High-pressure washer

A technology for high-pressure cleaners and cabinets, applied in spraying devices, single handheld devices, etc., can solve problems such as large power influence and unsatisfactory effect of viscous liquids, so as to improve spraying effect, expand the scope of use, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the accompanying drawings, the present invention will be described in detail through specific embodiments, but the use and purpose of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of any limitation on the actual protection scope of the present invention, let alone The protection scope of the present invention is limited thereto.

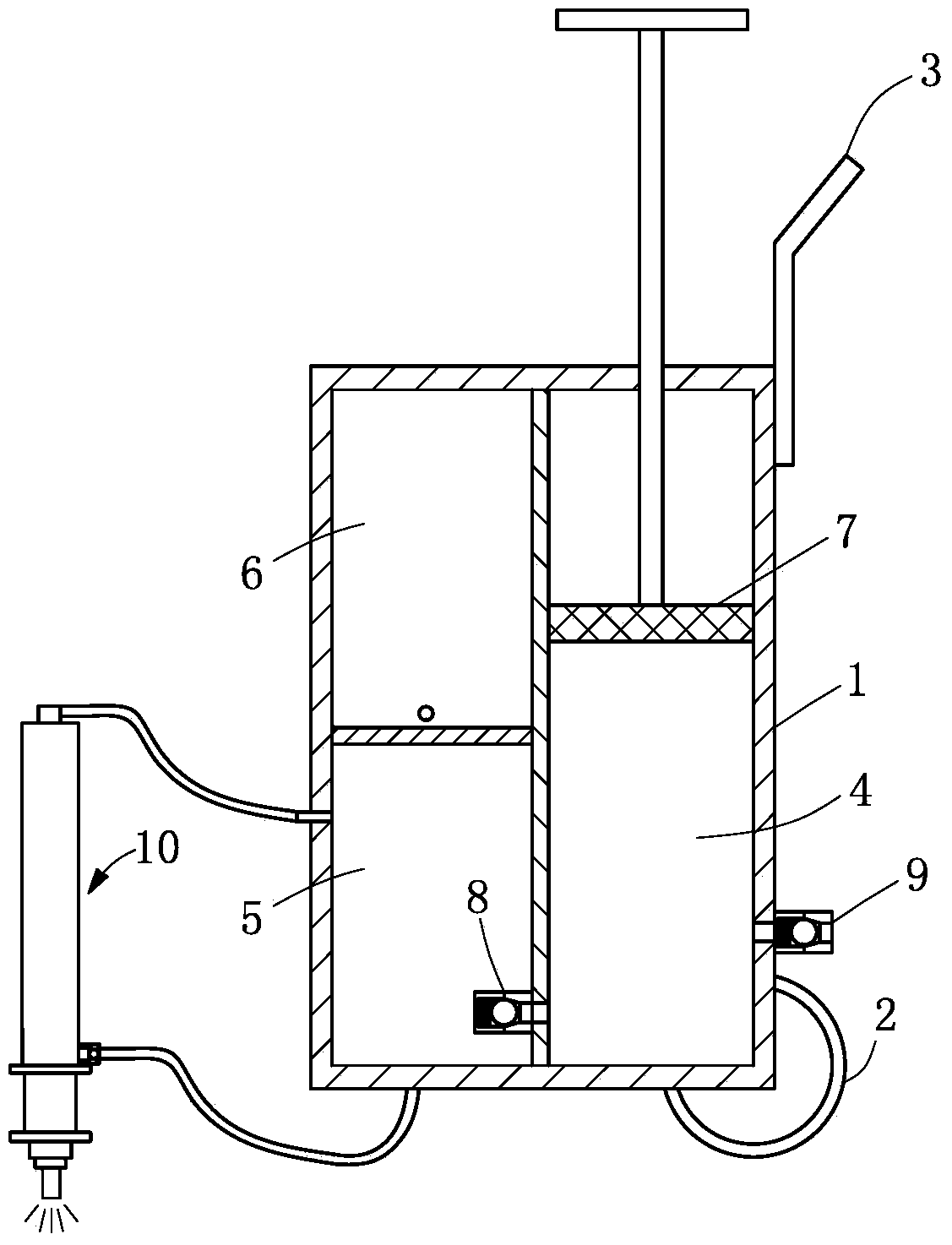

[0023] Such as figure 1 As shown, a high-pressure cleaning machine mainly includes a casing 1, a roller 2 is mounted on the bottom of the casing 1, a handrail 3 is provided on one side of the casing 1, and a piston chamber 4 is arranged in the casing 1. An air storage chamber 5 and a material storage chamber 6, the material storage chamber 6 is filled with lubricating oil, the air storage chamber 5 is located below the material storage chamber 6, the piston chamber 4 is located on one side of the air storage chamber 5 and passes through a one-way The val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com