Patents

Literature

209results about How to "Prevent fallback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

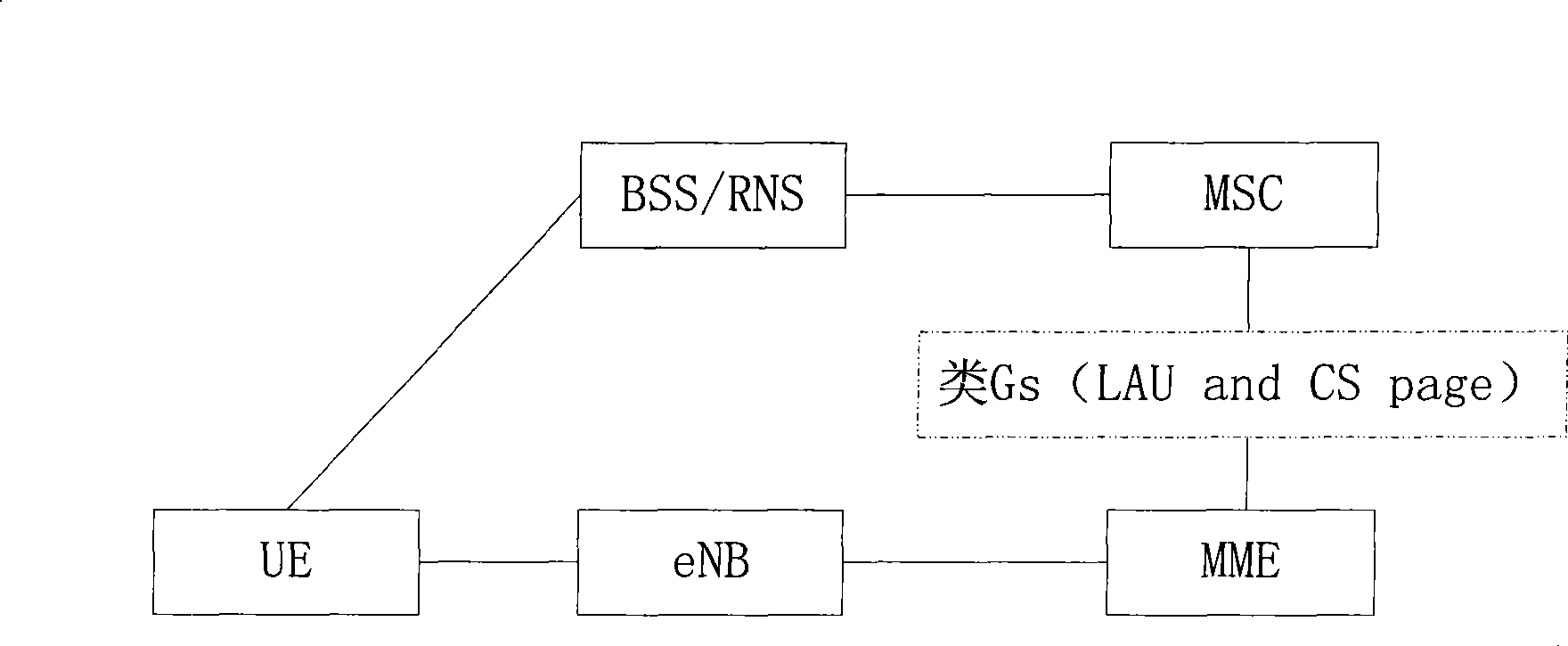

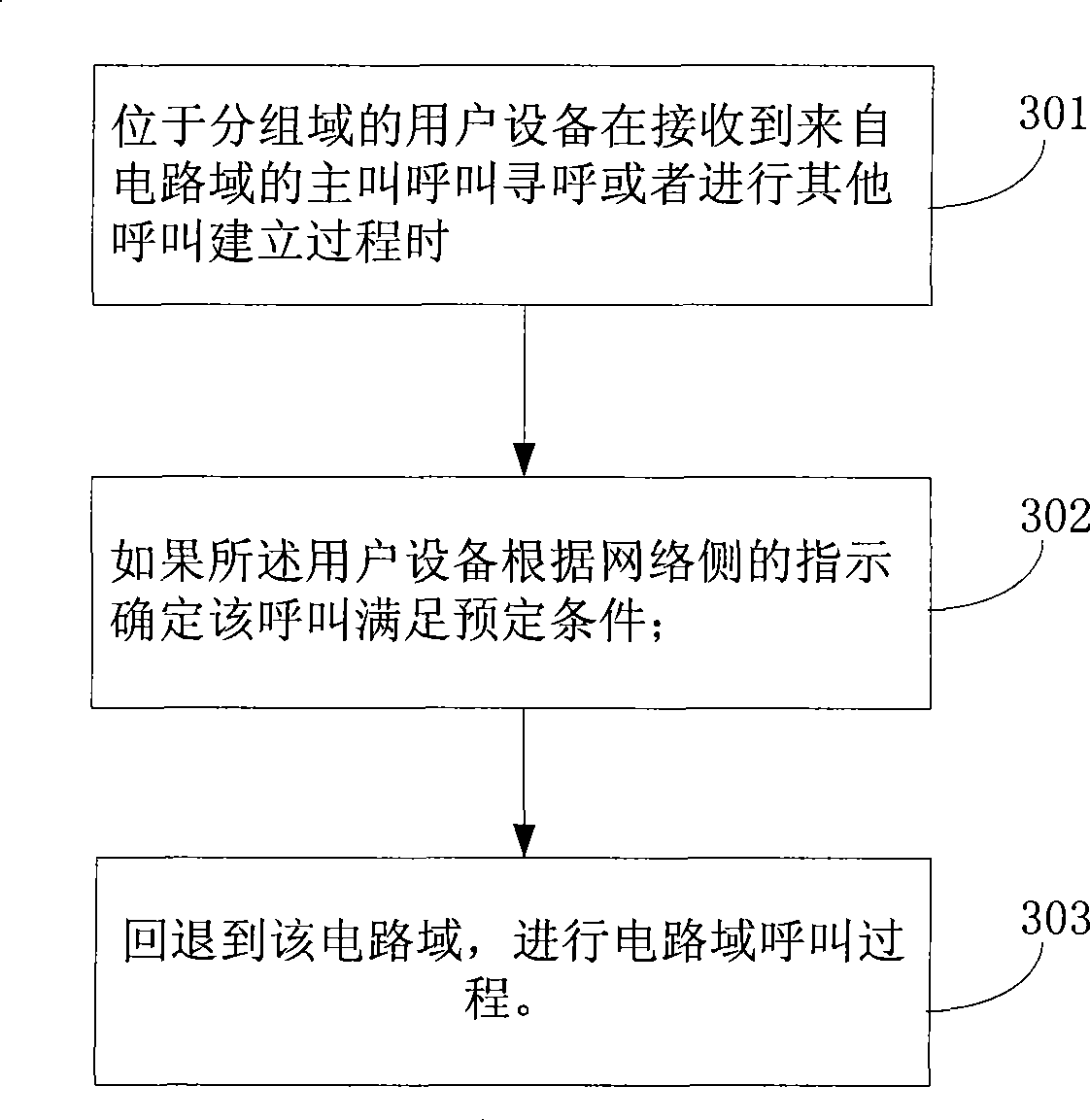

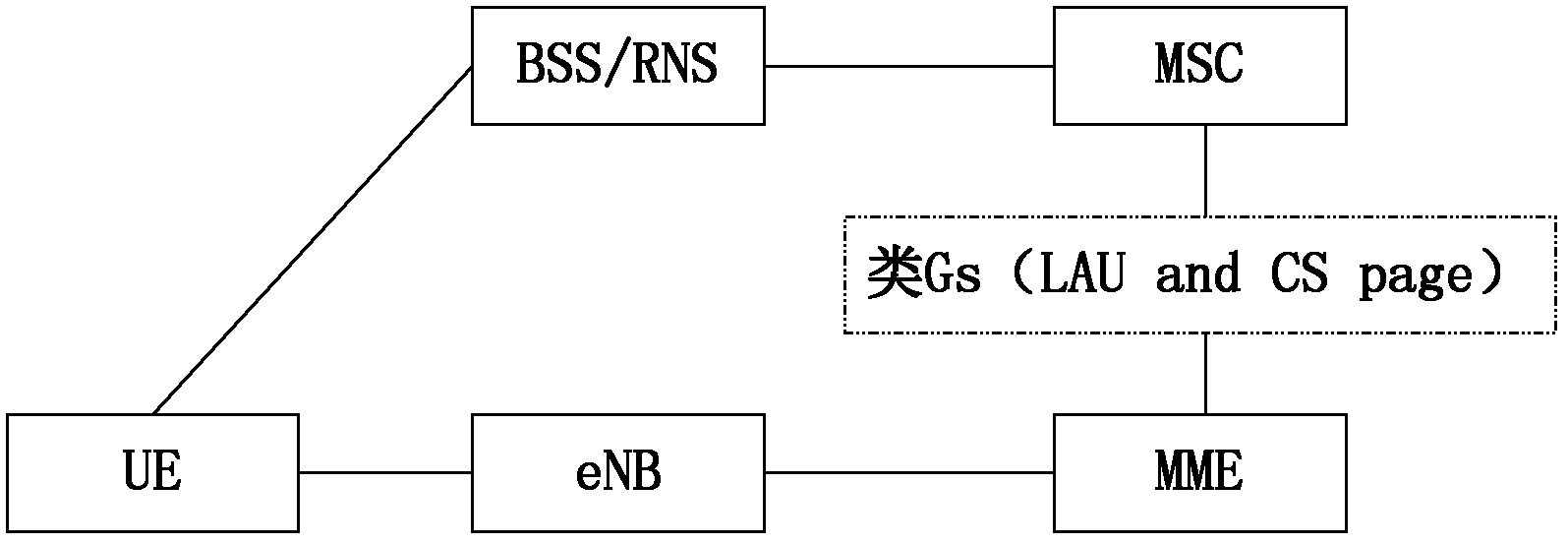

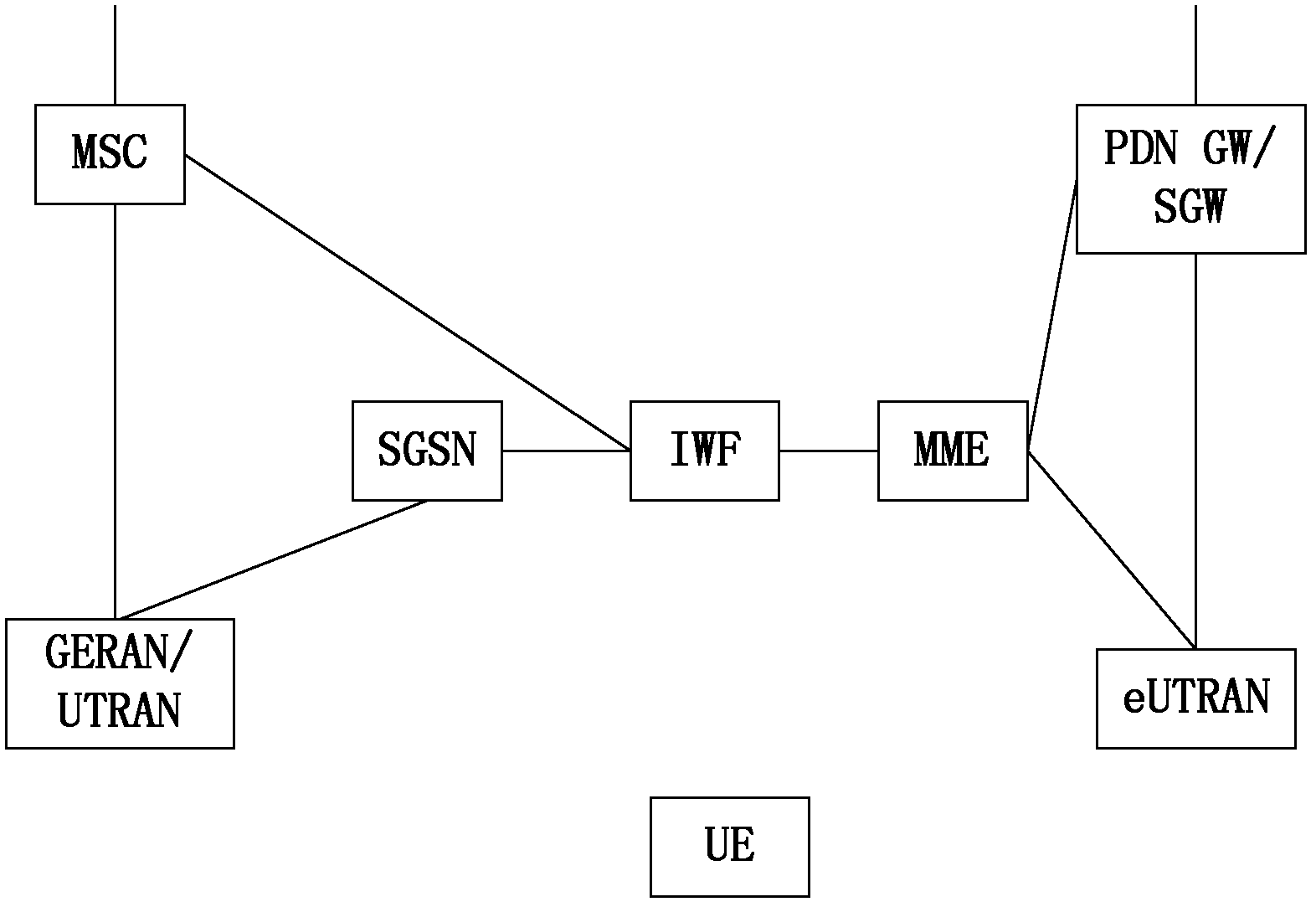

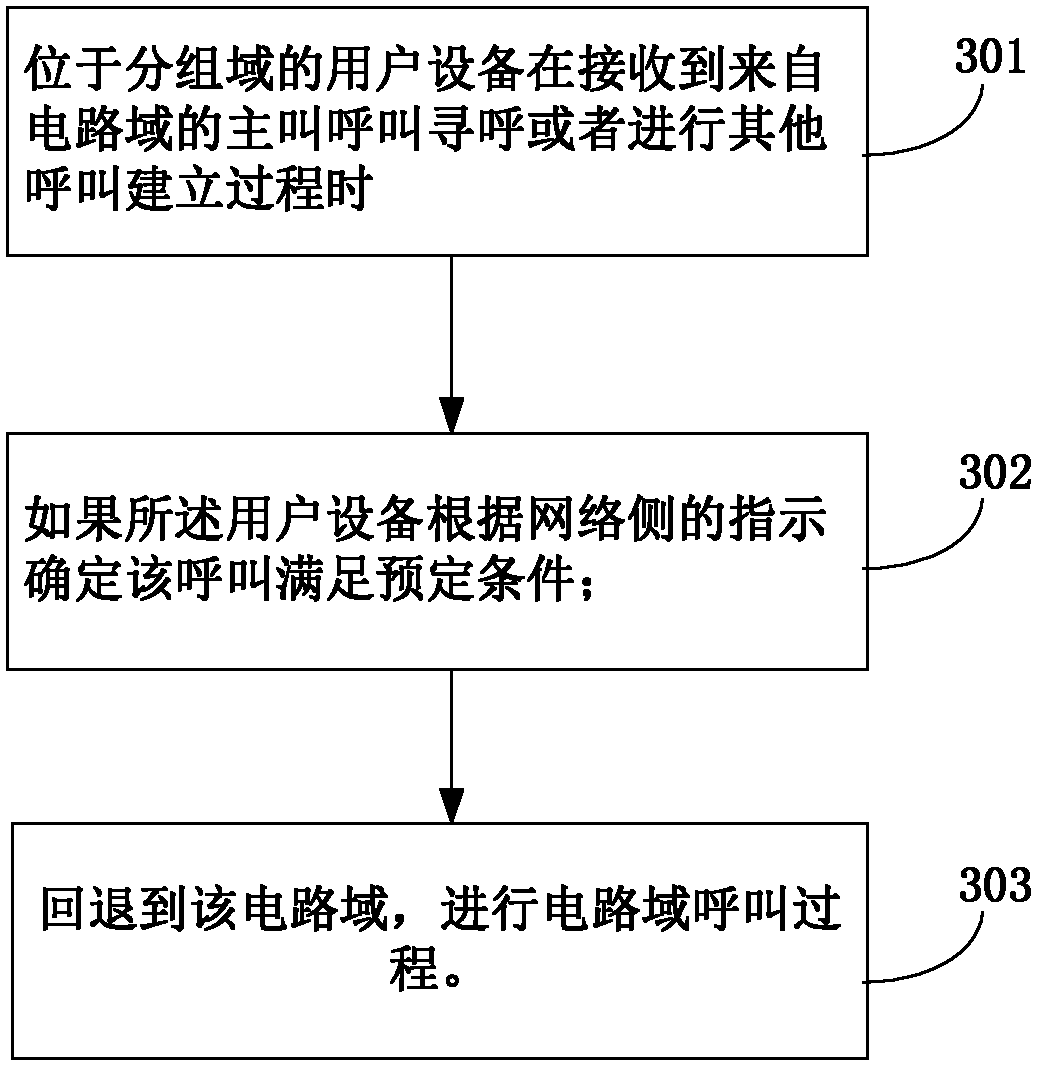

Method, apparatus and system for processing circuit domain service by packet domain user

ActiveCN101500212APrevent fallbackIncrease autonomyNetwork traffic/resource managementAssess restrictionTelecommunicationsMobile communication systems

The invention discloses a method, a device and a system for the user of PS domain to deal with the CS domain business and automatically choose whether to carry out the CS Fallback. When user equipment in the PS domain is adopted to deal with the call of the calling party from the CS domain and if the user equipment determines that the call meets the preset condition according to the instruction of the network side, the call is returned to the CS domain and the call of CS domain is carried out. The invention also discloses the user equipment and a mobile communication system. The invention leads the user equipment to carry out the CS Fallback automatically, which reflects the user desire that whether the user is willing to accept the calling; and as for the harassing calls which may come from the CS domain, the UE can avoid the unnecessary fallback.

Owner:HUAWEI TECH CO LTD

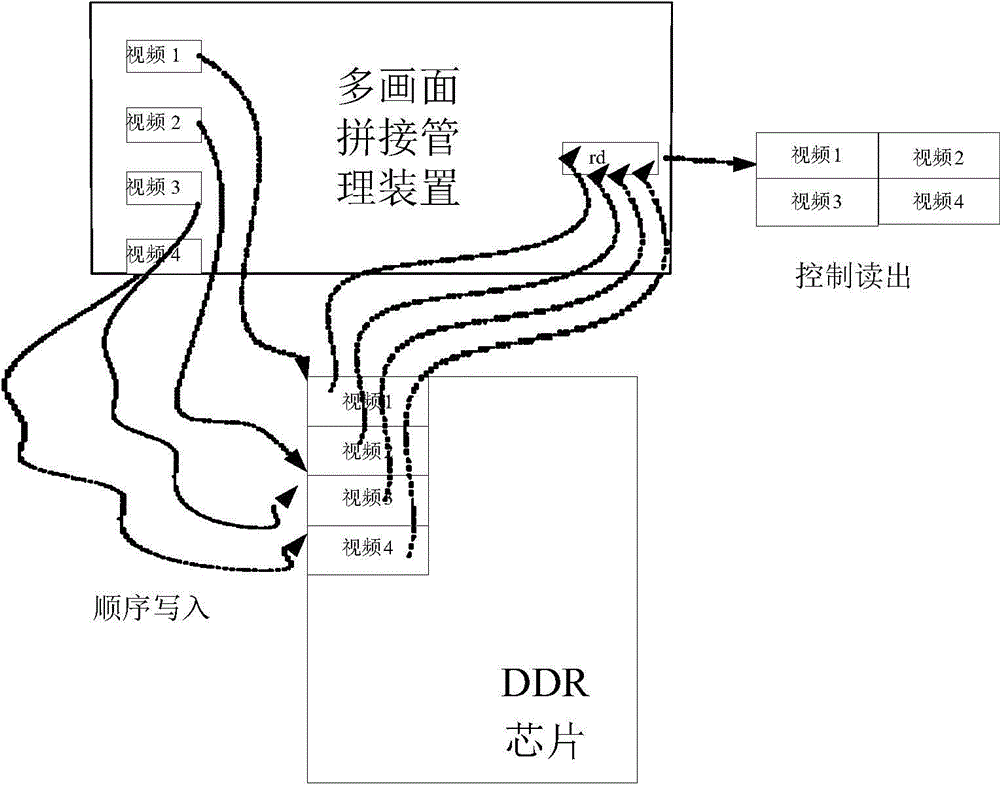

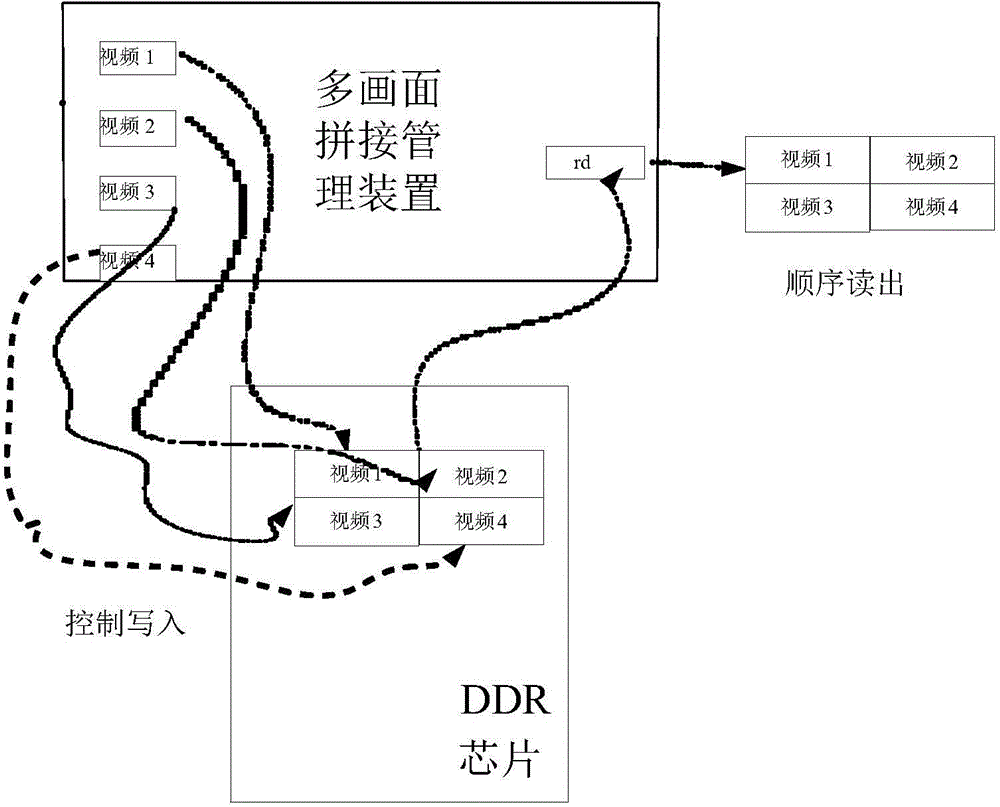

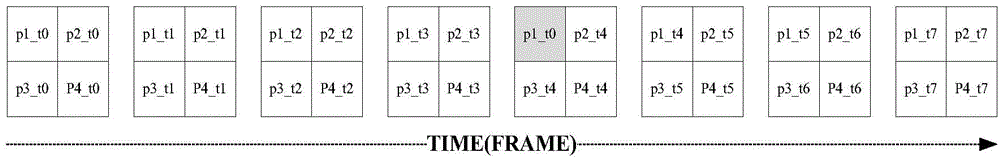

Image stitching method and device for preventing video rollback

ActiveCN104363508APrevent fallbackImprove experienceSelective content distributionMulti-imageComputer graphics (images)

The invention discloses an image stitching method and device for preventing video rollback. The method comprises the steps that A, video frames input by all sub video sources are synchronized to a standard frame rate; B, the synchronized video frames of all the sub video sources are made to generate video images through writing and stitching operation, and the video images are stored; C, the stored video images are output to a stitching display screen and displayed. According to the image stitching method and device for preventing video rollback, the problem that video rollback of multi-image image stitching is caused according to an existing writing and stitching mode is solved, and the visual experience of users is better.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

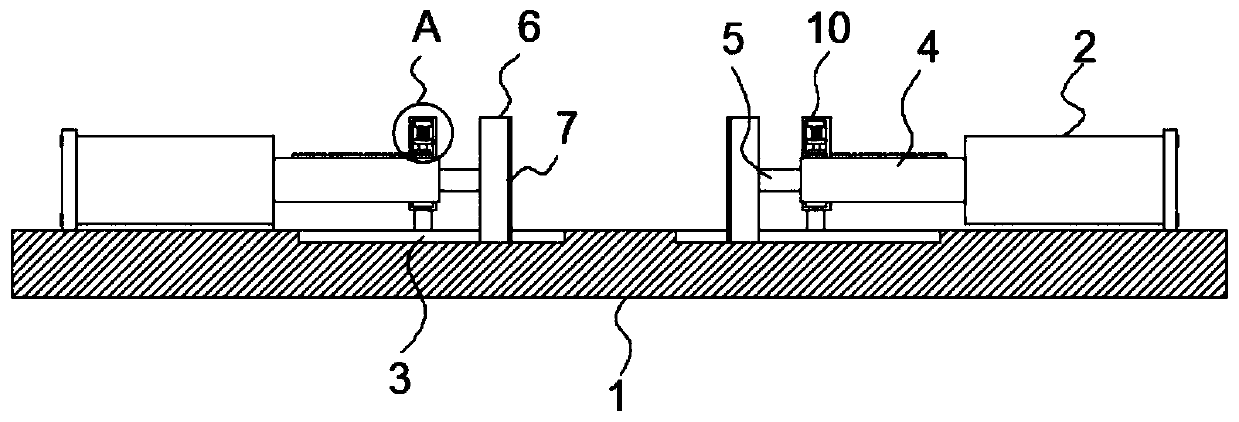

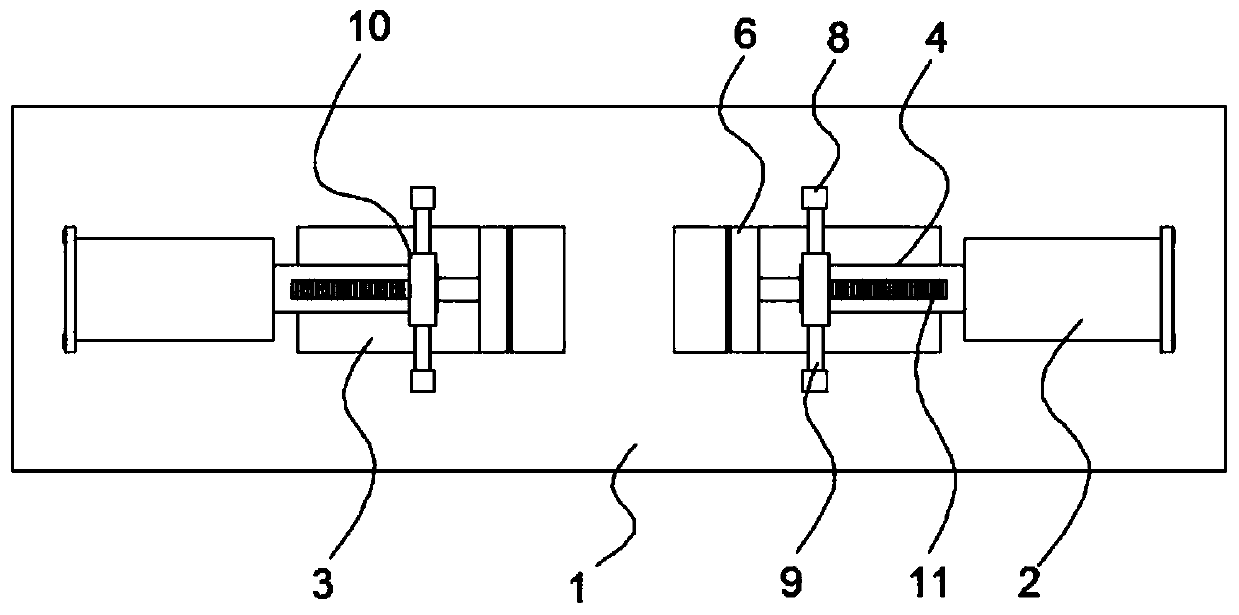

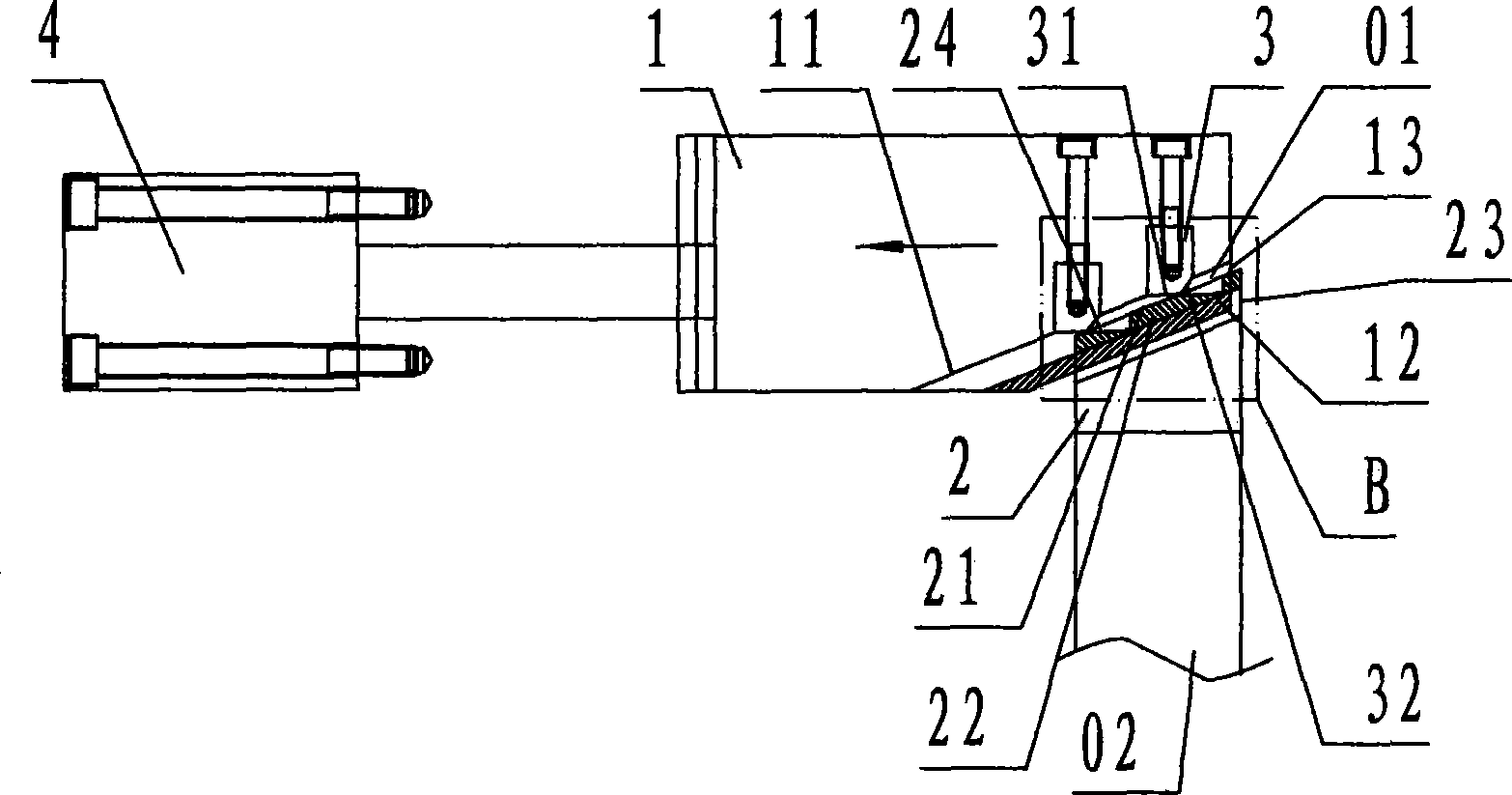

Machining fixture locking device

The invention discloses a machining fixture locking device. The machining fixture locking device comprises a base plate; two extension cylinders are symmetrically and fixedly mounted on the base plate; piston rods are arranged on the two extension cylinders, and are fixedly connected with tooth plates; buffer cavities are formed in the piston rods; piston blocks are slidingly connected into the buffer cavities; moving rods are fixedly connected to one sides of the piston blocks; the ends, far from the piston blocks, of the moving rods are fixedly connected with clamping plates; the other sidesof the piston blocks are fixedly connected with second springs; and the ends, far from the piston blocks, of the second springs are fixedly connected to the side walls of the buffer cavities. Tooth blocks adaptively slide up, and meanwhile, drive first springs to compress; and under the elastic effect of the first springs, the tooth blocks are engaged with the tooth plates again, and meanwhile, end surfaces B abut against the tooth plates to prevent retreating of the tooth plates, so that the locking effect on the piston rods is achieved, and the influence on the clamping effect of the pistonrods by instable air pressure of the extension cylinders is prevented.

Owner:浙江零捷网络科技有限公司

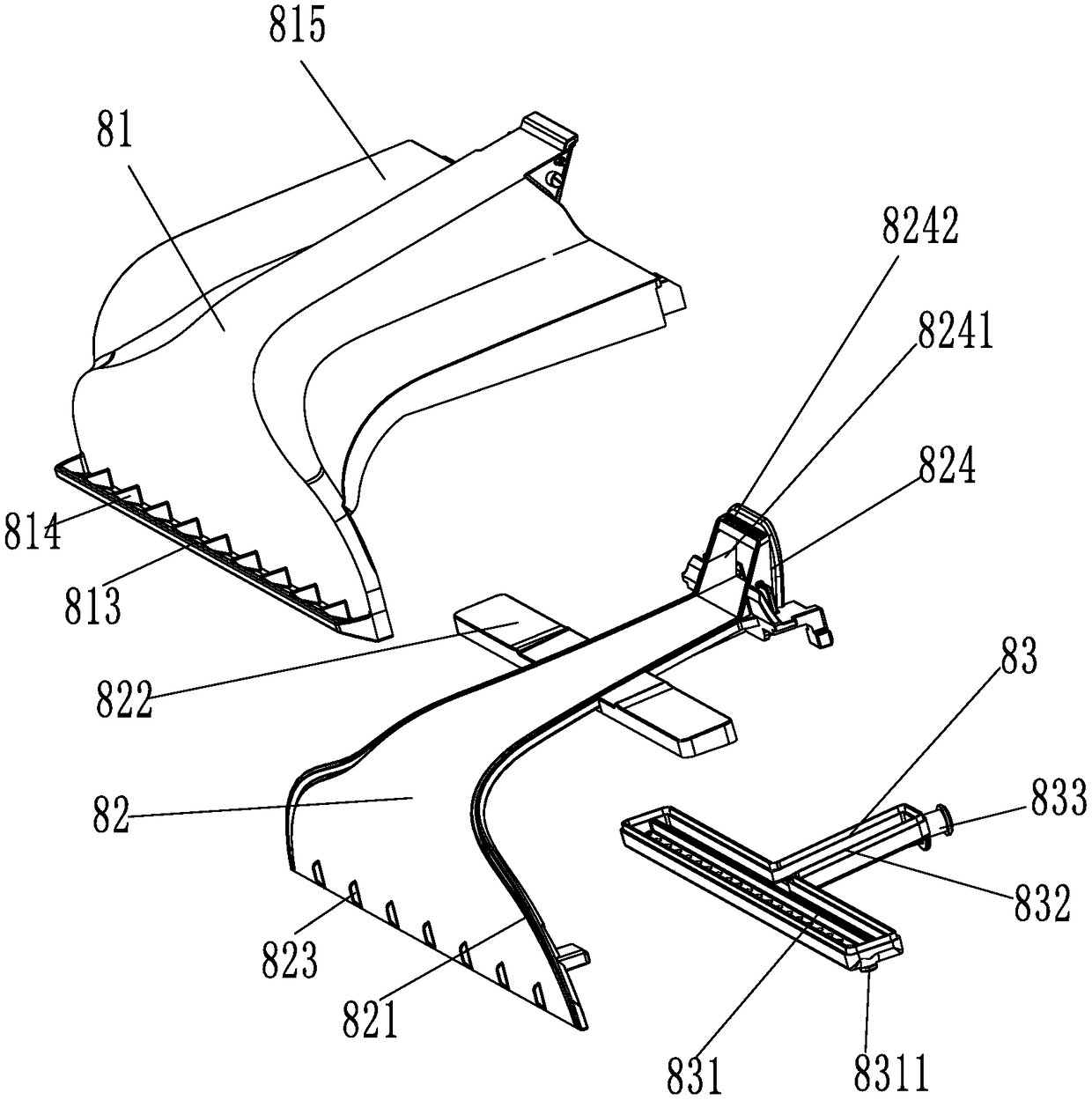

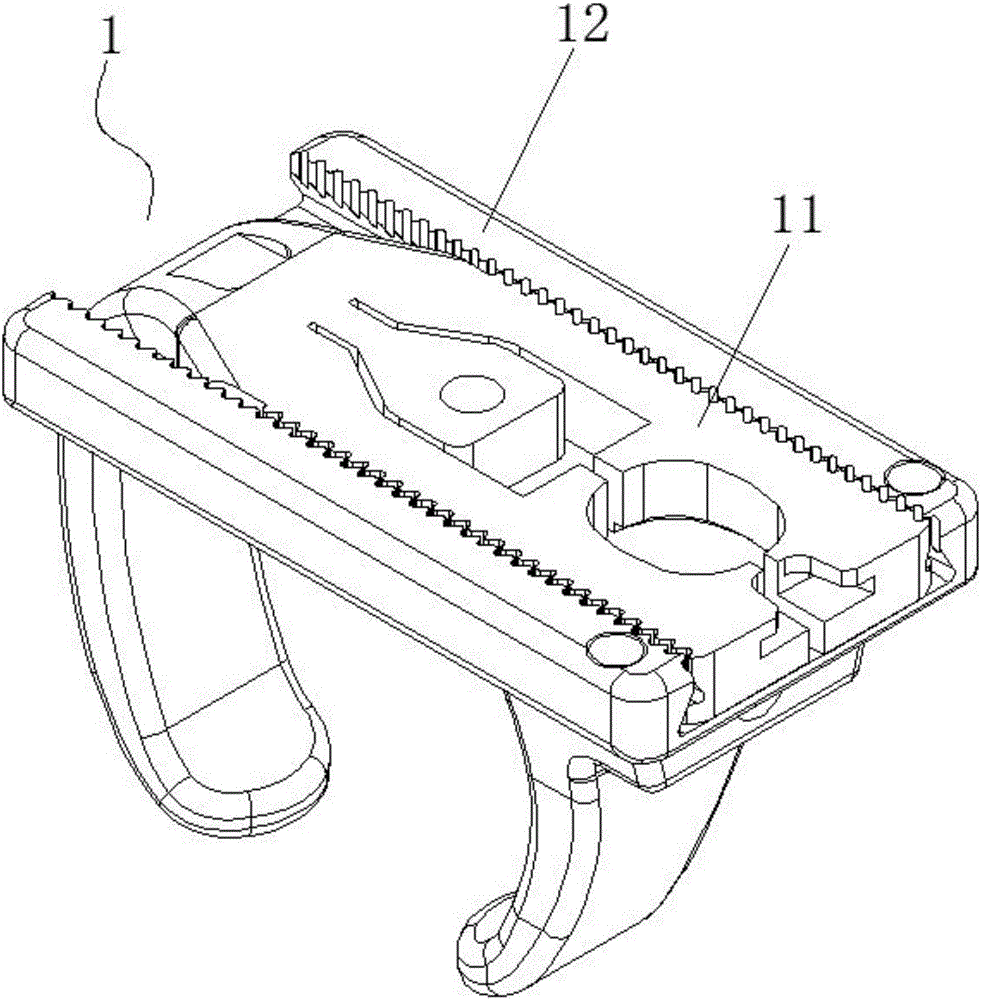

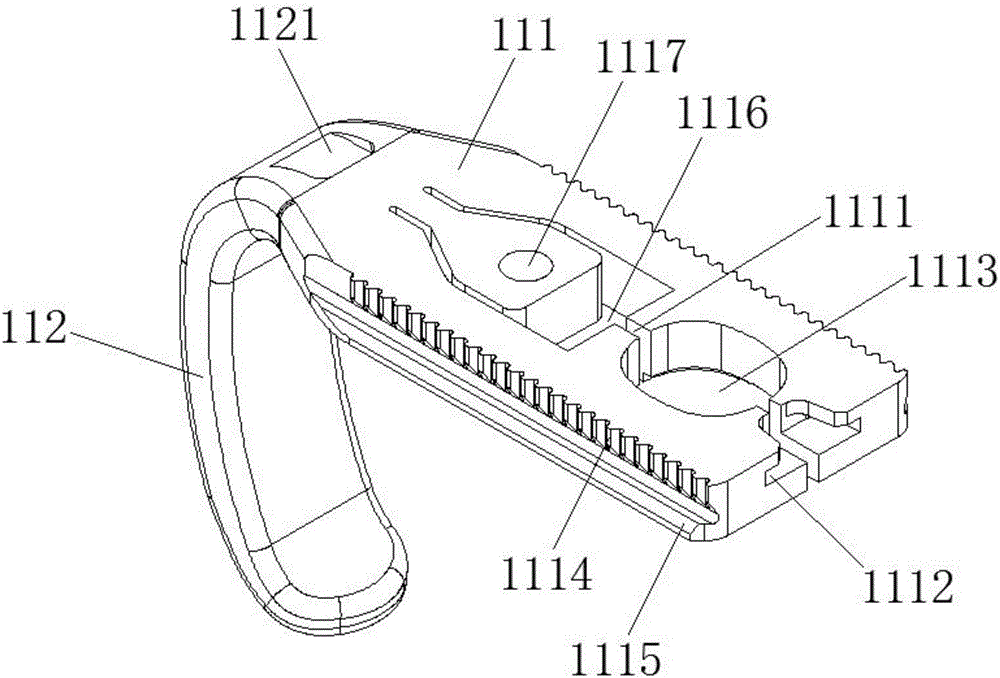

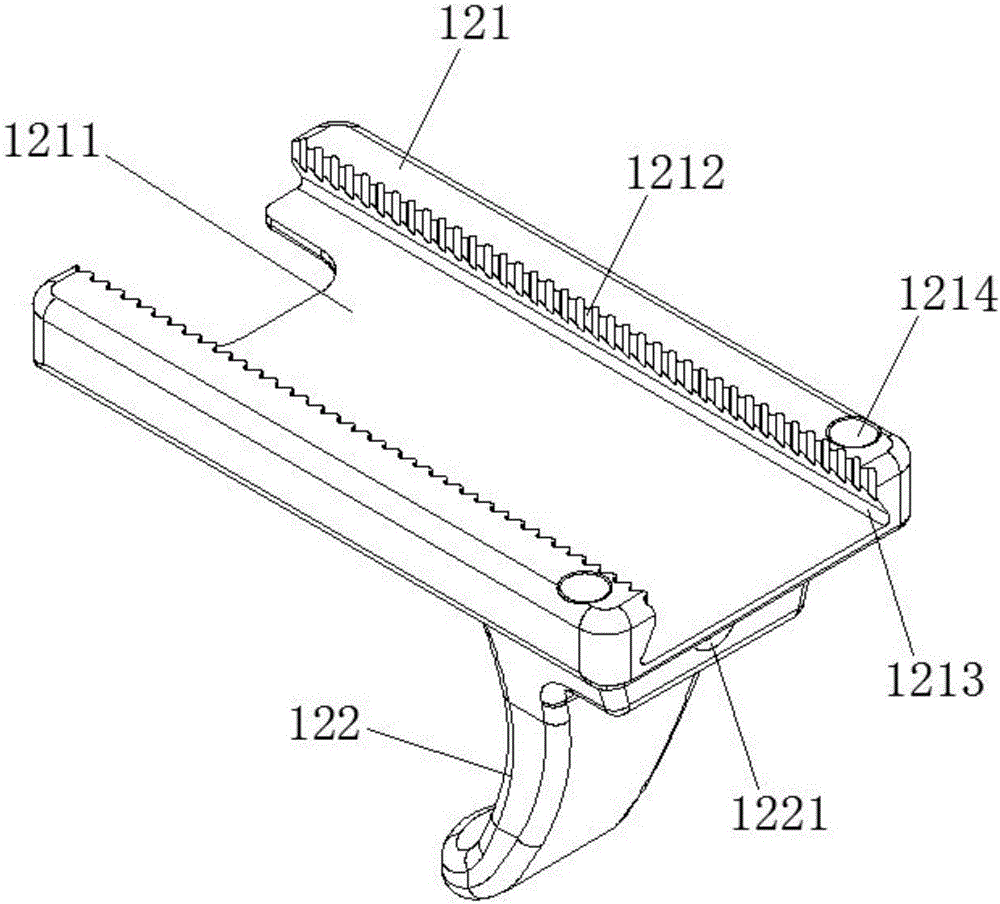

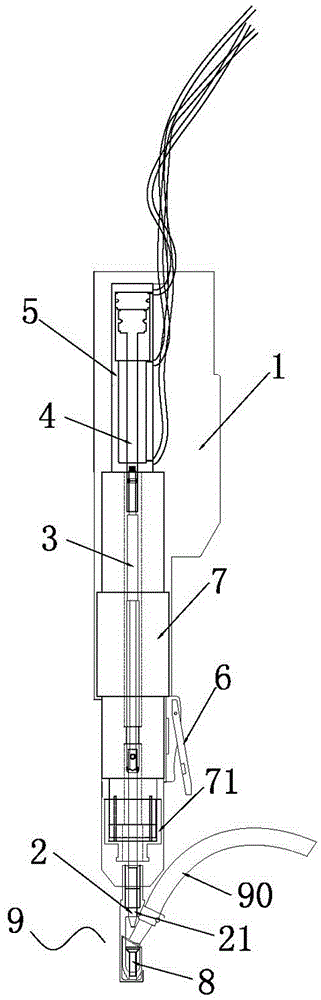

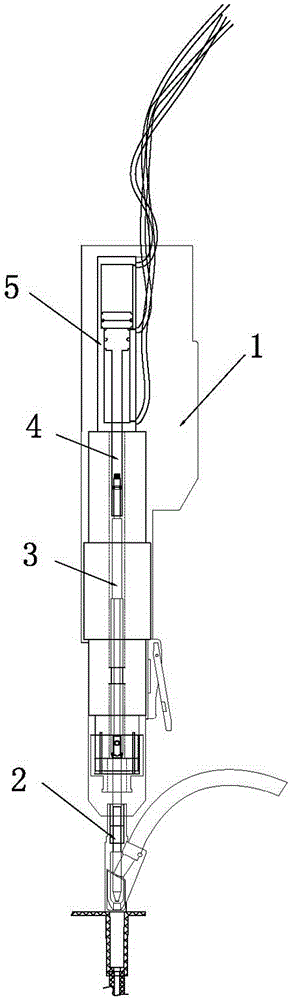

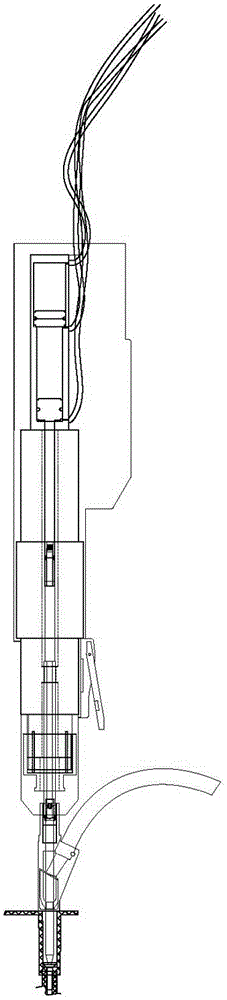

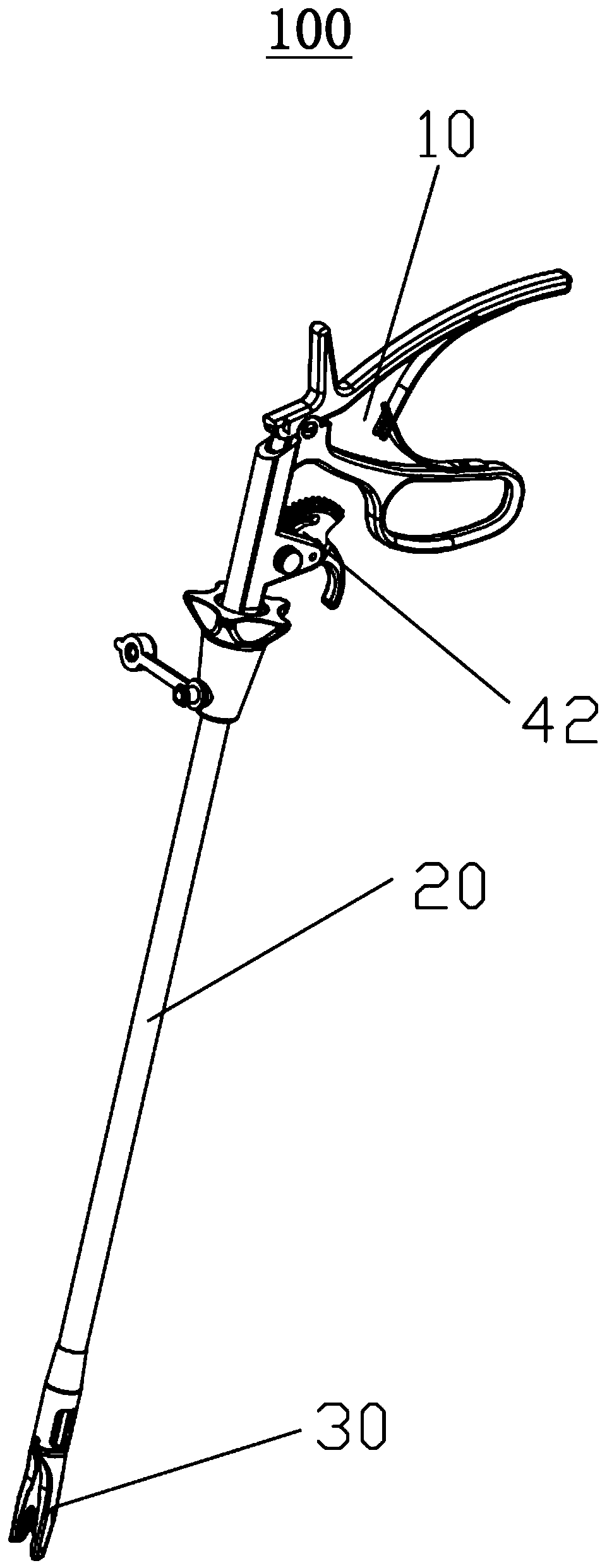

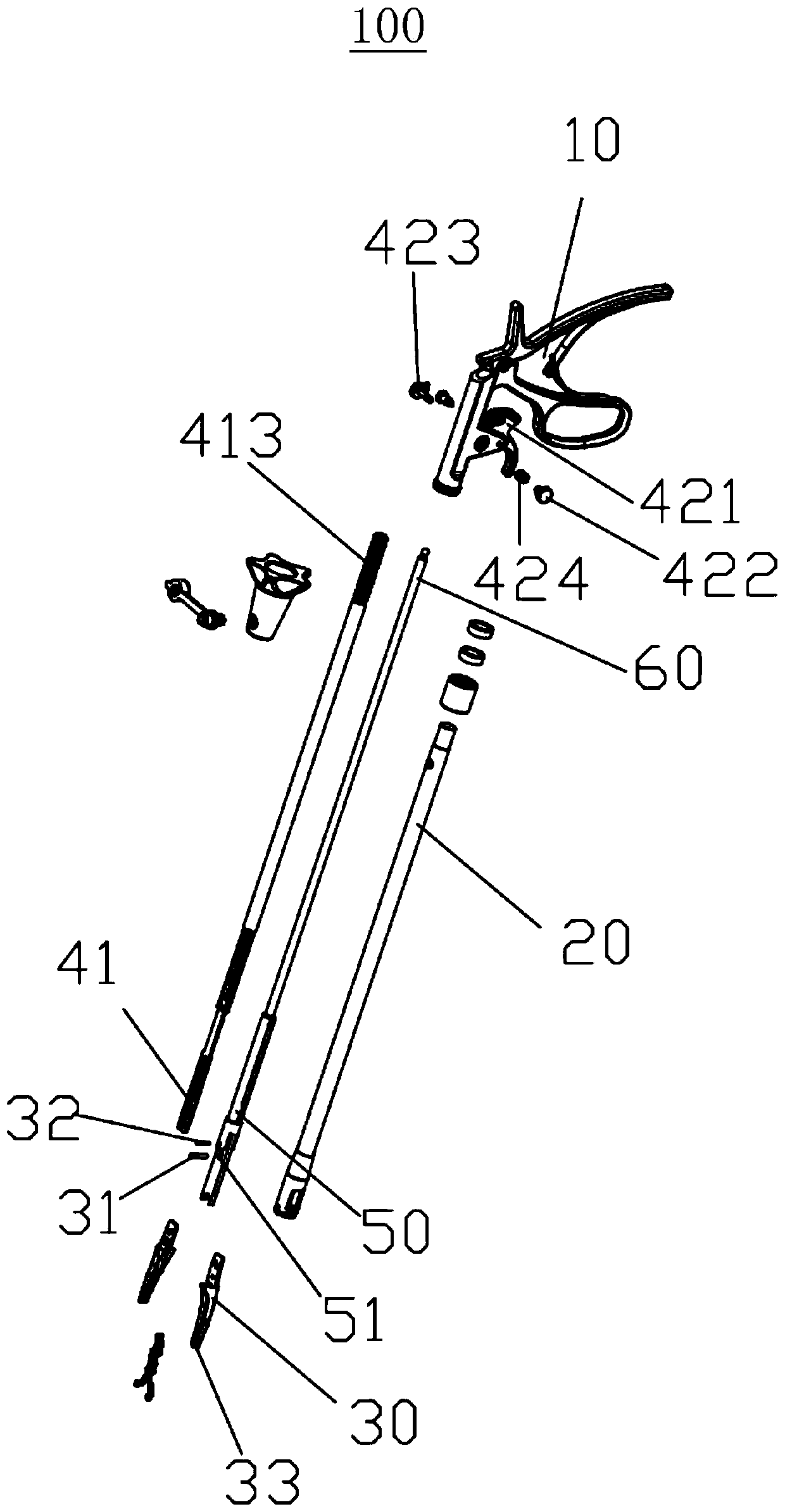

End effector, surgical operating instrument and purse-string forceps

ActiveCN104434243AAvoid exposurePrevent fallingSuture equipmentsSurgical staplesMedical equipmentPurse string suture

The invention relates to the technical field of medical equipment, and discloses an end effector and a surgical operating instrument comprising the end effector in order to simplify the operation process of a lumen tissue operation and shorten the operation time. The end effector comprises a first forceps arm, a second forceps arm, a suture mechanism, a purse-string suture mechanism and a cutting mechanism, wherein the first forceps arm and the second forceps arm can move relatively under the effect of an opening and closing mechanism so as to enable a forceps opening formed by the first forceps arm and the second forceps arm to be opened or closed, the suture mechanism is arranged on one side of the longitudinal direction of the two forceps arms, the purse-string suture mechanism is arranged on the other side of the longitudinal direction of the two forceps arms, and the cutting mechanism is arranged between the suture mechanism and the purse-string suture mechanism. The invention further provides purse-string forceps. The purse-string forceps can prevent needles from falling and improve the safety of the operation.

Owner:REACH SURGICAL

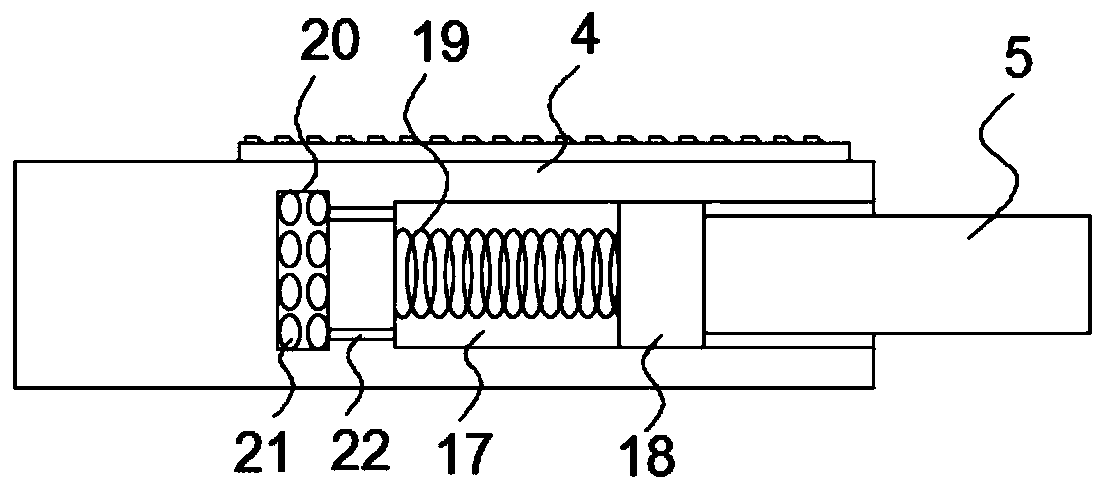

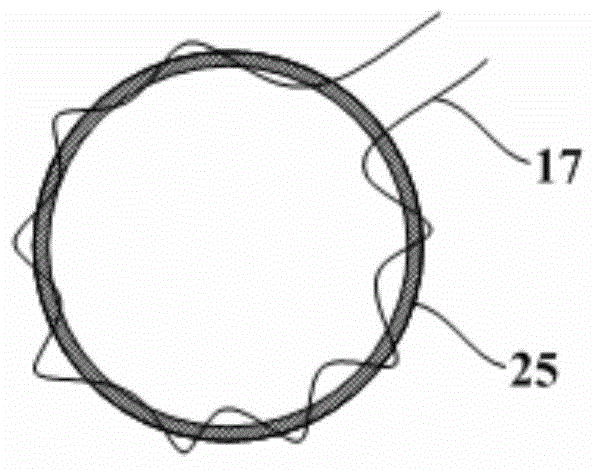

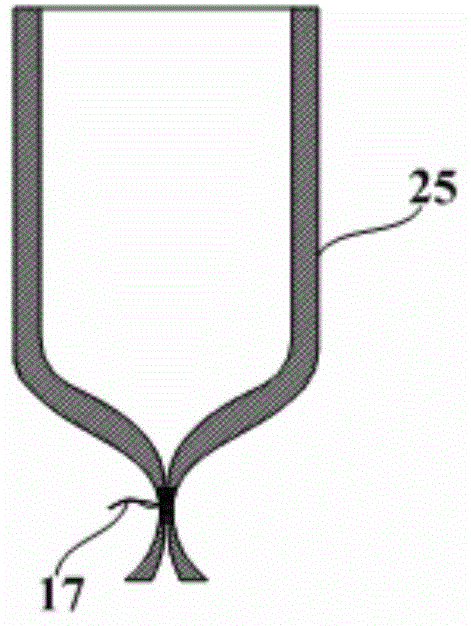

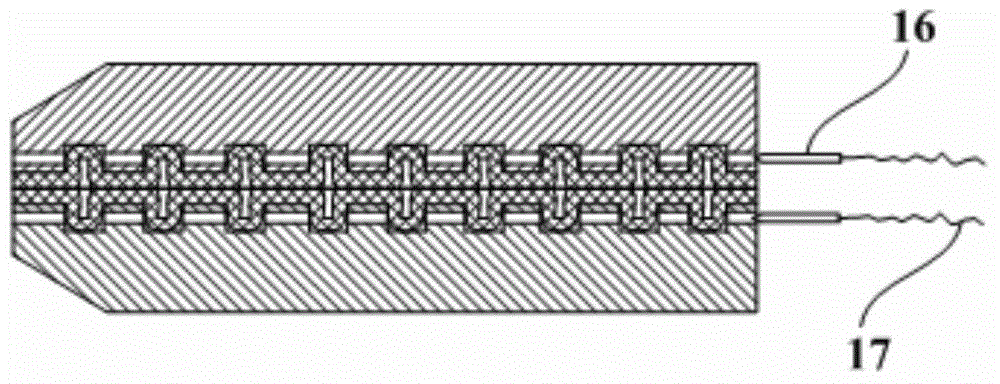

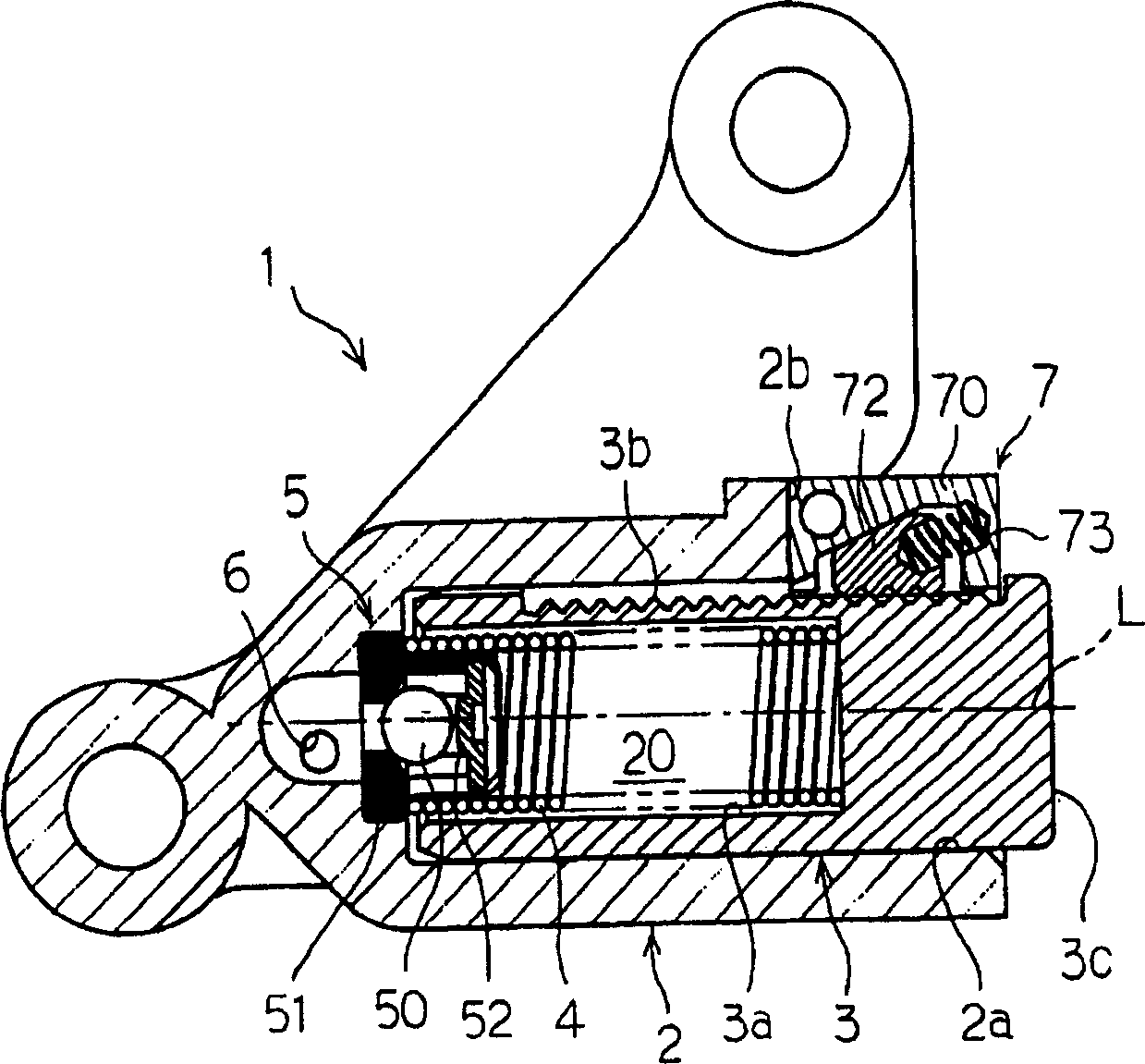

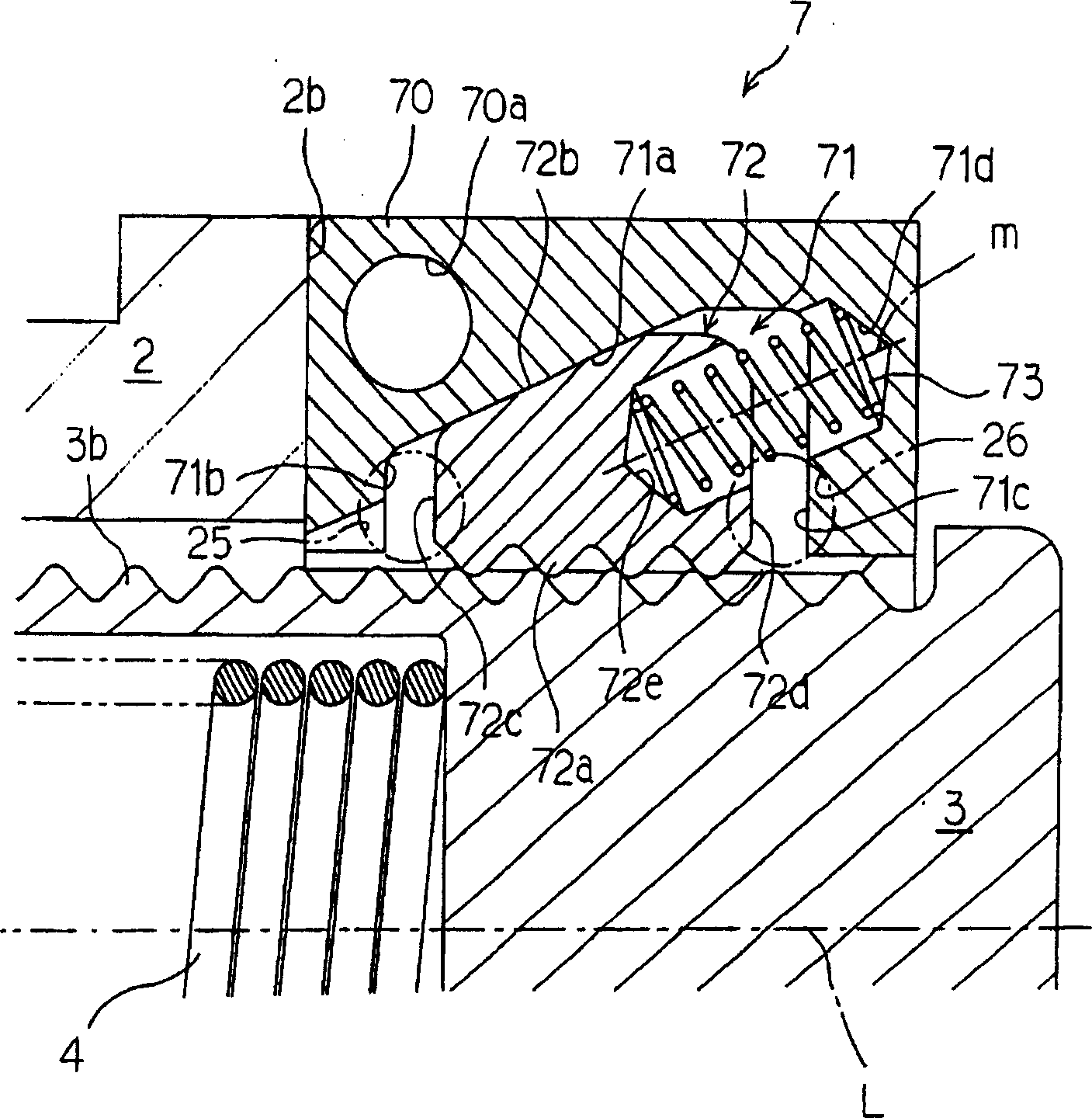

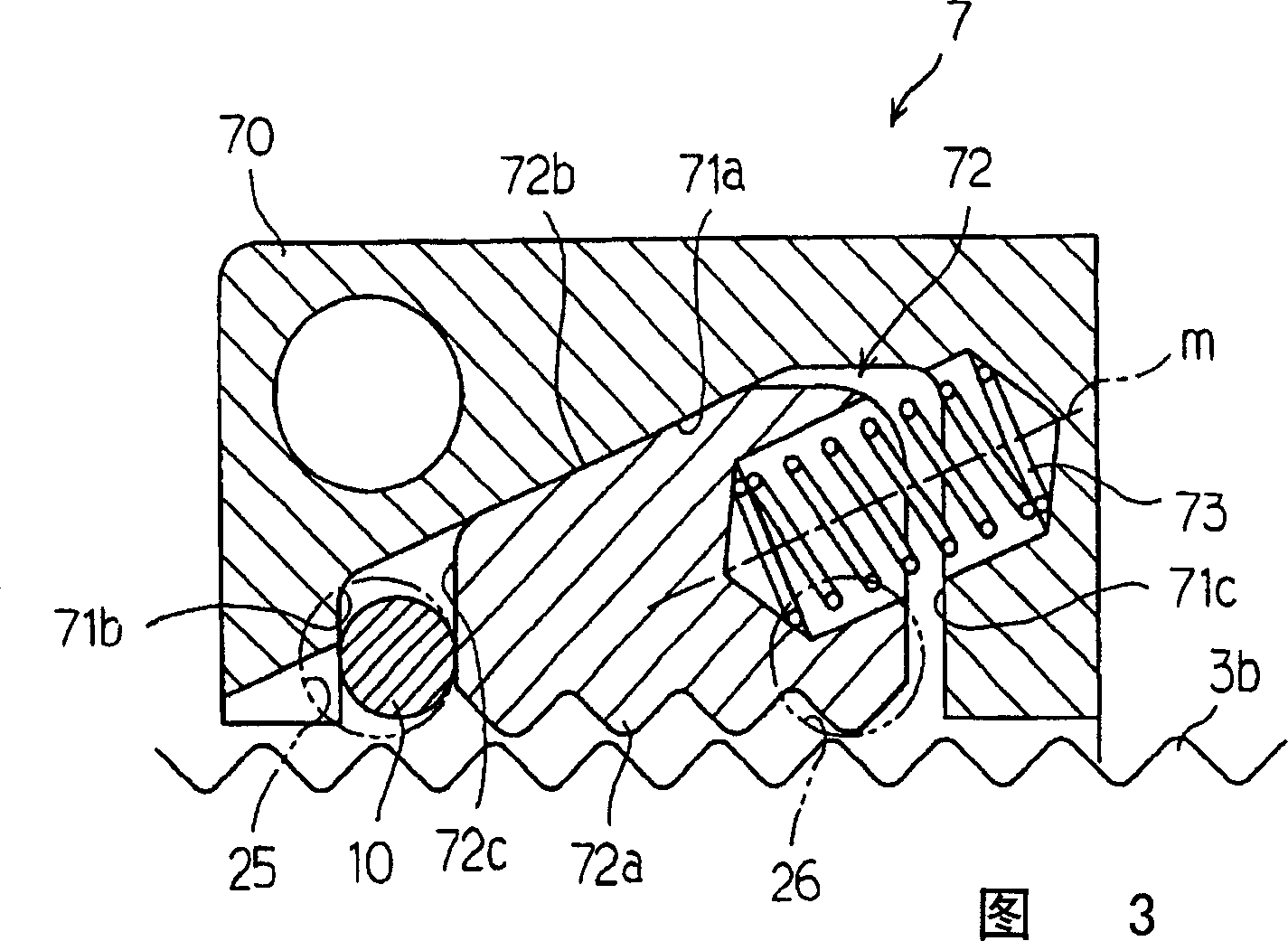

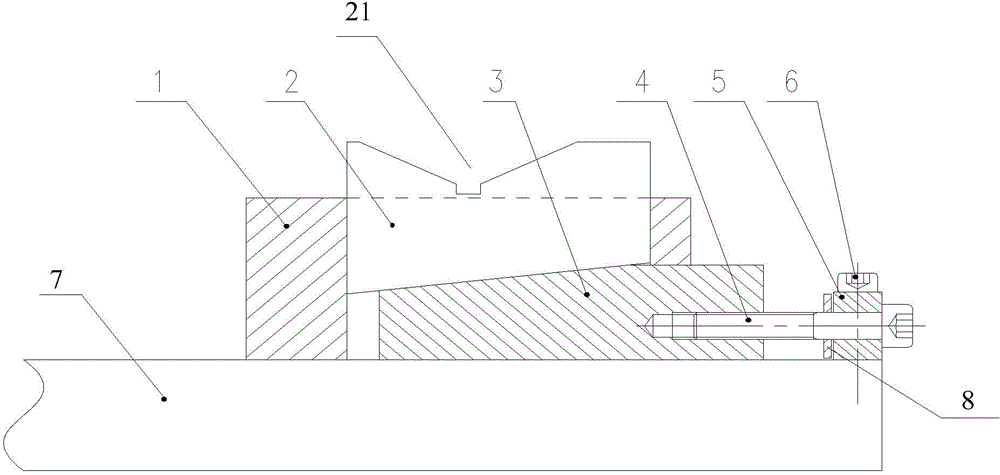

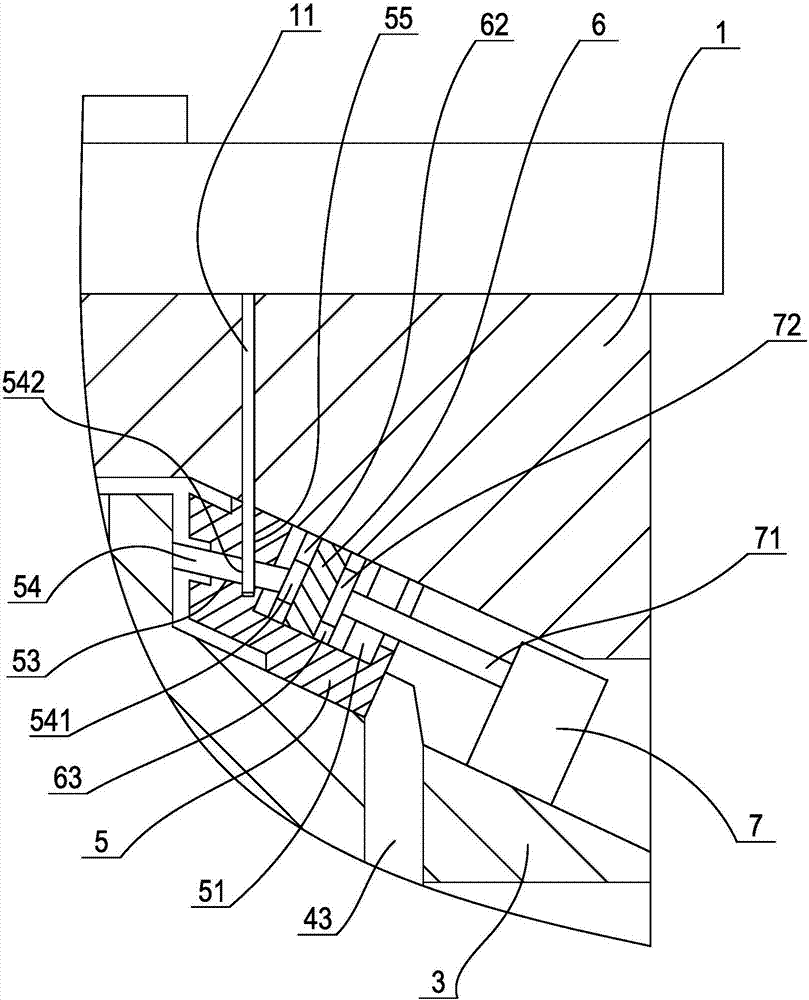

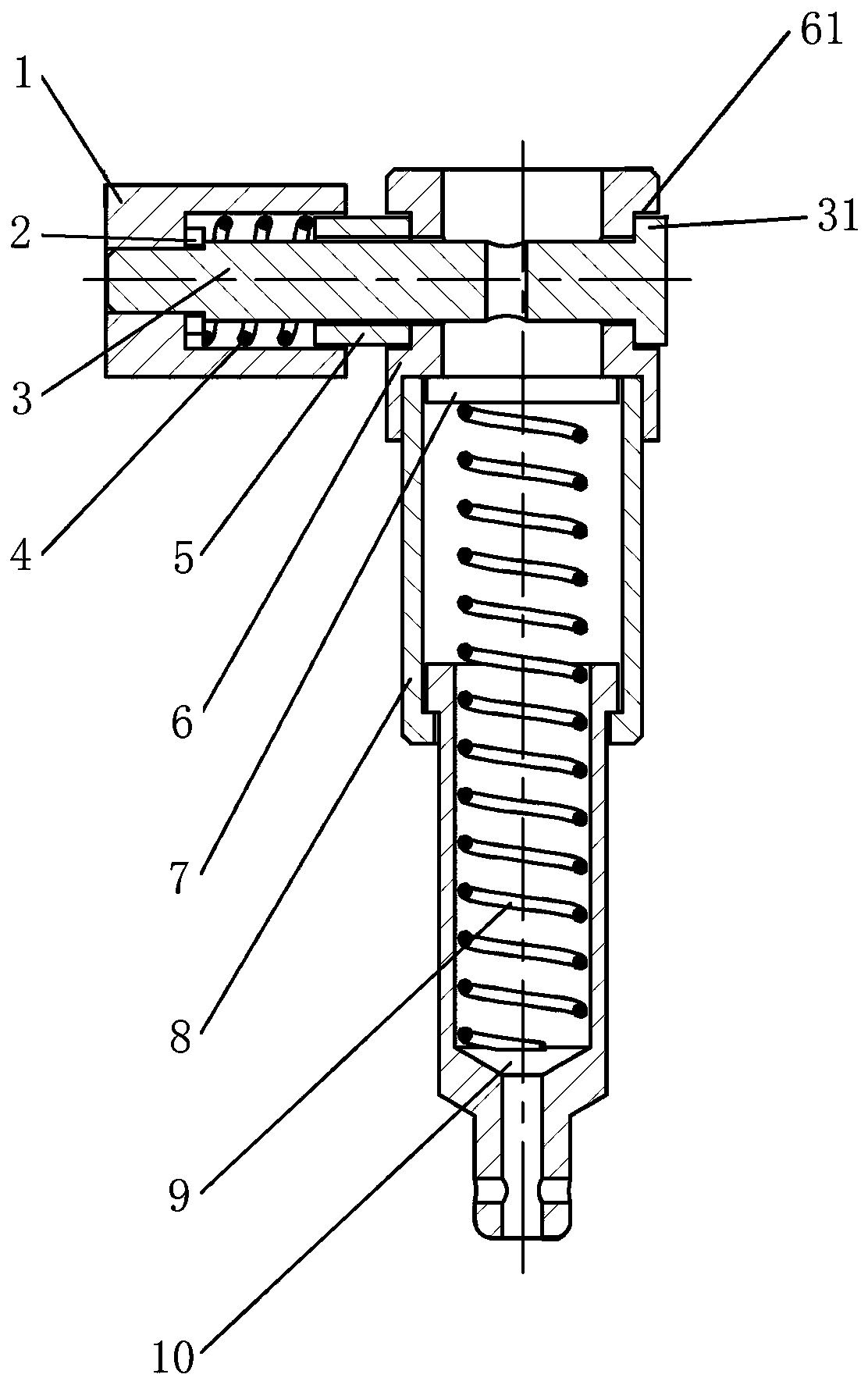

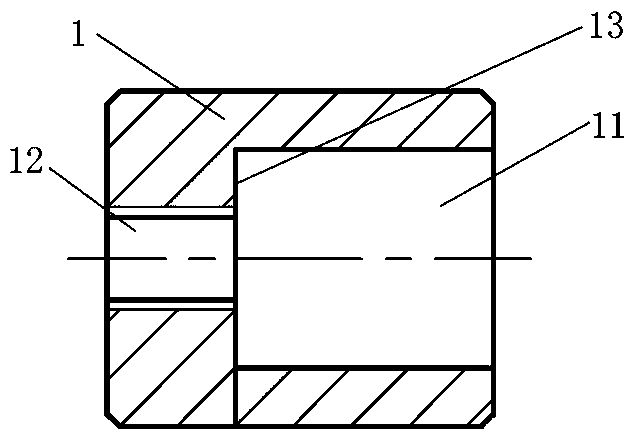

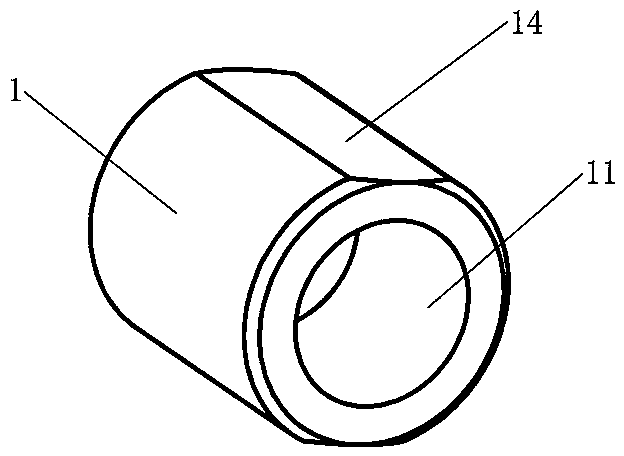

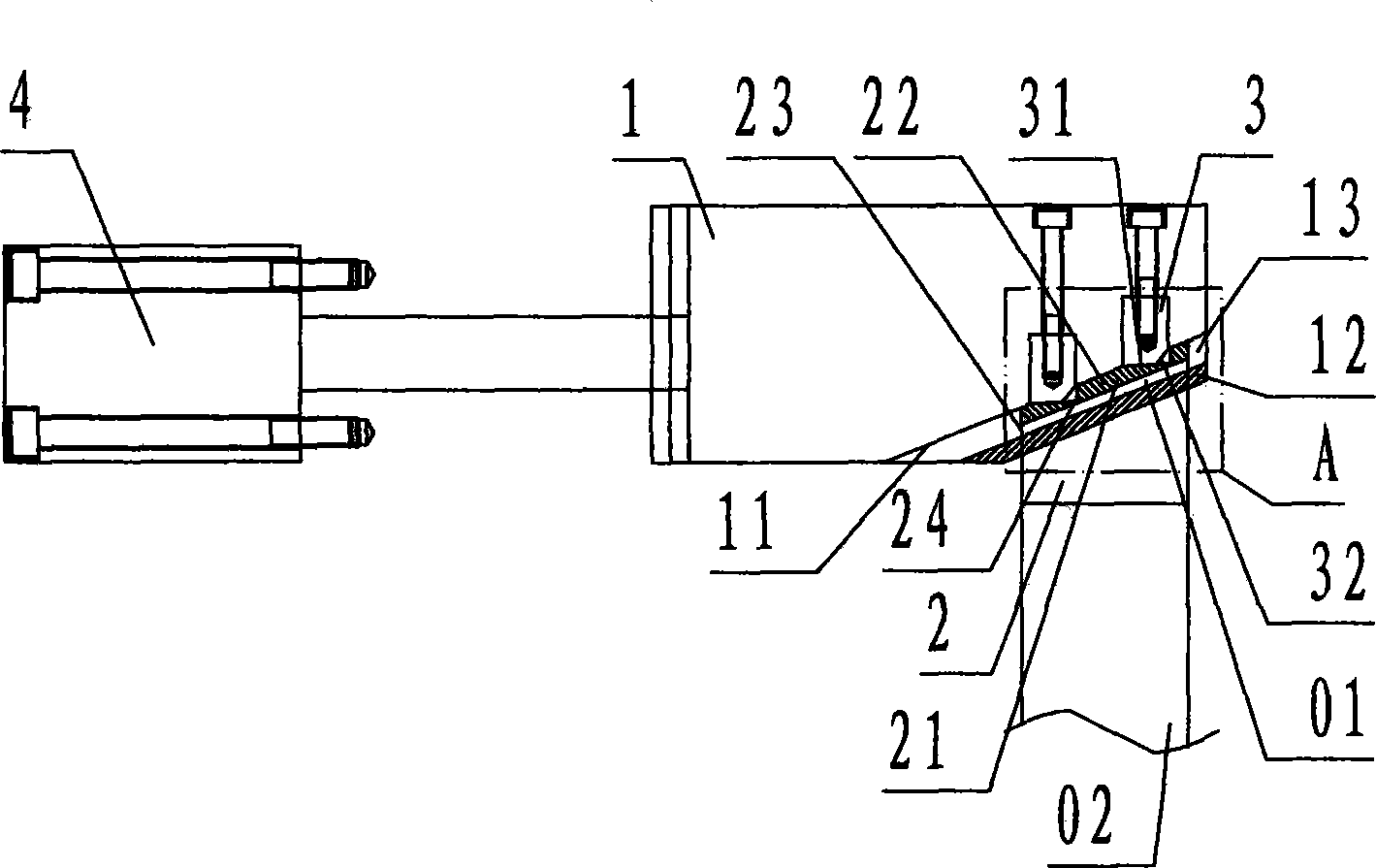

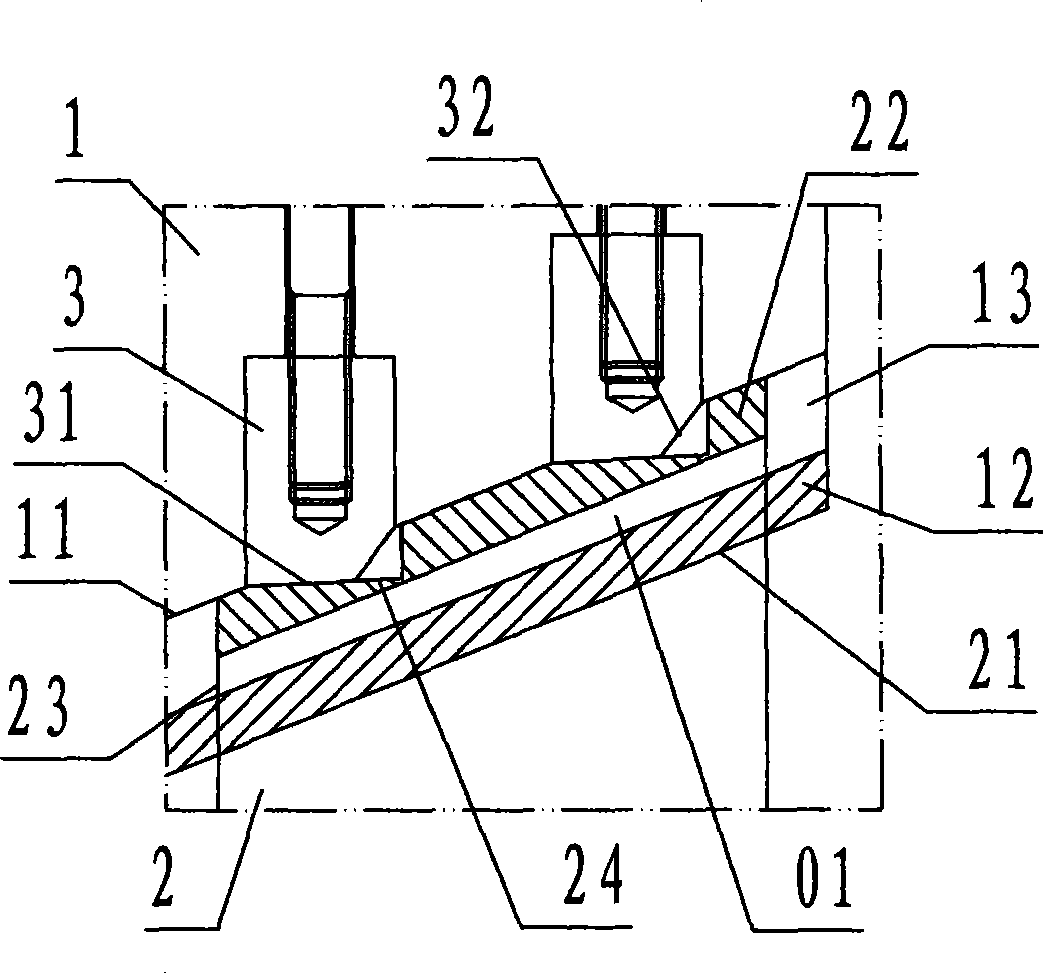

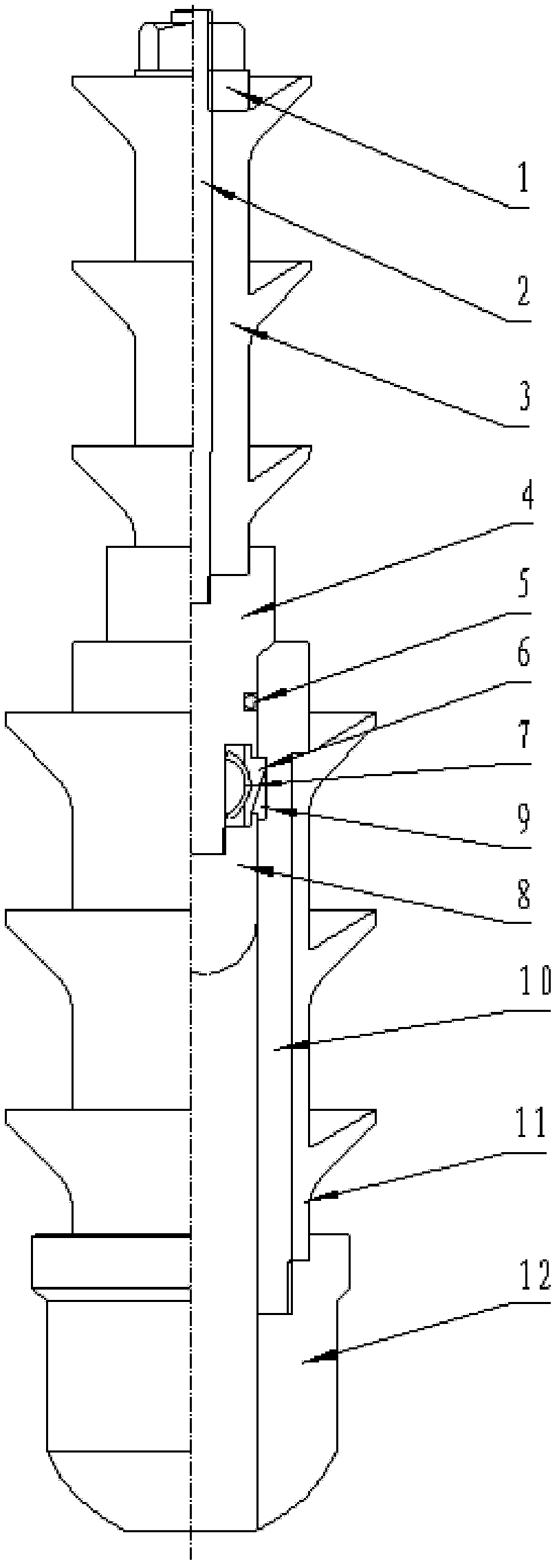

Hydraulic tensioner

A hydraulic tensioner is provided to reduce the number of parts, to secure the backlash, and to prevent the plunger from moving backward. A hydraulic tensioner comprising a hollow plunger having rack teeth formed on a portion of an outer circumferential surface, slidably received in a bore of the housing, where the plunger has an inner space to form a fluid chamber with the bore. A slider housing portion, having an inclined surface, located in the housing, receives a wedge-shaped slider having a ratchet portion adapted to engage with the rack teeth of the plunger and a second side surface. The wedge-shaped slider being slidable along the inclined surface of the slider housing portion in a direction crossing an axial centerline of the plunger. The hydraulic tensioner further includes a first spring biasing the plunger in a protruding direction, and a second spring biasing the slider such that the slider moves along the inclined slide surface of the slider housing portion. A ''wedge-effect'' prevents the plunger from moving backwards.

Owner:BORG WARNER MORSE TEC JAPAN KK

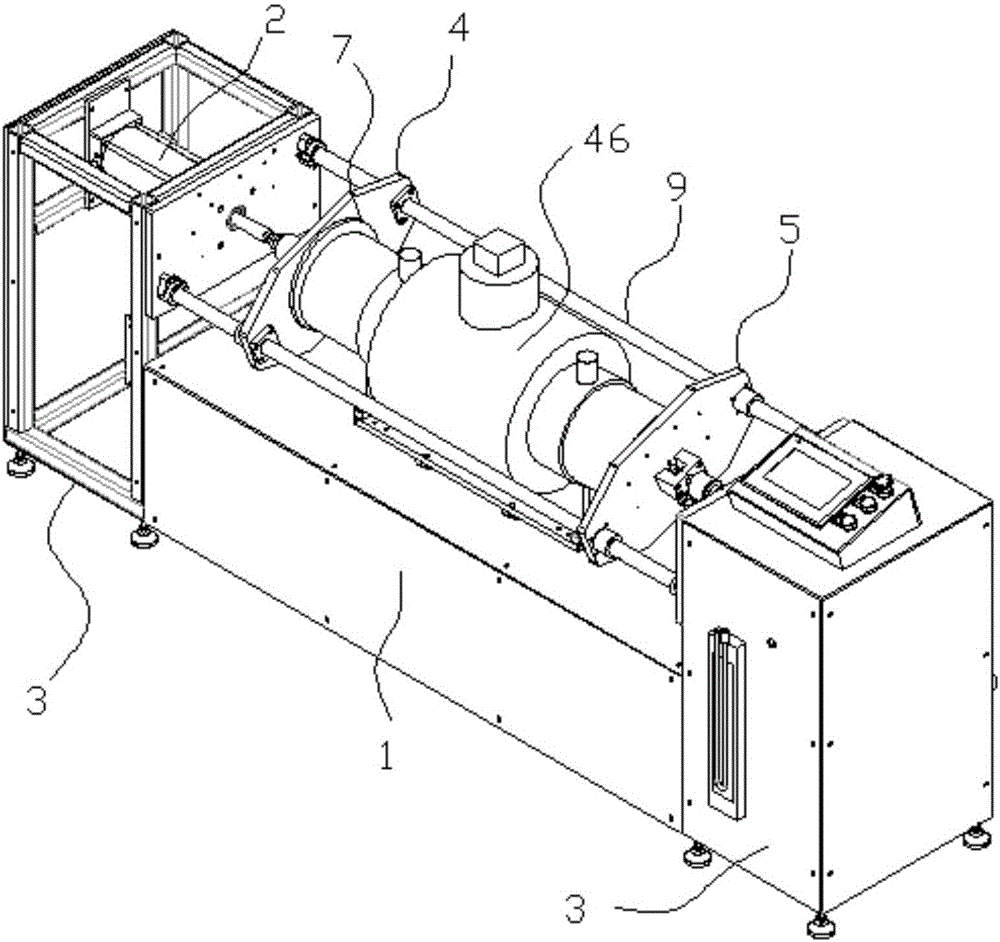

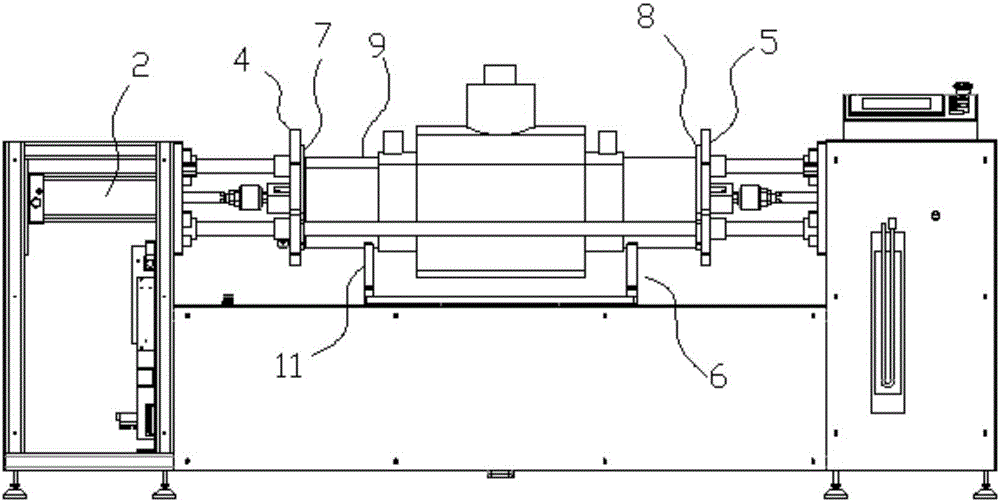

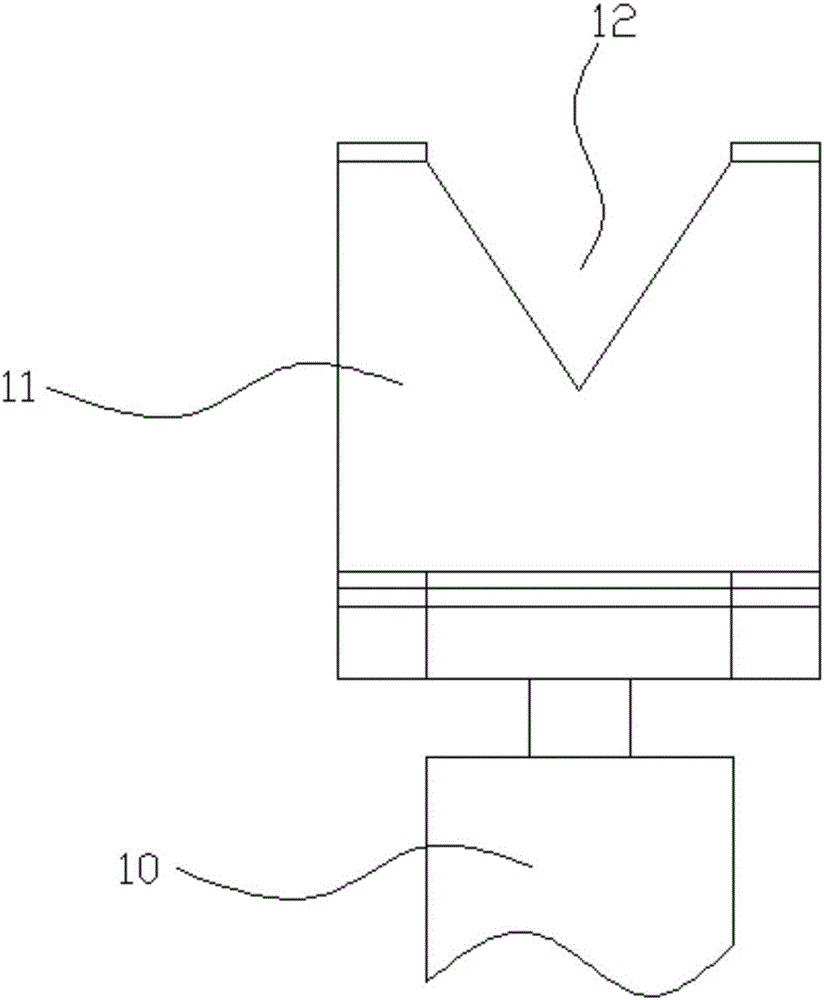

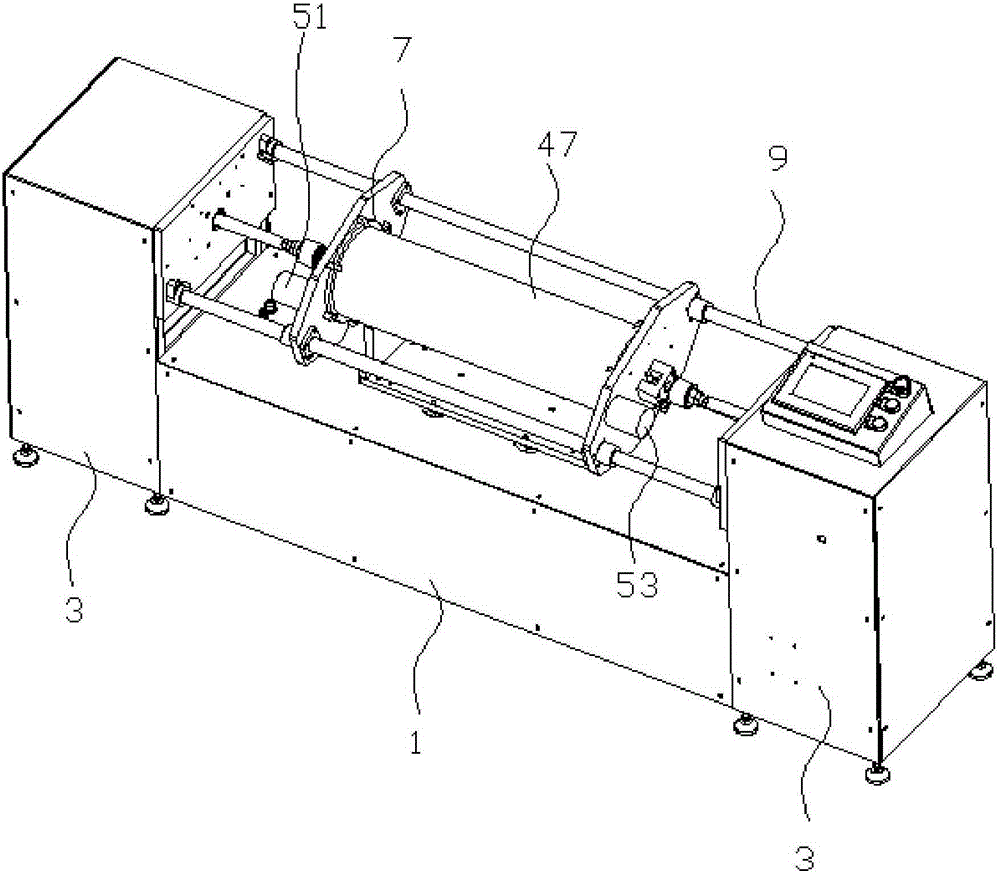

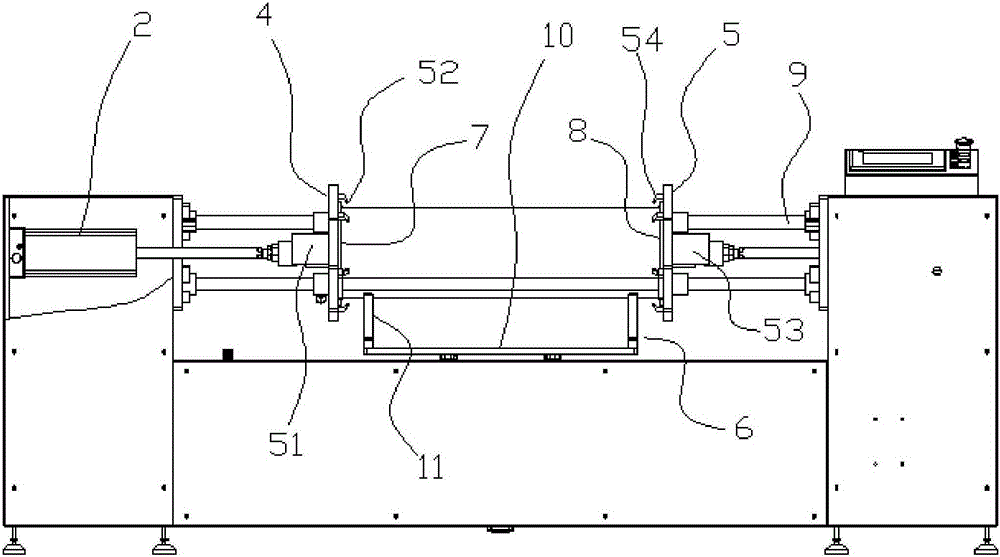

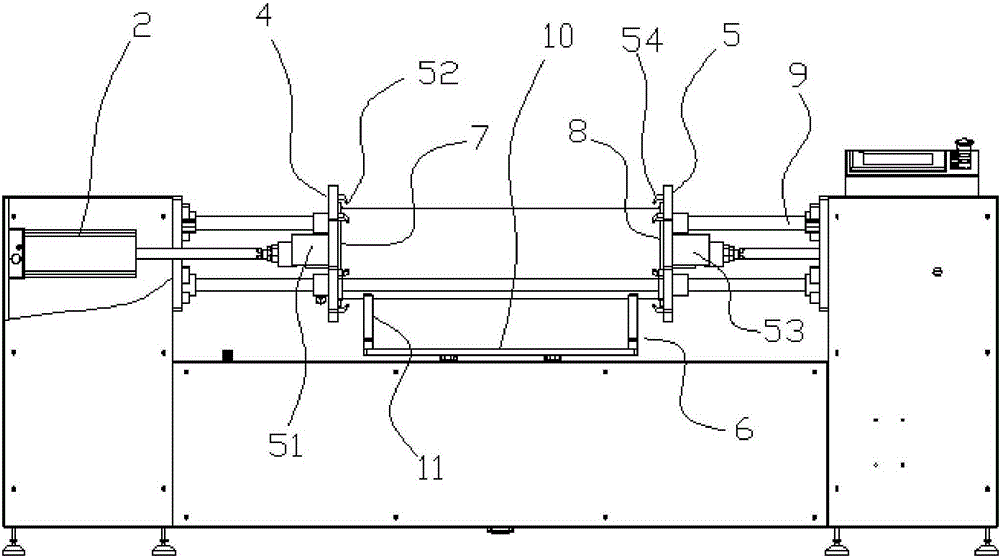

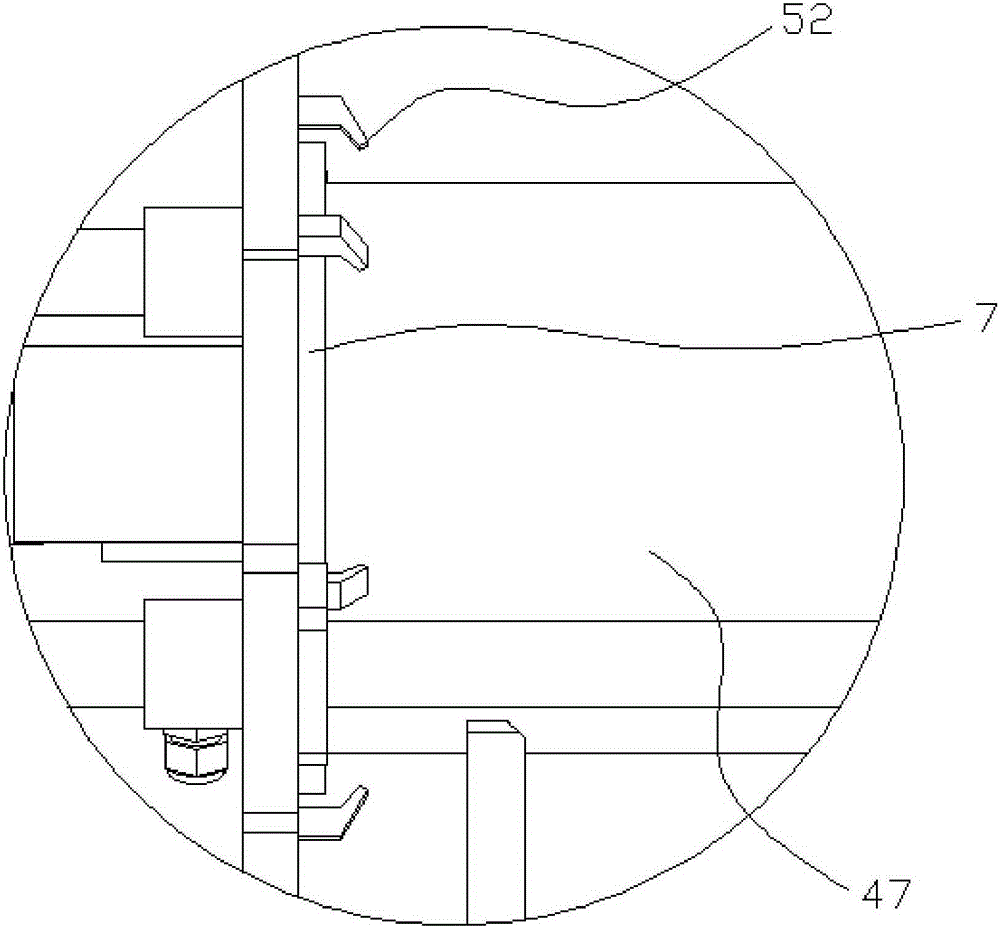

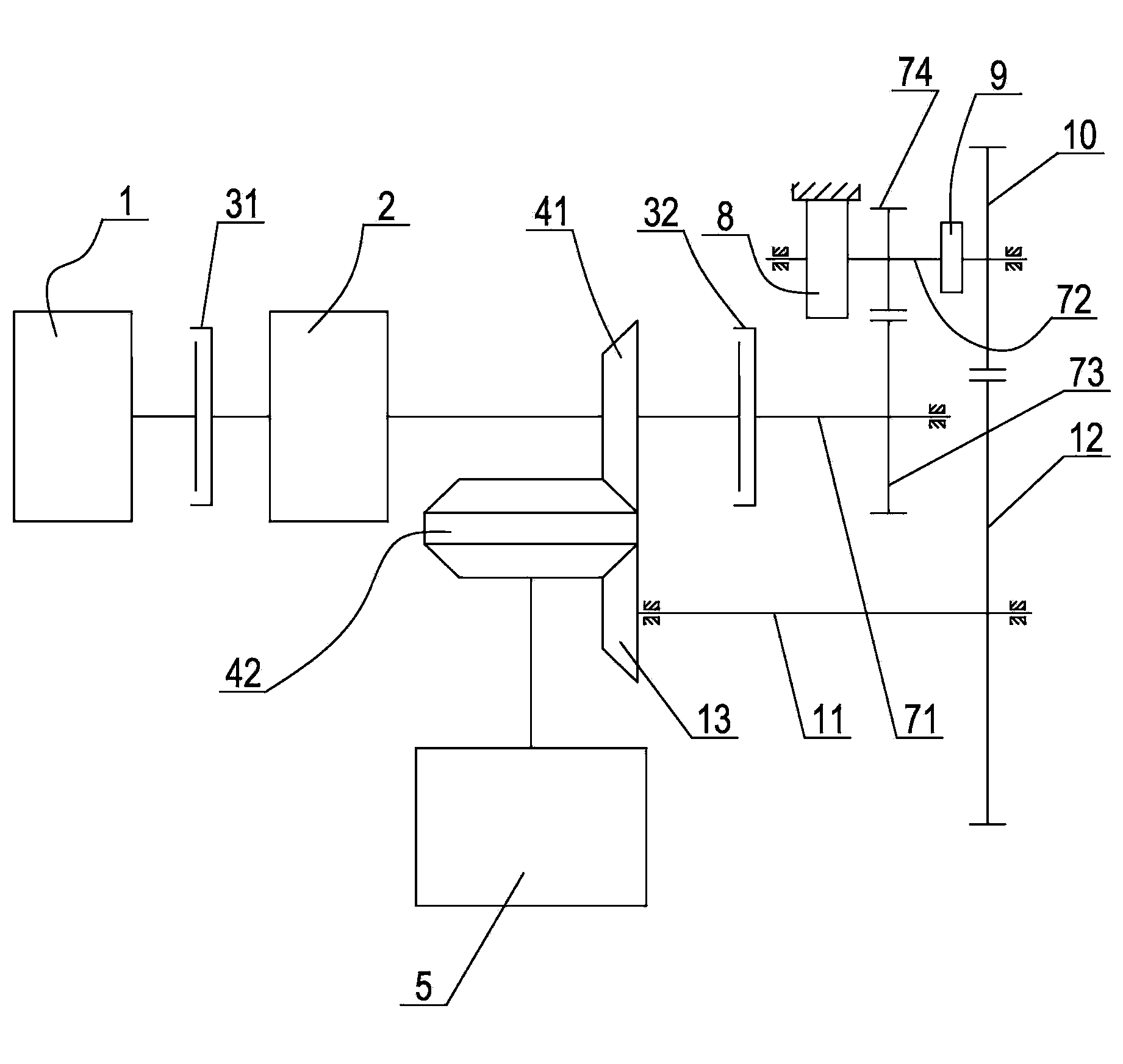

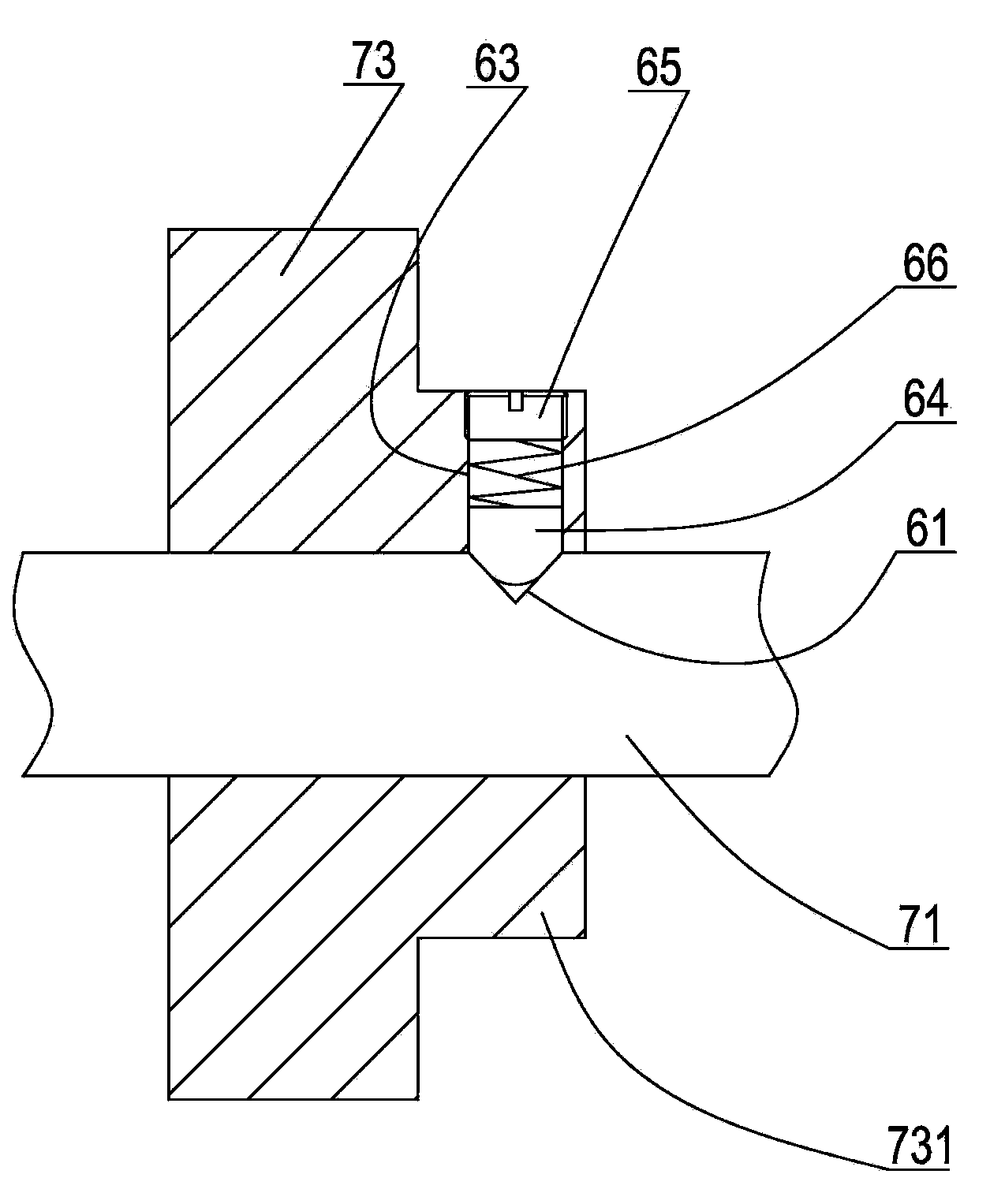

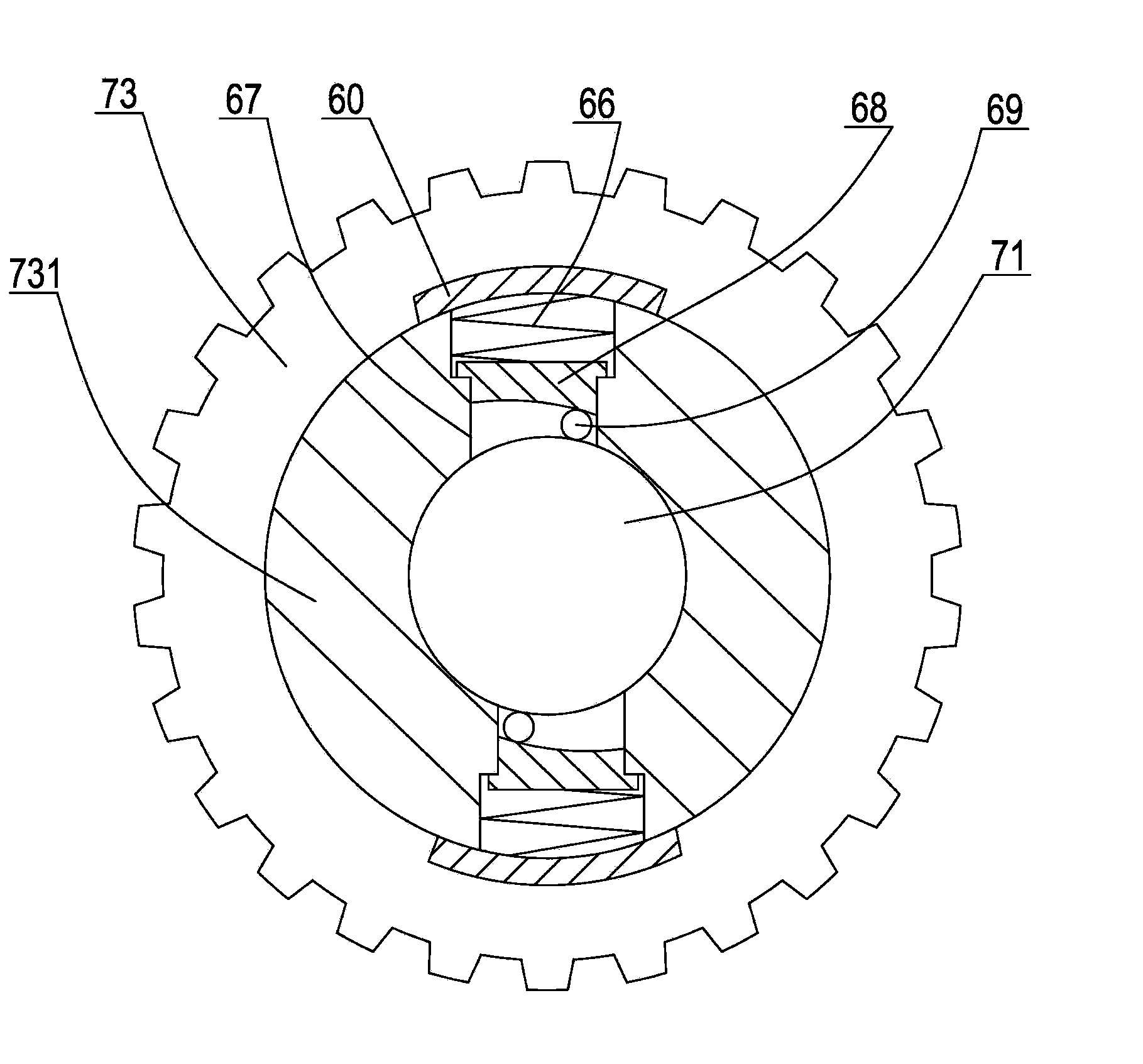

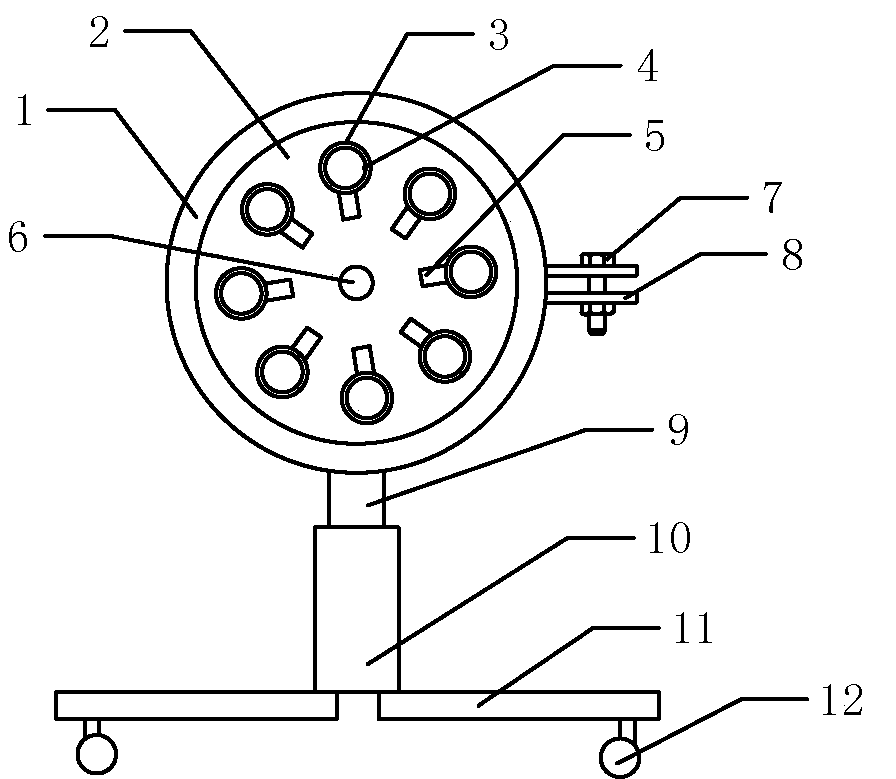

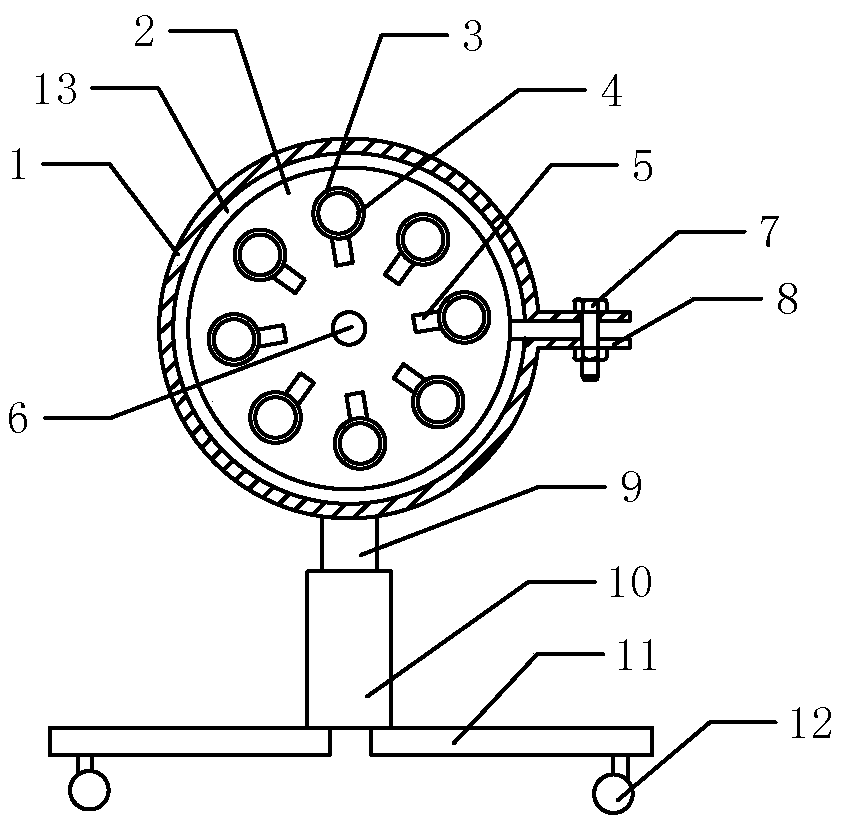

Ball valve gas tightness test apparatus

InactiveCN105043675ANo pinchingPrevent fallbackWork holdersFluid-tightness measurement using fluid/vacuumEngineeringAir tightness

The invention discloses a ball valve gas tightness test apparatus. The ball valve gas tightness test apparatus has the advantages of convenient operation and high accuracy. With the ball valve gas tightness test apparatus adopted, it can be ensured that two end pipes of a ball valve have little possibility of being damaged due to clamping. The ball valve gas tightness test apparatus includes an air feed pump, a pressure sensor, a main rack, two push plate air cylinders, two side racks, a main end cover and an auxiliary end cover; the two push plate air cylinders are respectively located on the two side racks; the piston rod of one of the push plate air cylinders is connected with the main end cover; the piston rod of the other push plate air cylinder is connected with the auxiliary end cover; the main end cover is provided with a main elastic sealing ring gasket; the auxiliary end cover is provided with an auxiliary elastic sealing ring gasket; and a main cover air hole is formed in the main end cover. With the ball valve gas tightness test apparatus of the invention adopted, a ball valve can be positioned and clamped in place, and gas tightness can be ensured, and at the same time, the ball valve will not be damaged due to clamping. The ball valve gas tightness test apparatus has an adaptively-adjustable sealing structure, so that a sealing effect in high-air pressure detection can be strengthened; the ball valve gas tightness test apparatus has an auxiliary positioning structure, the rollback of the end covers can be avoided, and the push plate air cylinders can be protected, and a sealing effect can be improved, and stability in a detection process can be maintained.

Owner:王国良

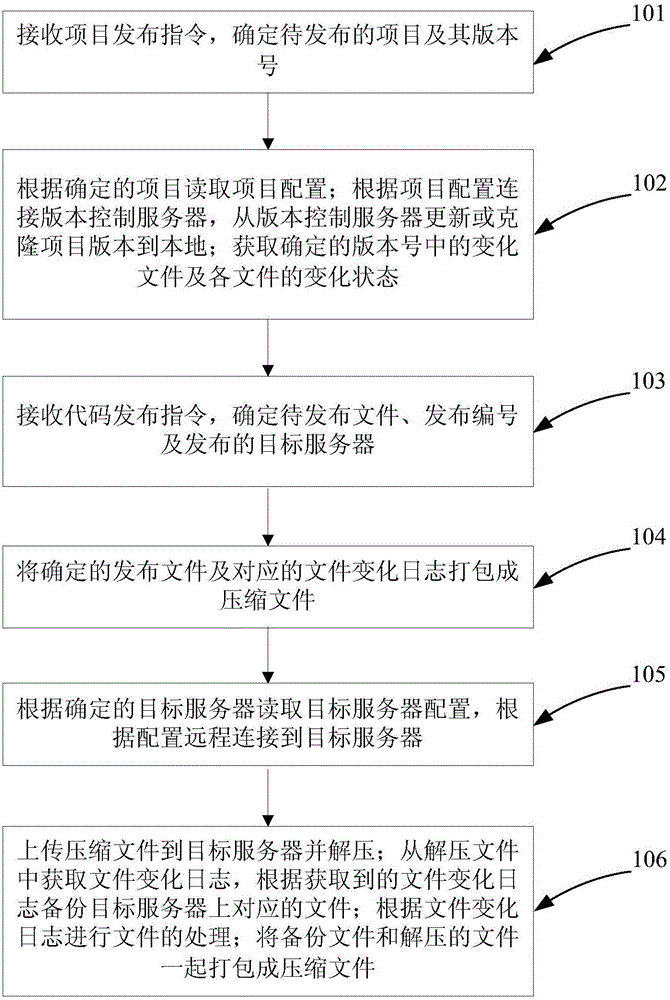

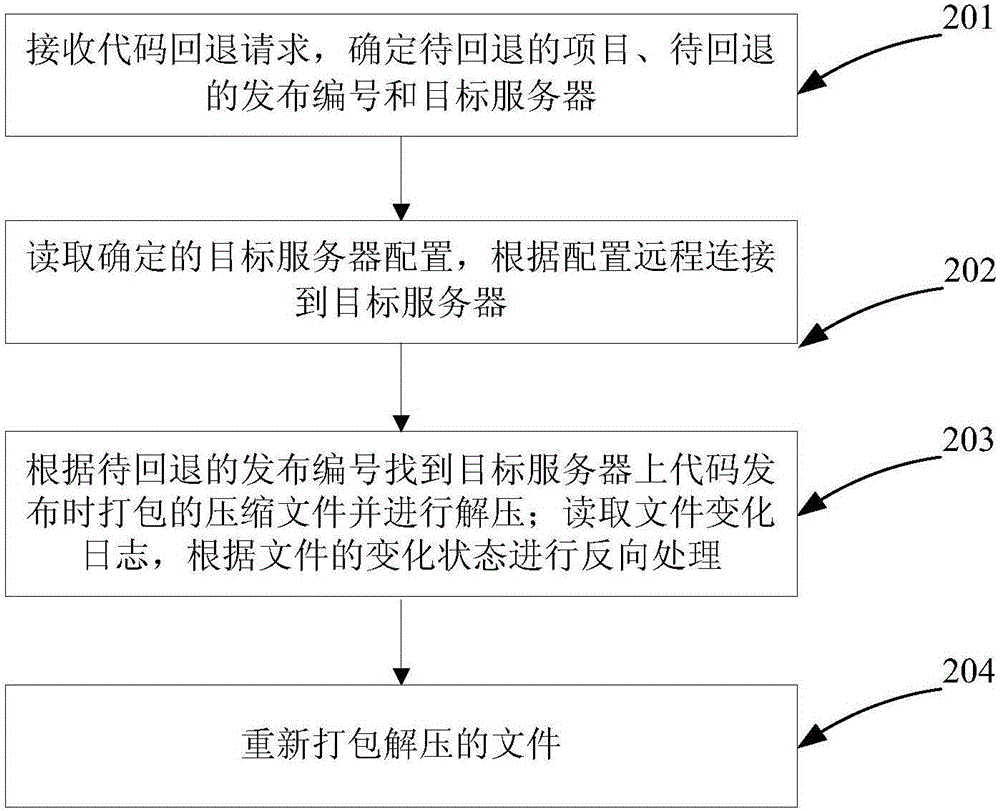

Code release and backspacing methods

InactiveCN106445488ASolve the problem of publishing errorsPrevent fallbackVersion controlSpecific program execution arrangementsOperating systemRevision control

The invention discloses code release and backspacing methods. The release method comprises the steps of receiving a project release instruction and determining a to-be-released project and a version number of the to-be-released project; reading project configuration, connecting a version control server, and updating or cloning a project version to a local end; obtaining a change file and a change state in the determined version number; receiving the code release instruction, and determining a to-be-released file, a release number and a released target server; packaging the determined release file and a corresponding file change log into a compressed file, and uploading the release file and the file change log to the target server for decompression; and backing up the corresponding file in the target server according to the file change log and performing addition, deletion or overwriting processing on the to-be-released file. According to the code release method, the beneficial effects of automatically releasing codes, saving manpower and time, and reducing release error rate can be achieved. According to the code backspacing method, the beneficial effect of avoiding influence on use of versions due to problems after code release can be achieved.

Owner:XIAMEN ENAME TECH CO LTD

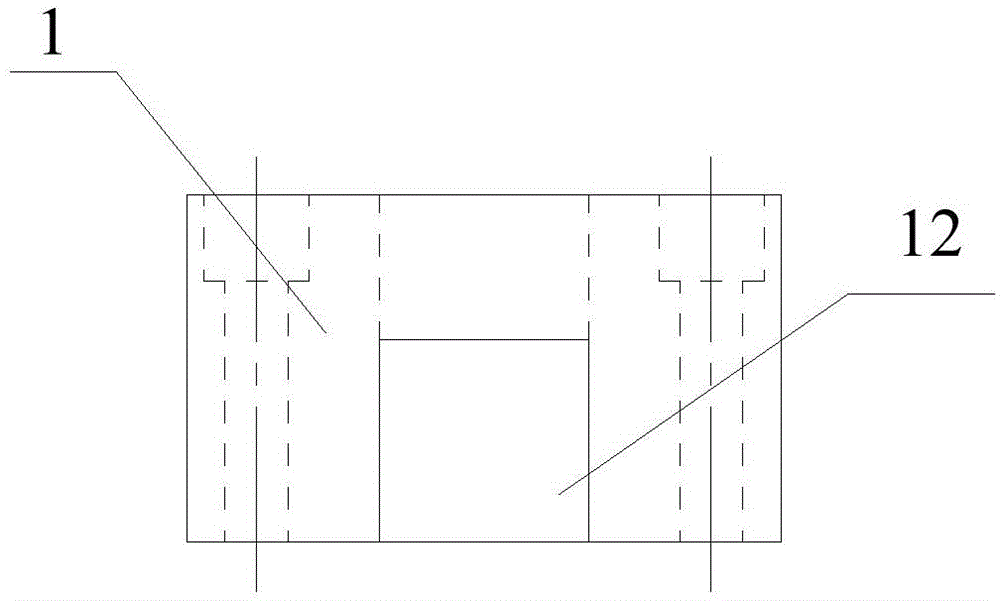

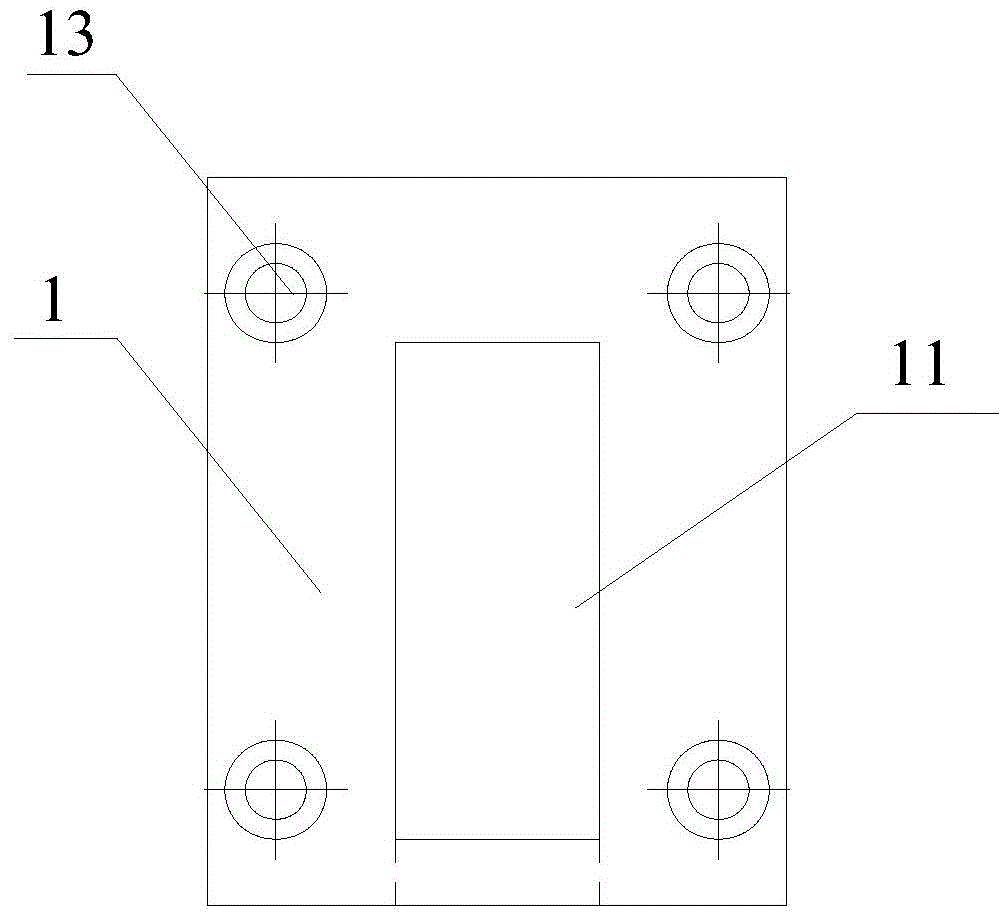

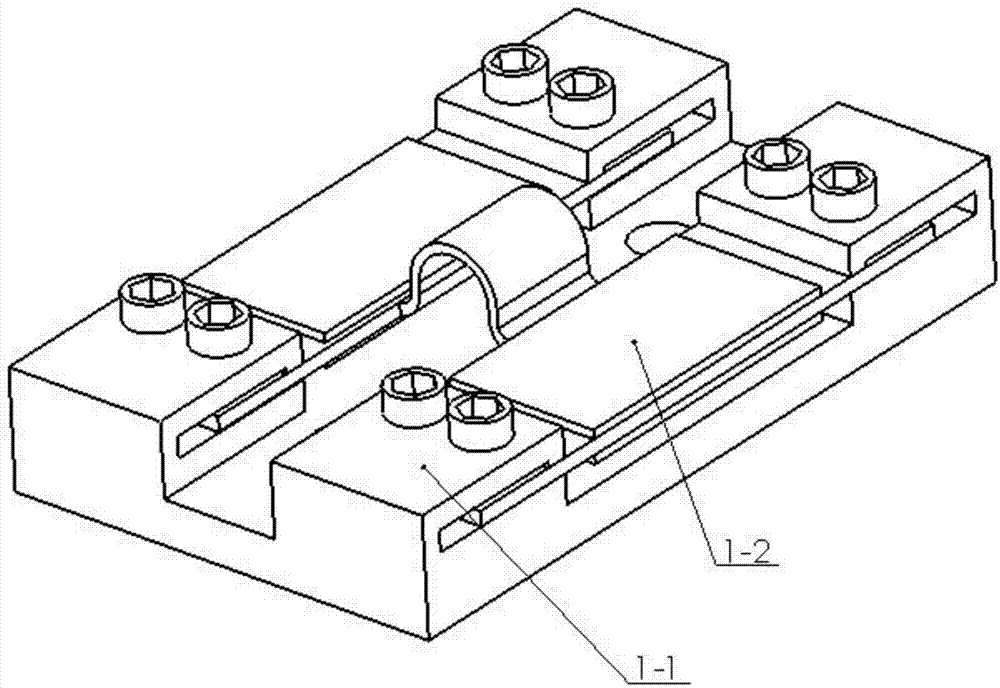

Double boring bottom cylinder supporting tool

InactiveCN104551755AEasy to operateClamping saves time and effortLarge fixed membersPositioning apparatusRelative displacementEngineering

The invention provides a double boring bottom cylinder supporting tool. The double boring bottom cylinder supporting tool comprises a pedestal, and a positioning base, a slide block and an adjusting supporting base which are arranged on the pedestal, wherein a chute is formed along the vertical direction in the positioning base; a supporting block is arranged in the chute; an adjusting bolt is horizontally arranged on the adjusting supporting base and is connected with the slide block; the slide block is arranged below the supporting block; the bolt is connected with the slide block; the slide block is arranged below the supporting block; the matched surface between the upper surface of the slide block and the lower end of the supporting block is an inclined surface; a workpiece supporting opening is formed in the upper end of the supporting block. The angle of the combination surface between the supporting block and the slide block is reasonably used, the telescopic height of the tool is adjusted by relative displacement between the supporting block and the slide block, replacement of the tool during machining is avoided, the structure is convenient to operate, the double boring bottom cylinder supporting tool can be suitable for clamping bottom cylinders or cylindrical workpieces with different diameters, time and labor are saved during clamping, convenience is improved for workers, the production efficiency is improved, and the cost is reduced.

Owner:CHONGQING YAOYONG SHOCK ABSORBER

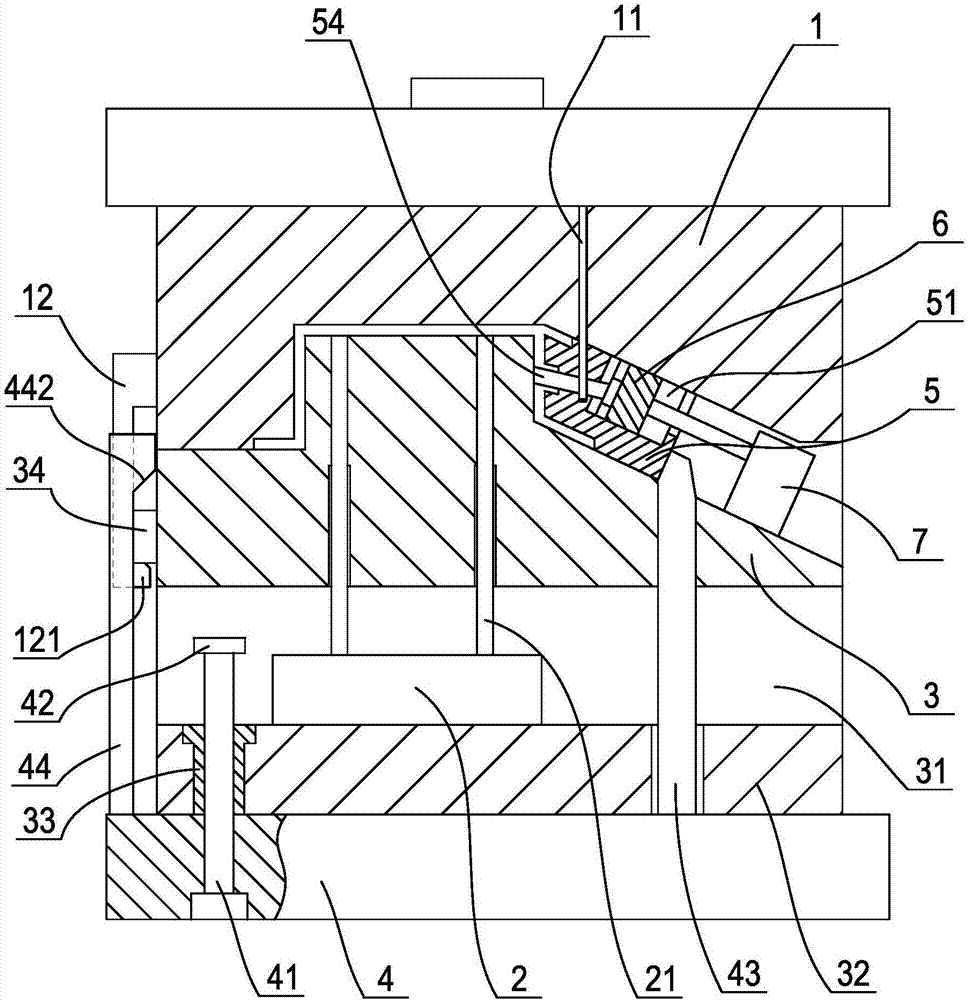

Injection-molded part forming method requiring two stages of core pulling

Owner:SHENTONG TECH GRP CO LTD

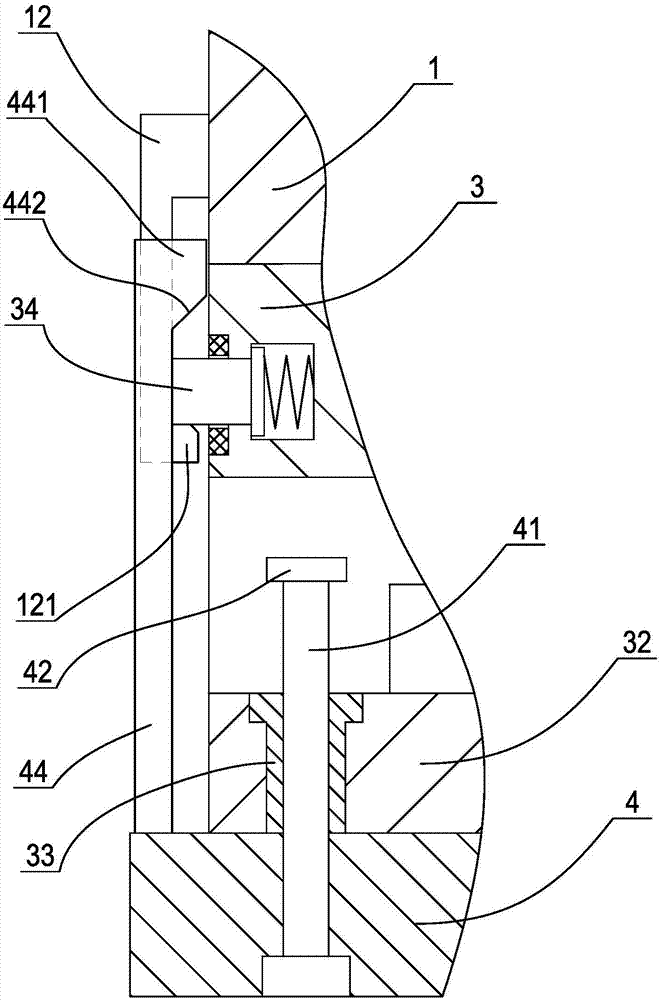

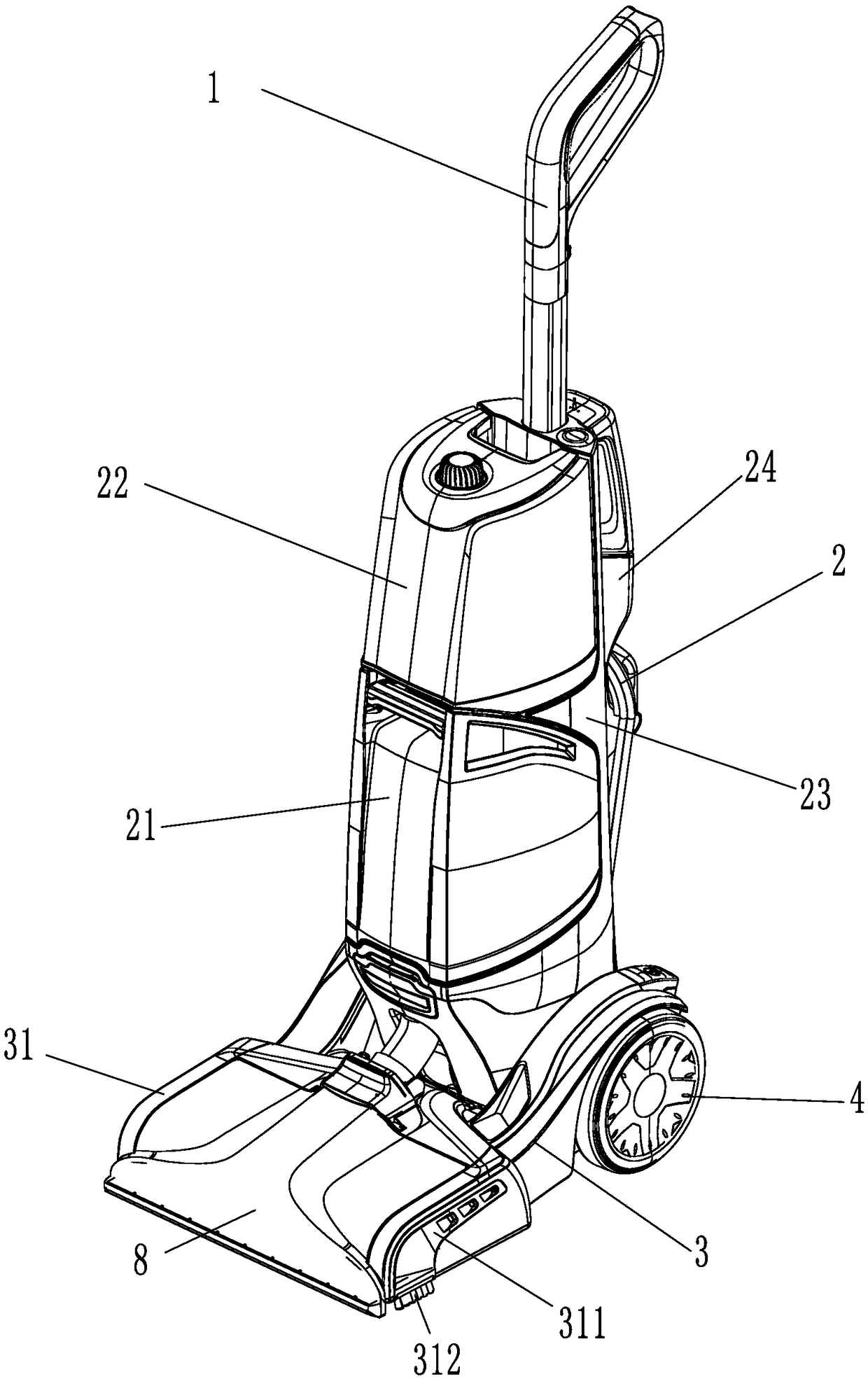

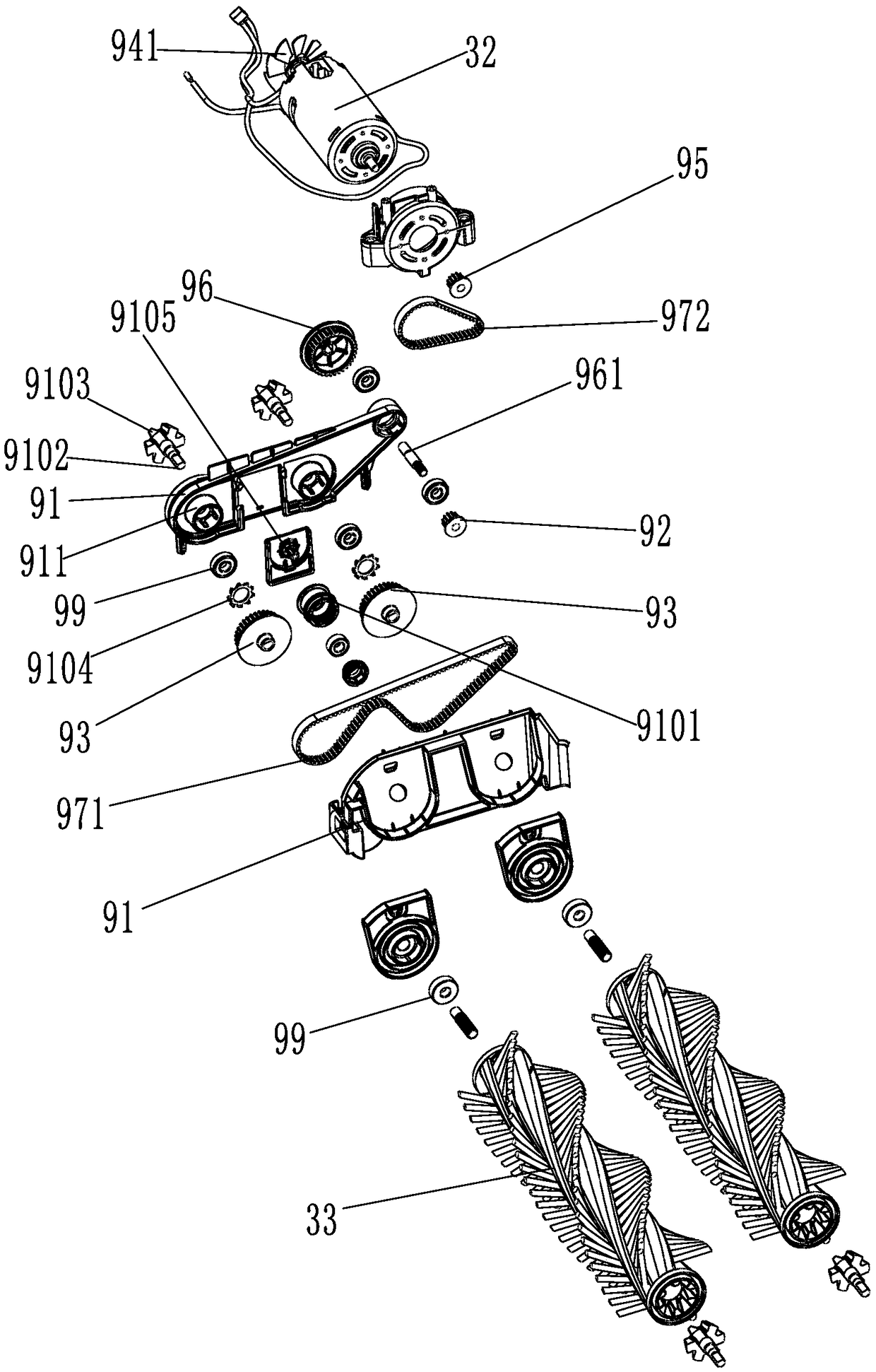

Cleaning machine capable of sensing automatic water spraying

The invention discloses a cleaning machine capable of sensing automatic water spraying. The cleaning machine comprises a handle assembly, a machine body assembly and a mop assembly which are arrangedin sequence from top to bottom; the lower end of the machine body assembly is connected with the mop assembly, the mop assembly comprises a mop shell body, double rolling brushes and an exhaust fan, wherein the double rolling brushes and the exhaust fan are located in the mop shell body, the mop assembly further comprises a sewage suction nozzle and a spray pipe, the sewage suction nozzle is communicated with the exhaust fan, the machine body assembly comprises a recycling bin and a scuttlebutt, the recycling bin is communicated with the sewage suction nozzle through a pipeline, the side faceof the scuttlebutt is provided with a wash fluid container, the wash fluid container and the scuttlebutt are connected with a mixing valve, the mixing valve is communicated with the spray pipe througha pipeline, a solenoid valve is arranged between the mixing valve and the spray pipe, the side, opposite to the sewage suction nozzle, of the mop shell body is provided with rollers, the mop shell body is internally provided with a Hall sensor capable of sensing the rotation of the rollers, a Hall sensor circuit is connected with a mainboard of the cleaning machine and controls a driving pump, and the driving pump drives a pipeline communicated between the mixing valve and the spray pipe. The cleaning machine capable of sensing automatic water spraying has the advantage of achieving the effect that the cleaning machine senses automatic water spraying when moving.

Owner:TECHTRONIC CORDLESS GP

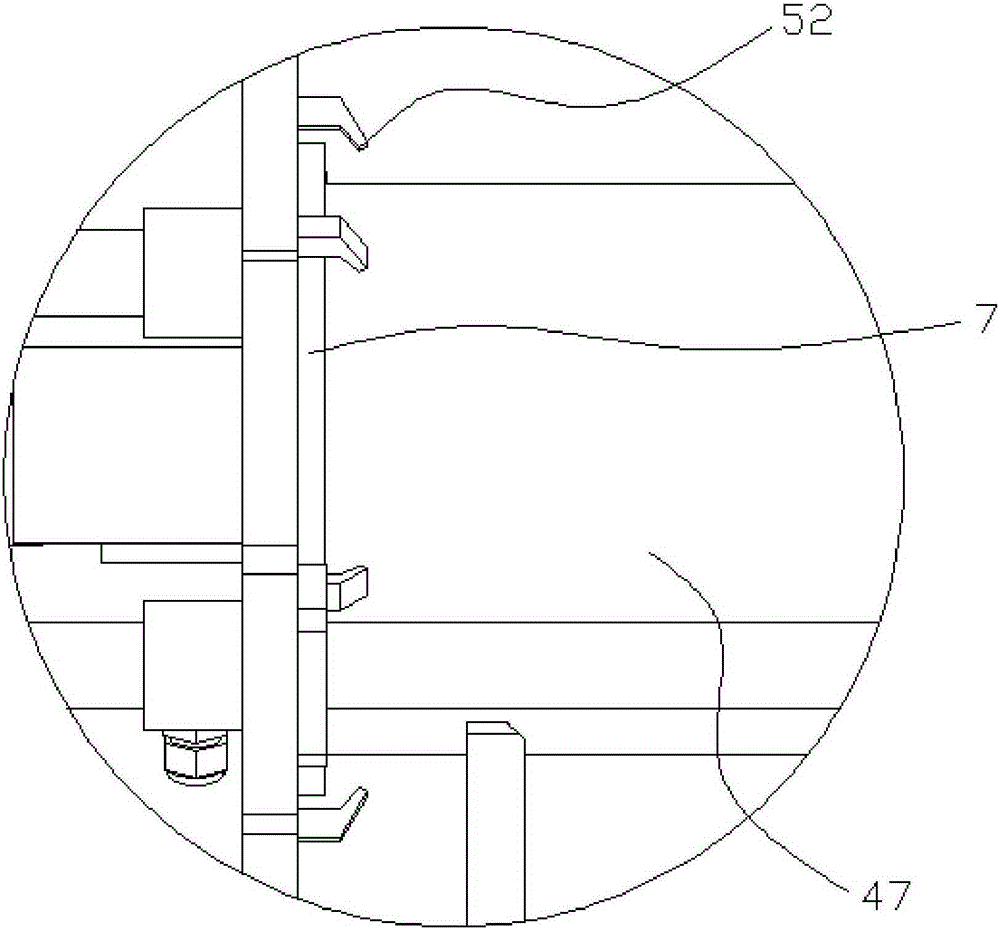

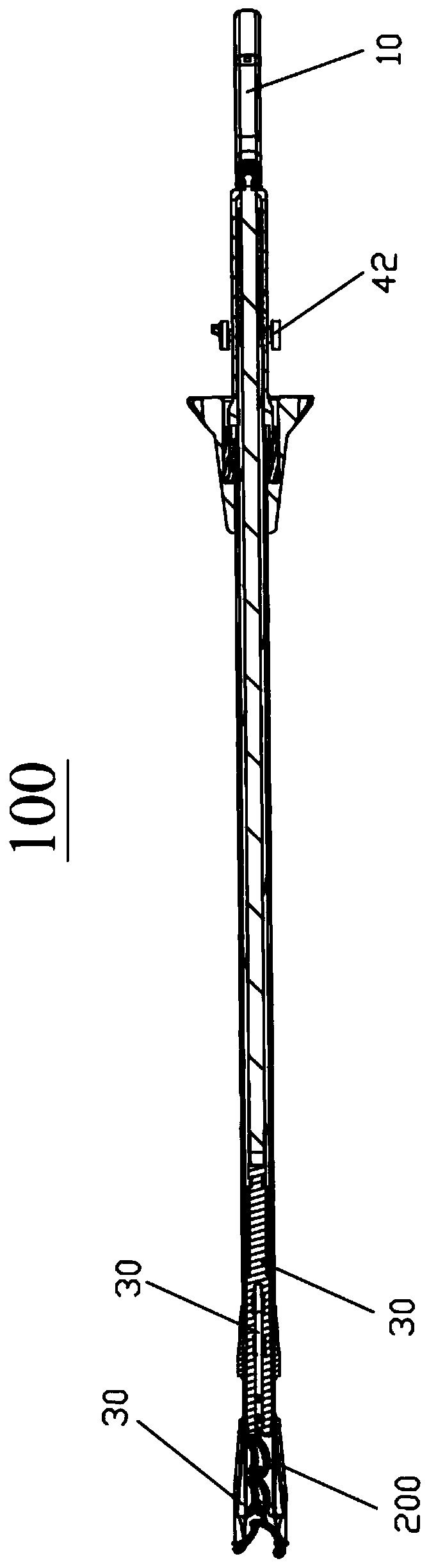

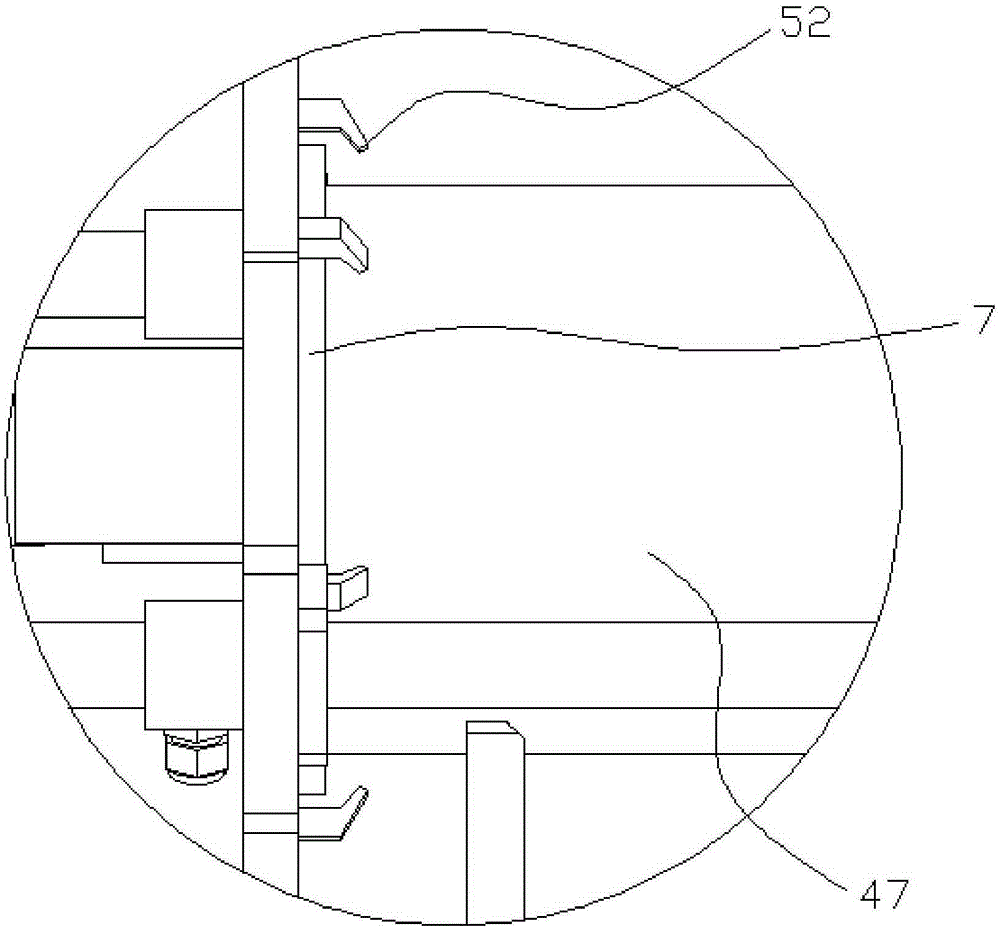

Skin pulling system and skin pulling device

PendingCN110432994AEasy to operatePrevent fallbackDiagnosticsSurgeryEngineeringMechanical engineering

The invention relates to a skin pulling system and a skin pulling device. When the skin pulling device is used, a winding roller is rotated to wind a pulling wire on the winding roller, the winding roller is in a locking position, locking is achieved through matching of a turn-stopping structure and a matching strucutre, thus the winding roller is prevented from returning, when the pulling wire isneeded to be loosened, the winding roller is pushed along the winding roller, thus the winding roller moves to an unlocking position from the locking position, in this way, the turn-stopping structure and the matching structure are separated from being matched, the winding roller is in a free state, the pulling wire loosens and is separated from the winding roller under the action of opposite acting force, thus loosening of the pulling wire is achieved. According to the skin pulling device, when unlocking and locking are conducted, the winding roller is only needed to be axially moved, operation on other parts is not needed, and operation is convenient in use.

Owner:ZHENGZHOU ONE MILLIMETER MEDICAL TECH CO LTD

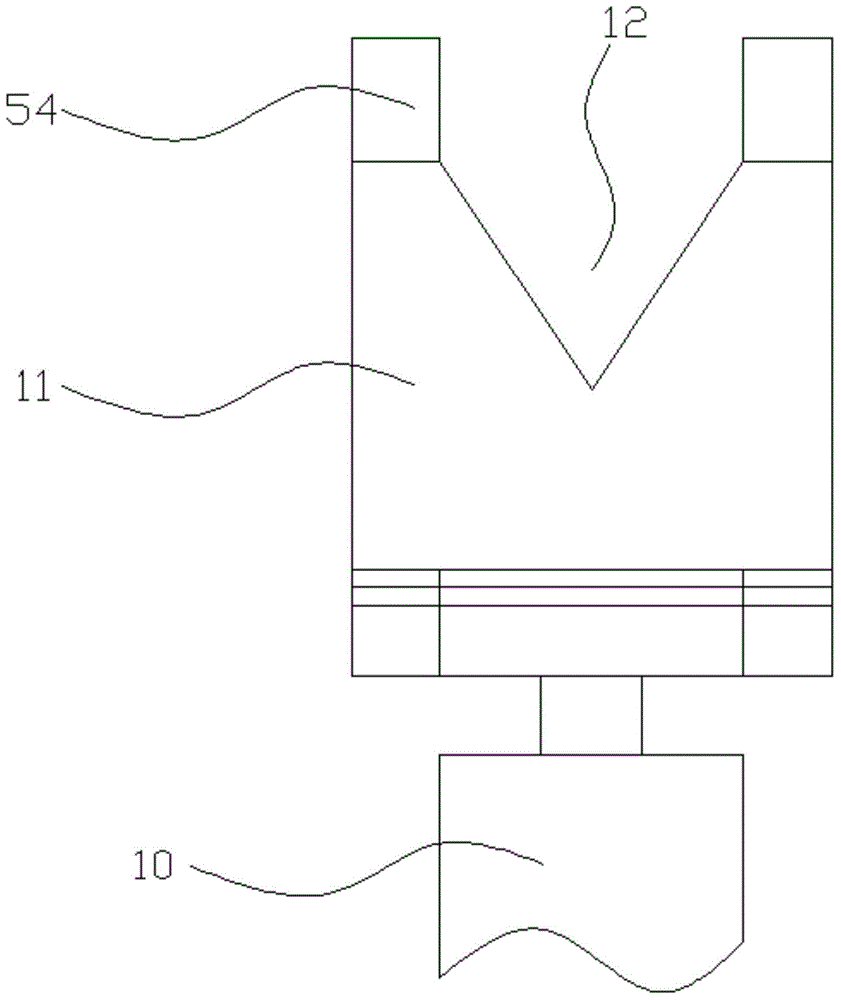

Surgical suite for sternal closure fixation

ActiveCN106108995AEfficient demolitionSolve the difficulty of dismantlingInternal osteosythesisBone platesOrthodontics

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

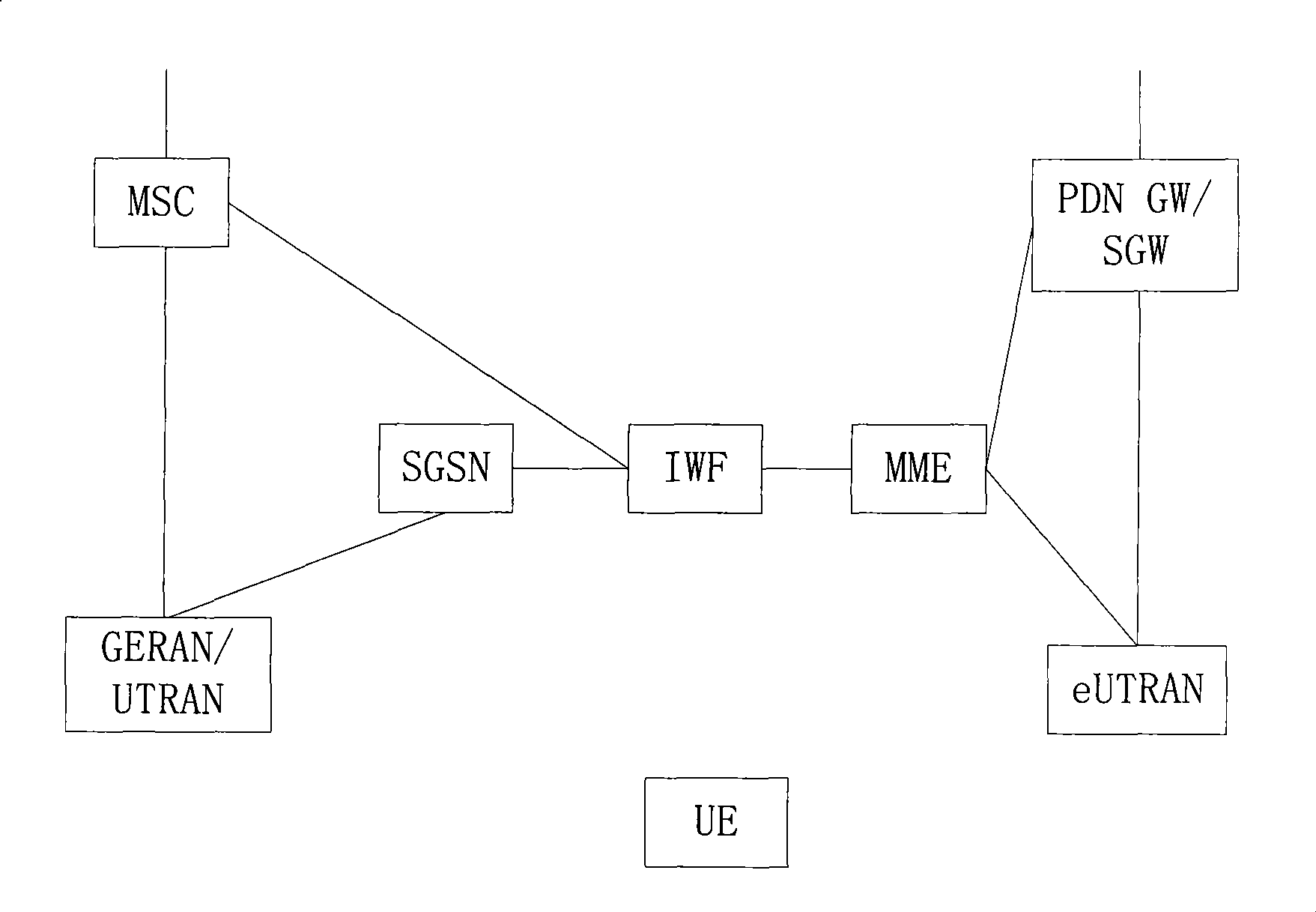

Method and device for processing short message service by packet switched domain user

ActiveCN102196386AIncrease autonomyPrevent fallbackMessaging/mailboxes/announcementsShort message service centerPacket switch

The invention discloses a method for processing a short message service by a packet switched domain user, so that the user can autonomously select whether to carry out CS (Customer Satisfaction) Fallback. When the short message service is carried out through user equipment located in a packet switched domain and user equipment located in a circuit domain, the user equipment in the packet switched domain confirms not to fall back to the circuit domain; and the short message service is carried out by the user equipment located in the packet switched domain in a network side of the packet switched domain in a signaling manner. When the method is adopted, the user equipment can fall back the CS autonomously, and the willing of the user to receive a call is represented. UE (User Equipment) can avoid an unnecessary fallback for a nuisance call which may come from a CS domain.

Owner:HUAWEI TECH CO LTD

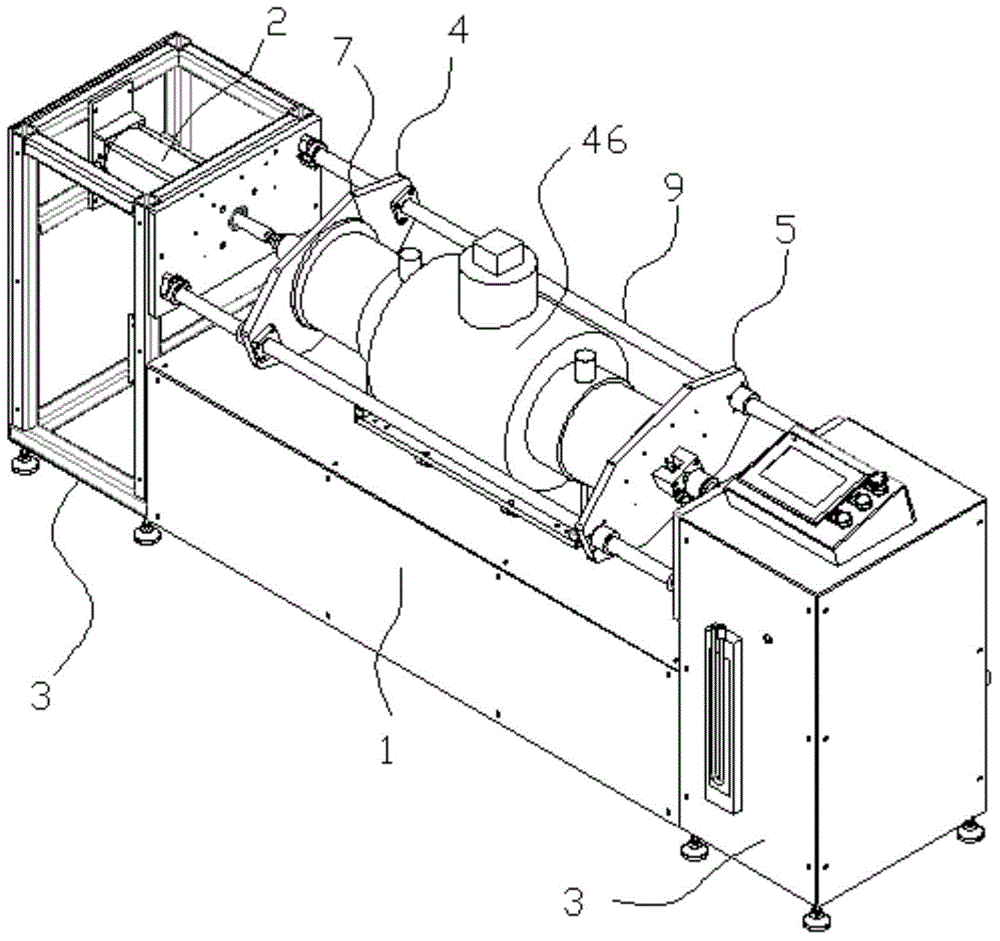

Straight pipe air tightness testing equipment

InactiveCN105203275ANo pinchingPrevent fallbackMeasurement of fluid loss/gain ratePipe fittingEngineering

The invention discloses straight pipe air tightness testing equipment. The straight pipe air tightness testing equipment is convenient to operate, high in testing result accuracy and capable of guaranteeing that the pipe end of a pipe fitting is not likely to be clamped to be damaged. The straight pipe air tightness testing equipment comprises an air feed pump, an air pressure sensor, a main rack, two push plate air cylinders, two side racks, a main end cover and an auxiliary end cover. The two push plate air cylinders are arranged on the two side racks respectively, a piston rod of one push plate air cylinder is connected with the main end cover, and a piston rod of the other push plate air cylinder is connected with the auxiliary end cover. A main elastic sealing ring pad is arranged on the main end cover, an auxiliary elastic sealing ring plate is arranged on the auxiliary end cover, and a main cover air hole is formed in the main end cover. The straight pipe air tightness testing equipment has the advantages that the pipe fitting is located in place, sealing performance can be guaranteed, and the pipe fitting cannot be clamped to be damaged; a sealing structure capable of achieving adaptive adjustment is arranged, and the sealing effect during high-air-pressure detection can be enhanced; an auxiliary locating structure is arranged, the end covers can be prevented from retreating, the push plate air cylinders can be protected, the sealing effect can be improved, and the stability of the detecting process can be maintained.

Owner:宁波新合博园林机械有限公司

Handheld screw locking tool and screw feeding and locking machine with handheld screw locking tool

ActiveCN105033923APrecise alignmentNo friction problemsPower driven toolsMetal-working hand toolsDrive shaftEngineering

The invention relates to a handheld screw locking tool and a screw feeding and locking machine with the handheld screw locking tool. The handheld screw locking tool comprises a tool shell, a hollow screwdriver, an air cylinder, a bit and a transmission shaft. The hollow screwdriver is arranged in the tool shell. The air cylinder comprises a piton rod capable of sliding in the air cylinder. The piston rod is connected with one end of the transmission shaft. The other end of the transmission shaft penetrates the hollow screwdriver to be connected with the bit. The hollow screwdriver is connected with the transmission shaft in a transmission manner. The invention further provides the screw feeding and locking machine with the handheld screw locking tool. The handheld screw locking tool and the screw feeding and locking machine have the beneficial effects that due to the structure of the screw locking tool, a screw and a screw hole can be easily aligned, and operation is easy and saves labor; when operation is carried out, compressed air serves as power, the bit is driven by the air cylinder to perform up-and-down movement, and when the bit ascends, the fed screw is received through a pipe; and when the bit performs downward pressing, the screw can be ejected or ejected out of a screw chuck and sucked on the bit, and convenience is brought to manual alignment.

Owner:KINGSUN AUTOMATION TECH DONGGUAN

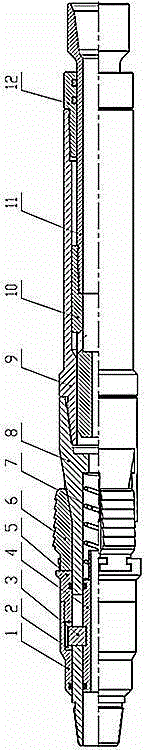

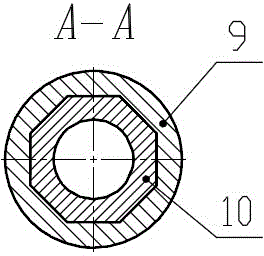

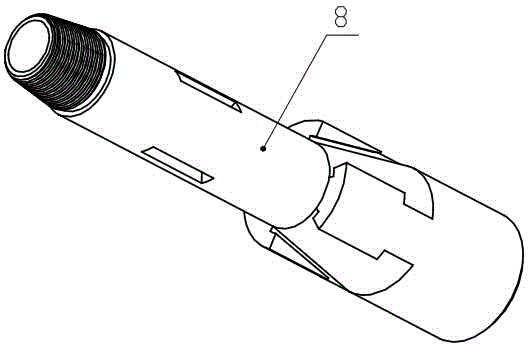

Hydraulic type anti-skidding bit feed tool

InactiveCN104912493ASimple controlReduce frictionConstructionsRotary-drilling machinesInternal cavityThrottle

The invention relates to a hydraulic type anti-skidding bit feed tool used for bit feed of a drill column of a horizontal section of a horizontal well with the purpose of solving the problem that the drill column of the horizontal well has difficulty in bit feed. The technical scheme is described in that screwed connection is realized between the upper end of a slip bowl and the lower end of a sleeve; a spring is installed into an inner hole step of an upper cylindrical shell; a central pipe is mounted into an inner hole of the upper cylindrical shell; an excircle step at the lower portion of the central pipe compresses the spring; three sliding blocks penetrate through three through grooves in the middle of the upper cylindrical shell; the inside of the upper cylindrical shell is embedded with a middle groove of the central pipe; two half rings internally provided with grooves sleeve outsides of the sliding blocks; screwed connection is realized between the upper end of an output shaft and a throttle pipe; screwed connection is realized between the lower end of the output shaft and a drill column at the lower portion; the throttle pipe and the output shaft are integrally disposed into an inner cavity of a lower cylindrical shell; screwed connection is realized between the upper portion of the lower cylindrical shell and the upper cylindrical shell; and screwed connection is realized between the lower portion of the lower cylindrical shell and an anti-dropping housing. The hydraulic type anti-skidding bit feed tool has following beneficial effects: drilling fluid is utilized for pushing the throttle pipe and the output shaft to perform axial motion; bit pressure is provided to the drill column at the lower portion; and the drill column is fed in.

Owner:SOUTHWEST PETROLEUM UNIV

Repeating compressing clamp

The invention discloses a repeating compressing clamp. The repeating compressing clamp comprises a pushing handle, a tube rod, a clamp head installed at the front end of the tube rod, a feeding devicearranged in the tube rod, a push-pull rod arranged in the tube rod and a storage cabin arranged in the tube rod, and the feeding device comprises a transferring piece and a driving piece pushing thetransferring piece to move. A shaft rod is arranged at the near front end of the tube rod, and the shaft rod is used for fixing the clamp head; the transferring piece is provided with a strip-shaped through groove, at least one pair of protruding anti-rollback clamping buckles are arranged on the groove walls of the two sides of the strip-shaped through groove; and two ends of the shaft rod are fixed to the tube rod after the shaft rod penetrates through the strip-shaped through groove, the tail end diameter of the anti-rollback clamping buckles is smaller than the diameter of the shaft rod, the shaft rod is arranged between the two anti-rollback clamping buckles in an elastic clamping mode after the transferring piece pushes closing clamps, rollback of the transferring piece can be prevented when the repeating compressing clamp is used normally, and the situation that the driving piece pushes the transferring piece to advance or retreat caused by misoperation can be prevented.

Owner:伟格尔(广州)医疗设备有限公司

Device for testing internal sealing property of piping

InactiveCN105277325ANo pinchingReasonable structureMeasurement of fluid loss/gain rateEngineeringHigh pressure

The invention discloses a device for testing the internal sealing property of a piping and aims to provide the device which is convenient for operation, provides high-accuracy testing results, and ensures that an end of the piping cannot be easily damaged by clamping. The device comprises an air supplying pump, an air pressure sensor, a main machine support, two push plate cylinders, two side machine supports, a main end cap, and an auxiliary end cap. The two push plate cylinders are arranged on the two side machine supports respectively. A piston rod of one of the push plate cylinders is connected with the main end cap, and a piston rod of the other push plate cylinder is connected with the auxiliary end cap. A main elastic sealing ring pad is arranged on the main end cap. An auxiliary elastic sealing ring pad is arranged on the auxiliary end cap. The main end cap is provided with a main cap vent. The device can precisely position a piping, ensures sealing property without damaging the piping through clamping, has an adaptive sealing structure, can reinforce the sealing effect during high-pressure testing, has an auxiliary positioning structure, can avoid end cap retreat and protect the push plate cylinders, is improved in sealing effect, and maintains the stability of the testing process.

Owner:宁波新合博园林机械有限公司

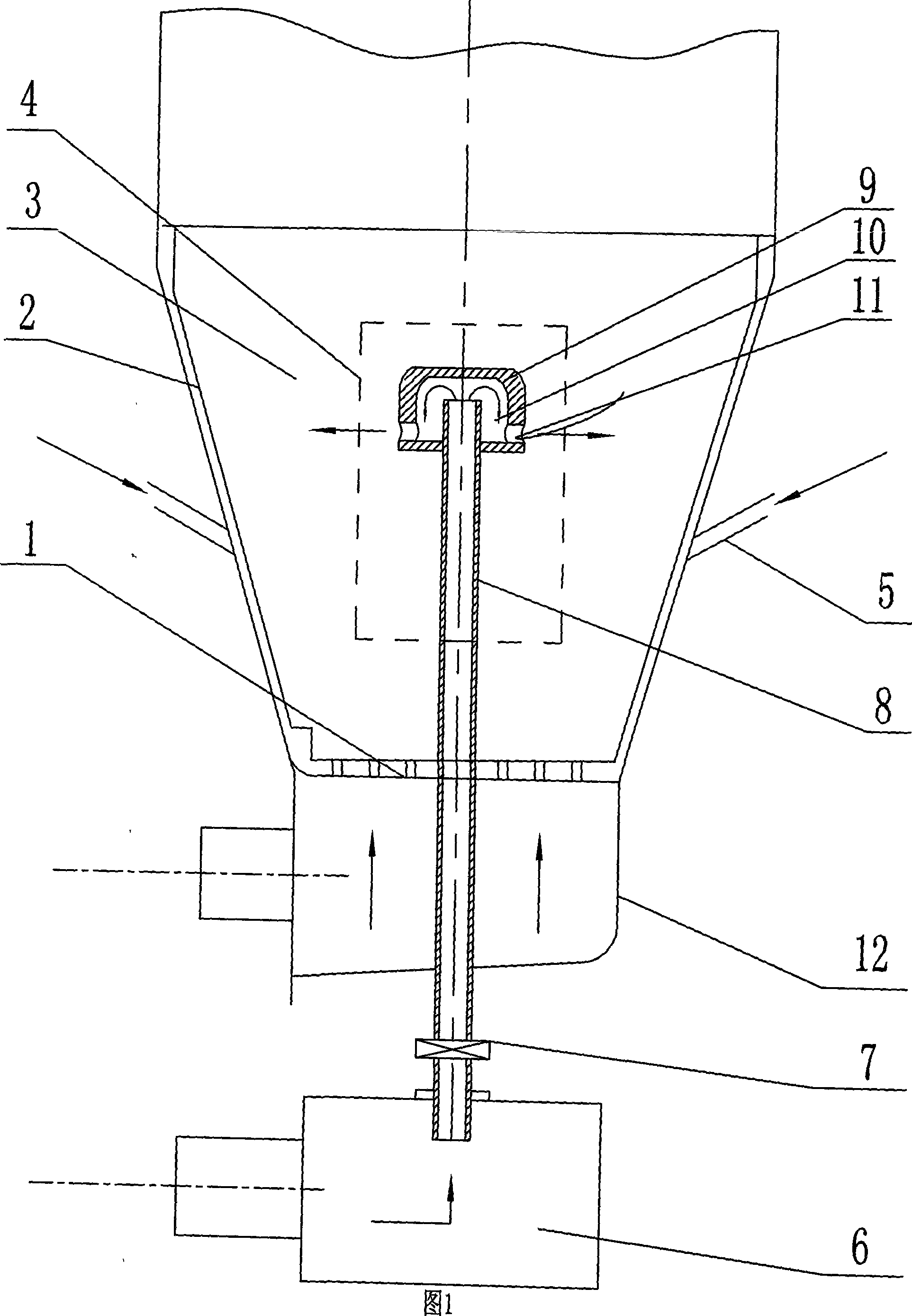

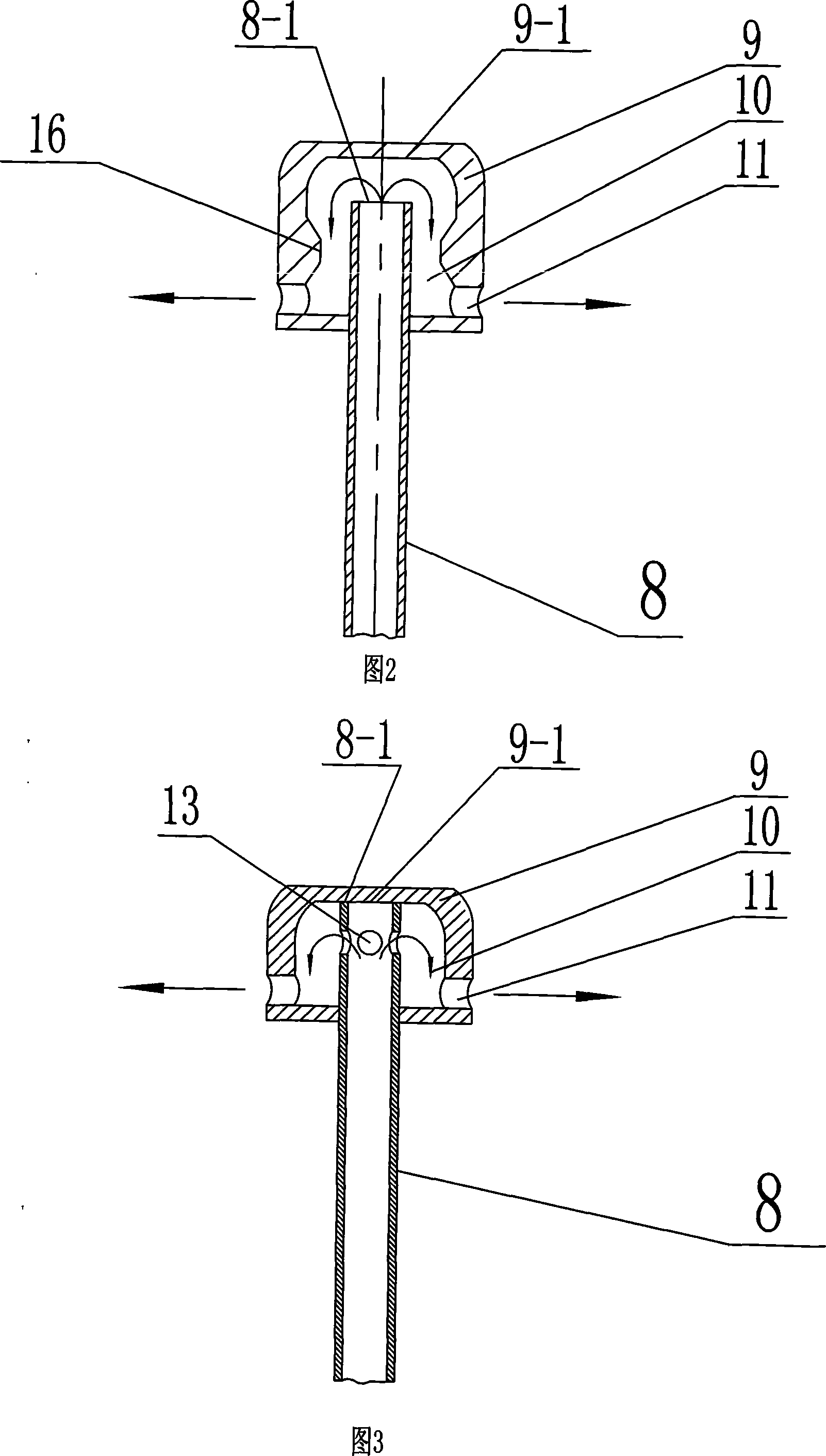

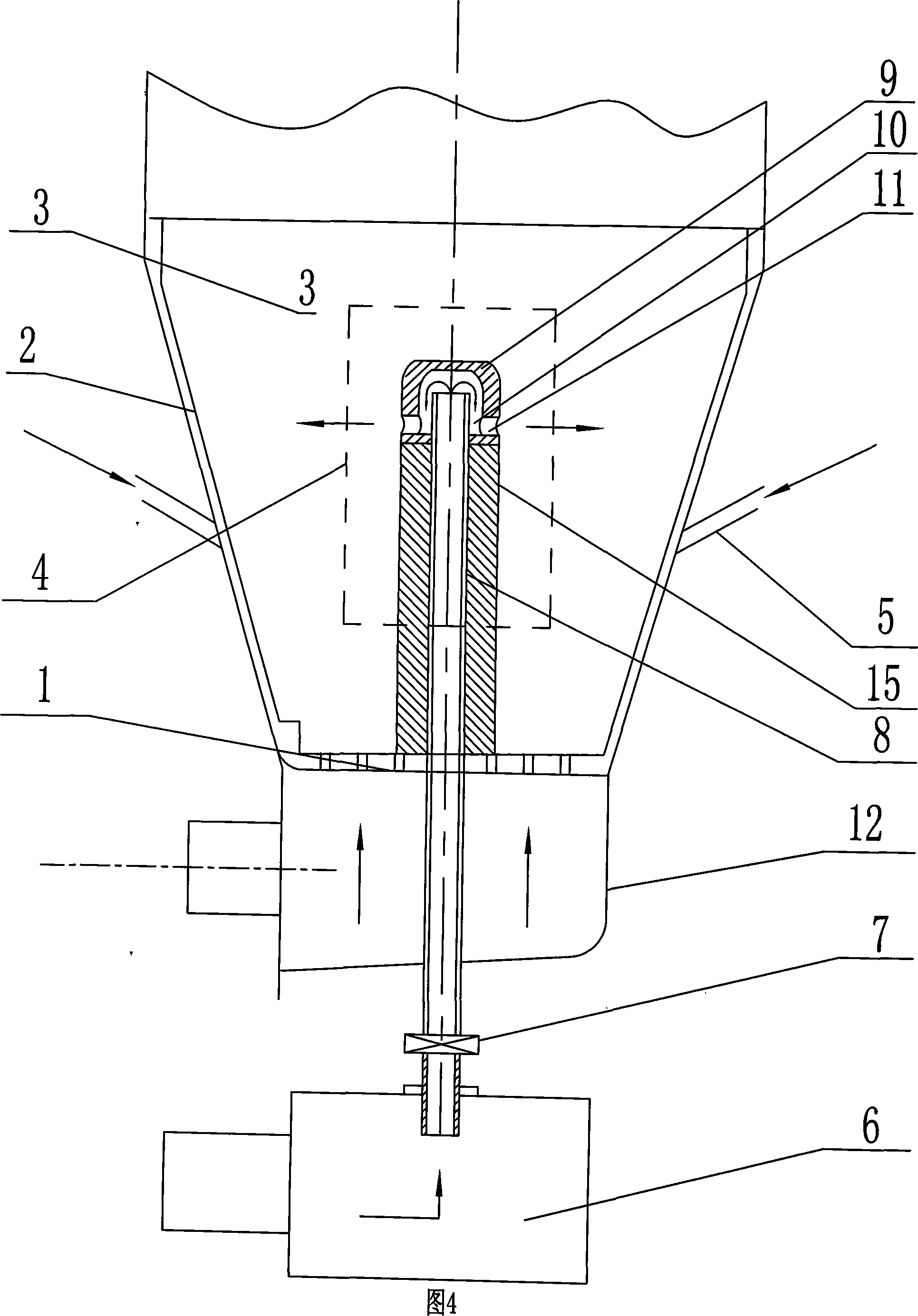

Fluidized bed combustion device with wall surface-center combined supplying secondary air

InactiveCN101196295AReduce uneven distributionPrevent fallbackFluidized bed combustionNon-combustible gases/liquids supplyBoiler furnaceCombustion chamber

A fluidized bed burning device for compositely providing secondary air by wall surface-center is provided, which relates to a burning device. The invention solves the problems as bad air supply effect, weak penetrating capacity of secondary air and bad operating performance when the materials are reversed into the secondary air transferring pipe at center of boiler of the existing fluidized bed burning device. The plurality of down-inclined secondary air pipes (5) are positioned on a side wall (2) of a fluidized bed firebox (3); the reversed secondary air post (4) is arranged at the central area in the fluidized bed firebox (3); a reversed pos head (9) is provided with a secondary air spraying port (11) on side wall; upper end of a secondary air transferring pipe (8) passes through the lower end surface of the reversed post head (9), which is mounted in the reversed post head (9) and is fixed and connected with the reversed post head (9). The invention supplies the air needed for burning at the central area of the boiler furnace and promotes the sufficient mixing and reaction of solid-gas two-phase in the furnace and realizes higher burning efficiency.

Owner:HARBIN INST OF TECH

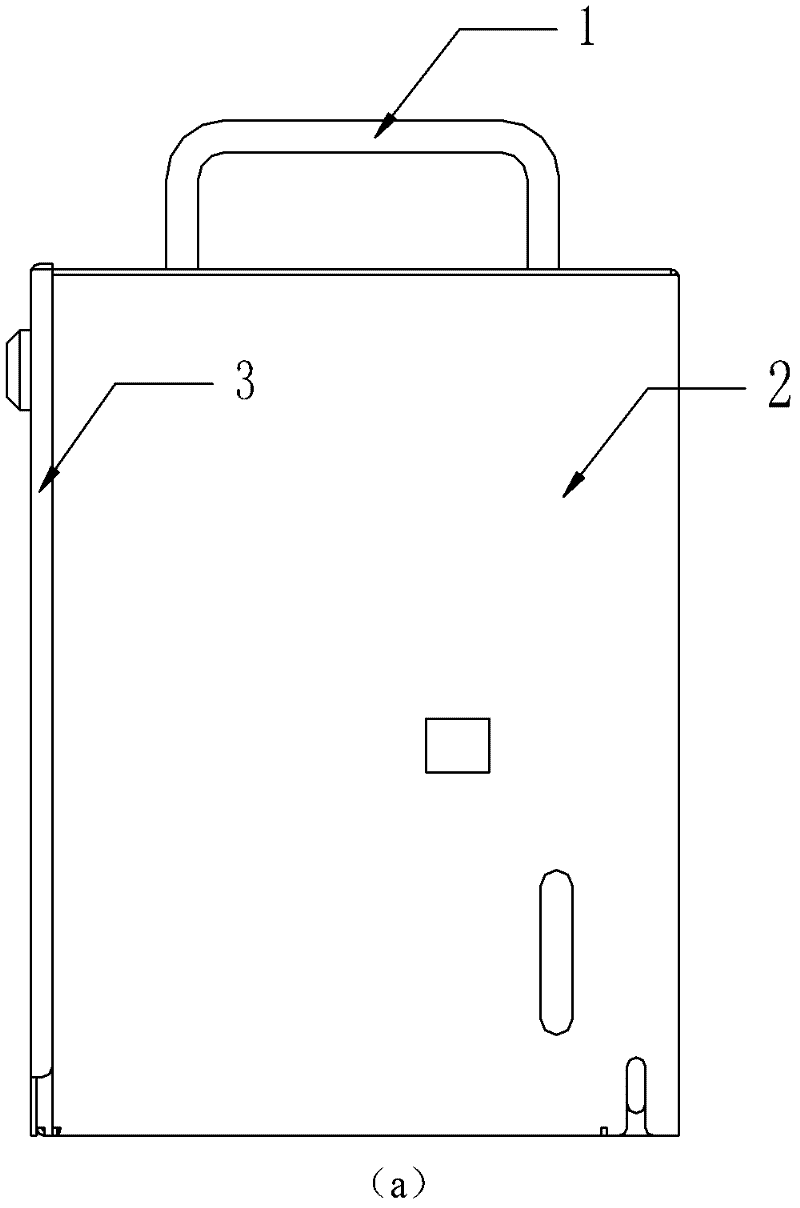

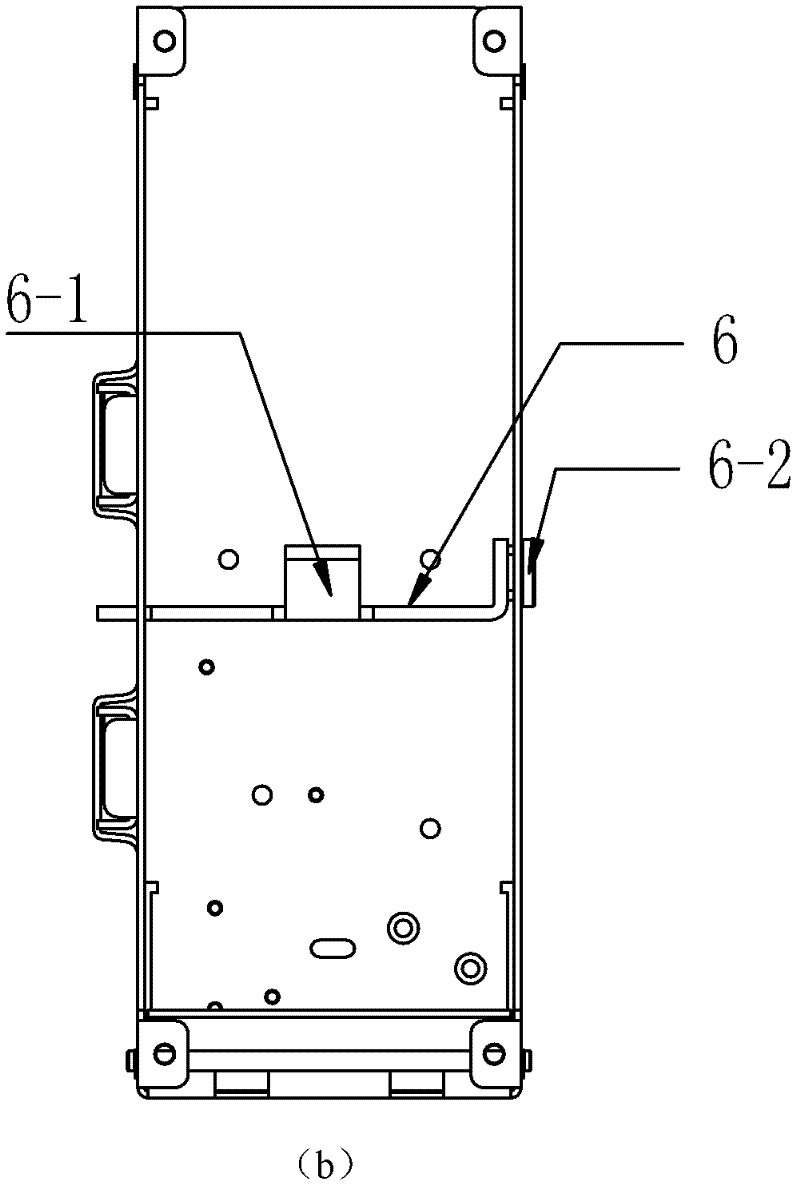

Mechanism for preventing card from overturning in card case

ActiveCN102419821ARealize automatic anti-turnover functionWithout human interventionConveying record carriersEngineeringTorsion spring

The invention discloses a mechanism for preventing a card from overturning in a card case. The mechanism is characterized in that: the mechanism comprises a pressing card mechanism and at least a set of overturn prevention mechanism; two relative side plates of the card case (card storage case) are respectively provided with a vertical long strip guide groove used for elevating guiding of the pressing card mechanism; two sides of the pressing card mechanism are provided with a guiding shaft or a guiding sheet; one side plate of the card case is provided with a sidewall guide rail used for horizontal guiding of the overturn prevention mechanism, and quantity of the sidewall guide rail is equal to quantity of the overturn prevention mechanism; the overturn prevention mechanism comprises an installation support and a locking plate; a front end of the installation support is provided with a locking plate rotating shaft, and both the locking plate and a reset torsion spring are sleeved on the locking plate rotating shaft; one end of the reset torsion spring is provided on the installation support, and the other end of the reset torsion spring is provided on the locking plate. According to the invention, the card is effectively and automatically prevented from overturning, operation is convenient, and conception is ingenious.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

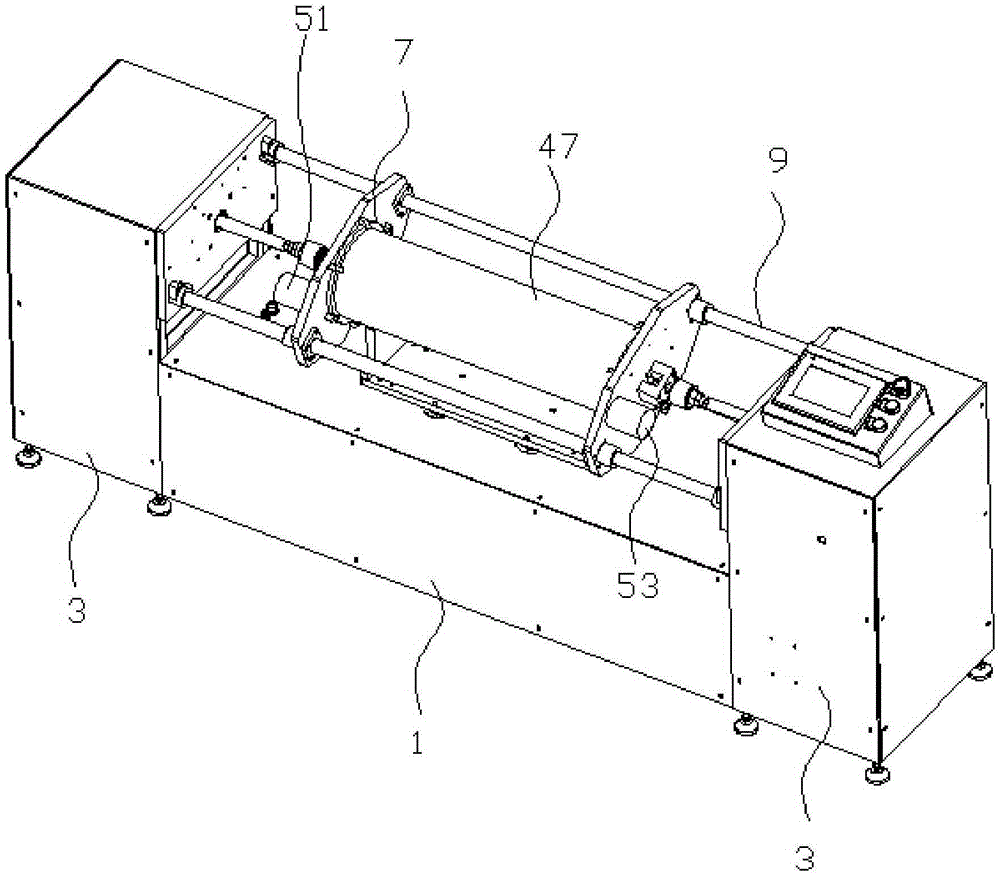

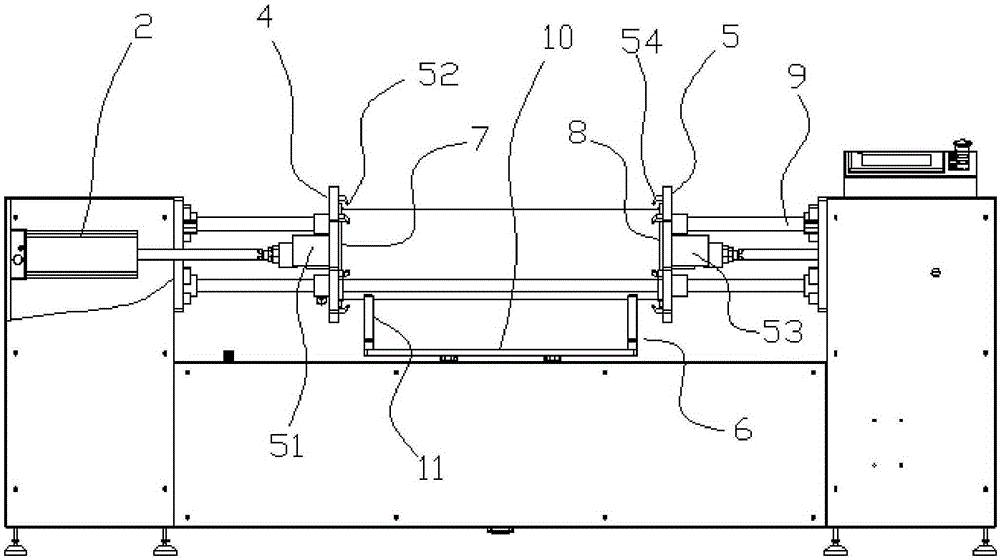

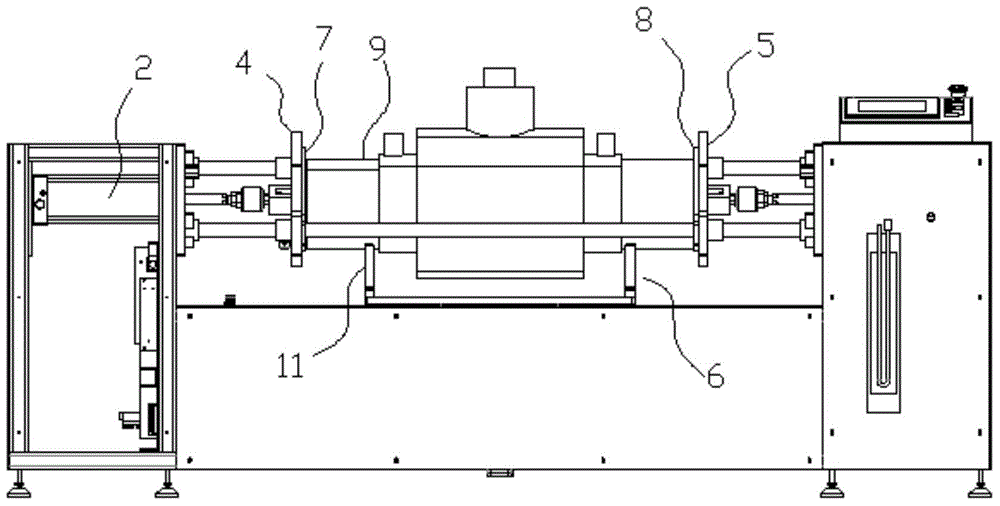

Pipe fitting airtightness testing machine

InactiveCN105203276AReasonable structureNo pinchingMeasurement of fluid loss/gain ratePipe fittingEngineering

The invention discloses a pipe fitting airtightness testing machine and aims at achieving the effects that the pipe fitting airtightness testing machine is convenient to operate, high in testing result accuracy and capable of guaranteeing that the two pipe ends of a pipe fitting are not prone to being damaged due to clamping. The machine comprises an air feed pump, a baroceptor, a main rack, two push plate air cylinders, two side racks, a main end cover and a subsidiary end cover, the two push plate air cylinders are arranged on the two side racks respectively, a piston rod of one of the push plate air cylinders is connected with the main end cover, a piston rod of the other push plate air cylinder is connected with the subsidiary end cover, a main elastic sealing ring pad is arranged on the main end cover, a subsidiary elastic sealing ring plate is arranged on the subsidiary end cover, and a main cover air hole is formed in the main end cover. The pipe fitting airtightness testing machine has the advantages that the pipe fitting can be positioned to the right position, the airtightness can be guaranteed, and the pipe fitting is not damaged due to clamping; the device is provided with a sealing structure which can be adjusted in a self-adaptation mode, and the airtightness effect in the high pressure testing process can be intensified; the machine is provided with an assistant positioning structure, the end covers can be prevented from moving backward, the push plate air cylinders can be protected, the sealing effect can be improved, and stability in the testing process can be maintained.

Owner:宁波新合博园林机械有限公司

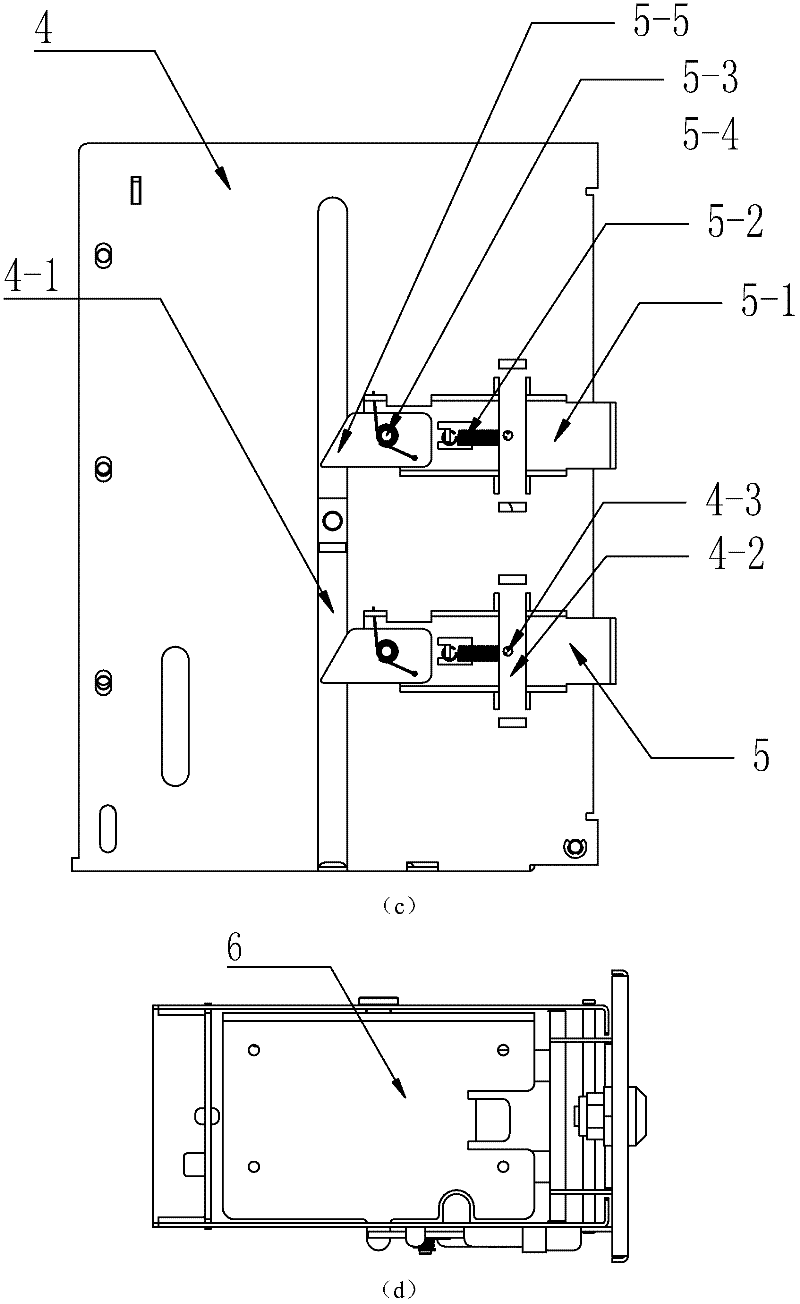

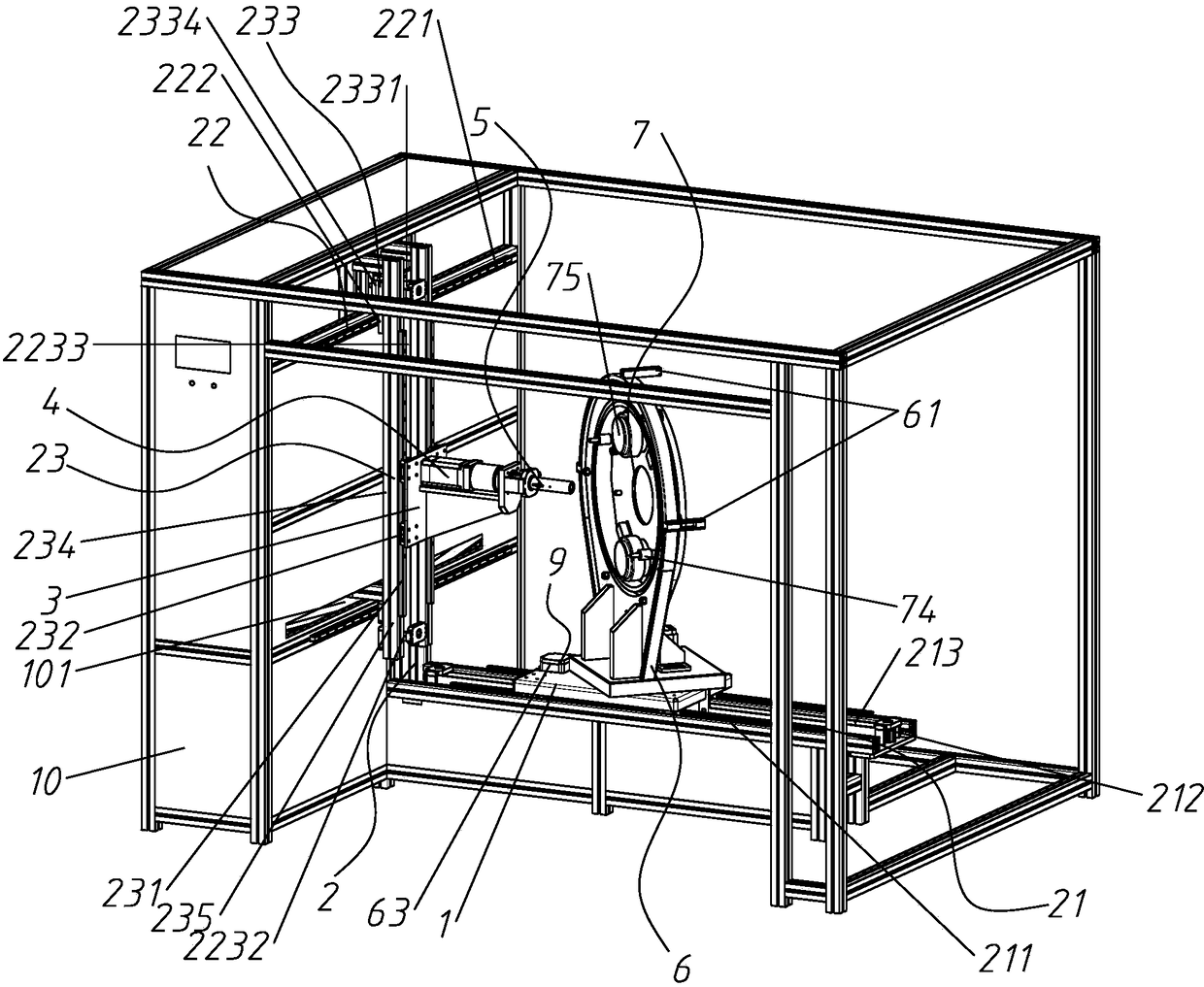

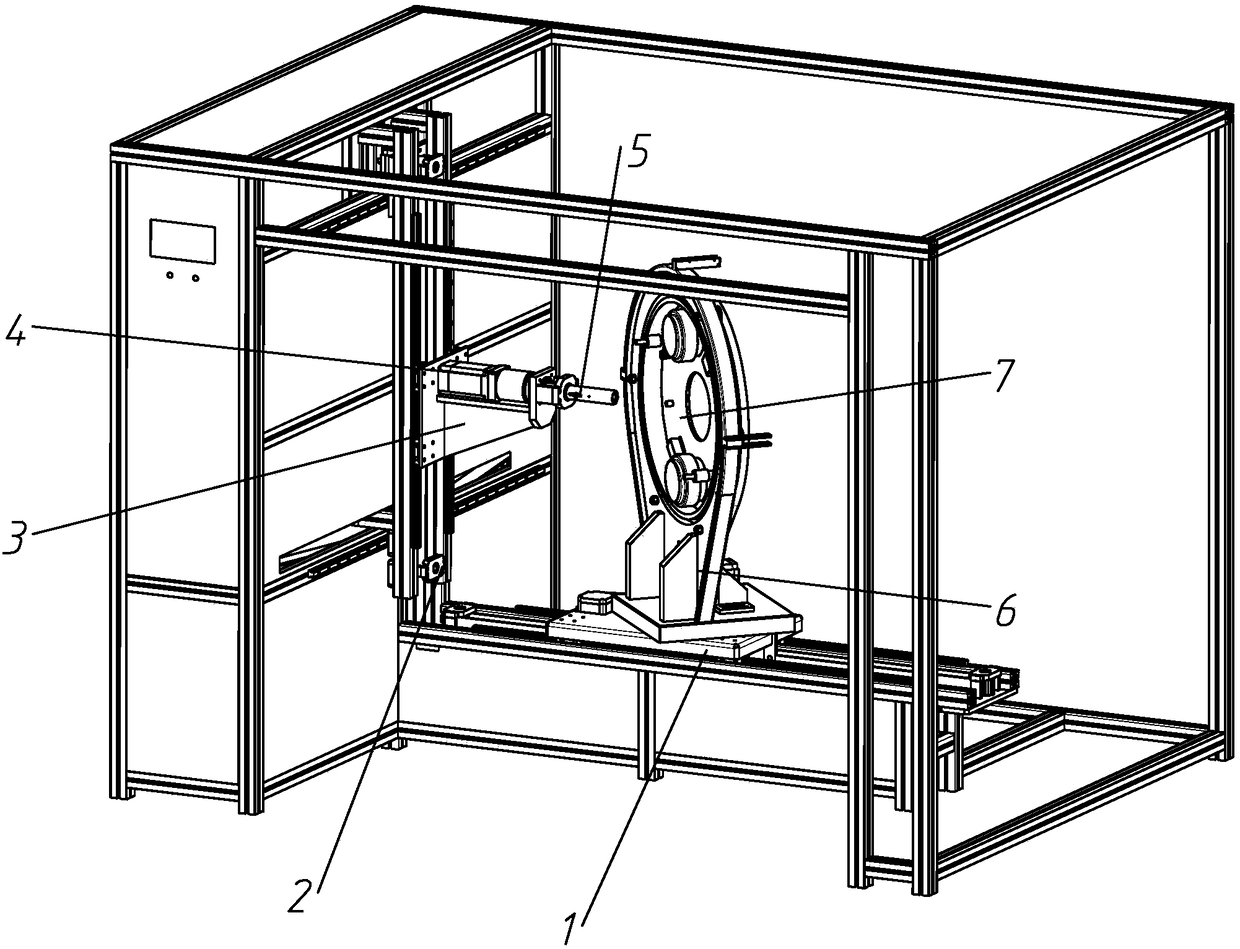

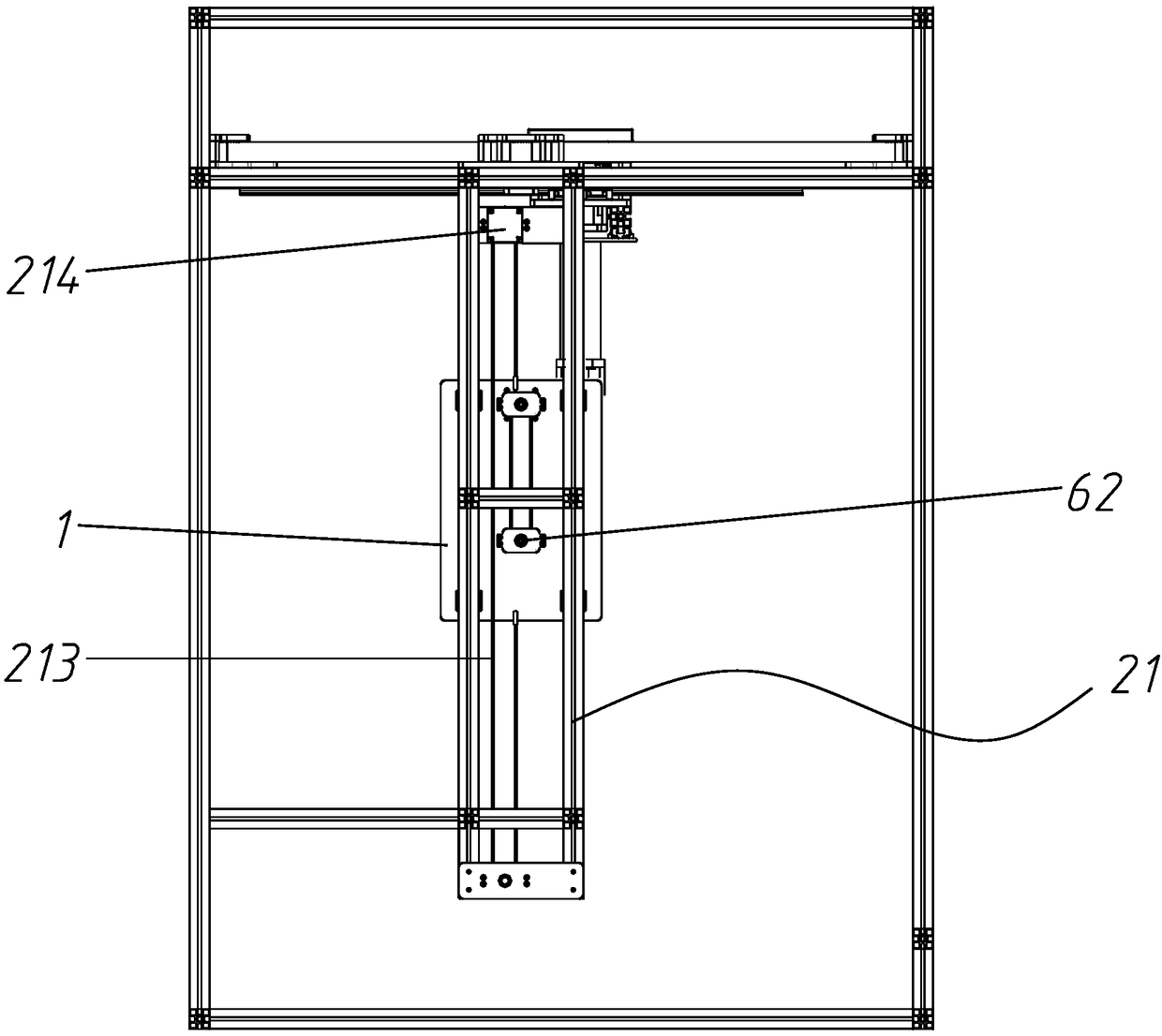

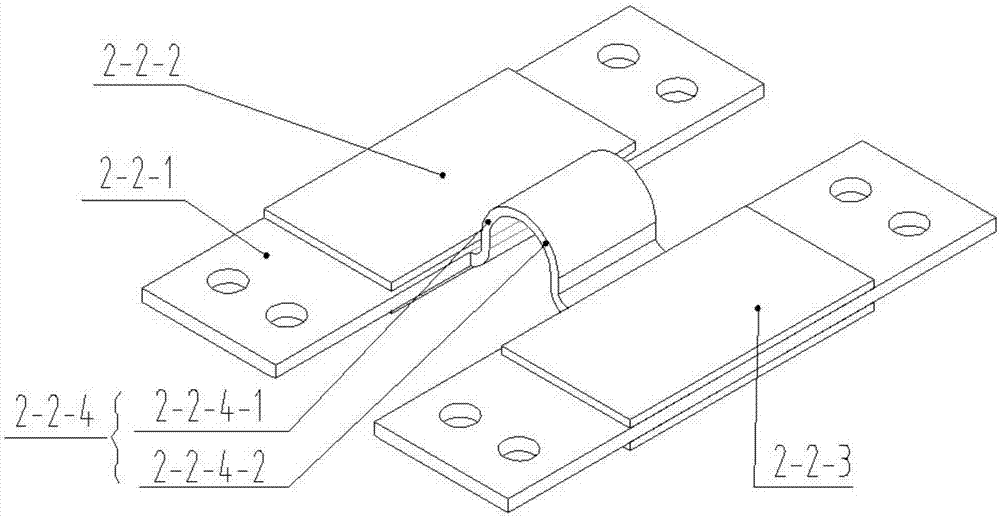

Multi-axis linkage winding machine for wrapping irregular pipe body

ActiveCN108423220AGuaranteed normal windingGuaranteed wrappingWrapping with article rotationWinding machineMulti axis

The invention belongs to the technical field of a winding machine, and provides a multi-axis linkage winding machine for wrapping an irregular pipe body. The multi-shaft linked winding machine comprises a foundation support, wherein the foundation support is connected with a clamping support by virtue of a moving apparatus, the clamping support makes the translation movement in a three-dimensionalspace relative to the foundation support by virtue of the moving apparatus, the clamping support is provided with a clamping portion in a rotating manner by virtue of a rotating apparatus I, the foundation support is provided with a winding frame in a rotating manner by virtue of a rotating apparatus II, a rotating shaft of the winding frame is perpendicular to a rotating shaft of the clamping support, the winding frame is provided with a winding disc in a rotating manner, and the winding disc is provided with a supporting apparatus for supporting a wound strip coil. By virtue of the technical scheme, the technical problems in the prior art that no winding machine for winding the irregular tubular article is provided can be solved.

Owner:河北海赞自动化科技有限公司

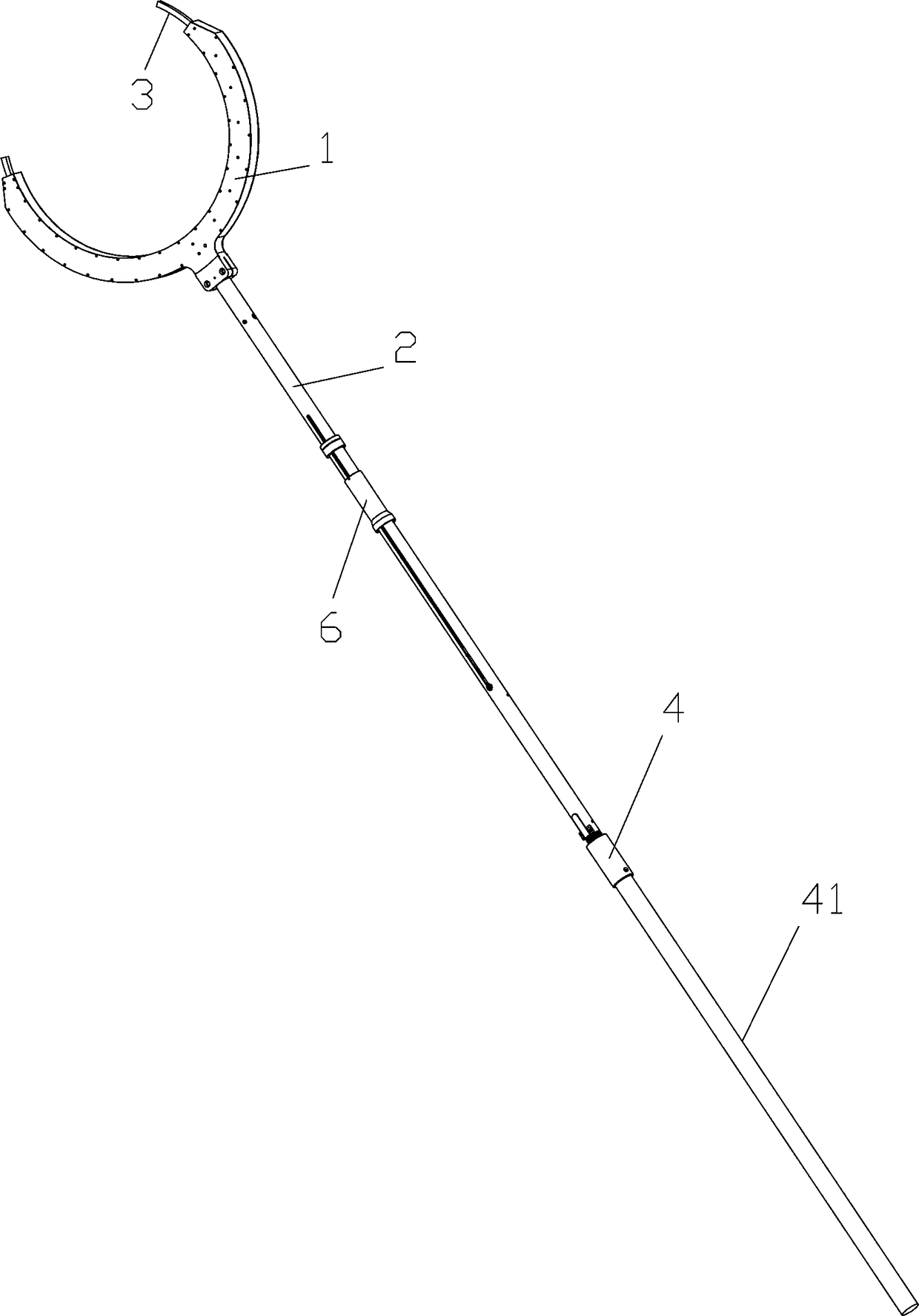

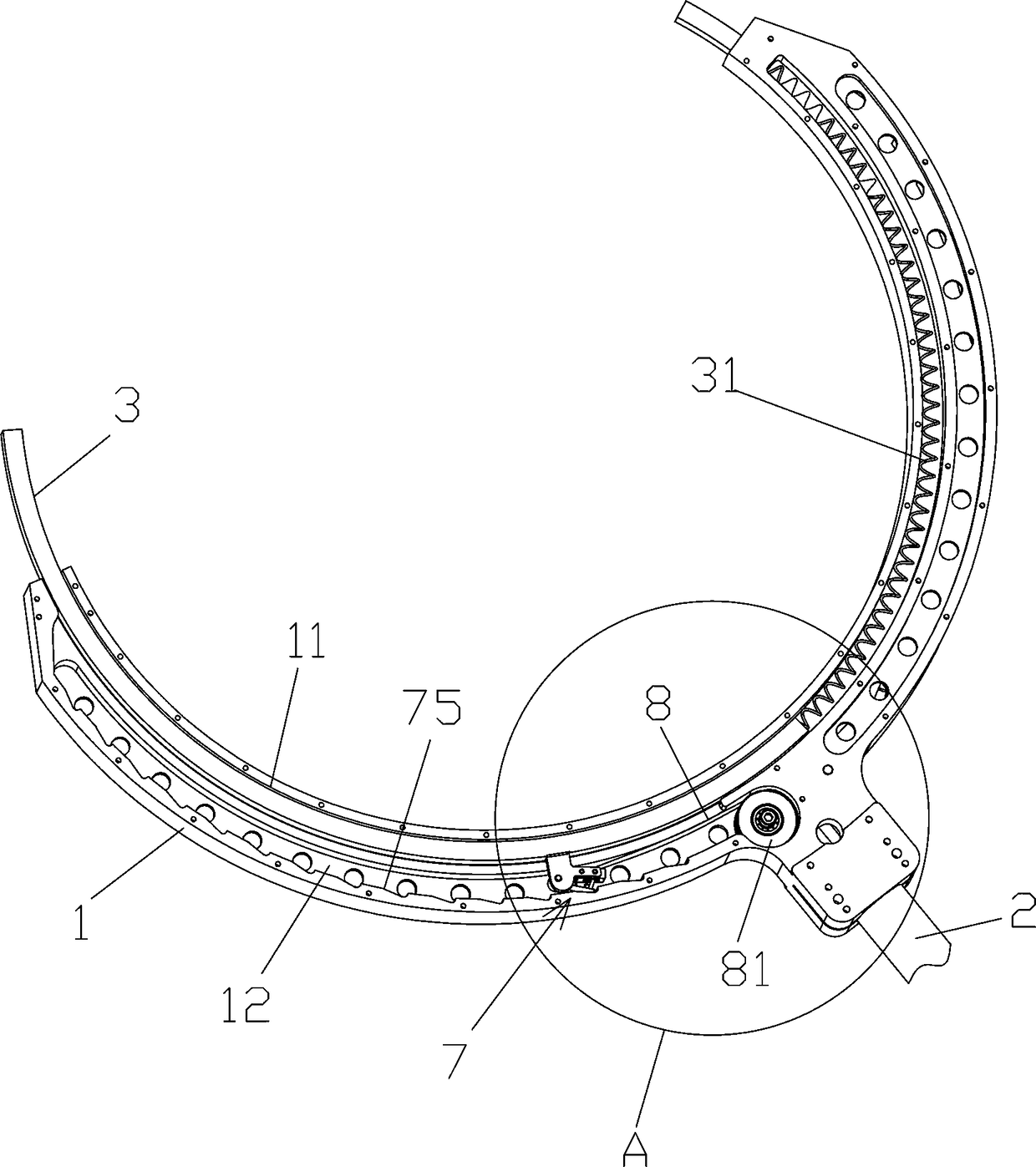

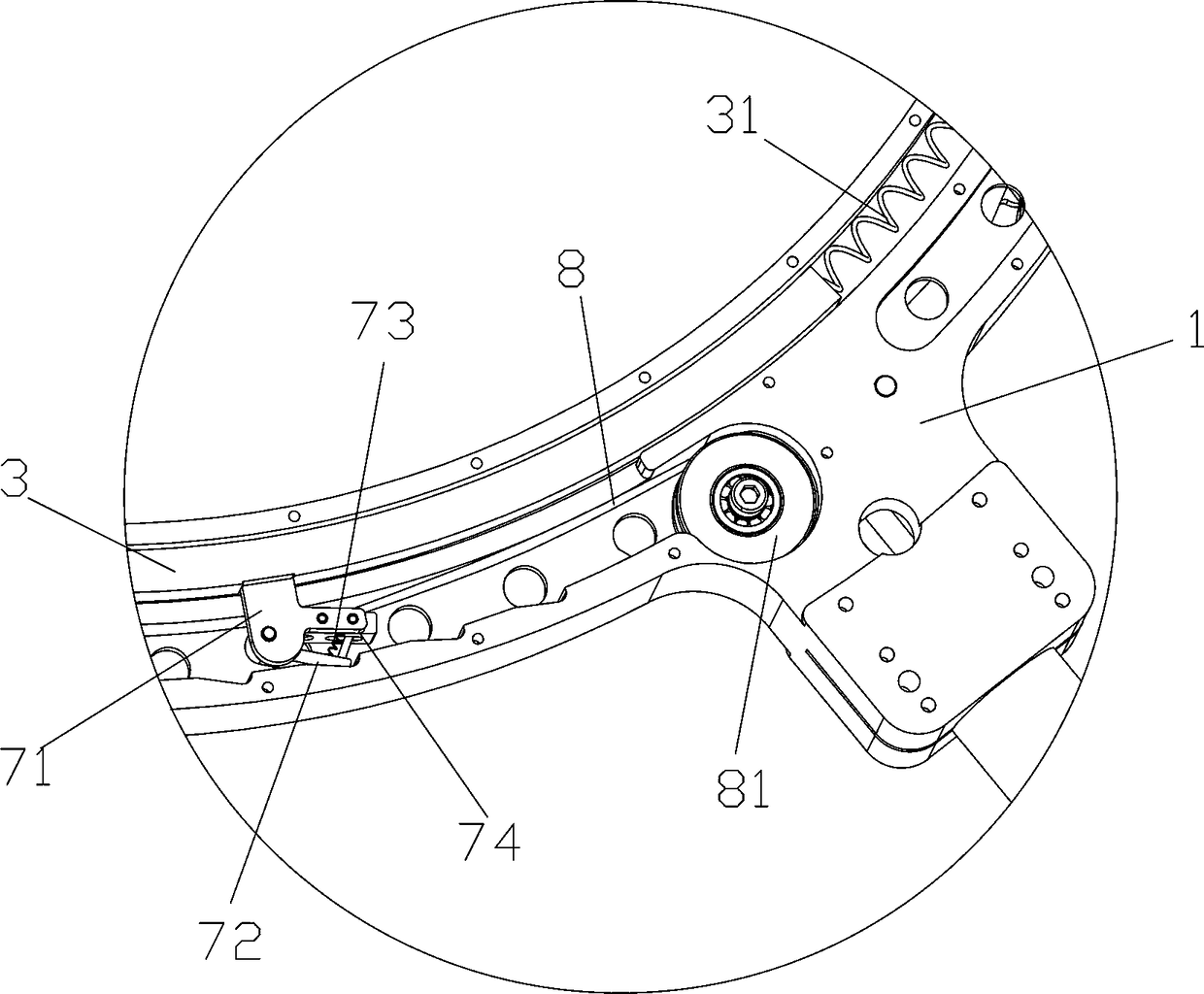

Anti-riot steel fork

The invention provides an anti-riot steel fork. The anti-riot steel fork comprises a steel fork body, the middle part of the steel fork body communicates with a steel pipe, two sets of locking mechanisms are arranged in the steel fork body, a trigger mechanism is installed on the steep pipe, and the two sets of locking mechanisms are correspondingly connected with the trigger mechanism through flexible ropes. The locking mechanisms comprise arc-shaped slide ways and arc-shaped cavities, wherein the steel fork body is internally provided with the arc-shaped slide ways and the arc-shaped cavities, and one sides of the slide ways communicate with the arc-shaped cavities; first springs and arc-shaped fork rods are installed in the arc-shaped slide ways in a matching mode; guide pulleys are connected to one ends, close to the steel pipe, of the arc-shaped cavities in a shaft mode; one-way stopping mechanisms connected with the fork rods are arranged in the arc-shaped cavities, and pressingrods are hinged in notches; second springs are arranged between the pressing rods and sliding columns, top blocks are fixedly connected to one ends of the pressing rods, and the second springs push the top blocks to be inserted into inserting holes. The anti-riot steel fork can quickly subdue a rioter, and can effectively prevent the rioter escaping from the steel fork body.

Owner:宜都市公安局

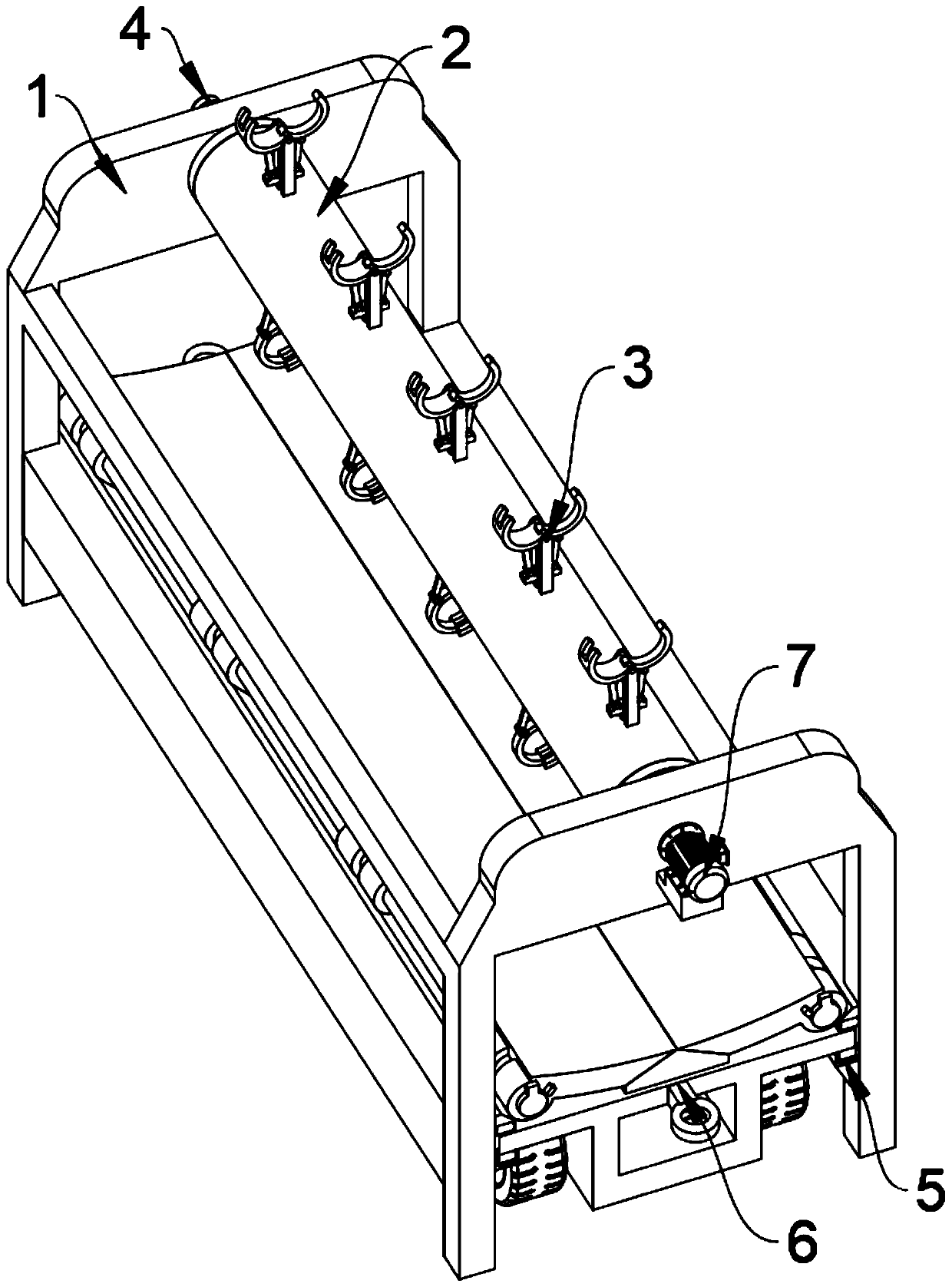

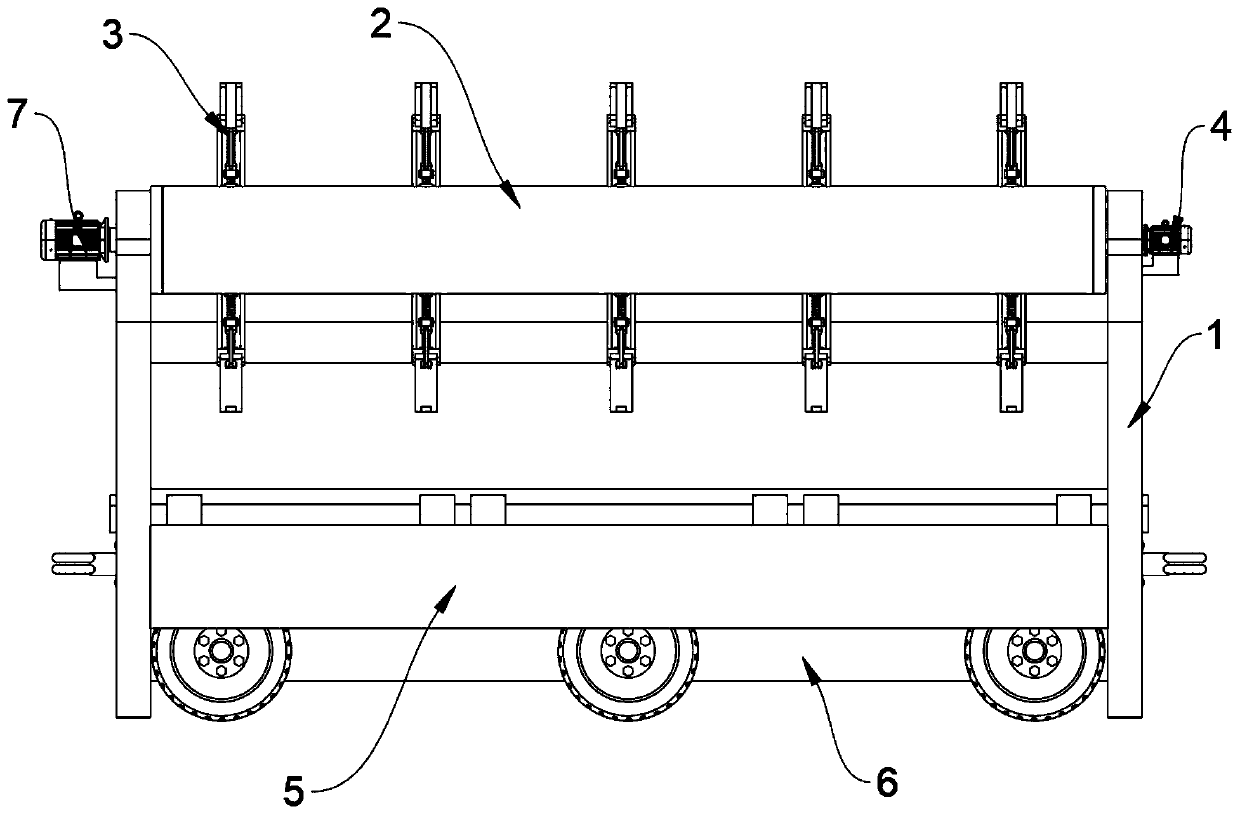

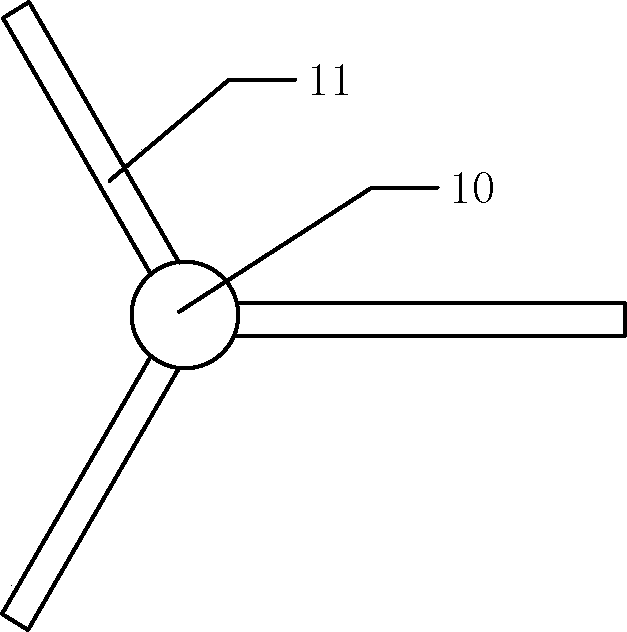

Traction unloading device for construction reinforcement straightening machine

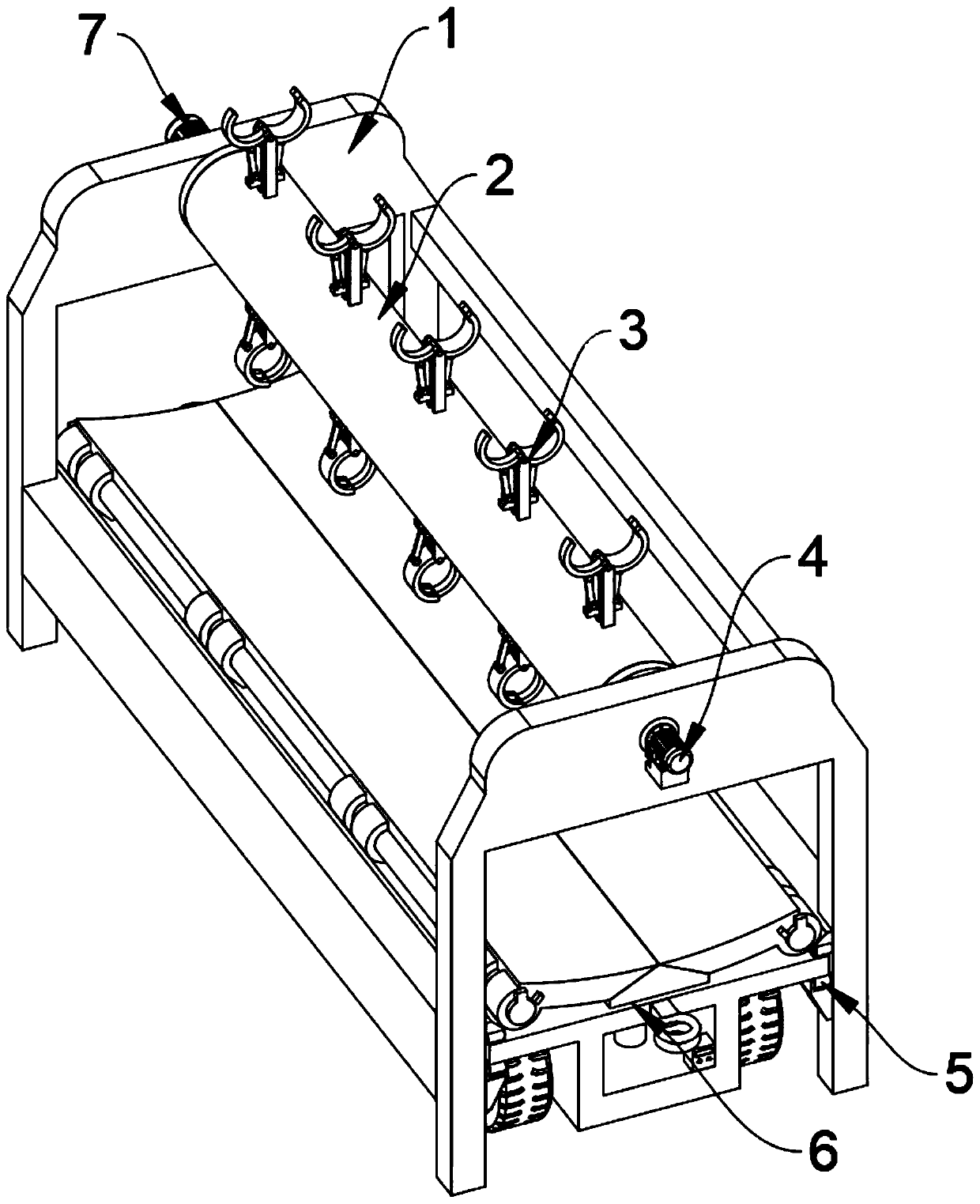

InactiveCN111392110ARealize the collectionConvenient bundling for transportationBundling machine detailsElectric machineryScrew thread

The invention provides a traction unloading device for a construction reinforcement straightening machine. The traction unloading device comprises a fixed mounting bracket and two rows of reinforcement fixing claws; a fixed revolving drum is rotationally mounted on the inner side wall of the top end of the fixed mounting bracket; each row of reinforcement fixing claws comprises five reinforcementfixing claws, and the reinforcement fixing claws are symmetrically mounted on the wall of the fixed revolving drum; and a revolving driving motor is fixed on the side wall of one end of the fixed mounting bracket through bolts. Each reinforcement fixing claw of the traction unloading device for the construction reinforcement straightening machine comprises two arc-shaped claw bodies, claw body control connecting rods, claw body adjusting thread blocks, a claw body supporting frame, a claw body drive bevel gear and a claw body drive screw, the arc-shaped claw bodies are of semi-circular arc-shaped structural design and are matched with each other to be connected to the frame body at the top end of the claw body supporting frame by a shaft, collection for straightened reinforcements is facilitated, and besides, the arc-shaped claw bodies are used for locking, so that bundling and transportation of the reinforcements are convenient for workers.

Owner:天长市天建建筑工程有限责任公司

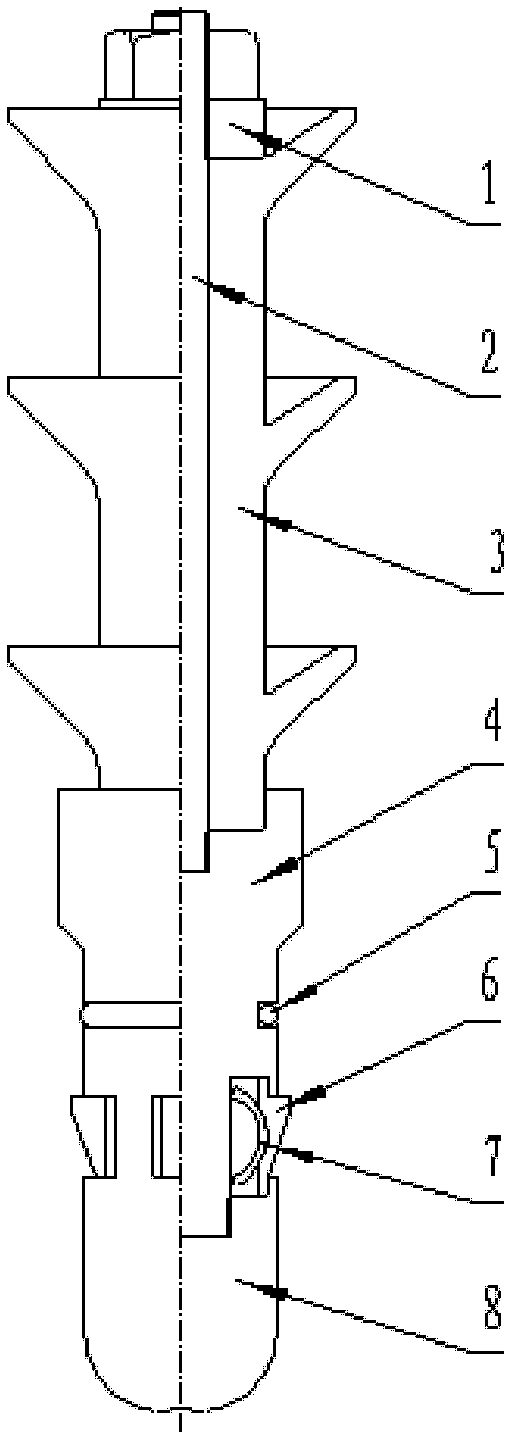

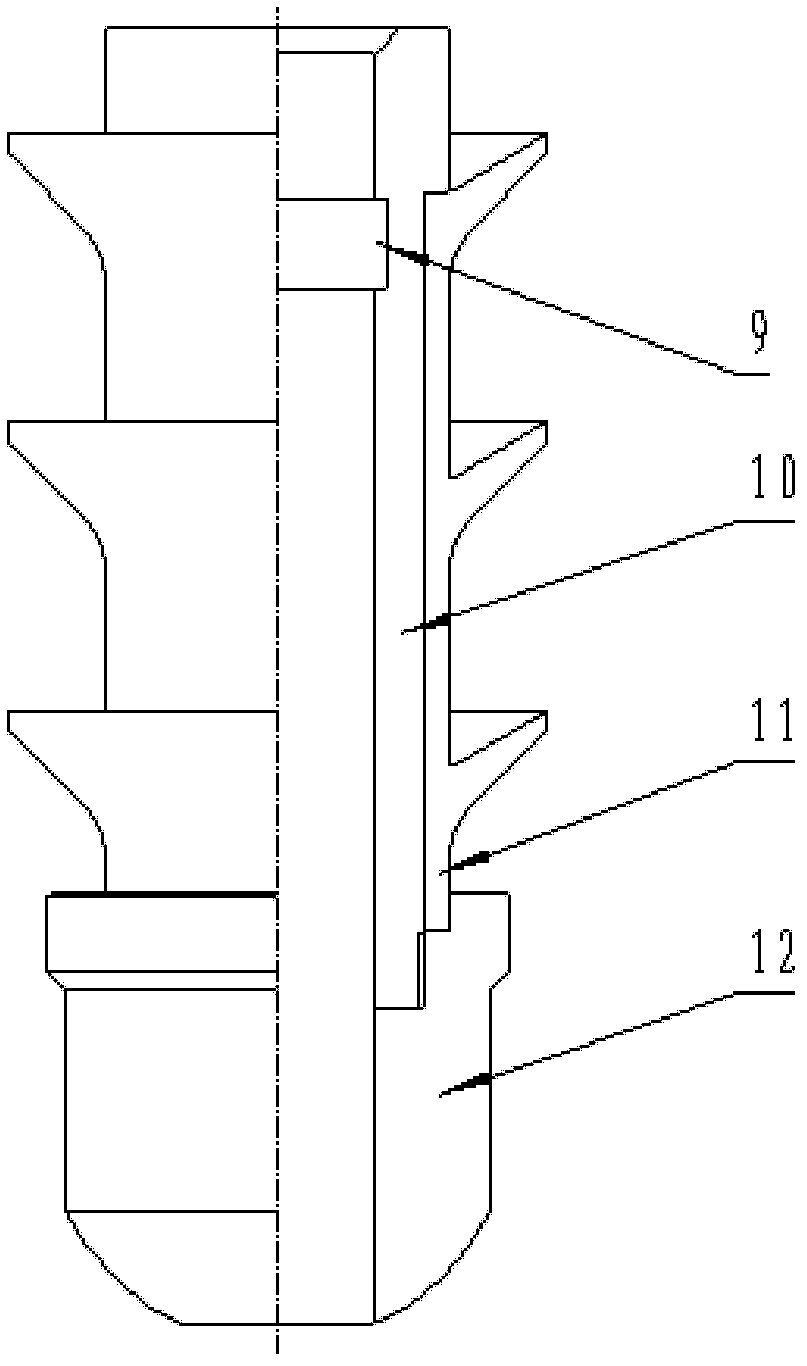

Drilling liner cementing rubber plug composite colliding device

InactiveCN102628347APrevent fallbackAvoid plug and low return problems outside the tubeSealing/packingEngineeringScrew thread

The invention relates to a petroleum drilling and cementing tool, in particular to a drilling liner cementing rubber plug composite colliding device. A drilling rod rubber plug of the device comprises a fixed nut, a connecting rod, a small rubber bowl and a bowl seat, the fixed nut, the connecting rod, the bowl seat and a guiding head are sequentially in threaded connection from top to bottom, the small rubber bowl is sleeved outside the connecting rod, a clamping block is installed on the outside of the bowl seat, and a back-moving spring is installed on the inside of the clamping block. A tail pipe tubular rubber plug comprises a tubular connector, a big rubber bowl and a tubular guiding bowl seat, the tubular connector is designed to be hollow, a clamping block groove matched with the clamping block is designed on the inner wall of the tubular connector, the lower end of the tubular connector is in threaded connection with the tubular guiding bowl seat, and the big rubber bowl is sleeved outside the tubular connector. The drilling liner cementing rubber plug composite colliding device is high in carrying power, reliable in fixation, simple in structure and convenient to use, and solves the problem that the existing well cementation rubber plug is low in carrying power, not safe in use and apt to cause cement inverse returning, low returning outside a pipe, and cement plug leaving in the pipe and the like.

Owner:CNPC GREATWALL DRILLING ENG

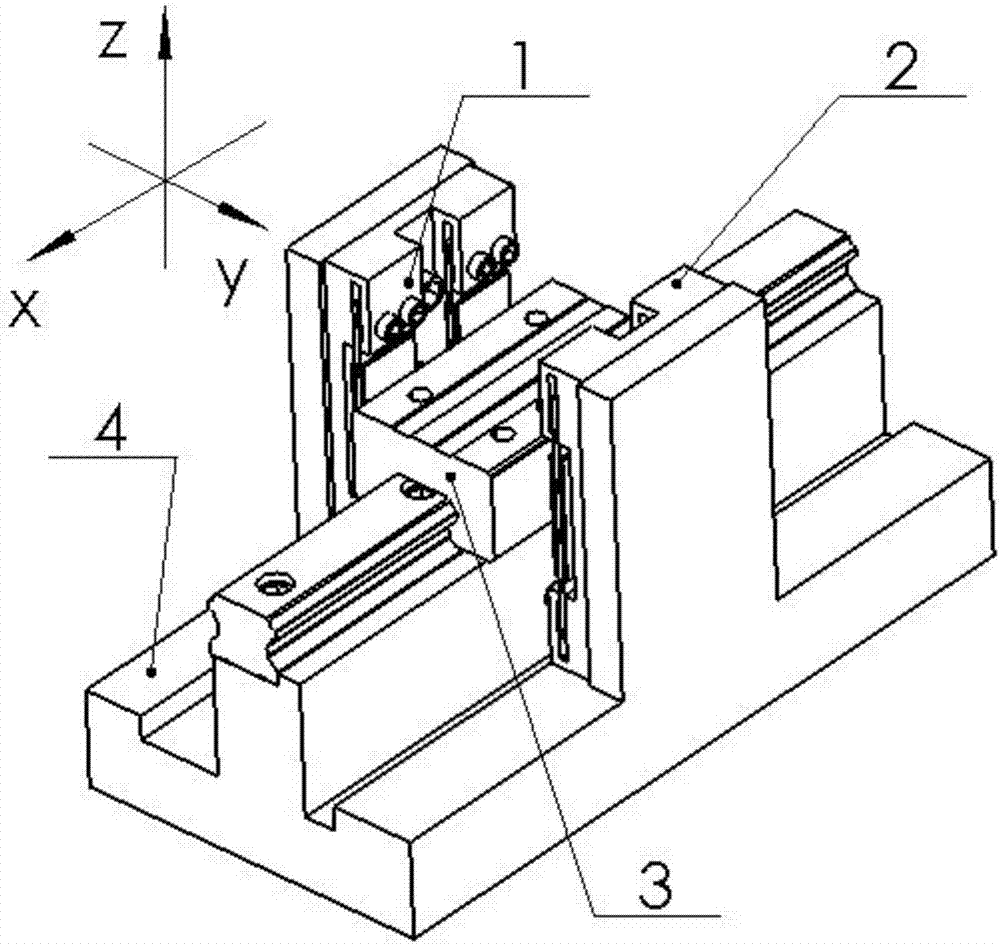

A double-butterfly-shaped stator piezoelectric linear actuator

PendingCN107124119ACompact structureIncrease the itineraryPiezoelectric/electrostriction/magnetostriction machinesAviationDrive by wire

The invention discloses a double-butterfly-shaped stator piezoelectric linear actuator belonging to the field of precision driving technology. The double-butterfly-shaped stator piezoelectric linear actuator comprises a butterfly-shaped stator 1 (1), a butterfly-shaped stator 2 (2), a mover (3) and a pedestal (4), wherein the butterfly-shaped stator 1 (1) and the butterfly-shaped stator 2 (2) are placed on both sides of the mover (3) in mirror symmetry and are in elastic contact with the mover (3) and fixedly mounted on the pedestal (4). The butterfly-shaped stator 1 (1) and the butterfly-shaped stator 2 (2) have the same structure. A sinusoidal drive electric signal for lagging behind the butterfly-shaped stator 1 (1) for half a cycle is applied to the butterfly-shaped stator 2 (2). The butterfly-shaped stator 1 (1) and the butterfly-shaped stator 2 (2) alternately step to drive the mover (3) to move to effectively overcome backing of the mover (3). The double-butterfly-shaped stator piezoelectric linear actuator of the invention has advantages of a simple and compact structure, a large stroke, high precision, a large load and being capable of effectively inhibiting backspacing and being applied to the fields such as micro-nano machining, space flight and aviation and precision optics.

Owner:JILIN UNIV

Vehicle auxiliary drive mechanism

InactiveCN103448696AAvoid secondary drivePrevent fallbackBraking element arrangementsTransmitted powerCoil spring

The invention discloses a vehicle auxiliary drive mechanism which comprises an engine, a transmission, a first clutch, a vehicle speed sensor and a controller. The first clutch is connected between the engine and the transmission. An output end of the transmission is connected with a differential mechanism through a reduction gear set. A position sensor is disposed on the first clutch. The output end of the transmission is connected with an input shaft of an accumulation transmission system through a second clutch which is connected with a brake pedal. An output shaft of the accumulation transmission system is provided with an accumulation coil spring and a locking device. The output shaft of the accumulation transmission system is connected with the differential mechanism through an auxiliary drive transmission system which can transmit power unidirectionally. The vehicle speed sensor and the position sensor are connected with an input end of the controller. An output end of the controller is connected with the locking device. By the vehicle auxiliary drive mechanism, brake energy during traveling of fuel vehicles can be fully absorbed, stored and used for driving vehicle starting, starting performance of the vehicles can be improved favorably, and oil consumption and emission can be lowered evidently.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

Cable pulling device

ActiveCN104348117APrevent fallbackAvoid confusionApparatus for laying cablesCable trayPetroleum engineering

The invention discloses a cable pulling device, which comprises a fixing device and a cable pulling disc, wherein the fixing device comprises a fixing frame and a fixing ring, the fixing frame comprises a base and a support rod, the support rod is positioned at the center of the base, and is connected with the base by thread, the fixing ring is fixedly connected with the upper end of the support rod, the fixing ring is in a circle shape and is provided with a notch, locking blocks are respectively arranged at the two sides of the notch of the fixing ring, a locking bolt is arranged between the two locking blocks, the fixing ring is provided with a clamping groove along the circumferential direction, and is an elastic clamping groove, the cable pulling disc is positioned in the clamping groove and is abutted against the clamping groove, a group of cable pulling holes are formed in the cable pulling disc, a binding belt is arranged in the inner wall of each cable pulling hole, and a hanging ring is arranged at the center of the cable pulling disc. The cable pulling device overcomes the technical defects of disordering of cables and difficult operation of cable connecting equipment in the cable pulling process in a cable tray, and has the advantages that the disordering of the cables is avoided and the operation of the cable connecting equipment is easy when the cable is pulled in the cable tray.

Owner:CHONGQING RUIPU CABLE

Ball valve sealing test machine

InactiveCN105181274ANo pinchingPrevent fallbackMeasurement of fluid loss/gain rateEngineeringHigh pressure

The invention discloses a ball valve sealing test machine and aims to provide the ball valve sealing test machine which is convenient to operate, has high-accuracy test result and can guarantee that two pipe ends of a ball valve are prevented from being damaged by clamping. The ball valve sealing test machine comprises an air feeding pump, an air pressure sensor, a main frame, two push cylinders, two side frames, a main end cover and a secondary end cover, wherein the two push cylinders are respectively arranged on the side frames, a piston rod of one push cylinder is connected with the main end cover, a piston rod of the other push cylinder is connected with the secondary end cover, the main end cover is provided with a main elastic sealing ring pad, the secondary end cover is provided with a secondary elastic sealing ring board, and the main end cover is provided with a main cover air hole. The ball valve sealing test machine is advantaged in that, sealing and avoidance of damage to the ball valve can be guaranteed through positioning and clamping the ball valve in position, an adaptively-adjustable sealing structure is realized, the sealing effect during high-pressure detection can be strengthened, the ball valve sealing test machine has an auxiliary positioning structure, the end cover can be prevented from backspacing, the push cylinders are protected, the sealing effect is improved, and stability of the detection process is maintained.

Owner:王国良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com