Finish machining machine for manufacturing three-phase asynchronous motor cast-aluminum rotor

A technology for precision machining machinery and cast aluminum rotors, which is applied in the manufacture of tools, metal processing equipment, and stator/rotor body manufacturing, etc. It can solve the problems of low processing efficiency and difficulty in cleaning and collecting debris, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

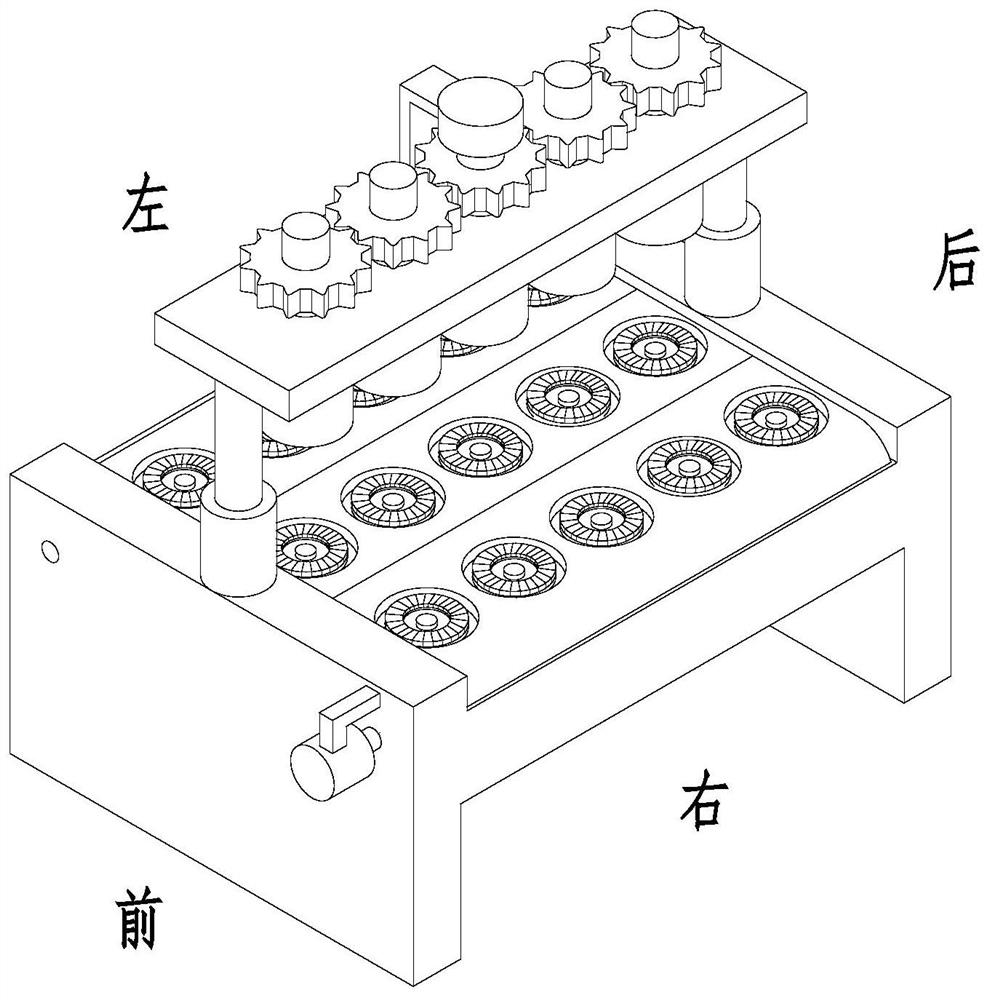

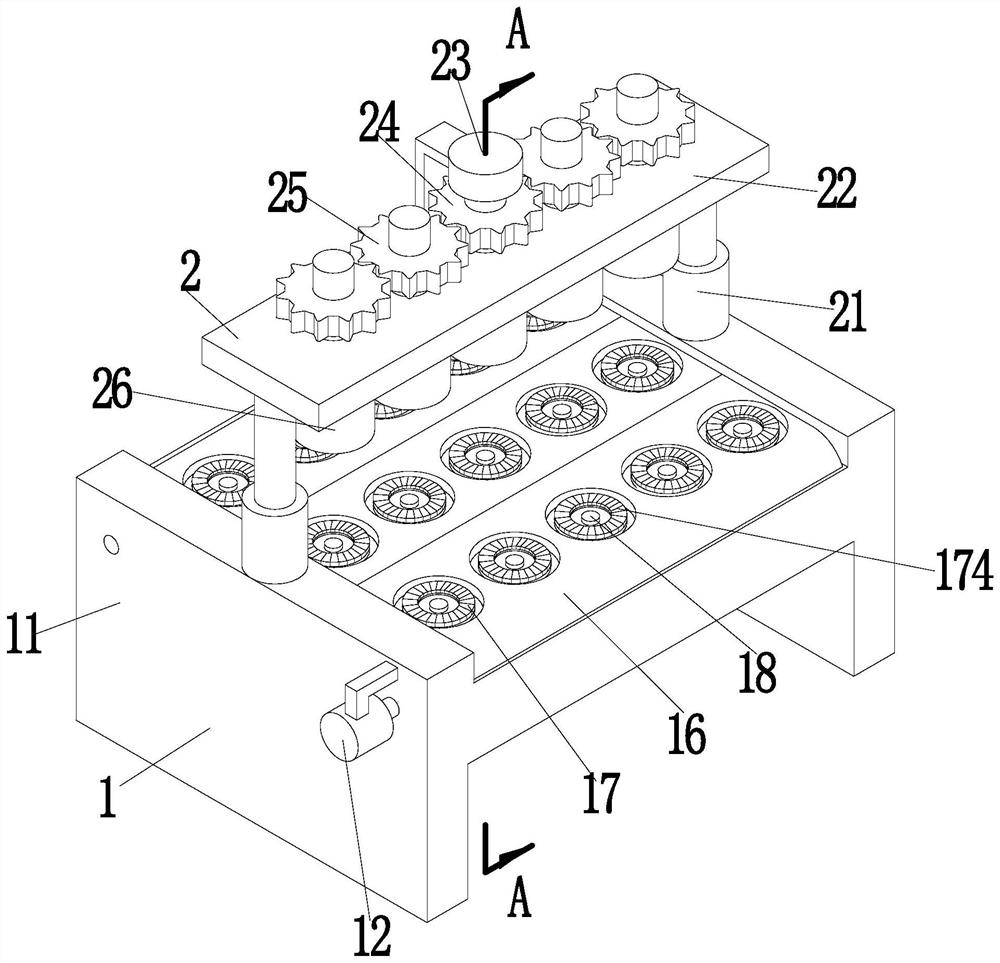

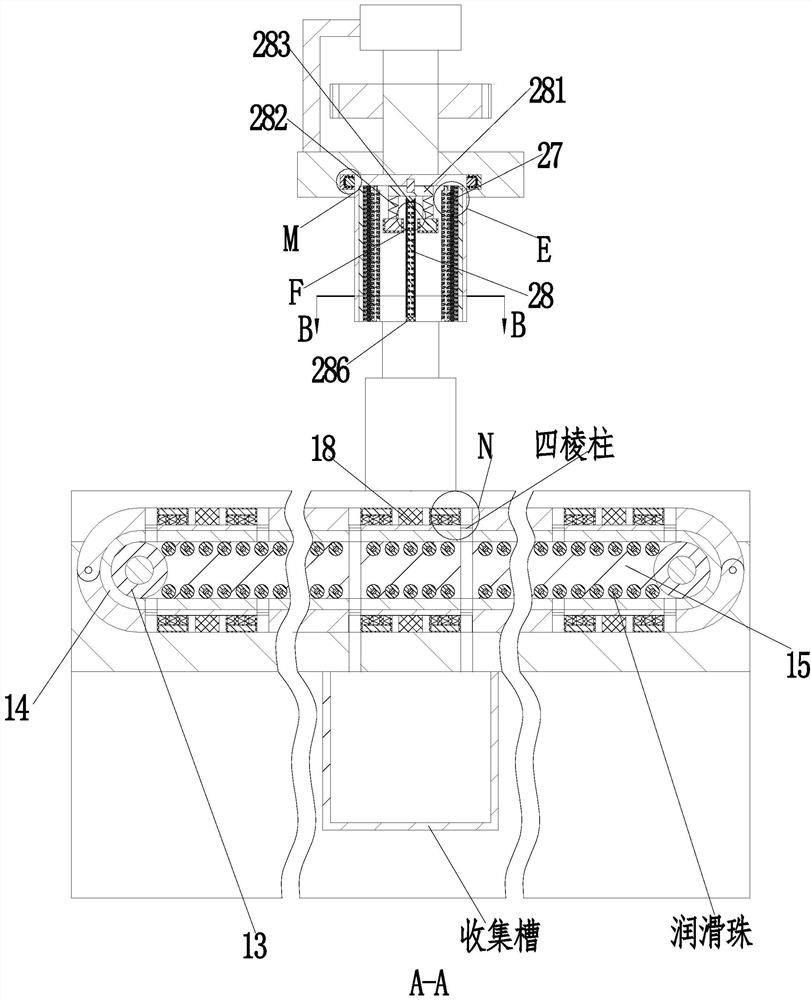

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0033] A three-phase asynchronous motor cast aluminum rotor manufacturing finishing machine, including a transport device 1 and a grinding device 2, the upper end of the transport device 1 is fixedly installed with a grinding device 2; wherein:

[0034] The transportation device 1 comprises a fixed platform 11, a stepping motor-12, a sprocket wheel-13, a tooth chain belt-14, a support plate 15, an arc-shaped long plate 16, a rubber ring plate 17 and an electromagnetic plate 18, and the front end of the fixed platform 11 is The surface is fixedly installed with a stepping motor 12 through the motor base, and the left and right sides of the fixed table 11 are symmetrically connected with a sprocket 13 in a rotationally connected manner, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com