Heat-sealing discharging mechanism of adhesive tape packaging device

A technology of discharging mechanism and adhesive tape, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of time-consuming, laborious, empty packages, heat-sealing machine processing omissions, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

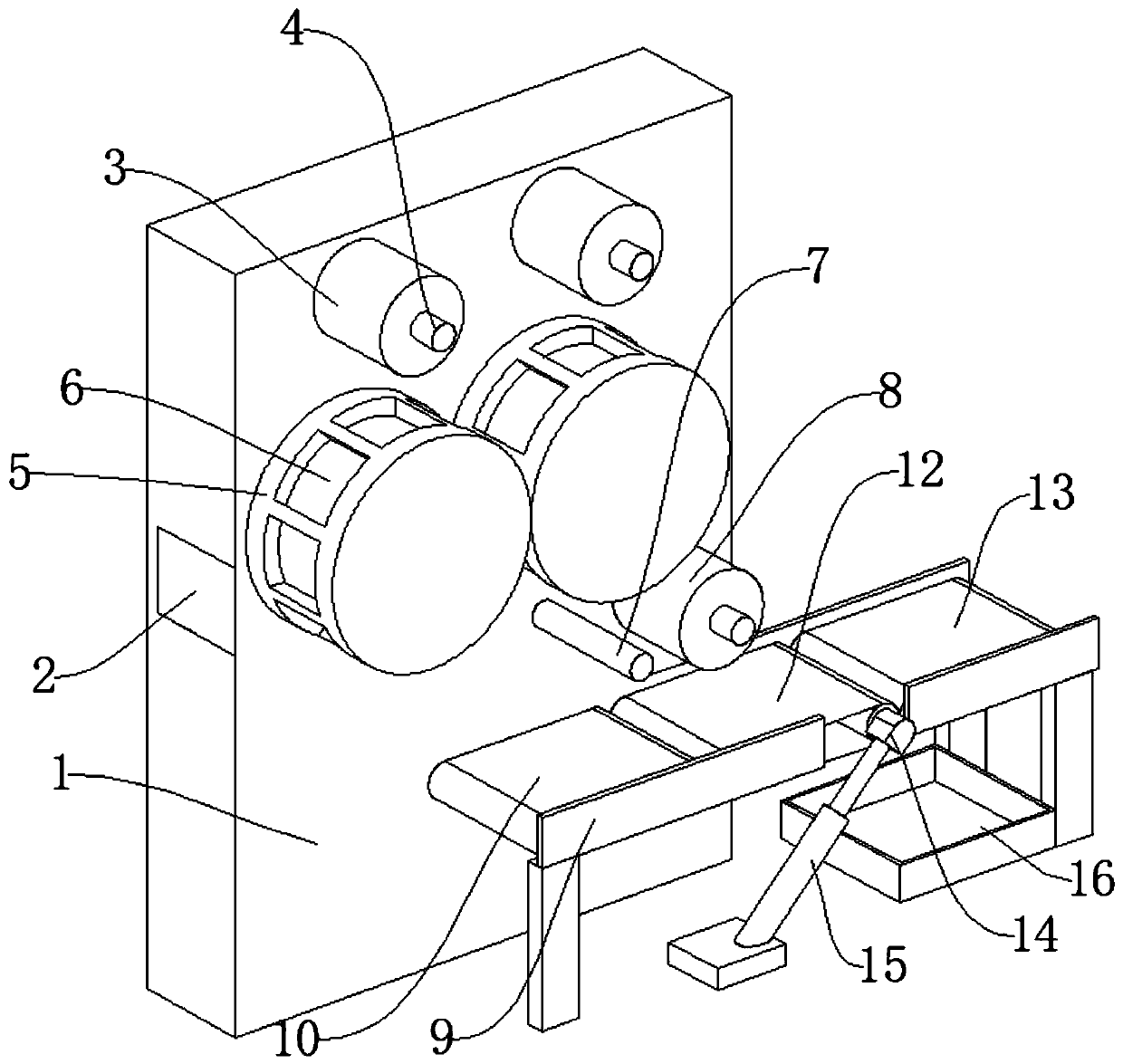

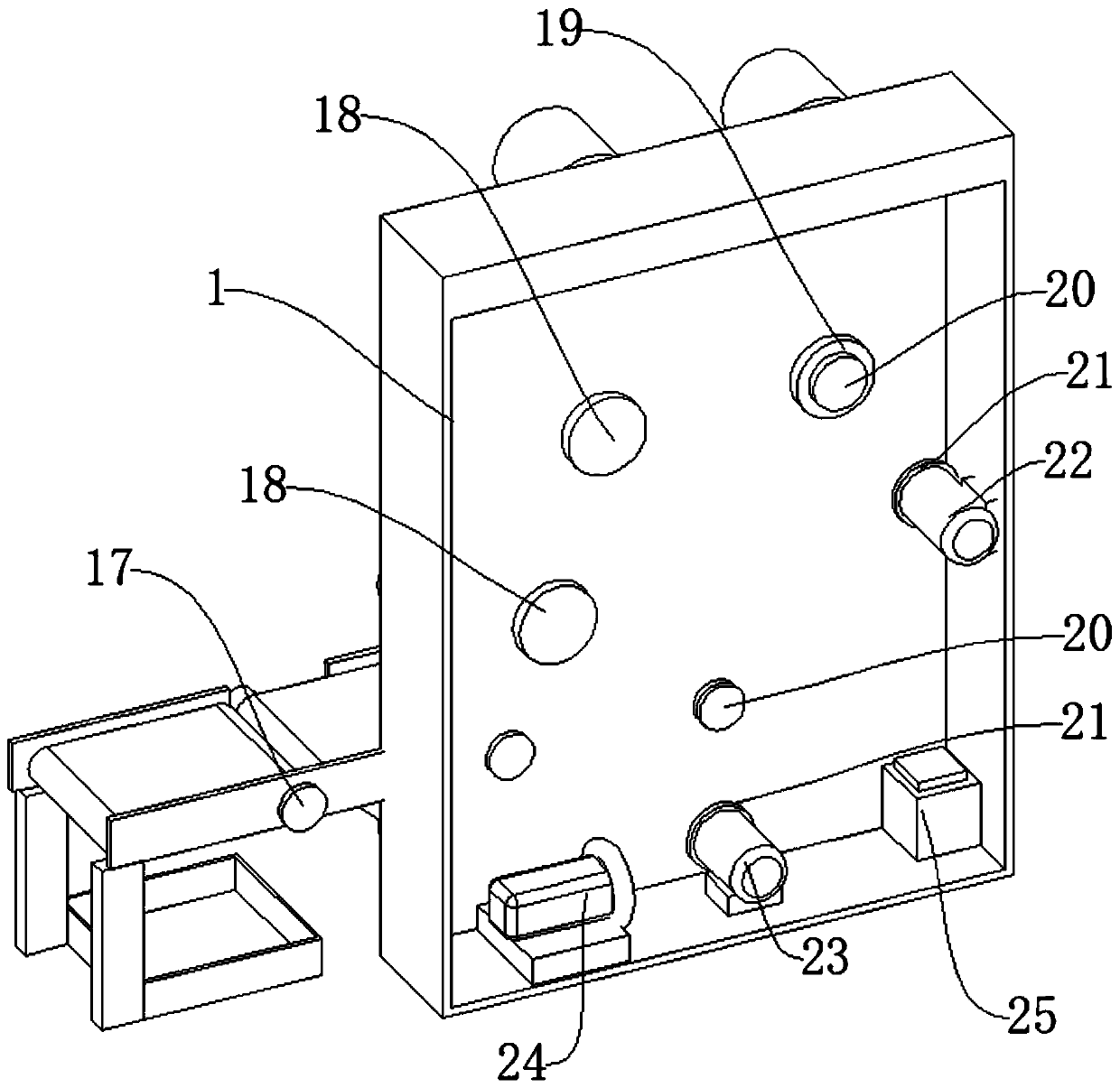

[0036] Such as Figure 1-Figure 5 As shown, a heat-sealing discharge mechanism of a tape packaging device includes a support base 1, a sealing wheel 5, a first conveyor belt 10, and a telescopic cylinder 15. Two raw material rolls 3 are arranged at the front end of the support base 1, and the support base 1 supports them together. function, the raw material roll 3 plays the role of providing raw materials, the sealing wheel 5 is set on the lower side of the raw material roll 3, and the sealing wheel 5 plays the role of packaging;

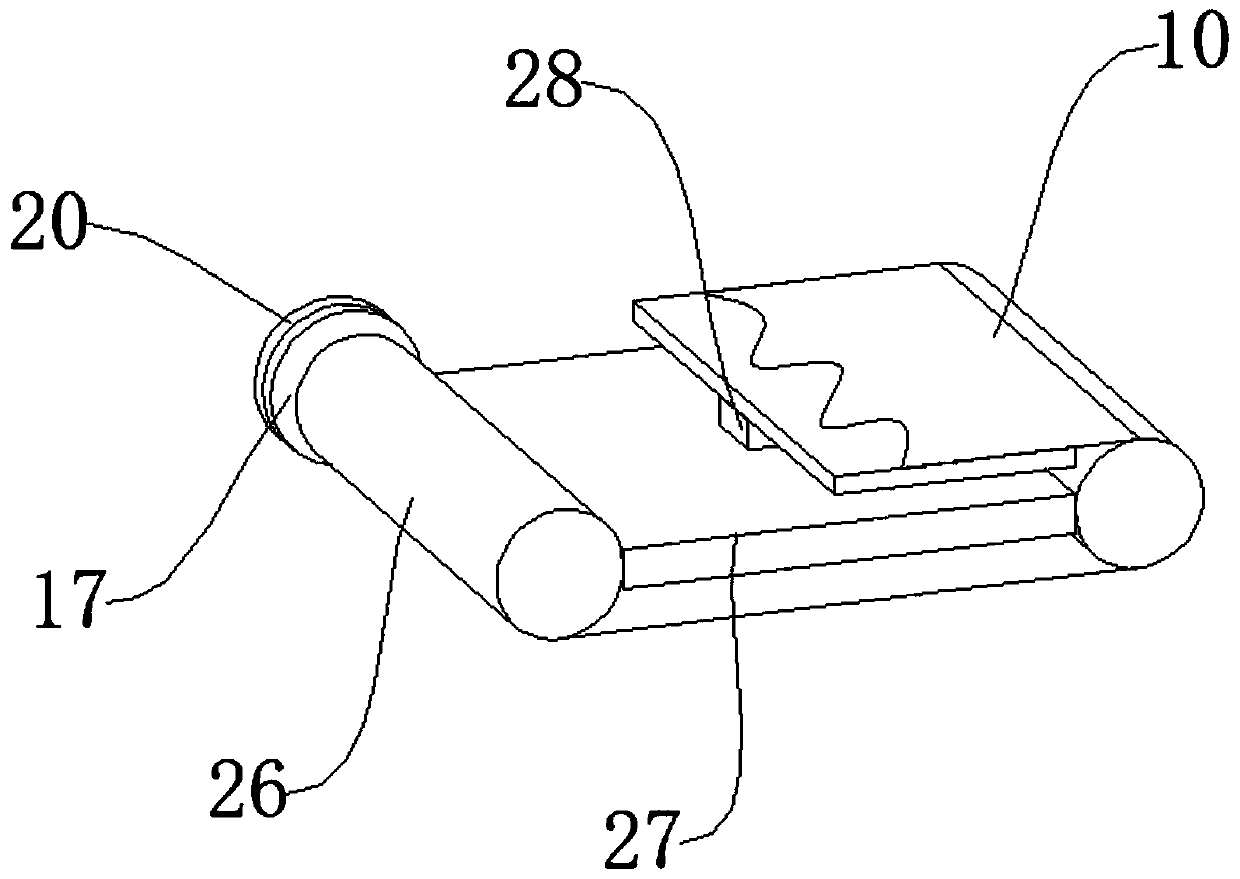

[0037] The push roller 7 is arranged on the lower side of the sealing wheel 5, and the push roller 7 acts as a top material. To collect waste materials, the raw material roll 3 and the receiving roll 8 are equipped with support rollers 4, the support rolls 4 play a supporting role, the support rolls 4 are rotatably connected to the raw material roll 3 and the receiving roll 8, and the groove 6 is set on the sealing wheel 5, the heating wire 11 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com