Electric power assisting brake auxiliary system of electric car

An electric power assist and auxiliary system technology, applied in the direction of brake transmission, brake, vehicle components, etc., can solve the problems of high energy consumption, high noise, etc., and achieve the effect of improving driving range, prolonging service life, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

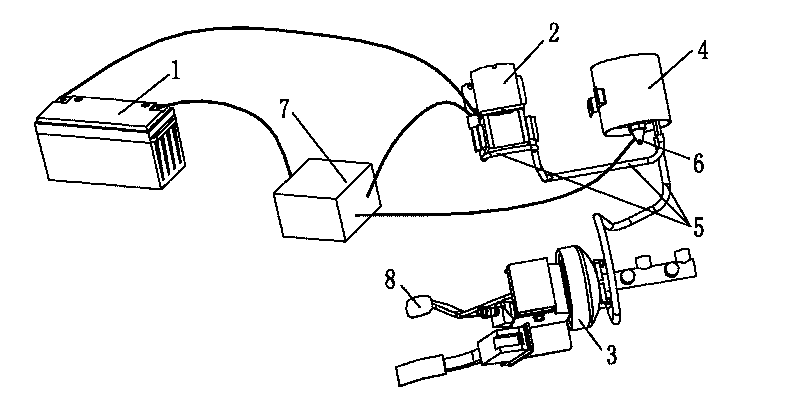

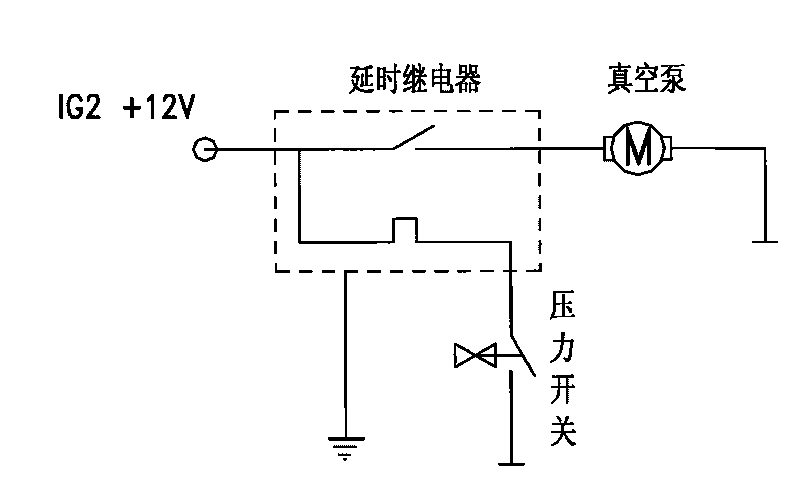

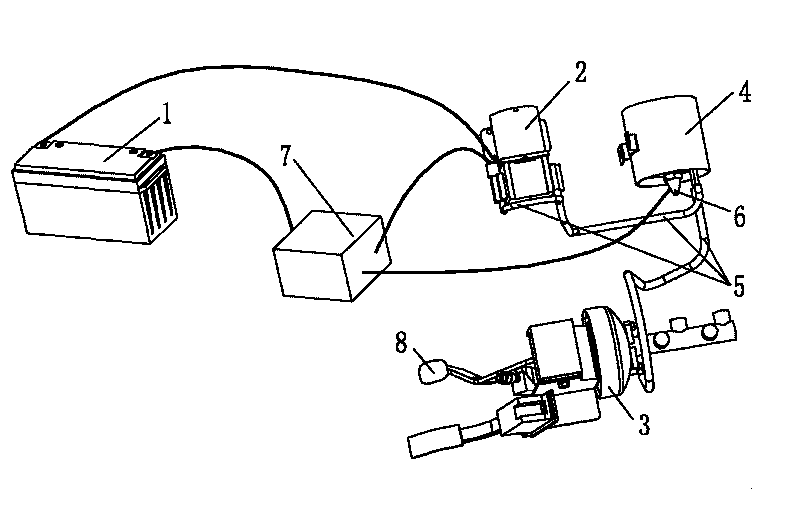

[0011] Such as figure 1 As shown, the electric power-assisted braking auxiliary system of an electric vehicle includes an electric vehicle auxiliary power supply 1, a vacuum pump 2, and a brake vacuum booster 3. 5 is connected to the vacuum gas storage tank 4 and then connected to the vacuum pump 2 through the vacuum pipeline 5, the vacuum gas storage tank 4 is provided with a pressure switch 6, the pressure switch 6 is connected to the delay relay 7, and the vacuum pump delay relay 7 is connected to the auxiliary power supply of the electric vehicle 1. Vacuum pump 2 circuit connection, the circuit schematic diagram is as follows figure 2 shown.

[0012] In this specific embodiment, adopt pressure switch 6 as vacuum pressure detector, pressure control range is set as 20kpa~40kpa, time-delay relay 7 is as vacuum pump time-delay control switch, and time-delay relay 7 is normally open state, and circuit is disconnected, Vacuum pump 2 does not work. When pressure switch 6 detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com