Bottle collating mechanism for medicinal glass bottle production line

A medicinal glass bottle and production line technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as machine jams, broken glass bottles, and poor integrity, to ensure accuracy and guarantee correctness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

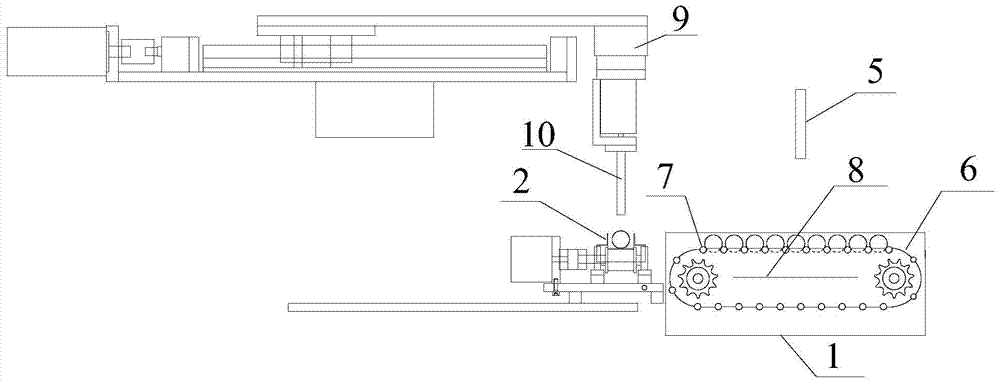

[0026] After the medicinal glass bottle is fired, it is sent to the whole bottle mechanism of the present invention, and first rolls down on the finishing device 1. Since the upper surface of the conveyor belt 7 in the finishing device 1 is uniformly fixed with a positioning strip 7, the glass bottle is It will be neatly arranged in the gap between the adjacent positioning bars 7 while rolling down, and the glass slag smaller than the gap will fall from the gap between the positioning bars 7 at the same time, realizing one-time removal.

[0027] With the movement of the conveyor chain 6, the neatly arranged glass bottles move to the bottom of the camera device 5, and the camera device 5 can realize visual detection and imaging in time. At the same time, the captured images are transmitted to the computer inspection system, which will complete Distinguish from incomplete medicinal glass bottles, and determine the orientation of the opening of the glass bottles, and then the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com