Equipment for cutting two sides of ring-pull can

The technology of a pop-top can and equipment is applied in the field of equipment for cutting both sides of pop-top cans, which can solve the problems of low work efficiency and high danger in the cutting process, and achieve the effects of improving efficiency and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

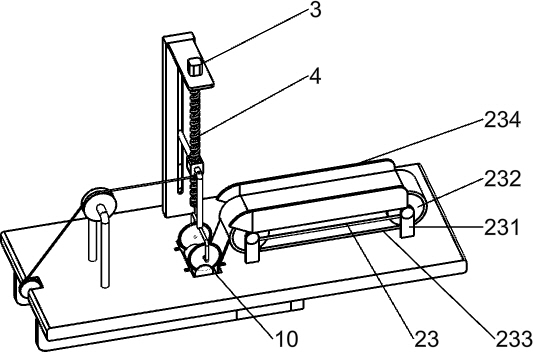

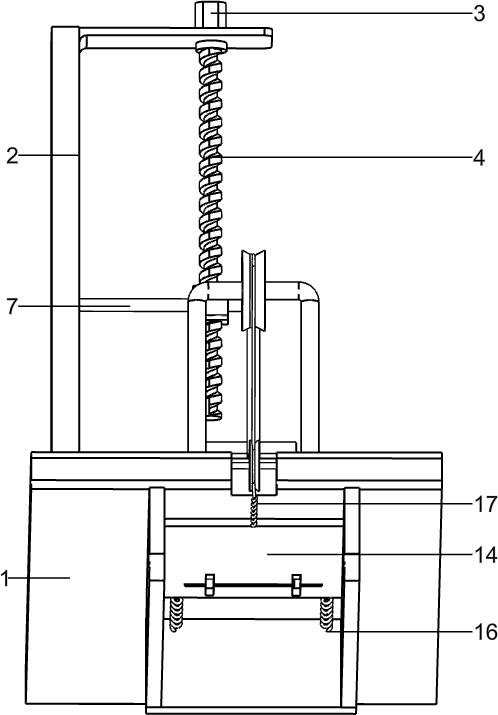

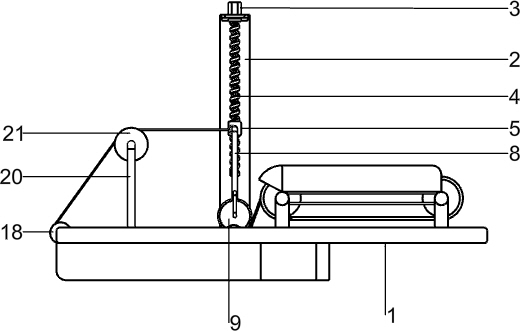

[0021] A device for cutting the sides of cans, such as Figure 1-4 As shown, it includes a base 1, a bracket 2, a motor 3, a lead screw 4, a nut 5, a slide bar 7, a connecting rod 8, an electric saw wheel 9 and a moving mechanism. A motor 3 is installed, and the front side of the top of the bracket 2 is rotatably connected to a screw 4, the output shaft of the motor 3 is connected to the top of the screw 4, the screw 4 is connected with a nut 5, and the front side of the bracket 2 has a first chute 6. A sliding rod 7 is slidingly connected to the first chute 6. The bracket 2 supports the screw 4 and the sliding rod 7. The front end of the sliding rod 7 is connected with the nut 5. A connecting rod 8 is provided on the front side of the nut 5. The lower end of connecting rod 8 is provided with electric saw wheel 9, and base 1 top right side has groove 10, and groove 10 is positioned at the just below electric saw wheel 9, and people can put pop can into groove 10, and pop can i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com