Patents

Literature

85results about How to "Guaranteed feed accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

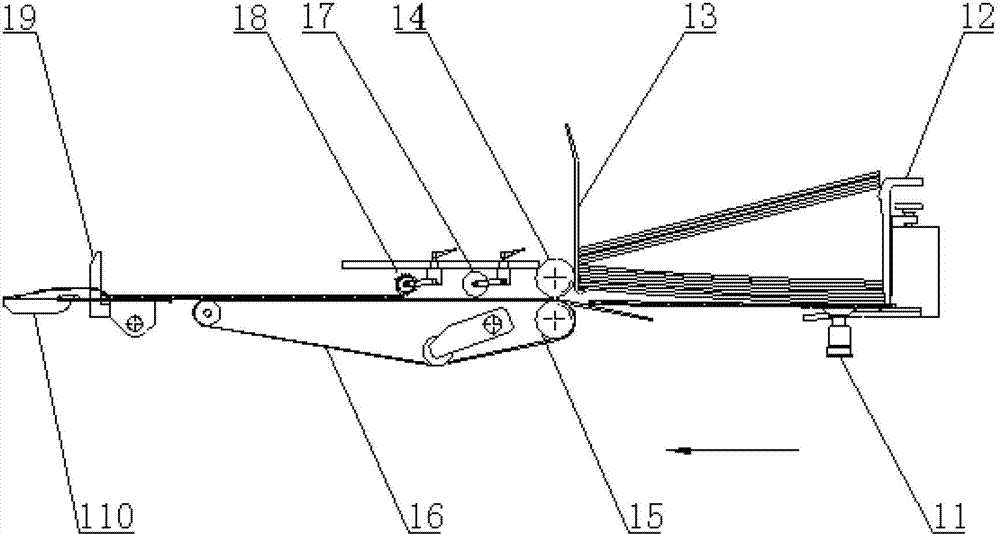

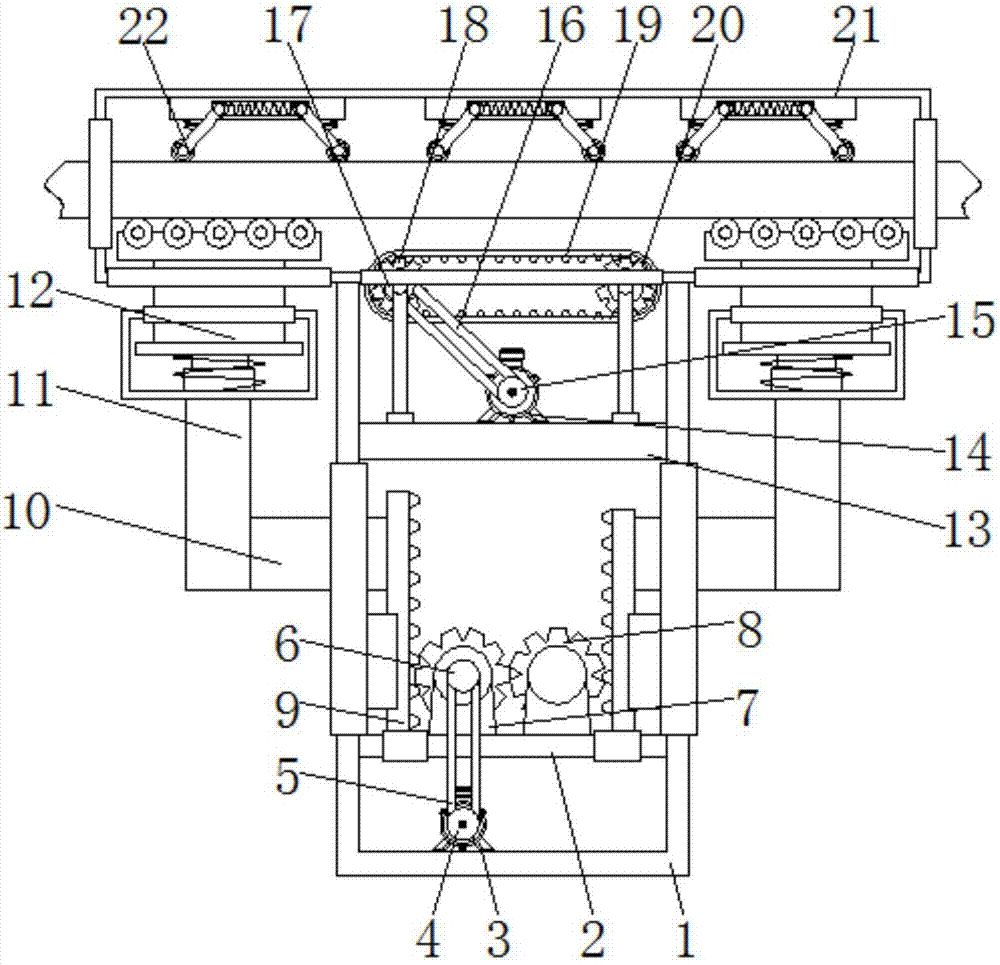

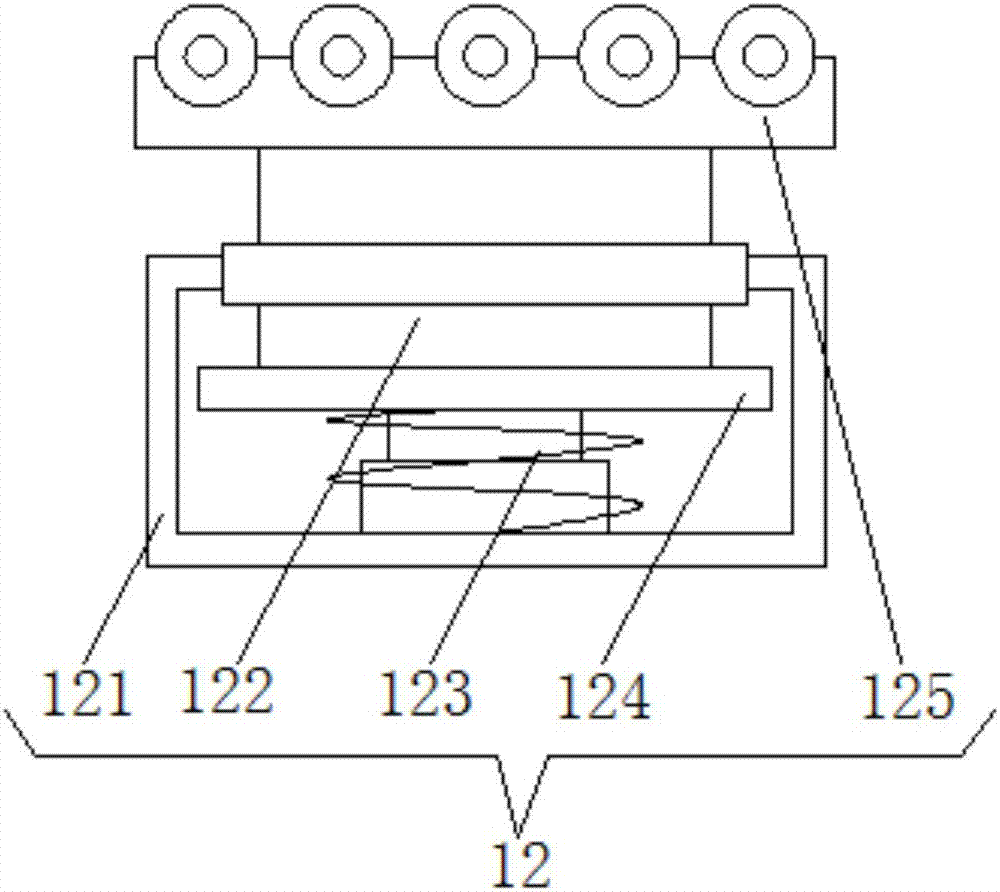

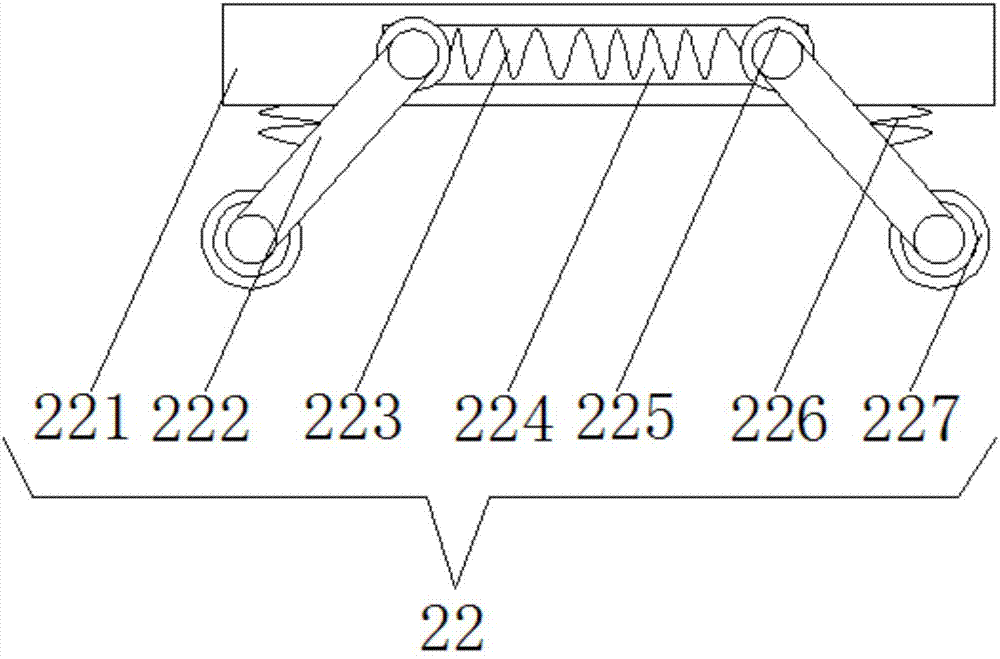

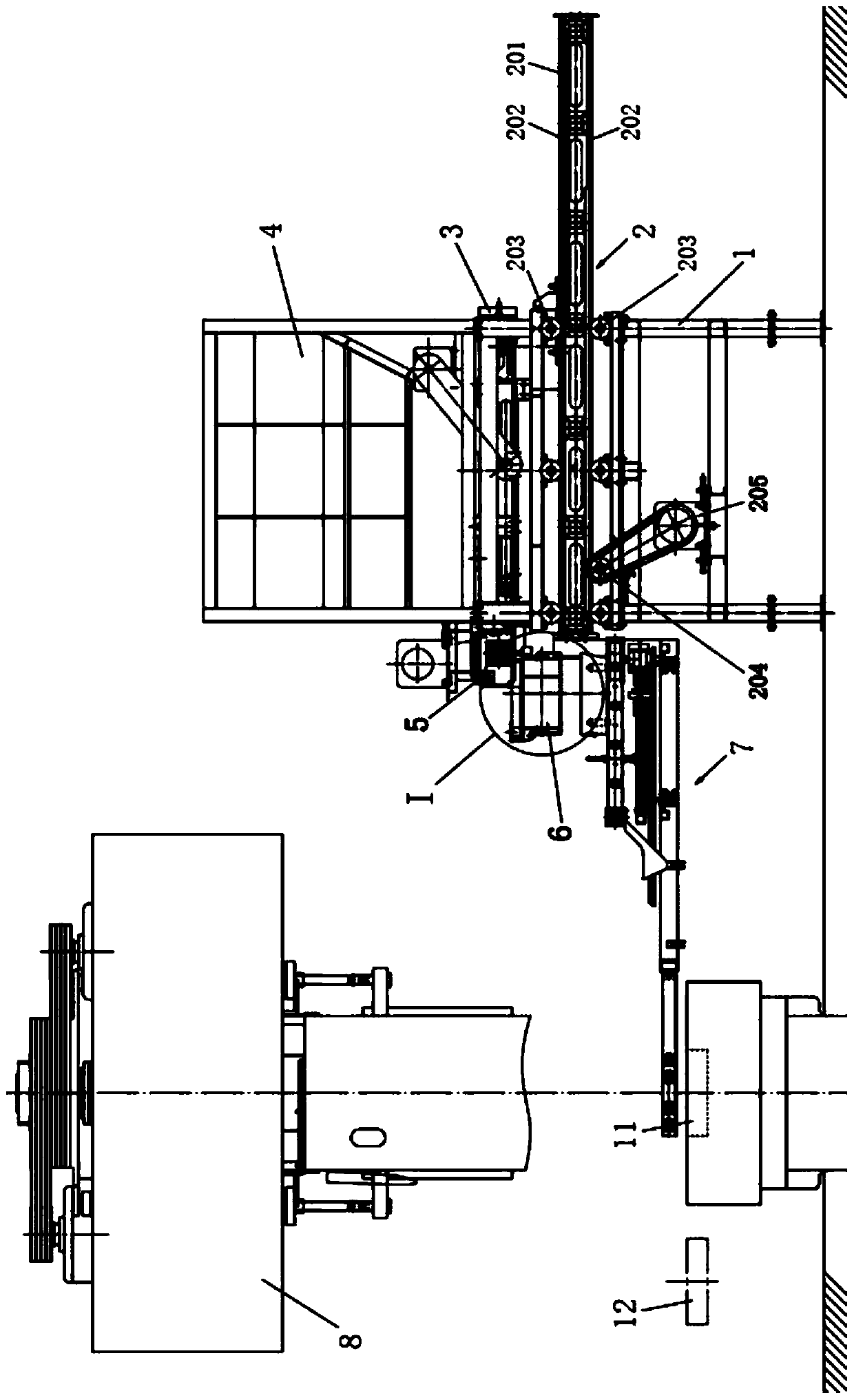

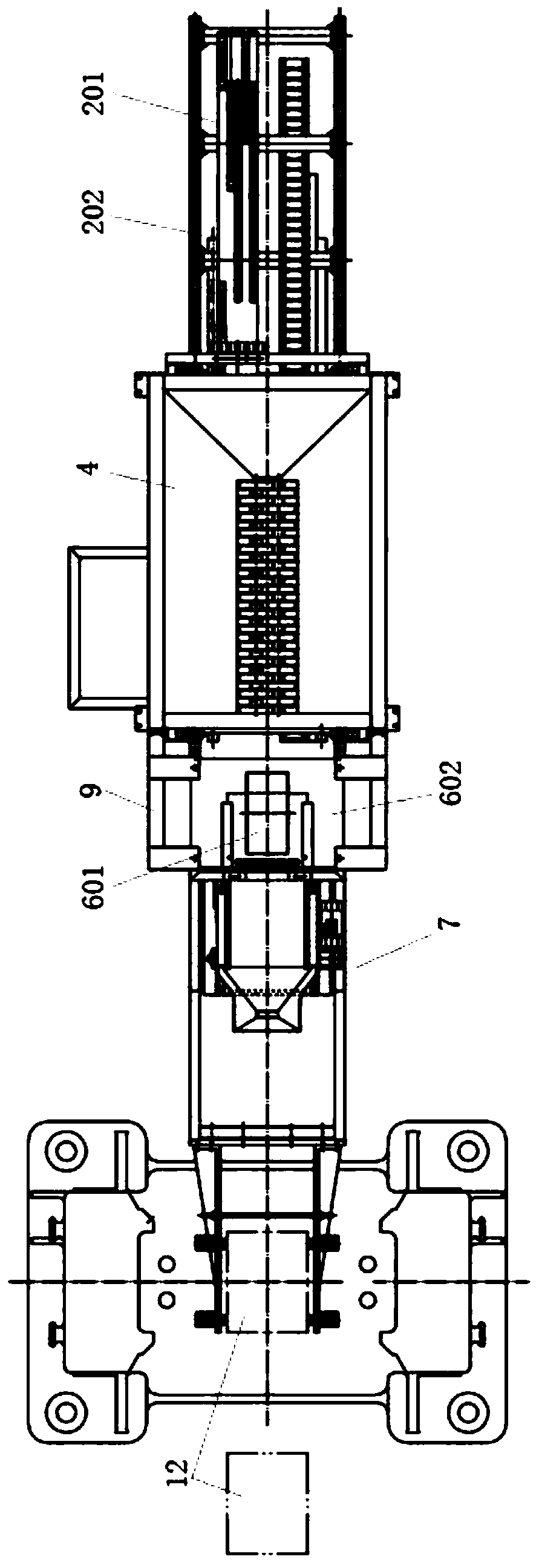

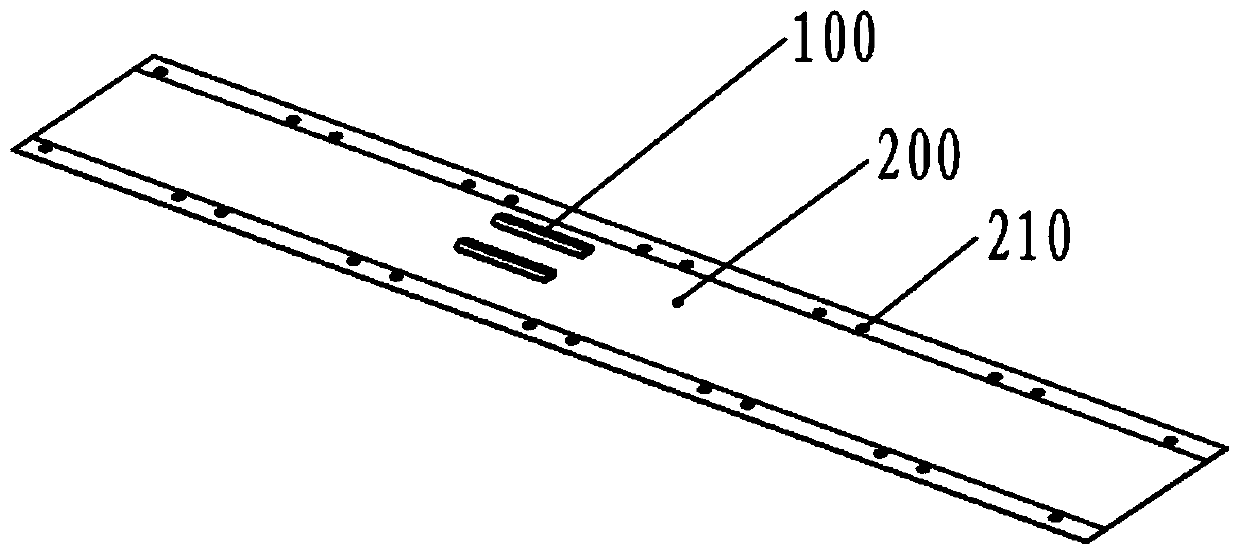

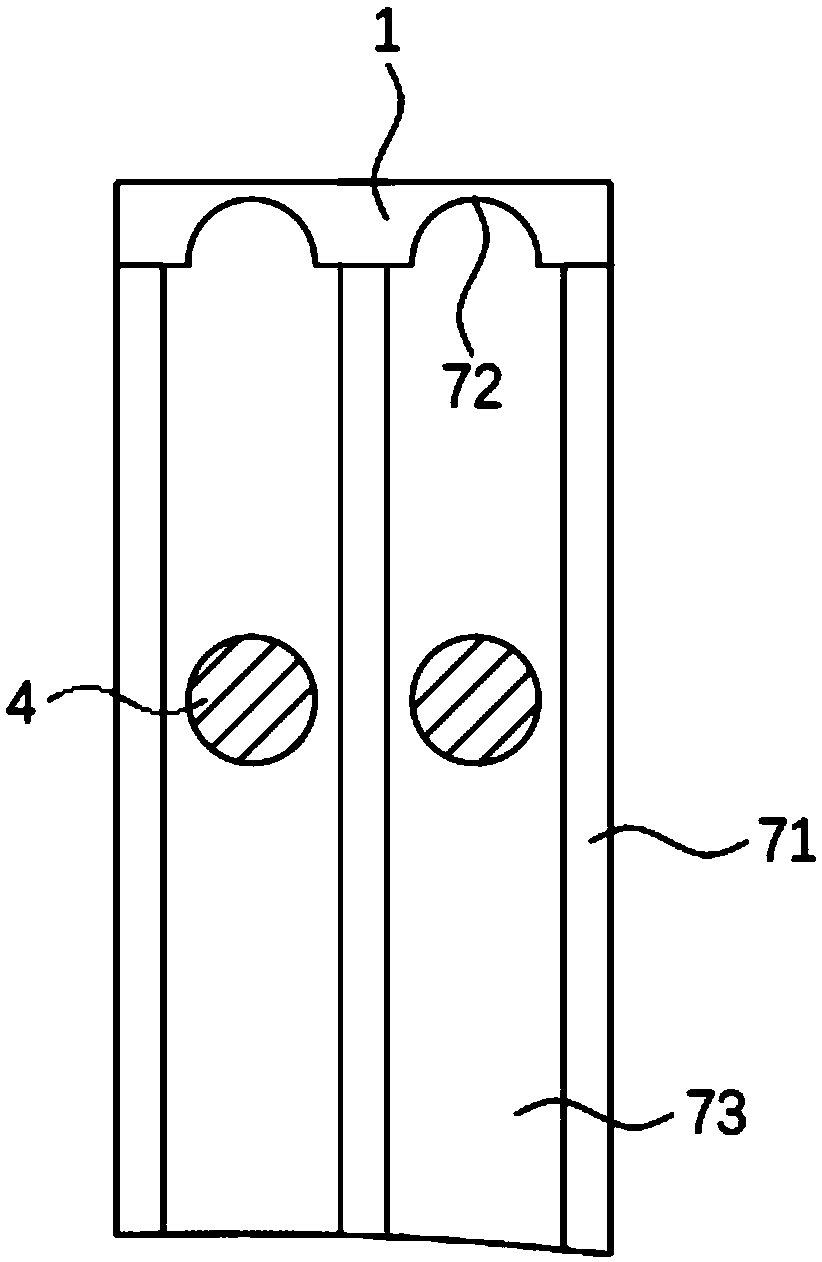

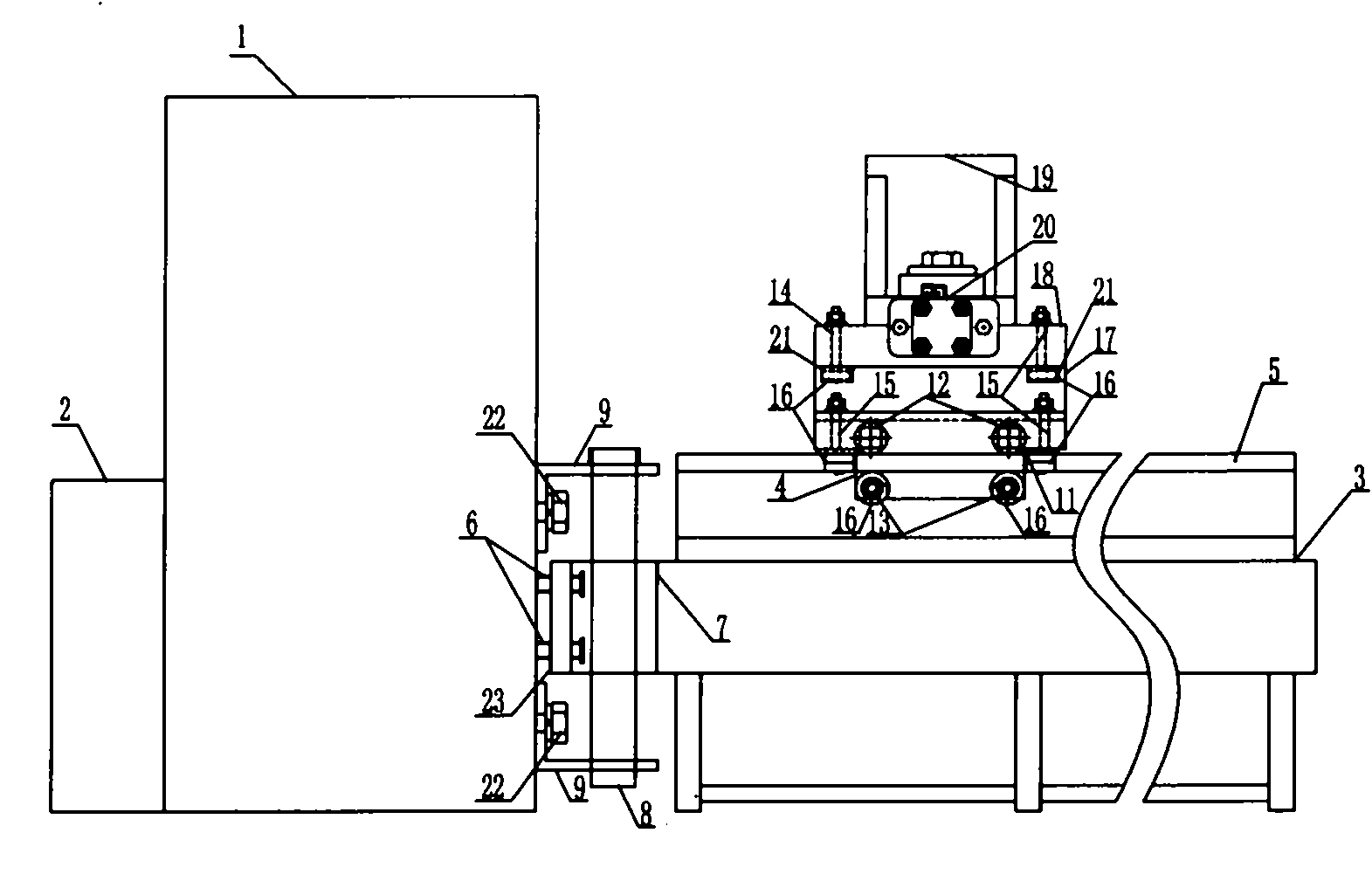

Device and method for positioning and conveying of automatic sheet-fed die-cutting machine

ActiveCN102862836AAchieve deterministic positioningGuaranteed feed accuracyRegistering devicesArticle feedersPaperboard

The invention discloses a device and a method for positioning and conveying of an automatic sheet-fed die-cutting machine. The device comprises a paper storage mechanism, a paper feed mechanism, a paper pushing mechanism and a positioning mechanism. The paper feed mechanism comprises an air suction box, a first drive mechanism and at least one belt drive mechanism group, each belt drive mechanism group comprises a conveying belt power roller, a conveying belt driven roller and an air suction conveying belt with uniformly distributed air suction holes, the air suction box is positioned between the upper layer and the lower layer of each air suction conveying belt, and a gap for a sheet to pass through is reserved between the upper surface of each air suction conveying belt and the lower end of a front retaining plate. The paper pushing mechanism comprises at least one paper support plate, at least two pushing handles and second drive mechanisms, and each pushing handle reciprocates along the direction perpendicular to the axis of each conveying belt power roller under the action of the corresponding second drive mechanism. The positioning mechanism comprises at least two front guides and two side guides, and each front guide corresponds to an inductive switch and one second drive mechanism set. Determinacy positioning of paperboards at a controllable state is achieved in the condition of poor flatness of the paperboards.

Owner:SHANGHAI YOCO PRINTING MACHINERY

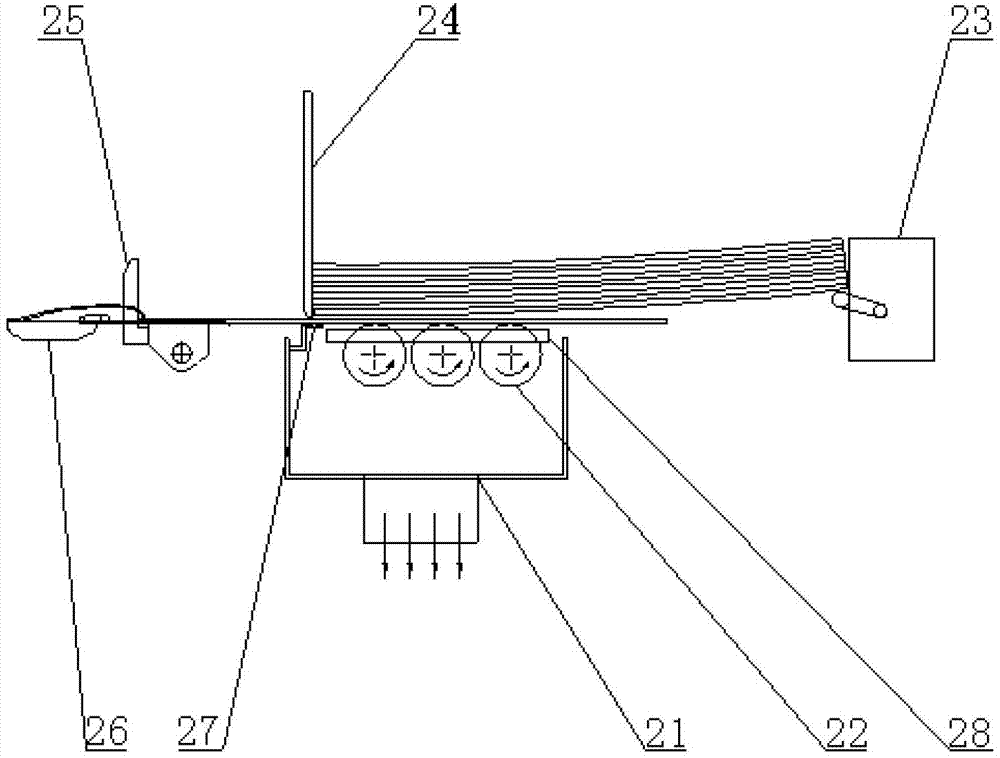

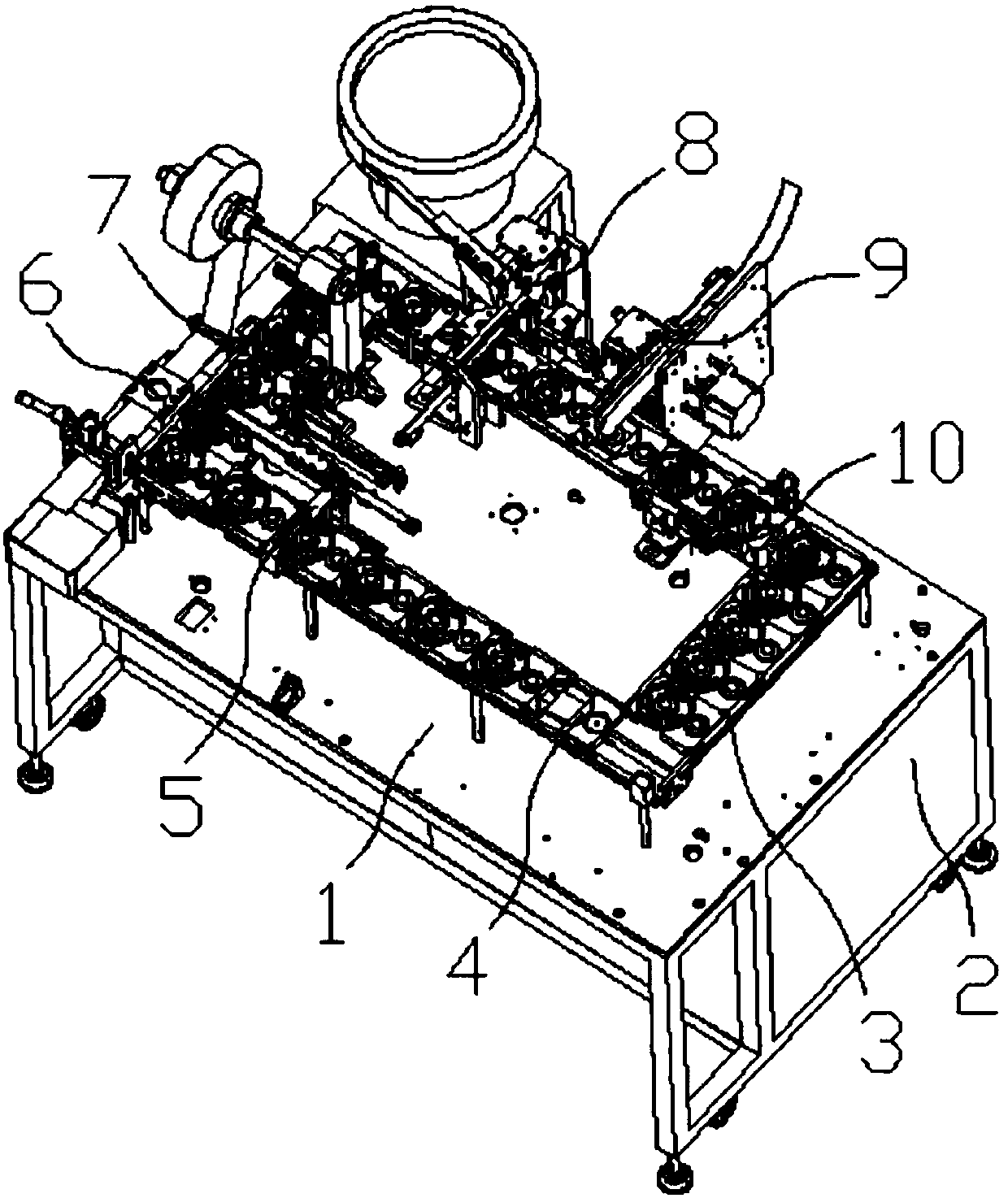

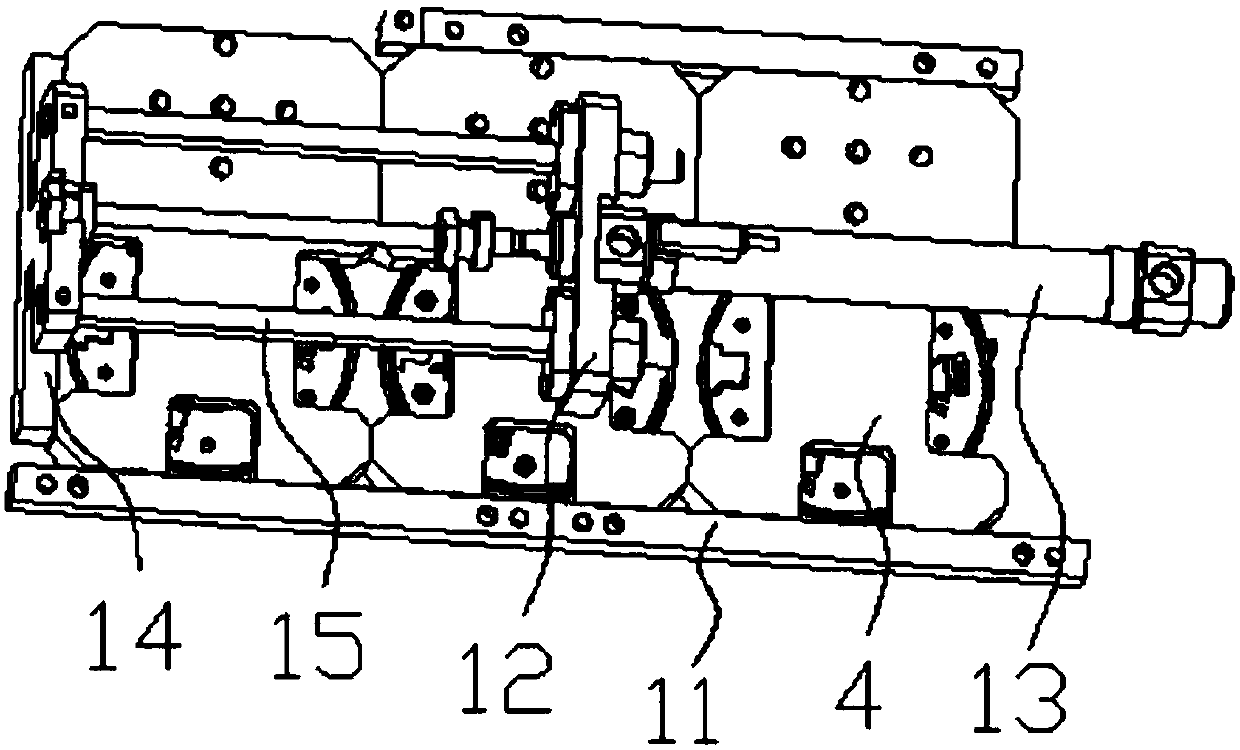

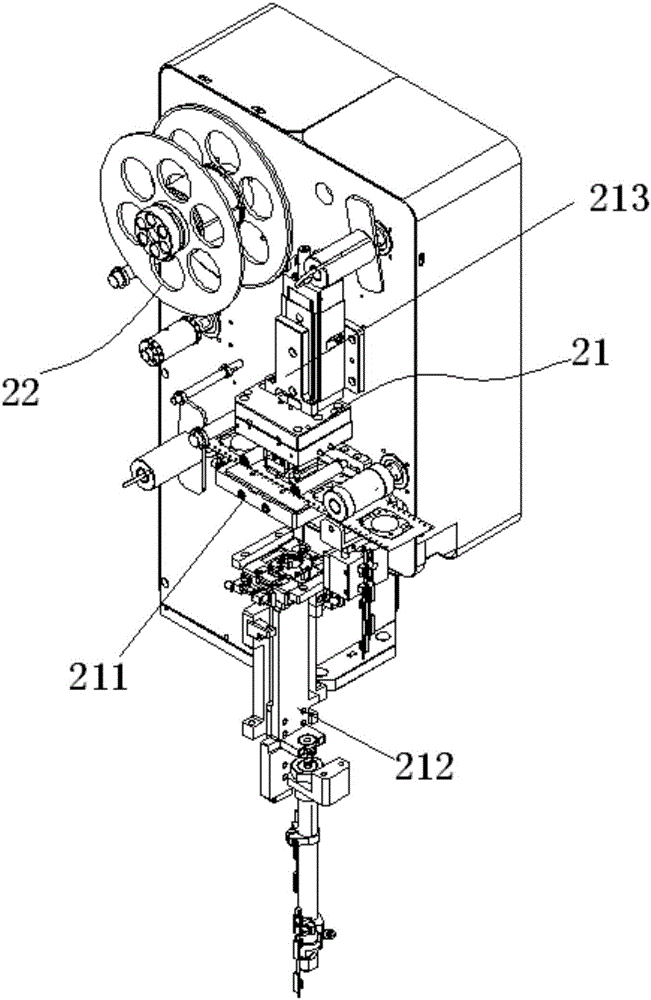

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

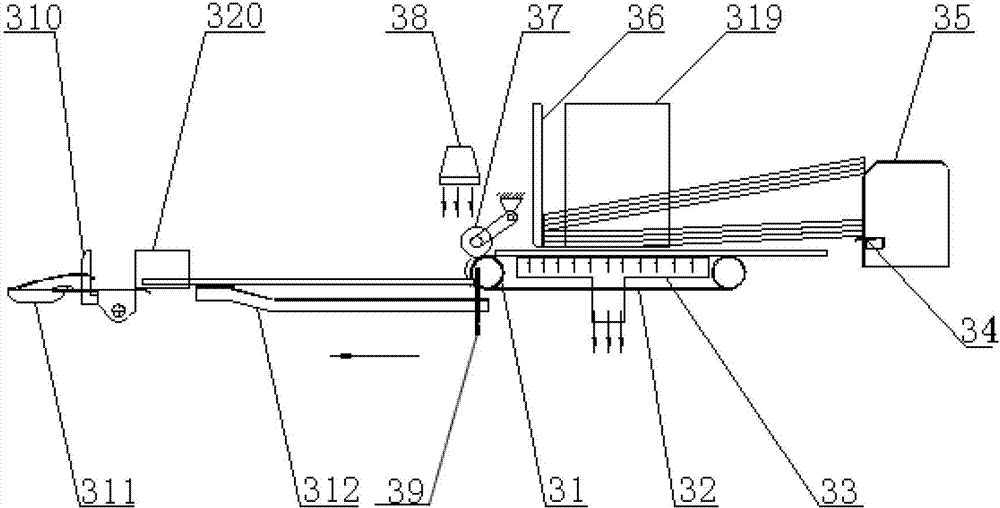

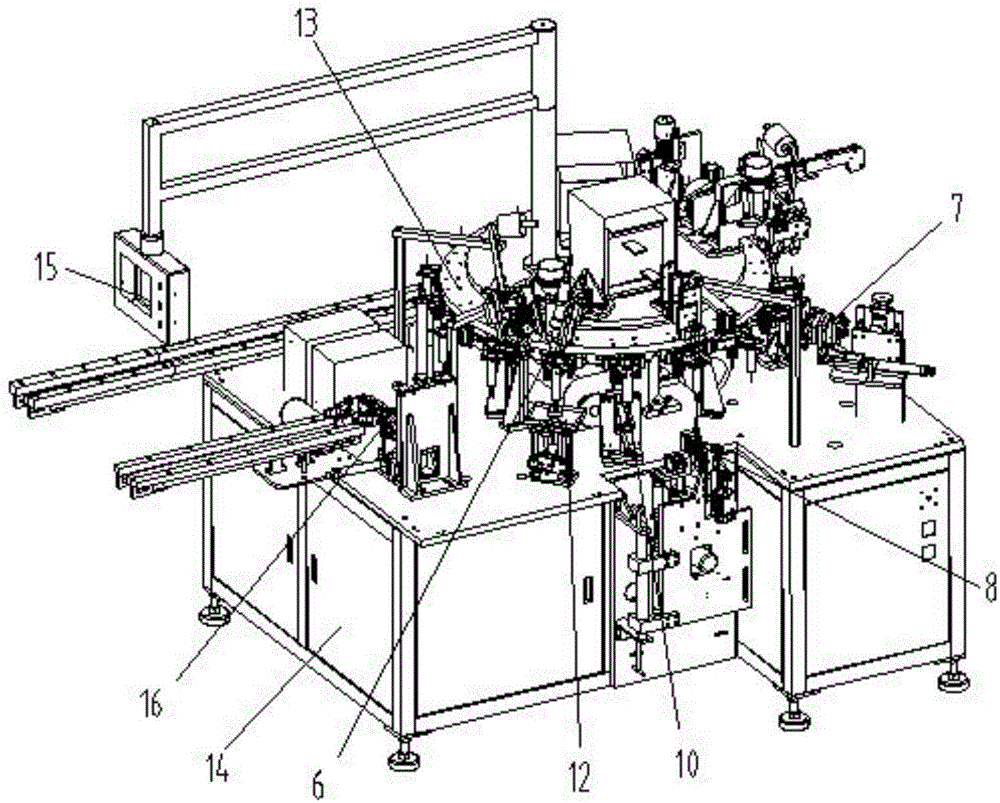

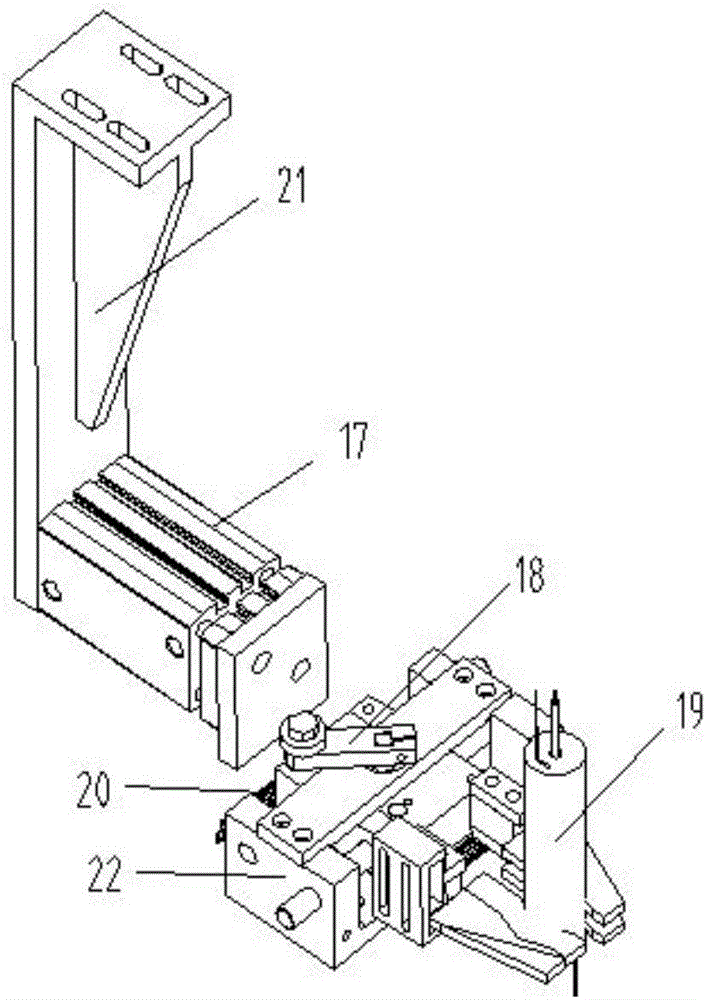

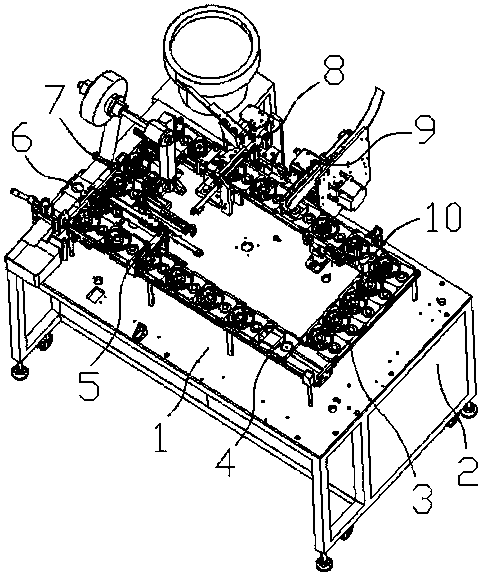

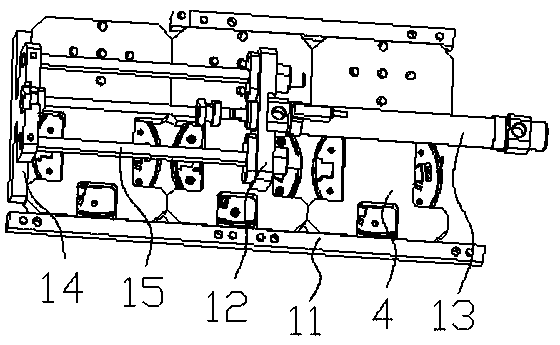

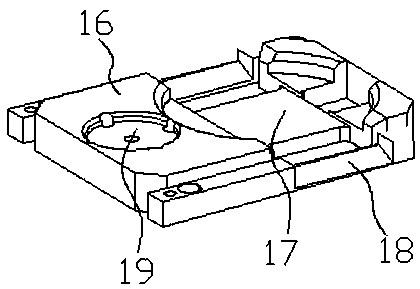

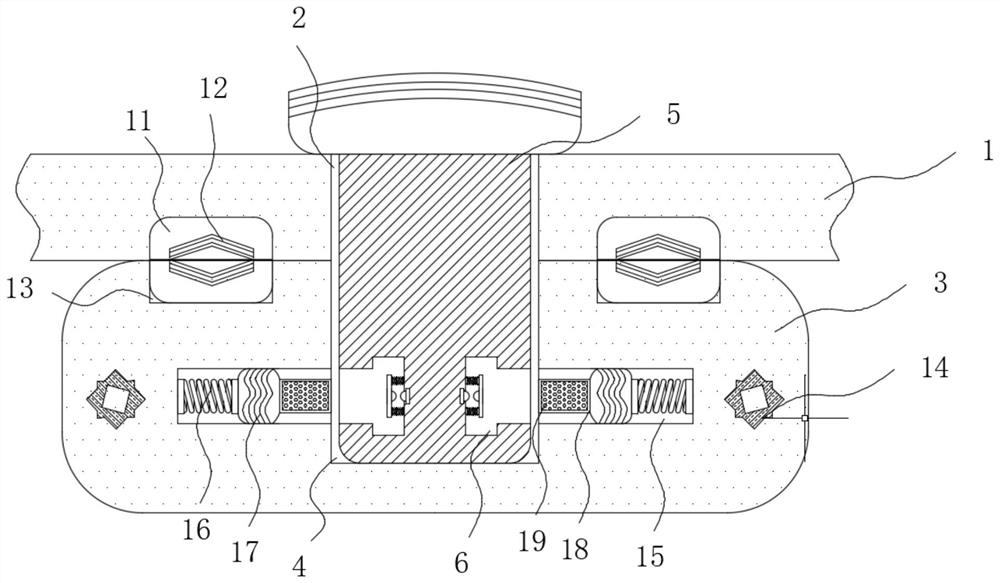

Full-automatic assembly machine for bottom shell component of hanging headphone

ActiveCN107770715AReduce collection and transportation costsIngenious structural designMicrophonesLoudspeakersLight barrierHeadphones

The invention relates to a full-automatic assembly machine for a bottom shell component of a hanging headphone. A rack is provided with a carrier transfer device transferring clockwise, the carrier transfer device comprises a carrier transfer trough, the carrier transfer trough is internally fitted with a carrier, the bottom of the carrier transfer trough is provided with a carrier transfer installation base, the carrier transfer installation base is provided with a carrier feed air cylinder parallel to the carrier transfer trough, a carrier feed trough is arranged in the middle of a feed endof the carrier transfer trough, the carrier feed air cylinder is connected with a carrier feed push block matched with the carrier feed trough, and the rack is provided with a dustproof net feed mechanism, a horn assembling device, a film assembling mechanism, a light barrier assembling mechanism and a horn dispensing device that are matched with the carrier. Through adoption of the full-automaticassembly machine, continuous, automatic assembling is realized, a bottom shell feeding position and an assembled bottom shell discharging position are at the same position, so that a bottom shell material tray can be used for collecting a material of the assembled bottom shell, therefore, the collecting and transporting costs are lowered.

Owner:CHONGQING TECH & BUSINESS UNIV

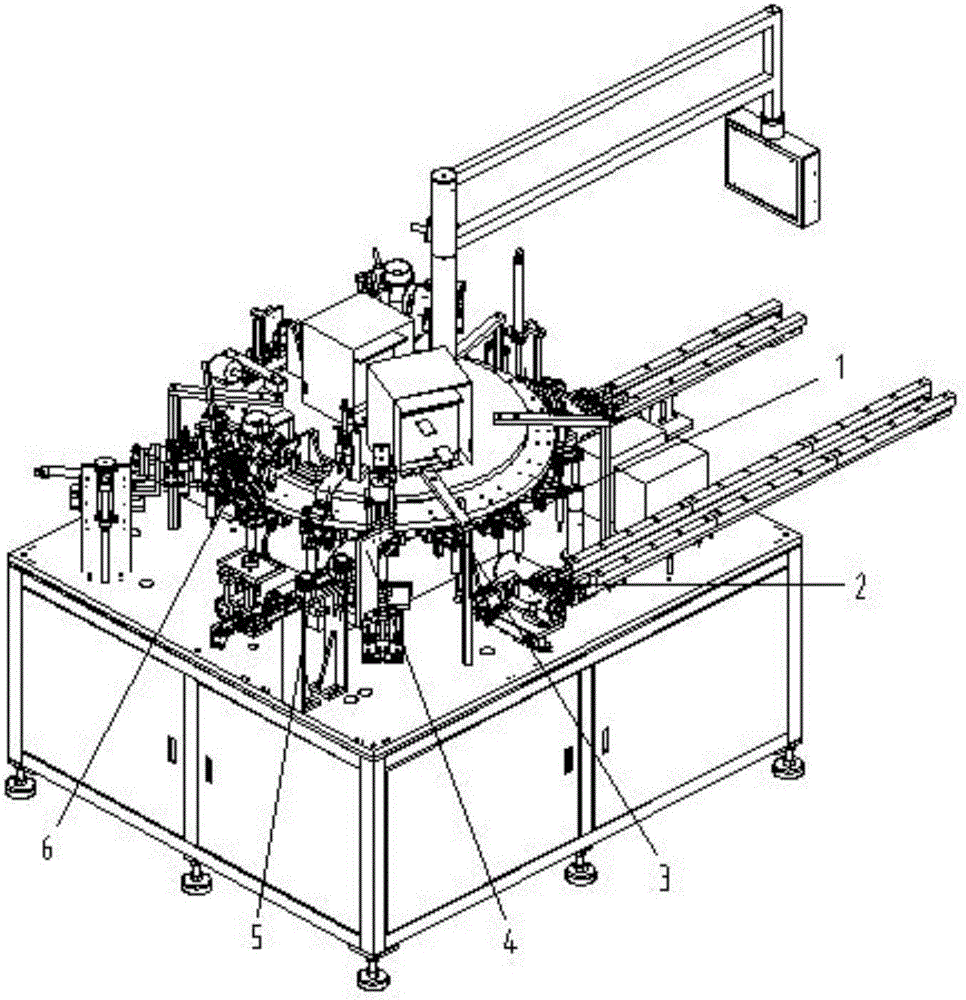

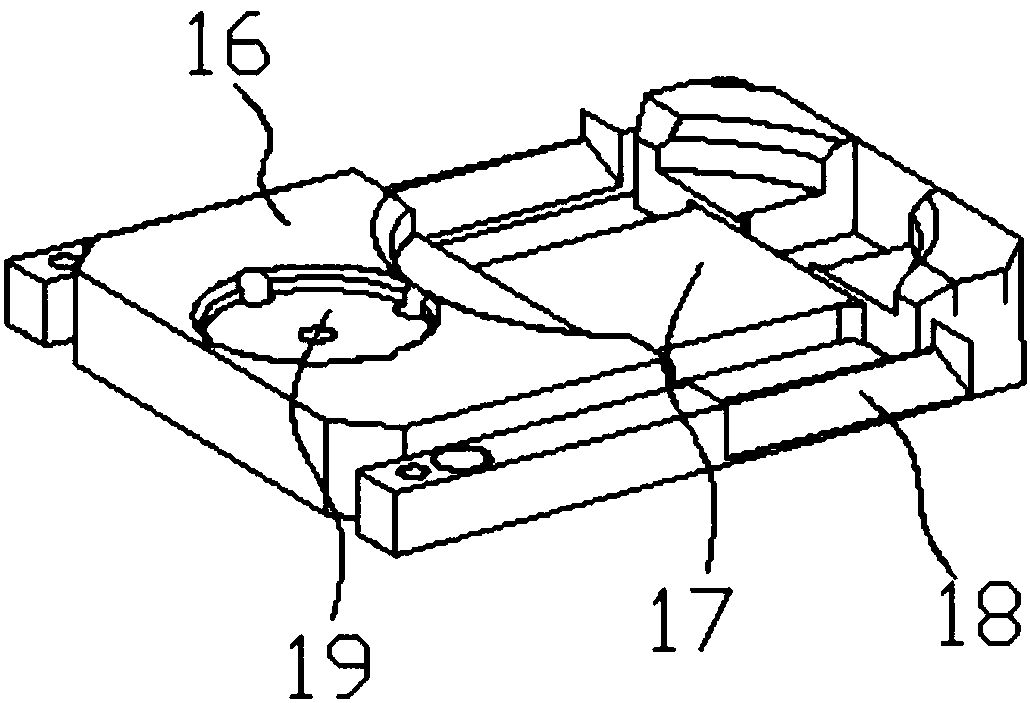

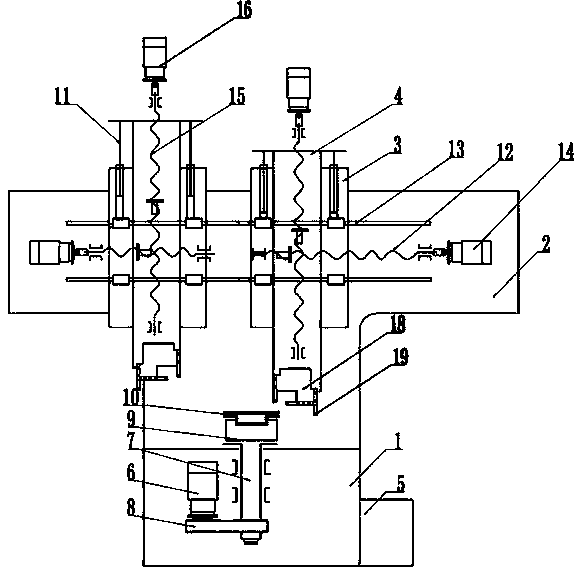

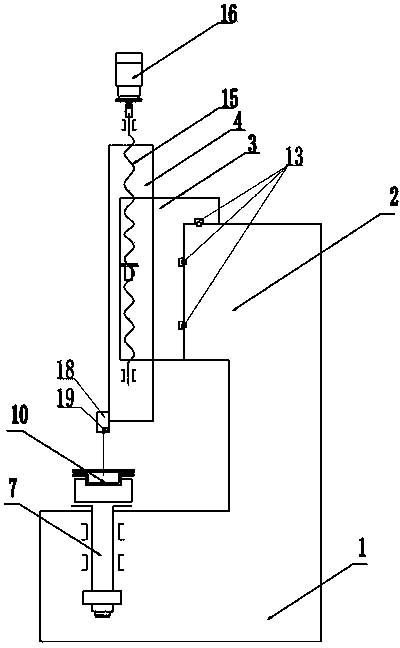

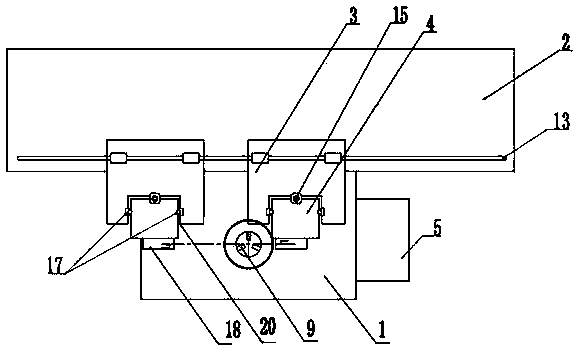

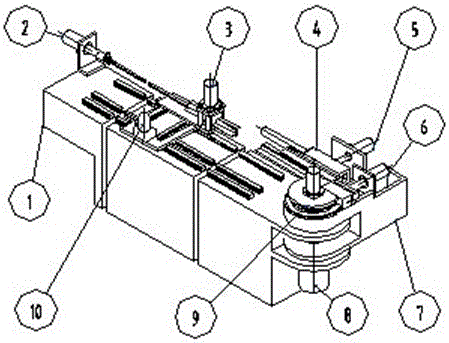

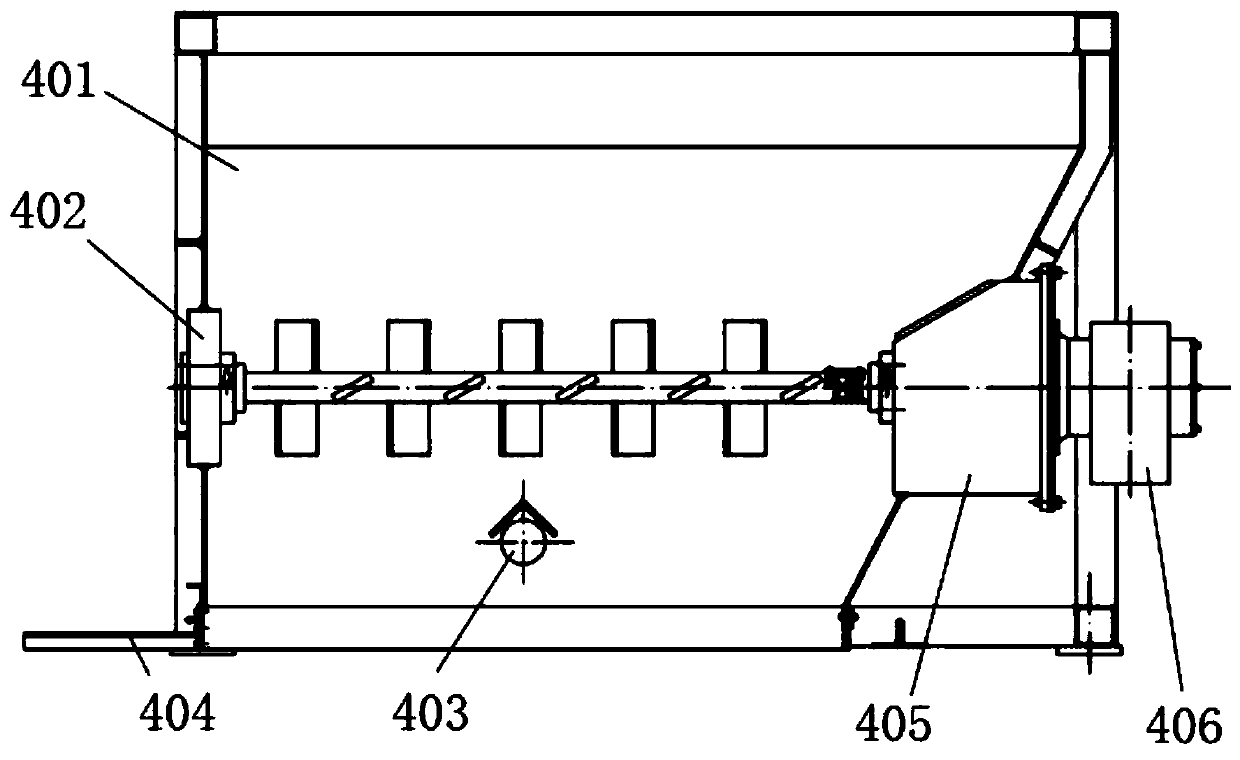

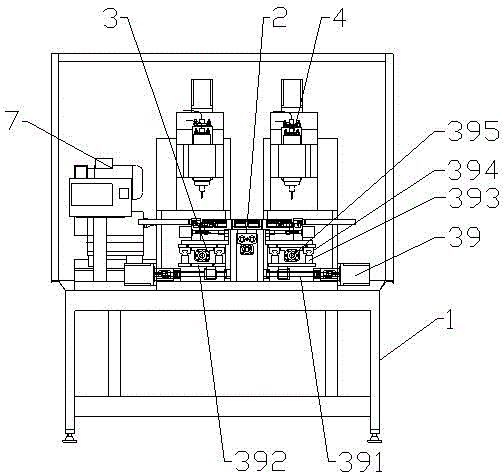

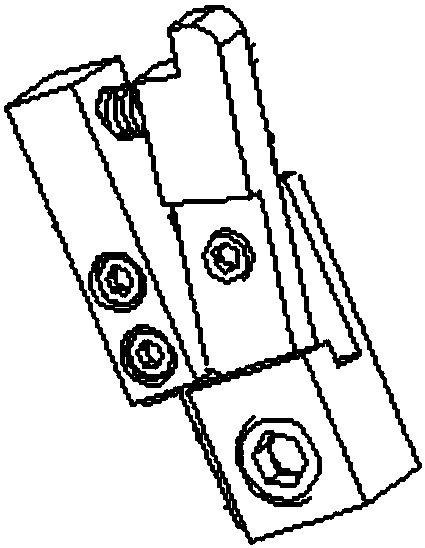

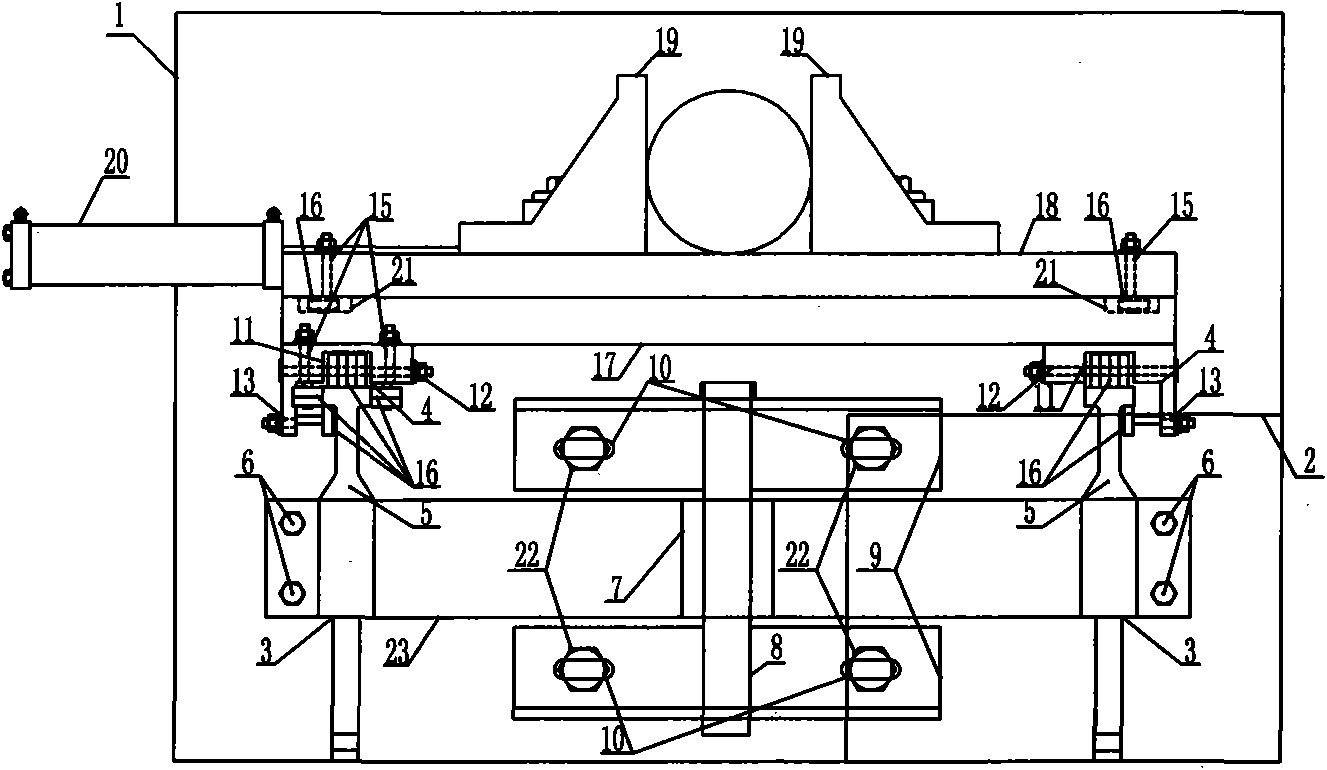

Numerical control lock cylinder combination machine

ActiveCN104308538AGuaranteed machining accuracyGuaranteed feed accuracyFeeding apparatusOther manufacturing equipments/toolsNumerical controlProgrammable logic controller

The invention relates to the field of manufacturing of locksets, and particularly discloses a numerical control lock cylinder combination machine, which comprises a rack and a PLC (Programmable Logic Controller) control system, wherein a fixture assembly is arranged on the rack; an automatic feed assembly, a groove milling mechanism assembly, a plane mechanism assembly, a chamfering mechanism assembly and a drilling mechanism assembly are arranged around the fixture assembly on the rack by surrounding the fixture assembly; a vibration plate is connected above the automatic feed assembly; an ejection air cylinder is arranged below a rotating platform. According to the numerical control lock cylinder combination machine, a linear guide rail and a guide rail sliding block are matched, and a stepping motor is combined with a gapless transmission ball screw, so that a groove milling mechanism, a plane mechanism and a chamfering mechanism are moved up and down, front and back, and right and left, and the feeding accuracy in movement is ensured; the rotation movement of a rotary table is completed through a precision divider, and the processing accuracy of workpieces is ensured; the whole automation telecontrol process of the workpieces is completed through automatic feeding by the vibration plate, and automatic pushing, automatic clamping and automatic ejection by the air cylinder, so that the automation degree and the production efficiency are greatly improved, the processing accuracy is ensured while the processing efficiency is improved.

Owner:曹县精锐机械锁业有限公司

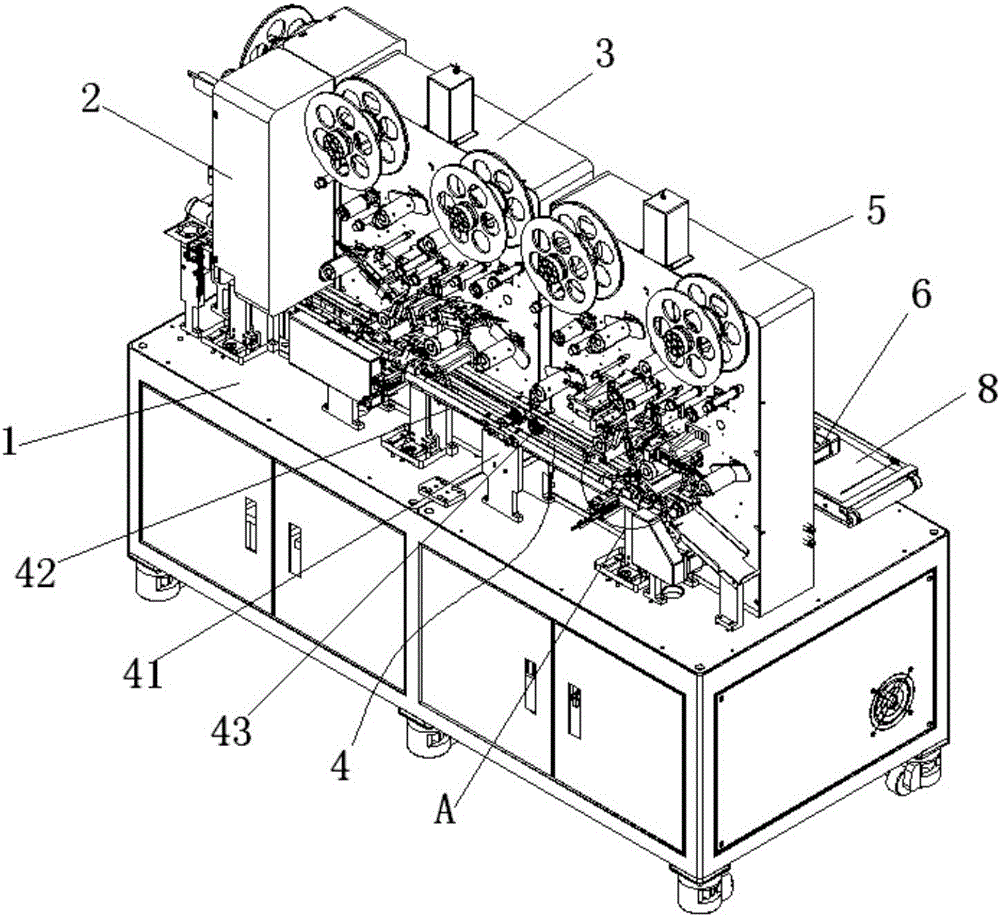

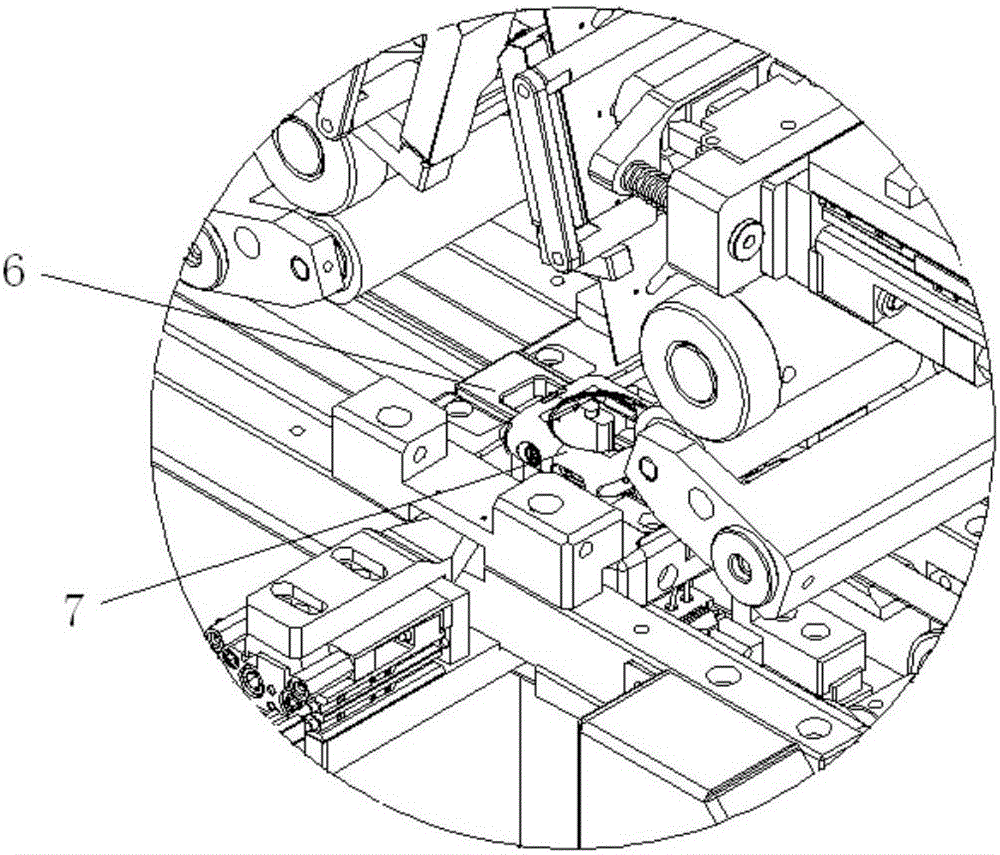

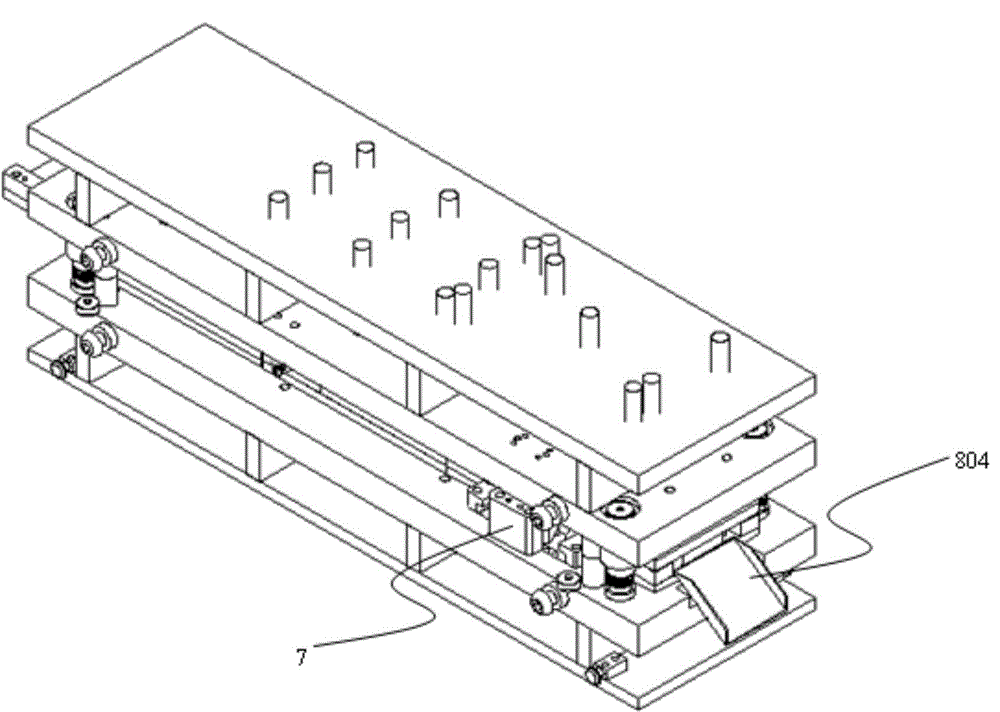

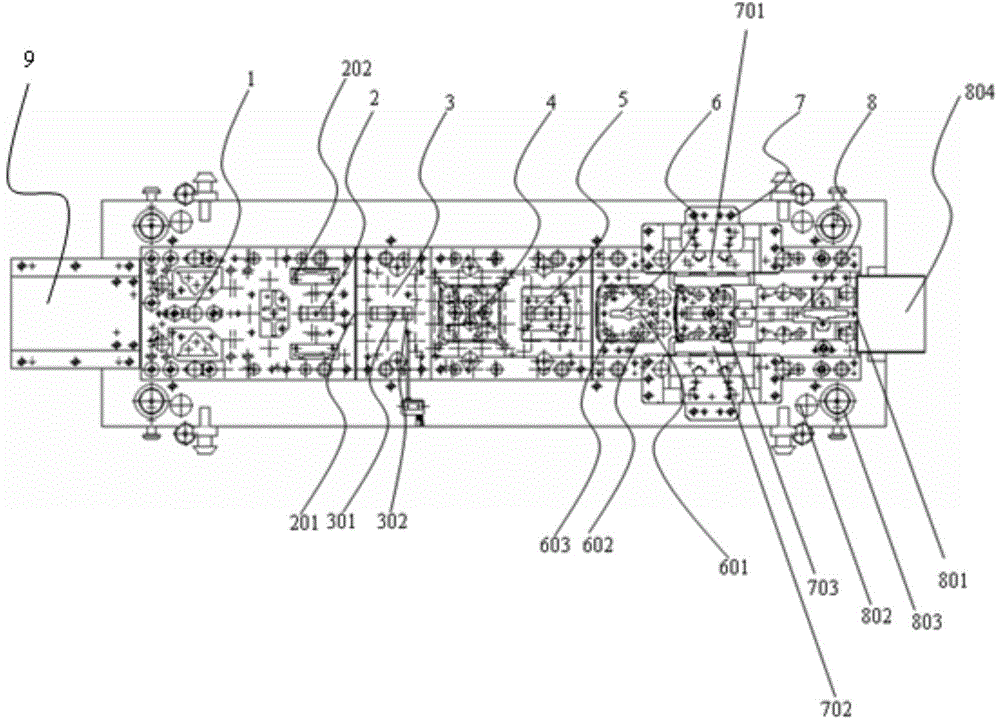

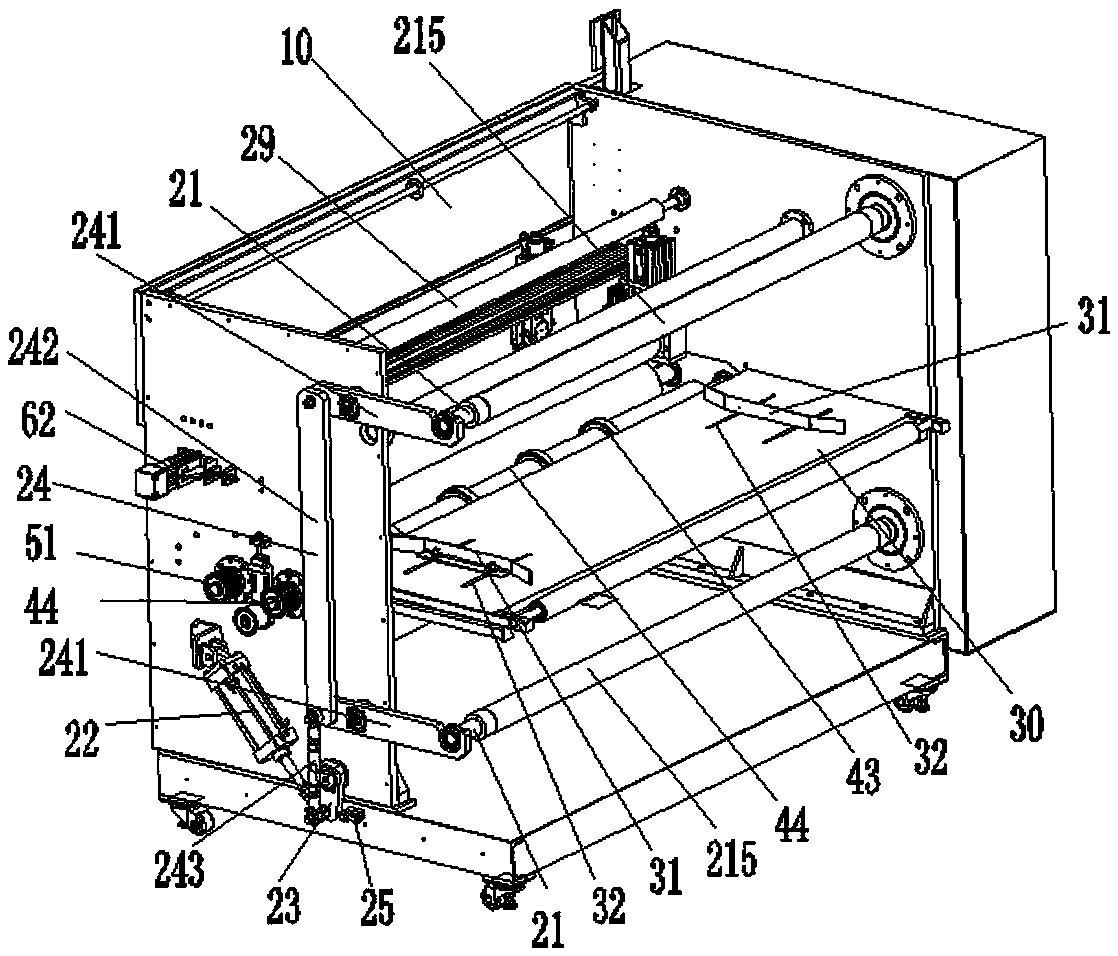

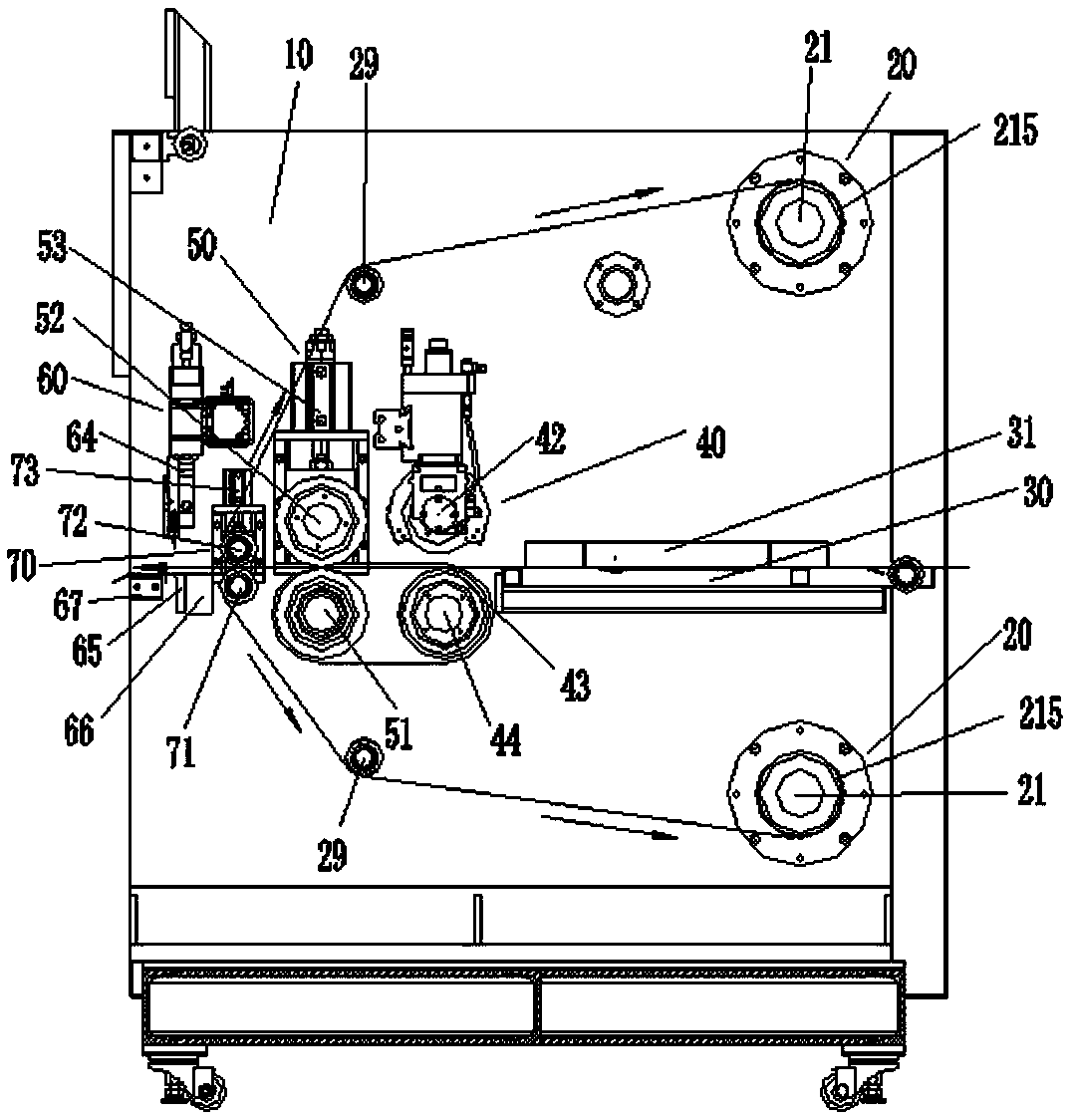

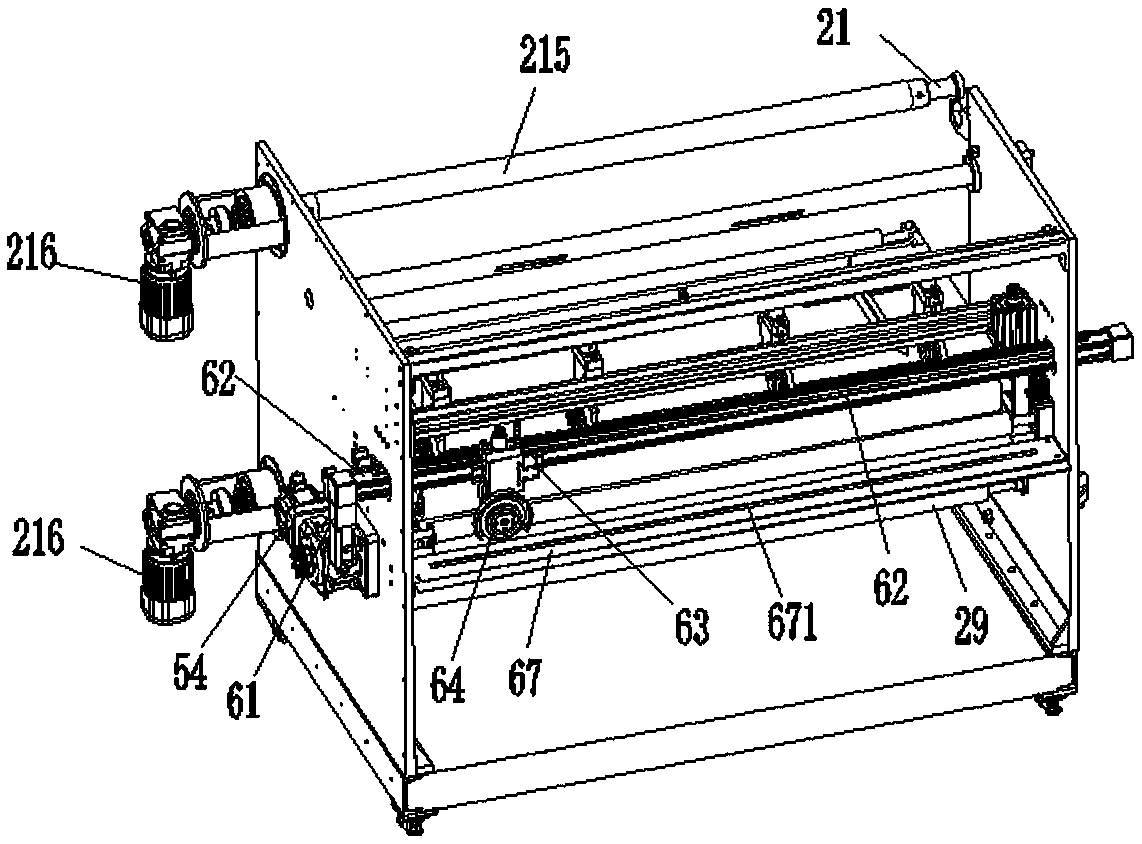

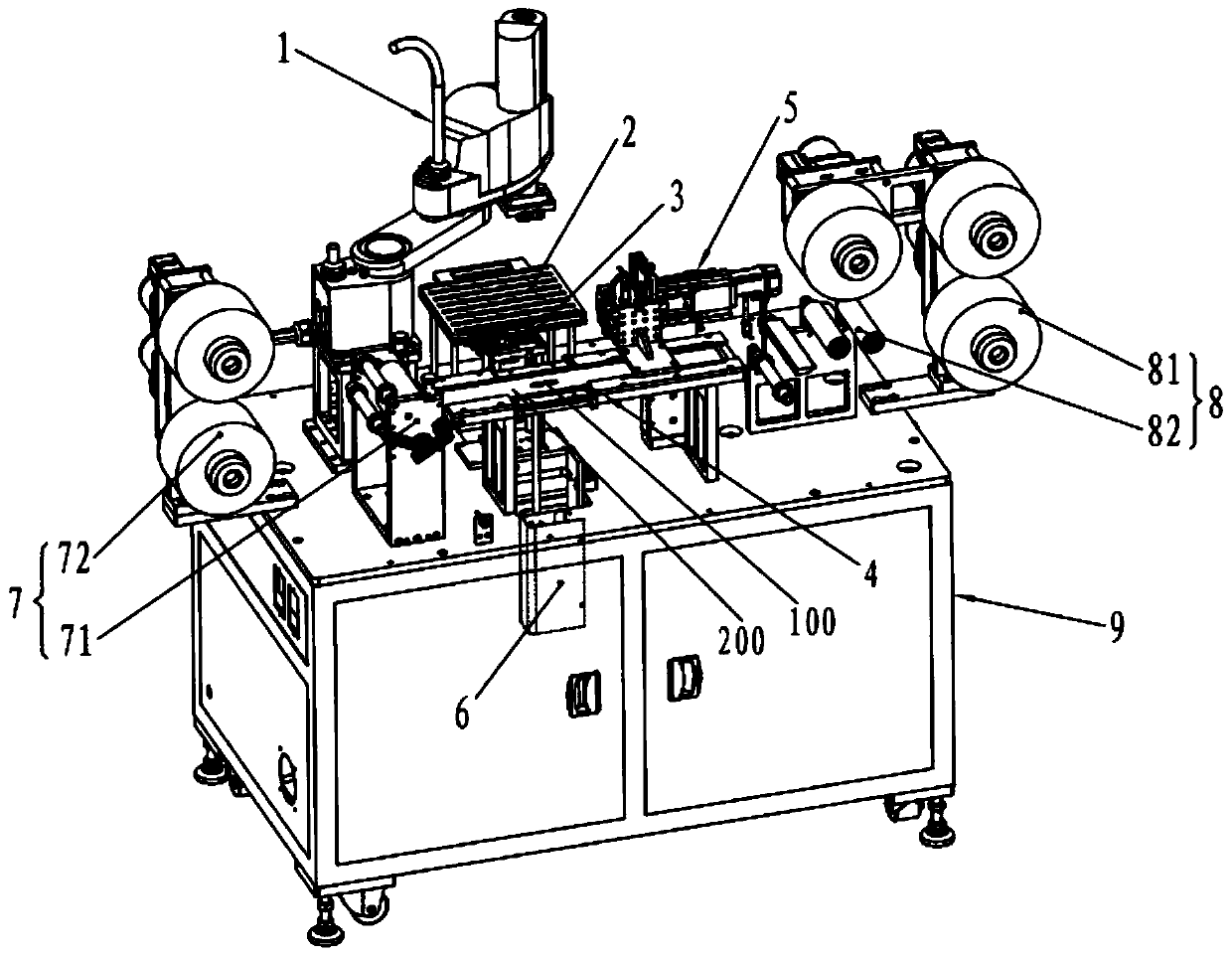

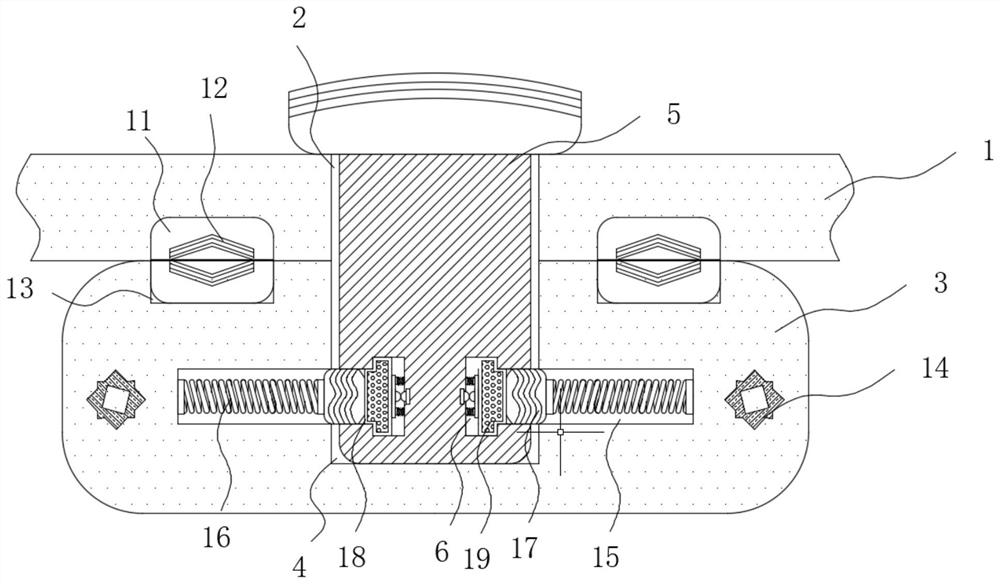

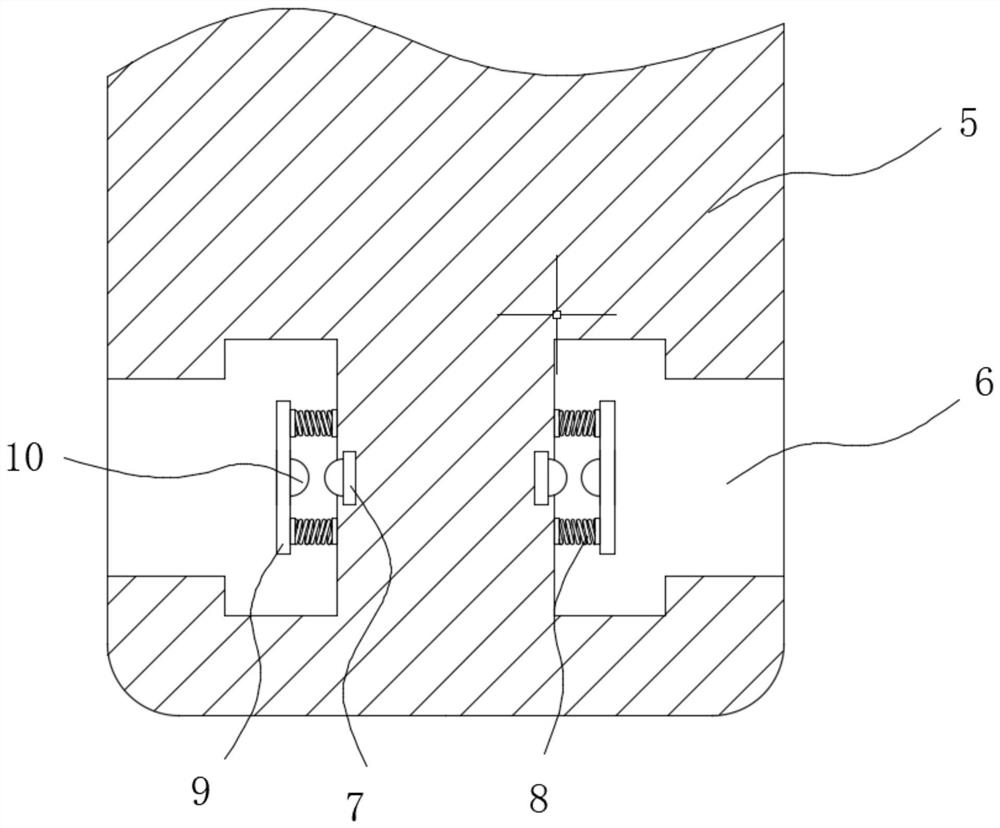

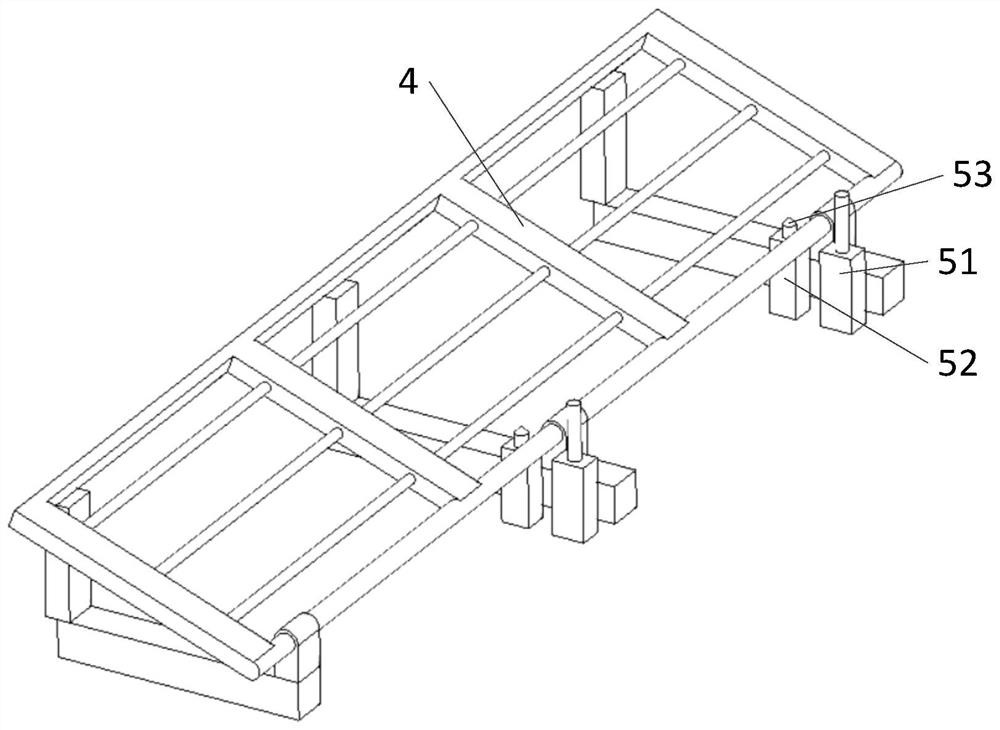

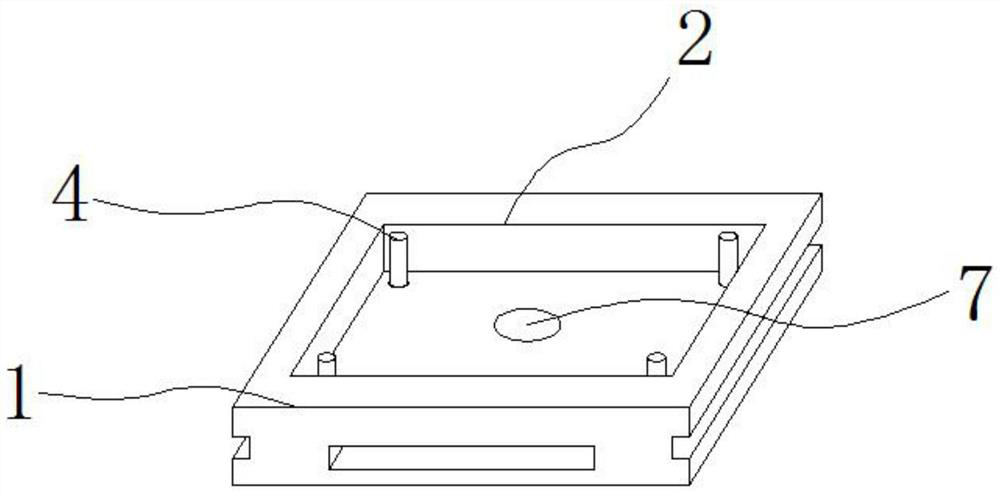

Multi-station automatic lamination equipment

ActiveCN105857715AGuaranteed feed accuracyWrinkle freeWrapping material feeding apparatusWebs handlingWrinkleMagnetic powder

The invention discloses multi-station automatic lamination equipment. According to the equipment, a top position lamination module, a left and right side position I lamination module, a left and right side position II lamination module and a product delivery passage are integrated on an operation platform, the function of laminating five positions of a product on the same machine can be achieved; by adopting the design of a protective film stiffening plate, the charging accuracy of the protective film can be guaranteed, and deformation of the protective film is prevented; a constant tension magnetic powder brake is used in the charging process, so that the tension is kept to be constant when a protective film belt is conveyed; a soft silica gel pressure head is used and is gradually deformed in the laminating process, so that the protective film is prevented from generating wrinkle or bubble, the aim of quick, efficiency and accurate full-automatic lamination is achieved, and the appearance yield is guaranteed to be 100 percent.

Owner:JIANGSU JUSTECH PRECISION IND CO LTD

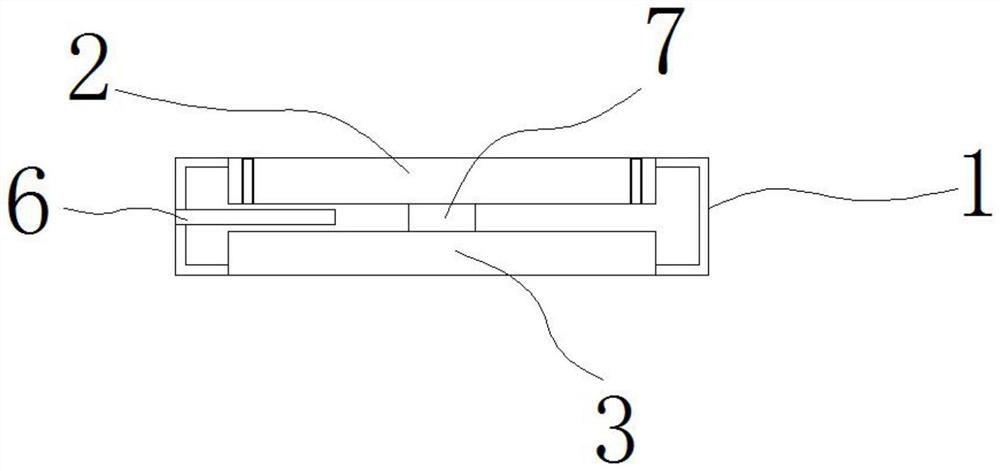

Continuous punching mold of vehicle engine cabin

InactiveCN104889243AExtended service lifeEliminate defective productsShaping toolsMetal-working feeding devicesNacelleEngineering

The invention discloses a continuous punching mold of a vehicle engine cabin. The mold comprises a guide traction lubrication structure, a leveling limiting fixed-length punching structure, a horizontal feeding structure, a hole position primary positioning punching and secondary horizontal positioning pull structure, a continuous punching waste dropping and feeding material detecting structure and a flat cutter discharge structure. A steel strip to be machined is sprayed with lubricant by itself, and is driven by a traction sub-mold to forwards move. Then, the steel strip enters the leveling limiting fixed-length punching structure to finish the striping fixed-width punching, and enters the horizontal feeding structure to perform the hole position primary positioning punching; the secondary horizontal positioning pull structure guarantees the continuous horizontal forward movement of materials; when the steel strip enters the continuous punching waste dropping, the product is basically molded; the steel strip is fed into the material detecting structure to detect the punching aperture and the striping fixed-length size; and finally, the flat cutter discharge structure performs the fixed-length cutting discharge. The six procedures of leveling, striping, feeding, punching, detection and discharge in the engine part machining process are integrated and finished by one set of mold, so that the production flow is shortened, the production efficiency is improved, the production cost is reduced, and the mold is suitable for continuous large-batch production.

Owner:HEFEI HAODONG PRECISION IND CO LTD

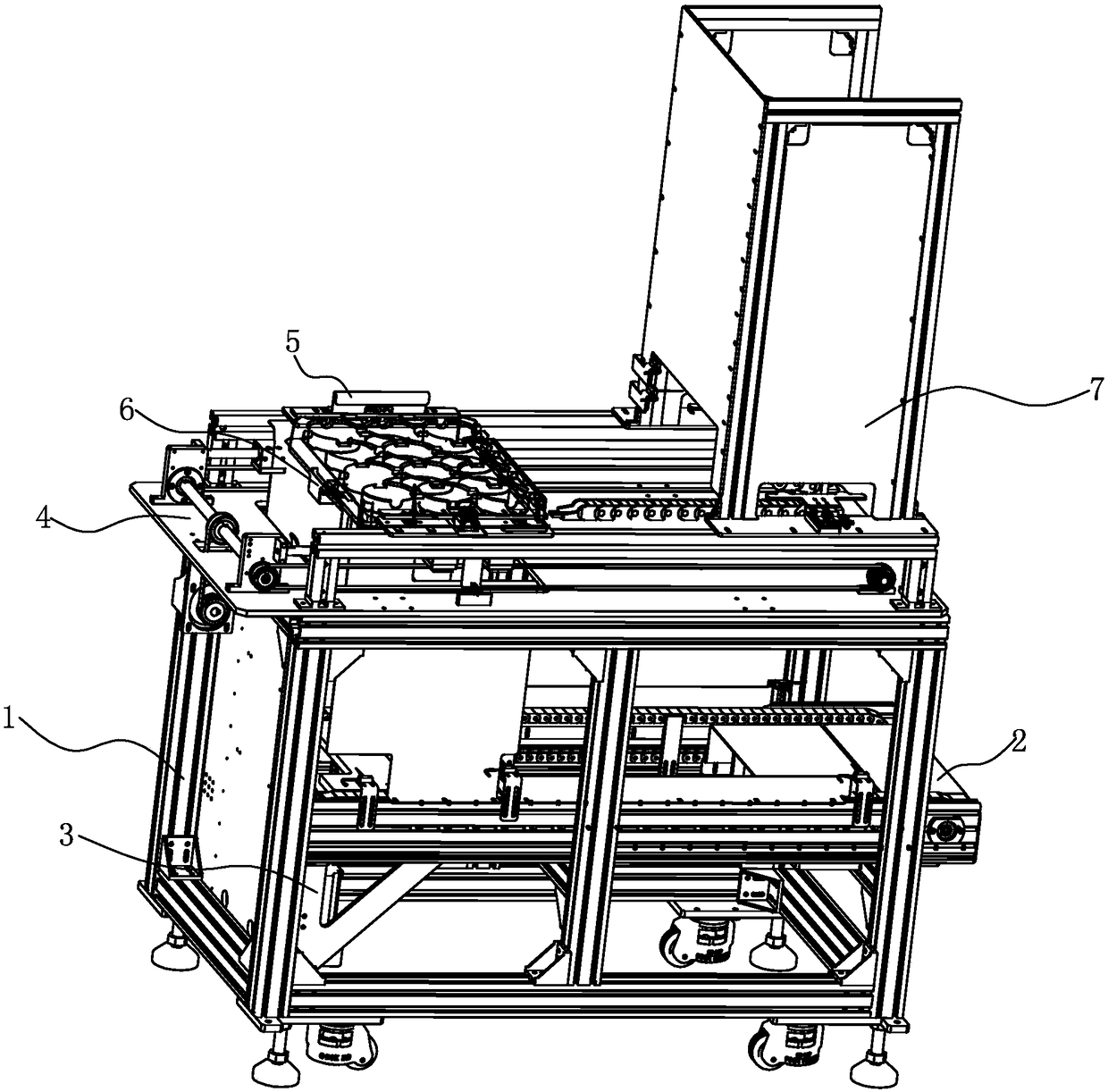

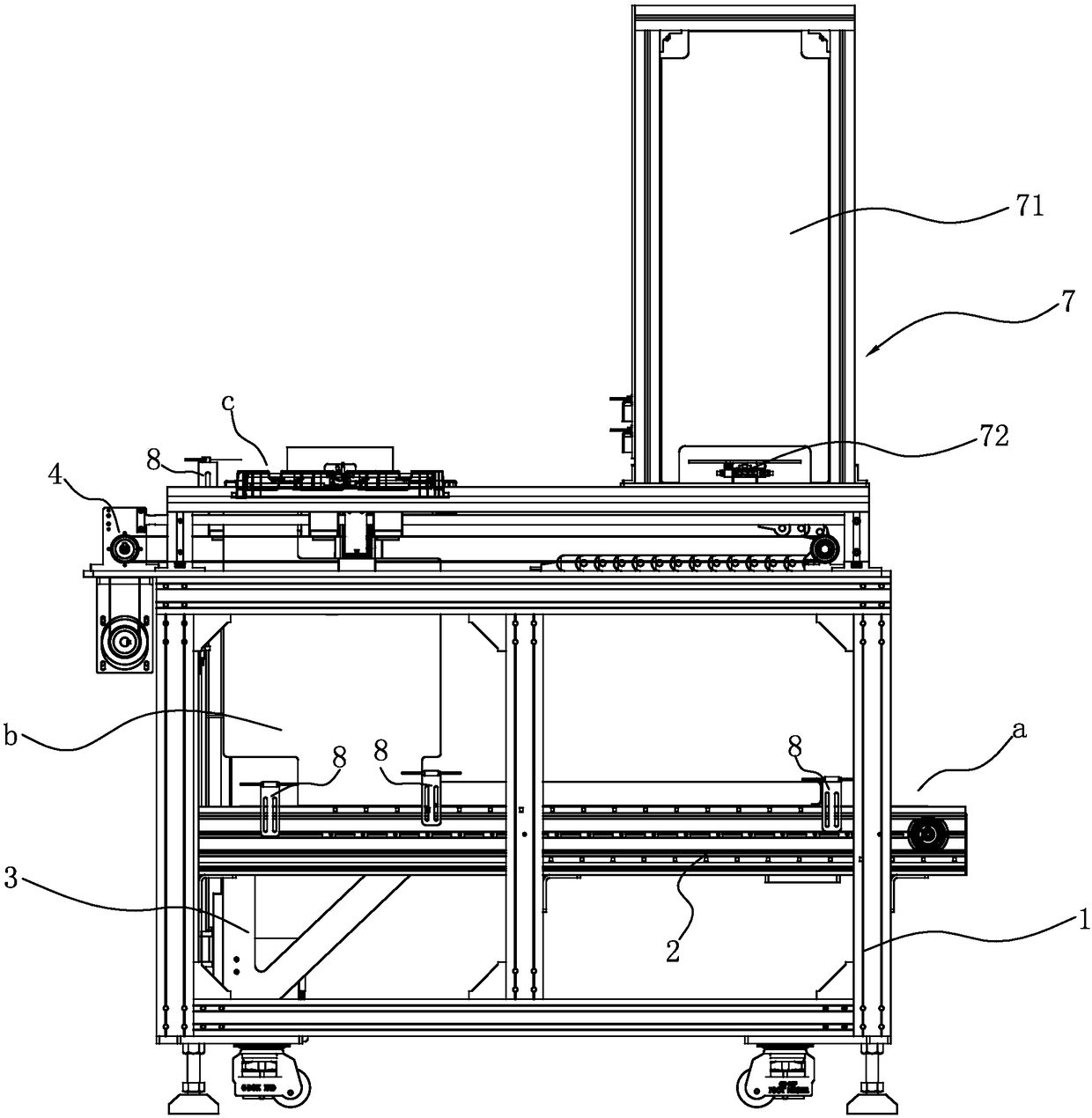

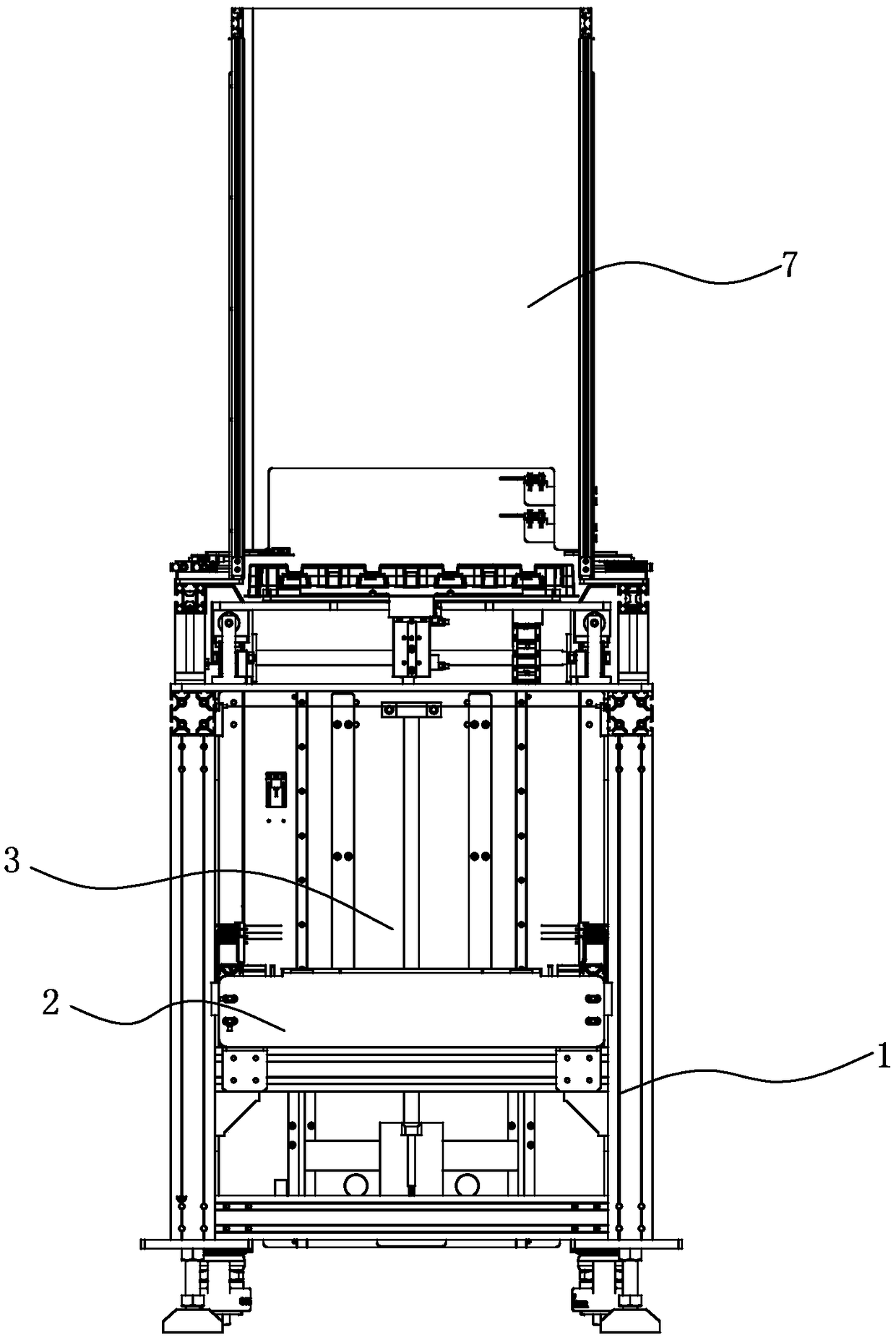

Automatic feeding device

ActiveCN109368234ASimple equipment structureLow procurement and processing costsConveyorsDe-stacking articlesAutomation

The invention discloses an automatic feeding device comprising a frame, a material conveying device for temporarily storing piles of material trays and horizontally conveying piles of material trays to a material lifting area, a material lifting device for lifting piles of material trays conveyed by the material conveying device to a material-tray separation area, a material horizontally draggingdevice for dragging and conveying the materials, a material-tray separation device for separating or releasing a single material tray from piles of material trays, a material holding device for conveying the released single material trays to a feeding area for feeding or conveying empty material trays to a material tray recycle area for recycling, and a material tray recycle device for holding theempty material trays conveyed by the material holding device. There is no need to manually place the material trays on the feeding device repeatedly back and forth, so that the production efficiencyis improved; the whole process from feeding to empty tray recycling can have high degree of automation; and the feeding accuracy can be ensured by the stability and reliability of the material conveying process.

Owner:GOERTEK INC

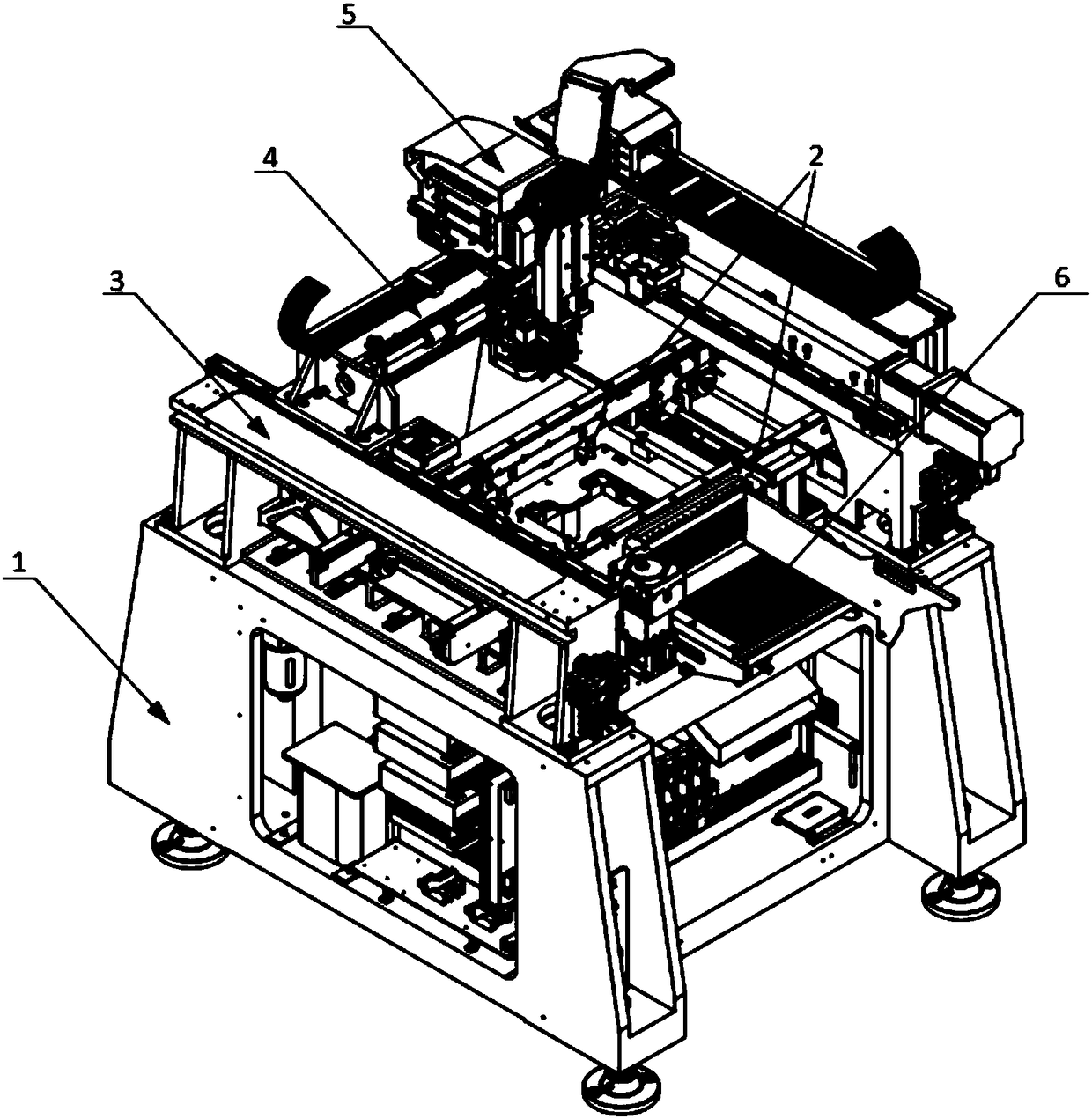

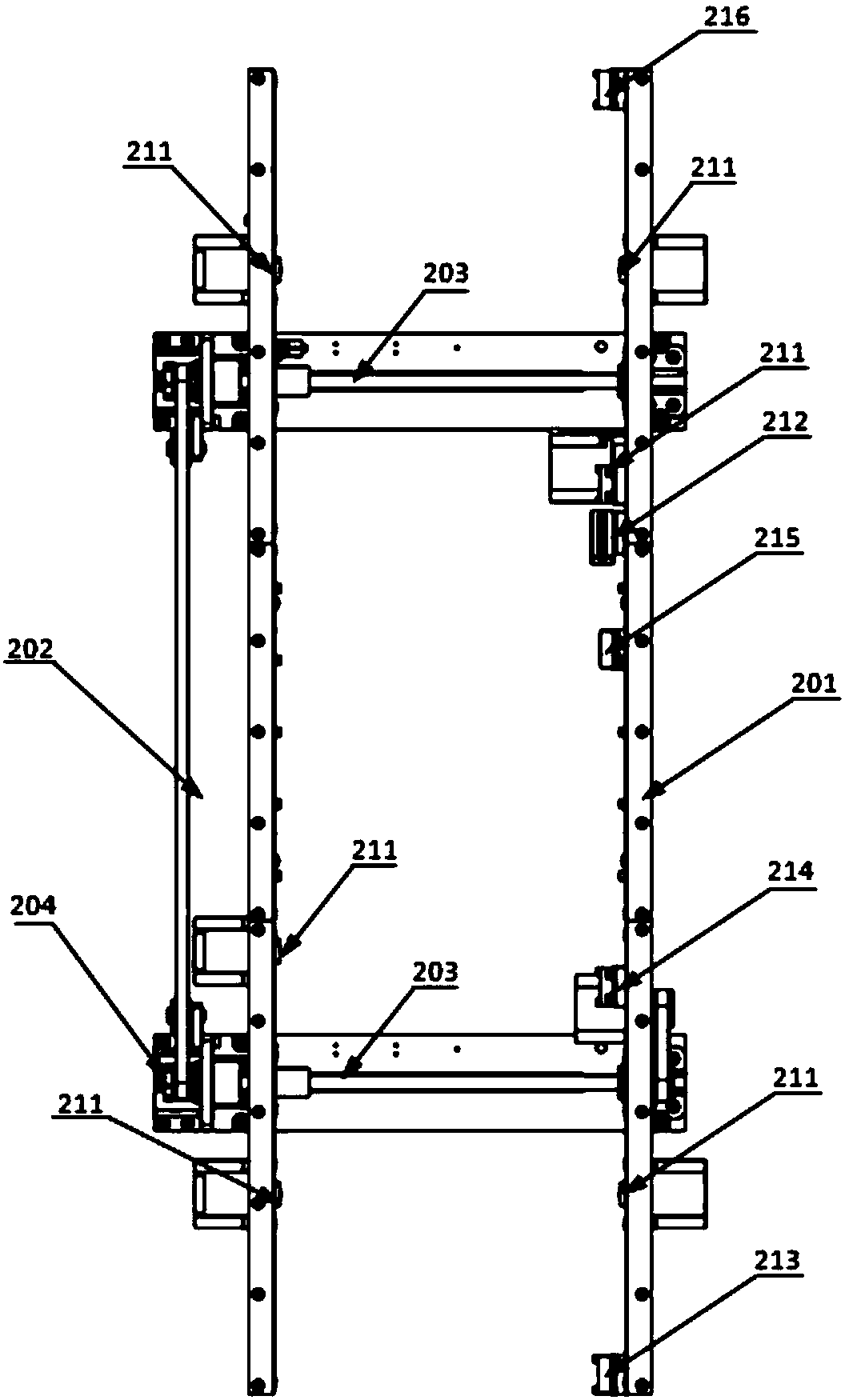

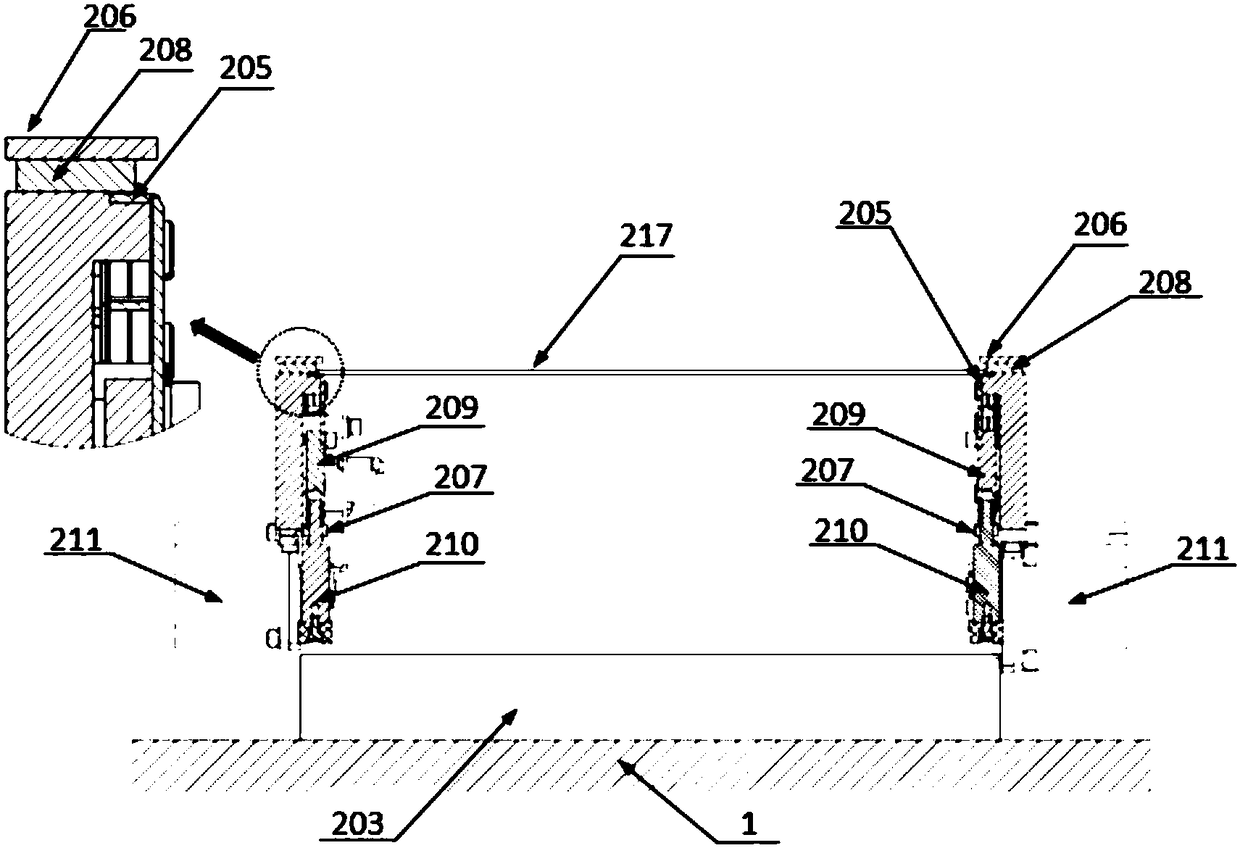

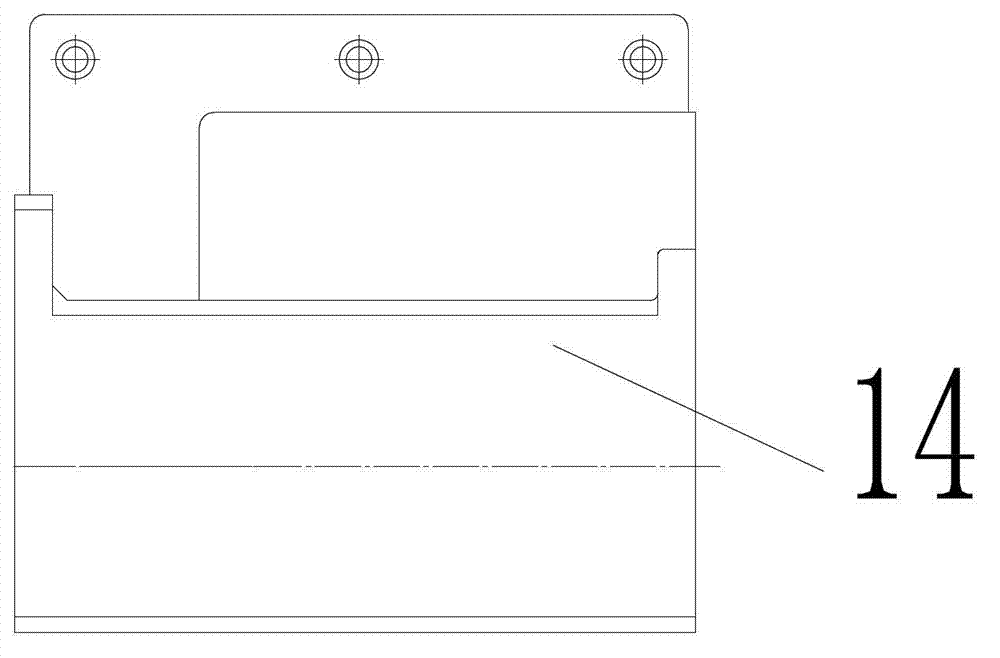

Special mounter for shielding cap

PendingCN108243580AFull match sizeSynchronous workabilityPrinted circuit assemblingCouplingEngineering

The invention discloses a special mounter for a shielding cap, which comprises a main frame, a board conveying device, a Y-axis arch frame assembly, an X-axis arch frame assembly, a mounting head assembly and a feeding platform, wherein the moving side edge of the board conveying device is provided with a width regulation motor; and the Y-axis arch frame assembly and the X-axis arch frame assemblyform an XY moving platform of the mounting head assembly. Through arranging the width regulation motor, a stop block, a board entering sensor, a mounting sensor, a board exiting sensor and the like,the size of the shielding cap can be matched, the width of the board conveying device is adjusted, and the board conveying working position is high in accuracy and safety; through arranging the special mounting head assembly, the size of the shielding cap can be matched thoroughly, nozzle synchronous working can be kept, and the mounting efficiency is effectively enhanced; through arranging a coupling to be connected with a motor shaft and a shaft, elastic movement in the moving process is avoided, and the mounting accuracy and the stability are ensured; and through arranging the special feeding platform, the feeding accuracy is ensured, and the feeding efficiency is improved.

Owner:广东木几智能装备有限公司

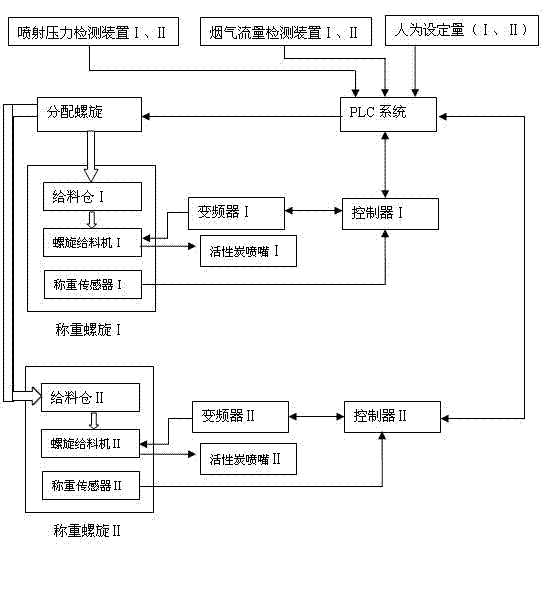

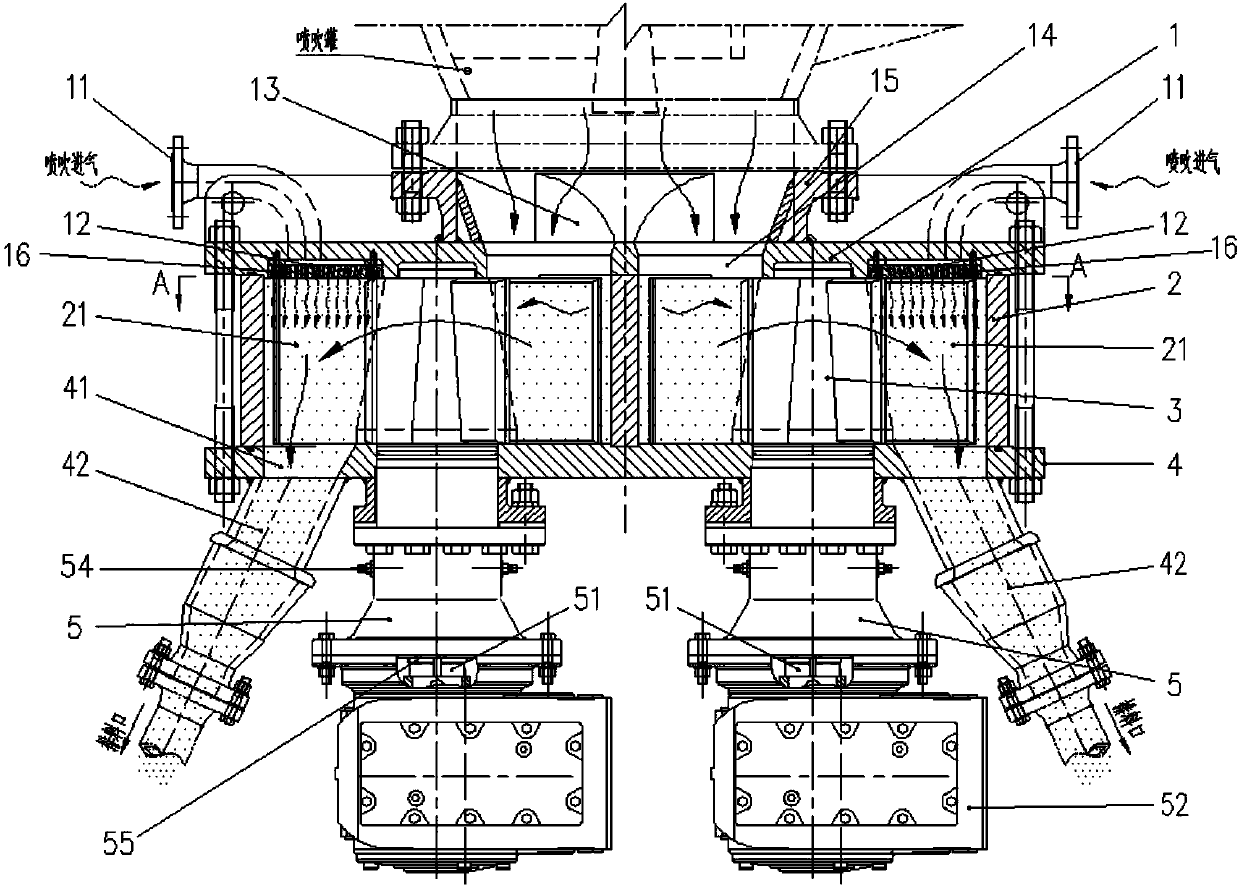

Special active carbon injection control system for purifying flue gas from refuse incineration

InactiveCN102784547AImprove purification efficiencyGuaranteed purification effectDispersed particle separationTotal factory controlInjection pressureFlue gas

The invention provides a special active carbon injection control system for purifying flue gas from refuse incineration. According to the special active carbon injection control system, on the premise that the purifying effect of the flue gas is ensured, the injection amount of active carbon is increased and changes along with the flue gas flow, the metering precision of the injection amount of the active carbon is improved, further the purifying efficiency of the flue gas is increased and the use cost is saved. The special active carbon injection control system comprises a distributing auger and devices required to be subjected to flue gas purification. The special active carbon injection control system is characterized by further comprising a PLC (Programmable Logic Controller) system, wherein a weighing screw, a frequency converter, a controller, a flue gas flow detection device, an injection pressure detection device and an active carbon spray nozzle are arranged inside each device required to be subjected to flue gas purification; each weighing screw specially comprises a feeding bin, a screw feeder and a weighing sensor; each screw feeder is communicated to the corresponding active carbon spray nozzle; the PLC system is respectively connected with the output ends of each flue gas flow detection device and each injection pressure detection device; and the PLC system is respectively in two-way connection with each controller.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

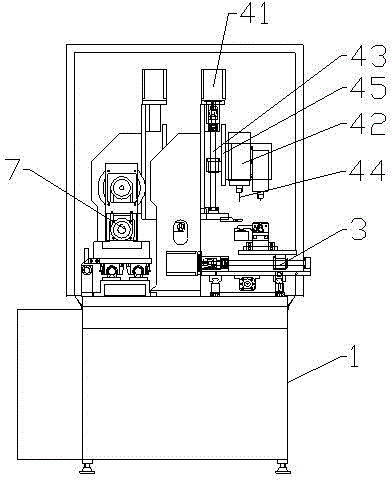

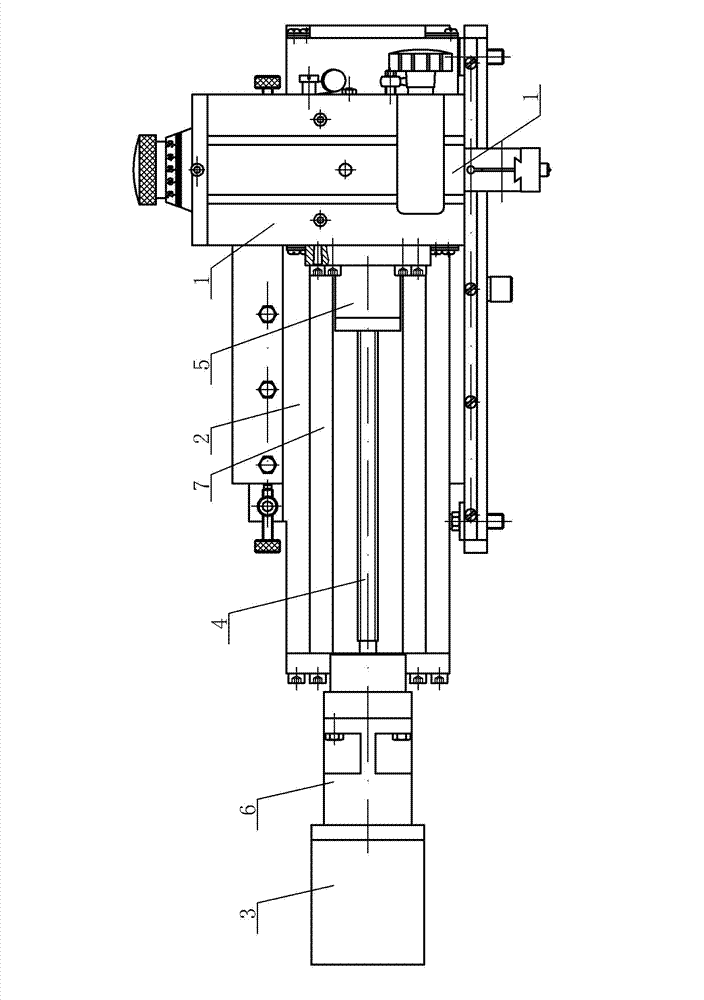

Vertical lathe for machining disc type workpieces and brake disc machining method

ActiveCN104139190ASave setup and adjustment timeImprove processing efficiencyFeeding apparatusTool holdersBall screwMechanical engineering

The invention relates to the technical field of machining, in particular to a vertical lathe for machining disc type workpieces and a brake disc machining method. The vertical lathe comprises a lathe bed, the lathe bed comprises a base and a cross beam, a workpiece rotating clamping device is arranged on the base, and the vertical lathe is characterized in that an X-direction linear guide rail is arranged on the cross beam, left and right rams are arranged on the X-direction linear guide rail, X-direction ball screw pairs and X-direction servo motors are respectively arranged between the X-direction linear guide rail and the left and right rams, Z-direction linear guide rails are arranged on the left and right rams respectively, stand columns are arranged on the Z-direction linear guide rails, Z-direction ball lead screw pairs and Z-direction servo motors are arranged between the Z-direction linear guide rails and the stand columns, and tool mounting bases are arranged at the lower ends of the stand columns. The invention further relates to the brake disc machining method. The method comprises the steps that a left tool and a right tool respectively and independently machine different faces, the workpieces are clamped and mounted by being turned, and the other faces are machined. Compared with the prior art, the vertical lathe and the brake disc machining method have the advantages of saving clamping adjusting time and improving the machining efficiency.

Owner:YANTAI LUCHEN SEAWOO CNC MACHINERY

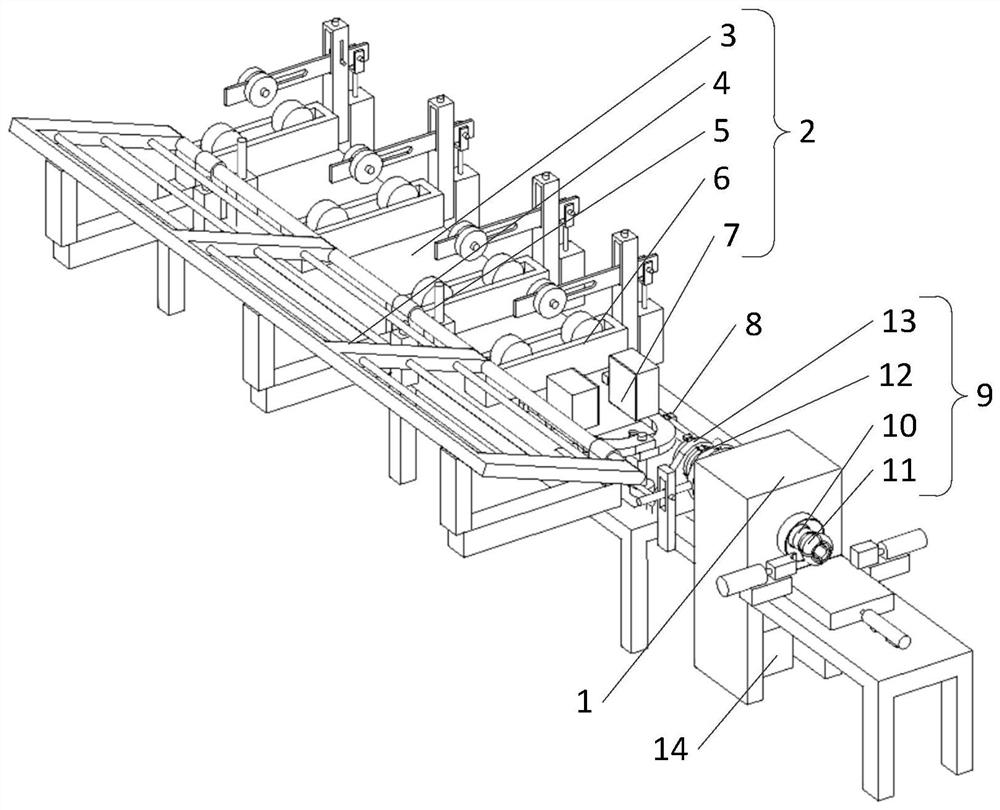

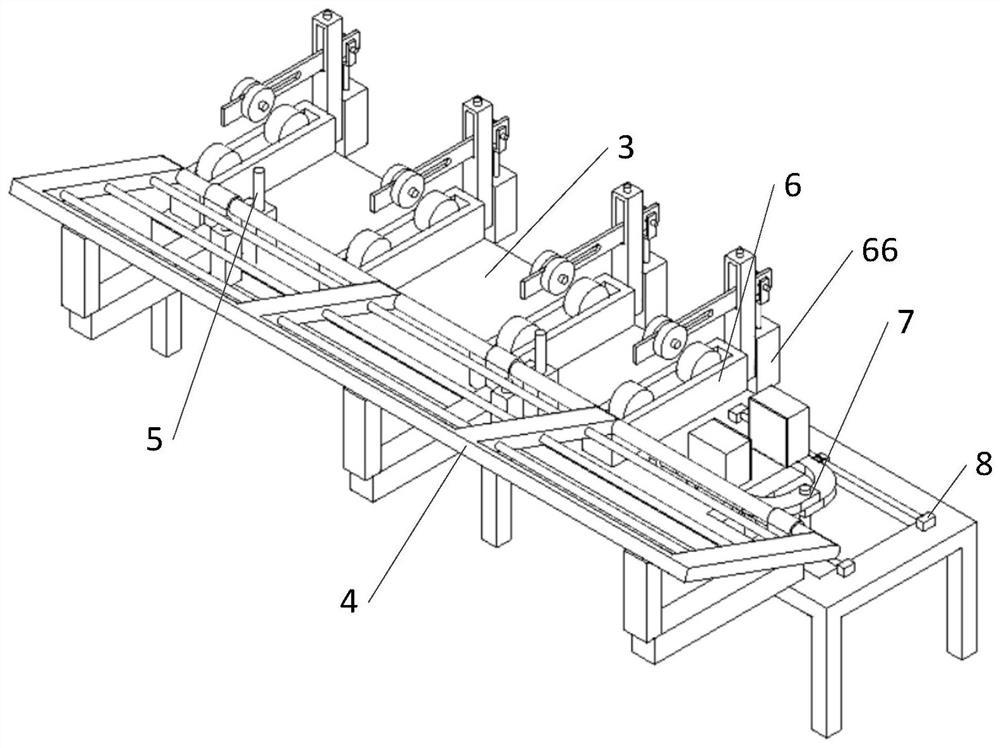

Sheet cutting machine

ActiveCN107932584AAchieving longitudinal cutsAchieving lateral cuttingLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention relates to a sheet cutting machine. The machine comprises a rack, a coiling mechanism, a charging platform, a longitudinal cutting tool mechanism, a main driving mechanism and a transverse cutting tool mechanism, wherein the charging platform, the longitudinal cutting tool mechanism, the main driving mechanism and the transverse cutting tool mechanism are fixed to the rack and sequentially distributed from front to back; the coiling mechanism is fixed to the front part of the rack and is parallel to the charging platform in top and bottom direction; the longitudinal cutting toolmechanism comprises a tool holding rack, a first pneumatic type shearing tool and a lower cutting tool roller; two ends of the tool holding rack are horizontally fixed to the rack; the first pneumaticshearing tool is fixed to the tool holding rack; the lower cutting tool roller is fixed below the tool holding rack; a rolling tool corresponding to the first pneumatic shearing tool is arranged on the lower cutting tool roller; the first pneumatic shearing tool is arranged corresponding to the rolling tool; when in cutting, the first pneumatic shearing tool and the rolling tool are matched to perform longitudinal cutting; the lower cutting tool roller is synchronously driven through the main driving mechanism; a sheet enters the longitudinal cutting tool mechanism through the charging platform and then is lengthways cut.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

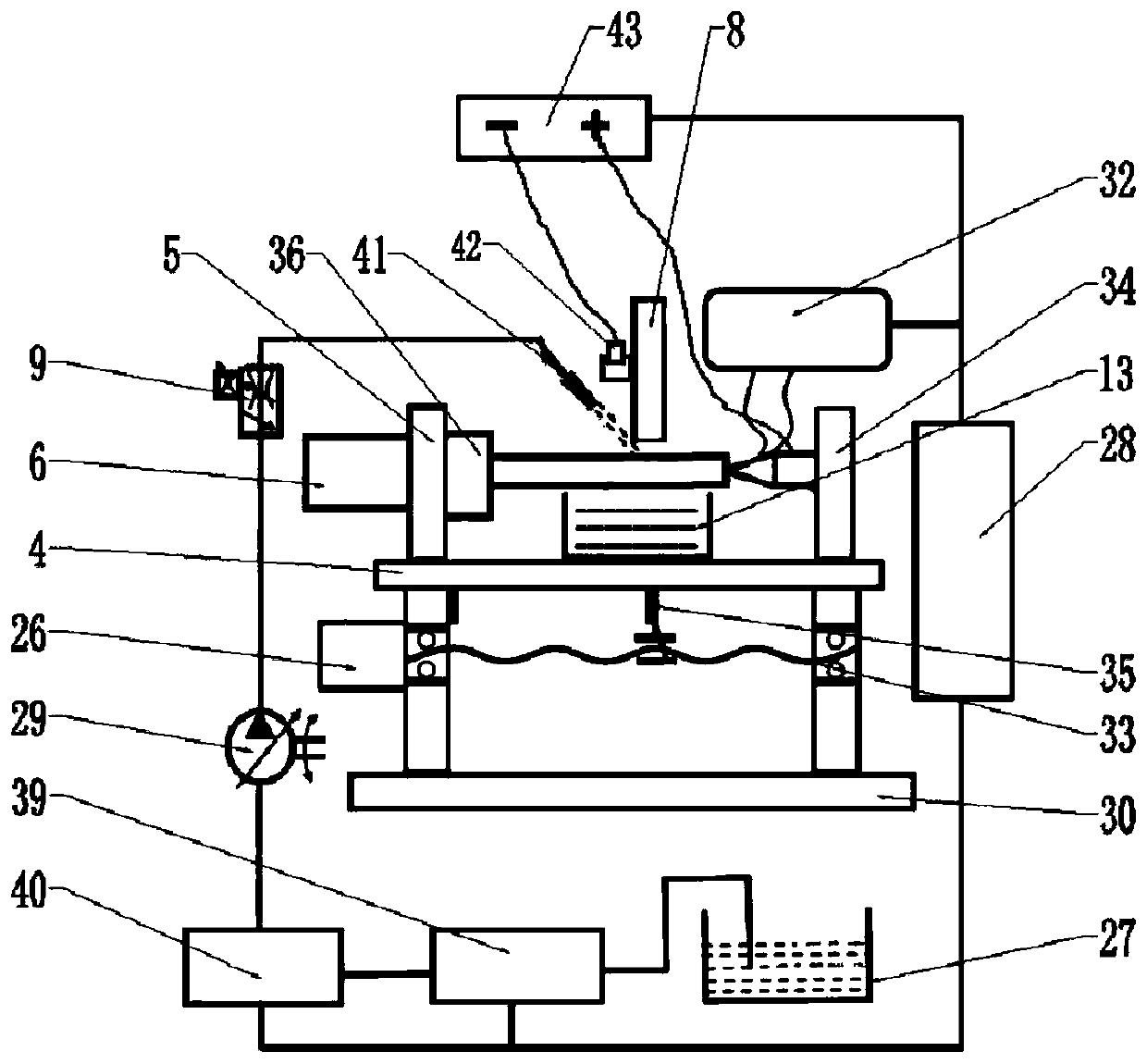

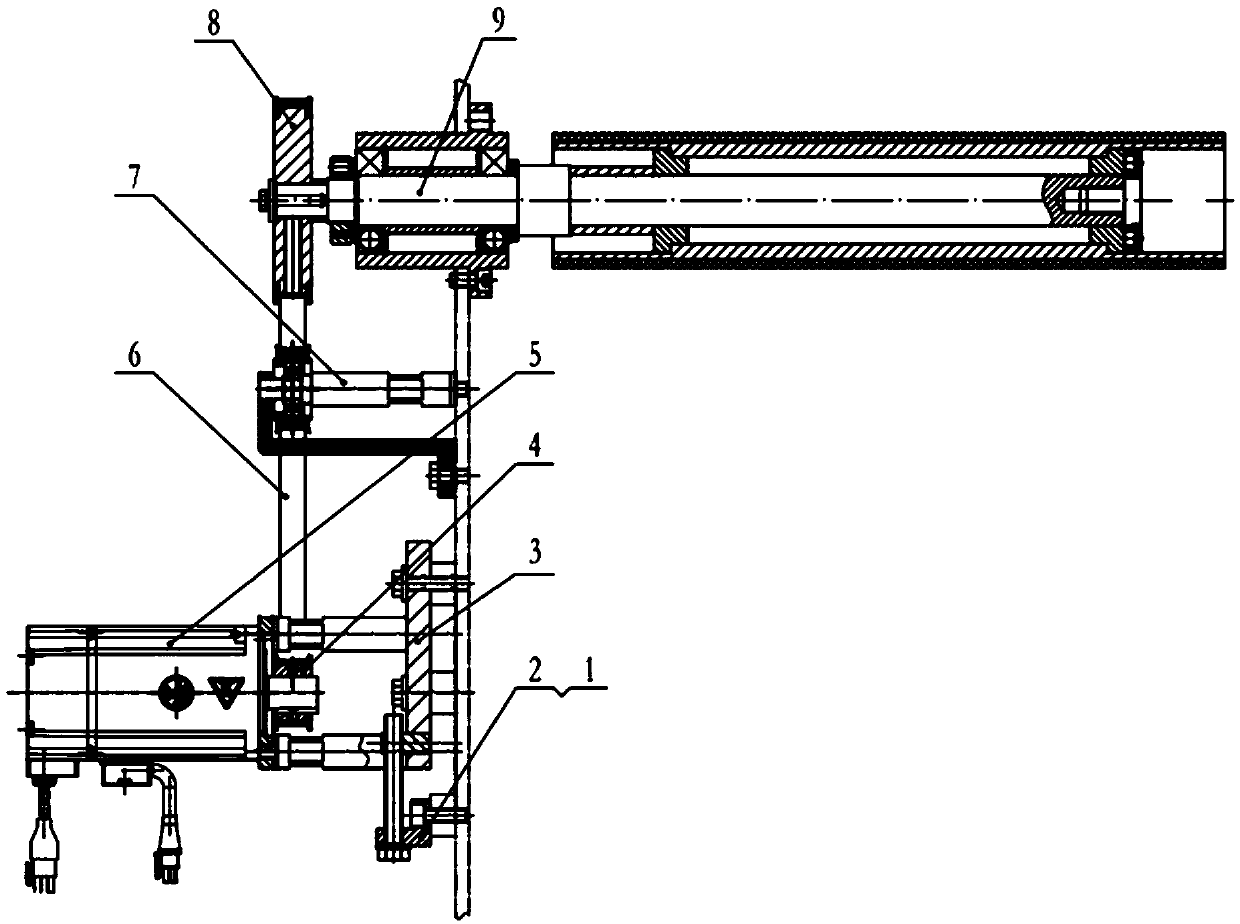

Ultrasonic enhancement electrochemistry grinding device

The invention discloses an ultrasonic enhancement electrochemistry grinding device. The ultrasonic enhancement electrochemistry grinding device is composed of a conductive grinding wheel spindle, an XZ servo shaft, an electrolyte supply system, a grinding moment detection part, an adjustable electrolysis power source, a controllable ultrasonic generator and the like. The grinding wheel spindle isdriven through a servo motor via synchronous belt drive, the grinding wheel spindle is supported through an angular contact ball ceramic bearing in triple fit, the XZ shaft is driven through the servomotor, a precise ball screw pair is adopted for transmission, a grating ruler is added, and a closed-loop detection system is formed; a positive pole of the power source is directly connected with aworkpiece tip, a negative pole is connected with the grinding wheel spindle through an electric brush, an ultrasonic transducer is in contact with a tail tip for mounting, ultrasonic waves sent out bythe ultrasonic transducer is transmitted to the workpiece through the tail tip, under the ultrasonic cavatition, grinding wheel sharpening is achieved, crack initiation and extension in an electrochemical reaction film can be promoted, the removal efficiency is improved, and through changing of parameters such as ultrasonic frequency, current, grinding wheel rotating speed and the like, the grinding process capable of improving the grinding efficiency and the quality of a material difficult to grind can be explored.

Owner:GUIZHOU UNIV

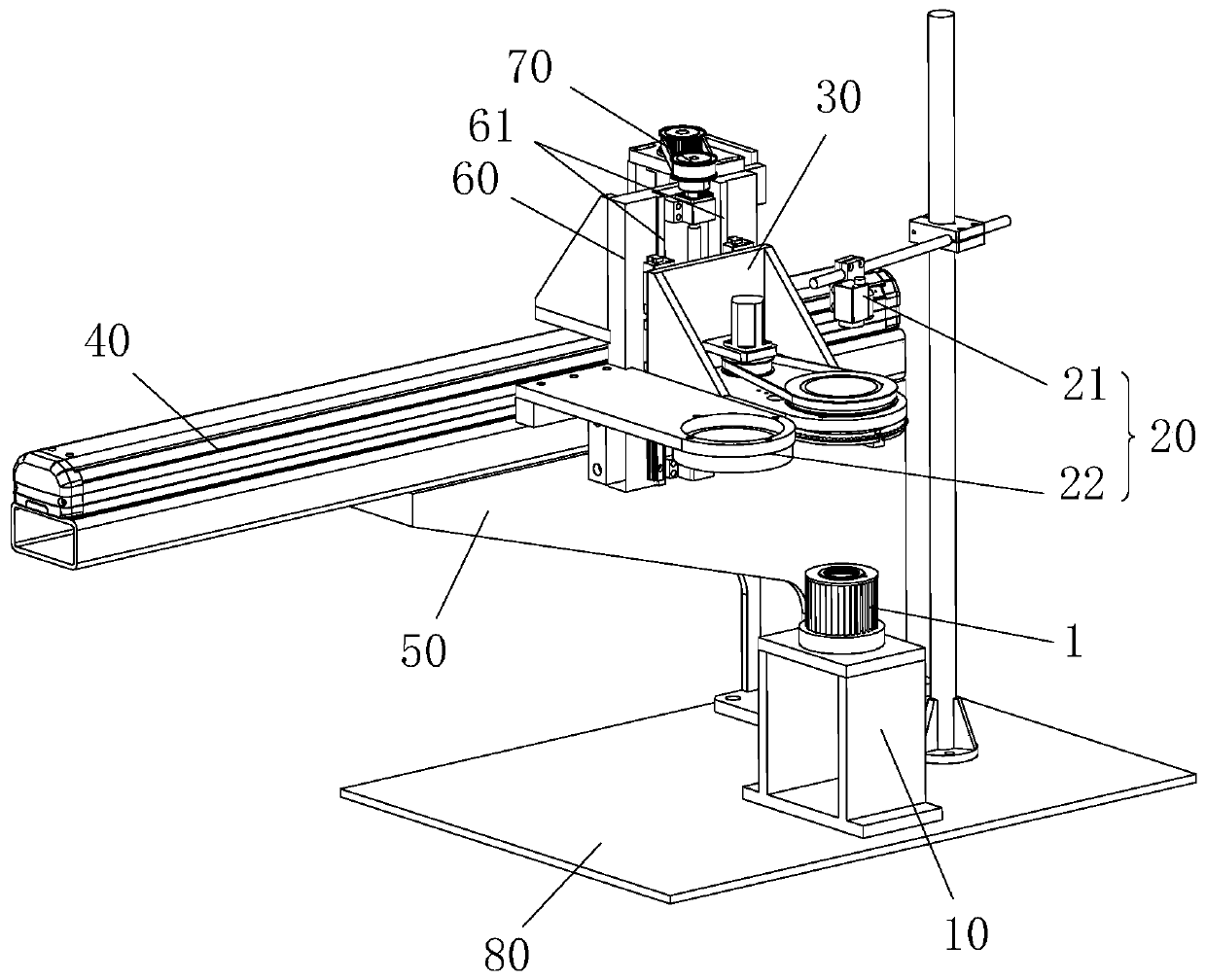

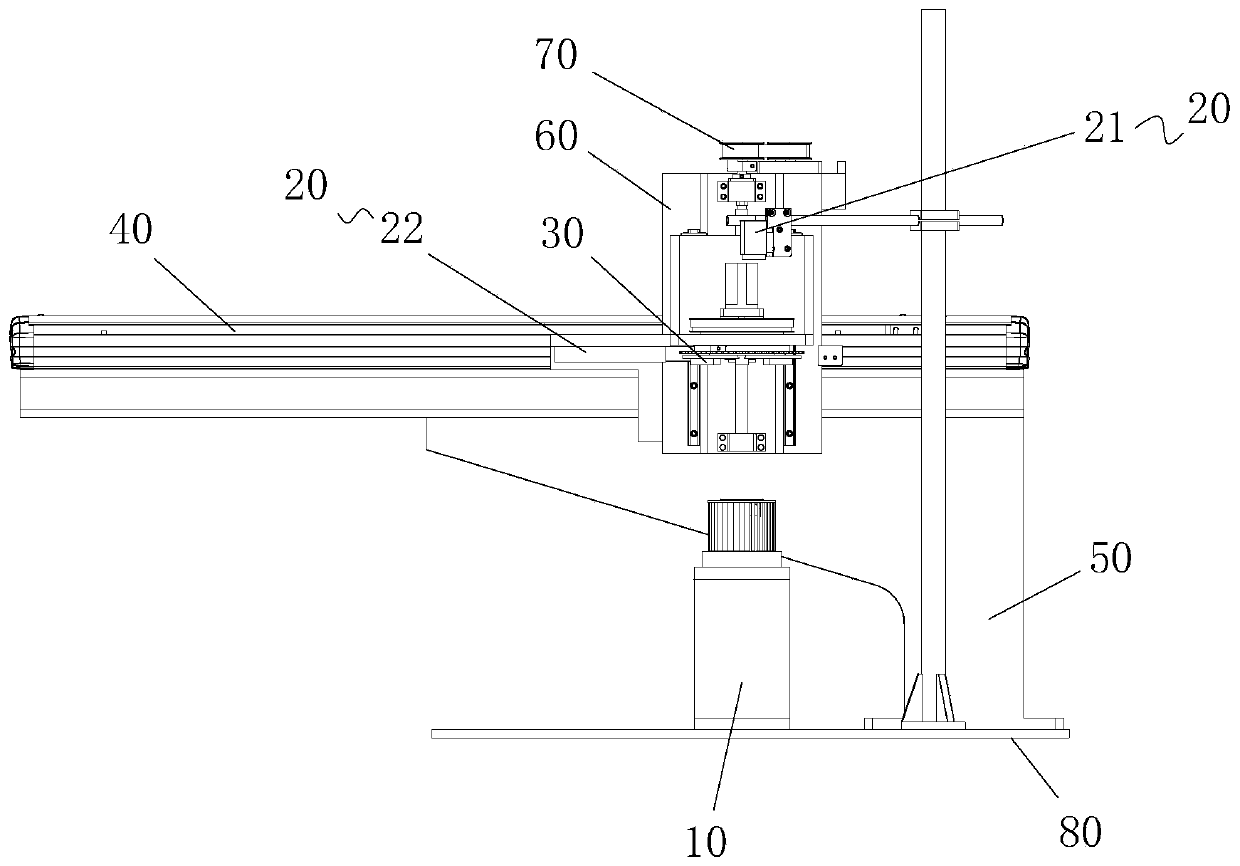

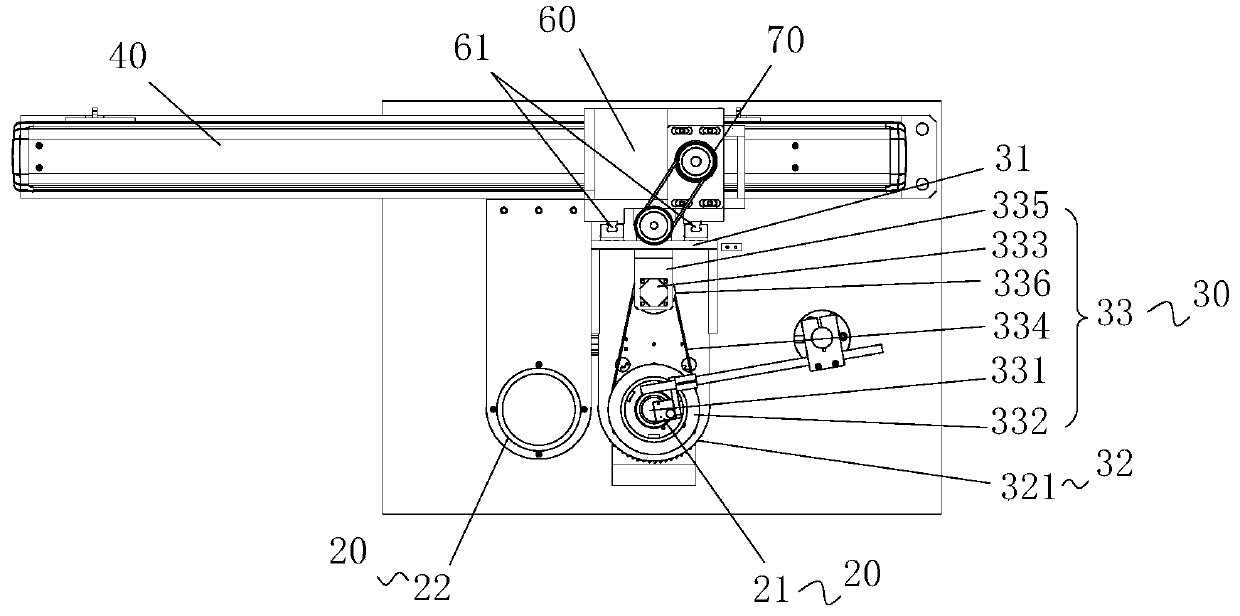

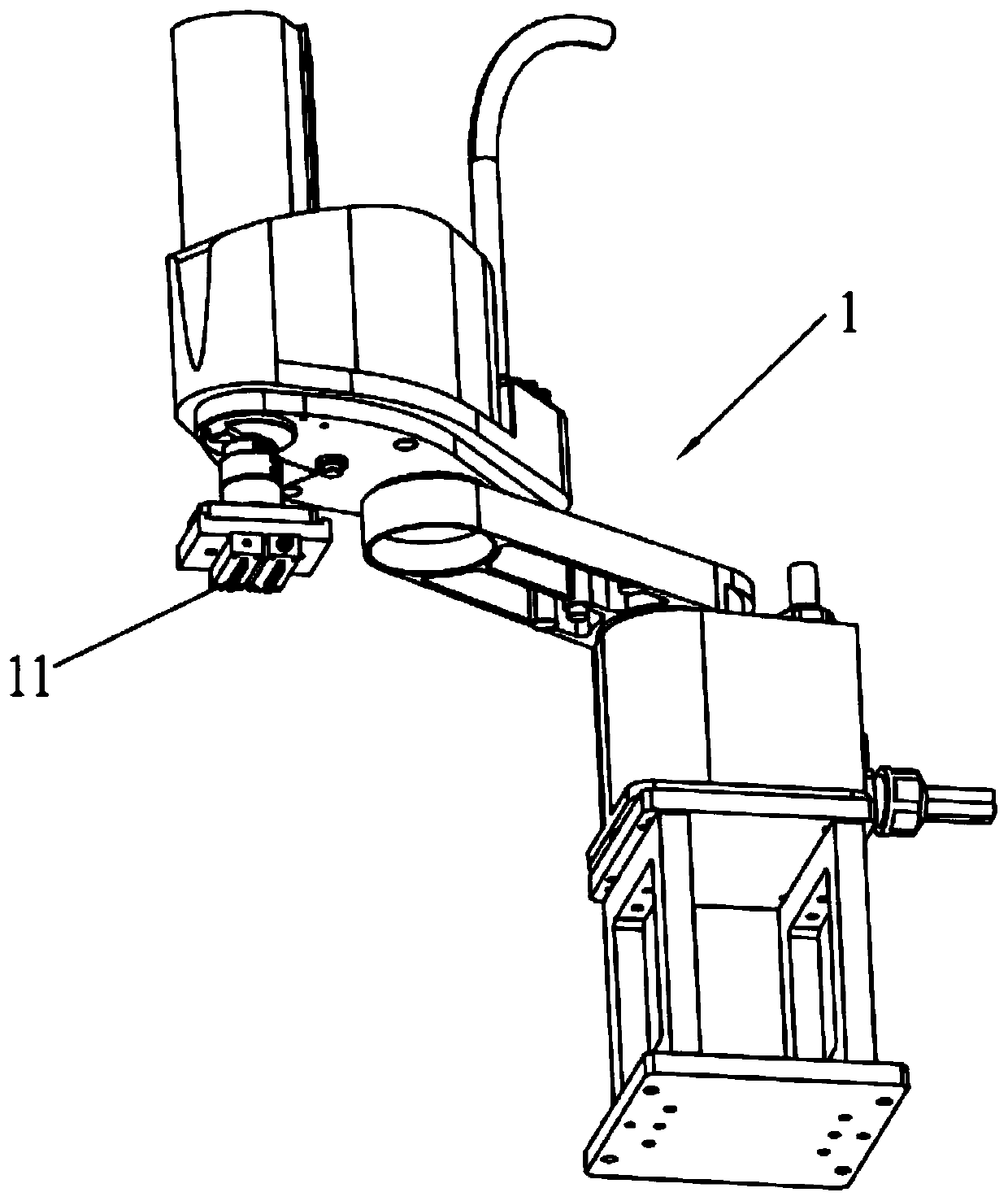

Feeding device, and production equipment of cross-flow fan blades

InactiveCN111069810ARealize automatic feeding processAccurate insertionProgramme-controlled manipulatorWelding/cutting auxillary devicesProcess engineeringFan blade

The invention provides a feeding device and a production equipment of cross-flow fan blades. The feeding device comprises a workbench, a visual positioning device and a material taking mechanism. Theworkbench is used for workpiece to be placed on. The visual positioning device comprises a camera and an analysis module. The camera is arranged above the workbench and is used to take pictures of theworkpieces and send image information to the analysis module. The analysis module is used to analyze the image information and is used to recognize the positions of feature points on the workpieces.The material taking mechanism is used to pick up the workpieces and drive the workpieces to turn according to the recognition results of the visual positioning device so as to enable the feature points to turn to the preset positions. With the technical schemes of the feeding device, and the production equipment of the cross-flow fan blades, the problem that in the prior art, because manual feeding is adopted for feeding multiple single-segment fan blades into a welding device in sequence, much time and much effort are needed is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Numerical control servo automatic bending machine

InactiveCN106694655AGuaranteed rotation accuracyGuaranteed feed accuracyNumerical controlMotor drive

A numerical control servo automatic bending machine comprises a machine body, a core pulling device, a feeding clamping device, an auxiliary pushing mechanism, an auxiliary pushing oil cylinder, a clamping oil cylinder, a driving arm, a rotary servo motor, a bending die and a feeding device. The bending die is divided into two bodies, an upper die body can move vertically to loosen and clamp workpieces. The numerical control servo automatic bending machine is characterized in that the rotary servo motor drives the die and drives feeding to be conducted, and the length and width precision and the angle precision of a frame are guaranteed; and the core pulling device acts to guarantee the precision of bent arc sections. According to the numerical control servo automatic bending machine, the servo motor is used for driving; loosening, clamping and feeding are achieved automatically; PLC control guarantees the rotating precision and the feeding precision; one-time feeding at four bent corners is conducted sequentially, the precision is high and stable, the efficiency is greatly improved and is 4-5 times that of a traditional machining mode.

Owner:束小芹

Milling machine automatic feeding and discharging equipment, using method and application thereof

The invention discloses milling machine automatic feeding and discharging equipment, a using method and application thereof, and belongs to the field of milling machine supporting equipment. The milling machine automatic feeding and discharging equipment comprises a conveying device and a picking manipulator arranged on one side of the conveying direction of the conveying device, the conveying device comprises a belt conveying mechanism, and a positioning controlling mechanism located on the belt conveying mechanism, the belt conveying mechanism is used for conveying workpieces, and a pickingposition is arranged in the conveying direction of the belt conveying mechanism; and the upper side of the picking position in the conveying direction is provided with a to-be-processed area, the lower side of the picking position in the conveying direction is provided with a finished product area, the positioning controlling mechanism is used for controlling the workpieces placed vertically in the to-be-processed area to be put down and conveyed to the picking position one by one, the picking manipulator is used for grasping the to-be-processed workpieces at the picking position of the belt conveying mechanism to be sent to a milling machine, or the workpieces after processing in the milling machine are sent back to the picking position of the belt conveying mechanism. The milling machineautomatic feeding and discharging equipment can realize automatic feeding and discharging of milling machine processing, effectively reduces the labor intensity, improves the production efficiency, and facilitates the automatic production.

Owner:安徽一众精密轴业有限公司

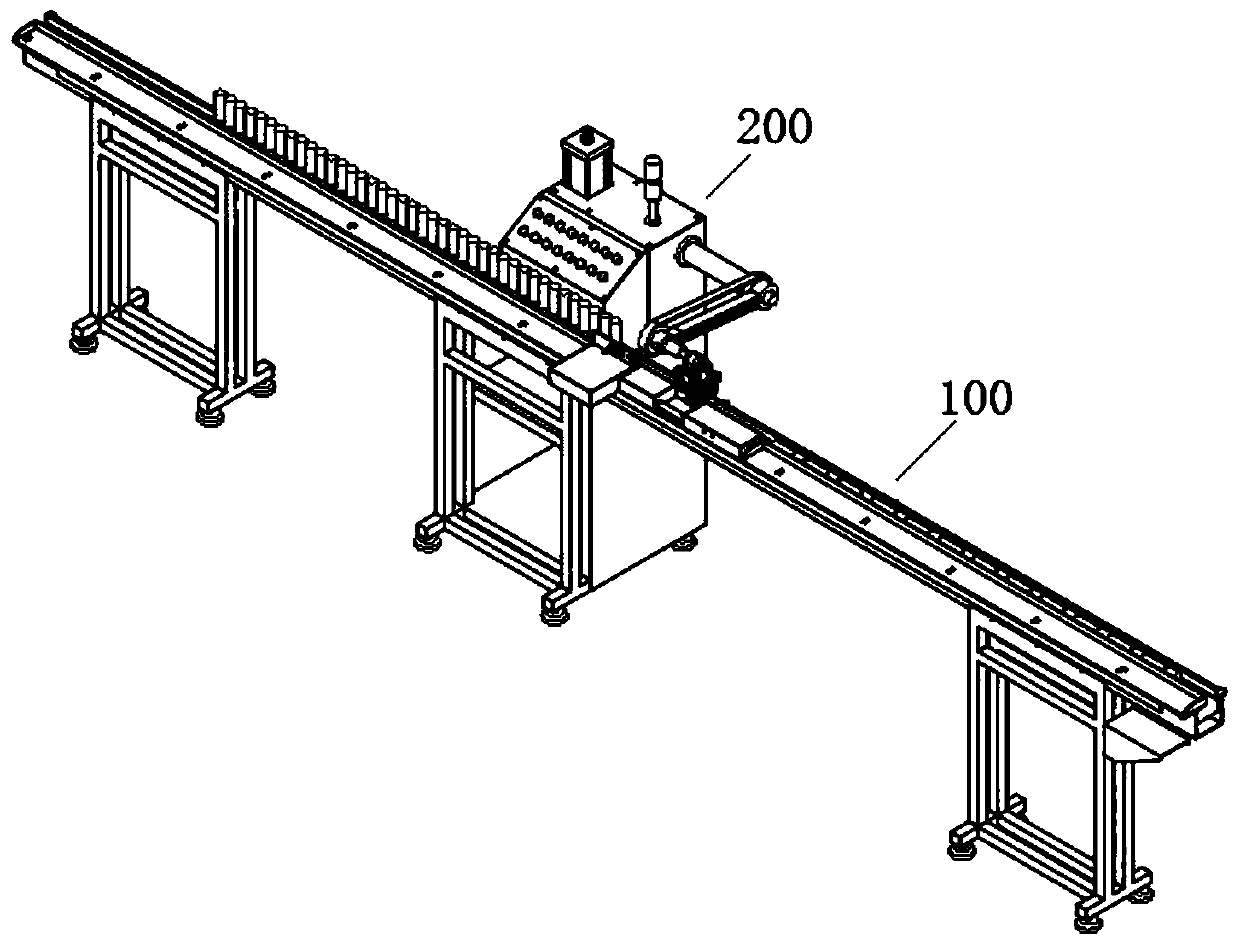

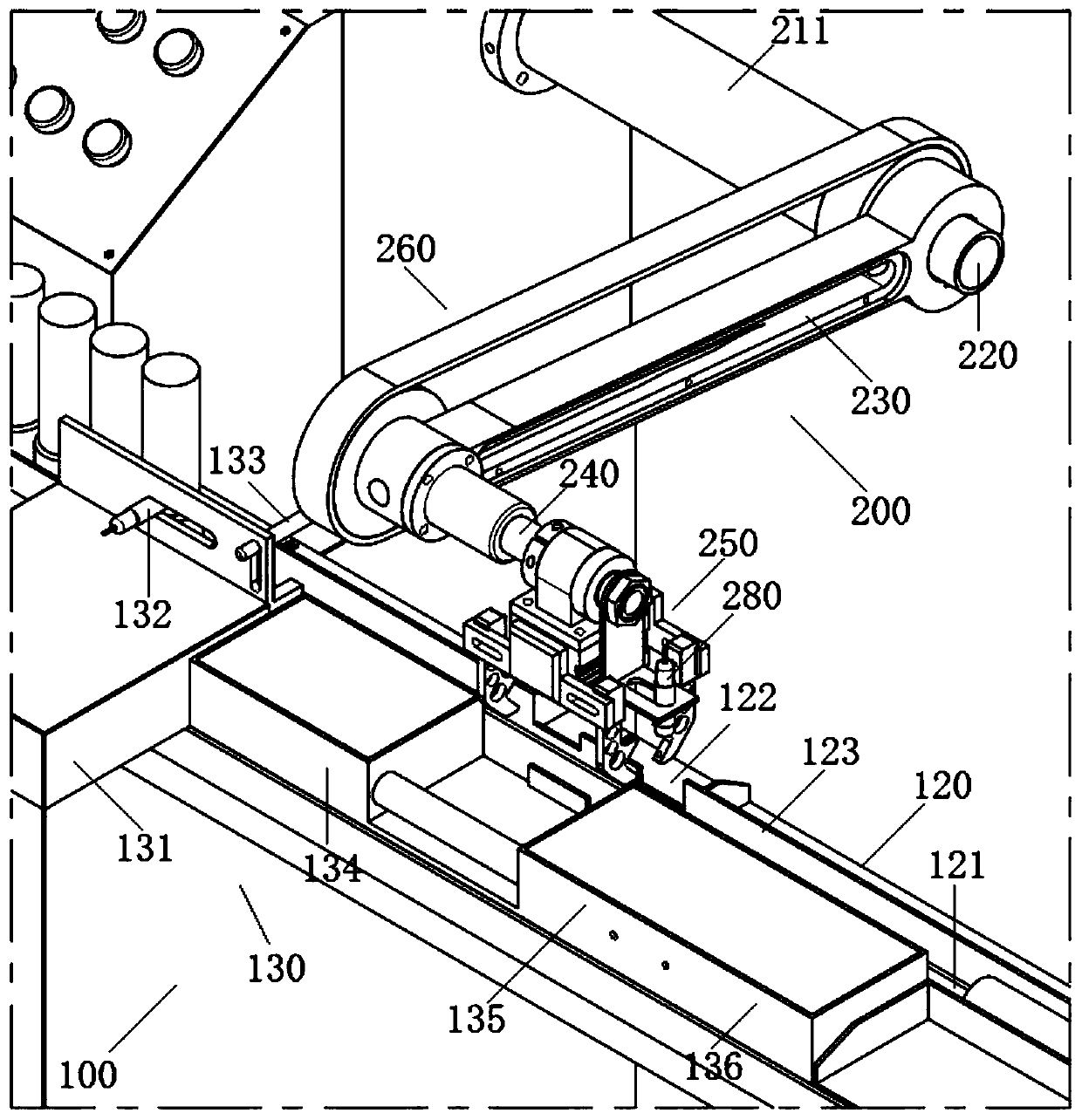

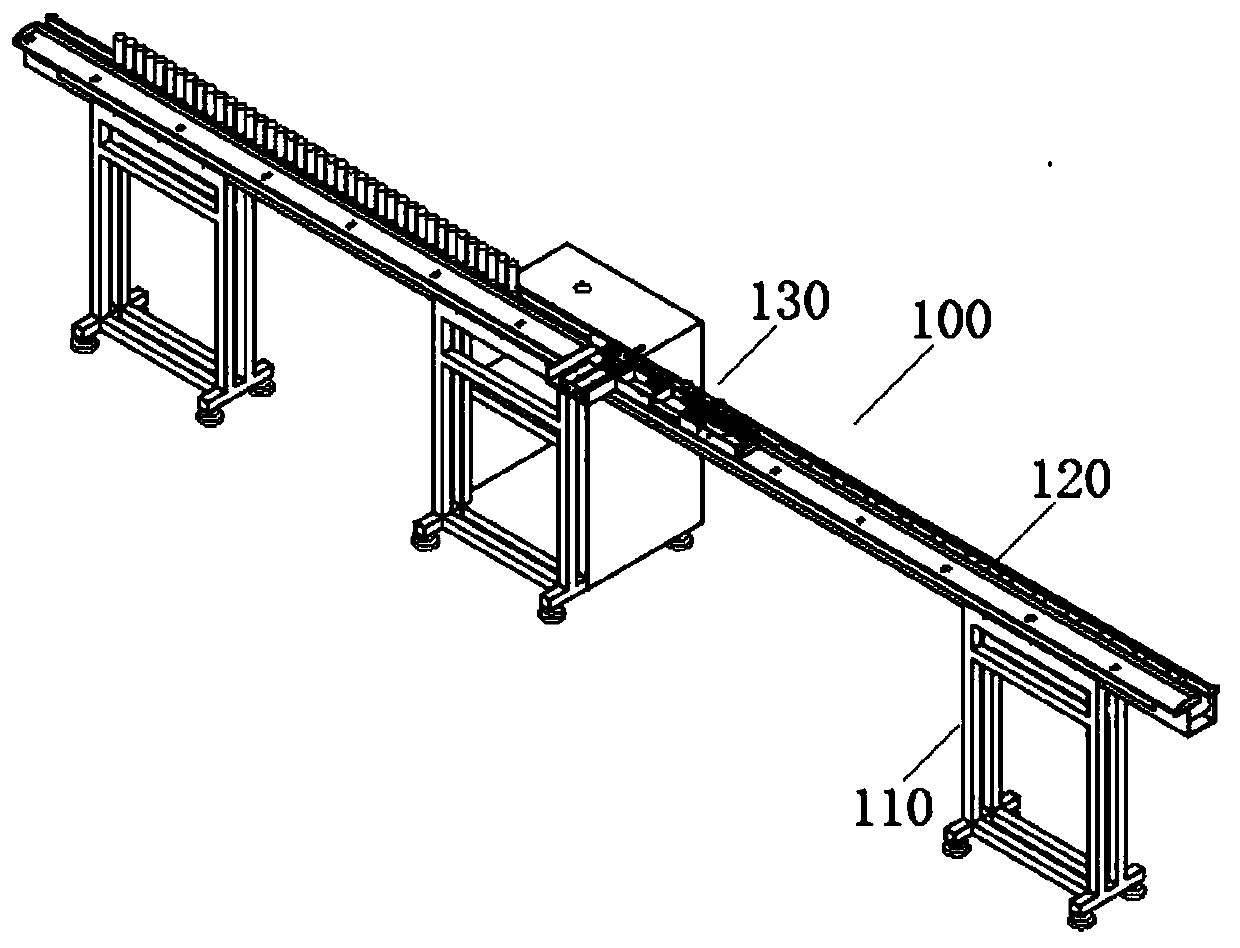

Automatic pipeline feeding device

ActiveCN107570576AEasy deliveryEasy to operateConveyorsMetal-working feeding devicesEngineeringMachining

The invention discloses an automatic pipeline feeding device and relates to the technical field of pipeline machining equipment. The automatic pipeline feeding device comprises an outer frame. A top plate and a bottom plate are fixedly connected between the two sides of the inner wall of the outer frame in sequence from top to bottom. The bottom of the inner wall of the outer frame is fixedly connected with a first motor. One end of an output shaft of the first motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The back face of the second belt wheel is fixedly connected with a first gear. One side of the first gear is engaged with a second gear. According to the automatic pipeline feeding device, a pipeline can be clamped and fixed to be prevented from deviating in the cutting process, and the fixing effect is improved; manual clamping and manual feeding are not needed, operationis easy, the labor quantity of workers is relieved, and using of people is facilitated; and feeding is facilitated, the using performance of the device is improved, feeding precision is guaranteed, and errors caused by manual feeding are avoided.

Owner:GUANGDONG JUNCHI TECH HLDG

Automatic weighing and distributing brick taking system of numerically controlled electric spiral brick press

ActiveCN109773951AHigh degree of automationGood linkageDischarging arrangementCeramic shaping plantsBrickMultiple sensor

The invention relates to an automatic weighing and distributing brick taking system of a numerically controlled electric spiral brick press. The automatic weighing and distributing brick taking systemcomprises a rack and is characterized in that a storage device is fixed to the top of the rack, and a belt conveying device is arranged below a bottom outlet of the storage device; a weighing deviceis arranged below the blanking end of the belt conveying device, and a distributing brick taking arm is arranged below the weighing device; a sliding supporting mechanism is arranged between a frame body of the belt conveying device and the rack, and a stopping mechanism is arranged at the position, corresponding to the belt blanking end, of the frame body of the belt conveying device; the weighing device is fixedly connected with the rack through a suspension arm frame, the top edge of the weighing device is supported on balance weight plates, and multiple sensors are evenly arranged betweenthe balance weight plates; and the balance weight plates are supported on the suspension arm frame through aseismic airbags. The automatic weighing and distributing brick taking system is simple in structure, convenient to maintain and stable in operation, the weighing stability, the distributing uniformity, the feeding accuracy and the weighing, distributing and brick taking linkage are remarkably improved, and therefore the brick pressing quality and production efficiency are improved, and potential safety hazards are greatly eliminated.

Owner:辽阳锻压机床股份有限公司

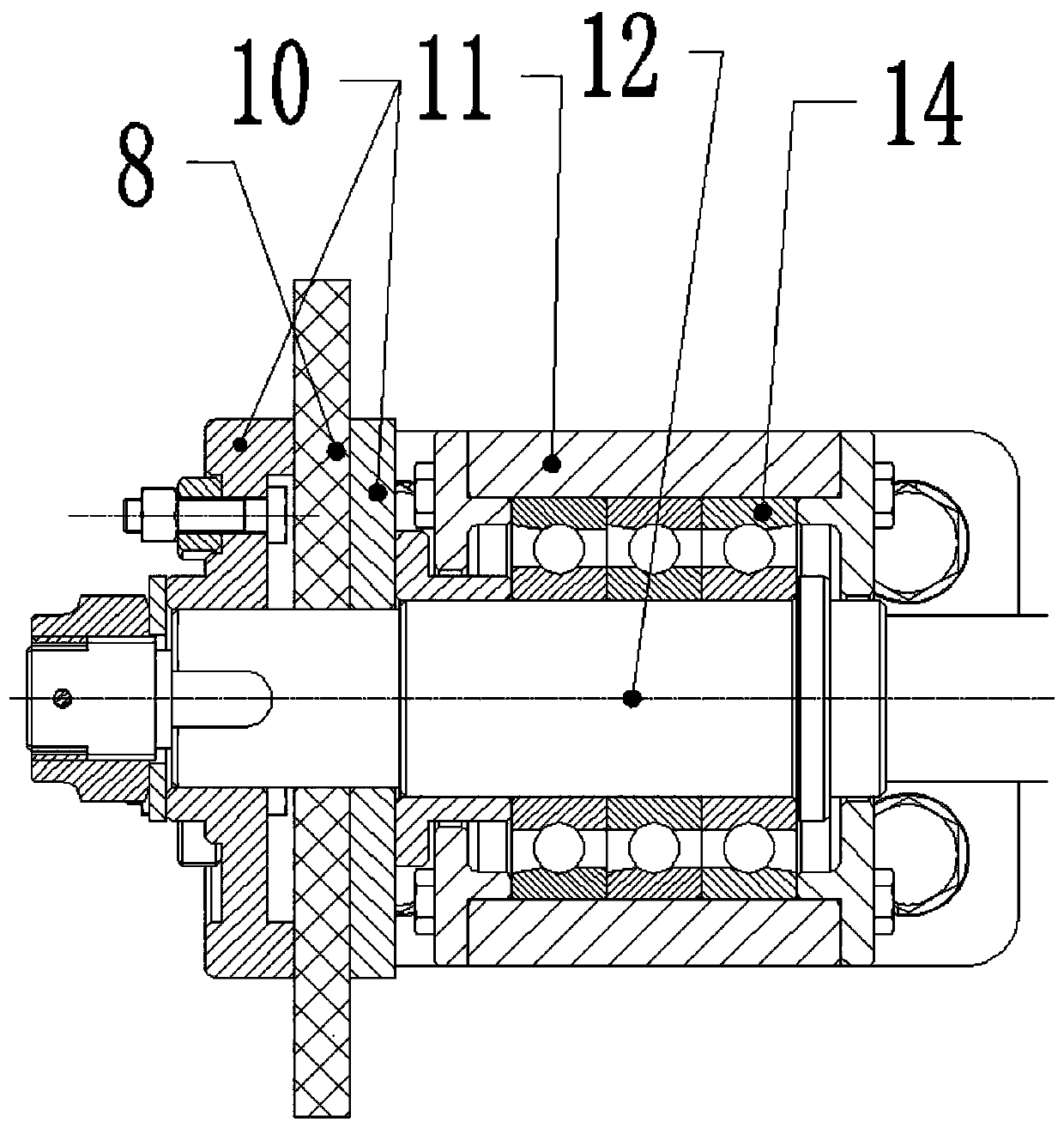

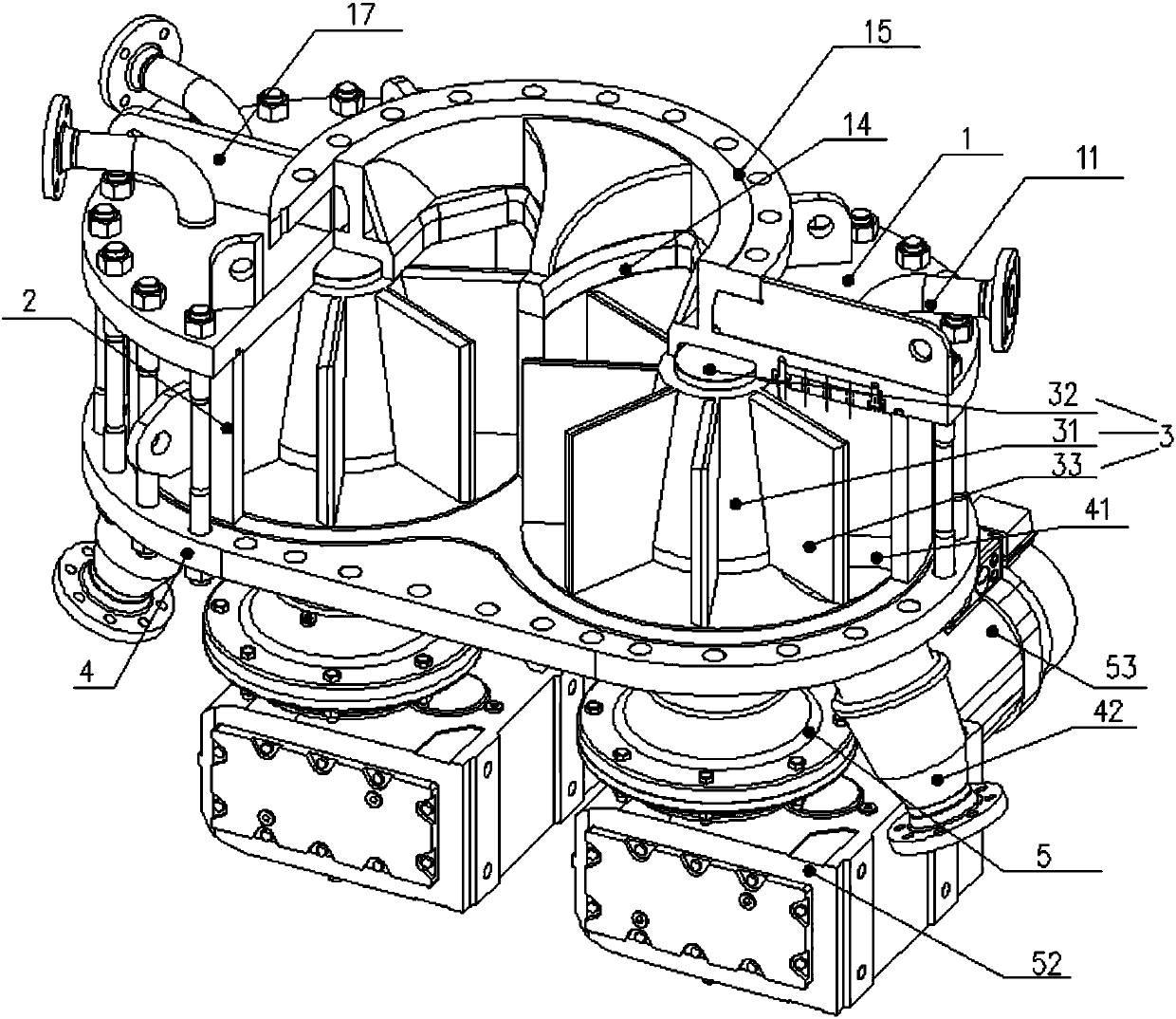

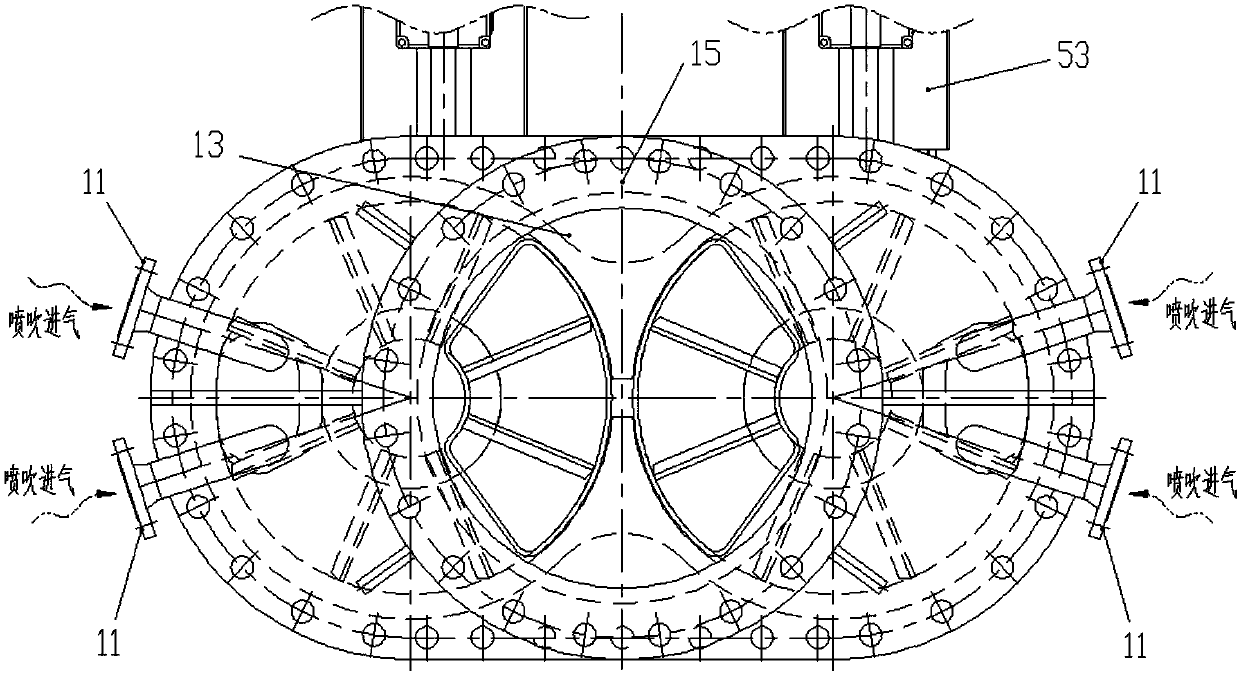

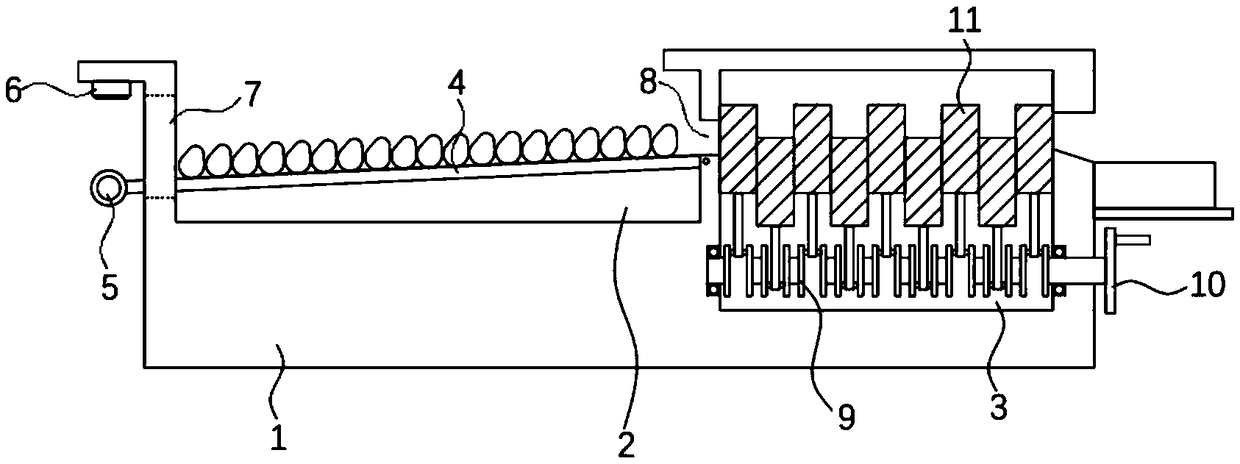

Parallel double-rotor pneumatic conveying feeder

ActiveCN107601056AGuaranteed feed accuracyImprove space utilizationBulk conveyorsImpellerControl system

The invention discloses a parallel double-rotor pneumatic conveying feeder applied to the field of bulk material conveying equipment. The parallel double-rotor pneumatic conveying feeder comprises a top cover, a middle shell, a baseplate and a seal bearing base; the middle shell, the top cover and the baseplate form impeller cavities; impellers are in the impeller cavities; rotating hubs of the impellers are connected with a rotating shaft in the seal bearing base; the rotating shaft is connected with a driving control system; two impeller cavities and two impellers are provided, and are arranged side by side; and two feed ports and discharge ports are correspondingly formed. The driving control system comprises a speed reducer, a variable frequency motor, a speed detecting element and aninduction plate. The parallel double-rotor pneumatic conveying feeder mainly solves the problems of low conveying precision, high intake resistance, inflexible adjusting mode, low equipment space utilization rate and low feeding capacity in traditional pneumatic conveying feeder equipment. The parallel double-rotor pneumatic conveying feeder has such advantages as high conveying precision, efficient, stable and reliable process and flexible and convenient control, and achieves excellent application prospect and value.

Owner:CISDI ENG CO LTD +2

Automatic laminating machine

PendingCN110451003AContinuous laminating operationImprove uniformityPackaging automatic controlEngineeringManipulator

The invention discloses an automatic laminating machine used for laminating special-shaped foam. The automatic laminating machine comprises a mechanical arm, a tray and a flow channel device. The trayis used for holding workpieces. The flow channel device comprises a feed laminating section provided with a material belt. The mechanical arm is provided with first suction cups capable of sucking the workpieces. The mechanical arm can move the workpieces to the feed laminating section and enable the workpieces to be laminated to the material belt. The automatic laminating machine further comprises a guiding device and a material belt pulling device. The automatic laminating machine can automatically laminate the workpieces, greatly improves work efficiency and saves labor.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

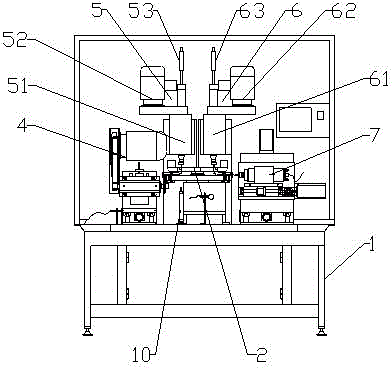

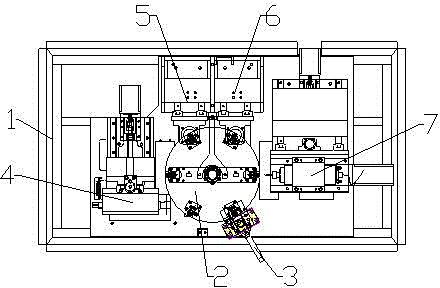

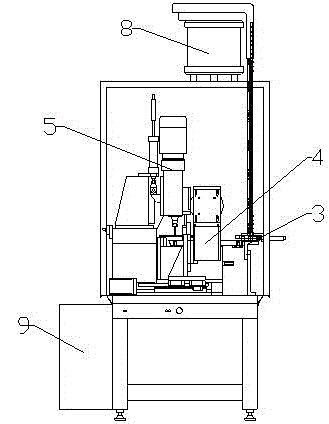

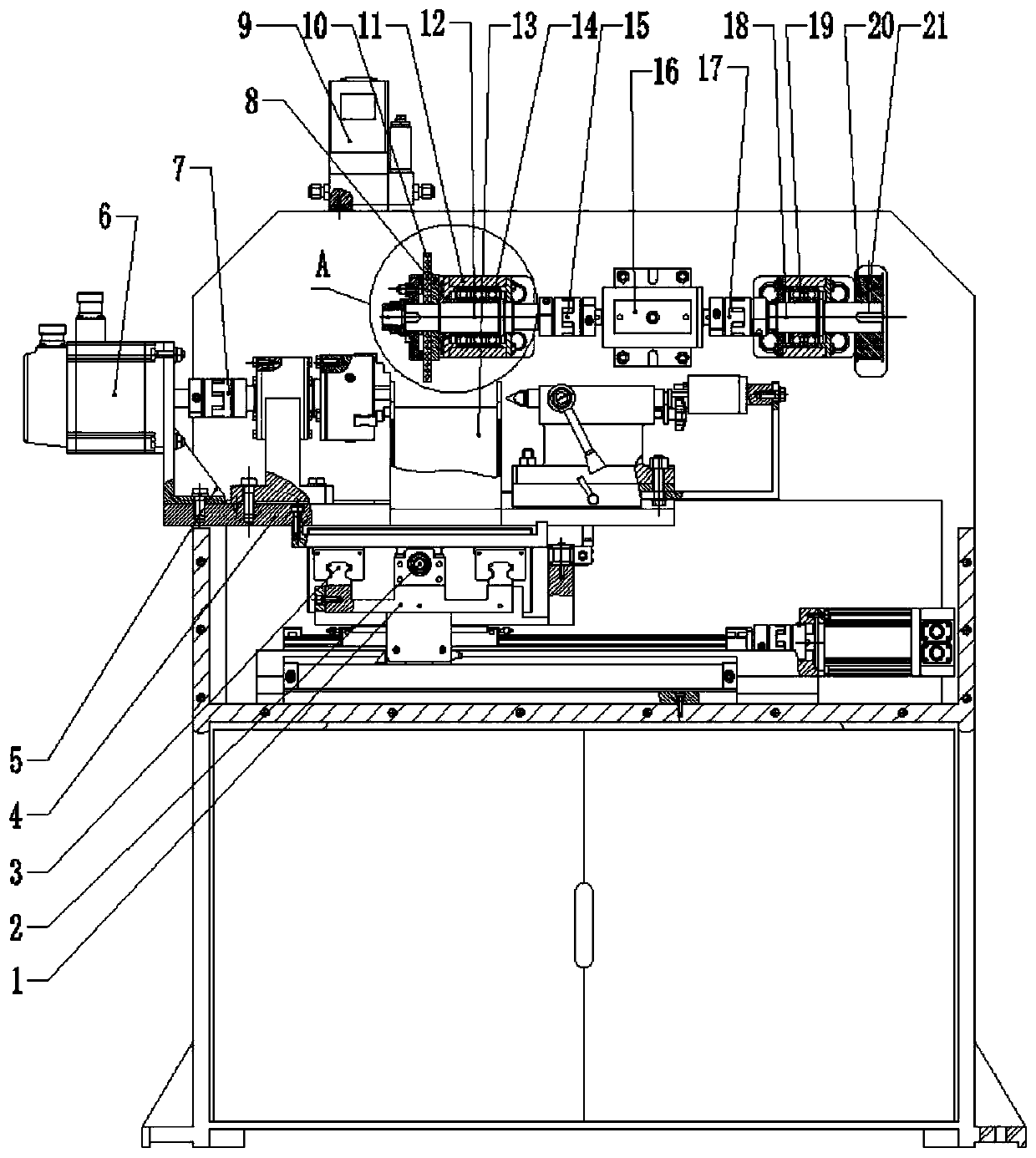

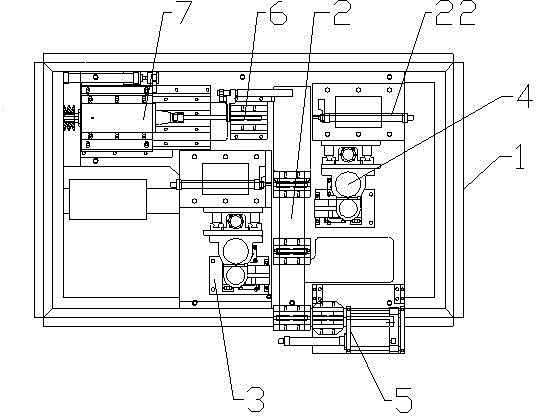

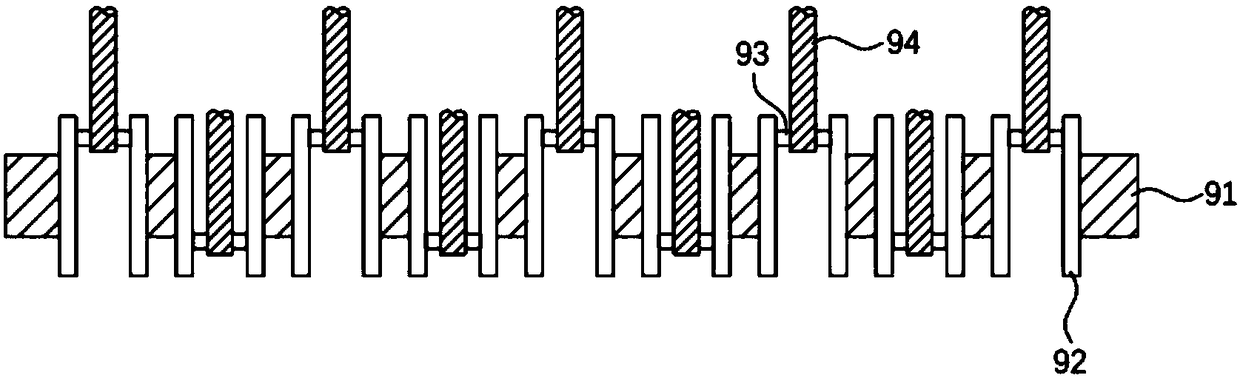

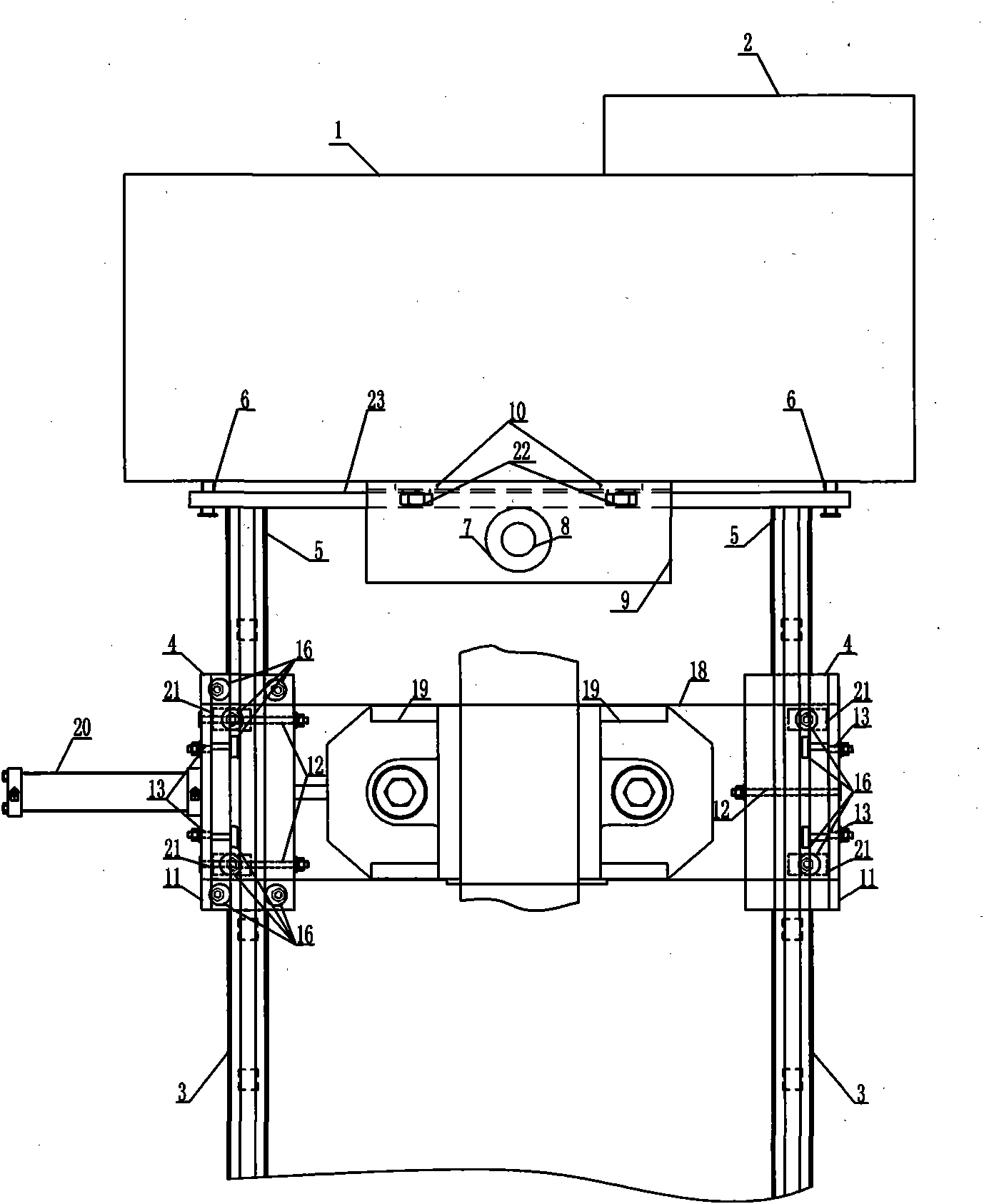

Numerical control double-end pin hole drilling machine

ActiveCN104148948AGuaranteed feed accuracyGuaranteed machining accuracyOther manufacturing equipments/toolsPositioning apparatusNumerical controlDrilling machines

The invention relates to the field of lock manufacturing, and particularly discloses a numerical control double-end pin hole drilling machine. The numerical control double-end pin hole drilling machine comprises a rack, a middle feeding mechanism in the front-and-back direction is arranged on the rack, clamp assemblies identical in structure and opposite in direction are arranged on the two sides of the middle feeding mechanism respectively, the clamp assemblies can slide on the rack front and back, and a drilling mechanism capable of moving vertically is arranged above each clamp assembly. An automatic feeding mechanism assembly is arranged at the front end of the rack. A reaming and polishing clamp assembly is arranged at the rear end of the clamp assembly at the front end, and a reaming and polishing mechanism assembly is arranged beside the reaming and polishing clamp assembly. The mechanisms can move front and back and left and right through guide rods, guide columns, air cylinders, stepping motors and the like, the feeding precision in the moving process is guaranteed, the whole automatic production process of a pin tumbler lock case is completed through automatic feeding, automatic material pushing, automatic clamping and automatic material flipping, the automation degree and production efficiency are greatly improved, and machining precision is guaranteed.

Owner:曹县精锐机械锁业有限公司

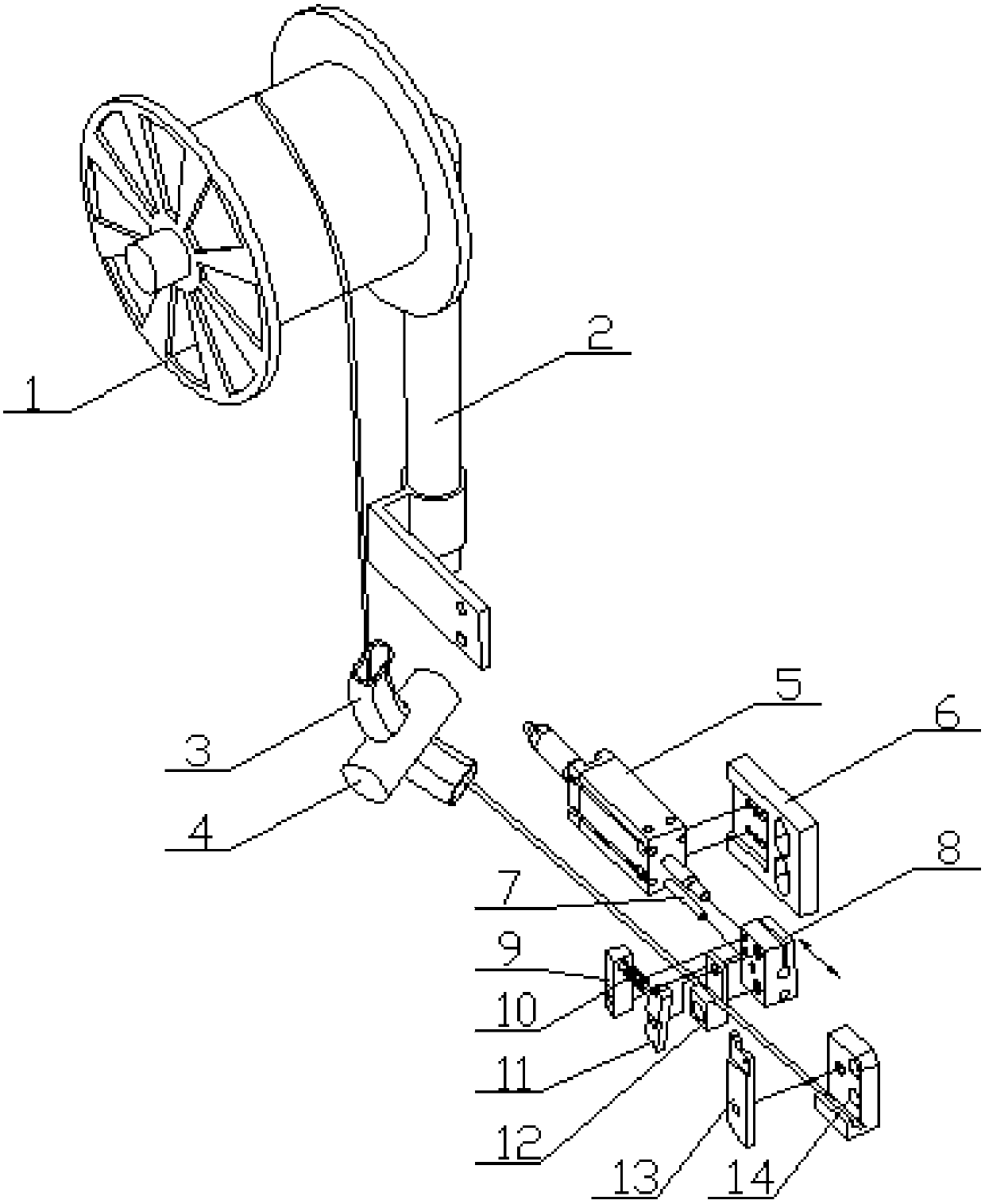

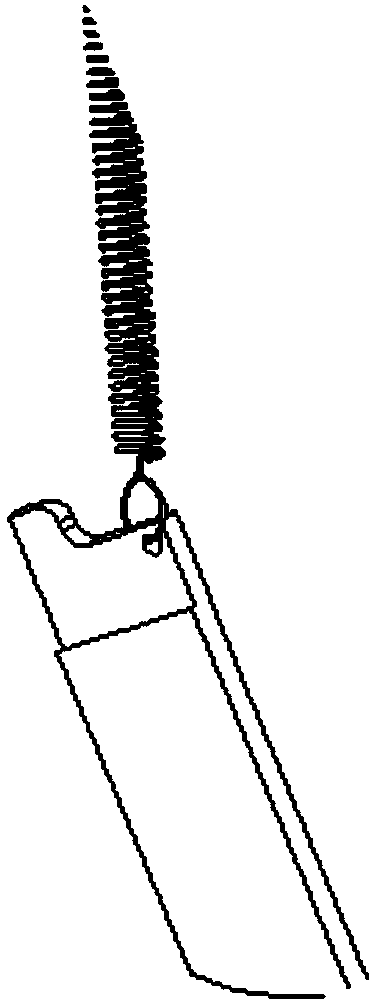

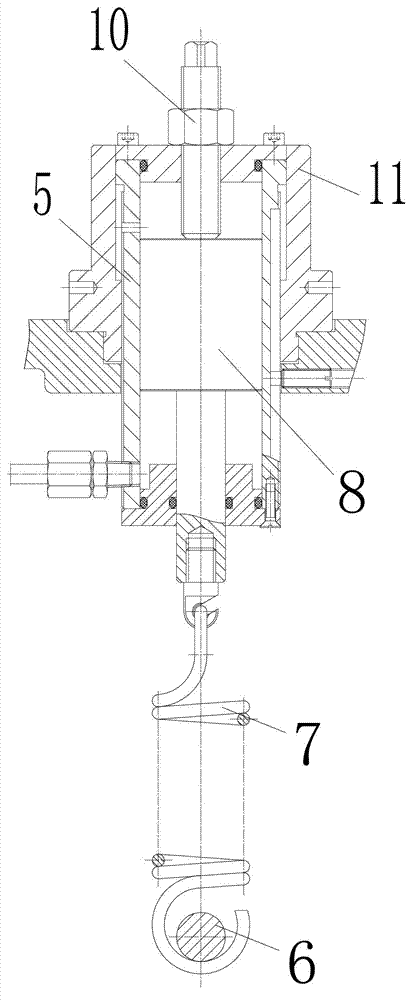

Pneumatic feeding system of copper belt machine

The invention relates to a pneumatic feeding system of a copper belt machine. The pneumatic feeding system of the copper belt machine comprises a feeding shaft and a fixing support thereof, wherein aguiding pipe and a fixing support thereof are arranged on the front lower part of the feeding shaft; an air cylinder and a fixing support thereof are arranged on the inner side of the guiding pipe; anair cylinder output shaft is connected with an air cylinder head; a spring supporting plate and a feeding support are fixed to the outer side of the air cylinder head side by side; a feeding plate ishinged onto the feeding support; the spring supporting plate and the feeding plate are connected through a spring; a damping base is arranged in front of the air cylinder head; a damping plate is hinged onto the damping base; wire slots are formed in the lower parts of the damping base and the feeding support; a copper belt sequentially passes through a wire shaft, the guiding pipe, the feeding wire slot and the damping wire slot; the bottom parts of the feeding plate and the damping plates are arc-shaped; the copper belt is located between the feeding wire slot and the feeding plate as wellas between the damping wire slot and the damping plate; a tension spring is connected between the right upper corner of the damping plate and a copper belt machine shell. The feeding precision of an air cylinder is ensured, the simplicity in adjustment is realized, the synchronism is good, the air cylinder is arranged close to a work mold for feeding so as to be good in rigidity, the energy of a host is not consumed, and a popularization value is high.

Owner:TIANJIN LIGAN TECH

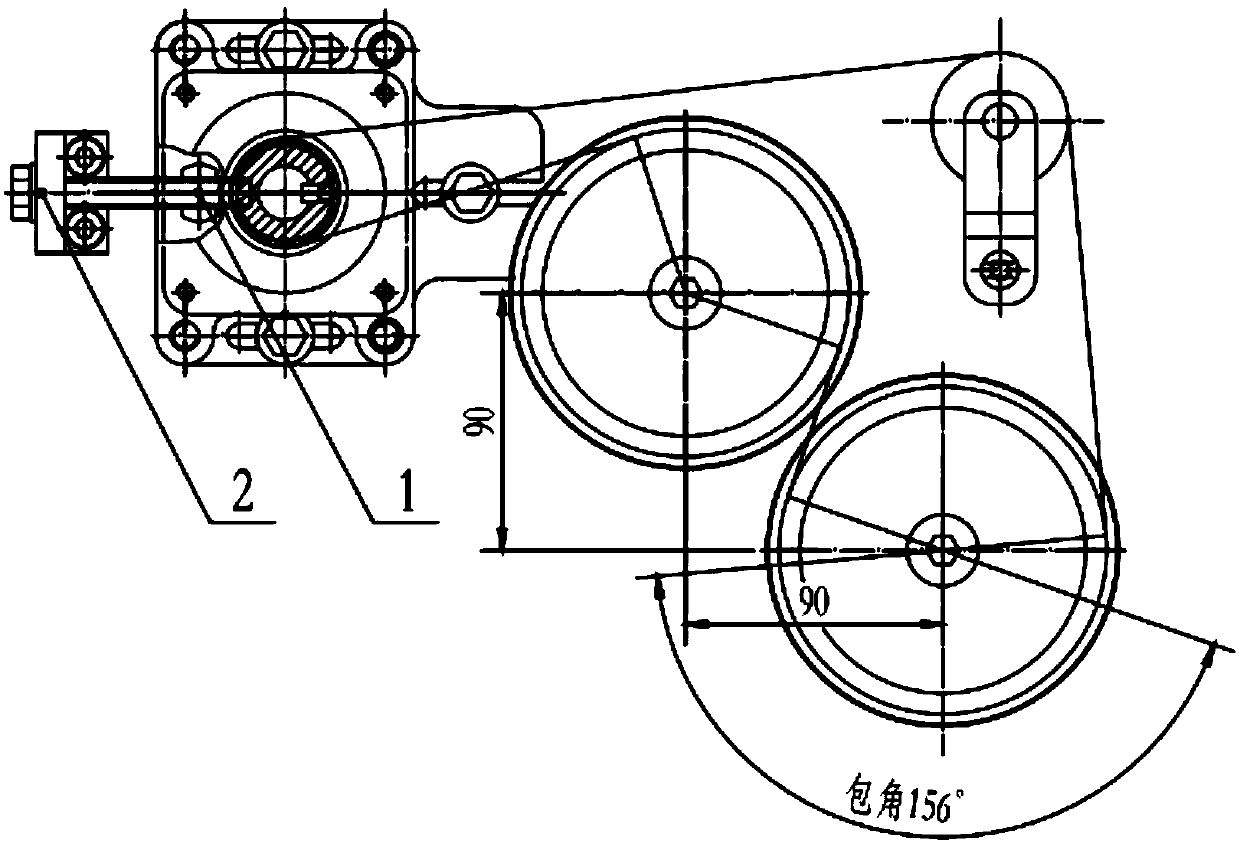

Computer numerically controlled (CNC) camshaft grinding machine

ActiveCN103170889AHigh speedIncrease productivityBelt grinding machinesAbrasive surface conditioning devicesEngineeringGrinding wheel

The invention provides a computer numerically controlled (CNC) camshaft grinding machine comprising a machine tool and an electric main shaft, wherein the electric main shaft is an external plane section flowing hydrostatic bearing motorized spindle, a sealed cavity structure is adopted for an outer box body, an oil pipe installation window is not reserved, and integrity of the CNC camshaft grinding machine is enhanced; a spring is loaded between an oil cylinder and a cocket centring, an oil cylinder piston is connected at the upper end of the spring, and the cocket centring is connected at the lower end of the spring; the width of a grinding carriage installation part of the machine tool is enlarged by 1 / 5-1 / 6, and inner rib plate arrangement is optimized; and the ratio of the distance from a guide rail to a lead screw, and a whole span is widened to 0.3-0.33, and the guide rail is a guide rail for a machine tool body and a padding plate. According to the CNC camshaft grinding machine, grinding wheel linear velocity is enhanced by strengthening machine tool intensity, and therefore grinding machine working efficiency is increased by 5-10 times.

Owner:湖南铱索数控装备股份有限公司 +1

Supermarket-egg quantitative discharging machine

ActiveCN109008489AEffective placementOrderly slideRacksService system furnitureSurface mountingPulp and paper industry

The invention discloses a supermarket-egg quantitative discharging machine. The supermarket-egg quantitative discharging machine comprises a machine body, a material cavity and a machine cavity are formed in the machine body, the material cavity is communicated with the machine cavity through an opening, two parallelly-arranged transverse rods are arranged in the machine cavity, the ends, close tothe machine cavity, of the transverse rods are rotationally connected to the bottom end of the opening, a limiting groove is formed in the end, away from the machine cavity, of the material cavity, the ends, away from the machine cavity, of the transverse rods penetrate through the limiting groove and extend outside the machine body, and an electromagnet is installed on the outer surface of the machine body; a horizontally-arranged crankshaft is arranged at the inner bottom end of the machine cavity, the two ends of the crankshaft are rotationally connected on the inner wall of the machine cavity, and a driving mechanism is connected to the crankshaft. According to the supermarket-egg quantitative discharging machine, a transverse-rod discharging mechanism is adopted, eggs can be effectively put along a straight line with the design mode, and therefore follow-up discharging is convenient; the electromagnet is arranged on the outer surface of the shell, the transverse rods can be closeunder magnetic adsorption of the electromagnet, and the eggs put on the transverse rods can orderly fall down.

Owner:汶上县联民超市有限公司

Full-automatic assembling machine of a hanging type earphone bottom shell part convenient for rubberizing

ActiveCN110602627ARealize continuous automatic assemblyReduce collection and transportation costsMicrophonesLoudspeakersBlock matchLoudspeaker

The invention relates to a full-automatic assembling machine of a hanging type earphone bottom shell part convenient for rubberizing. A carrier conveying device for clockwise conveying is arranged onthe rack; the carrier conveying device comprises a carrier conveying groove. A carrier is arranged in the carrier conveying groove in a matched mode. A carrier conveying mounting base is arranged at the bottom of the carrier conveying groove; a carrier feeding cylinder parallel to the carrier conveying groove is arranged on the carrier conveying mounting seat; a carrier feeding groove is formed inthe middle of the feeding end of the carrier conveying groove. The carrier feeding air cylinder is connected with a carrier feeding push block matched with the carrier feeding groove. A dustproof netfeeding mechanism, a loudspeaker assembling device, a film assembling mechanism, a light blocking piece assembling mechanism and a loudspeaker dispensing device which are matched with the carrier arearranged on the rack. By means of the automatic assembling machine, continuous and automatic assembling can be achieved, meanwhile, the bottom shell feeding station and the assembled bottom shell part discharging station can be located at the same position, then the assembled bottom shell parts can be loaded and collected through the bottom shell loading disc, and the collecting and transportingcost is reduced.

Owner:CHONGQING TECH & BUSINESS UNIV

Numerically-controlled machine tool carriage mounting structure with good stability

InactiveCN113084568AImprove stabilityPrevent looseningMeasurement/indication equipmentsFeeding apparatusNumerical controlLiquid state

The invention relates to the technical field of numerical control machine tools, and discloses a numerical control machine tool carriage mounting structure with good stability. The mounting structure comprises a carriage body and a screw rod sliding block, a mounting hole groove is formed in the carriage body, a threaded hole groove is formed in the screw rod sliding block, and the outer side of a tightening screw is movably connected in the threaded hole groove. A T-shaped containing groove is formed in the tightening screw, and a fixed contact is fixedly connected to the inner wall of the T-shaped containing groove. According to the numerical control machine tool carriage mounting structure with the good stability, when the tightening screw is loosened due to vibration, and a gap is formed between the carriage body and the lead screw sliding block, light leaks into the gap, an electromagnet is electrified and has magnetism, a magnet insertion shaft is pushed out along a moving long groove, accordingly, an elastic insertion shaft is pushed into the T-shaped containing groove, and an external electric field is switched on, so that the electrorheological fluid is changed into a solid state from a liquid state, and the tightening screw is stabilized in the threaded hole groove and is prevented from further loosening, so that the feeding precision is ensured, and product processing errors are prevented.

Owner:吴建和

Automatic pipe cutting machine

ActiveCN111055314BLow input costAvoid shakingMetal working apparatusReciprocating motionMaterial distribution

The invention discloses an automatic pipe cutting machine, which comprises a machine tool. The machine tool is provided with a feed pipe, a knife rest and a cylinder group for controlling the movement of the knife rest. The automatic clamping device on the top, the feeding device includes a frame, a storage rack, a material distribution device, a clamping mechanism and a pushing device; the automatic clamping device includes a hollow tube, a collet and a tensioner, The hollow tube is set in the feeding tube, and one end of the hollow tube close to the tool holder is connected with a collet for clamping the tube material, and the other end is installed with a tensioner that drives the hollow tube to reciprocate in the feeding tube. The end of the tube close to the tool holder is provided with a compression ring adapted to the collet. In the present invention, the pipe material is clamped by setting a feeding device and an automatic clamping device for clamping the pipe material on the machine tool, and then the pipe material is cut through the knife rest on the machine tool, so that the pipe material can be continuously cut, and at the same time The input cost of equipment is also reduced.

Owner:威远红卫橡胶有限公司

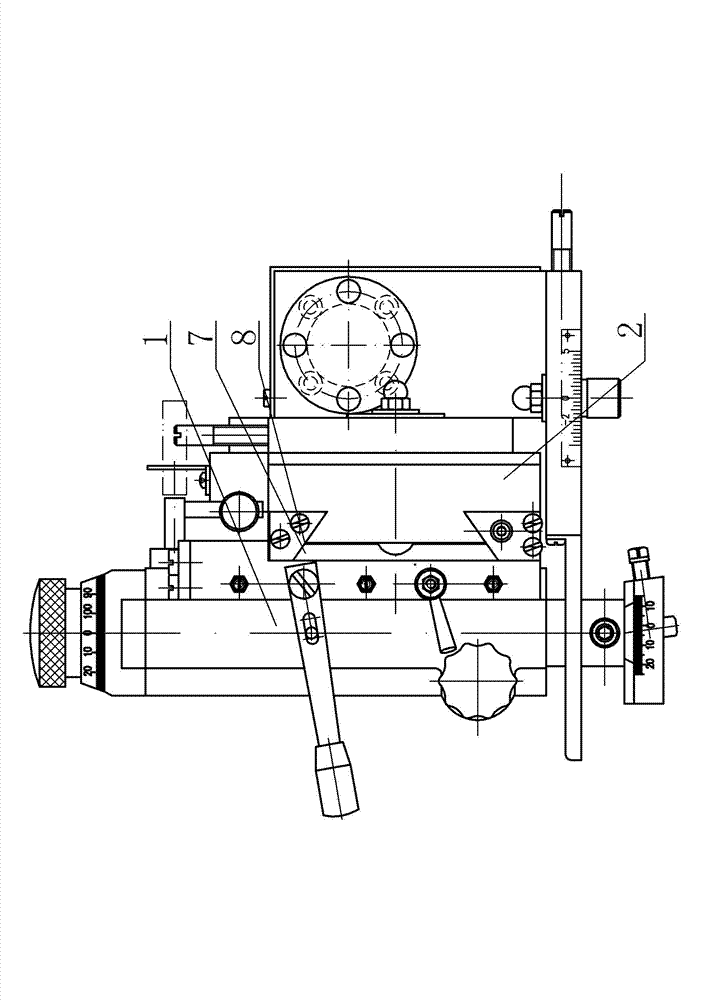

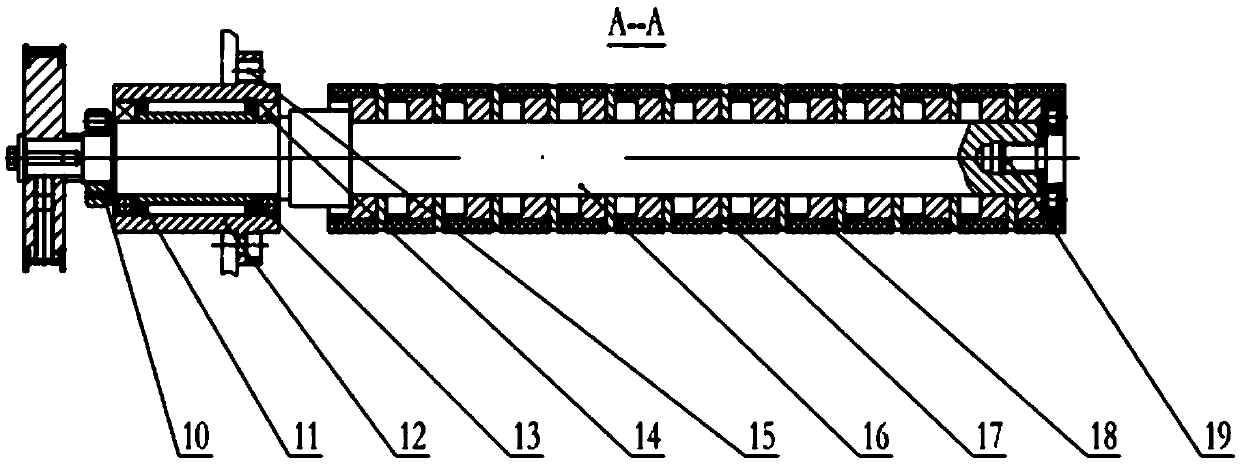

Guide wheel dresser feeding structure of air valve rod-part numerical control centerless grinding machine

InactiveCN102785134APrecise feedingGuaranteed feed accuracyRevolution surface grinding machinesAbrasive surface conditioning devicesCenterless grindingBall screw

The invention provides a guide wheel dresser feeding structure of an air valve rod-part numerical control centerless grinding machine, which can guarantee the straight feed accuracy of a guide wheel dresser, guarantee the feed precision of the guide wheel dresser, reduce the movement load of a ball screw and can ensure the long working service life of the ball screw. The guide wheel dresser feeding structure comprises a guide wheel dresser, a base, a servo motor, a ball screw and a screw nut, wherein the guide wheel dresser is supported on the base, the servo motor drives the ball screw, the ball screw is connected with the screw nut in a threading way, one end of the screw nut is tightly connected with the guide wheel dresser, and the guide wheel dresser feeding structure is characterized in that the upper end surface of the base is provided with a dovetail straight lead-rail groove, the bottom of the guide wheel dresser is provided with a dovetail lead rail, the dovetail lead rail is embedded inside the dovetail straight lead rail groove, the servo motor is connected with the input end of a reducer, and the output end of the reducer is connected with the input end of the ball screw.

Owner:WUXI JIANHE NUMERICAL CONTROL MACHINE TOOL

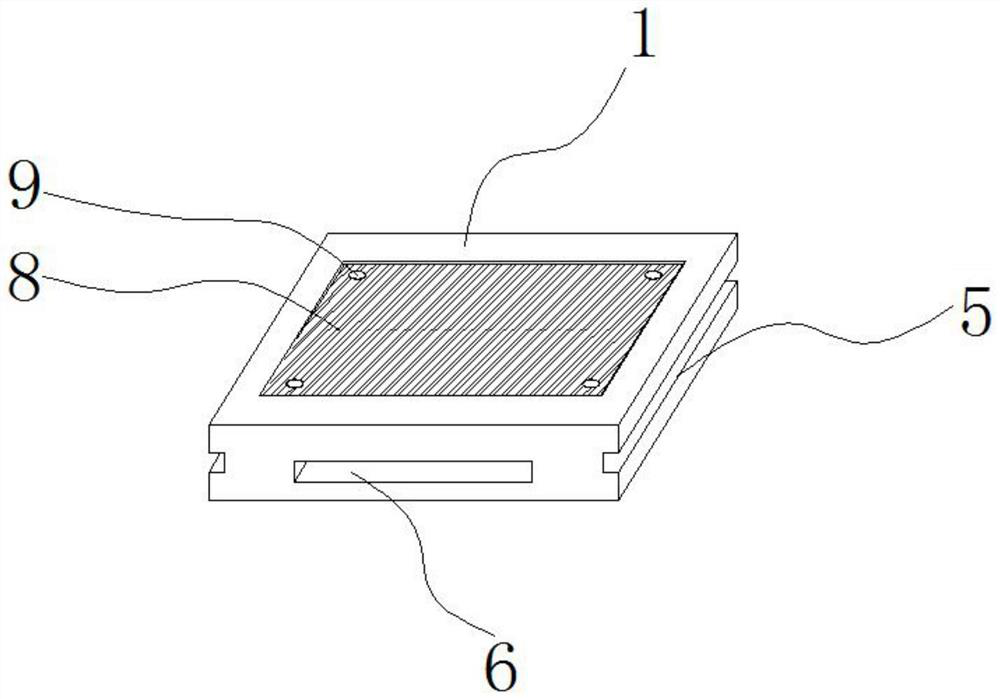

PCB and blade coating process thereof

ActiveCN113194672AGuaranteed scraping effectAvoid difficult cuttingPrinted circuit assemblingPrinted circuit detailsAir pumpStructural engineering

The invention discloses a PCB and a blade coating process thereof, and relates to the technical field of PCB blade coating, in particular to a protective shell and a circuit board, an upper groove position is formed in the upper surface of the protective shell, a lower groove position is formed in the lower surface of the protective shell, limiting columns are fixed to the four corners of the bottom surface of the upper groove position, clamping grooves are formed in the left side and the right side of the protective shell, a transfer groove is formed in the outer wall of the front end of the protective shell, a through opening is formed in the middle of the bottom face of the upper groove position, the circuit board is arranged in the upper groove position, hole positions are formed in the four corners of the upper surface of the circuit board, and fixing blocks are arranged on the left side and the right side of the conveying belt. According to the PCB and the blade coating process thereof, the air pump arranged in the bearing plate can jack up the circuit board in the protective shell and tightly attach the circuit board to the lower surface of the printing steel mesh for blade coating treatment, so that the blade coating effect is guaranteed, the air pump can enable the circuit board attached to the lower surface of the printing steel mesh to be separated through suction, and the problem that the printed material adheres to the printing steel mesh and is difficult to discharge is avoided.

Owner:益阳维胜科技有限公司

Fully-automatic metal band sawing machine

InactiveCN102151900AGuaranteed verticalityFasten the connectionMetal sawing devicesAutomatic control devicesNumerical controlEngineering

The invention discloses a fully-automatic metal band sawing machine which belongs to a metal band sawing machine. The fully-automatic metal band sawing machine structurally comprises a band sawing machine, a numerical control device, a feeding platform and a feeding trolley, wherein the band sawing machine is provided with the numerical control device, the feeding platform is arranged at one side of the band sawing machine, the feeding trolley is arranged on the feeding platform, and a single-chip microcomputer control module used for controlling the process flow of the fully-automatic band sawing machine is arranged in the numerical control device. Compared with the prior art, the fully-automatic metal band sawing machine can output continuous control quantity to a servo driving system, can ensure the precision, has simple structure and low cost, saves energy, has high efficiency, is flexible to operate, and has high reliability and stable performance.

Owner:山东宁联机械制造有限公司

S-shaped feeding device for inlay winding and conveying

Owner:HUBEI HUAWEIKE INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com