Method for preparing copolymer of polycarboxylic concrete water reducer

A technology of concrete water reducing agent and polycarboxylic acid series, which is applied in the field of copolymer preparation, can solve the problems of strong negative polar groups losing electrostatic repulsion and unsatisfactory dispersion retention, and achieve good dispersion retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

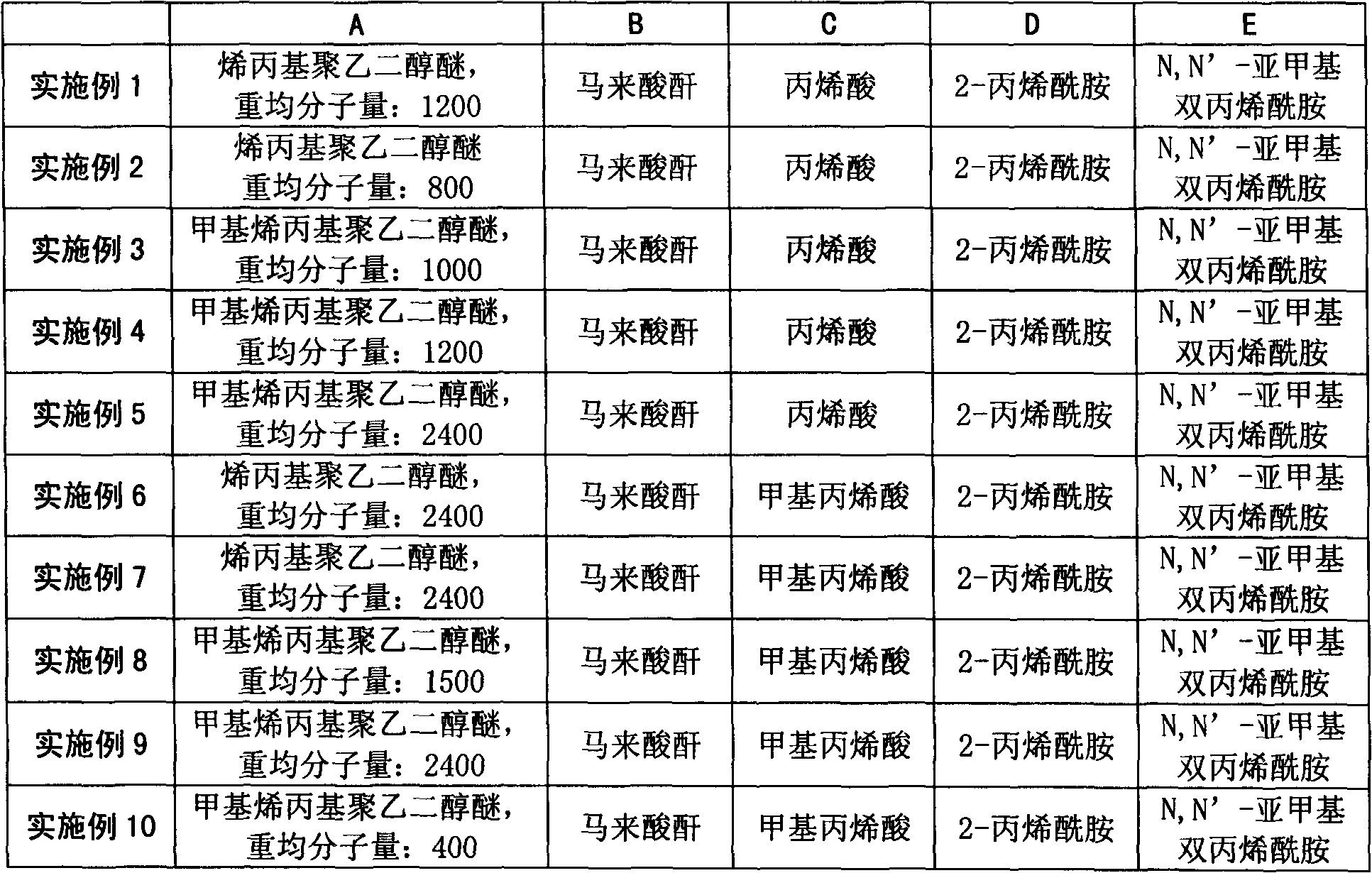

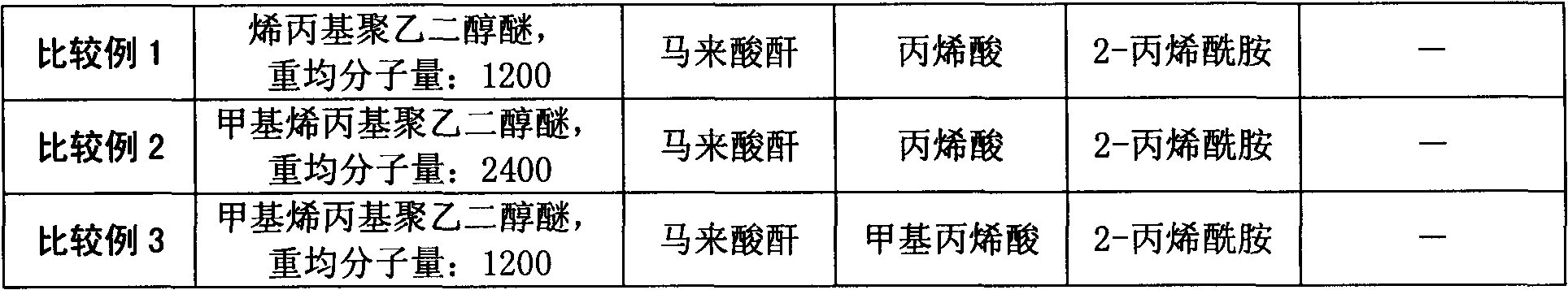

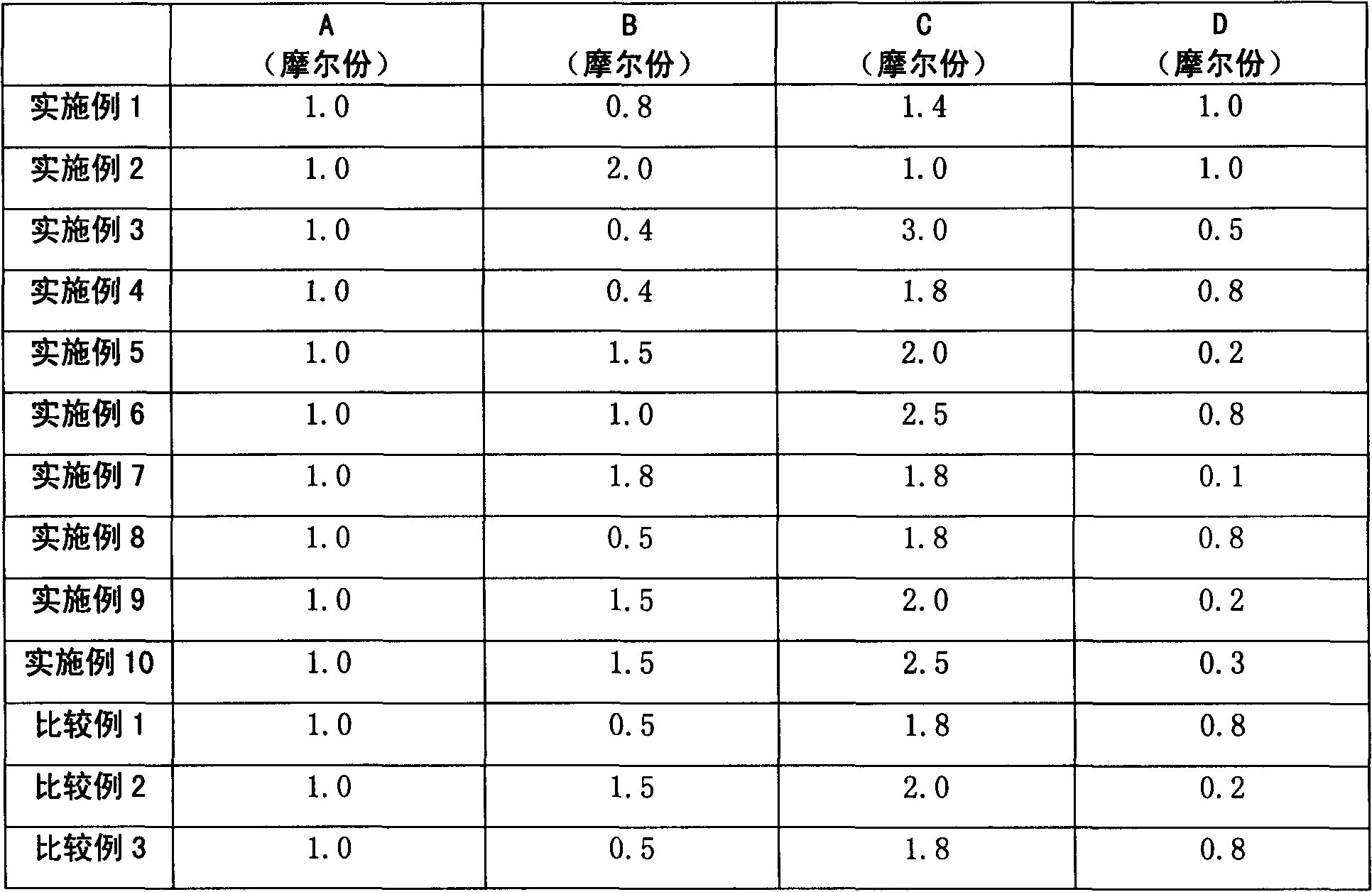

Embodiment 1~10

[0021] The synthesis reaction was carried out in a glass reactor with a volume of 800 mL and equipped with a stirrer, a thermometer and a dropping funnel.

[0022] 1) Put the required amount of monomers A, B and D into the reactor, heat properly and start stirring, and prepare the monomers into an aqueous solution of the mixture. Solution concentration is controlled as 60~80wt% with A, B and D total amount;

[0023] 2) The system is heated up to the reaction temperature, and at the same time, the monomers C and E diluted with water and the initiator ammonium persulfate are slowly and continuously added dropwise to the reactor to start the copolymerization reaction. The reaction temperature is controlled at 60-90° C., the duration of the dropping is controlled at 3.0-5.0 hours, and the reaction is continued for 1.0-3.0 hours after the dropping. The amount of the initiator added is based on the monomer A, which is 0.5-3.0wt%;

[0024] 3) After the reaction is completed, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com