A bimetallic band saw blade with 3/4t seven-variable tooth profile

A bimetal band and saw blade technology, applied in metal sawing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing costs and material costs, affecting the economic benefits of enterprises, and short service life. Unobstructed chip removal, improved cutting surface quality, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

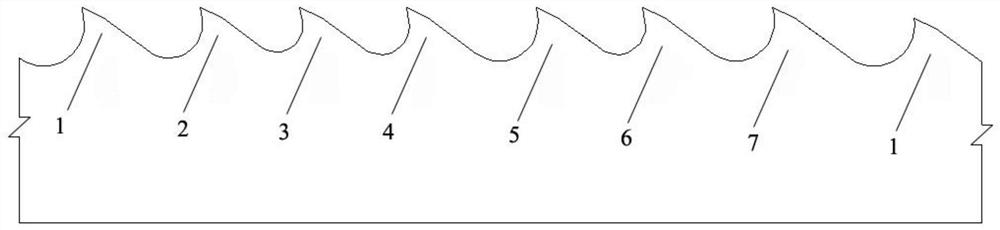

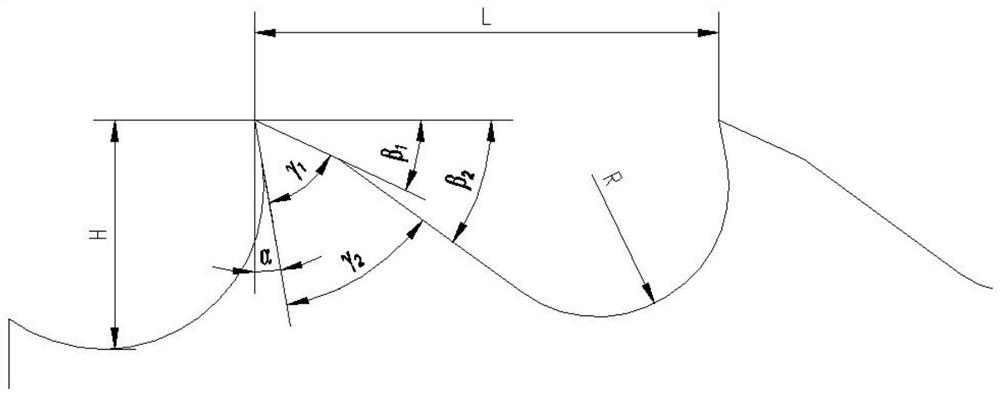

[0024] Such as figure 1 , figure 2 , image 3 Shown are the front view, left view and partial enlarged view of the bimetallic band saw blade with 3 / 4T seven-variable teeth variable tooth profile tooth profile respectively. The bimetallic band saw blade with 3 / 4T seven-variable-tooth variable-tooth profile of the present invention includes a saw blade tooth portion and a saw blade body, and is characterized in that seven consecutively arranged saw teeth form a set of saw teeth, and the set of saw teeth Repeatedly and continuously arranged to form the teeth of the saw blade;

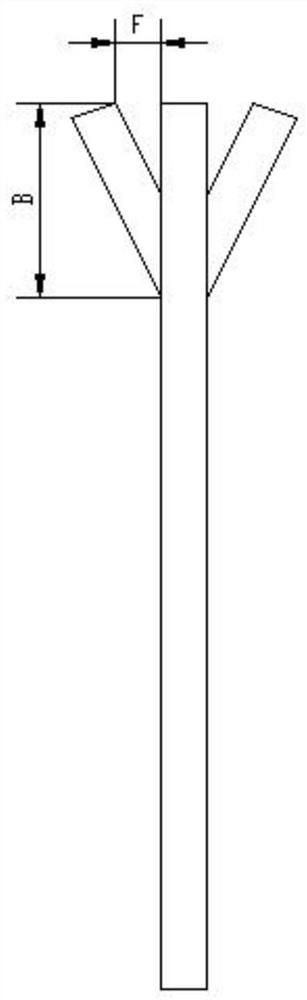

[0025] The set of saw teeth includes the first tooth, the second tooth, the third tooth, the fourth tooth, the fifth tooth, the sixth tooth, and the seventh tooth in turn; the first tooth is an intermediate guide tooth, and the second tooth , the third tooth is the first half tooth, the fourth tooth and the fifth tooth are the second half tooth, the sixth tooth and the seventh tooth are the third half ...

Embodiment 2

[0034] In the second embodiment, the divided tooth height B is 1.9mm, and the left divided tooth amount F of the second tooth 2 , The amount of right divided teeth of the third tooth F 3 , The amount of left divided teeth of the sixth tooth F 6 , The amount of right divided teeth of the seventh tooth F 7 Both are 0.39mm, and the left split tooth amount of the fourth tooth is F 4 , The amount of right divided teeth of the fifth tooth F 5 Both are 0.24mm; tooth front angle α is 9°30', first tooth back angle β 1 is 26°, the second tooth relief angle β 2 is 36°, so the first profile angle γ 1 =54°30', the second profile angle γ 2 =44°30'; the maximum tooth depth is 5.2mm, the minimum tooth depth is 4.1mm; the maximum tooth groove radius is 3.8mm, the minimum tooth groove radius is 2.2mm; the maximum tooth pitch is 8.3mm, and the minimum tooth pitch is 6.3mm.

[0035] It takes 18 minutes for the bimetallic band saw blade in Example 2 to cut a Φ160mm hot-work die steel round ...

Embodiment 3

[0037] In the third embodiment, the divided tooth height B is 2.0mm, and the left divided tooth amount F of the second tooth 2 , The amount of right divided teeth of the third tooth F 3 , The amount of left divided teeth of the sixth tooth F 6 , The amount of right divided teeth of the seventh tooth F 7 Both are 0.40mm, the left split tooth amount F of the fourth tooth 4 , The amount of right divided teeth of the fifth tooth F 5 Both are 0.25mm; tooth front angle α is 10°, first tooth back angle β 1 is 25°30', the second tooth relief angle β 2 is 35°30', so the first profile angle γ 1 =54°30', the second profile angle γ 2 =44°30'; the maximum tooth depth is 5.2mm, the minimum tooth depth is 4.1mm; the maximum tooth groove radius is 3.8mm, the minimum tooth groove radius is 2.2mm; the maximum tooth pitch is 8.4mm, and the minimum tooth pitch is 6.4mm.

[0038] The bimetallic band saw blade of Example 3 needs 15 minutes to cut a Φ160mm hot work die steel round bar, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com