Patents

Literature

874results about "Lubricant filling/draining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

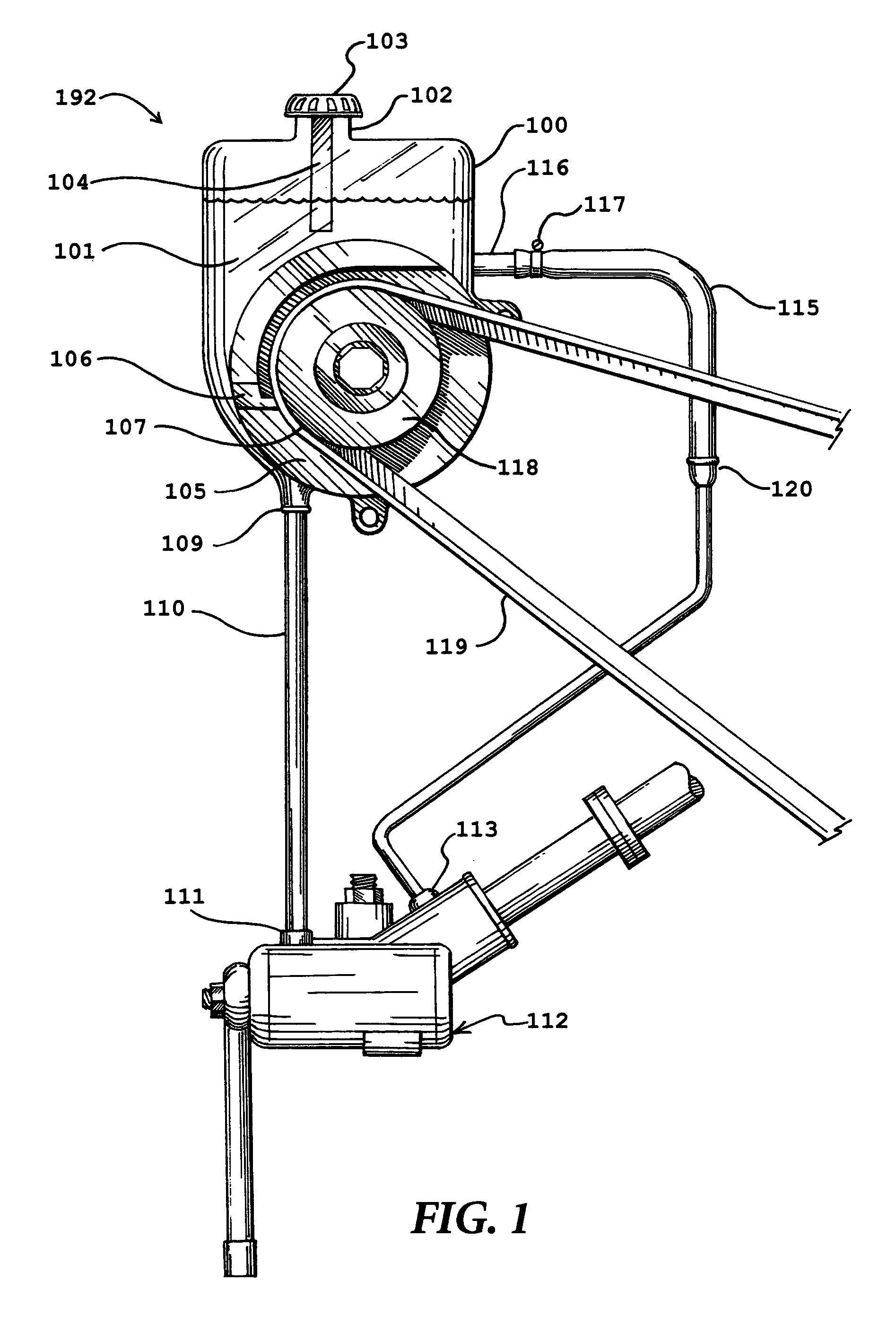

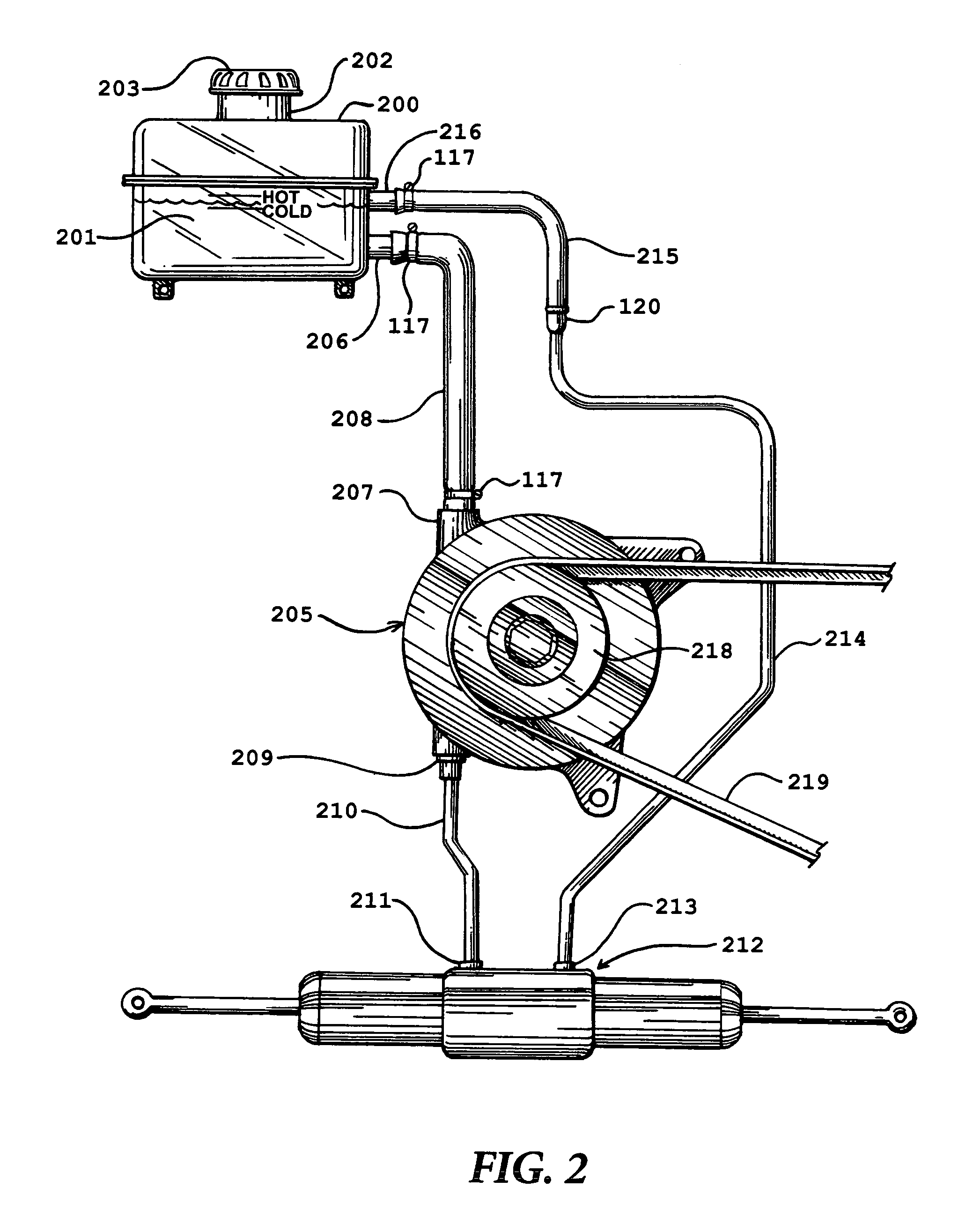

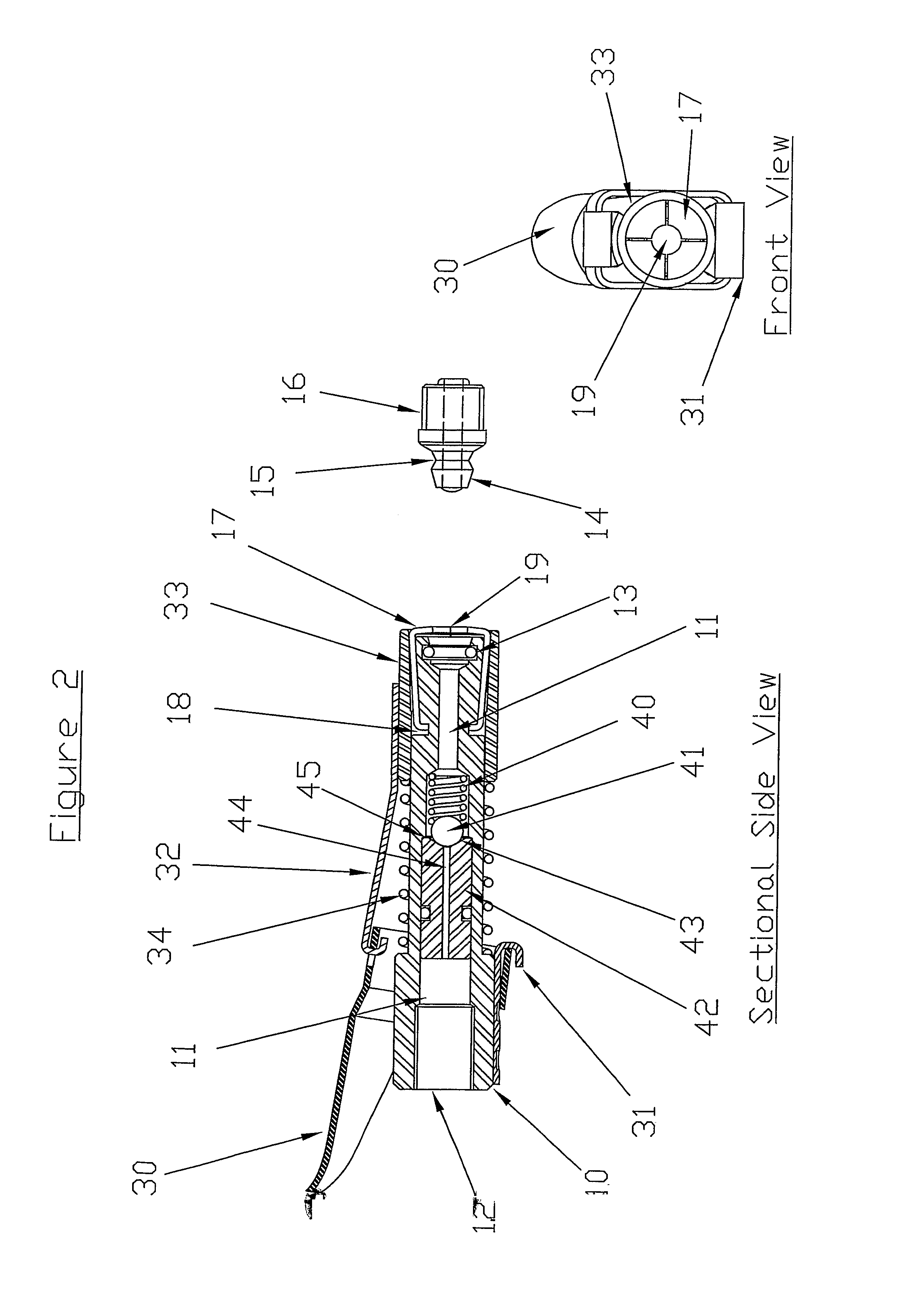

Automatic fluid exchanger

InactiveUS20050166993A1Preventing air infusionEffective blockingLiquid fillingPackaging by pressurising/gasifyingFluid controlPositive pressure

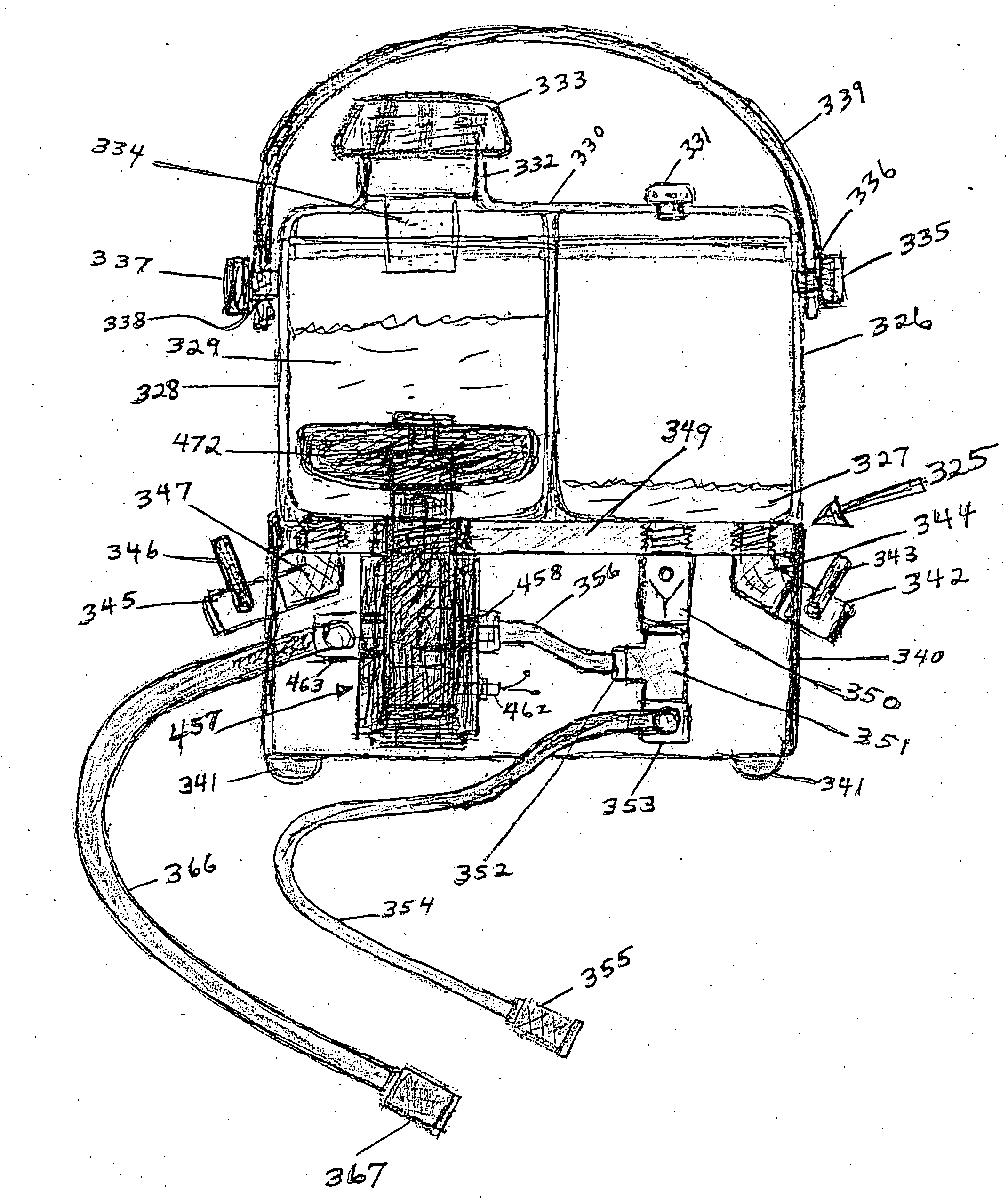

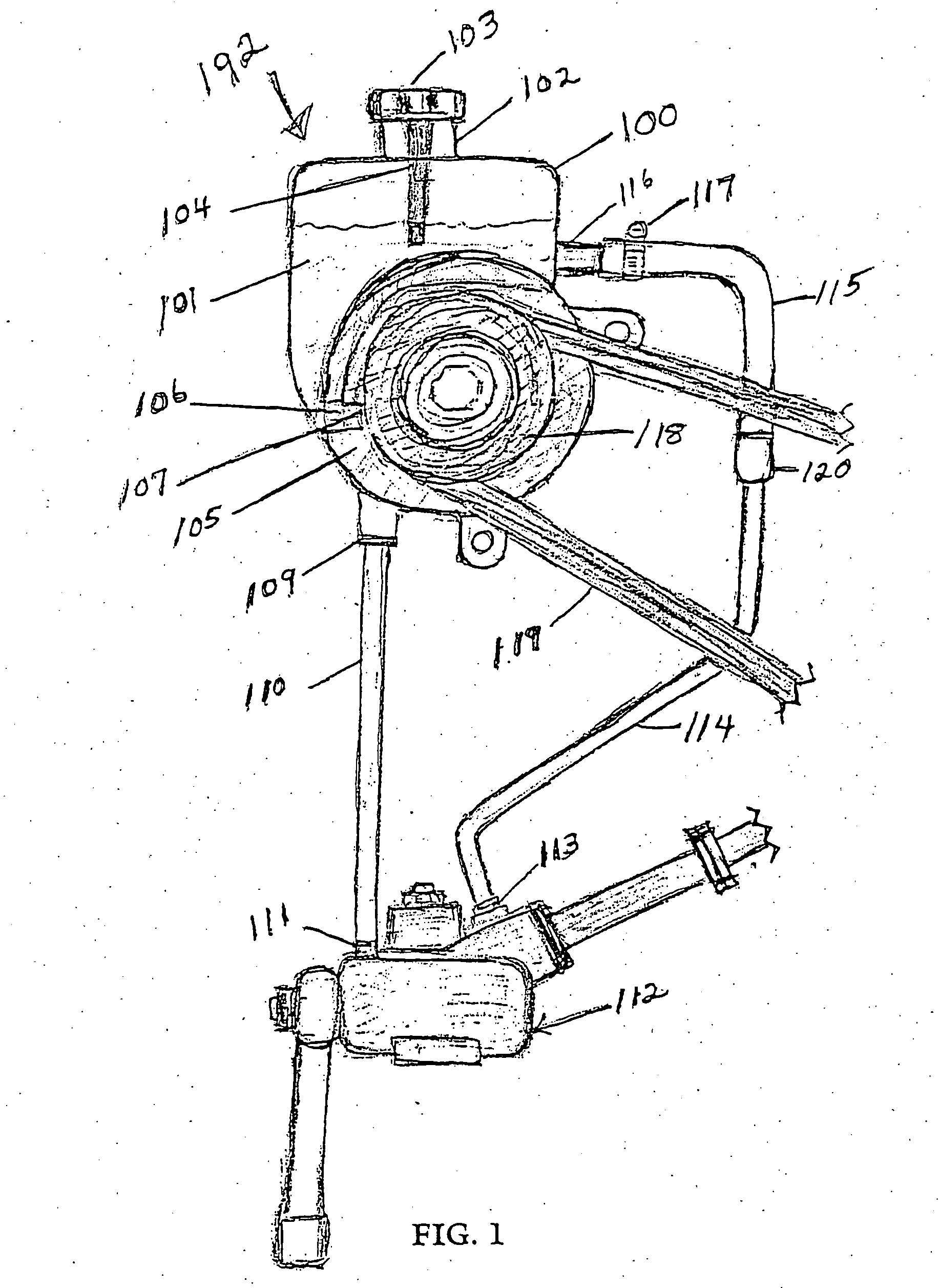

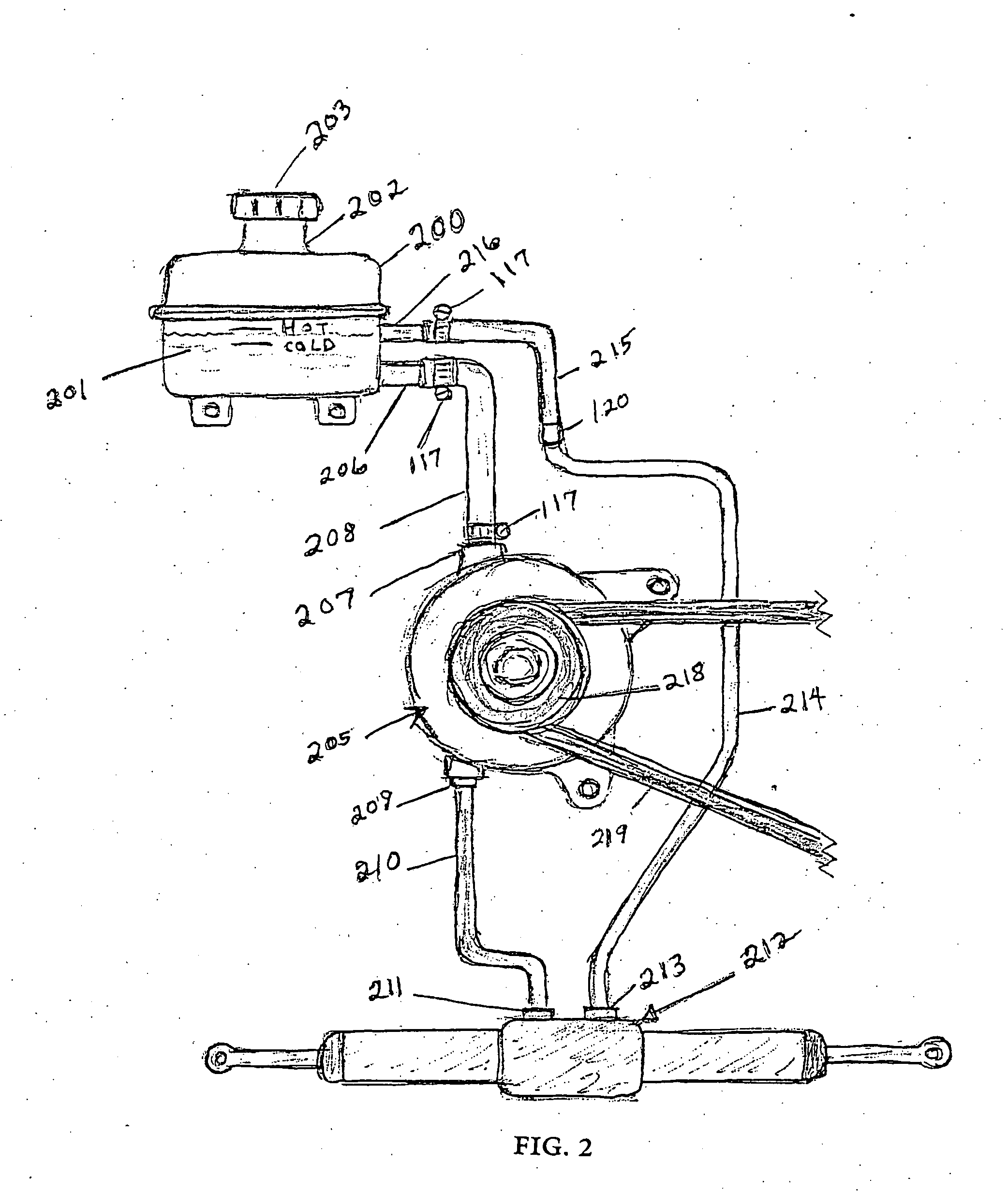

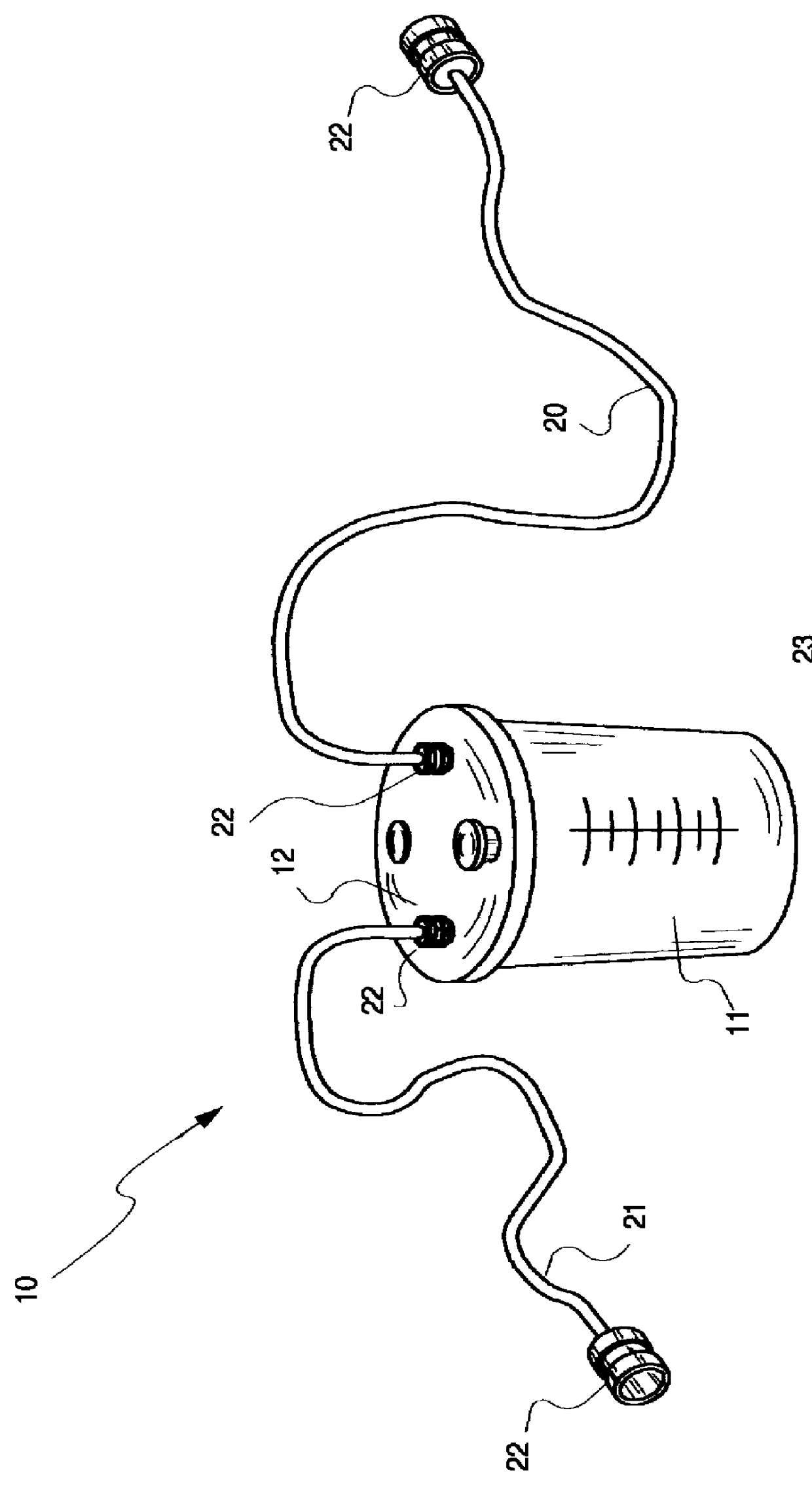

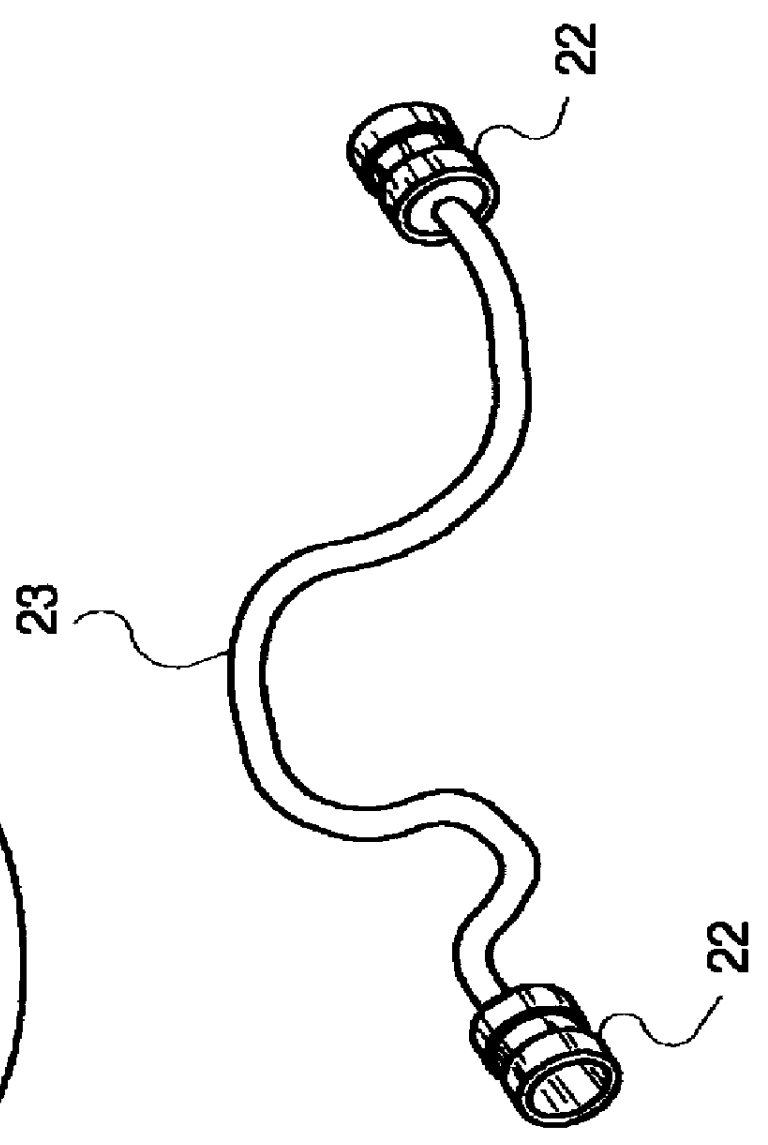

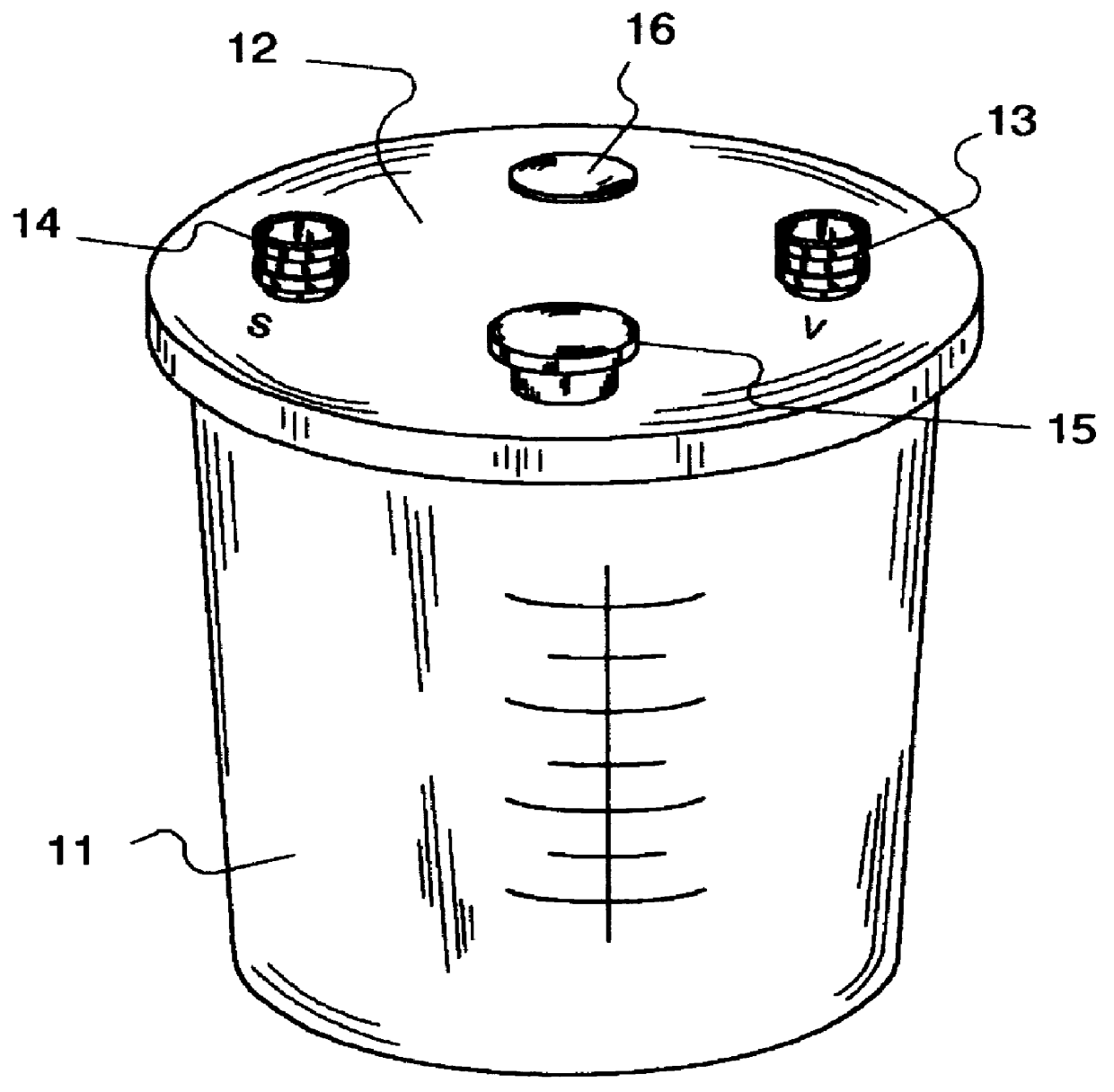

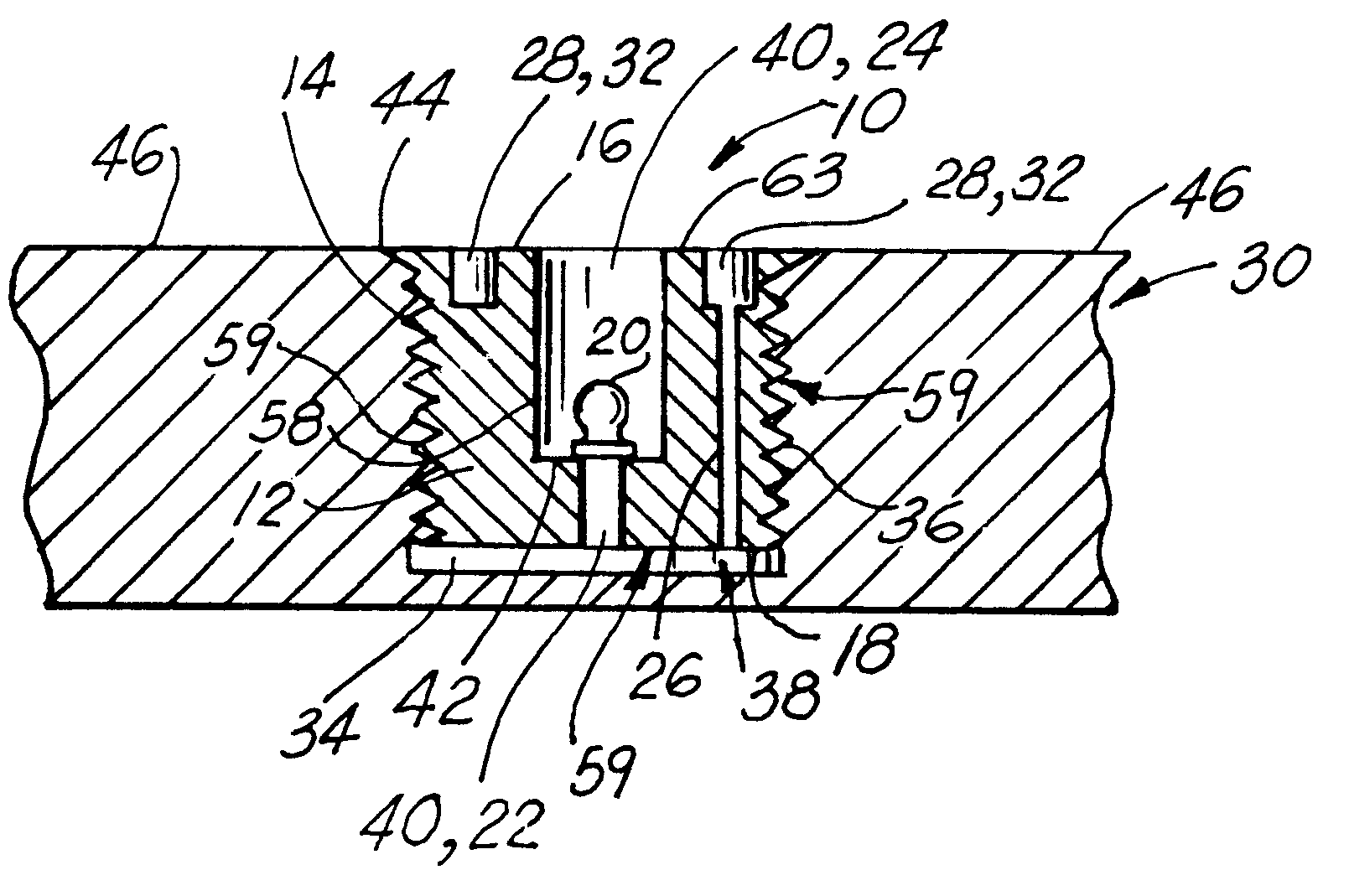

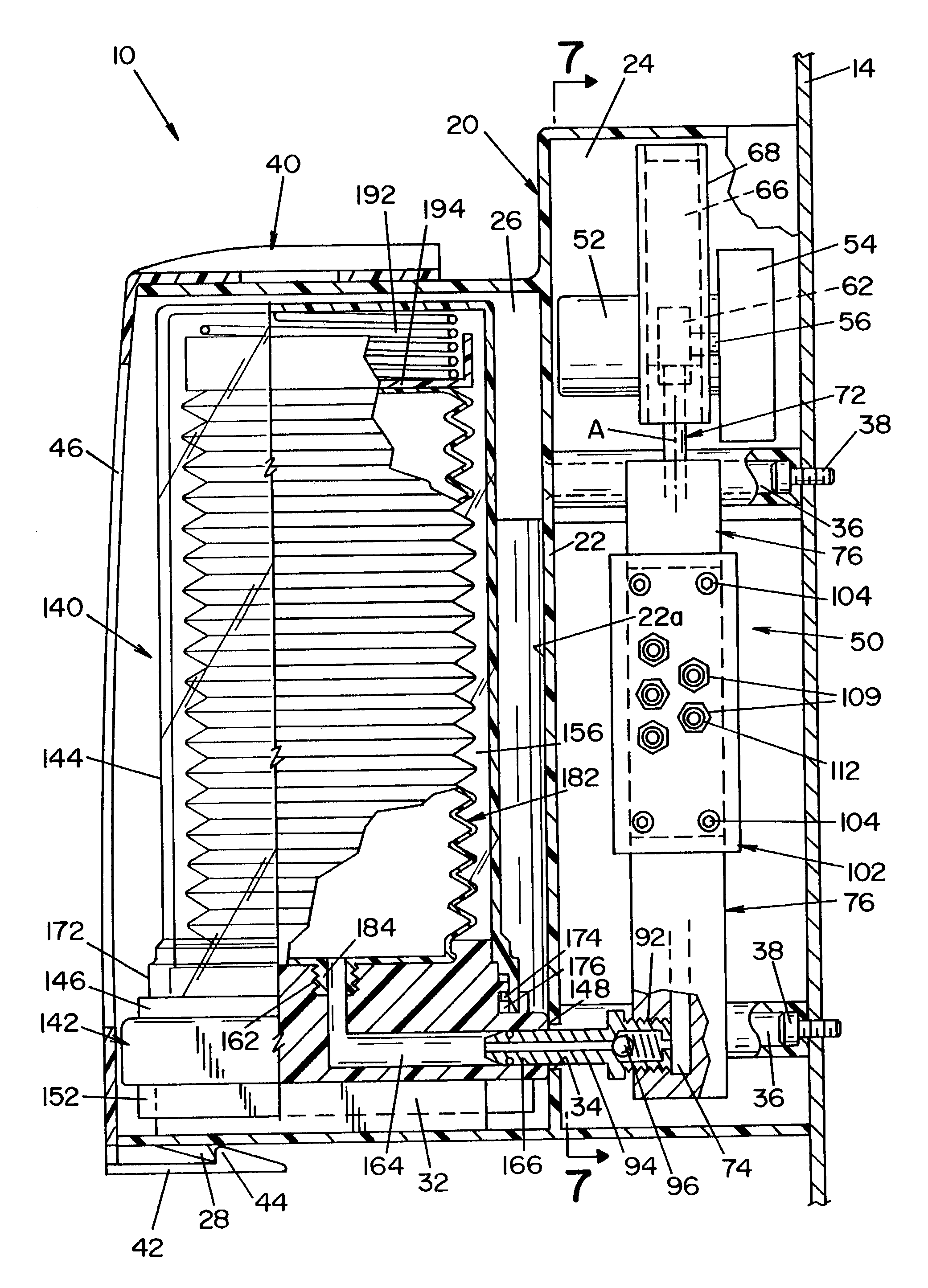

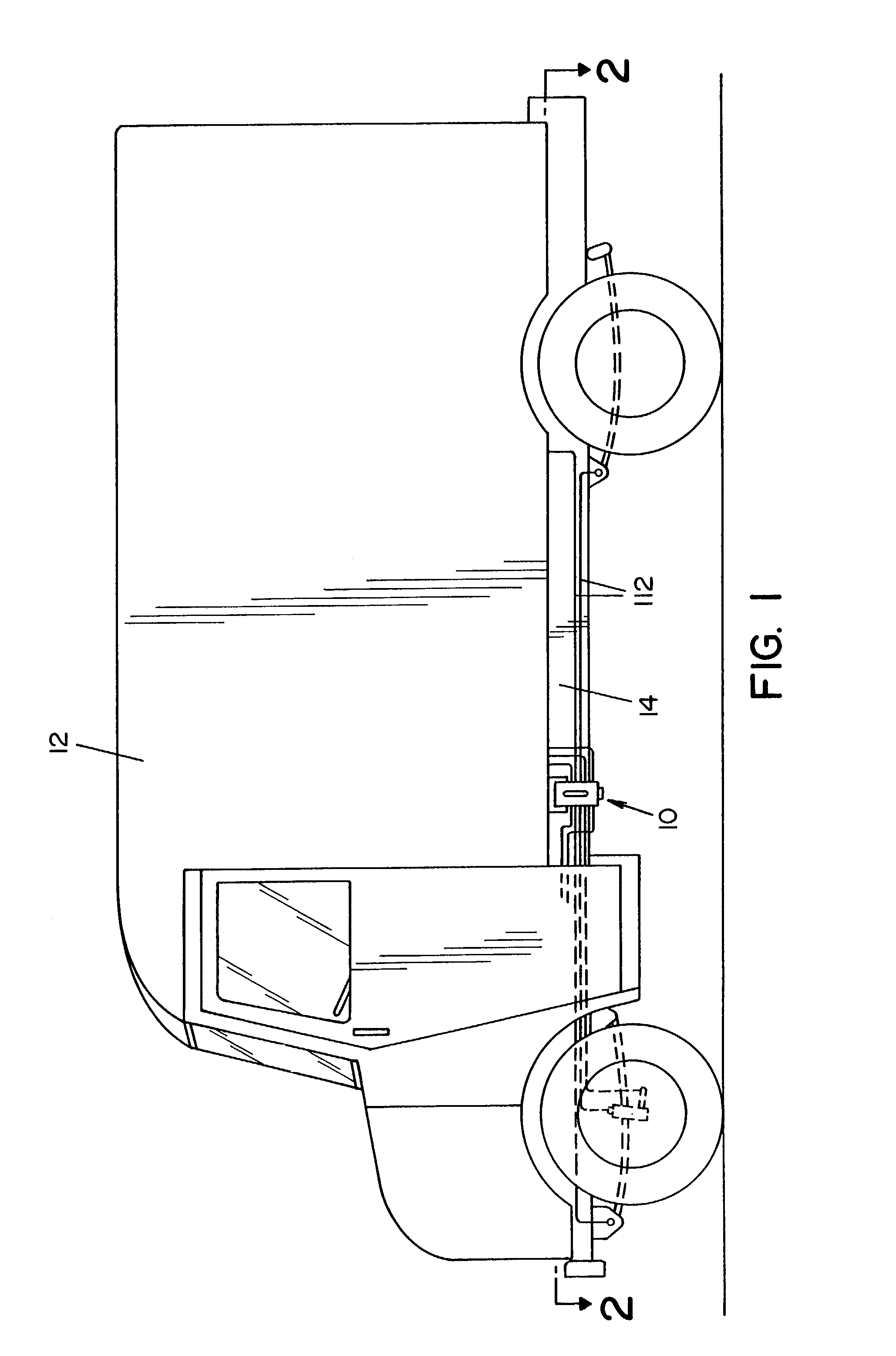

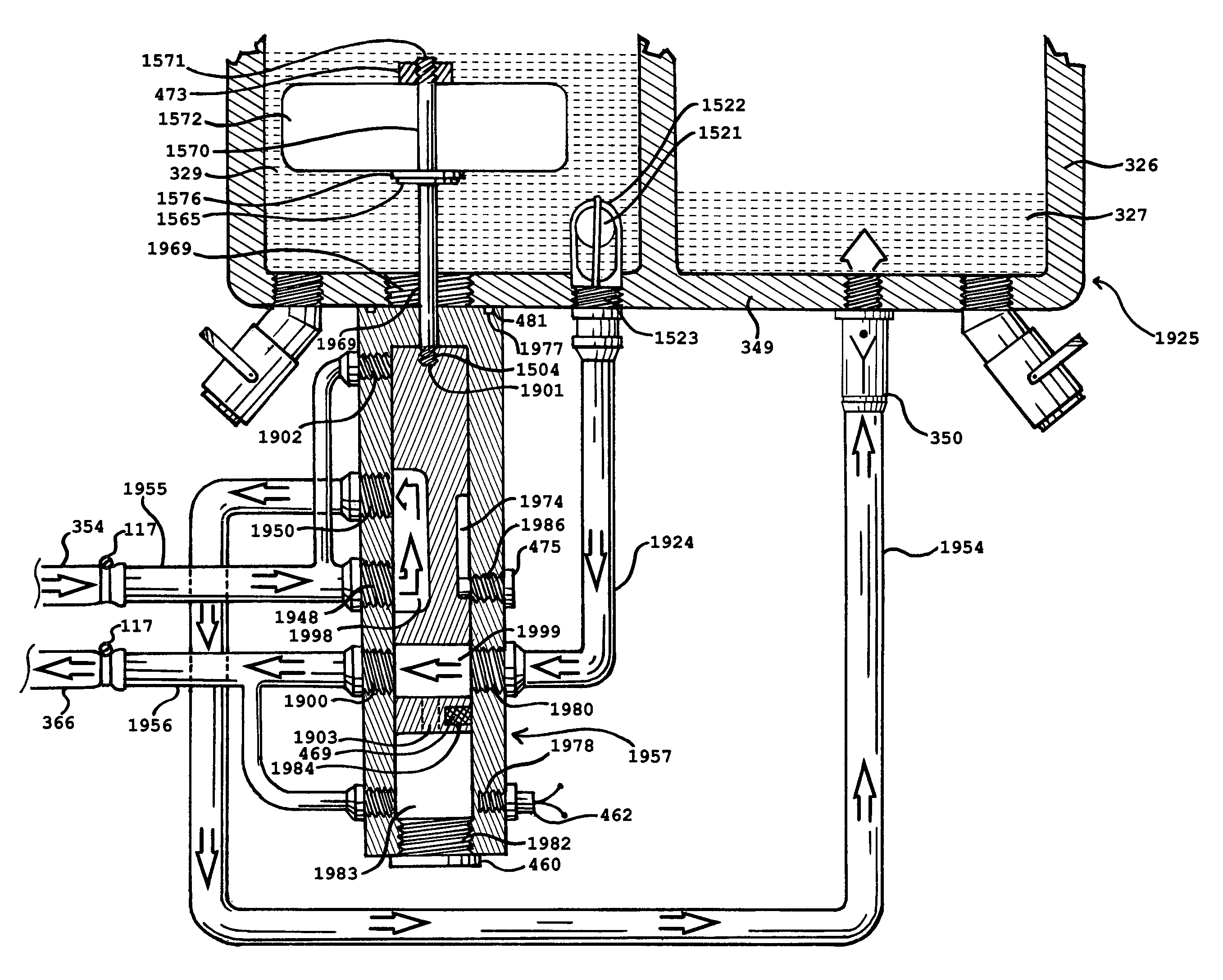

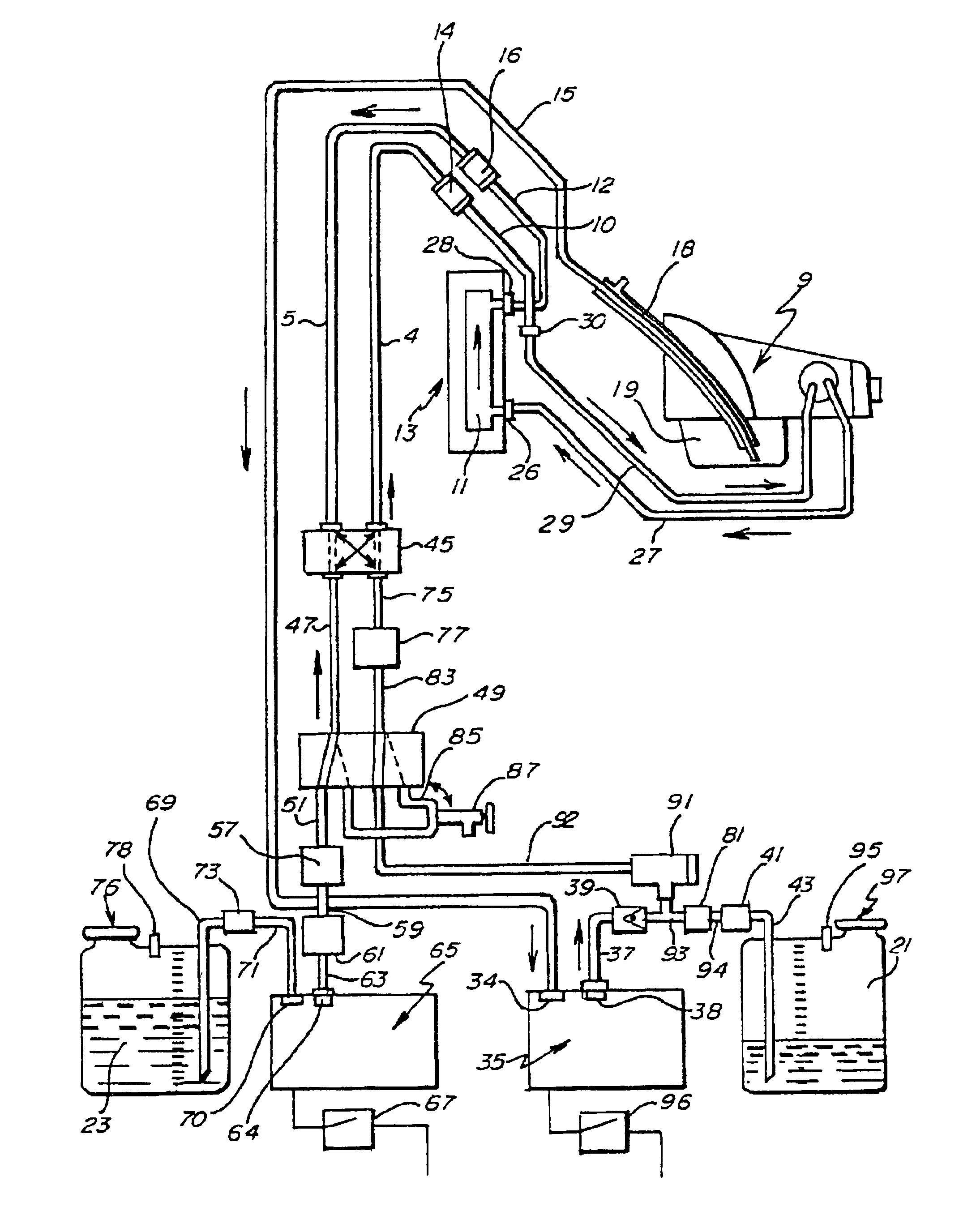

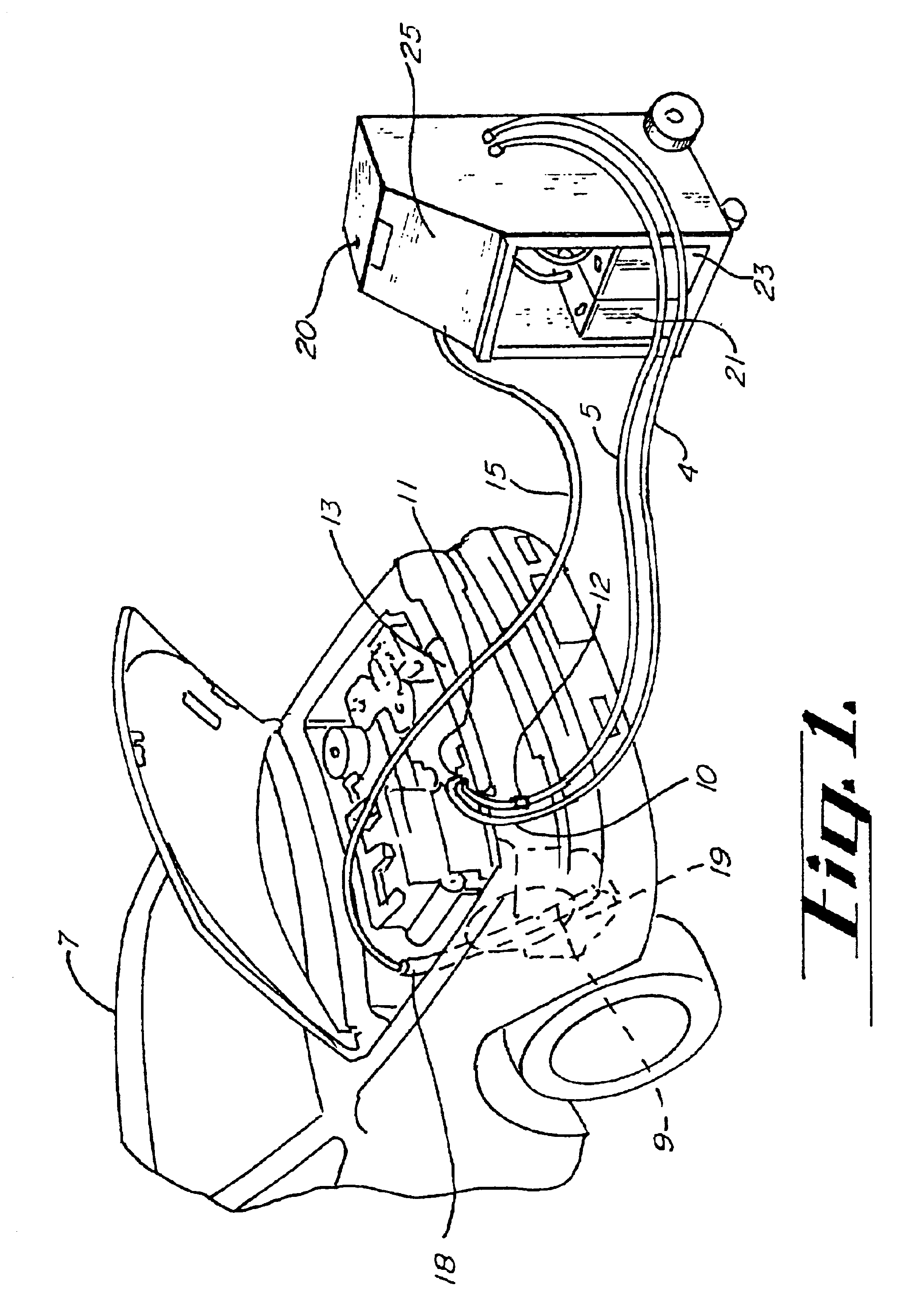

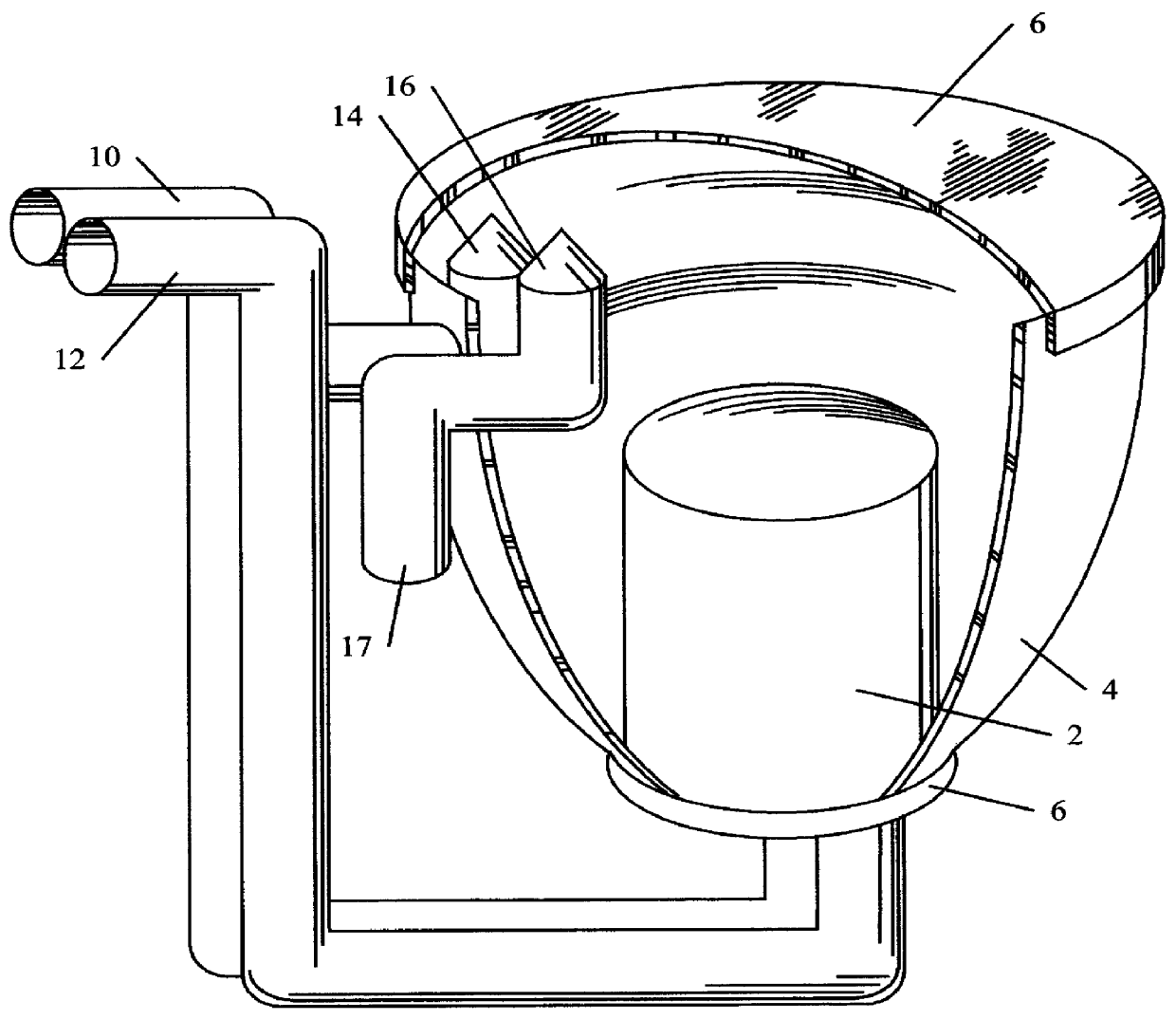

A fluid exchanger for servicing the fluid circuits of vehicular power steering systems and other fluid circulating or hydraulic circuits. The fluid exchanger uses a float operated fluid control valve to harness fluid pressure provided by a pump of an accessed hydraulic circuit. The fluid control valve uses both negative and positive pressure of the circuit's pump to control fluid flow patterns. The float and fluid control valve are matched to be either mechanical / hydraulic or electrical / hydraulic in design. If the exchanger is provided with a mechanically operated fluid control valve, a mechanical float is provided in the exchanger's fresh fluid reservoir and is directly connected to the valve slide of the fluid control valve. If the exchanger is provided with an electric solenoid operated fluid control valve, a float operated electrical switch is provided in the exchanger's fresh fluid reservoir and is wired to control the solenoid of the valve.

Owner:VIKEN JAMES P +1

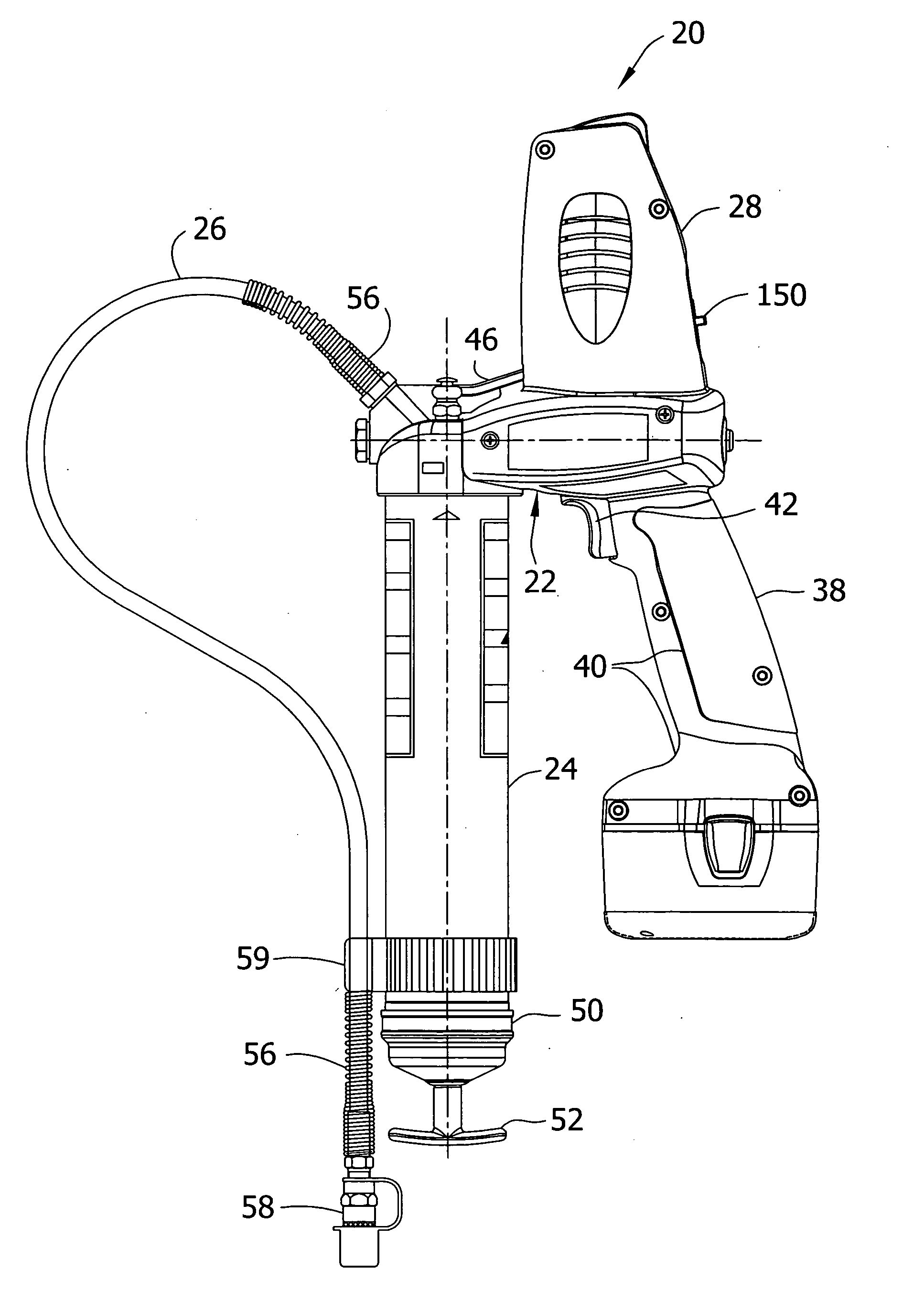

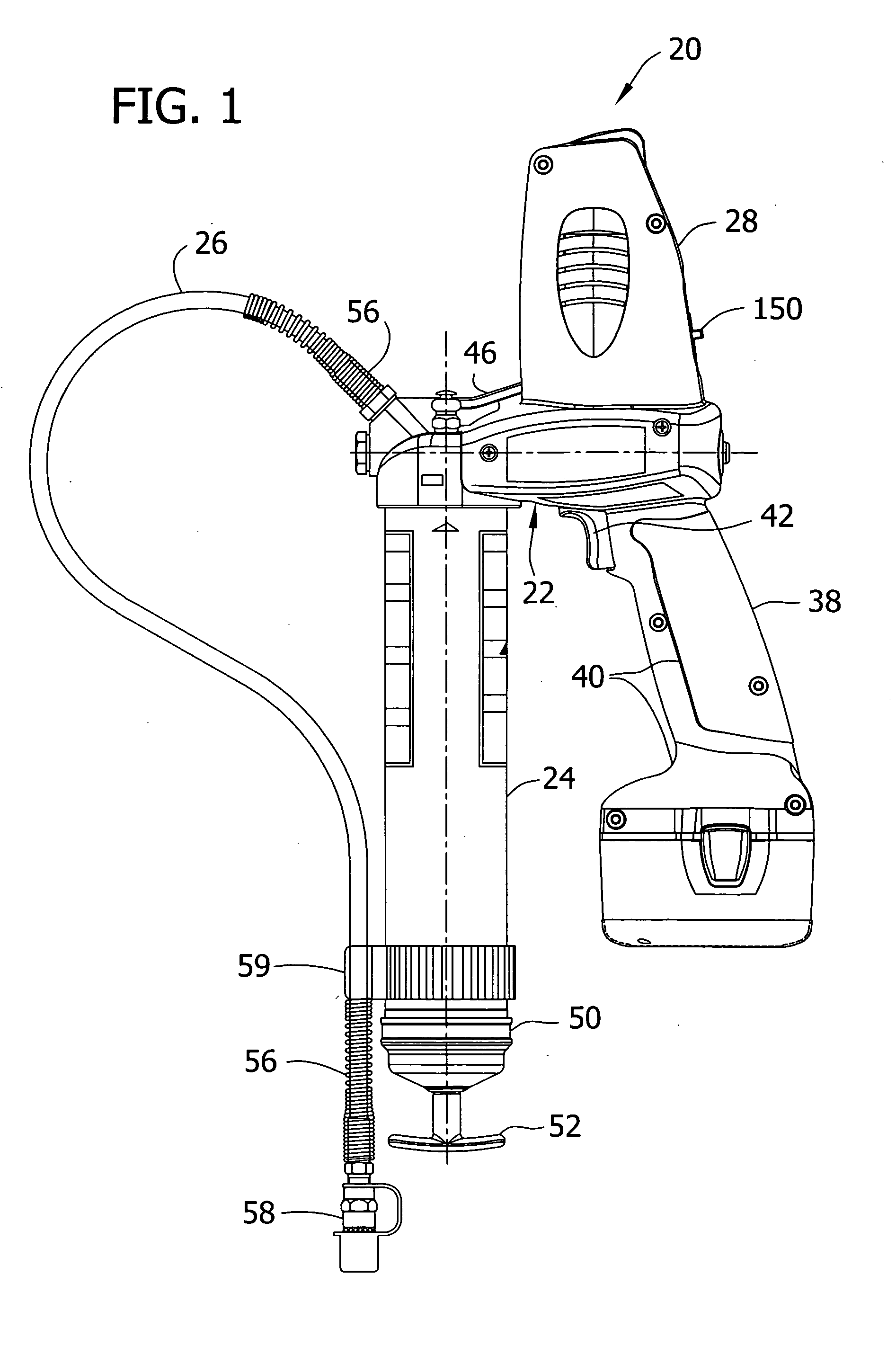

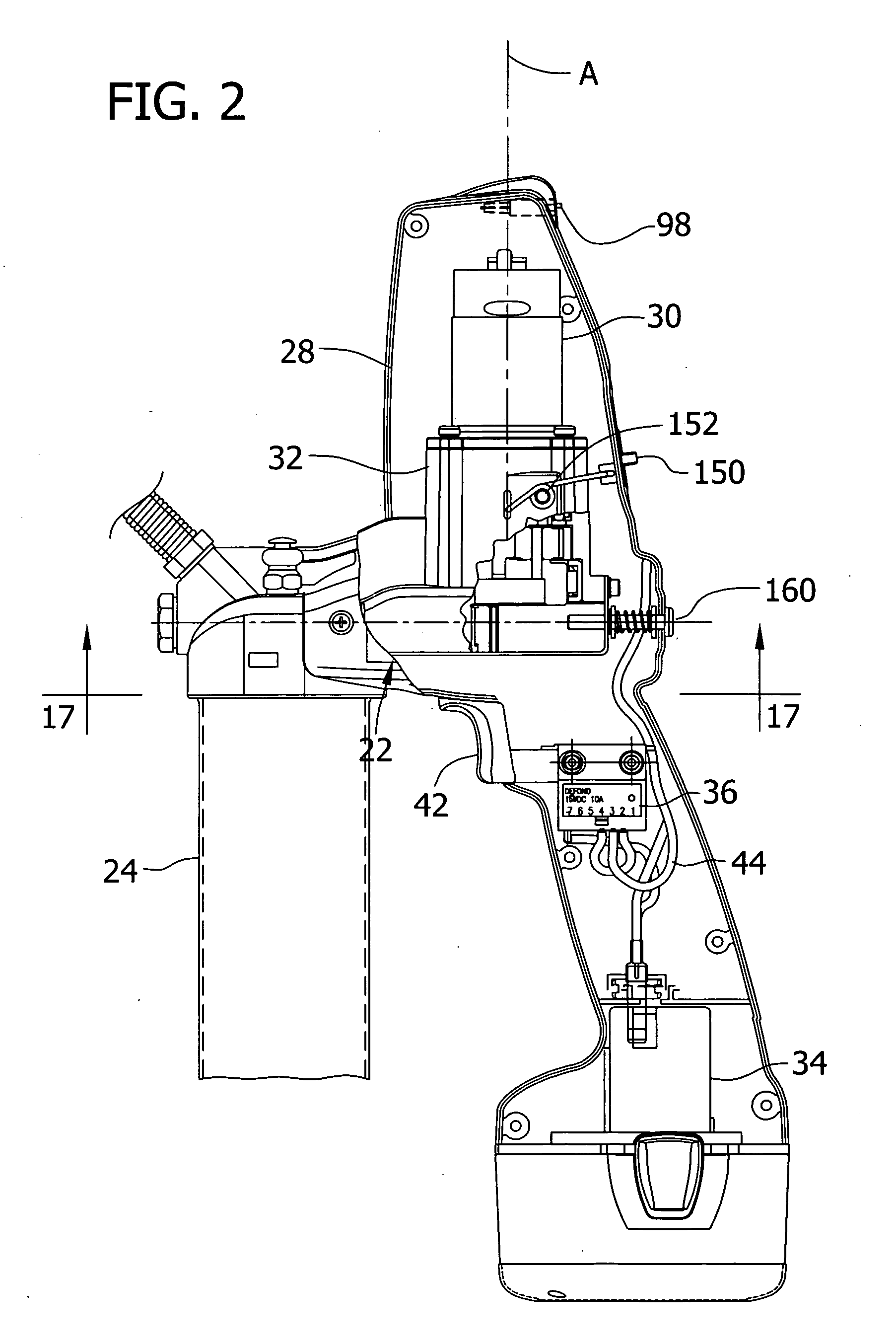

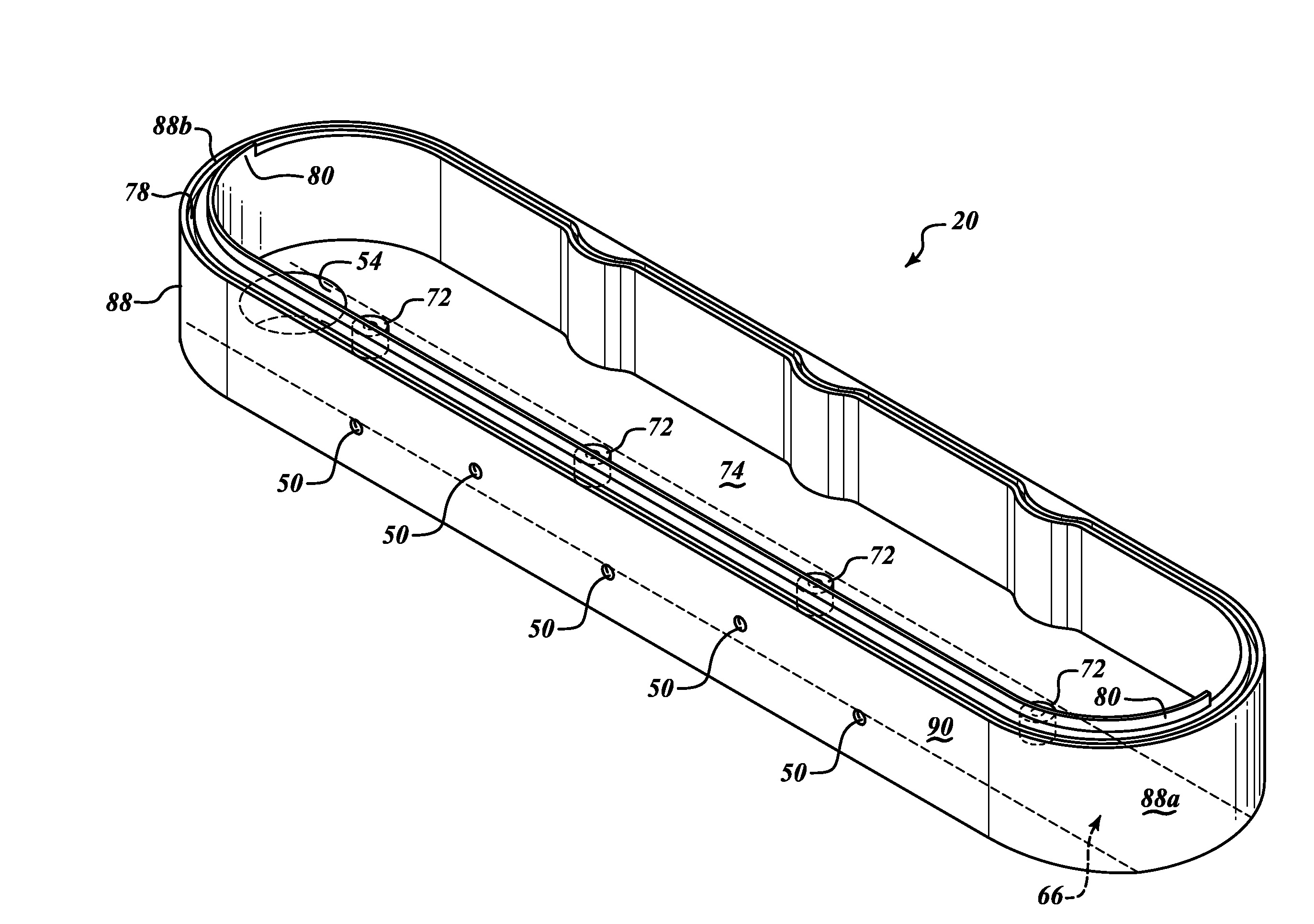

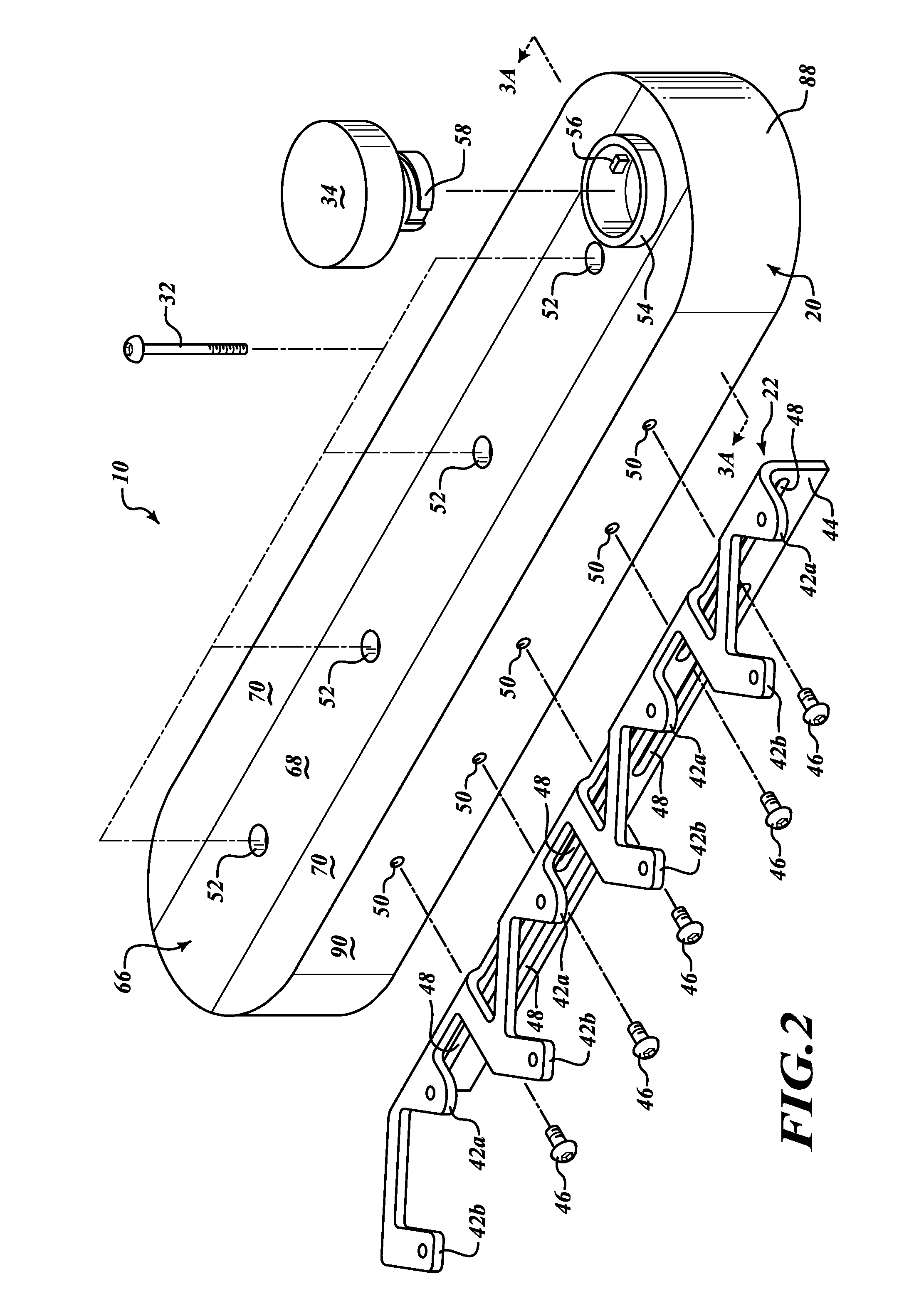

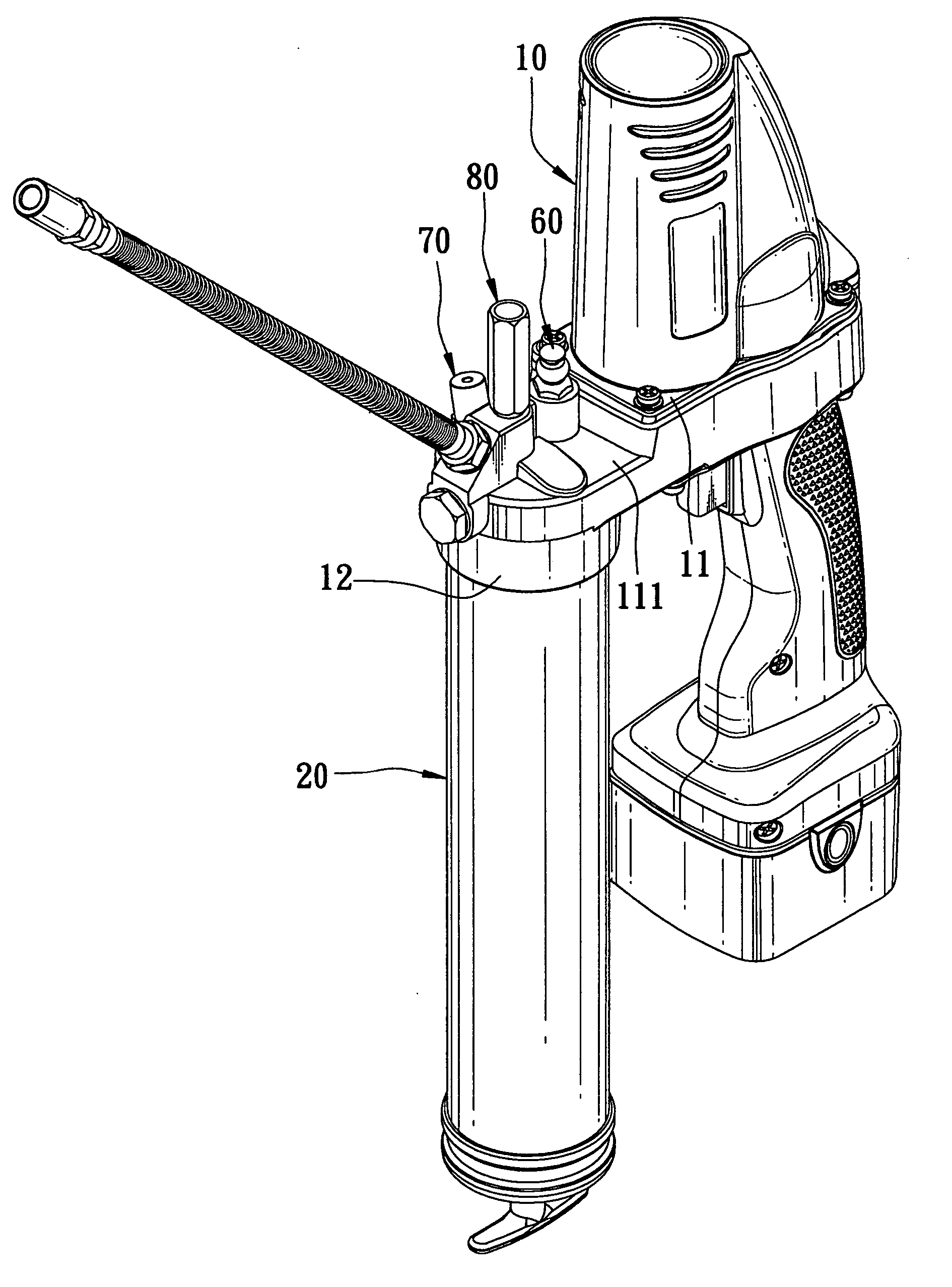

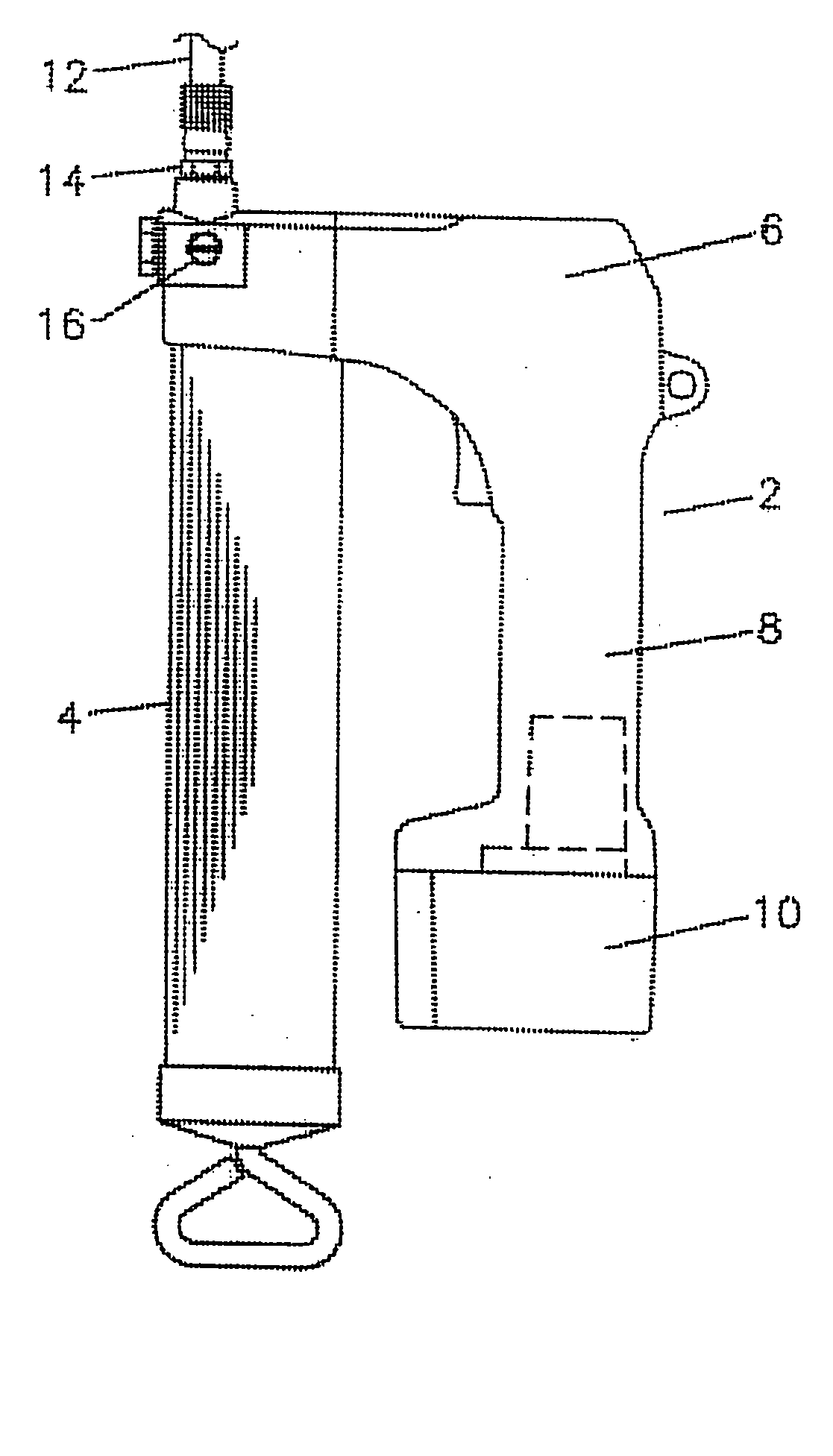

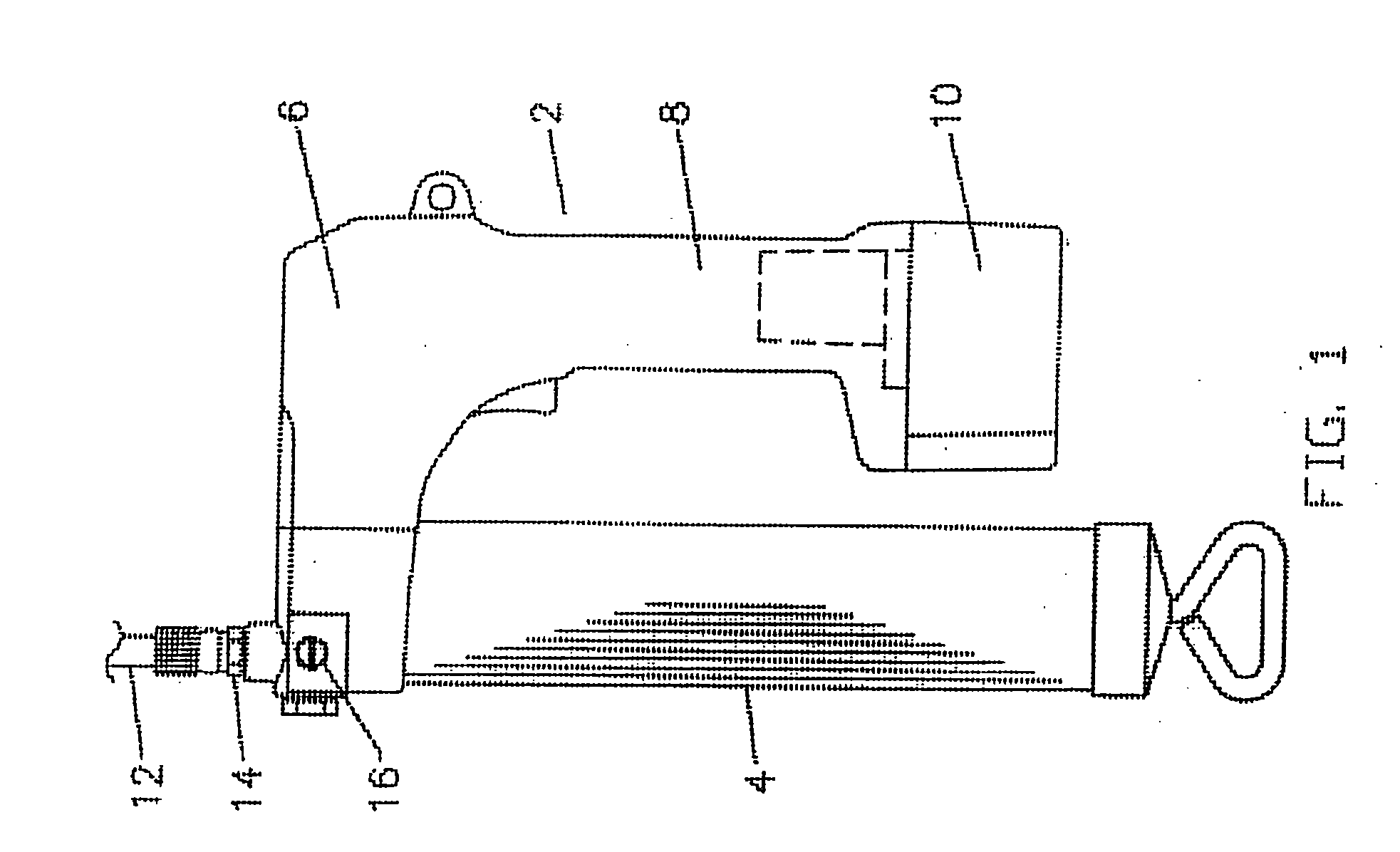

Grease gun

InactiveUS20060108180A1Avoid damageGuaranteed economic efficiencyManual lubricationMachines/enginesElectricityTransmitted power

A device for dispensing a viscous fluid, such as grease gun for dispensing lubricant. The grease gun delivers lubricant with a selectable variation in pressure and / or output. It includes a reservoir, a pump having a reciprocating plunger, an electric motor driving the pump, and a variable speed transmission for transmitting power from the motor to the pump. The transmission has at least two different output speed settings adapted to be selected for reciprocating the plunger at different cyclical frequencies. A cycle indicator provides an indication corresponding to a quantity of lubricant dispensed. Embodiments of the grease gun include a pressure relief valve which inhibits damage due to an over-pressure condition, and a circuit breaker which inhibits damage due to electrical overload.

Owner:LINCOLN INDUSTRIES CORP

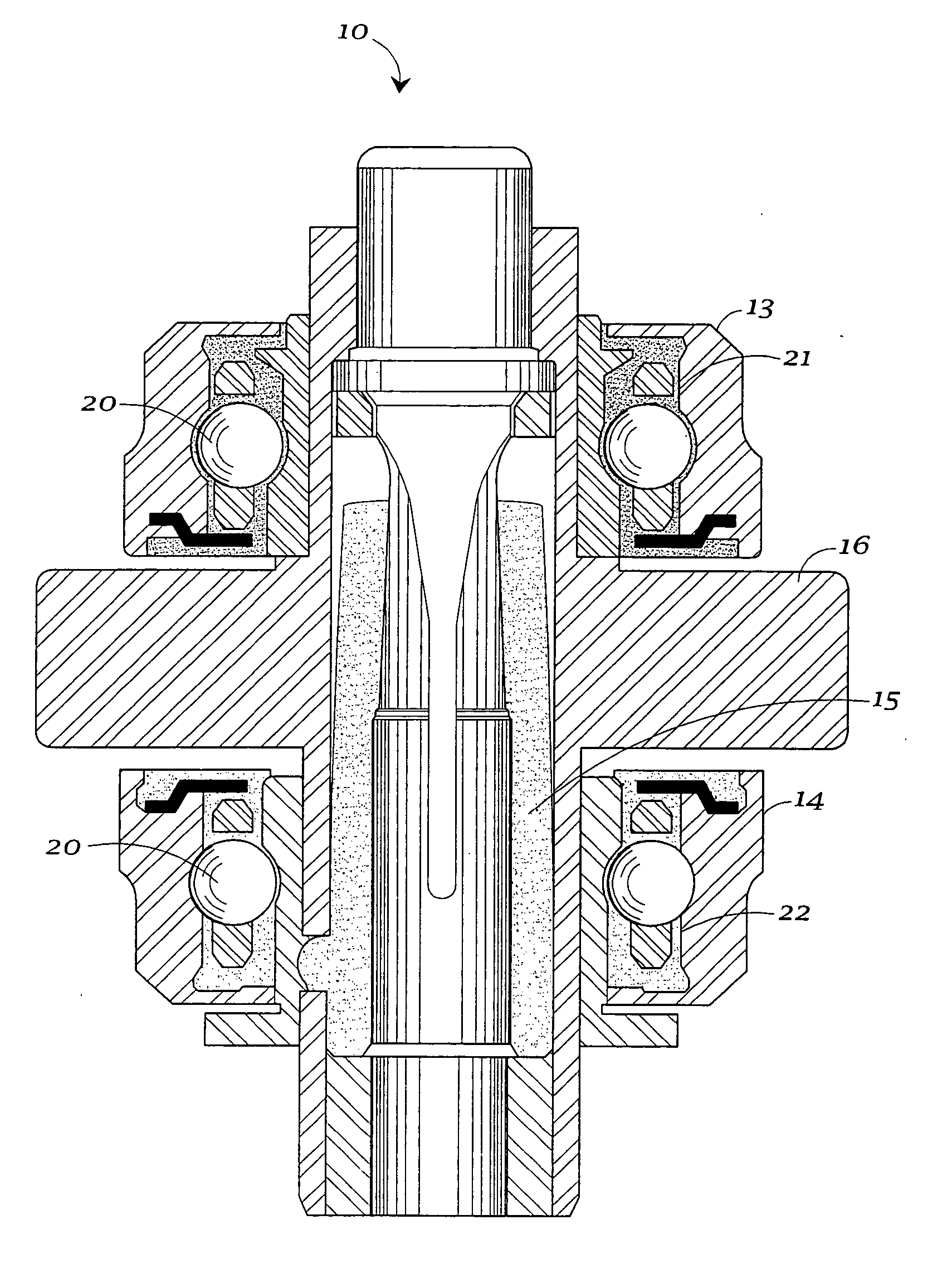

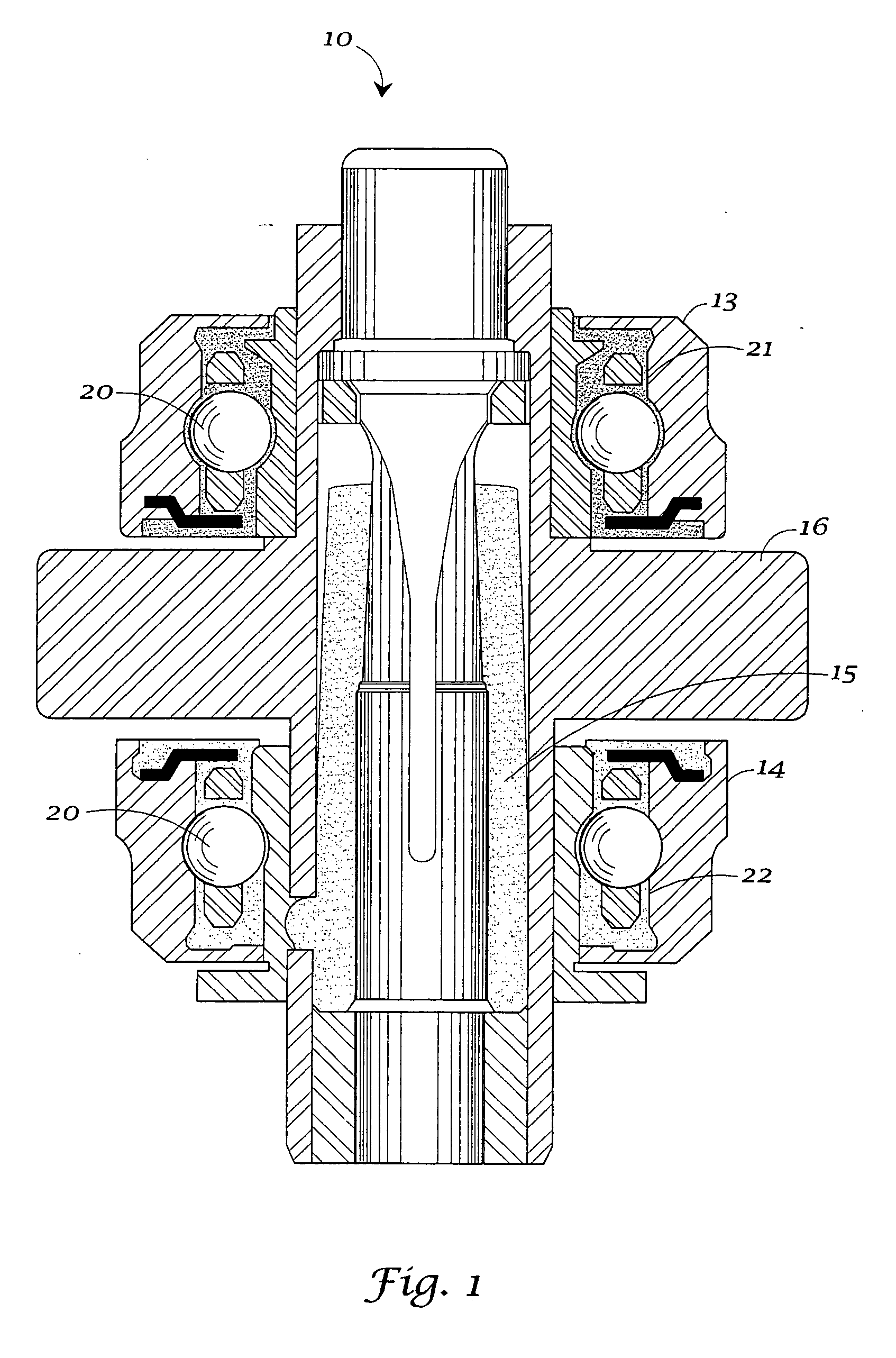

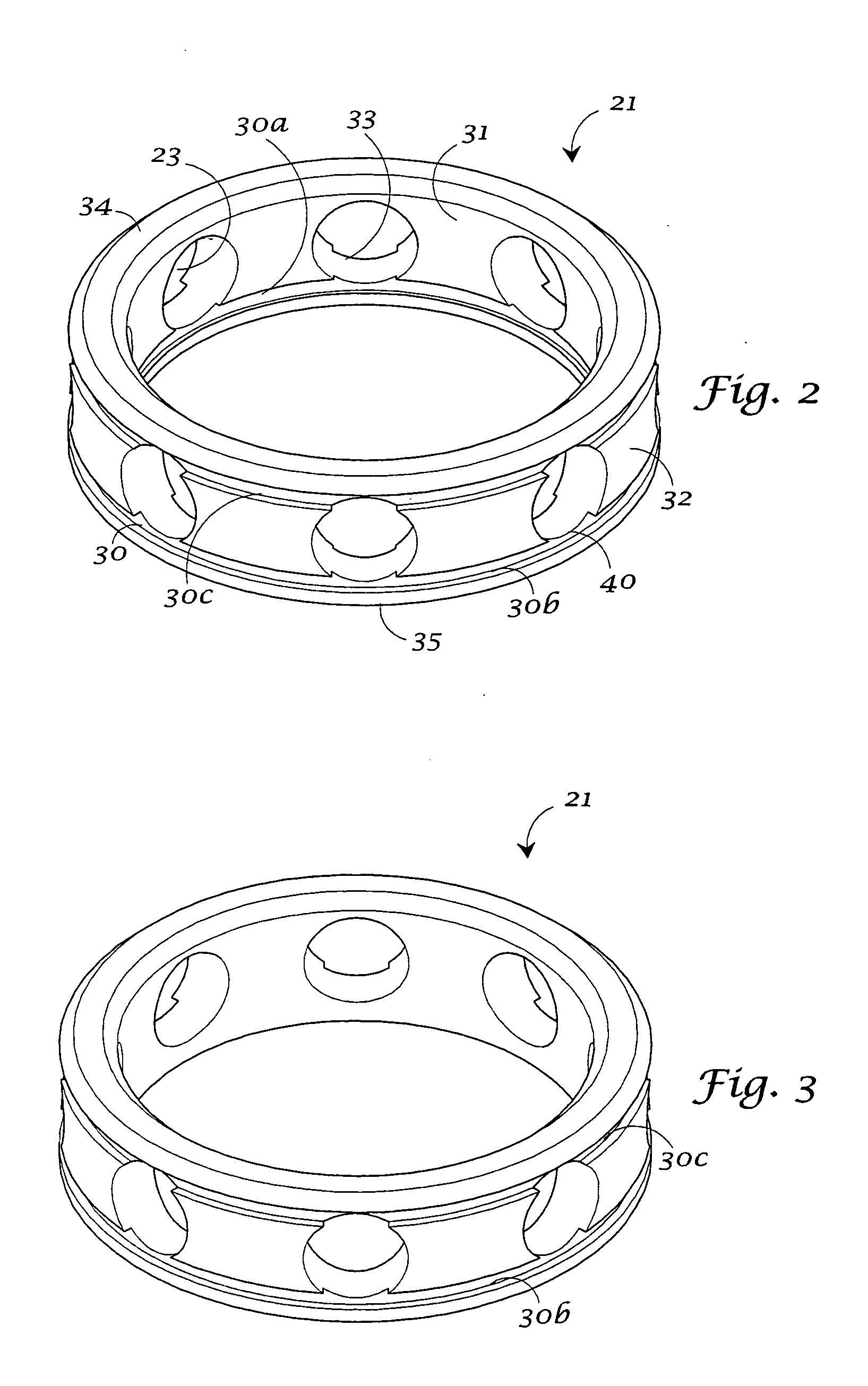

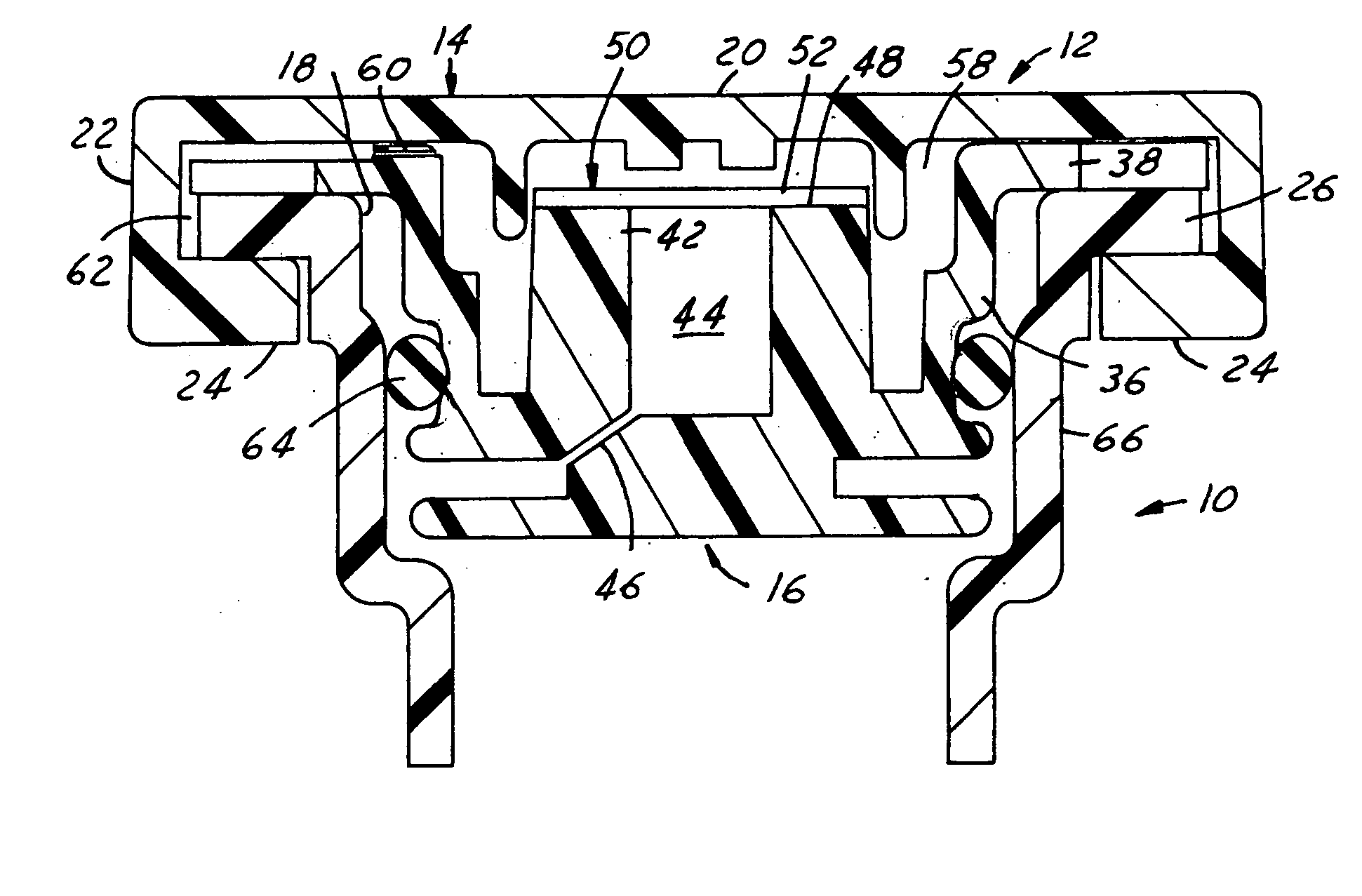

Dental handpiece with improved grease retention

InactiveUS20050287493A1Improved grease retention characteristicReduced dental procedure costRolling contact bearingsBearing componentsBall bearingEngineering

A dental handpiece (10) has a rotor (15) and a ball bearing assembly (13, 14) supporting the rotor (15). At least one of the ball bearing assemblies (13, 14) has a ball (20) and a retainer (21). The retainer (21) has at least one grease retaining groove (30, 50) or void (51) therein.

Owner:NOVAK EUGENE J +1

Two part oil or fluid drain plug with magnet

ActiveUS20060054402A1Precise positioningAvoid partialCrankshaftsElectrostatic separationEngineeringMagnet

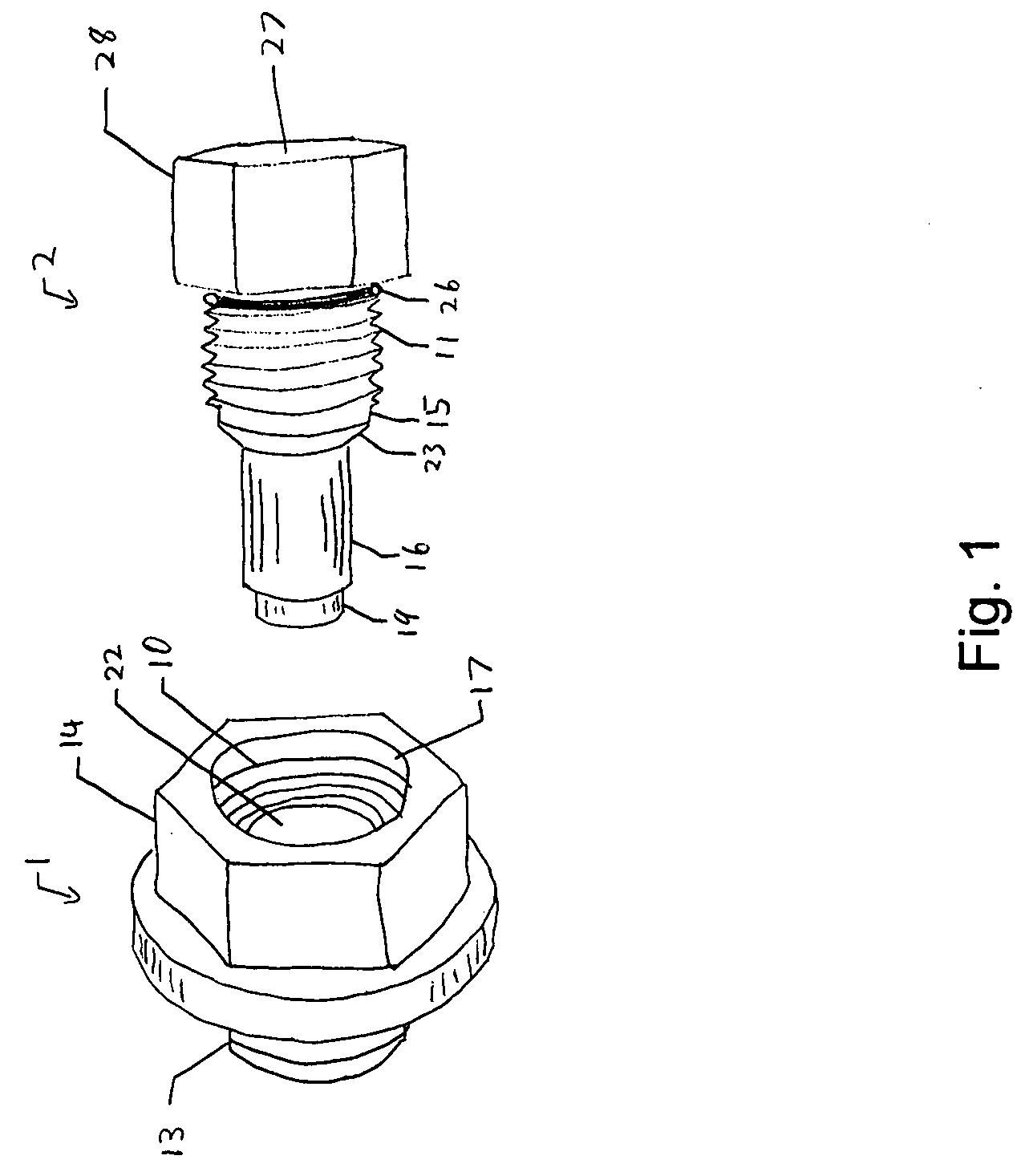

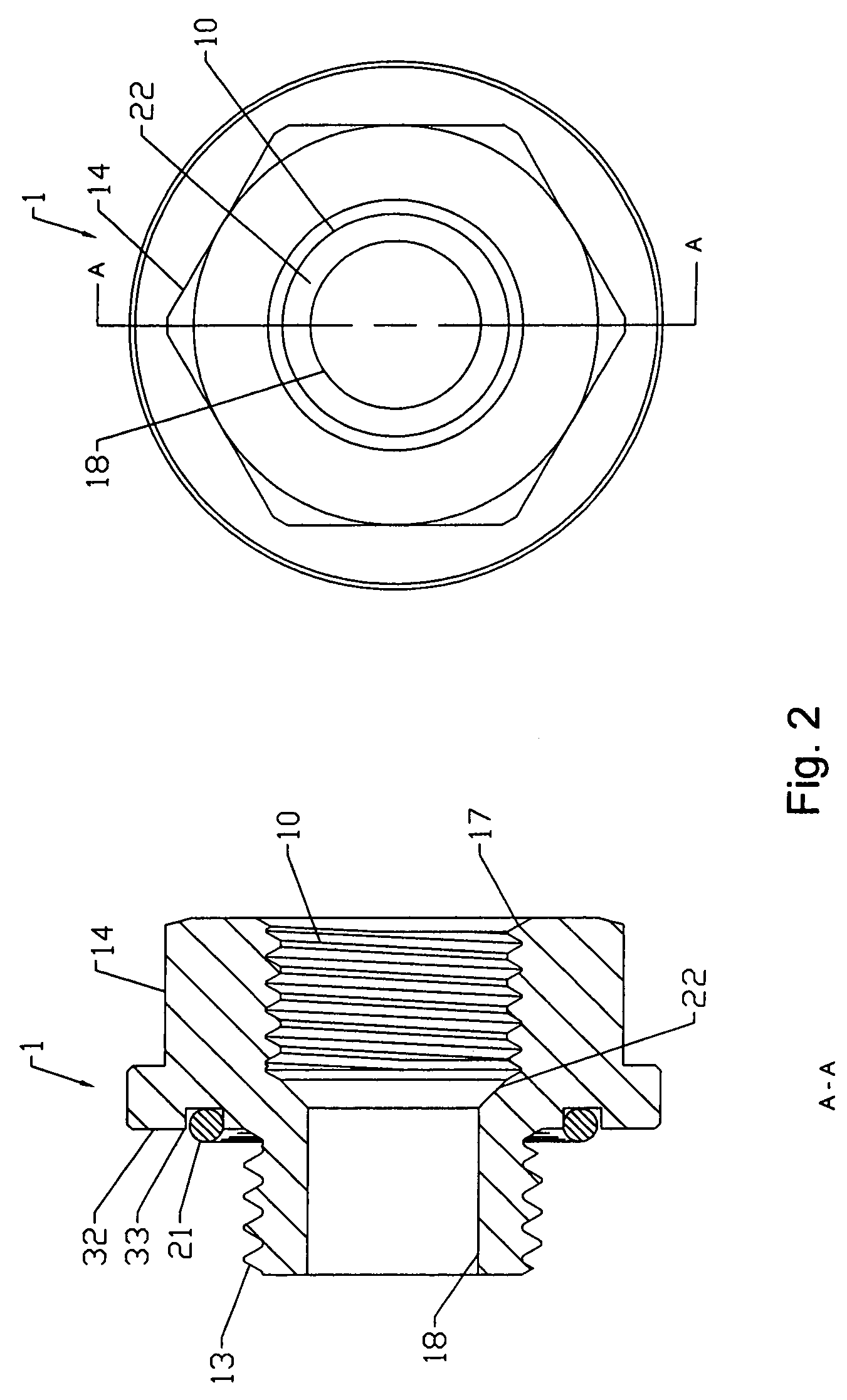

This invention performs several functions. First; facilitating the draining of oil or fluid from a sump. Second; as a proactive and preventive method of preventing the threads of the sump (which receive the drain plug) from becoming striped or damaged. Third; adding in the determination of the physical condition (ware) of the engine, transmission, or the like, in which the sump is attached to.

Owner:DORIAN GEORGE P

Portable, automatic, oil recovery system

InactiveUS6092390APrevent oil from overflowingPrevent overflowCrankshaftsMachines/enginesEngineeringAir conditioning

A compressor oil recovery device for use in removing oil from compressors typically found on condensing units used in air conditioning or refrigeration applications is disclosed. The device consists of a canister with a lid that contains a vacuum port, a suction port, a drain port, and a vacuum release port. A vacuum hose is connected at one end to the vacuum port and at the other end to an electric vacuum pump. A suction hose is connected at one end to the suction port and at the other end to the gauge manifold of a compressor. Upon activating the vacuum pump, a vacuum is created that draws the compressor oil into the canister where it is collected for disposal.

Owner:GRIFFITH JR DAVID R

Apparatus and method for automatically performing fluid changes

InactiveUS6123174AEfficient and successful completionMinimize the possibilityCrankshaftsPackaging by pressurising/gasifyingSequence controlControl signal

An environmentally sound apparatus and method for automatically extracting fluids such as lubricating fluids from a target reservoir such as a crankcase for a vehicle engine, and injecting the proper type and quantity of fresh fluid into the reservoir is disclosed. The apparatus includes one or more sources of lubricating fluid, a waste fluid tank, a pump, and a flow meter. A programmed microprocessor produces selected sequences of control signals to govern the flow of fluid among the fluid sources, the waste fluid tank, and the target reservoir in response to input identification information and signals produced by a flow monitoring pulse meter. Input identification information is compared with data in a stored database to determine the correct type and quantity of fresh fluid to inject. Operator identification information is compared with a stored operator database to determine what operations each operator is permitted to perform. A display and selection switches allows the operator to select from different procedure options. Evacuation, injection and clearing operations are initiated by an operator and executed automatically through status monitored sequences controlled by the microprocessor. All fluid exchange sequences are performed without exposing the operator or the environment to either waste or fresh fluid.

Owner:HLDG CAPITAL GRP

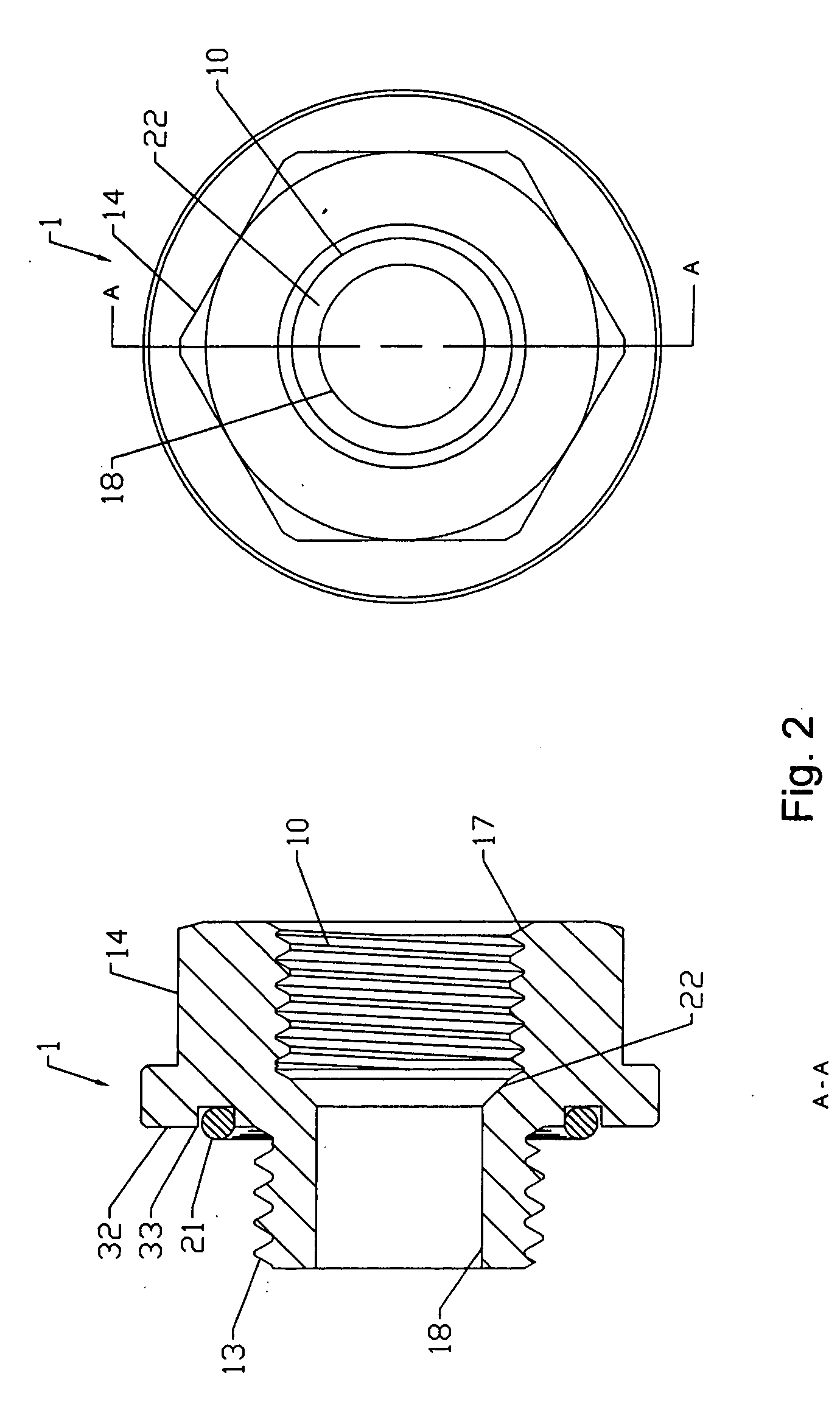

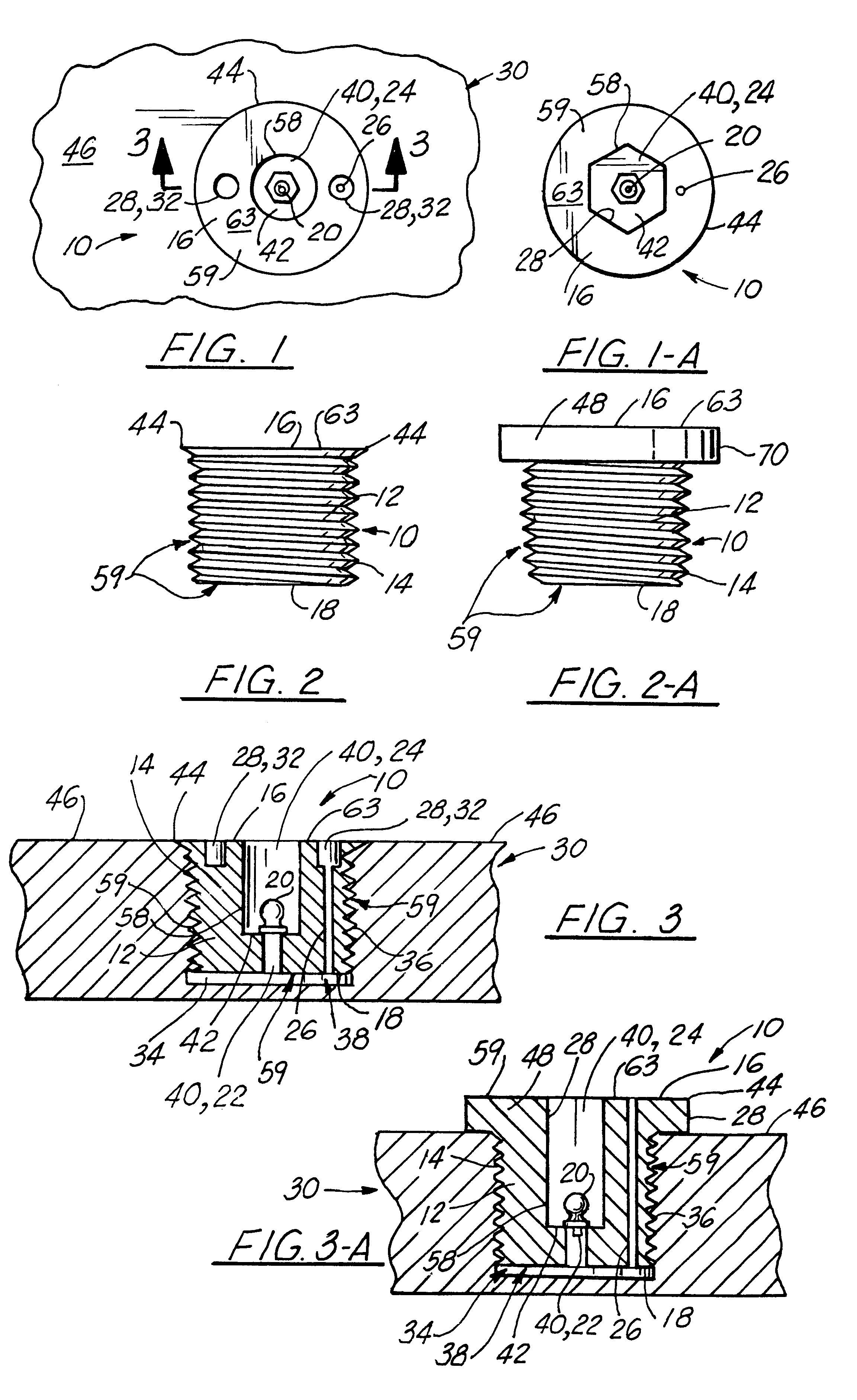

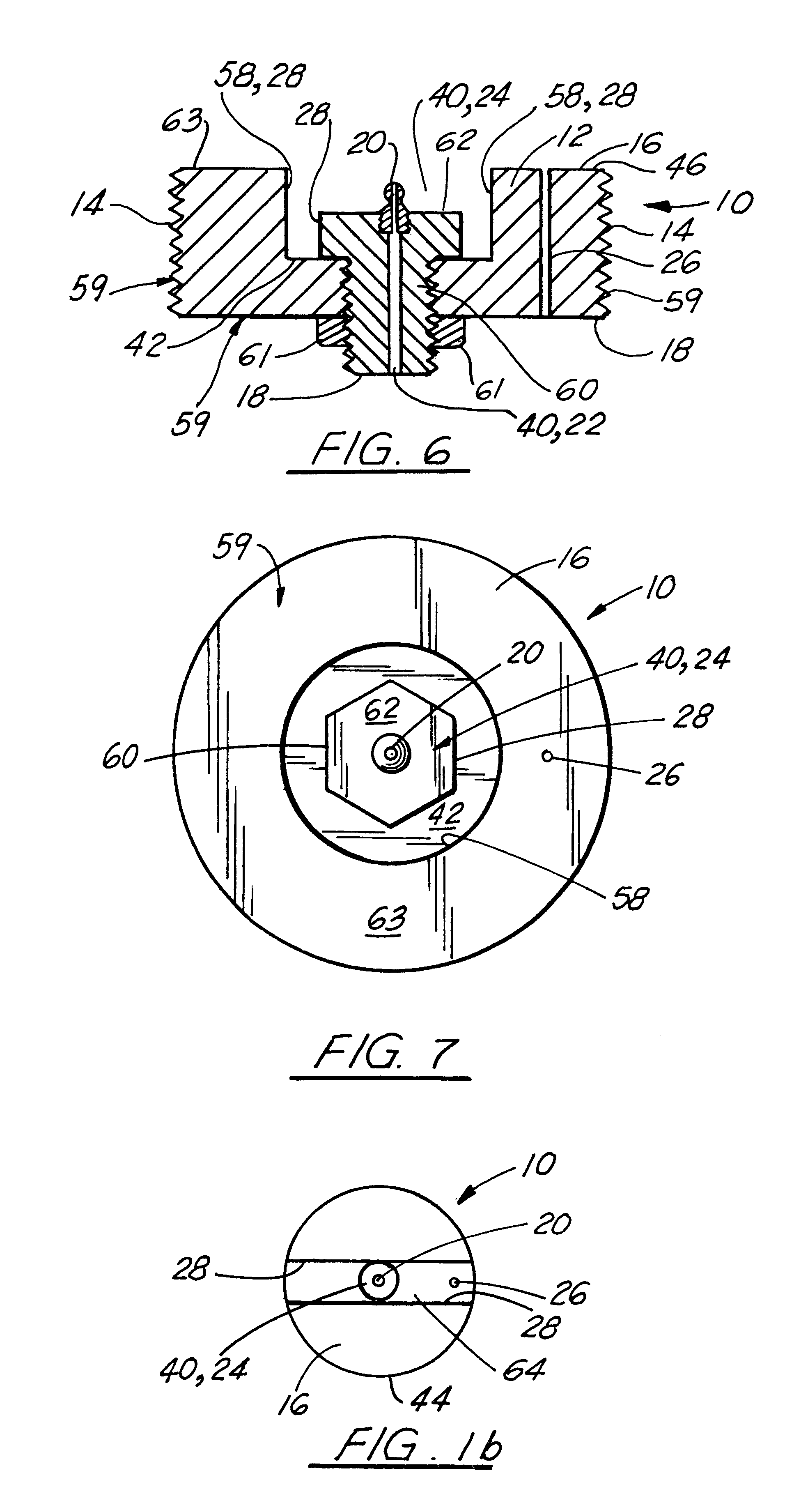

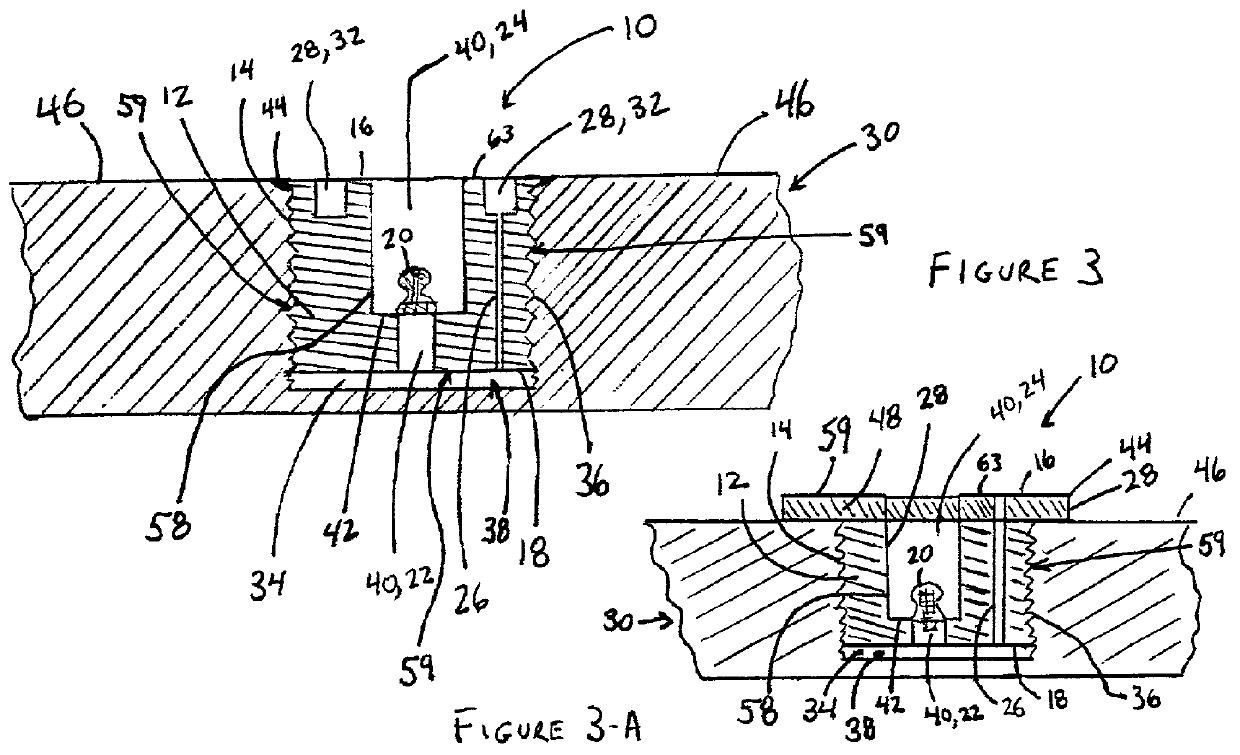

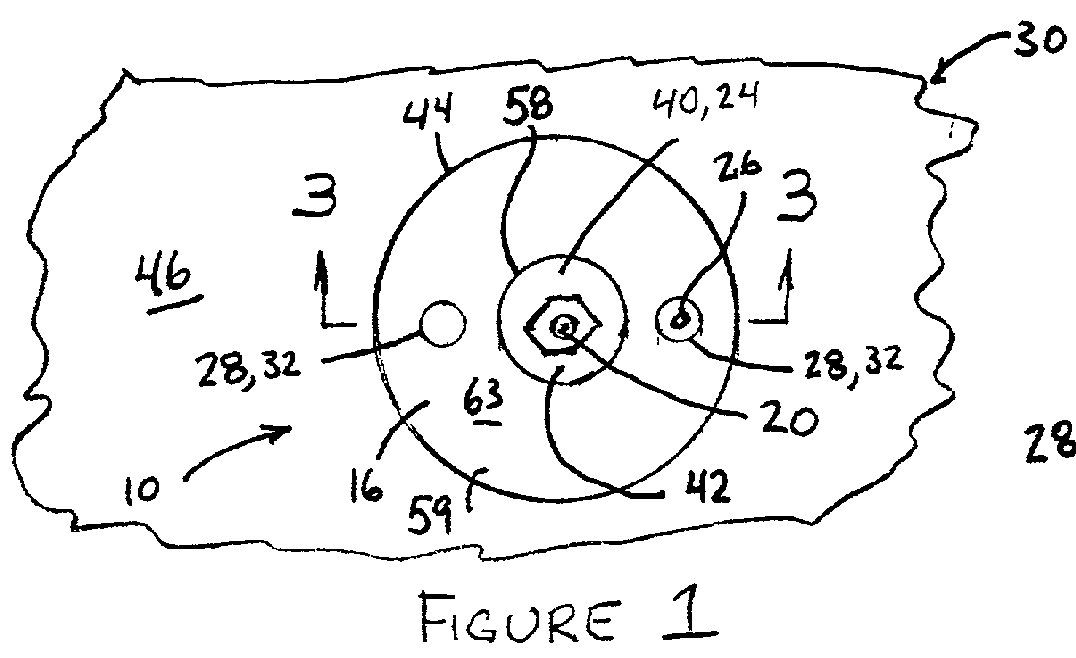

Protection plug

A plug for protecting the interior of a recessed area of a component during storage is disclosed herein. The plug includes a lubrication fitting positioned thereon to flow a protective material, such as grease, into the cavity between the lower end of the plug and the recessed area and any remaining voids between the walls of the plug and the walls of the recessed area. The plug may also include an engagement surface to assist in the insertion and removal of the plug into and out of recessed areas of a component.

Owner:TUCKER ROBERT C

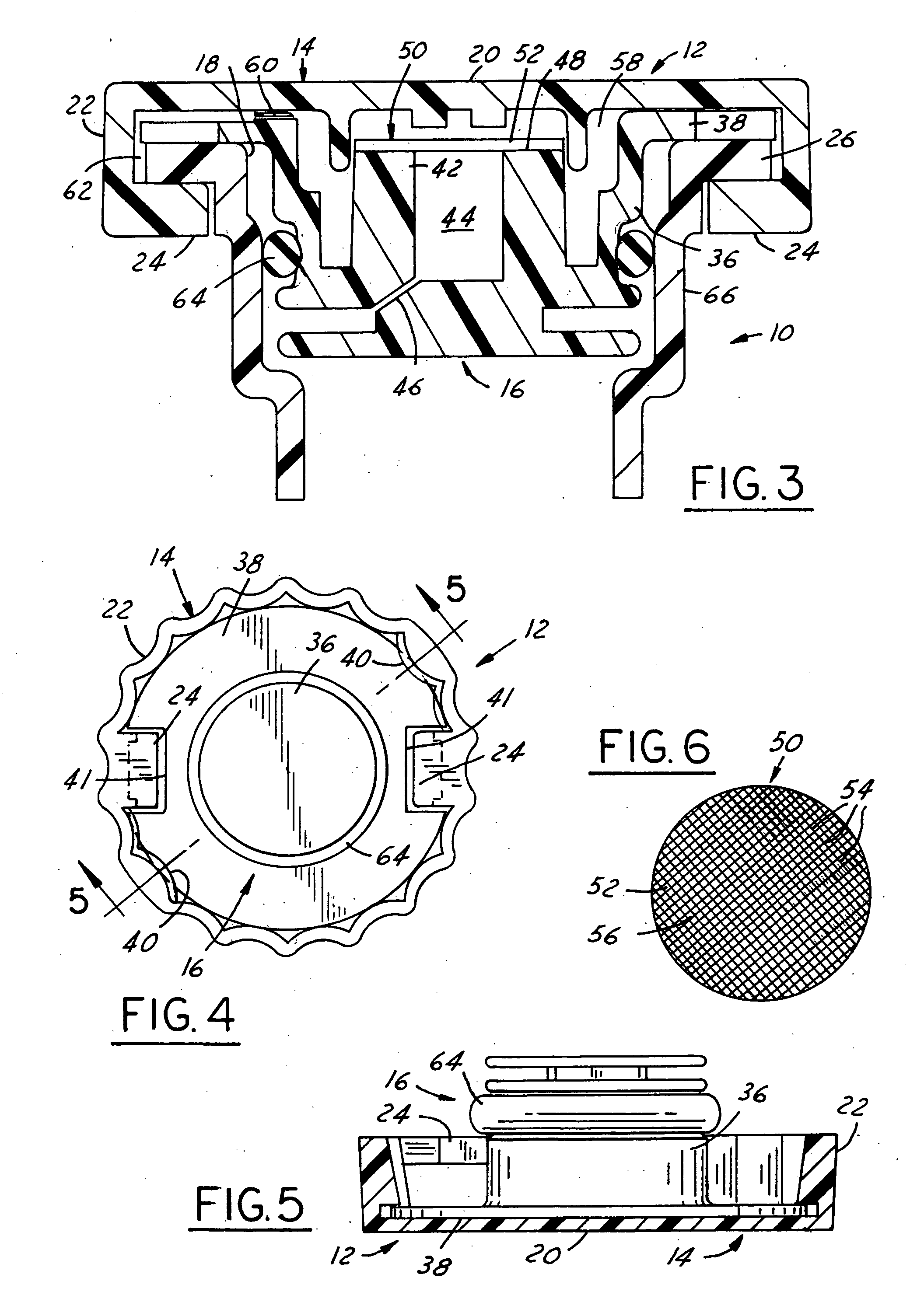

Protection plug

InactiveUS20010052438A1Avoid damageMachines/enginesLubricating pumpsMechanical engineeringLubrication

A plug for protecting the interior of a recessed area of a component during storage is disclosed herein. The plug includes a lubrication fitting positioned thereon to flow a protective material, such as grease, into the cavity between the lower end of the plug and the recessed area and any remaining voids between the walls of the plug and the walls of the recessed area. The plug may also include an engagement surface to assist in the insertion and removal of the plug into and out of recessed areas of a component.

Owner:TUCKER ROBERT C

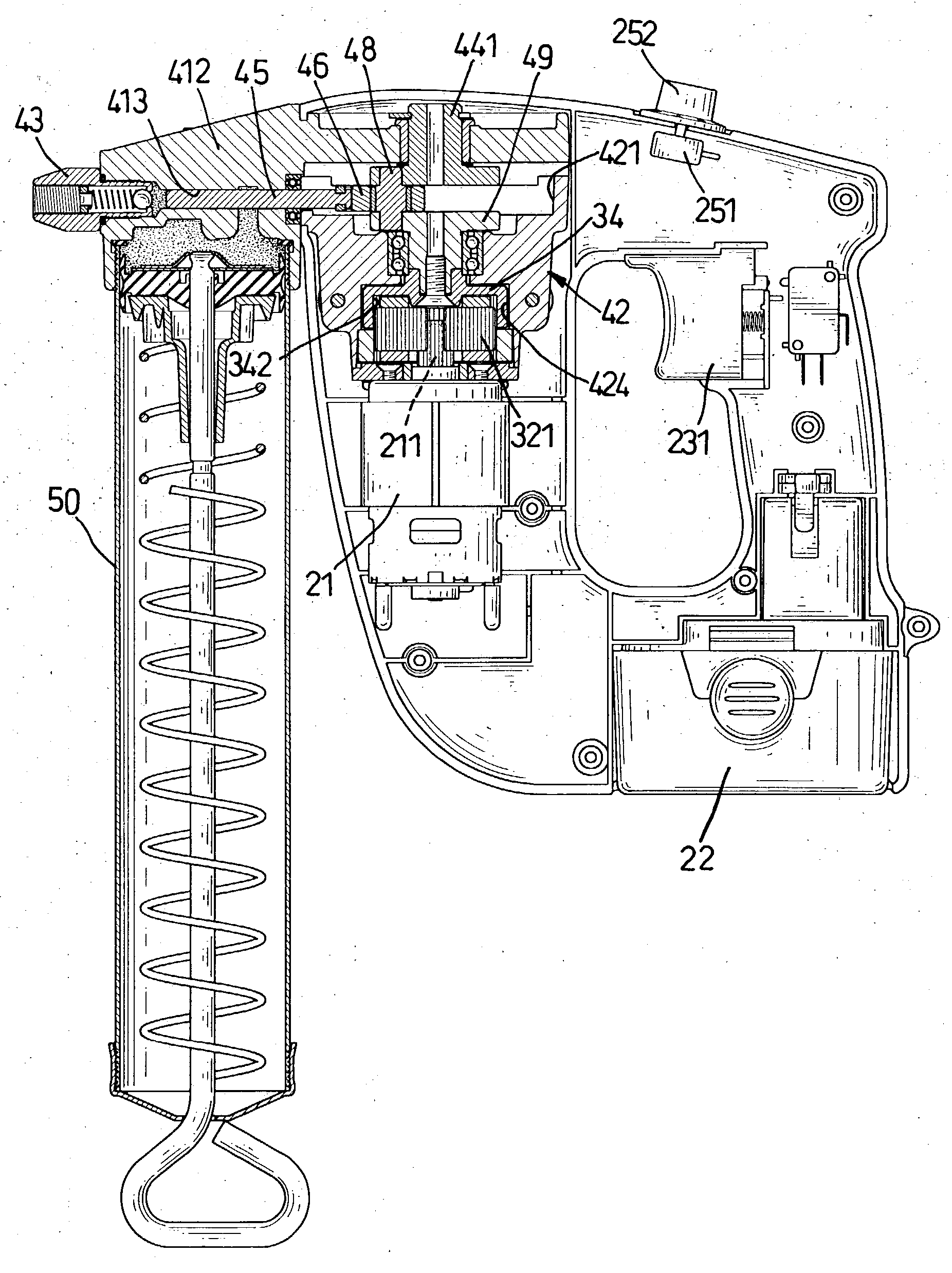

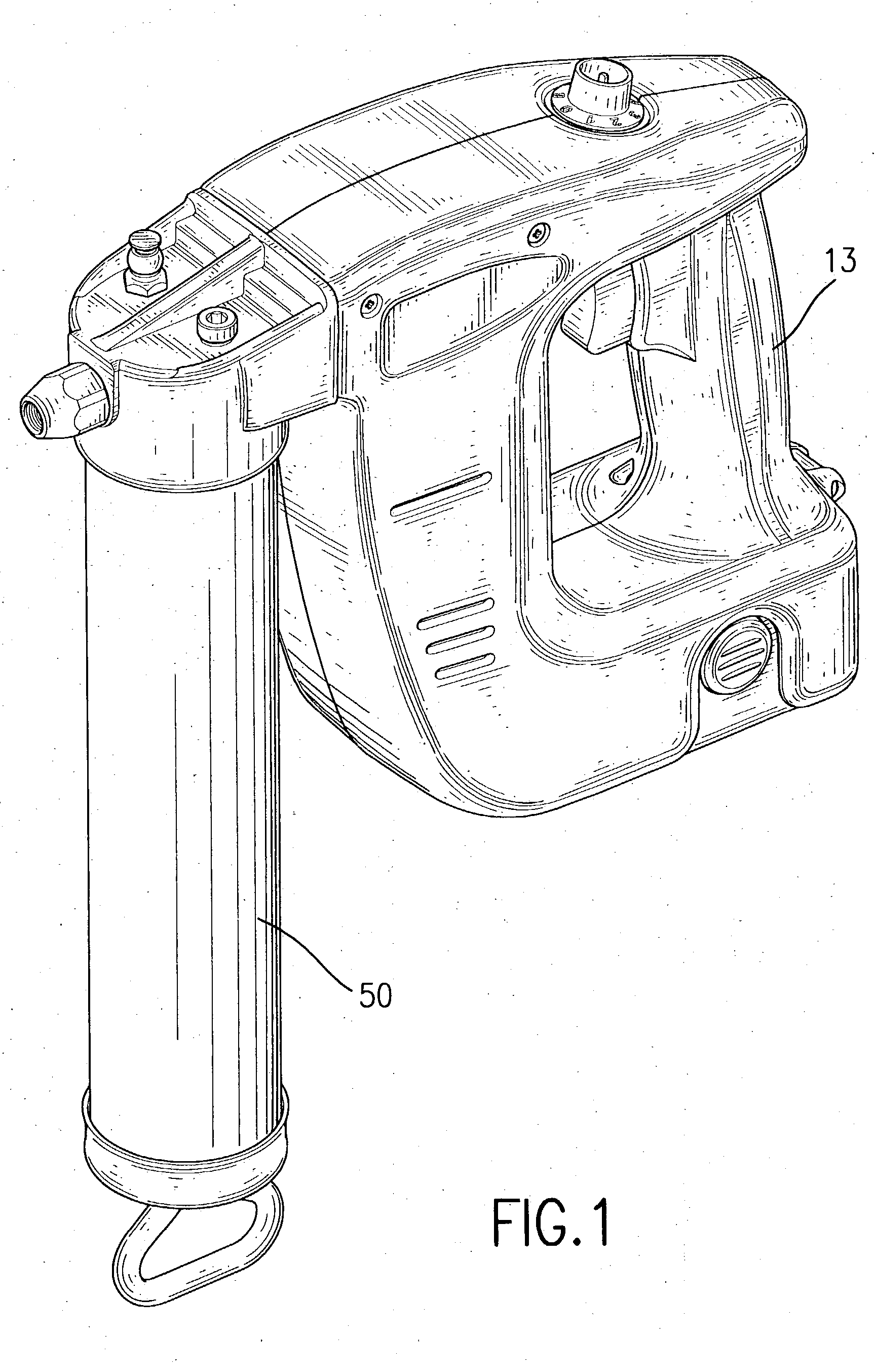

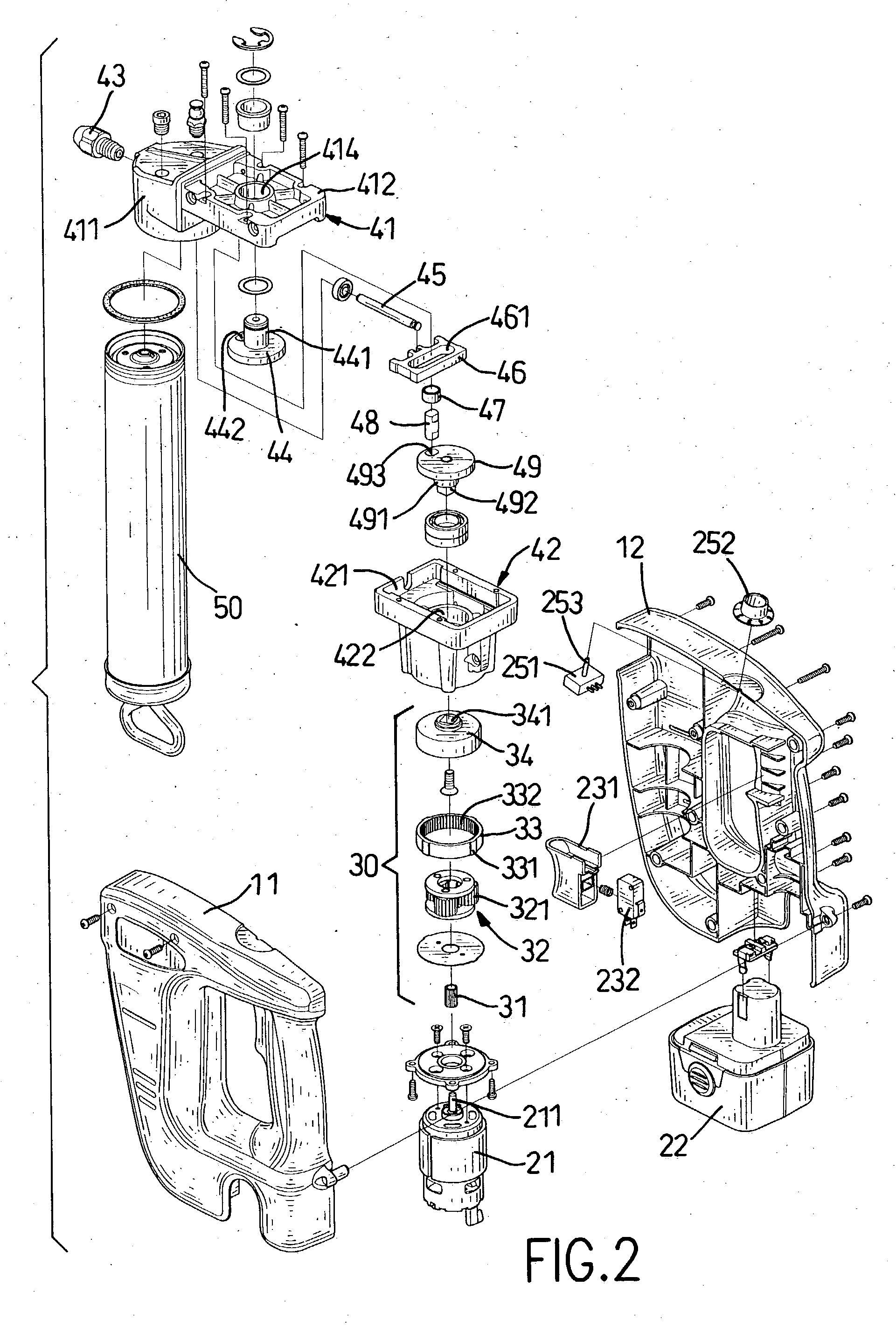

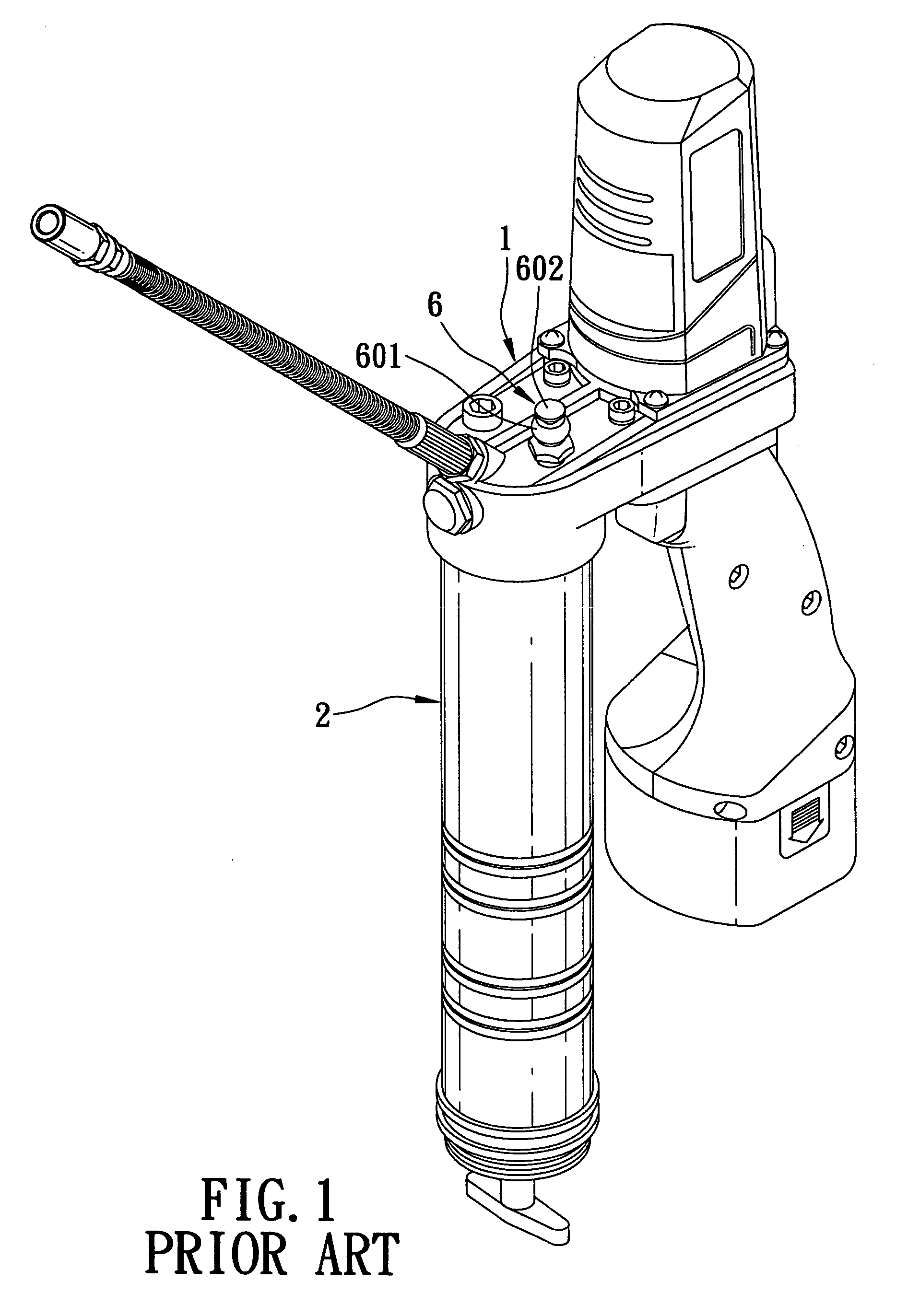

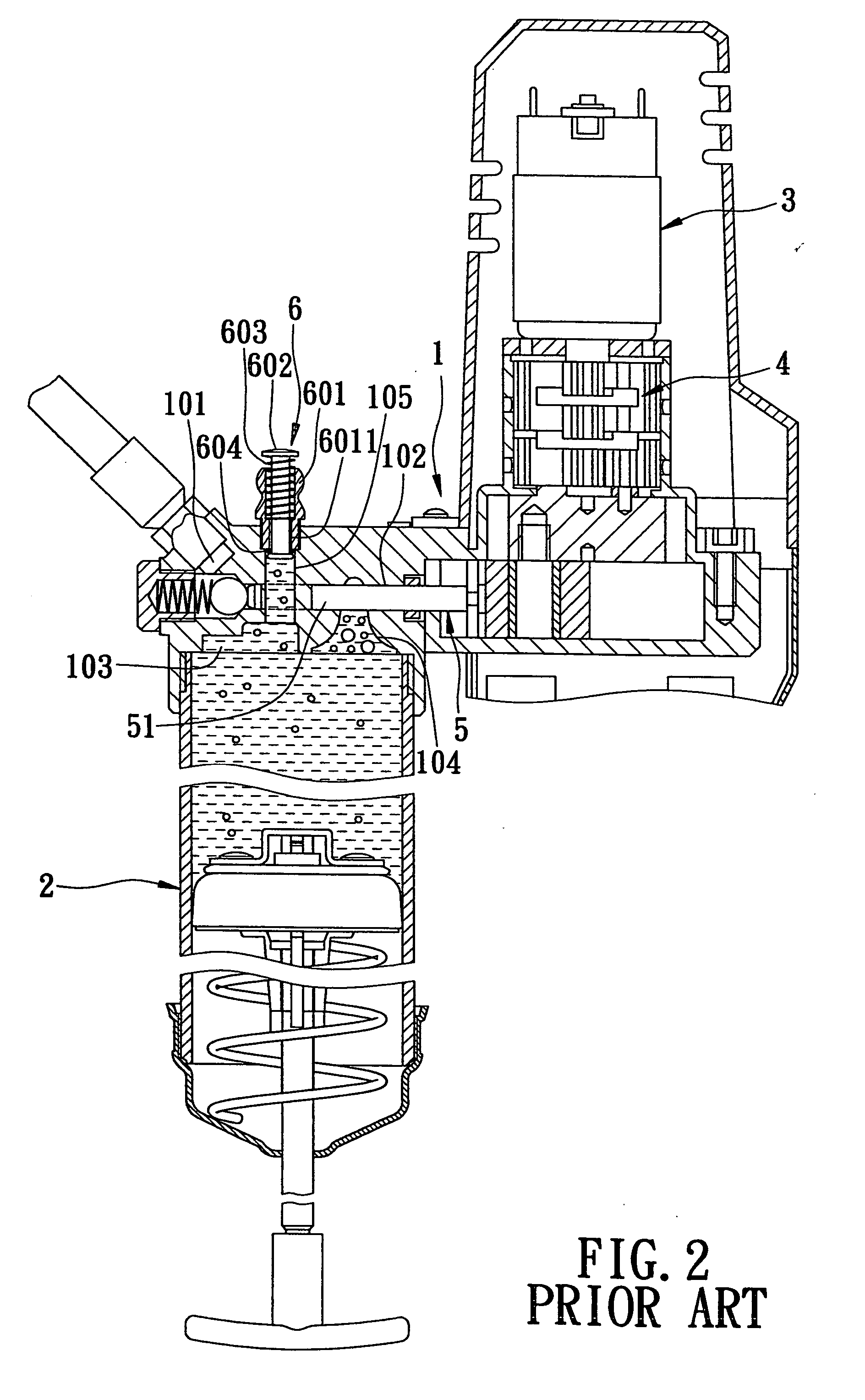

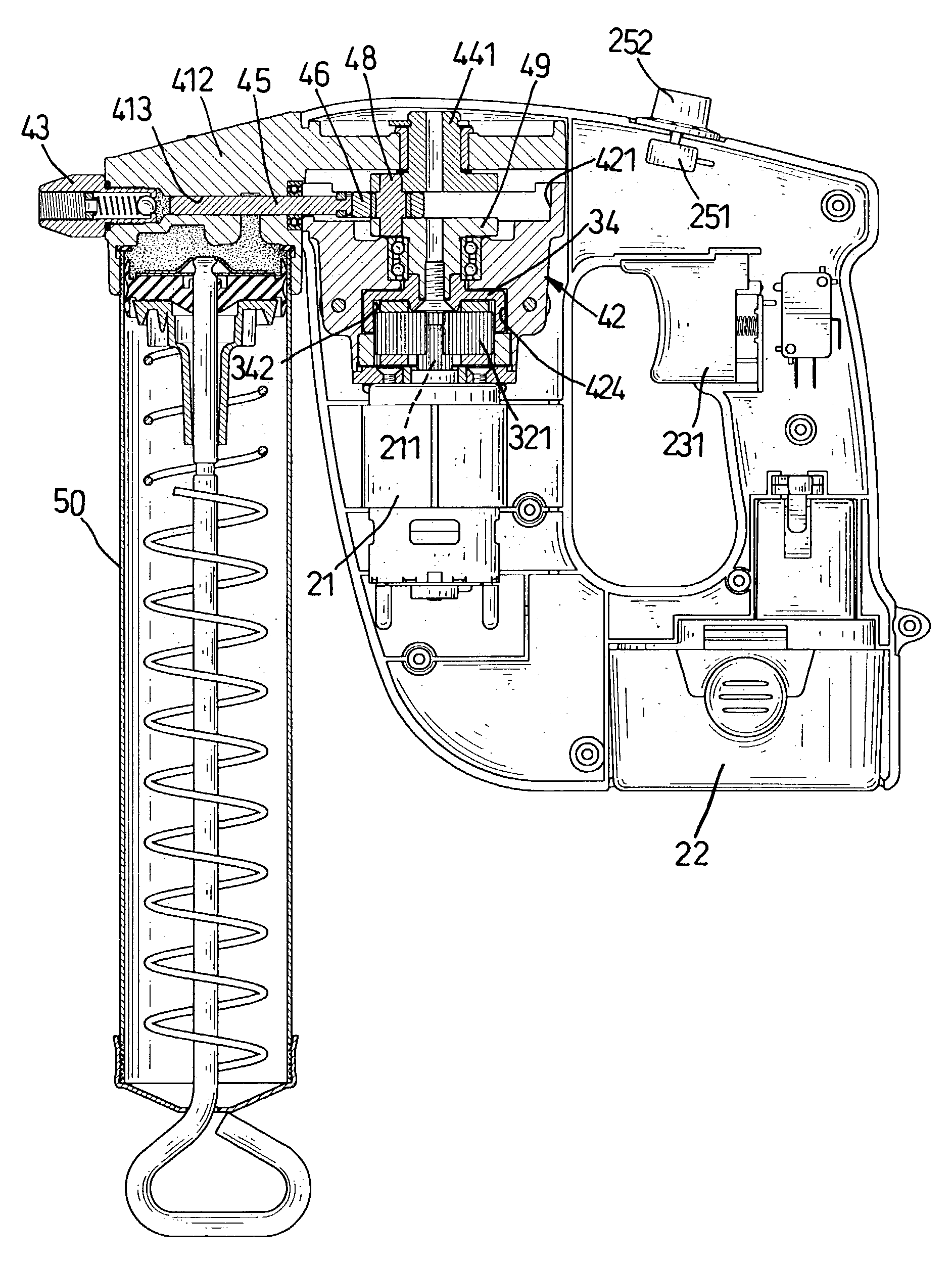

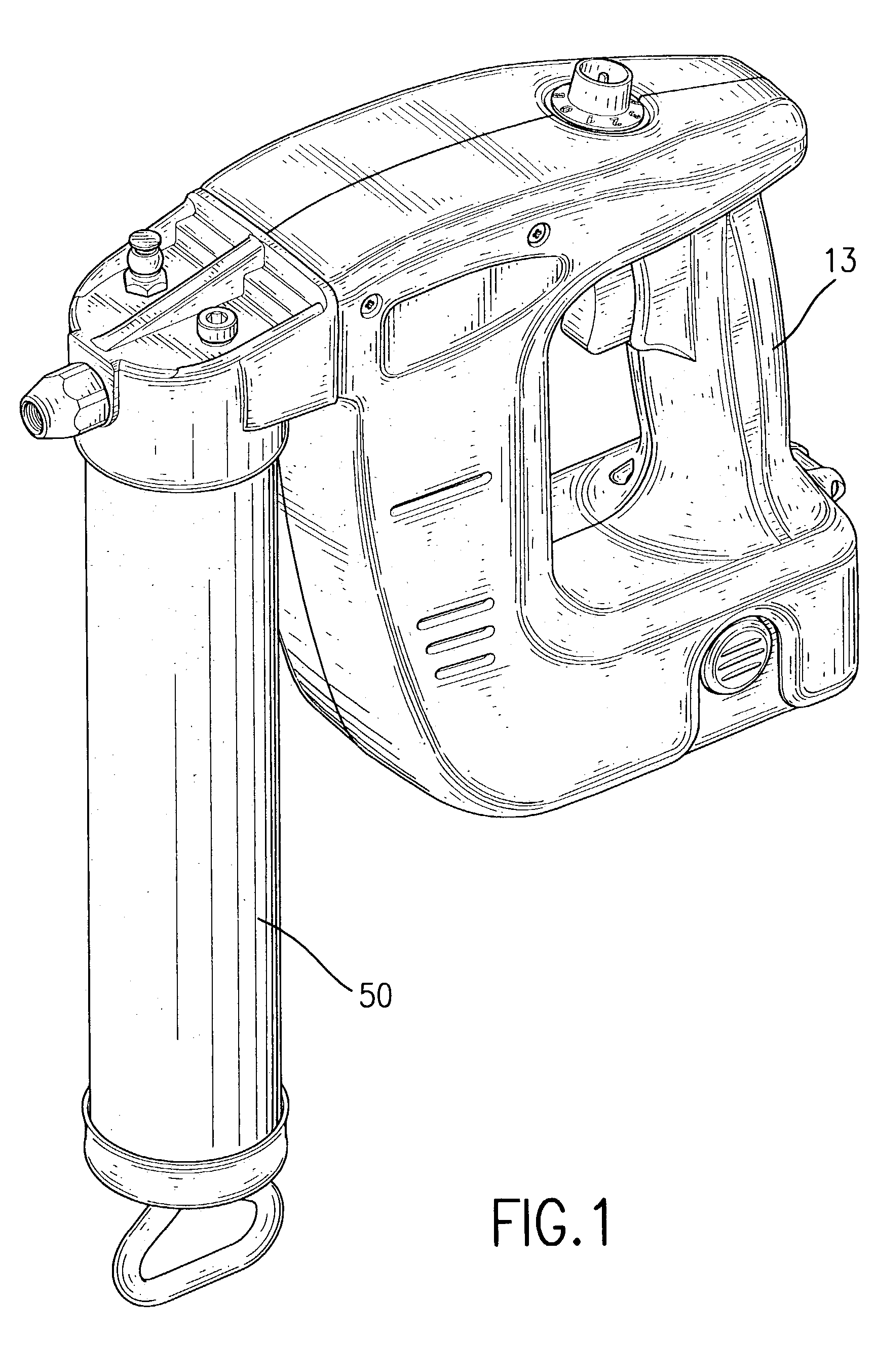

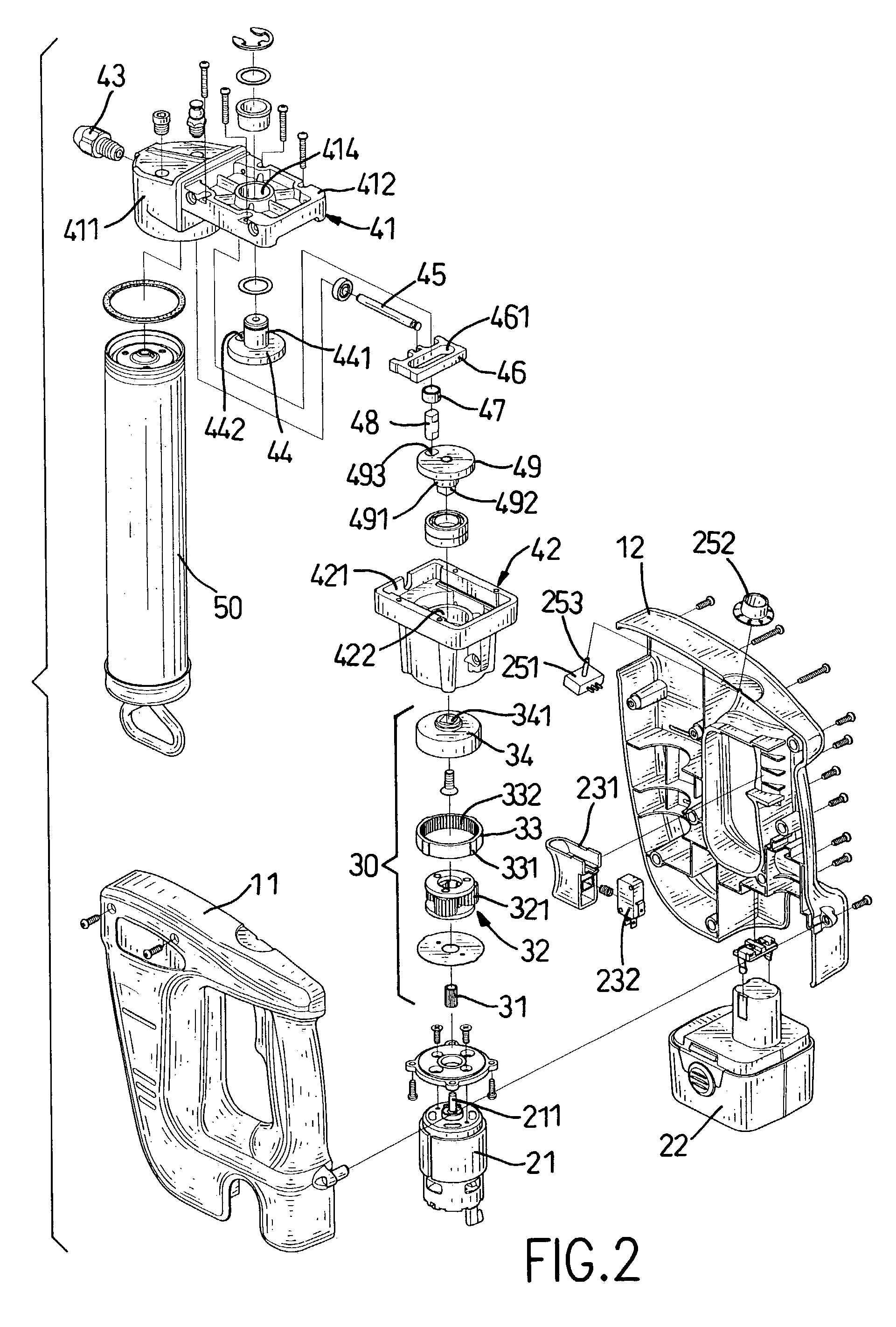

Battery-operated grease gun with an electronic pressure regulator for controlling pressure of the grease

InactiveUS20040231927A1Effective controlLarge containersMachines/enginesElectrical batteryGear wheel

A battery operated grease gun has a motor that drives a planetary gear assembly that is coupled to a pump assembly that drives a plunger reciprocally in an grease passage to discharge grease through a discharge spout. The pressure in the grease exerts a reaction force on the plunger that will change torque of the motor. The change of the torque of the motor will simultaneously effect voltage applied to the motor. When the voltage in the motor changes, an electronic pressure regulator measures the voltage in the motor to determine the pressure in the grease in the grease passage and stops the motor as the pressure in the grease reaches preset given valves in the pressure regulating device.

Owner:TECHWAY INDAL

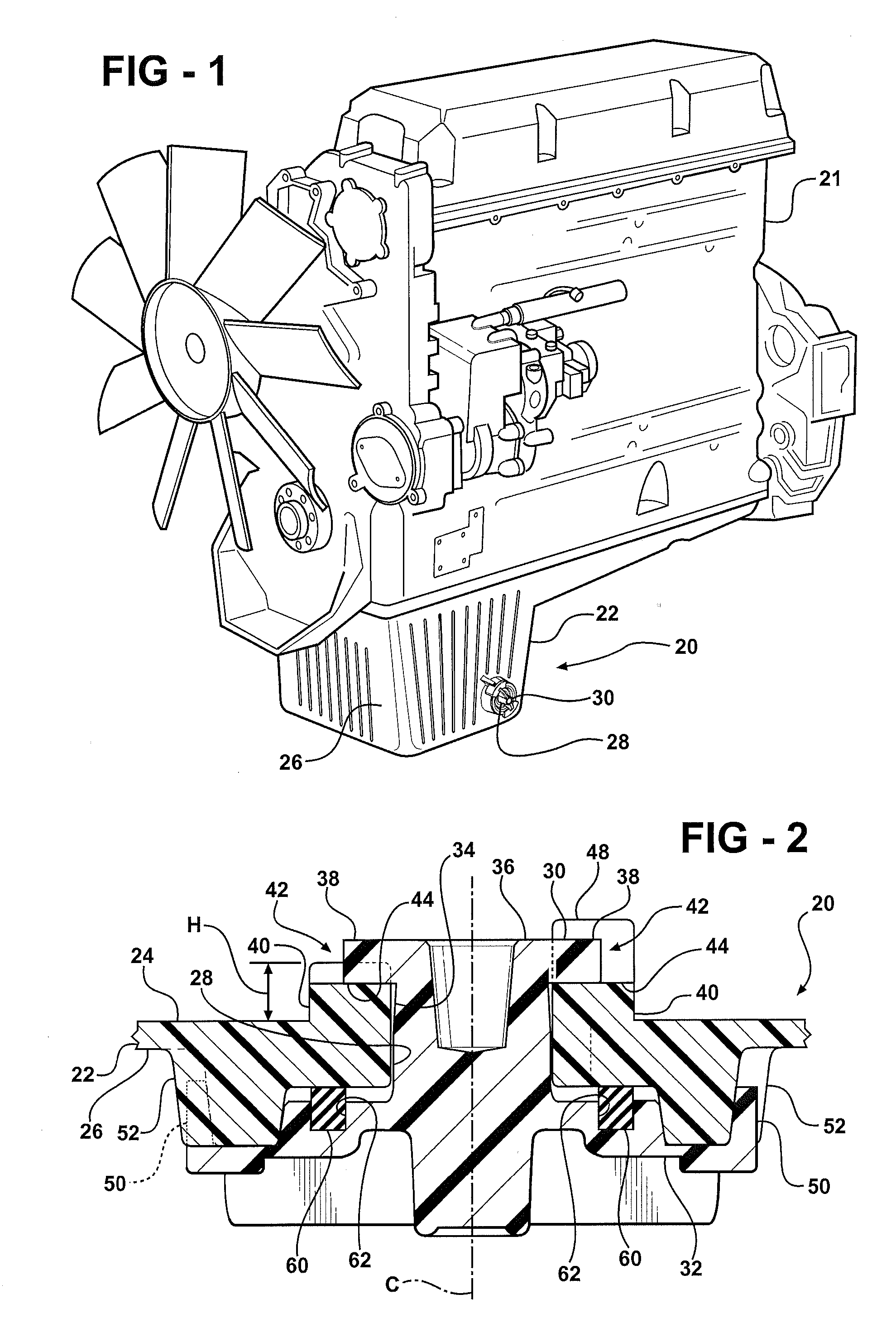

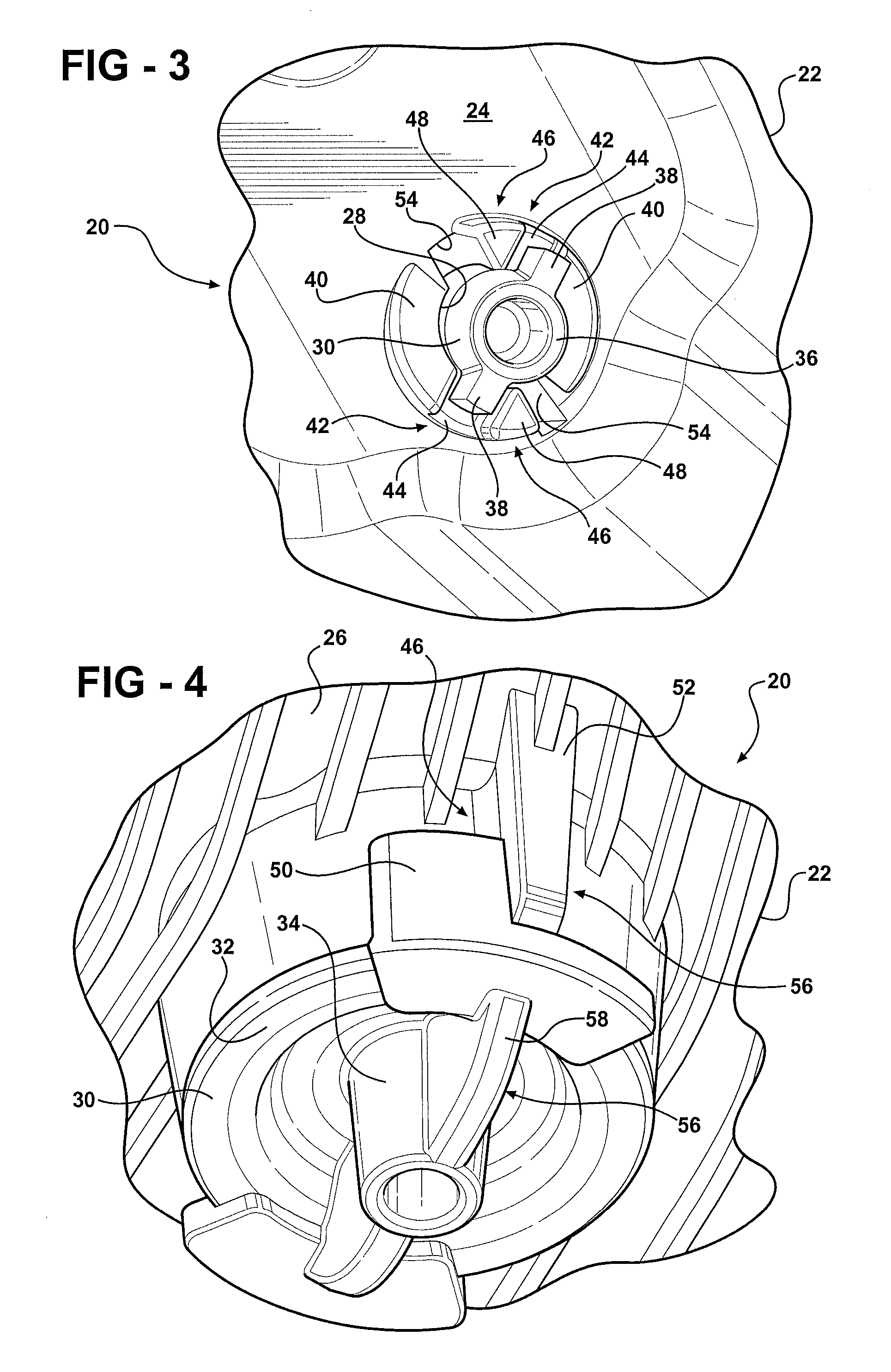

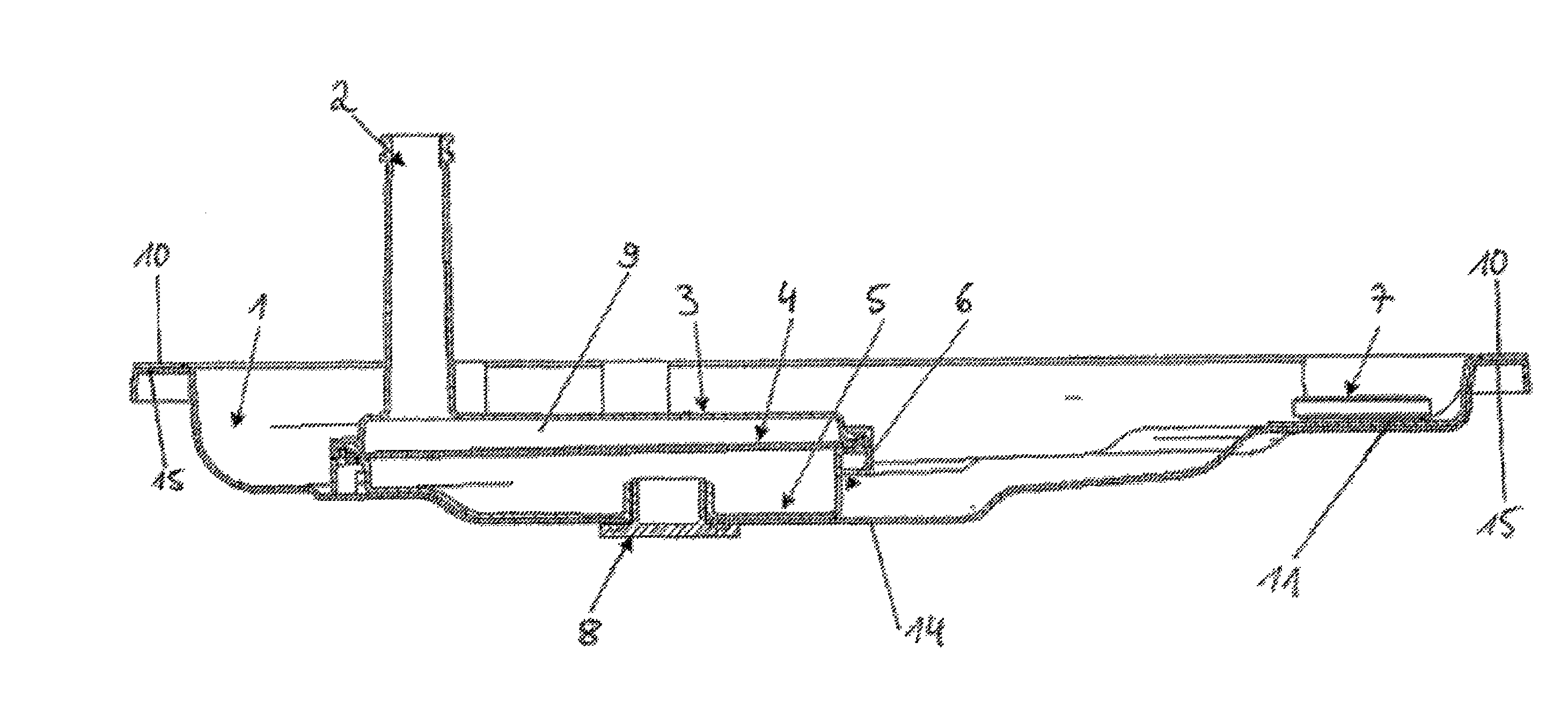

Fluid reservoir assembly

A fluid reservoir assembly having a pan defining a drain opening and a plug disposed therein is disclosed. The pan includes a pair of ramps disposed on an inner surface thereof adjacent the drain opening. The plug includes a pair of wings in engagement with the ramps. The ramps increase in height relative to the inner surface of the pan along a first direction of rotation about the central axis. The plug is drawn into sealing engagement with an outer surface of the pan by rotating the plug in the first direction of rotation about the central axis thereby moving the wings up the ramps. The pan includes at least one stop to prevent over-rotation of the plug. The ramps define a recess to secure the wings in a closed position.

Owner:BASF AG

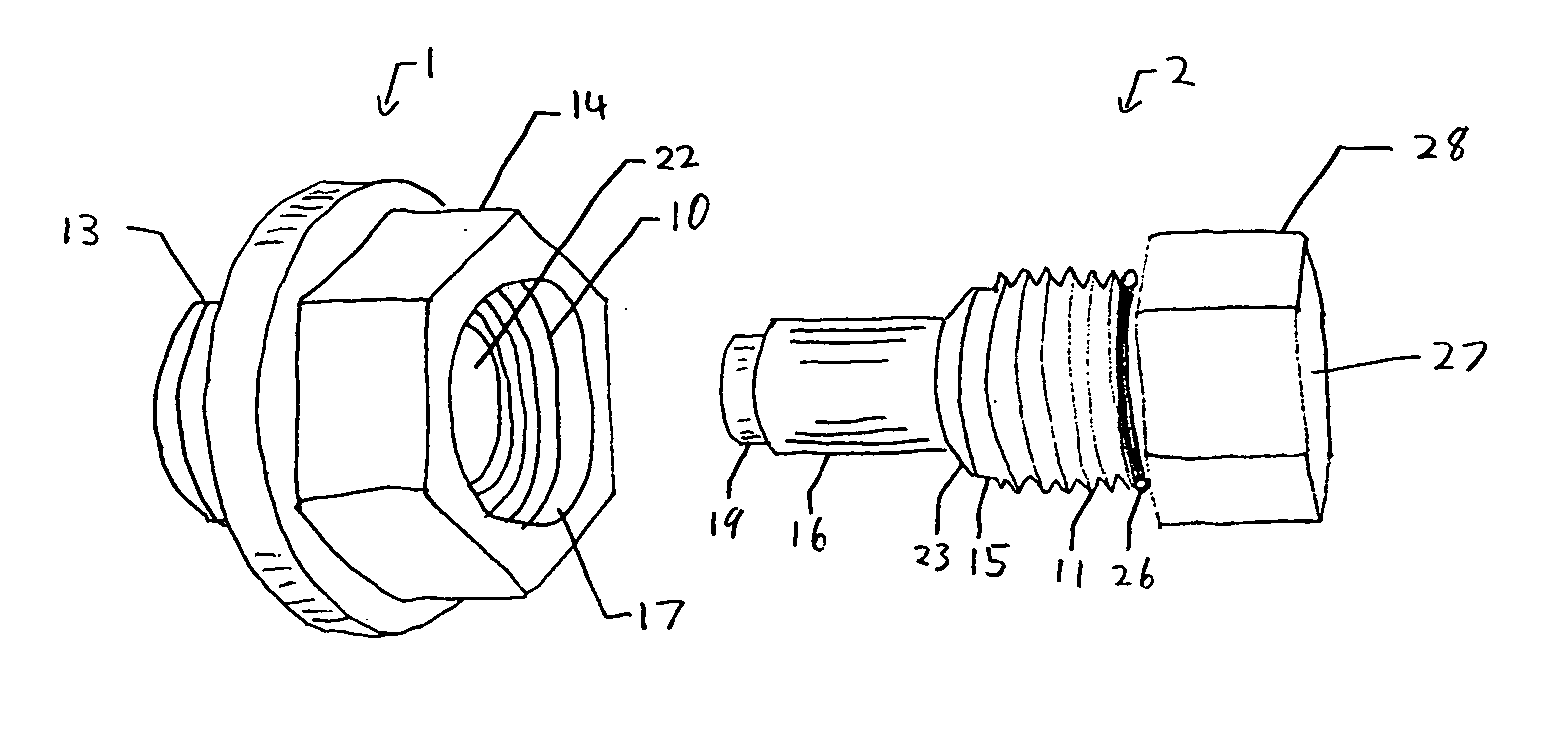

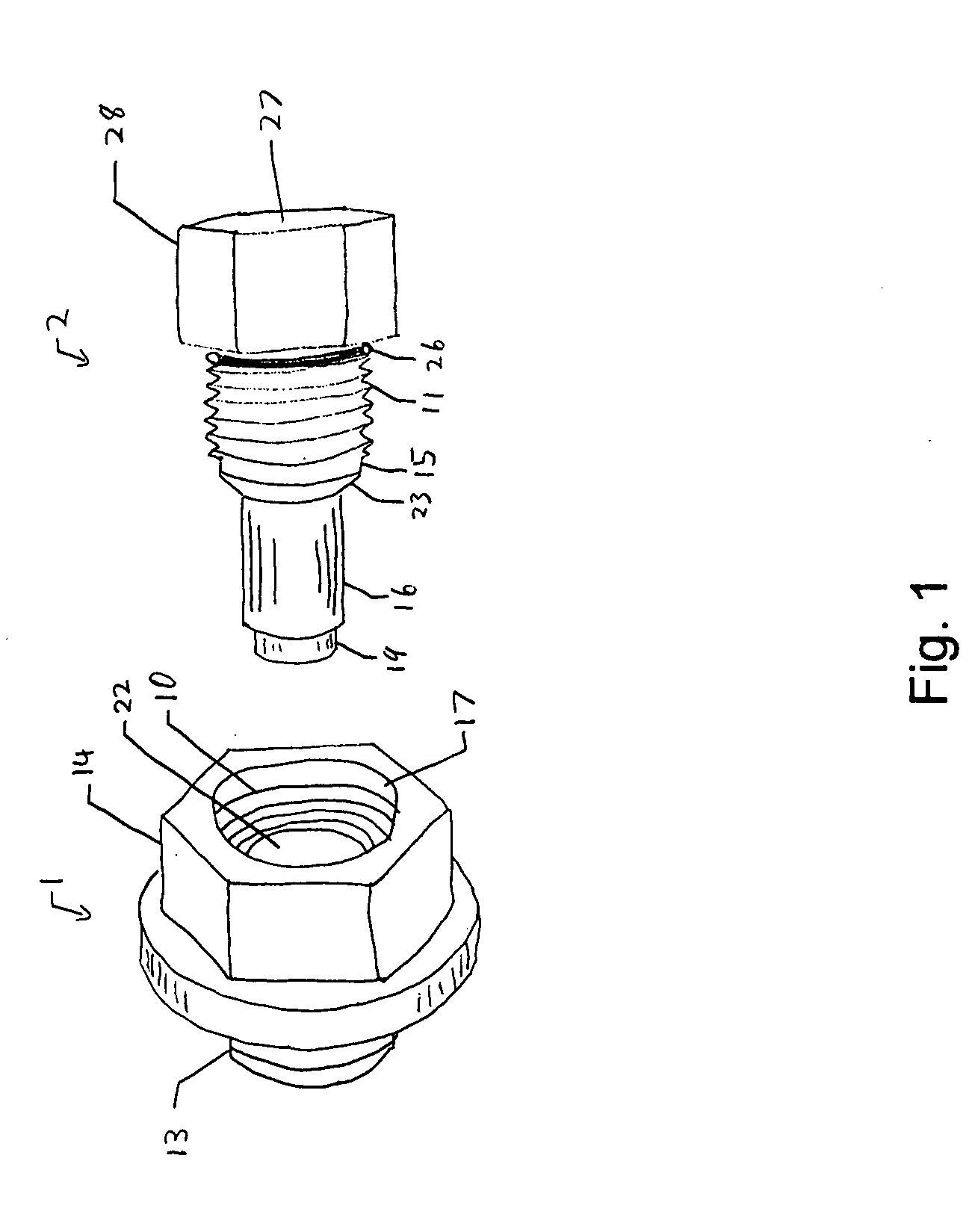

Two part oil or fluid drain plug with magnet

A two part oil drain plug assembly facilitates the draining of oil or fluid from a sump, and its use prevents the threads of the sump, which may be an automotive oil pan, from becoming stripped or damaged. Further, the device aids in the determination of the physical condition (wear) of the engine, transmission or the like to which the sump is attached, by attracting metal particles to an isolated magnet on the drain plug.

Owner:DORIAN GEORGE P

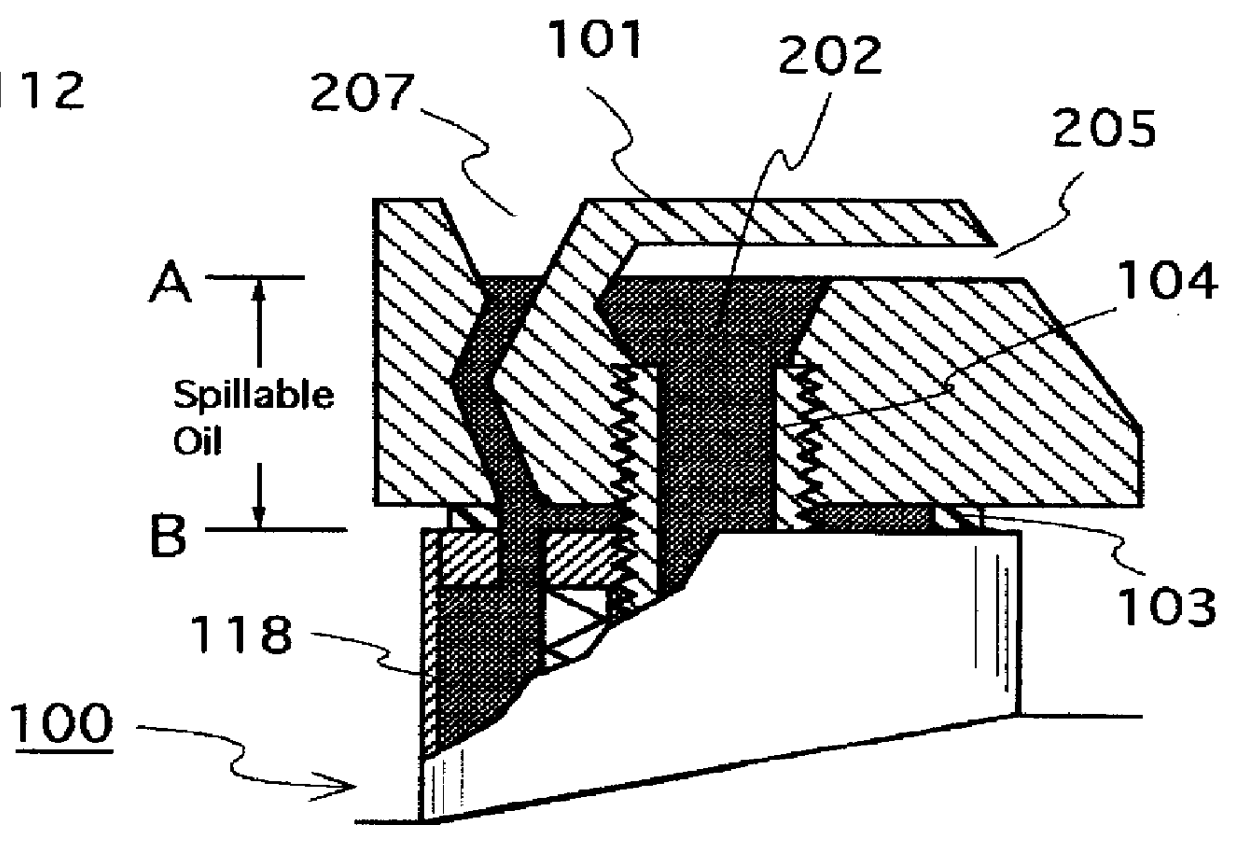

Piercing filter oil containment boot

InactiveUS6056874AFree from cleaningReduce internal volumeOther washing machinesMachines/enginesOil filterWrench

Spillable oil from an oil filter and adjacent engine cavities of trapped engine oil is transferred outwardly through filter housing sidewalls at designated low points to a temporary boot container by gravity following a piercing operation through the filter housing. Oil transfer to the container is performed prior to breaking the seal between the engine block and the filter. All of the spillable oil is caught in the boot containment device which incorporates internal tack like hollow piercing elements. The required piercing force to drive the tacks into the filter wall may be applied to the exterior of the filter boot using common filter strap wrenches, or by light taps from a hammer, wrench or similar tool.

Owner:GOODMAN LOWELL R

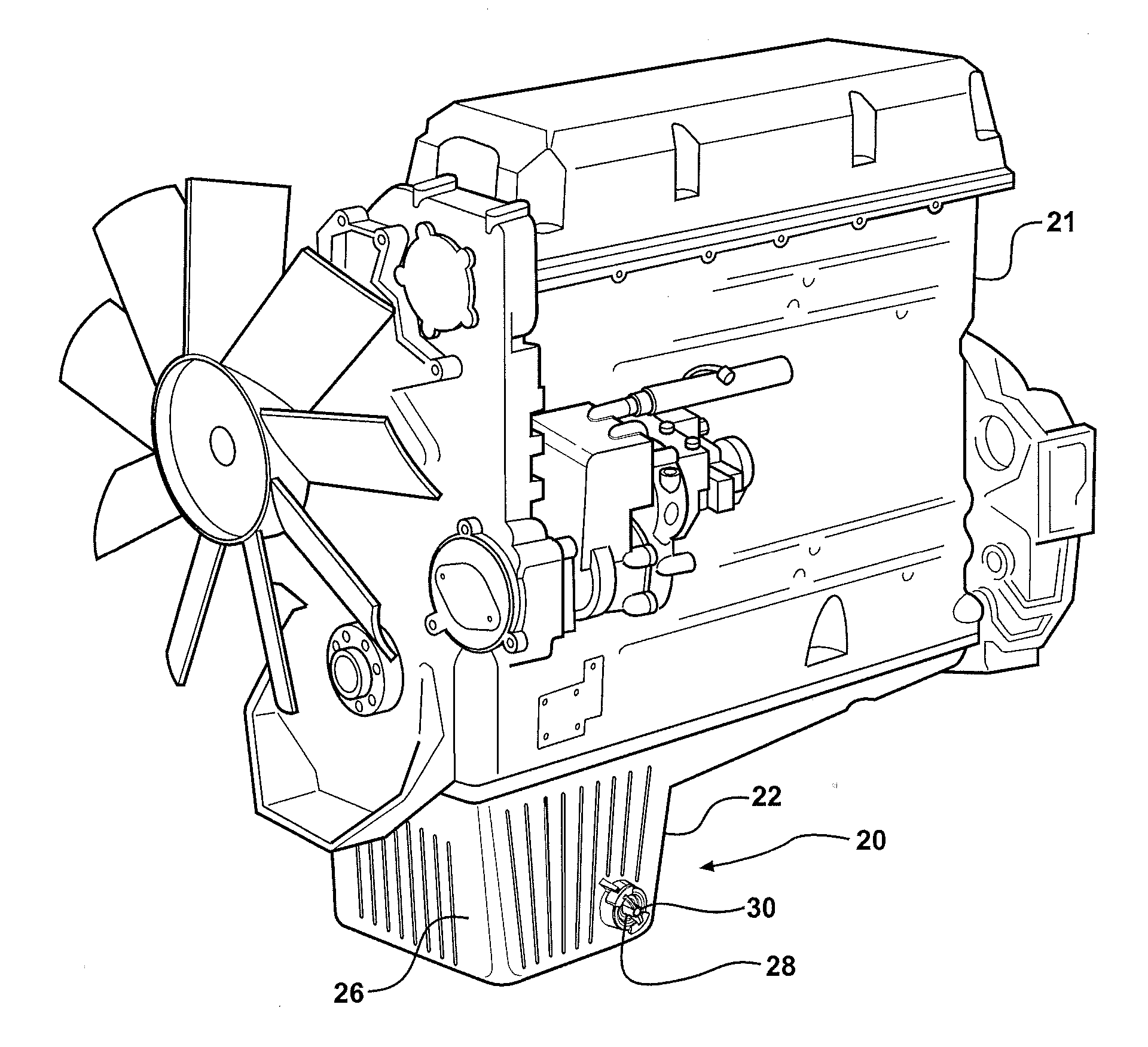

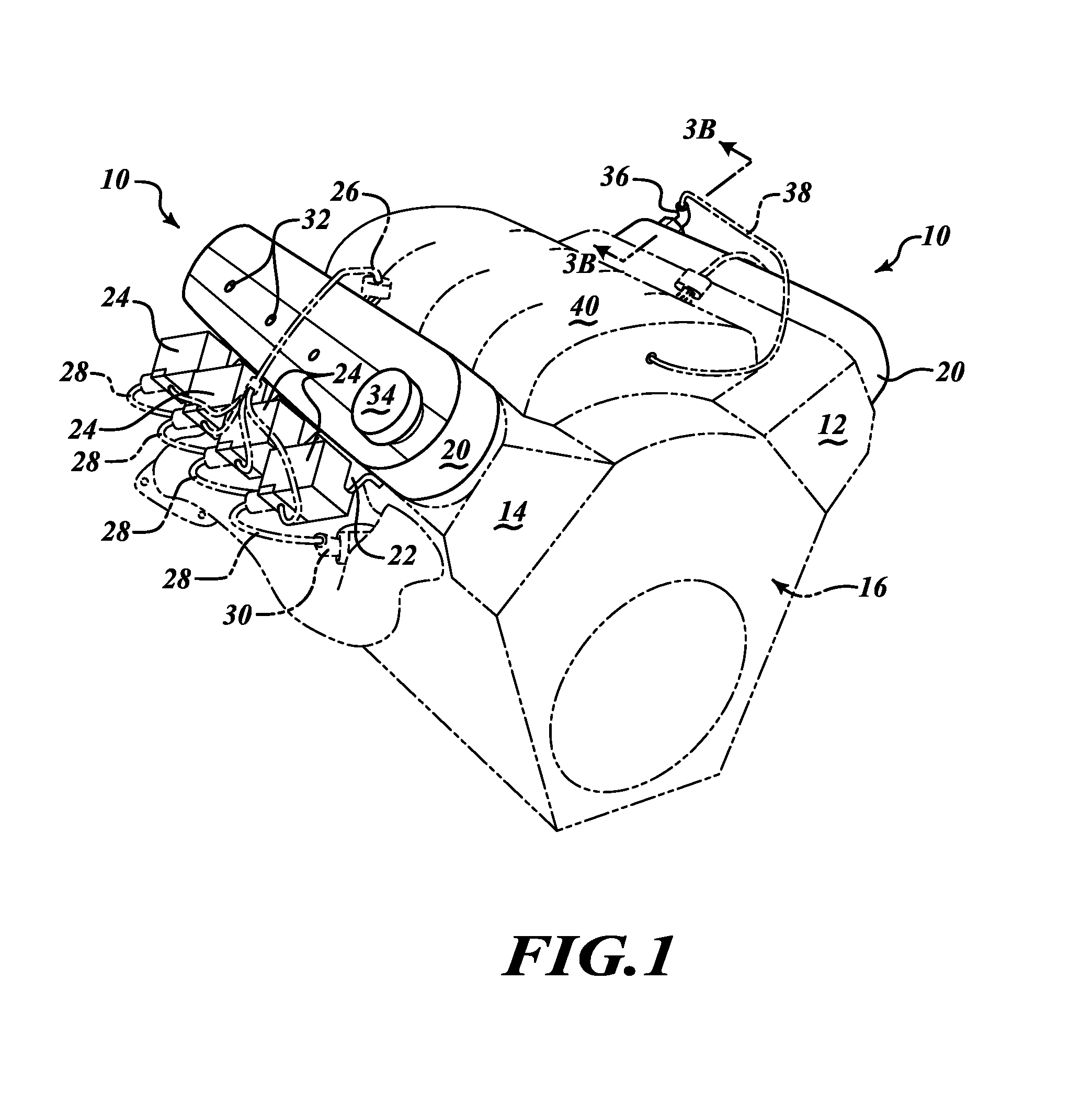

Exposed coil rocker arm cover assembly having external multi-coil mounting bracket

InactiveUS20090241879A1Reduce pollutionReduce degradationCasingsLubrication of auxillariesCrankcaseEngineering

An improved rocker arm cover assembly having an enclosed rocker arm chamber housing and a generally L-shaped bracket for mounting multiple coils to an exterior vertical side wall of the housing, so that the coils are exposed and laterally displaced from the housing. The bottom of the housing includes special seal and flange members to permit sealing mounting to the engine head so that the rocker arm chamber is isolated as a “wet” enclosure from the coil bracket assembly. The housing is mounted directly to the head via a plurality of through bolts. A fully isolated, dual function, oil fill / PCV valve conduit is provided through the top of the housing to permit adding lubrication oil or permitting exhaust of crankcase vapors without contaminating the coils, and permitting independent servicing of the coils. Several variations of coils and coil mounting brackets are disclosed.

Owner:HARBERT RICHARD H

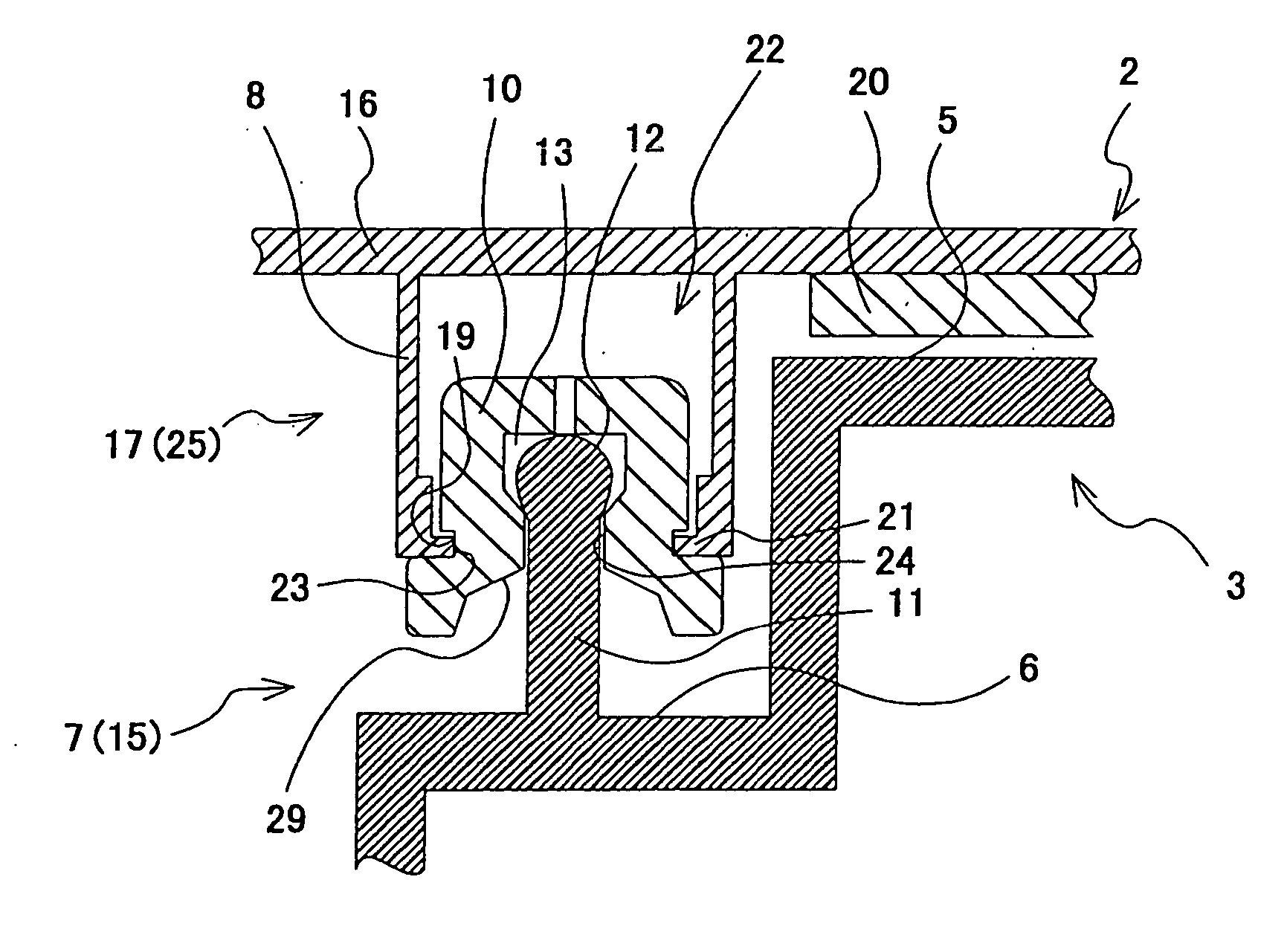

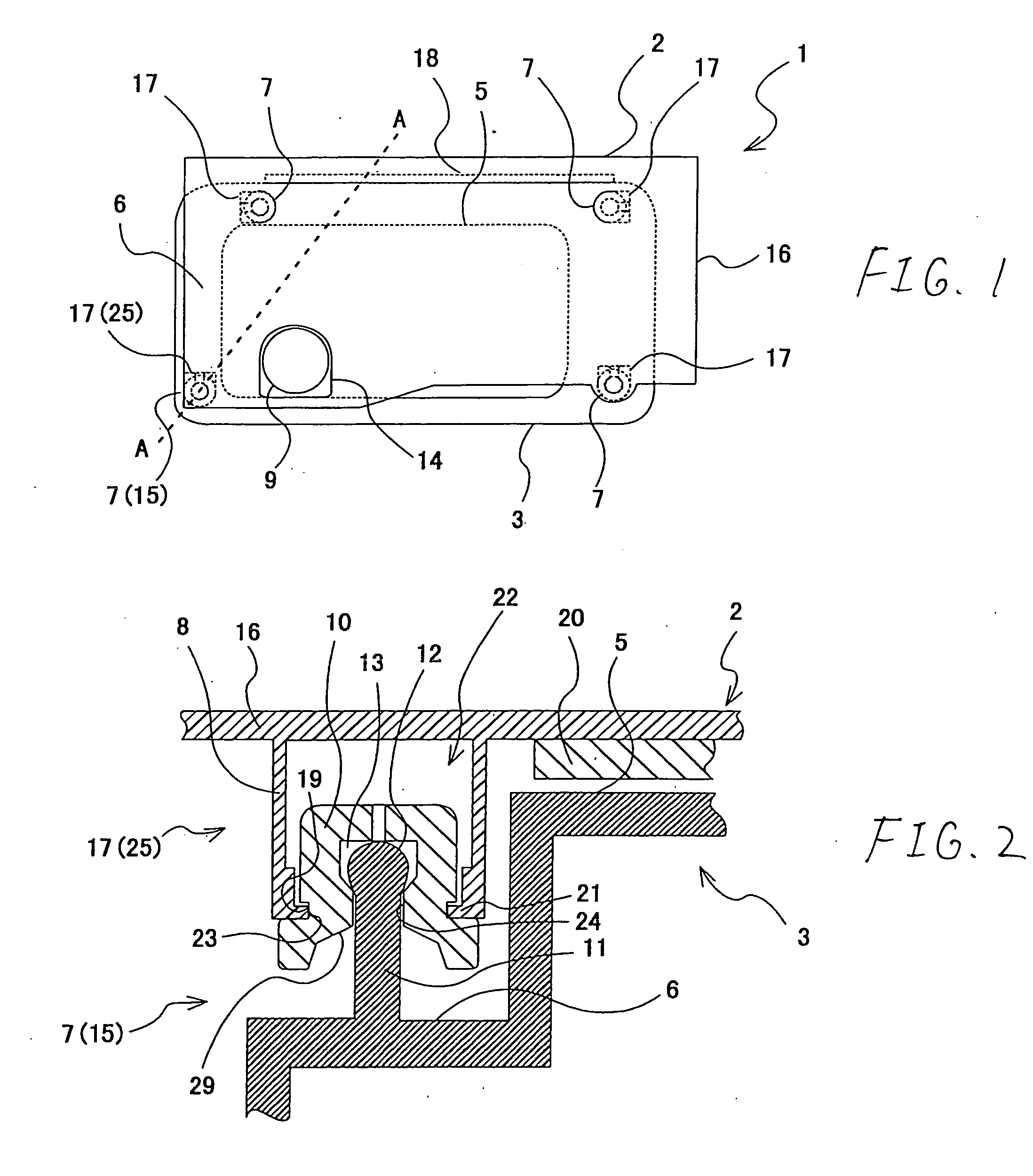

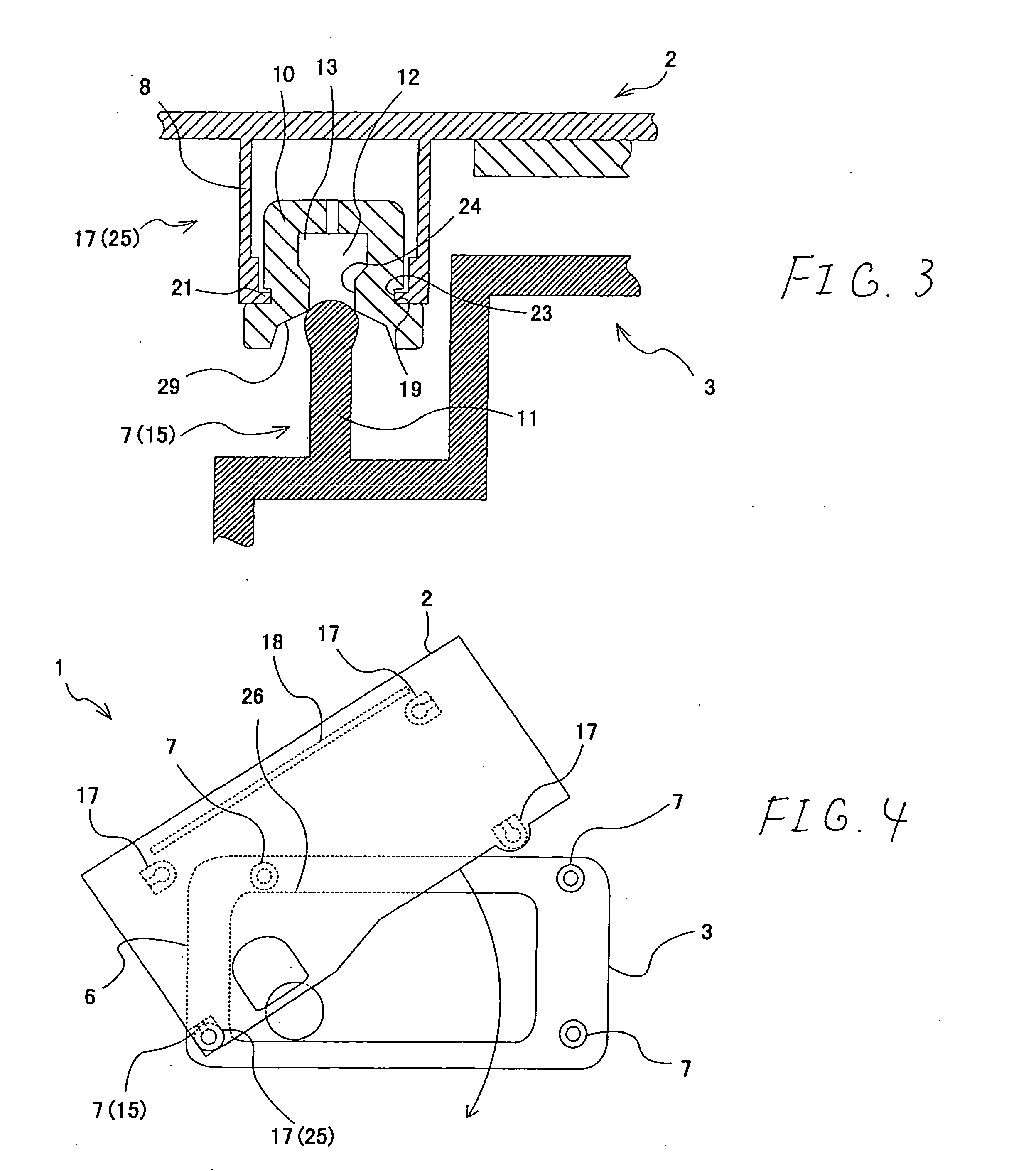

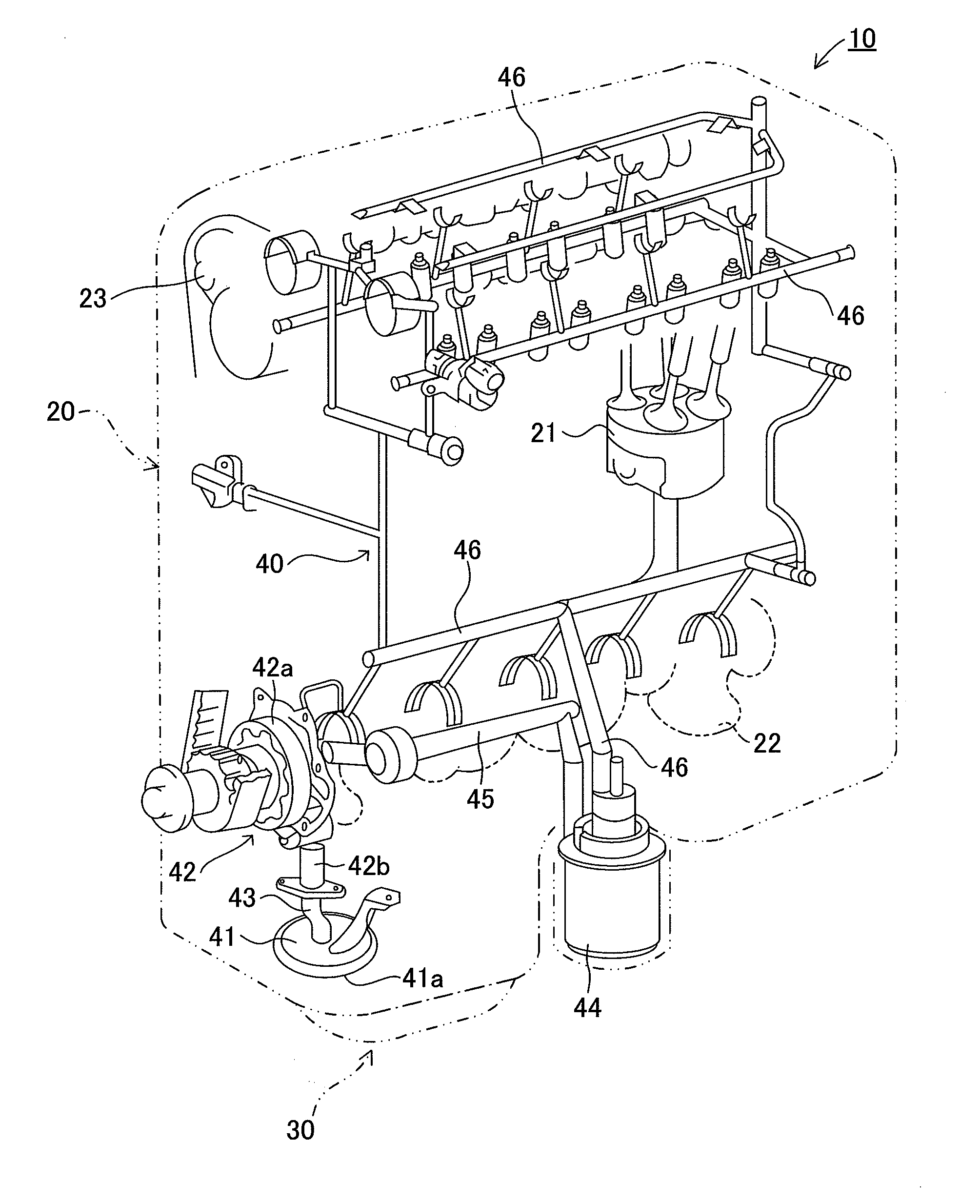

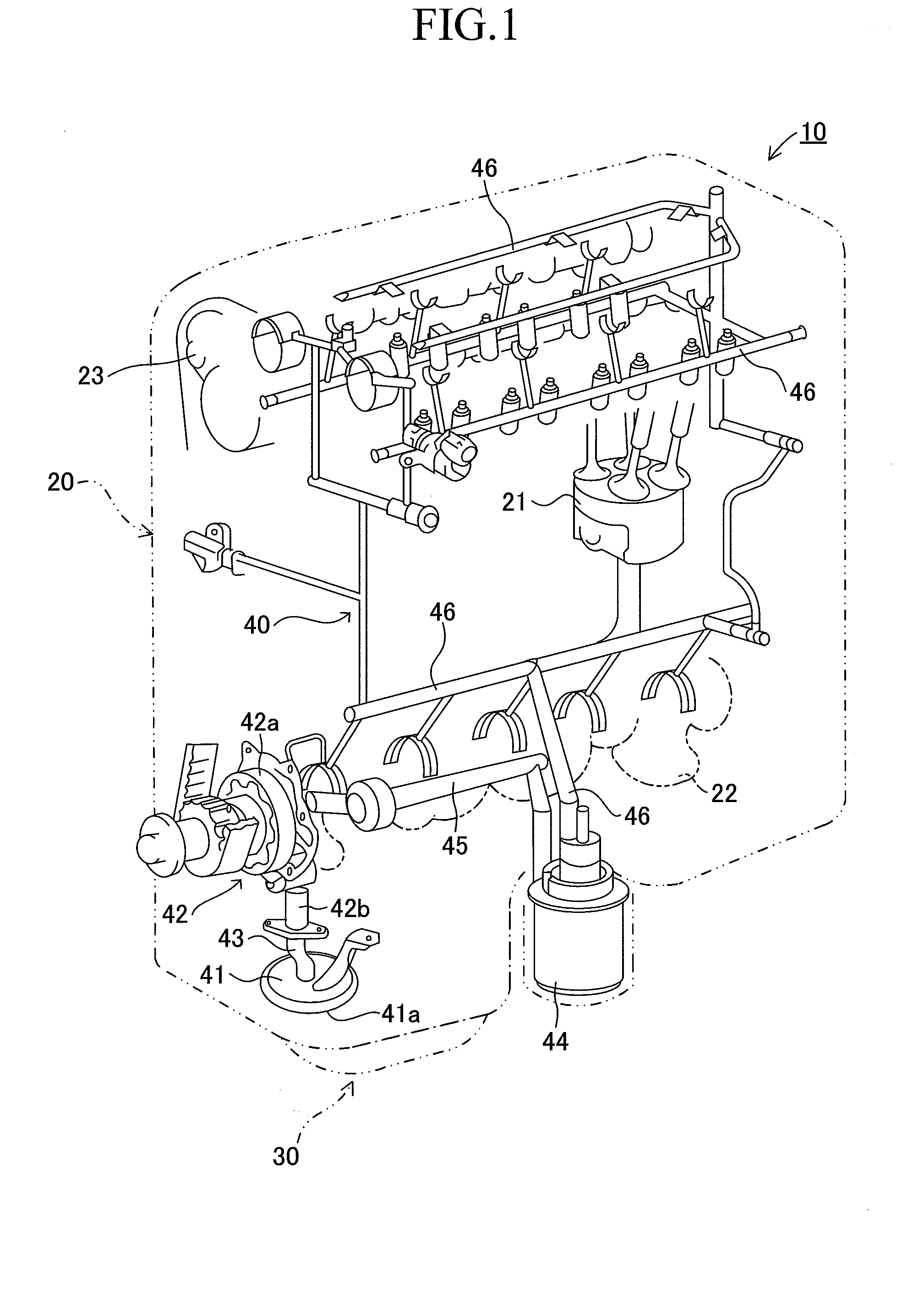

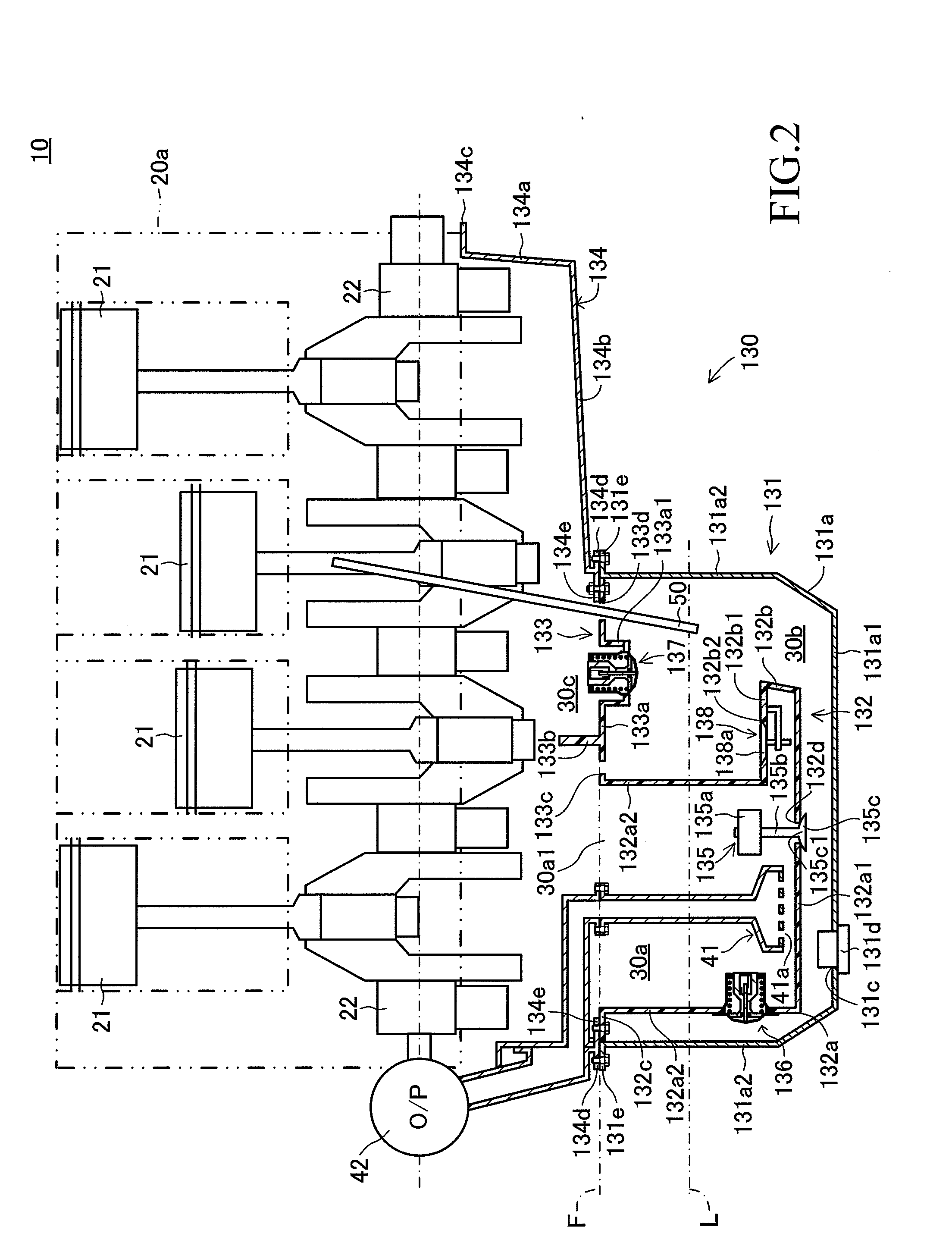

Mounting structure for engine cover

InactiveUS20050217634A1Improve Design PerformanceEasy to installCasingsNon-fuel substance addition to fuelCylinder headAbutment

An engine cover mounting structure comprising an engine member and an engine cover, wherein a plurality of portions to be fixed to which fixing portions provided on the engine cover are mounted are provided so as to be situated below an upper surface of a cylinder head cover of the engine member. In addition, a positioning portion is provided on the engine cover. Then, in a state where a base fixing portion is mounted or temporarily mounted to a base portion to be fixed, while the other fixing portions are not mounted to the other portions to be fixed, when the engine cover revolves about the base fixing portion, so that the positioning portion is brought into abutment with a surface of the engine member, the fixing portions other than the base fixing portion are disposed at positions facing the portions to be fixed, respectively.

Owner:TOYODA GOSEI CO LTD

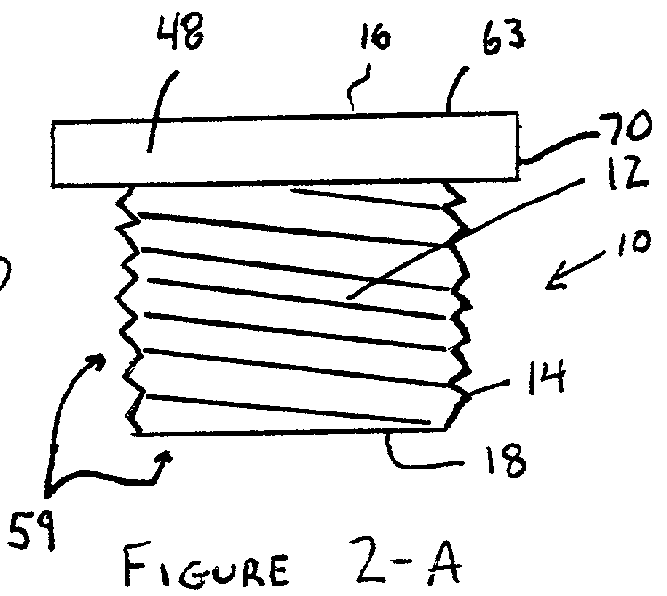

Lubricant gun

A lubricant gun includes a housing, a lubricant reservoir, a plunger, and an exhaust valve. The housing includes a discharge spout, a slide channel fluidly communicated with the discharge spout, a lubricant supply passage having a lubricant supply hole fluidly connected to the slide channel, and a gas-discharging hole fluidly communicated with the slide channel. The lubricant reservoir is connected to the housing and is fluidly communicated with the slide channel through the lubricant supply passage and the lubricant supply hole. The plunger has a pushing portion received in the slide channel for sliding reciprocatingly therein. The exhaust valve is mounted on the housing and is fluidly communicated with the gas-discharging hole.

Owner:TECHWAY INDAL

Automatic lubrication system

An automatic lubrication system for a vehicle, comprising a pump assembly having a plurality of outlet ports, a motor operable to drive the pump assembly, and a cartridge that is attachable to the pump assembly to provide a source of lubricant to the pump. The cartridge is removable from the pump assembly and has an interior space that is collapsible as lubricant is dispensed therefrom. A controller is provided to periodically initiate the motor to cause the pump to dispense lubricant to the outlet ports.

Owner:LIBRIQUIP INC

Automatic fluid exchanger

InactiveUS7004206B2Light weightEasy to carryLiquid fillingPackaging by pressurising/gasifyingElectricityFluid control

Owner:VIKEN JAMES P +1

Lubrication device and oil pan

ActiveUS20090014248A1Improve deteriorationCasingsGear lubrication/coolingLubricationWaste management

Owner:TOYOTA JIDOSHA KK

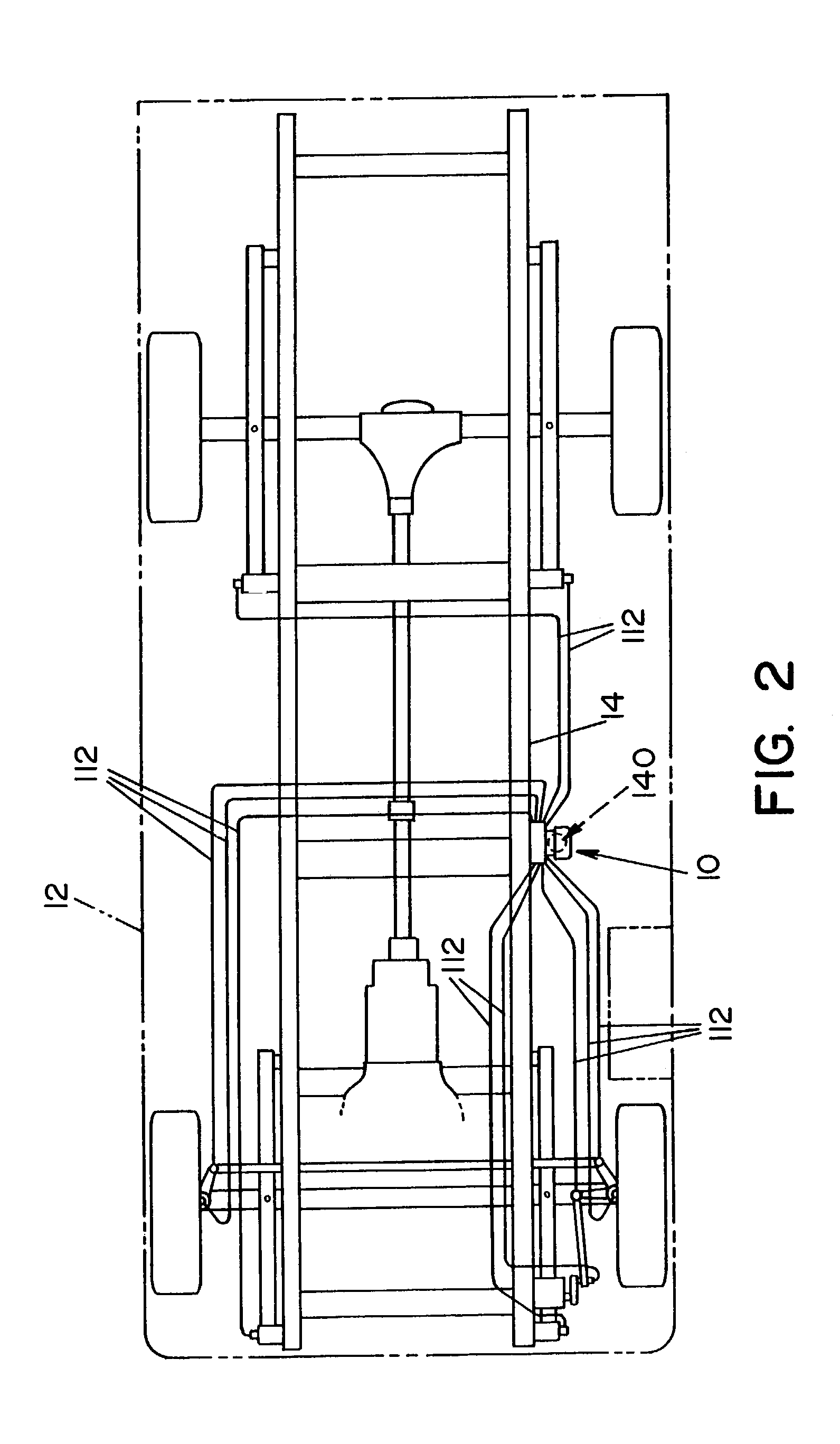

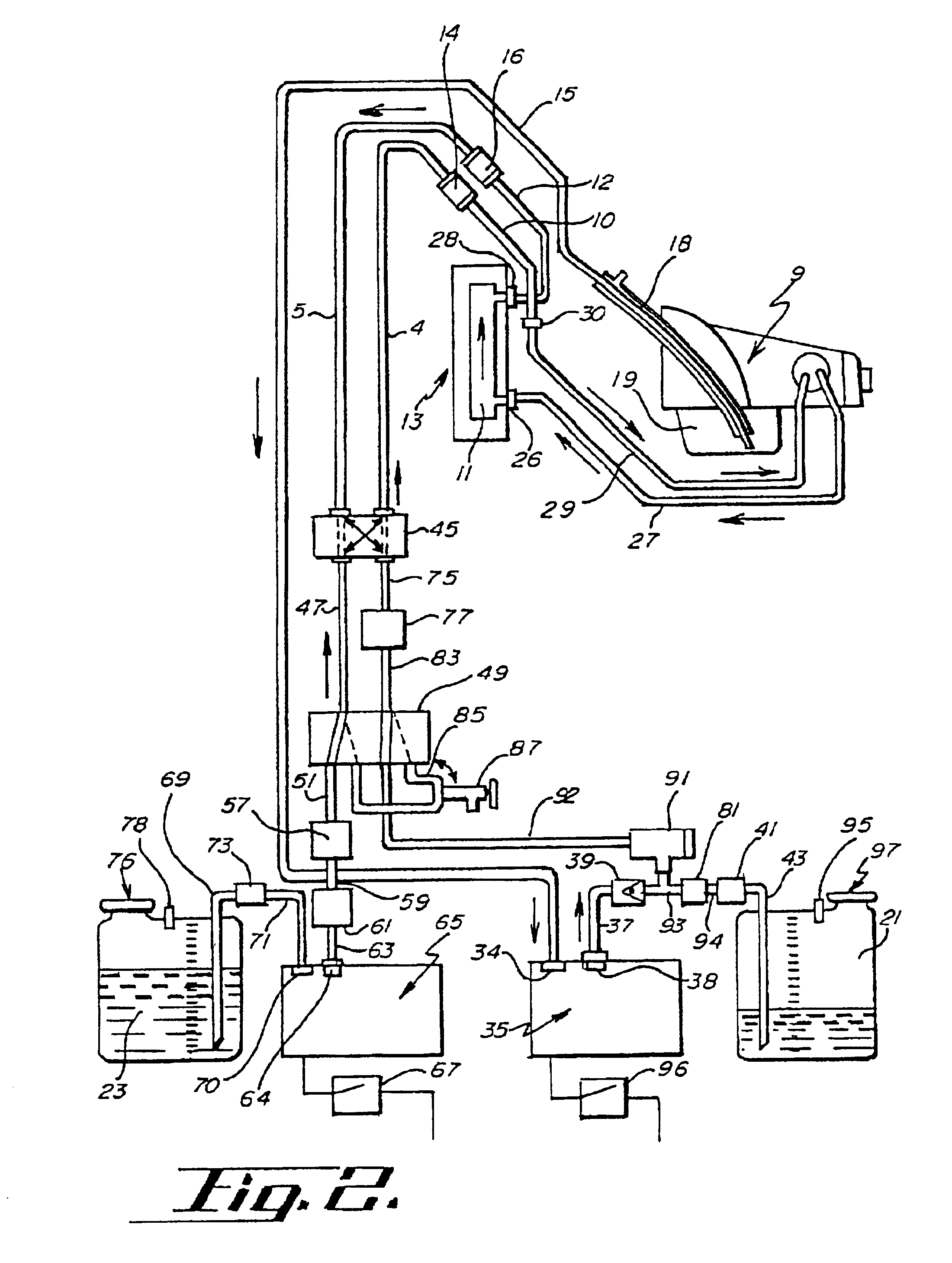

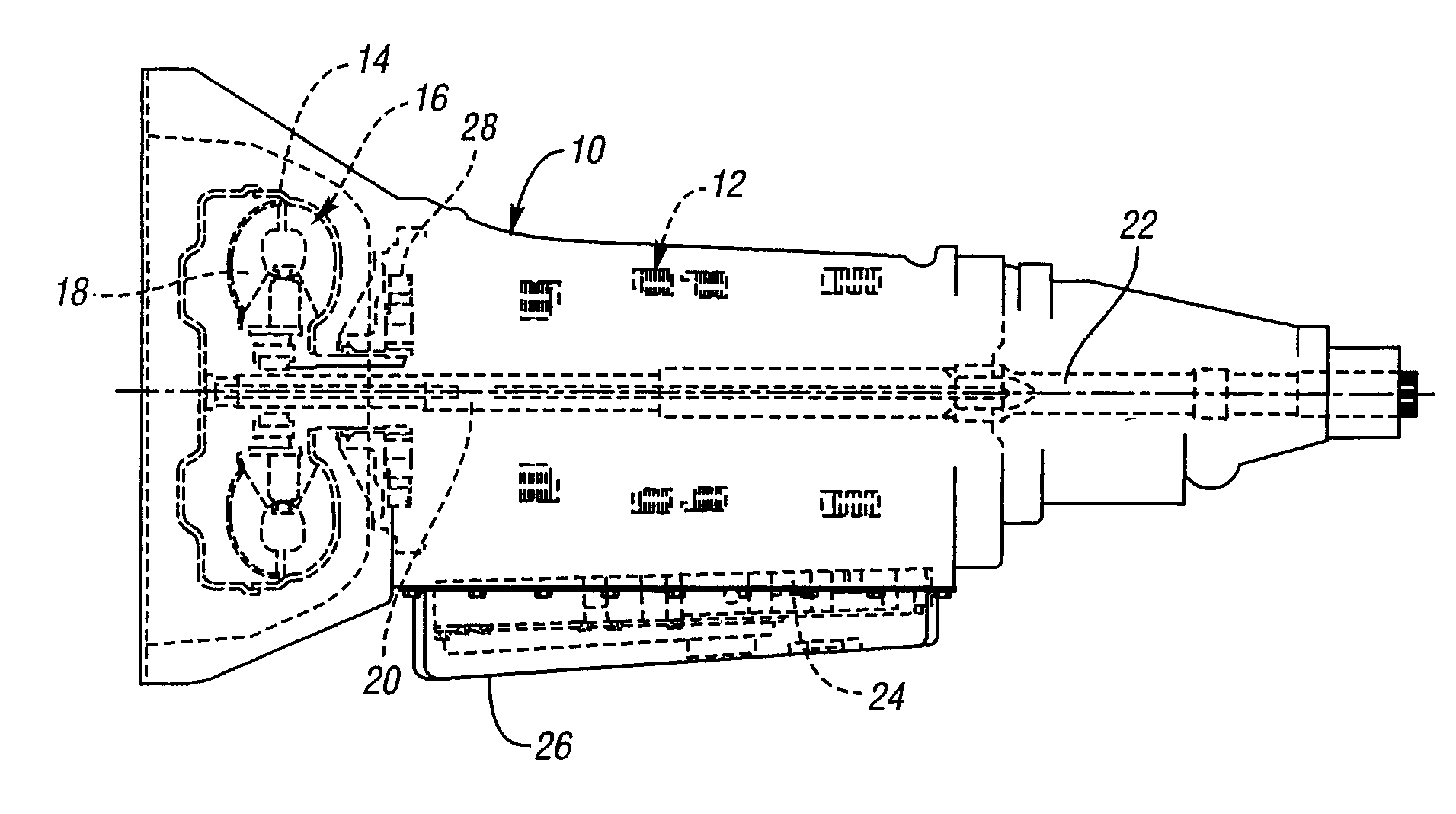

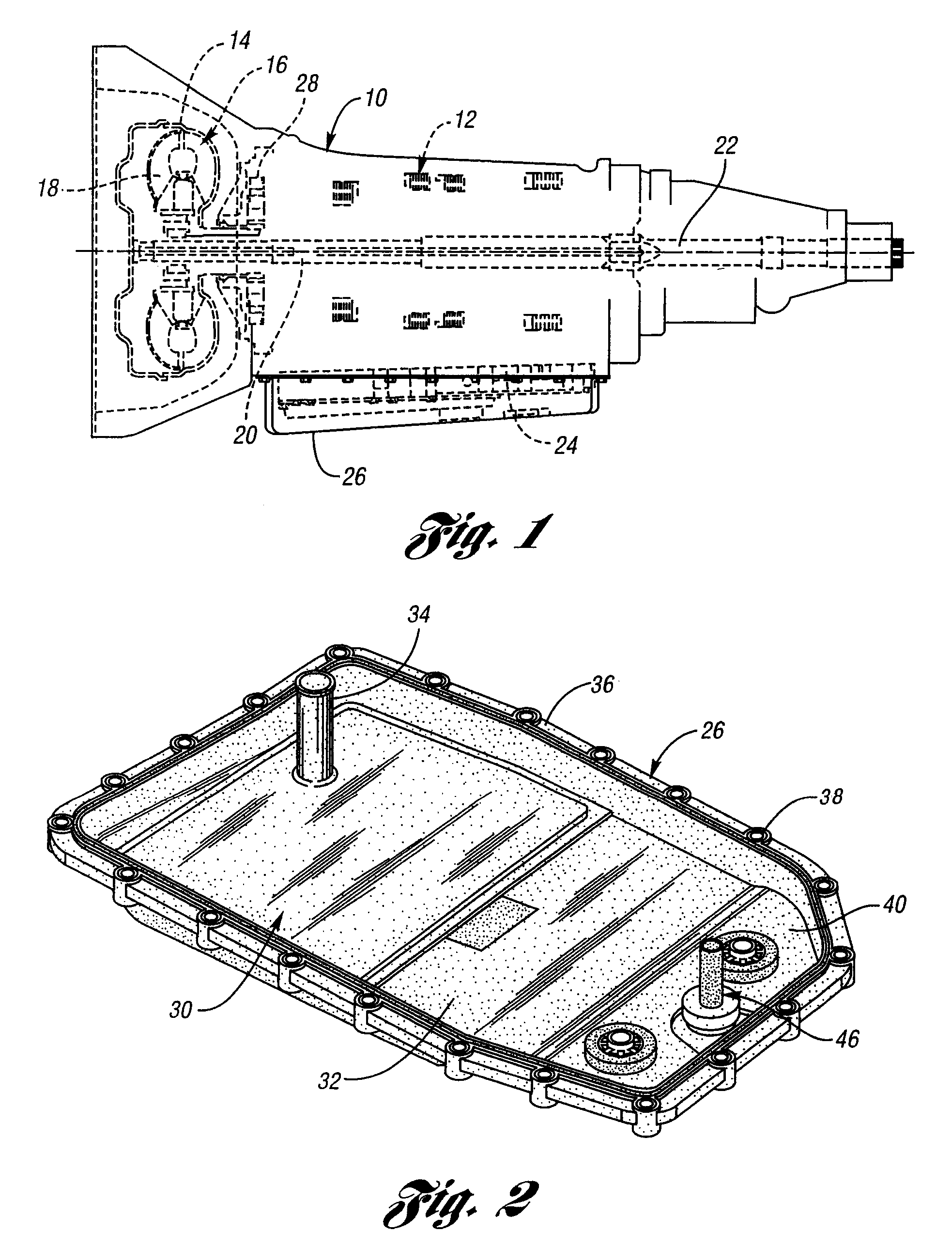

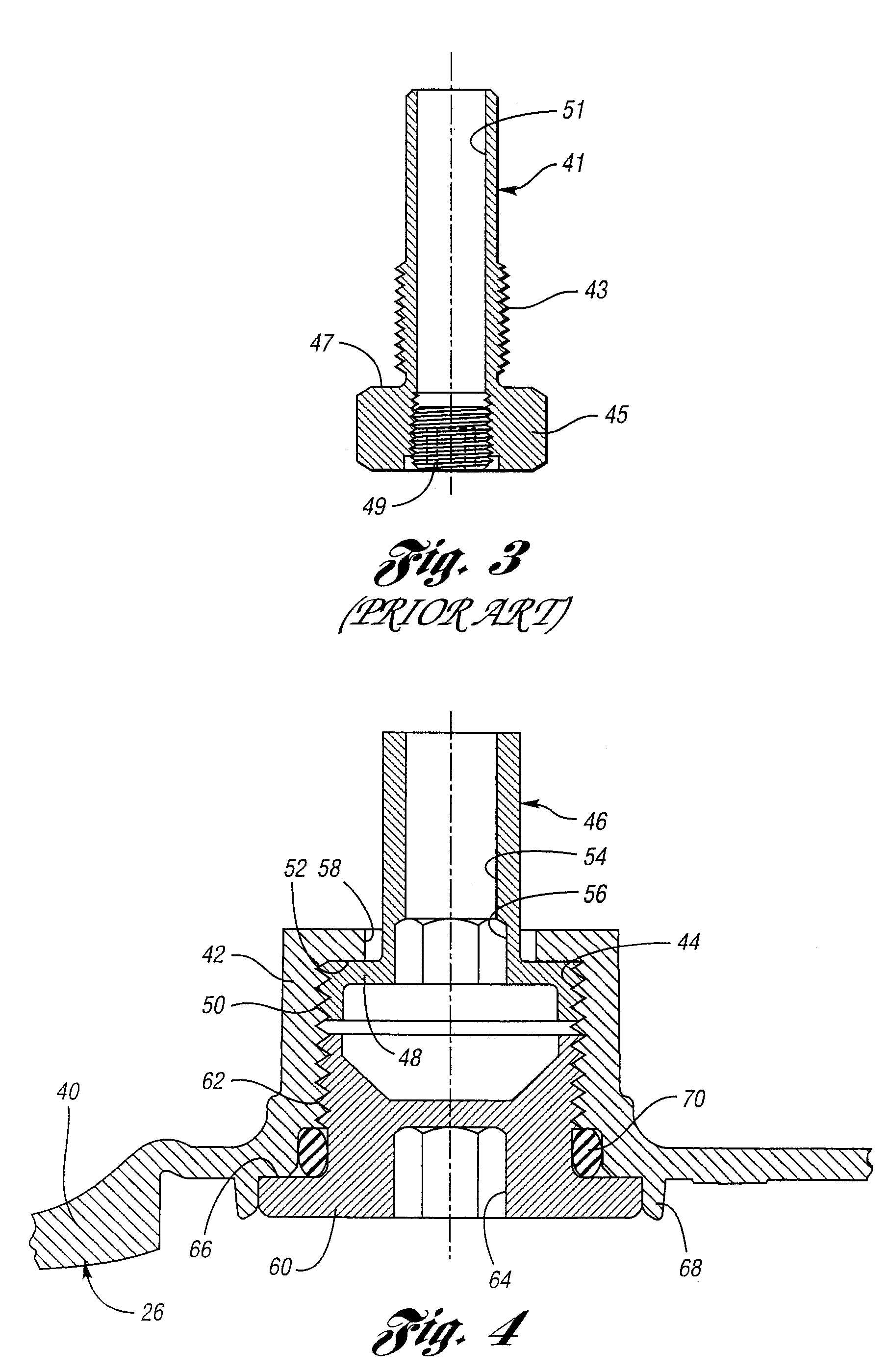

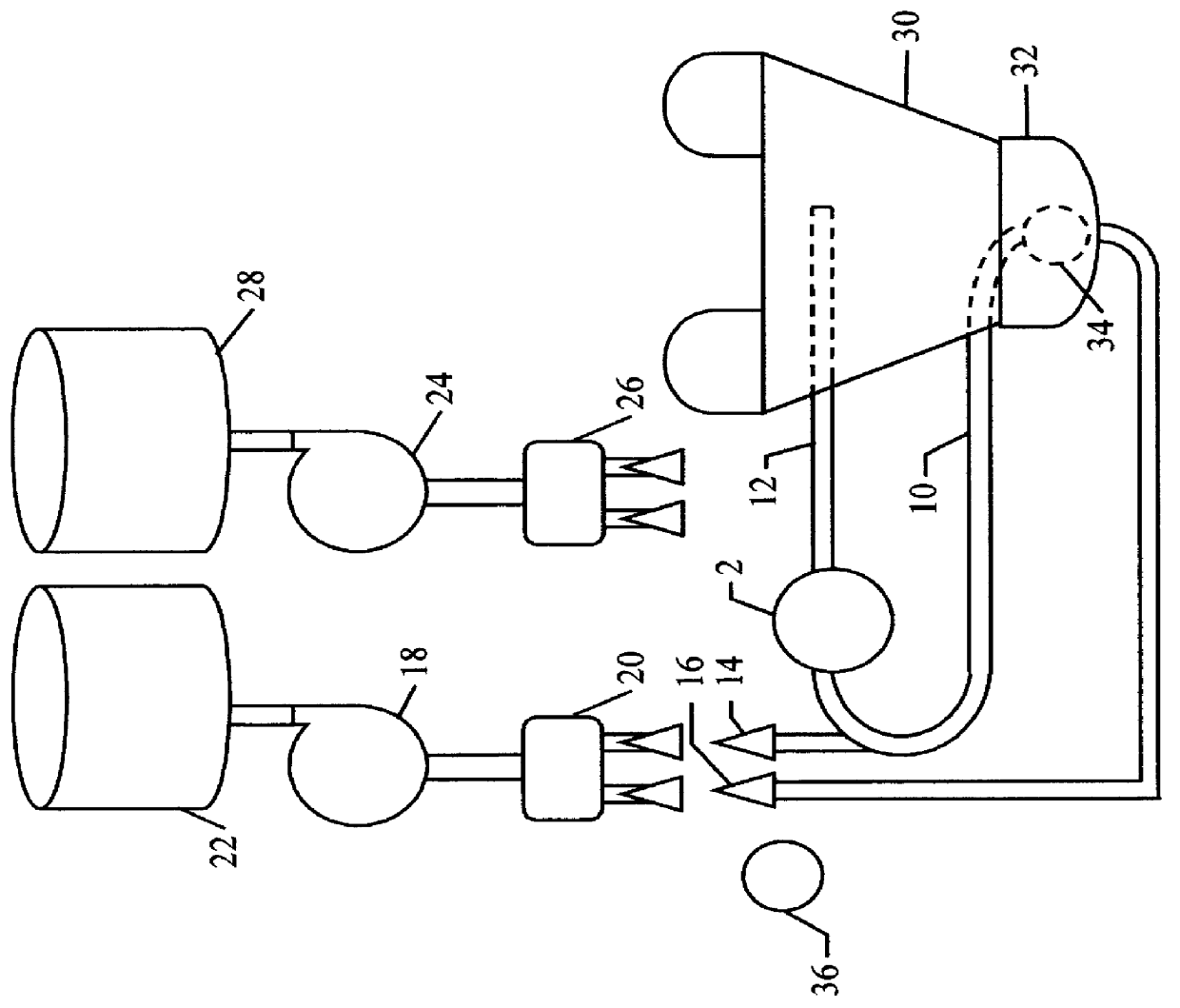

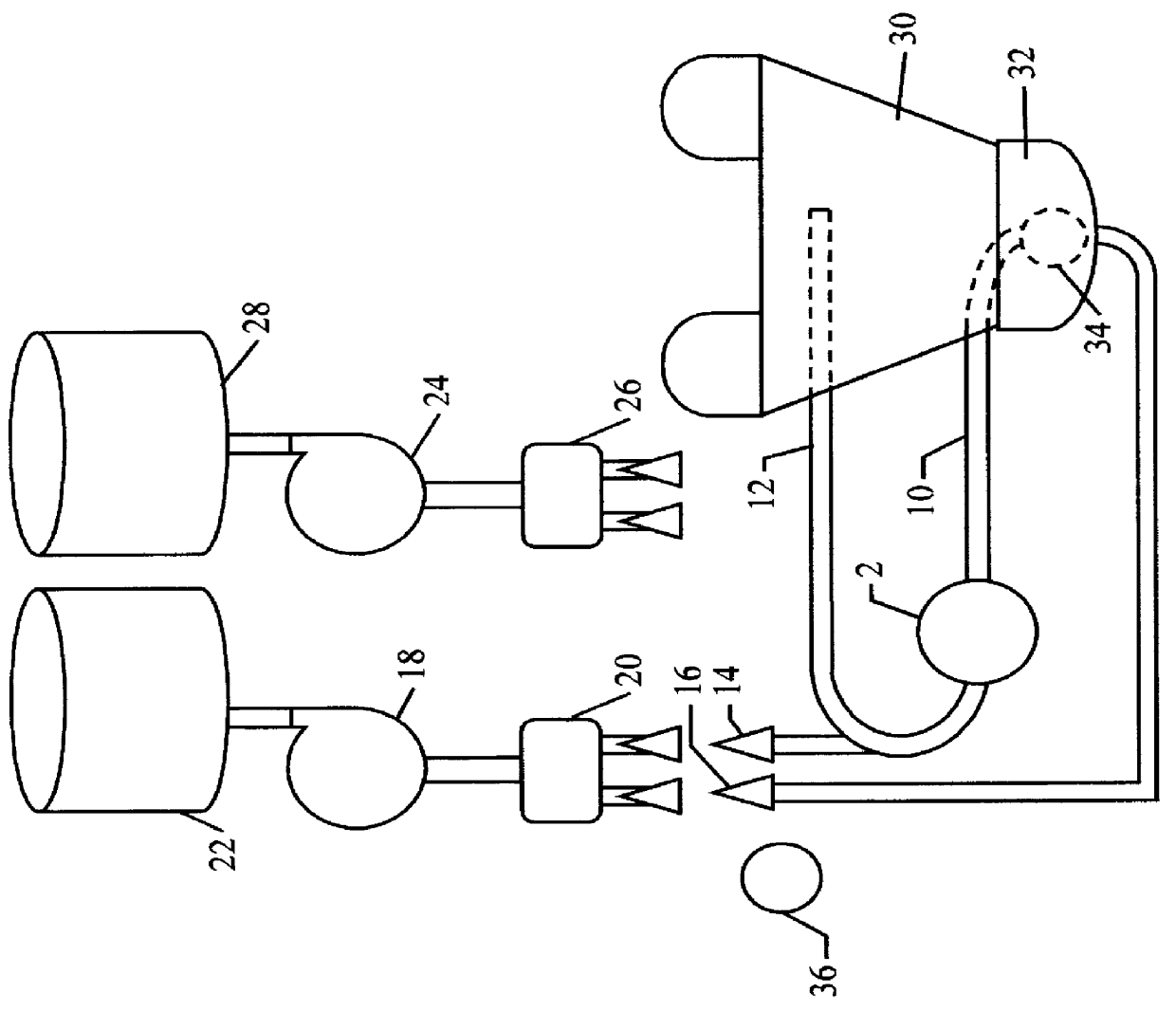

Complete fluid exchange system for automatic transmissions

InactiveUS6779633B2Highly effectiveEasy to operateCrankshaftsLiquid fillingAutomatic transmissionAutomotive industry

An improved system for changing the fluid of vehicular automatic transmissions and the like, which has the capability to provide a complete fluid exchange faster and with less usage of fresh fluid in a manner that is easier to operate. This is accomplished by the system's unique capability to extract used fluid and replace it with fresh fluid at a faster, balanced rate than before possible in prior art. This is accomplished by decreasing or removing restriction from the exhausting of the used fluid and introducing fresh fluid at more than one locus. The unique, novel capability of the invention to use a dual use pan access tube to combine a static change with a dynamic change, and to introduce fresh fluid into the transmission from two different loci instead of one as in all prior art, allows the fluid exchange to be completed in a shorter time with less use of fluid. These improvements increase the commercial utility and value of complete fluid changing in automatic transmissions and should extend its commercial viability as a routine maintenance procedure in the vehicular or automotive industry.

Owner:VIKEN JAMES P

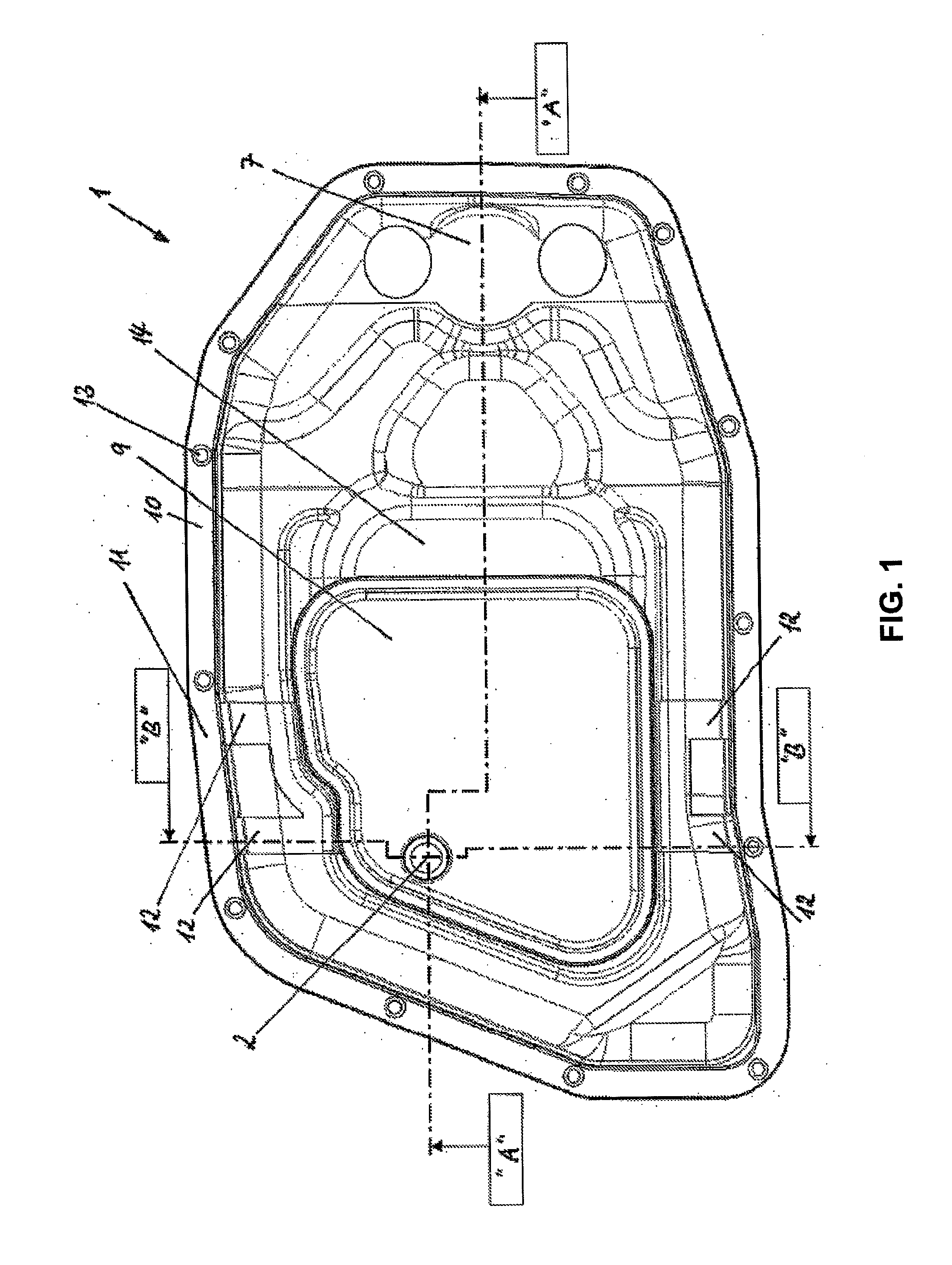

Oil Sump Having Oil Filter on Carrier Unit

ActiveUS20100038296A1Easy to engageReduce in quantityWater/sewage treatmentOilsumpsFilter mediaCylinder block

An oil sump, preferably made of plastic or metal, is provided for engines or transmissions, the oil sump comprising a filter housing including a filter housing top shell, a filter housing bottom shell, a filter medium, a filter inlet, and the filter outlet, and having an oil drain opening in a floor area of the oil sump, implemented in such a way that it is closable using an oil drain screw having external thread, which comes from the oil sump outer side. The oil sump also includes a carrier unit having a frame, on which the filter housing is fastened and which is used as a seal upon fastening of the oil sump on the associated unit, in particular on an engine block or a transmission unit.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

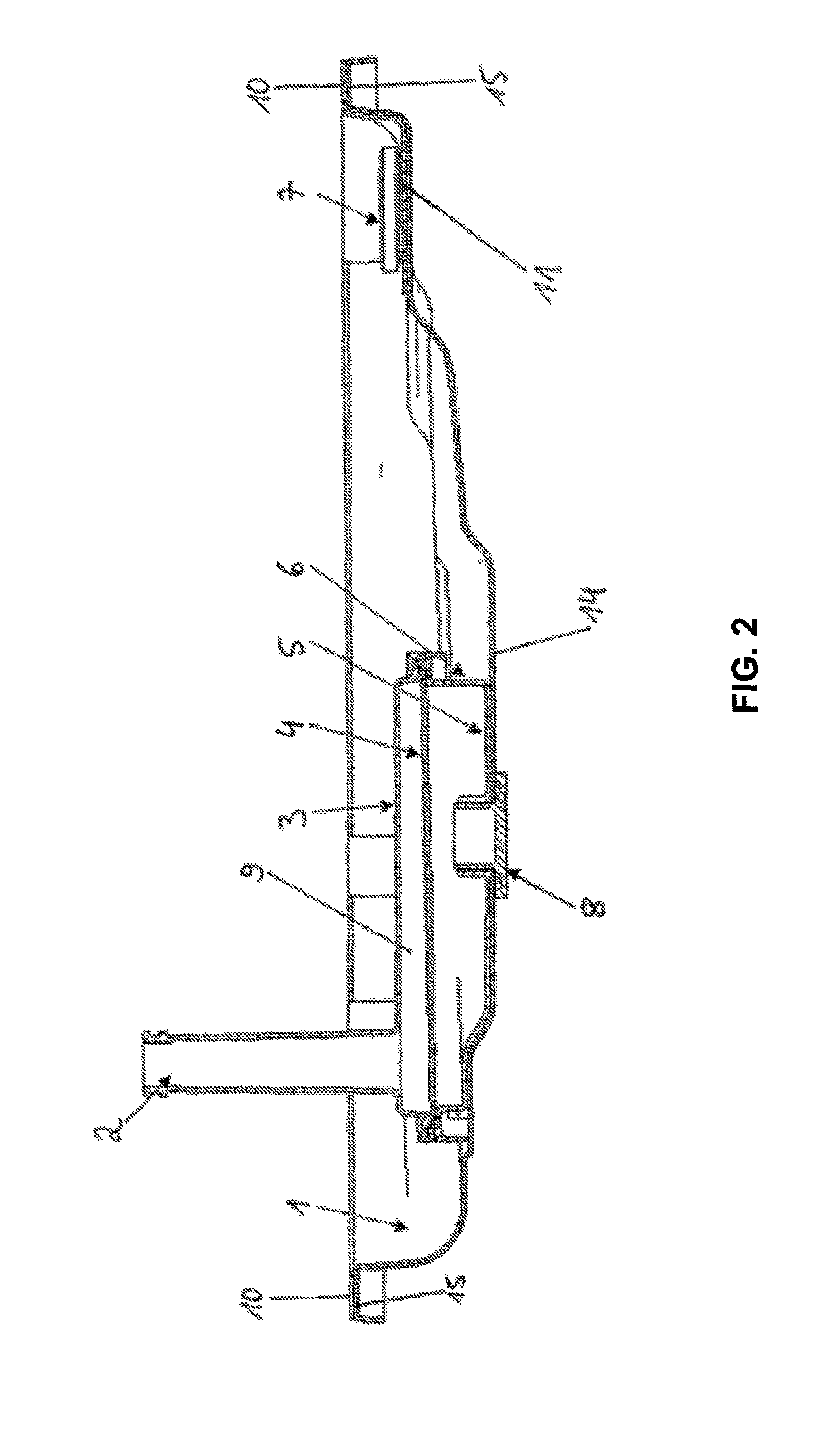

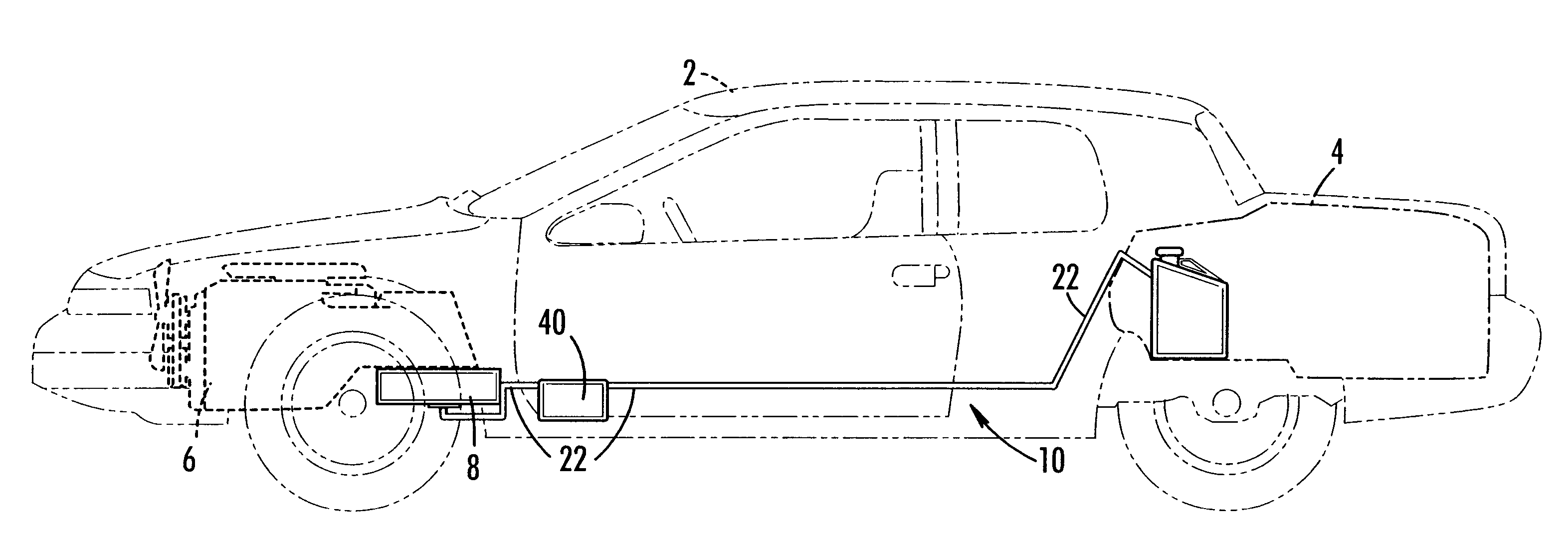

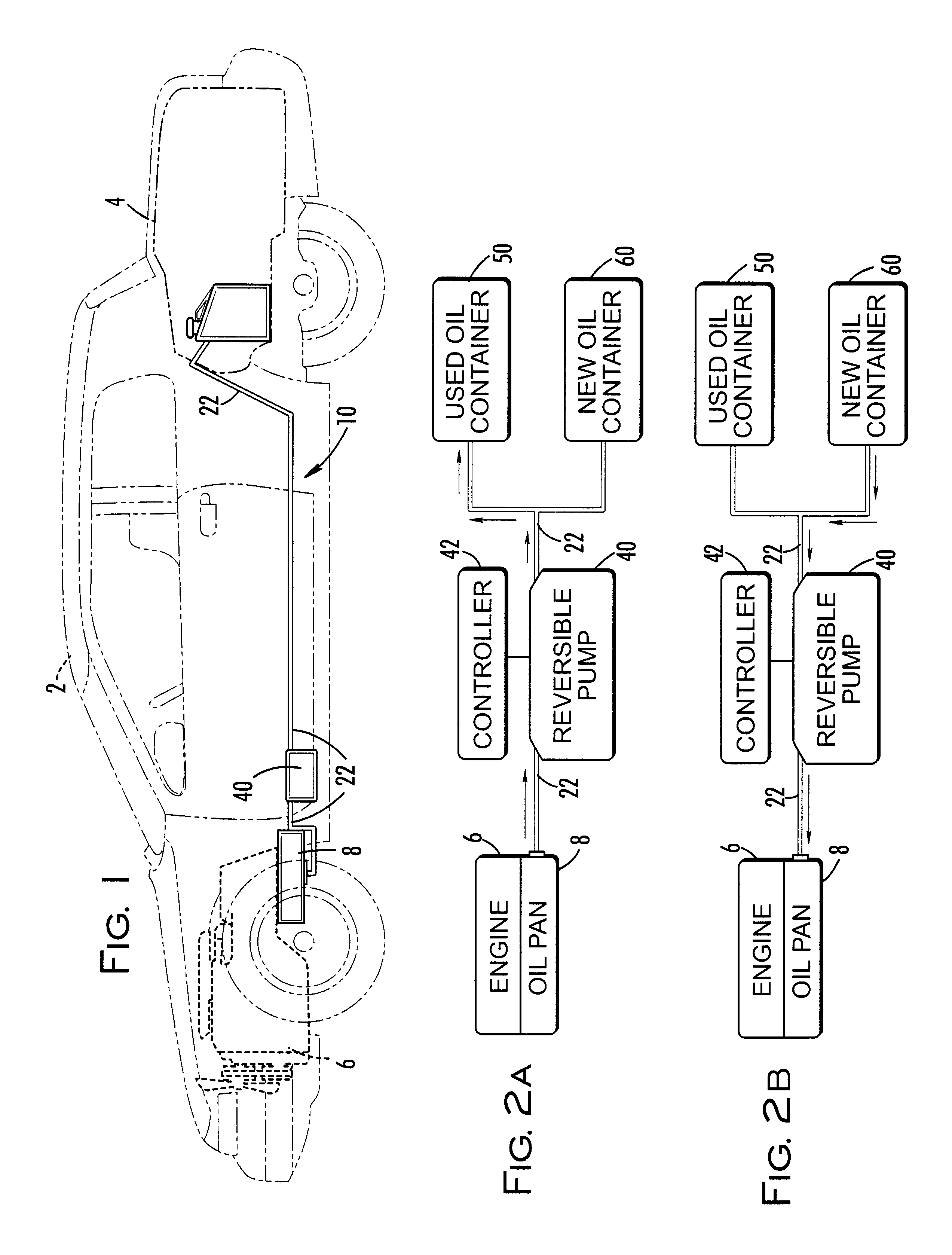

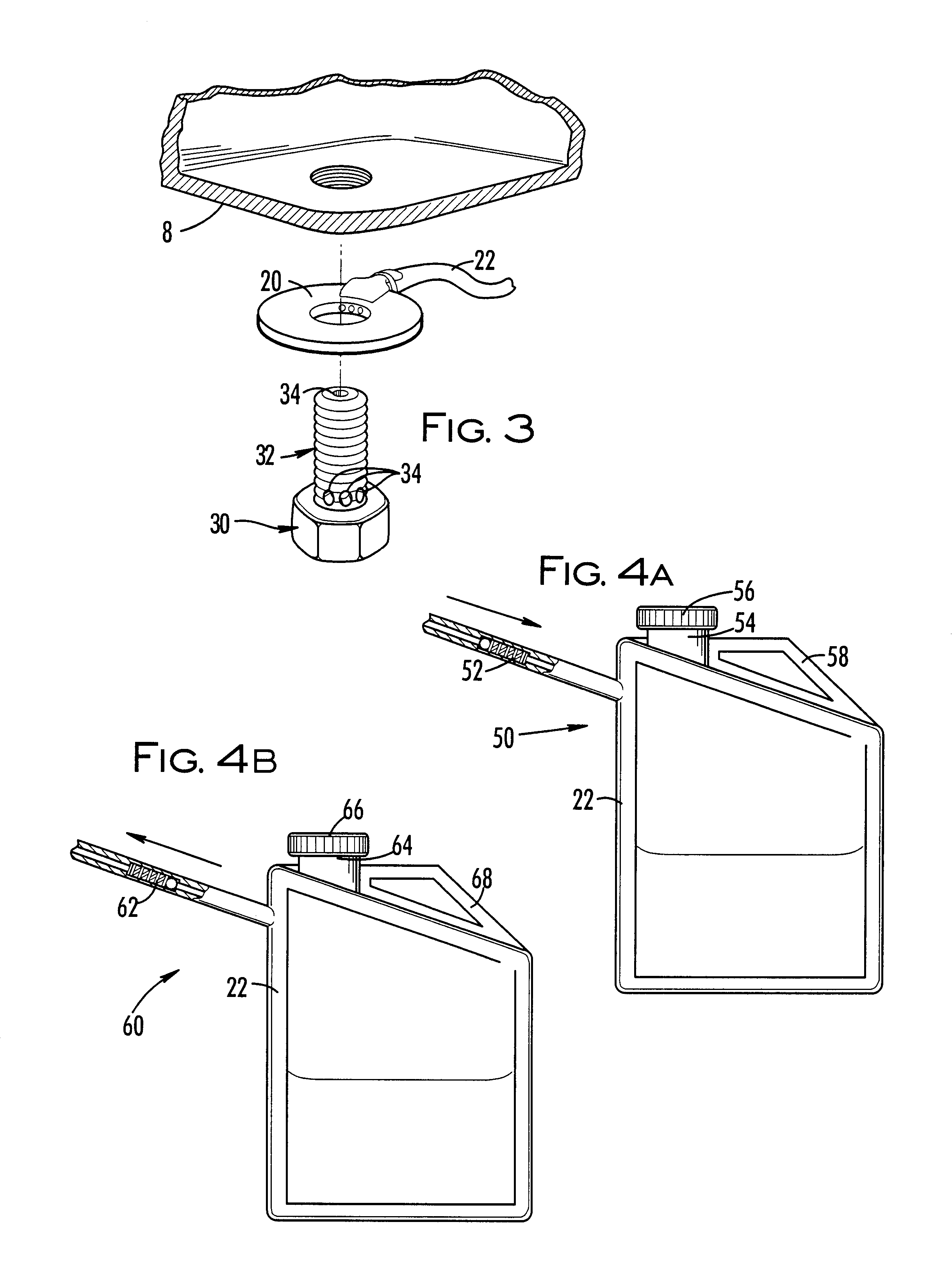

Automated oil changing system

An automated system for changing the motor oil in an engine. The system includes a drain plug having a plurality of channels coupled with tubing that extends to a reversible pump. Tubing extends from the pump to both a used oil container and a new oil container. Check valves positioned at the entrance of each container restrict flow so the oil can flow only to the used oil container and only flows from the new oil container. Preferably, both containers are located in the trunk of the vehicle for easy access. In use, the pump is engaged to draw the used motor oil from the engine into the used oil container. Next, the pump is reversed to draw fresh oil from the new oil container into the engine.

Owner:CANNON DAVID G

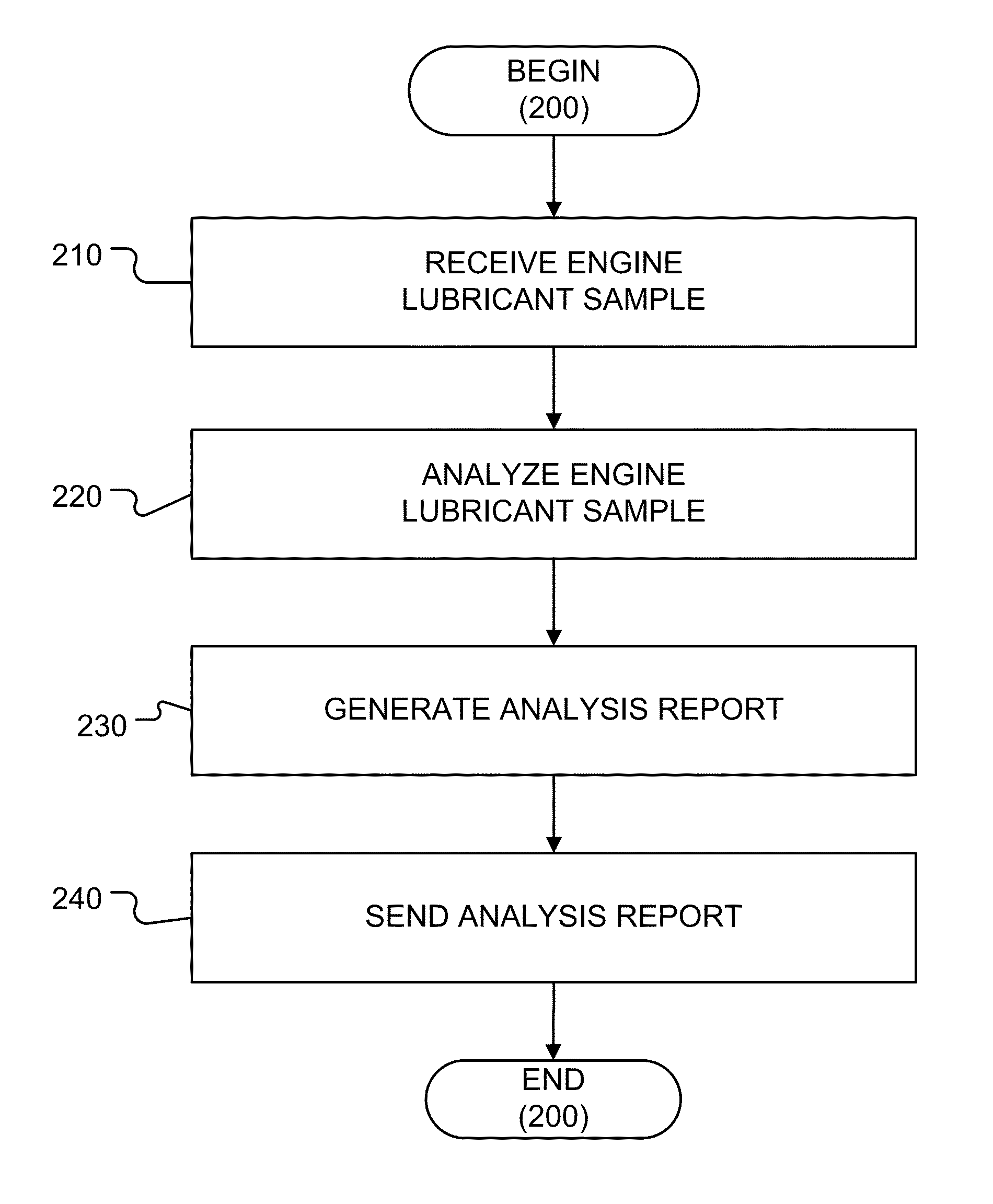

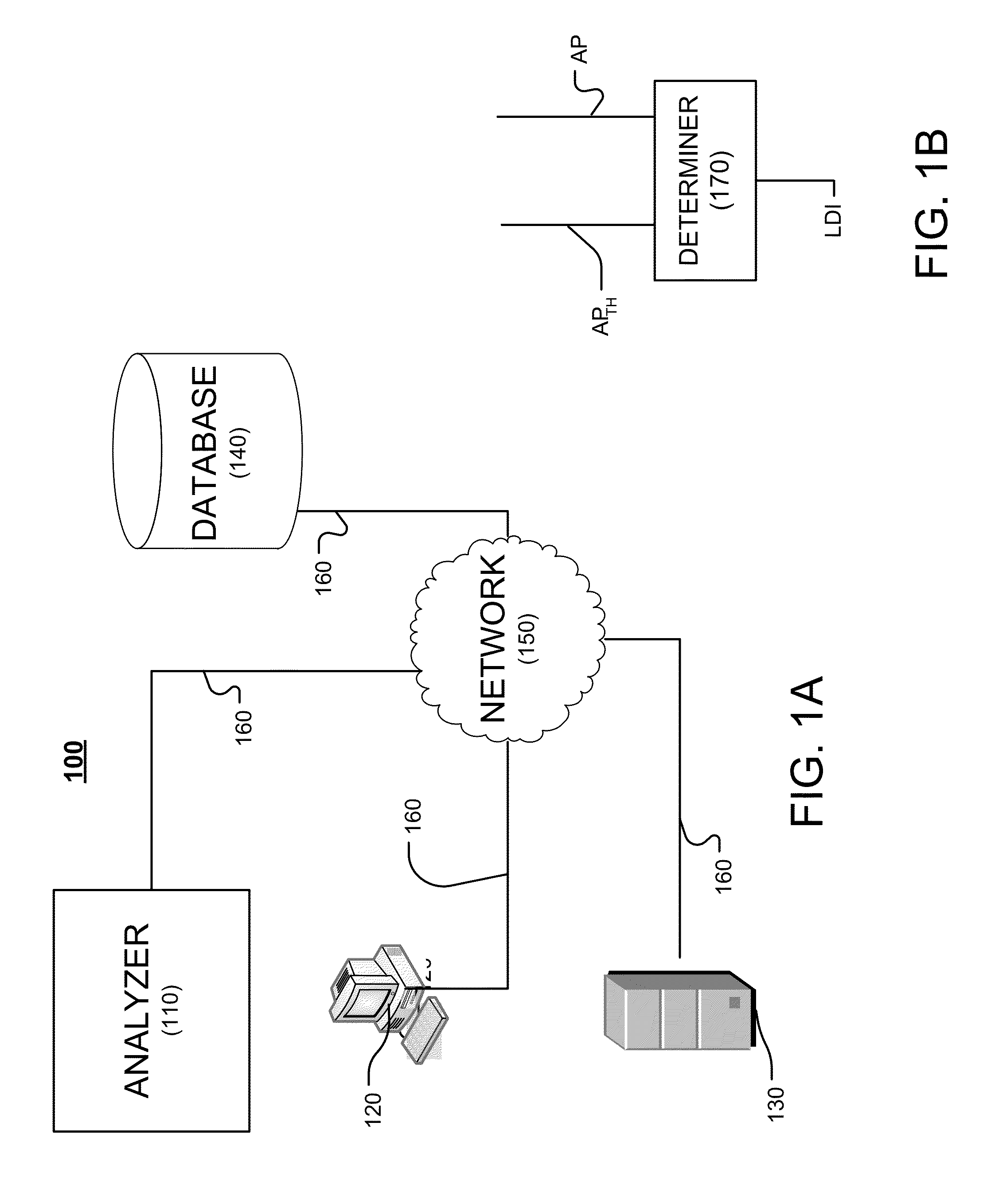

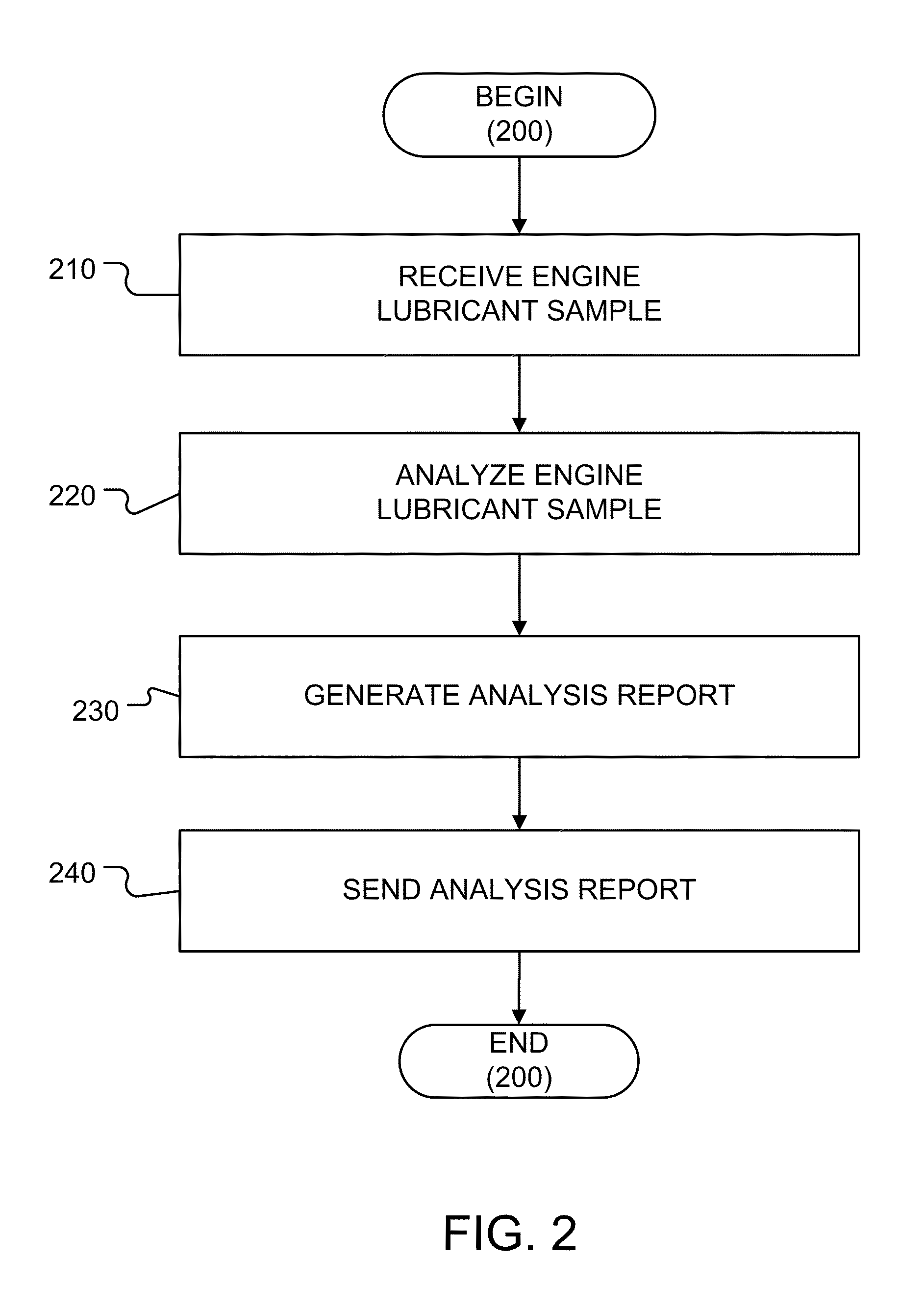

System and method for determining a lubricant discard interval

InactiveUS20130197738A1Minimize downtimeLow costVehicle testingInternal-combustion engine testingComputer scienceLubricant

A system, a method and a computer program to predict a portion of used lubricant in an engine that is to be drained and replaced by fresh lubricant based on an analysis parameter value that is measured in a sample of used engine lubricant from the engine. The system includes a first input that receives the analysis parameter value from the used lubricant and stores the analysis parameter value in a memory of a processor. A second input receives an analysis parameter threshold value for the used lubricant at the end of a service interval and stores the analysis parameter threshold value in a memory of the processor. A determiner predicts a future analysis parameter value of a mixture of used and fresh lubricant at the end of the service interval based on the analysis parameter value, and the analysis parameter threshold value.

Owner:AFTON CHEMICAL

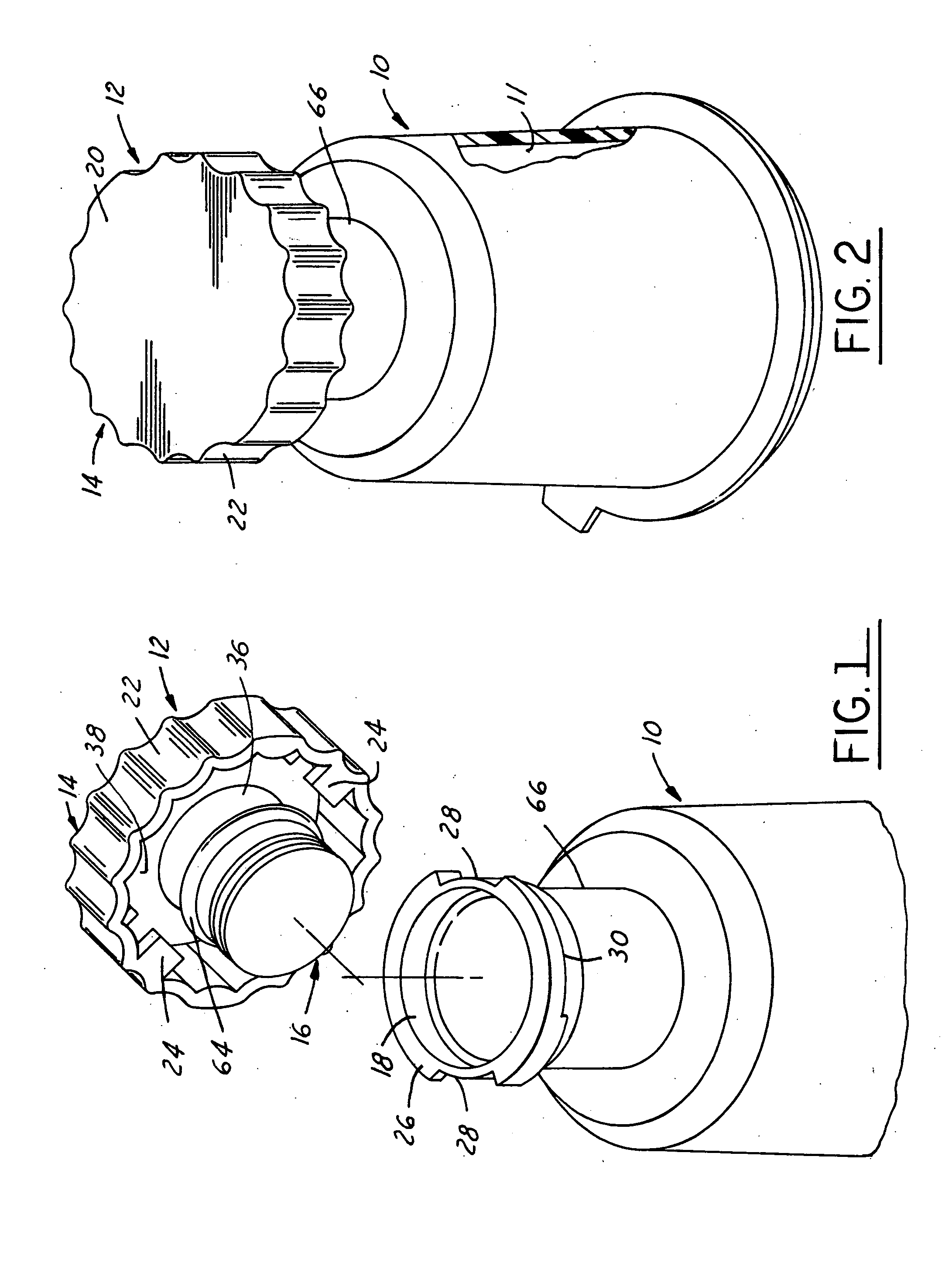

Power steering fluid reservoir cap with a mist condensing filter

A cap assembly is provided for a container that defines a reservoir for power steering fluid. The cap assembly has an outer cap adapted to be secured to an open mouth of the container and an inner cap secured to the outer cap and adapted to extend through the open mouth into a neck of the container. The inner cap has an O-ring adapted to seal against a neck of the container. A build-up of air in the reservoir is vented to the outside atmosphere through a passageway in the cap assembly. A filter in the passageway is adapted to pass the air but not to pass a mist emanating from the power steering fluid. The filter condenses the mist for return to the reservoir

Owner:DAIMLER CHRYSLER CORP +2

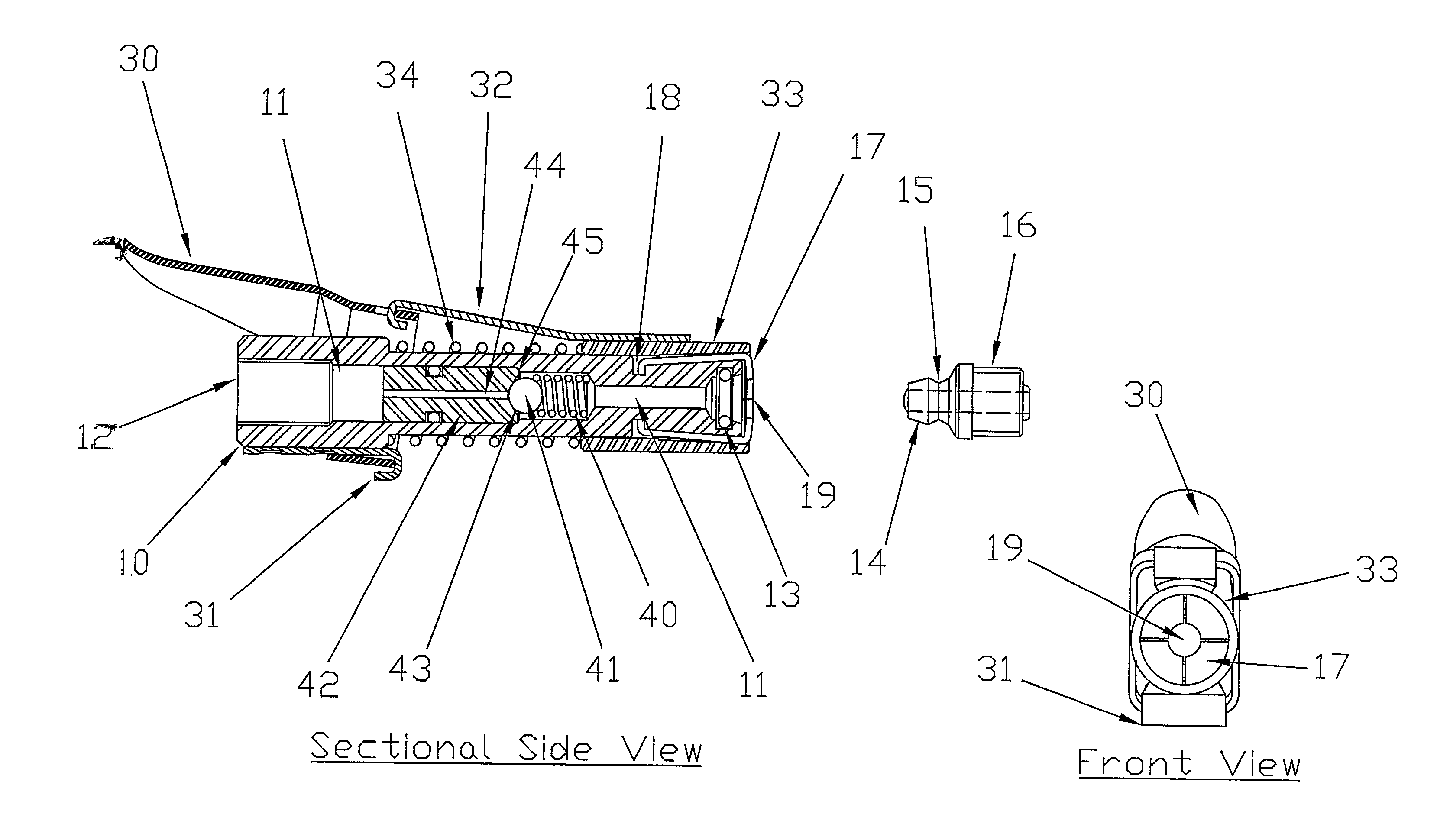

Grease coupler

An improved grease coupler 3 allows for positive, coupling and uncoupling from a grease nipple 4 via a manually operated trigger mechanism 30. The coupler includes a replaceable seal 13 and has an elongate body 10 with a grease passage 11 through the length of the body. A floating barrel plunger 42 acts as a check valve to prevent grease leaking from the discharge end of the elongate body 10 upon disconnection.

Owner:GURTECH

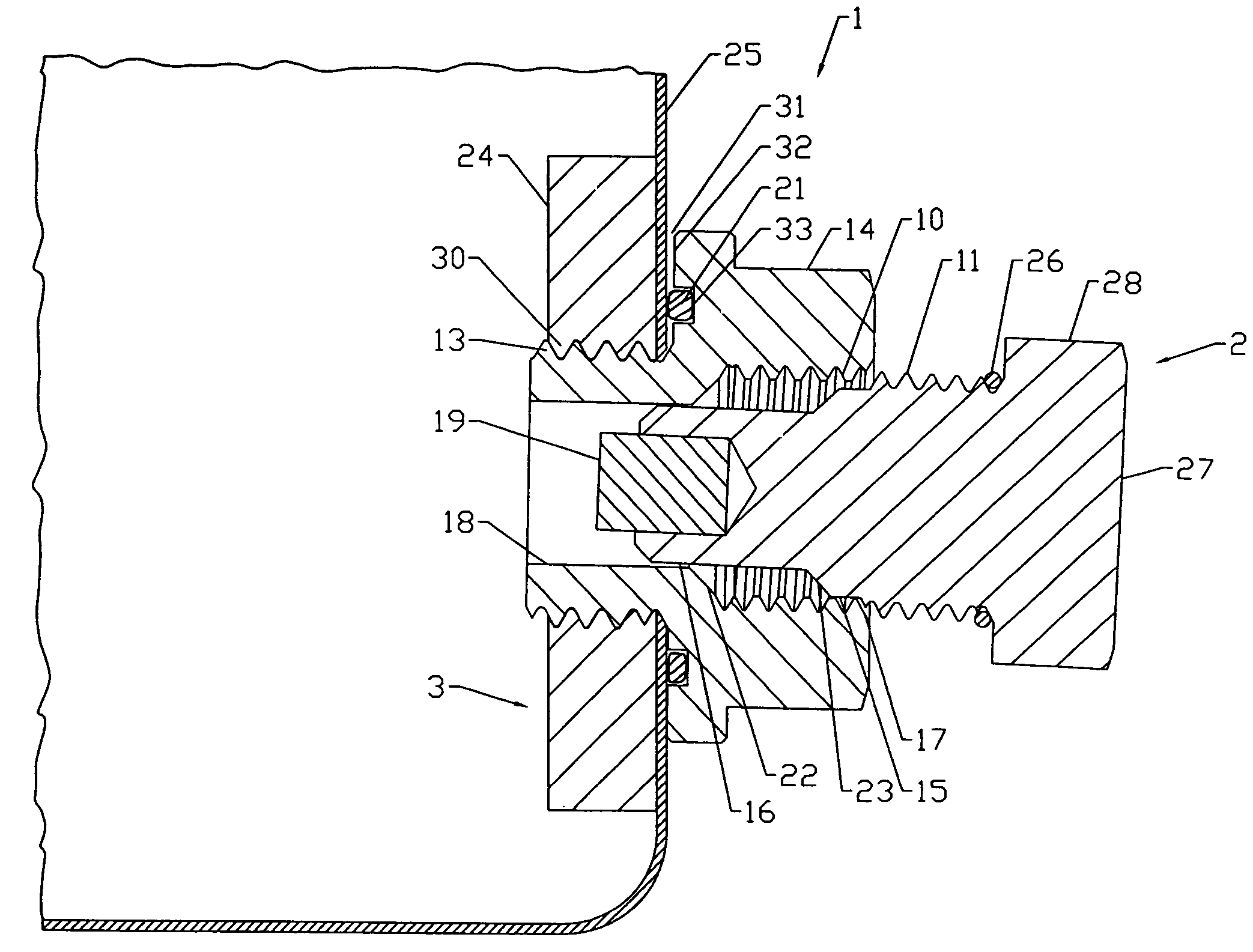

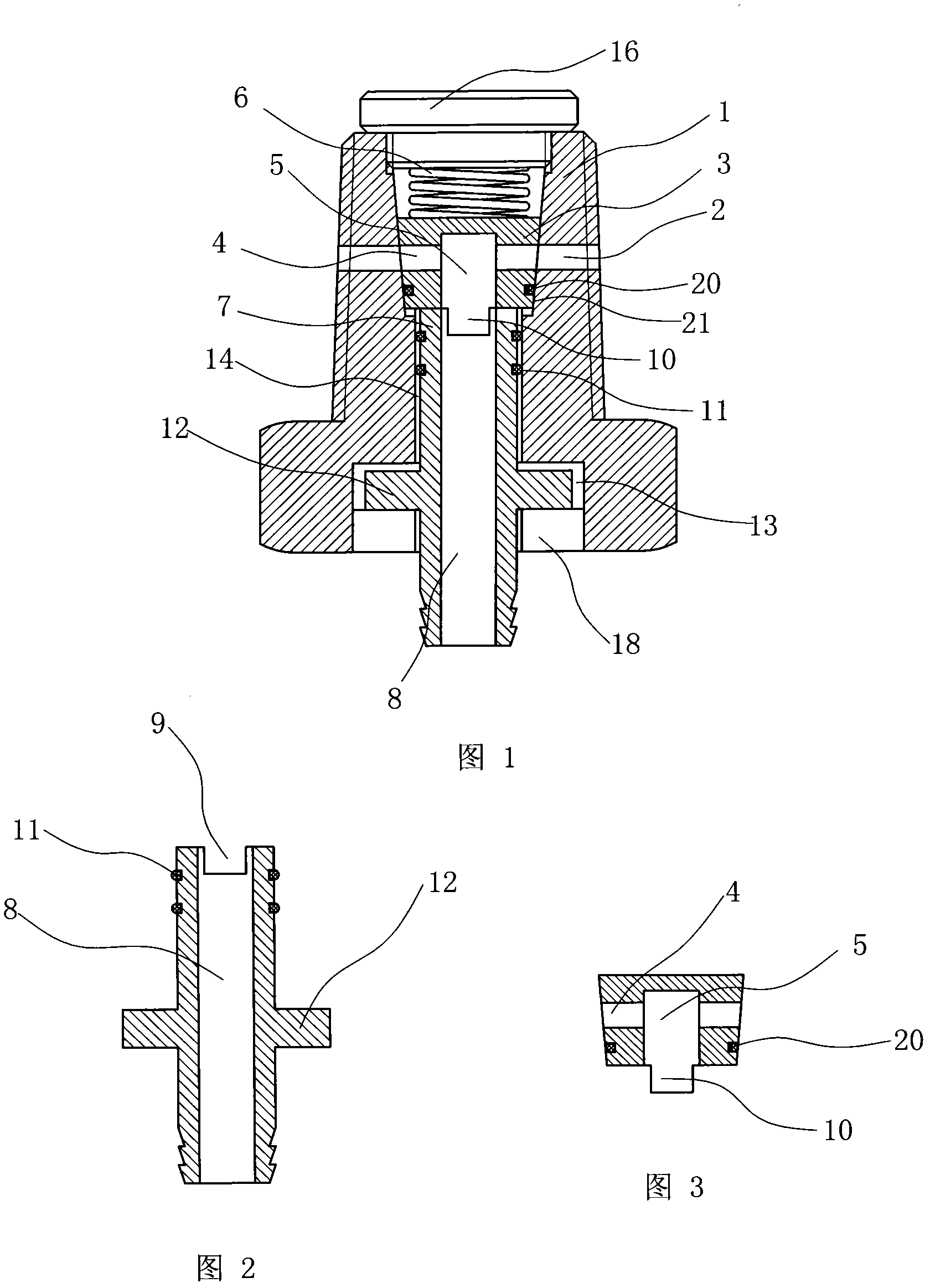

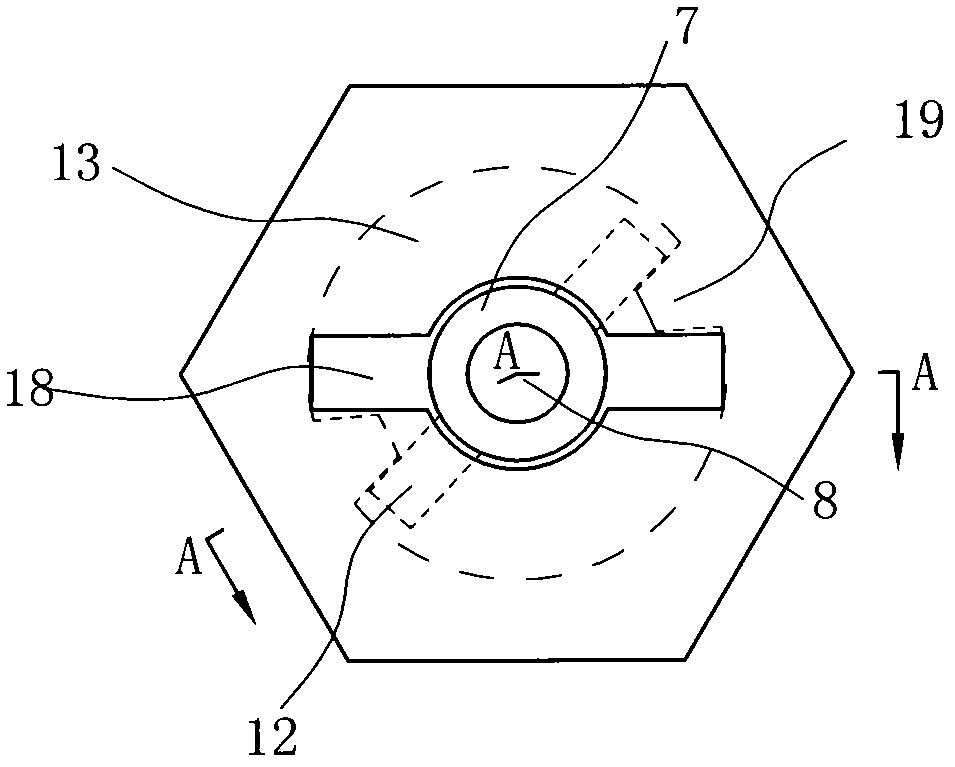

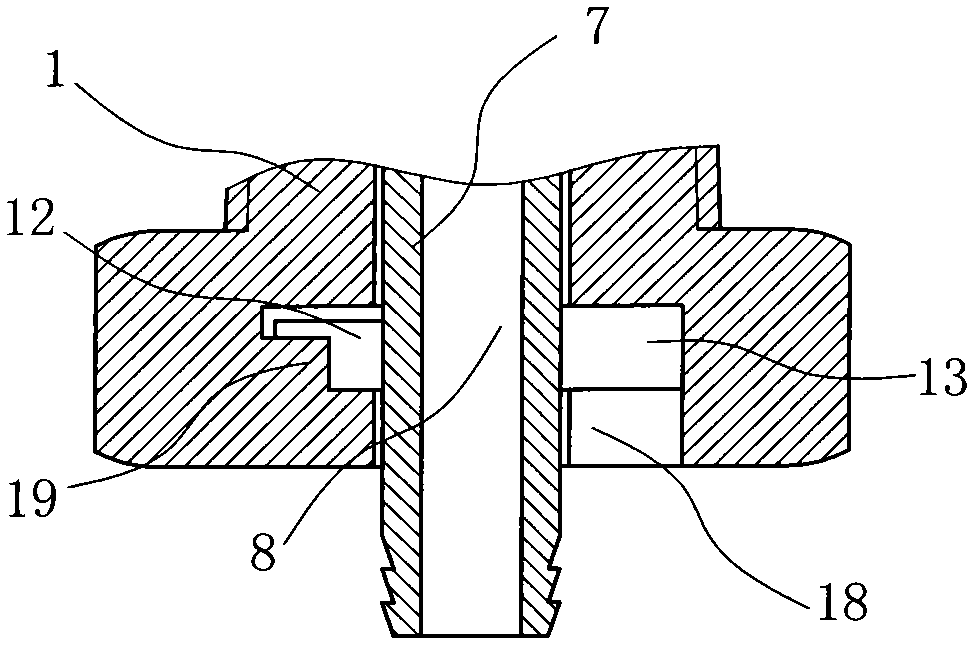

Detachment-free oil drainage bolt

The invention discloses a detachment-free oil drainage bolt, which comprises a valve body, a plug valve core and an oil drainage device. The valve body also serves as an oil drainage bolt and is provided with an external thread, a valve body oil inlet and a valve body oil outlet; the plug valve core is mounted in an inner cavity of the valve body and provided with a valve core oil inlet channel; a valve core oil outlet channel communicated with the valve core oil inlet channel is also arranged in the plug valve core; the valve core oil outlet channel is communicated with the valve body oil outlet; a valve core sealing device is arranged between the plug valve core and the valve body; the oil drainage device comprises an oil drainage pipe inserted into the valve body oil outlet; the oil drainage pipe is provided with an oil drainage channel communicated with the valve core oil outlet channel; a valve core opening device is arranged between the oil drainage pipe and the plug valve core;and an oil drainage pipe inserting / fixing device is also arranged between the oil drainage pipe and the valve body. The oil drainage pipe drives the plug valve core to rotate through the valve core opening device, the valve body oil inlet is opened, and the waste oil enters the valve core oil outlet channel through the valve core oil inlet channel from the valve body oil inlet and then flows out through the oil drainage pipe. Through the invention, the waste oil is prevented from spattering around, and the pollution is reduced.

Owner:铜陵市世纪朝阳数码科技有限责任公司

Battery powered grease gun with strain gauge based pressure transducer

InactiveUS20070137942A1Contracting/expanding measuring chambersLarge containersTransducerDisplay device

Owner:WEEMS IND INC

Externally serviceable transmission sump fill pipe and drain port assembly

ActiveUS20060037427A1Leakage problemImprove corrosion resistanceCrankshaftsGearboxesFuel tankAutomotive transmission

A transmission fluid sump for an automotive transmission comprising a reservoir portion, a threaded extension on the reservoir portion and a fill pipe threadably connected to the extension. A closure member seals a central opening in the extension independently of the fill pipe, thereby avoiding overlapping torque windows for the fill pipe and the closure member while providing a single leak flow path for the transmission fluid.

Owner:FORD GLOBAL TECH LLC

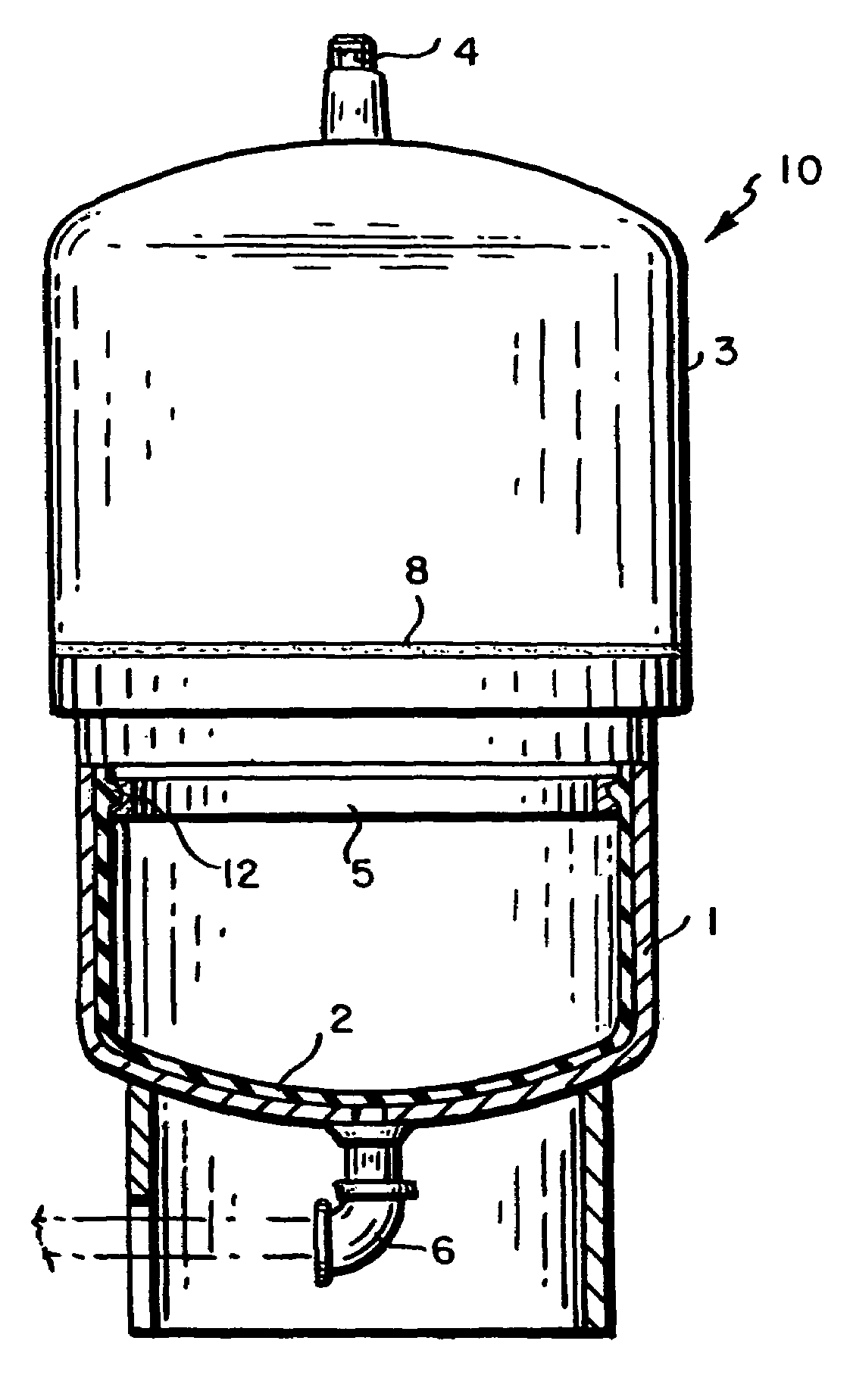

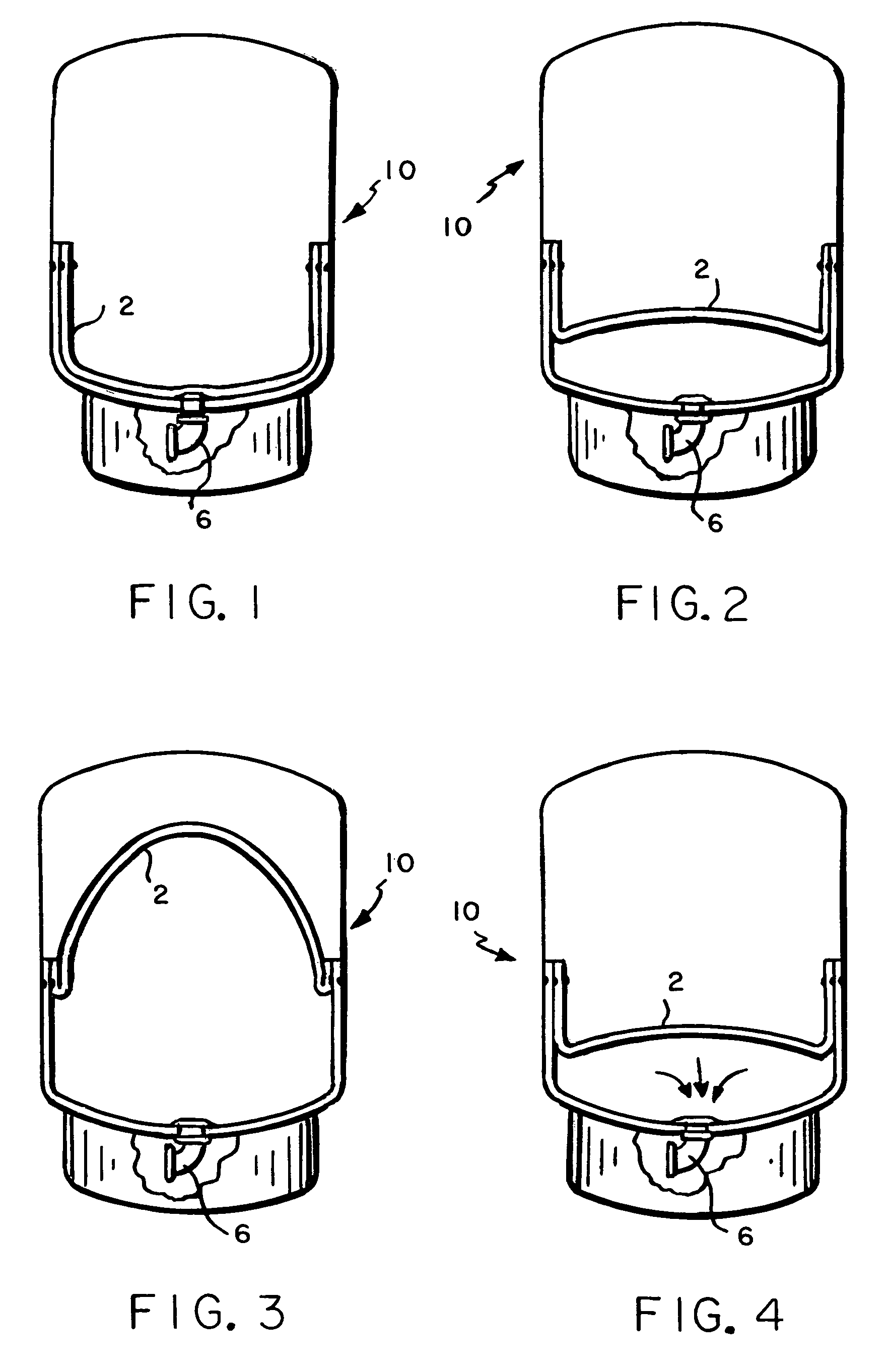

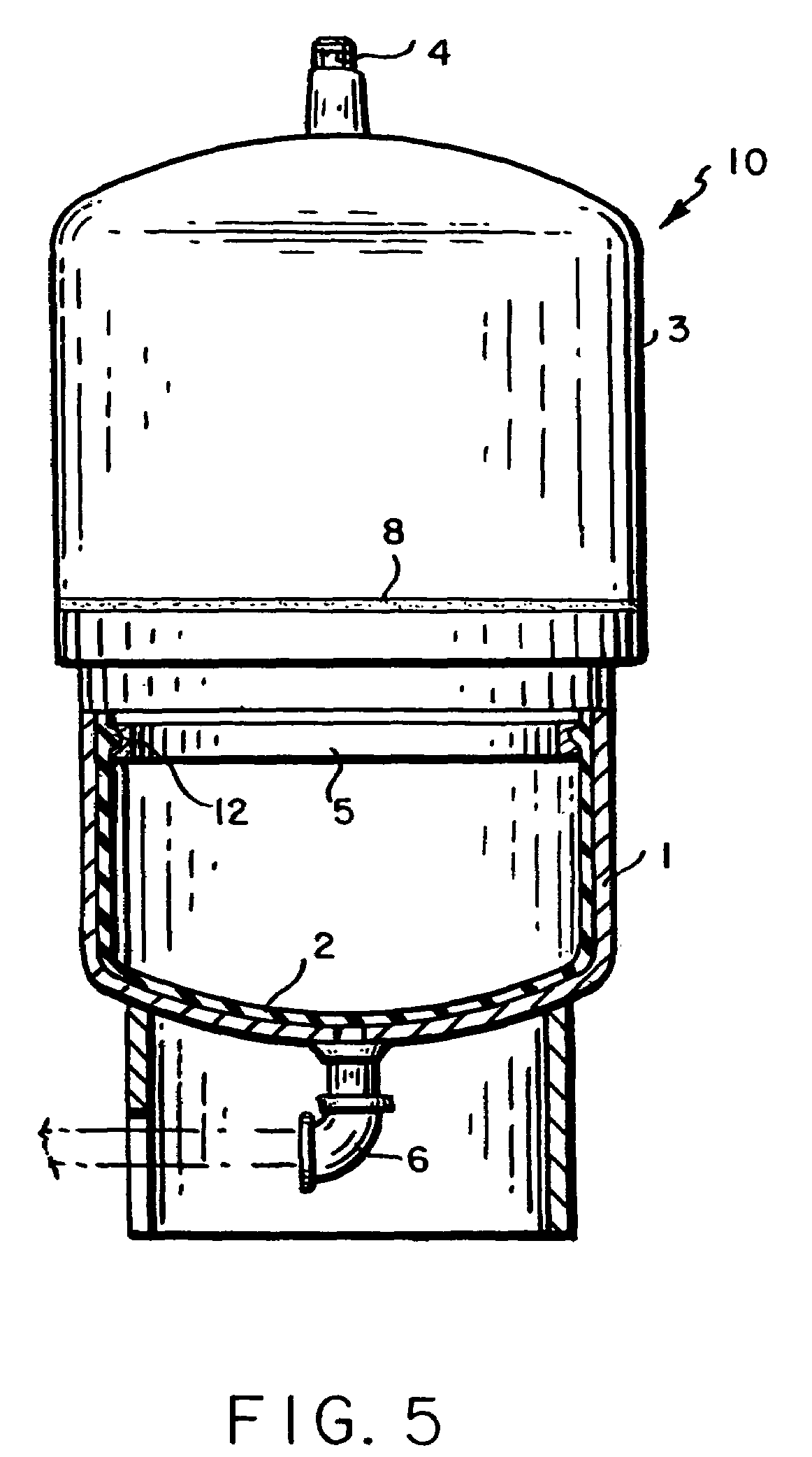

Mobile prepressurized diaphragm type fluid storage tank

A mobile prepressurized fluid storage tank is disclosed where the compressed air, completely separated from the fluid by a flexible diaphragm, dispenses the fluid under pressure, e.g., into an engine. The prepressurized diaphragm-type fluid storage tank is initially charged with a gas on one side of the diaphragm. A connector on the other end of the tank is connected to the fluid pumping system. Fluid is pumped into the tank until a predetermined pressure is reached and then the fill valve is shut off. A second connection attached to a bottom system connection has a hose. At the end of the hose there is a fluid shut off valve. Dispensing of the fluid takes place through the fluid shut off valve. The prepressurized fluid storage tank is mounted on a frame that contains wheels for mobility.

Owner:AMTROL LICENSING INC

Battery-operated grease gun with an electronic pressure regulator for controlling pressure of the grease

InactiveUS7032713B2Effective controlLarge containersMachines/enginesControl theoryPressure regulator

A battery operated grease gun has a motor that drives a planetary gear assembly that is coupled to a pump assembly that drives a plunger reciprocally in an grease passage to discharge grease through a discharge spout. The pressure in the grease exerts a reaction force on the plunger that will change torque of the motor. The change of the torque of the motor will simultaneously effect voltage applied to the motor. When the voltage in the motor changes, an electronic pressure regulator measures the voltage in the motor to determine the pressure in the grease in the grease passage and stops the motor as the pressure in the grease reaches preset given valves in the pressure regulating device.

Owner:TECHWAY INDAL

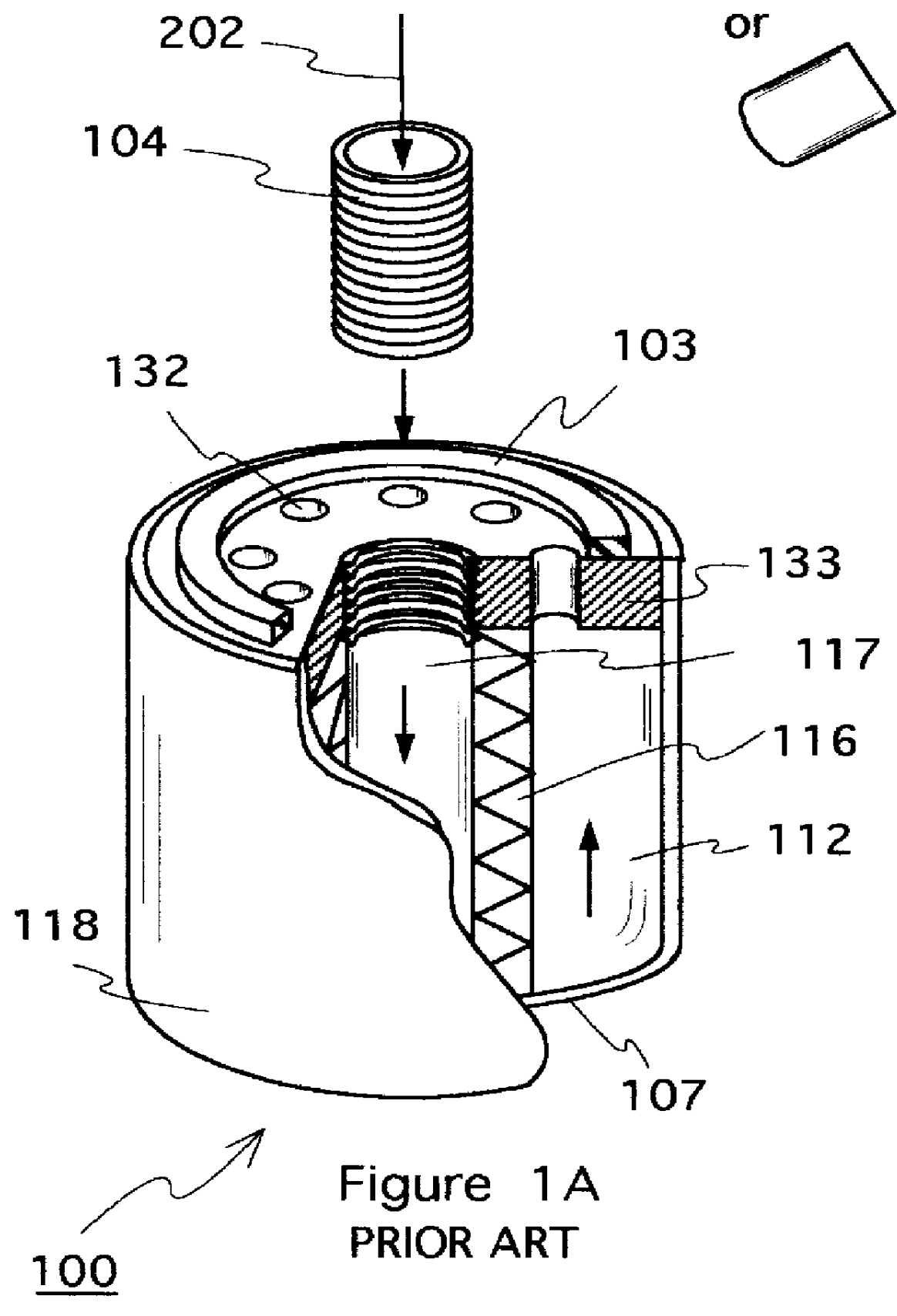

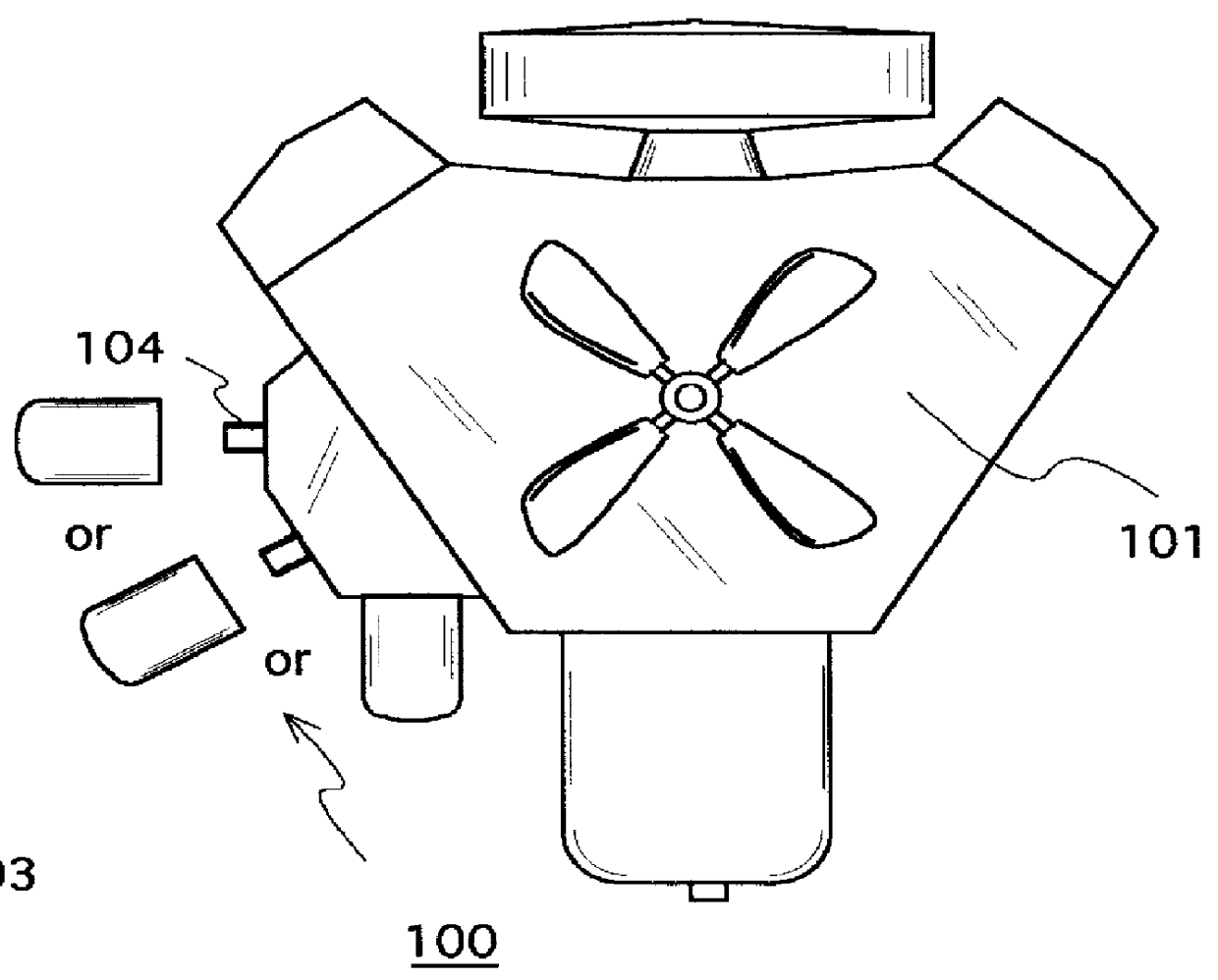

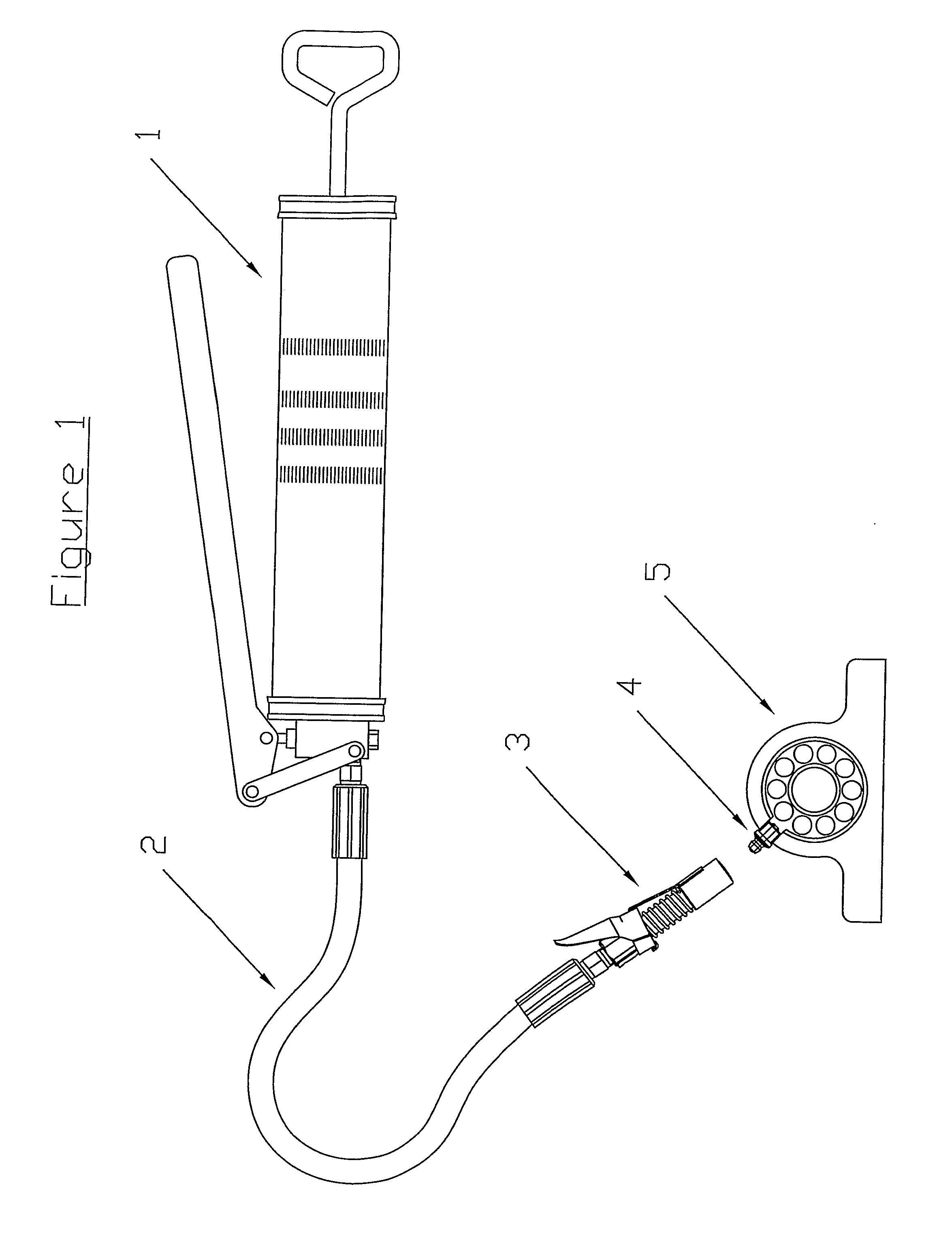

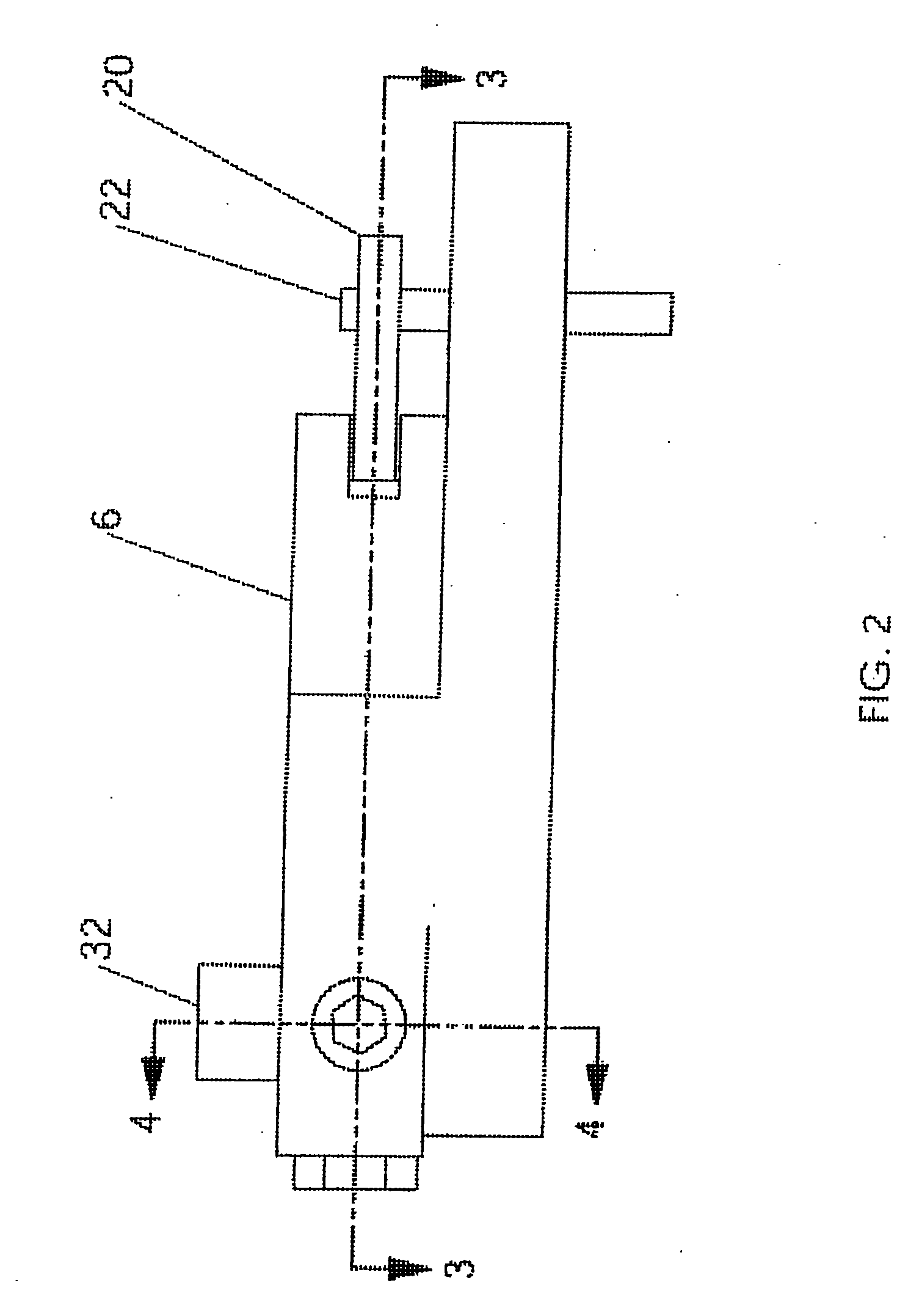

Environmentally safe fluid changing system

An oil changing device and process that allows a customer to service the fluids in an internal combustion engine or automatic transmission (their application) in a completely environmentally safe manner. The device is a conveniently located oil changing center where the entire process can be accomplished safely, quickly, cleanly, and at a low cost. The oil changing center includes a sealable container (4) containing an oil filter (2), a first quick disconnect coupling (14), and a second quick disconnect coupling (16). The couplings allow access to the application's oil sump (32) and lubrication system. When a customer wishes to change their oil, they attach an evacuation oil pump (18) to the quick disconnect couplings and evacuate all the dirty oil from the oil sump and lubrication system into a dirty oil holding tank (22). They then replace the oil filter. A fill oil pump (24) is attached to the quick disconnect couplings and fills the application with an appropriate amount of oil. During the entire process, neither the environment or the customer is ever endangered. This process and device allow for a completely clean operation.

Owner:MCCALEB DAVID A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com