Automatic high-speed cold sawing machine for superhard metals

A technology of hard metal and cold sawing machine, which is applied in the direction of metal sawing equipment, metal processing, metal processing equipment, etc. It can solve the problems of time-consuming and laborious, inconvenient cutting of workpieces, and affecting the surface finish of workpieces, so as to reduce costs, improve efficiency, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

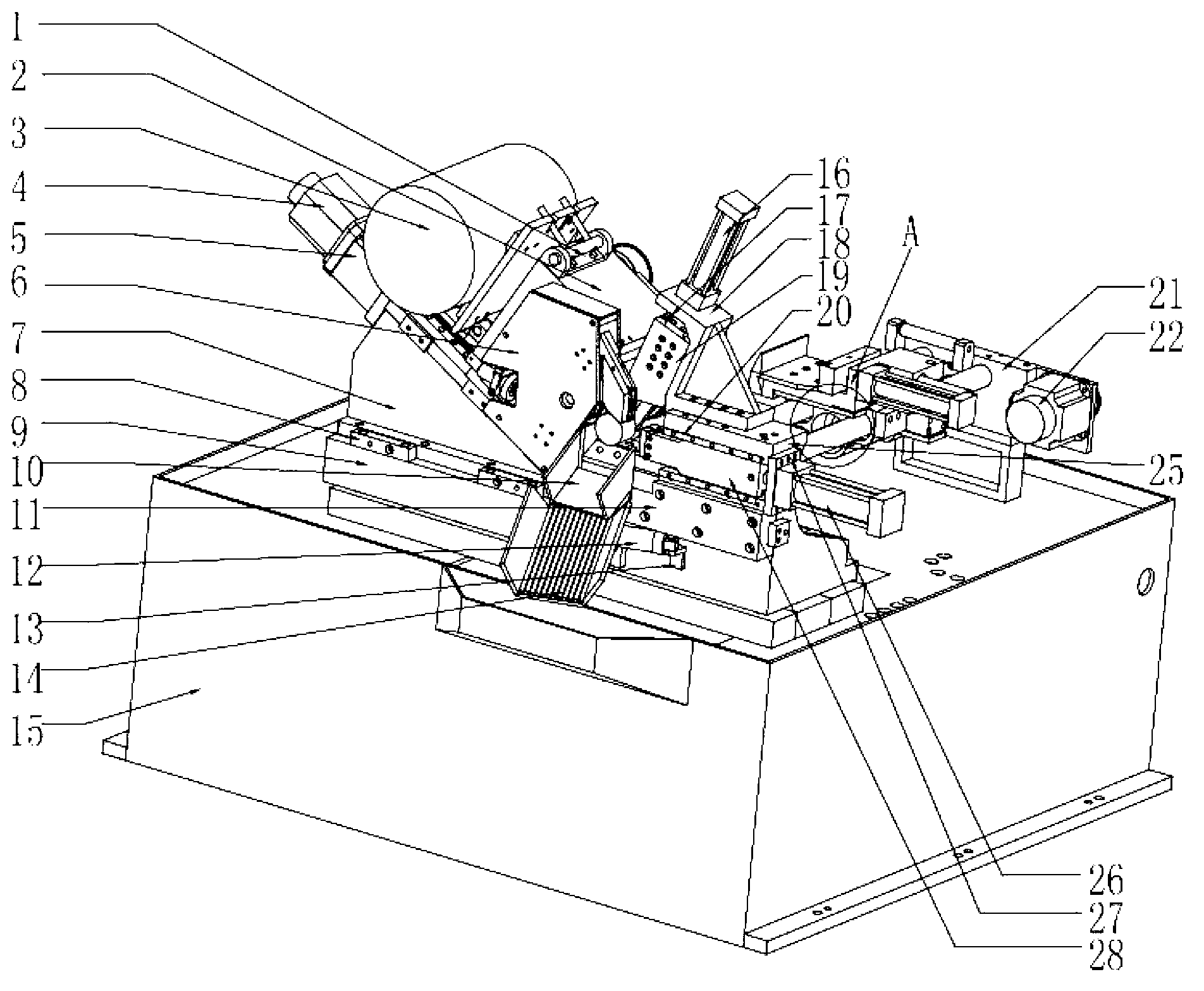

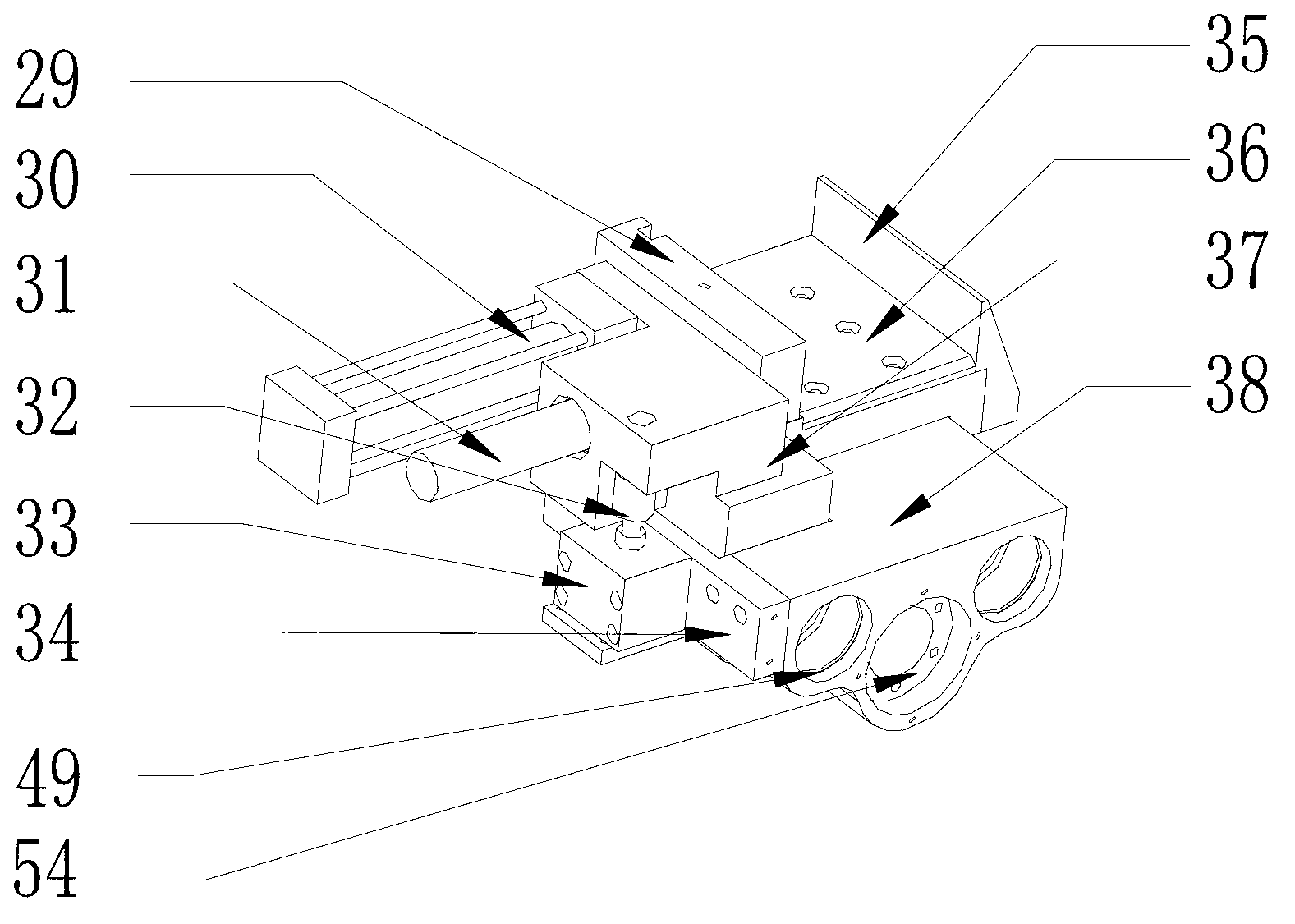

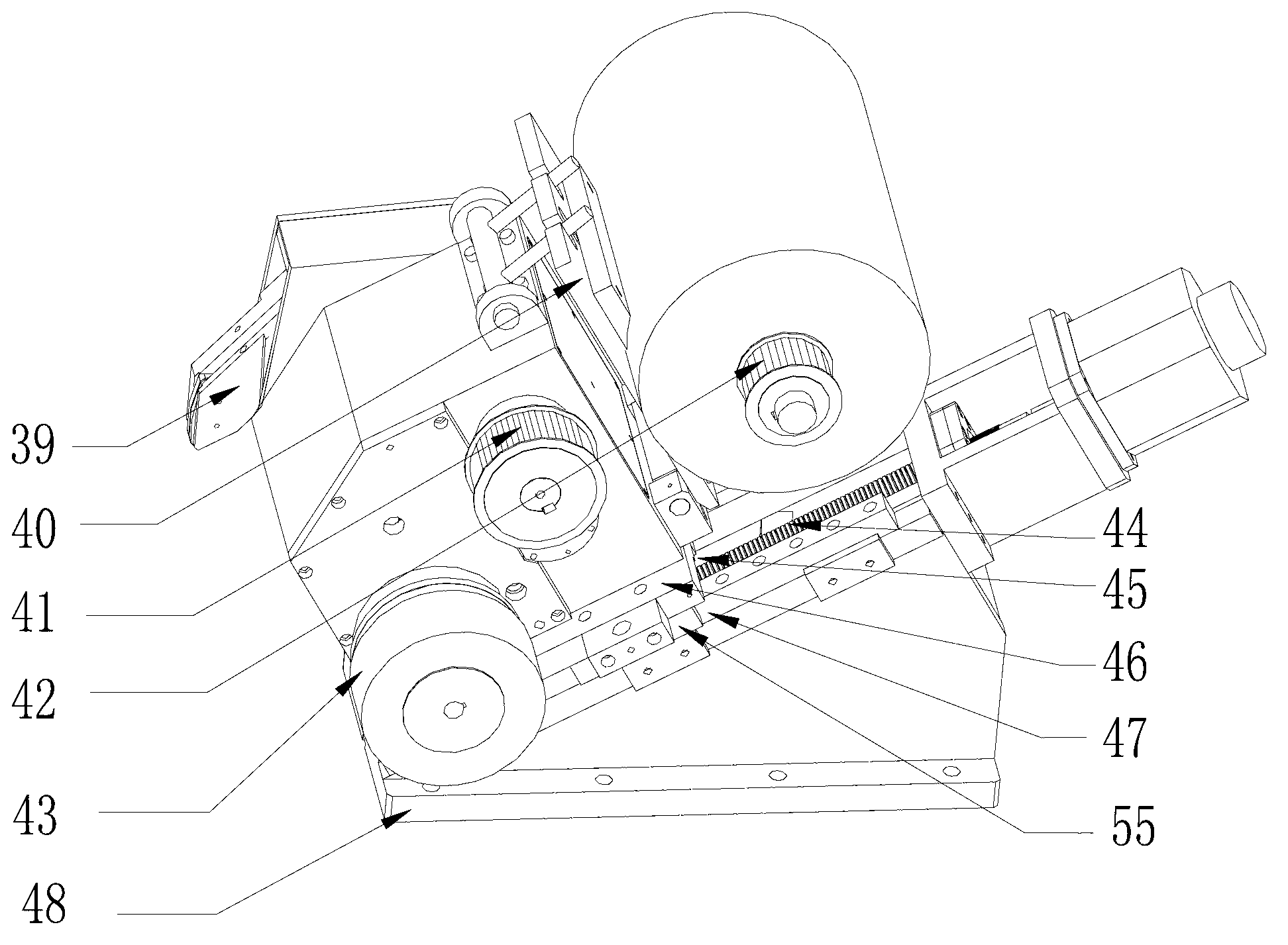

[0020] Such as Figure 1-5 As shown, an automatic superhard metal high-speed cold saw machine described in the embodiment of the present invention includes a fuselage 15 and a fuselage protective cover 53, a feeding device and a knife feeding device are arranged above the fuselage 15, and the feeder Material device comprises feeding seat 38, is provided with lifting seat 37 on the top of feeding seat 38, and is provided with feeding clamp pad 36 on the top of lifting base 37, is provided with feeding clamp 29 on the feeding clamp pad block 36, feeds clamping pad. The outer end of the block 36 is provided with a front guide plate 35 of the feed clamp, and the side wall of the feed seat 38 is provided with a fixed plate 34, and the fixed plate 34 is provided with an upper lift cylinder 33, and the upper lift oil cylinder 33 is connected with the upper lift seat 37 by a universal joint 32 , the upper seat 37 is provided with a matching guide rod 31 and a clamp oil cylinder 30 mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com