Polycarboxylic concrete water reducer

A technology of concrete water reducer and polycarboxylate series, which is applied in the field of concrete water reducer, can solve the problems of strong negative polar groups losing electrostatic repulsion and unsatisfactory dispersion retention, and achieve good dispersion retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

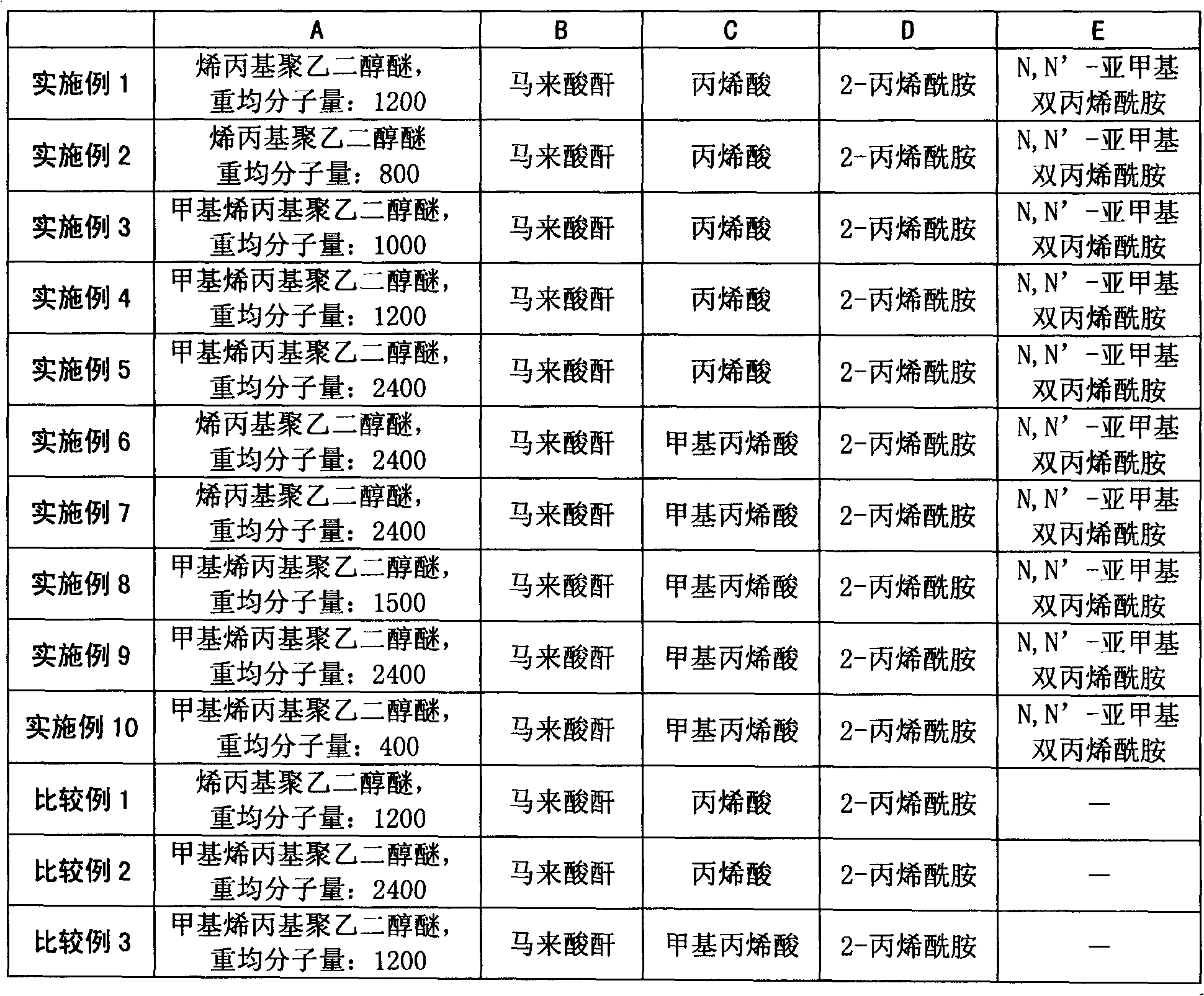

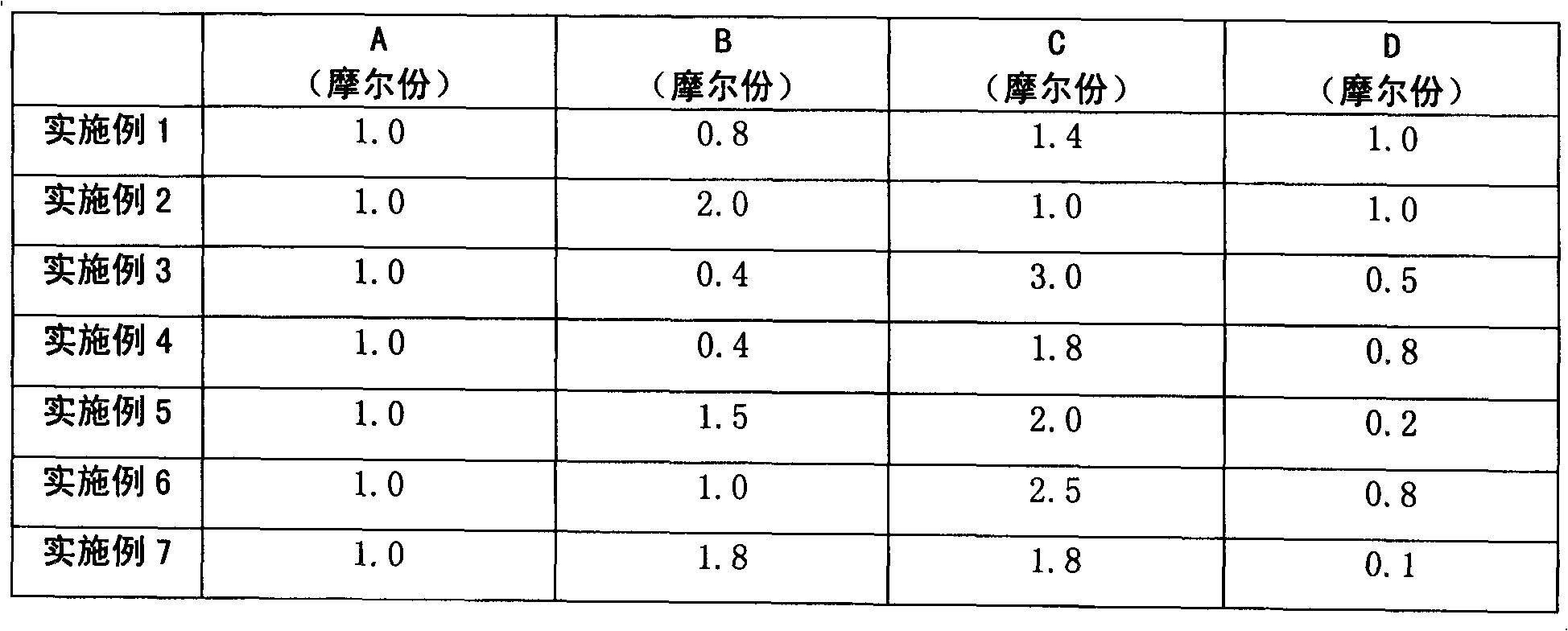

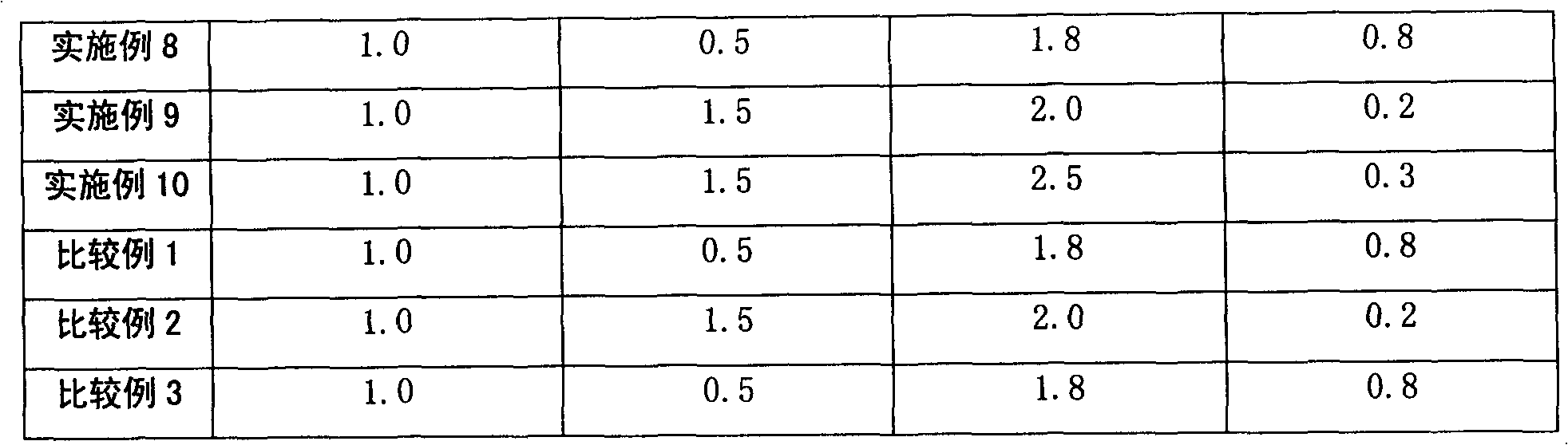

Examples

Embodiment 1~10

[0022] The synthesis reaction was carried out in a glass reactor with a volume of 800 mL and equipped with a stirrer, a thermometer and a dropping funnel.

[0023] Dilute the required amount of monomer A with water to a concentration of about 70 wt%, and put it into the reactor. Start stirring, heat up, and when the system temperature reaches 60°C, add the required amount of monomers B and D, and continue to heat up to 85°C. Take the required amount of monomers C and E, add water and dilute to a concentration of about 70wt% (concentration is the sum of monomers C and E), and prepare dropwise liquid I. Take an appropriate amount of initiator ammonium persulfate, add water to dilute to a concentration of 70 wt%, and prepare dropwise liquid II. The temperature of the system is controlled at 85°C, and the addition solution I and II are added dropwise to the system at the same time at a separate position, and the dropping time is controlled at 3 to 5 hours. After the dropwise add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com