Patents

Literature

148results about How to "Drop smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

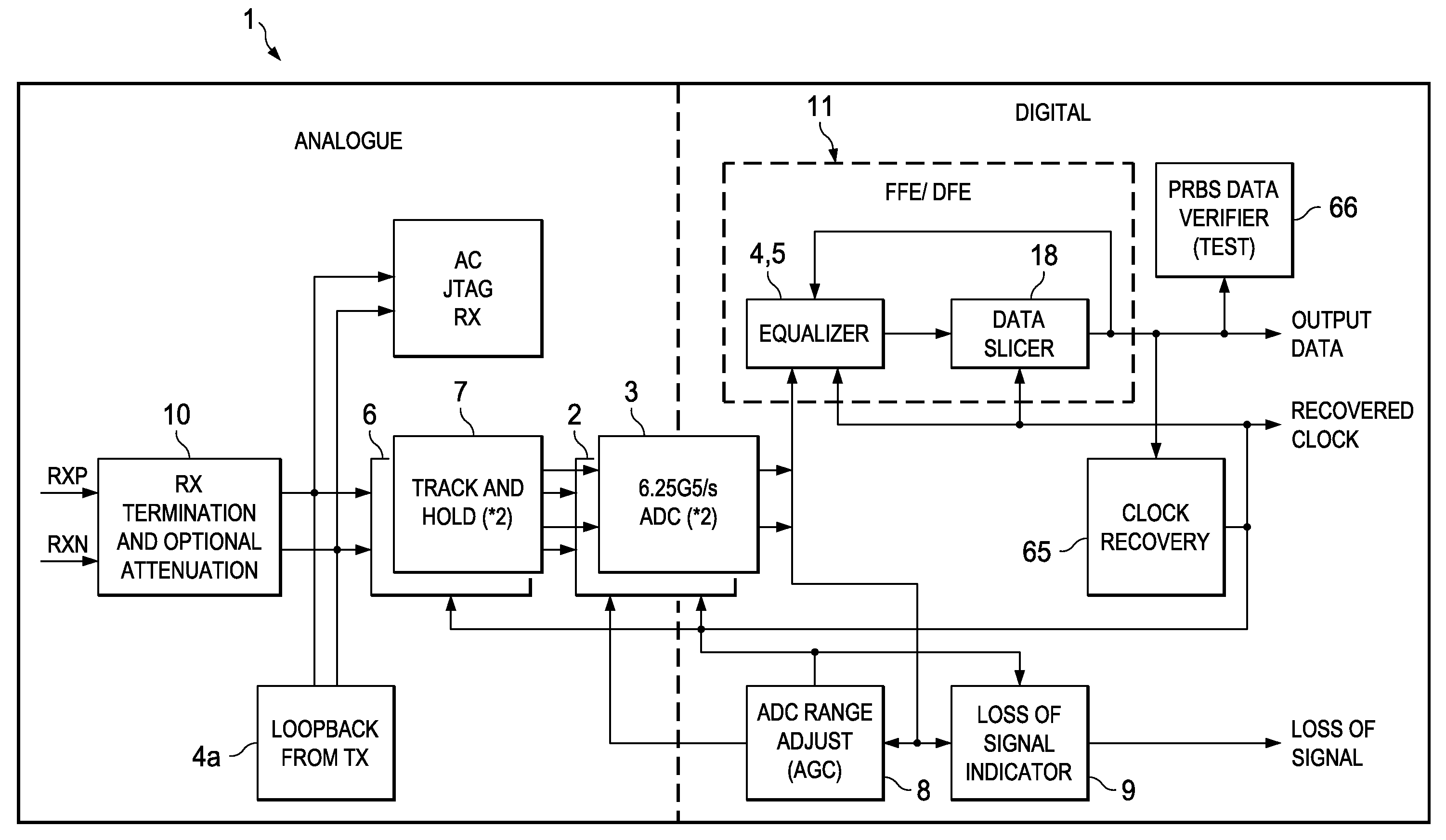

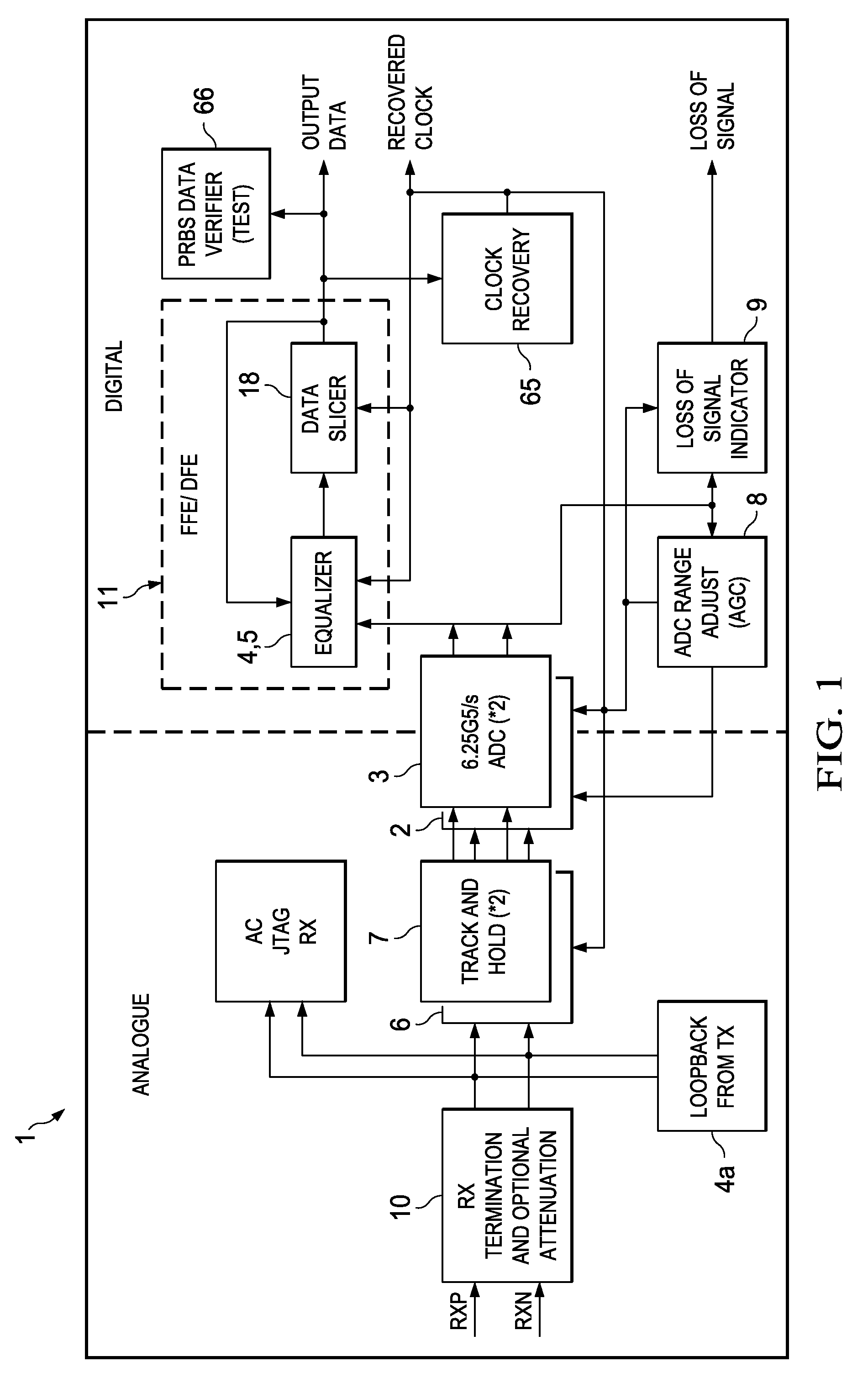

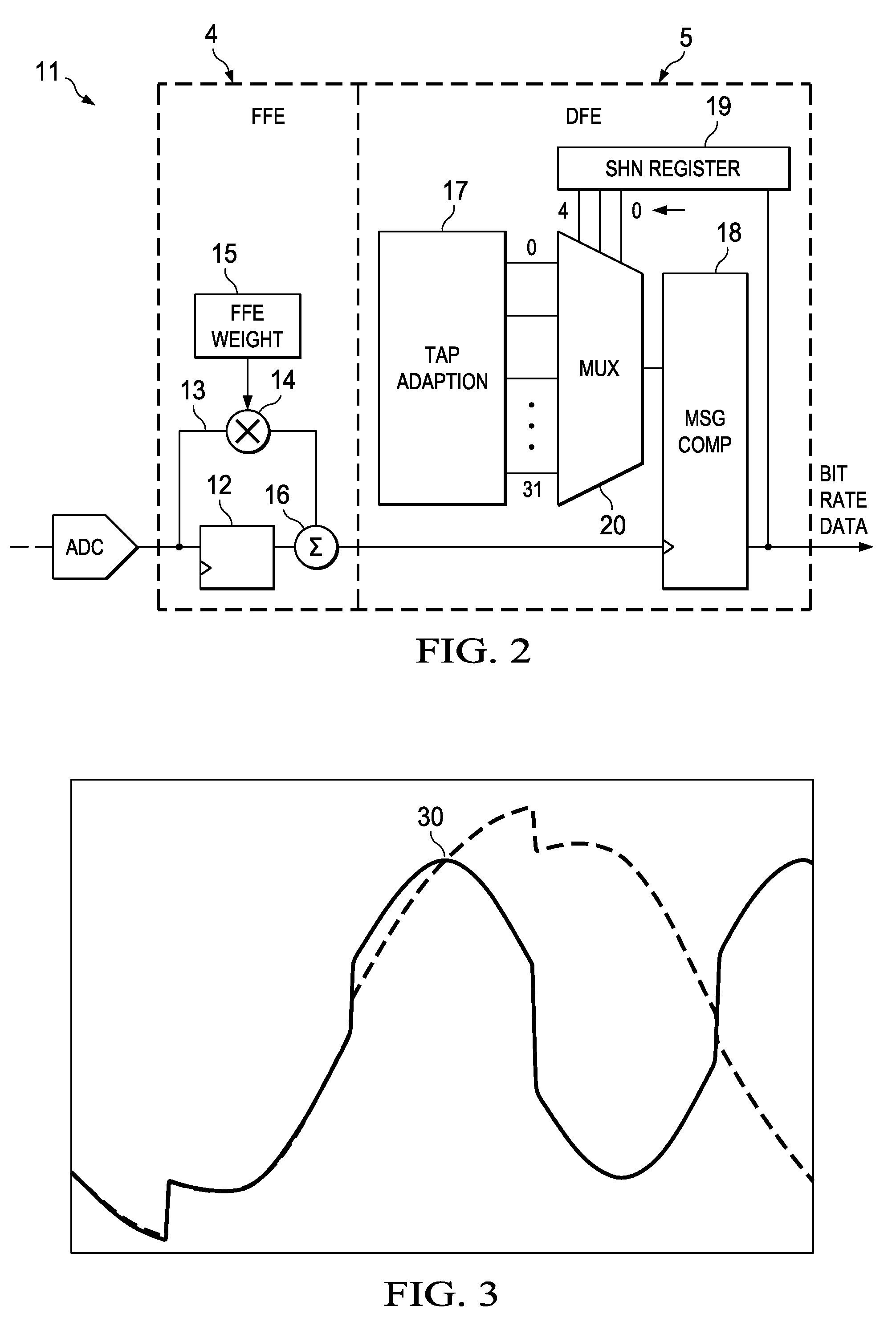

Analogue Signal Modelling Routine for a Hardware Description Language

InactiveUS20080195363A1Easily invertedHigh frequencyCAD circuit designSpecial data processing applicationsFloating pointAnalog signal

An analogue signal modelling routine for a hardware description language, wherein an output providing an analogue signal is represented by a value stored in an output variable, an input accepting the analogue signal is represented by a value stored in an input variable, and the routine is arranged to update the value stored in the input variable when the value stored on the output value is changed. The level of an analogue signal can be represented using a floating point number.

Owner:TEXAS INSTR INC

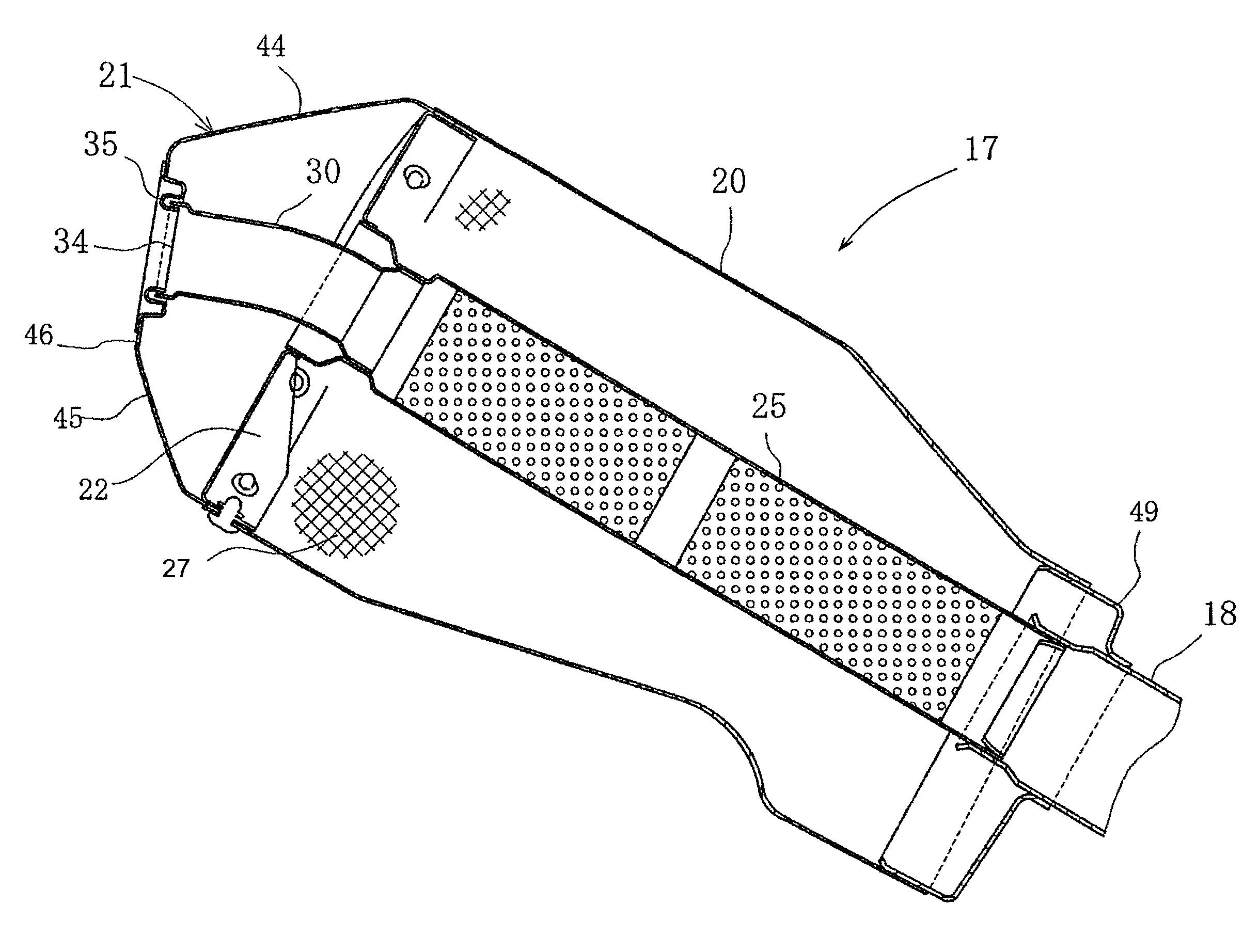

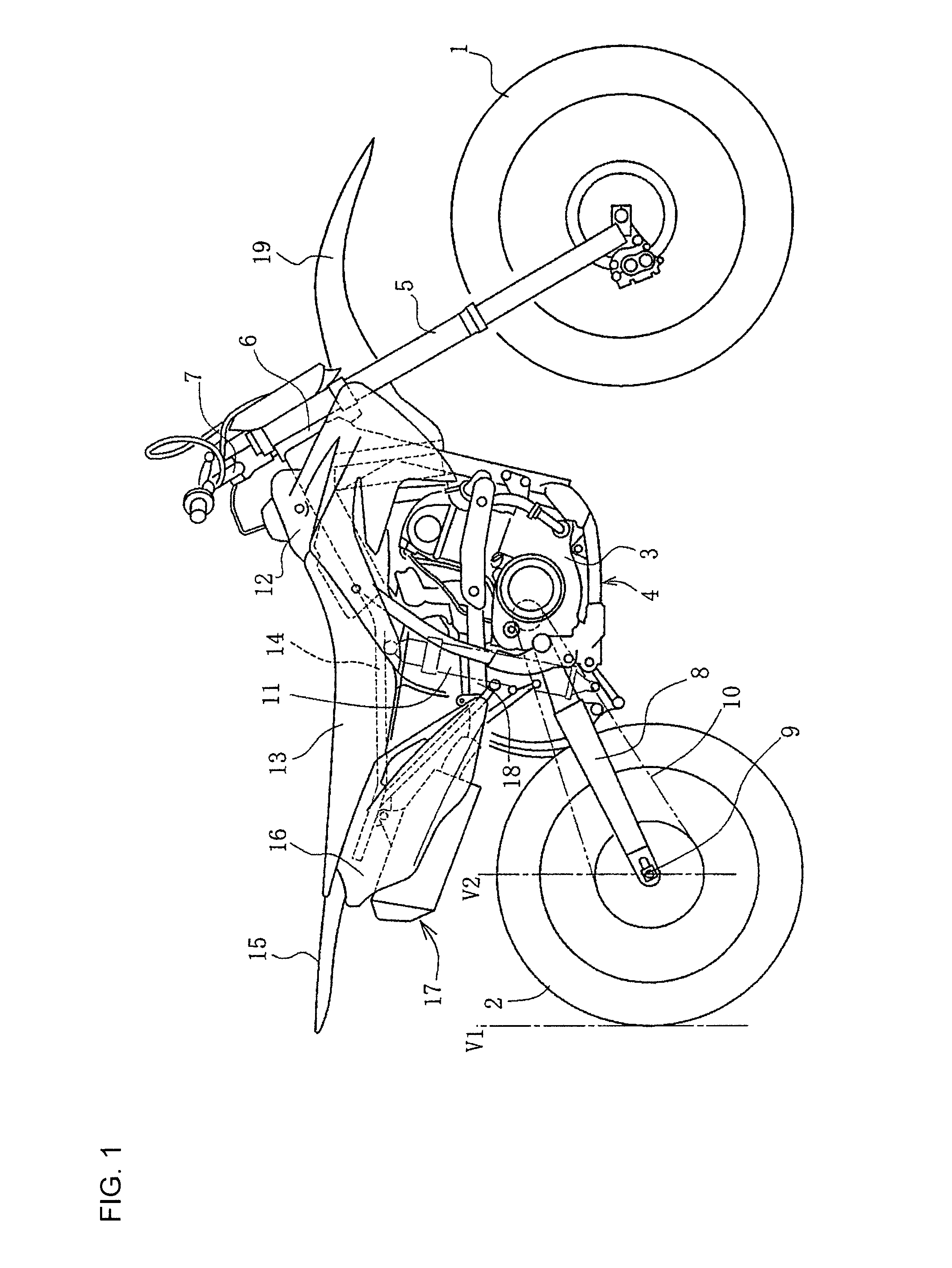

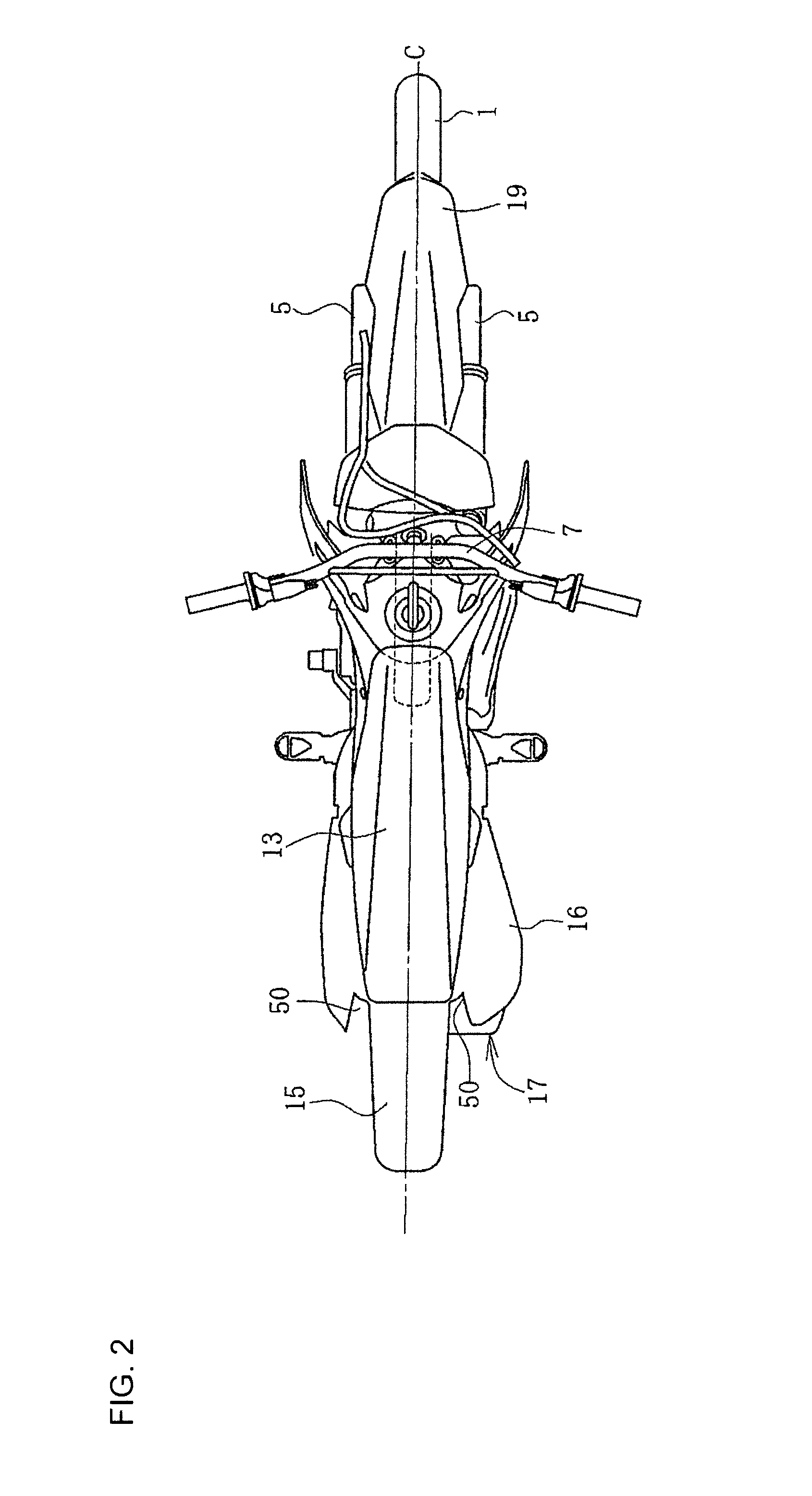

Muffler device for motorcycle

InactiveUS8151932B2Improve design flexibilityChange designExhaust apparatusSilencing apparatusEngineeringPipe support

Owner:HONDA MOTOR CO LTD

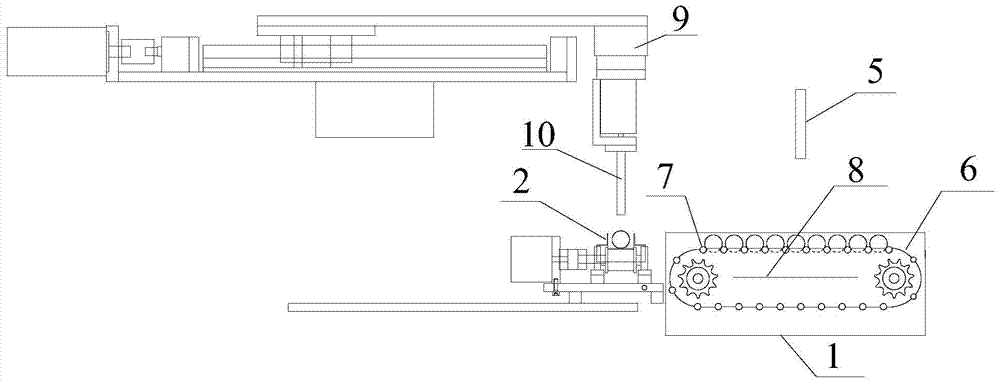

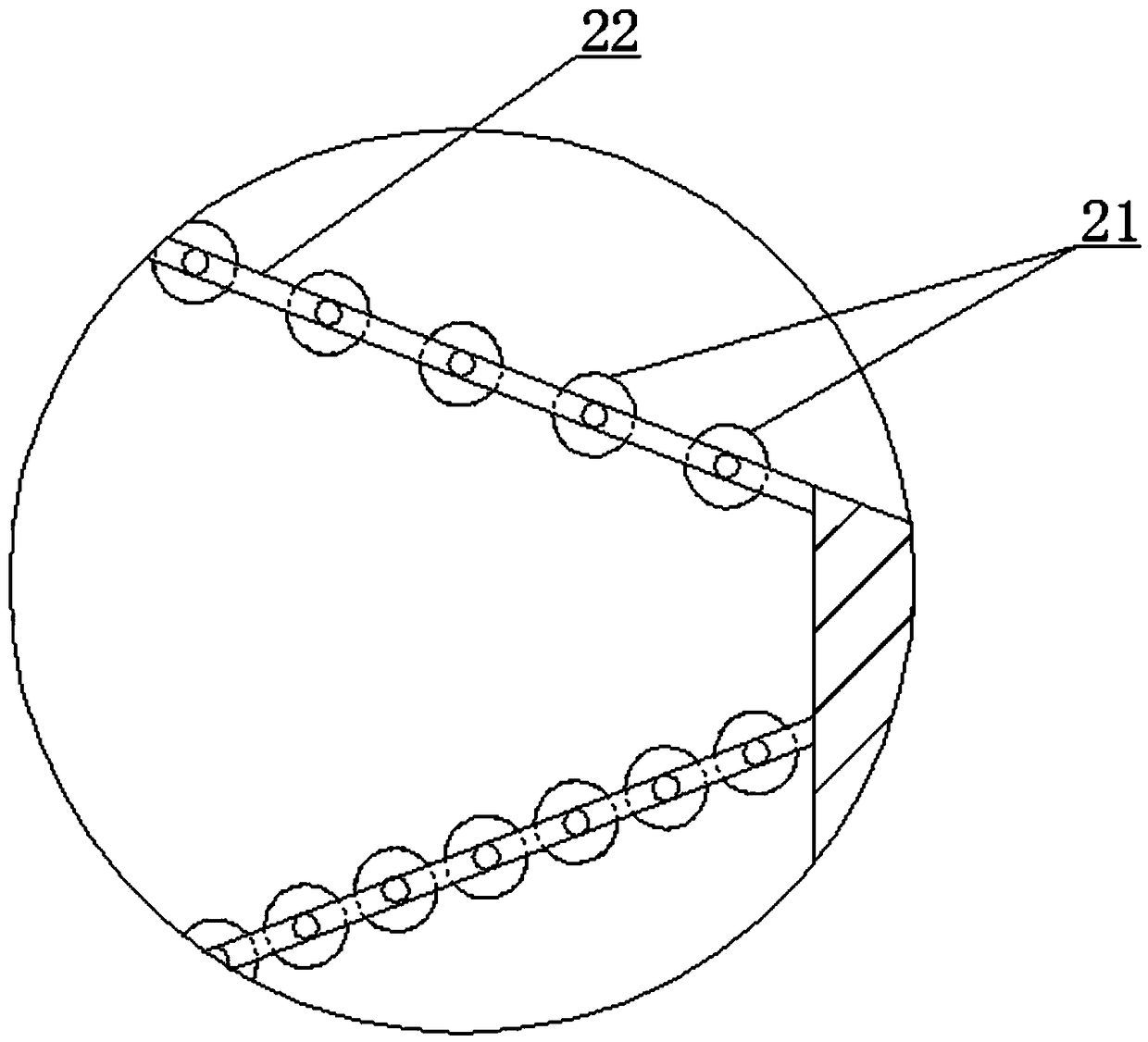

Bottle collating mechanism for medicinal glass bottle production line

ActiveCN103922110AArrange neatlyGuaranteed correctnessControl devices for conveyorsEngineeringBottle

The invention discloses a bottle collating mechanism for a medicinal glass bottle production line. The bottle collating mechanism comprises a collating device, a conveying device and a mechanical arm, and further comprises a detecting device, and the detecting device comprises a photographic device. The detecting device is additionally arranged on the bottle collating mechanism, incomplete glass bottles can be eliminated while bottle collating is carried out, clamping caused by the smashed glass bottles is avoided, and the normal working efficiency of the collating mechanism and a follow-up detecting mechanism is guaranteed.

Owner:INST OF APPLIED MATHEMATICS HEBEI ACADEMY OF SCI

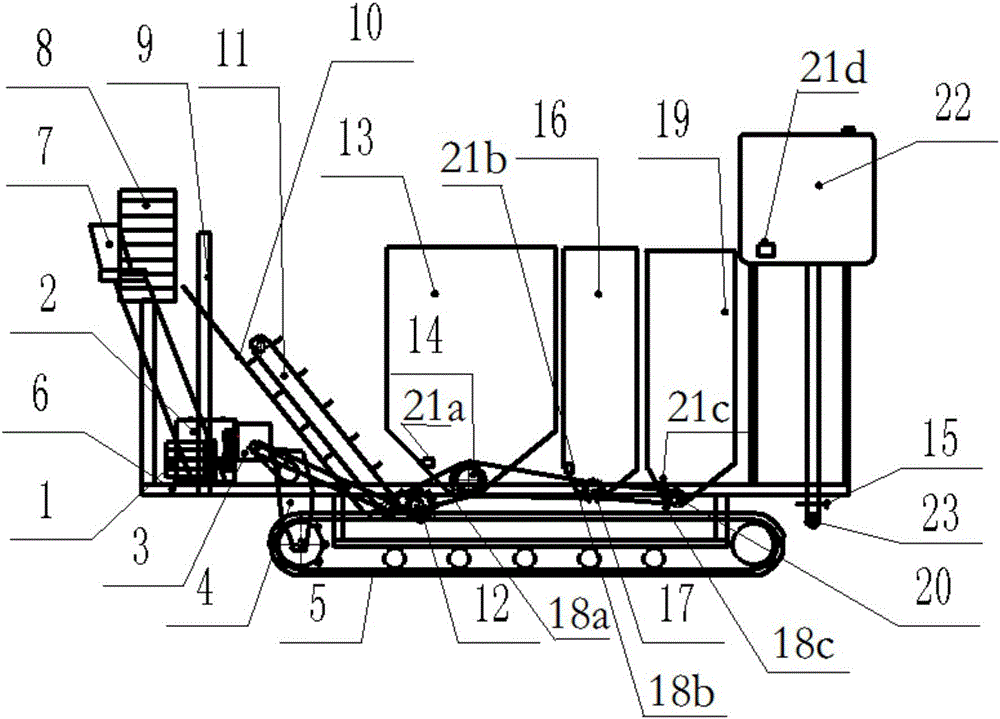

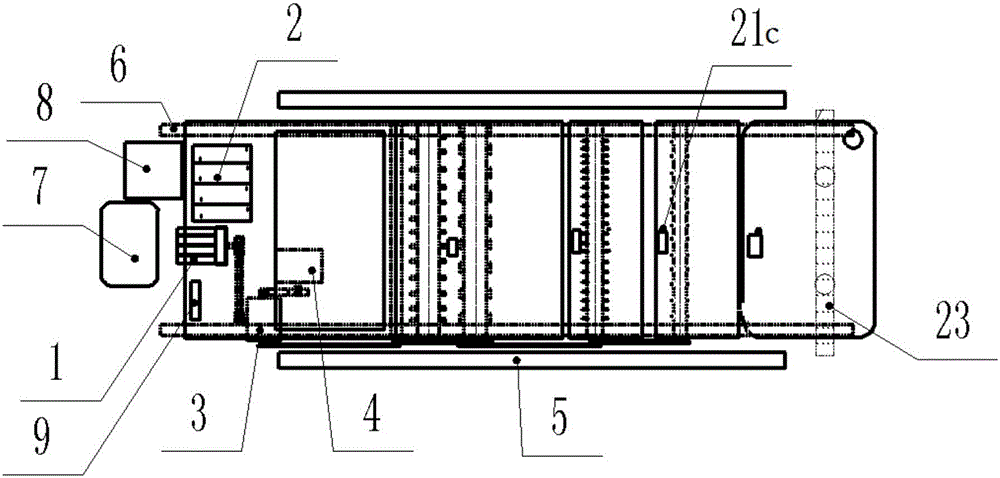

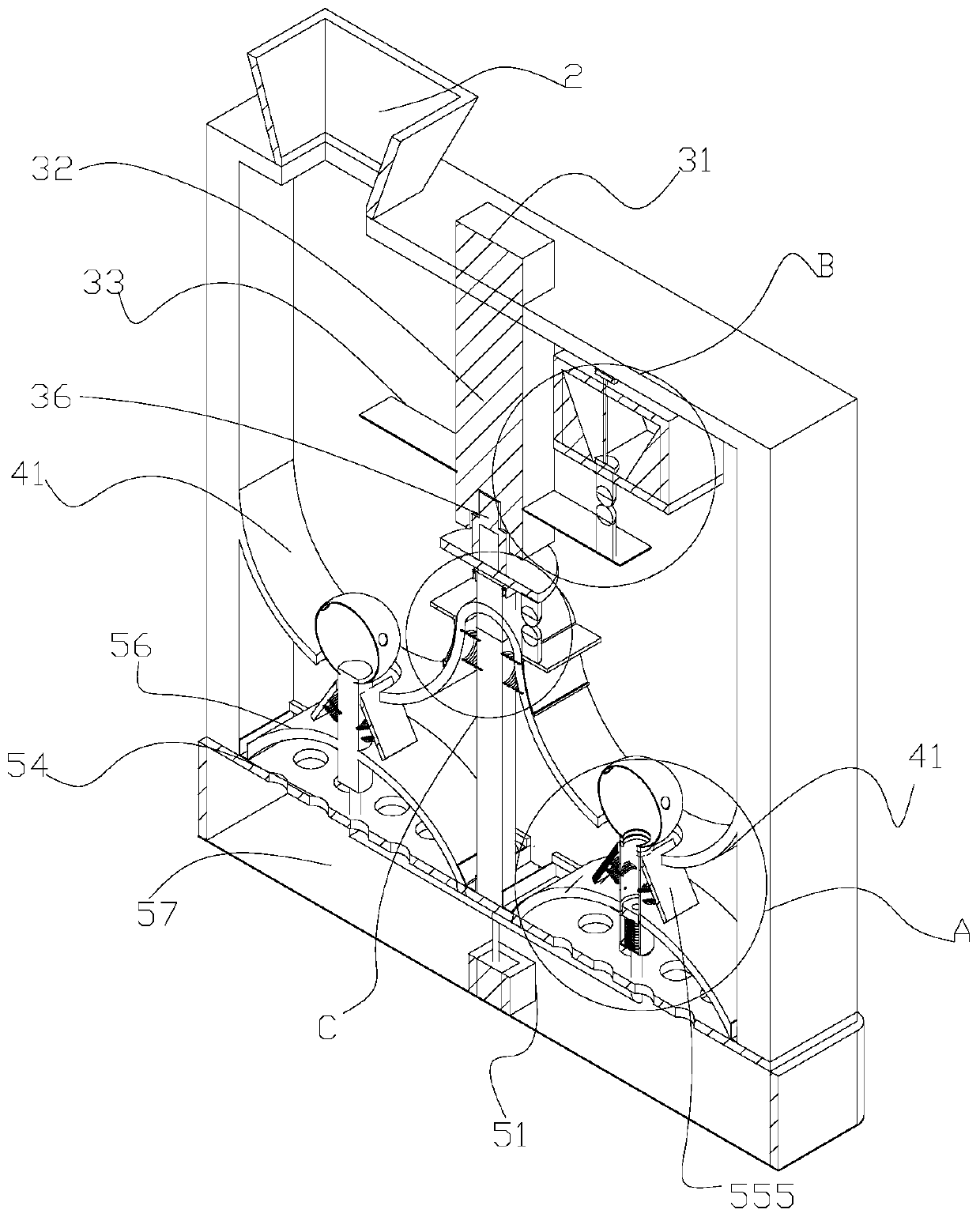

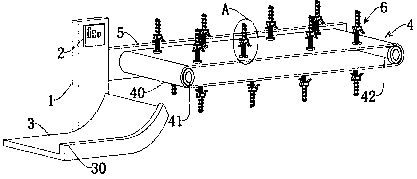

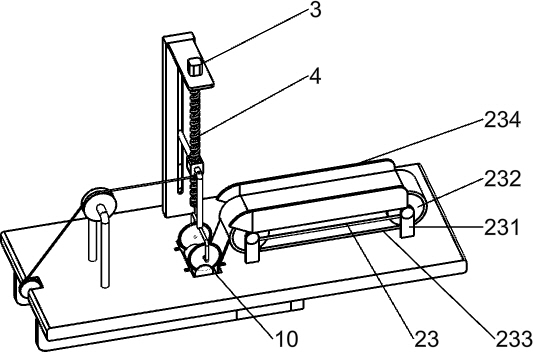

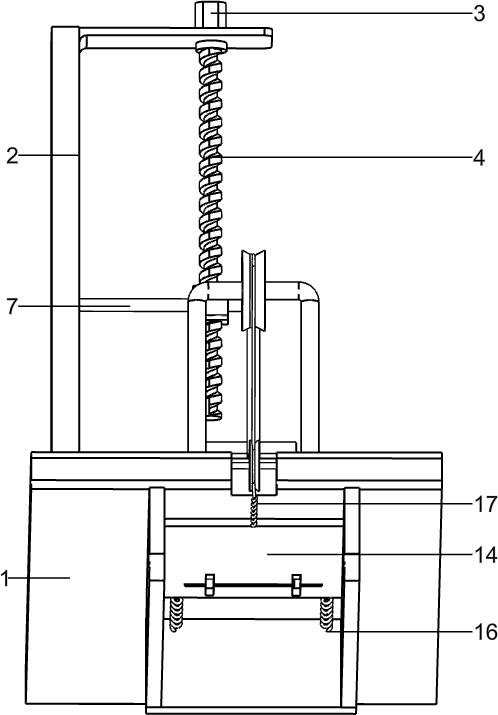

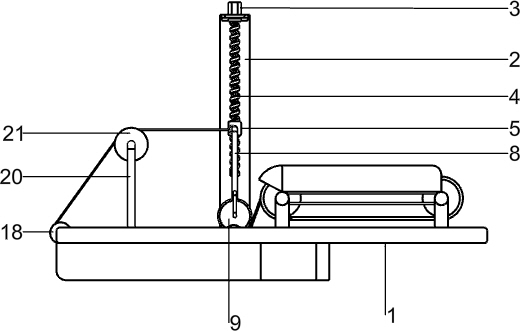

Tray arranging and sowing machine for seedling raising

ActiveCN106134831AAutomated program highSeedling effect guaranteeGrowth substratesCulture mediaSeederWater volume

The invention discloses a tray arranging and sowing machine for seedling raising and relates to the technical field of agricultural machinery. The tray arranging and sowing machine comprises a nutrient soil box, a seed box, a soil covering box and a water box, and is characterized by further comprising a nutrient soil amount sensor, a seed amount sensor, a soil covering amount sensor and a water volume sensor which are arranged in the nutrient soil box, the seed box, the soil covering box and the water box respectively and used for monitoring the quantity of remaining materials in the corresponding boxes, and the tray arranging and sowing machine further comprises a control device and an alarm device; each sensor sends a signal to the control device when monitoring that the quantity of remaining materials in the corresponding box is lower than a corresponding preset value, and the control device controls the alarm device to perform alarming to remind a worker to add the corresponding material timely.

Owner:JIANGXI ACAD OF AGRI SCI INST OF AGRI ENG

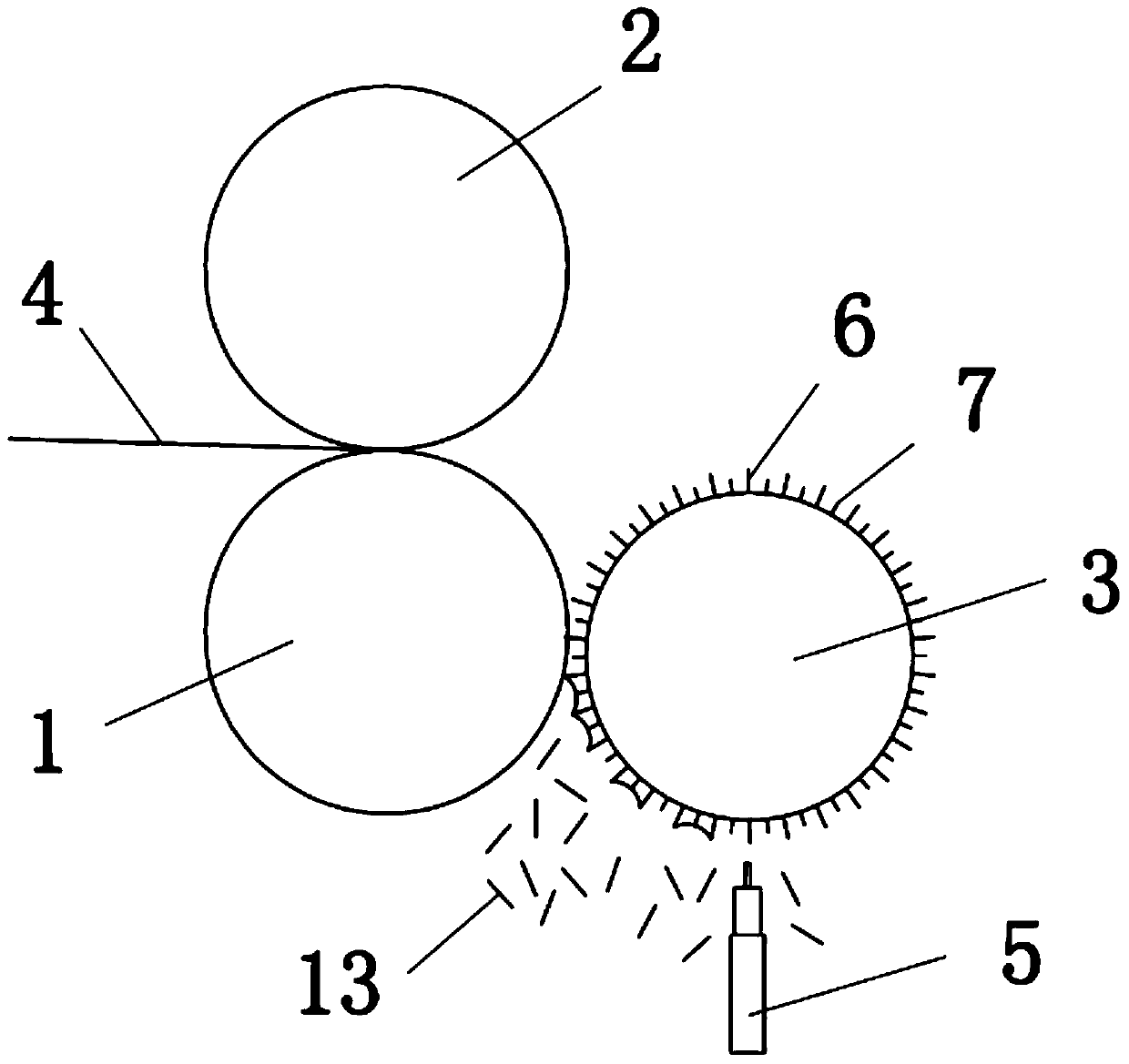

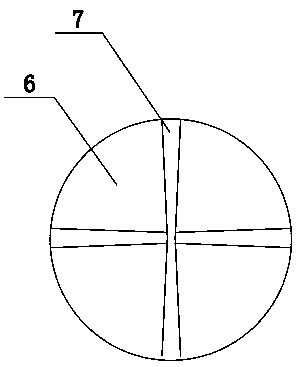

Carbon fiber yarn bundle chopping device and shearing method thereof

The invention discloses a carbon fiber yarn bundle chopping device and a shearing method thereof. The carbon fiber yarn bundle chopping device comprises a transmission mechanism for conveying carbon fiber yarn bundles, and a chopping mechanism for cutting off the carbon fiber yarn bundles, wherein the transmission mechanism comprises a pressing roller and a rubber roller arranged below the pressing roller; the chopping mechanism comprises a cutter roller and an air nozzle arranged below the cutter roller; a plurality of blades are distributed on the surface of the outer circumference of the cutter roller at intervals; jacking sheets are arranged between the blades; the cutting edges of the blades are in contact with the rubber roller; during shearing, the jacking sheets stop chopped carbon fibers from falling into clearances between the blades; meanwhile, the air nozzle below the cutter roller blows out air flow formed in the clearances between the blades and the jacking sheets so as to blow off the chopped carbon fibers attached to the cutter roller from the cutter roller and enable the chopped carbon fibers to fall off, so that the chopped carbon fibers are obtained. The device is simple in structure, and the shearing method is simple; the cutting technology is convenient and quick; compared with the prior art, the carbon fiber yarn bundle chopping device and the shearing method have the advantages that the cost is low, the production efficiency is high, and the technical measure is simple and feasible.

Owner:SOUTH CHINA UNIV OF TECH

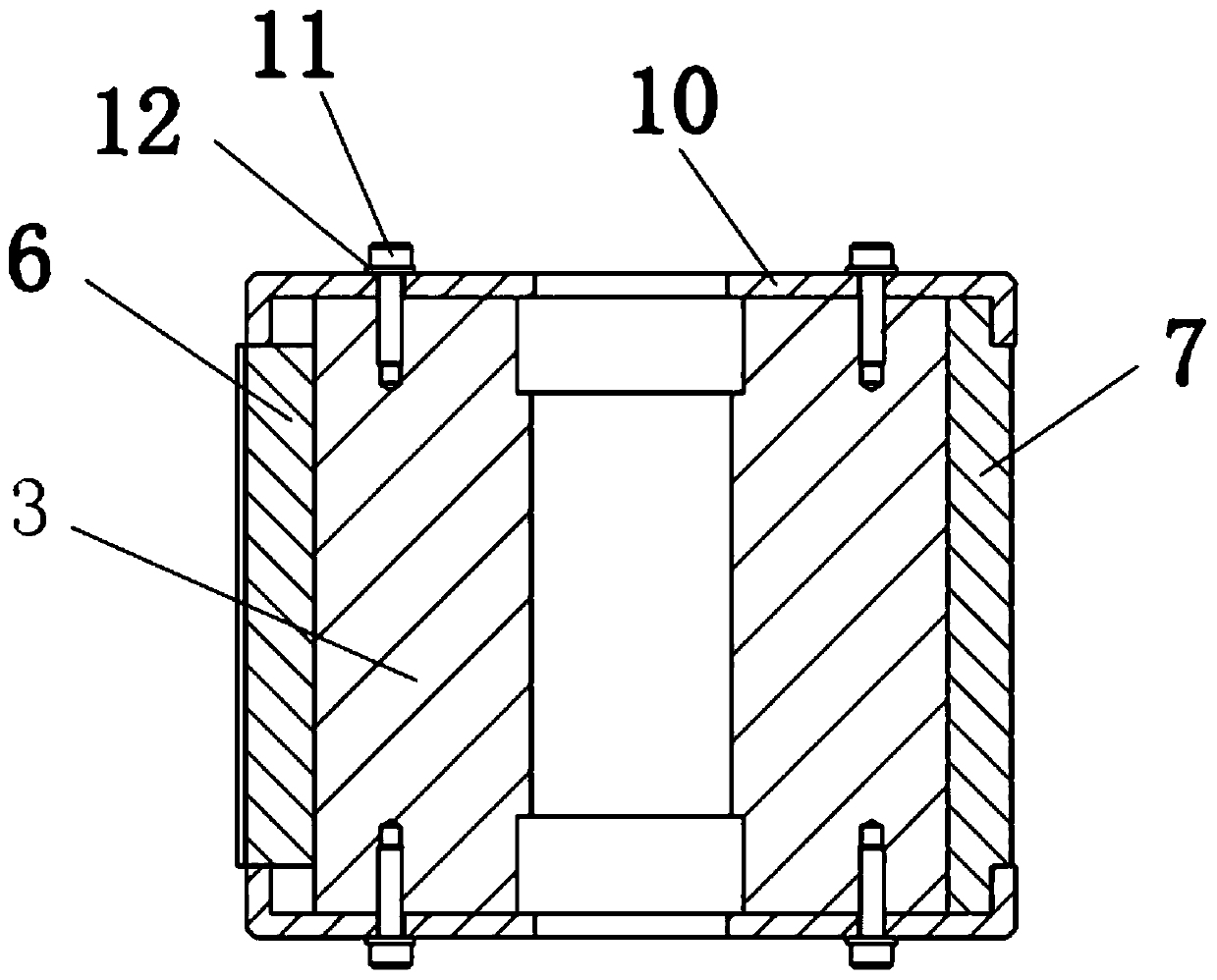

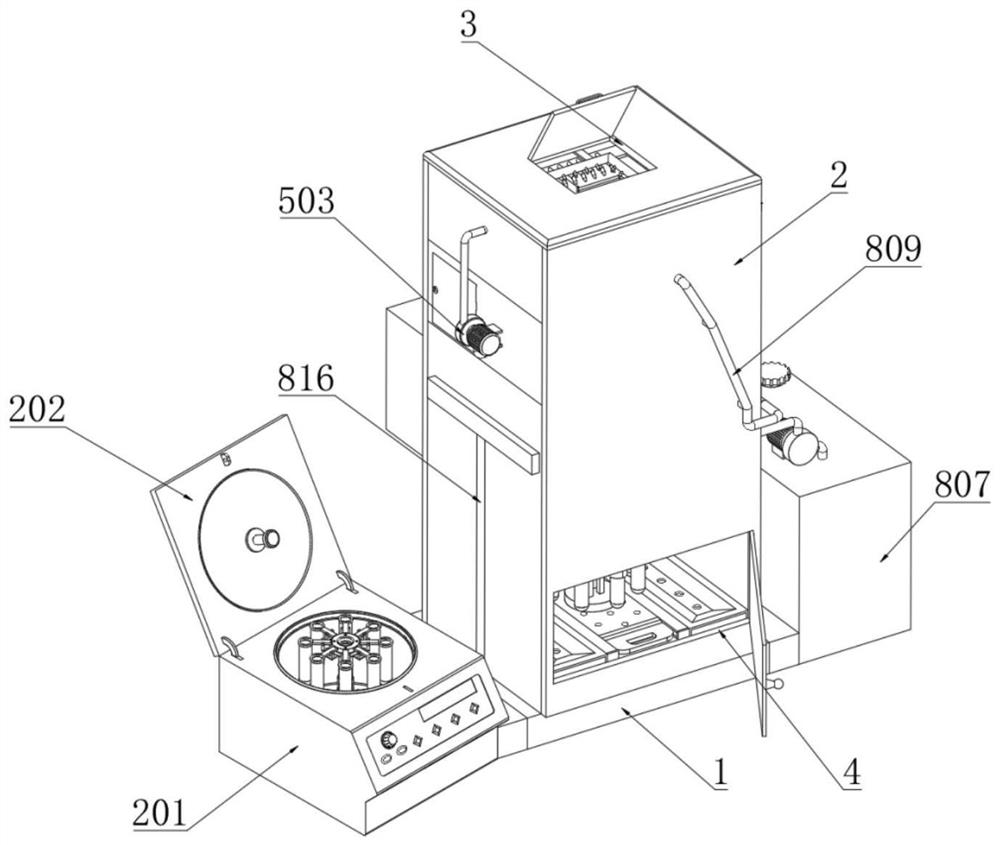

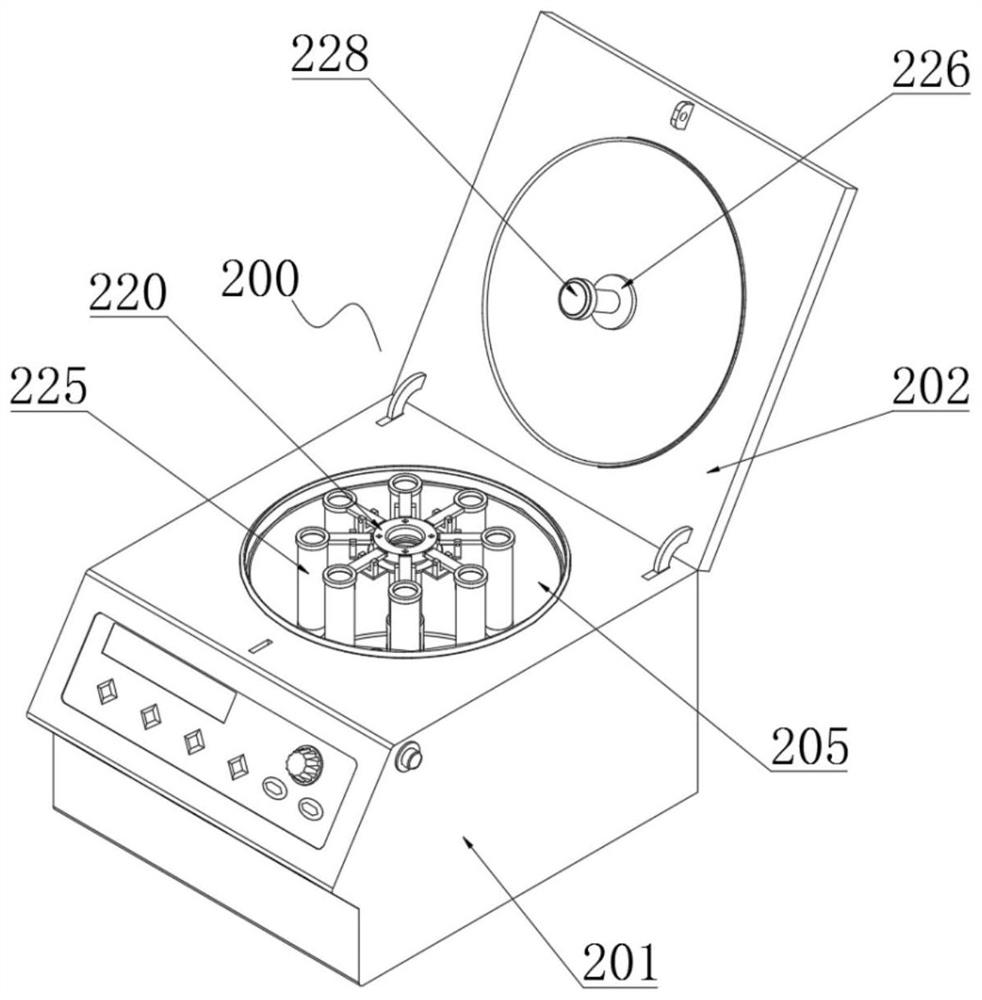

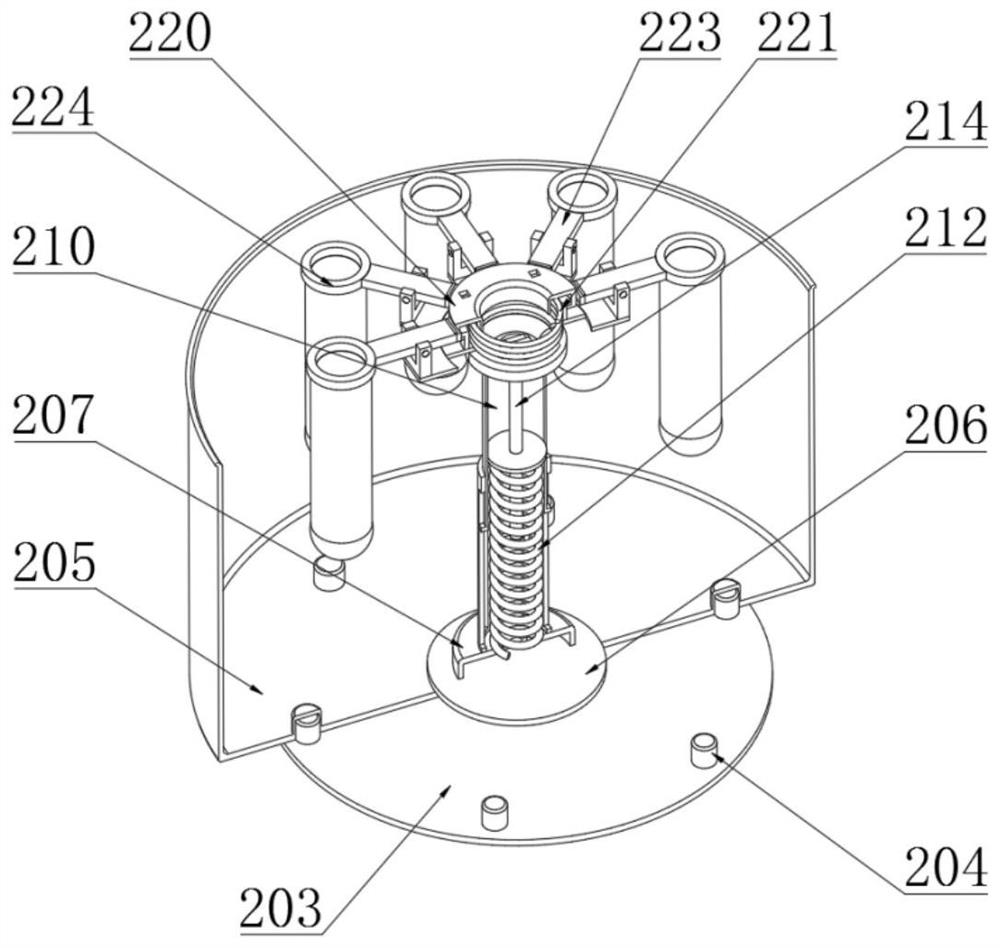

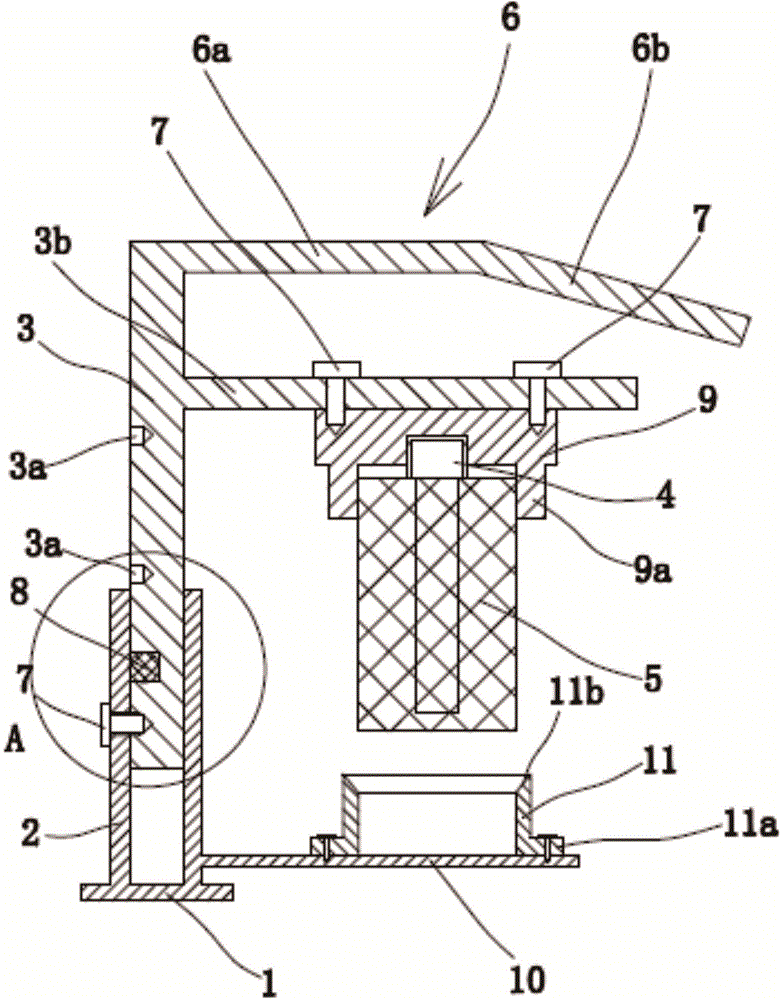

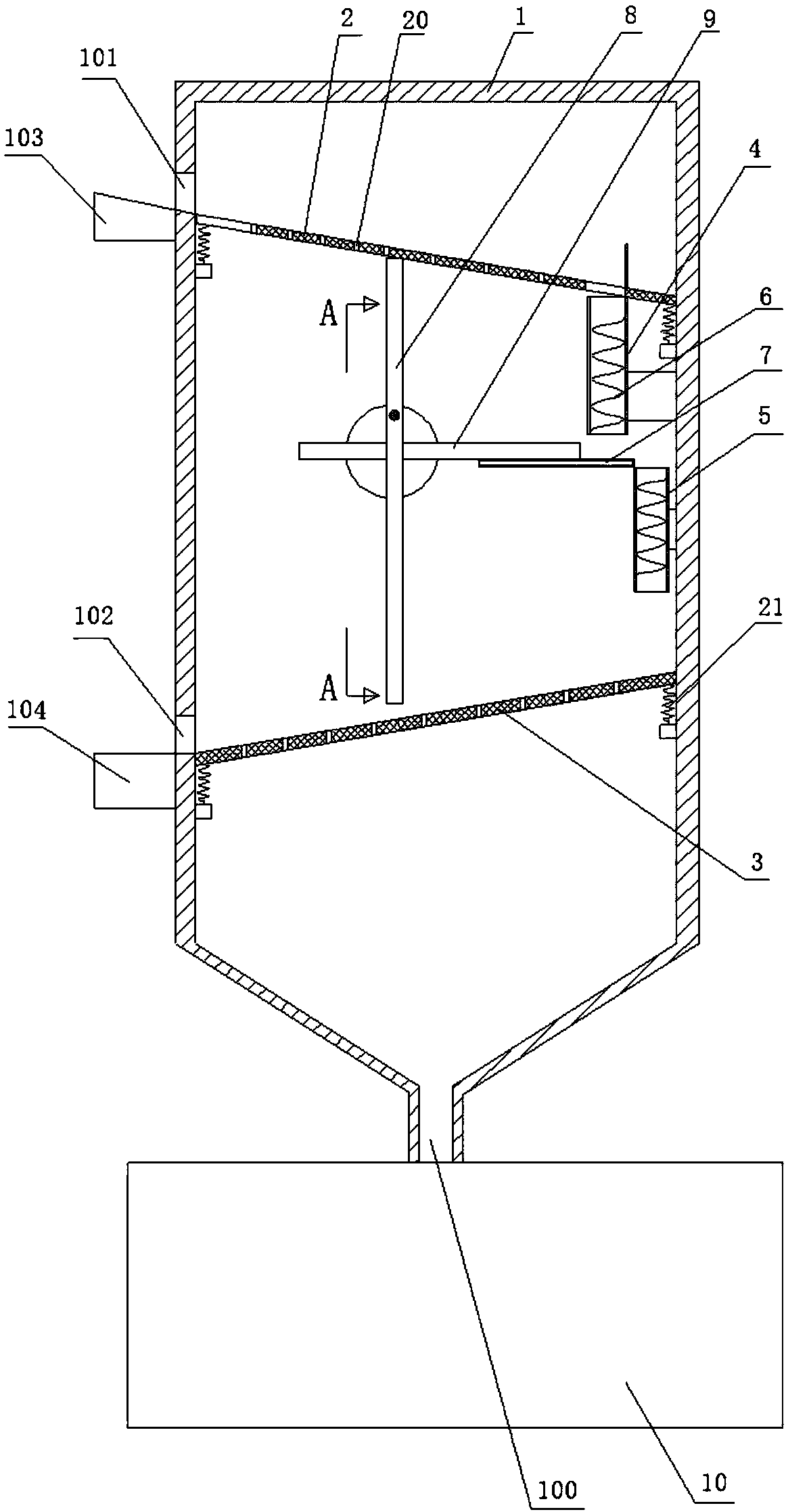

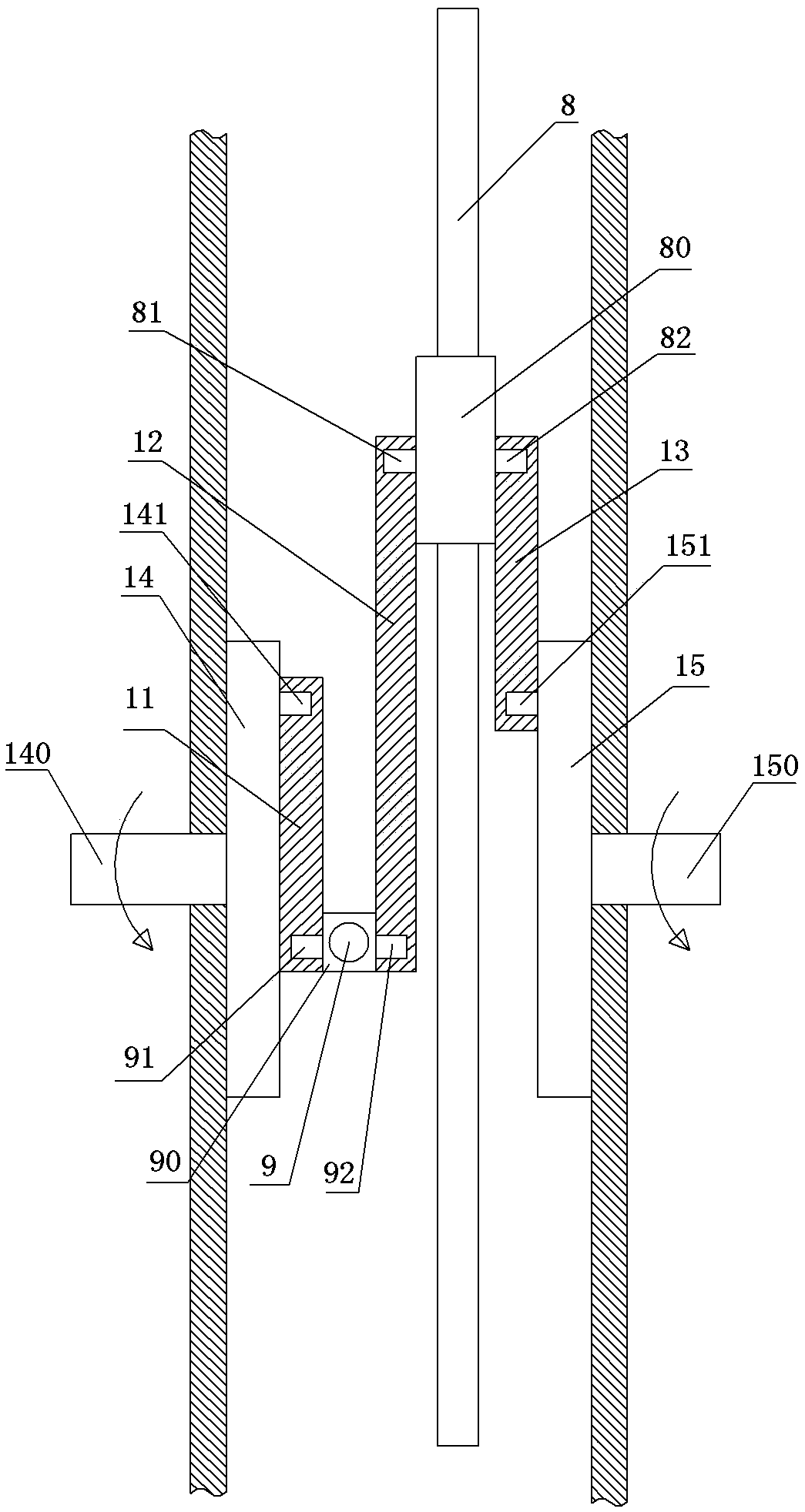

Stem cell culture system

InactiveCN112111400AGuaranteed levelEasy to take outBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringStem cell culture

The invention discloses a stem cell culture system. The stem cell culture system comprises a mounting box, a pretreatment mechanism, a cell dispersing mechanism, an isolating and cleaning mechanism, aconvenient test tube picking and placing mechanism, a temperature control mechanism and a cell centrifugation mechanism, wherein the bottom end of the mounting box is fixedly connected with a mounting bottom plate, the cell centrifugation mechanism is arranged on one side face of the outside of the mounting box and comprises a centrifuge main body, and a sealing cover is hinged to one side of oneside face, where the centrifuge main body is placed, of the outside of the mounting box. According to the stem cell culture system, a lifting outer tube can be lifted from the top of a lifting circular tube through an offsetting spring, a top end plane of a connecting flip plate can restores horizontal, thus, a fixing ring and a top end plane of a placement tube can be horizontal, then, the placement tube can correspond to a test tube position of the convenient test tube picking and placing mechanism, thus, a test tube can be more easily placed inside the placement tube, and thus, a cell dispersing device and a stem cell centrifugation mechanism can be more conveniently used in a matched manner.

Owner:孙震颖

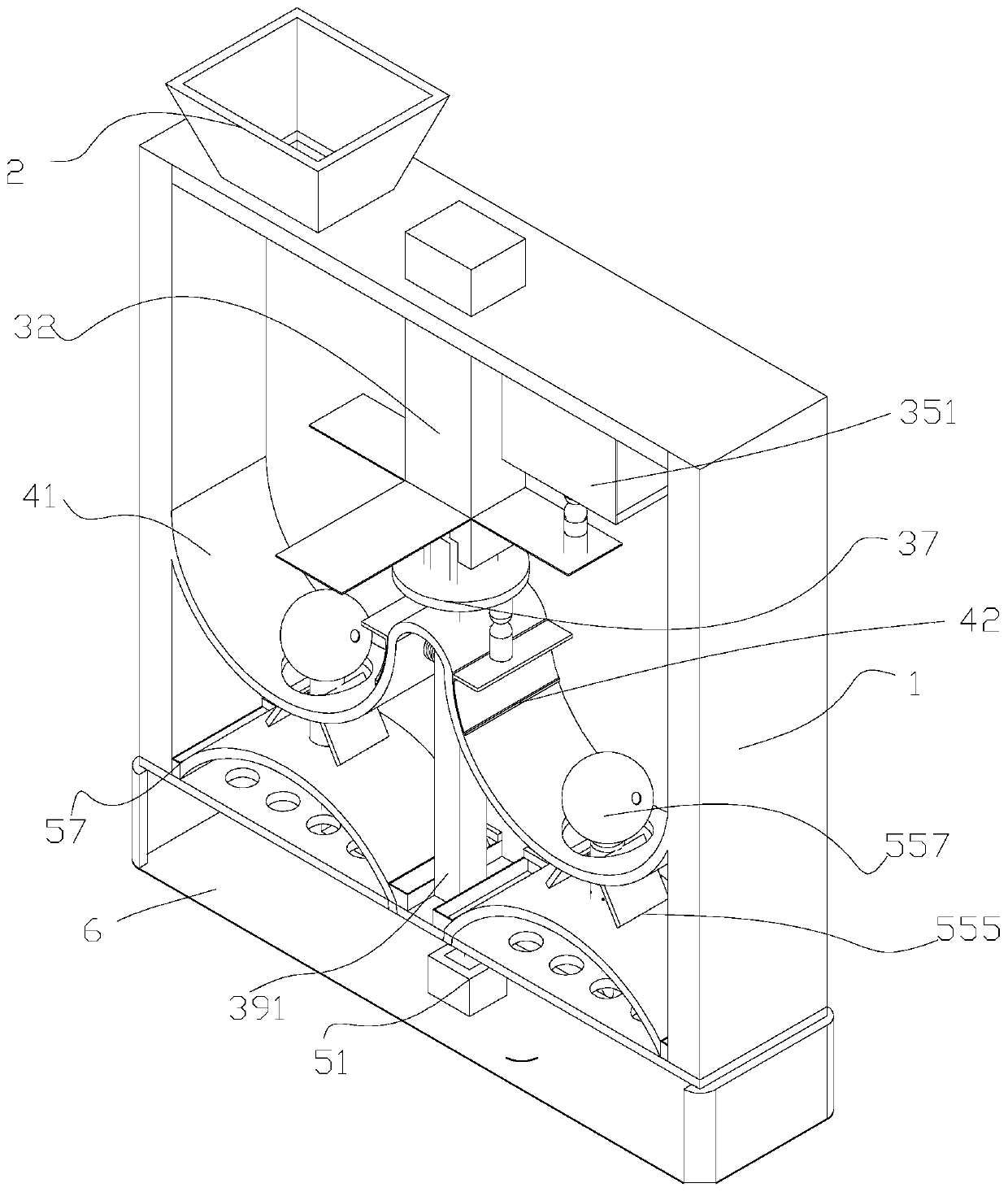

Rice huller

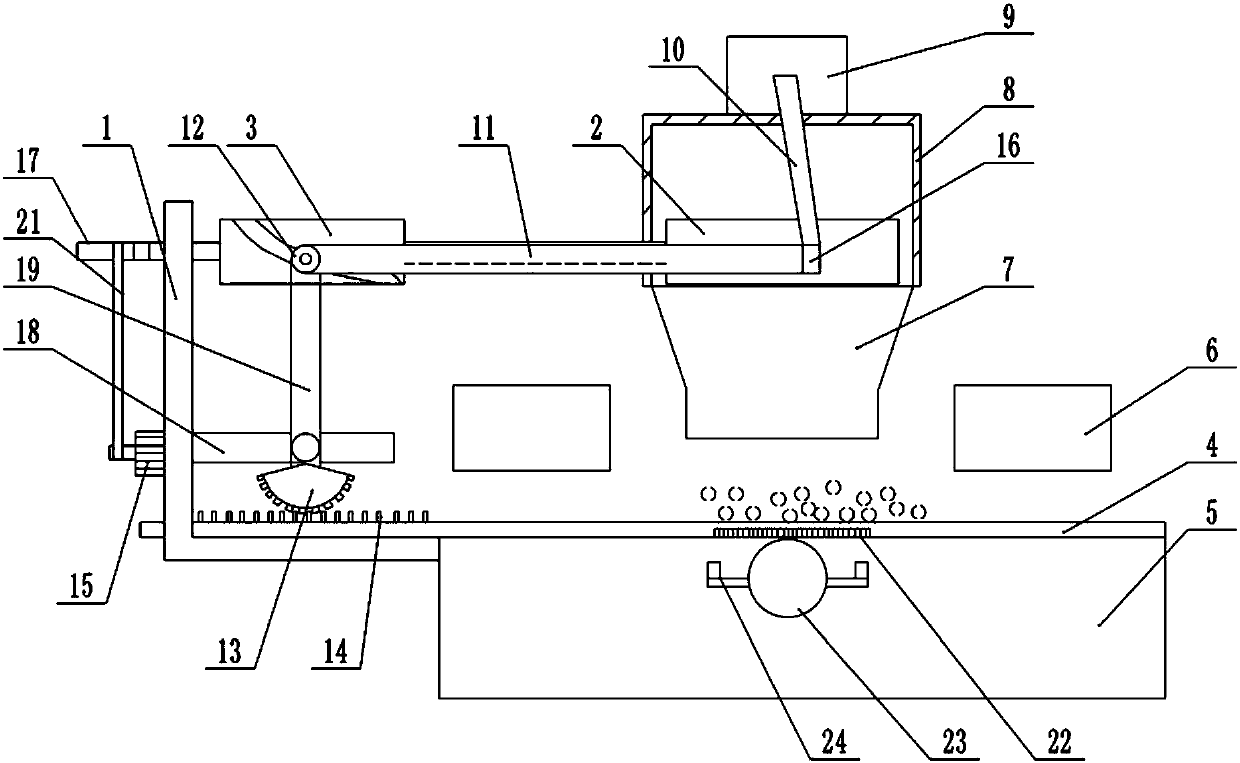

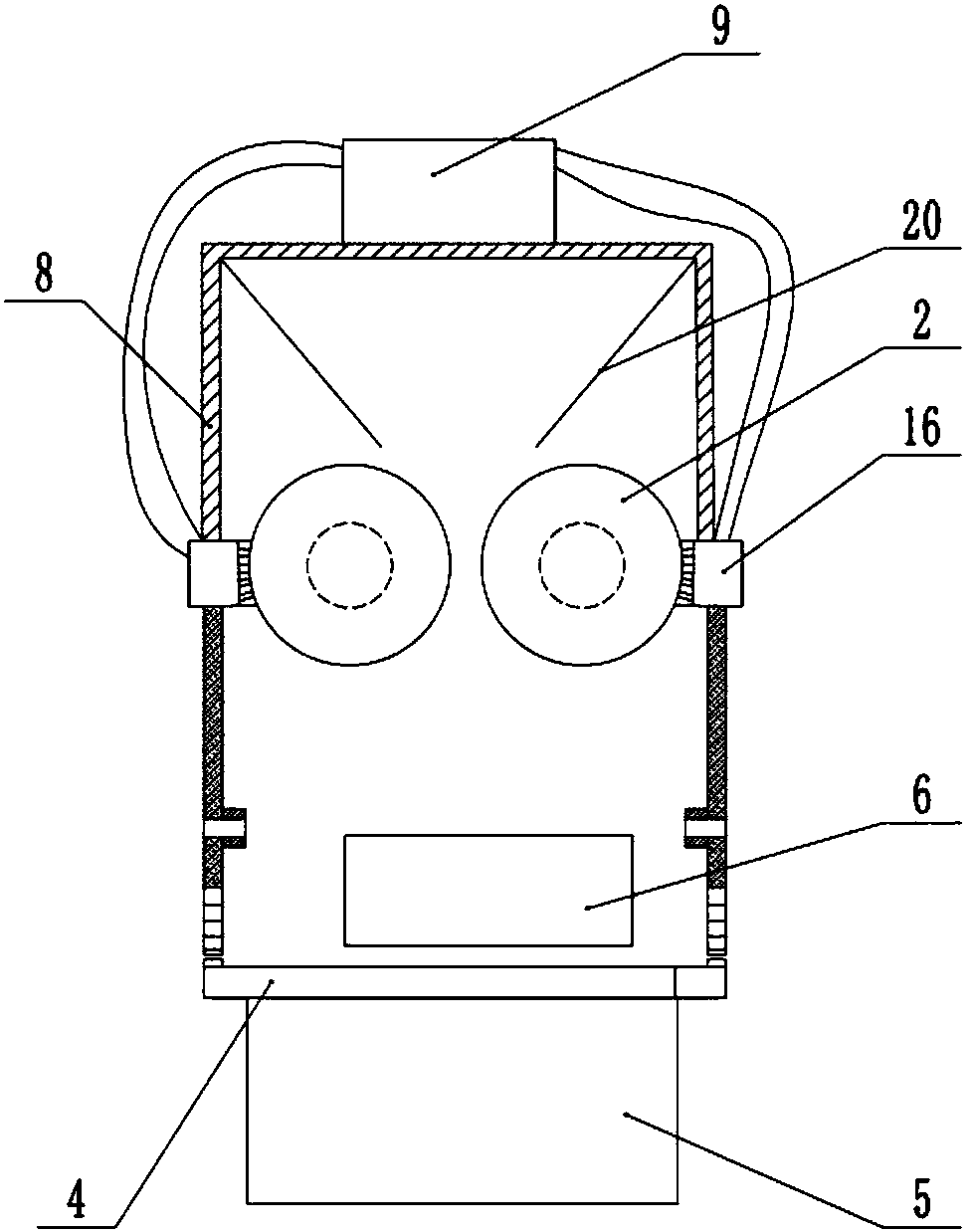

InactiveCN108043493ARealize automatic separationGood for fallingGrain huskingGrain polishingGear wheelSlide plate

The invention relates to the technical field of rice processing, in particular to a rice huller. The rice huller comprises a rack, wherein a pair of milling rollers are arranged in the rack; one endsof the milling rollers are connected with cylindrical cams; curved grooves are formed in the cylindrical cams; a transverse rod is arranged below the cylindrical cams; a pushing rod is connected between the transverse rod and the cylindrical cams; the top end of the pushing rod is rotationally connected with a slide block; the slide block is in sliding connection in the curved grooves; a cleaningrod is connected on the slide block; one end, away from the slide block, of the cleaning rod is equipped with a cleaning head; the bottom end of the pushing rod is rotatably connected on the transverse rod; the bottom end of the pushing rod is connected with a fan-shaped gear; a discharge hole is formed below the milling rollers; absorbers are arranged at the two sides of the discharge hole; a slide plate is arranged below the discharge hole; a plurality of through holes are formed in the slide plate; one end, close to the fan-shaped gear, of the slide plate is fixedly connected with a first rack; the bottom of the slide plate is connected with a second rack; a straight gear is arranged in a collecting box; and a pendulum bob is connected on the straight gear. The rice huller realizes automatic separation of rice hulls and rice grains.

Owner:重庆市合川区云天食品科技有限公司

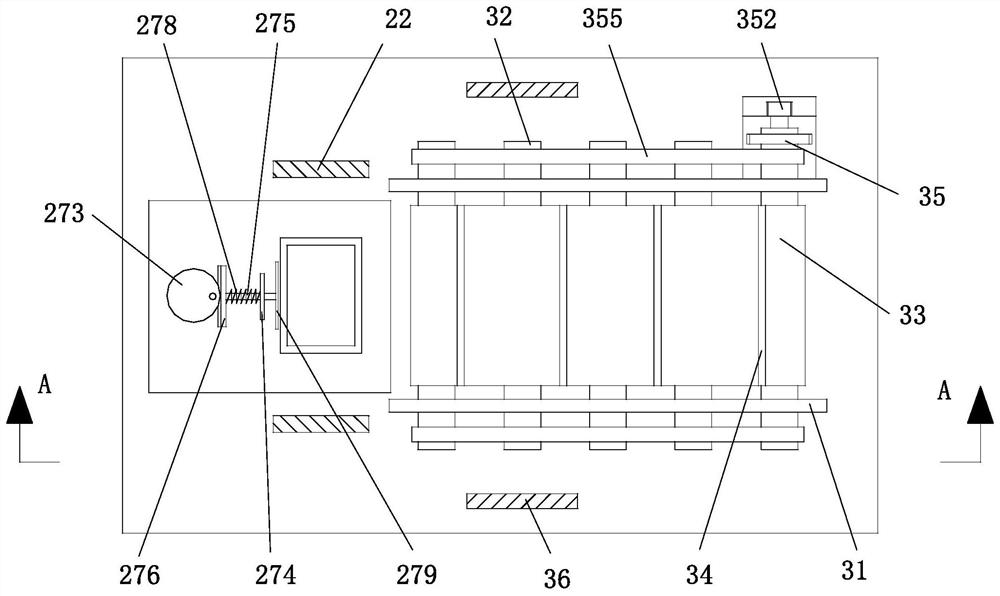

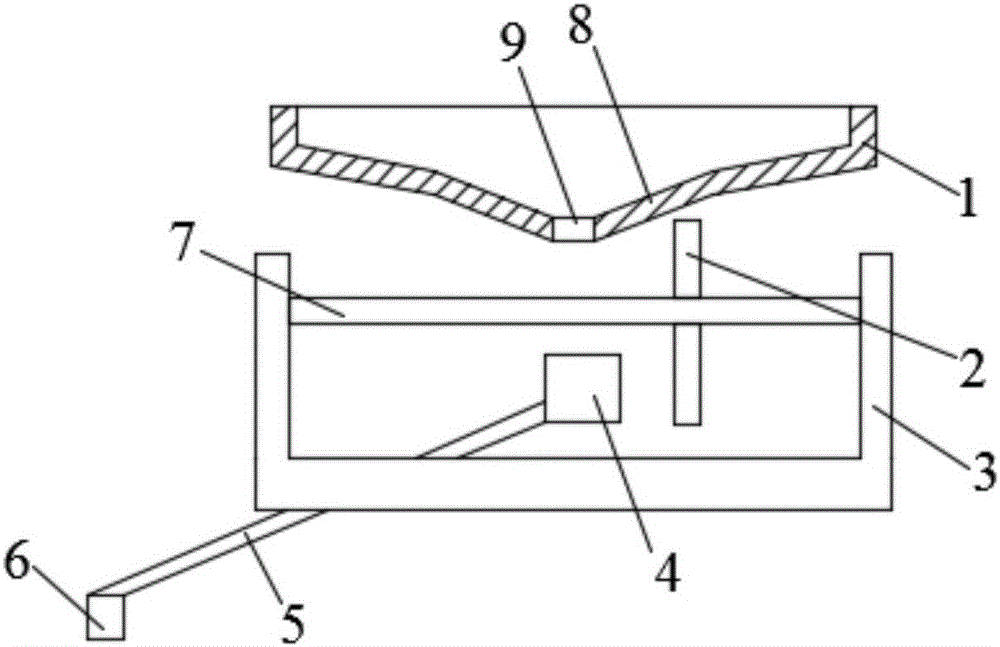

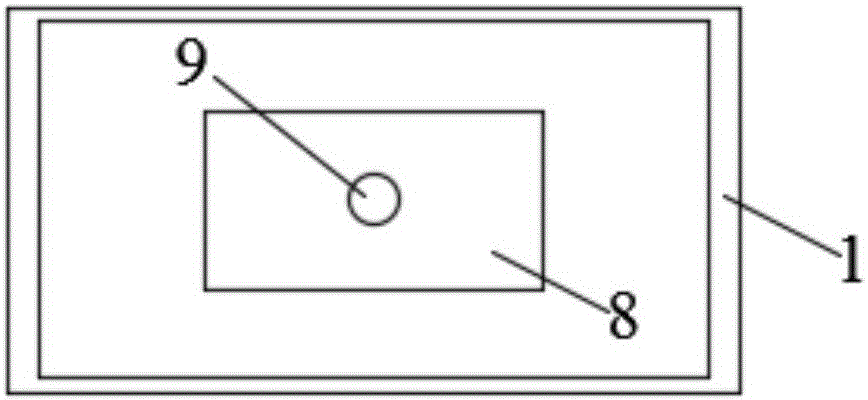

Computer hardware processing feeding device and feeding process

ActiveCN112919107AImprove pass rateImprove work efficiencyConveyor partsComputer hardwareComputer architecture

The invention relates to a computer hardware processing feeding device and a feeding process. The computer hardware processing feeding device comprises a workbench, a feeding mechanism and a conveying mechanism, wherein the feeding mechanism comprises a fixed support, a first C-shaped plate, a material containing box, an L-shaped supporting plate, a first electric push rod, a push plate and a movable frame. According to the computer hardware processing feeding device and the feeding process provided by the invention, through the cooperation of the arranged workbench, the arranged feeding mechanism and the arranged conveying mechanism, firstly, computer hardware needing to be processed is placed on the feeding mechanism, the computer hardware needing to be processed is fed to the conveying mechanism through the feeding mechanism, and then the computer hardware needing to be processed is adjusted and limited through the conveying mechanism, so that the computer hardware needing to be processed is located at a proper processing position, and the percent of pass is improved when the computer hardware is processed by the machine; and the computer hardware is transported by adopting an assembly line in the process of processing the computer hardware, so that the working efficiency of the machine is improved.

Owner:深圳市凯佳达智能显示有限公司

Aluminium honeycomb curtain wall panel manufacturing processing method

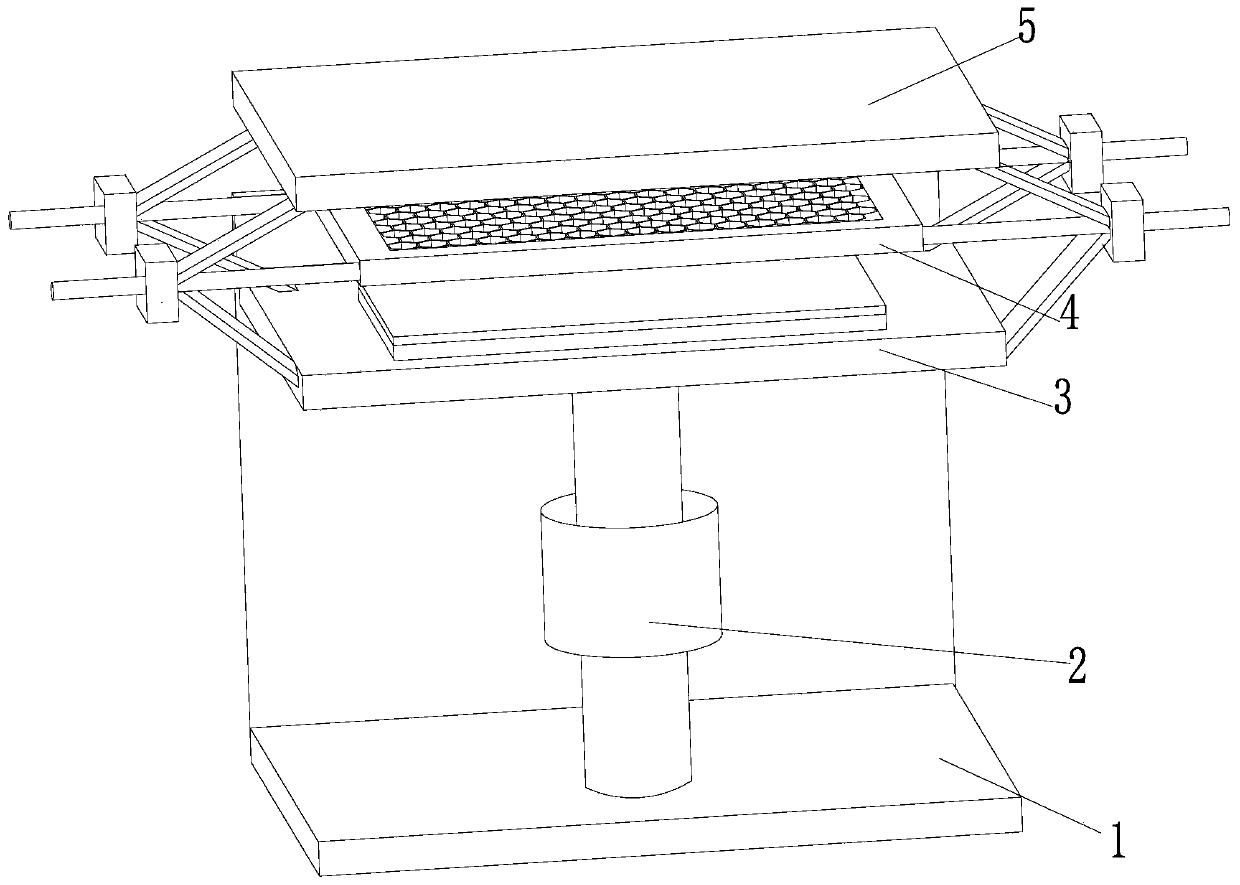

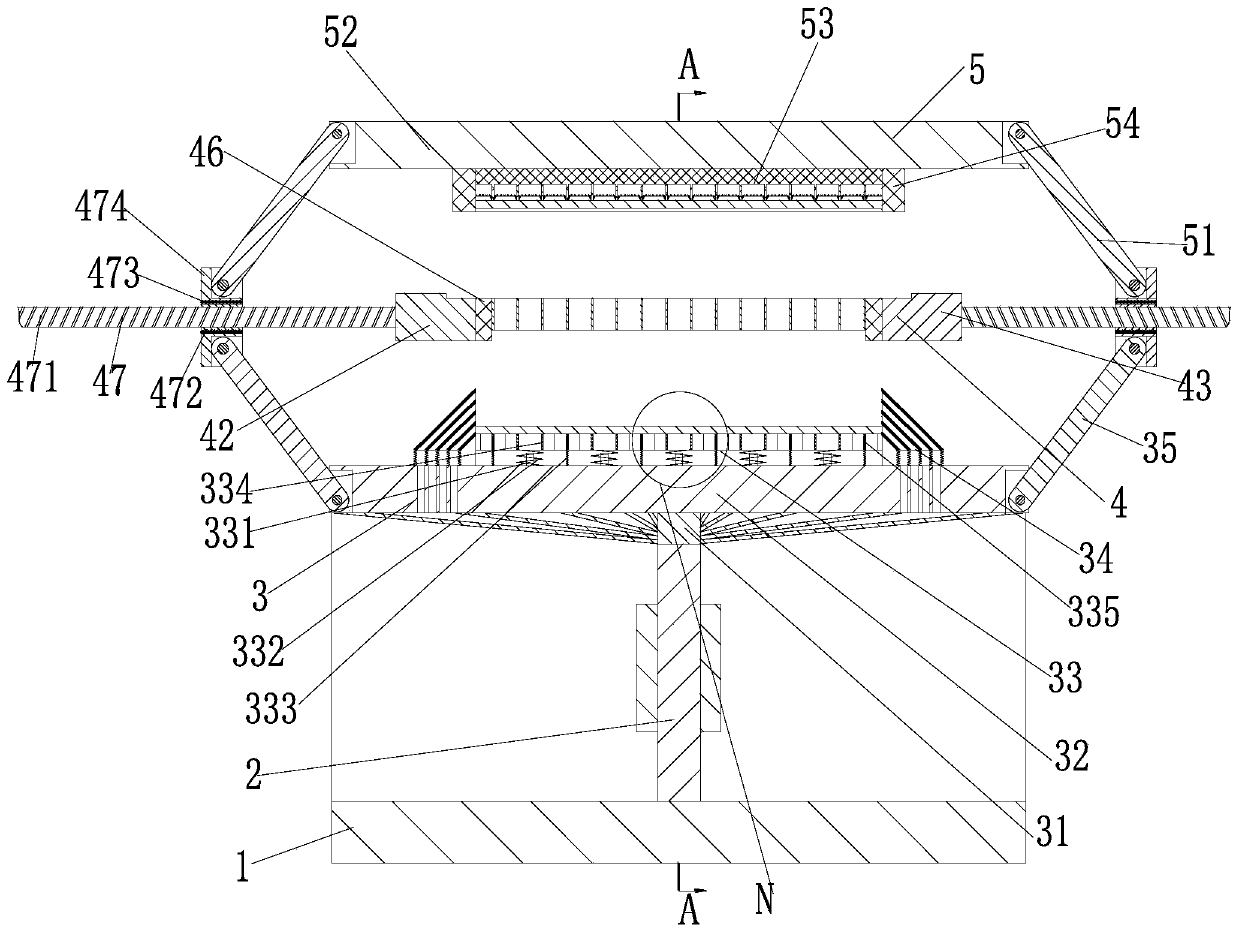

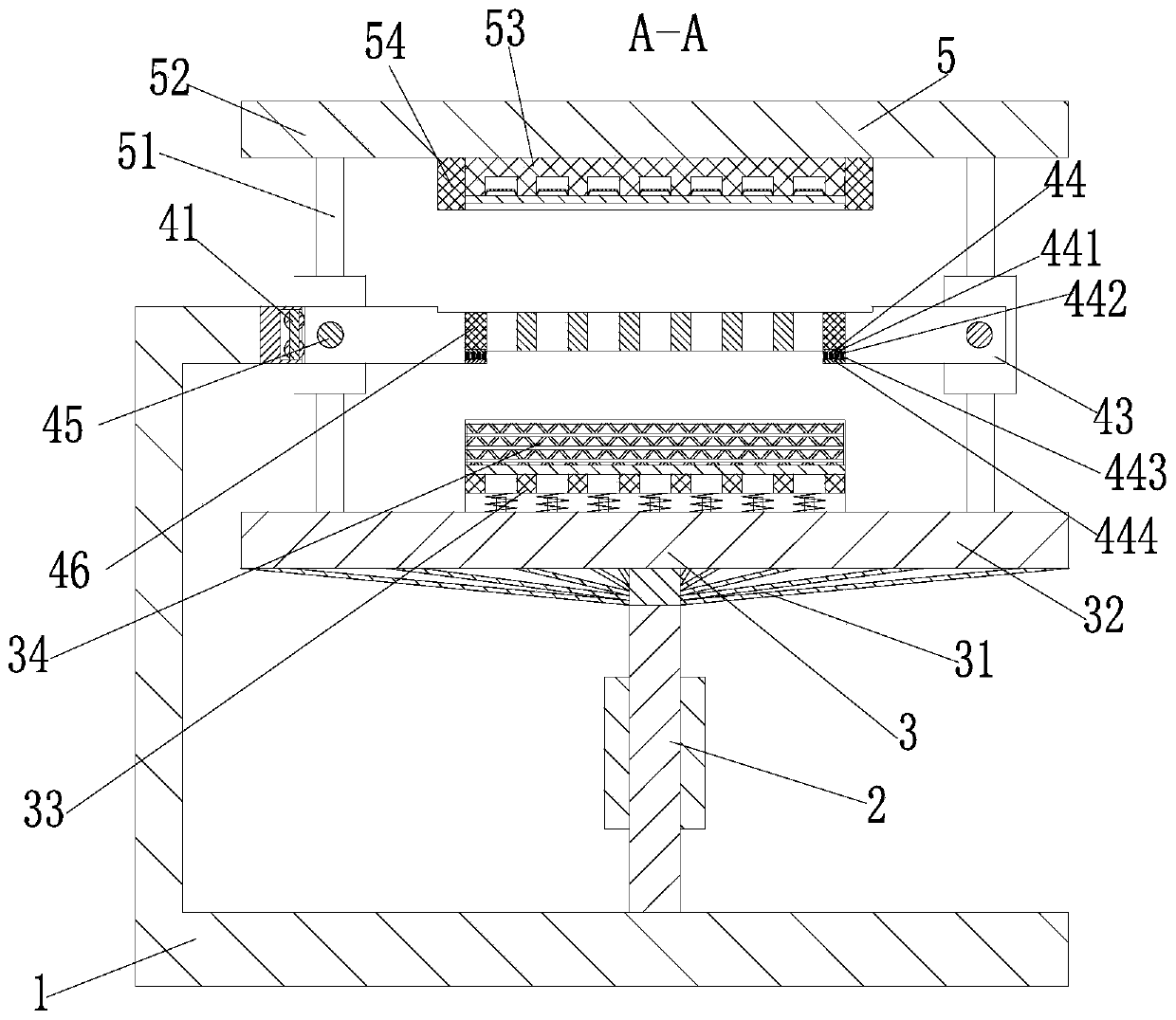

ActiveCN110814709AAchieve the purpose of bondingEven by forceMaterial gluingMetal working apparatusHoneycombStructural engineering

The invention relates to an aluminium honeycomb curtain wall panel manufacturing processing method. Aluminium honeycomb curtain wall panel manufacturing processing equipment comprises a worktable, anelectric air cylinder, a first supporting device, a clamping device and a second supporting device; the worktable is an L-shaped bracket; the electric air cylinder is fixedly mounted on the upper endsurface of a bottom plate of the worktable; the first supporting device is fixedly mounted at the upper end of the electric air cylinder; the left end and the right end of the first supporting deviceare connected with the left end and the right end of the clamping device; the left end and the right end of the clamping device are connected with the second supporting device; the first supporting device comprises radiation frames, supporting plates, rubber frames, cleaning scrapers and first arc-shaped plates; according to the aluminium honeycomb curtain wall panel manufacturing processing method, the first supporting device and the second supporting device are driven to move oppositely through the electric air cylinder to achieve the purpose of simultaneously bonding aluminium alloy platesat an upper end and a lower end to a honeycomb core; and after the processing of a honeycomb plate is completed, a bonding agent which overflows from the periphery of the honeycomb plate is cleaned bymatching the clamping device and the first supporting device.

Owner:常州鑫邦板业有限公司

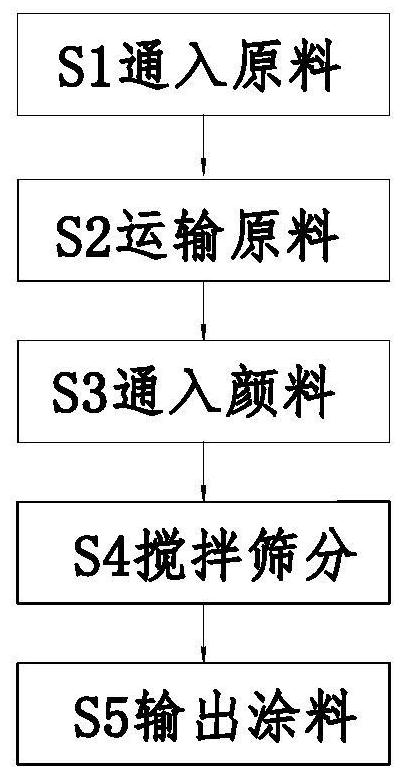

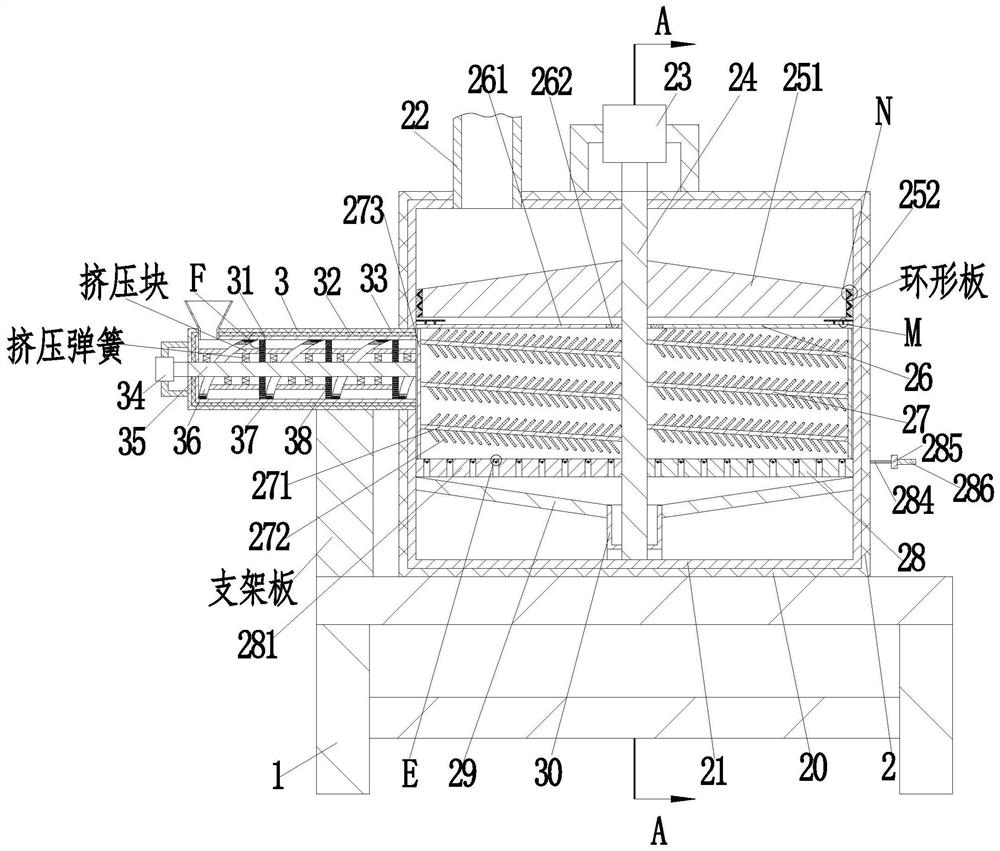

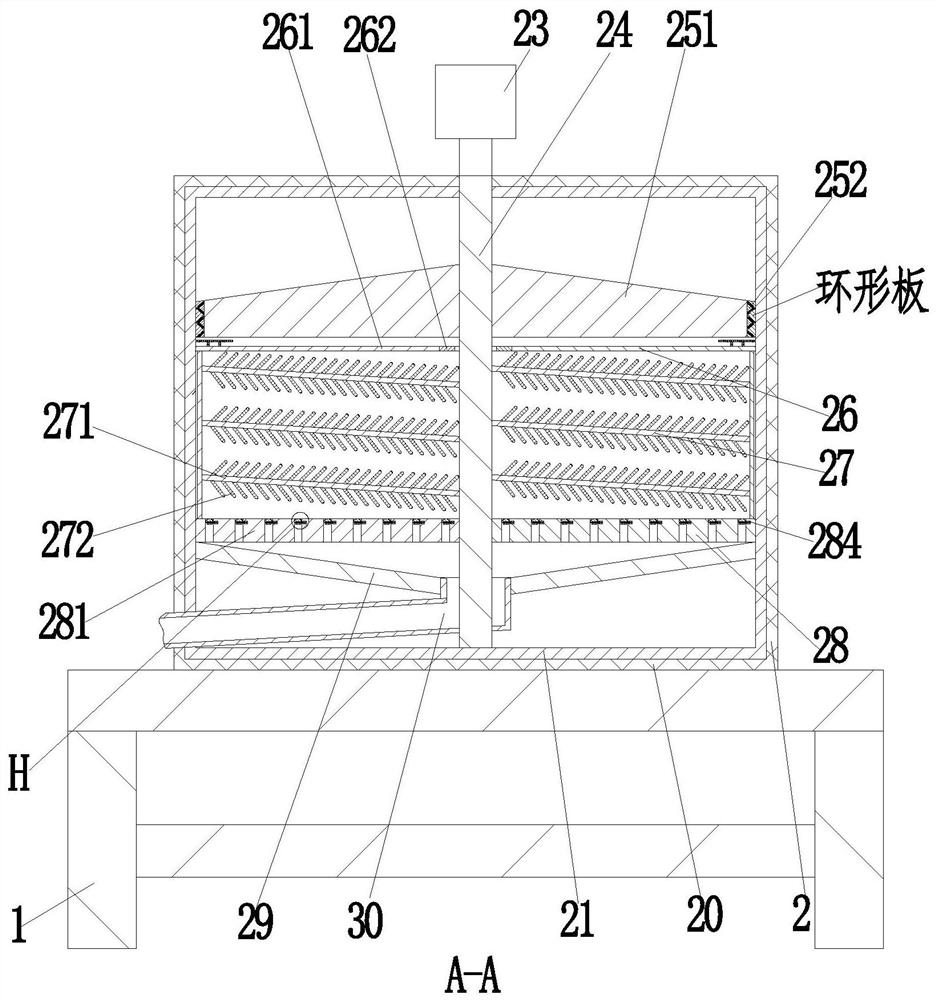

Polyurethane coating preparation method

InactiveCN112808137AAvoid accumulationPrevent impact on production qualityTransportation and packagingMixing methodsPolymer scienceEmulsion

The invention relates to a polyurethane coating preparation method, which comprises a workbench, a preparation device and a heating device; the preparation device is fixedly installed at the upper end of the workbench, the heating device is fixedly installed at the left end of the preparation device, the preparation device is fixedly installed at the upper end of the workbench, and the heating device is fixedly installed at the left end of the preparation device; the preparation device comprises a heat preservation plate, a cylindrical plate, a feeding pipe, a first motor, a rotating column, a grinding frame, a screening plate, a stirring frame, a screening circular plate, a conical barrel and a discharging pipe. According to the invention, the pigment is ground through the preparation device, and meanwhile, the pigment and a mixed emulsion of polyurethane and auxiliaries are stirred and mixed and are sieved, so that accumulation of pigments is prevented. The polyurethane and the auxiliaries are heated through the heating device, and meanwhile, the heated mixture is screened, so that the situation that solid polyurethane enters the preparation device along with liquid polyurethane, thereby preventing influence on the production quality.

Owner:李腾飞

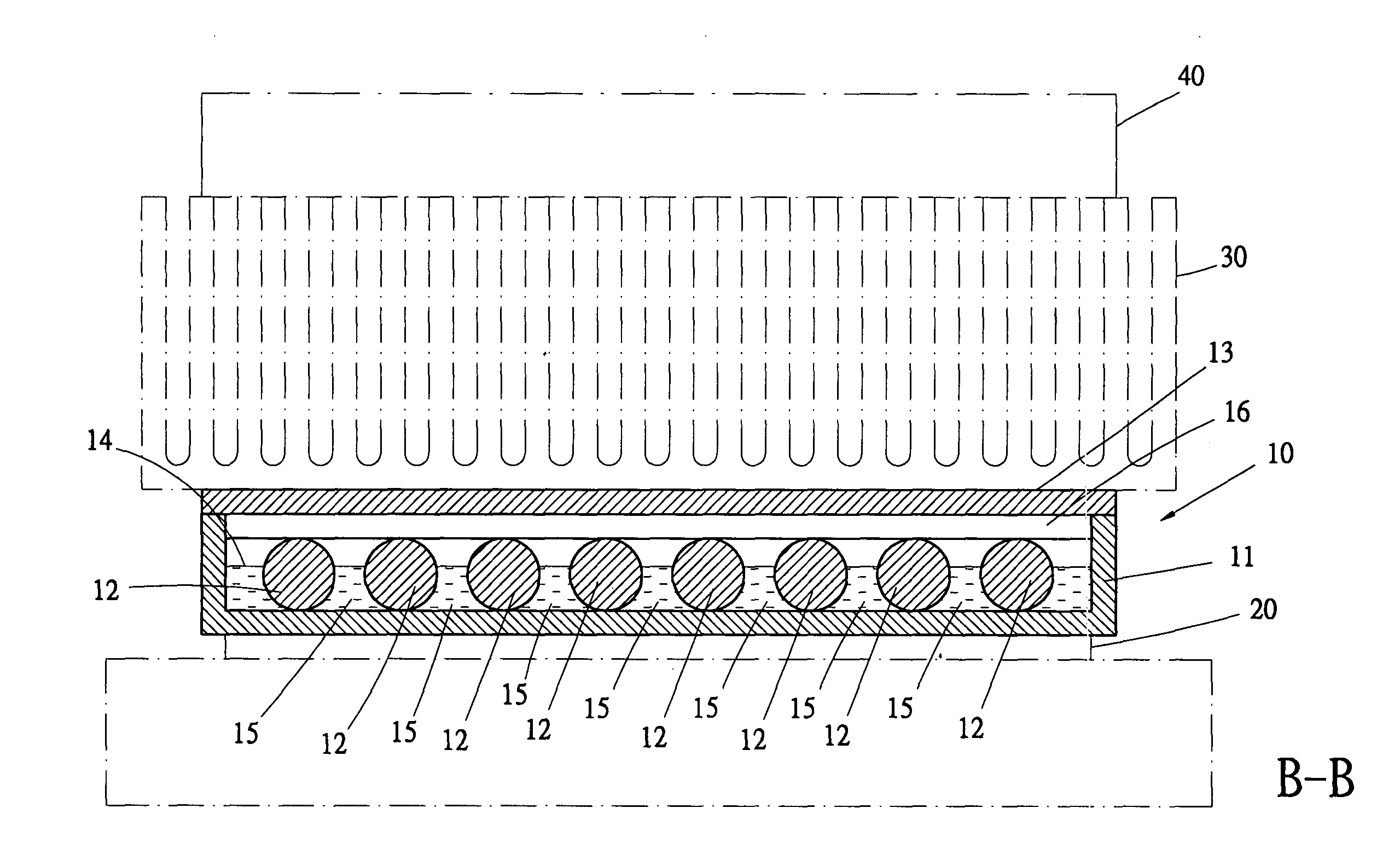

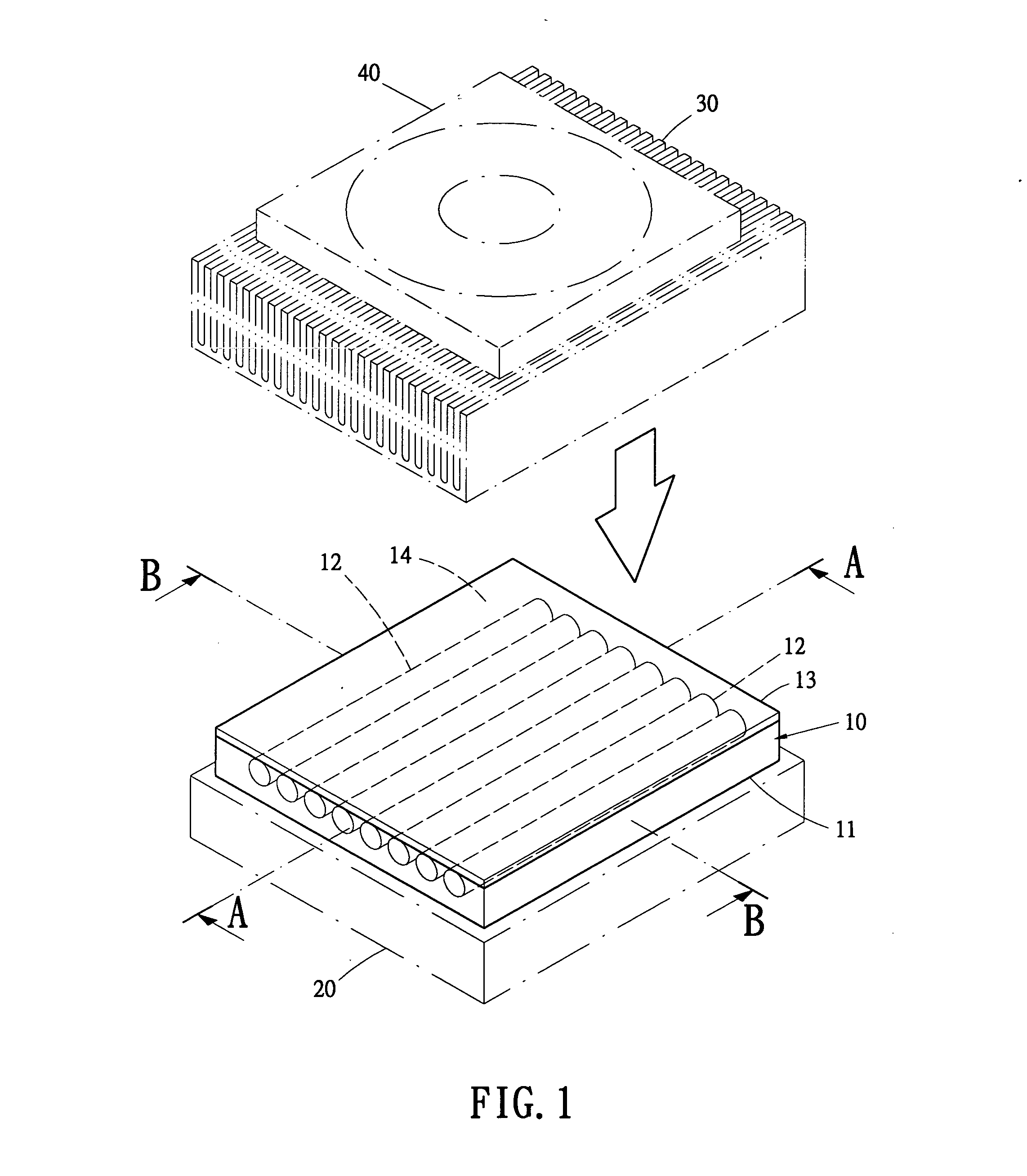

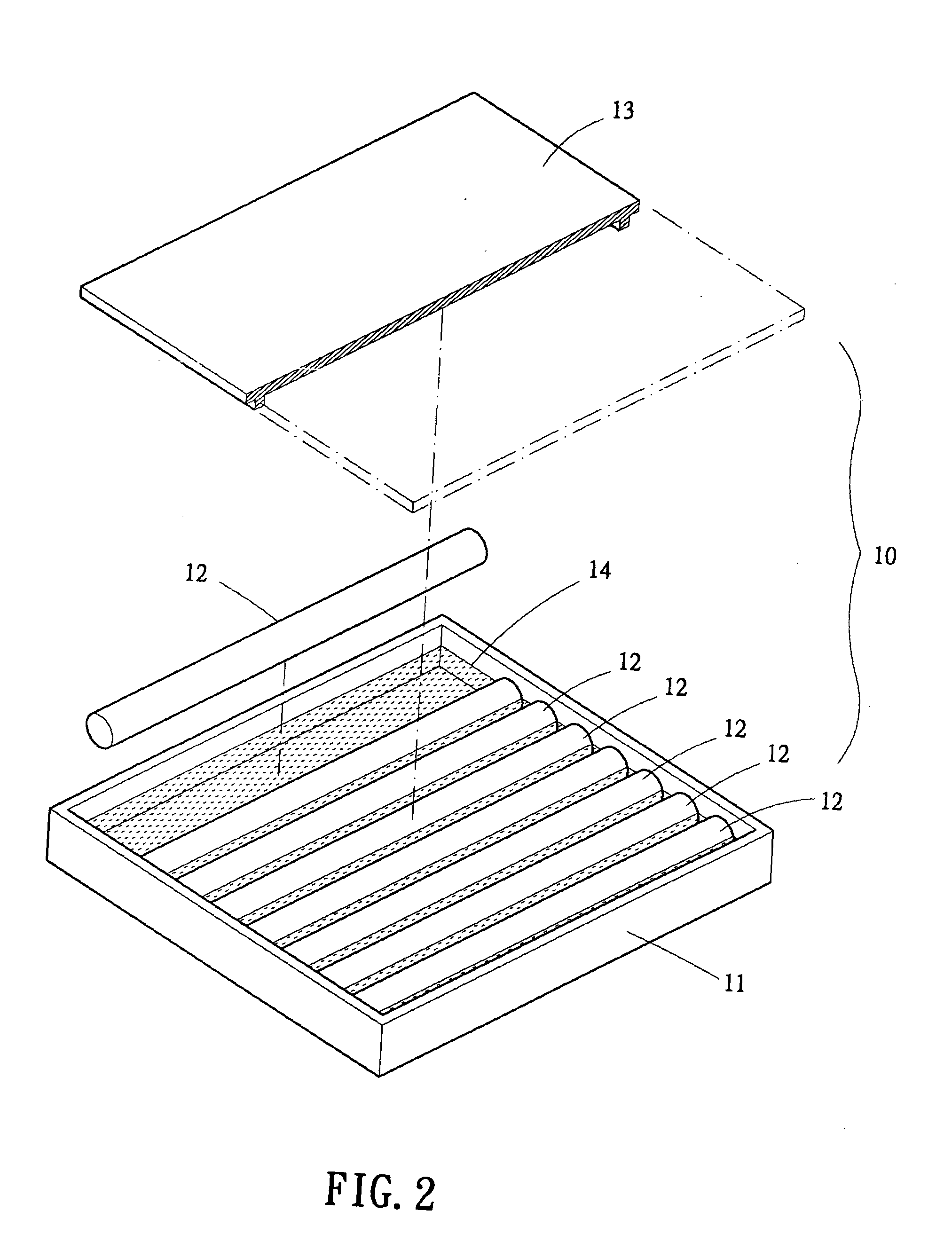

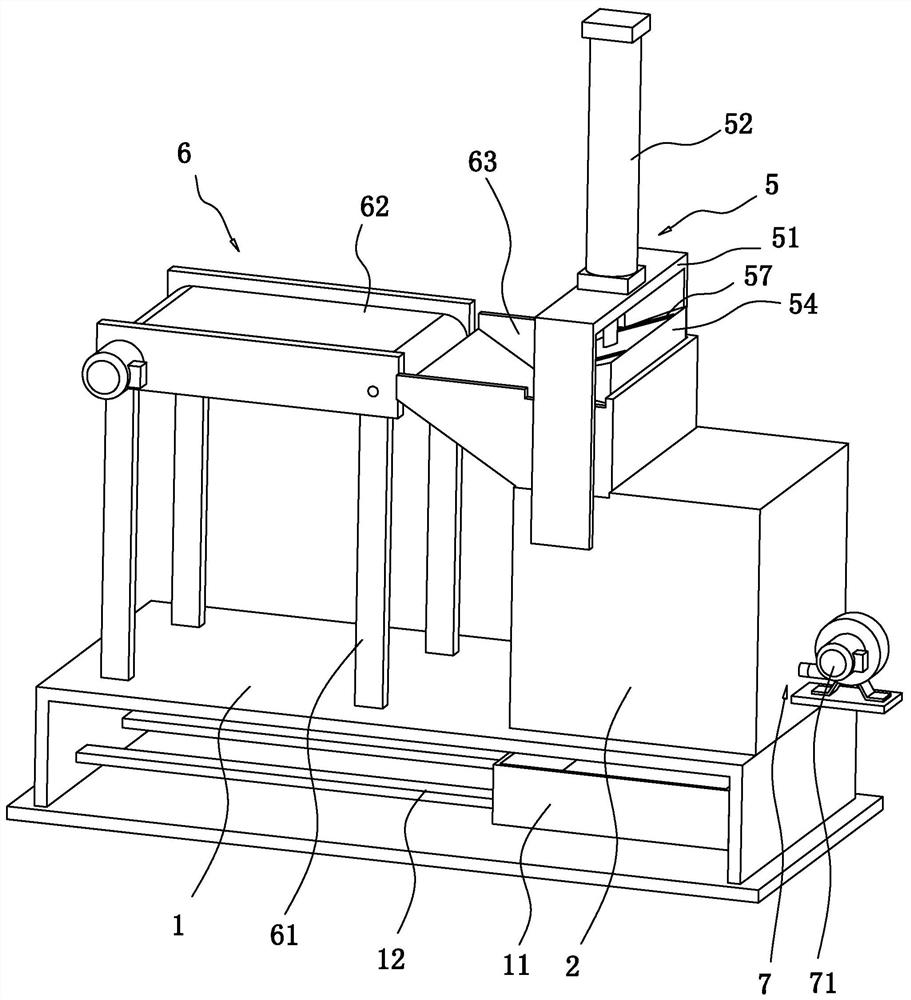

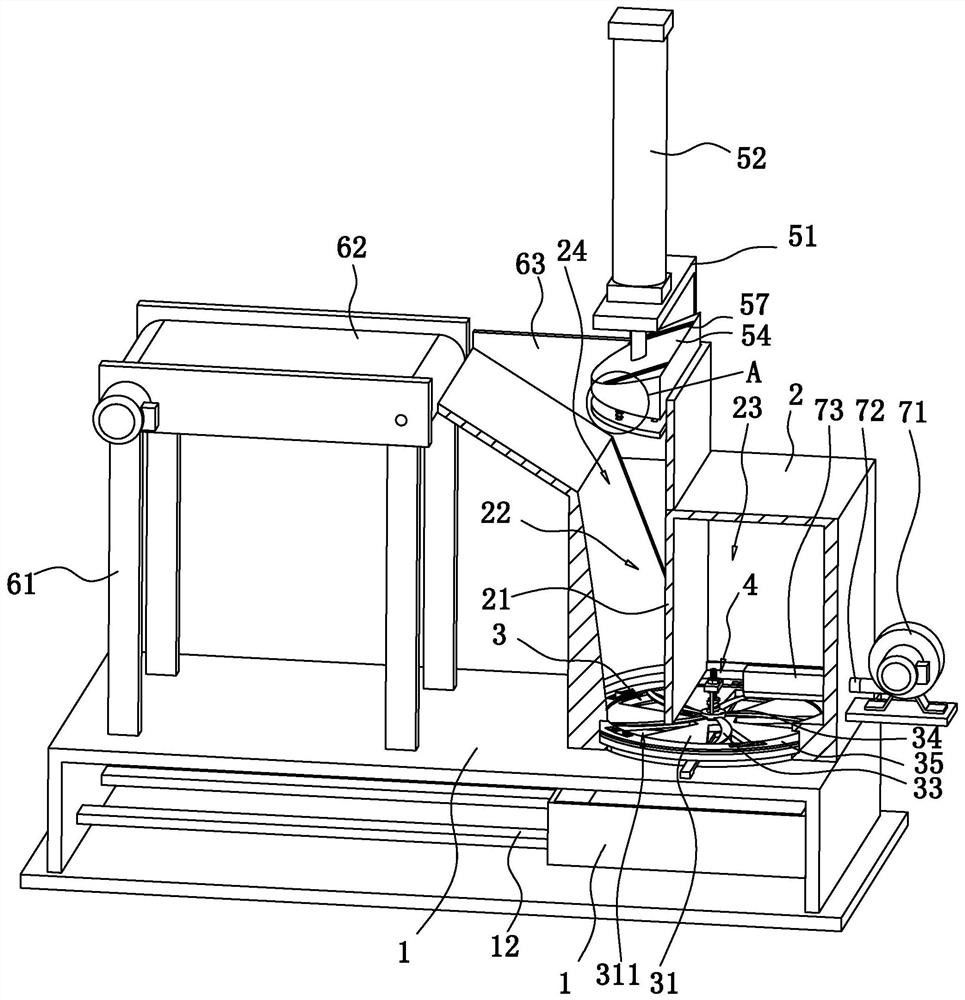

Heat conductive seat with liquid

InactiveUS20050067143A1Rapidly and uniformly transmittedGood effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

The conductive seat has parallelly arranged strip members in a bottom area of its base sealed therein with liquid, a plurality of flow channels are formed from and on the bottom of the strip members and are mutually spaced; a return area is formed between the top ends of the strip members and the lid; when the bottom of the base contacts with a heat-generating source, the liquid sealed in the base and absorbing the latent heat from the heat-generating source becomes a vapor flow flowing toward the return area to repeatedly circulate and transmit the heat, thereby the heat is rapidly and uniformly transmitted to the heat sink to further increase the effect of heat sinking.

Owner:GLACIALTECH

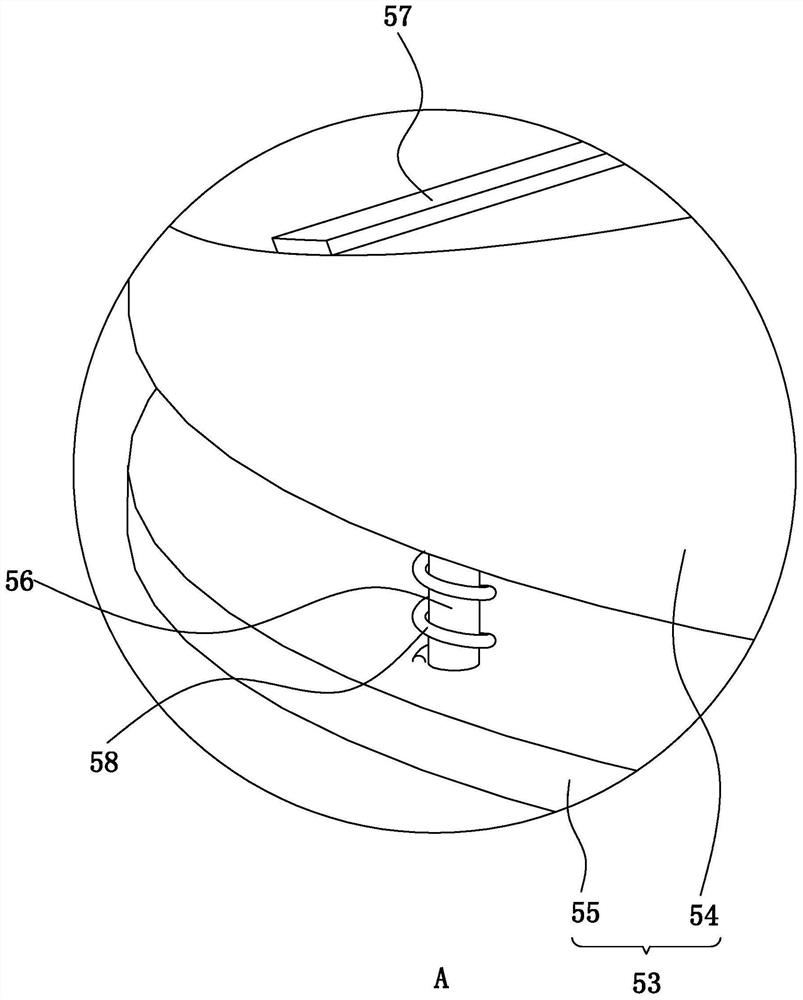

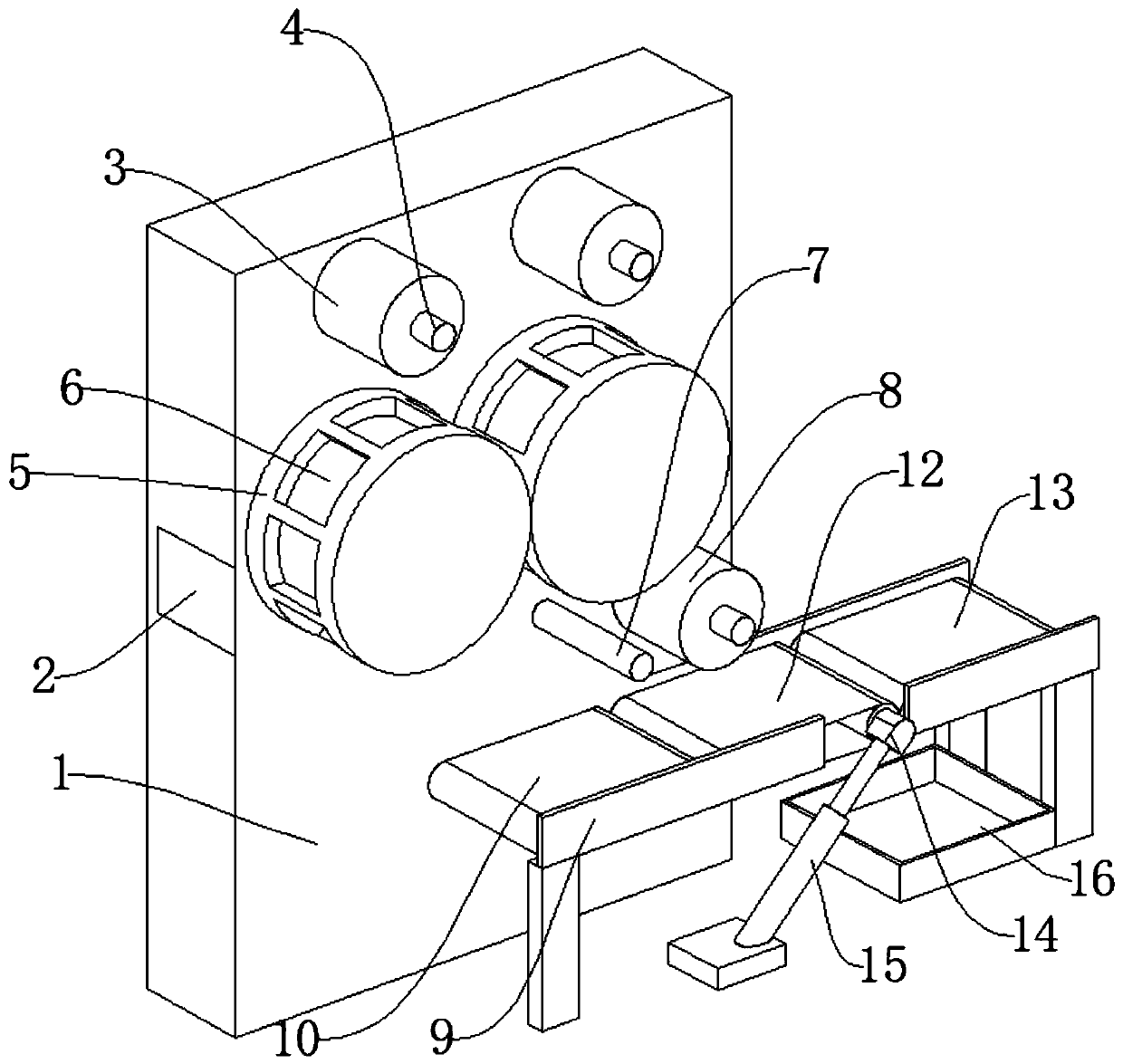

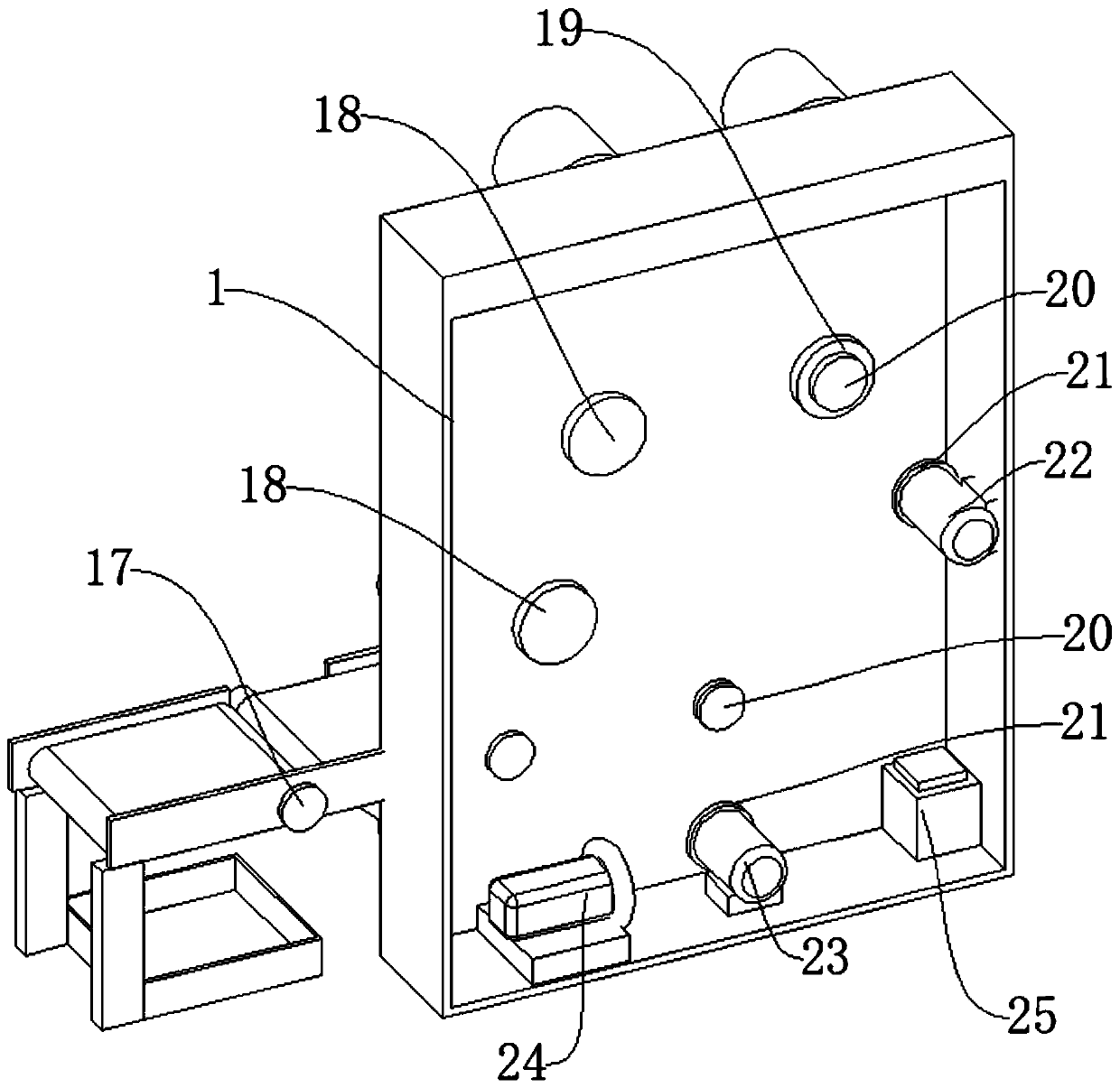

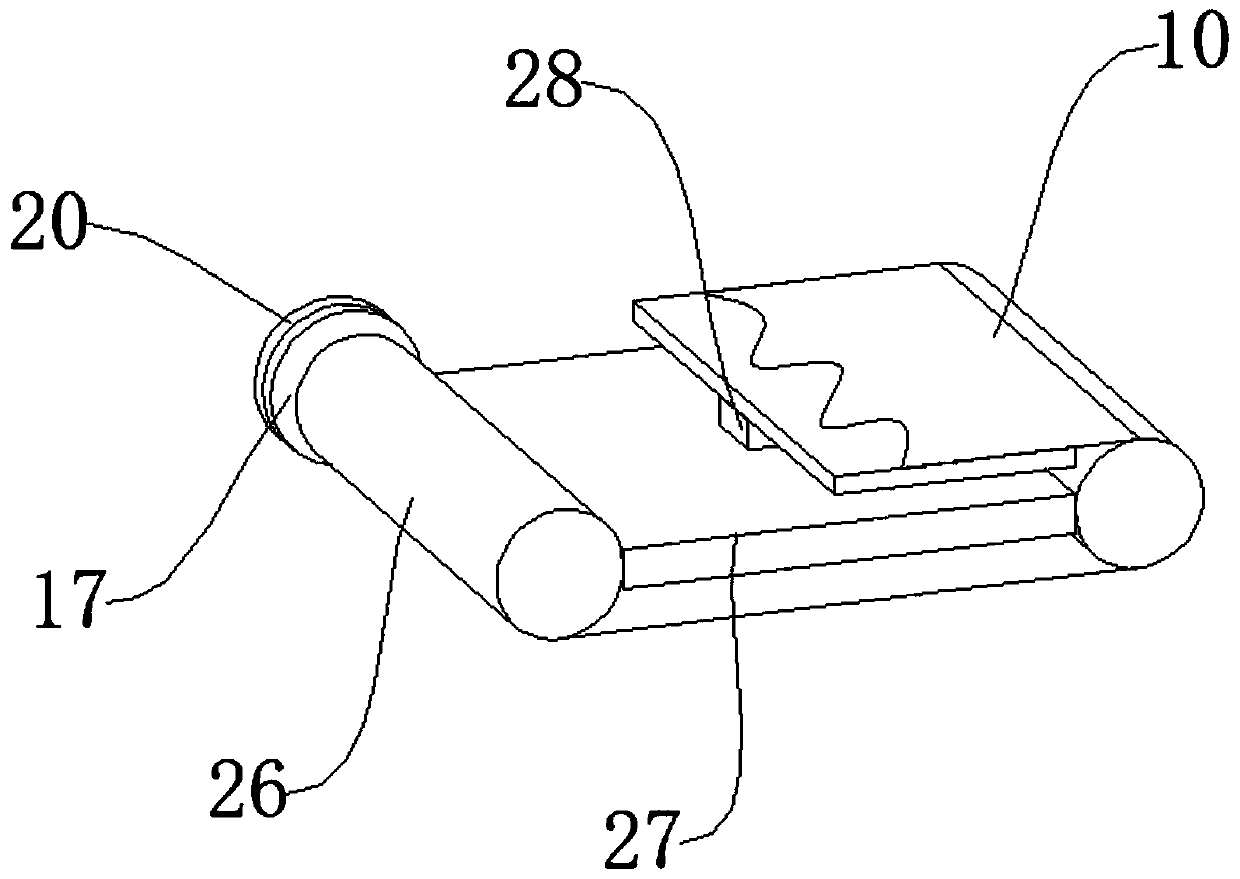

Pneumatic disc type slicer

ActiveCN112092054AImprove convenienceImprove stabilityMetal working apparatusElectric machineryScrew thread

The invention relates to the technical field of slicers, in particular to a pneumatic disc type slicer. The pneumatic disc type slicer comprises a rack, wherein a working box is arranged on the rack;a slicing component is arranged in the working box; a feeding port is formed in the top end of the working box; a pressing component is arranged above the feeding port; the slicing component comprisesa rotary disc; a rotating motor used for driving the rotary disc to rotate is arranged below the rotary disc; a plurality of working holes are formed in the surface of the rotary disc; a cutter is arranged above each working hole; the plane where the cutters are located is parallel to the plane where the rotary disc is located; the cutters are arc-shaped; the inner concave surfaces of the cuttersare cutting surfaces; the upper surface of the rotary disc is coaxially and fixedly connected with an adjusting shaft; an adjusting outer thread is formed in the outer circumferential surface of theadjusting shaft; the adjusting shaft is matched with a fixing ring in a thread fit manner; the outer circumferential surface of the fixing ring is fixedly connected with the end parts of the cutters;and the fixing ring is further provided with a fixing component used for fixing the fixing ring and the rotary disc together. The pneumatic disc type slicer provided by the invention achieves an effect of adjusting the slicing thickness.

Owner:北京春风中药股份有限公司

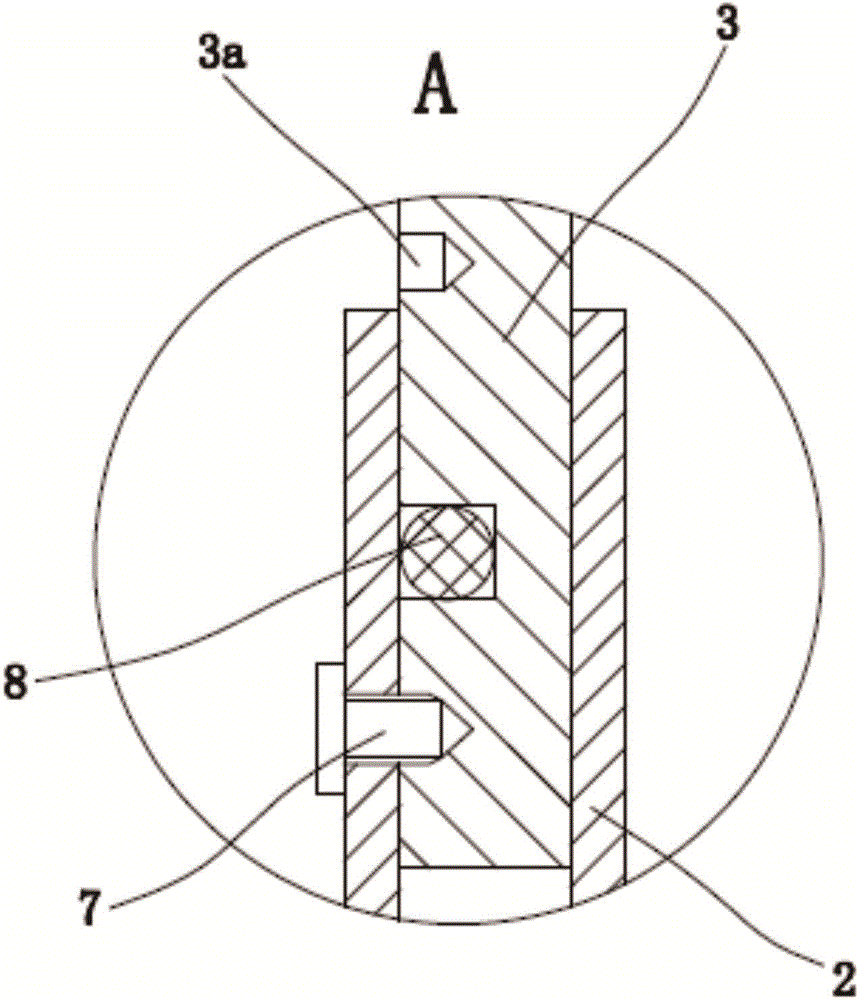

Heat-sealing discharging mechanism of adhesive tape packaging device

The invention belongs to the field of production of adhesive tape and particularly relates to a heat-sealing discharging mechanism of an adhesive tape packaging device. The mechanism comprises a supporting seat, sealing wheels, a first conveying belt and a telescopic cylinder. Two raw material rolls are arranged at the front end of the supporting seat. The sealing wheels are arranged on the lowersides of the raw material rolls correspondingly. A push roller is arranged on the lower sides of the sealing wheels and connected to the supporting seat through a bolt. A receiving roll is arranged atone side of the push roller. Backup rollers are arranged on the raw material rolls and the receiving roll correspondingly and rotationally connected to the raw material rolls and the receiving roll correspondingly. Profiled notches are formed in the sealing wheels correspondingly. Electric heating wires are arranged inside the sealing wheels correspondingly. A control panel is arranged on one side of the supporting seat in an embedded mode. According to the heat-sealing discharging mechanism of the adhesive tape packaging device, it is guaranteed that well-packaged adhesive tape can smoothlyfall, no omission occurs, double detection is achieved, empty packages are effectively detected, and the working efficiency is improved.

Owner:江苏惠聪科技有限公司

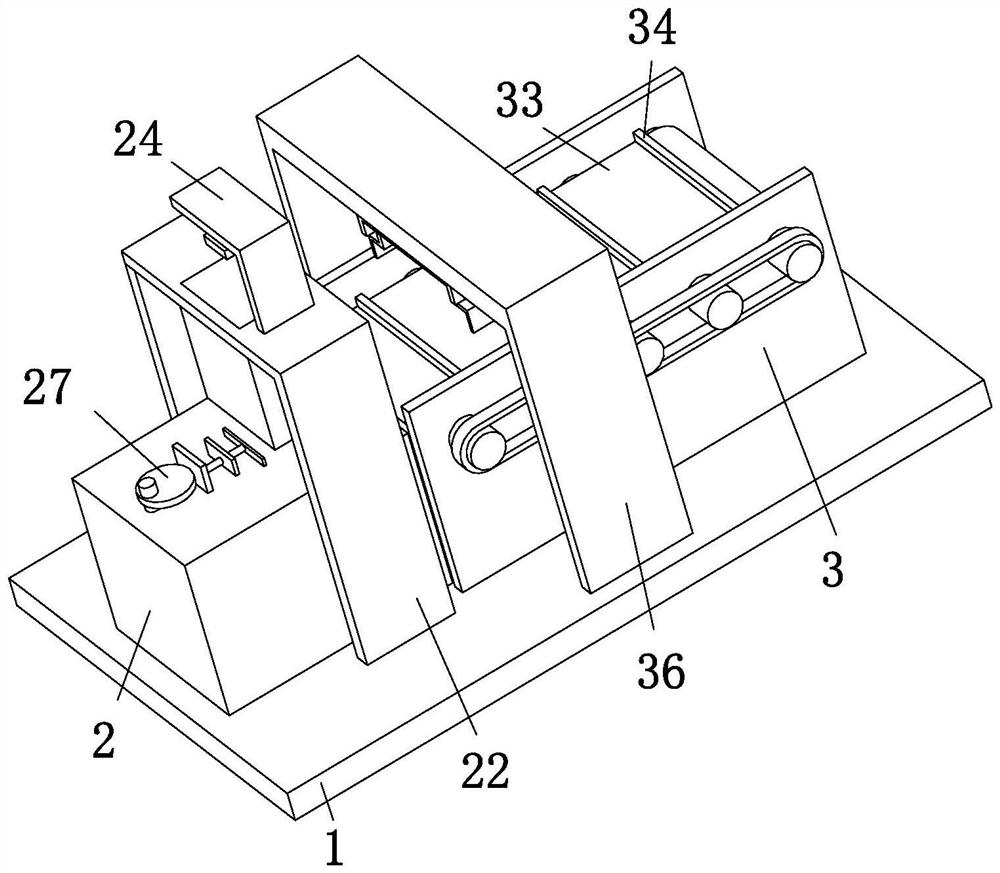

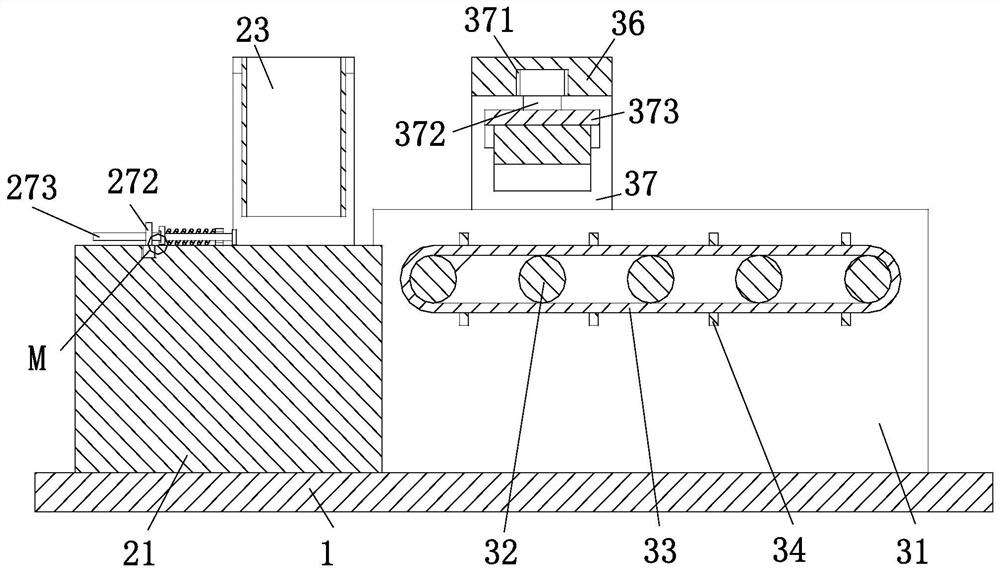

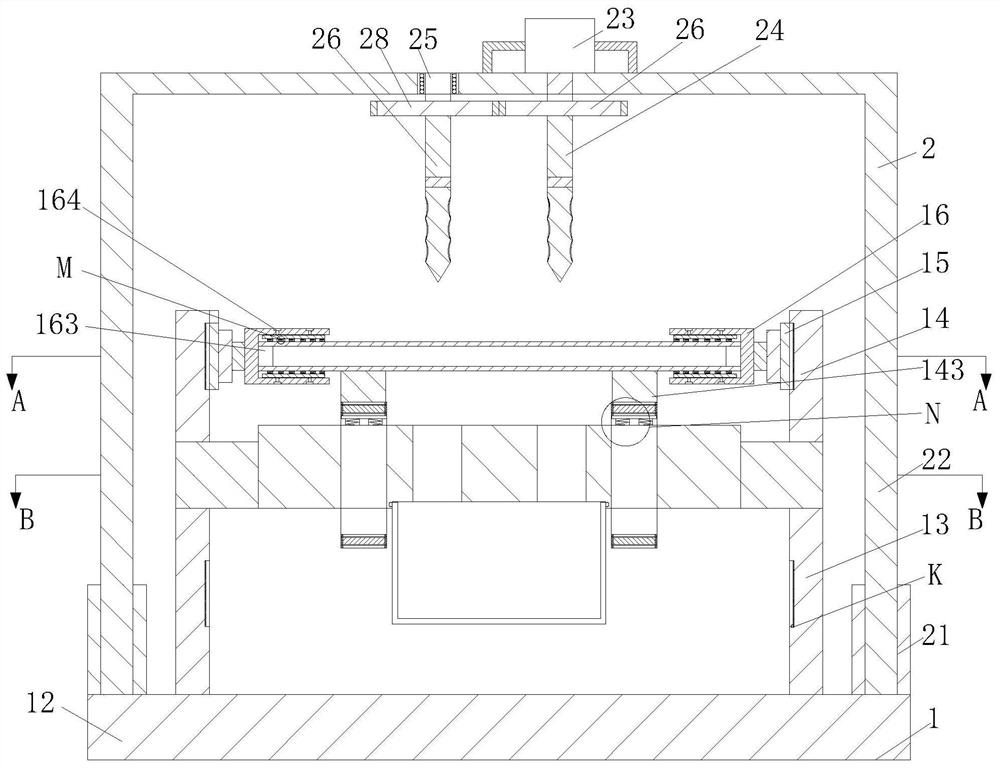

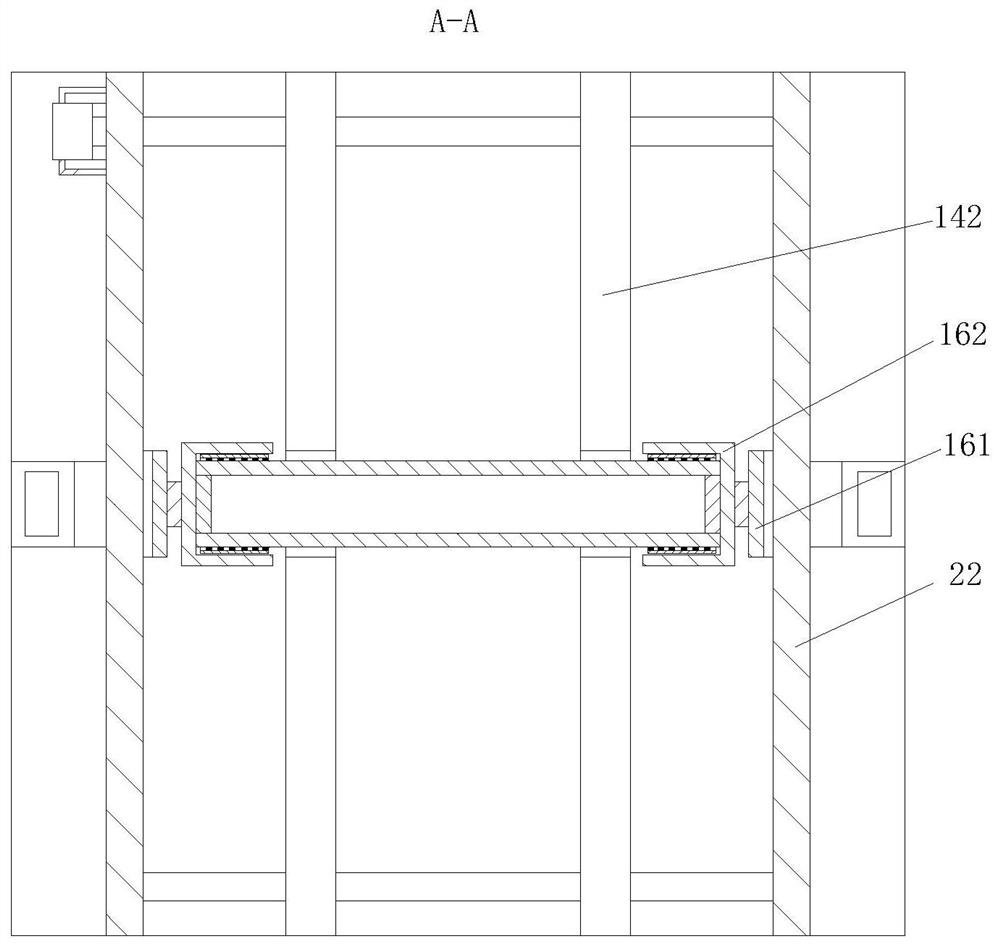

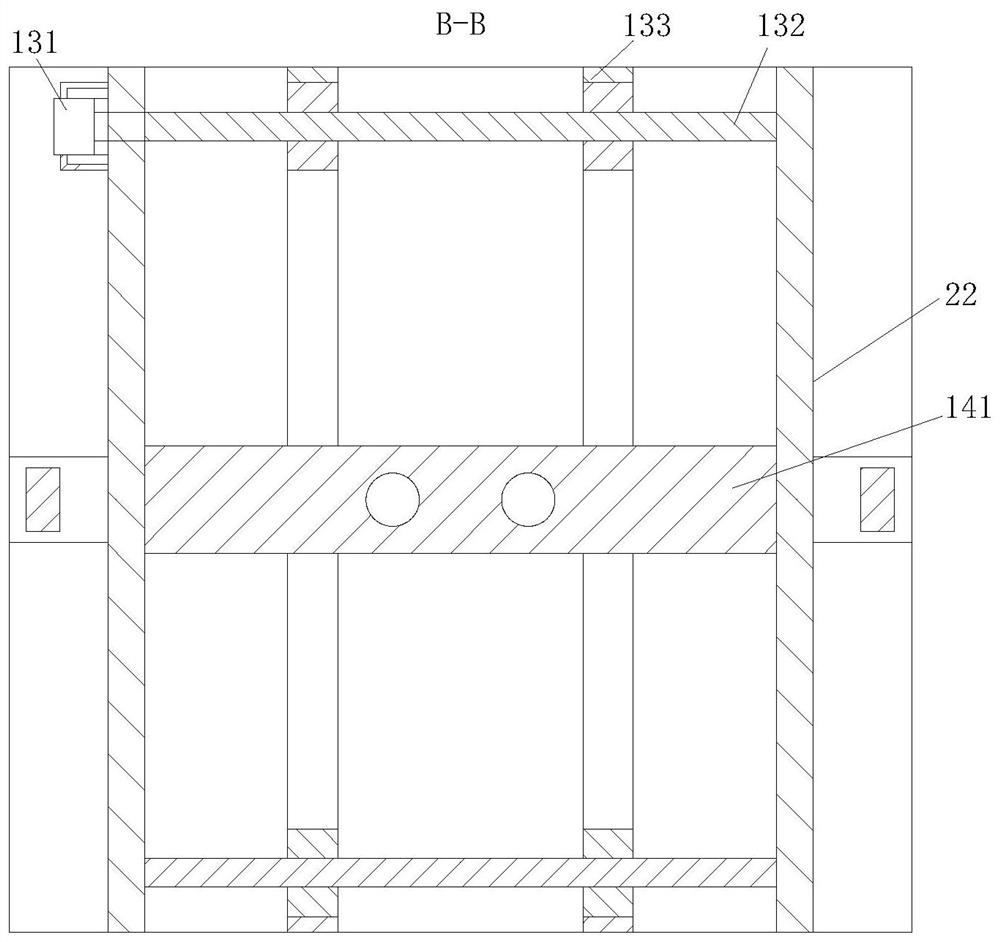

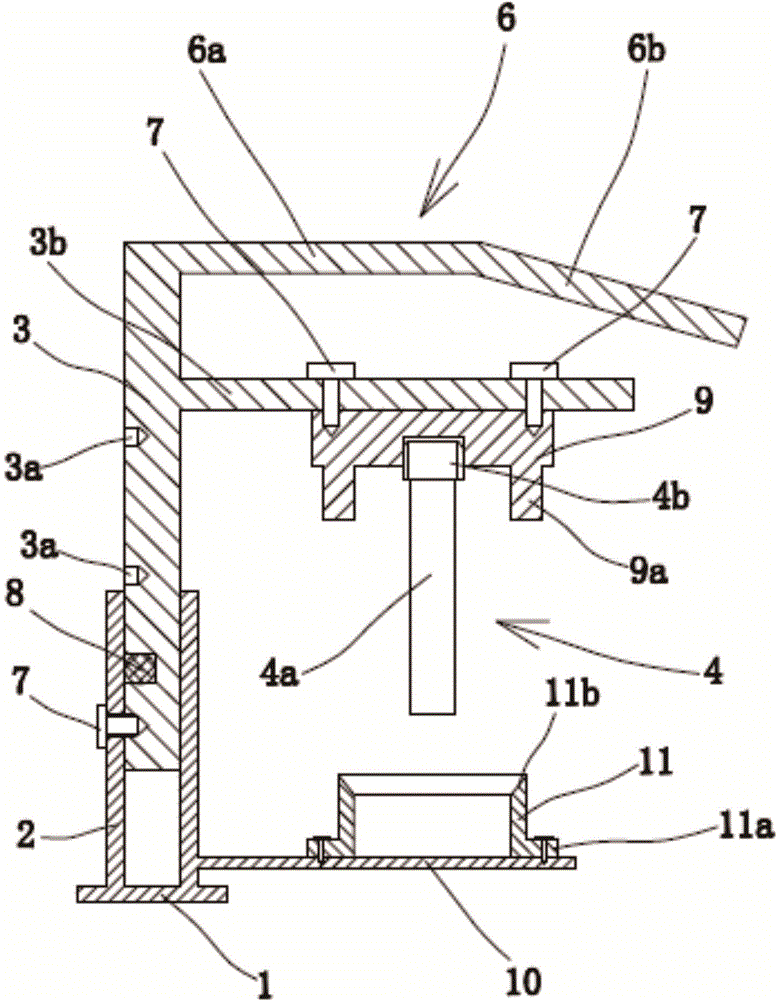

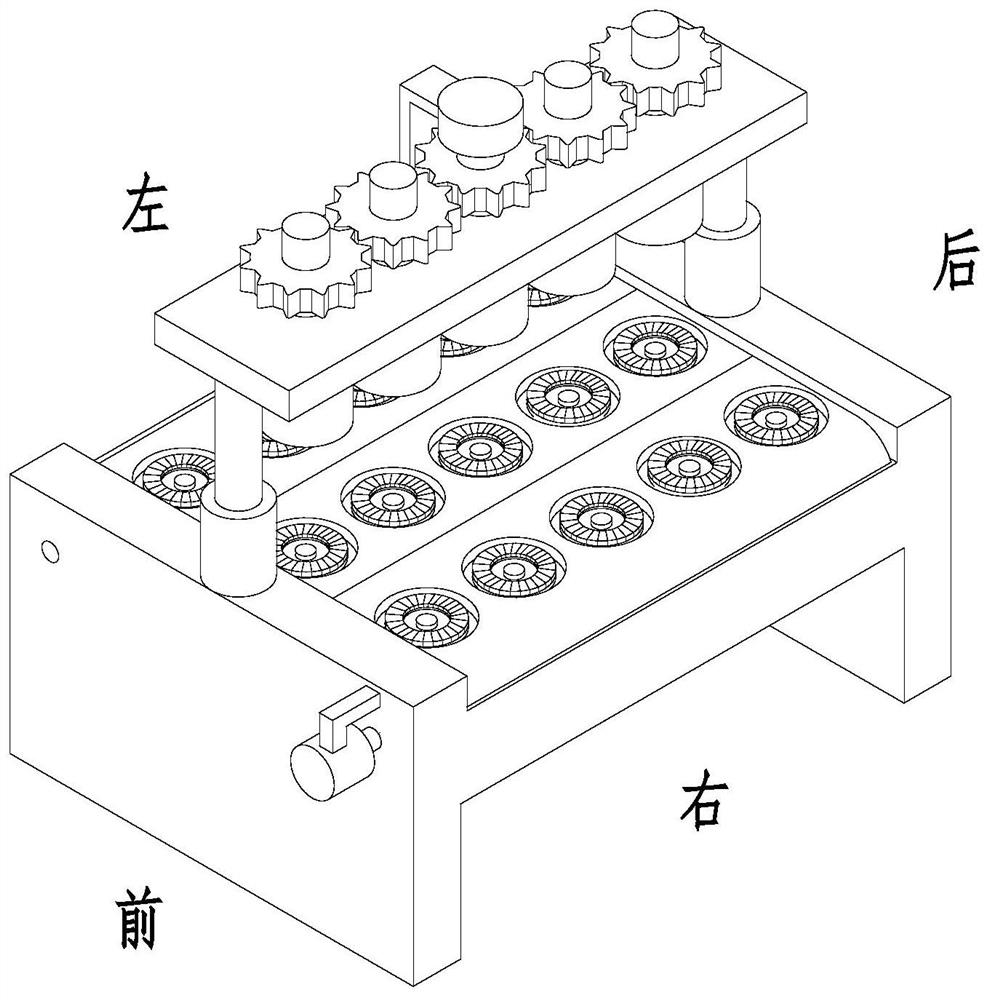

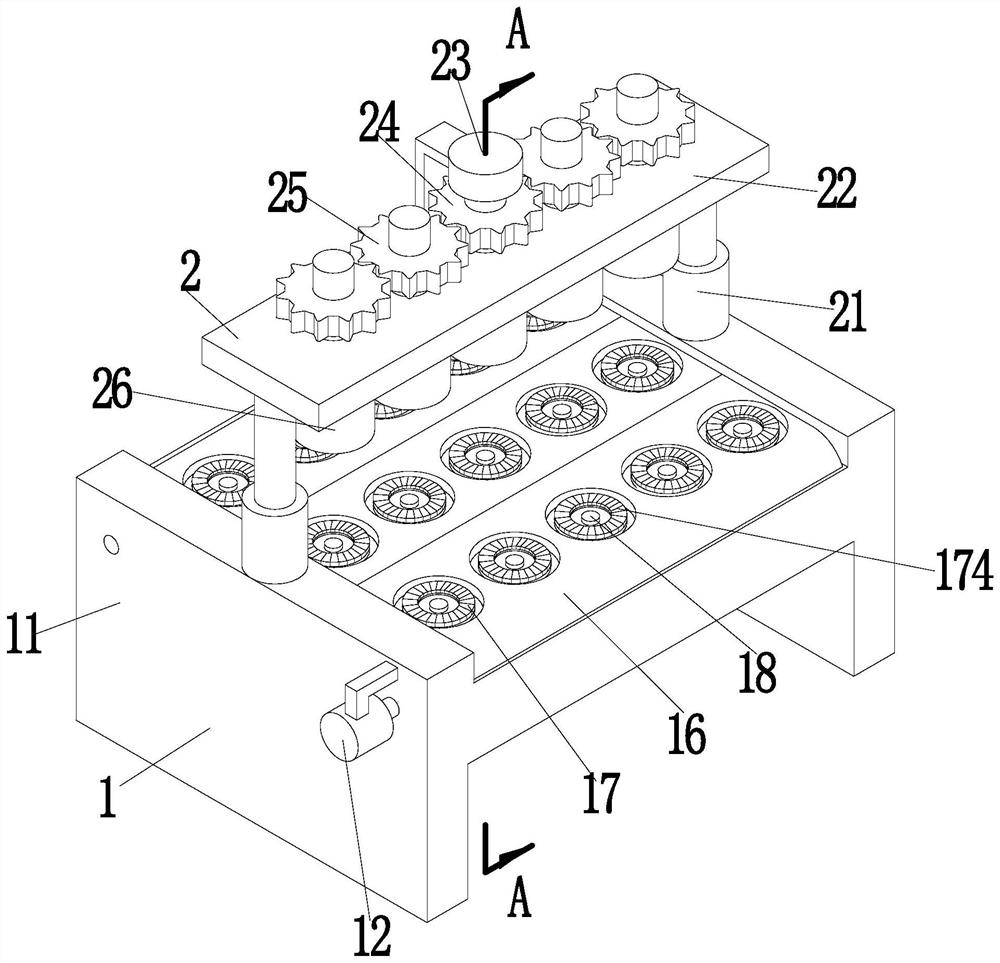

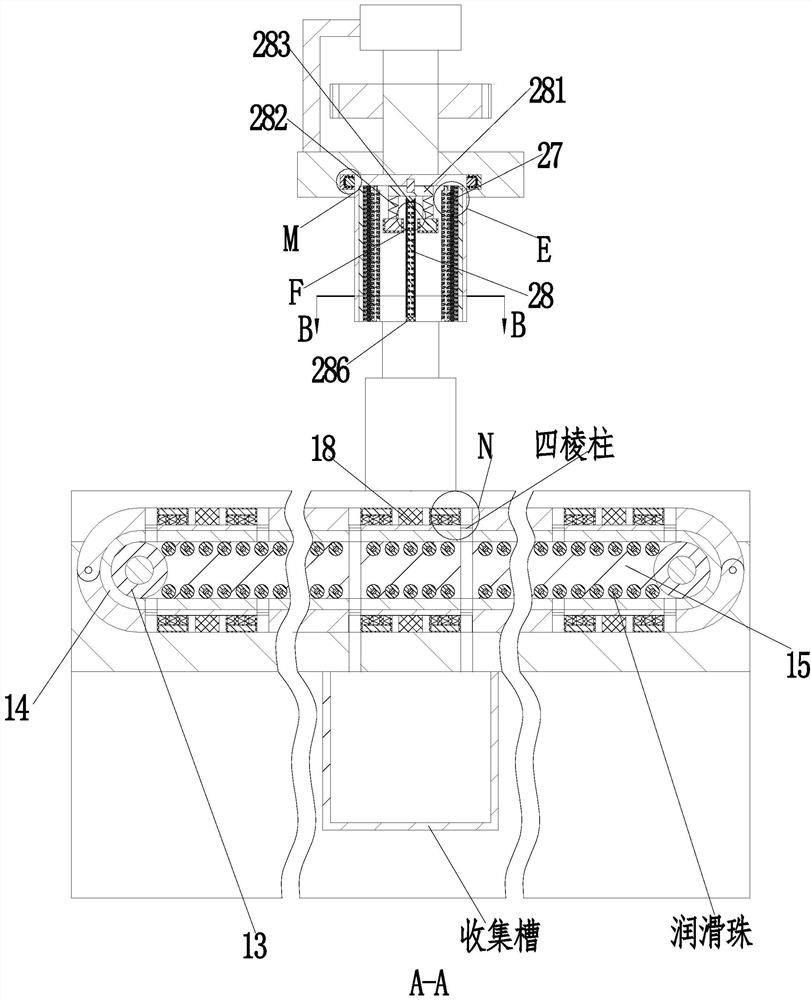

Powder metallurgy pipe fitting machining system

ActiveCN111745412AImprove work efficiencyImprove stabilityWork clamping meansOther manufacturing equipments/toolsGear wheelAssembly line

The invention relates to a powder metallurgy pipe fitting machining system. The powder metallurgy pipe fitting machining system comprises a fixing device and a drilling device. The drilling device isinstalled on the outer side of the upper end of the fixing device. The fixing device comprises a workbench, a rectangular long plate, a fixing frame, a sliding block and a clamping frame. The drillingdevice comprises a telescopic support rod, a U-shaped frame, a motor, a first drill rod, a bearing, a second drill rod, a first gear and a second gear. According to the powder metallurgy pipe fittingmachining system, through cooperation of the fixing device and the drilling device, when a pipe fitting is drilled, multiple holes can be drilled at the same time through gear transmission, through arranged chain transmission, the assembly line transportation state can be achieved, and the work efficiency is greatly improved.

Owner:株洲东亚工具有限公司

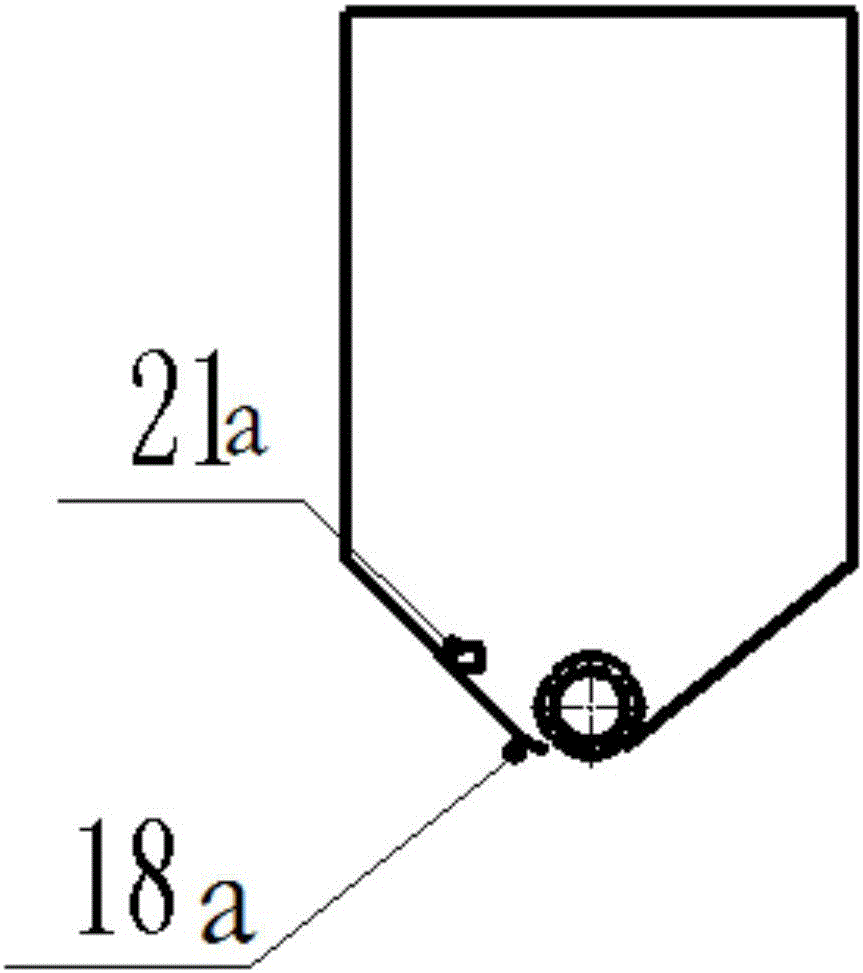

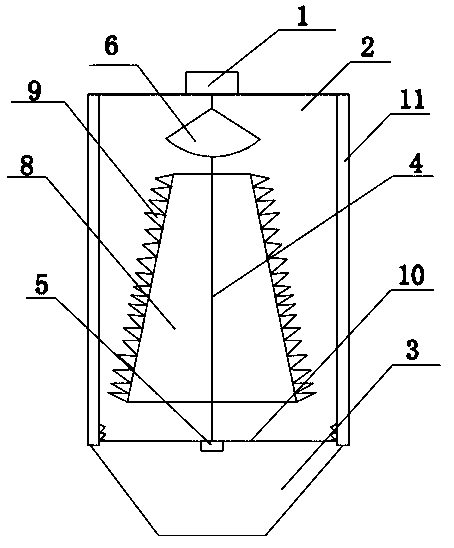

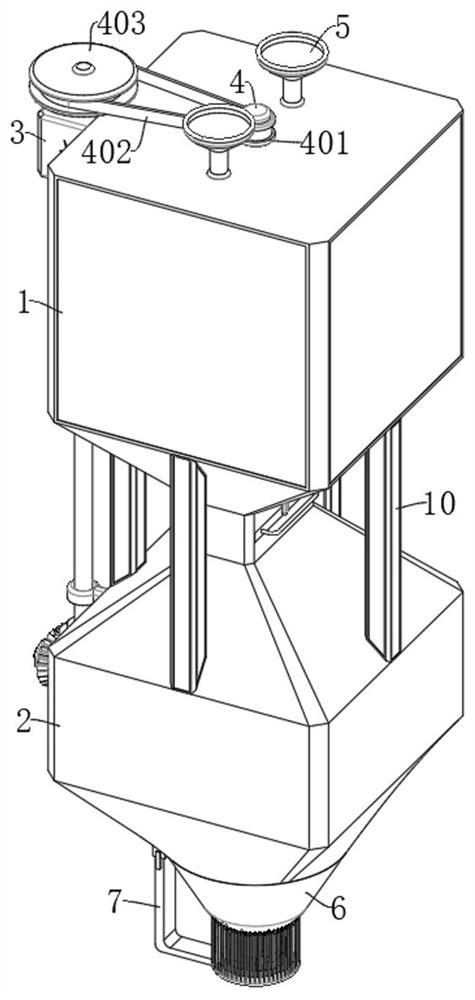

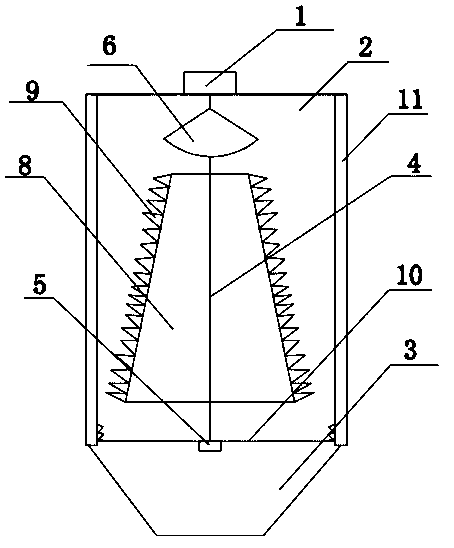

Thorough-crushing crusher

InactiveCN109465063ASimple structureImprove crushing efficiencyGrain treatmentsFiltrationElectric machinery

The invention relates to the field of crushers, in particular to an efficient crusher comprising a feed inlet, a crushing cavity and a discharge hopper. The feed inlet is located in the top of the crushing cavity. The discharge hopper is located at the bottom of the crushing cavity. The crushing cavity internally comprises a spindle. A motor is arranged at the bottom of the spindle and drives thespindle to rotate. A deflector is arranged in the position, below the feed inlet, of the crushing cavity, is fixed to the spindle and is provided with a plurality of convex dividing separation strips.The dividing separation strips are arranged on the deflector at intervals. A crushing roller is arranged below the deflector and is provided with roller teeth. The bottom structure of the crushing roller bulges outwards and is provided with a brush, and the two sides of the brush are provided with the roller teeth. A filtration sieve is arranged at the bottom of the crushing roller. The dischargehopper is arranged on the lower portion of the filtration sieve.

Owner:宜兴市申生催化剂有限公司

Lifting type working table for construction costs

ActiveCN109397937ANo manual wiping requiredRealize the collectionBoard cleaning devicesWriting boardsDisplay boardDrive shaft

The invention belongs to the field of equipment for construction costs, and particularly discloses a lifting type working table for the construction costs. The lifting type working table for the construction costs comprises a table top, wherein a vertical display board is arranged on the table top, and the display board is connected with a wiping mechanism. The wiping mechanism comprises a transverse sliding rail vertically and slidably connected to the table top, a sliding seat is transversely and slidably connected to the sliding rail, and a sliding driving piece for driving the sliding seatto slide on the sliding rail is connected to the sliding seat; a driving shaft is rotationally connected with the sliding seat, and a rotating rod is fixed to the driving shaft, and wiping brushes are separately connected to both ends of the rotating rod; and a pressing piece for driving the wiping brushes to move close to the display board is further arranged below the sliding seat, and a scraping board capable of scraping the wiping surfaces of the wiping brushes is fixed above the sliding seat. According to the lifting type working table for the construction costs, the problem that the wiping effect of a blackboard eraser to be poor due to the fact that chalk dust forms blocks on a sponge of the blackboard eraser when a display board on an existing working table for the construction costs is manually wiped.

Owner:CHONGQING VOCATIONAL INST OF ENG

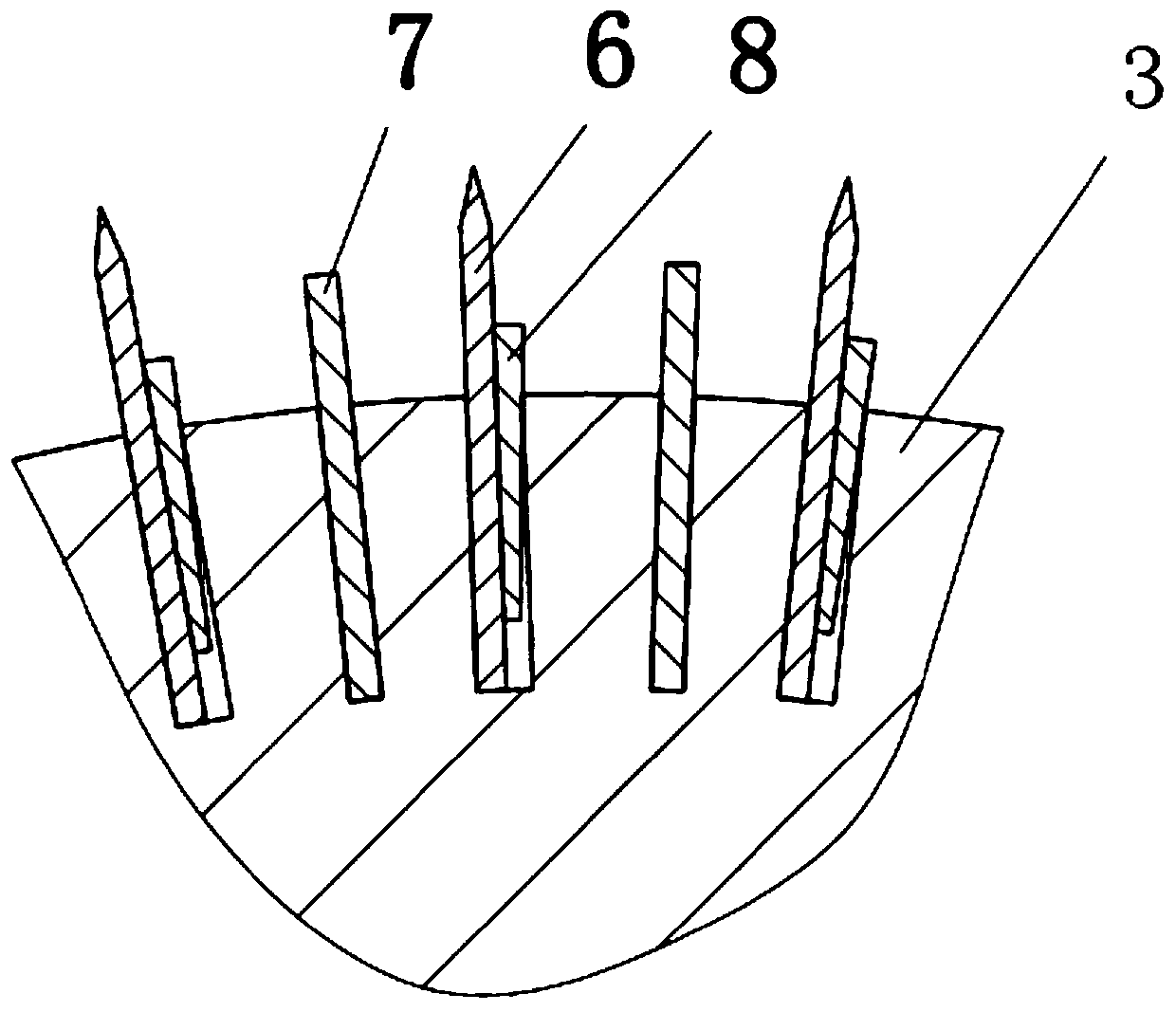

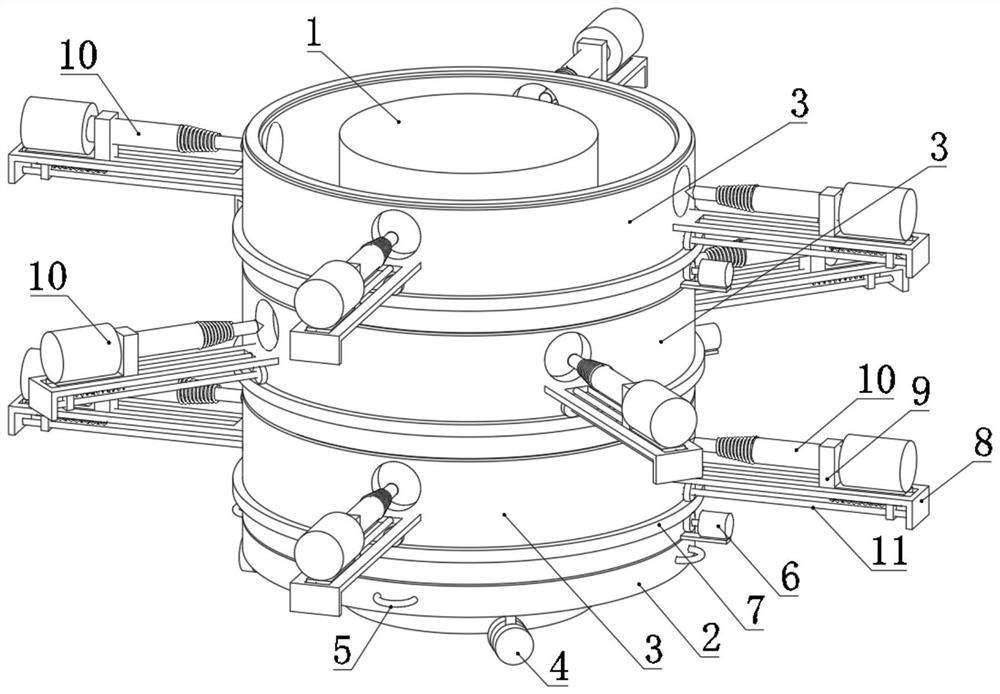

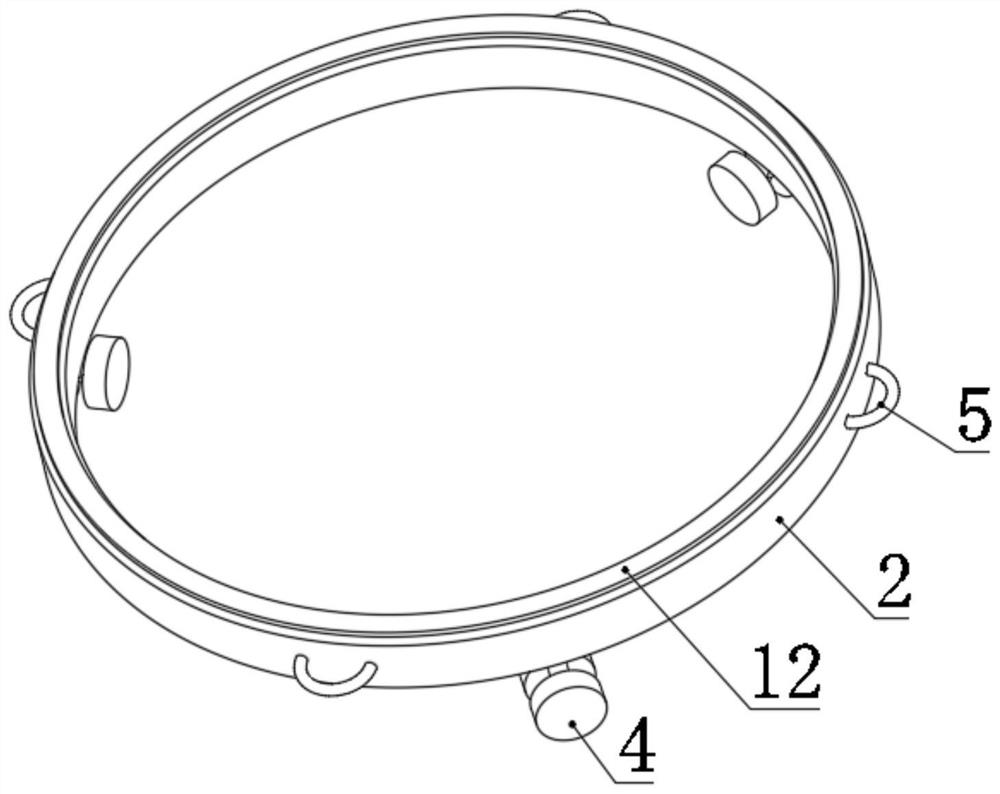

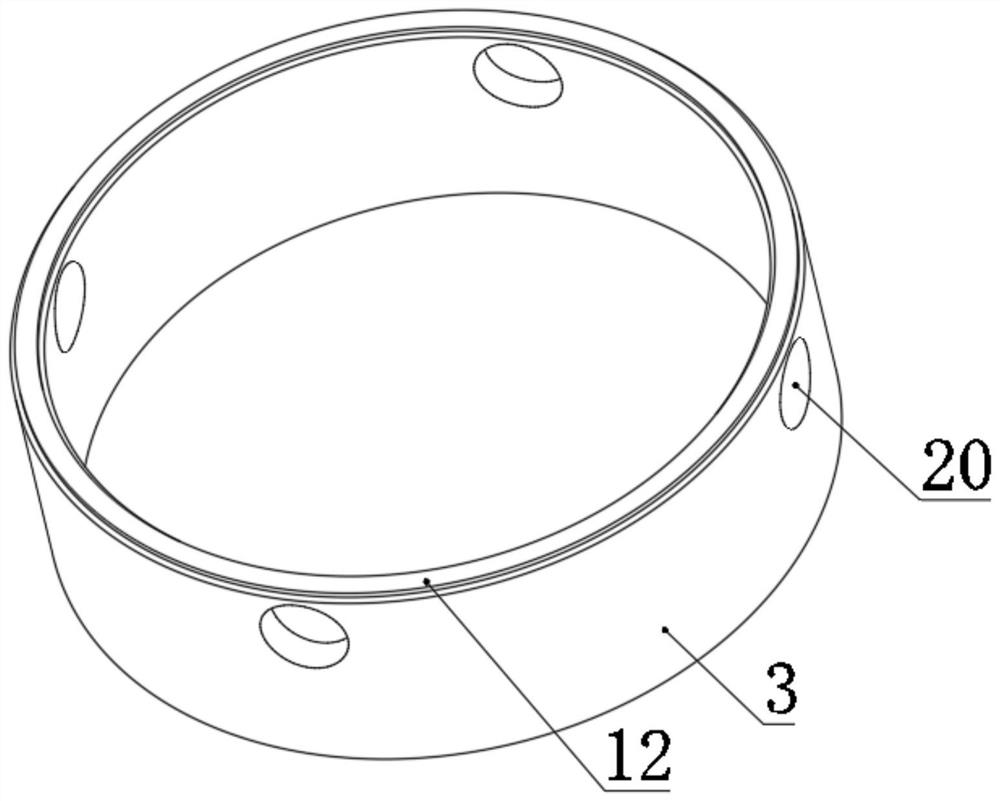

Flexibly adjustable pile head chiseling device for pile foundation construction

ActiveCN113718771AEasy chiselingReduce damage rateBulkheads/pilesArchitectural engineeringEngineering

The invention discloses a flexibly adjustable pile head chiseling device for pile foundation construction, and belongs to the field of building machinery. The flexibly adjustable pile head chiseling device comprises a base ring and a plurality of ring bodies, the base ring and the ring bodies sleeve the outer side of a pile head, the base ring and the multiple ring bodies sleeve the outer side of the pile head, the base ring is located on the lower side of the ring bodies, the base ring is in separable sliding connection with the ring bodies, the ring bodies are in separable sliding connection, a plurality of punched holes are formed in the ring bodies in a penetrating mode, and double-face gear rings are fixed to the outer sides of the ring bodies. The flexibly adjustable pile head chiseling device is formed by vertically splicing and assembling the base ring and the multiple ring bodies, the pile head is chiseled through an air pick with the adjustable angle and position, and the number of the ring bodies is set according to the height of the pile head, so that the pile heads with different heights are chiseled; an impact drill bit of the air pick can be buffered in the chiseling process, the damage probability of the air pick is further reduced, and the service life is prolonged; and in addition, concrete blocks can be crushed in the chiseling process, and the concrete blocks can be conveniently cleared and transported.

Owner:焦立征

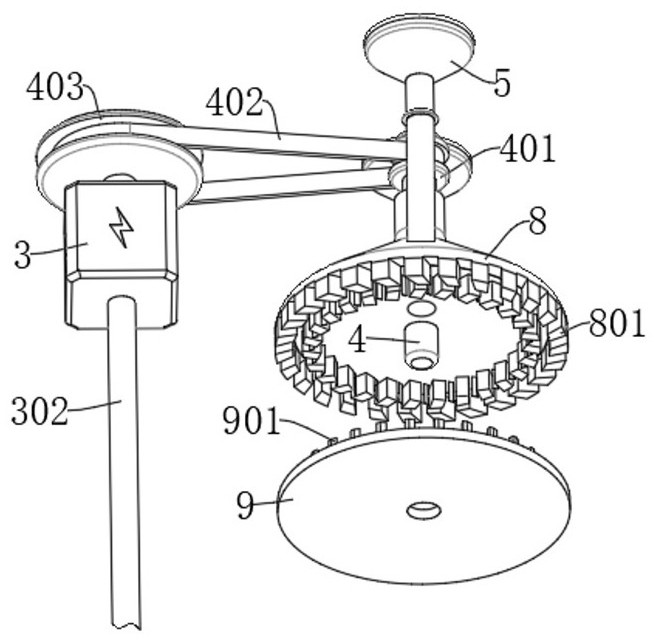

Grinding device for suspension production and grinding method thereof

The invention provides a grinding device for suspension production and a grinding method thereof, and belongs to the technical field of grinding equipment. The grinding device for suspension production comprises a crushing box, a solid crushing cover, a feeding hopper and a second rotating rod; a discharging opening is formed in the bottom of the crushing box; the solid crushing cover is fixed to the top wall of the crushing box, a plurality of inner crushing blocks and outer crushing blocks which are evenly distributed are fixed to the bottom of the solid crushing cover, and the outer crushing blocks are all located on the inner sides of the inner crushing blocks; the feeding hopper is fixed to the top of the crushing box; and the second rotating rod is rotationally connected to the top of the crushing box, and the lower end of the second rotating rod movably penetrates through the top wall of the crushing box and the bottom of the solid crushing cover and extends downwards. According to the device, traditional Chinese medicine particles are crushed through centrifugal force and then ground, so that the traditional Chinese medicine particles become small, the effect is better when the traditional Chinese medicine particles are ground through a grinding mechanism, large particles are not likely to be generated, and therefore the quality of a prepared suspension is higher.

Owner:江苏省徐州华泰工具有限责任公司

Sewage precipitation treatment device

InactiveCN111362461AQuality improvementAvoid accumulationTreatment involving filtrationMultistage water/sewage treatmentAir pumpSewage

The invention discloses a sewage sedimentation treatment device which comprises a box body, a feeding hole formed in the upper part of the box body, a stirring mechanism arranged at the upper part inthe box body, a scraping mechanism arranged below the stirring mechanism, a water collecting mechanism arranged below the scraping mechanism and a water collecting recovery tank arranged below the water collecting mechanism, the water collecting mechanism comprises an air pump, a telescopic pipe arranged at the upper part of the air pump and a U-shaped pipe arranged on the telescopic pipe, the center of the U-shaped pipe is a symmetry axis, filter plates are arranged on the left side and the right side of the U-shaped pipe, a water absorption part is arranged above the filter plates, and an arch-shaped plate is arranged outside the water absorption part in a sleeving mode. The water absorption part can move up and down in the arch-shaped plate, sediment recovery tanks are arranged on the left side and the right side of the arch-shaped plate, through the arrangement of the water absorption mechanism, clean water can be discharged out of the independent box body, secondary pollution of the water is avoided, and the quality of water precipitation is improved through additives.

Owner:浙江国千环境技术发展有限公司

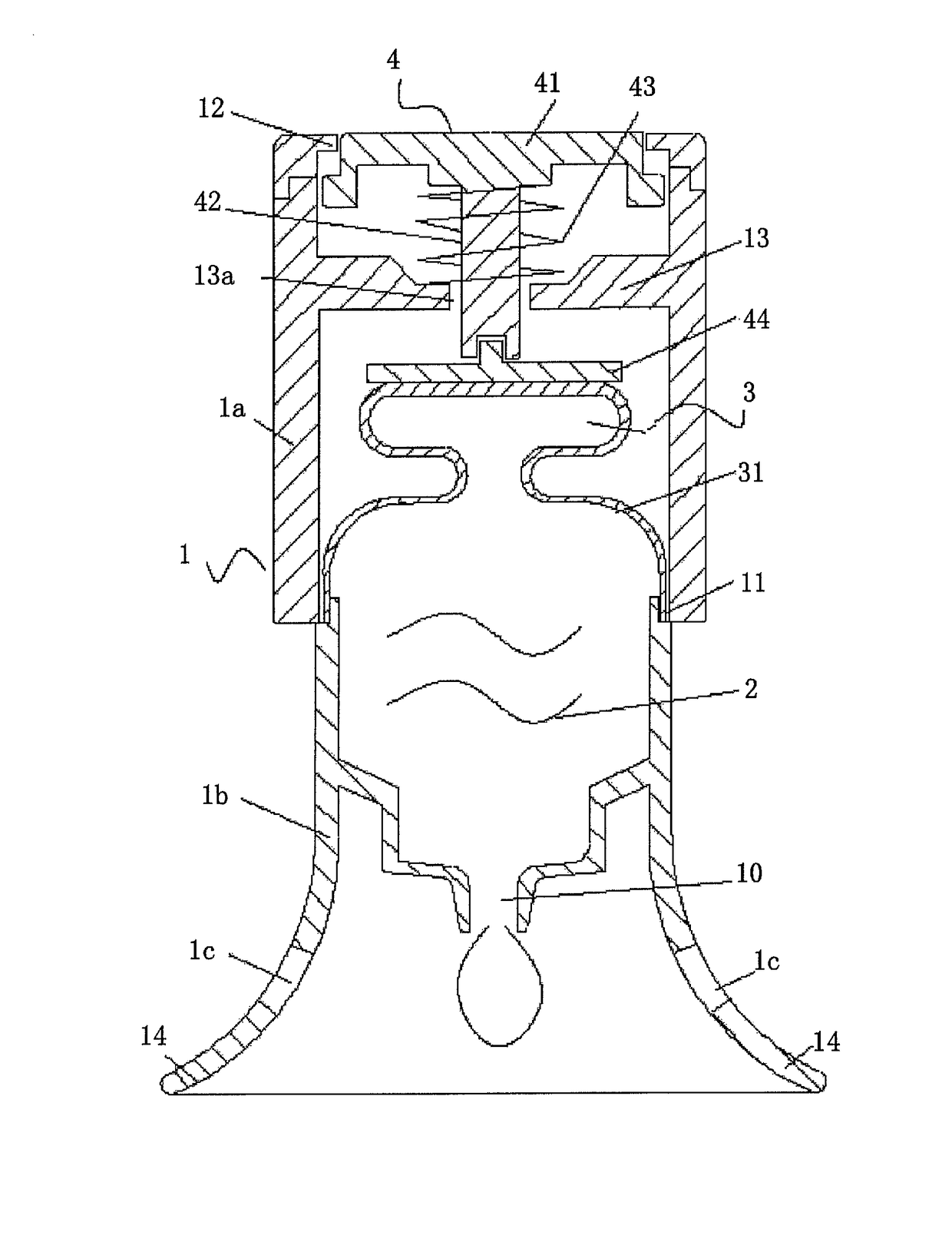

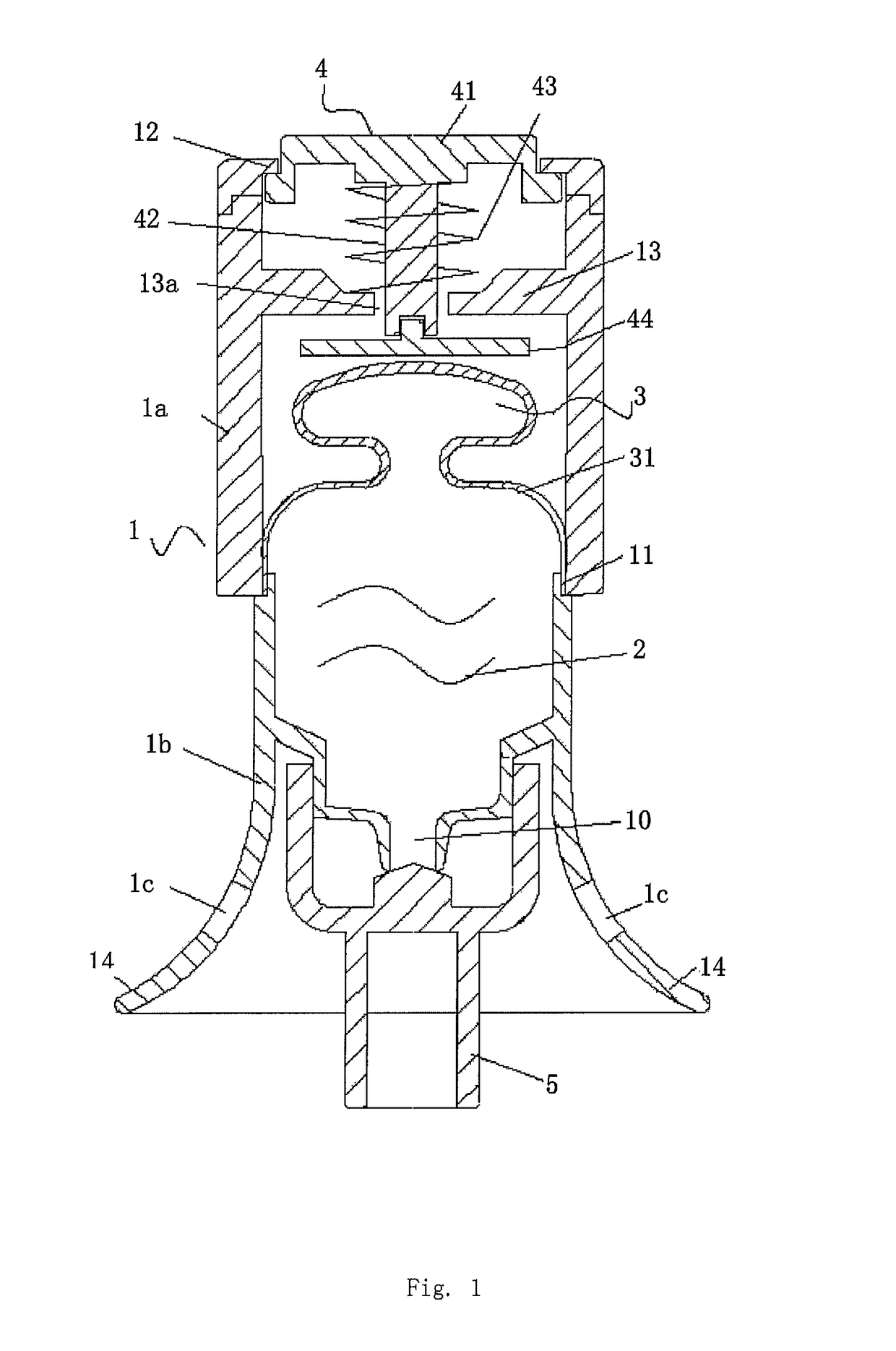

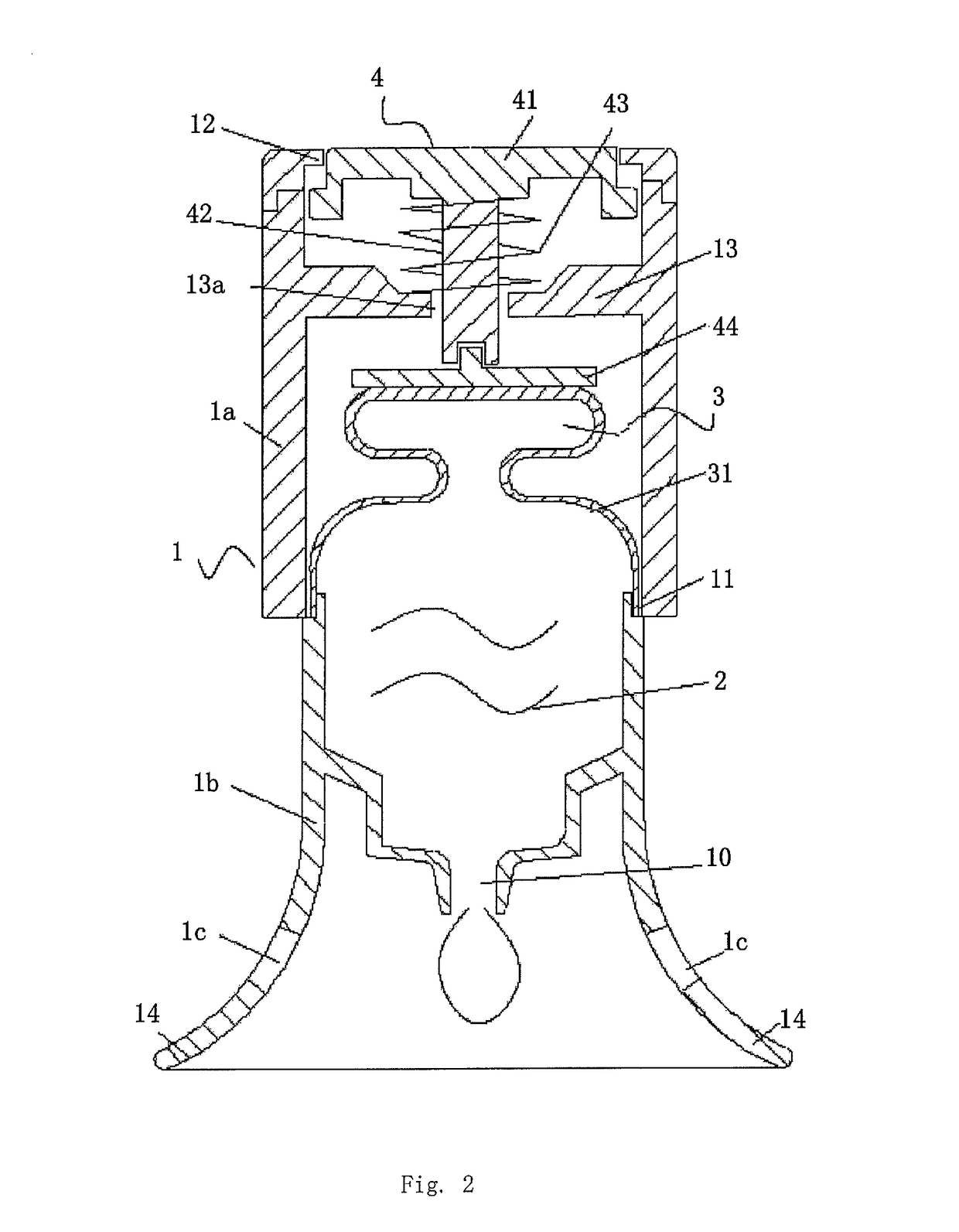

Dropper of eye drops

A dropper of eye drops comprises an eye drops storage for storing eye drops, which has an opening at the top and an eye drop outlet at the bottom; an elastic seal assembly installed inside the eye drop storage and forming a space for storing the eye drops together with the eye drop outlet; a pressing device installed at the top of the eye drop storage and configured to press the elastic seal assembly so as to compress the space for storing the eye drops, such that the eye drops are dropped out of the eye drop outlet. The dropper of eye drops eye drops by means of pressing the pressing device, and thus can be operated simply and safely, time- and energy-saving, and avoid waste. In addition, the dropper of eye drops has a simple design in structure and is convenient for use.

Owner:AFFILIATED HOSPITAL CHINA ACADEMY OF MILITARY MEDICAL SCI

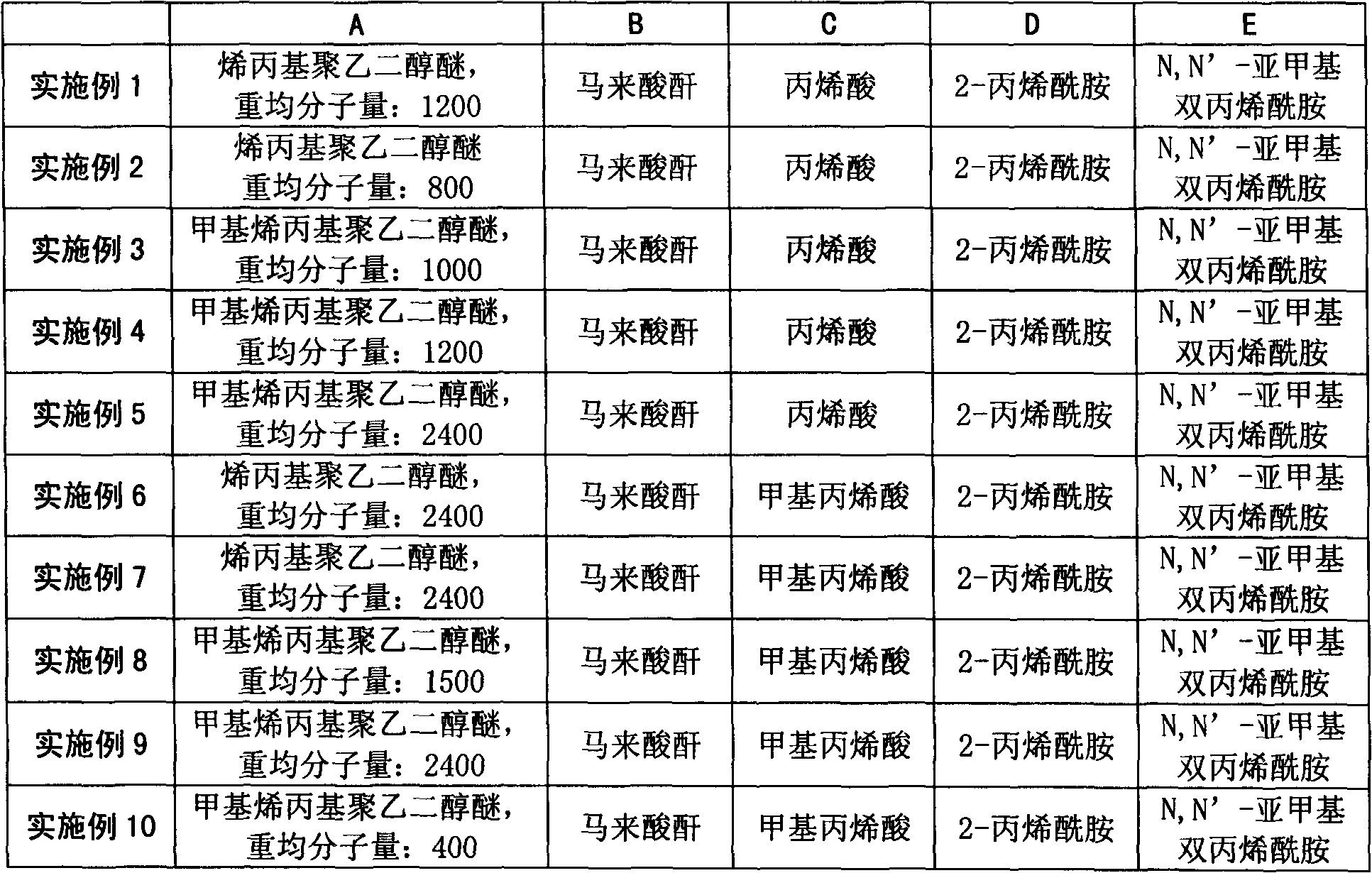

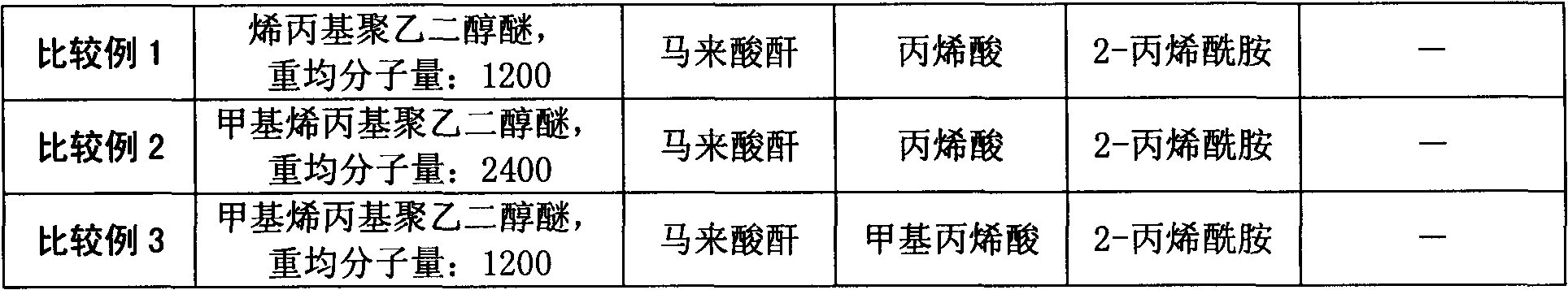

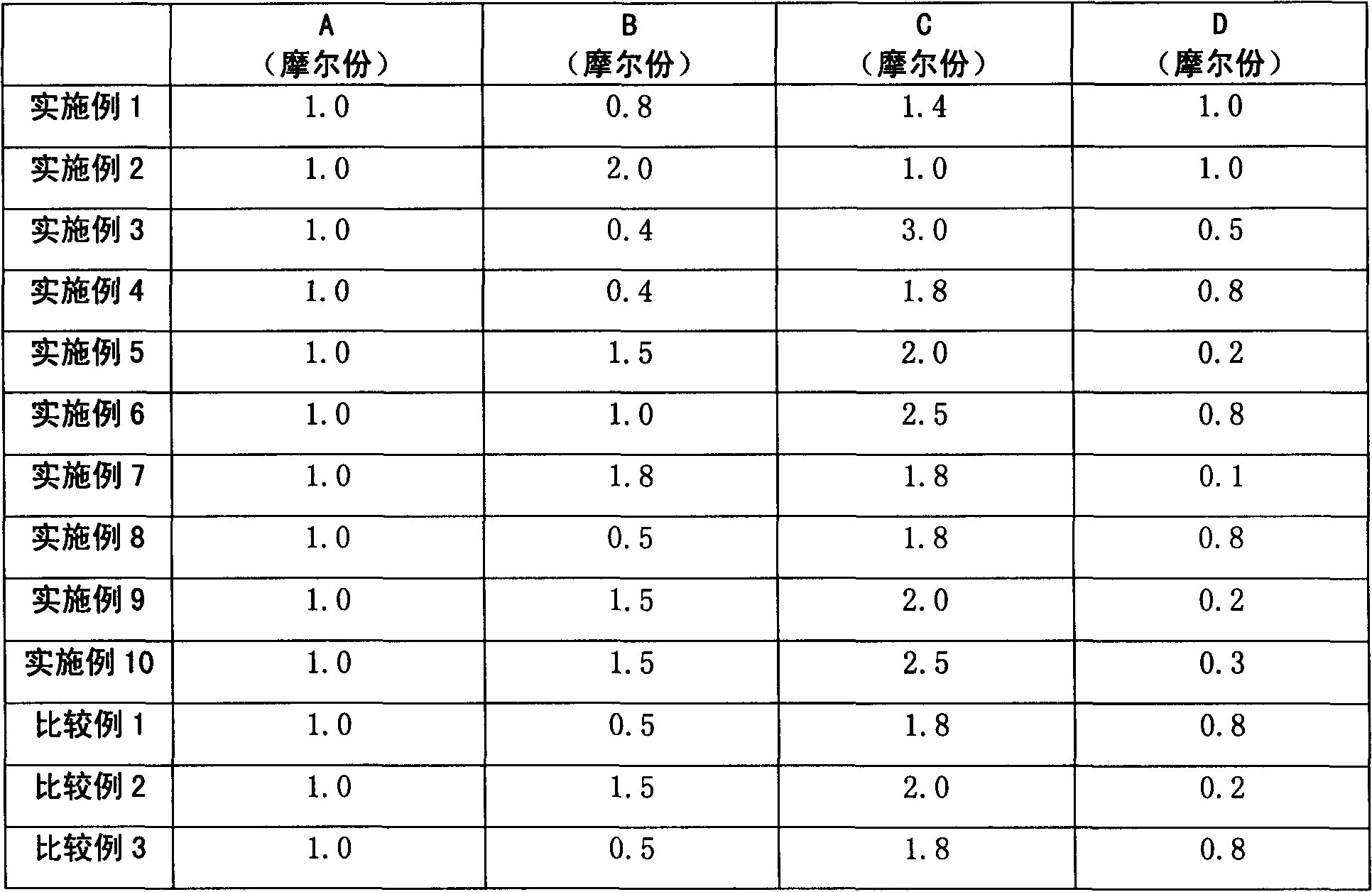

Method for preparing copolymer of polycarboxylic concrete water reducer

A method for preparing the copolymer of polycarboxylic concrete water reducer is used for copolymerizing monosomic A, B, C, D and E into a product, wherein A is allyl polyglycol ether or methyl-allyl-polyglycol ether; B is maleic anhydride; C is acrylic acid or methacrylic acid; D is 2-acrylamide; and E is N, N'-methylene-bis-acrylamide. The preparation process comprises the following steps: 1), preparing a water solution of the mixture of the monosomic A, B and D; 2), adding the monosomic C and E and an initiating agent dropwise to the water solution of the mixture for copolymerization, wherein the reaction temperature is 60 to 90 DEG C, the adding operation lasts for 3.0 to 5.0 h, and the reaction time is 1.0 to 3.0; and 3), carrying out neutralization reaction to obtain the product. Taken by molarity part, when A is 1.0, B is 0.4 to 2.0, C is 1.0 to 3.0, D is 0.1 to 1.0, and the ratio between A+B+C+D and E is 100 to (0.5 to 1.8).

Owner:SHANGHAI DUOLUN CHEM

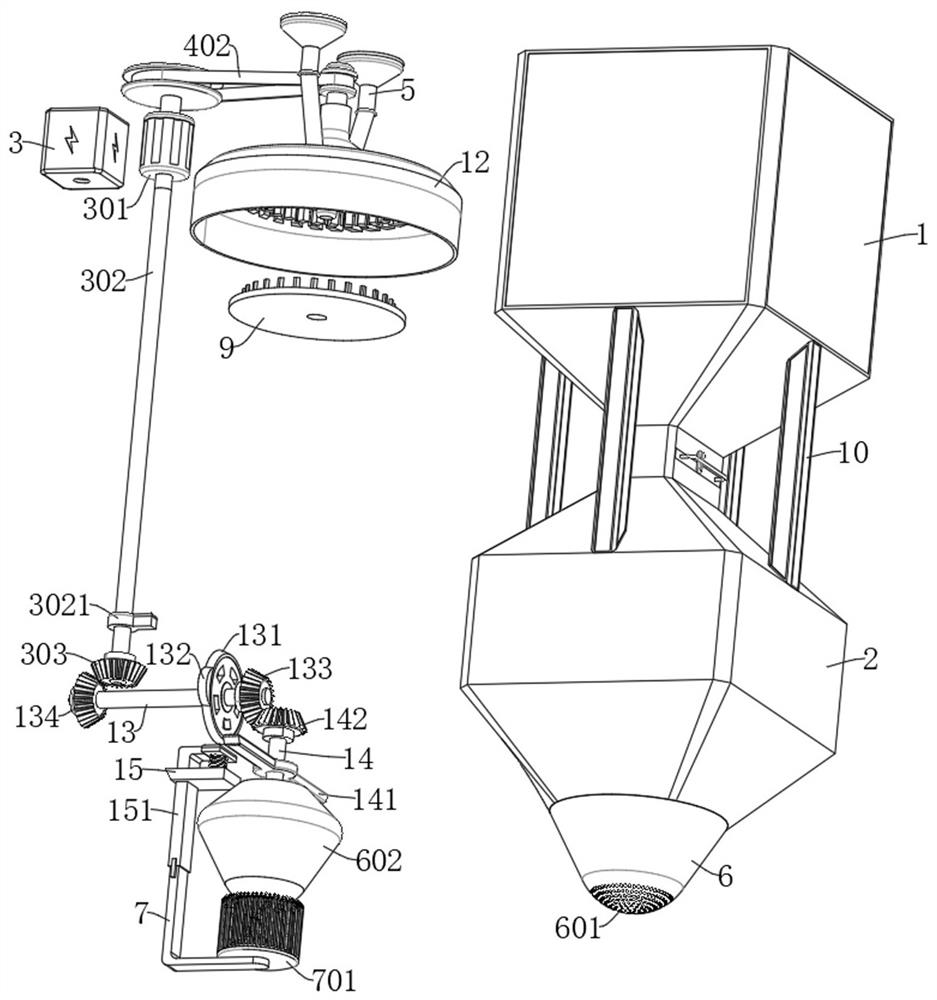

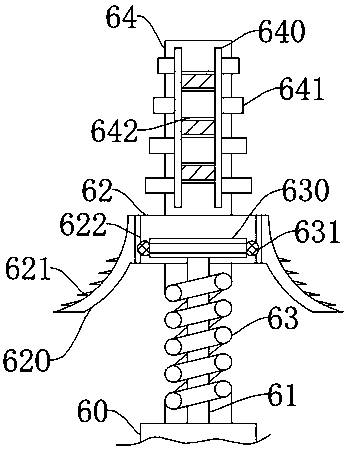

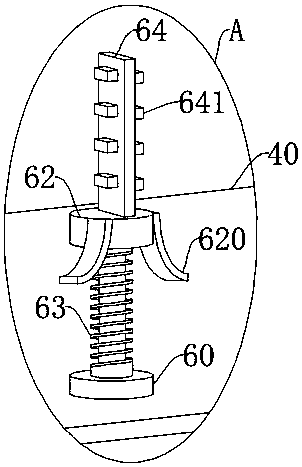

Garden deinsectization lamp

InactiveCN105707036AImprove the effect of pest controlEasy to replaceInsect catchers and killersPower gridStructural engineering

The invention provides a garden deinsectization lamp and solves the problem that the height of an existing garden deinsectization lamp cannot be adjusted. The garden deinsectization lamp comprises a base, a frequency vibration lamp and a cylindrical high-voltage power grid; a connecting cylinder is arranged on the base; the frequency vibration lamp comprises a frequency vibration lamp tube and a mounting sleeve which are mutually and fixedly connected with each other; a supporting rod is inserted into the connecting cylinder, and the outer end of the supporting rod extends out of the connecting cylinder; a threaded hole I is formed in the side wall of the connecting cylinder; a plurality of threaded holes II distributed along the length of the supporting rod are formed in the side wall of the supporting rod; the screws pass through the threaded hole I and are in threaded connection with one of the threaded holes II; a transversely-arranged supporting plate is arranged at the outer end of a support frame; a positioning plate is connected onto the supporting plate through the screws and is positioned between the base and the supporting plate; the mounting sleeve is in threaded connection with a central position at the bottom of the positioning plate; a ring-shaped connecting part I is arranged at the bottom of the positioning plate; the high-voltage power grid is arranged on the frequency vibration lamp in a sleeving manner, and the upper end of the high-voltage power grid is fixedly arranged in the connecting part I. The garden deinsectization lamp provided by the invention has the advantages that the height can be adjusted and the deinsectization effect is good.

Owner:李自甲

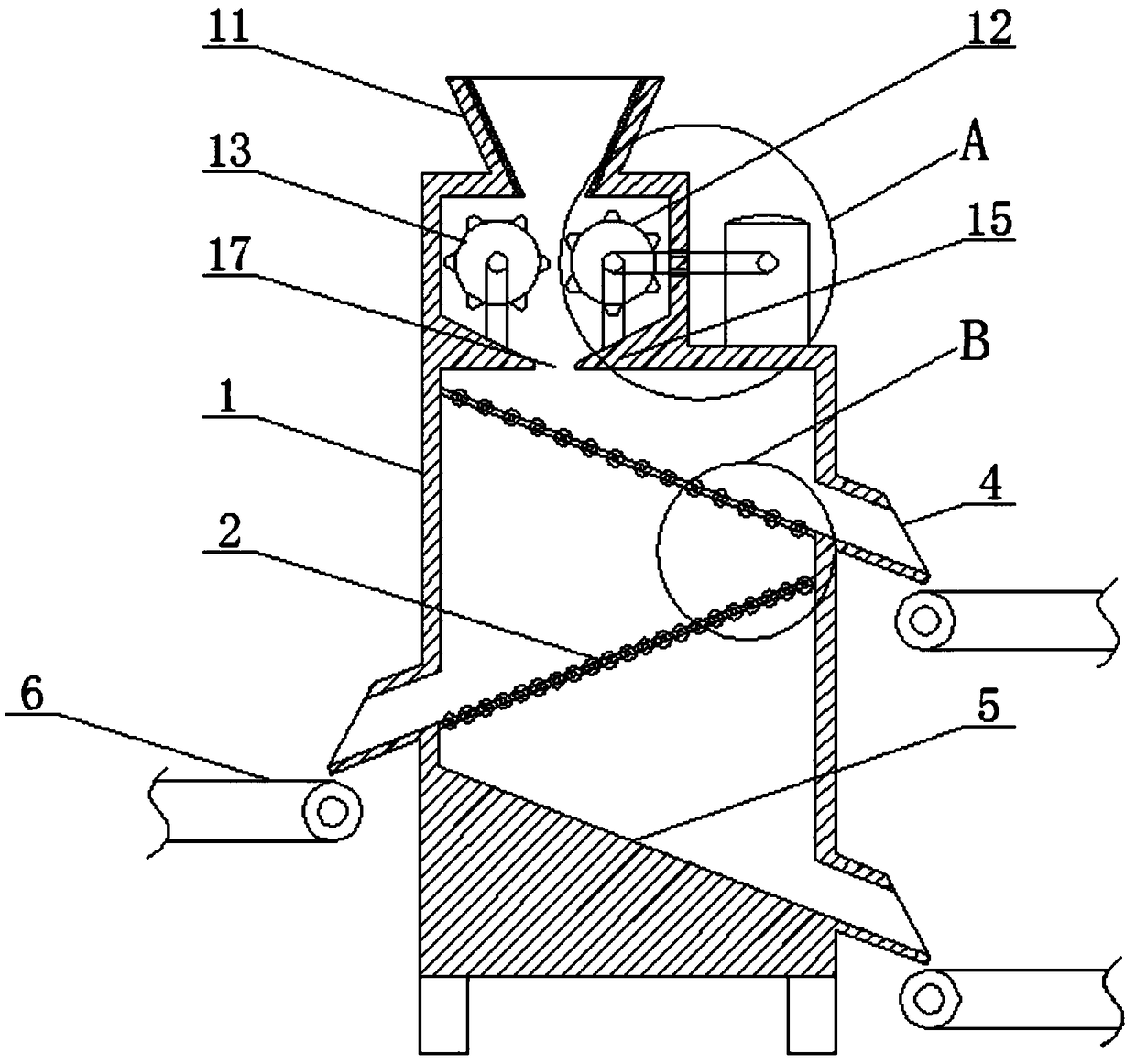

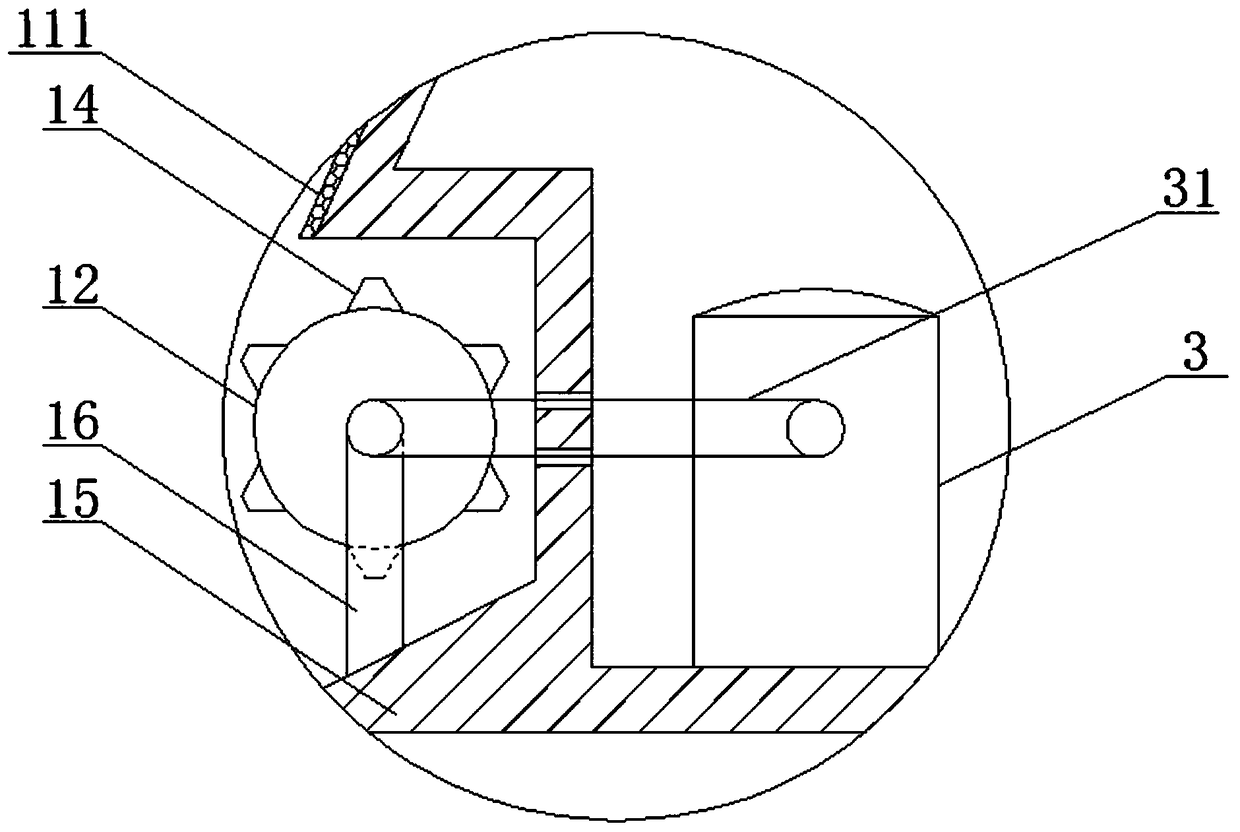

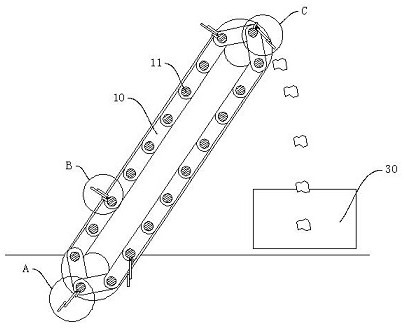

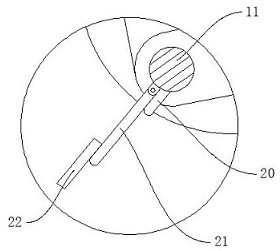

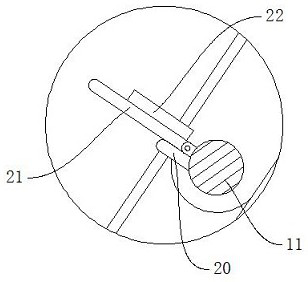

Ore smashing and screening device

The invention discloses an ore smashing and screening device. The ore smashing and screening device comprises a smasher body; a feeding hopper is arranged on the upper portion of the smasher body; a driving smashing roller and a driven smashing roller are arranged below the feeding hopper; an inclined conveying roller set is arranged below the driving smashing roller and the driven smashing roller; a discharging plane is arranged below the conveying roller set; and a discharging outlet is formed in the side wall of the smasher body. The ore smashing and screening device provided by the invention is ingenious in structure, can complete ore smashing, screening and conveying at the same time, and is stable in operation and low in failure rate, the production efficiency is improved, and the workload of workers is reduced.

Owner:衡阳泰源商砼有限公司

Casting sand removing device

The invention belongs to the field of casting equipment, and particularly discloses a casting sand removing device. The casting sand removing device comprises a sand removing box; a horizontal first movable plate and a horizontal second movable plate are sequentially arranged in the sand removing box from top to bottom in a sliding manner; the first movable plate and the second movable plate are both inclined; the first movable plate and the second movable plate are inclined in opposite directions; sand through holes are formed in the first movable plate and the second movable plate; a first push rod is vertically connected between the first movable plate and the second movable plate in a sliding manner; the top end of the first push rod is propped against the first movable plate; the bottom end of the first push rod is propped against the second movable plate; a first passage is arranged at the low end of the first movable plate; a second passage is rotationally connected with the inner side wall of the sand removing box below the first passage; spiral bulges are arranged on the inner wall of the first passage and the inner wall of the second passage; bristles are densely distributed on the bulges; a receiving slot is arranged between the first passage and the second passage; and a second push rod is connected with the receiving slot in a sliding manner. The device can turn over automatically when used for sand removal of castings.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

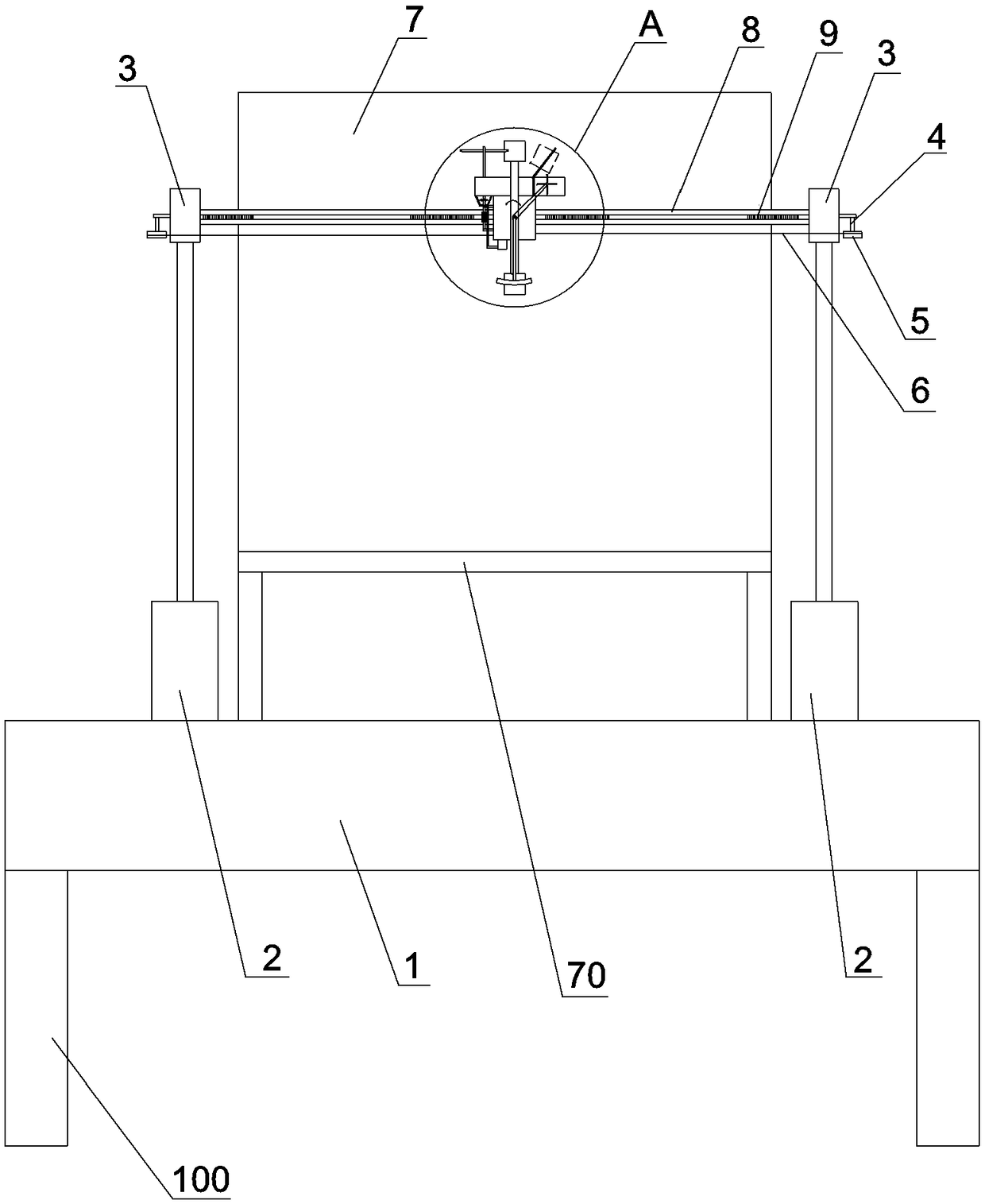

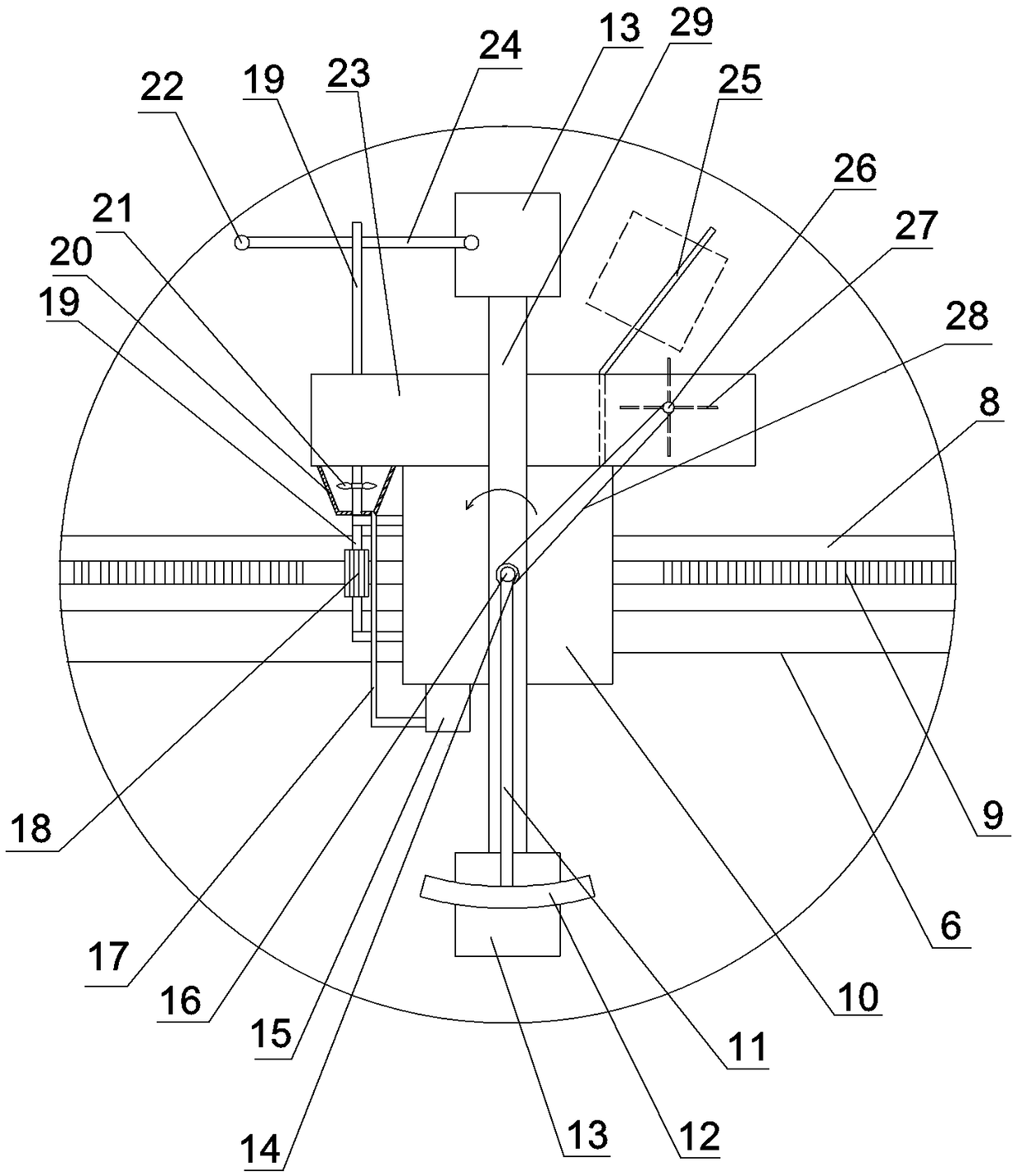

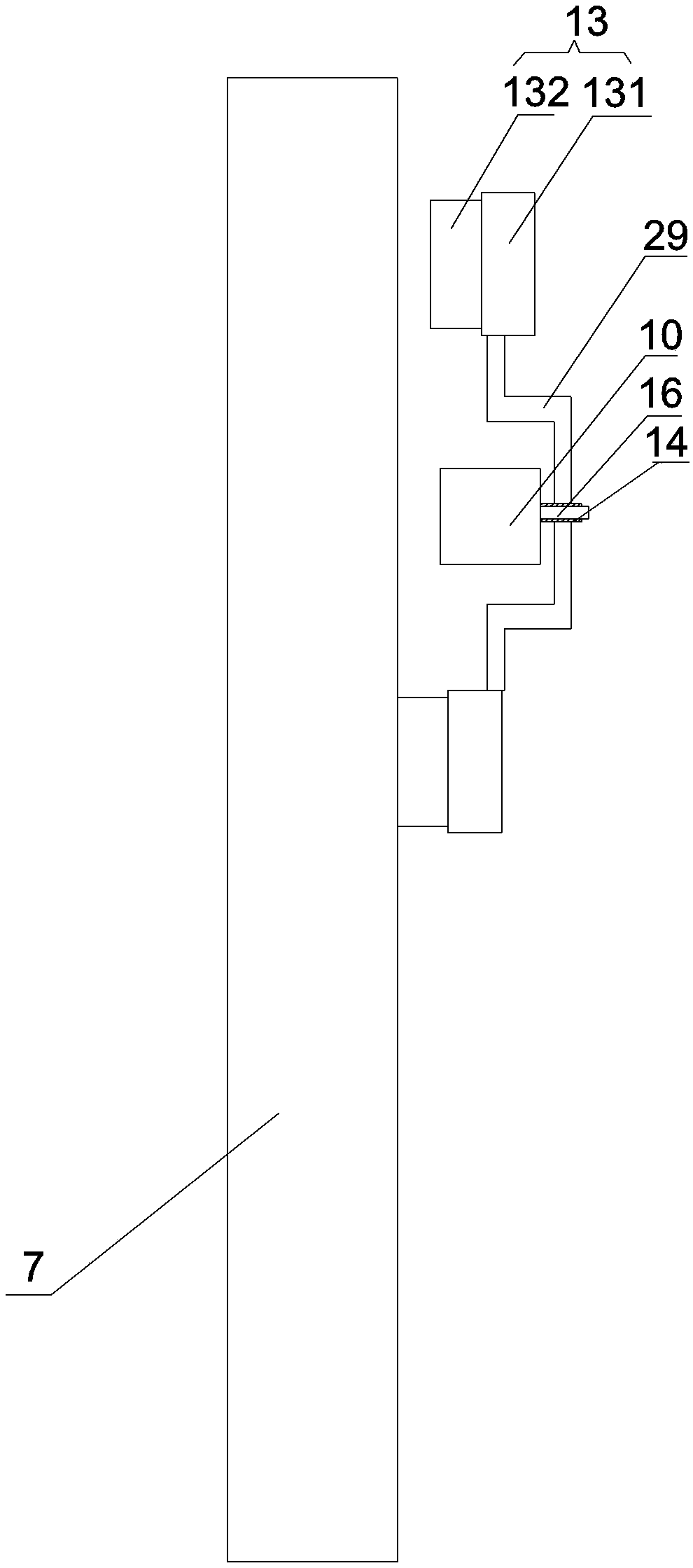

Automatic transporting device for round workpiece milling machine

The invention provides an automatic transporting device for a round workpiece milling machine. According to the automatic transporting device, a joining plate is arranged at the lower end of a conveying device, the width of the joining plate is larger than the width of a transmission device, the height of a fixing baffle is larger than the radius of a round workpiece, and therefore the falling process of the round workpiece is smooth after the round workpiece is machined, and workpiece damage is avoided; and sixteen clamping devices are arranged in the transverse direction of a conveying beltin a manner that every two clamping devices are symmetrical, a limiting plate is in a shape of a one sixth arc, and first limiting blocks are arranged on the limiting plate in a rubber pyramid shape.When the automatic transporting device works, the round workpiece is stably borne, the production requirements are met, four second limiting blocks are arranged in the longitudinal direction of a fixing plate in the manner than the lengths are increased gradually, four rodless cylinders are arranged in the longitudinal direction of the fixing plate and are electrically connected with a control terminal; and the workpiece can be stably clamped through the device, and the automatic degree is high.

Owner:滁州市成业机械制造股份有限公司

Nut feeding device

The invention discloses a nut feeding device, which belongs to the technical field of mechanical device design and includes a material storage box, a striking rod, a base, a material receiving box, a feeding rail, a fixed warehouse, a rotating shaft, a pyramid-shaped surface, a feeding hole, a storage The material box is located above the material receiving box, the rotating shaft is installed on the base, driven by the belt pulley, the impact rod is fixed at the middle right position of the rotating shaft, and an inclined feeding rail is arranged at the bottom of the left side of the material receiving box. The material box slides to the fixed warehouse on the left side through the feeding rail. The nut feeding device disclosed in the present invention has simple structure, low cost, and convenient feeding. Falling smoothly, the nut can be completely dropped into the receiving box without falling sideways.

Owner:杨世兵

Finish machining machine for manufacturing three-phase asynchronous motor cast-aluminum rotor

InactiveCN113245918AAffect qualityPrevent movementRevolution surface grinding machinesGrinding drivesRubber ringInduction motor

The invention relates to a finish machining machine for manufacturing a three-phase asynchronous motor cast-aluminum rotor. The machine comprises a conveying device and a grinding device, wherein the grinding device is fixedly installed on the upper end face of the conveying device, the conveying device comprises a fixing table, a first stepping motor, a first chain wheel, a first toothed chain belt, a supporting plate, an arc-shaped long plate, a rubber ring plate and an electromagnetic plate, and the grinding device comprises a telescopic support, a fixing plate, a second motor, a first gear, a second gear, a rotating cylinder, a grinding frame and a positioning frame. According to the machine, the cast-aluminum rotor is conveyed by means of the conveying device, the lower side of the cast-aluminum rotor is limited, meanwhile, ground chippings are discharged, and the plurality of cast-aluminum rotors are positioned and fixed by means of the grinding device, so that the cast-aluminum rotors are prevented from moving in a grinding process, and meanwhile are ground, in the grinding process, a grinding tool is cleaned, and then the situation that the quality of the grinding tool is affected by metal chippings is prevented.

Owner:黄秋红

High efficiency crusher

The invention relates to the field of crushers, in particular to a high efficiency crusher. The high efficiency crusher comprises a feeding port, a crushing chamber and a discharge hopper. The feedingport is located on the top of the crushing chamber. The discharge hopper is located at the bottom of the crushing chamber. The crushing chamber comprises a spindle. A motor is arranged at the bottomof the spindle. The motor drives the spindle to rotate. A flow guide plate is arranged inside the crushing chamber on the lower portion of the feeding port. The flow guide plate is fixedly arranged onthe spindle. The flow guide plate is provided with a plurality of protrudent diverging separation strips. The diverging separation strips are arranged on the flow guide plate at intervals. A crushingroller is arranged on the lower portion of the flow guide plate. The crushing roller is provided with roller teeth. The diameter of the upper part of the crushing roller is smaller than that of the lower part of the crushing roller. A filter screen is arranged at the bottom of the crushing roller; and the discharge hopper is arranged at the lower part of the filter screen.

Owner:宜兴市申生催化剂有限公司

Equipment for cutting two sides of ring-pull can

PendingCN111604542ASave human effortImprove cutting efficiencyMetal sawing devicesMetal sawing accessoriesElectric machinerySlide plate

The invention relates to cutting equipment and particularly relates to equipment for cutting the two sides of a ring-pull can. The equipment for cutting the two sides of the ring-pull can aims at achieving the technical purposes that the ring-pull can can be automatically cut safely and reliably, and the working efficiency can also be improved. According to the technical scheme, the equipment forcutting the two sides of the ring-pull can comprises a base, a support, a motor and the like; and the support is installed on one side of the top of the base, the motor is connected to the top of thesupport, a lead screw is connected to one side of the top of the support in a rotating mode, the end of the lead screw is connected with an output shaft of the motor, and a nut is connected to one side of the lead screw. According to the equipment, an electric saw wheel and a conveying mechanism can be made to run by starting the motor, ring-pull cans obtained after cutting is completed can go outthrough the conveying mechanism, labor is saved, and the efficiency is improved; and the safety of a user is also guaranteed, and the ring-pull can can be clamped through a sliding plate and the electric saw wheel together so as to carry out work.

Owner:彭杨杨

Grille cleaner

PendingCN113120981AImpact dropDestructive force balanceSpecific water treatment objectivesWater/sewage treatmentEngineeringZoology

The invention discloses a grille cleaner, belonging to the field of environment-friendly machinery. The grille cleaner comprises a cleaner body, wherein the cleaner body comprises a mounting shaft used for mounting rake teeth, the rake teeth comprise check blocks and fishing teeth, the check blocks are fixedly arranged on the mounting shaft, one ends of the fishing teeth are hinged to the mounting shaft, and the fishing teeth are located on the rear side of the check blocks in the moving direction of the mounting shaft. According to the invention, garbage can be prevented from being blocked by the rake teeth at the lower part when falling, so the falling of the garbage is not influenced; and viscous garbage attached to the fishing teeth can fall off easily, and the fishing teeth are staggered, so the garbage between the adjacent fishing teeth is balanced in destructive power under the action of dislocation formed between the fishing teeth and the garbage can fall off smoothly.

Owner:合肥市贵谦信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com