Tunnel furnace for terminal cable and use method of tunnel furnace

A technology of cable wire and tunnel furnace, applied in the field of terminal wire processing, can solve the problems of sticking, difficult to cut and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

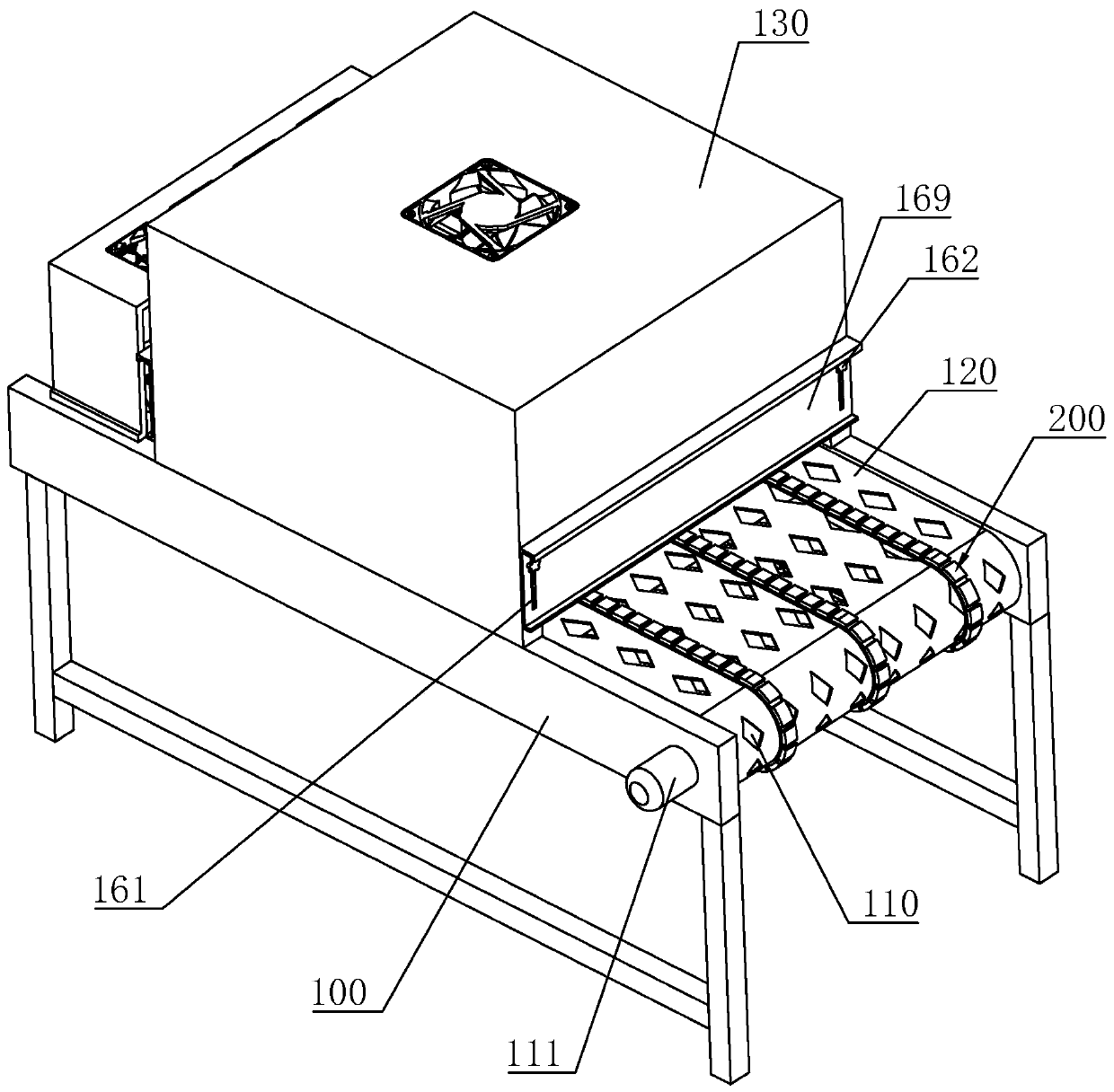

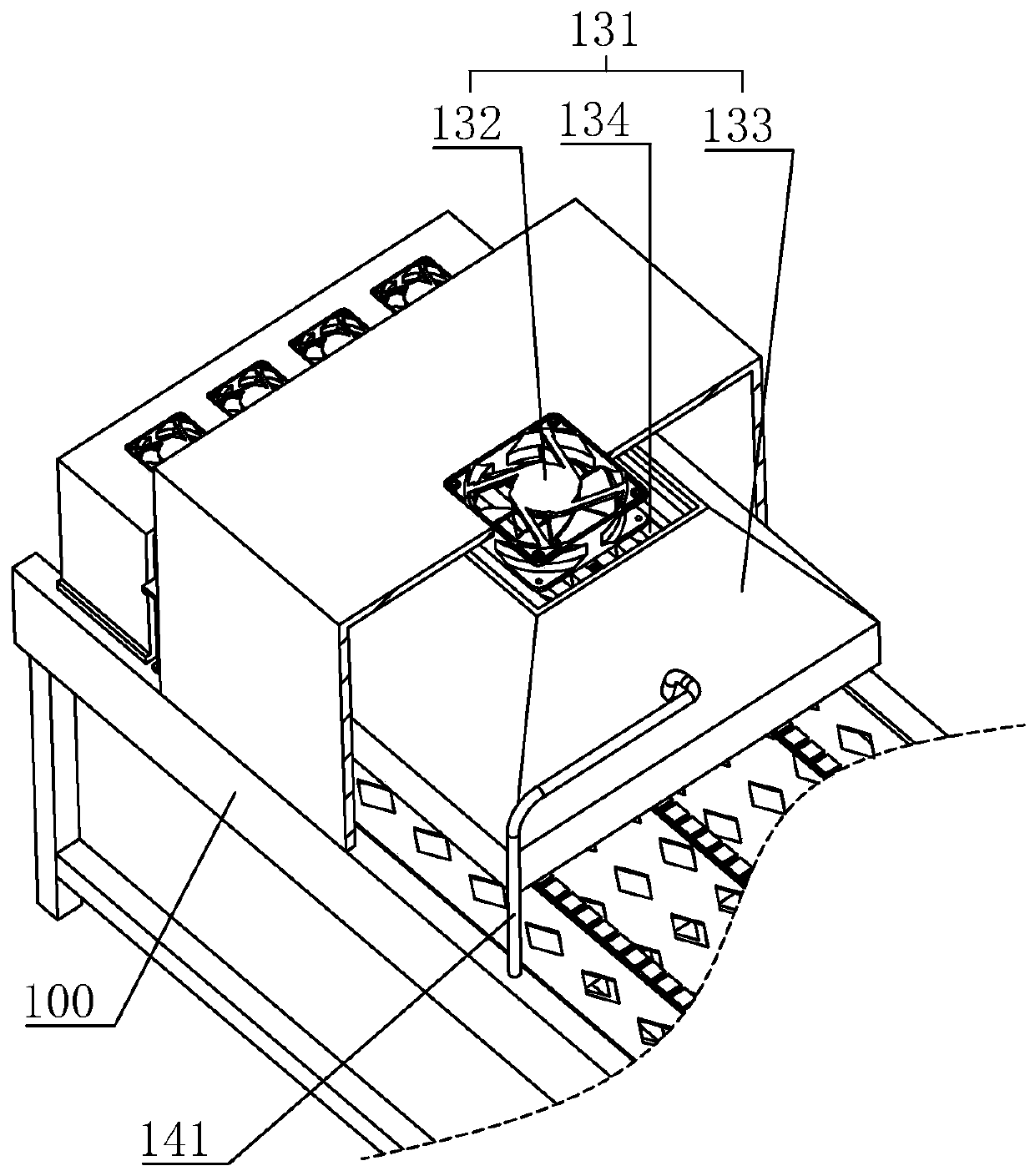

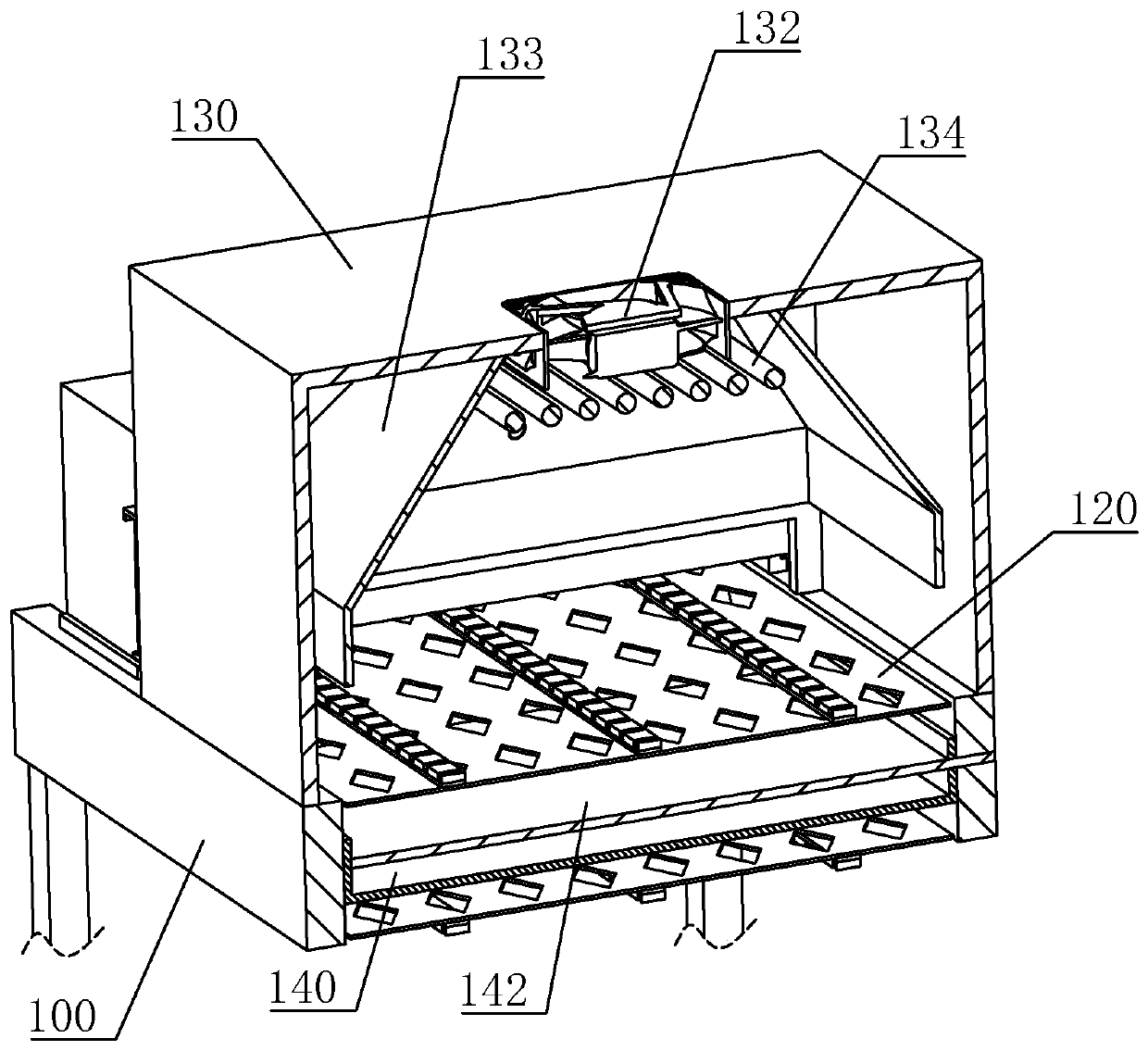

[0045] A tunnel furnace for terminal cables, refer to figure 1 , figure 2 , including a frame 100, both ends of the frame 100 are rotatably connected to conveying rollers 110, a conveying motor 111 is installed on the frame 100, and the output shaft of the conveying motor 111 is fixedly connected to one of the conveying rollers 110. The conveying roller 110 is sheathed with a conveying net 120 for conveying the wire, and in this embodiment the conveying net 120 is a stainless steel mesh chain. A drying box 130 is fixed in the middle of the frame 100 by bolts, and a drying device 131 is arranged in the drying box 130 . After placing the terminal cables covered with heat-shrinkable tubes on the conveying network 120, they are driven by the conveying roller 110 into the drying box 130, and the terminal cables are heated by the drying device 131, so that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com