Manual tightening type cable sample clamping mechanism and insulating layer stripping equipment

A manual tensioning and clamping mechanism technology, which is applied to equipment for dismantling/armouring cables, cable installation, cable installation devices, etc., can solve problems such as time-consuming and laborious, affecting cable efficiency, and inability to cut insulation layers, etc., to achieve Improve accuracy and efficiency, ensure quality, and save human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

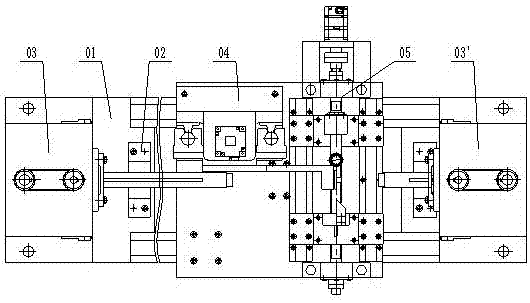

[0052] What should be explained at first is that in the context of the present invention, terms related to orientation such as "left end", "right end", "above" and "below" are used, and these terms are all based on the insulation layer peeled off of the cable sample. The direction of the front view of the equipment is used as the reference, while "axial" and "radial" are based on the axial and radial directions of the cable sample. In addition, each component is described as it is installed on the cable sample insulation stripping equipment, so the viewing directions of "left view", "right view" and "top view" are the same as those of the cable sample Corresponding view directions for insulation stripping equipment.

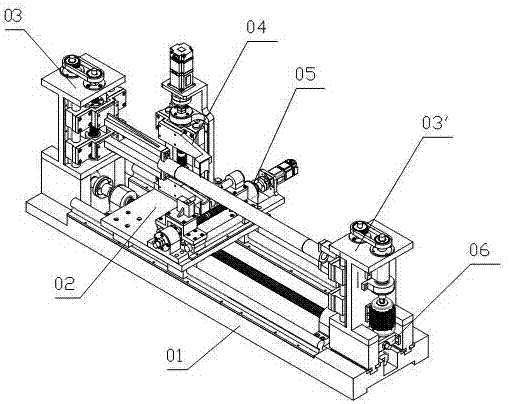

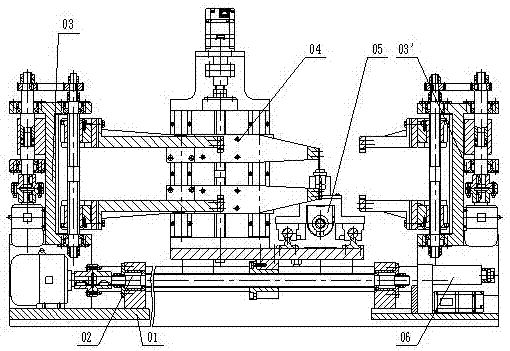

[0053] The following will refer to Figure 1-19 A preferred embodiment of a manual tensioning cable sample clamping mechanism and the corresponding cable sample insulation stripping equipment of the present invention will be described in detail.

[0054] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com