Ore smashing and screening device

A screening device and ore crushing technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of reducing production efficiency, increasing cost, reducing ore transportation efficiency, etc., to improve crushing efficiency, increase production efficiency, excellent The effect of the transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

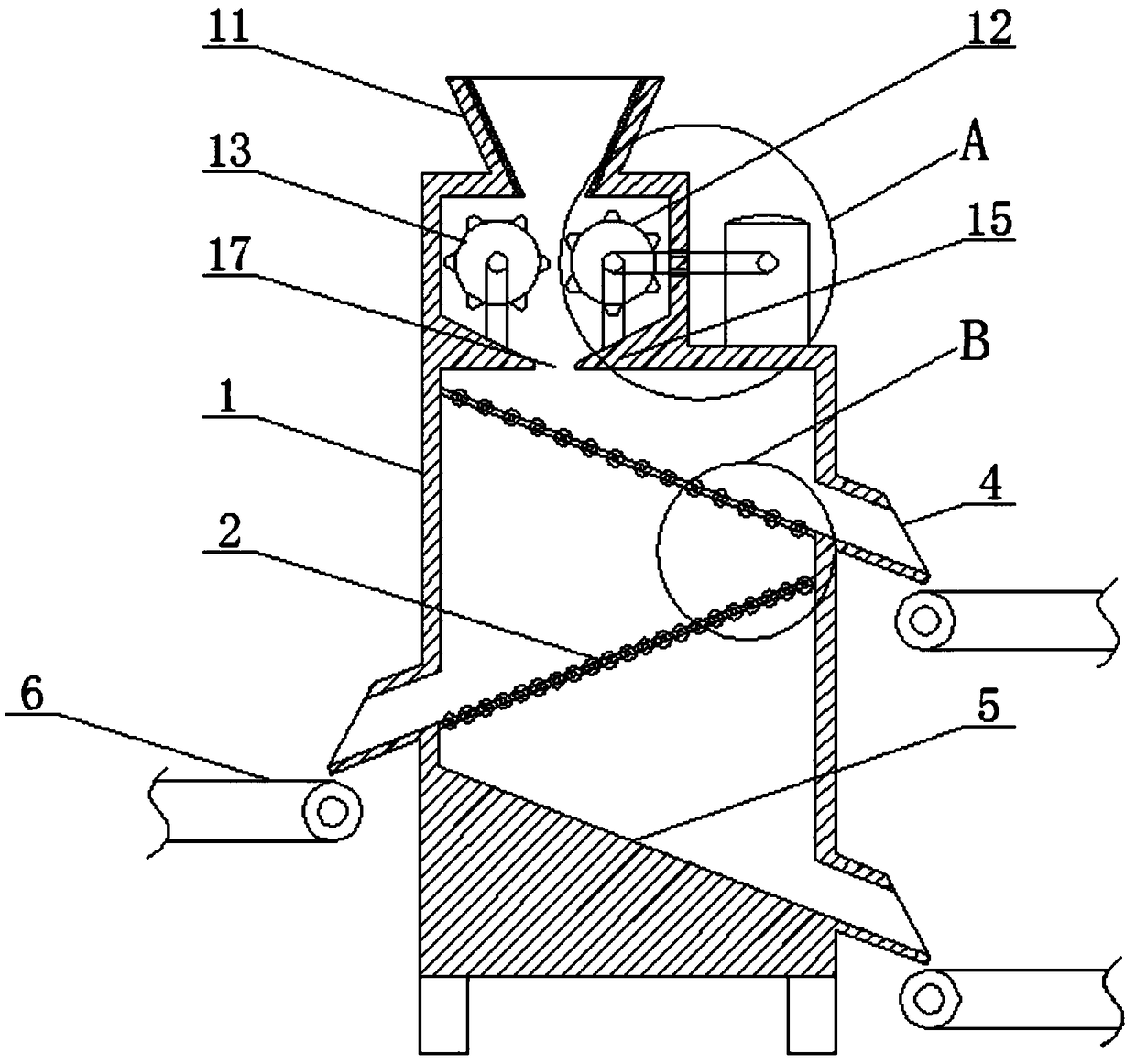

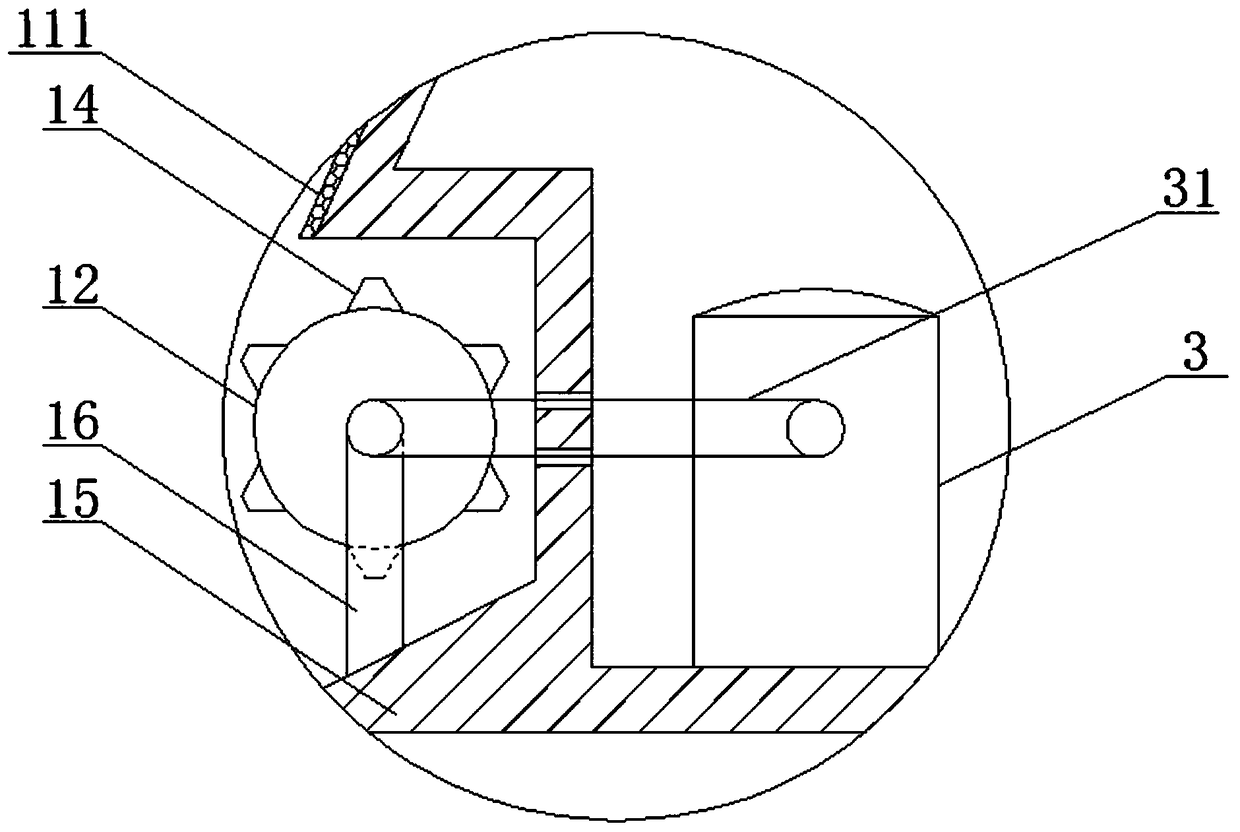

[0032] The specific embodiment of the present invention is as Figure 1-3 As shown, an ore crushing and screening device includes a pulverizer main body 1, wherein a feed funnel 11 is provided on the upper part of the pulverizer main body 1, and a buffer pad 111 is provided on the inner side wall of the feed funnel 11 to prevent the ore from bouncing. ; The bottom of the discharge end of the feed funnel 11 is oppositely provided with a driving crushing roller 12 and a driven crushing roller 13 for crushing ore.

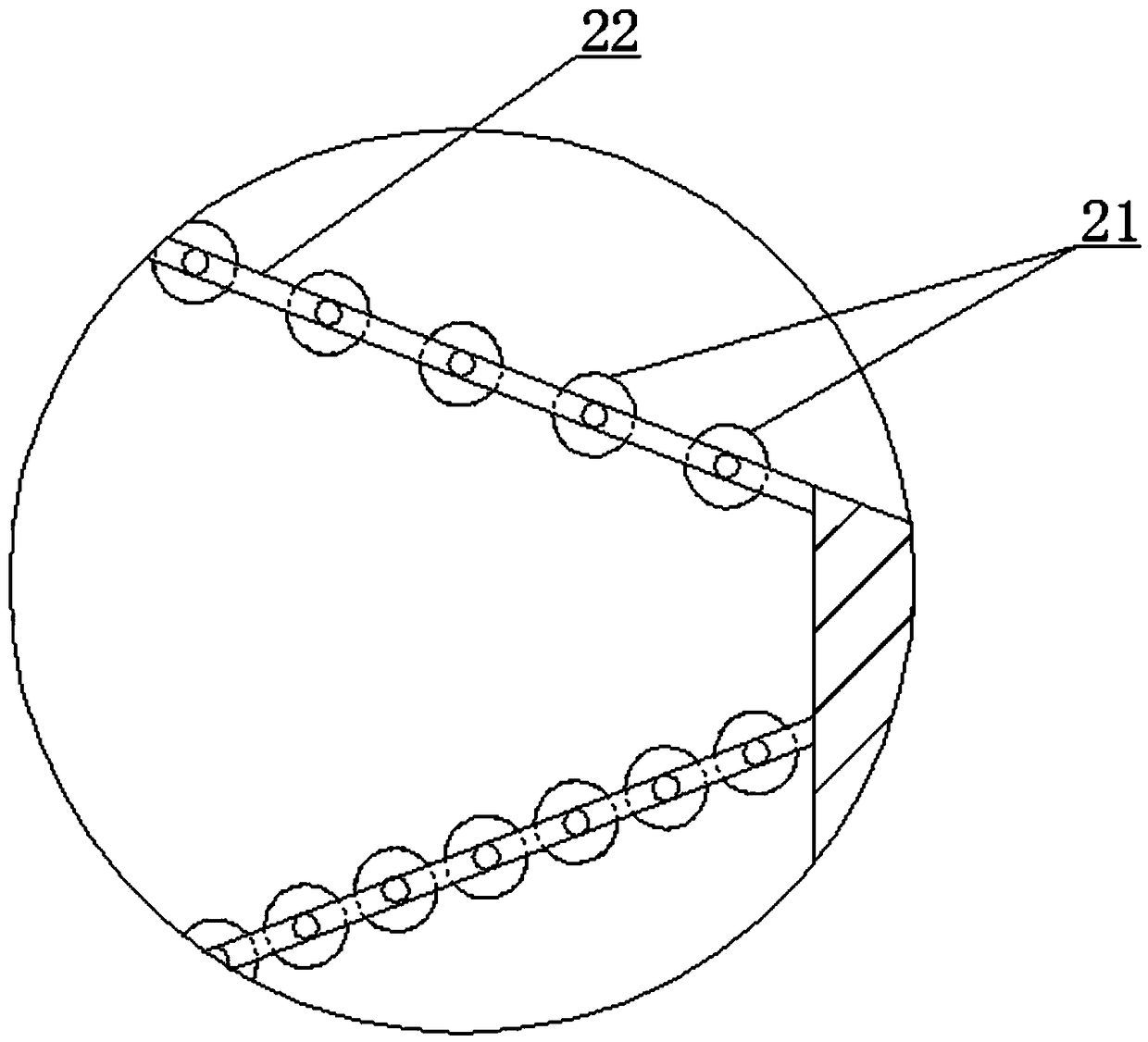

[0033] Below the active crushing roller 12 and the driven crushing roller 13, there are at least two inclined conveying roller sets 2 arranged successively. Roller 21 guides the gravel to move along the inclined direction of the conveying roller group 2. Compared with the traditional plate-shaped screening device, the conveying roller group 2 is not easily deformed by the impact of ore fragments, and has a better transmission effect, which is convenient for ore Trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com