Carbon fiber yarn bundle chopping device and shearing method thereof

A technology of carbon fiber tow and carbon fiber tow, which is applied in the field of carbon fiber tow chopping device and its shearing, which can solve the problems that chopped carbon fibers are difficult to fall smoothly and be blocked, and achieve convenient and fast cutting process, high production efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

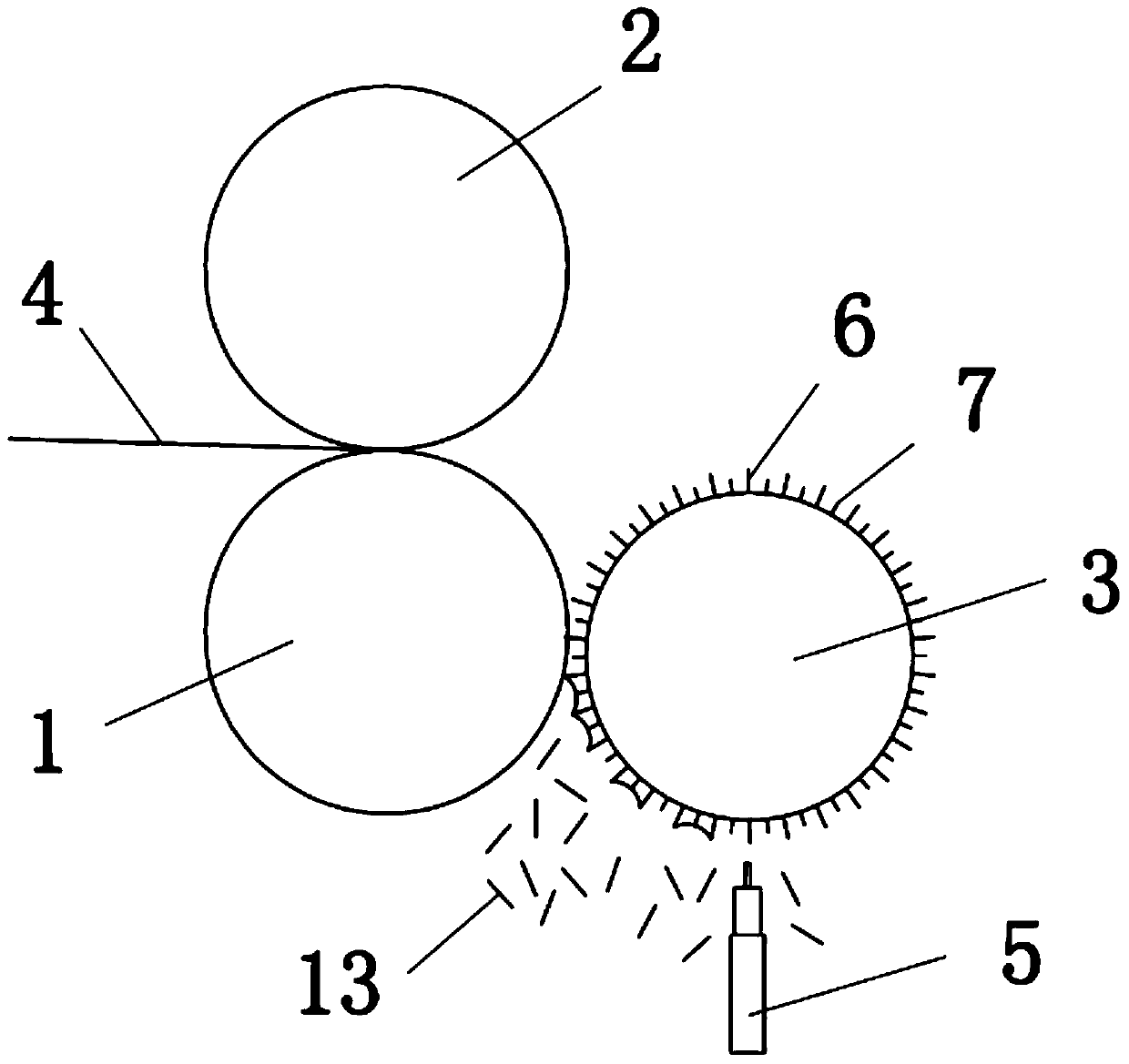

[0023] like Figures 1 to 3 shown. The invention discloses a carbon fiber tow chopping device, which comprises a transmission mechanism for conveying carbon fiber tow 4 and a chopping mechanism for cutting carbon fiber tow 4;

[0024] The transmission mechanism includes a pressing roller 2 and a rubber roller 1 arranged below the pressing roller 2, and the outer circumferential surfaces of the pressing roller 2 and the rubber roller 1 are in contact;

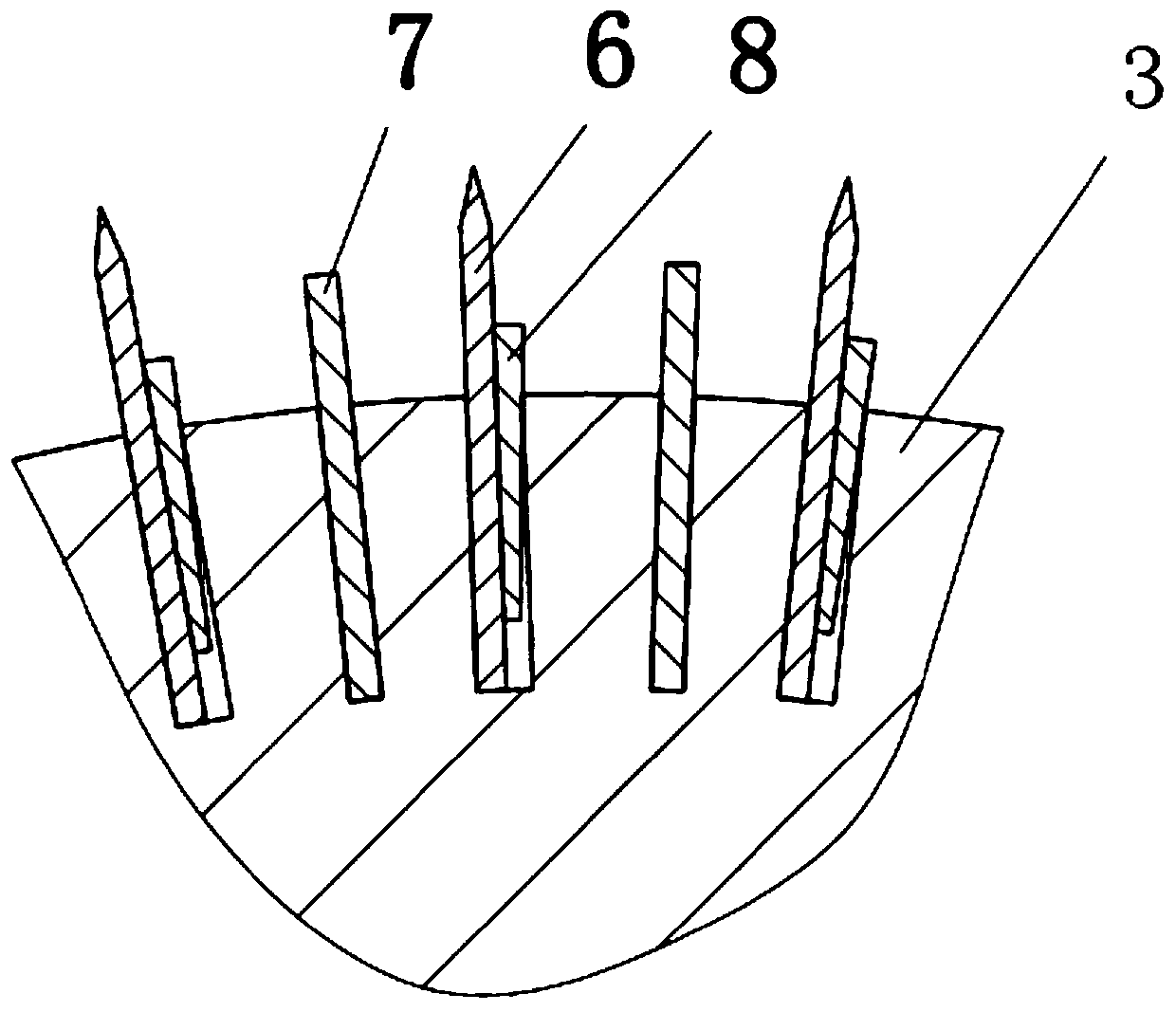

[0025] Described chopping mechanism comprises knife roll 3 and is arranged on the air nozzle 5 below knife roll 3, and the outer circumferential surface of knife roll 3 is distributed with a plurality of blades 6 at intervals, is provided with top sheet 7 between blade 6, and the edge of blade 6 The mouth is in contact with the rubber roller 1.

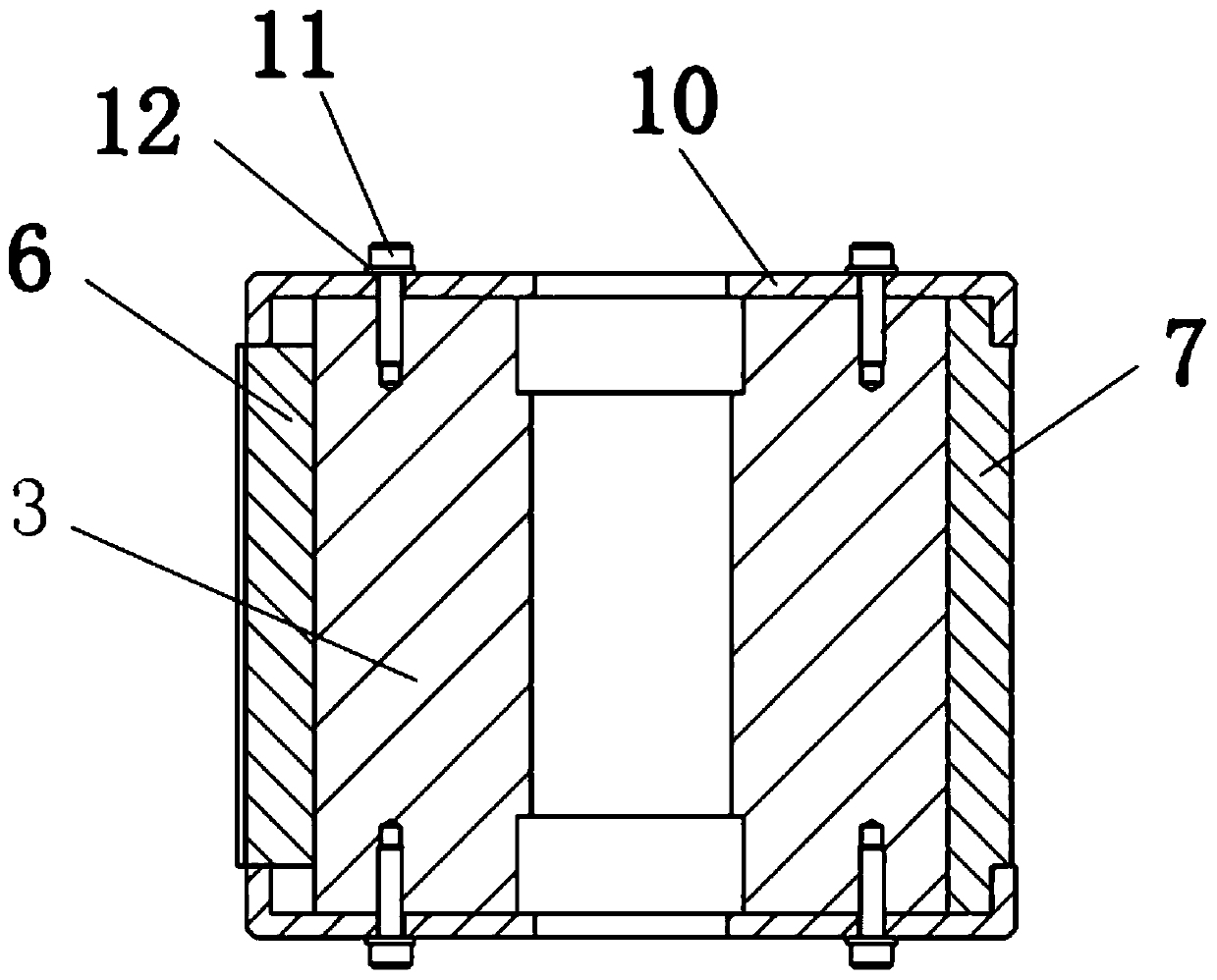

[0026] The blade 6 and the top sheet 7 are inserted on the outer peripheral surface of the cutter roller 3 through grooves arranged at intervals on the outer peripheral surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com