Uniform temperature type fluidized instant freezer spray nozzle capable of avoiding food adhesion

A fluidized, quick-freezing machine technology, applied in cooling fluid circulation devices, lighting and heating equipment, household appliances, etc., can solve problems such as affecting the quick-freezing of food and poor airflow control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

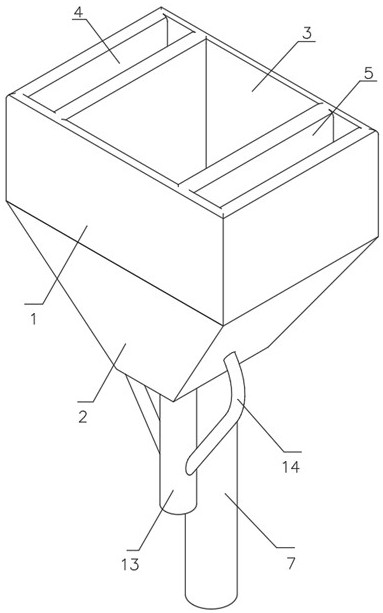

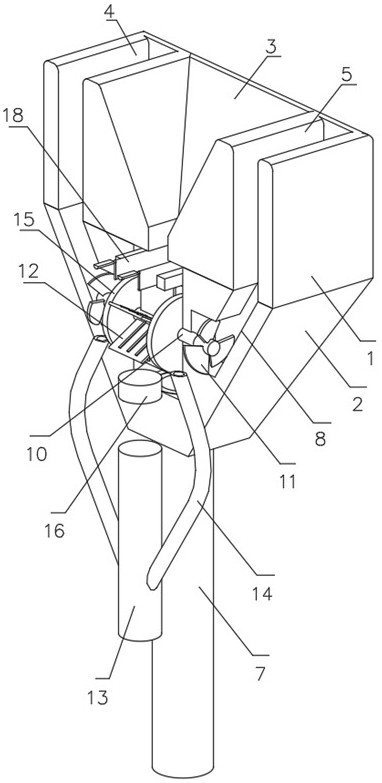

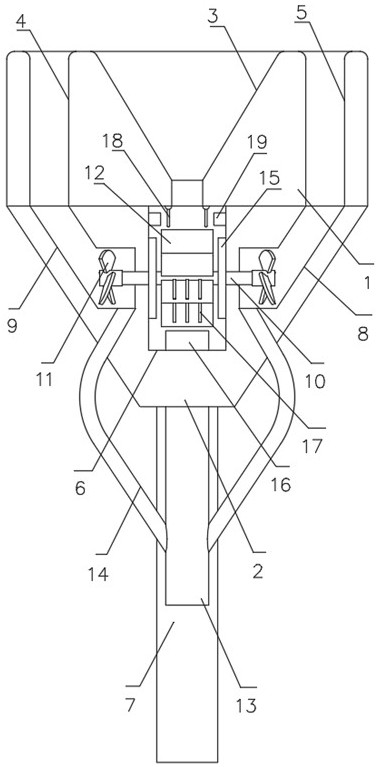

[0022] refer to figure 1 , a uniform temperature type fluidized quick-freezer nozzle for avoiding food sticking, comprising a differentiation platform 1, a transfer platform 2 is fixed on the bottom of the differentiation platform 1, and a main air groove 3 and an exhaust air groove 4 are opened through the upper end of the differentiation platform 1 With the air exhaust groove 5, the upper end of the transfer table 2 is provided with the drive groove 6 communicating with the main air groove 3, and the bottom of the transfer table 2 is inserted with the air inlet pipe 7 communicated with the drive groove 6 inside, and the air inlet pipe 7 is connected with the drive groove 6. The external cold air flow conveying equipment is connected to input high-pressure cold air flow to the inside of the nozzle. The differentiation table 1 is used to distinguish the state of the air flow, and the differentiation table 1 is in close contact with the food transportation table. The main air sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com