Brake system of empty container forklift

A braking system and stacker technology, which is applied in the direction of brakes, cooling brakes, brake transmissions, etc., can solve the problem of braking performance and braking safety without too much consideration, short service life of braking components, and inability to Use brake fluid and other problems to achieve the effect of shortening the braking distance of the whole vehicle, making the braking safe and reliable, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

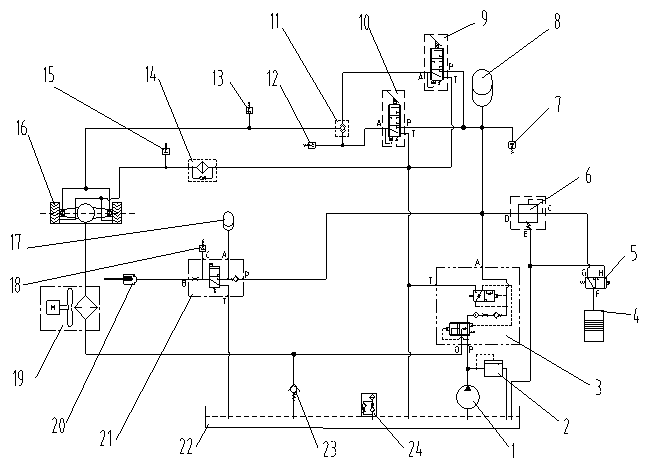

[0017] Relief valve 2, oil return filter 14, filter clogging alarm switch 15, second bladder accumulator 17, brake oil radiator 19, brake oil tank 22 and back pressure in the brake system of empty container stacker Valve 23 is a newly added part after improvement.

[0018] see figure 1 , the oil suction port of the gear pump 1 is connected to the brake oil tank 22, the oil outlet port of the gear pump 1 is connected to the P port of the charging valve 3, and the A port of the charging valve 3 is respectively connected to the pressure reducing valve 6 through the four-way pipe. D inlet, P port of the parking brake valve block 21 and the inlet of the first bladder accumulator 8, the inlet of the first bladder accumulator 8 is also connected to the low pressure alarm switch 7 and the brake pipe through the four-way pipe The brake pipe port is respectively connected to the P port of the right foot brake valve 9 and the P port of the left foot brake valve 10 through the three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com