Detachment-free oil drainage bolt

A technology of oil drain bolts and oil drain pipes, which is applied in the direction of adding/discharging lubricants and lubricating parts, etc., can solve the problems of pollution, failure to achieve functions, reduction of oil viscosity, etc., and achieve the effect of reducing pollution and avoiding splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

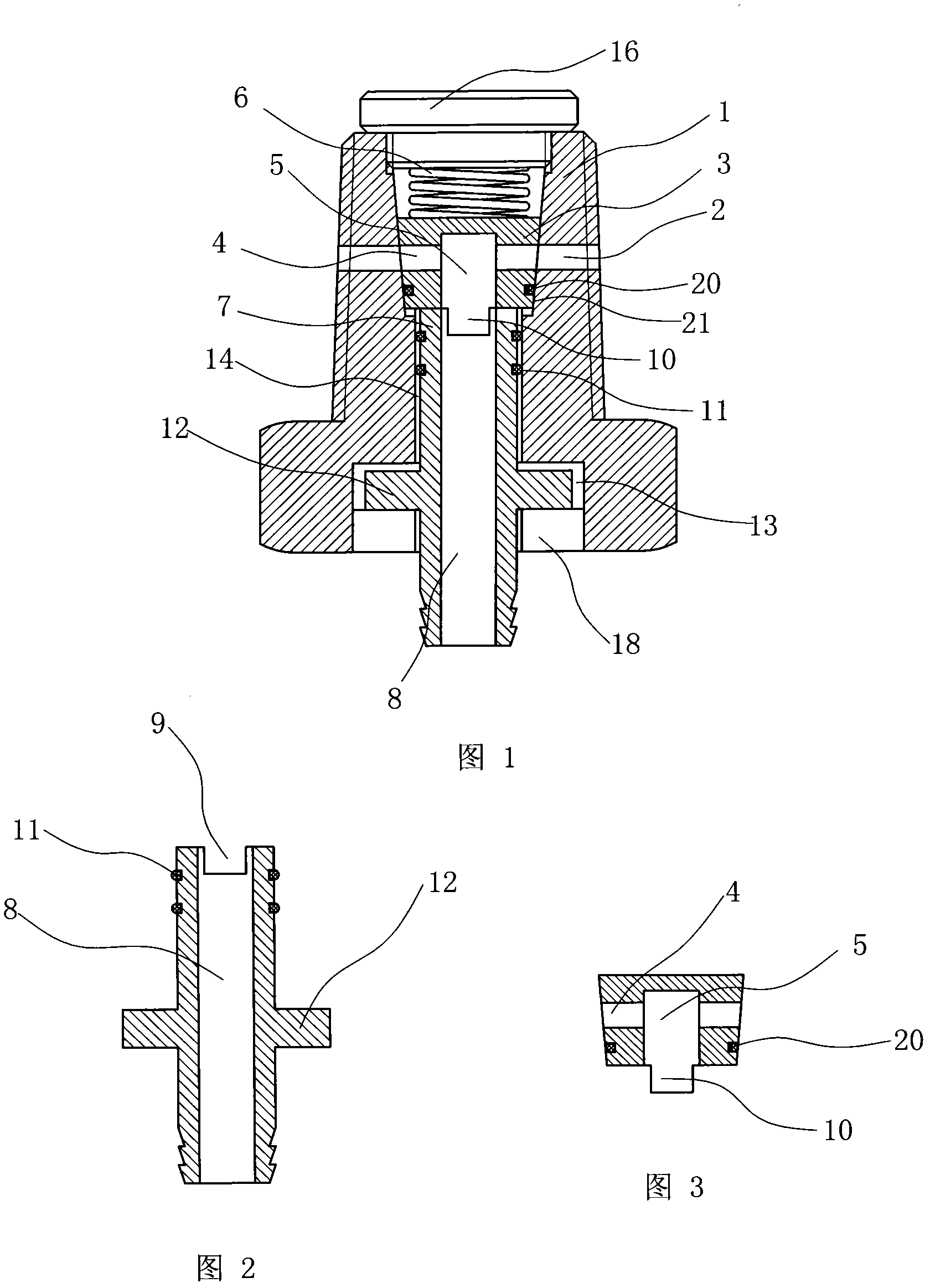

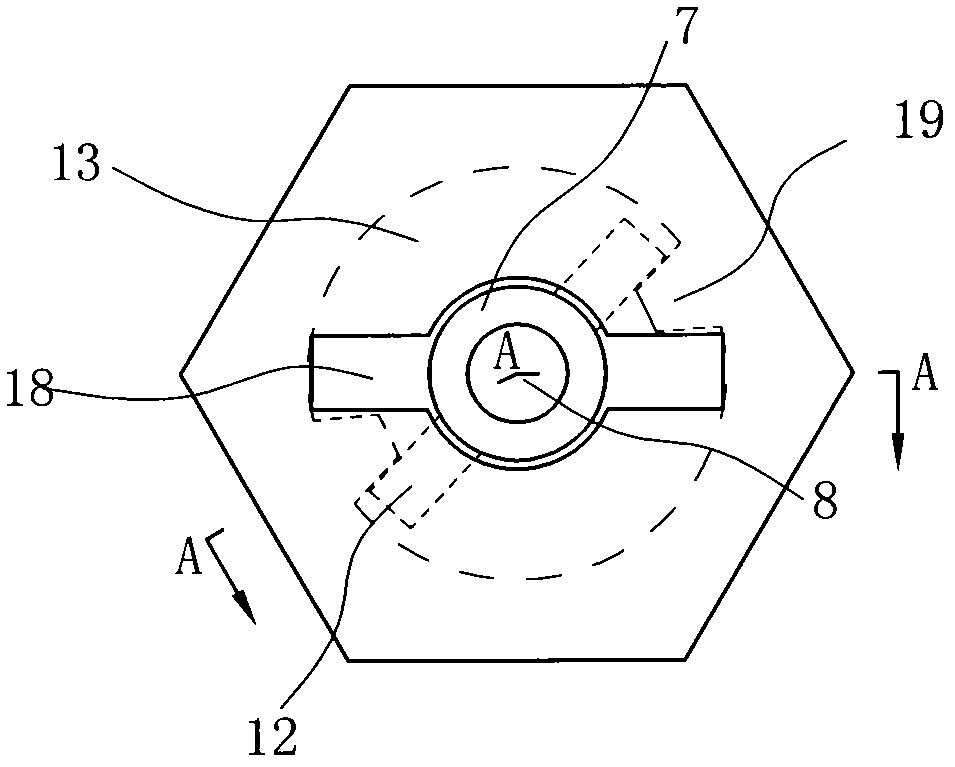

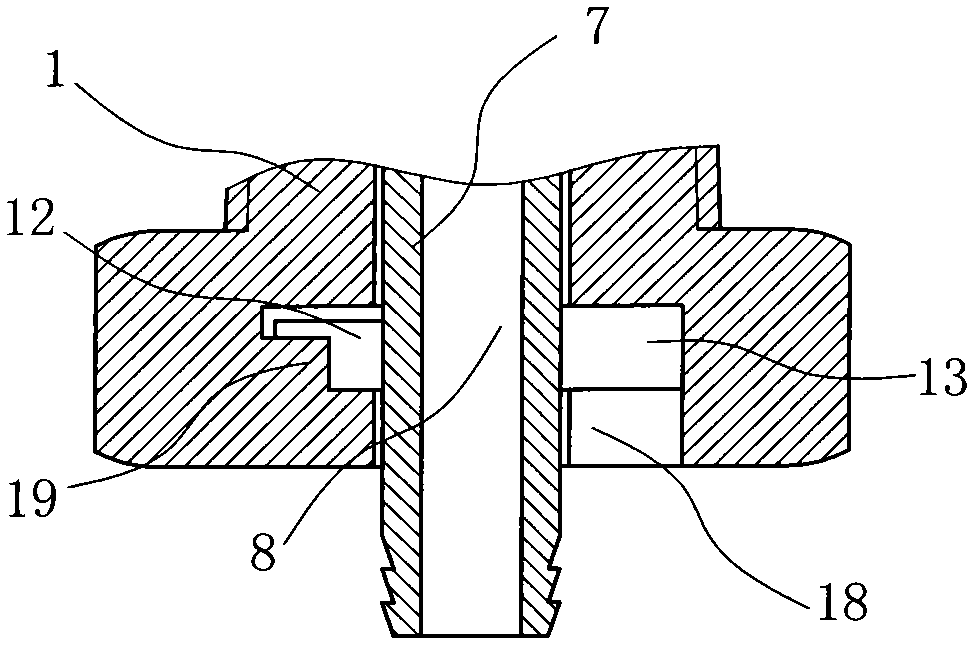

[0035] Such as figure 1 , figure 2 ,and image 3 As shown, the oil discharge bolt is not required to be disassembled, including: a valve body 1, which doubles as an oil discharge bolt, and the valve body 1 is provided with an external thread connecting the oil pan, and the valve body 1 is provided with a The valve body oil inlet hole 2 communicated with the inner cavity of the shell, the valve body 1 is also provided with the valve body oil outlet hole 14 communicated with the outside of the oil pan; the cock spool 3 is installed on the valve body 1 Inner cavity, the cock spool 3 is provided with a spool oil inlet channel 4 corresponding to the valve body oil inlet hole 2, and the cock spool 3 is also provided with a spool oil outlet channel 5, so The spool oil inlet channel 4 is connected with the spool oil outlet channel 5, and the spool oil outlet channel 5 is connected with the valve body oil outlet hole 14; the cock spool 3 is connected with the valve body A spool sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com