Pipe fitting airtightness testing machine

A technology for air tightness testing and pipe fittings, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve problems such as troublesome installation of pipe fittings, uneven end faces of pipe fittings, and misjudgment of quality. , to achieve a reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

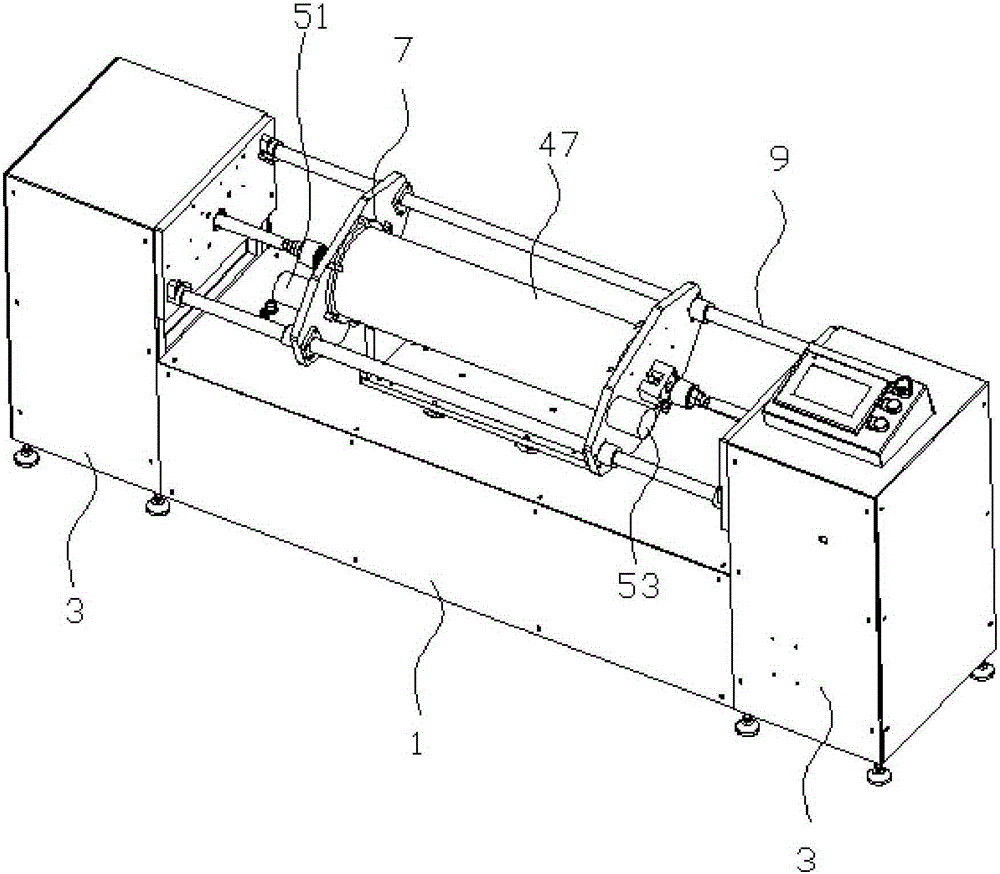

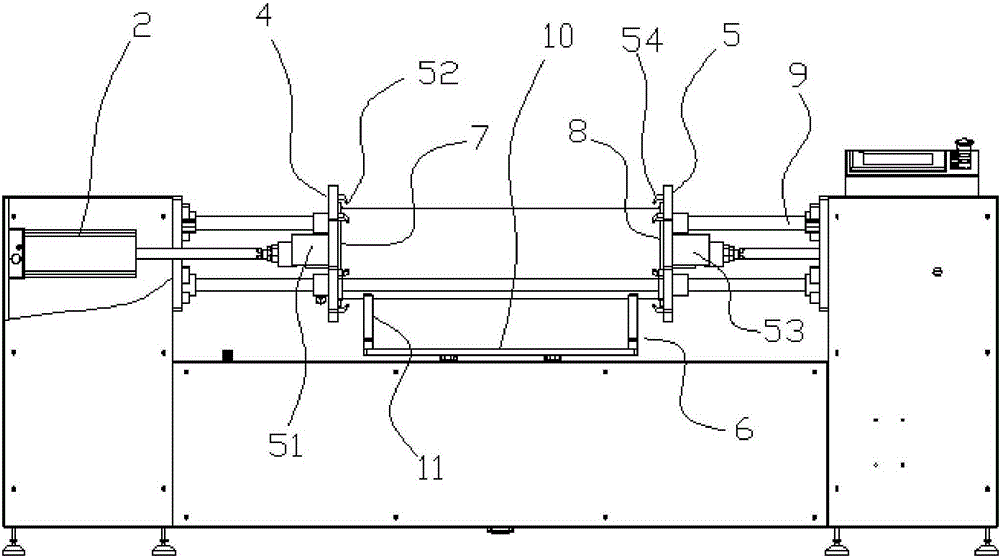

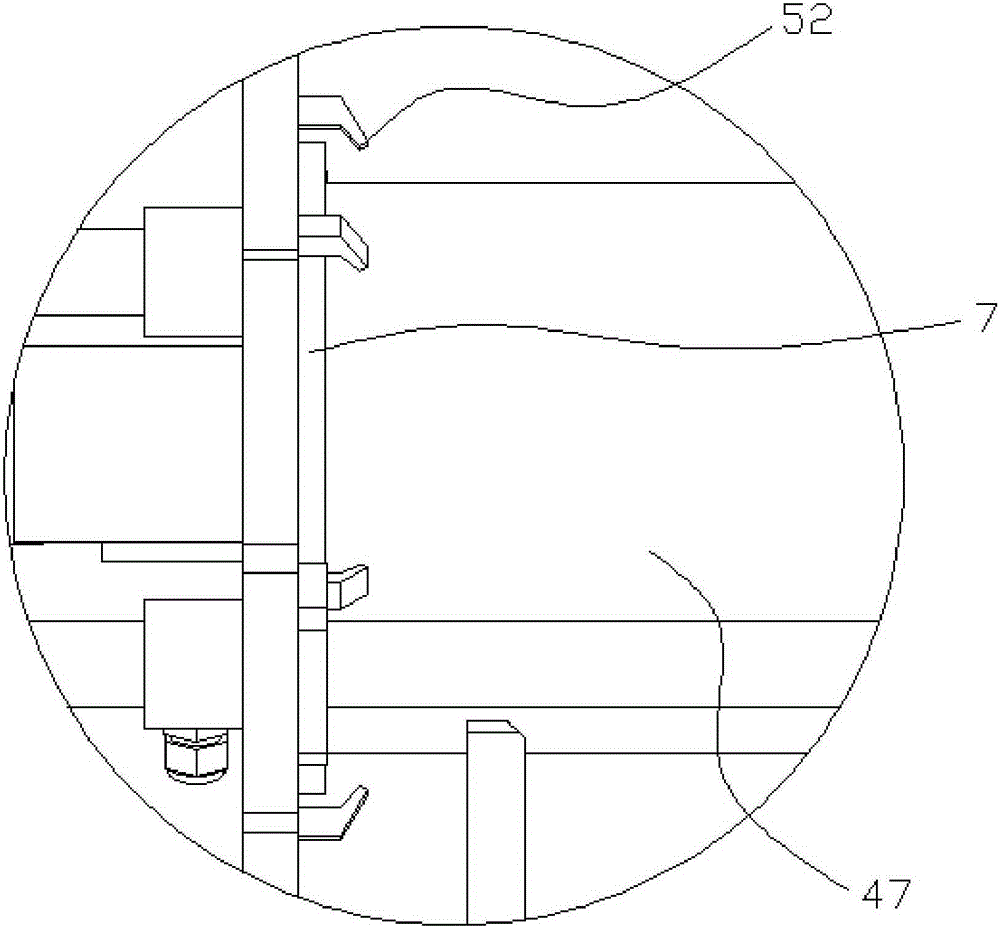

[0040] Example 1: Such as Figure 1 to Figure 5 In the illustrated embodiment, a pipe air tightness testing machine includes an air supply pump, an air pressure sensor 14, a main frame 1, two push plate cylinders 2, two side frames 3 with opposite inner sides, and a main end cover 4. , The secondary end cover 5, the main end cover and the secondary end cover are parallel to each other, the main frame is provided with a pipe supporting frame 6 for supporting the tested pipe, and two push plate cylinders are respectively arranged on the two side machines On the frame, the piston rod of one of the push plate cylinders is connected with the main end cover, and the piston rod of the other push plate cylinder is connected with the auxiliary end cover. The surface of the main end cover near the pipe support frame is provided for contact The main elastic sealing ring gasket 7 on the pipe end of the tested pipe is provided with a secondary elastic sealing ring plate 8 for contacting the ...

Embodiment 2

[0044] Example 2: Such as Figure 6 to Figure 8 In the illustrated embodiment, a pipe fitting air tightness testing machine includes an air supply pump 13, an air pressure sensor, a main frame, two push plate cylinders, two side frames with opposite inner sides, a primary end cover, and a secondary end cover , The main end cover and the auxiliary end cover are parallel to each other, the main frame is provided with a pipe fitting support frame for supporting the pipe under test, two push plate cylinders are respectively arranged on the two side frames, one of which pushes The piston rod of the plate cylinder is connected with the main end cover, and the piston rod of the other push plate cylinder is connected with the auxiliary end cover. The main end cover is provided with a main end cover for contacting the pipe end of the pipe under test on the surface near the pipe support frame. The elastic sealing ring gasket 7 is provided with a secondary elastic sealing ring plate 8 for ...

Embodiment 3

[0052] Embodiment 3: The basic structure and implementation of this embodiment are the same as those of Embodiment 2, and the difference lies in that: Figure 9 to Figure 12 Shown in the middle: It also includes two anti-return cylinders 31, one of which is fixed to the main end cover by an anti-return support 32, and the other anti-return cylinder is fixed to the secondary end cover by an anti-return support , The anti-return cylinder is provided with a push plate piston 33 that can slide up and down in the anti-return cylinder, and the push plate piston is connected to the inner end of a disc piston rod 34, and the outer end of the disc piston rod is provided There is a suction cup 35, the disc connecting piston rod is vertical, and the push plate piston divides the anti-return cylinder where it is located into an inflation chamber 36 and a movable chamber 37. The inflation chamber is connected to an anti-return air pipe 50 The airing end.

[0053] When the air pressure in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com