Patents

Literature

68results about How to "No pinching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

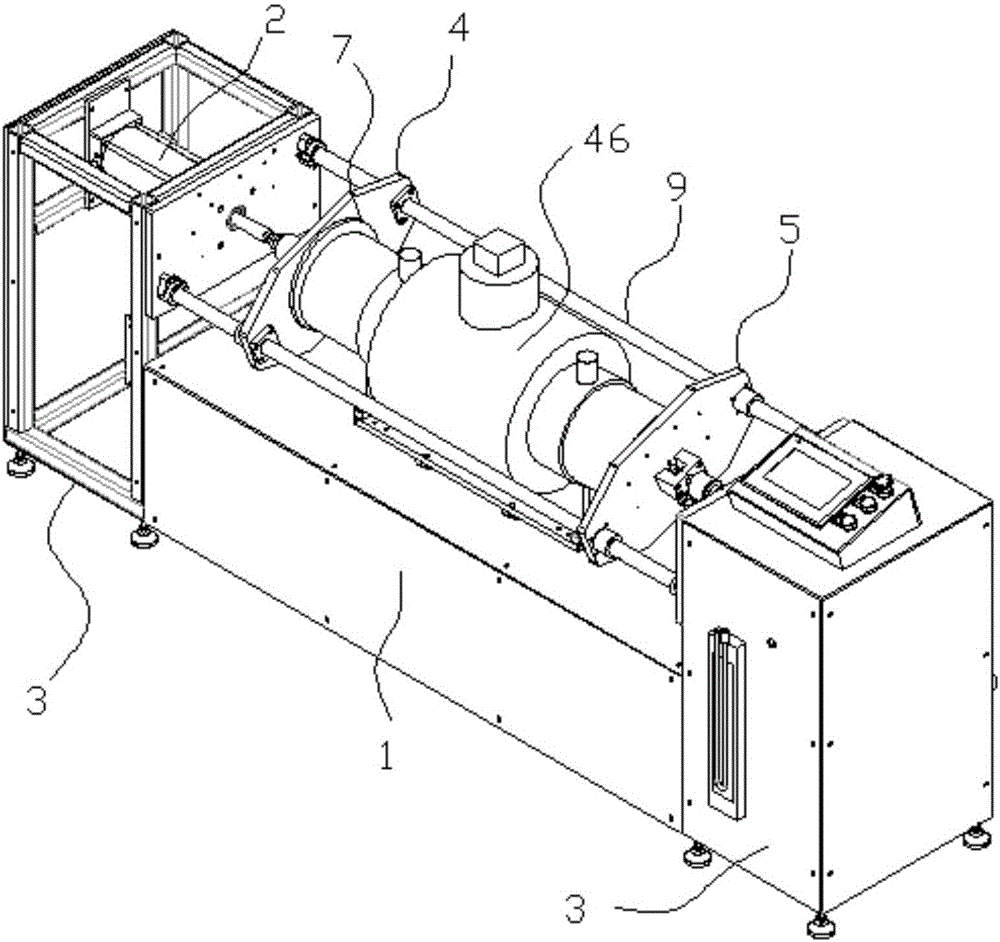

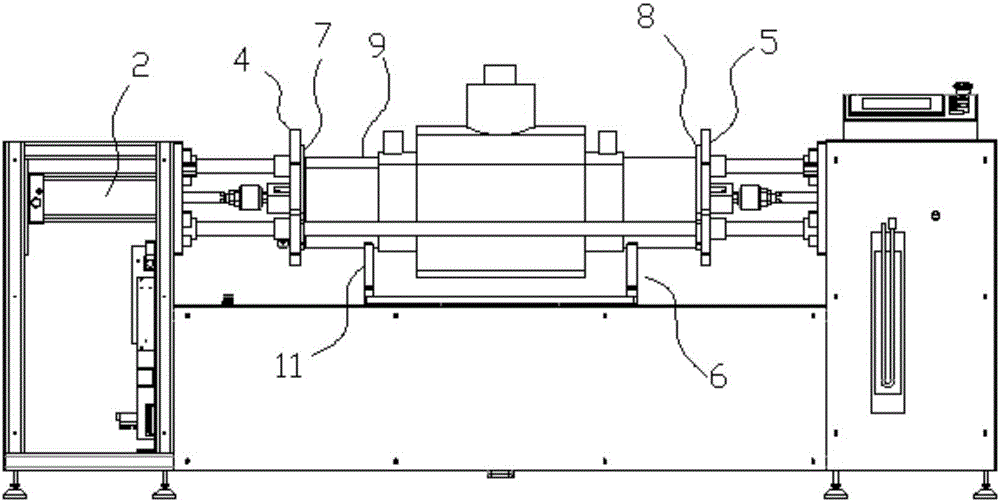

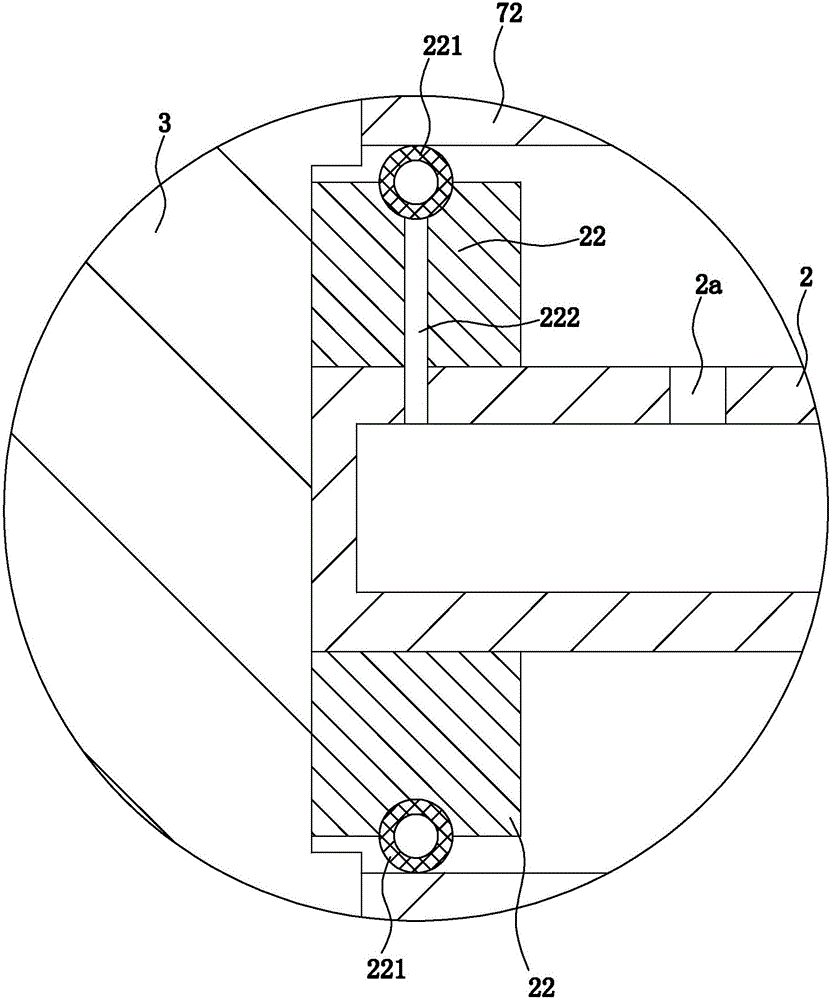

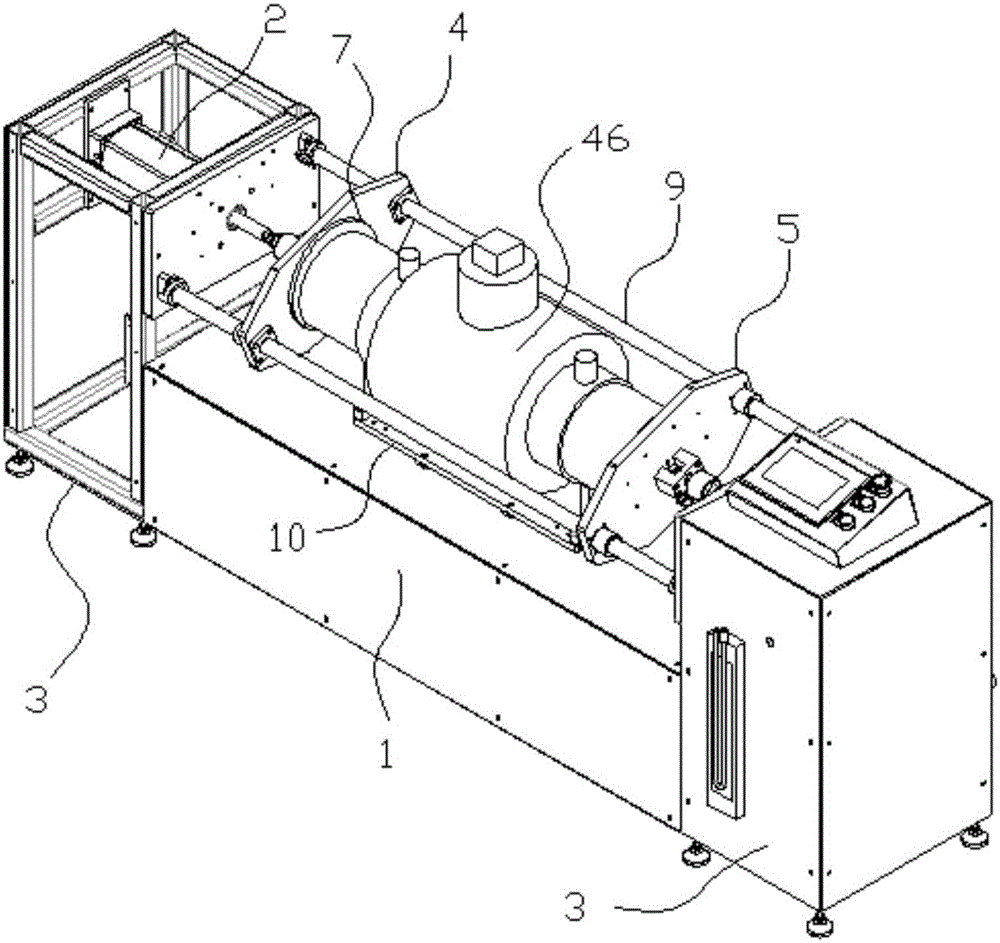

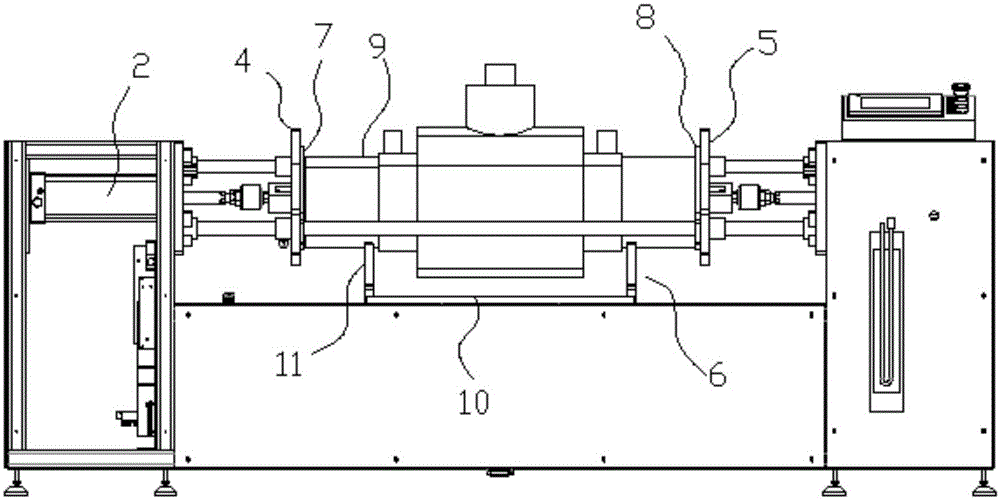

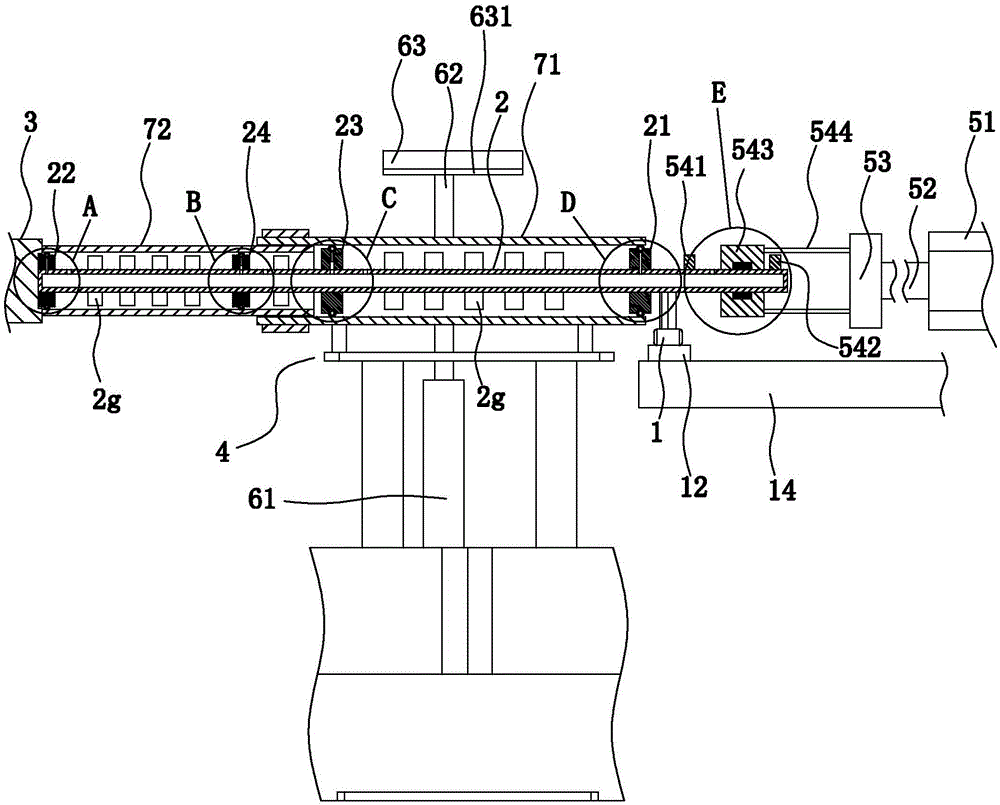

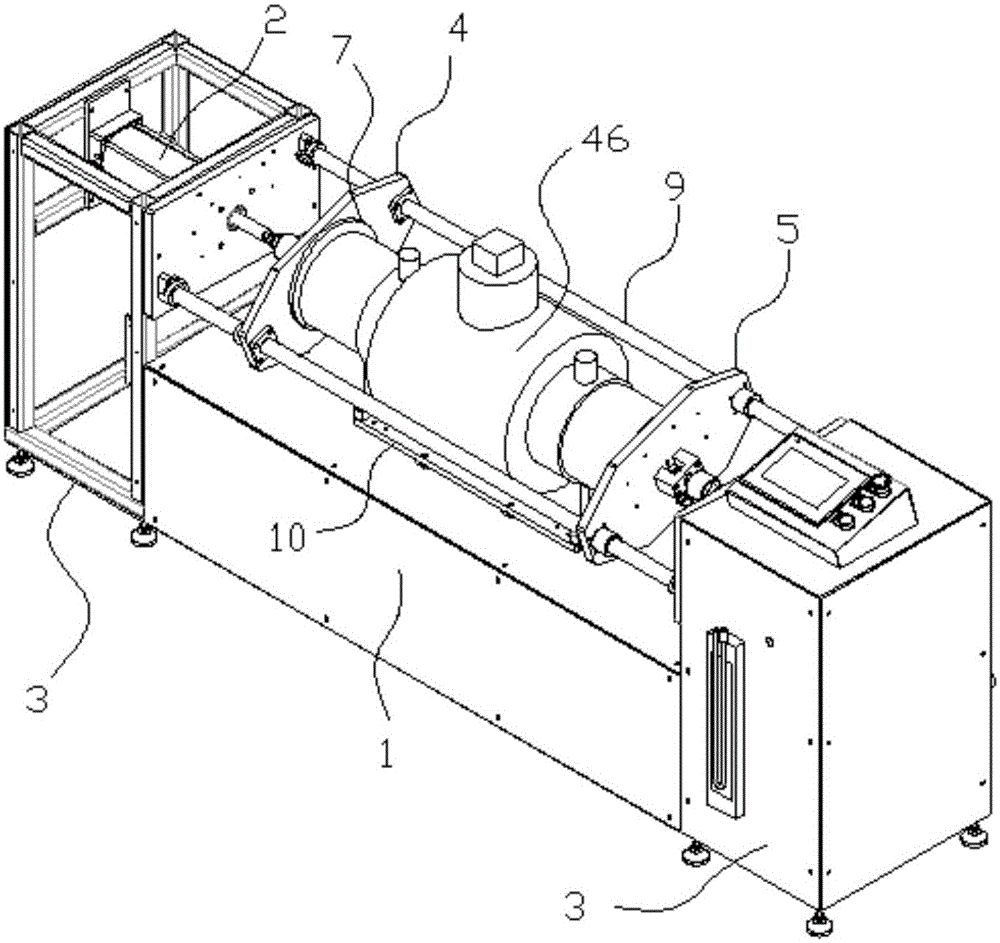

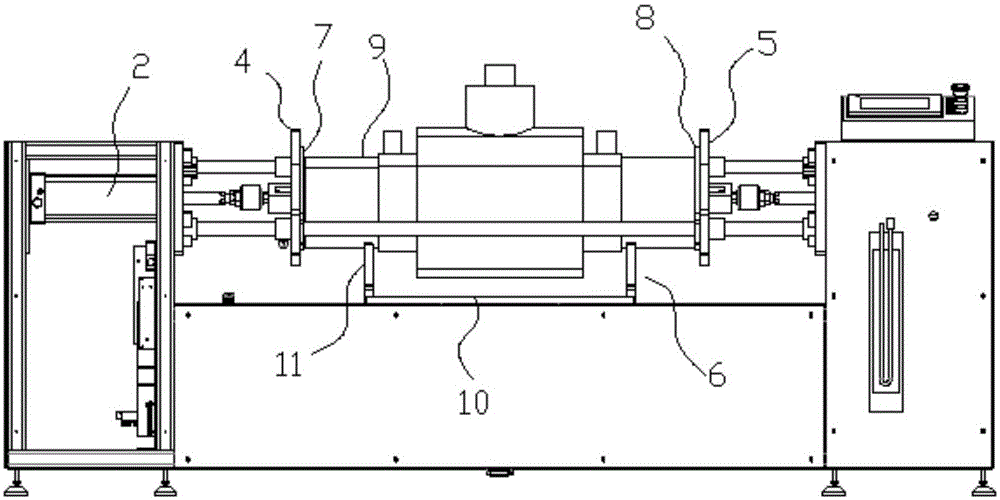

Ball valve gas tightness test apparatus

InactiveCN105043675ANo pinchingPrevent fallbackWork holdersFluid-tightness measurement using fluid/vacuumEngineeringAir tightness

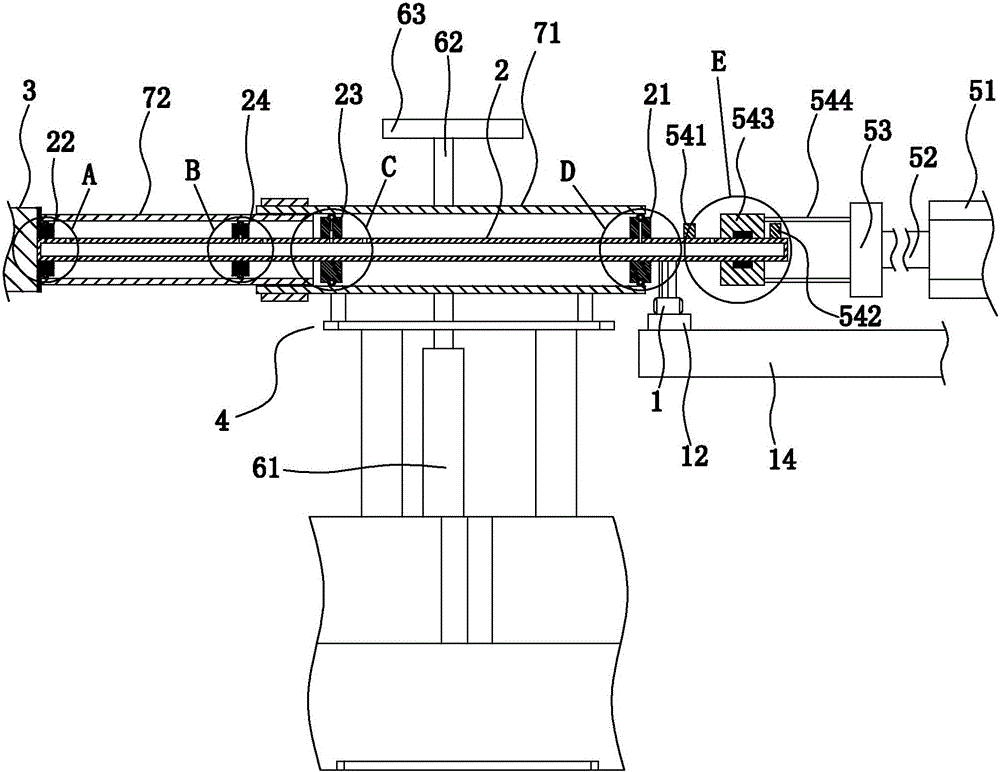

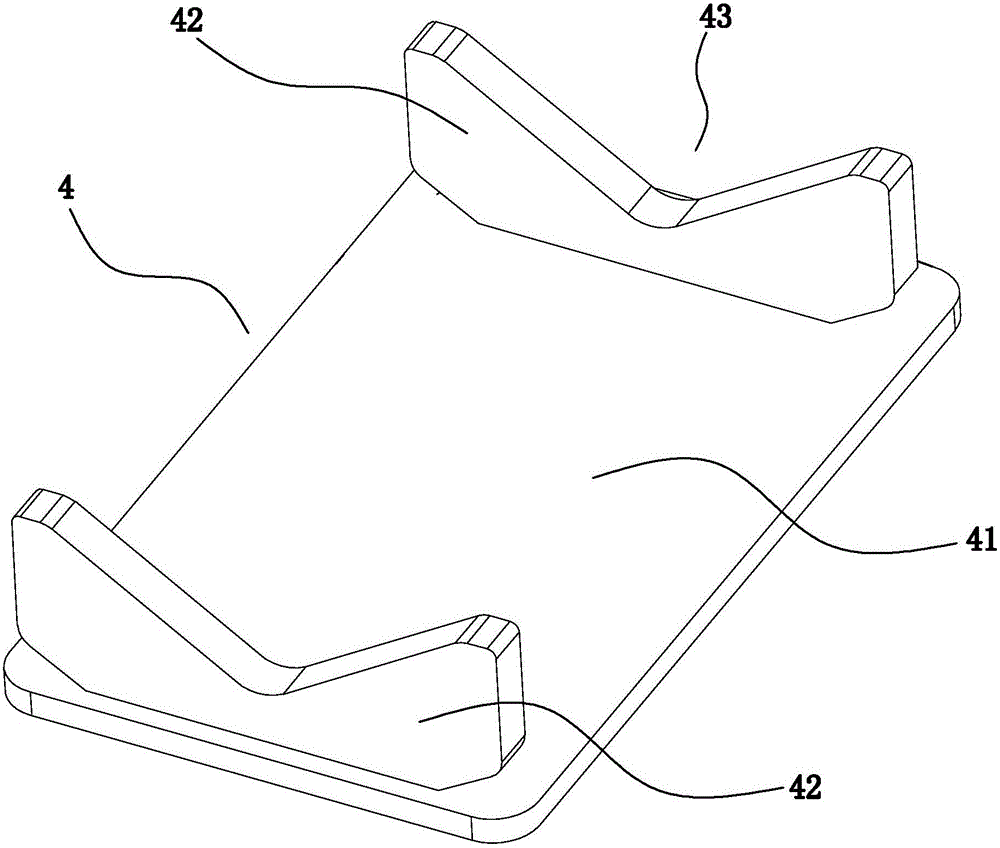

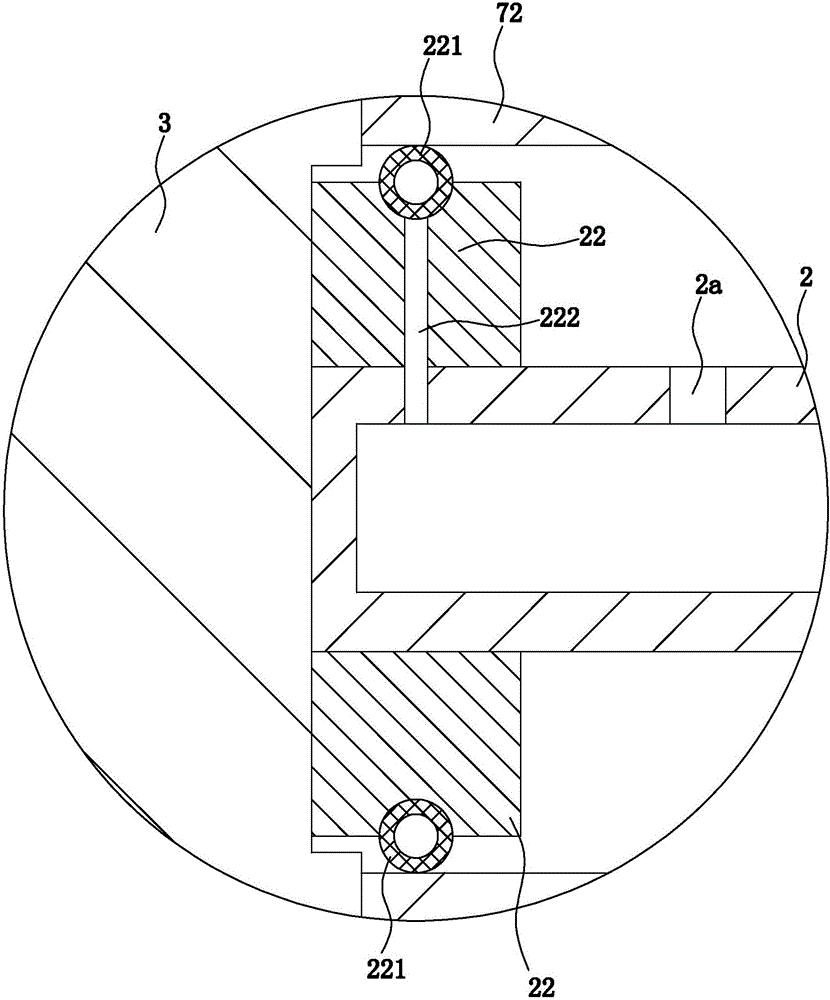

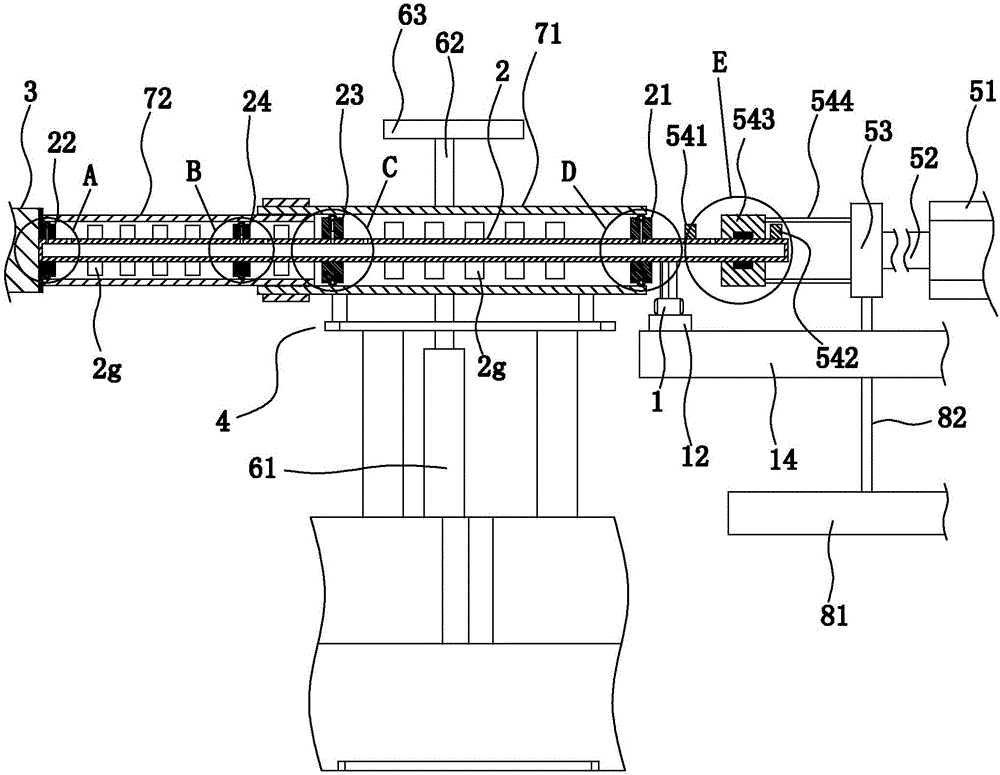

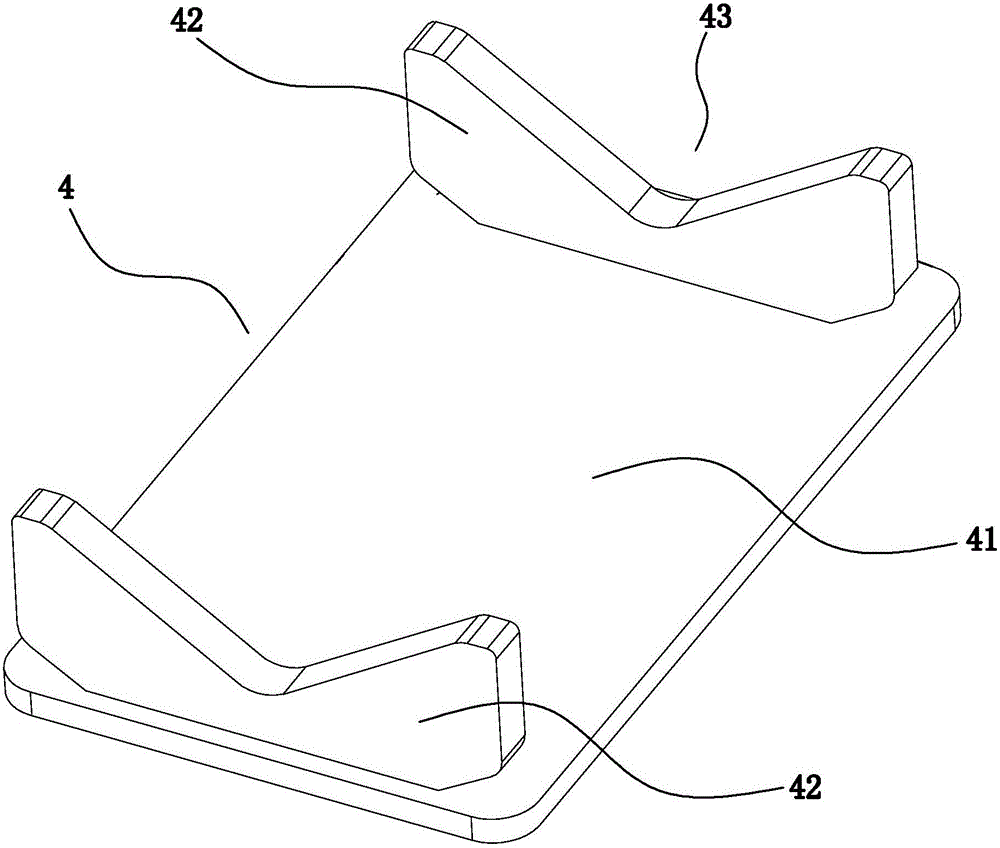

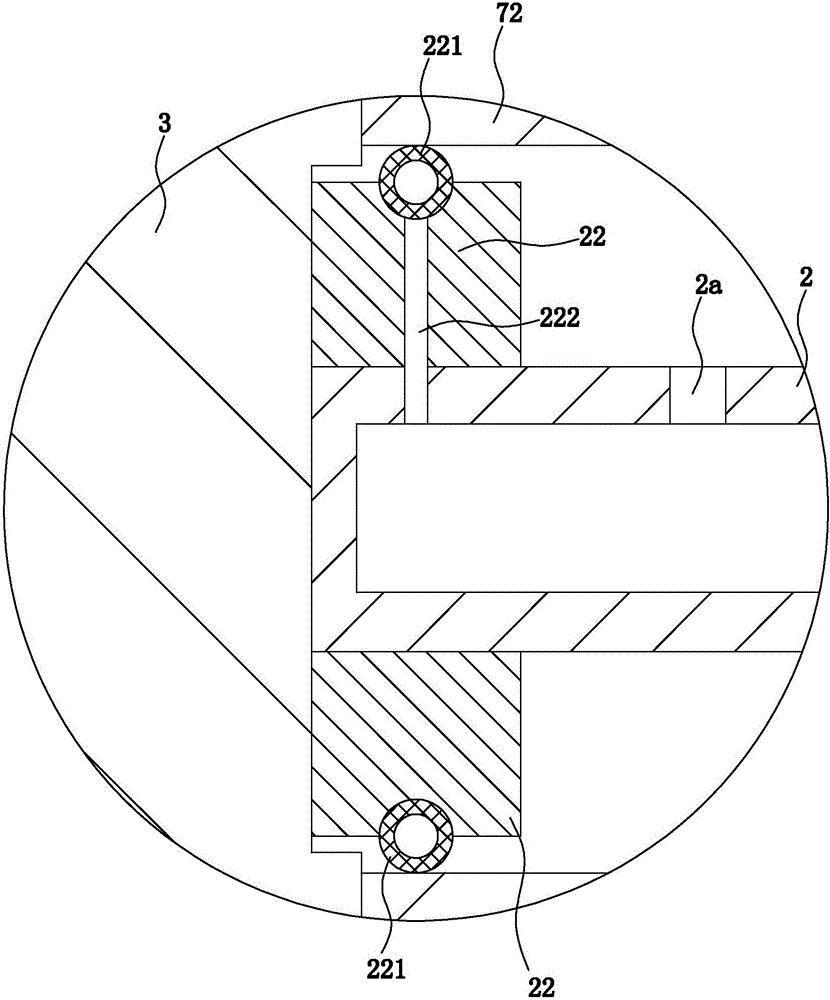

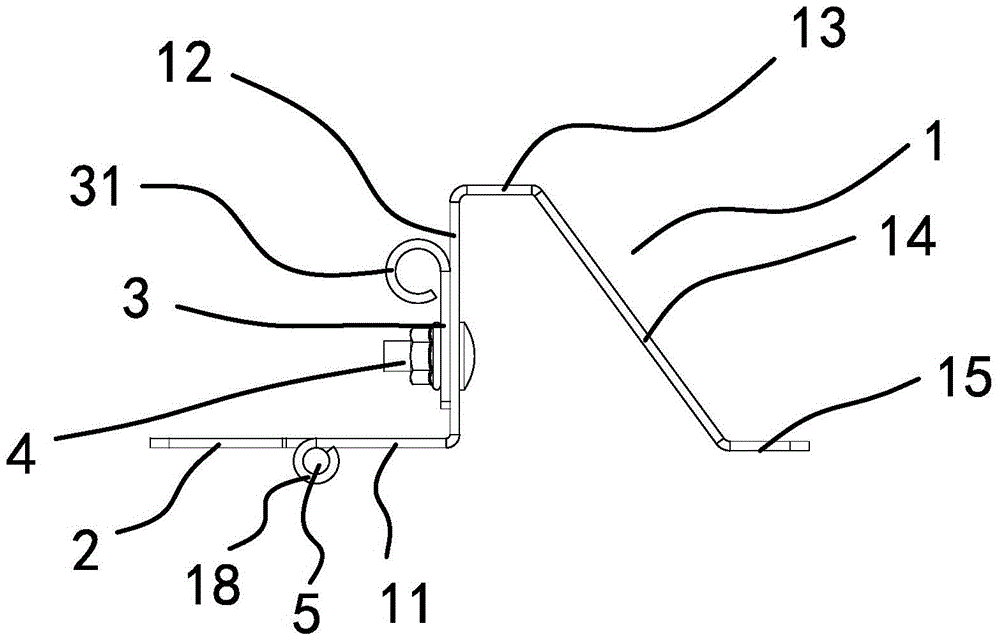

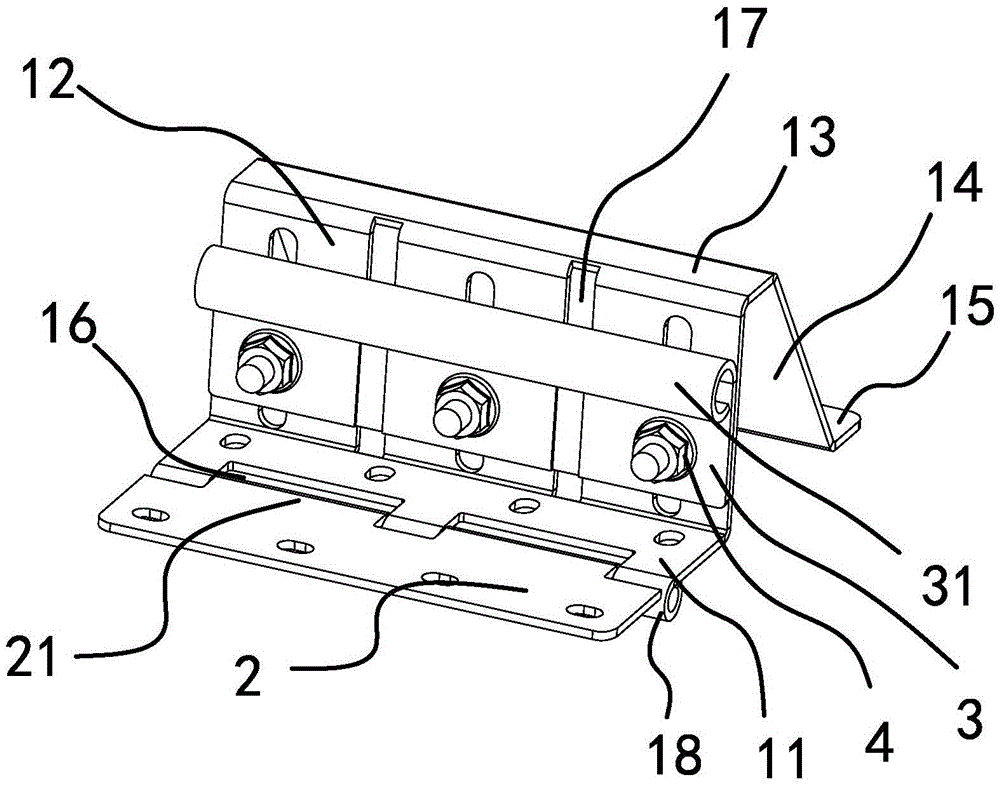

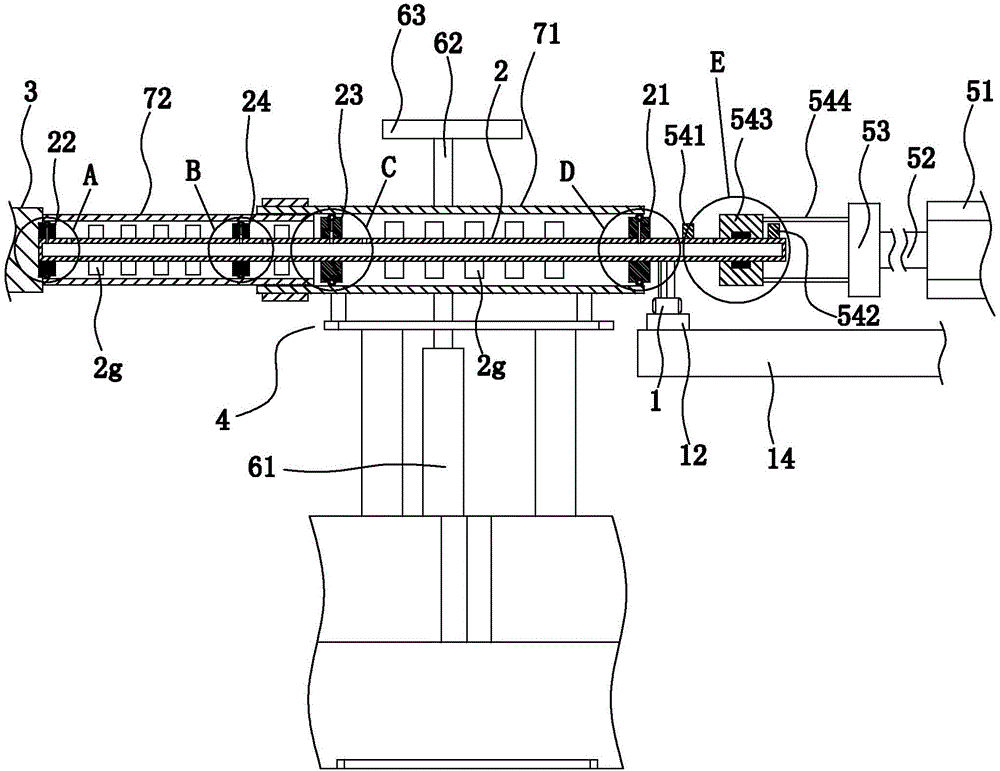

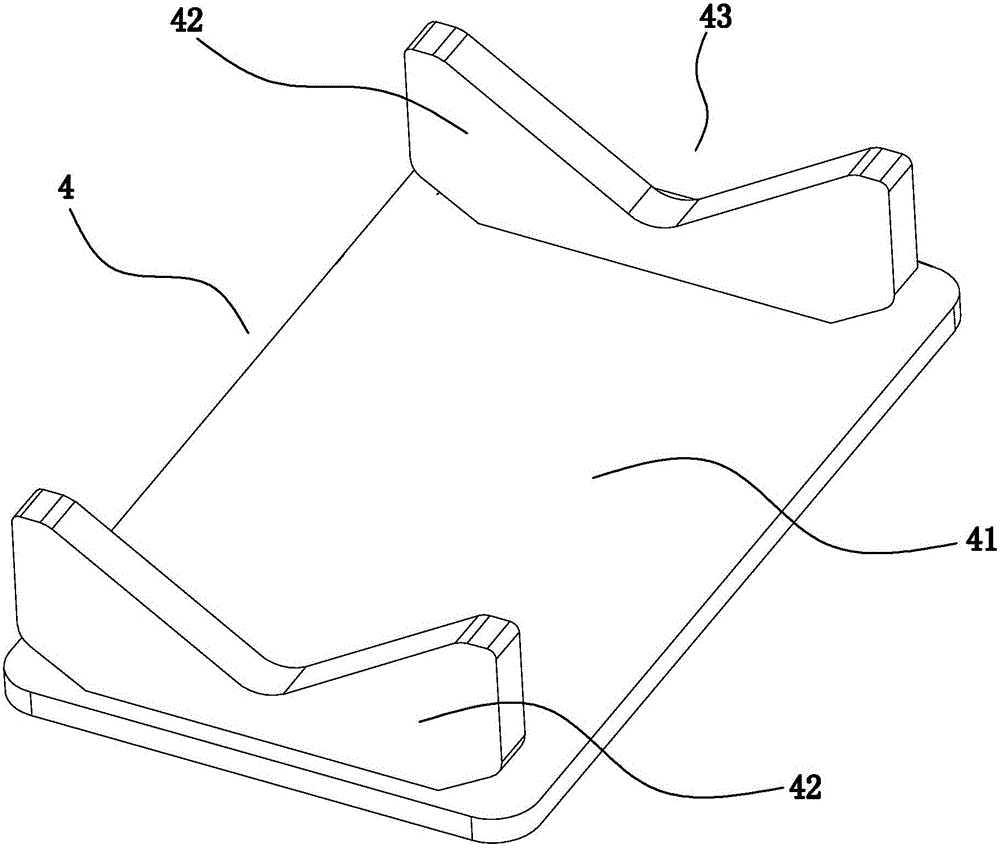

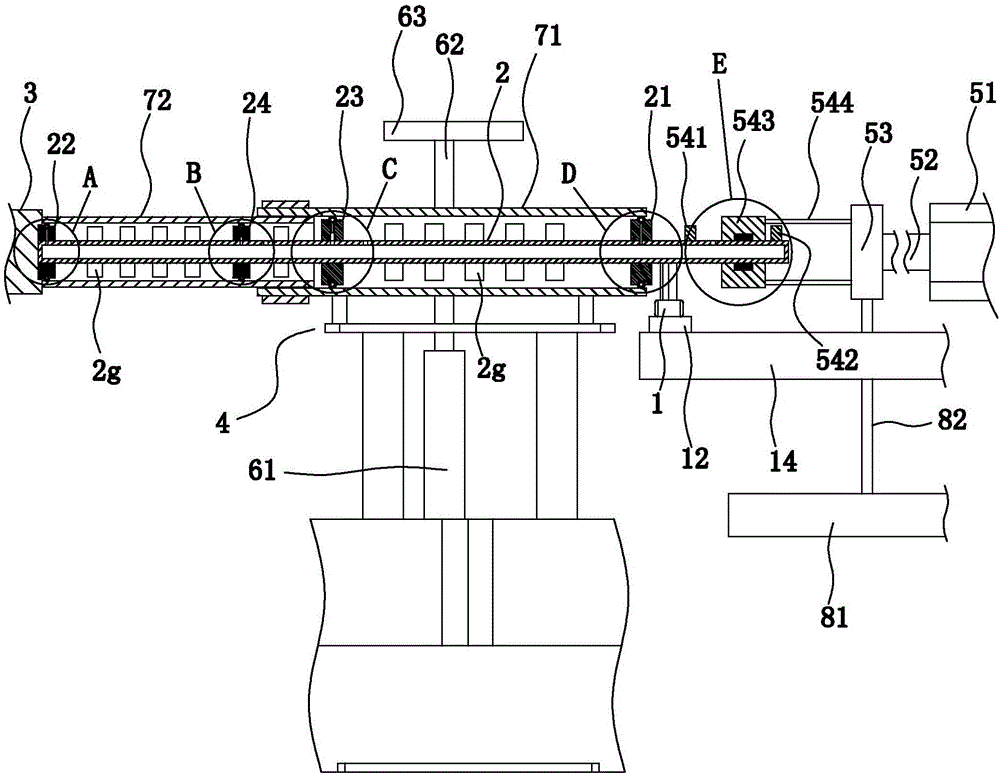

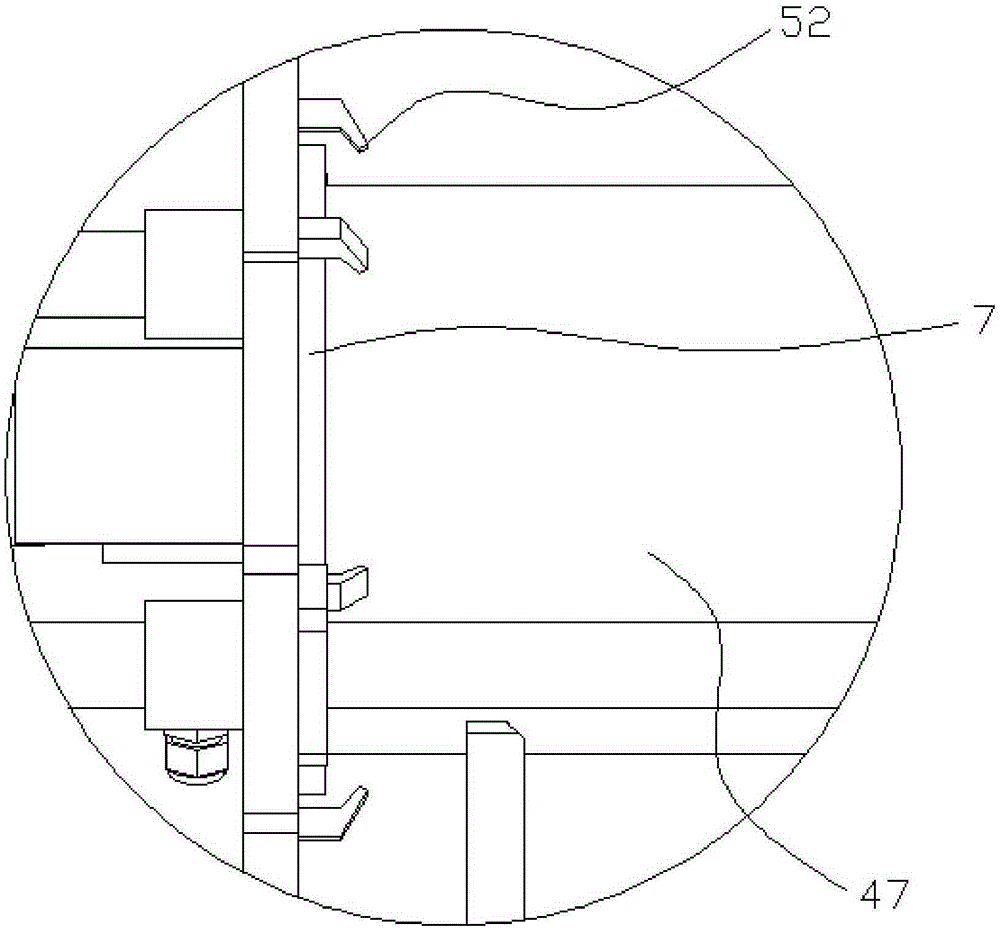

The invention discloses a ball valve gas tightness test apparatus. The ball valve gas tightness test apparatus has the advantages of convenient operation and high accuracy. With the ball valve gas tightness test apparatus adopted, it can be ensured that two end pipes of a ball valve have little possibility of being damaged due to clamping. The ball valve gas tightness test apparatus includes an air feed pump, a pressure sensor, a main rack, two push plate air cylinders, two side racks, a main end cover and an auxiliary end cover; the two push plate air cylinders are respectively located on the two side racks; the piston rod of one of the push plate air cylinders is connected with the main end cover; the piston rod of the other push plate air cylinder is connected with the auxiliary end cover; the main end cover is provided with a main elastic sealing ring gasket; the auxiliary end cover is provided with an auxiliary elastic sealing ring gasket; and a main cover air hole is formed in the main end cover. With the ball valve gas tightness test apparatus of the invention adopted, a ball valve can be positioned and clamped in place, and gas tightness can be ensured, and at the same time, the ball valve will not be damaged due to clamping. The ball valve gas tightness test apparatus has an adaptively-adjustable sealing structure, so that a sealing effect in high-air pressure detection can be strengthened; the ball valve gas tightness test apparatus has an auxiliary positioning structure, the rollback of the end covers can be avoided, and the push plate air cylinders can be protected, and a sealing effect can be improved, and stability in a detection process can be maintained.

Owner:王国良

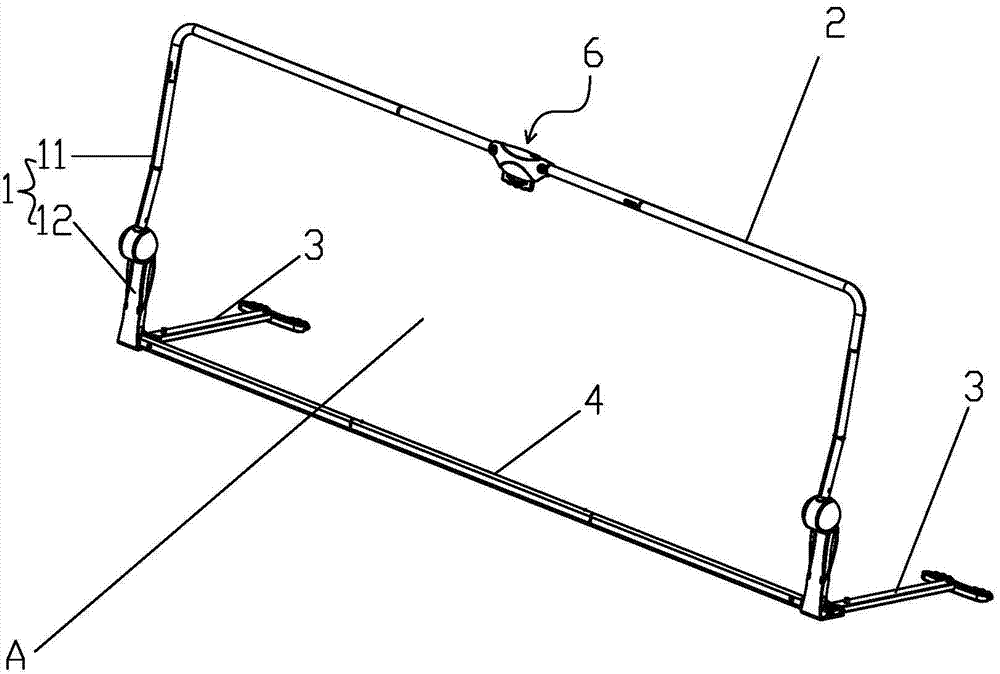

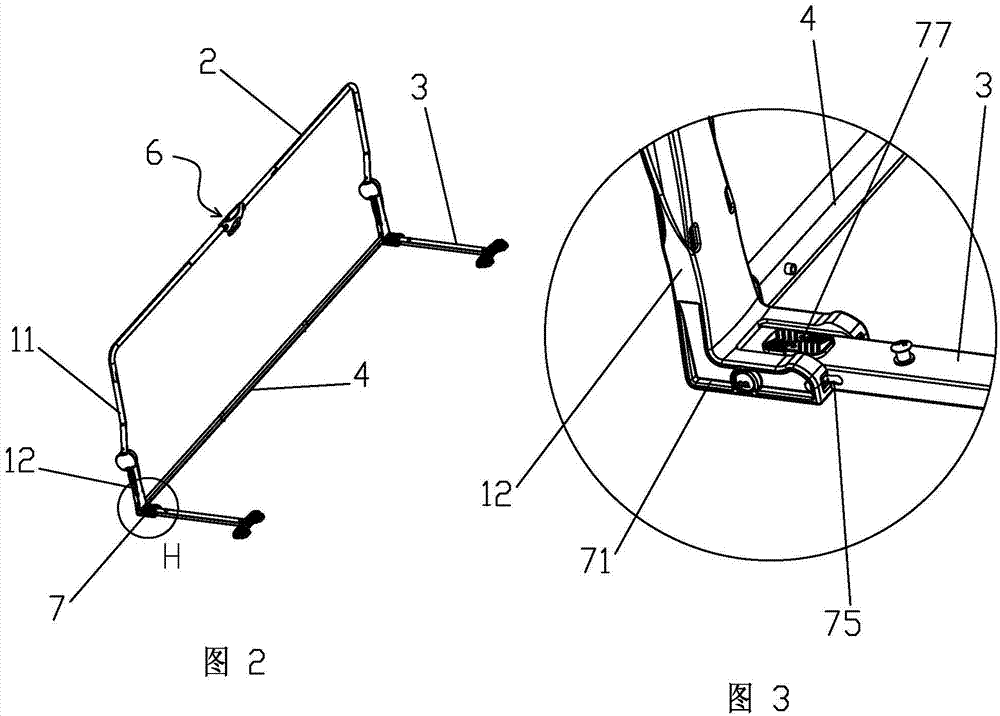

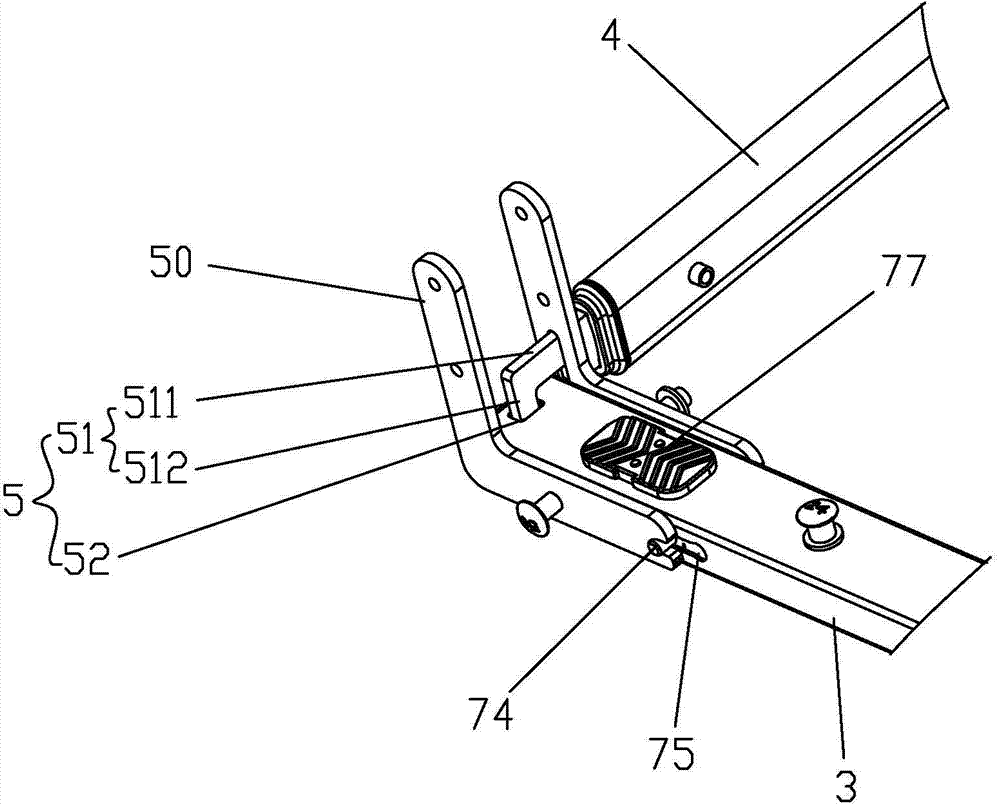

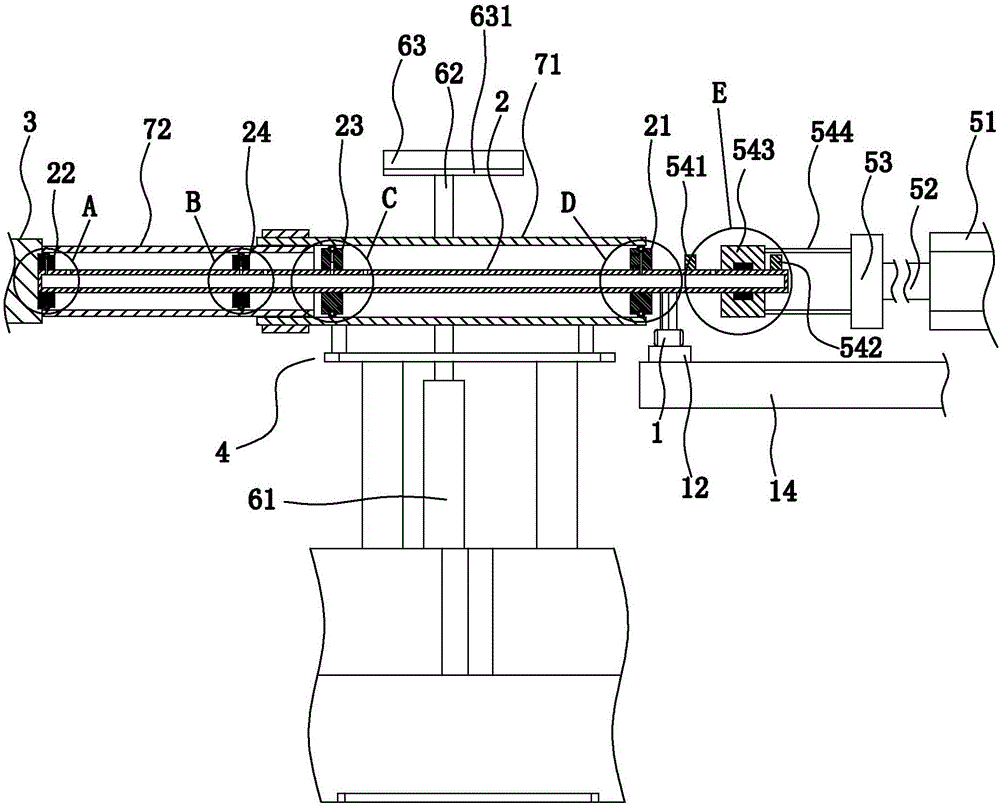

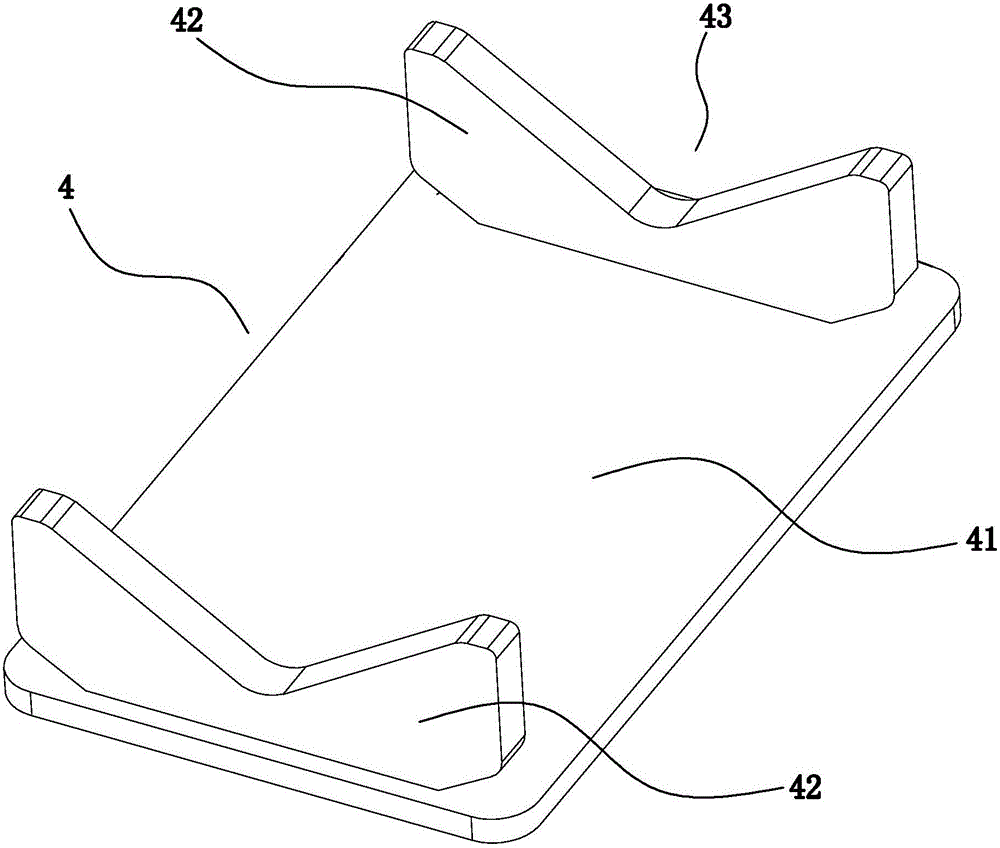

Novel folding bed guard bar

The invention discloses a novel folding bed guard bar which comprises folding vertical rods arranged on the left side and the right side, wherein the upper and lower ends of the left vertical rod and the right vertical rod are respectively connected with an upper transverse rod and a lower transverse rod; the two vertical rods are connected with the upper transverse rod and the lower transverse rod to form a guard bar framework; supporting legs which are connected with a bed body and are used for preventing the framework from turning over are arranged at the bottom of the framework; two ends of the lower transverse rod extends into the vertical rods; locking devices for locking the supporting legs and the lower transverse rod so as to lock the framework are arranged between the supporting legs and the end part of the lower transverse rod; driving devices for folding the supporting legs and driving the locking devices to realize unlocking are arranged between the supporting legs and the vertical rods; a folding device for folding the bed guard bar is arranged on the framework. The novel folding bed guard bar is simple in structure and is very convenient to assemble and disassemble.

Owner:ZHONGSHAN BLS DAILY PROD CO LTD

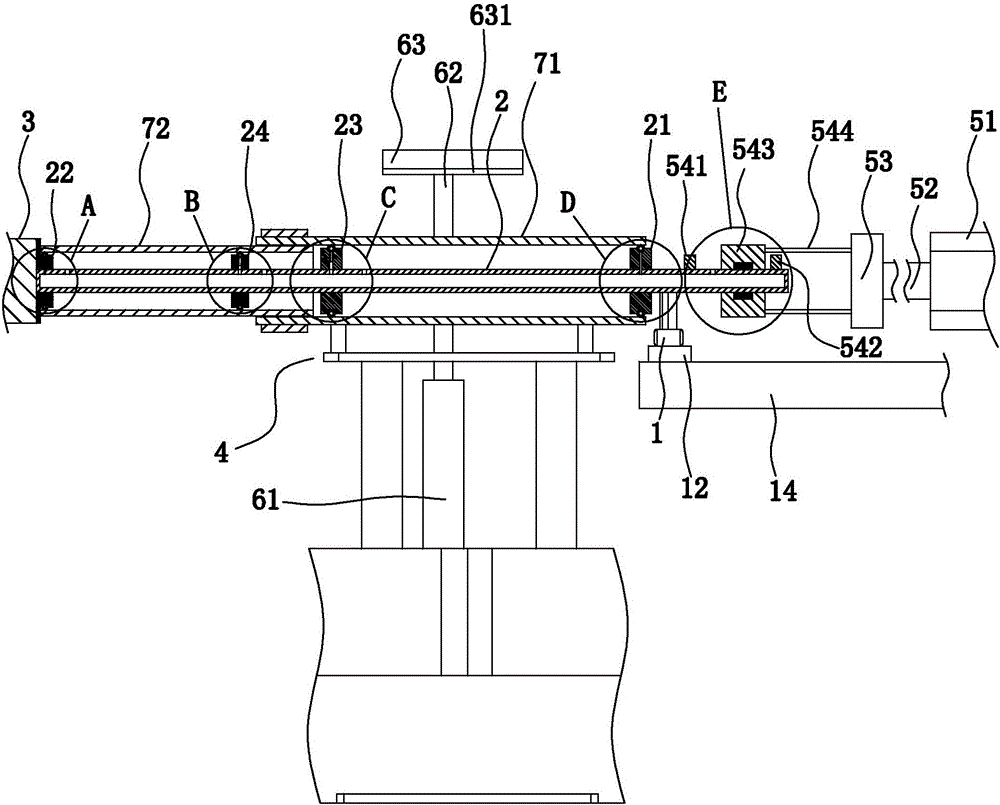

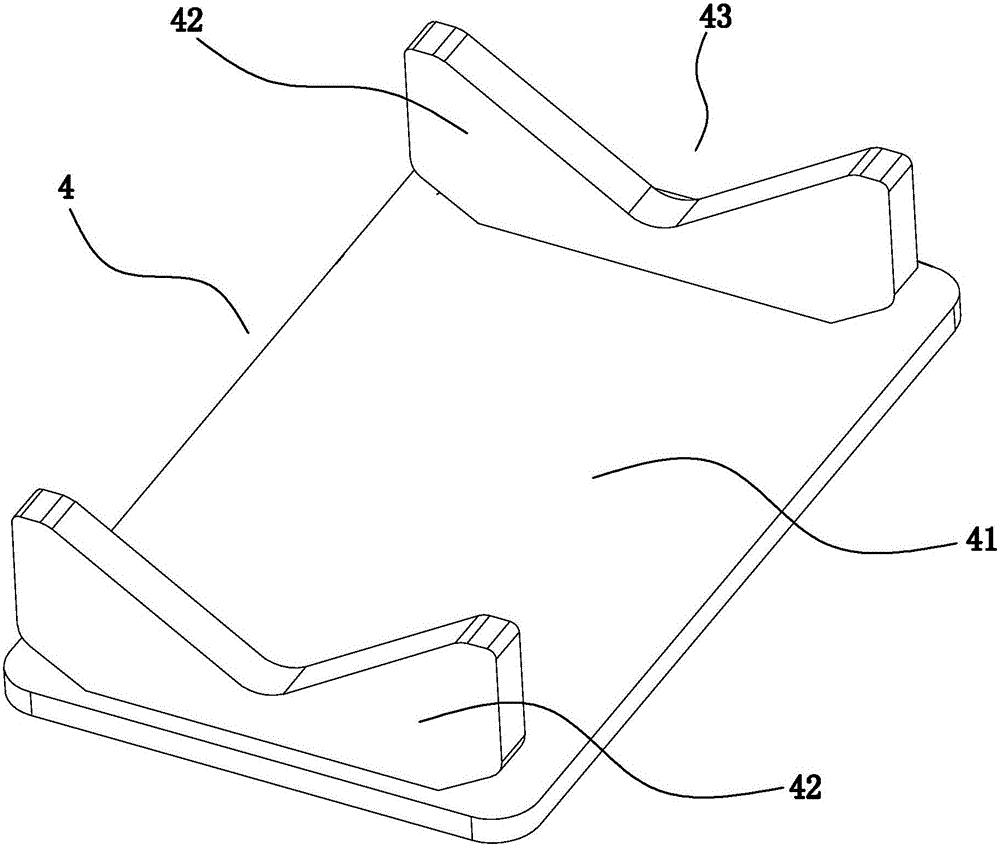

Device for testing sealing performance of steel plastic pipe

InactiveCN105841896ANo pinchingReasonable structureMeasurement of fluid loss/gain rateAir pumpEngineering

The invention discloses a device for testing the sealing performance of a steel plastic pipe. The device comprises a main device base, an air supply pump, a plugging cylinder, a compacting cylinder, a shaft pipe, a limiting base and a joint supporting stand. A positioning plate is arranged on a compacting piston rod, a driving stand is arranged on a seal-head piston rod, and a plastic pipe outer end sealing plate, a steal pipe outer end sealing plate, a plastic pipe outer end sealing ring and a steal pipe outer end sealing ring are arranged on the shaft pipe. A first air inlet is arranged in the shaft pipe, a first air inlet check valve is arranged in the first air inlet, and a first air pressure sensor is arranged on the outer wall of the shaft pipe. Steel plastic pipe switching joint supported by the joint supporting stand is arranged between the limiting base and the plugging cylinder, and the air supply end of the air supply pump communicates with the interior of the shaft pipe through an air supply pipe. The integral structure is reasonable, and positioning and clamping of the steel plastic pipe switching joint are properly in place. Sealing performance can be ensured, and the steel plastic pipe switching joint may not be damaged due to clamping. The sealing structure has self-adaptive performance, and the seal effect under high air pressure detection can be enhanced.

Owner:宁波宇华实业股份有限公司

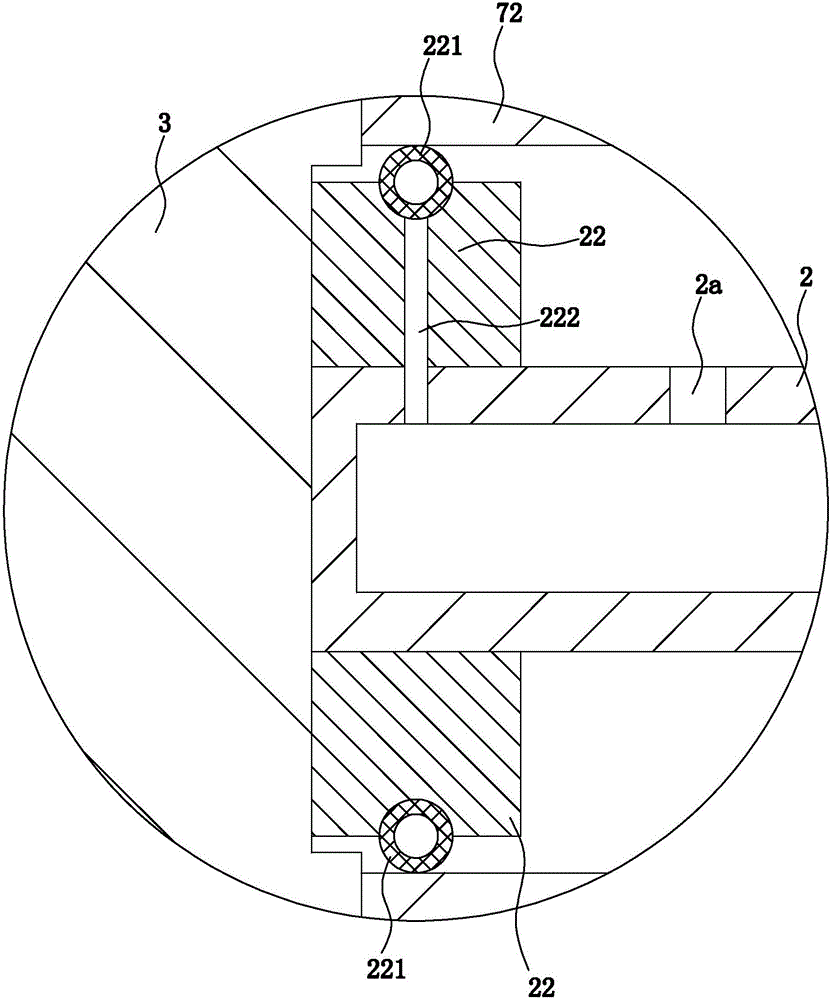

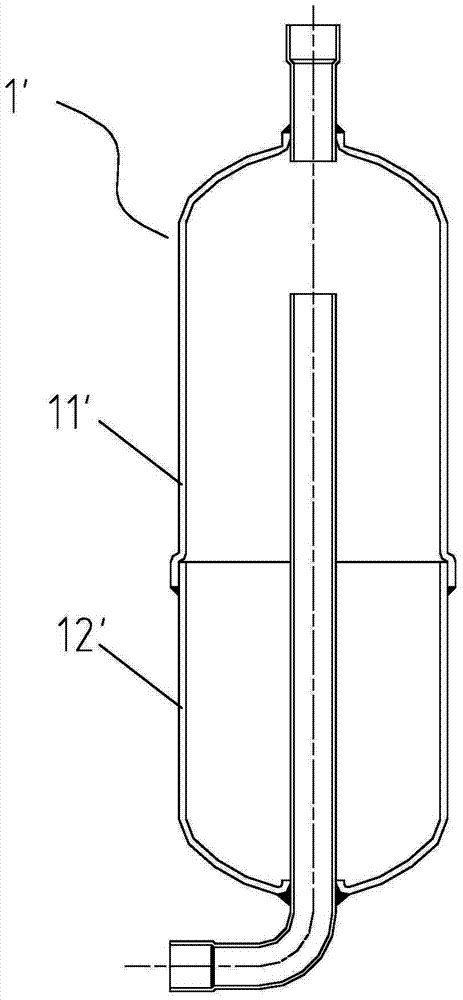

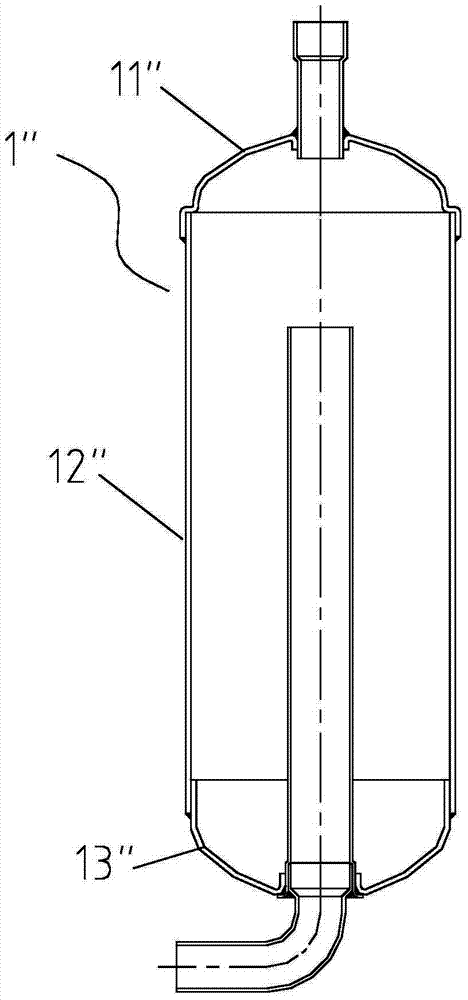

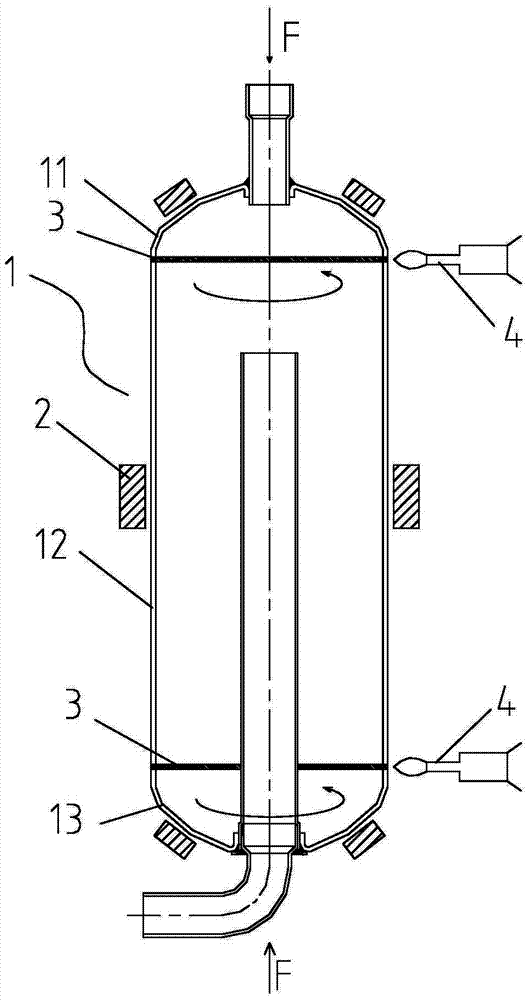

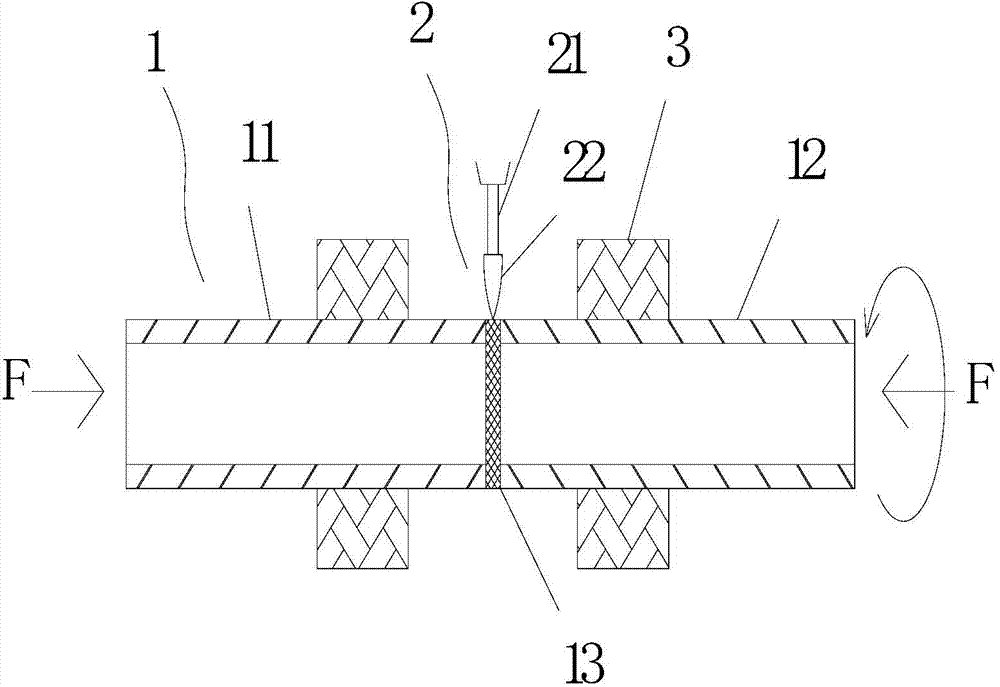

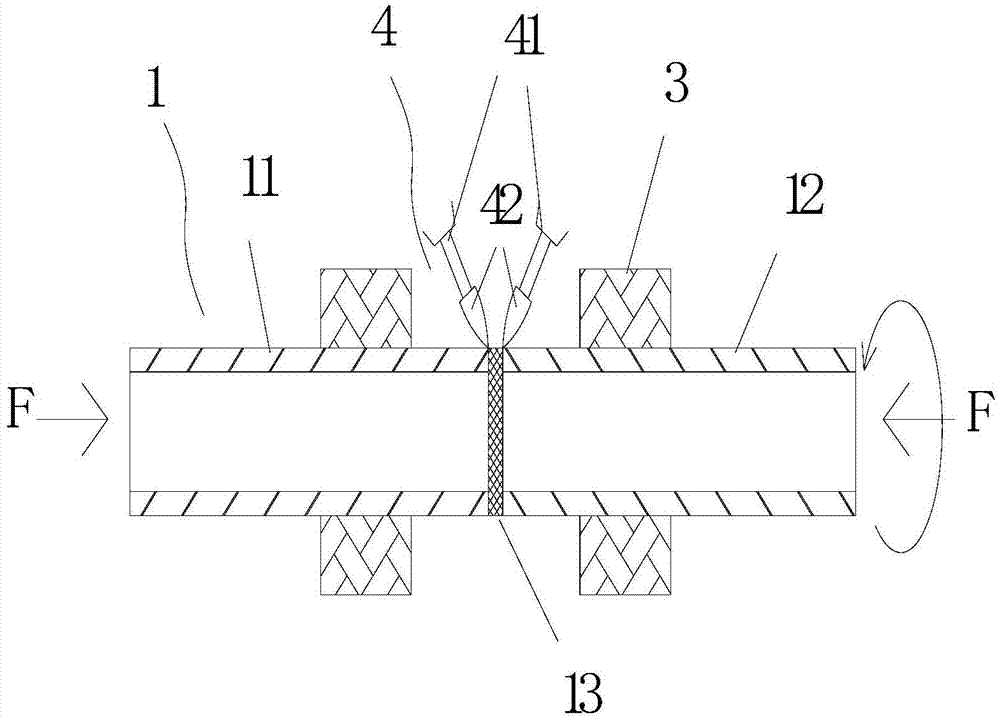

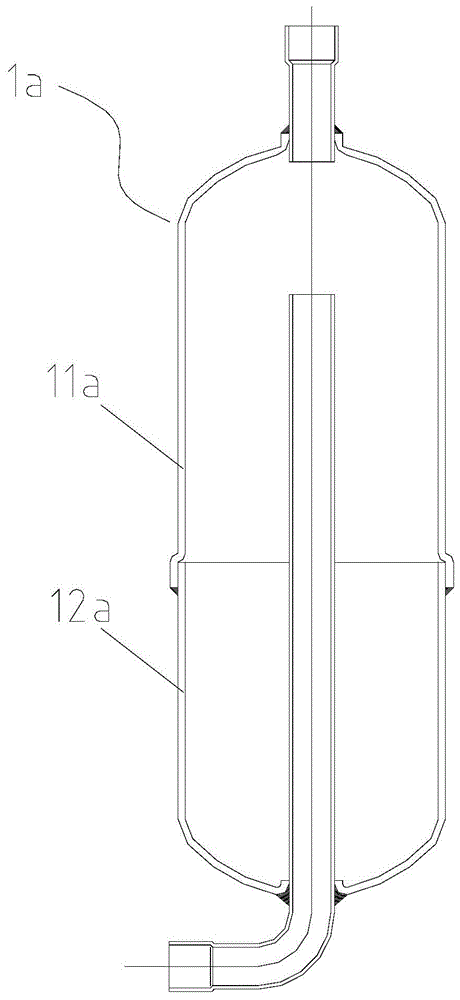

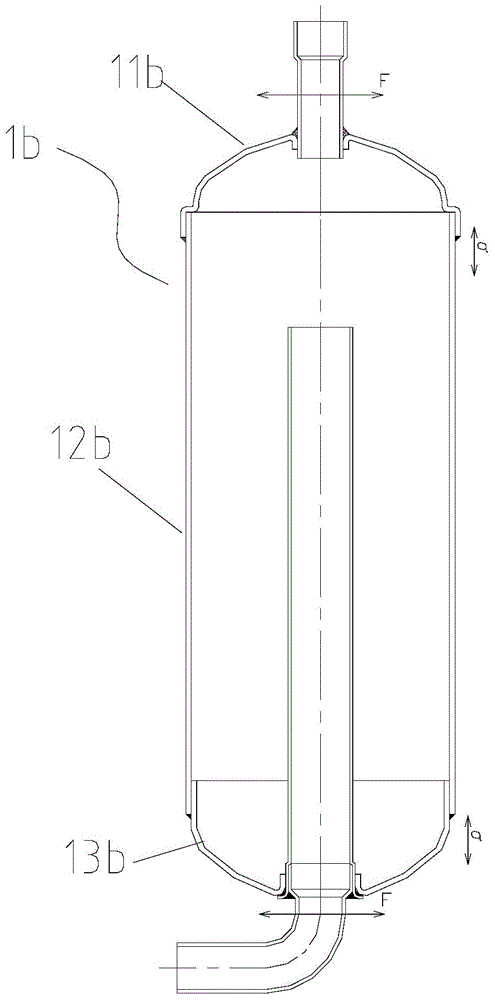

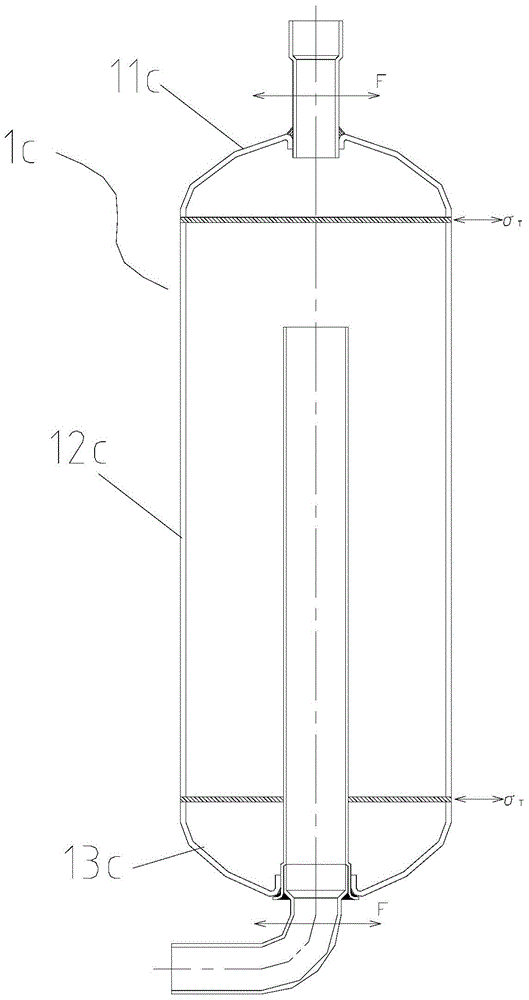

Shell, manufacturing method and application of shell

The invention relates to a shell, and a manufacturing method and the application of the shell. The shell refers to a liquid accumulator shell for a compressor, a muffler shell for an air conditioner, a gas-liquid separator shell for a central air conditioner or an oil-gas separator shell. The shell is formed by butt welding of at least two parts. A self-fluxing annular weld pass welding process of argon arc welding, plasma welding, positive ion welding, high frequency welding or laser welding is adopted to carry out synchronization self-fluxing butt welding on connector parts. During welding, heat of butt-joint parts of parts of the liquid accumulator shell or the muffler shell is stable and controllable, both sides reach the melting temperature at the same time, so good fusion is realized, the welding quality is improved, welding junctions are smooth and bright, the welding strength can be improved by more than 1.5 times in comparison with that of the traditional stove passing welding, and the production efficiency is improved by 3-6 times in comparison with that of the traditional stove passing welding, and 2-3 times in comparison with that of flashing welding. The force used for removing a pipe section is small during welding, and the clamping force is very small, so the clamping damage to the surface of the pipe section is not caused, and the equipment cost is only 1 / 5 to 1 / 3 that of the flash welding.

Owner:佛山晓世科技服务有限公司

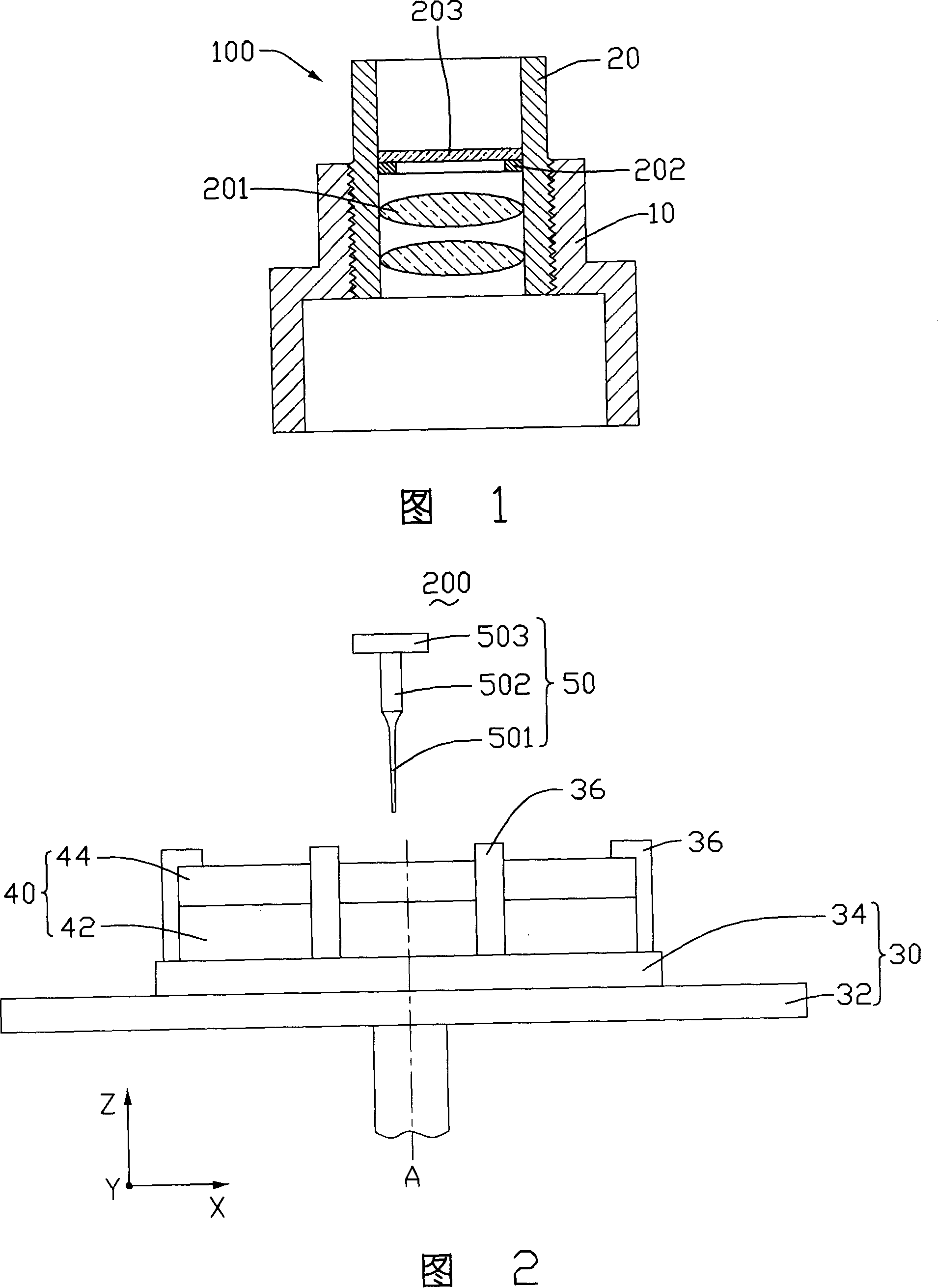

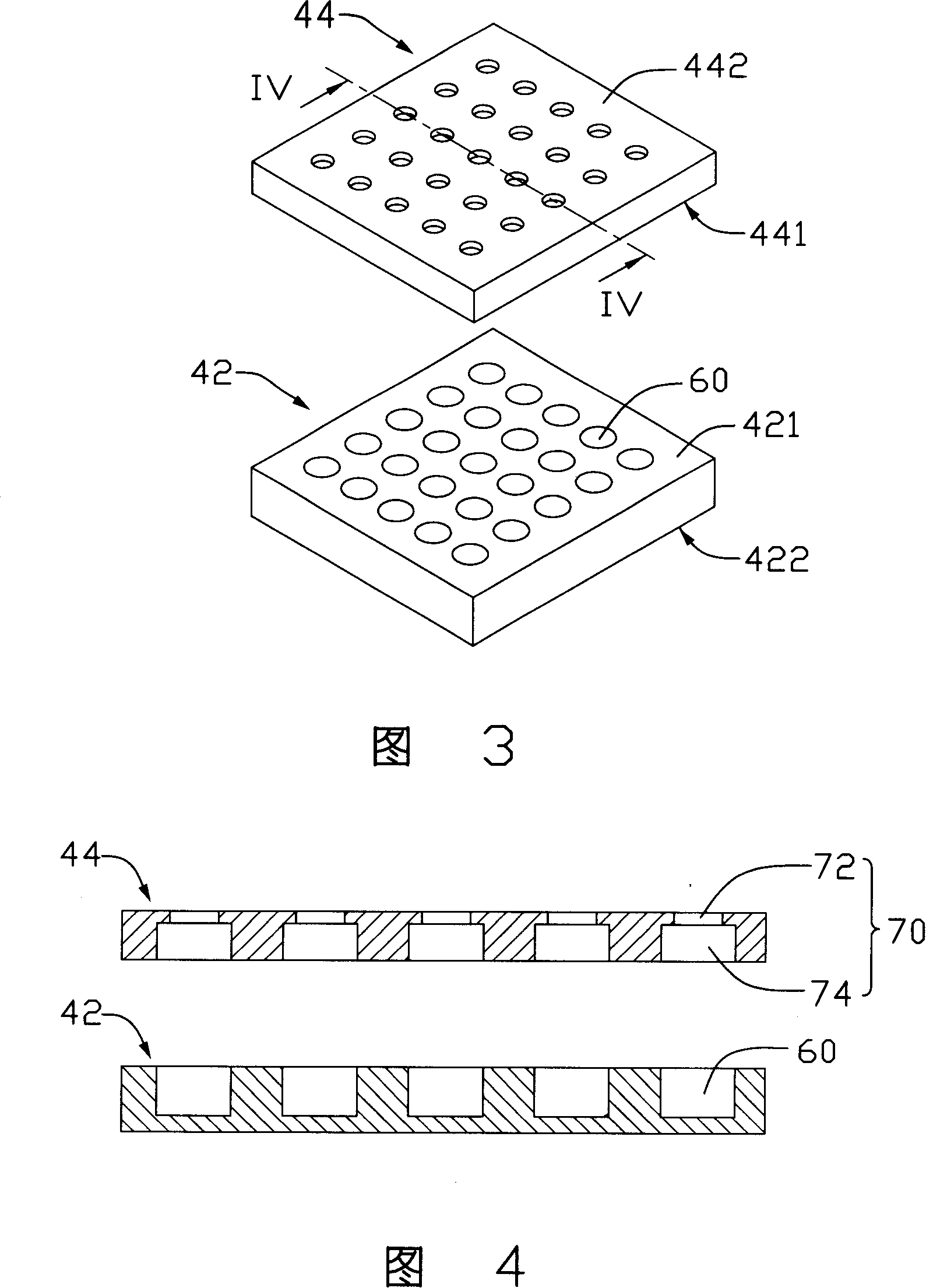

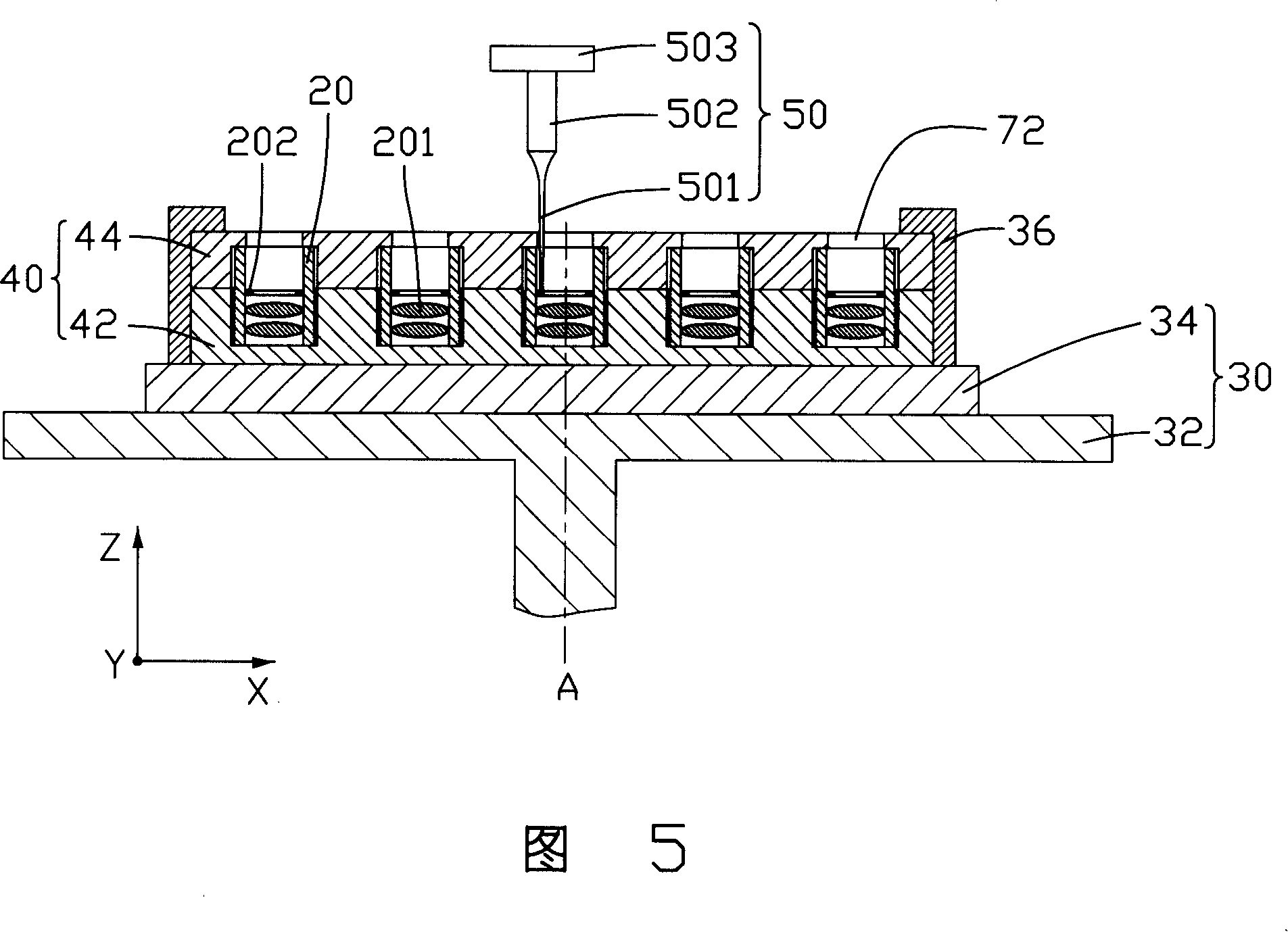

Rotary painting glue applying device and method

The present invention relates to one kind of rotary glue applying device, which includes one worktable, one fixer and one glue applying mechanism. The worktable includes one rotary platform and one horizontal moving assembly fixed on the top of the rotary platform. The horizontal moving assembly may be rotated by the rotary platform and shifted in both X and Y directions horizontally for regulating the position of the workpieces. The fixer fixed detachably on the horizontal moving assembly fixes workpieces to be glued. The glue applying mechanism over the worktable applies glue to the workpieces. The present invention also relates to the glue applying process with the device. The present invention has simple operation, no damage to the workpiece and high glue applying speed.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

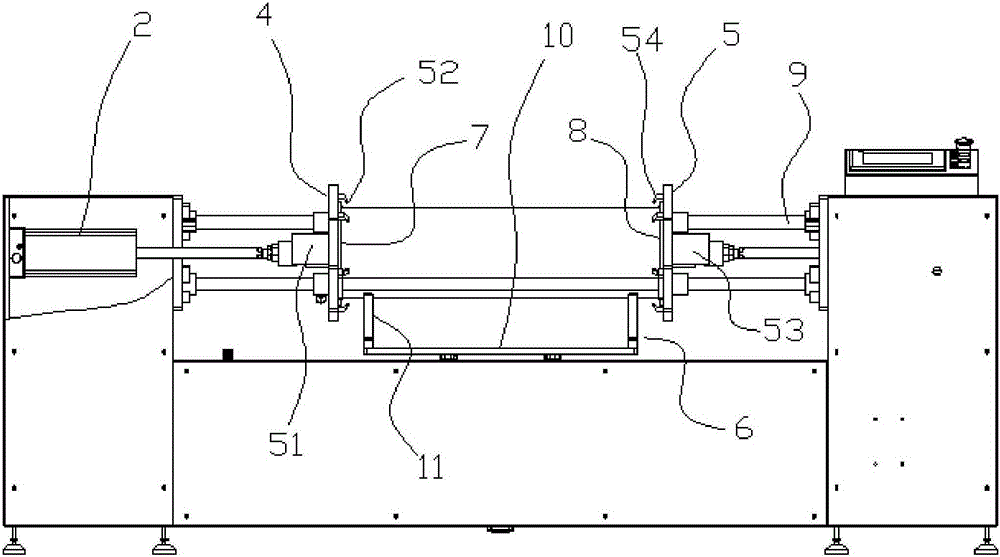

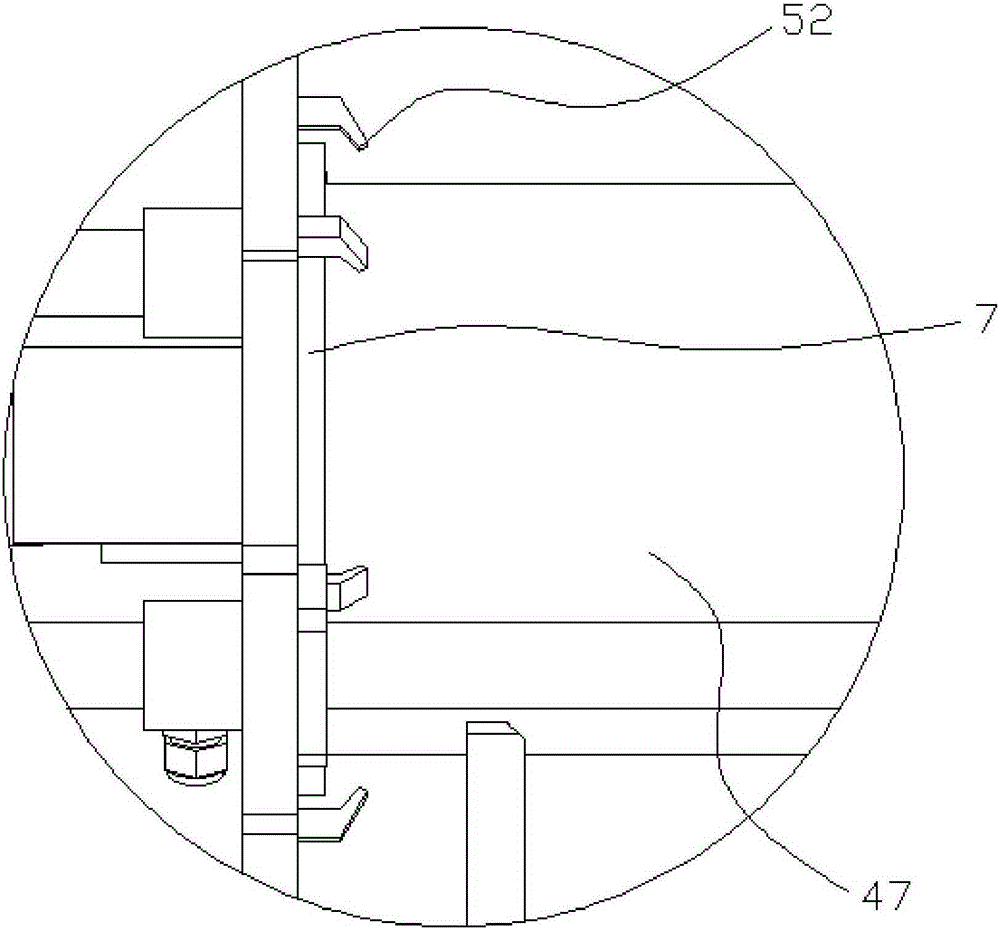

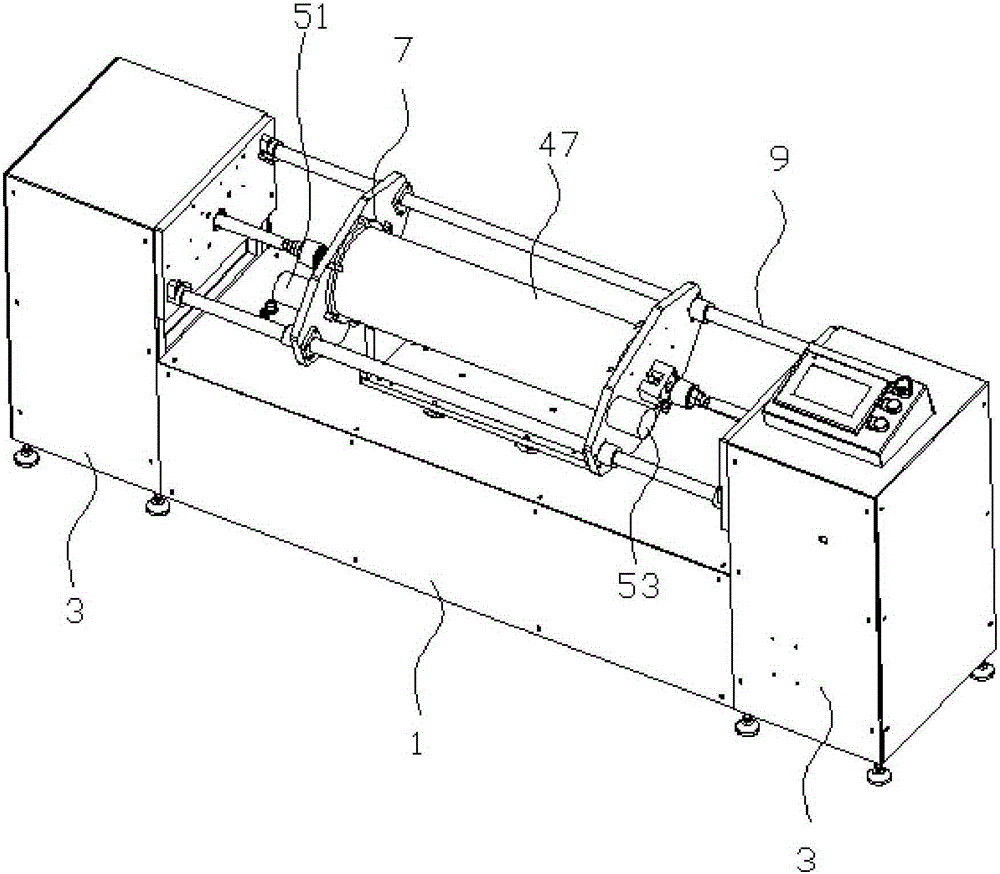

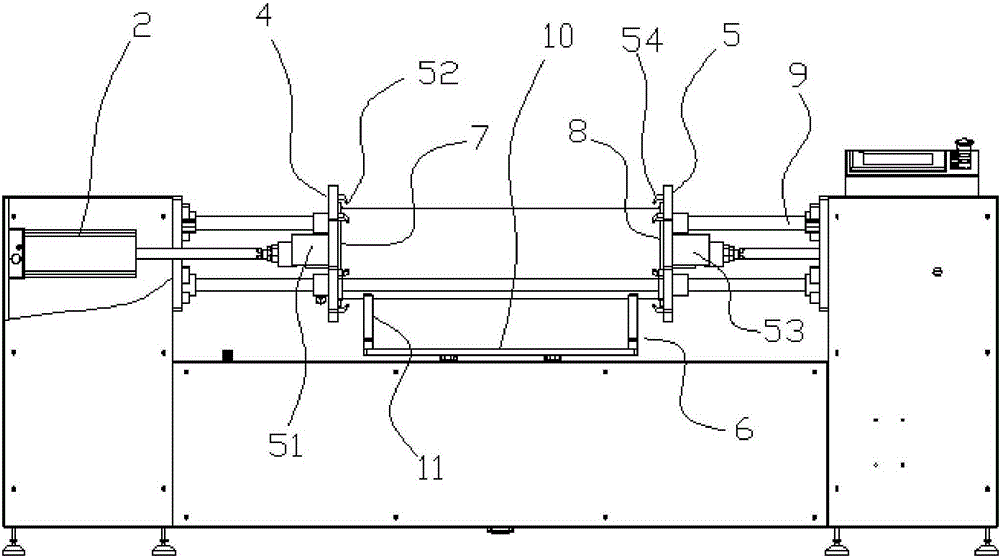

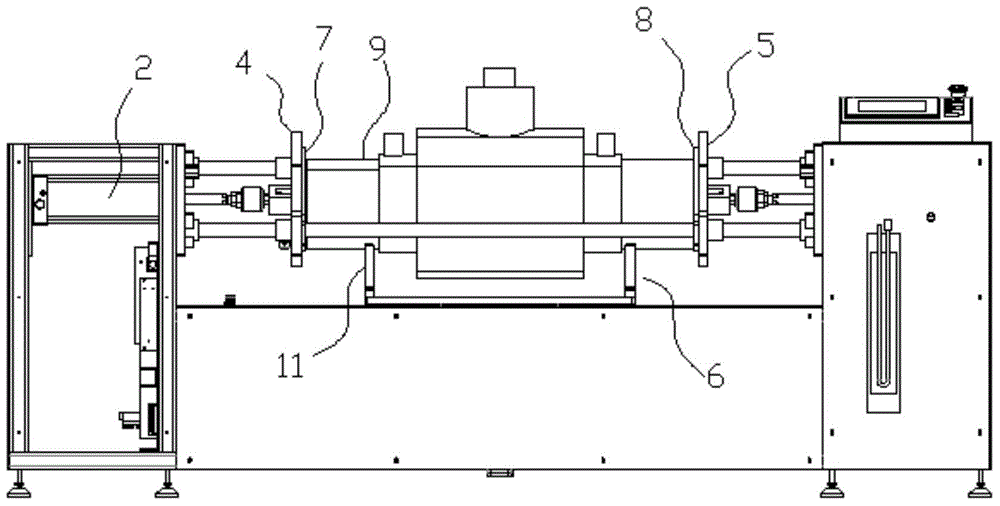

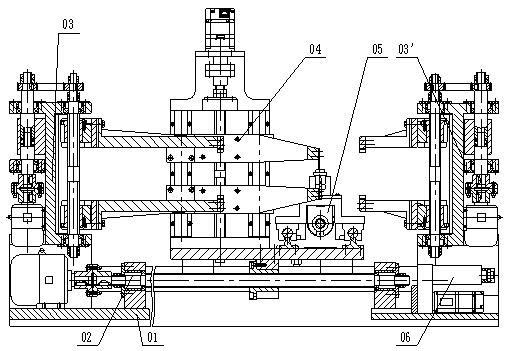

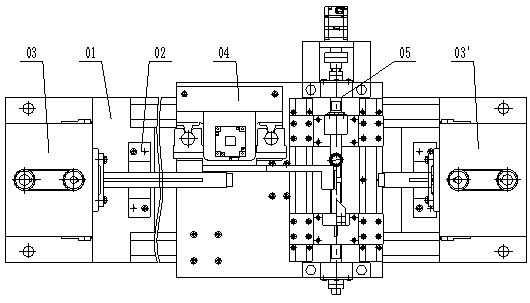

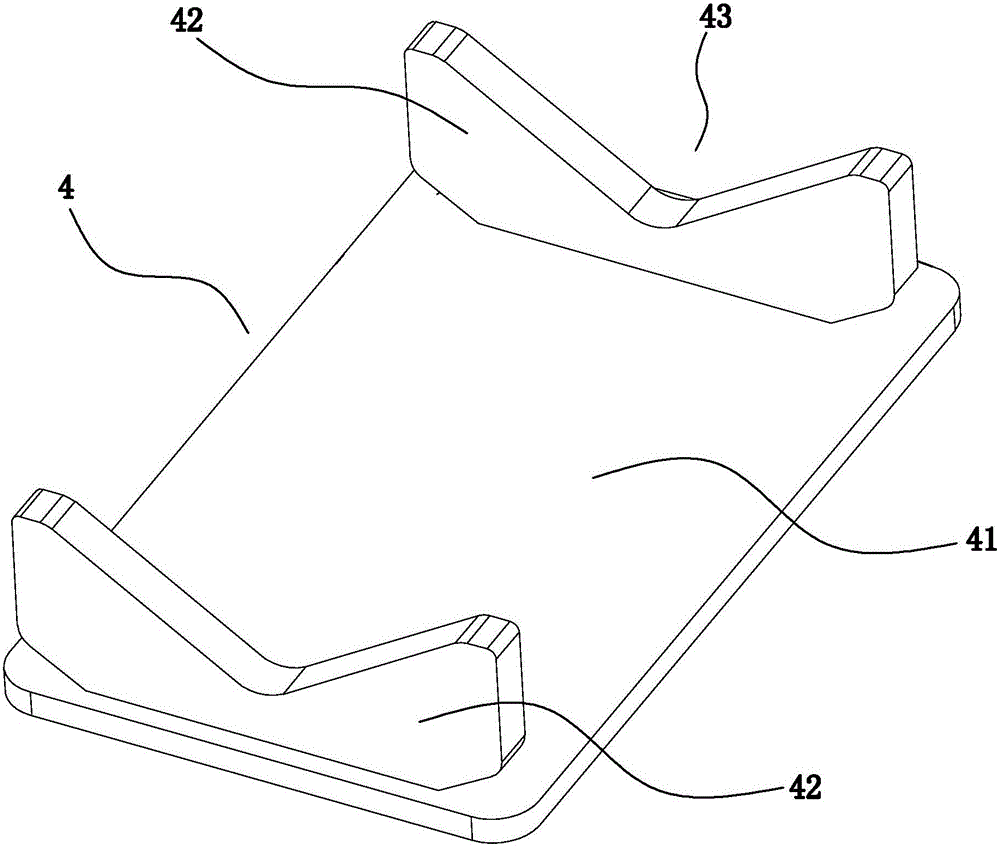

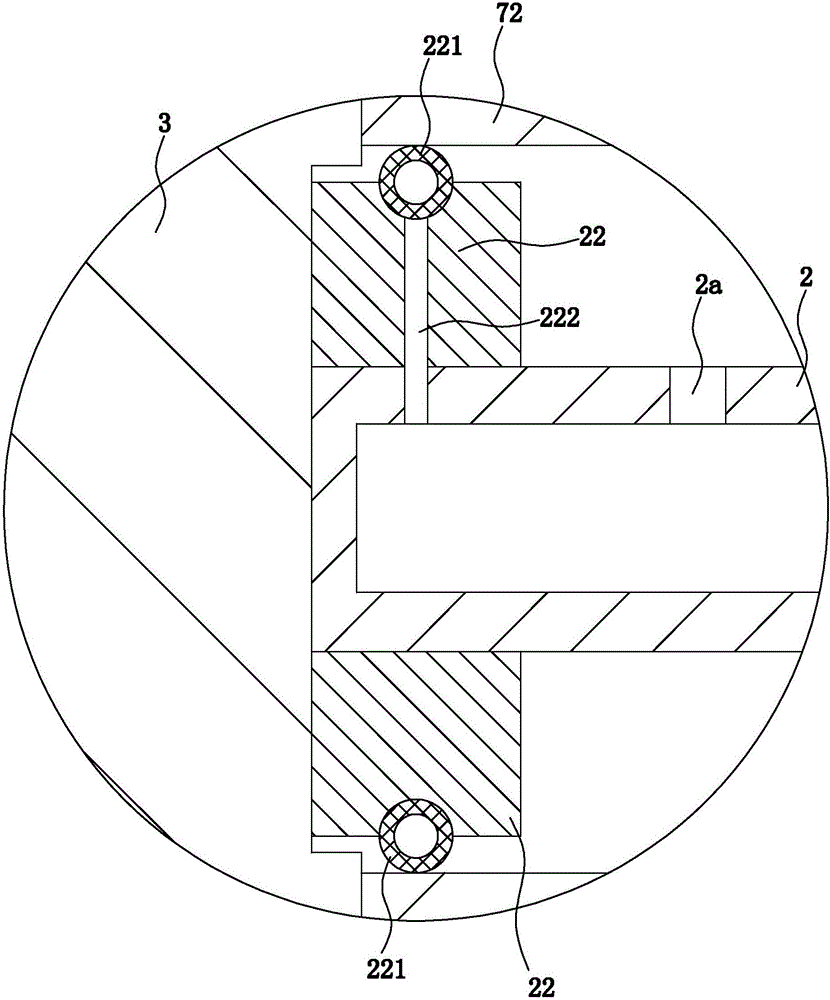

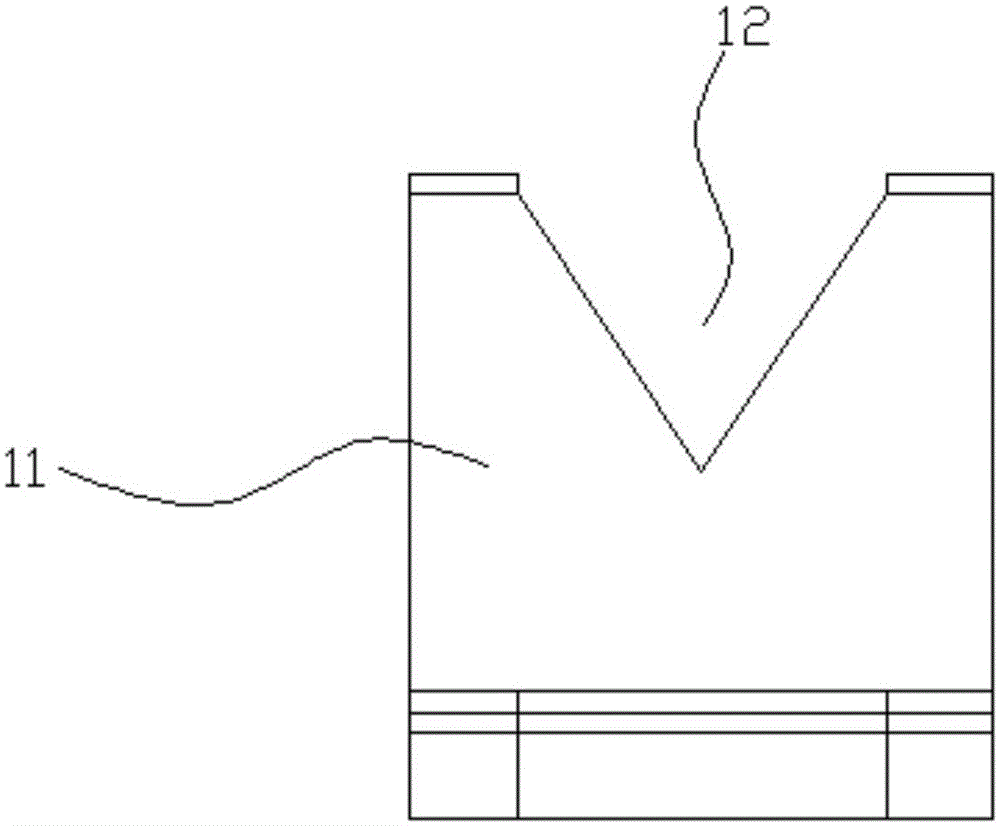

Straight pipe air tightness testing equipment

InactiveCN105203275ANo pinchingPrevent fallbackMeasurement of fluid loss/gain ratePipe fittingEngineering

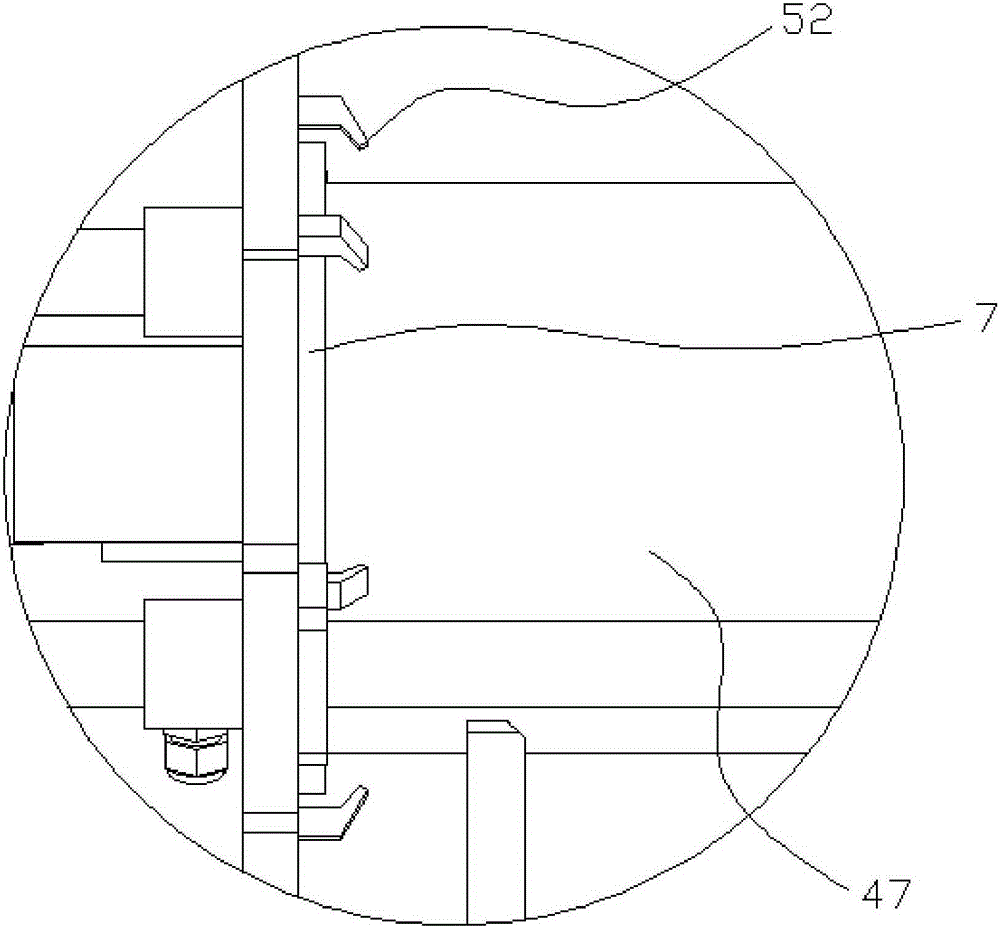

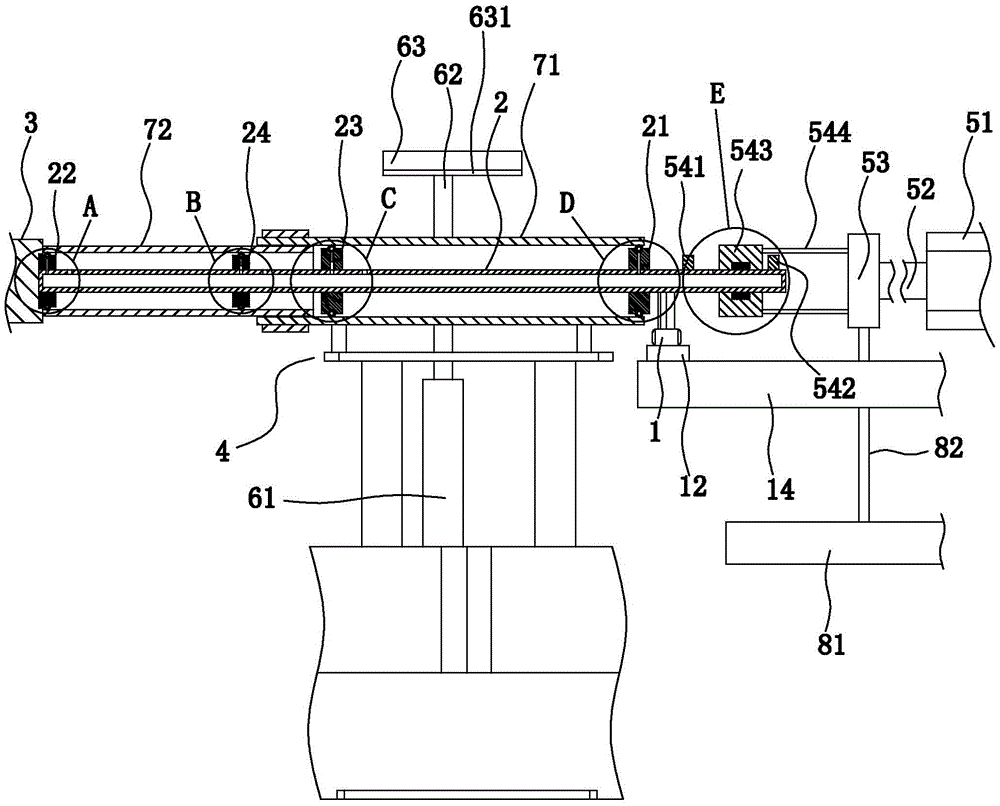

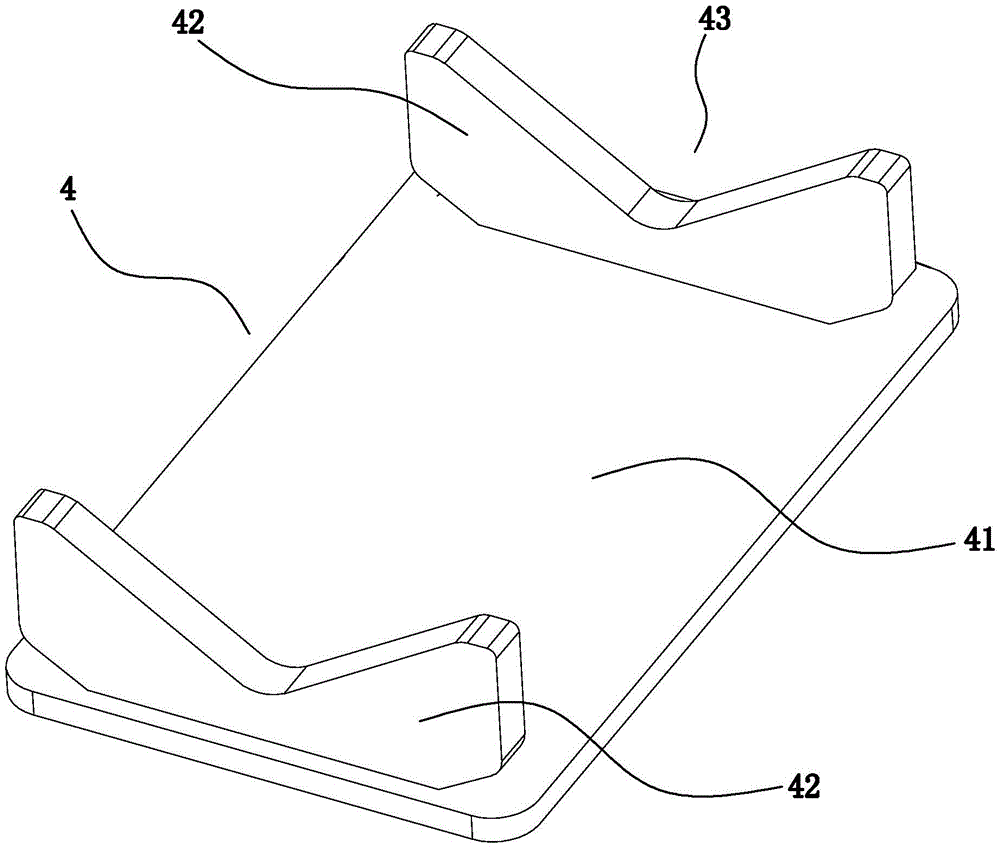

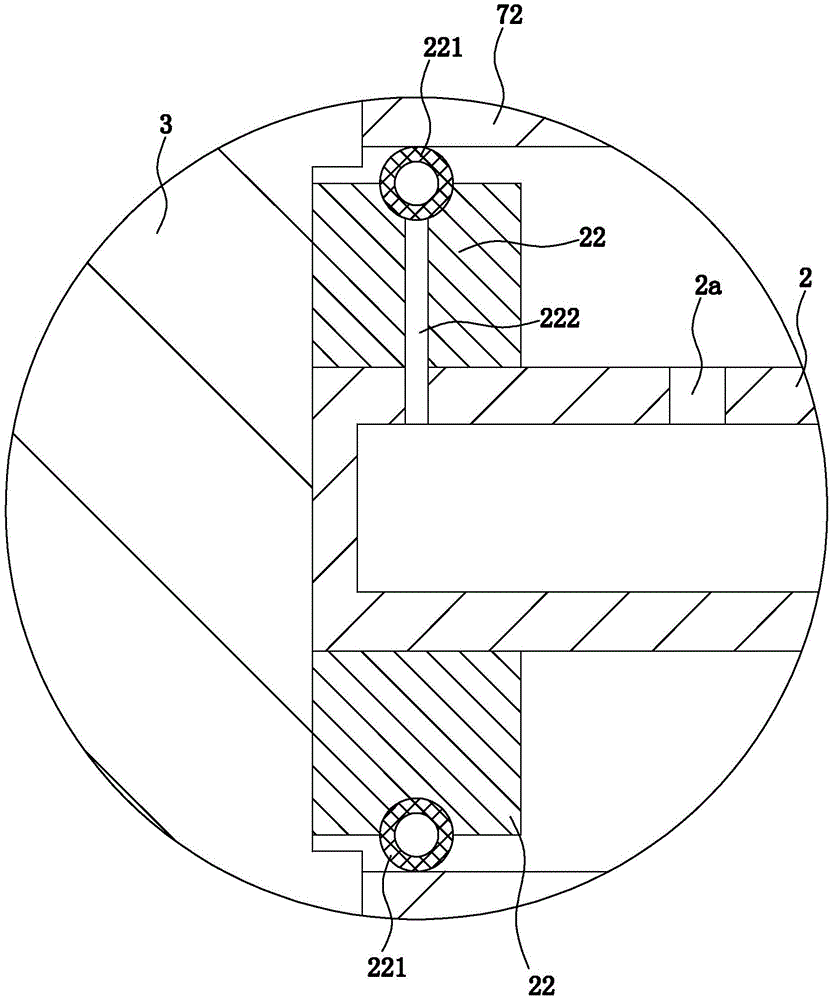

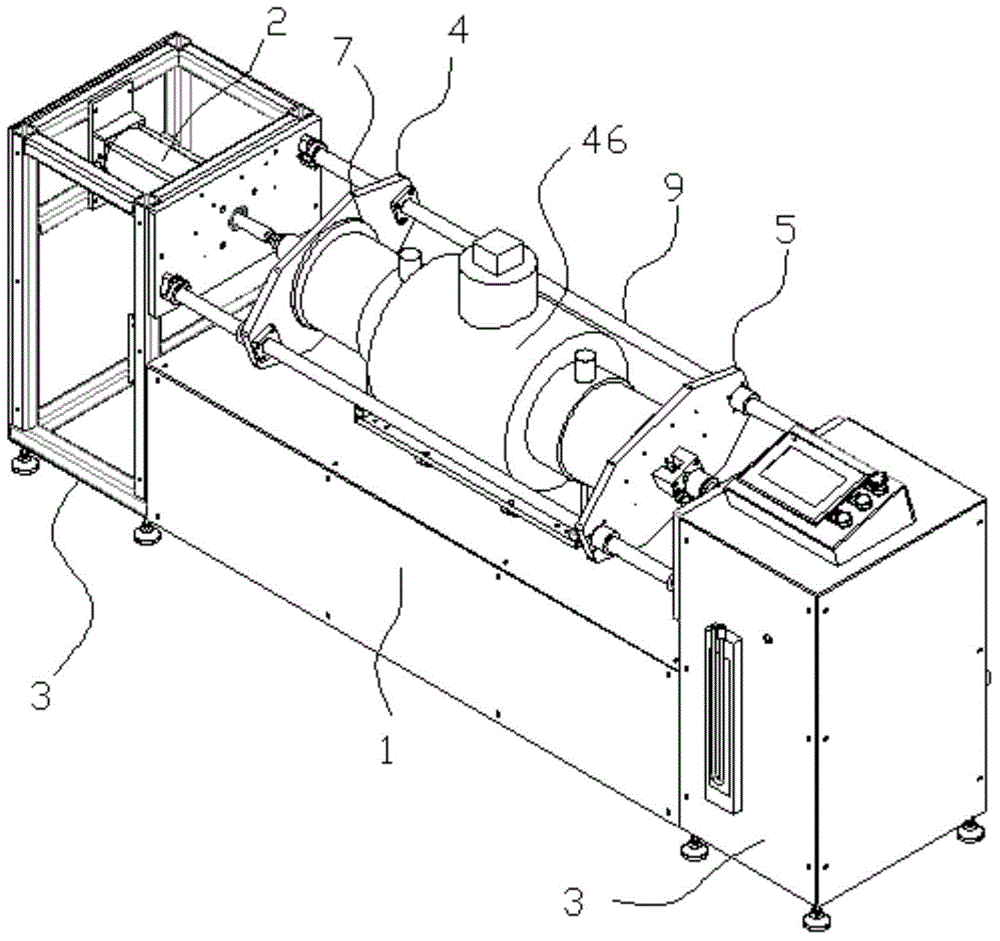

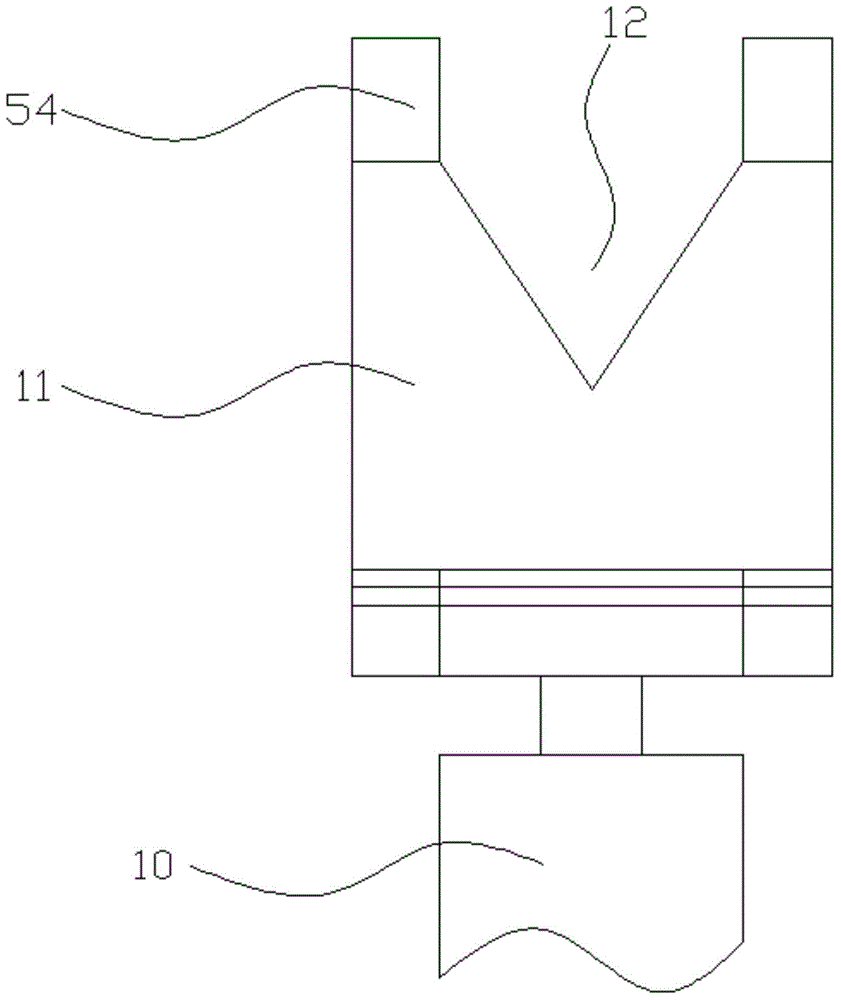

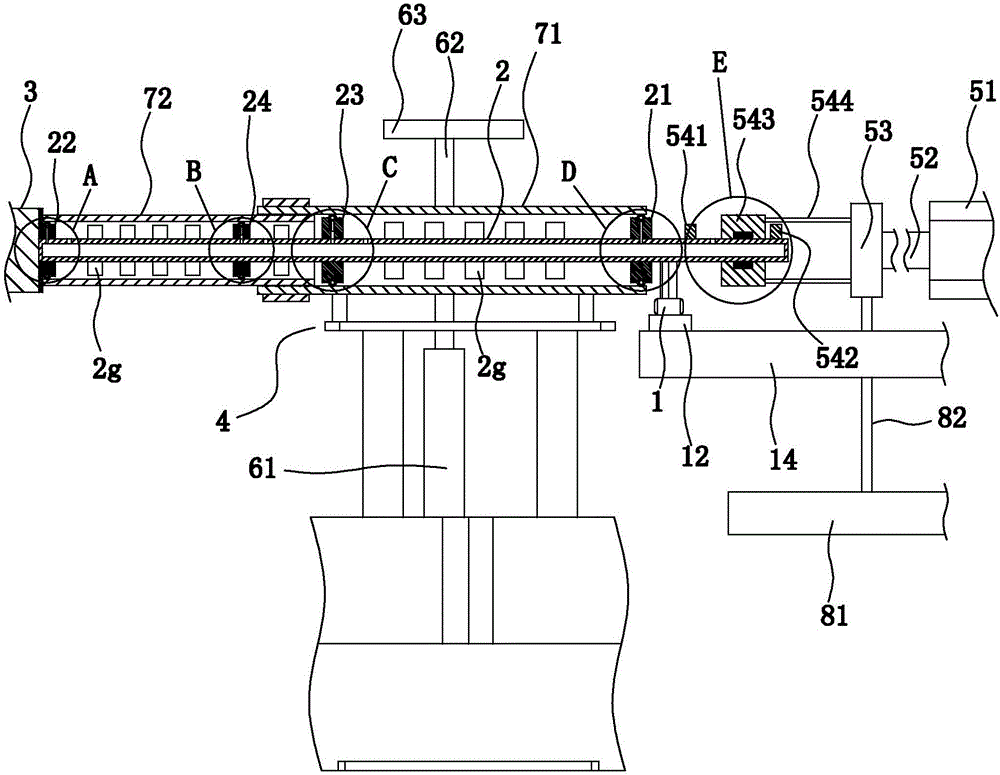

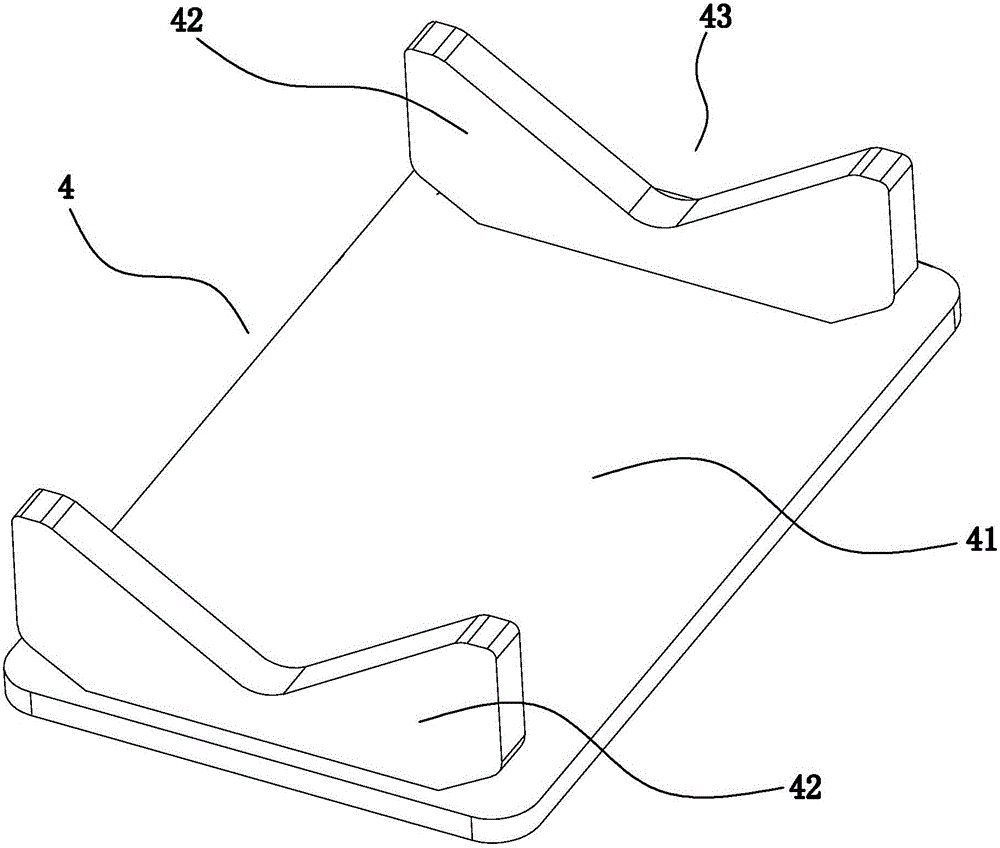

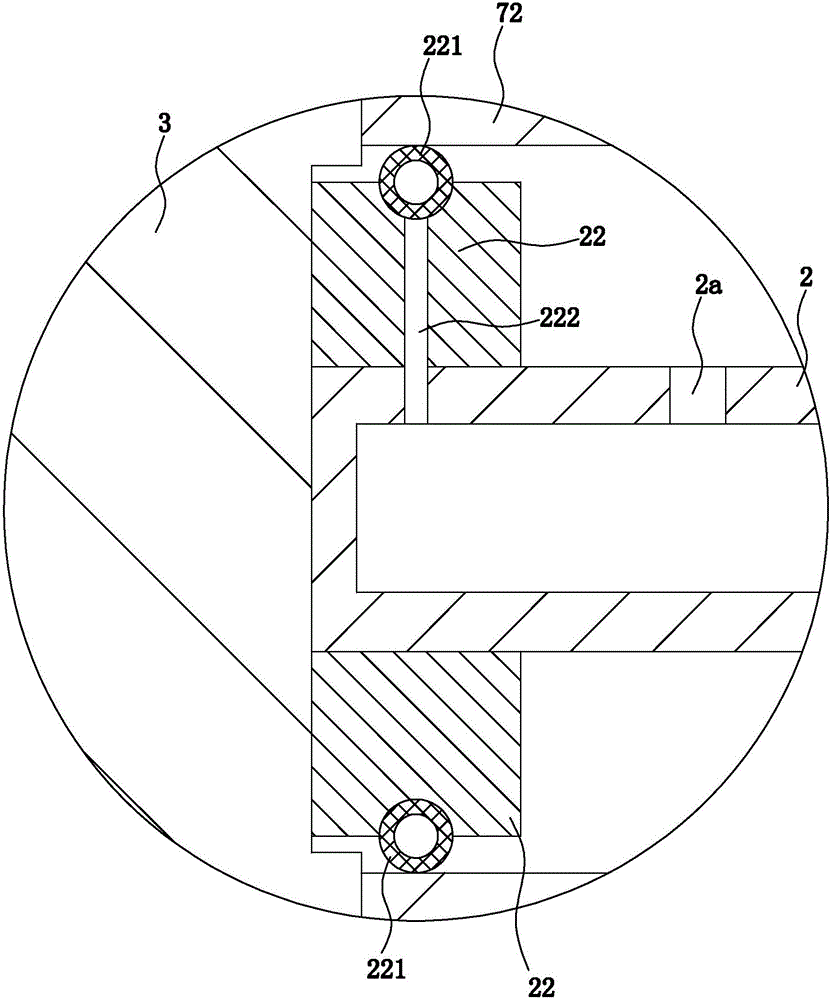

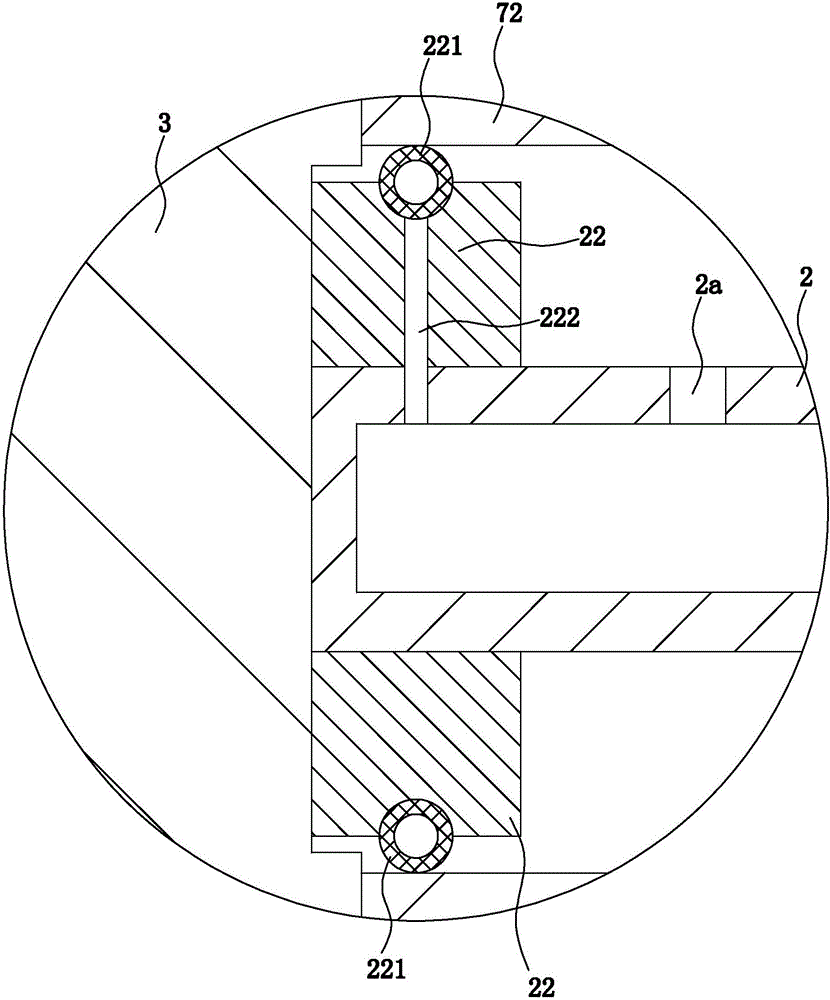

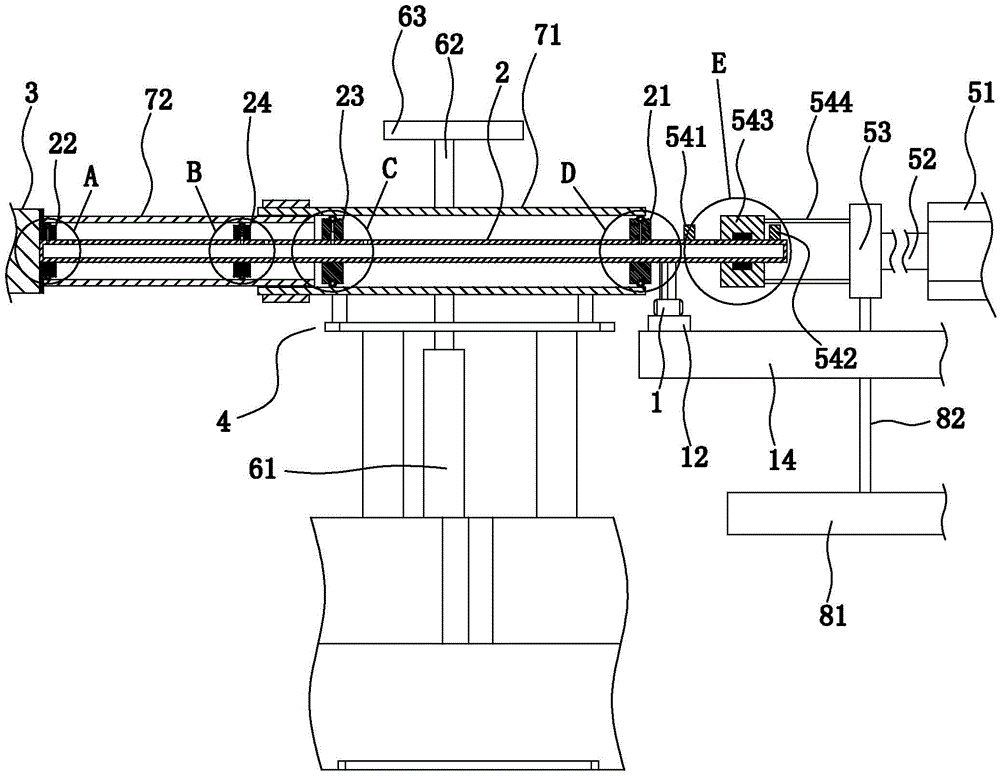

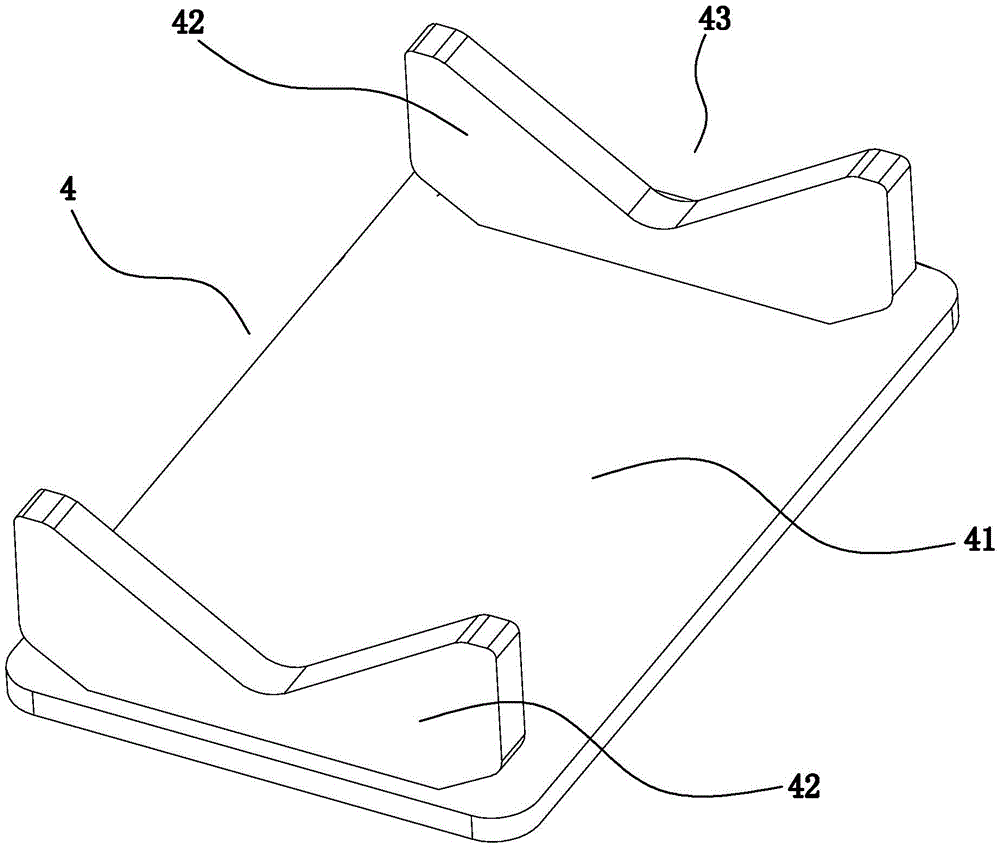

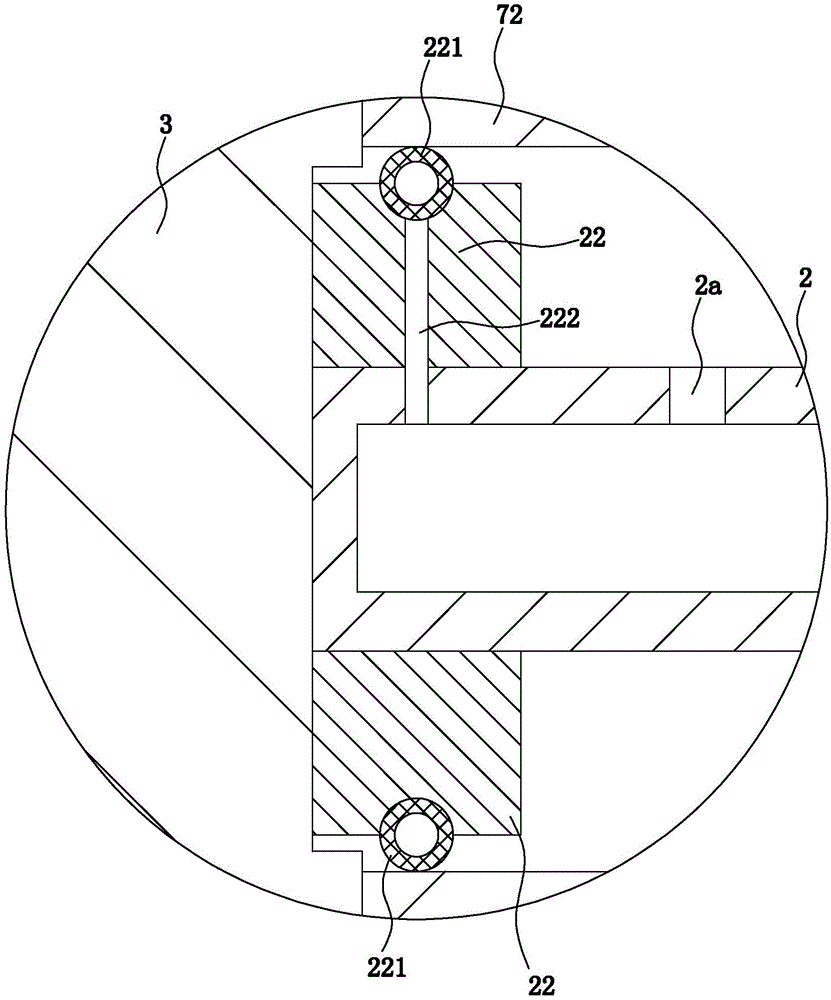

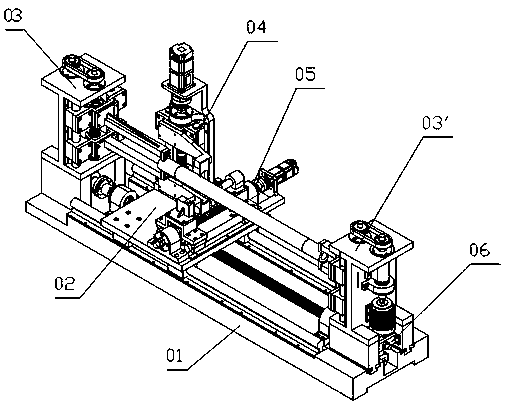

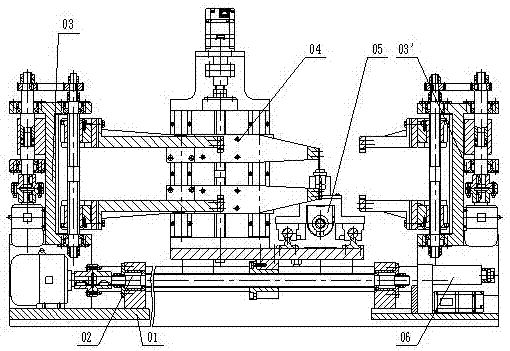

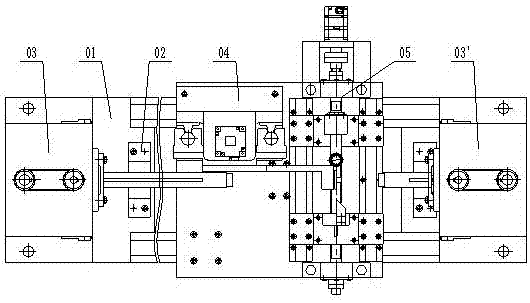

The invention discloses straight pipe air tightness testing equipment. The straight pipe air tightness testing equipment is convenient to operate, high in testing result accuracy and capable of guaranteeing that the pipe end of a pipe fitting is not likely to be clamped to be damaged. The straight pipe air tightness testing equipment comprises an air feed pump, an air pressure sensor, a main rack, two push plate air cylinders, two side racks, a main end cover and an auxiliary end cover. The two push plate air cylinders are arranged on the two side racks respectively, a piston rod of one push plate air cylinder is connected with the main end cover, and a piston rod of the other push plate air cylinder is connected with the auxiliary end cover. A main elastic sealing ring pad is arranged on the main end cover, an auxiliary elastic sealing ring plate is arranged on the auxiliary end cover, and a main cover air hole is formed in the main end cover. The straight pipe air tightness testing equipment has the advantages that the pipe fitting is located in place, sealing performance can be guaranteed, and the pipe fitting cannot be clamped to be damaged; a sealing structure capable of achieving adaptive adjustment is arranged, and the sealing effect during high-air-pressure detection can be enhanced; an auxiliary locating structure is arranged, the end covers can be prevented from retreating, the push plate air cylinders can be protected, the sealing effect can be improved, and the stability of the detecting process can be maintained.

Owner:宁波新合博园林机械有限公司

Combination welding pipe and manufacturing method and application thereof

ActiveCN103495811ALow costNo pinchingMetal working apparatusWelding apparatusButt weldingMetallic materials

The invention relates to a combination welding pipe and a manufacturing method and an application thereof. The combination welding pipe comprises pipe sections made of two different kinds of metal materials, higher heat is distributed to a high-melting metal pipe and lower heat is distributed to low-melting metal according to a heat distribution relation through a welding method of a self-melting annular weld bead of argon arc welding or plasma welding or high frequency welding or laser welding or submerged-arc welding or carbon-dioxide arc welding in pipe sections made of different metal materials, and thus synchronous self-melting and butt welding are carried out on butt joint openings of pipe sections of dissimilar materials. The welding process with controllable heat distribution is adopted to weld, the heat is controlled to be properly distributed according to melting points of metal of pipe sections in welding, the butt joint openings of adjacent pipe sections simultaneously or almost reach the melting temperature of metal of the adjacent pipe sections at the same time respectively in welding, thus good fusing is achieved, welding quality is improved, welding openings are smooth and bright, meanwhile pollution is reduced, and cost of welding flux is reduced. The combination welding pipe can be applied to the field of compressors or air-conditioners or the like.

Owner:佛山晓世科技服务有限公司

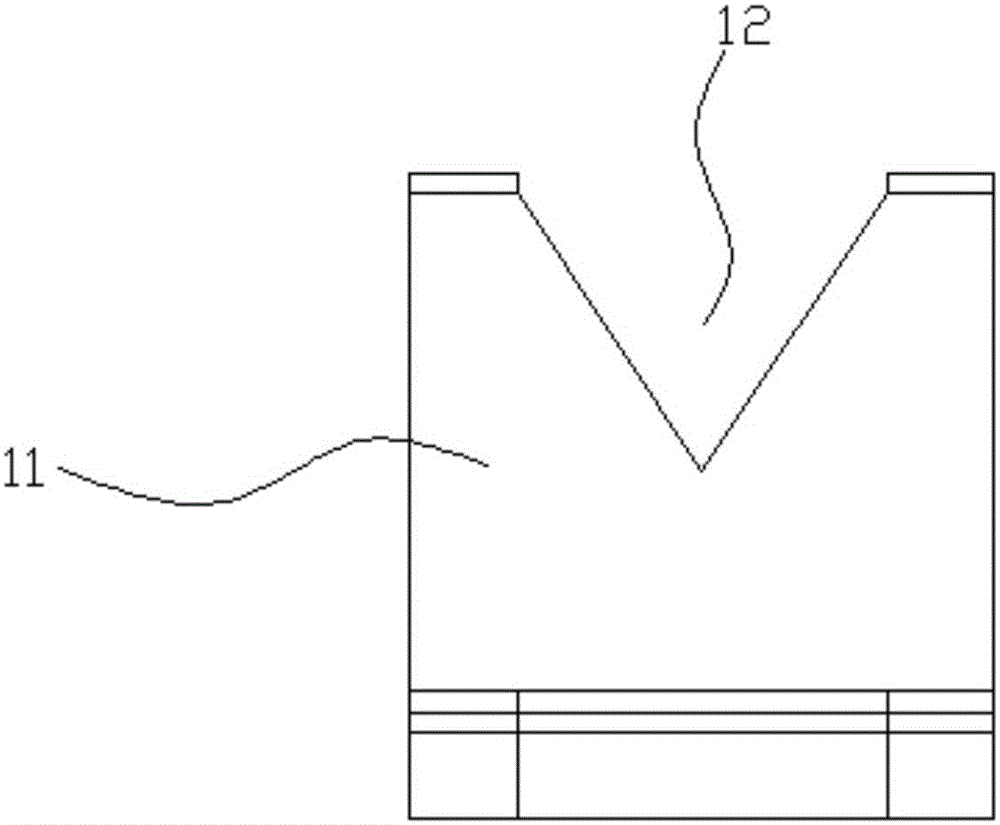

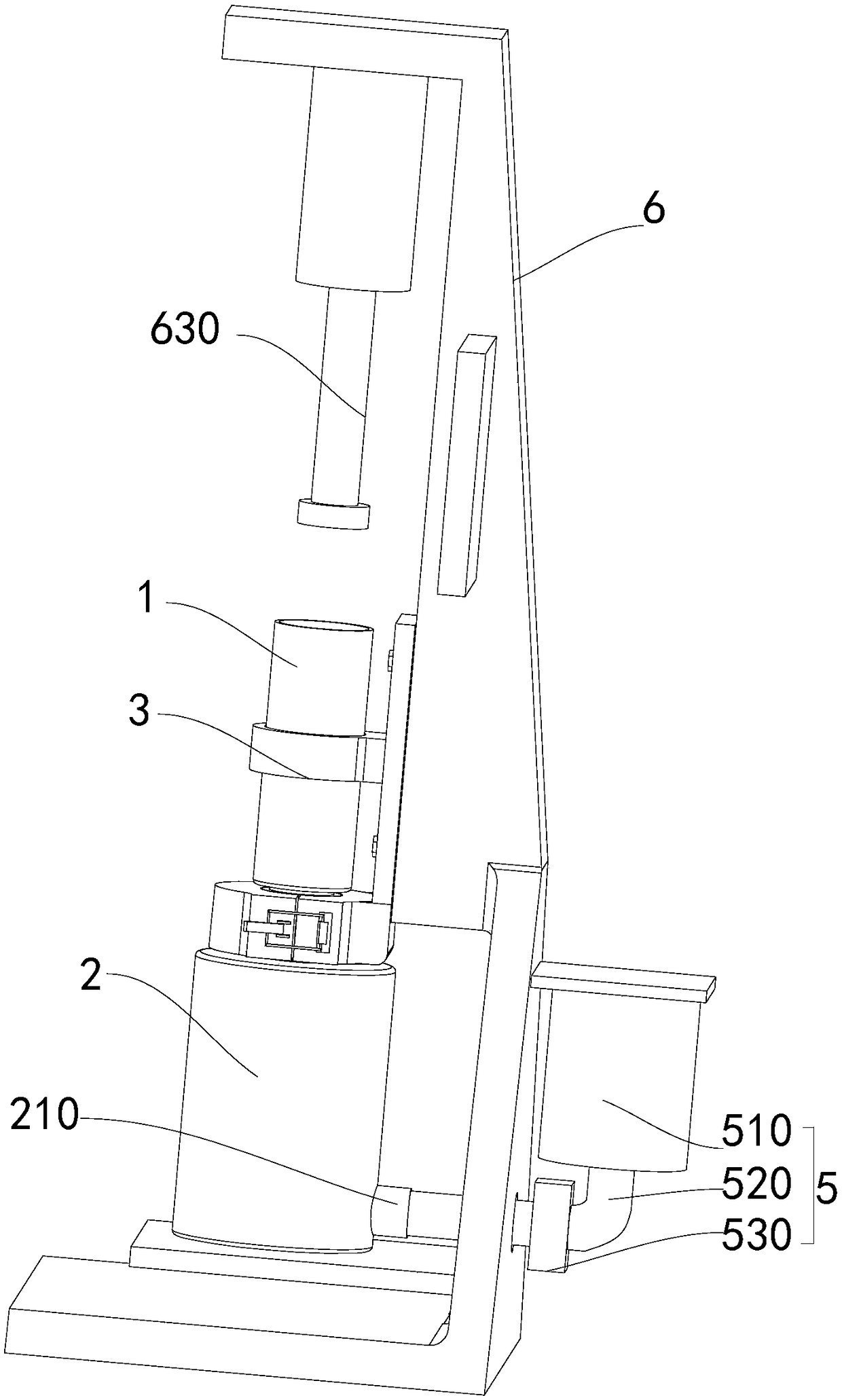

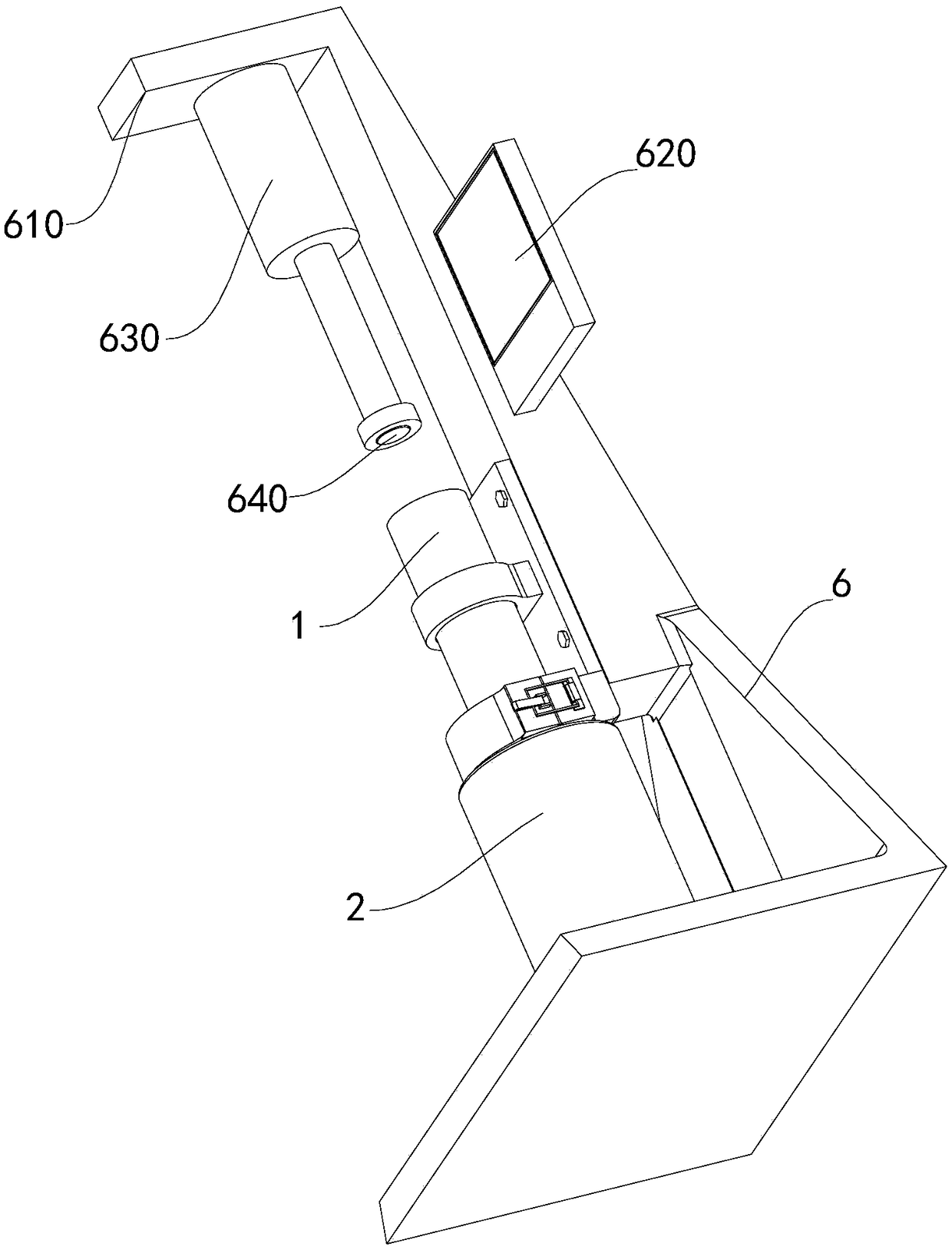

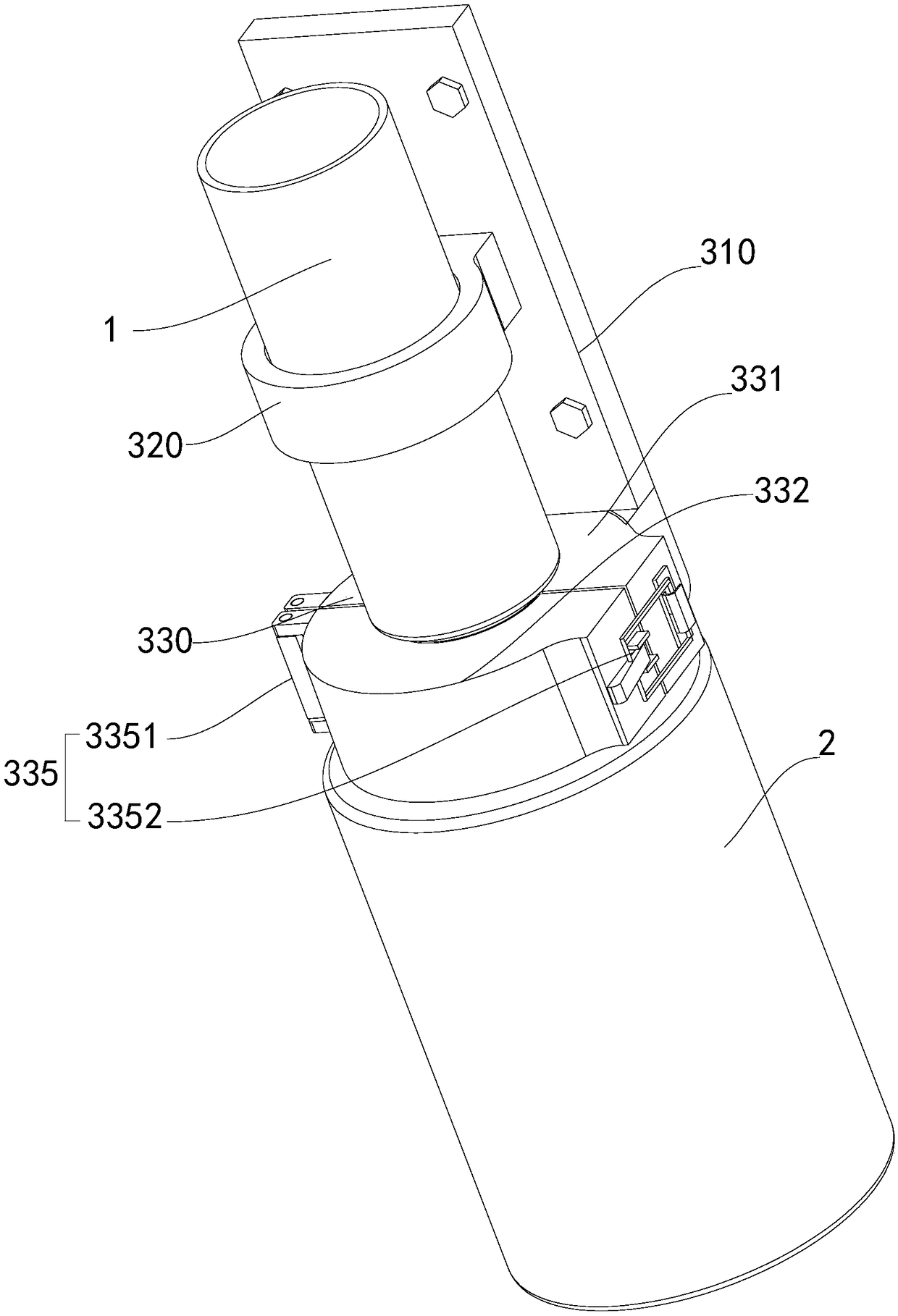

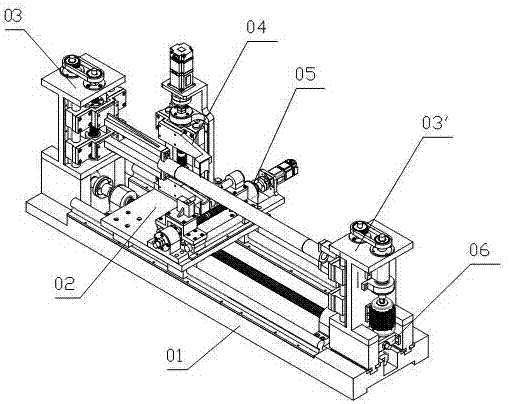

Cable test specimen clamping device and insulation layer peeling equipment

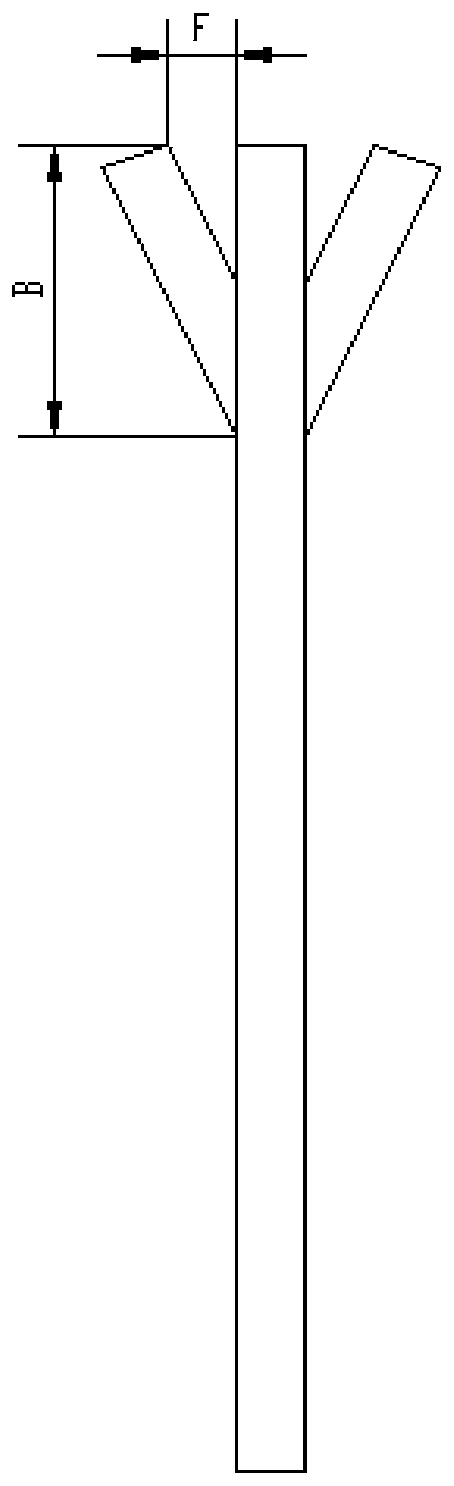

PendingCN108037330AAchieve clampingEasy to cutMeasurement instrument housingApparatus for removing/armouring cablesInsulation layerEngineering

The invention discloses cable test specimen clamping device and insulation layer peeling equipment. The cable test specimen clamping device comprises a pair of clamping arms and a clamping driving mechanism, wherein the free end of each clamping arm is provided with a clamping V-shaped block and is used for clamping the outer surface of a cable test specimen; one pair of clamping arms do synchronous movement in the mutual approaching or mutual leaving directions through being driven by the clamping driving mechanism; the centering clamping is realized. The clamping on a cable test specimen canbe conveniently realized through the cable test specimen clamping device; on one hand, the axial line position of the cable test specimen in the clamping process keeps unchanged, so that the operations such as the subsequent insulation layer cutting can be conveniently performed; on the other hand, the clamping device per se can adapt to the cable test specimens of various diameters.

Owner:UNIV OF JINAN

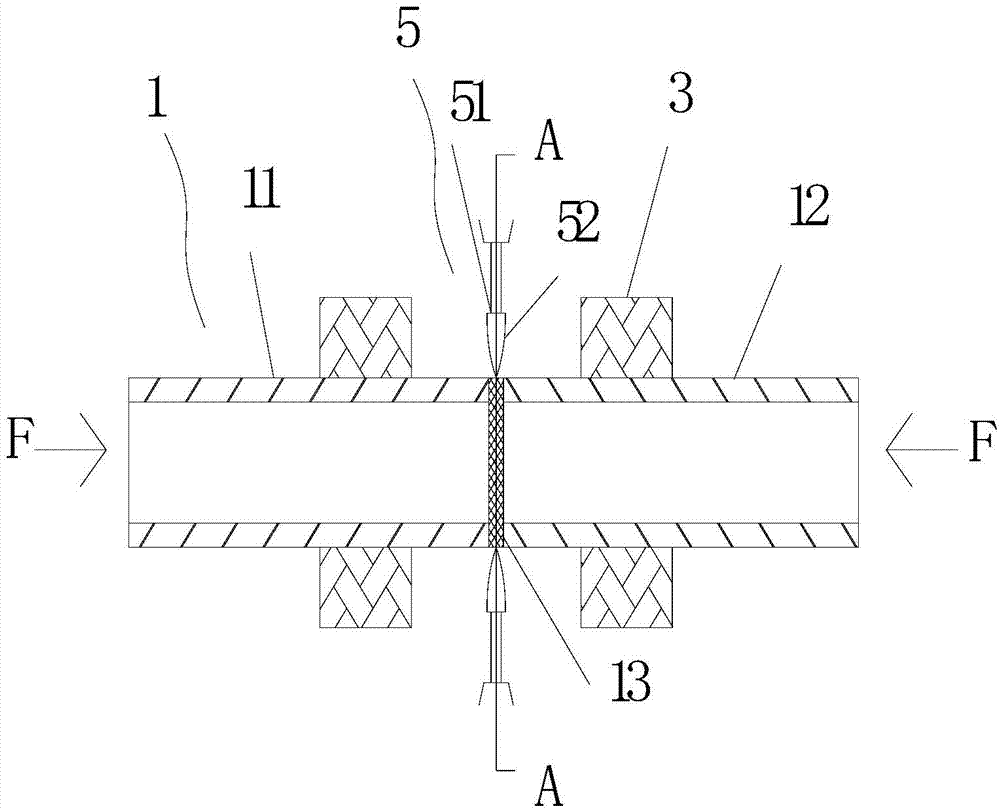

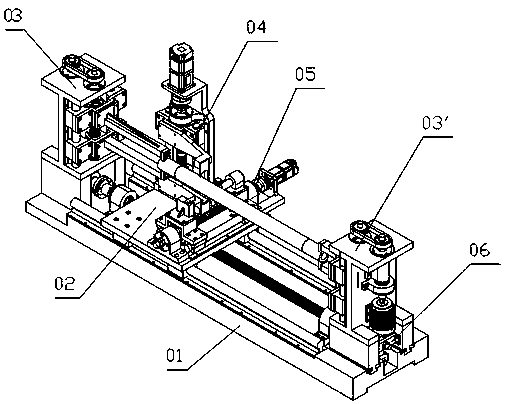

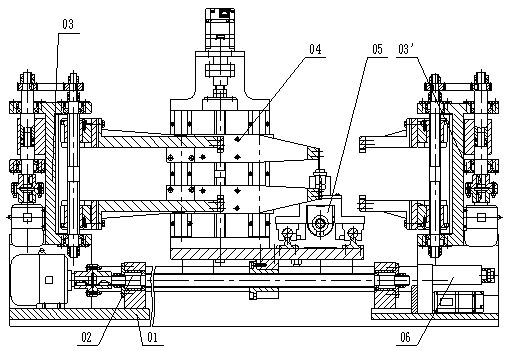

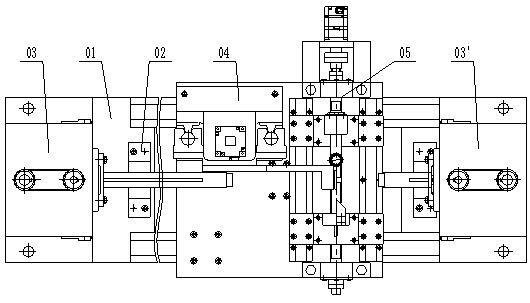

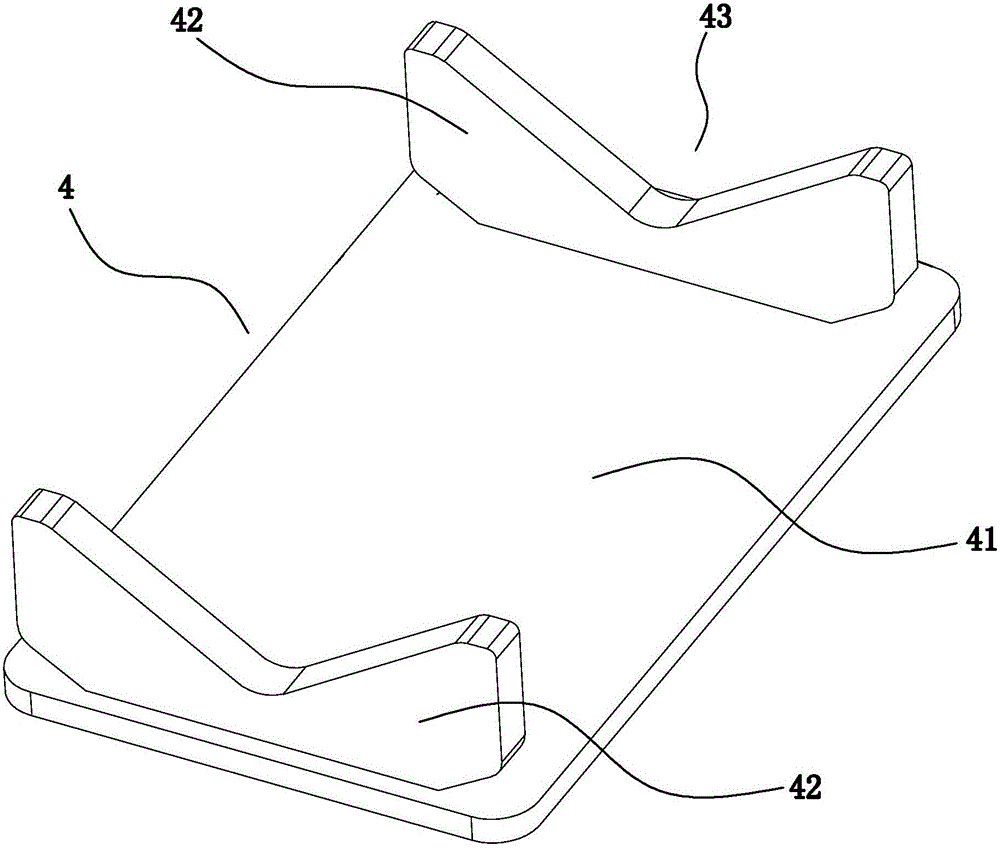

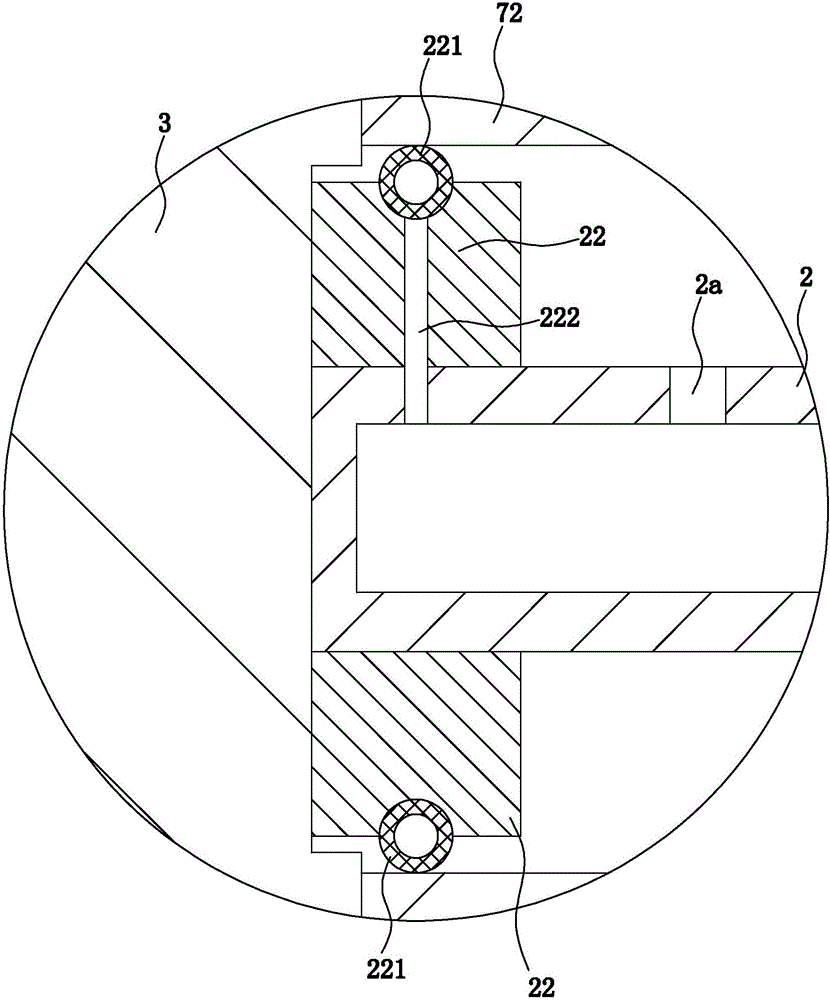

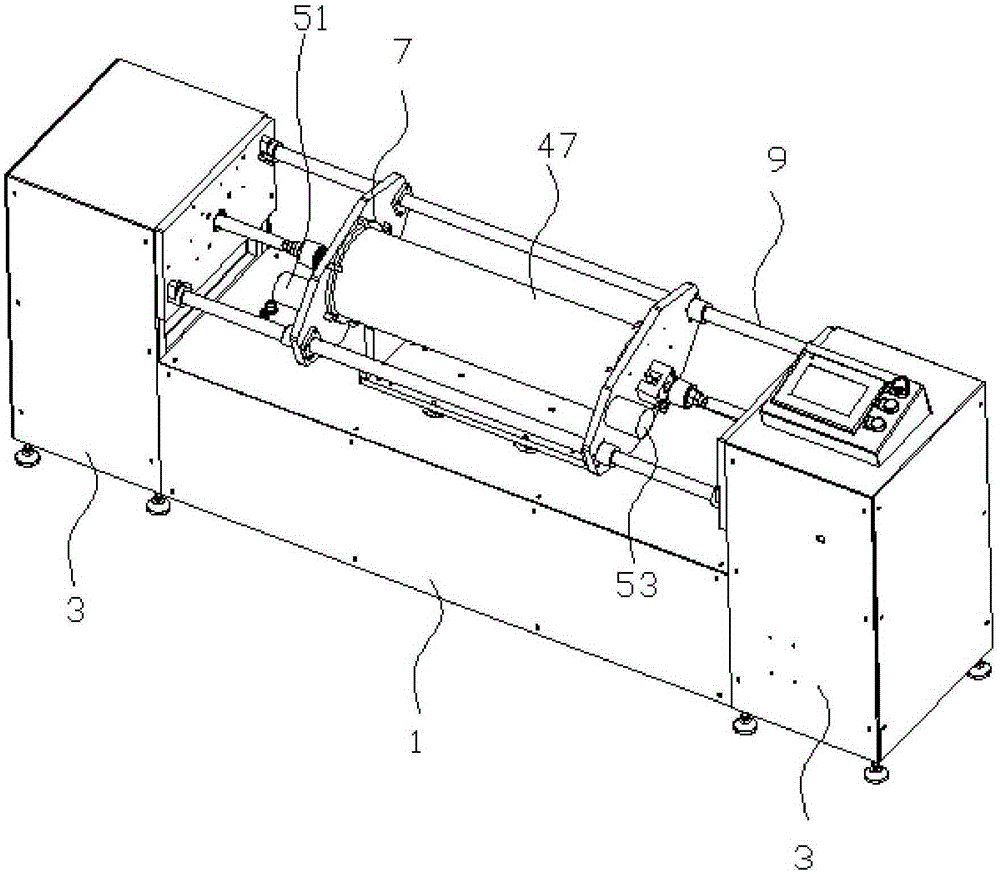

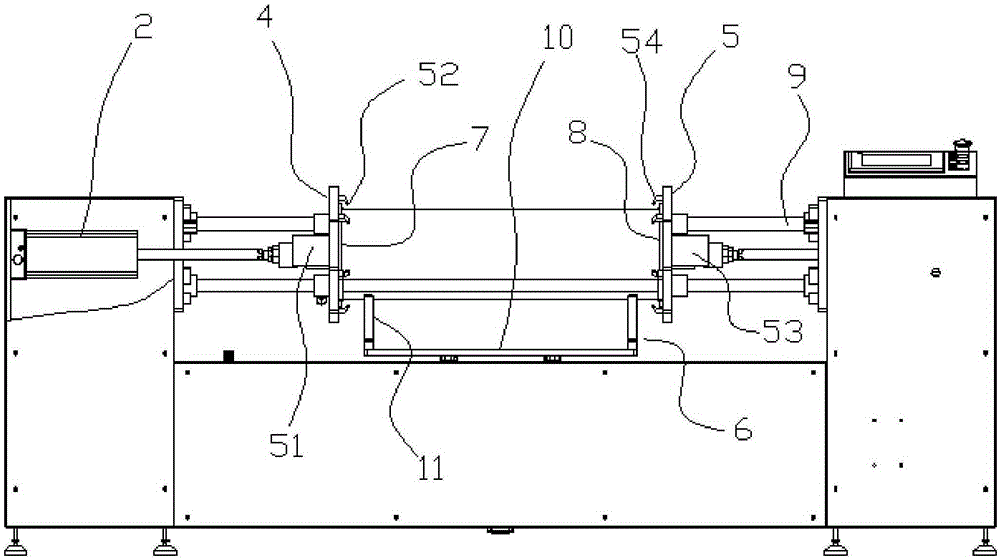

Pipe fitting airtightness testing machine

InactiveCN105203276AReasonable structureNo pinchingMeasurement of fluid loss/gain ratePipe fittingEngineering

The invention discloses a pipe fitting airtightness testing machine and aims at achieving the effects that the pipe fitting airtightness testing machine is convenient to operate, high in testing result accuracy and capable of guaranteeing that the two pipe ends of a pipe fitting are not prone to being damaged due to clamping. The machine comprises an air feed pump, a baroceptor, a main rack, two push plate air cylinders, two side racks, a main end cover and a subsidiary end cover, the two push plate air cylinders are arranged on the two side racks respectively, a piston rod of one of the push plate air cylinders is connected with the main end cover, a piston rod of the other push plate air cylinder is connected with the subsidiary end cover, a main elastic sealing ring pad is arranged on the main end cover, a subsidiary elastic sealing ring plate is arranged on the subsidiary end cover, and a main cover air hole is formed in the main end cover. The pipe fitting airtightness testing machine has the advantages that the pipe fitting can be positioned to the right position, the airtightness can be guaranteed, and the pipe fitting is not damaged due to clamping; the device is provided with a sealing structure which can be adjusted in a self-adaptation mode, and the airtightness effect in the high pressure testing process can be intensified; the machine is provided with an assistant positioning structure, the end covers can be prevented from moving backward, the push plate air cylinders can be protected, the sealing effect can be improved, and stability in the testing process can be maintained.

Owner:宁波新合博园林机械有限公司

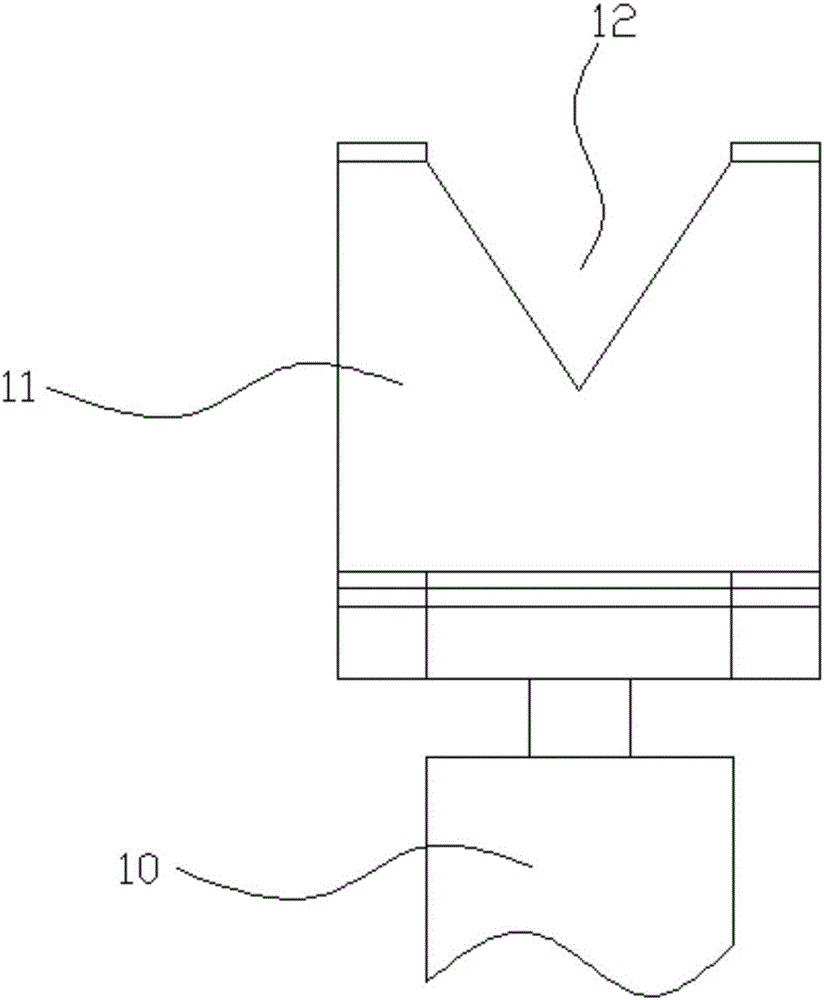

Gas tightness detection device

InactiveCN105841898ANo pinchingReasonable structureMeasurement of fluid loss/gain rateEngineeringHigh pressure

The invention discloses a gas tightness detection device comprising a main base, a gas supply pump, a plugging cylinder , a pressing cylinder, a shaft tube, a limiting base, and a joint supporting rack. A pressing piston rod is provided with a positioning plate, and an end socket piston rod is provided with a driving rack. The shaft tube is provided with a plastic tube outer end sealing plate, a steel pipe outer end sealing plate, a plastic tube outer sealing ring, and a steel pipe outer sealing ring. The shaft tube is provided with a first gas inlet opening, which is provided with a first gas inlet check valve, and the outer wall of the shaft tube is provided with a first air pressure sensor. The steel-plastic conversion joint supported by the joint supporting rack is disposed between the position-restricted seat and the plugging cylinder, and the communication of the gas supply end of the gas supply pump with the inner side of the shaft tube by the gas supply pipe. The gas tightness detection device is advantageous in that the whole structure is reasonable, the positioning and the clamping of the steel-plastic conversion joint are in place, the sealing performance can be guaranteed, and the steel-plastic conversion joint cannot be damaged; the self-adaption adjusting sealing structure is provided, and the sealing effect during the high pressure detection can be enhanced.

Owner:宁波宇华实业股份有限公司

Pressure-keeping detection device

ActiveCN105865727ANo pinchingReasonable structureMeasurement of fluid loss/gain rateEngineeringSelf adaptive

The invention discloses a pressure-keeping detection device which includes a main machine base, an air feed pump, a plugging cylinder, a compaction cylinder, a shaft pipe, a spacing seat, and a joint bracing frame. A compact piston rod is provided with a batter board thereon. A sealing head piston rod is provided with a driving rack thereon. The shaft pipe is provided with a plastic pipe external end sealing board, a steel pipe external end sealing board, a plastic pipe external sealing loop, and a steel pipe external sealing loop. The shaft pipe is provided with a first air inlet thereon. The first air inlet is provided with a non-return valve thereon. The external wall of the shaft pipe is provided with a first air pressure sensor. A steel-plastic adapter supported by the joint bracing frame is positioned between the spacing seat and the plugging cylinder. An air supply end of the air feed pump is in communication with the interior of the shaft pipe through an air supply pipe. According to the invention, the beneficial effects are: the device has a reasonable structure which can appropriately position and clamp the steel-plastic adapter, can guarantee sealing property and does not damage the steel-plastic adapter, has a self-adaptive sealing structure, and can strengthen sealing effects upon high air pressure detection.

Owner:DALIAN HERMETIC PUMP

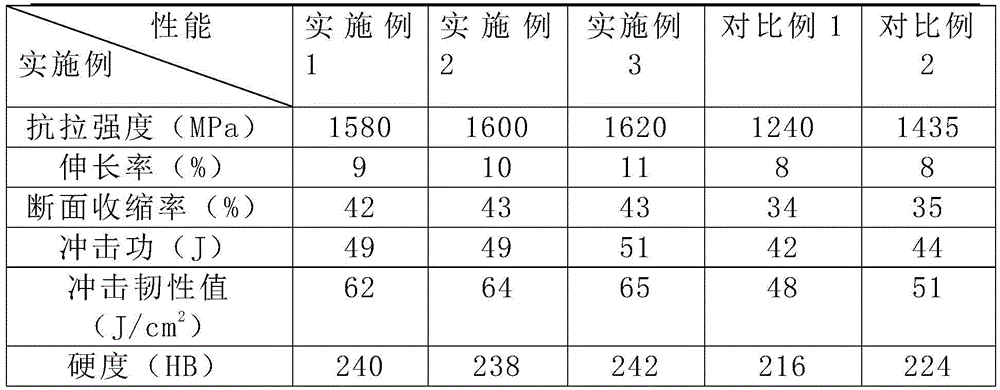

Anti-pinch hinge for industrial door

The invention provides an anti-pinch hinge for an industrial door, belongs to the mechanical technology field, and solves the problem of poor quality of the existing hinge for an industrial door. The anti-pinch hinge for the industrial door comprises an adjustment sheet, as well as a first hinge sheet and a second hinge sheet which are in hinge connection through a rotary shaft, wherein a winding drum is formed at the side of a first horizontal part of the first hinge sheet; a rotary shaft is arranged in the winding drum in a penetrating manner; strip-shaped holes are formed in a vertical part; location bolts are fixed in the strip-shaped holes in a penetrating manner; the first hinge part comprises a ceramic filling part and a metal layer arranged on the outer layer of the ceramic filling part; the ceramic filling part is formed by taking silicon carbide ceramic as a main body and at least partially arranging a silicon nitride ceramic surface layer on the outer layer of the main body; and the metal layer comprises the following composition ingredients in percentage by weight: 0.17-0.25% of C, 0.22-0.35% of Si, 1.2-1.3% of Cr, 0.05-0.2% of Ni, 0.3-0.8% of Mo, 0.3-0.8% of Mn, 0.06-0.12% of Ti, 0.05-0.3% of B and the balance iron. The anti-pinch hinge for the industrial door, which is provided by the invention, has the advantages of being simple in structure and high in safety.

Owner:宁波超亿门业有限公司

Sealing tester

ActiveCN105666100ANo pinchingReasonable structureMeasurement of fluid loss/gain rateMetal working apparatusGas supplyGas pressure transducer

The invention discloses a sealing tester. The sealing tester comprises a main engine base, a gas supply pump, a sealing air cylinder, a pressing air cylinder, a shaft tube, a limiting base and a joint supporting frame, wherein a positioning plate is arranged on a pressing piston rod; a drive frame is arranged on an end enclosure piston rod; a plastic tube outer end sealing plate, a steel tube outer end sealing plate, a plastic tube outer sealing ring and a steel tube outer sealing ring are arranged on the shaft tube; a first gas inlet is formed in the shaft tube; a first gas inlet one-way valve is arranged on the first gas inlet; a first gas pressure sensor is arranged on the outer wall of the shaft tube; a steel-plastic conversion joint supported by the joint supporting frame is positioned between the limiting base and the sealing air cylinder; and the gas supply end of the gas supply pump communicates with the inner part of the shaft tube through the gas supply tube. The sealing tester has the beneficial effects that: the integral structure is reasonable, the positioning and the clamping of the steel-plastic conversion joint are achieved, the sealing property can be guaranteed while the steel-plastic conversion joint is not damaged; and the sealing tester has a sealing structure which can be regulated in a self-adapting manner, and can strengthen the sealing effect during high gas pressure detecting.

Owner:CHINA JILIANG UNIV

Ball valve sealing test machine

InactiveCN105181274ANo pinchingPrevent fallbackMeasurement of fluid loss/gain rateEngineeringHigh pressure

The invention discloses a ball valve sealing test machine and aims to provide the ball valve sealing test machine which is convenient to operate, has high-accuracy test result and can guarantee that two pipe ends of a ball valve are prevented from being damaged by clamping. The ball valve sealing test machine comprises an air feeding pump, an air pressure sensor, a main frame, two push cylinders, two side frames, a main end cover and a secondary end cover, wherein the two push cylinders are respectively arranged on the side frames, a piston rod of one push cylinder is connected with the main end cover, a piston rod of the other push cylinder is connected with the secondary end cover, the main end cover is provided with a main elastic sealing ring pad, the secondary end cover is provided with a secondary elastic sealing ring board, and the main end cover is provided with a main cover air hole. The ball valve sealing test machine is advantaged in that, sealing and avoidance of damage to the ball valve can be guaranteed through positioning and clamping the ball valve in position, an adaptively-adjustable sealing structure is realized, the sealing effect during high-pressure detection can be strengthened, the ball valve sealing test machine has an auxiliary positioning structure, the end cover can be prevented from backspacing, the push cylinders are protected, the sealing effect is improved, and stability of the detection process is maintained.

Owner:王国良

Pressurization detection device

ActiveCN105823610ANo pinchingReasonable structureMeasurement of fluid loss/gain rateEngineeringHigh pressure

The present invention discloses a pressurization detection device. The pressurization detection device comprises a host base, an air feed pump, a blocking cylinder, a compaction cylinder, an axle tube, a spacing base and a joint bracing frame. The compaction piston rod is provided with a location board, and an end socket piston rod is provided with a driving rack; the axle tube is provided with a plastic pipe outer end blanking plate, a steel pipe outer end blanking plate, a plastic pipe external seal ring and a steel pipe external seal ring; the axle tube is provided with a first air intake, and the first air intake is provided with a first air intake non-return valve; the outer wall of the axle tube is provided with a first air pressure sensor, the steel-plastic conversion connector supported by the joint bracing frame is located between the spacing base and the blocking cylinder, and the air supply pipe of the air feed pump internally communicates with the axle tube through the air supply pipe. The high-pressure gas detector is reasonable in integration structure, is able to locate and clamp the steel-plastic conversion connector in place and guarantee the sealing without damaging the steel-plastic conversion connector, and has a sealing structure with adaptive regulation so as to reinforce the sealing effect at high-pressure detection.

Owner:DALIAN HERMETIC PUMP

Sealed leak detection device

ActiveCN105757056ANo pinchingReasonable structureFluid-pressure actuator testingHigh pressureLeak detection

The invention discloses a sealed leak detection device. The device comprises a main engine seat, a gas supply pump, a plugging cylinder, a compressed cylinder, a shaft pipe, a limit seat and a joint support frame, a locating plate is arranged on a compressed piston rod, a driving frame is arranged on a capped end piston rod, a plastic pipe outer end sealing plate, a steel pipe outer end sealing plate, a plastic pipe outer sealing ring and a steel pipe outer sealing ring are arranged on the shaft pipe, a first air inlet is formed in the shaft pipe, a first air inlet one-way valve is arranged on the first air inlet, a first pressure sensor is arranged on the outer wall of the shaft pipe, a steel-plastic conversion connector supported by the joint support frame is located between the limit seat and the plugging cylinder, and the gas supply end of the gas supply pump is communicated with the inner part of the shaft pipe through a gas supply pipe. The sealed leak detection device disclosed by the invention has the beneficial effects of reasonable whole structure, in-place positioning and clamping for the steel-plastic conversion connector, capacity of guaranteeing sealing without damaging the steel-plastic conversion connector by a clamping action, and adaptively adjusted sealing structure and capability of strengthening the sealing effect during high-pressure detection.

Owner:滁州市瑞景园林股份有限公司

Pressurization testing machine

InactiveCN105628315ANo pinchingReasonable structureMeasurement of fluid loss/gain rateAir pumpHigh pressure

The invention discloses a pressurization testing machine. The pressurization testing machine includes a main machine seat, an air feed pump, a sealing air cylinder, a pressing air cylinder, a shaft pipe, a limiting seat and an adapter support frame; a pressing piston rod is provided with a positioning plate; a sealing piston rod is provided with a driving frame; the shaft pipe is provided with a plastic pipe outer end sealing plate, a steel pipe outer end sealing plate, a plastic pipe outer sealing ring and a steel pipe outer sealing ring; the shaft pipe is provided with a first air inlet; the first air inlet is provided with a first air intake one-way valve; the outer wall of the shaft pipe is provided with a first pressure sensor; a steel-plastic adapter supported by the adapter support frame is located between the limiting seat and the sealing air cylinder; and the air feed end of the air feed pump is communicated with the interior of the shaft pipe through an air feed pipe. The overall structure of the pressurization testing machine is reasonable. With the pressurization testing machine adopted, in-place positioning and clamping of the steel-plastic adapter can be realized, airtightness can be ensured, and at the same time, the steel-plastic adapter will not be damage due to clamping. The pressurization testing machine adopts an adaptively-adjustable sealing structure, so that a sealing effect in high-pressure detection can be strengthened.

Owner:宁波宇华实业股份有限公司

Power-driven tightening type cable sample clamping mechanism and insulating layer peeling equipment

PendingCN108063405AAchieve clampingAchieve tautnessApparatus for removing/armouring cablesEngineeringMechanical engineering

Owner:UNIV OF JINAN

Blocking detection device

ActiveCN105716805ANo pinchingReasonable structureMeasurement of fluid loss/gain rateAir pumpEngineering

The invention discloses a blocking detection device which comprises a mainframe base, an air feed pump, a blocking cylinder, a compression cylinder, a shaft pipe, a limiting base and a connector supporting frame. A compression piston rod is provided with a positioning plate, a seal head piston rod is provided with a driving frame, and the shaft pipe is provided with a plastic pipe outer end seal plate, a steel pipe outer end seal plate, a plastic pipe outer seal ring and a steel pipe outer seal ring. The shaft pipe is provided with a first air inlet which is provided with a first air inlet check valve, the outer wall of the shaft pipe is provided with a first air pressure sensor, a plastics-steel conversion connector supported by the connector supporting frame is positioned between the limiting base and the blocking cylinder, and the air feed end of the air feed pump is communicated with the inside of the shaft pipe through an air feed pipe. The blocking detection device has the advantages that the blocking detection device is reasonable in integral structure and enables the positioning and clamping of the plastics-steel conversion connector to be in place, the sealing performance can be guaranteed, and the plastics-steel conversion connector is not damaged; and the blocking detection device has an adaptive control sealing structure and can strength sealing effects during the high air pressure detection.

Owner:CHINA JILIANG UNIV

Ball valve testing machine

InactiveCN105115715ANo pinchingPrevent fallbackMachine part testingMeasurement of fluid loss/gain rateEngineeringPiston rod

The invention discloses a ball valve testing machine, and aims at providing the ball valve testing machine which is convenient to operate, is high in accuracy of testing results and can guarantee that two pipe ends of a ball valve are not liable to be damaged. The machine comprises an air supply valve, an air pressure sensor, a main frame, two pushing plate cylinders, two side racks, a main end cover, and an auxiliary end cover, wherein the two pushing plate cylinders are respectively disposed on the two side racks, a piston rod of one pushing plate cylinder is connected with the main end cover and a piston rod of the other pushing plate cylinder is connected with the auxiliary end cover. The main end cover is provided with a main elastic sealing ring pad, and the auxiliary end cover is provided with an auxiliary elastic sealing ring plate. The main end cover is provided with a main cover air hole. The beneficial effects of the invention are that the positioning and clamping of the ball valve is proper; the sealing performance is guaranteed; the ball valve cannot be damaged; the machine has an adaptive adjustment sealing structure, and can improve the sealing effect during high-air-pressure detection; the machine has an auxiliary positioning structure, can prevent the end cover from withdrawing, protects the pushing plate cylinder, improves the sealing effect, and maintains the stability of a detection process.

Owner:宁波宇华实业股份有限公司

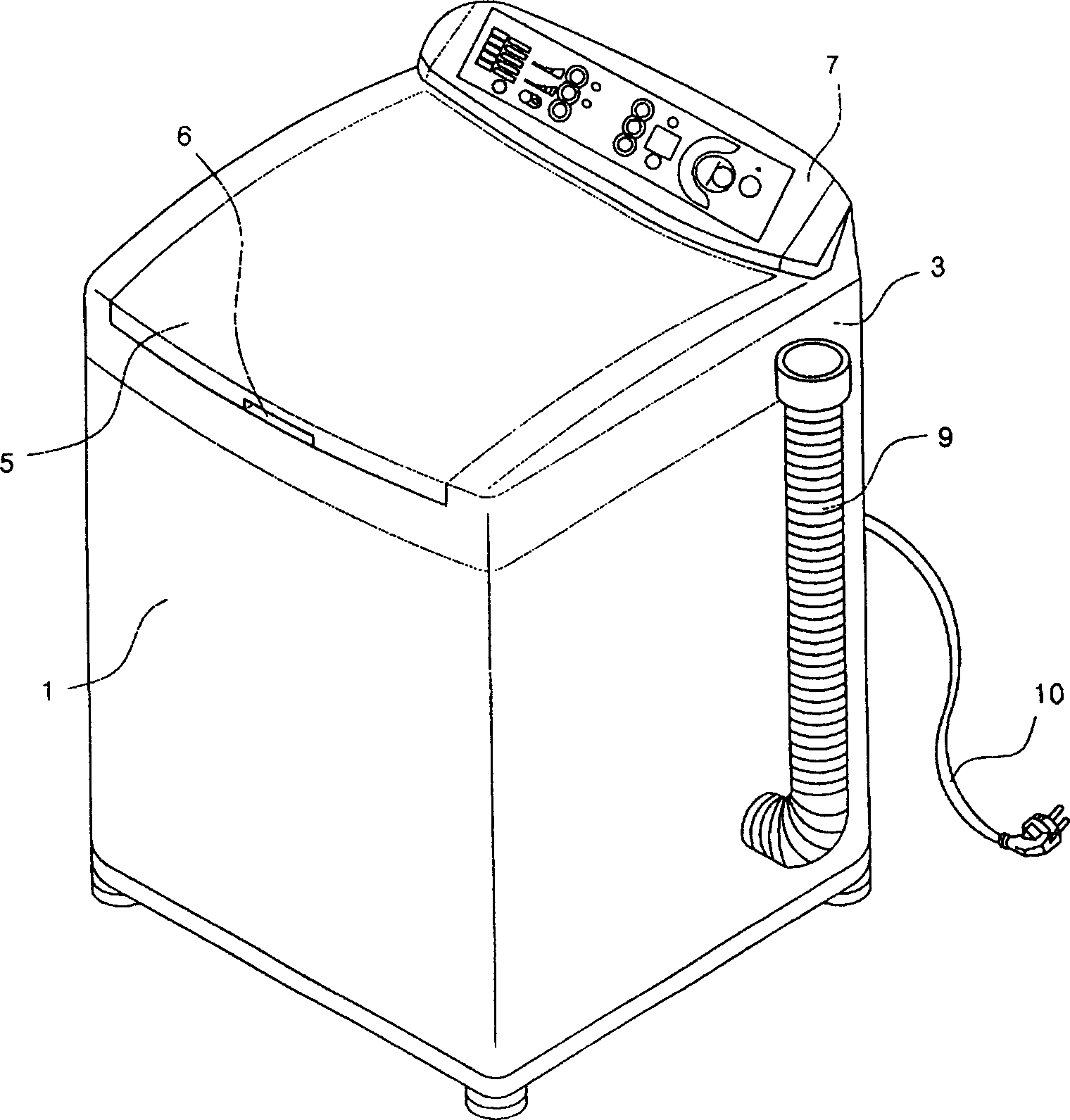

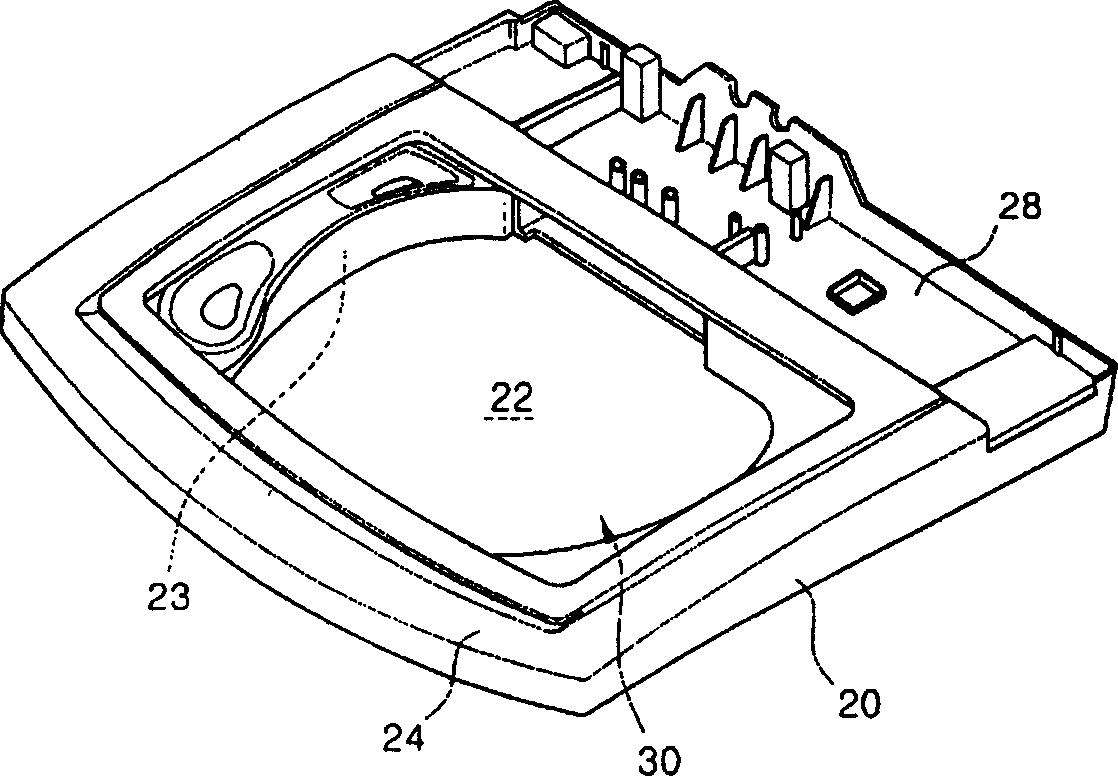

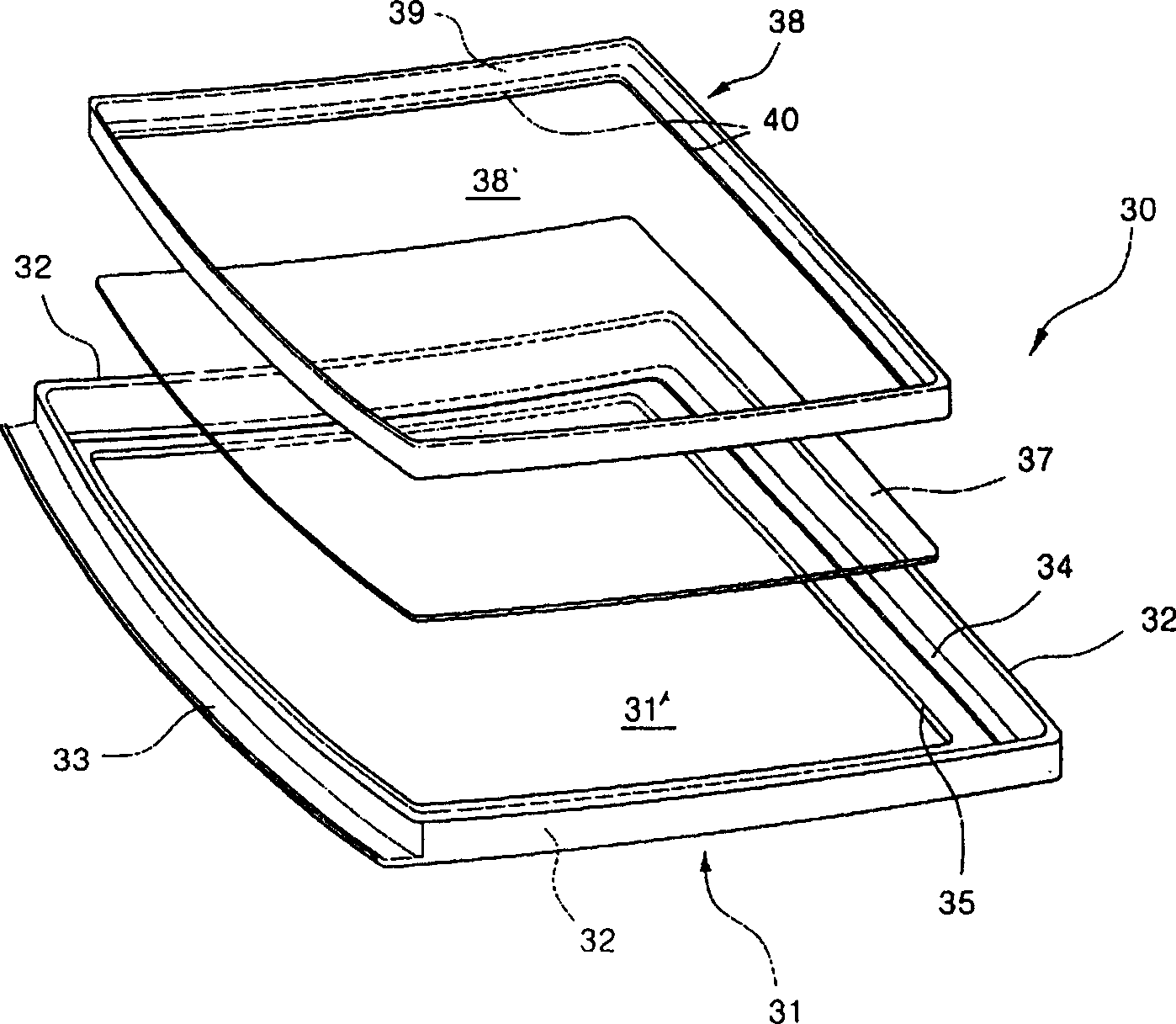

Assemble body of wicket in washing machine

InactiveCN1540078AEasy to operatePrecise workOther washing machinesTextiles and paperEngineeringMechanical engineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Joint sealing test device

ActiveCN105841895ANo pinchingReasonable structureMeasurement of fluid loss/gain rateSelf adaptivePneumatic pressure

The invention discloses a joint sealing test device which comprises a main device base, an air supply pump, a plugging cylinder, a compacting cylinder, a shaft pipe, a limiting base and a joint supporting stand. A positioning plate is arranged on a compacting piston rod, a driving stand is arranged on a seal-head piston rod, and a plastic pipe outer end sealing plate, a steal pipe outer end sealing plate, a plastic pipe outer end sealing ring and a steal pipe outer end sealing ring are arranged on the shaft pipe. A first air inlet is arranged in the shaft pipe, a first air inlet check valve is arranged in the first air inlet, and a first air pressure sensor is arranged on the outer wall of the shaft pipe. A steel plastic pipe switching joint supported by the joint supporting stand is arranged between the limiting base and the plugging cylinder, and the air supply end of the air supply pump communicates with the interior of the shaft pipe through an air supply pipe. The integral structure is reasonable, and positioning and clamping of the steel plastic pipe switching joint are properly in place. Sealing performance can be ensured, and the steel plastic pipe switching joint may not be damaged due to clamping. The sealing structure has self-adaptive performance, and the seal effect during high air pressure detection can be enhanced.

Owner:徐州博创建设发展集团有限公司

In-tube air tightness pre-detection device

InactiveCN105300629ANo pinchingPrevent fallbackMeasurement of fluid loss/gain rateEngineeringHigh pressure

Tube of the invention discloses an in-tube air tightness pre-detection device. The in-tube air tightness pre-detection device has the advantages of convenient operation and high accuracy of test results. With the in-tube air tightness pre-detection device adopted, end portions of tubes have low possibility of being damaged due to clamping. The in-tube air tightness pre-detection device includes an air supply pump, an air pressure sensor, a main rack, two push plate air cylinders, two side racks, an main end cover and an auxiliary end cover; the two push plate air cylinders are respectively arranged on the two side racks; the piston rod of one of the push plate air cylinders is connected with the main end cover, and the piston rod of the other push plate air cylinder is connected with the auxiliary end cover; the main end cover is provided with a main elastic sealing ring gasket; the auxiliary end cove is provided with an auxiliary elastic sealing ring gasket; and a main cover air hole is formed in the main end cover. With the in-tube air tightness pre-detection device adopted, the tubes can be positioned in place, and sealing performance can be ensured, and the tubes will not be damaged due to clamping. An adaptively-adjustable sealing structure is adopted, and therefore, sealing effects in high-pressure detection can be enhanced; and an auxiliary positioning structure is adopted, and therefore, the rollback of the end covers can be avoided, the push plate air cylinders can be protected, sealing effects can be improved, and the stability of a detection process can be maintained.

Owner:宁波新合博园林机械有限公司

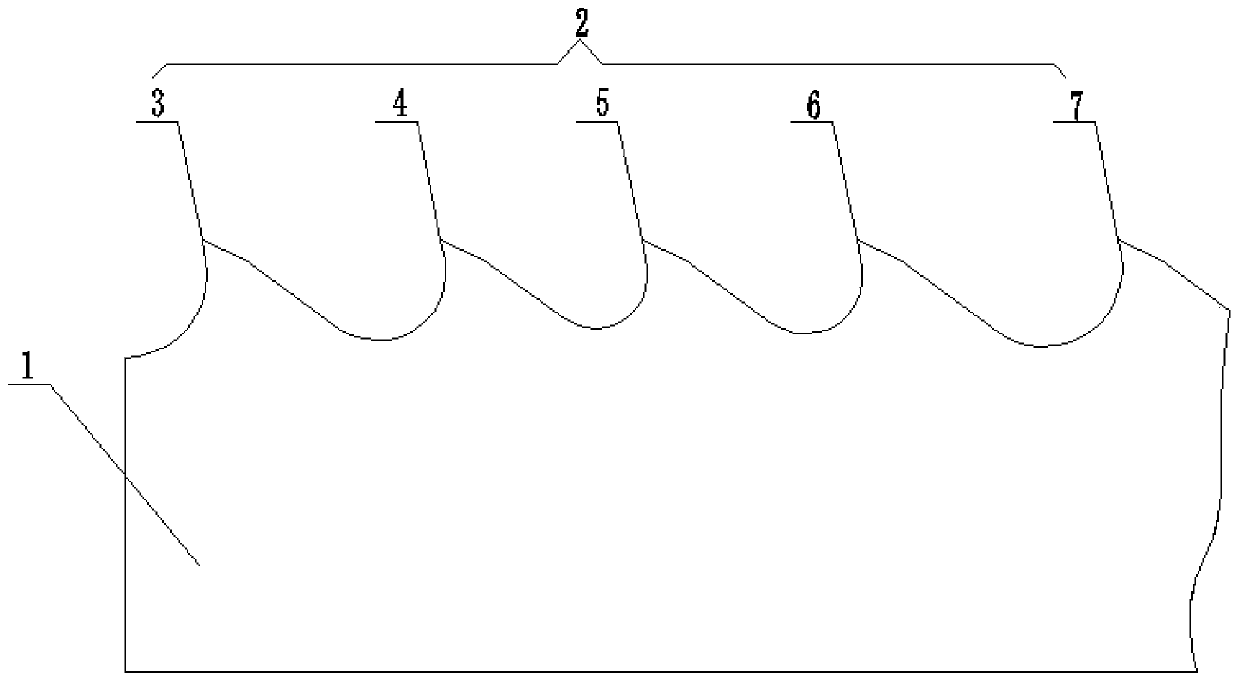

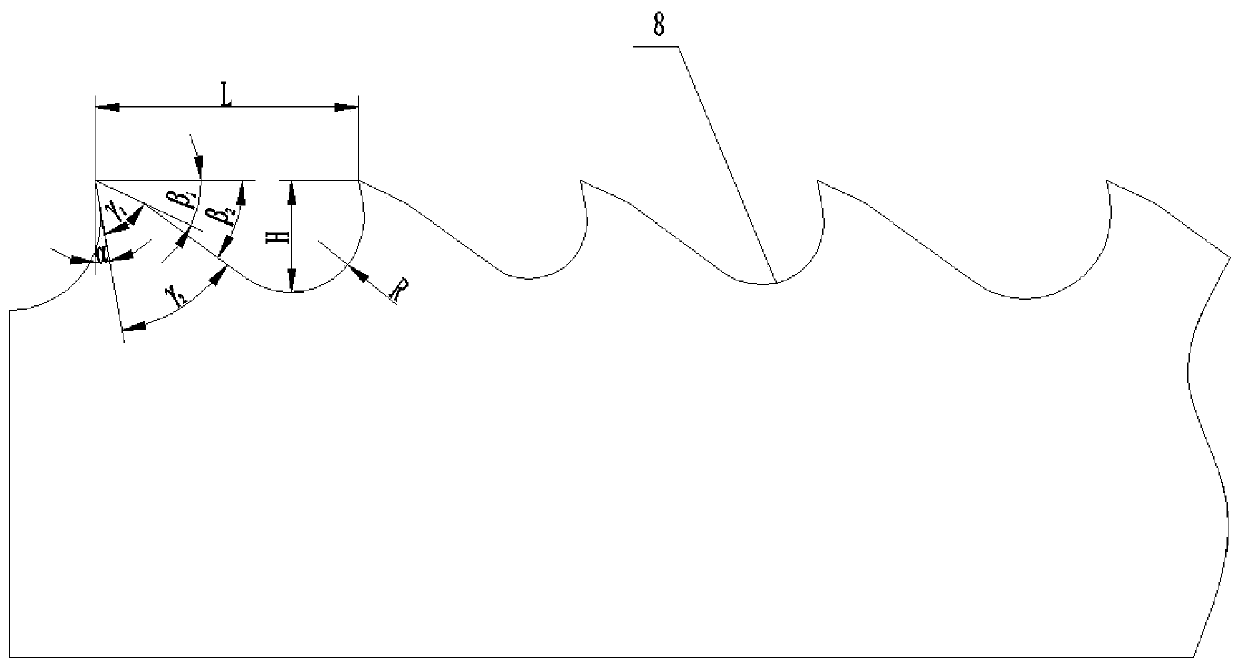

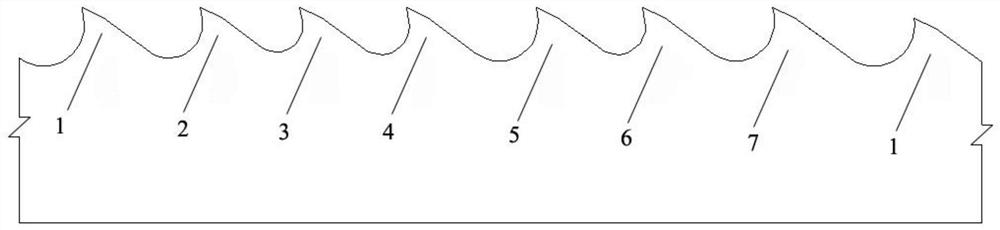

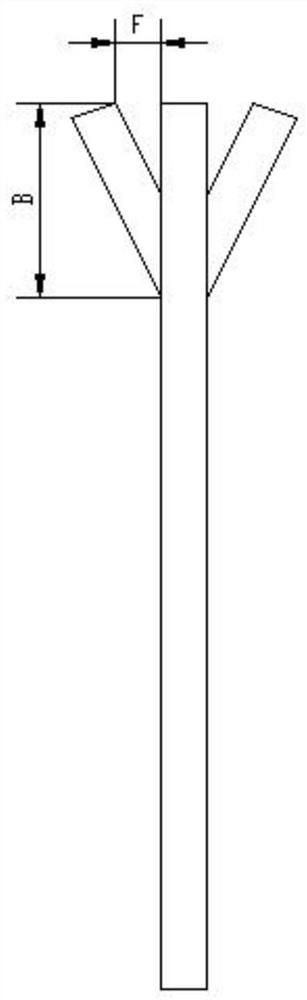

A Bimetallic Band Saw Blade with 2/3t Variational Tooth Quantity and Twisted Tooth Profile

Owner:LIAONING INST OF SCI & TECH +1

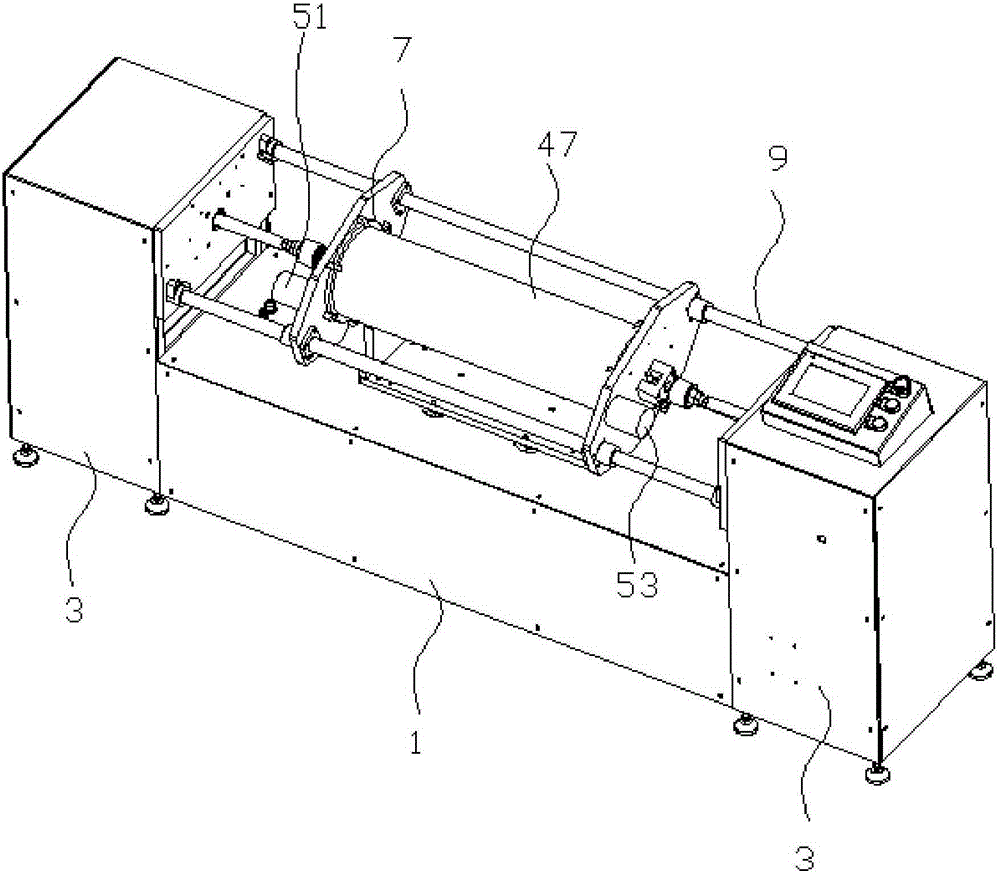

Internal pressurizing testing machine

ActiveCN105699024ANo pinchingReasonable structureMeasurement of fluid loss/gain rateAir pumpEngineering

The invention discloses an internal pressurizing testing machine which comprises a main seat, an air feeding pump, a blocking cylinder, a compaction cylinder, a shaft pipe, a spacing seat and a joint supporting rack. A compaction piston rod is provided with a positioning board. A capped piston rod is provided with a driving rack. The shaft pipe is provided with a plastic pipe outer-end sealing plate, a steel pipe outer-end sealing board, a plastic pipe outer sealing ring and a steel pipe outer-sealing ring. The shaft pipe is provided with a first air inlet. The first air inlet is provided with a first air inlet unidirectional valve. The outer wall of the shaft pipe is provided with a first air pressure sensor. A steel-plastic adapter which is supported by the joint supporting rack is arranged between the spacing seat and the blocking cylinder. The air feeding end of the air feeding pump is communicated with the inner part of the shaft pipe through an air supplying pipe. The internal pressurizing testing machine is advantageous in that reasonable integral structure is realized; in-place positioning and clamping is realized on the steel-plastic adapter; high sealing performance can be ensured without clamping damage of the steel-plastic adapter; the internal pressurizing testing machine has an adaptively adjusted sealing structure and furthermore sealing effect in high-air-pressure detection can be improved.

Owner:徐州博创建设发展集团有限公司

Sealing testing machine

InactiveCN105136409AThe overall structure is reasonableGuaranteed tightnessMeasurement of fluid loss/gain rateSelf adaptiveBall valve

The invention discloses a sealing testing machine and aims to provide the sealing testing machine which is convenient to operate, high in test result accuracy and capable of preventing two tube ends of a ball valve from being damaged by clamping. The sealing testing comprises an air feed pump, an air pressure sensor, a main frame, two push plate cylinders, two lateral frames, a main end cover and an auxiliary end cover. The two push plate cylinders are respectively arranged on the two lateral frames, wherein a piston rod of one push plate cylinder is connected with the main end cover, and a piston rod of the other push plate cylinder is connected with the auxiliary end cover. The main end cover is provided with a main elastic sealing ring pad. The auxiliary end cover is provided with an auxiliary elastic sealing ring plate. The main end cover is provided with a main cover air hole. The sealing testing has the advantages that the ball valve is positioned and clamped in position, the sealing performance is ensured, and the ball valve is prevented from being damaged by clamping; a sealing structure with a self-adaptive adjustment function is provided, and the sealing effect in a high pressure detection process is strengthened; in addition, an auxiliary positioning structure is provided, the end covers are prevented from returning, the push plate cylinders are protected, the sealing effect is improved, and the stability of the detection process is maintained.

Owner:宁波宇华实业股份有限公司

Cartridge bottle piston sliding property test device and method

ActiveCN109186966AJudgment of slidingAvoid Test Data ImpactMachine part testingGas supply equipmentBottle

The present invention relates to a cartridge bottle piston sliding property test device and a test method. The device comprises a cartridge bottle, an adjusting bottle, a fixing fixture, a gas pressure sensor, gas supply equipment and a test machine. The test method comprises the following steps: installing the adjusting bottle and the cartridge bottle on the fixing fixture, and installing a testpiston into the cartridge bottle from the end of the cartridge bottle; starting a pressing rod, and controlling the pressing rod to stop when the lower end of the pressing rod contacts the piston; injecting a certain amount of gas into the adjusting bottle via the gas supply equipment to allow the piston in the cartridge bottle to press on a pressure sensor at the lower end of the pressing rod under the action of the injected gas, and closing the gas supply equipment; starting the pressing rod again to allow the piston to move with a constant speed in the cartridge bottle under the action of pressing rod, drawing the curve of the difference varied with time, wherein a result is obtained by multiplying the gas pressure value measured by the gas pressure sensor by the piston area, and the difference is obtained by subtracting the result from the pressure value measured by the pressure sensor; and obtaining the curve of the friction force on the piston when the piston moves with the constant speed in the cartridge bottle. The obtained data is accurate and intuitive without the need of disposing waste water.

Owner:WUHAN BAIQI TECH CO LTD

Made in a shell

ActiveCN103659011BNo pinchingStable and controllable heatWorkpiece edge portionsWelding apparatusButt weldingEngineering

The invention relates to a manufacturing method of a casing, the casing is a liquid accumulator casing for a compressor, a muffler casing for an air conditioner, a gas-liquid separator casing or an oil-gas separator casing for a central air conditioner, the casing is The shell is formed by socket welding of at least two parts, which is characterized in that: the at least two parts are welded by argon arc welding, plasma welding, quasi-ion welding, laser welding or high-frequency welding, and the heat distribution relationship is the sleeve The outer layer of the interface distributes higher heat, and the inner layer of the socket distributes lower heat, so that the outer and inner metals at the socket are welded by self-fluxing. When the invention is welded, the heat of each part is stable and controllable, and both the inner layer and the outer layer can reach the melting temperature, so as to realize good fusion, improve the welding quality, the welding joint is smooth and bright, and the welding strength is high, and the welding seam strength is 10 times higher than that of butt welding times, the production efficiency is high, and it will not cause pinching on the surface of the pipe section, and the equipment cost is only 1 / 3‑1 / 5 of flash welding.

Owner:佛山晓世科技服务有限公司

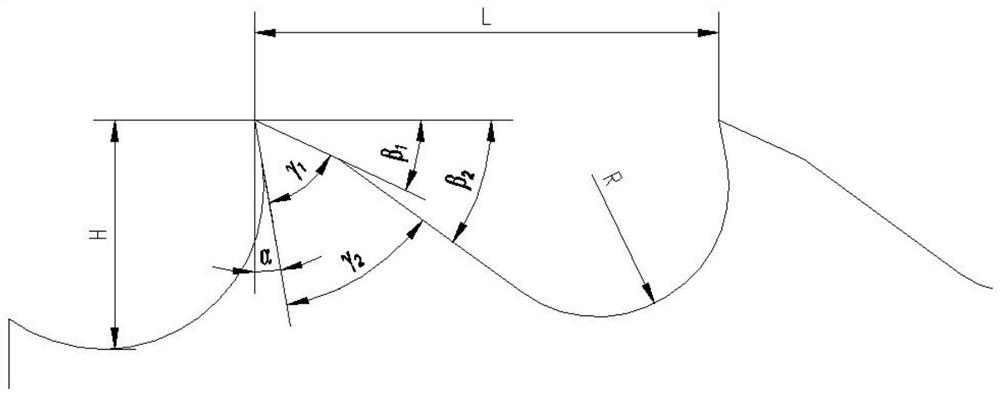

A bimetallic band saw blade with 3/4t seven-variable tooth profile

ActiveCN109807395BImprove cutting efficiencyIncrease cutting feedMetal sawing toolsEngineeringDentistry

The present invention relates to the technical field of cutting tools, and provides a bimetallic band saw blade with a 3 / 4T seven-variable-tooth variable-tooth tooth shape. Seven consecutively arranged saw teeth form a set of saw teeth, and a set of saw teeth is repeated and continuously arranged to form a saw blade. Teeth; the first tooth is the middle guide tooth, the height of all the sub-teeth is the same, the left sub-teeth of the second and sixth teeth are the same, the right sub-teeth of the third and seventh teeth are the same, the fourth tooth The amount of left teeth of the second tooth is the same as that of the fifth tooth, and the amount of left teeth of the second tooth is different from that of the fourth tooth; the rake angles of all the teeth are the same, and each tooth has two Tooth back angle; the slot of each tooth is arc-shaped, the tooth depth of each tooth in a set of teeth is different, the radius of each tooth slot is different, and the pitch of each tooth is different. The invention can improve cutting efficiency, smooth chip removal, avoid toothing, improve cutting surface quality and increase service life when sawing mold steel with high hardness and stainless steel with high viscosity.

Owner:LIAONING INST OF SCI & TECH +1

Manual tightening type cable sample clamping mechanism and insulating layer stripping equipment

PendingCN107968361AAchieve clampingAchieve tautnessApparatus for removing/armouring cablesMechanical engineeringEngineering

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com