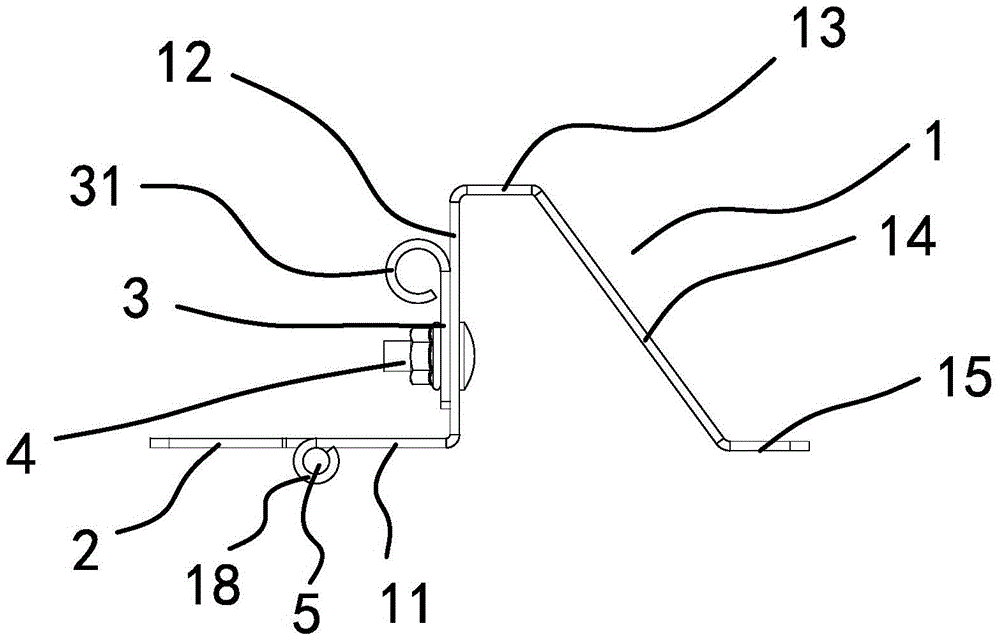

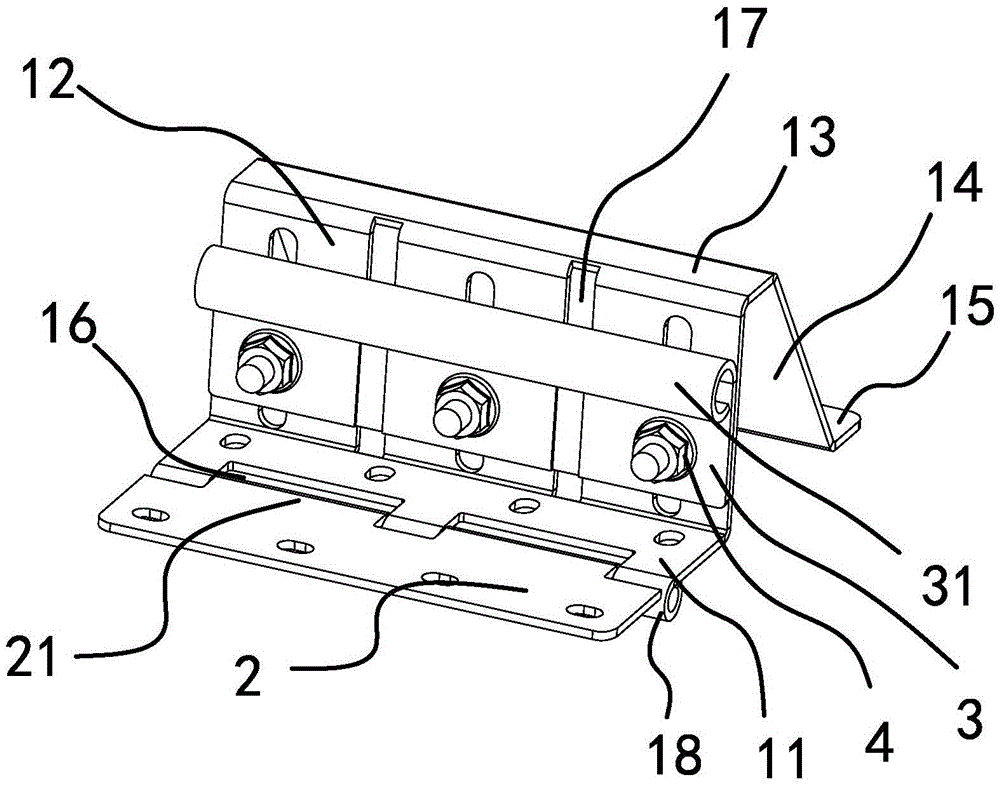

Anti-pinch hinge for industrial door

An anti-pinch hand, industrial door technology, applied in the direction of folding boards, door/window accessories, hinges with pins, etc., can solve the problems of easy separation of two boards, weak connection, hinge clips, etc., to reduce the quality. , Increase the high temperature performance, improve the effect of hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

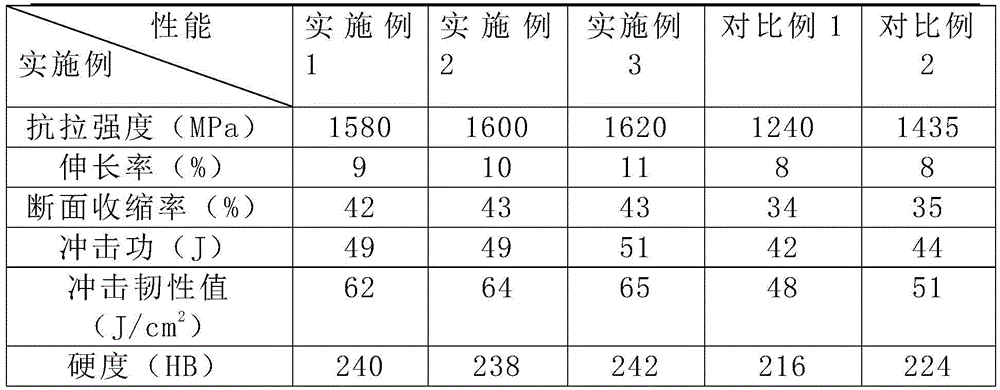

Embodiment 1

[0034] The first hinge sheet 1 includes a ceramic filling part and a metal layer arranged on the outer layer of the ceramic filling part. The ceramic filling part is mainly made of silicon carbide ceramics and at least part of the outer layer of the main body is a silicon nitride ceramic surface layer (that is, on the surface of the main body A certain area or some areas or the entire surface has a silicon nitride ceramic surface layer), the composition and weight percentage of the metal layer are: C: 0.20%, Si: 0.28%, Cr: 1.25%, Ni: 0.12% , Mo: 0.5%, Mn: 0.6%, Ti: 0.09%, B: 0.22%, and the balance is iron.

[0035] Among them, the ceramic filling part includes one (it can also be any of the following: the ceramic horizontal rods are provided with two, three, four, five or more parallel regular or irregular) columns (columns include cylinders) , elliptical prism, prism and other irregular prisms, prisms include triangular prisms, quadrangular prisms, pentagonal prisms, etc.) ce...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the composition and weight percentage of the metal layer in this embodiment are: C: 0.17%, Si: 0.35%, Cr: 1.2%, Ni: 0.2%, Mo: 0.3 %, Mn: 0.8%, Ti: 0.06%, B: 0.3%, and the balance is iron.

[0038] And the ceramic filling part also includes ceramic vertical rods, the ceramic vertical rods are perpendicular to the inside of the first hinge piece 1 and the minimum distance between the ceramic vertical rods and the surface layer of the metal layer is 1.0-1.5 mm.

Embodiment 3

[0040] The difference between this embodiment and Embodiment 3 is that the composition and weight percentage of the metal layer in this embodiment are: C: 0.25%, Si: 0.22%, Cr: 1.3%, Ni: 0.05%, Mo: 0.8 %, Mn: 0.3%, Ti: 0.12%, B: 0.05%, and the balance is iron.

[0041] And the ceramic filling part further includes ceramic oblique rods, and the ceramic oblique rods are obliquely arranged with the ceramic horizontal rods and the ceramic vertical rods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com