Check valve

a check valve and valve body technology, applied in the field of valves, can solve the problems of not providing the increased power boost desired to implement the brakes or other subsystems, and achieve the effect of preventing back pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The preferred embodiment of the invention herein described is not intended to be exhaustive or to limit the invention to the precise form disclosed. It is chosen and described to explain the principles of the invention, and its application and practical use to enable others skilled in the art to follow its-teachings.

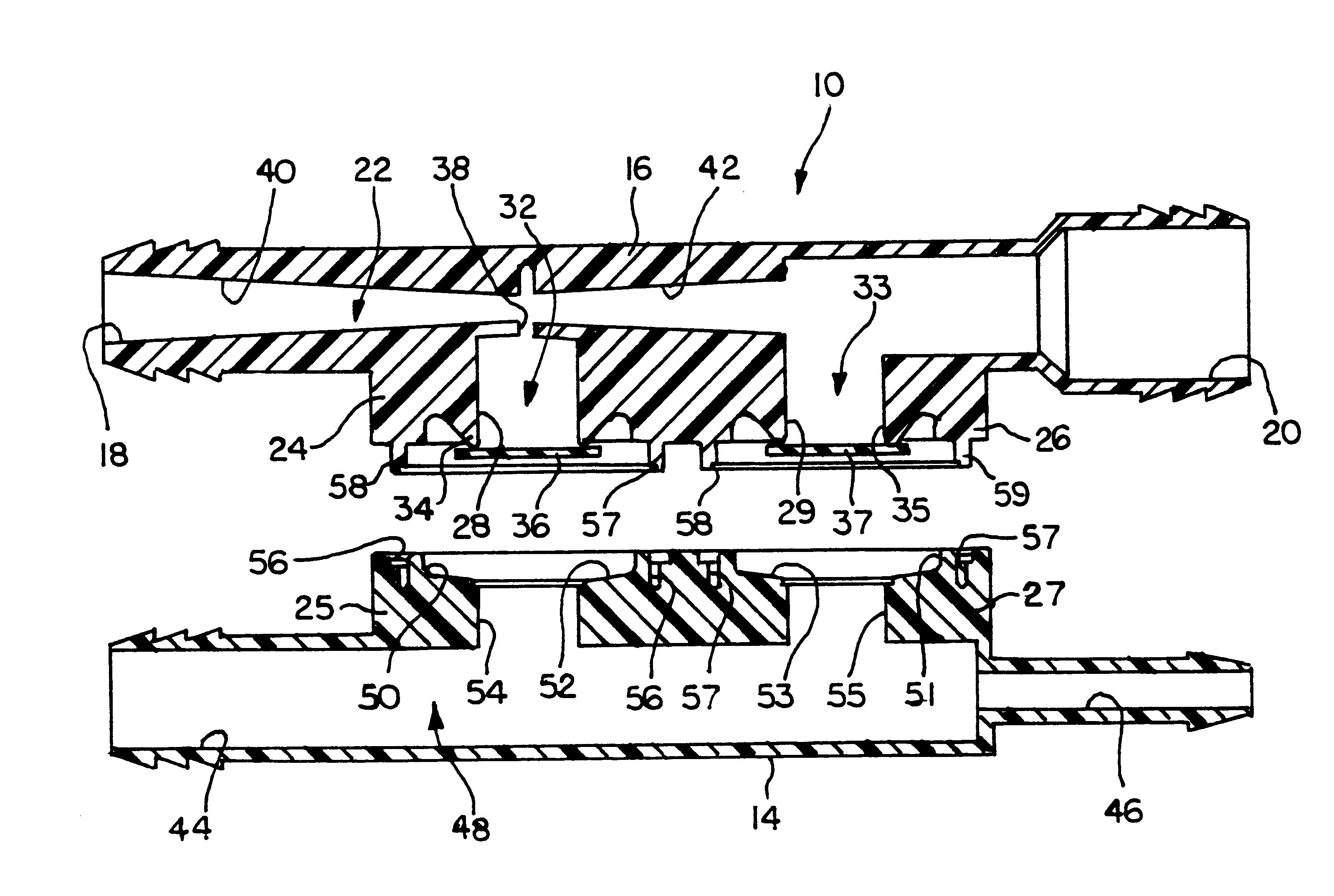

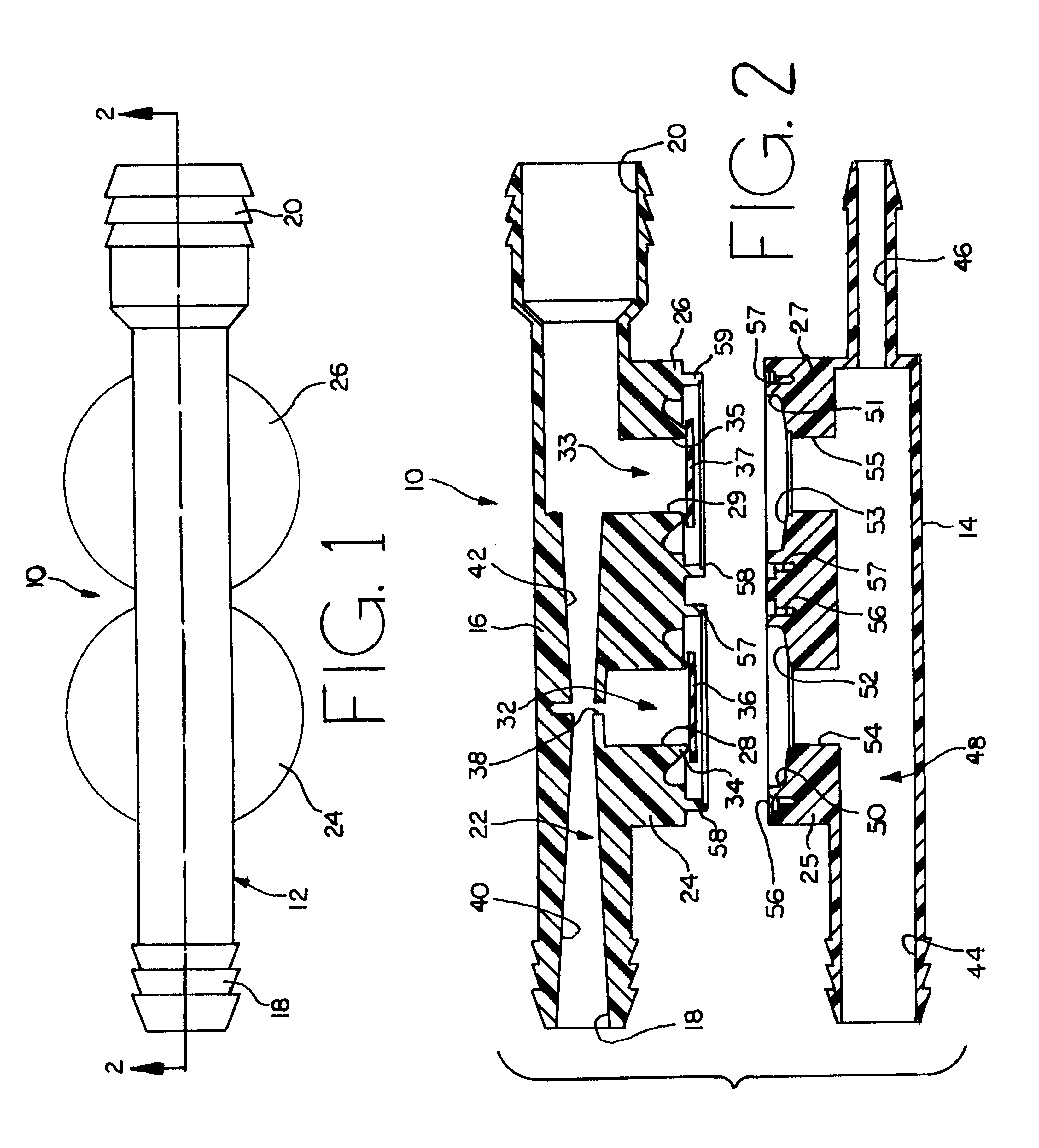

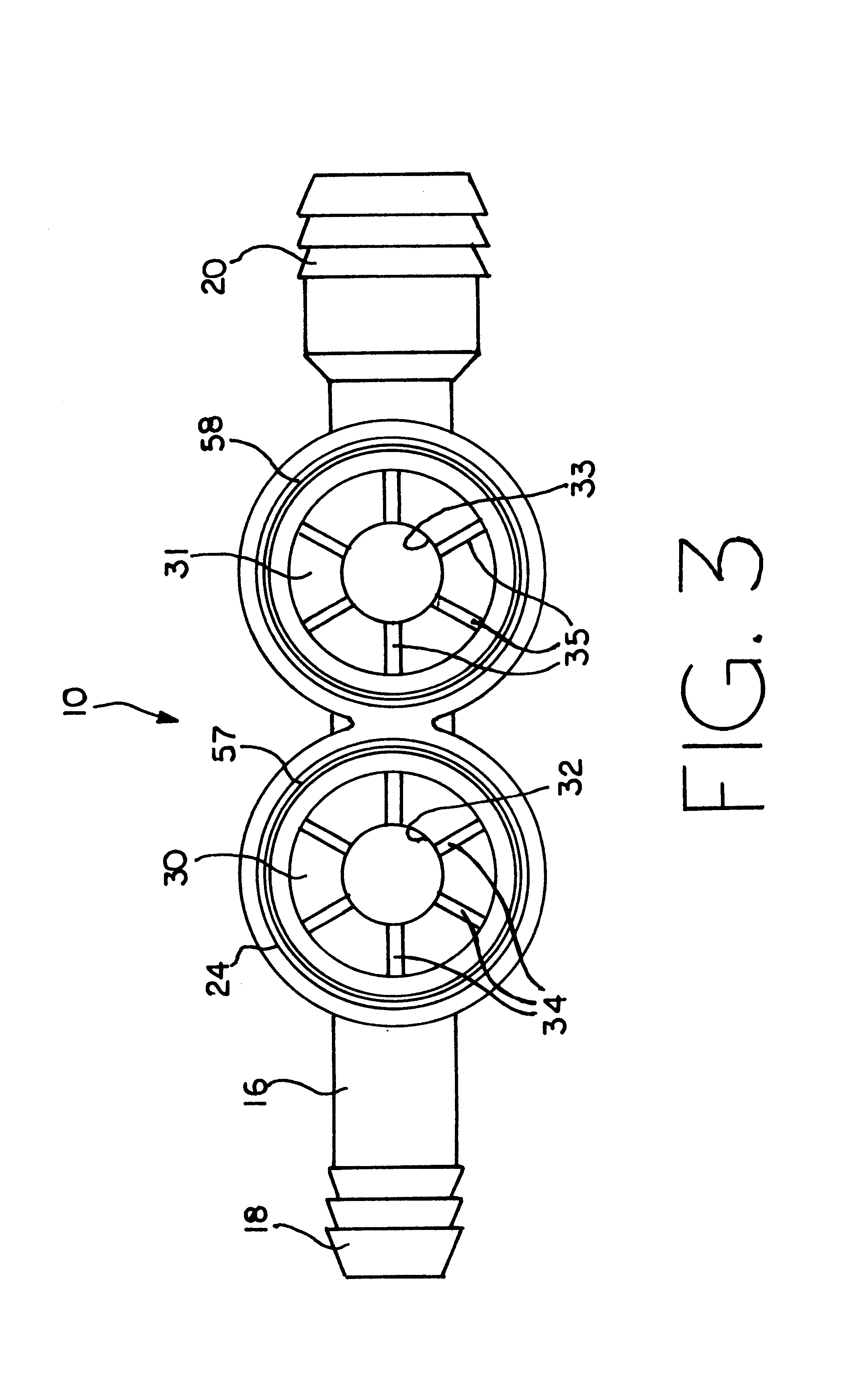

Referring now to the drawings, reference numeral 10 refers generally to the check valve of this invention. Check valve 10 is normally employed in an internal combustion engine in the air flow line between the engine block and the air intake port at the full mixing port, normally a carburetor or fuel injection port. For clarity, the engine, carburetor, hose connections, and subsystems are not shown, and it is understood that these ports are common to the internal combustion engines found in almost all vehicles.

The air flow system in the typical internal combustion engine operates on the principle that as the engine operates, a partial vacuum is created which pulls air thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com