Device for testing internal sealing property of piping

A technology for sealing detection and pipe fittings, which is applied in the use of liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rates of fluids, etc., which can solve the problems of pipe fitting deformation, troublesome pipe fitting installation, and uneven end face of pipe fittings. Guarantee the effect of sealing and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

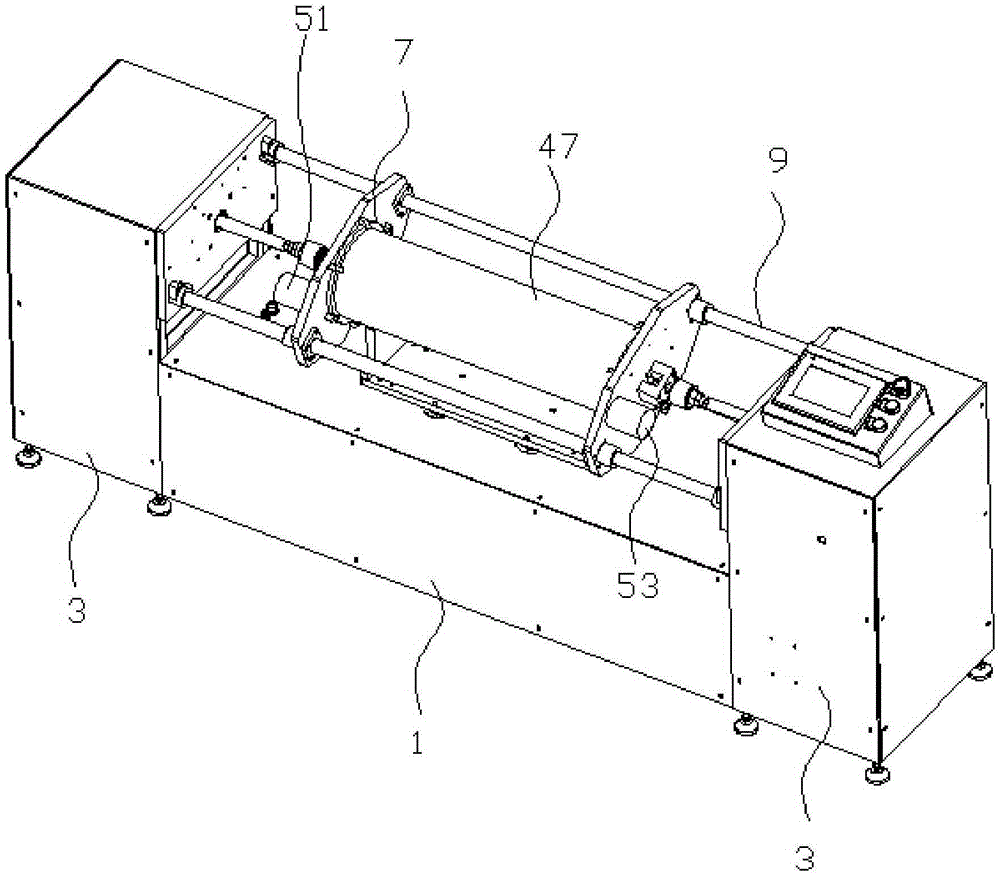

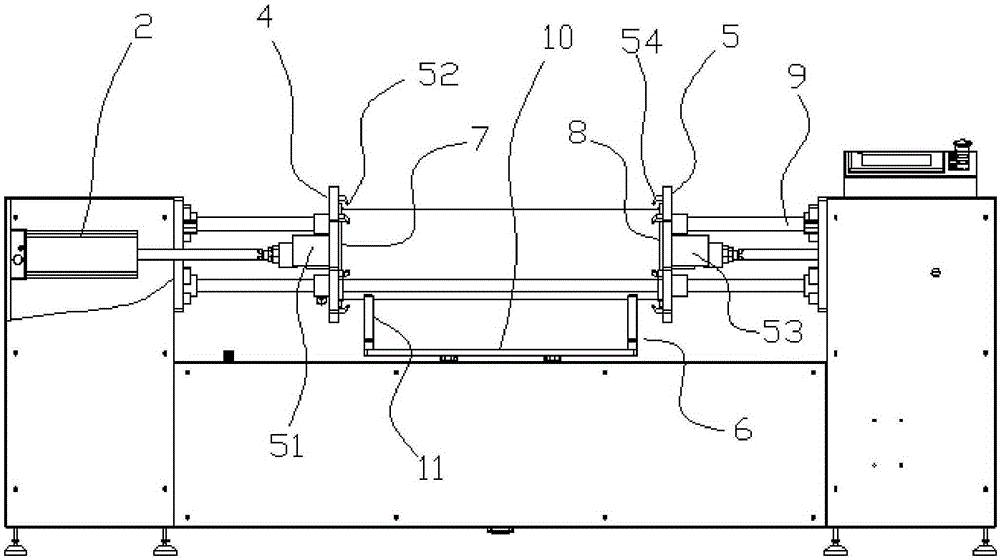

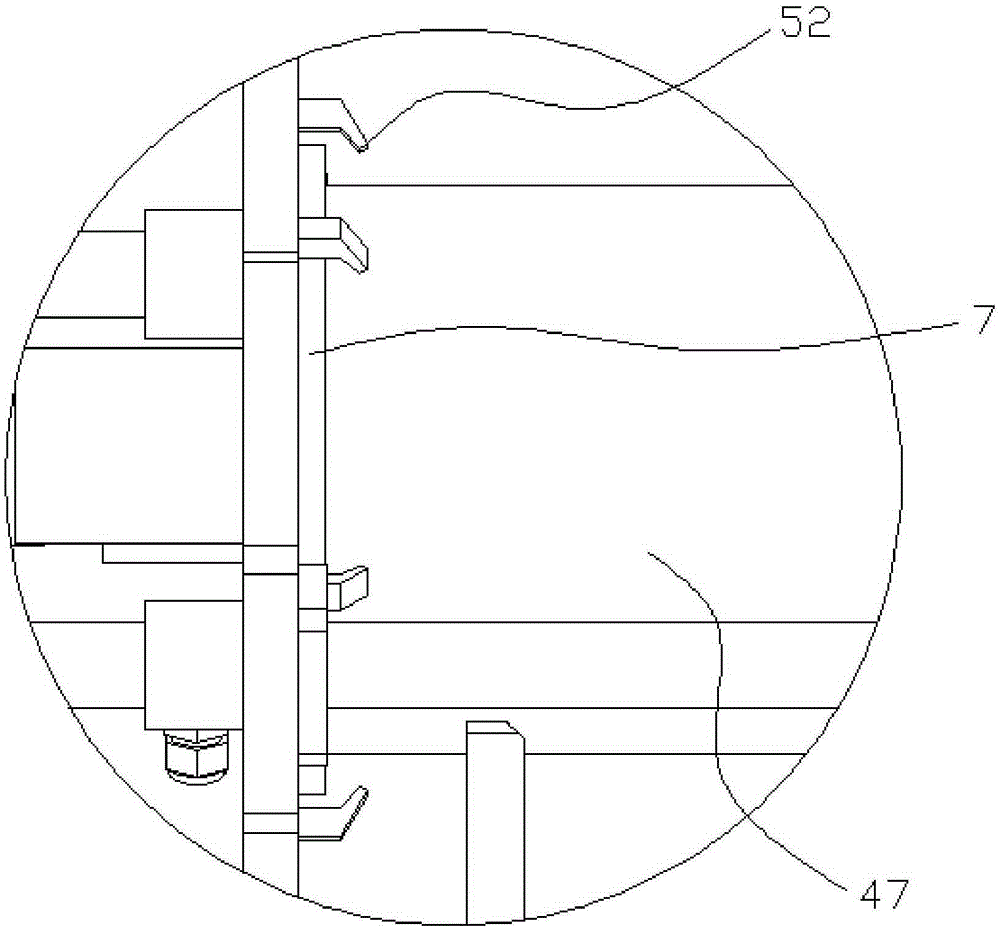

[0040] Embodiment 1: as Figure 1 to Figure 5 In the shown embodiment, a device for detecting the internal tightness of pipe fittings includes an air supply pump, an air pressure sensor 14, a main frame 1, two push plate cylinders 2, two side frames 3 with opposite inner surfaces, and a main end cover 4 , auxiliary end cover 5, described main end cover and auxiliary end cover are parallel to each other, described main frame is provided with the pipe fitting supporting frame 6 that is used to support tested pipe fitting, two push plate cylinders are respectively located at two side machine On the frame, the piston rod of one of the push pedal cylinders is connected to the main end cover, and the piston rod of the other push pedal cylinder is connected to the auxiliary end cover. The main elastic sealing ring gasket 7 of the pipe end of the pipe under test, the surface of the auxiliary end cover close to the pipe support frame is provided with an auxiliary elastic sealing ring p...

Embodiment 2

[0044] Embodiment 2: as Figure 6 to Figure 8In the shown embodiment, a device for detecting internal airtightness of pipe fittings includes an air supply pump 13, an air pressure sensor, a main frame, two push plate cylinders, two side frames with opposite inner surfaces, a main end cover, and a secondary end cover , the main end cover and the auxiliary end cover are parallel to each other, the main frame is provided with a pipe support frame for supporting the tested pipe, and two push plate cylinders are respectively arranged on the two side frames, one of which pushes The piston rod of the plate cylinder is connected to the main end cover, and the piston rod of the other push plate cylinder is connected to the auxiliary end cover. Elastic sealing ring pad 7, the surface of the auxiliary end cover near the side of the pipe fitting support frame is provided with an auxiliary elastic sealing ring plate 8 for contacting the pipe end of the measured pipe fitting, and the main e...

Embodiment 3

[0052] Embodiment 3: the basic structure and implementation mode of this embodiment are the same as embodiment 2, and its difference is, as Figure 9 to Figure 12 As shown in: It also includes two anti-retraction cylinders 31, one of which is fixed on the main end cover through an anti-retraction bracket 32, and the other anti-retraction cylinder is fixed on the secondary end cover through an anti-retraction bracket , the anti-retraction cylinder is provided with a push plate piston 33 that can slide up and down in the anti-retraction cylinder, the described push plate piston is connected with the inner end of a disc piston rod 34, and the outer end of the disc piston rod is provided with There is a suction cup 35, and the described connecting disk piston rod is vertical, and the described pushing disk piston divides the anti-retraction cylinder where it is located into an air chamber 36 and an active chamber 37, and the described inflatable chamber is connected with an anti-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com