Combination welding pipe and manufacturing method and application thereof

A manufacturing method and combined pipe technology, applied in applications, manufacturing tools, welding equipment, etc., can solve problems such as overburning of copper pipes, variability of pipes, general strength of welds, etc., achieve smooth and bright welding joints, and improve welding quality , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

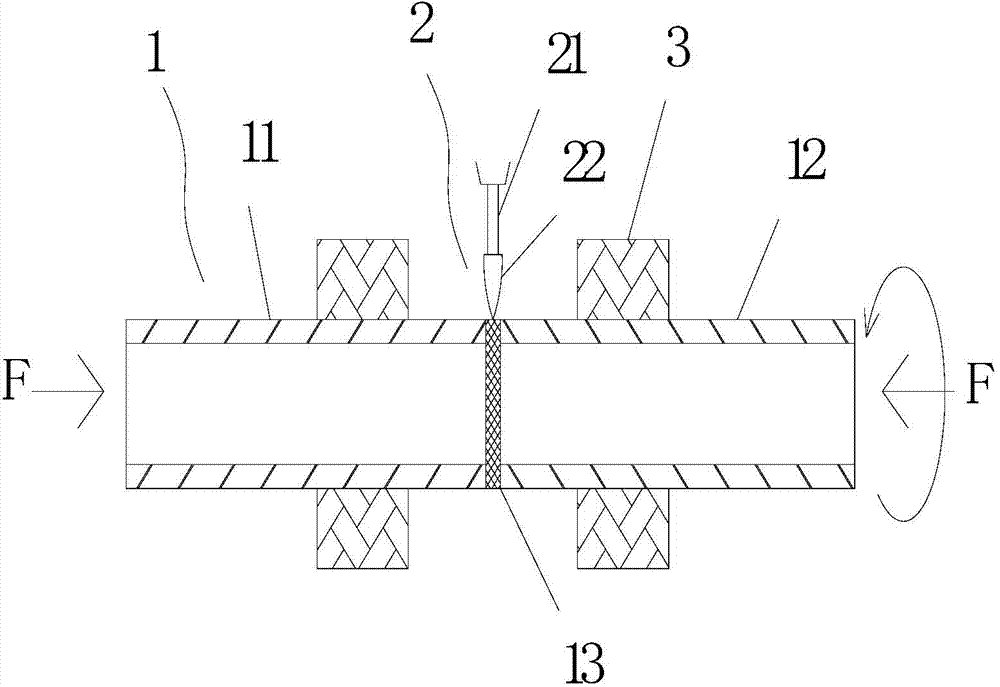

[0034] In this embodiment, an argon arc welding machine 2 is used to prepare the compressor exhaust pipe 1 . Such as figure 1 As shown, first, the copper pipe section 11 and the iron pipe section 12 with the same inner diameter and outer diameter are fixedly installed on the fixture 3 according to the butt position relationship, and the copper pipe section 11 and the iron pipe section 12 are in contact with each other before welding. . When the copper pipe section 11 is in contact with the iron pipe section 12 port, the other end of the copper pipe section 11 and the other end of the iron pipe section 12 respectively apply a force F in the opposite direction, so that the copper pipe section 11 and the iron pipe section 12 are connected at the interface. Contact is maintained throughout the soldering process. Then determine the relative position of the docking port 13 and the welding torch nozzle 21. The heating equipment adopted in this embodiment is a single welding torch, ...

Embodiment 2

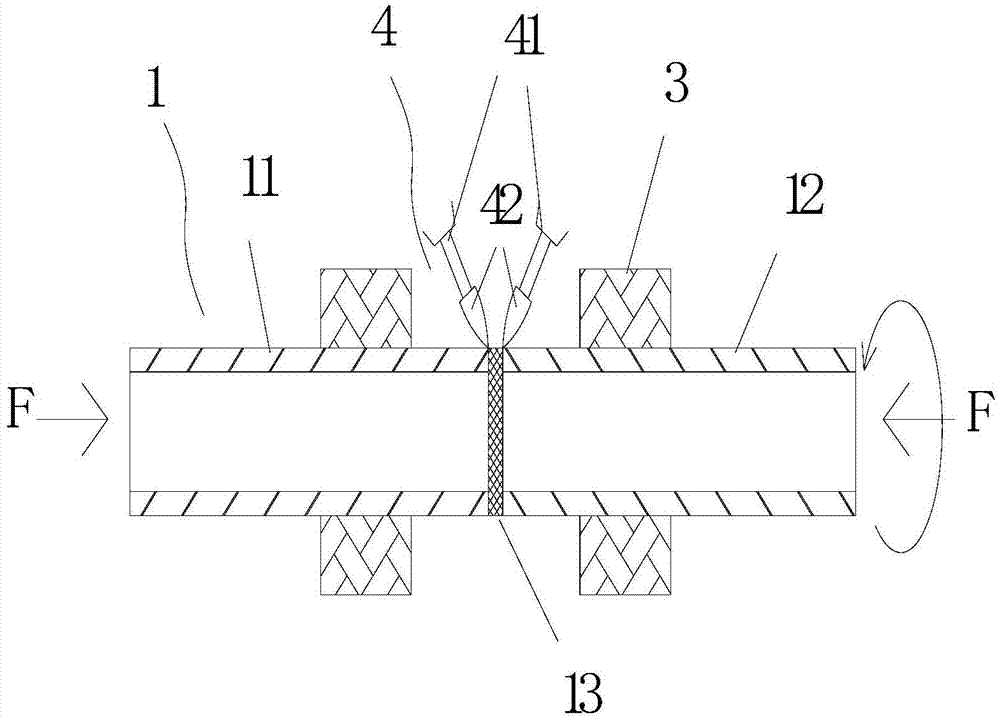

[0036] In this embodiment, the compressor exhaust pipe 1 was prepared using an argon arc welding machine 4, such as figure 2 As shown, firstly, the copper pipe section 11 and the iron pipe section 12 are fixedly installed on the fixture 3 according to the positional relationship of butt joint. When the copper pipe section 11 is in contact with the iron pipe section 12 port, the other end of the copper pipe section 11 and the other end of the iron pipe section 12 respectively apply a force F in the opposite direction, so that the copper pipe section 11 and the iron pipe section 12 are connected at the interface. Contact is maintained throughout the soldering process. Then determine the relative position of the docking port 13 and the welding torch nozzle 41, the heating equipment adopted in the present embodiment is a double welding torch, the output heat of the two welding torches is controlled independently respectively, and a welding torch nozzle 41 corresponding to the hea...

Embodiment 3

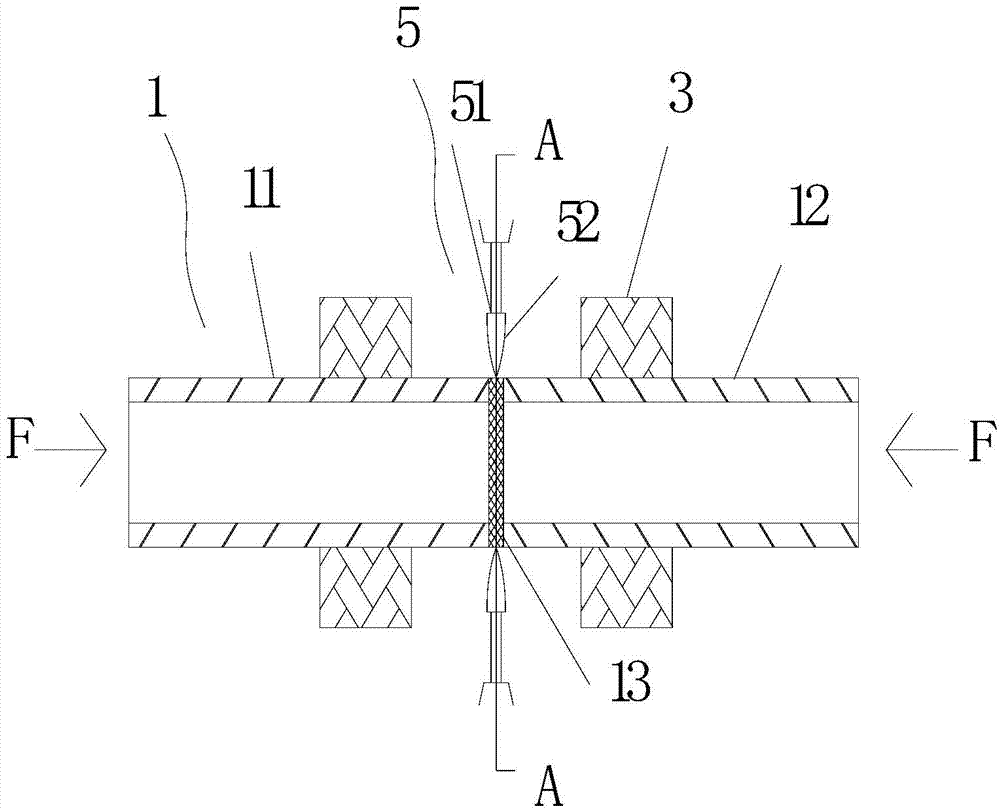

[0038] In this embodiment, an argon arc welding machine 5 is used to prepare the compressor exhaust pipe 1 . Such as Figure 3A As shown, firstly, the copper pipe section 11 and the iron pipe section 12 are fixedly installed on the fixture 3 according to the butt position relationship, and the butt joint 13 does not need solder. Before welding, the butt joints of the copper pipe section 11 and the iron pipe section 12 may contact first, or leave a gap less than 0.5mm.

[0039] The heating equipment adopted in this embodiment is a single annular multi-welding torch, such as Figure 3B As shown, more than 3 welding torches (4 in this embodiment) are evenly distributed around the circumference to form a circular ring. The distribution angles of the welding torches should be distributed reasonably. It is best to let the metal area melted by each welding torch overlap with the metal area melted by the adjacent welding torch. Then the entire welding circumferential surface can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com