Double boring bottom cylinder supporting tool

A bottom cylinder and tooling technology, applied in the field of tooling and fixtures, can solve the problems of restricting the effective working time of the assembly line, increasing the labor intensity of workers, and the height cannot be adjusted, so as to improve convenience, save time and effort for clamping, and avoid replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

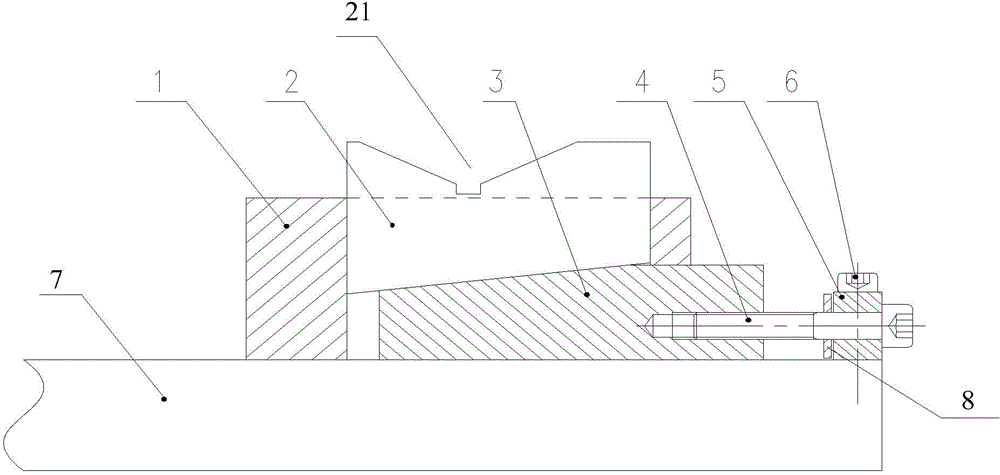

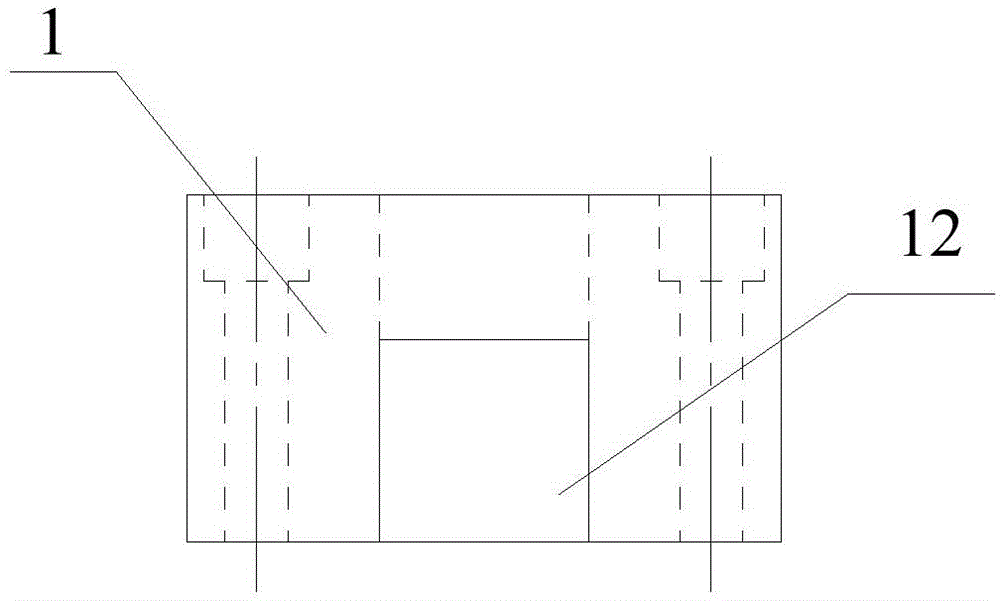

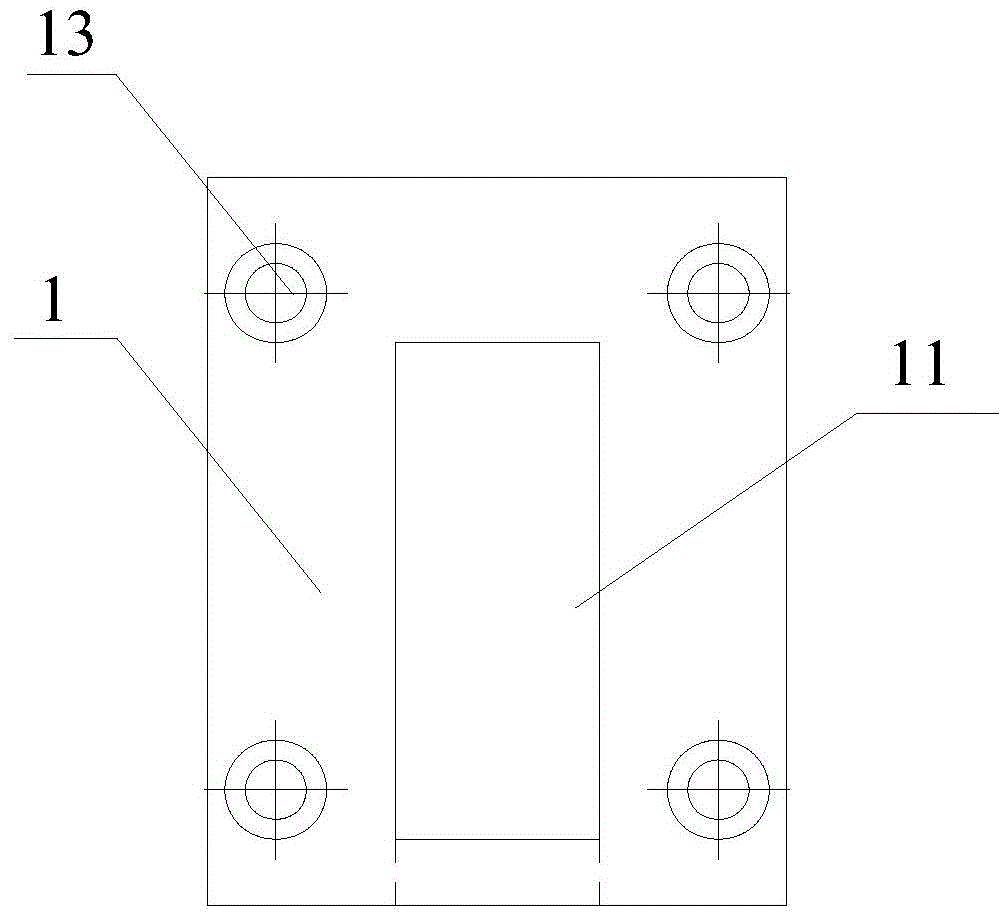

[0033] Such as Figure 1 to Figure 3 As shown, the present invention provides a double-headed bottom boring cylinder support tool, including a base 7 and a positioning seat 1, a slider 3 and an adjustment support seat 5 installed on the base 7, a rectangular block of the positioning seat 1, and four corners of the positioning seat 1 An installation hole 13 is provided, and the positioning seat 1 is connected with the base 7 through fastening bolts pierced in the installation hole 13. The middle part of the positioning seat 1 is vertically provided with a chute 11, and a support block 2 is arranged in the chute 11. 2 The upper end is provided with a V-shaped workpiece support port 21, and the lower part of the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com