One-way valve and automatic intermittent pumping system and method with one-way valve

A one-way valve and valve core technology, which is used in earth-moving drilling, wellbore/well valve device, wellbore/well components, etc. problems, to achieve the effect of simple installation process, digital management, and avoidance of traffic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

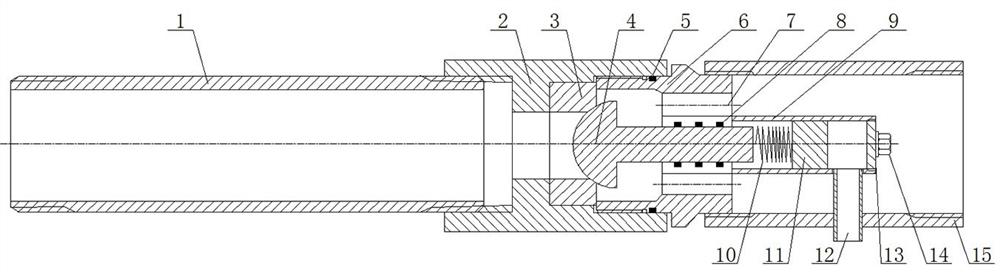

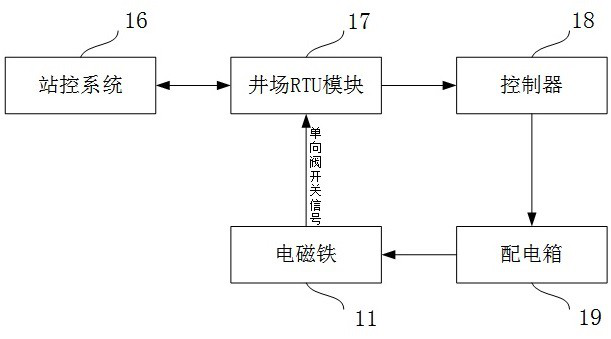

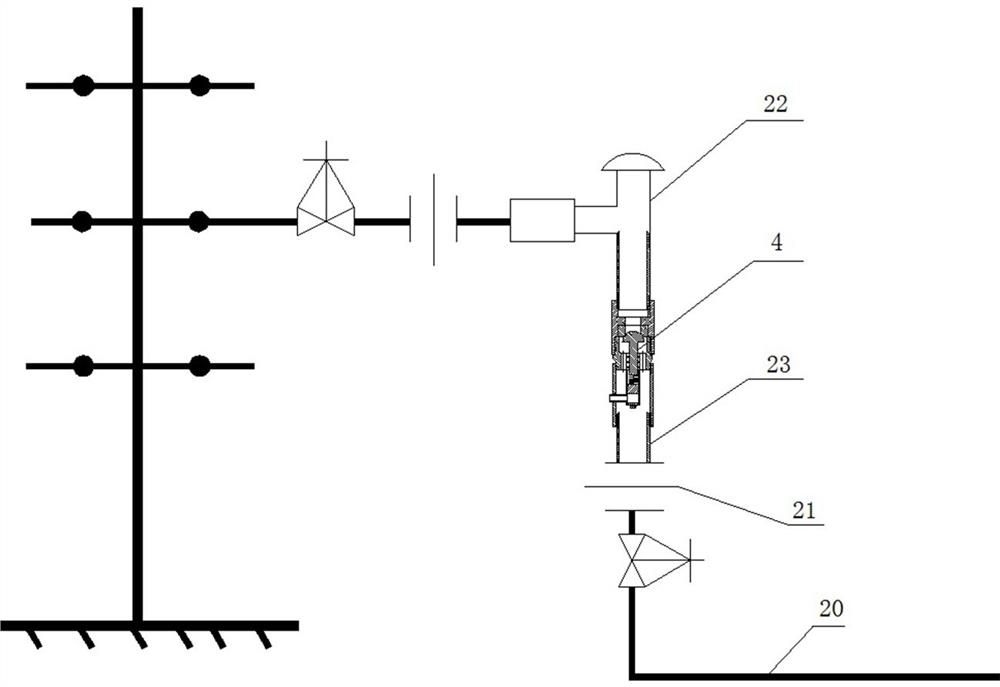

[0032] This embodiment relates to a check valve, see figure 1 , including the upper joint 1, the valve cover 2, the middle joint 6 and the lower joint 15 which are sequentially screwed together coaxially. After being coaxially screwed, it becomes a rotary body structure with an axial hollow channel, and the axial hollow channel of the hollow rotary body supplies oil The liquid flows through, and the valve seat 3, the valve core 4 and the protective sleeve 9 are arranged in the axial hollow passage, wherein the head of the valve core 4 can be contacted and set on the valve seat 3, and the tail of the valve core 4 is fixedly connected to the return spring 10 One end of the return spring 10 is fixedly connected to the electromagnet 11, the electromagnet 11 is placed in the protective cover 9, and the electromagnet 11 slides in the protective cover 9 after electrification and drives the valve core 4 to set or move away from the return spring 10. The valve seat 3 keeps the axial ho...

no. 2 approach

[0038] This embodiment relates to a check valve, see figure 1 , including the upper joint 1, the valve cover 2, the middle joint 6 and the lower joint 15 which are sequentially screwed together coaxially. After being coaxially screwed, it becomes a rotary body structure with an axial hollow channel, and the axial hollow channel of the hollow rotary body supplies oil The liquid flows through, and the valve seat 3, the valve core 4 and the protective sleeve 9 are arranged in the axial hollow passage, wherein the head of the valve core 4 can be contacted and set on the valve seat 3, and the tail of the valve core 4 is fixedly connected to the return spring 10 One end of the return spring 10 is fixedly connected to the electromagnet 11, the electromagnet 11 is placed in the protective cover 9, and the electromagnet 11 slides in the protective cover 9 after electrification and drives the valve core 4 to set or move away from the return spring 10. The valve seat 3 keeps the axial ho...

no. 3 approach

[0051] This embodiment provides a one-way valve, which includes an upper joint 1, a valve cover 2, an intermediate joint 6 and a lower joint 15 which are sequentially screwed together coaxially. The axial hollow channel of the hollow rotary body is used for the oil to flow through. The valve seat 3, valve core 4 and protective sleeve 9 are arranged in the axial hollow channel. The head of the valve core 4 can be contacted and set on the valve seat 3. The valve The tail of the core 4 is affixed to one end of the return spring 10, and the other end of the return spring 10 is affixed to the electromagnet 11. The electromagnet 11 is placed in the protective cover 9, and the electromagnet 11 slides in the protective cover 9 after power-on and passes the reset. The spring 10 drives the valve core 4 to set or move away from the valve seat 3 so that the axial hollow channel is in a blocked state or a smooth state.

[0052] The intermediate joint 6 is a cylindrical structure with two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com