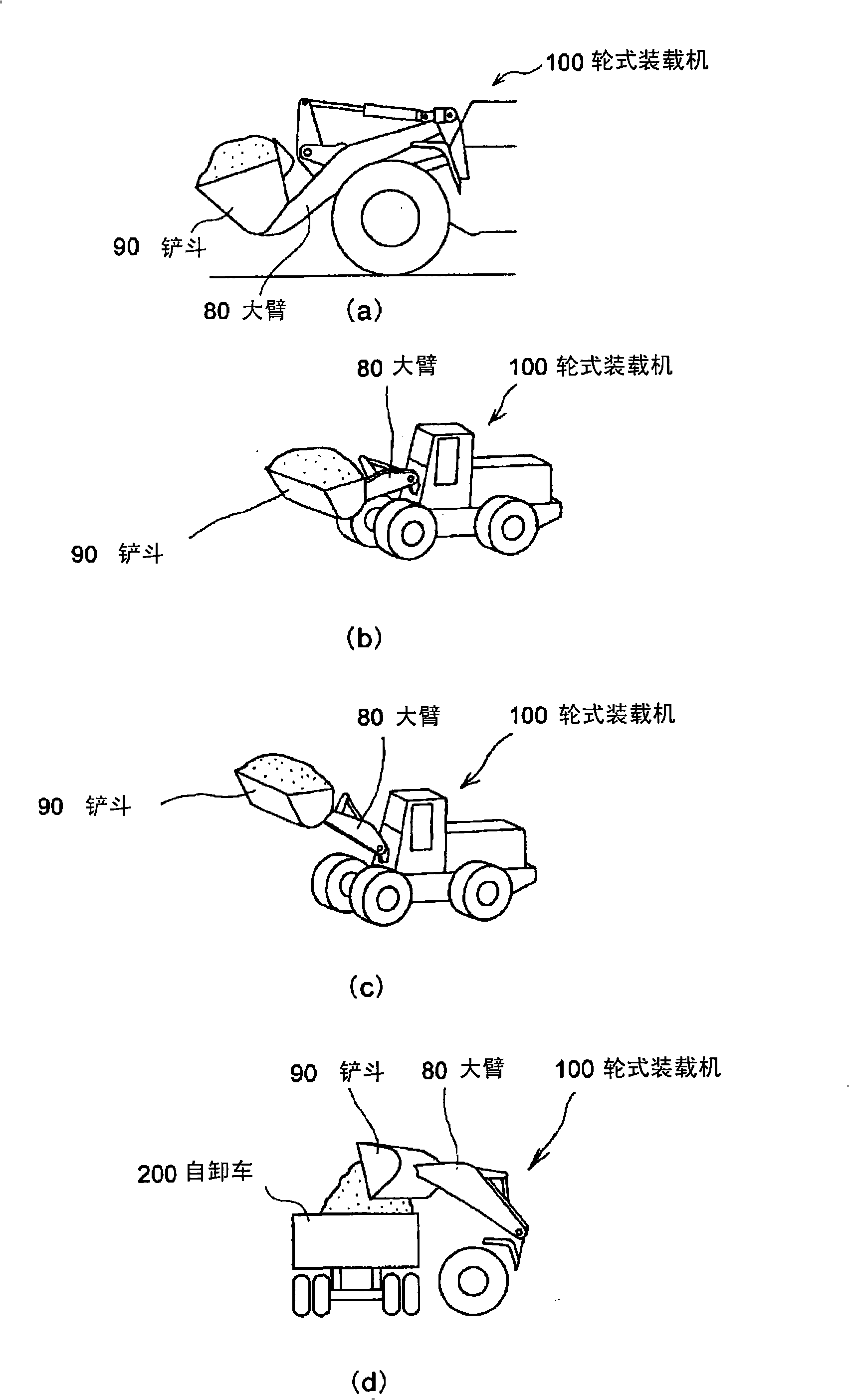

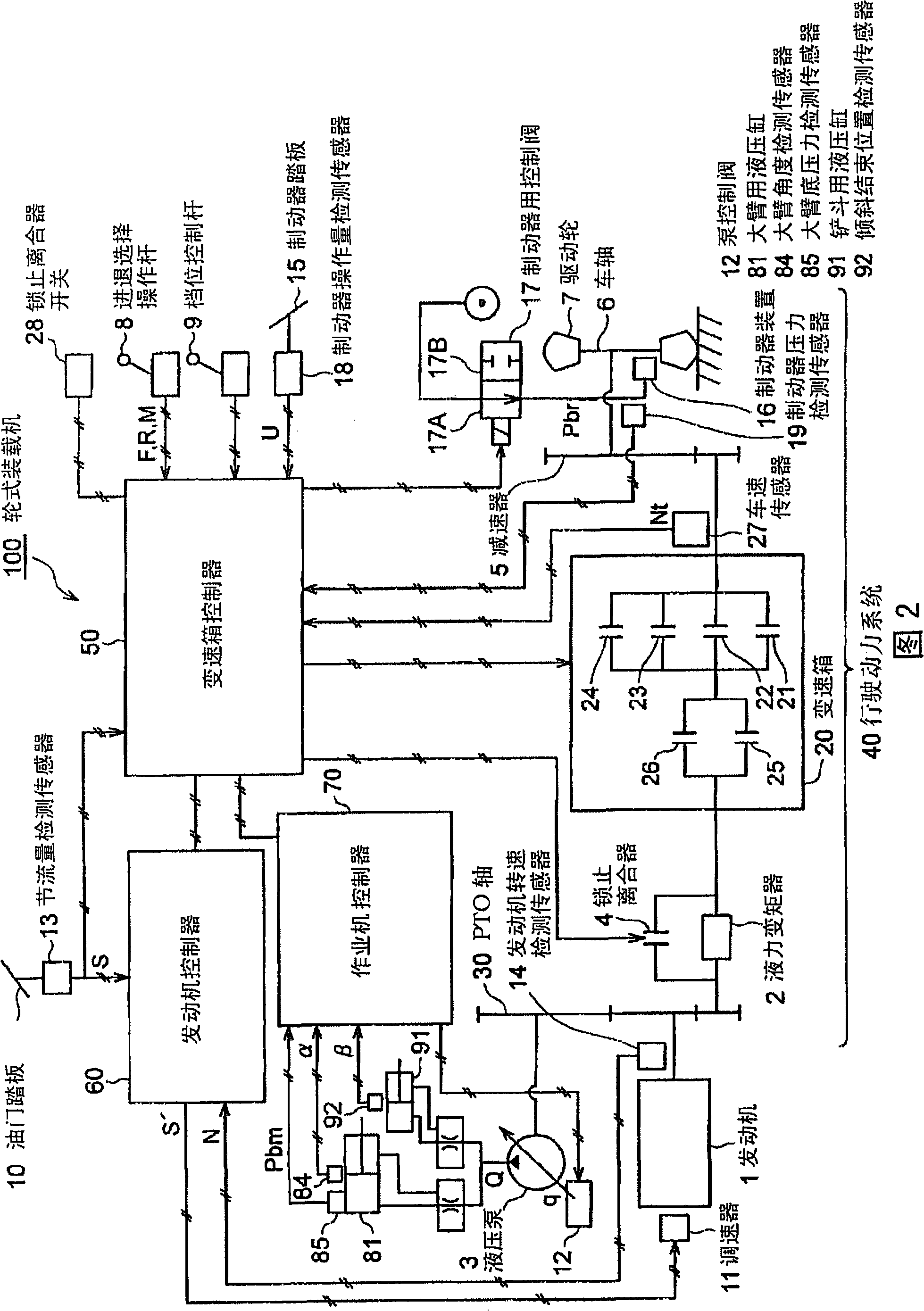

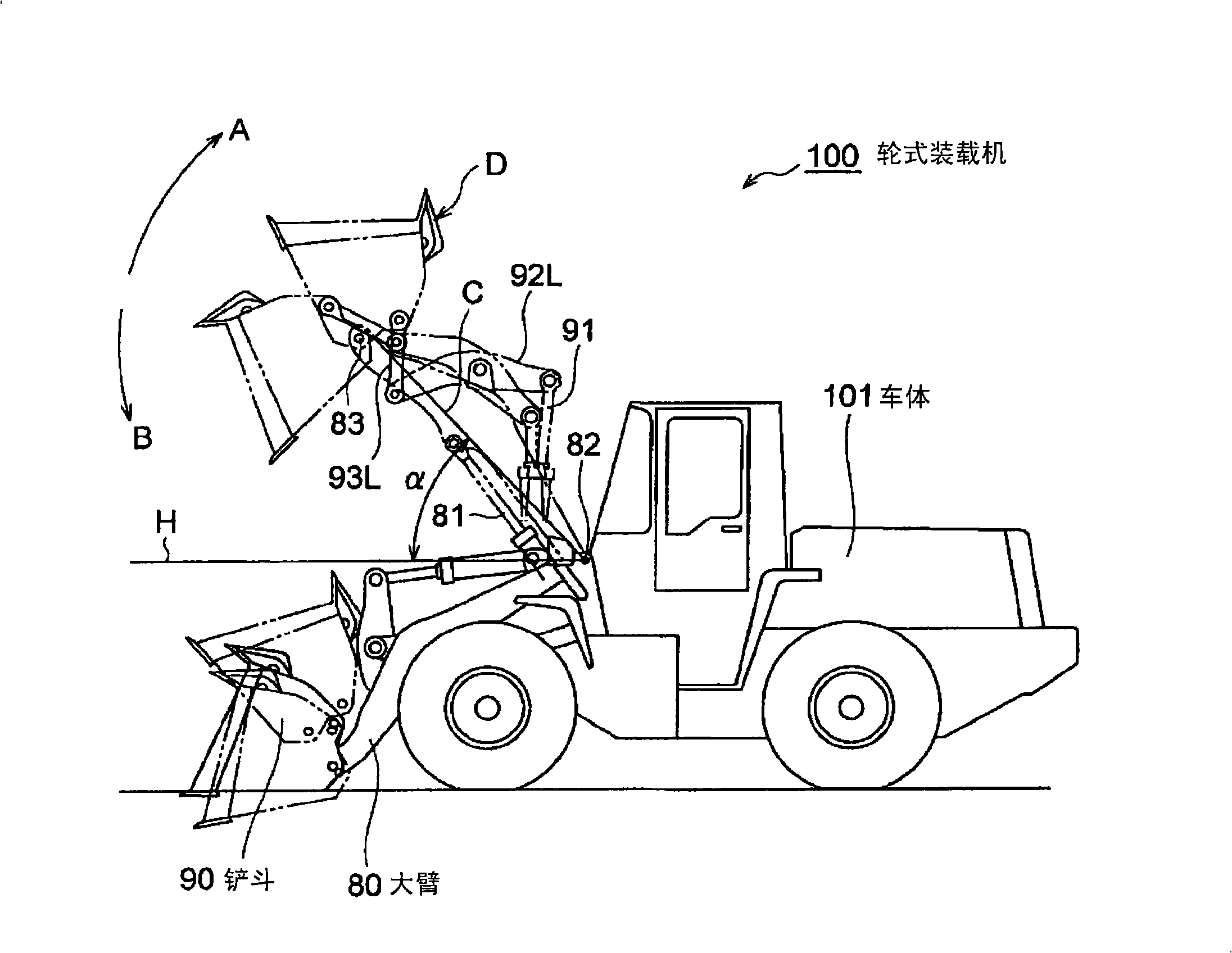

Engine of working truck, hydraulic pump controller and method for controlling hydraulic pump

InactiveCN101287876AReduce heatReduce loadSoil-shifting machines/dredgersEngine controllersHydraulic pumpCam

An engine of a working truck in which adverse effect of oil temperature rise is avoided, by lessening the load applied to an accelerator when the working truck is traveling while elevating the boom and approaching a place for discharging the load in the bucket during dump approach and, reducing heat generated through operation of a brake, and deterioration in work efficiency of the working truck is avoided by preventing the elevating speed of a boom from decreasing. A hydraulic pump controller and a method for controlling the hydraulic pump are also provided. On condition that a throttle amount sensor detects the operating amount of an acceleration pedal reaching a prescribed threshold value (operation amount 70%), a brake pressure sensor detects operation (brake on) of a brake, and a vehicle speed sensor detects the body speed reaching a prescribed threshold value, a transmission controller delivers a throttle correction command signal for reducing the target engine speed to a governor through an engine controller, and delivers a boom elevating time cam plate inclination angle alteration command for sustaining delivery flow rate of the hydraulic pump by supplementing reduction in delivery flow rate of the hydraulic pump by a throttle correction command to a pump control valve through a working machine controller.

Owner:KOMATSU LTD

Vehicular ejector system and control method thereof

InactiveUS7610140B2Reduce vehicle costReduce adverse effectsElectrical controlDigital data processing detailsInlet manifoldThrottle

A vehicular ejector system having an ejector that generates a negative pressure that is greater than the intake manifold negative pressure that is to be extracted from an intake manifold, a VSV that causes the ejector to function or stop functioning, and an ECU that controls the VSV. The ECU includes a control device that controls the VSV so as to cause the ejector to function if an ISC request amount for controlling, during idling, a throttle valve that adjusts the intake air flow amount supplied to the internal combustion engine is greater than a predetermined amount.

Owner:TOYOTA JIDOSHA KK

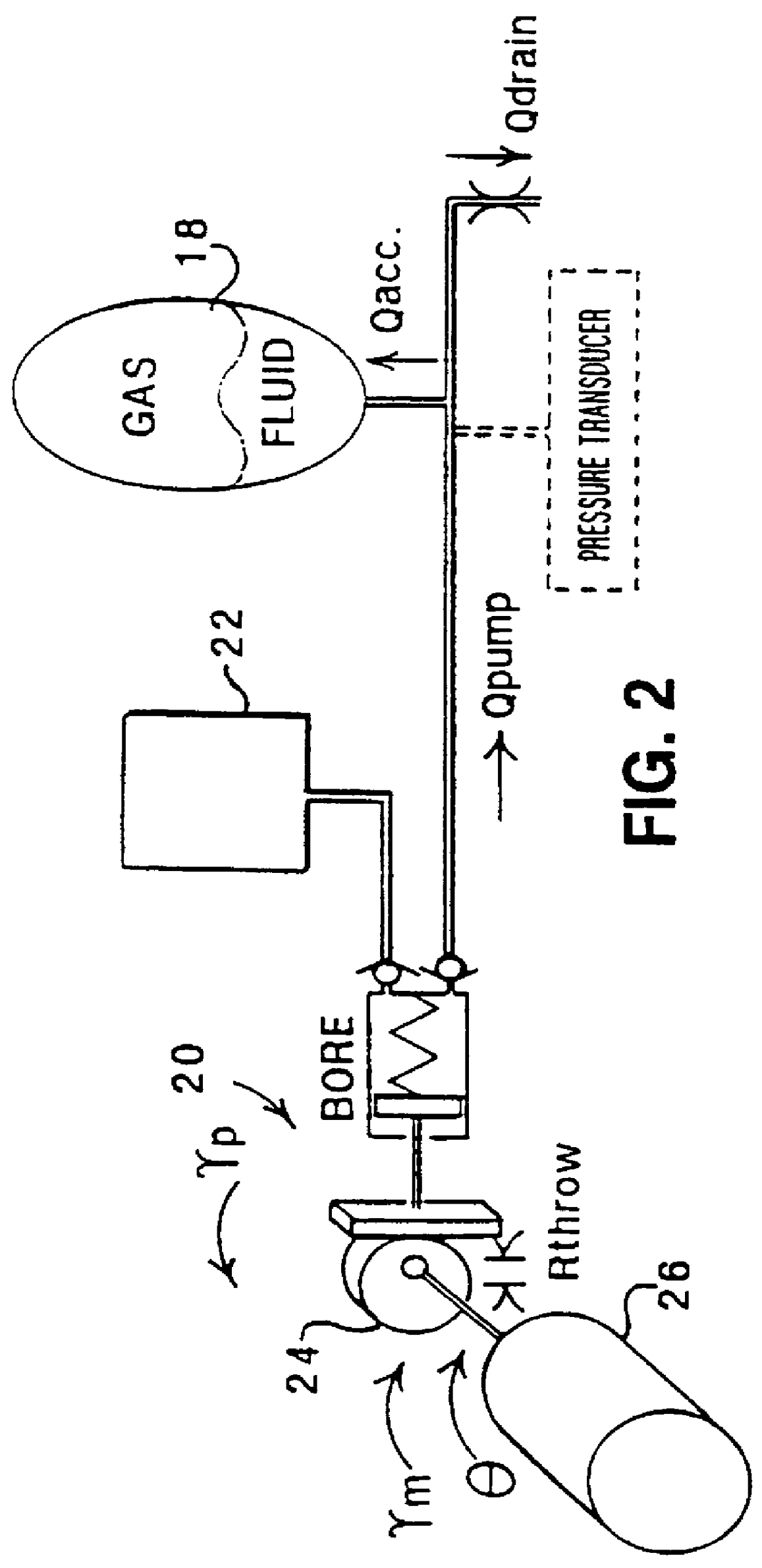

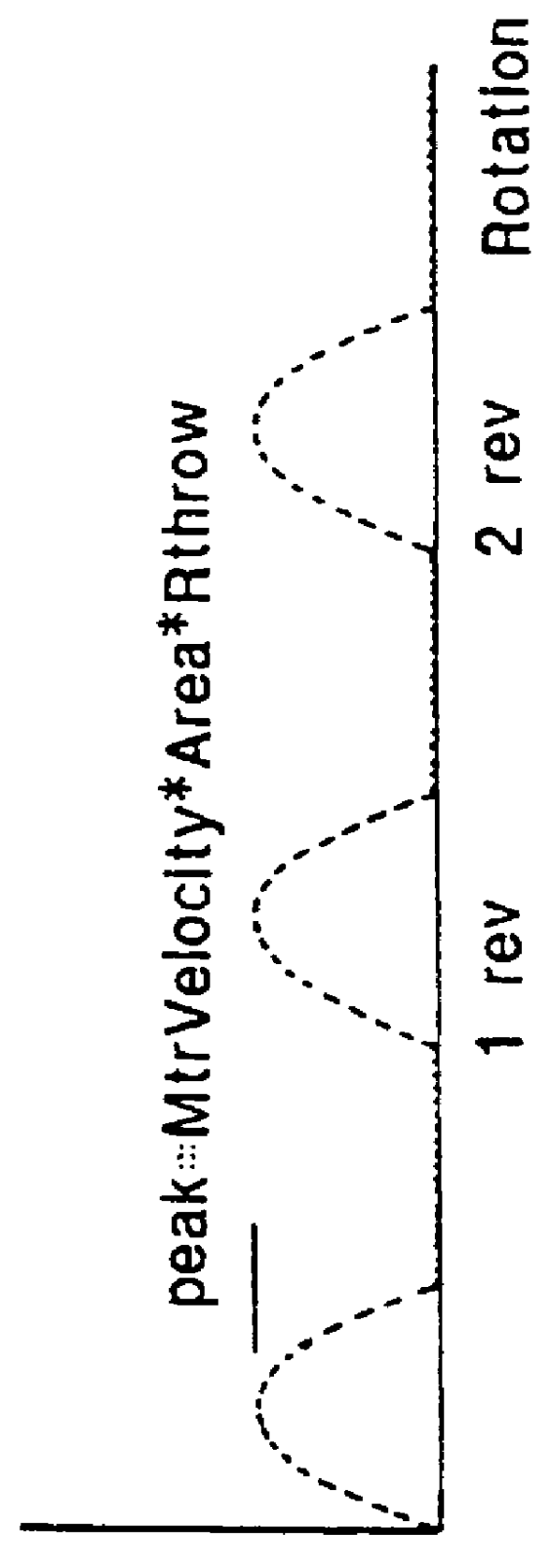

Accumulator pressure control in vehicle brake systems

PCT No. PCT / GB96 / 01731 Sec. 371 Date Apr. 17, 1998 Sec. 102(e) Date Apr. 17, 1998 PCT Filed Jul. 18, 1996 PCT Pub. No. WO97 / 05001 PCT Pub. Date Feb. 13, 1997A vehicle braking system in which a stored volume of working fluid is used by a brake control system to apply the brakes under the control of an electronic control unit. The stored volume is replenished by pumping additional working fluid using a pump driven by an electric motor. The electric motor is periodically energized. An inferred value is established for the accumulator pressure based on an assessment of the motor response during the periods of energization. The electric motor can be arranged to be energized for short periods at predetermined intervals and the motor response during these periods assessed. From this assessment, either the switch-on point for driving the pump motor for the purpose of recharging the stored volume of working fluid is determined from the level of motor torque applied during the short periods of energization, or, where the system includes a pressure sensor for detecting the working fluid pressure, a signal for corroborating the signal of the pressure sensor is established from the level of motor torque applied during the short periods of energization.

Owner:LUCAS IND PLC

Control apparatus and control method for negative pressure generating apparatus

InactiveUS20080267789A1Reduce stepsIncreased durabilityDigital data processing detailsCombustion-air/fuel-air treatmentInternal combustion engineInjector

A control apparatus for a negative pressure generating apparatus, includes an ejector that generates a negative pressure whose magnitude is larger than that of a negative pressure to be taken from an intake passage in an intake system for an internal combustion engine provided in a vehicle; a state change device that makes the ejector function or stop functioning; and a prohibition control device that prohibits the state change device from making the ejector function, when the vehicle is transiently decelerated.

Owner:TOYOTA JIDOSHA KK

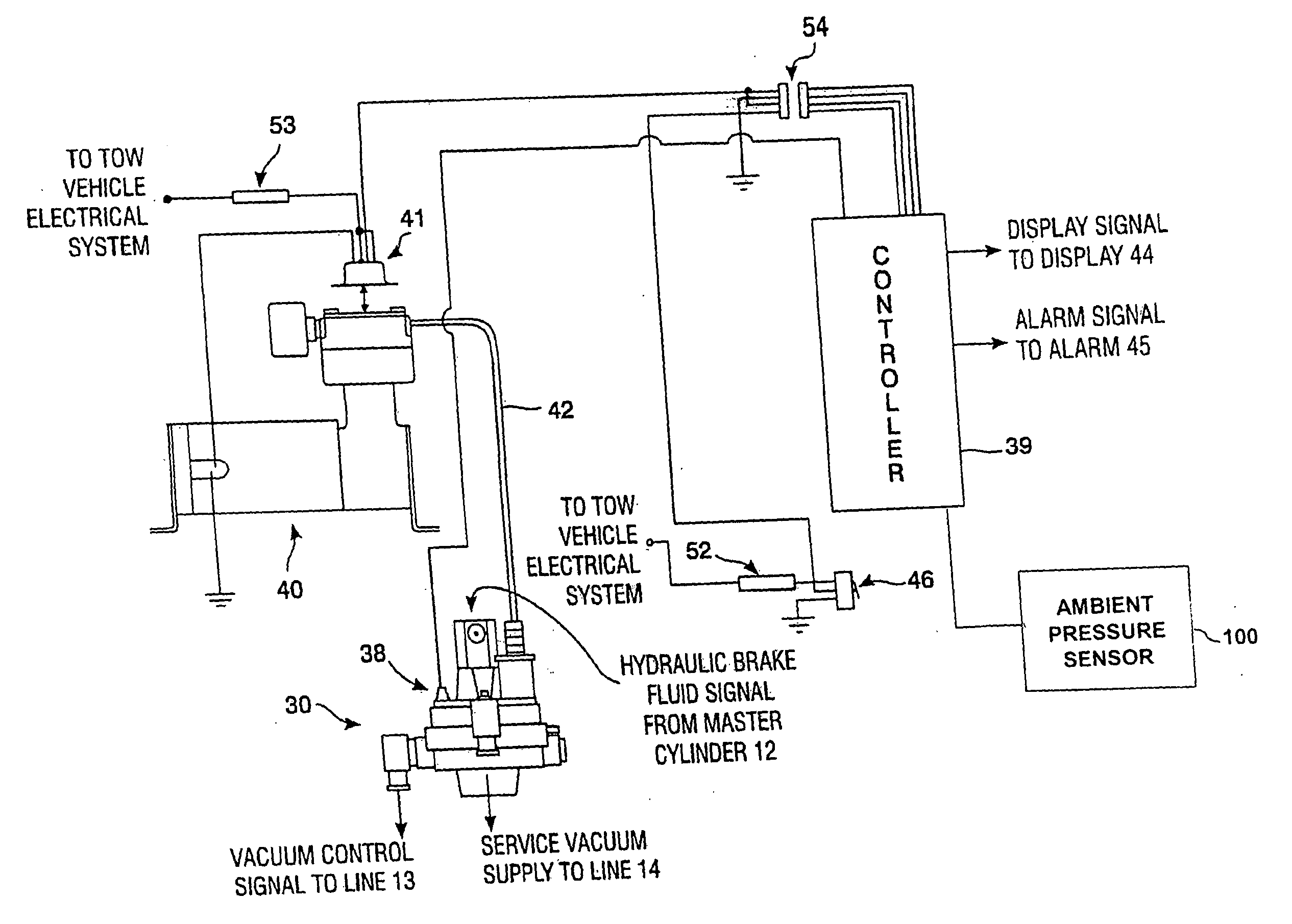

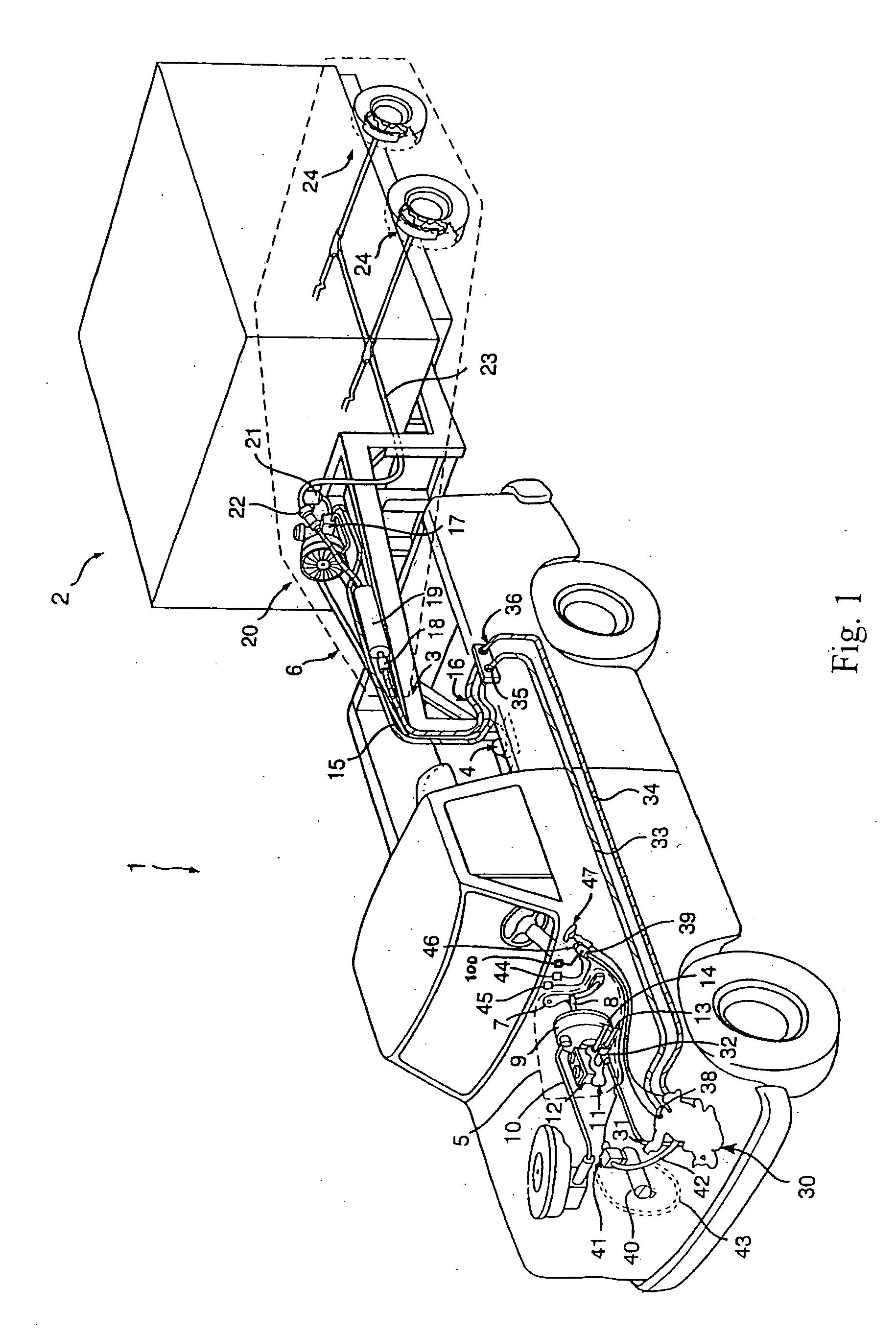

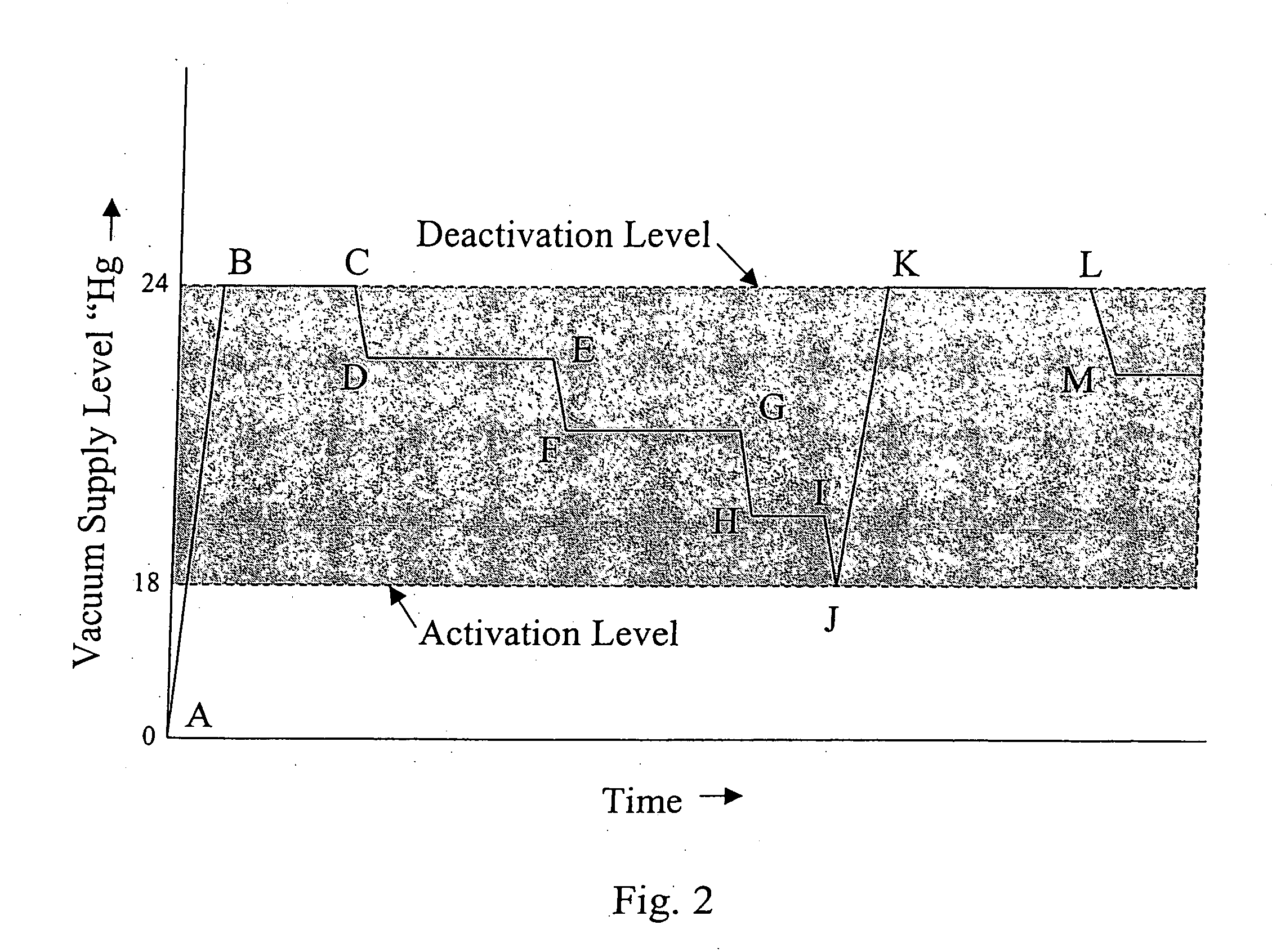

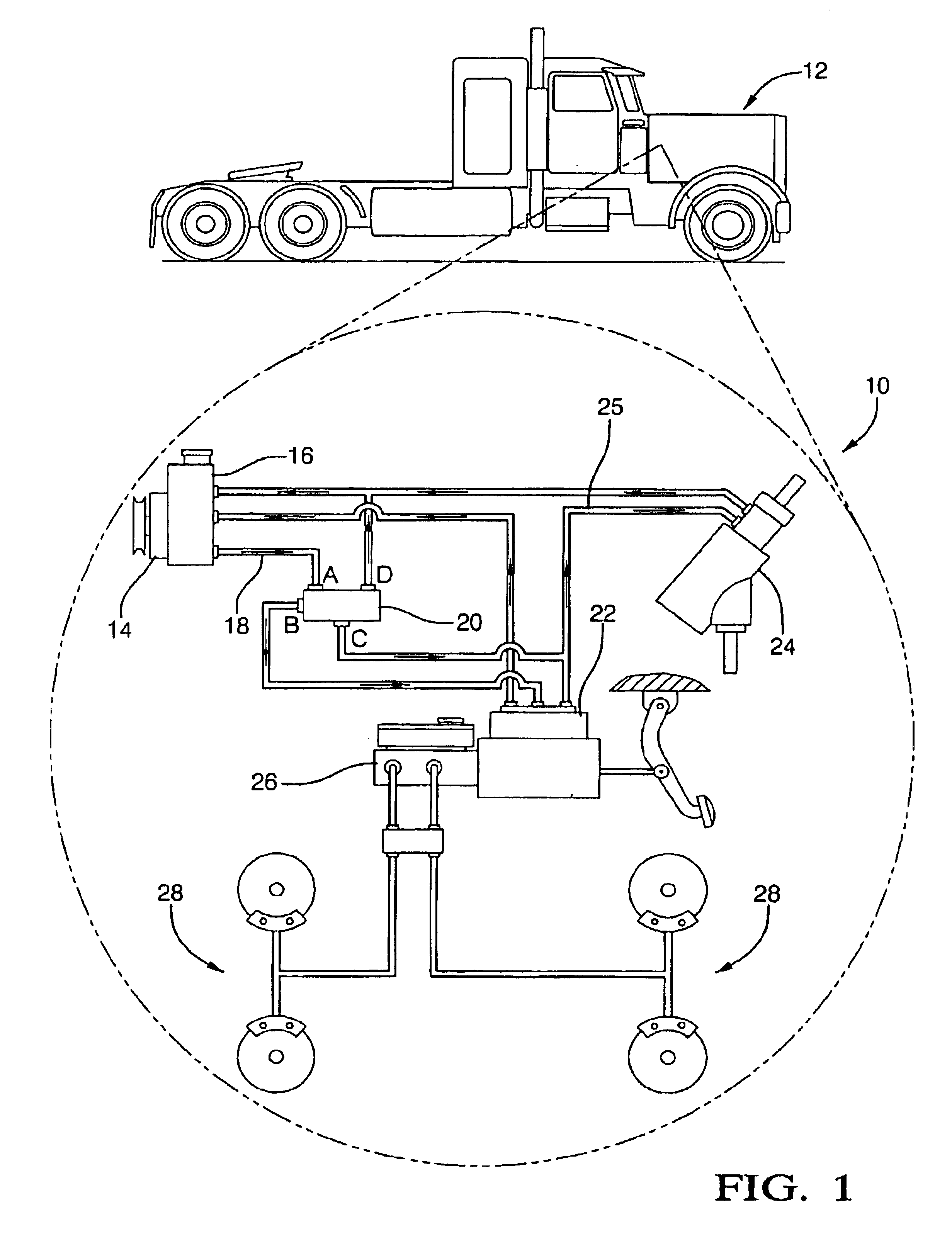

Altitude compensating trailer brake system

InactiveUS20050178622A1Generate efficientlyAxially engaging brakesBraking action transmissionAmbient pressureSwitching signal

The invented apparatus is designed for use with a tow vehicle and trailer combination. The apparatus comprises a controller, a vacuum supply sensor, and a sensor unit used to measure the barometric pressure and / or elevation of the current location of the tow vehicle / trailer combination. Using information from the sensor unit, the controller determines a vacuum pump activation level and / or deactivation level appropriate for the ambient pressure in which the apparatus is operating. By monitoring the signal supplied by the vacuum supply sensor and by operating a vacuum pump switch signal, the controller maintains a supply of vacuum between the activation and deactivation levels. In this manner, the controller can compensate for changes in local conditions so as to operate the vacuum pump in an efficient manner while maintaining an adequate supply of vacuum for operation of the trailer brake system.

Owner:BLUDOT

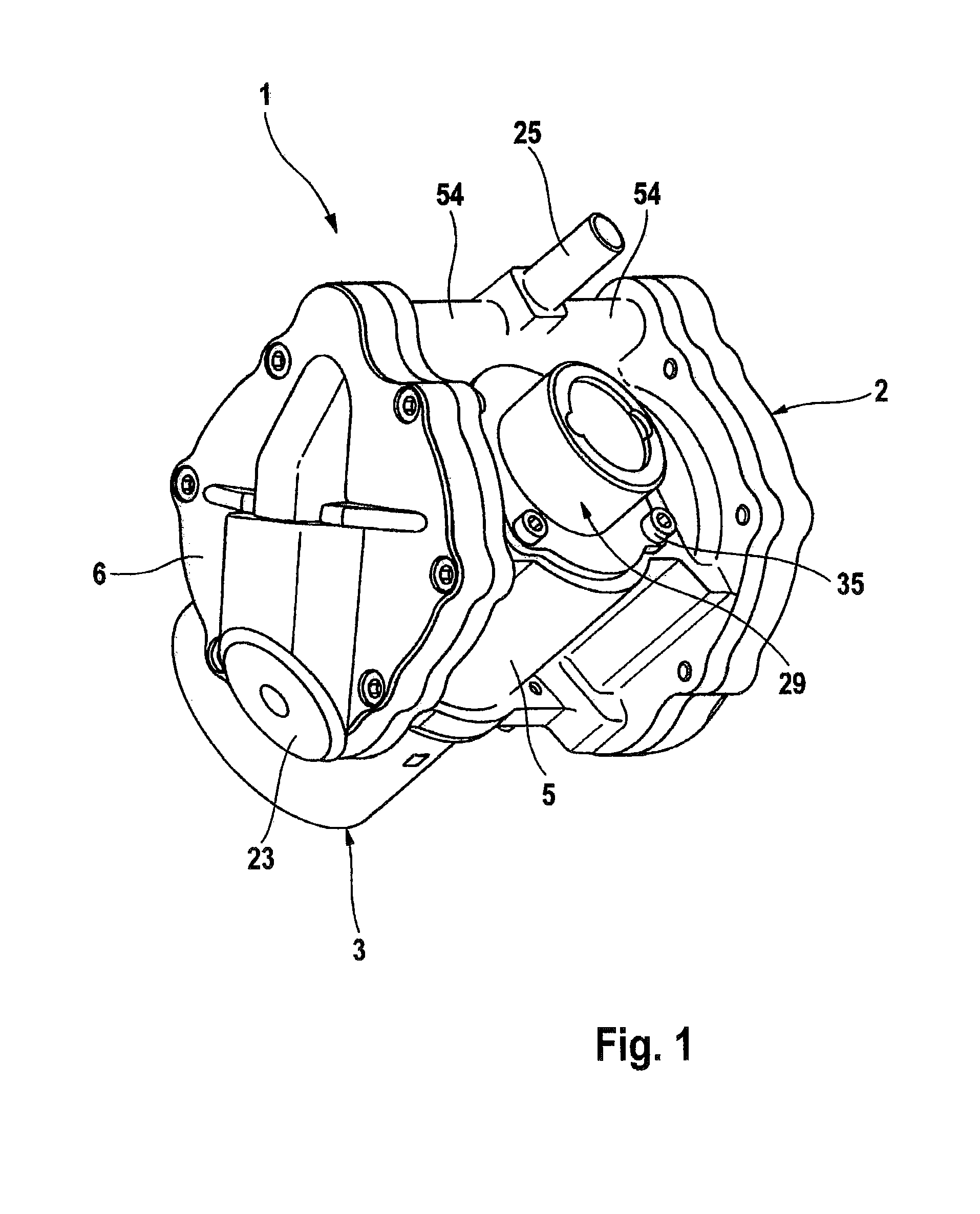

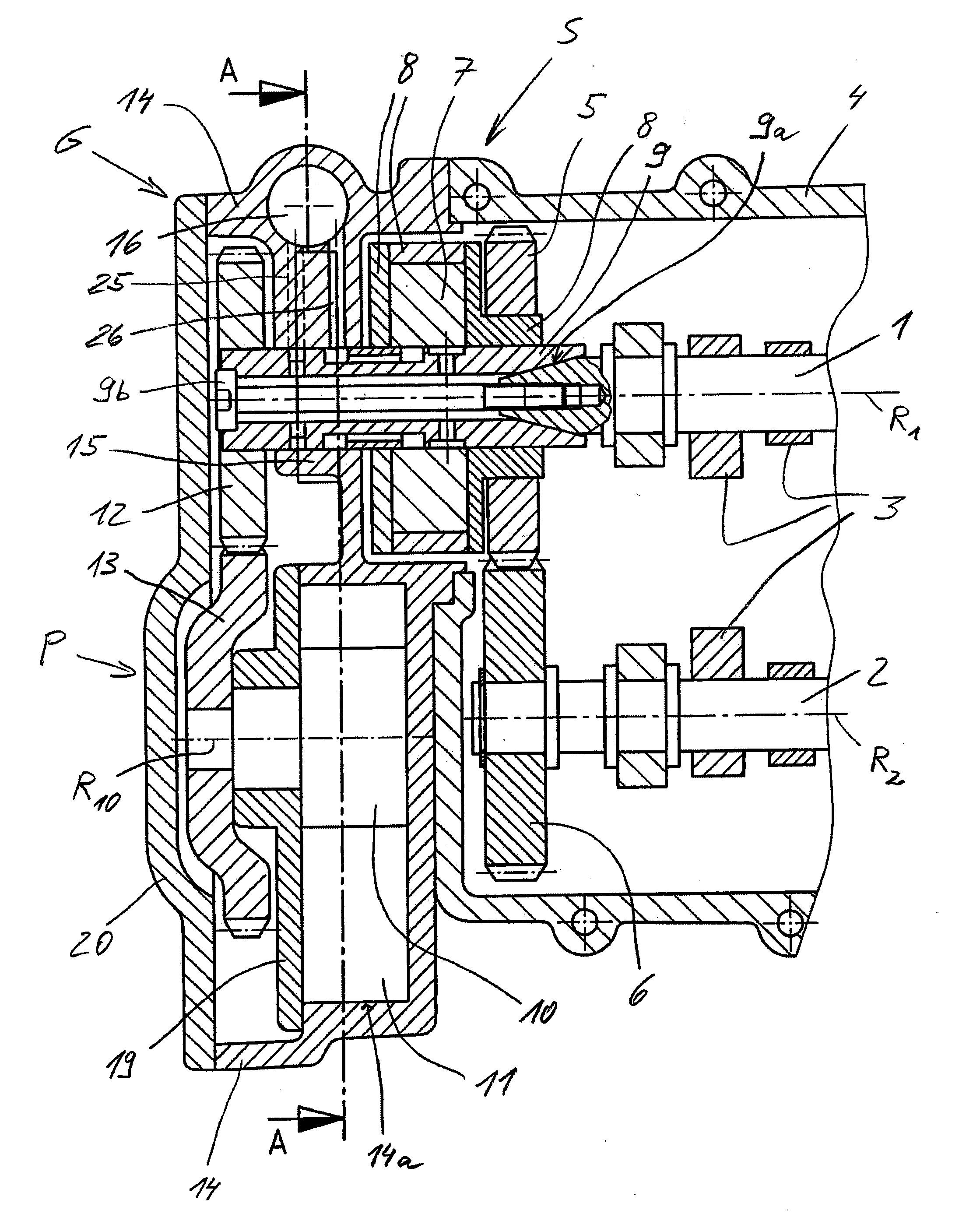

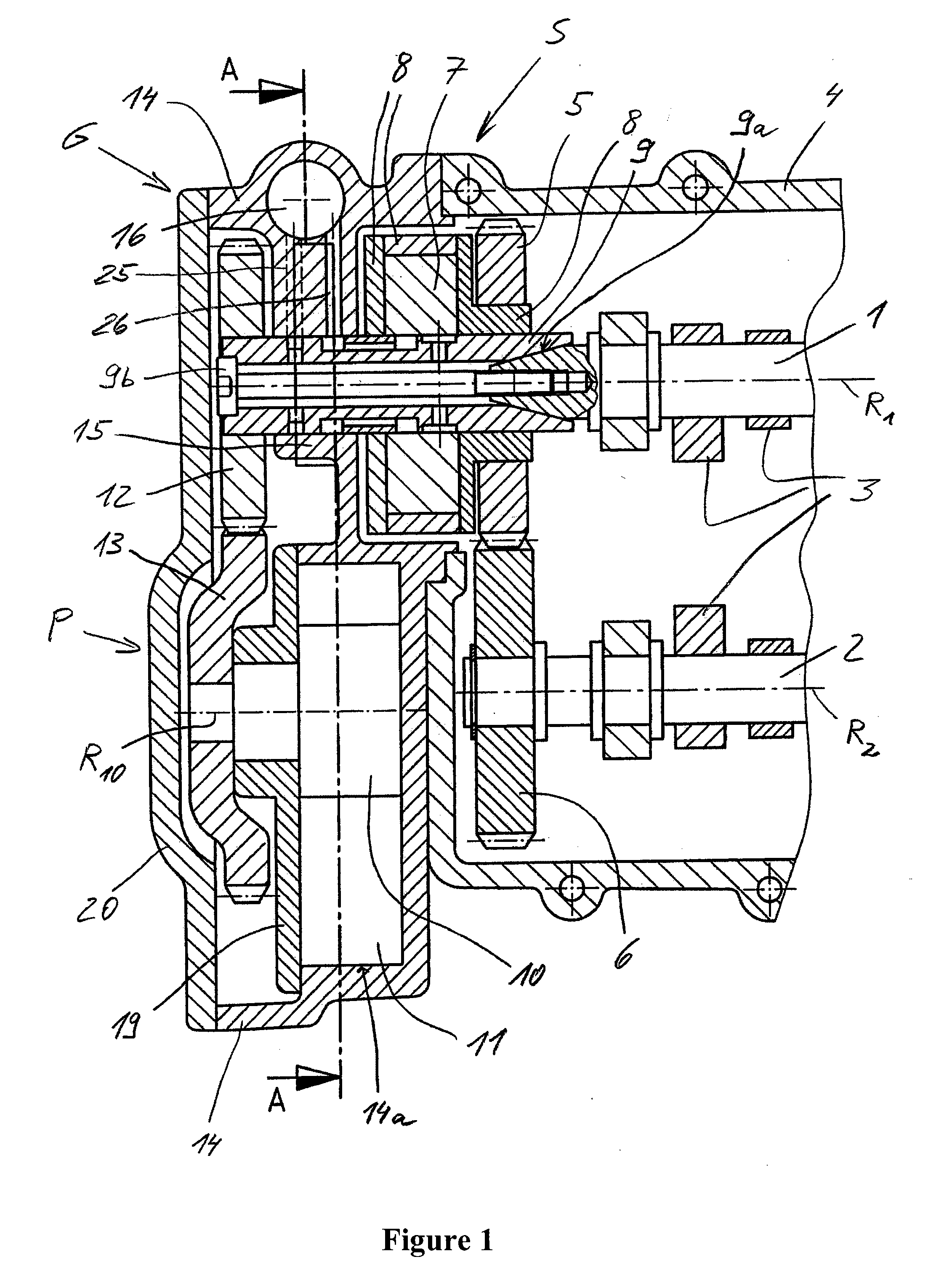

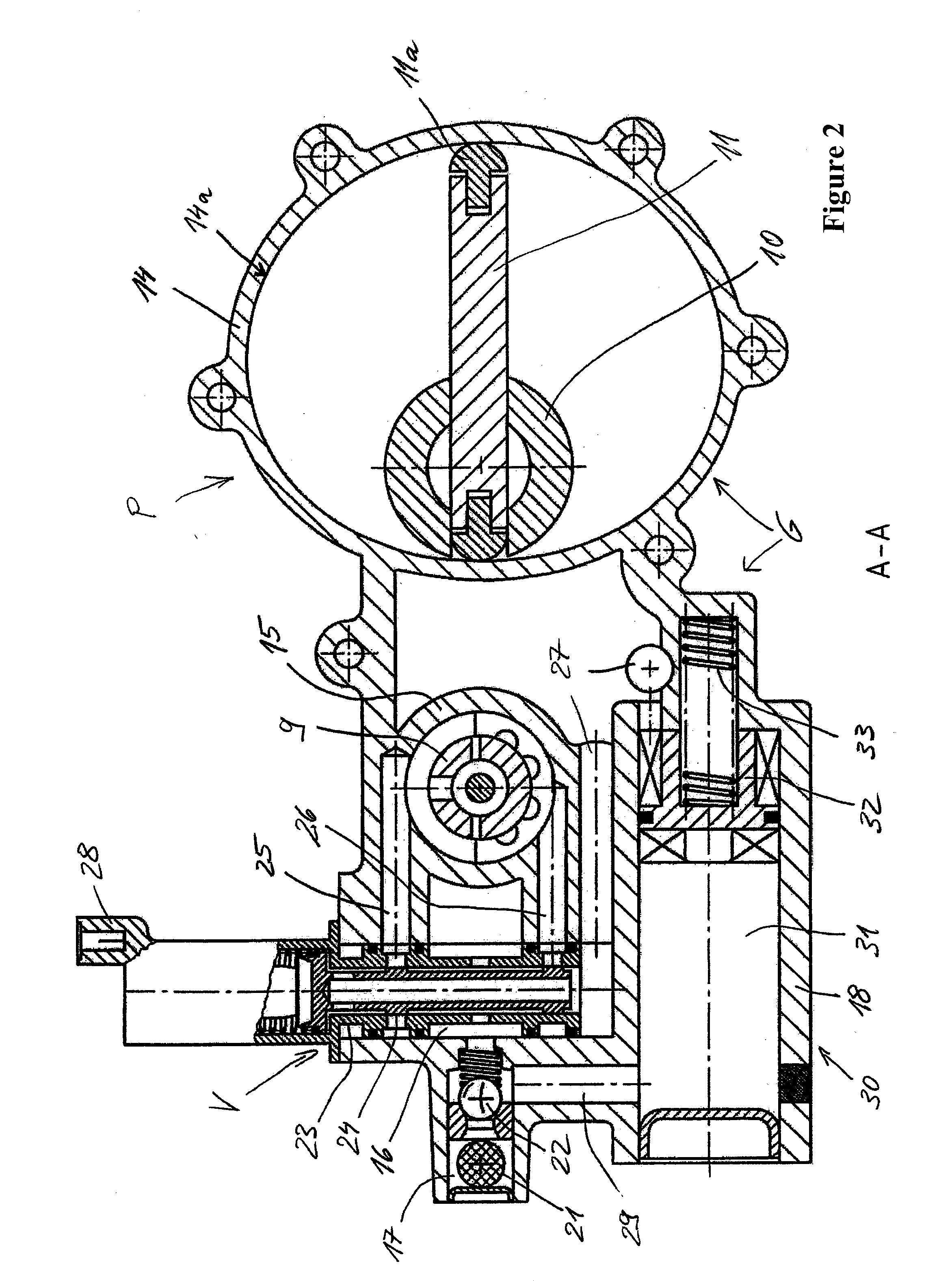

Cam shaft phase setter and vacuum pump for an internal combustion engine

ActiveUS20080283010A1Easy to installSave spaceValve drivesCombustion enginesEngineeringMechanical engineering

A device for adjusting the phase position of a cam shaft of an internal combustion engine and for supplying an assembly with a partial vacuum, said device comprising: a phase setter for adjusting the phase position of the cam shaft relative to a crankshaft of the internal combustion engine; a vacuum pump for the assembly; and an attachment housing for the vacuum pump, wherein the attachment housing is mounted on the internal combustion engine and forms a housing or at least a housing cover for the phase setter.

Owner:SCHWABISCHE HUTTENWERKE AUTOMOTIVE CMBH

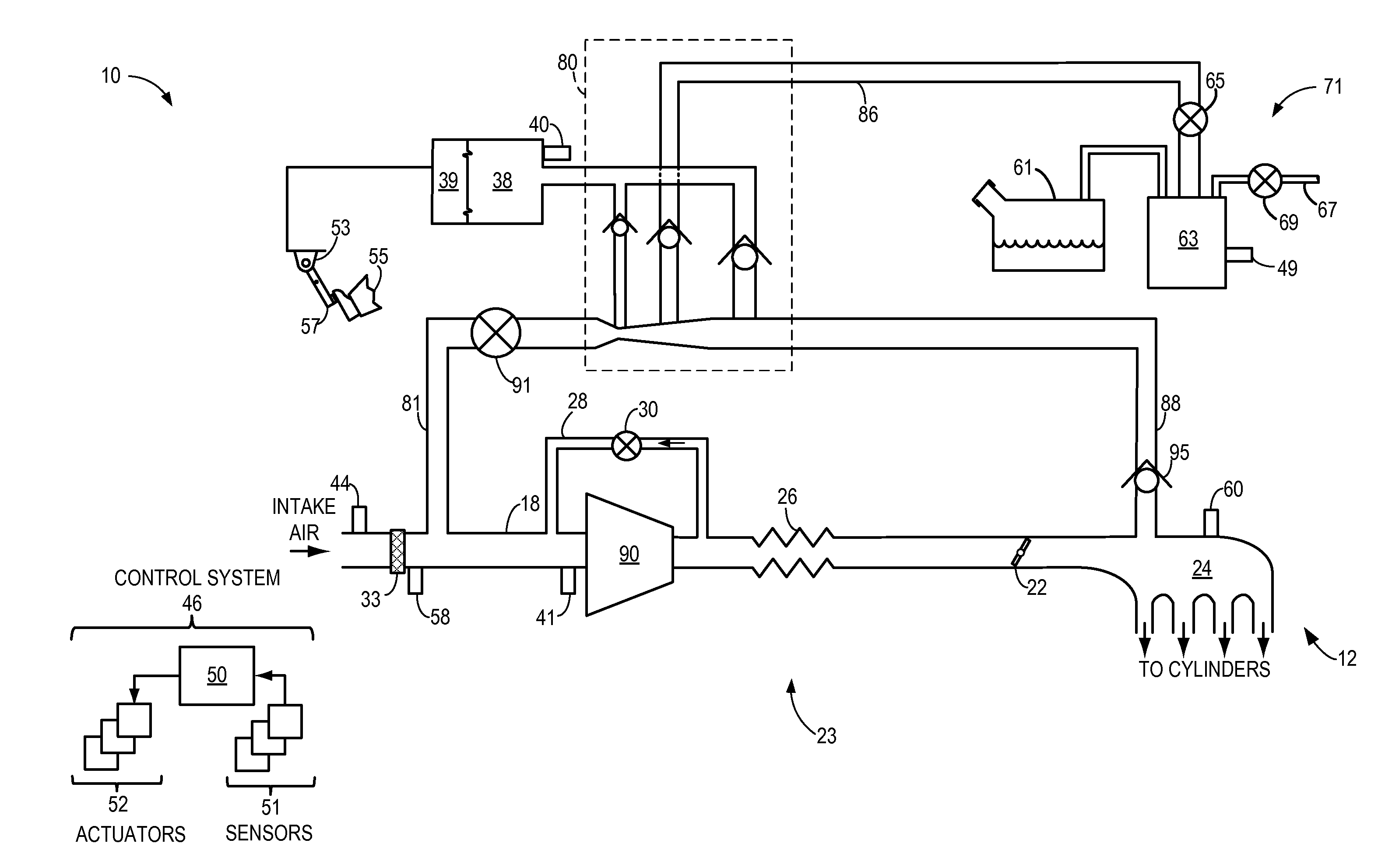

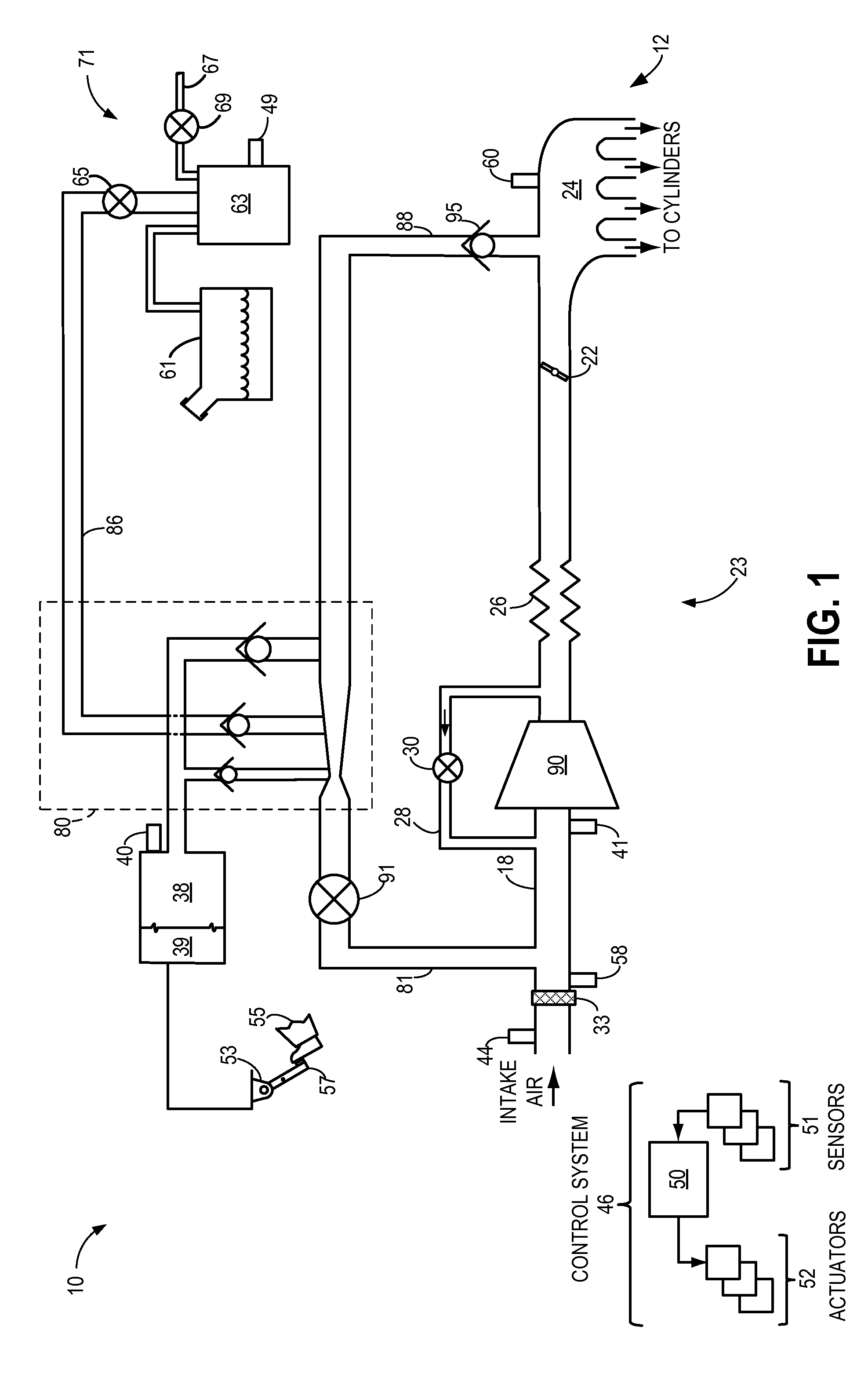

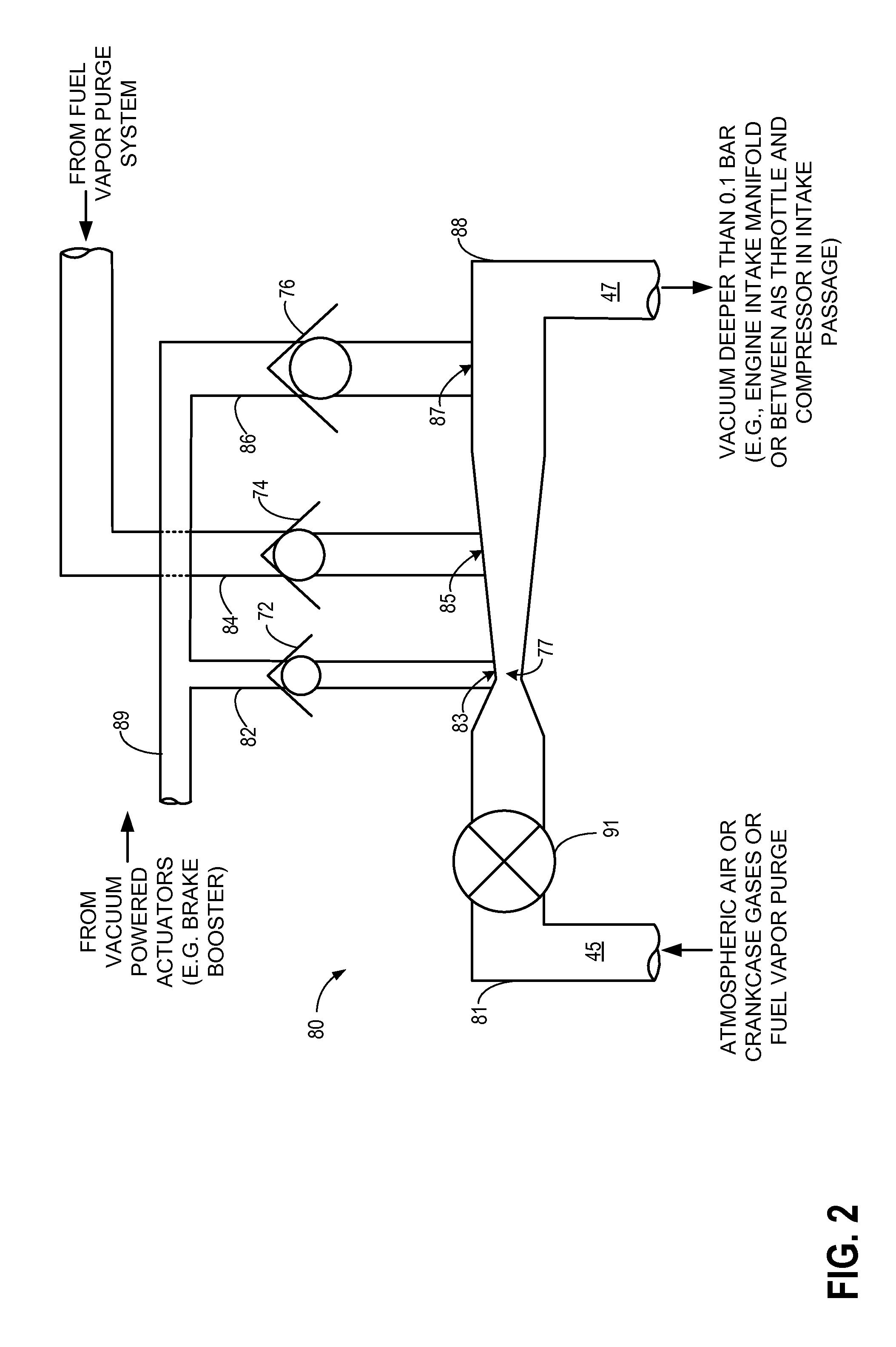

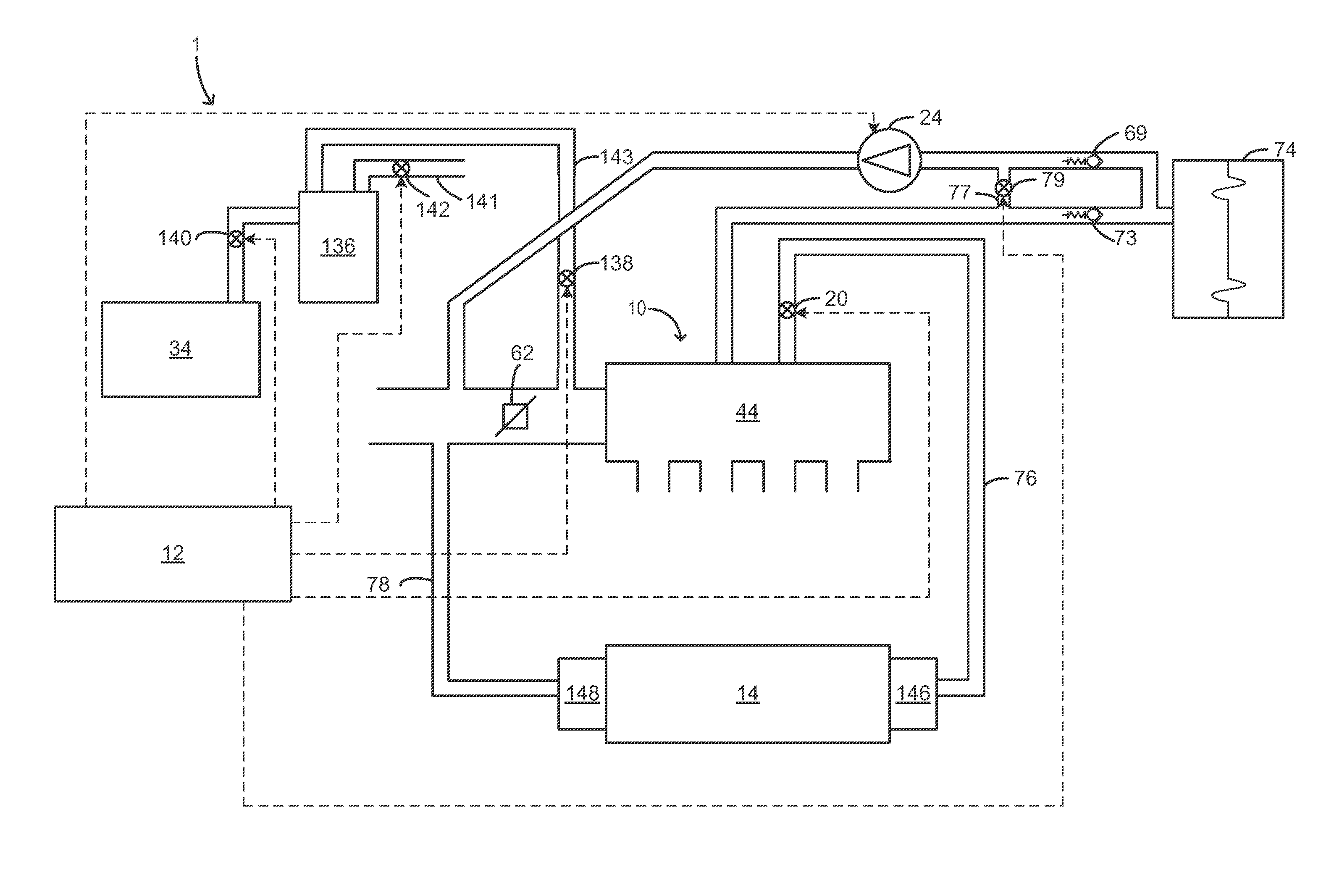

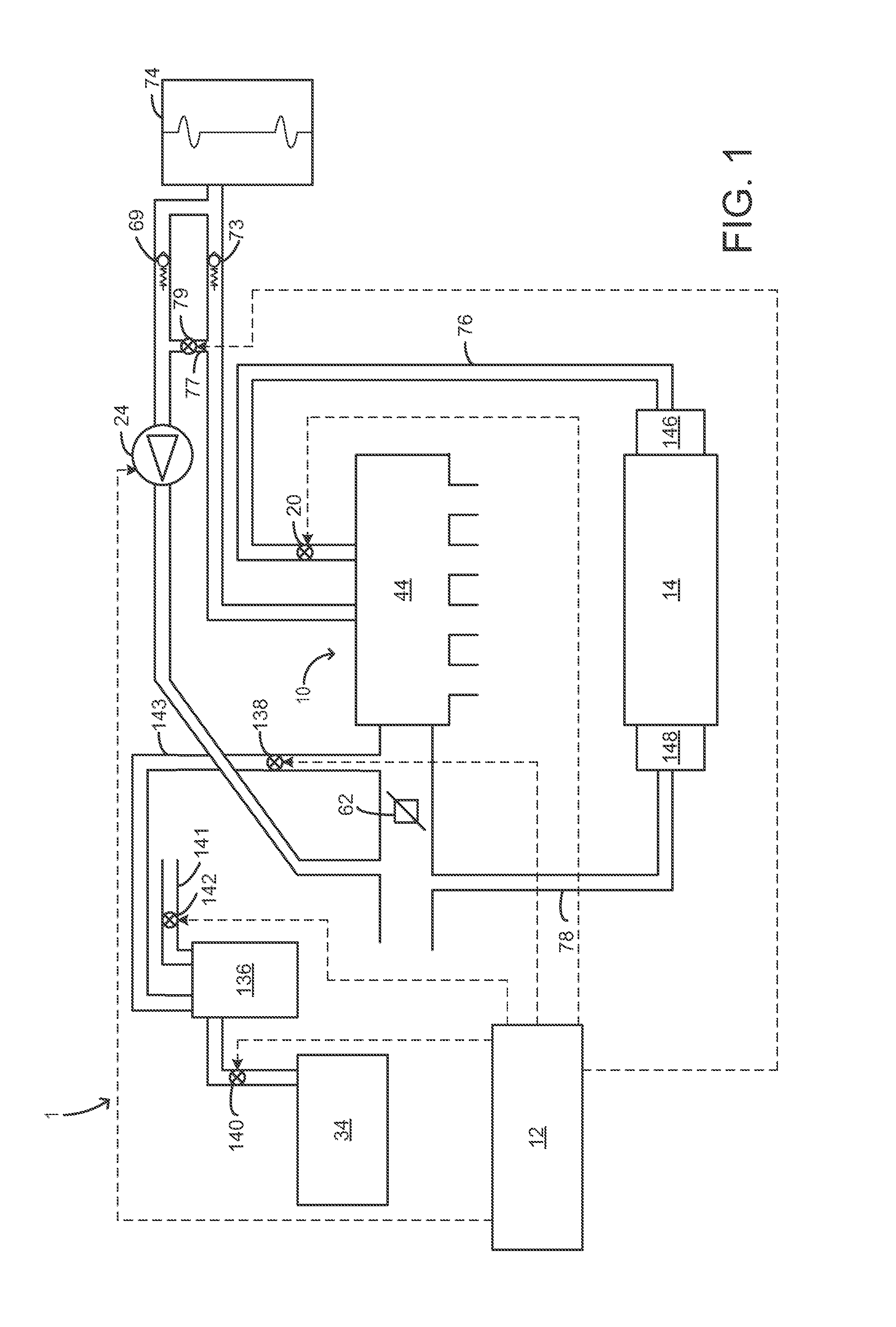

Multiple tap aspirator

ActiveUS20150114348A1Low-cost vacuum generationFast pull-downAuxillary drivesNon-fuel substance addition to fuelInspiratorVacuum level

Systems and methods are provided for engine systems including a vacuum-powered multiple tap aspirator coupled between atmospheric, an engine crankcase, or another source and a vacuum source such as a compressor inlet or engine intake manifold. The multiple tap aspirator includes a suction tap arranged in a throat of the aspirator, a suction tap arranged in a diverging cone of the aspirator, and a suction tap arranged in a straight exit tube downstream of the diverging cone of the aspirator. The aspirator provides vacuum generation and suction flow over a range of vacuum levels at the suction taps, and suction flow only passes through a single check valve before entering the aspirator.

Owner:FORD GLOBAL TECH LLC

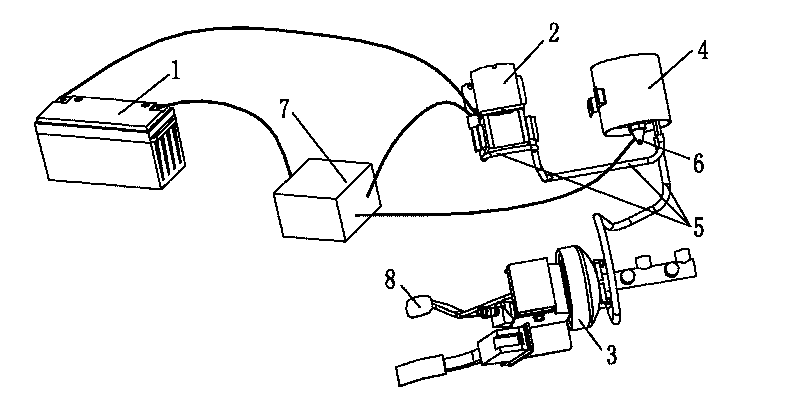

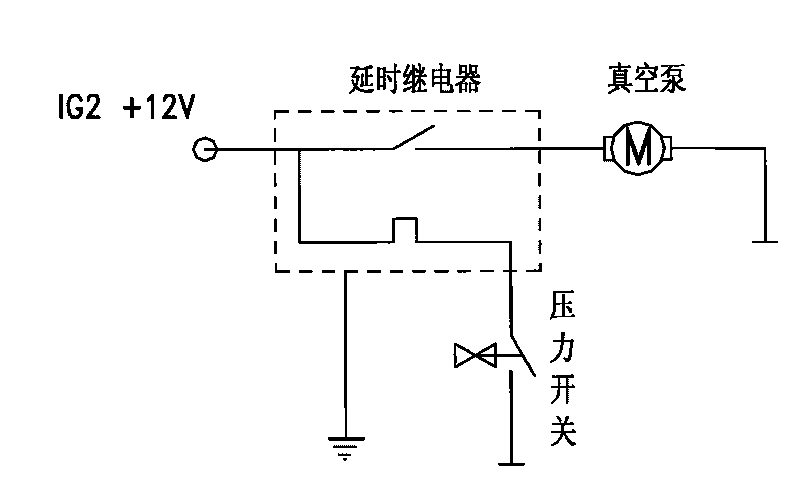

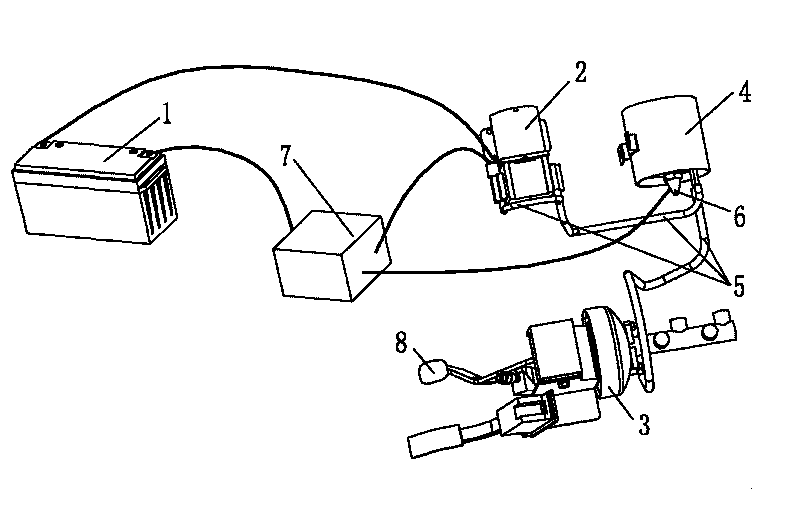

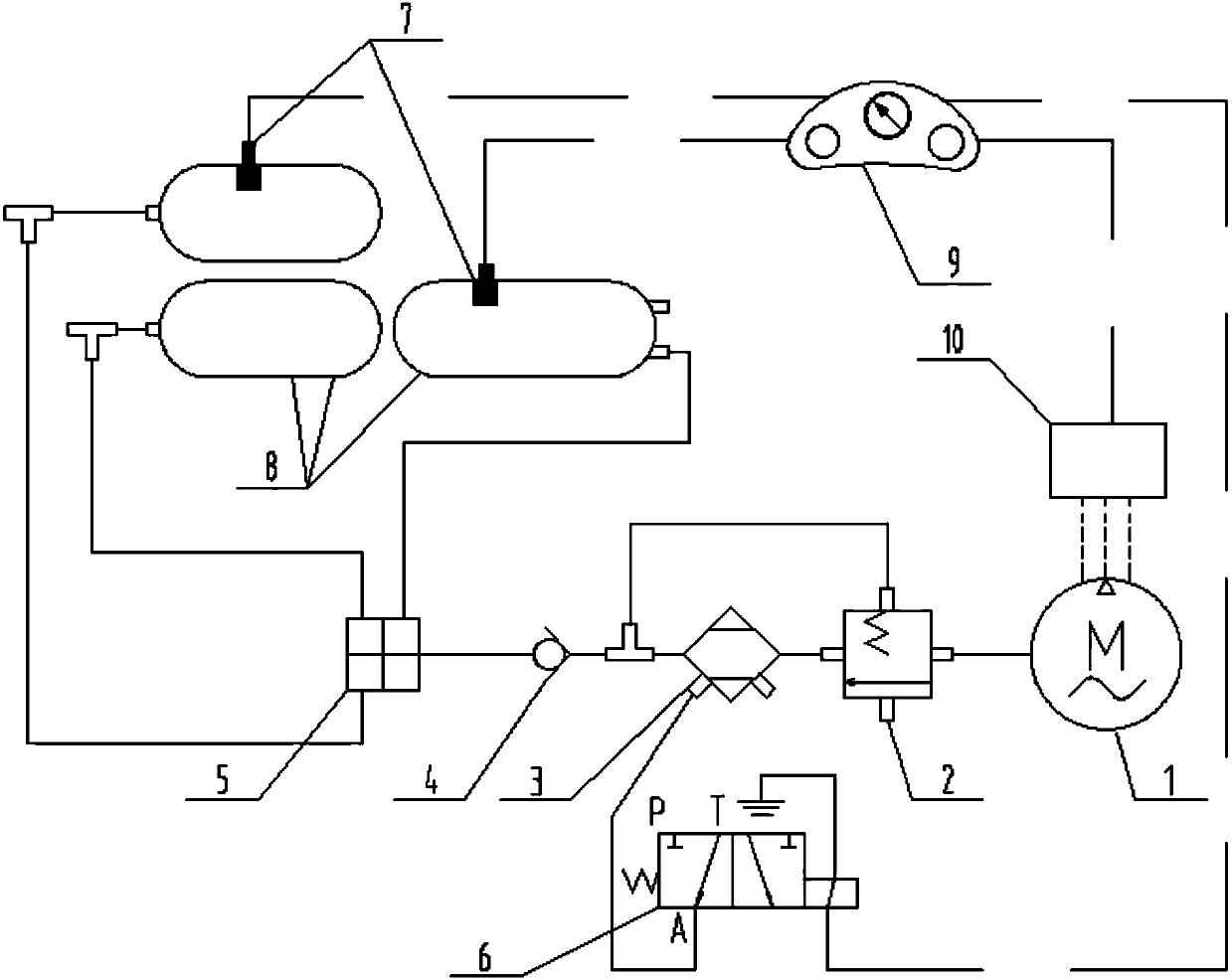

Electric power assisting brake auxiliary system of electric car

InactiveCN101695924AStable pressureReduce energy consumptionBraking action transmissionPump/compressor arrangementsVacuum pressureElectric power system

The invention discloses an electric power assisting brake auxiliary system of an electric car, which comprises an electric car auxiliary power supply, a vacuum pump, a brake vacuum booster and a vacuum air storage tank, wherein the brake vacuum booster is connected to the vacuum air storage tank through a vacuum pipe and is connected to the vacuum pump through a vacuum pipe, a vacuum pressure detector is arranged on the vacuum air storage tank, and the vacuum pressure detector is connected with a vacuum pump delay control switch which is connected with the electric car auxiliary power supply and a vacuum pump circuit. Vacuum pressure in the vacuum air storage tank is detected by the vacuum pressure detector, when the pressure in the vacuum air storage tank is lower than the set value, an electric vacuum pump power supply is not immediately switched off, and the vacuum pump is enabled to delay for working till set time, the pressure in the vacuum air storage tank is continuously lowered, the pressure in the vacuum air storage tank is kept stable, and the vacuum power assisting efficiency for braking at any time is ensured.

Owner:GREENWHEEL ELECTRIC VEHICLE

Check valve

A check valve which is positioned in the vacuum air line of an internal combustion engine. The check valve includes a single-piece valve body having an outlet port and two or more inlet ports, with one outlet port located substantially in line with the inlet port and connected by a venturi tube. The second inlet port is separated from the main air flow line by the valve stem and a diaphragm which allows communication there between and prevents back pressure. The second inlet port communicates with the outlet port through the valve stem and a second venturi tube which provides a vacuum boost to a device, usually vehicle brakes, connected to the inlet.

Owner:NYLONCRAFT INC

Reducing intake manifold pressure during cranking

InactiveUS20130276756A1Reduce dependenceReduce productionElectrical controlInternal combustion piston enginesInlet manifoldFuel injection

Embodiments for starting an engine are provided. In one embodiment, an engine control method comprises, during engine cranking, commencing fuel injection when intake manifold pressure drops below a threshold, the threshold based on fuel volatility. In this way, the stability of engine starts using low volatility fuels may be increased.

Owner:FORD GLOBAL TECH LLC

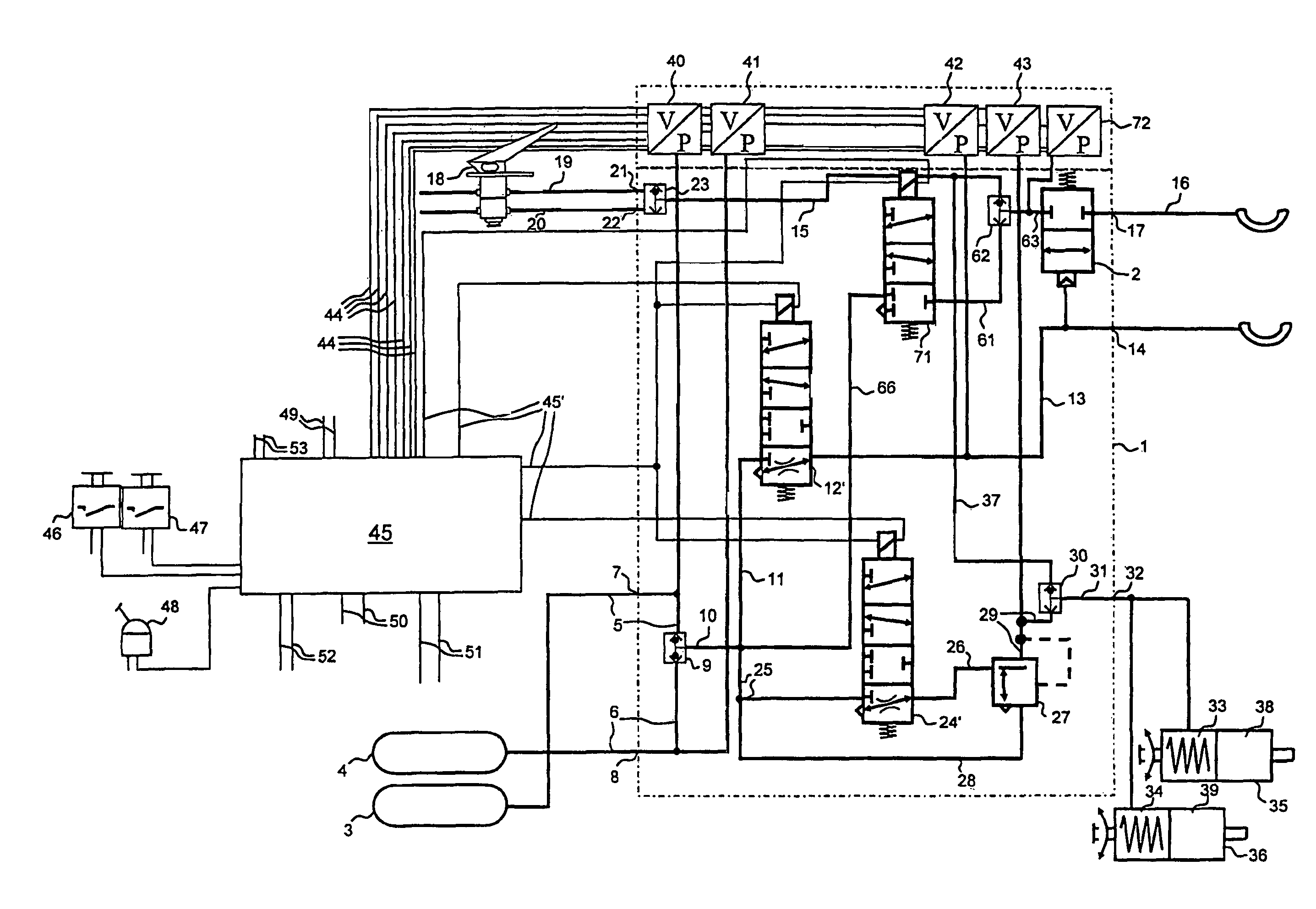

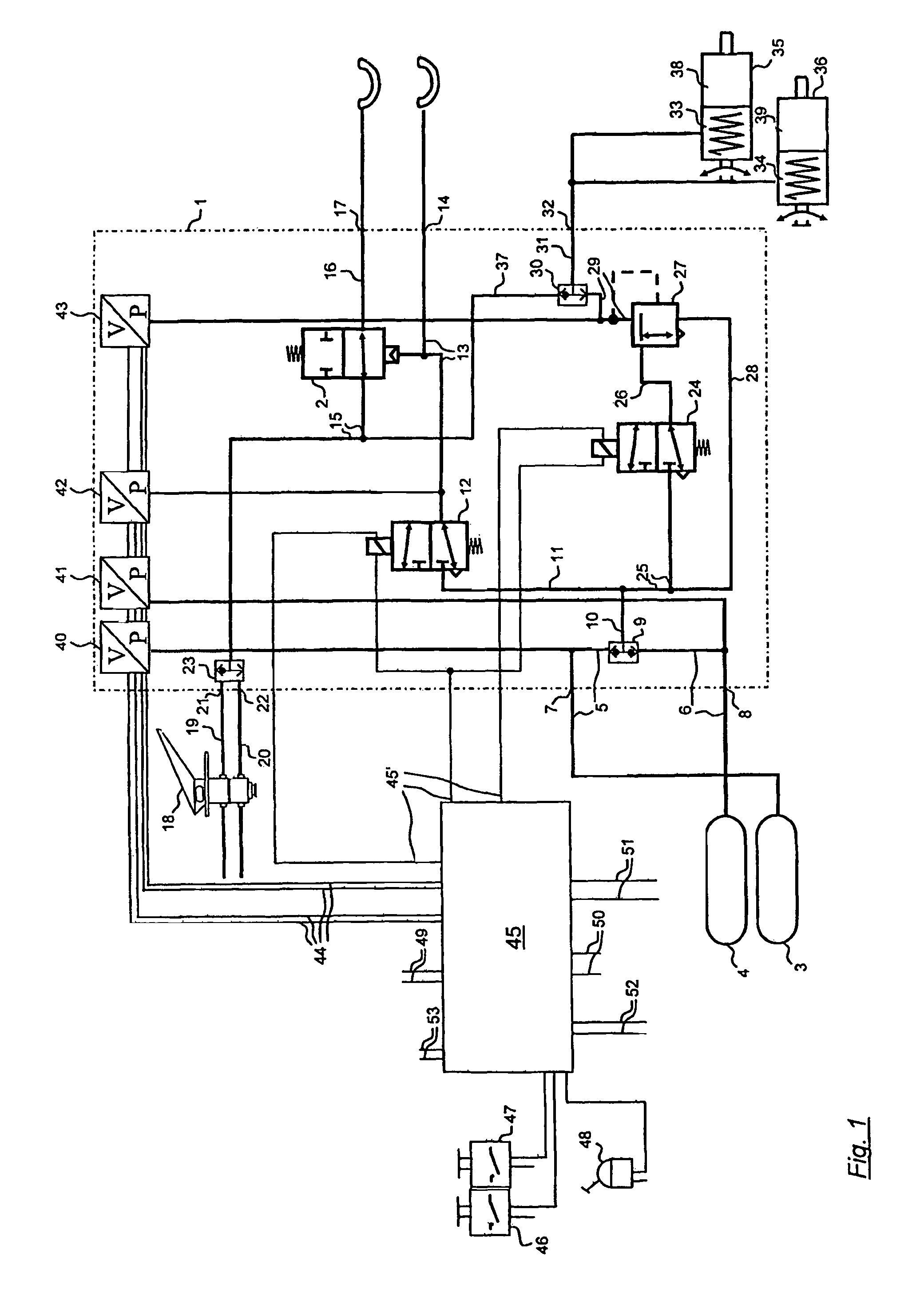

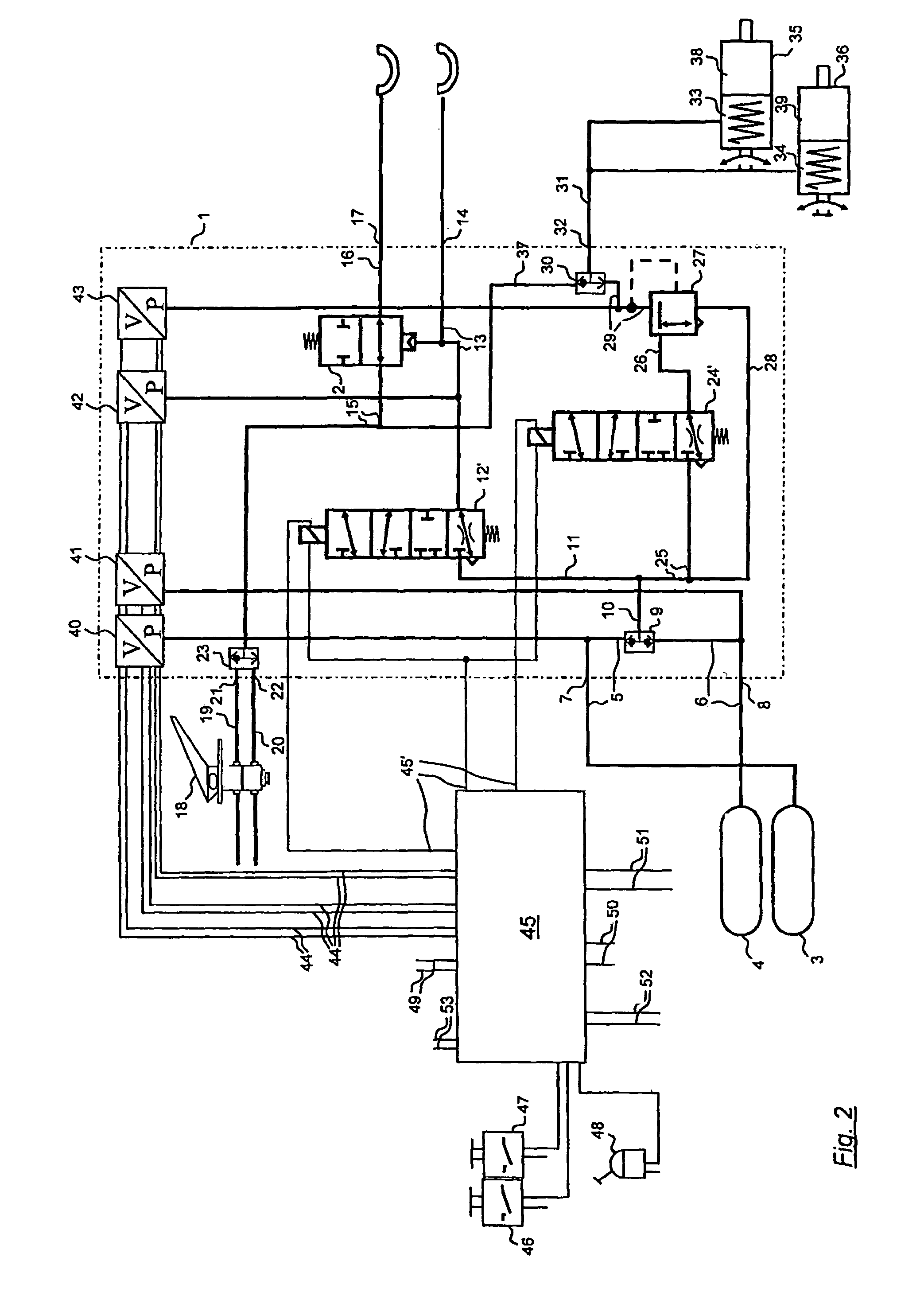

Compressed air processing apparatus for compressed air systems of motor vehicles

InactiveUS20050017474A1Reduce in quantityStructural expenditure in a motor vehicle requiredResilient suspensionsPump/compressor arrangementsAir treatmentAir dryer

A compressed air processing apparatus includes a pressure controller, an air dryer, a multi-circuit protection valve and an electronic control unit. A switching valve is designed and arranged to supply compressed air to an air suspension system and to deaerate the air suspension system. The electronic control unit is designed and arranged to control the pressure controller, the air dryer and the multi-circuit protection valve. The electronic control unit is designed and arranged to also control the switching valve of the air suspension system.

Owner:HALDEX BRAKE PROD GMBH

Electropneumatic parking brake modulator

ActiveUS8282173B2Increase pressureConstant pressureBraking action transmissionAutomatic initiationsParking brakeReservoir pressure

Owner:ZF CV SYST EURO BV

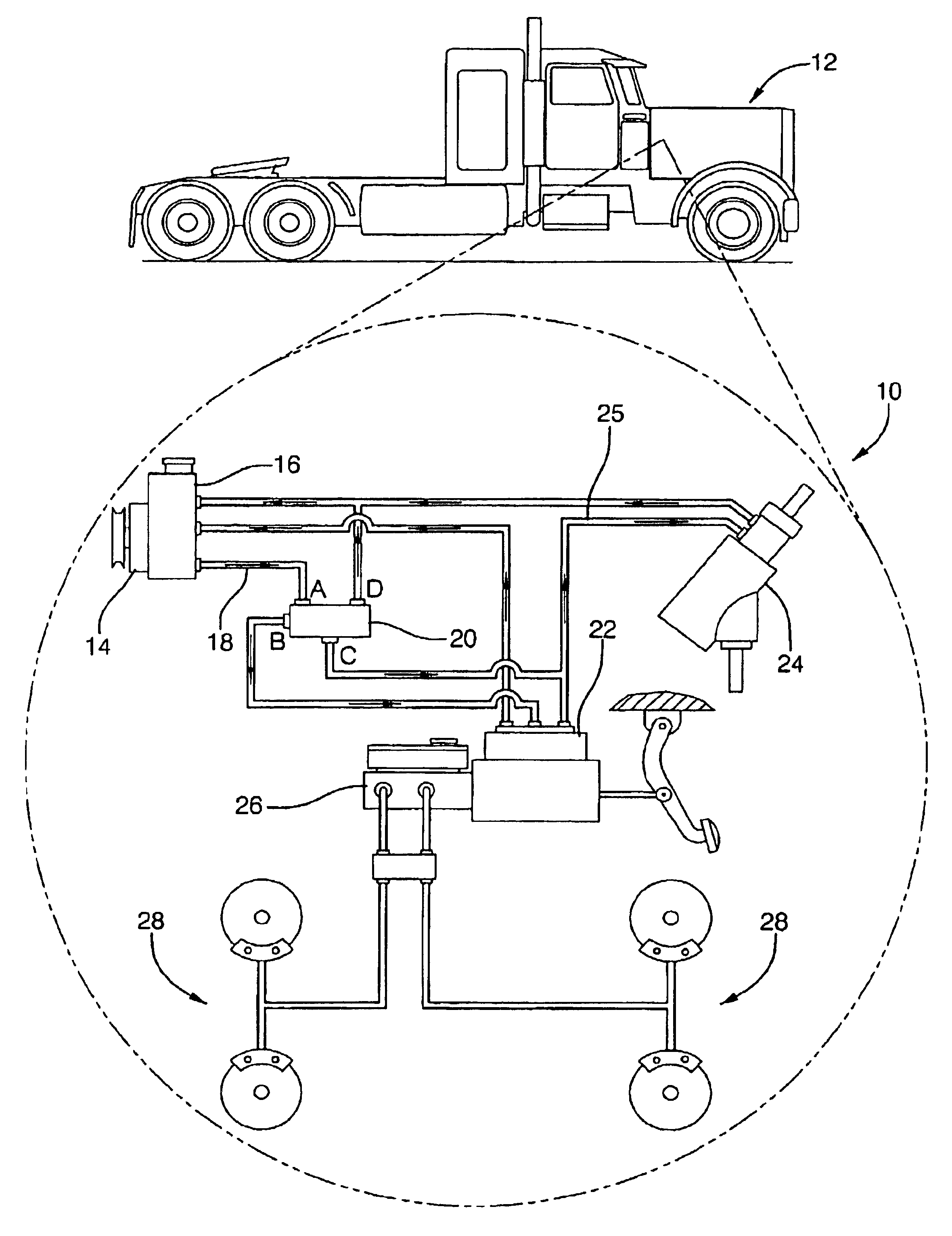

Hydraulic brake and steering assist system

InactiveUS6814413B2Simple designLess componentsBraking action transmissionServomotor componentsHydraulic pumpHeavy load

Owner:STEERING SOLUTIONS IP HLDG +1

Gas path-electric air compressor integrated control system and control method

ActiveCN103437986APrecise switching pressureControl start and stopPositive displacement pump componentsPump controlControl systemControl engineering

The invention particularly discloses a gas path-electric air compressor integrated control system and control method. The system comprises an electric air compressor, wherein the electric air compressor is connected with a pressure regulating valve; an outlet of the pressure regulating valve is connected with a dryer; an output end of the dryer is connected with a one-way valve; the one-way valve is connected with a four-loop protective valve; output ends of the four-loop protective valve are respectively connected with an air storage tank; two of the air storage tanks are respectively provided with an air pressure transducer which is connected with a digital instrument through an electric circuit; a pressure relief port of the dryer is connected with an electromagnetic valve; and the other end of the electromagnetic valve is communicated with atmosphere. The electromagnetic valve is added to the air outlet of the dryer to ensure that the discharge pressure of the dryer can be achieved in every air inflation, so that the dryer can discharge air and water, thereby prolonging the service life of the dryer.

Owner:ZHONGTONG BUS HLDG

Motor/pump assembly

ActiveUS8585372B2Reduce noise levelAvoid noisePositive displacement pump componentsBraking action transmissionLow noiseInterior space

A motor / pump assembly for a motor vehicle brake system including a pump and a motor driving the pump, the pump having opposite working diaphragms which are, in each case, mounted between a pump casing and a cover and thereby delimit a space and which can be moved by a crank drive, the space being assigned, in each case, an inlet duct with an inlet valve and an outlet duct with an outlet valve. The outlet ducts are arranged in the covers and in the pump casing such that air displaced out of the spaces is conducted into an inner space surrounding the crank drive of the pump casing and that an air outlet unit be provided, which allows a low-noise blow-out of the air from the inner space as a result of the deflection of the air.

Owner:CONTINENTAL TEVES AG & CO OHG

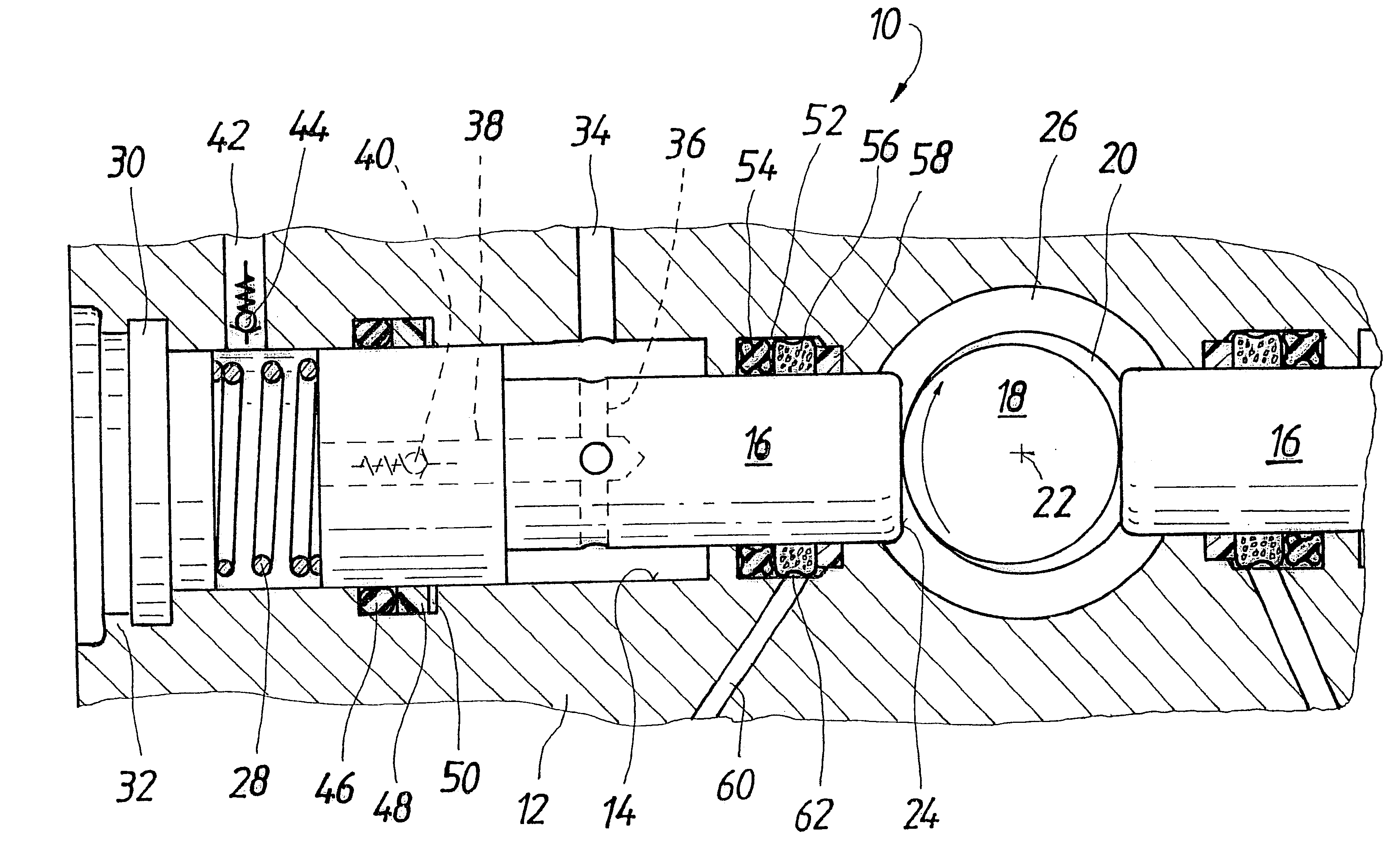

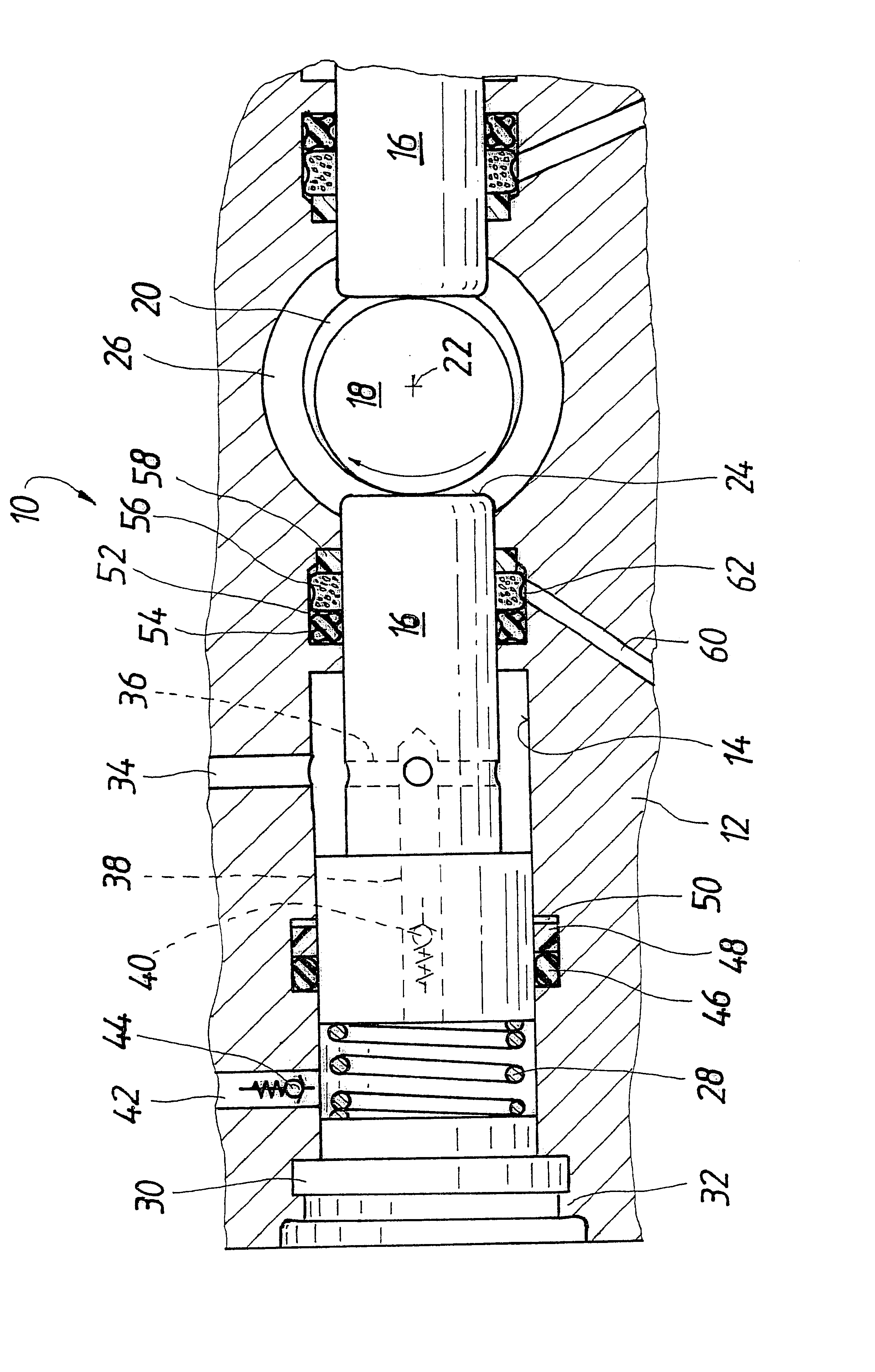

Pump assembly for a slip-controlled hydraulic brake system for a vehicle

InactiveUS6389955B1Avoid damagePrevent rotationEngine sealsPositive displacement pump componentsEngineeringBrake fluid

A pump assembly having a piston pump, which is driven by an eccentric element. To prevent leakage brake fluid from reaching an eccentric element chamber, a groove surrounds the pump piston in the pump housing and a seal and a porous metal sintered ring is inserted into the groove. A drain which extends obliquely downwardly from the groove drains leakage fluid from the sintered ring.

Owner:ROBERT BOSCH GMBH

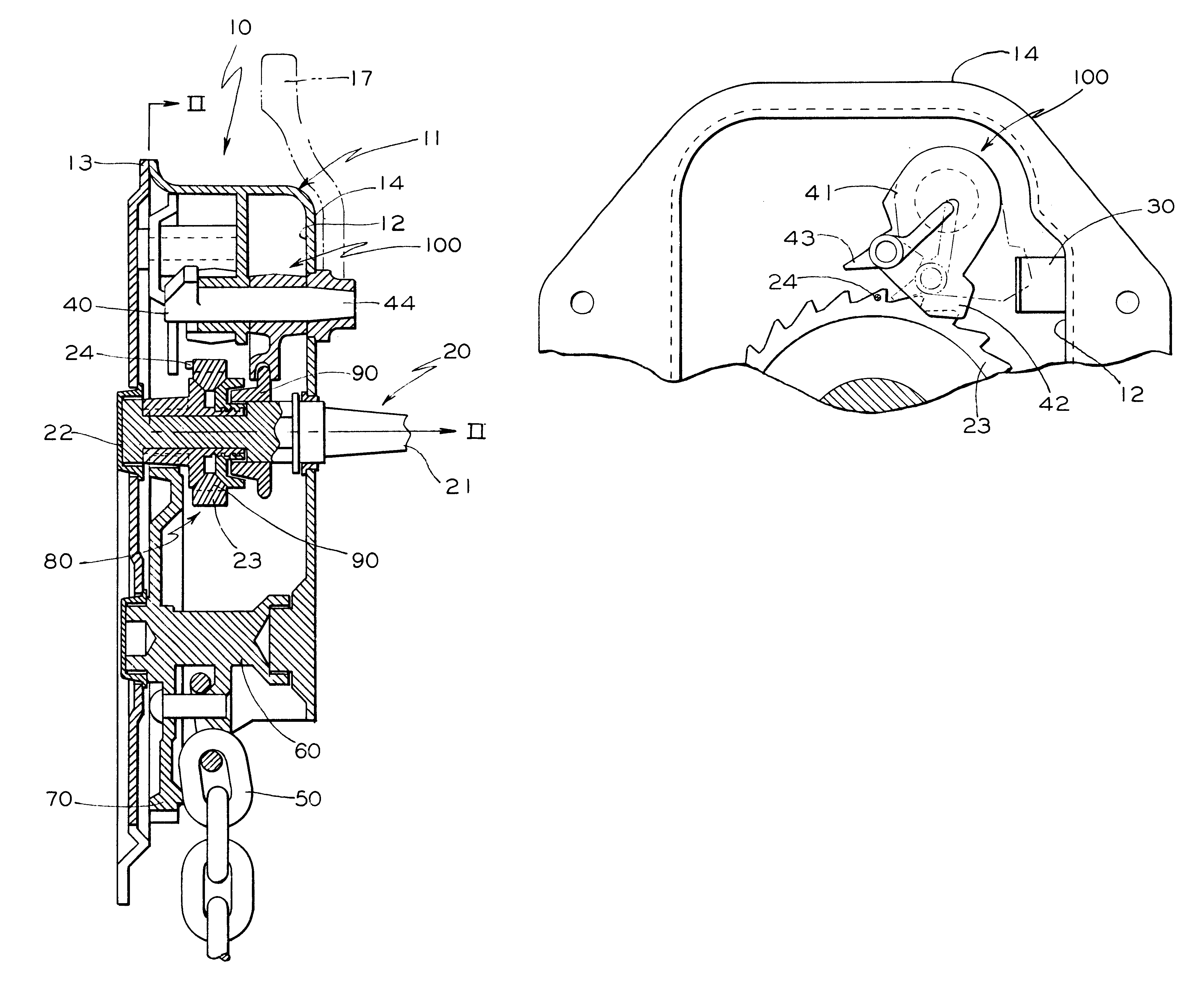

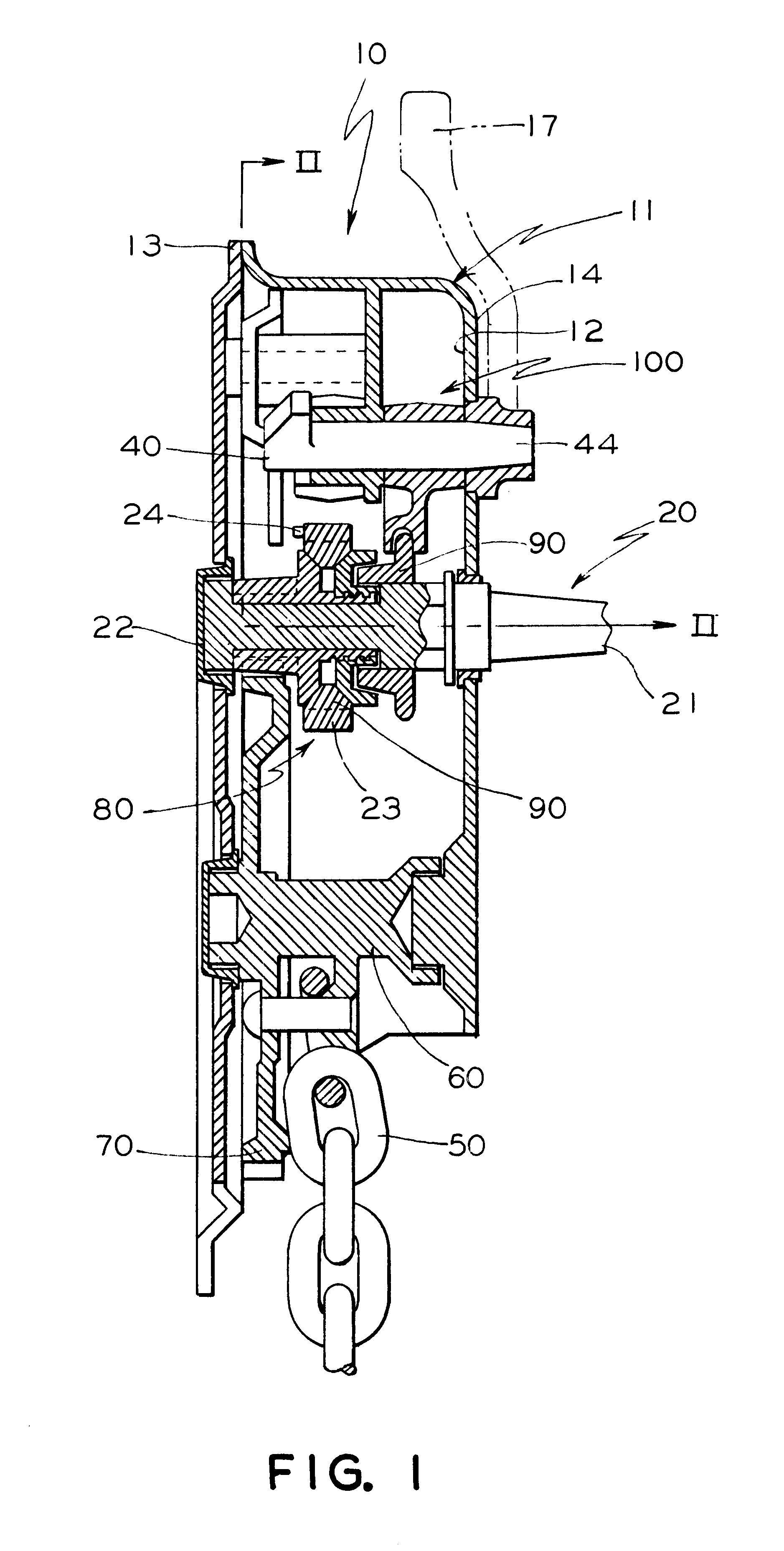

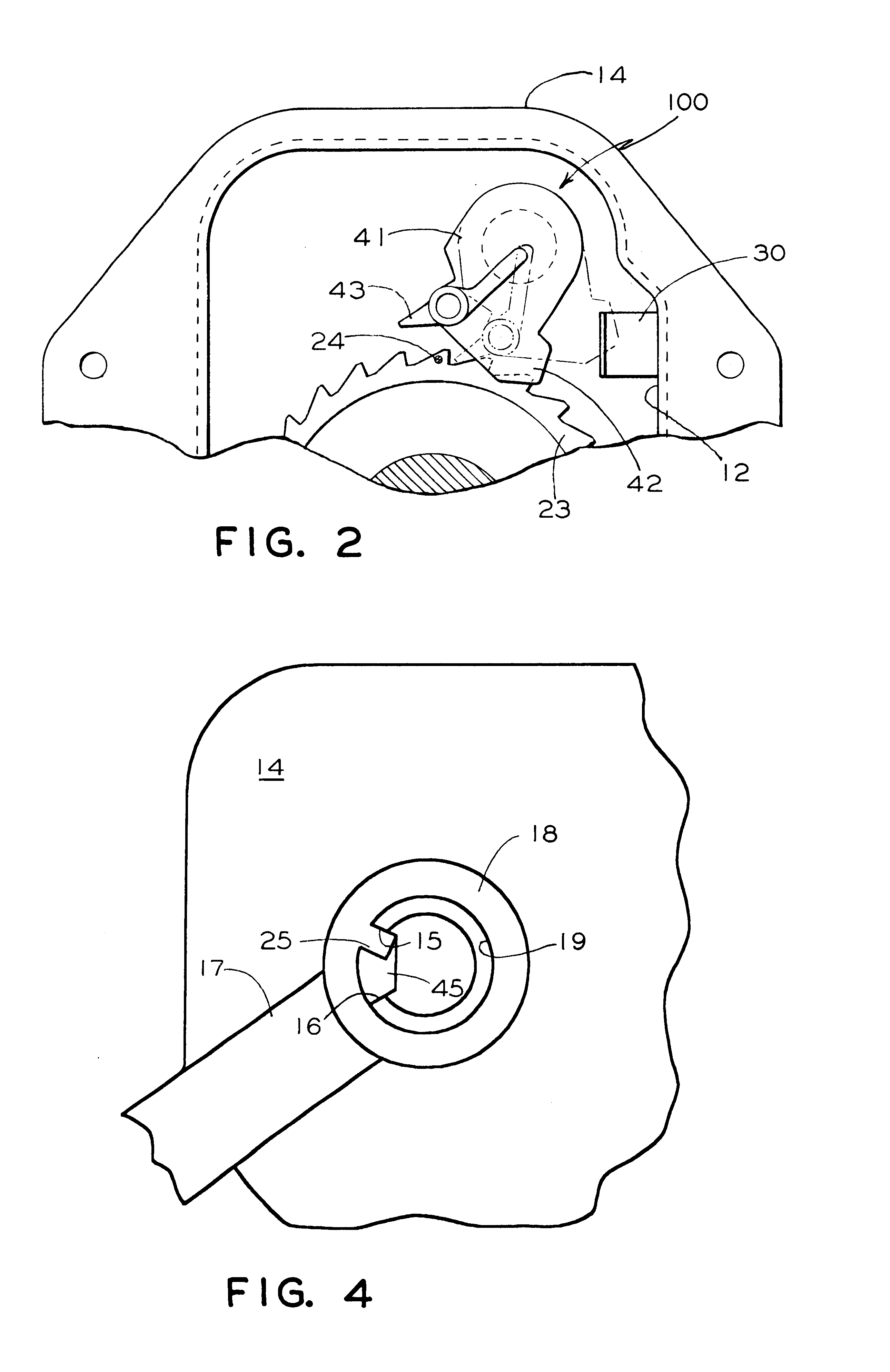

Apparatus for a quick release mechanism in a railcar hand brake

InactiveUS6364428B1Increase railcar wheel lifeSlow down premature wearControlling membersLimiting/preventing/returning movement of partsMechanical engineeringEngineering

An apparatus for a quick release mechanism in a railcar hand brake. The hand brake has a housing having a front casing with an inside wall of a predetermined size and shape, and a back plate. An operating shaft is rotatably mounted in the housing. The operating shaft includes a first end and a second end. The operating shaft further includes a ratchet wheel rotatable with the operating shaft intermediate the first and second ends thereof, and a release shaft rotatably mounted in the housing. The apparatus comprises a projection of a predetermined size and shape disposed substantially perpendicular to the ratchet wheel, and a flexible clamp of a predetermined size and shape mounted inside the housing. A member is disposed substantially perpendicular to, and about the circumference of the release shaft, having a first element disposed on the member wherein the first element interposes with the flexible clamp when the release shaft is rotated to achieve and maintain full brake release, and a second element disposed on the member and engageable with the projection when the operating shaft is rotated to disengage the first element from the flexible clamp to allow for brake application.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

Control system for brake vacuum pump

Owner:SUBARU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com