Diode ceramic packaging template

A technology of ceramic packaging and ceramic plates, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of short service life, non-wearable plastic templates, and decreased yield, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

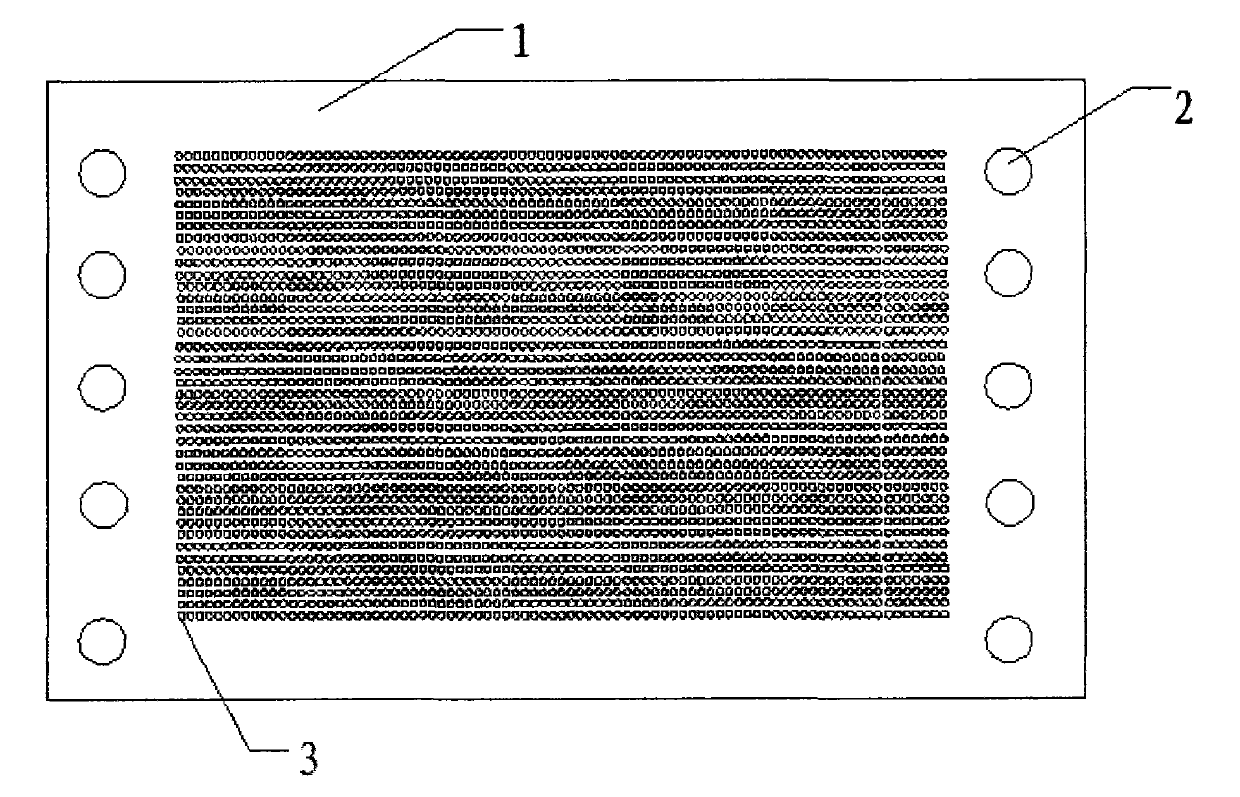

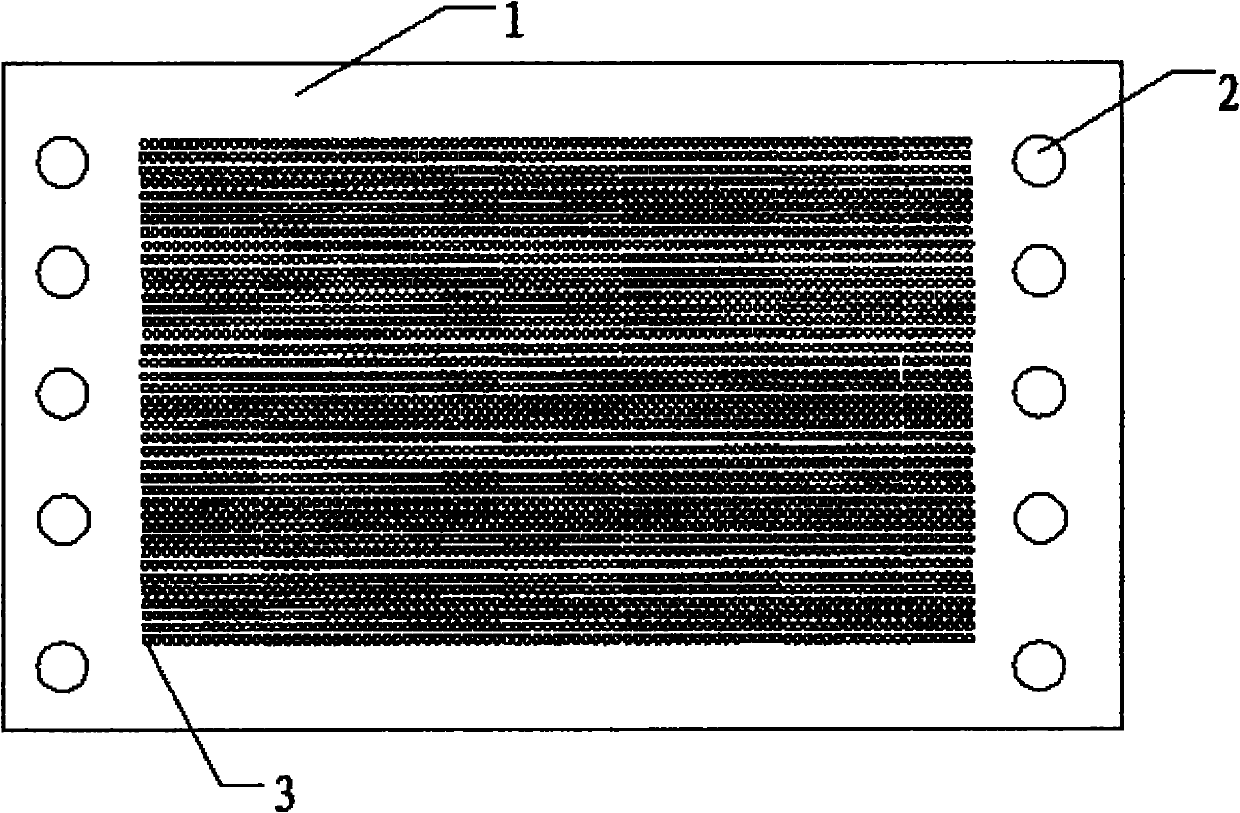

[0022] A diode ceramic packaging template includes a ceramic board body 1, screw holes 2 are opened on both sides of the ceramic board body 1, and pin positioning round holes 3 are opened in the middle of the ceramic board body 1.

[0023] Preferably, 800 pin positioning circular holes 3 are opened in the middle of the ceramic plate body 1 .

[0024] Preferably, 1000 pin positioning round holes 3 are opened in the middle of the ceramic plate body 1 .

[0025] Preferably, 1280 pin positioning circular holes 3 are opened in the middle of the ceramic plate body 1 .

[0026] Preferably, 1495 pin positioning round holes 3 are opened in the middle of the ceramic plate body 1 .

[0027] Preferably, 1500 pin positioning round holes 3 are opened on the ceramic plate body 1 .

[0028] Preferably, 2280 pin positioning round holes 3 are opened on the ceramic plate body 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com