Pressure-keeping detection device

A testing equipment, the technology of pressing the cylinder, which is applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc. The process is smooth and efficient, the overall structure is reasonable, and the effect of strengthening the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

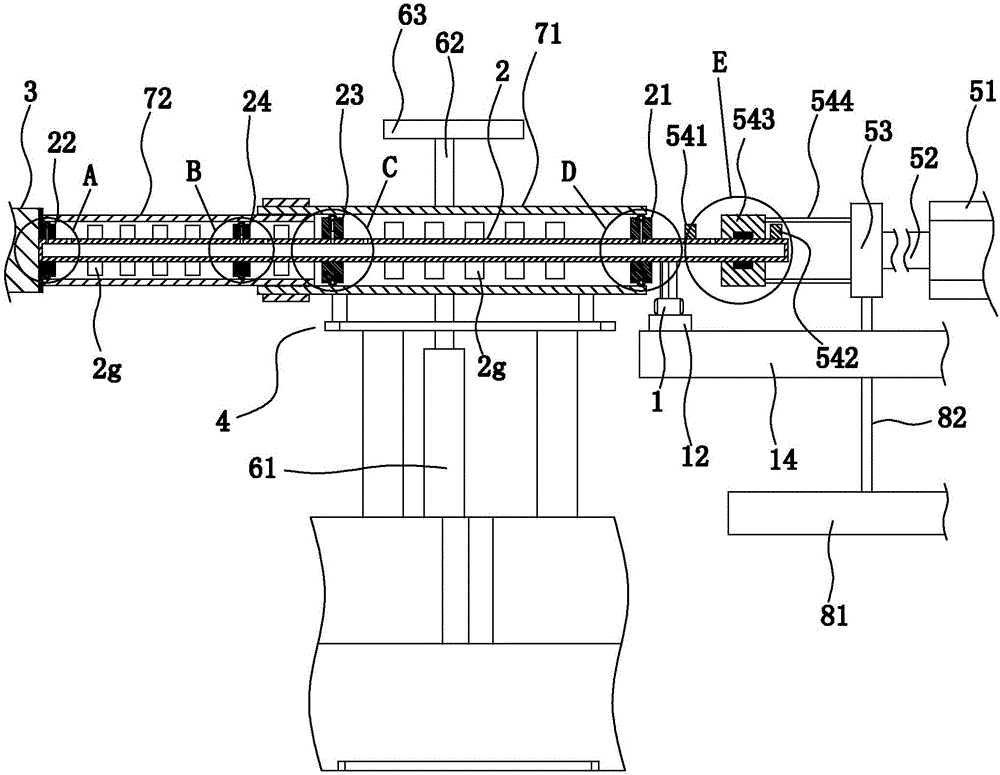

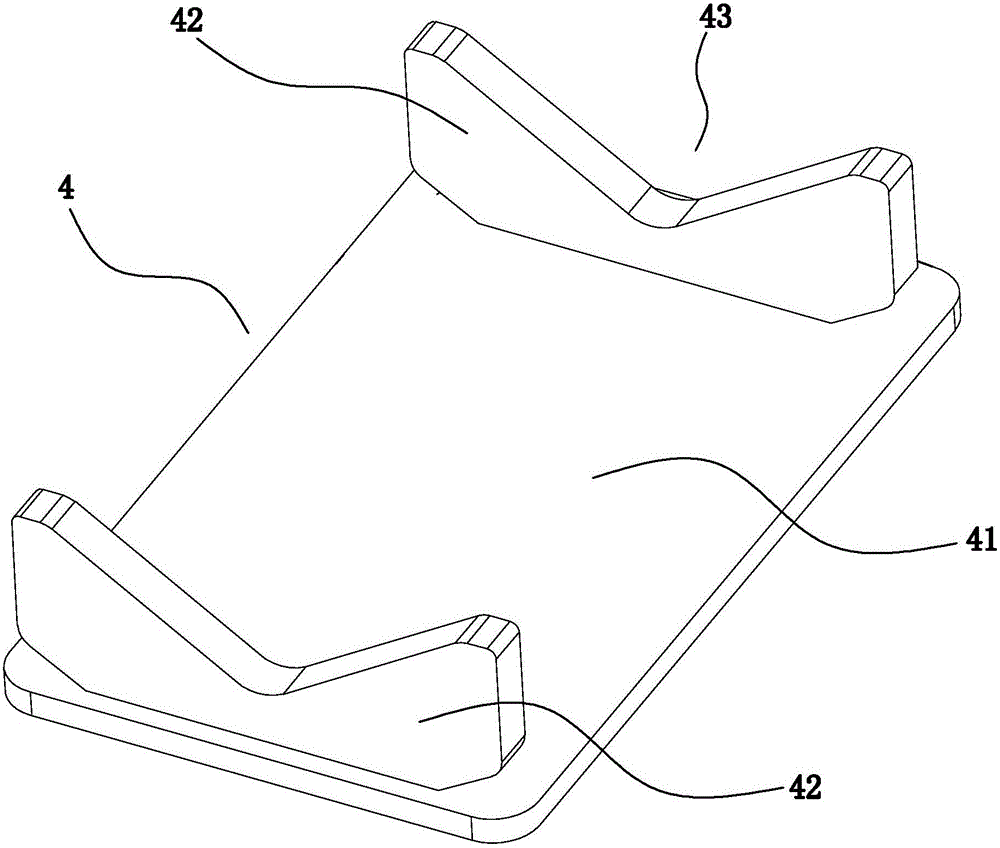

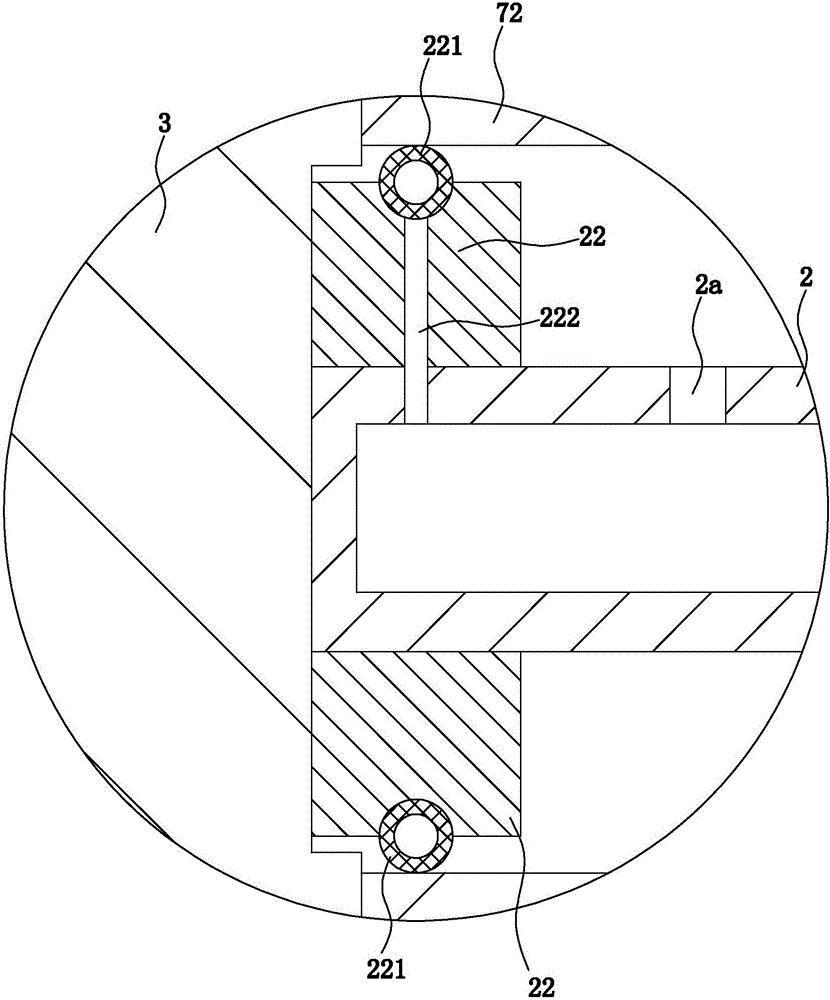

[0026] Such as Figure 1 to Figure 7 In the shown embodiment, a pressure maintaining detection device includes a main base, an air supply pump 1, a plugging cylinder, a compression cylinder, a limit seat 3, a horizontal shaft tube 2 with both ends closed, and a For the joint support frame 4 that supports the steel-plastic conversion joint and makes the axis of the steel-plastic conversion joint in a horizontal state, the plugging cylinder, the compression cylinder, and the joint support frame are all arranged on the main base, and the sealing cylinder includes a head cylinder Body 51, the head cylinder piston that is sliding and sealingly matched with the head cylinder body, the head piston rod 52 connected with the head cylinder piston, the head piston rod is horizontal and the retractable direction of the head piston rod is horizontal, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com