Patents

Literature

129 results about "Automatic lubrication system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

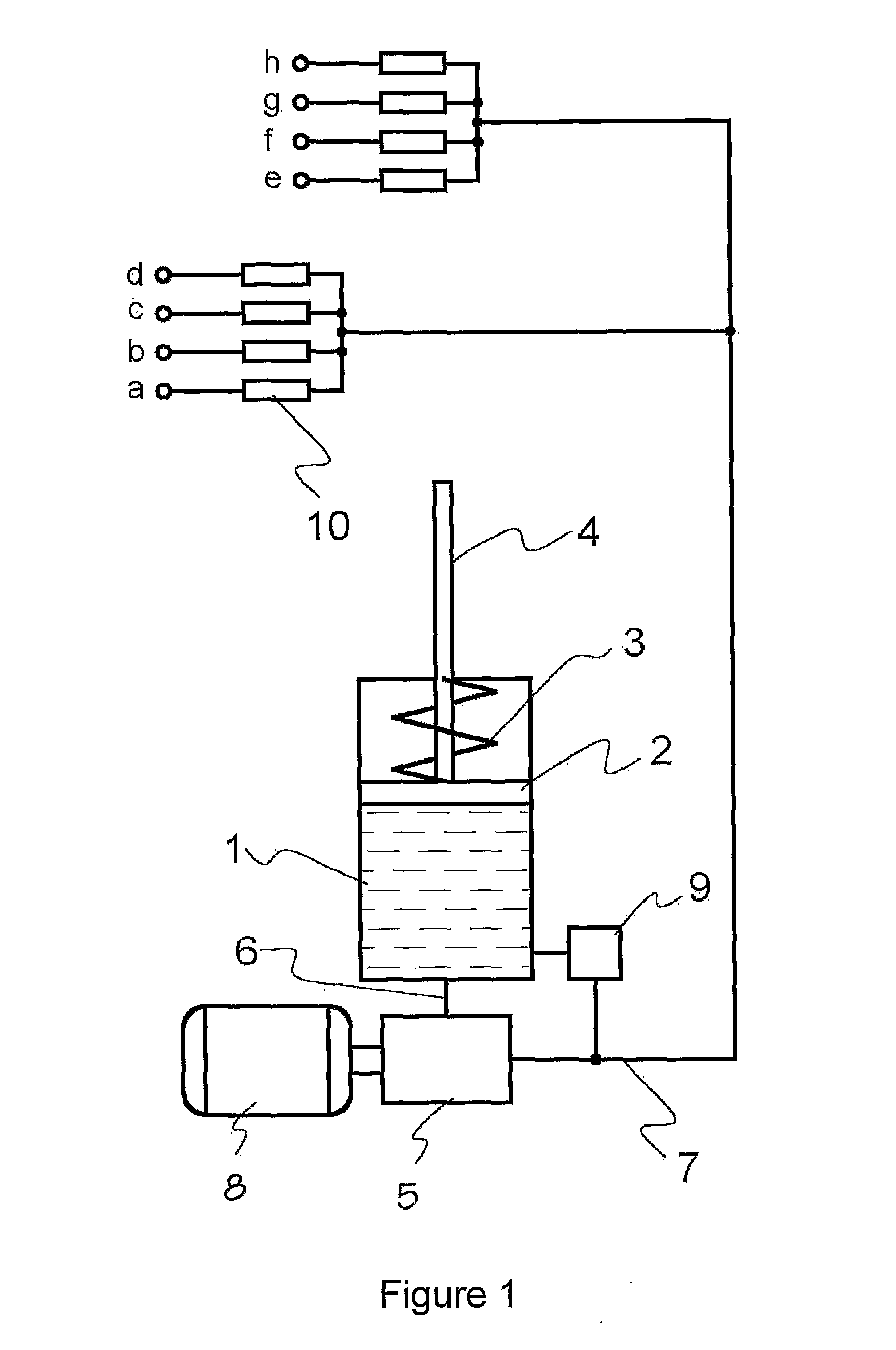

An automatic lubrication system (ALS), often referred to as a centralized lubrication system, is a system that delivers controlled amounts of lubricant to multiple locations on a machine while the machine is operating. Even though these systems are usually fully automated, a system that requires a manual pump or button activation is still identified as a centralized lubrication system. The system can be classified into two different categories that can share a lot of the same components.

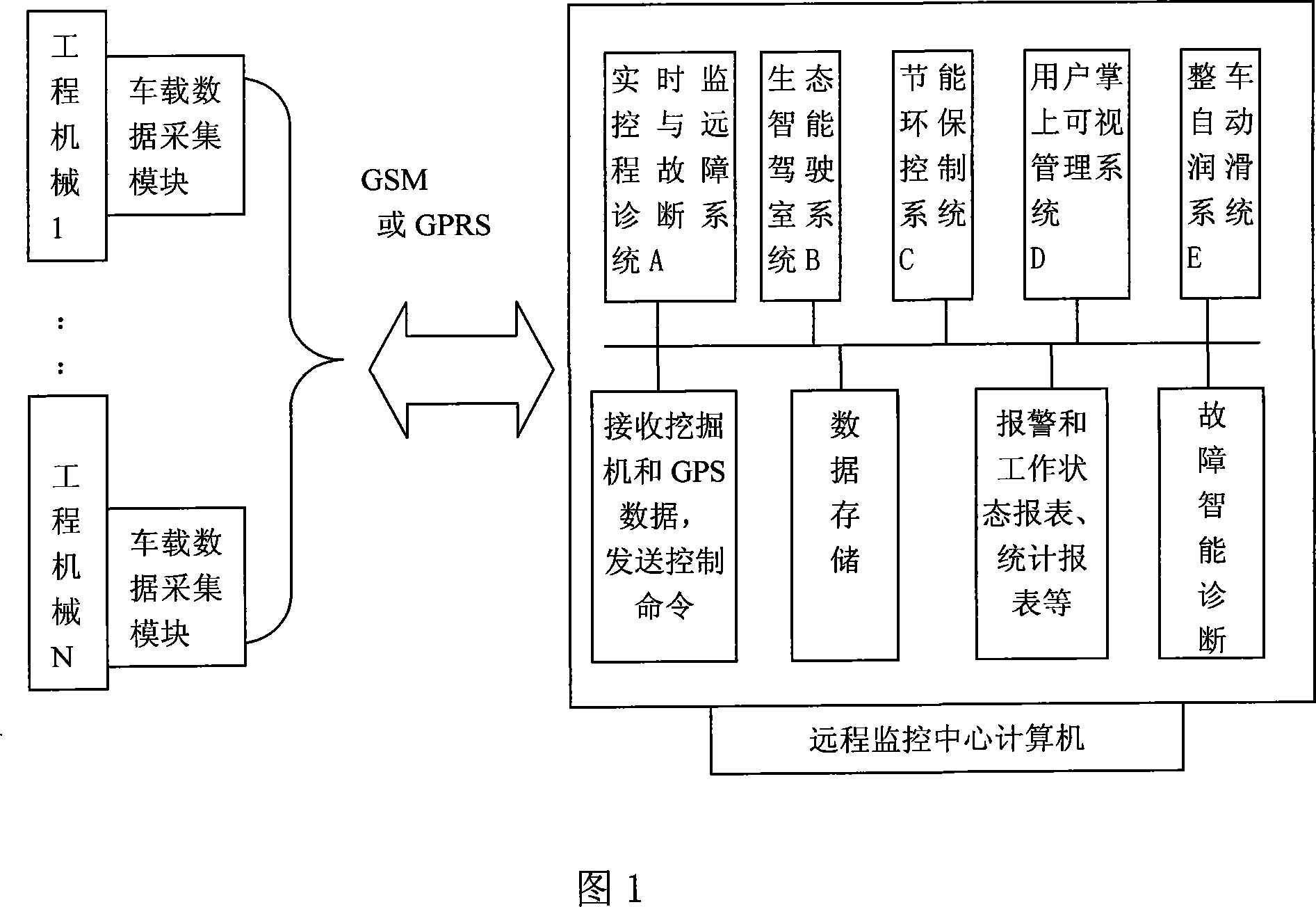

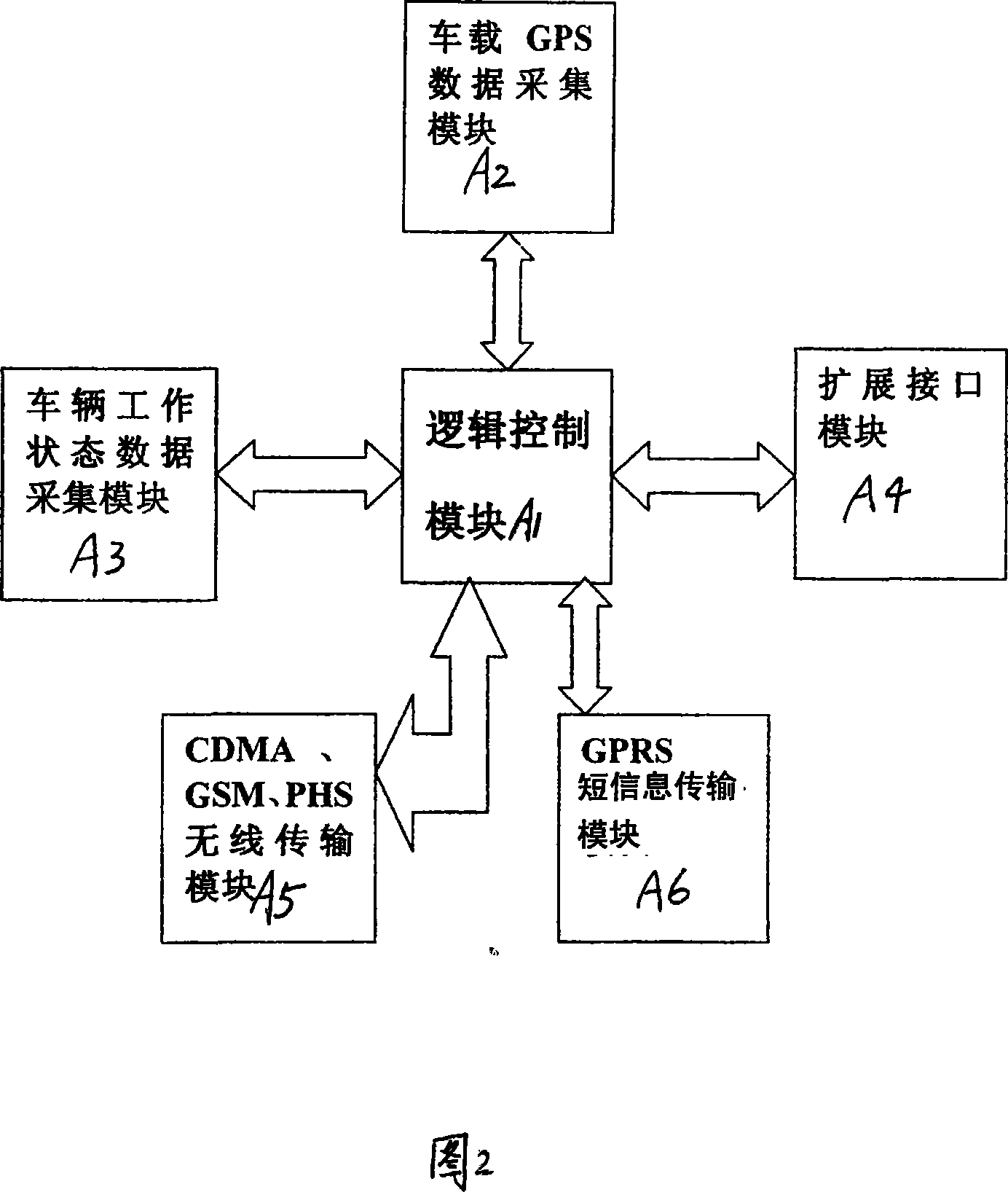

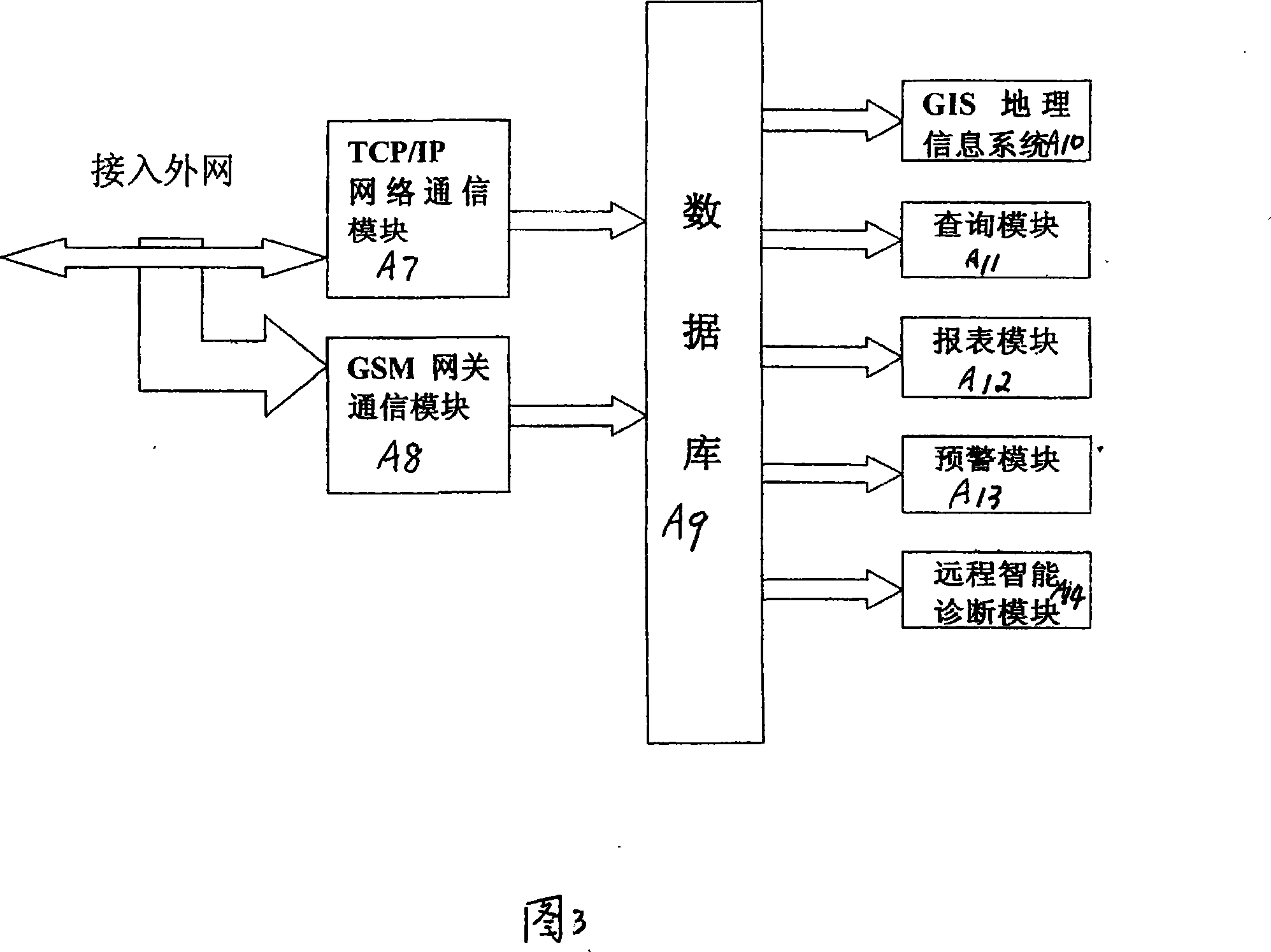

Engineering machinery intelligent vehicle mounted terminal based on multi-technology integration

InactiveCN101174140AReal-time remote control of precise locationProtection securityProgramme controlComputer controlWireless dataData acquisition

The invention discloses an engineering machinery intelligent vehicle-mounted terminal based on multi-technology integration, belonging to the technical field of mechanical automation, which comprises a remote control center computer and a plurality of devices connected with the computer such as an real-time monitoring and remote fault diagnosis system, an ecological intelligent cab system, an energy-saving and environment-friendly control system, user palmtop visual management system and a complete vehicle automatic lubrication system. An embedded data acquisition system and a GPS receiver are arranged on the vehicle for capturing the working data and position information of the engineering machine; through a remote wireless data communications network, the data and information are then transmitted to the remote data monitoring center computer, which processes and releases the data by means of a specific platform. The invention has the advantages that: accurate positioning can be performed on the engineering machine in use, the after-sale supporting departments can conveniently and remotely understand the precise positions of the faults on the equipment, thus the safety of the equipment can be ensured. The credit records of users can be managed, and the purchasers who default on the payment will be restrained remotely.

Owner:XUZHOU ZHILONG ELECTRONICS TECH

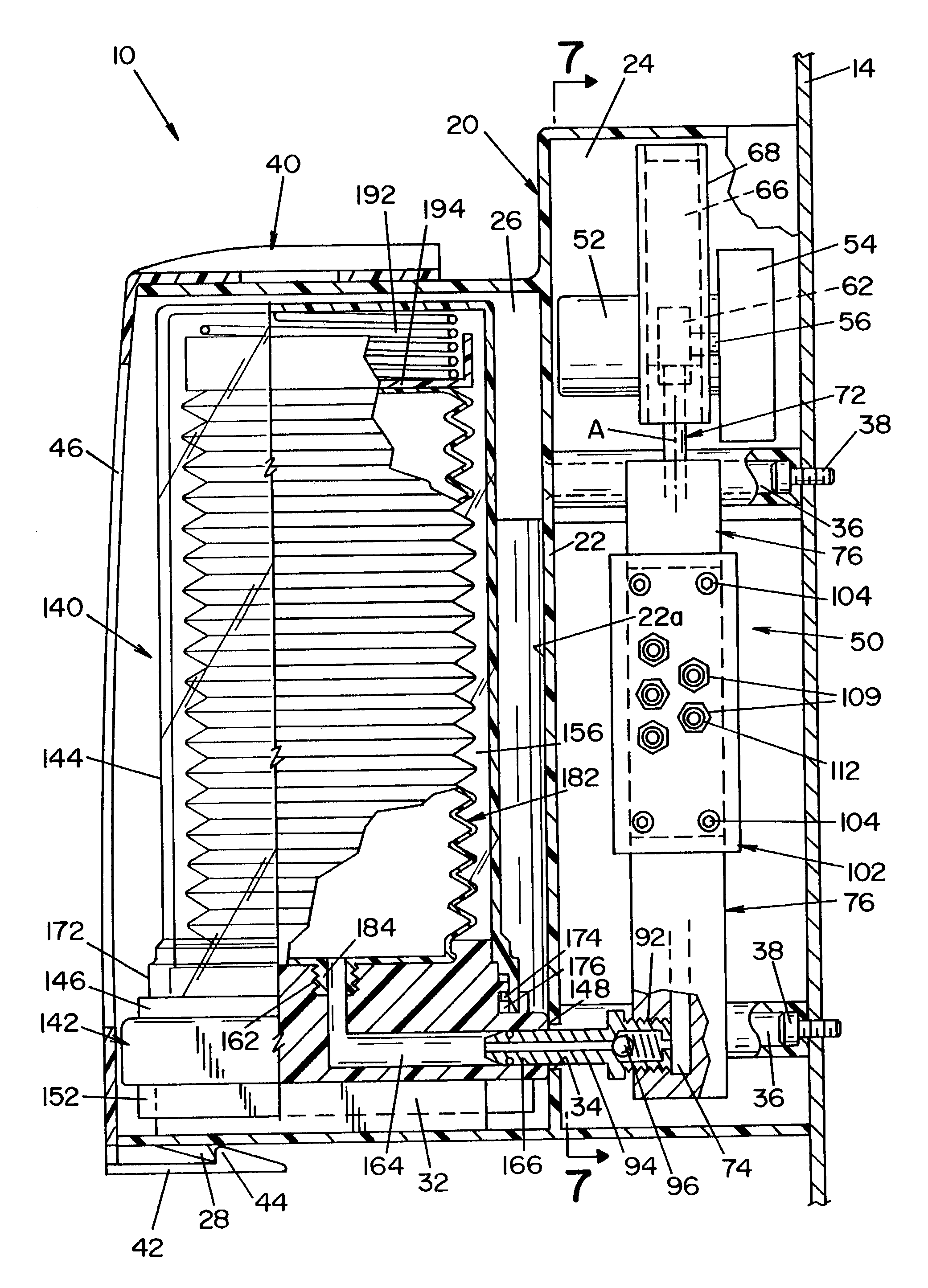

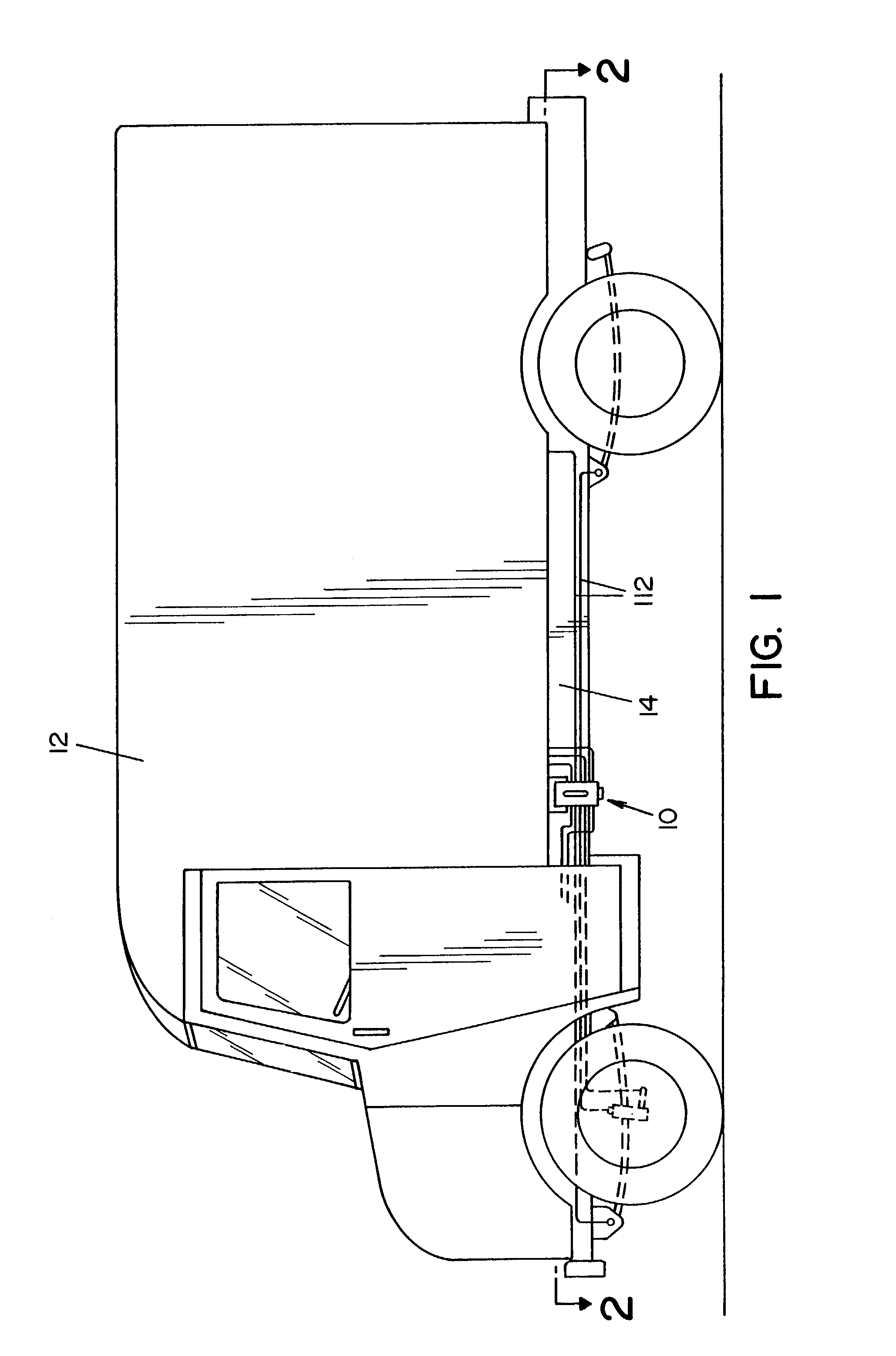

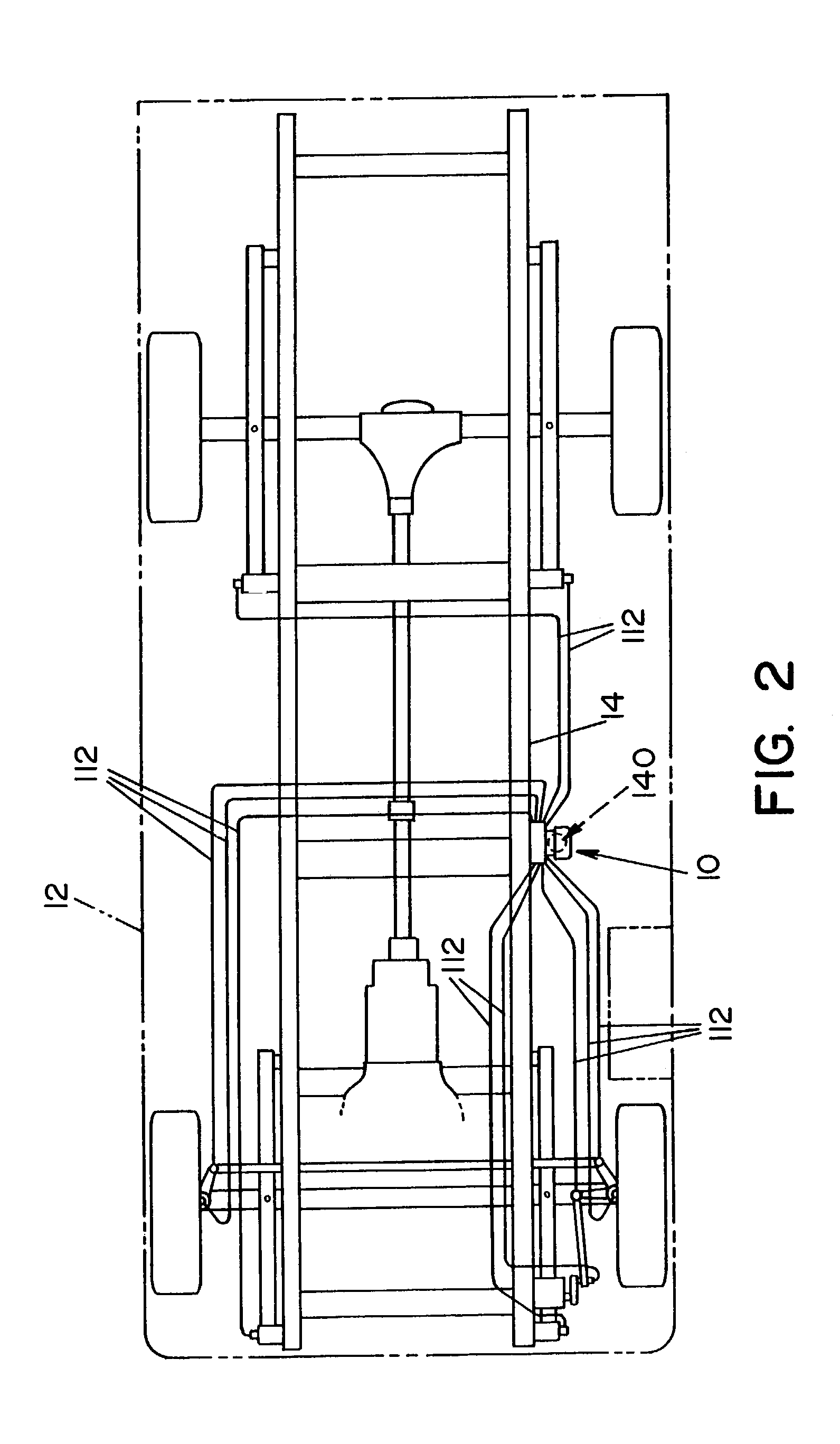

Automatic lubrication system

An automatic lubrication system for a vehicle, comprising a pump assembly having a plurality of outlet ports, a motor operable to drive the pump assembly, and a cartridge that is attachable to the pump assembly to provide a source of lubricant to the pump. The cartridge is removable from the pump assembly and has an interior space that is collapsible as lubricant is dispensed therefrom. A controller is provided to periodically initiate the motor to cause the pump to dispense lubricant to the outlet ports.

Owner:LIBRIQUIP INC

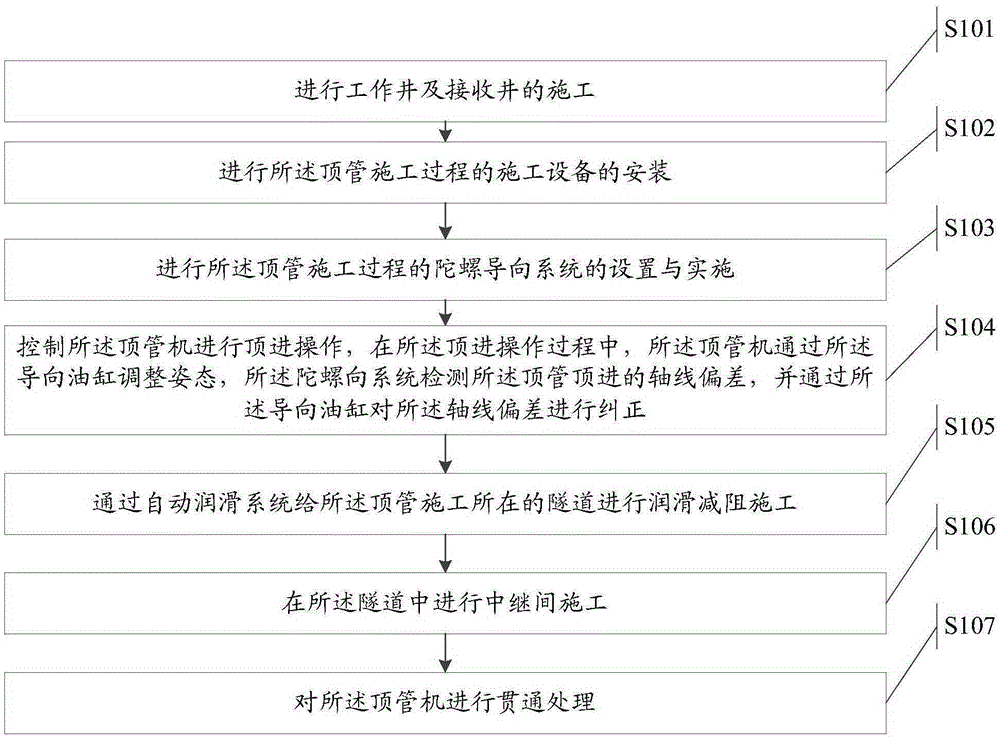

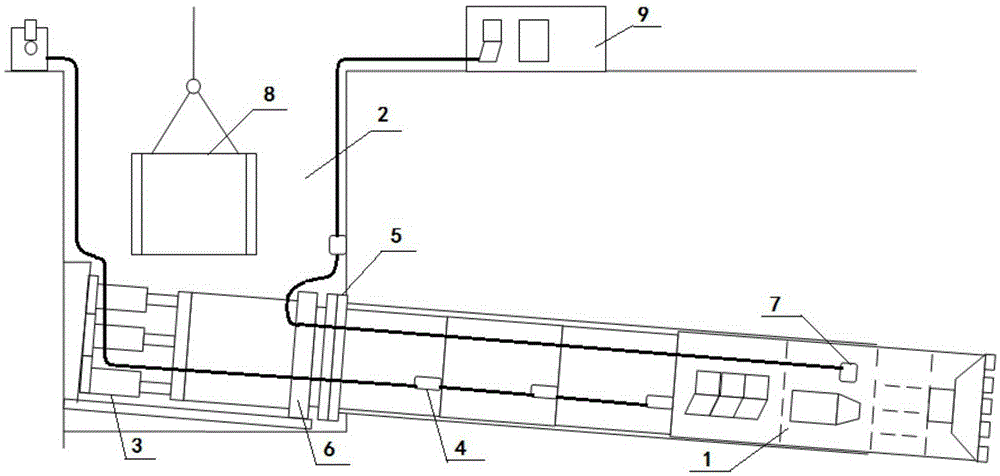

Pipe jacking construction method

ActiveCN105240019ASolve construction technical problems such as crossing rivers and lakesImprove economic efficiencyTunnelsGyroscopeAutomatic lubrication system

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

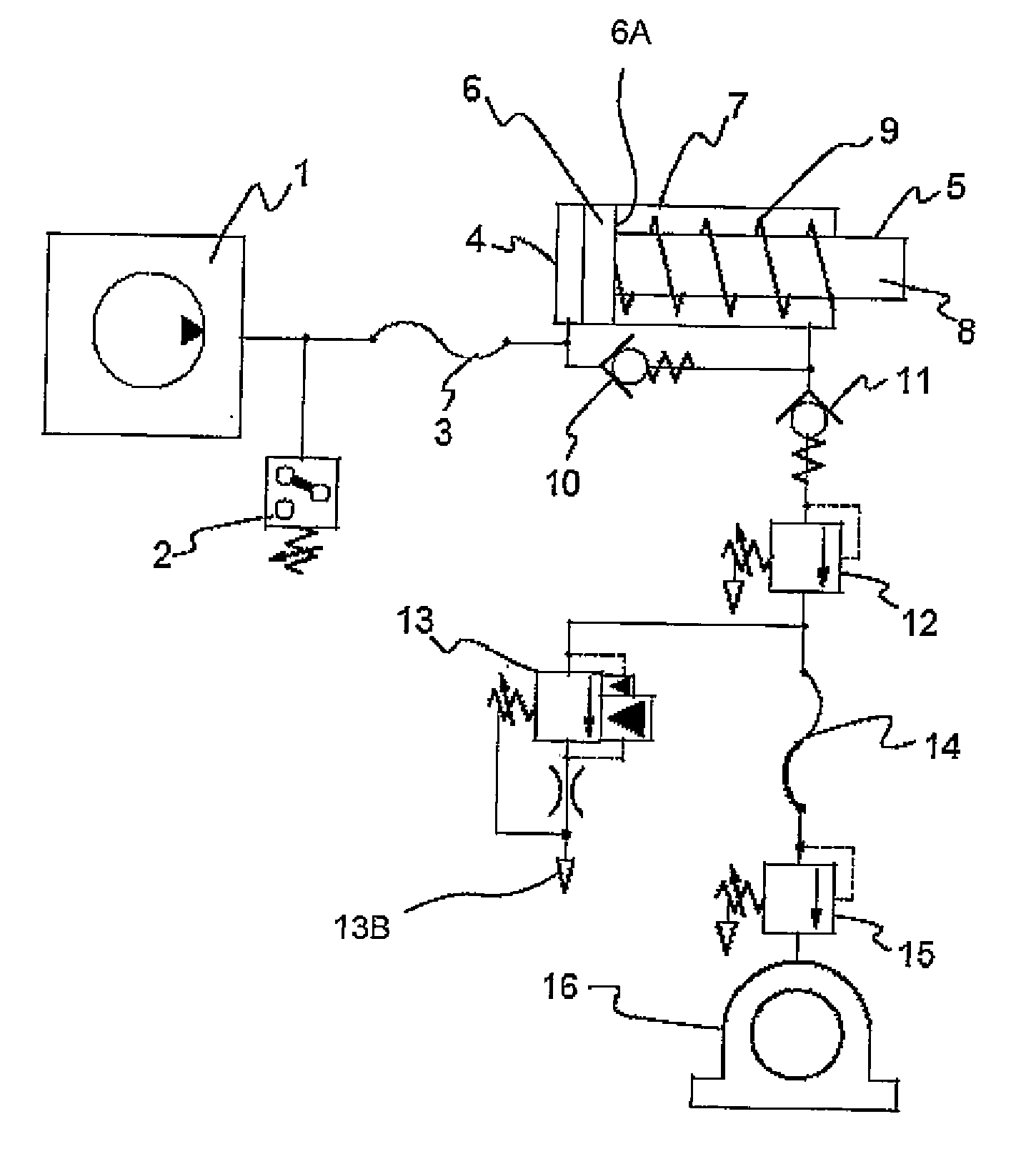

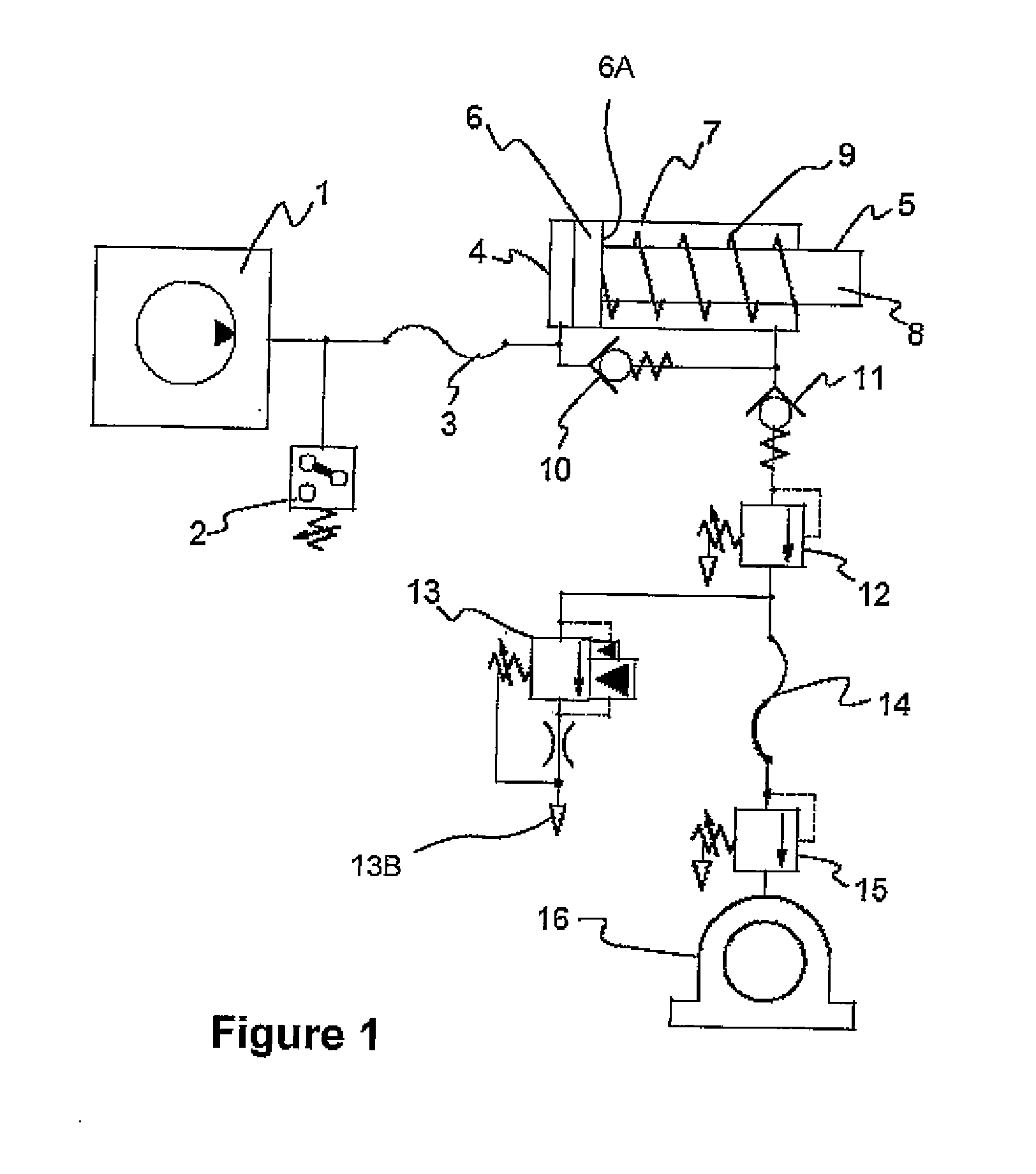

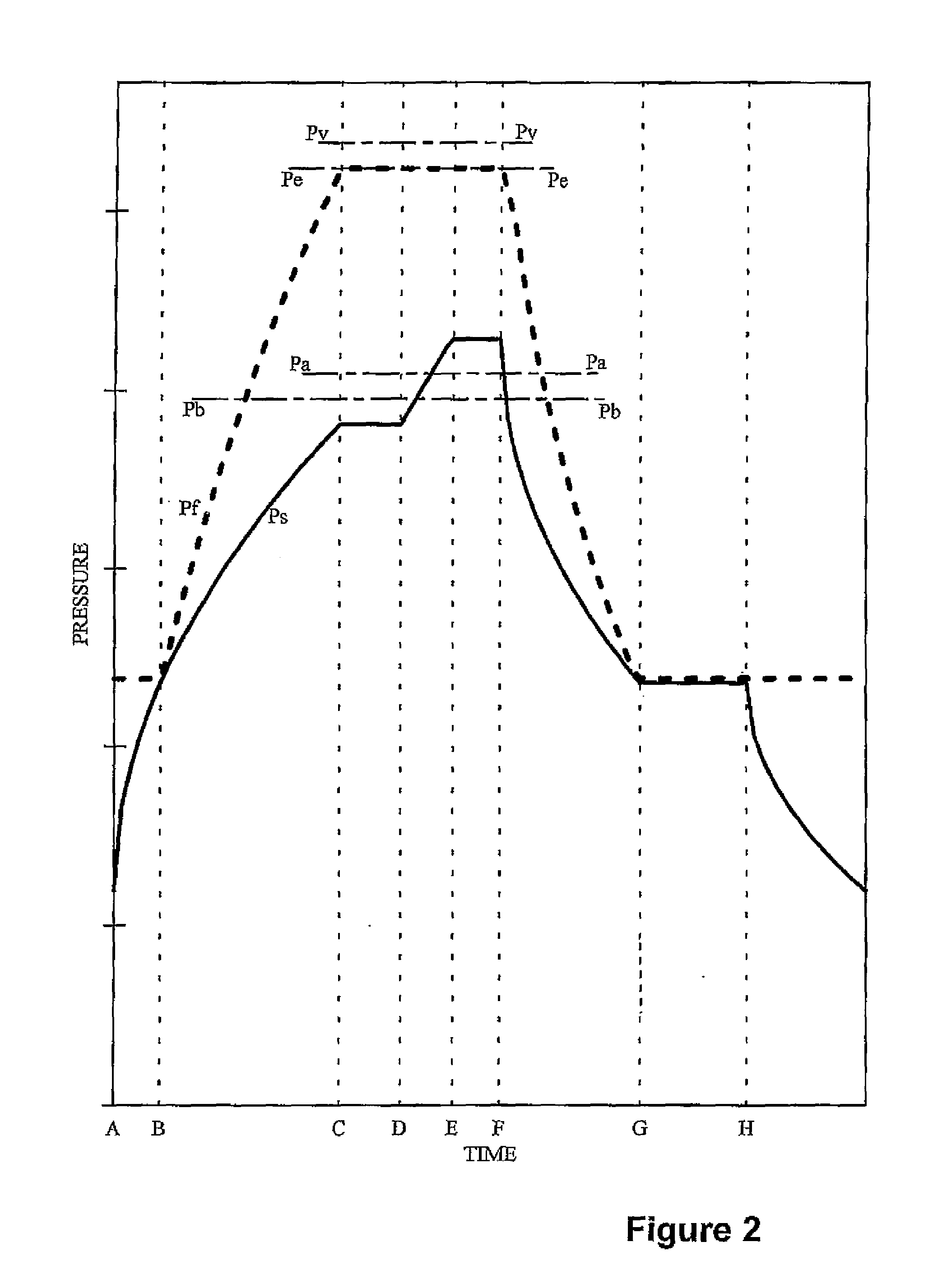

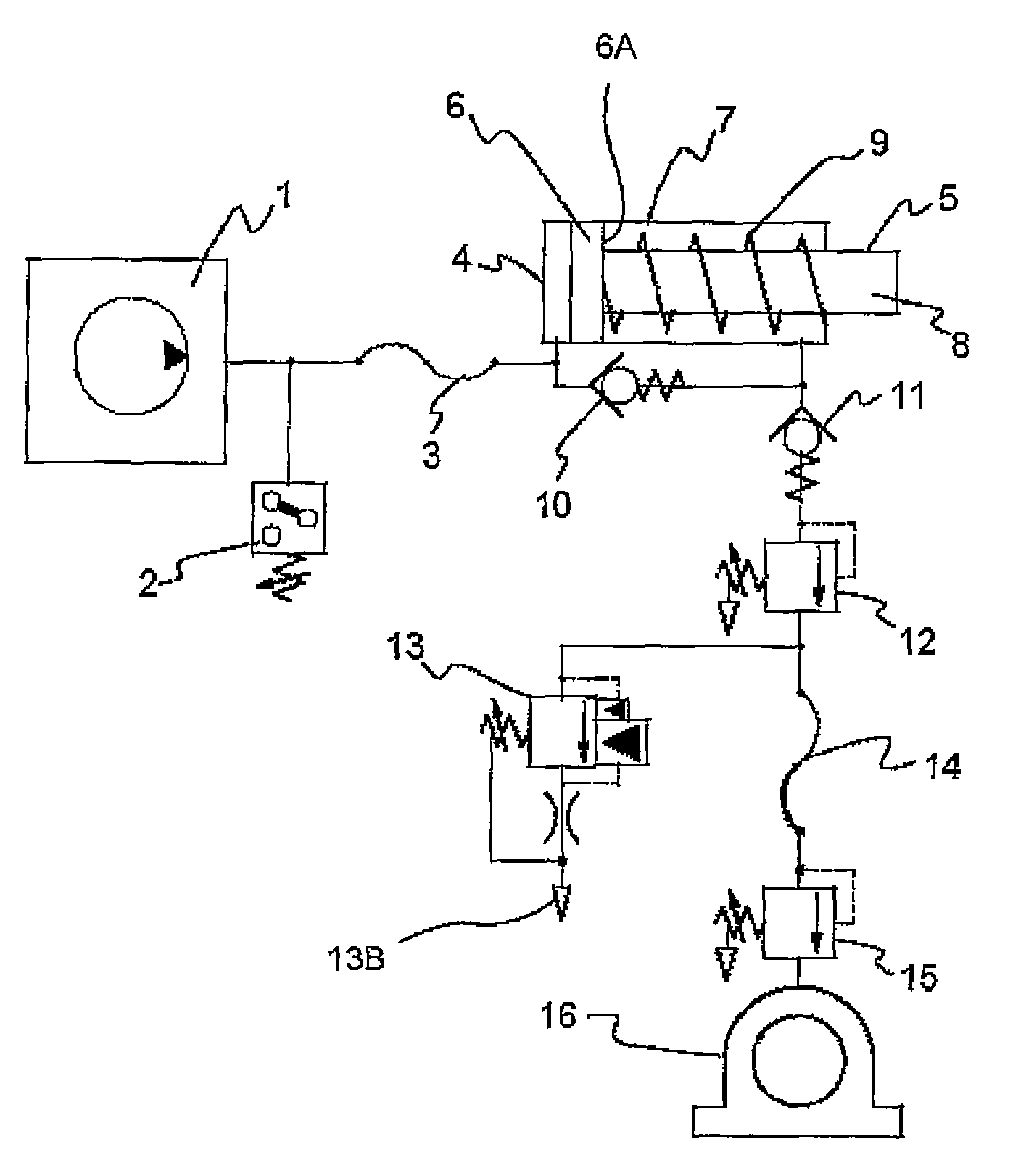

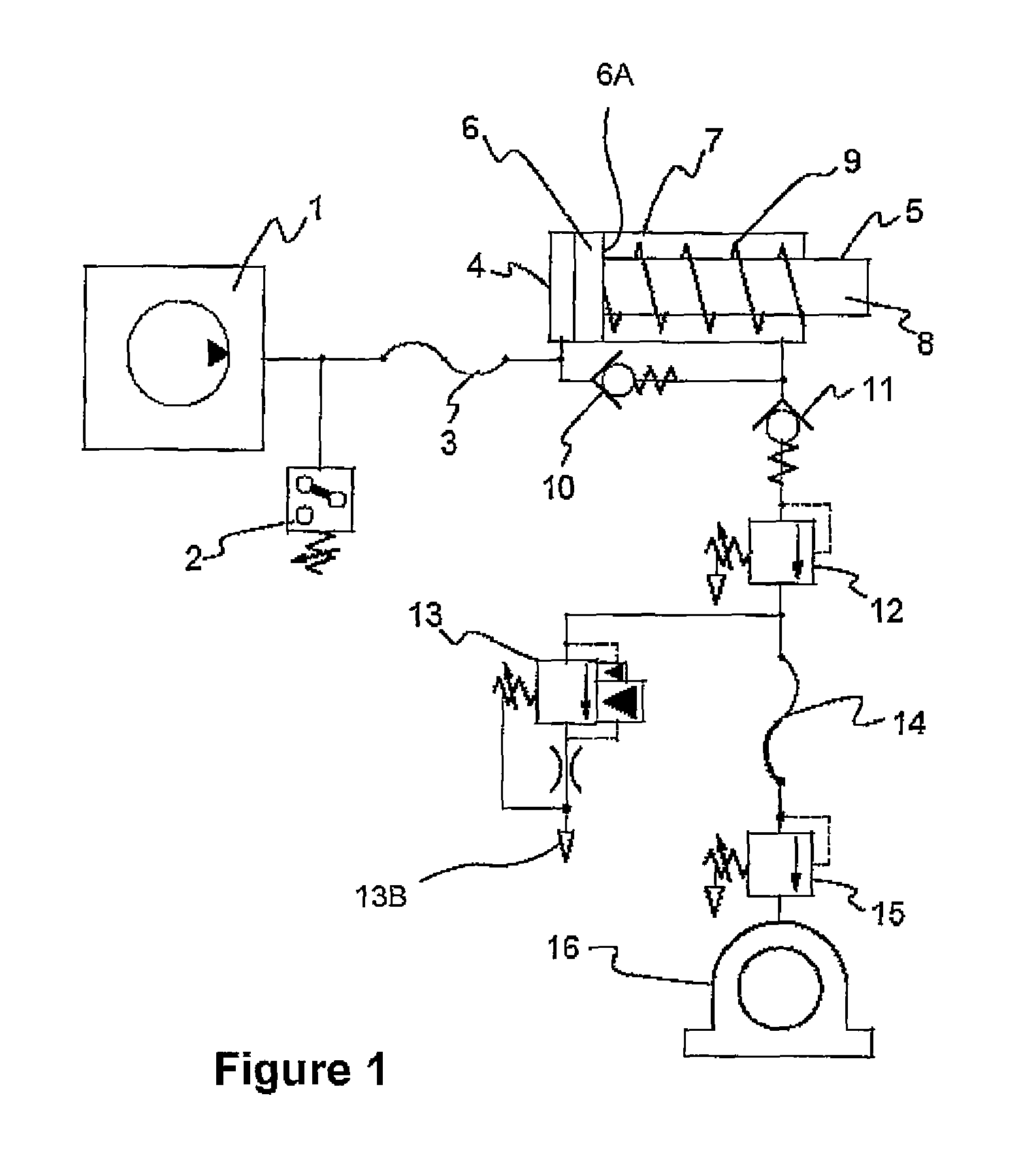

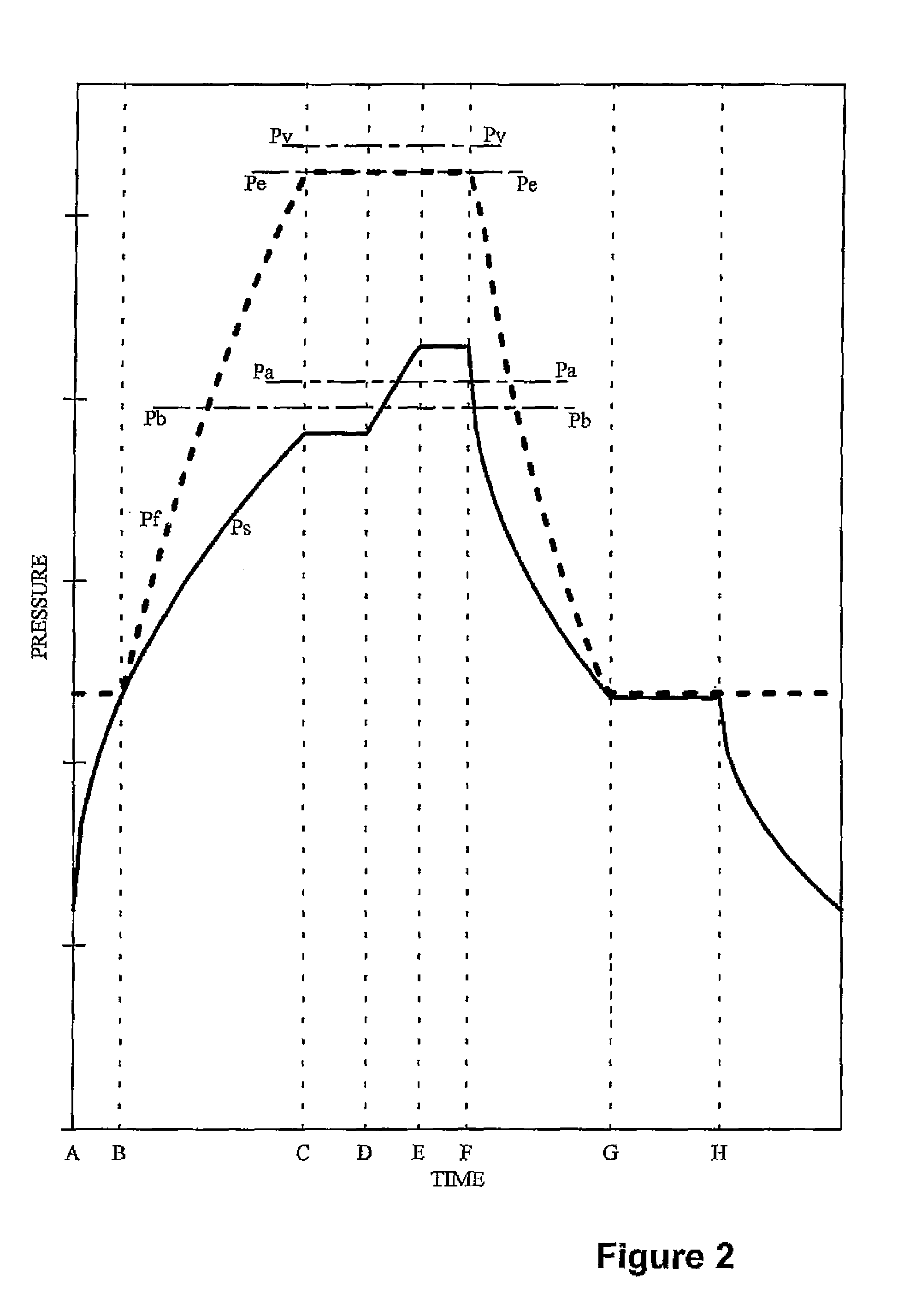

System for automatic lubrication

ActiveUS20120145482A1Prevent returnAvoid accidental rotationProportioning devicesDomestic plumbingInjection pressureExhaust valve

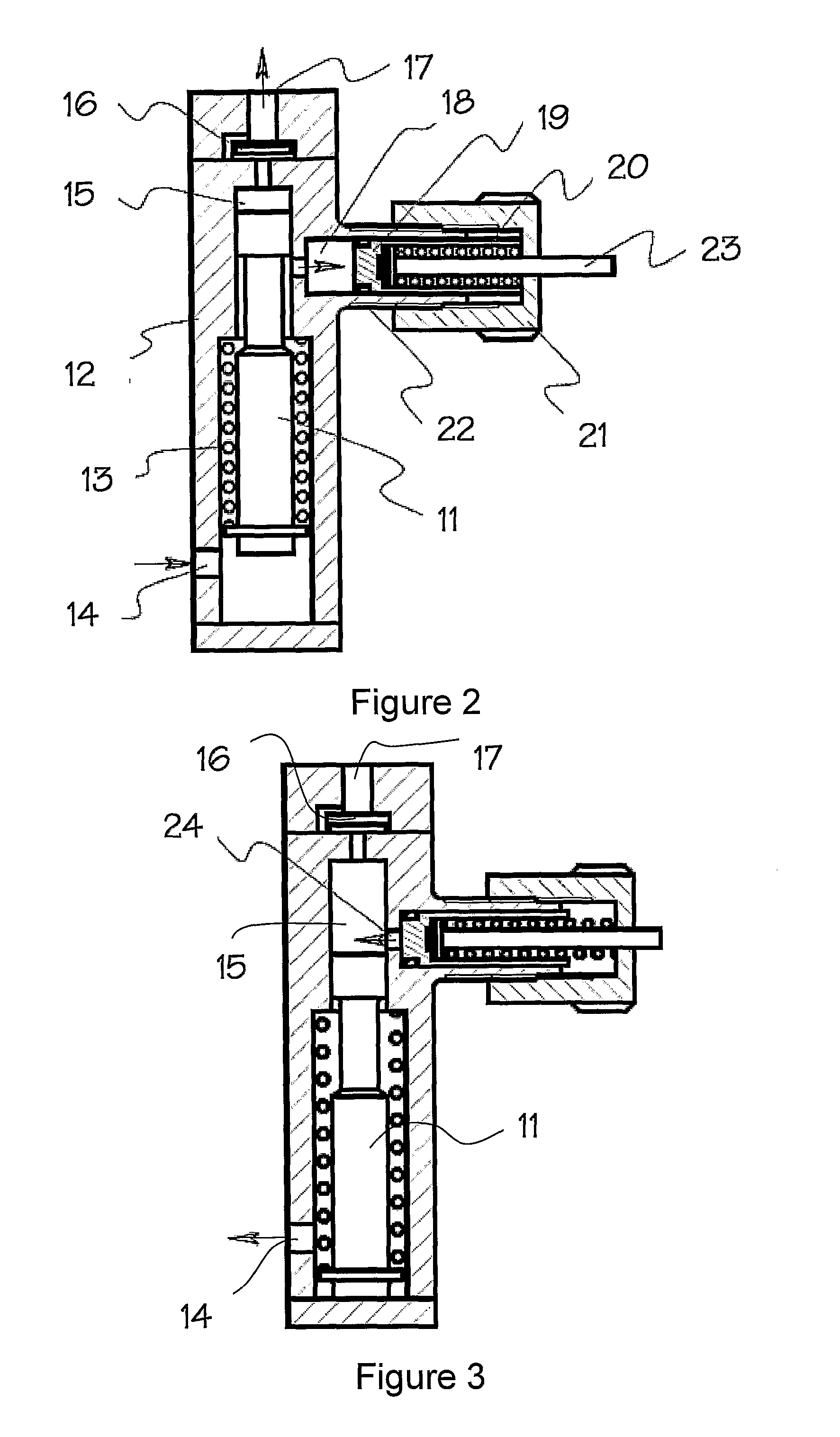

A system for automatically delivering lubricant to at least one bearing (16) has a lubricant pump (1) feeding lubricant under pressure through a supply line (3) to an injector (4). The injector, driven by the lubricant, sends a measured amount of lubricant down feed line (14) to bearing (16). A pressurising valve (15) maintains injection pressure in the feed line (14) enabling any failure of supply to be detected as a pressure drop at pressure switch (2). Preferred features include the incorporation of a second pressurising valve (12) at the injector end of the feed line (14), a blocked-line vent valve (13) to enable detection of a blocked or crushed feed line, and check valves (10) and (11). The injector (4) is preferably configured to produce a higher pressure at the outlet than the inlet, and various versions of this intensifying injector are described and claimed.

Owner:IFIELD ENG

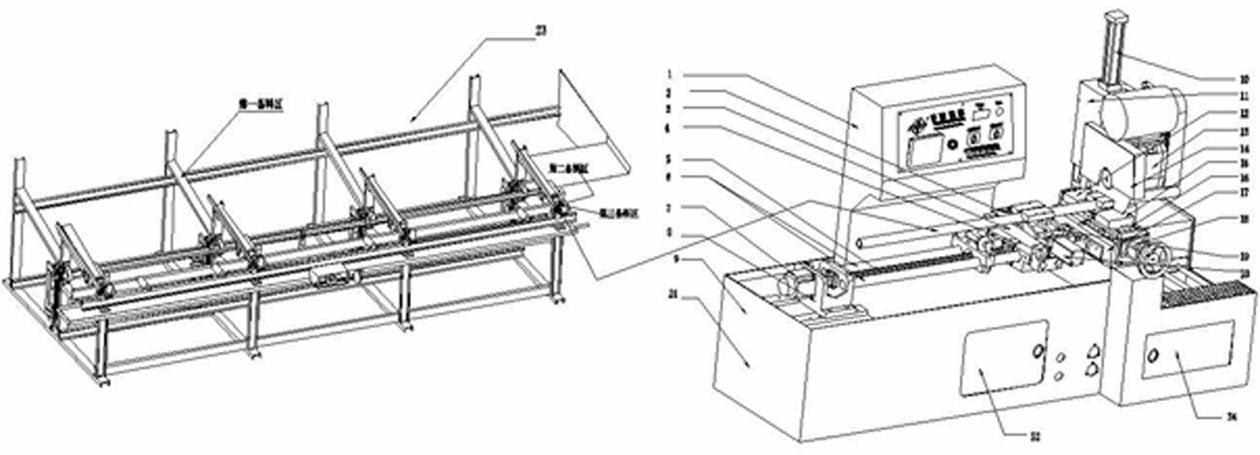

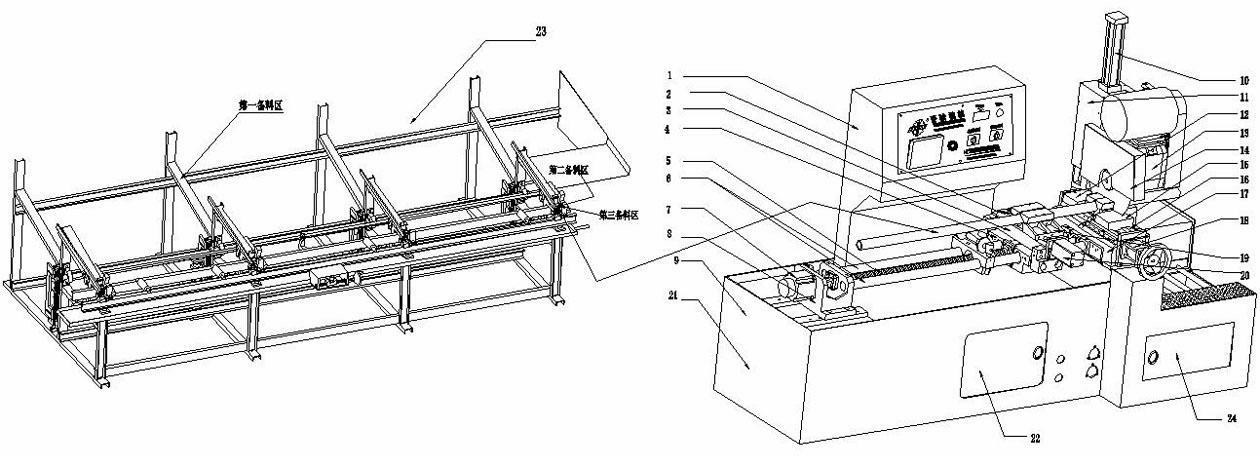

Slideway type metal circular sawing machine

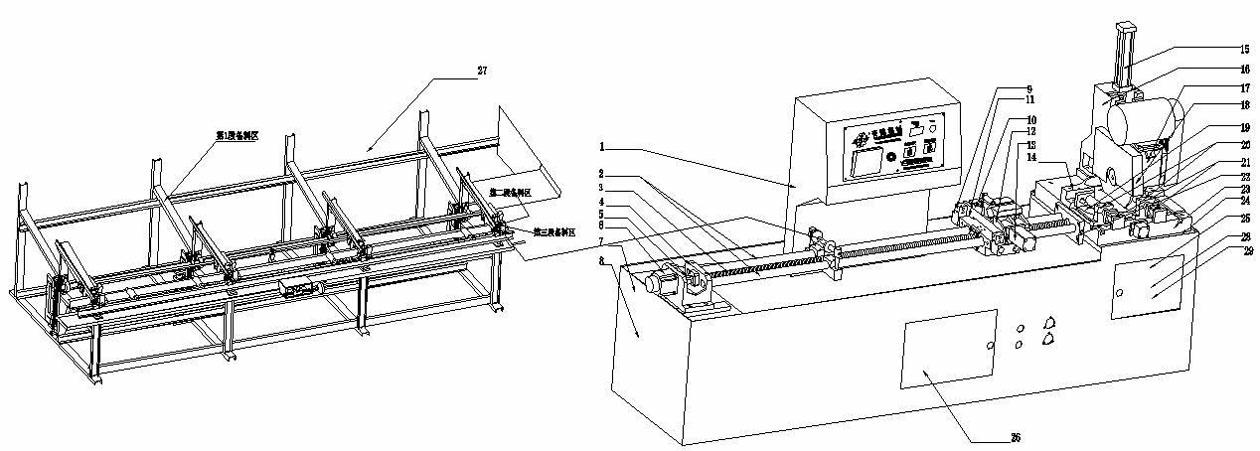

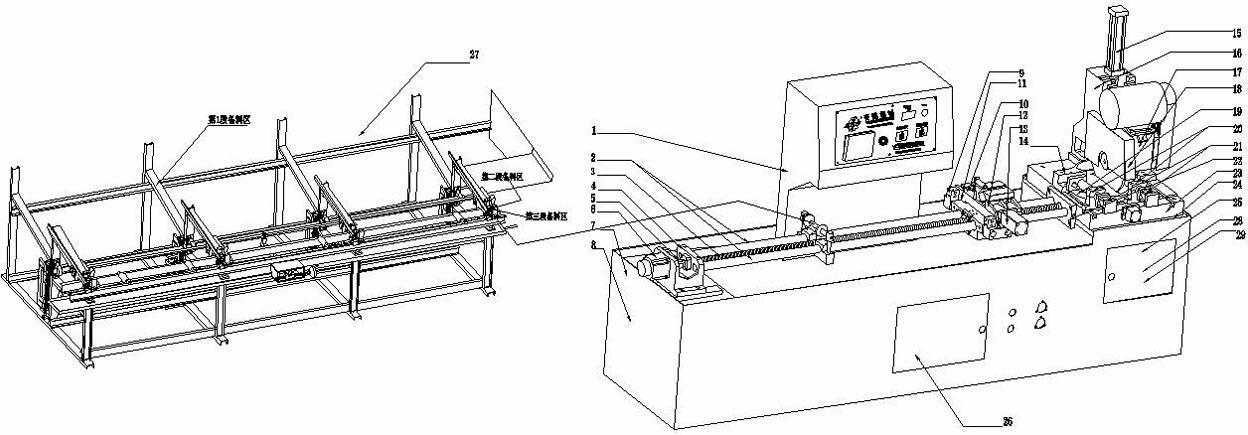

The invention discloses a slideway type metal circular sawing machine, which comprises a machine body, a feeding device, a cutter feeding device, a servo motor and an electric control cabinet which are arranged on the machine body, and an automatic feed preparation device for automatic loading and feeding by an oil cylinder and an inductor. By the slideway type metal circular sawing machine, metal materials such as steel materials, iron materials and the like which have various section shapes can be sawed quickly, the circular sawing machine shuts down automatically when the circular sawing machine does not have the materials, saw dust is collected intensively, and the circular sawing machine has integrated functions of automatic loading, automatic feeding, dimensioning, automatic clamping, cutting and the like of single or multiple materials; and each movable part of the integral machine is internally provided with an automatic lubricating system and is easy and convenient to maintain, so the work time is saved, the man-machine work efficiency is improved substantially, and the metal circular sawing machine is perfect and efficient in sawing accuracy.

Owner:东莞市晋诚机械有限公司

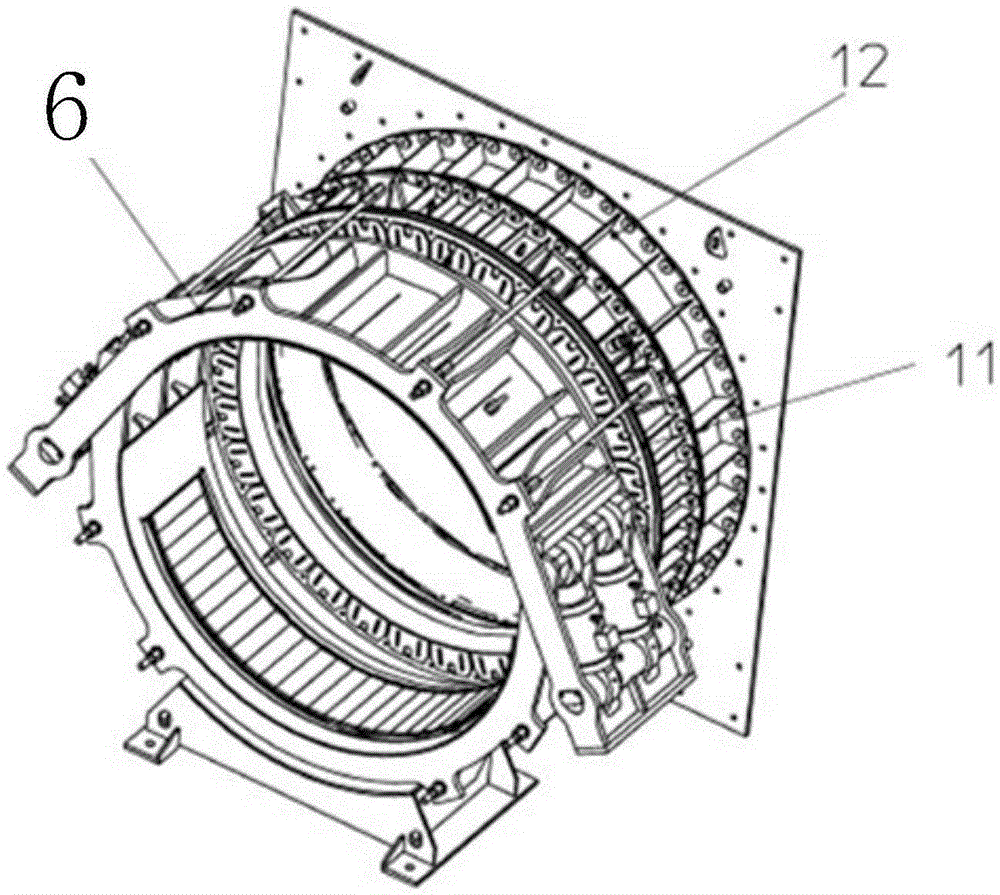

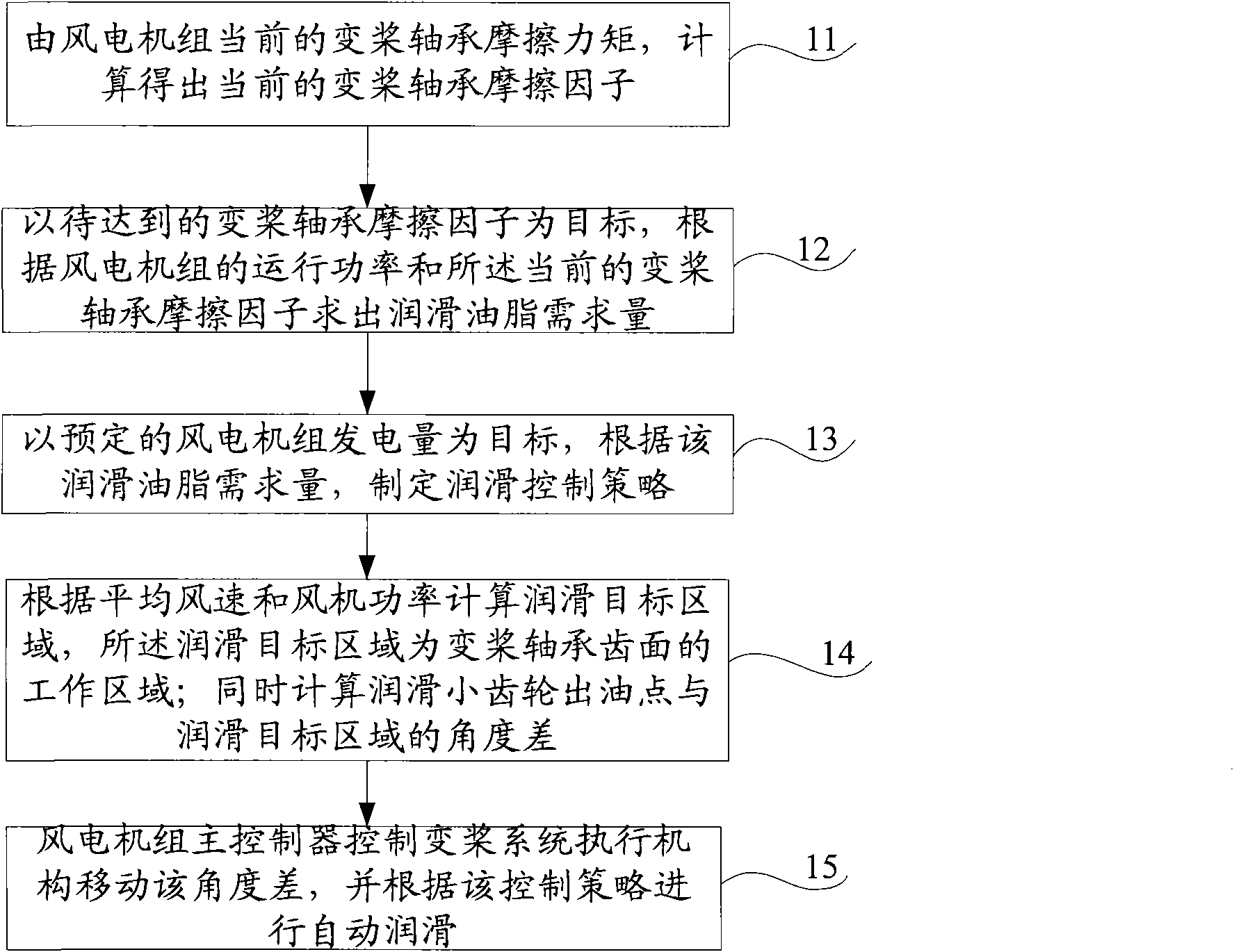

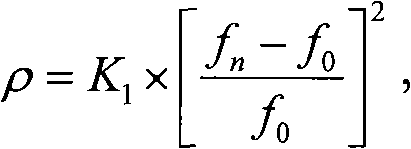

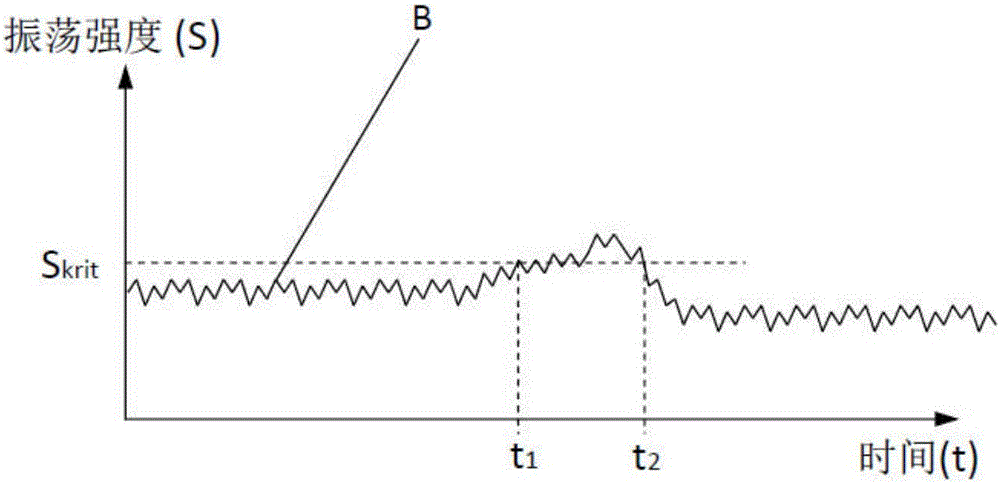

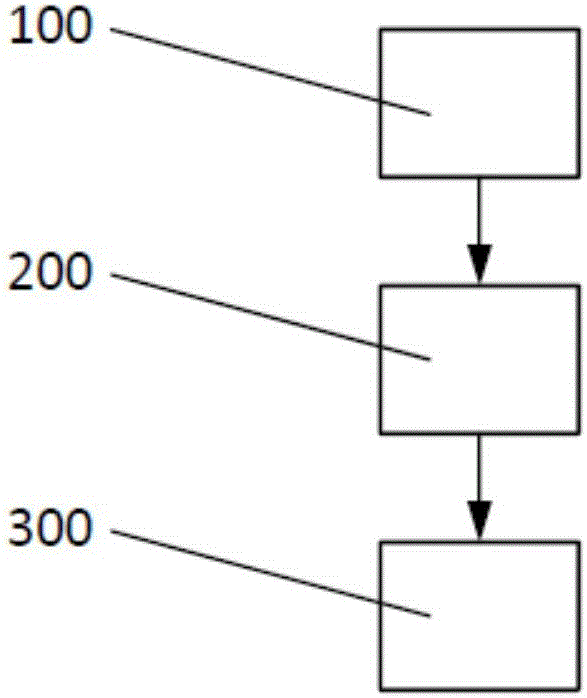

Control method for automatic lubrication system of pitch bearing for wind turbine

InactiveCN102374119AReduce usageImprove the lubrication effectTurbinesWind motor controlElectricityFriction torque

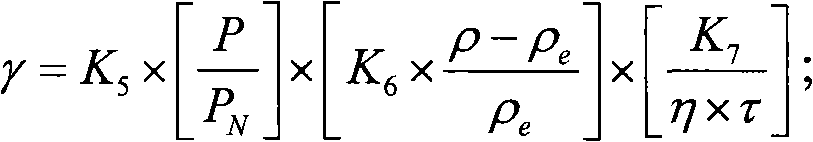

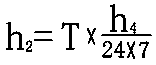

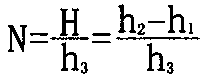

The invention provides a control method for an automatic lubrication system of a pitch bearing for a wind turbine, which comprises the following steps: working out the current friction factor of the pitch bearing by the current friction torque of the pitch bearing for the wind turbine; solving out the quantity demanded of lubrication grease by taking the to-be-reached friction factor of the pitch bearing as the target according to the operating power of the wind turbine and the current friction factor of the pitch bearing; generating a lubricating control strategy by taking the predetermined generated energy of the wind turbine as the target according to the quantity demanded of the lubrication grease; calculating a to-be-lubricated target area according to average air speed and blower power, wherein the to-be-lubricated target area is the working area of the tooth surface of the pitch bearing; simultaneously, calculating an angle difference between the oil outlet point of a lubricating pinion and the to-be-lubricated target area; and controlling a pitch system actuating mechanism to shift the angle difference by a main controller of the wind turbine, and performing automatic lubrication according to the control strategy. By adopting the control method for the automatic lubricating system of the pitch bearing for the wind turbine, the pitch bearing and the pitch tooth surface are well lubricated.

Owner:SINOVEL WIND GRP

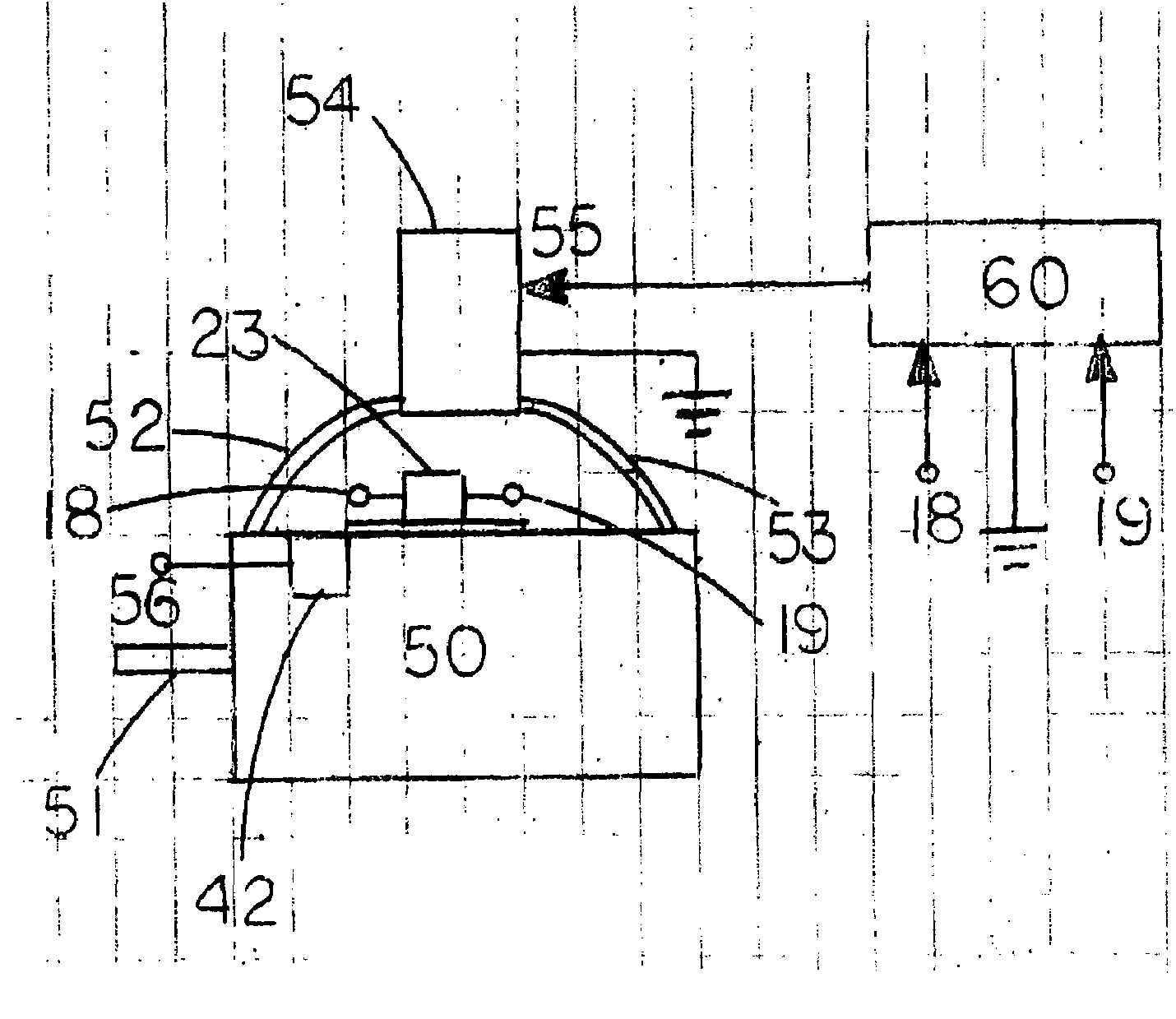

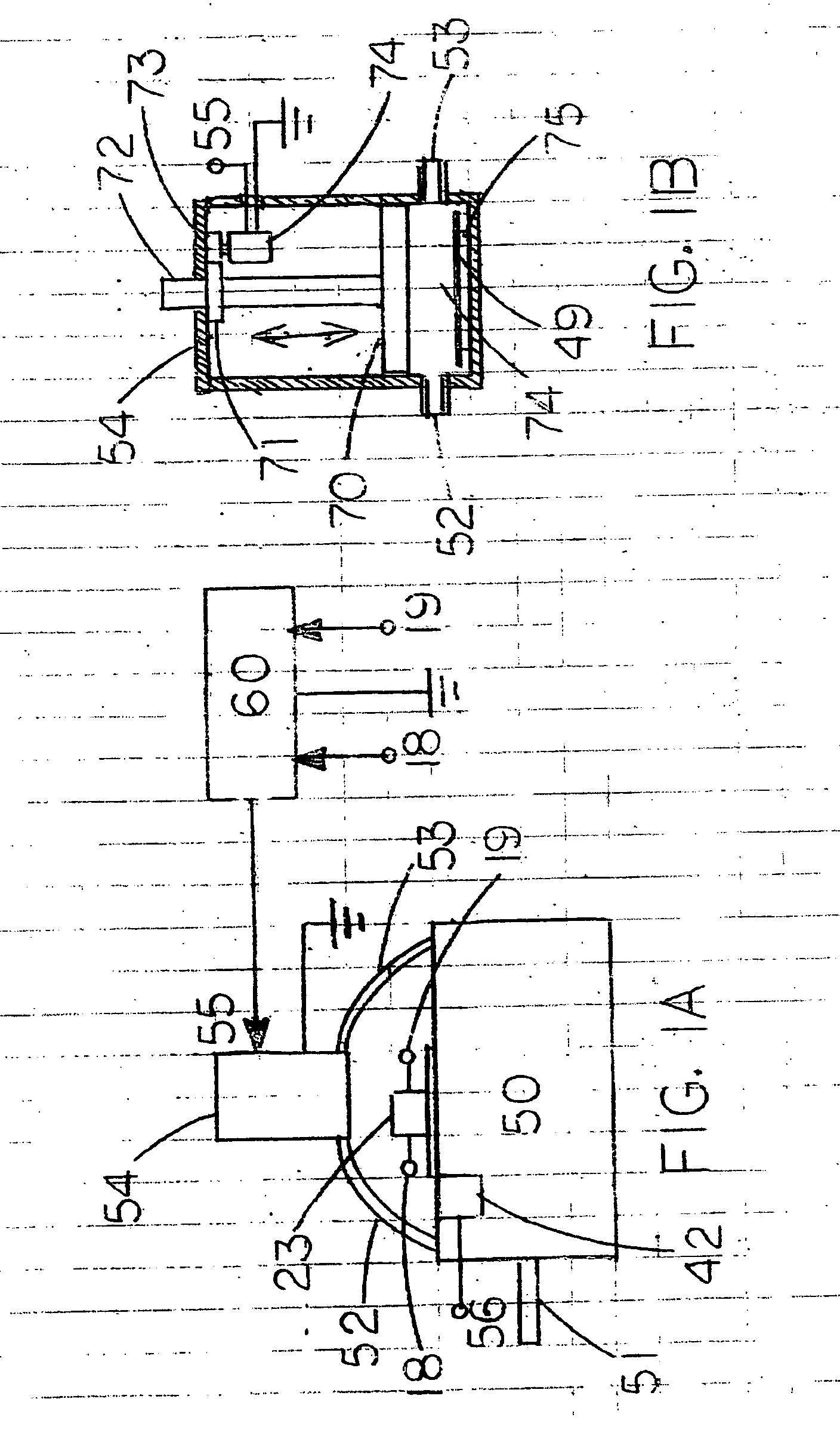

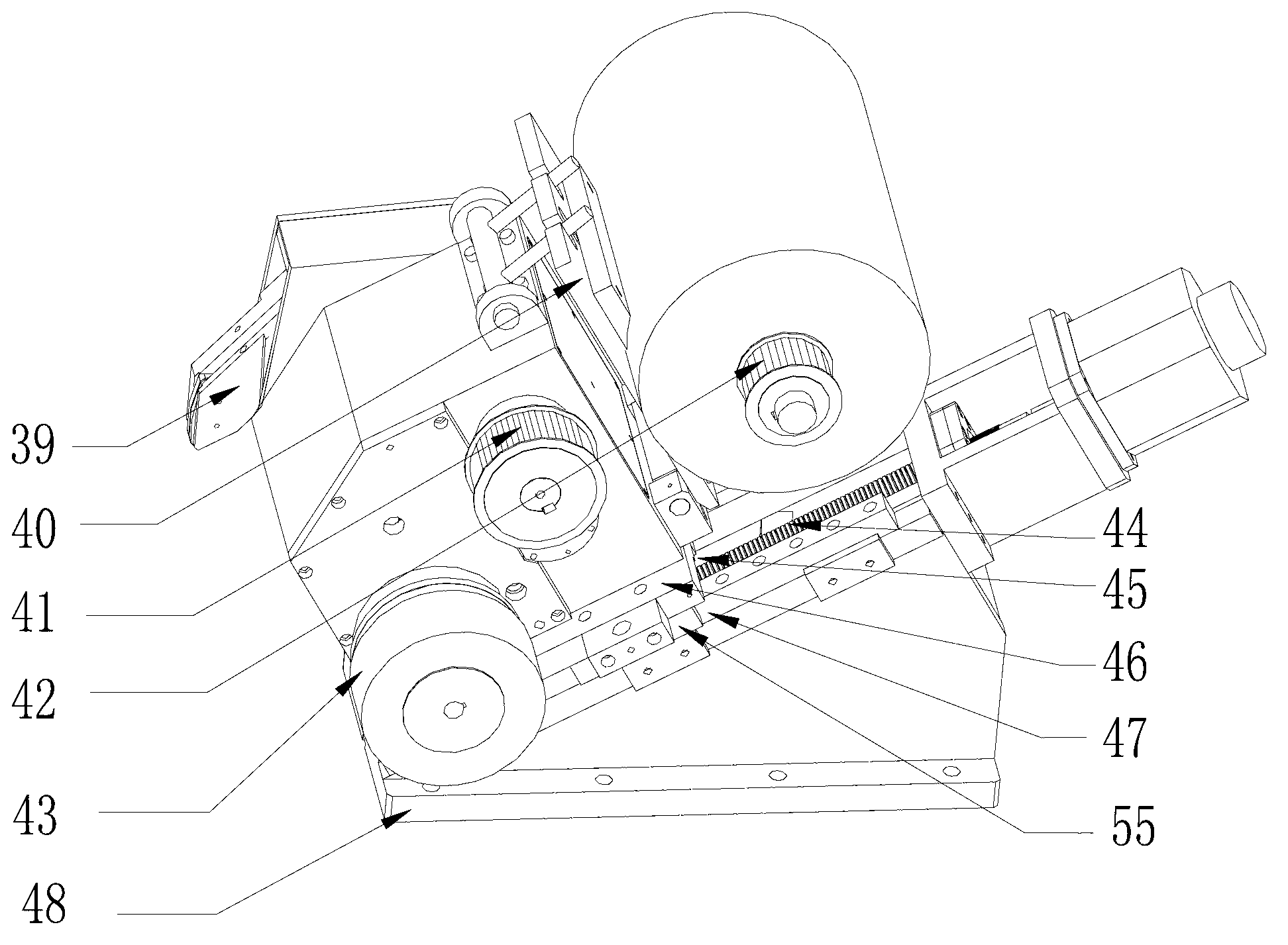

Method and apparatus for purging air from automatic lubrication systems

An automatic lubrication system where grease is dispensed to injectors from a pump having a grease piston (42) reciprocated by a connecting rod from an oil piston (43) driven by alternating hydraulic pressure, is provided with air purge valves (41) associated with each injector. The air purge valves detect abnormal operation of the piston movement due to air in the grease by way of indicators (45) and (46) communicating with chambers in the pump, and open the air purge valve to dump air laden grease into a recovery reservoir (48). A sensor in the air purge valve warns the operator of purge valve operation, alerting the operator to a possible system malfunction.

Owner:IFIELD ENG

Control method for variable pitch automatic lubricating system of megawatt wind power generator unit

ActiveCN103423087AImprove the lubrication effectLubrication will not affect theWind motor controlMachines/enginesEngineeringAutomatic lubrication system

The invention discloses a control method for a variable pitch automatic lubricating system of a megawatt wind power generator unit. The method comprises the steps of 1, setting time of one lubricating period and the lubricating time needed by the variable pitch system in one lubricating period, and setting the forcible lubricating time and the forcible lubricating interval time; 2, performing normal lubricating; 3, ending the normal lubricating, and counting the time of the lubricating time; 4, judging whether the time of the normal lubricating time is achieved; 5, computing the difference value of the two time points in the step 4, and computing the times for forcible lubricating according to the difference value; 6, performing forcible lubricating; 7, ending the forcible lubricating, judging whether times for the forcible lubricating are achieved after the forcible lubricating time interval; if the result of the step 4 is yes, performing step 2, otherwise performing step 5; and if the result of the step 7 is yes, performing step 2, otherwise performing step 6. The control method for the variable pitch automatic lubricating system of the megawatt wind power generator unit can realize a better lubricating effect on variable pitch bearings and gear rings.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Method and apparatus for purging air from automatic lubrication systems

InactiveCN102187142AOperating means/releasing devices for valvesMachines/enginesReciprocating motionPiston

An automatic lubrication system where grease is dispensed to injectors from a pump having a grease piston (42) reciprocated by a connecting rod from an oil piston (43) driven by alternating hydraulic pressure, is provided with air purge valves (41) associated with each injector. The air purge valves detect abnormal operation of the piston movement due to air in the grease by way of indicators (45) and (46) communicating with chambers in the pump, and open the air purge valve to dump air laden grease into a recovery reservoir (48). A sensor in the air purge valve warns the operator of purge valve operation, alerting the operator to a possible system malfunction.

Owner:IFIELD ENG

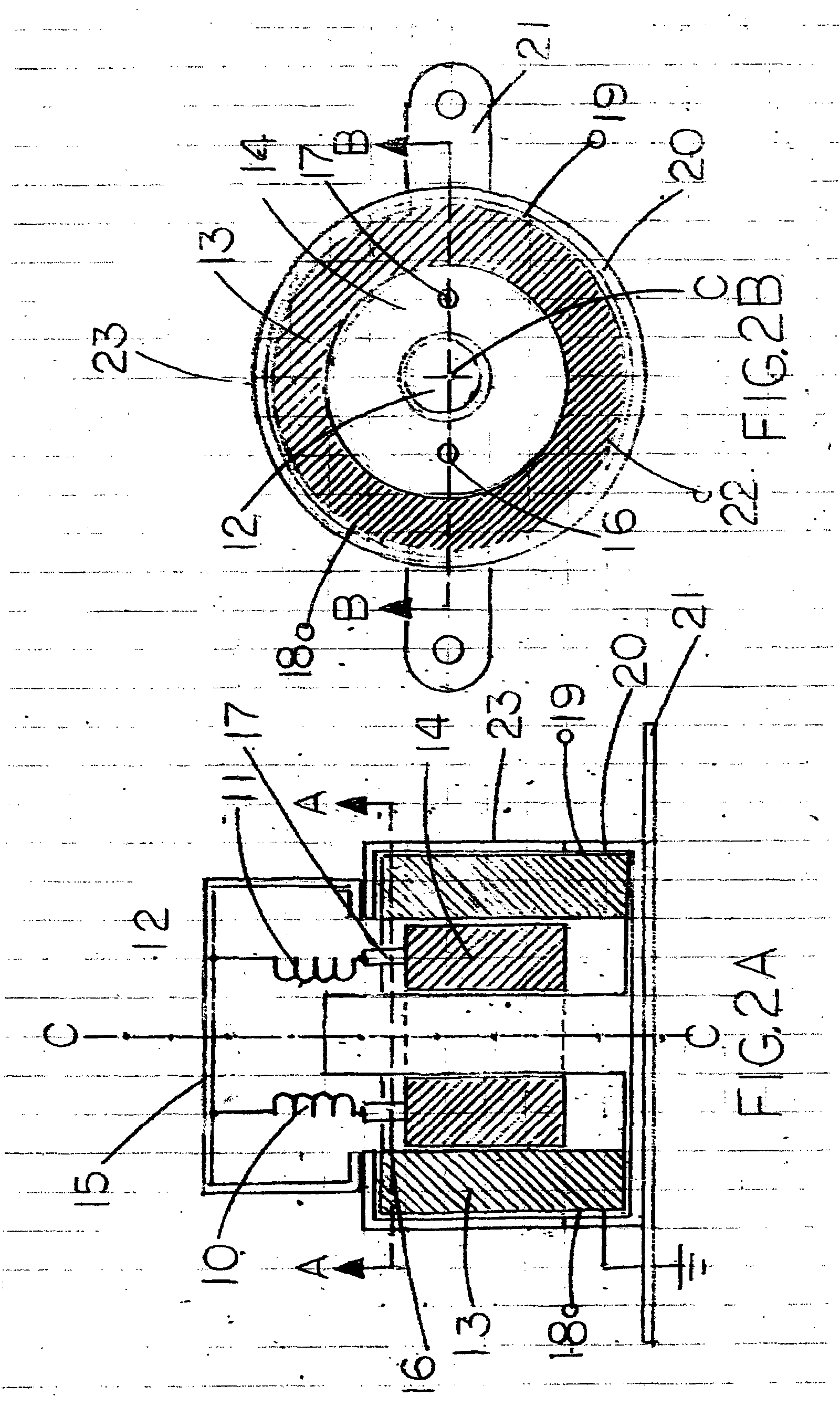

Controlling lubrication of moving bodies such as bearings of electric motors

InactiveUS20070144834A1Increase amplitudeHigh sensitivityAssociation with control/drive circuitsLubricating pumpsElectrical batteryFundamental frequency

A self-powered automatic lubrication system for electric motors utilizes an electromagnetic sensor / generator, which picks up motor vibrations that are synchronous with the rotations of the motor shaft, and in response, generates an alternating current. The current is rectified and used to charge a secondary battery that supplies power to the electronic control system. This control system utilizes the alternating current produced by the sensor / generator as an output signal to time the injection of the lubricant into the motor bearings. The sensor / generator comprises a coil and a permanent magnet suspended by springs within the coil. The magnet moves as the motor vibrates causing electric current to be generated in the coil. The physical parameters of the magnet and the springs are selected such that the movement occurs in resonance with the fundamental frequency of the motor vibrations.

Owner:MATZAN EUGENE

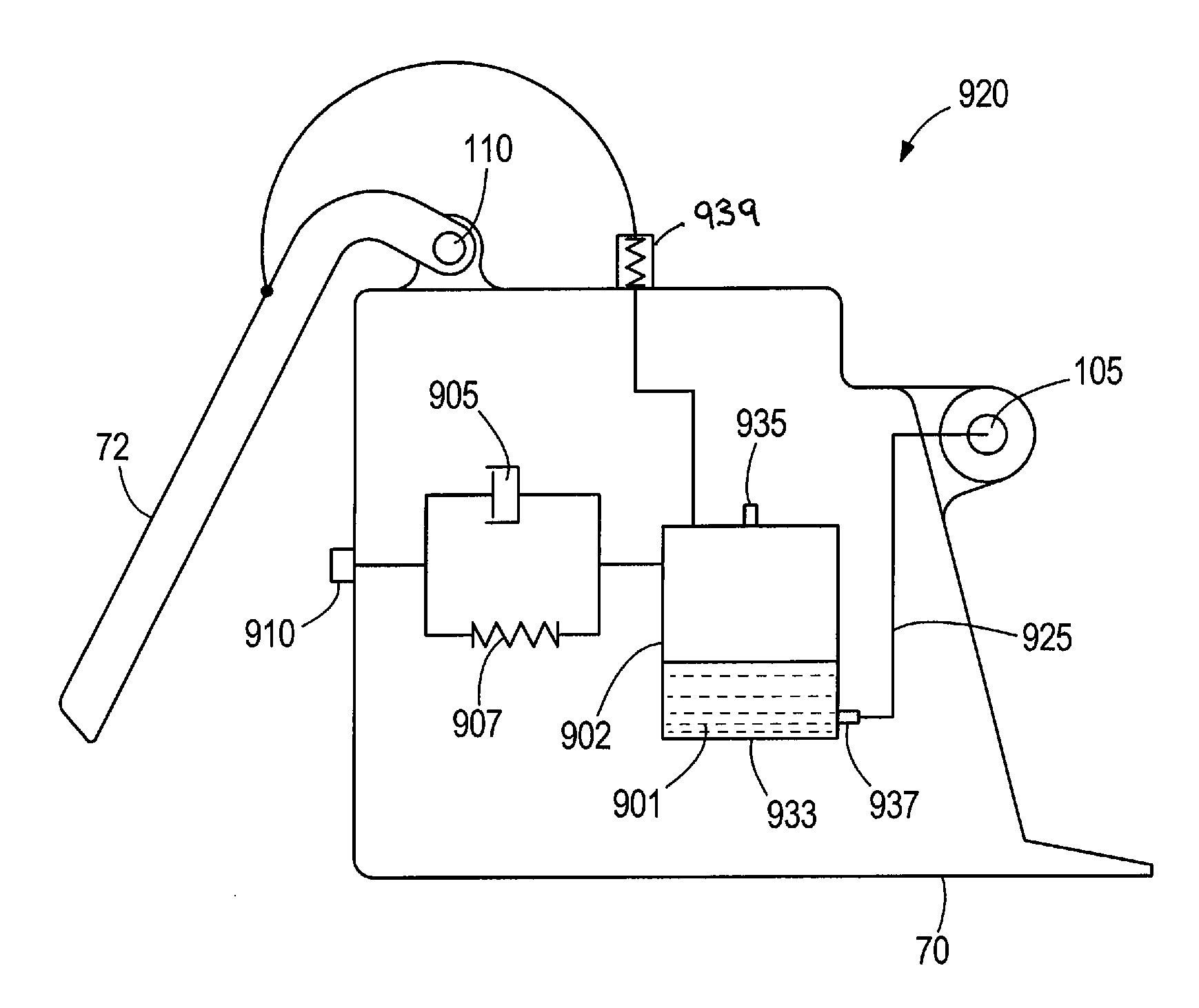

Automatic lubrication system

An automatic lubrication system includes a reservoir configured to be coupled to an industrial machine component, a lubricant line coupled to the reservoir, and a mechanism coupled to the reservoir, the mechanism configured to exact an amount of lubricant from the reservoir based solely on movement of the industrial machine component.

Owner:HARNISCHFEGER TECH

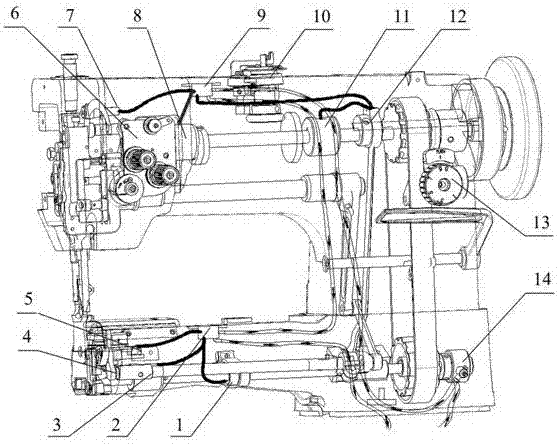

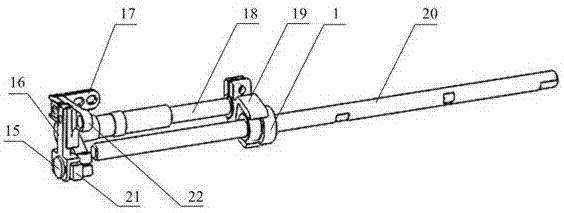

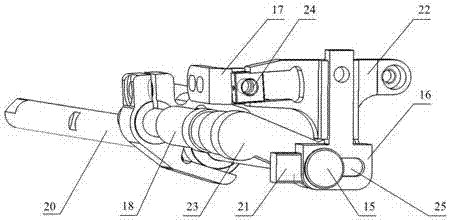

Novel barrel type sewing machine

ActiveCN107043999ASolve the problem of instability and affecting the quality of sewingStable stitchLubrication/cooling devicesWork-feeding meansLocking mechanismEconomic benefits

The invention relates to the technical field of sewing devices, in particular to a novel barrel type sewing machine. The novel barrel type sewing machine includes a sewing machine body, an oil tan, and a fabric feeding mechanism, a stitch length locking mechanism, a pre-winding device, a dual-clamping machine, and an automatic lubrication system which are arranged on the sewing machine body; the fabric feeding mechanism includes a lower shaft, a tooth lifting cam, a tooth lifting fork, a tooth lifting shaft, a fabric feeding tooth guide rack, a fabric feeding tooth guide rack slide block, a fabric feeding tooth support, a fabric feeding tooth support shaft, a fabric feeding support slide block, and a fabric feeding tooth support positioning plate; the stitch length locking mechanism includes a stitch length button, a locking pin and a locking pin spring; and the pre-winding device includes a base, a winding shuttle core, a shuttle core shaft, a cutter, a shuttle core seat, a winding positioning wheel, a friction wheel, a winding positioning hook, and a limiting adjustment wrench which are fixed on the sewing machine body. The mechanical structure of the conventional sewing machine is changed, the automatic lubrication system is added, the performance of the sewing machine is fully improved, and the novel barrel type sewing machine has good application prospect and economic benefits.

Owner:TYPICAL SEWING MACHINE WANPING MACHINERY

Automatic lubrication system for a bearing, and method for operating an automatic lubrication system

An automatic lubrication system for automatic and demand-driven charging of a bearing with a lubricant includes an automatic lubrication device configured to automatically charge the bearing with the lubricant, a detecting device configured to detect at least one operating parameter of the bearing, and a data-transmission device that is configured to transmit data from the detecting device to the lubrication device. The automatic lubrication device is configured to charge the bearing with the lubricant based on the operating parameters detected by the detecting device.

Owner:AB SKF

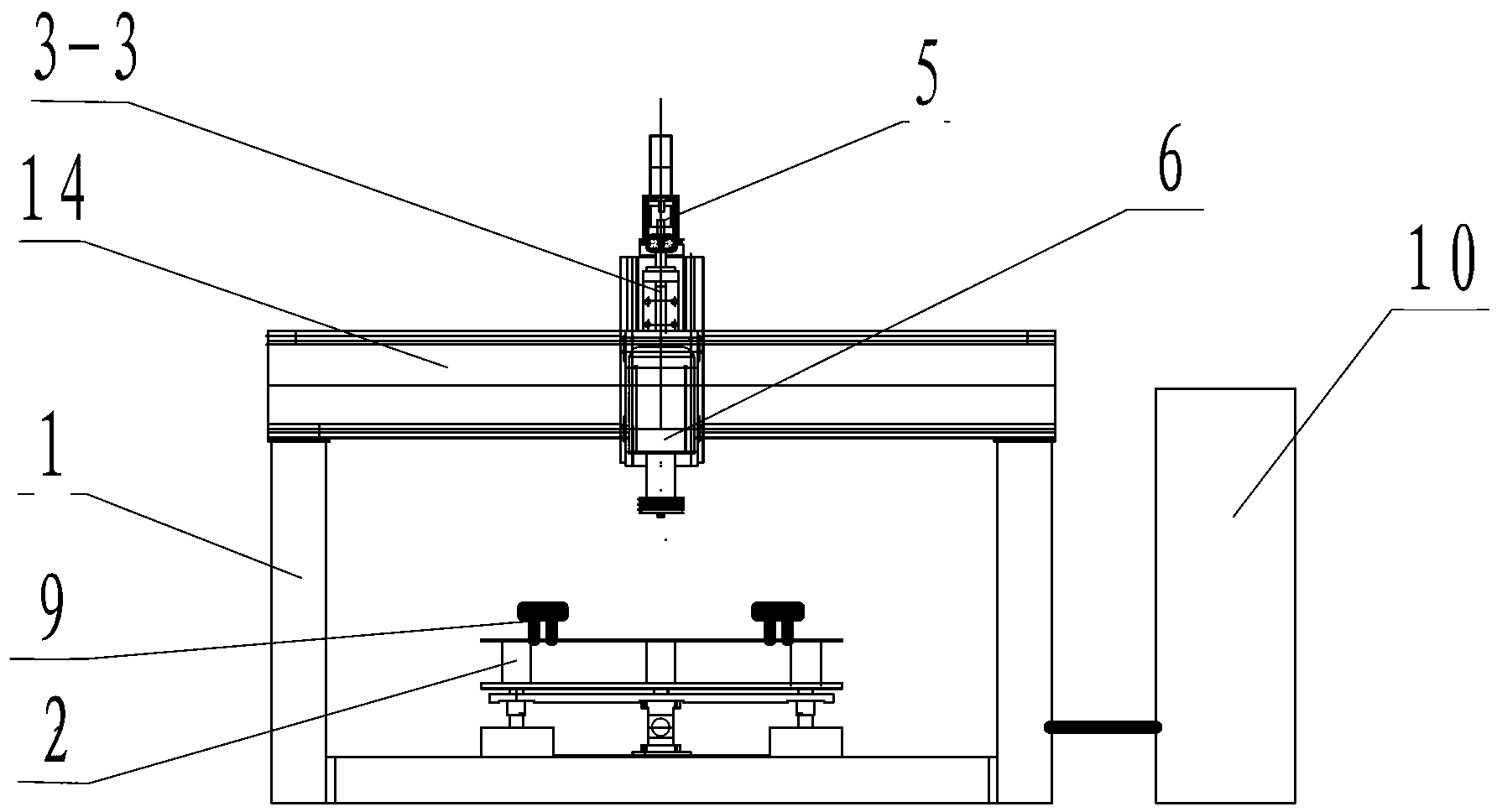

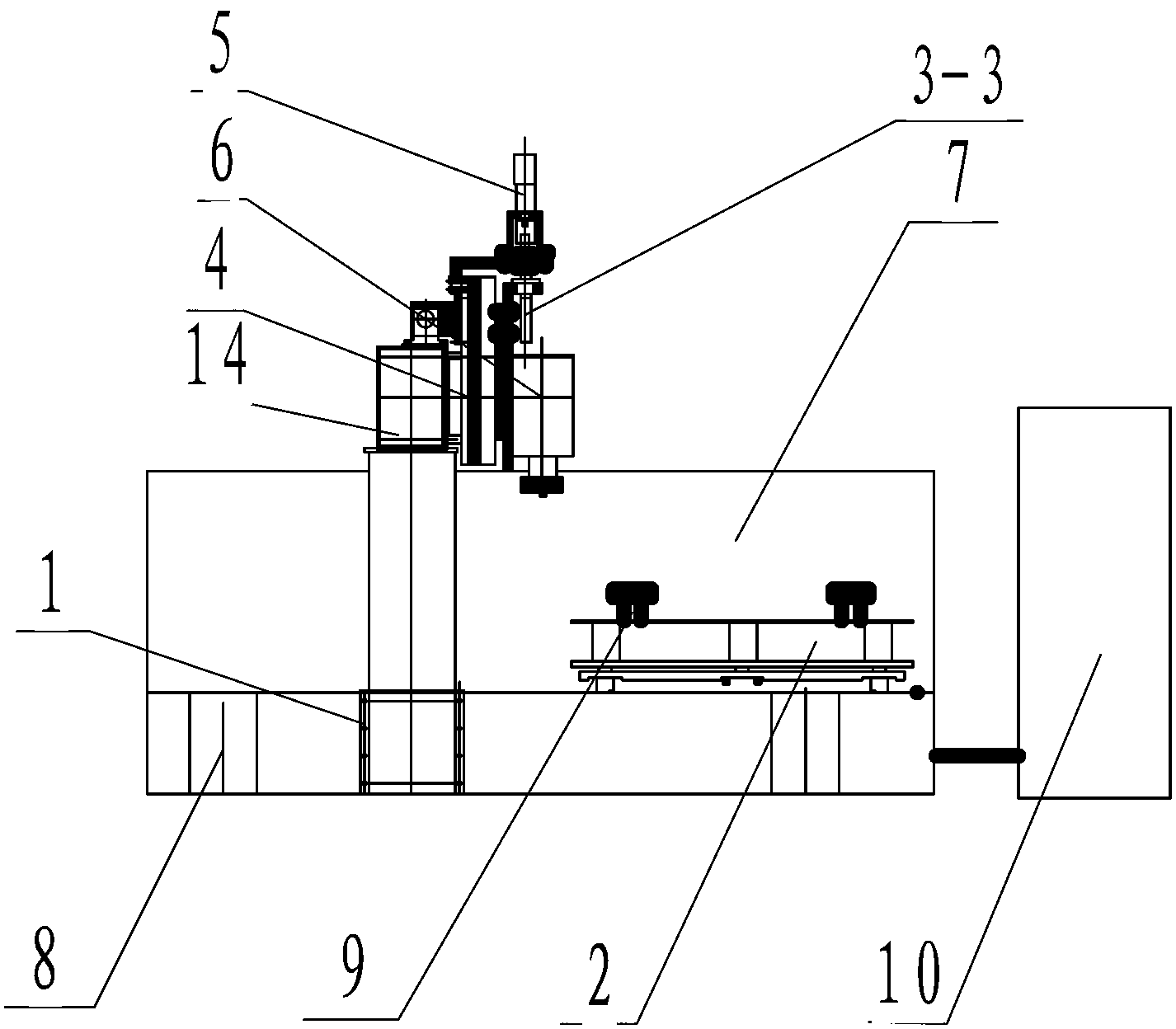

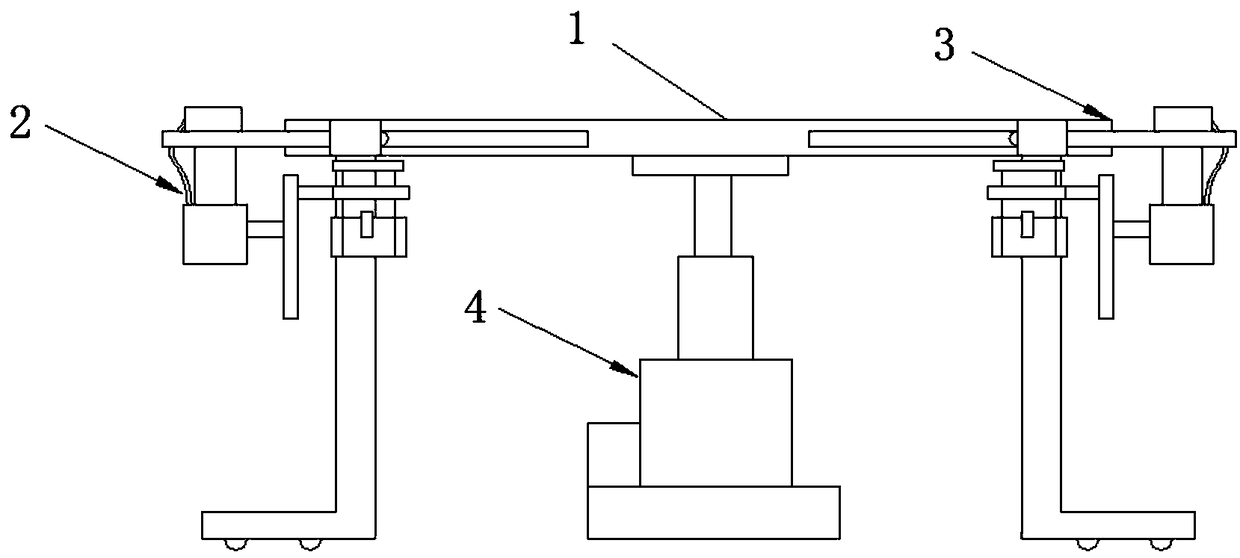

Method for processing special-shaped glass with data control

InactiveCN103252694AHigh dimensional accuracyReduce labor intensityEdge grinding machinesData controlControl system

The invention relates to a method for processing special-shaped glass with data control. A processing device is formed by a gantry frame, a mobile platform, a folding stepping / servo mechanism, a Y axis screw rod, an X axis screw rod, a Z axis screw rod, a transverse stepping / servo mechanism, an up-down stepping / servo mechanism, a grinding head mechanism, a waterproof baffle, a self-lubrication system, a positioning adsorbing disc, a control box, a polishing abrasion wheel, an accurate grinding abrasion wheel, a rough grinding abrasion wheel and a transverse rail. Quick positioning, one-button starting, automatic tool adjusting and automatic tool replacing are achieved, the grinding functions, including rough grinding, accurate grinding, polishing and the like, on complex special-shaped glass can be completed rapidly within a few minutes by a three-axis-association data control system, working efficiency is high, an edge grinding effect is ideal, personal safety of operating personnel is ensured, labor intensity of the operating personnel is reduced, processed top-grade glass are more beautiful, and processing technology is more precise.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

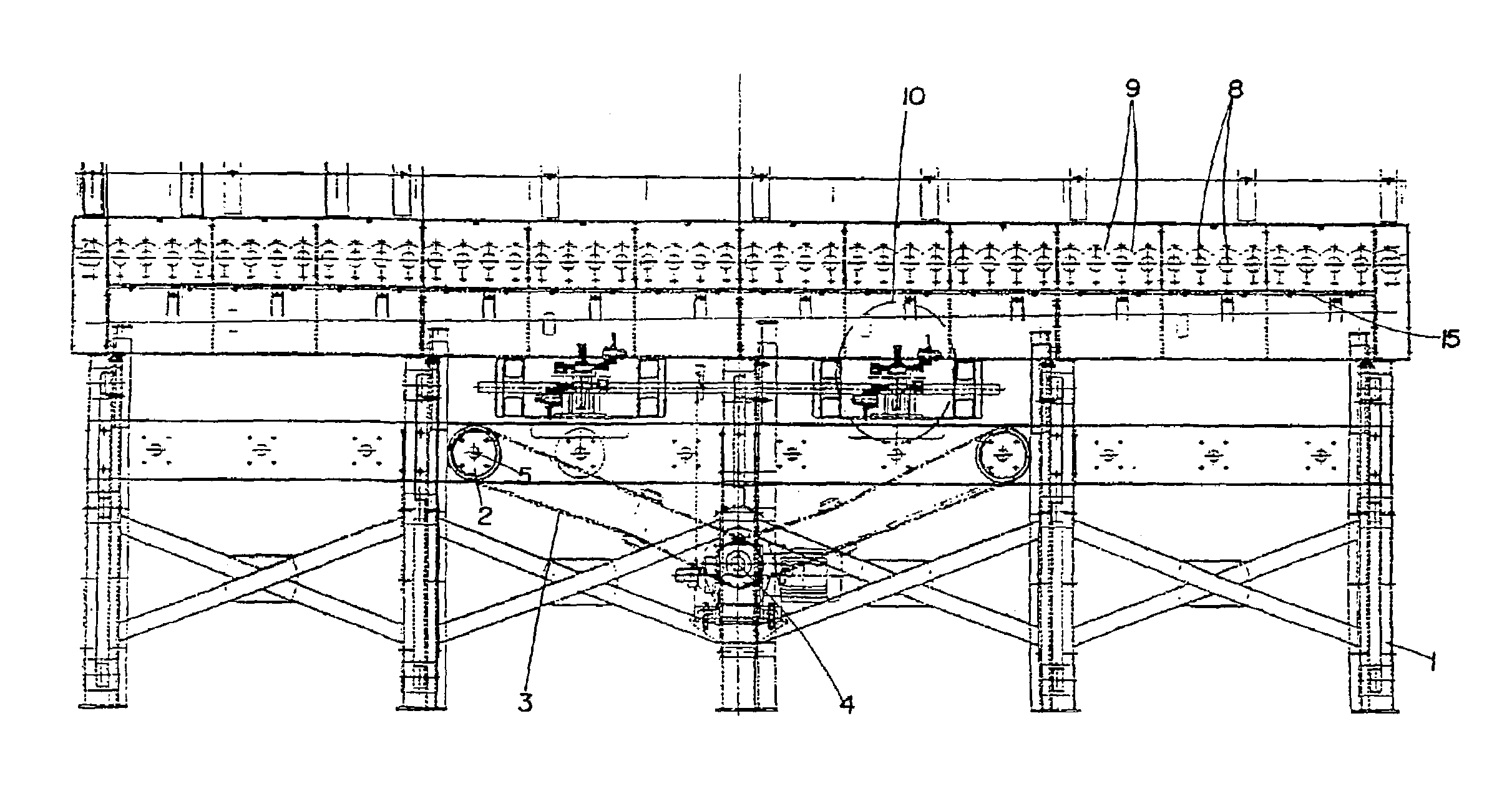

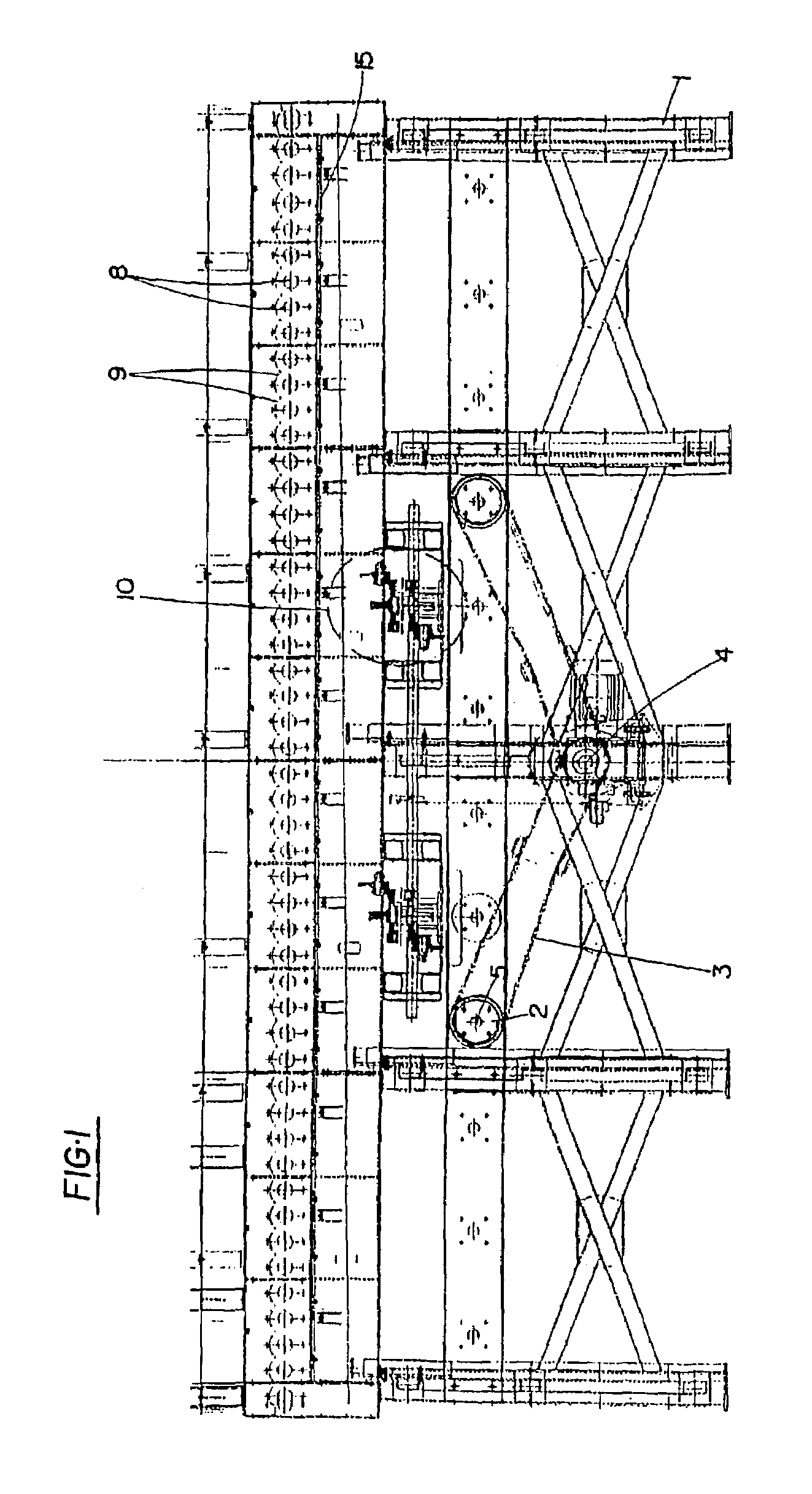

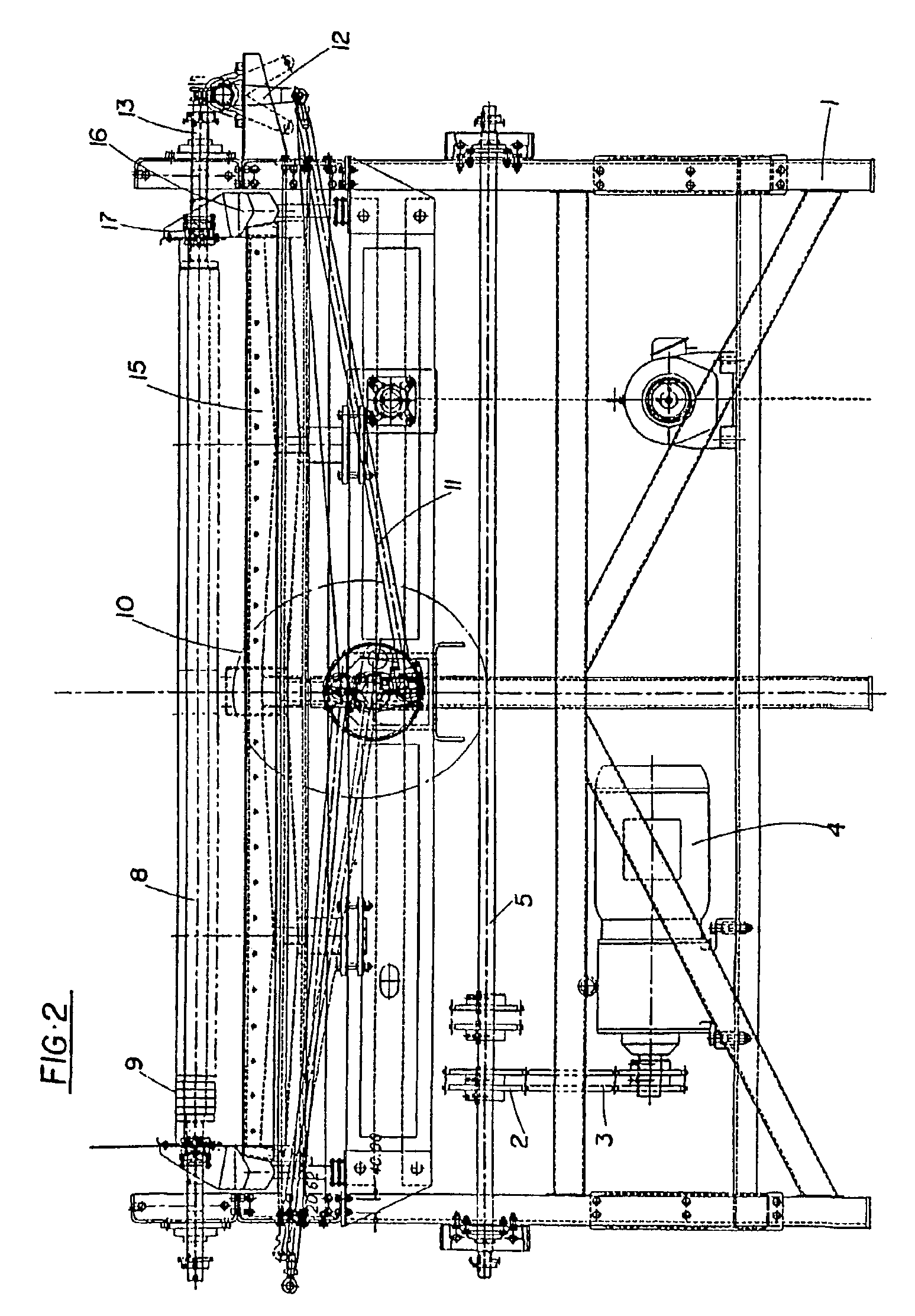

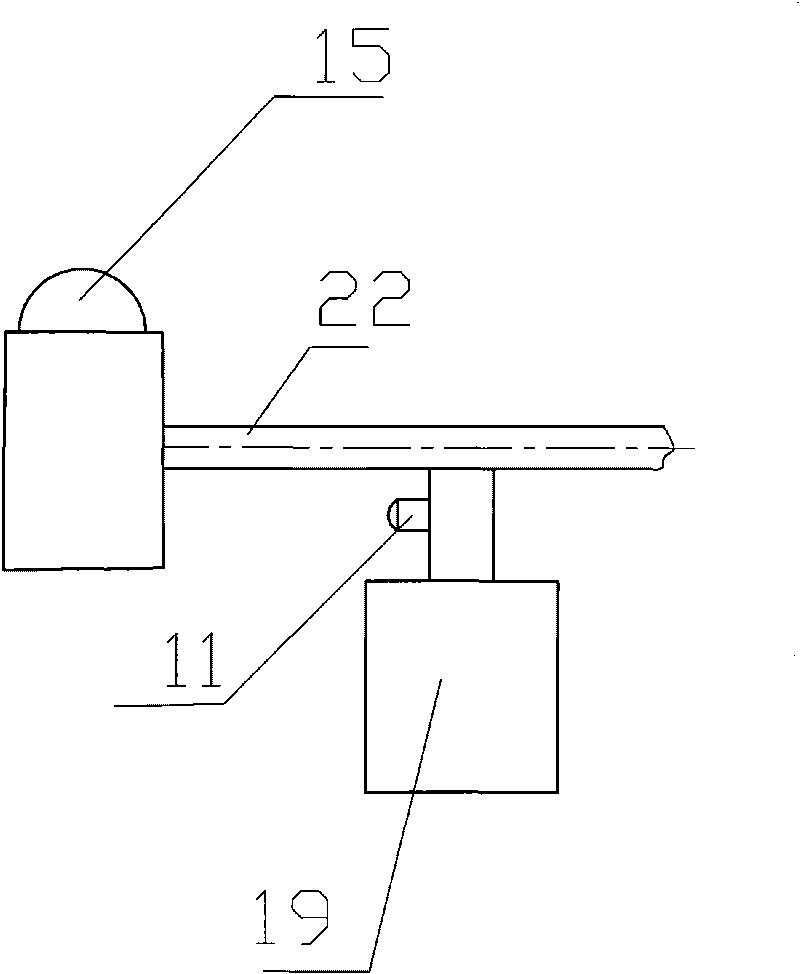

Machine to extract oil from fruit

InactiveUS7316181B2Improve extraction efficiencyImprove recycling efficiencyGrain huskingGrain polishingOil and greaseEmulsion

A modulating machine is used to extract and recover the essential oil from citrus fruit such as lemons, oranges, mandarins, grapefruit, etc. not removing their peel, but by microperforating it and disrupting oil cells. The oil thus extracted is trapped in water so as to form an aqueous emulsion. The created machine includes a set of grooved disks (9) mounted over corresponding supporting axes (8); a base structure (1) on which lower portion there is a transmission set installed, formed by pulleys (2) and chains or grooved belts (3) operated by a motor (4); a set of supporting axes (8) provided with alternate axial and rotational movement, by a set of operation members (10) interconnected to rod (11) transmitting alternate movement to the connected handles (12), alternating to the ends (13) of the supporting axes (8). The machine also includes an emulsion tank (15) laterally provided with collectors (16); spillway (30); disk cleaning set (9) fruit washing and drying unit; and an automatic lubrication system for application of oil and grease at specific points.

Owner:JOHN BEAN TECH CORP +1

Locomotive auxiliary engine self-lubrication method and system

PendingCN107842703AExtended service lifeUnimpeded or not monitoringBearing componentsVehicle componentsElectric machineryControl theory

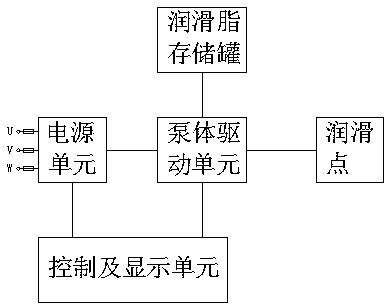

The invention discloses a locomotive auxiliary engine self-lubrication method and system. The method is realized through the locomotive auxiliary engine self-lubrication system and includes the stepsthat after a locomotive is started and a locomotive auxiliary engine begins to work, a power unit of the locomotive auxiliary engine self-lubrication system acquires the power from the locomotive auxiliary engine and transmits the power to all subsequent units so as to make the locomotive auxiliary engine self-lubrication system operate; and a control and display unit of the locomotive auxiliary engine self-lubrication system controls a pump body drive unit to drive a plunger to suck in lubricating grease from a lubricating grease storage tank and to convey the lubricating grease to all lubricating points needing to be lubricated of the auxiliary engine. By means of the locomotive auxiliary engine self-lubrication method and system, locomotive auxiliary fan motor bearings can be self-lubricated in timing and quantifying modes, the effect that the motor bearings are in a lubrication state all the time is guaranteed, the service life of the locomotive auxiliary fan motor bearings is prolonged, traffic safety is guaranteed, and the locomotive auxiliary engine self-lubrication method and system are suitable for self-lubrication of the auxiliary fan motor bearings of various sorts of DClocomotives and AC locomotives.

Owner:株洲中车电气科技有限公司

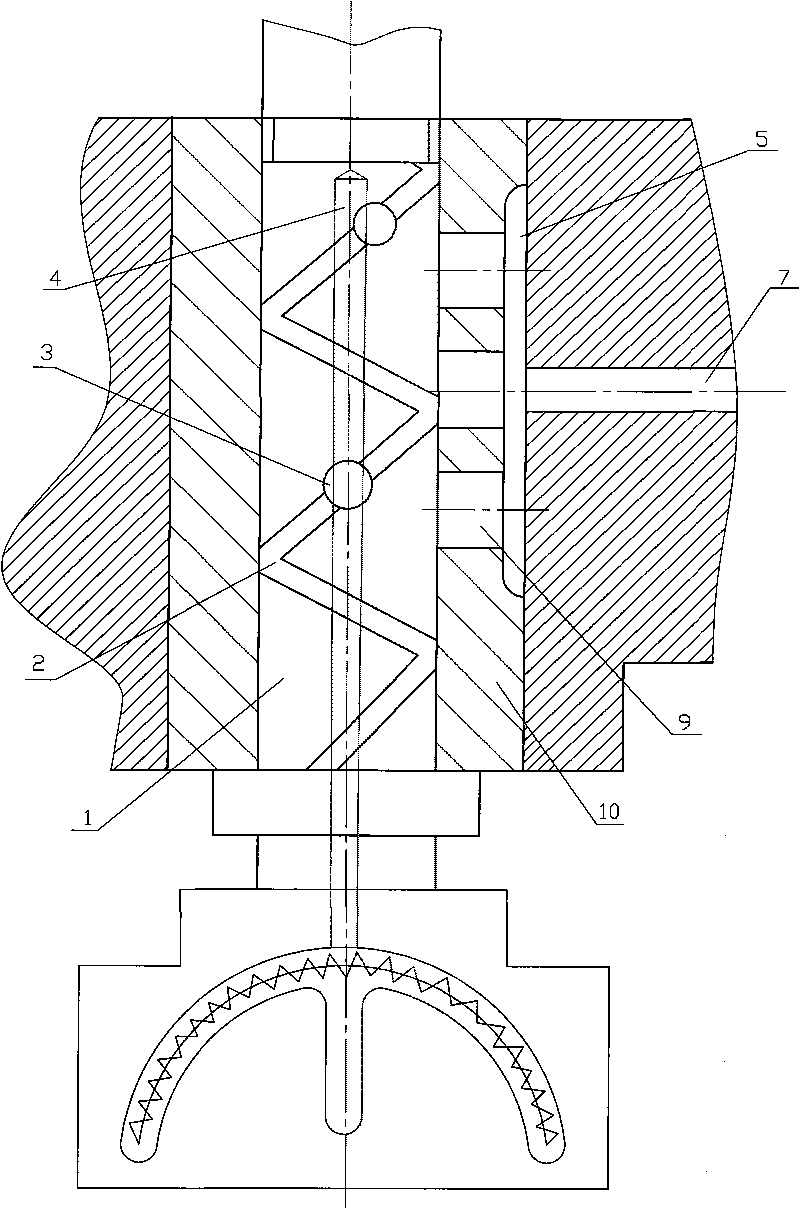

Automatic lubrication system of rotating shuttle assembly of embroidery machine

ActiveCN101718027AExtend your lifeIncrease rotation speedAuxillary devicesEngineeringAutomatic lubrication system

The invention relates to an automatic lubrication system of a rotating shuttle assembly of an embroidery machine, in particular to a lubrication system of a rotating shuttle assembly, which comprises a rotating shuttle, a rotating shuttle shaft and a rotating shuttle shaft sleeve, wherein a blind hole which is coaxial to the rotating shuttle shaft is arranged in the rotating shuttle shaft, the end of a through hole of the blind hole is communicated with an inner cavity of the rotating shuttle, and an oil through hole which is communicated with the blind hole is arranged on the surface of the rotating shuttle shaft. The invention can not only continuously charge oil into the rotating shuttle, the rotating shuttle shaft and the shaft sleeve thereof, but also can cool and clean the components.

Owner:ZHUJI CHUANGJIA ELECTRONICS EQUIP

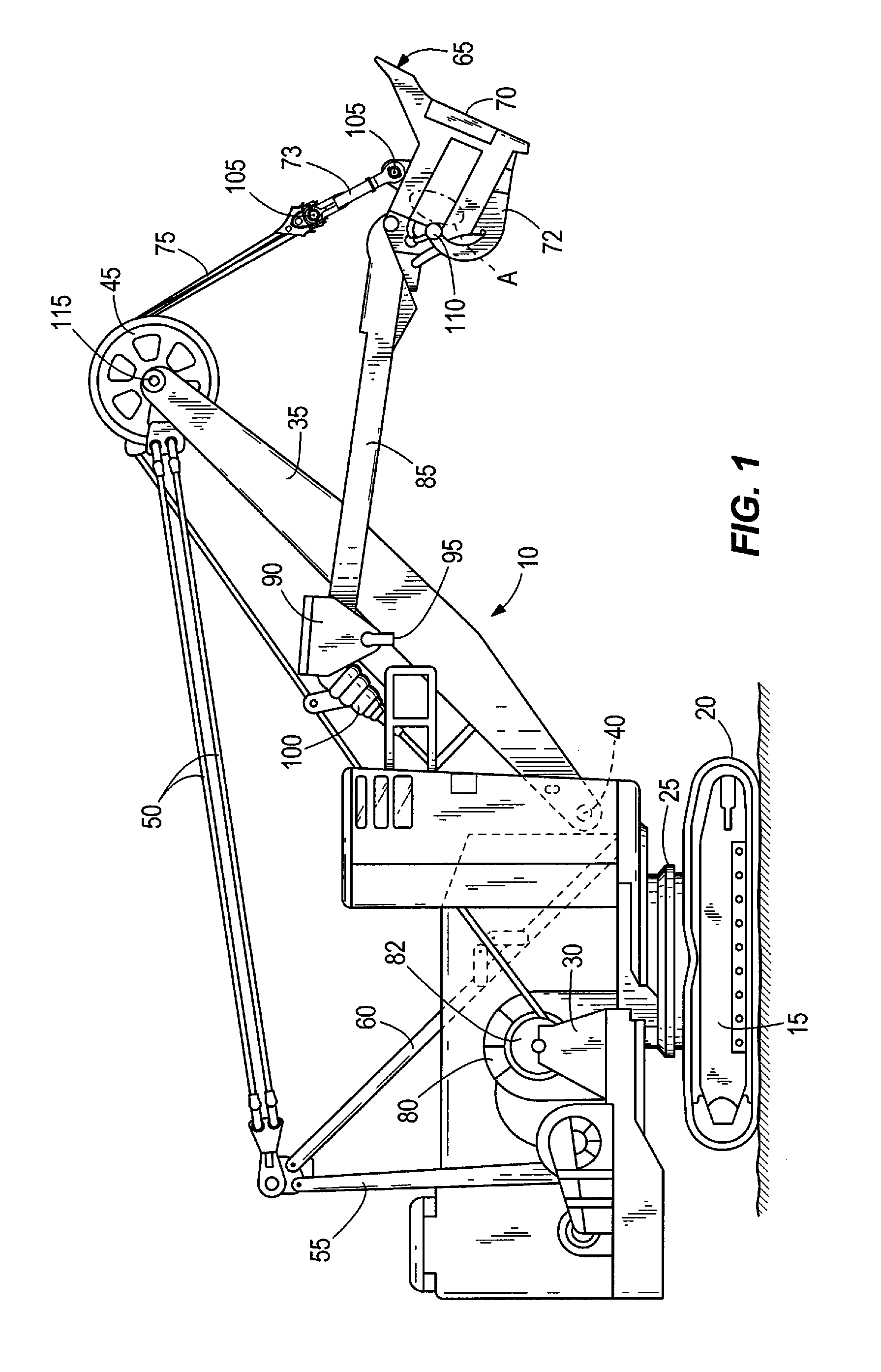

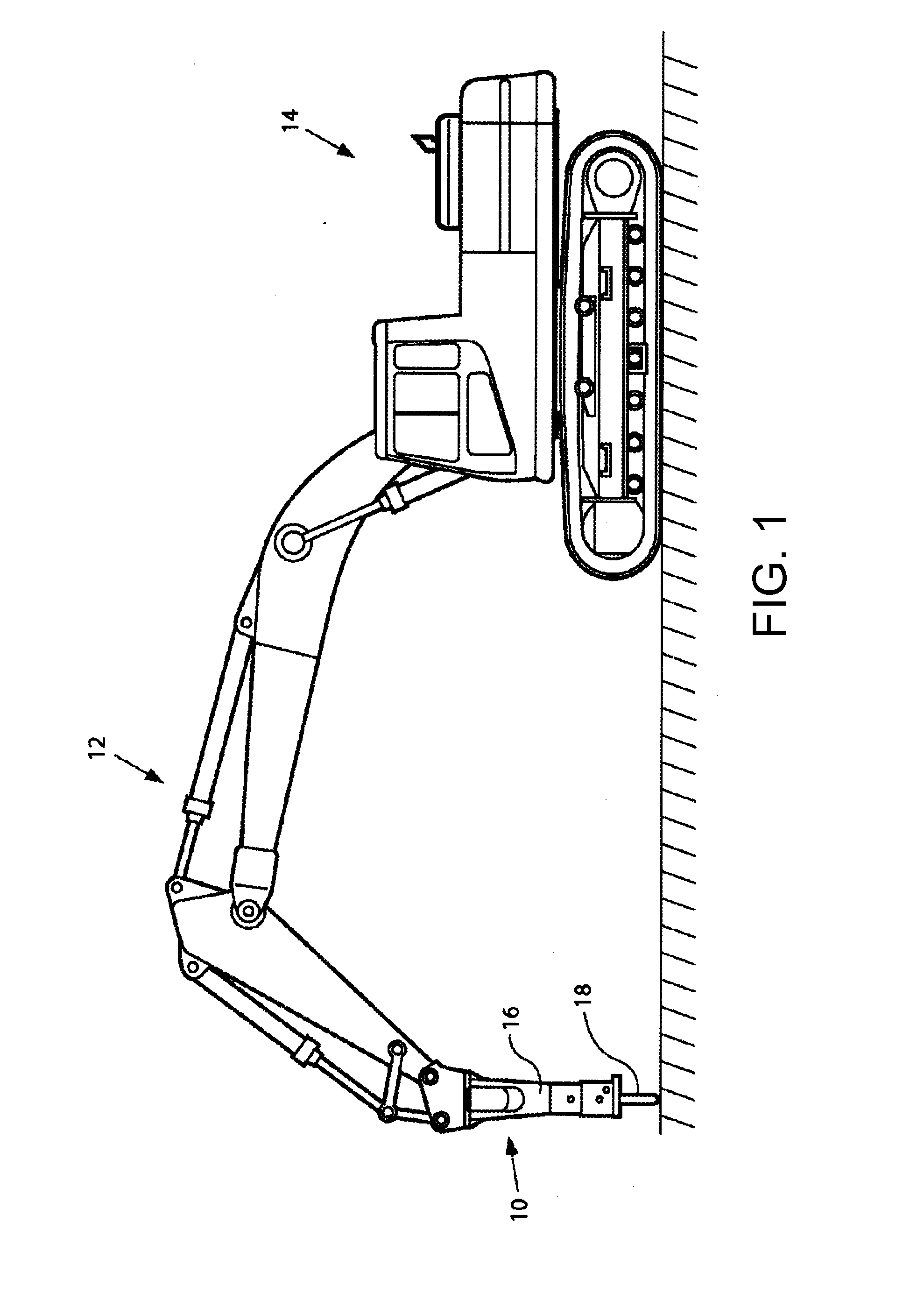

Automatic Lubrication System with Detune

ActiveUS20160046009A1Lower the volumeSoil-shifting machines/dredgersPortable percussive toolsEngineeringLubricant

Lubrication system includes a drive fluid valve member and a detune valve member. The drive fluid valve member is movable from a first to a second position in response to drive fluid pressure to reduce the volume of a variable volume lubricant charge chamber. The detune valve member is movable from a first to a second position in response to lubricant pressure within the lubricant charge chamber, and is adapted to permit fluid communication between inlet and bypass fluid passages in its the first position and to disengage the fluid connection in its second position.

Owner:CATERPILLAR INC

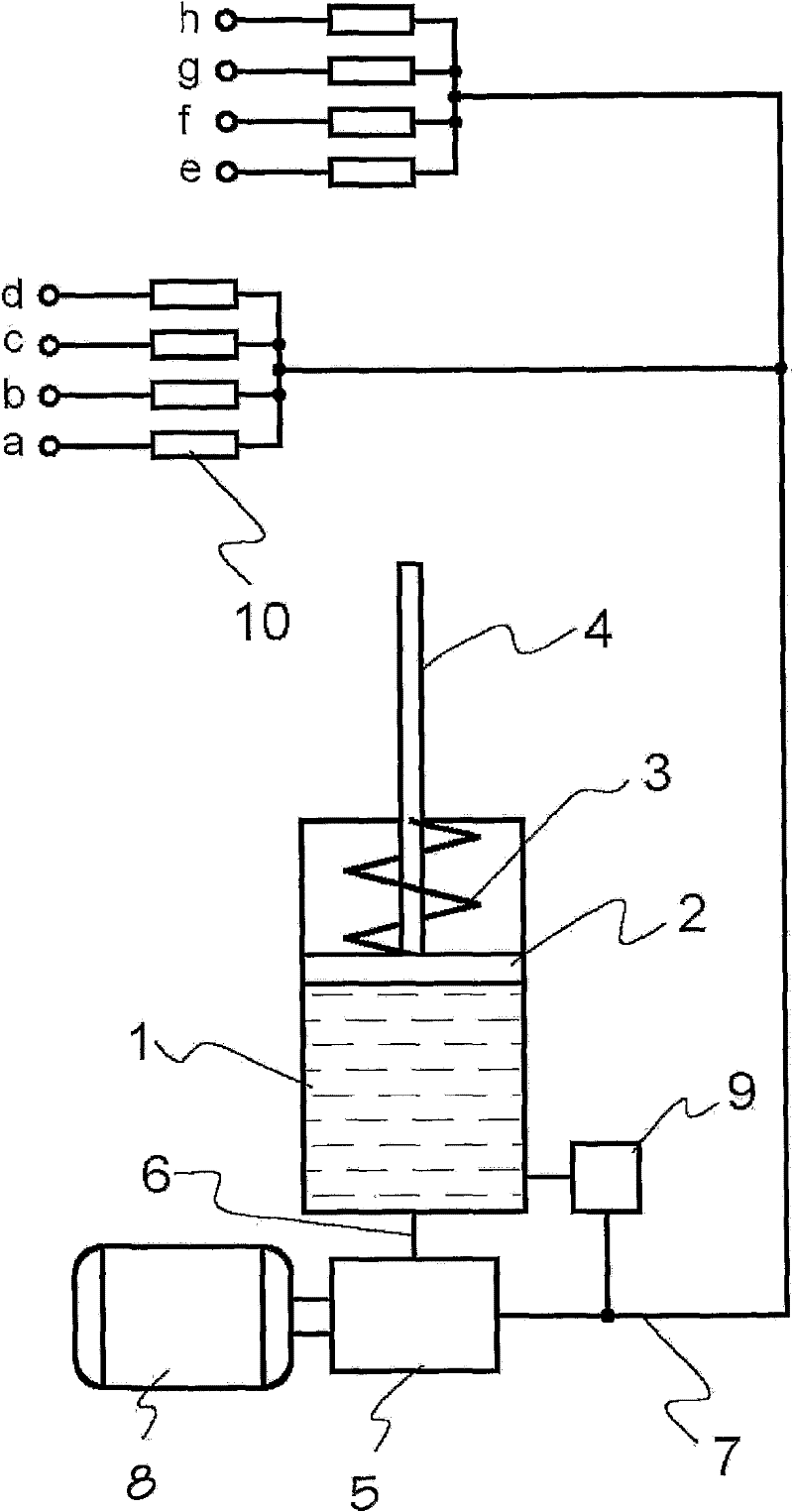

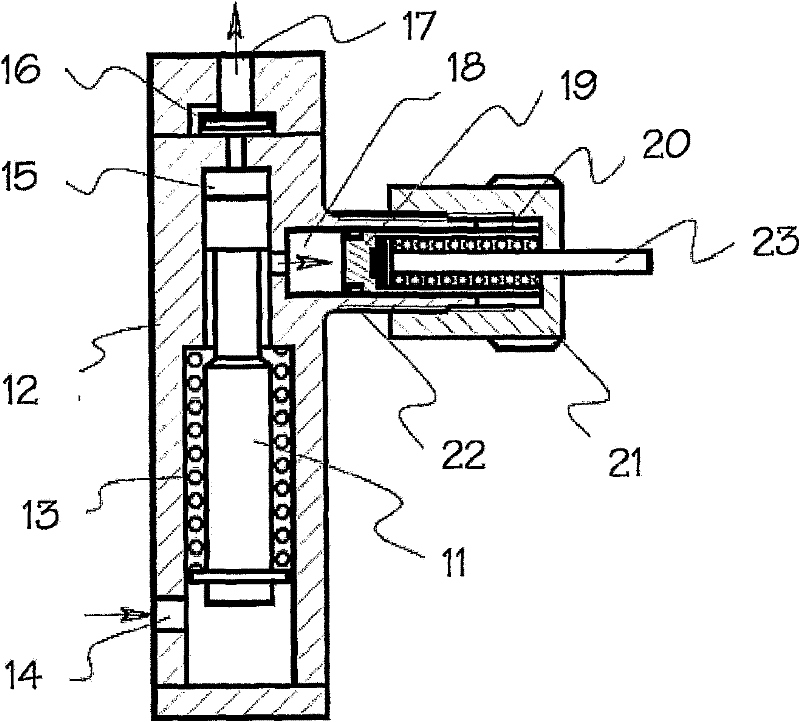

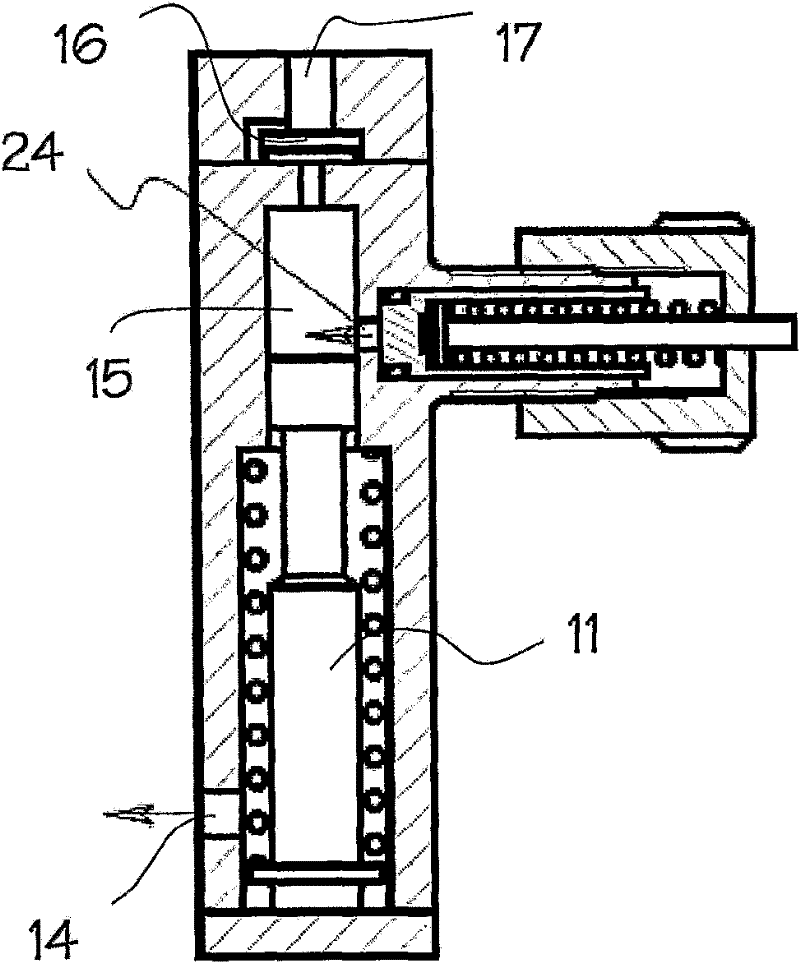

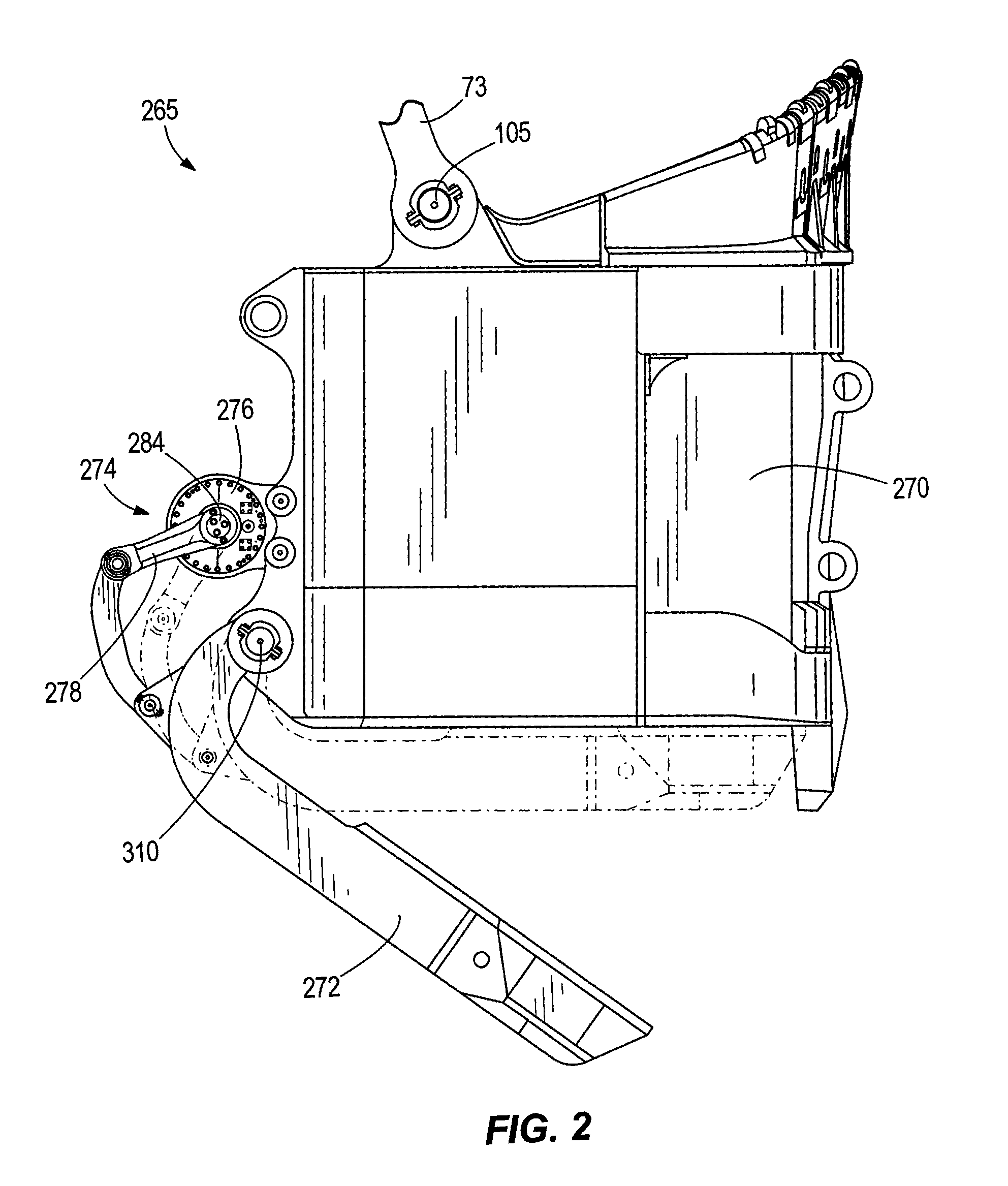

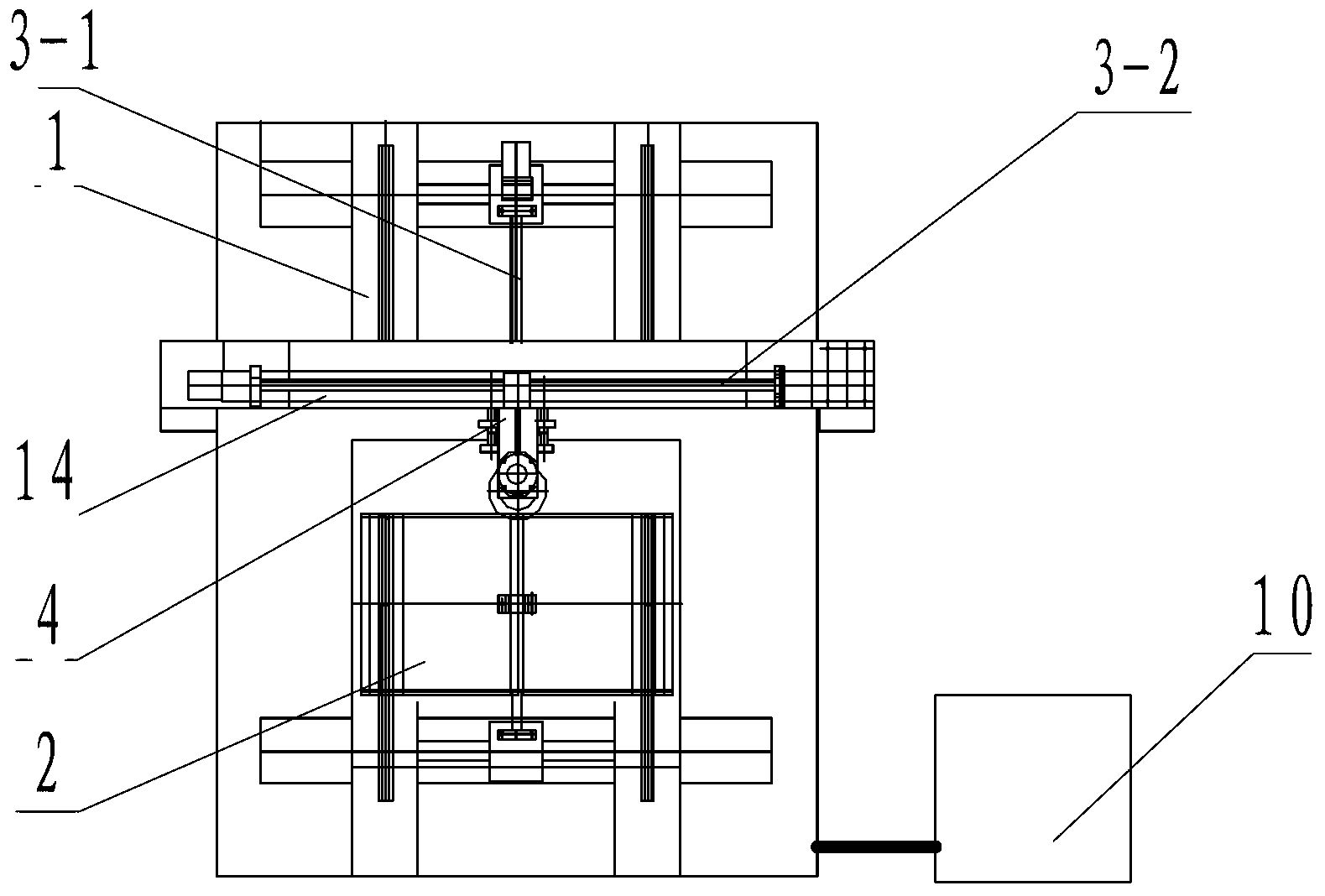

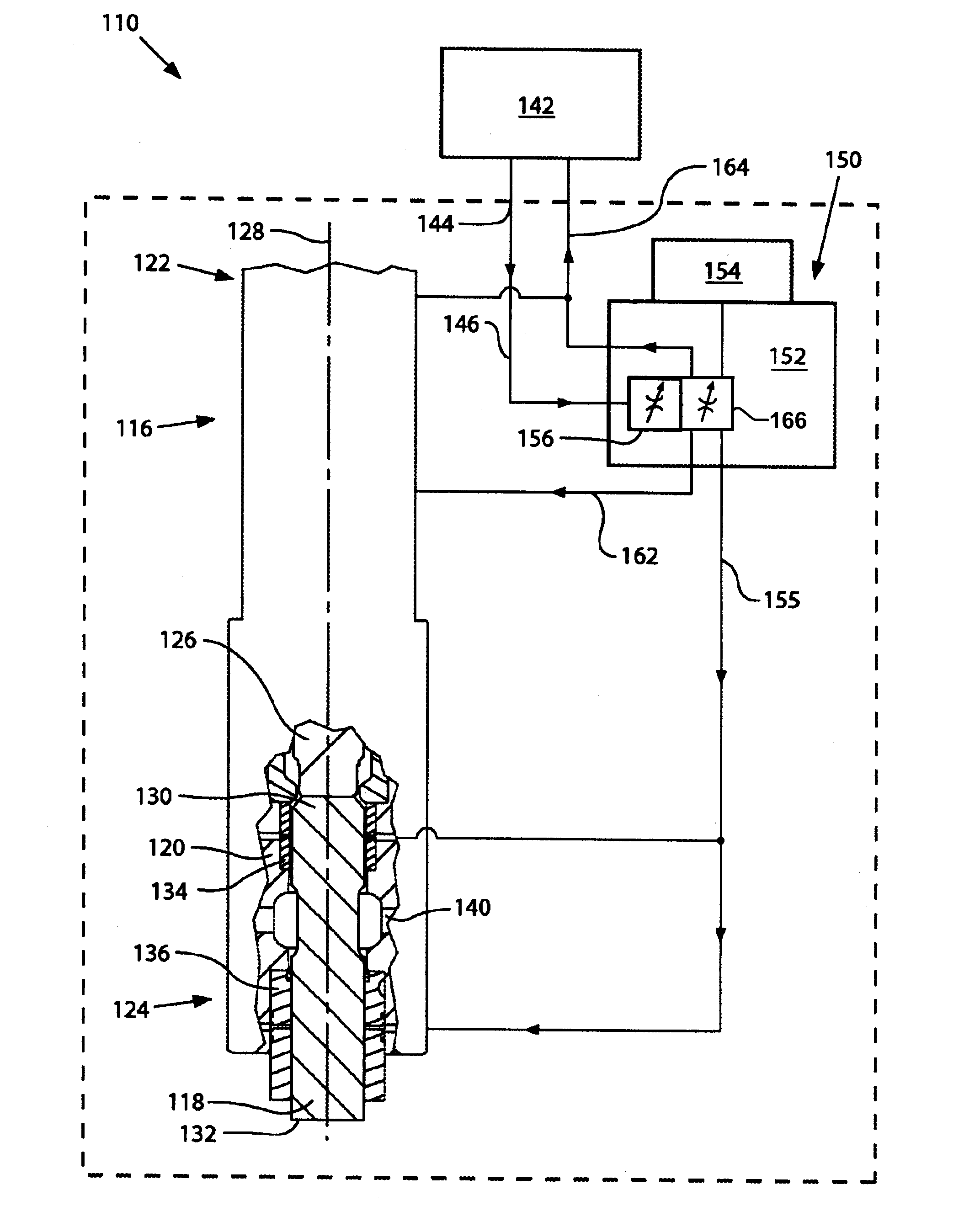

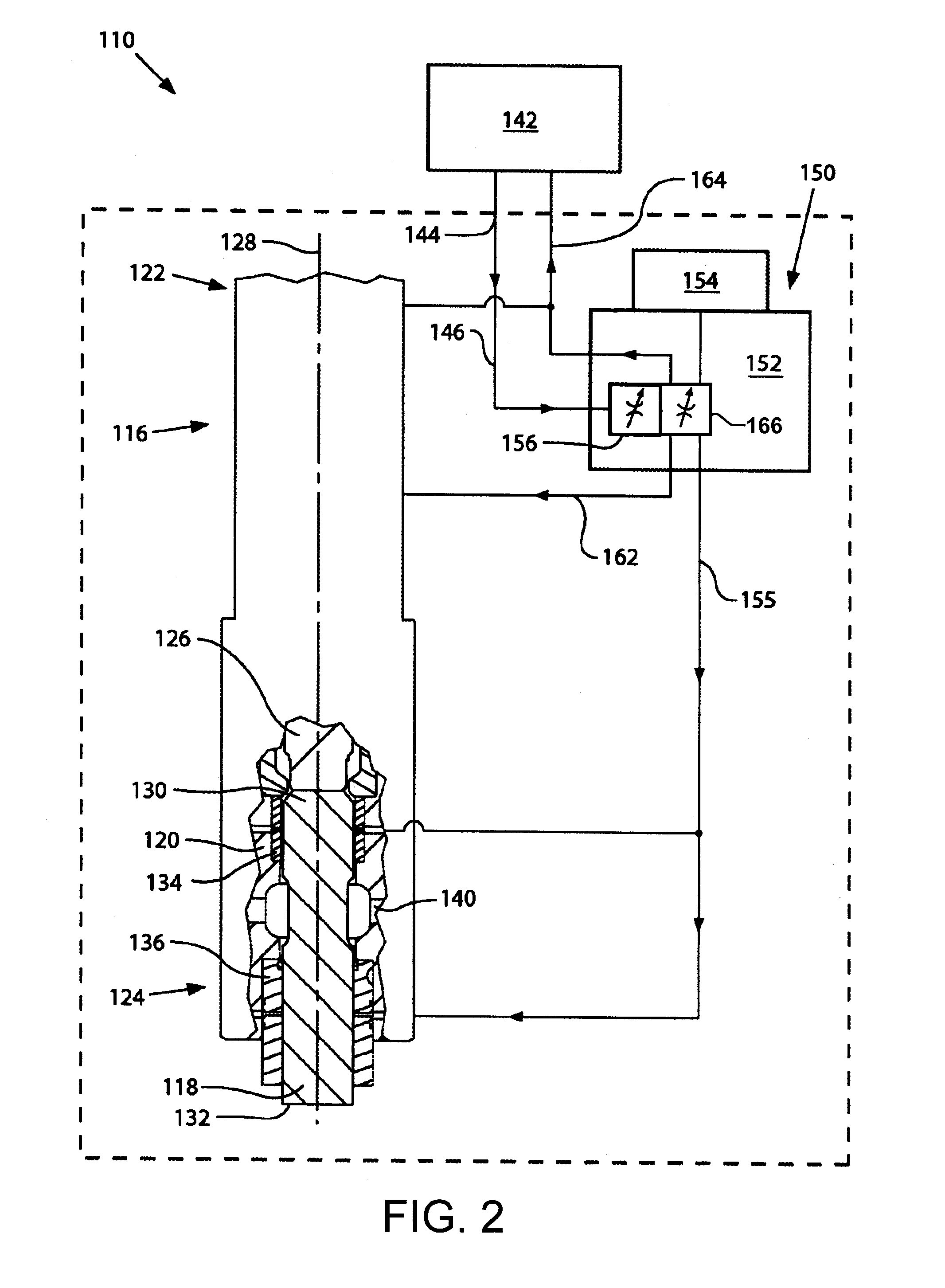

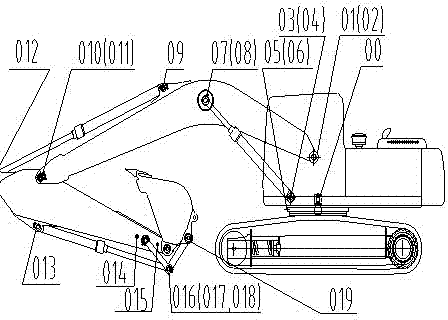

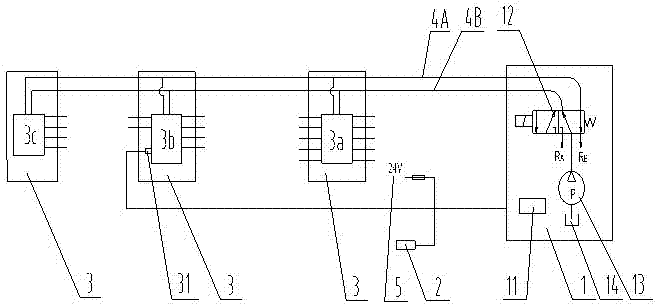

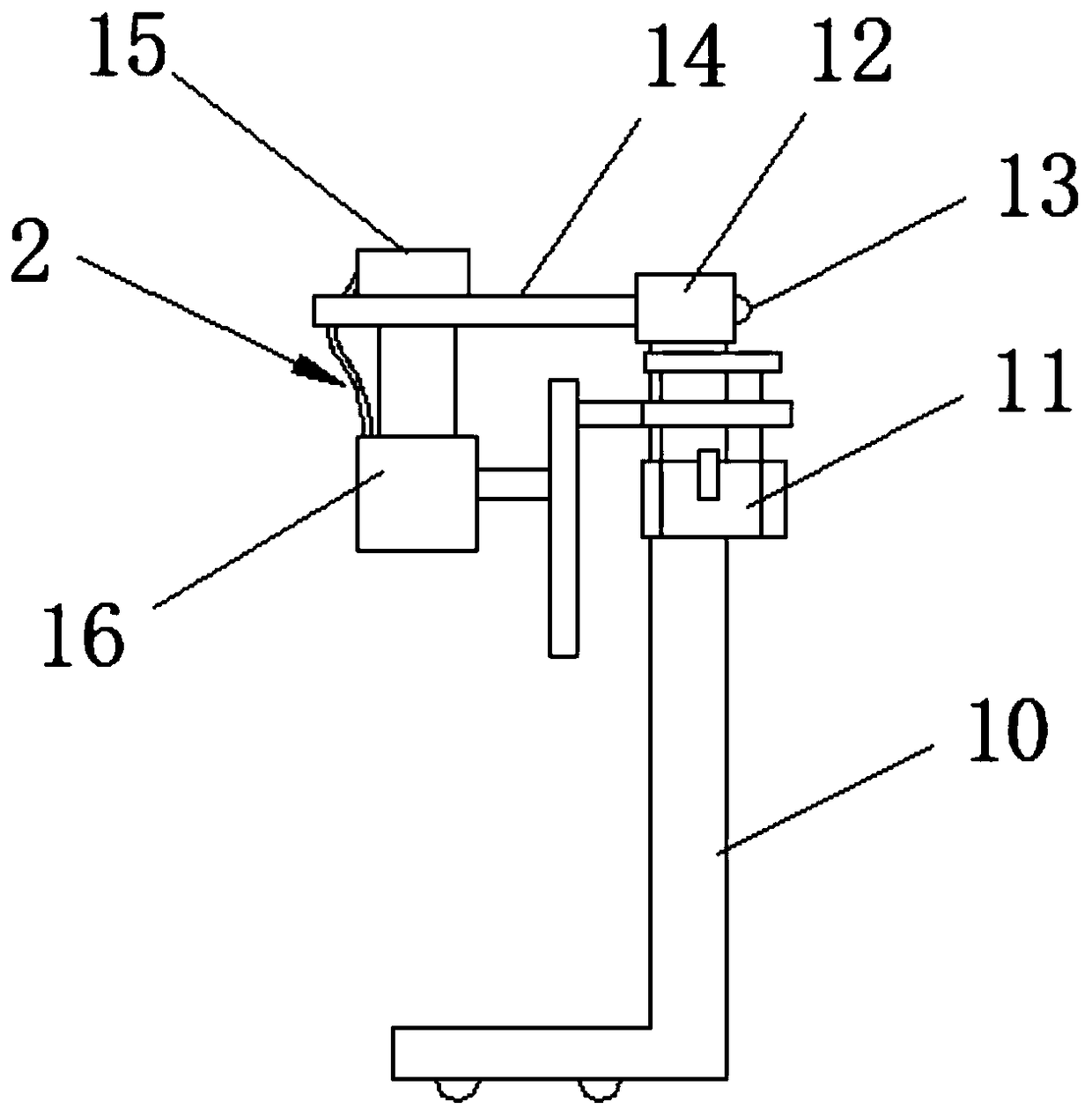

An automatic lubrication system for an excavator

InactiveCN102261102AEasy to installReasonable structure layoutSoil-shifting machines/dredgersEngine lubricationEngineeringDistributor

The invention discloses an automatic lubricating system of an excavator. The system comprises a pump unit, a display unit and a distributor unit, wherein the pump unit is arranged at rear of an upper frame of the excavator; the pump unit comprises a control unit, a two-position five-way electromagnetic valve, an electric plunger pump and an oil storage tank; two main lubricating pipelines are leaded out from the pump unit; the oil storage tank is communicated with the two main lubricating pipelines through the two-position five-way electromagnetic valve; the display unit is installed in a cab, connected to the control unit and used for observing and controlling a working state of the automatic lubricating system in real time; the distributor unit comprises a plurality of distributors which are respectively connected to the two main lubricating pipelines in parallel; and, according to lubricating grease required quantities of a lubricating points, oil lubricators of different standardsare installed on the plurality of distributors and then connected to various types of lubrication points. According to the system disclosed by the invention, the lubricating mode of the excavator is convenient to adjust; the injection flow is precise; and the system has the advantages of smooth and steady operation, high automation degree and simple and convenient installation, maintenance and operation.

Owner:SHANGHAI SANY HEAVY IND

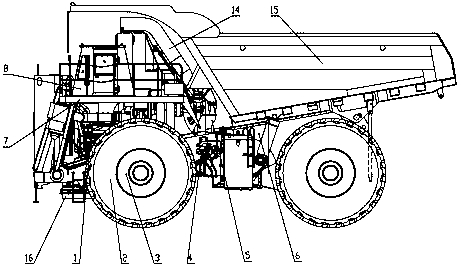

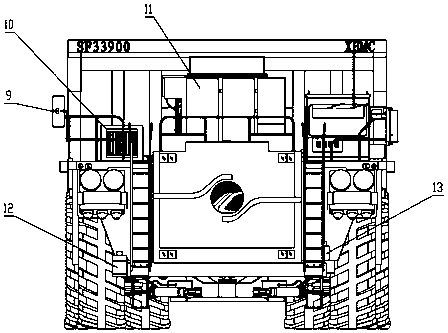

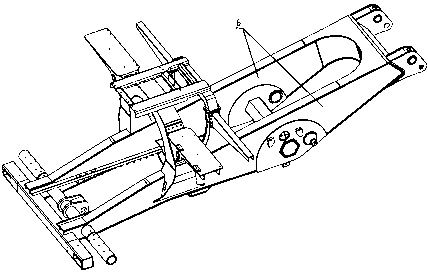

Electric wheel dump truck

InactiveCN102700615AImprove stabilityCompact structureUnderstructuresLoading/unloading vehicle arrangmentElectricityVehicle frame

An electric wheel dump truck comprises a power system, a traveling system, a brake system, a hydraulic system, an electricity transmission system, a frame assembly, a truck front plate assembly, a driving cab assembly, a rearview mirror assembly, a brake resistance box, an electrical cabinet, an automatic lubrication system, an automatic arc extinguishing system, a ventilation system and a compartment system, wherein the frame assembly is arranged on the traveling system; the truck front plate assembly, the electrical cabinet, the driving cab assembly and the compartment assembly are all arranged on the frame assembly; and the tail part of the longitudinal beam of the frame assembly is articulated with a hinge support seat at the bottom of the compartment assembly. The electric wheel dump truck is compact in structure, and safe and reliable; each system assembly is rational in arrangement and low in production cost; and all the system assemblies are arranged in mass symmetrical distribution and low in center of gravity; and therefore, the stability of the truck in running can be improved.

Owner:HUNAN XD HEAVY EQUIP

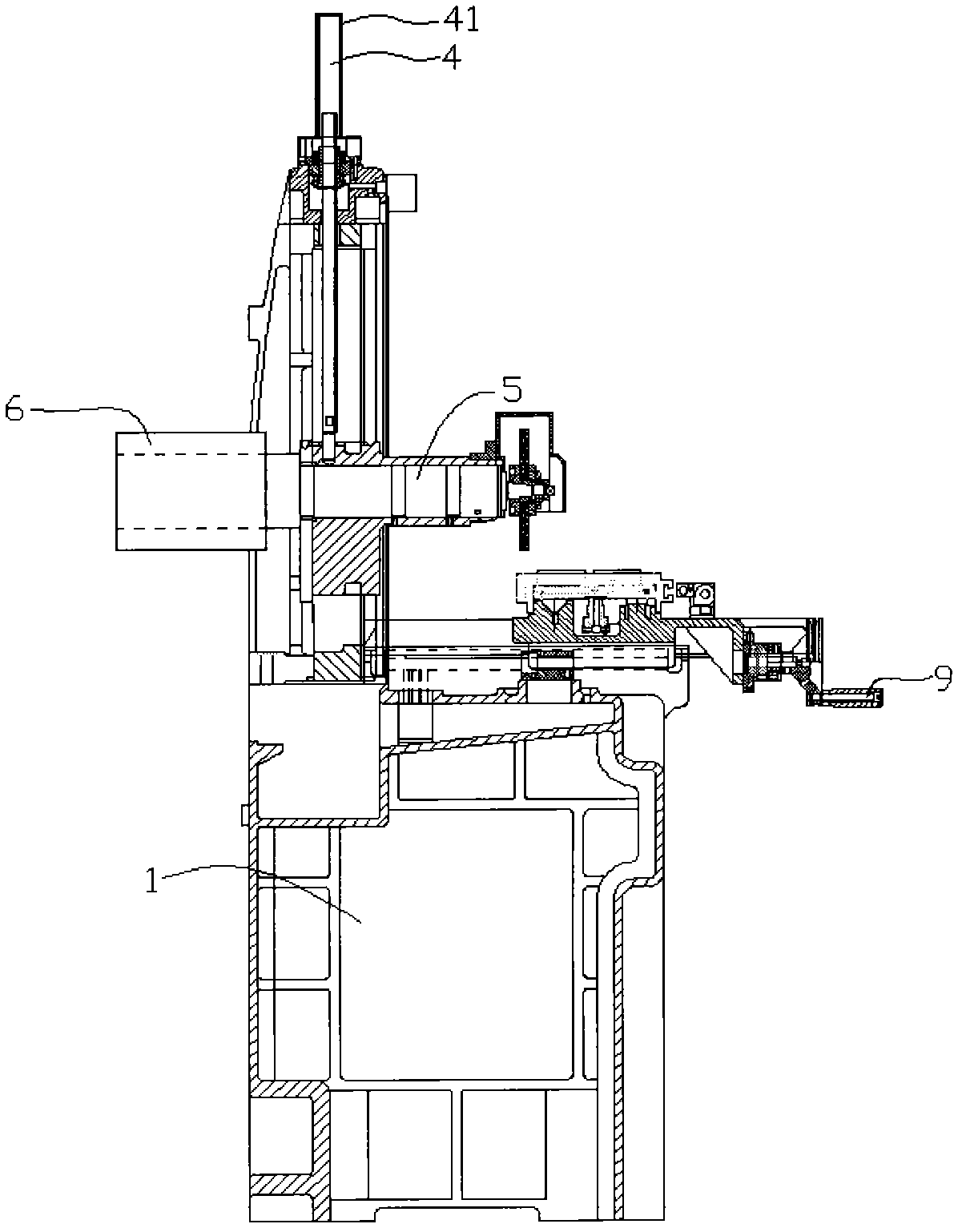

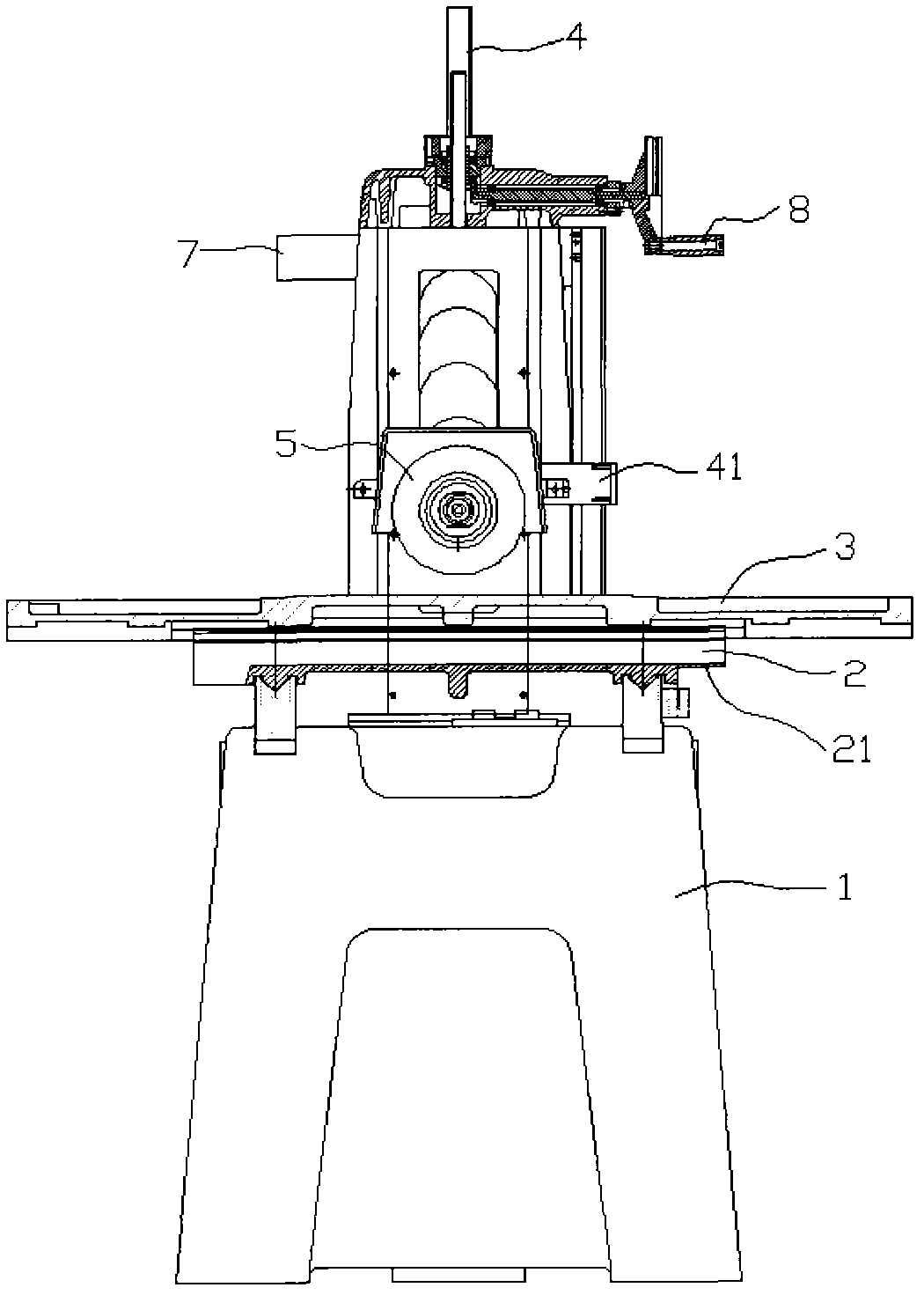

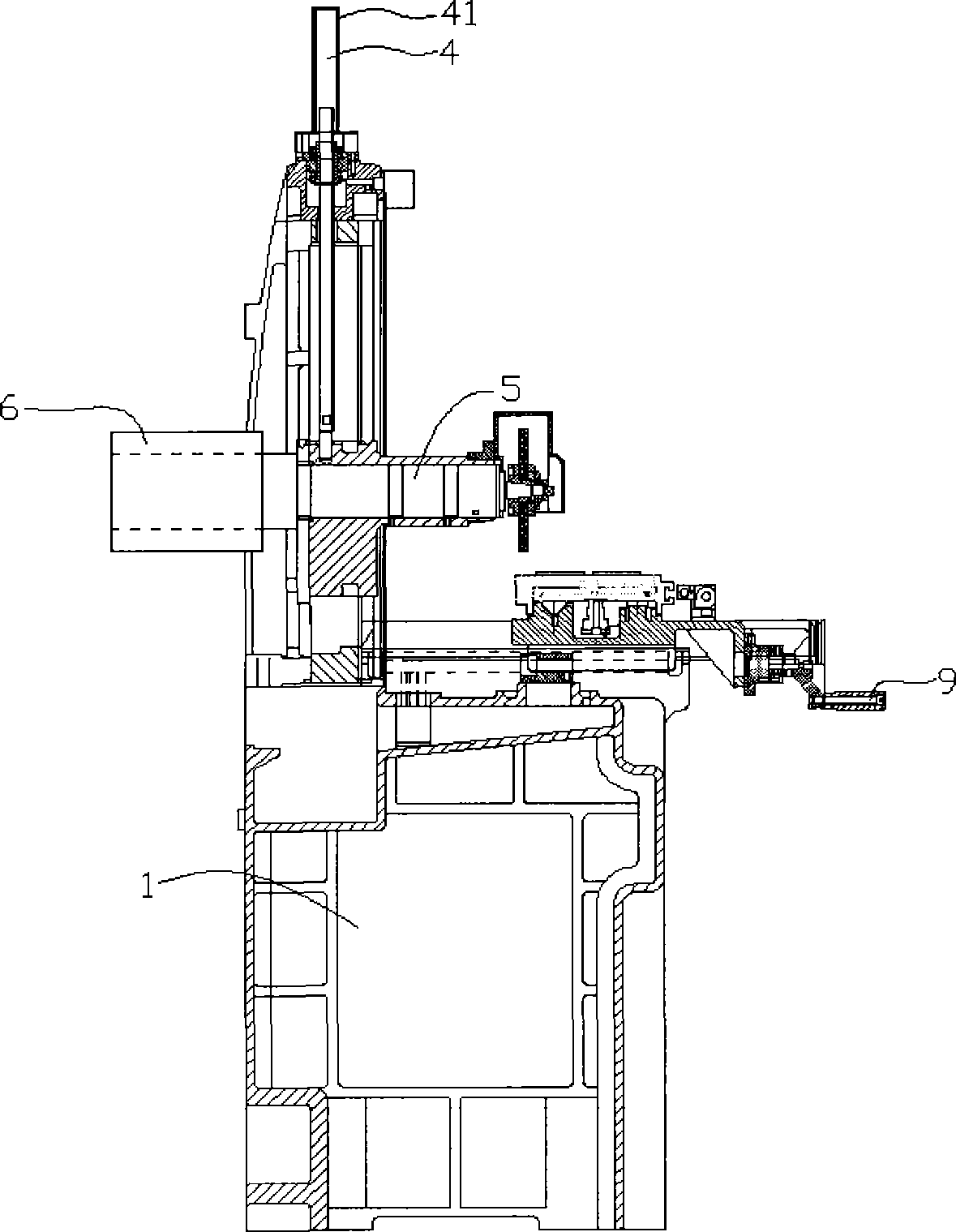

Precision surface grinding machine

InactiveCN102699782AImprove efficiencyReal-time display of operating conditionsPlane surface grinding machinesGrinding/polishing safety devicesLow noiseEngineering

Owner:CHANGSHA WANGCHENG SANJINGCHUAN PRECISION MACHINERY

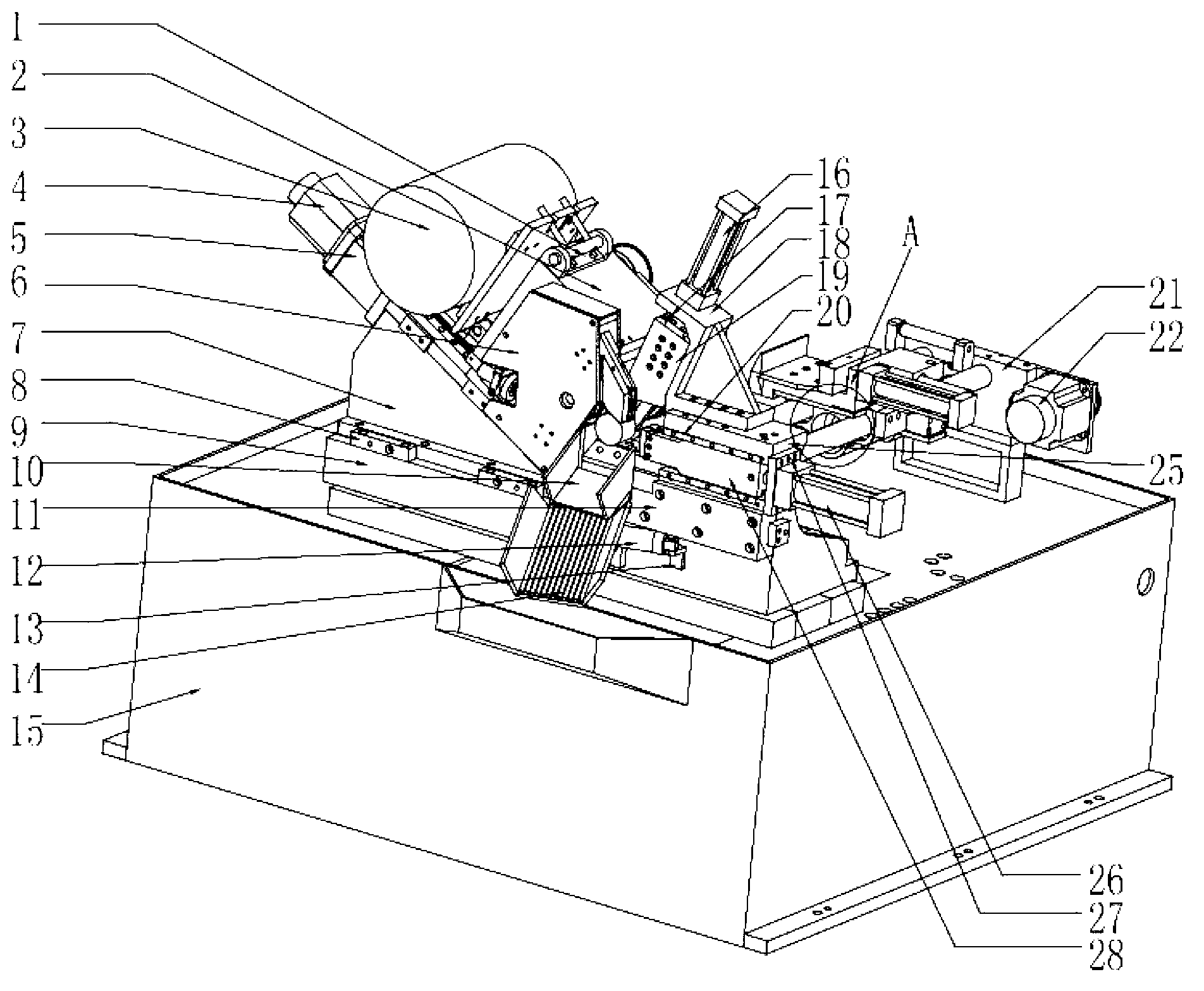

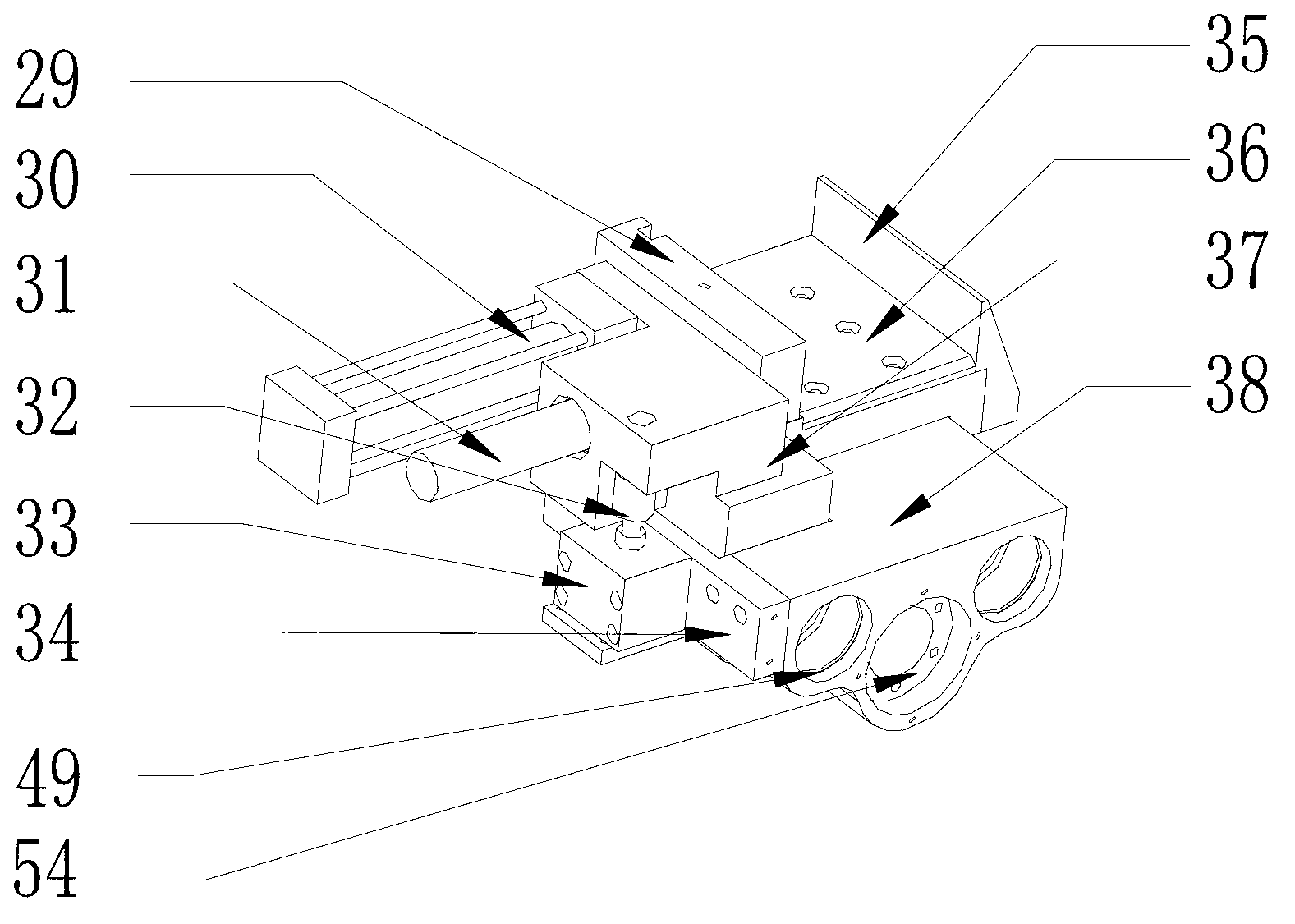

Automatic-turning slideway type metal circular sawing machine

ActiveCN102319929AImprove ergonomicsStable structureMetal sawing devicesMetal sawing accessoriesCircular sawMetallic materials

The invention discloses an automatic-turning slideway type metal circular sawing machine, which comprises a machine body, a feeding mechanism, a cutter-feeding mechanism, servomotors and an electric control cabinet, the feeding mechanism is arranged on the machine body, and the automatic-turning slideway type metal circular sawing machine also comprises an automatic preparing mechanism which can automatically load and feed materials by means of oil cylinders and sensors. The automatic-turning slideway type metal circular sawing machine can quickly saw steel materials, iron materials and othermetal materials with various cross-sectional shapes, can be automatically stopped when materials do not exist, can centrally collect chips, and has the integrated function of automatic loading, automatic feeding, length fixing, automatic turning, cutting and the like for a single material or a plurality of materials, each movable part of the whole machine is provided with a built-in automatic lubricating system, and the automatic-turning slideway type metal circular sawing machine is easy to maintain, can save working hours and greatly increase the human-machine working efficiency, and is a high-efficiency metal circular sawing machine with perfect sawing precision.

Owner:东莞市晋诚机械有限公司

Automatic high-speed cold sawing machine for superhard metals

ActiveCN103008779AGuaranteed smoothnessGuaranteed feed accuracyMetal sawing devicesMetal working apparatusEnergy consumptionMetal

The invention relates to an automatic high-speed cold sawing machine for superhard metals. The automatic high-speed cold sawing machine comprises a machine body and a machine body protective cover; a feeding device and a feed gear are arranged above the machine body; the feeding device comprises a feeding seat; a lifting seat is arranged above the feeding seat; and the top of the lifting seat is provided with a feeding clamp cushion block. The invention has the advantages that the automatic high-speed cold sawing machine for superhard metals fully automatically completes procedures from preparing materials to cutting the materials through machines, saves time and labor, can ensure the finish of workpiece surfaces and the feeding accuracy, and can also meet a requirement for cutting raw materials with different sections and lengths and different metal materials and recycling tailings; and each moving part of the whole machine is provided with an automatic lubrication system, the maintenance is simple and convenient, the efficiency is improved, secondary processing is eliminated, energy consumption is reduced, the cost is reduced and the automatic high-speed cold sawing machine is safe and environment-friendly.

Owner:东莞市晋诚机械有限公司

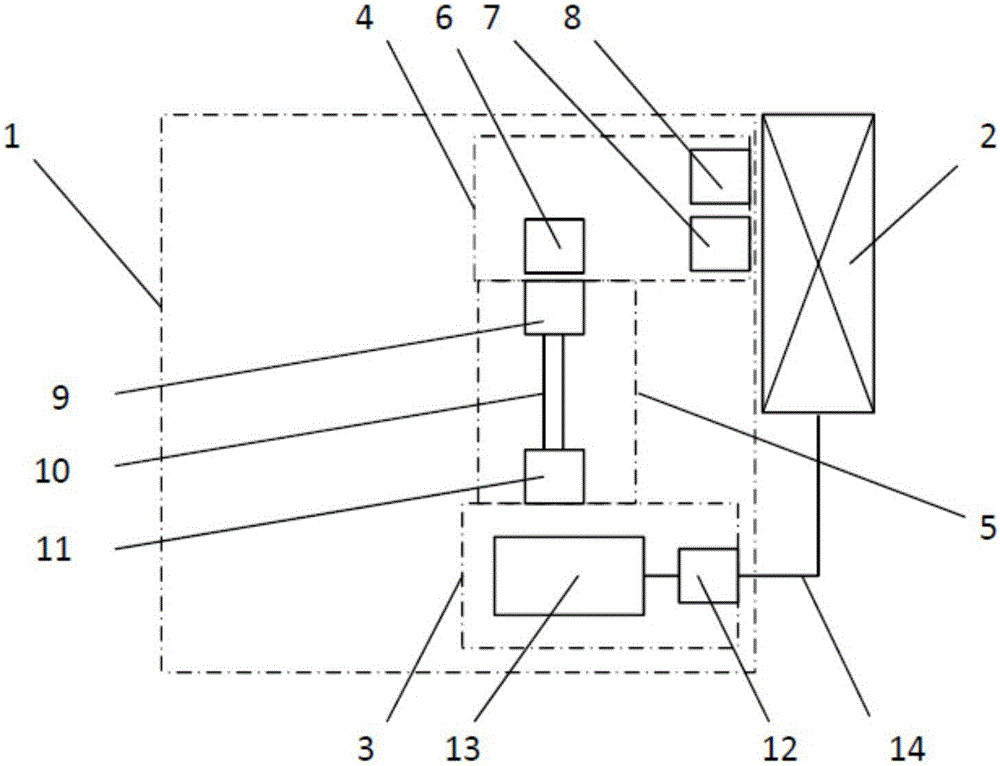

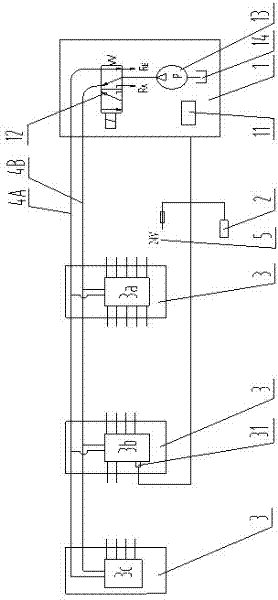

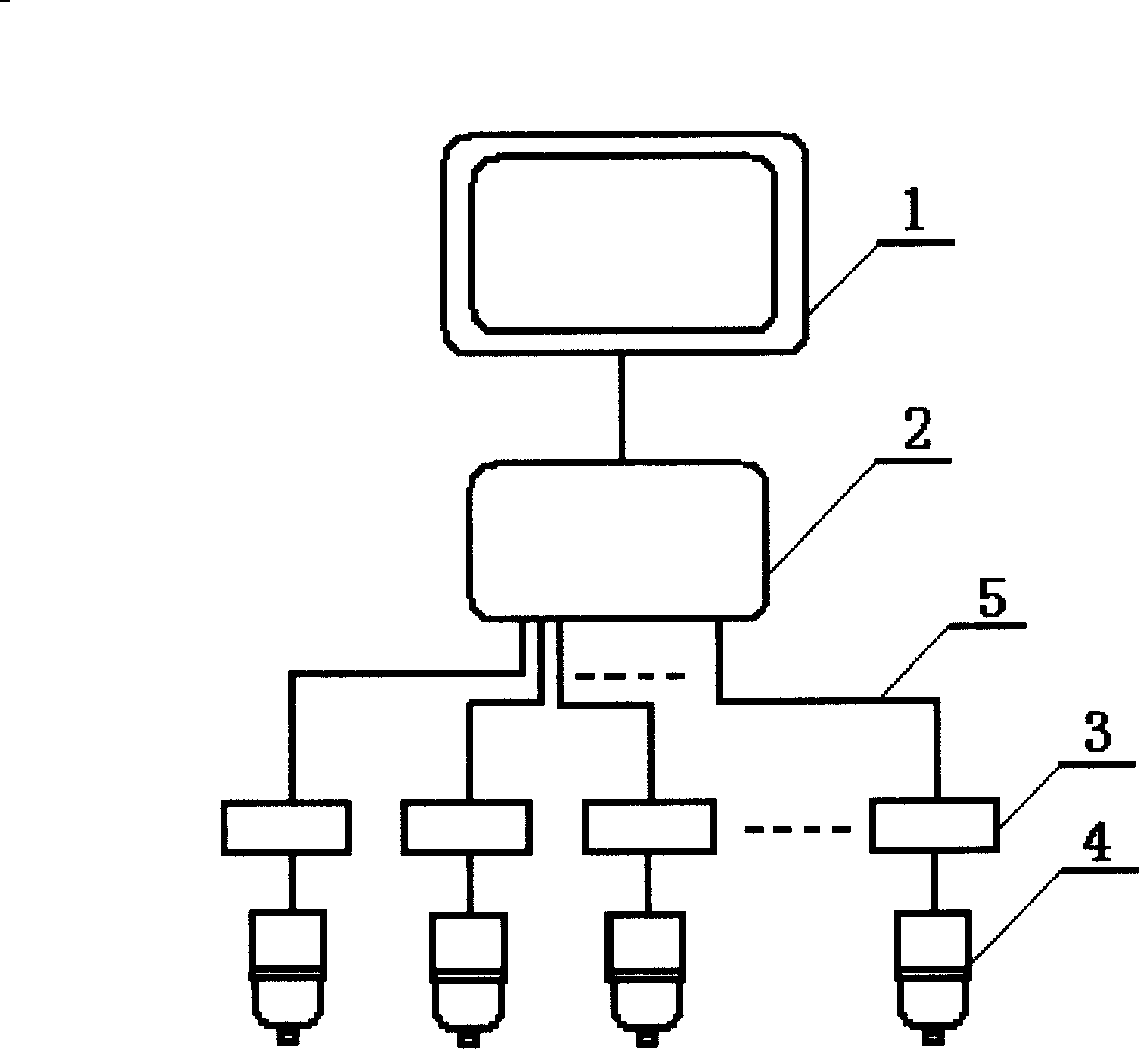

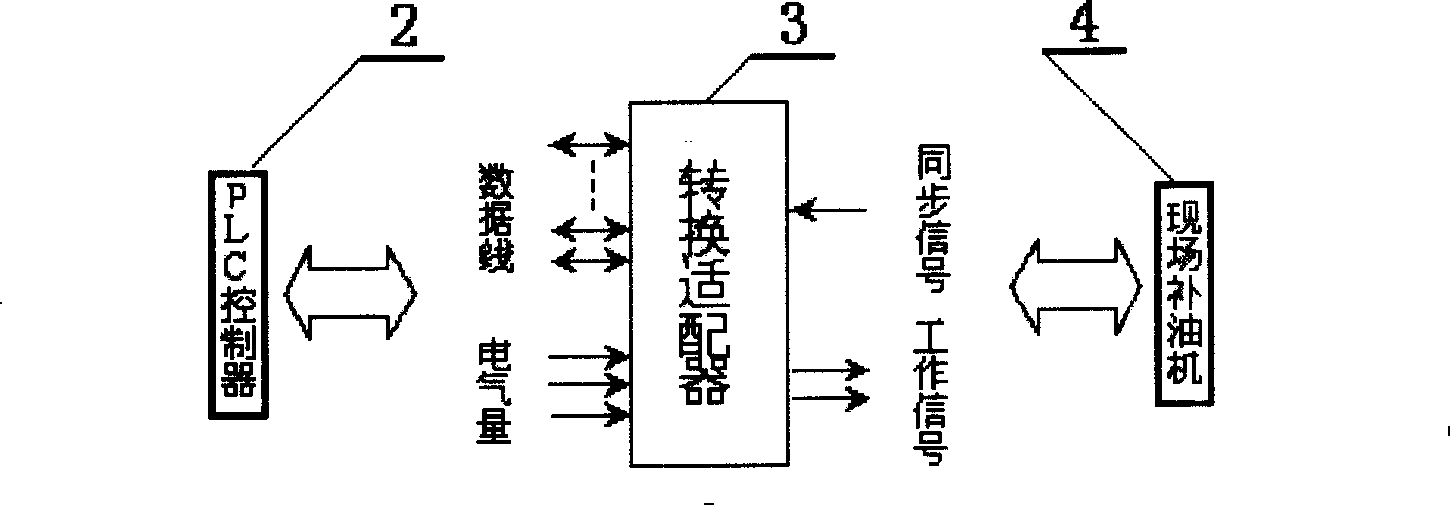

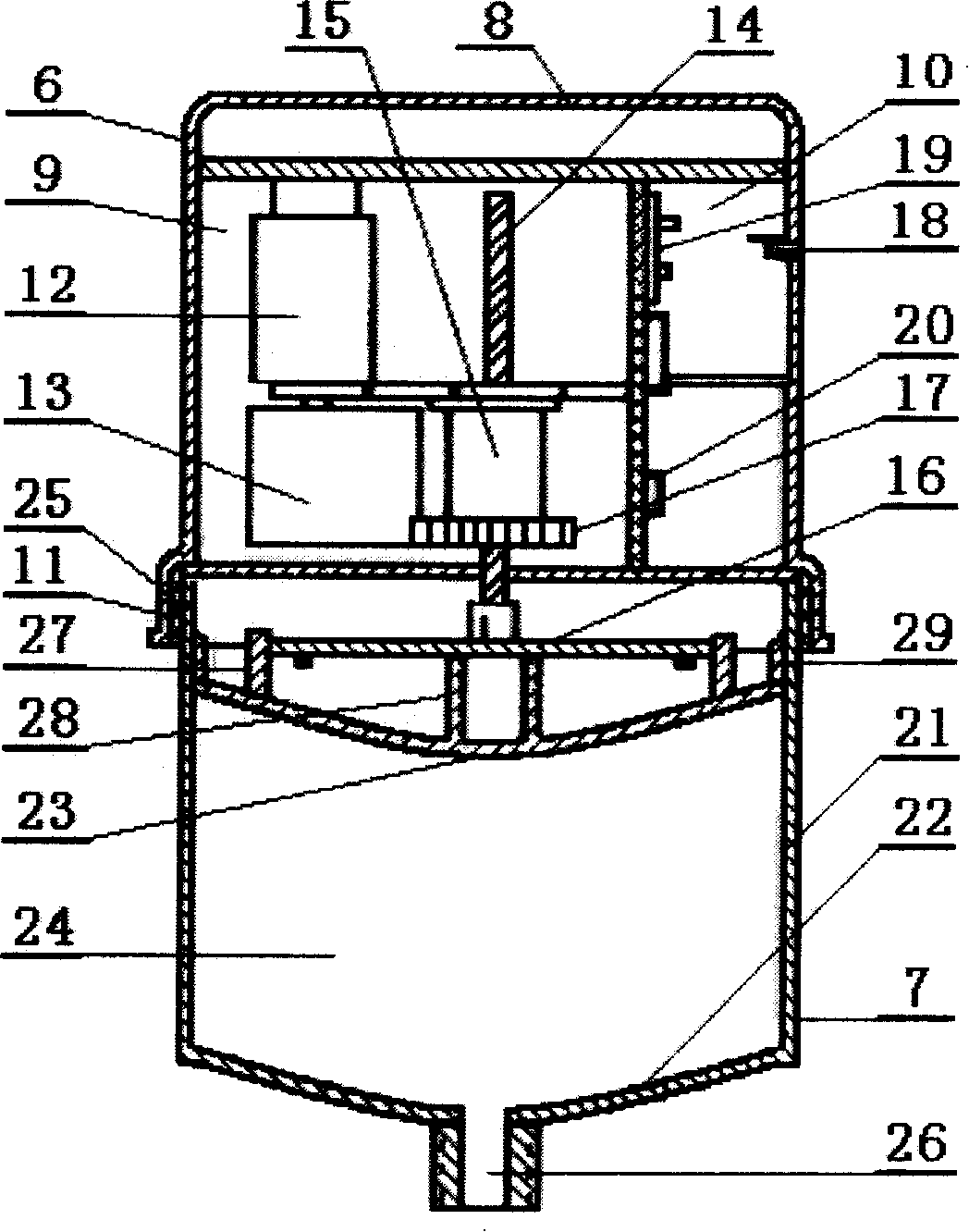

Distributed automatic lubricating system

InactiveCN101210645AGood lubrication working conditionIncrease productivityLubrication elementsCommunications systemWork cycle

The invention relates to a distributed-type automatic lubrication system which comprises a high-level man-machine interface (HMI), a controller, a conversion adapter, field oil supplement machines and a communication system. The high-level HMI consists of an industrial personal computer (IPC) or an integrated work station, system software and an application program. The controller is composed of a programmable controller PLC. The conversion adapter is arranged between the controller and each field oil supplement machine. The main bodies of the field oil supplement machines are provided with reusable oil storage cups. The field oil supplement machines are directly arranged on the working field of each lubricated point to automatically supplement lubricant oils at a constant pressure in a timely and quantitative manner under the control of the high-level HMI, thereby avoiding the damage to an oil seal of a bearing chamber and the reduction in oil quality and avoiding the oil leakage and poor lubrication effect. The high-level HMI can preset and regulate the operating cycle parameters of each field oil supplement machine; monitor the operational states of each field oil supplement machine, the relevant working shafts and the whole lubrication system; and ensure good lubrication operational state.

Owner:冯进才

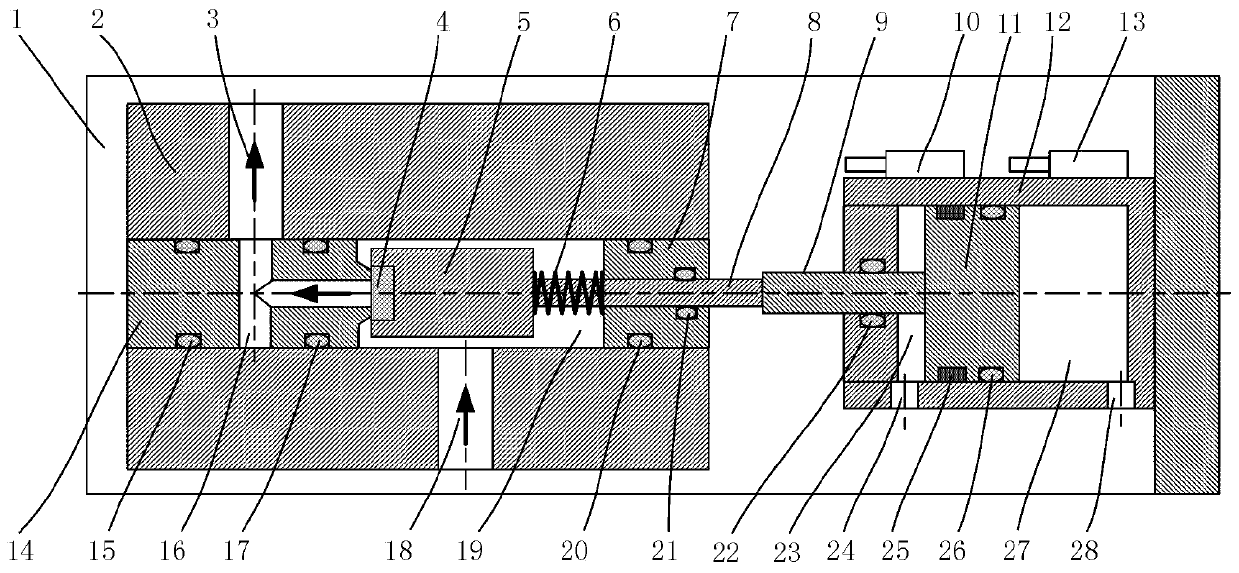

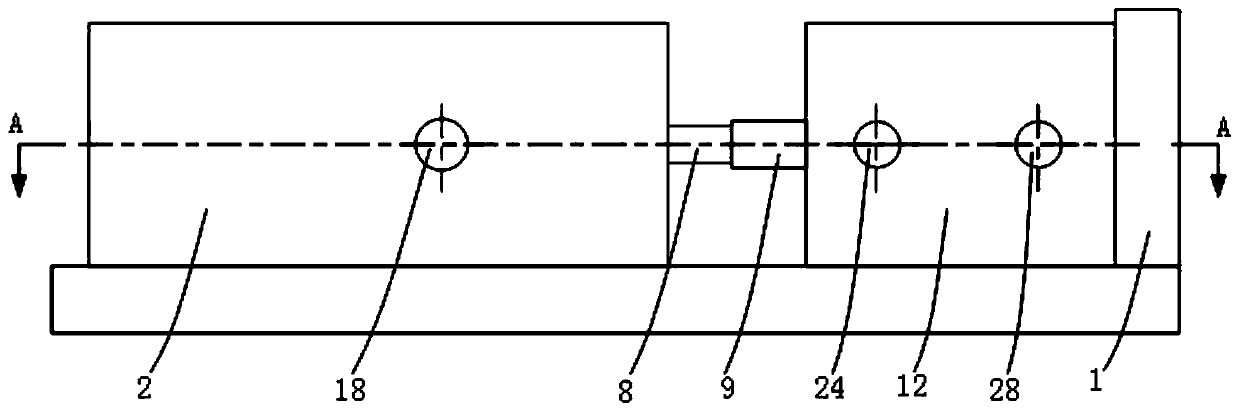

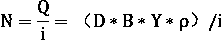

High-pressure dry oil pneumatic control valve

InactiveCN110701312AMeet high frequency work requirementsCompact structureOperating means/releasing devices for valvesLift valveEngineeringControl valves

The invention discloses a high-pressure dry oil pneumatic control valve and belongs to the technical field of mechanical lubrication control. The high-pressure dry oil pneumatic control valve comprises a base, the surface of the base is provided with a valve body, and a center through hole is formed in the valve body; a valve seat, a valve element and a sealing end cover are arranged in the centerthrough hole separately, a cavity formed among the valve body, the valve element and the sealing end cover is a valve cavity, and a T-shaped through hole is formed in the valve seat; the surface of the valve body is provided with an oil outlet and an oil inlet, a piston rod is connected to the valve element through a valve rod, and a piston is connected to one end of the piston rod. The high-pressure dry oil pneumatic control valve is compact in structure, high in response speed and high in reliability, when the piston rod is ejected out, the valve element and a sealing body of one end of thevalve element press one end of the valve seat, so that the T-shaped through hole in the valve seat is sealed, and the oil inlet is not communicated with the oil outlet; when the piston rod is drawn back, the valve cavity, the T-shaped through hole, the oil inlet and the oil outlet are in a communicated state, the operation state of the control valve is controlled accordingly, and the demand for high-frequency work of an automatic lubrication system is met.

Owner:HUATIAN ENG & TECH CORP MCC

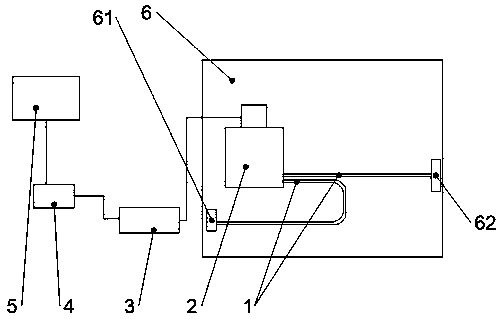

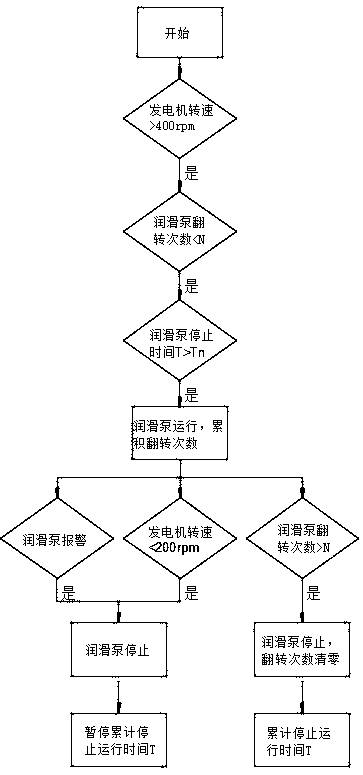

Wind driven generator bearing automatic lubricating device and automatic lubricating control method

ActiveCN108953964AAvoid timingAvoid uneven fat injectionLubrication elementsWind energy generationElectricityWind driven

The invention discloses a wind driven generator bearing automatic lubricating device and an automatic lubricating control method. The wind driven generator bearing automatic lubricating device comprises a lubricating pump installed on a generator, a lubricating oil pipe, an auxiliary junction box, a contactor and a controller. The lubricating pump is provided with a power signal line and a fault warning signal line. The power signal line and the fault warning signal line are in electric connection with the auxiliary junction box. The auxiliary junction box is in electric connection with the contactor. A contactor switch connector is in electric connection with the controller. According to the lubricating method of the wind driven generator bearing automatic lubricating device, the controller is used for obtaining the rotation speed of the generator, for recording the number of times of overturning of the lubricating pump, for recording stop time T of the lubricating pump, and for recording temperature data of a bearing. The lubricating pump is started and stopped according to setting, and the problems that a current automatic lubricating system is liable to cause oil separation andsaponification, consequently a lubricating oil way is blocked or the grease outlet amount is not enough are solved, and meanwhile the problems that when the generator does not rotate, grease is alsoconveyed in, timing is also conducted under the circumstance that a unit is stopped without power failure, grease is conveyed in unevenly, and the grease filling amount is inaccurate are avoided.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

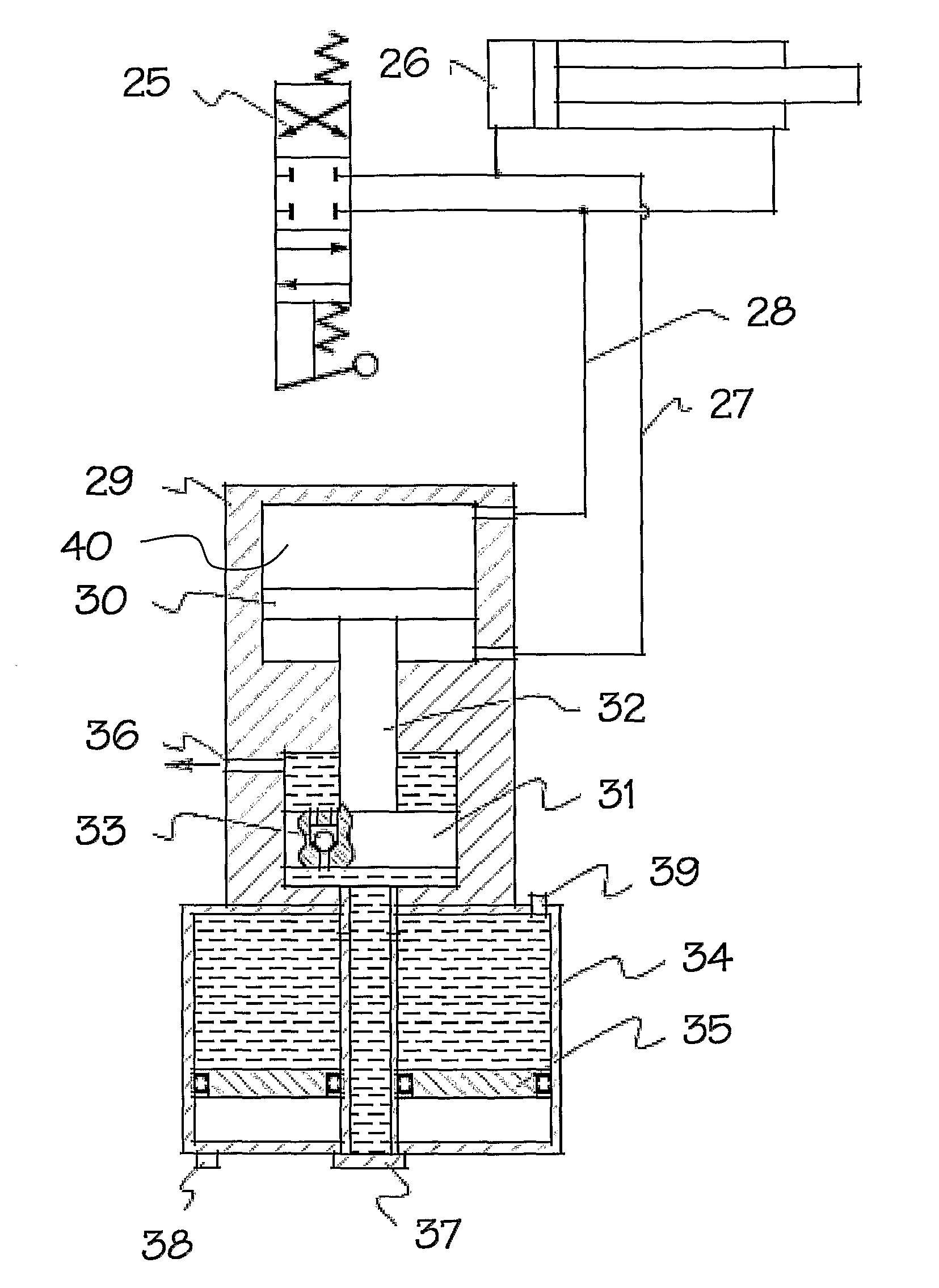

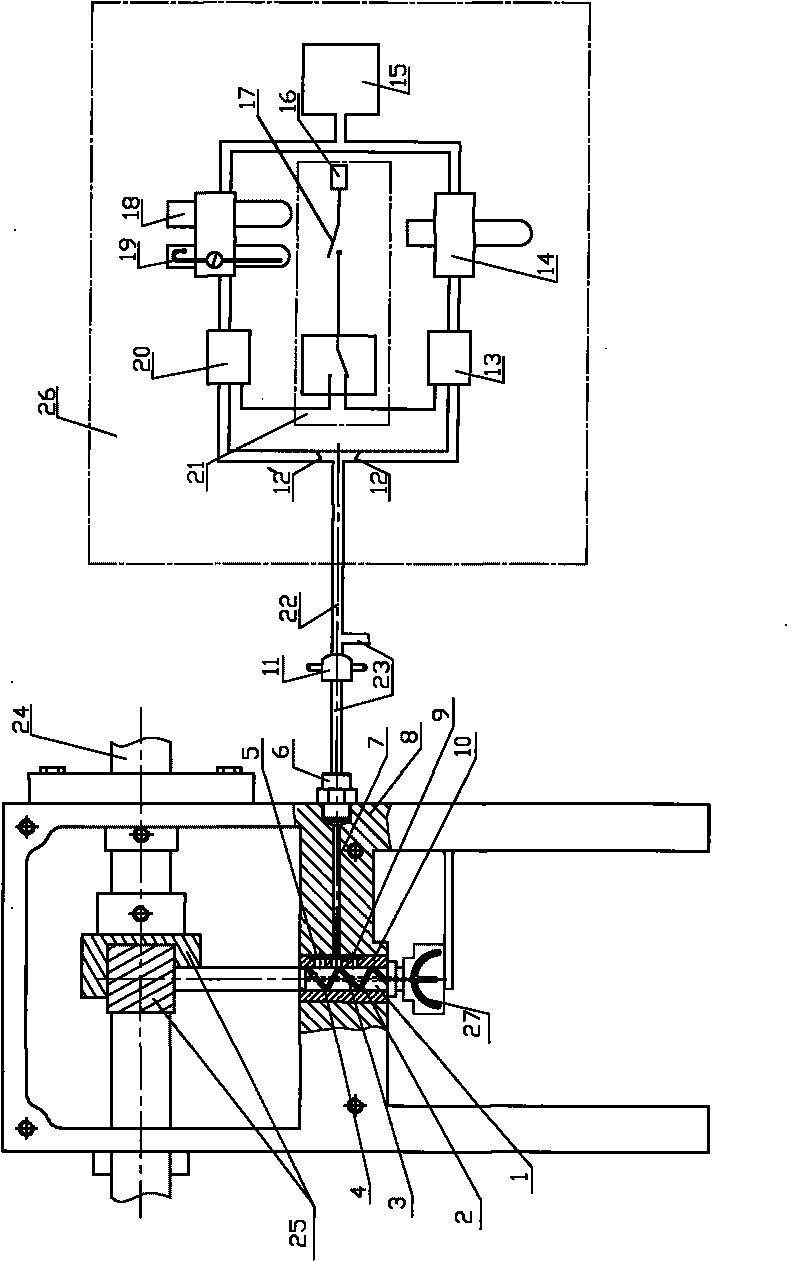

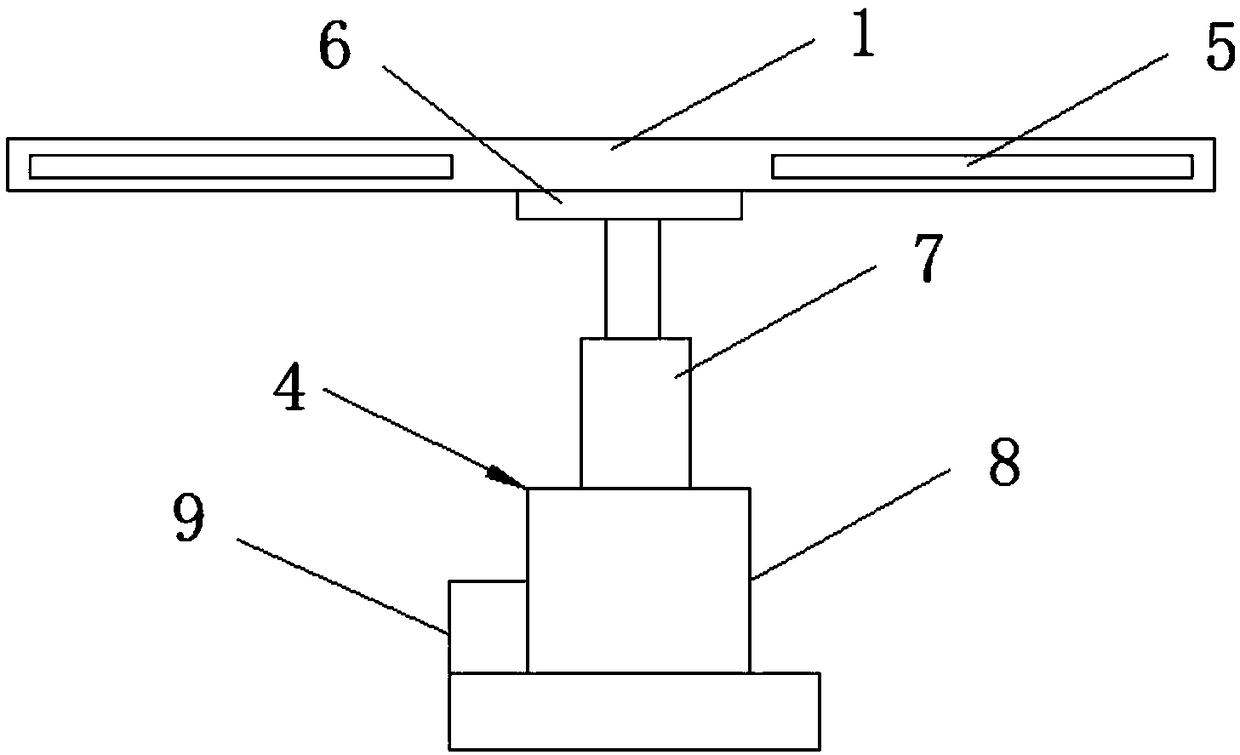

Single-source multi-way distributive automatic lubricating system

InactiveCN108591798AOil timingFixed point of oil injectionEngine lubricationMechanical engineeringAutomatic lubrication system

A single-source multi-way distributive automatic lubricating system comprises a grease storing cylinder, a stored grease outputting loading cylinder, a grease filling cylinder and a filled oil outputting driving box, wherein the grease storing cylinder is used for storing lubricating grease; a lubricating grease outlet of the grease storing cylinder is connected to a lubricating grease inlet of the grease filling cylinder through a first pipeline, and a first one-way valve is arranged on the first pipeline; the stored grease outputting loading cylinder is used for supplying power to the greasestoring cylinder during outputting lubricating grease; the grease filling cylinder is used for supplying lubricating grease to a device lubricating point, and the filled grease outputting driving boxis used for supplying power to the grease filling cylinder to output lubricating grease; a plurality of lubricating grease outlets which are distributed in the height direction and are provided withdifferent phase angles are distributed on a grease filling cylinder body; the lubricating grease outlet in the bottommost end in the height direction communicates with the lubricating grease inlet ina stored grease outputting loading cylinder body through a second pipeline, and a second one-way valve is arranged on the pipeline; and the grease filling cylinder is treated as a power source of thestored grease outputting loading cylinder. According to the system, a traditional manual grease filling mode is avoided; the grease can be quantitatively filled in fixed time and at a fixed point under a complex working condition; and the system is particularly suitable for devices with a plurality of lubricating points.

Owner:LIAONING TECHNICAL UNIVERSITY

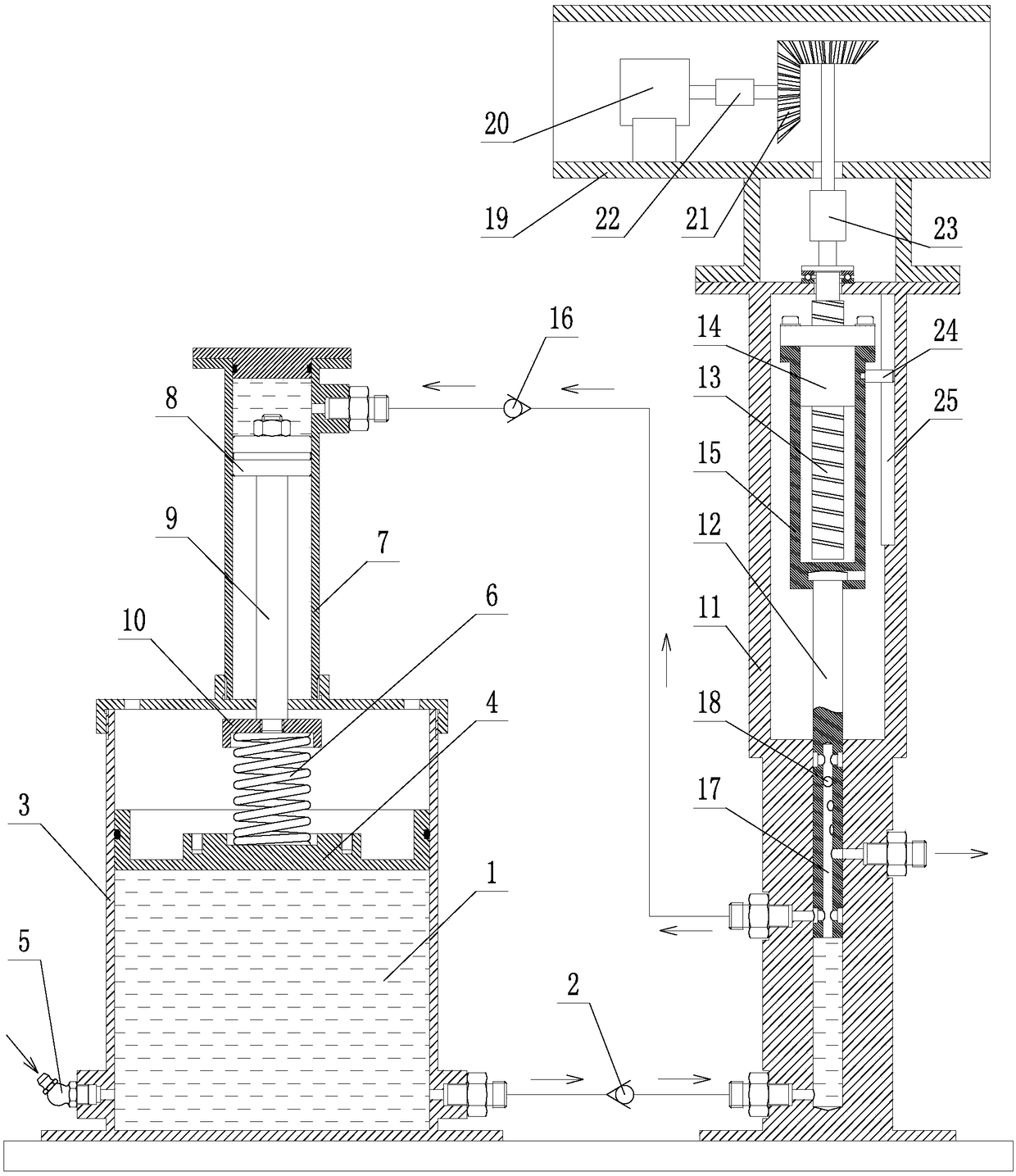

Automatic lubrication system for gear and rack of lifter in indoor building construction

ActiveCN108843952AImprove efficiencyRealize automatic drippingEngine lubricationHydraulic pumpAgricultural engineering

The invention discloses an automatic lubrication system for a gear and a rack of a lifter in indoor building construction. The automatic lubrication system comprises a cross rod, a left-side lubrication mechanism located at one end of the cross rod, and a right-side lubrication mechanism located at the other end of the cross rod, wherein a height adjustment mechanism connected with the cross rod is installed below the middle part of the cross rod; slide grooves are formed in the two ends of the cross rod separately; a hydraulic pump is installed at the bottom of the height adjustment mechanism; a bottom power supply is installed on the sidewall of the hydraulic pump, and a hydraulic telescopic rod is connected to the top of the hydraulic pump; a top plate is connected to the top of the hydraulic telescopic rod; and the top of the top plate is abutted against the cross rod. Due to the co-operation of the left-side lubrication mechanism and the right-side lubrication mechanism, higher speed and higher efficiency are achieved, and more uniform lubricant oil dripping can be completed for the gear; and meanwhile, uniform lubricant oil dripping can continue to be carried out on the rackafter the lubricant oil dripping is carried out on the gear, so that higher convenience and higher speed are achieved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

System for automatic lubrication

ActiveUS9303814B2Prevent returnAvoid accidental rotationProportioning devicesBearing componentsInjection pressureExhaust valve

Owner:IFIELD ENG

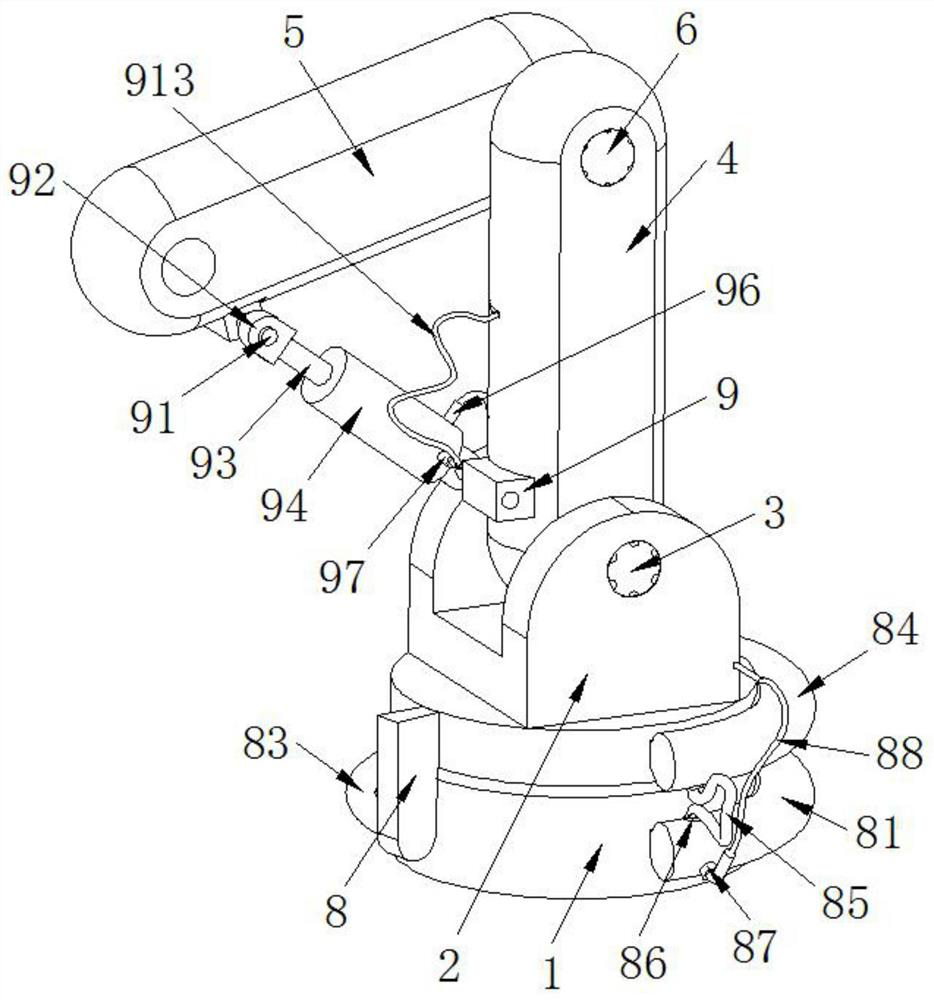

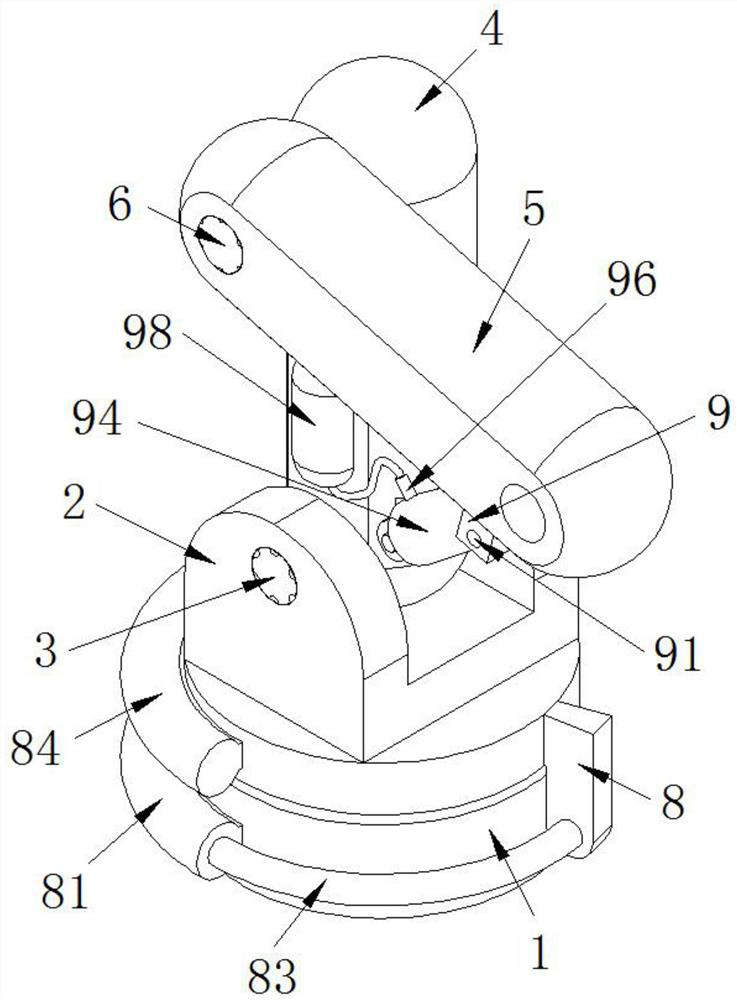

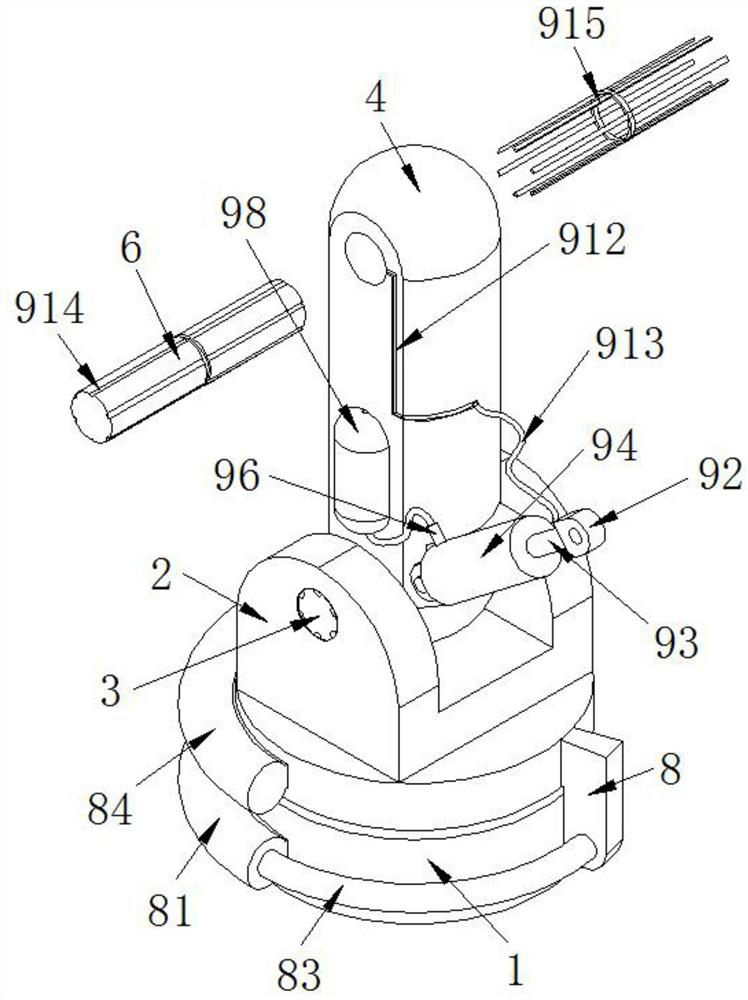

Industrial robot joint automatic lubricating system

The invention belongs to the technical field of industrial robot joint equipment, and particularly relates to an industrial robot joint automatic lubricating system. The system comprises a chassis, a rotating disc seat, a rotating disc shaft, a first joint, a second joint and a joint shaft in hinged rotation, and a rotating shaft is fixedly mounted at the bottom of the rotating disc seat. According to the automatic lubricating system for the joints of the industrial robot, by arranging a first automatic lubricating mechanism and a second automatic lubricating mechanism, a first push rod and a second push rod are driven to work when the rotating disc seat rotates or the first joint and the second joint rotate; the interior of a first lubricating pipe and the interior of a second lubricating pipe are controlled to generate suction force or pressure, lubricating oil in a first oil storage pipe and a second oil storage pipe is automatically controlled to flow out of a first smearing pipe and a second smearing pipe, the rotating disc shaft and the joint shaft are smeared, the lubricating oil can be injected in time, the lubricating efficiency is improved, joint abrasion is avoided, and the service life is prolonged.

Owner:NANJING YUQUN COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com